Page 1

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYS ICAL INJURY

1. Before disassembling or asse mblin g pa rts of the copie r and perip herals,

make sure that the copier power cord is unplu gg ed.

2. The wall outlet should be near the copier an d easily accessible.

3. Note that the optio na l a nt i-con de nsation heaters are supplied wit h

electrical voltage even if the main switch is turned off .

4. If any adjustment or operat ion check ha s to be made with exterior covers

off or open while the main switch is turned on, kee p ha nds away from

electrified or mechanically drive n comp on ents.

5. The inside and the met al pa rts of the fusin g un it be come extremely hot

while the copier is operat ing . Be careful to avoid touching those

components with your bare hands.

6. When the development unit, cleaning unit, drum unit, or the DF is

removed from the machine, the upper unit becomes lighter. If th e up per

unit is released under this condition, it tends to open very abrupt ly. The

service engineer might be injured if he is leaning over the machine at this

time. Also, the machine might move due to the shock of the up pe r unit

opening abruptly. To avoid possib le inju ry o r machine damage, hold the

upper unit firmly when opening the unloaded upper unit.

7. Due to variation in the tolerance of the torsion springs, the upper unit

cannot be held at an angle of 16 deg rees by itself when the DF is

installed. To avoid possible injury, always use the upper unit stand to

keep the upper unit op en.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozon e filt er inst alle d.

2. Always replace the ozone filter at 80K copy intervals.

3. Toner and developer are non-to xic, bu t if you get eith er of them in your

eyes by accident, it may cause temp ora ry e ye disco mfo rt. Try to remove

with eye drops or flush with wat er as first aid. If un succe ssfu l, ge t med ical

attention.

©1994 By Ricoh Company Ltd. All right s reserved

Page 2

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be insta lled and maintained by a

customer service represen tative who has completed the training course

on those models.

– CAUTION –

2. The RAM pack has a lithium battery which can explode if handled

incorrectly. Replace only with same RAM pa ck. Do not recharge, or

burn this battery. Used RAM pack must be handled in accord ance with

local regulations.

SAFETY AND ECOLOGICAL NOTES FOR DISP OS AL

1. Do not incinerate the toner cartridge or the used toner. Toner dust may

ignite suddenly when exposed to open flame.

2. Dispose of used tone r, developer, and organic photoconductors

according to local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in acco rda nce with local regulations.

4. When keeping used lithium batteries (main control boards) in order to

dispose of them later, do not store mo re th an 100 batte ries (main control

boards) per sealed box. Storing larg er nu mbe rs or n ot sealing them apart

may lead to chemical reactions and heat build -up .

Page 3

SECTION 1

OVERALL MACHINE

INFORMATION

Page 4

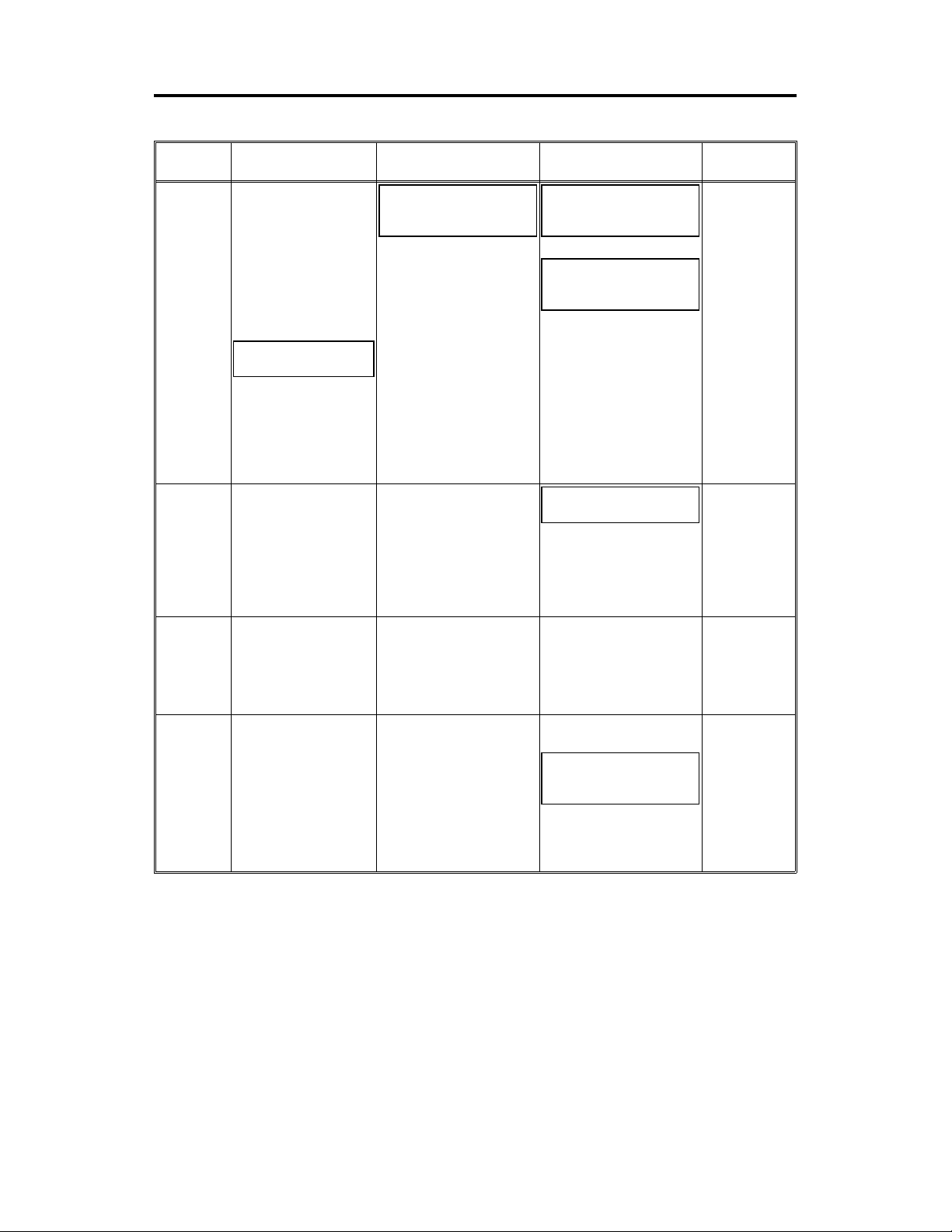

24 June 1994 SPECIFICATIONS

1. SPECIFICATIONS

Configuration : Desk top

Copy Process: Dry electrostatic transfer system

Original Type: Sheet/Book

Original Alignment: Left center

Original Size: Maximum: A3/11" x 17" (lengthwise) – A152

copier

B4/10" x 14" (lengthwise) – A151

copier

Copy Paper Size: Maximum: B4/10" x 14" (lengthwise)

Minimum:

Paper Tray: A5/51/2" x 81/2" (lengthwise)

Bypass Feed: A6/51/2" x 81/2" (lengthwise)

Copy Paper Weight: Paper tray feed – 64 to 90 g/m2 (17 to 24 lb)

Bypass feed – 52 to 105 g/m2 (14 to 28 lb)

Reproduction Ratios: 2 Enlargement and 3 Reduction (A152 copie r only)

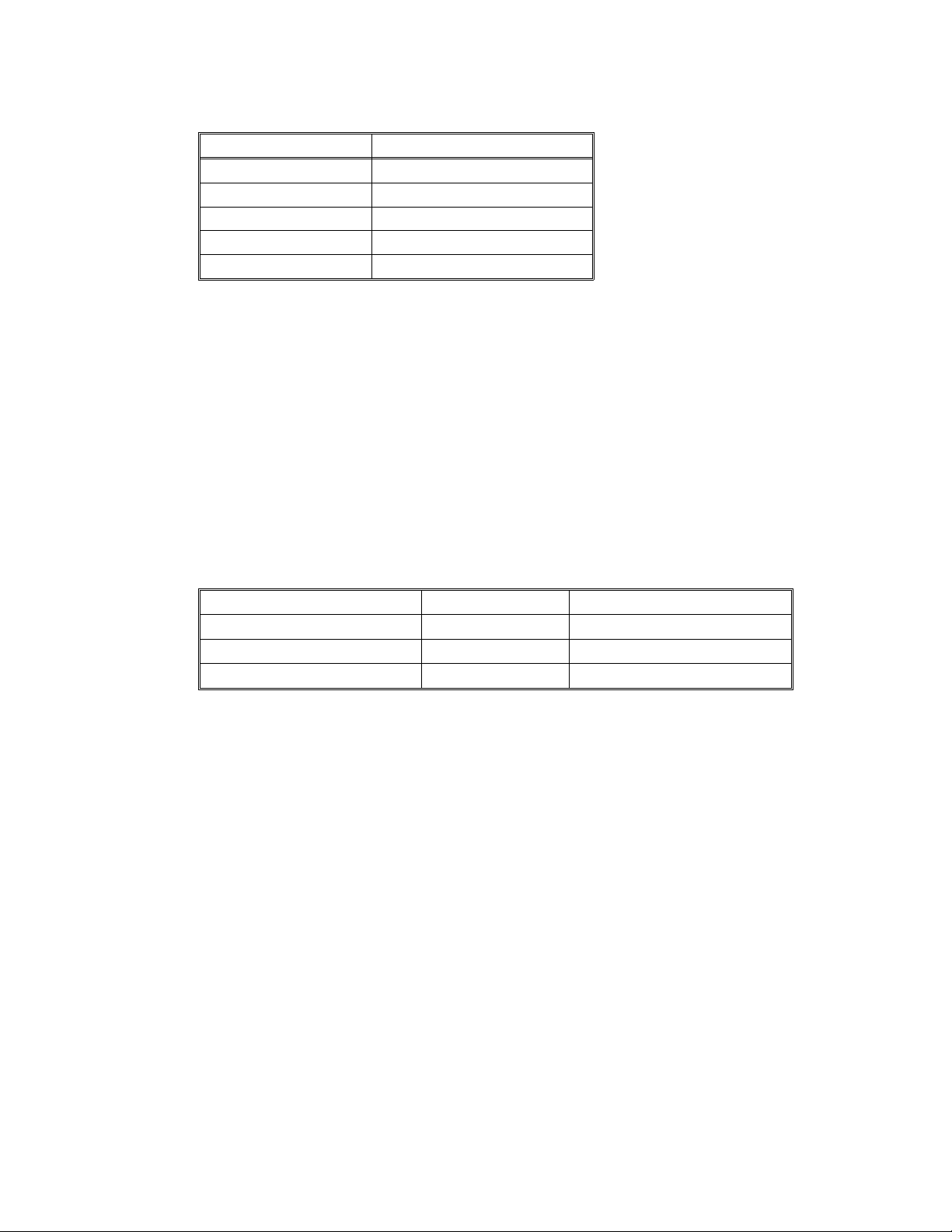

A4 Version Letter Version

Enlargement

Full size 100% 100%

Reduction

Zoom: From 61% to 141% in 1% steps

(A152 copier only)

Copying Speed: 13 copies/minute (A4 /81/2" x 11" lengthwise)

10 copies/minute (B4/81/2" x 14")

Warm-Up Time: 30 seconds (at 20°C/68°F)

First Copy Time: 9 seconds (A4/81/2" x 11" lengt hwise)

141%

122%

93%

82%

71%

129%

121%

93%

74%

65%

Copy Number Input: Number keys, 1 to 99

Manual Image Density

Selection:

7 steps

1-1

Page 5

SPECIFICATIONS 24 June 1994

Automatic Reset: 1 minute standard setting; can also be set to 3

minutes or no automatic reset.

Energy Saver Function: Automatic

Paper Capacity: Paper tray – 250 sheets

Bypass feed table – 1 she et

Toner Replenishment: Cartridge exchange (320 g/cartridge)

Copy Tray Capacity: 100 sheets (B4/10" x 14" or smaller)

Power Source: 110V / 60 Hz/ 15A (for Taiwan)

115V/ 60Hz/ 15A (for North America)

220V – 240V/ 50Hz/ 8A (for Europe)

220V/ 60Hz/ 8A (for Middle East)

220V/ 50Hz/ 8A (for Asia)

(Refer to the serial number plate (rating plat e) to

determine the power source required by the

machine.)

Power Consumption:

Noise Emission:

Dimensions:

Copier with platen cover and

copy tray

Copier with document feeder

and copy tray

Copier Only With DF

Maximum 1.4 kVA 1.5 kVA

Warm-up 620 VA (average) 640 VA (average)

Copy cycle 810 VA (average) 860 VA (average)

Ready 160 VA (average) 180 VA (average)

Copier Only With DF

Maximum 58 db 60 db

Copy cycle Less than 55 db Less than 55 db

Ready Less than 39 db Less than 39 db

Width Depth Height

713 mm (28.1") 592 mm (23.3") 400 mm (15.7")

713 mm (28.1") 592 mm (23.3") 463 mm (18.2")

1-2

Page 6

24 June 1994 SPECIFICATIONS

Weight: Copier only: 43 kg (94.8 lb)

With DF: 50 kg (110.2 lb)

Optional Equipment:

(Sales items)

Optional Equipment:

(Service items)

Document feeder (A152 copier only)

Key counter

Drum anti-condensation heater

Optics anti-condensation heater

Pre-transfer lamp

Optics cooling fan (for A151 copie r only)

• Specifications are subject to change witho ut notice.

