Page 1

RICOH

RICOH

FIELD:

PEMOHT

D6CnYXHBRHIE

9

88

oolnc~oA

TEKHHKH

H

FT4060/FP4030

SERVICE

RICOH

COMPANY,

MANUAL

ITD.

Page 2

Page 3

Page 4

1

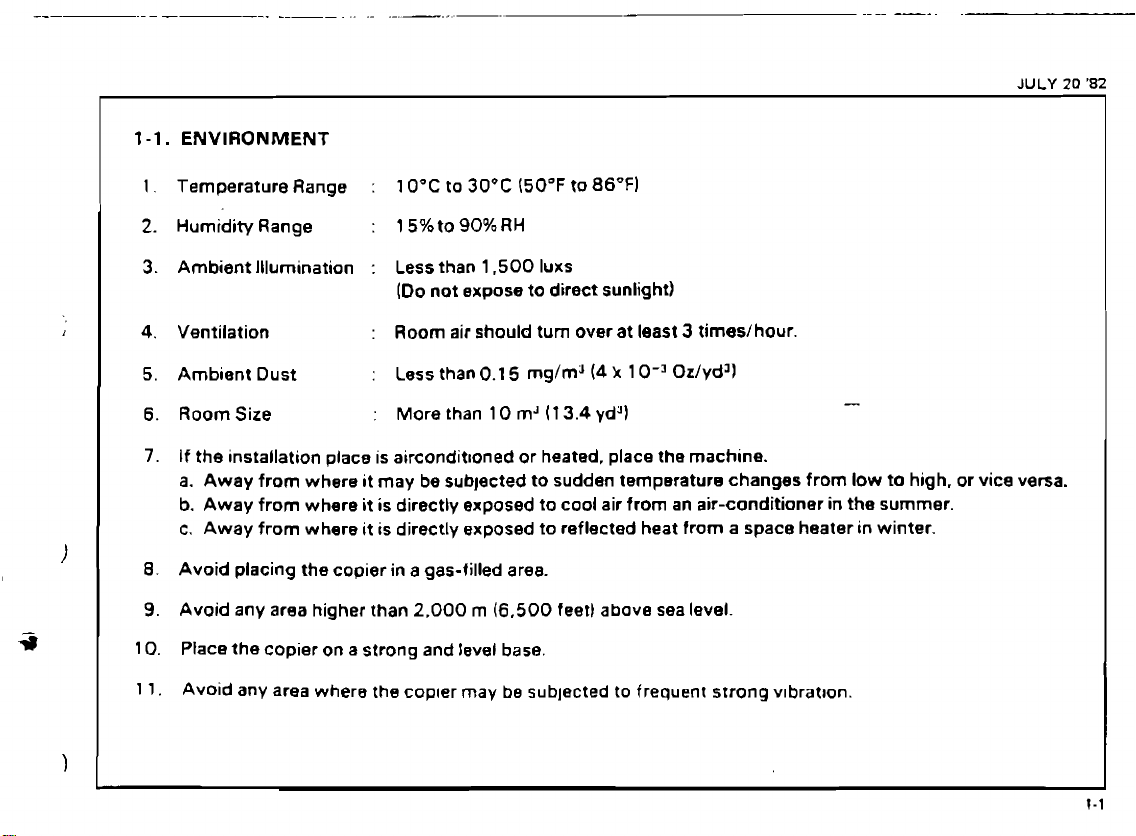

1-1.

ENVIRONMENT

1.

Temperature Range

2.

Humidity Range

3.

Ambient Illumination : Less than 1.500 Iuxs

4.

Ventilation

5. Ambient Dust

6.

RoomSize

7.

If

the

installation place

a.

Away

from where it may be subjected to sudden temperature changes from low

b.

Away from where

c.

Away from where

8.

Avoid placing the copier

9.

Avoid any area higher than 2,000

10. Place the copier on a strong and level

:

10°C to

:

15%to90%RH

(Do not expose to direct sunlight)

:

Room air should

:

Less than

:

More

is

aircondit~oned or heated, place the machine.

it

is directly exposed to cool air from

it

is directly exposed to reflected heat from a space heater in winter.

in

a

30°C

(50°F

0.1

5

mg/m"4

than

10

mJ

gas-filled area.

m

(6,500

base.

to

86°F)

turn

over at least 3 times/hour.

k

1

0-3

Oz/ydJl

(1

3.4

yd4)

an

air-conditioner

feet) above sea level.

-

to

in

the summer.

high.

or

vice

JULY

versa.

20

'82

I

I

I

I

I

1

1.

Avoid any area where the copter may be subjected to frequent strong v~bratron.

Page 5

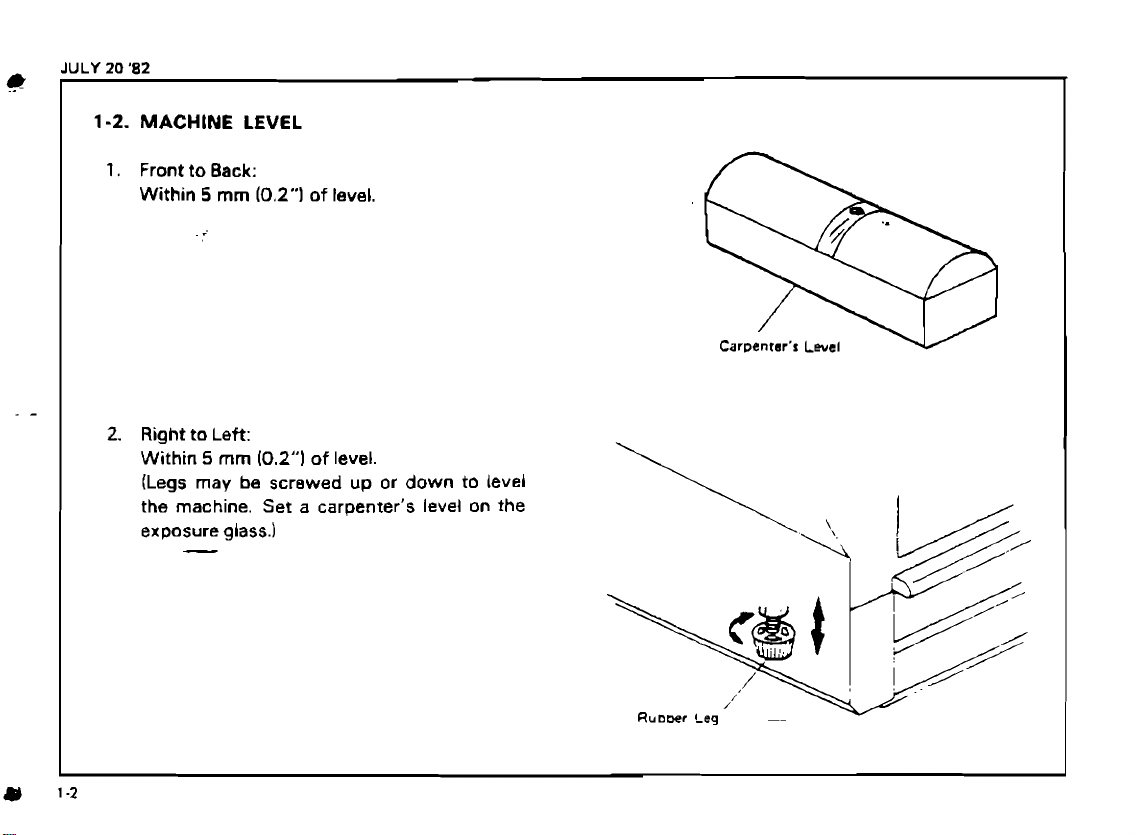

Car~entrr's Level

Page 6

L

'E-

WnWINIW

33VdS

SlN3M13HlfID3U

I

C'I

Page 7

i

JULY

20

'82

1-4.

1.

POWER

Input

1

15V/60Hz

SOURCE

Voltage

Level

:

More

than 12A

220V/50Hz : More than

240V/50Hz : More than

1

lP%~,..c,

,,I

I./\,L,.-

<

2. Permissible Voltage Fluctuation: = 10

3.

Permissible

--'At

least

rn

(1

6.4")

Extension

300V,

long.

30A

Cord:

capacity

7A

6A

and less

%

than

-

5

NOTE:

1.

8e

sure

to

ground the machine.

not connect the grounding wire

gas

pipe.)

2.

Make

sure

the

plug

is

firmly

the outlet.

3.

Avo~d

multi-w~ring.

4.

Do not set

anyrh~ng

on

the

power cord.

(Da

to

inserted

a

in

Page 8

Page 9

,

-

.

-..

,

.-.A,

2~~~?,~.i*A~.

UNPACKI IN^^^.^^;;;^,^:

.,

-r

-.- . -

....

Unpacking

_

,.

-

,

Accessory

-

..

.

-.

.a.

.

8

,

Procedure,LL;:,.

.-+

,

3*,.,,$@;2;i*::

,

,,

.

~l&k.

-

.;?2<?$':

.

-

+

,.;.

.

,A,

-9.-

,

.:-..

.

-a-

2.''

2-!.

_

-.

2-2.

.-

.

:,

...:...

.:&.

'.A*

..<,

.

%'.

c.,

.,-

.-.:

.

:

-

'4

A:,

,.

A,.;

-1;

I

I.

,

?;:,

.,-;,

-:

.

::;!

.......

.--.-... : ........-... L .......

Is;,'

L.

'

.,

.

-

:

,

-,:

:,-

.-,

"

*::I

..-

c.r,+-,

-

a

A?.

,-

--.

Page 10

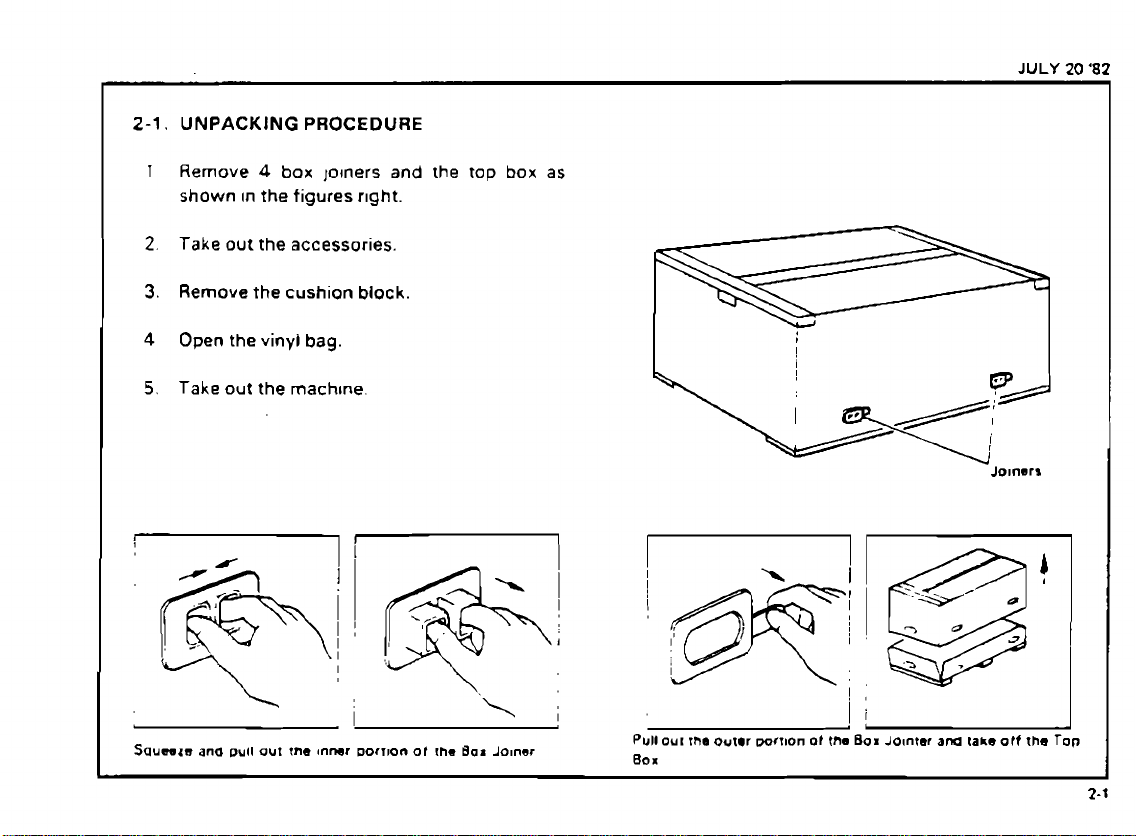

2-1.

UNPACKING

1

Remove

shown

2.

Take

3.

Remove

4

Open the vinyl

5.

Take

PROCEDURE

4

box

lolners

In

the

figures

r~ght.

out the accessories.

the

cushion

block.

bag.

out

the

machtne.

and

the

tap

box

as

JULY

20

'82

I

!

I

I

Jo~nerr

I

?

