Page 1

RICOH Technical

Bulletin

PAGE: 1/4

Model:

Subject:

From:

Tequila

Toner drops onto the copy

Technical Service Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Date:

Prepared by:

Part information

Electrical

Transmit/receive

22-Sep-99

Action required

Service manual revision

Retrofit information

No.:

M. Ishihara

RA289001

SYMPTOM

1. Toner drops onto the copy.

2. Dirty background on copies (Occasional)

3. Image density too high (Occasional)

CAUSE

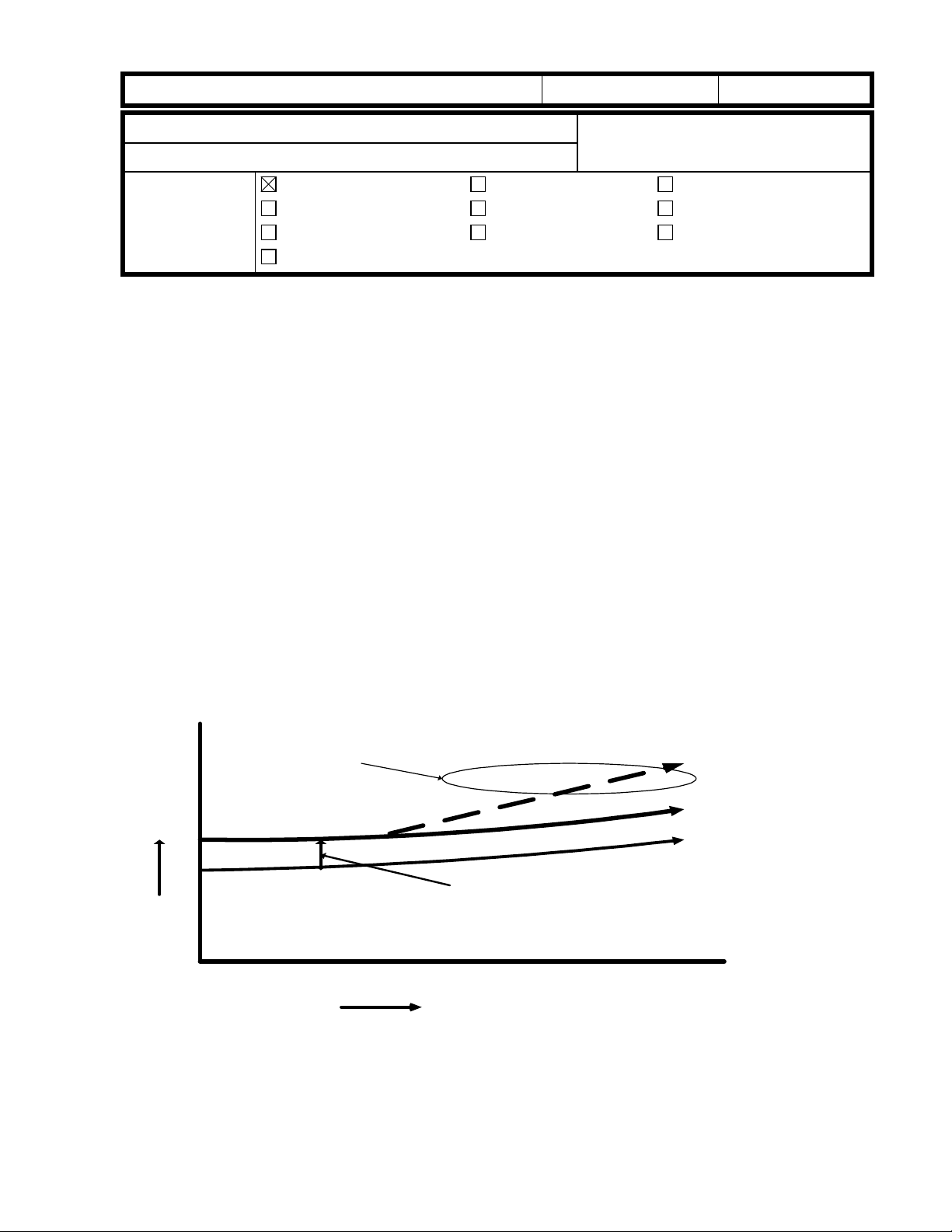

Although the toner concentration in the developer is maintained between 3 and 4%,

an increase can be observed when used over an extended period of time. This level

is normally kept under 5% even after 60K copies, however there are rare cases where this

limit is exceeded due to the environmental factors described below. These are thought to

cause the toner to fall onto the surface of the copy.

