Page 1

RICOH Technical

Bulletin

PAGE: 1/4

Model:

Subject:

From:

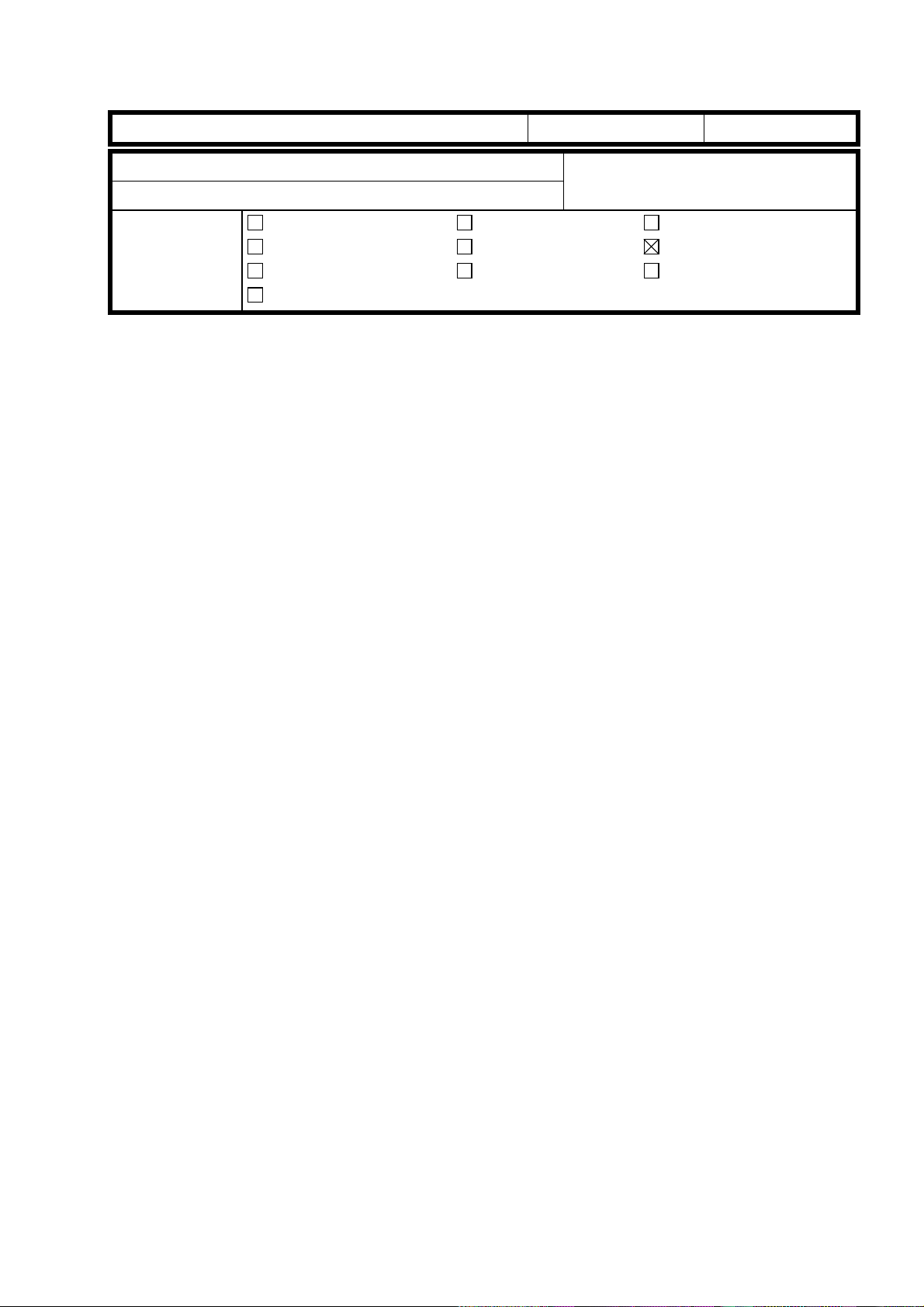

Classification:

The new models, “Kingfisher 2 (A298)” and “Grand Kingfisher 2” will be launched in

November ‘99. They are slightly modified versions of the already existing models

“Kingfisher (Ricoh FT4015, Gestetner 2715z, Nashuatec 3715, Rex-Rotary 8715Z, Savin

9115, Infotec 5151 z)” and “Grand Kingfisher (Ricoh FT4618, Gestetner 2718z, Nashuatec

3718, Rex-Rotary 8718Z, Savin 9118, Infotec 5181 z)”.

