Page 1

RICOH Technical B ulletin PAGE: 1/1

Model: Kingfisher Date: 15-Apr-97

No: 1

Subject: PM Parts Yield Prepared by: M. Inohana

From: QAC 1st Field Information Dept. Checked by: T. Inoue

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

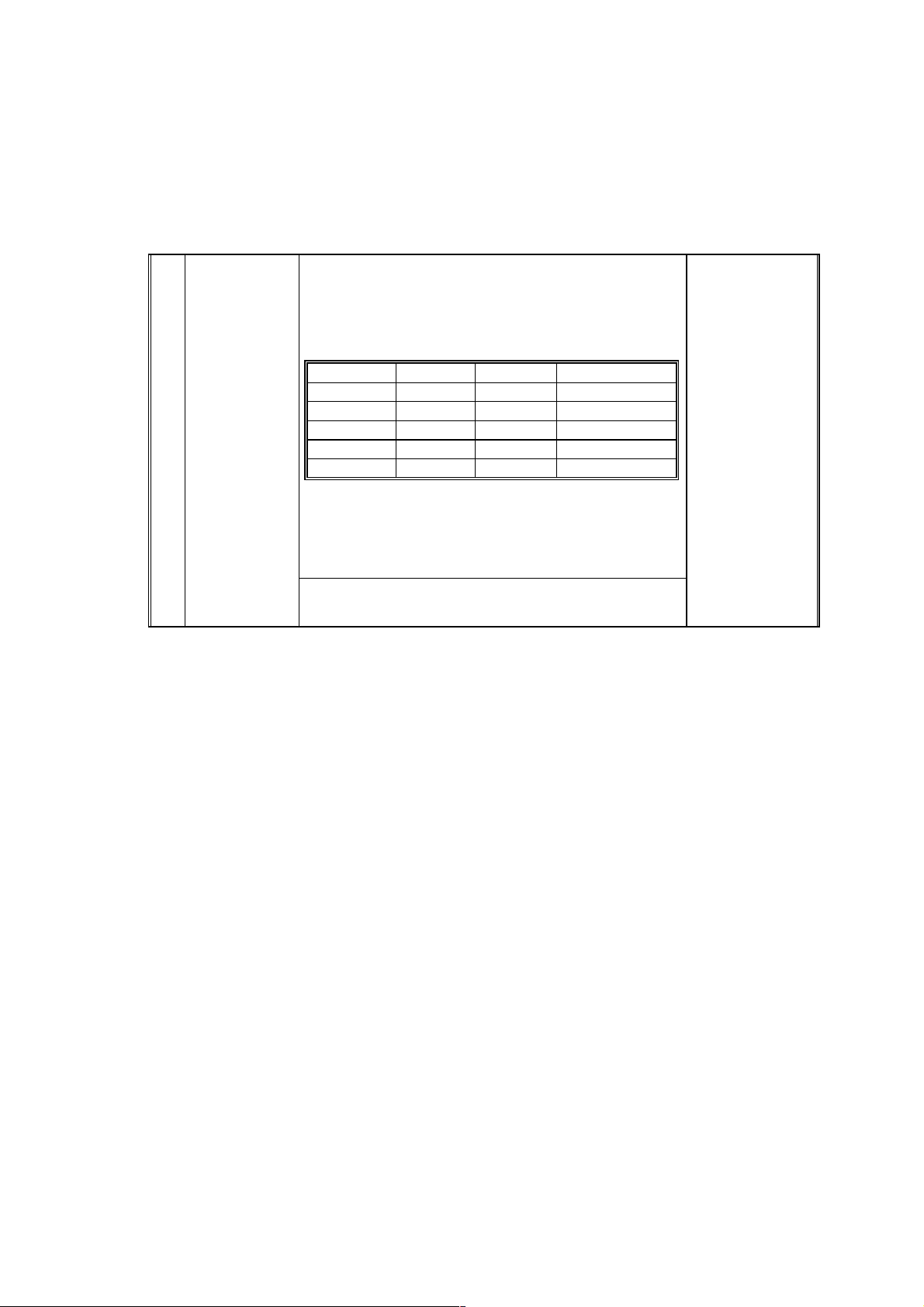

The yields for some PM parts have been reviewed.

Please correct your PM table as follows:

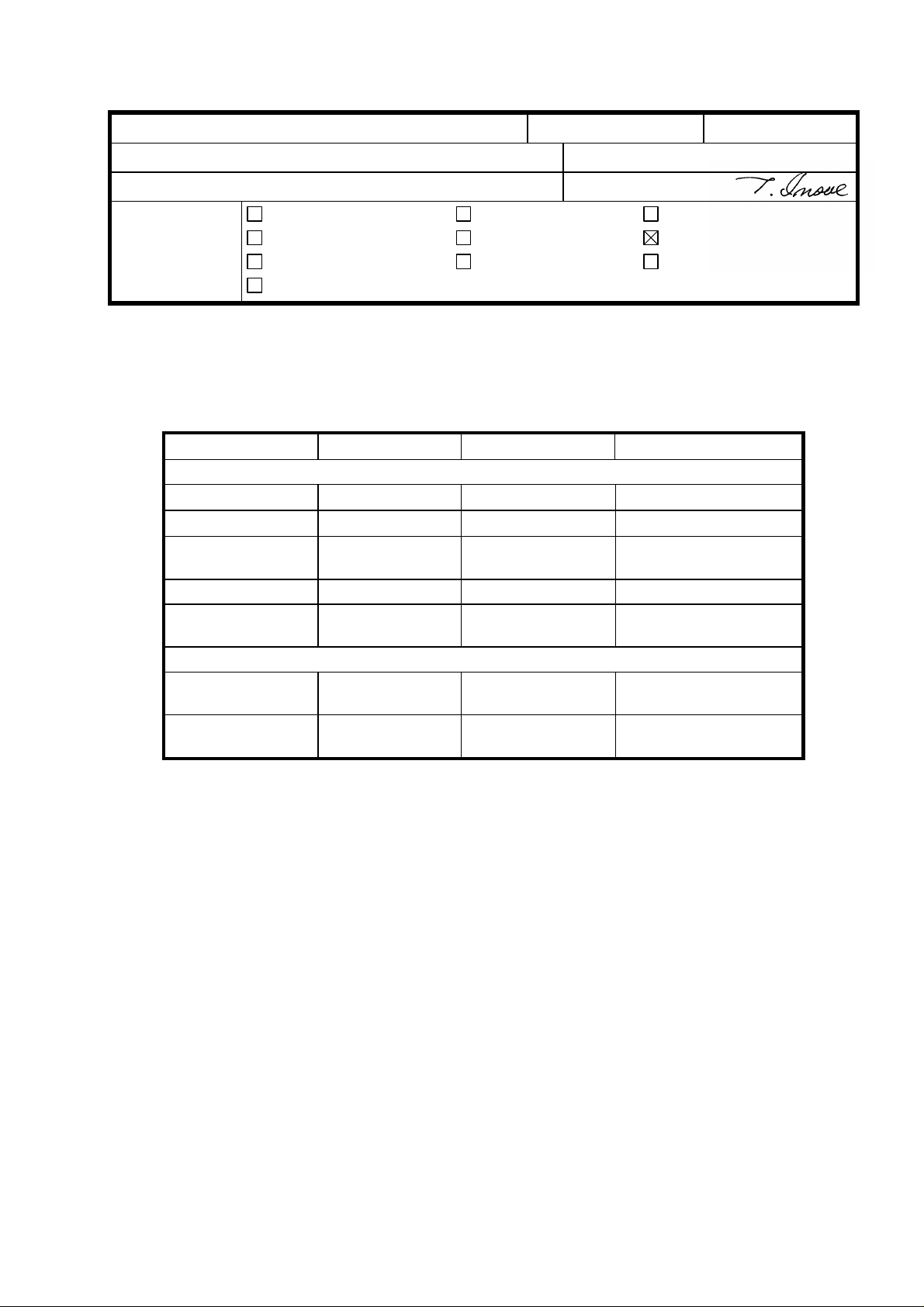

PM Parts Item Current New Note

COPIER (A219)

Hot Roller 45 K copies 90 K copies

Pressure Roller 45 K copies 90 K copies

Ozone Filter 45 K copies Clean every 45 K,

Replace every 90 K

Cleaning Blade 45 K copies 90 K copies Apply Setting Powder

Discharge Plate 45 K copies Clean every 45 K

copies

Document Feeder (A662) (for originals)

Transport Belt 24 K 80 K Clean with Belt Cleaner

Friction Belt 24 K 80 K Clean with Belt Cleaner

Vacuum Cleaner or

Blower Brush

Apply Blower Brush

at Copier PM

at Copier PM

Page 2

RICOH Technical B ulletin PAGE: 1/1

Model: Kingfisher Date: 15-Apr-97

No: 2

Subject: 1st Scanner Reinstallation Notice Prepared by: M. Inohana

From: QAC 1st Field Information Dept. Checked by: T. Inoue

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

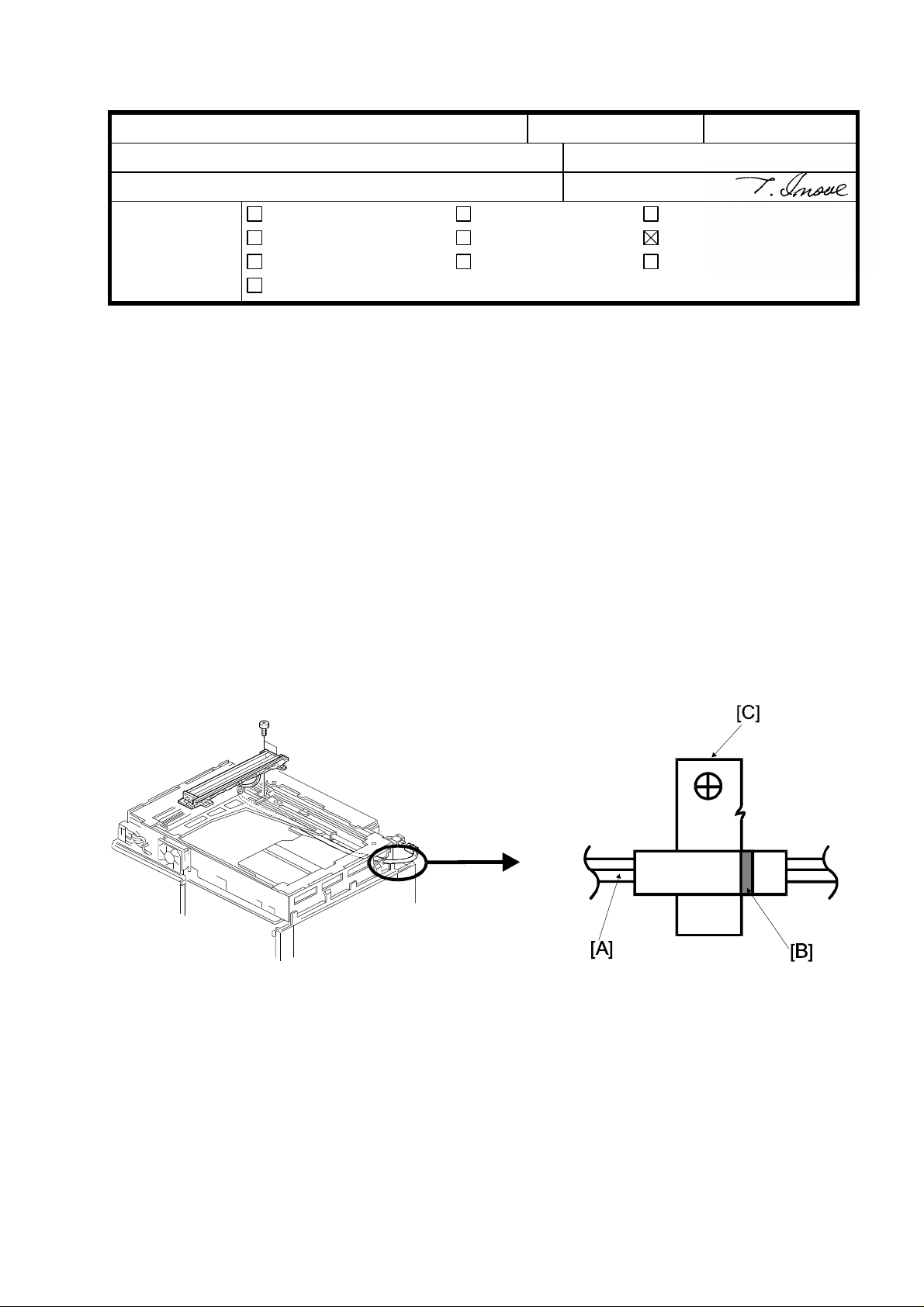

The following information was not mentioned in the service manual.

When reinstalling the 1st scanner, make sure to do the procedure described below. If it is

not performed, the scanner harness may fall from the 2nd scanner pulley, causing a

scanner lock condition.

NOTE: Clamp the scanner harness [A] at the position shown. The white paint mark [B]

should be aligned with the right side of the harness clamp [C].

Page 3

RICOH Technical B ulletin PAGE: 1/1

Model: Kingfisher Date: 30-Apr-97

No: 3

Subject: SC Code #14 Prepared by : M.Inohana

From: QAC 1st Field Information Dept. Checked by: T. Inoue

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

The following description should be added to the “SERVICE CALL CONDITIONS” in the

Service Manual.

CODE #14 - ZERO CROSS SIGNAL ERROR 2

Definition

The detected current is not 50 or 60 Hz.

Possible Causes

• Defective main control board

• Defective ac drive/dc power supply board

• Zero cross line open

• CN101 on the main control board or CN207 on the ac drive/dc power supply board

is not correctly connected.

• Power line not stable

* Remedy for the initial production machines

• Turn the main switch off and on.

Page 4

RICOH Technical Bulletin PAGE: 1/1

Model: Kingfisher Date: 30-May-97

No: 4

Subject: Service Manual Revision Prepared by: M. Inohana

From: QAC 1st Field Information Dept. Checked by: T. Inoue

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

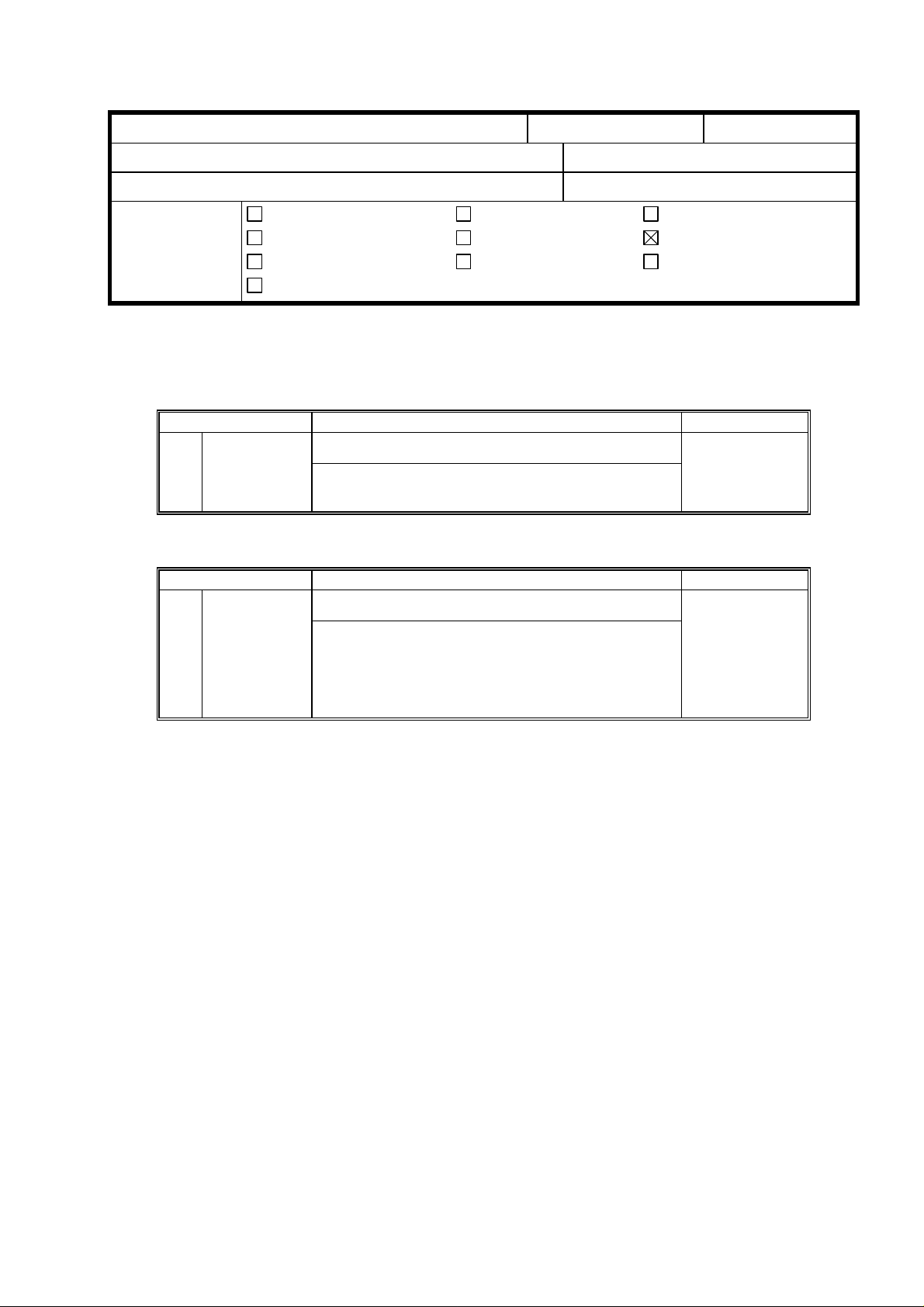

1. Please correct your Service Manual as follows:

Page 4-20

Mode No. Function Settings

Auto Shut Off Selects the “Automatic Shut off” mode. 0: Yes

77 (Energy Star)

On/Off

The copier automatically shuts itself off at the auto

shut off time selected (SP14).

1: No

↓↓

Mode No. Function Settings

Auto Shut Off Selects the “Automatic Shut off” mode. 120V Machines

(Energy Star)

77

On/Off

The copier automatically shuts itself off at the auto

shut off time selected (SP14).

0: Yes

1:No

230V Machines

0: Yes

1: No

2. The following description should be added to the “SERVICE CALL CONDITIONS” in

the Service Manual.

CODE #96 - MAIN SWITCH ERROR

Definition

The machine does not turn off within 8.5 seconds after Auto Shut Off is performed.

Possible Causes

• Defective main switch.

• Connectors of the main switch are not correctly connected.

• Poor connection of the DC Harness of the main switch (some lines must be cut)

* Remedy for the initial production machines

• Turn the main switch off and on.

Page 5

RICOH Technical Bulletin PAGE: 1/3

Model: Kingfisher Date: 31-Jul-97

Subject: Troubleshooting of copy quality problems Prepared by: M.Inohana

From: QAC 1st Field Information Dept.

Classification:

This explains how to troubleshoot copy quality problems at machine installation. Problems

may arise during machine transportation. Use the following countermeasures when

problems occur in the field.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

No: 5

Problems

1. The 1st Scanner is deformed or bent.

2. The 1st Scanner does not stay at the proper home position.

3. The Lens Unit moves to the wrong position and/or the lens locks and/or the lens does

not return to the home position.

4. Black copy or black band in the trailing area of copies.

(Cause: 3rd or 4th mirror moves to the wrong position )

5. Out of focus or poor sharpness on copies.

(Cause: 6th mirror angle in the wrong position )

6. Dirty background at the left side of copies.

(Cause: Abnormal condition of the optics unit and/or deformed main body )

Countermeasure for Transportation Damage at the Factory

1. 1st Scanner deformed or bent: Clamps will be added to the 1st Scanner

(from the August ’97 production machines onward).

2. The Lens Unit moves to the wrong position: A Lens Unit securing pin has been added

(from the end of July ’97 production machines onward).

3. The 3rd/4th Mirror moves to the wrong position: Double-sided tape has been added to

the back of the mirror and clamp area (from the end of May ’97 production machines

onward).

4. The 6th mirror angle varies: After adjustment of the angle, a screw lock has been

applied (from the end of May ’97 production machines onward).

5. Damage during transportation: 1 machine per pallet

(from the May ’97 production machines onward).

Page 6

RICOH Technical Bulletin PAGE: 2/3

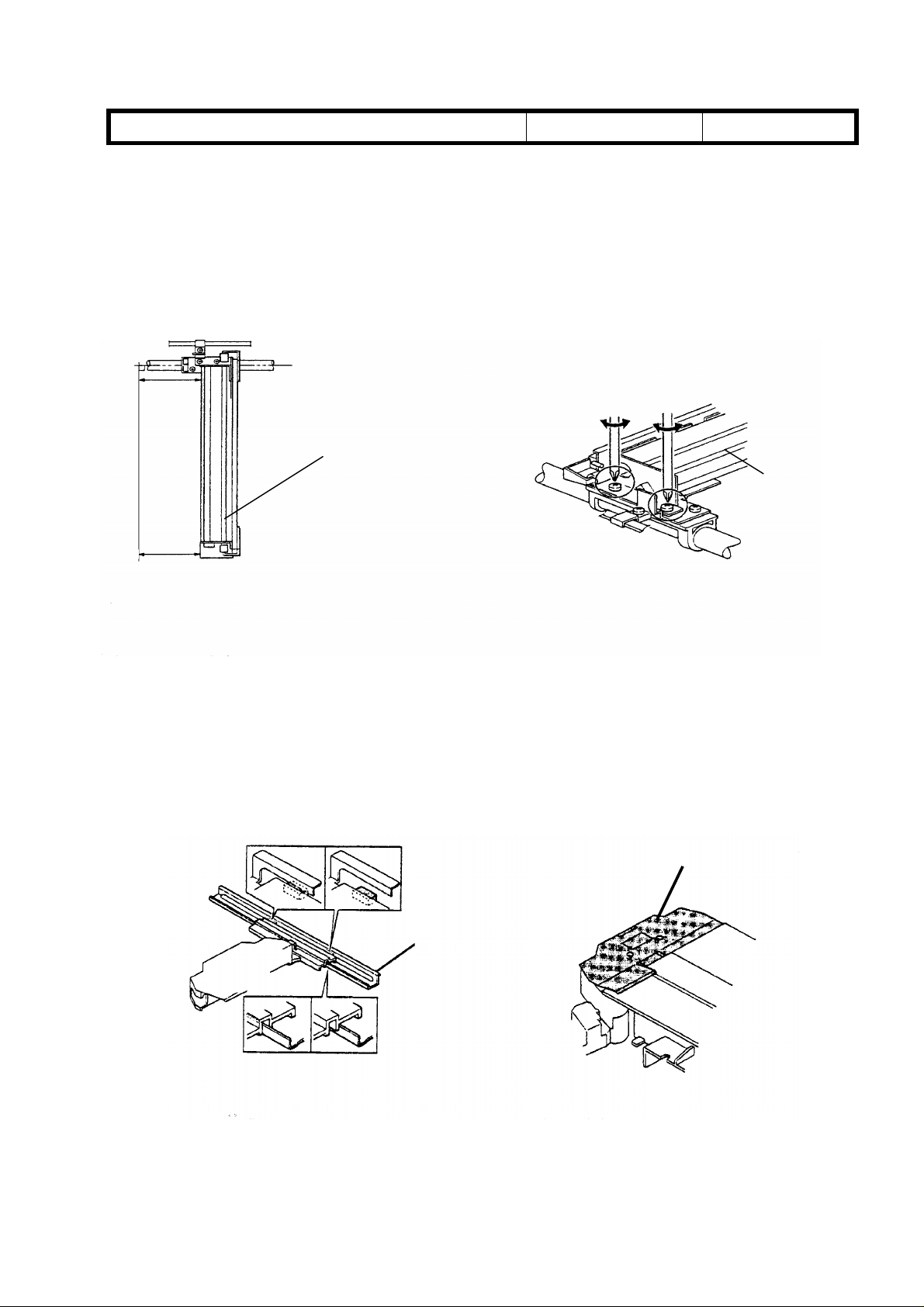

Fig.1

Fig.2

Model: Kingfisher Date: 31-Jul-97

No: 5

Action required in the field

For the machines which cannot be treated as described above, the following action is

required.

1) 1st Scanner deformed or bent

1st Scanner

1st Scanner

Cause : The front of the 1st Scanner is bent towards the right (Fig.1).

Action : Adjust the 1st scanner position (angle) as shown on page 6-7 of the Service

Manual (Fig.2).

2) Lens Unit moves to the wrong position, Lens Mylar out of position, Lens Unit locks.

Lens Mylar

Guide Rail

Fig.3

Fig.4

Page 7

RICOH Technical Bulletin PAGE: 3/3

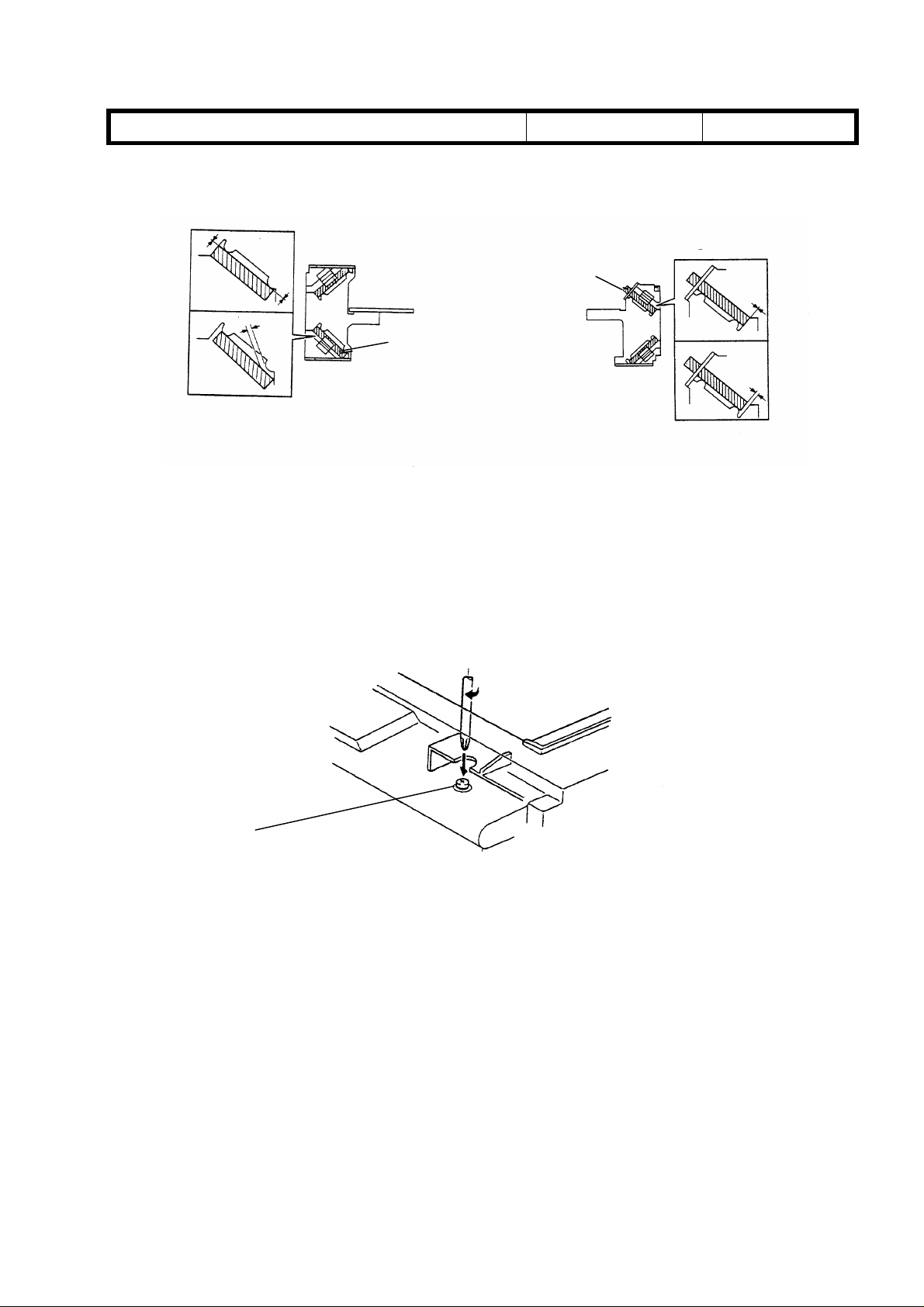

4th Mirror

Model: kingfisher Date: 31-Jul-97

3). Black copy or black band at the trailing area of copies.

GOOD

3rd Mirror

NG

Fig.5

Cause : Incorrect positioning of the 3rd/4th mirrors (Fig.5,6)

Action : Re-position the 3rd/4th mirrors.

No: 5

GOOD

NG

Fig.6

4) Out of focus or poor sharpness on copies.

Adjustment Screw

Fig.7

Cause : The adjustment screw for the 6th mirror has loosened, resulting in an incorrect

mirror angle.

Action : (Fig.7)

1. Mark the original position of the adjustment screw.

2. Turn the adjustment screw clockwise approximately 45 degrees.

3. Check the copy quality.

4. Repeat steps 2 and 3 until the copy quality becomes satisfactory.

Page 8

RICOH Technical Bulletin PAGE: 1/2

15

15

14

Model: Kingfisher Date: 31-Jul-97

Subject: Peeling off of the Mylar Blade Prepared by: M. Inohana

From: QAC 2nd Field Information Dept.

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

No: 6

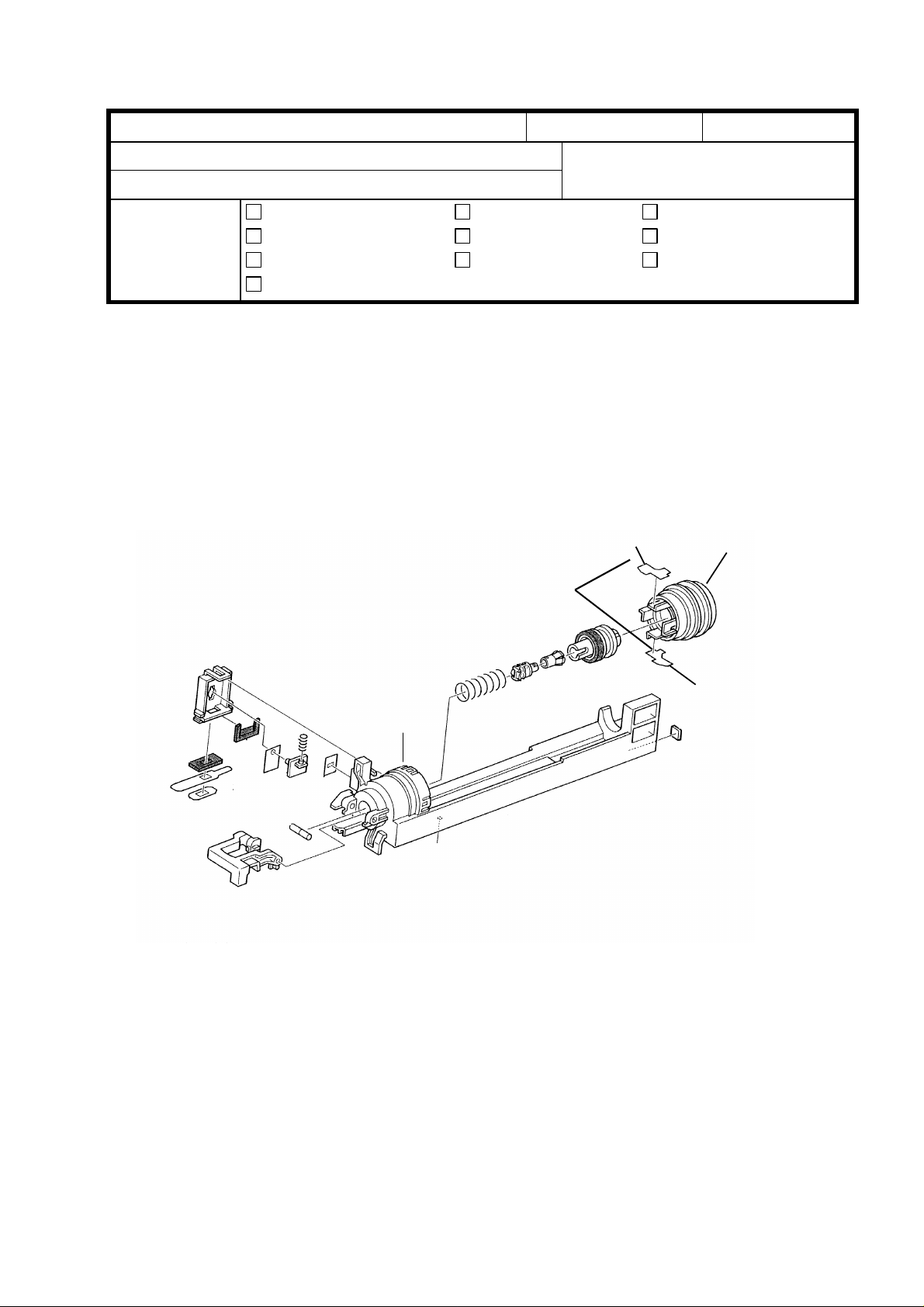

SYMPTOM:

1. Image density decreases

2. The toner end indicator turns on when not in a toner end condition

CAUSE:

The mylar blades peel off, resulting in toner not being supplied properly. Then toner in the

development unit gets low even if there is toner in the bottle.

Mylar Blade

9

Action required:

1) Remove the toner bottle holder unit from the machine.

2) Remove the toner bottle cover [14] from the toner supply unit case [9]

3) Remove the Mylar Blades [15] which are peeling off.

4) Clean the area where the mylar blades should be attached.

5) Attach new mylar blades to the original position.

Page 9

RICOH Technical Bulletin PAGE: 2/2

Model: Kingfisher Date: 31-Jul-97

Countermeasure at the factory:

The following improvement has been applied to the May’97 production machines onward.

1) Clean and remove oily material at the area where the mylar blade should be attached.

2) Attach the mylar blade by pressing evenly.

No: 6

Page 10

T

Model:

Kingfisher

echnical

ulletin

B

Date:

15-Sep-97

No:

PAGE: 1/2

7

Subject:

From:

Classification:

Shock during shipment

QAC 1st Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

T.Matsuno

Symptom

We have found that the first scanner went out of alignment, and the lens failed

before installation, during shipment in Europe and China.

Cause

It is assumed that since the Kingfisher is a lighter model, these units were handled more

roughly and as a result they were subjected to too much shock.

Countermeasure at the factory

The following improvement has been applied from the August ’97 production machines

onward.

1) Two scanner clamps (A2191851) were set beneath the scale to fix them

in the home position.

The setting position – 2 φ10mm holes on the scale.

2) A lens clamp (A2191850) was inserted into the φ3mm hole n the center

of the upper cover, so that lens carriage cannot be moved toward the

enlargement side.

(This means that the lens carriage will remain inside the lens cover.)

The purpose of both countermeasures is to make sure that the scanner and the lens

carriage are braced for shock during shipment before installation.

Page 11

T

Model:

Illustration

Kingfisher

Upper cover

Scale

echnical

Filament tape is attached so that the

lens clamp does not come off.

ulletin

B

Date:

15-Sep-97

No:

PAGE: 2/2

7

Tag

Scanner clamp

Filament tape

Filament tape is attached to prevent the

main switch from being pressed

before installation.

Page 12

T

Model:

Kingfisher (North America)

echnical

B

ulletin

Date:

15-Oct-97

No:

PAGE: 1/2

8

Subject:

From:

Classification:

Envelope for the NECR

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

T.Matsuno

Action required in the field

Please delete #9. “ Envelope for NECR (-17 machines)” on page 3-3 in the Service

Manual for the Kingfisher.

- Service Manual -

Cross out

No.9

3 – 3

Page 13

T

Model:

Reason

The NECRs for the Kingfisher have, in most cases, already been sent by fax for the North

America markets (-17 machines) and are stored in the box with the other accessories.

Since it is unnecessary to have an envelope for the NECR among the accessories in the

box, we will delete this (#9. Envelope for NECR) from the Accessory Check for the

Kingfisher.

Kingfisher (North America)

echnical

B

ulletin

Date:

15-Oct-97

No:

PAGE: 2/2

8

Page 14

T

echnical

B

ulletin

RTB Correction

Reissue date:

The items with a line drawn through them have been deleted.

Model:

Kingfisher

15-Dec-97

Date:

15-Oct-97

No:

PAGE: 1/2

9

Subject:

From:

Classification:

To meet Energy Star requirements, the following modification has been applied to the

production machines.

Energy Star

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

M.Inohana

SP Mode

∗ Setting No.5 has been added.

Mode No. Function Settings

Auto Reset

Time Setting

(Energy Star)

14

Selects the auto shut off time.

The copier main switch is shut off automatically

after the selected auto shut off time, if SP77 and

UP10 are at “0”.

0:30 min. (Factory

Setting)

1 : 15 min.

2 : 60 min.

3 : 90 min.

4 : 120 min

∗ 5 : 240 min.

User Code

The following UPs have been added.

U-Code Function Settings

Auto Shut Off

On/Off

10

5 Exactly same as SP14 shown above.

Note: The factory settings of SP77 and UP10 for the USA version are 0:Yes.

For the other area versions, the factory settings are 1:No.

Selects the “Auto Shut Off” mode. 0 : Yes (Factory

Setting)

1 : No

Page 15

T

Model:

Kingfisher

echnical

B

ulletin

Date:

15-Oct-97

ROM Suffix Numbers applied to this modification

Part Number Model Area

A2195103D Kingfisher 110V,120V/60HZ area

A2195104D Kingfisher 220V,240V/50HZ,60HZ area

Cut-in Machine Serial Numbers

No:

PAGE: 2/2

9

A219 - 10 : AJ07870001

-15 : 7A47870001

-17 : A7367874569

-19 : A7367870001

-22 : AJ97870001

-26 : 3L78770001

-27 : A7367870401

-29 : A7367874998

-39 : A7367884548

-50 : AK17870001

-59 : A7367870301

-69 : A7367865221

∼

∼

∼

∼

∼

∼

∼

∼

∼

∼

∼

∼

Page 16

T

Model:

Kingfisher

echnical

B

ulletin

Date:

31-Oct-97

No:

PAGE: 1/1

10

Subject:

From:

Classification:

SYMPTOM:

CAUSE:

that discharged ions flow to the exposed area on the photoconductor and

re-charge it. Then, the electrical potential on the photoconductor surface

increases so that blurring is caused.

SOLUTION:

mylar has been attached to it so that discharged ions are blocked by the

longer casing and the mylar. Please see MB No.15 issued on October

31, 1997, for further information concerning this modification.

Blurred image

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Blurring appears on copies of low-contrast originals.

The gap between the charge corona casing and grid plate was too wide, so

One side of the corona casing shown below (∗) has been elongated and a

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

M.Inohana

Note:

than before.

Therefore adjust the exposure lamp value using SP48 (decrease by 3 ∼ 4 steps).

When the improved corona unit is installed in the copier, the image becomes lighter

∗

Page 17

T

Model:

Kingfisher

echnical

B

ulletin

Date:

15-Dec-97

No:

PAGE: 1/1

11

Subject:

From:

Classification:

The following information should be added to the SP mode section in the service manual.

A3/11"x17" Double Count Mode

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

M.Inohana

SP Mode No. 27

Mode: A3/11”x17” Double Count

Function: Selects single or double count for the total counter with A3/11”x17” copies.

Double count is not applied for copies from the manual feed table.

0: Single (default)

1: Double

ROM: P/N A2195104C or newer versions

Cut-n Machine Serial Numbers

Code Serial Number

A219 – 10 AJ07810001

A219 – 15 7A47820001

A219 – 17 A7367813002

A219 – 19 A7367830001

A219 – 22 AJ97820001

A219 – 26 3L78270001

A219 – 27 A7367810177

A219 – 29 A7367821352

A219 – 59 A7367830151

Page 18

T

Model:

Kingfisher

echnical

B

ulletin

Date:

15-Mar-98

No:

PAGE: 1/2

12

Subject:

From:

Manual Correction

QAC Field Information Dept.

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

J. Kasamoto

Page 4-15

1. The description in the setting column for SP33 was incorrect. Correct as follows:

Old New

Settings Settings

0: Normal

1: Darker

2: Darkest

3: Lighter

4: Lightest

0: Normal

Darkest

1:

Darker

2:

3: Lighter

4: Lightest

→

2. Some descriptions for SP34 were incorrect. Correct as follows:

Old

Image Density

Adjustment

(ADS Mode)†

34

Selects the image density level in ADS mode.

The development bias and the exposure lamp

voltages are increased or decreased.

This adjustment affects copies made in ADS mode.

SP Setting Setting Dev. Bias Exposure Lamp

0Normal0 0

1 Lighter -40 V 0

2 Darker +40 V 0

3 Lightest -40 V +4 steps

4 Darkest +40 V -4 steps

The exposure lamp setting specifies the change

relative to the base exposure lamp voltage (Vo) in

SP48. 1 step of the lamp voltage equals 0.5 V for

120 V (NA), and 1.0 V for 230 V (EU) machines.

See “Detailed Descriptions - Development” f or more

details.

0: Normal

1: Light

2: Dark

3: Lighter

4: Darker

Page 19

T

New

echnical

↓

B

ulletin

PAGE: 2/2

34

NOTE:

Image Density

Adjustment

(ADS Mode)†

The items in bold italics have been corrected.

Selects the image density level in ADS mode.

The development bias and the exposure lamp

voltages are increased or decreased.

This adjustment affects copies made in ADS mode.

SP Setting Setting Dev. Bias Exposure Lamp

0Normal0 0

1

2

3 Lightest -40 V +4 steps

4 Darkest +40 V -4 steps

The exposure lamp setting specifies the change

relative to the base exposure lamp voltage (Vo) in

SP48, 1 step of the lamp voltage equals 0.5 V for

120 V (NA), and 1.0 V for 230 V (EU) machines.

See “Detailed Descriptions - Development” f or more

details.

Light

Dark

-40 V 0

+40 V 0

0: Normal

1: Light

2: Dark

3:

Lightest

Darkest

4:

Page 6-27

Please correct your service manual as follows:

5. Remove the optics cooling fan motor [A] (2 screws and 1 connector).

↓

5. Remove the optics

exhaust

fan motor [A] (2 screws and 1 connector).

Page 20

T

Model:

Kingfisher

echnical

B

ulletin

Date:

30-Apr-98

No:

PAGE: 1/2

13

Subject:

From:

Classification:

Double feed from the paper tray

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

M.Inohana

SYMPTOM

Double feeds occur when copies are made (especially with A-sized paper).

CAUSE

1. The friction coefficient of the paper is higher than that for which the machine was

designed. (Paper problem)

2. The paper is poorly cut so the sheets stick together and hinder paper separation.

(Paper problem)

3. The side fence in the paper tray is not set flush against the paper so the paper gets

caught on the paper guide and this hinders paper separation. (Paper setting problem)

SOLUTION

If double feeds occur in the field, please use the measures listed below.

1. Change the position of the paper feed roller and the paper feed guide to match the Asized paper. (Please refer to page 6-31 in the Service Manual)

Be sure to adjust the positions of both the paper feed roller and the paper guide.

2. Please pay attention to the instructions provided for setting the paper or the paper tray.

(Decal: A2192692)

(1) Set the paper correctly in the paper tray. (Align the edges of the paper)

(2) When adjusting the side fences, make sure that there are no gaps between the side

fences and the paper. (If gaps exist, the function of the side fences is reduced)

(3) When setting the paper tray, do not apply a lot of force, do it gently. (If the tray is

set with a lot of force, the paper will shift towards the back of the tray.)

3. If the customer has difficulty following the instructions listed above, get the permission

of the customer and secure the side fences in place with screws.

Procedure for securing the side fences

Set a few sheets in the tray, align the side fences so that they are flush against the

paper, and then secure the fences in that position with screws.

(Screws: M3X8 tapping screw: 04130082B)

If the measures listed above do not solve the problem, please try the following.

Replace the paper feed roller with the Double-feed countermeasure feed roller.

(A2192555: Paper feed roller)

Note: The modified roller has been implemented in the mass-production machines starting

from the April 1998 production run.

Page 21

T

Model:

Details of the Modification

1. Paper feed roller modified. (The difference in shape is shown below)

2. The setting positions of the paper feed roller and the paper guide have been adjusted

Kingfisher

to suit A-sized paper.

- OLD -

echnical

B

ulletin

Date:

30-Apr-98

No:

PAGE: 2/2

13

- NEW -

Slight Protrusion

Page 22

Technical

Bulletin

PAGE: 1/1

Model:

Subject:

From:

Kingfisher

Service Manual Correction

Technical Service Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

30-Jun-99

Prepared by:

No.:

M. Ishihara

Action required

Service manual revision

Retrofit information

Page 4-18

The default of SP54: 149 was printed in correctly. The correct default is 102

Incorrect

54 TD Sensor

Gain

Adjustment

When the TD Sensor initial setting is performed,

this mode is adjusted automatically

.

Normally, this value should not be changed.

0 255

Default =

(0.04 V per step

RA219014

149

Correct

54 TD Sensor

Gain

Adjustment

When the TD Sensor initial setting is

performed, this mode is adjusted

automatically.

0 255

Default =

102

(0.04 V per step)

Normally, this value should not be changed.

SP54 is used at the factory when test copies are made during the machine assembly

process. It should not be used in the field.

Page 23

T

echnical

B

ulletin

PAGE: 1/1

Model:

Subject:

From:

Classification:

Kingfisher/Grand Kingfisher/Tequila

Toner drops onto the copy

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

31-Aug-99

Prepared by:

No.:

RA219015

M.Ishihara

Action required

Service manual revision

Retrofit information

SYMPTOM

1. Toner drops onto the copy.

2. Dirty background on copies (Occasional)

3. Image density too high (Occasional)

CAUSE

1. Too much toner is supplied to the development tank due to misdetection by the toner

density sensor.

2. Used toner accumulates in the IU (Imaging Unit), preventing proper recycling.

ACTION REQUIRED

Please follow the procedure as shown below.

1. Remove the IU from the machine.

2. Completely remove the recycled toner in the toner collection coil and the toner recycling

belt area.

3. Install the IU in the machine.

4. Remove the toner bottle from the machine.

5. Make 20, A4 sideways, skyshot copies (solid black copies).

6. Set an original and make some copies to confirm that copy quality is normal.

7. Change the toner supply mode from “0” to “1” using SP30.

8. Make some copies while monitoring the TD sensor output (SP55).

9. Input the value obtained in step 8 in SP53 – TD Sensor Target Control Voltage

Adjustment.

10. Install the toner bottle in the machine.

11. Set an original and make some copies to confirm that copy quality is normal.

Note:

When the developer is replaced, please observe the following for efficient troubleshooting:

1) Do SP66.

2) Do not change the settings of SP30 and SP53. (SP30 must be at “1”. TD

Sensor control voltage must be kept at the same level in SP53, as entered in step

9 above.)

Page 24

RICOH Technical

Bulletin

PAGE: 1/4

Model:

Subject:

From:

Kingfisher

Toner drops onto the copy

Technical Service Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Date:

Prepared by:

Part information

Electrical

Transmit/receive

22-Sep-99

Action required

Service manual revision

Retrofit information

No.:

M. Ishihara

RA219016

SYMPTOM

1. Toner drops onto the copy.

2. Dirty background on copies (Occasional)

3. Image density too high (Occasional)

CAUSE

Although the toner concentration in the developer is maintained between 3 and 4%,

an increase can be observed when used over an extended period of time. This level

is normally kept under 5% even after 60K copies, however there are rare cases where this

limit is exceeded due to the environmental factors described below. These are thought to

cause the toner to fall onto the surface of the copy.

1. The presence of paper dust as well as conditions such as high humidity are thought to

cause an oversupply of toner to the development unit (by raising the limit of the toner

concentration control to over 6%), which in turn causes the toner to fall onto the copy

surface.

Too much toner

4%

3%

Controlled Limit

Toner

Consent

-ration

0 20K 60K40K

Copy Volume

6%

5%

4%

2. In addition, due to this oversupply of toner to the development unit, recycled toner

creates a blockage in the imaging unit and the toner falls from the cleaning area.

Page 25

RICOH Technical

Bulletin

PAGE: 2/4

Model:

Kingfisher

Date:

22-Sep-99

No.:

RA219016

ACTION REQUIRED

A. Countermeasure in the field:

Please follow the procedure as shown below if the toner dropping problem occurs in the

field.

1. Remove the IU from the machine.

2. Completely remove the recycled toner at the toner collection coil under the cleaning

blade and the toner recycling belt area. Install the IU in the machine.

3. Remove the toner bottle from the machine. Check that SP38 is 0. (Input "0" if it is not.)

4. Make 20, A4 sideways, skyshot copies (Black solid copies).

5. Set an original and make some copies to confirm that copy quality is normal.

6. Change the toner supply mode from “0” to “1” using SP30.

7. Make some copies while monitoring the TD sensor output (SP55).

8. Input the value obtained in step 7 into SP53 – TD Sensor Target Control Voltage

Adjustment. (If it is more than 127, input 127.)

9. Install the toner bottle in the machine.

10.Set an original and make some copies to confirm that copy quality is normal.

Note:

When the developer is replaced, please observe the following for efficient troubleshooting:

1) Perform the SP66 to initialize the developer .

2) Do not change the settings of SP30 and SP53. (SP30 must be at “1”. TD sensor control

voltage must be kept at the same level in SP53, as entered in step 8 above.)

B. Permanent Countermeasure:

This rise in the amount of toner being supplied will be prevented as determined by the

copy volume by modifying the software so that an oversupply does not result.

For the

machine of mass production. It is scheduled to be implemented in the

October 1999 mass production.

Kingfisher2

4%

Toner

Density

, this modification is scheduled to be implemented from the first

Kingfisher

5%

4%

0 20K 60K40K

from

Page 26

RICOH Technical

Bulletin

PAGE: 3/4

Model:

If the above symptom should occur in the field before preventative maintenance is

performed, please institute the temporary countermeasure described in the previous

section (A.) and refrain from upgrading the software.

The new software has two major differences from the previous version:

The overall process control and toner density control (maintained by lowering

it to a fixed value every 1K). Due to these differences, it is recommended that

the new firmware be used together with new developer.

NOTE:

Please upgrade the software at the next PM visit (when the developer is replaced).

Please refer to the flow chart on the following page.

(Note: When the developer is replaced, remove the old developer completely. Otherwise

the volume of the developer is increased and it causes the toner to drop.)

Kingfisher

Date:

22-Sep-99

No.:

RA219016

Page 27

RICOH Technical

Bulletin

PAGE: 4/4

Model:

Kingfisher

Date:

22-Sep-99

FLOW CHART FOR THE TONER DROPPING PROBLEM

START

Remove the Imaging Unit from the machine.

Remove the recycled toner in cleaning unit

(under the cleaning blade) and at the recycling belt area.

YES

To remove

excessive

toner from the

developing unit

Is PM required?

NO

Install the imaging Unit.

Remove the toner bottle from the machine.

Input "0" in SP38 if it is not.

Make 20(A4 sideways) skyshot copies to

confirm that copy quality is normal.

Set an original and make some copies to

confirm that the copy quality is normal.

Replace the developer in the imaging Unit.

Note: Completely remove the developer

from the imaging unit.

(Otherwise the amout of developer will

increase causing toner recycling process

not function properly.

Install the imaging Unit.

Replace the ROM.

Perform the toner initialization

(SP66).

If the SP30 is "1", set it to "0".

No.:

RA219016

To maintain

proper toner

density

NO

Change the toner supply mode from "0" to "1" (in the SP30).

Make several copies while monitoring the TD sensor output (SP55).

Input the value obtained in the previous step into SP53 - TD Sensor

Target Control VoltageAdjustment.

Install the toner bottle in the machine.

Set an original and make several copies to confirm that copy quality

is normal.

Is Image density

normal?

YES

END!

Loading...

Loading...