Page 1

Page 2

-

12 . CS1020

-

12-1 Unpacking Procedure

12-2 Accessory Check

12-3 Removal of Shipping Retainers

12-4 Checking Points 12-

12-5 Installation Procedure

123 Operation Check

1

2-7 Adjustment and Replacement

............................................................................................................................................

.....................................................................................................................................

............................................................................................................................

.............................................................................................................................................

............................................................................................................................

:

.....

12- 1

12- 2

12-

12-

12-1

12-1

3

6

8

3

4

Page 3

I

12-1.

1)

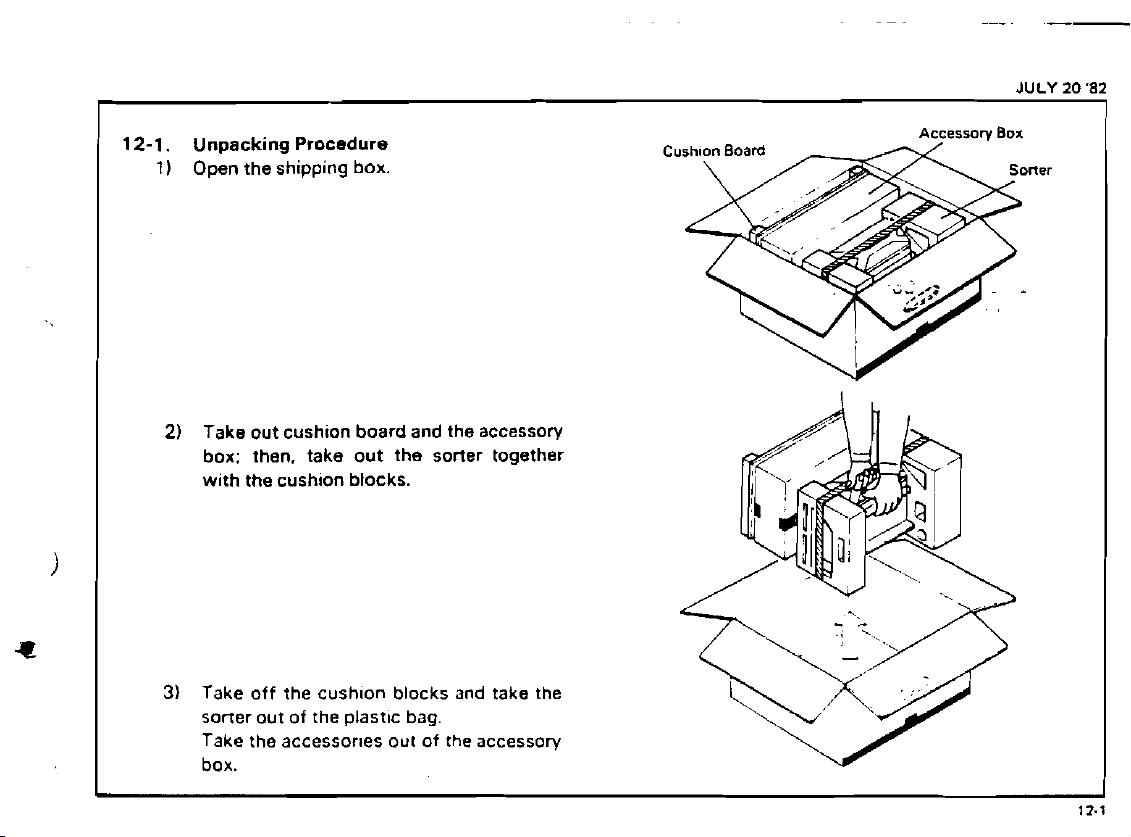

Unpacking Procedure

Open the shipping box.

Take out cushion board and the accessory

2)

box: then. take out the sorter together

with the cushion blocks.

Cushnon

Board

Accemrow

BOX

JULY

20 '82

I

i

3)

Take

off

the cushlon blocks and take the

sorter

out of the plastlc bag.

Take the

box.

accessories

out

of

the accessov

Page 4

SEP

I

30

'82

12-2.

Accessory Check

Check

quantlty and condition of the accessories according to the New Equipment Condition Report or the following list.

-.

1) New Equipment Condition Report

2)

Studs for Connection

3)

Knob Screw

41 Signal Cable

5) 12P Harness

61

10 Standard Bins and 1 Interrupt Bin

71 Orig~nal Receiver

8)

Philips Screw w~th Flat Washer

91 Envelope for NECK

101 Installation Procedure

1 11 Connector Holder

121 Pan Head Screw

...................................................

