Page 1

SORTER

Page 2

1 May 1993 SPECIFICATIONS

1. SPECIFICATIONS

Number of Bins: 10 bins

Paper Size for Bins: Maximum A3, 11" x 17"

Minimum A5, 51/2" x 81/2"

Paper Weight: 64 to 90 g/m2 (17 to 24 lb)

Bin Capacity: Sort/Stack 20 sheets / A4, 81/2" x11"

Mode 15 sheets / B4, 81/2" x 14"

10 sheets / A3, 11" x 17"

Top Bin Capacity:

(Non-Sort/Stack Mode)

Power Source: +5 volts and +24 volts from the copier

Power Consumption: 7.7 W

Dimensions:

(W x D x H)

Weight: 7.5 kg (16.5 lb)

100 sheets (all sizes)

402 mm x 443 mm x 217 mm

(15.8" x 17.4" x 8.5")

Sorter

1

Page 3

6

5

COMPONENT LAYOUT 1 May 1993

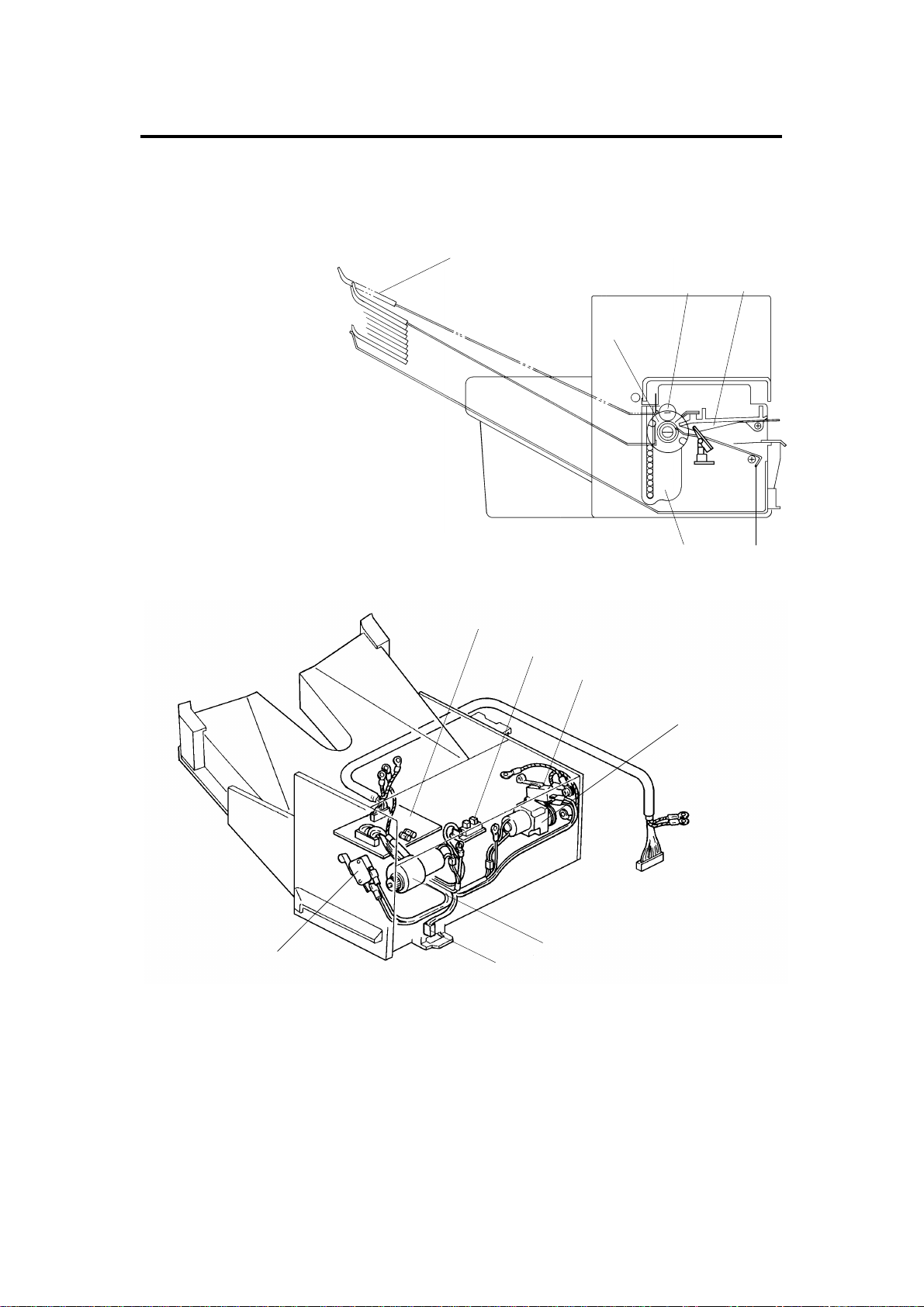

