Page 1

RICOH Technical B ulletin PAGE: 1/1

Model: BANTAM Date: 15-Apr-97

No: 1

Subject: PM Parts Yield Prepared by: M. Ishihara

From: QAC 1st Field Information Dept. Checked by: T. Inoue

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

The yields of the Document Feeder (A662) PM parts have been reviewed.

Please correct your PM table as follows.

OLD

EM 24 K 48 K Notes

DOCUMENT FEEDER (A662) (for originals)

Transport Belt C R R Belt cleaner

Friction Belt C R R Belt cleaner

Pick-up Roller C C C Soft cloth dampened with water

Feed Roller C C C Soft cloth dampened with water

↓↓

NEW

EM 80 K 160 K Notes

DOCUMENT FEEDER (A662) (for originals)

Transport Belt C R R Clean with belt cleaner at copier

PM.

Friction Belt C R R Clean with belt cleaner at copier

PM.

Pick-up Roller C C C Soft cloth dampened with water

Feed Roller C C C Soft cloth dampened with water

Page 2

RICOH Technical Bulletin PAGE: 1/2

Model: BANTAM Series Date: 31-May-97

No: 2

Subject: Service Manual Revision Prepared by: M.Ishihara

From: QAC 1st Field Information Dept.

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

Please correct your Service Manual as follows.

1. Page 2

Copy Tray Capacity:

1 sheet (OPC) →→ 1 sheet (OHP)

2. Page 2

Noise Emission:

Sound power level should be corrected as follows:

OLD

Copy cycle Less than 64 dB Less than 62 dB

Stand by Less than 55 dB Less than 40 dB

NEW

Copy cycle Less than 64 dB

Stand by

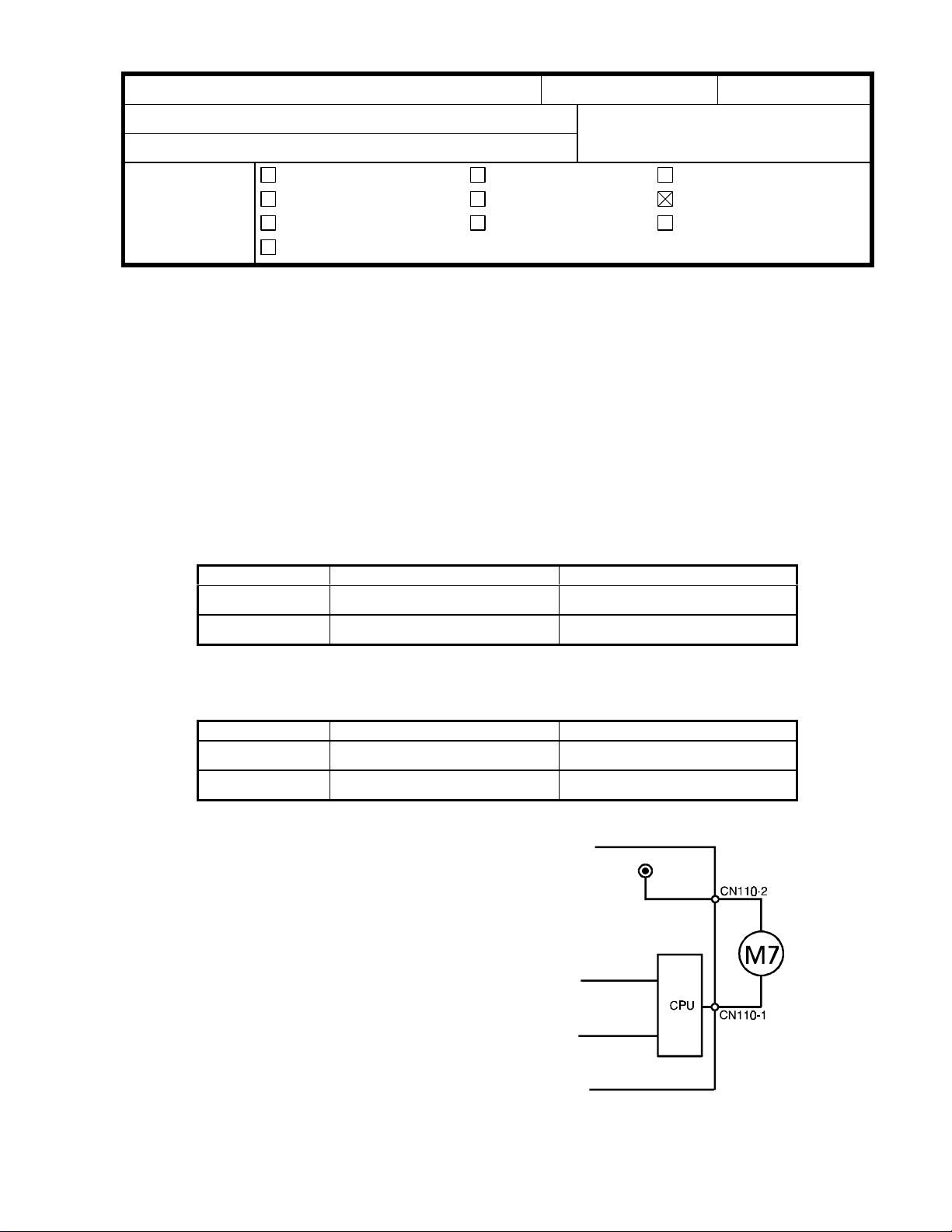

3. Page 17

Illustration correction:

The electrical component on the right side

of the circuit should be corrected as

follows:

MSC1 →→ M7

(For Bantam, toner supply is performed by

the Toner Supply Motor .)

Copier Only Copier with document feeder

↓↓

Copier Only Copier with document feeder

Less than 68 dB

Less than 40 dB

Less than 40 dB

Page 3

RICOH Technical Bulletin PAGE: 2/2

Model: BANTAM Series Date: 31-May-97

4. Page 36

CLEAR ALL MEMORY PROCEDURE:

Step number 5 should be eliminated.

The drum does not need to be replaced, since the Bantam does

not do the “Drum Wear Correction”.

5. Page 43

SP96 (Toner End Force Cancel):

This SP mode has been newly added from the Bantam series.

∗ ” should be added.

6. Page 44

NOTE 1: 1):

The following SP mode numbers are also applied for this note.

Please correct as follows: (The corrected items are shown in bold letters.)

SP mode numbers: 5, 6, 7, 52, 55, 56, 59, and 65

No: 2

7. Page 44

NOTE 1: 1):

The illustration of the “Auto Image Density” key is described as the “Darker” key.

Please correct the illustration.

→→

8. Page 46

- How to check sensor / switch inputs for the A203 copier - step 1:

The illustration of the “Auto Image Density” key is described as the “Darker” key.

Please correct the illustration.

→→

9. Page 52

Toner Supply Motor Replacement:

The NOTE should be eliminated. The motor can be reinstalled at both positions.

10. Page A662-1

Copying Speed:

15 copies/minute →→ 13 copies/minute

Page 4

T

Model:

BANTAM Series

echnical

ulletin

B

Date:

15-Jul-97

No:

PAGE: 1/2

3

Subject:

From:

Classification:

Please correct your Service Manual as follows.

1. Page 45

NOTE4:

The wrong key is shown.

Please correct the illustrations.

Service Manual Revision

QAC 1st Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

→*

Prepared by:

Action required

Service manual revision

Retrofit information

M. Ishihara

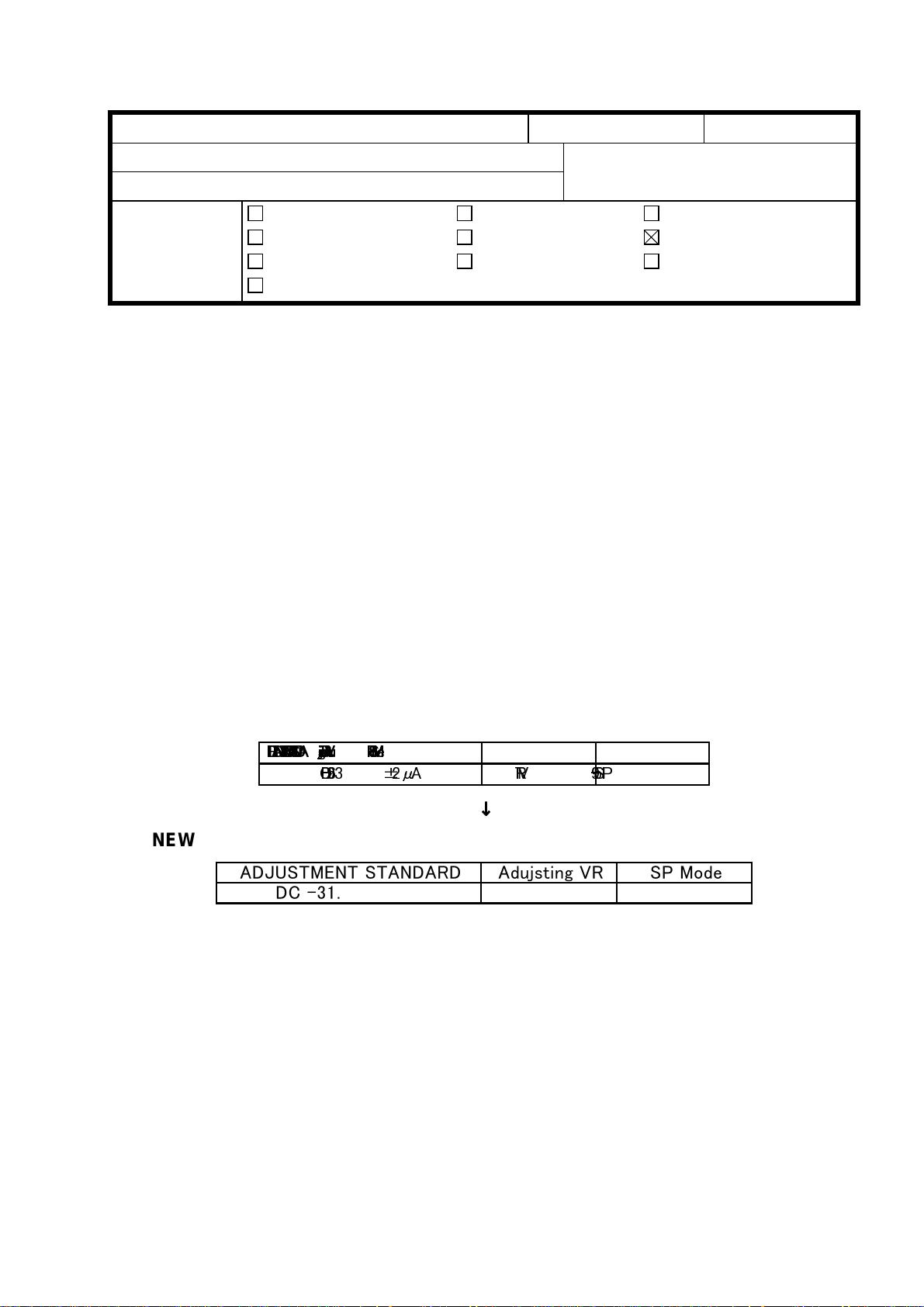

2. Page 57

TRANSFER CORONA CURRENT ADJUSTMENT (SP9-5)

ADJUSTMENT STANDARD should be corrected as follows:

OLD

¾ÁÇÒÐÑÊÂËÑÐѾËÁ¾ÏÁ ¾áòçðñæëäÓÏ ÐÍÊìáâ

ÁÀª¶°«³ p¯¾ ÓÏÑ ÐͶª²

↓

NEW

¾БЗТРСКВЛСРС¾ЛБ¾ПБ ¾бт зрсжл дУП РНКмбв

ÁÀª°®«p«²¾ ÓÏÑ ÐͶª²

Note: The new ADJUSTMENT STANDARD is the same as for the Robin series.

Page 5

T

Model:

3. Page 58

SEPARATION CORONA CURRENT ADJUSTMENT (SP9-6)

ADJUSTMENT STANDARD should be corrected as follows:

NEW

Note: The new ADJUSTMENT STANDARD is the same as for the Robin series.

BANTAM Series

OLD

¾БЗТРСКВЛСР С¾ЛБ ¾ПБ ¾бт зрсжл дУ П ÐÍÊìáâ

À®±²«³p²«¾ ÓÏÁ ÐͶª³

¾БЗТРСКВЛСР С¾ЛБ ¾ПБ ¾бт зрсжл дУ П ÐÍÊìáâ

À±¶p®«¾ ÓÏÁ ÐͶª³

echnical

↓

B

ulletin

Date:

15-Jul-97

No:

PAGE: 2/2

3

Page 6

RICOH Technical Bulletin PAGE: 1/1

Model: Bantam Date: 31-Aug-97

Subject: False E54 Prepared by: M.Mimura

From: QAC 1st Field Information Dept.

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

No: 4

SYMPTOM

False E54 – Fusing Error

1. At power-up

E54 is indicated after the warm-up, usually seconds after the fusing lamp has turned off at

185°C. This occurs only in the machines set up to use the fusing phase control mode.

2. Other Possible Occurrences

E54 may be also indicated in any mode – warm-up, stand-by, and copying. This occurs

regardless of the fusing control mode.

