Ricoh FAX500 Service Manual FX550 [E]

FAX550

SERVICE M ANUAL

Throug hout this manual, the machines are

referred to as follows.

Type A: FAX500

Type B: FAX550

Lithium Batteries (Memory Back-up)

CAUTION:

The danger of explosion exists if a battery of this type is incorrectly rep laced.

Replace only with the same or an equivalent type recommended by the

manufacturer. Discard used batteries in accordance with the manufacturer’s

instructions.

CONTENTS

1. OVERALL MACHINE INFORMATION

1.1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . 1-1

1.2. FEATURES . . . . . . . . . . . . . . . . . . . . . 1-2

1.3. COMPONENT LAYOUT . . . . . . . . . . . . . . . . 1-5

1.3.1. Mechanical Components . . . . . . . . . . . . . . 1-5

1.3.2. Drive Components . . . . . . . . . . . . . . . . . 1-6

1.3.3. Electrical Compon ents . . . . . . . . . . . . . . . 1-7

1.4. OVERALL SYSTEM CONTROL . . . . . . . . . . . . . 1-9

1.5. VIDEO DATA PATH . . . . . . . . . . . . . . . . . . 1-10

1.5.1. Transmission . . . . . . . . . . . . . . . . . . . 1-10

1.5.2. Reception . . . . . . . . . . . . . . . . . . . . 1-10

1.6. POWER DISTRIBUTION . . . . . . . . . . . . . . . . 1-11

1.6.1. Distribution Diagram . . . . . . . . . . . . . . . . 1-11

1.6.2. Memory Back-up Circuit . . . . . . . . . . . . . . . 1-12

2. DETAILED SECTION DESCRIPTIONS

2.1. SCANNER . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1. Mechanisms . . . . . . . . . . . . . . . . . . . 2-1

1. Document Detection . . . . . . . . . . . . . . . . . 2-1

2. Pick-up and Feed . . . . . . . . . . . . . . . . . . 2-2

2.1.2. Video Data Processing . . . . . . . . . . . . . . . 2-3

2.2. PRINTER . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.1. Mechanisms . . . . . . . . . . . . . . . . . . . 2-4

1. Paper Feed . . . . . . . . . . . . . . . . . . . . 2-4

2. Cutting . . . . . . . . . . . . . . . . . . . . . . 2-5

3. Cutter Jam Detection . . . . . . . . . . . . . . . . 2-5

2.2.2. Circuits . . . . . . . . . . . . . . . . . . . . . 2-6

1. Video Data Processing . . . . . . . . . . . . . . . . 2-6

2. Thermal Head . . . . . . . . . . . . . . . . . . . 2-6

2.3. PCBs AND THEIR FUNCTIONS . . . . . . . . . . . . . 2-7

2.3.1. FCU . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3.2. MBU . . . . . . . . . . . . . . . . . . . . . . 2-9

2.3.3. SBU . . . . . . . . . . . . . . . . . . . . . . 2-10

2.3.4. OPU . . . . . . . . . . . . . . . . . . . . . . 2-10

2.3.5. NCU . . . . . . . . . . . . . . . . . . . . . . 2-11

1. PCB Block Diagram . . . . . . . . . . . . . . . . . 2-11

2. Signal and Jumper Settings . . . . . . . . . . . . . . 2-12

2.3.6. PSU . . . . . . . . . . . . . . . . . . . . . . 2-13

3. INSTALLATION

3.1. CONNECTING UP THE MACHINE . . . . . . . . . . . . 3-1

3.2. INITIAL PROGRAMMING . . . . . . . . . . . . . . . 3-2

3.3. LANGUAGE ROM SELECTION . . . . . . . . . . . . . 3-2

4. SERVICE TABLES AND PROCEDURES

4.1. SERVICE LEVEL FUNCTIONS . . . . . . . . . . . . . 4-1

4.1.1. Bit Switch Programming (Function 91) . . . . . . . . . 4-1

4.1.2. System Parameter List (Function 92) . . . . . . . . . . 4-1

4.1.3. Error Code Display (Function 93) . . . . . . . . . . . 4-2

4.1.4. Service Monitor (Function 93) . . . . . . . . . . . . . 4-2

4.1.5. Protocol Dump (Function 94) . . . . . . . . . . . . . 4-2

4.1.6. RAM Display/Rewrite (Function 95) . . . . . . . . . . 4-3

4.1.7. RAM Dump (Function 95) . . . . . . . . . . . . . . 4-3

4.1.8. NCU Parameters (Function 96) . . . . . . . . . . . . 4-4

4.1.9. ADF Test (Functio n 97) . . . . . . . . . . . . . . . 4-4

4.1.10. Xenon Lamp Test (Function 97) . . . . . . . . . . . 4-5

4.1.11. DTMF Tone Test (Function 97) . . . . . . . . . . . . 4-5

4.1.12. Printer Test Patterns (Function 97) . . . . . . . . . . 4-6

4.1.13. Operation Panel Test (Function 97) . . . . . . . . . . 4-6

4.1.14. Modem Test (Function 97) . . . . . . . . . . . . . 4-7

4.1.15. Ringer Test (Function 97) . . . . . . . . . . . . . . 4-8

4.1.16. Buzzer Test (Function 97) . . . . . . . . . . . . . . 4-8

4.1.17. Sensor Initialization (Function 97) . . . . . . . . . . . 4-8

4.1.18. Serial Number (Function 98) . . . . . . . . . . . . . 4-9

4.1.19. Pulse Width (Function 99) . . . . . . . . . . . . . . 4-9

4.1.20. Bypassing Restricted Access . . . . . . . . . . . . 4-10

4.1.21. Printing all Memory Files . . . . . . . . . . . . . . 4-10

4.1.22. CSI Programming . . . . . . . . . . . . . . . . . 4-11

4.1.23. Telephone Line Type Selection . . . . . . . . . . . . 4-11

4.2. BIT SWITCHES . . . . . . . . . . . . . . . . . . . . 4-12

4.3. NCU PARAMETERS . . . . . . . . . . . . . . . . . . 4-24

4.4. DEDICATED TRANSMI SSION PARAMETERS . . . . . . . 4-39

4.4.1. Programming Procedure . . . . . . . . . . . . . . 4-39

4.4.2. Parameters . . . . . . . . . . . . . . . . . . . . 4-40

4.5. USEFUL RAM ADDRESSES . . . . . . . . . . . . . . 4-42

4.6. SPECIAL TOOLS AND LUBRICANTS . . . . . . . . . . . 4-44

5. REPLACEMENT AND ADJUSTMENT

5.1. COVERS . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1. Top Co ver . . . . . . . . . . . . . . . . . . . . 5-1

5.1.2. Front and Rear Covers . . . . . . . . . . . . . . . 5-1

5.2. SCANNER . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2.1. ADF Clutch and Pick-up and Feed Rollers . . . . . . . . 5-2

5.2.2. Separation Roller . . . . . . . . . . . . . . . . . 5-3

5.2.3. Tx Motor . . . . . . . . . . . . . . . . . . . . . 5-4

5.2.4. Timing Belt Tension Adjustments . . . . . . . . . . . 5-4

5.2.5. Xenon Lamp . . . . . . . . . . . . . . . . . . . 5-5

5.2.6. Xenon Lamp Driver . . . . . . . . . . . . . . . . . 5-5

5.2.7. SBU . . . . . . . . . . . . . . . . . . . . . . 5-6

5.2.8. SBU Adjustments . . . . . . . . . . . . . . . . . 5-6

5.3. PRINTER . . . . . . . . . . . . . . . . . . . . . . 5-10

5.3.1. Rx Motor . . . . . . . . . . . . . . . . . . . . 5-10

5.3.2. Thermal Head . . . . . . . . . . . . . . . . . . 5-10

5.3.3. Cutter . . . . . . . . . . . . . . . . . . . . . . 5-11

5.4. PCBs . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.4.1. FCU and Battery . . . . . . . . . . . . . . . . . . 5-12

