Page 1

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that the optional tray heater and the optional anti-condensation

heaters are supplied with electrical voltage even if the main switch is

turned off.

4. If any adjustment or operation check has to be made with exterior

covers off or open while the main switch is turned on, keep hands away

from electrified or mechanically driven components.

5. The inside and the metal parts of the fusing unit become extremely hot

while the copier is operating. Be careful to avoid touching those

components with your bare hands.

HEALTH SAFETY CONDITIONS

1. Toner and developer are non-toxic, but if you get either of them in your

eyes by accident, it may cause temporary eye discomfort. Try to remove

with eye drops or flush with water as first aid. If unsuccessful, get

medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course

on those models.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate toner cartridges or used toner. Toner dust may ignite

suddenly when exposed to open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

Page 2

Grand Kingfisher

(Machine Code:A245)

Service Manual

–

Insert Version

–

The A245 copier is based on the A219 copier.

Only the differences from the A219 copier are described in the

following pages. Refer to the A219 copier service manual

regarding the other information.

Page 3

26 September 1997 SPECIFICATIONS

1. SPECIFICATIONS

NOTE:

Only items marked with ✽ are different from the A219 copier.

Configuration: Desktop

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book

Original Size: Maximum: A3/11" x 17"

Copy Paper Size: Maximum: A3/11" x 17"

Minimum:

A5/5

A6/5

1/2

1/2

" x 8

" x 8

1/2

" sideways (Paper tray feed)

1/2

" lengthwise (By-pass feed)

Non-standard sizes:

Vertical 45 mm ~ 308 mm, 1.8" ~ 12"

Horizontal 148 mm ~ 432 mm, 5.8" ~ 17"

2

Copy Paper Weight: Paper tray feed: 64 to 90 g/m

By-pass feed: 52 to 157 g/m

Reproduction Ratios:

Enlargement

Full Size 100% 100%

Reduction

Metric Version Inch Version

200%

141%

122%

93%

82%

71%

50%

, 17 to 24 lb

2

, 14 to 42 lb

Copier

200%

155%

129%

93%

74%

65%

50%

Zoom: From 50% to 200% in 1% steps

✽ Copying Speed: 18 copies/minute (A4/8.5" x 11" sideways)

10 copies/minute (A3/11" x 17")

✽ Warm-up Time:

120 V machines: Less than 35 seconds (at 23°C)

230 V machines: Less than 45 seconds (at 23°C)

✽ First Copy Time: Less than 6.5 seconds (A4/8.5" x 11" sideways)

Copy Number Input: Number keys, 1 to 99

Manual Image Density

7 steps

Selection:

1

Page 4

SPECIFICATIONS 26 September 1997

Automatic Reset: 1 minute standard setting; can also be set to 3

minutes or no auto reset

✽ Paper Capacity: Paper tray: 250 sheets or less than 30 mm stack

height

By-pass feed entrance:

Standard paper 80 sheets

OHP 10 sheets

Others 1 sheet

Toner Replenishment: Bottle exchange (215 g/bottle)

Copy Tray Capacity: 100 sheets

Power Source: 120 V/60 Hz: More than 15 A (for North America)

220 ~ 240 V/50 Hz: More than 8 A (for Europe)

220 V/50 Hz: More than 8 A (for Asia)

220 V/60 Hz: More than 8 A (for Middle East/Asia)

110 V/60 Hz: More than 15 A (for Taiwan)

127 V/60 Hz: More than 15 A (for Middle East)

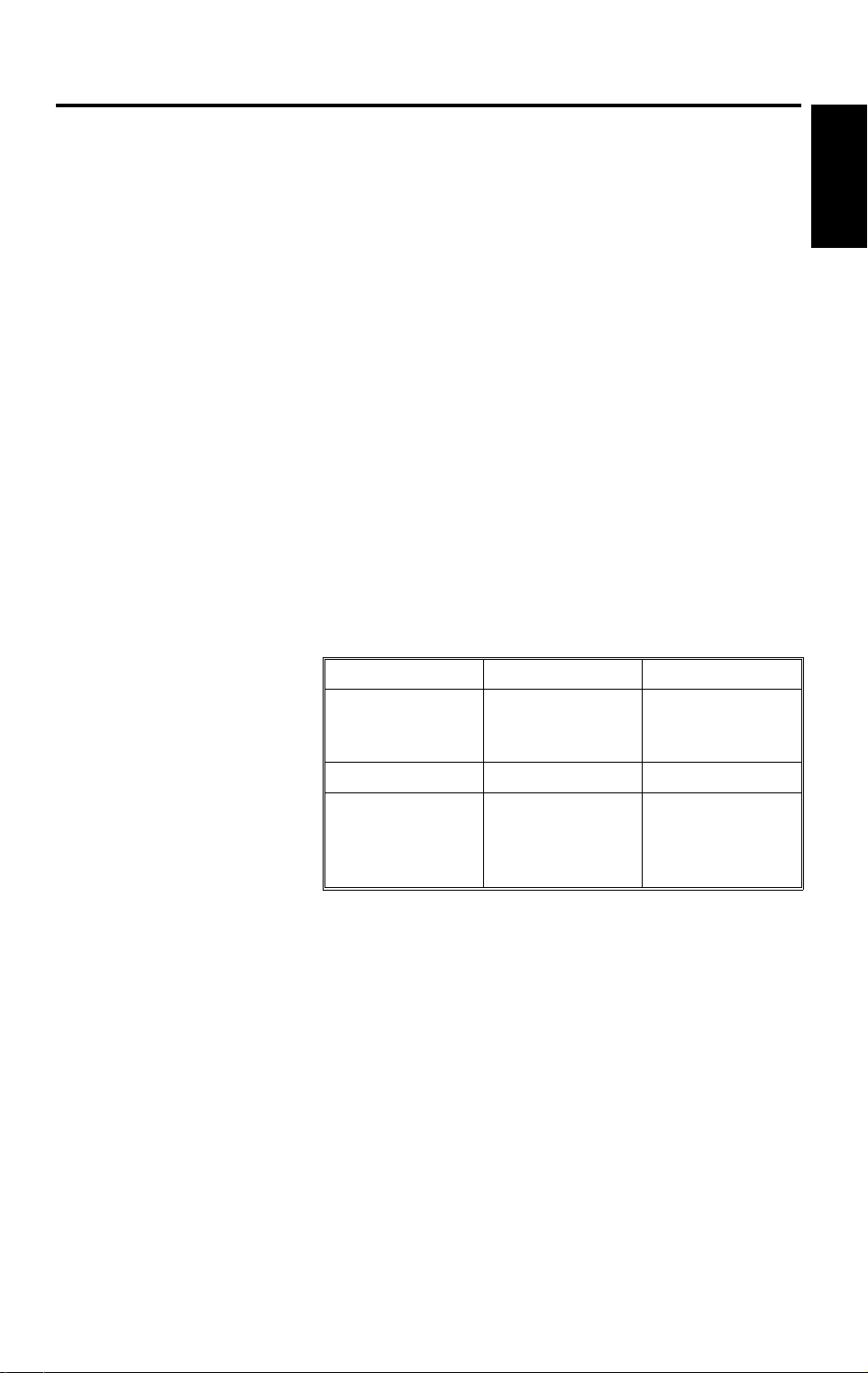

✽ Power Consumption:

✽ Dimensions:

Copier only Full system*

1.4 kW

Maximum

Copy cycle 0.82 kW 0.85 kW

Warm-up 0.95 kW 0.95 kW

Stand-by 0.16 kW 0.16 kW

Energy saver 0.12 kW 0.12 kW

*Full system : Copier with document feeder and 10 - bi n sorter

Copier

Full system*

*Full system : Co pi er w i th d ocument feeder an d 10- bi n sorter

(120 V machines)

1.1 kW

(230 V machines)

Width Depth Height

579 mm

(22.8")

775 mm

(30.2")

560 mm

(22.1")

560 mm

(22.1")

1.5 kW

(120 V machines)

1.2 kW

(230 V machines)

465 mm

(183.8")

563 mm

(21.5")

2

Page 5

26 September 1997 SPECIFICATIONS

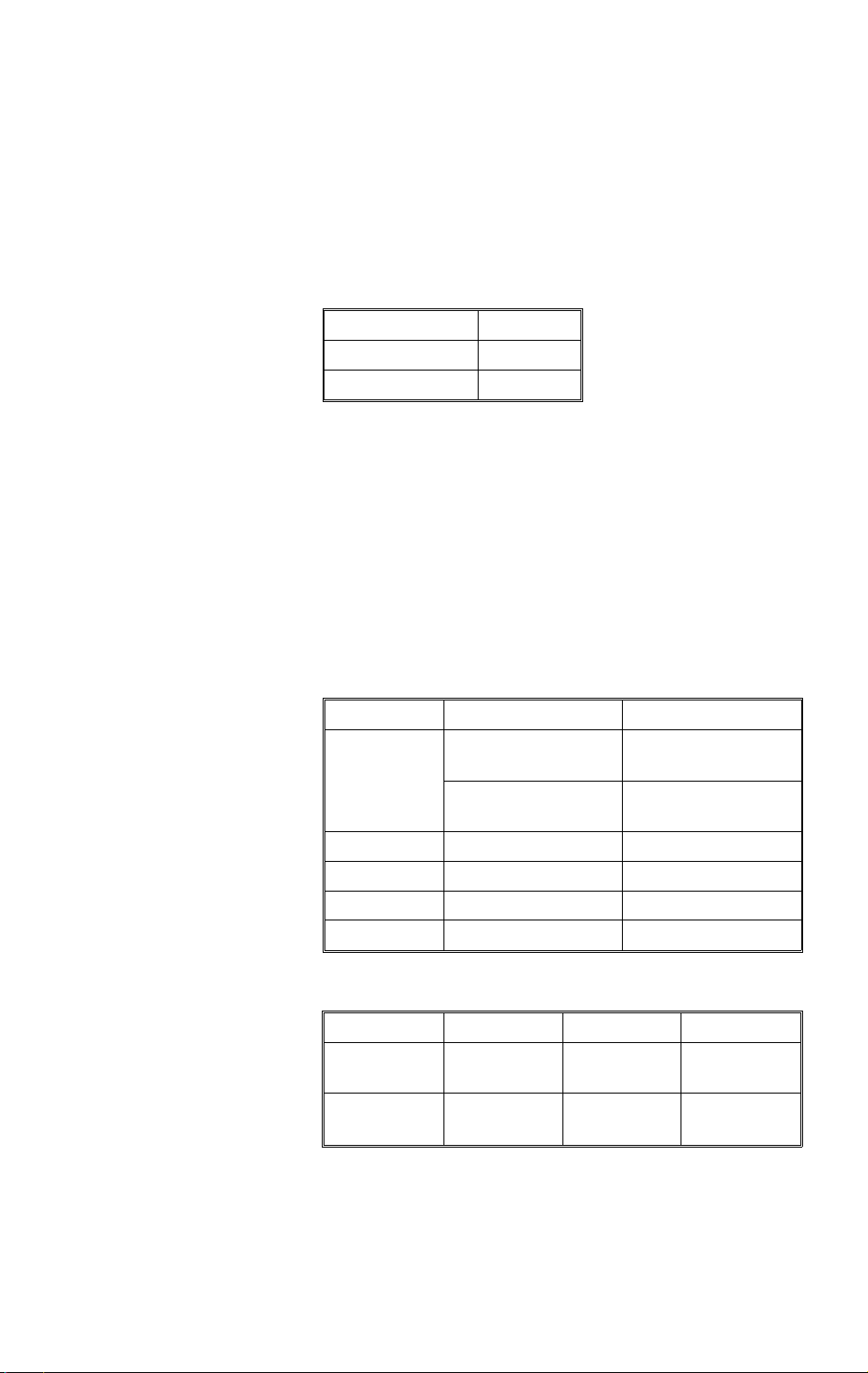

✽ Noise Emissions: Sound pressure level (the measurements are

made in accordance with ISO 7779 at the

operator position.)

✽ Weight:

Optional Equipment:

(Sales items)

Optional Equipment:

(Service items)

Copier only Full system*

Copyin g 58 dB or less 62 dB or less

*Full system : Co pi er w i th d ocument feeder an d 10- bi n sorter

Sound power level (the measurements are made

in accordance with ISO 7779)

Copier only Full system*

Stand- by 40 dB or less 40 dB or less

Copy cycl e 64 dB or less 68 dB or le ss

*Full system : Co pi er w i th d ocument feeder an d 10- bi n sorter

Copier only

Full system *

*Full system : Co pi er w i th d ocument feeder an d 10- bi n sorter

45 kg (99.2 lb)

58 kg (128 lb)

Document feeder (A662)

10-bin sorter (A657)

Optics anti-condensation heater

Tray heater

Copier

•

Specifications are subject to change without

notice.