........................

.................................................

.................................

..

....................

I1

15V only)

........................................

M4

x

6

...........................

.........

...

..............

.............

Page 5

JULY

20 '82

-

4

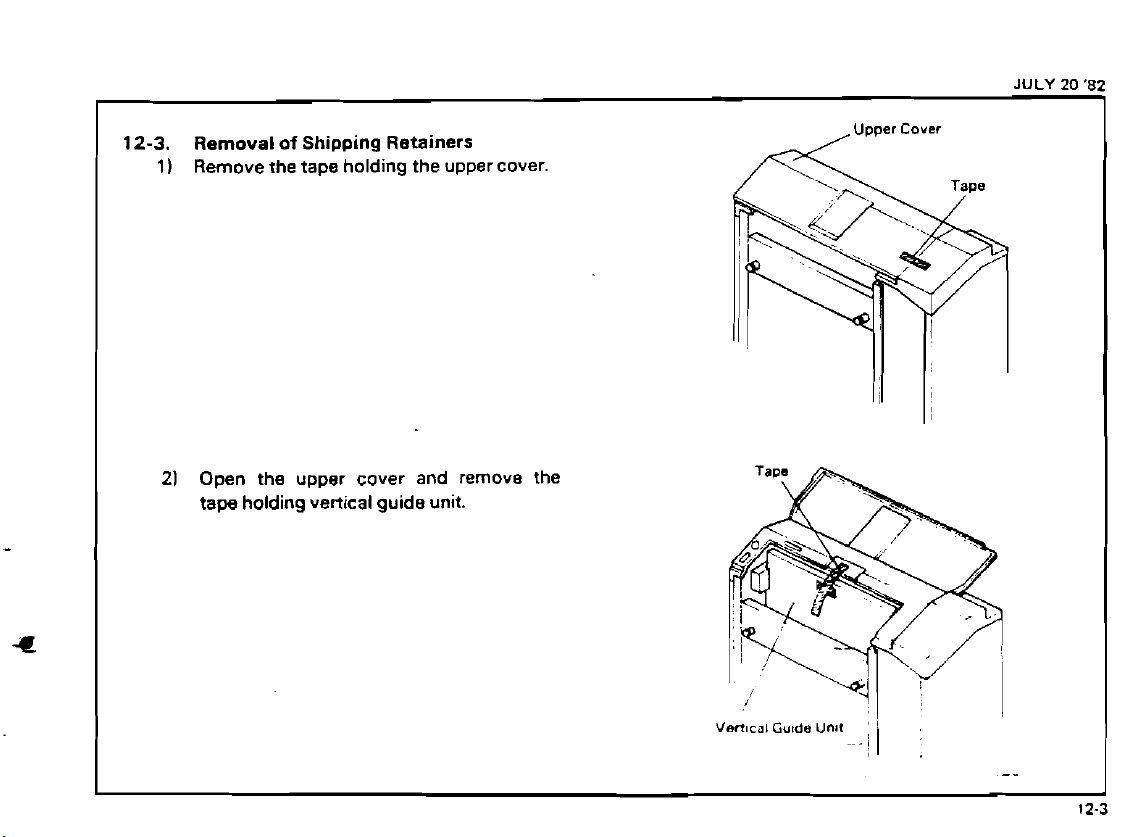

12-3.

Removal

Remove the tape holding the upper cover.

11

Open the upper cover and remove the

21

tape holding vertical guide unit.

of

Shipping Retainers

VBR~CQI

Gutde

Unar

I

-/I

;

-.