5.4.2. Memory . . . . . . . . . . . . . . . . . . . . . 5-12

5.4.3. MBU . . . . . . . . . . . . . . . . . . . . . . 5-13

5.4.4. PSU and NCU . . . . . . . . . . . . . . . . . . . 5-14

5.4.5. Operation Panel . . . . . . . . . . . . . . . . . . 5-14

6. TROUBLESHOOTING

6.1. COPY QUALITY TROUBLESHOOTING . . . . . . . . . . 6-1

6.1.1. Received Copies . . . . . . . . . . . . . . . . . . 6-1

6.1.2. Copies made in Copy Mode . . . . . . . . . . . . . 6-1

6.2. MECHANICAL PROBLEMS . . . . . . . . . . . . . . . 6-2

6.2.1. ADF/Scanner . . . . . . . . . . . . . . . . . . . 6-2

6.2.2. Printer . . . . . . . . . . . . . . . . . . . . . . 6-5

6.3. ERROR CODES . . . . . . . . . . . . . . . . . . . 6-7

6.4. DEFECTIVE SENSOR TABLE . . . . . . . . . . . . . . 6-1 3

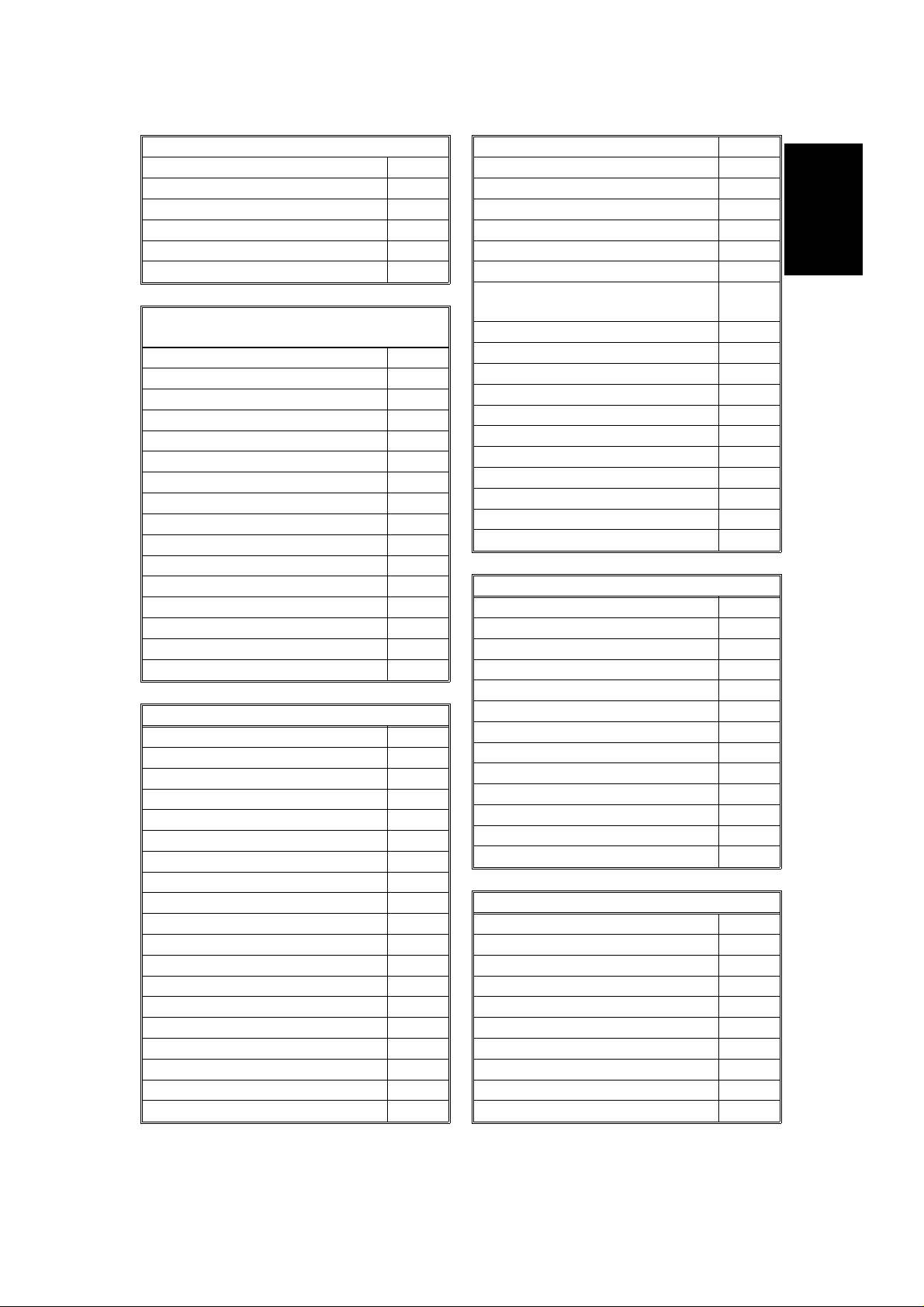

OVERALL MACHINE INFORMATION November 30th, 1991

SPECIFICATIONS

1. OVER ALL MACHINE INFORMATIO N

1.1. SPECIFICATIONS

Type

Desktop transceiver

Protocol

Group 3 with ECM

1

Circuit

PSTN, PABX

Connection

Direct couple

Document Size

Length: 105 - 1200 mm

[4.13 - 47.2 ins]

Up to 100 m [328 ft] after adjustment

Width: 148 - 216 mm

[5.8 - 8.5 ins]

Thickness: 0.05 to 0.15 mm

[2 to 6 mils]

Document Feed

Automatic feed, face down

ADF Capacity

30 sheets (using 80 g/m

Scanning Method

Flat bed, with CCD

Maximum Scan Width

216 mm [8.5 ins] ± 1%

Scan Resolution

Main scan: 8 dots/mm [203 dpi]

Sub scan:

Standard - 3.85 lines/mm [98 lpi]

Detail - 7.7 lines /mm [196 lpi]

Fine - 15.4 lines/mm [392 lpi]

Memory Capacity

ECM: 128 kbytes (double buffer)

SAF: 256 kbytes (14 pages), with

optional extra 1 Mbyte or

2 Mbytes (max 71 or 128

pages respectively)

Compression

MH, MR, E FC, MMR , SSC

Storage to SAF memory for tx: MH

MMR only with EC M

2

paper)

Data Rate

9600/7200/4800/2400 bps; automatic fallback

I/O Rate

With ECM : 0 ms/line

Without ECM: 5, 1 0, 20, or 40 ms/line

Transmi ssi o n Time

10 s at 9600 bps (G3 ECM using memory)

for a CCITT #1 test document (Slerexe letter) using standard resolution

Printing System

Thermal printing, automatic cutter

Pap er Size

216 mm (A4) x 100 m [8.5 ins x 328 ft]

Maximum Printout Width

210 mm [8.3 ins]

Ma ximu m Printer Resoluti o n

Main scan: 8 dots per mm [203 dpi]

Sub scan: 15. 4 lines/mm [392 lpi]

Power Supply

220 - 240 Vac, 50 Hz

Power Consumption (Base Machine Only)

Standby: 13 ± 5 W

Transmit: 29 ± 5 W

Receive: 22 ± 5 W

Copying: 41 ± 7 W

Operating Environment

Temperature: 17 - 28 °C [63 - 82 °F]

Humidity: 30 - 85 %Rh

Dimensions (W x D x H)

325 x 388 x 174 mm [12.8 x 15.3 x 6.9 ins]

Excluding handset, trays, and optional units

Weight

10 kg [22 lbs]

Modulation

V.29 (QAM), V.27ter (PHM), V.21 (FM)

1-1

November 30th, 1991 OVERALL MACHINE INFORMATION

FEATURES

1.2. FEATURES

KEY:

O = Used, X = Not Used,

A = With optional memory only,

G = Not used in Germany,

S = Service mode in some countries

Equipment

ADF O

Bar code reade r X

Built-in handset X

Cabinet X

Connection for ans. machine X

Connection for handset O

Cutter O

Handset O

Hard disk X

Magnetic card reader X

Manual f eed mechanism X

Marker X

Microphone X

Monitor speaker O

R emaining memory indicator O

Speakerphone X

Video Processing Features

Contrast O

Halftone (B asic & Error Dif fusion) O

MTF O

Reduction O

R e s olution O

Smoothing - 8 x 3.85 to 8 x 7 . 7 O

Smoothing - 8 x 7.7 to 8 x 15 . 4 X

Communication Features - Auto

Automatic fallback O

Automatic redialling O

Confidential reception A

Dual Acce ss O

Substitute r ecepti on O

Transmission Reserve O

Communication Features -

User Selectable

Action as a transfer broadcaster X

AI Redial O

Alternative Destination O

Answering machine X

Authorize d Reception O

Auto-answer dela y time X

Auto dialling (pulse or DTMF ) O

Auto Documen t O

Automatic Voice Message X

Auto-note X

Batch Transmission (max 5 files) A

Broadcasting O

Chain Dialling O

Confidential ID O v erride O

Confidential Transmission O

Forwarding (4 stations) A

Fre e Polling O

Gr oups (7 groups) O

Hold O (G)

Immediate Redialling O

Immediate transmission O

Keystr oke Program s O

Mailbox C

Memory transmission O

Notify X

On Hook Dial O (G )

Page Count O

Per sonal Codes O

Personal Codes with Conf ID A

Polling R eception O

Polling Transmission O

Quick Dial (3 0)

Reception mode s (Fax, Te l, Auto) O

Reduction X

Remote control features O

Remote Transfer O

Restricted Access (10 codes,

without cards)

Secured Polling O

Secured Polling with Stored ID

Override

Send Later O

Silent ringing detection X

O

O

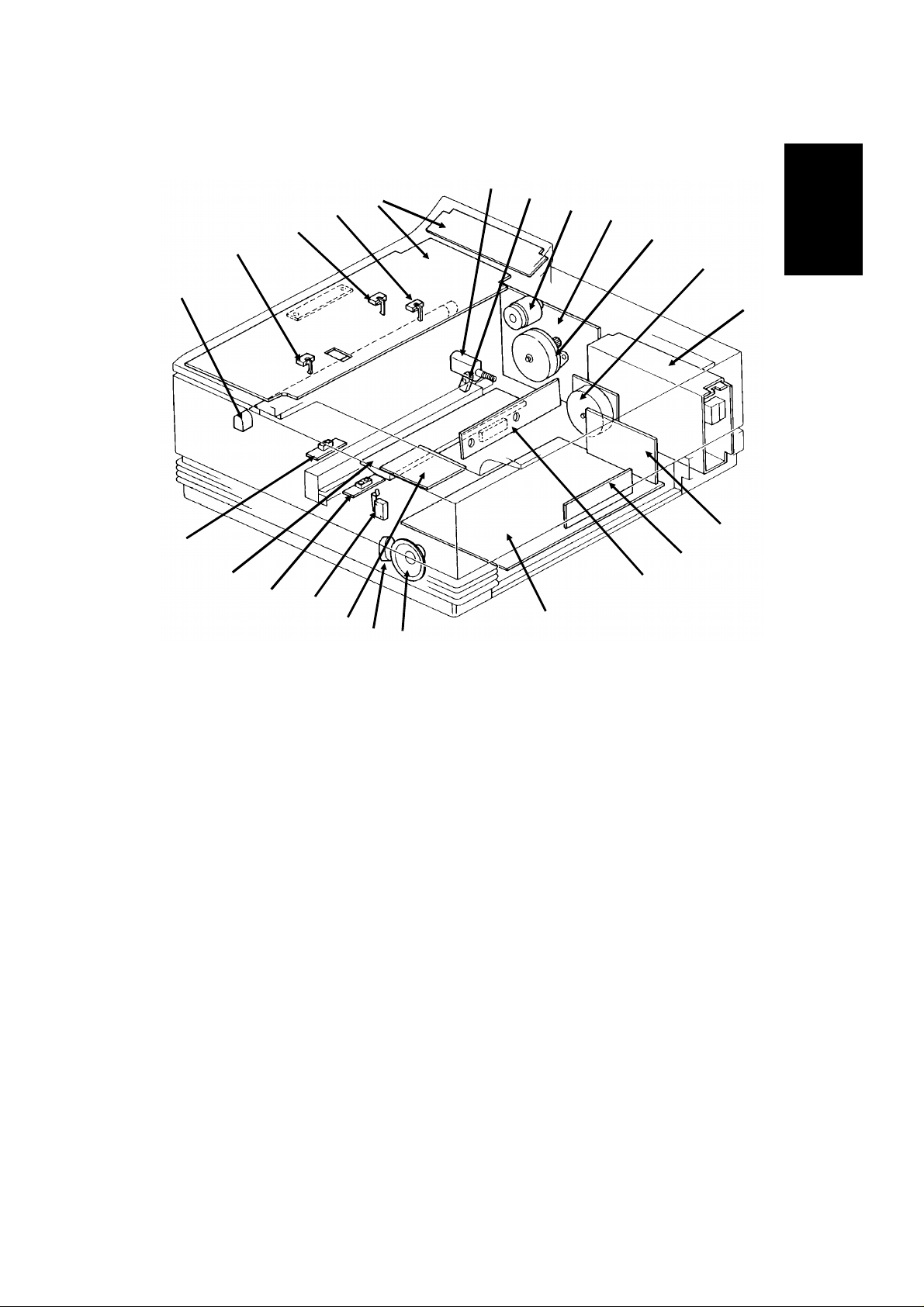

1-2

OVERALL MACHINE INFORMATION November 30th, 1991

FEATURES

Speed Dial (100)

Telephone Directory O

Tonal Signal Transmission O

Transfer Request: 30 stations O

Transmission Deadline X

Turnaround Polling X

Voice Request O

Communication Features -

Service Selectable

AI Short Protocol X

Auto-reduction override option X

Bus y tone detection O

Close d network (tx and rx) O

Continuous Polling Re ception O

Dedicate d t x paramete r s O

ECM O

EFC O

MV1200 compatibility X

Page retransmission O

Page separation m ark X

Polling tx file lifetime in the SAF O

Protection against wrong conn. O

R esol’n stepdown override option X

Short Preamble O

W ell log O

Other User Features

Auto Service Call X

Ce n ter mark X

Chequere d mark X

Clea ring a memory file O

Clea ring a polling file O

Clock O

Confidential ID A

Copy m ode O

Counters O

Di alled n umber che ck X

Direct entry of names O

Function Progr ams O

ID Code O

Label Insertion O

Language Selection O

LCD contrast control Se r vice

Memory L ock A

Memory L ock ID A

Modifying a memory file X

Mu lti So rt Document Rece p t ion X

Multicopy m ode X

Night Timer X

Own t elephone number O

Printing a memory file O

RDS on/off O

R eception Mode Switching Ti mer O

Reception Time (non- memory rx

only)

Re mote ID O

R everse Order Printing X

RTI, TTI, CSI O (S)

Speaker volume control O

Specified Cassette S election X

Substitute r ecepti on on /of f O

Telephone line type O (S)