1-3

Page 7

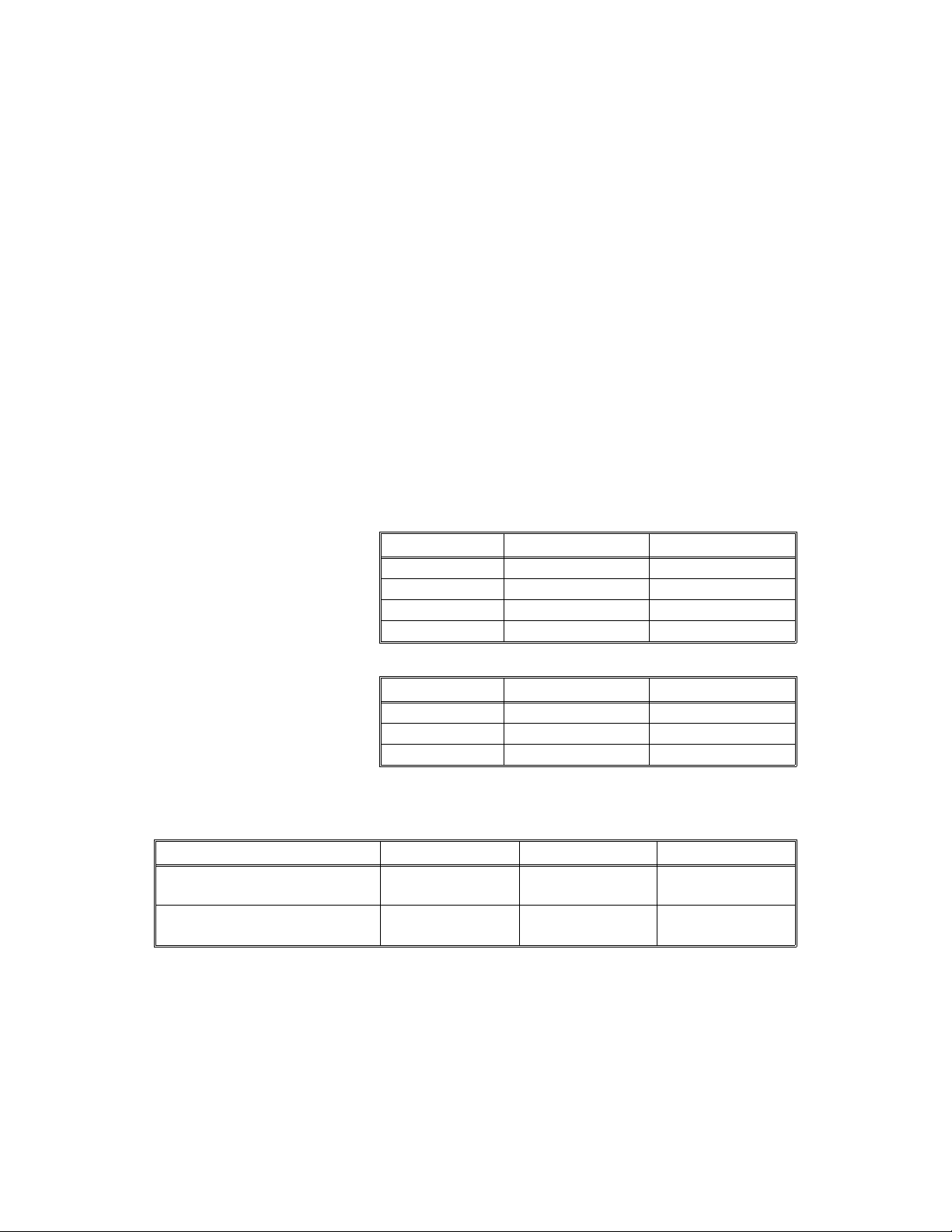

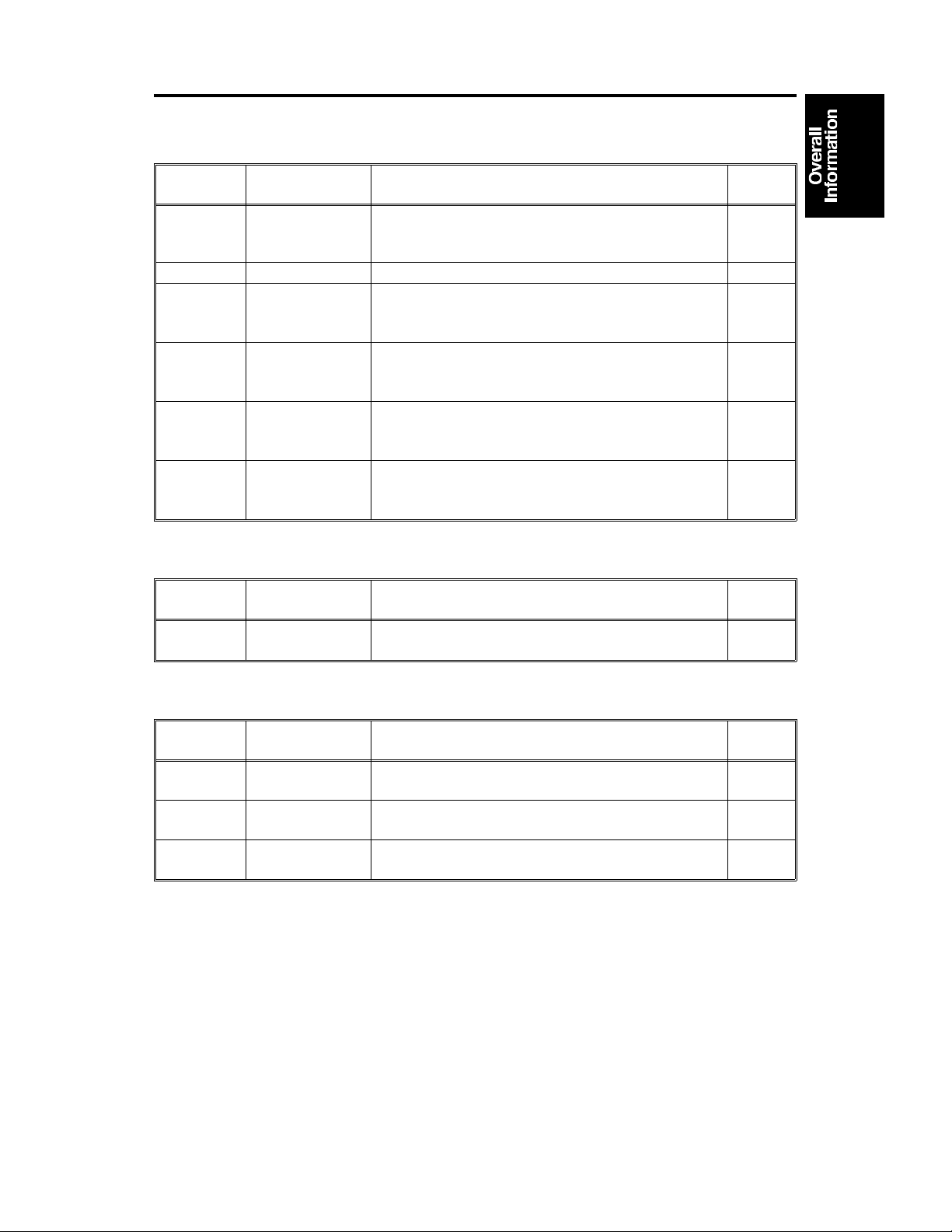

COPY PROCESSES AROUND THE DRUM 24 June 1994

2. COPY PROCESSES AROUND THE DRUM

2. EXPOSURE

1. DRUM CHARGE

3. ERASE

8. QUENCHING

4. DEVELOPMENT

7. CLEANING

6. PAPER

SEPARATION

5. IMAGE TRANSFER

1-4

Page 8

24 June 1994 COPY PROCESSES AROUND THE DRUM

1. DRUM CHARGE

In the dark, the charge corona unit gives a uniform negative charge to the organic

photoconductive (OPC) drum. The charge remains on the surface of the drum because the

OPC drum has a high electrical resistance in the dark.

2. EXPOSURE

An image of the original is reflected to the OPC drum surface via the optics assembly. The

charge on the drum surface is dissipated in direct proportion to the intensity of the reflected

light, thus producing an electrical latent image on the drum surface.

3. ERASE

The erase lamp illuminates the areas of the charged drum surface that will not be used for

the copy image. The resistance of the drum in the illuminated areas drops and the charge on

those areas dissipates.

4. DEVELOPMENT

Positively charged toner is attracted to the negatively charged areas of the drum, thus

developing the latent image. (The positive triboelectric charge is caused by friction between

the carrier and toner particles.)

5. IMAGE TRANSFER

Paper is fed to the drum surface at the proper time so as to align the copy paper and the

developed image on the drum surface. Then, a strong negative charge is applied to the back

side of the copy paper, producing an electrical force which pulls the toner particles from the

drum surface to the copy paper. At the same time, the copy paper is electrically attracted to

the drum surface.

6. PAPER SEPARATION

A strong ac corona discharge is applied to the back side of the copy paper, reducing the

negative charge on the copy paper and breaking the electrical attraction between the paper

and the drum. Then, the stiffness of the copy paper causes it to separate from the drum

surface. The pick-off pawl help to separate the paper from the drum.

7. CLEANING

The cleaning blade removes any toner remaining on the drum.

8. QUENCHING

Light from the quenching lamp electrically neutralizes the surface of the drum.

1-5

Page 9

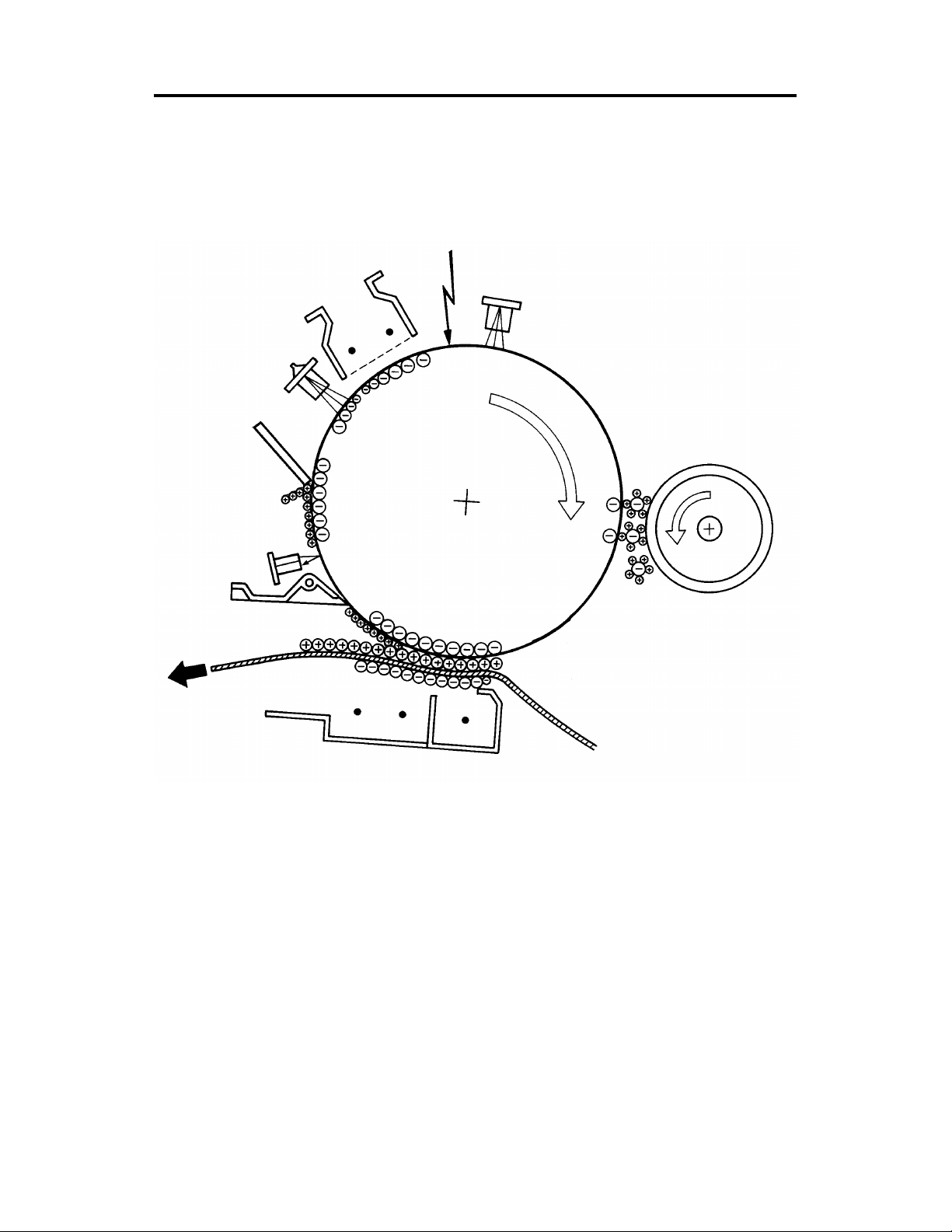

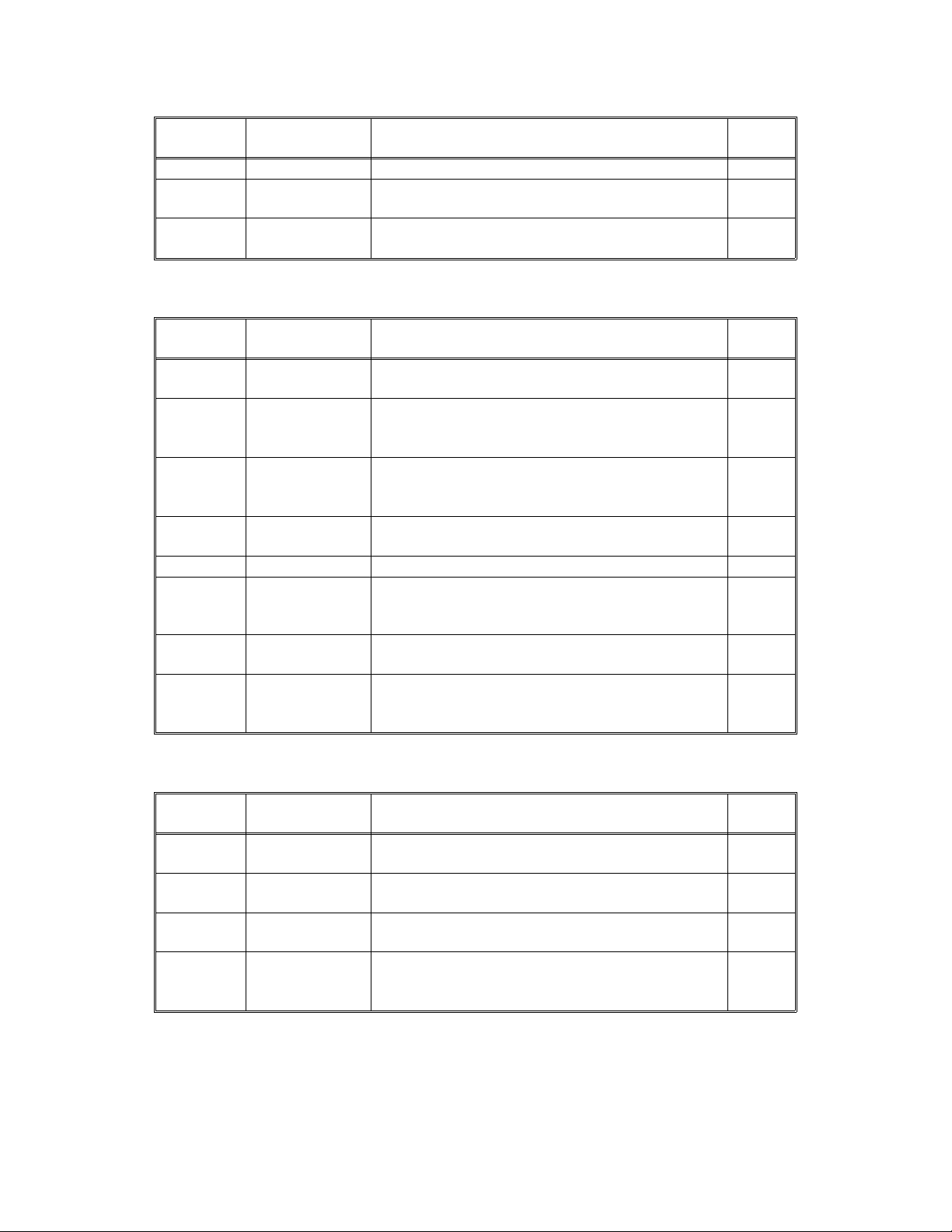

COPY PROCESS CONTROL 24 June 1994

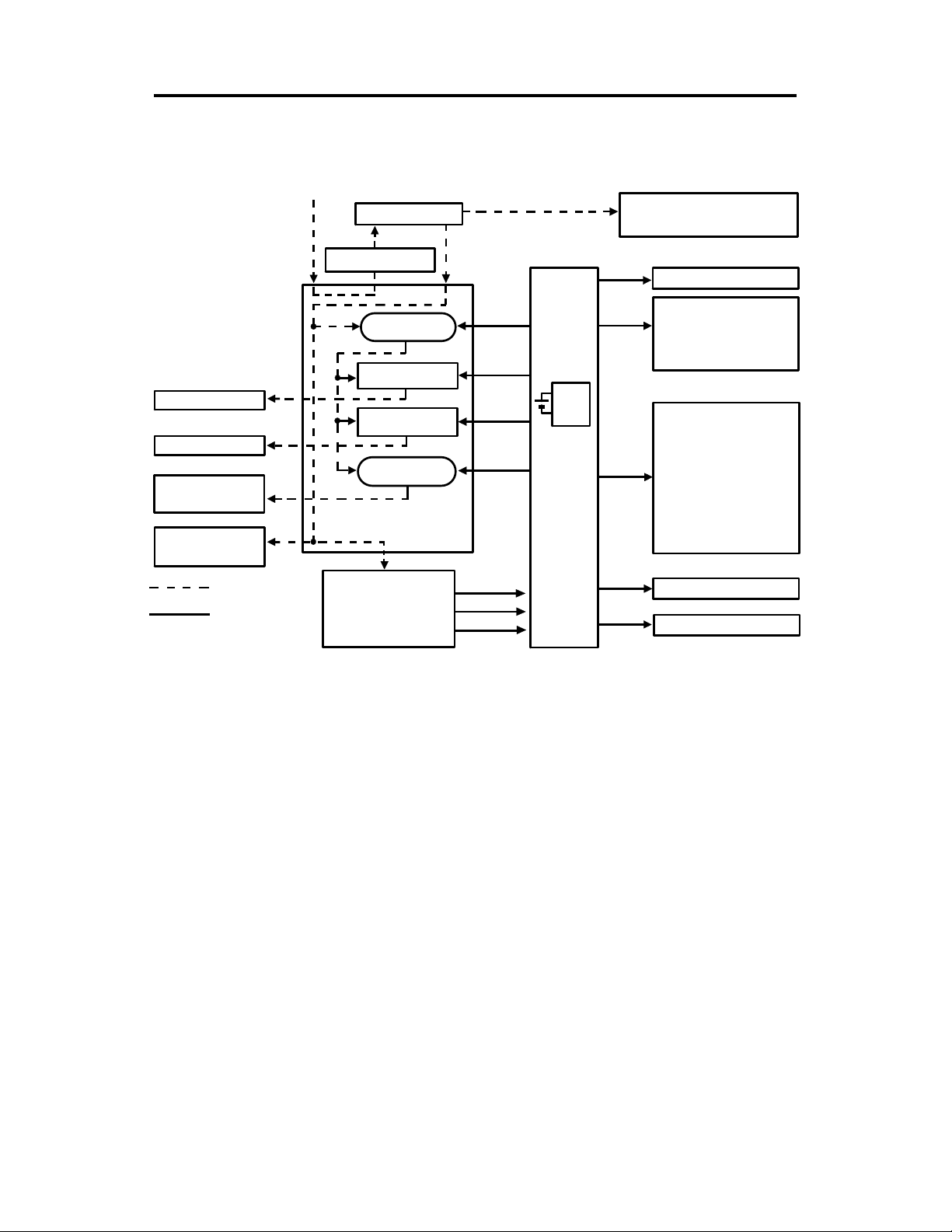

3. COPY PROCESS CONTROL

Image

Density

Control

Toner

Density

Detection

Residual

Voltage

(Vr)

