Page 1

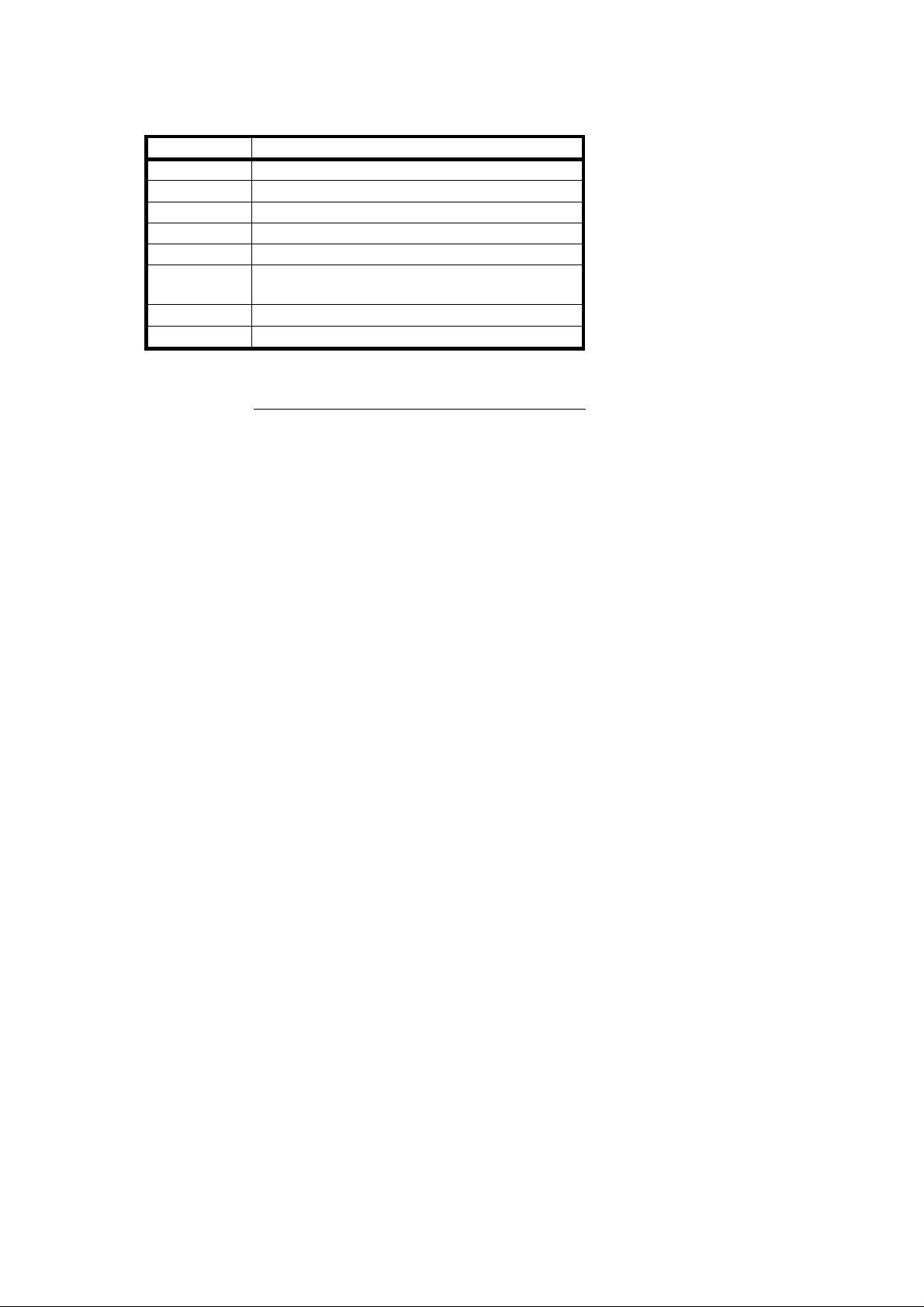

FACTORY SETTING P/N A0771391C

SP NUMBER FACTORY SETTING DATA

41 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

42 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

43 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

44

47

48 120 121 122 123 124 125 126 127 128

129 130 131 132 133 134 [ ]

60 0 1 2 3 4 5 6 7 8

62 0 1 2 3 4 5 6 7 8

SERIAL NO.

