Page 1

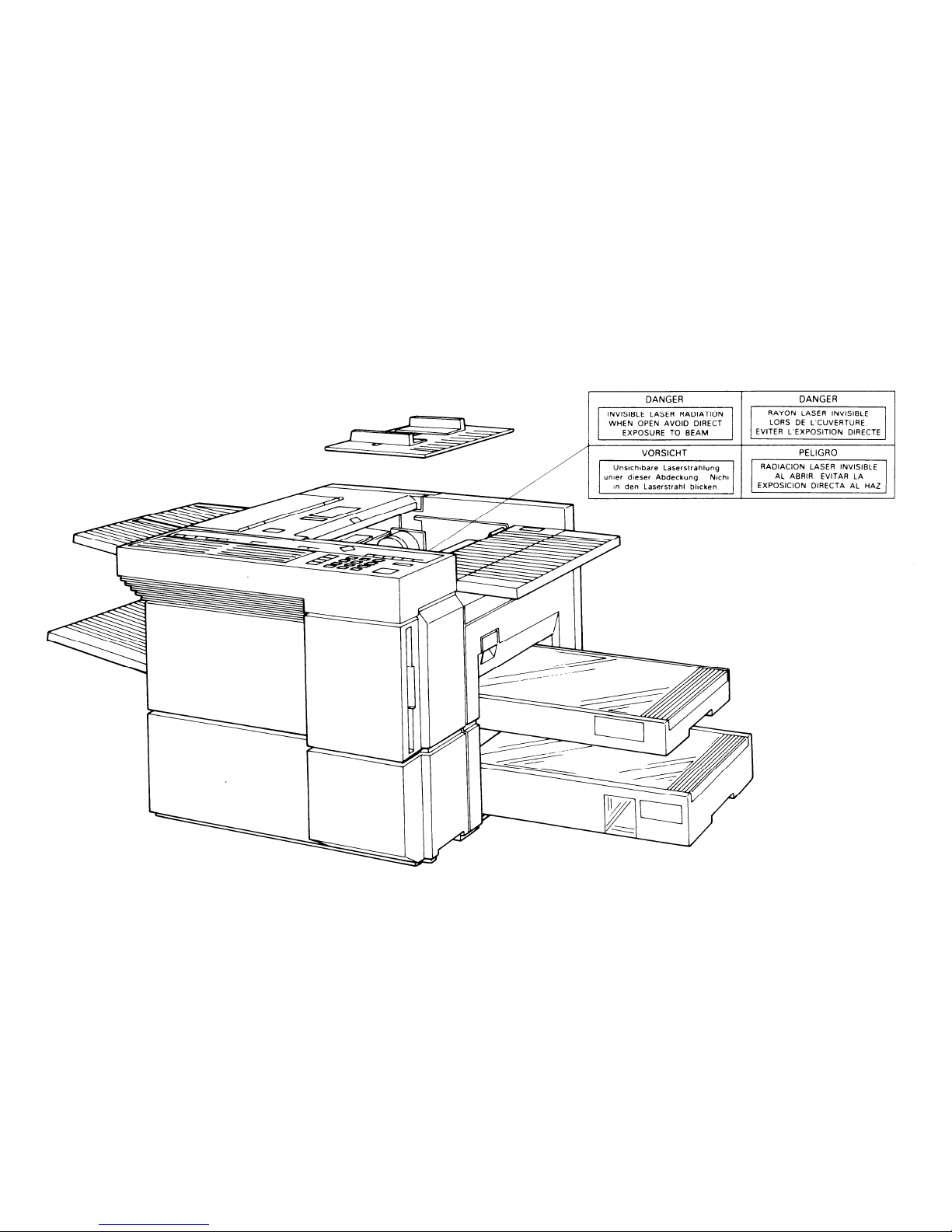

RICOH FAX7000L

FIELD SERVICE MANUAL

WARNING

THIS MACHINE CONTAINS A LASER BEAM GENERATOR. LASER

BEAMS CAN CAUSE PERMANENT EYE DAMAGE. DO NOT OPEN THE

LASER UNIT OR LOOK ALONG THE LASER BEAM PATH WHILE THE

MAIN POWER IS ON.

Page 2

Page 3

CONTENTS

SECTION 1. INSTALLATION

1-7-7. TTI #1 and TTl #2 - Function 85 . . . . 1-31

1-7-8. CSI - Function 86

1-1. Specifications . . . . . . . . . . . 1-1

1-2. Features . . . . . . . . . . . . . . 1-4

1-3. Installation Requirements . . . . . . 1-14

1-3-1. Environment . . . . . . . . . . . 1-14

1-3-2. Minimum Space Requirements . . . . 1-15

1-3-3. Power Requirements . . . . . . . . 1-16

1-4. Unpacking . . . . . . . . . . . . . 1-17

1-5. Accessory Check List . . . . . . . . 1-18

1-6. Installation Procedure . . . . . . . . 1-19

1-6-1. Master Unit . . . . . . . . . . . 1-19

1-6-2. Toner . . . . . . . . . . . . . . 1-20

1-6-3. Cassettes . . . . . . . . . . . . 1-22

1-6-4. Telephone . . . . . . . . . . . . 1-23

1-6-5. Cleaning Pad . . . . . . . . . . 1-23

1-6-6. Other Components . . . . . . . . 1-24

1-6-7. Power Connection . . . . . . . . 1-24

1-6-8. Hard Disk Initialization . . . . . . . 1-25

1-7. Initial Programming . . . . . . . . . 1-27

1-7-1. Country Code - Function 81 . . . . . 1-27

1-7-2. Fax Terminal’s Telephone Number -

Function 81 . . . . . . . . . . . 1-28

1-7-3. Transfer Station Number - Function 81 . 1-28

1-7-4. Polling ID Code - Function 82 . . . . 1-29

1-7-5. Confidential ID Code - Function 83 . . 1-29

1-7-6. RTI #1 and RTI #2 - Function 84 . . . 1-30

(W. Germany: Service Function 11) . . .1-31

1-7-9. Date and Time - Function 87 . . . . . 1-32

1-7-10. Telephone Line Type -

Service Function 12 . . . . . . . . 1-32

1-7-11. Reception Mode - Function 88 . . . . 1-33

1-8. Charge Control Parameter Programming . 1-34

1-9. Transporting the Machine . . . . . . . 1-39

SECTION 2. PROGRAMMING, TESTING,

AND PRINTING REPORTS

2-1. Operation Panel . . . . . . . .

2-2. User Level Programming . . . .

2-2-1. Function List . . . . . . . .

2-2-2. Others . . . . . . . . . . .

1. Multicopy Mode . . . . . . .

2. Keystroke Programs . . . . . .

2-3. Service Level Functions . . . . .

2-3-1. Function List . . . . . . . .

2-3-2. Entering and Exiting Service Mode

2-3-3. Bit Switches - Function 01 . . .

2-3-4. CCU - Function 02 . . . . . .

1. G3 CCU Test Mode . . . . . .

2. G3 Dump List 1 . . . . . . . .

3. G3 Dump List 2 . . . . . . . .

. .

2-1

. .

. 2-5

. . .

2-5

. . .

2-13

. . .

2-13

. . .

2-13

. .

. 2-14

. . .

2-14

. . .

2-18

. . .

2-19

. . .

2-20

. . .

2-20

. . .

2-22

. . .

2-22

Page 4

4. NCU Parameter Programming . . .

2-3-5. RAM - Function 03 . . . . . . .

1. RAM Read/Write . . . . . . . . .

2. Memory Dump List . . . . . . . .

3. Hard Disk Dump . . . . . . . . .

4. G3 CCU Handshake Logging Dump List

5. SPU Handshake Logging Dump List .

6. Error Code Logging Dump List . . .

7. Multicopy . . . . . . . . . . .

8. Counter Check . . . . . . . . .

9. Charge Control . . . . . . . . .

2-3-6. Service Station Number - Function 04

2-3-7. Counter Check - Function 05 . . .

2-3-8. Service Monitor Report Printing -

Function 06 . . . . . . . . . .

2-3-9. Parameter List Printing - Function 07

2-3-10. Serial Number Programming -

Function 08 . . . . . . . . . .

2-3-11. Tests - Function 09 . . . . . . .

1. Printer Tests . . . . . . . . . .

2. Fluorescent Lamp Lighting . . . . .

3. SPU Reset . . . . . . . . . . .

4. Operation Panel Test . . . . . . .

5. RAM Test . . . . . . . . . . .

6. DCR Test . . . . . . . . . . . .

7. ADF Mechanism Test . . . . . . .

8. SPU Test Menu . . . . . . . . .

9. Hard Disk Test . . . . . . . . .

2-3-12. Printer Status - Function 14 . . . .

2-3-13. Transmission Status Report -

Function 15 . . . . . . . . . .

.

2-23

.

2-24

.

2-24

.

2-25

.

2-26

2-27

.

2-27

.

2-28

.

2-28

.

2-29

.

2-29

.

2-30

.

2-30

.

2-31

.

2-31

.

2-32

.

2-32

.

2-32

.

2-33

.

2-34

.

2-34

.

2-35

.

2-36

.

2-36

.

2-37

.

2-37

.

2-38

.