Detection

Between

Copies

Grid Voltage

Standard image

density grid voltage

(–680 V)

+ + +

Drum residual voltage

(Vr) correction factor

(SP67)

+

Auto image density

level factor (SP34)

Standar d ID sensor

grid voltage

(–460 V)

+

Drum wear correction

factor (SP57)

Standar d ID sensor

grid voltage

(–460 V)

+

Drum wear correction

factor (SP57)

0 Volts (Fixed) Exposure lamp tu rns off –160 Volts (Fixed)

Exposure Lamp

Voltage

Base exposure lamp

voltage (Manual or ADS

mode) (SP48)

V

L correction factor

+

Reproduction ratio

correction factor (A152

copier on ly)

Same as image density

control

Same as image density

control

Development Bias

Voltage

Base bias voltage factor

(Manual or ADS mode

[SP34])

Image bias voltage

adjustme nt factor

(SP37)

+

Drum residual voltage

(Vr) correction factor

Note:

Base bias voltage at

manual ID level 7 can be

adjusted by SP50

Depends on I D sensor

bias setting (SP33)

Note:

For initial 499 copies

bias voltage is increased

by –20 volt s

0 Volts (Fixed) Full erase

+

Image bias voltage

adjustme nt factor

(SP37)

+

Drum residual voltage

(Vr) correction factor

Erase Lamp

Depends on

paper size

and

reproduction

ratio

ID sensor

pattern erase

(Vsg

detection:

Full erase)

(All LEDs ON)

Full erase

(All LEDs ON)

NOTE: The boxed items can be adjusted by SP mode.

1-6

Page 10

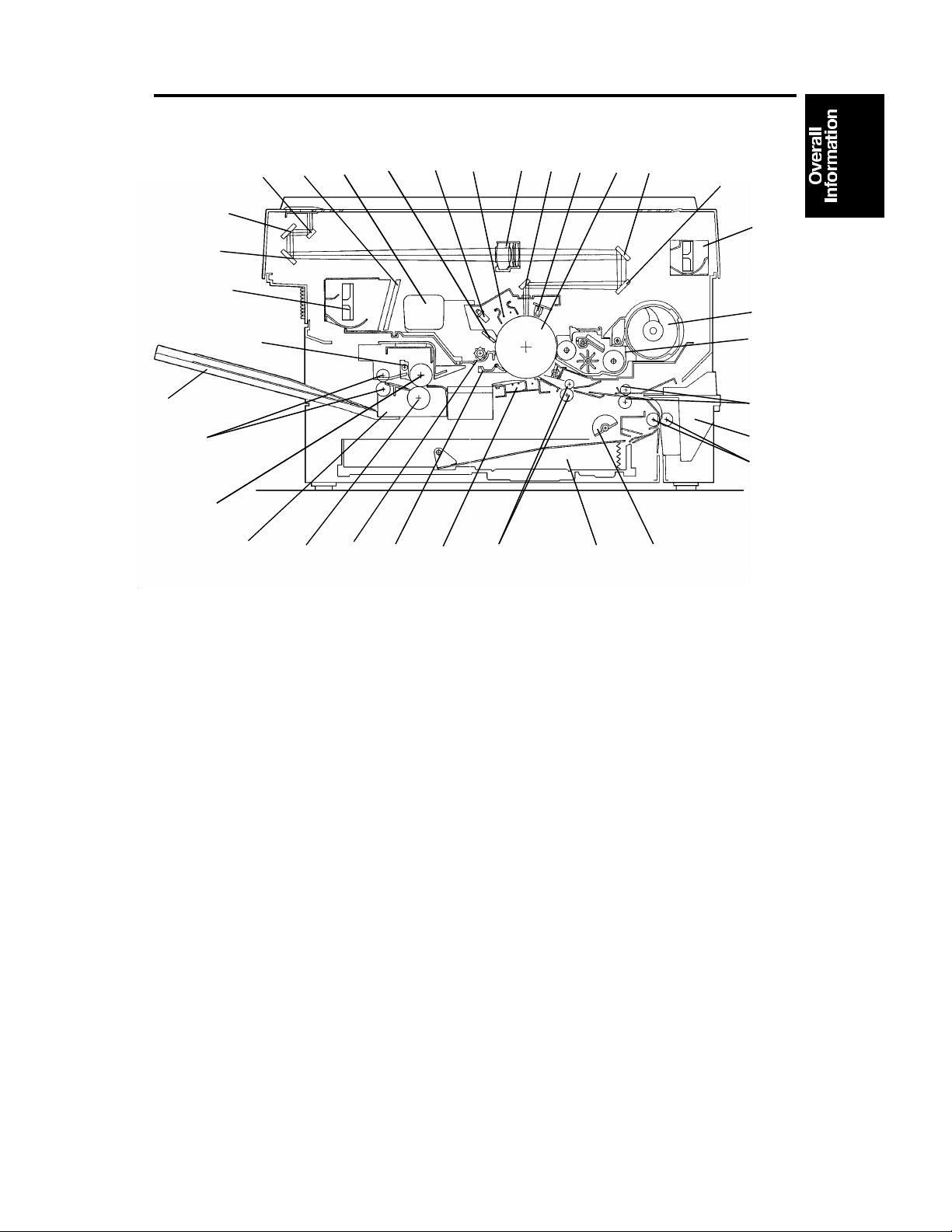

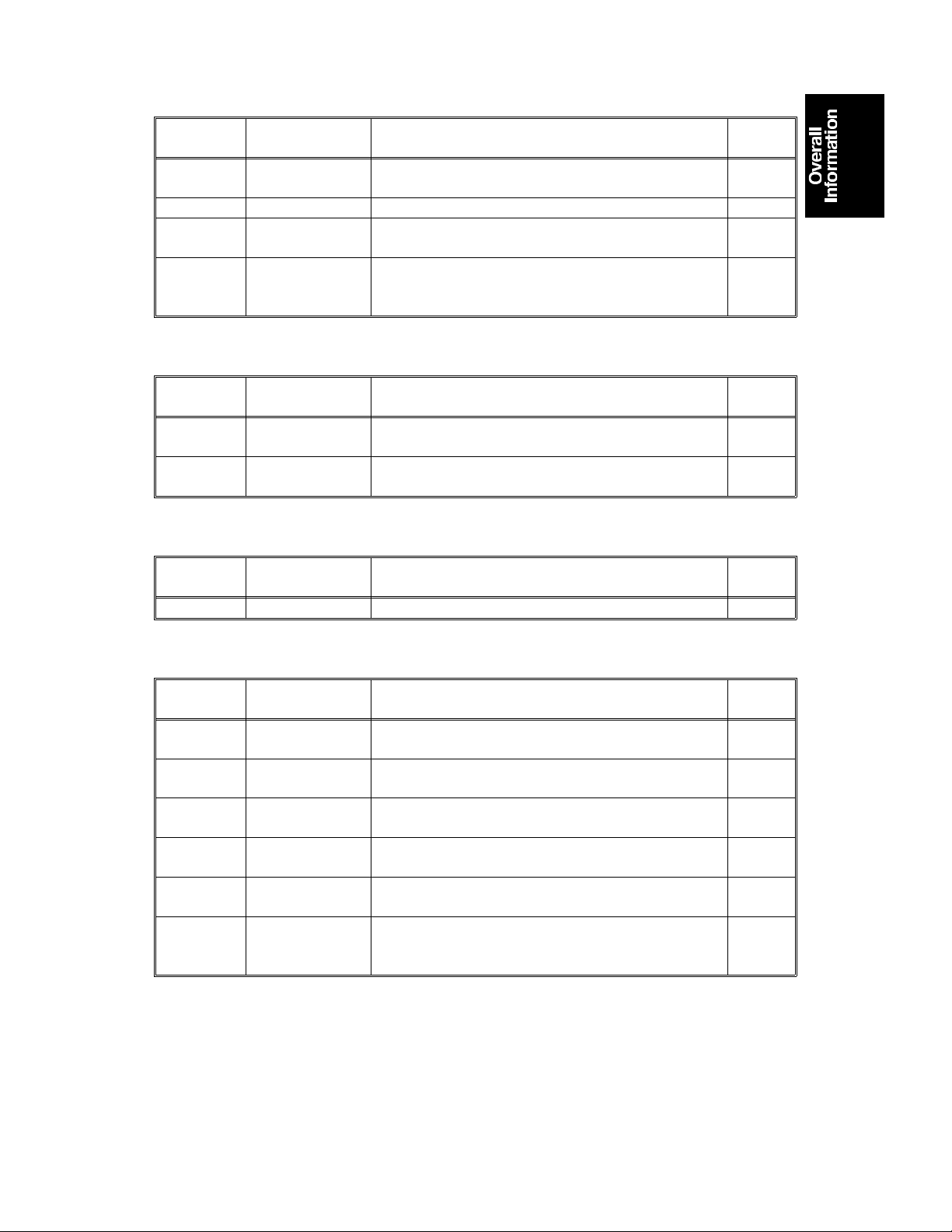

24 June 1994 MECHANICAL COMPONENT LAYOUT

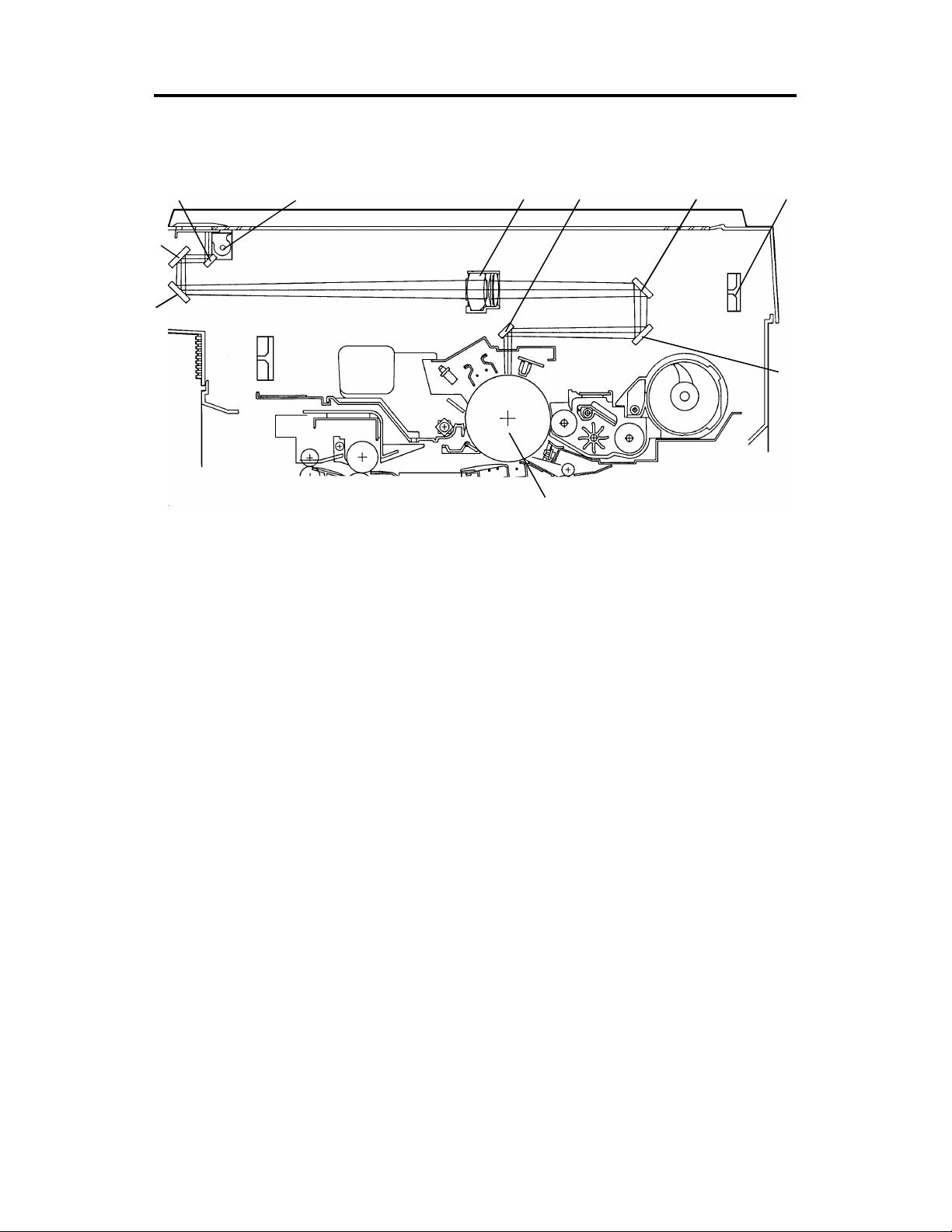

4. MECHANICAL COMPONENT LAYOUT

11

10

9

14

15

13

16

17

18

19

21 22 23

20

24 25

26

27

28

29

12

30

31

32

33

8

7

6

5

4

3

2

1

1. Semicircular Feed Rollers

2. Paper Tray

3. Registration Rollers

4. Transfer and Separation

Corona Unit

5. Pick-off Pawl

6. Cleaning Unit

7. Pressure Roller

8. Fusing Unit

9. Hot Roller

10. Exit Rollers

11. Copy Tray

12. Hot Roller Strippers

13. Exhaust Blower Motor

14. 3rd Mirror

15. 2nd Mirror

16. 1st Mirror

17. Ozone Filter

18. Used Toner Tank

19. Cleaning Blade

20. Quenching Lamp

21. Charge Corona Unit

22. Lens

23. 6th Mirror

24. Erase Lamp

25. Drum

26. 4th Mirror

27. 5th Mirror

28. Optics Cooling Fan Motor

(A152 Copier only)

