Page 1

FT1008/FT1208

(PLOVER, A226/A227)

SERVICE MANUAL

(SCREEN VERSION)

Issued April 8, 1998, Ricoh CO., LTD.

Page 2

IMPORTANT SAFETY NOTES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling any parts of the copier, make sure that the power cord is

unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off or open while the

main switch is turned on, keep hands away from electrified or mechanically driven components.

4. If the Start key is pressed before the copier completes the warm-up period the Ready indicator

will alternately light green and red. When in this condition, keep hands away from mechanical

and electrical components, as the copier will start making copies as soon as the warm-up period

is completed.

5. The inside and the metal parts of the fusing unit become extremely hot while the copier is

operating. Be careful to avoid touching those components with your bare hands.

i

Page 3

HEALTH SAFETY CONDITIONS

1. Toner and developer are non-toxic, but if you get either of them in your eyes by accident, it may

cause temporary eye discomfort. Try to remove with eye drops or flush with water as first aid. If

unsuccessful, get medical attention.

2. Never operate the copier without the ozone filter installed.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier must be maintained by a trained customer service representative.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate the CTDM. Toner dust may ignite suddenly when exposed to open flame.

2. Dispose of the CTDM and organic photoconductor in accordance with local regulations. (These

are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

ii

Page 4

April 8, 1998 Specifications

OVERALL MACHINE INFORMATION

SPECIFICATIONS

Configuration: Desk top

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book

Original Size: Maximum: A4/8½" x 14"

Copy Paper Size Paper tray feed:

A5, B5, A4, 5½" x 8½", 8½" x 11", 8½" x 13",

8½" x 14"

By-pass feed:

Maximum: A4/8½" x 14"

Minimum: A6/8½" x 5½"

Copy Paper weight: Paper tray feed: 60 to 90 g/m2, 16 to 24 lb

By-pass feed: 60 to 180 g/m2, 16 to 48 lb

1

Page 5

April 8, 1998 Specifications

Reproduction Ratios:

Enlargement 141%

Full Size 100% 100%

Reduction 82%

Metric Version Inch Version

141%

122%

93%

71%

78%

70%

Zoom (A227 model only): From 70% to 141% in 1% steps

Copy Speed: 8 copies/minute (A4/8½" x 11")

Wa rm-up Time:

Less than 15 seconds (at 23°C/73°F)

First Copy Time: Less than 10 seconds (A4/8½" x 11")

Copy Number Input: Up/Down key, 1 to 50

Manual Image Density

4 steps including halftone

Selection:

Automatic Reset: 1 minute standard setting; can also be set to 3 minutes or no auto

reset

Paper capacity: Paper Tray: 250 sheets (80 g/m2/20 lb)

By-pass feed entrance: 1 sheet (180 g/m2/48 lb)

2

Page 6

April 8, 1998 Specifications

Toner Replenishment: CTDM exchange (140g/CTDM)

Copy Tray Capacity: 50 sheets

Power Source: 120 V, 60 Hz, more than 10 A (for North America)

220 ~ 240 V, 50/60 Hz, more than 6 A

(for Europe/Asia)

220 V, 50/60 Hz, more than 6 A (for Asia)

Power Consumption:

Maximum 1,200 W/ 1, 300W

Copy cycle 400 W/450W

Warm-up 750 W/790W

Stand-by 55 W/91W

Auto Shut-off 5W/5W

Dimensions: Width: 485 mm, 19.1"

Depth: 385 mm, 15.2"

Height: 260 mm, 10.2"

Noise Emissions:

Sound pressure level at the operator position Less than 55 dB

Sound power level in stand-by condition Less than 40 dB

Sound power level during copy cycle Less than 62 dB

The measurements were made according to ISO 7779

(120 V machines/230 V machines)

3

Page 7

April 8, 1998 Specifications

Weight: Less than 16.5 kg, 36.4 lb

Energy Star Enabled by SP77—default is ON)

Sleep time selected by SP14—default is 30 minutes

(Note: When in sleep mode, only the Start indicator is on (blinking

green). To restore operation, press any key other than the Start key.)

4

Page 8

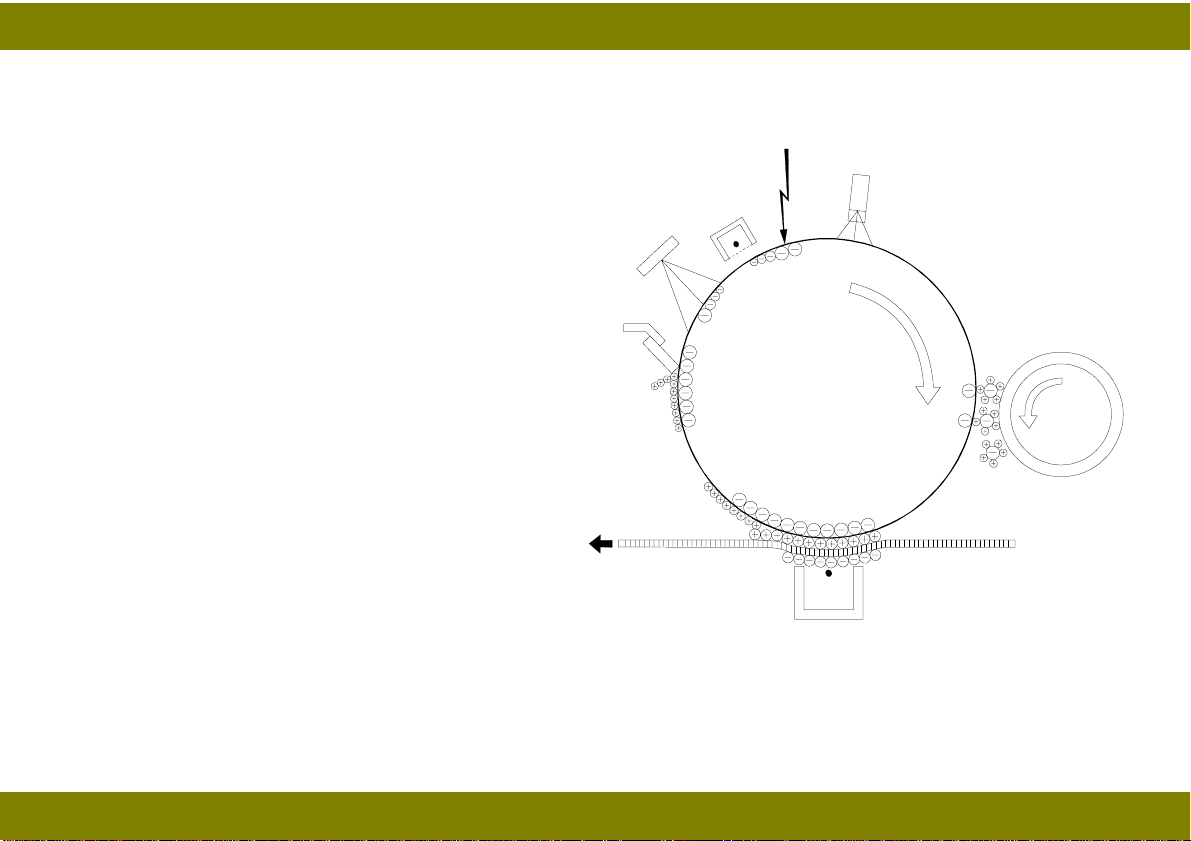

April 8, 1998 COPY PROCESSES AROUND THE DRUM

COPY PROCESSES AROUND THE DRUM

1. Drum Charge

In the dark, the charge corona unit gives a

uniform negative charge to the organic

7

2

3

photoconductor (OPC) drum. The charge

remains on the surface of the drum because the

OPC drum has a high electrical resistance in

the dark.

2. Exposure

6

4

An image of the original is reflected to the drum

surface via the optics assembly. The charge on

the drum surface is dissipated in direct

proportion to the intensity on the reflected light,

thus producing an electrical latent image on the

drum surface.

3. Erase

5

The erase lamp illuminates the area of the

charged drum surface tha t will not b e used for the copy image. The resistance of the drum in the

illuminated areas drops and the charge on those areas dissipates.

5

Page 9

April 8, 1998 COPY PROCESSES AROUND THE DRUM

4. Development

Positively charged toner is attracted to the negatively charged areas of the drum, thus developing the

latent image. (The positive triboelectric charge is caused by friction between the carrier and toner

particles.)

5. Image Transfer

Paper is fed to the drum surface at the proper time so as to align the copy paper and the developed

image on the drum surface. Then, a strong negative charge is applied to the back side of the copy

paper, producing an electrical force which pulls the toner particles from the drum surface to the copy

paper. At the same time, the copy paper is electrically attracted to the drum surface.

6. Cleaning

The cleaning blade scrapes any toner that was not transferred off of the drum.

7. Quenching

Light from the quenching lamp electrically neutralizes the drum surface.

