Page 1

Technical Bulletin No. RTB-001

SUBJECT: NIP BAND WIDTH AND TRAILING EDGE SKEW

ADJUSTMENT

PREPARED BY: M. Ishihara

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

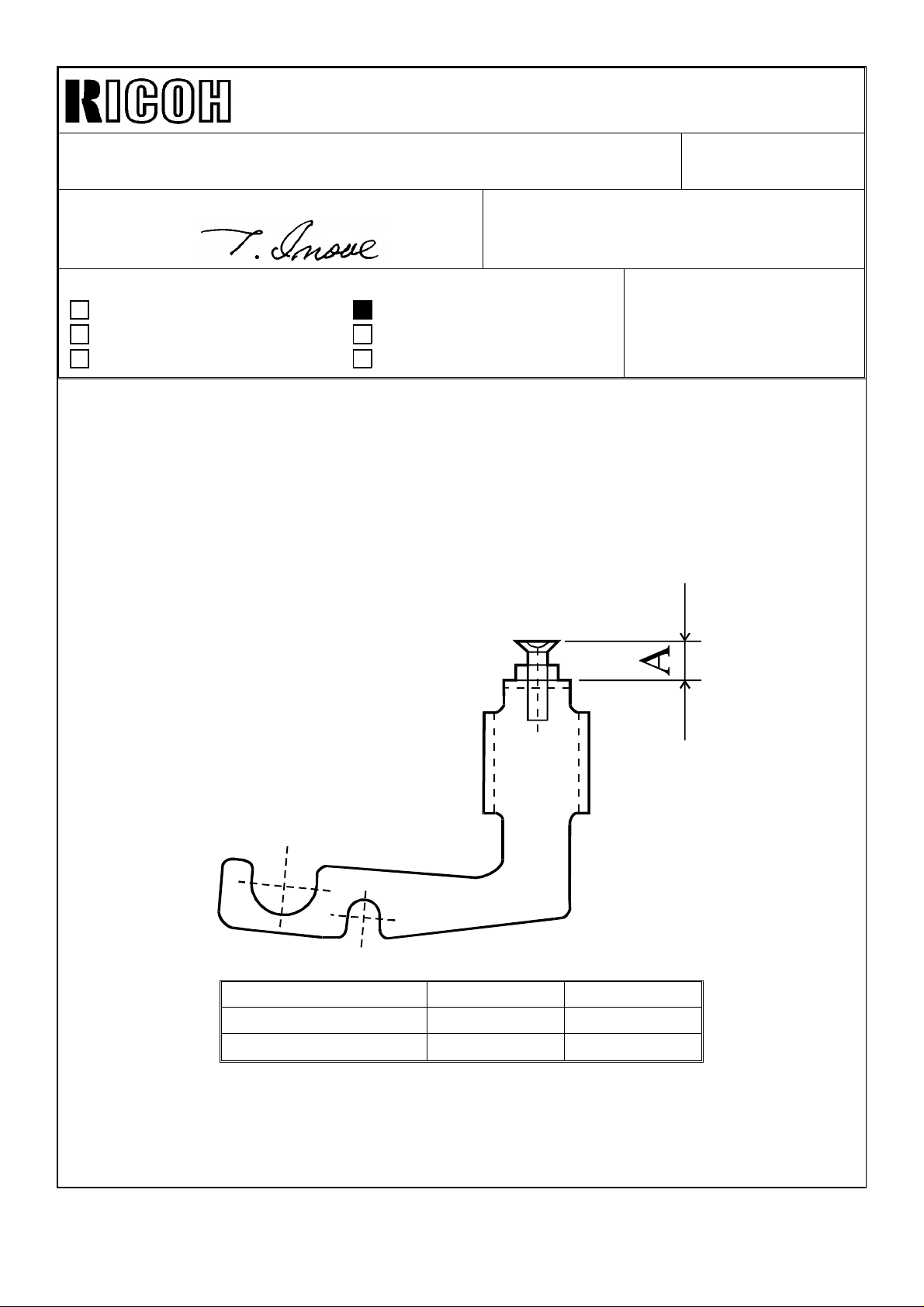

1. Nip Band Width Adjustment

The nip band width of this model is decided by the height of each screw on both fusing

unit pressure arms.

Adjust the height of the screw on each pressure arm as follows:

Revision of service manual

Information only

Other

FROM: 1st Field Information Dept. QAC

MODEL:

Skylark (A183/A184)

DATE: Oct. 31, ’96

PAGE: 1 of 2

Item Parts No. Specification

Right Pressure Arm

Left Pressure Arm

❋ Note that the adjustment specification differs between the two pressure arms.