2-40

2-3-14. G4 CCU Parameters - Function 16 . . 2-42

2-3-15. System Data List - Function 17 . . . . 2-42

2-3-16. Hard Disk Shipping Position -

Function 18 . . . . . . . . . . . 2-42

2-3-17. Dedicated Transmission Parameters . . 2-43

2-3-18. Back to Back Test . . . . . . . . . 2-46

2-3-19. Machine Reset . . . . . . . . . . 2-46

2-4. Bit Switches . . . . . . . . . . . . . 2-47

1. SCU - Factory Settings . . . . . . . . . 2-47

2. SCU - Bit Switch Tables . . . . . . . . . 2-49

3. G3 CCU - Factory Settings . . . . . . . 2-85

4. G3 CCU - Bit Switch Tables . . . . . . . 2-87

2-5. NCU Parameters . . . . . . . . . . . 2-112

2-6. Useful RAM Addresses . . . . . . . . 2-115

Redialling . . . . . . . . . . . . . . 2-115

Charge Control Parameters . . . . . . . . 2-115

Charge Control Report Printout Date . . . . 2-116

SECTION 3. REMOVAL AND

REPLACEMENT

3-1. Covers . . . . . . . . . . . . . . . 3-2

3-1-1. Lower Front Right, Lower Left, and

Upper Front Covers . . . . . . . . 3-2

3-1-2. Operation Panel . . . . . . . . . . 3-3

3-1-3. Upper Rear, Lower Rear, and

BSRU Covers . . . . . . . . . . . 3-4

3-1-4. Top Right and Top Covers . . . . . . 3-4

3-1-5. Rear Inner Cover, Right Inner Cover,

and Document Table . . . . . . . . 3-5

3-1-6. Front Inner Cover . . . . . . . . . 3-5

Page 5

3-2. ADF and Scanner . . . . . . . . . . 3-6

3-2-1. Document Feed and Pick-up Rollers . . 3-6

3-2-2. Document Separation Roller . . . . . 3-7

Separation Roller Adjustment . . . . . . 3-8

3-2-3. Fluorescent Lamp . . . . . . . . . 3-9

3-2-4. Fluorescent Lamp Driver . . . . . . 3-9

3-2-5. SBU . . . . . . . . . . . . . . 3-10

Scanner Adjustments . . . . . . . . . 3-11

3-2-6. Tx Motor Timing Belt Adjustment . . . 3-19

3-3. Printer - Charge . . . . . . . . . . . 3-20

3-3-1. Charge Corona Wire . . . . . . . . 3-20

3-4. Printer - Exposure . . . . . . . . . . 3-22

3-4-1. Second Cylindrical Lens . . . . . . 3-22

3-4-2. Pentagonal Mirror and Motor . . . . 3-23

3-4-3. Pentagonal Mirror Motor Driver

(SMDR) . . . . . . . . . . . . . 3-25

3-4-4. LSD . . . . . . . . . . . . . . 3-25

3-4-5. Laser Diode Unit . . . . . . . . . 3-26

3-5. Printer - Paper Feed . . . . . . . . . 3-27

3-5-1. Upper Paper Feed and Pick-up

Rollers . . . . . . . . . . . . . 3-27

3-5-2. Upper Paper Separation Roller and

Spring Clutch . . . . . . . . . . 3-28

3-5-3. Lower Paper Feed and Pick-up

Rollers . . . . . . . . . . . . . 3-29

3-5-4. Lower Paper Separation Roller . . . . 3-29

3-5-5. Master Belt Drive Motor Timing Belt

Adjustment . . . . . . . . . . . 3-30

3-5-6. Upper Paper Lift Mechanism

Adjustment . . . . . . . . . . . 3-30

3-6. Printing - Development . . . . . . . . 3-31

3-6-1. Development Unit . . . . . . . . . 3-31

3-6-2. Toner Metering Blade . . . . . . . . 3-31

3-6-3. Development Roller . . . . . . . . . 3-32

3-7. Printer - Transfer . . . . . . . . . . . 3-33

3-7-1. Transfer Corona Wire . . . . . . . . 3-33

3-7-2. Transfer Entrance Guide Plate

Adjustment . . . . . . . . . . . . 3-35

3-8. Printer - Fusing . . . . . . . . . . . 3-36

3-8-1. Fusing Unit . . . . . . . . . . . . 3-36

3-8-2. Thermostat . . . . . . . . . . . . 3-38

3-8-3. Fusing Lamp/Thermistor Assembly . . . 3-38

3-8-4. Hot Roller . . . . . . . . . . . . 3-39

3-8-5. Pressure Roller . . . . . . . . . . 3-40

3-8-6. Hot Roller Strippers . . . . . . . . . 3-40

3-9. Printer - Quenching . . . . . . . . . . 3-42

3-9-1. Quenching Lamp . . . . . . . . . 3-42

3-10. PUBs . . . . . . . . . . . . . . . 3-43

3-10-1. SPU, VPU, G3CCU, and Modem . . . 3-43

3-10-2. SCU and MBU . . . . . . . . . . 3-44

3-10-3. UIB . . . . . . . . . . . . . . 3-45

3-10-4. DSB . . . . . . . . . . . . . . 3-45

3-10-5. DRU . . . . . . . . . . . . . . 3-46

3-10-6. Power Pack . . . . . . . . . . . 3-46

3-10-7. PSU . . . . . . . . . . . . . . 3-48

3-10-8. Hard Disk . . . . . . . . . . . . 3-48

3-10-9. G3NCU . . . . . . . . . . . . . 3-50

3-10-10. LIB . . . . . . . . . . . . . . 3-50

3-10-11. BSRU . . . . . . . . . . . . . 3-51

3-11. Others

. . . . . . . . . . . . . . 3-51

3-11-1. Gas Spring Adjustment . . . . . . . 3-51

Page 6

SECTION 4. SERVICE TABLES

4-1. PM Table . . . . . . . . . . . . . 4-1

4-2. General Service Tables . . . . . . . . 4-3

4-2-1. Test Points . . . . . . . . . . . 4-3

4-2-2. Variable Resistors and Capacitors . . 4-5

4-2-3. Switches . . . . . . . . . . . . 4-5

4-2-4. LED Indicators . . . . . . . . . . 4-5

4-2-5. Jumpers . . . . . . . . . . . . 4-7

4-2-6. Special Tools and Lubricants . . . . 4-9

SECTION 5. TROUBLESHOOTING

5-1. Quality Checks . . . . . . . . . . . 5-1

1. Copy Quality . . . . . . . . . . . . 5-1

1. Copy Density . . . . . . . . . . . 5-2

2. Skew . . . . . . . . . . . . . . 5-2

3. Intelligibility . . . . . . . . . . . . 5-2

4. Copy Test . . . . . . . . . . . . 5-2

2. Operation Panel Display . . . . . . . . 5-3

3. Mechanism Test . . . . . . . . . . . 5-3

4. Communication Tests . . . . . . . . . 5-3

5-2. Copy Quality Troubleshooting . . . . . 5-4

5-3. Mechanical Problems . . . . . . . . 5-28

5-4. Service Call Conditions . . . . . . . 5-41

5-5. Error Codes . . . . . . . . . . . . 5-48

5-6. Hard Disk Troubleshooting Routines . . 5-64

1. Outline . . . . . . . . . . . . . . . 5-64

2. Entering and Exiting Hard Disk

Troubleshooting Mode . . . . . . . . 5-65

3. Functions . . . . . . . . . . . . . 5-65

3-1. System Start - Function 1 . . . . . . 5-65

3-2. Error Code Display - Function 2 . . . . 5-66

3-3. File Correction - Function 3 . . . . . 5-67

3-4. Random Read Test - Function 4 . . . . 5-67

3-5. All Read Test - Function 5 . . . . . . 5-67

3-6. Clear Address - Function 6 . . . . . 5-68

3-7. Clear Job - Function 7 . . . . . . . 5-68

3-8. Disk Format - Function 8 . . . . . . 5-69

4. Error Codes . . . . . . . . . . . . . 5-70

4-1. Power-up Error Codes . . . . . . . 5-70

4-2. Hard Disk Error Codes . . . . . . . 5-71

SECTION 6. OPTIONAL BAR CODE

READER

6-1. Accessory Check List . . . . . . . . . 6-1

6-2. Installation Procedure . . . . . . . . 6-2

SECTION 7. ELECTRICAL DATA

7-1. Point-to-point Diagram . . . . . . . . 7-1

7-2. Signal Tables . . . . . . . . . . . . 7-4

1. SCU . . . . . . . . . . . . . . . . 7-4

2. SPU . . . . . . . . . . . . . . . . 7-11

3. VPU . . . . . . . . . . . . . . . . 7-20

4. SBU . . . . . . . . . . . . . . . . 7-20

5. DRU . . . . . . . . . . . . . . . . 7-20

6. UIB . . . . . . . . . . . . . . . . 7-22

7. DSB . . . . . . . . . . . . . . . . 7-24

8. LIB . . . . . . . . . . . . . . . . . 7-25

9. OPU . . . . . . . . . . . . . . . . 7-26

Page 7

10. PSU

. . . . . . . . . . . . . . . 7-26

11. G3 CCU . . . . . . . . . . . . .7-28

12. G3 NCU . . . . . . . . . . . . . 7-30

13. BSRU . . . . . . . . . . . . . . 7-31

7-3. Block Diagrams . . . . . . . . . . . 7-32

1. Overall Machine Control . . . . . . . . 7-32

2. Video Data Path . . . . . . . . . . . 7-37

3. Power Distribution . . . . . . . . . . 7-40

4. Scanner . . . . . . . . . . . . . . 7-43

5. Communication Control . . . . . . . . 7-46

6. Printer . . . . . . . . . . . . . . . 7-47

7-4. Electrical Component Layout . . . . . 7-51

7-5. Timing Charts . . . . . . . . . . . 7-55

APPENDIX

A. Glossary . . . . . . . . . . . . . . A-1

Page 8

SECTION 1

Page 9

SECTION 1. INSTALLATION

1-1. Specifications . . . . . . . . . . . 1-1

1-2. Features . . . . . . . . . . . . . . 1-4

1-3. Installation Requirements . . . . . . 1-14

1-3-1. Environment . . . . . . . . . . . 1-14

1-3-2. Minimum Space Requirements . . . . 1-15

1-3-3. Power Requirements . . . . . . . . 1-16

1-4. Unpacking . . . . . . . . . . . . . 1-17

1-5. Accessory Check List . . . . . . . . 1-18

1-6. Installation Procedure . . . . . . . . 1-19

1-6-1. Master Unit . . . . . . . . . . . 1-19

1-6-2. Toner . . . . . . . . . . . . . . 1-20

1-6-3. Cassettes . . . . . . . . . . . . 1-22

1-6-4. Telephone . . . . . . . . . . . . 1-23

1-6-5. Cleaning Pad . . . . . . . . . . 1-23

1-6-6. Other Components . . . . . . . . 1-24

1-6-7. Power Connection . . . . . . . . 1-24

1-6-8. Hard Disk Initialization . . . . . . . 1-25

1-7. Initial Programming . . . . . . . . . 1-27

1-7-1. Country Code - Function 81 . . . . . 1-27

1-7-2. Fax Terminal’s Telephone Number -

Function 81 . . . . . . . . . . . . 1-28

1-7-3. Transfer Station Number - Function 81 . 1-28

1-7-4. Polling ID Code - Function 82 . . . . . 1-29

1-7-5. Confidential ID Code - Function 83 . . . 1-29

1-7-6. RTI #1 and RTI #2 - Function 84 . . . 1-30

1-7-7. TTl #1 and TTl #2 - Function 85 . . . . 1-31

1-7-8. CSI - Function 86

(W. Germany: Service Function 11) . . . 1-31

1-7-9. Date and Time - Function 87 . . . . . 1-32

1-7-10. Telephone Line Type -

Service Function 12 . . . . . . . . 1-32

1-7-11. Reception Mode - Function 88 . . . . 1-33

1-8. Charge Control Parameter Programming . 1-34

1-9. Transporting the Machine . . . . . . . 1-39

Page 10

1-1. Specifications

Type

Circuit

Connection

Document size

Length:

Width:

Thickness:

Weight:

Document feed

ADF capacity

Scanning method

Maximum scan width

Console-type transceiver

PSTN, PABX

Direct couple

Auto Doc. Feed Manual Doc. Feed

105 - 600 mm

105 - 1,200 mm

[4.13 - 23.6 ins]

[4.13 - 47.2 ins]

Unlimited length is available.