3

Page 6

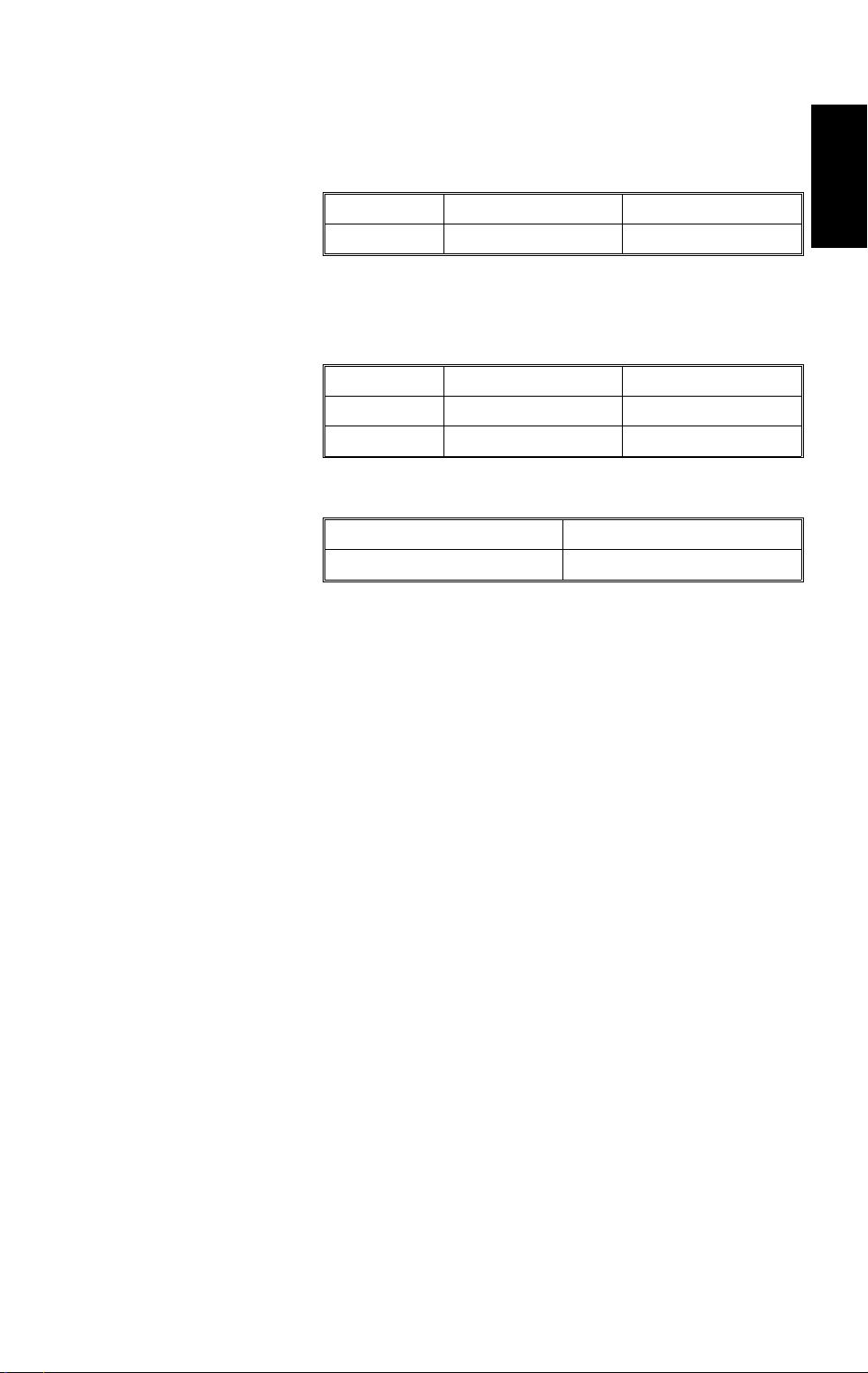

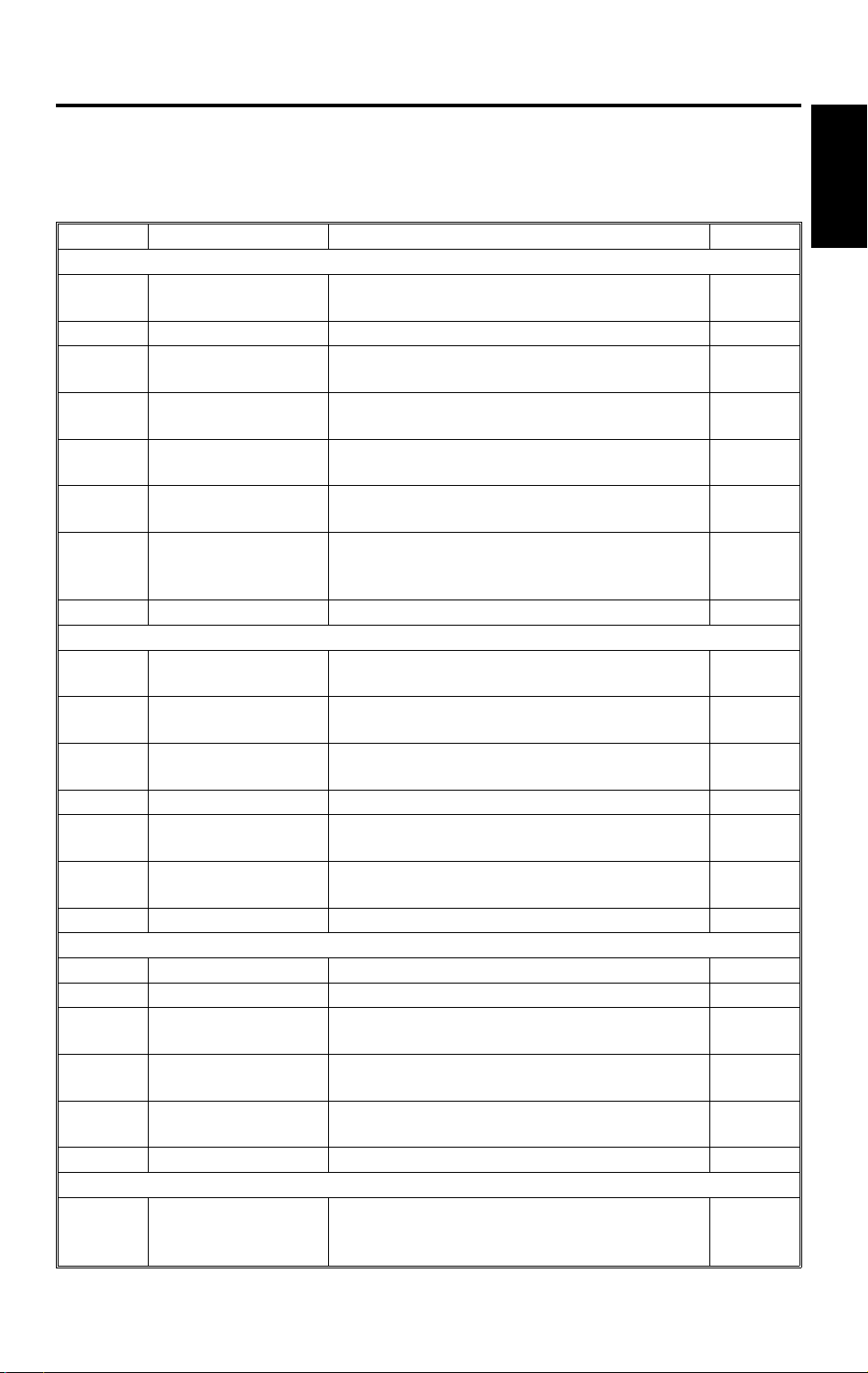

MECHANICAL CO M PO N EN T LAYO U T 26 September 1997

2. MECHANICAL COMPONENT LAYOUT

NOTE:

29

28

27

The paper feed area has been changed.

7

10

98654321

11

12

13

14

15

16

26

25

24

1. 2nd Mirror

2. 1st Mirror

3. Exposure Lamp

4. Hot Roller

5. Lens

6. Quenching Lamp

7. Charge Corona Unit

8. 6th Mirror

9. Erase Lamp

10. 4th Mi r r or

23 22 1920

11. 5th Mi r r or

12. Toner Bottle Holder

13. By-pass Feed Roller

14. By-pass Feed Table

15. Upper Relay Rollers

16. Upper Tray Pap er F eed

Rollers

17. Lower Relay Rollers

18. Lower Tray Paper Feed

Rollers

19. Registration Rollers

21

17

18

A245V500.wmf

20. Development Roller

21. Transfer/Separation Unit

22. Drum

23. Cleaning Bl ade

24. Pressure Roller

25. Lower Paper Tray

26. Upper Paper Tray

27. Copy Tray

28. Exit Rollers

29. 3rd Mi r ror

4

Page 7

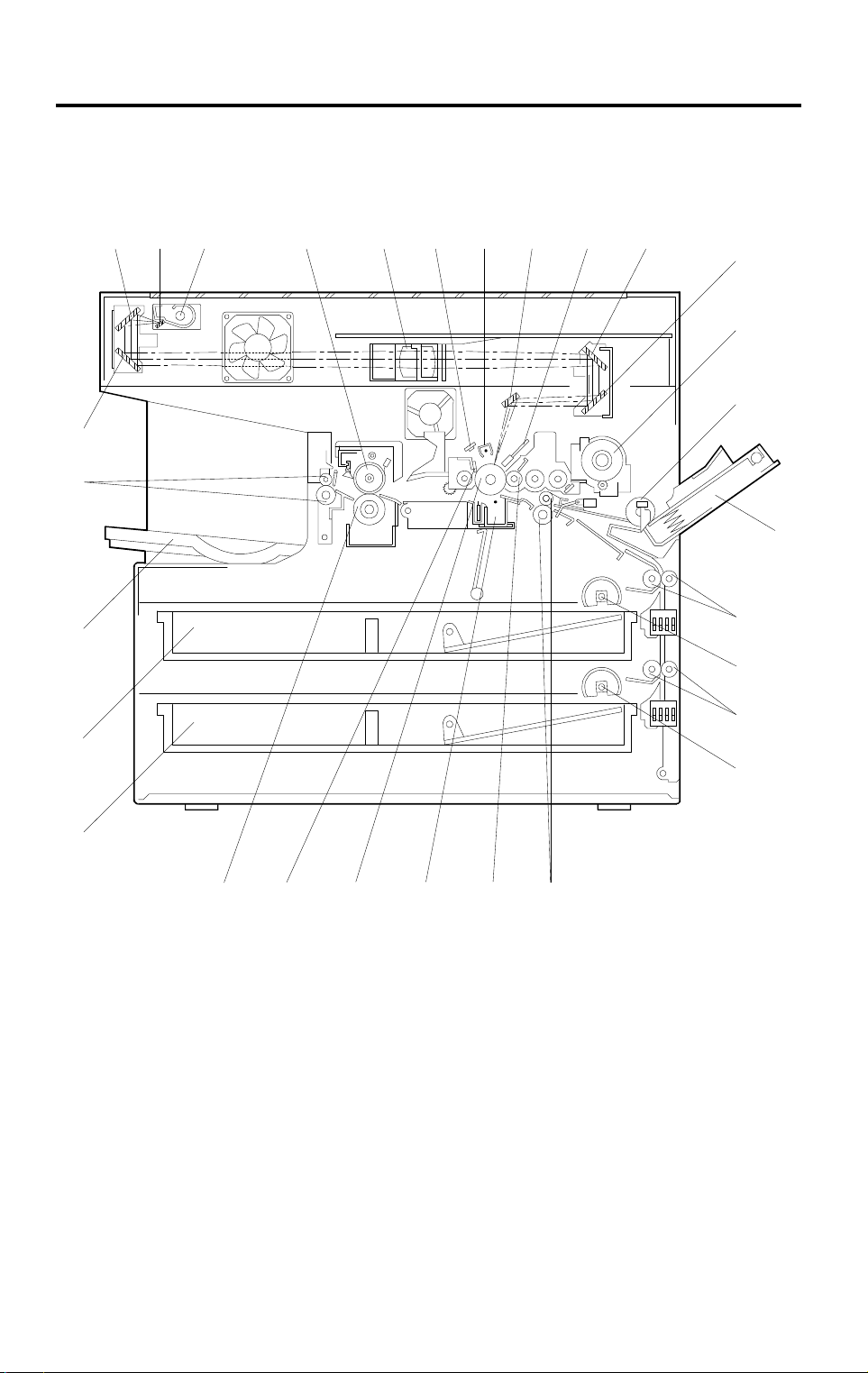

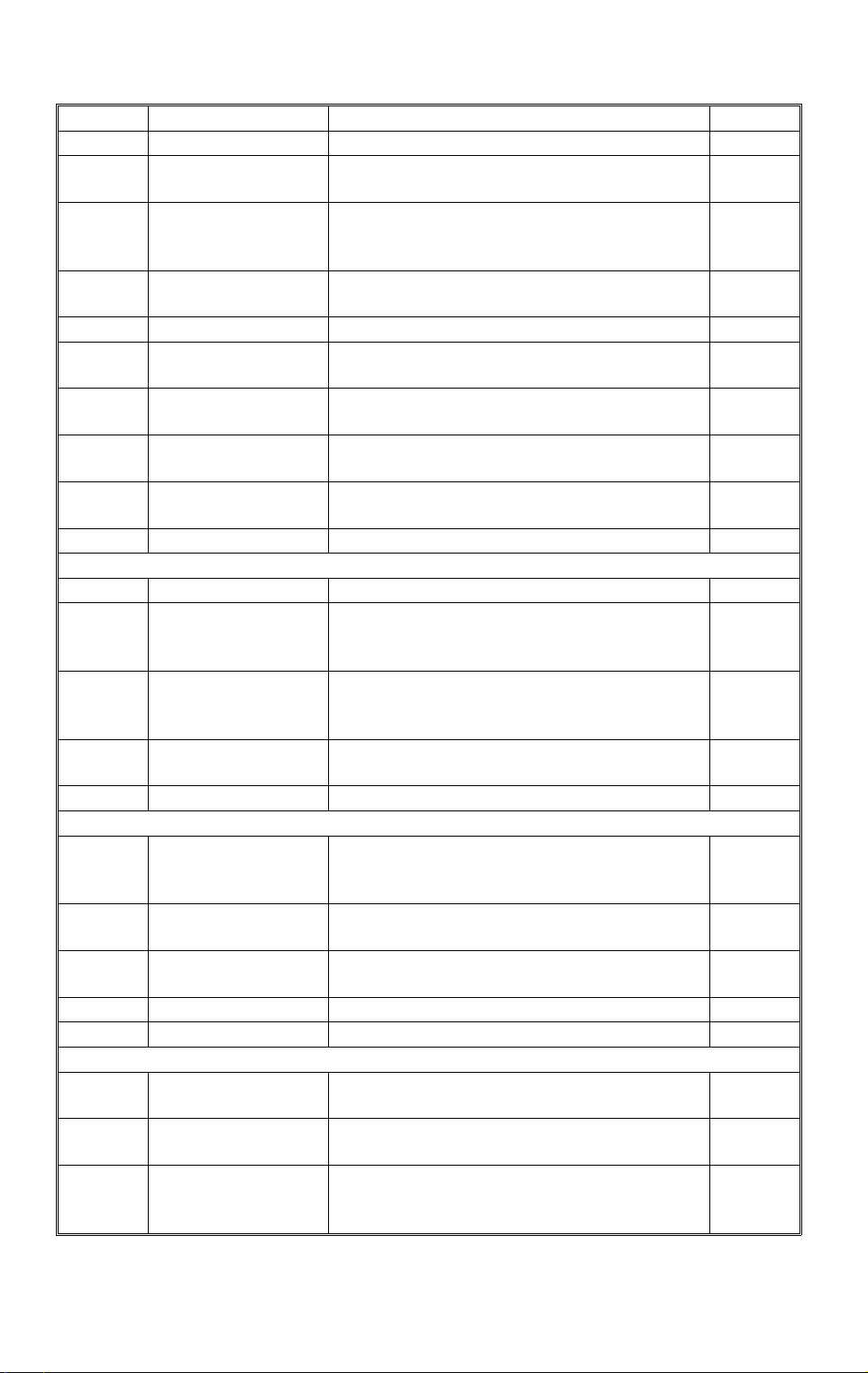

26 September 1997 DRIVE LAYOUT

3. DRIVE LAYOUT

NOTE:

12

11

10

9

8

The paper feed area has been changed.