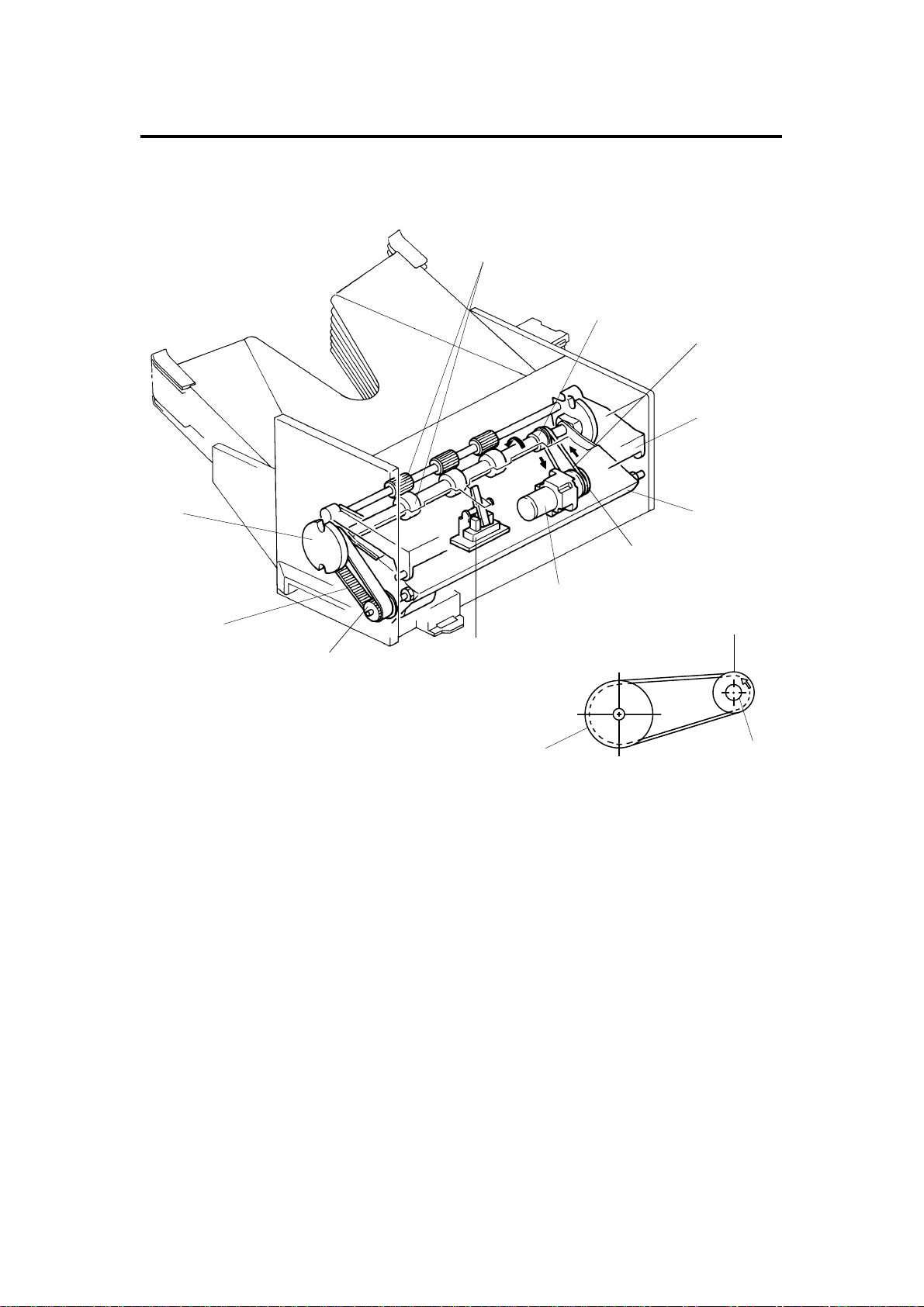

2. COMPONENT LAYOUT

– Mechanical Components –

1

1. Bin

2. Transfer Wheel

3. Exit Roller

4. Upper Paper Guide

5. Lower Paper Guide

6. Bin Guide

– Electrical Components –

3

2

6

1

2

3

4

4

5

7

1. Sorter Main Board 5. Sorter Switch

2. Paper Sensor 6. Bin Drive Mot or

3. Wheel Switch 7. Home Position Switch

4. Roller Drive Motor

2

Page 4

1 May 1993 ELECTRICAL COMPONENT DESCRIPTIONS

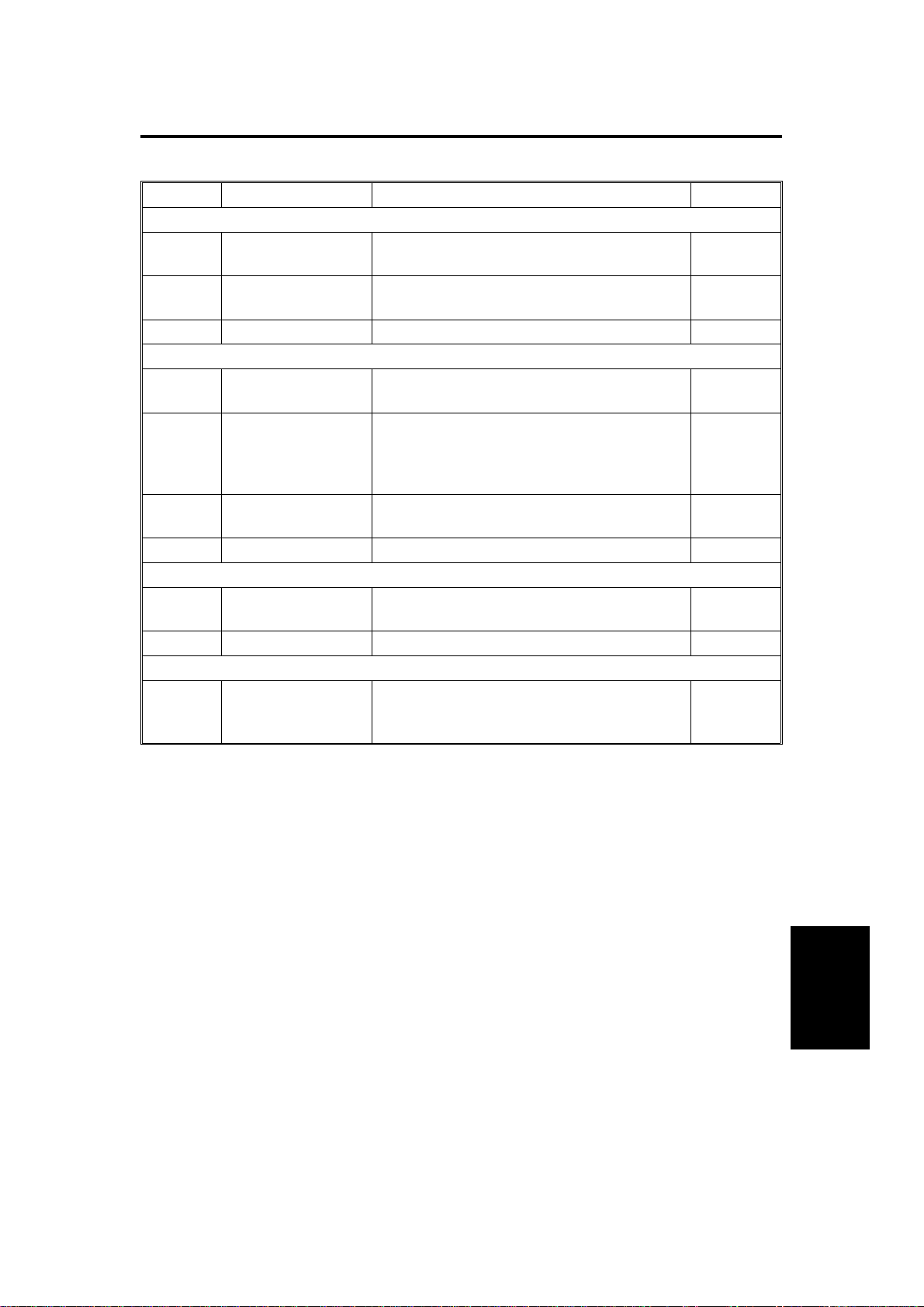

3. ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Name Function Index No.

Motors

M1 Roller Drive Motor DC motor that energizes to drive the lower

exit rollers.

M2 Bin Drive Motor Reversible DC motor that energizes to move

the bins up or down.

Switches

SW1 Wheel Switch Detects the rotation of the transfer wheel

and stops it in the correct position.

SW2 Sorter Switch Reed switch that becomes activated when

the sorter is in the proper position (aligned

next to the copier). Also works as a jam

reset switch for the sorter.

SW3 Home Position

Switch

Informs the CPU that all the bins are lowered. 7

4

6

3

5

Sensor

S1 Paper Sensor Serves as the misfeed sensor for the sorter

and also sets exit roller and bin drive timing.

Printed Circuit Board

PCB1 Sorter Main Board Serves as the communication board

between the copier main board and the

sorter.