User must support documents longer than

420 mm [16.5 ins]

105 - 304 mm

[4.1 - 12.0 ins]

0.05 - 0.2 mm

0.04 - 0.4 mm

[2 - 8 mils]

[2 - 16 mils]

About 50 to 80 g/m

2

About 40 to 120 g/m

2

Automatic feed, face down

30 sheets (using 75 g/m2 paper)

Flat bed, with CCD

304 mm [12.0 ins]

1-1

Page 11

Scan resolution

Main scan: Standard, Detail - 200 dpi (7.87 dots/mm)

Super Fine - 400 dpi (15.75 dots/mm)

Options: 8, 16 dots/mm

Sub scan:

Standard - 100 dpi (3.94 lines/mm)

Detail - 200 dpi (7.877 lines/mm)

Super Fine - 400 dpi (15.75 lines/mm)

Options: 3.85, 7.7, 15.4 lines/mm

300 x 300 dpi (11.8 x 11.8 dots per mm) is also

available after programming a user function key

(tx mode only).

Memory capacity

Hard disk, 18 M capacity after formatting

Compression

MH, MR, EFC, MMR, New EFC

Modulation

V.29, V.27ter, V.21, AM-PM-VSB, QAM

Protocol

Groups 2, and 3 with ECM; autocompatibility

Group 4 interface option available

Data rate

9600/7200/4800/2400 bps; automatic fallback

Transmission time

10 s for a CClTT #1 document (Slerexe letter)

using standard resolution

Printing system

Laser printing, plain paper, dry toner

1-2

Page 12

Paper size

Letter [8.5 x 11”]

Legal [8.5 x 14“]

B4

A4

Maximum printout width

250 mm [9.8 ins]

Maximum printer resolution Main scan - 400 dots/inch [15.75 dots/mm]

Sub scan - 400 lines/inch [15.75 dots/mm]

Power supply

220 Vac + 22/-33 V; 50/60 Hz +/- 1 Hz

240 Vac + 24/-36 V; 50/60 Hz +/- 1 Hz

Power consumption (W)

Standby: 90

Transmit:

140

Receive:

900

Copying:

900

Operating Environment

Temperature: 5 - 35 degC

[41 - 95 degF]

Humidity: 10 - 85 %Rh

Dimensions (W x D x H) 475 x 603 x 388 (mm)

18.7 x 23.7 x 15.3 (inches)

Excludes trays and cassette

Weight

55 kg [121 Ibs]

1-3

Page 13

1-2. Features

Equipment

Availability

Default

Built-in handset

x

Connection for external tel.

o

Base cabinet

o

KEY

Manual feed for thick originals

o o = Used

Monitor speaker

o x = Not used

Microphone

o

Speakerphone

x

o

Remaining memory indicator (Function mode) o

Video Processing

Availability

Default

Features

Contrast (Lighten, Normal, Darken)

o

See Note 1.

Resolution (Std, Dtl, Super Fine)

o

Halftone

o

MTF (selectable by service)

x

Reduction - A3 to A4

o

o

- A3 to B4

o

o

- B4 to A4

o

Smoothing (rx) - 200 x 100 to 400 x 400

o o

- 200 x 200 to 400 x 400

o o

1-4

Page 14

Communication Features -

Availability

Default

Automatic

Scanning and storing during tx or rx

o

Redialling

o

Four redials

G2, G3 compatibility

o

Automatic fallback o

Confidential/substitute reception

o

Confidential: Not used in W. Germany

Page retransmission from memory

o

Communication Features -

Availability

Default

User Selectable

Auto/Manual reception

o

On hook dial

x

Speed Dial

2,000

Quick Dial Keys

50

Keystroke programs (See Note 2)

50

Groups

32

- max no. of addresses/group

200

- max no. of full tel nos. in all groups

1,020

Alternative destination

o

(with Quick and Speed Dial only)

Department code

o

Batch numbering

o

MMR/EFC disabling option

o

ECM disabling option

o (Not available in machines from factory for W. Germany)

Turnaround polling

o

Continued on the next page

1-5

Page 15

Communication Features -

Availability

Default

User Selectable (continued)

Auto-reduction override option

o

Immediate redial

o

Auto-answer delay time

x

Hold

x

Voice Request

o

Automatic Voice Message

o

Not used in W. Germany

Communication Features -

Availability

Default

Service Selectable

Closed network

o x

MV1200 compatibility

x

Short preamble

o x

Well log (tx)

o x

Protection against bad connections

x

EFC

o

Tx - on, Rx - on

PSTN access through PBX

o x

Polling ID code security

x

ECM

o

o

Operator restriction by department code

o

x

Resol’n stepdown override option

x

Conf’l password override option

o

1-6

Page 16

Special Communication

Availability

Default

Features

Transmission from memory

o

- immediate

o

- send later

o

- max no. of addresses/file

200

- max no. of files

500

- max no. of addresses over all files

1,020

See Note 3 (p. 1-13).

Send Later

o

Confidential Transmission

o

Not used in W. Germany

- immediate

o

Not used in W. Germany

- send later

o

Not used in W. Germany

- broadcasting

o

Not used in W. Germany

- remote password override

o

Not used in W. Germany

Transfer Request

o

Not used in W. Germany

- max no. of broadcasters

200

Not used in W. Germany

- max no. of end receivers

30

Not used in W. Germany

- stored ID override

o

- from memory

o

- 1 day/1 polling memory duration option

o

1 day

Continued on the next page

1-7

Page 17

Special Communication

Availability

Default

Features (Continued)

Polling Reception

o

- free/secured option

o

- stored ID override

o

- poll later: max no. of files

500

: max addresses/file

200

: max addresses overall

1,020 See Note 3 (p. 1-13).

Batch transmission

o

o

Forwarding

o

Transmission deadline

o

Notify

x

Other Features

Availability

Default

Multicopy: max 99 copies/original

o

Copy mode

o

User function keys

o

See Note 2.

Dialled tel. number check

o

Auto note

o

A3-width transmission

o

LCD brightness adjustment

o

Night timer

o

Printing out a memory file

o

1-8

Page 18

Reports - Automatic

Availability

Default

Journal (optional)

o o

Charge Control Report

o

W. Germany/Italy: o, Others: x

Tx Result Report (optional)

o o

Error Report (optional)

o x

Transfer Result Report

o

Not used in W. Germany

Mode Change Report

o

W. Germany: o, Others: x

Polling File List

o

Memory Report (optional)

o

x

Power Failure Report

o

Polling Result Report (optional)

o o

Polling Reserve Report (optional)

o o

Polling Clear Report (optional)

o o

Reports - User

Availability

Default

Journal

o

Charge Control Report

o

W. Germany/Italy: o, Others: x

Telephone List (includes Group List)

o

Polling File List

o

SAF File List

o

User Function List

o

Department Code List

o

Transmission Status Report

o

Program List

o

1-9

Page 19

Reports - Service

Availability

Default

Group 3 Protocol Dump Lists

o

Auto Service Call

o

System Parameter List

o

RAM Address Dump

o

Hard Disk Dump

o

Handshake Logging Dump

o

(For G3CCU and SPU)

Error Code Logging Dump

o

Transmission Status Report

o

System Data List

o

Service Monitor Report

o

User Programming

Availability

Default

Clock

o

Auto/Manual Rx setting

o

Auto

Tx/Rx page counter display

o

Sheet feed counter display

o

Batch number on/off

o

x

Department code on/off

o

x

Speaker volume adjustment

o

Continued on the next page

1-10

Page 20

User Programming

Availability

Default

(Continued)

Automatic Voice Message recording

o

Automatic Voice Message playback

o

Automatic Voice Message on/off

o o

Quick Dial/Group programming

o

Polling ID code

o

RTI/TTI/CSl

o

See Note 4.

RTI #2, TTl #2

o

Direct entry of labels and identifiers

o

Changing the contents of a file

o

Polling file clearance

o

Memory file clearance

o

Own telephone number

o

Telephone line type (See Note 4.)

U. K.: o, Others: x

Pulse

TTl on/off

o o

ECM on/off

o

Substitute reception on/off

x

Forwarding

o

Stamp on/off

o

x

Password

o

Rx mode switching timer

x

Master unit counter reset

o

Keystroke programs

o

ECM on/off is not available in machines shipped for W. Germany. It can be made available by

bit switch adjustment.

1-11

Page 21

Service Mode and

Availability

Default

System Tests

Dedicated Tx Parameters

o

Printout of all memory files

x

Bit switches

o

RAM rewriting - to local fax only

o

Error code display

o

Printer status display

o

Counter check and rewrite

o

Chequered mark on 1st page on/off

o

o

Number of copies per printout

o

1

Rx fax printout in reverse page order

o x

Serial number programming

o

NCU parameters

o

Modem and DTMF tone tests

o

Operation panel test

o

Fluorescent lamp lighting

o

Back-to-back test

o

RAM tests

o

Hard disk tests and maintenance

o

SPU tests

o

DCR tests

o

SPU reset

o

Printer test patterns

o

Maximum address limitation

x

ADF/printer mechanism tests

o

1-12

Page 22

Notes

1.

2.

3.

4.

Contrast can also be selected in halftone mode.

The keystroke programs are stored in Quick Dial Keys, so the no. of programmed Quick Dial Keys

plus the no. of programs plus the number of user function keys programmed as Quick Dial Keys cannot exceed 50 (user function keys can also be stored as Quick Dial Keys if more than 5 keys are

needed).

The number of addresses programmed for polling reception and for memory transmission, when combined, cannot exceed 1,020.

CSI is a service function in W. Germany.

machines for the U.S.A. and the U. K..

