Page 1

SECTION

11

Page 2

11.

DF-10

1.

Unpacking

2.

Installation Procedure

3.

Feed Belt Removal

4.

Lift Switch Adjustment

....................................................................................................................

...................................................................................................................................

-

...........................................................................................................................................................

..................................................................................................................................................

::

................

-

'11-1

1

1-2

1 1-8

1

1-9

Page 3

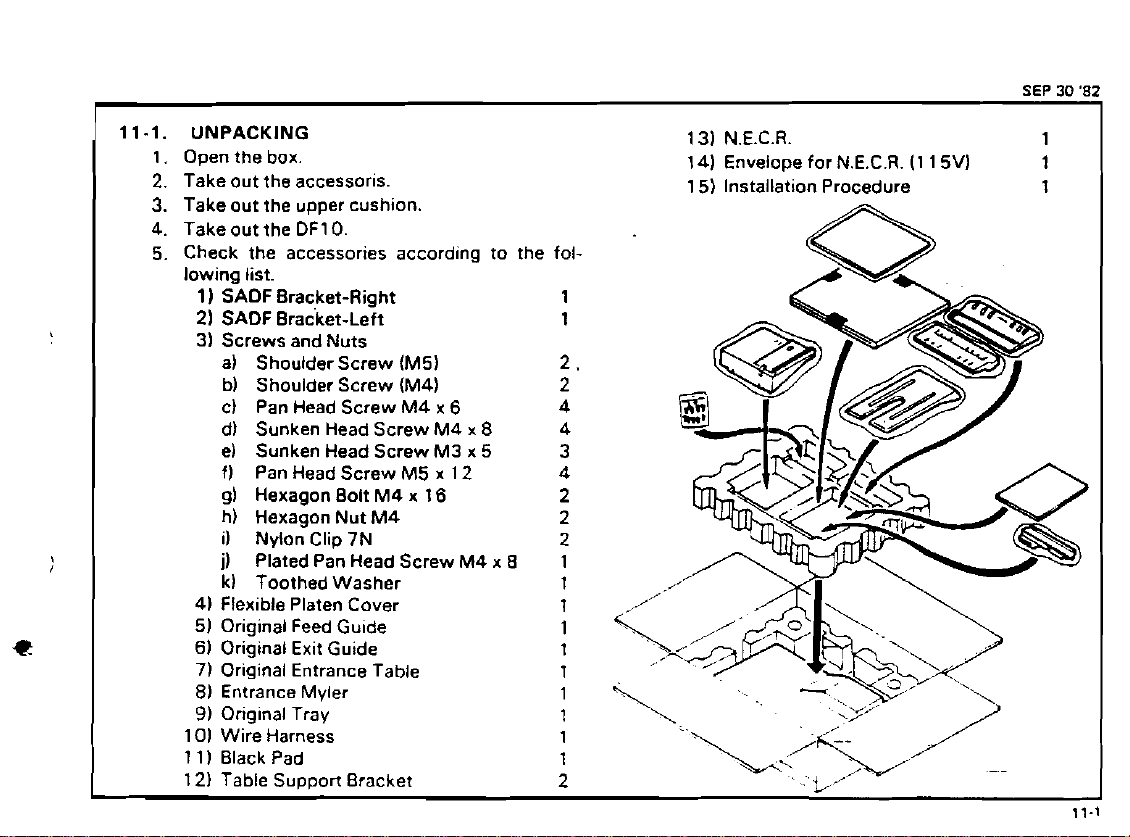

I

UNPACKING

Open the box.

Take out the accessoris.

Take out the upper cushion.

Take out the

Check the accessories according to the fol-

lowing list.

1)

2)

3)

4) Flexible Platen Cover 1

5) Original Feed Guide 1

6)

71 Original Entrance Table

8)

9)

1

Ol

1

1) Black Pad

I

121 Table Suooort Bracket

DF10.

SADF

Bracket-Right

SADF

Bracket-Left 1

Screws and Nuts

a) Shoulderscrew (M5)

b) Shoulder Screw (M4) 2

C)

Pan Head Screw M4

d) Sunken Head Screw M4

e) Sunken Head Screw M3 x 5 3

f)

Pan Head Screw M5 x 12 4

gl Hexagon Bolt

h) Hexagon Nut M4

il

Nylon Clip 7N

I)

Plated Pan Head Screw M4

k)

Toothed Washer

Original Exit Guide 1

Entrance Myler

Original Tray

Wire Harness

M4

x

6

x

8

x 16 2

x

4

4

2

2

8

1

2.

1

1

1

1

1

SEP

13) N.E.C.R. 1

14) Envelope for N.E.C.R.

15) Installation Procedure

(1

15V) 1

1

30

'82

I

Page 4

SEP

30

1

'82

i

11.

1.

2.

3.

4.

5.

