Page 1

A151/A152

SERVICE TRAINING

MANUAL

Page 2

Page 3

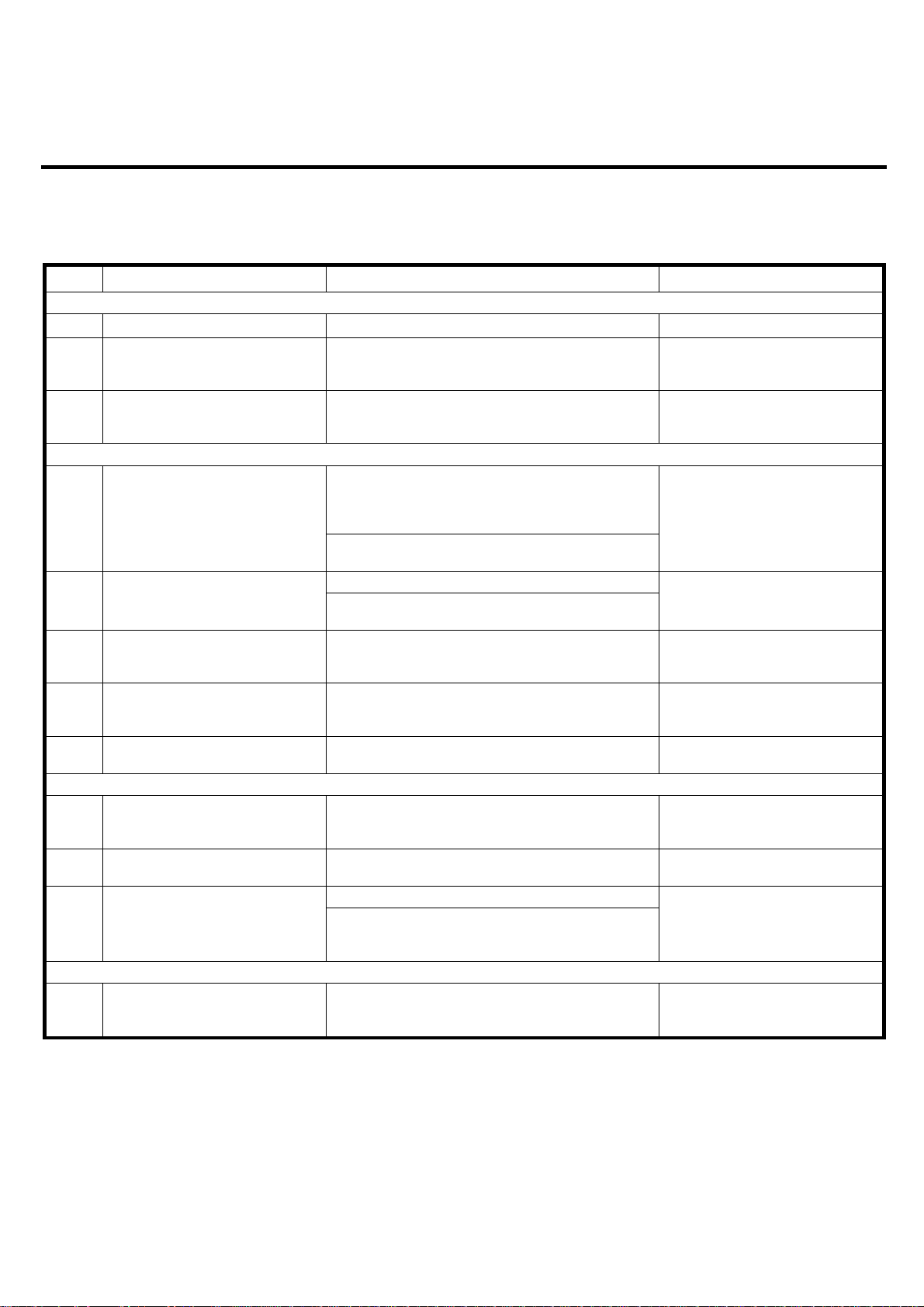

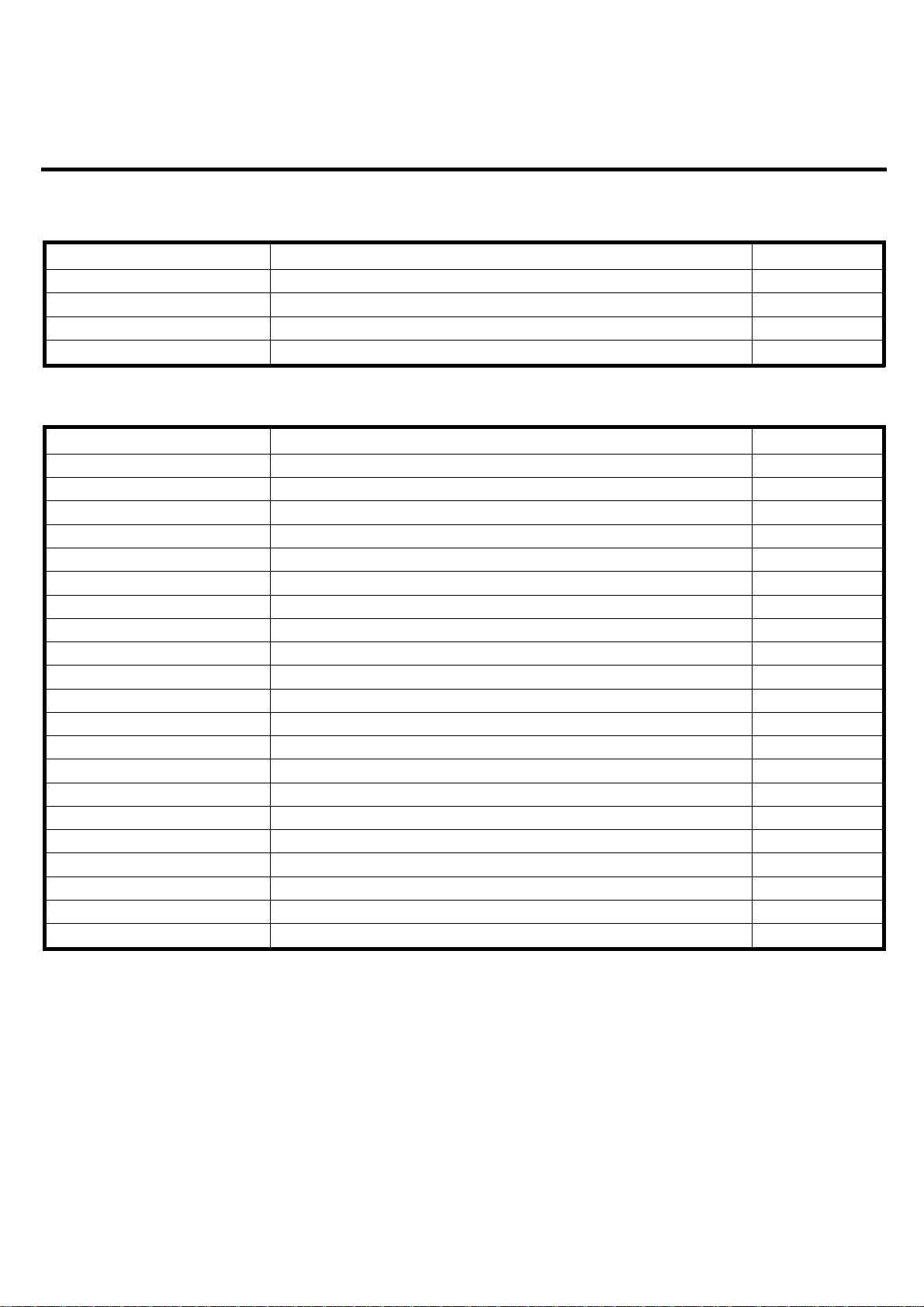

6. MAJOR DIFFERENCE BETWEEN THE FT3013/FT3213 AND

FT3113/FT3313 COPIERS

The FT3013/FT3213 (A151 and A152) are developed based on the FT3113/FT3313 (A076 and A077).

The following table lists the major differences between the FT3013/FT3213 series and the

FT3113/FT3313 series.

No. ITEM FT3013/FT3213 FT3113/FT3313

Overall

Energy Saver Function Newly added. Not available.

1

Copy Paper Weight The copy paper weight specification has been

2

Operation Panel 10 independent number keys for faster and

3

Around the Drum

Pre-Transfer Lamp The pre-transfer lamp has been removed. the

4

Cleaning Mechanism Counter blade system. Trailing system with brush.

5

Drum Drive Mechanism The main motor directly drives the drum. The

6

Erase Mechanism For the FT3013 copier, side erase is

7

Development Drive Mechanism The development clutch solenoid has been

8

Paper Feed

Paper Feed Mechanism

9

(Paper Tray)

Paper Feed Mechanism

10

(By-Pass feed table)

Misfeed Indication PE, J1 and J2. J1, J2, and J3.

11

Fusing

Fusing Lamp Control Fusing lamp control mechanism has changed

12

narrowed due to the changes in the paper feed

mechanism.

Quantity keys.

easier operation. The access to the SP modes

have been changed due to this reason.

The PTL is installed.

same PTL for the FT3113/3313 series is

available for the FT3013/3213 series as

optional service equipment.

Due to this, the transfer corona adjustment

standard has been changed.

Setting powder should be applied on the blade

and drum after servicing.

An independent drum motor

drum motor and the drum motor board have

been removed.

performed by the platen cover. (The FT3213

copier is the same as the FT3313)

removed.

Semicircular feed rollers and corner separator

system.

Auto feed mechanism is newly applied. No auto feed.

Indication change only.

The basic detection mechanism has not

changed.

to achieve stable temperature control of the

hot roller.

drives the drum.

FTR (Feed + Torque Roller)

feed system with corner

separators.

1

Page 4

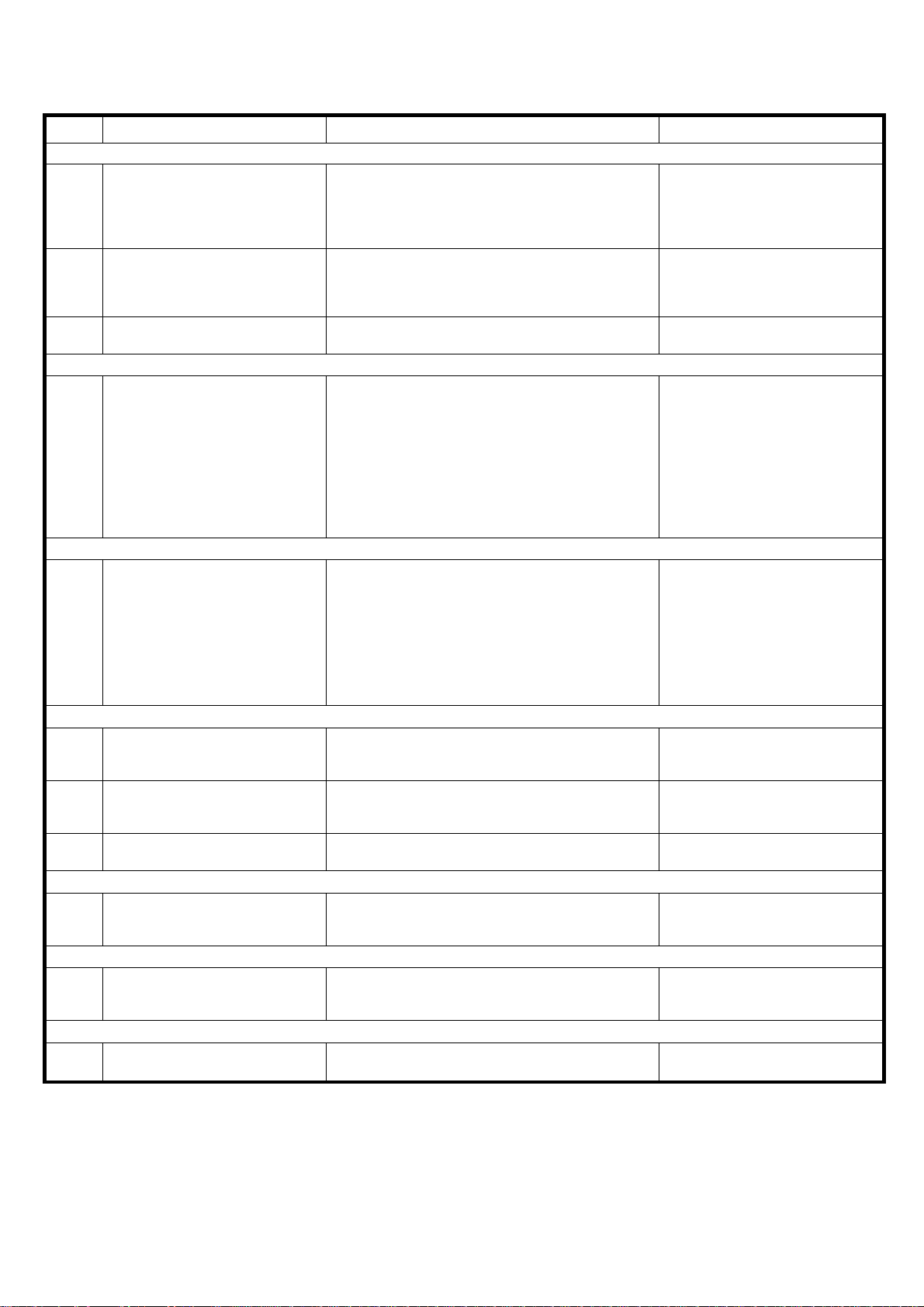

No. ITEM FT3013/FT3213 FT3113/FT3313

Copy Process Control

Grid Voltage for Image Density

13

Control

Exposure Lamp Voltage for

14

Image Density Control

Drum Temperature Correction The drum temperature correcton has been

15

Optics

Optics Thermistor and Cooling

16

Fan

Drum Cleaning

Used toner Overflow Detection Since the elimination of the PTL and the

17

Installation

Developer Developer is not equipped to the copier at the

18

220-230V to 240V Conversion The conversion for the exposure lamp is

19

Key Counter In order to install the optional key counter,

20

Document Feeder (A365)

Installation From the May production, to install the DF to

21

Service Program Mode

Sales Mode The salesman mode has been eliminated. Some SP modes can be

22

Service Call

E40 "Optics Thermistor Error"

23

The grid voltage does not change whether the

manual image density is selected or auto

image density is selected (with the exception

of SP34 setting).

The Vl correction method has changed to

prevent over applying of the exposure lamp

voltage. A white reference plate has been

added under the left scale supporting bracket.

eliminated.

An optics thermistor has been added to

monitor the optics temperature for the

operation of the optics cooling fan motor for

the FT3213 copiers. Since the cooling fan is

not installed on the FT3013 copier, the optics

thermistor monitors the optics temperature to

prevent overheating in the optics cavity.

However the copier may stop for some extra

waiting time when the thermistor detects a

certain high temperature condition.

change of the QL, the used toner overflow

detection cycle has been changed.

1. When the copy quantity

reaches 80K copies.

2. When the number of toner

end conditon reaches 9.

factory. A new pack is necessary when

installing the copier.

required. The conversion for the dc power

supply board is not required.

some service parts need to be ordered.

the FT3213, the ADF interface unit and the two

stud screws are an accessory of the DF.

has been eliminated.

The grid voltage is different

depending on whether the

image density is manually

selected or the auto image

density mode is used.

The Vl correction is applied at

set intervals.

The optics thermistor is not

equipped. The optics cooling

fan operates during the copy

cycle.

1. Same as the FT3013/3213.

2. When the number of toner

end condition reaches 11.

The coversion for the

exposure lamp and dc power

supply board is required.

The ADF interface unit and the

two stud screws are installed

on the FT3313.

accessed by the sales

representatives.

2

Page 5

No. ITEM FT3013/FT3213 FT3113/FT3313

Test Points

24 Test Points Some test points on the main control board

have been eliminated.

Replacement and Adjustment

25 Transfer Corona Current

Adjustment

26 Fusing Unit Removal the fusing unit removal procedure has been

The adjustment standard is

DC -34.0 ± 0.5 µA

modified to achieve faster servicing.