6

Page 10

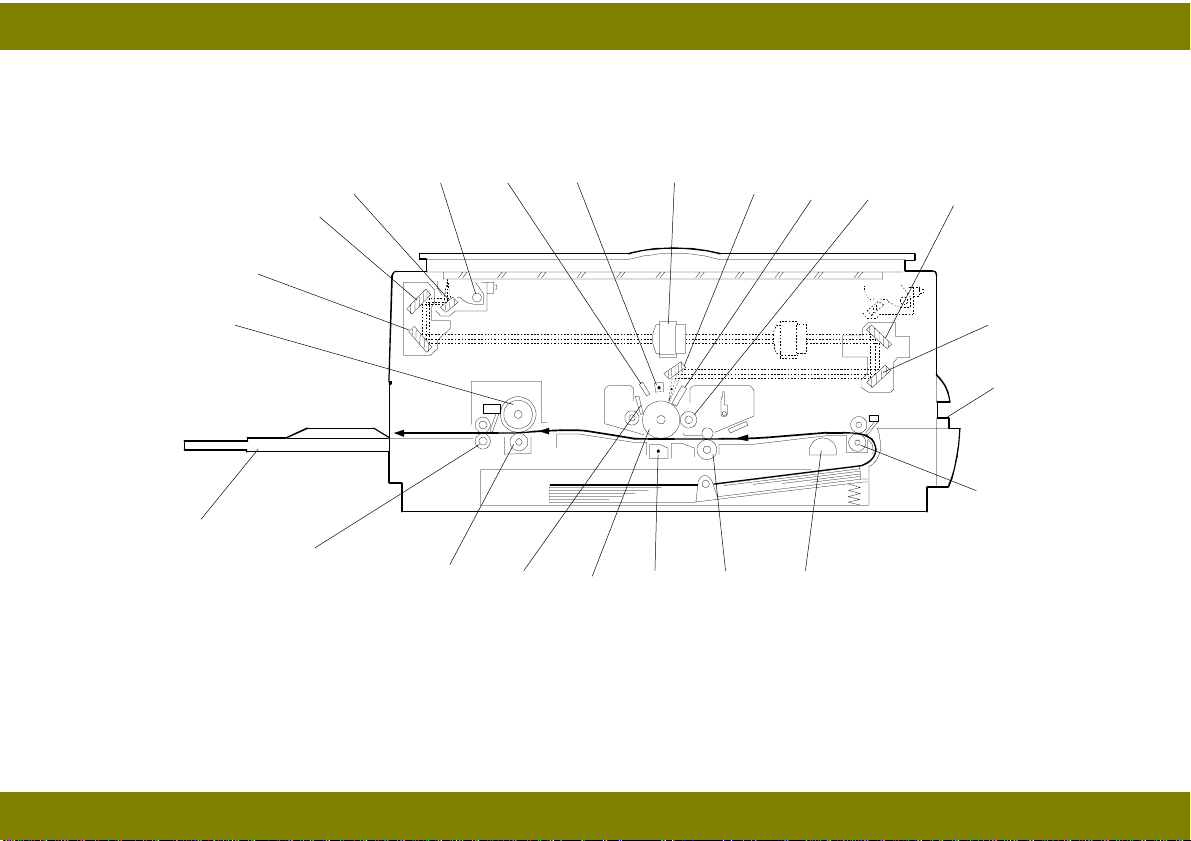

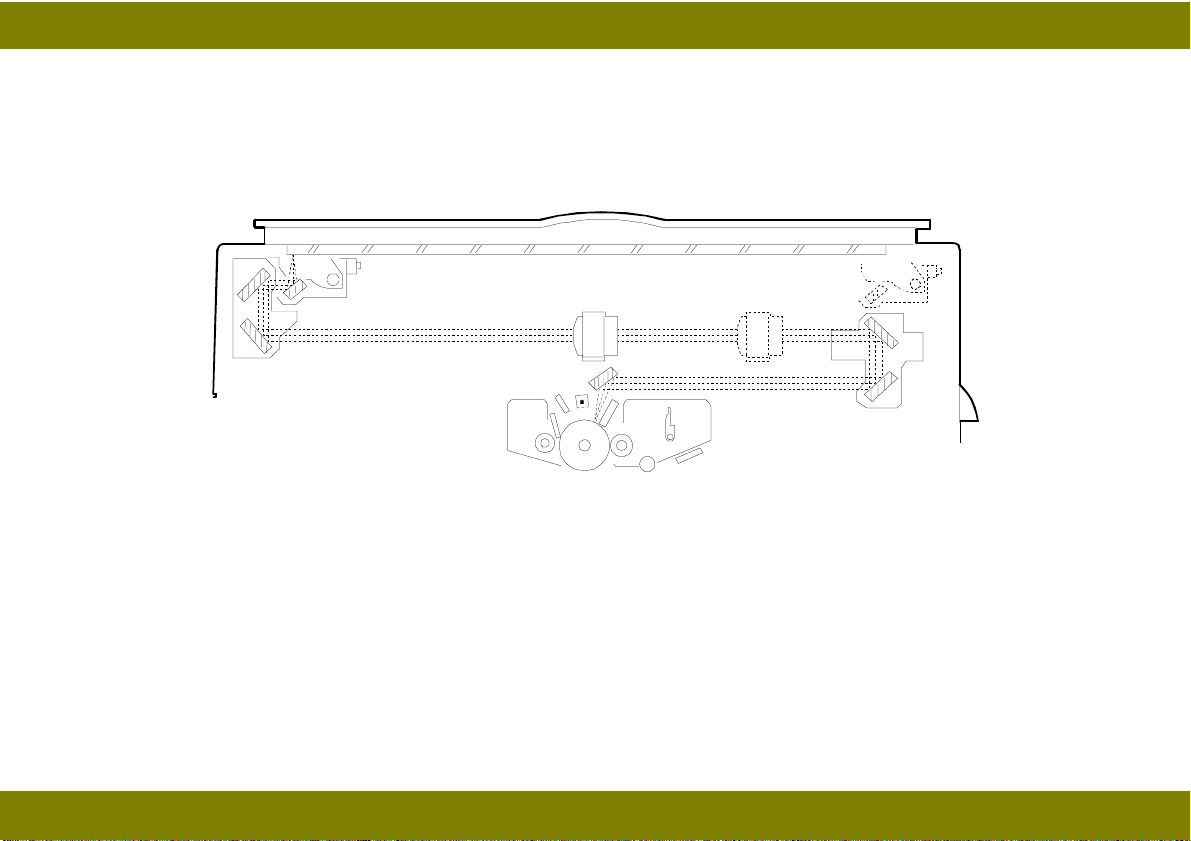

April 8, 1998 MECHANICAL COMPONENT LAYOUT

MECHANICAL COMPONENT LAYOUT

21

22

23

20

2

1

3 4 5 6

19

18

17

7

8 9

141516

10

11

12

13

7

Page 11

April 8, 1998 MECHANICAL COMPONENT LAYOUT

nd

1. 2

mirror

9. Development roller

17. Drum

2. 1st mirror

3. Exposure lamp

4. Quenching lamp

5. Charge corona unit

6. Lens

7. 6th mirror

8. Erase lamp

10. 4th mirror

11. 5th mirror

12. By-pass feed table

13. Relay rollers

14. Paper feed rollers

15. Registration rollers

16. Transfer corona unit

18. Cleaning blade

19. Pressure roller

20. Exit rollers

21. Copy tray

22. Hot roller

23. 3rd mirror

8

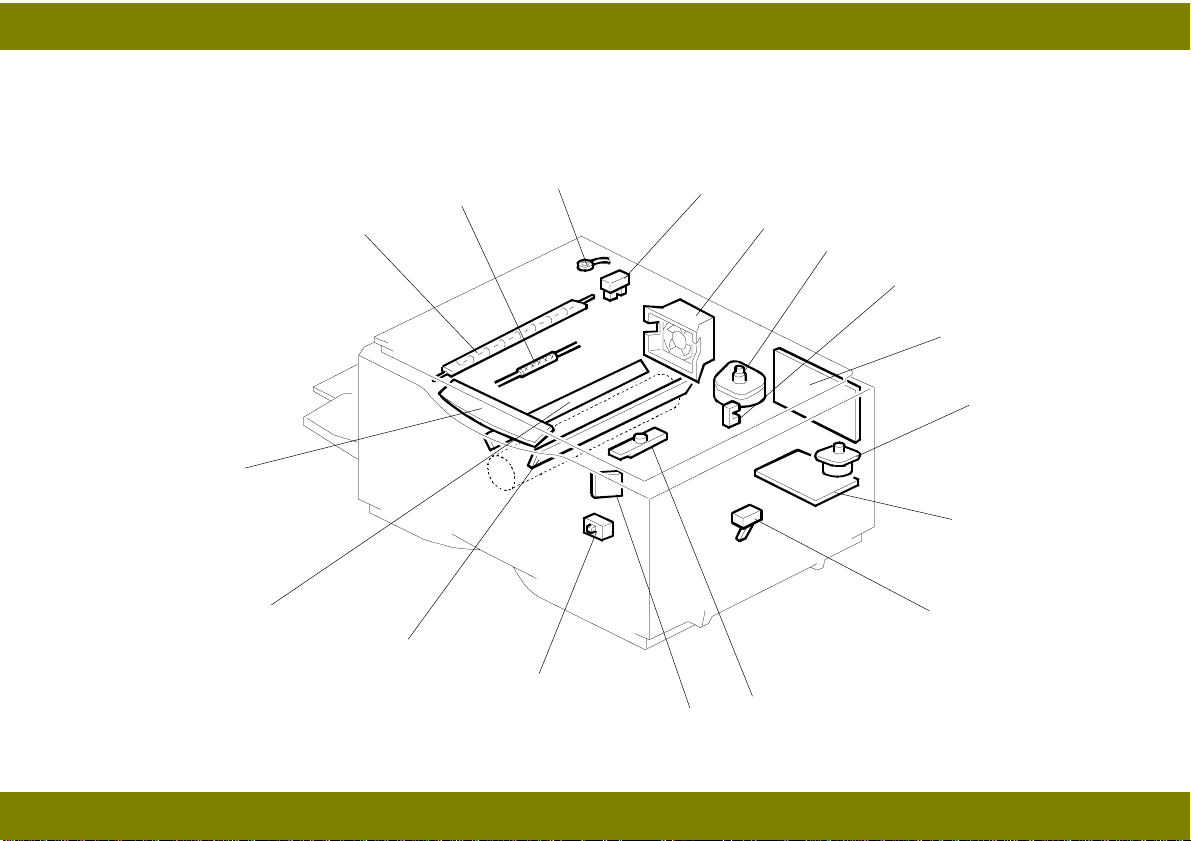

Page 12

April 8, 1998 ELECTRICAL COMPONENT LAYOUT

ELECTRICAL COMPONENT LAYOUT

17

16

2

3

1

15

14

4

13

5

6

7

8

9

10

11

12

9

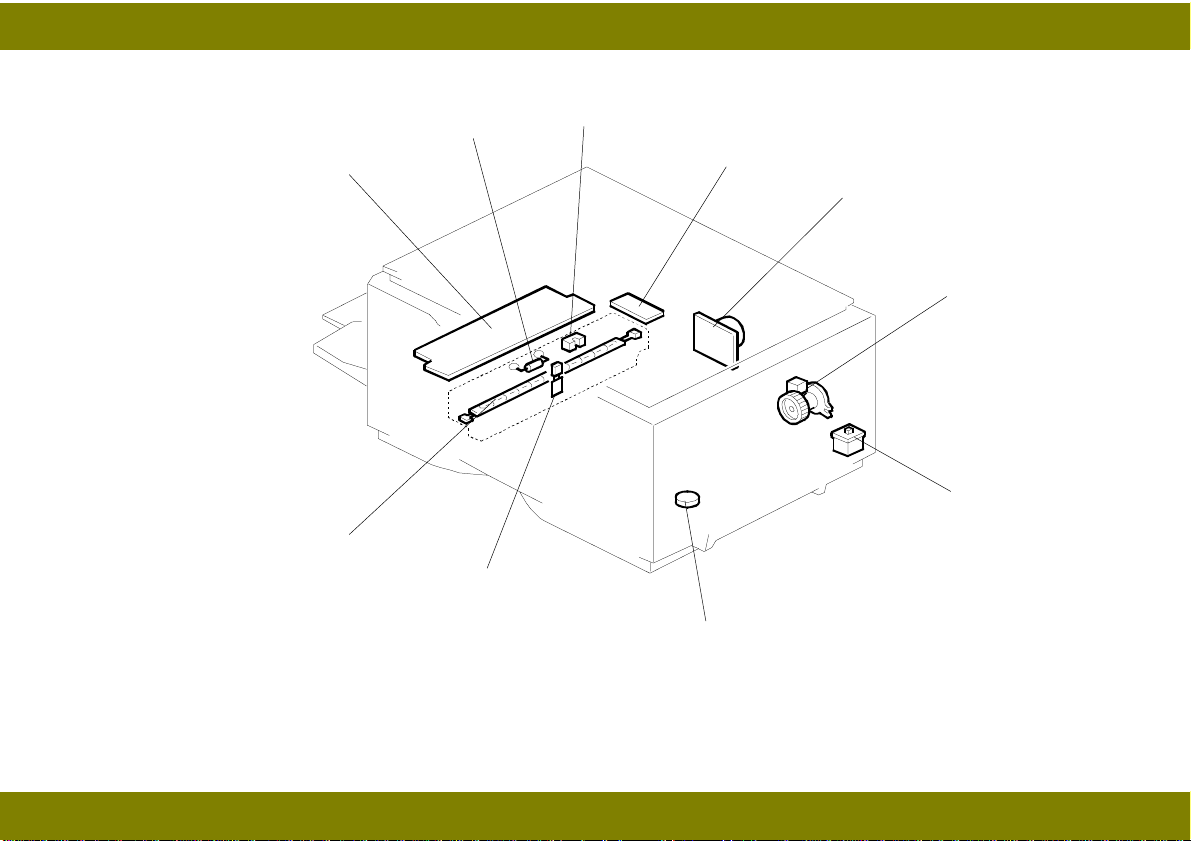

Page 13

April 8, 1998 ELECTRICAL COMPONENT LAYOUT

18

27

19

20

21

22

23

24

26

25

10

Page 14

April 8, 1998 ELECTRICAL COMPONENT DESCRIPTIONS

ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout and the point-to-point diagram on the waterproof foldout

sheet for symbols and index numbers.

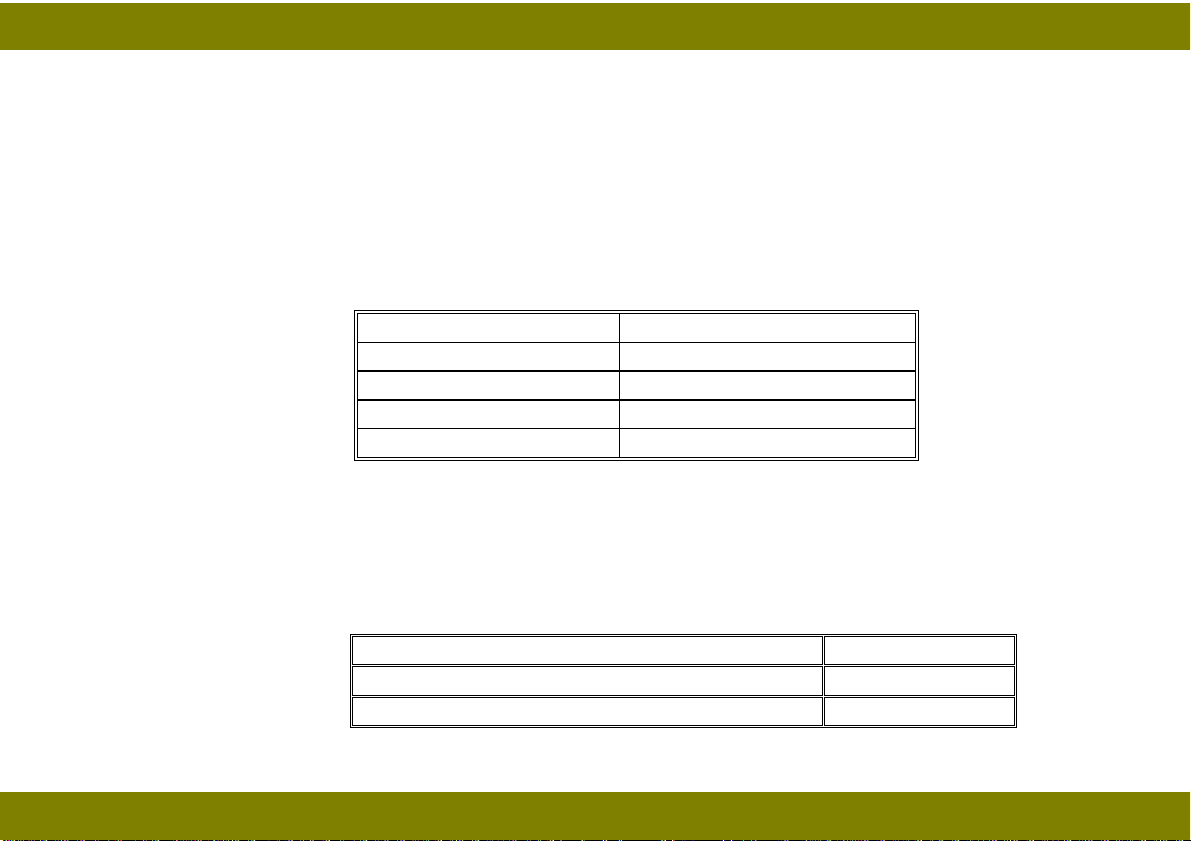

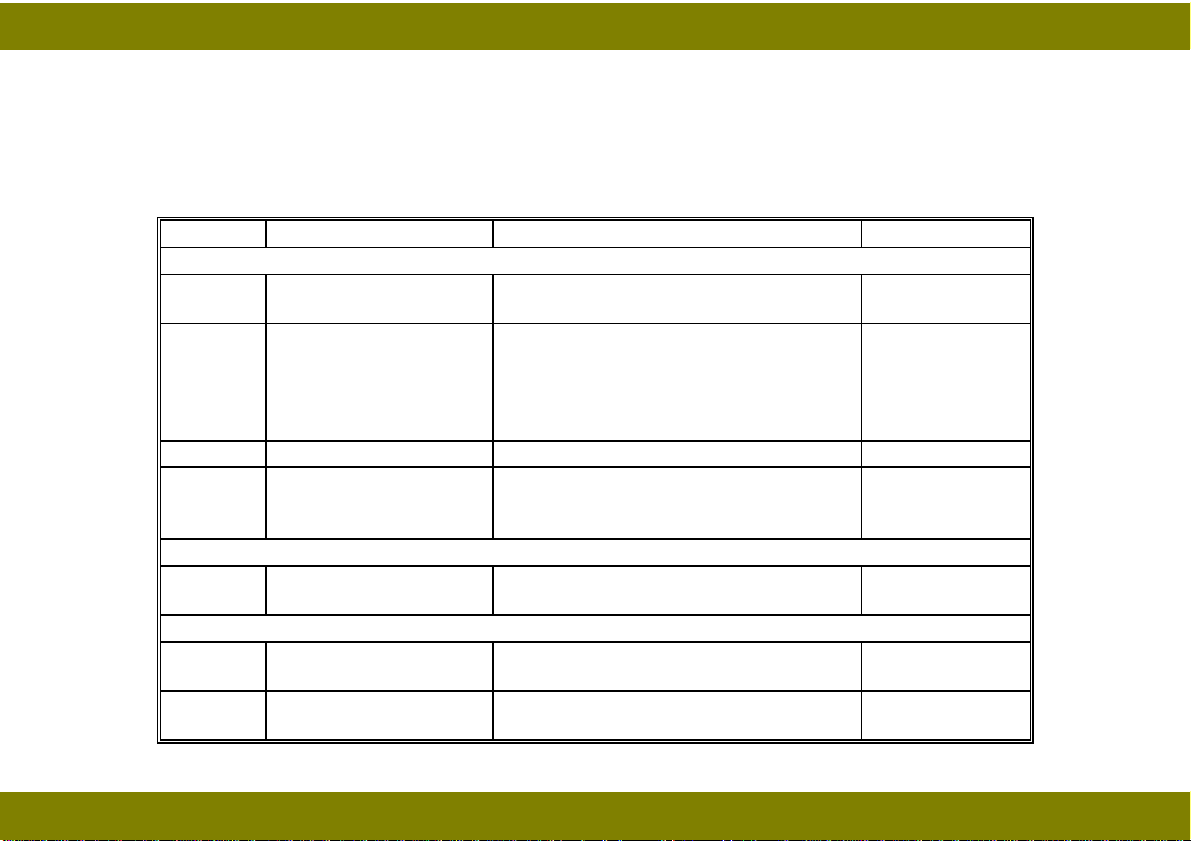

Symbol Name Function Index No.

Motors

M1 Main Motor Drives all the main unit components

except for the optics unit and fans.

M2 Exhaust Fan Motor Removes heat from around the fusing

unit and blows the ozone built up

around the charge corona unit to the

ozone filter. Prevents build-up of hot air

in the optics cavity.

M3 Scanner Drive Motor Drives the scanners (1st and 2nd). 6

M4 Lens and Mirror Motor

(A227 machines only)

Clutches

CL1 Paper Feed clutch Transfers main motor drive to the

Switches

SW1 Interlock Switch Cuts all power when the upper unit is

SW2 VL Switch Changes the light intensity of exposure

Moves the lens and 4th/5th mirror

positions in accordance with the

selected magnification.

paper feed roller.

opened.

lamp.

22

5

9

23

24

14

11

Page 15

April 8, 1998 ELECTRICAL COMPONENT DESCRIPTIONS

Sensors

S1 ADS Sensor Detects the background density of the

original.

S2 Registration Sensor Detects paper end condition. Checks if

paper is set on the by-pass feed table.

S3 Lens and Mirror H. P.

Sensor (A227

machines only)

Informs the CPU when the lens and

th/5th

mirror assembly are at the home

4

position (full size position).

S4 Scanner H. P. Sensor Informs the CPU when the 1st scanner

is at the home position.

S5 Toner End Sensor Detects toner end condition. 12

S6 Exit Sensor Detects misfeeds. 20

Solenoid

SOL1 Registration Solenoid Releases the stopper, synchronizing

the paper-feed timing with the original

scan.

Printed Circuit Boards

PCB1 Main Control Board Controls all copier functions. 8

PCB2 Power Pack Provides high voltage for the charge

corona, transfer corona, and

development bias.

PCB3 Power Supply Board Generates 5 Vdc and 24 Vdc outputs

from 120 Vac or 230 Vac inputs. Drives

the exposure lamp, fusing lamp, and

main motor.