CAUSE

Software bug

SOLUTION

1. Install the E version ROM.(A2025108E for Bantam and A2035108E for Bantam R)

2. If the ROM is not immediately available, select the ON/OFF control mode because

case #2 listed hardly ever occurs.

Note: Do not select the phase control mode unless needed.

Factory Cut-ins

TBA (Scheduled to start early September in ’97)

Page 7

T

Model:

Bantam

echnical

B

ulletin

Date:

15-Oct-97

No:

PAGE: 1/2

5

Subject:

From:

Classification:

To meet the Energy Star specifications, the following modification has been applied to the

production machines.

Energy Star

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

M.Ishihara

SP Mode 14

∗ Setting No.5 has been added.

Mode No. Function Settings

Auto Reset

Time Setting

(Energy Star)

14

Selects the auto shut off time.

The copier main switch is shut off automatically

after the selected auto shut off time, if SP77 and

UP10 are at “0”.

0:30 min. (Factory

Setting)

1 : 15 min.

2 : 60 min.

3 : 90 min.

4 : 120 min

∗ 5 : 240 min

User Program Mode

The following UP has been added.

U-Code Function Settings

Auto Shut Off

On/Off

10

Note: Factory settings of SP77 and UP10 for the USA version are 0:Yes.

For the other area versions, it is 1:No.

Selects the “Auto Shut Off” mode. 0 : Yes (Factory

Setting)

1 : No

ROM Suffix Numbers for this modification

Part Number Model Area

A2025108D Bantam Worldwide

A2035108D Bantam R Worldwide

Page 8

T

Model:

Bantam

echnical

Cut-in Machine Serial Numbers

- Bantam -

B

ulletin

Date:

15-Oct-97

No:

PAGE: 2/2

5

A202 - 10 : AJ77870001

-15 : 7A97870001

-17 : A7407872048

-76 : A7407872519

-22 : AJ87870001

-26 : AJ87870001

-27 : A7407870001

-29 : A7407872589

-39 : A7407881466

- Bantam R A203 -10 : AM87870001

-15 : 8A17870001

-17 : A7417871166

-76 : A7417871026

-22 : AM97870001

-26 : 3M18770001

-27 : A7417870001

-29 : A7417872555

-39 : A7417880940

-50 : AM47880001

∼

∼

∼

∼

∼

∼

∼

∼

∼

∼

∼

∼

∼

∼

∼

∼

∼

∼

∼

Page 9

T

echnical

RTB Correction

Reissue date:

Cut-in serial numbers have been added.

Model:

Bantam

31-Oct-97

B

ulletin

Date:

31-Aug-97

No:

PAGE: 1/2

4

Subject:

From:

Classification:

False E54

QAC 1st Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

M.Mimura

SYMPTOM

False E54 – Fusing Error

1. At power-up

E54 is indicated after the warm-up, usually seconds after the fusing lamp has turned off at

185°C. This occurs only in the machines set to use the fusing phase control mode.

2. Other Possible Occurrences

E54 may be also indicated in any mode – warm-up, stand-by, and copying. This occurs

regardless of the fusing control mode.

CAUSE

Software bug

SOLUTION

1. Install the E version ROM.(A2025108E for Bantam and A2035108E for Bantam R)

2. If the ROM is not immediately available, select the ON/OFF control mode because

case #2 listed hardly ever occurs.

Note: Do not select the phase control mode unless needed.

Page 10

T

Model:

Bantam

echnical

Cut – in Machine Serial Numbers

-Bantam-

A202 – 10 : AJ778890066

–15 : 7A97900001

–17 : A7407900066

–19 : A740790xxxx

–22 : AJ87890001

–26 : 3M08970001

–27 : A7407890001

–28 : A740790xxxx

–39 : A7407890643

–76 : A740790xxxx

-Bantam R-

B

ulletin

Date:

31-Aug-97

No:

PAGE: 2/2

4

A203 – 10 : AM87900001

–15 : 8A17900001

–17 : A7417900734

–19 : A741790xxxx

–22 : AM97890237

–26 : 3M19070001

–27 : A7417900001

–28 : A7417890803

–29 : A7417902134

–39 : A7417902019

–50 : AM47900001

–76 : A7417901779

Page 11

T

Model:

Bantam

echnical

B

ulletin

Date:

31-Dec-97

No:

PAGE: 1/1

6

Subject:

From:

Classification:

Updated ROM Information - Bantam R only

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

M.Ishihara

SYMPTOM

When an 11” x 17” original is copied to 8.5” x 11” or 8.5” x 14” (reduction), approximately

10 mm of the original trailing edge will be blank.