The adjustment standard is

DC -20.0 ± 0.5 µA

3

Page 6

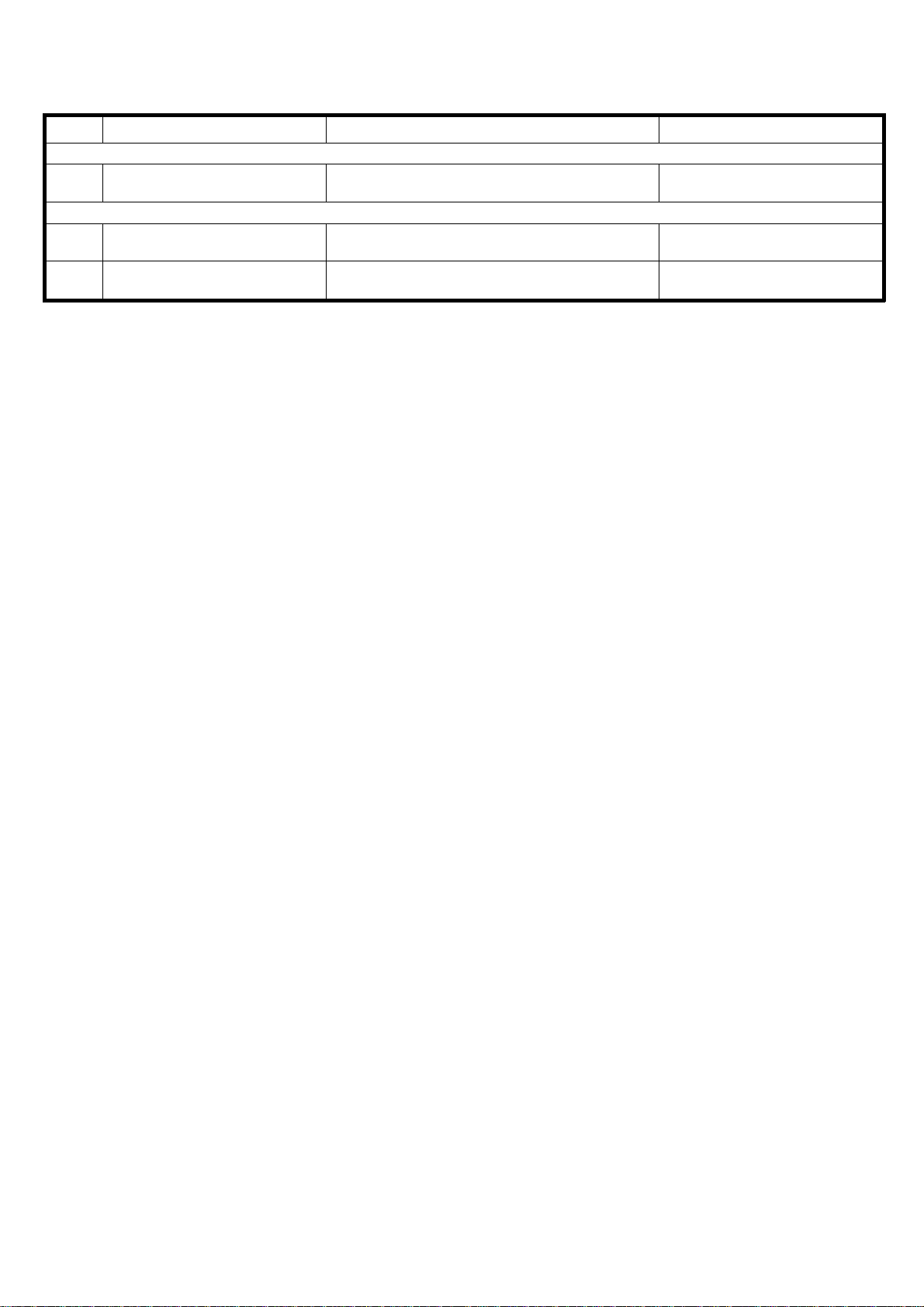

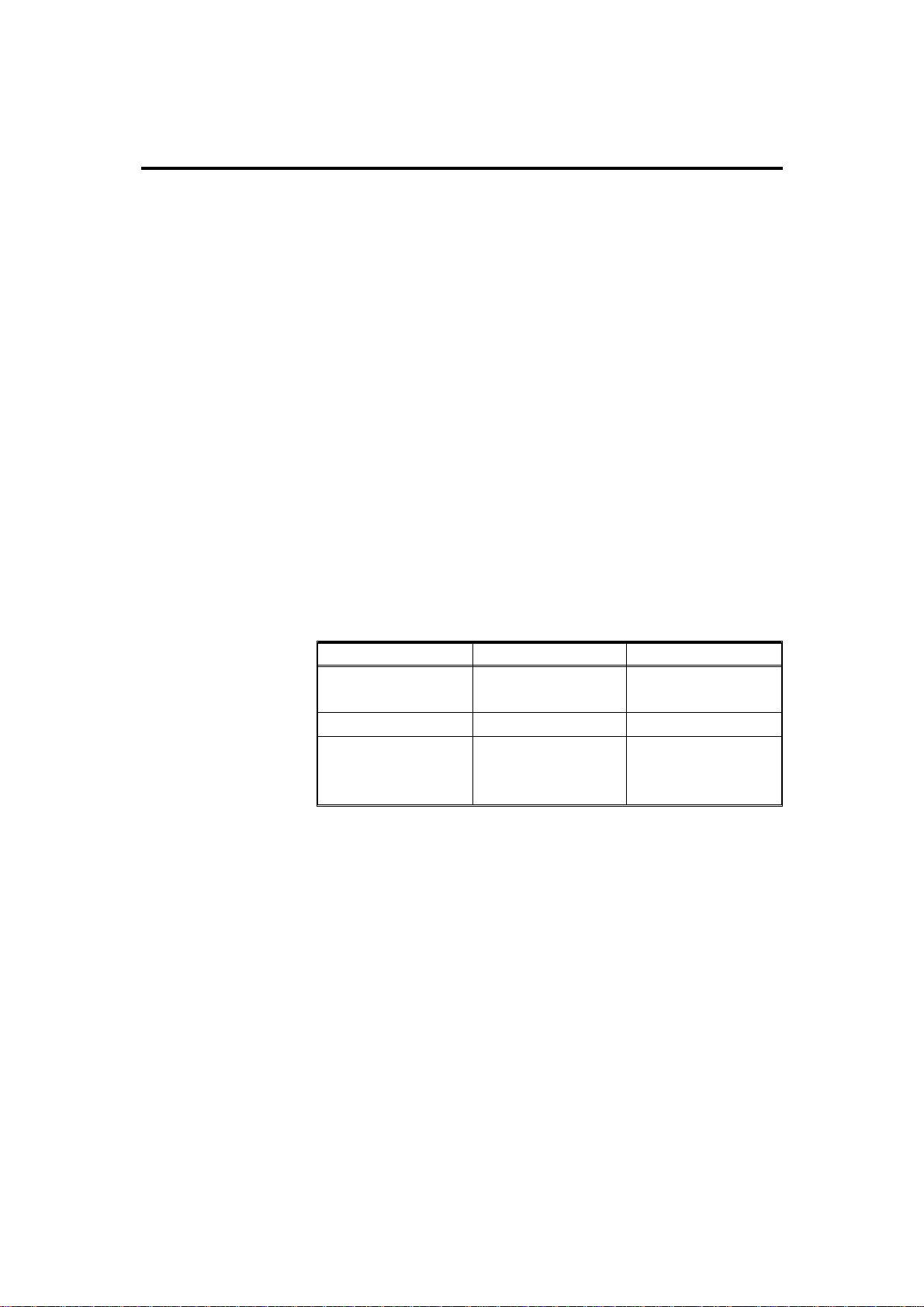

7. MAJOR UNIQUE PARTS FOR THE FT3013/FT3213

(Compared with the FT3113/FT3313)

PM Parts

Parts Number Description Remarks

AD002044

Electrical Parts

Parts Number Description Remarks

A1515100

A1525100

AZ220019

A1525660

AZ320075

AZ320076

A1515276

AX640056

AX640057

A1525610

AW100028

A1525120

A1525241

AW100033

A1535211

A1535213

AW020075

AX020078

AX520023

AG010049

AG010051

Cleaning Blade

Cleaning Brush eliminated

Paper Feed Roller eliminated

Torque Roller eliminated

Main Board for FT3013

Main Board for FT3212

DC Power Supply Board - 115V

AC Drive Board - 115V

Power Pack - CC/G/B

Power Pack - T/D

Erase Lamp for FT3013

Optics Cooling Fan Motor for FT3213

Exhaust Blower Motor

Quenching Lamp - 115V

Fusing Thermistor

Optics Control Board (Auto ID Sensor)

ID Sensor Board

Optics Thermistor

4th/5th Mirror Drive Motor

Lens Drive Motor

Photointerrupter

Main Motor - 115V

Exposure Lamp - 97V/220W

Operation Panel Assembly for FT3013

Operation Panel Assembly for FT3213

Consumables

The toner used by the FT3013/3213 is different from the FT3113/FT3313.

4

Page 7

SECTION 1

OVERALL MACHINE

INFORMATION

Page 8

1. SPECIFICATIONS

Configuration: Desk top

Copy Process: Dry electrostatic transfer system

Original Type: Sheet/Book

Original Alignment: Left center

Original Size: Maximum: A3/11" x 17" (lengthwise) -- FT3213

copier

B4/10" x 14" (lengthwise) -- FT3013

copier

Copy Paper Size: Maximum: B4/10" x 14" (lengthwise)

Minimum:

Paper Tray: A5/51/2" x 81/2" (lengthwise)

Bypass Feed: A6/51/2" x 81/2" (lengthwise)

Copy Paper Weight: Paper tray feed -- 64 to 90 g/m2 (17 to 24 lb)

Bypass feed -- 52 to 105 g/m2 (14 to 28 lb)

Reproduction Ratios: 2 Enlargement and 3 Reduction (FT3213 copier

only)

A4 Version Letter Version

Enlargement

Full size 100% 100%

Reduction

Zoom: From 61% to 141% in 1% steps

(FT3213 copier only)

Copying Speed: 13 copies/minute (A4/81/2" x 11" lengthwise)

10 copies/minute (B4/81/2" x 14")

Warm-Up Time: 30 seconds (at 20°C/68°F)

First Copy Time: 9 seconds (A4/81/2" x 11" lengthwise)

Copy Number Input: Number keys, 1 to 99

Manual Image Density: 7 steps

Toner Type: Type 320

141%

122%

93%

82%

71%

129%

121%

93%

74%

65%

Developer Type: Type 310

FT3013/3213 1-1 STM

Page 9

Automatic Reset:

1 minute standard setting; can also be set to 3

minutes or no automatic reset.

Energy Saver Function: Automatic

Paper Capacity: Paper tray -- 250 sheets

Bypass feed table -- 1 sheet

Toner Replenishment: Cartridge exchange (320 g/cartridge)

Copy Tray Capacity: 100 sheets (B4/10" x 14" or smaller)

Power Source: 110V/ 60Hz/ 15A (for Taiwan)

115V/ 60Hz/ 15A (for North America)

220V -- 240V/ 50Hz/ 8A (for Europe)

220V/ 60Hz/ 8A (for Middle East)

220V/ 50Hz/ 8A (for Asia)

(Refer to the serial number plate (rating plate) to

determine the power source required by the

machine.)

Power Consumption:

Copier Only With DF*

Maximum 1.4 kVA 1.5 kVA

Warm-up 620 VA (average) 640 VA (average)

Copy cycle 810 VA (average) 860 VA (average)

Ready 160 VA (average) 180 VA (average)

Noise Emission:

Copier Only With DF*

Maximum 58 db 60 db

Copy cycle Less than 55 db Less than 55 db

Ready Less than 39 db Less than 39 db

Dimensions:

Width Depth Height

Copier with platen cover and

copy tray

Copier with document feeder

and copy tray

713 mm (28.1") 592 mm (23.3") 400 mm (15.7")

713 mm (28.1") 592 mm (23.3") 463 mm (18.2")

*NOTE: The document feeder can be installed only on the FT3213 copier.

STM 1-2 FT3013/3213

Page 10

Weight: Copier only: 43 kg (94.8 lb)

With DF: 50 kg (110.2 lb)

Optional Equipment:

(Sales items)

Optional Equipment:

(Service items)

Document feeder (FT3213 copier only)

Key counter

Drum anti-condensation heater

Optics anti-condensation heater

Pre-transfer lamp

Optics cooling fan (for FT3013 copier only)

• Specifications are subject to change without notice.