Copier

13

1

2

7

6

1. Lens Motor

2. Fusing Unit Drive Gear

3. Main Motor

4. Drum Drive Gear

5. Lower Tray Paper Feed Clutch Gear

6. Upper Tray Paper Feed Clutch Gear

7. Lower Relay Roller Clutch Gear

54 3

A245V501.wmf

8. Upper Relay Roller Clutch Gear

9. By-pass Paper Feed Clut ch

10. Registration Clutch Gear

11. Toner Supply Motor

12. 4th/5th Mirror Motor

13. Scanner Drive Motor

5

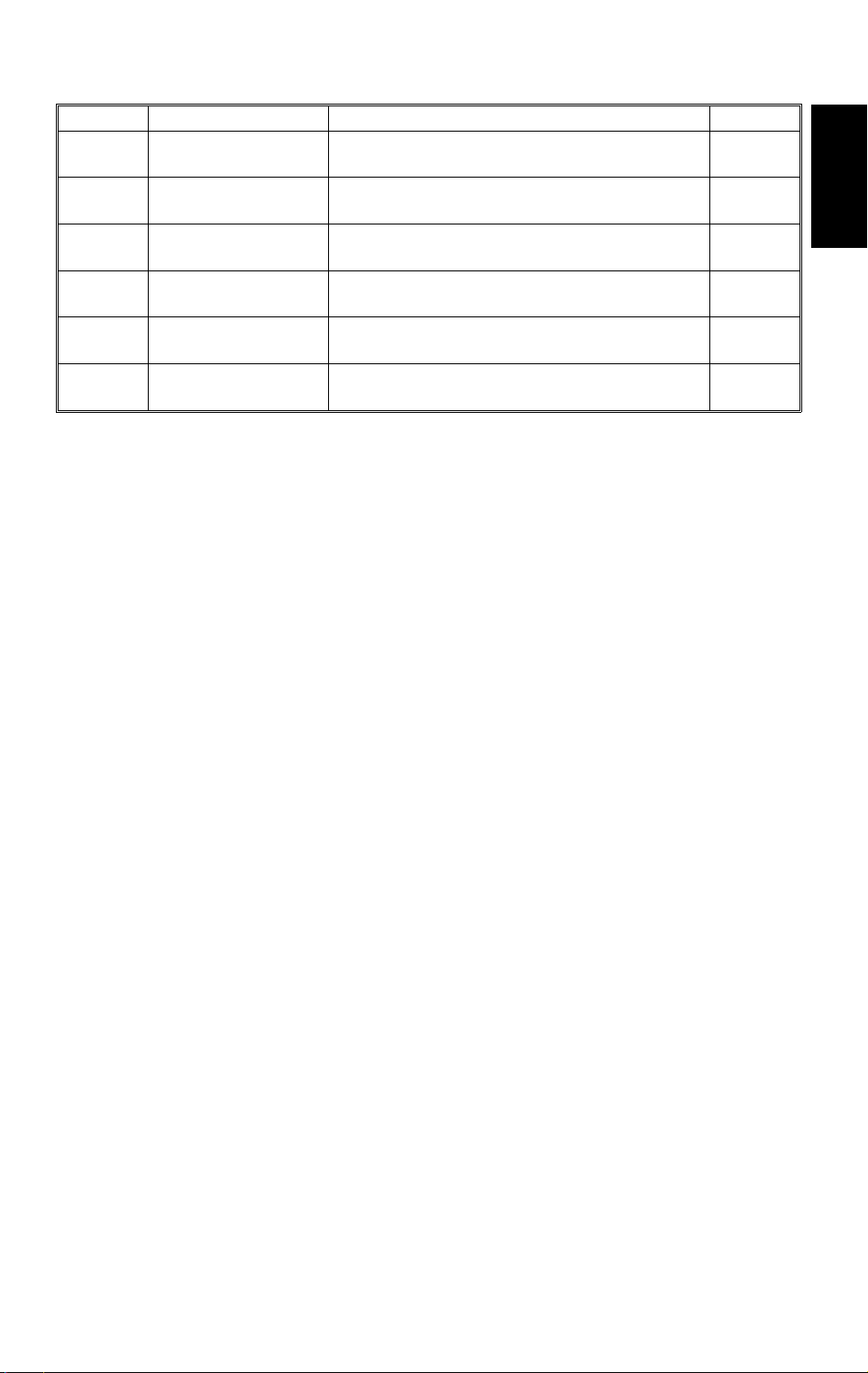

Page 8

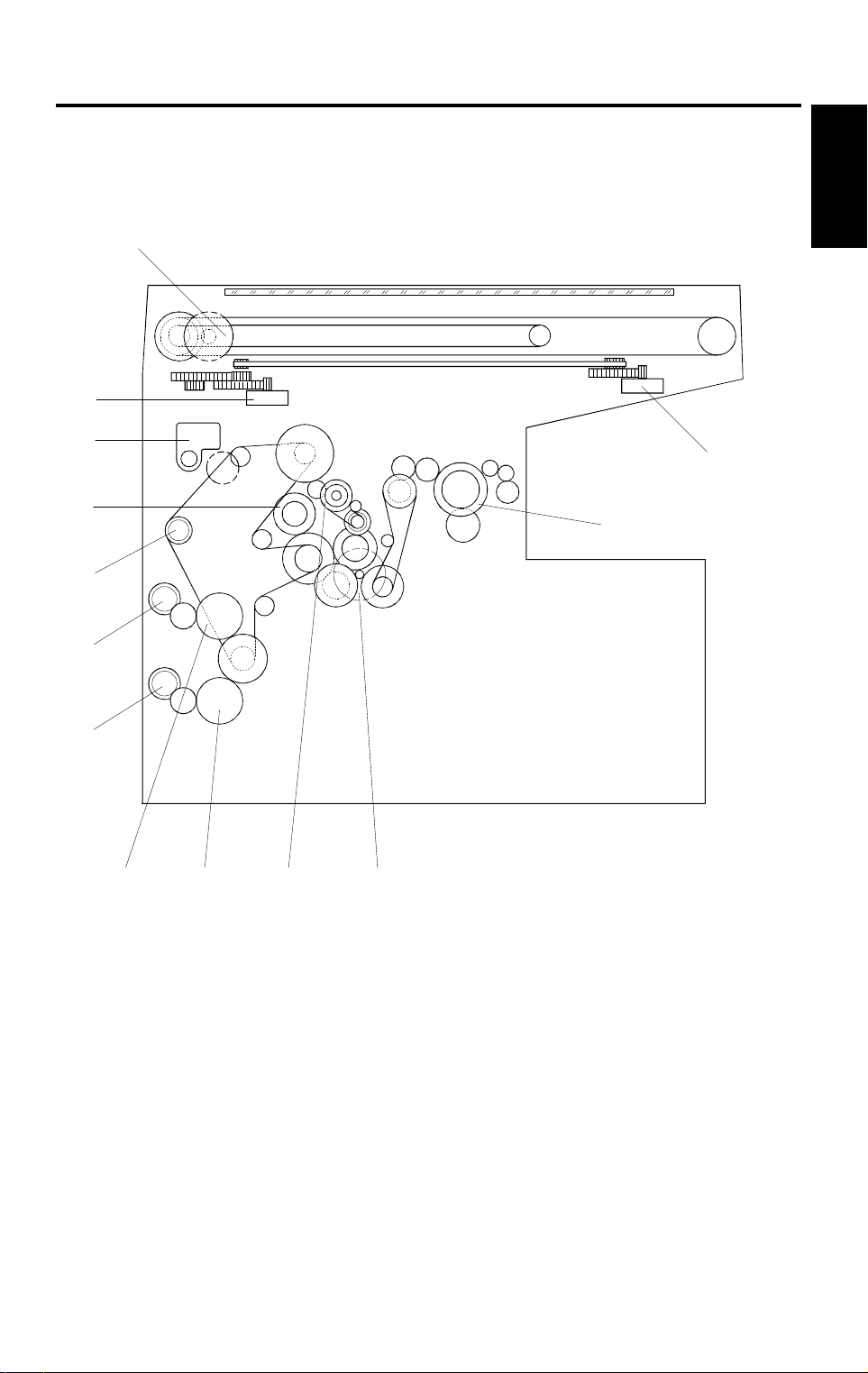

PAPER PATH 26 September 1997

4. PAPER PATH

NOTE:

4

The paper feed area has been changed.

1

1. By-pass Feed

2. Lower Paper Tray Feed

3. Upper Paper Tray Feed

4. Copy Tray

3

6

2

A245V502.wmf

Page 9

26 September 1997 ELECTRICAL COMPONENT DESCRIPTIONS

5. ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout and the point-to-point diagram on the

waterproof paper in the pocket for symbols and index numbers.

Symbol Name Function Index No.

Motors

M1

M2 Scanner Drive M ot or Dri ves the scanners (1s t and 2nd). 9

M3

M4

M5

M6

M7

Main Motor Drives all th e m ai n unit component s except for

the optics un i t an d fa ns.

Lens Motor Moves the lens position in accor dance with

the selecte d m agnification.

4th/5th Mirror Motor Moves the 4th/5th mirror position in

accordanc e w ith the selected magnification.

Toner Supply M ot or Rotates the to ner bot tle to supply toner to the

development uni t .

Optics Cooling Fan

Motor

Exhaust Fan Mot or Removes heat from a ro und the fusing unit and

Prevents buil d- up of hot air in the opti cs cavity.

blows the ozone built up around the charge

corona unit towards the ozone filter.

8

20

18

10

19

7

Copier

Clutches

CL1

CL2

CL3

CL4 Registration Clutch Drives the registration rollers. 11

CL5

CL6

Switches

SW1 Main Swit ch Supplies power to the copier. 43

SW2 Interlock Switch Cuts all power when the front cover is opened. 42

SW3

SW4

SW5

Upper Tray Paper

Feed Clutch

By-pass Paper F eed

Clutch

Lower Tray Paper

Feed Clutch

Upper Relay Roller

Clutch

Lower Relay Roller

Clutch

Upper Tray Paper

Size Switch

Right Vertical Guide

Switch

Lower Tray Paper

Size Switch

Transfers ma in motor drive to the upper paper

feed roller.

Starts paper fee d fr om t he by-pass feed tabl e.

Transfers ma in motor drive to the l ow er paper

feed roller.

Drives the upp er relay rollers for upper paper

tray feed.

Drives the lower relay rollers for lower paper

tray feed.

Determin es w hat size of paper is in t he upper

paper tray.

Cuts the +24 V dc power line of the relay roller

clutch.

Determines what size of paper is in the lower

paper tray.

13

12

16

14

15

36

30

35

Sensors

S1

4th/5th Mirro r Hom e

Position Sensor

Informs the CPU when the 4th/5th mirror

assembly is at the home position (full size

position).

7

28

Page 10

ELECTRICAL COMPONENT DESCRIPTIONS 26 September 199 7

Symbol Name Function Index No.

S2 ADS Sensor Detects the background density of th e or i gi nal. 26

S3

Upper Tray Paper

End Sensor

Informs the CPU w hen the upper paper tr ay

runs out of pape r.

31

Registratio n Sensor Detects the leading edge of th e copy paper to

S4

determine t he st op timing of the rela y roller

34

clutch, and det e ct s m i sf eeds.

S5

By-pass Feed Paper

End Sensor

Informs the CPU w hen there is no paper in the

by-pass tray .

33

S6 Exit Sensor Detects misfeeds. 25

S7

S8

S9

S10

Scanner Home

Position Sensor

Lens Home Posit ion

Sensor

Toner Density (TD)

Sensor

Lower Tray Paper

End Sensor

Informs the CPU w hen the 1st scanner i s at

the home position.

Informs the CPU w hen the lens is at the hom e

position.

Detec ts the ra tio of ton er to car rier in th e

developer.

Informs the CPU when the lower paper tray

runs out of pape r.

45

24

29

32

Printed Circuit Boards

PCB1 Main Control Boar d Controls all copier functions. 1

PCB2

High Voltage Supply

Board - C/G/B/T/S

Provides high voltage to the charge corona,

grid, development bias, transfer corona, and

2

discharge plate.

PCB3

AC Drive/DC Power

Supply Board

Drives the exp o sure lamp, fusing l amp, and

main motor. Rectifies 30 Vac and 8 Vac input

3

and outputs 5 Vdc and 24 Vdc.

PCB4

Operation Pane l

Board

Informs the CPU of the selected mode s and

displays the si t uation on the panel.

6

Lamps

Erase Lamp Discharges the dr um outside of the image

L1

area. (Provides leading/trailing edge and side

erases.)

L2

L3

Quenching Lamp Neutralizes any char ge r em a ining on the drum

surface after cl eaning.

Exposure Lamp Applies high intensity light to the original for

exposure.

L4 Fusing Lamp Provides hea t to the hot r oller. 27

Others

CO1

H1

H2

Total Counter Keeps track o f the t ot al num ber of copies

made.

Upper Tray Heat er

(Option)

Optics

Anti-condensat i on

Heater (Opti on)

Turns on when t he main switch is of f to keep

paper in the up per paper tray dry.

Turns on when t he main switch is of f to

prevent moisture from accumulating in the

optics.

8

4

5

22

39

38

44

Page 11

26 September 1997 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Name Function Index No.

H3

TF1

TF2

TH1

TH2

TR

Lower Tray Heat er

(Option)

Exposure Lamp

Thermofuse

Fusing Therm of u se Provide back-up overheat protection in the

Fusing Therm i st or M onitors the tem per ature around the ex posure

Optics Therm i st or Monitors th e te mperature around t he exposure

Transformer Steps down the wall vol t age to 30 Vac and 8

Turns on when t he main switch is of f to keep

paper in the lower paper tray dry .

Provide back-up overheat protection around

the exposure lamp.

fusing unit.

lamp for over heat protection.

lamp for over heat protection.

Vac.

37

23

41

40

21

17

Copier

9

Page 12

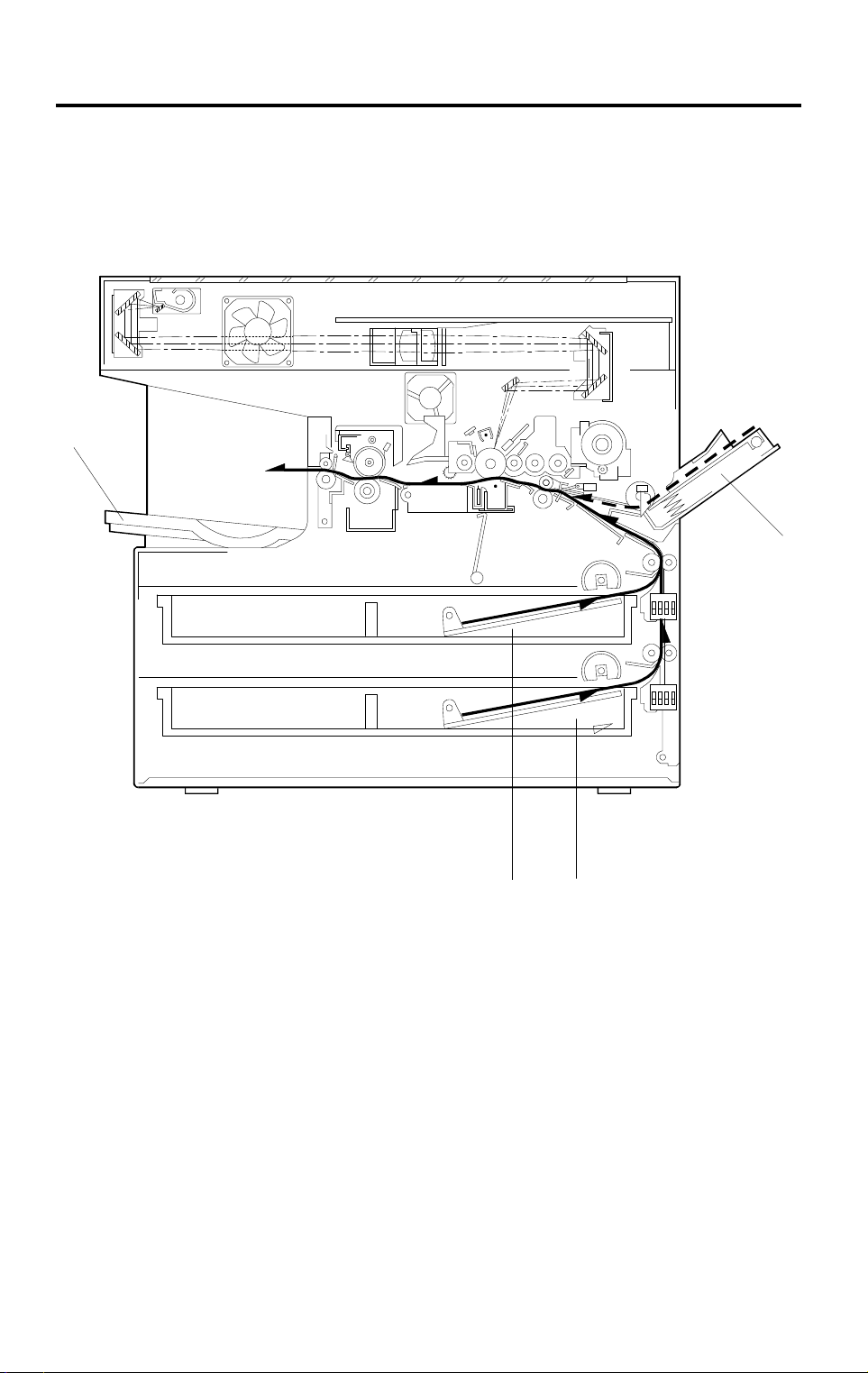

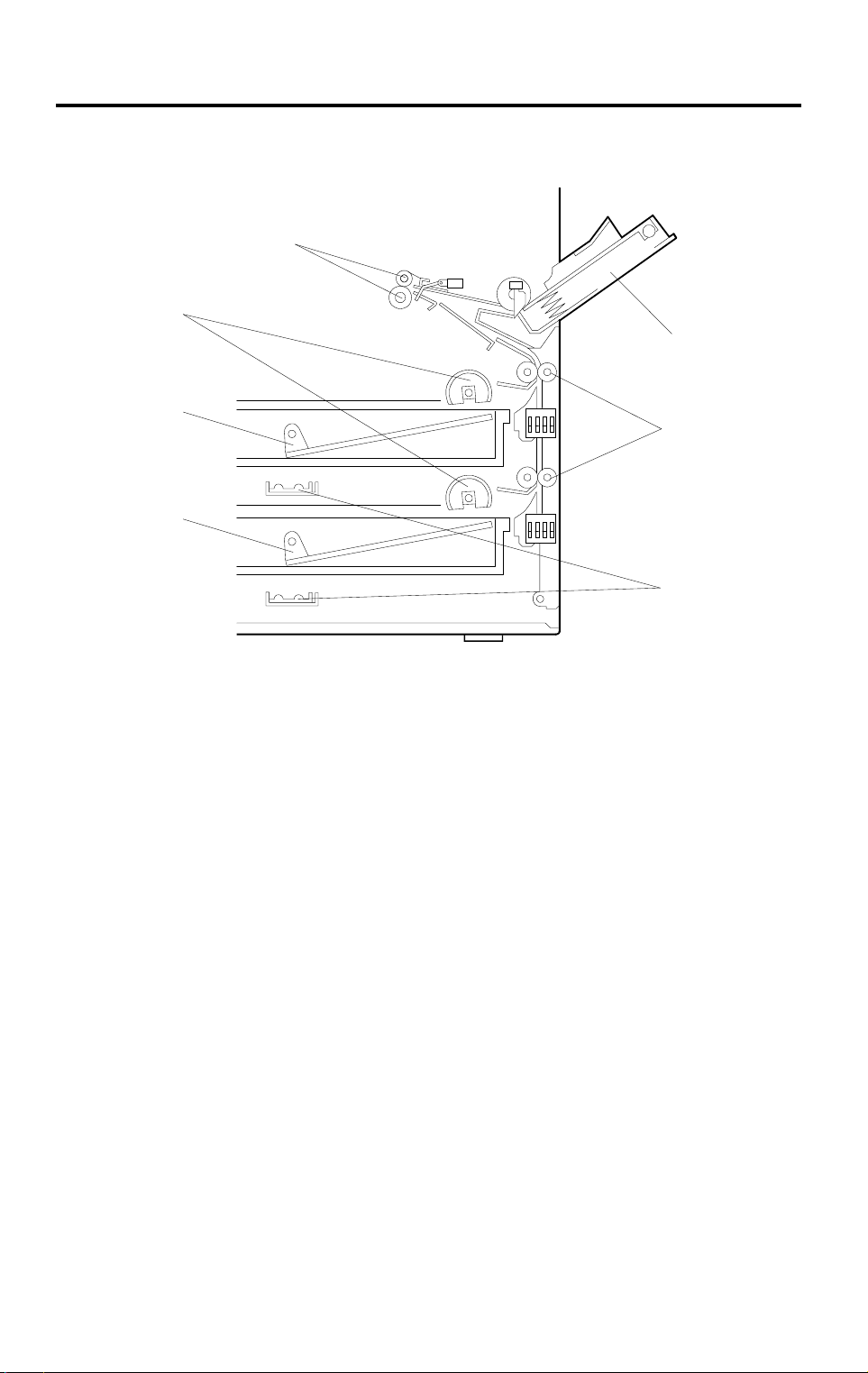

PAPER FEED 26 September 1997

6. PAPER FEED

6.1 OVERVIEW

[E]