2

1

Sorter

3

Page 5

OVERALL MACHINE CONTROL 1 May 1993

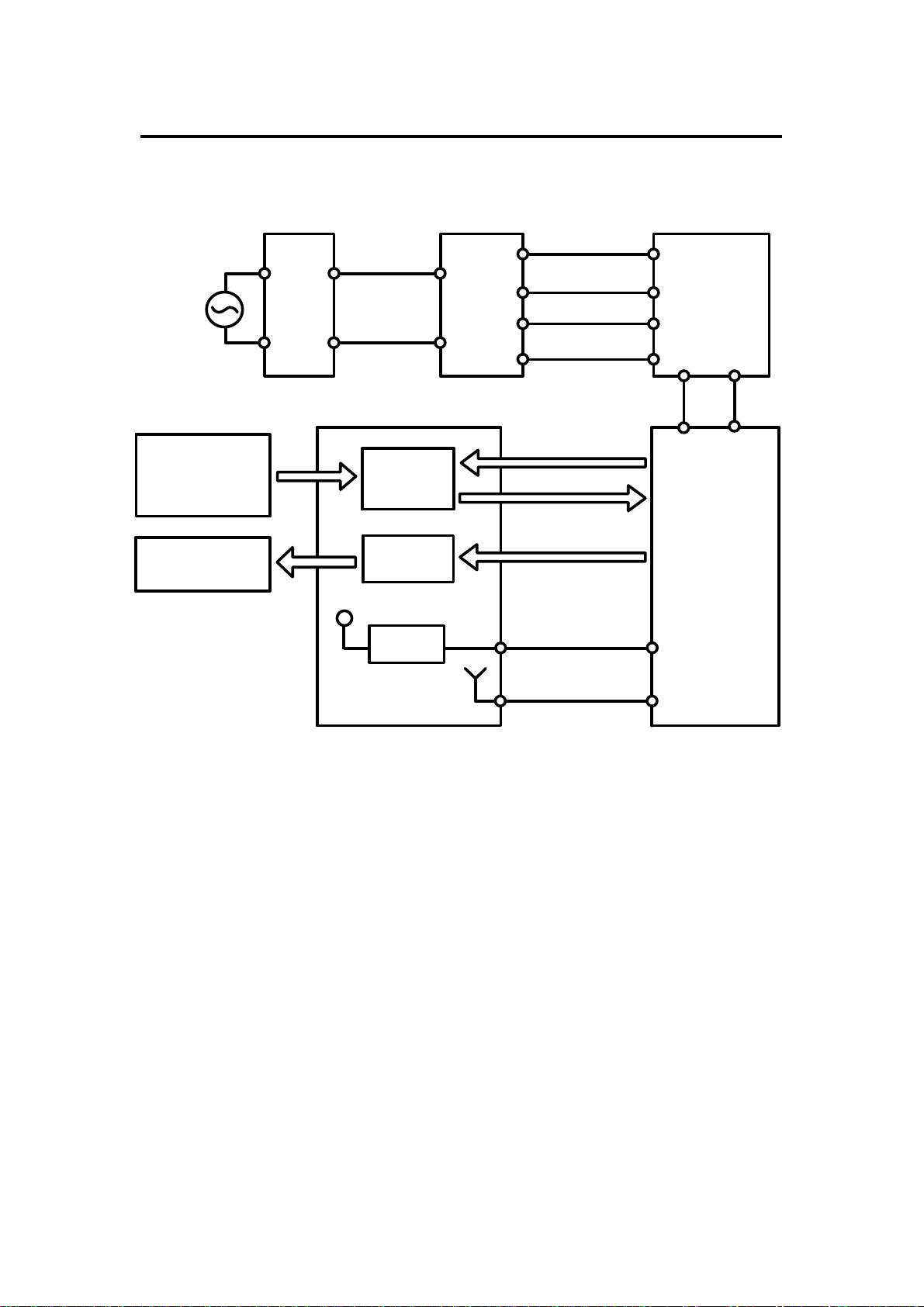

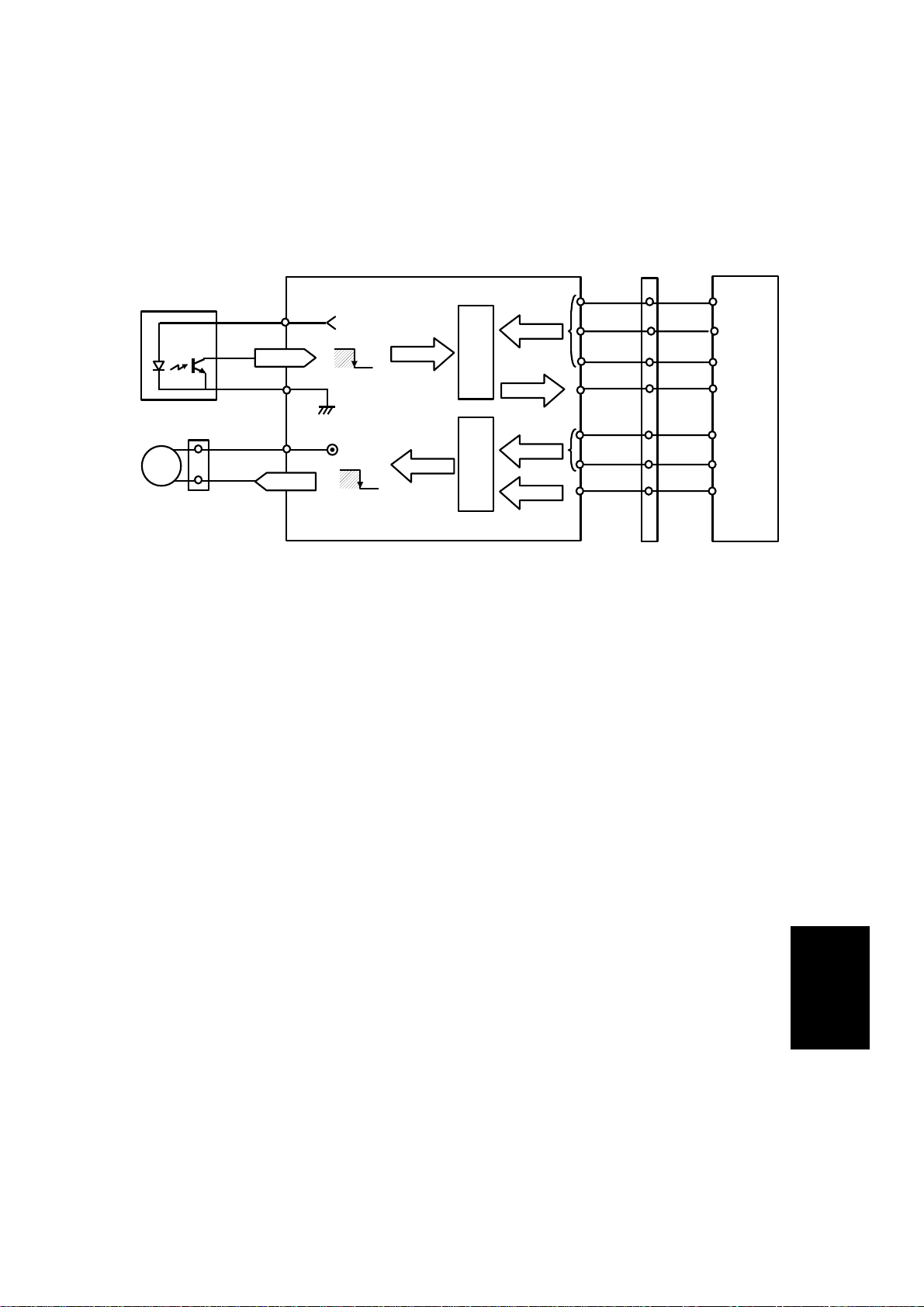

4. OVERALL MACHINE CONTROL

Paper Sensor

Sorter Switch

Home Position Switch

Wheel Switch

Roller Drive Motor

Bin Drive Motor

AC Drive Board

(PCB2)

+12V

115Vac

220/230/240Vac

Data Select

IC

Drive IC

Regulator

IC

Main Transformer

(TR1)

Scan Signal

Scan Output Signal

Sorter Drive Signal

+24V(VA)

26Vac (A110 copier)

31Vac (A111 copier)

10Vac

Main DC Power

Supply Board (PCB3)

+24V

(VA)

+5V

(VC)

+5V(VC)

Sorter Main Board (PCB1)

Copier Main Board (PCB1)

The copier main board provide s +24 volt s (VA) and +5 volts (VC) to the sorter

main board. +24 volts powers the roller drive motor, and +5 volts po wers all

sensors and switches. Also, +24 volts is changed to +12 volts by the

regulator IC, which powers the bin drive motor.

The copier main board controls t he drive and che cks t he stat us of the sorte r

via the sorter main board. The copie r main bo ard send s the scan sign als to

the data selected IC on the sorter main board. After receiving the scan

signals, the data select IC outputs th e sta tu s of th e sensor an d switch es as

the scan output signal.

The copier main board also sends the sorte r drive signal to the drive IC on

the sorter main board. Af te r receiving the drive signal, the drive IC turns on

the appropriate motors.

4

Page 6

1 May 1993 BASIC OPERATION

5. BASIC OPERATION

– Clear Mode –

When the main switch of the copier is turned on, the sorter automatically

assumes the clear mode. In this mo de, all copies are stacked on the first bin.

The sorter also assumes the clear mod e whe n eit he r the inte rrupt mode or

the manual feed mode is selected.

Sorter operation be gin s wh en a copy act ua te s t he copie r e xit sen sor. At this

time, the roller drive motor energizes. Whe n the paper exits onto the sorte r

bin, the paper sensor is de-activated and the roller drive motor is then

de-energized. The copier main board monitors the paper sensor through the

sorter main board to check for pape r misfee ds.