Model Designations: A151 = FT3013

A152 = FT3213

FT3013/3213 1-3 STM

Page 11

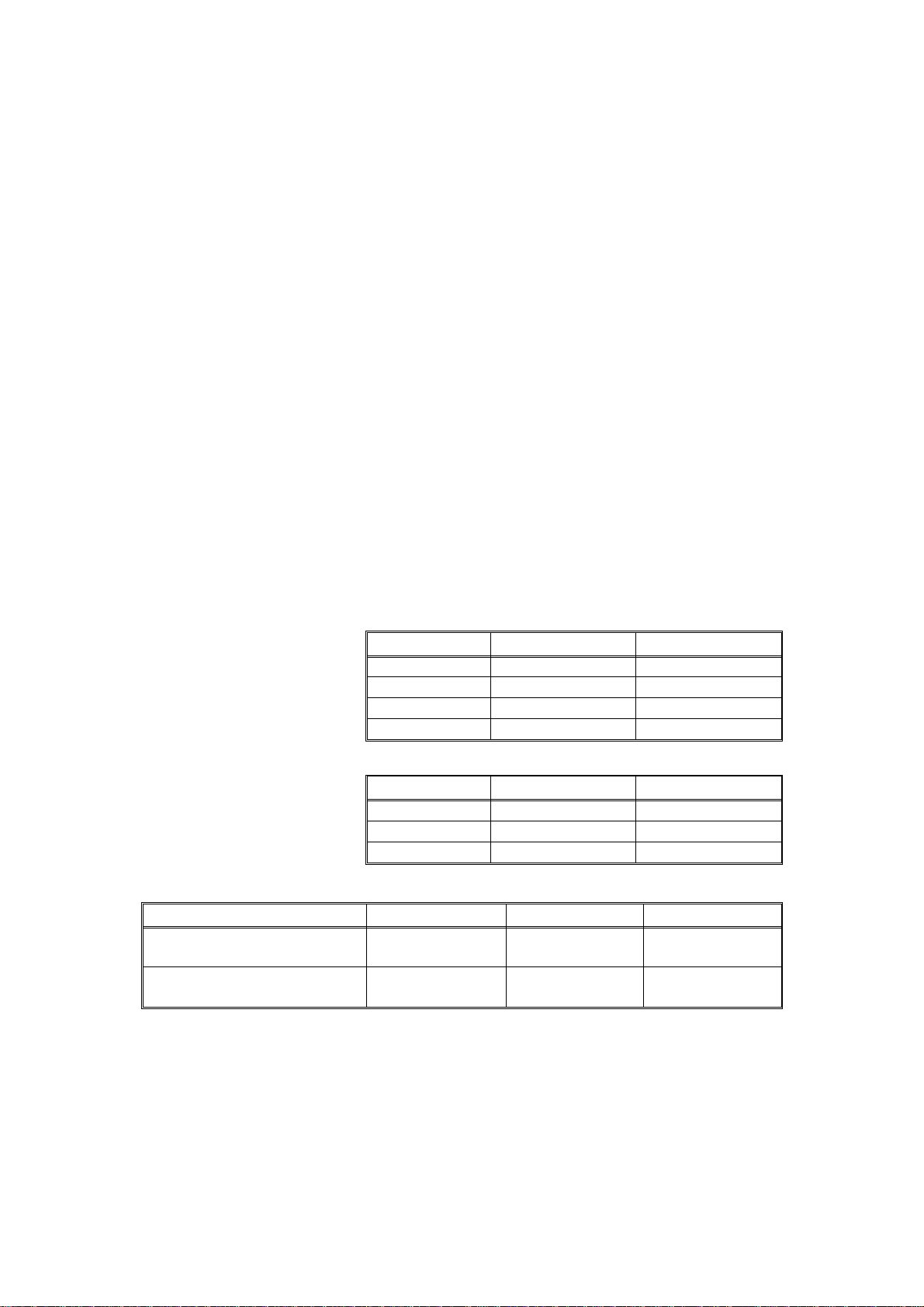

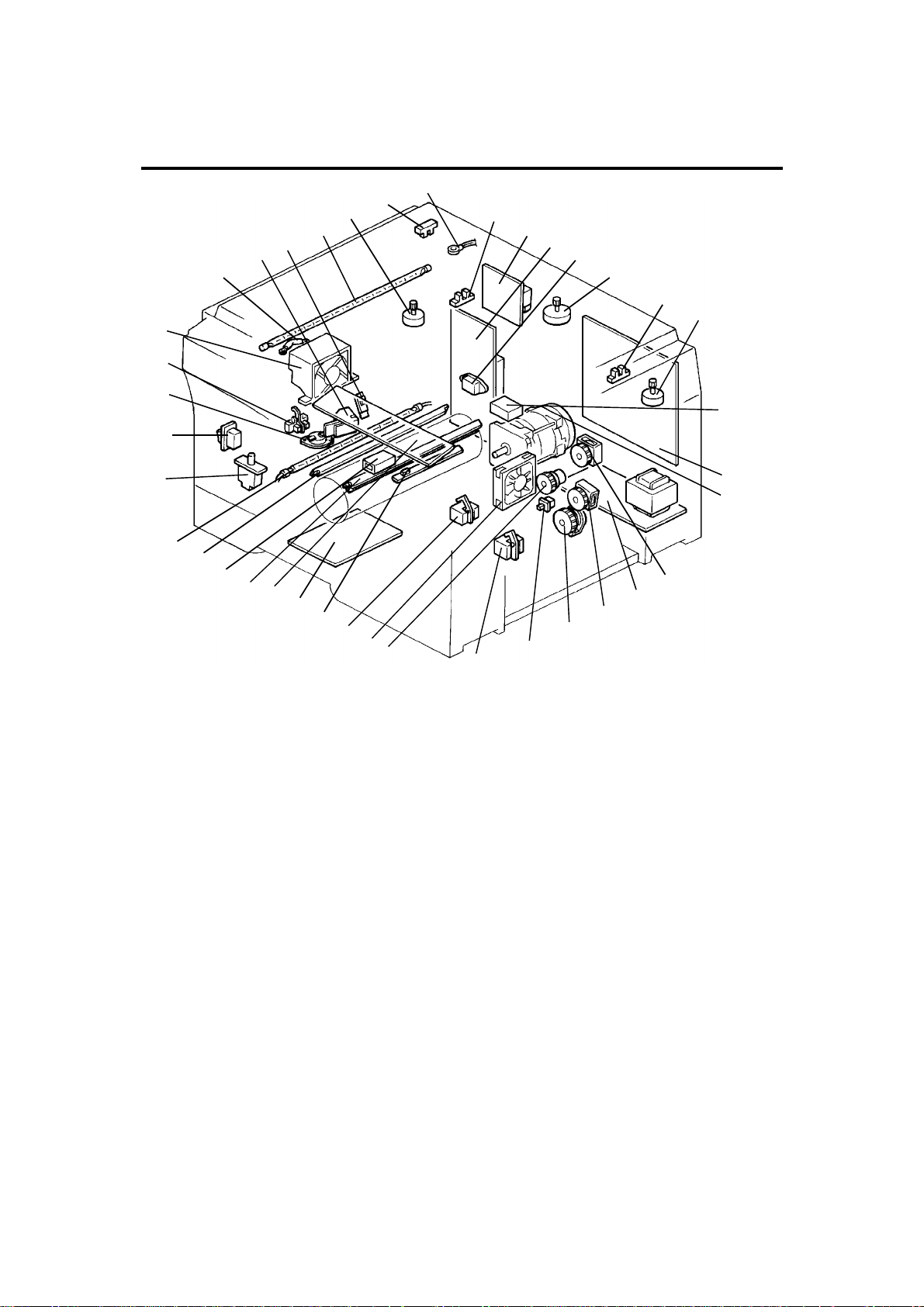

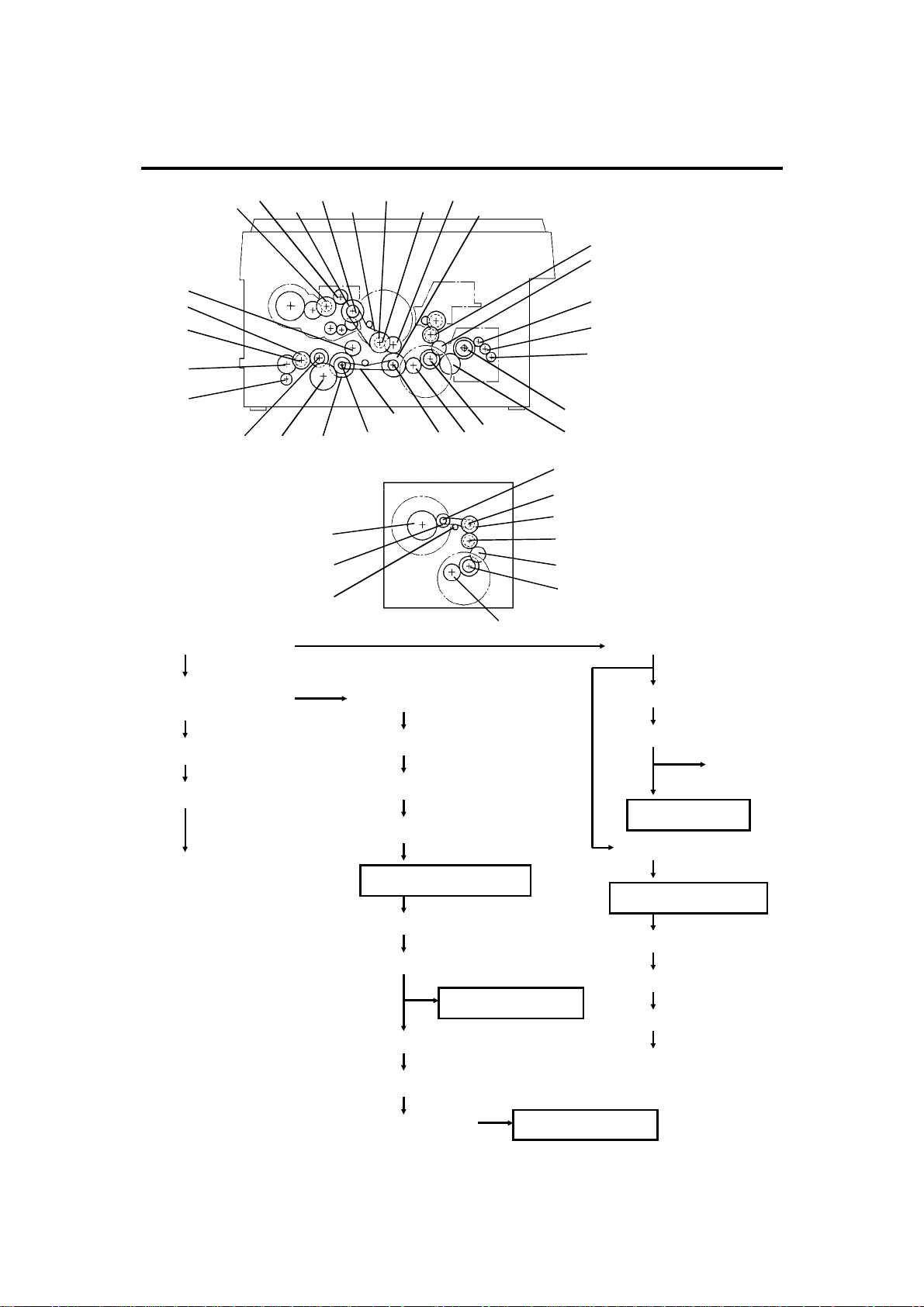

2. MECHANICAL COMPONENT LAYOUT

11

10

9

14

15

13

16

17

18

19

21 22 23

20

24 25

26

27

28

29

12

30

31

32

33

8

7

6

45

3

2

1

1. Semicircular Feed Rollers

2. Paper Tray

3. Registration Rollers

4. Transfer and Separation

Corona Unit

5. Pick-off Pawl

6. Cleaning Unit

7. Pressure Roller

8. Fusing Unit

9. Hot Roller

10. Exit Rollers

11. Copy Tray

12. Hot Roller Strippers

13. Exhaust Blower Motor

14. 3rd Mirror

15. 2nd Mirror

16. 1st Mirror

17. Ozone Filter

18. Used Toner Tank

19. Cleaning Blade

20. Quenching Lamp

21. Charge Corona Unit

22. Lens

23. 6th Mirror

24. Erase Lamp

25. Drum

26. 4th Mirror

27. 5th Mirror

28. Optics Cooling Fan Motor

(FT3213 Copier only)

29. Toner Supply Unit

30. Development Unit

31. 2nd Relay Rollers

32. By-pass Feed Table

33. 1st Relay Rollers

STM 1-4 FT3013/3213

Page 12

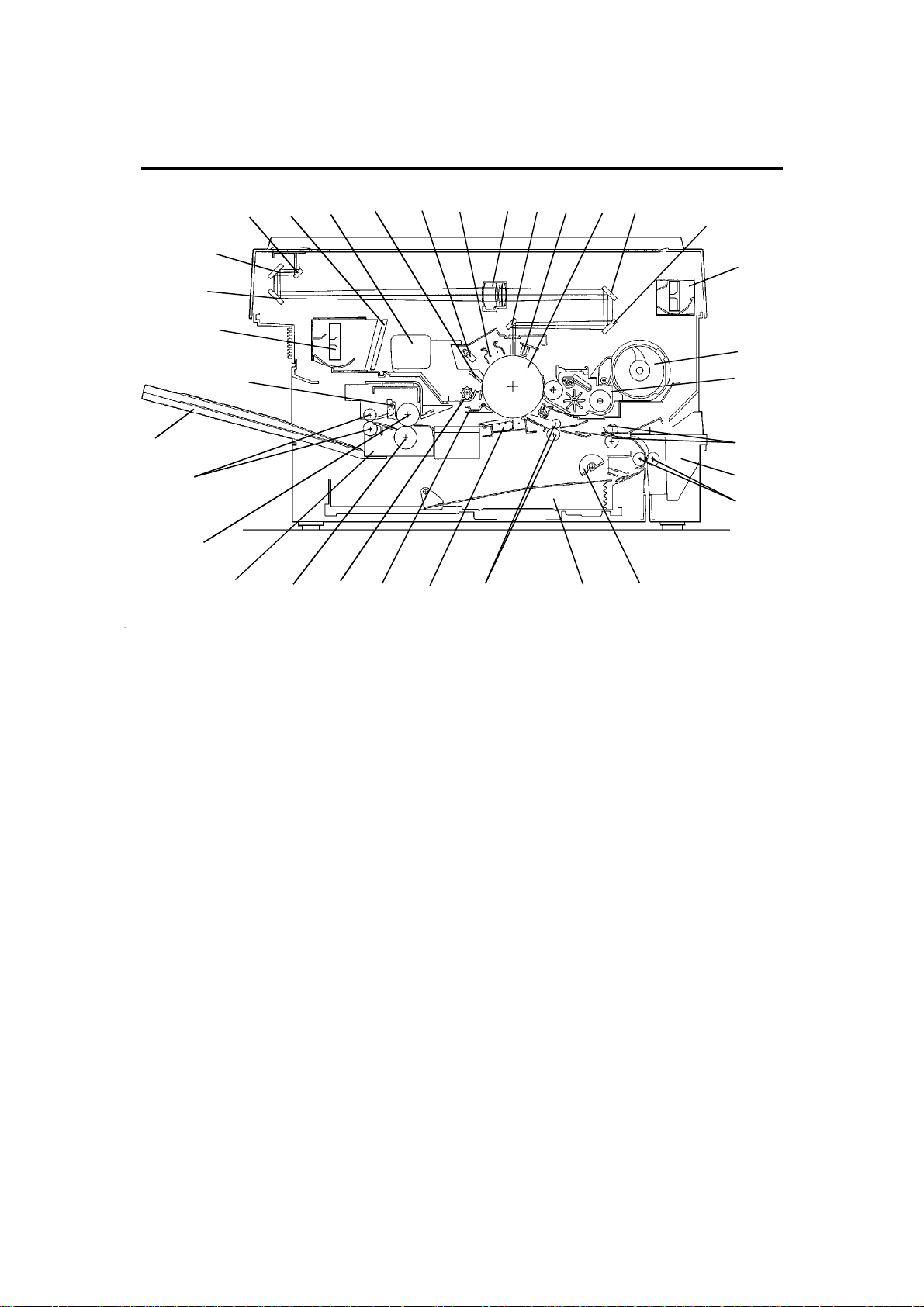

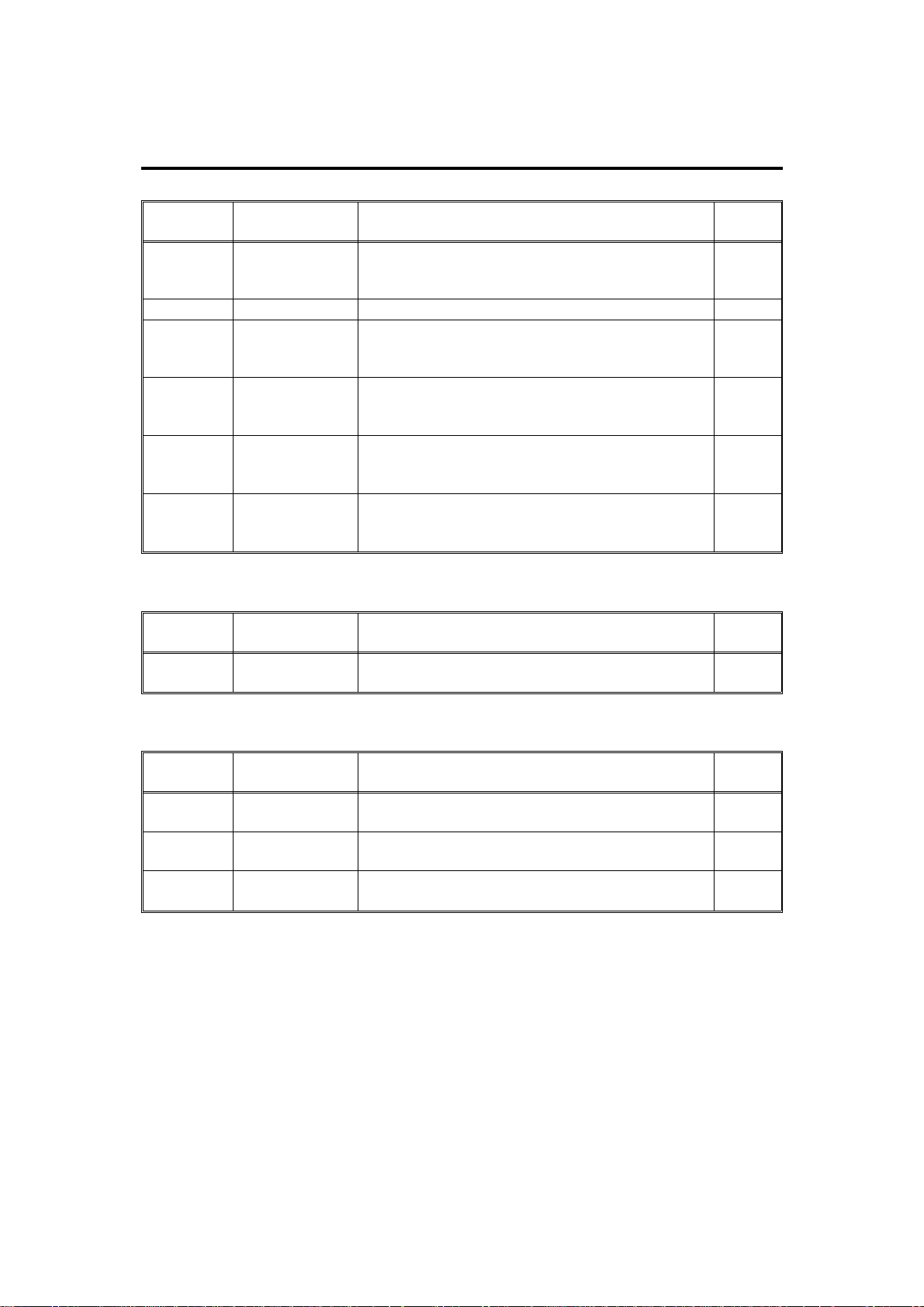

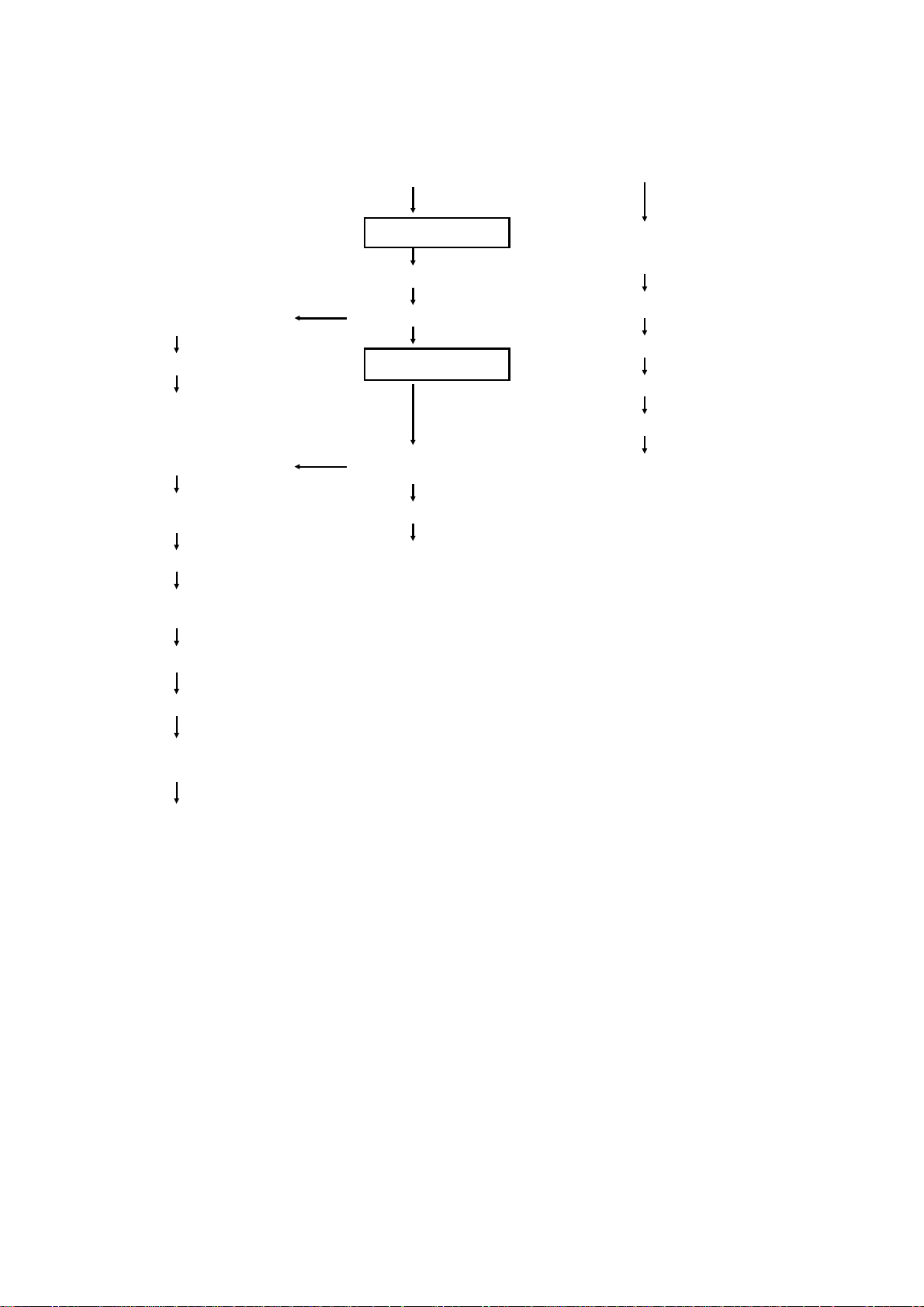

3. ELECTRICAL COMPONENT LAYOUT

17

16

15

13

14

12

11

18

10

9

19

24

23

22

21

20

25

26

27

28

29

30

31

32

33

34

8

7

6

5

4

3

2

1

37

38

35

36

1. Paper Tray Switch

2. Relay Sensor

3. Registration Clutch

4. Optics Cooling Fan Motor

(FT3213 only)

5. Registration Sensor

6. Image Density Sensor

7. Power Pack-TC/SC

8. Operation Panel Board

9. Erase Lamp

10. Total Counter

11. Quenching Lamp

12. Fusing Lamp

13. Front Cover Safety Switch

14. Main Switch

15. Fusing Thermoswitch

16. Exit Sensor

17. Exhaust Blower Motor

18. Optics Thermofuse

19. Auto Image Density Sensor

20. Fusing Thermistor

21. Exposure Lamp

22. Lens Motor

(FT3213 copier only)

23. Scanner Home Position

Sensor

24. Optics Thermistor

25. Lens Home Position

Sensor

(FT3213 copier only)

26. Power Pack-CC/Grid/Bias

27. AC Drive Board

28. Fusing Triac (115 V only)

29. Scanner Motor

30. 4th/5th Mirror Home

Position Sensor

(FT3213 copier only)

31. 4th/5th Mirror Motor

(FT3213 copier only)

32. Main Motor Capacitor

33. Main Board

34. Main Motor

35. Toner Supply Clutch

36. DC Power Supply Board

37. Relay Roller Clutch

38. Paper Feed Clutch

FT3013/3213 1-5 STM

Page 13

Rev. 1/95

4. ELECTRICAL COMPONENT DESCRIPTIONS

Motors

SYMBOL NAME FUNCTION

Drives all the main unit components except for the

M1 Main Motor

M2 Scanner Motor Drives the scanners (1st and 2nd). (dc stepper) 29

M3 Lens Motor

M4

M5

M6

4th/5th Mirror

Motor

Optics Cooling

Fan Motor

Exhaust Blower

Motor

optics unit and fans. (115/220--240 Vac [ac

synchronous])

Positions the lens according to the selected

magnification. (dc stepper)

… FT3213 copier only

Positions the 4th/5th mirrors according to the

selected magnification. (dc stepper)

… FT3213 copier only

Prevents a build up of hot air in the optics cavity.

(24 Vdc)

… FT3213 copier only

Removes heat from around the fusing unit and

moves the ozone built up around the charge

section to the ozone filter. (24 Vdc)

INDEX

NO.

34

22

31

4

17

Magnetic Clutch

SYMBOL NAME FUNCTION

MC1

Registration

Clutch

Drives the registration rollers. 3

Magnetic Spring Clutches

SYMBOL NAME FUNCTION

MSC1

MSC2

MSC3

Toner Supply

Clutch

Relay Roller

Clutch

Paper Feed

Clutch

Drives the toner supply roller. 35

Drives the 1st and 2nd relay rollers. 37

Starts paper feed. 38

INDEX

NO.

INDEX

NO.

STM 1-6 FT3013/3213

Page 14

Switches

SYMBOL NAME FUNCTION

SW1 Main Switch Supplies power to the copier. 14

SW2

SW3

Front Cover

Safety Switch

Paper Tray

Switch

Cuts the ac power line, when the front cover is

open.

Detects when the paper tray is set. 1

Sensors

SYMBOL NAME FUNCTION

S1

S2

S3

S4

S5 Exit Sensor Detects misfeeds. 16

S6 Relay Sensor

S7

S8

Scanner Home

Position Sensor

Lens Home

Position Sensor

4th/5th Mirror

Home Position

Sensor

Registration

Sensor

Image Density

(ID) Sensor

Auto Image

Density Sensor

(ADS)

Informs the CPU when the 1st scanner is at the

home position.

Informs the CPU when the lens is at the home

position (full size position).

… FT3213 copier only

Informs the CPU when 4th/5th mirrors assembly is

at the home position (full size position).

… FT3213 copier only

1) Detects misfeeds.

2) Controls the relay roller clutch stop timing.

1) Detects when copy paper is set on the

by-pass feed table.

2) Detects misfeeds.

Detects the density of the image on the drum to

control the toner density.

Senses the background density of the original. 19

INDEX

NO.

13

INDEX

NO.

23

25

30

5

2

6

Printed Circuit Boards

SYMBOL NAME FUNCTION

PCB1 Main Board

PCB2 AC Drive Board

PCB3

PCB4

FT3013/3213 1-7 STM

DC Power

Supply Board

Operation Panel

Board

Controls all copier functions both directly and

through the other PCBs.

