Page 1

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYS ICAL INJURY

1. Before disassembling or asse mblin g pa rts of the copie r and perip herals,

make sure that the copier power cord is unplu gg ed.

2. The wall outlet should be near the copier an d easily accessible.

3. Note that some compo ne nt s of th e copier and the paper tray unit are

supplied with electrical voltage even if the main switch is turned off.

4. If any adjustment or operat ion check has to be made with exterior covers

off or open while the main switch is turned on, keep hands away from

electrified or mechanically drive n comp on ents.

5. The inside and the met al parts of the fusing unit become extre mely ho t

while the copier is operat ing . Be ca ref ul to avoid touching those

components with your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozon e filt er inst alle d.

2. Always replace the ozone filter with the specified one at the specifie d

interval.

3. Toner and developer are non-toxic, but if you get either of them in your

eyes by accident, it may cause temp ora ry e ye disco mfo rt. Try to remove

with eye drops or flush with wat er as first aid. If un succe ssfu l, ge t med ical

attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripheral must be installed and maintained by a

customer service represen tative who has completed the training course

on those models.

2. The RAM pack has a lithium battery which can explod e if hand led

incorrectly, replace only with same RAM pack. Do not recharge, or burn

this battery. Used RAM pack must be handle d in accordance with local

regulations.

Page 2

SAFETY AND ECOLOGICAL NOTES FOR DISP OS AL

1. Do not incinerate the toner cartridge or the used toner. Toner dust may

ignite suddenly when exposed to open flame.

2. Dispose of used tone r, developer, and organic photoconductors

according to local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in acco rda nce with local regulations.

Page 3

SECTION 1

OVERALL MACHINE

INFORMATION

Page 4

15 January 1992 SPECIFICATIONS

1. SPECIFICATIONS

Configuration : Desk top

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book

Original Size: Maximum A3/11" x 17" – A077/A078 copiers

B4/10" x 14" – A076 copier

Copy Paper Size: Maximum – B4/10" x 14"

Minimum – A5 (lengthwise)/51/2" x 81/2"

Copy Paper Weight: Paper tray feed – 52 to 90 g/m2 (14 to 24 lb)

Manual feed – 52 to 157 g/m2 (14 to 42 lb)

Reproduction Ratios: 2 Enlargement and 3 Reduction

(A077/A078 copiers only)

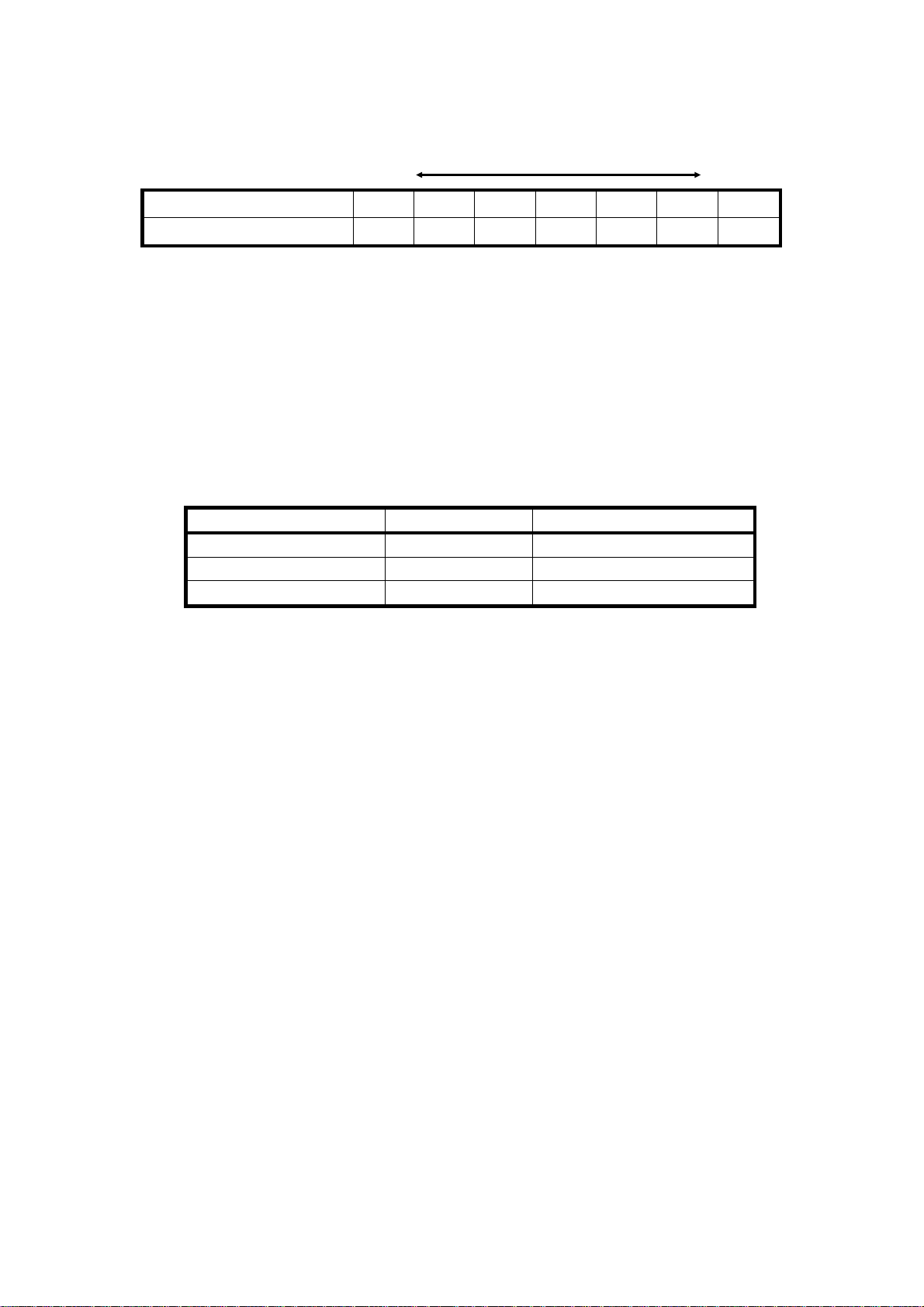

A4 Version Letter Version

Enlargement

Full size 100% 100%

Reduction

Zoom: From 61% to 141% in 1% steps

(A077/A078 copiers only)

Copying Speed: 13 copies/minute (A4 leng th wise/81/2" x 11")

10 copies/minute (B4/10" x 14")

Warm-Up Time: 30 seconds (at 20°C/68°F)

First Copy Time: 9 seconds (A4 lengthwise/81/2" x 11")

Copy Number Input: Quantity keys, 1 to 99 (count up)

Manual Image Density

Selection:

7 steps

141%

122%

93%

82%

71%

129%

121%

93%

74%

65%

1-1

Page 5

SPECIFICATIONS 15 January 1992

Automatic Reset: 1 minute standard setting; can also be set to 3

minutes or no auto reset.

Automatic Start: When the Start key is pressed bef ore the copier

finishes the warm-up cycle, the copier starts

making copies as soon as the warm-up cycle is

completed.

Paper Capacity: Paper tray – 250 sheets

Manual feed table – 1 sheet

Toner Replenishment: Cartridge exchange (320 g/cartridge)

Copy Tray Capacity: 100 sheets (B4/10" x 14" or smaller)

Power Source: 110V / 60Hz/ 15 A (fo r Taiwan)

115V/ 60Hz/ 15A (for North America)

220~230V/ 50Hz/ 8A (for Europe)

220V/ 60Hz/ 8A (for Middle East)

240V/ 50Hz/ 8A (for Europe)

(Refer to the serial number plate (rating plat e) to

determine the power source required by the

machine.)

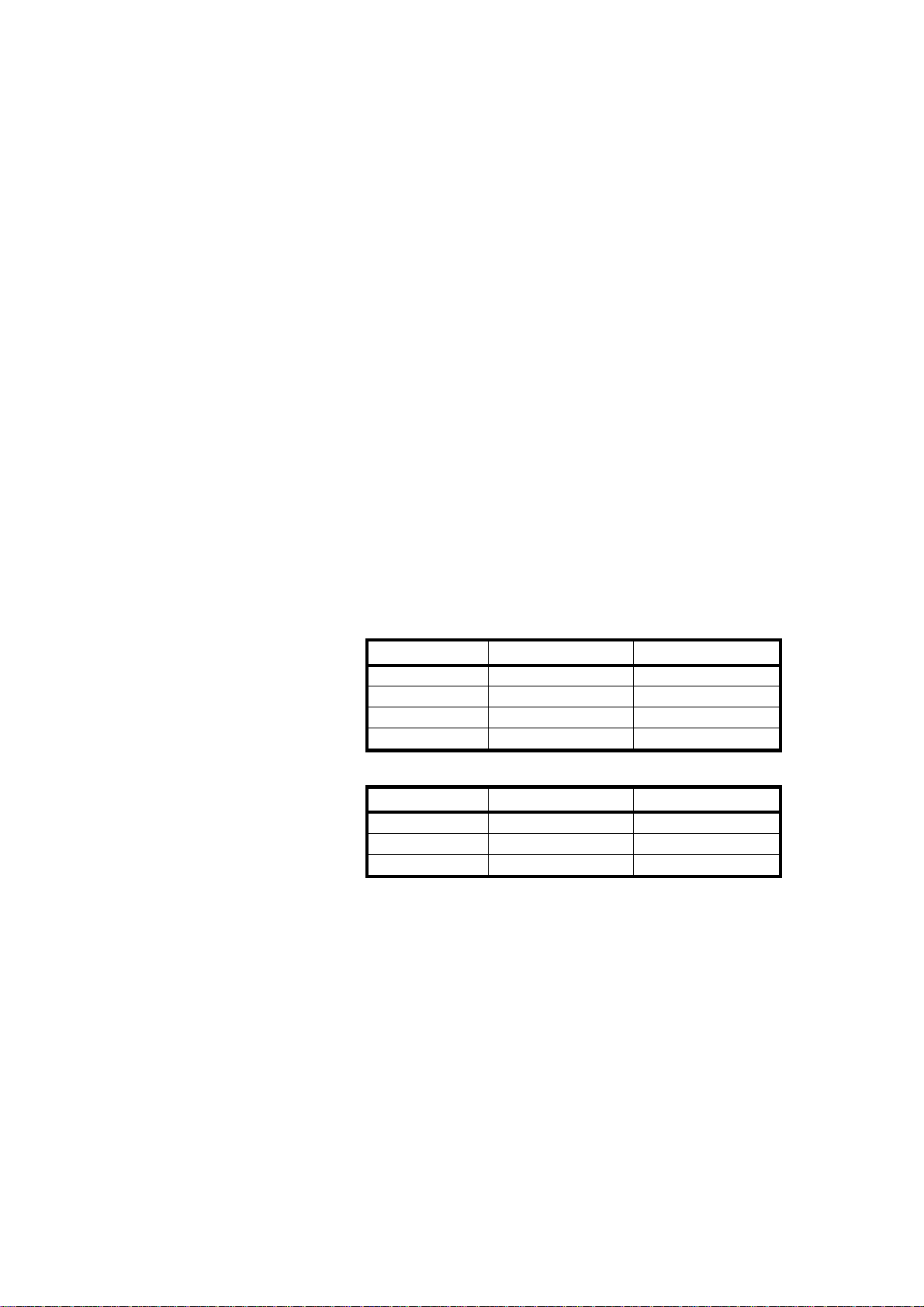

Power Consumption:

Noise Emission:

Copier Only With DF

Maximum 1.4 kVA 1.5 kVA

Warm-up 0.60 kVA (average) 0.62 kVA (average)

Copy cycle 0.81 kVA (average) 0.86 kVA (average)

Stand-by 0.16 kVA (average) 0.18 kVA (average)

Copier Only With DF

Maximum 58 db 60 db

Warm-up Less than 40 db Less than 40 db

Copy cycle Less than 55 db Less than 55 db

1-2

Page 6

15 January 1992 SPECIFICATIONS

Dimensions:

Width Depth Height

Copier only

With DF

A076/A077

copiers

A078 copier 830 mm (32.7") 582 mm (23.0") 503 mm (19.9")

A077 copier 830 mm (32.7") 582 mm (23.0") 463 mm (18.3")

A078 copier 830 mm (32.7") 582 mm (23.0") 563 mm (22.2")

830 mm (32.7") 582 mm (23.0") 403 mm (15.9")

Weight: Copier only – A076/A077 Copiers 43 kg (94.8 lb)

A078 Copier 51 kg (112.5 lb)

With DF – A077 Copier 50 kg (110.3 lb)

A078 Copier 58 kg (127.9 lb)

Optional Equipment: Document feeder

Key counter

Drum anti-condensation heater

Optics anti-condensation heater

• Specifications are subject to chan ge witho ut notice.

