Page 1

T

Model:

Grand Kingfisher

echnical

B

ulletin

Date:

30-Jun-98

No:

PAGE: 1/4

1

Subject:

From:

Classification:

A new model "Tequila (A289)" designed for the Latin American market will be launched in

September 98. Tequila is a slightly modified version of the already existing model "Grand

Kingfisher (Ricoh FT4018/Gestetner 2718z)", especially designed to meet the needs for

the Latin America market.

There will be two destination codes depending on the input voltage: -14 is for 120V areas,

and -24 is for 220V areas. Inch units are the default units for both destination codes.

This RTB clarifies the differences between the base copier and Tequila (based on the style

of the service manual). Also note that the following information is based on the Grand

Kingfisher 120V (inch size) machines.

Differences from Grand Kingfisher (A245)

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

J. Kasamoto

1. OVERALL MACHINE INFORMATION

1. SPECIFICATIONS

Reproduction Ratios: 6R 4E (50, 65, 71, 77, 85, 93, 121, 129, 141, 200%)

Power Source: 120 V, 60Hz: More than 15 A (Destination code -14 machines)

220/230 V, 50/60Hz: More than 8 A (Destination code -24

machines)

2. DETAILED DESCRIPTIONS

1. PAPER HANDLING

The paper size actuator for detecting paper size for the upper tray differs from that for the

lower tray. The upper tray has an actuator for the North American market (inch version),

and the lower tray has an actuator for the European market (metric version). The following

shows the available paper sizes for each paper tray.

Upper Tray: 11" x 17" lengthwise, 8

lengthwise, 8

* mark

" x 13" lengthwise, A4 sideways / lengthwise,

1/2

" x 11" sideways / lengthwise, 8

1/2

1/2

" x 14"

Lower Tray: A3 lengthwise, A4 sideways / lengthwise, A5 sideways, 8

sideways / lengthwise, F lengthwise, * mark

1/2

x 11"

Page 2

T

Model:

Also, the following paper sizes used in the Latin American market can be set in the paper

trays. When setting these sizes in the paper tray, select the * mark on the paper size

actuator.

216 mm x 340 mm lengthwise: Lower tray

•

8.5" x 12.5" lengthwise: Upper tray

•

B5 sideways / lengthwise: Lower tray

•

B4 lengthwise: Lower tray

•

The above paper can also be fed from the by-pass feed table.

Grand Kingfisher

echnical

B

ulletin

Date:

30-Jun-98

No:

PAGE: 2/4

1

2. OPERATION

Series copies mode (making one-sided copies from facing pages) has been added

•

Stack mode when the optional sorter is installed is not available for this model.

•

10 codes (any 3 digit number except 000) can be registered as user codes (there were

•

only 5 preset codes for the base copier).

The following toner types are used.