1. The presence of paper dust as well as conditions such as high humidity are thought to

cause an oversupply of toner to the development unit (by raising the limit of the toner

concentration control to over 6%), which in turn causes the toner to fall onto the copy

surface.

Too much toner

4%

3%

Controlled Limit

Toner

Consent

-ration

0 20K 60K40K

Copy Volume

6%

5%

4%

2. In addition, due to this oversupply of toner to the development unit, recycled toner

creates a blockage in the imaging unit and the toner falls from the cleaning area.

Page 2

RICOH Technical

Bulletin

PAGE: 2/4

Model:

Tequila

Date:

22-Sep-99

No.:

RA289001

ACTION REQUIRED

A. Countermeasure in the field:

Please follow the procedure as shown below if the toner dropping problem occurs in the

field.

1. Remove the IU from the machine.

2. Completely remove the recycled toner at the toner collection coil under the cleaning

blade and the toner recycling belt area. Install the IU in the machine.

3. Remove the toner bottle from the machine. Check that SP38 is 0. (Input "0" if it is not.)

4. Make 20, A4 sideways, skyshot copies (Black solid copies).

5. Set an original and make some copies to confirm that copy quality is normal.

6. Change the toner supply mode from “0” to “1” using SP30.

7. Make some copies while monitoring the TD sensor output (SP55).

8. Input the value obtained in step 7 into SP53 – TD Sensor Target Control Voltage

Adjustment. (If it is more than 127, input 127.)

9. Install the toner bottle in the machine.

10.Set an original and make some copies to confirm that copy quality is normal.

Note:

When the developer is replaced, please observe the following for efficient troubleshooting:

1) Perform the SP66 to initialize the developer .

2) Do not change the settings of SP30 and SP53. (SP30 must be at “1”. TD Sensor

control voltage must be kept at the same level in SP53, as entered in step 8 above.)