[D]

[A]

[B]

[F]

[C]

[G]

A245D500.wmf

There are two paper trays and a by-pass feed table [A].

The upper [B] and lower [C] paper trays each hold 250 sheets. The by-pass

feed table can hold 1, 10, or 80 sheets of paper, depending on the paper type.

The semicircular feed rollers [D] drive the top sheet of paper from the tray to

the registration rollers [E] through the relay rollers [F].

The tray has two corner separators (see [F] in the diagram in the "Paper Lift

Mechanism" section), which allow only one sheet to feed at a time. The

corner separators, along with the tray’s springs, also serve to set the height

of the paper stack.

When the tray is closed after the paper is loaded, the paper size actuator

located at the front right of the tray pushes the paper size sensor. This

informs the cpu what paper size is loaded in the tray and that the tray is in

place.

The by-pass feed table uses a feed roller and friction pad system to feed the

top sheet of paper to the registration rollers.

In humid environments, copy paper may crease as it comes out of the fusing

unit. The optional tray heaters [G] are available as service parts to keep copy

paper dry. It can be installed for both paper trays.

10

Page 13

26 September 1997 PAPER FEED

6.2 PAPER LIFT MECHANISM

[F]

[D]

[E]

[A]

[C]

[B]

[F]

A245D501.wmf

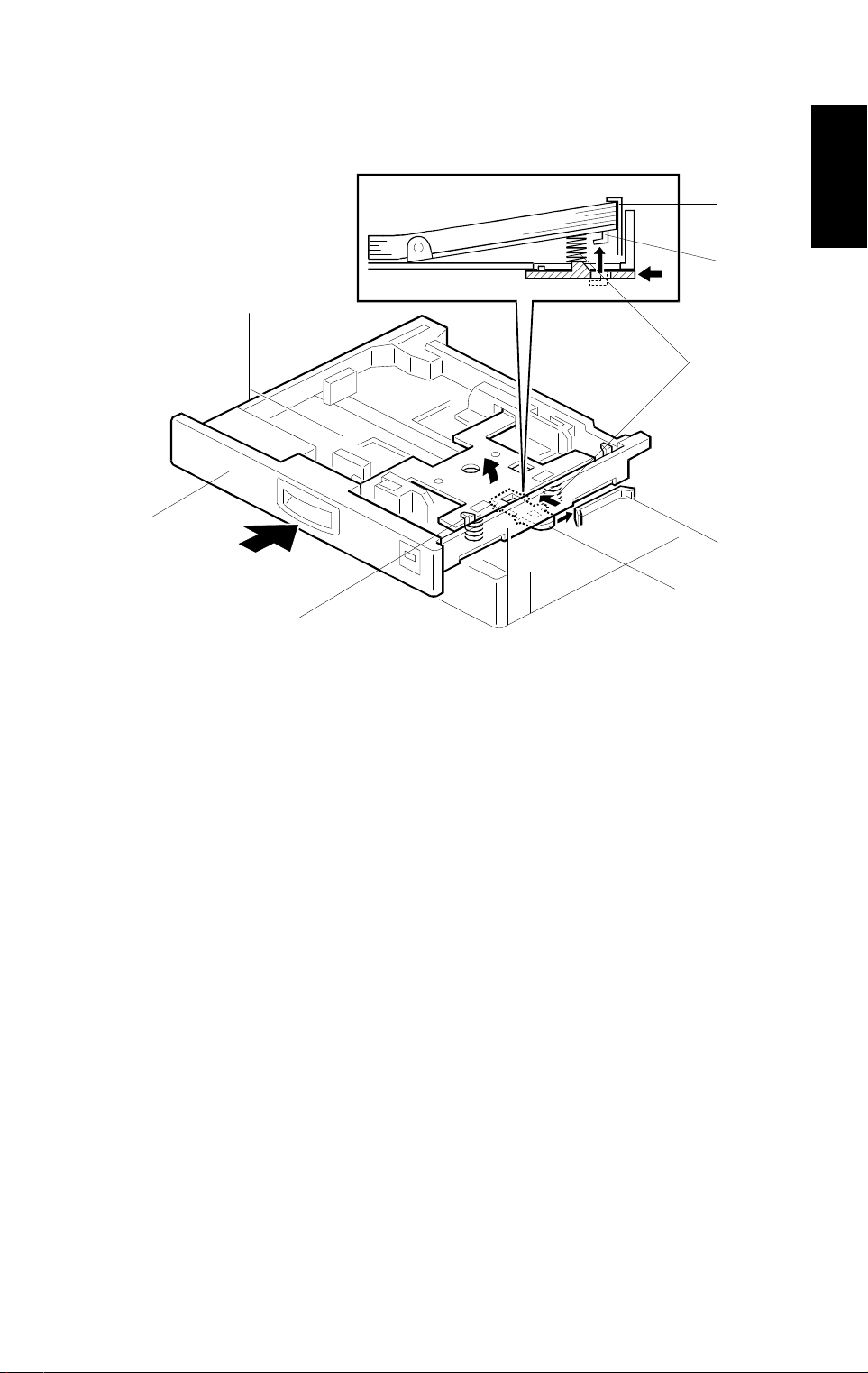

When the paper tray [A] is closed after paper is loaded, the release slider [B],

which is mounted on the bottom part of the tray, is pushed by the projection

[C] on the main frame and the release slider comes off the bottom plate hook

[D].

Copier

Once the release slider comes off, the bottom plate is raised by the pressure

springs [E] and the top sheet pushes up the corner separators [F]. This keeps

the stack of paper at the correct height.

11

Page 14

PAPER FEED 26 September 1997

6.3 PAPER FEED AND DRIVE MECHANISM

[E]

[D]

[C]

A245D502.wmf

[A]

[F]

[B]

[G]

A245D503.wmf

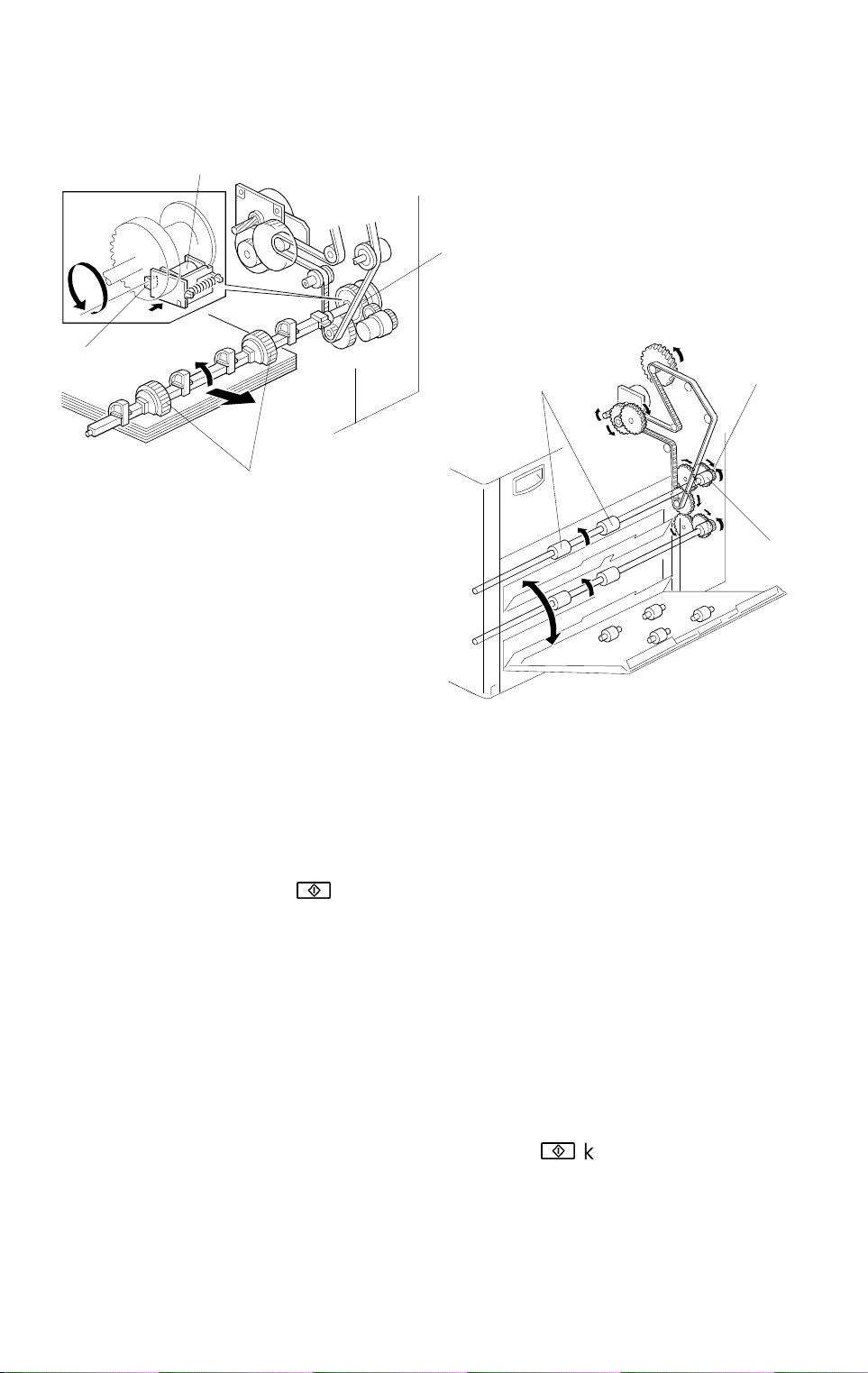

Through several gears and a timing belt, main motor rotation is transmitted to

the tray paper feed clutch gear [A] and the relay roller clutch gear [B].

-Feed rollers-

The tray paper feed clutch gear is on the same shaft as the semicircular

feed rollers [C]. After the

!

key is pressed, the tray paper feed clutch [D] is

energized for 250 milliseconds to release the stopper [E]. Then main motor

drive is transmitted, and the feed rollers make one complete rotation to feed

the top sheet of paper, which is enough for the leading edge of the paper to

be caught by the relay rollers [F]. The feed rollers stop when the stopper

drops back into the notch at the end of one complete turn.

-Relay rollers-

The relay roller clutch gear is on the same shaft as the relay rollers. The

rotation timing of the relay rollers is controlled by the relay roller clutch [G].

The CPU energizes the relay roller clutch after the

!

key is pressed (at the

same time as the tray paper feed clutch). Paper is fed from the relay rollers to

the registration rollers.

12

Page 15

26 September 1997 PAPER FEED

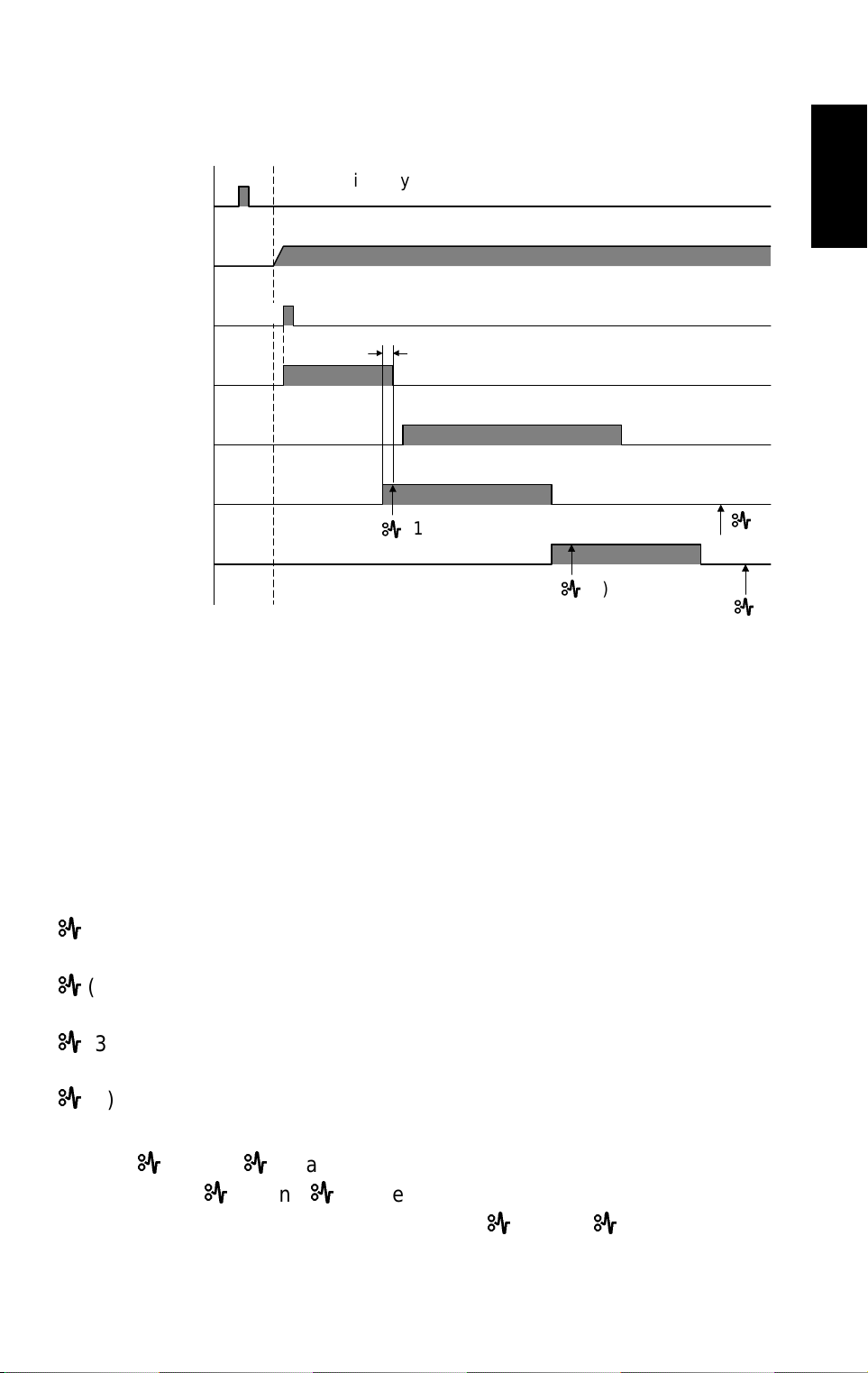

6.4 PAPER FEED AND MISFEED DETECTION TIMING

Start Key

Main Motor

Upper Tray

Paper Feed Clutch

Upper Relay Roller

Clutch

Registration Clutch

Registration Sensor

Exit Sensor

0

A4 sideways

0.30 0.55

0.30

A

0.10

2.13

2.05

(1)

4.48

A

(2)

(seconds)

6.50

(3)

A

6.78

(4)

A

A245D508.wmf

The registration sensor and the exit sensor are used for misfeed detection. If

the CPU detects a misfeed, the Check Paper Path and the Location

indicators turn on.

