Page 1

A151/A152/A202/A203

SERVICE MANUAL

RICOH GROUP COMPANIES

PN: RCFM3213

Page 2

®

®

A151/A152/A202/A203

SERVICE MANUAL

RICOH GROUP COMPANIES

Page 3

A151/A152/A202/A203

FIELD SERVICE

MANUAL

PN: RCFM3213

Page 4

Page 5

WARNING

The Field Service Manual contains information

regarding se rvice techniques, procedures, processes

and spare parts of office equ ipment distributed by

Ricoh Corporation. Users of this manual should be

either service trained or certified by successfully

completing a Ricoh Technical Training Program.

Untrained and uncertified users utilizing information

contained in this service manual to repair or modify

Ricoh equip ment risk person al injury, damage to

property or loss of warranty protection.

Ricoh Corporation

Page 6

Page 7

LEGEND

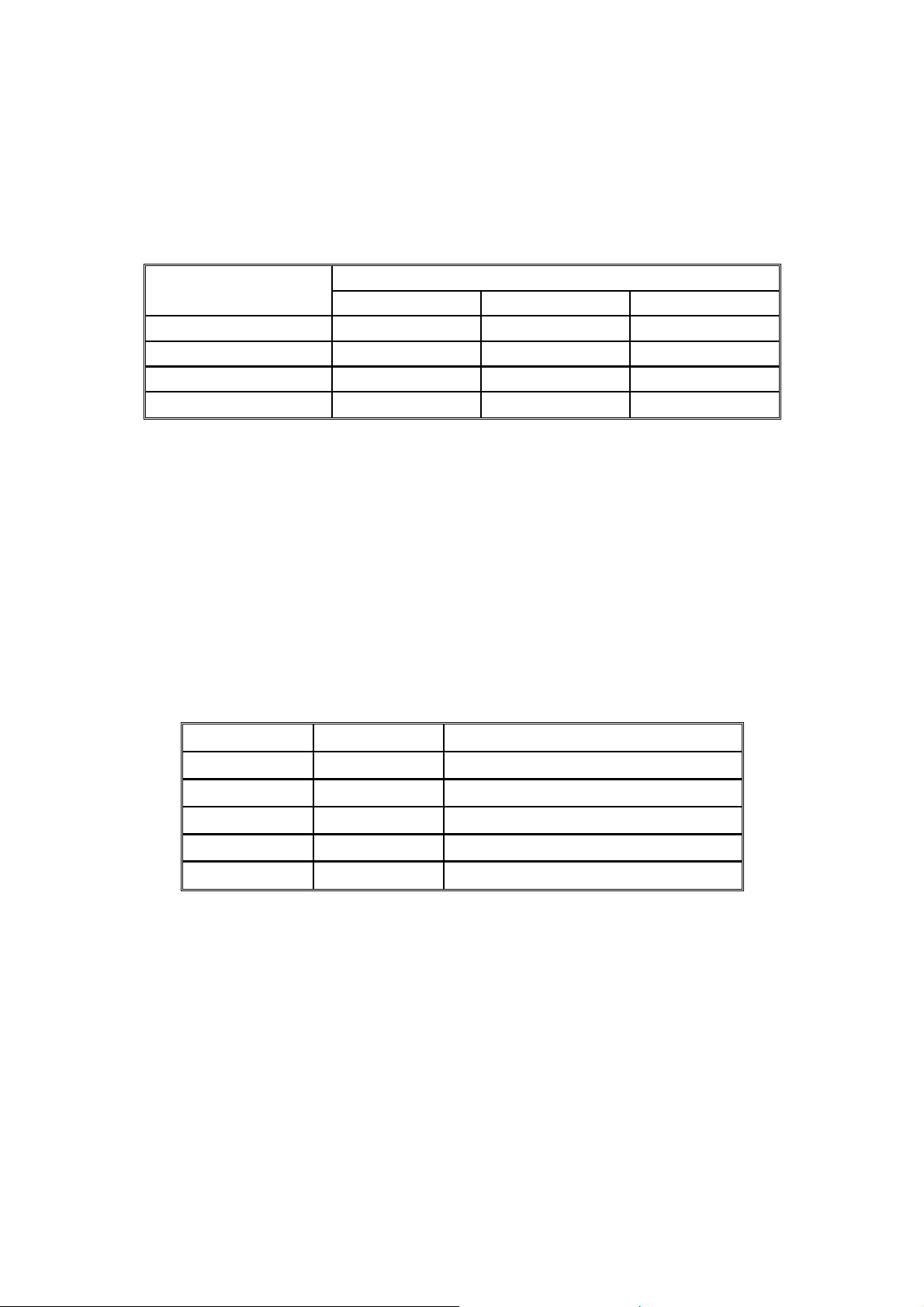

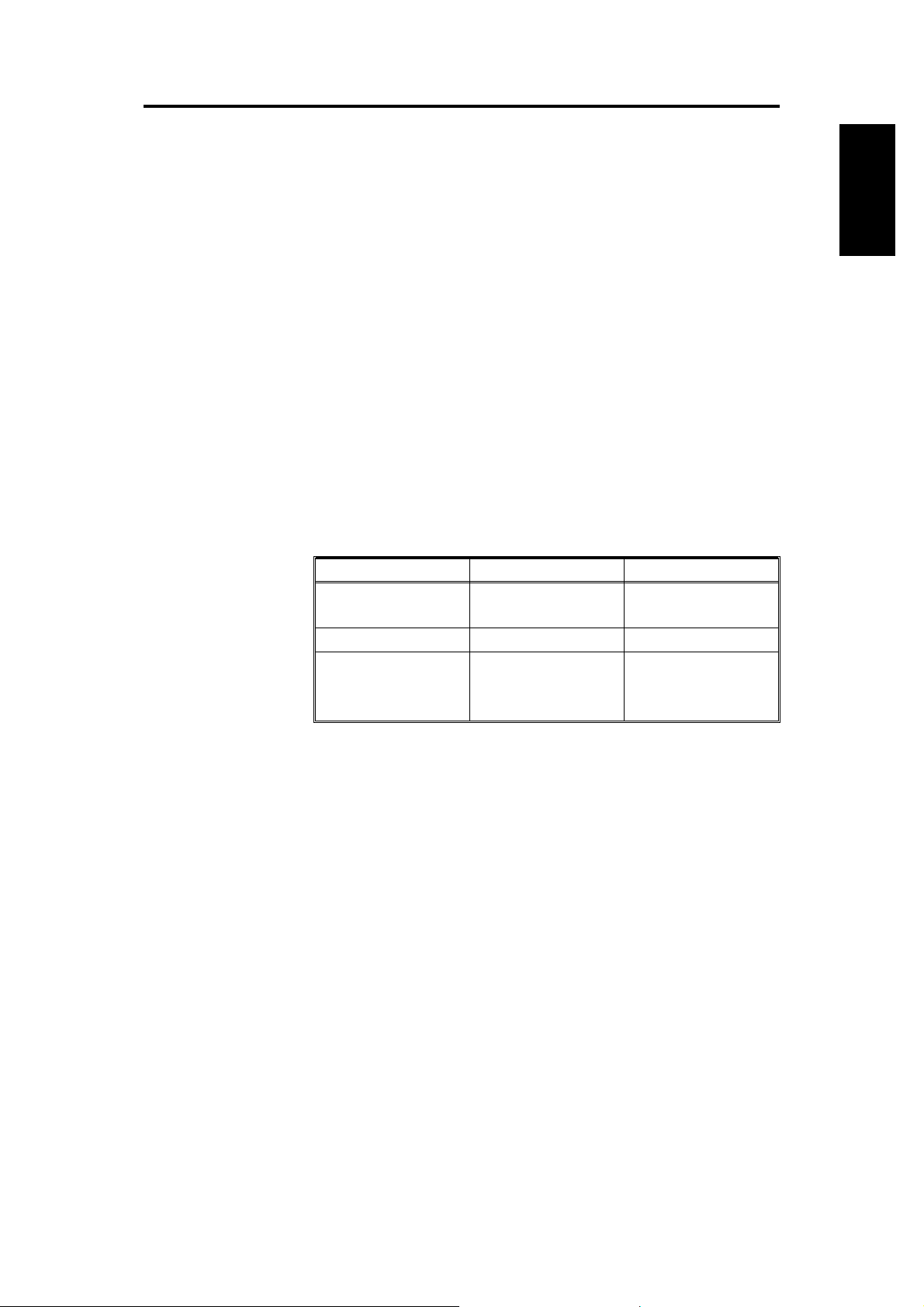

PRODUCT CODE COMPANY

GESTETNER RICOH SAVIN

A151 2613 FT3013 9013

A152 2613Z FT3213 9013Z

A202 2713 FT3513 9113

A203 2613 FT3713 9013Z

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

*

1 6/96 Reprint

2 4/97 A202/A203 Addition

3 7/98 Reprint

9/94 Original Printing

Page 8

Page 9

Table of Contents

SECTION 1 OVERALL MACHINE INFORMATION

1. SPECIFICATIONS . . . . . . . . . . . . . . . 1-1

SECTION 2 GUIDE TO COMPONENTS

1. MECHANICAL COMPONENT LAYOUT . . . . . . 2-1

2. ELECTRICAL COMPONENT LAY OUT . . . . . . . 2-2

3. ELECTRICAL COMPONENT DESCRIPTIONS . . . . 2-3

4. DRIVE LAYOUT . . . . . . . . . . . . . . . . 2-6

SECTION 3 INSTALLATION

1. INSTALLATION REQUIREMENTS . . . . . . . . 3-1

1.1 ENVIRONMENT . . . . . . . . . . . . . . . . . . . 3-1

1.2 MACHINE LEVEL . . . . . . . . . . . . . . . . . . 3-1

1.3 MINIMUM SPACE REQUIREMENTS . . . . . . . . . . . 3-2

1.4 POWER REQUIREMENTS . . . . . . . . . . . . . . . 3-2

2. INSTALLATION PROCEDURE . . . . . . . . . . 3-3

2.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . 3-3

2.2 COPIER INSTALLATION PROCEDURE . . . . . . . . 3-4

2.3 KEY COUNTER HOLDER INSTALLAT ION (OPTION) . . . . 3-10

SECTION 4 SERVICE TABLES

1. SERVICE REMARKS . . . . . . . . . . . . . . 4-1

1.1 GENERAL CAUTION . . . . . . . . . . . . . . . . . 4-1

1.2 DRUM . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.3 CHARGE CORONA . . . . . . . . . . . . . . . . . 4-2

1.4 OPTICS . . . . . . . . . . . . . . . . . . . . . . 4-3

FSM i A151/A152/A202/A203

Page 10

1.5 DEVELOPMENT . . . . . . . . . . . . . . . . . . . 4-4

1.6 TONER SUPPLY . . . . . . . . . . . . . . . . . . . 4-4

1.7 TRANSFER AND SEPARATION . . . . . . . . . . . . . 4-5

1.8 CLEANING UNIT . . . . . . . . . . . . . . . . . . . 4-5

1.9 FUSING UNIT . . . . . . . . . . . . . . . . . . . . 4-5

1.10 PAPER FEED . . . . . . . . . . . . . . . . . . . 4-6

1.11 DOCUMENT FEEDER . . . . . . . . . . . . . . . . 4-6

1.12 OTHERS . . . . . . . . . . . . . . . . . . . . . 4-6

2. SERVICE PROGRAM MODE . . . . . . . . . . . 4-8

2.1 SERVICE PROGRAM MODE OPERATION . . . . . . . . 4-8

2.1.1 Service Program Access Procedure . . . . . . . . . 4-8

2.1.2 Change Adjustment Values or Modes . . . . . . . . 4-9

2.1.3 Memory Clear Procedure . . . . . . . . . . . . . 4-10

2.2 SERVICE PROGRAM MODE TABLE . . . . . . . . . . . 4-13

2.3 SP MODE 8–INPUT CHECK . . . . . . . . . . . . . . 4-21

2.4 SP MODE 9–OUTPUT CHECK . . . . . . . . . . . . . 4-22

2.5 SERVICE CALL AND USER CODE TABLE . . . . . . . . 4-23

3. SERVICE TABLES . . . . . . . . . . . . . . . 4-25

3.1 TEST POINTS . . . . . . . . . . . . . . . . . . . . 4-25

3.2 DIP SWITCHES AND JUMPER SWITCHES . . . . . . . . 4-26

3.3 VARIABLE RESISTORS . . . . . . . . . . . . . . . . 4-27

4. SPECIAL T OOLS AND LUBRICANTS . . . . . . . 4-28

5. PREVENTIVE MAINTENANCE SCHEDULE . . . . 4-29

5.1 PM TABLE . . . . . . . . . . . . . . . . . . . . . 4-29

5.2 EXPLANATION OF REGULAR PM . . . . . . . . . . . 4-32

5.3 REGULAR PM PROCEDURE . . . . . . . . . . . . . 4-34

6. DEFECTIVE COMPONENT TABLES . . . . . . . 4-36

A151/A152/A202/A203 ii FSM

Page 11

6.1 DEFECTIVE SENSOR TABLE . . . . . . . . . . . . . 4-36

6.2 DEFECTIVE SWITCH ES OR OTHER ELECTR ICAL COMPONENTS 4-37

6.3 OPEN FUSE & CIRCUIT BREAKER TABLE . . . . . . . . 4-38

SECTION 5 REPLACEMENT & ADJUSTMENT

1. EXTERIOR AND INNER COVERS . . . . . . . . 5-1

1.1 EXTERIOR COVER REMOVAL . . . . . . . . . . . . . 5-1

1.1.1 Front Cover . . . . . . . . . . . . . . . . . . 5-1

1.1.2 Right Cover . . . . . . . . . . . . . . . . . . 5-1

1.1.3 Upper Left Cover . . . . . . . . . . . . . . . . 5-2

1.1.4 Lower Left Cover . . . . . . . . . . . . . . . . 5-2

1.1.5 Upper Rear Cover . . . . . . . . . . . . . . . . 5-2

1.1.6 Lower Rear Cover . . . . . . . . . . . . . . . . 5-2

1.1.7 Upper Cover . . . . . . . . . . . . . . . . . . 5-3

1.2 INNER COVER REMOVAL . . . . . . . . . . . . . . . 5-4

2. OPTICS . . . . . . . . . . . . . . . . . . . 5-5

2.1 EXPOSURE GLASS REMOVAL . . . . . . . . . . . . . 5 -5

2.2 1ST MIRROR REMOVAL . . . . . . . . . . . . . . . 5-6

2.3 2ND AND 3RD MIRROR REMOVAL . . . . . . . . . . . 5-8

2.4 4TH AND 5TH MIRROR REPLACEMENT . . . . . . . . . 5-10

2.5 EXPOSURE LAMP REPLACEMENT . . . . . . . . . . . 5-11

2.6 THERMOFUSE REPLACEMENT . . . . . . . . . . . . 5-13

2.7 SCANNER DRIVE WIRE REPLACEMENT . . . . . . . . 5-14

2.7.1 Wire Removal . . . . . . . . . . . . . . . . . 5-14

2.7.2 Wire Installation . . . . . . . . . . . . . . . . . 5-15

2.8 SCANNER MOTOR REPLACEMENT . . . . . . . . . . 5-21

2.9 LENS DRIVE MOTOR REPLACEMENT (FT3213 Copier only) 5-22

2.10 4TH/5TH MIRROR MOTOR REPLACEMENT (FT3213 Copier Only) 5-24

FSM iii A151/A152/A202/A203

Page 12

3. DEVELOPMENT AND TONER SUPPLY . . . . . . 5-25

3.1 DEVELOPMENT UNIT REMOVAL . . . . . . . . . . . . 5-25

3.2 TONER SUPPLY UNIT REMOVAL . . . . . . . . . . . . 5-26

3.3 DEVELOPER REPLACEMENT . . . . . . . . . . . . . 5-27

3.4 INLET SEAL REMOVAL . . . . . . . . . . . . . . . . 5-28

3.5 TONER SUPPLY CLUTCH REPLACEMENT . . . . . . . . 5-29

3.6 DEVELOPMENT BIAS VOLTAGE ADJUSTMENT (SP9-38) . . 5-30

4. CLEANING . . . . . . . . . . . . . . . . . . 5-31

4.1 CLEANING UNIT REMOVAL . . . . . . . . . . . . . . 5-31

4.2 CLEANING BLADE REPLACEMENT . . . . . . . . . . . 5-32

4.3 USED TONER COLLECTION . . . . . . . . . . . . . 5-33

4.4 ENTRANCE SEAL REPLACEMENT . . . . . . . . . . . 5-34

5. PAPER FEED . . . . . . . . . . . . . . . . . 5-35

5.1 FEED ROLLER REPLACEMENT . . . . . . . . . . . . 5-35

5.2 PAPER TRAY SWITCH REPLACEMENT . . . . . . . . . 5-37

5.3 RELAY SENSOR AND REGISTRATION SENSOR REPLACEMENT 5-38

5.4 RELAY ROLLER CLUTCH, PAPER FEED CLUTCH AND

REGISTRATION CLUTCH REPLACEMENT . . . . . . . . 5-40

6. AROUND THE DRUM . . . . . . . . . . . . . 5-42

6.1 DRUM REPLACEMENT . . . . . . . . . . . . . . . . 5-42

6.2 QUENCHING LAMP REPLACEMENT . . . . . . . . . . 5-44