29. Toner Supply Unit

30. Development Unit

31. 2nd Relay Rollers

32. By-pass Feed Table

33. 1st Relay Rollers

1-7

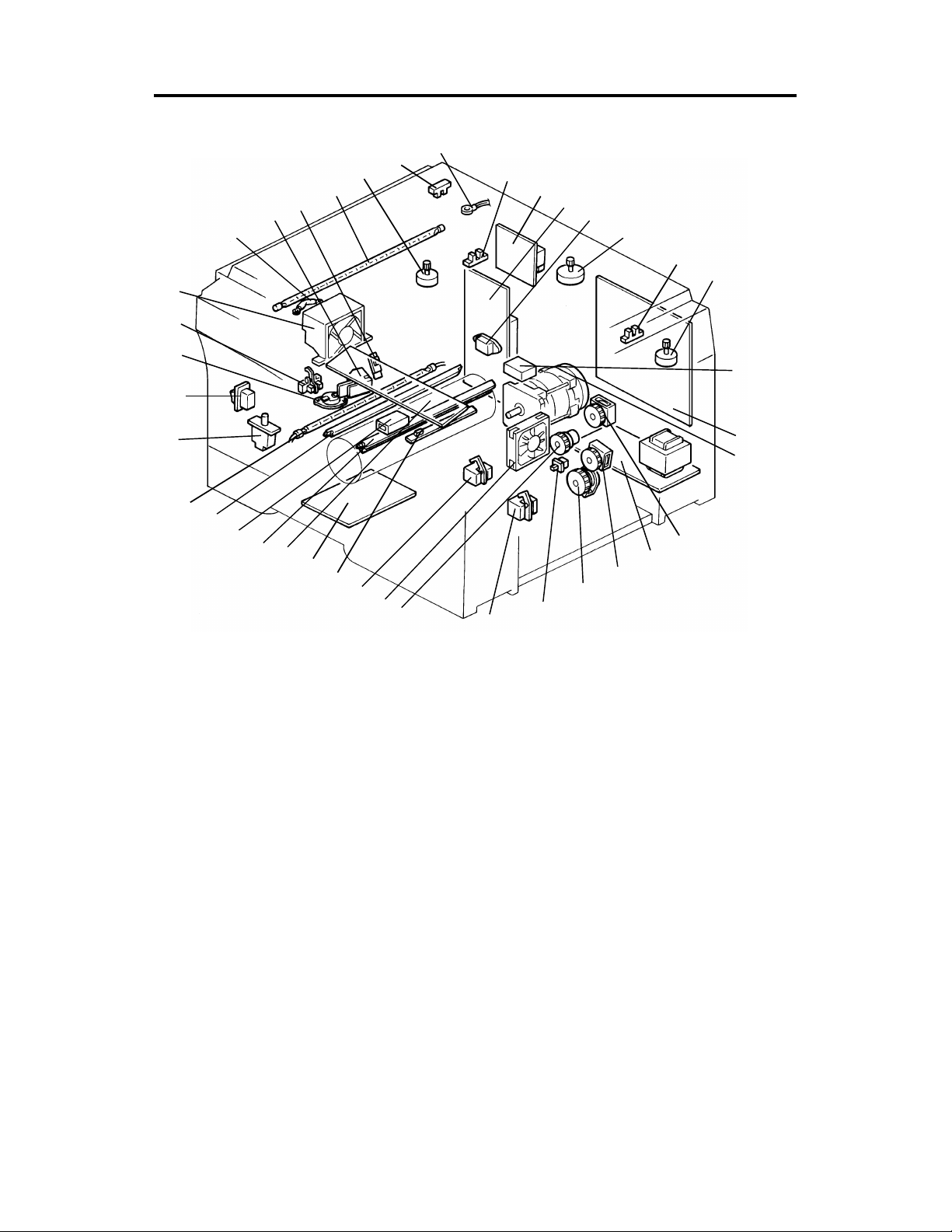

Page 11

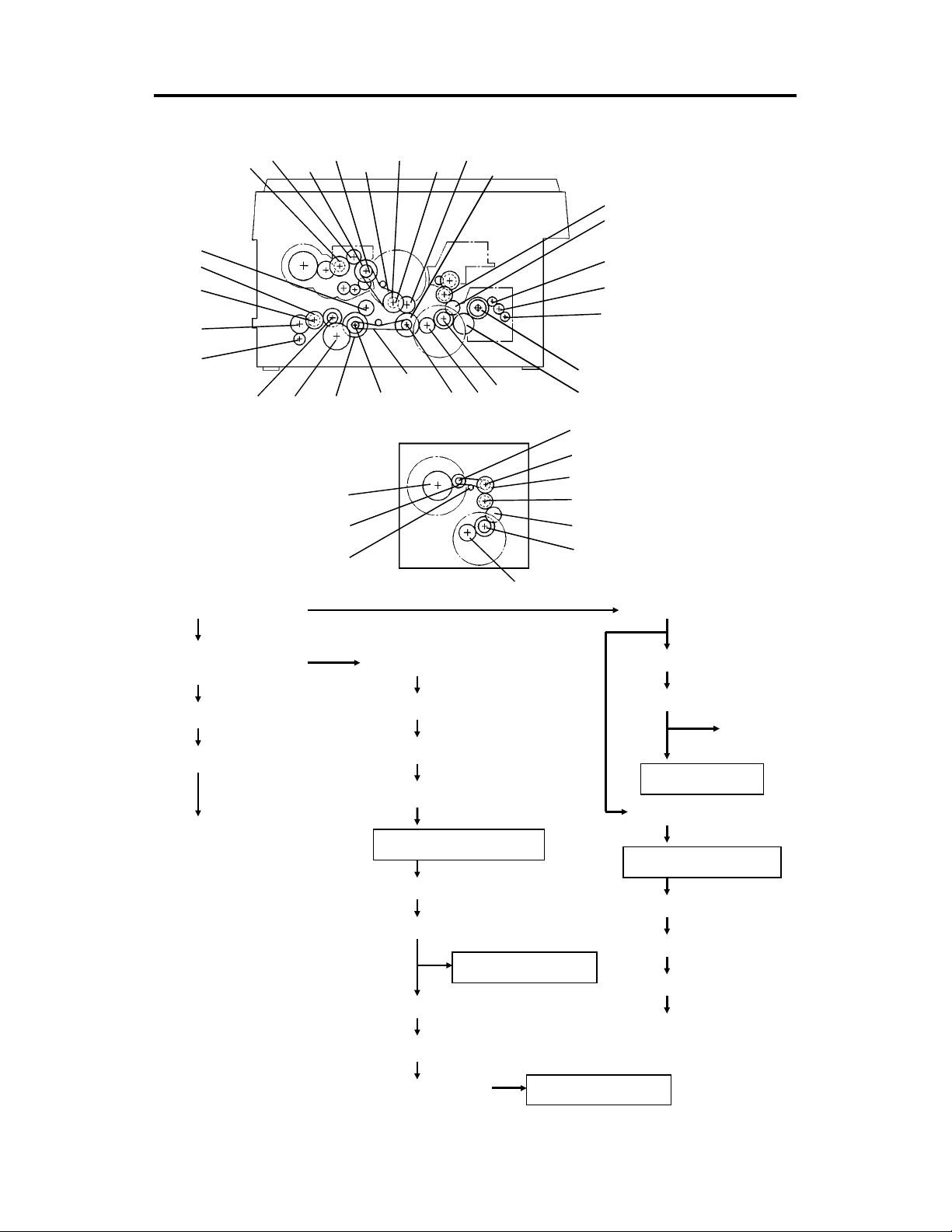

ELECTRICAL COMPONENT LAYOUT 24 June 1994

5. ELECTRICAL COMPONENT LAYOUT

17

16

15

13

14

12

11

18

10

19

9

24

23

22

21

20

25

26

27

28

29

30

31

32

33

34

8

7

6

5

4

3

2

1

37

38

35

36

1. Paper Tray Switch

2. Relay Sensor

3. Registration Clutch

4. Optics Cooling Fan Motor

(A152 only)

5. Registration Sensor

6. Image Density Sensor

7. Power Pack-TC/SC

8. Operation Panel Board

9. Erase Lamp

10. Total Counter

11. Quenching Lamp

12. Fusing Lamp

13. Front Cover Safety Switch

14. Main Switch

15. Fusing Thermoswitch

16. Exit Sensor

17. Exhaust Blower Motor

18. Optics Thermofuse

19. Auto Image Density Sensor

20. Fusing Thermistor

21. Exposure Lamp

22. Lens Motor

(A152 copier only)

23. Scanner Home Position

Sensor

24. Optics Thermistor

25. Lens Home Position

Sensor

(A152 copier only)

26. Power Pack-CC/Grid/Bias

27. AC Drive Board

28. Fusing Triac (115 V only)

29. Scanner Motor

30. 4th/5th Mirror Home

Position Sensor

(A152 copier only)

31. 4th/5th Mirror Motor

(A152 copier only)

32. Main Motor Capacitor

33. Main Board

34. Main Motor

35. Toner Supply Clutch

36. DC Power Supply Board

37. Relay Roller Clutch

38. Paper Feed Clutch

1-8

Page 12

24 June 1994 ELECTRICAL COMPONENT DESCRIPTIONS

6. ELECTRICAL COMPONENT DESCRIPTIONS

Motors

SYMBOL NAME FUNCTION

Drives all the main unit components except for the

M1 Main Motor

M2 Scanner Motor Drives the scanners (1st and 2nd). (dc stepper) 29

M3 Lens Motor

M4

M5

M6

4th/5th Mirror

Motor

Optics Cooling

Fan Motor

Exhaust Blower

Motor

optics unit and fans. (115/220–240 Vac [ac

synchronous])

Positions the lens according to the selected

magnification. (dc stepper)

… A152 copier only

Positions the 4th/5th mirrors according to the

selected magnification. (dc stepper)

… A152 copier only

Prevents built up of hot air in the optics cavity.

(24 Vdc)

… A152 copier only

Removes heat from around the fusing unit and

moves the ozone built up around the charge

section to the ozone filter. (24 Vdc)

INDEX

NO.

34

22

31

4

17

Magnetic Clutch

SYMBOL NAME FUNCTION

MC1

Registration

Clutch

Drives the registration rollers. 3

Magnetic Spring Clutches

SYMBOL NAME FUNCTION

MSC1

MSC2

MSC3

Toner Supply

Clutch

Relay Roller

Clutch

Paper Feed

Clutch

Drives the toner supply roller. 35

Drives the 1st and 2nd relay rollers. 37

Starts paper feed. 38

INDEX

NO.

INDEX

NO.

1-9

Page 13

ELECTRICAL COMPONENT DESCRIPTIONS 24 June 1994

Switches

SYMBOL NAME FUNCTION

SW1 Main Switch Supplies power to the copier. 14

SW2

SW3

Front Cover

Safety Switch

Paper Tray

Switch

Cuts the ac power line, when the front cover is

open.

Detects when the paper tray is set. 1

INDEX

NO.

13

Sensors

SYMBOL NAME FUNCTION

S1

S2

S3

S4

S5 Exit Sensor Detects misfeeds. 16

S6 Relay Sensor

S7

S8

Scanner Home

Position Sensor

Lens Home

Position Sensor

4th/5th Mirror

Home Position

Sensor

Registration

Sensor

Image Density

(ID) Sensor

Auto Image

Density Sensor

(ADS)

Informs the CPU when the 1st scanner is at the

home position.

Informs the CPU when the lens is at the home

position (full size position).

… A152 copier only

Informs the CPU when 4th/5th mirrors assembly is

at the home position (full size position).

… A152 copier only

1) Detects misfeeds.

2) Controls the relay roller clutch stop timing.

1) Detects when copy paper is set on the

by-pass feed table.

2) Detects misfeeds.

Detects the density of the image on the drum to

control the toner density.

Senses the background density of the original. 19

INDEX

NO.

23

25

30

5

2

6

Printed Circuit Boards

SYMBOL NAME FUNCTION

PCB1 Main Board

PCB2 AC Drive Board

PCB3

PCB4

DC Power

Supply Board

Operation Panel

Board

Controls all copier functions both directly and

through the other PCBs.

Drives the main motor, exposure lamp, fusing

lamp, and quenching lamp.

Converts the wall outlet ac power input to +5 volts,

+24 volts, and a zero cross signal.

Informs the CPU of the selected modes and

displays the copier status and condition on the

panel.

1-10

INDEX

NO.

33

27

36

8

Page 14

24 June 1994 ELECTRICAL COMPONENT DESCRIPTIONS

Lamps

SYMBOL NAME FUNCTION

L1 Exposure Lamp

L2 Fusing Lamp Provides heat to the hot roller. 12

L3 Quenching Lamp

L4 Erase Lamp

Applies high intensity light to the original for

exposure.

Neutralizes any charge remaining on the drum

surface after cleaning.

Discharge the drum outside of the image area.

Provides leading/trailing edge erase and side

erase.

INDEX

NO.

21

11

9

Power Packs

SYMBOL NAME FUNCTION

P1

P2

Power Pack

–CC/Grid/Bias

Power Pack

–TC/SC

Provides high voltage for the charge corona, grid,

and development roller.

Provides high voltage for the transfer and

separation corona.

INDEX

NO.

26

7

Counter

SYMBOL NAME FUNCTION

CO1 Total Counter Keeps track of the total number of copies made. 10

Others

SYMBOL NAME FUNCTION

TH1

TH2

TS

TF

C

TR Fusing Triac

Fusing

Thermistor

Optics

Thermistor

Fusing

Thermoswitch

Optics

Thermofuse

Main Motor

Capacitor

Monitors the fusing temperature. 20

Monitors the optics temperature. 24

Provides back-up overheat protection in the fusing

unit.

Provides back-up overheat protection around the

exposure lamp.

Start capacitor. 32

Switches the fusing lamp on and off. (115 V only)

Note: In the 220V-230V/240V version, the triac

is built-in the ac drive board

INDEX

NO.

INDEX

NO.

15

18

28

1-11

Page 15

G2: Relay Gear

G8: Relay Gear

BP4

DRIVE LAYOUT 24 June 1994

7. DRIVE LAYOUT

G14

G13

G15

G16

G17

G18

G19

G1: Main Motor Gear

BP6 BP5

G22 BP1G21G20

G26

G25

TB2

TB3

TB1

BP2

G12 G11

G10

G23

G2G1

G9

G8

G7

G6

G5

G4

G3

BP3

G24

G9

G8

G2

G1

G23: Timing Belt Drive

Gear

BP1: Timing Belt Pulley

TB1: Timing Belt

A

G10 Relay gear

G11: Timing Belt Drive Gear

BP5: Timing Belt Pulley

TB3: Timing Belt

Development Section

BP6: Timing Belt Pulley

G12: Development Gear

Development Unit

G13: Relay Gear

G14: Toner Supply CL Gear

Toner Supply CL

Toner Supply Unit

G9: Relay Gear

B

Cleaning Unit

G3: Fusing Drive Gear

Fusing and Exit Unit

G4: Hot Roller Gear

G7: Relay Gear

G6: Relay Gear

G5: Exit Roller Gear

1-12

Page 16

B

24 June 1994 DRIVE LAYOUT

A

G15: Registration CL

Gear

Registration CL

Registration Rollers

G20: Relay Gear

G17: Relay Roller CL

Gear

Relay Roller CL

G16: 2nd Relay Roller

Gear

2nd Relay Rollers

Paper Feed Section

BP2: Timing Belt Pulley

G22: Relay Gear

Paper Feed Section

G21: Paper Feed CL

Gear

Paper Feed CL

Feed Rollers

G24: Timing Belt Drive

Gear

BP3: Timing Belt Pulley

TB2: Timing Belt

BP4: Timing Belt Pulley

G25: Relay Gear

G26: Drum Drive Gear

G18: Relay Gear

G19: 1st Relay Roller

Gear

1st Relay Rollers

1-13

Page 17

POWER DISTRIBUTION 24 June 1994

8. POWER DISTRIBUTION

AC Power (115V or 220V – 240V)

Fusing Lamp

Exposure Lamp

Main Motor

Quenching Lamp

Document Feeder

(Option)

AC power

DC power

Main SW

Cover Safety SW

Power Relay

(RA401)

Fusing Lamp

Drive Circuit

Exposure Lamp

Drive Circuit

Main Motor

Relay (RA402)

AC Drive Board

DC Power

Supply Board

24V (VA)

24V (VA)

24V (VA)

24V (VA)

24V (VA)

5V (VC)

Zero Cross

RAM

Pack

Main

Board

Anti-condensation Heaters

-Drum (Option)

-Optics (Option)

5V

Scan

Signal

5V (VC)

24V (VA)

5V (VC)

24V (VA)

Operation Panel Board

Sensors

Switches

DF Interface Board

(A152 copier only)

Thermistors

Solenoids

Clutches

Power Packs

Lens Motor

(A152 copier only)

4th/5th Mirror Motor

(A152 copier only)

Optics Cooling Fan

Motor (A152 copier only)

Exhaust Blower

Motor

Image Density Sensor

Scanner Motor

When this copier is plugged in and the main switch is turned off, ac power is

supplied via the ac drive board to the optio na l ant i-con de nsa tio n heat ers.

When the front cover and/or the exit cove r is open , th e cove r sa fe ty switch

completely cuts off power to all ac and dc compo nent s. The RAM pack has a

back up power supply (dc battery) for th e service prog ram mode data and

misfeed job recovery.

When the main switch is turned on, the ac power sup ply to the

anti-condensation heat er is cut of f an d ac power is supp lied to the ac drive

board. The dc power supply board receive s wa ll out let ac powe r through the

ac drive board.

The dc power supply board converts th e wall outle t ac po wer inp ut to +5

volts, +24 volts, and a zero cross signa l, all of wh ich are supp lied to th e main

board.