TTI on/off O

Use r Function Keys X

User Parameters O

Wild Cards O

Reports - Automatic

Charge Control Report X

Communication Failure Report O

Confidential File Report A

Error Report O

Memory Storage Report O

Mode Chan ge Report X

Polling Clea r Report O

Polling R eserve Report O

Polling R esult Report O

Power Failure Report O

Journal O

Transfer Result Report X

Transmission Result Report O

Reports - User-initiated

Authorized Reception List O

Charge Control Report X

File L is t O

Forwarding List O

Gr oup List O

Per sonal Code List O

Program List O

Quick Dial List O

Specified Cassette Selection List X

Speed Dial List O

O

1

1-3

November 30th, 1991 OVERALL MACHINE INFORMATION

FEATURES

Reports - User-initiated

Journal O

Transmission Status Report X

User Function List X

Use r Paramete r List O

Service Mode Features

Back-to-back t est O

Bit switch programming O

Buzzer test O

Cable equaliz er (rx only) O

Comm. par ameter display O

DTMF tone test O

Echo countermeasure O

Error code display O

LCD contrast control O

Memory file forwarding O

Memory file printout (all files) O

Modem te st O

NCU parameters O

Operation panel test O

Printer mechanism test X

Printer te st patterns O

Progra mmable atten u ation X

Protocol dum p list O

R AM display/rewrite O

RAM dump O

R inger tes t X

Scanner la mp test O

Scan n er mechanism test O

Sens or initialization O

Serial number programming O

Service m onitor repor t O

Serv ice s tation number X

Syste m parameter list O

Technical data on the Journal O

T h ermal head parameters O

Transmission Status Report X

Memory Files

Max. number of files: 100

Max. number of stations/file: 142

Max. number of stations overall: 299

Max. number of pages overall: 200

(including pages stored as Auto

Documents)