1-3

Page 7

COPY PROCESSES AROUND THE DRUM 15 January 1992

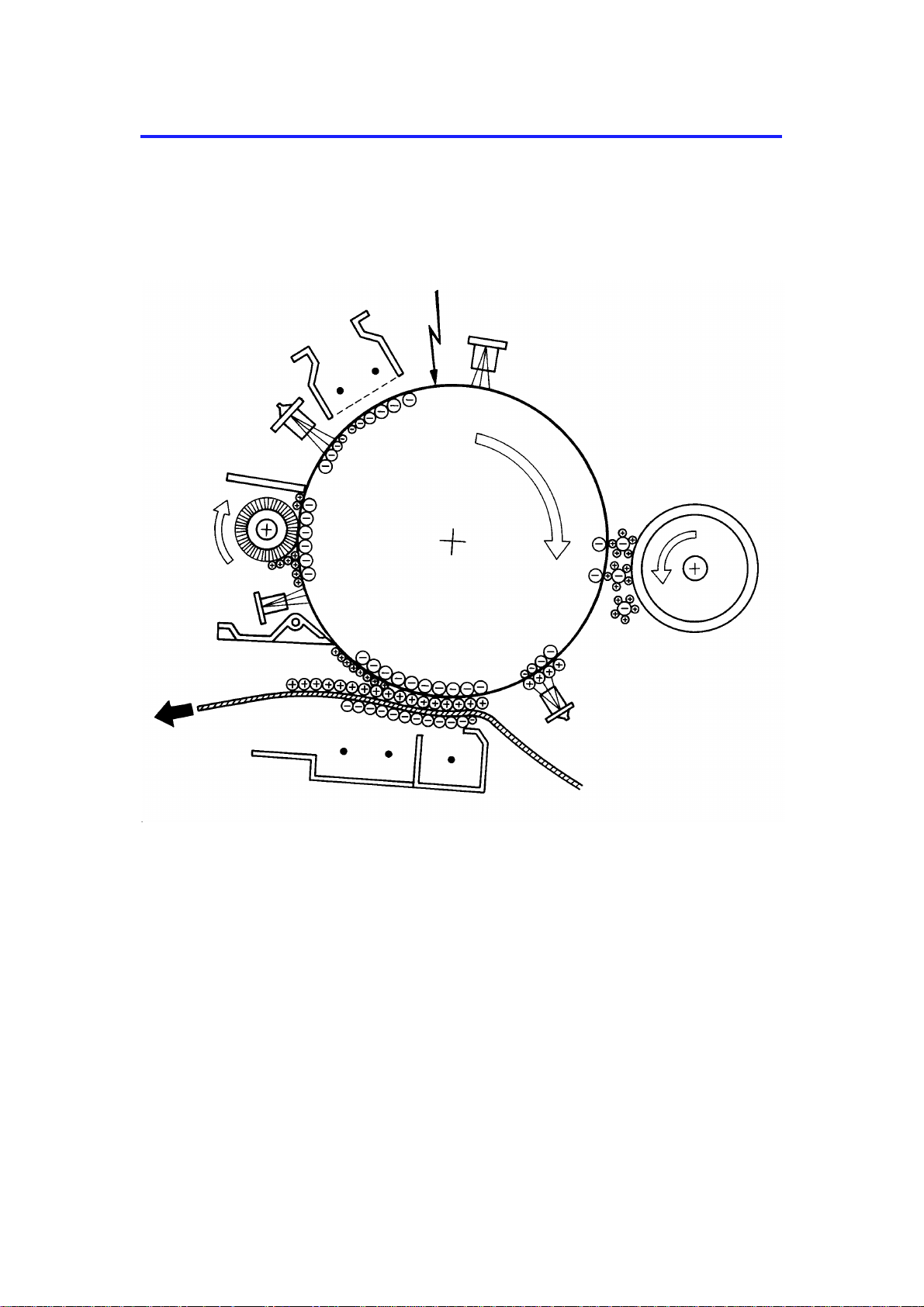

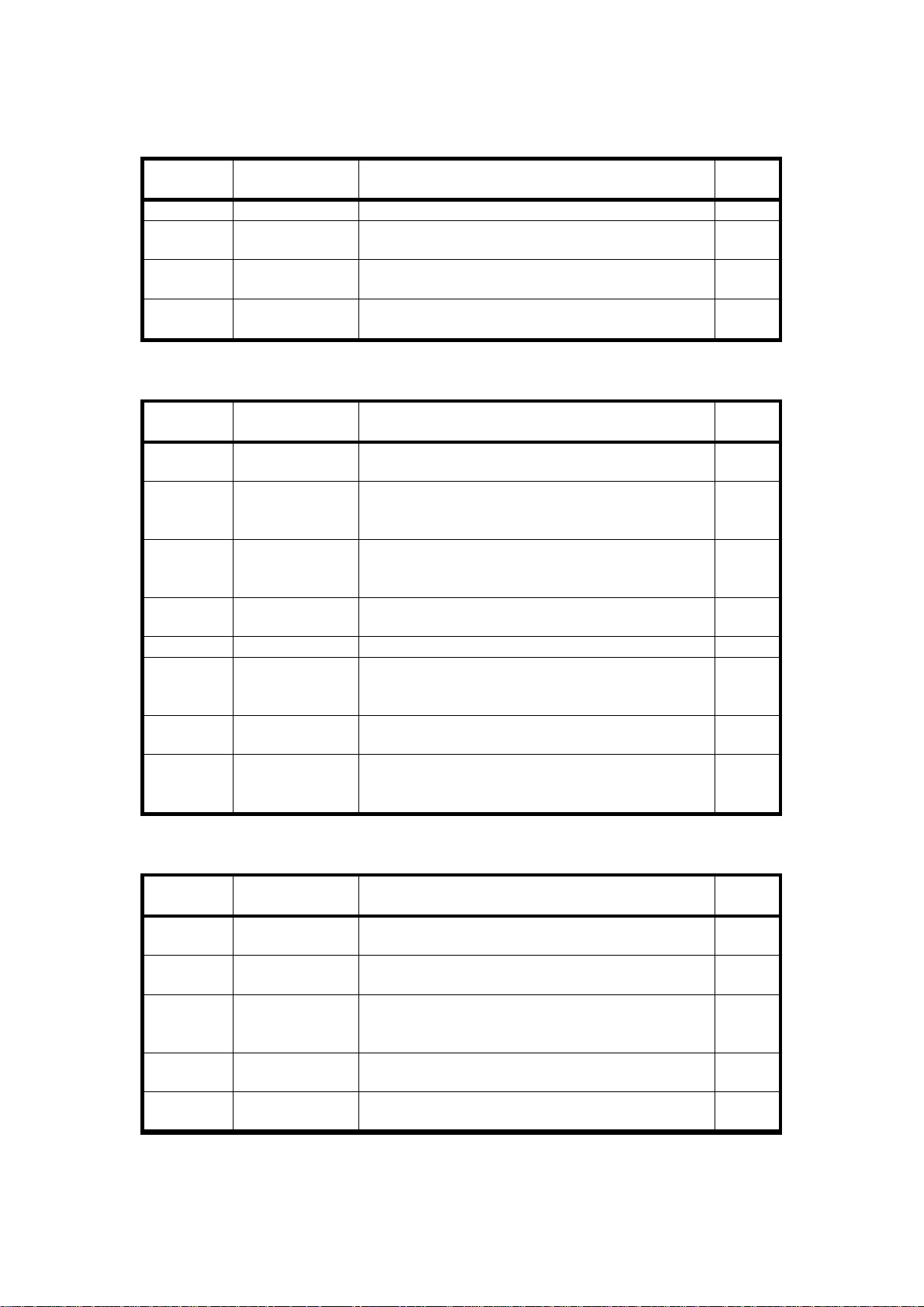

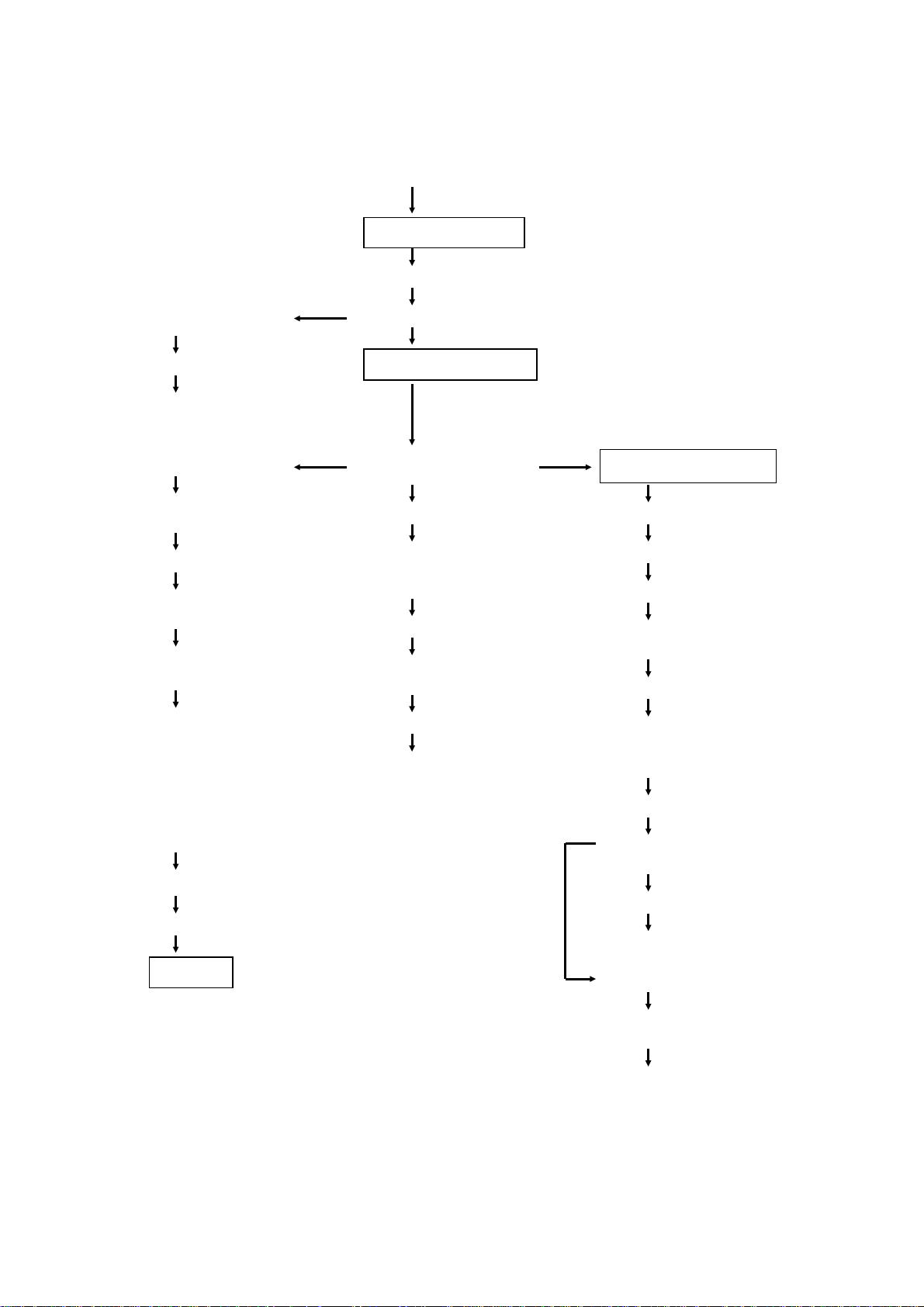

2. COPY PROCESSES AROUND THE DRUM

2. EXPOSURE

1. DRUM CHARGE

3. ERASE

9. QUENCHING

4. DEVELOPMENT

8. CLEANING

7. PAPER

SEPARATION

5. PRE-TRANSFER LAMP

(PTL)

6. IMAGE TRANSFER

1-4

Page 8

15 January 1992 COPY PROCESSES AROUND THE DRUM

1. DRUM CHARGE

In the dark, the charge corona unit gives a uniform negative charge to the organic

photoconductive (OPC) drum. The charge remains on the surface of the drum because the

OPC drum has a high electrical resistance in the dark.

2. EXPOSURE

An image of the original is reflected to the OPC drum surface via the optics assembly. The

charge on the drum surface is dissipated in direct proportion to the intensity of the reflected

light, thus producing an electrical latent image on the drum surface.

3. ERASE

The erase lamp illuminates the areas of the charged drum surface that will not be used for

the copy image. The resistance of the drum in the illuminated areas drops and the charge on

those areas dissipates.

4. DEVELOPMENT

Positively charged toner is attracted to the negatively charged areas of the drum, thus

developing the latent image. (The positive triboelectric charge is caused by friction between

the carrier and toner particles.)

5. PRE-TRANSFER LAMP (PTL)

The PTL illuminates the drum to remove all negative charge from the exposed areas of the

drum. This prevents the toner particles from being reattracted to the drum surface during

paper separation and makes paper separation easier.

6. IMAGE TRANSFER

Paper is fed to the drum surface at the proper time so as to align the copy paper and the

developed image on the drum surface. Then, a strong negative charge is applied to the back

side of the copy paper, producing an electrical force which pulls the toner particles from the

drum surface to the copy paper. At the same time, the copy paper is electrically attracted to

the drum surface.

7. PAPER SEPARATION

A strong ac corona discharge is applied to the back side of the copy paper, reducing the

negative charge on the copy paper and breaking the electrical attraction between the paper

and the drum. Then, the stiffness of the copy paper causes it to separate from the drum

surface. The pick-off pawls help to separate paper.

8. CLEANING

The cleaning brush removes most of the toner on the drum and loosens the remainder. Then

the cleaning blade scrapes off the loosened toner.

9. QUENCHING

Light from the quenching lamp electrically neutralizes the surface of the drum.

