Ricoh FT2260 Service manual

FT2260

RICOH COMPANY, LTD.

SERVICE MANUAL

Table of Contents

OVERALL MACHINE INFORMATION

1. SPECIFICATIONS.............. . . . . . . . . . . . . . . . . . . . . . . ...1-1

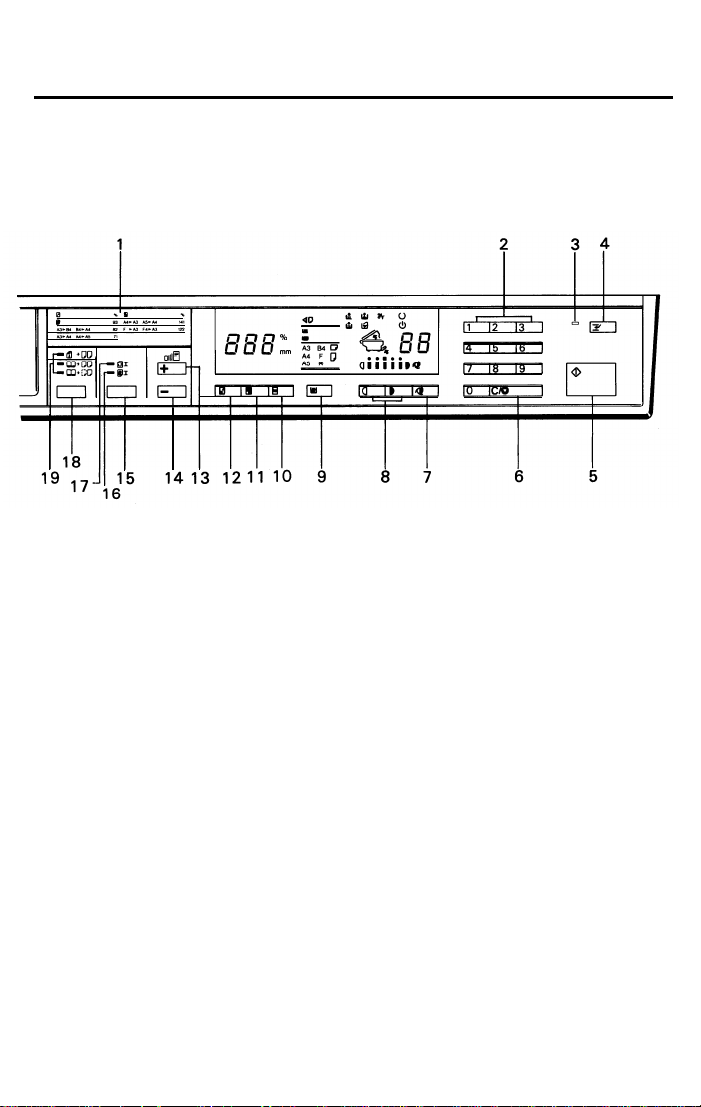

2. OPERATION PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

2.1 KEYS AND LABELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1-4

2.2 INDICATOR SCREEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1-6

3. COPY PROCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

4. FUNCTIONAL OPERATION ......

5. COPY CYCLE ....

■✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎

1-10

1-11

6. MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . ...1-15

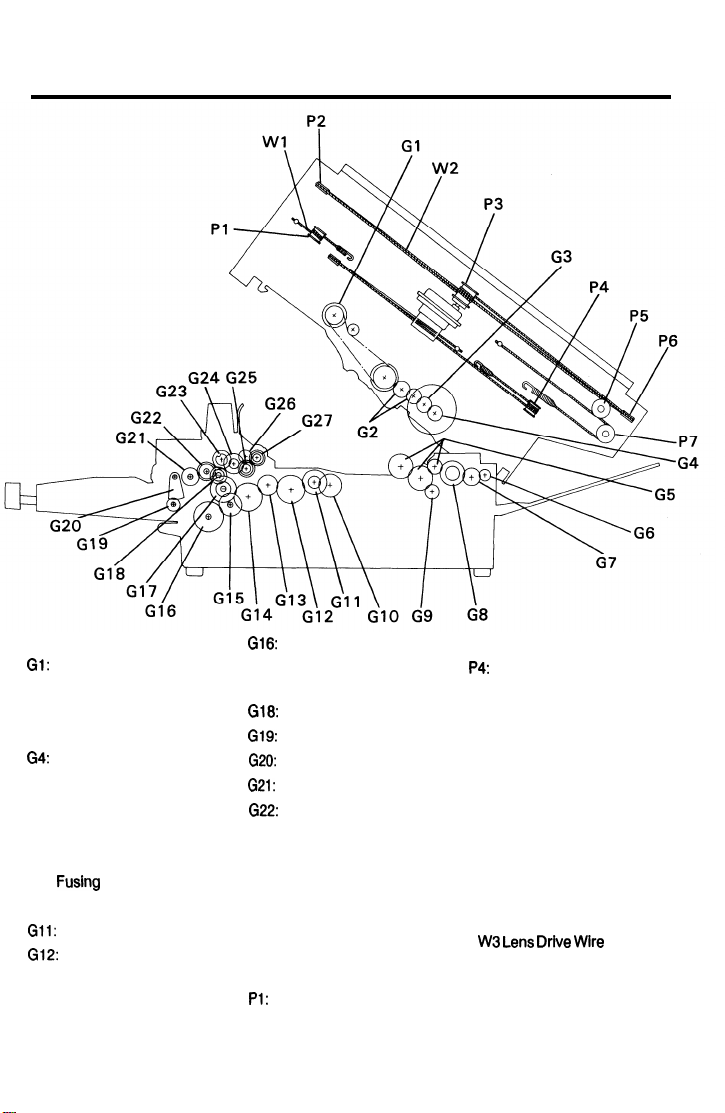

7. DRIVE LAYOUT

1-16

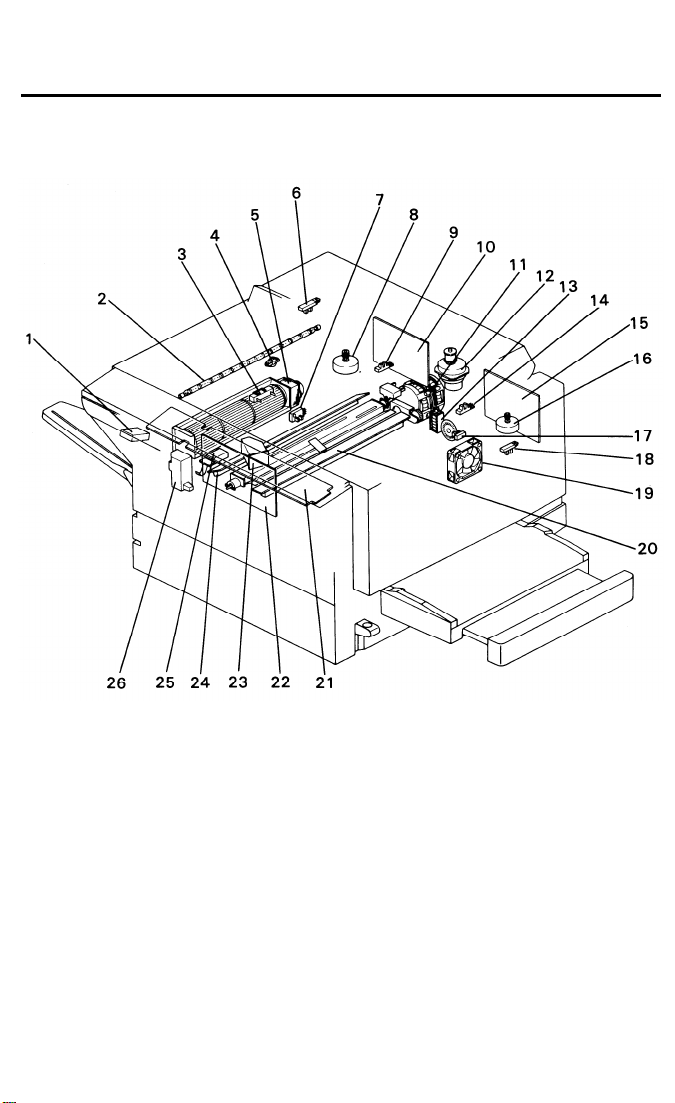

8. ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . ...1-17

8.1 UPPER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1-17

8.2 LOWER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1-18

9. ELECTRICAL COMPONENT DESCRIPTIONS . . . . . . . . . . . . ...1-19

10. OVERALL MACHINE CONTROL . . . . . . . . . . . . . . . . . . . . . . ...1-22

11. AC POWER DISTRIBUTION. . . . . . . . . . . . . . . . . . . . . . . . . . ...1-23

12. DC POWER DISTRIBUTION. . . . . . . . . . . . . . . . . . . . . . . . . . ...1-24

DETAILED SECTION DESCRIPTIONS

1.MASTER UNIT . . . . .