1-14

Page 18

24 June 1994 POWER DISTRIBUTION

The main board supplies dc powe r to all cop ier dc comp on ents. All sensors,

switches, thermistors, and the DF interf ace board (op tio n) op era te on +5

volts. The operatio n pane l o per at es on +5 vo lts sup plied by the main board.

All other dc components includin g the power relay (RA401) and the main

motor relay (RA402) operat e on +24 volt s.

When the main board receives power, it act ivat es th e power rela y (RA401)

which then supplies ac power to the fusin g lamp drive circuit, and the

exposure lamp drive circuit on the ac drive board. The fusing lamp drive

circuit receives a trigger signal from th e main boa rd and the fusing lamp

lights. The exposure lamp do es no t tu rn on unt il t he ma in bo ard send s a

trigger pulse to the exposure lamp drive circu it.

When the Start key is pressed, the main bo ard ene rgize s the main mot o r

relay (RA402). Then, the ma in mot or an d the quenching lamp turn on.

When the main switch is turned off, power is cut off to the main board an d to

RA401, and the optional drum and optics anti-condensation heaters are

turned on.

1-15

Page 19

SECTION 2

DETAILED SECTION

DESCRIPTIONS

Page 20

24 June 1994 DRUM

1. DRUM

1.1 DRUM CHARACTERISTICS

An organic photoconductor (OPC) dru m is used in this mo del.

The OPC drum has the characteristics of :

1. Being able to accept a high negative electrical charge in the dark. (Th e

electrical resistance of a photocon ductor is high in the absence of light.)

2. Dissipating the electrical charge when exposed to light. (Exposure to light

greatly increases the conduct ivity of a photo con du cto r.)

3. Dissipating an amount of charge in dire ct pro po rtio n to the inte nsity of the

light. That is, where strong er ligh t is directed to the photoconductor

surface, a smaller voltage remains on the drum.

4. Being less sensitive to changes in tempe rature (when compared to

selenium F type drums).

5. During the drum’s life, drum residu al voltage gradually increases and the

photoconductive surface becomes worn.

Therefore, some compen sat ion for these characteristics is required.

2-1

Page 21

DRUM 24 June 1994

1.2 DRUM UNIT

[E]

[A]

[G]

[F]

[C]

[D]

[B]

[C]

[D]

The drum unit [A] consists of an OPC drum [B], ID sensor board [C] and a

pick-off pawl [D]. When the drum, the pick-off pawl, or th e ID sensor is

replaced or cleaned, the drum unit must be removed from the copier.

Therefore, the drum has a coupling device wh ich is connected to the drum

drive gear [E]. The ID sensor conne cto r [ F] is used for th e ID sen sor.

The main motor provides rotat ion direct ly to th e drum thro ug h a series of

gears.

The pick-off pawl [D] is always in cont act with the drum surface.

2-2

Page 22

24 June 1994 DRUM CHARGE

2. DRUM CHARGE

2.1 OVERVIEW

[A]

[B]

[D]

[A]

This copier uses a double wire scorotro n and a highly sensitive OPC drum

[A]. The corona wires [B] ge ne rat e a corona of negative ions when the

CC/Grid/Bias power pack [C] applies a high voltage. The CC/Grid/Bias power

pack also applies a negative high volta ge to a stainless steel grid plate [D].

This insures that the drum coating receives a uniform negative charg e as it

rotates past the corona unit.

[C]

[D]

The exhaust fan, located abo ve the cop y exit, causes a flow of air from the

upper area of the development unit through the ch arg e coro na unit . This

prevents an uneven bu ild-u p of negative ions that can cause uneven image

density. The exhaust fan runs at half spe ed when in the st and-by condition

and at full speed while copying.

The exhaust fan has an ozo ne filte r (a ctive ca rbo n) which adsorbs ozone (O3)

generated by the cha rge corona. The ozone filte r decre ases in efficiency over

time as it adsorbs ozone. The ozone filter should be replaced at every 80K

copies.

The flow of air around the charge corona wires may deposit paper dust or

toner particles on the corona wire . The se pa rticle s may interfere with

charging and cause low density ba nds on cop ies. The wire cleaner cleans

the corona wire when the op era tor slides the corona unit out and in.

2-3

Page 23

DRUM CHARGE 24 June 1994

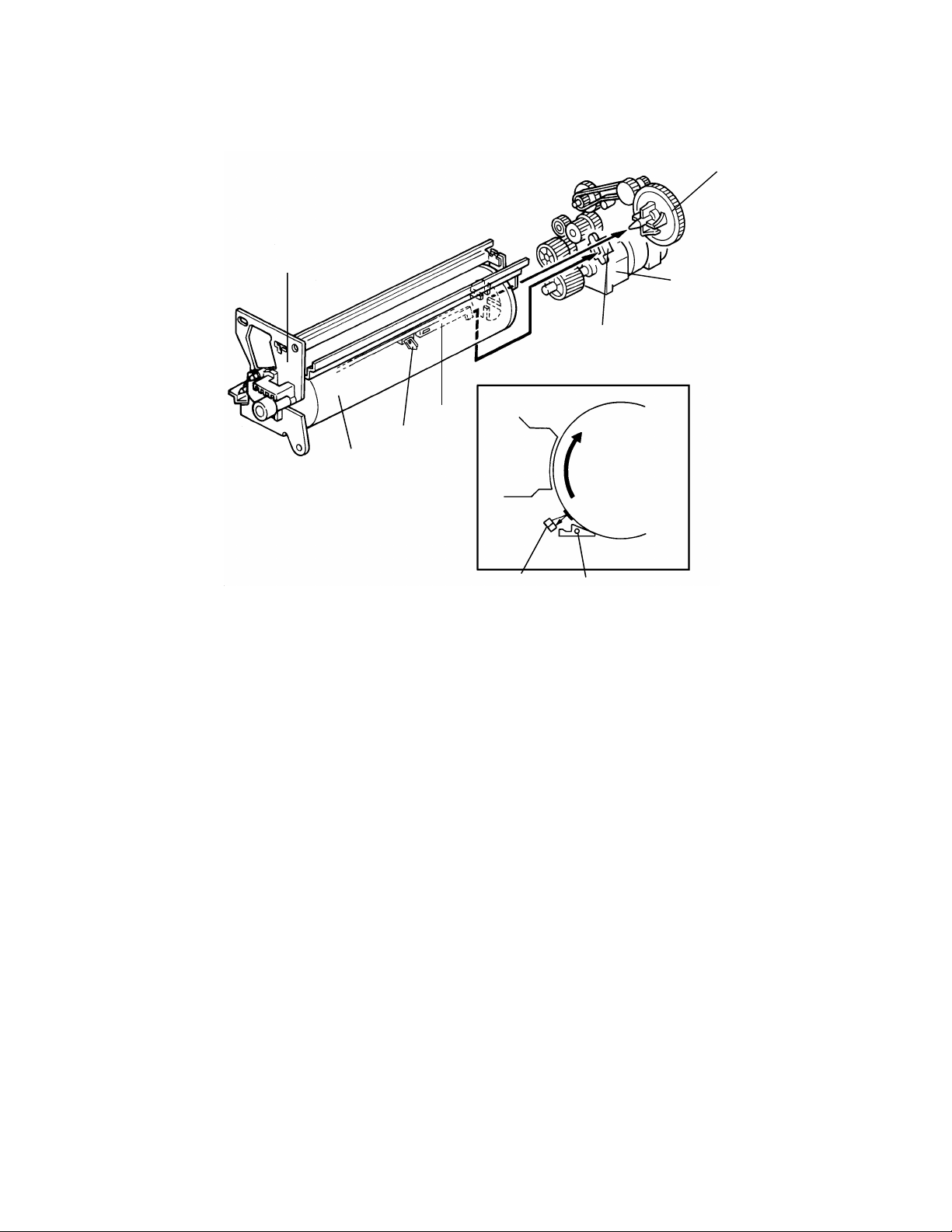

2.2 CHARGE CORONA WIRE CLEANER MECHANISM

[B]

[A]

[D]

[C]

Pads [A] above and below th e charge corona wires clean the wires as th e

charge unit is manually slid in and out.

The cleaner pad bracket [B ] rotates when the charge unit is fully e xte nd ed

and the bracket is pulled up against the rear en dblock [C]. This moves the

pads against the corona wires (see illu stra tio n). If the charge unit is not fully

extended, the pads do not tou ch th e corona wires.

The pads move away from the wires when the charg e unit is fu lly inse rte d

and the cleaning bracket is pushed against the front endblock [D].

After copier installa tio n the key operator should be instru cte d to use this

mechanism when copies have whit e stre aks.

2-4

Page 24

Power Pack CC/Grid/Bias

(P1)

Charge Corona

Development

Bias

24 June 1994 DRUM CHARGE

2.3 CHARGE CORONA CIRCUIT

t2

CN1-1

CN1-2

CN1-3

CN1-5

CN1-7

t1

C

G

B

PWM Duty cycle

=t2/t1 x 100 (%)

Grid

CC Trig [

Grid Trig (PWM) [

Main Board (PCB 1)

▲0→0/5]

GND [0]

VA [24]

VC [5]

▼24]

CN119-7

CN119-6

CN119-5

CN119-3

CN119-1

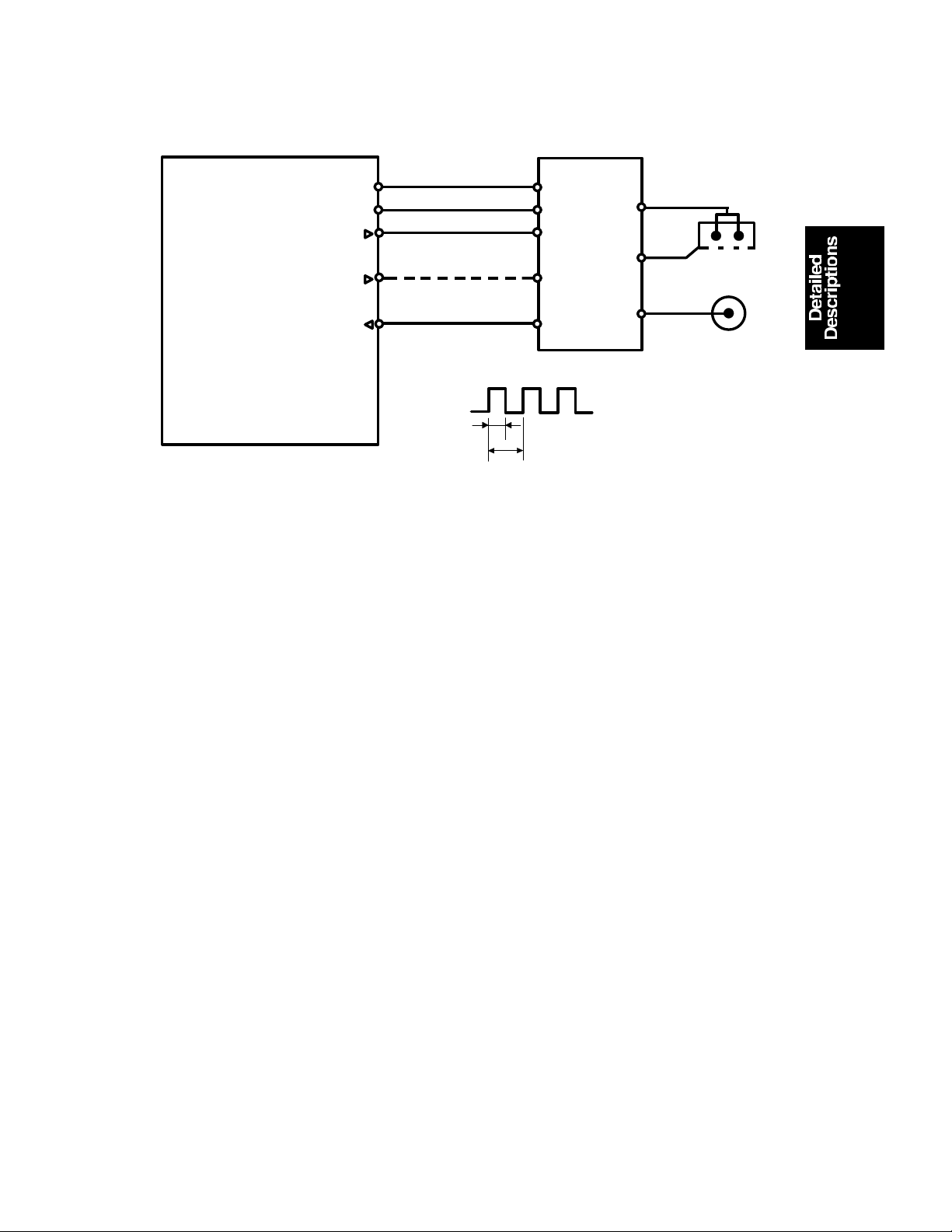

The main board supplies +24 volt s to th e CC/G rid/Bias power pack at CN1-1

as the power supply source. Afte r t he Sta rt key is pressed the CPU drops

CN1-3 from +24 volts to 0 volts. This energizes the charge coron a circuit

within the CC/Grid/Bias power pack, which applies a high nega tive volta ge of

approximately –7.0 K volts to th e cha rge corona wires. The corona wires then

generate a negative corona charge.

The grid plate limits the cha rge voltage to ensure that the charge does not

fluctuate and that an even charge is applied to the drum surfa ce.

The grid trigger pulse applied to CN1-5 is a pulse width modulated signal

(PWM signal). This signal is not only a trigger signal, it also chan ges the

voltage level of the grid. As the width of the pulse ap plie d incre ases, the

voltage of the grid also incre ases.

2-5

Page 25

DRUM CHARGE 24 June 1994

2.4 GRID VOLTAGE CORRECTI ON

To maintain good copy quality ove r the drum’s life , th e grid volta ge is

changed by the following:

• Drum residual voltage correction (Vr correction)

• Drum wear correction

2.4.1 Drum Residual Voltage Correction (Vr correction)

During the drum’s life, the dru m may fat igue electrically and residual voltag e

(Vr) on the drum may gradually in crea se. Wh en this ha ppen s, th e corona

charged voltage on th e dru m is not discharged enough in the quenching and

exposure processes. Even if the development bias is applied in the

development pro cess, the backg round area of the original on th e drum may

attract some toner. This may cause dirty background on copies. The Vr

correction prevents this ph enomenon as follows:

A pattern (Vr pattern) is develope d on the drum eve ry 1,0 00 copie s and its

reflectivity is detected by the ID sensor to measu re th e residua l volta ge . This

is called residual voltage detect ion . (If the reflectivity is low, the residual

voltage will be high.) When the Vr pattern is developed, all blocks of the

erase lamp turn on, and th e de velo pment bias voltage is 0 volt.

The CPU determines what level of Vr co rrect ion is necessa ry dep en din g on

the output (Vr ratio [L]) from the ID sensor.

Vrp

L =

x 100 (%)

Vsg

Vrp: ID sensor outp ut for Vr pattern

Vsg: ID sensor output for bare drum

The current Vr ratio is disp laye d by SP67.

The CPU increases the development bias voltage depending on the Vr ratio

to prevent dirty backgrou nd on copies, (See page 2-30 for more informatio n. )

The CPU also increases the grid volta ge to ensure prop er imag e de nsit y

depending on the Vr ratio. (See page 2-8.)

2-6

Page 26

24 June 1994 DRUM CHARGE

2.4.2 Drum Wear Correction

During the drum’s life, the photoco nd uct ive surf ace of the drum becomes

worn by contact with the cle an ing blad e an d de veloper on the development

roller. This effects ability of th e dru m t o hold a cha rge . This cha racteristic

especially affects develo ping of the ID sensor patte rn. Th e ID sen sor pa ttern

developed on the dru m becomes lighter causing highe r ton er concentration in

the developer. The drum we ar corre ctio n is made to pre ven t th is

phenomenon and is as follows:

The CPU keeps track of the drum motor rota tion time that corresponds to the

wear of the photoconductive layer. The grid voltage for the toner density

detection increases at set int erval. The grid voltage for the residual voltage

(Vr) detection also increase s at th e same interval. (See page 2-9.) The drum

motor rotation time is displayed by SP57.

2.5 GRID VOLTAGE FOR IMAGE DENSITY CONTROL

The main board controls the grid volt age fo r the copy imag e through the

CC/Grid/Bias power pack. As the grid voltage for the imag e densit y control

becomes less, the copy image become s light er an d vice versa .