1-5

Page 9

COPY PROCESS CONTROL 15 January 1992

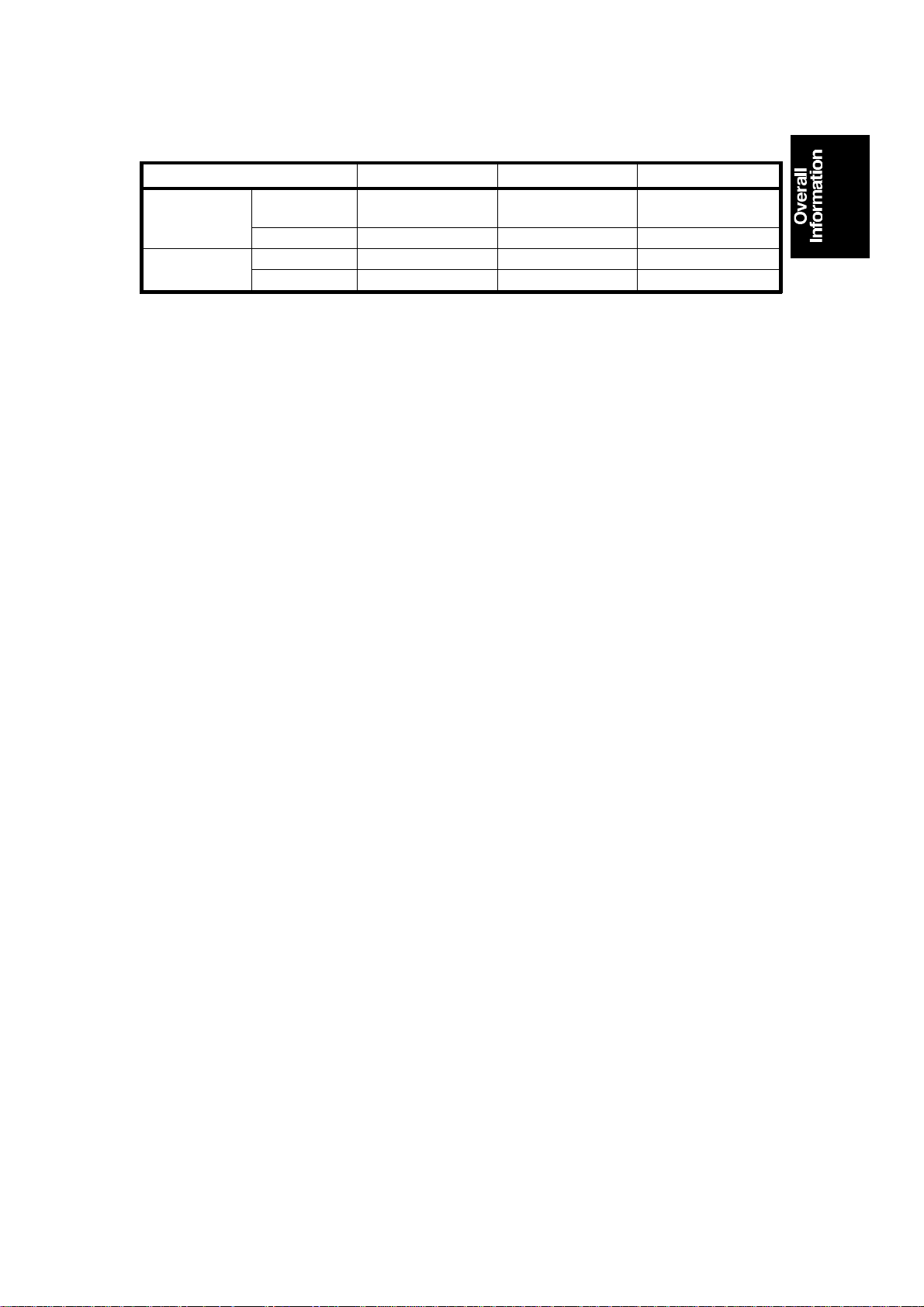

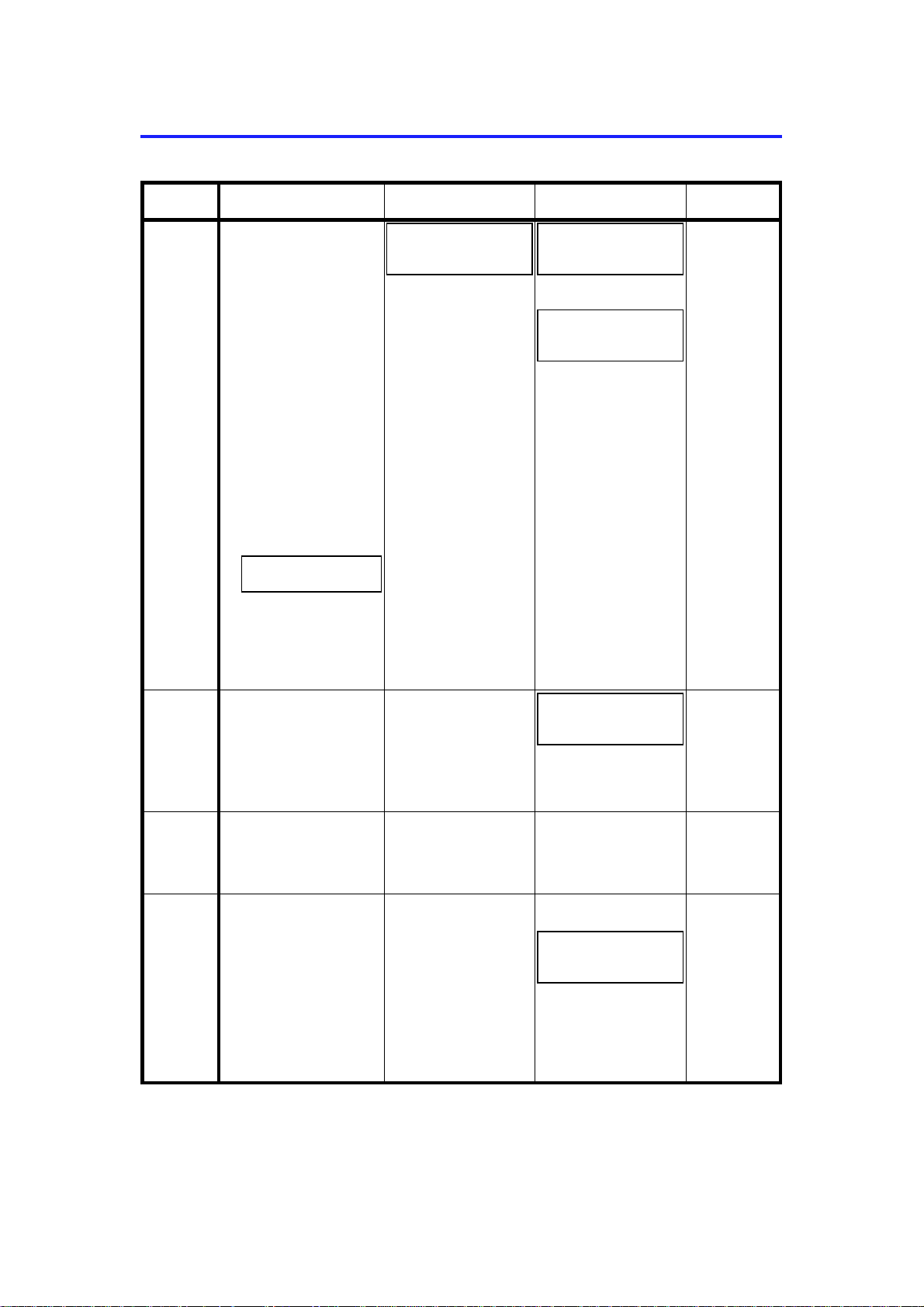

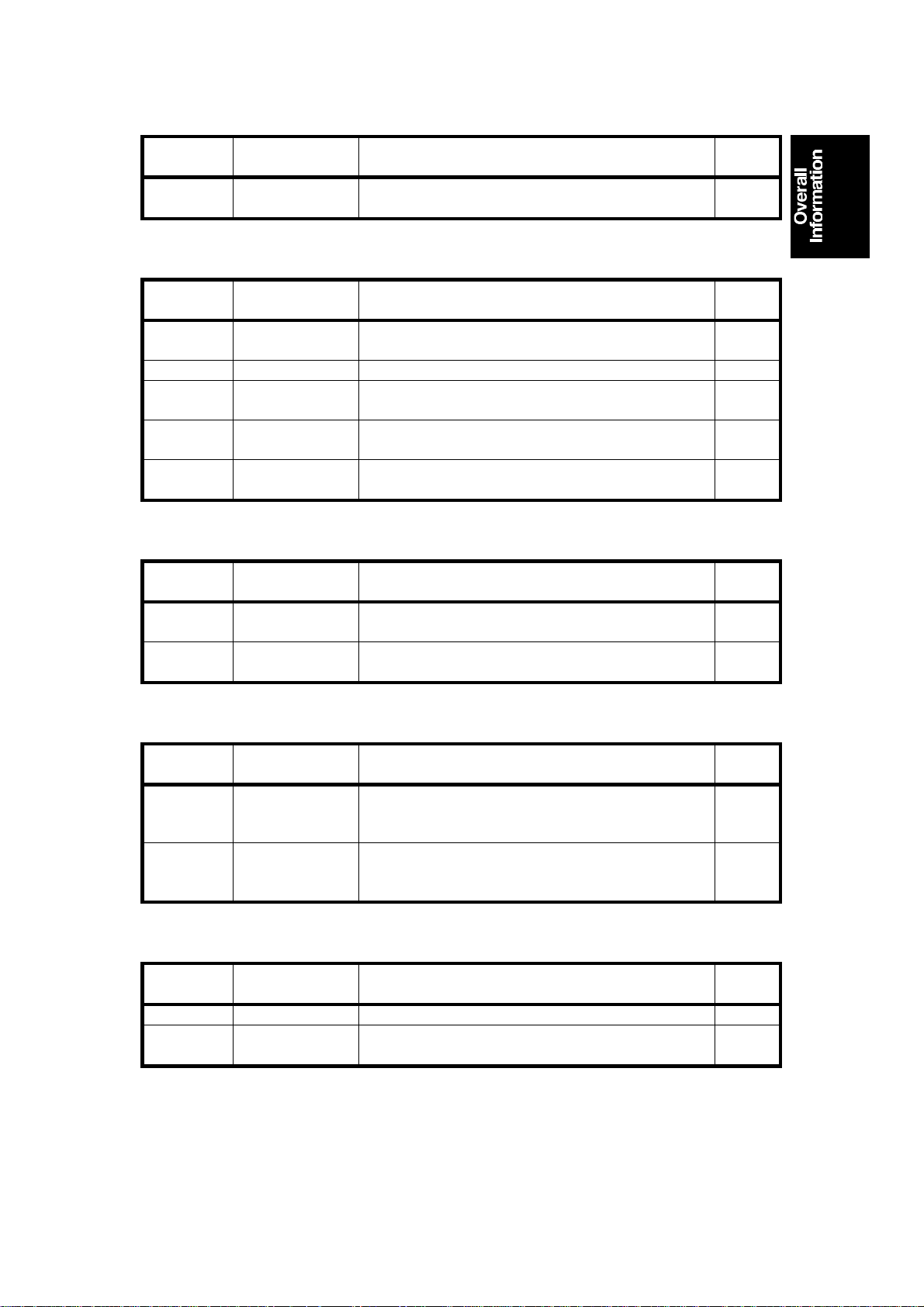

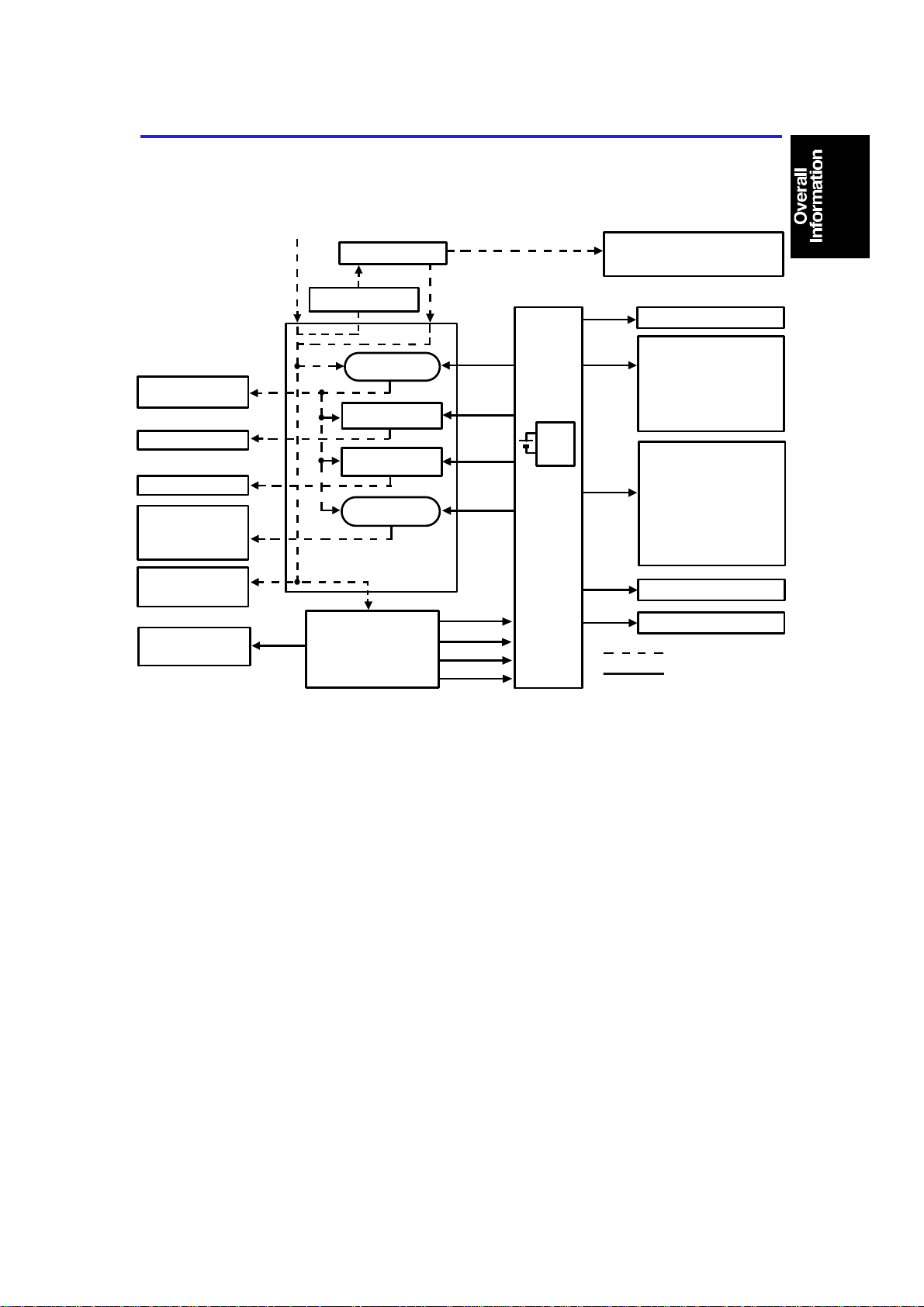

3. COPY PROCESS CONTROL

Image

Density

Control

Toner

Density

Detection

Residual

Voltage

(Vr)

Detection

Between

Copies

Grid Voltage

1. Manual image

density mode

Standard ima ge

density grid voltage

+ +

Manual image density

level fact or

+

Drum residual voltage

(Vr) correction factor

+

Drum temperature

correction factor

2. Auto imag e density

mode

Standard ima ge

density grid voltage

+

Auto image density

level factor (SP34 )

+

Drum residual voltage

(Vr) correction factor

+

Drum temperature

correction factor

Standar d I D sensor gri d

voltage

+

Drum wear correction

factor (SP57)

Standar d I D sensor gri d

voltage

+

Drum wear correction

factor (SP57)

0 volts (Fix ed) Ex p osure lamp turns

Exposure Lamp

Voltage

Base exposure lamp

voltage (Manual or

ADS mode) (SP48)

Reproduct ion ratio

correction factor

(A077/A078 copiers

only)

+

Drum temperature

correction factor

+

Drum residual voltage

(Vr) correction factor

Same as image

density co ntrol

Same as image

density co ntrol

off.

Developmen t Bia s

Voltage

Base bias voltage

factor (Manual or

ADS mode [SP34])

+

Image bias voltage

adjustment factor

(SP37)

+

Drum residual voltage

(Vr) correction factor

+

Drum temperature

correction factor

Note:

Base bias voltage at

manual ID level 7 can

be adjusted by SP50.

Depends on ID

sensor b ias settin g

(SP33)

Note:

For initial 499 copies

bias volt age is

increased by –20 volts.

0 volts (Fixed) Full erase

–160 volt s (F ixed)

+

Base bias voltage

adjustment factor

(SP37)

+

Drum residual voltage

(Vr) correction factor

+

Drum temperature

correction factor

Erase Lamp

Depends on

paper size

and

reproducti on

ratio.

ID sensor

pattern eras e

(Vsg

detectio n:

Full erase)

(All LEDs ON)

Full erase

(All LEDs ON)

NOTE: The boxed item can be adjusted by SP mode.

1-6

Page 10

12

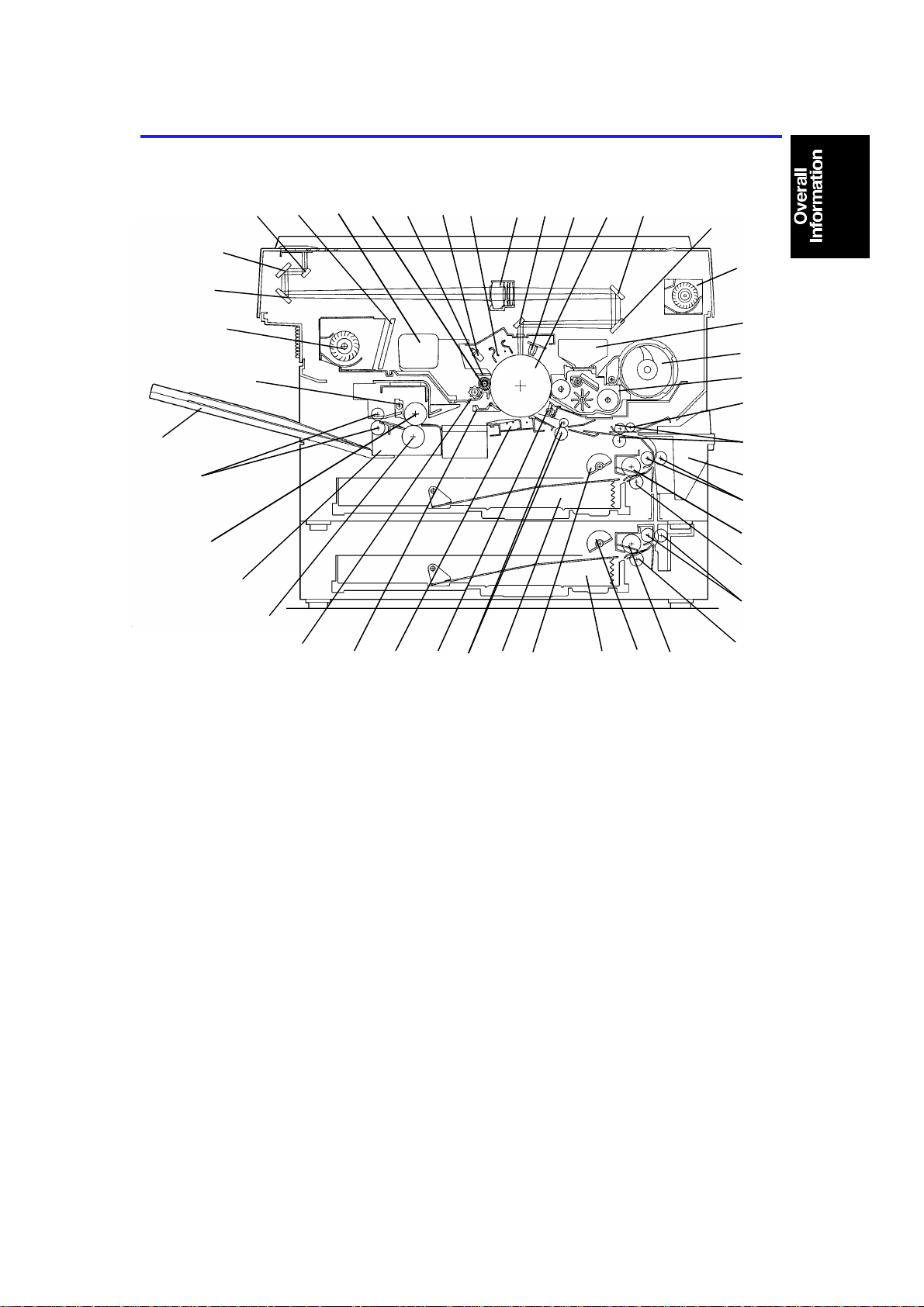

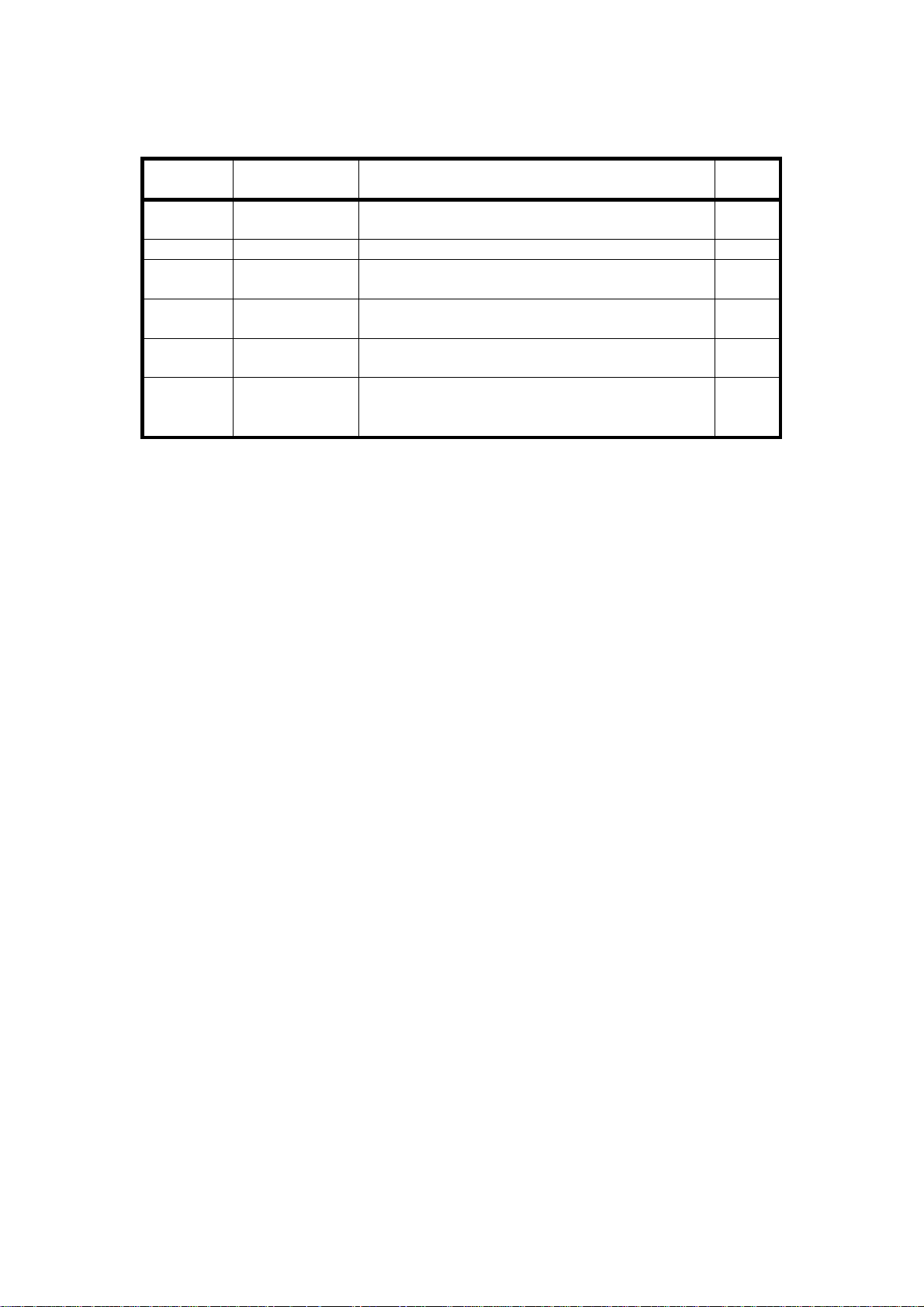

15 January 1992 MECHANICAL COMPONENT LAYOUT

4. MECHANICAL COMPONENT LAYOUT

17

18

20 21 22

19

23 24 25

26 27

28

29

16

30

15

14

31

32

13

33

34

35

11

36

37

10

38

39

9

40

8

7

1. 1st Semicircular Pick-up

rollers

2. 1st Paper Tray

3. Registration Rollers

4. Pre-transfer Lamp (PTL)

5. Transfer and Separation

Corona Unit

6. Pick-off Pawls

7. Cleaning Unit

8. Pressure Roller

9. Fusing Unit

10. Hot Roller

11. Exit Rollers

12. Copy Tray

13. Hot Roller Strippers

14. Exhaust Blower Motor

15. 3rd Mirror

16. 2nd Mirror

17. 1st Mirror

18. Ozone Filter

19. Used Toner Tank

20. Cleaning Brush

21. Cleaning Blade

22. Quenching Lamp

23. Charge Corona Unit

24. Lens

25. 6th Mirror

26. Erase Lamp

27. Drum

28. 4th Mirror

29. 5th Mirror

30. Optics Cooling Fan

31. Developer Tank

32. Toner Supply Unit

123456

33. Development Unit

34. Manual Feed Roller

35. 1st Relay Rollers

36. Manual Feed Table

37. 2nd Relay Rollers

38. 1st Paper Feed Roller

39. 1st Torque Roller

40. 2nd Feed Relay Rollers

(A078 copier only)

41. 2nd Torque Roller

(A078 copier only)

42. 2nd Paper Feed Roller

(A078 copier only)

43. 2nd Semicircular Pick-up

Rollers (A078 copier only)

44. 2nd Paper Tray

(A078 copier only)