13

11

7

4

25

10

18

12

Page 16

April 8, 1998 ELECTRICAL COMPONENT DESCRIPTIONS

PCB4 Operation Panel Board Informs the CPU of the selected

modes and displays the machine

condition on the panel.

PCB5 Noise Filter Removes electrical noise from the

input power.

Lamps

L1 Exposure Lamp Applies high intensity light to the

original for exposure.

L2 Fusing Lamp Provides heat to the hot roller. 27

L3 Quenching Lamp (QL) Neutralizes any charge remaining on

the drum surface after cleaning.

L4 Erase Lamp Discharges the drum outside of the

image area. (Provides leading/trailing

edge and side erase.)

Others

TH1 Optics Thermistor Monitors the temperature around the

exposure lamp for overheat protection.

TH2 Fusing Thermistor Monitors the fusing temperature. 26

TF1 Exposure Lamp

Thermofuse

TF2 Fusing Thermofuse Provides back up overheat protection

CO Total Counter Keeps a count of the total copies

Provides back up overheat protection

around the exposure lamp.

in the fusing unit.

made. (option)

17

21

1

16

15

3

2

19

—

13

Page 17

April 8, 1998 DRUM

DETAILED DESCRIPTIONS

DRUM

OPC DRUM CHARACTERISTICS

The OPC (Organic Photoconductor) Drum used in this machine is small in diameter (30 mm),

ensuring good paper separation. An OPC drum has the characteristics of:

1. Being able to accept a high negative electrical charge in the dark. (The electrical resistance of a

photoconductor is high in the absence of light.)

2. Dissipating the electrical charge when exposed to light. (Exposure to light greatly increases the

conductivity of a photoconductor.)

3. Dissipating an amount of charge in direct proportion to the intensity of the light. That is, where

stronger light is directed to the photoconductor surface, a smaller voltage remains on the drum.

4. Being less sensitive to changes in temperature (when compared to selenium F type drums).

5. During the drum’s life, drum residual voltage gradually increases and the photoconductive

surface becomes worn. Therefore, some compensation for these characteristics is required.

14

Page 18

April 8, 1998 CHARGE

CHARGE

OVERVIEW

This machine uses a single wire scorotron to charge

the drum. The corona wire [A] generates a corona of

negative ions when the power pack applies a negative

voltage (approximately -4.7 kV). The stainless steel

grid plate [B] ensures that the drum coating receives a

uniform negative charge (-880 V applied by the power

pack) as it rotates past the corona.

The charge corona unit contains a wire cleaner for

user maintenance.

[A]

[B]

15

Page 19

April 8, 1998 CHARGE

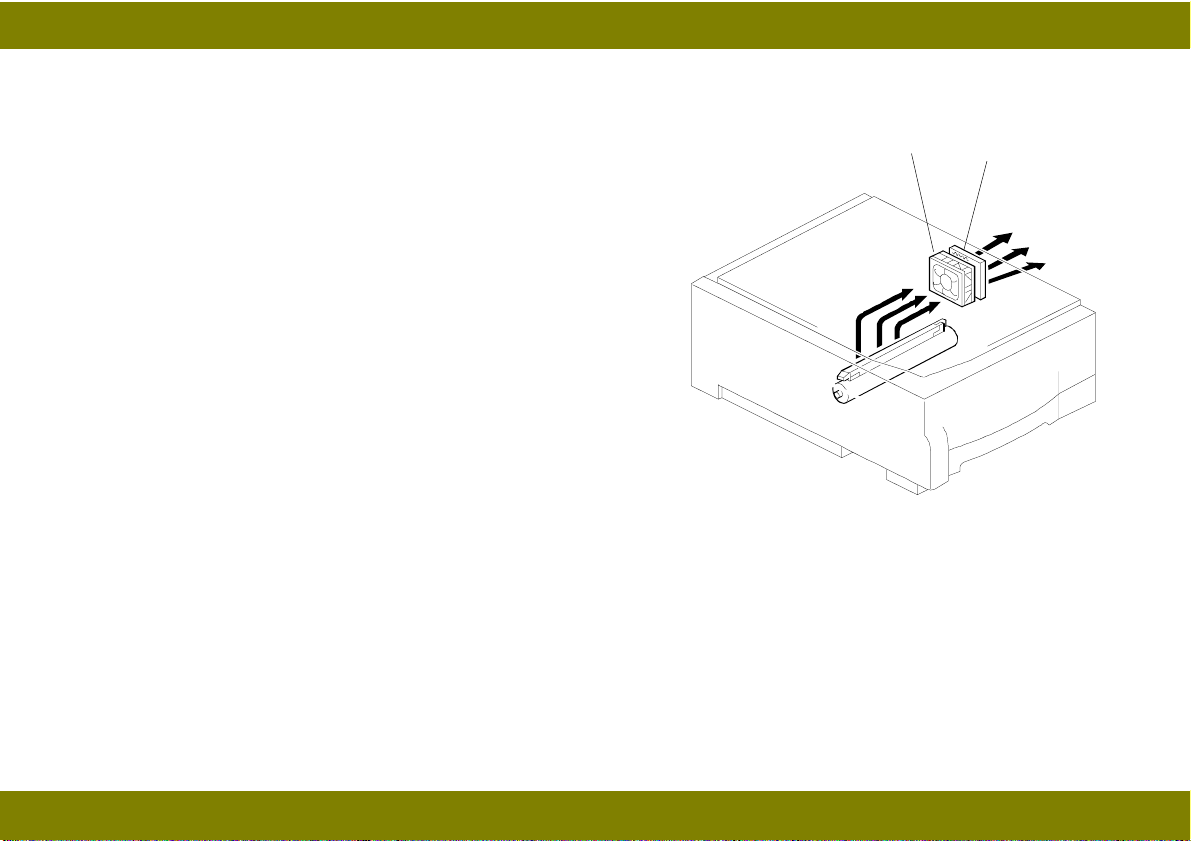

EXHAUST FAN AND OZONE FILTER

The exhaust fan [C] causes a flow of air through the

charge corona section. This prevents an uneven build-up

of negative ions that can cause uneven image density.

The exhaust fan also cools the optics cavity.

An ozone filter [D], which adsorbs ozone (O3) generated

by the charge corona, is located behind the exhaust fan.

The ozone filter decreases in efficiency over time as it

adsorbs ozone. The expected life of the ozone filter is

30k copies.

[C]

[D]

16

Page 20

April 8, 1998 OPTICS

OPTICS

OVERVIEW

During the copy cycle, an image of the original on the exposure glass is reflected onto the drum

surface through the optics assembly.

This machine has five (metric version) or four (inch version) standard reproduction ratios (A227

machine only), and reproduction ratios in one-percent steps from 70% to 141% by zoom function. A

stepper motor is used to change the positions of the lens and the 4th/5th mirrors to enlarge/reduce

17

Page 21

April 8, 1998 OPTICS

the image perpendicular to the scanning direction. Changes in reproduction ratio in the scanning

direction are achieved by changing the scanner speed (A227 machine only).

The CPU monitors the temperature around the optics through a thermistor that is located on the

scanner frame. When the temperature reaches 43°C, the machine stops copying and displays “U1”

on the operation panel. Then the machine moves the scanner to the return position, turns off the

fusing lamp, and starts rotating the exhaust fan faster to cool the optics cavity. After the temperature

drops below 40°C, the machine returns the scanner to the home position, turns on the fusing lamp,

and rotates the fan at the normal speed.

Additionally, a thermofuse on the first scanner provides back up overheat protection. It opens if the

temperature reaches 128°C and cuts ac power to the exposure lamp.

18

Page 22

April 8, 1998 OPTICS

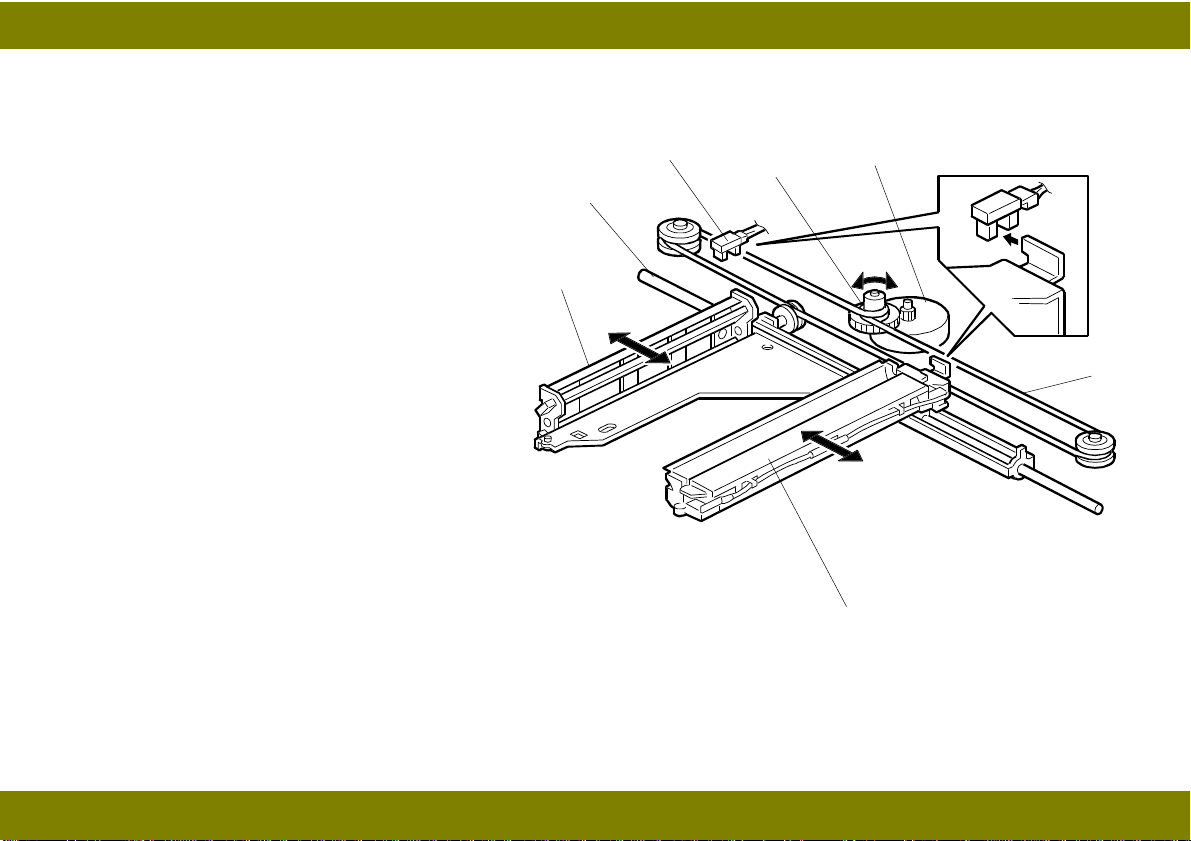

SCANNER DRIVE

A stepper motor [A] is used to drive the

scanner.

The first scanner [B] consists of the

exposure lamp and the first mirror. The

second scanner [C] consists of the second

and third mirrors. The scanner drive motor

drives the first and second scanners using

a scanner drive wire [D] via a pulley [E].

Both of the scanners move along the

guide rod [F]. The second scanner speed

is a half of the first scanner speed.

The home position sensor [G] detects

when the scanner is at the home position.

The scanner return position is determined

by counting the scanner motor drive

pulses.

[C]

[F]

[G]

[E]

[A]

[D]

[B]

19

Page 23

April 8, 1998 OPTICS

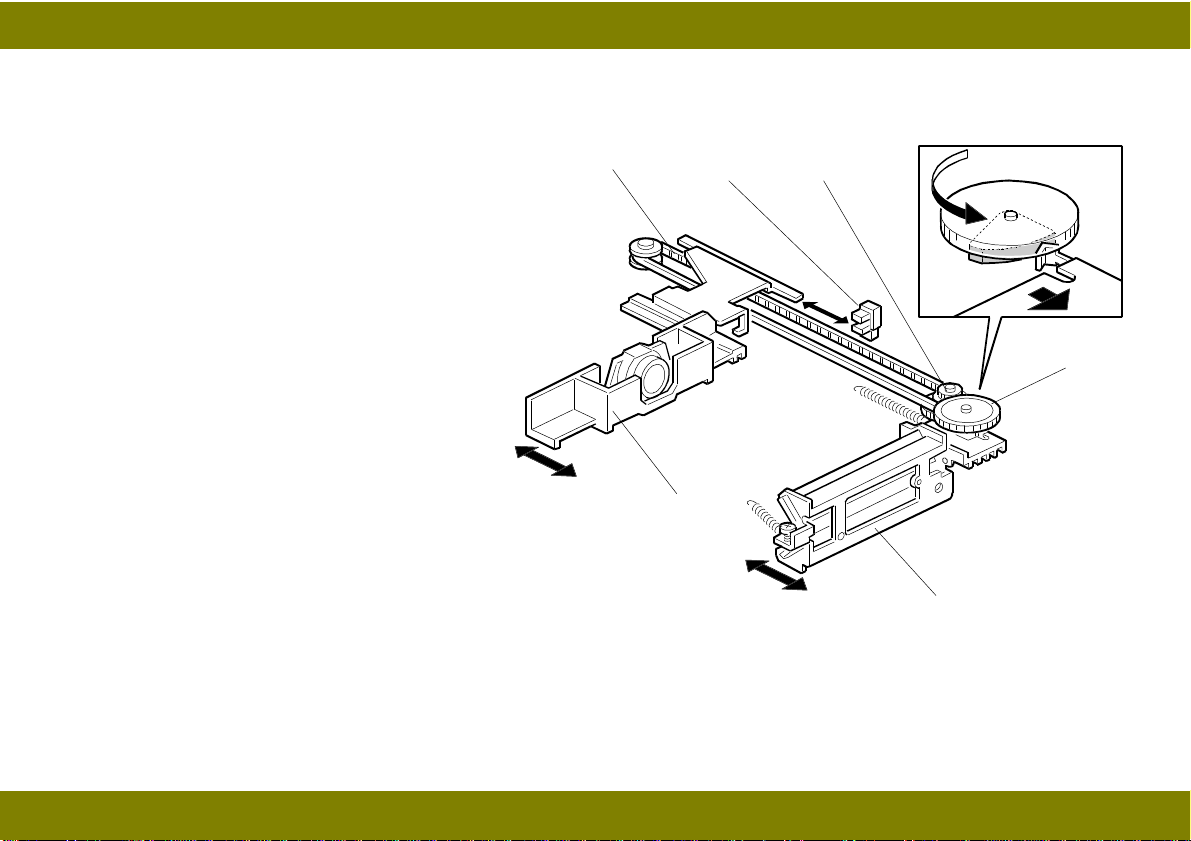

LENS AND 4TH/5TH MIRROR DRIVE (A227 MACHINE ONLY)

Drive from the lens motor [A] is

transmitted to the timing belt [B] on

which the lens unit [C] is clamped. The

lens position is changed to provide the

proper optical distance between the lens

and the drum surface corresponding to

the selected reproduction ratio. The

home position sensor [D] detects when

the lens is at its home position. The main

control boards keeps track of the lens

position based on the number of pulses

sent to the lens motor.

Drive from the lens motor is also

transmitted to the 4th/5th-mirror drive

cam [E]. As the lens unit position is

changed, the cam rotates to change the

4th/5th-mirror [F] position to provide

proper the focal distance between the

lens and the drum surface.