•

Ricoh RICOH TONER TYPE 1205 BLACK

Gestetner Gestetner Toner 2818/2818z

3. INSTALLATION

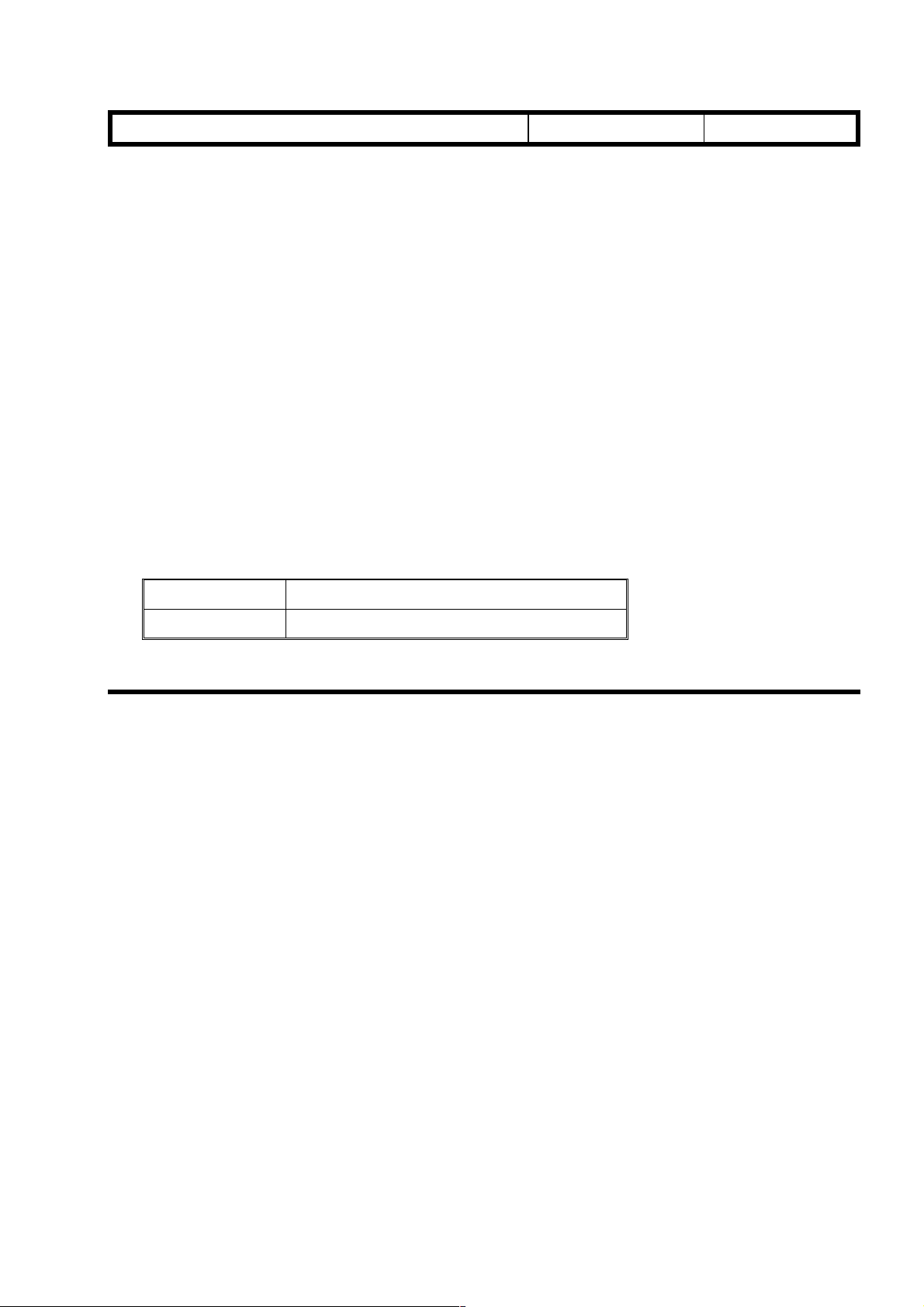

1. COPIER ACCESSORY CHECK

The following shows the copier accessory list for Tequila. Check the quantity and

condition of the accessories in the box against the following list:

1. Copy tray

2. Safety information sheet

3. Branding kit

A branding kit (A847-00 through -05), which is issued by the sales department, must be

installed on the machine to meet the user’s requirements.. The kit code will depend on the

machine brand, and on which language (Spanish, English, or Portugese) the user

requests. The following lists the accessories for each Tequila branding kit.

Page 3

T

Model:

Grand Kingfisher

1. Operating instructions

2. Operating instructions title decal

3. Model name plate

4. Operation panel sheet - large

5. Operation panel sheet - small

6. Symbol explanation / Paper set direction decal

7. Model name decal (operation panel)

8. Quick guide

NOTE:

The panel sheets are not accessories for the Spanish branding kits (-01 and -

04), since they are already attached to the machine at the factory. Also, item

No. 7 is for Gestetner branding kits (-03, -04 and -05) only.

echnical

B

ulletin

Date:

2. COPIER INSTALLATION PROCEDURE

30-Jun-98

No:

PAGE: 3/4

1

After finishing all the procedures described in the base copier service manual, open the

branding kit and do the following.

[A]

[C]

[D]

[B]

1. If the user requests English or Portuguese descriptions on the operation panel, attach

the three operation panel sheets [A] to the operation panel as shown. Also, pull out the

paper trays, and attach the desired paper set direction decals [B] on top of the existing

ones as shown.