Copier

Just after the main switch is turned on, the CPU checks these sensors for

any jammed paper.

During the copy cycle, the CPU performs four kinds of misfeed detection. The

following explains jam detection timing for copying on A4 sideways paper

from the upper paper tray unit.

A

(1): Checks whether the registration sensor is actuated within 2.05

seconds after the main motor starts rotating.

A

(2): Checks whether the exit sensor is actuated within 4.48 seconds after

the main motor starts rotating.

A

(3): Checks whether the copy paper has passed through the registration

sensor 6.50 seconds after the main motor starts rotating.

A

(4): Checks whether the copy paper has passed through the exit sensor

6.78 seconds after the main motor starts rotating.

NOTE:

A

(1) and A (2) are detected from the leading edge of the copy

A

paper.

copy paper. The detection timing for

(3) and A (4) are detected from the trailing edge of the

A

(3) and A (4) will vary with

the copy paper size in use.

13

Page 16

IMAGE FUSING 26 September 1997

7. IMAGE FUSING

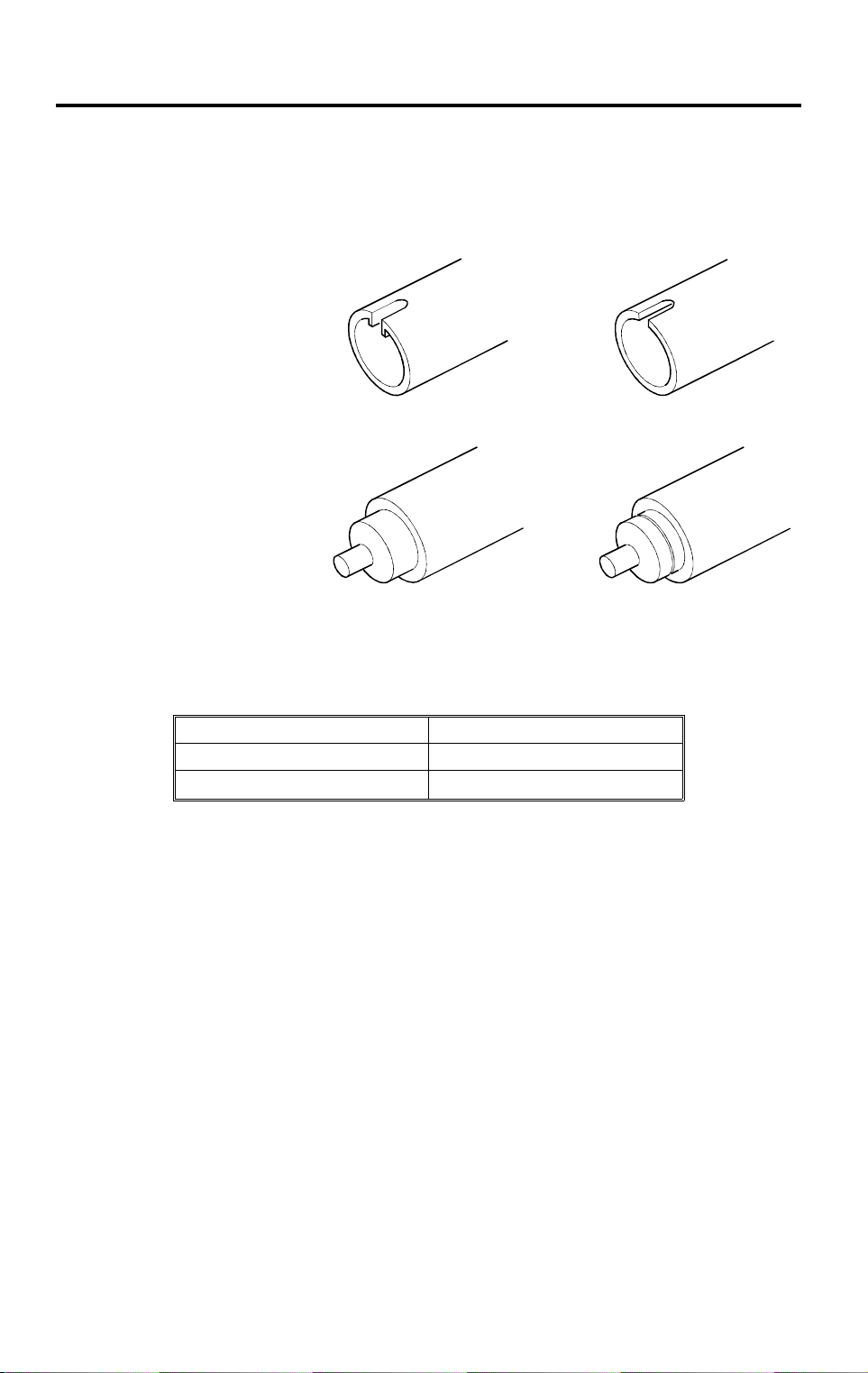

1. Both the hot roller and pressure roller for the A245 are different from the

A219. To distinguish between the two types of roller, check the end of the

roller shaft as described below.

HOT ROLLER

- A219 -

- A245 -

A245D504.wmf

PRESSURE ROLLER

- A219 -

A245D505.wmf

- A245 -

A245D506.wmf

A245D507.wmf

2. Due to the increase in copier CPM, the thickness of the metal core of the

hot roller has been increased for the A245 copier. This causes the ready

temperature to be higher, and the temperatures are as follows:

A245 copier A219 copier

172°C: 120 V machines 165°C: 120 V machines

177°C: 230 V machines 172°C: 230 V machines

Also, to achieve the same warm-up time as for the A219 copier in the 230 V

machines, the fusing lamp wattage has been increased from 650 W to 760 W.

For the 120 V machine, the warm-up time specification is slightly longer than

for the A219, so the lamp is not changed.

3. FUSING IDLING (SP116)

Fusing idling can be selected with SP116. This mode should be used

when the copier has fusing problems with copies which are made soon

after warm up. This problem is most likely to occur in low temperature

locations where the wall outlet condition is also not stable. Please note

that when this mode is selected, copier warm-up will take a couple of

seconds extra, and the first copy time will not be within specification.

When the start key is pressed, fusing idling is performed for 2 seconds. If

the temperature of the fusing unit is below the operating temperature by

up to 10°C, copying starts. If the detected temperature is more than 10°C

lower than the operating temperature, fusing idling will continue until the

detected temperature reaches 180°C. This will take 6 ~ 7 seconds longer

to warm up than if fusing idling is not used.

14

Page 17

26 September 19 97 INSTALLATION

8. INSTALLATION

8.1 COPIER ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the

followings list :

1. Model Name Decal (-10, -22 machines)

2. Symbol Explanation Decal - Multi-language

3. Installation Procedure - Multi-language (-10, -15, -22, -26 machines)

4. Operation Instructions English (-10, -15, -17, -19, -22, -26, -29, -39

machines)

5. NECR - English (-17 machines)

6. NECR - Multi-language (-27, -29, -39 machines)

7. Copy Tray

Copier

8. User Survey Card (-17 machines)

9. Paper Set Direction Deal - Multi-language (-22, -26, -27 machines)

15

Page 18

INSTALLATION 26 September 1997

8.2 COPIER INSTALLATION PROCEDURE

[B]

[A]

A245I500.wmf

[D]

[C]

[F]

[H]

A245I501.wmf

CAUTION

[E]

A245I506.wmf

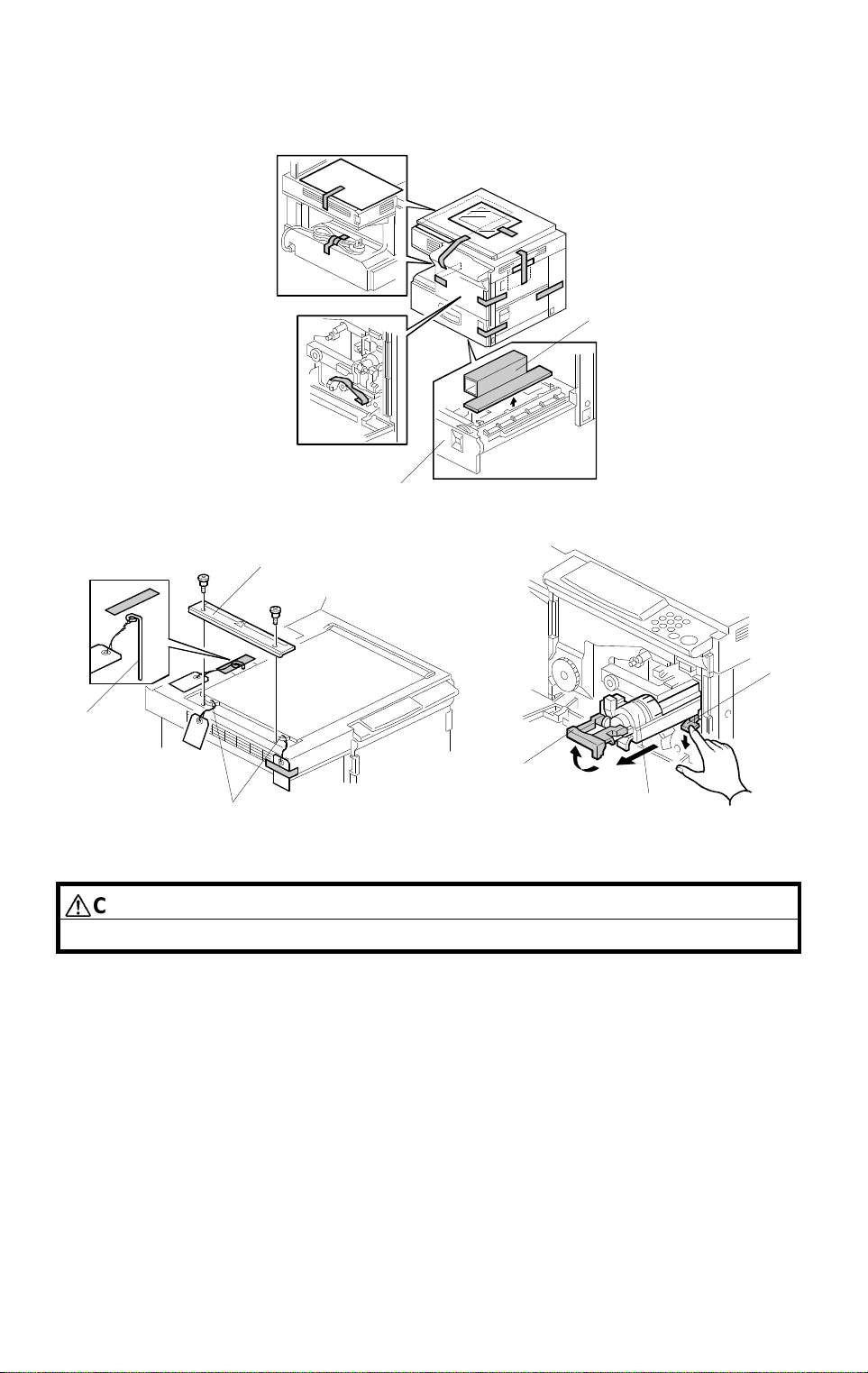

Do not plug in the power cord before starting the following procedure.

1. Remove all strips of tape shown above.

[G]

2. Pull out the paper trays [A], and remove the cardboards [B].

3. Open the platen cover and remove the lock pin [C].

NOTE:

Save the lock pin for future shipping.

4. Remove the left side scale [D] (2 screws) and remove the lock pins [E].

NOTE:

Save the lock pins for future shipping.

5. Open the front cover and raise the toner bottle holder lever [F].

Then pull down the securing lever [G], and remove the toner bottle holder

[H].

16

Page 19

26 September 19 97 INSTALLATION

[B]

Copier

[F]

[C]

[E]

[D]

[A]

A245I502.wmf

[G]

A245I503.wmf

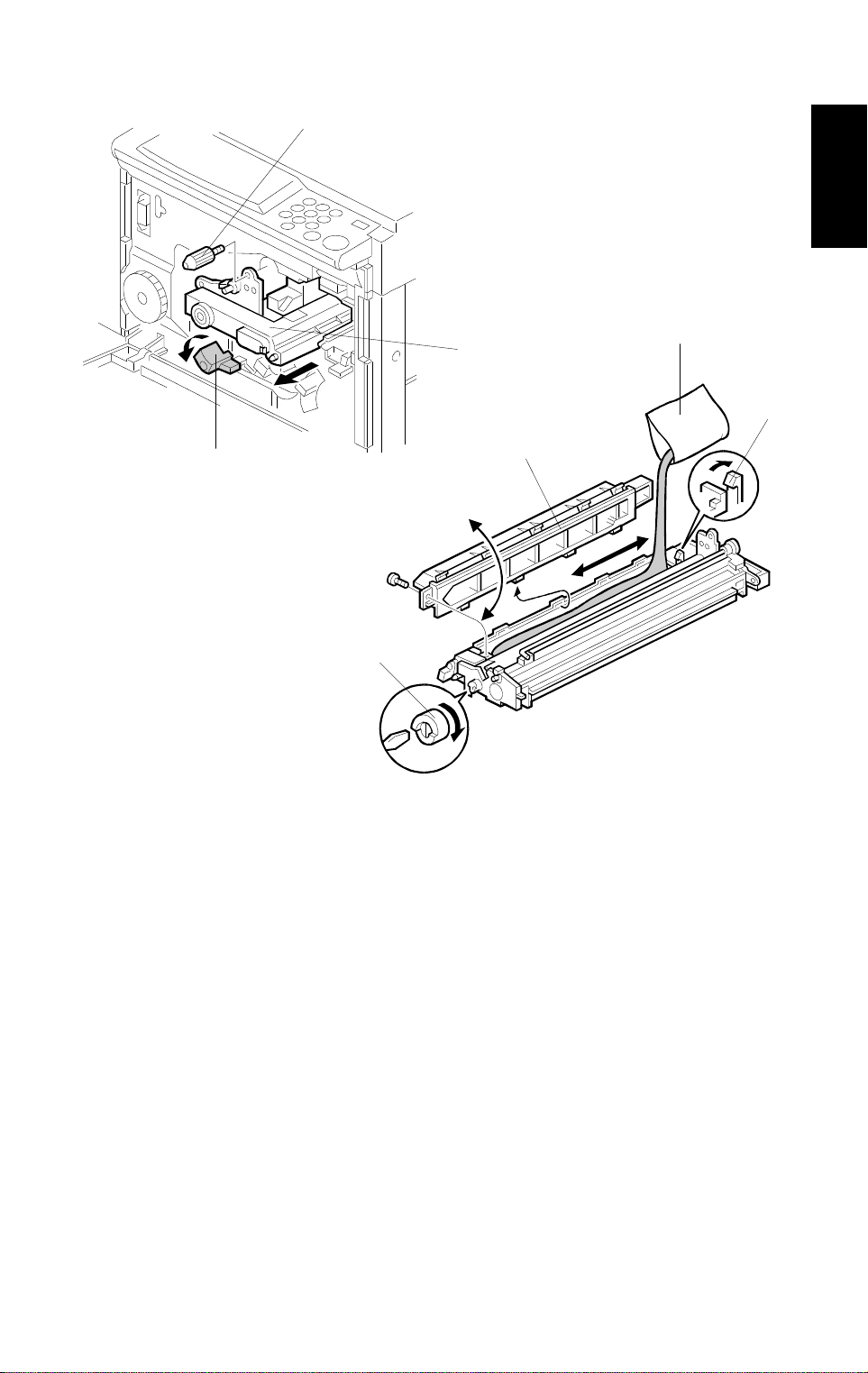

6. Turn the "B1" lever [A] counterclockwise to lower the transfer corona unit.

7. Remove the knob screw [B] and gently pull out the imaging unit [C].

Then place it on a clean sheet of paper.