Telephone line type selection is a service mode in all except

1-13

Page 23

1-3. Installation Requirements

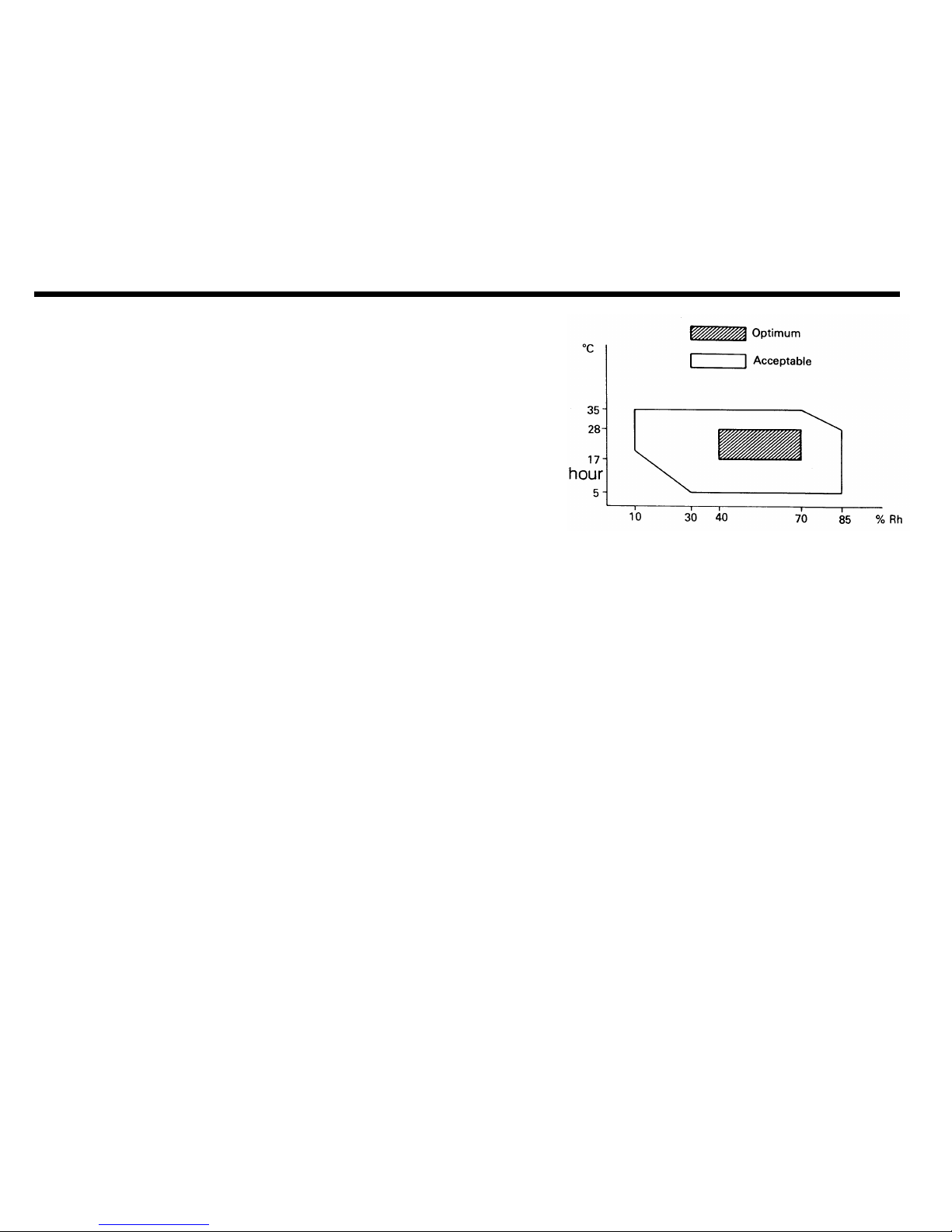

1-3-1. Environment

Temperature range: 17 to 28 degrees C [63 to 82 degrees F]

Humidity range: 40 to 70 %Rh - no condensation

Ventilation: Room air should turn over at least three times per

Ambient dust: Less than 0.15 mg/m3 [4 x 10¯³ oz/yd3]

Avoid placing the machine where it will be exposed to corrosive gases.

Place the machine on a strong and level base.

Place the machine where it will be:

• Not subject to direct sunlight

• Not subject to strong vibration

• Condensation free

• Away from other electronic equipment, to avoid interference

• Away from heaters and air conditioners, to avoid sudden temperature changes.

1-14

Page 24

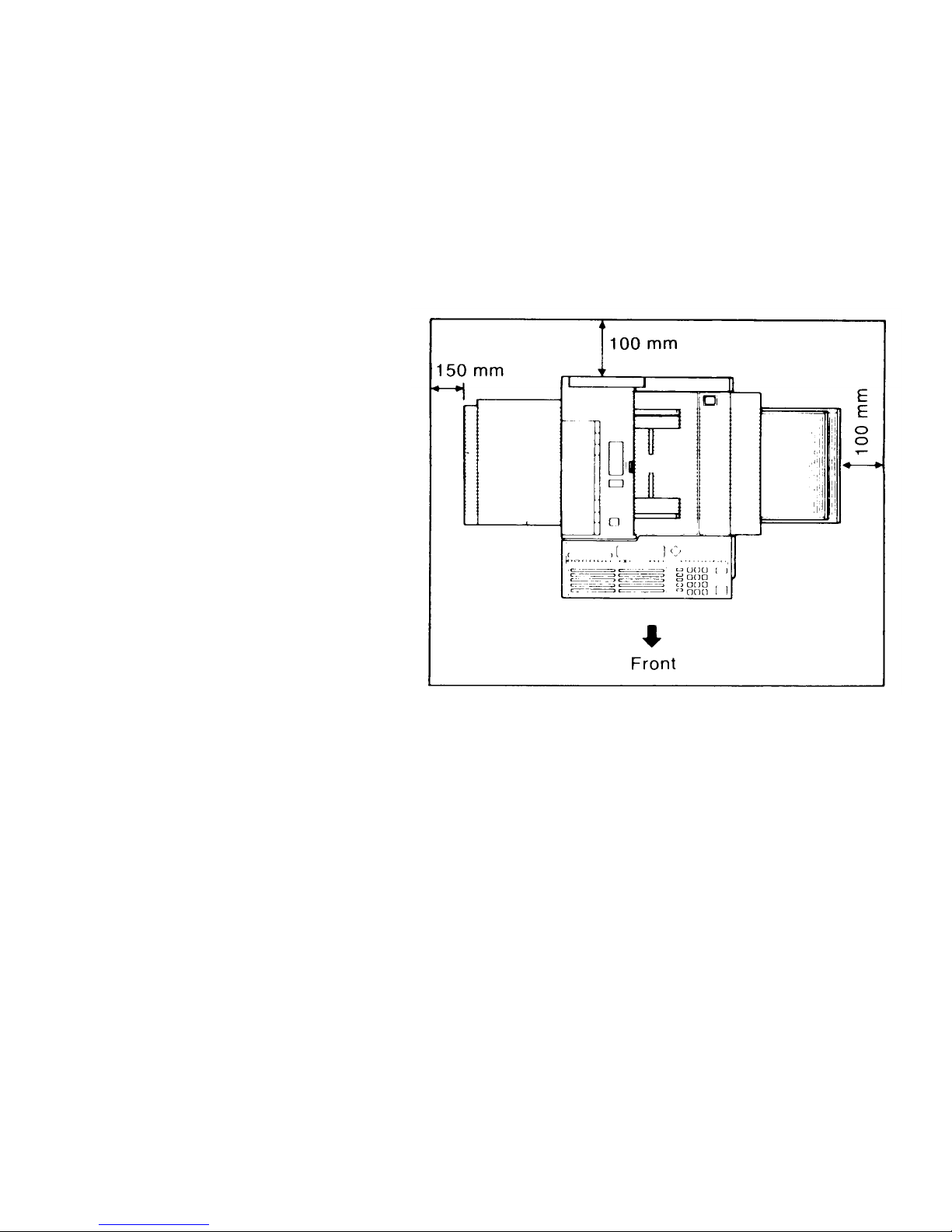

1-3-2. Minimum Space Requirements

1-15

Page 25

1-3-3. Power Requirements

Voltage

• 220 Vac + 22/-33 V, or 240 Vac + 24/-36 V, 50/60 Hz, capable of supplying more than 10 A

Power Outlet

• Must be properly grounded

• If possible, do not connect other equipment to the same outlet.

• Insert the plug securely.

1-16

Page 26

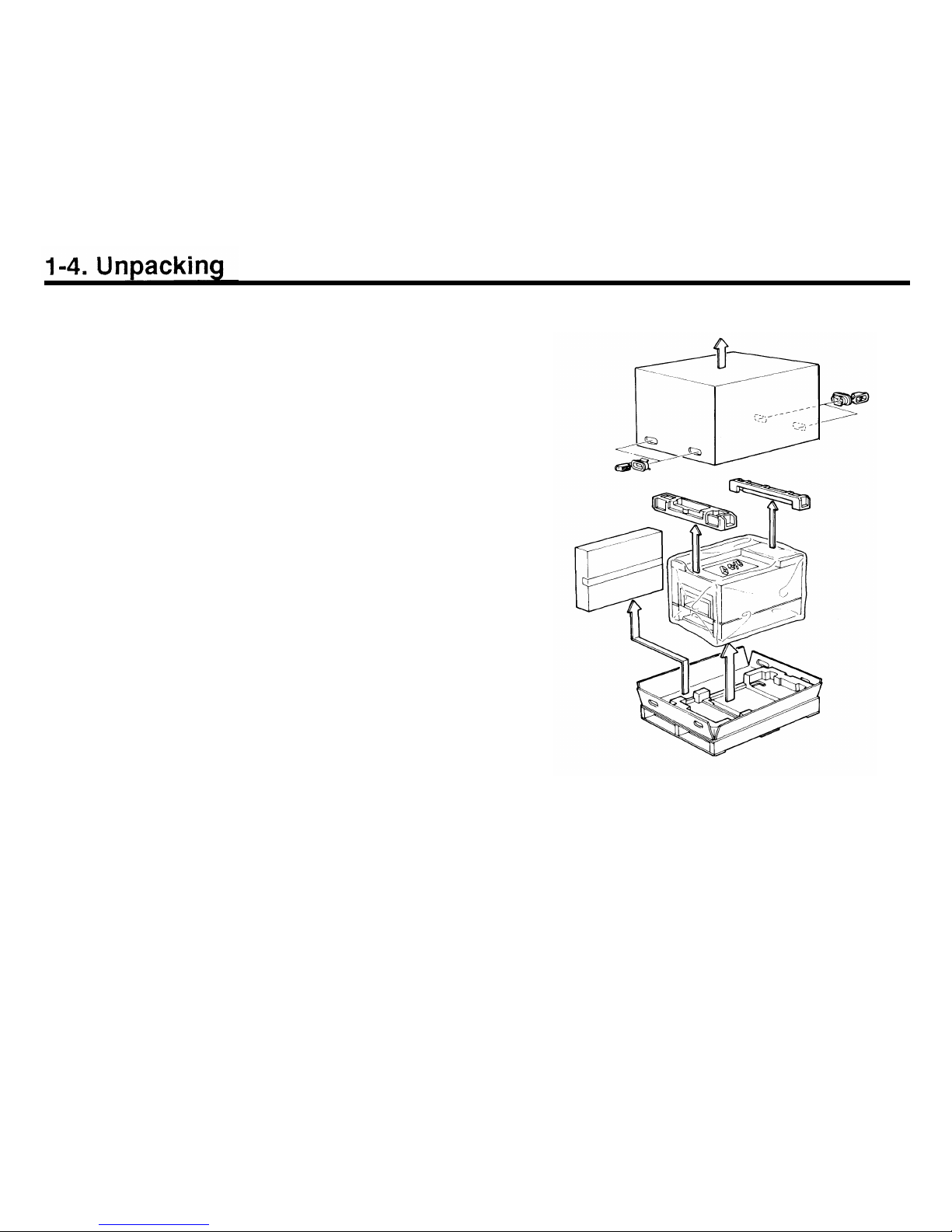

1.

2.

3.

4.

5.

6.

7.

8.

Remove the packing clips from the carton.

Remove the two cushion blocks.

Take the accessories box and the machine out of the

carton.

Open the vinyl envelope and take out the machine.

Peel off the packing tapes from the outside of the

machine.