1-4

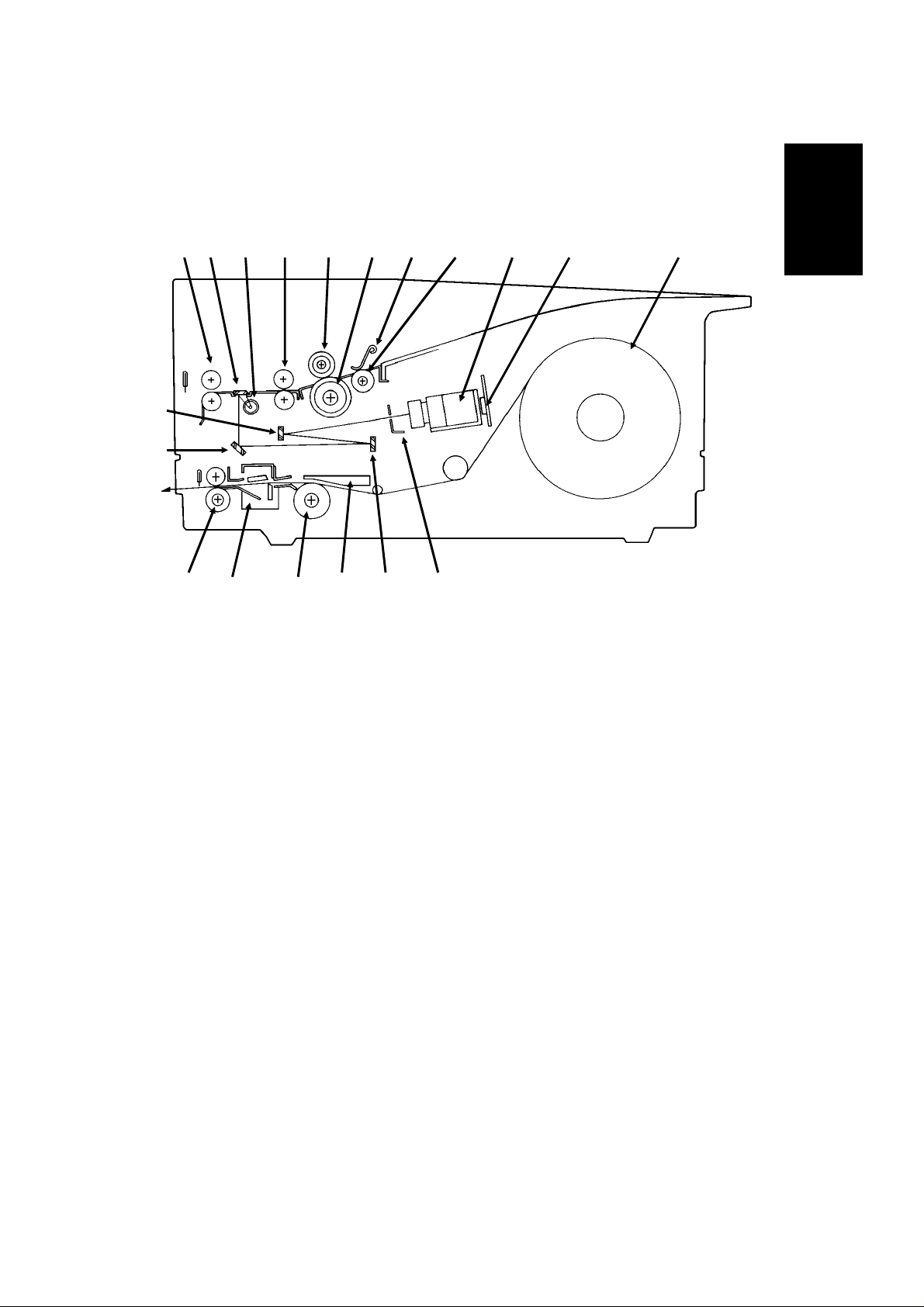

OVERALL MACHINE INFORMATION November 30th, 1991

COM PONEN T LAYOUT

1.3. COMPONENT LAY O UT

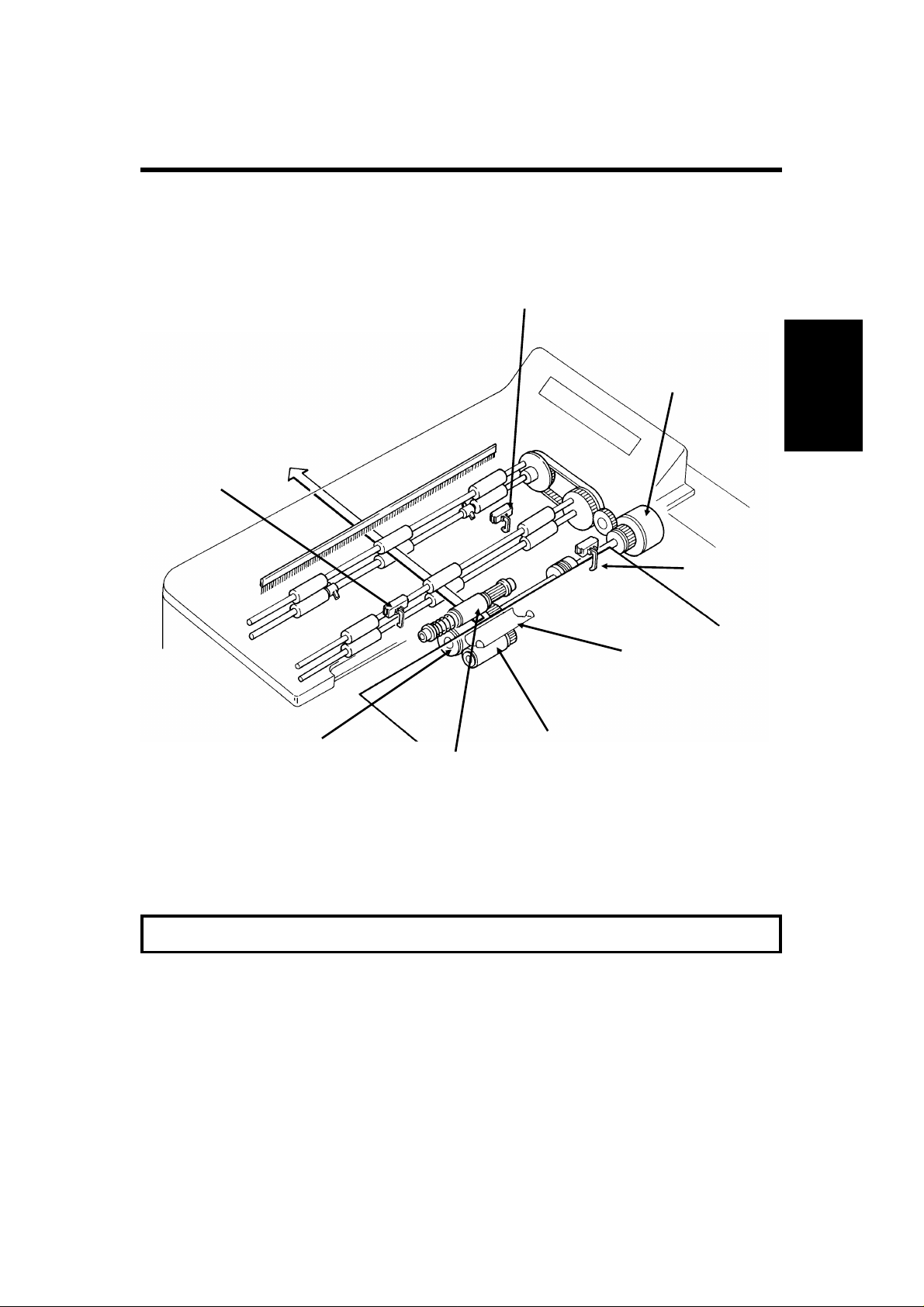

1.3.1. Mechanical Components

123456 78 9 10 11

19

18

1

121317 16 15 14

1. R2 Rollers Feed the document through the scanner.

2. Exposure Glass E xposes the original to light from the xenon lamp.

3. Xenon Lamp Illuminates the document.

4. R1 Rollers Feed the document through the scanner.

5. Separation Roller Allows one page into the scanner .

6. Document Feed Roller Feeds the document into the scanner.

7. Separation P lat e Spreads out the leading edges of the pages fed into the

scanner.

8. Pick-up Roller Picks up pages of the document from t he document

table .

9. Lens Block Focuses light reflected from the document onto the

CCD.

10. CCD (Charge Coupled

Device)

11. Thermal Paper Roll Thermal paper for printing.

12. Shading Plate Allows more light through from the ends of the xenon

13. Second Mirror Ref l ects light from the document towards the CCD.

14. Thermal Head P rints received data on the therma l paper.

15. Platen Roller Feeds the pa per through the printer.

16. Cutter Cuts off the printed page.

17. Feed-out R ollers Feed out the page which has been cut off.

18. First Mirror Refle cts light from the document towards the CCD.

19. Third Mirror Refle cts light from the document towards the CC D.

This converts the light reflected from the document into

an analog video signal.

lamp than from the centre, to counteract the relative

dimness at the ends of the lamp.

1-5

November 30th, 1991 OVERALL MACHINE INFORMATION

COM PONEN T LAYOUT

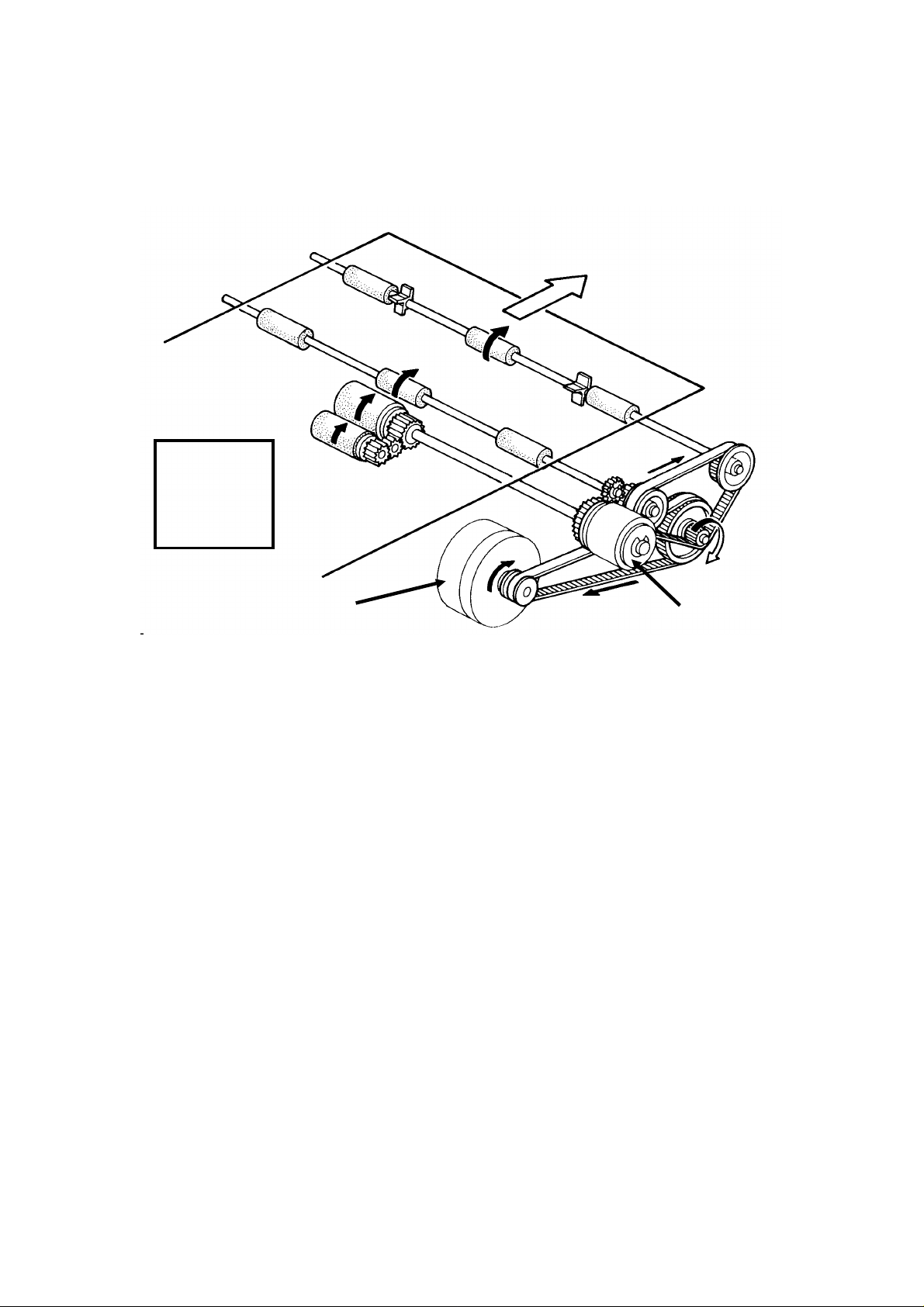

1.3.2. Drive Components

12 34 5 6

10

9

8

7

1. R2 Roller Drive Gear Drives the R2 roller.

2. Scanner Drive Gear Transfers drive from the Tx mo tor to th e

scanner and ADF.

3. R1 Roller Drive Gear Drives the R1 roller.

4. Document Feed Idle

Gear

5. ADF

Clutch/Document

Transfers drive from the Tx motor to the

document feed roller.

Drive the document feed roller, which feeds

the document into the scanner.

Feed Drive Gear

6. Tx Motor Drives the ADF and scanner.

7. Rx Motor Drives the printer.

8. Printer Drive Gears Tr ansfer Rx motor drive to the pr inter.

9. Platen Roller Drive

Gear

10. Feed-out Roller Drive

Gear

Drives the platen roller, which pulls the

thermal paper through the printer

Drives the feed-out roller, which feeds the

printed copy out of the machine.