Page 2

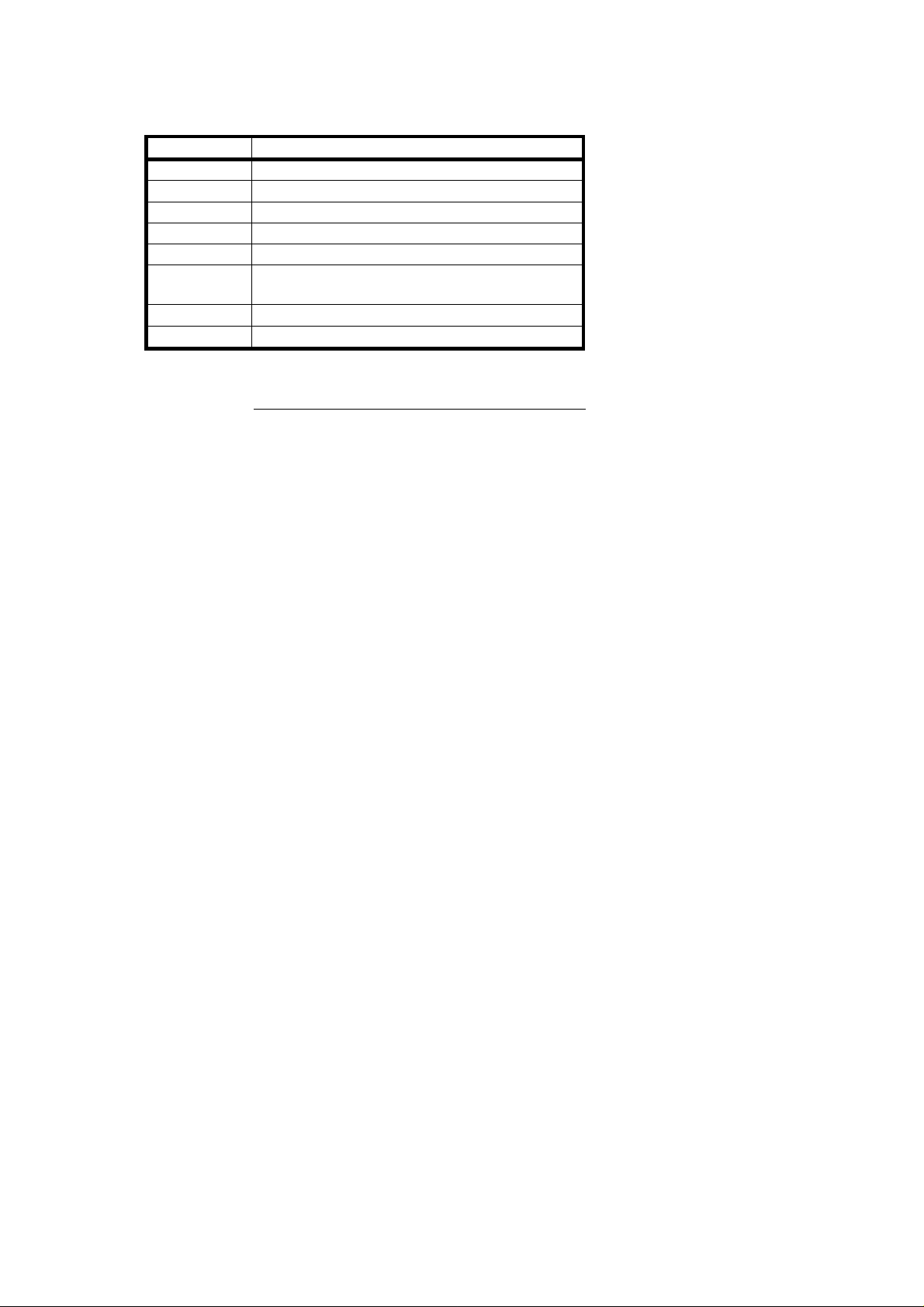

FACTORY SETTING P/N A0771390C

SP NUMBER FACTORY SETTING DATA

41 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

42 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

43 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

44

47

48 120 121 122 123 124 125 126 127 128

129 130 131 132 133 134 [ ]

60 0 1 2 3 4 5 6 7 8

62 0 1 2 3 4 5 6 7 8

SERIAL NO.