The grid voltage is based on the standard grid voltage and correction factors

as follows:

Grid Voltage = Standard image density grid volt age (–6 80 volts [SP60 = 4])

+

Vr correction factor

+

Auto image density level facto r (S P34)

2.5.1 Standard Image Density Grid Voltage

The standard image density grid voltage (SP60) is set at the factory and the

setting is differen t for each machine. The setting of SP60 is described on the

SP mode data sheet located inside the inner cover of the machine.

2-7

Page 27

DRUM CHARGE 24 June 1994

2.5.2 Drum Residual Voltage (Vr) Correction Factor

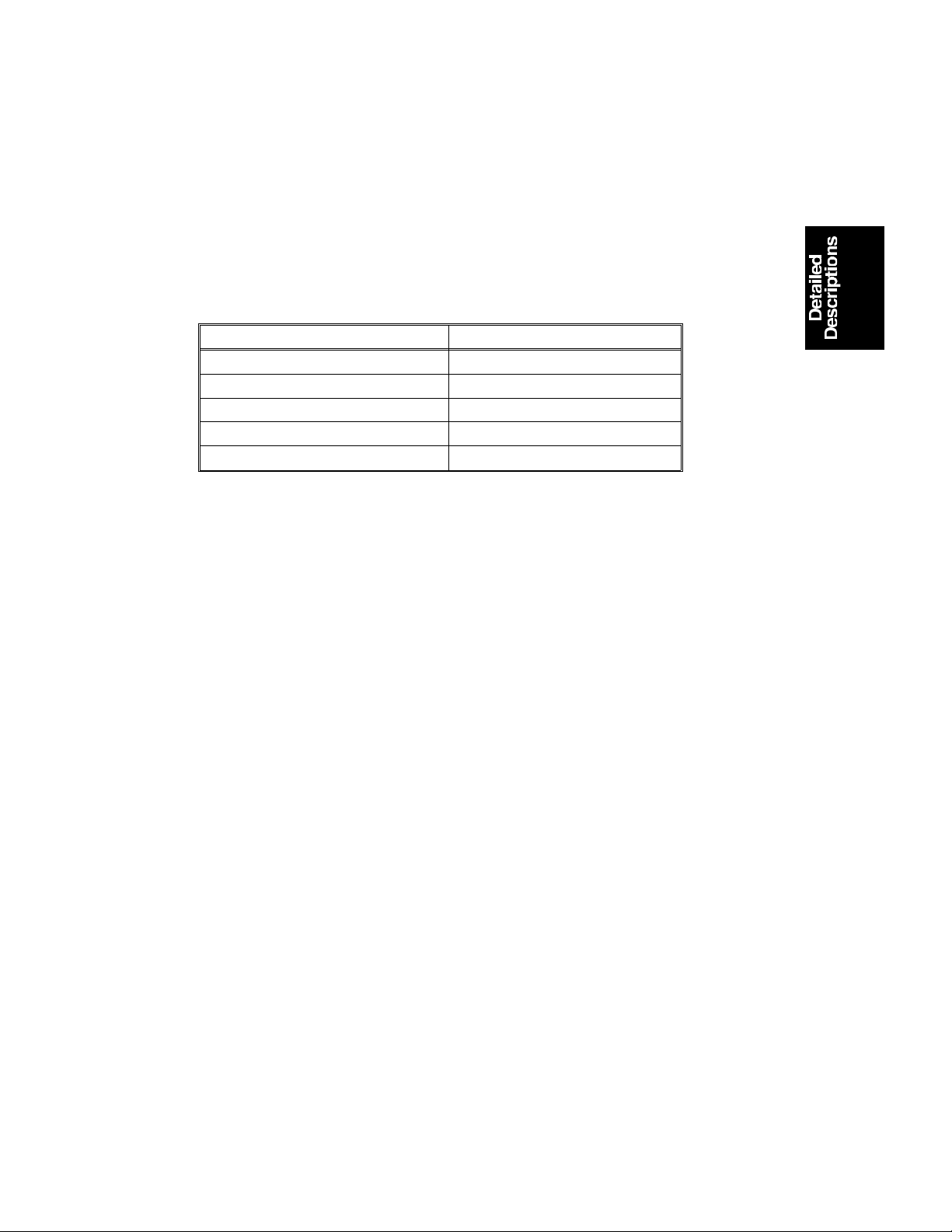

Vr ratio (L) (%) (SP67) Change of grid voltage (volts)

100 to 84

83 to 58 –40

57 to 41 –80

40 to 28 –120

27 to 0 –160

±0

L = Vrp/Vsg x 100 (%)

Vrp: ID sensor output for Vr pattern

Vsg: ID sensor output for bare drum

During the drum’s life, drum residual volt age (Vr) may gradually increase. Vr

correction compensate s fo r the resid ua l voltage on the drum. The Vr

correction is done every 1000 copies. The CP U increa ses the development

bias voltage and the grid volta ge . The above table shows how the grid

voltage changes depending on the Vr ratio.

2.5.3 Auto Image Density Level Factor (SP34)

Auto image density level Data (SP34) Change of grid voltage (volts)

Normal 0 *

Darker 1 –40

Lighter 2

±0

±0

* Factory setting

The grid voltage and the expo sure la mp volt ag e are co nst an t reg ardless of

the output from the auto image de nsit y sensor. Only the development bia s

voltage varies depending on the output from the auto image density sen sor.

But only when the auto image density level data in SP34 is set to darker, the

grid voltage is changed –40 volts as shown in the above ta ble . Whe n it is set

to lighter, the grid vo lta ge doe s not chan ge . Howe ver, the development bias

voltage is corrected.

2-8

Page 28

24 June 1994 DRUM CHARGE

2.6 GRID VOLTAGE FOR TONER DE NSITY DETECTION AND

RESIDUAL VOLTAGE (Vr) DETECTION

The guid voltage is the same fo r both toner density detectio n an d resid ua l

voltage correction.

Grid voltage = Standard ID sensor grid voltage (–460 volt s [SP 62 =4] )

+

Drum wear correction factor (SP57)

Drum Wear Correction Factor (SP57)

Main motor rotation time (SP57) Change of grid voltage (volts)

0 to 2H

2 to 65H –20

65 to 112H –40

112 to 157H –60

More than 157H –80

±0

The grid voltage for toner density detection is the same as it is for th e

residual voltage (Vr) detection. However, the developme nt bias volt ag e is

different. (See page 2-30 and 2-35.)

2-9

Page 29

[E]

OPTICS 24 June 1994

3. OPTICS

3.1 OVERVIEW

[B]

[C]

[D]

During the copy cycle, an image of the original is reflecte d onto the drum

surface through the optics assembly as follows.

Light Path:

Exposure Lamp [A] → Original → First Mirror [B] → Second Mirror [C]

→ Third Mirror [D] → Lens [E] → Fourth Mirror [F]→ Fifth Mirror [G]

→ Sixth Mirror [H] → Drum [I]

[A]

[H] [F] [J]

[I]

[G]

This copier has six standard reprod uct ion ratios (A152 copier only), three

reduction ratios, two enlarg eme nt ra tio s, an d full size. It also has a zoom

function. The opera tor can change the reprod uct ion ratio in one percent steps

from 61% to 141%.

Stepper motors are used to cha nge th e positio ns of the lens and mirrors

(A152 copier only). Separate mot ors are used beca use the wide ran ge of

reproduction ratios make s it mechanically difficult for one motor to posit ion

both the lens and mirrors. A ste pp er motor is also used to drive the scanner.

This motor changes the scanner spe ed accord ing to th e rep rod uction ratio.

2-10

Page 30

24 June 1994 OPTICS

The CPU monitors the temperature aro un d the optics cavit y thro ugh a

thermistor which is located at the up per le ft rear side of the copier frame.

When the temperature reaches 45°C, the optics cooling fan [J] (A15 2 cop ier

only) starts rotating to draw cool air into the optics cavit y. However, A151

copier is not equipped with a cooling fan. The machine will stop if the optics

cavity overheats. (Se e pa ge 6-52.) In this case, the Energy S ave r in dica tor

blinks and the Start key turns red.

The air flows from the right to the left , and exh au sts th rou gh the vent s in the

left side of the upper cover. This fan operates until t he te mp erature drops

below 45°C.

The thermofuse pro vides back-up overheat prot ect ion. It opens at 128°C and

removes ac power to the exp osure lamp.

2-11

Page 31

[B]

[F]

[C]

OPTICS 24 June 1994

3.2 SCANNER DRIVE

[D]

[E]

[A]

[G]

3.2.1 1st and 2nd Scanner Drive Mechanism

This model uses a stepper mot or [A ] to drive the scanners. Both ends of ea ch

scanner are driven to prevent skewin g. The scanners have sliders [B], wh ich

ride on guide rails.

The scanner home position is detected by the home positio n sensor [C]. The

scanner return position is determine d by cou nt ing the scann er mot or drive

pulses.

The first scanner [D], which consists of the exposu re lamp and the first mirror,

is connected to the scanner drive wire by the wire clamps [E]. The second

scanner [F], which consists of th e seco nd and third mirro rs, is conn ect ed to

the scanner drive wire by movable pulleys (the second scann er pulleys [G ]).

The pulleys move the second scanne r at half the velocity of the first scanner.

This maintains the focal distance between the original and the lens during

scanning. This relationship can be expressed as:

V1r = 2 (V2r) = VD/r

where r = Reproduction rat io

V1r = First scanner velocity (when the reproduction ra tio

is "r")

V2r = Second scanner velocity (when the reprod uct ion ra tio

is "r")

VD = Drum peripheral velocity (100 mm/s)

2-12

Page 32

: Reduction

: Enlargement

24 June 1994 OPTICS

3.3 LENS DRIVE (A152 copier only)

[C]

[D]

[B]

[A]

3.3.1 Lens Drive

The lens motor [A] (stepper motor) changes the lens [B] position through the

lens drive wire [C] in accordance with the selected reprod uction ratio to

provide the proper optical distan ce between the lens and the drum surface.

The rotation of the lens drive pulley moves the lens back and fort h in discre te

steps. The home position of the len s is dete cte d by th e home position sensor

[D]. The main board keeps track of the lens position base d on the numb er of

pulses sent to the lens mo to r.

2-13

Page 33

[B]

OPTICS 24 June 1994

3.3.2 Lens Positioning

[C]

[A]

Home Position (100%)

(100% → 141/129%)

[D]

Reduction SideEnlargement Side

(141/129% → 71/65%)

(71/65% → 93%)

(93% → 71/65%)

(71/65% → 141/129%)

(141/129% → 122/121%)

(122/121% → 141/129%)

(122/121% → 100%)

(100% → 71/65%)

(71/65% → 100%)

The lens home position sensor [A] informs the main board when the lens is at

full size position (home position). The main board dete rmine s the lens sto p

position in reduction an d en largement modes by countin g th e nu mbe r of

steps the motor makes with reference to the lens home position. When a new

reproduction ratio is select ed , th e lens [B] moves directly to the selected

magnification position.

The lens home position is registe red each time the lens starts from or passes

through the lens ho me posit ion sensor. As the lens moves from t he

enlargement side to the reduction side, the senso r re gist ers the home

position. This occurs when the actu at or plate [C] enters the lens home

position sensor.

A small vibration can be observed when the lens moves through home

position from the red uct ion side to the enlargement side because the lens is

going in the wrong direction to register the home positio n. The len s

overshoots the home position by on ly one pulse before going back to register

the home position.

The lens always stops while moving from lef t to rig ht (as viewed from the

front) to minimize the erro r cause d by mechanical play in the drive gears [D].

2-14

Page 34

(71/65% → 100%)

24 June 1994 OPTICS

3.4 4TH/5TH MIRROR DRIVE (A152 copier only)

[B]

[A]

Home Position (100%)

(100% → 141/129%)

(141/129% → 71/65%)

(71/65% → 93%)

(93% → 71/65%)

(71/65% → 141/129%)

(141/129% → 122/121%)

(122/121% → 141/129%)

(122/121% → 100%)

(100% → 71/65%)

3.4.1 Drive

The 4th/5th mirror drive motor (stepper motor) changes the 4th/5th mirror

assembly position throug h th e pin ion gears [A] and the rack gear [B] in

accordance with the selected reproduction ratio to provide the proper optical

distance between the lens and drum surf ace .

3.4.2 Positioning

The positioning mechanism is similar to that of lens po sitio ning, as shown in

the above positioning chart. The 4th/5th mirror assembly always st ops while

moving from right to left (a s viewed from th e front).

2-15

Page 35

OPTICS 24 June 1994

3.5 AUTOMATIC IMAGE DENSITY SENSING

[C]

[B]

[A]

Sampled area

70 mm

a

b

Light from the exposure lamp is reflected from the original and travels to the

lens [A] via the mirrors. The auto ID senso r [B] , a phot odiode, is mounted on

the upper front frame. The sensor cover [C] has a hole in it to allow light to

fall directly onto the sensor. Sampling starts 10 millimete rs from th e leadin g

edge of the original and continues for 50 millimeters from the leadin g edge of

original in full size mode. The length of "a" and "b" will vary depending on the

selected reproduction rat io (A152 copier only).

The lengths "a" and "b" in each reproduction ratio are calcu lated as follows:

a =

Reproduction Ratio (%)

10 mm

x 100 b =

Reproduction Ratio (%)

50 mm

x 100

The photosensor circuit converts the light intensity to a voltage. The dete cte d

voltage is amplified and sent to the main PCB. The CPU stores the voltage of

each sampled point in RA M. It the n comp utes the image density of the

original from the maximum sample volt ag e and changes the development

bias accordingly. (See page 2-2 8 for d et ails. ) The exposure lamp voltage is

constant regardless of the image density of the origin al.

2-16

Page 36

24 June 1994 OPTICS

3.6 EXPOSURE LAMP VOLTAGE CONTROL

The main board controls the expo sure lamp voltage through the ac drive

board. The exposure lamp voltage is based on the base lamp vo lta ge and

various correction factors. The method of control is different dep ending on

whether the image density is manually selected or the auto image density

mode is selected.

The exposure lamp voltage consist s of th e followin g fa cto rs:

Exposure lamp voltage = Base exposure lamp voltage

(Manual or auto image density mode)

+

VL correction factor

+

Reproduction ratio correction factor

(A152 copier only)

3.6.1 Base Lamp Voltage In Manual Image Density Mode

Manual ID Level

Exposure Lamp Data

Darker Lighter

123456 7

Vo –4 Vo –4 Vo –2

Vo ±0

Vo+2 Vo+2 Vo+4

The above table shows chan ge s in the expo sure lamp data in the manual

image density mode.

SP48 sets the exposure lamp data for level 4 (Vo) of manual image density

mode. A value from 100 to 15 0 can be sele cte d.

3.6.2 Base Lamp Voltage In Auto Image Density Mode

In the auto ID mode, the CPU selects the level 4 (Vo) exposu re lamp data

(SP48) regardless of the inpu t fro m the auto imag e de nsit y senso r.

2-17

Page 37

OPTICS 24 June 1994

3.6.3 VL Correction Factor

The light intensity may decrea se be cause of dust accumulated on th e op tics

parts. This may cause dirty backgrou nd on copies. To compensate for this

phenomenon, VL correction is done as follows:

Whenever SP56 (ADS reference volt age adjust men t) is p erf orme d, before

sampling starts for the ADS adjustment, the auto ID sensor measure s the

amount of light reflected through the 1st , 2nd and 3rd mirrors from th e white

plate located under the left frame. The photosensor circuit converts th is lig ht

intensity to a voltage and the CPU stores it in memory as the initial dat a.

The machine has a softwa re cou nter for the VL correction. At every 500

copies the machine measures the light intensity reflected from the white

plate, and this is compared wit h th e init ial da ta stored in memory.

If the measured volt ag e dif ference is/or more than 0.1 volts, +1 will be added

to the exposure lamp dat a as the VL correction factor.

If the difference is less than 0.1 volts, no correction will be applied .

The total increase fo r VL correction cannot exceed +2 0. Aft er cleaning the

optics parts, the following act ion s must be perf orme d in ord er.

• SP95: Clear the exposure lamp data and the softwa re cou nter

by entering "1".

• SP48: Perform the light intensity adjust men t.

• SP56: Perform the ADS adjustment (to sto re the new initial

data and to adjust the ADS reference voltage.)