6.3 ERASE LAMP REPLACEMENT . . . . . . . . . . . . . 5 -45

6.4 CHARGE CORONA WIRE REPLACEMENT . . . . . . . . 5-46

6.5 CHARGE CORONA GRID PLATE REPLACEMENT . . . . . 5-47

6.6 TRANSFER/SEPARATION CORONA WIRE REPLACEMENT . 5-48

6.7 ID SENSOR REPLACEMENT . . . . . . . . . . . . . 5-51

6.8 PICK-OFF PAWL REPLACEMENT . . . . . . . . . . . . 5-52

6.9 TRANSFER/SEP ARATION POWER P ACK REPLACEMENT . 5-53

A151/A152/A202/A203 iv FSM

Page 13

6.10 CORONA CURRENT ADJUSTMENT . . . . . . . . . . 5-55

6.10.1 Charge Corona Current Adjustment (SP9-2) . . . . . 5-57

6.10.2 Grid Voltage Adjustment (SP9-48) . . . . . . . . . 5-59

6.10.3 Transfer Corona Current Adjustment (SP9-5) . . . . . 5-60

6.10.4 Separation Corona Current Adjustment (SP9-6) . . . . 5-61

7. FUSING . . . . . . . . . . . . . . . . . . . 5-62

7.1 EXIT UNIT REMOVAL . . . . . . . . . . . . . . . . . 5-62

7.2 FUSING UNIT REMOVAL . . . . . . . . . . . . . . . 5-63

7.3 HOT ROLLER REPLACEMENT . . . . . . . . . . . . . 5-66

7.4 PRESSURE ROLLER REPLACEMENT . . . . . . . . . . 5-68

7.5 FUSING LAMP REPLACEMENT . . . . . . . . . . . . 5-69

7.6 FUSING THERMOSWITCH REPLACEMENT . . . . . . . 5-70

7.7 FUSING THERMISTOR REPLACEMENT . . . . . . . . . 5-71

7.8 FUSING PRESSURE ADJUSTMENT . . . . . . . . . . . 5-72

8. COPY QUALITY ADJUSTMENT . . . . . . . . . 5-73

8.1 LIGHT INTENSITY ADJUSTMENT . . . . . . . . . . . . 5-74

8.2 SIDE-TO-SIDE EXPOSURE ADJUSTMENT . . . . . . . . 5-75

8.3 IMAGE BIAS VOLTAGE ADJUSTMENT . . . . . . . . . . 5-76

8.4 TONER DENSITY ADJUSTMENT . . . . . . . . . . . . 5-77

8.5 FIXED TONER SUPPLY MODE SELECTION . . . . . . . 5-77

8.6 TONER SUPPLY RATIO SELECTION . . . . . . . . . . 5-77

8.7 ID SENSOR (Vsg) ADJUSTMENT . . . . . . . . . . . . 5-78

8.8 ADS (Auto Image Density Sensor) ADJUSTMENT . . . . . 5-79

8.9 HORIZONTAL MAGNIFICATION ADJUSTMENT . . . . . . 5-80

8.10 VERTICAL MAGNIFICATION ADJUSTMENT . . . . . . . 5-81

8.11 FOCUS ADJUSTMENT . . . . . . . . . . . . . . . . 5-82

8.12 LEADING EDGE ERASE MARGIN ADJUSTMENT . . . . . 5-83

FSM v A151/A152/A202/A203

Page 14

8.13 REGISTRATION ADJUSTMENT . . . . . . . . . . . . 5-83

8.14 SIDE-TO-SIDE REGISTRATION ADJUSTMENT . . . . . . 5-84

8.15 4TH/5TH MIRROR HEIGHT ADJUSTMENT . . . . . . . 5-87

9. OTHERS . . . . . . . . . . . . . . . . . . . 5-88

9.1 OZONE FILTER REPLACEMENT . . . . . . . . . . . . 5-88

9.2 220∼230/240V CONVERSION . . . . . . . . . . . . . 5-89

9.3 OPTIONAL EQUIPMENT INSTALLATION . . . . . . . . . 5-90

9.3.1 Optics Anti-condensation Heater Installation . . . . . . 5-90

9.3.2 Drum Anti-condensation Heater Installation . . . . . . 5-91

9.3.3 Pre-transfer Lamp (PTL) Installation . . . . . . . . . 5-92

9.3.4 Optics Cooling Fan Installation (FT3013 Copier Only) . . 5-93

9.4 TORSION BAR FORCE ADJUSTMENT . . . . . . . . . . 5-94

SECTION 6 TROUBLESHOOTING

1. COPY QUALITY . . . . . . . . . . . . . . . . 6-1

1.1 BLANK COPY (WHITE COPY) . . . . . . . . . . . . . 6-1

1.2 DIRTY BACKGROUND . . . . . . . . . . . . . . . . 6-4

1.3 UNEVEN IMAGE DENSITY . . . . . . . . . . . . . . 6-7

1.4 VERTICAL BLACK BANDS . . . . . . . . . . . . . . 6-8

1.5 VERTICAL BLACK LINES . . . . . . . . . . . . . . . 6-9

1.6 VERTICAL WHITE LINES OR BANDS—1 (DULL OR BLURRED) 6-10

1.7 VERTICAL WHITE LINES OR BANDS—2 (THIN, DISTINCT) . 6-11

1.8 HORIZONTAL BLACK/WHITE LINES . . . . . . . . . . . 6-12

1.9 JITTER . . . . . . . . . . . . . . . . . . . . . . 6-13

1.10 BLACK SPOTS ON THE COPY IMAGE . . . . . . . . . 6-14

1.11 SKEWED (OPTICAL) COPY IMAGE . . . . . . . . . . 6-15

1.12 TONER DENSITY TOO HIGH . . . . . . . . . . . . . 6-16

1.13 TONER DENSITY TOO LOW . . . . . . . . . . . . . 6-18

1.14 TONER SCATTERING . . . . . . . . . . . . . . . . 6-20

A151/A152/A202/A203 vi FSM

Page 15

1.15 UNFUSED COPY IMAGE . . . . . . . . . . . . . . . 6-21

1.16 PAPER MISFEED . . . . . . . . . . . . . . . . . . 6-22

1.17 TRANSFER FAILURE . . . . . . . . . . . . . . . . 6-23

1.18 DF ORIGINAL MISFEED OR SKEW . . . . . . . . . . 6-24

2. SERVICE CALL CONDITIONS . . . . . . . . . . 6-25

2.1 CODE #11 — EXPOSURE LAMP ERROR . . . . . . . . . 6-25

2.2 CODE #12 — EXPOSURE LAMP ERROR . . . . . . . . 6-27

2.3 CODE #13 — ZERO CROSS SIGNAL ERROR . . . . . . . 6-28

2.4 CODE #21 — SCANNER HOME POSITION ERROR . . . . 6-29

2.5 CODE #22 — SCANNER HOME POSITION ERROR . . . . 6-31

2.6 CODE #28 — LENS HOME POSITION ERROR

(FT3213 COPIER ONLY) . . . . . . . . . . . . . . . . 6-33

2.7 CODE #29 — LENS HOME POSITION ERROR

(FT3213 COPIER ONLY) . . . . . . . . . . . . . . . . 6-35

2.8 CODE #2A — 4TH/5TH MIRROR HOME POSITION ERROR

(FT3213 COPIER ONLY) . . . . . . . . . . . . . . . 6-37

2.9 CODE #2B — 4TH/5TH MIRROR HOME POSITION ERROR

(FT3213 COPIER ONLY) . . . . . . . . . . . . . . . 6-39

2.10 CODE #40 – OPTICS THERMISTOR ERROR . . . . . . . 6-41

2.11 CODE #52 — FUSING WARM-UP ERROR . . . . . . . . 6-42

2.12 CODE #53 — FUSING OVERHEAT . . . . . . . . . . . 6-44

2.13 CODE #55 — FUSING THERMISTOR OPEN . . . . . . . 6-45

2.14 CODE #96 — DF TIMING PULSE ERROR . . . . . . . . 6-47

2.15 DF COMMUNICATION ERROR . . . . . . . . . . . . 6-49

2.16 ABNORMAL CONDITION IN TONER DENSITY DETECTION 6-50

2.17 OPTICS OVER HEAT PROTECTION (FT3013 Copier Only) . 6-52

3. ELECTRICAL COMPONENT DEFECTS . . . . . . 6-53

3.1 DEFECTIVE SENSOR TABLE . . . . . . . . . . . . . 6-53

3.2 DEFECTIVE SWITCHES OR OTHER ELECTRICAL

COMPONENTS . . . . . . . . . . . . . . . . . . . 6-54

3.3 OPEN FUSES & CIRCUIT BREAKERS . . . . . . . . . . 6-55

FSM vii A151/A152/A202/A203

Page 16

SECTION 7 DOCUMENT FEEDER A365

1. SPECIFICATIONS . . . . . . . . . . . . . . . 7-1

2. COMPONENT LAY OUT . . . . . . . . . . . . . 7-2

2.1 MECHANICAL COMPONENTS . . . . . . . . . . . . . 7-2

2.2 ELECTRICAL COMPONENTS . . . . . . . . . . . . . 7-2

3. ELECTRICAL COMPONENT DESCRIPTIONS . . . . 7-3

4. INSTALLATION PROCEDURE . . . . . . . . . . 7-4

5. REPLACEMENT AND ADJUSTMENT . . . . . . . 7-8

5.1 TRANSPORT BELT REPLACEMENT . . . . . . . . . . 7-8

4.2 FEED-IN UNIT REMOVAL . . . . . . . . . . . . . . . 7-10

4.3 PICK-UP ROLLER REPLACEMENT . . . . . . . . . . . 7-11

4.4 FEED ROLLER REPLACEMENT . . . . . . . . . . . . 7-12

4.5 FRICTION BELT REPLACEMENT . . . . . . . . . . . . 7-13

4.6 PICK-UP SOLENOID ADJUSTMENT . . . . . . . . . . . 7-14

SECTION 8 A202/A203 COPIER

MAJOR DIFFERENCES BETWEEN THE A202/A203 AND

A151/A152 COPIERS . . . . . . . . . . . . . . . 1

1. SPECIFICATIONS . . . . . . . . . . . . . . . 8-1

2. COPY PROCESS CONTROL . . . . . . . . . . 8-4

3. MECHANICAL COMPONENT LAYOUT . . . . . . 8-5

4. ELECTRICAL COMPONENT LAY OUT . . . . . . . 8-6

5. ELECTRICAL COMPONENT DESCRIPTIONS . . . . 8-7

6. DRIVE LAYOUT . . . . . . . . . . . . . . . . 8-8

7. POWER DISTRIBUTION . . . . . . . . . . . . 8-10

8. DRUM CHARGE . . . . . . . . . . . . . . . . 8-12

