Page 1

RICOH Technical

Bulletin

PAGE: 1/4

Model:

Subject:

From:

Tequila

Toner drops onto the copy

Technical Service Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Date:

Prepared by:

Part information

Electrical

Transmit/receive

22-Sep-99

Action required

Service manual revision

Retrofit information

No.:

M. Ishihara

RA289001

SYMPTOM

1. Toner drops onto the copy.

2. Dirty background on copies (Occasional)

3. Image density too high (Occasional)

CAUSE

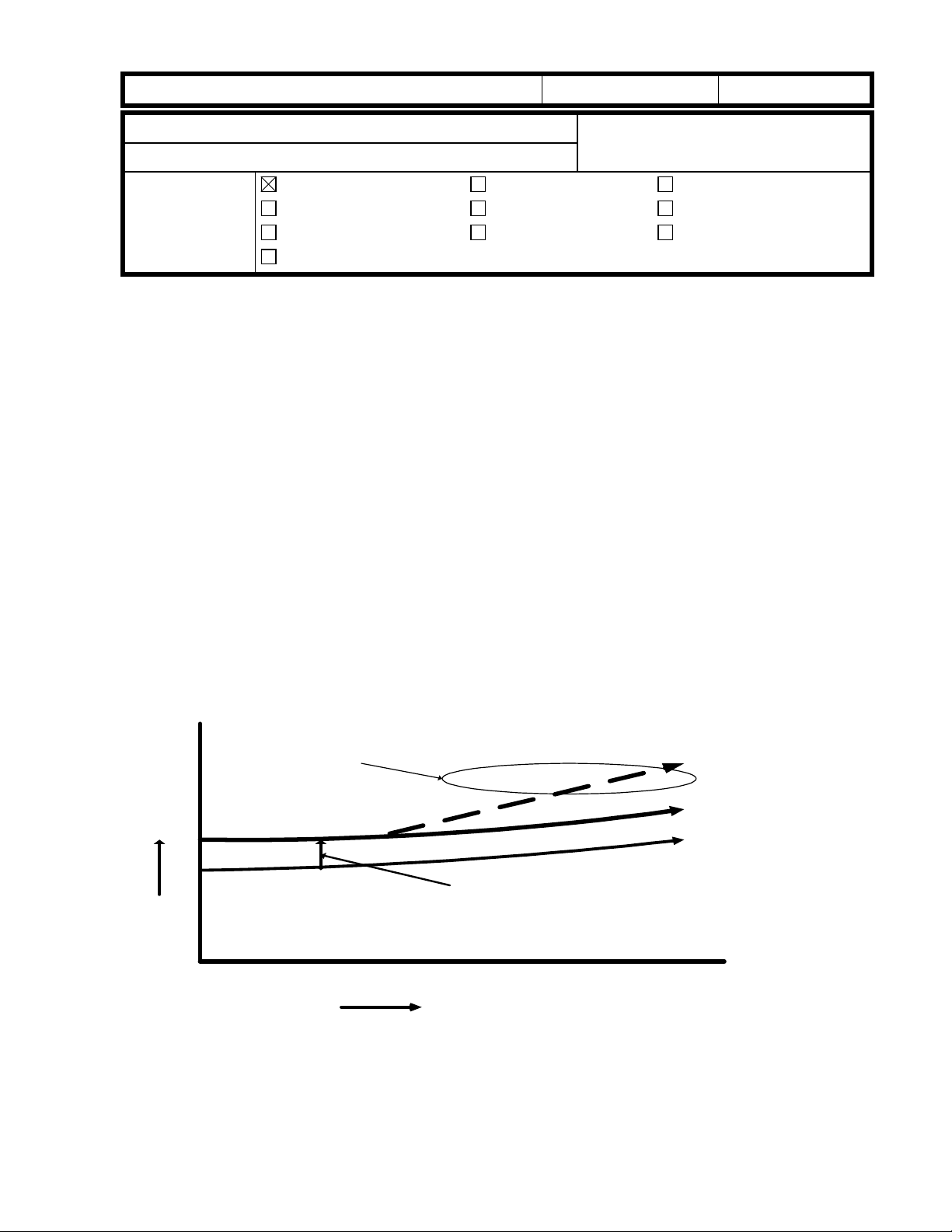

Although the toner concentration in the developer is maintained between 3 and 4%,