3.6.4 Reproduction Ratio Correction Factor (A152 copier only)

Reproduction ratio (%) Change of exposure lamp data

61 and 62 +2

63 to 119

120 to 129 +2

130 to 141 +4

±0

The exposure lamp data is in crea sed depending on the selected

magnification ratio in ord er to compensate for the change in the concen tra tio n

of light on the drum.

2-18

Page 38

24 June 1994 OPTICS

3.7 EXPOSURE LAMP CONTROL CI RCUIT

Main Board (PCB1)

Zero

Cross

CN107-1

AC Drive Board (PCB2)

B

CPU

TP111

(EXPO)

E

Feed back

signal

0V

+24V

C

24V

0V

Trigger Pulse

AC power

Zero cross

Trigger pulse

CN114-2

CN114-1

CN114-7

CN114-3

CN401-7

CN401-8

CN401-2

CN401-6

VR401

R403

R401

A

B

C

PC401

R404

R405

C401

ZD

401ZD402

ZD

403ZD404

R411

TRC401

D401

R406

R413

D404

~D407

CR401

L401

L402

CN421

240V

220V

220V Only

TR401

C411

T402

CN419-1

Thermofuse (TF)

Exposure

Lamp

D

CN419-2

T407

(L1)

A

AC115V

AC220V

AC240V

Lamp power

Feedback

signal

D

E

Feedback

The main board sends lamp trigg er (LO W sig nal) p ulse s to th e ac drive boa rd

from CN114-3. PC401 activates TRC401, which provides ac power to the

exposure lamp, at the lead edge of each trigger pulse.

The voltage applied to the expo sure lamp is also provided to the fee dback

circuit. The feedback circuit steps down (TR401), rectif ies (D404 ∼ 407), and

smoothes (zener diodes and capacitors) the lamp voltage. The CPU monit ors

the lowest point of the smoot he d wave (f eedb ack sign al), which is directly

proportional to the actu al lamp voltage.

The CPU changes the timing of the trigger pulses in response to the

feedback voltage. If the lamp voltage is too low, the CPU sends the trigg er

pulses earlier so that more ac power is applie d to the expo sure lamp. This

feedback control is performed instantly; so, the lamp voltage is always stable

even under fluctuating ac power conditions.

The voltage applied to the expo sure lamp can be changed with SP48 (Light

Intensity Adjustment). The ADS volta ge adju stme nt (SP5 6) must be done

whenever the light intensity adjustment is done.

2-19

Page 39

[A]

LE

EL

ERASE 24 June 1994

4. ERASE

4.1 OVERVIEW

[B]

SE

ES

LO

LC

LE: Lead edge erase margin 2.5 ± 1.5 mm

SE: Side erase margin 2.0 ±2.0 mm on each side ;

total of both sides 4 mm or less

LO: Original width

LC: Charged width of drum

EL: Lead edge erase

ES: Side erase (A152 copier only)

The erase lamp [A] consists of a sing le row of LEDs (29 LEDs) ext en din g

across the full width of th e dru m [B] .

The erase lamp has the fo llowin g functions: lead edge erase , side erase

(A152 copier only), and trail edge erase.

2-20

Page 40

24 June 1994 ERASE

abcde

h

g

fc

abde

4.1.1 Lead Edge Erase

The entire line of LEDs turn on when the main mot or tu rns on . The y stay on

until the erase margin slight ly overla ps the lead edge of the original image

area on the drum (Lead Ed ge Erase Ma rgin ). This prevents the toner density

sensor pattern fro m being developed every copy cycle and th e sha do w of the

original edge from being deve loped on the paper. At this point , side erase

starts (A152 copier only). The width of the lead edge erase ma rgin can be

adjusted using SP 41 .

During the toner density detection cycle (once every ten copy cycles), a block

of erase lamps (labeled "g" above) turns off long enough for th e sen sor

pattern to be developed.

The entire line of LEDs turn on when the re sidu al volt ag e on the OPC dru m is

being detected (Vr detectio n).

4.1.2 Side Erase

Based on the combinat ion of copy paper size and the reprod uct ion ratio data,

the LEDs turn on in blocks (labeled "a" – "g" above ). This reduces toner

consumption and drum cleaning load.

2-21

Page 41

ERASE 24 June 1994

– A152 copier–

This machine has no sensors or switches to detect the copy paper size.

Instead, the CPU measures the copy paper lengt h usin g the registration

sensor during the first copy cycle. Base d on this len gt h data , th e CPU

determines which copy paper size is used in the paper tray. (See page 2-49

for more information.)

The LEDs turn on in blocks as labe led "a" – "h" on the previous page.

In the full size copy mode, the CPU determines which blocks turn on base d

on the copy paper len gt h da ta as follows:

Paper length Paper size Blocks ON

364 mm and 356 mm B4, 10" x 14", 8

1/2" x 13", 81/4" x 13" (F4), 8" x 13", 81/2" x

330 mm and 279 mm

297 mm, 267 mm, and 254 mm A4R, 8" x 10

257 mm, 216 mm, and 210 mm B5R, 5

For toner density detection cycles. a – f, h

For residual voltage (Vr) detection cycles. All

8

11"

1/2" x 81/2", A5R a – e

1/2" x 14", 81/4" x 14" None

a – b

1/2", 8" x 10" a – c

NOTE: Since the CPU cannot distinguish different paper widt hs, the CPU

determines the size to be the larger standard width based on the

measured length.

(EX: 10" x 14", 81/2" x 14" → The CPU recognizes as 10" x 14".)

In the reduction or enlarge ment copy mode, the CPU determines which

blocks turn on based on the selected repro du ctio n rat io as fo llows:

Reproduction ratio (%) Blocks ON

83 to 99, 101 to 141 None

78 to 82 a

73 to 77 a to b

68 to 72 a to c

64 to 67 a to d

61 to 63 a to e

2-22

Page 42

24 June 1994 ERASE

– A151 copier –

Since this model has only two modes for the erase lamp, full erase mode (all

blocks on) and toner density detection cycle mode (all blocks on except block

"g"), side erasing is not performe d by th e era se lamp.

When making copies with th e platen cover open condition, and the original

and the copy paper is smaller than B4 (10" x 14"), the part without the original

will be developed as black image area on the drum.

NOTE: If the customers makes copies without the platen cover closed

frequently, the used toner ta nk may be come full in a fa ster period

than expected. For t ho se cust omers, the toner tank must be checked

and cleaned frequently.

4.1.3 Trailing Edge Erase

The entire line of LEDs turns on after the trailing edge of the latent image has

passed. Therefore, a trailing erase margin cannot be obse rved on the copy.

The LEDs stay on to erase th e leading edge of the lat en t imag e in the next

copy cycle. After the fin al copy, the erase lamps turn off at th e same time as

the main motor.

2-23

Page 43

[D]

DEVELOPMENT 24 June 1994

5. DEVELOPMENT

5.1 OVERVIEW

[E]

[B]

[C]

[A]

When the main motor turns on, th e pa ddle roller [A], development roller [B],

auger [C], and the agitator [D] start turnin g. The paddle rolle r picks up

developer in its paddles and transports it to the development roller. Internal

permanent magnets in the development roller attract the developer to the

development roller sleeve .

The turning sleeve of the deve lop ment roller then carries the developer past

the doctor blade [E]. The doct or blade trims the developer to the desired

thickness and creates deve lop er ba ckspill to the cross-mixing me cha nism.

The development roller con tin ue s to tu rn, carrying the deve lop er to the OPC

drum. When the developer bru sh con ta cts th e dru m surface, the negatively

charged areas of the drum surfa ce at tra ct an d hold th e positive ly ch arg ed

toner. In this way, th e lat en t imag e is d eve loped.

The development roller is given a negat ive bia s to pre ven t toner from being

attracted to the non-image areas on the drum which may have a residua l

negative charge. The bias also cont rols image density.

After turning abou t 10 0 de gre es more, the development roller releases the

developer to the deve lopment unit. The develope r is agita ted by the paddle

roller [A], agitator [D], and the cross- mixing mecha nism.

2-24

Page 44

24 June 1994 DEVELOPMENT

5.2 DRIVE MECHANISM

[F]

[C]

[G]

[B]

[E]

[D]

[A]

When the main motor [A] turns, the rota tio n is tran smitted from the

development drive gear [B] to th e de velopment roller gear [C] throug h the

development gear [D] , timin g belt [E ] an d rela y gea rs. The rota tio n is

transmitted from the develo pment roller gear to the paddle roller gear [F]

through an idler gear [G].

NOTE: This copier is not equipped with a knob on the paddle roller shaft like

some other machines. When inst allin g new d eve lop er or manually

rotating the develop men t rolle r, alwa ys ma ke sure to tu rn th e ge ars in

the direction shown in th e ab ove . It might cause damage to th e

copier if turned in the opposite direction.

2-25

Page 45

DEVELOPMENT 24 June 1994

5.3 CROSS-MIXING

[E]

[A]

[D]

[B]

[C]

[F]

This copier uses a standard cross-mixing mechanism to keep the toner and

developer evenly mixed . It also he lps ag ita te the developer to prevent

developer clumps from forming and help s create the trib oelectric charge.

The developer on the turnin g de velo pment roller is split into two parts by the

doctor blade [A]. The deve loper that stays on the develop ment roller [B]

forms the magnetic brush an d de velo ps the latent image on the drum. The

remaining developer th at is trimmed off by th e doctor blade goes to the

backspill plate [C].

As the developer slides down the backspill plate to the agit ator [D], the mixing

vanes [E] move it slightly toward the re ar of the unit . Pa rt of the developer

falls into the auger inlet and is transported to the fro nt of the unit by the auge r

[F].

2-26

Page 46

24 June 1994 DEVELOPMENT

5.4 DEVELOPMENT BIAS FOR IMAGE DENSI TY CONTROL

Image density is controlled by chan gin g th ree items: (1) the amount of bias

voltage applied to the develo pment roller sleeve, (2) the amount of voltag e

applied to the exposure lamp, an d (3) the amo un t of voltage applied to the

grid plate.

Applying a bias voltage to the development sleeve reduce s the pot en tia l

between the develo pment roller and the drum, thereby reducing the amoun t

of toner transferred. As the bias voltage becomes greater, the copy image

becomes lighter and vice versa.

The method of control is different dependin g on whethe r the ima ge density is

manually selected or the auto image density mode is used.

The development bias volt ag e ap plied to the development rolle r sle eve has

the following factors:

Development bias volta ge = Base bias voltage factor

(Manual or auto image density mode )

+

Image bias voltage adjustment factor (SP37)

+

Drum residual voltage (Vr) correctio n factor

The base bias voltage for non-image area s (bet ween copies) is –160 volts.

The above correction factors are also applied.

2-27

Page 47

DEVELOPMENT 24 June 1994

5.4.1 Base Bias Voltage Factor In Manual Image Density Mode

Manual ID Level 1 2 3 4 5 6 7

Base Bias Voltage (volts) –120 –160 –160 –160 –160 –200 –240 *Note

Exposure Lamp Data Vo –4 Vo –4 Vo –2

Vo: Exposure Lamp Data for ID level 4 (SP48)

Darker Lighter

Vo ±0

Vo +2 Vo+2 Vo+4

In manual ID mode, the base bia s voltage depends on the manually selected

ID level. The voltage applied at each ID level is shown in the abo ve ta ble.

The base exposure lamp vo lta ge also varie s dep en ding on the manual ID

level as shown in the table .

*Note: The base bias voltage at ID level 7 can be changed using SP5 0 as

follows.

Image density Data (SP50) Bias voltage (volts)

Normal 0 –240

Darker 1 –200

Lighter 2 –280

Lightest 3 –320

(Factory Setting: –240 volts)

5.4.2 Base Bias Voltage Factor In Automatic Image Density Mode

In auto image density mode, the base expo sure lamp voltage is fixed at Vo

(SP48). Image density is con tro lled by chan gin g on ly the base bias volt age.

The base bias voltage depends on the background image density of the

original, which is measured using the auto ID sen sor. (See page 2-16 for

more information.)

The CPU checks the voltage output from the automa tic ID circuit . This circuit

has a peak hold function. The peak hold volta ge corresp on ds to the

maximum reflectivity of the original. The CPU then det ermin es the pro per

base bias level with refere nce to th e pe ak ho ld voltage.

The table on the following page gives the base bia s voltages at each ADS

output level.

When the automatic density level is set to lighter by SP34, the base bia s

voltage shifts –40 volts as shown in th e fo llowin g table.

2-28

Page 48

24 June 1994 DEVELOPMENT

K

K ≥ TL1

TL1 > K ≥ TL2

TL2 > K ≥ TL3

TL3 > K ≥ TL4

TL4 > K ≥ TL5

TL5 > K

Normal or Darker (SP34 = 0 or 1) Lighter (SP34 = 2)

–160 –200

–200 –240

–240 –280

–280 –320

–320 –360

–360 –400

Base Bias Voltage (volts)

ADS Output Voltage (Peak Hold Voltage)

K =

ADS Reference Voltage (SP56)

TL1 to TL5: Threshold le vel (Se e the following table.)

To maintain the correct image density, the exposure lamp data is

incremented when the reproduction rat io is chan ged or the V L corre ctio n is

applied. This increment in the lamp data increases the intensity of ligh t

reflected from the origin al. Therefore, the auto ID sensor output volta ge also

changes. In order to main tain a constant voltage for the same original when

the lamp data is incremented, the threshold levels a re shif ted up with each

increment in the lamp data as shown in the following table.

Increase of

exposure lamp data+0 +1+2 +3+4 +5+6 +7+8 +9

TL1 0.80 0.85 0.90 0.95 1.00 1.05 1.11 1.16 1.20 1.23

TL2 0.75 0.80 0.84 0.88 0.92 0.97 1.01 1.06 1.11 1.16

TL3 0.70 0.74 0.78 0.82 0.86 0.90 0.94 0.99 1.03 1.08

TL4 0.61 0.65 0.69 0.73 0.77 0.81 0.84 0.88 0.92 0.96

TL5 0.29 0.31 0.33 0.35 0.37 0.38 0.40 0.42 0.44 0.46

+10

+11

+12

+13

+14

+15

+16

+17

+18

+19

5.4.3 Image Bias Voltage Adjustment Factor

Image Bias Adjustment (SP37)

Image density Data (SP37) Change of bias voltage (volts)

Normal 0

Darkest 1 +40

Darker 2 +20

Lighter 3 –20

Lightest 4 –40

±0

The image bias voltage can be changed by SP 37 to adjust the image density

level. The above table gives the image bias volt ag e fo r SP mod e set tin g. This

adjustment should be done only if the expo sure la mp volt ag e adjustment

(SP48) fails to achieve the desire d image density.

2-29

Page 49

DEVELOPMENT 24 June 1994

5.4.4 Drum Residual Voltage (Vr) Correction Factor

During the drum’s life, drum residual volt age (Vr) will g rad ually in crea se. The

Vr correction compensate s fo r the resid ua l voltage on the drum. The Vr

correction is done every 1,000 copies. The fo llowin g table shows how the

development bias voltage changes depending on the Vr ratio.

Vr ratio (L) (%) (SP67) Change of bias voltage (volts)

100 to 84

83 to 58 –40

57 to 41 –80

40 to 28 –120

27 to 0 –160

±0

L = Vrp/Vsg x 100 (%)

Vrp: ID sensor output for Vr correction pattern

Vsg: ID sensor output for bare drum

When the Vr correction is made (every 1,0 00 copie s), all blocks of erase

lamps turn on and the development bias becomes 0 volt to develo p the Vr

pattern.

2-30

Page 50

Power Pack CC/Grid/Bias

(P1)

Charge Corona

24 June 1994 DEVELOPMENT

5.5 DEVELOPMENT BIAS CIRCUIT

t2

CN1-1

CN1-2

CN1-4

CN1-6

CN1-7

t1

C

G

B

PWM Duty cycle

=t2/t1 x 100 (%)

Grid

Development

Bias

Bias Trig (PWM) [

Main Board (PCB1)

VA [24]

VC [5]

▲0→0/5]

Bias FB

GND [0]

CN119-7

CN119-6

CN119-4

CN119-2

CN119-1

The main board supplies +24 volt s to th e CC/G rid/Bias power pack at CN1-1.

