Page 1

T

Model:

Skylark 2

echnical

B

ulletin

Date:

15-Oct-98

No:

PAGE: 1/6

1

Subject:

From:

Classification:

A new model “Skylark 2 (A270/A271)” will be launched in January 98. Skylark 2 is a

slightly modified version of the already existing model “Skylark (Ricoh FT2012/2212,

Gestetner 2812/2812z, Nashuatec 3612s/3612, Rex-Rotary 8612/8612z, Infotec

5121/5121 z)”.

There will be seven destination codes depending on the are a: -57 is Middle East / South

America (Ricoh), -27 is Europe (Ricoh), -29 is Asia and Africa (Ricoh), -23 is Russia

(Ricoh), -10 is Middle East/South America (Gestetner and Nashuatec), -22 is Europe and

Asia (Gestetner, Nashuatec and Rex-Rotary), -26 is Europe (Infotec).

This RTB clarifies the differences between the base copier and Skylark 2 (based on the

style of the service manual).

Differences from Skylark

GTS and S Field Infomation Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

K. Miura

1. OVERALL MACHINE INFORMATION

1. SPECIFICATIONS

Copy Paper Size: A4, 8.5’’ x 11’’, 8.5’’ x 13’’, 8.5’’ x 14’’, A5, 5.5’’ x 8.5’’

Warm-up Time: Less than 15 seconds (at 23 °C)

5 stepsManual Image Density:

Selection

Power Source: 120V/60Hz:

More than 10 A (for Middle East/South America)

220~240 V/50Hz:

More than 6 A (for Europe)

230V/50Hz:

More than 6 A (for Middle East/Asia)

Power Consumption:

Maximum 0.9 kW

Copy cycle 0.5 kW

Warm-up 0.7 kW

Stand-by 0.1 kW

Page 2

T

Model:

Skylark 2

echnical

B

ulletin

Date:

15-Oct-98

No:

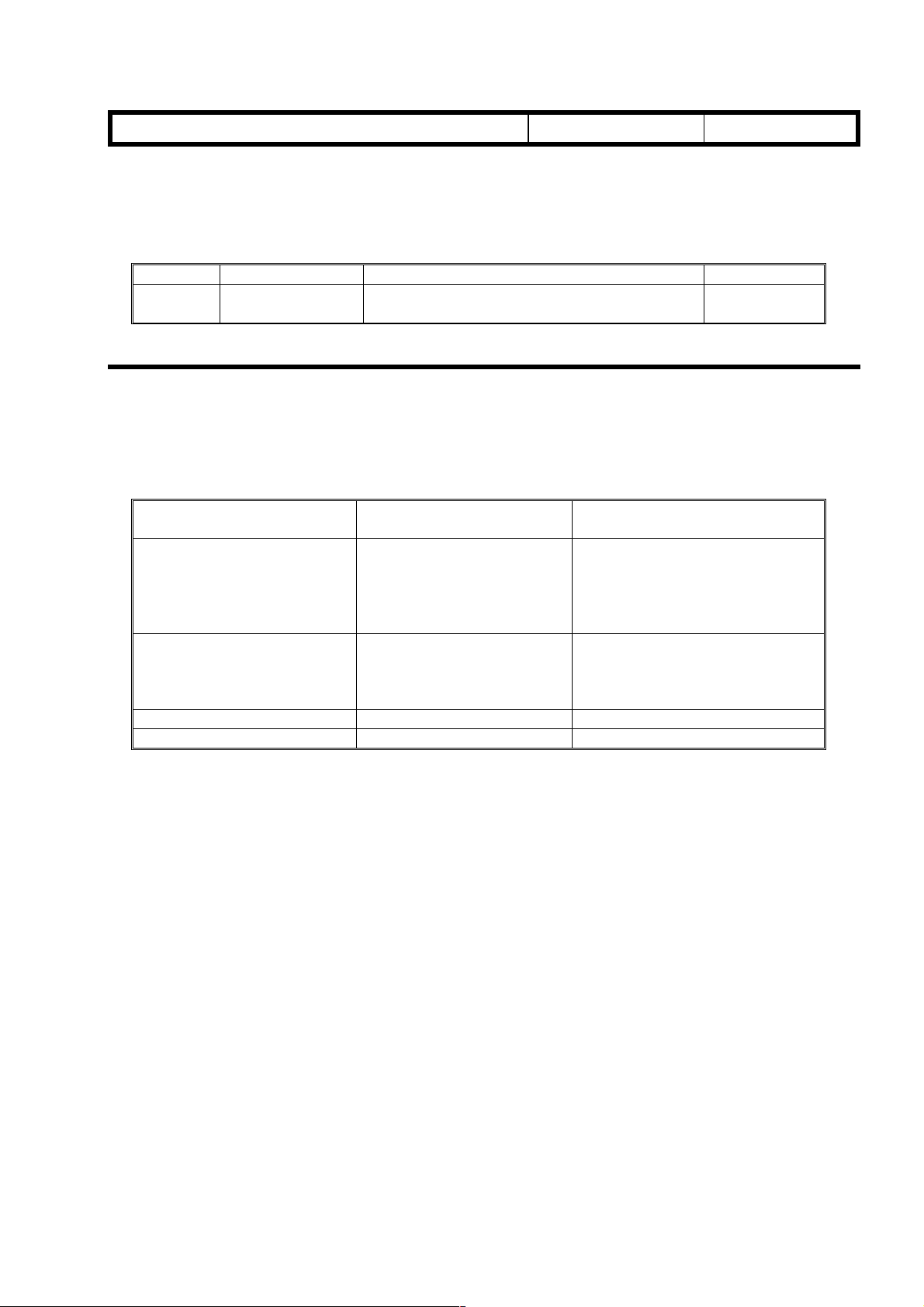

2. ELECTRICAL COMPONENT DESCRIPTIONS

The following transformer is not included in this copier.

Symbol Name Function Index No.

TR Transformer Steps down the wall voltage t o 30 Vac and 8

Vac.

2. DETAILED DESCRIPTIONS

1. FUSING LAMP CONTROL

To reduce warm-up time, fusing lamp control has been changed as follows:

PAGE: 2/6

1

31

Machine Condition Fusing Lamp

ON/OFF Threshold

After the main switch is

turned on, until one minute

has past after the fusing

temperature reaches

°C

.

After the above time period

During copying 185 °C

After copying is finish ed

130

185 °C After using temperature reaches

110 °C

110 °C

Remarks

130 °C

fusing lamp is kept on unt il it

reaches 185 °C.

When the Start key is pressed,

the red indicator blinks and

copying starts after the fusing

temperature reaches

(ready temperature), the

130 °C

.

Page 3

T

Model:

Skylark 2

echnical

B

ulletin

Date:

15-Oct-98

3. INSTLLATION PROCEDURE

1. COPIER ACCESSORY CHECK

1. Imaging Unit

2. Error Code Decal - English (except for -23 machines)

3. Error Code Decal - German (-26 machines)

4. Error Code Decal - French (-26 machines)

5. Error Code Decal - Italian (-26 machines)

6. Error Code Decal - Spanish (-26, -57 machines)

7. Error Code Decal - Portuguese (-57 machine s )

8. Operating Instructions - English (except for -27 machines)

9. Operating Instructions - German (-26 machines)

10. Operating Instructions - French (-26 machines)

11. Operating Instructions - Italian (-26 machines)

12. Operating Instructions - Spanish (-26, -57 machines)

13. Operating Instructions - Portuguese (-57 machines)

14. Model Name Decal (-22 machines)

15. NECR - English (-57 machines)

16. NECR - Multi-language (-23, -27, -29 machines)

17. User Survey Card (-57 machines)

18. Installation Procedure - English (except for -23 machines)

19. Installation Procedure - German (-22, -26, -27 machines)

20. Installation Procedure - French (-22, -26, -27 machines)

21. Installation Procedure - Italian (-22, -26, -27 machines)

22. Installation Procedure - Spanish (-22, -26, -27, -57 machines)

23. Installation Procedure - Portuguese (-57 machines)

24. Installation Procedure - Russian (-23 machines)

No:

PAGE: 3/6

1

2. COPIER INSTALLATION PROCEDURE

The paper cassette is not wrapped with a clear wrapper. It is initially installed in the paper

tray.

Page 4

T

Model:

Skylark 2

echnical

B

ulletin

Date:

15-Oct-98

No:

PAGE: 4/6

1

4. SERVICE TABLES

Access to and operation of SP mode has been changed for Skylark 2 due to the layout

change of the operation panel. Details of difference in the operation are listed below. The

differences are shown in bold letters.