8. Remove the cover [D] from the imaging unit (1 screw and 1 snap [E]).

9. Pour in the developer [F] evenly into the imaging unit. Then rotate the

outer gear [G] for one or two turns to distribute the developer as shown.

NOTE:

When installing new developer or manually rotating the

development roller, always make sure to turn the gear in the

direction shown above. Also do not rotate the gear more than 3

turns to prevent damage to the unit.

10. Remount the cover on the imaging unit, and install the unit in the copier

(1 knob screw).

17

Page 20

INSTALLATION 26 September 1997

[B]

[D]

[F]

[C]

[H]

[G]

[A]

[E]

A245I504.wmf

11. Install the toner bottle holder [A] in the copier as shown.

12. Shake the toner bottle [B] well.

NOTE:

Do not remove the bottle cap [C] of the toner bottle at this time.

13. Unscrew the bottle cap and insert the toner bottle into the holder, so that

the rib [D] rides the rail [E].

NOTE:

Do not open the inner bottle cap [F].

14. Reposition the holder by making sure that the securing lever [G] clicks.

Then press down the holder lever [H] to secure the bottle. Close the front

cover.

18

Page 21

26 September 19 97 INSTALLATION

[E]

[C]

[B]

[A]

[C]

[D]

A245I505.wmf

15. Pull the paper tray [A] out and turn the paper size dial [B] to select the

appropriate size. Adjust the side guides [C] and the end guide [D] to

match the paper size.

NOTE:

1) Make sure the stack of paper is aligned, and that there is no

space between the side guides and the paper stack.

Copier

2) Always push the paper tray in gently.

16. Plug in the copier and turn on the main switch. Wait until it warms up. (It

takes about 45 seconds.)

17. Enter the SP mode as follows:

1) Press the "Clear Modes" key.

2) Enter "107" using the numeric keys.

3) Hold down the "Clear/Stop" key for more than 3 seconds.

18. Perform the TD sensor initial setting as follows:

1) Enter "66" using the numeric keys.

2) Press the "Auto Image Density" key.

NOTE:

The machine will automatically stop when completed. (It takes

about 1 minute.)

19. Turn the main switch off and on to exit SP mode.

20. Check the copy quality and machine operation.

21. Inform the customer of the notes in step 13 concerning the paper tray.

Also find out if the customer changes paper sizes frequently. If not, inform

the customer that the side guides can be fixed with a screw [E] to achieve

better paper feed quality (use a tapping screw less than 8 mm long).

19

Page 22

INSTALLATION 26 September 1997

8.3 UPPER AND LOWER TRAY HEATER INSTALLATION

(OPTION)

[G]

[H]

[A]

[D]

[E]

[B]

[F]

A245I507.wmf

NOTE:

[C]

1) The optional tray heaters keep copy paper dry. In humid

environments, copy paper may crease as it comes out of the

fusing unit. The heaters are available as service part. (See the

parts catalog.)

2) Tell the customer that even when the copier main switch is turned

off, the copier power cord should be plugged in.

Otherwise, the tray heater will not function.

CAUTION

Unplug the copier power cord before star ting the follo wing procedure.

1. Remove the rear cover [A] (2 screws).

2. Remove the paper trays.

3. Connect the interface harness [B] to the tray heater [C]. Then mount the

heater on the heater bracket [D] as shown (1 screw).

- LOWER TRAY -

4. Mount the heater bracket on the bottom of the copier main frame, while

passing the connector [E] through the opening [F] in the copier main

frame as shown (1 screw).

5. Remove the transformer [G] (2 screws).

6. Locate the red two-pin connector [H] at the rear of the copier, and

connect it to the heater’s connector (red), as shown.

20

Page 23

26 September 19 97 INSTALLATION

[K]

[I]

[J]

A245I507-2.wmf

Copier

- UPPER TRAY -

4. Mount the heater bracket while passing the connector [I] through the

round opening [J] in the copier main frame as shown (1 screw).

5. Locate the red two-pin connector [K] at the rear of the copier, and

connect it to the heater’s connector (red), as shown.

21

Page 24

PROGRAM MODE 26 September 1997

9. PROGRAM MODE

9.1 SP MODE QUICK REFERENCE TABLE

NOTE:

1) Items written in

bold italic letters

are newly added service

programs.

2) Items written in

SP Mode

No.

4 Forced Start (Free Run) 36 TD Sensor Sensitivity Setting

5

6 Misfeed Detection Off

7

8 Input Check

9 Output Check

10

11 All Indicators On 45 Registration Buckle Adjustment

14

15

16 Count Up/Down Selection *48 Light Intensity Adjustment

17 Narrow Paper Select Mode 49 Fusing Temperature Adjustment

18

19 ADS Priority 51 Exposure Lamp Voltage Displ ay

22 SADF Shut Off Time 52 Fusing Temperature Disp l ay

24

27 A3/DLT Double Count

28 Auto Sort Select 55 TD Sensor Output Display Data

29

30 Toner Supply Mode Selection 57 ADS Output Voltage Display

31

32

33

34

35

Free Run with Exposure Lamp

Off

Free Run

Scanner Free Run

Auto Shut Off Time

(Energy Star)

Auto Reset Time Setting

(Energy Saver)

Auto Feed Station Shi ft

Horizontal Edge Margin Wid th

Adjustment

Fusing Temperature Control

Selection

Toner Supply Amount

(TD Sensor Mode)

Toner Supply Amount

(Fixed Supply M ode)

Image Bias Adjustment

(Manual ID Mode)

Image Density Adj ustment

(ADS Mode)

Total Toner Supply ON Time

During Tone r Near/End Conditi on

Function

are modified service programs.

bold

SP Mode

No.

38

39 VL2 Correction Interval

*41

*42 Registration Adjustment

*43 Vertical Magni fication Adjustment

*44

46

*47

50

53

54 TD Sensor Gain Adjustment

56

58

59

60

61

62

Toner Density Adjustment

Lead Edge Erase Margin

Adjustment

Horizontal Mag nification

Adjustment

Registration Buckl e Adjustment A5 Paper

Focus Adjustment

Fusing Ready Temperature

Adjustment

TD Sensor Target Cont r ol

Voltage Adjustment

ADS Reference Voltage

Adjustment

Image Adjustment at ID Level 1

Optics Temper at ur e D i splay

Drum Potential Measurement

(With Paper)

Drum Potential Measurement

(Without Paper)

Correction Interval

V

L

Function

* Items listed on the factory setting data sheet

22

Page 25

26 September 19 97 PROGRAM MODE

SP Mode

No.

63 Forced Toner Supply 90 Factory Data and Counter Clear

R

64 V

66 TD Sensor Initial Setting 93 VR Correction Reset

67 TD Sensor Initial Output Display 94 V

68 V

69 Imaging Unit Counter Displ ay 96 Toner End Force Cancel

Correction Value

L2

Correction Selection 95 VL Correction Reset

Function

70 User Code Mode

71 Sorter Operation 98 Total Counter Clear

73 User Code Counter Display

74

76

77

78 Auto Energy Saver Mode On/Off 106 DF Original Counter Display

81 Factory Initialization

82 Data Communication 130 Total Service Calls

83 Factory Potential Adjust ment 131 Total Misf eeds

88 Total Copy Counter Display

* Items listed on the factory setting data sheet

Special Paper Size Setting

Sorter Bin Capacity

Auto Shut Off (Energy Star)

On/Off

SP Mode

No.

Function

92 User Code Co unt er Clear

L2

Correction Reset

97 Servic e Call (E5) Reset

99 Clear All Memory

100

101

102

By-pass Feed Copy Co unter

Display

Upper Paper Feed Tray Copy

Counter Display

Lower Paper Feed Tray Copy

Counter Display

116 Fusing Id ling

Copier

9.2 UP MODE AND SP MODE CROSS REFERENCE TABLE

NOTE:

UP Mode No. SP Mode No. Function

Items written in

1 34 Image Density Adjustment (ADS Mode)

2 17 Narrow Paper Select Mode

3 15 Auto Res et Ti m e Set ting (Energy Saver)

4 78 Auto Energy Saver Mode On/Off

5 14 Auto Shut Of f Tim e Setting (Energy Sta r)

6 38 Toner D ensity Adjustment

7 16 Count Up/Down Selection

bold italic letters

8 73 User Code Counter Display

9 92 User Code Counter Clear

10 77 Auto Shut Off (Energy Star) On/Off

11 58 Image Adjustment at ID Level 1

are newly added programs.

23

Page 26

PROGRAM MODE 26 September 1997

9.3 SERVICE PROGRAM MODE TABLE

1. In the

2. In the

Function

Settings

column, comments (extra information) are in italics.

column, the default value is printed in bold letters.

3. If there is a ✝ mark in the Mode No. column, copies can be made within

this SP Mode.

Mode No. Function Settings

Forced Start

(Free Run)

4

Free Run with

Exposure

Lamp Off

5

Misfeed

Detection Off †

6

Free Run Performs a free run with the exposure lamp on.

7

Performs a free run with a forced start.

Press the ! key to start the free tun.

Press the $ key to stop the free run.

If this mode is swi t ched on, the copier st ar ts the free

run even if the fusing temperature has not reached

the required value yet.

This mode i s per f o r m ed w i t h the selected paper size

and magnif i cat i on ratio without the paper feed clutch

or total counter increment.

Normally, use SP7 to prevent fusing-related

service call conditions from occurring.

A free run is performed without exposure.

Press the ! key to start the free run.

Press the $ key to stop the free run.

This mode i s per f o r m ed w i t h the selected paper size

and magnif i cat i on ratio without the paper feed clutch

or total counter increment.

Normally, u se SP7 t o reduce the cleaning blade

load.

Copies are made without misf eed detection by the

registration, exit sensors, and sorter paper sensor.

Press the ! key to make a copy. It stops when

reaching th e set count, or when the $ key is

pressed.

Use this mode to check whether a pap er misfeed

was caused b y a sensor malfunction.

The total counter increments when copi es ar e

made in this mode.

Press the ! key to start the free run.

Press the $ key to stop the free run.

This mode i s per f o r m ed w i t h the selected paper size

and magnif i cat i on ratio without the paper feed clutch

or total counter increment.

Before starting, close the platen cover to reduce

the clea n ing blade lo ad.

24

Page 27

26 September 19 97 PROGRAM MODE

Mode No. Function Settings

Input Check †

Enter the desir ed number given in th e following

table. The magnification in di cator is used to disp l ay

the input data from the sensors whi l e making a

normal copy.

Press the ! key to perform this mode.

Copier

Component

No.

1

2

3

*4

*5

8

9

10

8

12

13

14

16

17

18

19

20

21 ADF Lift Switch ADF Closed ADF Opened

22

Sensor/

Switch/Signal

Registrat ion Sensor Paper Not

Exit Sensor Paper Not

By-pass Feed

Paper End Se nsor

Upper Tray Paper

End Sensor

Lower Tray Pa per

End Sensor

High Voltage Leak

Signal

Power Suppl y

Board Signal

Right Vertical

Guide Switch

Scanner HP Sensor

4th/5th Mirror HP

Sensor

Lens HP Sensor

Sorter Paper Sensor Paper Not

Sorter Wheel Switch Switch

Sorter Bin HP

Switch

Sorter Switch Sorter

ADF Installation ADF Not

Key Counter Set

Signal (Not Used)

Sensor Not

Sensor Not

Sensor Not

Key Counter

Reading

01

Present

Present

Paper Not

Present

Paper

Present

Paper

Present

No Leak

Signal

120 V 230 V

Cover

Closed

Actuated

Actuated

Actuated

Detected

Actuated

(Switch

Pushed in:

Wheel

Moving)

Switch Not

Actuated

Closed

Installed

Not Set

Paper

Present

Paper

Present

Paper

Present

Paper Not

Present

Paper Not

Present

Leak Signal

Detected

Cover Open

Sensor

Actuated

(HP)

Sensor

Actuated

(HP)

Sensor

Actuated

(HP)

Paper

Detected

Switch Not

Actuated

Switch

Actuated

(HP)

Sorter

Opened

ADF

Installed

Key Counter

Set

* Newly added or modified items from the A219 copier.

25

Page 28

PROGRAM MODE 26 September 1997

Mode No. Function Settings

Output Check

Use to turn on in di vi dual electrical components.

Enter the desir ed number given in th e following

table.

Press the ! key to turn on the electrical

component.

Press the $ key to turn off the electrical

component.

Component

No.

1

2 Charge Corona

3 Transfer Corona

4 Discharg e Plate

5

6 Erase Lamp All LEDs On

7

8

9

9 Optics Cooling Fan

10

11 Toner Supply Motor

12

14 Sorter Roller Drive Motor

15

16

17 Registration Clutch

18 By-pass Paper Feed Clutch

*19

*20

*21 Upper Relay Roller Clutch

*22 Lower Relay Roller Clutch

23 Total Counter

24 Key Counter Not Used

Electrical Component Note

Main Motor + Quenching

Lamp + Exhaust F an

Motor (H i g h Speed)

Development Bias Voltage Standard Voltage

Machine Shut Off Main Switch Relay

Exhaust Fan Motor

(High Speed)

Exposure Lamp + Optics

Cooling Fan

Toner Supply Motor

(Reverse)

Sorter Bin Drive Mo to r

(Bin Up)

Sorter Bin Drive Mo to r

(Bin Down)

Upper Tray Paper Feed

Clutch

Lower Tray Pa per Feed

Clutch

for Manual ID Level

4.

Off.

Moves One Bin Up.

Moves One Bin

Down.

* Newly added or modified items from the A219 copier.

26

Page 29

26 September 19 97 PROGRAM MODE

Mode No. Function Settings

Scanner Free

Run

10

Start a scanner free run.

Press the ! key to start the free run.

Press the

key to stop the free ru n.

$

This mode i s per f o r m ed i n accordance wit h t he

selected paper size and magn i fication ratio.

All IndicatorsOnTurns on all the indicators on the operation panel for

11

30 seconds. They will turn off automatically after 30

seconds.

To turn off the indicators, press the key.

Auto Shut Off

Time Setting

(Energy Star)

14

Selects the auto shut off time.

The copier m ai n sw i t ch is shut off autom at i cal l y after

the selecte d aut o shut off time, if SP77 i s at "0".

0: 30 min .

1: 15 min.

2: 60 min.

3: 90 min.

4: 120 min.

5: 240 min.

Copier

Auto Reset

Time Setting

15

(Energy Saver)

Selects an aut o re set time of 1 or 3 minutes, or

cancels this m ode.

The copier goes to energy saver mode

automatically after the selected auto reset time, if

SP78 is at "1".

Count

16

Up/Down

Selection

Narrow Paper

Select Mode

17

Selects count up or count down.

Selects narrow paper feed mode fo r the by-pass

feed table.

Use this mode to f eed non-standard paper sizes

that are too narr ow to be detected by the b y- pass

feed paper end sensor. In this case, the copier will

operate even if the Add Paper indicator is on.

Auto Feed

Station Shift

18

Selects auto feed station shift m ode.

The copier aut om atically shift s t o th e ot her paper

feed station when paper runs out, if it holds the

same size of p aper.

ADS Priority Specifies whether th e copier defaults to ADS or

19

SADF Shut Off

22

Time

Horizontal

Edge Margin

24

Width

Adjustment

Manual mode when the main switch is turned on.

Selects the shut o ff time for SADF mode.

The DF must be installed on the m achine.

Selects wheth e r the side erase mech ani sm changes

when the optio nal document feeder i s i nst al l ed.