424344

41

1-7

Page 11

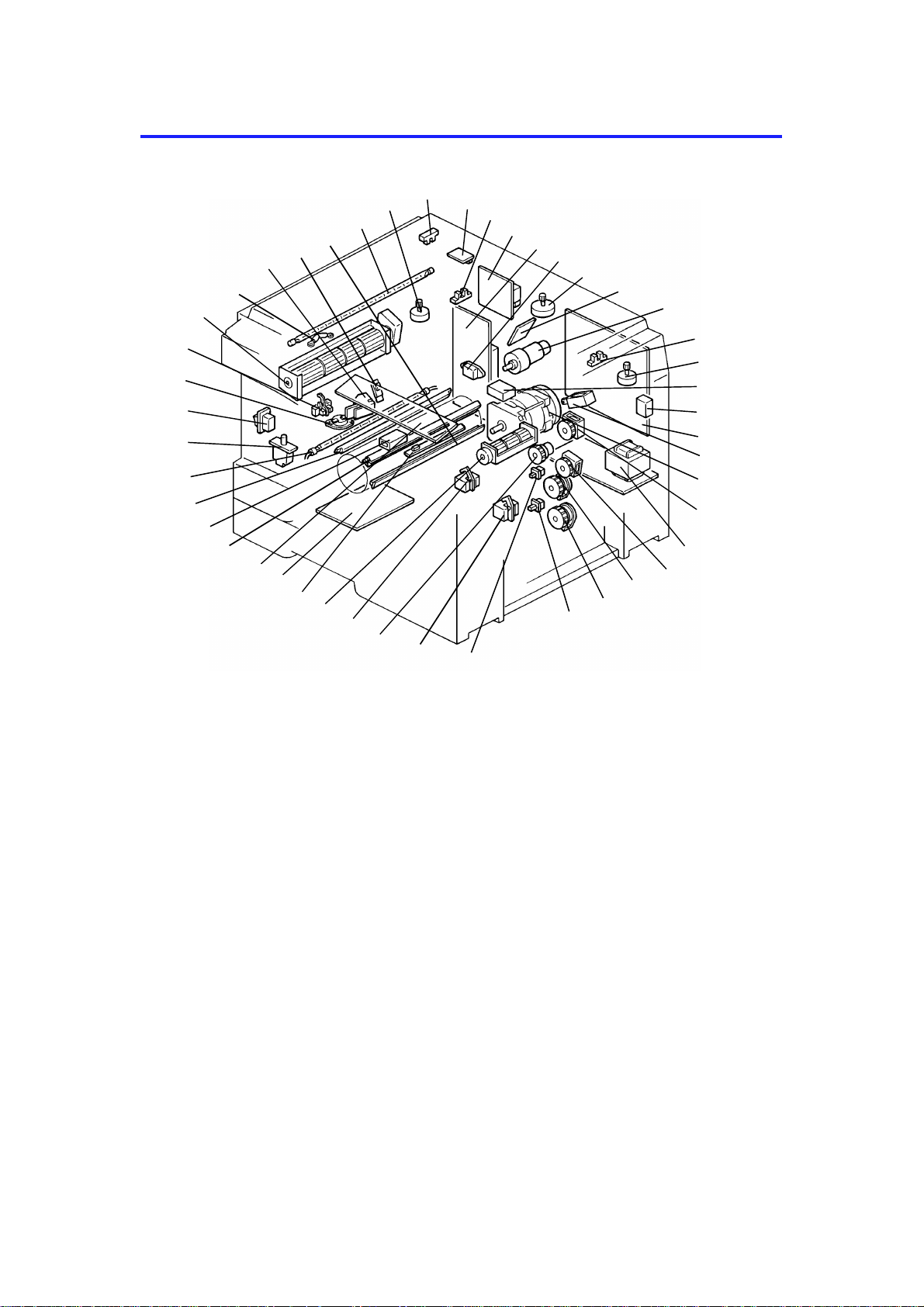

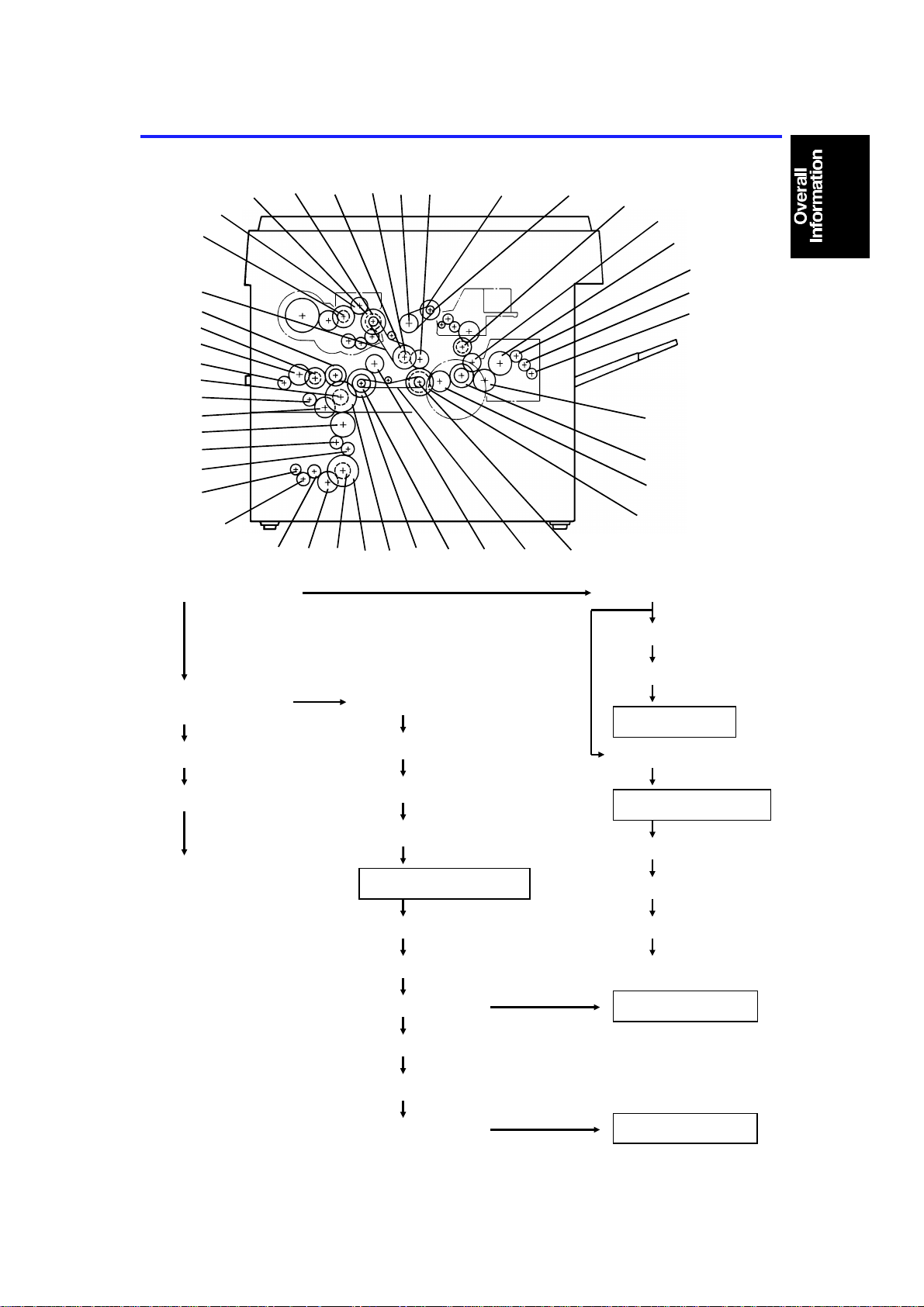

ELECTRICAL COMPONENT LAYOUT 15 January 1992

5. ELECTRICAL COMPONENT LAYOUT

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

1. 1st Paper Tray Switch

2. Relay Sensor

3. Registration Clutch

4. Registration Sensor

5. Optics Cooling Fan Motor

6. Image Density Sensor

(with drum thermistor)

7. Power Pack-TC/SC

8. Operation Panel Board

9. Erase Lamp

10. Total Counter

11. Quenching Lamp

12. Fusing Lamp

13. Front Cover Safety Switch

14. Main Switch

15. Fusing Thermoswitch

16. Exit Sensor

17. Exhaust Blower Motor

24

23

22

25

26

27

4

3

2

18. Optics Thermofuse

19. Auto Image Density Sensor

20. Fusing Thermistor

21. Pre-transfer Lamp

22. Exposure Lamp

23. Lens Motor

(A077/A078 copiers only)

24. Scanner Home Position

Sensor

25. DF Interface Board

(A077/A078 copiers only)

26. Lens Home Position

Sensor

(A077/A078 copiers only)

27. Power Pack-CC/Grid/Bias

28. AC Drive Board

29. Fusing Triac (115 V only)

30. Scanner Motor

31. Drum Motor Board

1

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

32. Drum Motor

33. 4th/5th Mirror Home

Position Sensor

(A077/A078 copiers only)

34. 4th/5th Mirror Motor

(A077/A078 copiers only)

35. Main Motor Capacitor

36. Key Counter (Option)

37. Main Board

38. Development Clutch

Solenoid

39. Main Motor

40. Toner Supply Clutch

41. DC Power Supply Board

42. Relay Roller Clutch

43. 1st Paper Feed Clutch

44. 2nd Paper Feed Clutch

(A078 copier only)

45. 2nd Paper Tray Switch

(A078 copier only)

1-8

Page 12

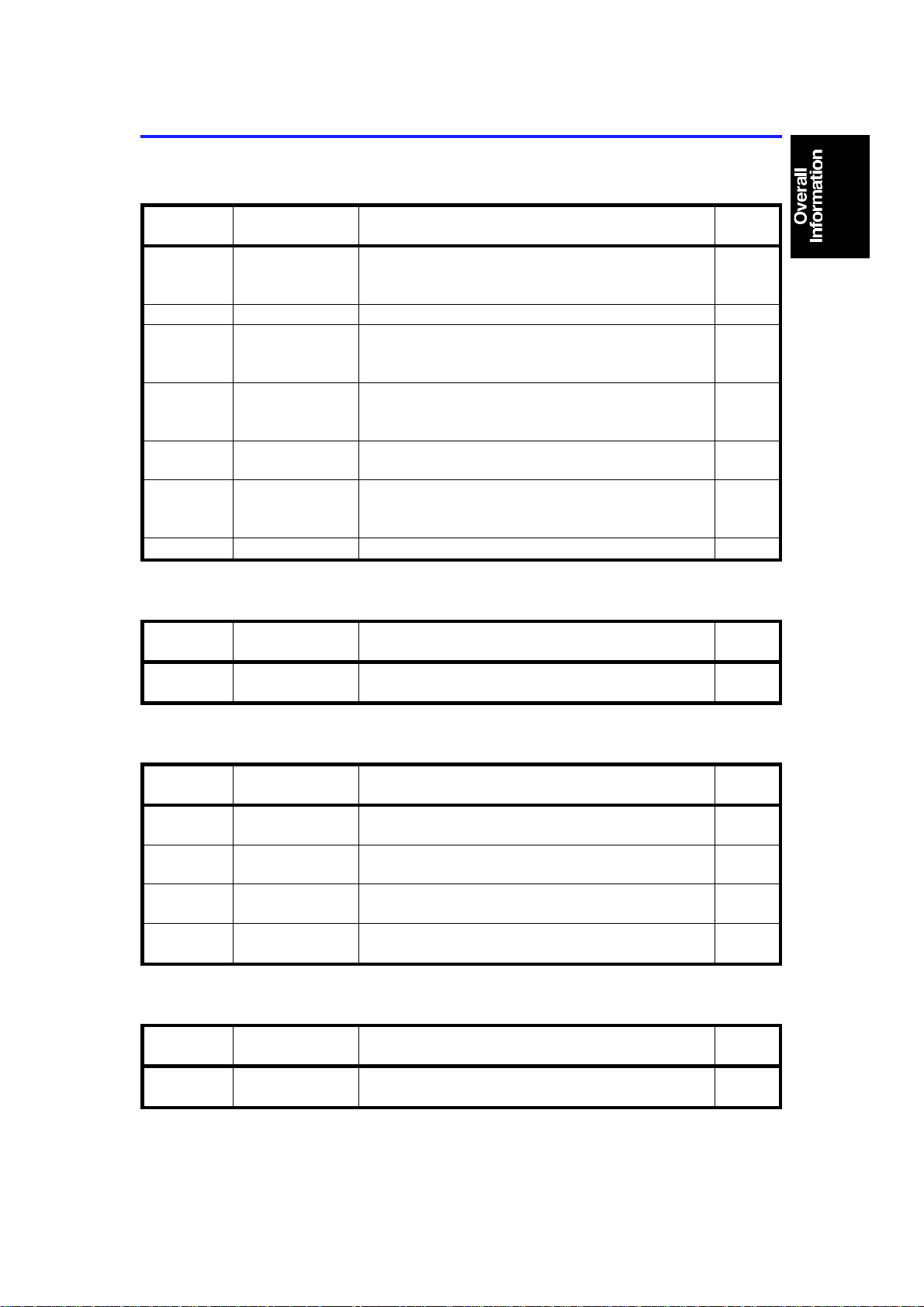

15 January 1992 ELECTRICAL COMPONENT DESCRIPTIONS

6. ELECTRICAL COMPONENT DESCRIPTIONS

Motors

SYMBOL NAME FUNCTION

Drives all the main unit components except for the

M1 Main Motor

M2 Scanner Motor Drives the scanners (1st and 2nd). (dc stepper) 30

M3 Lens Motor

M4

M5

M6

M7 Drum Motor Drives the drum. (dc servo) 32

4th/5th Mirror

Motor

Optics Cooling

Fan Motor

Exhaust Blower

Motor

optics unit, drum unit and fans.

(115/220–230/240 Vac [ac synchronous])

Moves the lens position according to the selected

magnification. (dc stepper)

… A077/A078 copiers only

Positions the 4th/5th mirrors according to the

selected magnification. (dc stepper)

… A077/A078 copiers only

Prevents built up of hot air in the optics cavity.

(24 Vdc)

Removes heat from around the fusing unit and

moves the ozone built up around the charge

section to the ozone filter. (115/220–230/240 Vac)

INDEX

NO.

39

23

34

5

17

Magnetic Clutch

SYMBOL NAME FUNCTION

MC1

Registration

Clutch

Drives the registration rollers. 3

Magnetic Spring Clutches

SYMBOL NAME FUNCTION

MSC1

MSC2

MSC3

MSC4

Toner Supply

Clutch

Relay Roller

Clutch

1st Paper Feed

Clutch

2nd Paper Feed

Clutch

Drives the toner supply roller. 40

Drives the 1st and 2nd relay rollers. 42

Starts paper feed from the 1st paper feed station. 43

Starts paper feed from the 2nd paper feed station.

… A078 copier only

Solenoid

SYMBOL NAME FUNCTION

SOL1

Development

Clutch Solenoid

Transmits the main motor drive to the

development drive gears.

INDEX

NO.

INDEX

NO.

44

INDEX

NO.

38

1-9

Page 13

ELECTRICAL COMPONENT DESCRIPTIONS 15 January 1992

Switches

SYMBOL NAME FUNCTION

SW1 Main Switch Supplies power to the copier. 14

SW2

SW3

SW4

Front Cover

Safety Switch

1st Paper Tray

Switch

2nd Paper Tray

Switch

Cuts the ac power line, when the front cover is

open.

Detects when the 1st paper tray is set. 1

Detects when the 2nd paper tray is set.

… A078 copier only

INDEX

NO.

13

45

Sensors

SYMBOL NAME FUNCTION

S1

S2

S3

S4

S5 Exit Sensor Detects misfeeds. 16

S6 Relay Sensor

S7

S8

Scanner Home

Position Sensor

Lens Home

Position Sensor

4th/5th Mirror

Home Position

Sensor

Registration

Sensor

Image Density

(ID) Sensor

Auto Image

Density Sensor

(ADS)

Informs the CPU when the 1st scanner is at the

home position.

Informs the CPU when the lens is at the home

position (full size position).

… A077/A078 copiers only

Informs the CPU when 4th/5th mirrors assembly is

at the home position (full size position).

… A077/A078 copiers only

1) Detects misfeeds.

2) Controls the relay roller clutch stop timing.

1) Detects when the copy paper is set in the

manual feed table.

2) Detects misfeeds.

Detects the density of the image on the drum to

control the toner density.

Senses the background density of the original. 19

INDEX

NO.

24

26

33

4

2

6

Printed Circuit Boards

SYMBOL NAME FUNCTION

PCB1 Main Board

PCB2 AC Drive Board

PCB3

PCB4

PCB5

DC Power

Supply Board

DF Interface

Board

Operation Panel

Board

Controls all copier functions both directly and

through the other PCBs.

Drives all ac motors, the exposure lamp, fusing

lamp, quenching lamp, exhaust blower motor.

1) Steps down the wall voltage to 28 Vac.

2) Rectifies 28Vac input and outputs dc

voltages. (30 volts, 24 volts, 5 volts)

Interfaces between the copier main board and DF.

… A077/A078 copiers only

Informs the CPU of the selected modes and

displays the situations on the panel.

1-10

INDEX

NO.

37

28

41

25

8

Page 14

15 January 1992 ELECTRICAL COMPONENT DESCRIPTIONS

SYMBOL NAME FUNCTION

PCB6

Drum Motor

Board

Controls the drum motor speed. 31

Lamps

SYMBOL NAME FUNCTION

L1 Exposure Lamp

L2 Fusing Lamp Provides heat to the hot roller. 12

L3 Quenching Lamp

L4 Erase Lamp

L5

Pre-transfer

Lamp

Applies high intensity light to the original for

exposure.

Neutralizes any charge remaining on the drum

surface after cleaning.

Discharge the drum outside of the image area.

Provides leading/trailing edge and side erases.

Reduces charge on the drum surface before

transfer.

Power Packs

SYMBOL NAME FUNCTION

P1

P2

Power Pack

–CC/Grid/Bias

Power Pack

–TC/SC

Provides high voltage for the charge corona, grid,

and the development roller bias.

Provides high voltage for the transfer and

separation corona.

INDEX

NO.

INDEX

NO.

22

11

9

21

INDEX

NO.

27

7

Heaters

SYMBOL NAME FUNCTION

H1

H2

Drum Anticondensation

Heater (Option)

Optics Anticondensation

Heater (Option)

Prevents moisture around the drum.

When the main switch is turned on (off) the heater

turns off (on).

Prevents moisture from forming on the optics.

When the main switch is turned on (off) the heater

turns off (on).