an increase can be observed when used over an extended period of time. This level

is normally kept under 5% even after 60K copies, however there are rare cases where this

limit is exceeded due to the environmental factors described below. These are thought to

cause the toner to fall onto the surface of the copy.

1. The presence of paper dust as well as conditions such as high humidity are thought to

cause an oversupply of toner to the development unit (by raising the limit of the toner

concentration control to over 6%), which in turn causes the toner to fall onto the copy

surface.

Too much toner

4%

3%

Controlled Limit

Toner

Consent

-ration

0 20K 60K40K

Copy Volume

6%

5%

4%

2. In addition, due to this oversupply of toner to the development unit, recycled toner

creates a blockage in the imaging unit and the toner falls from the cleaning area.

Page 2

RICOH Technical

Bulletin

PAGE: 2/4

Model:

Tequila

Date:

22-Sep-99

No.:

RA289001

ACTION REQUIRED

A. Countermeasure in the field:

Please follow the procedure as shown below if the toner dropping problem occurs in the

field.

1. Remove the IU from the machine.

2. Completely remove the recycled toner at the toner collection coil under the cleaning

blade and the toner recycling belt area. Install the IU in the machine.

3. Remove the toner bottle from the machine. Check that SP38 is 0. (Input "0" if it is not.)

4. Make 20, A4 sideways, skyshot copies (Black solid copies).

5. Set an original and make some copies to confirm that copy quality is normal.

6. Change the toner supply mode from “0” to “1” using SP30.

7. Make some copies while monitoring the TD sensor output (SP55).

8. Input the value obtained in step 7 into SP53 – TD Sensor Target Control Voltage

Adjustment. (If it is more than 127, input 127.)

9. Install the toner bottle in the machine.

10.Set an original and make some copies to confirm that copy quality is normal.

Note:

When the developer is replaced, please observe the following for efficient troubleshooting:

1) Perform the SP66 to initialize the developer .

2) Do not change the settings of SP30 and SP53. (SP30 must be at “1”. TD Sensor

control voltage must be kept at the same level in SP53, as entered in step 8 above.)