There will be nine destination codes for Kingfisher 2 depending on the area: -27 is Europe

(Ricoh), -29 is Asia (Ricoh), -19 is Taiwan (Ricoh), -23 is China (Ricoh), -69 is Russia

(Ricoh), -22 is Europe and Asia (Gestetner, Nasuatec and Rex-Rotary), -50 is Taiwan

(Gestetner), -62 is China (Gestetner), -26 is Europe (Infotec).

There will be four destination codes for the Grand Kingfisher 2 depending on the area: -27

is Europe (Ricoh), -29 is Asia (Ricoh), -22 is Europe and Asia (Gestetner, Nasuatec and

Rex-Rotary), -26 is Europe (Infotec).

Kingfisher 2

Differences from Kingfisher

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

15-Sep-99

Prepared by:

Action required

Service manual revision

Retrofit information

No.:

K. Miura

RA298001

This RTB clarifies the differences between the base copier and Kingfisher 2 and Grand

Kingfisher 2 (based on the style of the service manual).

Page 2

RICOH Technical

Bulletin

PAGE: 2/4

Model:

Kingfisher 2

Date:

15-Sep-99

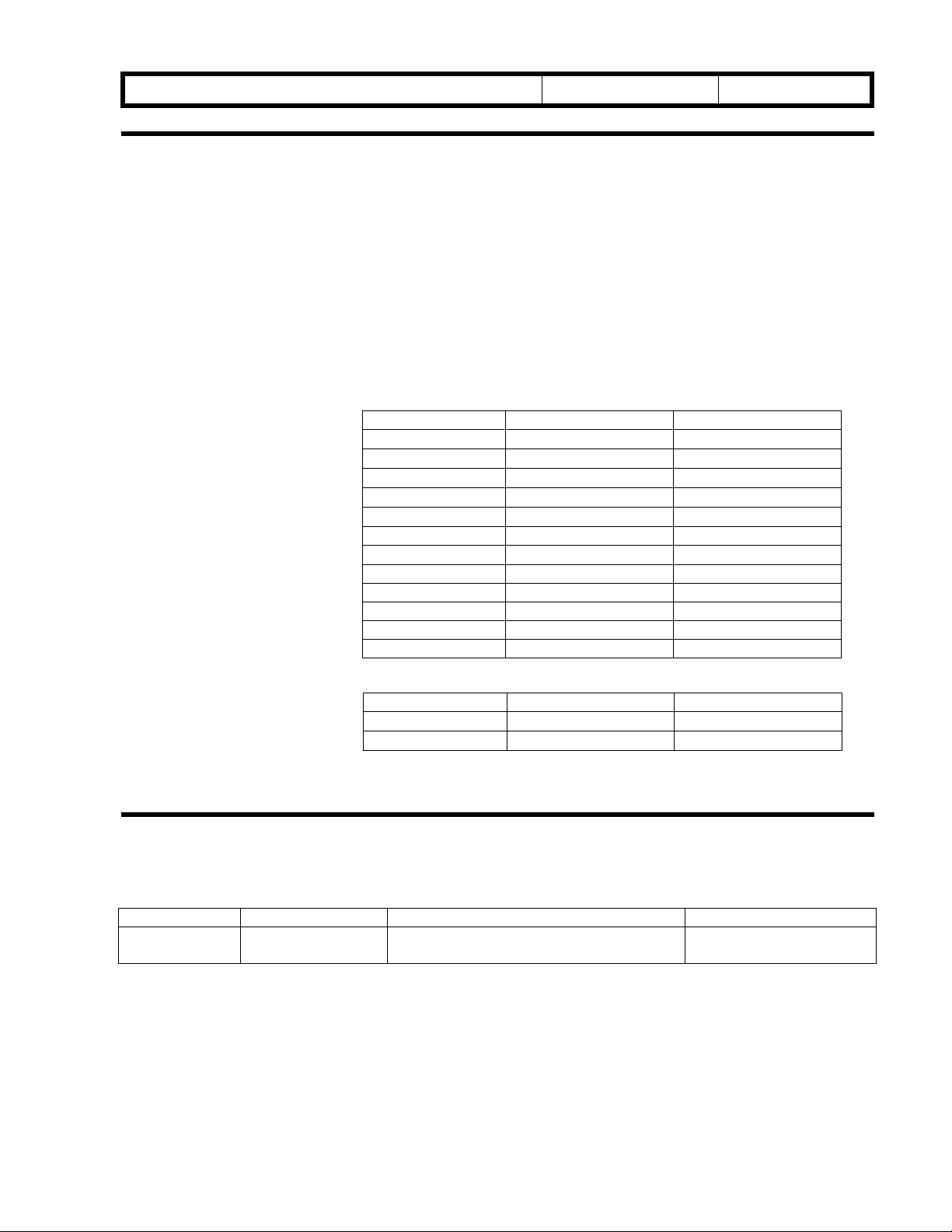

1. OVERALL MACHINE INFORMATION

1-1. SPECIFICATIONS

NOTE:

First Copy Time:

*

Warm-up Time:

Power Consumption:

*

Only items marked * are different from the base copiers.

Less than 6 seconds (A4/8.5” x 11” sideways)

NOTE:

It can be changed in SP mode.

120 V machines of A298: Less than 30 seconds (at 23 °C)

230 V machines of A298: Less than 35 seconds (at 23 °C)

*

120 V machines of A299: Less than 35 seconds (at 23 °C)

230 V machines of A299: Less than 45 seconds (at 23 °C)

A298 machines Copier only Full system

Warm up

Stand-by

Copying

Maximum

Energy saver

0.95 0.95

0.16 0.16

0.70 0.70

1.4 1.5

0.12 0.12

No.:

RA298001

Weight:

*

A299 machines

Warm up 0.95 0.95

Stand-by 0.16 0.16

Copying 0.70 0.70

Maximum 1.4 1.5

Energy saver 0.12

A298 machines

A299 machines

Copier only Full system

0.12

Copier only Full system

40.5 kg (89.3 1b) 53.5 kg (118.0 1b)

43.5 kg (95.9 1b) 56.5 kg (124.6 1b)

2. ELETRICAL COMPONENT DESCRIPTIONS

The following transformer is not included in these copiers.

Symbol Name Copier only Full system

TR Transformer Steps down the wall voltage to 30 Vac

and 8 Vac.

A219 machines: 15

A245 machines: 17

Page 3

RICOH Technical

Bulletin

PAGE: 3/4

Model:

Kingfisher 2

Date:

15-Sep-99

No.:

RA298001

3. INSATLLATION PROCEDURE

3-1. COPIER ACCESSORY CHECK

1. NECR – Multi-language (-19, -23, -27, -29, -69 machines)

2. Sheet – Operate Keytop – TWN (-19, -50 machines)

3. Sheet – Operate Keytop – CHN (-62, -69 machines)

4. Decal – Symbol Explanation – TWN (-19, 50 machines)

5. Decal – Symbol Explanation – Multi-language (-22, -23, -26, -27, 29 machines)

6. Decal – Symbol Explanation – CHN (-62, -69 mach ines)

7. Operating Instructions – Taiwanese (-19, -50 machines)

8. Operating Instructions – English (-22, -26, -29 machines)

9. Operating Instructions – Russian (-23 machines)

10. Operating Instructions – Germany (-26 machines)

11. Operating Instructions – French (-26 machines)

12. Operating Instructions – Italy (-26 machines)

13. Operating Instructions – Spanish (-26 machines)

14. Operating Instructions – Chinese (-62, -69 machines)

15. Exit Tray

16. Power Code Socket (-19, -50 machines)

17. Model Name Decal (-22, -50, -62 machines)

18. Decal – Keytop Cover (-22, -50, -62 machines)

19. Large Decal – Energy Star

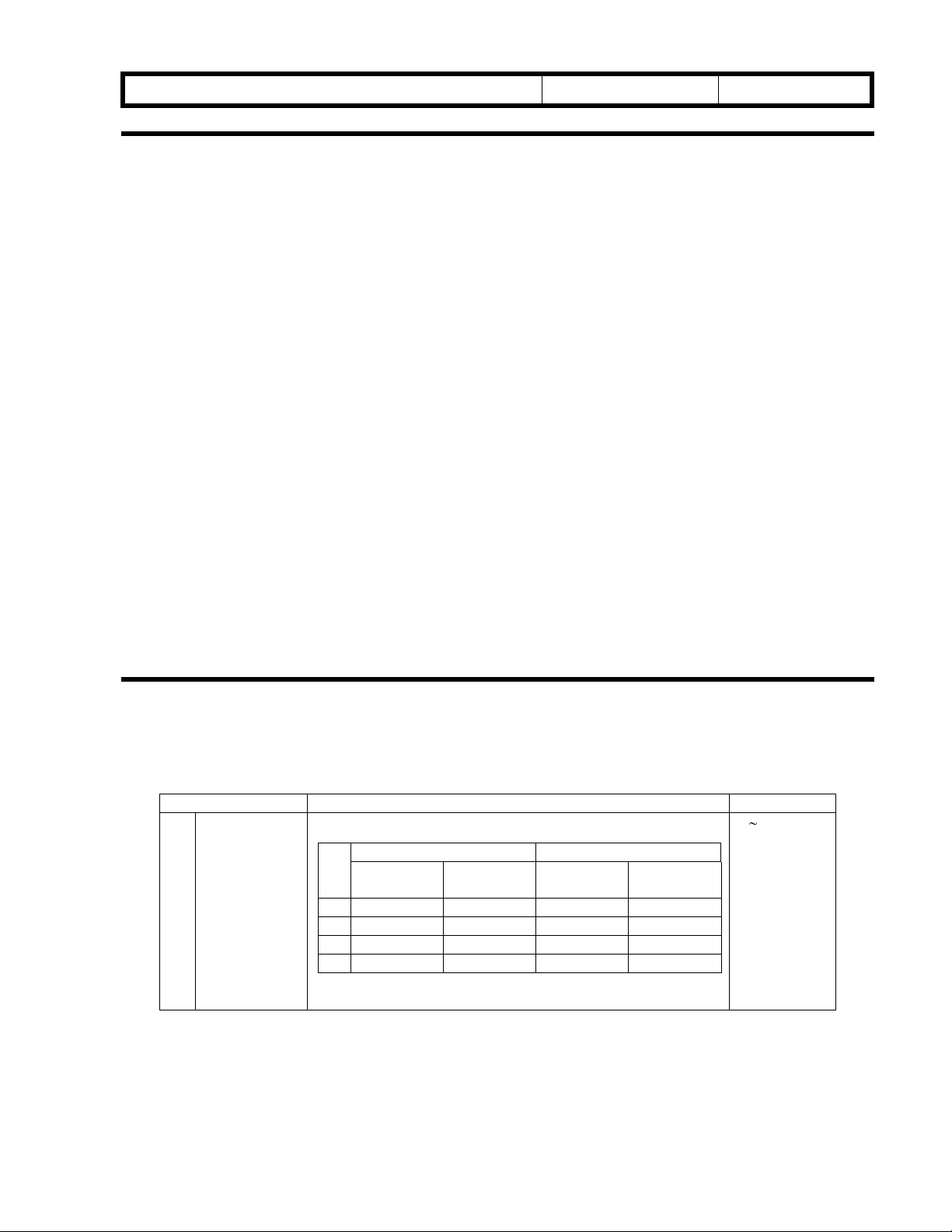

4. SERVICE TABLES

4-1. SERVICE PROGRAM MODE TABLE

The following mode was added.

Mode No. Function Settings

79 Fusing

Temperature

Setting for

Energy saver

mode

Sets the fusing temperature in energy saver mode.