0

*

Squwzn

ana

pull

out

tne

Inner

I

Dorrron

ot

!he

Bar

Joiner

Pull OUI

80

x

I

the

outer

wrnon

of

the Box

Jointer

am

fake

otf

the

Top

Page 11

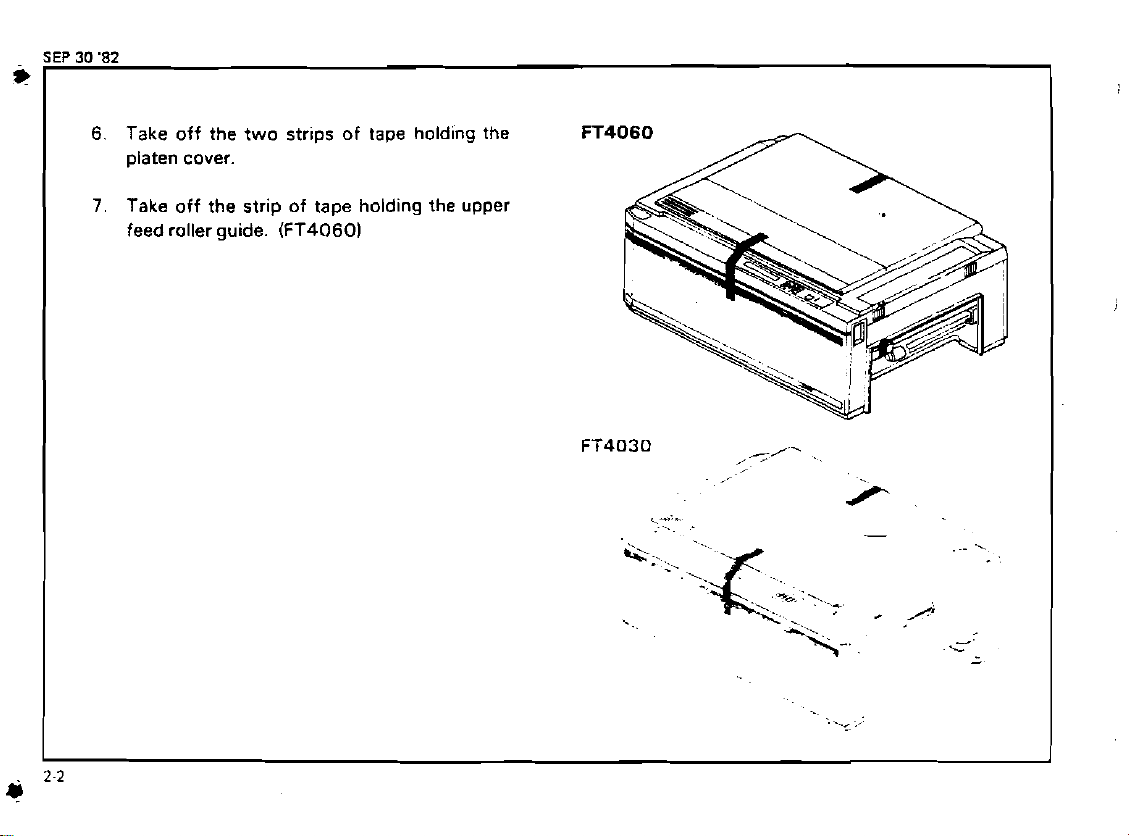

SEP

30

'82

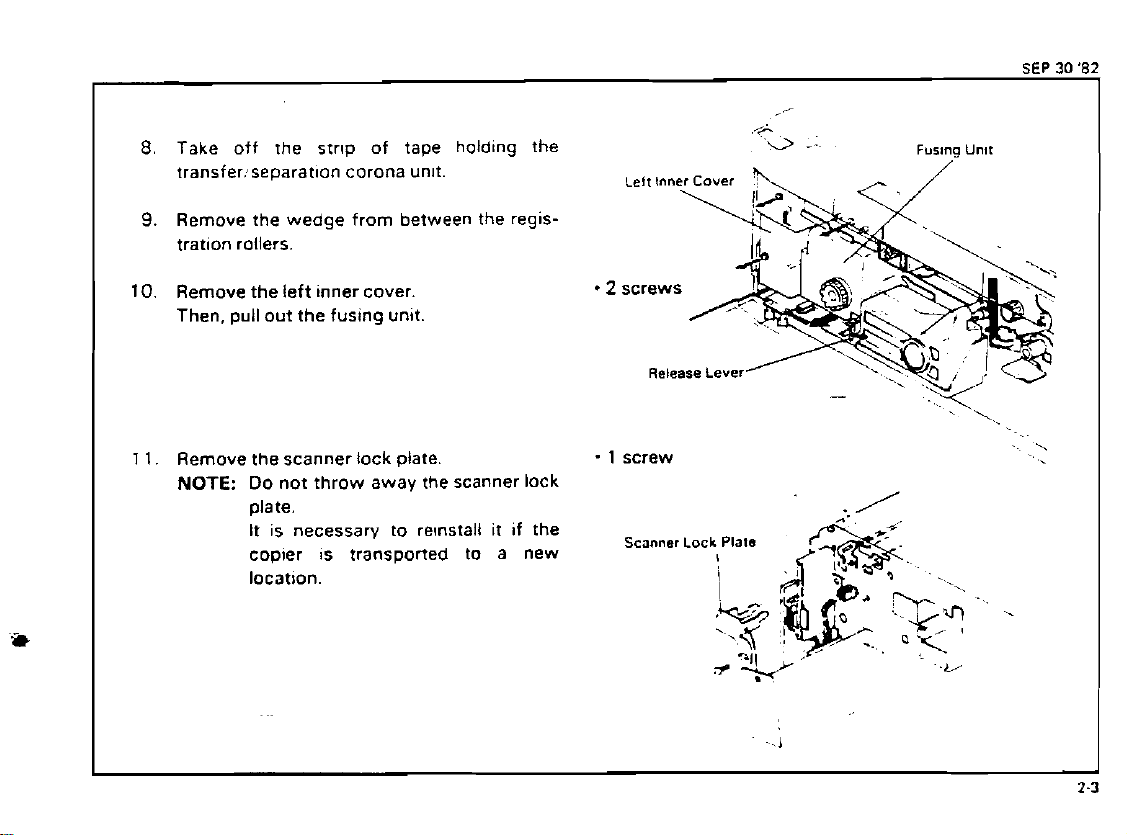

6.

Take off the two strips of tape holding the

platen cover.

7.

Take

off the strip of tape holding the upper

feed roller guide.

(FT40601

FT4060

Page 12

Take off the strlp of tape

transfer:separatlon corona unlt.

Remove the wedge from between the reglstratlon rollers.

Remove the left inner cover.

Then. pull out the fusing unit.

1

1.

Remove the scanner lock plate

NOTE:

Do

not throw away the scanner lock

date.

It is necessary to re~nstall it if the

copier

location.

is

transported to a new

holding

the

-

1

screw

Scanner Lock

Release

Lever

Plats

.I

-

-L/

'..

-.

Page 13

SEP

30

82

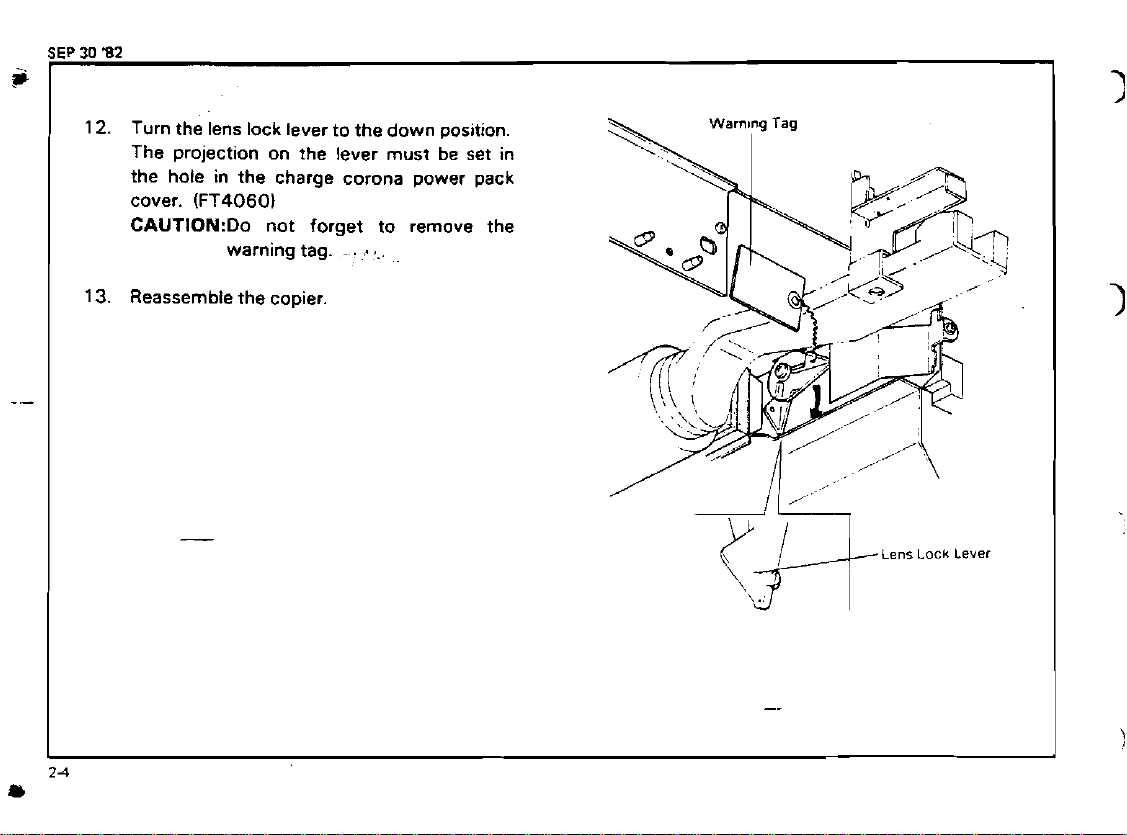

i+

1

12.

Turn the ,ens lock lever to the down position.

The projection on the lever must be set in

the hole in the charge corona power pack

cover.

CAUTI0N:Do not forget to remove the

13.

Reassemble the copier.

(FT4060l

warning tag.

.

.

...

Page 14

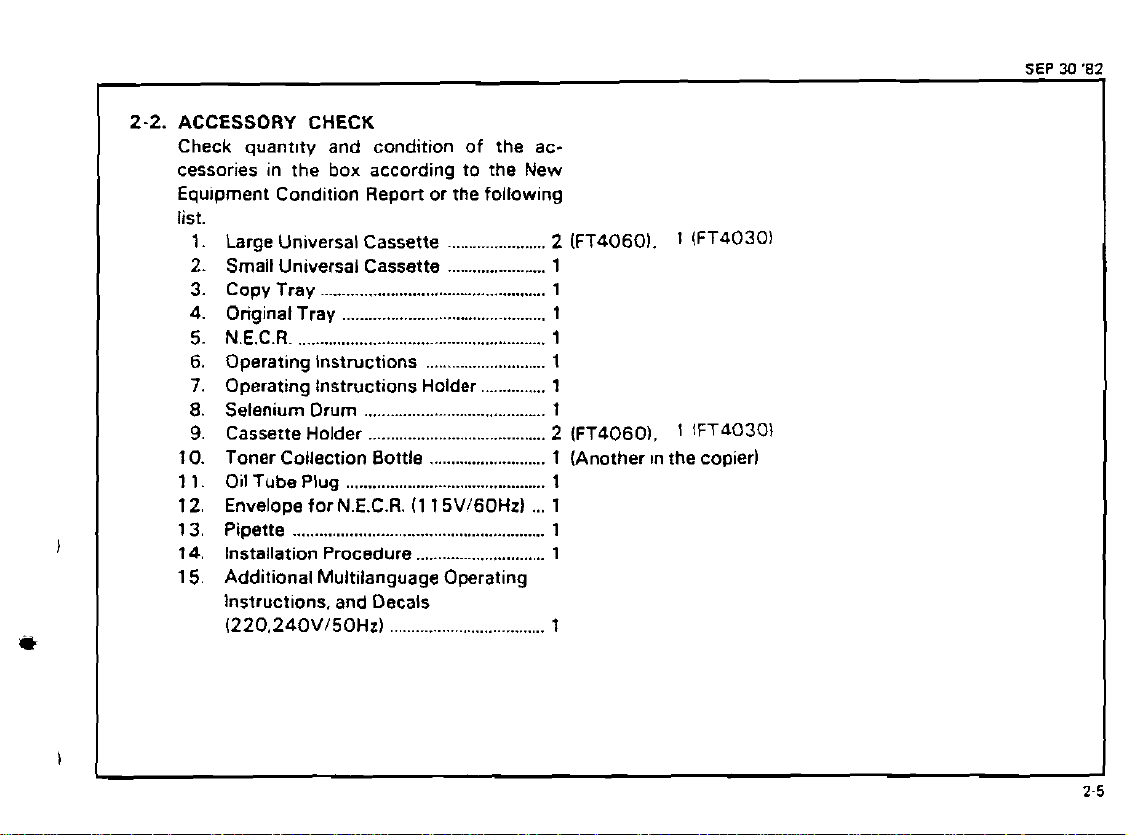

2-2.