Page 3

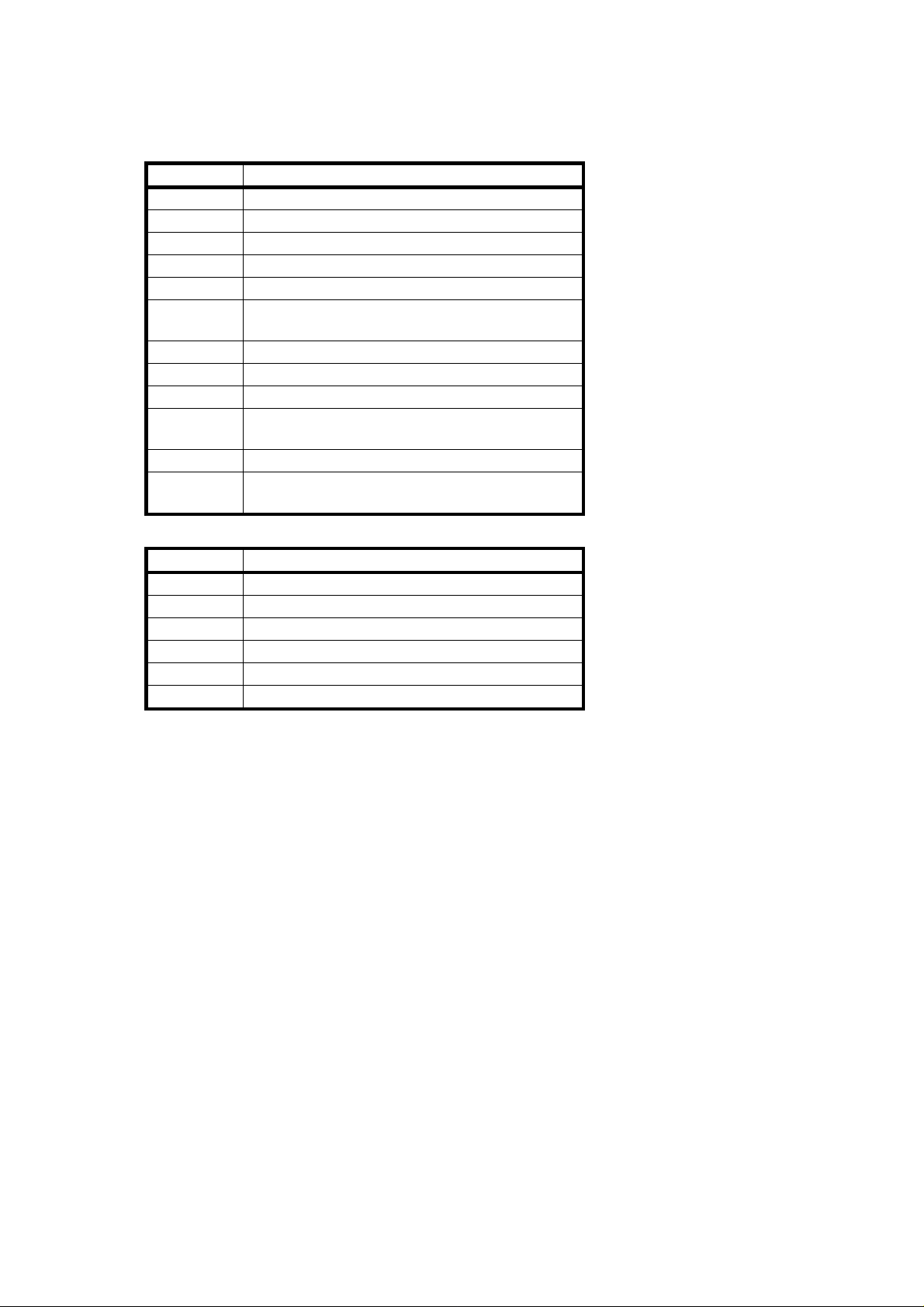

TEST POINTS

Copier Main Board

NUMBER FUNCTION

TP101 GND

TP102 HET (Fusing Thermistor)

TP103 GND

TP104 GIN (Grid Voltage Feed Back)

TP105 BIN (Development Bias Feed Back)

TP106 ADS (Auto Image Density Sensor)

Adjust the voltage to +2.5 ± 0.1 volts by VR101.