B. Permanent Countermeasure:

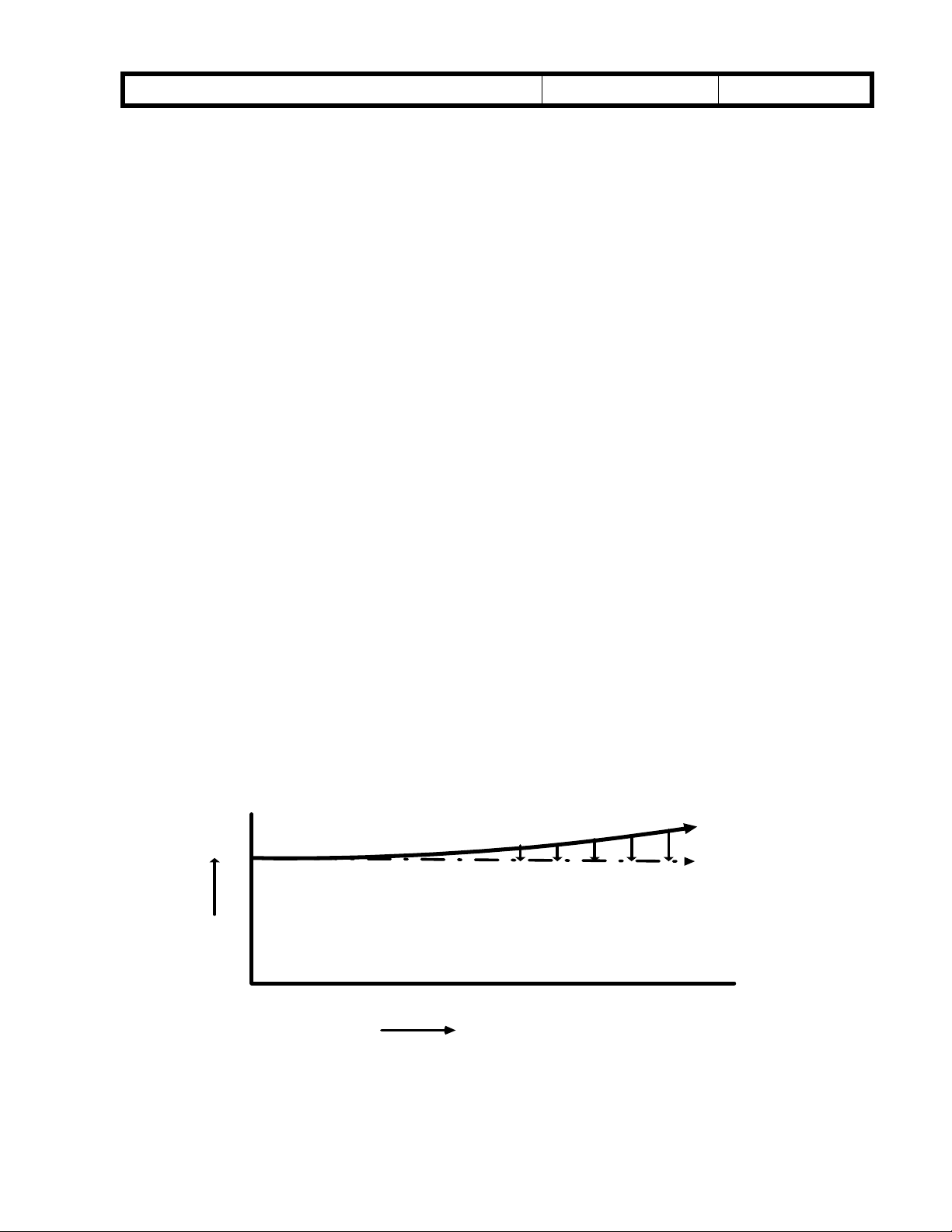

This rise in the amount of tone r being supplied will be prevented as de termined by the

copy volume by modifying the software so that an oversupply does not result.

For the

machine of mass production. It is scheduled to be implemented in the

October 1999 mass production.

Kingfisher2

4%

Toner

Density

, this modification is scheduled to be implemented from the first

Kingfisher

5%

4%

0 20K 60K40K

from

Page 3

RICOH Technical

Bulletin

PAGE: 3/4

Model:

If the above symptom should occur in the field before preventative maintenance is

performed, please institute the temporary countermeasure described in the previous

section (A.) and refrain from upgrading the software.

The new software has two major differences from the previous version:

The overall process control and toner density control (maintained by lowering

it to a fixed value every 1K). Due to these differences, it is recommended that

the new firmware be used together with new developer.

NOTE:

Please upgrade the software at the next PM visit (when the developer is replaced).