ACCESSORY CHECK

Check

cessories in the box according to the New

Equ~prnent Condition Report or the following

list.

10. Toner Collection Bottle

1

1

15. Additional Multilanguage Operating

quantlty and condition of the ac-

1. Large Universal Cassette

2.

Small Universal Cassette

3.

Copy Tray

4.

Original Tray

5. N.E.C.R

6.

Operating Instructions

7.

Operating Instructions Holder

8.

Selenium Drum 1

9.

Cassette Holder

.................................................

..........................................

....................................................

........................................

.......................

.......................

..........................

...........................

1.

Oil Tube

2.

Envelope for N.E.C.R. (1 1 5Vl60Hz)

Instructions, and Decals

1220.240VI50Hz)

Plug

..........................................

....................................

...............

2

(FT40601. 1 (FT4030)

1

1

1

1

1

1

.

2

(FT4060). 1 fFT4030I

1 (Another in the copier)

1

...

1

1

Page 15

.

.,

.

.

.

.

....

.'

,-.-I.

-

.

-.

<

.?,,

.

.

...

-

.

.

,.

.

*..

...

.......

-

?*.

'

..,.

tf-

v

.....

.

.-

-.

-.

..,*,,*:a*J.'.

..

%.

-.

._

.

...

..

..~

.*.

-.

I

I.'

:

*

.'

.,

.

.

........

..-.

Page 16

Page 17

JULY

20

'82

I

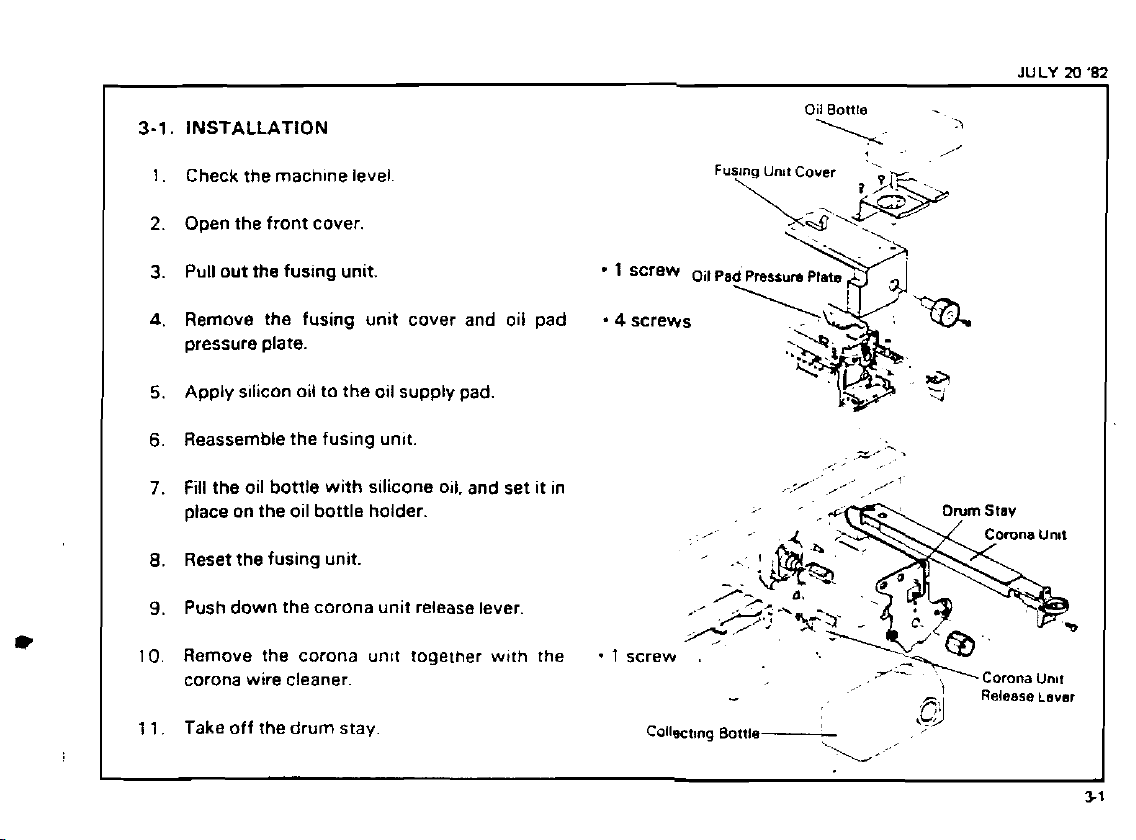

3-1.

INSTALLATION

1.

Check the machfne level

2.

O~en the front cover.

Pull out the fusing unit.

3.

A.

Remove the fusing unit cover and oil pad -4screws

pressure plate.

Apply sflicon oil to the oil supply pad.

5.

6.

Reassemble the fusing unft.

7.

Fill the oil bottle with silicone oil. and set it in

place on the oil bottle holder.

8.

Reset the fusing unit.

Push down the corona unit release lever.

9.

Oil Bottle

,

,..,

\.~

-

'>

.

'

/I

z-

'

.

,

,

/-1

,,

i

I

10.

Remove the corona unlt togelher w~th the

corona wire cleaner.

1 1.

Take off the drum stay.

.

1

screw

Collscttng Bottle

.

Corona

-

,

,L9

\

\;,'

Release

Unnr

Lavar

Page 18

+

JULY

20

'82

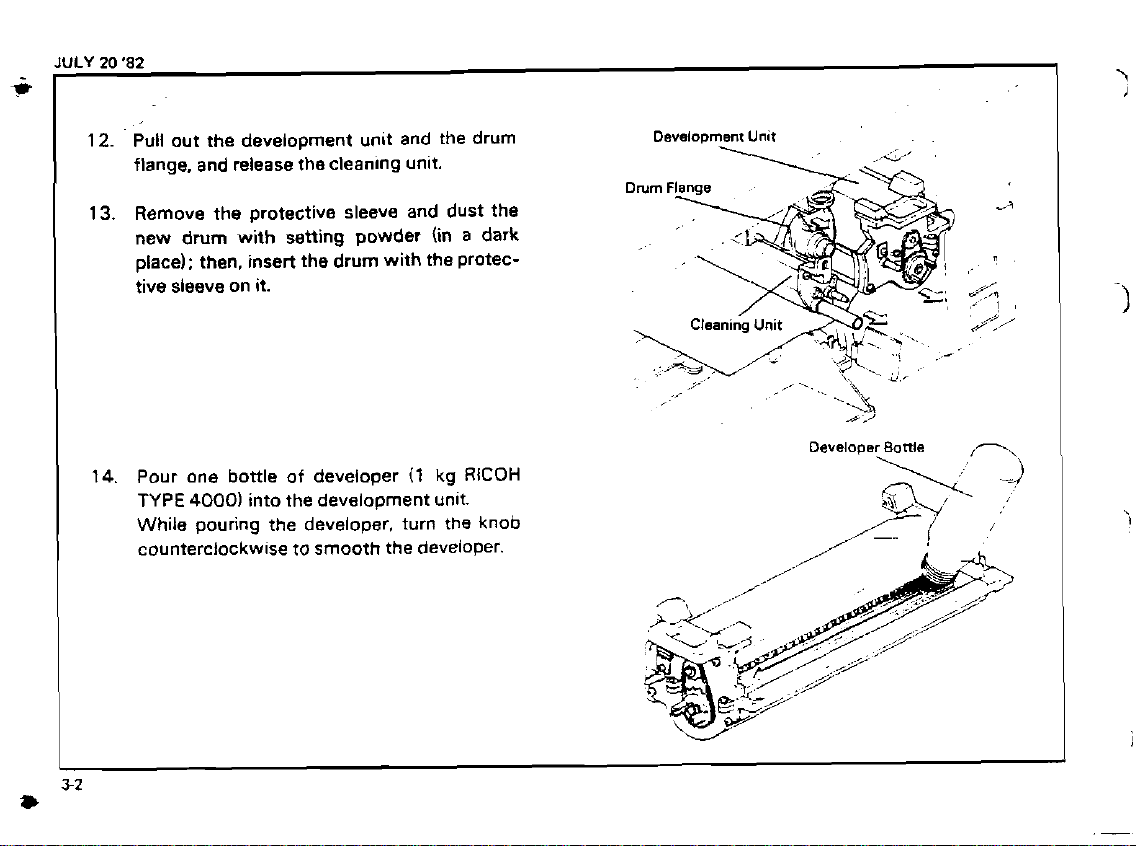

Pull out the development unit and the drum

12.

flange, and release the cleanlng unit.

Remove the protective sleeve and dust the

13.

new drum with setting powder (in

place): then, insert the drum with the protective sleeve on it.

14.

Pour one bottle of developer

TYPE

4000)

into the development unlt.

While pouring the developer. turn the knob

counterclockwise to smooth the

(1

a

dark

kg

RlCOH

deveioper.

Development

Unit

s:'

Developer

Battle

,

I

Page 19

JULY

20 '82

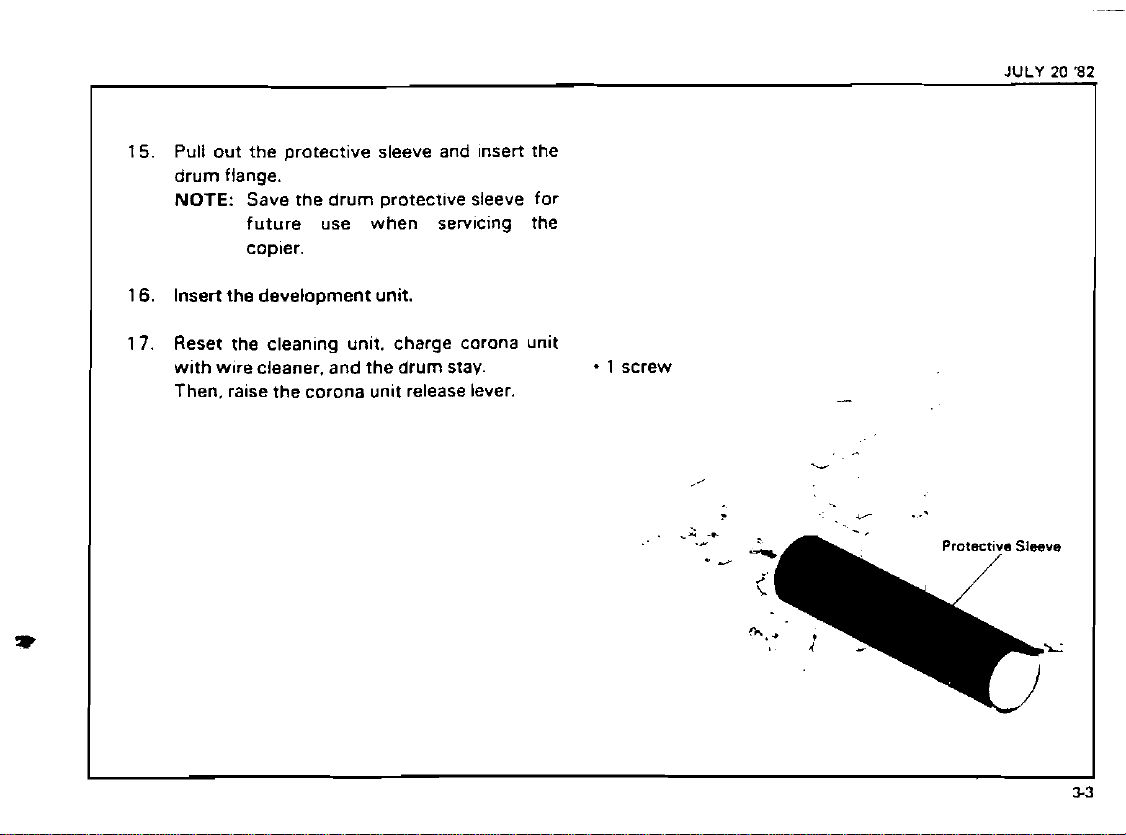

2

Pull out the protectlve sleeve and Insert the

15.

drum flange.

NOTE:

16.

Insert the development unit.

Reset the clean~ng unlt. charge corona unlt

17.

w~th wore cleaner. and the drum stav.

Then.

Save the drum protectlve sleeve for

future use when

copler.

ralse the corona unlt release lever.

serv~cing the

-

1

screw

-

Page 20

6

.