2. Attach the model name plate [C] to the front cover as shown.

3. Attach the appropriate operating instruction title decal [D] to the operating instructions

as shown.

Page 4

T

Model:

Grand Kingfisher

echnical

B

ulletin

Date:

30-Jun-98

No:

1

4. SERVICE TABLES

1. SERVICE PROGRAM MODE

The following SP modes have been newly added.

Mode No. Function Settings

PAGE: 4/4

72

(UP Mode

No.12)

The following SP modes have been changed.

Mode No. Function Settings

73

(UP Mode

No.8)

User Code Number

Setting

Mode

User Code Counter

Display

Use this mode to input t he user code numbers

(max. 3 digits).

Up to 10 user codes can be set. To in put a

code, enter it at the numeric keypad, then press

the Auto Image Density ke y. The user code

number will be displayed in the magnification

ratio indicator. You can pres s t he Zoom Up (+)

key or Zoom Down (-) key to enter another.

Enables user code mode.70 User Code

JP101 on the main board must be cut.

If this mode is set, operators must enter a code

to make copies.

Displays the contents of each user code

counter.

A number from 1 to 10 is applied starting from

the lowest user code number that the operator

has inputted. This number is displayed in the

copy counter. Use the Zoom Up (+) key or

Zoom Down (-) key to select the user code

counter to display. The user code counter

counts from 0 to 999999. The first t hree di git s

are displayed in the m agnif ication ratio

indicator.

Press the Darker key to display the last three

digits.

Page 5

T

echnical

B

ulletin

PAGE: 1/1

Model:

Subject:

From:

Classification:

Kingfisher/Grand Kingfisher/Tequila

Toner drops onto the copy

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

31-Aug-99

Prepared by:

No.:

RA219015

M.Ishihara

Action required

Service manual revision

Retrofit information

SYMPTOM

1. Toner drops onto the copy.

2. Dirty background on copies (Occasional)

3. Image density too high (Occasional)

CAUSE

1. Too much toner is supplied to the development tank due to misdetection by the toner

density sensor.

2. Used toner accumulates in the IU (Imaging Unit), preventing proper recycling.

ACTION REQUIRED

Please follow the procedure as shown below.

1. Remove the IU from the machine.

2. Completely remove the recycled toner in the toner collection coil and the toner recycling

belt area.

3. Install the IU in the machine.

4. Remove the toner bottle from the machine.

5. Make 20, A4 sideways, skyshot copies (solid black copies).

6. Set an original and make some copies to confirm that copy quality is normal.

7. Change the toner supply mode from “0” to “1” using SP30.

8. Make some copies while monitoring the TD sensor output (SP55).

9. Input the value obtained in step 8 in SP53 – TD Sensor Target Control Voltage

Adjustment.

10. Install the toner bottle in the machine.

11. Set an original and make some copies to confirm that copy quality is normal.

Note:

When the developer is replaced, please observe the following for efficient troubleshooting:

1) Do SP66.

2) Do not change the settings of SP30 and SP53. (SP30 must be at “1”. TD

Sensor control voltage must be kept at the same level in SP53, as entered in step

9 above.)

Page 6

RICOH Technical

Bulletin

PAGE: 1/4

Model:

Subject:

From:

Grand Kingfisher

Toner drops onto the copy

Technical Service Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Date:

Prepared by:

Part information

Electrical

Transmit/receive

22-Sep-99

Action required

Service manual revision

Retrofit information

No.:

M. Ishihara

RA245002

SYMPTOM

1. Toner drops onto the copy.

2. Dirty background on copies (Occasional)

3. Image density too high (Occasional)

CAUSE

Although the toner concentration in the developer is maintained between 3 and 4%,

an increase can be observed when used over an extended period of time. This level

is normally kept under 5% even after 60K copies, however there are rare cases where this

limit is exceeded due to the environmental factors described below. These are thought to

cause the toner to fall onto the surface of the copy.

1. The presence of paper dust as well as conditions such as high humidity are thought to

cause an oversupply of toner to the development unit (by raising the limit of the toner

concentration control to over 6%), which in turn causes the toner to fall onto the copy

surface.

