Ricoh FT3013 S Service Manual

A202/A203 COPIER

SERVICE MANUAL

The A202 copier is based on the A151 copier.

The A203 copier is based on the A152 copier.

Only the differences from the A151/A152 copier are described in

the following pages. Refer to the A151/A152 copier service manual

regarding the other information.

24 February 1997 SPECIFICATIONS

1. SPECIFICATIONS

NOTE: Only items marked with ✽ are different from A151 and A152 copiers.

Configuration: Desk top

Copy Process: Dry electrostatic transfer system

Original Type: Sheet/Book

Original Alignment: Left center

Original Size: Maximum:A3/11" x 17" (lengthwise) - A203 copier

B4/10" x 14" (lengthwise) - A202 copier

Copy Paper Size: Maximum:B4/10" x 14" (lengthwise)

Minimum:

Paper Tray: A5/51/2" x 81/2" (lengthwise)

Bypass Feed: A6/51/2" x 81/2" (lengthwise)

Copier

A202/A203

Copy Paper Weight: Paper tray feed -- 64 to 90 g/m2 (17 to 24 lb)

Bypass feed -- 52 to 105 g/m2 (14 to 28 lb)

Reproduction Ratios: 2 Enlargement and 3 Reduction (A203 copier only)

A4 Version Letter Version

Enlargement

Full size 100% 100%

Reduction

141%

122%

93%

82%

71%

129%

121%

93%

74%

65%

Zoom: From 61% to 141% in 1% steps

(A203 copier only)

Copying Speed: 13 copies/minute (A4/81/2" x 11" lengthwise)

10 copies/minute (B4/81/2" x 14")

Warm-up Time:

30 seconds (at 20°C/68°F)

First Copy Time: 9 seconds (A4/81/2" x 11" lengthwise)

Copy Number Input: Number keys, 1 to 99

Manual Image Density

7 steps

Selection:

1

SPECIFICATIONS 24 February 1997

Automatic Reset: 1 minute standard setting; can also be set to 3

minutes or no automatic reset.

Energy Saver Function: Automatic

Paper Capacity: Paper tray -- 250 sheets or less than 28 mm stack

height

Bypass feed table -- 1 sheet

Toner Replenishment: Cartridge exchange (320 g/cartridge)

Copy Tray Capacity: 100 sheets (B4/10" x 14" or smaller)

1 sheet (OPC)

✽ Power Source: 110 V/60 Hz/15 A (for Taiwan)

120 V/60 Hz/15 A (for North America)

220 V ~ 240 V/50 Hz/8 A (for Europe)

220 V/50 Hz/8 A (for Middle East)

220 V/60 Hz/8 A (for Saudi Arabia)

220 V/50 Hz/8 A (for Asia)

Refer to the serial number plate (rating plate) to

determine the power source required by the

machine.

Power Consumption:

Copier Only With DF

Maximum 1.4 kVA 1.5 kVA

Warm-up 620 VA (average) 640 VA (average)

Copy cycle 810 VA (average) 860 VA (average)

Ready 160 VA (average) 180 VA (average)

✽ Noise Emission:

Sound power level (The measurements are made in accordance with ISO

7779.)

Copier Only Copier with document feeder

Copy cycle Less than 64 dB Less than 62 dB

Stand by Less than 55 db Less than 40 dB

Sound pressure level (The measurements are made in accordance with ISO

7779 at the operator position.)

Copier Only Copier with document feeder

Copy cycle Less than 58 dB Less than 62 dB

2

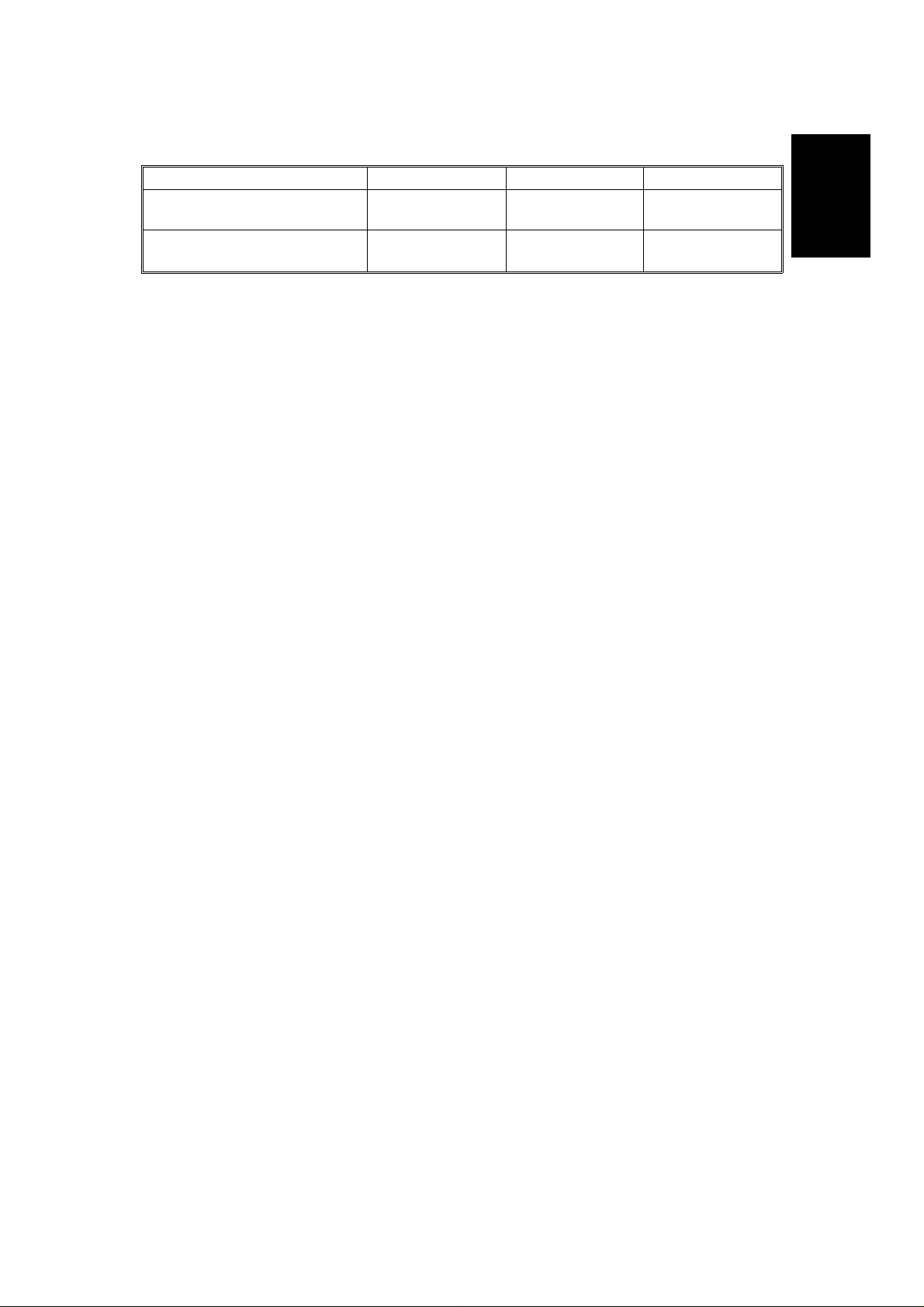

24 February 1997 SPECIFICATIONS

Dimensions:

Width Depth Height

Copier with platen cover and

copy tray

Copier with document feeder

and copy tray

713 mm (28.1") 592 mm (23.3") 400 mm (15.7")

713 mm (28.1") 592 mm (23.3") 463 mm (18.2")

Weight: Copier only: 43 kg (94.8 lb)

With DF: 50 kg (110.2 lb)

Copier

A202/A203

Optional Equipment:

(Sales items)

Optional Equipment:

(Service items)

Document feeder (A203 copier only)

Key counter

Drum anti-condensation heater

Optics anti-condensation heater

Pre-transfer lamp

• Specifications are subject to change without notice.

3

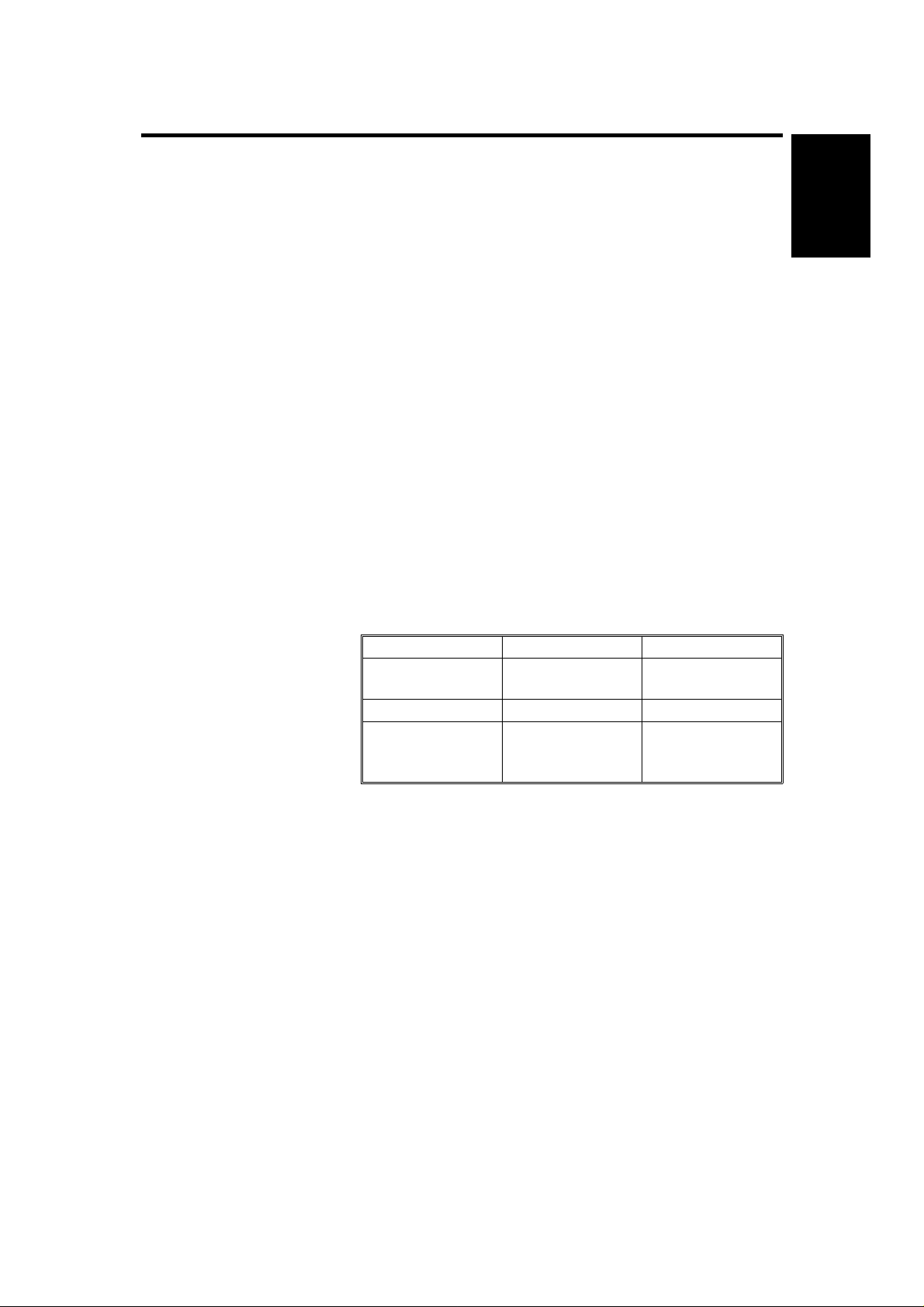

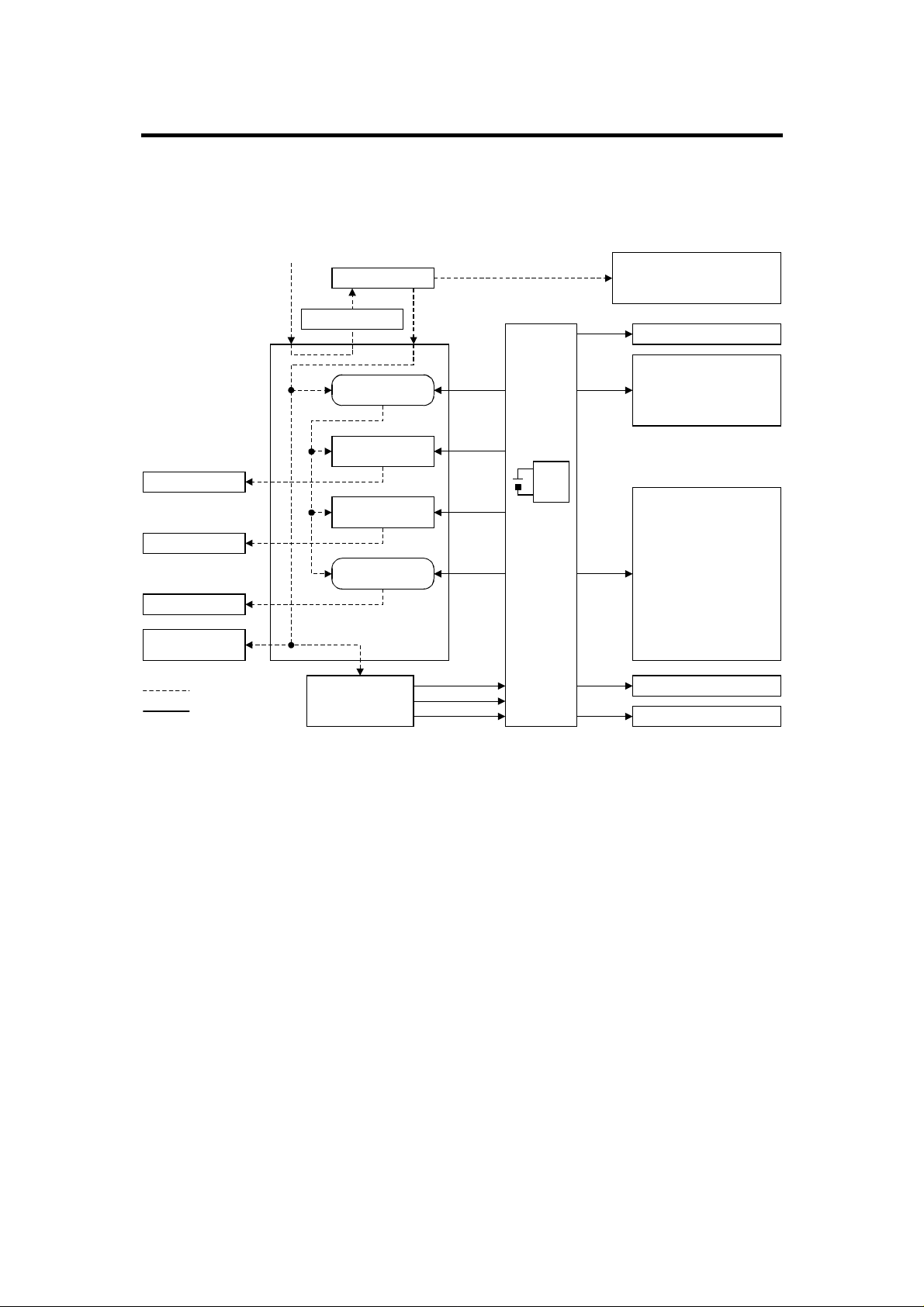

COPY PROCESS CONTROL 24 February 1997

2. COPY PROCESS CONTROL

• Drum residual voltage (VR) correction and detection have been

eliminated.

• Drum wear correction has been eliminated.

Image

Density

Control

Toner

Density

Detection

Grid Voltage

Standard image

density grid voltage

(--680 V)

+

Auto image density

level factor (SP34)

Standard ID sensor

grid voltage

(--460 V)

Exposure Lamp

Voltage

Base exposure

lamp voltage

(Manual or ADS

mode) (SP48)

+

VL correction factor

+

Reproduction ratio

correction factor

(A203 copier only)

Same as image

density control

Development Bias

Voltage

Base bias voltage

factor

(Manual or ADS

mode) (SP34)

+

Image bias voltage

adjustment factor

(SP37)

+

Note:

Base bias voltage at

manual ID level 7

can be adjusted with

SP50

Depends on ID

sensor bias setting

(SP33)

Note:

For the initial 499

copies, bias voltage

is increased by --20

volts

Erase Lamp

Depends on

paper size

and

reproduction

ratio

ID sensor

pattern

erase (Vsg

detection:

Full erase)

Between

Copies

0 Volts (Fixed) Exposure lamp turns

off

--160 Volts (Fixed)+Full erase

Image bias voltage

adjustment factor

(SP37)

NOTE: The boxed items can be adjusted by SP mode.

4

(All LEDs

ON)

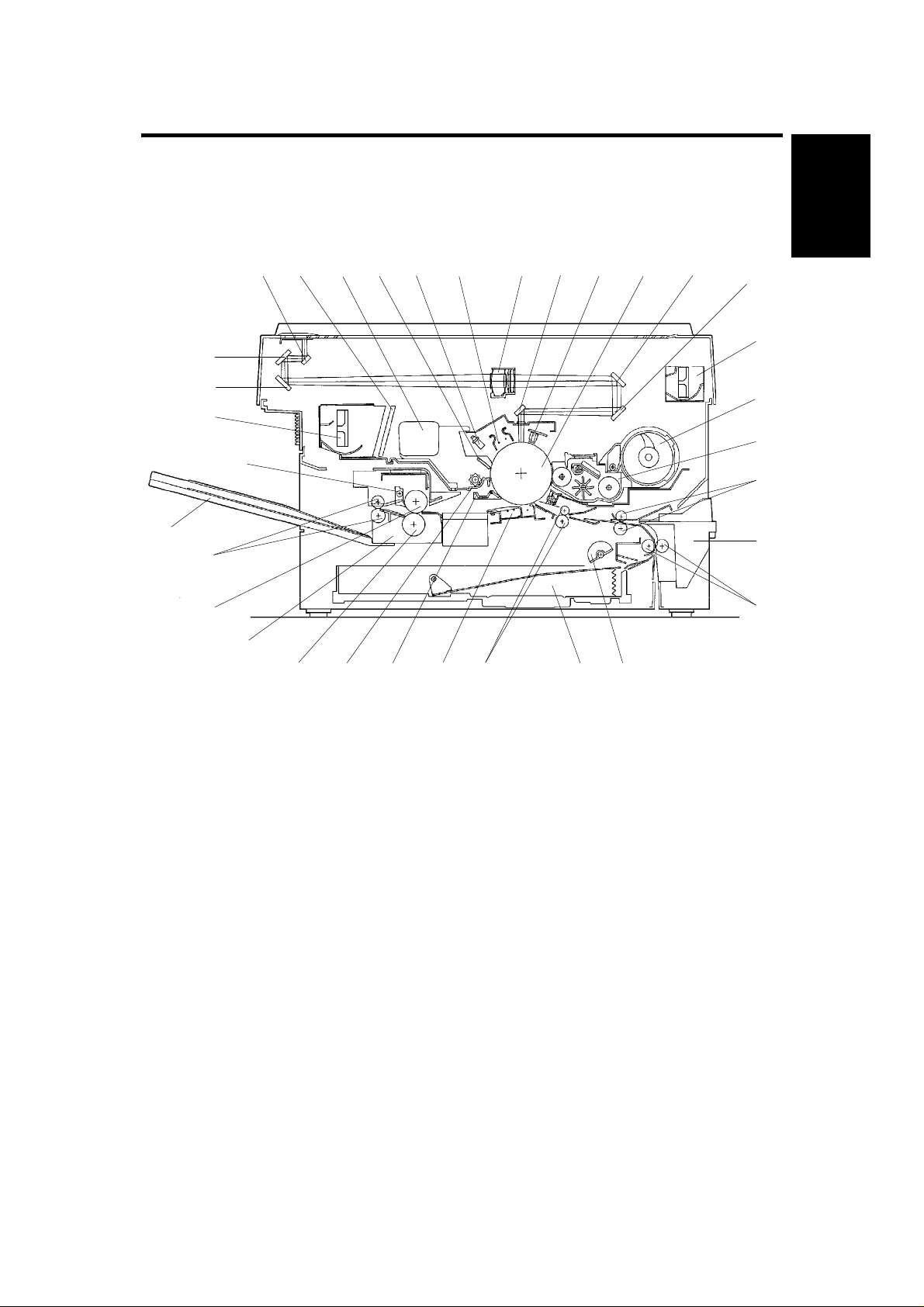

24 February 1997 MECHANICAL COMPONENT LAYOUT

3. MECHANICAL COMPONENT LAYOUT

NOTE: Only items marked with ✽ are different from A151 and A152 copiers.

16

18 19 20 21 22

17

23 24 25

26

27

Copier

A202/A203

15

14

13

12

11

10

9

8

7

1. Semicircular Feed

Rollers

2. Paper Tray

3. Registration Rollers

4. Transfer and

Separation Corona Unit

5. Pick-off Pawl

6. Cleaning Unit

7. Pressure Roller

8. Fusing Unit

9. Hot Roller

10. Exit Rollers

11. Copy Tray

12. Hot Roller Strippers

13. Exhaust Blower Motor

14. 3rd Mirror

15. 2nd Mirror

16. 1st Mirror

17. Ozone Filter

18. Used Toner Tank

19. Cleaning Blade

20. Quenching Lamp

21. Charge Corona Unit

22. Lens

123456

A203V500.img

23. 6th Mirror

24. Erase Lamp

25. Drum

26. 4th Mirror

27. 5th Mirror

28. Optics Cooling Fan

✽

Motor (in A202 & A203)

29. Toner Supply Unit

30. Development Unit

31. 2nd Relay Rollers

32. By-pass Feed Table

33. 1st Relay Rollers

28

29

30

31

32

33

5

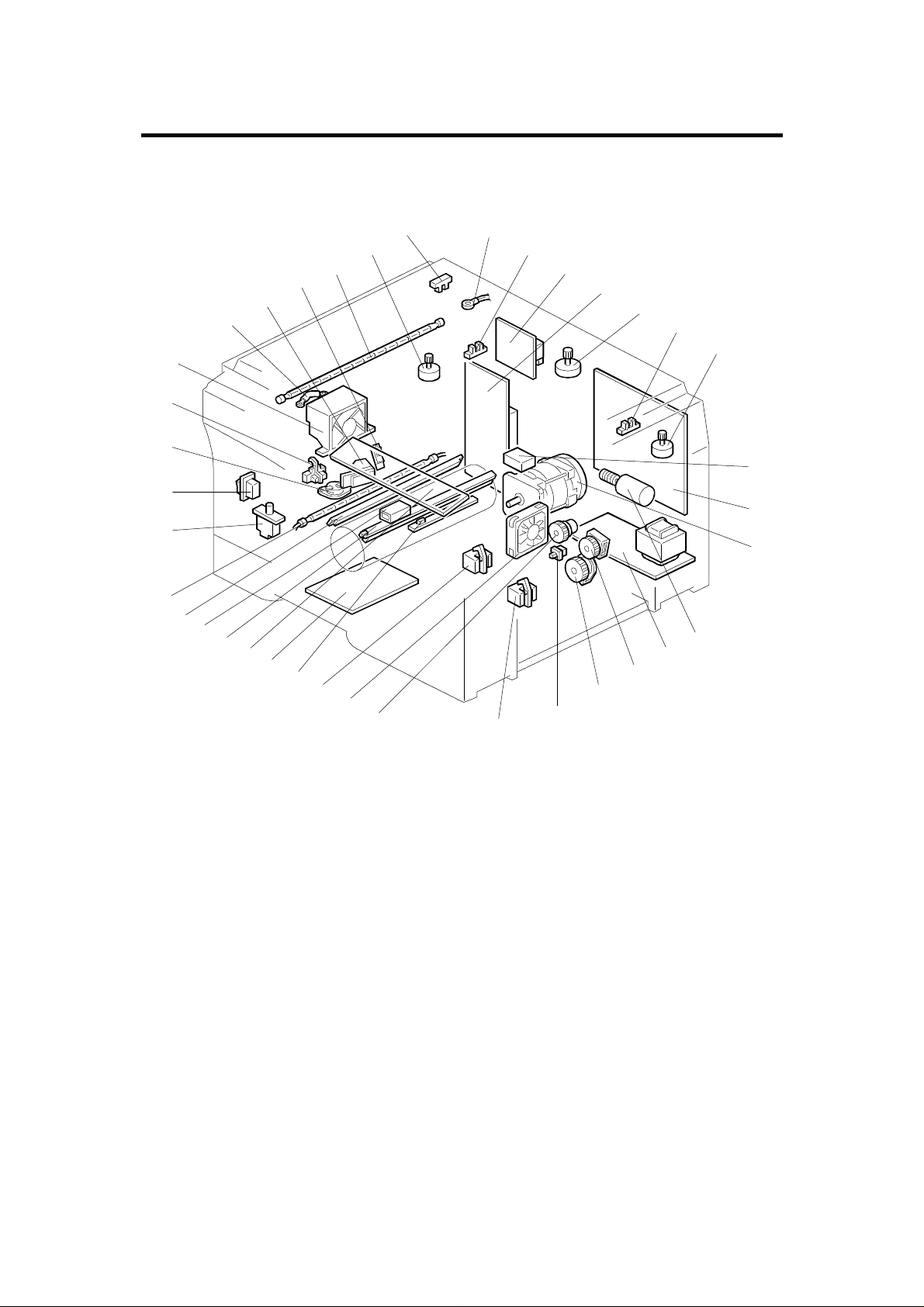

ELECTRICAL COMPONENT LAYOUT 24 February 1997

4. ELECTRICAL COMPONENT LAYOUT

NOTE: Only items marked with ✽ are different from A151 and A152 copiers.

17

16

15

14

13

12

11

10

9

18

23

22

21

20

19

24

25

26

27

29

30

31

32

33

34

8

7

6

5

4

3

1

37

38

2

35

36

A203V501.img

1. Paper Tray Switch

2. Relay Sensor

3. Registration Clutch

✽

4. Optics Cooling Fan Motor

5. Registration Sensor

6. Image Density Sensor

7. Power Pack-TC/SC

8. Operation Panel Board

9. Erase Lamp

10. Total Counter

11. Quenching Lamp

12. Fusing Lamp

13. Front Cover Safety Switch

14. Main Switch

15. Fusing Thermoswitch

16. Exit Sensor

17. Exhaust Blower Motor

18. Optics Thermofuse

19. Auto Image Density

Sensor

20. Fusing Thermistor

21. Exposure Lamp

22. Lens Motor

(A203 copier only)

23. Scanner Home Position

Sensor

24. Optics Thermistor

25. Lens Home Position

Sensor (A203 copier only)

26. Power Pack-CC/Grid/Bias

NOTE: Index No. 28 is not applicable for this model.

6

27. AC Drive Board

28. N/A

✽

29. Scanner Motor

30. 4th/5th Mirror Home

Position Sensor

(A203 copier only)

31. 4th/5th Mirror Motor

(A203 copier only)

32. Main Motor Capacitor

33. Main Board

34. Main Motor

35. Toner Supply Motor

✽

36. DC Power Supply Board

37. Relay Roller Clutch

38. Paper Feed Clutch

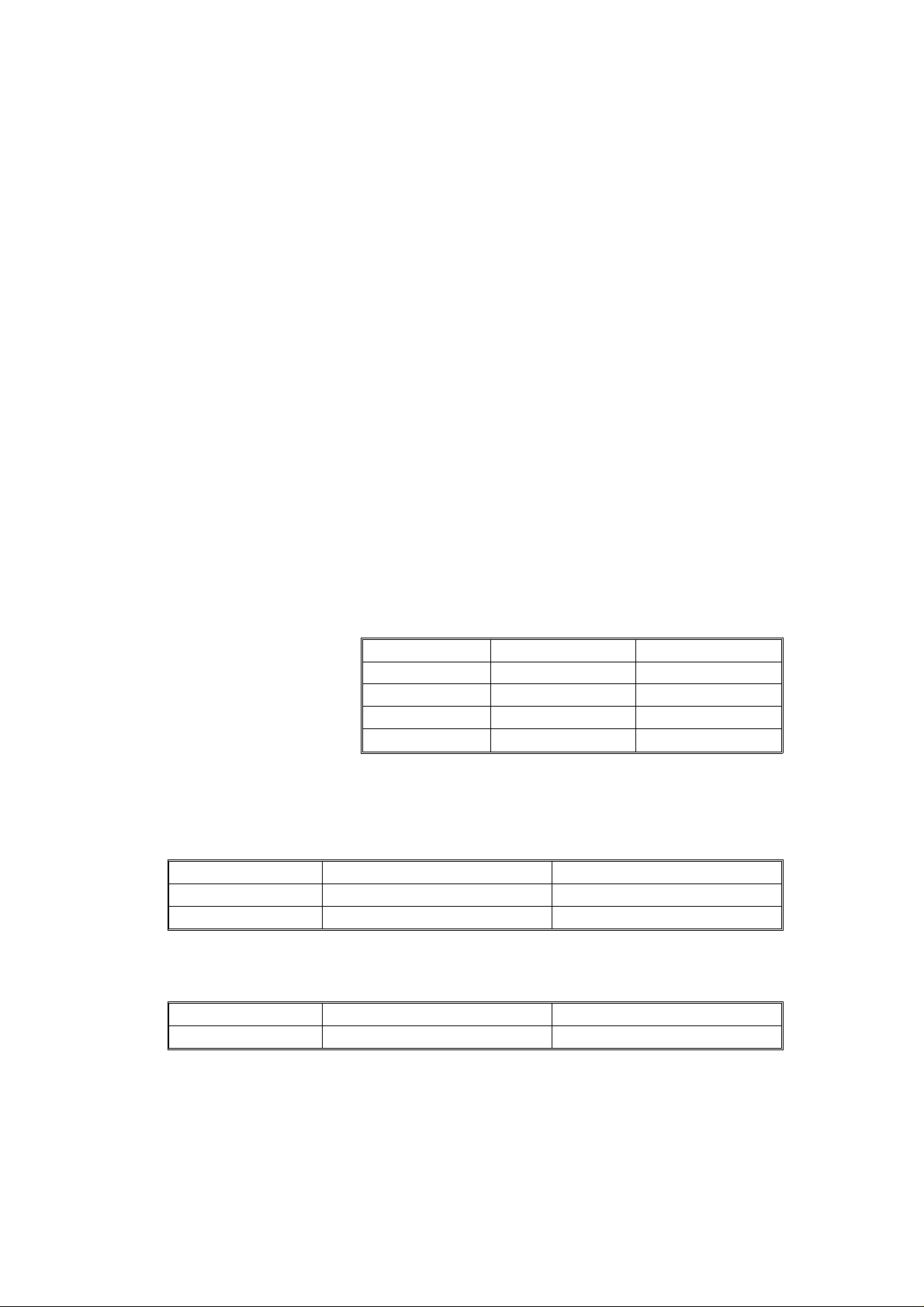

24 February 1997 ELECTRICAL COMPONENT DESCRIPTIONS

5. ELECTRICAL COMPONENT DESCRIPTIONS

The following motor is included as an electrical component.

Symbol Name Function Index No.

M7 Toner Supply Motor Drives the toner supply roller. 35

The following clutch and triac are not included in this copier.

Symbol Name Function Index No.

MSC1 Toner Supply Clutch Drives the toner supply roller. 35

Copier

A202/A203

TR

Fusing Triac

(115 V only)

Switches the fusing lamp on and off.

28

The following part has been changed.

Symbol Name Function Index No.

Quenching Lamp Receives dc power from the main board (the

L3

lamp in the A151/A152 received ac power

from the ac drive board).

11

7

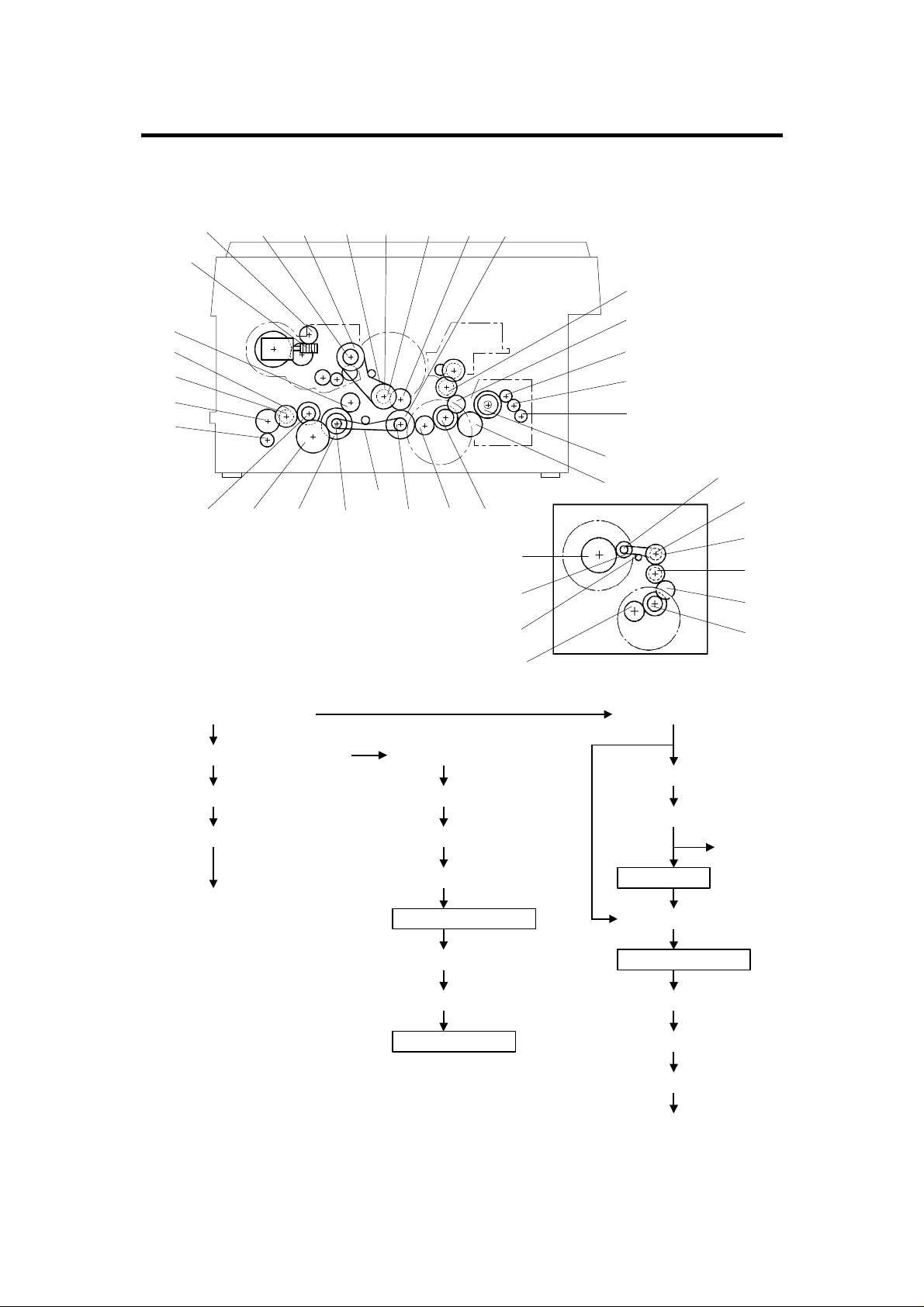

DRIVE LAYOUT 24 February 1997

6. DRIVE LAYOUT

NOTE: Only items marked with ✽ are different from A151 and A152 copiers.

BP5 G11

✽ G13

✽ G14

TB3BP6G12

G10 G23

G9

G15

G16

G17

G18

G19

G20 G21 G22 BP2

Main Motor Gear

G1:

Timing Belt Drive Gear

G23:

Timing Belt Pulley

BP1:

Timing Belt

TB1:

TB1

BP1 G1 G2

A203V502.img

G26

G25

TB2

G1

Relay GearG10:

Timing Belt Drive GearG11:

Timing Belt PulleyBP5:

G4

G3

G8

G7

G6

G5

BP4

BP3

G24

G9

G8

G2

A203V503.img

Relay GearG2:

Relay GearG8:

Relay GearG9:

B

A

A203V504.wmf

Timing BeltTB3:

Development Section

Timing Belt PulleyBP6:

Development GearG12:

Development Unit

8

G3:

Cleaning Unit

Fusing Drive Gear

G3:

Fusing and Exit Unit

Hot Roller GearG4:

Relay GearG7:

Relay GearG6:

Exit Roller GearG5:

24 February 1997 DRIVE LAYOUT

Registration CL Gear

G1:

Registration CL

Registration Rollers

Relay GearG20:

Relay Roller CL GearG17:

Relay Roller CL

2nd Relay Roller GearG16:

2nd Relay Rollers

A B

Paper Feed Section

BP2: Timing Belt Pulley

Relay GearG22:

Paper Feed Section

Paper Feed CL GearG21:

Paper Feed CL

Feed Rollers

G24:

G25:

✽ G13:

Copier

A202/A203

Timing Belt Drive

Gear

Timing Belt PulleyBP3:

Timing BeltTB2:

Timing Belt PulleyBP4:

Relay Gear

Drum Drive GearG26:

Toner Supply Motor

Gear

1st Relay Rollers GearG19:

1st Relay Rollers

✽ G14:

✽

Toner Supply Gear

Toner Supply Unit

A203V505.wmf

9

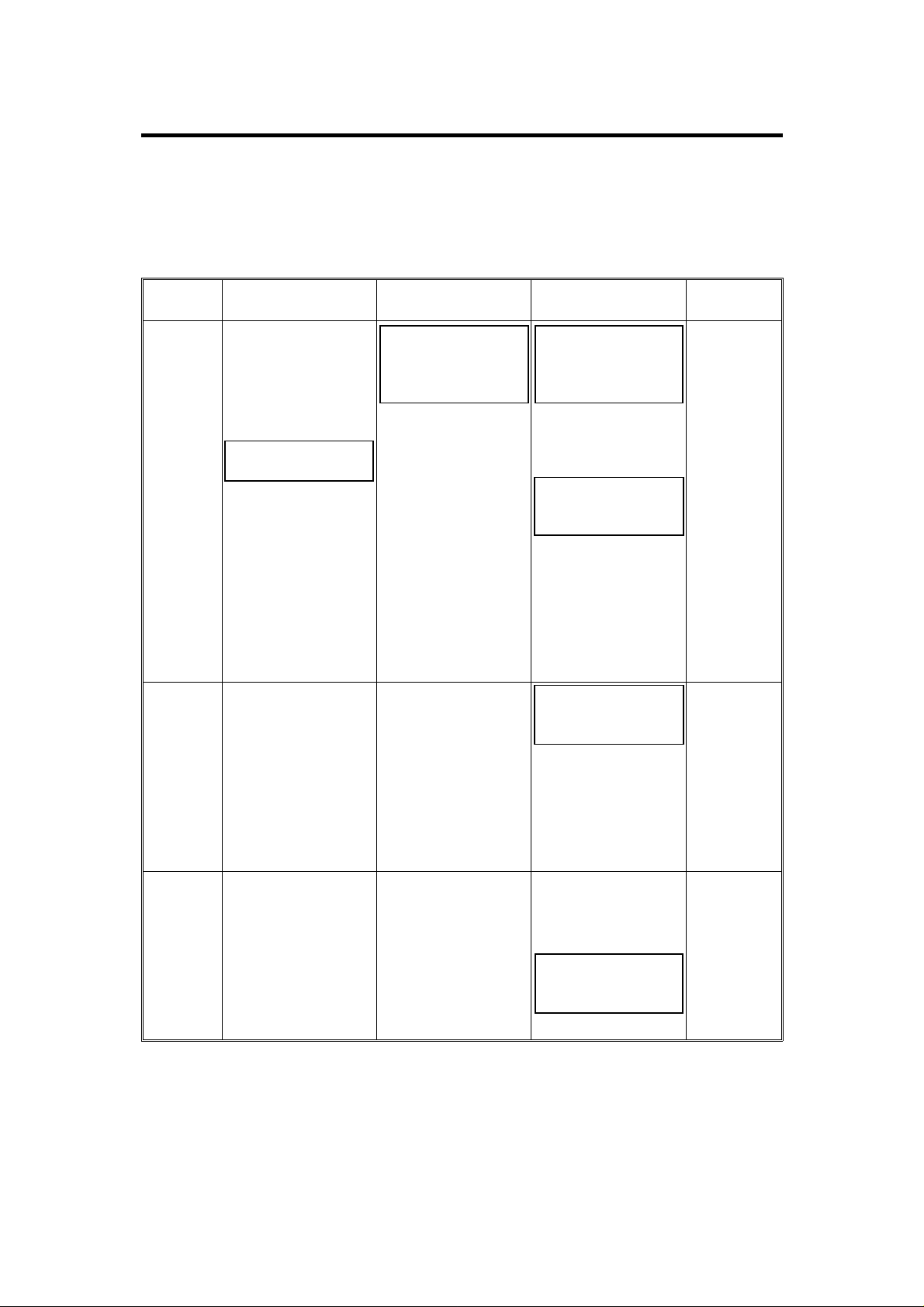

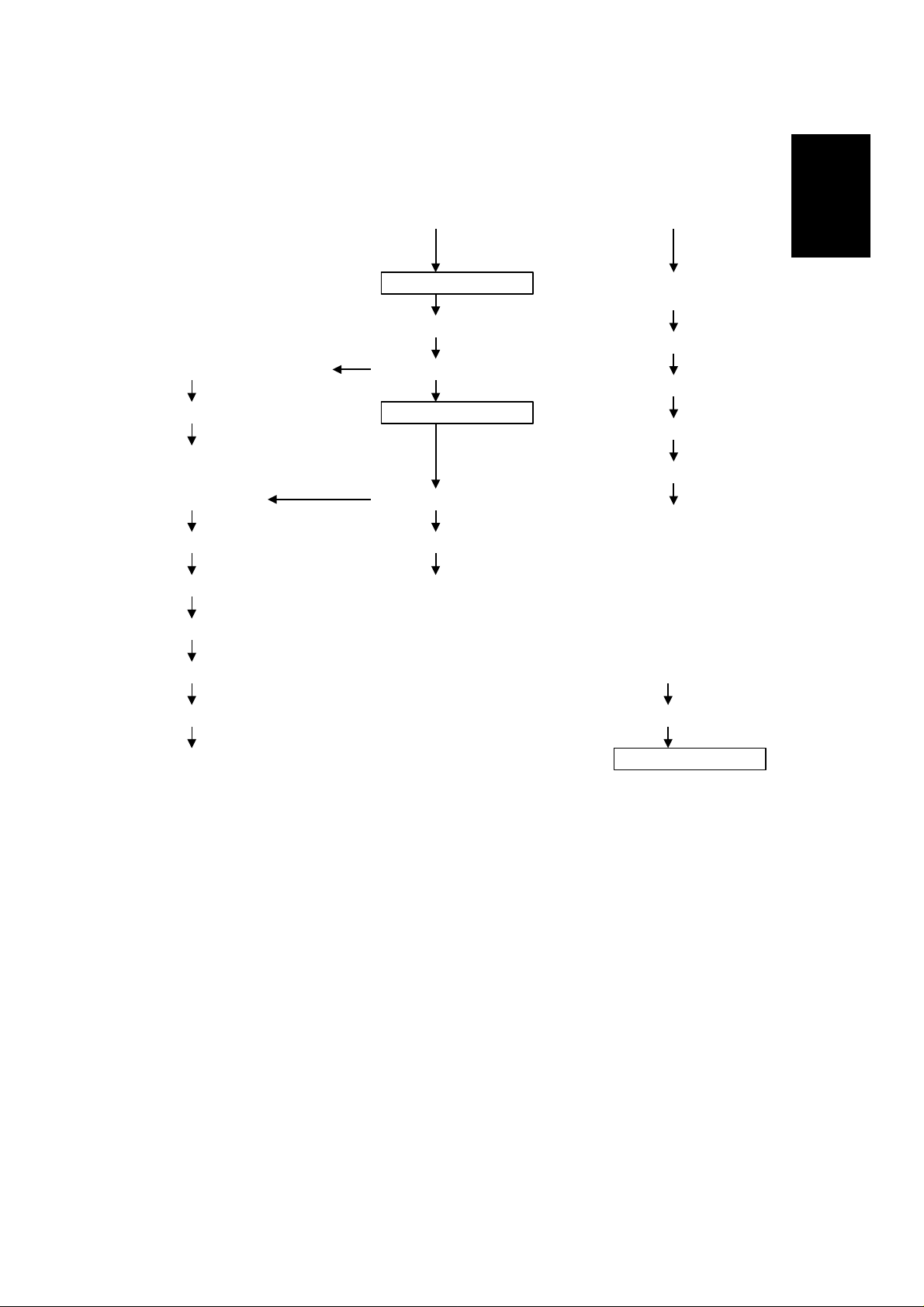

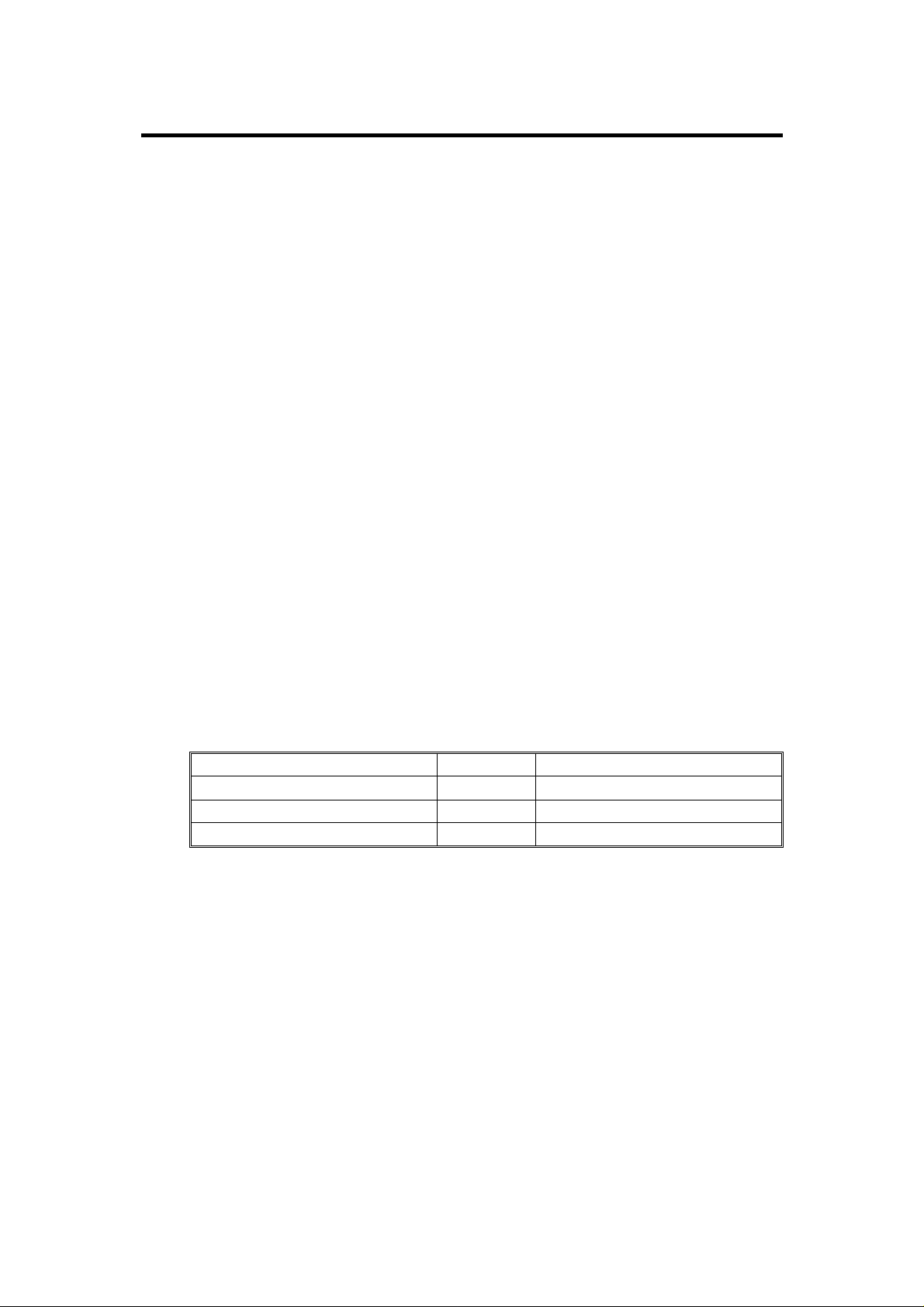

POWER DISTRIBUTION 24 February 1997

7. POWER DISTRIBUTION

NOTE: Only items marked with ✽ are different from A151 and A152 copiers.