JULY

M

'82

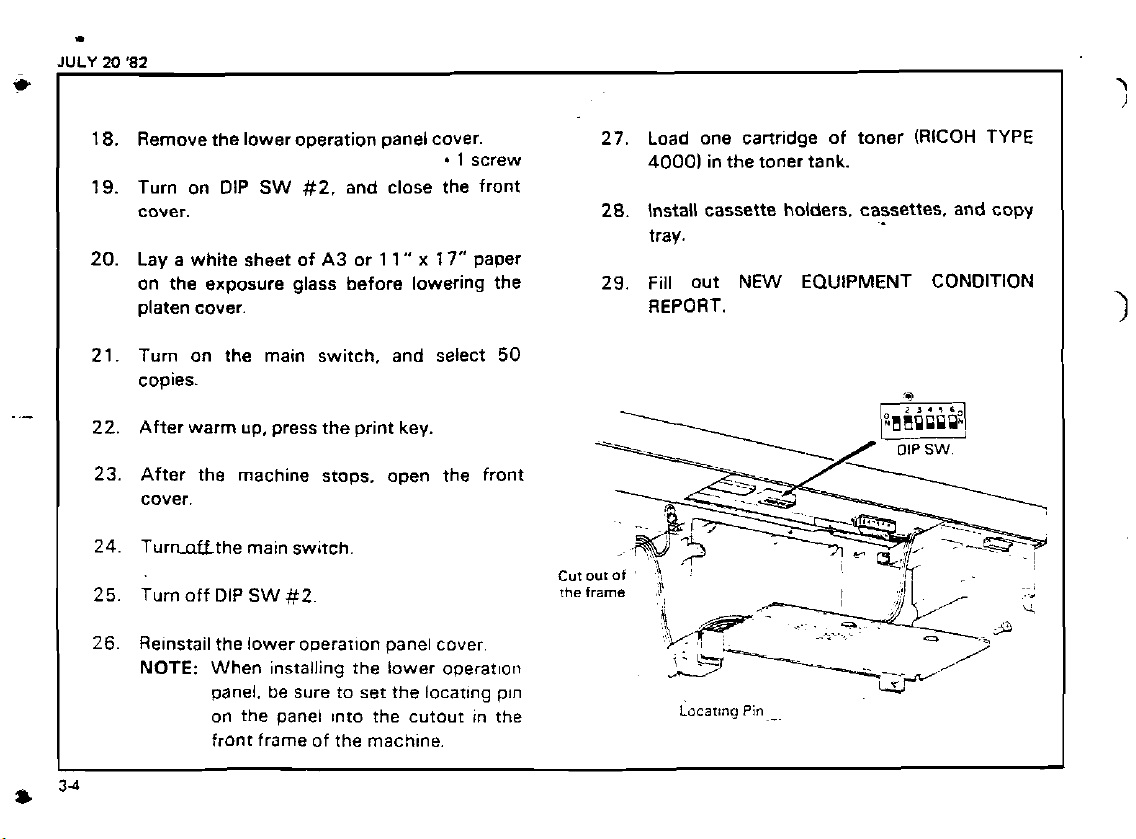

18.

Remove the lower operation panel cover.

.

I

screw

19.

Turn on DIP

cover.

20.

Lay a white sheet of

on the exposure glass before lowering the

platen cover. REPORT.

SW

#2.

and close the front

A3

or

1

1"

x

17"

Paper

27.

28.

29.

Load one cartridge of toner (RICOH TYPE

40001

in the toner tank.

Install cassette holders. cassettes. and copy

tray.

Fill out

NEW

EQUIPMENT CONDITION

Turn on the main switch. and select

copies.

After warm up, press the print key.

After the machine stops. open the front

cover.

Turnnffthe main sw~tch

Turn off DIP

Relnstail the lower ooerarlon panel cover

NOTE: When

SW

#2

~nstalltng the lower operatloll

panel. be sure to set the locatlng pln

on the panei Into the cutout in the

front frame of the

machlne.

50

Locating

1

pin-^

Page 21

I

3-2.

CASSETTE MODIFICATION

1.

Take off the cassette cover

2.

Install the s~de fences. Secure each fence

w~th two screws. The small size cassette

uses two side fences and one rear fence; the

large cassette uses four side fences and one.

rear fence.

NOTE: The fence

paper sues are printed on the

bottom of the cassette.

Stick

3.

the proper paper size decals on the

cassette at the

pos~tions for the varlous

positions

shown.

SEP

30

'82

-

!

Page 22

Push and stick actuator magnets firmly on

4.

the cassette according to the table to the

right.

NOTE:

Make sure the magnet positions are

clean before installing the magnets.

5.

Replace the cassette cover and insert the

cassette in the cassette holder. Check the

paper size indicator on the FL screen.

6.

Load paper in thecassette and make coples.

Check copy speed and copy image.

M1

Pawr

Sirs

A3

&)

A4 Lsngthwida

AQSidrmirs

85

Lsngthwisa

85

Saewiu

A5186

Lengthwise

A6

Langrhwira

ll"x17" 01000

8-llt" x 11"

8.112" x 11"

8-112"

8-112 x 14 10011

8-112" n 5-112" 11001

8-114" x 13" 10110

8.114~ 14" 10110

8"

x

8"

x

10 x 14". 10 x 15" 1 0

Option

L:

Lame

S:

Small

Lsngrhw~o

Sidewise

x

13"

10" 1010r)

13" 00111

Unlvarral

Unlvarral

M2 M3

0

0 0 0-1

00100

0

0 0.1 0

00011

00101

00110

10001

11000

0 1 0 0

0 1 0 1 0

10010

10000

M4

M5

Caizp

1

1

0

1

L

L

L

S

S

S

S

S

L

L

5

L

L

S

L

L

L

L

L

Page 23

3-3.

1

KEY COUNTER HOLDER INSTALLATION

1.

For the FT4060 remove the right cover. - 4

For the

cover.

2.

Open the front cover and remove the right

inner cover.

3.

Remove the cover plate and fixing plate

from the key counter bracket.

4. Hold the fixing plate on the inside of the key

counter bracket and

holder.

Align the holes in the fixing plate with the

5.

mounting holes of the

and secure the key counter holder.

NOTE: This copier can use three types of

6.

Remove the shoRlng plug from the key

counter connector.

FT4030 remove the

insert the key counter

key

counter holder

the counter. Make sure to use the

in

correct holes

the fixtng plate.

csv

counter

2

-

3

screws

screws

screws

7.

Plug in the key counter holder.

8.

Reassemble the copier and check key counter operation.

Key

Counter

Holder

.

.

Page 24

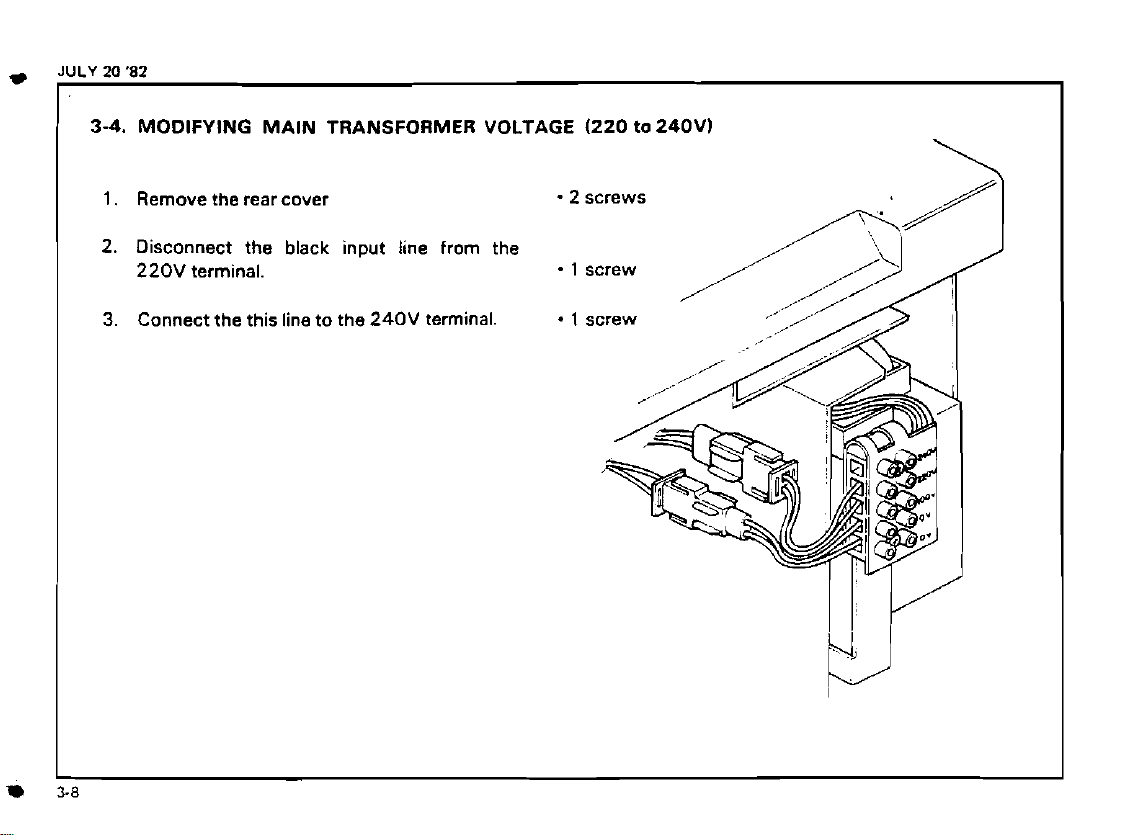

3-4.

MODIFYING MAIN TRANSFORMER VOLTAGE

1.

Remove the rear cover

2.

Disconnect the black input line from the

220V

terminal.

Connect the this line to the

3.

240V

terminal.

2

.

1

(220

tO240V)

screws

screw

\

Page 25

Page 26

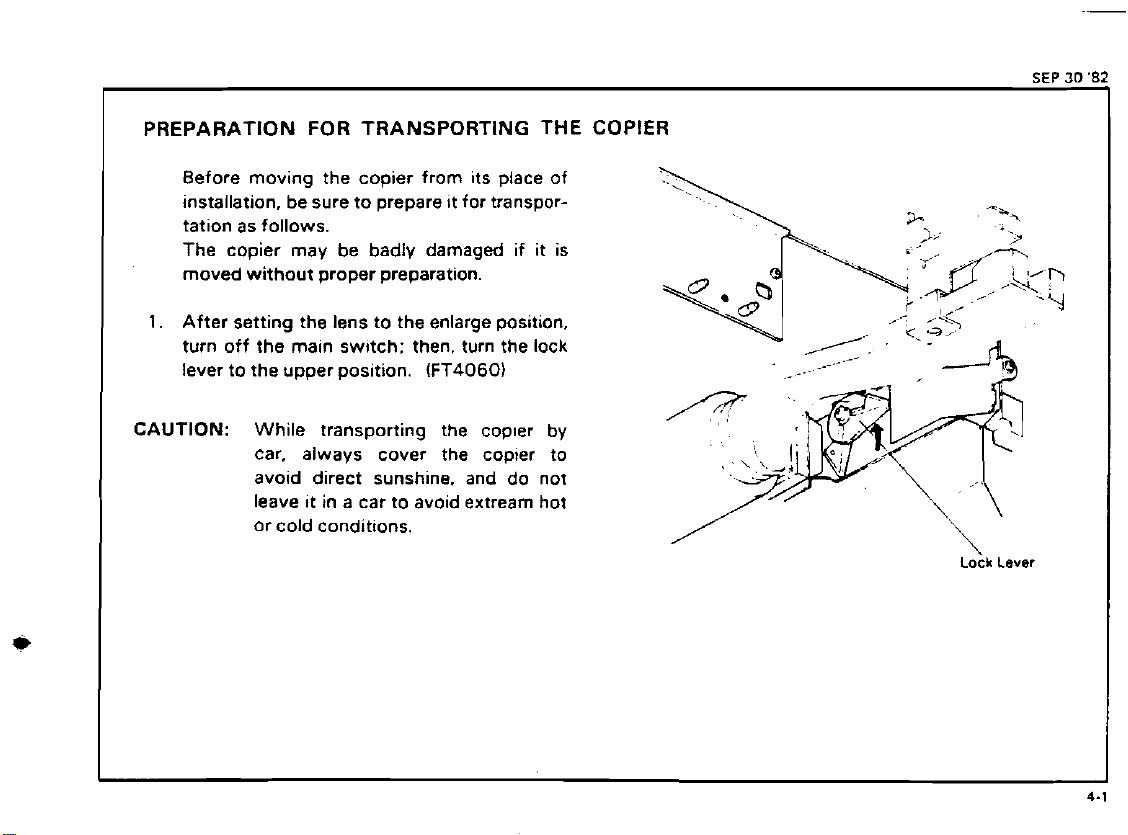

PREPARATION FOR TRANSPORTING THE COPIER

Before moving the copier from its place of

installation, be sure to prepare

tation as follows.

The copier may be badly damaged if

moved without proper preparation.

1.