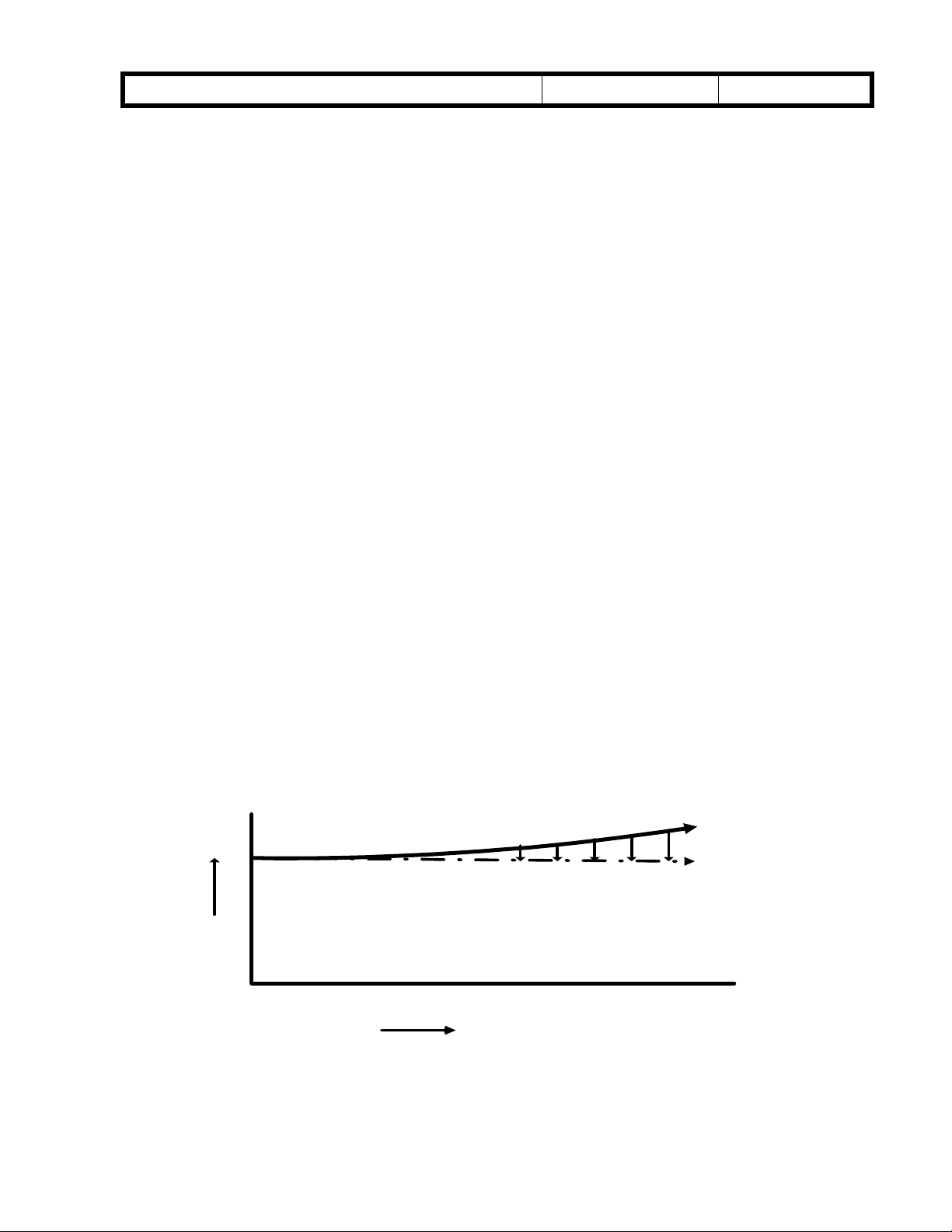

B. Permanent Countermeasure:

This rise in the amount of tone r being supplied will be prevented as de termined by the

copy volume by modifying the software so that an oversupply does not result.

For the

machine of mass production. It is scheduled to be implemented in the

October 1999 mass production.

Kingfisher2

4%

Toner

Density

, this modification is scheduled to be implemented from the first

Kingfisher

5%

4%

0 20K 60K40K

from

Page 3

RICOH Technical

Bulletin

PAGE: 3/4

Model:

If the above symptom should occur in the field before preventative maintenance is

performed, please institute the temporary countermeasure described in the previous

section (A.) and refrain from upgrading the software.

The new software has two major differences from the previous version:

The overall process control and toner density control (maintained by lowering

it to a fixed value every 1K). Due to these differences, it is recommended that

the new firmware be used together with new developer.

NOTE:

Please upgrade the software at the next PM visit (when the developer is replaced).

Please refer to the flow chart on the following page.

(Note: When the developer is replaced, remove the old developer completely. Otherwise

the volume of the developer is increased and it causes the toner to drop.)

Tequila

Date:

22-Sep-99

No.:

RA289001

Page 4

RICOH Technical

Bulletin

PAGE: 4/4

Model:

Tequila

Date:

22-Sep-99

FLOW CHART FOR THE TONER DROPPING PROBLEM

START

Remove the Imaging Unit from the machine.

Remove the recycled toner in cleaning unit

(under the cleaning blade) and at the recycling belt area.

YES

To remove

excessive

toner from the

developing unit

Is PM required?

NO

Install the imaging Unit.

Remove the toner bottle from the machine.

Input "0" in SP38 if it is not.

Make 20(A4 sideways) skyshot copies to

confirm that copy quality is normal.

Set an original and make some copies to

confirm that the copy quality is normal.

Replace the developer in the imaging Unit.

Note: Completely remove the developer

from the imaging unit.

(Otherwise the amout of developer will

increase causing toner recycling process

not function properly.

Install the imaging Unit.

Replace the ROM.

Perform the toner initialization

(SP66).

If the SP30 is "1", set it to "0".

No.:

RA289001

To maintain

proper toner

density

NO

Change the toner supply mode from "0" to "1" (in the SP30).

Make several copies while monitoring the TD sensor output (SP55).

Input the value obtained in the previous step into SP53 - TD Sensor

Target Control VoltageAdjustment.

Install the toner bottle in the machine.

Set an original and make several copies to confirm that copy quality

is normal.

Is Image density

normal?

YES

END!

Loading...

Loading...