Exposure Lamp

Document Feeder

(Option)

AC Power (115V or 220V ~ 240V)

Fusing Lamp

Main Motor

AC power

DC power

Main SW

Cover Safety SW

Power Relay

(RA401)

Fusing Lamp

Drive Circuit

Exposure Lamp

Drive Circuit

Relay (RA402)

AC Drive Board

DC Power

Supply Board

24V (VA)

24V (VA)

24V (VA)

24V (VA)

24V (VA)

5V (VC)

Zero Cross

RAM

Pack

Main

Board

5V

Scan

Signal

5V (VC)

24V (VA)

5V (VC)

24V (VA)

Anti-condensation Heaters

-Drum (Option)

-Optics (Option)

Operation Panel Board

Sensors

Thermistors

Solenoids

Clutches

Power Packs

Lens Motor

(A203 copier only)

4th/5th Mirror Motor

(A203 copier only)

✽ Optics Cooling Fan Motor

✽

Toner Supply Motor

✽ Quenching Lamp

Scanner Motor

A203D500.wmf

When this copier is plugged in and the main switch is turned off, ac power is

supplied via the ac drive board to the optional anti-condensation heaters.

When the front cover and/or the exit cover is open, the cover safety switch

completely cuts off power to all ac and dc components.

When the main switch is turned on, the ac power supply to the

anti-condensation heater is cut off and ac power is supplied to the ac drive

board. The dc power supply board receives wall outlet ac power through the

ac drive board.

The dc power supply board converts the wall outlet ac power input to +5

volts, +24 volts, and a zero cross signal, all of which are supplied to the main

board.

10

24 February 1997 POWER DISTRIBUTION

The main board supplies dc power to all copier dc components. All sensors,

switches, thermistors, and the DF interface board (option) operate on +5

volts. The operation panel operates on +5 volts supplied by the main board.

All other dc components, including the power relay (RA401) and the main

motor relay (RA402), operate on +24 volts.

When the main board receives power, it activates the power relay (RA401),

which then supplies ac power to the fusing lamp drive circuit and the

exposure lamp drive circuit on the ac drive board. The fusing lamp drive

circuit receives a trigger signal from the main board and the fusing lamp

lights. The exposure lamp does not turn on until the main board sends a

trigger pulse to the exposure lamp drive circuit.

When the key is pressed, the main board energizes the main motor relay

(RA402). Then, the main motor turns on.

When the main switch is turned off, power to the main board and to RA401 is

cut off, and the optional drum and optics anti-condensation heaters are

turned on.

Copier

A202/A203

11

DRUM CHARGE 24 February 1997

8. DRUM CHARGE

8.1 GRID VOLTAGE CORRECTION

This machine does not correct drum residual voltage correction (VR

correction) or drum wear correction.

8.2 GRID VOLTAGE FOR IMAGE DENSITY CONTROL

The main board controls the grid voltage through the CC/Grid/Bias power

pack. As the grid voltage for the image density control becomes less, the

copy image becomes lighter, and vice versa.

The grid voltage for image density is based as follows:

Grid Voltage = Standard image density grid voltage (--680 volts [SP60 = 4])

+

Auto image density level factor (SP34)

8.2.1 Standard Image Density Grid Voltage

The standard image density grid voltage (SP60) is set at the factory and the

setting is different for each machine. The setting of SP60 is printed on the SP

mode data sheet located inside the inner cover of the machine.

8.2.2 Auto Image Density Level Factor (SP34)

Auto image density level Data (SP34) Change of grid voltage (volts)

Normal 0 *

Darker 1 --40

Lighter 2

±0

±0

* Factory setting

The grid voltage and the exposure lamp voltage are constant regardless of

the output from the auto image density sensor. Only the development bias

voltage varies depending on the output from the auto image density sensor.

When the auto image density level data in SP34 is set to darker, the grid

voltage is changed --40 volts as shown in the above table. When it is set to

lighter, the grid voltage does not change. However, the development bias

voltage is corrected.

12

24 February 1997 DRUM CHARGE

8.3 GRID VOLTAGE FOR TONER DENSITY DETECTION

The grid voltage for toner density detection is based on the standard ID

sensor grid voltage.

Grid voltage = Standard ID sensor grid voltage (--460 volts [SP62=4])

The standard ID sensor grid voltage (SP62) is set at the factory and the

setting is different for each machine.

The setting of SP62 is printed on the SP mode data sheet located inside the

inner cover of the machine.

Copier

A202/A203

13

OPTICS 24 February 1997

9. OPTICS

9.1 LENS POSITIONING

[A]

[D]

[C]

A203D501.img

[B]

Home Position (100%)

I

I

I

I

I

I

Enlargement Side Reduction Side

I

: Initialize

(100% → 141/129 %)

(141/129% → 71/65 %)

(71/65% → 93 %)

(93% → 71/65 %)

(71/65% → 141/129 %)

(141/129% → 122/121 %)

(122/121% → 100 %)

(100% → 71/65 %)

(71/65% → 100 %)

A203D502.wmf

The lens home position sensor [A] informs the main board when the lens is at

the full size position (home position). The main board determines the lens

stop position in reduction and enlargement modes by counting the number of

steps the motor makes with reference to the lens home position. When a new

reproduction ratio is selected, the lens [B] moves directly to the selected

magnification position.

The lens home position is registered each time the lens starts from or passes

through the lens home position sensor. As the lens moves from the

enlargement side to the reduction side, the sensor registers the home

position. This occurs when the actuator plate [C] enters the lens home

position sensor.

A small vibration can be observed when the lens moves through home

position from the enlargement side to the reduction side because the lens is

going in the wrong direction to register the home position. The lens

overshoots the home position by four pulses before going back to register the

home position.

The lens always stops while moving from left to right (as viewed from the

front) to minimize the error caused by mechanical play in the drive gears [D].

14

24 February 1997 OPTICS

9.2 BASE LAMP VOLTAGE IN MANUAL IMAGE DENSITY

MODE

SP48 sets the exposure lamp data for level 4 (Vo) of manual image density

mode. A value from 100 to 170 can be selected.

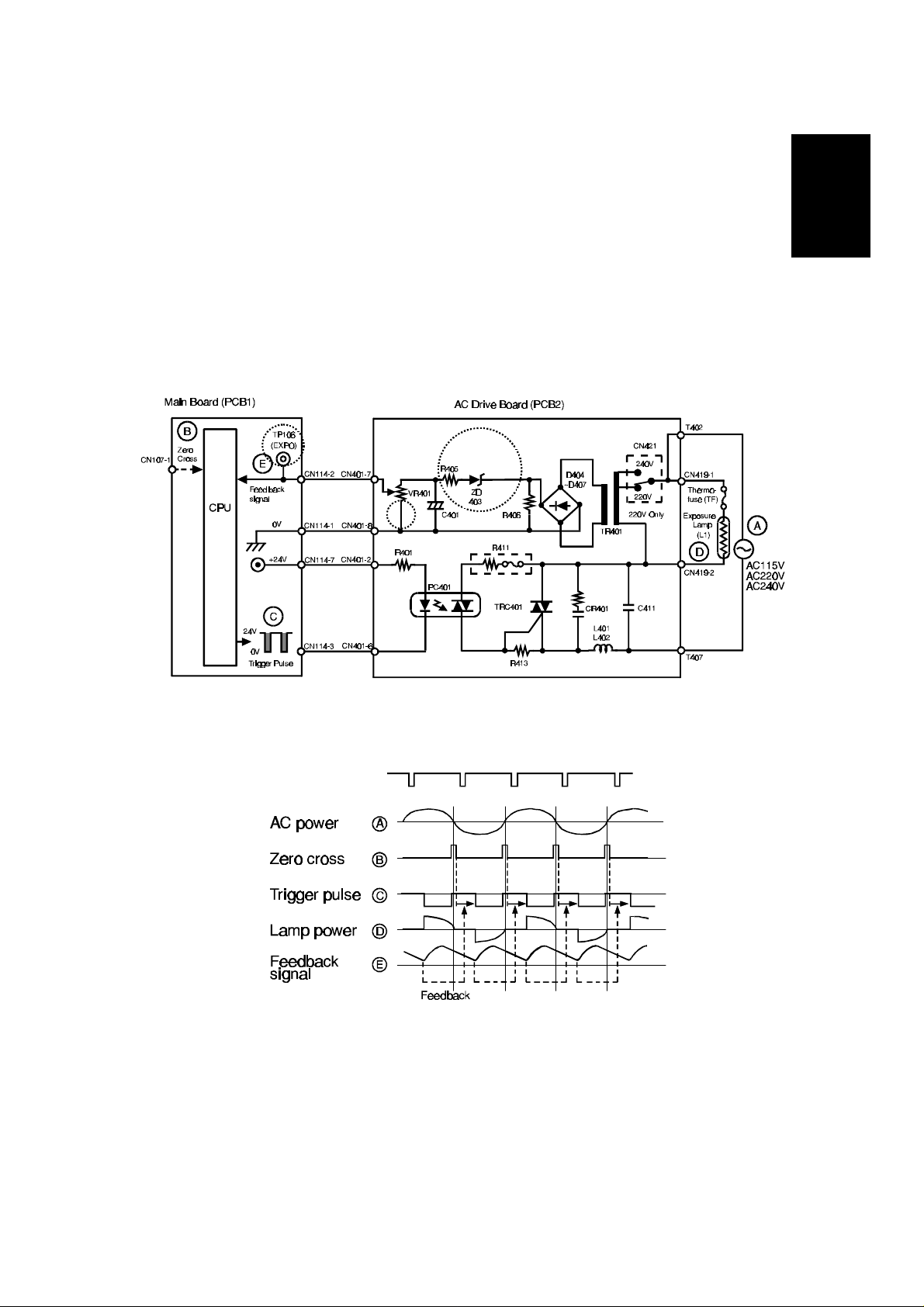

9.3 EXPOSURE LAMP CONTROL CIRCUIT

The circuit is different from A151 and A152 copiers at the indicated locations.

Copier

A202/A203

A203D504.wmf

A203D503.wmf

15

DEVELOPMENT 24 February 1997

10. DEVELOPMENT

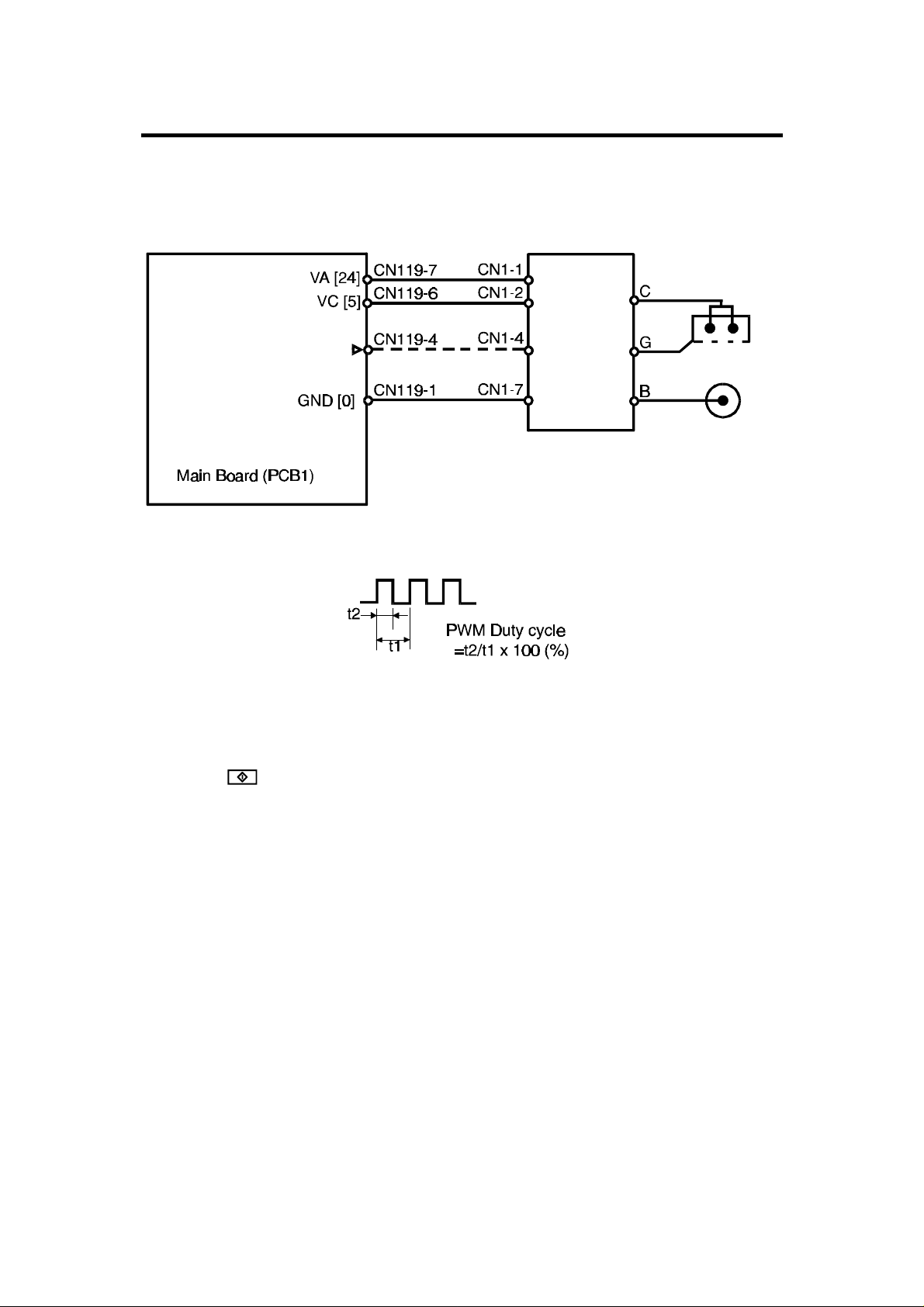

10.1 DEVELOPMENT BIAS CIRCUIT

Charge Corona

Power Pack -

Bias Trig (PWM) [▲0→0/5]

CC/Grid/Bias

(P1)

Grid

Development

Bias

A203D505.wmf

A203D506.wmf

The main board supplies +24 volts to the CC/Grid/Bias power pack at CN1-1.

When the key is pressed, the CPU starts sending the bias trigger pulses

to CN1-4. This energizes the development bias circuit within the

CC/Grid/Bias power pack, which applies a high negative voltage to the

development roller. The development bias is applied whenever the drum is

rotating.

The bias trigger pulse applied to CN1-4 is a pulse width modulated signal

(PWM signal). The width of the pulses controls the voltage level of the

development roller. As the width of the trigger pulses increase, the voltage to

the development roller also increases. The power pack is equipped with its

own feedback circuit to monitor the development bias voltage.

16

24 February 1997 TONER DENSITY DETECTION AND TONER SUPPLY

11. TONER DENSITY DETECTION AND TONER

SUPPLY

11.1 ID Sensor Control Circuit

This circuit is different from A151 and A152 copiers at the indicated location.

A203D509.wmf

Copier

A202/A203

17

Loading...

Loading...