After setting the lens to the enlarge position.

turn off the main

lever to the upper

CAUTION: While transporting the copler by

car. always cover the copier to

avoid direct sunshine. and do not

leave it in a car to avoid extream hot

or cold conditions.

sw~tch: then, turn the lock

pos~tion.

tt for transpor-

(FT4060)

it

is

,

Lock

Lever

SEP

30

Page 27

**

JULY

20

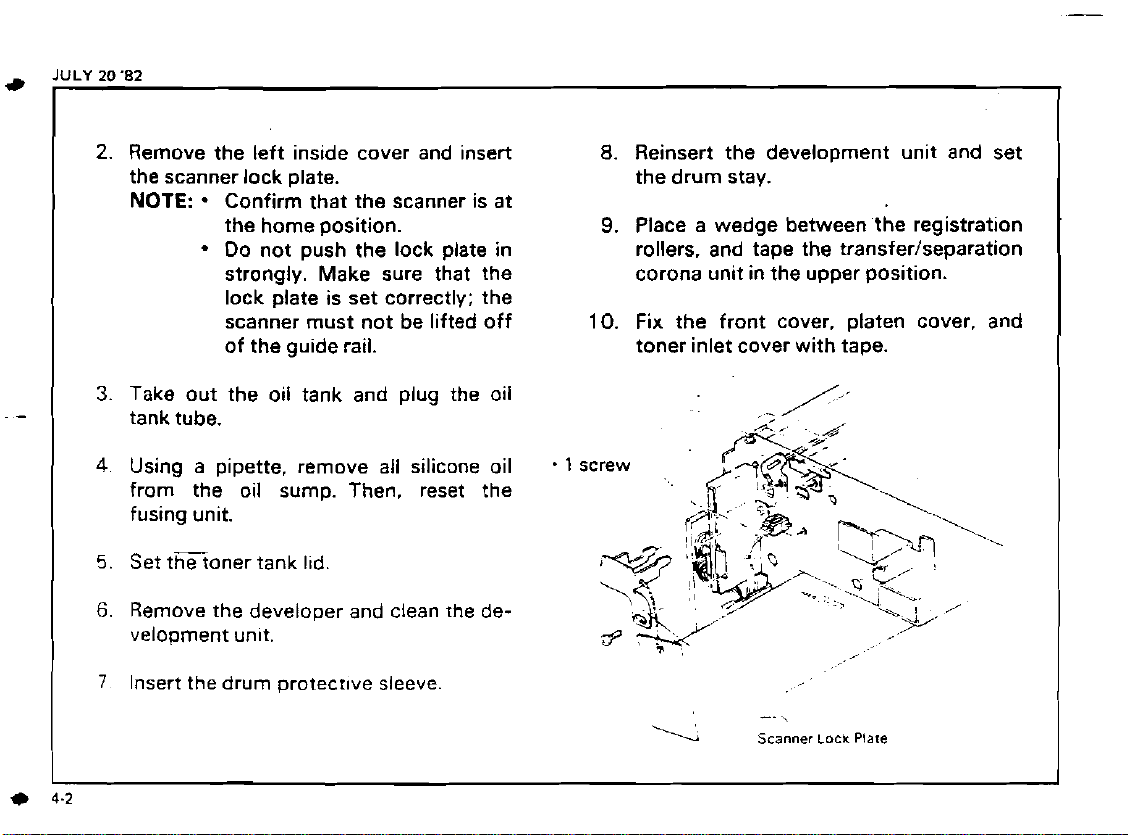

2.

3.

4.

5.

6.

7

(

1

'82

Remove the left inside cover and insert

the scanner lock plate.

NOTE:

Take out the oil tank and plug the oil

tank tube.

Using a pipette, remove all silicone oil

from the oil sump. Then, reset the

fusing unit.

Set tEoner tank l~d.

Remove the developer and clean the de-

velopment

Insert the drum protectwe sleeve

.

Confirm that the scanner is at

the home position.

Do not push the lock plate in

strongly. Make sure that the

lock plate is set correctly; the

scanner must not be lifted off

of the guide rail.

unlt.

.

10.

1

screw

8.

Reinsert the development unit and set

the drum stay.

9.

Place a wedge between the registration

rollers. and tape the

corona unit in the upper position.

Fix the front cover. platen cover. and

toner inlet cover with tape.

'Y

--

Scanner

transferlseparation

,

\

Lock

Plare

-.

I

I

Page 28

*

-

.

,?

._k*.'.

...?$*.;-

,:?h

-.

..I*.<

...

,.;~,.

.,

It

.q%%..ey

.

.

~.

.

-.

.

..

,+-..

.

:-,

.r

::?-

.-

,.(:-..-

I

:e*tx*$y;&,

;

.

.

,

,.

.

'L5

..

-

.

,.'

-. .

~f.

-

=

-

:.

:;,

..

,.,:

.

.Z

-...

.I.

-*

h..

:-..c.

r:,.

.:.s>:

.

.

-

,

,

.

:,

'..

.?

--

.;:

&~$:*~4:#y$*$4::.

.

%.

:.d&;

kaK$<+<.*,&&&::

,

,

. . .

.

'.',~.2

.;:+!'.;-.

.. .

..,..

1

.

.-<.;

:'Y

.

.

:

'

.

:>,

...

1.:,

T

.

.-.

.

.

.

,,<

..:.

,.

.-.

.:

3.

,

,

.

.

.

.

. . .".

.,

41-

,

,

LI.

-

;:

,

,

"L

.

.. .

:

.

.

.

.

.

...

.

--

.

,

-

..

;.

*.

..

.

Page 29

Page 30

5-1.

POINTS TO

Drum Charge

1.

2.

3.

Exposure

1.

2.

3.

REMEMBER

The corona wlres should be cleaned at

servtce call by sliding the corona

every

4.

unit or with dry cloth.

Do not use emery paper or alcohol for

wire cleaning.

Do not touch the corona wires with oily

Launa

used to

a. Scanner Guide Rod (cleaning)

b. Scanner Guide Rod Pads (Lubrication)

011

or an equivalent oil should be

lubr~cate or clean the following

hands. c. Scanner Guide Plate

Make sure that the corona wires are correctly inserted between the cleaner pads.

ILubrication/Cleaning)

d. Lens Drive Screw Shaft (Lubrication)

CAUTI0N:Do not use silicone oil or any

DO not adjust the follow~ng parts:

a : First and second scanner height ad-

lusting cams.

b

:

Scanner Guide Plate

:

Lens AXIS Adjusting Cam

c

:

Lens Posltion Adjusting Screw.

d

:

Fourth Mirror Angle Adjusting Screw.

e

11

screw each1 er and a dry cloth.

(3

screws1

(1

screw)

The scanner home sensor and the lens

home sensor should be

when iewly

installed.

adlusted only

.

,

5.

Clean the exposure glass with glass clean-

6.

Do not touch the following parts with

bare hands:

a.

Reflectors

b. Exposure Glass

c. Mirrors and Lens

7.

DO not adjust the

other kind of

VR

..

on the optics PCB.

Do not bend or damage the lens support

plate or the mylar

strtp.

011.

JULY

20

82

-

~

..

5

Page 31

JULY

20

'82

Development

1.

Be careful not to nick or scratch the development roller sleeve.

2.

DO not turn the development roller in the

opposite direction.

3.

Place a sheet of paper under the development unit when it is out of the copier.

4.

Clean the development unit guide plate

before reinstalling the

Toner

1.

Toner density sensor should be cleaned

everyEM or PM with a blower brush.

at

2.

Do not touch the sensor pattern w~th bare

hands.

3.

Toner density sensor adjustment is required when:

a.

A

b.

The sensor (first quenching unit) is

taken out and reinstalled.

c.

The first quenching

I

5-

2

unlt.

new drum is installed.

PCB

is reolaced.

Cleaning

1.

Do not damage the edge of the cleanlng

blade.

2.

Do

not touch the cleaning brush with oily

hands.

3.

Before pulling out the cleaning unit. place

the sheet of paper under

4.

Be careful not to damage the d~m with

the pick-off pawls when pulling out or inserting the unit.

5.

Toner collected from the cleaning unit

can not be used again.

Second Quenching

1

Clean the lamp surface w~th finger or w~th

a dry cloth.

After

cleanlng it w~th a

charge any static elect~c~ty before

stalling it.

Never use a wet cloth to clean the

lamp.

Paper Feed

1

Lubr~cate the paper feed motor worm

with

Launa

per~odlcally

011

or an

it.

dry

equivalent

cloth, dls-

rein-

E.L.

011

Page 32

Fusing

1

After replacement of the

hot roller. apply silicone

the

011

blade

2.

Be careful not to damage the edge of the

hot roller

3.

Be

strippers.

4

Be sure that the fus~ng lamp 1s not in contact

strtppers or thew tenslon springs.

careful not to bend the pressure roller

Wlth the Inner surface of the hot

011

blade and the

011

to the top of

roller

JULY

20

'82

I

Page 33

5-2. HANDLING THE DRUM

1.

Never touch the drum surface wlth bare

hands.

2.

Store the drum in a cool dry place.

3.

When cleaning the drum, always wear a pair

of glooves.

4.

Always prime the drum with setting powder

after cleaning the drum. or before installing a

new drum. This should be done within one

minute in a

light.

5.

To protect the drum. always apply settlng

poweder to a new cleaning blade and/or

new cleanlng brush before installing them

6.

Drum conditioning

drum is installed. In

done at the

locatlng not exposed to strong

is

necessary when a new

add~tion, thls should be

followtng tlmes:

1)

When image density is reduced due to

overexposure of the drum..

2)

After cleaning the drum.

3)

When thedrum is lightly scratched.

7.

Always keep the drum in the protective

sleeve when inserting or pulling the drum

out of the copier. (Except when applying setting

powder.1

8.

Before insert~ng or pulling out the drum. the

cleaning unit should be pulled slightly out to

avoid drum damage by the

Before lnsertlng the

9

a

drum while

the development

ed whlle the develooment unit 1s In the

comer the edge of the sleeve w~ll scrape developer orf of the development roller

lt

1s

protective

in the cople~lways rake out

unlt If the sleeve is insen-

'

plck-off pawls.

sleeve on the

Page 34

5-3.

TONER COLLECTION BOTTLE

When

toner

remove

servtclng the copler. always check the

collection

it and install a new bottle as follows.

bottle If

rt

is full or nearly full

SEP

30

'82

I

Remove the full bottle and men the cap

1

the month.

Clean the toner collect~on bottle sensor with

2.

a blower brush

Install a new toner collect~on bottle

3

NOTE:

1

I

Each carton of toner

tains three new toner collect~on bottles.

21

The toner collection bottle w~ll'fill in

15K

to

25K

coples.

31

At

each vis~t to the customer gather up

all full toner collect~on bottles. and

return them to the

disposal Jccordlng to local regulat~ons

(1

0

bottles) con-

servlce center for

in

Page 35

Page 36

6.

REPLACEMENT AND ADJUSTMENT

-

6-1. Optics 6-

1

6-2.

Development

6-3. Toner

6-4.

6-5. Paper

6-6.

6-7.

-Fusing 6-55

6-8. Copy

6-9.

.......................................................................................

Cleaning

Fwd

Transport

Image 6-71

Others

..................................................................................................................................................................................

-

*

-

-

6-1

6-25

...

6-31

6-37

6-5

6-81

9

1

Page 37

OPTICS

DEVELOPMENT

TONER

CLEANING

PAPER FEED

TRANSPORT

FUSING

COPY IMAGE

OTHERS

Page 38

6-1.

OPTICS

1

-

1 Exposure Glass Removal 6-

1

-

2.

Exposure Lamp Replacement 6-

2

3

1 - 3. Uneven Exposure Adjustment

1

-

4. Scanner Drive Wire Replacement (FT4060)

1

-

5.

Scanner Drtve Wire Replacement IFT4030)

1 - 6. Scanner Drive Motor Replacment (FT4060) 6-10

-

7

Scanner Or~ve Clutch Removal IFT30301 6-1

1

1

-

8.

Scanner Home Position Sensor Adjustment (FT4060)

1

-

9.

Scanner Drive Belt Tension Adjustment IFT40301 6-14

1-10. Lens Drive Motor Replacement

1-1

1.

Lens Home Position Sensor Adiustment (FT40601 6-1

IFT4060)

......................

6-

6-1

6-1

4

1

2

5

7

Page 39

JULY

20

'82

1-1.

EXPOSURE

1.

Take off the left scale.

2.

Loosen the two screws that tighten the right

GLASS

REMOVAL

glass holder.

3.

Remove the exposure glass.

CAUTI0N:Be sure not to dislodge the three

rubber pads that support the

exposure glass.

Always use two

5)

to the left scale. If long screws

iM4

x

81

are used,

shon-screws

they

scanner, resulting in optia service

call.

(M4

will hit the

x.

Page 40

1-2.

EXPOSURE LAMP REPLACEMENT

1.

Remove the exposure glass.

2.

Move the scanner to the posltion where the

iscut out.

frame

3.

Unscrew the exposure lamp cover and slip it

off to the right.

4.

Rotate the lamp terminal as shown and take

out the lamp.

5.

Install a new lamp.

6.

Check the lamp position and light intensihr.

CAUTION:.

Do not handle the exposure

lamp with your bare hands.

Use a strip of paper as shown.

(Finger marks

the lamp or reflectors will be

affected by heat. resulting in

discolorat~on.)