1-6

2

4

11

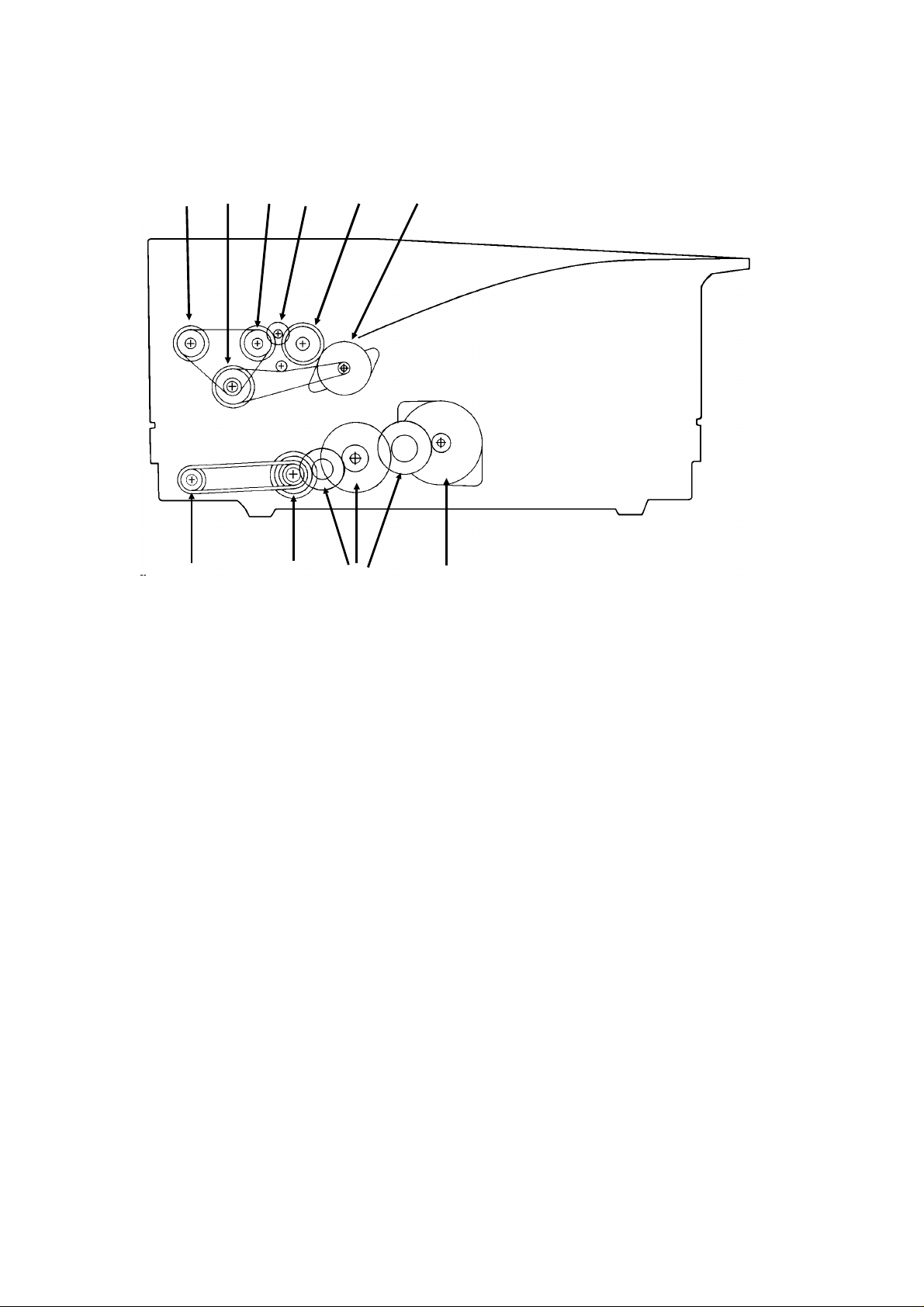

OVERALL MACHINE INFORMATION November 30th, 1991

COM PONEN T LAYOUT

1.3.3. Electrical Components

1

23

22

21

20

3

5

6

1

19

18

17

16

15

14

13

9

10

12

7

8

Name Description No.

PCBs

FCU This board controls the machine. 11

MBU This board contains the system ROM and RAM

8

for storing system parameters such as bit switch

settings and programmed telephone numbers.

SBU This board co ntains the CCD. 10

OP-PORT This board controls the operation panel. 23

NCU This board c ontains relays and switches for

4

interfacing the machine to the telephone network

and the handset.

PSU This board sup plies power to the machine. 7

Xenon Lamp

This supplies power to the xenon lamp. 14

Driver

MOTORS

Tx Motor This drives the scanner. 5

Rx Motor This drives the printer. 6

Cutter Motor This drives the cutter. 1

1-7

November 30th, 1991 OVERALL MACHINE INFORMATION

COM PONEN T LAYOUT

Name Description No.

CLUTCHES

ADF Clutch This transfers drive fr om the tx motor to the

3

document feed roller.

SENSORS

Document Sensor This detects the presence of a document in the

22

feeder.

Scan Line Sensor This detects when a page is approaching th e

21

auto shading position.

Trailing Edge Sensor

This detects when the trailing edge of t he page is

passing the scan line.

20

Paper End Sensor This detects when the thermal paper has run out. 16

Printer Jam Sen-

This detect s jams in the printer. 18

sor

Cutter Sensor This monitors the operation of the cutter. 2

Cover Switch This detects whether the cover is open or closed. 15

OTHERS

Thermal Head This prints on the thermal paper. 17

SAF Memory Modules

Speaker This allows the user to listen to the condition of

These memory modu les each contain 1 Mbyte of

memory for storing fax messages.

9

12

the telephone lin e.

Xenon Lamp This lamp illuminates the document. 19

Battery This rechargeable battery backs up the SAF

13

memory when the main power is switched off.