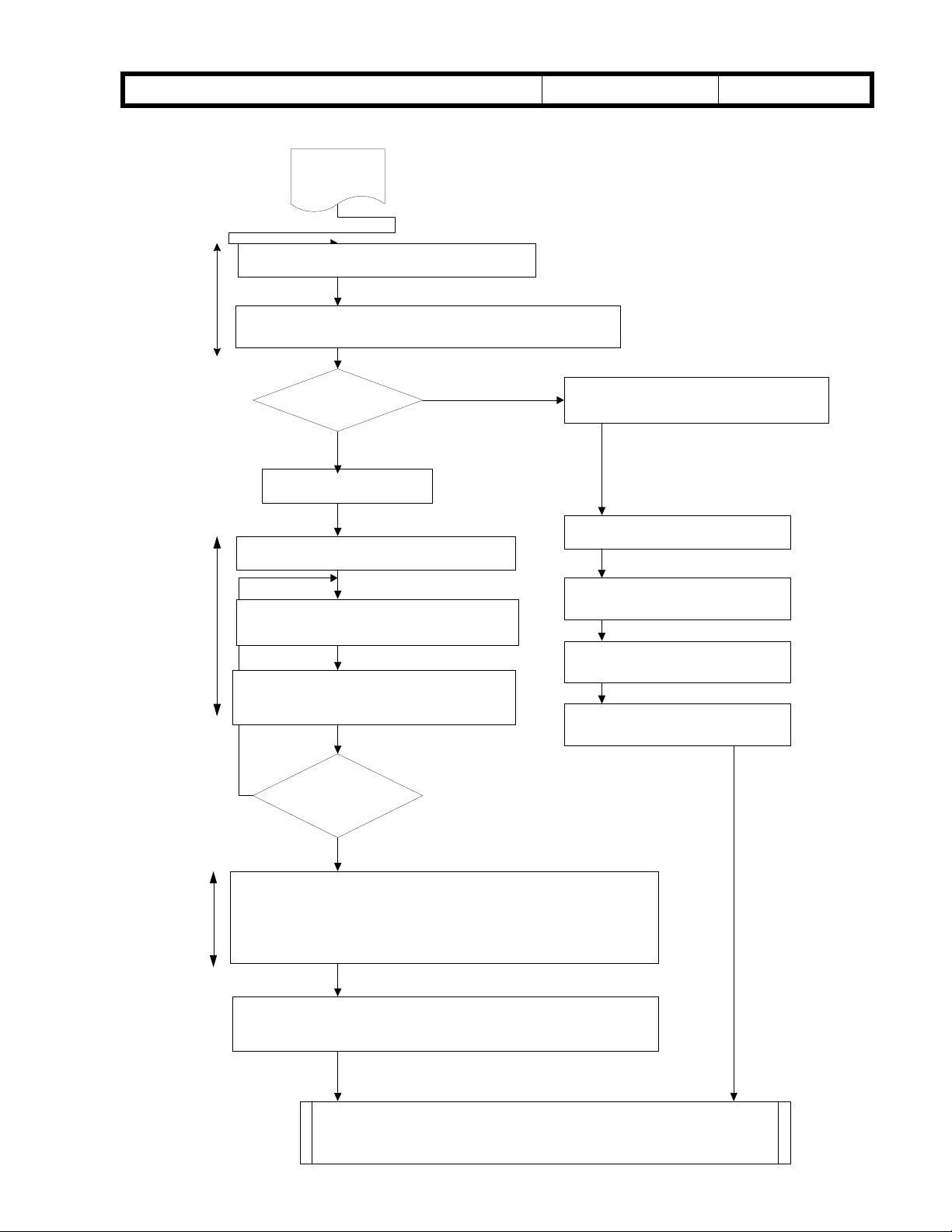

Please refer to the flow chart on the following page.

(Note: When the developer is replaced, remove the old developer completely. Otherwise

the volume of the developer is increased and it causes the toner to drop.)

Tequila

Date:

22-Sep-99

No.:

RA289001

Page 4

RICOH Technical

Bulletin

PAGE: 4/4

Model:

Tequila

Date:

22-Sep-99

FLOW CHART FOR THE TONER DROPPING PROBLEM

START

Remove the Imaging Unit from the machine.

Remove the recycled toner in cleaning unit

(under the cleaning blade) and at the recycling belt area.

YES

To remove

excessive

toner from the

developing unit

Is PM required?

NO

Install the imaging Unit.

Remove the toner bottle from the machine.