8.1 GRID VOLTAGE CORRECTION . . . . . . . . . . . . . 8-12

A151/A152/A202/A203 viii FSM

Page 17

8.2 GRID VOLTAGE FOR IMAGE DENSITY CONTROL . . . . . 8-12

8.2.1 Standard Image Density Grid Voltage . . . . . . . . 8-12

8.2.2 Auto Image Density Level Factor (SP34) . . . . . . . 8-12

8.3 GRID VOLTAGE FOR TONER DENSITY DETECTION . . . . 8-13

9. OPTICS . . . . . . . . . . . . . . . . . . . 8-14

9.1 LENS POSITIONING . . . . . . . . . . . . . . . . . 8-14

9.2 BASE LAMP VOLTAGE IN MANUAL IMAGE DENSITY MODE . 8-15

9.3 EXPOSURE LAMP CONTROL CIRCUIT . . . . . . . . . 8-15

10. DEVELOPMENT . . . . . . . . . . . . . . . 8-16

10.1 DEVELOPMENT BIAS CIRCUIT . . . . . . . . . . . . 8-16

11. TONER DENSITY DETECTION AND TONER SUPPLY 8-17

11.1 ID Sensor Control Circuit . . . . . . . . . . . . . . . 8-17

11.2 TONER SUPPLY AND AGITATOR DRIVE MECHANISM . . . 8-18

12. PAPER FEED . . . . . . . . . . . . . . . . 8-19

12.1 PAPER LENGTH DETECTION (Paper Feed Station) . . . . 8-19

13. IMAGE FUSING . . . . . . . . . . . . . . . 8-20

13.1 FUSING LAMP CONTROL CIRCUIT . . . . . . . . . . 8-20

13.2 OVERHEAT PROTECTION . . . . . . . . . . . . . . 8-20

14. INSTALLATION . . . . . . . . . . . . . . . 8-21

14.1 COPIER (A 202/ A2 03) ACCESSORY CHECK . . . . . . . 8-21

14.2 COPIER (A202/A203) INSTALLATION PROCEDURE . . . . 8-22

14.3 DOCUMENT FEEDER (A662) ACCESSORY CHECK . . . . 8-28

14.4 DOCUMENT FEEDER (A662) INSTALLATION PROCEDURE 8-29

15. SERVICE PROGRAM MODE . . . . . . . . . . 8-34

15.1 ACCESS PROCEDURE 1-KEY OPERATION . . . . . . . 8-34

15.2 MEMORY CLEAR PROCEDURE . . . . . . . . . . . . 8-35

15.3 CLEAR ALL MEMORY PROCEDURE . . . . . . . . . . 8-36

15.4 SERVICE PROGRAM MODE TABLE . . . . . . . . . . 8-38

15.5 SP MODE 8-INPUT CHECK . . . . . . . . . . . . . . 8-46

15.6 SP MODE 9–OUTPUT CHECK . . . . . . . . . . . . 8-47

FSM ix A151/A152/A202/A203

Page 18

15.7 SERVICE CALL AND USER CODE TABLE . . . . . . . . 8-48

16. SERVICE TABLES . . . . . . . . . . . . . . 8-50

16.1 TEST POINTS . . . . . . . . . . . . . . . . . . . 8-50

16.2 DIP SWITCHES AND JUMPER SWITCHES . . . . . . . 8-50

16.3 VARIABLE RESISTORS . . . . . . . . . . . . . . . 8-50

17. PREVENTIVE MA INTENANCE SCHEDULE . . . . 8-51

17.1 PM TABLE . . . . . . . . . . . . . . . . . . . . . 8-51

18. REPLACEMENT AND ADJUSTMENT . . . . . . 8-52

18.1 TONER SUPPLY MOTOR REPLACEMENT . . . . . . . 8-52

18.2 QUENCHING LAMP REPLACEMENT . . . . . . . . . . 8-53

18.3 CHARGE CORONA CURRENT ADJUSTMENT . . . . . . 8-54

18.4 GRID VOLTAGE ADJUSTMENT (SP9-46) . . . . . . . . 8-55

18.5 DEVELOPMENT BIAS VOLTAG E ADJUSTMENT (SP9-38) . 8-56

18.6 TRANSFER CORONA CURRENT ADJUSTMENT (SP9-5) . . 8-57

18.7 SEPARATION CORONA CURRENT ADJUSTMENT (SP9-6) . 8-58

SECTION 9 DOCUME N T FEEDER A662

1. SPECIFICATIONS . . . . . . . . . . . . . . . 9-1

2. COMPONENT LAY OUT . . . . . . . . . . . . . 9-2

2.1 MECHANICAL COMPONENTS . . . . . . . . . . . . . 9-2

2.2 ELECTRICAL COMPONENTS . . . . . . . . . . . . . 9-2

3. ELECTRICAL COMPONENT DESCRIPTIONS . . . . 9-3

4. POWER DISTRIBUTION . . . . . . . . . . . . 9-4

5. BASIC OPERATION . . . . . . . . . . . . . . 9-5

6. INTERFACE CIRCUIT . . . . . . . . . . . . . 9-6

7. ORIGINAL FEED . . . . . . . . . . . . . . . 9-7

7.1 ORIGINAL PICK-UP MECHANISM . . . . . . . . . . . . 9-7

7.2 ORIGINAL SEPARATION MECHANISM . . . . . . . . . 9-8

A151/A152/A202/A203 x FSM

Page 19

7.3 ORIGINAL FEED-IN MECHANISM . . . . . . . . . . . . 9-9

7.4 ORIGINAL FEED-OUT MECHANISM . . . . . . . . . . . 9-10

7.5 DF MOTOR CIRCUIT . . . . . . . . . . . . . . . . . 9-11

7.6 ORIGINAL FEED AND MISFEED DETECTION TIMING . . . 9-12

8. SERVICE TABLES . . . . . . . . . . . . . . . 9-13

8.1 DIP SWITCHES . . . . . . . . . . . . . . . . . . . 9-13

8.2 VARIABLE RESISTORS . . . . . . . . . . . . . . . . 9-13

8.3 FUSE . . . . . . . . . . . . . . . . . . . . . . . 9-13

9. REPLACEMENT AND ADJUSTMENT . . . . . . . 9-14

9.1 TRANSPORT BELT REPLACEMENT . . . . . . . . . . 9-14

9.2 FEED-IN UNIT REMOVAL . . . . . . . . . . . . . . . 9-16

9.3 PICK-UP ROLLER REPLACEMENT . . . . . . . . . . . 9-17

9.4 FEED ROLLER REPLACEMENT . . . . . . . . . . . . 9-18

9.5 FRICTION BELT REPLACEMENT . . . . . . . . . . . . 9-19

9.6 PICK-UP SOLENOID ADJUSTMENT . . . . . . . . . . . 9-20

FSM xi A151/A152/A202/A203

Page 20

Page 21

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power co rd is unplugged.

2. The wall outlet should be near the cop ier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main switc h is turn ed off.

4. If any adjustment or operation check has to be made with exterior covers

off or open while the main switch is turned on, keep hands away from

electrified or mechanically driven components.

5. If the hot roller temperature is low when the main switch is turned on, the

copier starts idling automatically when the warm-up period is completed.

Keep hands away from the mechanical and the electrical components to

avoid any injury.

6. If the start key is pressed before the copier completes the warm-up

period (Ready ind icator starts blinking ), keep hands aw ay from the

mechanical and the electrical components as the copier starts making

copies as soon as the warm-up period is completed.

7. The inside and the metal parts of the fusing unit become extremely hot

while the copier is operating. Be careful to avoid touching those

components with your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the sp ecified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your

eyes by accident, it may cause temporary eye discomfort. Try to remove

with eye drops or flush with water as first aid. If unsuccessful, get

medical attentio n.

FSM a A151/A152

Page 22

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The cop ier and its peripherals must be ins talled and maintain ed by a

customer service representative who has completed the training course

on those models.

- CAUTION -

The RAM board on the main control board has a lithium battery which

can explode if rep laced incorrectly. Replace the battery only with an

identical one. The manufacturer recommends replacing the entire RAM

board. Do not recharge or burn this battery. Used batteries must be

handled in accorda nce with loc al regulations.

SAF ETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate the toner cartridge or the used toner. Toner dust may

ign ite suddenly when exposed to o pen flame.

2. Dispose of used toner, developer, and organic photoconductor

according to local regulations. (Th ese are non-toxic supplies .)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, d o

not put more than 100 batter ies per sealed box. Storing larger numbers

or not sealing them apart may lead to c hemical reactions and heat

build-up.

A151/A152 b FSM

Page 23

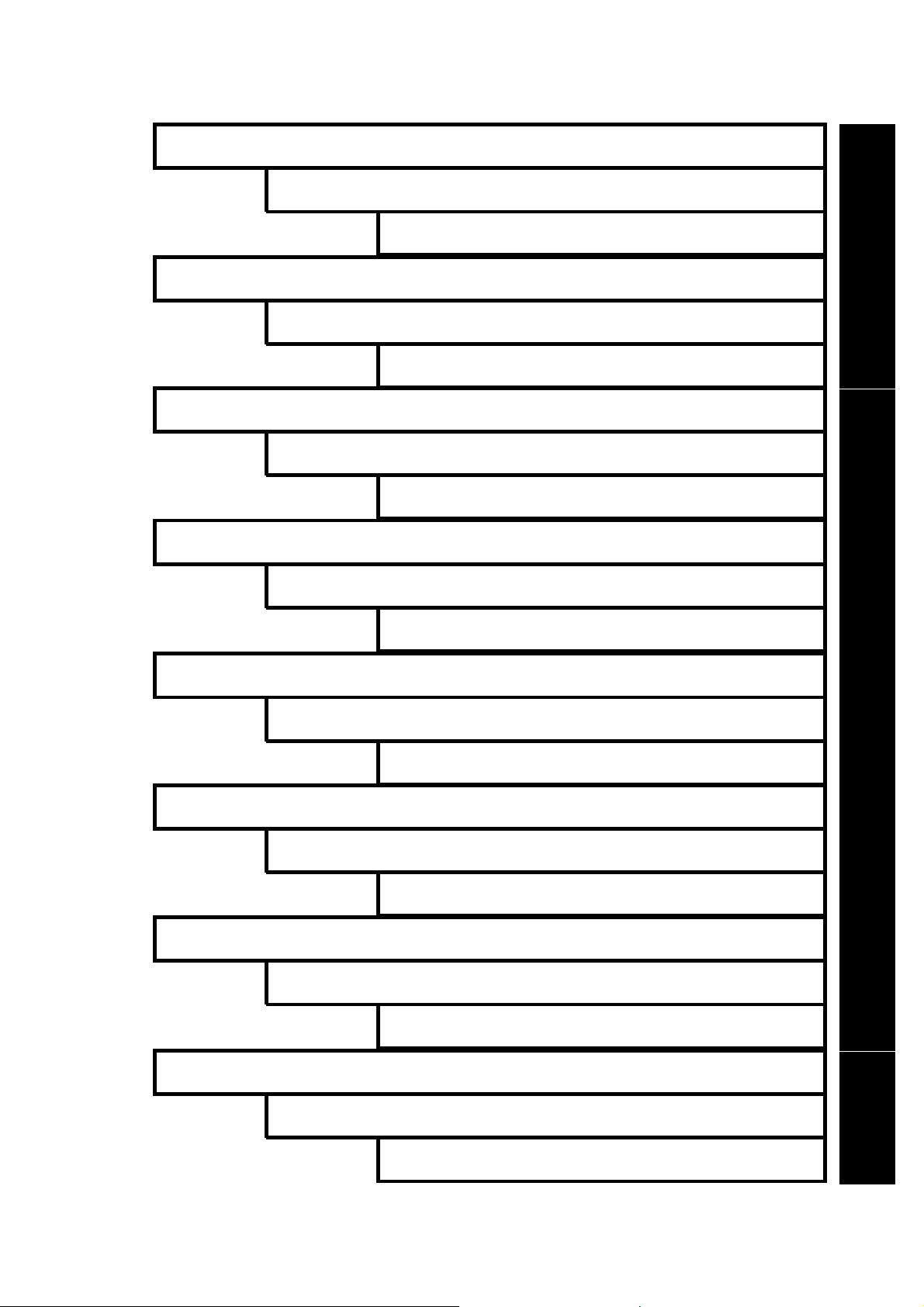

TAB INDEX

A151/A152 OVERALL MACHINE INFORMATION

DOCUMENT FEEDER A662

A151/A152 GUIDE TO COMPONENTS

A151/A152 INSTALLATION

Rev. 4/97

TAB POSITION 1

TAB POSITION 2TAB POSITION 3

A151/A152 SERVICE TABLES

A151/A152 REPLACEMENT AND ADJUSTMENT

A151/A152 TROUBLESHOOTING

DOCUMENT FEEDER A296

TAB POSITION 4

TAB POSITION 5TAB POSITION 6TA B PO SIT I ON 7TAB POSITION 8

A202/A203 SERVICE MANUAL

Page 24

Page 25

OVERALL MACHINE

INFORMATION

Page 26

Page 27

1. SPECIFICATIONS

Configuration: Desk top

Copy Process: Dry electrostatic transfer system

Original Type: Sheet/Book

Original Alignment: Left center

Original Size: Maximum: A3/11" x 17" (lengthwise) – FT3213

copier

B4/10" x 14" (length wise) – FT30 13

copier

Copy Paper Size: Maximum: B4/ 10" x 14" (length wi se)

Minimum:

Paper Tray: A5/5

Bypass Feed: A6/5

Copy Paper Weight: Paper tray feed – 64 to 90 g/m2 (17 to 24 lb)

Bypass feed – 52 to 105 g/m2 (14 to 28 lb)

Reproduction Ratios: 2 E n l a r g e m en t a n d 3 R e d u c t i on ( F T 3 2 1 3 co p i e r o n l y)

1/2

" x 8

1/2

" (lengthwise)

1/2

" x 8

" (lengthwise )

1/2

MACHINE

OVERALL

INFORMATION

A4 Version Letter Version

Enlargement

141%

122%

Full size 100% 100%

93%

Reduction

82%

71%

Zoom: From 61% to 141% in 1% steps

(FT3213 copier only)

Copying Speed: 13 copies/minute (A4/8

10 copies/minute (B4/8

" x 11" lengthwise)

1/2

" x 14")

1/2

Warm-Up Time: 30 seconds (at 20°C/68°F)

First Copy Time: 9 seconds (A4/8

" x 11" lengthwise)

1/2

Copy Number Input: Number keys, 1 to 99

Manual Image Density: 7 steps

Toner Type: Type 320

129%

121%

93%

74%

65%

Developer Type: Type 310

FSM 1-1 A151/A152

Page 28

Automatic Reset: 1 minute standard setting; can also be set to 3

minutes or no automatic reset.

Energy Saver Function: Automatic

Paper Capacity: Paper tray – 250 sheets

Bypass feed table – 1 sheet

Toner Repleni shme nt: Cartridge exchange (32 0 g/ cart ridg e)

Copy Tray Capacity: 100 sheets (B4/10" x 14" or smaller)

Power Source: 110V/ 60Hz/ 15A (for Taiwan)

115V/ 60Hz/ 15A (for North Amer ica)

220V – 240V/ 50Hz/ 8A (for Europ e)

220V/ 60Hz/ 8A (for Middle East)

220V/ 50Hz/ 8A ( for Asia)

(Refer to the serial number plate (rating plate) to

determine the power source required by the

machine.)

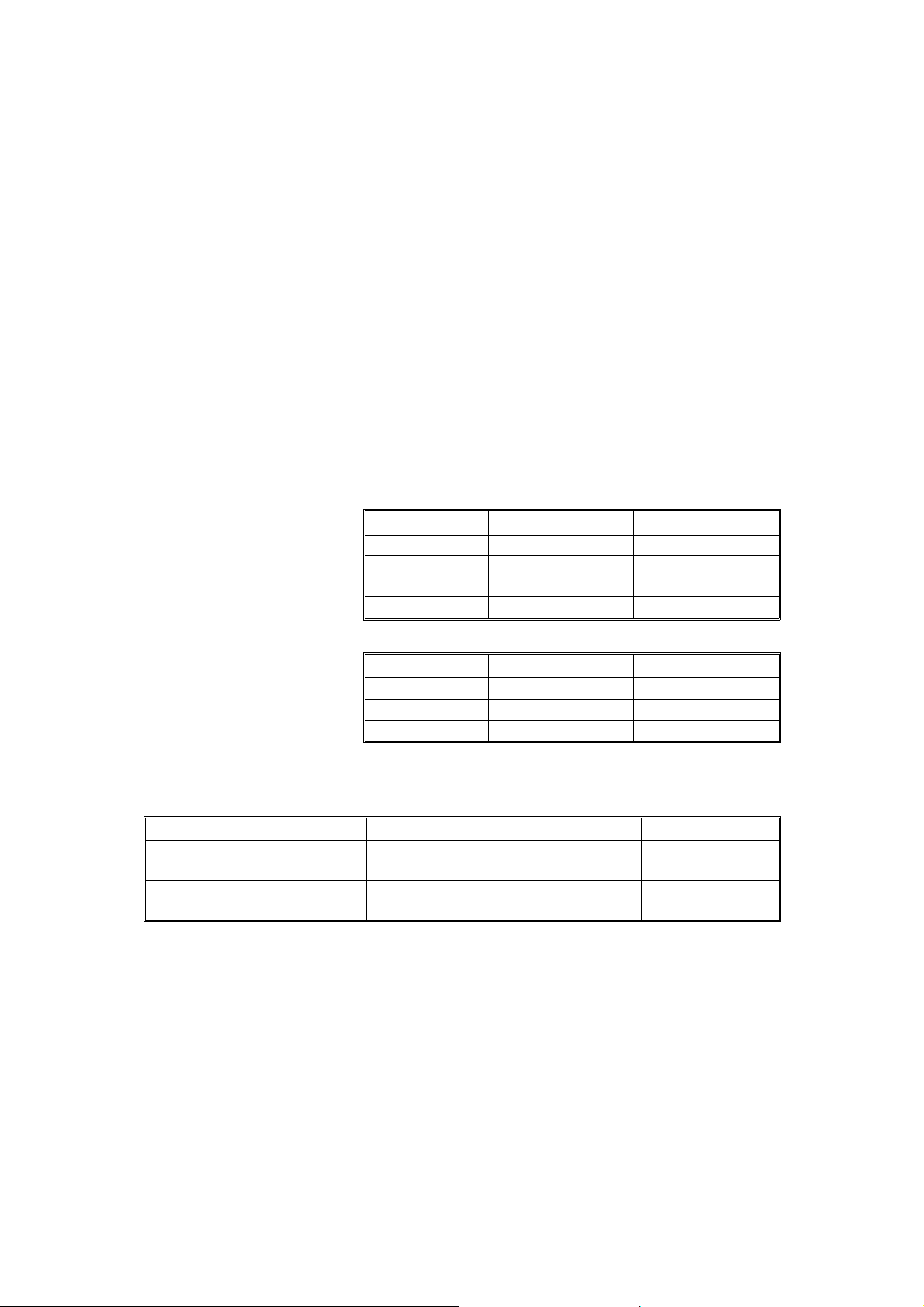

Power Consumptio n:

Copier Only With DF*

Maximum 1.4 kVA 1.5 kV A

Warm-up 620 VA (average) 640 VA (average)

Copy cycle 810 VA (average) 860 VA (average)

Ready 160 VA (average) 180 VA (average)

Noise Emission:

Copier Only With DF*

Maximum 58 db 60 db

Copy cycle Less than 55 db Less than 55 db

Ready Less than 39 db Less than 39 db

Dimensions:

Width Depth Height

Copier with platen cover and

copy tray

Copier with document feeder

and copy tray*

713 mm (28.1") 592 mm (23.3") 400 mm (15.7")

713 mm (28.1") 592 mm (23.3") 463 mm (18.2")

*NOTE: The document feeder can be installed only on the FT3213 copier.

FSM 1-2 A151/A152

Page 29

Weight: Copier only: 43 kg (94.8 lb)

With DF: 50 kg (110.2 lb)

Optional Equipment:

(Sales items)

Optional Equipment:

(Service items)

Document feeder (FT3213 copier only)

Key counter

Drum anti-condensation heater

Optics anti-condensation heater

Pre-transfer lamp

Optics cooling fan (for FT3013 copi er only)

• Specifications are subject to change without notice.

Model Designation: A151 = FT3013

A152 = FT3213

MACHINE

OVERALL

INFORMATION

FSM 1-3 A151/A152

Page 30

Page 31

GUIDE TO COMPONENTS

Page 32

Page 33

1. MECHANICAL COMPONENT LAYOUT

11

10

9

14

15

13

16

17

18

19

21 22 23

20

24 25

26

27

28

12

29

30

GUIDE TO

COMPONENTS

31

32

33

8

67

45

3

2

1

1. Semicircular Feed Rollers

2. Paper Tray

3. Registration Rollers

4. Transfer and Separation

Corona Unit

5. Pick-off Pawl

6. Cleaning Unit

7. Pressure Roller

8. Fusing Unit

9. Hot Roller

10. Exit Rollers

11. Copy Tray

12. Hot Roller Strippers

13. Exhaust Blower Motor

14. 3rd Mirror

15. 2nd Mirror

16. 1st Mirror

17. Ozone Filter

18. Used Toner Tank

19. Cleaning Blade

20. Quenching Lamp

21. Charge Corona Unit

22. Lens

23. 6th Mirror

24. Erase Lamp

25. Drum

26. 4th Mirror

27. 5th Mirror

28. Optics Cooling Fan Motor

(FT3213 Copier only)

29. Toner Supply Unit

30. Development Unit

31. 2nd Relay Rollers

32. By-pass Feed Table

33. 1st Relay Rollers

FSM 2-1 A151/A152

Page 34

2. ELECTRICAL COMPONENT LAYOUT

24

21

20

19

18

17

16

22

23

25

26

27

28

29

30

31

15

14

13

12

11

10

9

8

7

6

1. Paper Tray Switch

2. Relay Sensor

3. Registration Clutch

4. Optics Cooling Fan Motor

(FT3213 only)

5. Registration Sensor

6. Image Density Sensor

7. Power Pack-TC/SC

8. Operation Panel Board

9. Erase Lamp

10. Total Counter

11. Quenching Lamp

12. Fusing Lamp

13. Front Cover Safety Switch

14. Main Switch

15. Fusing Thermoswitch

16. Exit Sensor

17. Exhaust Blower Motor

18. Optics Thermofuse

5

4

3

19. Auto Image Density Sensor

20. Fusing Thermistor

21. Exposure Lamp

22. Lens Motor

(FT3213 copier only)

23. Scanner Home Position

Sensor

24. Optics Thermistor

25. Lens Home Position

Sensor

(FT3213 copier only)

26. Power Pack-CC/Grid/Bias

27. AC Drive Board

28. Fusing Triac (115 V only)

29. Scanner Motor

30. 4th/5th Mirror Home

Position Sensor

(FT3213 copier only)

31. 4th/5th Mirror Motor

(FT3213 copier only)

32. Main Motor Capacitor

2

1

32

33

34

35

36

37

38

33. Main Board

34. Main Motor

35. Toner Supply Clutch

36. DC Power Supply Board

37. Relay Roller Clutch

38. Paper Feed Clutch

A151/A152 2-2 FSM

Page 35

3. ELECTRICAL COMPONENT DESCRIPTIONS

Motors

SYMBOL NAME FUNCTION

Drives all the main unit components except for the

M1 Main Motor

M2 Scanner Motor Drives the scanners (1st and 2nd). (dc stepper) 29

M3 Lens Motor

M4

M5

M6

4th/5th Mirror

Motor

Optics Coo l i n g

Fan Motor

Exhaust Blower

Motor

optics unit and fans. (115/220–240 Vac [ac

synchronous])

Positions the lens according to the selected

magnification. (dc stepper)

…

FT3213 copier only

Positions the 4th/5th mirrors according to the

selected magnification. (dc stepper)

…

FT3213 copier only

Prevents built up of hot air in the optics cavity.

(24 Vdc)

…

FT3213 copier only

Removes heat from around the fusing unit and

moves the ozone built up around the charge

section to the ozone filter. (24 Vdc)

Magnetic Cl utch

SYMBOL NAME FUNCTION

MC1

Registration

Clutch

Drives the registration rollers. 3

INDEX

NO.

34

22

31

4

17

INDEX

NO.

GUIDE TO

COMPONENTS

Magnetic Spring Clutches

SYMBOL NAME FUNCTION

MSC1

MSC2

MSC3

Toner Supply

Clutch

Relay Roller

Clutch

Paper Feed

Clutch

Drives the toner supply roller. 35

Drives the 1st and 2nd relay rollers. 37

Starts paper feed. 38

INDEX

NO.

FSM 2-3 A151/A152

Page 36

Switches

SYMBOL NAME FUNCTION

SW1 Main Switch Supplies power to the copier. 14

SW2

SW3

Front Cover

Safet y Switch

Paper Tray

Switch

Cuts the ac power line, when the front cover is

open.

Detects when the paper tray is set. 1

Sensors

SYMBOL NAME FUNCTION

S1

S2

S3

S4

S5 Exit Sensor Detects misfeeds. 16

S6 Relay Sensor

S7

S8

Scanner Home

Position Sensor

Lens Home

Position Sensor

4th/5th Mirror

Home Position

Sensor

Registration

Sensor

Image Density

(ID) Sensor

Auto Image

Density Sensor

(ADS)

Informs the CPU when the 1st scanner is at the

home position.

Informs the CPU when the lens is at the home

position (full size position).

…

FT3213 copier only

Informs the CPU when 4th/5th mirrors assembly is

at the home position (full size position).

…

FT3213 copier only

1) Detects misfeeds.

2) Controls the relay roller clutch stop timing.

1) Detects when copy paper is set on the

by-pass feed table.

2) Detects misfeeds.

Detects the density of the image on the drum to

control the toner density.

Senses the background density of the original. 19

INDEX

NO.

13

INDEX

NO.

23

25

30

5

2

6

Printed Circuit Boards

SYMBOL NAME FUNCTION

PCB1 Main Board

PCB2 AC Drive Board

PCB3

PCB4

A151/A152 2-4 FSM

DC Power

Supply Board

Operation Panel

Board

Controls all copier functions both directly and

through the other PCBs.

Drives the main motor, exposure lamp, fusing

lamp, and quenching lamp.

Converts the wall outlet ac power input to +5 volts,

+24 volts, and a zero cross signal.

Informs the CPU of the selected modes and

displays the copier status and condition on the

panel.

INDEX

NO.

33

27

36

8

Page 37

Lamps

SYMBOL NAME FUNCTION

L1 Exposure Lamp

L2 Fusing Lamp Provides heat to the hot roller. 12

L3 Quenching Lamp

L4 Erase Lamp

Applies high intensity light to the original for

exposure.

Neutralizes any charge remaining on the drum

surface after cleaning.

Discharge the drum outside of the image area.

Provides leading/trailing edge erase and side

erase.

INDEX

NO.

21

11

9

Power Packs

SYMBOL NAME FUNCTION

P1

P2

Power Pack

–CC/Grid/Bias

Power Pack

–TC/SC

Provides high voltage for the charge corona, grid,

and development roller.

Provides high voltage for the transfer and

separation corona.

Counter

SYMBOL NAME FUNCTION

CO1 Total Counter Keeps track of the total number of copies made. 10

Others

SYMBOL NAME FUNCTION

TH1

TH2

TS

TF

C

TR Fusing Triac

Fusing

Thermistor

Optics

Thermistor

Fusing

Thermoswitch

Optics

Thermofuse

Main Motor

Capacitor

Monitors the fusing temperature. 20

Monitors the optics temperature. 24

Provides back-up overheat protection in the fusing

unit.

Provides back-up overheat protection around the

exposure lamp.

Start capacitor. 32

Switches the fusing lamp on and off. (115 V only)

Note: In the 220V-230V/240V version, the triac

is built-in the ac drive board

INDEX

NO.

26

7

INDEX

NO.

INDEX

NO.

15

18

28

GUIDE TO

COMPONENTS

FSM 2-5 A151/A152

Page 38

4. DRIVE LAYOUT

G13

G14

G15

G16

G17

G18

G19

G1: Ma in Mot or Gear

BP6 BP5

G22 BP1G21G20

G26

G25

TB2

TB3

TB1

BP2

G12 G11

G10

G23

G2G1

G9

G8

G7

G6

G5

G4

G3

BP4

BP3

G24

G9

G8

G2

G1

G2: Relay Gear

G23: Timing Belt Drive

Gear

BP1: Timing Belt Pulley

TB1: Timing Belt

A

G10 Relay gear

G11: Timing Belt Drive Gear

BP5: Timing Belt Pul le y

TB3: Timing Belt

Development Section

BP6: Timing Belt Pul le y

G12: Development Gear

Development Unit

G13: Relay Gear

G14: Toner Supply CL Gear

Toner Supply CL

Toner Supply Unit

G8: Relay Gear

G9: Relay Gear

B

Cleaning Unit

G3: Fusing Drive Gear

Fusing and Exit Unit

G4: Hot Roller Gear

G7: Relay Gear

G6: Relay Gear

G5: Exit Roller Gear

A151/A152 2-6 FSM

Page 39

G15: Registration CL

Gear

Registration CL

Registration Rollers

G20: Relay Gear

G17: Relay Roller CL

Gear

Relay Roller CL

G16: 2nd Relay Roller

Gear

A

Paper Feed Section

BP2: Timing Belt Pulley

G22: Relay Gear

Paper Feed Section

G21: Paper Feed CL

Gear

Paper Feed CL

Feed Rollers

B

G24: Timing Belt Drive

Gear

BP3: Timing Belt Pul ley

TB2: Timing Belt

BP4: Timing Belt Pul ley

G25: Relay Gear

G26: Drum Drive Gear

GUIDE TO

COMPONENTS

2nd Relay Rollers

G18: Relay Gear

G19: 1st Relay Roller

Gear

1st Relay Rollers

FSM 2-7 A151/A152

Page 40

Page 41

INSTALLATION

Page 42

Page 43

1. INSTALLATION REQUIREMENTS

1.1 ENVIRONMENT

1. Temperature Range: 10°C to 30°C (50°F to 86°F)

2. Humidity Range: 15% to 90% RH

3. Ambient Illumination: Less than 1500 lux (do not exposure to direct

sunlight)

4. Ventilation: Room of more than 20 m3. Room air should turn over at least

30 m3/hour/person.

5. Ambient Dust: Less than 0.15 mg/m3 (4 x 10-3 oz/yd3)

6. If the installation place is air-conditioned or heated, place the machine as

follows:

a) Where it will not be subjected to sudden temperature changes.

b) Where it will not be directly exposed to cool air from an air-conditioner

in the summer.

c) Where it will not be directly exposed to reflected heat from a space

heater in winter.

INSTALLATION

7 . Avoid placing the machine in an area filled with corrosive gas.

8. Avoid any places higher than 2000 meters (6500 feet) above sea level.

9. Place the machine on a strong and level base.

10. Avoid any area where the machine may be subjected to frequent strong

vibration.

1.2 MACHINE LEVEL

1. Front to back: Within 5 mm (0.2") of level

2. Right to left: Within 5 mm (0.2") of level

FSM 3-1 A151/A152

Page 44

1.3 MINIMUM SPACE REQUIREMENTS

10 cm (3.9")

30 cm (11.8")

70 cm (27.6")

60 cm (23.6")

1. Front: 70 cm (27.6")

2. Back: 10 cm (3.9")

3. Right: 60 cm (23.6")

4. Left: 30 cm (11.8")

NOTE: A space of at least 10cm (3.9") at the rear of the machine is

necessary for smooth air inlet into the machine.

1.4 POWER REQUIREMENTS

1. Input voltage level:

110 V/60 Hz : More than 15 A

115 V/60 Hz : More than 15 A (U.S. Version)

220–240 V/50 Hz : More than 8 A

220 V/60 Hz : More than 8 A

220 V/50 Hz : More than 8 A

2. Permissible voltage fluctuation: ±10%

3. Do not set anything on the power cord.

NOTE: a) Be sure to ground the machine. (Do not connect the

grounding wire to a gas pipe.)

b) Make sure the plug is firmly inserted in the outlet.

c) Avoid multi-wiring.

A151/A152 3-2 FSM

Page 45

2. INSTALLATION PROCEDURE

2.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box according to

the following list:

1. Copy Tray........................................................1

2. Envelope for NECR (–17 Only).......................1

3. NECR..............................................................1

4. Operating Instructions (Except –27) ...............1

5. Decal–Symbol Explanation.............................1

6. User Survey Card (–17 Only) .........................1

NOTE: (-17 = U.S. Version)

INSTALLATION

FSM 3-3 A151/A152

Page 46

2.2 COPIER INSTALLATION PROCEDURE

[B]

[A]

1. Remove the strips of tape from the copier as shown.

2. Pull out the paper tray [A], then remove the foam block [B] and tapes.

Close the paper tray.

A151/A152 3-4 FSM

Page 47

[B]

[A]

[H]

[G]

[F]

[C]

[F]

[E]

INSTALLATION

[D]

[I]

[J]

3. Open the platen cover [A] and remove the pieces of tape & the lock pins

[B]. (FT3013 copier: 2 pins, FT3213 copier: 4 pins)

NOTE: Save the lock pins for future shipping use.

4. Open the front cover [C], and remove the foam block [D].

5. Remove the shipping retainer [E] and tape & seal [F].

NOTE: Save the shipping retainer for future shipping use.

6. Open the upper unit [G] by pressing the release lever [H] (See "Caution:"

below). Gently remove the shipping spacers [I] from both ends of the

transfer/separation corona unit [J]. Remove the strip of tape [K] and

close the upper unit.

CAUTION: Be sure to place and hold your left hand on top of the

upper unit while pushing the release lever to the right with

your right hand. The upper unit will raise with force, and

holding the upper unit will prevent it from lifting too rapidly.

FSM 3-5 A151/A152

Page 48

[C]

[A]

[F]

[B]

[E]

[D]

[F]

7. Remove the two screws as illustrated above and pull out the

development unit [A] by pulling the left side of the development cover [B]

and place it on a clean sheet of paper.

[G]

8. Remove the toner supply unit [C] from the development unit [D] (2 gold

colored screws).

NOTE: Make sure to remove only the indicated screws.

9. Shake the developer package [E] well, and pour one pack of developer

into the development unit while rotating the gears [F] on both sides to

distribute the developer evenly as shown in the illustration.

NOTE: This copier is not equipped with a knob on the paddle roller shaft

like other machines. When installing new developer or manually

rotating the development roller, always make sure to turn the

gears in the direction shown in the illustration above. The copier

might be damaged if they are turned in the opposite direction.

10. Reinstall the toner supply unit on the development unit.

NOTE: Make sure that there is no gap [G] between the toner supply unit

and the development unit. (See illustration.)

A151/A152 3-6 FSM

Page 49

[B]

[C]

[A]

CN421

220 ∼230V

240V

[A]

INSTALLATION

[E]

[D]

11. Reinstall the development unit.

12. Shake the toner cartridge [A] well and insert the cartridge while pulling off

the seal [B].

NOTE: Position the cartridge as shown in the a bove illustr ation when

inserting into copier.

13. Close the front cover.

CAUTION: This procedure (step 14) must be done only in 240 volt

areas.

14. Perform the conversion from 220 ∼ 230 V to 240 V as follows:

1) Remove the upper rear cover [C] (2 screws).

2) Disconnect the short connector [D] (2P/White) on the ac drive board

[E] from CN421 and reconnect it to CN421 as shown in the illustration.

3) Reinstall the upper rear cover.

FSM 3-7 A151/A152

Page 50

4) Plug in the machine and turn on the main switch, then lower the platen

cover.

5) Enter the SP mode as follows:

a) Enter "71" using the numeral keys.

b) Press and hold the Clear/Stop key until a dot (•) appears in the top

left corner of the copy counter.

c) Release the Clear/Stop key and again press the Clear/Stop key.

d) Press the Lighter key.

6) Perform SP 12 as follows:

SP Mode Number Procedure

Enter "12" using the numeral keys. Then, press

the Auto Image Density key.

Conversion from

12

220 ∼ 230V to

240V.

Change the data from "0" to "1" using numeral

key.

Then, press the Auto Image Density key.

"12" will start blinking.

Go to the step 15. 3).

15. Perform the developer initial setting.

1) Plug in the machine and turn on the main switch, then lower the platen

cover.

2) Enter the SP mode as follows:

a) Enter "71" using the numeral keys.

b) Press and hold the Clear/Stop key until a dot (•) appears in the top

left corner of the copy counter.

c) Release the Clear/Stop key and again press the Clear/Stop key.

d) Press the Lighter key.

3) Perform SP 65 as follows:

SP Mode Number Procedure

Enter "65" using the numeral keys and press the

Developer Initial

65

Setting

Auto Image Density key. "50" will be displayed

in the copy counter. Press the Start key for

initial setting.

A151/A152 3-8 FSM

Page 51

[A]

[C]

[A]

[B]

INSTALLATION

[D]

[E]

16. Place the symbol explanation decal [A] on the platen cover as shown, or

when the DF [B] is installed on the machine, place the decal on the DF

as shown.

17. Install the copy tray [C].

18. Load paper into the paper tray [D] according to the instructions on the

paper tray.

19. Change the paper size plate [E] to display the correct paper size.

20. Check the machine operation and copy quality.

FSM 3-9 A151/A152

Page 52

2.3 KEY COUNTER HOLDER INSTALLATION (OPTION)

[D]

[C]

[E]

NOTE: To install the key counter holder, the following parts are required.

• Key counter bracket [A]

• Key counter harness [B]

• Two M3X6 sunken head screws [C]

1. Turn off the main switch.

2. Open the front cover.

3. Open the upper cover by pressing the release lever.

[F]

[B]

[A]

NOTE: Be certain to hold the upper unit while releasing.

4. Remove the right cover (2 screws).

5. Cut off the key counter cover on the right cover with a pair of pliers.

6. Remove the upper rear cover (2 screws).

7. Install the key counter harness [B] to CN121 on the main board.

8. Connect the 4P connector [D] of the key counter holder [E] to the key

counter harness [B] through the key counter access hole.

9. Position the key counter bracket [A] as shown in the illustration and

insert the key coun ter holder.

10. Align the holes in the key counter bracket with the mounting holes of the

key counter holder and secure the key counter holder (2 screws).

NOTE: The fixing plate has three different hole sizes. Use the holes that

match those on the counter that you are installing.

11. Cut the jumper wire (JP101) [F] with a pair of diagonal cutters or other

suitable tool.

12. Reinstall all covers.

A151/A152 3-10 FSM

Page 53

SERVICE TABLES

Page 54

Page 55

1. SERVICE REMARKS

1.1 GENERAL CAUTION

1. To prevent physical injury, keep hands away from the mechanical drive

components when the main switch is on (especiall y durin g the warm- up

cycle). If the Start key is pressed before the copier finishes the warm-up

cycle, (Start indicato r starts blinking) the copier starts making copies as

soon as the warm-up cycle is completed.

2. When the development unit, cleaning unit, drum unit or the DF is

removed from the machine, the upper unit becomes lighter. If the upper

unit is released under this condition, it tends to open very abruptly. The

service engineer might be injured if he is leaning over the machine at this

time. Also, the machine might move due to the shock of the upper unit

opening abruptly. To avoid possible injury or machine damage, hold the

upper unit firmly when opening the unloaded upper unit.

3. Even with the above mentioned components installed the upper unit can

open rather rapidly. Due to this possibility it is important to always hold

the upper unit with one hand when releasing it from the lower unit. It is

also important that the operator also be familiar with the proper method

of releasing the upper unit. This condition is not a concern if the DF is

installed to the FT3213.

4. Due to variation in the tolerance of the torsion springs, the upper unit

cannot hold at an angle of 16 degrees by itself when the DF is installed.

To avoid possible injury, always use the upper unit stand to keep the

upper unit open.

1.2 DRUM

The organic photoconductor drum is comparatively more sensitive to light

and ammonia gas than a selenium drum.

1. Never expose the drum to direct sunlight.

2. Never expose the drum to direct light of more than 1,000 Lux for more

than a minute.

3. Never touch the drum surface with bare hands. When the drum surface

is touched with a finger or becomes dirty, wipe with a dry cloth or clean

with wet cotton. Wipe with a dry cloth after cleaning with wet cotton.

4. Never use alcohol to clean the drum. Alcohol dissolves the drum surface .

5. Store the drum in a cool, dry place away from heat.

6. Take care not to scratch the drum as the drum layer is thin and can be

damaged.

TABLES

SERVICE

7. Never expose the drum to corrosive gases such as ammonia gas.

FSM 4-1 A151/A152

Page 56

8. Always keep the drum in the protective sheet when inserting or pulling

the drum unit out of the copier to avoid exposing it to bright light or direct

sunlight. This will protect the drum from light fatigue.

9. Before pulling out the drum unit, place a sheet of paper under the unit to

catch any spilled toner.

10. When installing a new drum, do the following:

a) Apply setting powder to the entire surface of the drum.

b) Perform the drum initial setting (SP66).

NOTE: This is not necessary at installation of a new machine as the

drum initial setting is performed at the factory.

c) Perform the Vsg adjustment (SP54).

11. Dispose of used drums according to local regulations.

1.3 CHARGE CORONA

1. Clean the corona wire by sliding the corona unit in and out. (The cleaner

pads come into contact with the corona wire when the corona unit is slid

all the way out.) The wire and casing can also be cleaned with water or

dry cloth. Do not use any abrasives or solvents.

2. Do not touch the corona wire and the grid plate with oily hands. Oil stains

may cause uneven image density on copies.

3. Make sure that the corona wire is correctly positioned between the

cleaner pads and that there is no foreign material on the casing.

4. When adjusting the charge corona current, always make sure that the

center of the drum shoe is aligned with the middle of the corona wires.

5. Clean the charge grid with a blower brush (not with a cloth).

6. The corona height should only be adjusted in the following two cases:

a) When the front end block is replaced

b) When the drum charge current is uneven

A151/A152 4-2 FSM

Page 57

1.4 OPTICS

1. The position of following parts are very difficult to adjust. Do not adjust

them.

a) 4th/5th Mirror Home Position Sensor

b) Lens Home Position Sensor

c) Lens and 4th/5th Mirror Guide Rails

NOTE: Before removing a sensor bracket to replace a sensor, mark the

position of the bracket. Check the copy image (magnification and

focus)to confirm that the sensor bracket has been properly

repositioned.

2. Clean the exposure glass with glass cleaner and a dry cloth to reduce

the amount of static electricity on the glass surface.

3. When reinstalling the exposure glass, make sure that the red mark on

the edge of the glass is positioned on the right hand side facing upward.

This side has received a special treatment to make it smoother and

generate less static electricity. This is especially important when the DF

is installed.

4. Clean the following parts with a dry cloth:

a) Lens and 4th/5th Mirror Guide Rails

b) Scanner Guide Plates

5. Only use a clean soft cloth damped with alcohol or water to clean the

mirrors and lens.

6. Do not touch the following parts with your bare hands:

a) Reflectors

b) Exposure Lamp

c) Mirrors and Lens

7. Whenever one of the actions listed bel ow need s to be perform ed, all the

following actions must be done in order.

a) Optics cleaning

b) SP95 (VL Correction Reset)

c) SP48 (Light Intensity Adjustment)

d) SP56 (ADS Reference Voltage Adjustment)

8. Do not adjust VR401 on the AC drive board.

TABLES

SERVICE

FSM 4-3 A151/A152

Page 58

1.5 DEVELOPMENT

1. Be careful not to nick or scratch the development roller sleeve.

2. Place the development unit on a sheet of paper after removing it from the

copier. This prevents any small metal objects (staples, paper clips,

E-rings, etc.) from being attracted to the development roller and getting

inside the unit.

3. Never loosen the two screws securing the bias terminal block. The

position of the terminal block is set with a special tool and instr ume nt at

the factory to ensure the proper gap between the drum and the

development roller.

4. Never loosen the three screws securing the doctor plate and the four

screws securing the doctor plate mounting bracket. The position of the

doctor plate is set with a special tool at the factory to ensure the proper

gap between the doctor blade and the development roller.

5. Clean the drive gears after removing used developer.

6 . Developer initial setting (SP65) is necessary when the developer is

replaced.

7. Dispose of used developer according to lo cal regula ti ons.

8. When installing new developer or manually rotating the development

roller, always make sure to turn the gears in the direction shown in Sec.

5 (Developer Replacement). The copier might be damaged if they are

turned in the opposite direct i on.

1.6 TONER SUPPLY

1. Clean the image density sensor with a blower bru s h.

2. Do not touch the sensor pattern with bare hands.

3. Image density sensor adjustment (Vsg Adjustment [SP54]) is required in

the following cases:

a) When the image density sensor is replaced

b) When the main board is replaced

c) When the drum has been replaced and Vsg is out of specification

d) When there have been problems with toner supply and Vsg is out of

specification

A151/A152 4-4 FSM

Page 59

1.7 TRANSFER AND SEPARATION

1. Clean the corona wires and casing with wat er or dry cloth.

2. When adjusting the corona current, always make sure that the center of

the drum shoe is aligned with the corona wire.

1.8 CLEANING UNIT

1. Be careful not to damage the edge of the cleaning blade.

2. After installing a new cleaning blade, be sure to apply setting powder

evenly on the surface and edge of the blade.

3. The bottom plate of the cleaning unit may be hot from the heat of the

fusing unit. Remove the unit by supporting your left hand on the cushion

attached under the bottom plate.

4. When inserting the cleaning unit into the copier, be sure that the cleaning

unit rail is properly engaged with the unit guide rail on the copier.

5. Empty the used toner tank every service call and clear the toner end

counter (SP58) by SP83 (toner end counter clear ) . Esp ecial ly, since the

FT3013 copier does not have side erasing by the erase lamp, the used

toner tank may become full in a faster period than expected under

certain conditions.

6. Do not perform toner end counter cl ear (SP83) without emp t ying the

used toner tank.

TABLES

SERVICE

7. Dispose of used toner according to local regulation s.

1.9 FUSING UNIT

1. Be careful not to damage the edges of the hot roller strippers or their

tension springs.

2. Do not touch the fusing lamp with bare hands.

3. Make sure that the fusing lamp does not touch the inner surface of the

hot rol ler.

FSM 4-5 A151/A152

Page 60

1.10 PAPER FEED

1. Do not touch the feed and relay rollers with oily hands.

2. A worn out registration roller can crease paper. Worn rollers should be

replaced.

3. The side fences and the end fence of the paper tray should be positioned

correctly so that they securely hold the paper. Otherwise, paper misfeeds

may occur.

1.11 DOCUMENT FEEDER

1. When installing or removing the document feeder, make sure that the

document feeder is in the open position.

2. A build-up of static electricity on the exposure glass can cause originals

to misfeed. Apply a small amount of silicon oil to the glass using a clean

cloth lightly dampened with silicon oil. This will reduce the amount of

friction.

1.12 OTHERS

1. When replacing the main board, remove the RAM pack from the old main

board and place it on the new main board. Then install the new main

board in the copier.

2. After installing a new main board with a new RAM pack, the Clear All

Memory (SP99) procedure (see page 4-10) must be performed. (Do not

perform SP99 if you have placed the old RAM pack on the new main

board.)

3. Never perform SP99 (Clear All Memory) except for the following two

cases:

a) When the copier malfunctions due to a damaged RAM pack.

b) When replacing the RAM pack.

4. Whenever SP99 (Cle ar All Mem or y) is perfor med , all the steps of the

procedure must be followed. Otherwise, copy quality might be seriously

affected.

5. When replacing a sensor, do not overtight en the screws. Thi s may

damage the sensor.

6. If a customer reports that red image areas on the original do not appear

on the copy, instruct the customer to select the desired image density by

the Manual Image Density keys.

A151/A152 4-6 FSM

Page 61

7. Tighten securely the screws used for grounding the following PCBs

when reinstalling them.

• AC Drive Board • DC Power Supply Board

• TC/SC Power Pack • CC/Grid/Bias Power Pack

8. The RAM pack must be handled as follows:

WARNING: The RAM pack has a lithium battery which can explode if

handled incorrectly. Replace only with the same type RAM

pack. Do not recharge, or burn this battery. Used RAM

pack must be handled in accordance with local

regulations.

TABLES

SERVICE

FSM 4-7 A151/A152

Page 62

2. SERVICE PROGRAM MODE

2.1 SERVICE PROGRAM MODE OPERATION

The service program (SP) mode is used to check electrical data and change

modes or adjustment values.

2.1.1 Service Program Access Procedure

There are two ways to access an SP mode.

(1) By the operation panel

(2) By turning on DPS101-2 on the main board

All SP modes except for SP98, and SP99 can be accessed by key operation.

When accessing SP98, and SP99, JPS101-C must be short-circuited.

Access Procedure 1–Using The Oper ation Panel

1. Turn on the main switch.

2. Enter "71" by using the numeral keys.

3. Press and hold the Clear/Stop key until a dot (•) appears in the top left

corner of the Copy Counter and then release it.

4. Press the Clear/Stop key again and then press the Lighter key.

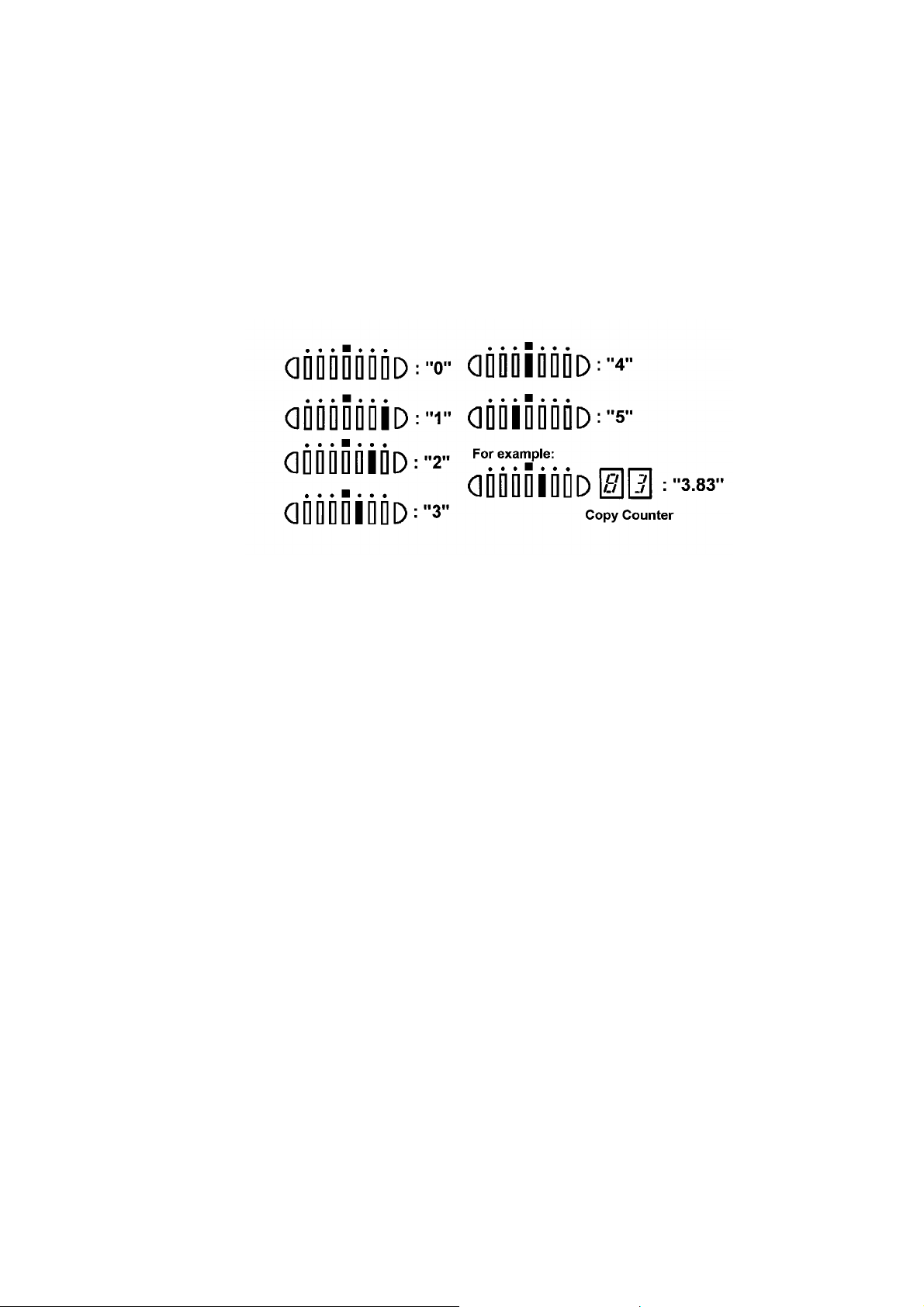

NOTE: "5" will blink in the Copy Counter to show that the SP mode has

been accessed.

5. Enter the desired SP mode number using the numeral keys. The SP

mode numbers are given in the Service Program Mode Table.

NOTE: "•" is displayed instead of "1" in the Copy Counter when SP

mode numbers over "100" ar e entered. The maximum number is

"127".

6. Press the Auto Image Density key to view the data.

NOTE: To enter a different SP mode number, press the Auto Image

Density key again.

7. To leave SP mode, open and close the front cover or turn the main

switch off and on.

A151/A152 4-8 FSM

Page 63

Access Procedure 2 - Using DPS101-2

1. Turn the main switch off.

2. Remove the upper rear cover and turn on DPS101-2, then turn on the

main switch. "5" will blink in the Copy Counter.

3. Enter the desired SP mode number by the numeral keys. SP mode

numbers are given in the Service Program Mode Table.

4. Press the Auto Image Density key to view the data.

5. To leave SP mode, turn off DPS101-2.

NOTE: To cancel an already entered SP mode, press the Auto Image

Density key.

2.1.2 Change Adjustment Values or Modes

1. Follow the steps from 1 to 6 in Access Procedure 1 or the steps from 1 to

4 in access procedure 2.

2. The factory-set or the default setting will be displayed in the

Magnification indicator (FT3213 copier) or in the Copy Counter (FT3013

copier).

3. Enter the desired value or mode using the numeral keys and then press

the Auto Image Density key. (SP mode data are given in the Service

Program Mode Table.)

4. To leave SP mode, open/close the front cover or turn off/on the main

switch (Access Procedure 1) or turn off DPS 101-2 (Access Procedure 2).

TABLES

SERVICE

FSM 4-9 A151/A152

Page 64

2.1.3 Memory Clear Procedure

– Clear Counters (SP98) –

NOTE: This SP mode clears the following counters:

• SP88: PM Counter Display

• SP100: By-pass Feed Copies

• SP101: Paper Tray Copies

• SP103: Total Copi es

• SP106: DF Originals

• SP110: Total Misfeed s

• SP111: Number of Misfeeds by Location

• SP120: Total Service Calls

• SP121: Optics Section Service Calls

• SP122: Exposure Lamp Se rvice Cal ls

• SP124: Fusing Section Service Calls

• SP125: DF Communication Service Calls

1. Turn off the main switch.

2. Turn on DPS101-2 and short-circuit JPS101-C (Lower).

3. Turn on the main switch.

4. Enter "98" by the numeral keys and then press the Auto Image Density

key to view data.

5. Enter "1" by the numeral key and then press the Auto Image Density key.

NOTE: The data "1" blinks 4 times when the above procedure is

completed.

6. Turn off the main switch.

7. Turn off DPS101-2 and open-circuit JPS101-C (Lower).

A151/A152 4-10 FSM

Page 65

– Clear All Memory (SP99) –

CAUTION: Memory all clear mode (SP99) clears all the correction data

for process control and software counters, and returns all

the modes to the default settings. Normally, SP99 should

not be used.

This procedure is required only when the copier

malfunctions due to a damaged RAM Pack or when

replacing the RAM Pack for any reason.

1. Turn off the main switch.

2. Turn on DPS101-2 and short-circuit JPS101-C (Lower).

3. Turn on the main switch.

4. Enter "99" by the numeral keys and then press the Auto Image Density

key to view data.

5. Enter "1" by the numeral key and then press the Auto Image Density key.

NOTE: The data "1" blinks 5 times when the above procedure is

completed.

6. Clean the used toner tank since the toner end counter has been cleared.

(See Used Toner Removal.)

CAUTION: Skipping this step will cause the used toner overflow

condition not to be detected properly.

7. Replace the OPC drum with a new one. (See Drum Replacement.)

CAUTION: Since the drum motor rotation time (SP57) for the drum

wear correction has been cleared, the old drum cannot be

used. If the old drum is used after all memory is cleared,

dirty background may occur.

8. Load new developer. (See Developer Replacement.)

NOTE: Since the software counter for the development bias voltage in

the toner detection cycle has been cleared, –20 volts will be

applied to the development roller for the initial 499 copies.