[B]

[C]

[D]

[A]

[E]

[F]

20

Page 24

April 8, 1998 OPTICS

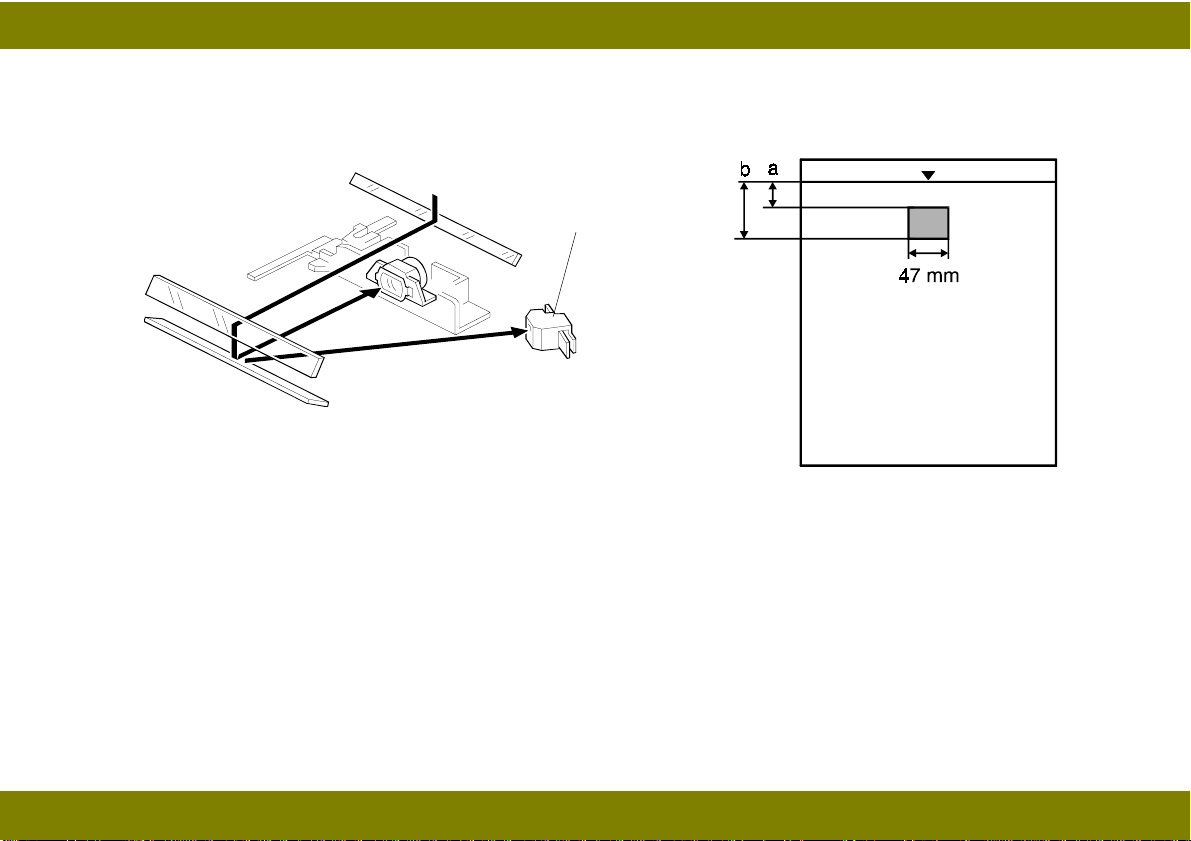

AUTOMATIC IMAGE DENSITY CONTROL SYSTEM (ADS)

[A]

In ADS mode, the original background density is sensed by the ADS sensor [A] and the CPU

determines an appropriate development bias voltage for the original to prevent dirty background from

appearing on copies.

The sensor, a photodiode, is mounted on the upper front frame. The sensor cover has a hole to allow

the light reflected from the original to fall directly onto the sensor.

Sampling starts 6 millimeters “a” from the leading edge of the original and continues for 15.0

millimeters “b” from the leading edge of original in full size mode. These lengths “a” and “b” will vary

depending on the selected reproduction ratio.

21

Page 25

April 8, 1998 OPTICS

The photosensor circuit converts the light intensity to a voltage. The detected voltage is amplified

and sent to the main control board. The output from the sensor is adjusted to 2.5 volts for a normal

white original. The sensor outputs a lower voltage as less light is reflected from the original (the

background is darker). The CPU compares the maximum detected voltage with the ADS reference

voltage (2.5 ± 0.2 volts) and compensates the copy image density by changing the development bias

voltage.

22

Page 26

April 8, 1998 OPTICS

EXPOSURE LAMP VOLTAGE CONTROL

The main board controls the exposure lamp voltage through the power supply board. The copy

image density is controlled by the lamp intensity and development bias.

This section explains how the exposure lamp voltage control affects the copy image density.

Base Lamp Voltage Setting

The base lamp voltage is determined by the SP48 setting.

Base Lamp Voltage =

SP48 value x 0.5 (120 V machines)

SP48 value x 1.0 (230 V machines)

The default settings (may not equal to factory settings) of SP48 are:

128

for 120 V machines (= 64 V)

120

for 230 V machines (= 120 V)

Increasing the value makes the copy image lighter.

The maximum value of the lamp voltage setting including compensation factors (see following) is 180

for 230-volt models and 194 for 120-volt models. For 120-volt machines, the actual lamp voltage is

one-half the lamp voltage setting; therefore, the maximum lamp voltage is 97 volts. For 230-volt

machines the actual lamp voltage is the same as the lamp voltage setting; so, the maximum voltage

is 180 volts.

23

Page 27

April 8, 1998 OPTICS

Compensation Factors

The base lamp voltage is shifted by several factors as discussed in the following sections.

NOTE:

In the following tables, the default settings are in bold type.

1. Reproduction Ratio Correction

The exposure lamp voltage increases or decreases depending on the magnification ratio. This

compensates for the change in concentration of light on the drum.

Magnification Ratio Exposure Lamp

70% to 99% -1 step

100% 0

101% to 141% +1 step

2. Image Density Adjustment Setting (SP34)

SP34 can adjust the copy image density to adapt the machine to its operating environment.

Depending on the SP34 setting, both the exposure lamp voltage and the development bias may

change.

24

Page 28

April 8, 1998 OPTICS

SP34 (This can also be changed by UP1.)

SP34 Setting Setting Exposure Lamp

Voltage Change

0Normal 0 0

1 Light 0 -40 V

2 Dark 0 +40 V

3 Lighter +3 steps -40 V

4 Darker -3 steps +40 V

5 Lightest +7 steps -40 V

6 Darkest -7 steps +40 V

Development

Bias Change

1 step = 0.5 V (120 V machines) or 1.0 V (230 V machines)

3. Image Density Setting Position

The operation panel has four image density level positions. Depending on the position, the exposure

lamp base voltage is changed. (ADS is the default.)

Photo Mode Darker ADS Lighter

0 - 6 steps 0 + 6 steps

In the photo mode, the exposure lamp voltage is unchanged; however, the development voltage is

changed to improve the copy image for halftone originals. (Refer to Development section.)

25

Page 29

April 8, 1998 OPTICS

(Image Density Adjustment At Darker Setting Position)

There are two SP modes which can adjust the image density when the “Darker” position is selected

on the operation panel.

Both SP modes change the exposure lamp voltage as shown below.

SP35: Coarse Adjustment (This can also be changed by the UP2)

SP35 Setting Setting Exposure Lamp Voltage

0 Normal -6 steps

1 Darker -8 steps

2 Darkest -10 steps

SP38: Fine Adjustment

Setting SP38 Setting Lamp Voltage Change

Darkest 0 -3 steps

1 -2 steps

2 -1 step

30

4 +1 step

5 +2 steps

Lightest 6 +3 steps

26

Page 30

April 8, 1998 OPTICS

(Image Density Adjustment at Lighter Setting Position)

There are two SP modes which can adjust the image density when the “Lighter” position is selected

on the operation panel.

Only the SP mode (SP39) for the fine adjustment of the image density changes the exposure lamp

voltage. The coarse adjustment (SP36) changes the development bias (see Development section).

SP39: Fine Adjustment

Setting SP39 Setting Lamp Voltage Change

Darkest 0 -3 steps

1 -2 steps

2 -1 step

30

4 +1 step

5 +2 steps

Lightest 6 +3 steps

(Image Density Adjustment At Photo Mode Position)

The image density in the Photo mode can be changed by the SP64.

The exposure lamp voltage and the base development bias are changed by SP64 as shown in the

table.

SP64 (This can also be changed by UP4.)

27

Page 31

April 8, 1998 OPTICS

Settings No. Base Bias Voltage Exposure Lamp

Change

Lightest 0 -270 V +4 steps

1 -270 V +2 steps

2 -270V 0

3 -230 V 0

4 -210 V 0

Darkest 5 -190 V 0

4. VL Correction

The light intensity may decrease because of dust accumulated on the optics parts. Additionally, the

drum sensitivity gradually decreases during the drum’s life. This may cause dirty background on

copies. This is automatically compensated for by the VL correction.

The exposure lamp voltage is increased by +1.0 volts (230-V machines), or +0.5 volts (120-V

machines) at the set copy count interval. The VL correction counter tracks the copy count interval.

Note that if the VL counter is cleared, an improper correction will be applied. The table below shows

the relationship between the SP setting and the interval.

28

Page 32

April 8, 1998 OPTICS

SP63 Setting Exposure Lamp Voltage Special UP31

0 +1 step/4000 copies 0

1 +1 step/3000 copies 1

2 +1 step/2500 copies 2

3 +1 step/2000 copies 3

4 +1 step/1500 copies 4

5 +1 step/1000 copies 5

6 +1 step/500 copies 7 +1 step/250 copies 8 No Correction -

(Special UP Modes)

There are thirteen user program modes on this model (refer to the operator’s manual and UP mode

and SP mode cross-reference table). The operator’s manual, however, explains only eight modes of

them.

The UP modes numbered from 30 to 34 are special UP modes. If it is necessary to change any

settings related to the special UP modes, the service representative may ask the user to change it

and thus avoid a visit.

Please note that UP31 accepts settings only from 0 to 5.

29

Page 33

April 8, 1998 OPTICS

(VL Switch)

Depending on the environment, the default automatic VL correction may not be enough to correct

the image density. The VL switch is located on

the upper registration roller assembly in the

machine and allows the operator to correct image

density manually.

The exposure lamp voltage is increased

according to the VL switch position.

Position 0 Position 1 Position 2

0

+10 steps +20 steps

The amount of increase in each position can be changed by SP62 as shown below:

SP62 Setting Special UP Mode Exposure Lamp Voltage

UP32 SW Position 0 SW Position 1 SW Position 2

0 0 0 +10 steps +20 steps

1 1 0 +5 steps +10 steps

2 2 0 +15 steps +30 steps

3 3 0 +20 steps +40 steps

30

Page 34

April 8, 1998 ERASE

ERASE

OVERVIEW

The erase lamp [A], which is installed in

the upper unit, consists of a single row of

LEDs extended across the full width of the

drum. The erase lamp has the following

functions:

• Leading edge erase

• Side erase (A227 machines only)

• Trail edge erase

abcdefg abcdefgh

[A]

31

Page 35

April 8, 1998 ERASE

LEAD EDGE ERASE

The entire line of LEDs turns on when the main motor turns on. They stay on until the erase margin

slightly overlaps the lead edge of the original image area on the drum (Lead Edge Erase Margin).

This prevents the shadow of the original edge from being developed on the copy. At this point, side

erase starts (A227 machines only). The width of the leading erase margin can be adjusted using

SP41.

SIDE ERASE (A227 MACHINES ONLY)

Based on the reproduction ratio, the LEDs turn on blocks (labeled “a” to “h” on the previous page).

This reduces toner consumption and drum cleaning load.

The CPU determines which blocks to turn on based on the selected reproduction ratio as follows.

Reproduction Ratio (%) Blocks ON

70 to 72 a - g

73 to 76 a - f

77 to 80 a - e

81 to 85 a - d

86 to 88 a - c

89 to 92 a - b

93 to 97 a

98 to 100 All Off

32

Page 36

April 8, 1998 ERASE

TRAILING EDGE ERASE

This minimizes toner consumption.

The entire line of LEDs turns on after the trailing edge of the latent image has passed 10 mm from

the erase lamp. The length of the latent image is determined by the paper length, which is checked

by the registration sensor. The LEDs stay on to erase the leading edge of the latent image in the next

copy cycle. After the final copy, the erase lamps and the main motor turn off at the same time.

33

Page 37

April 8, 1998 development

DEVELOPMENT

OVERVIEW

The development unit is contained in

the CTDM (Cleaning Toner Development Magazine). When the main motor

turns on, the development roller [A] and

agitator [B] start turning.

There are permanent magnets in the

development roller which attract the

developer to the roller. The turning

sleeve of the development roller carries

the developer past the doctor blade,

which trims the developer to the desired

thickness.

The development roller sleeve continues to turn, carrying the developer to the drum [C]. When the

developer brush contacts the drum surface, the negatively charged areas of the drum surface attract

and hold the positively charged toner. In this way, the latent image is developed. The amount of

toner consumed during development is supplied from the toner bottle automatically.

[A]

[C]

[D]

[B]

The development roller is given a suitable negative bias to prevent toner from being attracted to the

non-image areas, which may have a residual negative charge. The bias also controls image density.

The toner end sensor [D] detects when toner in the CTDM has run out.

34

Page 38

April 8, 1998 development

TONER SUPPLY MECHANISM

Before the two seals [A, B] and are

removed from a new CTDM, the developer

is divided into six cells to prevent developer

in it from biasing during shipment. Toner

and developer mix when the seals are

removed. Whenever a new CTDM is

installed into the machine, CTDM initialization must be performed to mix the toner

and developer evenly, and create the

triboelectric charge.

CTDM initialization is performed at the

following times:

• when the main switch is turned off and on at the toner end condition

• when the upper cover is opened and closed at the toner end condition

• SP12 is performed

[A]

[C]

[B]

[D]

NOTE:

CTDM initialization must be performed by using SP12 if the CTDM is replaced when the

toner end condition does not exist.

The developer case is full of developer and toner after CTDM initialization. Toner density in the

developer case [C] is kept uniform all the time since the amount of consumed toner is supplied from

the toner case [D] automatically.

35

Page 39

April 8, 1998 development

DEVELOMENT BIAS FOR IMAGE DENSITY CONTROL

Image density is controlled by changing two items—the amount of bias voltage applied to the

development roller sleeve, and the amount of voltage applied to the exposure lamp.

Applying a bias voltage to the development sleeve reduces the potential between the development

roller and the drum, thereby reducing the amount of toner transferred. As the bias voltage becomes

greater, the copy becomes lighter.

The method of control depends on whether the image density is manually selected or auto image

density is used.

Base Bias Voltage in Each Image Density Mode

The base bias voltage for non-image areas (between copies) is fixed at -150 Volts. This value is

also be compensated by the factors explained later.

The base bias voltage for image areas is determined according to the setting of the image density

mode. The following table shows the base development bias. The exposure lamp base voltage

correction value is included as a reference.

Photo Mode Darker ADS Lighter

Base Bias -230 V -150 V -150 V -190 V

Exposure Lamp Voltage 0 -6 steps 0 +6 steps

36

Page 40

April 8, 1998 development

Compensation Factors

1. Automatic Image Density (ADS) Mode

In ADS mode, the exposure lamp base voltage is fixed at a value that is determined by SP48 (see

Optics section). Image density is controlled by changing only the development bias voltage.

The bias voltage for ADS mode depends on the background image density of the original as

measured by the ADS sensor.

The CPU checks the voltage output from the automatic ID circuit. This circuit has a peak hold

function. The peak hold voltage corresponds to the maximum reflectivity of the original. The CPU

then determines the proper development bias level with reference to the peak hold voltage.

The table below shows the ratio of the ADS voltage (actual original background density) to the ADS

reference voltage (standard white background density) and the development bias voltage.

ADS Voltage Ratio (%) Development Bias Voltage

80 to 100 (light) -150 V

73 to 79 -190 V

60 to 72 -230 V

30 to 59 -270 V

0 to 29 (dark) -290 V

37

Page 41

April 8, 1998 development

2. Image Density Adjustment Setting (SP34)

Based on SP34, compensation will be applied to the development base bias voltage as shown in the

following table. This compensation is applied to all the image density adjustment positions.