12-3

Page 6

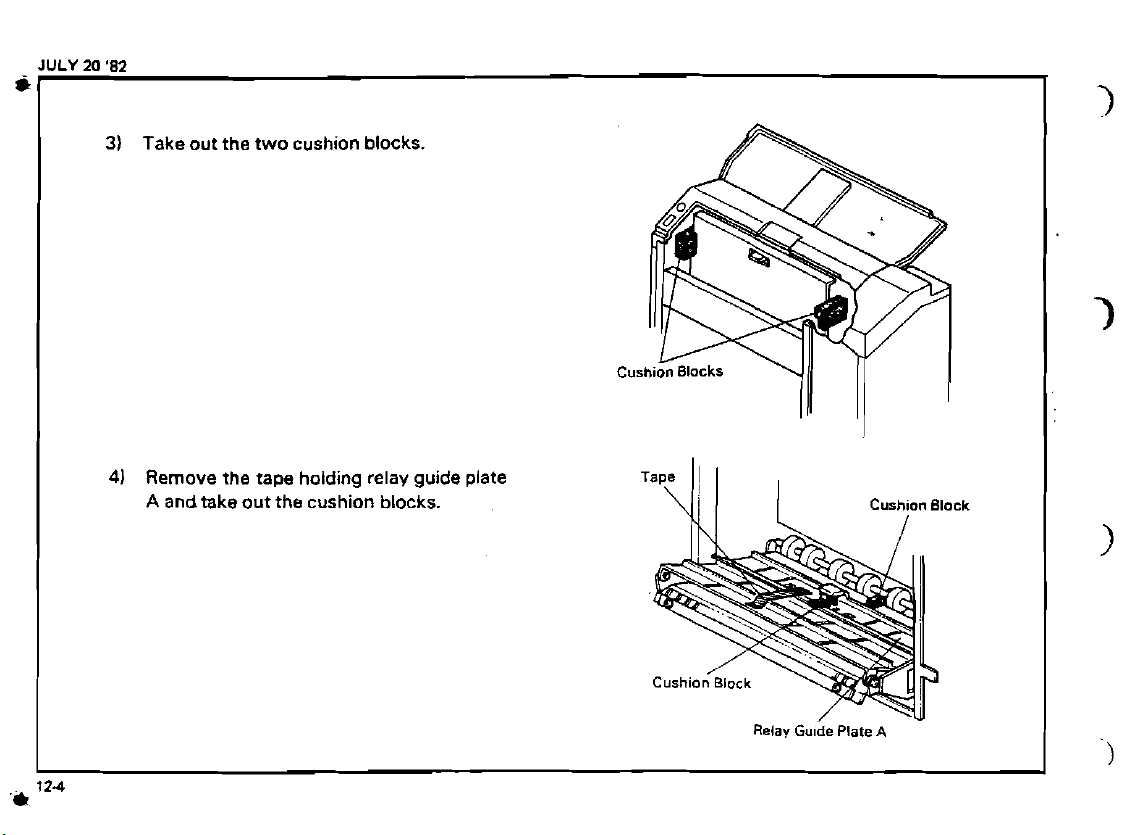

41

Remove the tape holding relay guide plate

A

andtake

out the cushion blocks.