A298 machines A299 machines

120V

machines

0 120 130 130 140

1 130 140 140 150

2 140 150 150 160

3 150 160 160 170

230V

machines

120V

machines

230V

machines

0 ~ 3

Default = 0

Page 4

RICOH Technical

Bulletin

PAGE: 4/4

Model:

Kingfisher 2

Date:

15-Sep-99

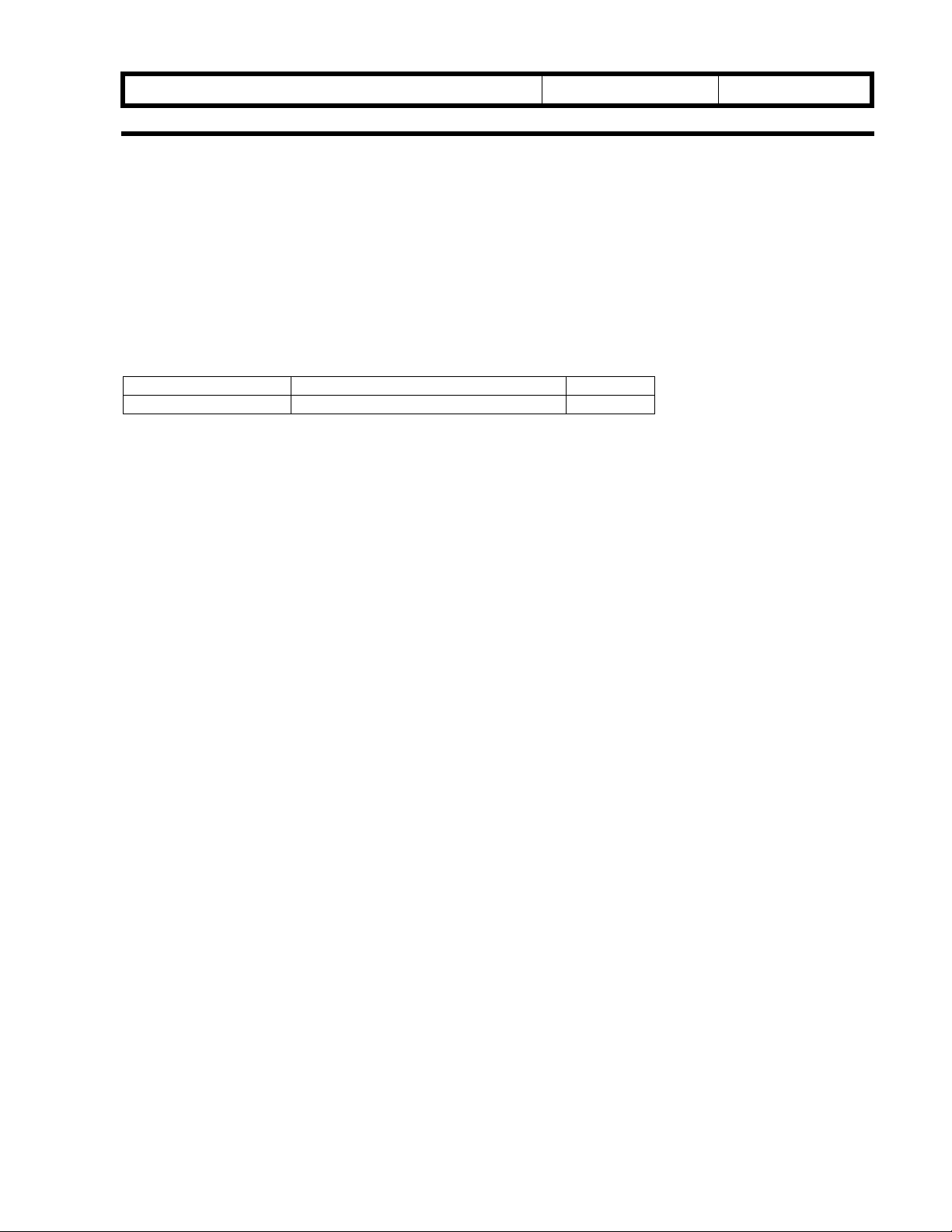

5. PREVENTIVE MAINTENANCE SCHEDULE

5-1. PM TABLE

All the 45K PM parts are changed to 60K.

5-2. SPECIAL TOOLS AND LUBRICANTS

The Digital Multimeter has been changed.

Part Number Description Q’ty

A0299387 Digital Multimeter 1

No.:

RA298001

Page 5

T

echnical

B

ulletin

PAGE: 1/2

Model:

Subject:

From:

Classification:

The following SP modes have been added to the KF2/GKF2.

SP 70 (No UP mode)

-User Code Mode selectionFunction: Enables User Code Mode.

Procedure:

1) Access SP mode 70.

2) Select 1:user code mode (Default is 0: No user code).

3) The machine is then ready to access the next mode number.