Counters

SYMBOL NAME FUNCTION

CO1 Total Counter Keeps track of the total number of copies made. 10

CO2

Key Counter

(Option)

Used for control of authorized use. Copier will not

operate until installed.

1-11

INDEX

NO.

N/A

N/A

INDEX

NO.

36

Page 15

ELECTRICAL COMPONENT DESCRIPTIONS 15 January 1992

Others

SYMBOL NAME FUNCTION

TH1

TH2 Drum Thermistor Monitors the temperature around the drum. 6

TS

TF

C

TR Fusing Triac

Fusing

Thermistor

Fusing

Thermoswitch

Optics

Thermofuse

Main Motor

Capacitor

Monitors the fusing temperature. 20

Provides back-up overheat protection in the fusing

unit.

Provides back-up overheat protection around the

exposure lamp.

Start capacitor. 35

Switches the fusing lamp on and off. (115 V only)

Note: In the 220V-230V/240V version, the triac

is built-in the ac drive board

INDEX

NO.

15

18

29

1-12

Page 16

G23

G27

G29

A

G28: Relay Gear

15 January 1992 DRIVE LAYOUT

7. DRIVE LAYOUT

G22

TB2

G21

G20

G19

G18

G17

G16

G15

G14

G13

G12

G11

G24

G10

G25

TB3 BP6G26BP5BP4BP3

G28

G30

G31

G32

G33

G34

G1

G2

G9

G1: Main Motor Gear

G2: Timing Belt Drive

Gear

BP1: Timing Belt Pulley

TB1: Timing Belt

G8

G7

G6

G5

G26 Relay gear

G25: Timing Belt Drive Gear

BP4: Timing Belt Pulley

TB2: Timing Belt

Development Section

BP3: Timing Belt Pulley

G24: Development CL Gear

Development CL

G4

BP2

G3

TB1 BP1

G34: Relay Gear

G27: Cleaning Drive Gear

Cleaning Unit

G33: Fusing Drive Gear

Fusing and Exit Unit

G29: Hot Roller Gear

G30: Relay Gear

G31: Relay Gear

G32: Exit Roller Gear

Development Unit

G23: Relay Gear

G22: Toner Supply CL Gear

Toner Supply CL

1-13

Toner Supply Unit

Page 17

G14: Relay Gear

G13: Relay Gear

G12: Relay Gear

G8: Relay Gear

2nd Torque Roller

G10: Relay Gear

DRIVE LAYOUT 15 January 1992

A

Paper Feed Section

BP2: Timing Belt Pulley

G3: Registration CL

Gear

Registration CL

Registration Rollers

G21: Relay Gear

G20: Relay Roller CL

Gear

Relay Roller CL

2nd Relay Rollers

G19: Relay Gear

G18: 1st Relay Roller

Gear

1st Relay Rollers

G4: Relay Gear

1st Paper Feed Section

G5: 1st Paper Feed CL

Gear

1st Paper Feed CL

1st Pick-up Rollers

G17: 1st Pick-up Roller

Gear

G15: Relay Gear

G16: 1st Paper Feed Roller

Gear

1st Paper Feed Roller

1st Torque Roller

2nd Paper Feed Section

G6: 2nd Paper Feed CL

Gear

2nd Paper Feed CL

2nd Pick-up Rollers

G7: 2nd Pick-up Roller

Gear

BP6: Drum Motor Pulley

TB3: Timing Belt

BP5: Drum Drive Pulley

Drum

G9: 2nd Paper Feed

Roller Gear

2nd Paper Feed Roller

G11: 2nd Feed Relay Roller

Gear

2nd Feed Relay Rollers

1-14

Page 18

15 January 1992 POWER DISTRIBUTION

8. POWER DISTRIBUTION

AC Power (115V or 220~230V/240V)

Exhaust Blower

Motor (L)

Fusing Lamp

Exposure Lamp

Main Motor

Quenching Lamp

Exhaust Blower

Motor (H)

Document Feeder

(Option)

Drum Motor Board

(Drum Motor)

24V (VA)

Main SW

Cover Safety SW

Power Relay

(RA401)

Fusing Lamp

Drive Circuit

Exposure Lamp

Drive Circuit

Main Motor

Relay (RA402)

AC Drive Board

DC Power

Supply Board

24V (VA)

24V (VA)

24V (VA)

24V (VA)

30V (VM)

24V (VA)

5V (VC)

Zero Cross

RAM

Pack

Main

Board

Anti-condensation Heaters

-Drum (Option)

-Optics (Option)

9V

Scan

Signal

5V (VC)

24V (VA)

30V (VM)

9V (VB)

Operation Panel Board

Sensors

Switches

Drum Motor Board

(Encoder)

DF Interface Board

(A077/A078 copiers only)

Thermistors

Solenoids

Clutches

Power Packs

Lens Motor

(A077/A078 copiers only)

4th/5th Mirror Motor

(A078 copier only)

Optics Cooling Fan

Motors

Image Density Sensor

Scanner Motor

AC power

DC power

When this copier is plugged in and the main switch is turned off , ac power is

supplied via the ac drive board to the anti-condensation heate rs. Whe n the

front cover and/or the exit cove r is open, the cover safety switch complete ly

cuts off power to all ac and dc components. The RAM pack has a back up

power supply (dc battery) for the service program mode data and misfee d job

recovery.

When the main switch is turned on, the ac power sup ply to the

anti-condensation heat er is cut of f an d ac power is supp lied to the ac drive

board. The dc power supply board receives wall outlet ac power through the

ac drive board.

The dc power supply board converts th e wall outle t ac po wer inp ut to +5

volts, +24 volts, +30 volts and a zero cro ss signal.

1-15

Page 19

POWER DISTRIBUTION 15 January 1992

The +24 volts is supplied to both the main board and the drum motor board.

The +5 volts, +30 volts and th e zero cross sig na l are sup plied to the main

board.

The main board supplies dc p owe r to all copier dc components except for th e

drum motor. All sensors (except for the ID sensor), switches, thermisto rs, th e

drum motor encoder, plus the DF interface board operate on +5 volts. The

image density sensor as well as the operatio n pane l operates on +9 volts,

supplied by the main board. The scann er mot or op era te s on +30 volts. All

other dc components including the power relay (RA401) and th e main motor

relay (RA402) operate on +2 4 volt s. The document feeder has a separate dc

power supply.

When the main board receives power, it act ivat es the power rela y (RA 401)

which then supplies ac power to the fusin g lamp drive circuit, and the

exposure lamp drive circuit on the ac drive board. The exhaust blower motor

begins rotating at low speed. The fusing lamp drive circuit receives a trigger

signal from the main board an d the fusing lamp lights. The exp osure lamp

does not turn on until the main boa rd send a trigger pulse to the exp osu re

lamp drive circuit.

When the Start key is pressed, the main bo ard ene rgize s the main mot or

relay (RA402). Then, the main motor and the quenching lamp turn on an d th e

exhaust blower starts rotating at high speed.

When the main switch is turned off, power is cut off to the main board and to

RA401, and the optional drum and optics anti-condensation heaters are

turned on.

1-16

Page 20

SECTION 2

DETAILED SECTION

DESCRIPTIONS

Page 21

15 January 1992 DRUM

1. DRUM

1.1 DRUM CHARACTERISTICS

The drum has the characteristics o f:

1. Being able to accept a high negative electrical charge in the dark. (Th e

electrical resistance of a photocon ductor is high in the absence of light.)

2. Dissipating the electrical charge when exposed to light. (Exposure to light

greatly increases the conduct ivity of a photo con du cto r.)

3. Dissipating an amount of charge in dire ct pro po rtio n to the inte nsity of the

light. That is, where stronger light is directed to the photoconductor

surface, a smaller voltage remains on the drum.

4. Under low temperatures, drum photose nsit ivity dro ps an d residua l volta ge

increases. This makes it necessary t o monitor the drum temperature and

some compensation is require d.

5. During the drum’s life, drum residu al volt ag e gra du ally increases and the

photoconductive surface becomes worn.

Therefore, some compen sat ion for these characteristics is required.

2-1

Page 22

DRUM 15 January 1992

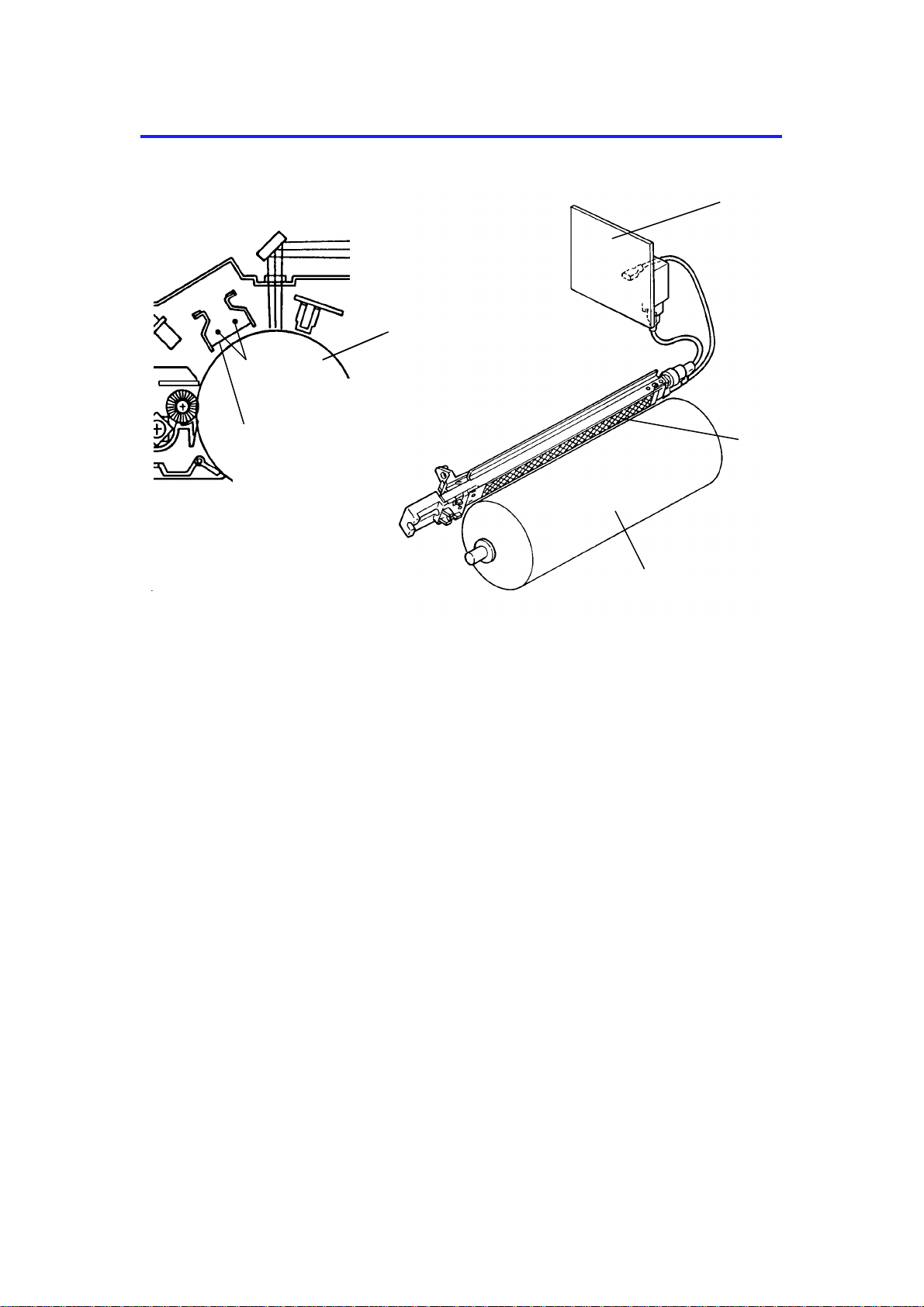

1.2 DRUM UNIT

[F]

[E]

[B]

[G]

[A]

[C]

[D]

An organic photoconductor (OPC) dru m [A] is used in this mode l.

A drum unit [B] holds the drum and preve nts stress on the drum. The drum

unit consists of an OPC drum, ID sensor bo ard [C] an d pick-o ff pawls [D] .

When the drum, the pick-off pawls, or the ID sensor is replaced or clean ed,

the drum unit must be removed from the copier.

The drum is driven by an independent drum motor [E] thro ugh a timing belt

[F] and the drum drive pulley [G].

The pick-off pawls are always in contact with the drum surface.

The ID sensor board consists of the ID sen sor and th e dru m the rmisto r.

2-2

Page 23

Drum Motor

(M7)

15 January 1992 DRUM

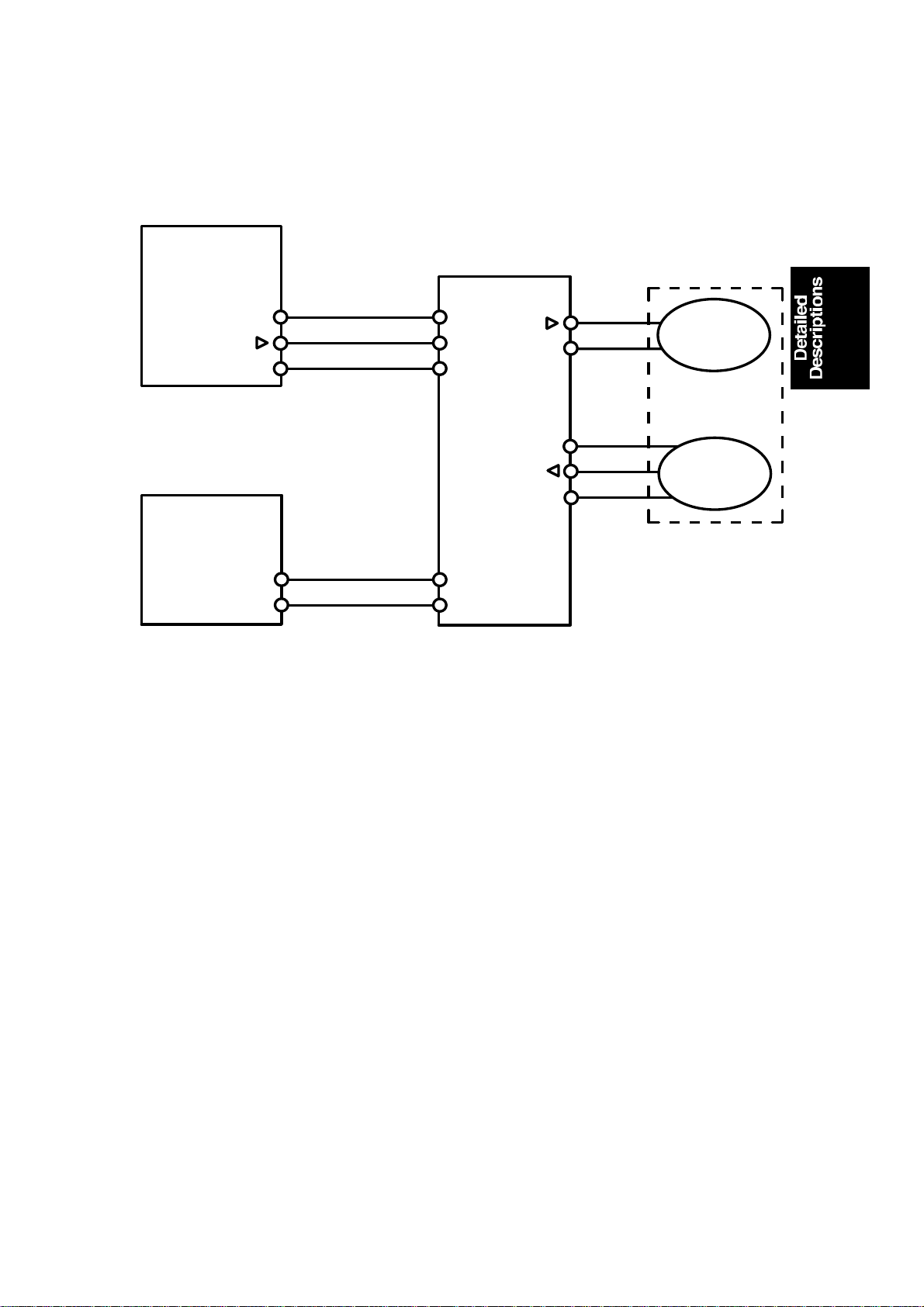

1.3 DRUM MOTOR CONTROL

Main Board

(PCB 1)

VC [5]

ON signal [▼5]

GND [0]

DC Power

Supply Board

(PCB 1)

VA [24]

GND [0]

CN131-3

CN131-2

CN131-1

CN204-3

CN204-1

CN801-1

CN801-2

CN801-3

CN802-3

CN802-1

▼24]

[

24 V

5 V

IN

GND [0]

Drum Motor

Board

(PCB 1)

CN803-1

CN803-2

CN804-3

CN804-2

CN804-1

Encoder

The drum motor is a dc servomotor. The drum motor board controls the

speed of this servomotor.

When the Start key is pressed, the main bo ard send s an "ON sig nal" to the

drum motor board (CN131-2) to energize the drum motor.

The encoder on the servomotor has a phot oin te rrupter that generates a

series of pulse signals. The drum mot or board monitors these pulse signals

to regulate the motor speed (10 0 mm/se con d).

2-3

Page 24

DRUM CHARGE 15 January 1992

2. DRUM CHARGE

2.1 OVERVIEW

[A]

[A]

[B]

[D]

[A]

This copier uses a double wire scorotro n and a highly sensitive OPC drum

[A]. The corona wires [B] ge ne rat e a corona of negative ions when the

CC/Grid/Bias power pack [C] applies a high voltage. The CC/Grid/Bias power

pack also applies a negative high volta ge to a stainless steel grid plate [D].

This insures that the drum coating receives a uniform negative charg e as it

rotates pa st the corona unit.