Input "0" in SP38 if it is not.

Make 20(A4 sideways) skyshot copies to

confirm that copy quality is normal.

Set an original and make some copies to

confirm that the copy quality is normal.

Replace the developer in the imaging Unit.

Note: Completely remove the developer

from the imaging unit.

(Otherwise the amout of developer will

increase causing toner recycling process

not function properly.

Install the imaging Unit.

Replace the ROM.

Perform the toner initialization

(SP66).

If the SP30 is "1", set it to "0".

No.:

RA289001

To maintain

proper toner

density

NO

Change the toner supply mode from "0" to "1" (in the SP30).

Make several copies while monitoring the TD sensor output (SP55).

Input the value obtained in the previous step into SP53 - TD Sensor

Target Control VoltageAdjustment.

Install the toner bottle in the machine.

Set an original and make several copies to confirm that copy quality

is normal.

Is Image density

normal?

YES

END!

Page 5

T

echnical

B

ulletin

PAGE: 1/2

Model:

Subject:

From:

Classification:

The troubleshooting procedures for this problem have been outlined in previous RTBs.

The software for the following ROMs have been modified:

Model: ROM P/N: Suffix:

Kingfisher A2195104 G

Grand Kingfisher A2455104 D

Tequila A2895104 D

Modifications:

Tequila

Overtoning / black spots on copies

Technical Services Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

31-Jan-00

Prepared by:

No.:

RA289002

M. Ishihara

Action required

Service manual revision

Retrofit information

1. The method for calculating the target TD sensor output (Target VT) has been changed.

The previous Target VT will be called “VTref”, and its default value has been changed

from 1.9 to 1.5V. The alpha and beta corrections described below will be added to

VTref. The new Target VT is then calculated as:

Target VT = VTref + α + β

2. For toner density correction, SP37 (alpha correction) has been added as a new

SP Mode. In addition, items 5 and 6 in the second table below have been added to SP38

(beta correction).

Alpha Correction:

This correction is designed to operate gradually, over a period of time. Therefore,

it should not be used to achieve quick results.

SP37 Correction Level: Variable Correction Target:

0 No correction

1 +0.06V / 1K copies

2 +0.04V / 1K copies

- -

-

Lighter

Light

3 +0.02V / 1K copies Default

4 +0.02V / 2K copies

5 +0.02V / 4K copies

+

++

Dark

Darker

Page 6

T

echnical

B

ulletin

PAGE: 2/2

Model:

Beta Correction:

Please note that items 5 and 6 have been newly added to SP38.

SP38

0 No correction

1 Darker +0.5% -0.375V

2 Lighter -0.5% +0.375V

3 Dark +1.0% -0.75V

4 Light -1.0% +0.75V

5 Darkest +1.3% -1.0V

6 Lightest -1.3% +1.0V

Tequila

Target Toner Density

Date:

Correction Target:

31-Jan-00

No.:

Target VT

Correction:

RA289002

Limitations:

-The maximum absolute value of the combined alpha and beta corrections is 1V.

Therefore:

-When SP66 is performed, the correction counter resets.

+ β ≤ 1.

α

Page 7

!"#$% T

echnical Bulletin

PAGE: 1/2

Model:

Subject:

From:

Tequila

Overtoning and toner dropping onto copies

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

19-Apr-00

Prepared by:

No.:

RA289003

M. Kitajima

Action required

Service manual revision

Retrofit information

SYMPTOM:

1) At machine installation or after the developer is replaced, SP66 (TD sensor Initial

Setting) that would usually take approximately 60 seconds stops after only a few

seconds.

2) After a new machine is installed, copies have high ID and/or toner drops onto copies.

This occurs until approximately 100 copies are made.

CAUSE:

The TD sensor connector (A1905346: Development Unit Harness) which is mounted on

the I/U (Imaging Unit) is not properly connected to the connector of the Development

Relay Board (A1905145). The board is mounted on the rear side plate of the mainframe.