Inside the machine, remove the packing tapes from

the development unit, registration roller, jam removal

lever (lower cassette), and the upper and lower paper

lift arms.

Open the lower front cover and remove the cushion

block from inside the lower cassette.

Place the machine on a table.

Caution: The table must be horizontally level within 2

degrees.

1-17

Page 27

1-5. Accessory Check List

Open the accessories box and check that the following items are present.

1. Vinyl Gloves

2. Plastic Bag

3. Toner Cartridges

4. Cleaning Pad

5. Cassettes

(upper and lower)

6. Paper Size Actuators

7. Paper Size Decals

8. Sub-document Table

9. Document Tray

10. Copy Tray

11. Quick Dial Labels

12. User Function Key Cards

13. User Function Label

14. Speed Dial Address

Decal

15. Operator’s Manual

16. Stamp Ink

17. Pack of Paper

18. Power Cord

19. Master Unit

20. NECR

21. Scanner Pick-up Roller

22. Microphone

1 set

1

2

1

2

6

2 sets

1

1

1

2

2

1

5 pcs

1

1

1

1

1

1

1

1

1-18

Page 28

1-18a

Page 29

1-6. Installation Procedure

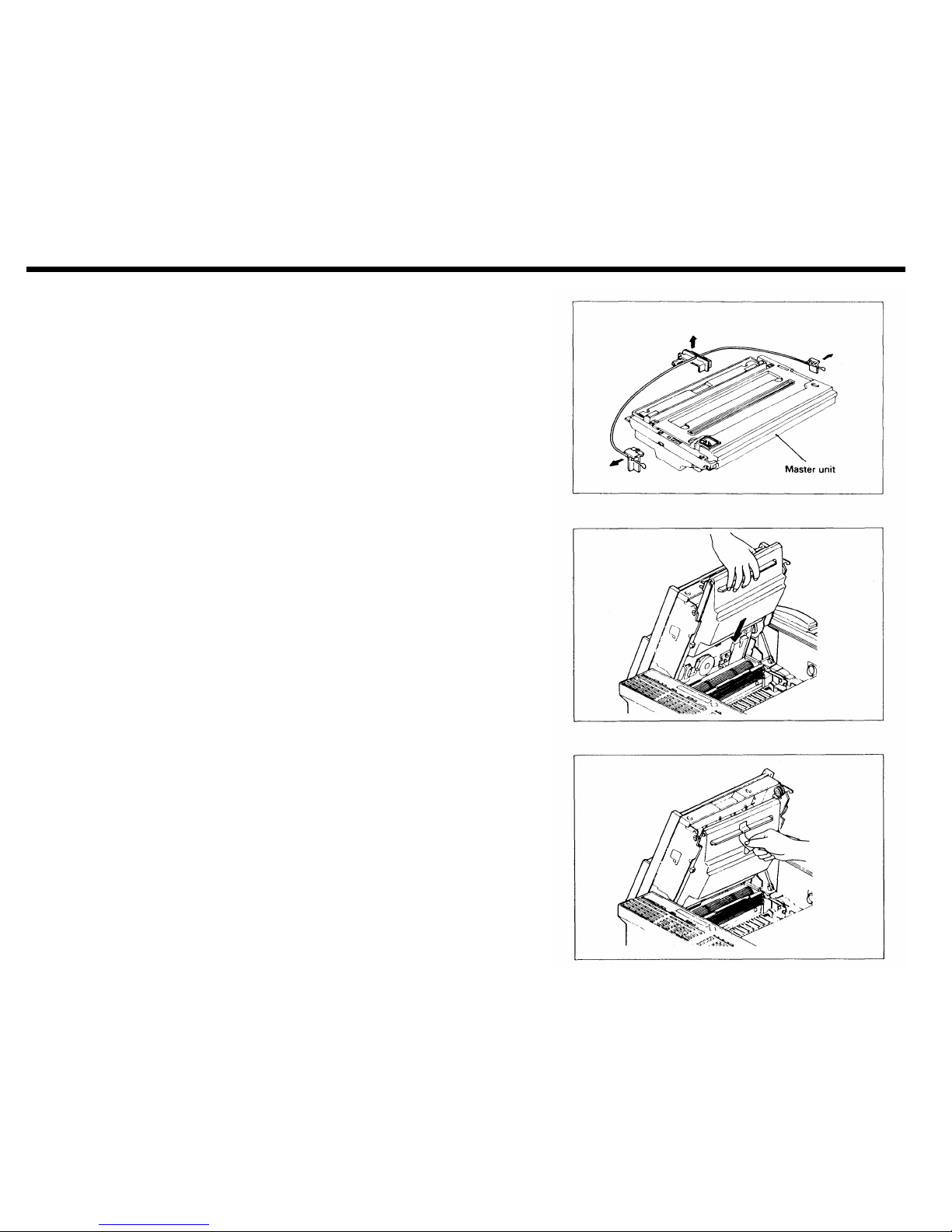

1-6-1. Master Unit

1.

2.

3.

4.

Remove the three plastic wedges from the master unit.

Caution: Do not remove the green plastic cover.

Open the upper unit and insert the master unit into the

machine with the green plastic cover facing out.

Take off the green plastic cover.

Note: Do not touch the master belt surface (purple

sheet), and do not expose it to direct sunlight

or bright light.

Close the upper unit.

1-19

Page 30

1-6-2. Toner

1. Open the right cover.

2. Shake a toner cartridge well.

3. Remove the cartridge crank from the cartridge.

4. Set the pins on the toner cartridge into the slots on

the development unit.

5. Rotate the cartridge up until it snaps into position.

1-20

Page 31

6.

7.

8.

9.

Fit the cartridge crank (or winding lever) onto the pin

on the bottom left of the cartridge.

Turn the crank (or winding lever) clockwise to strip off

the cartridge seal, until you see the yellow band. Then

remove the cartridge crank (or winding lever).

CAUTION:

If the yellow band is not showing, the plastic strip could become caught in the toner

mixing mechanism, leading to machine

damage.

Remove the empty toner cartridge and install another

(refer to steps 2 to 7). Place the empty cartridge in the

disposal bag.

Note: When adding toner during normal operation,

only one cartridge should be replaced.

Close the right cover.

1-21

Page 32

1-6-3. Cassettes

Remove the tape from the trays in the upper and lower

cassettes.

Put some copy paper in the cassettes, attach the cas-

sette top covers, and install the cassettes.

Note: The cassettes are set up for Letter-size paper. If

1.

2.

3.

4.

5.

6.

the user wishes to use a different paper-size than

this, modify the cassette(s) as follows.

Move the rear and side fences to the appropriate positions.

Attach the appropriate paper size decal to the tray.

Change the paper size actuator to the appropriate

one.

Add paper.

Attach the top cover.

Install the cassette.

1-22

Page 33

1-6-4. Telephone

1. If you connect a telephone to the rear of the machine,

make sure that the type of dialling signal generated by

the telephone matches the type of signal that the local

exchange accepts (pulse or tone dialing).

1-6-5. Cleaning Pad

1.

2.

3.

Open the copy exit cover.

Install the cleaning pad (4 screws).

Close the copy exit cover.

1-23

Page 34

1-6-6. Other Components

1.

Attach the function label.

2. Attach the copy tray.

3. Attach the document tray.

1-6-7. Power Connection

1.

2.

3.

4.

Connect the power cord to a supply of the type

specified on page 1-16.

Voltage must not fluctuate more than the limits

specified on page 1-16.

Make sure that the plug is firmly inserted into the out-

let.

A dedicated circuit is recommended.

1-24

Page 35

1-6-8. Hard Disk Initialization

1. Switch the main power on.

If an error message is displayed at this time, there is a

problem with the hard disk. See page 5-70 (Power-up

Error Codes).

2. Within 3 seconds of switching the power on, press

Function, then *, then #. An error message is displayed. However, there is no problem unless an error

code is displayed in the central line of the LCD. If an

error message is displayed at this time, there is a

problem with the hard disk. See page 5-70 (Power-up

Error Codes).

3. Press Function, then *, then # once more.

4. The hard disk troubleshooting menu is displayed.

Press 8 then Yes.

1-25

Page 36

5. When ENTER PASSWORD is displayed, enter 1988, then press Yes.

6. When “Initialize System? Y/N” is displayed, press Yes.

7. Enter the bad spot information listed on the decal inside the lower front cover.

The format of data on the label is shown in the following example:

CYL HD BYTE

319

1 8132

In the above example, press 31918132.

Press the down arrow on the scroll key to enter the next bad spot.

If there are no more bad spots, press Yes.

Note: Bad spots that develop after shipment from the factory and during machine use are automat-

ically discovered and stored in the system RAM when the following conditions occur. Such

areas will be avoided when storing messages and parameters to the disk.

• During formatting, either at installation or at any other time

• During use, if an error occurs, the machine will avoid the area of the disk that caused the

error. In this case, the memory capacity display will read less than 100%, even if there are

no fax messages on the hard disk.

8. “Initialize System Y/N’ is displayed again. Press Yes to format the hard disk.

9. After formatting, the machine automatically enters initial programming mode. After doing the initial

programming (see section 1-7), press Function to return the machine to standby.

10. Program the CSI (section 1-7-8), telephone line type (section 1-7-10), charge control parameters (section 1-8), serial number (section 2-3-10) and the service station telephone number (section 2-3-6).

1-26

Page 37

1-7. Initial Programming

After installation, the following items should be programmed. They can all be programmed by the user. They

can all be programmed in sequence by using Function 81. In this manual, each individual procedure will be explained.

1-7-1. Country Code - Function 81

Program the international dial access code then the country code.

1.

2.

3.

4.

5.

Make sure that the machine is in standby mode.

Press Function, then enter 80, then enter 2222.

Enter 81.

Enter the international dial access code then the country code. For example, enter 00144 (Internation-

al code

= 001, country code = 44).

To correct a mistake, press Clear (erases the last digit or the cursor digit), or No (erases the entire

code).

Press Yes to store the displayed codes, then press Function to return the machine to standby mode.

1-27

Page 38

1-7-2. Fax Terminal’s Telephone Number - Function 81

If this number is not programmed, Transfer Request is impossible.

1.

2.

3.

4.

5.

Make sure that the machine is in standby mode.

Press Function, then enter 80, then enter 2222.

Enter 81, then press Yes.

Enter the fax terminal’s telephone number. Place a pause after the area code, using the Pause key.

To correct a mistake, press Clear (erases the last digit or the cursor digit), or No (erases the entire

number).

Press Yes to store the displayed number, then press Function to return the machine to standby mode.

1-7-3. Transfer Station Number - Function 81

If this machine will be used as the first stage in a two-step transfer operation, the number of the terminal

acting as the second stage must be stored here. This function is only used in Group 4 communications.

1.

2.

3.

4.

5.

Make sure that the machine is in standby mode.

Press Function, then enter 80, then enter 2222.

Enter 81, then press Yes twice.

Enter the transfer station number.