A1844085

A1844086

8 ± 0.2

7.5 ± 0.2

Page 2

Technical Bulletin No. RTB-001

SUBJECT: NIP BAND WIDTH AND TRAILING EDGE SKEW

ADJUSTMENT

2. Trailing Edge Skew Adjustment Procedure

Perform the following procedure in the field to decrease the amount of trailing edge skew:

1) Measure the height of the screw on both fusing unit pressure arms. (The factory

standard specification is described on the previous page.)

2) Change the screw height, making sure of the following:

NOTE: • The skew will be reduced 0.1 mm by turning the screw once.

• The height of the screw will change 0.7 mm by turning once.

• Do not turn the screw more than 3 turns.

✩ If the skew on the copy paper is to the right, turn the left pressure arm screw

clockwise.

DATE: Oct. 31 ’96

PAGE: 2 of 2

✩ If the skew on the copy paper is to the left, turn the right pressure arm screw

clockwise.

Page 3

RICOH Technical Bulletin PAGE: 1/1

Model: Skylark Date: 31-Mar-97

Subject: SC Code #96 Prepared by: M.Ishihara

From: QAC 1st Field Information Dept. Checked by: T. Inoue

Classification:

The following should be added to the “SERVICE CALL CONDITIONS” in the Service

Manual.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

No: 2

CODE #96 - MAIN SWITCH ERROR

Definition

The machine does not turn off within 8.5 seconds after Auto Shut Off is performed.

Possible Causes

• Defective main switch.

• Connectors of the main switch are not correctly connected.

• Defective dc harness of the main switch connection (some lines must be cut.)

∗Remedy for the initially produced machines

• Turn the main switch off and on.

Page 4

RICOH Technical Bulletin PAGE: 1/1

Model: Skylark Date: 15-Apr-97

Subject: Additional Procedures for Operation Panel change Prepared by: M.Ishihara

From: QAC 1st Field Information Dept. Checked by: T. Inoue

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

No: 3

SYMPTOM : Wrong indication on the Operation Panel

CAUSE : Bad connection of the 11P and 6P connectors

SOLUTION:

To confirm whether the two connectors are connected properly or not, the following steps

are required when there is an operation panel change from the horizontal position to the

vertical position or vice versa.

1) After connecting the 4 connectors (1.11P:from the main harness to the relay harness,

2.11P: from the relay harness to the operation panel, 3. 6P: from the main harness to

the relay harness, 4. 6P: from the relay harness to the operation panel), confirm that

the connectors are securely connected.

2) Confirm that all indicators can be lit using SP mode No. 11. (This turns on all

indicators on the operation panel for 30 seconds. It will turn off automatically after 30

seconds. To turn off the indicators immediately, press the lighter key.) The red and

green parts of the copy start indicator turn on together. So the color must be mixed.

3) Turn the main switch off and on.

4) Check all key functions by pressing all keys.

Page 5

RICOH Technical Bulletin PAGE: 1/3

Model: Skylark Date: 15-Apr-97

No: 4

Subject: ADS Adjustment Procedure Prepared by: M. Ishihara

From: QAC 1st Field Information Dept. Checked by: T. Inoue

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

Please correct your Service Manual as follows:

Page 6-41

*: Changed or Newly Added parts

7.6 ADS Adjustment

When: 1. After light intensity is changed

2. Image density in ADS mode is too light or too dark

Purpose: To maintain correct ADS mode operation.

Adjustment

Standard:

Method: SP56 and VR100 on the main board

How it works: The bias voltage thresholds which correspond to image density will all change.

ADS Voltage = 2.5 +-0.2V

1. Place 5 sheets of A4 paper on the exposure glass.

2. Access SP56. The ADS sensor output is displayed.

*3. Adjust to 2.5+-0.2 V by turning VR100 on the main board.

*NOTE:

1) SP56 should not be used for observing the output value. The standard setting

inside the EEPROM is overwritten when this SP mode is accessed.

2) The machines from the factory may not always be within 2.5+-0.2 V. This is not a

problem. When adjusting in the field, adjust it to the value described above.

- Reasons for correction -

1. Note 1 has been added to make sure that SP56 (ADS Adjustment) is used to memorize

the adjustment standard value, not for checking the output value.

2. VR101 should always be adjusted after opening SP56, to adjust the voltage to the

standard value.