Drives the main motor, exposure lamp, fusing

lamp, and quenching lamp.

Converts the wall outlet ac power input to +5 volts,

+24 volts, and a zero cross signal.

Informs the CPU of the selected modes and

displays the copier status and condition on the

panel.

INDEX

NO.

33

27

36

8

Page 15

Lamps

SYMBOL NAME FUNCTION

L1 Exposure Lamp

L2 Fusing Lamp Provides heat to the hot roller. 12

L3 Quenching Lamp

L4 Erase Lamp

Applies high intensity light to the original for

exposure.

Neutralizes any charge remaining on the drum

surface after cleaning.

Discharge the drum outside of the image area.

Provides leading/trailing edge erase and side

erase.

Power Packs

SYMBOL NAME FUNCTION

P1

P2

Power Pack

--CC/Grid/Bias

Power Pack

--TC/SC

Provides high voltage for the charge corona, grid,

and development roller.

Provides high voltage for the transfer and

separation corona.

Counter

SYMBOL NAME FUNCTION

CO1 Total Counter Keeps track of the total number of copies made. 10

INDEX

NO.

21

11

9

INDEX

NO.

26

7

INDEX

NO.

Others

SYMBOL NAME FUNCTION

TH1

TH2

TS

TF

C

TR Fusing Triac

Fusing

Thermistor

Optics

Thermistor

Fusing

Thermoswitch

Optics

Thermofuse

Main Motor

Capacitor

Monitors the fusing temperature. 20

Monitors the optics temperature. 24

Provides back-up overheat protection in the fusing

unit.

Provides back-up overheat protection around the

exposure lamp.

Start capacitor. 32

Switches the fusing lamp on and off. (115 V only)

Note: In the 220V-230V/240V version, the triac

is built-in the ac drive board

INDEX

NO.

15

18

28

STM 1-8 FT3013/3213

Page 16

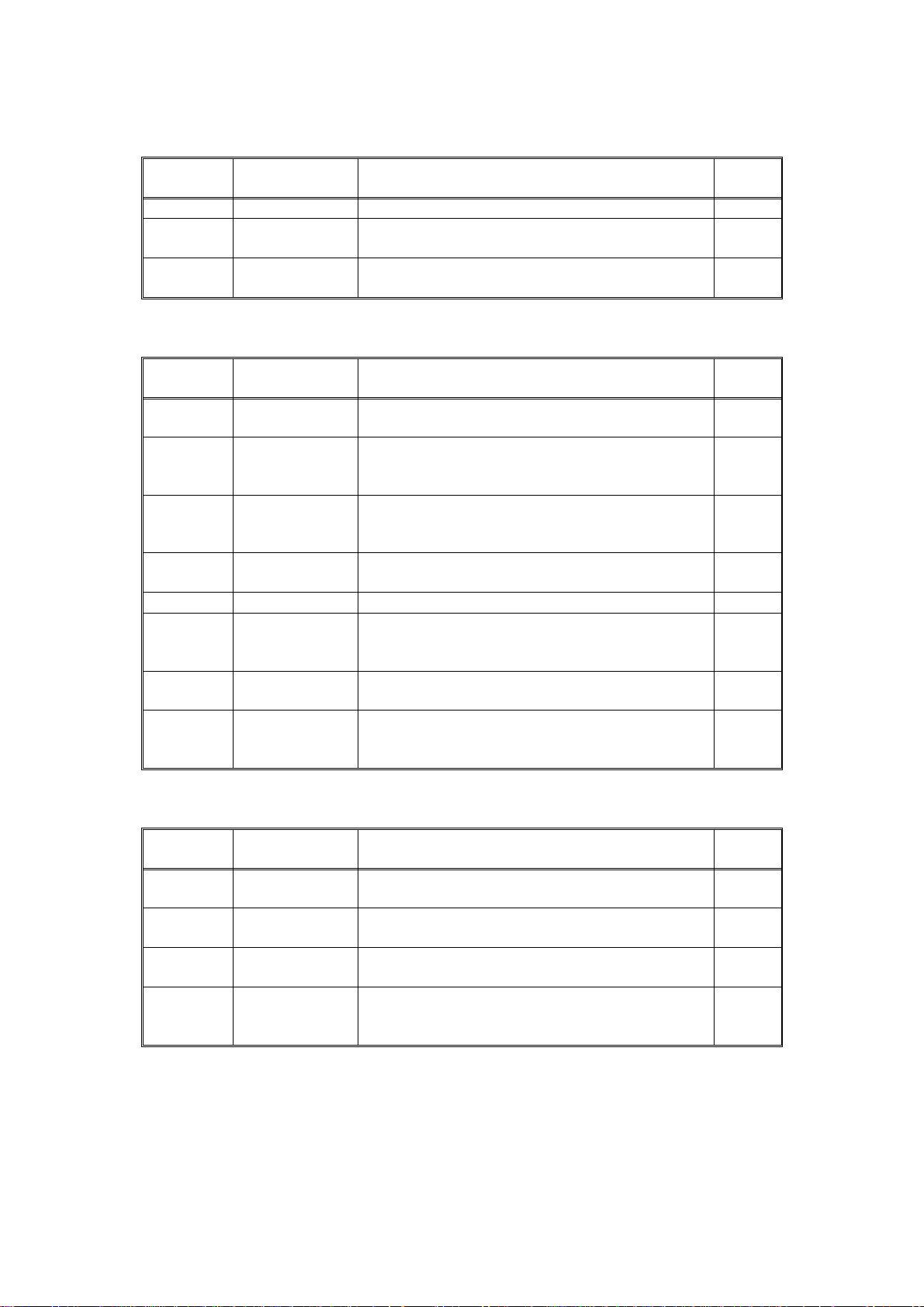

5. DRIVE LAYOUT

G14

G13

G15

G16

G17

G18

G19

G1: Main Motor Gear

BP6 BP5

G22 BP1G21G20

G26

G25

TB2

TB3

TB1

BP2

G12 G11

G10

G23

G2G1

G9

G8

G7

G6

G5

G4

G3

BP4

BP3

G24

G9

G8

G2

G1

G2: Relay Gear

G23: Timing Belt Drive

Gear

BP1: Timing Belt Pulley

TB1: Timing Belt

A

G10 Relay gear

G11: Timing Belt Drive Gear

BP5: Timing Belt Pulley

TB3: Timing Belt

Development Section

BP6: Timing Belt Pulley

G12: Development Gear

Development Unit

G13: Relay Gear

G14: Toner Supply CL Gear

Toner Supply CL

Toner Supply Unit

G8: Relay Gear

G9: Relay Gear

B

Cleaning Unit

G3: Fusing Drive Gear

Fusing and Exit Unit

G4: Hot Roller Gear

G7: Relay Gear

G6: Relay Gear

G5: Exit Roller Gear

FT3013/3213 1-9 STM

Page 17

A

B

G15: Registration CL

Gear

Registration CL

Registration Rollers

G20: Relay Gear

G17: Relay Roller CL

Gear

Relay Roller CL

G16: 2nd Relay Roller

Gear

2nd Relay Rollers

Paper Feed Section

BP2: Timing Belt Pulley

G22: Relay Gear

Paper Feed Section

G21: Paper Feed CL

Gear

Paper Feed CL

Feed Rollers

G24: Timing Belt Drive

Gear

BP3: Timing Belt Pulley

TB2: Timing Belt

BP4: Timing Belt Pulley

G25: Relay Gear

G26: Drum Drive Gear

G18: Relay Gear

G19: 1st Relay Roller

Gear

1st Relay Rollers

STM 1-10 FT3013/3213

Page 18

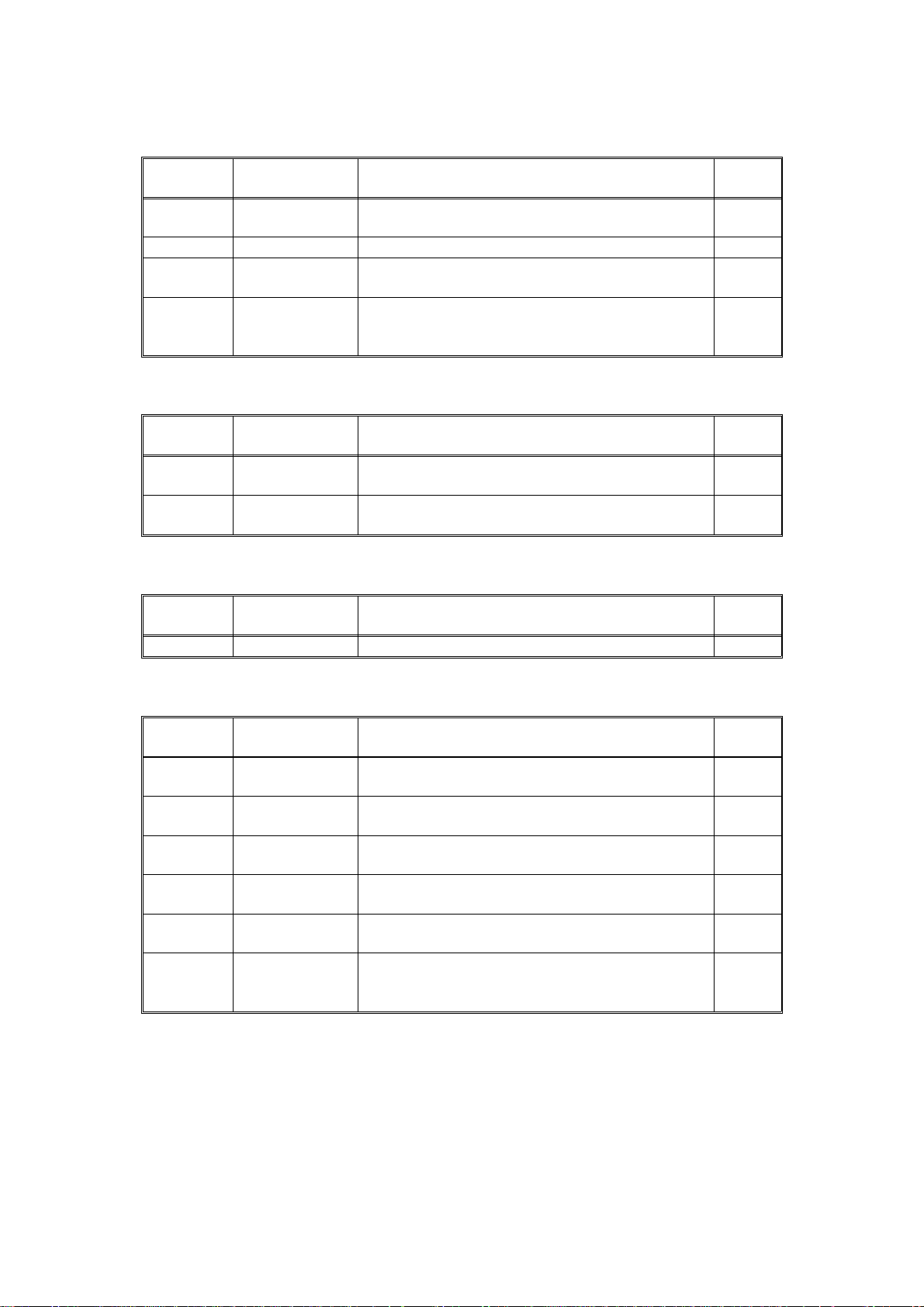

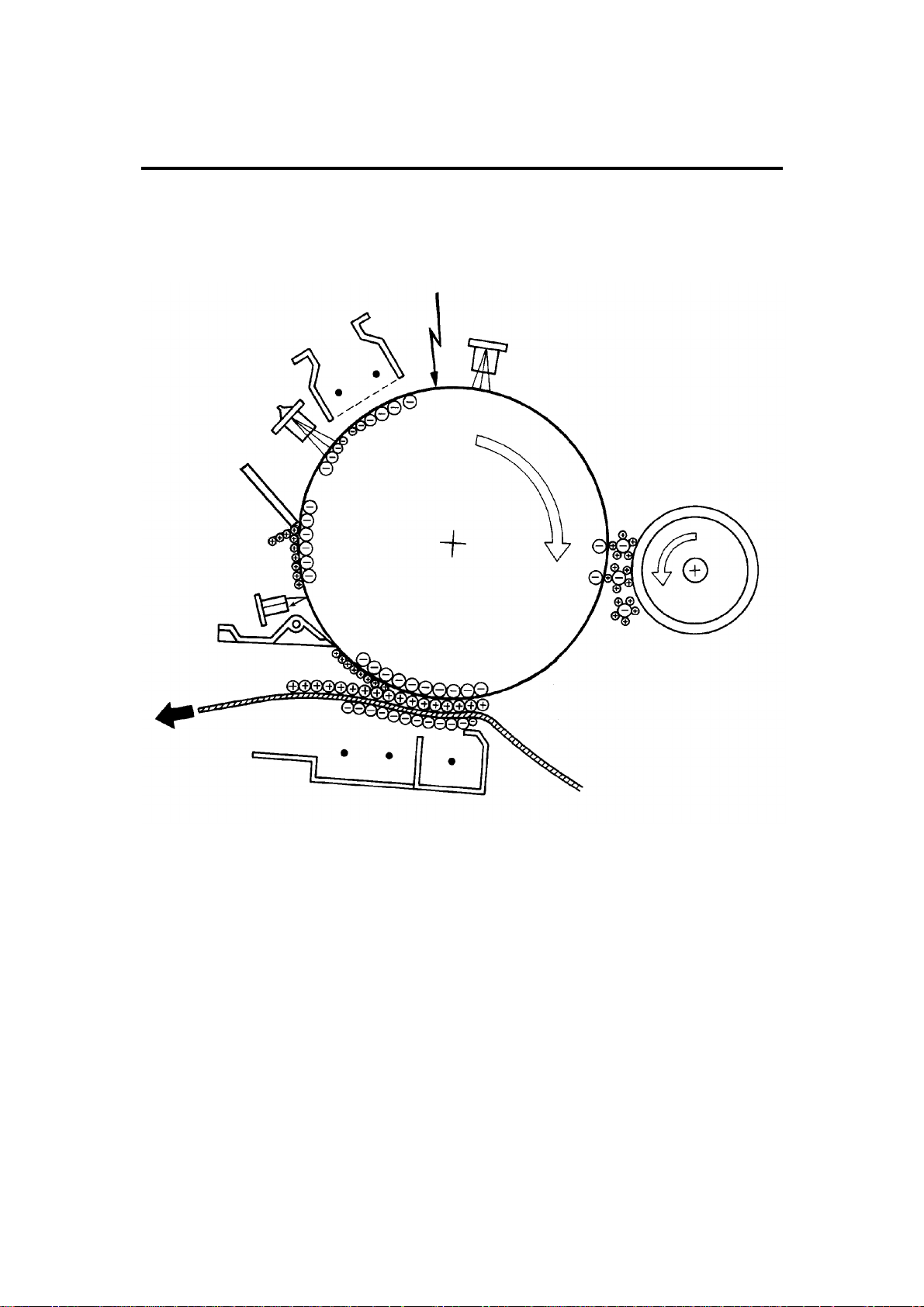

6. COPY PROCESSES AROUND THE DRUM

2. EXPOSURE

1. DRUM CHARGE

3. ERASE

8. QUENCHING

4. DEVELOPMENT

7. CLEANING

6. PAPER

SEPARATION

FT3013/3213 1-11 STM

5. IMAGE TRANSFER

Page 19

1. DRUM CHARGE

In the dark, the charge corona unit gives a uniform negative charge to the organic

photoconductive (OPC) drum. The charge remains on the surface of the drum because the

OPC drum has a high electrical resistance in the dark.

2. EXPOSURE

An image of the original is reflected to the OPC drum surface via the optics assembly. The

charge on the drum surface is dissipated in direct proportion to the intensity of the reflected

light, thus producing an electrical latent image on the drum surface.

3. ERASE

The erase lamp illuminates the areas of the charged drum surface that will not be used for

the copy image. The resistance of the drum in the illuminated areas drops and the charge on

those areas dissipates.

4. DEVELOPMENT

Positively charged toner is attracted to the negatively charged areas of the drum, thus

developing the latent image. (The positive triboelectric charge is caused by friction between

the carrier and toner particles.)

5. IMAGE TRANSFER

Paper is fed to the drum surface at the proper time so as to align the copy paper and the

developed image on the drum surface. Then, a strong negative charge is applied to the back

side of the copy paper, producing an electrical force which pulls the toner particles from the

drum surface to the copy paper. At the same time, the copy paper is electrically attracted to

the drum surface.

6. PAPER SEPARATION

A strong ac corona discharge is applied to the back side of the copy paper, reducing the

negative charge on the copy paper and breaking the electrical attraction between the paper

and the drum. Then, the stiffness of the copy paper causes it to separate from the drum

surface. The pick-off pawl help to separate the paper from the drum.

7. CLEANING

The cleaning blade removes any toner remaining on the drum.

8. QUENCHING

Light from the quenching lamp electrically neutralizes the surface of the drum.