SP34 (This can also be changed by UP1)

SP34 Setting Setting Development

Bias Change

0Normal +0 V 0

1 Light -40 V 0

2 Dark +40 V 0

3 Lighter -40 V +3 steps

4 Darker +40 V -3 steps

5 Lightest -40 V +7 steps

6 Darkest +40 V -7 steps

Exposure Lamp

Voltage Change

NOTE:

The value in the list will be added to the base bias voltage.

Example)

Operation panel set to “Darker”

Base bias voltage = -150 Volts

SP34 Setting = 3

Development bias = -150 + (-40) = -190 Volts

38

Page 42

April 8, 1998 development

3. Image Density Adjustment at Lighter Setting Position (SP36)

SP36 can change the base bias voltage when the “Lighter” position is selected on the operation

panel.

SP36 (This can also be changed by UP3)

SP36 Setting Image Density Base Bias Voltage at Lighter Position

0 Normal -190 V

1 Lighter -230 V

2 Lightest -270 V

4. Photo Mode Correction (SP64)

The image density in the Photo mode can be changed by the SP64 as shown in the following table.

SP64 (This can also be changed by UP4)

No. Setting Base Bias Voltage Exposure Lamp

0 Lightest -270 V +4 steps

1 Lighter -270 V +2 steps

2 Light -270V 0

3 Normal -230 V

4 Dark -210 V 0

5 Darker -190 V 0

0

39

Page 43

April 8, 1998 development

TONER END CONDITION

Toner end condition is determined by the toner end sensor, which is located below the toner bottle of

the CTDM.

Toner Near-end Condition

While the main motor is rotating, the machine monitors the voltage output from the toner end sensor.

The voltage from the sensor is high when the toner bottle of the CTDM is full and becomes low when

the toner bottle is almost empty.

If the CPU detects a low output from the toner end sensor more than 3 times in a row, the CPU starts

to blink the Replace CTDM indicator (). This is the toner near-end condition. After it detects this

condition, the machine can make 50 copies.

The machine clears the toner near-end condition if the output from the toner end sensor goes back

high for 5 seconds.

Toner End Condition

If the machine makes more 50 sheets of copies during toner near-end condition or the CPU detects

a low output for more than 5 seconds, it disables copying and lights the Replace CTDM indicator

().

40

Page 44

April 8, 1998 development

The machine clears the toner end condition if the output from the toner end sensor goes back high

for 5 seconds.

Toner End Recovery

Replacing the CTDM clears the toner end condition. If the main switch is turned off and back on, or

the upper cover is opened and closed during the toner near-end condition or toner end condition, the

machine expects that the CTDM has been replaced. It then rotates the main motor for CTDM

Initialization, and then the CPU monitors an output from the sensor. The machine clears the toner

end condition if the CPU detects a high output from the toner end sensor for more than 5 seconds.

NOTE:

1) The machine also detects the toner end condition when the CTDM is

not installed in it.

2) CTDM initialization can be executed using SP12.

41

Page 45

April 8, 1998 IMAGE TRANSFER

IMAGE TRANSFER

A high negative voltage (approximately -5.5 kV) is applied to the transfer corona wire [A] by the power pack,

and the corona wire generates negative ions. These negative ions are

applied to the back side of the copy

paper. This negative charge forces the

paper against the drum and attracts

the positively charged toner onto the

paper.

The paper separates from the drum

automatically because of the drum’s

small diameter. Due to the paper’s

stiffness, it cannot make the sharp

turn and separates without any assistance. This is sometimes referred to

as

curvature separation

.

[A]

42

Page 46

April 8, 1998 DRUM CLEANING

DRUM CLEANING

The cleaning unit and the used toner

tank are contained in the CTDM.

A counter blade system is used for drum

cleaning. The cleaning blade [A] scrapes

off any toner remaining on the drum

after the image is transferred to the

paper.

There is no used toner overflow

detection mechanism because the used

toner tank is large enough for the

lifetime of the CTDM.

[A]

43

Page 47

April 8, 1998 QUENCHING

QUENCHING

[A]

In preparation for the next copy cycle, light from the quenching lamp (LEDs) [A] neutralizes any

charge remaining on the drum. The quenching lamp is installed on the charge corona unit.

44

Page 48

April 8, 1998 PAPER FEED AND REGISTRATION

PAPER FEED AND REGISTRATION

OVERVIEW

This machine has one paper feed station and a

by-pass feed table.

The paper feed station uses a paper tray [A]

which can hold 250 sheets. The by-pass feed

table [B] can hold 1 sheet.

The paper tray uses two semicircular feed

rollers [C] and a corner separator. The

semicircular feed rollers make one rotation to

drive the top sheet of the paper stack to the

relay rollers [D].

The paper tray has two corner separators,

which allow only one sheet to feed. They also

serve to hold the paper stack.

If a sheet of paper is set on the by-pass feed

table, the registration sensor [E] is actuated and

the machine goes to by-pass feed mode.

[D]

[E]

[A]

[B][C]

45

Page 49

April 8, 1998 PAPER FEED AND REGISTRATION

PAPER FEED MECHANISM

The main motor rotation is transmitted to the paper feed

clutch gear [A] though several gears. The rotation of the

paper feed clutch gear is transmitted to the relay roller

gear [B] through an idle gear.

After the Start key is pressed, the solenoid [C] of the

paper feed clutch is energized to release the stopper [D],

and the rotation of the relay roller gear is transmitted to

the feed roller shaft [E]. The solenoid stays on for 250

milliseconds and then turns off. The feed rollers stop

when they complete one rotation.

Before the feed rollers stop, the relay rollers [F] catch the

leading edge of the paper and continue feeding it.

[C]

[A]

[E]

[D]

[B]

[F]

46

Page 50

April 8, 1998 PAPER FEED AND REGISTRATION

REGISTRATION MECHANISM

The relay rollers always rotate while the main

motor rotates. They transport the paper to

the registration rollers [A]. The registration

rollers are also driven by the main motor

through idle gears.

There is a paper stopper [B] between the

relay rollers and the registration rollers. After

the leading edge of the paper reaches the

stopper, it buckles slightly to remove skew.

Then, 2.9 seconds after the paper feed

clutch is turned on, the registration solenoid

[C] is energized to release the stopper,

synchronizing the paper feeding with the

image on the drum. After 0.6 seconds, the

registration solenoid is de-energized.

The registration sensor detects paper length

and paper end.

[A]

[B]

[C]

47

Page 51

April 8, 1998 PAPER FEED AND REGISTRATION

BY-PASS FEED

[C]

[B]

[A]

[D]

If a sheet of paper is inserted in the by-pass feed table [A], the registration sensor [B] is actuated and

the machine goes to by-pass feed mode. 300 milliseconds after the registration sensor is actuated,

the main motor turns on for 230 milliseconds to drive the relay roller [C] to catch the leading edge of

the paper. The relay roller then transports the paper to the registration roller [D]. The registration

solenoid is energized 2358 milliseconds after the main motor starts rotating.

48

Page 52

April 8, 1998 PAPER FEED AND REGISTRATION

PAPER FEED AND MISFEED DETECTION TIMING

%&

" #$

!

The registration sensor and the exit sensor are used for misfeed detection. If the CPU detects a

misfeed, the Check Paper Path indicator () turns on or “PE” is displayed on the copy counter.

When the main switch is turned on, the CPU checks these sensors for initial misfeed.

During the copy cycle, the CPU performs four kinds of misfeed detection:

49

Page 53

April 8, 1998 PAPER FEED AND REGISTRATION

PE: Checks whether the registration sensor is actuated within 1.2 seconds after the Start key is

pressed. Since this machine has no indicator or sensor to detect paper end, the “PE” indicator is

lit in the paper end condition as well.

” (1): Checks whether the copy paper has passed through the registration sensor 6.7 seconds after

the Start key is pressed.

” (2): Checks whether the exit sensor is actuated within 6.7 seconds after the Start key is pressed.

” (3): Checks whether the copy paper has passed through the exit sensor 12.4 seconds after the

Start key is pressed.

50

Page 54

April 8, 1998 IMAGE FUSING

IMAGE FUSING

OVERVIEW

[F]

After the image is transferred, the copy

paper enters the fusing unit. The image is

fused to the copy paper by the process of

heat and pressure through the use of a hot

roller [A] and pressure roller [B].

The CPU monitors the hot roller temperature

through a thermistor [C] that is in contact

with the hot roller surface. A thermofuse [D]

protects the fusing unit from overheating.

[H]

[E]

[A]

The hot roller strippers [E] separate the copy

paper from the hot roller and direct it to the

exit rollers. The exit sensor [F] monitors the

progress of the copy paper through the

fusing unit and acts as a misfeed detector.

The exit rollers drive the copy paper to the

copy tray.

When the upper unit is closed, the pressure roller is pushed up by the arms [G]. The springs [H] of

front and rear apply the proper fusing pressure between the hot roller and the pressure roller.

[G]

[B]

[D]

[C]

51

Page 55

April 8, 1998 IMAGE FUSING

FUSING LAMP CONTROL

The CPU monitors the temperature of the hot roller surface using a thermistor. The fusing lamp is

turned on and off to keep the hot roller surface at the target temperature. The target temperature

depends on the machine condition as follows.

200 C°

160 C°

150 C°

Room Temp.

Fusing

Lamp

ON

OFF

M ain SW is tu r n e d o n

Copy starts

Pa p e r fe e d s tarts

Start key is pressed

Copy finishes

52

Page 56

April 8, 1998 IMAGE FUSING

Machine Condition Fusing Lamp

After the main switch is turned on

and the fusing temperature has

°

reached 160

During copying

Within 30 minutes after copying is

finished

Over 30 minutes after copying is

finished

C.

ON/OFF Threshold

°

160

C

°

200

C

°

160

C

°

150

C

When the Start key is pressed

the red indicator lights and the

fusing temperature increases.

Paper feed starts after the fusing

temperature reaches 160

Remarks

°

C.

When the main switch is turned on, the CPU turns on the fusing lamp. When the fusing thermistor

detects 160°C, the machine enters the ready condition.

If the fusing temperature is higher than 160°C when the Start key is pressed, the machine starts

copying immediately. Otherwise, copying starts after the fusing temperature reaches 160°C. The

fusing temperature is controlled at 200°C during copying.

Within 30 minutes after copying is finished, the fusing temperature is controlled at 160°C. Over 30

minutes after copying is finished, the fusing temperature is controlled at 150°C. If auto shut off is

selected, the fusing lamp is turned off when the time selected by SP14 passes after copying is

finished.

53

Page 57

April 8, 1998 IMAGE FUSING

FUSING LAMP CONTROL CIRCUIT

Overview

The main control board monitors the fusing temperature through a thermistor to control the applied

power. Two fusing lamp control systems are provided for this machine.

On/Off Control

On

Off

A227D522.WMF

The voltage applied to the fusing lamp is the full duty cycle of the ac waveform. The power is applied

to the lamp until the operating temperature is reached.

54

Page 58

April 8, 1998 IMAGE FUSING

Phase Control Mode

Phase

A227D523.WMF

The amount of time that power is applied to the fusing lamp depends on the temperature of the hot

roller.

NOTE:

Overheat Protection

There is an overheat protection circuit in the main control board. If the hot roller temperature reaches

230°C, the resistance of the thermistor becomes too low. If the main control board detects this

condition for 3 seconds continuously, “E-53” is displayed on the operation panel and power to the

fusing lamp is cut.

Phase control mode is used only if the customer has a problem with electrical noise or

interference.

If the thermistor overheat protection circuit fails, the thermofuse opens when it reaches 169°C,

removing power from the fusing lamp.

55

Page 59

April 8, 1998 INSTALLATION REQUIREMENTS

INSTALLATION

INSTALLATION REQUIREMENTS

ENVIRONMENT

1. Temperature Range:

2. Humidity Range: 15% to 80% RH

3. Ambient Illumination: Less than 1,500 lux (Do not expose to direct

4. Ventilation: Minimum space 30 m3.

5. Ambient Dust: Less than 0.15 mg/m3 (4 x 10-3 oz/yd3)

6. If the place of installation is air-conditioned or heated, do not place the machine:

1) Where it will be subjected to sudden temperature changes.

2) Where it will be directly exposed to cool air from an air-conditioner.

3) Where it will be directly exposed to heat from a heater.

7. Do not place the machine where it will be exposed to corrosive gasses.

8. Do not install the machine at any location over 2,000 m (6,500 feet) above sea level.

10°C to 35°C (50°F to 95°F)

sunshine.)

Room air should turn over at least 3 times per hour

56

Page 60

April 8, 1998 INSTALLATION REQUIREMENTS

9. Place the machine on a strong and level base.

10. Do not place the machine where it may be subjected to strong vibration.

MACHINE LEVEL

1. Front to back: Within 3 mm (0.12") of level

2. Right to left: Within 3 mm (0.12") of level

57

Page 61

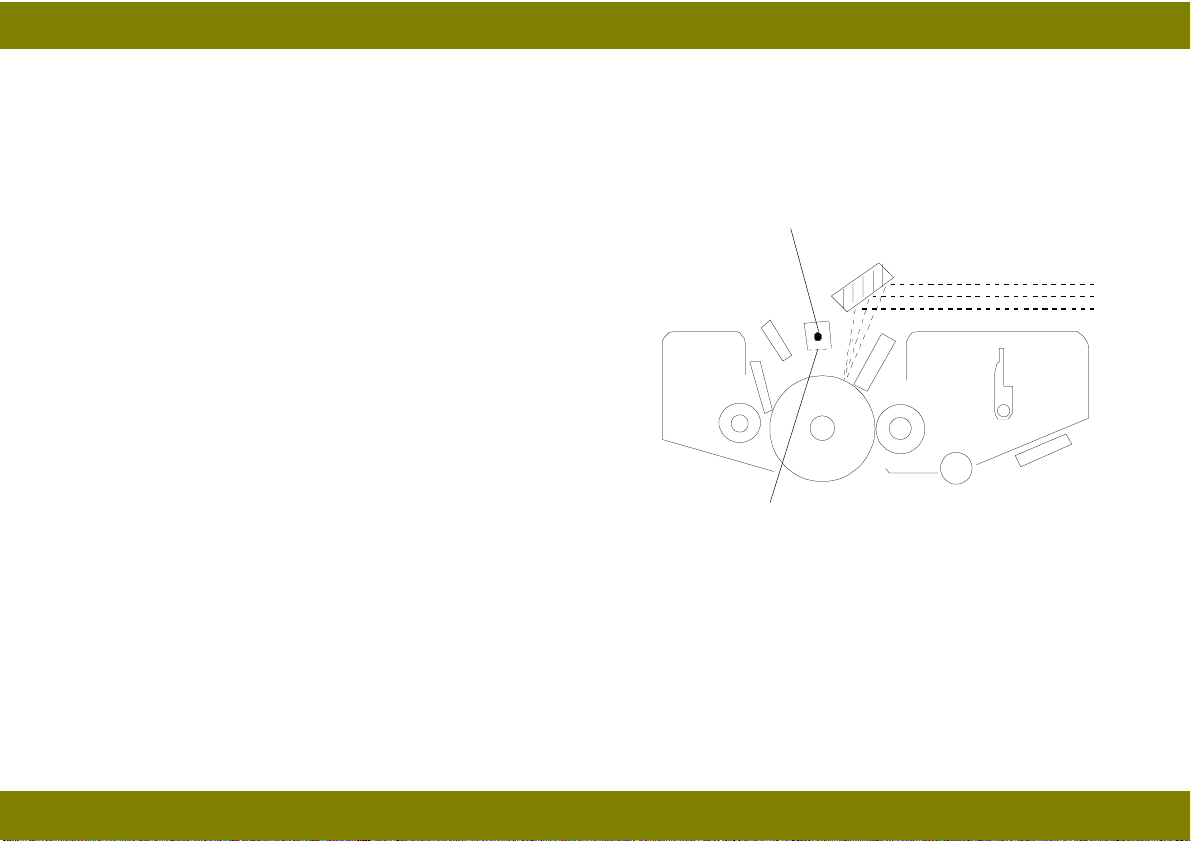

April 8, 1998 INSTALLATION REQUIREMENTS

MINIMUM SPACE REQUIREMENTS

Place the machine near the power source, providing clearance as shown:

M o r e th a n 2 0 c m (7.9 “ )

Machine

M o r e th a n

11 cm (4.3“ )

M o r e th a n 3 0 c m (11.8 “)

M o r e th a n

10 cm (3.9“)

58

Page 62

April 8, 1998 MACHINE INSTALLATION

POWER REQUIREMENTS

1. Input voltage level: 120 V, 60 Hz: More than 10 A

220 ~ 240 V, 50/60 Hz: More than 6 A

2. Permissible voltage

fluctuation:

Do not set anything on the power cord.