3. To perform SP56, the Start key does not have to be pressed.

Page 6

RICOH Technical Bulletin PAGE: 2/3

Model: Skylark Date: 15-Apr-97

Page 7-3

1.2 DIRTY BACKGROUND

“Possible Causes” should be corrected as follows. Item No. 5 has been eliminated

since this copier does not use a fiber optics cable for the ADS sensor.

-Possible Causes-

1. Dirty optics

2. Toner scattering

• High toner density

• The inlet seal of the development unit is stripped off.

• User/SP mode setting error

3. The exposure lamp is not bright enough. This may be caused by deterioration of the

exposure lamp or low lamp voltage.

No: 4

4. In ADS mode, light reflected from the original is too intense.

5. The development bias is grounded.

Page 7-4

1.2 DIRTY BACKGROUND

The last paragraph of “Action ” should be corrected as follows.

If dirty background occurs only in ADS mode, do the following:

• Clean the optics and perform the necessary SP modes in order

(see Section 4 - Service Remarks for details)

• If the signal at CN112-3 stays HIGH, check the harness and sensor, and replace any

defective parts.

• If the signal at CN112-2 stays LOW, replace the main board.

Page 7

RICOH Technical Bulletin PAGE: 3/3

Model: Skylark Date: 15-Apr-97

- Reasons for correction -

1. SP56 (ADS Adjustment) should not be performed by itself. It should be performed as a

part of the procedure starting from cleaning the optics.

2. By performing SP56, the image density with ADS compared from the center notch

(manual ID) may become lighter, but will not become darker. So, if dirty background

occurs only in ADS mode, the standard image density may be out of specification.

3. Since SP56 is used to memorize the adjustment standard value, not for output value

checking, the words “If the ADS voltage is not within +-0.2 volts of the standard voltage

(2.5V) ” has been eliminated.

No: 4

Page 8

RICOH Technical Bulletin PAGE: 1/4

Model: Skylark Date: 30-Apr-97

Subject: Paper Jam Prepared by :M.Ishihara

From: QAC 1st Field Information Dept. Checked by: T. Inoue

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

No: 5

SYMPTOM: Paper jam

CAUSE:

(1) Paper is not fed smoothly at the paper turn section on the paper tray.

(2) The paper tray is not set in the machine correctly.

(3) The middle driven roller ( A184 2585 ) does not turn smoothly.

SOLUTION:

(1) A mylar has been prepared in the event that this problem occurs. See the mylar

installation procedure and Fig.1 attached.

Though the part number of the Mylar is not fixed yet, it will be announced by MB

(Modification Bulletin) when the production line starts to use the Mylar.

(2) The paper tray can be set as shown in Fig.2. The rail is not set on the Rear Rib as shown

in Fig.2. So both the left and right upper rails must be on the rear and front as

shown in Fig.3. Sometimes the upper or lower rail of the paper tray can be set as

shown in Fig.4. Remove the paper tray from the machine and re-set it as shown in

Fig.3.

(3) There is a possibility that the middle driven roller ( A184 2585 ) has burr on it and this

makes the roller stick. So file off the burr and check to see if the roller turns smoothly.

Page 9

RICOH Technical Bulletin PAGE: 2/4

Model: Skylark Date: 30-Apr-97

Mylar installation procedure

C

D

A

C

C

No: 5

E

Paper Tray

C

B

Fig.1

1. Remove the anti-stick cover from the Mylar [A]

2. Remove 4 small mylars [B] from the Paper Tray.

3. Attach the Mylar [A] to the ribs at the paper turn position in the paper tray.

Caution:

1) The Mylar [A] must be placed under the three mylars [C]

2) The length of the D portion must be 0 to 1 mm.

3) The length of the E portion must be 0 to 0.5 mm.

Drawing Part No. Description P/C Page Index No. Q’ty

B A184 2569 Paper Guide Mylar 13 13 4

C A184 2566 Paper Feed Guide 13 9 3

Page 10

RICOH Technical Bulletin PAGE: 3/4

Rail

Model: Skylark Date: 30-Apr-97

Paper Tray

Rear Rib

Front Rib

Rail

No: 5

Fig. 2

Fig. 3

Page 11

RICOH Technical Bulletin PAGE: 4/4

Model: Skylark Date: 30-Apr-97

No: 5

Fig. 4

Page 12

RICOH Technical Bulletin PAGE: 1/1

Model: Skylark Date: 15-May-97

No: 6

Subject: Remaining top of toner bottle Prepared by: M.Ishihara

From: QAC 1st Field Information Dept.

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

When replacing an empty toner bottle with a new one, the top [ A ] of the toner bottle may

remain in the IU (Imaging Unit) due to procedural error such as removing the empty bottle

from the IU without lifting up the lever [ B ].