TP107 AVSS (GND)

TP108 EXP (Exposure Lamp Voltage Feed Back)

TP109 VCC (+5 volts)

TP110 PSE (ID Sensor Voltage)

Adjust the voltage to +4.0 ± 0.2 volts by VR102.

TP112 +9 volts (ID Sensor Power)

JP101 Key Counter (Cut this jumper wire when

installing the key counter on the machine.)

DF Main Board

NUMBER FUNCTION

TP1 Factory use

TP2 Factory use

TP3 GND

TP4 +5 volts

TP5 GND

TP6 +24 volts

Page 4

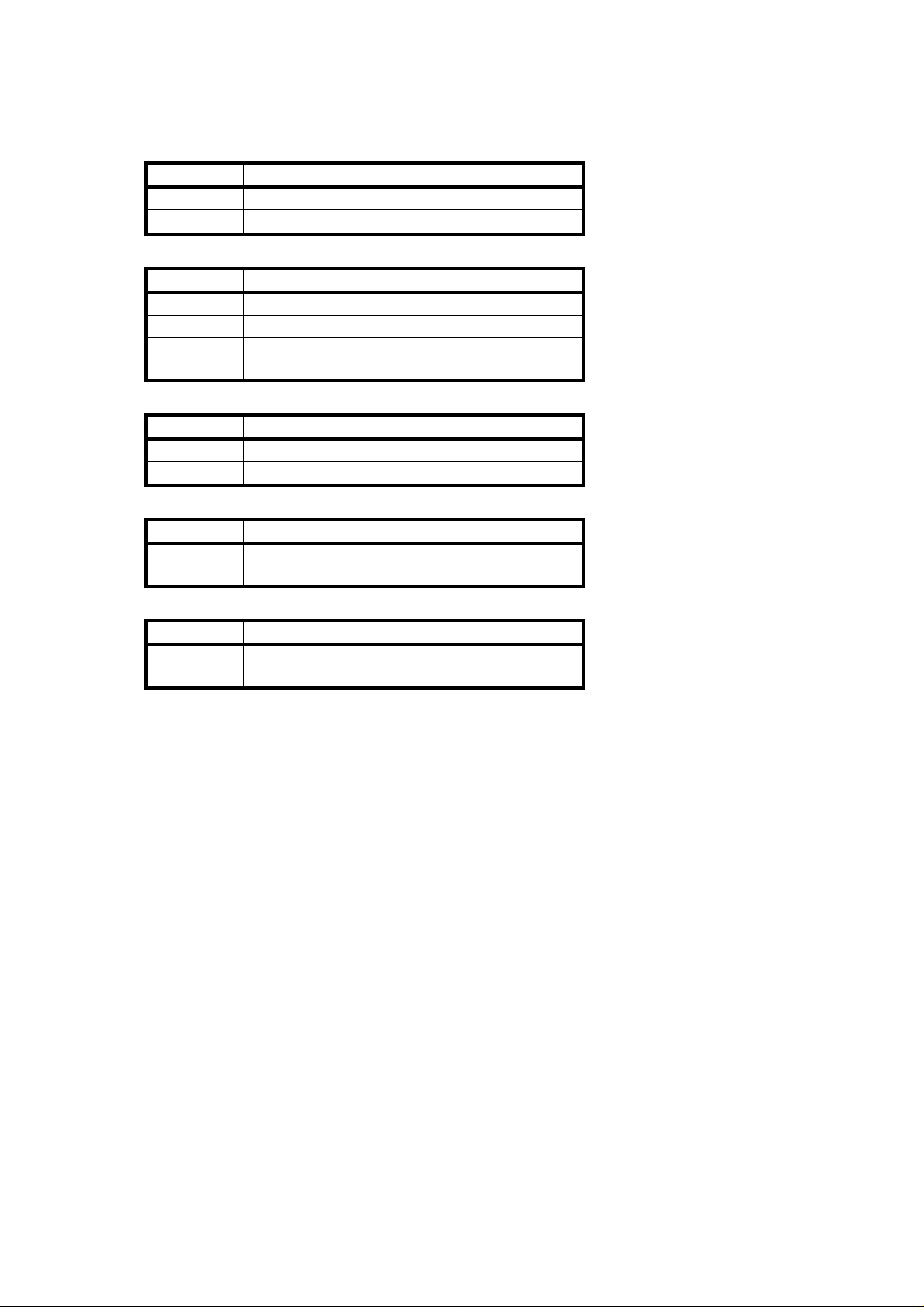

VARIABLE RESISTORS

Copier Main Board

NUMBER FUNCTION

VR101 Adjusts ADS voltage (+2.5 ± 0.1 volts)

VR102 Adjusts ID sensor voltage (+4.0 ± 0.2 volts)

CC/Grid/Bias Power Pack

NUMBER FUNCTION

VRM Adjusts charge corona current

VRG Adjusts standard grid voltage

VRB Adjusts standard development bias

(Factory use)

TC/SC Power Pack

NUMBER FUNCTION

VRT Adjusts transfer corona current

VRD Adjusts separation corona current

AC Drive Board

NUMBER FUNCTION

VR401 Adjusts base exposure lamp voltage

(Factory use)

DF Main Board

NUMBER FUNCTION

VR1 Adjusts original stop position

(Factory use)

Page 5

DIP SWITCHES AND JUMPER SWITCHES

Copier Main Board

DIP SWITCH NORMAL FUNCTION

DPS101-1 OFF Free run

DPS101-2 OFF Service program mode

access

JUMPER SWITCH NORMAL FUNCTION

JPS101-R (Upper) Open Ready temp. bypassed

(Factory use)

JPS101-C (Lower) Open To clear counters by

SP#98 or to clear all

memory by SP#99

DF Main Board

SW1

1234

OFF OFF OFF OFF Normal (Factory setting)

ON OFF OFF ON Free run (Insert paper)

OFF OFF ON ON Solenoid test

ON ON OFF ON Motor test

ON ON ON ON All indicators ON

FUNCTION

Lift SW

must be ON.

Page 6

SERVICE CALL AND USER CODE TABLE

SERVICE CALL CODE

E-code Contents

11 Exposure Lamp Error

The feed back signal becomes higher than 4.2 volts

(r.m.s) for 1.0 second when the exposure lamp is on, or it