Note:

Cut JP101 on the main board.

Procedure to set the user code:

1) "U2" is displayed in the copy counter. Using the number keys, input the three-digit user

code number (e.g.111,123,999). Please note that 000 is invalid.

2) Press the Auto Image Density key.

3) "U2" is no longer displayed and the machine becomes ready to copy.

If any invalid values are entered or other keys are pressed, "U2" will rema in displayed

and copies cannot be made.

4) After the copy job is completed (or one minute after the last key is pressed), the

machine initiates Auto Reset and becomes ready to set the next user code. At this time,

"U2" will be displayed and copies cannot be made.

5) As an alternative, you can set the next user code by pressing the Clear Mode/Energy

Star key and then the Clear/Stop key when the machine is in Copy Ready condition.

The machine will then become ready to accept the next user code.

Kingfisher 2

User Code Mode

Technical Services Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

31-Jan-00

Prepared by:

No.:

RA298002

M. Ishihara

Action required

Service manual revision

Retrofit information

User codes:1 - 999(*)

SP 72 (UP 12)

-Registering User Numbers-(*)

Function: Registers user numbers.

The user number (1-10) is displayed in the copy counter and code numbers are displayed

in the three digit indicator (Zoom, %).

To change the user code numbers, use the Zoom key.

Page 6

T

echnical

B

ulletin

PAGE: 2/2

Model:

Procedure:

1) Access mode number 72 in SP mode (12 for UP mode).

2) "1" is displayed in the copy counter.

A 3-digit number can be displayed in the three digit indicator (Zoom,%).

Press the Zoom Up(+) key or Zoom Down (-) key to see the ne xt user codes.

3) Enter the new user code with the number keys. This can be a 3-digit number from 1 to

999.

4) Press the Auto Image Density key. The old user code is then changed to the new code.

5)To exit from the User Tools, turn the main switch off and on.

User Numbers: User code:

1

2

. .

. .

10 1 - 999

Note: User codes are set to "0" when the machine is shipped from the factory.

Kingfisher 2

1 - 999

1 - 999

3 1 - 999

Date:

31-Jan-00

No.:

RA298002

SP 73 ( UP 8)

- User Code Counter Check Function:

Displays the copy counter value for each user number registered.

The user number (1-10) is displayed in the copy counter and the corresponding total copy

counter value is displayed in the 3-digit indicator (Zoom,%). Using the Zoom key

(up:+,down:-), you can view how many copies each registered user has made.

Procedure:

1) Access mode number 73 (number 8 for UP mode).

2) "1" is displayed in the copy counter.

3) At first, only 3 digits are displayed in the 3-digit indicator (6th, 5th and 4th).

4) After you press the "Darker" key, the next 3 digits will be displayed (3rd , 2nd and 1st).

5) To exit, press the Auto Image Density key and turn the main switch off and on.

SP 92 (UP 9)

-User Code Counter ClearFunction: Clears the total copy counter values for all registered users.

Procedure:

1) Access mode number 92 (number 9 for UP mode).

2) Press "1" on the number key pad.

3) Press the Auto Image Density key and the "Darker" key at the same time.

4) The Image density indicator will blink and begin to clear the counter values.

5) The image density indicator then turns off and all total copy counter values are

cleared. The machine will then wait for the next SP mode number to be input.

6) To exit, turn the main switch off and on.

Page 7

RICOH Technical

Bulletin

PAGE: 1/

2

Model:

Subject:

From:

Classification:

Kingfisher 2

Overtoning and toner drops on copies

Technical Services Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Date:

Prepared by:

Part information

Electrical

Transmit/receive

29-Feb-00

Action required

Service manual revision

Retrofit information

No.:

M. Ishihara

RA298003

SYMPTOM:

1) At machine installation or after the developer is replaced, SP66 (TD sensor Initial

Setting) that would usually take about 60 seconds stops after only a few seconds.

2) After a new machine is installed, copies have high ID and/or toner drops onto copies.

This occurs until about 100 copies are made.

CAUSE:

The TD sensor connector (A1905346: Development Unit Harness) which is mounted on

the I/U (Imaging Unit) is not properly connected to the connector of the Development

Relay Board (A1905145). The board is mounted on the rear side plate of the mainframe.