1.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-1

1.2 MASTER SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-2

1.3 MASTER SENSOR CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-3

1.4 DRlVE MECHANlSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-4

1.5 MASTER SOLENOID CIRCUIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-5

1.6 SERVlCE CALL CONDlTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-5

2-1

2.CHARGE . .

2.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-6

2.2 CHARGE CORONA ClRCUlT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-7

2-6

3.EXPOSURE

3.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-8

3.2 EXPOSURE LAMP CONTROL ClRCUlT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-9

3.3 SCANNER DRIVE MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-11

3.4 SCANNER DRIVE CIRCUIT . . . . . . . . . . . . . . . . . . . . . .... . . . . . . . . . ...2-12

3.5 LENS DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-13

3.6 LIGHT SHADING MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-14

3.7 MIRROR DRIVE MECHANISM.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-15

3.8 STEPPER MOTOR CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-16

3.9 AUTOMATIC IMAGE DENSITY CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-17

3.10 AUTO ID EXPOSURE CORRECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..2-18

3.11 REDUCTION/ENLARGEMENT EXPOSURE CORRECTION . . . . . . . . . . . . . ...2-19

3.12 SERVlCE CALL CONDITIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-20

4. ERASE

4.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-22

4.2 LEADING AND TRAILING EDGE ERASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

4.3 SIDE ERASE . . . . . . . . . . . . . . . . . . . . . . . . .. ..... . . . . . . . . . . . . . . . . . . ...2-24

4.4 ERASE LAMP CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-26

2-8

2-22

5. DEVELOPMENT . . . ........ . . . . .. . . . . .. . ... .. ..2-27

BLACK DEVELOPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-27

5.1

5.1.11ntroduction . . . . . . . ..... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-27

5.1.2 BIack FerriteToner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-27

5.1.3 Development Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-28

5.1.4Toner Metering Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-28

5.2 COLOR DEVELOPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-29

5.2.1 ColorToner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-29

5.2.2 Color Development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-29

5.2.3 Color Development Roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-30

5.3 BIAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-31

5.3.1 Black Development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-31

5.3.2 Color Development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-31

5.4 DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-32

5.5 TONER END MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-33

5.6 DEVELOPMENT COVER MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..2-34

5.7 BIAS ClRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-35

5.8 TONER END SENSOR ClRCUlT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-36

6. TRANSFER AND IMAGE SEPARATION . . . . . . . . . . . . . . . . . ...2-37

6.1 OVERVlEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-37

6.2 TRANSFER CORONA CIRCUIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-38

7.CLEANING..

7.1 OVERVlEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-39

7.2 TONER OVERFLOW DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-40

7.3 TONER OVERFLOW DETECTION CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-41

2-39

8.QUENCHING

8.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-42

8.2 Quenching LAMP ClRCUlT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...243

2-42

9. PAPER FEED AND REGISTRATION . . . . . . . . . . . . . . . . . . . . ...2-44

9.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-44

9.2 CASSETTE FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-45

9.2.1 Paper Feed System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-45

9.2.2 Cassette Feed Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-46

9.2.3 Cassette Tray Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-47

9.3 PAPER TRAY FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-48

9.3.1 Paper Tray Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-48

9.3.2 Paper Tray Feed Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-50

9.3.3 Tray Feed Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-51

9.3.4 Pick-up Clutch Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-52

9.4 RELAY FEED AND REGlSTRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-54

9.5 PAPER SIZE DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-55

9.5.1 Cassette Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-55

9.5.2 Cassette Paper Size Detection Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-56

9.5.3 Paper Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-57

9.5.4 Tray Paper Size Detection Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-58

9.6 PAPER FEED CONTROL CIRCUlT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-59

10. IMAGE FUSING

10.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-60

10.2 DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-61

10.3 FUSING CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-62

2-60

10.4 FUSING LAMP CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..2-64

5. GENERAL SERVICE TABLES ..... . . . . . .

10.5 EXIT SENSOR CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-66

10.6 SERVICE CALL CONDITIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-67

11. OTHER COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-68

11.1 SAFETY SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-68

11.2 JAM SENSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-69

11.3 OPERATION PANEL ClRCUlT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-70

11.4 PULSE GENERATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-71

11.5 SERVICE CALL CONDITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-71

11.6 DATA BACK-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-72

11.7 COUNTER ClRCUITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-73

INSTALLATION

1. ENVIRONMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-1

2. MINIMUM SPACE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . ...3-2

3. POWER SOURCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-3

4.ACCESSORY CHECK ..................

5. INSTALLATION PROCEDURE

3-4

3-5

6. KEY COUNTER HOLDER INSTALLATION . . . . . . . . . . . . . . . ...3-12

7. CASSETTE MODIFICATION.. . . . . . . . . . . . . . . . . . . . . . . . . . ...3-13

8. TRANSFORMER CONVERSION (220-240V) . . . . . . . . . . . . ...3-14

9. PREPARATION FOR TRANSPORTATION . . . . . . . . . . . . . . . . ...3-15

9.1 SHORT HAUL TRANSPORTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-15

9.2 LONG HAUL TRANSPORTATION BY VEHICLE . . . . . . . . . . . . . . . . . . . . . . . ...3-16

SERVICE TABLES

1. MAINTENANCE GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-1

2. MAINTENANCE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-2

3. LUBRICATION TABLE . .

4. EXPECTED LIFE OF PARTS

4-4

4-5

4-6

5.1 TEST POINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-6

5.1.1 Main PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-6

5.1.2 AC Drive PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-6

5.1.3 DF Main PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-6

5.2 VARIABLE RESISTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....4-7

5.2.1 Main PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-7

5.2.2 Power Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-7

5.2.3 Master Sensor(Erase LampUnit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-7

5.2.4 DF Main PUB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-7

5.3 DIP SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-8

5.3.1 Main PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-8

5.3.2 Optics PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-8

5.3.3 DF PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-9

6.TEST MODE

4-10

7. SERVICE REMARKS . . . . . . . . . . . . .......

7.1 MASTER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-11

7.2 CHARGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-11

7.3 OPTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-11

7.4 DEVELOPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-12

7.5 TRANSFER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-12

7.6 PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-12

7.7 FUSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-12

8.SPECIALTOOLS AND LUBRICANTS

● mmmmmmm ■ mmm*mmm ● mmmmm

4-11

4-13

REPLACEMENT AND ADJUSTMENT

1. EXTERIOR . . .

1.1 UPPER CLAMSHELL COVER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..5-1

1.1.1 Platen Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-1

1.1.2 Upper Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-1

1.1.3Upper Right Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-1

1.1.4 Upper Left Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-1

1.1.5 InnerCover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-2

1.1.6 Operation Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-2

5-1

1.1.7Upper Rear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-2

1.1.8 Copy Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-2

1.2 LOWER CLAMSHELL COVER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..5-3

1.2.1 Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-3

1.2.2 CassetteTray Cover.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-3

1.2.3 Paper Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-3

1.2.4Lower Right Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-3

1.2.5Lower Rear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-4

1.2.6Lower Left Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-4

1.2.7 Exit Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-4

2. OPTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-5

2.1 EXPOSURE GLASS REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-5

2.2 ERASE LAMP UNIT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-6

2.3 EXPOSURE LAMP REPUCEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-7

2.4 EXPOSURE LAMP POSlTION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-9

2.4.1 -Horizontal Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-9

2.4.2 -Vertical Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..5-10

2.5 SCANNER DRIVE WIRE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

2.6 LENS DRIVE WIRE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-13

2.7 LENS DRIVE MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..5-15

2.8 MIRROR DRIVE WIRE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..5-16

2.9 MIRROR DRIVE MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17

2.10 5TH MIRROR REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-18

3. DEVELOPMENT and QUENCHING . . . . . . . . . . . . . . . . . . . . . ...5-19

3.1 TONER METERING BLADE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . ...5-19

3.2 QUENCHING LAMP REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-20

4. PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-21

4.1 CASSETTE FEED ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-21

4.2 CASSETTE FRICTION PAD REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . ...5-22

4.3 PlCK-UP ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-23

4.4TRAY FEED ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..5-24

4.5 CASSETTE FEED CLUTCH LUBRlCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

4.6 PlCK-UP AND TRAY FEED CLUTCH LUBRICATION . . . . . . . . . . . . . . . . . . . ...5-27

4.7 REGlSTRATION CLUTCH LUBRlCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-28

4.8 PAPER SIZE SWITCH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-29

8.4 TONER OVERFLOW SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . ...5-58

4.9 PAPER END SENSOR REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-30

4.10 PAPER WIDTH SENSOR REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-31

4.11 PAPER LENGTH SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . ...5-32

5. FUSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-33

5.1 HOT ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-33

5.2 PRESSURE ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-37

5.3 THERMISTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-38

5.4 THERMOFUSE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-39

5.5 HOT ROLLER STRIPPERS REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-40

5.6 EXIT SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-41

5.7 FUSING PRESSURE ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-42

6. CORONAS

6.1 CHARGE CORONA WIRE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-43

6.2 TRANSFER CORONA WIRE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . ...5-44

5-43

7. COPY IMAGE . . . . . . . . . . . . . . . . . . . . . . ........ . . . . . . ...5-45

7.1 LIGHT INTENSITY ADJUSTMENT.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-45

7.2 AUTO ID SENSOR ADJUSTMENT.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-46

7.3 LEADING EDGE REGISTRATION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . ...5-49

7.4 LEADING EDGE ERASE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-50

7.5 UNEVEN IMAGE DENSITY ADJUSTMENT (uneven exposure) . . . . . . . . . . . ...5-51

7.6 HORIZONTAL MAGNIFICATION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . ...5-52

7.6.1 -Resolution Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-52

7.6.2- Horizontal Magnification Adjustment - . . . . . . . . . . . . . . . . . . . . . . . . . ...5-52

7.7 VERTICAL MAGNIFICATION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-53

8. OTHERS . . . .

8.1 50Hz/60 Hz CONVERSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-54

8.2 MASTER CLUTCH LUBRICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-55

8.3 MASTER DRIVE ASSEMBLY REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . ...5-57

8.3.1 Master Drive Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-57

8.3.2 Master Drive Assembly Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-57

5-54

TROUBLESHOOTING

3. COPIER TIMING CHART.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

1. COPY QUALITY . . . . . . . . . . . . . . . . .

1.1 UNEVEN IMAGE DENSITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-1

1.2 WHITE LINES OR STREAKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-1

1.3 FUZZY COPY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-1

1.4 DlRTY BACKGR0UND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-2

1.5 DIRTY BACKSIDE OR LEADING EDGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-2

1.6 BLANK AREAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-2

1.7 INSUFFlClENT lMAGE DENSlTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-2

1.8 WHlTE COPY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-3

1.9 FAINT COPY AT LEADING OR TRAILING EDGE . . . . . . . . . . . . . . . . . . . . . . . ...6-3

1.10 WRINKLED COPY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-3

1.11 BLACK LINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-4

1.12 JlTTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-4

2. SERVlCE CALL CONDITlONS. . . . . . . . . . . . . . . . . . . . . . . . . . . ..6-5

2.1 E1 EXPOSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-5

2.2 E2 OPTlCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-7

2.3 E5 FUSlNG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-12

2.4 E6 FUNCTIONAL DRlVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-16

2.5 E7 MASTER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-17

2.6 E9 OPTlCS BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-18

2.7 EA SORTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-18

..........................6-1

3.DEFECTlVE SENSOR/SWlTCH TABLE

3.1 COPIER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-20

3.2 DOCUMENT FEEDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 SORTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-23

. . . . . . . ...6-20

. . . . . . ...6-22

COPIER ELECTRICAL DATA

1. COPIER MAIN BOARD SCHEMATIC . . . . . . . . . . . . . . . . . . . . . ...7-1

2. OPTICS BOARD SCHEMATIC. . . . . . . . . . . . . . . . . . . . . . . . . . ...7-2

DOCUMENT FEEDER

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-1

2. COMPONENT LAYOUT

●✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎✎

8-2

3. ELECTRICAL COMPONENT DESCRIPTIONS . . . . . . . . . . . . . ...8-3

4. OVERALL MACHINE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . ...8-5

5. BASIC OPERATION

8-7

6. POWER DISTRIBUTION . . . . . ... . . . . . . . . . . . ... . . . . . . . . . . . . . .8-9

7. INTERFACE CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .......8-10

8. ORIGINAL FEED . . . . . . . . ....... . . . . . . . . .... . . . . ..... . .....8-11

8.1 ORIGINAL PICK-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-11

8.2 ORIGINAL SEPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-12

8.3 ORIGINAL FEED-lN MECHANlSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-13

8.4 ORlGlNAL SlZE DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-15

8.5 ORIGINAL lNVERSION MECHANlSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-16

8.6 ORIGINAL FEED-OUT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-18

8.7 BELT DRlVE MOTOR ClRCUlT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-19

8.8 FEED-OUT MOTOR CIRCUIT.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-20

8.9 INPUT AND OUTPUT ClRCUlTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-21

9. LIFT MECHANISM . . . . . . . . . . . . . . . . . . . . ......... . ... . ...8-22

10. ORIGINAL MISFEED SENSING . . . . .. . . . . . .. . . . . . . . . . . ...8-23

11. ACCESSORY HECK . . . . . . . . . . . . . . . .

8-25

12. INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . ....8-27

13. REPARATION FOR RANSPORTATION . . . . . . . . . . . . . . . ...8-32

14. REPLACEMENT AND ADJUSTMENT

14.1 FEED-IN UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-33

14.1.1 Transport Belt Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-33

14.1.2 Feed-in Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-34

14.1.3 Pick-up Roller Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-35

14.1.4 Feed-in Clutch Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-36

14.1.5 Pick-up Solenoid Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-37

14.1.6 Feed Roller Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-39

m*m*m88m ● m.mm

● .......

8-33

14.1.7 Feed-in Solenoid Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 8-40

8.2 Bin Drive Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9-11

16. SORTER MAIN BOARD SCHEMATIC . . . . . . . . . . . . . . . . . . ...9-27

14.1.8 Friction Belt Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-41

14.2 FEED-OUT UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-42

14.2.1 Feed-out Unit Removal.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-42

14.2.2 Inverter Solenoid Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-43

14.2.3 DF Leading Edge Registration Adjustment . . . . . . . . . . . . . . . . . . . . . ...8-44

15. DF MAIN BOARD SCHEMATIC . . . . . . . . . . . . . . . . . . . . . . . ...8-46

16. DF TIMING CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-47

SORTER

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9-1

2. OPERATION PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9-2

3. COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9-3

4. ELECTRICAL COMPONENT DESCRIPTIONS . . . . . . . . . . . . . ...9-4

5. OVERALL MACHINE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . ...9-5

6. BASIC OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9-6

7. EXIT ROLLER DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-7

7.1 Roller Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9-7

7.2 Roller Drive Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9-8

8. BIN DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9-9

8.1 Bin Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9-9

9. OPERATION PANEL CIRCUlT. . . . . . . . . . . . . . . . . . . . . . . . . ...9-12

10. JAM SENSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9-13

11. ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9-14

12. lNSTALLATlON PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . ...9-15

13.PREPARATION FOR TRANSPORTATION . . . . . . . . . . . . . . . ...9-24

14. ROLLER DRIVE BELT REPLACEMENT . . . . . . . . . . . . . . . . . ...9-25

15. BIN GUIDE LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9-26

17. SORTER TIMING CHART

SERVICE TABLES

VINYL ENVELOPE

POINT-TO-POINT

ELECTRICAL COMPONENT AND CONNECTOR LAYOUT - COPIER

ELECTRICAL COMPONENT AND CONNECTOR LAYOUT-DF

ELECTRICAL COMPONENT AND CONNECTOR LAYOUT-SORTER

TABLE OF ADJUSTMENTS

9-28

SECTION 1

INFORMATION

OVERALL MACHINE

1. SPECIFICATIONS

1-1

1 August 988

Configuration:

Copy Process:

Originals:

Maximum Original Size:

Copy Paper Size:

Copy Paper Weight:

Maximum Original Weight:

Reproduction Ratio:

Zoom:

Copying Speed:

Desktop

Mono-component dry toner process

Book/sheet

A3, (11" X 17")

Maximum: A3, 11" x 17"

Minimum: A6, 8½" x 5½"

Cassette Feed:

52 to 105 g/m

14 to 28 lb

Paper Tray Feed: 52 to 157 g/m

2

2

14 to 42 lb

5 kg (11 lb)

[115 V/60 Hz]

1:1.55

[220, 220 V/50 Hz]

1:1.41

1:1.29 1:1.22

1:1

1:0.93

1:0.74

1:0.65

1:1

1:0.93

1:0.82

1:0.71

From 50% to 200% in 1% increments

15 copies per minute (A4, 8½" x 11"

sideways)

7.5 copies per minute (A3, 11" x 17")

First Copy:

Reproduction Ratio Change:

Warm-up Time:

Operation Control:

Copy Counter:

Image Density:

8.5 seconds

Less than 6 seconds

Within 40 seconds (Room temperature 20

degrees Celsius)

Microprocessor

1 to 99 copies (Count-up/down)

Exposure lamp intensity control (5 steps

and auto image density)

1 August 1988

Automatic Reset:

Photoconductor:

Master Charge:

Exposure System:

Exposure Lamp:

Optics:

Erase:

Development:

Toner Replenishment:

Toner Consumption:

(A4/8½" x 11" 6% Originals)

After 60 seconds

- Copy Counter:

1

- Image Density: Auto ID

– Book Mode: OFF

– Reproduction Ratio:

Full size

– Interrupt Mode: OFF

Organic photoconductor (Master)

Single-wire with grid plate (Negative

Charge)

Slit exposure, fixed platen

Halogen Lamp :

97V,300W(115V)

180V, 300W (220/240V)

Through type lens: F= 8, f= 180 mm

LEDs

Mono-component dry toner system

Cartridge:

- Black toner cartridge:

- Color toner cartridge:

170g

100 g (red,

green, blue)

3,000 copies/cartridge - black toner

2,600 copies/cartridge - color toner

Development Bias:

Image Transfer:

Cleaning:

Quenching:

Paper Feeding:

Paper Feed System:

Negative fixed bias

– 225 volts for black development

-180 volts for color development

Single wire dc corotron (Negative charge)

Cleaning blade

LEDs

Cassette (250 sheet capacity) and Paper

Tray (100 sheet capacity, 1 sheet for OHP

transparencies)

Cassette feed:

Feed roller and friction

pad system

Paper tray feed:

Pick-up roller, feed roller,

and friction pad system

1-2

1 August 1988

Image Fusing:

Fusing Lamp:

Copy Tray Capacity:

Self-diagnostic Codes:

Power Source:

Power Consumption:

Dimensions (W x D x H):

Weight:

Optional Equipment:

Heat and pressure type, teflon and

silicone rubber rollers

Halogen lamp, 960 W

100

sheets

21 codes, indicated in the magnification

ratio display

115V/60Hz:

220V, 240V/50Hz: 6A

220V/60Hz: 6A

Maximum: 1.4 kW

Warm-up: 1.0 kW

Stand-by:

Copy cycle: 560 W

640 x 618x 389 mm,

25.2 x 23.3x 15.3 inches

Approximately 50 kg (110.2 lb)

- Cassette (Universal)

- Color Development Unit

- Sorter

- Document Feeder (requires power supply

unit)

12A

110W

1-3

1 August

1-4

1988

2. OPERATION PANEL

2.1 KEYS AND LABELS

-

A4/A3

VERSION -

1. Magnification Ratio Plate

Shows the standard reproduction

ratios.

2.

Number Keys

The number keys are used to enter

the desired number of copies. They

are also used to input the data for

the size magnification mode.

3.

Interrupt Indicator

Lights when

selected.

4.

Interrupt Key

Press to make interrupt copies

during a copy run.

5.

Start Key

Press to start operation.

interrupt mode is

6.

Clear/Stop Key

Press to cancel the copy number

entered. While copying, press to

stop copy operation.

7.

Auto Image Density Key

Press to select or cancel automatic

image density mode.

8.

Manual Image Density Keys

Press to make copies lighter or

darker. Use these keys to cancel

automatic control and manually

select the image density level.

9.

Select Paper Key

Press to select cassette or paper

tray.

10. Full Size Key

Press to make the copy image the

same size as that of the original.

- LT/LDG version -

11. Enlarge Key

Press to make enlarged copies.

12.

Reduce Key

Press to make reduced copies.

13. Zoom Up Key

Press to increase the reproduction

ratio in 1% steps.

14.

Zoom Down Key

Press to decrease the reproduction

ratio in 1% steps.

1 August 1988

17.

Original Image Size Indicator

Lights to show when to enter the

original size when in size magnifica-

tion mode.

18 Series Copies Key

Press to make series copies.

19. Series Copies Indicators

Shows which series copies mode is

selected.

1$. Size Magnification Key

Press to select size magnification

mode.

16. Copy Image Size Indicator

Lights to show when to enter the

copy size when in size magnification

mode.

1-5

1 August 1988

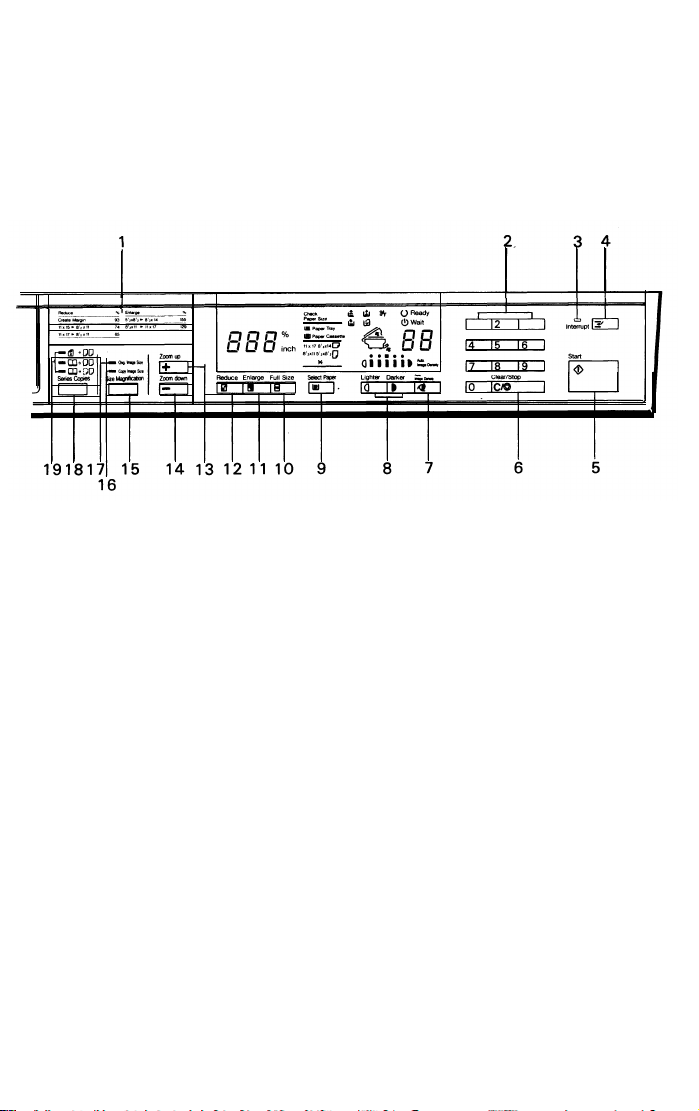

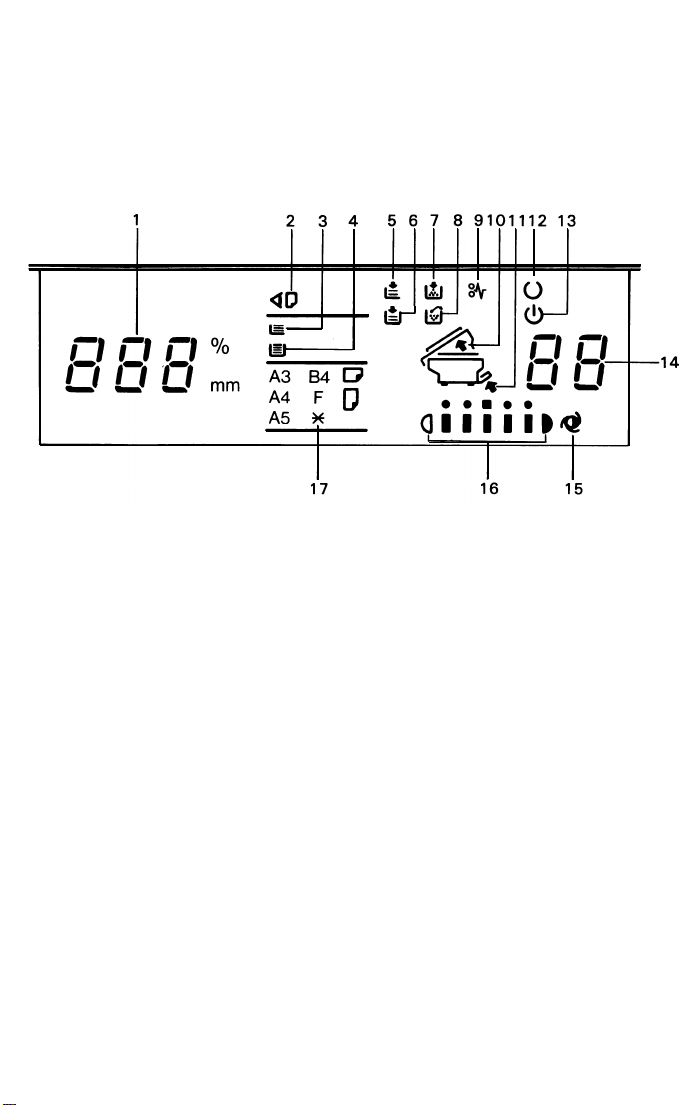

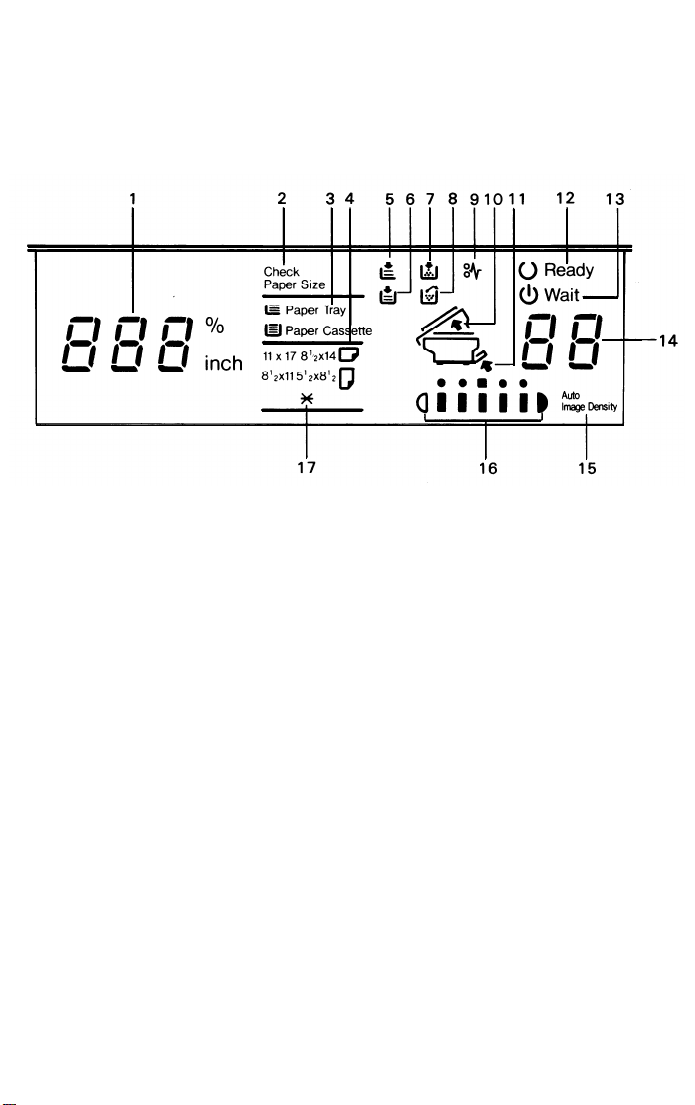

2.2 INDICATOR SCREEN

-

A4/A3 version -

1. Magnification Ratio Indicator

Shows the selected reproduction

ratio and the data for the size magnification mode.

2.

Check Paper Size Indicator

Blinks when the paper size selected

does not match the selected mode.

(Copying is impossible.)

3. Paper Tray Feed Indicator

Shows the paper tray feed.

4.

Cassette Feed Indicator

Shows the cassette feed.

5. Check Paper Tray Indicator

Lights when either no paper is in the

paper tray or there is a paper mis-

feed at the paper tray.

6. Load Paper Indicator

Lights when either no paper is in the

cassette or the cassette is not

properly positioned.

7. Add Toner Indicator

Lights when the development unit is

not installed or it is time to change

the toner cartridge.

8. Replace Toner Collection Unit

Indicator

Lights when it is time to change the

toner collection unit.

1-6

- LT/LDG version -

9.

Check Paper Path Indicator

Lights when there is a paper misfeed

within the copier.

10. Lift Top Unit Indicator

Lights to show when to lift the top

unit when misfed occurs within the

copier.

11.

Lift Paper Tray Indicator

Lights to show when to lift the paper

tray when misfed occurs within the

copier.

12.

Ready Indicator

Lights when the machine is ready to

make copies.

13.

Wait Indicator

Indicates that the machine is not

ready to copy.

1 August 1988

14. Copy Counter

Shows the number of copies

entered. While copying, this counter

shows the number of copies made.

(Count up type)

15.

Auto Image Density Indicator

Lights when the copier is automatically controlling the image density.

16. Manual Image Density

Indicators

Show the manually selected image

density.

17.

Paper Size Indicator

Shows the size and direction of

paper in the cassette or the paper

tray.

1-7

1 August 1988

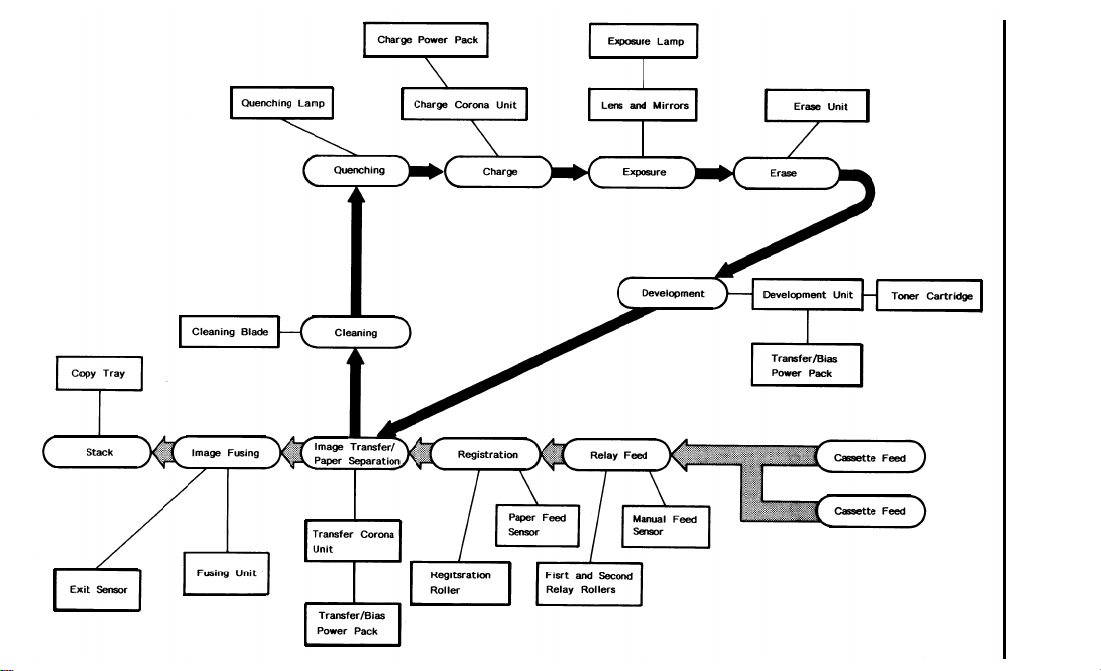

3. COPY PROCESS

1. Charge

In the dark the charge corona unit applies a negative charge to the master.

The grid plate ensures the charge is applied uniformly. The charge remains

on the surface of the master because the photoconductive master has a high

electrical resistance in the dark.

2.

Exposure

High intensity light is reflected from the original to mirrors and through the

lens to the surface of the master. The charge on the photoconductor surface

is dissipated in direct proportion to the intensity of the exposure light, thus

producing an electric latent image on the master surface.

3.

Erase

The erase lamp illuminates the areas of the charged master surface that will

not be used for the copy image.

luminated areas drops and the charge on those areas dissipates.

The resistance of the master in the il-

1-8

1 August 1988

4. Development

A thin layer of positively charged toner on the development roller comes in

contact with the latent image on the master surface. Toner particles are

electrostatically attracted to the negatively charged areas of the master surface.

5. image Transfer

Copy paper is fed to the master surface while a strong negative charge is ap-

plied to the back side of the paper. The negative charge pulls the toner particles from the master surface onto the paper. The paper then separates from

the master and moves to the fusing unit.

6.

Cleaning

In preparation for the next copy, the cleaning blade removes any toner

remaining on the master surface.

7. Quenching

The light from the quenching lamp electrically neutralizes the surface of the

master.

8.

Paper Feed

Paper can be fed either from the cassette or from the paper tray. The relay

rollers carry the paper to the registration rollers.

9.

Registration

The registration rollers stop the paper to correct skew and control the

registration timing.

10. Fusing

The image is fused to the copy paper by two rollers which apply heat and

pressure.

1-9

1-10

4. FUNCTIONAL OPERATION

1 August 1988

1 August 1988

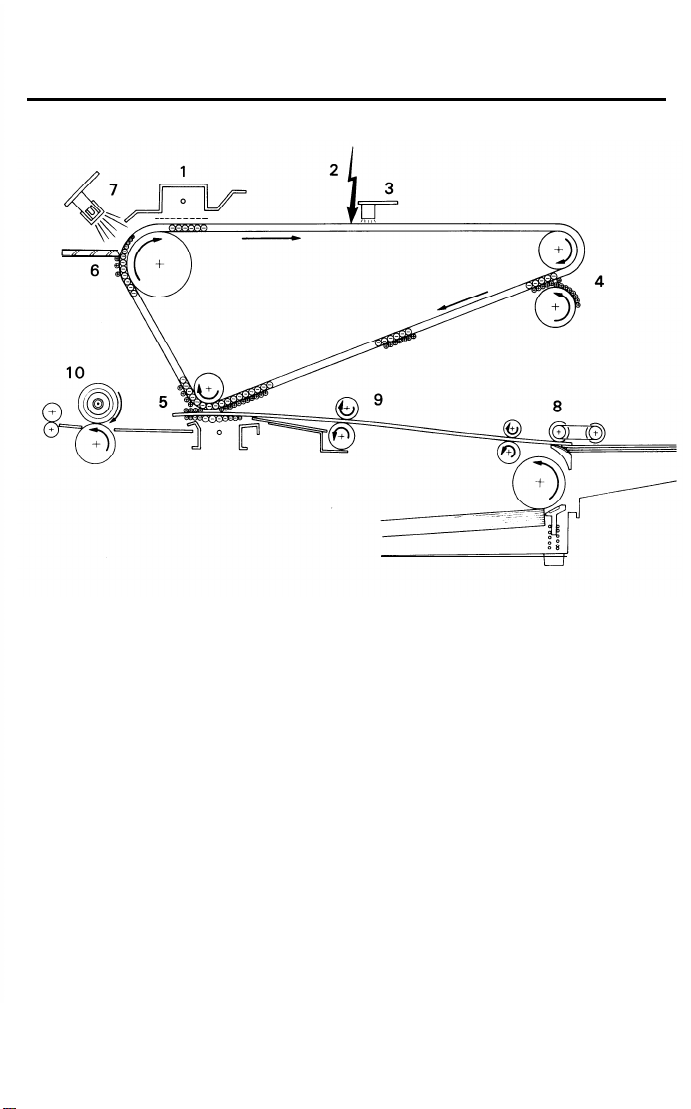

5. COPY CYCLE

NOTE: This section describes a single A4/letter copy cycle. The details of

timing events for multiple copy cycles or different paper sizes may

vary. See the timing charts for details.

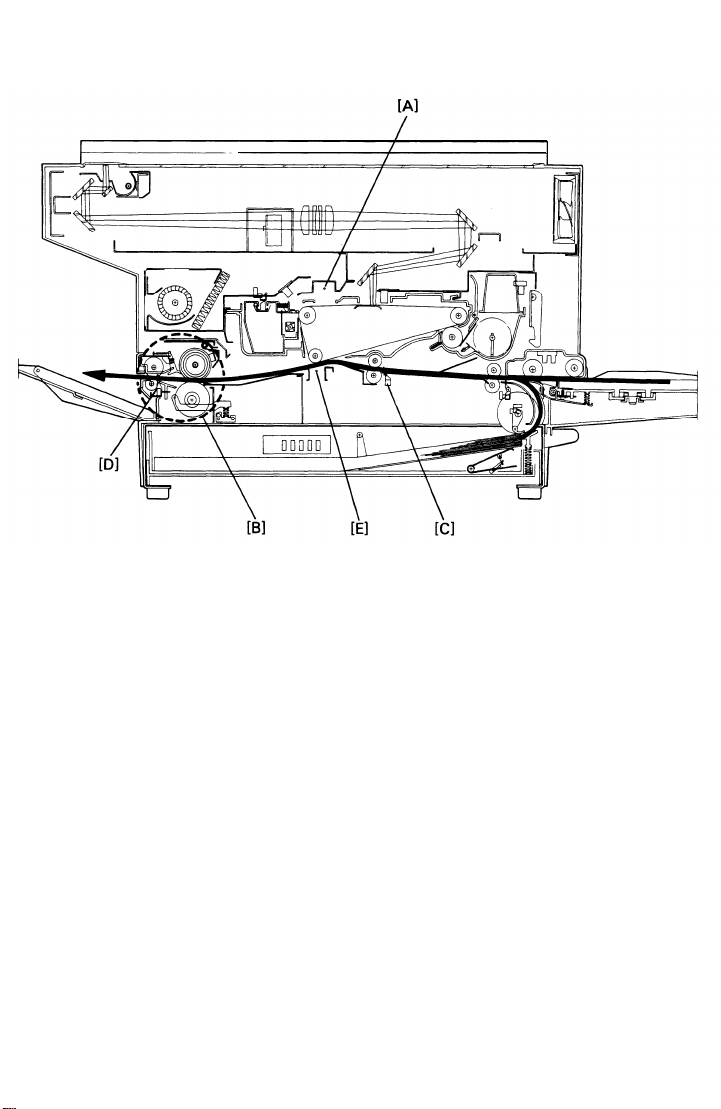

The copy cycle has two phases. The first phase begins when the Start key is

pressed. At that time the Ready indicator turns off and the Wait indicator

turns on. At the same time the master solenoid, exposure lamp [A], feed

solenoid (either tray or cassette), and total counter all turn on. The paper

feed mechanism [B] separates one sheet of paper from the paper stack at

this time. Just after the Start key is pressed (0.1 second delay), the main

motor and scanner motor turn on. The scanner [C] moves 100 mm away

from the left scale and then reverses. While it is returning to the home position, the original image density is scanned.

About 93 timing pulses (1 pulse

the paper actuates the feed sensor [D]. The feed solenoid turns off 22 pulses

later. The relay rollers [E] then continue feeding the paper.

At about the same time that the feed solenoid turns off, the scanner reaches

the home position. The scanner motor and exposure lamp then turn off. At

the same time, the development bias turns on to apply a high voltage to the

development roller [F]. Also, the quenching lamp [G] turns on, and the

master solenoid turns off (to start the master belt [H] turning). At this time the

leading edge of the copy paper is between the relay rollers and the registration rollers [I].

= 11.38 ms) after the Start key is pressed,

1-11

1 August 1988

1-12

The second phase of the copy cycle begins the next time the master sensor

detects the sensor plate on the master belt. At this time, the LEDs of the

erase lamp unit [A] all turn on for leading edge erase, and the pulse count is

reset to 0. The exposure lamp [B] turns on 1 pulse later, and the charge

corona [C] turns on an additional 8 pulses after that. The scanner drive

motor turns on soon after the charge corona turns on; the exact timing

depends on the reproduction ratio.

Just after the leading edge of the latent image on the master passes the erase

lamp unit the erase lamp switches from leading edge erase to side erase.

Next, the leading edge of the paper actuates the registration sensor [D]. Nine

pulses after that, the relay feed solenoid turns on, disengaging the relay roller

spring clutch. The paper waits at this point until the proper time for it to be

fed to the image transfer area [E] (registration timing). Just before registration start timing, the erase lamp unit switches from side erase to trail edge

erase.

1 August 1988

About 182 pulses after the leading edge of the latent image passes the erase

lamp position (exact timing depends on DIP switch setting), the registration

solenoid turns on and the relay feed solenoid turns off. Paper then starts

feeding to the image transfer section [A]. At the same time, the scanner

motor reverses to return the scanner to the home position and the exposure

lamp turns off.

Just before the paper reaches the transfer position (at the 287th pulse), the

transfer corona turns on. At about the same time, the trailing edge of the

paper passes the feed sensor and the scanner reaches to the home position

[B]

.

As the paper passes between the transfer corona and the master belt, the

positive toner image on the drum is pulled from the drum onto the passing

paper by the negative transfer corona.

1-13

1 August 1988

At the 355th pulse the charge corona [A] turns off. About this time the paper

enters the fusing unit [B]. Slightly after that at about the 401st pulse, the trailing edge of the paper passes the registration sensor [C]. The registration

solenoid turns off 17 pulses later. Soon after that (about 30 pulses) the leading edge of the paper actuates the exit sensor [D].

Next the transfer corona [E] turns off (at the 469th pulse) and after that the

paper exits the the copier.

The Ready indicator turns on when the paper

starts exiting the copier.

Shortly after the paper exits the copier, the main motor, quenching lamp,

erase lamp, and development bias all turn off. The master solenoid turns on

at the same time to stop the master belt. The master solenoid stays on for

2.3 seconds after the copy cycle has finished.

1-14

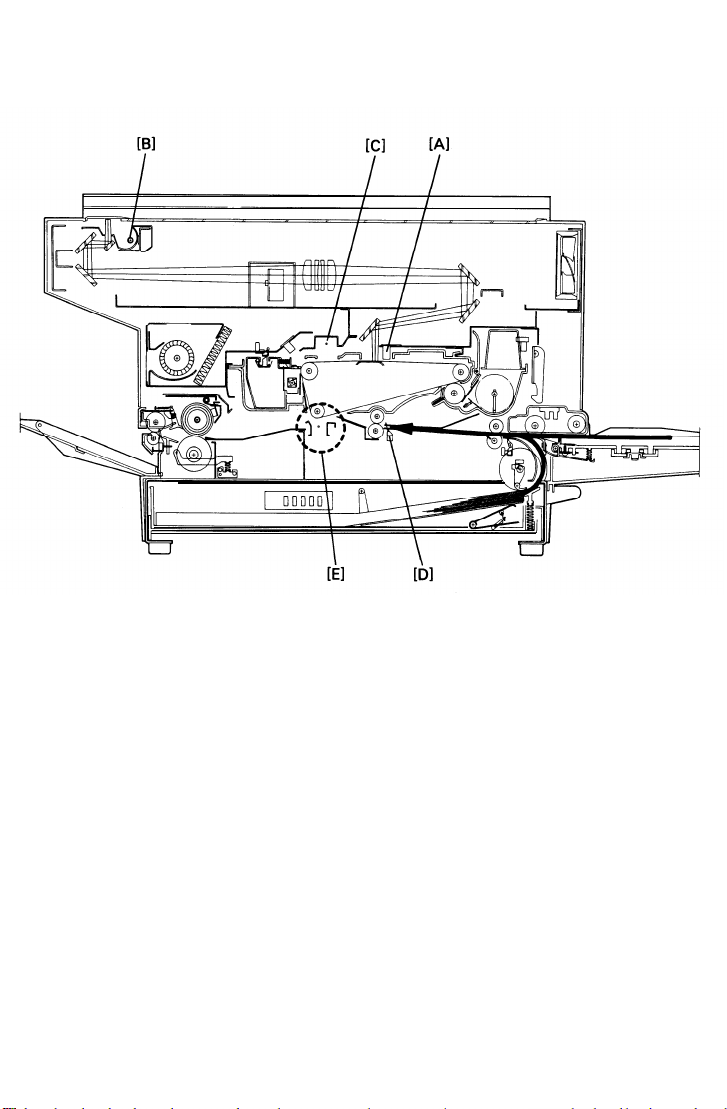

6. MECHANICAL COMPONENT LAYOUT

1 August 1988

1. Third Mirror

2. Second Mirror

3. First Mirror

4. Exposure Lamp

5. Master belt

6. Lens

7.

Sixth

Mirror

8. Fourth Mirror

9. Fifth Mirror

10. inlet Cooling Fan

11. Toner Cartridge

12. Toner Mixing Bar

13. Tray Feed Roller

14. Pick-up Roller

15. Paper Tray

16. Friction Pads

17. Cassette Feed Roller 27. Hot Roller

18. Relay Rollers

19. Paper Cassette

20. Development Roller

1-15

21. Registration Rollers

22. Cleaning Blade

23. Used Toner Tank

24. Pressure Roller

25. Copy Tray

26. Exit Rollers

28. Exhaust Blower

1 August 1988

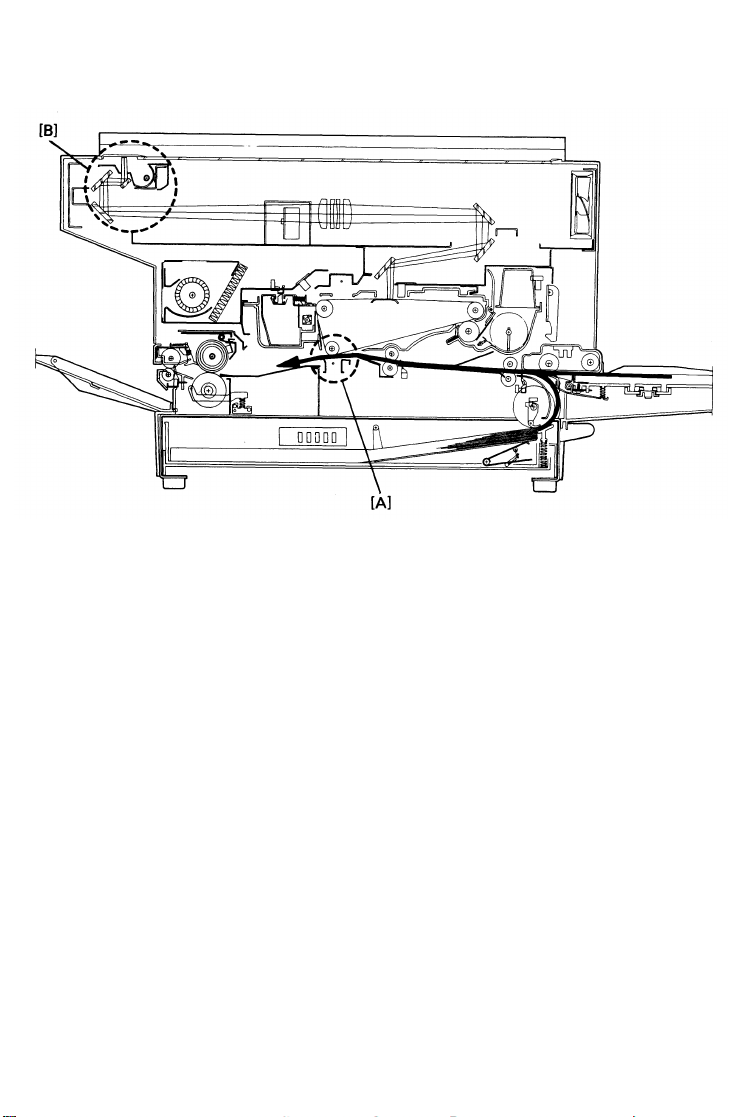

7. DRIVE LAYOUT

Gears:

G1:

Master/Developtnent

Drive Gear

G2: Drive Relay Gears

G3: Main Motor Gear

G4:

Fusing Drive Gear

G5: Idle Gears

G6: Exit Roller Gear

G7: Idle Gear

G8: Hot Roller Gear

G9:

Fusing

Knob Idle Gear

G1O: Engage Gear

G11:

Registration Roller Gear

G12:

Idle Gear

G13: Idle Gear

G14: Idle Gear

G15: Idle Gear

G16:

Cassette Feed Roller

Gear

G17: Relay Roller Drive Gear

G18:

Idle Gear

G19:

Pick-up Roller Cam Gear

GZO:

Sector Gear

Gzl:

Tray Feed Roller Gear

Gz:

Idle Gear

G23: Toner Agitator Gear

G24: Idle Gear

G25: Toner Supply Gear

G26: Idle Gear

(327:

Development Roller Gear W3

Pulleys:

P1:

Mirror Drive Pulley

P2: Idle Pulley

1-16

P3: Scanner Drive Pulley

PA:

Lens Drive Pulley

P5: Second Scanner Pulley

P6: Idle Pulley

P7: Idle Pulley

P8: idle Pulley

Belt:

91: Timing Belt

Wires:

W1: Mirror Drive Wire

W2: Scanner Drive Wire

Lens Drive wire

.

.

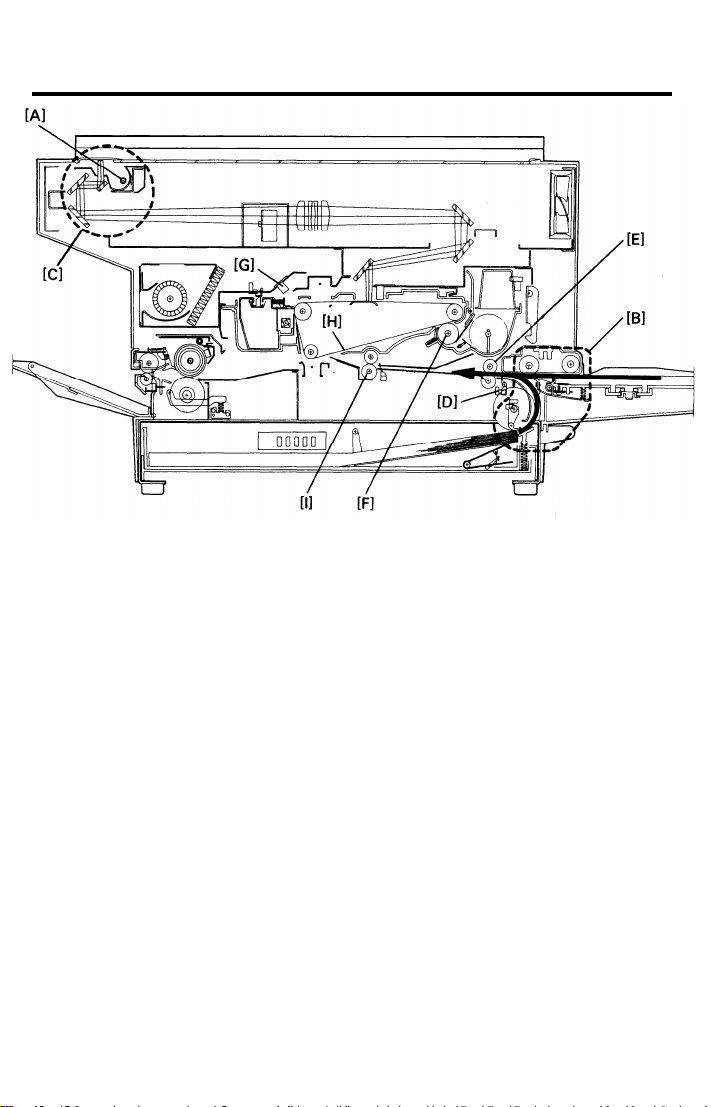

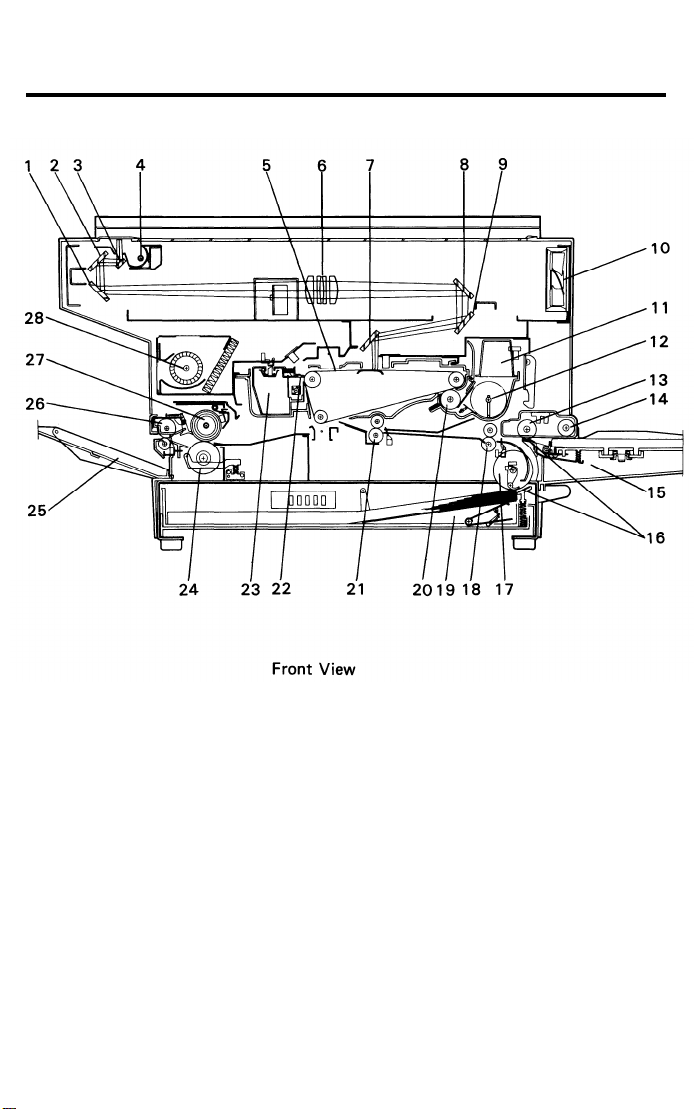

8. ELECTRICAL COMPONENT LAYOUT

1-17

8.1 UPPER UNIT

1 August 1988

1. Total counter

2. Exposure lamp

3. Optics anti-condensation

heater

4. Thermoswitch

5. Exhaust blower

6. Home position sensor

7. Toner overflow sensor

8. Lens drive motor

9. Lens home position sensor

10. AC drive board

11. Main motor

12. Scanner drive motor

13. Master solenoid

14. Mirror home position

sensor

15. Optics board

16. Mirror drive motor

17. Pulse generator sensor

18. Toner end sensor

19. Inlet cooling fan

20.

Erase lamp unit/master

sensor

21. Operation panel board

22.

Main board

23. Auto ID sensor

24. Quenching lamp

25. Charge varistor

26. Charge power pack

Loading...

Loading...