When the Start key is pressed, the CPU starts sending the bias trigger pulses

to CN1-4. This energizes the develo pme nt bias circuit within the

CC/Grid/Bias power pack, which applies a high negative volta ge to the

development roller. The deve lopment bias is applied whenever the drum is

rotating except when the Vr pattern is developed.

The bias trigger pulse applied to CN1-4 is a pulse width modulated signal

(PWM signal). The width of the pulses controls the volta ge level of the

development roller. As th e widt h of the trigg er pulses increase, the voltage to

the development roller a lso incre ase s. The CPU monitors the development

bias voltage at CN119-2 an d con trols the width of the bias trigg er pu lses

based on this feedback.

2-31

Page 51

A

TONER DENSITY DETECTION AND TONER SUPPLY 24 June 1994

6. TONER DENSITY DETECTION AND TONER

SUPPLY

6.1 OVERVIEW

Sensor

Pattern

Original Lead

Edge

Original

ON OFF ON OFF

BC

RAM Clear

1234567891011121314 202122

Toner Density Detection Toner Density Detection Toner Density

DE

1st

Leading Edge Erase

Detection

Low Toner Density

Toner Supply Timing

Toner Add

Toner Supply Clutch ON

(10 times)

ID Sensor

Pattern

2nd 3rd

Detection

Detection

Development

Bias

The CPU checks toner density by directly se nsin g th e image density every 10

copy cycles. If the RAM is cleared (SP99), or a new RAM is installed, the

CPU checks the image densit y at th e be ginning of the first copy cycle.

During the check cycles, the sensor pat te rn is exposed prior to the exposure

of the original. Afte r the senso r p atte rn is d eve lop ed , its ref lectivity is checked

by the image density sensor (a photose nso r). The CP U not es th e reflectivity

and if the reflected ligh t is t oo stron g, indicating a too low tone r den sity

condition, toner is add ed to th e de velopment unit.

The toner is not added all at once. The CPU will energize the toner supply

clutch for the prope r amount of time in order to add a selected amount of

toner over the next 10 cycles.

When the free run mode (turn DIP switch 10 1-1 ON) is sele cte d, the CPU

checks the toner density every co py cycle.

2-32

Page 52

Low Density

24 June 1994 TONER DENSITY DETECTION AND TONER SUPPLY

6.2 ID SENSOR FUNCTION

6.2.1 Detect Supply Mode

ID Sensor

B

A

K

R

C

E

C

ID Sensor Output

A

Vsg 4V

CN112-2

CN112-1

CN112-3

ID Sensor LED

+5V (VB)

TP 110

(PSE)

VR102

Main Board

A)

+24V (V

CPU

High Density

CN110-2

MSC1

CN110-1

Toner

Supply

Clutch

Vsp

(0.103 Vsg ≈ 0.41 V)

High Density

The image density senso r checks the density of the sensor patt ern image

once every 10 copy cycles. The CPU receives two voltage values directly

from the sensor: the value for the bare drum (Vsg) and th e valu e for the

sensor pattern (Vsp). The se two values are then compared to determine

whether more toner should be added .

Vsp

1.

2.

x 100 <10.3 ..... No toner is added. (High density)

Vsg

Vsp

x 100 ≥10.3 ..... Toner is added. (Low density)

Vsg

When the image density is too low, the CPU activates the toner supply clu tch

to add toner over the next 10 copy cycles. The amount of toner added

depends on the value of Vsp , th e selected toner supply ratio (SP31), and ID

sensor data. (See pag e 2-3 7 fo r mo re inf ormation.)

When SP35 is set to "1" (fact ory set ting = "0"), the CPU changes the int erval

of the toner density detection from every 10 copies to eve ry 5 copies.

2-33

Page 53

TONER DENSITY DETECTION AND TONER SUPPLY 24 June 1994

6.2.2 Fixed Supply Mode

When SP30 is set to "1" (factory setting = "0"), the fixed supply mode is

selected. In this case, a fixed amount of toner is added every cop y cycle

depending on the selected ton er sup ply rat io (SP32) and the paper size in

use. (See page 2-39 for more inf orma tion.) However, the toner supp ly clutch

is de-energized to prevent over-toning when Vsp is lower t han 0.103 Vsg.

(≈ 0.41 volts when Vsg = 4.0 volts).

Vsg 4V

Low Density

Vsp

(0.103 Vsg ≈ 0.41 V)

High Density

6.3 ABNORMAL CONDITION IN TONER DENSITY

DETECTION

If Vsg goes below 2.5 volts (LOW Vsg) or Vsp goes above 2.5 volts (HIGH

Vsp) on 5 consecutive toner density detection cycles, the CPU det ermin es

that the toner density detection is abnormal. The CPU changes from th e

detect supply mode to th e fixe d supply mode. At the same time eithe r t he

Auto ID indicator or the selected manual ID level starts blinking. The machine

can be operated in this con dit ion.

Abnormal Condition In Toner Density Detection

SP55 display

Vsp Vsg

varies 0.00

varies 5.00

Conditions

Vsg ≤ 2.5 (LOW Vsg)

Vsp ≥ 2.5 (HIGH Vsp)

2-34

Page 54

24 June 1994 TONER DENSITY DETECTION AND TONER SUPPLY

6.4 DEVELOPMENT BIAS VO LTAGE FOR TONER DENSITY

DETECTION

The development bias fo r t on er de nsit y detection can be adjusted by SP33 in

order to change the toner density level. The following tab le shows the

development bias volta ge corresp on din g to sett ing of SP33. This SP mode

should be used only when th e exp osure lamp intensity adjustme nt (SP48)

and the base bias adjustmen t (SP37) for copy image cannot achie ve the

desired image density.

Toner density SP data (SP33)

Normal 0 –240 –220

Low 1 –200 –180

High 2 –260 –240

Higher 3 –280 –260

Development bias voltage (volts)

0 to 499 copies More than 500 copies

After the developer initia l se tt ing (S P65) is p erf ormed, the triboelectric charge

is still low. In this condition, the ID sensor pattern densit y is highe r than it

should be. This will cause the toner concentration in the developer t o become

too low.

To compensate for th is p he nomenon, the development bias volt ag e for the

initial 499 copies is increased by –2 0 volt s aut oma tically as shown in the

above table.

2-35

Page 55

[F]

TONER DENSITY DETECTION AND TONER SUPPLY 24 June 1994

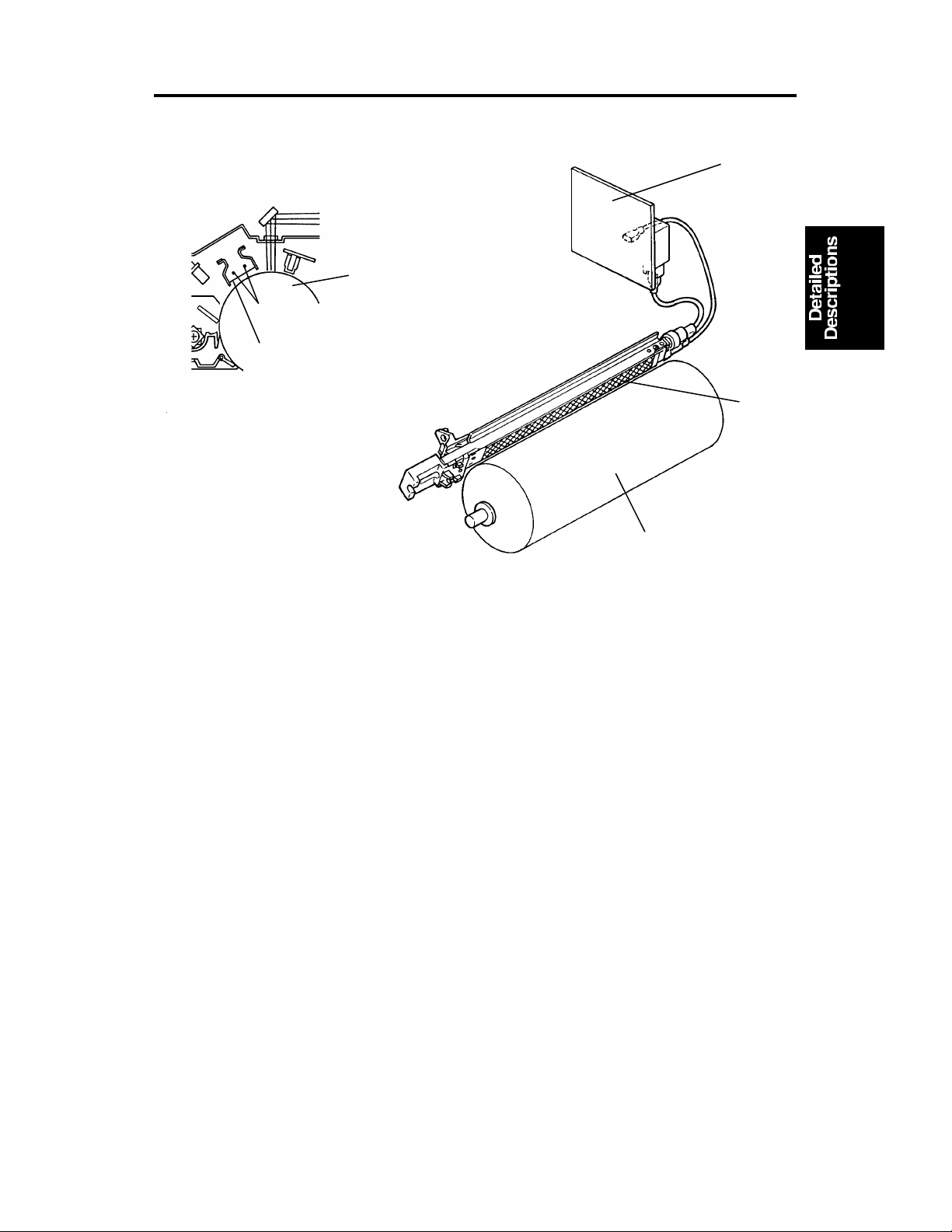

6.5 TONER SUPPLY AND AGITATOR DRIVE ME CHANI SM

[A]

[D]

[E]

[C]

[A]

[D]

[H]

[B]

[J]

[I]

[G]

The toner supply clutch gear [A] turns when the main motor [B] is on. The

transmission of this rotation to the toner supply drive gear [C] is controlled by

the toner supply clutch [D].

When the toner supply clutch energ izes, the toner supply drive gear starts

turning and drives the toner supply roller ge ar [E ]. Toner catches in the

grooves on the toner supply roller [F]. Then, as the groove s t urn past the pin

hole plate [G], the toner drops into the develo pment unit through th e pin holes.

The toner agitator [H] mecha nism, which is contained in the toner cartridg e,

prevents toner from clu mpin g. The toner agitator gear [I] turns whenever the

toner supply clutch energizes. Rotation passes through the toner cartridge

casing to the agitator junction [J].

2-36

Page 56

24 June 1994 TONER DENSITY DETECTION AND TONER SUPPLY

6.6 TONER SUPPLY AMOUNT

This copier has two different ways of controlling the amount of toner supplied.

Normally, the detect supply mode controls toner supply; however, a fixed

supply mode also can be selecte d by SP 30 .

6.6.1 Detect Supply Mode (SP30 = 0)

The amount of toner sup plied depends on the ID sensor data and the det ect

toner supply ratio data. The ton er sup ply clut ch on time in each copy cycle is

calculated as follows:

Toner Supply Clutch ON Time = I x T (pulses)

Where : I = ID Sensor Data

T = Detect Toner Supply Ratio Data (SP 31 )

ID Sensor Data

Vsp/Vsg x 100

(Vsp, if Vsg = 4.0 volts)

0 to 10.3%

(0 to 0.41 volts)

10.3 to 10.8%

(0.41 to 0.43 volts)

10.8 to 11.8%

(0.43 to 0.47 volts)

11.8 to 15.2%

(0.47 to 0.61 volts)

15.2 to 62.5%

(0.61 to 2.5 volts)

(See note below.)

62.5 to more than 100%

(2.5 to 5.0 volts)

Toner supply level

(Toner supply ratio, SP31 = 0)

No toner supply

(0%)

1

(3.75%)

2

(7.5%)

3

(15%)

4

(30%)

Fixed supply mode

ID sensor data

0

22

44

87

174

(Toner End level)

N/A

(Abnormal Condition)

NOTE: If this condition is detecte d two times consecutively, the toner

supply ratio rises to 60% (ID Sensor Data = 348), which is double

that at toner supply level 4.

2-37

Page 57

TONER DENSITY DETECTION AND TONER SUPPLY 24 June 1994

Detect Toner Supply Ratio Data (SP31)

Data (SP31) Toner supply ratio at toner supply level 3 Toner supply ratio data

0 15% 2

17% 1

2 30% 4

3 60% 8

For example: Vsp = 0.45 volts, which means the tone r

supply level is "2" and the ID sensor da ta is 44.

The data of SP31 is set to "0".

The toner supply ratio is 15% and the ton er

supply data is 2.

Toner Supply Clutch ON Time

= I x T

= 44 x 2

= 88 (pulses)

= 352 (msec.) (1 pulse = 4.0 msec.)

2-38

Page 58

24 June 1994 TONER DENSITY DETECTION AND TONER SUPPLY

6.6.2 Fixed Supply Mode (SP30 = 1)

The amount of toner sup plied depends on the fixed to ner su pp ly ratio data

and the paper size data. The toner sup ply clut ch on time in each copy cycle

is calculated as follows:

Toner Supply Clutch ON Time = T x P x 2 (pulses)

Where: T = Fixed Toner Supply Ratio Data (SP32)

P = Paper Size Data

Fixed Toner Supply Ratio Data (SP32)

Data (SP32) Toner supply ratio Toner supply ratio data

0 7.0% 2

1 3.5% 1

2 10.5% 3

3 14.0% 4

Paper Size Data

10" x 14", 8

8

1/2" x 13", 81/4" x 13" (F4), 8" x 13" 33

8

1/2" x 11", 8" x 101/2"29

For example: The data of SP32 is set to "0".

Toner Supply Clutch ON Time

Paper size Paper size data

B4 43

A4R 29

B5R 23

A5R 15

1/2" x 14", 81/4" x 14" 43

8" x 10" 27

5

1/2" x 81/2"14

The toner supply ratio is 7.0 % an d th e toner

supply data is 2.

Paper size is A4R. The paper size data is 29.

= T x P x 2

= 2 x 29 x 2

=116 (pulses)

= 464 (msec.) (1 pulse = 4.0 msec.)

2-39

Page 59

TONER DENSITY DETECTION AND TONER SUPPLY 24 June 1994

6.7 TONER END CONDITIO N

The image density senso r is used to detect a toner end condit ion in bot h

detect and fixed supply modes.

6.7.1 Near Toner End Condition

When the Vsp/Vsg x100 becomes greater than 15.2, the toner density

detection cycle changes from eve ry 10 cop ies to 5 copie s. Whe n th is

condition is detected again, the toner supply ratio becomes two time s the

amount of toner supply level 4 (Ton er sup ply ratio = 60%, ID sensor data =

348). Then, when this condit ion is dete cte d five times consecutively, the CPU

determines that there is a near toner end condition and start s blinkin g the

Add Toner indicator.

6.7.2 Toner End Conditi on

After the Add Toner ind icat or sta rts blinking (Near Toner End Condition ), the

operator can make 50 copies. If a new tone r cartridge is not added within that

50 copy interval, copying is inhib ited and a toner end condition is determin ed .

In this condition, the Add Tone r indicator lights and the Start indicat or tu rns

red.

Example: (Detect Mode)

Copy number

1st∼5th copies

6th∼10th copies

11th∼15th copies

16st∼20th copies

21st∼25th copies

•

•

•

•

71st copy — — —

Toner density

detection cycle

1st copy 15.3 30%

6th copy 15.3 60%

11th copy 15.3 60%

16th copy 15.3 60%

21st copy 15.3 60%

•

•

•

•

Vsp/Vsg

x 100

•

•

•

•

Toner supply

ratio

(If SP31=0)

•

•

•

•

Indicator

Add Toner indicator starts

blinking.

(Near toner end condition)

Add Toner indicator blinks.

(Near toner end condition)

Add Toner indicator lights.

(Toner end condition)

2-40

Page 60

24 June 1994 TONER DENSITY DETECTION AND TONER SUPPLY

When the Vsp/Vsg x 100 becomes greater than 28.0 for two consecutive