The prolectlon on the lamp

must

patnt toward the mouth

of the reflector.

1011

marks) on

SEP

30

'82

./

,'

..

-.

V'

,

.

\..

..

.

,

-'..

'

,

,.

,.

-

.a

.r*/:

r/

Page 41

SEP

M

'82

1-3.

UNEVEN EXPOSURE ADJUSTMENT

I. Exposure Lamp Position (First check and

adjust this)

1.

Remove the top cover.

2.

Remove the exposure glass.

Correct the horizontal position by tightening

3.

or loosening the two adjusting screws.

4.

Correct the vertical position by turning the

adjusting knobs.

(Be sure to tighten the ad-

justing knob screws after adjusting the lamp

position.)

11.

Adjusting Plate

If

uneven

exposure still exists after the

above adjustment. do the following:

1.

Remove the exposure glass.

2.

Move the

crease or decrease edge

NOTE:

adjusting

plates as shwn to in-

illuminat~on.

The leading edges of the three

adjusting plates must be aligned

where they meet.

(To avoid white streak.)

.8

screws

..

Adjusting

Plate

Page 42

1-4.

SCANNER DRIVE WIRE REPLACEMENT

(FT40601

1.

Remove the platen cover and the platen

cover mounting studs.

2.

Remove the top cover. 8 screws

3.

Remove the exposure glass.

Remove the rear cover and lower the

4.

plate.

5.

Remove the following parts:

Inlet cooling fan

Platen cover mounting brackets

Bias transformer

NOTE: All screws installed in the horizontal

direction must be short screws

x

6).

Unhook the ends of the wire and take out

6.

the magnification change clamp.

7

Remove the old ware.

8.

Clamp the new wtre to the magnaficataon

change clamp

180 mrn

about

as

shown. The left end is

17.09")

.

CPU

2

screws 1 connector

2

screws each

2

screws 1 connector

IM4

.

1 screw

.

1

screw

Bias

Tranrtormer

180

mm

17

,,

09-1

6

Page 43

JULY

20

4

'82

9.

Reinstall the magnification change clamp.

10.

Move the second scanner to the return

position.

11.

Working from the clamp, thread the long

end of the wire in the lower groove of the

clamp and run it under the inside track of the

tension pulley.

12.

Then, run the wire under the outer track of

the second scanner pulley

the wire clamp

around the lower track of

.

(WPl

)

(WPZ),

(below. the screw), and

WP3.

~,<?,!W

through

*.I

.

1 screw

-

.T

'

Clamp

-

-Second

Scanner

Pulley (WP21

-

13. Run the wire around the outer track of

and then give it three and half (3.51 turns

around the drive pulley starting form the

inside edae.

la.

Next, run the wire over the inner track of

WP4.

track of

-

the lower track of

WP2.

and the innertrack of

WP6,

WP4.

the Inner

WP7.

?.

t&-kL

,

--:

-

-

-.,

k*,

.

c

~-:;

-.

'<

~

.:.-.

3

-

,:<

..

.

,-

15.

Guide the left end of the wlre through the

upper groove of the

clamp; then, pull the ends

er and hook them.

rnagnificat~on change

of

the wire togeth-

Page 44

Tighten the wire clamp. (Be careful not to

16.

bend the bracket.)

NOTE:

17.

Manually rotate scanner drive pulley and

check far overlapping of the scanner drive

wire.

18.

Reassemble the parts removed in step

19.

Check and adjust magnification.

20.

Reassemble the cooier.

Move the first scanner to the posi-

@

tion

scanner to

and then move the second

the position

$1.

5.

Second

Scanner

,

,,

Page 45

1-5.

SCANNER DRIVE

1

Remove the platen cover and platen cover

mountlng screws.

2.

Remove the top cover.

3. Remove the left scale and the exposure

glass.

4.

Remove.the rear cover and rotate the

plate down.

5.

Remove the follow~nq parts:

Inlet coollng fan

Platen cover suoports

Elas

transformer

3emove the ou~lev snarr suoport olare.

.

.

:

.nhoon

tne scanner

WIRE

r,raKP

REPLACEMENT

a

8

screws

2

screws eacn

2

screws 1 connecror

-

4

screws each

-

2

screws 1 connector

2

jcrews

str:o.

CPU

IFT40301

!,"go?

&&?..

...

t

-1

inlet

Cooling

t>

-2"/

.

.-

.

>.,:

%<

A_/

DrcvePullev

Fan

27

,

Y'.&

,

*

.~.

--.\

-

Q.

?

4

.‘,

3%

Pulley

Knob

*.

..

-1

.

-:

.

.:

,.

y.

hai it

Plate

Scanner

,

?...

/

aias

Transiormel

Brake

>

'

Stnp

-sosen [he Nlre

.vlre

c;arno

dilo

remove :ne

'3'0

Page 46

Hook one eno ot :he new wlre to rhe anchor

10

hook.

gun the ,wore unoer the lnsloe track of WP1

i

1

and around the lower track of WPS.

i

2.

Next. run the Wlre over the lns~de track of

WP3.

13.

Run the wlre over the pulley, and wrap

around the pulley

the inside edge of !he pulley.

Then, run the wlre over the outer track of

14

WP3 and around the lower track of

Run the wlre through the wlre clamp tbelow

IS.

the screw) and over the outslde track of

WP1.

16.

Hook the free end of the w~re to the tension

bracket.

17

Tighten the ware cl3mp.

NOTE:

Manually rotate the main pullev and check

18.

;or overlapD!nq

.

Be cxerul not tobend the bracket.

Seepaqe6-7

3-1

2

times. starting from

=16

ot

the scanner urlve wlre.

WPZ.

.

<

WP2'

I

'Nlre

Clam0

,

it

Maln

..

WP~/\\ Wire

-..

-..

.,I\\.

..

\,-

-

A,

,'/P3

.

'.

.

.

Pullev

Secona

Pulley

Anchor

'

;.

.

-5

,3kT

Scanner

IWPlI

Hook

Clamu

Tenston

,

'

-

a

..

-2..

-.

SEP

Bracket

.

..

Y

30

'82

:

Y

fieassemole the cooler

19

check and aulust rn3gnlilc3t1o1i

-%

*,,.I,~

P,,,I~V

;~:cu,w

?,II'FV

Sc~iuier

lWP"

6-9

Page 47

JULY

..

.

.

20

'82

1-6.

SCANNER DRIVE MOTOR REPLACEMENT

1.

Take off the rear cover and lower the

plate.

Take off the top cover. and remove the

exposure glass.

Remove the right cover.

Uncouple the scanner drive motor connec-

tors and unscrew the ground wire.

Tape the drive wire to the pulleys as shown

to the right.

CPU

2

screws each

8

screws

2

studs

-

4

screws

(FT4060)

Slide the

Replace the scanner drive motor.

maln oullev off of the motor shaft

2

allen screws

.4

screws

Main

-/

~"llev

Page 48

'-7.

SCANNER DRIVE CLUTCH REMOVAL

;zke

oif

the rear cover an0 lower tne

3!~:e

2.

Take off the ~nlet cool~ng fan.

3.

Take off the ma~n pulley knob.

-I

Semove the pulley shaft support olate

5.

Unhook theclutch brake strlp.

5.

Tdpe the wlre lo the ma~n pulley and

and unhook the wlre

i

Take off the maln pullev

Slio the scanner dr~ve belt off ot the oullev

3.

shaft

.

7-111,.p

'C?

-.

scanner

tightener

O:lvr

:Iutc!l

sprlng.

IFT40301

CPU

2

screws each

-

2

screws

.

1

E-r~ng

-

2

screws

WP3. .-. .

WP~--~

~a~n

~ullev

.

:

-:-

2

,.-

,

2

allen screws

:

;crr?~vs

'

connector

Z

wtre

P

cl,imps

..

y,

Scanner

Dr,ul:

..:,

-

*'..

7-

.,

Sc~nnrr

Clurcl

.

. .

~.

-,T

'.

..\

-.

.;'.;

,;45,$>.,.3

.

.I(;

,,

:

.-,

'.

Y

P

,

-.

Orwe

Belt

Page 49

SEP

30

'82

1-8.

SCANNER HOME POSITION SENSOR ADJUSTMENT (FT4060)

1. Select full size mode.

2.

Take off the rear cover and lower the

plate.

CPU

2

screws

M3

Truss

Screw

3. Turn the main pulley to move the scanner

until the center of the M3 truss screw is 14

mm 10.55") from the left scale.

4.

Connect the digital multimeter input line to

4

pin

CN403-05). and connect the multimeter

COM line to logic ground. (The wire securing

OSCl is good for this.)

5.

Remove the plate from the access slot

above-the home position sensor.

6.

Loosen the home position sensor screw.

Slide the home position sensor just to the

7.

point where the multimeter changes from

OV

Tighten the sensor screw at this position.

CAUTION

of IC21 on the optics PCB lor

-

to +5V.

Be careful not to damage

pattern.

-

El

PCB

...~

..

.

i

scanner

Poslrron

.

~

"

i

Home

Sensor

-,P

'-LC-&?

+--

-r

b

"

.

.

-

Y'

,.

,

,.

Page 50

8.

Check the adjustment:

Move the scanner away from the home

position until the multimeter changes to

low.

it

Then slowly move

back until the multimeter turns high again.

Check that at this position

0.5

mm.

(0.55" ? 0.02")

-@I'

is

14

SEP

JO

7

I?:

NOTE:

When the home .wnsor is properly

positioned. the lead edge margin (erase.

and registration) will be almost equal for

all five magnifications.

Page 51

JULY

20

'82

-.

SCANNER

Adjustment Standard: 750

Remove the top cover.

Take off the inlet cooling fan

Loosen the belt tightener bracket screw.

Pull up on the belt

tenslon gauge. Tighten the bracket screw

when the gauge reads 750 g (1.65

NOTE:

DRIVE

Make- sure the lower end

t~ghtener bracket 1s in the gu~de slot.

BELT

TENSION

(1.65 2 0.55 lbs)

t~ghtener bracket w~th a

ADJUSTMENT

t

250 g

lbs).

of

the

-

8

screws. 2 studs

-

2

screws

(~~40301

,m-

-

750

,,

-

.

-

11

-

,'

*

I!

i+)

Scanner

/

Drwe

Belt

Page 52

'2

440

aye1

.ajeld

.

nd3

eq) lamol pue JaAoa leal aq;

q3ea smelas

.&

.p

.g

.g

A'/

Bulse3

WNQ

,-

3-

enoqpr

4

-

~

&.

-

&

aq; 6uuna%s

suoloa afi~eq:, pue janp i!e aqj enowau

sme~as

SMaJlS

>

.

..

,

.-

@

s~a~as orm aqt a~owen

.bu!se:, wn~p a~oqe eqa lo ep!s leer

'JaAO3 qaed Iemod

'aleid Aeas wnlp aq~ijo aye1

.6u1se:, wnlp moqe aql lno eyel

Page 53

7.

Remove the light shield cover.

8.

Disconnect the lens drive motor connector

it

and disengage

9.

Unscrew the two wire clamps holding the

lens drive motor harness.

10.

Remove the lens drive motor assembly.

1 1.

Take off the motor cover.

12.

Remove the motor gear.

13.

Replace the lens drive motor.

14:

Reassemble.

from the rear side plate.

3

screws

2

screws

1

screw

-

1

alien screw

2

screws

Mot

Page 54

1-1

1.

LENS HOME

1.

Remove the exposure glass, light shield

cover, and rear cover.

2.

By tumlng the lens drive shaft. move the

lens to the position where the center of the

cam follower is aligned with the two holes in

the second scanner drive cam as shown.

Connect the multimeter's COM line to logic

3.

ground and connect the input line to'pin

of lC2l (orCN403-A71.

4.

Loosen the sensor fixing screw

5.

Slide the sensor as far as posstble toward

the right.

6.

Slowly slide the sensor back unt~l the multimeter readlng changes from

Tighten the sensor screw at thts posltlon.

7.

Make a copy and check the hor~zontal

component of magn~ftcatton.

NOTE: If the resolutton or focus becomes worse when the wlre clamp lhor~zontal rnagntf~catlon) 1s

correctly posttloned. ~t 1s necessary to adjust the lens home sensor.

POSITION SENSOR ADJUSTMENT

-

2.3.

10

+5V

to

OV.

(FT4060)

and 2 screws

Lena

Horns

Pos#tton

Sensor

Dr~vs Cam

~s&

I

Drira

Shan

SEP

30

Page 55

6-2.

DEVELOPMENT

JULY

20

'E

2-1. Developer Replacement

2-2.

Doctor

2-3. Magnet Angle Adjustment

2-4.

Bias Power

Gap

Adjustment

Pack

...........................

Check 6-23

......................................................................................

..

.....

............

6-20

6-2

1

6-22

Page 56

SEP

30

'82

2-1.

DEVELOPER

1. Insert the end of the development unit in a

vinyl bag and hold it as shown.

2.

Turn the development unit knob counterclockwise.