Page 7

Page 8

SEP

30

'82

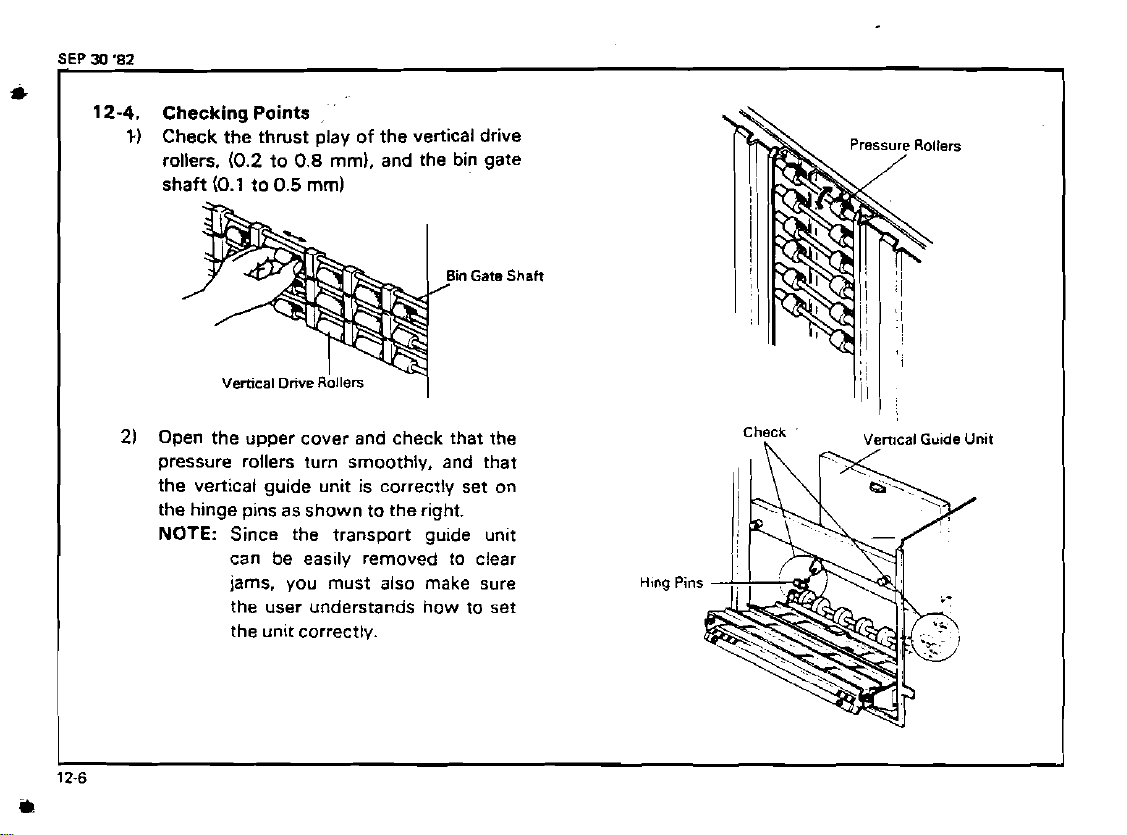

12-4.

21

Checking

Check the thrust play of the vertical drive

1)

rollers.

(0.2

Points

to

0.8

,

'

mm),

and the bin gate

Open the upper cover and check that the

pressure rollers turn smoothly. and that

the vertical guide unit is correctly set on

the hinge pins as shown to the right.

NOTE:

Since the transport guide unit

can be easily removed to clear

jams, you must also make sure

the user understands how to set

the unit correctly.

in

Gata

Shafi

Hlng

Pins

leal

Guide

Unit

12-6

Page 9

3)

Visually check that the bin gates do not

protrude into the paper path.

(Gap

A

must be 1 to

Check that the bin gates pivot smoothly.

4)

1.5

mm)

Page 10

12-5.

2)

Installation Procedure

1)

Remove the four plastic caps from the

docking holes.

NOTE:

Screw in the lower mounting studs.

If the

machine, remove the original receiving tray and reinstall two

screws.

OF10

is mounted on the

Page 11

4)

Remove the cover plate from the connector

bracket.

5)

a).Bend down C156, C157, and RAY108

on the copier main PCB as shown to the

left.

b).Connect the 18P adapt harness to

CN402 o the interface PCB.

c).lnstall the interface PCB to CN106 on the

copier main PCB.

d). Bind the 18P adapt harness to the harness

from CN103 with a nylon fastener.

e).Mount the connector for the signal cable

onthe connector bracket as shown to the

left.

Note:

-

Sorter

6) Take off the upper cover and the front cover

of the

Triangle mark on both the

connector and the connector

lock plate should be pos~tioned

upward.

-

sorter.

.

2

screws

3

screws

2

screws

Cover Plats Conmtor

lnterfacd PCB

IBP

Adapt

Canneclo<

Harness

Lock

"

Plate

.:

SEP

3

'82

racket

Cop!er

Ma~n

PCB

'-..