[C]

[D]

The exhaust fan, located abo ve the cop y exit, causes a flow of air from the

upper area of the deve lop ment unit through the charg e coro na unit . This

prevents an uneven bu ild-u p of negative ions that can cause uneven image

density. The exhaust fan runs at half spe ed when in the st and-by condition

and at full speed while copying.

The exhaust fan has an ozo ne filte r (a ctive ca rbo n) which adsorbs ozone (O3)

generated by the coro na charge. The ozone filter decre ases in efficiency over

time as it adsorbs ozone. The ozone filter should be replaced at every 80000

copies.

The flow of air around the charge corona wires may deposit paper dust or

toner particles on the corona wire . The se pa rticle s may interfere with

charging and cause low density ba nd s on cop ies. The wire clea ne r clean s

the corona wire when the op era to r slides the corona unit out and in.

2-4

Page 25

15 January 1992 DRUM CHARGE

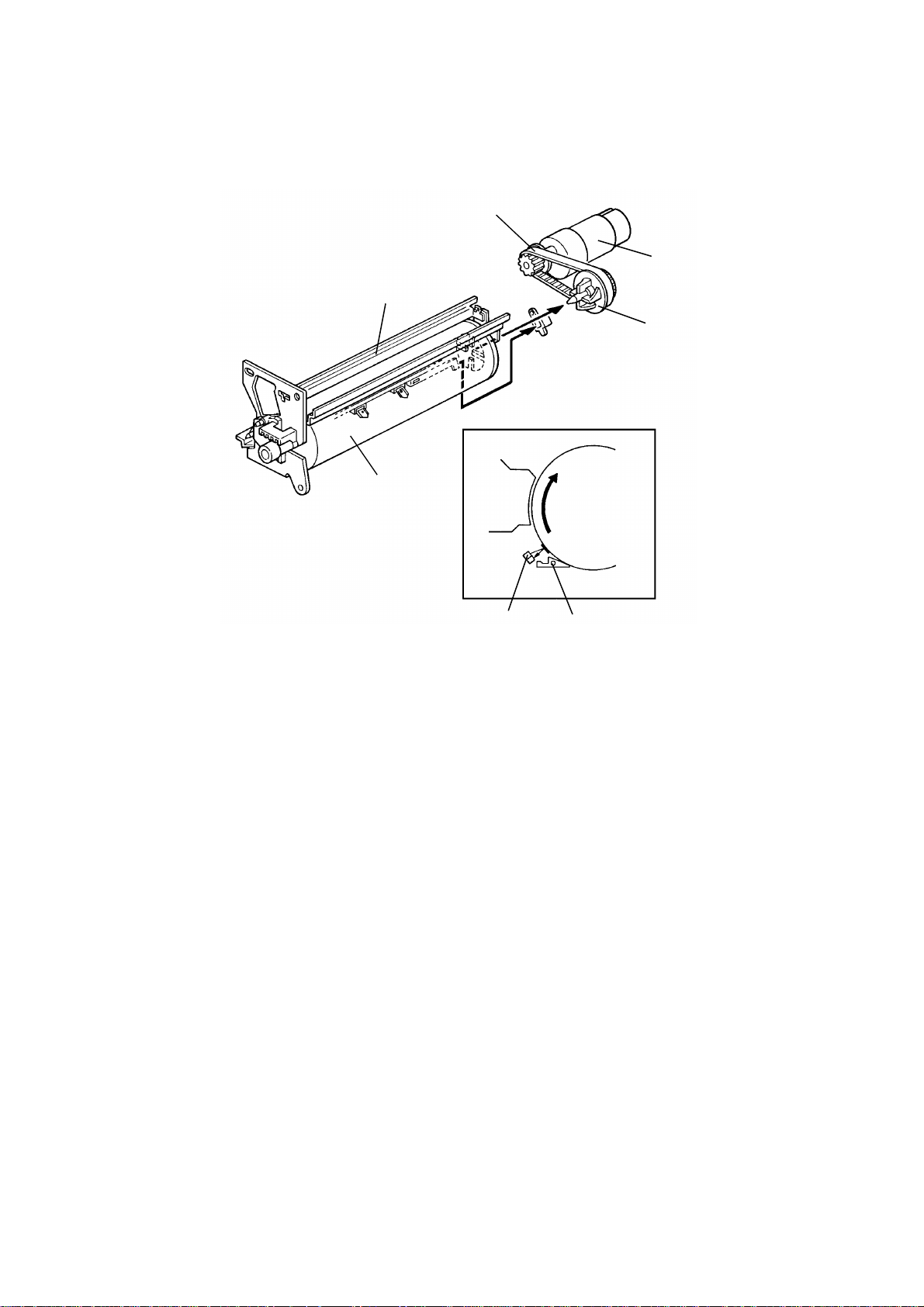

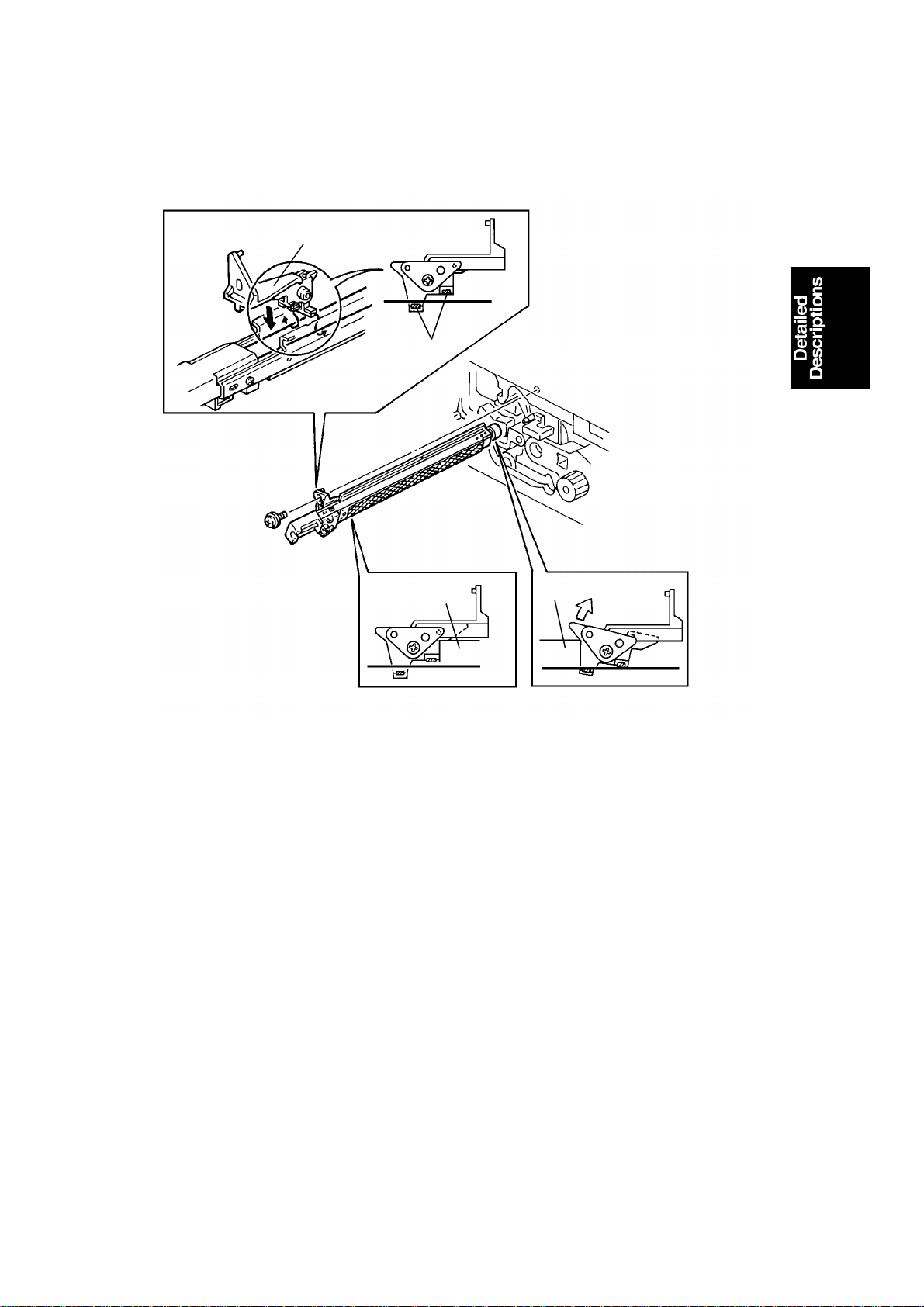

2.2 CHARGE CORONA WIRE CLEANE R MECHANI S M

[B]

[A]

[D]

[C]

Pads [A] above and below th e charge corona wires clean the wires as th e

charge unit is manually slid in and out.

The cleaner pad bracket [B ] rotates when the charge unit is fully e xte nd ed

and the bracket is pulled up against the rear en dblock [C]. This moves the

pads against the corona wires (see illustra tion). If the charge unit is not fu lly

extended, the pads do not tou ch th e corona wires.

The pads move away from the wires when the charg e unit is f ully inse rted

and the cleaning bracket is pushed against the front endblock [D].

After copier installa tio n the key operator should be instru cted to use this

mechanism when copies exhibit low ima ge den sity band s.

2-5

Page 26

Power Pack CC/Grid/Bias

(P1)

Charge Corona

Development

Bias

DRUM CHARGE 15 January 1992

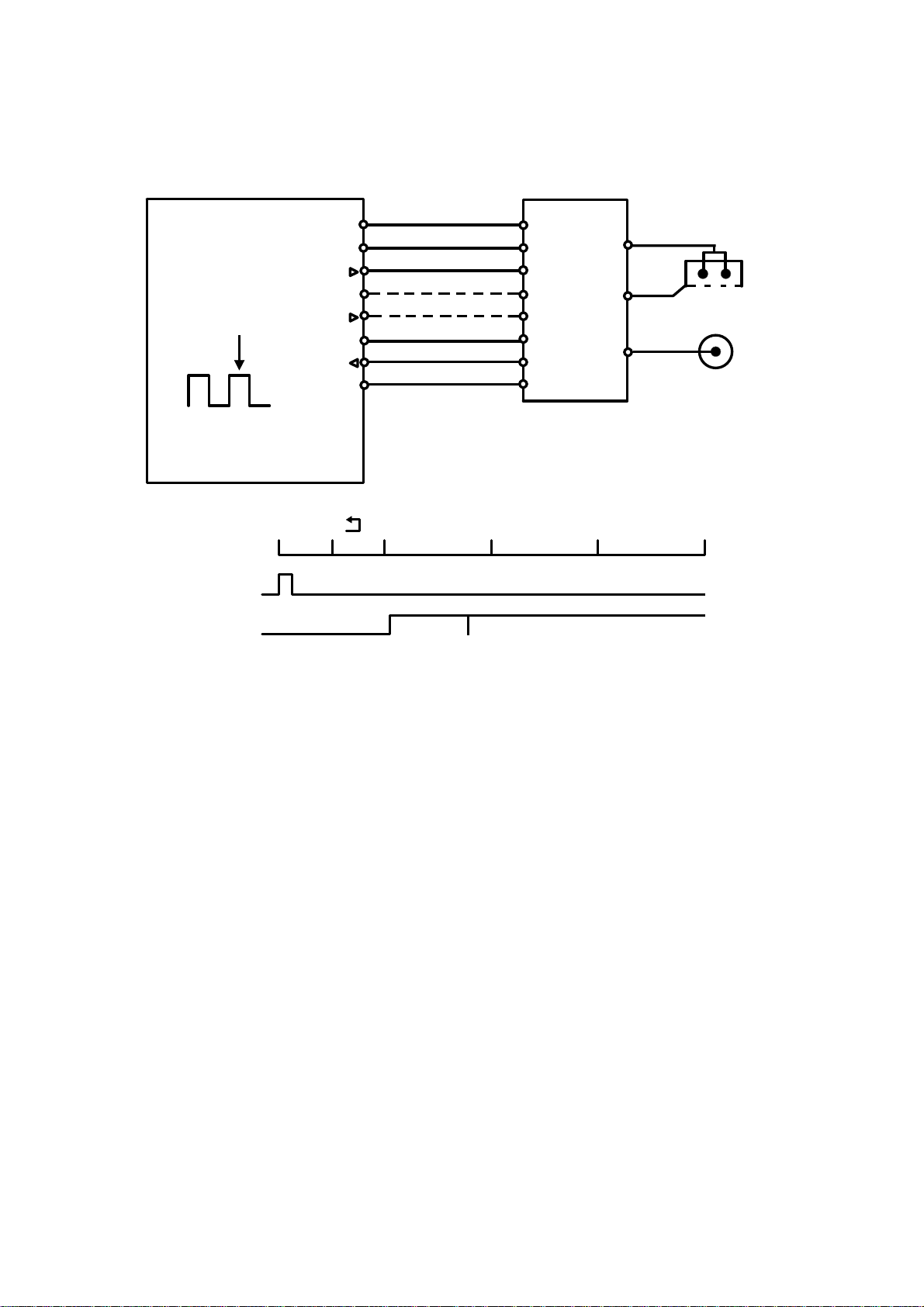

2.3 CHARGE CORONA CIRCUIT

VA [24]

VC [5]

CC Trig [▼24]

Grid Trig (PWM) [▲0→0/5]

Grid FB

GND [0]

Main Board (PCB 1)

1350

0

Timing Pulse

(1pulse=4msec)

Start Key

Charge Corona

and Grid Voltage

200

CN119-8

CN119-7

CN119-6

CN119-5

CN119-4

CN119-3

CN119-2

CN119-1

1500

1589 1782

Toner Density

Detection Cycle

CN1-1

CN1-2

CN1-3

CN1-4

CN1-5

CN1-6

CN1-7

CN1-8

2000 2500 3000

Image Area

M

G

B

Grid

(Pulse)

The main board supplies +24 volt s to th e CC/G rid/Bias power pack at CN1-1

as the power supply source. About 2.5 seconds after th e Start key is pressed

(during the toner d en sity detection cycle about 1.8 second s), th e CPU drops

CN1-3 from +24 volts to 0 volts. This energizes the charge coron a circuit

within the CC/Grid/Bias power pack, which applies a high nega tive volta ge of

approximately –7.0 K volts to th e cha rge corona wires. The corona wires then

generate a negative corona charge.

The grid plate limits the cha rge voltage to ensure that the charge does not

fluctuate and that an even charge is applied to the drum surfa ce.

The grid trigger pulse applied to CN1-5 is a pulse width modulated signal

(PWM signal). This signal is not only a trigger signal, it also chan ges the

voltage level of the grid. As the width of the pulse ap plie d incre ases, the

voltage of the grid also incre ases. The CPU monitors the grid volta ge at

CN119-2 and controls the width of the grid trigger pulses based on th is

feedback.

2-6

Page 27

15 January 1992 DRUM CHARGE

2.4 GRID VOLTAGE CORRECTION

To maintain good copy quality ove r the drum’s life , th e grid volta ge is

changed by the following:

• Drum residual voltage correction (Vr correction)

• Drum temperature correction

• Drum wear correction

2.4.1 Drum Resi dual Volta ge Corr ec tion (Vr corr ection)

During the drum’s life, the dru m may fat igu e electrically and residual voltage

(Vr) on the drum may gradually increase. When this happens, the corona

charged voltage on th e dru m is not disch arged enough in the quenching an d

exposure processes. Even if the development bia s is applie d in th e

development process, the background area of th e orig inal on the drum may

attract some toner. This may cause dirty background on copies. The Vr

correction prevents this ph enomenon as follows:

A pattern (Vr pattern) is develope d on the drum eve ry 100 0 cop ies and its

reflectivity is detected by the ID sen sor to measu re th e resid ua l volta ge . This

is called residual voltage detect ion . (If the reflectivity is low, the residual

voltage will be high.) When the Vr pattern is developed, all blocks of the

erase lamp turn on, and th e de velo pment bias voltage is 0 volt.

The CPU determines what level of Vr co rrect ion is necessa ry dep en din g on

the output (Vr ratio [L]) from the ID sensor.

Vrp

L =

x 100 (%)

Vsg

Vrp: ID sensor outp ut for Vr pattern

Vsg: ID sensor output for bare drum

The current Vr ratio is disp laye d by SP67.

The CPU increases the development bias voltage depending on the Vr ratio

to prevent dirty backgrou nd on copies, (See page 2-33 for more informatio n. )

The CPU also increases the grid volta ge to ensure prop er imag e de nsit y

depending on the Vr ratio. (See page 2-11.)

Because the grid voltag e is increased, the charge volta ge on th e dru m ’s

surface is also increased. To compe nsate for the charge voltage increase,

the exposure lamp voltage is also incre ased. (See page 2-21.)

2-7

Page 28

DRUM CHARGE 15 January 1992

2.4.2 Drum Temperature Correction

During a low drum temperature condition, the drum’s residual voltage

increases and drum photosen sitivity drops due to the characterist ics of th e

drum. This may cause dirty background on copies.

A drum temperature correct ion is made to compe nsa te for th is phe nomenon

as follows:

A drum thermistor on the ID sensor board mon itors the temperature around

the drum. When the drum temperature is less than 20°C, the CPU increases

the development bia s vo lta ge to pre vent dirty background on copies. (S ee

page 2-33.) The CPU also increases th e grid voltage to ensure proper image

density. (See page 2-11.) The exp osu re lamp voltage is also increased to

compensate for the drum p hoto sensitivity drop. (See page 2-20.) Whe n the

drum temperature is 20°C or higher, the drum te mpe rat ure correct ion is not

made.

2.4.3 Drum Wear Correction

During the drum’s life, the photoco nd uct ive surf ace of the drum becomes

worn by contact with the cleaning brush. This effects ability of the drum to

hold a charge. This characte ristic esp ecially affects developing of th e ID

sensor pattern. The ID sensor pattern developed on th e dru m b eco mes

lighter causing high er to ne r co nce ntration in the developer. The drum wear

correction is made to prevent this phenomenon and is as follows:

The CPU keeps track of the drum motor ro ta tio n time that corre sponds to the

wear of the photoconductive layer. The grid voltage for the toner density

detection increases at set int erval. The grid voltage for the residu al volt ag e

(Vr) detection also increase s at th e same interval. (See page 2-12.) The dru m

motor rotation time is displayed by SP57.