The developer will fall into the bag.

3. Reassemble the paddle gear and idle gear.

4

After dumping the developer. check the

movement of the vibrating plate. The

paddle roller should move

10 mm. (0.08" to 0.39")

I.

1

Pour one bottle

development unlt wile turnlng the develop-

rnentunit-knob.

CAUTION:.

REPLACEMENT

it

about 2 mm to

il

kg) of developer into the.

-

Be careful not to bend the bias

terminal.

-

After removing used

developer. clean

gears.

the

drive

A

1

,/

ye&,

-A

g

Plate

I

I

pad&

Roller

I

Page 57

i.

i;

2-2.

DOCTOR

.

Adjustment Standard: 1.26 f 0.1 mm

1. Take out the development unit and empty

the developer.

2:

Take off the upper cover. 2 screws

3.

Before making the adjustment. confirm that

both surfaces where the thickness gauge

will

4.

Loosen screws @ and

5. Insert a 1.26 mm (0.05") thickness gauge

into the

press the

blade lightly contacts the doctor blade.

G&

ADJUSTMENT

be

inserted are clean.

DG

at the shown positions, and

DG

plate down until the doctor

(0.05" 2 0.0041

@.

J

~.

--

-

--

~

.-

----

-

JULY

20

'82

.<>':

DG

Plate

6. Tighten screws

7.

Check that the

both positions.

NOTE:

Confirm that the

whenever the upper and lower sections

seoarated.

!@

and

'01.

DG

is correct and even on

DG

is correct

of

the development unit are

@

@

Page 58

*

I

JULY

20

'82

2-3.

MAGNET ANGLE ADJUSTMENT

1.

Loosen the magnet plate screw. and turn the

magnet plate

possible.

2.

Turn

the plate slowly

one graduat~on to the left

NOTE:

Adjust the magnet angle after

replacing the development roller.

counterclockw~se as far as

clockwise

of

center.

and fix

-.

-

-

-

-

it

-

-

Page 59

I

2-4.

BIAS

POWER PACK CHECK

1.

Tuin off the bias thermistor swltch and turn

on the free run switch

2.

Set the density control at the center (4th)

position.

3.

Press the print key; then. with a digital

multimeter, check the development bias. At

the center setting, the bias should be

f300V 2 12V

4.

Check that the bias value changes approxi-

60V

mately

If the bias value is incorrect. disconnect the

5.

bias cable and check bias output directly

from the cable.

If the bias is now correct. check for a bias

leak from the development roller.

.

If

the bias is stdl wrong. replace the bias

power pack.

at each step.

(DIP

SW100

during forward scan.

#ll.

DC

Bias

Power

Pack

SEP

30

'82

-

L-

NOTE:

When the therm~stor sw~fch

becomes

f~xed at the

30°C

value.

IS

off, the bias temperature

compensation

w~ll not work, and output

-.

-

623

Page 60

6.3

. TONER

3.1 . Toner Density Sensor (First Quenching Lamp) Replacement

.

Toner Density Sensor Adjustment

3.2

3.3

.

Toner Tank Removal (FT4060)

3.4 . Toner Tank Removal lFT4030)

.-

....................

..

.....................................................................................................

...........................................................................

......................................................................

-

. .

..

6-26

6-28

6-29

6-30

Page 61

JULY

M

'82

3-1.

TONER DENSITY SENSOR (FIRST QUENCHING LAMP) REPLACEMENT

1

Lower the transferlseparation unit.

2.

Take off the charge corona unit and the

.

1

drum stay.

3.

Take out the toner collection bottle and the

cleaning unit.

4.

Take out the development unit and put

a clean sheet of paper.

5.

Slide the protective sleeve over the drum

and take off the drum flange.

6.

Pull out the drum and the drum heater.

7.

Remove the rear cover

plate.

8.

Remove the wlre clamp and clamp bracket.

and disconnect the two harnesses

3P) golng

to

the first quenching unlt.

and

lower the

(5P

screw

it

on

. 1

C-ring

CPU

2

screws each

and

5P

Connector

626

Page 62

9.

Pull the connectors and wires through the

rear side plate.

10.

Take out the first quenching assembly.

1

1.

Remove the wire clamp and loosen the two

screws on the first quenching assembly.

12.

Replace the first quenching P.C.B.

13.

Reassemble the copier and adjust the toner

density sensor.

NOTE:

Make sure the rear end of quenching

assembly is properly set in its

bracket.

.

2

I

screws

screw

'.

'.\+,

.:I!.

;-4

..,

Page 63

SEP

3

&

"82

3-2.

TONER- DENSITY SENSOR ADJUSTMENT

1.

Clean the following parts.

Toner density sensor with blower brush or

solder sucker.

Optics Mirrors and reflectors with silicon

cloth.

Lens with blower brush.

Toner shield glass with

Charge corona wire with dry cloth.

2.

Place 2 or 3 sheets of

exposure glass.

3. Select drum conditioning mode

under the operation panel).

4.

Insert small paper clips in CN3-613. and

CN3-Bt4 on the main PCB while the main

switch is off.

NOTE: Cut the end of the clips to a point to

make

it

easy to insert.

CAUTION:

8e careful not to let these two

clips contact.

LDGlA3

dry cloth.

paper on the

(DIP

SW

#2

FT4030

FT4060

Maln

PCB

.

.Is£.

d<

14

014

'V

Page 64

5. Turn on the main sw~tch, and wa~t for warm-

1

6.

After warm-up. turn off the main switch and

connect the multimeter and short wire as

follows;

FT4060 Multimeter Hot line: CN3-B13

1

Short wire: CN3-B14 and TP100

FT4030 Multirneter Hot line: CN3-614

I:

Short wire: CN3-813 and TPlOO

CAUTION

7.

8.

9.

Apply tape to TPl 01 and TP102 to

prevent electrical shortage of these

two pins to

Turn on the maln switch. set 50 copies. and

select the 3rd level of

Press the punt key. and check the voltage

durlng the forward scan.

Adlustrnent Standard:

Adjust the

quenching unit.

Lround line: TPl 00

TGround line: TPlOO

,

,

8.

TP100.

dens~ty connol.

4

0

f

0.2

VR

on the front end of the first

I

V

6.28.1

Page 65

3-3.

TONER TANK REMOVAL lFT4060)

1.

Remove the top cover.

2.

Remove the right cover.

3.

Take off the inner right cover.

4.

Take off the rear cover and lower the

plate.

5.

Remove the hamess cover.

6.

Take off the right side plate.

7.

Put a sheet of paper on the upper feed roller

to catch any dropping toner.

8.

Take out the toner tank.

-

8

screws

2

studs

4

screws

3

screws

CPU

2

screws each

5

screws

4

screws

1

connector

1

ground wire

4

screws

2

connectors

Harness

a

Cover

-

Page 66

I

3-4. TONER TANK REMOVAL IFT403OI

1.

Take off the top cover and inner right cover.

2.

Remove both right side covers.

3.

Remove the rear cover and lower the

plate.

4.

Take off the by-pass paper guide.

I

5.

Remove the right side plate.

6.

Remove the harness cover.

7.

Remove the by-pass entrance brace.

Put

a

3

9,

sheet of paper on the by-oass feed

roller to catch any dropping toner.

Take our tne toner tann.

CPU

-

4

screws

2

connectors

1

ground wire

2

screws

.

4

screws

1

connector

-

d

screws

2

connectors

8

screws.

2

studs.

3

screws

2

screws each

2

screws each

.

1

screw

.

Toner Tank

I

I

I

Page 67

Page 68

4-1.

CLEANING

1.

Take out the cleaning unit.

2.

Remove the old blade.

3.

Dust a new blade with setting powder.

NOTE:

4.

Install the new cleaning blade.

CAUTION:

BLADE REPLACEMENT

Clean the inside

Be careful not to touch the edge

of the new blade.

of

1

the cleaning unit.

screw

Page 69

4-2.

PICK-OFF PAWL REPLACEMENT

1.

Unscrew the cam holder. Be sure to grasp

the inner part of the holder when

unscrewing.

2.

Remove the pawl shaft pin.

3.

Remove the spring.

4.

Remove the cam rider.

5.

Take off the old pawls and slide new pawls

onto the shaft. Do

6.

Fix

the spring.

NOTE: The spring screw must enter the

shaft from the top.

IOposite side from the pawl pins.)

Set the pawl shaft. Make sure the sprlng

7.

end is in the small hole.

not set the E-rings yet.

.

1

screw

1

allen screw

Page 70

8.

Tighten the spring by rotating the shaft

counterclockwise viewed from the front

2

(about

shaft pin.

9.

Set the cam rider.

10.

Set the pawls and fix them in place with the

E-rings.

1 1.

Screw in the cam holder.

12.

Check that the

the pick-off pawls is smooth by pressing the

pawl shaft pin to the black arrow direction.

turns); then, screw in the pawl

up

and down movement of

NOTE:

Before pressing the pawl shaft pin, the

pa& should be in the down position

(white arrow position).

Page 71

4-3.

CLEANING BRUSH REPLACEMENT

1.

Remove the front bushing from the front

end.

2.

Remove the gear and rear bushing from the

rear end.

3.

Take off the brush shaft holder, and takeout

the old brush.

NOTE: Clean the inside of cleaning unit.

4.

Prime a new brush by dusting :'with setting

powder.

NOTE: Do not touch the new brush: handle

the shaft only.

5.

Install the new cleaning brush.

.

.

1

1

2

E-ring

E-ring

screws

Clesnlng

Brush

Shaft

,

.

Holder

Rasr

~ushing4

Yp

Gear4

-.

.

..",l

"KT

JULY

a,

20

'82

Page 72

JULY

20

'82

4-4.

TONER COLLECTION COIL REPLACEMENT

-.

I

1.

Take

off

the coil gear.

2.

Remove the old coil and insert a new one.

3.

Reassemble.

.

1

E-ring

-

-

Page 73

6-5.

PAPER

FEED

JULY 20

82

Feed Roller Replacement (FT4060l

5-1.

5

-2.

Feed Roller Replacement (FT4030) 6-39

...

:

....................................................................................................................

6-38

-

...

.,"

?<,,'

w

..

.-

5-3. Friction Pad Replacement

Paper Feed Adjustment

5-4.

5-5.

Upper By-pass Feed Roller Replacement IFT40301 6-43

5-6.

By-pass Feed Solenoid Position iFT40301 6-45

5-7.

Upper Paper Size Detector Replacement (FT4060) 6-46

5-8. Lower Paper Size Detector Replacement

5-9. Paper Size Detector Replacement (FT4030l 6-49

5-1

0. Crimp Clutch Adjustrnant

.

.

.............................................................................................................................................

..........................................................................................

(FT4060)

................................

...........................................................................................................................................

.............

.

~

.

.

..

....................................................

-

-.

-3s

'33

J,,'-64,,

t)r?

.

-

6-41

6-48

6-50

-

-

.

.

Page 74

*

JULY 20

I

.

5-1.

'82

FEED ROLLER REPLACEMENT

1.

Loosen the feed roller allen screws, and slide

the feed roller off the shaft.

2.

Install a new feed roller.

The end of the feed roller must be flush with

the end of the roller shaft.

NOTE:

Removal procedure

both upper and lower rollers. For

access to the upper roller, first

remove the upper front guide plate.

lFT40601

is

the same for

I

-2

Feed

/

Roller

'<\

Upper

Front

b

Guide

Plate

Page 75

5-2

FEED

ROLLER

1.

Open the front cover.

2.

Remove the r~ght Inner cover, and remove

the feed roller shaft

3.

Remove the cassette holder.

4.

Loosen two feed roller allen screws. and

push the feed roller to the front end of the

feed roller shaft.

5.

Take off the rear cover.

6.

Turn down the

7.

Push the roller shaft out to the rear about

60

mm

(2.36").

roller off the front end of the shaft.

Be careful not to damage the paper end

detector feeler or actuator.

8.

Sltde a new feed roller on the shaft and

reassemble.

REPLACEMENT

bushlng.

CPU

plate.

and slide

the

lFT40301

2

screws

-

1

E-ring

2

screws

-2

screws

old feed

'i

Cgea

NOTE:

Roller

When installing the feed roller.

the

allen screws should be tight-

ened at the extreme left of the

positioning

. .

.

Fasd

Rolhr

Shaft

groovax

..

,

>

!>st2

.:.,,,>

./

I

Page 76

s

SEP

33

5-

'82

3.

FRICTION PAD REPLACEMENT

1.

Remove the friction pad bracket.

2.

Strip the worn friction pad off the bracket.

3.

Stick the new pad in place.

Check that is

(0.002"

NOTE:

4.

Before remounting the friction pad bracket.

grease point

NOTE:

to

0.01

Do not touch the surface of the

friction pad.

@.

Check the swivel movement

of the bracket.

0.05

to

4)

(Swivel point)

0.35

mm.

'

1

screw

Friction

Pad

Page 77

SEP

30

'82

I

5-

4.

PAPER FEED ADJUSTMENT

i

Adjustment Standard:

Upper Cassette: 150

2

mm (5.91

35 0 59.