If the service technician does not tighten the knob screw while pushing the I/U against the

raised portion of the mainframe front side plate, the TD sensor connector will not be fully

inserted into the receiving connector on the board.

To check whether or not the connection is stable, make some copies and check the

reading of SP55. If the connection is unstable, the SP55 reading will also be unstable (e.g.

71,125,13,17,117,35).

Page 8

!"#$% T

echnical Bulletin

PAGE: 2/2

Model:

Tequila

Date:

19-Apr-00

No.:

RA289003

SOLUTION:

I/U installation procedure

1) Insert the I/U into the mainframe.

2) Push the I/U toward the back so that the I/U front side plate (A1902280) remains flush

against the raised portion of the front side plate of the mainframe (see the illustration

below). While holding the unit in this position (pushing on the handle), tighten the knob

screw (A1902320) by hand until the I/U is secure.

Front Side Plate of the Mainframe

Front Side Plate (A1902280) of the I/U

Knob Screw (A1902320)

3) Use a slotted screwdriver or coin for the final tightening.

Page 9

echnical Bulletin

T

PAGE: 1/2

Model:

Subject:

From:

Tequila

Low image density in leading (top) area

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

03-Aug-00

Prepared by:

No.:

RA289004

M.Ishihara

Action required

Service manual revision

Retrofit information

SYMPTOM:

The image density of the leading (top) half of the copy becomes lighter when specific light or

halftone originals are copied.

CAUSE:

When the 1st and 2nd scanners start to move, part of the light from the 1st scanner is directly sent

to the mirror of the 2nd scanner, as the two scanners are relatively close. This "extra light" received

by the mirror will cause the image to appear lighter. As scanning continues, the 1st scanner

increases to twice the speed of the 2nd scanner, causing the two scanners to get farther and

farther apart. Therefore, less and less light "extra light" reaches the 2nd scanner mirror. This is why

the image is lighter near the leading edge.

SOLUTION:

A shading seal (A2981684) should be attached to ensure proper image density at the leading edge

(when making copies with very light/halftone originals). Because the extra light passes from the

2nd scanner mirror to the photoconductor via the base plate of the optics unit and lens carriage

(A1901682), the seal should be attached to the lower portion of the lens carriage. This will prevent

the extra light from passing between the optic base plate and lens carriage.

This modification will be applied from August 2000 production.

Please see the procedure as shown below.

Lens Carriage (A1901682)

B

A

Adhesive portion

A: 0-1mm from the edge, B: 0-0.5mm from the surface

Shading Seal (A2981684)

Page 10

echnical Bulletin

T

PAGE: 2/2

Model:

Procedure:

1. Remove the power plug from the wall outlet.

2. Remove the lens carriage from the optics unit.

Note: Before removing the lens carriage, remove the left scale, the exposure glass

and the lens cover.

3. Attach the shading seal to the lens carriage as shown in the illustration.

Tequila

Date:

03-Aug-00

No.:

RA289004

Page 11

echnical Bulletin

T

PAGE: 1/1

Model:

Subject:

From:

Tequila

SC ”E14”

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

12-Apr-01

Prepared by:

No.:

RA289005

M.Ishihara

Action required

Service manual revision

Retrofit information

SYMPTOM:

SC ”E14” (220-240V region).

CAUSE:

-The power input (voltage and/or frequency) is out of standard, or

-Electrical noise interferes with the power input.

SOLUTION:

There are two solutions:

1) Use a power source where the actual power input is within machine standards:

220-240V,50/60Hz +, - 10%.

2) Use the following PSU (Power Supply Unit) that has been arranged for specific

customers and contains a countermeasure for SC ”E14”:

Part Number Description

A2989501 Power Supply Unit-230V

*Modification: This is the A2985651 PSU with a 0.01µF capacitor soldered (added) to its

rear face.

Loading...

Loading...