If the service technician does not tighten the knob screw

raised portion of the mainframe front side plate, the TD sensor connec tor will no t be fully

inserted into the receiving connector on the board.

To check whether or not the connection is stable, make some copies and check the

reading of SP55. If the connection is unstable, the SP55 reading will also be unstable (e.g.

71,125,13,17,117,35).

pushing the I/U against the

while

Page 8

RICOH Technical

Bulletin

PAGE: 2/

2

Model:

Kingfisher 2

Date:

29-Feb-00

No.:

RA298003

SOLUTION:

I/U installation procedure

1) Insert the I/U into the mainframe.

2) Push the I/U toward the back so that the I/U front side plate(A1902280) remains flush

against the raised portion of the front side plate of the mainframe (see the illustration

below). While holding the unit in this position (pushing on the handle), tighten the knob

screw (A1902320) by hand until the I/U is secure.

Front Side Plate of the Mainframe

Front Side Plate (A1902280) of the I/U

Knob Screw (A1902320)

3) Use a slotted screwdriver or coin for the final tightening.

Page 9

T

echnical

B

ulletin

PAGE: 1/1

Model:

Subject:

From:

Classification:

The procedure for installing the imaging unit in the copier has been replaced with a more

detailed description. Please make sure to in stall the unit in this way after pouring in the

new developer at machine installation or developer replacement.

Previous:

8. Remount the cover on the imaging unit, and install the unit in the copier (1 knob screw).

Then turn the “B1” lever clockwise to raise the transfer corona unit.

Revised:

Kingfisher 2

Installation Procedure for the Imaging Unit

Technical Services Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

10-Mar-00

Prepared by:

No.:

RA298004

M.Ishihara

Action required

Service manual revision

Retrofit information

8. Remount the cover on the imaging unit and insert the unit into the mainframe. Push

the unit toward the back until it stops. While holding the unit in this position, tighten

the knob screw by hand. For the final tightening, use a screwdriver or coin as shown in

the illustration. Then turn the B1 lever clockwise to raise the transfer corona unit.

Page 10

echnical Bulletin

T

PAGE: 1/2

Model:

Subject:

From:

Kingfisher2

Low image density in leading (top) area

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

03-Aug-00

Prepared by:

No.:

RA298005

M.Ishihara

Action required

Service manual revision

Retrofit information

SYMPTOM:

The image density of the leading (top) half of the copy becomes lighter when specific light or

halftone originals are copied.

CAUSE:

When the 1st and 2nd scanners start to move, part of the light from the 1st scanner is directly sent

to the mirror of the 2nd scanner, as the two scanners are relatively close. This "extra light" received

by the mirror will cause the image to appear lighter. As scanning continues, the 1st scanner

increases to twice the speed of the 2nd scanner, causing the two scanners to get farther and

farther apart. Therefore, less and less light "extra light" reaches the 2nd scanner mirror. This is why

the image is lighter near the leading edge.

SOLUTION:

A shading seal (A2981684) should be attached to ensure proper image density at the leading edge

(when making copies with very light/halftone originals). Because the extra light passes from the

2nd scanner mirror to the photoconductor via the base plate of the optics unit and lens carriage

(A1901682), the seal should be attached to the lower portion of the lens carriage. This will prevent

the extra light from passing between the optic base plate and lens carriage.

This modification will be applied from August 2000 production.

Please see the procedure as shown below.

Lens Carriage (A1901682)

B

A

Adhesive portion

A: 0-1mm from the edge, B: 0-0.5mm from the surface

Shading Seal (A2981684)

Page 11

echnical Bulletin

T

PAGE: 2/2

Model:

Procedure:

1. Remove the power plug from the wall outlet.

2. Remove the lens carriage from the optics unit.

Note: Before removing the lens carriage, remove the left scale, the exposure glass

and the lens cover.

3. Attach the shading seal to the lens carriage as shown in the illustration.

Kingfisher2

Date:

03-Aug-00

No.:

RA298005

Page 12

echnical Bulletin

T

PAGE: 1/2

Model:

Subject:

From:

Kingfisher2

DF Harness damage

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

28-Dec-00

Prepared by:

No.:

RA298006

M.Ishihara

Action required

Service manual revision

Retrofit information

SYMPTOM:

Damage to the harness connecting the DF44 and the copier.