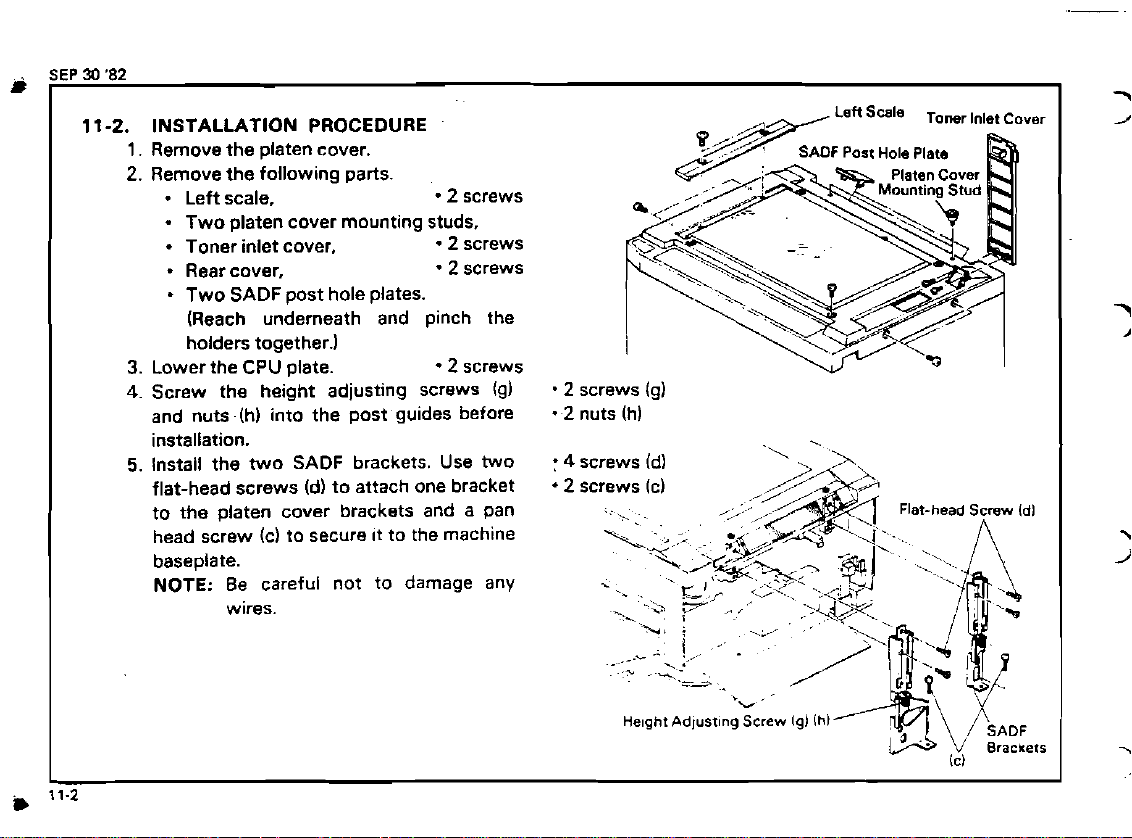

INSTALLATION PROCEDURE

Remove the platen cover.

Remove the following parts.

.

Left scale.

Two platen cover mounting studs,

.

Toner inlet cover.

Rear cover,

-

Two

SADF

post hole plates.

(Reach underneath and pinch the

holders together.)

Lower the CPU plate.

Screw the height adjusting screws (g)

and nuts (h) into the post guides before

installation.

Install the two

flat-head screws

to the platen cover brackets and a pan

head screw

baseplate.

NOTE: Be careful not to damage any

wires.

SADF

brackets. Use two

(d) to attach one bracket

(cl to secure it to the machine

2

screws

2

screws

2

screws

2

screws

-

2

screws (g)

2

nuts (h)

:

4

screws (dl

2

screws (c)

.

. ..

. .

-...

ne~ght

-b

,

r4./

7

!

Adjusting

*,

.

"

,_.

,'

Screw

lgl

'

ihl

Page 5

6.

Install the entrance myler.

NOTE:

7.

Install the black pad on the left of the

upper

8.

Replace the

shown with shoulder screws.

9.

Fix the original exit guide at the left scale

position.

NOTE:

10.

Mount the original feed guide on the

hinge

NOTE

1

1.

Mount the original entrance table together

with the table support bracket on the

right side of the

(Use the two long

Ing the r~ght slde of the top cover

12.

Install the or~g~nal tray (Use the two long

M4

the top cover)

The stainless part of the entrance

myler must touch the exposure

glass holder.

cover at the position shown.

two

t~ss head screws

Confirm that the black pad is

placed just under the hole on the

exit guide.

of

the toner inlet cover.

Check that the toner tank cover

switch is actuated when the original feed guide is lowered.

copler.