9. Clean the optics, sensors, and inside of the copier if necessary.

10. Refer to the "FACTORY SETTING" table located inside the upper slit of

the inner cover and enter the data for:

(1) SP60: Standard Image Grid Voltage Setting

(2) SP62: Standard ID Sensor Grid Voltage Setting

TABLES

SERVICE

FSM 4-11 A151/A152

Page 66

10. Perform the following SP modes in sequence:

(1) SP66: Drum Initial Setting

(2) SP65: Developer Initial Setting

(3) SP48: Light Intensity Adjustment

(4) SP56: ADS Voltage Adjustment

(5) SP54: Vsg Adjustment

(6) SP42: Registration Adjustment

(7) SP41: Leading Edge Erase Mar gin Ad justm ent

(8) SP43: Vertical Magnification Adjustment

(9) SP44: Horizontal Magnification Adjustment (FT3213 copier only)

(10) SP47: Focus Adjustment (FT3213 copier only)

11. Turn off the main switch.

12. Turn off DPS101-2 and open-circuit JPS101-C (Lower).

A151/A152 4-12 FSM

Page 67

2.2 SERVICE PROGRAM MODE TABLE

Rev. 1/26/96

1. A "❐" after the mode name means that copies can be made while in the

SP mode. (Copies can be made by pressing the Start key after pressing

the Auto Image Density key.)

2. In the

3. In the

Function

Data

column, comments (extra information) are in italics.

column, the default value is printed in bold letters.

4. In some SP modes, data display is different between the FT3013 and

FT3213 models because of the difference in the operation panel. After

entering the desired SP mode number, refer to the notes written at the

end of the table to correctly observe the displayed data. (Which note to

refer is described inside the Function column.)

Mode No. Function Data

⇒

5 Exposure Lamp

❐

OFF

6 Misfeed

Detection Off

7 Aging Mode Factory use.

8 Input Check

9 Output Check Electrical components turn on. For data, see

11 All Indicators

ON

12 220-230V /240V

Conversion

14 Auto "OFF" Auto-off mode can be selected

15 Auto Reset

Time (Energy

Saver Mode)

16 Count Up/Down Selects count up or count down.

17 Open No function.

18 Reduce/Enlar ge

Key Function

(FT3213 copier

only)

Exposure lamp OFF

Turn on DPS101-1, then press the Start key to

start free run. Press the C/S key to stop free run.

Press the Auto Image Density key in Ready

mode to turn off this mode.

Use this mode for the scanner movement check.

To save toner, remove the development unit.

Copies are made without misfeed detection.

Press the Start key to make a copy. Press the

❐

Auto Image Density key in Ready mode to turn

off this mode.

Use this mode to check whether the paper

misfeed was caused by a sensor malfunction.

The total counter increments when copies are

made in this mode.

❐

Displays the input data from sensors and

switches.

Turns on all the indicators on the operation panel.

To turn off the indicators, press the Auto Image

Dens ity k ey.

Selects 220-230 or 240 volts.

If the rated voltage is 240V, this data must be

changed to "1".

Selects auto reset time of 1 or 3 minutes, or

cancels this mode.

The copier automatically goes to the energy

saver mode at the selected reset time when

SP78 is set to "1".

Specifies whether reduction or enlargement is

selected first when the Reduce/Enlarge key is

pressed.

Refer to NOTE 2.

For data, see

page 4-20.

page 4-21.

0: 220-230V

1:240V

0: 30 mins

(default)

1: 15 mins

2: 1 hour

3: 1.5 hours

4: 2 hours

0: 1 min.

1: 3 min.

2: None

0: Up

1: Down

0: Reduction

1: Enlargement

TABLES

SERVICE

FSM 4-13 A151/A152

Page 68

Mode No. Function Data

19 ADS Priority Specifies whether the copier defaults to ADS or

manual mode when the main switch is turned on.

29 Fusing

Temperature

Control

Selects fusing temperature control mode.

After selecting the control mode and turning the

main switch off/on, the fusing temperature

control is changed.

30 Toner Supply

Mode

31 Toner Supply

Ratio

(Detect Mode)

32 Toner Supply

Ratio

(Fixed Mode)

33 ID Sensor Bias Sets the bias voltage applied to the development

Selects toner supply system.

See SP31/SP32 for toner supply amount.

Determines how much toner is supplied in detect

mode.

Determines how much toner is supplied in fixed

mode.

roller for the ID Sensor Pattern.

0: Vo

1: Vo+40V

2: Vo–20V

3: Vo–40V

34 ADS Level Selects the image density level in ADS mode.

Data: 1

Increases grid voltage (–40V). Development bias

voltage is not changed.

Data: 2

Increases development bias voltage (–40V). Grid

voltage is not changed.

35 ID Detec ti o n

Interv a l

ID sensor check is performed every 5 copies or

10 copies.

If low image density occurs in the near end

condition, change the data to "1".

37 Image Bias

Adjustment

Adjusts image bias output if the image density at

level 4 cannot be adjusted by Light Intensity

adjustment (SP48).

0: Vo

1: Vo+40V

2: Vo+20V

3: Vo–20V

4: Vo–40V

39 Ex posure LampONFactory use.

0: ADS

1: Manual

0: ON/OFF

control

1: Phase control

0: Detect Mode

1: Fixed Mode

0: 15%

1: 7%

2: 30%

3: 60%

0: 7.0%

1: 3.5%

2: 10.5%

3: 14.0%

Toner Density

0: Normal (Vo)

1: Low

2: High

3: Higher

0: Normal

1: Darker

2: Lighter

0: 10 copies

1: 5 copies

0: Normal (Vo)

1: Darkest

2: Darker

3: Lighter

4: Lightest

41 Lead Edge

Erase Margin

Adjustment

42 Registration

Adjustment

43 Vertic al

Magnification

Adjustment

A151/A152 4-14 FSM

Adjusts the lead edge erase margin. 0–15

0.4 mm per step. (–3.2 mm to +2.8 mm)

❐

Adjusts registration. 0–15

❐

0.4 mm per step. (+3.2 mm to –2.8 mm)

Adjusts magnification in the paper travel

direction.

❐

0.2% per step. (–1.6% to +1.4%)

Default = 8

Default = 8

0–15

Default = 8

Page 69

Mode No. Function Data

44 Horizontal

Magnification

Adjustment

(FT3213 copier

❐

only)

45 Registration

Buckle – Paper

❐

Feed

47 Focus

Adjustment

(FT3213 copier

❐

only)

48 Light Intensity

Adjustment

Adjusts magnification perpendicular to the

direction of paper travel.

0.2% per step. (–1.6% to +8.4%)

Adjust the amount of paper buckle in registration

area.

0.4 mm per step. (–3.2 mm to +2.8 mm)

Adjusts the 4th/5th mirror position to correct

focus.

This mode must be done after horizontal and

vertical magnification adjustment (SP43 and 44).

Adjusts the exposure lamp voltage. 100–145

❐

Before performing this mode, clean the optics

and perform SP95. After performing this mode,

perform SP56. The exposure lamp voltage is

adjusted on the production line.

Refer to NOTE

3 for FT3013 copier.

50 Image Bias

Adjustment at

ID Level 7

❐

Adjusts image bias voltage at ID level 7.

0: Vo

1: Vo+40V

2: Vo–40V

3: Vo–80V

51 Ex posure Lamp

Data Display

Displays the exposure lamp data with a

reference number.

The exposure lamp, and optics cooling fans turn

on for 10 seconds when the Auto Image Density

key is pressed. Press the C/S key to turn this

mode off. Do not repeat more than 5 times to

avoid overheating the optics cavity.

Refer to

NOTE 3 for FT3013 copier.

52 Fusing

Temperature

Display

54 Vsg Display Displays Vsg.

Displays the fusing temperature.

Refer to NOTE 3 for FT3013 copier.

Adjust Vsg to 4.0 ± 0.2 V using VR102 on the

main board. The main motor and the ID sensor

LED turn on when the Auto Image Density key is

Refer to NOTE 4 for FT3013 copier.

55 Vsg & Vsp

Display

❐

pressed.

Displays the Vsg and Vsp readings.

The Vsg reading is displayed while the "0" key is

held down. FT3013 copier displays the Vsp

reading while the "1" key is held down. To stop

this mode, press the C/S key.

The Vsp and Vsg voltage readings are updated

every 10 or 5 copies depending on SP35

selection. In free run mode, the Vsg and Vsp

readings are updated every copy cycle.

Refer to

NOTE 4 for FT3013 copier.

0–50

Default = 8

0–15

Default = 8

0–100

Default = 40

Default = 126

0: Normal (Vo)

1: Darker

2: Lighter

3: Lightest

100–150

TABLES

SERVICE

FSM 4-15 A151/A152

Page 70

Mode No. Function Data

56 ADS Reference

Voltage Display

Displays ADS reference voltage.

Before performing this mode, clean the optics,

perform SP95 and SP48.

After adjusting the light intensity (SP48), place 5

sheets of A3 (LDG) white paper on the exposure

glass and select this mode. Adjust ADS voltage

to 2.5

0.1 V using VR101 on the main board.

±

Refer to NOTE 4 for FT3013 copier.

57 Drum Rotation

Time

Displays the total time that the drum has rotated.

"Minute" is displayed first. Press and hold the

Lighter key to display "Hour".

58 Toner End

Counter

Displays the toner end condition count.

The toner end counter counts up 1 after 200

copies are made following toner cartridge

replacement.

59 Open No function.

60 Standard

Image Grid

Voltage Setting

61 Standard ID

Sensor Bias

Voltage Setting

62 Standard ID

Sensor Grid

Voltage Setting

63 Open No function.

64 Toner Density

Level Display

Factory use.

Do not change data.

Refer to NOTE 6.

Factory use.

Do not change data.

Factory use.

Do not change data.

Refer to NOTE 6.

Displays the toner density level detected by

initial setting (SP65).

Data Vsp/Vsg(%)

0: 12–15

1: 0–7

2: 8–11

3: 16–21

4: 22–100

65 Developer

Initial Setting

Agitates new developer for about 5 minutes.

"50" is displayed on the copy counter when the

Auto Image Density key is held down. Press the

Start key to start the initial setting.

Initial setting must be done when new

developer is installed.

The copier automatically returns to normal mode

after initial setting is completed.

66 Drum Initial

Setting

Used to set new drum condition.

Initial setting must be done when a new drum

is insta lled.

The Drum Rotation Time (SP57) and the OPC

counter (SP69) are cleared.

0–8

Default = 4

0–8

Default = 2

0–8

Default = 4

0–4

0: No

1: Yes

A151/A152 4-16 FSM

Page 71

Mode No. Function Data

67 Vr Ratio Display Displays the present Vr ratio. 0–100

L = Vrp/Vsg x 100

L (%) Grid voltage

100 to 84 Vo

83 to 58 Vo–40V

57 to 41 Vo–80V

40 to 28 Vo–120V

27 to 0 Vo–160V

Refer to NOTE 3 for FT3013 copier.

68 Vr Forced

Detection

Detects Vrp and perform Vr correction.

1. Turn off the DPS 101-2 after pressing the

0: No

1: Yes

Auto

Image Density key if it is on.

2. Make 5 copies.

69 OPC Counter Shows the total number of copies made with the

drum installed on the machine.

Refer to NOTE 5.

78 Auto Energy

Saver Mode

79 Fusing

Temperature

Adjustment

(Maximum

temperature

during copying)

80 Open No function.

83 Toner End

Counter Clear

Selects the "Automatic Energy Saver" mode.

The copier automatically goes to Energy Saver

mode at the auto reset time selected (SP15).

Adjusts the maximum temperature of the hot

roller during copying.

188°C to 202°C in 1°C steps.

Refer to NOTE 3 for FT3013 copier.

Clears the toner end counter (SP58). Resets the

used toner overflow condition (E70) if it is

detected.

0: No

1: Yes

188–202°C

Default=198°C

0: No

1: Yes

This mode must be performed when the used

toner tank is cleaned.

86 Ener gy Saving

Ratio

Selects energy saving ratio.

The greater the saving ratio, the longer the

waiting time until the copier returns to the ready

condition.

0: 56%

1: 47%

2: 37%

3: 25%

Saving Ratio Waiting Time

0: 56% 25 sec.

1: 47% 19 sec.

2: 37% 12 sec.

3: 25% 5 sec.

87 PM Interval

Setting

88 PM Counter

Display

Sets the interval of the PM counter.

Displays contents of the PM counter.

Refer to NOTE 5.

When the PM counter

0: No PM

1: 40K

2: 60K

3: 80K

4: 100K

exceeds to the selected setting of SP87, the

Magnification indicator (FT3213 copier) or the

Copy Counter (FT3013 copier) blinks.

89 PM Counter

Clear

Resets the PM counter.