1-8

OVERALL MACHINE INFORMATION November 30th, 1991

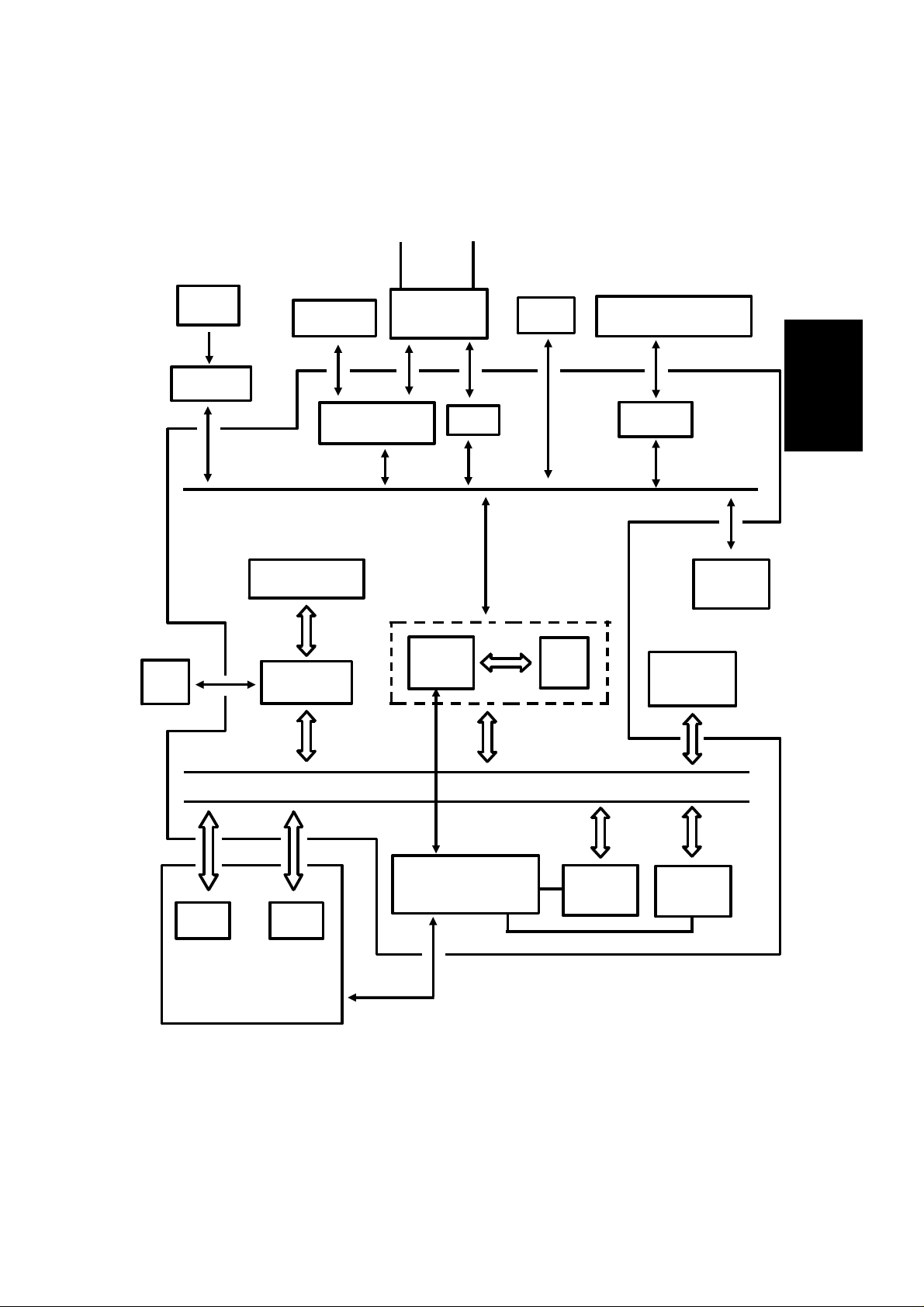

OVERALL SYSTEM C O NTROL

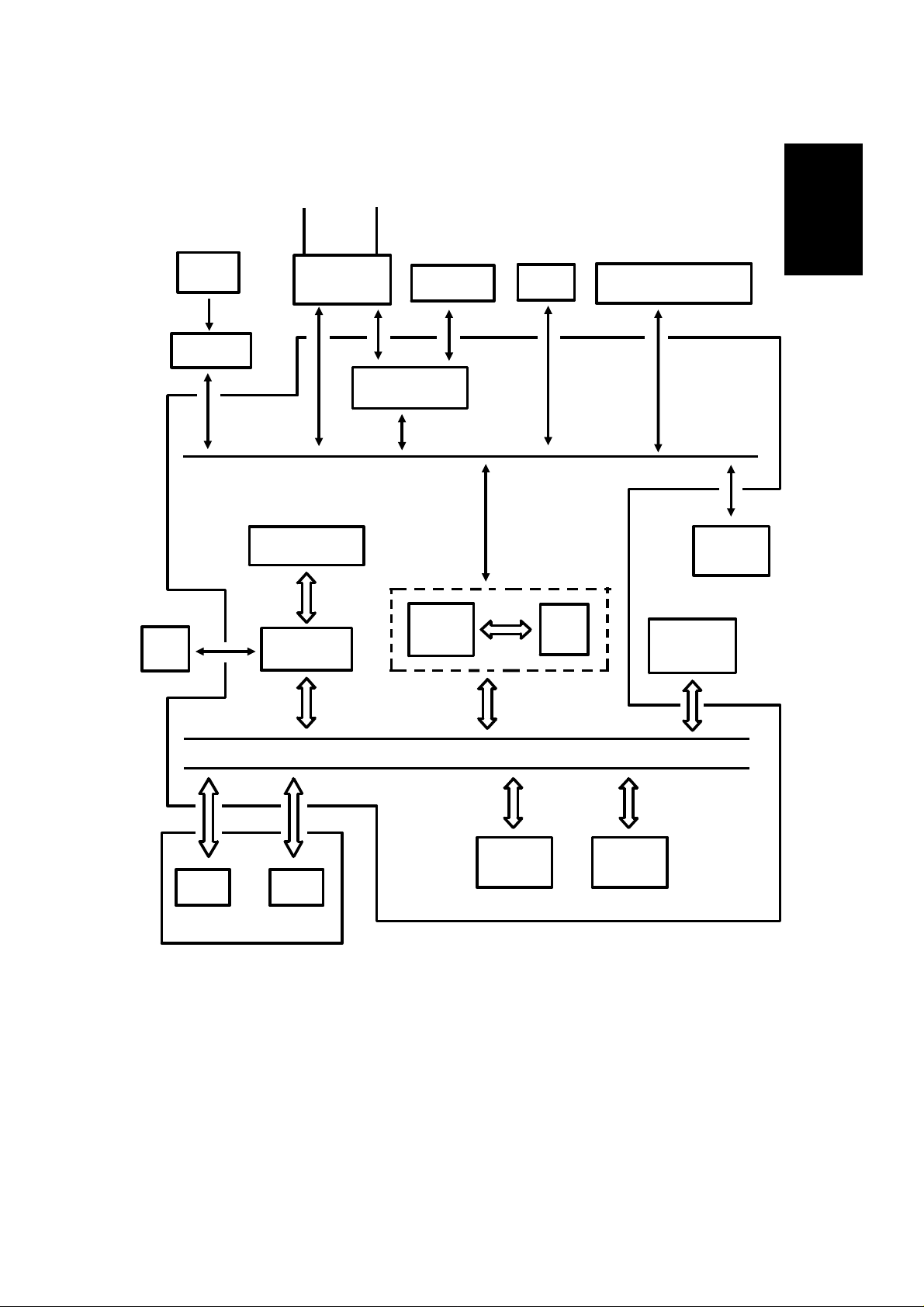

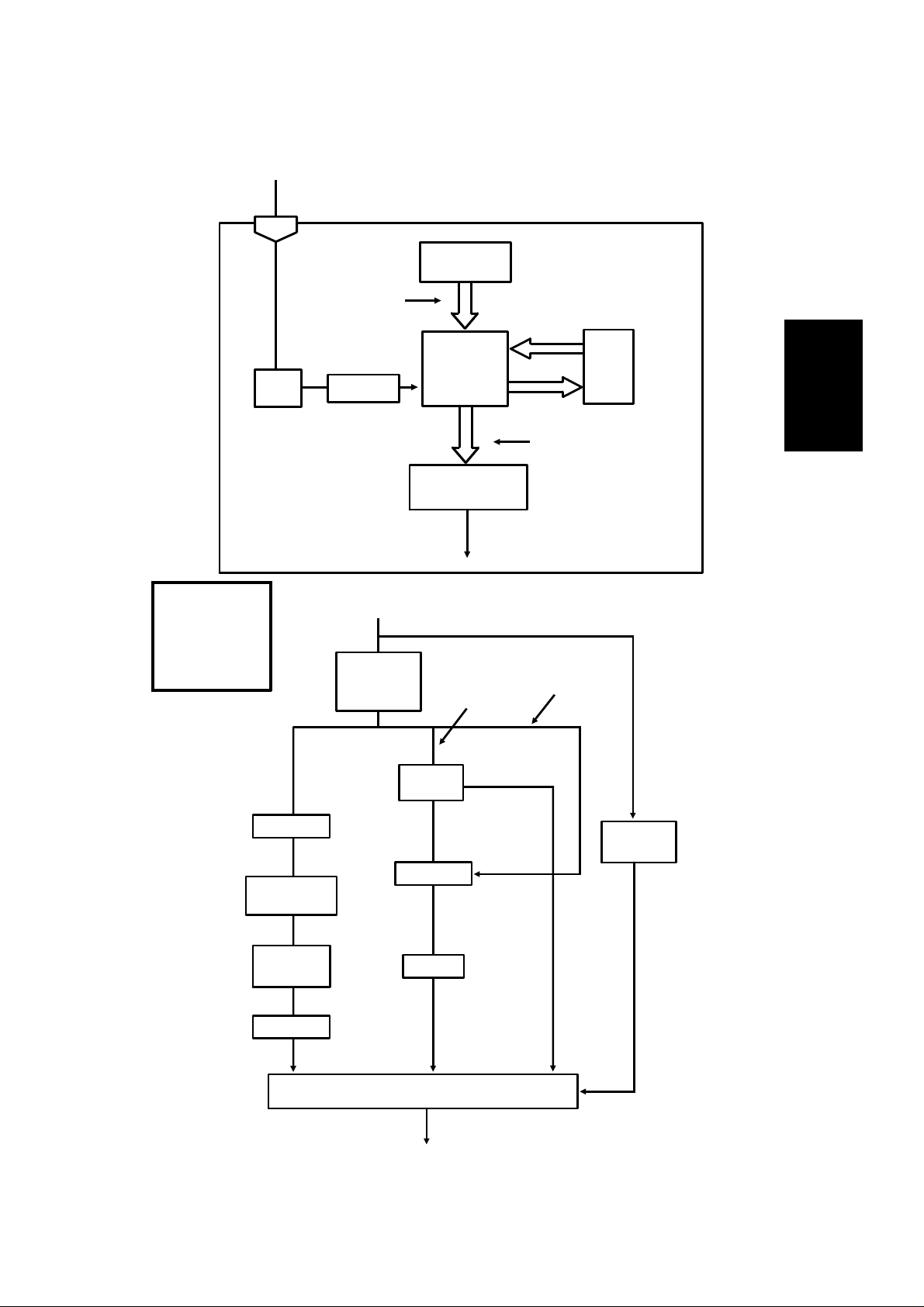

1.4. OVERALL SYSTEM CONTROL

HandsetLine

1

SBU

(CCD)