Too much toner

4%

3%

Controlled Limit

Toner

Consent

-ration

0 20K 60K40K

Copy Volume

6%

5%

4%

2. In addition, due to this oversupply of toner to the development unit, recycled toner

creates a blockage in the imaging unit and the toner falls from the cleaning area.

Page 7

RICOH Technical

Bulletin

PAGE: 2/4

Model:

Grand Kingfisher

Date:

22-Sep-99

No.:

RA245002

ACTION REQUIRED

A. Countermeasure in the field:

Please follow the procedure as shown below if the toner dropping problem occurs in the

field.

1. Remove the IU from the machine.

2. Completely remove the recycled toner at the toner collection coil under the cleaning

blade and the toner recycling belt area. Install the IU in the machine.

3. Remove the toner bottle from the machine. Check that SP38 is 0. (Input "0" if it is not.)

4. Make 20, A4 sideways, skyshot copies (Black solid copies).

5. Set an original and make some copies to confirm that copy quality is normal.

6. Change the toner supply mode from “0” to “1” using SP30.

7. Make some copies while monitoring the TD sensor output (SP55).

8. Input the value obtained in step 7 into SP53 – TD Sensor Target Control Voltage

Adjustment. (If it is more than 127, input 127.)

9 .Install the toner bottle in the machine.

10.Set an original and make some copies to confirm that copy quality is normal.

Note:

When the developer is replaced, please observe the following for efficient troubleshooting:

1) Perform the SP66 to initialize the developer .

2) Do not change the settings of SP30 and SP53. (SP30 must be at “1”. TD Sensor

control voltage must be kept at the same level in SP53, as entered in step 8 above.)

B. Permanent Countermeasure:

This rise in the amount of tone r being supplied will be prevented as de termined by the

copy volume by modifying the software so that an oversupply does not result.

For the

machine of mass production. It is scheduled to be implemented in the

October 1999 mass production.

Kingfisher2

4%

Toner

Density

, this modification is scheduled to be implemented from the first

Kingfisher

5%

4%

0 20K 60K40K

from

Page 8

RICOH Technical

Bulletin

PAGE: 3/4

Model:

If the above symptom should occur in the field before preventative maintenance is

performed, please institute the temporary countermeasure described in the previous

section (A.) and refrain from upgrading the software.

The new software has two major differences from the previous version:

The overall process control and toner density control (maintained by lowering

it to a fixed value every 1K). Due to these differences, it is recommended that

the new firmware be used together with new developer.

NOTE:

Please upgrade the software at the next PM visit (when the developer is replaced).

Please refer to the flow chart on the following page.

(Note: When the developer is replaced, remove the old developer completely. Otherwise

the volume of the developer is increased and it causes the toner to drop.)

Grand Kingfisher

Date:

22-Sep-99

No.:

RA245002

Page 9

RICOH Technical

Bulletin

PAGE: 4/4

Model:

Grand Kingfisher

Date:

22-Sep-99

FLOW CHART FOR THE TONER DROPPING PROBLEM

START

Remove the Imaging Unit from the machine.

Remove the recycled toner in cleaning unit

(under the cleaning blade) and at the recycling belt area.

YES

To remove

excessive

toner from the

developing unit

Is PM required?

NO

Install the imaging Unit.

Remove the toner bottle from the machine.

Input "0" in SP38 if it is not.

Make 20(A4 sideways) skyshot copies to

confirm that copy quality is normal.

Set an original and make some copies to

confirm that the copy quality is normal.

Replace the developer in the imaging Unit.

Note: Completely remove the developer

from the imaging unit.

(Otherwise the amout of developer will

increase causing toner recycling process

not function properly.

Install the imaging Unit.

Replace the ROM.

Perform the toner initialization

(SP66).

If the SP30 is "1", set it to "0".

No.:

RA245002

To maintain

proper toner

density

NO

Change the toner supply mode from "0" to "1" (in the SP30).

Make several copies while monitoring the TD sensor output (SP55).

Input the value obtained in the previous step into SP53 - TD Sensor

Target Control VoltageAdjustment.

Install the toner bottle in the machine.

Set an original and make several copies to confirm that copy quality

is normal.

Is Image density

normal?

YES

END!

Loading...

Loading...