STM 1-12 FT3013/3213

Page 20

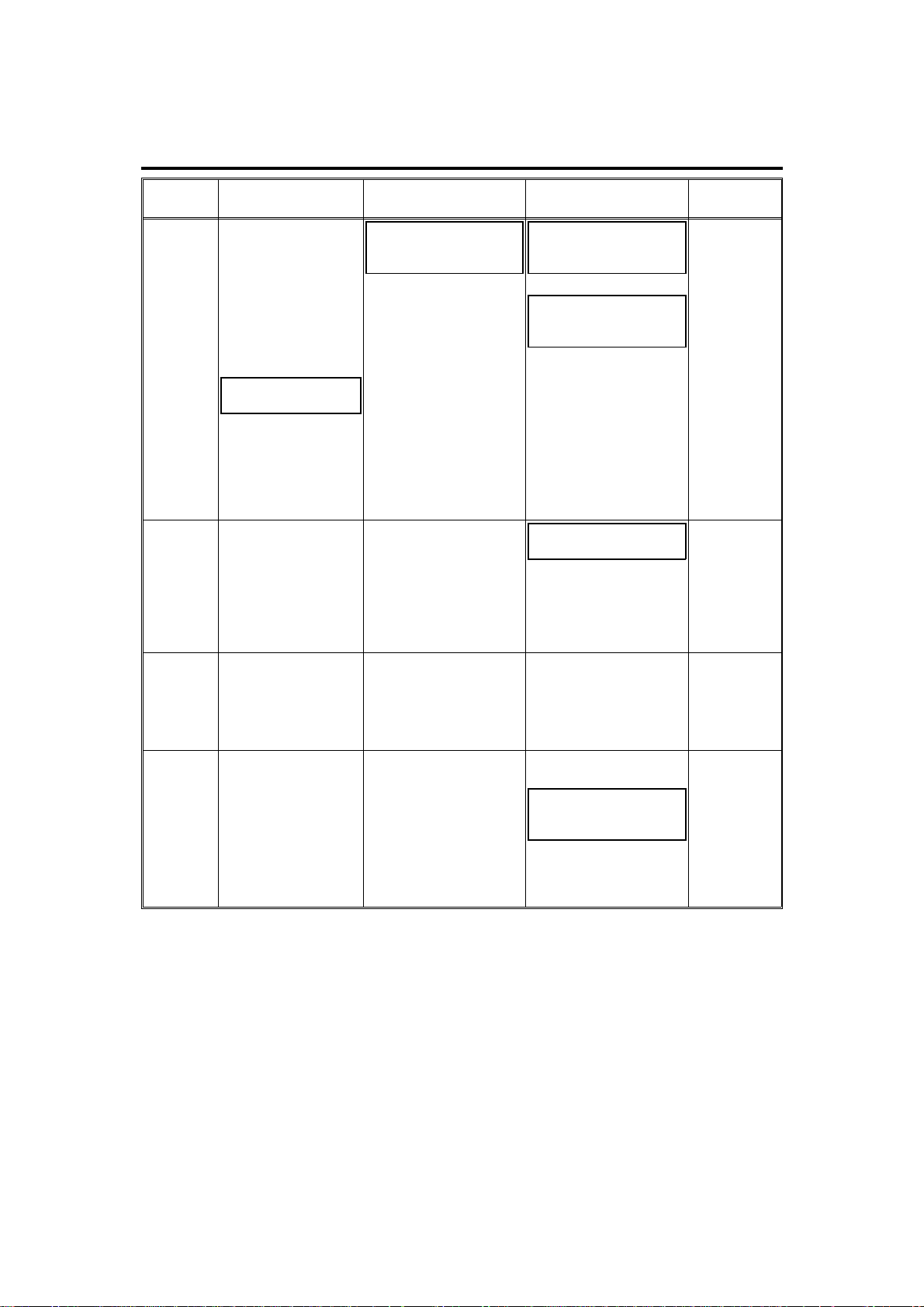

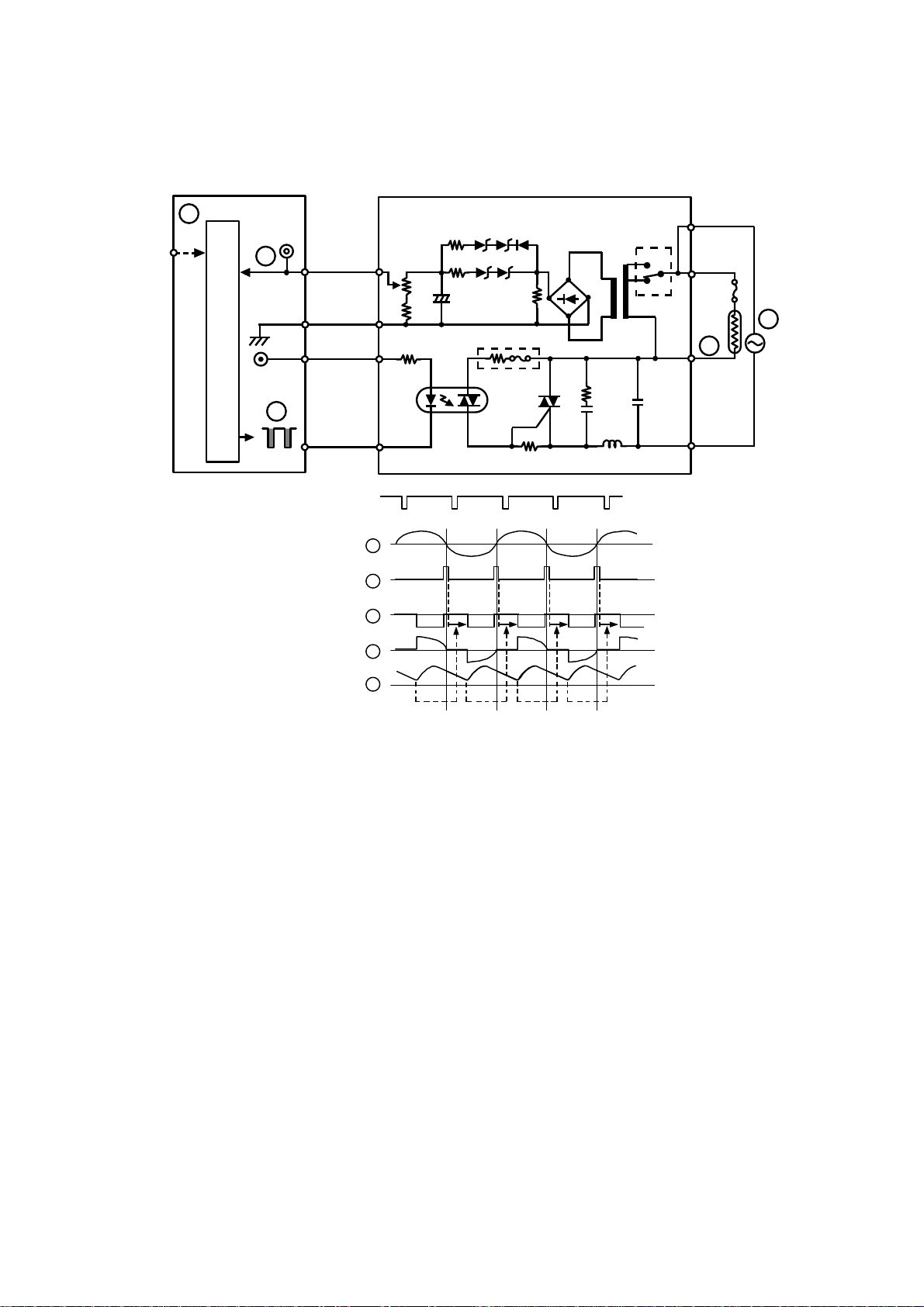

7. COPY PROCESS CONTROL

Image

Density

Control

Toner

Density

Detection

Residual

Voltage

(Vr)

Detection

Between

Copies

Grid Voltage

Standard image

density grid voltage

(--680 V)

+ + +

Drum residual voltage

(Vr) correction factor

(SP67)

+

Auto image density

level factor (SP34)

Standard ID sensor

grid voltage

(--460 V)

+

Drum wear correction

factor (SP57)

Standard ID sensor

grid voltage

(--460 V)

+

Drum wear correction

factor (SP57)

0 Volts (Fixed) Exposure lamp turns off --160 Volts (Fixed)

Exposure Lamp

Voltage

Base exposure lamp

voltage (Manual or ADS

mode) (SP48)

VL correction factor

+

Reproduction ratio

correction factor

(FT3213 copier only)

Same as image density

control

Same as image density

control

Development Bias

Voltage

Base bias voltage factor

(Manual or ADS mode

[SP34])

Image bias voltage

adjustment factor

(SP37)

+

Drum residual voltage

(Vr) correction factor

Note:

Base bias voltage at

manual ID level 7 can be

adjusted by SP50

Depends on ID sensor

bias setting (SP33)

Note:

For initial 499 copies

bias voltage is increased

by --20 volts

0 Volts (Fixed) Full erase

+

Image bias voltage

adjustment factor

(SP37)

+

Drum residual voltage

(Vr) correction factor

Erase Lamp

Depends on

paper size

and

reproduction

ratio

ID sensor

pattern erase

(Vsg

detection:

Full erase)

(All LEDs ON)

Full erase

(All LEDs ON)

NOTE: The boxed items can be adjusted by SP mode.

FT3013/3213 1-13 STM

Page 21

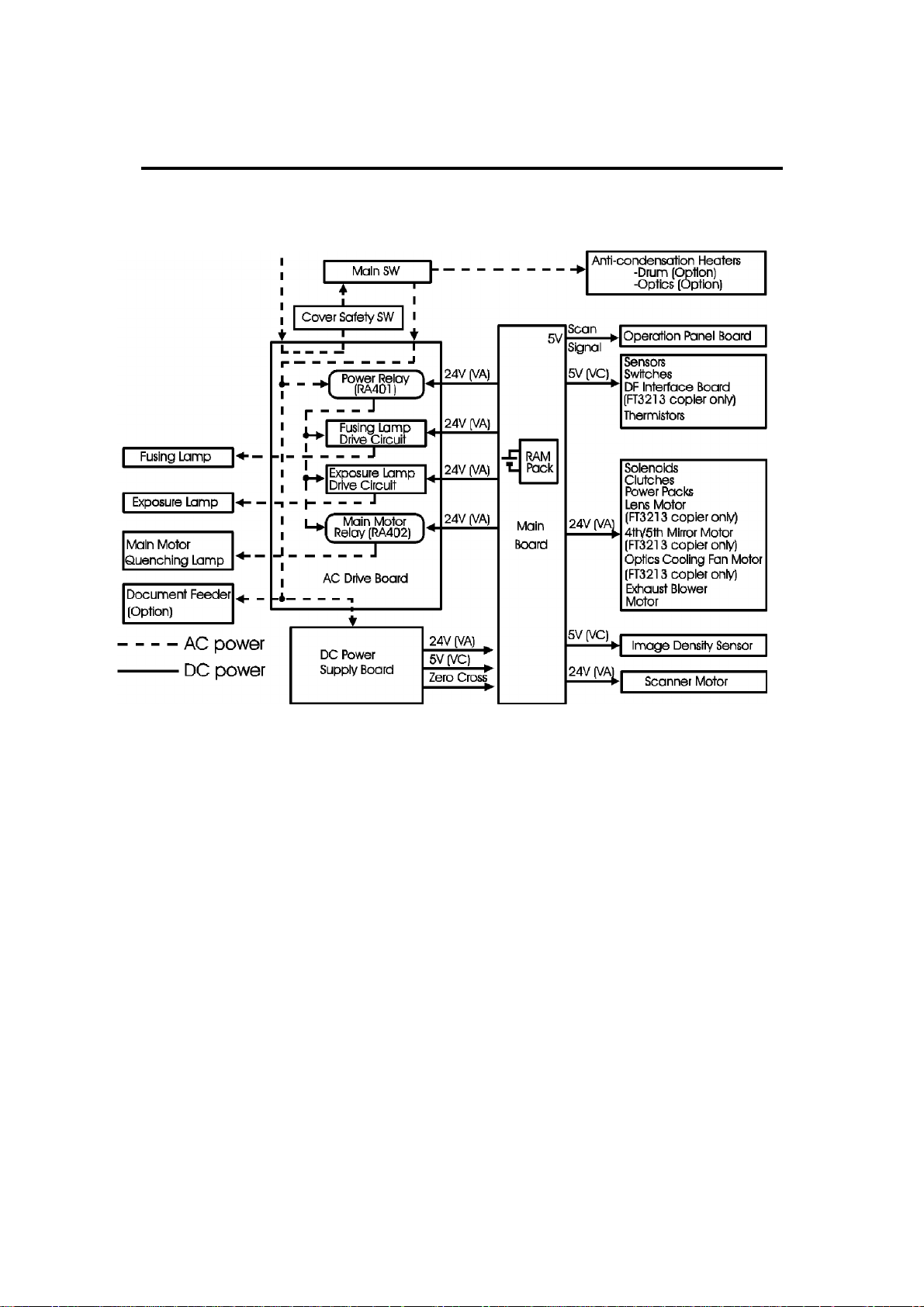

8. POWER DISTRIBUTION

AC Power (115V)

When this copier is plugged in and the main switch is turned off, ac power is

supplied via the ac drive board to the optional anti-condensation heaters.

When the front cover and/or the exit cover is open, the cover safety switch

completely cuts off power to all ac and dc components. The RAM pack has a

back up power supply (dc battery) for the service program mode data and

misfeed job recovery.

When the main switch is turned on, the ac power supply to the

anti-condensation heater is cut off and ac power is supplied to the ac drive

board. The dc power supply board receives wall outlet ac power through the

ac drive board.

The dc power supply board converts the wall outlet ac power input to +5

volts, +24 volts, and a zero cross signal, all of which are supplied to the main

board.

STM 1-14 FT3013/3213

Page 22

The main board supplies dc power to all copier dc components. All sensors,

switches, thermistors, and the DF interface board (option) operate on +5

volts. The operation panel operates on +5 volts supplied by the main board.

All other dc components including the power relay (RA401) and the main

motor relay (RA402) operate on +24 volts.

When the main board receives power, it activates the power relay (RA401)

which then supplies ac power to the fusing lamp drive circuit, and the

exposure lamp drive circuit on the ac drive board. The fusing lamp drive

circuit receives a trigger signal from the main board and the fusing lamp

lights. The exposure lamp does not turn on until the main board sends a

trigger pulse to the exposure lamp drive circuit.

When the Start key is pressed, the main board energizes the main motor

relay (RA402). Then, the main motor and the quenching lamp turn on.

When the main switch is turned off, power is cut off to the main board and to

RA401, and the optional drum and optics anti-condensation heaters are

turned on.

FT3013/3213 1-15 STM

Page 23

Page 24

SECTION 2

DETAILED SECTION

DESCRIPTIONS

Page 25

Page 26

1. DRUM

1.1 DRUM CHARACTERISTICS

An organic photoconductor (OPC) drum is used in this model.

The OPC drum has the characteristics of:

1. Being able to accept a high negative electrical charge in the dark. (The

electrical resistance of a photoconductor is high in the absence of light.)

2. Dissipating the electrical charge when exposed to light. (Exposure to light

greatly increases the conductivity of a photoconductor.)

3. Dissipating an amount of charge in direct proportion to the intensity of the

light. That is, where stronger light is directed to the photoconductor

surface, a smaller voltage remains on the drum.

4. Being less sensitive to changes in temperature (when compared to

selenium F type drums).

5. During the drum’s life, drum residual voltage gradually increases and the

photoconductive surface becomes worn.

Therefore, some compensation for these characteristics is required.

FT3013/3213 2-1 STM

Page 27

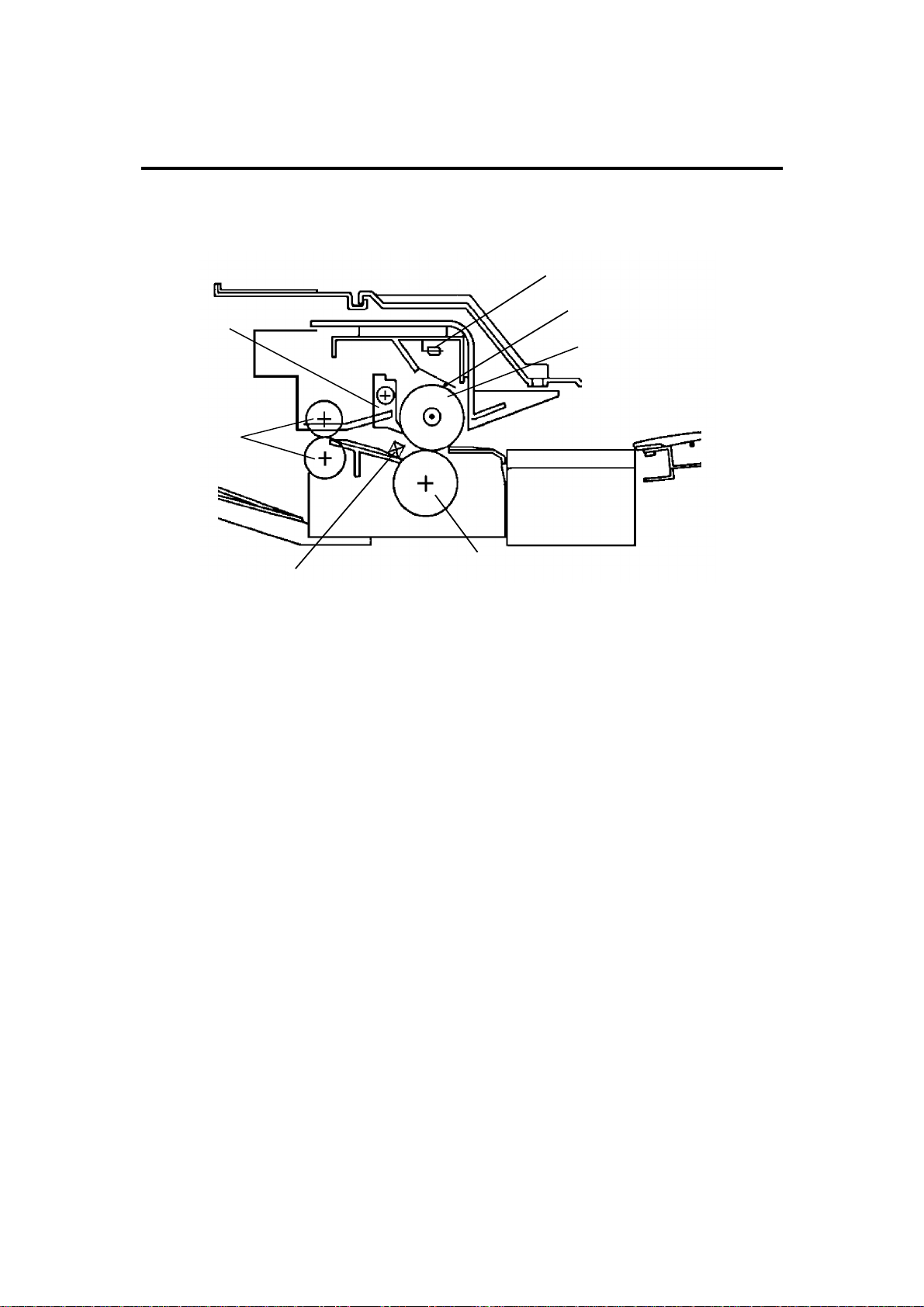

1.2 DRUM UNIT

[A]

[E]

[G]

[F]

[C]

[D]

[B]

[C]

The drum unit [A] consists of an OPC drum [B], ID sensor board [C] and a

pick-off pawl [D]. When the drum, the pick-off pawl, or the ID sensor is

replaced or cleaned, the drum unit must be removed from the copier.

Therefore, the drum has a coupling device which is connected to the drum

drive gear [E]. The ID sensor connector [F] is used for the ID sensor.

The main motor provides rotation directly to the drum through a series of

gears.

The pick-off pawl [D] is always in contact with the drum surface.