2-8

Page 29

15 January 1992 DRUM CHARGE

2.5 GRID VOLTAGE FOR IMAGE DENSITY CONTROL

The main board controls the grid volt age fo r a copy imag e th rou gh the

CC/Grid/Bias power pack. As the grid volta ge beco mes less, the copy imag e

becomes lighter and vice versa. The grid voltage is based on the stand ard

image grid voltage (Vg) and various correction fact ors.

The method of control is different dependin g on whethe r the ima ge density is

manually selected, or the auto imag e de nsit y mode is used.

The grid voltage for non-image areas (betwee n cop ies) is 0 volt (Fixed ).

The grid voltage while cop ying consists of the following facto rs:

1. Manual image density mode

Grid voltage = Standard image density grid voltage

(Vg = –680 volts [SP60=4])

+

Manual image density level factor

+

Drum residual voltage (Vr) correction factor

+

Drum temperature correction factor

2. Auto image density mode

Grid voltage = Standard image density grid voltage

(Vg = –680 volts [SP60=4])

+

Auto image density level fact or (SP 34 )

+

Drum residual voltage (Vr) correction factor

+

Drum temperature correction factor

2-9

Page 30

DRUM CHARGE 15 January 1992

2.5.1 Manua l Image Density Level Factor

Darker Lighter

Manual ID level 1 2 3 4 5 6 7

Change of grid voltage (volts) ±0 ±0 ±0 ±0 ±0 +50 +50

The grid voltage does not change for manual image density levels 1 through

5. However, the exposure lamp volt ag e an d th e de velo pme nt bias volt ag e

does vary depending on the manual imag e de nsit y le vel. (See page 2-1 9 and

2-31.)

The grid voltage at the manual image density level 6 is the same as the one

at level 7, however, the exp osure lamp voltage and the deve lop ment bias

voltage are different. (See page 2-19 and 2-31.)

2.5.2 Auto Ima ge Dens ity Level Factor (SP34)

Auto image density level Data (SP34) Change of grid voltage (volts)

Normal 0 ±0

Darker 1 –50

Lighter 2 ±0

The grid voltage and the expo sure la mp volt ag e are co nst an t reg ardless of

the output from the auto image de nsit y senso r. Only the development bias

voltage varies depending on the output from the auto image density sen sor.

When the auto image densit y le vel data is set to lighter, the chang e of the

grid voltage is 0 volt. However, th e de velo pme nt bias volt ag e is chan ged –4 0

volts.

2-10

Page 31

15 January 1992 DRUM CHARGE

2.5.3 Drum Residual Voltage (Vr) Correction Factor

Vr ratio (L) (%) (SP67) Change of grid voltage (volts)

100 to 84 ±0

83 to 58 –40

57 to 41 –80

40 to 28 –120

27 to 0 –160

L = Vrp/Vsg x 100 (%)

Vrp: ID sensor output for Vr pattern

Vsg: ID sensor output for bare drum

During the drum’s life, drum residu al volt ag e (Vr) may gra du ally incre ase. Vr

correction compensate s for th e resid ua l volta ge on the dru m. The Vr

correction is done every 1000 copies. The CP U increa ses the development

bias voltage, the grid volt age, and the exposure lamp voltag e. The ab ove

table shows how the grid volta ge chan ge s dep en din g on the Vr ra tio .

2.5.4 Drum Temperature Correction Factor

Drum Temperature Change of grid voltage (volts)

20°C or higher ±0

Lower than 20°C –40

2-11

Page 32

DRUM CHARGE 15 January 1992

2.6 GRID VOLTAGE FOR TONER DENSITY DETECTION AND

RESIDUAL VOLTAGE (Vr) DETECTION

2.6.1 Grid Vol tage for Toner Density Detection

Grid voltage = Standard ID sensor grid voltage (– 460 volt s [SP 62 =4] )

+

Drum wear correction factor (SP 57)

Drum Wear Correction Factor (SP57)

Drum motor rotation time (SP57) Change of grid voltage (volts)

0 to 2H ±0

2 to 65H –20

65 to 112H –40

112 to 157H –60

More than 157H –80

2.6.2 Grid Vol tage for Residual Voltage (Vr) Detection

Grid voltage = Standard ID sensor grid voltage (– 460 volt s [SP 62 =4] )

+

Drum wear correction factor

(SP57 [See the above table.])

The grid voltage for th e to ne r den s ity de te ction is the same as the one for the

residual voltage (Vr) detection, however, the development bias voltage is

different. (Se e page 2-33 and 2-39.)

2-12

Page 33

[E]

15 January 1992 OPTICS

3. OPTICS

3.1 OVERVIEW

[B]

[C]

[D]

During the copy cycle, an image of the original is reflecte d onto the drum

surface through the optics assembly as follows.

Light Path:

Exposure Lamp [A] → Original → First Mirror [B] → Second Mirror [C]

→ Third Mirror [D] → Lens [E] → Fourth Mirror [F]→ Fifth Mirror [G]

→ Sixth Mirror [H] → Drum [I]

[A]

[H] [ F] [J]

[I]

[G]

The optics cooling fan [J] draws cool air into the optics cavit y. The air flows

from the right to the left in the optics ca vity and exh au sts th rou gh the vent s in

the left side of the upp er cove r. This fan operates during the copy cycle.

This copier has six standard reproduction ratios (A077/A078 copiers only),

three reduction ratios, two enlargement ratios, and full size. It also has a

zoom function. The ope rat or can change the reproductio n rat io in on e

percent steps from 61% to 141%.

Stepper motors are used to cha nge th e positio ns of the lens and mirrors

(A077/A078 copiers only). Separate motors are used because the wide rang e

of reproduction ratio s makes it mechanically difficult for one moto r to position

both the lens and mirrors. A ste pp er motor is also used to drive the scanne r.

This motor changes the scanner spe ed accord ing to th e rep rod uction ratio.

The thermofuse open s at 12 6°C and removes ac power to the exposure lamp

to prevent overheating.

2-13

Page 34

OPTICS 15 January 1992

3.2 SCANNER DRIVE

[B]

[D]

[E]

[F]

[C]

[A]

[G]

3.2.1 1st and 2nd Scanner Drive Mechanism

This model uses a stepper mot or [A ] to drive the scanners. Both ends o f each

scanner are driven to prevent skewin g. The scanners have sliders [B], wh ich

ride on guide rails.

The scanner home position is detected by the home positio n sensor [C]. The

scanner return position is determine d by cou nt ing the scanner motor drive

pulses.

The first scanner [D], which consist s of the exp osure lamp and the first mirror,

is connected to the scanner drive wire by the wire clamps [E]. The second

scanner [F], which consists of th e seco nd and third mirro rs, is conn ect ed to

the scanner drive wire by movable pulleys (th e second scanner pulleys [G]).

The pulleys move the second scanne r at half the velocity of the first scanner.

This maintains the focal distance between the original and the lens during

scanning. This relationship can be expressed as:

V1r = 2 (V2r) = VD/r

where r = Reproduction ratio

V1r = First scanner velocity (when the reproduct ion ratio

is "r")

V2r = Second scanner velocity (when the reprod uction ratio

is "r")

VD = Drum peripheral velocity (100 mm/s)

2-14

Page 35

: Reduction

: Enlargement

15 January 1992 OPTICS

3.3 LENS DRIVE (A077/A078 copiers only)

[C]

[D]

[B]

[F]

[E]

[A]

[G]

3.3.1 Lens Drive

The lens motor [A] (stepper motor) changes the lens [B] position through the

lens drive wire [C] in accordance with the selected reproduction ratio to

provide the proper optical distan ce between the lens and the drum surface.

The rotation of th e len s drive pu lley moves the lens back and forth in discrete

steps. The home position of th e lens is dete cte d by th e home position sensor

[D]. The main board keeps track of the lens position base d on the numb er of

pulses sent to the lens mo to r.

3.3.2 Sha ding Mechanism

The shading plate s [E] are installed on the lens housin g [F] and are slid op en

and shut by the groove cams [G]. When the lens move s in the redu ctio n

direction, the groove cams mo ve th e shading plates closer together. The

plate blocks part of the light passing through the lens to keep the intensity of

the light on the drum even.

2-15

Page 36

OPTICS 15 January 1992

3.3.3 Lens Positioning

[C]

[A]

Home Position (100%)

[B]

(100% → 141/129%)

[D]

(141/129% → 71/65%)

(71/65% → 93%)

(93% → 71/65%)

(71/65% → 141/129%)

(141/129% → 122/121%)

(122/121% → 141/129%)

(122/121% → 100%)

(100% → 71/65%)

(71/65% → 100%)

Reduction SideEnlargement Side

The lens home position sensor [A] informs the main board when the lens is at

full size position (home position). The main board de termine s the lens sto p

position in reduction and enlargement modes by counting the number of

steps the motor makes with refe rence to the lens home position. When a new

reproduction ratio is select ed , th e lens [B] moves directly to the selected

magnification position.

The lens home position is registe red each time the lens starts from or passes

through the lens home position sensor. As the len s mo ves fro m t he

enlargement side to th e red uction side, the sensor regist ers the home

position. This occurs when the actu at or plate [C] enters the lens home

position sensor.

A small vibration can be observed when the lens moves through home

position from the red uct ion side to the enlargement side because the lens is

going in the wrong dire ctio n to register the home position. The lens

overshoots the home position by on ly one pulse before going back to register

the home position.

The lens always stops while moving from lef t to rig ht (as viewed from the

front) to minimize the error ca use d by mech an ical pla y in the drive gears [D].

2-16

Page 37

(71/65% → 100%)

15 January 1992 OPTICS

3.4 4TH/5TH MIRROR DRIVE (A077/A078 copiers only)

[B]

[A]

Home Position (100%)

(100% → 141/129%)

(141/129% → 71/65%)

(71/65% → 93%)

(93% → 71/65%)

(71/65% → 141/129%)

(141/129% → 122/121%)

(122/121% → 141/129%)

(122/121% → 100%)

(100% → 71/65%)

3.4.1 Drive

The 4th/5th mirror drive motor (stepper motor) changes the 4th/5th mirror

assembly position through the pinion gears [A] and the rack gear [B] in

accordance with the selected reprodu ctio n ratio to provid e the prope r optical

distance between the lens and drum surf ace .

3.4.2 Positioning

The positioning mechanism is similar to that of lens po sitio ning, as shown in

the above positioning chart. The 4th/5th mirror assembly always st ops wh ile

moving from right to left (a s viewed from th e front).

2-17

Page 38

70 mm

a

Sampled area

b

OPTICS 15 January 1992

3.5 AUTOMATIC IMAGE DENSITY SENSING

[C]

[B]

[A]

Light from the exposure lamp is refle cted from the original and travels to the

lens [A] via the mirrors. The auto ID senso r [B] , a phot od iod e, is mount ed on

the upper front frame. The senso r cover [C] has a hole in it to allow light to

fall directly onto the sensor. Sampling starts 10 millimete rs from th e leadin g

edge of the original and continues for 40 millimeters from the leadin g edge of

original in full size mode. The length of "a" and "b" will vary depending on the

selected reproductio n ratio (A077/A078 copiers only).

The lengths "a" and "b" in each reproduction ratio are calcu lated as follows:

a =

10 mm

Reproduction Ratio (%)

x 100 b =

Reproduction Ratio (%)

40 mm

x 100

The photosensor circuit converts the light intensity to a voltage. The dete cte d

voltage is amplified and sent to the main PCB. The CPU stores the voltage of

each sampled point in RA M. It the n comp utes the image density of the

original from the maximum sample volt ag e an d cha ng es th e de velo pme nt

bias accordingly. (See page 2-3 1 for d eta ils. ) The exposure lamp voltage is

constant regardless of the image density of the origin al.

2-18

Page 39

15 January 1992 OPTICS

3.6 EXPOSURE LAMP VOLTAGE CONTROL

The main board controls t he expo sure la mp volt ag e th rough the ac drive

board. The exposure lamp voltage is based on the base lamp volta ge and

various correction factors.

The exposure lamp voltage consist s of th e followin g fo ur fa cto rs:

Exposure lamp voltage = Base exposure lamp voltage factor

(Manual or auto image density mode)

+

Reproduction ratio correction factor

(A077/A078 copiers only)

+

Drum temperature correction factor

+

Drum residual voltage (Vr) correction factor

3.6.1 Bas e Lam p Voltage Factor In Manual Image Density Mode

Manual ID Level

Exposure Lamp Data

Darker Lighter

123456 7

Vo –4 Vo –4 Vo –2 Vo ±0 Vo+2 Vo+2 Vo+4

The above table shows chan ge s in the expo sure lamp data in the manual

image density mode.

SP48 sets the exposure lamp data for level 4 (Vo) of manual image density

mode. A value from 100 to 15 0 can be sele cted.

3.6.2 Bas e Lamp Voltage Factor In Auto Image Density Mode

In the auto ID mode, the CPU selects the level 4 (Vo) exposure lamp data

(SP48) regardless of the inpu t fro m the auto imag e de nsit y senso r.

2-19

Page 40

OPTICS 15 January 1992

3.6.3 Reproduction Ratio Correction Factor (A077/A078 copiers only)

Reproduction ratio (%) Change of exposure lamp data

61 to 62 –2

63 to 119 ±0

120 to 129 +2

130 to 141 +4

The exposure lamp data is in crea sed or decreased depending on th e

selected magnificatio n ratio in order to compensate for the chang e in the

concentration of ligh t on the drum.

3.6.4 Drum Temperature Correction Factor

Drum temperature Change of exposure lamp data

20°C or higher ±0

Lower than 20°C +2

The exposure lamp data is in crea sed to compensate for the drum

photosensitivity drop under low te mperature.

If the temperature is lower than 20°C when the main switch is turned on, the

CPU increases the exposu re lamp data by +2 as shown in the above tab le.

When the temperature go es to 20°C or higher, this correction is cancele d.

2-20

Page 41

15 January 1992 OPTICS

3.6.5 Drum Residual Voltage (Vr) Correction Factor

During the drum’s life, drum residu al volt ag e (Vr) may gra du ally incre ase. Vr

correction compensate s for th e resid ua l volta ge on the dru m. The Vr

correction is done every 1,000 copies. Depe nd ing on the Vr rat io (SP 67 ), th e

CPU increases the develo pme nt bias voltage, the grid voltage an d the

exposure lamp voltage. The following table shows ho w the lamp da ta

changes depending on the Vr ratio.

Vr ratio (L) (%) (SP67) Change of exposure lamp data

100 to 84 ±0

83 to 58 +2

57 to 41 +4

40 to 28 +6

27 to 0 +8

L = Vrp/Vsg x 100 (%)

Vrp: ID sensor output for Vr pattern

Vsg: ID sensor output for bare drum

2-21

Page 42

OPTICS 15 January 1992

3.7 EXPOSURE LAMP CONTROL CIRCUIT

Main Board (PCB1)

AC Drive Board (PCB2)

CN107-1

B

Zero

Cross

CPU

TP111

(EXPO)

E

Feed back

signal

0V

+24V

C

24V

0V

Trigger Pulse

AC power

Zero cross

Trigger pulse

Lamp power

CN114-2

CN114-1

CN114-7

CN114-3

CN401-7

CN401-8

CN401-2

CN401-6

ZD

ZD

401

R404

R405

VR401

C401

R403

R401

PC401

A

B

C

D

402

ZD

403ZD404

D401

R406

R411

TRC401

R413

DB401

CR401

L401

L402

CN421

240V

220V

220V Only

TR401

C411

T402

CN419-1

Thermofuse (TF)

Exposure

Lamp

(L1)

D

CN419-2

T407

A

AC115V

AC220V

AC240V

Feedback

signal

E

Feedback

The main board sends lamp trigg er (LO W sig nal) p ulse s to th e ac drive boa rd

from CN114-3. PC401 activates TRC401, which provides ac power to the

exposure lamp, at the lead edge of each trigger pulse.

The voltage applied to the expo sure lamp is also provided to the fee db ack

circuit. The feedback circuit steps down (TR401), rectif ies (DB401), and

smoothes (sensor diodes and cap acitors) the lamp voltage. The CPU

monitors the lowest point of th e smoo thed wave (feedback signal), which is

directly proportional to the actu al lamp volta ge .

The CPU changes the timing of the trigger pulses in response to the

feedback voltage. If the lamp voltage is too low, the CPU sends the trigg er

pulses earlier so that more ac power is applie d to the expo sure lamp. This

feedback control is performed instantly; so, the lamp voltage is always stable

even under fluctuating ac power conditions.

The voltage applied to the expo sure lamp can be changed with SP48 (Light

Intensity Adjustment). The ADS volta ge adju stme nt (S P56) must be done

whenever the light intensity adjustment is done.

2-22

Page 43

15 January 1992 OPTICS

3.8 OPTICS COMPONENT CONTROL TIMING

1350

Timing Pulse

(1pulse=4msec)

200

0

1500

2000 2500 3000

(Pulse)

Start Key

Scanner Motor

Exposure Lamp

Auto Image

Density Sensing

1587

Toner Density

Detection Cycles

1787 2767

1678

Image Area

1892 1986

B4 scan

Reproduction ratio 100%

The exposure lamp turn s on ab ou t 2. 1 seconds (on toner density dete ctio n

cycles about 1.7 seconds) and the scanner motor energizes about 2.5

seconds for the forwa rd scan after the Start key is pressed.

About 6.5 seconds af te r (B 4 scan ) t he Sta r t key is pressed, the exposure

lamp turns off and the scanner motor de-energize s and reverses for the

returns scan.

In the auto image density mode, the aut o image de nsit y senso r se nse s the

original background density between about 3 seconds a nd 3.3 seconds after

the Start key is pressed.