1. SERVICE PROGRAM MODE ACCESS PROCEDURE

1. Turn off the main switch.

2. While pressing

switch.

3. A dot(•) will appear in the top left corner of the Copy Counter.

4. Release

Lighter key (if not pressed within 5 seconds, the machine will return to the copy mode).

The copier is ready to accept the program number.

the Auto Density key

the Auto Density key

and Clear/Stop key, and within 5 seconds, press the

and Clear/Stop key together, turn on the main

2. HOW TO SELECT THE PROGRAM NUMBER

1. By using the Increase or De crease Quantity (“+” or “-“) keys, enter the required

number. At this point, the Copy Counter will be blinking, and the dot (•) will be lit.

2. When the

Copy Counter will be entered as the selected program number.

Auto Density key

is pressed, the number which is currently blinking in the

3. CHANGING THE VALUE OF AN SP MODE

1. Enter the desired value or setting using the Increase or Decrease Quantity (“+” or “-“)

keys. For some modes, since the Copy Counter has only digits, the first digit is

displayed in the Manual Image Density indicator as shown below.

NOTE:

2. When

Copy Counter will be entered as the new value or setting, and will be stored in memory.

3. The copier is ready to accept the new program number. Repeat from step 1 or leave

SP mode by turning the main switch off/on.

After changing the value (setting), the previous value (setting) can be recalled

again if the Clear/Stop key is pressed at this point.

the Auto Density key

is pressed, the number which is currently displayed in the

Page 5

T

Model:

Skylark 2

echnical

4. SERVICE PROGRAM MODE TABLE

Mode No. Function Settings

14 Auto Shut Off Selects the auto shut off time. 0: 5 min.

Timing Setting The copier main switch is shut off automatically

after the selected auto shut o f f t ime if SP77 is at

This part has been

changed!

19 ADS Priority

Setting

34 Image Density

Adjustment

This part has been

changed!

“0”.

Specifies whether the cop ier de faults to APS or

manual mode when the ma in switch is turned on,

auto reset, or mode cleared.

Selects the image dens it y level in ADS and

manual ID mode.

The exposure lamp data is in creased or

decreased. This adjust ment affects ADS mode

and all manual ID settings.

SP Setting Setting Exposure lamp

0

1

2

3

4

5

6

The exposure lamp setting specifies the change

relative to the base exposure lamp voltage (Vo)

in SP48, 1 step of the lamp voltage equals 0.5 V

for 120 V, and 1.0V for 230V (EU) machines.

Normal

Light

Dark

Lighter

Darker

Lightest

Darkest

B

ulletin

Date:

15-Oct-98

0

+3 steps

-3 steps

+6 steps

-6 steps

+10 steps

-10 steps

No:

1

1: 10 min.

2: 15 min.

3: 20 min.

4: 25 min.

5: 30 min.

6: 60 min.

7: 240 min.

0: ADS

1: Manual ID

Level 3

0: Normal

1: Light

2: Dark

3: Lighter

4: Darker

5: Lightest

6: Darkest

PAGE: 5/6

For only SP34 and SP57, the copies are made

with ADS mode (ot her SP modes use man ual

ID level 3).

5. PREVENTIVE MAINTENANCE

1. SPECIAL TOOLS AND LUBRICANTS

The digital multimeter has been changed.

Part Number Description Q’ty

A0299387 Digital Multimeter 1

Page 6

T

Model:

Skylark 2

echnical

B

ulletin

Date:

15-Oct-98

No:

PAGE: 6/6

1

6. POINT-TO-POINT DIAGRAM

The AC drive / DC power supply board has been changed and the transformer has been

eliminated as shown.

T408

T407

FUSING LAMP

DRIVE CIRCUIT

TR

SWITCHING

CIRCUIT

FUSING LAMP

EXPOSURE LAMP

CN405-1

CN405-2

CN405-3

CN405-4

CN405-5

CN403-1

CN403-2

CN403-3

CN403-4

CN403-5

CN404-1

CN404-2

CN404-3

CN404-4

CN404-5

CN404-6

CN404-7

CN404-8

CN404-9

T405

T406

T404

T403

T401

T402

CN402-1

FUSE1

CN402-2

EXPOSURE LAMP

DRIVE CIRCUIT

RY1

Loading...

Loading...