Make sure the plug is firmly inserted in the outlet.

Avoid multi-wiring.

10 %

MACHINE INSTALLATION

Refer to the procedure packed in the box with the machine or to the procedure in the operator’s

manual.

59

Page 63

April 8, 1998 SERVICE REMARKS

SERVICE TABLES

SERVICE REMARKS

GENERAL CAUTIONS

1. To prevent physical injury, keep hands away from the mechanical drive components when the

main switch is on (especially during the warm-up cycle). If the Start key is pressed before the

machine finishes the warm-up cycle, the Start key indicator starts blinking and the machine starts

making copies as soon as the warm-up cycle is completed.

2. Before disassembling or assembling any parts of the machine, make sure that the power cord is

unplugged.

3. To avoid possible injury or machine damage, always hold the upper unit firmly with one hand

while opening the upper unit or releasing the gas spring with the other.

4. Keep all the shipping retainers for future shipping use.

5. Do not loosen any of the paint-locked screws. Such screws are used for optic components, the

drum stay, and doctor blade of the CTDM.

6. Do not release the gas spring from the pin while the upper unit is closed. Otherwise the gas

spring will expand suddenly and may cause injury.

60

Page 64

April 8, 1998 SERVICE REMARKS

7. To prevent the upper unit from falling when separating the gas spring from it, hold the upper unit

firmly with one hand while releasing the gas spring with the other.

8. Do not leave the upper unit fully opened. Otherwise, the unit or whole machine may be fall over.

DRUM

1. Never expose the drum to direct sunlight.

2. Never touch the drum surface with bare hands. If the drum surface is touched with fingers or

becomes dirty, wipe it with a clean, dry cloth.

3. Never use alcohol to clean the drum; alcohol dissolves the drum surface.

4. Store the drum in a cool, dry place away from heat.

5. Take care not to scratch the drum as the drum’s surface layer is thin and easily damaged.

6. Never expose the drum to corrosive gasses such as ammonia gas.

7. Always keep the drum in its protective sheet when it is out of the machine.

CTDM (CLEANING TONER DEVELOPMENT MAGAZINE)

1. Place the CTDM on a clean and level place when it is out of the machine.

61

Page 65

April 8, 1998 SERVICE REMARKS

2. Do not turn the CTDM upside down. Toner and developer may fall from the unit.

3. Be careful not to damage the edge of the cleaning blade.

4. Do not store the CTDM under high temperature and high humidity conditions.

CHARGE CORONA UNIT

1. Do not touch the charge corona wire or grid plate with bare hands. Oil stains may cause uneven

image density on copies.

2. Clean the charge corona wire by sliding the wire-cleaning tool from front to rear.

3. Clean the charge grid with a blower brush (not with a cloth).

4. Clean the quenching lamp (LED) with a blower brush or a dry cloth.

ERASE LAMP

1. Clean the erase lamp with a blower brush or dry cloth.

62

Page 66

April 8, 1998 SERVICE REMARKS

OPTICS

1. Clean the exposure glass with glass cleaner and a damp cloth to reduce the amount of static

electricity on the glass surface.

2. Only use a clean soft cloth to clean the mirror and reflectors.

3. Only use a blower brush to clean the lens.

4. Do not touch the following parts with bare hands:

a) Reflectors

b) Exposure Lamp

c) Mirrors and Lens

5. Whenever cleaning the optics, all the following actions must be done in order.

a) Optics cleaning

b) SP95 (VL Correction Reset)

c) Copy Quality Adjustment

d) SP56 (ADS Reference Voltage Adjustment) See the SP mode table for details.

TRANSFER CORONA

1. Clean the corona wire by sliding the wire-cleaning tool from front to rear.

63

Page 67

April 8, 1998 SERVICE REMARKS

FUSING UNIT

1. Be careful not to damage the edges of the hot roller strippers.

2. Be careful not to damage the tension springs of the hot roller strippers.

3. Do not touch the fusing lamp with bare hands.

4. Make sure that both fusing lamp insulators are properly set in the holders, and that fusing lamp

does not touch the inner surface of the hot roller.

PAPER FEED

1. Do not touch the feed roller with bare hands.

2. The side fences and the end fence of the paper tray should be positioned correctly so that they

securely hold the paper. Otherwise, paper misfeeds may occur.

3. Avoid storing paper for a long time. At high temperature and high humidity, or at low temperature

and low humidity, store paper in a plastic bag. This is especially important to decrease the

amount of curling or waving of the paper that would lead to paper misfeeds.

64

Page 68

April 8, 1998 SERVICE REMARKS

OTHERS

1. When replacing the main control board, remove the EEPROM (IC105) from the old board and

replace it on the new board. Then install the new main board in the machine.

2. Never perform SP99 (Clear All Memory) except for the following two cases:

a) When the copier malfunctions due to a damaged EEPROM.

b) When using a brand-new EEPROM.

3. When SP99 is performed, copy quality may be affected. Adjust copy quality if necessary.

4. Tighten securely the screws used for grounding the following PCBs when reinstalling them.

• Main Control Board

• Power Supply Board

• High Voltage Power Pack

65

Page 69

April 8, 1998 PROGRAM MODES

PROGRAM MODES

BASIC OPERATION

Component

This machine is equipped with two program modes. One is the Service Program (SP) mode for

factory and field technician usage, and the other is the User Program (UP) mode for user usage.

These program modes have a different access procedures, but all the UP mode functions can be

accessed from the SP mode.

To make it possible to reset a service call (E5x) condition such as a fusing error using the SP mode,

the SP mode can be accessed while the error condition exists.

Operation

To access these program modes, a certain key must be held down while turning on the main switch.

After accessing, select the required mode number and perform the necessary procedures needed for

that function. It is possible to move on to the next required mode without exiting each time.

To leave the SP or UP mode, turn the main switch off and on.

66

Page 70

April 8, 1998 PROGRAM MODES

Display

To display and to distinguish various conditions using the Copy Counter, the appearance of the Copy

Counter varies. When the Copy Counter is blinking, the machine is ready to accept a program mode

number, and it displays the program mode number.

When the Copy Counter stops blinking, the machine is ready to accept an adjustment value, and it

may be displaying the current adjustment value.

The Photo mode indicator is always blinking when in the program modes.

Notes

1. Since the Image Density key is used during the SP modes, image density cannot be changed

using the Image Density key while in the SP modes.

2. With the exception of SP57 and SP58, all copies made inside the SP modes are made with ADS

setting without ADS compensation.

3. Since the Copy Counter is used to display the adjustment values and data, it cannot display the

number of copies.

67

Page 71

April 8, 1998 PROGRAM MODES

SP MODE

Service Program Mode Access Procedure

1. Turn off the main switch.

2. While pressing the Increase Quantity “+” key and Clear/Stop key together, turn on the main

switch.

3. Release the Increase Quantity “+” key and the Clear/Stop key, and within 5 seconds, press the

Image Density key (If not pressed within 5 seconds, the machine will return to the copy mode).

The machine is ready to accept the program number.

How to Select the Program Number

1. By using the Increase or Decrease Quantity (“+” or “-”) keys, select the required program number.

At this point, the Copy Counter and Photo Mode indicator will blink.

2. Press the Image Density key. The number that is currently blinking in the Copy Counter will be

entered as the selected program number.

NOTE:

To access the UP mode, turn on the main switch while pressing the Clear/Stop key.

68

Page 72

April 8, 1998 PROGRAM MODES

Changing the Value of an SP Mode

1. Select the desired value or setting using the Increase or Decrease Quantity (“+” or “-”) key. For

some modes, since the Copy Counter has only 2 digits, the hundred digit is shown by the

combination of indicators turned on in the Manual Image Density indicator as shown below.

= "1"

For example:

= "2"

= "3"

+

Copy Counter

= "152"

2. When the Image Density key is pressed, the number which is currently displayed in the Copy

Counter will be entered as the new value or setting, and will be stored in memory.

3. The machine is ready to accept the new program number. Repeat to select the program number

or leave SP mode by turning the main switch off/on.

69

Page 73

April 8, 1998 PROGRAM MODES

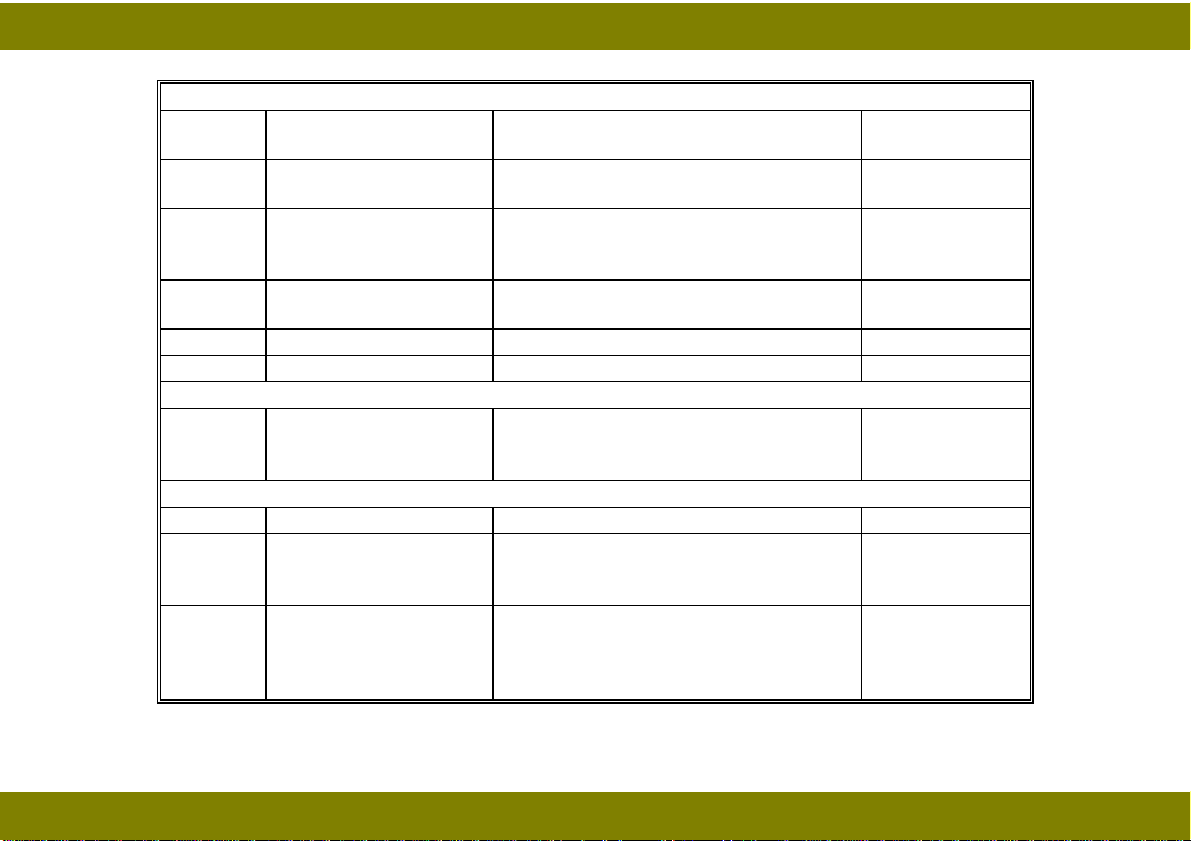

SP MODE QUICK REFERENCE TABLE

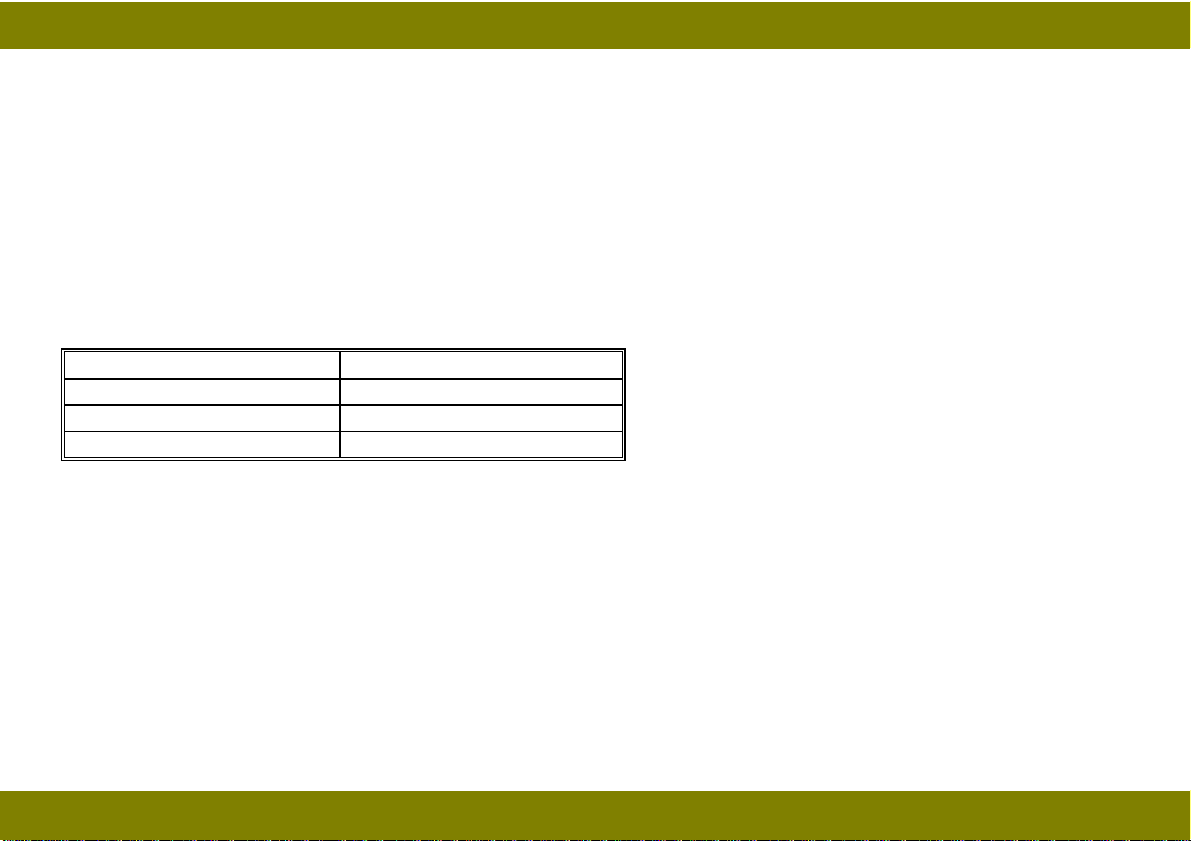

SP Mode

No.