CAUSE

Software bug in original scanning and erase timing.

SOLUTION

The bug has been fixed. Install the F version ROM

Note: The problem does not appear for A3 originals.

Factory Cut-in Machine Serial Numbers:

A203-10: AM87910644∼

-15: 8A17910001∼

-17: A7417910563∼

-19: No Production

-22: AM97910385∼

-26: 3M19170001∼

-27: A7417910001∼

-28: No Production

-29: A7417911854∼

-39: A7417911728∼

-50: AM47920001∼

-76: A7417911588∼

Page 12

T

Model:

Bantam Series

echnical

B

ulletin

Date:

15-Apr-98

No:

PAGE: 1/3

7

Subject:

From:

Manual Correction

QAC Field Information Dept.

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

K. Miura

Please correct your service manual as follows:

The 2nd description described in service call No.14 should be an item for service call code

No.54. Also, we have added a flow chart for SC No.54.

1. Page 48

Service Call Code

OLD

Frequency Detection Error

∗

14

The detected frequency is not within 45 ∼ 65 Hz.

•

The fusing lamp stays on for longer than 38 seconds

•

while the main motor is off.

NEW

14

∗

2. Page 49

OLD

54

∗

New

54

∗

Frequency Detection Error

The detected frequency is within 45 ∼ 65 Hz.

Fusing Error

The temperature detected by the thermistor does not

rise more than 20°C within 12 seconds when the fusing

lamp is turned on continuously in the main motor off

condition.

Fusing Error

The temperature detected by the thermistor does not

•

rise more than 20 °C within 12 seconds when the

fusing lamp is turned on continuously while the main

motor is off.

The fusing lamp stays on for longer than 38 seconds

•

while the main motor is off.

Page 13

T

Model:

-Possible Causes-

• Thermistor open

• Defective main board

• Defective ac drive board

• Fusing lamp open

• Thermoswitch open

• Defective ac harness

-Action-

Bantam Series

Is the thermistor open?

No Yes

Replace the thermistor.

echnical

B

ulletin

Date:

15-Apr-98

No:

PAGE: 2/3

7

Clear the service call condition.

Does the fusing lamp turn on?

No Yes

Replace the main board.

Is the fusing lamp open?

No

Is the thermoswitch open?

No Yes

Is the ac harness defective?

No

Yes

Replace the fusing lamp.

Replace the thermoswitch.

Yes

Replace the ac harness.

Page 14

T

Model:

Bantam Series

No

Check the voltage at CN114-6 on the main board.

echnical

B

ulletin

Date:

15-Apr-98

No:

PAGE: 3/3

7

0 volts

Check the voltage at CN 114-4 on the main board.

0 volts

Check the voltage at CN114-8 on the main board.

Replace the ac drive board.

24 volts

Replace the main board.

24 volts

Replace the main board.

0 volts24 volts

Replace the main board.

Page 15

T

Model:

Bantam Series

echnical

B

ulletin

Date:

15-Jun-98

No:

PAGE: 1/2

8

Subject:

From:

Classification:

Page 41

SP57 (Drum Rotation Time)

Since there is no drum wear correction, this SP mode is not effective even though it can be

accessed. Please change the description as follows:

OLD

57

Service Manual Correction

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Drum Rotation

Time

Displays the total time that the drum has rotated.

“Minutes” is displayed first. Press and hold the

key to display “Hours”.

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

&

K. Miura

↓

NEW

57 Drum Rotation

Time

Page 42

SP66 (Drum Initial Setting):

It is not necessary to use SP66 when installing a new drum because there is no Vr

correction or drum wear correction for this model. Please change the description as

follows:

OLD

Drum Initial

Setting

66

Not used

Used to condition the new drum.

Initial setting must be done when a new drum is

installed.

The Drum Rotation Time (SP57) and the OPC

counter (SP69) are cleared.

↓

NEW

66 Drum Initia l

Setting

Not used

Page 16

T

Model:

SP 69 (OPC Counter):

Since there is no Vr correction for this model, this SP mode is not effective even though it

can be accessed. Please change the description as follows:

OLD

Bantam Series

echnical

ulletin

B

Date:

15-Jun-98

No:

PAGE: 2/2

8

OPC Counter

69

NEW

69OPC Counter Not used

Shows the total number of copies made with the

drum installed in the machine.

Refer to NOTE 4.

↓

Loading...

Loading...