[D]

STM 2-2 FT3013/3213

Page 28

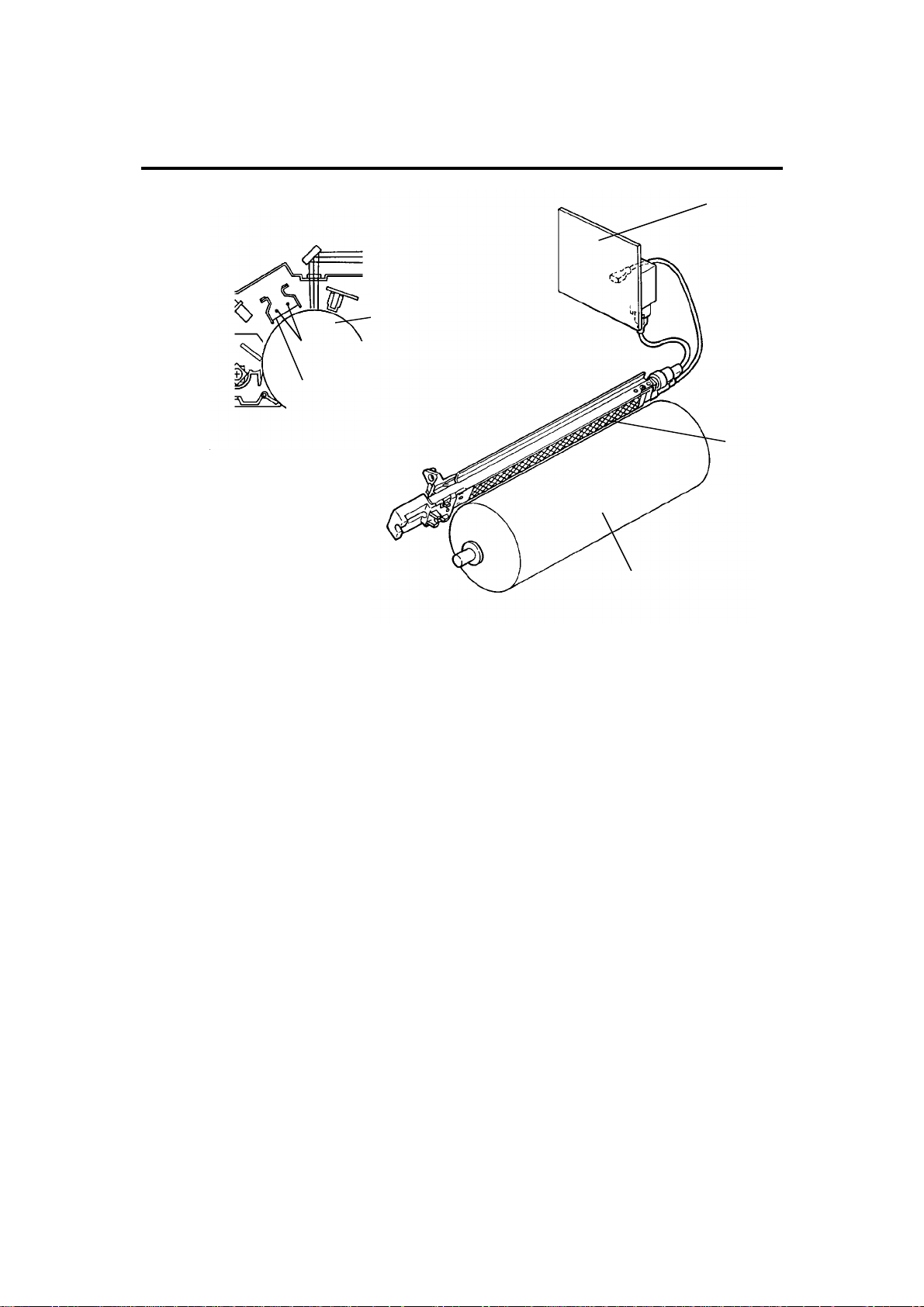

2. DRUM CHARGE

2.1 OVERVIEW

[A]

[B]

[D]

[A]

This copier uses a double wire scorotron and a highly sensitive OPC drum

[A]. The corona wires [B] generate a corona of negative ions when the

CC/Grid/Bias power pack [C] applies a high voltage. The CC/Grid/Bias power

pack also applies a negative high voltage to a stainless steel grid plate [D].

This insures that the drum coating receives a uniform negative charge as it

rotates past the corona unit.

[C]

[D]

The exhaust fan, located above the copy exit, causes a flow of air from the

upper area of the development unit through the charge corona unit. This

prevents an uneven build-up of negative ions that can cause uneven image

density. The exhaust fan runs at half speed when in the stand-by condition

and at full speed while copying.

The exhaust fan has an ozone filter (active carbon) which adsorbs ozone (O3)

generated by the charge corona. The ozone filter decreases in efficiency over

time as it adsorbs ozone. The ozone filter should be replaced at every 80K

copies.

The flow of air around the charge corona wires may deposit paper dust or

toner particles on the corona wire. These particles may interfere with

charging and cause low density bands on copies. To help prevent this, a wire

cleaner cleans the corona wire when the operator slides the corona unit out

and in.

FT3013/3213 2-3 STM

Page 29

2.2 CHARGE CORONA WIRE CLEANER MECHANISM

[B]

[A]

[D]

Pads [A] above and below the charge corona wires clean the wires as the

charge unit is manually slid in and out.

The cleaner pad bracket [B] rotates when the charge unit is fully extended

and the bracket is pulled up against the rear endblock [C]. This moves the

pads against the corona wires (see illustration). If the charge unit is not fully

extended, the pads do not touch the corona wires.

The pads move away from the wires when the charge unit is fully inserted

and the cleaning bracket is pushed against the front endblock [D].

After copier installation the key operator should be instructed to use this

mechanism when copies exhibit white streaks, (low image density bands).

[C]

STM 2-4 FT3013/3213

Page 30

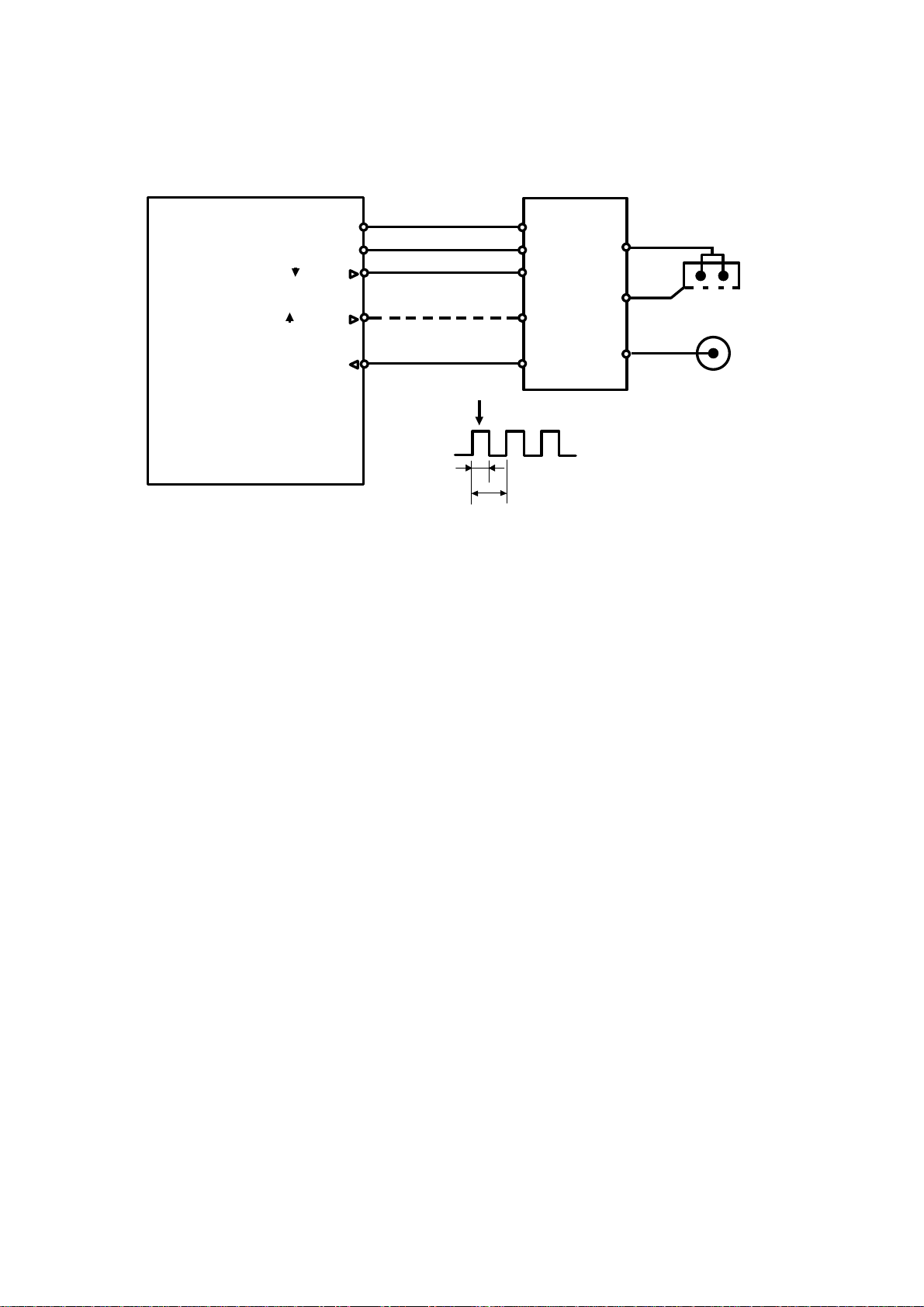

2.3 CHARGE CORONA CIRCUIT

t2

CN1-1

CN1-2

CN1-3

CN1-5

CN1-7

t1

Power Pack CC/Grid/Bias

(P1)

PWM Duty cycle

=t2/t1 x 100 (%)

Charge Corona

C

G

B

Development

Bias

Grid

VA [24]

VC [5]

CC Trig [ 24]

Grid Trig (PWM) [ 0→0/5]

GND [0]

Main Board (PCB 1)

CN119-7

CN119-6

CN119-5

CN119-3

CN119-1

The main board supplies +24 volts to the CC/Grid/Bias power pack at CN1-1

as the power supply source. After the Start key is pressed the CPU drops

CN1-3 from +24 volts to 0 volts. This energizes the charge corona circuit

within the CC/Grid/Bias power pack, which applies a high negative voltage of

approximately --7.0 K volts to the charge corona wires. The corona wires then

generate a negative corona charge.

The grid plate limits the charge voltage to ensure that the charge does not

fluctuate and that an even charge is applied to the drum surface.

The grid trigger pulse applied to CN1-5 is a pulse width modulated signal

(PWM signal). This signal is not only a trigger signal, it also changes the

voltage level of the grid. As the width of the pulse applied increases (see

arrow in above illustration), the voltage of the grid also increases (becomes

more negative).

FT3013/3213 2-5 STM

Page 31

2.4 GRID VOLTAGE CORRECTION

To maintain good copy quality over the drum’s life, the grid voltage is

changed due to the following:

• Drum residual voltage correction (Vr correction)

• Drum wear correction

2.4.1 Drum Residual Voltage Correction (Vr correction)

During the drum’s life, the drum may fatigue electrically and residual voltage

(Vr) on the drum may gradually increase. When this happens, the corona

charged voltage on the drum is not discharged enough in the quenching and

exposure processes. Even though development bias is applied during the

development process, the background area of the original on the drum may

still attract some toner. This may cause dirty background on copies. The Vr

correction prevents this phenomenon as follows:

A pattern (Vr pattern) is developed on the drum every 1,000 copies and its

reflectivity is detected by the ID sensor to measure the residual voltage. This

is called residual voltage detection. (If the reflectivity is low, the residual

voltage will be high.) When the Vr pattern is developed, all blocks of the

erase lamp turn on, and the development bias voltage is 0 volt.

The CPU determines what level of Vr correction is necessary depending on

the output (Vr ratio [L]) from the ID sensor.

Vrp

L =

x 100 (%)

Vsg

Vrp: ID sensor output for Vr pattern

Vsg: ID sensor output for bare drum

The current Vr ratio is displayed by SP67.

The CPU increases the development bias voltage depending on the Vr ratio

to prevent dirty background on copies, (See page 2-30 for more information.)

The CPU also increases the grid voltage to ensure proper image density

depending on the Vr ratio. (See page 2-8.)

STM 2-6 FT3013/3213

Page 32

Rev. 1/95

2.4.2 Drum Wear Correction

During the drum’s life, the photoconductive surface of the drum becomes

worn by contact with the cleaning blade and developer on the development

roller. This effects the ability of the drum to hold a charge. This characteristic

especially affects the development of the ID sensor pattern. The ID sensor

pattern developed on the drum becomes lighter causing higher toner

concentration in the developer. The drum wear correction is made to prevent

this phenomenon and is as follows:

The CPU keeps track of the drum’s rotation time that corresponds to the wear

of the photoconductive layer. The grid voltage for the toner density detection

increases at a set interval. The grid voltage for the residual voltage (Vr)

detection also increases at the same interval. (See page 2-9.) The drum

rotation time is displayed by SP57.

2.5 GRID VOLTAGE FOR IMAGE DENSITY CONTROL

The main board controls the grid voltage for the copy image through the

CC/Grid/Bias power pack. As the grid voltage for the image density control

becomes less, the copy image becomes lighter and vice versa.

The grid voltage is based on the standard grid voltage and correction factors

as follows:

Grid Voltage = Standard image density grid voltage (--680 volts [SP60 = 4])

+

Vr correction factor

+

Auto image density level factor (SP34)

2.5.1 Standard Image Density Grid Voltage

The standard image density grid voltage (SP60) is set at the factory and the

setting is different for each machine. The setting of SP60 is described on the

SP mode data sheet located inside the inner cover of the machine.

FT3013/3213 2-7 STM

Page 33

2.5.2 Drum Residual Voltage (Vr) Correction Factor

Vr ratio (L) (%) (SP67) Change of grid voltage (volts)

100 to 84 ±0

83 to 58 --40

57 to 41 --80

40 to 28 --120

27 to 0 --160

L = Vrp/Vsg x 100 (%)

Vrp: ID sensor output for Vr pattern

Vsg: ID sensor output for bare drum

During the drum’s life, drum residual voltage (Vr) may gradually increase. Vr

correction compensates for the residual voltage on the drum. The Vr

correction is done every 1000 copies. The CPU increases the development

bias voltage and the grid voltage. The above table shows how the grid

voltage changes depending on the Vr ratio.

2.5.3 Auto Image Density Level Factor (SP34)

Auto image density level Data (SP34) Change of grid voltage (volts)

Normal 0 * ±0

Darker 1 --40

Lighter 2 ±0

* Factory setting

The grid voltage and the exposure lamp voltage are constant regardless of

the output from the auto image density sensor. Only the development bias

voltage varies depending on the output from the auto image density sensor.

However, when the auto image density level data in SP34 is set to darker,

the grid voltage is changed --40 volts as shown in the above table. When it is

set to lighter, the grid voltage does not change, in this case the development

bias voltage is corrected.

STM 2-8 FT3013/3213

Page 34

2.6 GRID VOLTAGE FOR TONER DENSITY DETECTION AND

RESIDUAL VOLTAGE (Vr) DETECTION

The grid voltage is the same for both toner density detection and residual

voltage correction.

Grid voltage = Standard ID sensor grid voltage (--460 volts [SP62=4])

+

Drum wear correction factor (SP57)

Drum Wear Correction Factor (SP57)

Main motor rotation time (SP57) Change of grid voltage (volts)

0 to 2H ±0

2 to 65H --20

65 to 112H --40

112 to 157H --60

More than 157H --80

The grid voltage for toner density detection is the same as it is for the

residual voltage (Vr) detection. However, the development bias voltage is

different. (See pages 2-30 and 2-35.)

FT3013/3213 2-9 STM

Page 35

3. OPTICS

3.1 OVERVIEW

[B]

[C]

[D]

During the copy cycle, an image of the original is reflected onto the drum

surface through the optics assembly as follows.

Light Path:

Exposure Lamp [A] → Original → First Mirror [B] → Second Mirror [C]

→ Third Mirror [D] → Lens [E] → Fourth Mirror [F]→ Fifth Mirror [G]

→ Sixth Mirror [H] → Drum [I]

[A]

[E] [H] [F] [J]

[I]

[G]

This copier has six standard reproduction ratios (FT3213 copier only), three

reduction ratios, two enlargement ratios, and full size. It also has a zoom

function. The operator can change the reproduction ratio in one percent steps

from 61% to 141%.

Stepper motors are used to change the positions of the lens and mirrors

(FT3213 copier only). Separate motors are used because the wide range of

reproduction ratios makes it mechanically difficult for one motor to position

both the lens and mirrors. A stepper motor is also used to drive the scanner.

This motor changes the scanner speed according to the reproduction ratio.

STM 2-10 FT3013/3213

Page 36

The CPU monitors the temperature around the optics cavity through a

thermistor which is located at the upper left rear side of the copier frame.

When the temperature reaches 45°C, the optics cooling fan [J] (FT3213

copier only) starts rotating to draw cool air into the optics cavity. However, the

FT3013 copier is not equipped with a cooling fan. The machine will stop if the

optics cavity overheats. (See page 6-52.) In this case, the Energy Saver

indicator blinks and the Start key turns red.

The air flows from the right to the left, and exhausts through the vents in the

left side of the upper cover. This fan operates until the temperature drops

below 45°C.

The thermofuse provides back-up overheat protection. It opens at 128°C and

removes ac power to the exposure lamp.

FT3013/3213 2-11 STM

Page 37

3.2 SCANNER DRIVE

[E]

[B]

[D]

[F]

[C]

[A]

3.2.1 1st and 2nd Scanner Drive Mechanism

This model uses a stepper motor [A] to drive the scanners. Both ends of each

scanner are driven to prevent skewing. The scanners have sliders [B], which

ride on guide rails.

The scanner home position is detected by the home position sensor [C]. The

scanner return position is determined by counting the scanner motor drive

pulses.

The first scanner [D], which consists of the exposure lamp and the first mirror,

is connected to the scanner drive wire by the wire clamps [E]. The second

scanner [F], which consists of the second and third mirrors, is connected to

the scanner drive wire by movable pulleys (the second scanner pulleys [G]).

The pulleys move the second scanner at half the velocity of the first scanner.

This maintains the focal distance between the original and the lens during

scanning. This relationship can be expressed as:

V1r = 2 (V2r) = VD/r

where r = Reproduction ratio

V1r = First scanner velocity (when the reproduction ratio

is "r")

V2r = Second scanner velocity (when the reproduction ratio

is "r")

VD = Drum peripheral velocity (100 mm/s)

[G]

STM 2-12 FT3013/3213

Page 38

3.3 LENS DRIVE (FT3213 copier only)

[C]

[D]

[B]

[A]

: Reduction

: Enlargement

3.3.1 Lens Drive

The lens motor [A] (a stepper motor) changes the lens [B] position through

the lens drive wire [C] in accordance with the selected reproduction ratio to

provide the proper optical distance between the lens and the drum surface.

The rotation of the lens drive pulley moves the lens back and forth in discrete

steps. The home position of the lens is detected by the home position sensor

[D]. The main board keeps track of the lens position based on the number of

pulses sent to the lens motor.

FT3013/3213 2-13 STM

Page 39

3.3.2 Lens Positioning

[A]

[D]

[C]

[B]

Home Position (100%)

(100% → 129%)

(129% → 65%)

(65% → 93%)

(93% → 65%)

(65% → 129%)

(129% → 121%)

(121% → 129%)

(121% → 100%)

(100% → 65%)

(65% → 100%)

Reduction SideEnlargement Side

The lens home position sensor [A] informs the main board when the lens is at

the full size position (home position). The main board determines the lens

stop position in reduction and enlargement modes by counting the number of

steps the motor makes with reference to the lens home position. When a new

reproduction ratio is selected, the lens [B] moves directly to the selected

magnification position.

The lens home position is registered each time the lens starts from or passes

through the lens home position sensor. As the lens moves from the

enlargement side to the reduction side, the sensor registers the home

position. This occurs when the actuator plate [C] enters the lens home

position sensor.