To correct a mistake, press Clear (erases the last digit or the cursor digit), or No (erases the entire

number).

Press Yes to store the displayed number, then press Function to return the machine to standby mode.

1-28

Page 39

1-7-4. Polling ID Code - Function 82

This four-digit code is necessary for secured polling, closed network communication, and transfer re-

quest. All terminals in these types of communications must decide on the same ID code or the

communication will fail.

1. Make sure that the machine is in standby mode.

2. Press Function, then enter 80, then enter 2222.

3. Enter 82.

4. Enter the code. Do not use 0000 or FFFF.

5. Press Yes to store the displayed code, then press Function to return the machine to standby mode.

1-7-5. Confidential ID Code - Function 83

This ID code is used to print confidential messages stored on the hard disk.

This function is not used in W. Germany.

1. Make sure that the machine is in standby mode.

2. Press Function, then enter 80, then enter 2222.

3. Enter 83.

4. Enter the code.

5. Press Yes to store the displayed code, then press Function to return the machine to standby mode.

1-29

Page 40

1-7-6. RTI #1 and RTI #2 - Function 84

The RTI (Remote Terminal Identification) identifies your terminal at the other end. It is displayed on the

operation panel at the other end during communication. RTI #1 will normally be used. However, when

you program a number as a Speed Dial or Quick Dial, you can select either RTI #1 or RTI #2 for use

when sending to that terminal. Note that if RTI #1 is selected, TTI #1 will also be used, and if RTI #2 is

selected, TTl #2 will be used.

Each RTI can have up to 20 characters.

1.

2.

3.

4.

5.

6.

7.

Make sure that the machine is in standby mode.

Press Function, then enter 80, then enter 2222.

Enter 84.

Type in RTI #1. For numbers use the ten-key pad. For letters and punctuation marks, use the Quick

Dial keys. For a space, use Quick Dial 27.

To correct a mistake, press Clear (erases the last letter or the cursor letter), or No (erases the entire

name).

Press Yes to store the displayed RTI.

Type in RTI #2 in the same way, then press Yes to store it.

Press Function to return the machine to standby mode.

1-30

Page 41

1-7-7. TTI #1 and TTl #2 - Function 85

The TTl (Transmit Terminal Identification) is another label which identifies you at the other end. It is

printed at the other end on the top line of each page that you send. Each TTl can have up to 32 charac-

ters.

1. Make sure that the machine is in standby mode.

2. Press Function, then enter 80, then enter 2222, then enter 85.

3. Either:

•

If RTI #1 can be easily added to or edited to make the TTl #1, then press 2. (Then, if TTl #1 is the

same as RTI #1, press Yes and go to step 5.) To edit RTI #1, press 1 then go to step 4.

•

To enter a TTl, press 1 and go to step 4.

4. Enter TTl #1 as explained for RTI #1 (page 1-30). Then press Yes twice to store it.

5. Repeat steps 3 and 4 for TTI #2.

6. Press Function to return the machine to standby mode.

1-7-8. CSI - Function 86 (W. Germany: Service Function 11)

In W. Germany, this is service function 11. The CSI (Called Subscriber Identification) is used instead of

the RTI when the machine communicates with another maker’s facsimile terminal.

1. Make sure that the machine is in standby mode.

2. W. Germany: Enter the service mode as shown on page 2-18, then enter 11.

Other areas: Press Function, then enter 80, then enter 2222 then 86.

3. Enter the CSI. It is best to use the fax machine’s telephone number.

To correct a mistake, press Clear (erases the last digit), or No (erases the entire CSI).

4. Press Yes to store the displayed CSI, then press Function to return the machine to standby mode.

1-31

Page 42

1-7-9. Date and Time - Function 87

1. Make sure that the machine is in standby mode.

2. Press Function, then enter 80, then enter 2222.

3. Enter 87.

4. Use the left and right arrows of the scroll key to highlight the parts of the display that need changing,

and type in the new values at the ten key pad. For the month, press the down arrow on the scroll key

until the correct month appears. The time is typed in using the 24 hour format.

5. Press Yes to store the displayed date and time, then press Function to return the machine to standby

mode.

1-7-10. Telephone Line Type - Service Function 12 (U. K.: User Function 88)

This must match the dialling method accepted by the local exchange, or the machine will not be able to

dial.

1. Make sure that the machine is in standby mode.

2. U.K. and U. S.A.: Press Function, enter 80, then 2222, then 88.

Other areas: Enter the service mode as shown on page 2-18, then enter 12.

3. Use the left and right arrows of the scroll key to highlight the required setting.

4. Press Function to store the displayed setting and return the machine to standby mode.

1-32

Page 43

1-7-11. Reception Mode - Function 88

Select either Automatic Reception (the machine receives fax messages automatically without intervention

by the user) or Manual Reception (the user must be present by the machine when a fax message comes

in).

1.

2.

3.

4.

5.

1-7-12.

1.

2.

3.

4.

5.

1-7-13.

1.

2.

3.

4.

Make sure that the machine is in standby mode.

Press Function, then enter 80, then enter 2222.

Enter 88, then press Yes.

Use the left and right arrows of the scroll key to highlight the required setting.

Press Function to store the displayed setting and return the machine to standby mode.

Service Station Number - Service Function 04

Make sure that the machine is in standby mode.

Enter the service mode as shown on page 2-18, then enter 04.

Type in the service station telephone number. Press Yes to store the number.

Type in the second service station number. Press Yes to store the number.

Press Function to return to standby mode.

Serial Number Programming - Service Function 08

Make sure that the machine is in standby mode.

Enter the service mode as shown on page 2-18, then enter 08.

Type in the serial number. Press Yes to store the number.

Press Function to return to standby mode.

1-33

Page 44

1-8. Charge Control Parameter Programming

Using charge control, the user can check the cost of each call made with the machine. Charge control is only

available on numbers that have been stored using Quick Dial, Speed Dial, Speed Dial # 1, or Speed Dial # 2,

and is controlled using option 7 of the option menu for Quick/Speed Dial programming.

Using option 7, the user selects the time per unit cost for a particular charge period (see Charge Control

Codes, M to P, below); the user selects the correct value for the address from a menu of values stored by the

service technician.

Figures for West Germany and Italy have been programmed in the software. For other areas, a service tech-

nician must enter the following values in advance:

• Number of periods in the day having different rates (maximum 4 charge periods)

• Number of zones, in which the charge varies with distance (maximum 7 charge zones)

• Basic charge unit

• The charge periods

• The time per basic charge unit for each zone, during each period

The procedure is as follows.

1. Enter the service mode. See page 2-18.

2. When the service mode menu is displayed, enter 03 at the ten-key pad.

3. When the RAM menu is displayed, press 9. A table of 80 two-digit codes is displayed. An example is

shown below.

0207 302E 3233 2044

4D00 FFFF 0800 1800

1-34

Page 45

4.

5.

6.

7.

Only two rows (16 codes) are visible at once. More rows in the charge control table can be seen by pressing the down arrow on the cursor key.

Press the left and right arrows on the cursor key to highlight the number to be changed.

Type in any changes as required. The meanings of the codes are explained after this procedure.

Press Yes when all numbers have been entered.

Press Function if all service mode operations have been finished.

Charge Control Codes

To illustrate how to program the charge control parameters, let us represent the table of codes in the following

manner. Remember that only two rows are visible at once. Following this explanation, an example will be

given.

AB

CD

EF GH

IJ

KL MN

OP

QR

ST

UV

WX

YZ

ab cd

ef

gh

ij

kl

mn

op qr

st

uv

wx

ab

cd

ef

gh

ij

kl

mn

op

qr

st

uv

yz

A: This shows the number of different charge periods in the day. For example, if there are only two, enter 02.

1-35

Page 46

B: This shows the number of charge zones. For example, if there are seven zones, enter 07.

C to L: These 10 ASCII codes show the basic charge unit. A table of ASCII codes follows at the end of this

section. For example, to enter ’0.23 DM’ (0.23 German marks), enter 30 2E 32 33 20 44 4D 00 FF FF. ’00’ is

entered at the end, after the ’M’ in the example, and ’FF’ is added to make the total up to 10 ASCII codes.

M to X: These show the charge periods. Up to four periods can be used. Enter all the periods except one; the

missing one is deduced from the three entered periods. For example, if there are two periods, one from 08:00

to 18:00, and the other from 18:00 to 08:00, enter 08 00 18 00 in M, N, O, P, then enter 00 in codes Q to X.

The machine will assume that there is another period from 18:00 to 08:00 to fill up the 24 hour day.

Note: When the customer enters the time per basic charge unit for a destination with Quick/Speed Dial

option 7, the choices displayed will be based on the period entered in codes M to P. Therefore,

in most cases, this should represent the peak rate, or the period in which the machine is most

often used. Consult the user about which period to enter here.

The rest of the

codes are a table of times allowed per basic charge unit, for each zone, and for each period.

The column YZ

to

uv shows the times allowed for calling during the period programmed in codes M to P, for

up to 7 zones. These are the values from which the user selects using Quick/Speed Dial option 7.

The column ab to

wx shows the times per charge unit during the period programmed in codes Q to T, for up

to 7 zones. However, if there are only two charge periods, this column will show the times for the period

deduced

by the

machine

to fill up the 24 hour day.

The column cd to yz shows the times per charge unit during the period programmed in codes U to X, for up

to

7 zones. However, if there are only three charge periods, this column will show the times for the period

deduced

by

the machine to

fill up the 24 hour day.

The column ef to shows the times per charge unit during the fourth period, which is deduced by the

machine from the other three periods. If there are less than four charge periods, this column is all blank.

The codes are programmed as shown in the following examples: if the value is 3.8 seconds, enter 00 38; if the

value is 12 seconds, enter 01 20; if the value is 480 seconds, enter 48 00. Any codes that do not need to be

programmed must contain FF.

1-36

Page 47

Example

Number of charge periods: 2

Number of charge zones: 7

Basic charge unit: 0.23 DM (Deutschmarks)

Charge periods: (1) 08:00 to 18:00, (2) 18:00 to 08:00

Times allowed (seconds) in charge period 1 for each zone: 3.8, 10.7, 12, 12, 20, 45, 480

Times allowed (seconds) in charge period 2 for each zone: 3.8, 10.7, 16, 38.6, 38.6, 67.5, 720

The user wishes to see the times allowed for charge period 1 when programming Quick/Speed Dial.

Program the table as follows.

0207

302E

3233 2044

4D00

FFFF

0800

1800

0000

0000

0000

0000

4800 7200

FFFF FFFF

0450

0675 FFFF

FFFF

0200

0386 FFFF

FFFF

0120

0386 FFFF FFFF

0120

0160

FFFF

FFFF

0107

0107

FFFF

FFFF

0038

0038 FFFF

FFFF

1-37

Page 48

ASCII Codes

Do not use other codes than listed here, or Japanese characters will appear.

Symbol

Code Symbol

Code Symbol Code

Symbol

Code

Space

20

0 30

@

40

P

50

!