becomes higher than 1.0 volt (r.m.s) for 1.0 second when

the exposure lamp is off.

12 Exposure Lamp Error

The feed back signal falls below 0.5 volt (r.m.s) for

1.0 second when the exposure lamp is on, or the

exposure lamp stays on for longer than 10 seconds.

13 Zero Cross Signal Error

The CPU does not receive the zero cross signal within

0.56 second.

21 Scanner Home Position Error

The scanner home position sensor’s output remains LOW

(de-actuated) for 9 seconds after the main switch is turned

on.

22 Scanner Home Position Error

The scanner home position sensor’s output remains HIGH

(actuated) for 1.0 second after the scanner starts.

28 Lens Home Position Error (A077/A078 copiers only)

The lens home position sensor’s output remains LOW

(de-actuated) for 6.0 seconds after the lens move to the

home position.

29 Lens Home Position Error (A077/A078 copiers only)

The lens home position sensor’s output remains HIGH

(actuated) for 3.5 seconds after the lens leaves the home

position.

2A 4th/5th Mirror Home Position Error

(A077/A078 copiers only)

The 4th/5th mirror home position sensor’s output remains

LOW (de-actuated) for 2.5 seconds after the 4th/5th mirror

assembly moves to the home position.

2B 4th/5th Mirror Home Position Error

(A077/A078 copiers only)

The 4th/5th mirror home position sensor’s output remains

HIGH (actuated) for 2.5 seconds after the 4th/5th mirror

assembly leaves the home position.

SP Mode No.

(SC Counter)

SP122

(Exposure Lamp)

–

SP121 (Optics)

Page 7

E-code Contents

52 Fusing Warm-up Error

The temperature detected by the thermistor does not

reach 150°C within 30 seconds after the main switch is

turned on.

53 Fusing Overheat

The temperature detected by the thermistor becomes

higher than 240°C.

55 Fusing Thermistor Open

The temperature detected by the thermistor does not

reach 2°C within 20 seconds after the main switch is

turned on.

70 Used Toner Overflow

When the used toner overflow condition is detected, E70

blinks. An additional 250 copies can be made before the

Start indicator turns red and copying is inhibited.

96 DF Timing Pulse Error

The DF CPU does not receive a DF timing pulse within

100 milliseconds.

SP Mode No.

(SC Counter)

SP124

(Fusing Section)

Refer to NOTE.

–

SP125

(DF Timing Pulse)

NOTE: When the service call (E52, 53, 55) conditions occur, for saf et y

reason they canno t be cle are d by turning off and on the main

switch. The following procedure must be performed to clear these

service call conditions:

1. Turn on the main switch.

2. Turn DPS 101-1 on and off.

3. Turn the main switch off and on.

User Code

U-code Contents

2 Key Counter Not Set

Page 8

SP MODE OVERVIEW

Mode No. Function Data

Operation Check

5 Exposure Lamp OFF – EM

6 Misfeed Detection OFF – EM

7 Aging Mode Factory use –

8 Input Check (Refer to Sensor/Switch Data Check Table) EM

9 Output Check (Refer to Electrical Component Check Table) EM

Installation and/or Sales Demonstration

11 All Indicators ON – –

12 220–230V/240V Conversion 0: 220–230V

1: 240V

Customer Request

15 Auto Reset Time 0: 1 min. 2: None

1: 3 min

16 Count Up/Down 0: Up 1: Down –

17 Increase/Decrease Quantity Key Function Acceleration Recycle

0: ON ON (1-99-1)

1: OFF ON (1-99-1)

2: ON OFF (1-99)

3: OFF OFF (1-99)

18 Reduce/Enlarge Key Function 0: Reduction

1: Enlargement

19 ADS Priority 0: ADS

1: Manual

29 Fusing Temperature Control 0: ON/OFF

1: Phase

Copy Quality Check and Adjustment

30 Toner Supply Mode 0: Detect

1: Fixed

31 Toner Supply Ratio (Detect Mode) 0: 15% 2: 30%

1: 7% 3: 60%

32 Toner Supply Ratio (Fixed Mode) 0: 7% 2: 10.5%

1: 3.5% 3: 14%

33 ID Sensor Bias

0: Normal (Vo) 2: High (Vo–20V)

1: Low (Vo+40V) 3: Higher (Vo–40V)

34 ADS Level 0: Normal

1: Darker

2: Lighter

35 ID Detection Interval 0: 10 copies

1: 5 copies

When

performed

Installation

–

–

–

–

EM or PM

EM or PM

EM or PM

EM or PM

EM or PM

EM or PM

Page 9

Mode No. Function Data

37 Image Bias Adjustment

0: Normal (Vo) 3: Lighter (Vo–20V)

1: Darkest (Vo+40V) 4: Lightest (Vo–40V)

2: Darker (Vo+20V)

39 Exposure Lamp ON Factory Use –

41 Leading Edge Erase Margin Adjustment 0–15 EM

42 Registration Adjustment 0–15 EM

43 Vertical Magnification Adjustment 0–15 EM

44 Horizontal Magnification Adjustment

(A077/A078 copiers only)

45 Registration Buckle - 1st Feed 0–15 EM

46 Registration Buckle - 2nd Feed

(A078 copier only)

47 Focus Adjustment (A077/A078 copiers only) 0–100 EM

48 Light Intensity Adjustment 100–150 EM or PM

49 Fusing Temperature Adjustment 175–190°C EM

50 Image Bias Adjustment at ID Level 7

0: Normal (Vo) 2: Lighter (Vo–40V)

1: Darker (Vo+40V) 3: Lightest (Vo–80V)

51 Exposure Lamp Data Display 100–150 EM

52 Fusing Temperature Display 175–190°C –

54 Vsg Adjustment (VR102 on the main board) 4.0 ± 0.2V EM or PM

55 Vsg & Vsp Display – –

56 ADS Reference Voltage Adjustment 2.5 ± 0.1V –

57 Drum Motor Rotation Time –

58 Toner End Counter –

59 Open –

60 Standard Image Grid Voltage Setting Factory Use –

61 Standard ID Sensor Bias Voltage Setting Factory Use –

62 Standard ID Sensor Grid Voltage Setting Factory Use –

63 Open – –

64 Toner Density Level Display 0–4 –

65 Developer Initial Setting – –

66 Drum Initial Setting – After re-

67 Vr Ratio Display – –

68 Vr Forced Detection – –

69 OPC Counter – –

0–50 EM

0–15 EM

performed

EM or PM

Customer

request

placement

When

Page 10

Mode No. Function Data

Others

83 Toner End Counter Clear 0: No

1: Yes

87 PM Interval Setting 0: No PM 3: 80K

1: 40K 4: 100K

2: 60K

88 PM Counter Display – –

89 PM Counter Clear 0: No 1: Yes PM

93 Max Copy Quantity 1–99 Customer

Clear Mode

98 Clear Counters 0: No 1: Yes –

99 Clear all Memory 0: No 1: Yes –

Copy and Original Counters

100 Manual Feed Copies – EM or PM

101 1st Paper Tray Copies – EM or PM

102 2nd Paper Tray Copies (A078 copier only) – EM or PM

103 Total Copies – EM or PM

106 DF Originals – EM or PM

Misfeed Counters

110 Misfeeds (Total) – EM

111 Number of Misfeeds by Location 1: Paper Feed

2: Exit

3: (Open) 4: DF

Service Call Counters

120 Total Service Calls – EM

121 Optics Section Service Calls – EM

122 Exposure Lamp Service Calls

124 Fusing Section Service Calls

125 DF Timing Pulse Service Calls

–

–

–

When

performed

"E70" and

when the

used toner

tank is

cleared.

request

–

EM

EM

EM

EM

SP MODE 8 SENSOR/SWITCH DATA CHECK

Data

Number Sensor/Switch/Signal

1 Registration Sensor Paper not detected (HIGH) Paper detected (LOW)

2 Exit Sensor

"0" (A077/A078 copiers)

or

"None" (A076 copier)

"1" (A077/A078 copiers)

"•" (A076 copier)

or

Page 11

3 1st Paper Tray Switch Paper tray opened (HIGH) Paper tray closed

4 2nd Paper Tray Switch

(A078 copier only)

7 Relay Sensor Paper not detected (HIGH) Paper detected (LOW)

8 Product Identification A077/A078 copiers A076 copier

9 Drum Temperature ≥ 20°C < 20°C

13 Scanner HP Sensor Sensor actuated (HIGH) Sensor not actuated

14 Lens HP Sensor

(A078 copier only)

15 4th/5th Mirror HP Sensor

(A078 copier only)

(LOW)

(LOW)

SP MODE 9 ELECTRICAL COMPONENT CHECK

Number Electrical Component

1 Main Motor + PTL + Quenching Lamp + Drum Motor

2 Charge Corona + Standard Image Grid

3 Charge Corona + Standard ID Sensor Grid

4 Charge Corona + Standard Vrp Grid

5 Transfer Corona

6 Separation Corona

8 Erase Lamp

9 ID Sensor LED

10 Development Clutch Solenoid

11 Toner Supply Clutch + Main Motor (Development Clutch Solenoid OFF)

Note: Press and hold the Darker key to turn the toner supply clutch on and the

development clutch solenoid off.

12 Registration Clutch

13 1st Paper Feed Clutch

14 2nd Paper Feed Clutch (A078 copier only)

15 Relay Roller Clutch

19 Optics Cooling Fan

20 Exposure Lamp + Optics Cooling Fan

22 Charge Corona + Image Grid with correction + Transfer Corona + Separation

Corona

23 Charge Corona + ID Sensor Grid with correction + Transfer Corona +

Separation Corona

24 Charge Corona + Vrp Grid with correction + Transfer Corona + Separation

Corona

25 Charge Corona + Image Grid with correction

26 Charge Corona + ID Sensor Grid with correction

27 Charge Corona + Vrp Grid with correction

30–37 Development Bias Voltage in 40 volts steps starting at –120 volts

38 Development Bias Voltage = –500 volts

40–48 Grid Voltage in 60 volts steps starting at –400 volts

Loading...

Loading...