Page 1

13 September 1994

MAJOR DIFFERENCES BETWEE N THE RO BI N AND E7

SERIES.

The ROBIN (A151 and A152) were developed based on the E7 (A0 76 and

A077).

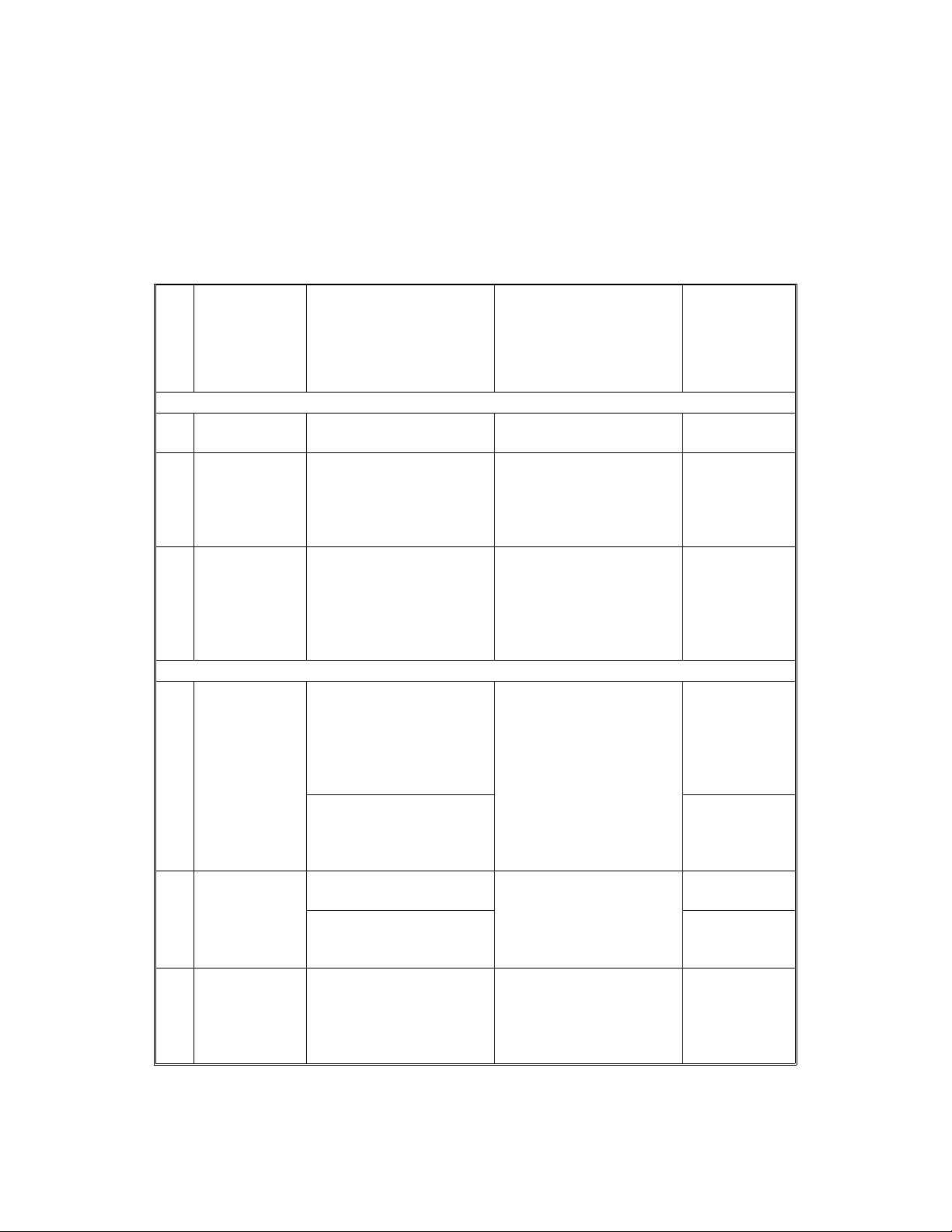

The following table lists the major differences between the ROBIN series and

the E7 series, and the pages to refer on your service manual.

