Page 1

Technical Bulletin No. RTB-001

SUBJECT: NIP BAND WIDTH AND TRAILING EDGE SKEW

ADJUSTMENT

PREPARED BY: M. Ishihara

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

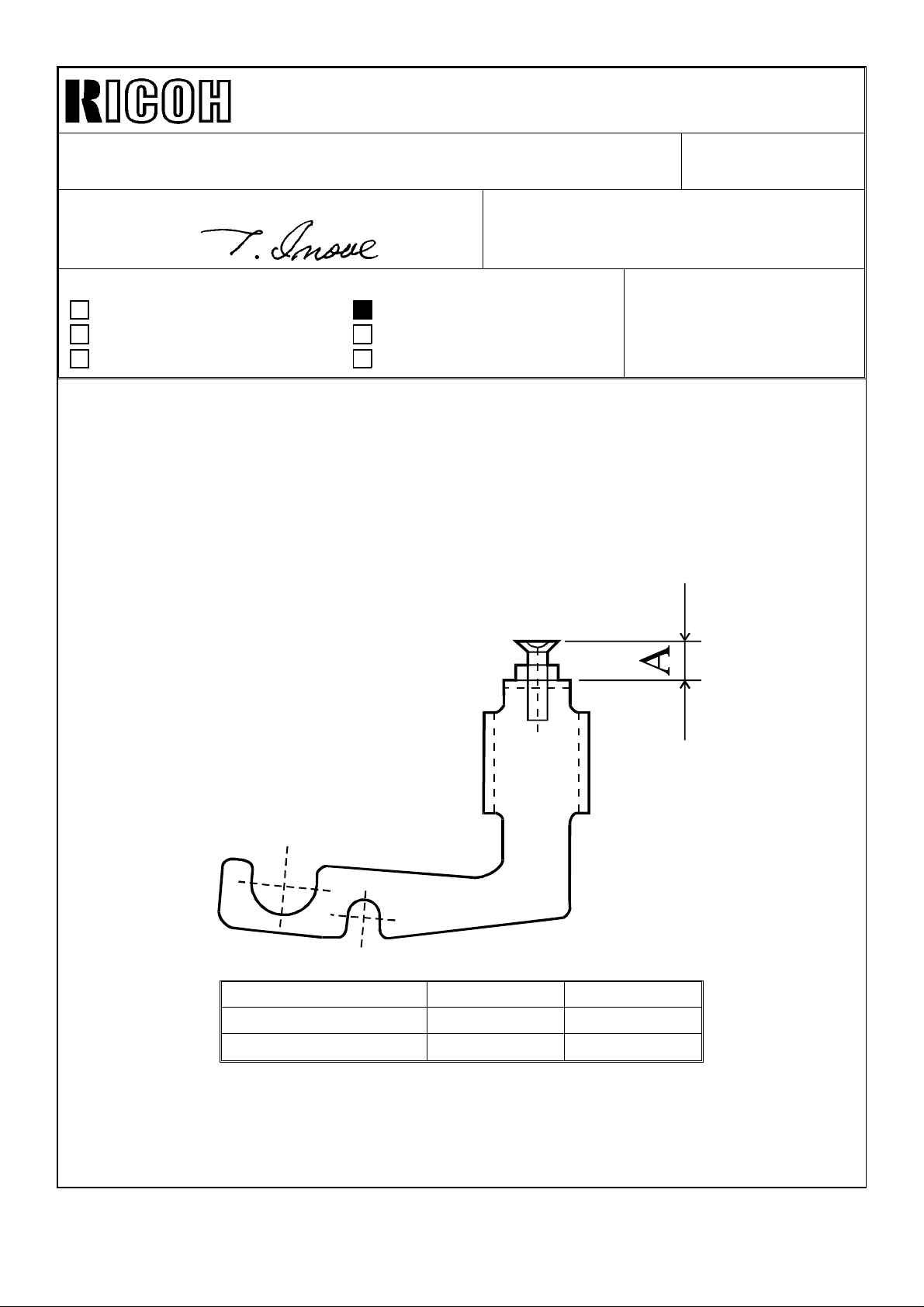

1. Nip Band Width Adjustment

The nip band width of this model is decided by the height of each screw on both fusing

unit pressure arms.

Adjust the height of the screw on each pressure arm as follows:

Revision of service manual

Information only

Other

FROM: 1st Field Information Dept. QAC

MODEL:

Skylark (A183/A184)

DATE: Oct. 31, ’96

PAGE: 1 of 2

Item Parts No. Specification

Right Pressure Arm

Left Pressure Arm

❋ Note that the adjustment specification differs between the two pressure arms.

A1844085

A1844086

8 ± 0.2

7.5 ± 0.2

Page 2

Technical Bulletin No. RTB-001

SUBJECT: NIP BAND WIDTH AND TRAILING EDGE SKEW

ADJUSTMENT

2. Trailing Edge Skew Adjustment Procedure

Perform the following procedure in the field to decrease the amount of trailing edge skew:

1) Measure the height of the screw on both fusing unit pressure arms. (The factory

standard specification is described on the previous page.)

2) Change the screw height, making sure of the following:

NOTE: • The skew will be reduced 0.1 mm by turning the screw once.

• The height of the screw will change 0.7 mm by turning once.

• Do not turn the screw more than 3 turns.

✩ If the skew on the copy paper is to the right, turn the left pressure arm screw

clockwise.

DATE: Oct. 31 ’96

PAGE: 2 of 2

✩ If the skew on the copy paper is to the left, turn the right pressure arm screw

clockwise.

Page 3

RICOH Technical Bulletin PAGE: 1/1

Model: Skylark Date: 31-Mar-97

Subject: SC Code #96 Prepared by: M.Ishihara

From: QAC 1st Field Information Dept. Checked by: T. Inoue

Classification:

The following should be added to the “SERVICE CALL CONDITIONS” in the Service

Manual.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

No: 2

CODE #96 - MAIN SWITCH ERROR

Definition

The machine does not turn off within 8.5 seconds after Auto Shut Off is performed.

Possible Causes

• Defective main switch.

• Connectors of the main switch are not correctly connected.

• Defective dc harness of the main switch connection (some lines must be cut.)

∗Remedy for the initially produced machines

• Turn the main switch off and on.

Loading...

Loading...