The following procedure is required when the top of the toner bottle remains in the IU.

1) Lift up the lever [ B ] of the IU.

2) Pick the top [ A ] of the toner bottle out from the IU.

B

IU

A

Page 13

RICOH Technical Bulletin PAGE: 1/1

Drive Unit

Model: Skylark Date: 31-May-‘97

No: 7

Subject: Noise from the Drive Unit Prepared by: M.Ishihara

From: QAC 1st Information Dept.

Classification:

Troubleshooting

Mechanical

Paper path

Other ()

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

SYMPTOM : Noise from the Drive Unit ( A1841050 )

CAUSE : Too much play in the gear [ A ]

SOLUTION : Install a spacer [ C ] on the shaft between the gear [ A ] and the side

plate [ D ] ( position [ B ] as shown below ).

If necessary, apply grease on the other side of the [ B ] position.

[ A ]

[ B ]

[ D ]

[ C ]

Page 14

T

Model:

Skylark

echnical

B

ulletin

Date:

15-Nov-97

No:

PAGE: 1/2

8

Subject:

From:

Classification:

The ozone filter and the charge corona unit are assembled or included inside the carton

box of the imaging unit, and will be replaced by the customer at each 30k cycle.

Please correct your Service Manual as follows:

Page 5-2 PM Table

Others

ADS A Adjust when the lamp

PM Item Revision

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

EM 30 k 60 k 90 k 120 k Notes

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

voltage is changed.

M.Ishihara

Exit and Registration Sensors I I

Bearings I I

Ozone Filter R R R R

Page 5-3 Regular PM Procedure

OLD NEW

Page 15

T

echnical

B

ulletin

PAGE: 2/2

Model: Skylark Date:

Page 5-4 Regular PM Procedure

1. Replace the ozone filter.

2. Inspect the exit and registration sensors.

3. Inspect the bearings.

15-Nov-97

No: 8

Page 16

RICOH Technical

[A]

[B]

Model:

Skylark (Ricoh Hong Kong only)

Bulletin

Date:

15-May-98

No:

PAGE: 1/1

9

Subject:

From:

Classification:

When replacing the 230V Power Supply Board (P/N: A1845651) in China, the varistor

which is installed in socket “V1” should also be changed to a 680V varistor.

Power Supply Board for China

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Old Varistor [A] New Varistor [B]

P/N: 14040352 (470V)

Part information

Electrical

Transmit/receive

Þ

Prepared by:

P/N: 14040377 (680V)

J. Kasamoto

Action required

Service manual revision

Retrofit information

Page 17

T

Model:

Skylark

echnical

B

ulletin

Date:

30-Sep-98

No:

PAGE: 1/2

10

Subject:

From:

Image Density Adjustment Factor (SP34)

QAC Field Information Dept.

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

K. Miura

The Image Density Adjustment Factor (SP34) criteria have been changed to achieve

better output results. Previously, both the development bias and the exposure lamp

settings were increased or decreased. The new system now only changes the exposure

lamp setting to adjust image density. Taking this into account, please correct the related

pages in your service manual that contain the table for this SP mode.

Page 2-9

Page 2-19

Page 4-15

OLD

NEW

SP Setting Setting Dev. Bias Exposure Lamp

0 Nomal 0 0

1 Light -40 V 0

2 Dark +40 V 0

3 Lighter -40 V +3 steps

4 Darker +40 V -3 steps

5 Lightest -40 V +7 steps

6 Darkest +40 V -7 steps

SP Setting Setting Exposure Lamp

0 Nomal 0

1Light +3 steps

2 Dark -3 steps

3 Lighter +6 steps

4 Darker -6 steps

5 Lightest +10 steps

6 Darkest -10 steps

Page 18

T

Model:

Page 6-35

Page 6-37

OLD

- SP34 (Image Density Adjustment) -

Skylark

Setting 0123456

echnical

B

ulletin

Date:

30-Sep-98

No:

PAGE: 2/2

10

Bias Voltage

Change [V]

Exposure Lamp

Change

Image Density Normal Lighter Darker Lighter Darker Lightest Darkest

NEW

- SP34 (Image Density Adjustment) -

Setting 0123456

Exposure Lamp

Change

Image Density Normal Lighter Darker Lighter Darker Lightest Darkest

±

0

±

0

±

0

-40 +40 -40 +40 -40 +40

±

0

+3 steps -3 steps +6 steps -6 steps +10 steps -10 steps

±

0

+3 steps -3 steps +7 steps -7 steps

Loading...

Loading...