"

2

0397

Lower Cassette: 135

<,

?,

,

7

%

'O

mm 15.31"

I5

[Rough Adjustmantl

NOTE: This adjustment

is

required only after re-

placement of the paper feed PCB.

1. On the Main CPU board connect

IC300-10 (or CN102-811 for FT4060.

CN102-813 for FT40301 and TPlOO

(GND). (When the main switch is turned

on, the paper feed motor will

continuously. so turn down the upper

cassette handle.)

2. Turn on the main switch. Measure the voltage between

CN2-1

(+I

and CN2-3

on the paper feed P.C.B.

Adjust this potential to

+

16.5V + 0.5V

w~th VR1

3. Remove the jumper line from the Maln

CPU board.

?

0397

0

run

(-1

59-

Page 78

JULY

20

'82

0

[Fine

Adjustment1

NOTE:

2.

3.

4.

5.

Before adjustment, clean the paper feed

rollers and friction pad.

1.

Remove the cover from the large

universal cassette and insert

upper position.

Make three

momentary stop position of the trailing

edge for each sheet (On the sheet

underneath).

Measure the distance from the mark to

the trailing edge of each sheet (This is the

paper feed amount) and compute the

average.

If the paper feed amount is outside the

standard adjust with

After adjustment, insert the cassette in

the lower position and check that the

lower feed amount is correct.

A3

(LDG)

copies. Mark the

VR

1

it

in the

\

Page 79

5-5.

UPPER BY-PASS FEED ROLLER REPLACEMENT lFT40301

1.

Open the by-pass feed table. and remove

.

1

.2

screw

screws

the by-pass paper guide.

2.

Unhook the support arms and let the by-pass

feed table hang straight down.

3.

Take off the key counter cover.

4.

Open the front cover and remove the right

inner cover.

.

-

JULY

20

'82

..

.

5.

Take off the rear cover and lower the

plate.

6.

Remove the harness cover.

7.

Disconnect the by-pass feed sensor 3P

connector.

8.

Remove the by-pass entrance brace.

CPU

2

screwseach

2

screws

4

screws

w

R'ght

/

'-

her

Cover

uey

counter

Bv-pass Paper Guide

Bvpass Entrance Brace

cover

Page 80

JLY

20

10.

1

12.

13.

'82

9.

Remove the front bushing.

Remove the by-pass roller gear and the

rear bushing.

Take out the feed roller shaft.

1.

Replace the entire by-pass feed roller

shaft

as

a

set.

Reassemble.

-.

1

E-ring each

-

/

Feed

Roller

Shaft

-

.

.

.<

.A

'L

-

.

y

..

.

;

"

e;;s

.

Page 81

5-6.

BY-PASS

Adjustment Standard.

1

Take off the rear cover an0 lower the

CPU

SOLENOID POSITION (FT40301

0

5

to

1.0

(0.02"

to

plate.

mm

0.04")

2

screws each

2. Push

3.

4.

5.

In the plunger of the by-pass soleno~d and check that the clearance between the rubber

to 1 0 mm

If ~t 1s not. do the follow~ng

Loosen the solenoid bracket screw.

lnsen a 0.5

between the

of the plunger.

Push up the plunger untll the by-pass

feed rollers

tighten the bracket screw.

10

rlng and solenold 1s 0

02" to 0 04")

mm

(0.02")

solenold and the rubber rlng

lightly

thickness

touch. At that posltlon

5

gauge

Page 82

+-

JULY

20

'82

I

I

5-7

UPPER PAPER

1.

Remove the rear cover, the right cover.

and the right front inner cover.

2.

Take off the counter bracket.

3.

Lower the

4.

Remove the harness cover.

5.

Uncouple the paper size detector

connector.

6.

Remove the paper feed motor.

7.

Take

off the upper feed roller gear and

the upper paper end detector.

8.

Remove the upper of two cassette holder

prns and the cassette holder gu~de

CPU

SIZE

DETECTOR REPLACEMENT

.2,

.

plate.

-.-.-

-.

band 3 screws

...

"

1

screw

2

screws

4

screws

6P

-1

screw

1

E-ring

block.

......,,

(FT4060l

'.

Paper

Size

Detector

I

I

Connector

Ca~sens

Holder

Pin

Page 83

9.

Remove the upper feed roller shaft.

10.

Take off the actuator of the upper paper

end switch (be careful not to damage

and remove the feeler shaft.

1 1.

Take off the upper feed roller shaft holder.

12.

Replace the paper size detector

13.

Reassemble the copier.

NOTE:

When reassembling, make sure

the

groove in the feeler shaft is

-

hooked in the feed roller shaft

holder and locked

plastic lock plate on the feed

roller shaft.

in

place by the

PCB.

it)

-

.3

Upper

1

E-ring

screws

2

screws

Feed

Roller

Shaft

JULY

M

'82

I

I

I

'U/

t&/

\,

Feeler

Upper

Shalt

Few

~oisr

Shaft

Holdar

Page 84

JULY

I

20

5-8.

'82

LOWER

1.

Take

CPU

PAPER

off the rear cover and lower the

plate.

SIZE DETECTOR REPLACEMENT

.

.

(Fr4060J

2

screws each

2. Uncouple the

paper size detector.

3.

Remove the paper size detector plate.

4.

Replace the paper size detector

5.

Reassemble.

NOTE:

Confirm that the lower paper size

detector plate

plate within

hamess connector of the

is

parallel to the base

0.5

mm (0.02").

PCB

2

screws

Page 85

5-9.

PAPER SIZE DETECTOR REPLACEMENT (FT4030)

1.

Take off the rear cover and

and lower the CPU plate.

2.

Take off the paper feed motor.

3.

Remove the paper size detector plate.

4.

Replace the paper size detector

5.

Reassemble

right

P.C.E.

rear cover.

2

screws each

-

1

screw. 1 connector

,

..

2

screws. 1 connector

2

screws

.

.

-

Page 86

(

I

5-10.

1.

2.

3.

4.

CRIMP CLUTCH ADJUSTMENT

Take off the rear cover and lower the

CPU plate.

Remove the transport/separation power

pack from its bracket.

Unhook the registration roller brake belt.

Unhook the chain tightener spring.

5.

Remove the crimp clutch.

6.

Loosen the clutch allen screw and position

0.5

is

0.05

to

to

the sleeve so that is

10.02''

to

0.04").

Measure @ while turning the sprocket

clockwise as shown and holding the

sleeve.

-

7.

Check that thrust play

(0.002"

8.

Reinstall the clutch.

to

0.004"l.

2

screws each

1

allen screw

1.0

rnm

0.1

mm

J

J

,,.

,c

"'"L""'

,'

Push in the solenoid plunger and confirm

9.

that

clearance:@ is

1.0

to

3.0

rnm

(0.04''

Page 87

6-6.

TRANSPORT

6-1.

Transport Unit Remova

6-2. Transport

Belt

Replacement

........................................................................

..............................

JULY

6-52

6-53

20

'82

r

6-3. Pick-off Pawl Solenoid Adjustment

....

.

.

,

6-54

.

I"

.

661

Page 88

6-1.

TRANSPORT

1.

Take off the rear cover.

2.

Lower the CPU plate.

3.

Remove the transportlseparation power

pack from its bracket.

4.

Uncouple the 4 connectors attached to the

transport unit.

5.

Open the front cover and take out the toner

collection bottle and the cleaning unit.

6.

Remove the toner collection bottle holder.

7.

Lift and take out the transport unit.

NOTE:

UNIT

REMOVAL

Confirm the gear engagement after

reassembling this unit.

2

screws

2

screws

2

screws

1

shoulderscrew.

1

E-ring

'

1

screw

-

Transport

Unit

pc;i

TransferiSeparator

....

Power

.

Pack

I/

Toner

Collect~an Bottle Holder

Page 89

6-2.

TRANSPORT BELT REPLACEMENT

Take out the transport unlt.

1.

2.

Remove the three screws

@

securing the

transpoa belt assembly to the vacuum

assembly.

3.

Remove the transport belt assembly from

the vacuum assembly.

4.

Replace the vacuum belts.

NOTE:

5.

Reassemble

The belts must be shiny stde out

JULY

20

'82

Page 90

..

*

JULY

20 '82

6-3.

PICK-OFF PAWL SOLENOID ADJUSTMENT

1.

Take out the transport unit.

2.

With the adjusting screw, adjust solenoid

stroke to

3.

Reinsert the transport unit and confirm that:

a. The pick-off pawls do not touch the drum

b.

NOTE:

5

f

:,5

mm

(0.20"

when the solenoid is off.

(Gap:

1.5

k

1.0

mm

The pick-off pawls touch the drum when

the solenoid is on.

This adjustment is only necessary

after replacing the pick-off pawls or.

pick-off pawl solenoid.

f

10.06"

:,02'')

t

0.04"))

15

r

(0.06"

l.Omm

*

0.04'1

5s.

Orum

Pick-off

Pick-OR

Pawl

Pawl

Solenoid

Page 91

6.7

.

FUSING

7-

1

.

Hot Roller Replacement

7-

2

.

Pressure Roller Replacement

...............................................................................................................................................

....................................................................................................................................

JULY

6-56

6-59

20

'

7-

3

.

Thermistor Replacement

7-

4 . Thermistor Gap Adjustment

7-

5 . Thermofuse Replacement and Positioning

7-

6 . Oil Supply Pad Replacement

7-

7

.

Oil Blade Replacement

7-

8 . Hot Roller Strippers Replacement

7-

9

.

Pressure Roller Strippers Replacement

7-1

0

.

Operating Temperature Adjustment

7-1 1

.

Ready Temperature Adjustment

..................................................................................................................

................................................................................................................................

......................................................................................................................................

............................

...........................................................................................................................

................

:

>.,

.........................................................................................................

.......................

.......................................................................................................................

....

........................................................................................

...............................................................................................................

qm*

e-6f

6-82

6-63

6-64

.

6-65

6-66

6-67

6-68

6-70

.

Page 92

JULY

I

20

32

7-1.

HOT ROLLER REPLACEMENT

1.

Take out the unit.

2.

Take off the oil bottle.

3.

Remove the oil bottle holder.

1

screw

2

screws

7

i

6-56

4.

Take off the fusing unit knob.

5.

Slide the fusing unit cover toward the front

and take

it

off.

1

-

1

screw

screw

Fusing

011

Catcher

Unit

1

,

Cover

.

I

-,

Page 93

6.

Open the exlt assembly and remove the

catcher.

7.

Unhook the pressure springs.

8.

Pull and rotate the front fusing lamp

and

terminal.

9.

Take out the oil pad pressure plate.

10.

Remove the oil supply assembly.

take out the fusing lamp.

.

2

011

screws

-

&t

Assembly

011

Pad

Pressure

Plata

1 1.

Take off the oil blade assembly.

-

.

2

springs

011

SUDPIV Arrarnblv

--

-v.\

'.

'.

3

3

Page 94

Take off the rear lamp terminal.

Remove the hot roller gear.

Carefully slide the hot roller out through the

front bearing opening.

CAUTION:

Remove the bearing from the front end of

the hot roller.

Tear the protective paper from the ends of a

new hot roller: then set the bearing on the

front

17.

Carefully insert the new roller. After it is set.

tear off the protective paper.

Do not damage the thermistor1

(short1 end of the roller.

-

18.

Reassemble the fusing unit.

NOTE:

Apply extra silicone

blade to avoid excess

it

tween

Confirm that the fusing lamp does

not contact the inside

roller by turning the hot roller.

and the new hot roller.

oil

frict~on be-

1

screw

-

1

C-ring

1

C-ring

to the oil

oi

the hot

Protectwe

/

Paper

Hot

Roller

I

Page 95

7-2.

PRESSURE ROLLER REPLACEMENT

1.

Follow the same steps 1 through 7 of the

hot roller replacement procedure.

2.

Take out the

011

cleaning pad.

-

2

screws

Oil

/

Cleantng

Pad

SEP

30

'8

.

.

I

:

.

..+i

Page 96

&

SEP

30

'82

3.

Take off the front pressure lever.

4.

Remove the oil pan screw.

5.

Lift up the upper part of the fusing unit and

take out the pressure roller.

6.

Install a new pressure roller.

NOTE:

Make sure to set the pressure roller

bearing from the inside.

.

1

E-ring

-.

Oil

Pan

Screw

-

Front

Pressure

ever

-

-

I

-3

I

Pressure

I

Roller

Bearinq

-.

s

..

-

Page 97

1

7-3.

I

THERMISTOR REPLACEMENT

1.

Follow steps 1 to

ment procedure.

2.

Disconnect the two white lead wires.

3.

Remove the thermistor bracket.

4.

Separate the thermistor assembly and the

thermistor bracket.

5.

Install a new thermistor and adjust the

thermistor gap.

10

of the hot roller replace-

1

screw each

'

1

screw

-

2

screws

JULY

20 '82

Page 98

1EP

30

'82

7-4.

THERMISTOR

Adjustment Standard: