Page 1

RICOH GROUP COMPANIES

A219/A245/B019

SERVICE MANUAL

000917MIU

Page 2

Page 3

SERVICE MANUAL

A219/A245/B019

RICOH GROUP COMPANIES

Page 4

Page 5

A219/A245/B019

SERVICE MANUAL

000917MIU

Page 6

Page 7

WARNING

The Service Manual contains information

regarding service techniques, procedures,

processes and spare parts of office equipment

distributed by Ricoh Corporation. Users of this

manual should be either service trained or

certified by successfully completing a Ricoh

Technical Training Program.

Untrained and uncertified users utilizing

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property or loss of warranty

protection.

Ricoh Corporation

Page 8

Page 9

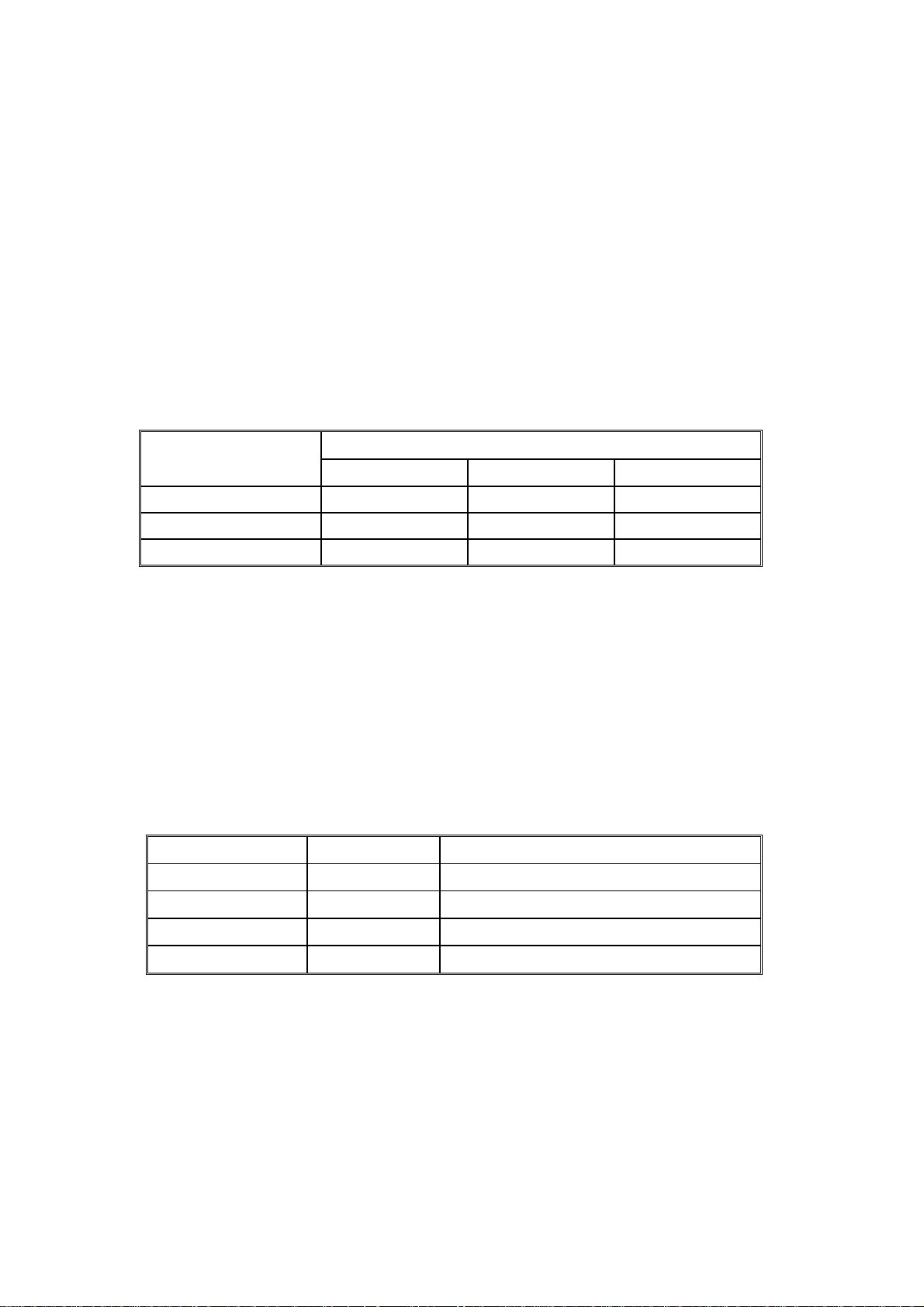

LEGEND

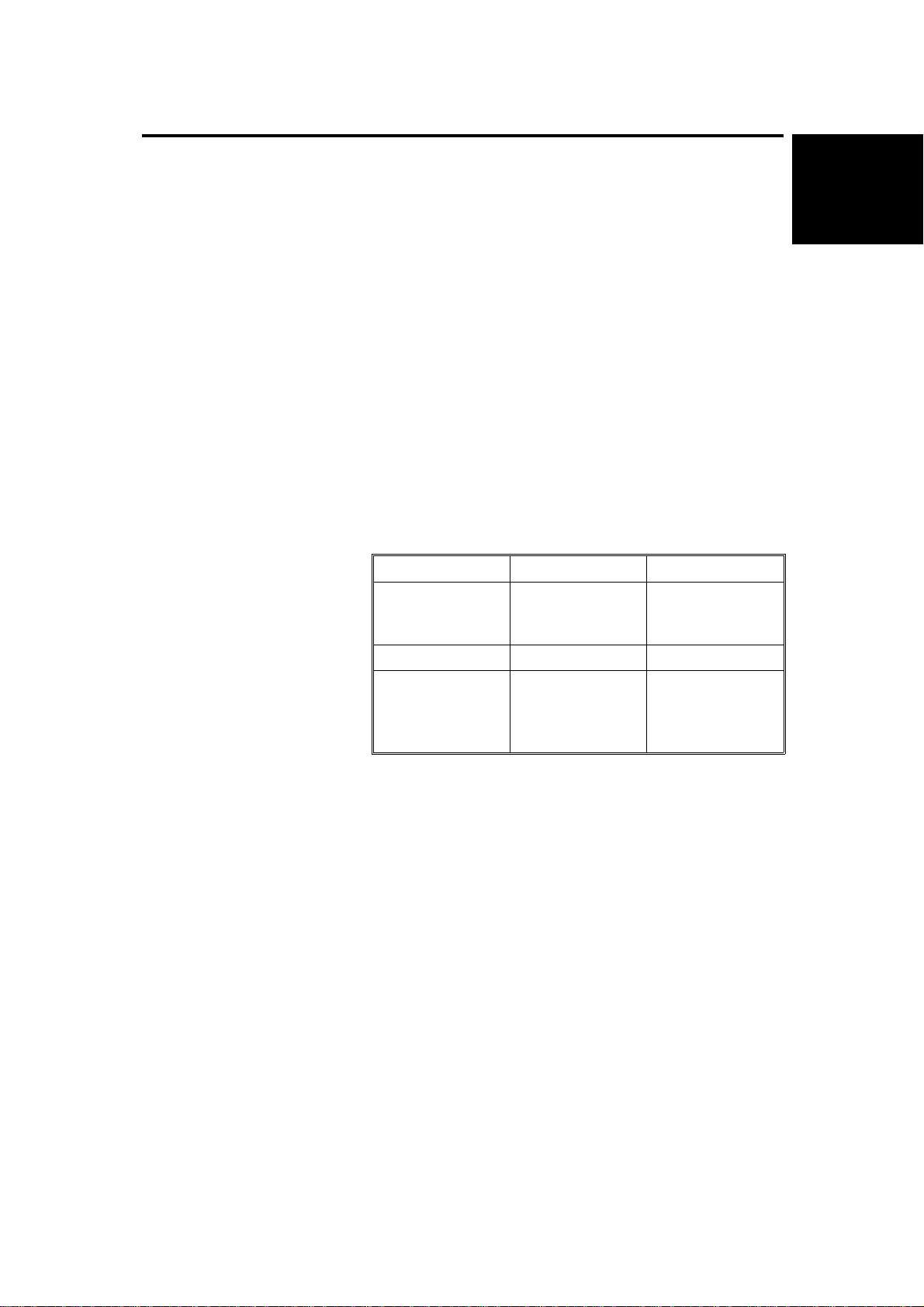

PRODUCT CODE COMPANY

GESTETNER RICOH SAVIN

A219 2715X FT4015 9115

A245 2718 FT4018 --B019 2913Z FT3813 2013Z

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

*

2 7/98 Reprint

3 2/99 A245 Addition

4 3/2000 B019 Addition

3/97 Original Printing

Page 10

Page 11

Table of Contents

OVERALL MACHINE INFORMATION

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. COPY PROCESS AROUND THE DRUM. . . . . . . . . . . . . . . . . . . . . 1-4

3. MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . 1-6

4. DRIVE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

5. PAPER PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

6. ELECTRICA L COMPONENT DESCRIPTIONS. . . . . . . . . . . . . . . . 1-9

DETAILED DESCRIPTIONS

1. DRUM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.1 OPC DRUM CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.2 DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2. CHARGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.1 OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2 CHARGE CORONA WIRE CLEANER MECHANISM . . . . . . . . . . . . . . . . . . . 2-4

2.3 CHARGE CORONA CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

3. OPTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

3.1 OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

3.2 SCANNER DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

3.3 LENS DRIVE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

3.4 4TH/5TH MIRROR DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

3.5 AUTOMATIC IMAGE DENSITY SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3.6 EXPOSURE LAMP VOLTAGE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

4. ERASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

4.1 OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

4.2 LEAD EDGE ERASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

4.3 SIDE ERASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

TOC i A219/A245/B019

Page 12

4.4 TRAILING EDGE ERASE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

5. DEVELOPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

5.1 OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

5.2 DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

5.3 CROSS-MIXING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

5.4 DEVELOPMENT BIAS FOR IMAGE DENSITY CONTROL. . . . . . . . . . . . . . 2-21

5.4.1 Base Bias Voltage Factor in Manual Image Density Mode. . . . . . . . . . . 2-22

5.4.2 Base Bias Voltage Factor in Automatic Image Density (ADS) Mode . . . 2-23

5.4.3 Drum Residual Voltage (V

5.5 DEVELOPMENT BIAS CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

) Correction Factor. . . . . . . . . . . . . . . . . . . . 2-23

R

6. TONER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

6.1 TONER BOTTLE REPLENISHMENT MECHANISM . . . . . . . . . . . . . . . . . . . 2-25

6.2 TONER SUPPLY MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

6.3 TONER DENSITY DETECTION MECHANISM . . . . . . . . . . . . . . . . . . . . . . . 2-27

6.4 TD SENSOR CHECK AND TONER SUPPLY TIMING . . . . . . . . . . . . . . . . . 2-28

6.5 TONER SUPPLY CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

6.5.1 Modes Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

6.5.2 Detect Supply Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

6.5.3 Fixed Supply Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

6.5.4 Abnormal Condition in Toner Density Detection . . . . . . . . . . . . . . . . . . . 2-32

6.6 TONER END. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

6.6.1 Toner Near End. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

6.6.2 Toner End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

6.6.3 Toner End Recovery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

7. IMAGE TRANSFER AND PAPER SEPARATION. . . . . . . . . . . . . 2-35

7.1 OVERALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

7.2 TRANSFER CORONA AND DISCHARGE PLATE CIRCUIT. . . . . . . . . . . . . 2-36

8. DRUM CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

8.1 OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

8.2 TONER RECYCLING MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

9. QUENCHING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

A219/A245/B019 ii TOC

Page 13

10. PAPER FEED AND REGISTRATION . . . . . . . . . . . . . . . . . . . . . 2-40

10.1 OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

10.2 PAPER TRAY FEED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

10.2.1 Paper Lift Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

10.2.2 Paper Feed Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

10.3 BY-PASS FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

10.3.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

10.3.2 Paper Feed Mechanism and Paper End Detection. . . . . . . . . . . . . . . . 2-44

10.4 PAPER REGISTRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

10.5 SIDE FENCE DOUBLE STOPPER MECHANISM . . . . . . . . . . . . . . . . . . . . 2-46

10.6 PAPER END DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

10.7 PAPER FEED AND MISFEED DETECTION TIMING . . . . . . . . . . . . . . . . . 2-48

10.8 OTHERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

10.8.1 Paper Size Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

10.8.2 Shock Absorber. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

11. IMAGE FUSIN G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5 0

11.1 OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

11.2 FUSING DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

11.3 FUSING LAMP CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

11.4 FUSING LAMP CONTROL CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

11.4.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

11.4.2 On/Off Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

11.4.3 Phase Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

11.4.4 Overheat Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-56

3. INSTALLATION

1. INSTALLATION REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.1 ENVIRONMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.2 MACHINE LEVEL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.3 MINIMUM SPACE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1.4 POWER REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

TOC iii A219/A245/B019

Page 14

2. COPIER (A219). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

2.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

2.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3. DOCUMENT FEEDER (A662) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

4. SORTER (A657) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

4.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

4.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

5. OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

5.1 OPTICS ANTI-CONDENSATION HEATER INSTALLATION (OPTION) . . . . 3-16

5.2 TRAY HEATER INSTALLATION (OPTION). . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

SERVICE TABLES

1. SERVICE REMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.1 GENERAL CAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.2 IMAGING UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.3 OPTICS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

1.4 TRANSFER CORONA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

1.5 FUSING UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

1.6 PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

1.7 OTHERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

2. PROGRAM MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

2.1 BASIC OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

2.2 SP MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

2.3 SP MODE QUICK REFERENCE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

2.4 UP MODE AND SP MODE CROSS REFERENCE TABLE . . . . . . . . . . . . . . . 4-9

2.5 SERVICE PROGRAM MODE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

2.6 CLEAR ALL MEMORY PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

3. PRACTICAL SP MODE USE TABLE . . . . . . . . . . . . . . . . . . . . . . 4-26

A219/A245/B019 iv TOC

Page 15

4. SERVICE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

4.1 TEST POINTS (Main Control Board) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

4.2 VARIABLE RESISTORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

PREVENTIVE MAINTENANCE

1. PREVENTIVE MAINTENANCE SCHEDULE. . . . . . . . . . . . . . . . . . 5-1

1.1 PM TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.2 REGULAR PM PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

2. SPECIAL TOOLS AND LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . 5-7

REPLACEMENT AND ADJUSTMENT

1. EXTERIOR AND INNER COVERS. . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

1.1 EXTERIOR COVER REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

1.1.1 Front Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

1.1.2 Front Right Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

1.1.3 Rear Right Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

1.1.4 Lower Right Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

1.1.5 Lower Left Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

1.1.6 Upper Left Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

1.1.7 Rear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

1.1.8 Upper Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

1.2 INNER COVER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

2. OPTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

2.1 EXPOSURE GLASS REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

2.2 1ST SCANNER/EXPOSURE LAMP REMOVAL . . . . . . . . . . . . . . . . . . . . . . . 6-6

2.3 SCANNER BELT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

2.4 1ST AND 2ND SCANNER POSITION ADJUSTMENT . . . . . . . . . . . . . . . . . . 6-9

2.5 SCANNER DRIVE MOTOR REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

2.6 LENS DRIVE MOTOR REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

2.7 4TH/5TH MIRROR DRIVE MOTOR REMOVAL. . . . . . . . . . . . . . . . . . . . . . . 6-12

TOC v A219/A245/B019

Page 16

2.8 2ND MIRROR REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

2.9 3RD MIRROR REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

2.10 4TH AND 5TH MIRROR REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

2.11 ADS SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

3. AROUND THE DRUM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

3.1 IMAGING UNIT REMOVAL AND TONER BOTTLE REMOVAL . . . . . . . . . . 6-18

3.2 CHARGE CORONA WIRE AND CHARGE CORONA GRID

REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

3.3 CLEANING BLADE REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

3.4 DRUM REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

3.5 TONER COLLECTION COIL AND TONER RECYCLING BELT

REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

3.6 DEVELOPER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

3.7 REPLACEMENT THE TONER DENSITY SENSOR (TD SENSOR) . . . . . . . 6-24

3.8 AGITATOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

3.9 TONER SUPPLY MOTOR ASS’Y REPLACEMENT . . . . . . . . . . . . . . . . . . . 6-26

3.10 ERASE LAMP REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

3.11 QUENCHING LAMP REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

4. PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

4.1 PAPER TRAY REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

4.2 TRAY FEED ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

4.3 TRAY PAPER FEED ROLLER ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . 6-31

4.4 BY-PASS FEED ROLLER AND FRICTION PAD REPLACEMENT . . . . . . . . 6-32

4.5 BY-PASS PAPER FEED CLUTCH, HIGH VOLTAGE SUPPLY BOARD,

AND REGISTRATION CLUTCH REPLACEMENT. . . . . . . . . . . . . . . . . . . . . 6-34

4.6 RIGHT VERTICAL GUIDE SWITCH REPLACEMENT . . . . . . . . . . . . . . . . . 6-35

4.7 RELAY ROLLER CLUTCH AND PAPER FEED CLUTCH

REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-36

4.8 PAPER SIZE SWITCH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

4.9 BY-PASS PAPER END SENSOR AND REGISTRATION SENSOR

REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-38

5. FUSING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-39

5.1 FUSING UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-39

5.2 HOT ROLLER REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-40

A219/A245/B019 vi TOC

Page 17

5.3 PRESSURE ROLLER REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-41

5.4 HOT ROLLER STRIPPER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . 6-42

5.5 FUSING ENTRANCE GUIDE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . 6-43

5.6 FUSING PRESSURE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-44

6. TRANSFER/SEPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-45

6.1 TRANSFER CORONA WIRE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . 6-45

6.2 DISCHARGE PLATE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-46

7. OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-47

7.1 OZONE FILTER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-47

7.2 MAIN CONTROL BOARD REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . 6-48

8. COPY QUALITY ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 6-49

8.1 LIGHT INTENSITY ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-50

8.1.1 Base Exposure Lamp Voltage Adjustment . . . . . . . . . . . . . . . . . . . . . . . 6-50

8.1.2 Image Density Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-51

8.2 DEVELOPMENT BIAS VOLTAGE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 6-52

8.2.1 Base Bias Voltage Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-52

8.2.2 SP Bias Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-53

8.3 TONER DENSITY ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-54

8.4 TONER SUPPLY RATIO SELECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-54

8.5 GRID VOLTAGE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-55

8.6 TRANSFER CURRENT ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-56

8.7 CHARGE CURRENT ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-57

8.8 HORIZONTAL MAGNIFICATION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . 6-58

8.9 VERTICAL MAGNIFICATION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . 6-58

8.10 FOCUS ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-59

8.11 LEADING EDGE ERASE MARGIN ADJUSTMENT. . . . . . . . . . . . . . . . . . . 6-59

8.12 REGISTRATION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-59

8.13 4TH/5TH MIRROR HEIGHT ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . 6-60

8.14 ADS (Auto Image Density Sensor) ADJUSTMENT . . . . . . . . . . . . . . . . . . . 6-61

8.15 SIDE-TO -SIDE REGISTRATION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 6-62

TOC vii A219/A245/B019

Page 18

TROUBLESHOOTING

1. COPY QUALITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

1.1 BLANK COPY (WHITE COPY). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

1.2 DIRTY BACKGROUND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

1.3 UNEVEN IMAGE DENSITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

1.4 VERTICAL BLACK BANDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

1.5 VERTICAL BLACK LINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

1.6 VERTICAL WHITE LINES OR BANDS-1 (DULL OR BLURRED) . . . . . . . . . . 7-8

1.7 VERTICAL WHITE LINES OR BANDS-2 (THIN, DISTINCT). . . . . . . . . . . . . . 7-9

1.8 HORIZONTAL BLACK/WHITE LINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

1.9 JITTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

1.10 BLACK SPOTS ON THE COPY IMAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

1.11 SKEWED (OPTICAL) COPY IMAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

1.12 TONER DENSITY ON COPIES TOO HIGH. . . . . . . . . . . . . . . . . . . . . . . . . 7-14

1.13 TONER DENSITY ON COPIES TOO LOW . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

1.14 UNFUSED COPY IMAGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

1.15 CREASING PAPER AFTER FUSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

1.16 PAPER MISFEED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

1.17 ABNORMAL CONDITION IN TONER DENSITY DETECTION . . . . . . . . . . 7-21

2. SERVICE CALL CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

3. ELECTRICAL COMPONENT DEFECTS . . . . . . . . . . . . . . . . . . . . 7-29

3.1 SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

3.2 SWITCHES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

4. BLOWN FUSE CON DITIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

5. USER CODES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

A219/A245/B019 viii TOC

Page 19

DOCUMENT FEEDER A662

– DOCUMENT FEEDER (A662) –

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. COMPONENT LA YOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

2.1 MECHANICAL COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

2.2 ELECTRICAL COMPONENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

3. ELECTRICA L COMPONENT DESCRIPTIONS. . . . . . . . . . . . . . . . 8-3

4. POWER DISTRIBUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

5. BASIC OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

6. INTERFACE CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

7. ORIGINAL FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

7.1 ORIGINAL PICK-UP MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

7.2 ORIGINAL SEPARATION MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

7.3 ORIGINAL FEED-IN MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

7.4 ORIGINAL FEED-OUT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

7.5 DF MOTOR CIRCUIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

7.6 ORIGINAL FEED AND MISFEED DETECTION TIMING. . . . . . . . . . . . . . . . 8-12

8. SERVICE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

8.1 DIP SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

8.2 VARIABLE RESISTORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

8.3 FUSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

9. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . 8-14

9.1 TRANSPORT BELT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

9.2 FEED-IN UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

9.3 PICK-UP ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

9.4 FEED ROLLER REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

9.5 FRICTION BELT REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

9.6 PICK-UP SOLENOID ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

TOC ix A219/A245/B019

Page 20

SORTER A657

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

2. COMPONENT LA YOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

3. ELECTRICA L COMPONENT DESCRIPTIONS. . . . . . . . . . . . . . . . 9-3

4. BASIC OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

5. EXIT ROLLER DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . 9 -5

6. BIN DRIVE MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

7. MISFEED DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

8. SERVICE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

8.1 FUSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

9. PREPARATION FOR TRANSPORTATION. . . . . . . . . . . . . . . . . . . 9-9

10. ROLLER DRI VE BELT REPLACE MENT. . . . . . . . . . . . . . . . . . . 9-1 0

11. BIN GUIDE LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

APPENDIX

ELECTRICAL COMPONENT LAYOUT (A219) (A662) (A657) . . . . . 10-1

COPIER TIMING CHART (A219) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

A245 SERVICE MANUAL

1. SPECIFICA TIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

2. MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . 11-4

3. DRIVE LAUOU T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

4. PAPER PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

5. ELECTRICAL COMPONENT DESCR IPTIONS. . . . . . . . . . . . . . . 11-7

6. PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

6.1 OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

6.2 PAPER LIFT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-11

A219/A245/B019 x TOC

Page 21

Rev. 03/17/2000

6.3 PAPER FEED AND DRIVE MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . 11-12

6.4 PAPER FEED AND MISFEED DETECTION TIMING . . . . . . . . . . . . . . . . . 11-13

7. IMAGE FUSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-14

8. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 -15

8.1 COPIER ACCESSORY CHECK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-15

8.2 COPIER INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-16

8.3 UPPER AND LOWER TRAY HEATER INSTALLATION (OPTION). . . . . . . 11-20

9. PROGRAM MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-22

9.1 SP MODE QUICK REFERENCE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-22

9.2 UP MODE AND SP MODE CROSS REFERENCE TABLE . . . . . . . . . . . . . 11-23

9.3 SERVICE PROGRAM MODE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-24

10. PREVENTIVE MAINTENANCE SCHEDULE. . . . . . . . . . . . . . . 11-39

10.1 MODIFIES PM TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-39

11. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . 11-42

11.1 PAPER FEED ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . 11-42

11.2 RELAY ROLLER CLUTCH AND PAPER FEED

CLUTCH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-43

11.3 PAPER SIZE SWITCH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 11-44

11.4 PAPER END SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-45

12. REGULAR PM PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . 11-46

13. SERVICE CA LL CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . 11-49

B019 SERVICE MANUAL

1. SPECIFICA TIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

2. ELECTRICAL COMPONENTS DESCRIPTION. . . . . . . . . . . . . . . 12-2

3. INSTALLATION PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

3.1 COPIER ACCESSORY CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

4. SERVICE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

4.1 SERVICE PROGRAM MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

5. PM TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

TOC xi A219/A245/B019

Page 22

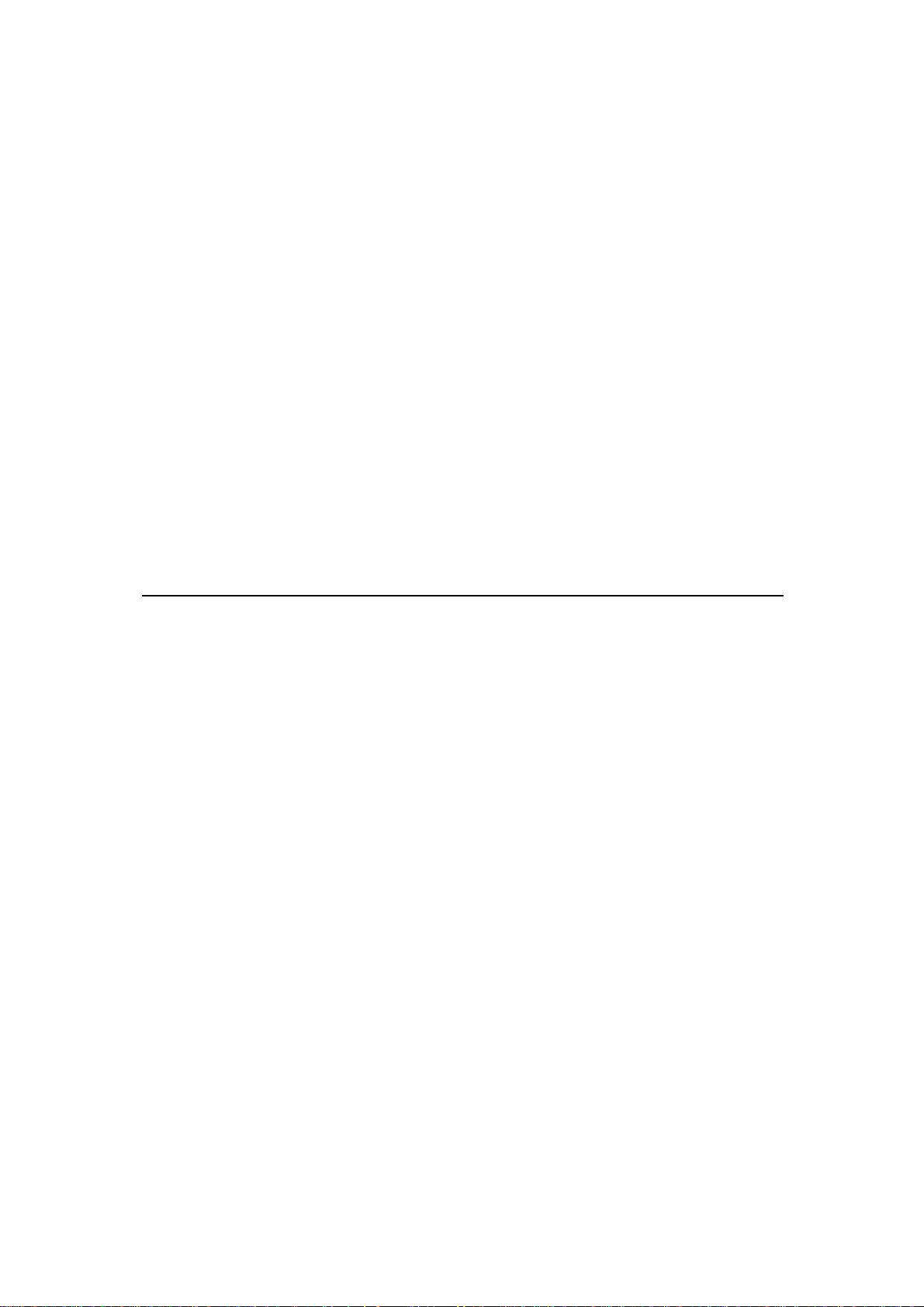

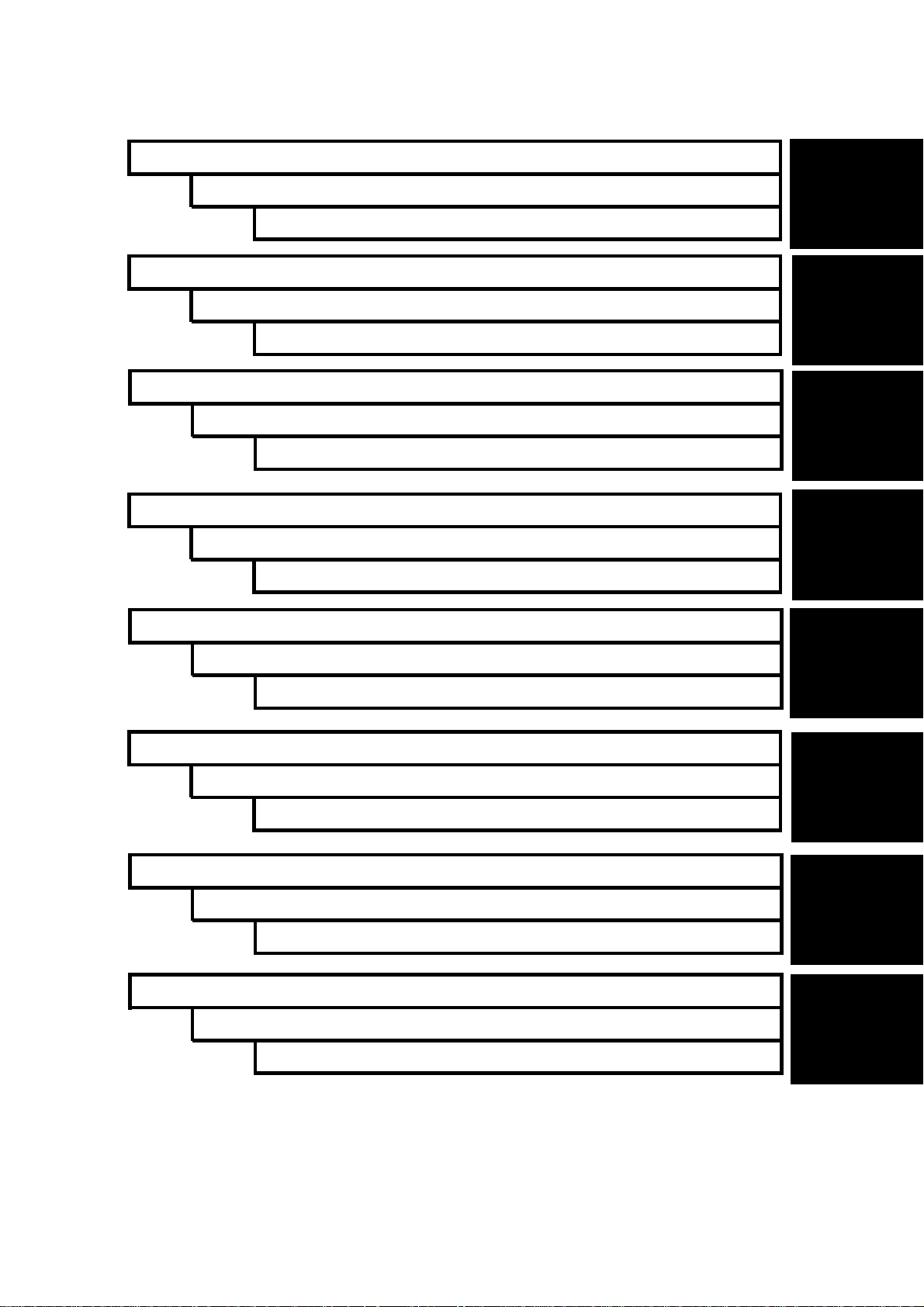

OVERALL MACHINE INFORMATION

SORTER A657

A245 SERVICE MANUAL

DETAILED DESCRIPTIONS

ELECTRICAL COMPONENTS &TIMING CHART

B019 SERVICE MANUAL

INSTALLATION

SERVICE TABLES

PREVENTIVE MAINTENANCE

TAB

POSITION 1

TAB

POSITION 2

TAB

POSITION 3

TAB

POSITION 4

REPLACEMENT & ADJUSTMENT

TROUBLESHOOTING

DOCUMENT FEEDER A662

TAB

POSITION 5

TAB

POSITION 6

TAB

POSITION 7

TAB

POSITION 8

Page 23

Page 24

A219

SERVICE MANUAL

Page 25

Page 26

OVERALL

MACHINE INFORMATION

Page 27

Page 28

SPECIFICATIONS

1. SPECIFICATIONS

Configuration: Desk Top

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book

Original Size: Maximum: A3/11" x 17"

Copy Paper Size: Maximum: A3/11" x 17"

Minimum:

A5/5

A6/5

Non-standard sizes:

Vertical 45 mm ~ 30 8 m m , 1.8" ~ 12"

Horizontal 148 m m ~ 43 2 mm , 5.8" ~ 17"

Copy Paper Weigh t: Paper tray feed: 64 to 90 g/m2, 17 to 24 lb

By-pass feed: 52 to 157 g/ m2, 14 to 42 lb

1/2

1/2

" x 8

" x 8

" sideways (Paper tray feed )

1/2

" lengthwise (By-pass feed)

1/2

Overall

Information

Reproduction Ratios:

Enlargement

Full Size 100% 100%

Reduction

Metric Version Inch Version

200%

141%

122%

93%

82%

71%

50%

200%

155%

129%

93%

74%

65%

50%

Zoom: From 50% to 200% in 1% step s

Copying Speed: 15 copies/minute (A4/8.5" x 11" sideways)

9 copies/minute (A3/11" x 17")

Warm-up Time:

120 V machines: Less than 30 seconds (at 23°C)

230 V machines: Less than 45 seconds (at 23°C)

First Copy Time: Less than 6.9 seconds (A4/8. 5" x 11" side w ays)

Copy Number Input: Number keys, 1 to 99

Manual Image Density

7 steps

Selection:

Automatic Reset: 1 minute standard settin g; can also be set to 3

minutes or no auto reset

SM 1-1 A219

Page 29

SPECIFICATIONS

Paper Capacity: Paper tray: 500 sheets or less than 56 mm stack

height

By-pass feed entrance:

Standard paper 80 sheets

OHP 10 sheets

Others 1 sheet

Toner Replenishment: Bottle exchange (215 g/bottle)

Copy Tray Capacity: 100 sheets

Power Source: 120 V/60 Hz: More than 15 A (for North Amer i ca)

220 ~ 240 V/50 Hz: More than 8 A (for Europe)

220 V/50 Hz: More than 8 A (for Asia)

220 V/60 Hz:More than 8 A (for Middle East/Asia)

110 V/60 Hz: More than 15 A (for Taiwan)

127 V/60 Hz: More than 15 A (for Middle East)

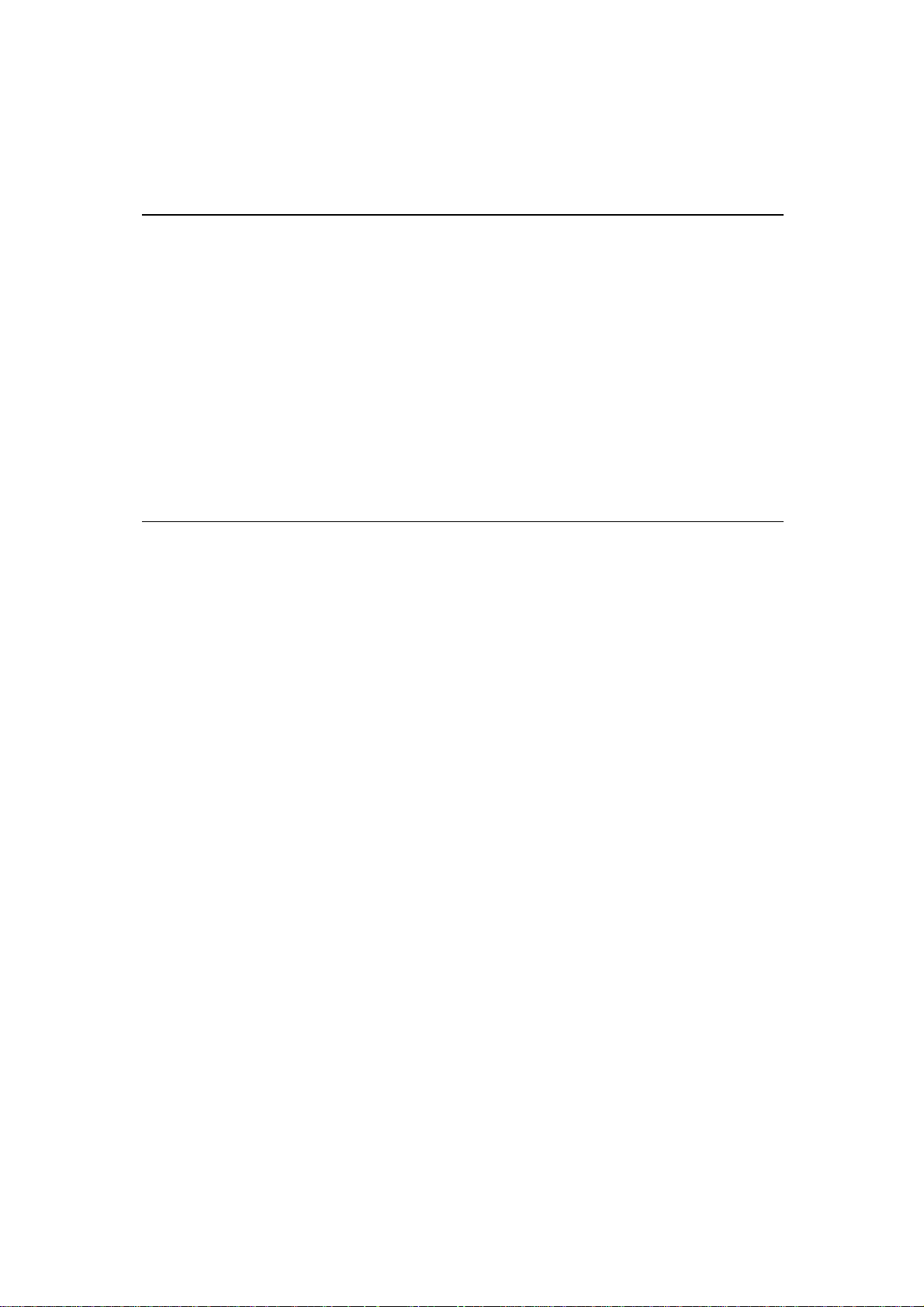

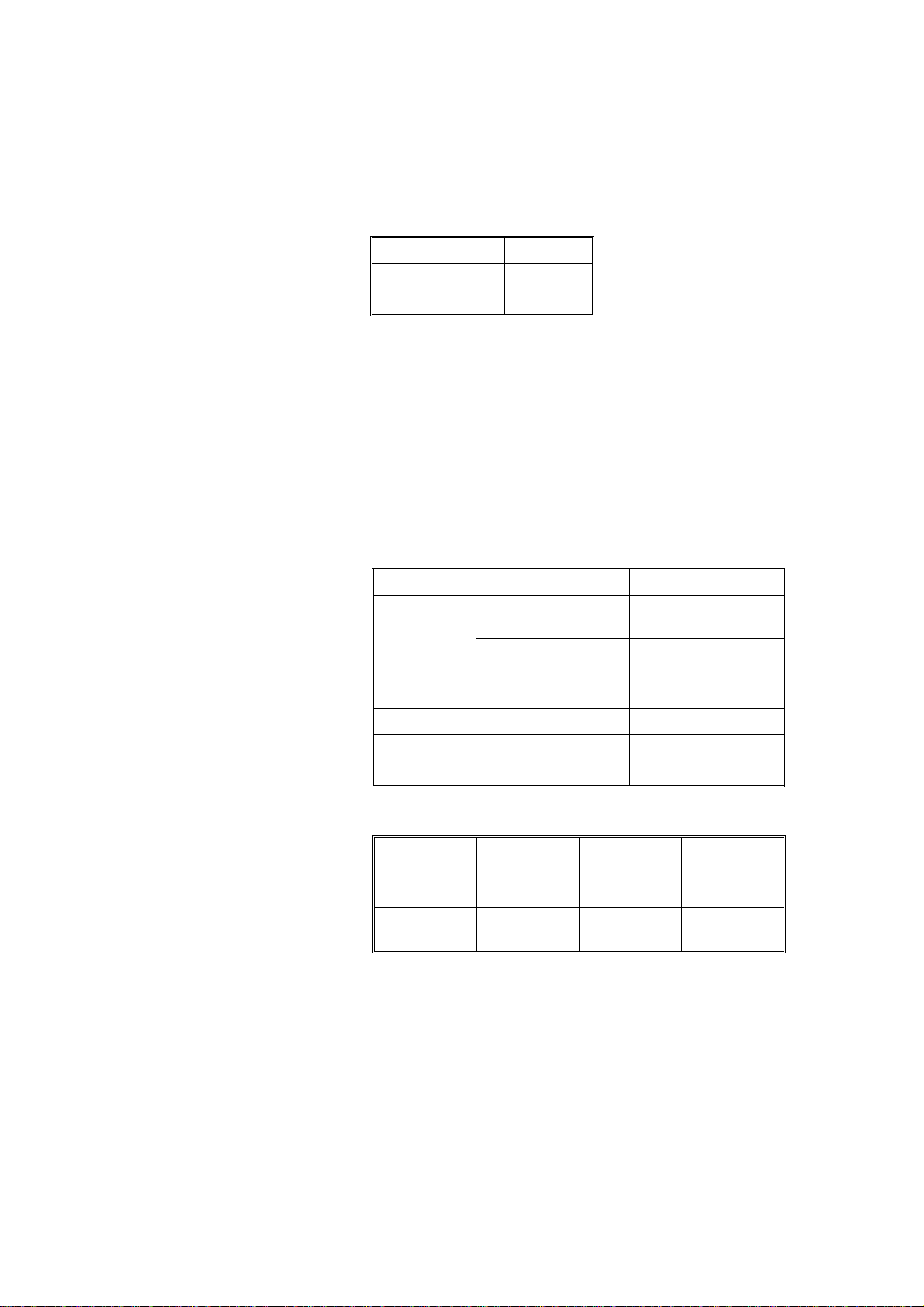

Power Consumption:

Dimensions:

Copier only Full system*

Maximum 1.4 kW

(120 V machines)

0.9 kW

(230 V machines)

Copy cycle 0.71 kW 0.74 kW

Warm-up 0.95 kW 0.95 kW

Stand-by 0.25 kW 0.25 kW

Energy saver 0.2 kW 0.2 kW

*Full system: Copier with document feeder and 10-bin sorter

Width Depth Height

Copier 579 mm

(22.8")

Full system* 775 mm

(30.2")

*Full system: Copier with document feeder and 10-bin sorter

560 mm

(22.1")

560 mm

(22.1")

1.5 kW

(120 V machines)

1.0 kW

(230 V machines)

420 mm

(16.6")

508 mm

(19.8")

A219 1-2 SM

Page 30

SPECIFICATIONS

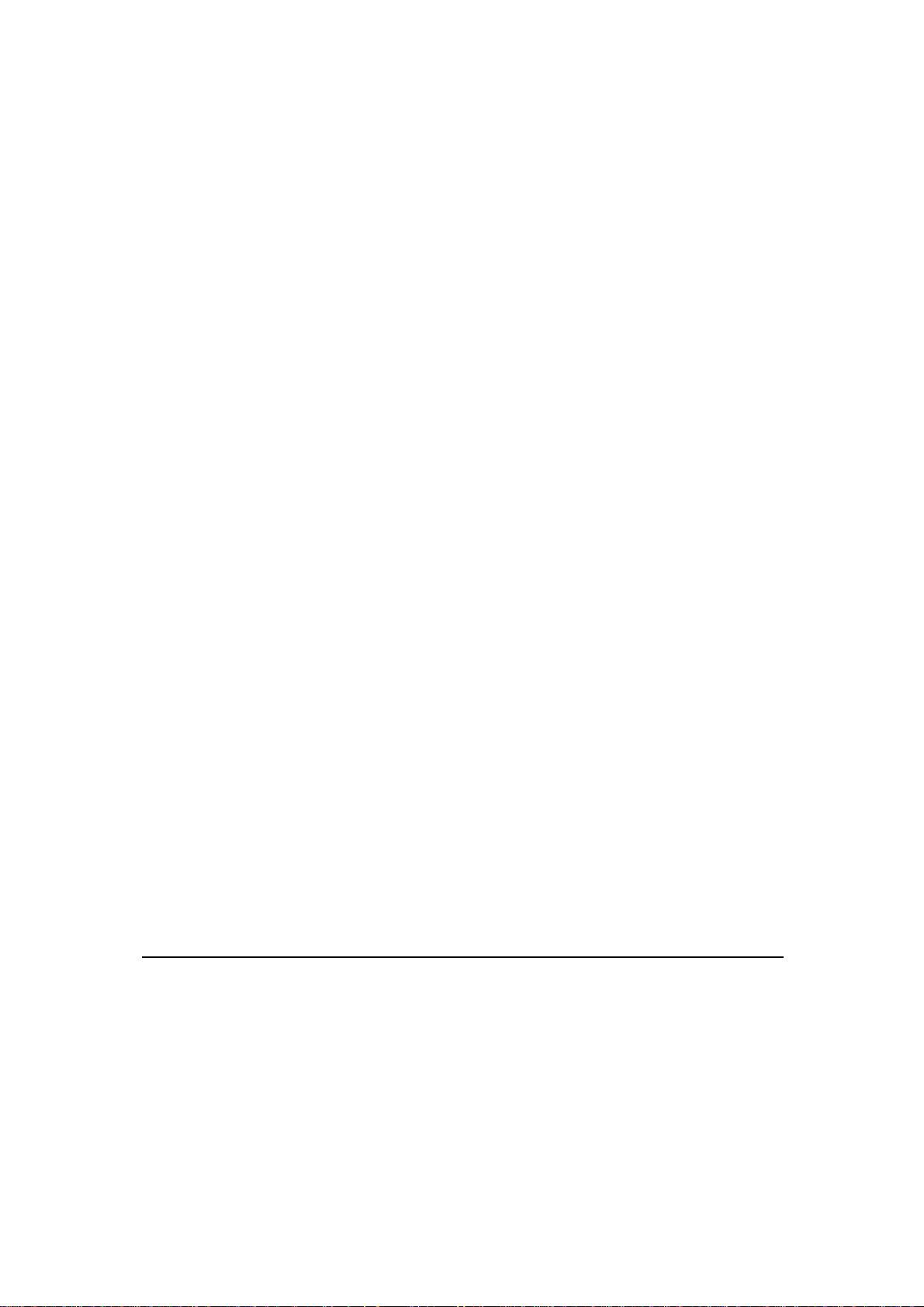

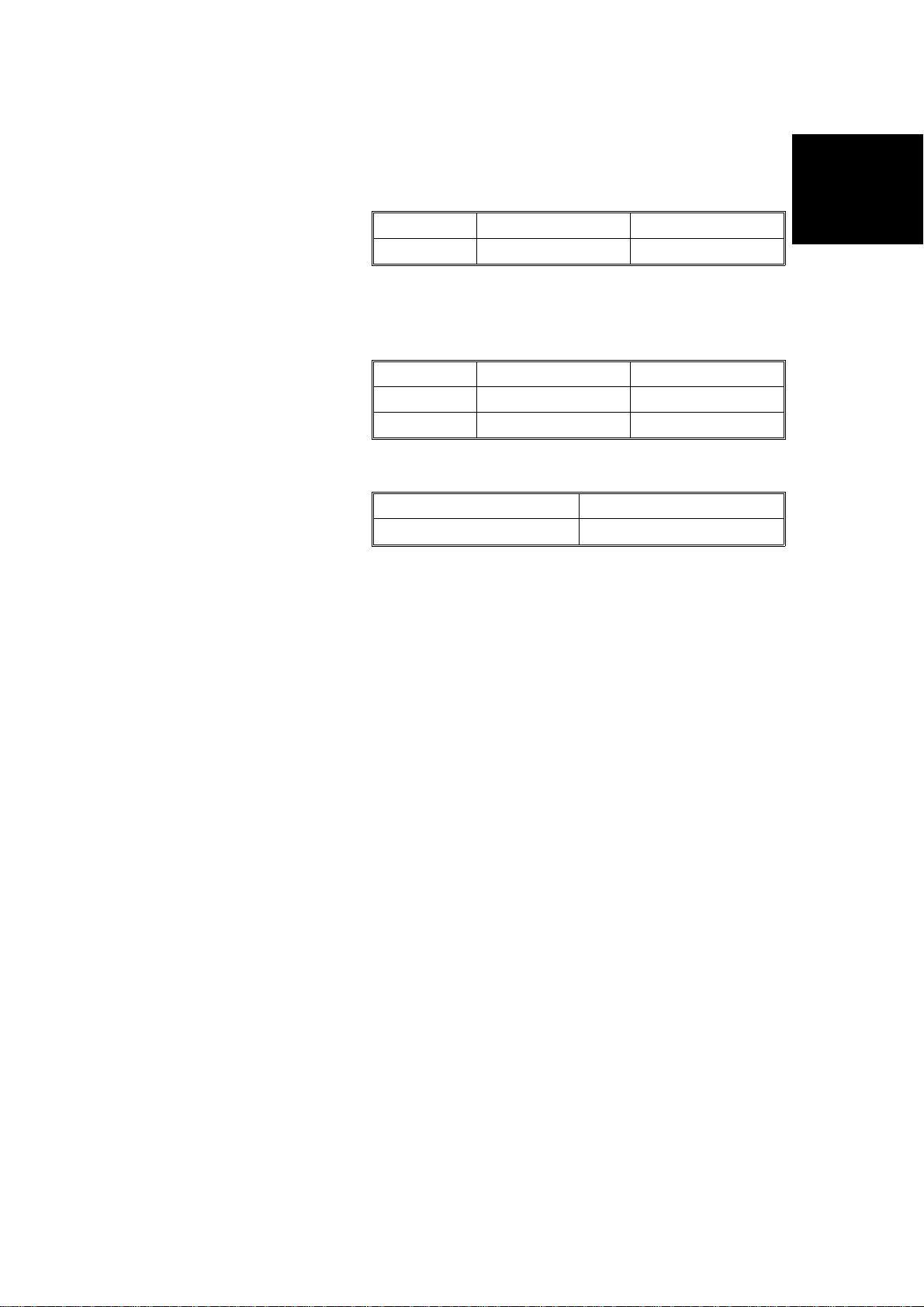

Noise Emissions: Sound pressure level (the m ea sur e ments are

made in accordance with ISO 7779 at the

operator positio n.)

Copying Less than 57 dB Less than 61 dB

*Full system: Copier with document feeder and 10-bin sorter

Copier only Full system*

Sound power level (the measurements are made

in accordance with ISO 7779)

Overall

Information

Stand-by Less than 40 dB Less than 40 dB

Copy cycle Less than 63 dB Less than 67 dB

*Full system: Copier with document feeder and 10-bin sorter

Weight:

Optional Equi p m en t:

(Sales items)

Optional Equi p m en t:

(Service items)

*Full system: Copier with document feeder and 10-bin sorter

Document feeder (A662)

10-bin sorter (A657)

Optics anti-condensation heater

Tray heater

• Specifications are subject to change without

Copier only

Full system*

notice.

Toner Yield: 6K / Bottle.

Dev. Yield: 45K / Bag.

Copier only Full system*

42 kg (93.0 lb)

55 kg (121 lb)

SM 1-3 A219

Page 31

COPY PROCESS AROUND THE DRUM

2. COPY PROCESS AROUND THE DRUM

2

8

1

3

7

4

6

A219 1-4 SM

5

A219V503.wmf

Page 32

COPY PROCESS AROUND THE DRUM

1. DRUM CHARGE

In the dark, the charge corona unit gives a uniform negative charge to the

organic photoconductive (OPC) drum. The charge remains on the surface

of the drum because th e OP C drum ha s a high el ect r ic al r esistance in the

dark.

2. EXPOSURE

An image of the origi nal is ref l ect ed to th e dr u m surfa c e via th e op ti cs

assembly. The charge on the drum surface is dissipated in direct

proportion to the int ensity of the reflected light, thus producing an

electrical latent image on the drum surface.

3. ERASE

The erase lamp illuminates the area of the charged drum surface that will

not be used for the copy image. The resistance of the dr um in the

illuminated areas drops and the charge on those areas dissipates.

4. DEVELOPMENT

Positively charged toner is attached to the negatively charged areas of

the drum, thus develo ping the latent image. (The positive tribo el e ctri c

charge is caused by friction between the carrier and toner particles.)

Overall

Information

5. IMAGE TRANSFER

Paper is fed to the drum surface at the proper time so as to align the copy

paper and the develo ped image on the drum surface. Then, a strong

negative charge is appl ied to th e ba ck side of the copy pa pe r , pr o du cing

an electrical force which pulls the toner particles from the drum surface to

the copy paper. At the same ti m e, the copy pa pe r is electrically attracted

to the drum surface.

6. PAPER SEPARATION

A strong positive dc charge is applied to the back side of the copy paper

via a discharge plate, r ed ucin g th e ne ga ti ve charg e on the copy pa pe r

and breaking the ele c tri cal attraction between the paper and the dr um.

Then, the stiffness of the copy paper causes the paper to separate from

the drum surface.

7. CLEANING

The cleaning blade scrapes the toner off the drum. The collected toner is

recycled.

8. QUENCHING

Light from the qu en ching lamp electrically neutralizes the drum surface.

SM 1-5 A219

Page 33

MECHANICAL COMPONENT LAYOUT

3. MECHANICAL COMPONENT LAYOUT

26

25

24

23

7

10

98654321

11

12

13

14

15

16

22

1. 2nd Mirror

2. 1st Mirror

3. Exposure Lamp

4. Hot Roller

5. Lens

6. Quenching Lamp

7. Charge Corona Unit

8. 6th Mirror

9. Erase Lamp

10. 4th Mirror

11. 5th Mirror

12. Toner Bottle Holder

13. By-pass Feed Roller

21 20

19

18

17

A219V500.wmf

14. By-pass Feed Table

15. Relay Rollers

16. Tray Paper Feed Rollers

17. Registration Rollers

18. Development Roller

19. Transfer/Sep ara ti o n U nit

20. Drum

21. Cleaning Blade

22. Pressure Roller

23. Paper Tray

24. Copy Tray

25. Exit Rollers

26. 3rd Mirror

A219 1-6 SM

Page 34

4. DRIVE LAYOUT

DRIVE LAYOUT

10

11

9

8

2

1

Overall

Information

7

6

543

1. Lens Motor

2. Fusing Unit Drive Gear

3. Main Motor

4. Drum Drive Gear

5. Tray Paper Feed Clutch Gear

6. Relay Roller Clutch Gear

A219V501.wmf

7. By-pass Paper Feed Clutch

8. Registration Clutch Gear

9. Toner Supply Motor

10. 4th/5th Mi r ror M ot or

11. Scanner Drive Motor

SM 1-7 A219

Page 35

PAPER PATH

5. PAPER PATH

3

1

1. By-pass Feed

2. Paper Tray Feed

3. Copy Tray

2

A219V502.wmf

A219 1-8 SM

Page 36

ELECTRICAL COMPONENT DESCRIPTIONS

6. ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout and the point-to-point diagram on the

waterproof paper in the pocket for symbols and index numbers.

Symbol Name Function Index No.

Motors

M1

M2 Scanner Drive Motor Drives the scanners (1st and 2nd). 9

M3

M4

M5

M6

M7

Main Motor Drives all the main unit components except

for the optics unit, fans and toner supply.

Lens Motor Moves the lens position in accordance with

the selected magnification.

4th/5th Mirror Motor Moves the 4th/5th mirror position in

accordance with the selected magnification.

Toner Supply Motor Rotates the toner bottle to supply toner to the

development unit.

Optics Cooling Fan

Motor

Exhaust Fan Motor Removes heat from around the fusing unit

Prevents build-up of hot air in the optics

cavity.

and blows the ozone built up around the

charge corona unit towards the ozone filter.

8

18

16

10

17

7

Overall

Information

Clutches

CL1

CL2

CL3 Relay Roller Clutch Drives the relay rollers for paper tray feed. 13

CL4 Registration Clutch Drives the registration rollers. 11

Switches

SW1 Main Switch Supplies power to the copier. 38

SW2

SW3

SW4

Sensors

S1

S2

Tray Paper Feed

Clutch

By-pass Paper Feed

Clutch

Interlock Switch Cuts all power when the front cover is

Tray Paper Size

Switch

Right Vertical Guide

Switch

4th/5th Mirror Home

Position Sensor

ADS Sensor Detects the background density of the

Transfers main motor drive to the paper feed

roller.

Starts paper feed from the by-pass feed

table.

opened.

Determines what size of paper is in the

paper tray.

Cuts the +24 V dc power line of the relay

roller clutch.

Informs the CPU when the 4th/5th mirror

assembly is at the home position (full size

position).

original.

14

12

37

31

27

33

24

SM 1-9 A219

Page 37

ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Name Function Index No.

S3

S4

S5

S6 Exit Sensor Detects misfeeds. 23

S7

S8

S9

Printed Circuit Boards

PCB1 Main Control Board Controls all copier functions. 1

PCB2

PCB3

PCB4

Tray Paper End

Sensor

Registration Sensor Detects the leading edge of the copy paper

By-pass Feed Paper

End Sensor

Scanner Home

Position Sensor

Lens Home Position

Sensor

Toner Density (TD)

Sensor

High Voltage Supply

Board - C/G/B/T/S

AC Drive/DC Power

Supply Board

Operation Panel

Board

Informs the CPU when the paper tray runs

out of paper.

to determine the stop timing of the relay

roller clutch, and detects misfeeds.

Informs the CPU when there is no paper in

the by-pass tray.

Informs the CPU when the 1st scanner is at

the home position.

Informs the CPU when the lens is at the

home position.

Detects the ratio of toner to carrier in the

developer.

Provides high voltage to the charge corona,

grid, development bias, transfer corona, and

discharge plate.

Drives the exposure lamp, fusing lamp, and

main motor. Rectifies 30 Vac and 8 Vac input

and outputs 5 Vdc and 24 Vdc.

Informs the CPU of the selected modes and

displays the situation on the panel.

28

30

29

40

22

26

2

3

6

Lamps

Erase Lamp Discharges the drum outside of the image

L1

L2

L3

L4 Fusing Lamp Provides heat to the hot roller. 25

Others

CO1

H1

H2

TF1

Quenching Lamp Neutralizes any charge remaining on the

Exposure Lamp Applies high intensity light to the original for

Total Counter Keeps track of the total number of copies

Tray Heater (Option) Turns on when the main switch is off to keep

Optics

Anti-condensation

Heater (Option)

Exposure Lamp

Thermofuse

area. (Provides leading/trailing edge and

side erases.)

drum surface after cleaning.

exposure.

made.

paper in the paper tray dry.

Turns on when the main switch is off to

prevent moisture from accumulating in the

optics.

Provide back-up overheat protection around

the exposure lamp.

4

5

20

34

32

39

21

A219 1-10 SM

Page 38

ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Name Function Index No.

TF2

TH1

TH2

TR

Fusing Thermofuse Provide back-up overheat protection in the

fusing unit.

Fusing Thermistor Monitors the temperature around the

exposure lamp for overheat protection.

Optics Thermistor Monitors the temperature around the

exposure lamp for overheat protection.

Transformer Steps down the wall voltage to 30 Vac and 8

Vac.

36

35

19

15

Overall

Information

SM 1-11 A219

Page 39

Page 40

DETAILED DESCRIPTIONS

Page 41

Page 42

DRUM

1. DRUM

1.1 OPC DRUM CHARACTERISTICS

The OPC (Organic Photoconductor) drum used in this copier is small in

diameter (30 mm), ensuring good paper separation. An OPC drum has the

following characteristics.

1. The drum is able to accept a high negative electrical charge in the dark.

(The electrical resistance of a photoconductor is high in the absence of

light.)

2. It dissipates the electrical charge when exposed to light.

(Exposure to light greatly increases the conductivity of a photoconductor.)

3. The amount of charge dissipated is in direct proportion to the intensity of

the light. That is, w he re str o ng er l igh t i s di rect ed t o the photoconductor

surface, a smaller voltage remains on the drum.

4. An OPC drum is less sensitive to changes in temperature (when

compared to selenium F type drums).

Detailed

Descriptions

5. During the drum’s life, drum res i dual voltage gradually increases and the

photoconductive surfa c e be comes worn. Therefor e, some com p en sat i on

for these characteristics is required.

SM 2-1 A219

Page 43

DRUM

1.2 DRIVE MECHANISM

[C]

[E]

[D]

[B]

[A]

A219D520.wmf

The drive from the main motor [A] is transmitted to the drum [B] through a

series of gears, a timing belt [C], and the drum drive sha ft [D].

When the imaging unit is i nst al led in the copier, the drum drive shaft en ga ge s

inside the drum’s fl an ge [E] as show n .

A219 2-2 SM

Page 44

2. CHARGE

2.1 OVERVIEW

CHARGE

[A]

[B]

A219D505.wmf

[C]

Detailed

Descriptions

[D]

A219D521.wmf

This copier uses a single wire scorotron to charge the drum. The corona wire

[A] generates a coro na of ne ga tive ions when the high voltage supply unit

applies a negative voltage. The stai nless stee l grid pla te [B] ensures th at the

drum coating receive s a unif or m ne ga tive char g e as it r ot at es pa st th e cor o na

unit.

The exhaust fan [C] caus es a flo w of ai r ab ove and through the cha r ge

corona section. This preve nt s an uneve n bu i ld- u p of neg at ive i on s tha t can

cause uneven image de nsity.

An ozone filter [D], which absorbs ozone (O3) generated by the charge

corona, is located be side the exhaust fan. The oz one filter decreases in

efficiency over time as it ab sor b s ozon e. The ozo ne fil te r shou ld be repl a ced

every PM cycle (45 k copies).

SM 2-3 A219

Page 45

CHARGE

2.2 CHARGE CORONA WIRE CLEANER MECHANISM

[C]

[D]

[A]

[B]

A219D536.wmf

Pads [A] move along the cha r ge coron a w ir e as th e w ir e clea ner knob [B] is

manually slid in and out.

The cleaner pad bracket [C ] i s conn ect ed to th e wi re cl ea ne r knob . Whe n th e

knob is pulled out, the pads move into contact with the corona wire as shown,

since the casing [D] is narrower away from the home position.

The pads move away from the wire when the wire cleaner knob is fully

inserted and the pad br a cket is pu she d ba ck to th e ho m e po siti o n.

After copier installation, the key operator should be instructed to use this

mechanism when copies ha ve white streaks or uneven image density.

Instruct the operato r to fi rm l y pu sh th e pa d br a cket in to the home position.

Poor copy quality will result if the cleaning pads remain in contact with the

charge corona wire.

A219 2-4 SM

Page 46

2.3 CHARGE CORONA CIRCUIT

gg

gg

gg

Main Board High Voltage Supply Board

24 V

C Tri

GND

er

CN102-7

CN102-6

CN102-5

DC/DC

Converter

CHARGE

T Tri

B-PWM

S Tri

4.7 k

er

er

5 V

CN102-4

CN102-3

CN102-2

CN102-1

DC/DC

Converter

DC/DC

Converter

Zener

Diode

DC/DC

Converter

Protection

Circuit

GC

Drum

B

S

T

A219D506.wmf

Detailed

Descriptions

The main board suppli es + 24 V to th e hig h vol t ag e sup pl y bo ar d at C N10 2- 7 .

After the ! key is pressed , th e C PU dr o ps CN 102- 5 fr om + 5V to LO W .

This activates the charge cor ona ci rc uit wh ic h ap pli e s a high negative voltage

of approximately –5 k volts to the charge corona wire. The corona wire then

generates a negative cor ona cha r ge .

The grid plate limits the charge voltage to ensure that the charge does not

fluctuate and that an even charge is applied to the entire drum surface. The

grid plate is connect ed to gr o un d th r ou gh a zene r diod e i n th e high voltage

supply unit. The grid pl at e dr a ins an y char g e in exce ss of –9 10 V, whi ch is

discharged to ground through the zener diode.

SM 2-5 A219

Page 47

OPTICS

3. OPTICS

3.1 OVERVIEW

[C][C] [A][B] [K] [E] [I] [G]

[D]

[F]

[H]

[J]

A219D507.wmf

During the copy cycle, an image of the original is reflect ed onto th e dru m

surface through the op ti cs asse mbl y as fo ll ows:

Light path:

Exposure Lamp [A] → Original → First Mirror [B] → Second Mirror [C] →

Third Mirror [D] → Lens [E] → Blue Filter [F] → Fourth Mirror [G] → Fifth

Mirror [H] → Sixth Mirror [I] → Drum [J]

This copier has eight standard reproduction ratios and a zoom function. The

operator can also chan ge the repr o du cti o n r at io i n on e- p erc e nt step s fr om

50% to 200%. Stepper motors are used to change the positions of the lens

and 4th/5th mir r ors to enla r ge /r e du ce th e i m ag e acr o ss the pag e. Changes in

reproduction ratio down the page are achieved by changing the sc anner

speed.

The CPU monitors the temperature around the optics through a thermistor

which is located on the scanner frame. When the temperature reaches 40°C,

the optics cooling fan [K] starts rotating to draw cool air into the optics cavity.

The fan operates until the temp erature drops below 38°C.

Additionally, a the rm of use on th e 1st scann er pr o vi des back-u p ove r he at

protection. It opens when the temperature reaches 128°C and cuts ac power

to the exposure lamp.

A blue filter is located jus t after the lens to improve the reproduction of red

areas of the original on copi e s.

A219 2-6 SM

Page 48

3.2 SCANNER DRIVE

[H]

[F]

[D]

OPTICS

Detailed

Descriptions

[C]

[A]

[E]

[B]

A219D522.wmf

[G]

A stepper motor [A] is used to drive the scanners.

The first scanner [B], which consists of the exposure lamp and the first mirror,

is connected to the first scanner belt [C]. The second scanner [D], which

consists of the second and third mirrors, is connected to the second scanner

belt [E]. Both the scanners move along the guide rod [F].

There are no scanner drive wires, and only one side of the scanner is

supported (by a rod and guide rail). Therefore, the scanners should be

moved by moving the timing be lt, and never by moving the scanner s di re ctl y.

The pulley [G] drives both the fir st an d seco nd scann er be l ts. The 2n d

scanner moves at half the speed of the first scanner. This maintains the focal

distance between the original and the lens during scanning.

The scanner home position is detected by a home position sensor [H]. The

scanner return position is determined by counting the scanner motor drive

pulses.

SM 2-7 A219

Page 49

OPTICS

3.3 LENS DRIVE

[A]

[C]

A219D509.wmf

[B]

: Reduction

: Enlargement

The lens motor [A] (stepper motor) changes the lens [B] position through the

timing belt [C] in accordanc e with the selected reproduction ratio to provide

the proper optical di st an ce between the lens and the drum surface.

[D]

The rotation of the lens driv e pulley moves the lens back and fort h in discrete

steps. The home position of the lens is detected by a home position sen sor

[D]. The main board keep s tr ack of the lens po si tio n ba sed on th e nu m be r of

pulses sent to the lens motor.

A219 2-8 SM

Page 50

3.4 4TH/5TH MIRROR DRIVE

OPTICS

[D]

[A]

[C]

[B]

A219D510.wmf

The 4th/5th mirror drive motor [A] (stepper motor) changes the 4th/5th mirror

assembly position thr ou gh the pi nio n ge ar s [B ] an d th e r ack ge ar [C ] in

accordance with the sele cte d r epr od uction ratio to provide the proper optical

distance between the le ns an d dr u m sur fa c e.

Detailed

Descriptions

The home position of the 4th/5th mirror assembly is detected by a home

position sensor [D]. The ma in bo ar d keep s track of the lens position ba sed on

the number of pulses sent to the 4th/5th mirror motor.

SM 2-9 A219

Page 51

OPTICS

3.5 AUTOMATIC IMAGE DENSITY SENSOR

A219D511.wmf

[A]

The auto image density (ADS) sensor [A], a photodiode, is mounted on the

A219D512.wmf

upper front fram e. The sen sor cove r has a hol e in i t to all ow l igh t to fal l

directly onto the sensor.

Sampling starts 6 millimeters from the leading edge of the original and

continues for 11.5 millimeters from the leading edge of original in full size

mode. These lengths "a" and "b" will vary dependin g on the selected

reproduction ratio. The lengths "a" and "b" for each reproduction ratio are

calculated as follows:

For every original in ADS mo de , th e ph ot ose nso r circu i t con ver t s the lig ht

intensity into a voltage. The detected voltage is amplified and sent to the

main board. If less light is reflect ed from the original (the image is darker), the

sensor outputs a lower voltage. The CPU compares the maximum ADS

output voltage with the st andard ADS reference voltage and compensates

the copy image density by changing the development bias voltage in

accordance with the di fference. The standard ADS reference voltage (2.5 ±

0.1 V) is generated by SP 56. De ta i ls about changes to the develo pm e nt bi as

voltage are expla i ne d i n "De v elopment Bias for Image Density Con trol".

A219 2-10 SM

Page 52

OPTICS

3.6 EXPOSURE LAMP VOLTAGE CONTROL

The main board control s th e exp osu r e lam p volta ge thr o ug h th e ac dr iv e /d c

power supply board . The expo sur e lam p voltage is based on the base lamp

voltage and various correction factor s. The method of contro l is diffe ren t

depending on wheth er th e i m ag e de nsity is manually select ed or t he auto

image density mode is selected.

The exposure lamp voltage is determined by the following factors:

Lamp Voltage = Base Lamp Voltage Setting (SP48)

+

*Image Density Adjustment Factor (SP34)

+

*Manual Image Den s ity Se tting Factor

+

VL Correction 1 Factor (SP62)

+

VL Correction 2 Factor

+

Reproduction Ratio Correction Factor

Detailed

Descriptions

*NOTE:

SP34 (Image Density Adjustment Factor) is applied for ADS mode

only.

The "Manual Image Density Factor" is applied for manual ID mode

only.

1) Base Lamp Voltage Setting

The lamp voltage is determined by the SP48 setting.

Base Lamp Voltage = SP48 setting x 0.5 (120 V machi n es)

SP48 setting x 1.0 (230 V machines)

The default setting is: 140 = 70 V (120 V machines)

140 = 140 V (230 V machines)

The current lamp voltage (after all correction factors are included) can be

viewed with SP 51.

SM 2-11 A219

Page 53

OPTICS

2) Image Density Adjustment Factor (SP34)

Depending on the SP34 setting, the development bias and the exposure

lamp settings are increas ed or decreased during ADS mode.

SP34 Setting Setting Dev. Bias Exposure Lamp

0 Normal 0 0

1 Light –40 V 0

2 Dark +40 V 0

3 Lightest –40 V +4 steps

4 Darkest +40 V –4 steps

1 step = 0.5 V (120 V machines) or 1. 0 V ( 23 0 V mach i ne s)

3) Manual Image Density Setting Factor

Depending on the ma nu al im ag e de nsi t y setting on the operation panel, the

exposure lamp voltage is changed as shown in the ta ble below:

LighterDarker

Manual ID

Level

Exposure

Lamp Voltage

Factor

Development

Bias Voltage

(Volts)

1234567

V

– 6

0

steps

–200 –200 –200 –200 –200 –240 –240

V0 – 4

steps

V0 – 2

steps

V

0

V0 + 2

steps

V

: Base lamp voltage setting (SP48)

0

1 step = 0.5 V (120 V machines) or 1. 0 V ( 23 0 V mach i ne s)

V0 + 6

steps

V0 + 12

steps

A219 2-12 SM

Page 54

OPTICS

4) VL Correction 1 Factor

The light intensity may de crease because of dust accumulated on the optical

parts. Addition ally, the drum sensitivity gradually decreases during the drum’s

life. This may cause dirty background on copies. To compensate for this, V

L

corrections 1 and 2 are don e.

The exposure lamp voltage is increased by two steps at the set copy count

interval (a step is +2.0 V for 230 V machines, and +1 V for 120 V machines).

The table below shows the relationship between the SP setting and the copy

interval.

SP62 Setti ng VL Correction Interval

0 2 steps/8,000 copies

1 2 steps/6,000 copies

2 2 steps/4,000 copies

3 2 steps/2,000 copies

4 2 steps/1,000 copies

5 No correction

(Default setting: 2)

Detailed

Descriptions

VL correction 1 compensates for the decrease of drum sensit ivity and th e

decrease in reflectivity of the 4th, 5th, and 6th mirrors due to dust.

5) VL Correction 2 Factor

VL correction 2 compensates for dust on the lens and mirrors 1 to 3, but is

independent of the drum condition.

The ADS sensor receives th e l i gh t r ef lected through the 1st, 2nd and 3rd

mirrors from the white plate located under the middle of the left scale. The

photosensor circuit con v ert s this l i ght i nt en si ty int o a vol t ag e. The C PU sto r es

this voltage in memory as the white plate reference voltage. This is done

every time SP56 (ADS ref er e nce volta ge adju stm e nt) is done, before

sampling starts for the ADS sensor adjustment.

Every 500 copies, the machine reads the intensity of light reflected from the

white plate and compares it with the white plate reference voltage.

If the measured voltage difference is more than 0.1 volt, +2 steps will be

added to the exposure la m p set ti n g as th e VL correction 2 factor.

The sum of VL correction factors 1 and 2 cannot exceed +40 steps.

VL correction factors 1 and 2 are automatically reset every time the light

intensity is adjusted with SP48. (SP56 must be done immediately after SP48;

see Service Remarks for details.)

SM 2-13 A219

Page 55

OPTICS

6) Reproduction Ratio Correction Factor

The exposure lamp volta ge is increased depending on the selected

magnification ratio in ord er to compensate for the change in concentration of

light on the drum.

Magnification Ratio Reproduction Ratio Correction Factor

50% to 61% +2 steps

62% to 119% 0

120% to 139% +2 steps

140% to 159% +4 steps

160% to 179% +8 steps

180% to 200% +12 steps

1 step = 0.5 V (120 V machines) or 1. 0 V ( 23 0 V mach i ne s)

A219 2-14 SM

Page 56

4. ERASE

j

4.1 OVERVIEW

ERASE

A219D513.wmf

bcdefghai

k lm mlkjihgfedcban

[A]

Detailed

Descriptions

A219D527.wmf

The erase lamp [A], which is installed in the copier main frame, consists of a

single row of white LEDs (38 LEDs) extended across the full width of the

drum. The erase lamp has the following functions: lea ding edge erase, side

erase and trail edge erase. (Trail edge erase begins after the trailing edge of

the copy paper; therefore, the trailing edge of the copy will not be erased.)

In side erase mode, the appropriate LEDs turn on in accordance with the

modes selected by the user.

SM 2-15 A219

Page 57

ERASE

4.2 LEAD EDGE ERASE

The entire line of LEDs turn on when the main motor turns on. They stay on

until the erase margin slightly overlaps the lead edge of the original image

area on the drum (Lead Edge Erase Margin). This prevents the shadow of

the original edge from being developed on the copy. At this point, side erase

starts. The width of the lead i ng er ase mar gin can be adju sted using SP41.

4.3 SIDE ERASE

Based on the combination of copy paper size and the reproduction ratio data,

the LEDs turn on in blocks (labeled "a" to "n" on the previous page). This

reduces drum cleaning load.

Also, to prevent horizontal black lines from appearing on the edge of copies

as a result of light leaki n g un de r the edg e of t he DF be lt, the side erase

combination is changed between platen mode and DF mode; in DF mode,

more of the image is erased at the sides. (The setting of SP24 must be 0.)

-Platen Mode-

Blocks On Paper Size

None 99% to 200%

a to b 95% to 98%

a to c

a to d 88% to 91%

a to e

a to f 80% to 83%

a to g 75% to 79%

a to h

a to i

a to j 63% to 67%

a to k B5 59% to 62%

a to l 54% to 58%

a to m 50% to 53%

All (a to n)

11" x 17",

11" x 8

B4, B5

sideways

" x 11",

8

1/2

8

" x 5

1/2

A4

Lengthwise

Lead Edge and Trail Edge

Erase

Reproduction

"

1/2

"

1/2

Ratio (%)

92% to 94%

84% to 87%

72% to 74%

68% to 71%

-DF Mode-

Blocks On Paper Size

None 99% to 200%

a to b 97% to 98%

a to c

a to d 90% to 92%

a to e

a to f 81% to 85%

a to g 77% to 80%

a to h

a to i

a to j 65% to 69%

a to k B5 61% to 64%

a to l 56% to 60%

a to m 50% to 55%

All (a to n)

11" x 17",

11" x 8

B4, B5

sideways

" x 11",

8

1/2

8

" x 5

1/2

A4

Lengthwise

Lead Edge and Trail Edge

Erase

Reproduction

"

1/2

"

1/2

Ratio (%)

93% to 96%

86% to 89%

73% to 76%

70% to 72%

A219 2-16 SM

Page 58

ERASE

4.4 TRAILING EDGE ERASE

This minimizes toner consumption.

The entire line of LEDs turns on when the drum has turned 9 mm at the end

of scanning (about 100 ms). The LEDs stay on to erase the leading edge of

the latent image in the next copy cycle. Af te r the fina l copy, the erase lamps

turn off at the same time as the main motor.

Detailed

Descriptions

SM 2-17 A219

Page 59

DEVELOPMENT

5. DEVELOPMENT

5.1 OVERVIEW

[C]

[A]

[E]

[D]

[B]

A219D514.wmf

When the main motor turns on, the development roller [A] and two agitators

[B] and [C] start turning.

There are permanent magnets in the development roller which attract the

developer particles (which are about 50 µm in diameter) to the roller. The

turning sleeve of the development roller carries the developer past the doctor

blade [D] which trims the developer to the desired thickness.

The development roller slee ve continues to turn, carrying the developer to the

drum [E]. When the de vel o pe r brush contacts the drum surface, the

negatively charged areas of the drum surface attract and hold the positively

charged toner. In this way, the latent image is developed.

The development roller is given a suitable negative bias to prevent toner from

being attracted to th e no n- im a ge ar ea s on th e dru m wh ic h may ha ve a

residual negative char ge . The bias al so cont rol s im ag e de nsi t y.

A219 2-18 SM

Page 60

5.2 DRIVE MECHANISM

DEVELOPMENT

[B]

[C]

[A]

A219D515.wmf

When the main motor [A] turns on, the drive is transmitted to the

development dri ve sha f t [B] through gears an d a ti m ing belt. The rotation of

the development ro l ler ge ar is transmitted to the agitator gears [C] thr ou gh

other gears.

Detailed

Descriptions

SM 2-19 A219

Page 61

DEVELOPMENT

5.3 CROSS-MIXING

[C]

[B]

[D]

[A]

A219D516.wmf

A cross-mixing mechanis m is use d to keep the toner an d de veloper evenly

mixed. It also helps agitate the developer to prevent developer clumps from

forming and helps create the triboelectric charge.

Two agitators (helical coils) [A] and [B] are used for cross-mixing. The 1st

agitator [A] moves the developer from left to right. The toner supplied from

the cutout in the toner cartridge holder is mixed with the developer by the 1st

agitator. The 2nd agitator [B] rotates to move the developer back from right to

left. In this way, the de vel o pe r is eve nly distributed in the development unit.

The magnets in the development roller [C] attract the developer, and the

development roller sleeve rotates to carry the developer to the drum. The

doctor blade [D] trims the developer on the development roller to the desired

thickness.

A219 2-20 SM

Page 62

DEVELOPMENT

5.4 DEVELOPMENT BIAS FOR IMAGE DENSITY CONTROL

The image density is controlled by changing two items: the amount of bias

voltage applied to the development roller sleeve, and the amount of voltage

applied to the exposure lamp.

Applying a bias voltage to the development sleeve reduces the potential

between the development roller and the drum, th ereby reducing the amount

of toner transferred. As the bias voltage becomes greater, the copy becomes

lighter.

The method of control depends on whether the image density is manually

selected or auto image density is used.

The development bias voltage applied to the development roller sleeve has

the following factors:

Development bias voltag e = Base Bias Voltage

(Manual or auto image density mode)

+

*Image Bias Adjust men t Fact or ( SP 33)

+

*Image Density Adjustment Factor (SP34)

+

Drum Residual Voltage (VR) Correction Factor

Detailed

Descriptions

*NOTE:

Image Bias Adjustment Factor (SP33) is applied for manual ID mode

only.

Image Density Adjustment Factor (SP34) is applied for ADS mode

only.

SM 2-21 A219

Page 63

DEVELOPMENT

5.4.1 Base Bias Voltage Factor in Ma nual Ima ge D ensit y Mode

Manual ID

Level

Exposure

Lamp Voltage

Factor

Development

Bias Voltage

(Volts)

1234567

V

– 6

0

steps

–200 –200 –200 –200 –200 –240 –240

V0 – 4

steps

V0 – 2

steps

V

0

V0 + 2

steps

V

: Depends on the setting of SP48

0

V0 + 6

steps

LighterDarker

V0 + 12

steps

When manual ID level 6 or 7 is select ed, –40 V is added to the base bias

voltage.

Using SP33 (Image Bias Adjustment), the base bias voltage can be

increased or decreased for all manual ID levels as follows:

SP Setting Setting Dev. Bias Note

0 Normal 0 Default

1 Darkest +40 V

2 Darker +20 V

3 Lighter –20 V

4 Lightest –40 V

A219 2-22 SM

Page 64

DEVELOPMENT

5.4.2 Base Bias Voltage Factor in Auto m at i c Im age De nsi ty ( A DS) Mode

The bias voltage for AD S mod e de pe nds on the background i m ag e de nsity of

the original which is measured by the ADS sensor. (See "Automatic Image

Density Sensor" for more information about the ADS sensor.)

The CPU checks the voltage output from the automatic ID circuit. This circuit

has a peak hold function. The pe ak ho ld vol t ag e is the maxi mum ADS senso r

output voltage, which corr espon ds to the maxi mum ref l ect i vity of the ori gin al .

The CPU then determ ine s t he prop er ba se bi a s le vel by com p ar ing this

voltage (read fro m the ori gi n al) w it h the stan da r d ADS reference volt age.

The table below shows the relationship between the original background

density (ADS voltag e r at i o) an d the base bias voltage.

Detailed

Descriptions

ADS Voltage Ratio [α] (%)

80 to 100 (light) –200 V

75 to 79 –240 V

70 to 74 –280 V

60 to 69 –320 V

29 to 59 –360 V

0 to 28 (dark) –380 V

ADS Voltage Ratio [α]

V

: Standard ADS Reference Voltage (2.5 ± 0.1 V)

ADS0

Maximum ADS Output Voltage

=

Bias Voltage

V

ADS0

Using SP34, the base bias voltage and the exposure lamp setting can be

increased or decreased for th e ADS mo de as fol lo w s:

SP Setting Setting Dev. Bias Exposure Lamp

0 Normal 0 0

1 Lighter –40 V 0

2 Darker +40 V 0

3 Lightest –40 V +4 steps

4 Darkest +40 V –4 steps

(Default Setting: 0)

5.4.3 Drum Residual Voltage (VR) Correction Factor

During the drum’s life, drum residual voltage (VR) will gradually increase. To

compensate for this, the bias voltage is increased by –20 V every 5 k copies.

The VR correction is done up to 20 k copies. The VR correction will not

change after 20 k copies.

SM 2-23 A219

Page 65

gg

gg

gg

DEVELOPMENT

5.5 DEVELOPMENT BIAS CIRCUIT

Main Board High Voltage Supply Board

24 V

C Tri

GND

er

CN102-7

CN102-6

CN102-5

DC/DC

Converter

T Tri

B-PWM

S Tri

4.7 k

er

er

5 V

CN102-4

CN102-3

CN102-2

CN102-1

DC/DC

Converter

DC/DC

Converter

Zener

Diode

DC/DC

Converter

Protection

Circuit

GC

Drum

B

S

T

A219D506-2.wmf

The main board supplies +24 volts to the high voltage supply board from

CN102-7. When the ! key is pressed, the CPU starts sending the bias

trigger pulses fr om C N10 2- 3 . Thi s en er g izes th e development bias circuit

within the high volt ag e supply board, which applies a high negative vol ta ge to

the development roller. The development bias is applied whenever the drum

is rotating.

A219 2-24 SM

Page 66

TONER SUPPLY

6. TONER SUPPLY

6.1 TONER BOTTLE REPLENISHMENT MECHANISM

[F]

[E]

[I]

[A]

[J]

[H]

Detailed

Descriptions

[G]

[D][C] [B]

A219D517.wmf

[K]

A219D518.wmf

When a toner bottle is placed on the bottle holder unit [A] and pushed back in

completely, the following happens automatically.

• The pin [B] on the imaging unit toner shutter [C] is pushed out (shutter

opened) by the proj ect i on [D].

• The pin [E] on the toner shutt er [F] is pu l led up ( shu tter opened) as a

result of the shape of the dev eloper cartridge.

When the toner bottle holder lever [G] is pushed down to the operation

position, the following happens automatically to allow toner to be supplied to

the development unit.

•

The shaft [H] is pushed out fr o m the machi n e by th e cur ve d r ail be hin d

the toner bottle holder lever, and this pulls out the cap [I] into the chuck

[J], where it is held.

The toner end detection system determines whe n to dr ive the to ne r bot tle

replenishment mechanism (see Toner End Detection). The toner supply

mechanism transports toner from the bottle to the development unit. The

toner bottle has a spiral groove [K] that helps move toner to the development

unit.

When the bottle holder unit is pulled out to add new toner, the following

happens automatica l ly t o pre vent toner from scattering.

• The chuck releas es the toner bottle cap into its proper position.

• Both shutters close as a result of pressure from their springs.

SM 2-25 A219

Page 67

TONER SUPPLY

6.2 TONER SUPPLY MECHANISM

[A]

[F]

[B]

[E]

[C]

[D]

A219D519.wmf

The toner supply motor [A] drives the toner bottle [B] and the mylar blades

[C]. First, the toner falls down into the toner holder. The two toner supply

mylar blades transfer the toner to the opening [D], then the toner falls down

into the developme nt unit.

There is a notch [E] on the to ner bottle, and a roller [F] locate d under the

toner bottle. They both shake the toner bottle to prevent toner clumps from

forming. They also help to transport the toner inside the toner bottle when the

amount of toner inside is low.

A219 2-26 SM

Page 68

6.3 TONER DENSITY DETECTION MECHANISM

[A]

TONER SUPPLY

Detailed

Descriptions

[B]

A219D516-2.wmf

A toner density sensor (TD senso r) [A] is use d fo r ton er de nsi t y cont r ol.

The TD sensor is located under the 1st agitator [B]. The developer being

conveyed by the 1st agitat or pa sses ove r t he top of th e sen s or. As the toner

in the developer is cons umed during development, the toner to carr i er r at i o

changes, resulting in a change in the magnetic permeability of the develo per.

This in turn is converted to a corresponding voltage. The CPU monitors the

voltage to control the toner supply mechanism.

When new developer is installed, and SP66 (TD Sensor Initial Setting) is

done, the machine starts idling for developer initialization. During developer

initialization, the CPU adjusts the TD sensor control voltage so that the TD

sensor outputs 1.9 ± 0.1 V for the ton er to carrier ratio of new developer

(4.0% by weight). This voltage is used as the standard TD sensor voltage.

SM 2-27 A219

Page 69

g

y

(

)

TONER SUPPLY

6.4 TD SENSOR CHECK AND TONER SUPPLY TIMING

Original Scan

seconds

Drum Char

TD Sensor

Toner Suppl

e

Motor