See "Detaile d D escriptions - Eras e" f or more details.

0: 1 min.

1: 3 min.

2: None

0: Up

1: Down

0: No

1: Yes

0: Auto Shift

1: Manual

0: ADS

1: Manual

0: 5 s.

1: 60 s.

0: DF Mode

1: Always stays

in Platen Mode

27

Page 30

PROGRAM MODE 26 September 1997

Mode No. Function Settings

A3/DLT

Double Count

Specifies whether the counter is doubled for A3/DLT

paper.

0: OFF

1: ON

If "ON" is selected, the total coun te r, el ectrical total

27

counter (SP88), and the current user code counter

count up twice when A3/DLT copy paper is used.

This function is not applicab l e w hen using the

by-pass feed t abl e, since the by-pass feed table can

not detect cop y paper size.

Auto Sort

Select

In Auto Sort Mode, the sorter is automatically

selected when more than 1 original is set on the DF

0: Manual

1: Auto Sort

table and the ent ered copy quantity i s greater than 1

28

and less than 11 .

In Manual mode, sort mode has to be selected at

the operation panel.

The sorter and DF must be install ed on the machine.

Fusing

Temperature

29

Control

Selection

Toner Supply

Mode Selection

Selects the fusing temperature control mode.

After selecting the control mode and turning th e

main switch off/on, the fusing temperature control

mode is changed.

Selects the tone r supply system.

Normally, this value should not be changed.

0: ON/OFF

control

1: Phase

control

Default = 0

30

Toner Supply

Amount

(TD Sensor

31

Mode)

SP

Setting

Toner Supply System Note

Detect supp ly mode using

0

the initial TD sensor

setting.

Detect supp ly mode using

1

the target TD sensor

voltage set with SP53.

Detect supp ly mode (fixed

2

amount) using the initial

TD sensor setting.

Detect supp ly mode (fixed

amount) using the target

3

TD sensor vol tage set

with SP53.

Fixed supply mode. Use only in abnormal TD

4

Default

sensor conditions.

See SP31/SP32 for the toner supply amount.

Determin es how much toner is su ppl i ed in detect

supply mode .

Select the toner supply time from 0. 0 s t o 5. 0 s i n

0.1 s step s.

See "Detaile d D escriptions-Toner Supply Contr ol "

for more details.

0 ~ 50

Default = 4

(0.4 s)

28

Page 31

26 September 19 97 PROGRAM MODE

Mode No. Function Settings

Toner Supply

Amount

(Fixed Supply

Mode)

Determines how much toner is supplied in fixed

supply mode a nd i n detect supply (fixed amount)

mode.

For exampl e, if the user normall y makes copies of

0 ~ 7

Default = 0

A4 originals that are about 7% black, select the 7%

setting for be st results.

Copier

32

Image Bias

Adjustment

(Manual ID

Mode)

33

SP

Setting

0 3.5% 0.3 s Default

1 7.0% 0.6 s

2 15% 1.2 s

3 30% 2.4 s

4 45% 3.6 s

5 60% 4.8 s

6—

7 0% 0 No toner supply

Ratio

Supply

Time

∞

Continuous supply

Note

See "Detailed Descriptions - Toner Supply Control"

for more details.

Adjusts the devel opment bias volt age used in

manual ID m ode. This adjustm ent af fe ct s al l manual

ID settings. Use this SP mode to adjust the density

of pale gray areas.

SP Setting Setting Dev. Bias Note

0 Normal 0 Default

1 Darkest +40 V

2 Darker +20 V

3 Lighter –20 V

4 Lightest –40 V

0: Nor mal

1: Darker

2: Darkest

3: Lighter

4: Lightest

See "Detaile d D escriptions - Devel opment" for more

details.

29

Page 32

PROGRAM MODE 26 September 1997

Mode No. Function Settings

Image Densi ty

Adjustment

(ADS Mode) †

Selects the imag e density level in ADS mode.

The development bias and the e xposure lamp

voltages are i ncreased or decreased.

This adjustment affects copi es made in ADS mode.

0: Nor mal

1: Light

2: Dark

3: Lighter

4: Darker

SP Setting Setting Dev. Bias Exposure Lamp

0 Normal 0 0

1 Lighter –40 V 0

34

2 Darker +40 V 0

3 Lightest –40 V +4 steps

4 Darkest + 40 V –4 steps

The exposure l amp setting spec i fies the change

relative to the base exposure lamp voltage (Vo) in

SP48, 1 step of the lam p vol t age equals 0.5 V for

120 V (NA), and 1.0 V for 230 V (EU ) machines.

See "Detaile d D escriptions - Devel opment" for more

details.

Total Toner

Supply ON

Time During

35

Toner

Near/End

Condition

Selects the tone r supply motor on time after every

copy job during a toner near/end condition.

See "Detaile d D escriptions - Toner Supply" for mor e

details.

This SP mode is intended for designer use only.

1: 10 s

2: 20 s

3: 30 s

4: 40 s

5: 50 s

6: 60 s

TD Sensor

Sensitivity

Setting

36

Adjust the sensitivity of the TD sensor.

Normally, this value should not be changed.

SP Setting Sensitivity (V/wt%) Note

00

10.05

20.10

Å

12 0.60

13 0.65

14 0.70

15 0.75 Default

16 0.80

Å

19 0.95

20 1.00

↓

↓

0.05 per step

0.05 per step

The toner supply motor on time and/or the toner

density are ch anged by this setting. See

"Detailed Descriptions - Toner Supply Control"

for mo re details.

0 ~ 20

Default = 15

30

Page 33

26 September 19 97 PROGRAM MODE

Mode No. Function Settings

Toner Density

Adjustment

38

V

L2

Correction

39

Interval

Adjusts copy qu al i t y by changing the tone r

concentrati on i nside the develo pm ent unit.

This can be ad j ust ed using a UP mod e.

See "Detailed Descriptions - Toner Supply Control"

for more details.

Selects the inter val for detectin g th e st andard light

L2

intensity of th e w hi t e pl at e f o r the V

correction.

For Small CV users in a dusty envir onment, 200

0: Nor mal

1: Darker

2: Lighter

3: Darkest

4: Lightest

0: 500 copies

1: 200 copies

copies may be a better setting.

Lead Edge

Erase Margin

41

Adjustment †

Registration

Adjustment †

42

Adjusts the lea d edge erase marg in . 0 ~ 15

0.5 mm per step (–4.0 mm to +3.5 mm).

See "Replace ment and Adjustment - Copy Quali ty

Adjustment" for details.

Adjusts the registration. 0 ~ 15

0.5 mm per step (–4.0 mm to +3.5 mm). See

Default = 8

(2.5 mm from

leading edge)

Default = 8

"Replacement and Adjustment - Copy Quality

Adjustment" for details.

Vertical

Magnification

Adjustment †

43

Adjusts mag ni f i cat i on in the paper travel di rection by

changing the scanner speed.

0.2% per step (–3.2% to +3.0%).

Check the foc usi ng after doing this SP mode, and

0 ~ 31

Default = 16

adjust with SP47 if necessary.

See "Replace ment and Adjustment - Copy Quali ty

Adjustment" for details.

Horizontal

Magnification

Adjustment

44

Adjusts mag ni f i cat i on perpendicul ar to the direction

of paper travel , by changing the home position of

the lens and m i rrors.

✝

0.2% per step (–4.0% to +6.0%).

0 ~ 50

Default = 20

Check the foc usi ng after doing this SP mode, and

adjust with SP47 if necessary.

See "Replace ment and Adjustment - Copy Quali ty

Adjustment" for details.

Registration

45

Buckle

Adjustment †

Registration

Buckle

46

Adjustment A5 Paper †

Focus

Adjustment †

47

Adjusts the amount of paper buckle in the

registration area.

0.5 mm per step (–4.0 mm to +3.5 mm).

When feedin g A5 si deways paper, th e registration

buckle can b e adj usted separately from the SP45

setting to reduc e t he buckle .

0.5 mm per step (0 mm to –5.0 mm).

Adjusts the 4th/5t h mirror positi on t o cor rect the

focus.

This mode m u st be done after vertical and

horizonta l magnification adj ustments (SP43 an d

0 ~ 15

Default = 8

Default = 0

0 ~ 100

Default = 40

(0.1 mm per

step)

SP44).

See "Replace ment and Adjustment - Copy Quali ty "

for details on how to do this adjustm ent.

Copier

31

Page 34

PROGRAM MODE 26 September 1997

Mode No. Function Settings

Light Intensit y

Adjustment †

Clean the optics, then adjust the e xposure lamp

voltage. The V

L

and VL2 corrections ar e reset

automatically when entering this mode.

120 V Machines

100 ~ 194

Default = 140

48

Fusing

Temperature

Adjustment

49

Fusing Ready

Temperature

Adjustment

50

Exposure

Lamp Voltage

Display

51

SP Setting

100 50.0 100

101 50.5 101

102 51.0 102

Å

150 75.0 150

Å

180 90.0 180 Max

Å

193 96.5 —

194 97.0 Max —

120 V (NA) Version 230 V (EU) Version

Lamp Voltage (V)

↓↓

↓↓

↓

—

Before performing this mode, clean the optics.

Then open SP33 and return the setting to the

normal value if it has been changed. Then adjust

the light intensity using an OS-A3 Test Chart with

the platen co ver pl aced over it. After adj usting the

light intensity, adjust the ADS Reference Voltage

Adjustment (SP56).

See "Replace ment and Adjustment - Copy Quali ty "

for details on how to do this adjustm ent.

Adjusts the cont rol temperature of the hot roller

during copying in 1°C steps.

Adjusts the ready temperature of th e hot roller

during the warm-up period in 1°C steps.

Normally, this value should not be changed.

Displays the current exposure lamp voltage.

For 120 V mach ines, the actual appl i ed

voltage = displayed value/2

The exposur e l am p t urns on for 10 secon ds w hen

this mode is selected. Do not repeat more than 5

times, to avoid overheating the optics cavity.

230 V Machines

100 ~ 180

Default = 140

120 V Machines

180°C ~ 195°C

Default = 190°C

230 V Machines

180°C ~ 200°C

Default = 190°C

120 V Machines

160°C ~ 175°C

Default = 172°C

230 V Machines

165°C ~ 180°C

Default = 177°C

0 ~ 247

32

Page 35

26 September 19 97 PROGRAM MODE

Mode No. Function Settings

Fusing

Temperature

52

Display †

Displays the fusing temperat ure detected by the

fusing thermi st or.

Press the ! key to monitor the te mperature

during the normal copy cycle.

TD Sensor

Target Contr ol

53

Voltage

Adjustment

TD Sensor

54

Gain

Adjustment

TD Sensor

Output Display

Data †

55

If the setting of SP30 (T oner Supply Mode

Selection) is 1 or 3, this value is used for the TD

sensor targe t vo l tage.

Normally, this value should not be changed.

When the TD Sens or initial setting i s per f ormed, this

mode is adjust ed automatica l l y.

Normally, this value should not be changed.

Displays the TD sensor output vol ta ge.

Press the ! key to monitor the out put voltage

during the normal copy cycle.

The output voltage will display "0" when this mode is

1 ~ 200

Default = 97

(0.02 V per step)

0 ~ 255

Default = 102

(0.04 V per step)

(0.02 V per

step) x Data

accessed after turning on the main switch without

making any copies.

ADS

Reference

Voltage

56

Adjustment

ADS Output

Voltage

Display †

57

Adjusts the ADS reference voltage.

After adjustin g th e li ght i nt ensity (SP48), place 5

sheets of A4(LT) white paper on the exposure glass

and select th i s m ode. Adjust the ADS voltage to 2.5

0.1 V using VR101 on the mai n control board.

V

±

Displays the ADS o ut put volt age.

Press the ! key to monitor the out put voltage

during the normal copy cycle.

For only this SP mode, the copies are ma de w i t h th e

ADS mode (other SP modes use manual ID lev el 4) .

Image

Adjustment at

Adjusts the image density at ID level 1 by changing

the development bias voltage.

0: Normal

1: Darker

ID Level 1

58

SP Setting Setting Dev. Bias Note

0 Normal –200 Default

1 Darker –140

Copier

Optics

Temperature

59

Display †

Drum Potential

60

Measurement

(With Paper)

Drum Potential

61

Measurement

(Without Paper)

Displays the optics temperat ur e det ected by the

optics therm istor.

Press the ! key to monitor the temperature

during the normal copy cycle.

Factory use only.

Factory use only.

33

Page 36

PROGRAM MODE 26 September 1997

Mode No. Function Settings

Correction

V

L

Interval

Sets the interval for V

lamp voltage (SP48) is increased by 1 step at the

L

correction. The exposure

0 ~ 8

Default = 2

set copy count interval.

SP Setting Exposure Lamp Note

0 + 2 steps/8,00 0 co pies

1 + 2 steps/6,00 0 co pies

2 +2 steps/4,000 copies Default

62

3 + 2 steps/2,00 0 co pies

4 + 2 steps/1,00 0 co pies

5 No Correction

6 +2 steps/500 copies

7 +2 steps/200 copies

1 step of the lamp voltage equals 0. 5 V for

N-American, and 1. 0 V fo r European machines.

See "Detailed Section Descriptions - Exposure

Lamp Voltage Control" for details.

Forced Toner

Supply

Forces the toner bottle to supply toner to the

development uni t .

0: 6 seconds

1: 3 seconds

This mode starts when the ! key is pressed,

63

and stops auto m atically after th e selected time.

Use this mode to achieve standard image

density whe n copy quality problem s i ndi cate

low toner.

R

Correction

V

64

Value

TD Sensor

Initial Setting

Sets the VR correction val ue.

Keep this at the default setting.

Performs the TD sensor initial setting.

This SP mode contr ol s t he voltage applied to the TD

Default = 0

sensor to mak e th e TD sensor output 1.9 ± 0.1 V.

After using SP66, check SP67 to see if the sensor i s

66

working corr ectly.

This mode is started by pressing the key

and stops auto m atically after about 1 minute.

Use this mode only af t er ins ta lli ng new

developer .

TD Sensor

67

Initial Output

Display

L2

V

Selection

68

Correction

Display the TD sensor initial setting output.

Selects or deselects VL2 correction.

Keep this setting a t 0.

(0.02 V x

displayed

value)

0: V

L2

Correction

1: No V

L2

Correction

34

Page 37

26 September 19 97 PROGRAM MODE

Mode No. Function Settings

Imaging Unit

Counter

Display

69

User Code

Mode

70

Sorter

71

Operation

User Code

Counter

Display

73

Special Paper

Size Setting

74

Shows the total num ber of copies ma de so far by

the imaging unit installed in the machine. This

counter is reset by SP93.

The first three di gi ts are dis played in t he

magnifica tion indicator.

Press the

Enables user code mode.

JP101 on th e main board must be cut.

It this mode is set, operators must enter a code to

make copies. The user codes are the following 5

numbers:

1101, 2202, 3303, 4404, 5505

Enables sorter oper at i on.

Displays the contents of each user code counter.

Use the 9 or : key to select a use r co de. The last

digit of the user code is displayed in the copy

counter. User counters count from 0 to 999999.

The first three di gi ts are dis played in t he

magnifica tion indicator.

Press the

Sets the appropriate paper size for special paper

loaded in the paper feed tray.

The "" mark on the paper si ze dial must be

selected to use this special feature.

When the pap er feed tray is selecte d, the

appropria te p aper size or the "

displayed and the copier will operate in accordance

with the set paper size.

key to view the last three digits.

*

key to display the last three digits.

*

" mark will be

0: No

1: Yes

0: No Sorte r

1: Sorter Installed

0:

(Universal)

1: A3

2:

(Universal)

3: B4

4: A4

5: A4R

6: B5

7: B5R

8: A5

9: B6

13: DLT

14: LG

15: LT

16: LTR

17: HLT

19: F

27: 8 k

28: 16 k

(Sideways)

29: 16 k

(Lengthwise)

Copier

Sorter Bin

76

Capacity

Sets the stock quantity limits. If set to 1, the

maximum am ount of copies dep ends on the paper

size (see the specifications for the sorter).