M4

truss screws hold-

truss screws securlng the left s~de of

Ongtnal

Exn

Gundo

Black

Pad

2

screws (b)

I

\

~~porureGlass

\

€roosure

\

Glass

Onglnal

/

Holder

/

Feed

/

Guld,

u

Page 6

i.

SEP

#)

'82

13.

Install the SADF by inserting the posts

into

the SADF brackets.

14.

Lower the SADF.

.4

15.

Lightly fix the four SADF post screws If).

16.

Remove the SADF cover.

screws If)

4

screws

-.

17.

Remove the feed belt: (See page

and reinstall left and rlght locktng plates.

1

1-8).

,'

Page 7

18.

Level the

a.

Front Side

The two nylon spacers on the front side

of the

mm

glass.

To adjust the level, move the magnets up

or down slightly.

b. Rear Side

With the height adjusting screws, adjust

the height

clearance between the srays and the

exposure glass is the same on the rear

side as at the front.

SADF

10.08"

SADF

as follows.

should be level and

zt

gtA$lfrom the exposure

of

the rear side so that the

A = 8.

C

=

0.2

D.

k

SUvs

A

-

Exposure Glass

Exposure Glass

Page 8

SEP

30

'82

Confirm that the

c.

On the

the spacers on either side of the original

entrance guide must be the same.

On the left side.

lower exit roller movement as the upper

exit rollers contact them. The amount of

movement should be equal.

19.

Tighten the

20.

Check the front and rear clearances betweeo-the stays and the exposure glass

on both right and left sides again.

NOTE:

21.

If

repeat step

then. install the feed belt.

&ht iide, the clearances between

When tightening the post

screws. rear side- of the clearances will sometimes slightly

change.

the

SAOF

SADF

is level

observe the amount of

SADF

post-screws.

level becomes inproper.

17.

18

and

19

agatn. and

=

Spacer

Upper

Exit

-.

Roller

Page 9

22. Lift the

ness through the hole in the

SADF.

Then. insert the

SADF

SADF

plate.

har-

23. Connect the harness to CN5 on the Main

CPU board and to

CN201 on the

SADF

board. 2P connector

24.

Connect the ACl

OOV

power line. Then.

screw one end of the ground wire to the

SADF,

and the other end to the copier

frame.

25. Tighten the

nylon clips, while lifting the

SAOF

harness with two 7N

SADF.

'

Two 7N nylon clips

2 screws

CAUTION:

If two clamp are installed

while the

SADF

is lowered.

the harness will be pulled

when the

SAOF

is lifted, resulting in damage of the

harness.

(c)

N

Clip

AClOOv

Screw

(il,

Screw

iil

lcl

Line

Page 10

SEP

30

'82

*w

26. Check copier registration before using

the SADF and adjust it if

Adjustment Standard: 2.0

27.

Check SADF registration with the test

sheet as shown

test sheet for five times.

Adjustment

Standard: using the SADF when the

necessaw.

+-

2.0 mlm

in

the right, inserting the

1.5

-c

2.0 mm in average

copier registration is

mm.

+

2.0

10mm

-

Lead Edgn

Registrat~on

LDGJAJ

Sida

to

Side

Regstration

and Skaw

200

mm

Page 11

28.

Adjust registration using

the SADF CPU board according to the

right table.

NOTE:

29.

Mount the SADF cover.

30.

Remount the rear cover of the copier.

31.

Install shoulder screws la1 in the platen

cover stud holes.

NOTE:

32.

Make a final reg~stration and copy Image

check.

33.

Fill out the

tlon Report.

When SW

tion will increase because the DF

motor tums off early.

The flexible platen cover will

be set to these shoulder

screws when book

are made.

DF-10

New Equ~prnent Condi-

DIP SWlOO

#4

is off, the registra-

on

coples

4

screws

2

screws

.

2

screws (a)

#1

#2

1

0

#3

:ON

:

OFF

Change

&

Av

Registration

DIP

SW.

Page 12

*

SEP

I

30

'82

11-3.

FEED BELT

1.

Remove the

2.

Loosen the right locking plate screws and

turn it out

3.

Slide the left locking plate to th right.

REMOVAL

SADF

cover.

4

screws

-

1

screw

SADF

I

Cover

4.

Take

off

the two rubber rings.

5.

Rotate the belt release bracket clockwise.

and slide

off

the feed belt.

.

1

screw

'-4

..I

---

Left

Locking

Feed

Plate

Belt

.-.

,A

.A

Page 13

JULY

20

'82

I

11-

4.

LIFT SWITCH ADJUSTMENT

1.

Check that "Insert Originar indicator

lights.

2.

Lift the SADF and check that "Insert Original" indicator goes off when the distance

between the original stopper and the

bonom

mm and 30

Adjust by repositioning the switch.

3.

Confirm that the original inserted indicator

4.

does not light when lifting

of

the feed belt

mm. (0.63" to

is

up

1

.I

I

between 16

89

the SADF.

Loading...

Loading...