– Sort Mode –

Pressing the Sorter ke y once shifts the copier to the sort mode . In this mode,

all copies of the first original are delivered to separa te bins sta rtin g from the

top. The copies of the second original are delivered to th e same bins, but

starting from the bottom. The cop ies of the third origin al sta rt from the top and

so on. The bin drive motor turns on to advance th e bin one step , 25 0

milliseconds after the copy has gone th rou gh the pape r sen sor. If th e Cop y

Quantity, Clear/St op , Book Copy, or Sorter key is pressed durin g th e sort

mode, all bins shift to the ho me po sition.

– Stack Mode –

Pressing the Sorter ke y twice shif ts the copier to the stack mode. In th is

mode, all copies of the first origina l are de livere d to the first bin , all copies of

the second original are delivere d to the secon d bin , an d so on. The bin drive

motor turns on to advance the bin one ste p, 250 milliseconds after the last

copy of the original has gone through the pap er sen sor. If th e Sorter key is

pressed during stack mode, all bins shif t to home posit ion.

Sorter

5

Page 7

EXIT ROLLER DRIVE 1 May 1993

6. EXIT ROLLER DRIVE

6.1 ROLLER DRIVE MECHANISM

[A]

[I]

[D]

[J]

[F]

[L]

[C]

[G]

[B]

[H]

[L]

F: Transfer Wheel

G: Bin Drive Belt

H: Bin Drive Pulley

I: Exit Roller Pulley

J: Upper Paper Guide

K: Lower Paper Guide

L: Roller Drive Motor Pulley

The exit rollers [A] take over pape r tra nsp ort from the copier. When the copy

paper actuates the copier exit sensor, the exit rollers start rotatin g. The exit

rollers continue to rotate for 2 50 millise con ds af te r the copy pape r has go ne

through th e pa per sensor [B].

[K]

[H]

[E]

The roller drive motor [C] rotates the lower exit roller via the rolle r drive belt

[D]. The shaft of the lower exit roller is a cylindrical cavity type which rotates

around the transfer whee l shaf t [E]. The paper sensor is positioned just in

front of the exit rollers. The paper sensor detects misfeeds in the sorter.

6

Page 8

1 May 1993 EXIT ROLLER DRIVE

6.2 ROLLER DRIVE CIRCUIT

Copier Main

Board

Sorter Main Board (PCB1)

CN2

(PCB1)

Paper Sensor

Roller

Drive

M

CN53-1

CN53-2

CN102-5

CN102-4

CN102-6

CN102-13

CN102-7

+5V

+24V

+5V

+24V

CN101-3

Scan Signal

Data

Select

0V

0V

IC

Drive

IC

Scan Output

Drive Signal

Clock Pulse

CN101-4

CN101-5

CN101-6

CN101-7

CN101-8

CN101-9

CN126-1

CN126-2

CN126-3

CN126-10

CN126-4

CN126-5

CN126-6

To turn on the roller drive motor, the copier main board sends a drive signal

to the drive IC on the sorter main board. Aft er receiving the drive signal, the

drive IC drops CN102-7 from +24 to 0 volt to turn on the roller drive moto r.

When the paper sensor is actu at ed , CN102-13 drops to LOW. The cop ier

main board outputs th ree scan signals to the data select IC. The sta tus of the

sensor changes the resulting scan output signal. Using the scan output

signal, the copier main board dete rmine s the stat us of the senso r. For safety

reasons, the CPU limits the operation time of the roller drive motor to 5

seconds.

Sorter

7

Page 9

[E]

[C]

BIN DRIVE 1 May 1993

7. BIN DRIVE

7.1 BIN DRIVE MECHANISM

[E]

[D]

[B]

G : Exit Roller

H : Upper Paper Guide

I: Lower Paper Guide

[F]

[A]

[G]

[G]

[D’]

[B’]

[H]

The bin drive mechanism moves

the bins up and down to receive

copies under the dire ctio n of the

copier CPU. The main

components in this mechanism

are the bin drive motor [A], two

transfer wheels [B, B ’] , the wheel

switch [C], and the bins

themselves.

Pins on either side of each bin are

inserted into slots called bin

guides [D,D’]. The bins slide up

and down in the bin guides. The

bins sit on each other with the

lower bin resting on the

permanently-mounted 10th bin.

The upper and lower paper guides

pivot up and down depending on

the height of the bin to be picked

up or released.

[I]

[B]

8

Page 10

OFF

OFF

1 May 1993 BIN DRIVE

The home position switch [E]

informs the CPU when all the bins

are lowered.

To move the bins up, the bin drive

motor turns clockwise (as viewed

from the front). A timing belt [F]

turns the transfer wheels.

The transfer wheels have two

slots in them 180 degrees ap art .

As the transfer wheels turn, these

slots engage the bins and lift them

up. Each time the transfer wheels

turn 180 degrees, they raise one

bin.

To move the bins down, the CPU

reverses the bin drive motor and

the above processes reverses.

The CPU monitors the position of

the bins through pulses generated

by the wheel switch and the

actuator cam [J]. The actu at or

cam has two flat sides that are

180 degrees apart and is mounted

behind the rear transfer wheel. A

pulse is generated each time one

of the lobes of the actu ator cam

passes the wheel switch.

[B]

[J]

[C]

ON

Sorter

9

Page 11

BIN DRIVE 1 May 1993

7.2 BIN DRIVE CIRCUIT

Copier Main

Board

Home Position Switch

T51

CN102-11

CN102-1

T52

Wheel Switch

T53

CN102-12

CN102-2

T54

Sorter Main Board (PCB1)

+5V

0V

+5V

0V

Data

Select

IC

Scan Signal

Scan Output

CN101-3

CN101-4

CN101-5

CN101-6

CN2

CN126-1

CN126-2

CN126-3

CN126-10

(PCB1)

Down

Drive Signal

0V

+12V

0V

Drive

IC

Clock Pulse

CN101-7

CN101-8

CN101-9

CN126-4

CN126-5

CN126-6

Bin

Drive

M

CN51-1

CN51-2

CN102-8

CN102-9

Up

+12V

0V

0V

To turn on the bin drive motor, the copie r ma in board sends drive signals to

the drive IC on the sorter main board. After receivin g the drive signa ls, the

drive IC either raises CN102-8 or CN102-9 to +12 volts. This tu rns on the bin

drive motor which respectively moves a bin up or down. The sorter main

board monitors the output of bot h sorter switches through the data select IC.

When either the home position switch or wheel switch is actuat ed, CN102-11

or CN102-12 drops to LOW. The copier main board outputs three scan

signals to the data select IC. The stat us of the swit che s chan ges the resulting

scan output signal. Using the scan output signal, the copier main board

determines the status of the switch.

The CPU monitors the on-time of the bin drive motor to dete ct a malfun ctio n

of the bin drive motor. If the bin drive mot or con tin ue s to rot at e more than

twelve seconds, the CPU stops machine operation.

10

Page 12

1 May 1993 MISFEED DETECTION

8. MISFEED DETECTION

J1 J2 J1 J2

2942

2942

Paper Sensor

2.75 sec ((A4 sidewise)

2.80 sec (LT sidewise)

2.75 sec (A4 sidewise)

2.80 sec (LT sidewise)

In addition to being used for th e exit roller and bin drive timin g, the paper

sensor checks for a misfeed in th e sort er. The copier CPU checks whether

the paper sensor is actuated within 942 pulses (3.8 seconds) after the

registration clutch turn s on (at 2,000 pulse s). (J1: Pap er Sensor ON Check)

Also, the copier CPU starts a timing cycle when the paper sensor is actuated.

Then, at 2.75 (A4 sideways) or 2.8 0 (Le tt er sideways) seconds, the CPU

checks whether the cop y pap er ha s passed through the paper sensor. (J2:

Paper Sensor OFF Check)

In misfeed condition, the "Check P aper Pa th " and "Misf eed Lo cat ion "

indicators lights and copie r o peration is inhibited. To recover the sort er from

the misfeed condition, th e sort er has to be slide awa y from th e cop ier, then,

after misfed paper removal, ret urned to its original position.

11

Sorter

Page 13

INSTALLATION PROCEDURE (for Machine Code: A110/A111) 1 May 1993

9. INSTALLATION PROCEDURE

(for Machine Code: A110/A111)

9.1 ACCESSORY CHECK

Check the quantity and cond itio n of the accessories in the box according to

the following list:

1. Magnet Catch..................................................................................1

2. Sorter Holder Bracket............ .. .................... .. ..................................1

3. Sorter Holder Bracket Cover......... .. .. .. .. .. ................ .. ................ .. ....1

4. Philips Pan Head Screw - M4 x 8....................................................8

5. Philips Pan Head Screw - M4 x 8....................................................1

6. Screw M4 x 8............... .. ............................................................ .. ....1

7. Snap Ring........................................................................................1

8. Toothed Washer..............................................................................1

9. Spring Washer.................................................................................1

10. Interfa ce Harness ............................................................................1

12

Page 14

[F]

1 May 1993 INSTALLATION PROCEDURE (for Machine Code: A110/A111)

9.2 INSTALLATION PROCEDURE

[C]

[A]

[B]

[G]

[D]

[I]

[H]

[E]

NOTE: Do not grasp the sorter by the top cover and stay as shown by [A].

Hold both sides of the sorter as shown by [B]. This is to prevent

anti-static brush [C] damage.

1. Turn off the main switch and un plu g the power supply cord of the copier.

2. Remove the strips and styrofoam blo cks [D].

3. Remove the receiving tray [E].

4. Remove the rear cover [F] (4 screws).

5. Remove the caps [G] on the upper left side cover with the pliers.

6. Install the magnet catch [H] on the exit unit [I] (2 scre ws).

13

Sorter

Page 15

[H]

INSTALLATION PROCEDURE (for Machine Code: A110/A111) 1 May 1993

[B]

[C]

[A]

[D]

[G]

[F]

[E]

7. Install the sorter holder bracket [A ] (3 screws) so th at the two ho les [B ] on

the bracket align with the hole s [C] on the copie r f rame as shown .

8. Install the sorter [D] on th e sort er ho lder bracket (1 snap ring) as shown .

9. Remove the ac harness [E] from the wire clamp [F] as shown .

10. Install the sorter harne ss bracket [G] with the harness (2 screws).

11. Reinstall the ac harness into the wire clamp.

12. Install the sorter holde r bracket cover [H] (1 screw).

14

Page 16

1 May 1993 INSTALLATION PROCEDURE (for Machine Code: A110/A111)

[D]

[C]

[F]

[E]

[I]

[H]

[G]

[B]

[A]

13. Connect the sorte r dc harness [A] (10P/Brown) to the interface harness

connector [B].

14. Connect the interfa ce harness connector [C] to CN126 on the main board

[D].

15. Set the interface harness [E] into the clamps [F] as shown.

16. Secure the grounding wire [G ] (1 screw, too th ed wa she r [H], and spring

washer [I]) on the bottom plate as shown.

17. Plug in the copier power supply cord.

18. Change the SP71 data to "1" (sorter instruction).

19. Reinstall the rear cover and turn on the main switch.

20. Check the operatio n of the sorter.

Sorter

15

Page 17

PREPARATION FOR TRANSPORTATION 1 May 1993

10.PREPARATION FOR TRANSPORTATION

CAUTION: When removing and transporting the sor ter , be ca re ful not

to carry it in a vertical position as the bins will become

dislocated.

CAUTION: Before moving the sorter, be sure to prepa re it for

transportation as follows. The sorter may be badly

damaged if it is moved without proper preparation.

1. If the bins are not at the home position, tu rn on the main switch of the

copier to move the bins to the home position.

2. Secure the bins with strips of tape as shown in the illu stra tio n.

3. Remove the sorter from the copier. (See the Installation Procedure

[Sorter] section.)

16

Page 18

[D]

[M]

1 May 1993 ROLLER DRIVE BELT REPLACEMENT

11.ROLLER DRIVE BELT REPLACEMENT

[E]

[F]

[B]

[J]

[I]

[G]

[K]

[L]

[C]

[H]

[A]

1. Remove the front covers [A] (5 screws) and rear cover [B] (2 screws).

2. Lift off the top cover [C].

3. Remove the top stay [D].

NOTE: Be sure that the discharge brush on the top stay is facing the exit

side of the sorter when reinsta lling it.

4. Lift the upper paper guide [E] up and out of position.

5. Lift the lower paper guide [F] out of position and tu rn it ove r t o remove th e

roller drive belt [G].

NOTE: Be careful not to damage the sorte r home posit ion swit ch

actuator [H] when reassemb ling.

6. Remove the transfer wheel [I], spacer [J], pin [K] and bushing [L] (1

C-ring).

7. Slide the wheel shaft [M] towards the front and remove the roller drive

belt.

17

Sorter

Page 19

BIN GUIDE LUBRICATION 1 May 1993

12.BIN GUIDE LUBRICATION

A

B

A

B

C

B

C

B

C

B

C

Grease 501

[A]

C

Grease 501

[B]

[B]

1. Remove the lower paper guide. (See Roller Drive Be lt Rep lacement

section.)

2. Remove all bins [A] from the bin guide s [B] .

3. Apply Grease 501 to the groo ves of the bin gu ide s.

NOTE: There are three kinds of bin s. Therefore, when installin g the bins,

be sure that they are installed in the correct order.

18

Page 20

1 May 1993 BIN GUIDE LUBRICATION

Table of Contents

SPECIFICATIONS 1

COMPONENT LAYOUT 2

ELECTRICAL COMPONENT DESCRIPTI ONS 3

OVERALL MACHINE CONTROL 4

BASIC OPERATION 5

EXIT ROLLER DRIVE 6

ROLLER DRIVE MECHANISM 6

ROLLER DRIVE CIRCUIT 7

BIN DRIVE 8

BIN DRIVE MECHANISM 8

BIN DRIVE CIRCUIT 10

MISFEED DETECTION 11

INSTALLATION PROCEDURE (for Mach ine Code A110/A111) 12

ACCESSORY CHECK 12

INSTALLATION PROCEDURE 13

PREPARATION FOR TRANSPORTATION 16

ROLLER DRIVE BELT REPLACEMENT17

BIN GUIDE LUBRICATION 18

19

Sorter

Loading...

Loading...