Section and

page to refer

No. Item

Overall

1 Energy Saver

Function

2 Copy Paper

Weight

3 Operation

Panel

Around the Drum

4 Pre-transfer

Lamp

5 Cleaning

Mechanism

6 Drum Drive

Mechanism

ROBIN

(A151 and A152)

Newly added. Not available. Sec. 2, page

The copy paper weight

specification has been

narrowed due to the

changes in the paper

feed mechanism.

10 independent number

keys for faster and easier

operation. The access to

the SP mode has been

changed due to this

reason.

The pre-transfer lamp has

been removed. The same

PTL for E7 series is

available for the Robin

series as optional service

equipment.

Due to this, the transfer

corona adjustment

standard has been

changed.

Counter blade system Trailing system with

Setting powder should be

applied on the blade and

drum after servicing.

The main motor directly

drives the drum. The

drum motor and the drum

motor board have been

removed.

(A076 and A077)

Quantity keys. Sec. 4, page 8.

The PTL is installed. Sec. 5, page

brush.

An independent drum

motor drives the drum.

E7

– Sec. 1, page 1.

to in the

Robin

Service

Manual

59.

92 and Sec. 6,

page 23.

Sec. 5, page

60.

Sec. 2, page

44.

Sec. 4 and 5

Sec. 2, page 2.