21

1

31

A

41

Q

51

22

2

32

B

42

R

52

#

23

3 33 C 43

S

53

$

24

4

34

D

44

T

54

%

25

5

35

E

45

U

55

&

26

6 36

F

46

V

56

,

27

7

37

G

47

W

57

(

28

8

38

H

48

X

58

)

29

9 39

I

49 Y

59

2A

:

3A

J

4A

Z

5A

+

2B

3B

K

4B

[

5B

Comma

2C

<

3C

L

4C

Yen

5D

2D

=

3D

M

4D

]

5D

Full stop

2E

>

3E

N

4E

Inverted v

5E

/

2F

?

3F

O

4F

5F

—

Page 49

1-9. Transporting the Machine

When moving the machine to a new location, it is important to move the hard disk read/write head back to its

shipping position. Do the following procedure.

1.

2.

3.

4.

Press Function, then enter 80 at the ten-key pad.

Enter 1988 then press Yes.

Enter 18 at the ten-key pad. The head moves to the shipping position.

The display indicates “Please Power Off”. Switch off the power. Do not switch on again until the

machine is in its new location. When the power is switched back on, the head will automatically move

away from the shipping position.

1-39

Page 50

SECTION 2

PROGRAMMING, TESTING,

Page 51

SECTION 2. PROGRAMMING, TESTING, AND PRINTING REPORTS

2-1. Operation Panel . . . . . . . . . . 2-1

2-2. User Level Programming . . . . . . . 2-5

2-2-1. Function List . . . . . . . . . . . 2-5

2-2-2. Others . . . . . . . . . . . . . 2-13

1. Multicopy Mode . . . . . . . . . . 2-13

2. Keystroke Programs . . . . . . . . 2-13

2-3. Service Level Functions . . . . . . . 2-14

2-3-1. Function List . . . . . . . . . . . 2-14

2-3-2. Entering and Exiting Service Mode . . 2-18

2-3-3. Bit Switches - Function 01 . . . . . . 2-19

2-3-4. CCU - Function 02 . . . . . . . . 2-20

1. G3 CCU Test Mode . . . . . . . . . 2-20

2. G3 Dump List 1 . . . . . . . . . . 2-22

3. G3 Dump List 2 . . . . . . . . . . 2-22

4. NCU Parameter Programming . . . . 2-23

2-3-5. RAM - Function 03 . . . . . . . . 2-24

1. RAM Read/Write . . . . . . . . . . 2-24

2. Memory Dump List . . . . . . . . . 2-25

3. Hard Disk Dump . . . . . . . . . . 2-26

4. G3 CCU Handshake Logging Dump List

2-27

5. SPU Handshake Logging Dump List . . 2-27

6. Error Code Logging Dump List . . . . 2-28

7. Multicopy . . . . . . . . . . . . 2-28

8. Counter Check . . . . . . . . . . 2-29

9. Charge Control . . . . . . . . . . 2-29

2-3-6. Service Station Number - Function 04 . 2-30

2-3-7. Counter Check - Function 05 . . . . 2-30

2-3-8. Service Monitor Report Printing -

Function 06 . . . . . . . . . . . . 2-31

2-3-9. Parameter List Printing - Function 07 . . 2-31

2-3-10. Serial Number Programming -

Function 08 . . . . . . . . . . . 2-32

2-3-11. Tests - Function 09 . . . . . . . . 2-32

1. Printer Tests . . . . . . . . . . . . 2-32

2. Fluorescent Lamp Lighting . . . . . . 2-33

3. SPU Reset . . . . . . . . . . . . . 2-34

4. Operation Panel Test . . . . . . . . . 2-34

5. RAM Test . . . . . . . . . . . . . 2-35

6. DCR Test . . . . . . . . . . . . . 2-36

7. ADF Mechanism Test . . . . . . . . 2-36

8. SPU Test Menu . . . . . . . . . . . 2-37

9. Hard Disk Test . . . . . . . . . . . 2-37

2-3-12. Printer Status - Function 14 . . . . . 2-38

2-3-13. Transmission Status Report -

Function 15 . . . . . . . . . . . 2-40

2-3-14. G4 CCU Parameters - Function 16 . . 2-42

2-3-15. System Data List - Function 17 . . . . 2-42

2-3-16. Hard Disk Shipping Position -

Function 18 . . . . . . . . . . . 2-42

2-3-17. Dedicated Transmission Parameters . . 2-43

2-3-18. Back to Back Test . . . . . . . . . 2-46

2-3-19. Machine Reset . . . . . . . . . . 2-46

Page 52

2-4. Bit Switches . . . . . . . . . . . . 2-47

1. SCU - Factory Settings . . . . . . . . 2-47

2. SCU - Bit Switch Tables . . . . . . . . 2-49

3. G3 CCU - Factory Settings . . . . . . . 2-85

4. G3 CCU - Bit Switch Tables . . . . . . . 2-87

2-5. NCU Parameters . . . . . . . . . . 2-112

2-6. Useful RAM Addresses . . . . . . . 2-115

Redialling . . . . . . . . . . . . . . 2-115

Charge Control Parameters . . . . . . . 2-115

Charge Control Report Printout Date . . . . 2-116

Page 53

2-1. Operation Panel

2-1

Page 54

1. Indicators

Transmitting Indicator

Lights when the machine is sending a fax message.

Receiving Indicator

Lights when the machine is receiving a fax message.

Storing Indicator

Lights when the machine is storing a fax message to the

hard disk.

Confidential File Indicator

Lights when a confidential message has been received.

Receive File Indicator

Lights when a message was received but could not be

printed because the printer was out of order (copy jam,

no toner, or no paper).

Memory Full Indicator

Blinks when the remaining memory space falls below

5%, and lights when there is no more space on the hard

disk.

Line Fail Indicator

Blinks when transmission fails.

Call Service Indicator

Blinks when the machine diagnostics detect a problem

that requires service.

Clear Original Indicator

Blinks when a document has jammed in the scanner.

Clear Copy Indicator

Blinks when paper has jammed in the printer.

Add Paper 1 Indicator

Blinks when the upper cassette is almost empty, and

lights when it is empty.

Add Paper 2 Indicator

Blinks when the lower cassette is almost empty, and

lights when it is empty.

Add Toner Indicator

Blinks when the toner cartridge is almost empty, and

lights when it is empty.

Toner Collection Indicator

Blinks when the toner collection tank is almost full, and

lights when it is full.

Close Cover Indicator

Blinks when a cover is open.

Replace Master Indicator

Blinks when it is time to replace the master unit.

2-2

Page 55

2. Character Display

Displays prompts, status, warnings, and selected modes.

3. Power Indicator

Lights when the power switch is on and when power is

supplied to the machine.

4. User Function Keys

Each of these keys (except F6) can be programmed to

execute a function or option during programming or communication. Note that F6 is only used with keystroke

programs.

5. Function Key

Press this key to use one of the user or service program-

ming functions, or to return the machine to standby

during programming.

6. Yes/No Keys

Use these to answer questions on the character display.

7. Scroll Key

When an arrow is displayed on the character display,

use this key to access the options, items, or functions indicated by this arrow. Also use it to shift the cursor when

programming or editing an item on the display.

8. Selector Keys

Digital and Analog Indicators and Key

When dialling, press this key to light the indicator that corresponds with the type of network that will be used for

dialling. The Digital setting is only available if you have installed the optional G4 interface.

Halftone Indicator and Key

If you are transmitting a photograph, press the key to

light the Halftone indicator.

Contrast Indicators and Key

The indicator that is lit shows the contrast that is now

selected. Press the key if you wish to change the setting.

Resolution Indicators and Key

The indicator that is lit shows the resolution that is now

selected. Press the key if you wish to change the setting.

Memory Indicator and Key

If the indicator is lit, the document will be stored to the

hard disk before it is transmitted. If it is not lit, the document will be sent immediately, without being stored.

Press the key if you wish to change the setting.

Copy Key

Press this key to copy the page(s) now in the feeder.

You can do this to check whether your contrast, resolution, and halftone settings are appropriate.

2-3

Page 56

9. Quick Dial Keys

You can program each of these to dial a number, a

group of numbers, or enter a sequence of numbers

and settings, with just one touch. You can also use

these keys to enter and edit labels, such as the RTI,

TTl, and CSI.

10. Keys

Speed Dial Key

Press this when you wish to dial using a Speed Dial

Code.

Voice Request/On Hook Dial Indicator and Key

Press this key during fax communication if you wish to

talk to the person at the other end on the same call.

Also, to make a phone call, press this key then dial on

the ten-key pad. There is no need to pick up the handset during dialling.

Pause Key

When entering a telephone number at the ten-key pad,

press this key when you need to enter a pause.

Clear Key

This is used during programming to clear the last char-

acter entered, or to clear the character at the cursor,

depending on the mode in use.

11. Ten-key Pad

Acts as a telephone keypad. Also used for entering

other numbers, such as Speed Dial Codes, depending

on the mode in use.

12. Stop Key

Press this to stop the machine during communication

and return it to standby.

13. Start Key

Press this to start transmission.

Redial Key

Press this key when you wish to redial the last number

that was dialled.

2-4

Page 57

2-2. User Level Programming

2-2-1. Function List

To select a function, press the Function key, then enter the number at the ten key pad. The functions are explained very briefly below. For full details, see the Operator’s Manual.

No

Function Details

10

Function List

This displays a menu of functions 11 to 14.

11

Confidential Transmis-

Use this function to send a confidential message. This function is

sion

not used in W. Germany.

12

Secured Polling Trans-

Use polling transmission to store a message on the hard disk for

mission

another fax terminal to pick up. If this type of polling is used, the

other end’s Polling ID code must be the same as this machine’s.

13

Free Polling Transmis-

This is like function 12, except that the Polling ID is not checked.

sion

14

Polling Reception

Use this function to pick up a fax message that has been stored

for polling transmission in another terminal.

30

Printing a confidential To print the message, enter the password then press Start. Note

message that if the sender has over-ridden the machine’s confidential ID, the

message will not be printed. In this case, contact the sender. This

function is not used in W. Germany.

2-5

Page 58

No

Function Details

40

41

42

43

44

45

Function List

Changing the contents

of a stored memory file

Checking stored

memory files

Displaying the remaining memory space

Forwarding a substitute reception

Forwarding a confidential reception

Displays a list of functions 41 to 45

Using this function, you can add or remove an address from a

memory or polling file, or change the time when the communication is scheduled to start, or you can delete the file altogether. You

can also print out the contents of a message that has been stored

for polling or memory transmission.

Use this to check whether the messages (and polling operations)

stored in the memory have been transmitted successfully.

Use this to check how much space is remaining on the hard disk.

When printer supplies have run out, use this to send any non-confidential receptions on to another fax machine. Dial the number,

then press Yes, then Start.

This is the same as for function 44, except that this is used for forwarding confidential messages. Before dialling the number, the

confidential ID must be entered. This function is not used in W. Ger-

many.