CAUSE:

Sometimes, the DF is forced past its normal stop position when it is opened. If this

happens many times, the harness may be damaged.

SOLUTION:

1. User Instruction

Request the users not to force the DF past the stop position when they open it.

2. DF Bracket

A DF bracket (PN A2989500) has been registered as a service part. Place it on the

copier upper cover as shown below to prevent the DF unit from being forced too far

back.

DF

Copier Upper Cover

DF Bracket

100 ± 20mm

DF Harness

Double-sided

Tape

Page 13

echnical Bulletin

T

PAGE: 2/2

Model:

3. Upper Cover Slit

Model Code Machine serial number Applying date

A298-19 N/A N/A

-22 H2106900001 00/09/07

-23 H2106902854 00/09/04

-26 4A18900001 00/09/14

-27 H2106803121 00/08/23

-29 H2106902914 00/09/06

-50 H2107003536 00/10/27

-62 H2106903169 00/09/06

-69 H2106903269 00/09/26

Kingfisher2

A slit has been made in the upper cover to prevent the harness from being pinched

even if the DF unit is forced too far back. This change was applied from the August,

September, and October production as shown in the following table.

Date:

28-Dec-00

No.:

RA298006

Page 14

echnical Bulletin

T

PAGE: 1/1

Model:

Subject:

From:

Kingfisher2

Toner Supply Motor failure

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

10-Jan-01

Prepared by:

No.:

RA298007

M.Ishihara

Action required

Service manual revision

Retrofit information

SYMPTOM:

The toner supply motor breaks down so that the toner supply system malfunctions.

CAUSE:

The tip of the worm gear on the motor shaft wears out.

SOLUTION:

1) Apply grease to the tip and spiral threads of the present worm gear of the toner supply

motor (P/N A2983371).

Recommended grease:

Part Number Description

A1909002 Grease-CP501 (5 pcs/set)

52039502 Grease-501

- Cosmos No.1

An equivalent grease for plastic can be used instead of the above ones.

Note: Cosmos No.1 grease was applied to the tip and spiral threads of the worm gear at

the motor vendor as of July 2000 production motors onward.

2) Replace the worm gear with a new one (P/N A2983388) and apply grease to the tip and

spiral threads of the gear.

Note: The material of the new worm gear was changed to NW-02 to improve durability,

and it will be applied from the February 2001 production machines onward. We

will issue a modification bulletin (MB) to inform you of the new part number of the

toner supply motor (the motor service part includes the worm gear) and the cut-in

machine serial numbers.

Please do not order the new parts until the MB is issued, as they are not yet in

stock.

Page 15

echnical Bulletin

T

PAGE: 1/1

Model:

Subject:

From:

Kingfisher 2

SC”E14”

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

12-Apr-01

Prepared by:

SYMPTOM:

SC ”E14” (220-240V region).

CAUSE:

-The power input (voltage and/or frequency) is out of standard, or

-Electrical noise interferes with the power input.

SOLUTION:

There are two solutions:

No.:

RA298008

M.Ishihara

Action required

Service manual revision

Retrofit information

1) Use a power source where the actual power input is within machine standards:

220-240V,50/60Hz +, - 10%.

2) Use the following PSU (Power Supply Unit) that has been arranged for specific

customers and contains a countermeasure for SC ”E14”:

Part Number Description

A2989501 Power Supply Unit-230V

*Modification: This is the A2985651 PSU with a 0.01µF capacitor soldered (added) to its

rear face.

Page 16

!"#$% T

echnical Bulletin

PAGE: 1/1

Model:

Subject:

From:

Kingfisher 2

SC Code E-90

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

14-Nov-01

Prepared by:

No.:

RA298009

M. Ishihara

Action required

Service manual revision

Retrofit information

Please add the following SC description to the Service Call Conditions in the Service

Manual.

SC Code E-90 (Exposure Lamp Off)

Definition

Detects that the exposure lamp is off at 50 mm from the edge of the original.

Possible causes

Exposure lamp control system failure.

! Connectors not connected properly

! Exposure lamp failure

! Lamp regulator failure

! Main board failure

! PSU failure (AC/DC Power Supply Unit)

Remedy

Check the above causes, then turn the main switch off and on.

Loading...

Loading...