2-23

Page 44

[A]

LE

EL

ERASE 15 January 1992

4. ERASE

4.1 OVERVIEW

[B]

SE

ES

LO

LC

LE: Lead edge erase margin 2.5 ±1.5 mm

SE: Side erase margin 2.0 ±2.0 mm on each side;

total of both sides 4 mm or less

LO: Original width

LC: Charged width of drum

EL: Lead edge erase

ES: Side erase

The erase lamp [A] consists of a sing le row of LEDs (29 LEDs) ext en din g

across the full width of th e dru m [B] .

The erase lamp has three functio ns: lead edge era se, side erase, and trail

edge erase. Trail edge erase begins after the trailing edge of the copy paper;

therefore, the trailing edge of the copy will not be era sed .

2-24

Page 45

15 January 1992 ERASE

abcde

h

g

fc

abde

4.1.1 Lead Edge Erase

The entire line of LEDs turn on when the main mot or tu rns on . The y stay on

until the erase margin slight ly overla ps the lead edge of the original image

area on the drum (Lead Ed ge Erase Ma rgin ). This prevents the toner density

sensor pattern fro m being developed every copy cycle and th e shadow of the

original edge from being deve loped on the paper. At this point , side erase

starts. The width of th e lead edge erase margin can be adjusted using SP41.

During the toner density detection cycle (once every ten copy cycles), a block

of erase lamps (labeled "g" above) turns off long enough for th e sensor

pattern to be developed.

The entire line of LEDs turn on when the re sidu al volt ag e on the OPC dru m is

being detected (Vr detectio n).

4.1.2 Side Erase

This machine has no sensors or switches to detect the copy paper size.

Instead, the CPU measures the copy paper lengt h usin g the registration

sensor during the first copy cycle. Base d on this len gt h data , th e CPU

determines which copy paper size is used in the paper tray. (See page 2-5 7

for more information.)

The LEDs turn on in blocks as labeled "a" – "h" above.

2-25

Page 46

ERASE 15 January 1992

In the full size copy mode, the CPU determines which blocks turn on base d

on the copy paper len gt h da ta as follows:

Paper length Paper size Blocks ON

364 mm and 356 mm B4, 10" x 14", 8

1/2" x 13", 81/4" x 13" (F4), 8" x 13", 81/2" x

330 mm and 279 mm

297 mm, 267 mm, and 254 mm A4R, 8" x 10

257 mm, 216 mm, and 210 mm B5R, 5

For toner density detection cycles. a – f, h

For residual voltage (Vr) detection cycles. All

8

11"

1/2" x 81/2", A5R a – e

1/2" x 14", 81/4" x 14" None

a – b

1/2", 8" x 10" a – c

NOTE: Since the CPU cannot distinguish the differe nt paper width, the CPU

will determine the size to be the larger standard width based on the

measured length.

(EX: 10" x 14", 81/2" x 14" → The CPU recognizes as 10" x 14".)

In the reduction or enlarge ment copy mode (A077/A078 copiers only), the

CPU determines which blocks turn on base d on the selected reproduction

ratio as follows:

Reproduction ratio (%)

(A077/A078 copiers only)

83 – 99, 101 – 141 None

78 – 82 a

73 – 77 a – b

68 – 72 a – c

64 – 67 a – d

61 – 63 a – e

Blocks ON

4.1.3 Tra iling Edge Erase

The entire line of LEDs turns on after the trailing edge of the latent image has

passed. Therefore, a trailing erase margin cannot be observed on the copy.

The LEDs stay on to erase th e leading edge of the lat en t image in the next

copy cycle. After the fin al copy, the erase lamps turn off at th e same time as

the main motor.

2-26

Page 47

[F]

[D]

15 January 1992 DEVELOPMENT

5. DEVELOPMENT

5.1 OVERVIEW

[E]

[B]

[C]

[A]

When the main motor turns on , an d th e de velopment clutch solenoid is

de-energized, the paddle roller [A ], development roller [B], auge r [C], and the

agitator [D] start turn ing . The paddle roller picks up developer in its paddles

and transports it to the develop ment roller. Internal permanent magn et s in the

development roller att ract the deve lop er to the deve lop men t rolle r sle eve .

The turning sleeve of the deve lopment roller then carries the deve loper past

the doctor blade [E]. The doct or blade trims the developer to the desired

thickness and creates a developer backspill to the cross-mixing mechanism.

The development roller con tin ue s to tu rn, carrying the deve lop er to the OPC

drum. When the developer bru sh con ta cts th e dru m surface, the negatively

charged areas of the drum surfa ce at tra ct an d hold th e positive ly ch arg ed

toner. In this way, the latent image is developed.

The development roller is given a negat ive bia s to pre ven t toner from being

attracted to the non-image areas on the drum which may have a resid ual

negative charge. The bias also cont rols image density.

After turning abou t 10 0 de gre es more, the development roller rele ases the

developer to the deve lopment unit. The develope r is agita ted by the paddle

roller, agitator, and the cross-mixing mechanism.

The developer is installed in the machine in advance. Whe n installing the

machine, you must load the deve lop er into the development unit from th e

developer tank [F] by pulling out the sea l. Then, use SP65 to agitate the

developer.

2-27

Page 48

DEVELOPMENT 15 January 1992

5.2 DRIVE MECHANISM

[G]

[E]

[B]

[A]

[H]

[C]

[D]

[F]

[J]

[I]

[M]

[K]

[L]

When the main motor [A] turns, the rota tio n is tran smitt ed from th e

development drive gea r [ B] to th e de velopment roller gear [C] thro ug h th e

development clutch [D] , timin g be lt [E ] an d relay gea rs. (The ro tation is

transmitted to the de velo pment drive gear when the develo pme nt clu tch

solenoid [F] is de-energize d. ) Then , th e rot ation is transmitted from the

development roller gear to the paddle rolle r gear [ G] throug h the idler g ear [H].

A gear [I] on the front end of the paddle roller shaft drives the auger gear [J]

and the agitator gear [K]. The padd le rolle r shaf t ha s a knob [L] on the fro nt

end so that it can be turned man ua lly t o exch an ge toner. The knob has a

spring clutch [M] inside. The sprin g clut ch prevents the development roller

from being turned in the wrong direction.

The development clutch solenoid energizes aft er imag e de velopment during

the last copy cycle is completed. This sto ps th e rolle rs, thereby reducing

developer fatig ue.

2-28

Page 49

15 January 1992 DEVELOPMENT

5.3 CROSS-MIXING

[E]

[A]

[D]

[B]

[C]

[F]

This copier uses a standard cross-mixing mechanism to keep the toner and

developer evenly mixed . It also he lps ag ita te the developer to prevent

developer clumps from forming and help s create the trib oelectric charge.

The developer on the tu rning development roller is split int o two parts by the

doctor blade [A]. The deve loper that stays on the develop ment roller [B]

forms the magnetic brush an d de velo ps the latent image on the drum. The

remaining developer th at is trimmed off by th e doctor blade goes to the

backspill plate [C].

As the developer slides down the backspill plate to the agit ator [D], the mixing

vanes [E] move it slightly to ward the rear of the unit. Part of the developer

falls into the auger inlet and is transp ort ed to the fro nt of the unit by th e auge r

[F].

2-29

Page 50

DEVELOPMENT 15 January 1992

5.4 DEVELOPMENT BIAS FOR IMAGE DENSITY CONTROL

Image density is controlled by changing three items: (1) the amount of bias

voltage applied to th e de velo pment roller sleeve, (2) the amou nt of voltage

applied to the exposure lamp, an d (3) the amo un t of voltage applied to the

grid plate.

Applying a bias voltage to the development sleeve reduce s the pot en tia l

between the develo pment roller and the drum, thereby reducing the amount

of toner transferred. As the bias voltage beco mes gre at e r, the copy image

becomes lighter and vice versa.

The method of control is different dependin g on whethe r the ima ge density is

manually selected or the auto image density mode is used.

The development bias voltag e applied to the development roller sle eve has

the following four factors:

Developmen t bia s voltage = Base bias voltage factor

(Manual or auto image density mode)

+

Image bias voltage adjustment factor (SP37)

+

Drum residual voltage (Vr) correctio n factor

+

Drum temperature corre ctio n factor

The base bias voltage for non-image area s (bet wee n cop ies) is – 160 volt s.

The above correction factors are also applied.

2-30

Page 51

15 January 1992 DEVELOPMENT

5.4.1 Bas e Bias Voltage Factor In Manual Image Dens ity Mode

Manual ID Level 123456 7

Base Bias Voltage (volts) –120 –160 –160 –160 –200 –200 –240 *Note

Exposure Lamp Data Vo –4 Vo –4 Vo –2 Vo ±0 Vo +2 Vo+2 Vo+4

Grid Voltage (volts) Vg ±0 Vg ±0 Vg ±0 Vg ±0 Vg ±0 Vg +50 Vg +50

Vo: Exposure Lamp Data for ID level 4 (SP48)

Vg: Standard Image Grid Voltage (–680 volts)

Darker Lighter

In manual ID mode, the base bia s voltage depends on the manually selected

ID level. The voltage applied at each ID level is shown in the abo ve ta ble.

The base exposure lamp vo lta ge and the grid voltage also vary depending on

the manual ID level as shown in the table.

*Note: The base bias voltage at ID level 7 can be cha ng ed using SP5 0 as

follows.

Image density Data (SP50) Bias voltage (volts)

Normal 0 –240

Darker 1 –200

Lighter 2 –280

Lightest 3 –320

(Factory Setting: –240 volts)

5.4.2 Bas e Bia s Vol tage Factor In Automatic Image Density Mode

In auto image density mode, the base expo sure lamp voltage is fixed to Vo

(SP48). Image density is con tro lled by chan gin g on ly the base bias volt age.

The base bias voltage depends on the background image density of the

original, which is measured using the auto ID sen sor. (See page 2-18 for

more information.)

The CPU checks the voltage output from the automa tic ID circuit . This circuit

has a peak hold function. The peak hold voltage corresponds to the

maximum reflectivity of the original. The CPU then determines the proper

base bias level with refere nce to th e pe ak ho ld voltage.

The table on the following page gives the base bia s voltages at each ADS

output level.

When the automatic density level is set to lighter by SP34, the base bias

voltage shifts –40 volts as shown in th e fo llowin g table.

2-31

Page 52

DEVELOPMENT 15 January 1992

K

K ≥ TL1

TL1 > K ≥ TL2

TL2 > K ≥ TL3

TL3 > K

K =

Normal or Darker (SP34 = 0 or 1) Lighter (SP34 = 2)

ADS Output Voltage (Peak Hold Voltage)

ADS Reference Voltage (SP56)

–160

–220

–280

–340

Base Bias Voltage (volts)

–200

–260

–320

–380

TL1 to TL3: Threshold le vel (Se e the following table.)

To maintain the correct image density, the exposure lamp data is

incremented when the repro duction ratio is changed or drum temperatu re

correction or drum residual voltage correct ion is done. This incre ment in the

lamp data increases the int en sity of light reflected from the original.

Therefore, the aut o ID sen sor ou tput voltage also changes. In ord er to

maintain a constant volt age for the same original when the lamp data is

incremented, the threshold levels are shifted up with each increment in the

lamp data as shown in the following table.

Increase of

exposure lamp data

TL1 0.70 0.75 0.80 0.85 0.89 0.94 0.98 1.03 1.08 1.12

TL2 0.66 0.70 0.74 0.78 0.83 0.87 0.91 0.96 1.00 1.04

TL3 0.29 0.31 0.33 0.35 0.37 0.39 0.41 0.43 0.45 0.48

+0 +1 +2 +3 +4 +5 +6 +7 +8 +9

5.4.3 Image Bias Voltage Adjustment Factor

Image Bias Adjustment (SP37)

Image density Data (SP37) Change of bias voltage (volts)

Normal 0 ±0

Darkest 1 +40

Darker 2 +20

Lighter 3 –20

Lightest 4 –40

The image bias voltage can be changed by SP 37 to adjust the image density

level. The above table gives the image bias volt ag e fo r SP mod e set ting. This

adjustment should be done only if the expo sure la mp volt ag e adjustment

(SP48) fails to achieve the desire d image density.

2-32

Page 53

15 January 1992 DEVELOPMENT

5.4.4 Drum Residual Voltage (Vr) Correction Factor

During the drum’s life, drum residual volt age (Vr) may gradually increase.

The Vr correction compensat es fo r t he re sidu al volt ag e on the drum. The Vr

correction is done every 1,000 copies. The fo llowin g table shows how the

development bias voltage changes depending on the Vr ratio.

Vr ratio (L) (%) (SP67) Change of bias voltage (volts)

100 to 84 ±0

83 to 58 –40

57 to 41 –80

40 to 28 –120

27 to 0 –160

L = Vrp/Vsg x 100 (%)

Vrp: ID sensor output for Vr correction pattern

Vsg: ID sensor output for bare drum

When the Vr correction is made (eve ry 1,0 00 copies), all blocks of erase

lamps turn on and the development bias becomes 0 volt to develop the Vr

pattern.

5.4.5 Drum Temperature Correction Factor

Drum temperature Change of bias voltage (volts)

20°C or higher ±0

Lower than 20°C –40

To compensate for the drum p hoto sen sitivity drop under low temperature, th e

development bias vo lta ge is increased.

If the temperature is lower than 20°C when the main switch is turned on, the

CPU increases the develo pme nt bias voltage by –40 volts as shown in the

above table.

When the temperature go es to 20°C or higher, this correction is cancele d.

2-33

Page 54

Power Pack CC/Grid/Bias

(P1)

Charge Corona

DEVELOPMENT 15 January 1992

5.5 DEVELOP MENT BI AS CIRCUIT

VA [24]

VC [5]

Bias Trig (PWM) [▲0→0/5]

Bias FB

GND [0]

Main Board (PCB 1)

CN119-8

CN119-7

CN119-6

CN119-5

CN119-4

CN119-3

CN119-2

CN119-1

CN1-1

CN1-2

CN1-3

CN1-4

CN1-5

CN1-6

CN1-7

CN1-8

M

G

B

Grid

Development

Bias

The main board supplies +24 volt s to th e CC/G rid/Bias power pack at CN1-1.

When the Start key is pressed, the CPU starts sending the bias trigger pulses

to CN1-4. This energizes the develo pme nt bias circuit wit hin the

CC/Grid/Bias power pack, which applies a high negative volta ge to the

development roller. The deve lop ment bias is applied whenever the drum is

rotating except when the Vr patter n is developed.

The bias trigger pulse applied to CN1-4 is a pulse width modulated signa l

(PWM signal). The width of the pulses controls the volta ge level of the

development roller. As th e width of the trigger pulses increase, the voltage to

the development roller also increases. The CPU monitors the development

bias voltage at CN119-3 an d con trols the width of the bias trigg er pu lses

based on this feedback.

2-34

Page 55

15 January 1992 DEVELOPMENT

5.6 DEVELOP MENT CO MPO NENT CO NTROL TI MI NG

Timing Pulse

(1pulse=4msec)

Start Key

Main Motor

Development

Bias

Development

Clutch Solenoid

1350

0

200

1500

Non Image Area

1591

2000 2500 3000

1991

1857

Image Area

Toner Density Detection Cycles

When the Start key is pressed, the main motor starts rotating and the

development clutch sole no id is ene rgize d. At th is time, the rotation from the

main motor is not transmitted to the rolle rs in the deve lop men t un it. The

development clutch solenoid is de-energized abou t 1. 8 seconds after the

Start key is pressed. At this time, the ro llers in th e de velo pme nt unit start

rotating.

(Pulse)

When the Start key is pressed, the deve lopment bias circuit in the

CC/Grid/Bias power pack is energized to apply the negative voltage for the

non image areas to the development roller. The value of the bias volt age will

be different for t he ima ge area s. The shift to the image area bias vo lta ge

occurs about 3.4 seconds after the Start key is pressed on normal copy

cycles. During on toner density detection cycles it occurs about 2.8 seconds

after the Start key is pressed. This is necessary since the value of th e bia s

voltage is also changed fo r t on er de nsit y det ection.

2-35

Page 56

Development

Bias

ID Sensor

Pattern

TONER DENSITY DETECTION AND TONER SUPPLY 15 January 1992

6. TONER DENSITY DETECTION AND TONER

SUPPLY

6.1 OVERVIEW

Sensor

Pattern

ON OFF ON OFF

ABC

RAM Clear

1234567891011121314 202122

Original Lead

Edge

DE

Leading Edge

Erase

Original

Toner Density Detection Toner Density Detection Toner Density

1st

Detection

Toner Supply Clutch ON

2nd 3rd

Low Toner Density

Toner Supply Timing

Toner Add

(10 times)

Detection

Detection

The CPU checks toner density by directly se nsin g th e image density every 10

copy cycles. If the RAM is cleared (SP99), or a new RAM is installed, the

CPU checks the image densit y at th e be ginning of the first copy cycle.

During the check cycles, the sensor pat te rn is exposed prior to the exposure

of the original. Afte r the senso r p at tern is d eve lop ed , its ref lectivity is checked

by the image density sensor (a photose nso r). The CP U not es the ref lectivity

and if the reflected ligh t is t oo stron g, indicating a too low tone r den sity

condition, toner is add ed to th e de velopment unit.

The toner is not added all at once. The CPU will energize the toner supply

clutch for the prope r amount of time in order to add a selected amount of

toner over the next 10 cycles.

When the free run mode (turn DIP switch 10 1-1 ON) is sele cte d, the CPU

checks the toner density every co py cycle.

2-36

Page 57

Low Density

15 January 1992 TONER DENSITY DETECTION AND TONER SUPPLY

6.2 ID SENSOR FUNCTION

6.2.1 Detect Supply Mode

ID Sensor

B

A

K

R

C

E

C

ID Sensor Output

A

Vsg 4V

CN112-6

CN112-5

CN112-7

ID Sensor LED

+9V (VB)

TP 110

(PSE)

VR102