Nvlon Fastener

12-9

Page 12

JULY

20

'82

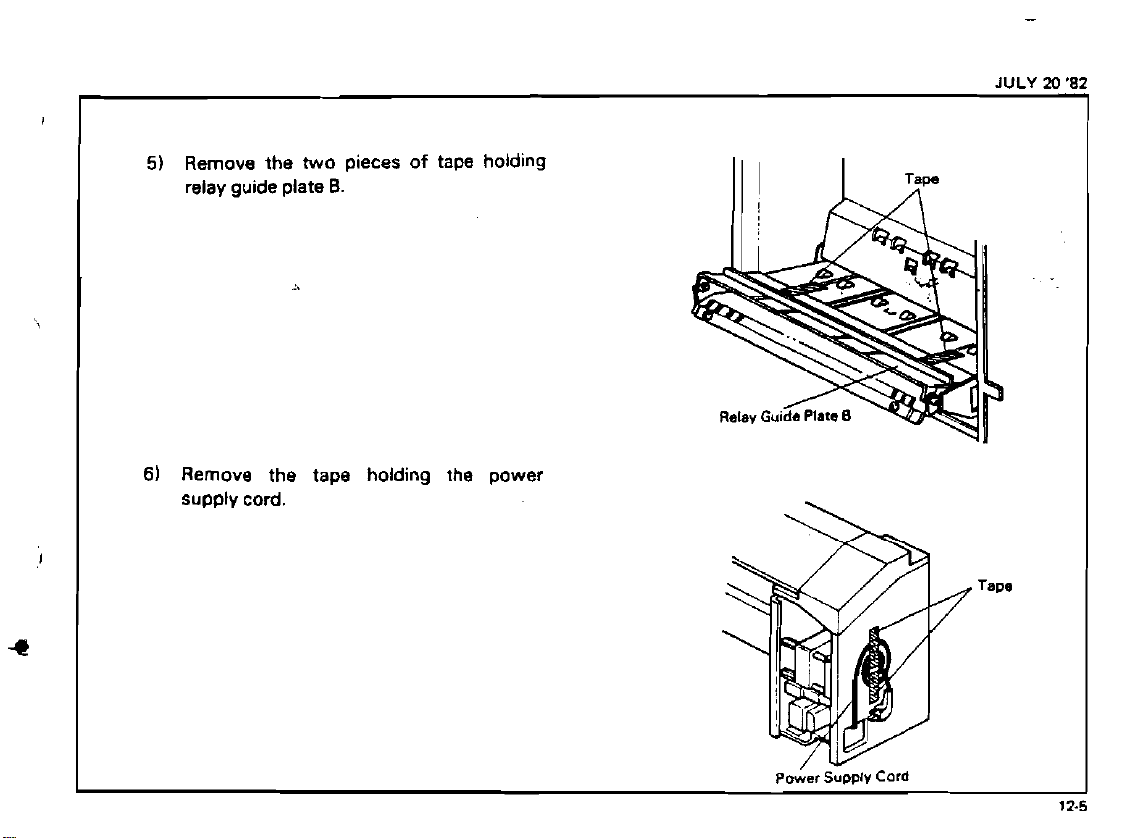

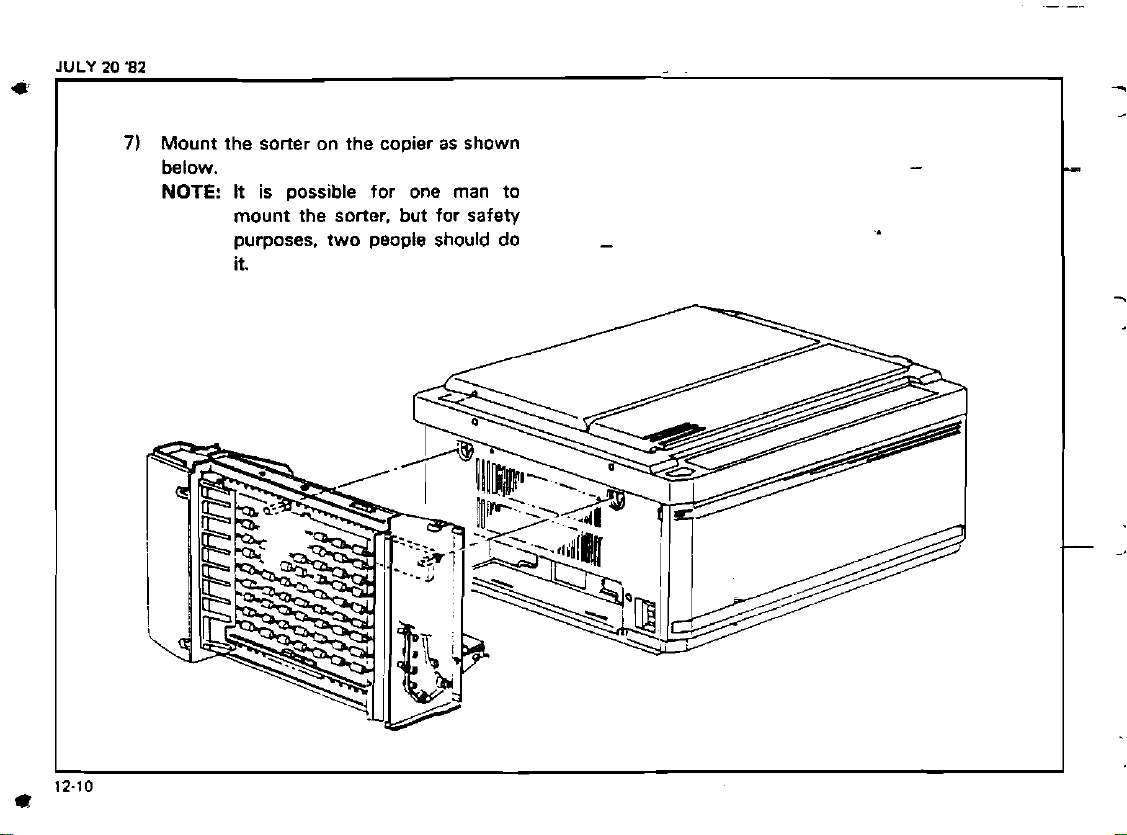

71

Mount the sorter on the copier as shown

below.

NOTE:

It is possible for one man to

mount the sorter, but for safety

purposes, two people should do

it.

-.

-

>

Page 13

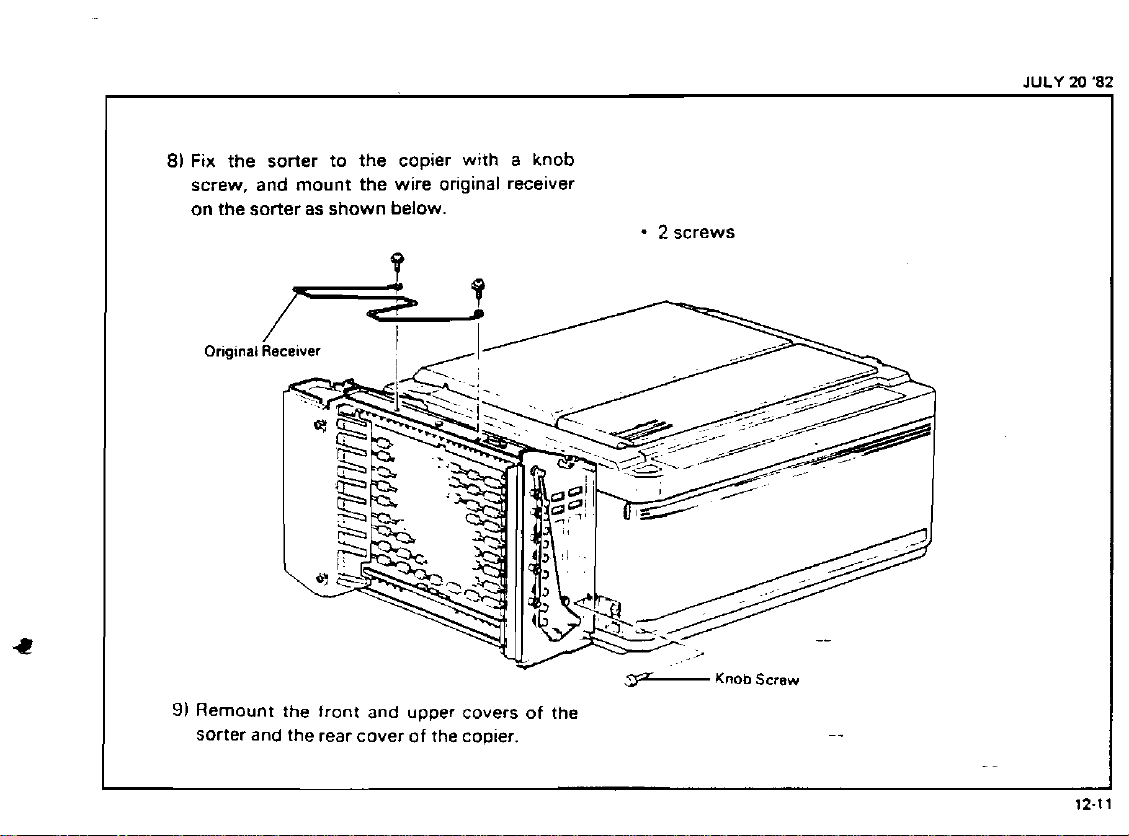

81

Fix

the sorter to the copier with a knob

screw, and mount the wire original receiver

on the sorter as shown below.

-

2

screws

JULY M '82

91

Remount the front and upper covers of the

Sorter and the rear cover of the copier.

Knob

Sctsw

Page 14

SEP

J)

'82

10)

After confirming that the main switch is

off, connect the signal cable between the

copier and sorter, and plug in the sorter

and install the connector holder.

11)

Set the bins from bottom to top starting

with the interrupt bin. Make sure each bin

is fully set as shown to the right.

NOTE:

The standard bin without untistatic brush should be mounted

in the 10th bin position.

Stanaard

Bins

0th

>

1

Bin

Page 15

SEP

30

82

12-6.

2)

3)

4)

5)

6)

7)

8)

Operation Check

Tum on the main switch.

1

)

Press the sort and stack keys and check

that the each indicator turns on correctly.

Insert a sheet of paper into the first bin.

Press the sort key. The print key should

change from green to red.

Then take out the sheet. The print key

should change back to green.

Repeat steps 3 and 4 using the stack key.

Open

the sorter cover. The check sonar

indicator

i

<

)

should light.

Press the son key and then enter 11

copies. The print key should change from

green to red.

Press the stack key and enter 41 copies.

The print key should change from green

to red.

CAUTION: Do not remove the

cable without first turning off

main switch.

s~gnal

.,:;

-

-,*.

.

*,

.

.

..

. .

-

?

d

.

~

12-13

Page 16

1

12-7.

Adjustment and Replacement

-

Bin Copy Sensor Adjustment

1.

Operate the copier in free run mode (DIP

SW100

minutes. (To allow

up.)

2. Confirm that there

3.

Check the voltage of the sensor signal by

connecting the hot line of the tester to

the rear side of

to CN212-2

Adjustment Standard:

(LED1 05: OFF)

4.

Adjust with VR2.

5. Place a sheet of translucent paper in a bin.

6.

Check thevoltage.

Adjustment Standard: Less than

(LED1 05: ON)

NOTE:

#l.

-

on the main PCB) for three

the sensors to warm

is

no paper in bins.

"R2", and the neutral line

(red. ground).

+

7.5 to + 8.OV

+

2.OV

LED105 w~ll light when the

sensor

than +5.95V.

s~onal voltaoe

-

-

IS

less

Jam

Sensor

Bin

CO&

I

Signal

Sensor

Signal

GND

(Redl

CNZ12

I

Page 17

I

-

Jam Sensor Adjustment

1. Operate the copler in free run mode (DIP

SwlOO

minutes.

up.)

Confirm that three is no paper in bins and

2.

between the vertical drive rollers.

Check the voltage of the sensor signal by

3.

connecting the hot line of the tester to

the rear side of

to

CN212-2 Ired. ground).

Adjustment Standard:

(LED1 04: OFF)

4. Adjust with VRl.

Place a sheet of translucent paper in a bin.

5.

6.

Check the voltage.

Adjustment Standard: Less than

(LED1 04: ON)

NOTE: LED104 will light when the

-

#l.

on the main PCB) for three

(To allow the sensors to warm

"Rl", and the neutral line

+

7.5

to + 8.OV

+

2.OV

sensor signal voltage is less

than

+5.95V.

1

11

SEP

30

'82

Page 18

-

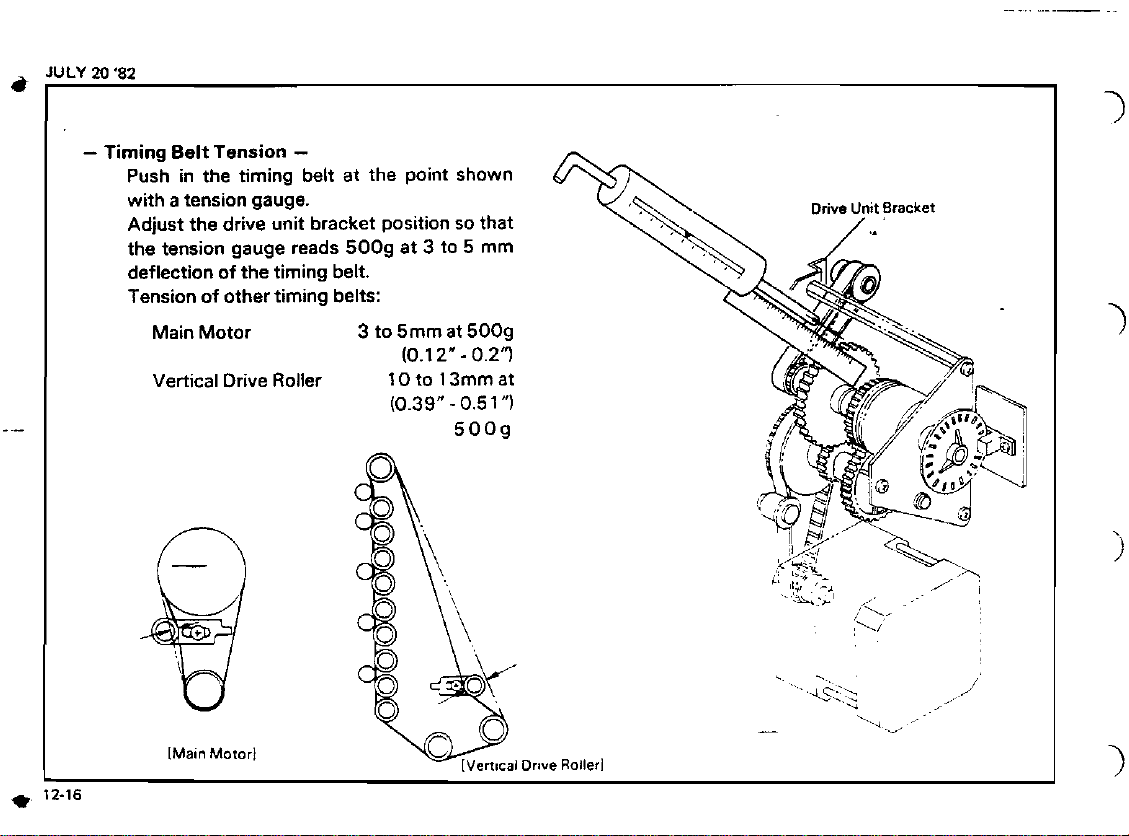

Timing Belt Tension

Push in the timing belt at the point shown

with a tension gauge.

Adjust the drive unit bracket position so that

the tension gauge reads

deflection of the timing belt.

Tension of other timing belts:

Main Motor

Vertical Drive Roller 10to 13mmat

IMam

Motor1

-

5009 at 3 to 5 mm

3

to 5mm

(0.39"

(0.1

at

5009

2"

-

-

0.5

5009

0.2'7

1")

..

...

....

.L~::\

..

.

v

-

.

_.

.,

/

Page 19

.

.

,

,

-

Gate Solenoid Replacement

1)

Take off the top cover and rear cover.

21 Disconnect all connectors from the

sorter CPU board.

3)

Remove the CPU board together with

its bracket

'4)

Loosen the three screws securing the

solenoid bracket.

5)

Unhook the solenoid spring.

6)

Replace the solenoid and reassemble

the sorter.

NOTE:

1.

Check the thrust play of the

bin gate shaft

mml.

2.

Check that the bin gates

pivot smoothly.

/:I

-

'I

(0.1

to

.I

0.5

SEP

30

'82

,.

4

screws

2

screws

Page 20

JULY

20

i

1

'82

-

Sponge Roller Replacement

1)

Remove all bins and take the sorter

off of the copier.

2) ~ake off the rear sorter

cover and remove the trans-

former.

3)

Lay the sorter on its side.

4) Remove the upper 4 screws and

loosen the lower

the lower relay guide plate.

5)

Draw the outline of the belt

bracket on the side plate. (This is to

make readjustment easier duringreassembly.)

61

Remove the belt tightener bracket.

7)

Remove the sponge roller drive pulley

and bearing from the front end of the

shaft, and remove the bushing from

the rear end

81

Replace the sponge roller shait.

of

-

2

screws holding

the shaft.

4

screws

2 screws

3

connectors

tightener

*

1

screw

-

1

E-ring each end

-.

Lower

Relay

Guide

Plate

-

I

7

I

Belt

Tightener

,

Bracket

Page 21

I

-

Speed-up Clutch Replacement

I

I

Take off the top cover and rear cover.

2)

Draw the outline of the drive unit

bracket on the side plate.

31

Loosen the three screws securing the

drive unit bracket, and take off the

wire clamp bracket.

41

Uncouple the drive motor, speed-up

clutch, and pulse generator connectors.

Lift off the drive unit.

51

61

Remove the pulse generator

and perforated disk.

-

PCB

-3

screws and 4 screws

-

1

screw

1

allen screw

JULY 20 '82

I

.-

Page 22

I

-

Reassembly Notes

7)

Take off the two E-rings and bearings

shown. (Don't lose the small bearings)

8)

Remove the three screws holding the

stay plate and take off the

clutch together with the shaft and

plate.

9)

Take off the belt pulley

and the large

10)

Remove the collar

and stay plate.

11

Take off the inside collar.

12)

Install

assemblv.

(The replacement part consists of the

clutch, shaft. and high speed gear.)

geai.-

a

new speed-up clutch

speed up

'

1

1

.

1

and

-

-

1)

Make sure to mount the stay plate

with the pulse counter mount pointing

outward.

2)

The large (low speed) gear must be

mounted with the one way clutch

facing inward.

31

Mount the perforated disk with the

Allen screw side in, and tighten the

Allen screw on the flat surface of the

shaft.

allen screw

E-ring

ailen screw

2

screws

1

E-ring, 1 allen screvr

4)

Do not tlghten the Allen screw of the

timing belt pulley until after

ing the shaft bearings.

reinstall-

2.20

Page 23

-

Cover Safety Switch Replacement

1)

Take off the top cover and rear cover.

2)

Take off the switch bracket.

31

Remove the four wire clamps from

the safety switch harness.

41

Uncouple the five connectors.

51

Cut off the five wire binders holding

the harness, and replace the safety

switch assembly.

-

-

3

screw and 4 screws

2

screws

-

4

screws

JULY

20

'82

NOTE:

When mounting the new switch

harness. make sure the wire

clamps are oriented as shown in

the figure to the right. If they are

mounted in the other direction.

the upper cover cannot be

mounted.

12-21

Loading...

Loading...