3 Destination Setting 49 Fusing Temperature Adjustment

4 Forced Free Run 51 Exposure Lamp Voltage Display

5 Forced Free Run with Exposure

Lamp Off

6 Misfeed Detection Off 55 ADS Reference Voltage Display

7 Free Run 56 ADS Reference Voltage

8 Input Check 57 ADS Output Voltage Display

9 Output Check 58 Development Bias Voltage Display

10 Scanner Free Run 59 Optics Temperature Display

11 All Indicators On 60 Drum Potential Measurement

12 CTDM Initialization 61 Drum Potential Measurement

14 Auto Shut Off (Energy Star) Time

Setting

15 Auto Reset Time Setting 63 VL Correction Interval

16 Count Up/Down Selection 64 Photo Mode Compensation

19 Disable ADS Compensation 66 OPC Counter Clear

21 A4 Lengthwise Erase Selection 69 OPC Counter Display

23 CTDM Initialization Time Setting 70 VL Correction Display

Function SP Mode

No.

52 Fusing Temperature Display

62 VL Switch Setting

Function

Adjustment

(With Paper)

(Without Paper)

Setting

70

Page 74

April 8, 1998 PROGRAM MODES

SP Mode

No.

29 Fusing Temperature Control

Selection

30 Exhaust Fan Speed Setting 81 Factory Initialization

34 Image Density Adjustment 82 Data Communication

35 Coarse Image Density Adjustment at

Darker Setting Position

36 Coarse Image Density Adjustment at

Lighter Setting Position

38 Fine Image Density Adjustment at

Darker Setting Position

39 Fine Image Density Adjustment at

Lighter Setting Position

*41 Lead Edge Erase Margin

Adjustment

*42 Registration Adjustment 97 Service Call (E5x) Reset

*43 Vertical Magnification Adjustment 98 Total Counter Clear

*44 Horizontal Magnification Adjustment 99 All Memory Clear

*48 Light Intensity Adjustment

Function SP Mode

No.

77 Auto Shut Off (Energy Star)

88 Total Copy Counter Display

90 Factory Data and Counter Clear

91 Optics Cooling Fan Operation

95 VL Correction Counter Clear

96 Forced Toner End Reset

Function

Selection

*For these items, values set in the fact or y are list ed on “ SP MODE FACTORY SET DATA” sheet.

71

Page 75

April 8, 1998 PROGRAM MODES

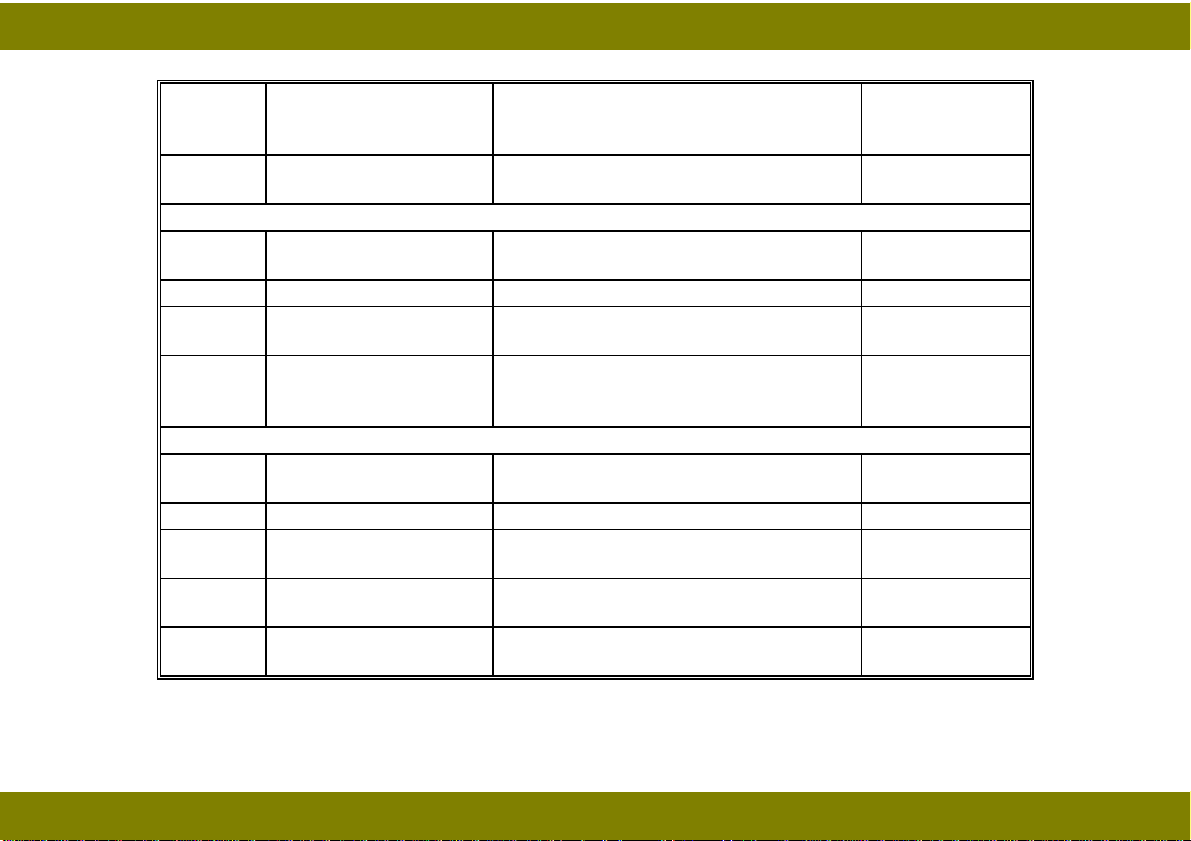

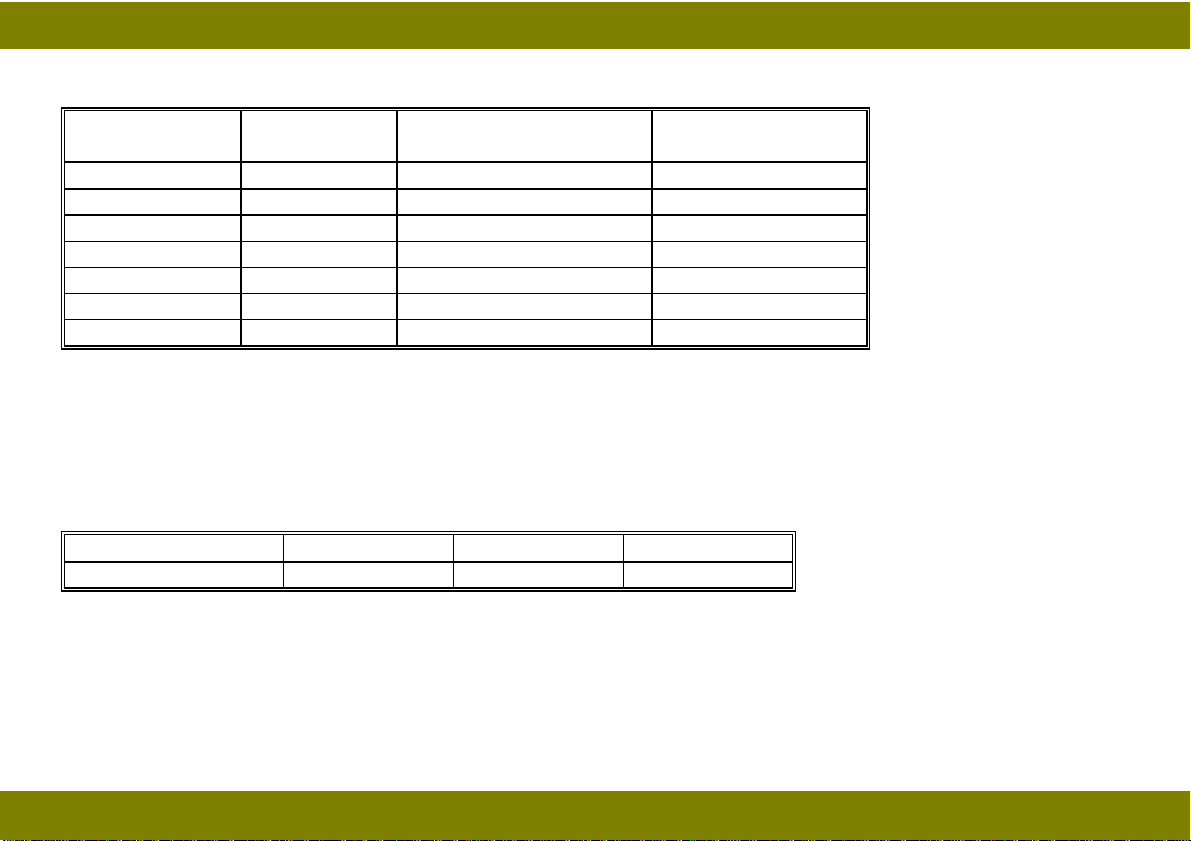

UP MODE AND SP MODE CROSS REFERENCE TABLE

UP Mode No. SP MODE No. Function

1 34 Image Density Adjustment

2 35 Coarse Image Density Adjustment at Darker Setting Position

3 36 Coarse Image Density Adjustment at Lighter Setting Position

4 64 Photo Mode Compensation Setting

5 14 Auto Shut Off (Energy Star) Time Setting

6 15 Auto Reset Time Setting

7 16 Count Up/Down Selection

8 88 Total Copy Counter Display

30 69 OPC Counter Display

31 63 VL Correction Interval

32 62 VL Switch Setting

33 12 CTDM Initialization

34 77 Auto Shut Off (Energy Star) Selection

NOTE:

The UP modes numbered from 30 to 34 are special UP modes, which are not explained in

the operator’s manual. If it is necessary to change any settings related to the special UP

modes, the service representative may ask the end user to change it (and thereby avoid a

service visit).

72

Page 76

April 8, 1998 PROGRAM MODES

SERVICE PROGRAM MODE

NOTE:

The default value is printed in bold letters.

SP3: Destination Setting

This mode must be set depending on the paper size being used.

No. Settings Copy Count

(SP16 Setting)

0 --- --- --1 Inch Count up Factory setting for 120 V machines

2 Metric 1 Count up Factory setting for 230 V machines

3 Metric 2 Count up Factory setting for 100 V machines

SP3 does not have any relationship to the electrical power supply. Only erase and magnification ratio

mechanisms are changed. For example, changing this mode will allow European machines to use

inch size paper.

NOTE:

1) The error code “E15” is displayed in the copy counter if SP3 is set to

“0”.

2) Lengthwise erase timing of 8½” x 11” is always performed as A4 if SP3

is set to “2” or “3”.

Note

73

Page 77

April 8, 1998 PROGRAM MODES

SP4: Forced Free Run

In this mode, free run can be performed even if the fusing unit does not reach the required

temperature. See free run mode (SP7) for more details.

SP5: Forced Free Run with Exposure Lamp Off

This mode forces free run mode (SP4) with exposure lamp off.

SP6: Misfeed Detection Off

This mode allows operation without misfeed detection by the registration and exit sensors. Press the

Start key to make a copy. Copying stops upon reaching the set count, or when the C/S key is

pressed.

Use this mode to check whether the paper misfeed was caused by a sensor malfunction. The total

counter increments when copies are made in this mode.

74

Page 78

April 8, 1998 PROGRAM MODES

SP7: Free Run

In this mode, free run is performed. Press the Start key to start the free run. Press C/S to stop the

free run.

The machine operates with the normal copy process for 8½” x 14” paper and selected reproduction

ratio with no paper feed and no total counter increment.

NOTE:

Before starting, close the platen cover to minimize toner consumption.

SP8: Input Check

The Manual Image Density and the Reproduction Ratio Indicators are used to display the data from

the sensors while making a normal copy.

Press the Start key to perform this mode. Press the Image Density key to stop this mode.

Sensor Indication Display Condition

Registration Darker Image Density ON: Paper Present

Exit ADS ON: Paper Present

Scanner HP Lighter Image Density ON: Home Position

Lens HP* Reproduction Ratio 141% ON: Actuator inside Sensor

*A227 machine only

75

Page 79

April 8, 1998 PROGRAM MODES

SP9: Output Check

SP9 is used to turn on individual electrical components. Select the desired number from the following

table. Press the Start key to turn on the electrical component. Press the C/S key to turn off the

electrical component.

No. Electrical Components Note

1 Main Motor, Quenching Lamp, and

Exhaust Fan Motor (High Speed)

2 Charge Corona, Transfer Corona,

and Development Bias

3 Exhaust Fan Motor (High Speed)

4 --- Not used

5 Registration Solenoid

6 Paper Feed Clutch

7 Eraser Lamp All LEDs on

8 Exposure Lamp and Exhaust Fan

Motor (High Speed)

Development bias is the base voltage

without correction.

SP10: Scanner Free Run

SP10 is used to perform the scanner free run. Scanner free run starts a few seconds after pressing

the Start key. Press the C/S key to stop the free run. Scanner free run is performed with the scanner

process for 8½” x 14” paper size and selected reproduction ratio.

76

Page 80

April 8, 1998 PROGRAM MODES

SP11: All indicators On

SP11 is used to turn on all the indicators on the operation panel for 30 seconds. To turn off the

indicators manually (before 30 seconds have passed), press the Image Density key.

SP12: CTDM Initialization (UP33)

SP12 is used to initialize developer in a brand-new CTDM. Press the Start key to start the CTDM

initialization. The initialization time can be changed by using SP23.

NOTE:

This mode is performed automatically if the main switch is turned off and on, or the upper

unit is opened and closed during toner end condition.

SP14: Auto Shut Off (Energy Star) Time Setting (UP5)

SP14 is used to select the auto shut off time.

The main switch is shut off automatically after the selected auto shut off time if SP77 is at “0”.

No. Settings No. Settings

0 5 min. 4 1.5 h

1 10 min. 5 2 h

2 30 min.

31 h74 h

63 h

77

Page 81

April 8, 1998 PROGRAM MODES

SP15: Auto Reset Time Setting (UP6)

SP15 is used to select an auto-reset time of 1 or 3 minutes, or to cancel auto-reset.

No. Settings

01 min.

13 min.

2 None

SP16: Count Up/Down Selection (UP7)

SP16 is used to select count up or count down in the copy number display.

No. Settings

0Up

1Down

SP19: Disable ADS Compensation

SP19 is used to disable ADS compensation while adjusting the base exposure lamp voltage (SP48:

Light intensity adjustment).

Always change the setting to 1 when adjusting the base exposure lamp voltage. Do not forget to

change it back to 0 after adjustment.

78

Page 82

April 8, 1998 PROGRAM MODES

No. Settings

0ADS

1 Disable ADS compensation

SP21: A4 Lengthwise Erase Selection

SP21 is used to set the trailing edge erase timing to A4 lengthwise on a machine in which the setting

of SP3 (Destination Setting) is set to “1” (inch).

Set this to 1 for customers that make copies of A4 paper occasionally on the 120 volt machines.

No. Settings

0 8½” x 11”

1A4

NOTE:

The setting of this mode is ignored if SP3 is set to “2” or “3” (metric).

79

Page 83

April 8, 1998 PROGRAM MODES

SP23: CTDM Initialization Time Setting

SP23 is used to select the CTDM initialization time. This SP mode is provided for designers’

evaluation. There is no need to change the setting in the field.

No. Settings No. Settings

0 15 s 4 35 s

1 20 s 5 40 s

2 25 s 6 50 s

3 30 s

71 min.

SP29: Fusing Temperature Control Selection

SP29 is used to select the fusing temperature control mode. It should be set to “1” only if the cutomer

has a problem with electrical noise or interference.

After selecting the control mode, you must turn the main switch off/on to change the fusing

temperature control mode.