35

0: No limit

1: Limit

Page 38

PROGRAM MODE 26 September 1997

Mode No. Function Settings

Auto Shut Off

(Energy Star)

77

On/Off

Selects the "Auto m at i c Shut of f" mode. 0: Yes

The copier aut om atically shut s i ts el f off at the auto

shut off time selected (SP14).

1: No

Default = 0 (NA)

Default = 1

(Others)

Auto Energy

78

Saver Mode

On/Off

Factory

81

Initialization

Data

82

Communic at i on

Factory

83

Potential

Selects the "Auto m at i c Ener gy Saver" mode. 0: No

The copier aut om atically goes t o Ener gy Saver

1: Yes

mode at the auto r eset time selected (SP15).

Factory use only.

Factory use only.

Factory use only.

Adjustment

Total Copy

Counter

Display

88

Displays the total (electrical) copy counter.

The first three di gi ts are dis played in t he

magnifica tion indicator.

Press the

key to view the last three digits.

*

The mechani cal total counte r and the electric al

total count er may not always di splay the same

value, becaus e of initial differences in the

counter va lues.

Factory Data

90

and Counter

Factory use only.

Clear

User Code

Counter Clear

92

R

V

Correction

Reset

93

Resets all the user code counters (SP73).

To clear, enter "1" then press the key and the

key at the same time.

*

Resets the drum residual volta ge correction cou nt er

for the VR correcti on.

To clear, enter "1" then press the key and the

key at the same time.

*

0: No

1: Yes

0: No

1: Yes

Use this mode only af t er ins ta lli ng a new drum.

L2

Correction

V

Reset

Resets the exposure lamp data a nd counter for the

L2

correction. Always perform this mode with SP95

V

0: No

1: Yes

as a set.

94

To Clear, ent er "1" t hen press the key and the

key at the same time.

*

Normally not needed in the fiel d, as this is handl ed

by SP48.

L

Correction

V

Reset

Resets the exposure lamp data a nd counter for the

L

V

correction. Always perform this mode with SP94

0: No

1: Yes

as a set.

95

To clear, enter "1" then press the key and the

key at the same time.

*

Normally not needed in the fiel d, as this is handl ed

by SP48.

36

Page 39

26 September 19 97 PROGRAM MODE

Mode No. Function Settings

Toner End

96

Force Cancel

The Toner End co ndi t i on is canceled forci bly.

By pressing the key to enter this SP mode, th e

toner end condi t i on is canceled.

Service Call

97

(E5) Reset

Resets a service call (E5) condition.

Turn the main swi t ch off and on to chec k i f the

service call condition is reset.

Total Counter

Clear

98

Clears the total (electrical) counter.

Normally, this SP mode should not be

performed.

To clear, enter "1" then press the key and the

key at the same time.

*

0: No

1: Yes

To avoid reset t i ng t he counter by mistake, the

counter is reset only when the

key and the

*

key are pressed at the same time .

Clear All

Memory

99

Clears all counters and returns all modes to the

default settings. See the Clear All Memory

Procedure in this section for more details.

Normally, this SP mode should not be

performed.

This SP mode is required only when replacing the

EEPROM, or when the copier malfunctio ns due to a

damaged EEPROM.

0: No

1: Yes

To clear, enter "1" then press the key and the

key at the same time.

*

To avoid reset t i ng t he counter by mistake, the

counter is reset only when the

key and the

*

key are pressed at the same time .

By-pass Feed

Copy Counter

Display

100

Displays the total (electrical) copy counter for the

by-pass feed t able.

Since the copy co unt er for displaying t he current SP

mode number has only 2 digits, the m anual image

density indi cator is used to disp l ay t he f i rst digit.

The first three di gi ts are dis played in t he

magnifica tion indicator.

Upper Paper

Feed Tray

Copy Counter

Display

101

Press the

Displays the total (electrical) copy counter for the

upper paper fe ed t ray.

Since the copy co unt er for displaying t he current SP

mode number has only 2 digits, the m anual image

density indi cator is used to disp l ay t he f i rst digit.

key to view the last three digits.

*

The first three di gi ts are dis played in t he

magnifica tion indicator.

Press the

key to view the last three digits.

*

Copier

37

Page 40

PROGRAM MODE 26 September 1997

Mode No. Function Settings

Lower Paper

Feed Tray

Copy Counter

Display

102

DF Original

Counter

Display

106

Displays the total (electrical) copy counter for the

lower pape r feed tray.

Since the copy co unt er for displaying t he current SP

mode number has only 2 digits, the m anual image

density indi cator is used to disp l ay t he f i rst digit.

The first three digits are displayed in the

magnifica tion indicator.

Press the * key to view the last thr ee di gits.

Displays the total (electrical) number of originals fed

from the DF.

Since the copy co unt er for displaying t he current SP

mode number has only 2 digits, the m anual image

density indi cator is used to disp l ay t he f i rst digit.

The first three di gi ts are dis played in t he

magnifica tion indicator.

Fusing Idling

116

Press the

Selects fusing idling during warm-up. This mode

should be used f or tr oubleshooting purposes only.

See "Detaile d D escriptions" for m ore details.

If this mode is selected, inform the customer

key to view the last three digits.

*

0: No

1: Yes

that the first copy time will not be within

specification.

This mode i s enabled after turn i ng t he main switch

off/on.

Total Service

Calls

130

Displays the total number of ser vi ce call conditions.

Since the copy co unt er for displaying t he current SP

mode number has only 2 digits, the m anual image

density indi cator is used to disp l ay t he f i rst digit.

The first three di gi ts are dis played in t he

magnifica tion indicator.

Press the

Total Misfeeds Displays th e to ta l n um ber of misfeeds excluding

original mi sf eeds in the DF.

Since the copy co unt er for displaying t he current SP

131

mode number has only 2 digits, the m anual image

density indi cator is used to disp l ay t he f i rst digit.

key to view the last three digits.

*

The first three di gi ts are dis played in t he

magnifica tion indicator.

Press the

key to view the last three digits.

*

38

Page 41

26 September 1997 PREVENTIVE MAINTENANCE SCHEDULE

10. PREVENTIVE MAINTENANCE SCHEDULE

10.1 MODIFIED PM TABLE

Below lists the modified PM table for the A219 and A245 copiers.

This information is also released in A219 RTB no. 1.

Copier

NOTE:

1) The amounts mentioned as the PM interval indicate the number of

copies.

2) Refer to "REGULAR PM PROCEDURE" in this section.

Symbol key: L: Lubricate R: Replace C: Clean I: Inspect A: Adjust

EM 45 k 90 k 135 k 180 k Notes

Optics

Reflector C C C C Silicone cloth

1st to 5th Mirrors C C C C Silicone cloth

6th Mirror C C C C Blower brush

Lens C C C C Blower brush

Exposure Glass

Platen Cover Sheet

Scanner Guide R od C , L C, L C, L C, L Dry cloth, Grease - CPL501

Scanner Guide Rai l

4th/5th Mirror Guide Rod

4th/5th Mirror Guide Rail

Blue Filter CCCCSoft cloth

Exposure Lamp /1 st

Scanner Ass’y

CCCCC

CCRCR

C, L C, L C, L C, L

C, L C, L C, L C, L

C, L C, L C, L C, L

Soft cloth dampened with

alcohol or water

Soft cloth dampened with

water

Dry cloth, Silicone Grease G501

Dry cloth, Silicone Grease G501

Dry cloth, Silicone Grease G501

Replace at 200 k copi es

Around the Drum

Charge Corona Wire C R R R R Blower brush

Transfer Cor ona Wire C C R C R Blower brush

Charge Corona Grid R R

Transfer Guide Plate C C C C C Soft cloth

End Blocks and Ca si ngs C C C C Blower br ush or dry cloth

Charge Corona Cleaning

Pad

Erase Lamp C C C C C Blower brush or dry cloth

QL C C C C C Blower brush or dry cloth

Discharge Plat e I C C C C Blower brush

IRRRR

39

Page 42

PREVENTIVE MAINTENANCE SCHEDULE 26 September 1997

EM 45 k 90 k 135 k 180 k Notes

Cleaning

Cleaning Blade I R I R Apply setting powder

Inside the Cleaning Unit

Cleaning Entra nce Seal

Development Unit

Developer R R R R

Development Unit

Entrance Seal

Toner Supply Unit I I I I

Development Drive Gear LLLLGrease - CPL501

Imaging Unit Low er Cover C C C C Dry cloth

Paper Feed (for each paper feed station)

Feed Roller

By-pass Feed Roller

Friction Pad

Tray Bottom Plate Pad

By-pass Bottom Plate Pad

Registration Roller

Paper Feed Guide

Paper Dust Mylar CCCCCSoft cloth

CRR

CRR

CRR

CCRCR

CCCCC

CCCCC

CCCC

CCCC

IIII

CCCC

Remove all toner and

developer

Dry cloth. Replace if

necessary

Soft cloth dampened with

water

Soft cloth dampened with

water

Soft cloth dampened with

water

Soft cloth dampened with

water

Soft cloth dampened with

water

Soft cloth dampened with

water

Soft cloth dampened with

water

Fusing

Hot Roller R R

Pressure Roller R R

Stripper Pawls C C R C Suitable solvent

Fusing Entrance and Exit

Guide Plates

Fusing Thermistor C C C C Suitable solvent

Hot Roller Bearings C, L C, L C, L C, L Barrierta JFE55/2

Pressure Roller Bearings I I I I

Others

ADS

A

CCCC

40

Suitable solvent

Adjust when the lamp voltage

is changed.

Page 43

26 September 1997 PREVENTIVE MAINTENANCE SCHEDULE

EM 45 k 90 k 135 k 180 k Notes

Exit and

Registrati on Sensors

Bearings I I I I

Ozone Filter

Driving Belts I I I I

DOCUMENT FEEDER (A662) (for originals)

Transport Belt

Friction Belt

Pick-up Roller

Feed Roller

CRCR

EM 80 k 160 k Notes

CRR

CRR

CCC

CCC

II

Vacuum cleaner or bl ow er

brash

Clean with belt cleaner at

copier PM

Clean with belt cleaner at

copier PM

Soft cloth dampened with

water

Soft cloth dampened with

water

Copier

EM Notes

SORTER (A657)

Bin Guide/Wheel

Bushings

Exit Rollers C Alcohol

L

L

Silicone Grease - G501:

If movement is not smooth.

Launa oil:

If bushings generate noise.

41

Page 44

REPLACEMENT AND ADJUSTMENT 26 September 1997

11. REPLACEMENT AND ADJUSTMENT

11.1 PAPER FEED ROLLER REPLACEMENT

[E]

[D]

[A]

[C]

[B]

A245R500.wmf

Paper Feed Rollers

1. Remove both paper trays.

2. Remove the front door and the inner cover only when replacing the 1st

paper feed roller.

3. Remove the paper feed bushing [A] (1 screw).

4. Pull the paper feed roller shaft [B] out.

5. Replace the paper feed roller [C].

NOTE:

When reinstalling the feed roller assembly, make sure of the

following:

1) Do not touch the feed rollers with bare hands.

2) Reinstall the feed rollers face up as shown.

3) Ensure that the pin [D] on the end of the feed roller shaft fits into

the slot [E] on the end of the drive shaft.

42

Page 45

26 September 1997 REPLACEMENT AND ADJUSTMENT

11.2 RELAY ROLLER CLUTCH AND PAPER FEED CLUTCH

REPLACEMENT

[G]

[D]

[J]

[I]

[F]

[B]

[K]

[A]

[E]

[C]

[L] [M]

[I]

A245R501.wmf

1. Turn off the main switch and unplug the power supply plug.

2. Remove the rear cover and the rear right cover. (See Rear Cover

Removal.)

Copier

[H]

[I]

A245R502.wmf

3. Remove the switch bracket [A] (2 screws and 1 connector).

4. Remove the securing bracket [B] (2 screws).

5. Remove the paper feed clutch assembly [C] (2 screws).

6. Replace the upper [D] and lower [E] relay roller clutches (1 E-ring and 1

connector each).

NOTE:

When reinstalling a new clutch, engage the notch [F] with the

stopper [G].

7. Remove the paper feed shafts [H] and bearings [I] (1 snap ring each).

8. Replace the upper [J] and lower [K] paper feed clutches.

NOTE:

When reinstalling a new clutch, engage the notch [L] with the

stopper [M].

- Reinstallation -

When reinstalling the paper feed clutch assembly, it is easier to operate if

one of the paper feed roller shaft is removed from the copier. (See Paper

Feed Roller Replacement.)

43

Page 46

REPLACEMENT AND ADJUSTMENT 26 September 1997

11.3 PAPER SIZE SWITCH REPL ACEM ENT

[C]

[A]

[B]

[C]

A245R503.wmf

1. Remove the front right cover. (See Exterior and Inner Covers Removal.)

2. Remove the both paper trays.

3. Remove the brackets [A] (2 screws each).

4. Remove the paper size switch bracket [B] (3 screws).

5. Replace the tray paper size switches [C] (2 snap fits and 1 connector).

44

Page 47

26 September 1997 REPLACEMENT AND ADJUSTMENT

11.4 PAPER END SENSORS

Copier

[B]

[A]

A245R504.wmf

1. Remove both paper trays.

2. Remove the rear cover. (See Exterior and Inner Covers Removal.)

3. Remove the paper end sensor assemblies [A] (1 screw and 1 connecotr

each).

4. Replace the paper end sensors [B].

NOTE:

When reinstalling, manually make sure that the paper end sensing

mechanism properly works.

45

Page 48

REGULAR PM PROCEDURE 26 September 1997

12. REGULAR PM PROCEDURE

1. Make a copy Make a copy of an OS-A3 test chart at manual

2. Optics (every 45 k) 1. Clean the reflector and 1st to 5th mirrors

Replace the

platen cover

sheet (every 90 k)

Replace the

exposure lamp

(at 200 k)

Every 45 k

image density level 4.

2. Clean the 6th mirror and lens with a blower

3. Clean the exposure glass with a soft cloth

4. Clean the platen cover sheet with a soft

5. Lubricate the scanner guide rod with

6. Remove the oil on the scanner guide rail,

Every 90 k

with a silicone cloth.

brush.

dampened with alcohol or water.

cloth dampened with water (replace every

90 k).

Grease - CPL501.

4th/5th mirror guide rail, and 4th/5th mirror

guide rod. Then lubricate them all with

Silicone Grease - G501.

Others

3. Around the drum

(every 45 k)

Replace the

transfer corona

wire, charge

corona grid, and

cleaning blade

(at 90 k)

7. Clean the blue filter with a silicone cloth.

1. Clean the transfer corona wire, the transfer

entrance guide plate, and the charge

corona grid with a blower brush or dry cloth.

2. Clean the end blocks and casings with a

blower brush or dry cloth.

3. Remove the old developer.

46

Page 49

26 September 1997 REGULAR PM PROCEDURE

4. Remove all toner, developer and the drum

from the imaging unit. Clean the

whole

imaging unit, especially the lower cover

with a dry cloth.

5. Inspect the development entrance seal,

toner supply unit, and development drive

gears in the imaging unit (lubricate the

latter with 2 or 3 spots of CPL501).

6. Install new developer.

7. Clean the cleaning entrance seal and

inspect the cleaning blade. If replaced,

apply setting powder evenly on the surface

and edge of the new cleaning blade.

8. Clean the erase lamp and the quenching

lamp with a blower brush or dry cloth.

Copier

6. Paper Feed

(every 45 k)

Replace the feed

roller, by-pass

feed roller, friction

pad tray bottom

plate pad

(every 90 k)

9. Replace the charge corona wire and

charge corona cleaning pad.

10. Inspect the discharge plate. Clean it with a

blower brush.

1. Clean the bottom plate pad with a soft cloth

dampened with water.

2. Clean the registration roller with a soft cloth

dampened with water.

3. Clean the paper feed guide with a soft cloth

dampened with water.

4. Clean the paper dust mylar with a soft dry

cloth.

47

Page 50

REGULAR PM PROCEDURE 26 September 1997

7. Fusing Unit

(every 45 k)

1. Clean the stripper pawls with a suitable

solvent. (Replace every 135 k.)

2. Clean the fusing entrance and exit guide