A small vibration can be observed when the lens moves through home

position from the reduction side to the enlargement side because the lens is

going in the wrong direction to register the home position. The lens

overshoots the home position by only one pulse before going back to register

the home position.

The lens always stops while moving from left to right (as viewed from the

front) to minimize the error caused by mechanical play in the drive gears [D].

STM 2-14 FT3013/3213

Page 40

3.4 4TH/5TH MIRROR DRIVE (FT3213 copier only)

[B]

[A]

Home Position (100%)

(100% → 129%)

(129% → 65%)

(65% → 93%)

(93% → 65%)

(65% → 129%)

(129% → 121%)

(121% → 129%)

(121% → 100%)

(100% → 65%)

(65% → 100%)

3.4.1 Drive

The 4th/5th mirror drive motor (a stepper motor) changes the 4th/5th mirror

assembly position through the pinion gears [A] and the rack gear [B] in

accordance with the selected reproduction ratio to provide the proper optical

distance between the lens and drum surface.

3.4.2 Positioning

The positioning mechanism is similar to that of lens positioning, as shown in

the above positioning chart. The 4th/5th mirror assembly always stops while

moving from right to left (as viewed from the front).

FT3013/3213 2-15 STM

Page 41

3.5 AUTOMATIC IMAGE DENSITY SENSING

[A]

[C]

[B]

Sampled area

70 mm

a

b

Light from the exposure lamp is reflected from the original and travels to the

lens [A] via the mirrors. The auto ID sensor [B], a photodiode, is mounted on

the upper front frame. The sensor cover [C] has a hole in it to allow light to

fall directly onto the sensor. Sampling starts 10 millimeters from the leading

edge of the original and continues for 50 millimeters from the leading edge of

original in full size mode. The length of "a" and "b" will vary depending on the

selected reproduction ratio (FT3213 copier only).

The lengths "a" and "b" in each reproduction ratio are calculated as follows:

a =

10 mm

Reproduction Ratio (%)

x 100 b =

Reproduction Ratio (%)

50 mm

x 100

The photosensor circuit converts the light intensity to a voltage. The detected

voltage is amplified and sent to the main PCB where it is digitized. The CPU

stores the digital value of each sampled point in RAM. It then computes the

image density of the original from the maximum sampled value and changes

the development bias accordingly. (See page 2-28 for details.) The exposure

lamp voltage is constant regardless of the image density of the original.

STM 2-16 FT3013/3213

Page 42

3.6 EXPOSURE LAMP VOLTAGE CONTROL

The main board controls the exposure lamp voltage through the ac drive

board. The exposure lamp voltage is based on the base lamp voltage and

various correction factors. The method of control is different depending on

whether the image density is manually selected or the auto image density

mode is selected.

The exposure lamp voltage consists of the following factors:

Exposure lamp voltage = Base exposure lamp voltage

(Manual or auto image density mode)

+

VL correction factor

+

Reproduction ratio correction factor

(FT3213 copier only)

3.6.1 Base Lamp Voltage In Manual Image Density Mode

Manual ID Level

Exposure Lamp Data

Darker Lighter

1 2 3 4 5 6 7

Vo --4 Vo --4 Vo --2 Vo ±0 Vo+2 Vo+2 Vo+4

The above table shows changes in the exposure lamp data in the manual

image density mode.

SP48 sets the exposure lamp data for level 4 (Vo) of manual image density

mode. A value from 100 to 150 can be selected.

3.6.2 Base Lamp Voltage In Auto Image Density Mode

In the auto ID mode, the CPU selects the level 4 (Vo) exposure lamp data

(SP48) regardless of the input from the auto image density sensor.

FT3013/3213 2-17 STM

Page 43

3.6.3 VL Correction Factor

The light intensity may decrease because of dust accumulated on the optics

parts. This may cause dirty background on copies. To compensate for this

occurance, VL correction is done as follows:

Whenever SP56 (ADS reference voltage adjustment) is performed, before

sampling starts for the ADS adjustment, the auto ID sensor measures the

amount of light reflected through the 1st, 2nd and 3rd mirrors from the white

plate located under the left frame. The photosensor circuit converts this light

intensity to a voltage. This voltage is then digitized and the CPU stores the

digital value in memory as the initial data.

The copier utilizes a software counter for the VL correction. At every 500

copies the machine measures the light intensity reflected from the white

plate, "new" value is then compared with the initial data stored in memory.

If the measured voltage difference is equal to or more than 0.1 volts, +1 will

be added to the exposure lamp data as the VL correction factor.

If the difference is less than 0.1 volts, no correction will be applied.

The total increase for VL correction cannot exceed +20. After cleaning the

optics section, the following actions must be performed in order.

• SP95: Clear the exposure lamp data and the software counter

by entering "1".

• SP48: Perform the light intensity adjustment.

• SP56: Perform the ADS adjustment (to store the new initial

data and to adjust the ADS reference voltage.)

3.6.4 Reproduction Ratio Correction Factor (FT3213 copier only)

Reproduction ratio (%) Change of exposure lamp data

61 and 62 +2

63 to 119 ±0

120 to 129 +2

130 to 141 +4

The exposure lamp data is increased depending on the selected

magnification ratio in order to compensate for the change in the concentration

of light on the drum.

STM 2-18 FT3013/3213

Page 44

3.7 EXPOSURE LAMP CONTROL CIRCUIT

Main Board (PCB1)

B

Zero

Cross

CN107-1

CPU

TP111

(EXPO)

E

Feed back

signal

0V

+24V

C

24V

0V

Trigger Pulse

AC power

Zero cross

Trigger pulse

CN114-2

CN114-1

CN114-7

CN114-3

CN401-7

CN401-8

CN401-2

CN401-6

AC Drive Board (PCB2)

T402

CN419-1

Thermofuse (TF)

Exposure

Lamp

D

CN419-2

T407

(L1)

A

AC115V

AC220V

AC240V

R401

VR401

R403

PC401

R404

R405

C401

ZD

401ZD402

ZD

403ZD404

R411

TRC401

D401

R406

R413

D404

~D407

CR401

L401

L402

CN421

240V

220V

220V Only

TR401

C411

A

B

C

Lamp power

Feedback

signal

D

E

Feedback

The main board sends lamp trigger (LOW signal) pulses to the ac drive board

from CN114-3. PC401 activates TRC401, which provides ac power to the

exposure lamp, at the lead edge of each trigger pulse.

The voltage applied to the exposure lamp is also provided to the feedback

circuit. The feedback circuit steps down (TR401), rectifies (D404 ∼ 407), and

smoothes (zener diodes and capacitors) the lamp voltage. The CPU monitors

the lowest point of the smoothed wave (feedback signal), which is directly

proportional to the actual lamp voltage.

The CPU changes the timing of the trigger pulses in response to the

feedback voltage. If the lamp voltage is too low, the CPU sends the trigger

pulses earlier so that more ac power is applied to the exposure lamp. This

feedback control is performed instantly; so, the lamp voltage is always stable

even under fluctuating ac power conditions.

The voltage applied to the exposure lamp can be changed with SP48 (Light

Intensity Adjustment). The ADS voltage adjustment (SP56) must be done

whenever the light intensity adjustment is done.

FT3013/3213 2-19 STM

Page 45

4. ERASE

4.1 OVERVIEW

[A]

LE

EL

[B]

SE

ES

LO

LC

LE: Lead edge erase margin 2.5 ±1.5 mm

SE: Side erase margin 2.0 ±2.0 mm on each side;

total of both sides 4 mm or less

LO: Original width

LC: Charged width of drum

EL: Lead edge erase

ES: Side erase (FT3213 copier only)

The erase lamp [A] consists of a single row of LEDs (29 LEDs) extending

across the full width of the drum [B].

The erase lamp has the following functions: lead edge erase, side erase

(FT3213 copier only), and trail edge erase.

STM 2-20 FT3013/3213

Page 46

a b c d e

h

g

f c

abde

4.1.1 Lead Edge Erase

The entire line of LEDs turn on when the main motor turns on. They stay on

until the erase margin slightly overlaps the lead edge of the original image

area on the drum (Lead Edge Erase Margin). This prevents the toner density

sensor pattern from being developed every copy cycle and the shadow of the

original edge from being developed on the paper. At this point, side erase

starts (FT3213 copier only). The width of the lead edge erase margin can be

adjusted using SP41.

During the toner density detection cycle (once every ten copy cycles), a block

of erase lamps (labeled "g" above) turns off long enough for the sensor

pattern to be developed.

The entire line of LEDs turn on when the residual voltage on the OPC drum is

being detected (Vr detection).

4.1.2 Side Erase

Based on the combination of copy paper size and the reproduction ratio data,

the LEDs turn on in blocks (labeled "a" -- "g" above). This reduces toner

consumption and drum cleaning load.

FT3013/3213 2-21 STM

Page 47

-- FT3213 copier --

This machine has no sensors or switches to detect the copy paper size.

Instead, the CPU measures the copy paper length using the registration

sensor during the first copy cycle. Based on this length data, the CPU

determines which copy paper size is used in the paper tray. (See page 2-49

for more information.)

The LEDs turn on in blocks as labeled "a" -- "h" on the previous page.

In the full size copy mode, the CPU determines which blocks turn on based

on the copy paper length data as follows:

Paper length Paper size Blocks ON

364 mm and 356 mm B4, 10" x 14", 81/2" x 14", 8 1/4" x 14" None

330 mm and 279 mm

297 mm, 267 mm, and 254 mm A4R, 8" x 101/2", 8" x 10" a -- c

257 mm, 216 mm, and 210 mm B5R, 51/2" x 81/2", A5R a -- e

For toner density detection cycles. a -- f, h

For residual voltage (Vr) detection cycles. All

81/2" x 13", 8 1/4" x 13" (F4), 8" x 13", 81/2" x

11"

a -- b

NOTE: Since the CPU cannot distinguish different paper widths, the CPU

determines the size to be the larger standard width based on the

measured length.

(EX: 10" x 14", 81/2" x 14" → The CPU recognizes as 10" x 14".)

In the reduction or enlargement copy mode, the CPU determines which

blocks turn on based on the selected reproduction ratio as follows:

Reproduction ratio (%) Blocks ON

83 to 99, 101 to 141 None

78 to 82 a

73 to 77 a to b

68 to 72 a to c

64 to 67 a to d

61 to 63 a to e

STM 2-22 FT3013/3213

Page 48

-- FT3013 copier --

Since this model has only two modes for the erase lamp, full erase mode (all

blocks on) and toner density detection cycle mode (all blocks on except block

"g"), side erasing is not performed by the erase lamp.

When making copies with the platen cover open condition, and the original

and the copy paper is smaller than B4 (10" x 14"), the part without the original

will be developed as a black image area on the drum.

NOTE: If the customers makes copies without the platen cover closed

frequently, the used toner tank may become full in a shorter period of

time, than expected. For those customers, the toner tank must be

checked and cleaned frequently.

4.1.3 Trailing Edge Erase

The entire line of LEDs turns on after the trailing edge of the latent image has

passed. Therefore, a trailing erase margin cannot be observed on the copy.

The LEDs stay on to erase the leading edge of the latent image in the next

copy cycle. After the final copy, the erase lamps turn off at the same time as

the main motor.

FT3013/3213 2-23 STM

Page 49

5. DEVELOPMENT

5.1 OVERVIEW

[E]

[B]

[C]

[A]

When the main motor turns on, the paddle roller [A], development roller [B],

auger [C], and the agitator [D] start turning. The paddle roller picks up

developer in its paddles and transports it to the development roller. Internal

permanent magnets in the development roller attract the developer to the

development roller sleeve.

The turning sleeve of the development roller then carries the developer past

the doctor blade [E]. The doctor blade trims the developer to the desired

thickness and creates a developer backspill to the cross-mixing mechanism.

The development roller continues to turn, carrying the developer to the OPC

drum. When the developer brush contacts the drum surface, the negatively

charged areas of the drum surface attract and hold the positively charged

toner. In this way, the latent image is developed.

The development roller is given a negative bias to prevent toner from being

attracted to the non-image areas on the drum which may have a residual

negative charge. The bias also controls image density.

[D]

After turning about 100 degrees more, the development roller releases the

developer to the development unit. The developer is agitated by the paddle

roller [A], agitator [D], and the cross-mixing mechanism.

STM 2-24 FT3013/3213

Page 50

5.2 DRIVE MECHANISM

[F]

[C]

[G]

[B]

[E]

Rev. 1/95

[D]

[A]

When the main motor [A] turns, the rotation is transmitted from the

development drive gear [B] to the development roller gear [C] through the

development gear [D], timing belt [E] and relay gears. The rotation is

transmitted from the development roller gear to the paddle roller gear [F]

through an idler gear [G].

NOTE: This copier is not equipped with a knob on the paddle roller shaft like

some other machines. When installing new developer or manually

rotating the development roller, always make sure to turn the gears in

the direction shown above. Damage may occur to the copier if turned

in the opposite direction.

FT3013/3213 2-25 STM

Page 51

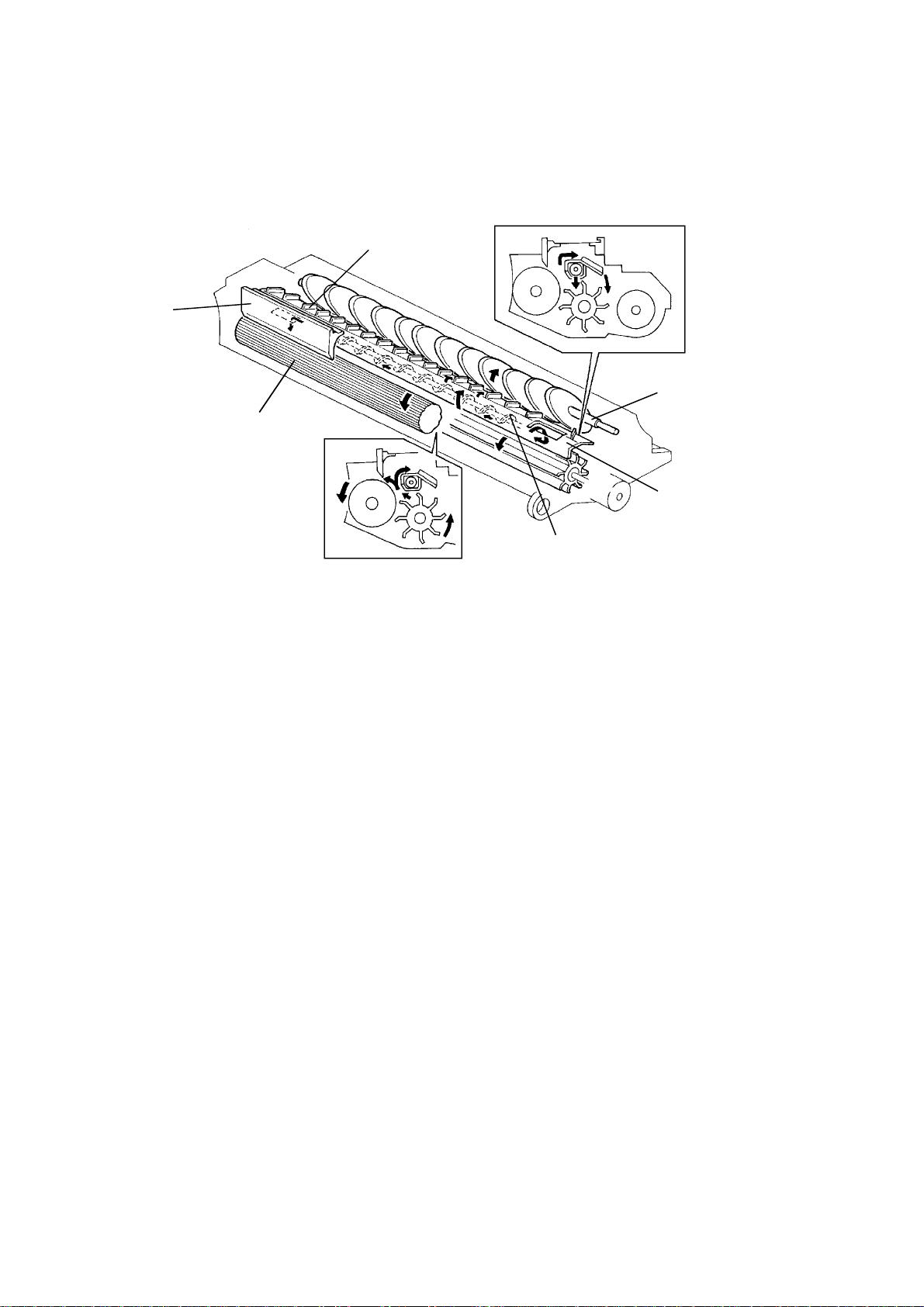

5.3 CROSS-MIXING

[A]

[B]

[E]

[D]

[C]

[F]

This copier uses a standard cross-mixing mechanism to keep the toner and

developer evenly mixed. It also helps agitate the developer to prevent

developer clumps from forming and helps create the triboelectric charge.

The developer on the turning development roller is split into two parts by the

doctor blade [A]. The developer that stays on the development roller [B]

forms the magnetic brush and develops the latent image on the drum. The

remaining developer that is trimmed off by the doctor blade goes to the

backspill plate [C].

As the developer slides down the backspill plate to the agitator [D], the mixing

vanes [E] move it slightly toward the rear of the unit. Part of the developer

falls into the auger inlet and is transported to the front of the unit by the auger

[F].

STM 2-26 FT3013/3213

Page 52

5.4 DEVELOPMENT BIAS FOR IMAGE DENSITY CONTROL

Image density is controlled by changing three items: (1) the amount of bias

voltage applied to the development roller sleeve, (2) the amount of voltage

applied to the exposure lamp, and (3) the amount of voltage applied to the

grid plate.

Applying a bias voltage to the development sleeve reduces the potential

between the development roller and the drum, thereby reducing the amount

of toner transferred. As the bias voltage becomes greater, the copy image

becomes lighter and vice versa.

The method of control is different depending on whether the image density is

manually selected or the auto image density mode is used.

The development bias voltage applied to the development roller sleeve has

the following factors:

Development bias voltage = Base bias voltage factor

(Manual or auto image density mode)

+

Image bias voltage adjustment factor (SP37)

+

Drum residual voltage (Vr) correction factor

The base bias voltage for non-image areas (between copies) is --160 volts.

The above correction factors are also applied.

FT3013/3213 2-27 STM

Page 53

5.4.1 Base Bias Voltage Factor In Manual Image Density Mode

Darker Lighter

Manual ID Level 1 2 3 4 5 6 7

Base Bias Voltage (volts) --120 --160 --160 --160 --160 --200 --240 *Note

Exposure Lamp Data Vo --4 Vo --4 Vo --2 Vo ±0 Vo +2 Vo+2 Vo+4

Vo: Exposure Lamp Data for ID level 4 (SP48)

In manual ID mode, the base bias voltage depends on the manually selected

ID level. The voltage applied at each ID level is shown in the above table.

The base exposure lamp voltage also varies depending on the manual ID

level also shown in the table above.