No. Settings

0 ON/OFF control

1 Phase control

80

Page 84

April 8, 1998 PROGRAM MODES

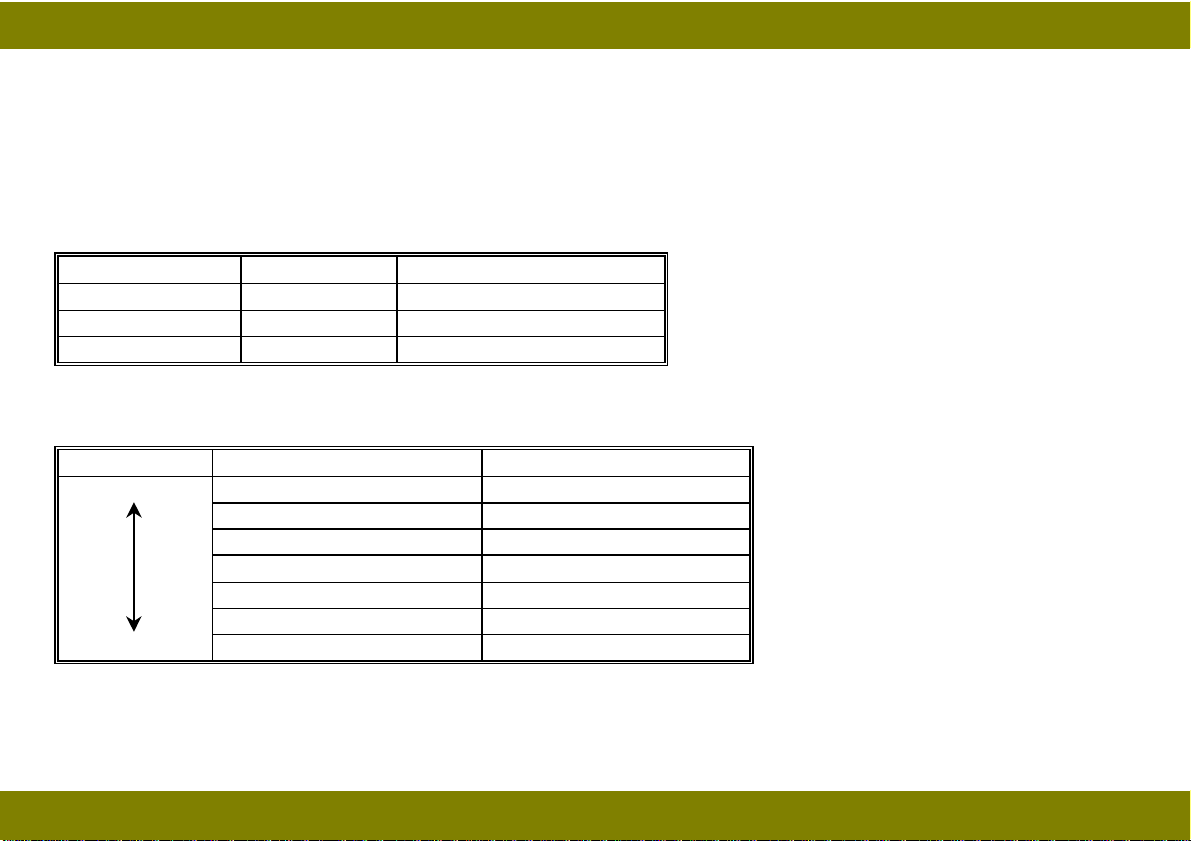

SP30: Exhaust Fan Speed Setting

SP30 is used to select the exhaust fan speed. SP30 was provided for designers’ evaluation. There is

no need to change the setting in the field.

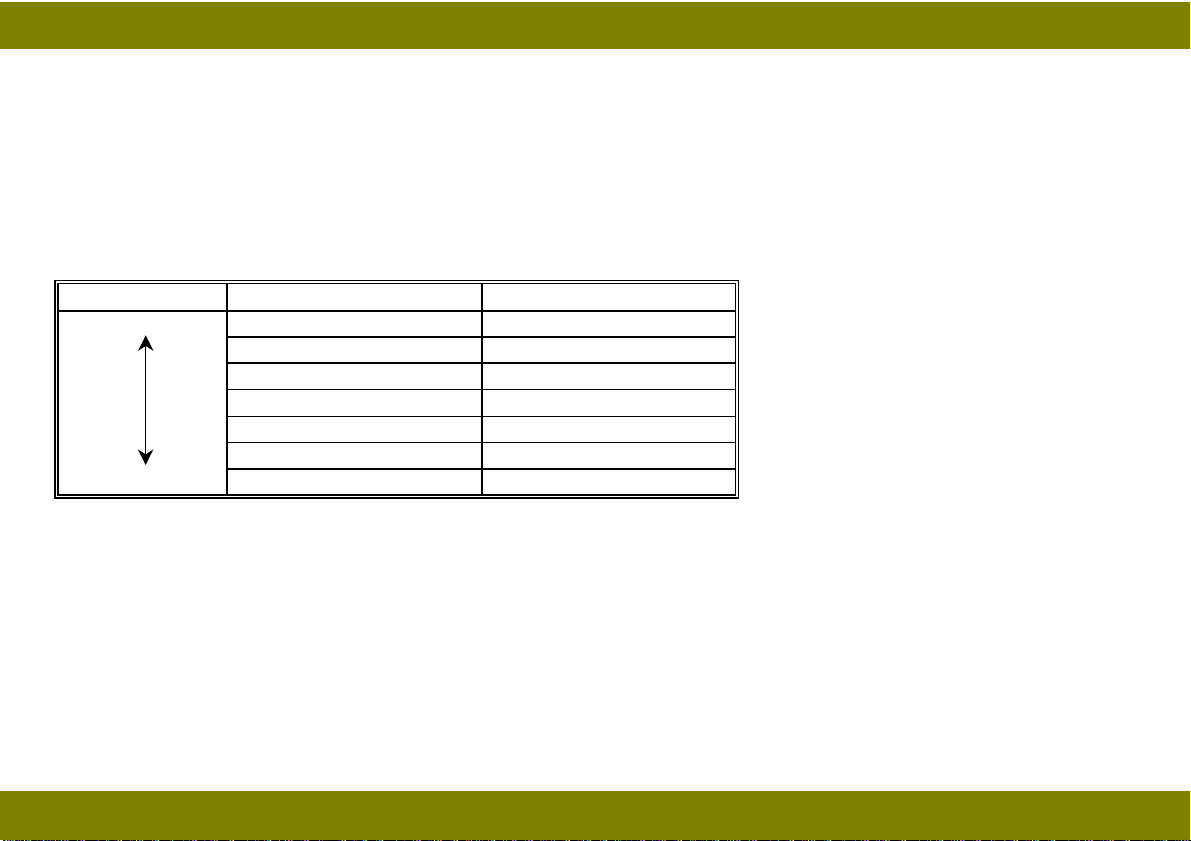

No. Speed Duty

0 Slow 30 %

1

2

3

4

5

6

7

8 High 70 %

↓

↓

↓

↓

↓

↓

↓

35 %

40 %

45 %

50 %

55 %

60 %

65 %

81

Page 85

April 8, 1998 PROGRAM MODES

SP34: Image Density Adjustment (UP1)

SP34 can adjust the copy image density. Both the development bias and the exposure lamp may be

changed. To make a copy in this mode after adjusting, press the Start key.

No. Settings Development

Bias Change

0Normal 0 0

1 Light -40 V 0

2 Dark +40 V 0

3 Lighter -40 V +3 steps

4 Darker +40 V -3 steps

5 Lightest -40 V +7 steps

6 Darkest +40 V -7 steps

Exposure Lamp

Change

1 step = 0.5 V (120 V machines) or 1.0 V (230 V machines)

82

Page 86

April 8, 1998 PROGRAM MODES

SP35: Coarse Image Density Adjustment at Darker Setting Position (UP2)

SP35 adjusts the copy image density at the Darker setting position on the operation panel by

changing the exposure lamp voltage. To make a copy in this mode after adjusting, press the Start

key.

No. Settings Exposure Lamp Change

0 Normal -6 steps

1 Darker -8 steps

2 Darkest -10 steps

1 step = 0.5 V (120 V machines) or 1.0 V (230 V machines)

SP36: Coarse Image Density Adjustment at Lighter Setting Position (UP3)

SP36 adjusts the copy image density at the Lighter setting position on the operation panel by

changing the development bias voltage. To make a copy in this mode after adjusting, press the Start

key.

No. Settings Development Bias Change

0 Normal -40 V

1 Lighter -80 V

2 Lightest -120 V

83

Page 87

April 8, 1998 PROGRAM MODES

SP38: Fine Image Density Adjustment at Darker Setting Position

SP38 adjusts the copy image density at the Darker setting position on the operation panel by

changing the exposure lamp voltage. To make a copy in this mode after adjusting, press the Start

key.

No. Settings Exposure Lamp Change

0 Darkest -3 steps

1 Darker -2 steps

2 Dark -1 step

3Normal 0

4 Light +1 step

5 Lighter +2 steps

6 Lightest +3 steps

1 step = 0.5 V (120 V machines) or 1.0 V (230 V machines)

84

Page 88

April 8, 1998 PROGRAM MODES

SP39: Fine Image Density Adjustment at Lighter Setting Position

SP39 adjusts the copy image density at the Lighter setting position on the operation panel by

changing the exposure lamp voltage. To make a copy in this mode after adjusting, press the Start

key.

No. Settings Exposure Lamp Change

0 Darkest -3 steps

1 Darker -2 steps

2 Dark -1 step

3Normal 0

4 Light +1 step

5 Lighter +2 steps

6 Lightest +3 steps

1 step = 0.5 V (120 V machines) or 1.0 V (230 V machines)

SP41: Lead Edge Erase Margin Adjustment

SP41 adjusts the lead edge erase margin. The lead edge erase margin can be adjusted by 0.5

millimeters per step (-4.0 mm to +3.5 mm). To make a copy in this mode after adjusting, press the

Start key. See “Replacement and Adjustment — Copy Quality adjustment” for details.

Default setting: 8

85

Page 89

April 8, 1998 PROGRAM MODES

SP42: Registration Adjustment

SP42 adjusts image to paper registration. Registration can be adjusted by 0.5 mm per step (-4.0 mm

to +3.5 mm). To make a copy in this mode after adjusting, press the Start key. See “Replacement

and Adjustment — Copy Quality adjustment” for details.

Default setting: 8

SP43: Vertical Magnification Adjustment

SP43 adjusts magnification in the paper travel direction by changing the scanner speed.

Magnification can be adjusted by 0.2% per step (-3.2% to +3.0%). To make a copy in this mode after

adjusting, press the Start key. See “Replacement and Adjustment — Copy Quality adjustment” for

details.

Default setting: 16

SP44: Horizontal Magnification Adjustment (A227 copier only)

SP44 adjusts magnification perpendicular to the direction of paper travel by changing the home

position of the lens and mirrors. The magnification can be adjusted by 0.2% per step (-3.2% to

+3.0%). See “Replacement and Adjustment — Copy Quality adjustment” for details.

Default setting: 16

86

Page 90

April 8, 1998 PROGRAM MODES

SP48: Light Intensity Adjustment

SP48 adjusts the exposure lamp voltage. To make a copy in this mode after adjusting, press the

Start key.

No. Lamp Voltage (V)

120 V (NA) Version 230 V (EU) Version

100 50.0 100

101 50.5 101

102 51.0 102

↓↓ ↓

120

↓↓ ↓

128 64.0

↓↓ ↓

180 90.0 180

↓↓

193 96.5 --194 97.0 ---

=

↓

sequence continues at 0.5 volt/step for 115 V machines and 1.0 volt/step for 230 V machines.

60.0

120

128

---

Do this adjustment whenever the optics are cleaned or VL correction counter is cleared (SP95). After

doing this adjustment, adjust the ADS reference voltage using SP56. See “Replacement and

Adjustment — Copy Quality adjustment” for details.

87

Page 91

April 8, 1998 PROGRAM MODES

SP49: Fusing Temperature Adjustment

SP49 adjusts the control temperature of the hot roller during coping. The fusing temperature can be

adjusted between 195°C and 205°C in 1°C steps. The fusing temperature can be calculated from the

displayed value by adding 15 (i.e. 180 = 195°C).

Default setting: 185 (200

°C)

SP51: Exposure Lamp Voltage Display

SP51 displays the current exposure lamp voltage. For 120 V machines, the actual applied voltage

equals to half of the displayed voltage. The exposure lamp turns on for 10 seconds when this mode

is selected.

The Image Density Indicators are used to display the hundreds digit.

NOTE:

Do not repeat more than 5 times to avoid overheating the optics cavity.

SP52: Fusing Temperature Display

This mode is performed to display the fusing temperature detected by the fusing thermistor. Press

the Start key to monitor the temperature during the normal copy cycle. The Image Density Indicators

are used to display the hundreds digit.

88

Page 92

April 8, 1998 PROGRAM MODES

SP55: ADS Reference Voltage Display

SP55 displays the ADS reference voltage adjusted by SP56. The number to two decimal places is

displayed in the counter. The Image Density Indicators are used to display the unit digit as shown

below.

= "1"

For example:

= "2"

= "3"

+

Copy Counter

= "2.53"

89

Page 93

April 8, 1998 PROGRAM MODES

SP56: ADS Reference Voltage Adjustment

SP56 is used to adjust the ADS reference voltage using VR100 on the main control board. The

number to two decimal places of ADS sensor output is displayed in the counter. The Image Density

Indicators are used to display the unit digit. After 10 seconds, the output is stored as the ADS

reference voltage. The voltage is displayed as shown in the SP55 example.

The adjustment standard voltage is 2.5 ± 0.2 volts. See “Replacement and Adjustment — Copy

Quality adjustment” for details.

SP57: ADS Output Voltage Display

SP57 displays the ADS output voltage.

Press the Start key to monitor the output voltage during the normal copy cycle. The number to two

decimal places is displayed in the counter. The Manual Image Density Indicators are used to display

the unit digit. The voltage is displayed as shown in the SP55 example.

When in SP57 mode, the machine makes copies in the ADS mode.

90

Page 94

April 8, 1998 PROGRAM MODES

SP58: Development Bias Voltage Display

SP58 displays the development bias voltage.

Press the Start key to monitor the development bias voltage during the normal copy cycle. The

Manual Image Density Indicators are used to display the hundreds digit.

When in SP58 mode, the machine makes copies in the ADS mode.

SP59: Optics Temperature Display (SP59)

SP59 displays the optics temperature detected by the optics thermistor.

Press the Start key to monitor the optics temperature during the normal copy cycle.

SP60: Drum Potential Measurement (With Paper)

Factory use only using special tools.

SP61: Drum Potential Measurement (Without Paper)

Factory use only using special tools.

91

Page 95

April 8, 1998 PROGRAM MODES

SP62: VL Switch Setting (UP32)

SP62 sets the effective level for the VL switch inside of the machine.

SP62 Settings Special UP Mode Exposure Lamp Voltage Change

UP32 SW Position 0 SW Position 1 SW Position 2

0 0 0 +10 steps +20 steps

1 1 0 +5 steps +10 steps

2 2 0 +15 steps +30 steps

3 3 0 +20 steps +40 steps

1 step = 0.5 V (120 V machines) or 1.0 V (230 V machines)

92

Page 96

April 8, 1998 PROGRAM MODES

SP63: VL Correction Interval (UP31)

SP63 sets the interval for VL correction. The exposure lamp voltage (SP48) is increased by 1 step at

the set copy count interval. Based on copy count, VL correction is performed at the intervals shown in

the below table.

SP63 Settings Exposure Lamp Voltage change Special UP Mode

UP31

0 +1 step/4000 copies 0

1 +1 step/3000 copies 1

2 +1 step/2500 copies 2

3 +1 step/2000 copies 3

4 +1 step/1500 copies 4

5 +1 step/1000 copies 5

6 +1 step/500 copies --7 +1 step/250 copies --8 No Correction ---

1 step = 0.5 V (120 V machines) or 1.0 V (230 V machines)

93

Page 97

April 8, 1998 PROGRAM MODES