2-6

Page 59

No

Function

50

Function List

51

Programming Speed

Dial

52

Programming Quick

Dial Keys

53

Programming Groups

54

Labelling or Erasing a

Keystroke Program

Details

Displays a list of functions 51 to 57.

Enter the two-digit code that you wish to program, then press Yes.

Press the line selector key to select either Analog or Digital. Enter

the number, then press Yes. Press Yes twice more then press No

to start to enter another Speed Dial Code.

Press the key that you wish to program, then press Yes. The proce-

dure from this point is the same as for Speed Dial Codes.

Enter the group number that you wish to program, then press Yes.

Press the Quick Dial Key that you wish to store the group in (to

select this group during dialling, you will press this key). Type in a

label for the group, then press Yes. Press 1. Store numbers in the

group: first, select the line type (Analog or Digital), then enter the

number, then press Yes. Press Function when you have finished

with the group.

Use this function to label or erase a keystroke program. Press the

key that contains the program. To label the program, press 1, type

in the label, then press Yes. To erase the program, press 2 then

Yes.

To store a keystroke program, see page 2-13.

2-7

Page 60

No

Function Details

55

Programming the User

Keys F1 to F5 can be programmed as user function keys. F6 is not

Function Keys

programmable; it is used for storing keystroke programs. Quick

Dial Keys can also be programmed as user function keys. Press

the key that you wish to program, then press Yes. Enter the twodigit code that corresponds to the function that you wish to program into this key (see the Operator’s Manual for a full list of

codes). Then press Yes.

56

Programming Speed

Enter the three-digit code (from 000 to 999) that you wish to pro-

Dial #1

gram. Then proceed as for Programming Speed Dial (Function 51).

57

Programming Speed Enter the three-digit code (from 000 to 899) that you wish to proDial #2

gram. Then proceed as for Programming Speed Dial (Function 51).

60

Function List Displays a list of functions 61 to 72

61

Printing the Journal The Journal contains information on the most recent communica-

tions. Press Start to print the Journal.

62

Printing the File List This report lists information on all files (polling and memory) still on

Report

the hard disk. Press Start to print the report.

63

Printing the Depart- This report lists all department codes that have been programmed

ment Code List with function 96.

2-8

Page 61

No

Function Details

64

Printing the Speed Dial This is a list of all telephone numbers stored as Speed Dial Codes.

List

65

Printing the Quick Dial

This is a list of all telephone numbers stored as Quick Dial Keys.

List

66

Printing the Program This is a list of all the stored keystroke programs.

List

67

Printing the Group List This is a list of all the groups.

68

Printing the Transmis- This shows information on selected stored memory or polling

sion Status Report operations. You can either list information on a particular file, or

you can list information on all files stored under a particular department code. Use the scroll key to select the desired method, then

type in the file number or department code. Then, press Start.

69

Printing the Speed Dial

This is a list of all telephone numbers stored as Speed Dial #1

#1 List

Codes.

70

Printing the Speed Dial This is a list of all telephone numbers stored as Speed Dial #2

#2 List

Codes.

71

Printing the User Func- This is a list of all the user function keys that have been

tion Key List programmed.

72

Printing the Charge

This lists the calls made by the machine and the line charges.

Control Report

2-9

Page 62

No

Function

Details

80

Entering initial setting See page 1-27 for details.

mode

81

Storing the country

See pages 1-27 and 1-28 for details. You can also use this function

code, fax terminal’s as a starting point for running through all the initial settings.

own telephone number, and transfer sta-

tion number

82

Programming the poll-

See page 1-29 for details.

ing ID code

83

Programming the con- See page 1-29 for details. This function is not used in W. Germany.

fidential ID code

84

Programming the RTI See page 1-30 for details.

#1 and RTI #2

85

Programming the TTl See page 1-31 for details.

#1 and TTI #2

86

Programming the CSI

See page 1-31 for details. This function is a service mode in W. Germany.

87

Programming the date

See page 1-32 for details.

and time

2-10

Page 63

No

Function

Details

88

93

94

95

96

Programming the

reception mode and

telephone line type

Programming the

heater on/off timer

Switching the heater

on/off

Adjusting the speaker

volume

Programming department codes

See page 1-33 for details.

This timer controls the on/off timing of the fusing lamp. The user

can keep the fusing lamp off when absent; received faxes will be

kept on the hard disk. The timer can be programmed differently for

each day of the week. Type in the required on and off times for

each day. Press # to change from AM to PM, or from PM to AM.

Press the up arrow on the scroll key to change the day.

After entering this mode, the status of the fusing lamp is changed.

This can be used to switch the fusing lamp on to print an urgent

message in the middle of the night. If the printer is idle for five

minutes at any time after using Function 94 to switch the lamp on,

the lamp switches off automatically, or the user can use Function

94 to switch the fusing lamp back off again.

First adjust the transmission mode monitor - use the left and right

arrows of the scroll key to adjust the volume, and to check the

volume, press Start. Press Yes to store the volume. Then repeat

the procedure for the voice message monitor.

Enter the department code that you wish to register, then press

Yes. Type in the department name, then press Yes.

2-11

Page 64

No

Function Details

97

Checking the counters

98

Storing the voice message, playing back the

voice message, and

switching voice message on/off

99

Master belt rotation

counter reset

The tx, rx, scan, and print counters are displayed. Press Function

after viewing the counters.

To store a voice message, press 1, pick up the handset, press

Start, and speak. Press Stop when you have finished. To play back

the voice message, press 2. The current on/off setting is high-

lighted on the bottom right of the screen. To change the setting,

press 3.

After installing a new master belt, use this function. Press Yes then

Function to reset the counter.

2-12

Page 65

2-2-2. Others

1. Multicopy Mode

You can use the machine to make up to 99 copies of an original.

Place the document in the feeder, press Copy, type in the number of copies that you need, use the scroll key

to select the required copy paper size, then press Start.

2. Keystroke Programs

If the user regularly transmits to or polls a particular destination or set of destinations using the same fea-

tures, a lot of repetitive keypad operation can be saved by storing the settings as a keystroke program.

1.

2.

3.

4.

5.

6.

7.

Place a sheet of paper in the feeder (unless you are making a polling reception program).

Press F6.

Press the key that you wish to store the program in.

Select all required settihgs (such as contrast), features (such as Send Later), options (such as ID Trans-

mission), and destinations.

Press Start.

Press F6 to store the program (or press Stop if there was an error).

Remove the paper from the feeder.

2-13

Page 66

2-3. Service Level Functions

2-3-1. Function List

No

Function

Details

01

Bit Switches

Use this function to change a bit switch setting. See page 2-19.

02

CCU

0: G3 test - Use this to test tone generation. See page 2-20.

1: G3 dump 1 - Use this to print a protocol dump list for communication troubleshooting. Forward the printout to Ricoh

Technical Services for assistance. See page 2-22.

2: G3 dump 2 - Use this to print a table of recent software commands. Send this list to Ricoh Technical Services if there is a

communication problem. See page 2-22.

3: NCU data - Use this to adjust NCU parameters for ringing detection and auto-dialling. See page 2-23.

03

RAM

0: RAM read/write - Use this to display the contents of a RAM address, and to change the data if necessary. This function cannot

be used to rewrite remote terminal RAM. See page 2-24.

1: Memory dump - Use this to print a table of RAM address contents. See page 2-25.

2: Hard disk dump - This function is intended to help find

problems with missing files. With the help of Ricoh Technical Services, use it to print the contents of a hard disk sector in hex code.

This function is unlikely to be practical in the field. See p. 2-26.

Continued on the next page

2-14

Page 67

No

Function Details

03

RAM (continued)

3: G3 CCU Handshake List - Use this to print a table of software

commands that recently passed between the SCU and the G3

CCU. Send this list to Ricoh Technical Services if there is an unsolvable hardware or communication problem. See page 2-27.

4: SPU Handshake List - Use this to print a table of software

commands that recently passed between the SCU and the SPU.

Send this list to Ricoh Technical Services if there is an unsolvable

hardware problem. See page 2-27.

5: Error Code Logging - Send this list to Ricoh Technical Services

if the machine is defective and cannot be repaired. See page 2-28.

6: Multicopy - Use this to determine how many copies of each

received page is printed. See page 2-28. Bit 1 of SCU bit switch 18

must be set to 1 for this feature to work.

7: Counter Check - Use this to check and/or alter the Toner End,

Toner Full, and Master counters. See page 2-29.

9: Charge Control - Use this to enter charge control parameters.

See section 1-8.

04

Service Station Number

05

Counter Check

06

Service Monitor Report

Use this to program the service station number. The machine automatically calls this number when there is an Auto Service Call condition. See page 2-30.

Use this to check and/or alter the Scan, Print, Tx, and Rx counters.

See page 2-30.

This report lists the most recent error codes and gives information

on the most recent communications that experienced errors. See

page 2-31.

2-15

Page 68

No

Function

Details

07

Parameter List

This report lists information such as bit switch settings and current

counter values. See page 2-31.

08

Serial Number

Use this to program the machine’s serial number. This number is

used by the Auto Service Call administration system. See page 2-

32.

09

Tests

0: Printer test patterns. See page 2-32.

1: Scanner - 0: Fluorescent lamp lighting. See page 2-33.

- 1: SPU Reset - Use this to reset the machine after

clearing an Auto Service Call condition. See p. 2-34

2: Operation panel test - Use this to check the operation of the

operation panel LEDs. See page 2-34.

3: RAM test - Use this to test the function of the various RAM

chips inside the machine. See page 2-35. Note that the tested

RAM will be cleared.

4: DCR test - Use this to test the function of the data compression/reconstruction chips on the SCU. This function does not test

the DCR chip on the VPU. See page 2-36.

5: ADF mechanism test - See page 2-36.

6: SPU tests - There are three tests to check motor operation,

master home position detection, and charge corona operation.

See page 2-37.

7: Hard disk tests - Factory use only. Do not use.

10

Not used

2-16

Page 69

No

Function Details

11

12

13

14

15

16

17

18

Programming the CSI

Telephone line type

selection

Not used

Printer Status

Transmission Status

Report

G4 CCU Parameters

System Data List

Set Hard Disk to Shipping Position

W. Germany only.

See page 1-32 for details.

Use this to display the most recent printer error messages. See

page 2-38.

This report is similar to the user report of the same name, except

that in the service mode, it lists the status of all files on the hard

disk. See page 2-40.

See the service manual for the Group 4 interface kit.

This report contains software data. Pass this report to Ricoh Tech-

nical Services if the machine malfunctions. See page 2-42.

If the machine is to be moved to a new location, do this function to

move the hard disk head to the shipping position. See page 1-39.

2-17

Page 70

2-3-2. Entering and Exiting Service Mode

ENTERING SERVICE MODE

Do the following procedure.

1. Make sure that JP19 is installed on the G3 NCU board.

2. Press Function then enter 80 at the keypad.

3. Enter 1988.

4. Press Yes.