*Note: The base bias voltage at ID level 7 can be changed using SP50 as

follows.

Image density Data (SP50) Bias voltage (volts)

Normal 0 --240

Darker 1 --200

Lighter 2 --280

Lightest 3 --320

(Factory Setting: --240 volts)

5.4.2 Base Bias Voltage Factor In Automatic Image Density Mode

In auto image density mode, the base exposure lamp voltage is fixed at Vo

(SP48). Image density is controlled by changing only the base bias voltage.

The base bias voltage depends on the background image density of the

original, which is measured using the auto ID sensor. (See page 2-16 for

more information.)

The CPU checks the voltage output from the automatic ID circuit. This circuit

has a peak hold function. The peak hold voltage corresponds to the

maximum reflectivity of the original. The CPU then determines the proper

base bias level with reference to the peak hold voltage.

The table on the following page gives the base bias voltages at each ADS

output level.

When the automatic density level is set to lighter by SP34, the base bias

voltage shifts --40 volts as shown in the following table.

STM 2-28 FT3013/3213

Page 54

K

Normal or Darker (SP34 = 0 or 1) Lighter (SP34 = 2)

K ≥ TL1 --160 --200

TL1 > K ≥ TL2 --200 --240

TL2 > K ≥ TL3 --240 --280

TL3 > K ≥ TL4 --280 --320

TL4 > K ≥ TL5 --320 --360

TL5 > K --360 --400

Base Bias Voltage (volts)

K =

ADS Output Voltage (Peak Hold Voltage)

ADS Reference Voltage (SP56)

TL1 to TL5: Threshold level (See the following table.)

To maintain the correct image density, the exposure lamp data is

incremented when the reproduction ratio is changed or when VL correction is

applied. This increment in the lamp data increases the intensity of light

reflected from the original. Therefore, the auto ID sensor output voltage also

changes. In order to maintain a constant voltage for the same original when

the lamp data is incremented, the threshold levels are shifted up with each

increment in the lamp data as shown in the following table.

Increase of

exposure lamp data+0 +1+2 +3+4 +5+6 +7+8 +9

TL1 0.80 0.85 0.90 0.95 1.00 1.05 1.11 1.16 1.20 1.23

TL2 0.75 0.80 0.84 0.88 0.92 0.97 1.01 1.06 1.11 1.16

TL3 0.70 0.74 0.78 0.82 0.86 0.90 0.94 0.99 1.03 1.08

TL4 0.61 0.65 0.69 0.73 0.77 0.81 0.84 0.88 0.92 0.96

TL5 0.29 0.31 0.33 0.35 0.37 0.38 0.40 0.42 0.44 0.46

+10

+11

+12

+13

+14

+15

+16

+17

+18

+19

5.4.3 Image Bias Voltage Adjustment Factor

Image Bias Adjustment (SP37)

Image density Data (SP37) Change of bias voltage (volts)

Normal 0 ±0

Darkest 1 +40

Darker 2 +20

Lighter 3 --20

Lightest 4 --40

The image bias voltage can be changed by SP37 to adjust the image density

level. The above table gives the image bias voltage for this SP mode setting.

This adjustment should be done only if the exposure lamp voltage adjustment

(SP48) fails to achieve the desired image density.

FT3013/3213 2-29 STM

Page 55

5.4.4 Drum Residual Voltage (Vr) Correction Factor

During the drum’s life, drum residual voltage (Vr) will gradually increase. The

Vr correction compensates for the residual voltage on the drum. The Vr

correction is done every 1,000 copies. The following table shows how the

development bias voltage changes depending on the Vr ratio.

Vr ratio (L) (%) (SP67) Change of bias voltage (volts)

100 to 84 ±0

83 to 58 --40

57 to 41 --80

40 to 28 --120

27 to 0 --160

L = Vrp/Vsg x 100 (%)

Vrp: ID sensor output for Vr correction pattern

Vsg: ID sensor output for bare drum

When the Vr correction is made (every 1,000 copies), all the LED’s of the

erase lamp turn on and the development bias becomes 0 volts so as to

develop the Vr pattern.

STM 2-30 FT3013/3213

Page 56

5.5 DEVELOPMENT BIAS CIRCUIT

t2

CN1-1

CN1-2

CN1-4

CN1-6

CN1-7

t1

Power Pack CC/Grid/Bias

(P1)

PWM Duty cycle

=t2/t1 x 100 (%)

Charge Corona

C

G

B

Development

Bias

Grid

VA [24]

Bias Trig (PWM) [ 0→0/5]

Bias FB

GND [0]

Main Board (PCB1)

VC [5]

CN119-7

CN119-6

CN119-4

CN119-2

CN119-1

The main board supplies +24 volts to the CC/Grid/Bias power pack at CN1-1.

When the Start key is pressed, the CPU starts sending the bias trigger pulses

to CN1-4. This energizes the development bias circuit within the

CC/Grid/Bias power pack, which applies a high negative voltage to the

development roller. The development bias is applied whenever the drum is

rotating except when the Vr pattern is developed.

The bias trigger pulse applied to CN1-4 is a pulse width modulated signal

(PWM signal). The width of the pulses controls the voltage level of the

development roller. As the width of the trigger pulses increase, the voltage to

the development roller also increases (becomes more negative). The CPU

monitors the development bias voltage at CN119-2 and controls the width of

the bias trigger pulses based on this feedback.

FT3013/3213 2-31 STM

Page 57

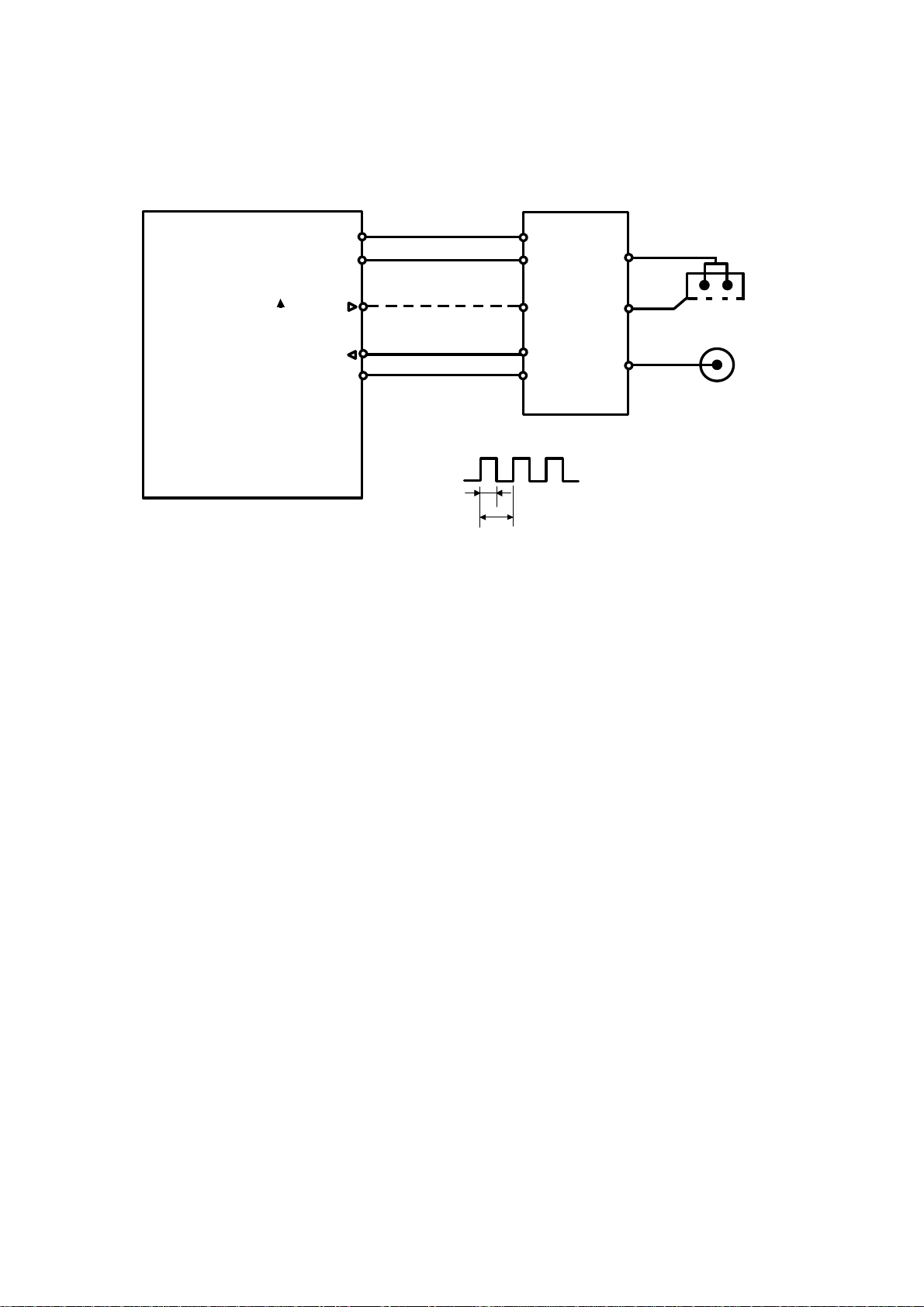

6. TONER DENSITY DETECTION & TONER SUPPLY

6.1 OVERVIEW

Sensor

Pattern

Original Lead

Edge

Original

ON OFF ON OFF

A B C

RAM Clear

1 2 3 4 5 6 7 8 9 10 11 12 13 14 20 21 22

Toner Density Detection Toner Density Detection Toner Density

D E

1st

Leading Edge Erase

2nd 3rd

Low Toner Density

Toner Supply Timing

Detection

ID Sensor

Pattern

Detection

Development

Bias

Toner Add

Toner Supply Clutch ON

(10 times)

Detection

The CPU checks toner density by directly sensing the image density every 10

copy cycles. If the RAM is cleared (SP99), or a new RAM is installed, the

CPU checks the image density at the beginning of the first copy cycle.

During the check cycles, the sensor pattern is exposed prior to the exposure

of the original. After the sensor pattern is developed, its reflectivity is checked

by the image density sensor (a photosensor). The CPU notes the reflectivity

and if the reflected light is too strong, indicating a too low toner density

condition, toner is added to the development unit.

The toner is not added all at once. The CPU will energize the toner supply

clutch for the proper amount of time in order to add a selected amount of

toner over the next 10 cycles.

When the free run mode (DIP switch 101-1, ON) is selected, the CPU checks

the toner density every copy cycle.

FT3013/3213 2-32 STM

Page 58

6.2 ID SENSOR FUNCTION

6.2.1 Detect Supply Mode

ID Sensor

B

A

K

R

C

E

C

ID Sensor Output

A

Vsg 4V

CN112-2

CN112-1

CN112-3

ID Sensor LED

+5V (VB)

TP 110

(PSE)

VR102

Main Board

+24V (VA)

CPU

Low Density

High Density

CN110-2

MSC1

CN110-1

Toner

Supply

Clutch

Vsp

(0.103 Vsg ≈ 0.41 V)

High Density

The image density sensor checks the density of the sensor pattern image

once every 10 copy cycles. The CPU receives two voltage values directly

from the sensor: the value for the bare drum (Vsg) and the value for the

sensor pattern (Vsp). These two values are then compared to one another in

order to determine whether more toner should be added.

Vsp

1.

2.

x 100 <10.3 ..... No toner is added. (High density)

Vsg

Vsp

x 100 ≥10.3 ..... Toner is added. (Low density)

Vsg

When the image density is too low, the CPU activates the toner supply clutch

to add toner over the next 10 copy cycles. The amount of toner added

depends on the value of Vsp, the selected toner supply ratio (SP31), and ID

sensor data. (See page 2-37 for more information.)

When SP35 is set to "1" (factory setting = "0"), the CPU changes the interval

of the toner density detection from every 10 copies to every 5 copies.

STM 2-33 FT3013/3213

Page 59

6.2.2 Fixed Supply Mode

When SP30 is set to "1" (factory setting = "0"), the fixed supply mode is

selected. In this case, a fixed amount of toner is added every copy cycle

depending on the selected toner supply ratio (SP32) and the paper size in

use. (See page 2-39 for more information.) However, the toner supply clutch

is de-energized to prevent over-toning when Vsp is lower than 0.103 Vsg.

(≈ 0.41 volts when Vsg = 4.0 volts).

Vsg 4V

Low Density

Vsp

(0.103 Vsg ≈ 0.41 V)

High Density

6.3 ABNORMAL CONDITION IN TONER DENSITY

DETECTION

If Vsg goes below 2.5 volts (LOW Vsg) or Vsp goes above 2.5 volts (HIGH

Vsp) for 5 consecutive toner density detection cycles, the CPU determines

that the toner density detection is abnormal. The CPU changes from the

detect supply mode to the fixed supply mode. At the same time, either the

auto ID indicator or the selected manual ID level starts blinking. The machine

can be operated in this condition.

Abnormal Condition In Toner Density Detection

SP55 display

Vsp Vsg

varies 0.00 Vsg ≤ 2.5 (LOW Vsg)

varies 5.00 Vsp ≥ 2.5 (HIGH Vsp)

Conditions

FT3013/3213 2-34 STM

Page 60

6.4 DEVELOPMENT BIAS VOLTAGE FOR TONER DENSITY DETECTION

The development bias for toner density detection can be adjusted by SP33 in

order to change the toner density level. The following table shows the

development bias voltage corresponding to setting of SP33. This SP mode

should be used only when the exposure lamp intensity adjustment (SP48)

and the base bias adjustment (SP37) for copy image cannot achieve the

desired image density.

Toner density SP data (SP33)

Normal 0 --240 --220

Low 1 --200 --180

High 2 --260 --240

Higher 3 --280 --260

Development bias voltage (volts)

0 to 499 copies More than 500 copies

After the developer initial setting (SP65) is performed, the triboelectric charge

is still low. In this condition, the ID sensor pattern density is higher than it

should be. This will cause the toner concentration in the developer to become

too low.

To compensate for this occurance, the development bias voltage for the initial

499 copies is increased by --20 volts automatically as shown in the above

table.

STM 2-35 FT3013/3213

Page 61

6.5 TONER SUPPLY AND AGITATOR DRIVE MECHANISM

[A]

[D]

[C]

[B]

[A]

[D]

[E]

[J]

[H]

[F]

[I]

[G]

The toner supply clutch gear [A] turns when the main motor [B] is on. The

transmission of this rotation to the toner supply drive gear [C] is controlled by

the toner supply clutch [D].

When the toner supply clutch energizes, the toner supply drive gear starts

turning and drives the toner supply roller gear [E]. Toner catches in the

grooves on the toner supply roller [F]. Then, as the grooves turn past the pin

hole plate [G], the toner drops into the development unit through the pin holes.

The toner agitator [H] mechanism, which is contained in the toner cartridge,

prevents toner from clumping. The toner agitator gear [I] turns whenever the

toner supply clutch energizes. Rotation passes through the toner cartridge

casing to the agitator junction [J].

FT3013/3213 2-36 STM

Page 62

6.6 TONER SUPPLY AMOUNT

This copier has two different ways of controlling the amount of toner supplied.

Normally, the detect supply mode controls toner supply; however, a fixed

supply mode also can be selected by SP30.

6.6.1 Detect Supply Mode (SP30 = 0)

The amount of toner supplied depends on the ID sensor data and the detect

toner supply ratio data. The toner supply clutch on time in each copy cycle is

calculated as follows:

Toner Supply Clutch ON Time = I x T (pulses)

Where : I = ID Sensor Data

T = Detect Toner Supply Ratio Data (SP31)

ID Sensor Data

Vsp/Vsg x 100

(Vsp, if Vsg = 4.0 volts)

0 to 10.3%

(0 to 0.41 volts)

10.3 to 10.8%

(0.41 to 0.43 volts)

10.8 to 11.8%

(0.43 to 0.47 volts)

11.8 to 15.2%

(0.47 to 0.61 volts)

15.2 to 62.5%

(0.61 to 2.5 volts)

(See note below.)

62.5 to more than 100%

(2.5 to 5.0 volts)

Toner supply level

(Toner supply ratio, SP31 = 0)

No toner supply

(0%)

1

(3.75%)

2

(7.5%)

3

(15%)

4

(30%)

Fixed supply mode

ID sensor data

0

22

44

87

174

(Toner End level)

N/A

(Abnormal Condition)

NOTE: If this condition is detected two times consecutively, the toner

supply ratio rises to 60% (ID Sensor Data = 348), which is double

that at toner supply level 4.

STM 2-37 FT3013/3213

Page 63

Detect Toner Supply Ratio Data (SP31)

Data (SP31) Toner supply ratio at toner supply level 3 Toner supply ratio data

0 15% 2

1 7% 1

2 30% 4

3 60% 8

For example: Vsp = 0.45 volts, which means the toner

supply level is "2" and the ID sensor data is 44.

The data of SP31 is set to "0".

The toner supply ratio is 15% and the toner

supply data is 2.

Toner Supply Clutch ON Time

= I x T

= 44 x 2

= 88 (pulses)

= 352 (msec.) (1 pulse = 4.0 msec.)

FT3013/3213 2-38 STM

Page 64

6.6.2 Fixed Supply Mode (SP30 = 1)

The amount of toner supplied depends on the fixed toner supply ratio data

and the paper size data. The toner supply clutch on time in each copy cycle

is calculated as follows:

Toner Supply Clutch ON Time = T x P x 2 (pulses)

Where: T = Fixed Toner Supply Ratio Data (SP32)

P = Paper Size Data

Fixed Toner Supply Ratio Data (SP32)

Data (SP32) Toner supply ratio Toner supply ratio data

0 7.0% 2

1 3.5% 1

2 10.5% 3

3 14.0% 4

Paper Size Data

Paper size Paper size data

B4 43

A4R 29

B5R 23

A5R 15

10" x 14", 81/2" x 14", 81/4" x 14" 43

81/2" x 13", 81/4" x 13" (F4), 8" x 13" 33

81/2" x 11", 8" x 101/2" 29

8" x 10" 27

51/2" x 81/2" 14

For example: The data of SP32 is set to "0".

The toner supply ratio is 7.0% and the toner

supply data is 2.

Paper size is 8.5" x 11". The paper size data is 29.

Toner Supply Clutch ON Time

= T x P x 2

= 2 x 29 x 2

=116 (pulses)

= 464 (msec.) (1 pulse = 4.0 msec.)

STM 2-39 FT3013/3213

Page 65

6.7 TONER END CONDITION

The image density sensor is used to detect a toner end condition in both

detect and fixed supply modes.

6.7.1 Near Toner End Condition

When the Vsp/Vsg x100 becomes greater than 15.2, the toner density

detection cycle changes from every 10 copies to 5 copies. When this

condition is detected again, the toner supply ratio becomes two times the

amount of toner supply level 4 (Toner supply ratio = 60%, ID sensor data =

348). Then, when this condition is detected five times consecutively, the CPU

determines that there is a near toner end condition and starts blinking the

Add Toner indicator.

6.7.2 Toner End Condition

After the Add Toner indicator starts blinking (Near Toner End Condition), the

operator can make 50 copies. If a new toner cartridge is not added within that