1

Page 2

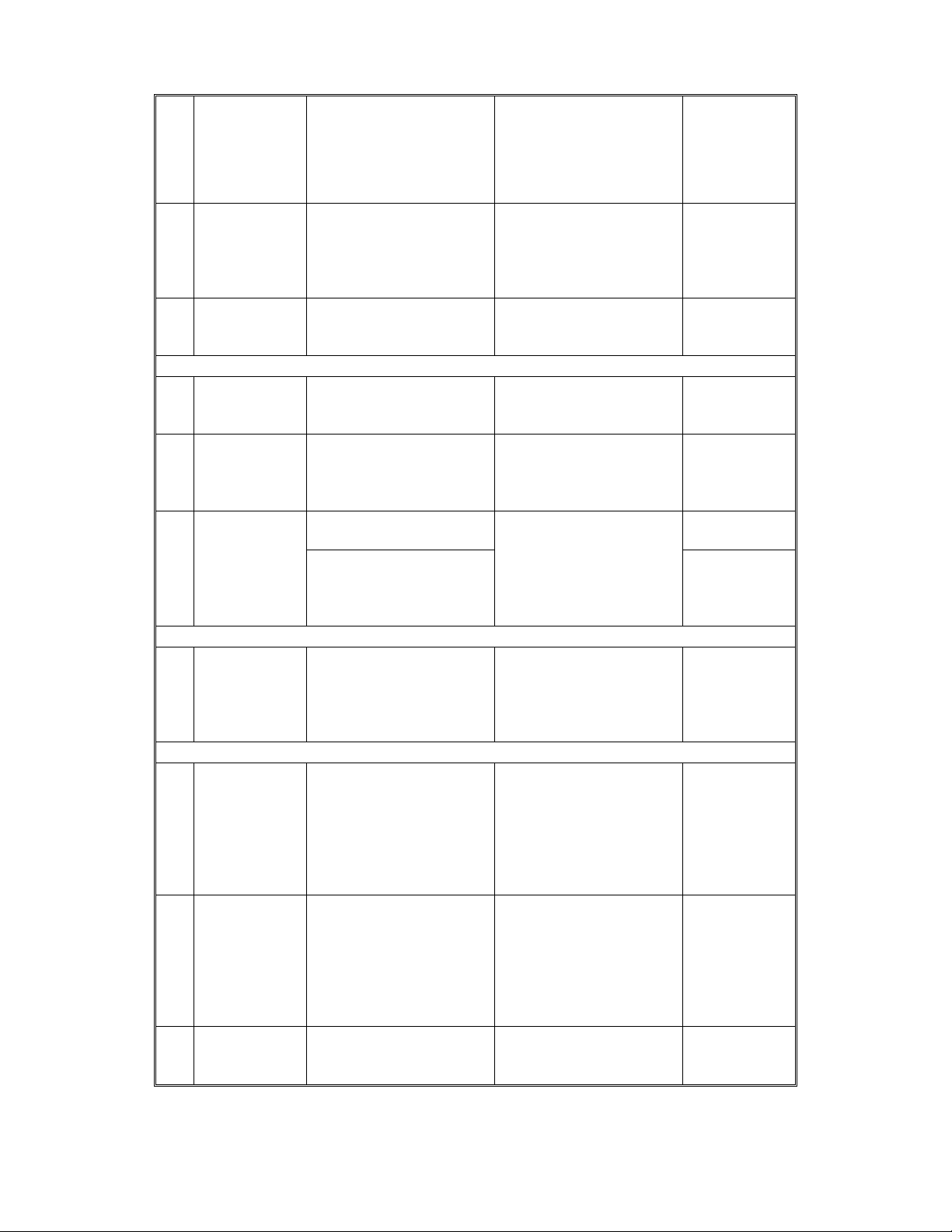

No. Item

7 Erase

Mechanism

8 Development

Drive

Mechanism

Paper Feed

9 Paper Feed

Mechanism

(Paper Tray)

10 Paper Feed

Mechanism

(By-pass feed

table)

11 Misfeed

Indication

Fusing

12 Fusing Lamp

Control

Copy Process Control

13 Grid Voltage

for Image

Density Control

14 Exposure

Lamp Voltage

for Image

Density Control

15 Drum

Temperature

Correction

13 September 1994

Section and

page to refer

ROBIN

(A151 and A152)

For A151 copier, side

erase is performed by the

platen cover.

(A152 copier is the same

as E7 series.)

The development clutch

solenoid has been

removed.

Semicircular feed rollers

and corner separator

system.

Auto feed mechanism is

newly applied.

PE, J1 and J2. J1, J2 and J3. Sec. 2, page

Indication change only.

The basic detection

mechanism has not

changed.

Fusing lamp control

mechanism has changed

to achieve stable

temperature control of the

hot roller.

The grid voltage does not

change whether the

manual image density is

selected or auto image

density is selected (with

the exception of SP34

setting).

L correction method

The V

has changed to prevent

over applying the

exposure lamp voltage. A

white reference plate has

been added under the left

scale supporting bracket.

The drum temperature

correction has been

eliminated.

(A076 and A077)

FTR (Feed + torque

roller) feed system with

corner separators.

No auto feed. Sec. 2, page

The grid voltage is

different depending on

whether the image

density is manually

selected or the auto

image density mode is

used.

The V

applied at set intervals.

E7

– Sec. 2, page

– Sec. 2, page

–

L correction is

–

to in the

Robin

Service

Manual

23.

25.

Sec. 2, page

47.

51.

64.

Sec. 2, page

59.

Sec. 2, page 7.

Sec. 2, page

18.

2

Page 3

13 September 1994

No. Item

Optics

16 Optics

Thermistor

and Cooling

Fan

Drum Cleaning

17 Used Toner

Overflow

Detection

Installation

18 Developer Developer is not equiped

19 220 ~ 230V to

240V

Conversion

An optics thermistor has

been added to monitor

the optics temperature for

the operation of the optics

cooling fan motor (A152

copier).

Since the cooling fan is

not installed on the A151

copier, the optics

thermistor monitors the

optics temperature to

prevent overheating in

the optics cavity.

However the copier may

stop for some extra

waiting time when the

thermistor detects a

certain high temperature

condition.

Since the elimination of

the PTL and the cost

reduction change to the

QL, the used toner

overflow detection cycle

has been changed.

1. When the copy

quantity reaches 80K

copies.

2. When the number of

the toner end condition

reaches 9.

to the copier at the

factory. A new pack is

necessary when installing

the machine.

The conversion for the

exposure lamp is

required. The conversion

for the dc power supply

board is not required.

ROBIN

(A151 and A152)

E7

(A076 and A077)

The optics thermistor is

not equipped. The optics

cooling fan operates

during the copy cycle.

1. Same as Robin.

2. When the number of

the toner end condition

reaches 11.

– Sec. 3.

Conversions for the

exposure lamp and dc

power supply board are

required.

Section and

page to refer

to in the

Robin

Service

Manual

Sec. 2, page

11.

Sec. 2, page

11 and Sec. 6,

page 52.

Sec. 2, page

46.

3

Page 4

No. Item

20 Key Counter In order to install the

optional key counter,

some service parts must

be ordered.

Document Feeder (A365)

21 Installation From the May production,

to install the DF to the

ROBIN, the ADF

interface unit and the 2

stud screws are

accessory of the DF.

Service Program Mode

22 Sales Mode The salesman mode has

been eliminated.

Service Call

23 E40 "Optics Thermistor Error"

has been added.

Test Points

24 Test Points Some test points on the

main control board have

been eliminated.

Replacement and Adjustment

25 Transfer

Corona

Current

Adjustment

26 Fusing Unit

Removal

the adjustment standard

is DC –31.0 ± 0.5 µA.

The fusing unit removal

procedure has been

modified to achieve faster

servicing.

ROBIN

(A151 and A152)

13 September 1994

E7

(A076 and A077)

The ADF interface unit

and the 2 stud screws are

installed to the E7.

Some SP modes can be

accessed by the sales

representatives.

– Sec. 4, page

– Sec. 4, page

The adjustment standard

is DC –20.0 ± 0.5 µA.

– Sec. 5, page

Section and

page to refer

to in the

Robin

Service

Manual

Sec. 3, page

10.

DF Sec. page

14.

Sec. 4, page 8.

23 and Sec. 6,

page 41.

25.

Sec. 5, page

60.

63.

4

Page 5

13 September 1994

MAJOR UNIQUE PARTS FOR ROBI N S ERI E S

(Compared with the E7 series )

PM Parts

Parts Number Description Remarks

AD002044 Cleaning Blade –

– Cleaning Brush eliminated

– Paper Feed Roller eliminated

– Torque Roller eliminated

Electrical Parts

Parts Number Description Remarks

A1515100 Main Board for A151 Copier

A1525100 Main Board for A152 Copier

AZ220019 DC Power Supply Board - 115V

AZ220020 DC Power Supply Board - 230V

A1525660 AC Drive Board –115V

A1525670 AC Drive Board –230V

AZ320075 Power Pack - CC/G/B

AZ320076 Power Pack - T/D

A1515276 Erase Lamp for A151 Copier

AX640056 Optics Cooling Fan Motor for A152 Copier

AX640057 Exaust Blower Motor

A1525611 Quenching Lamp - 115V

A1525610 Quenching Lamp -230V

AW100028 Fusing Thermistor

A1525120 Optics Control Board (Auto ID Sensor)

A1525241 ID Sensor Board

AW100033 Optics thermistor

A1535211 4th/5th Mirror Drive Motor

A1535213 Lens Drive Motor

AW 020075 Photointerrupter

AX020078 Main Motor - 115V 60 Hz

AX020079 Main Motor - 230V 50 Hz

AX020080 Main Motor - 230V 60 Hz

AX520023 Exposure Lamp - 97V/220W

AX520024 Exposure Lamp - 180V/280W

AG010049 Operation Panel Assembly for A151-17

AG010050 Operation Panel Assembly for A151-27, 28, 29

AG010051 Operation Panel Assembly for A152-17

AG010052 Operation Panel Assembly for A152-27, 28, 29

AG010053 Operation Panel Assembly for A151-15

AG010054 Operation Panel Assembly for A151-10, 16

AG010055 Operation Panel Assembly for A151-22, 25

5

Page 6

13 September 1994

Parts Number Description Remarks

AG010056 Operation Panel Assembly for A151-26

AG010057 Operation Panel Assembly for A152-15

AG010058 Operation Panel Assembly for A152-10, 16

AG010059 Operation Panel Assembly for A152-22, 25

AG010060 Operation Panel Assembly for A152-26

Consumables

• The toner is different fro m the E7 series.

6

Loading...

Loading...