Scanner

Sensors

Operation

Panel

NCU

CONTROL SIGNALS

Video Processing

Memory

Video

Processor

Speaker

Modem AFE

CPU

PSU

Port

Scanner and Printer Drive

Components and Sensors

Thermal

Head

I/O

RS-232C

Interface

DATA AND ADDRESS BUS

SAF

Memory

RAMROM

ECM

Memory

FCU

MBU

The cpu on the FCU board controls the machine, as shown in the above

drawing.

There is no modem board in the m achine. The cpu performs the digital functions of a modem and carries out digital to analog conversion of facsimile

data. There is a separate analog modem chip (called the Modem AFE) which

does the rest of the modem operations.

1-9

November 30th, 1991 OVERALL MACHINE INFORMATION

VIDEO DATA PATH

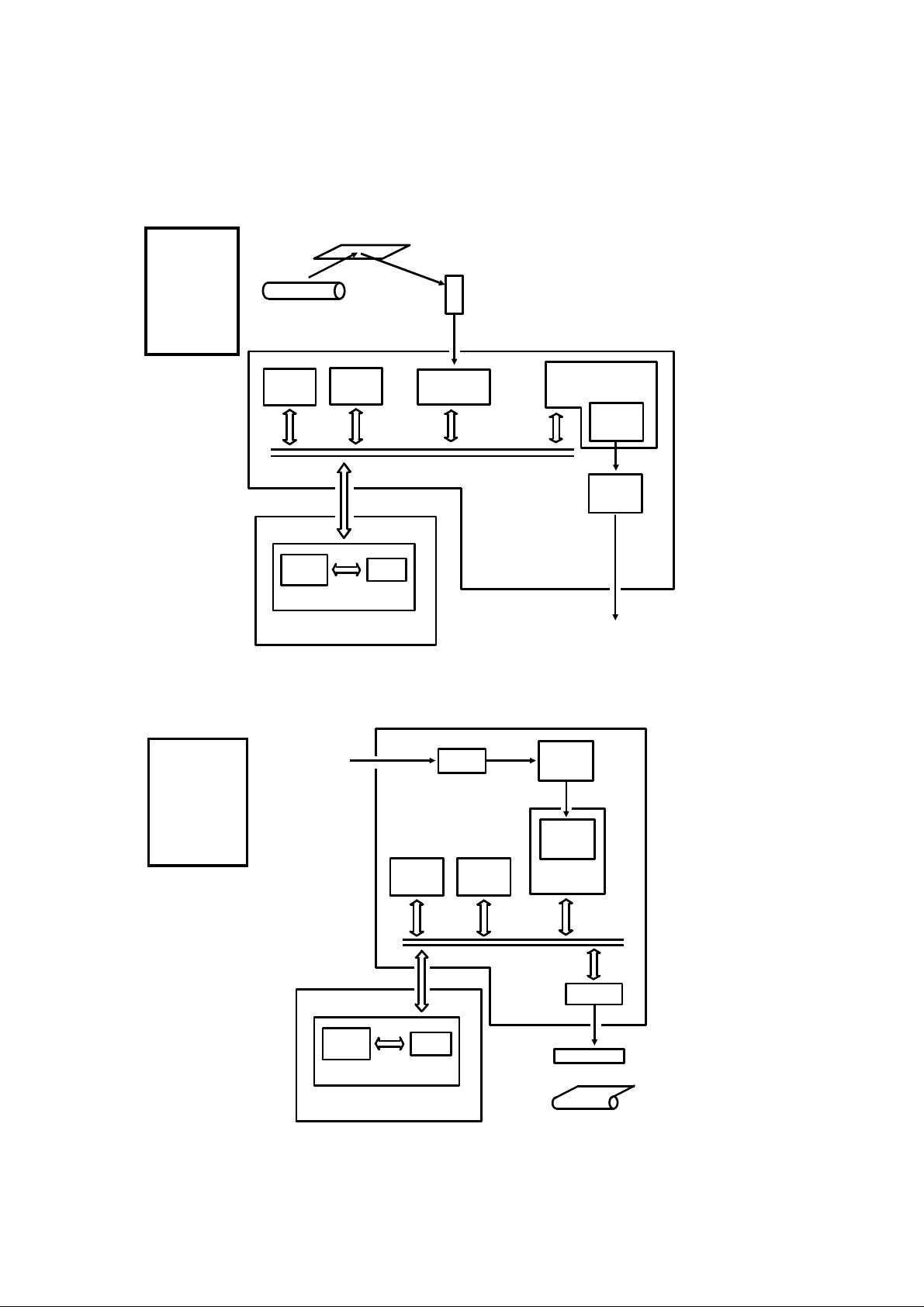

1.5. VIDEO DATA PATH

1.5.1. Transmission

Reference:

Group 3

Facsimile

Manual,

section

1-3-1

Xenon

Lamp

ECM

Memory

Line

Buffer

Original

SAF

Memory

RAM

FIFO

CCD

Analog Signal

Video

Processor

The fo llowing diagrams show

the data path for this model.

CPU

Modem

(Digital)

MODEM

AFE

FCU

Modem

(Analog)

1.5.2. Reception

Reference:

Group 3

Facsimile

Manual,

section

1-3-2

MBU

From the

Network

(via the NCU)

Line

Buffer

RAM

FCU

SAF

Memory

FIFO

Filter

HYBRID IC

Memory

ECM

Thermal

Head

Modem

(Analog)

Modem

(Digital)

CPU

I/O Port

To the

Network

(via the NCU)

MODEM

AFE

MBU

Thermal

Paper

1-10

OVERALL MACHINE INFORMATION November 30th, 1991

POWER DISTRIBUTION

1.6. POWER DISTRIBUTION

1.6.1. Distribution Diagram

Motors, ADF Clutch

Xenon Lamp

+24VD

NCU

+5V

Thermal

+24VD

Head

+5V

+5V

+5V

+24VS

FCU

+5V

+5V

MBU

RS-232C

Interface

1

+5V

SBU

+12V

+5V

OPU

+5V

Scanner

Sensors

PSU

Printer

Sensors

+24VS

+24VD

-12V

+5V

+12V

Regulator

+24VS

+24VD

Regulator

- 5V

- 12V

The PSU supplies power to the machine through the FCU, except for the thermal head power, which it supplies directly. The FCU contains regulators

which generate other voltages needed by the machine.

There are two + 24V power supplies:

• + 24VS: This is always on when the main swit ch is on.

• + 24VD: This is switched on by the cpu when a ringing signal is de-

tected, or when the user presses the Start or Copy key. It is not interrupted if the cover s witch is opened ; however, printing stops and th e

document is fed out.

In some documentation for this model, + 24VD may sometimes be referred

to as + 24VA.

1-11

November 30th, 1991 OVERALL MACHINE INFORMATION

POWER DISTRIBUTION

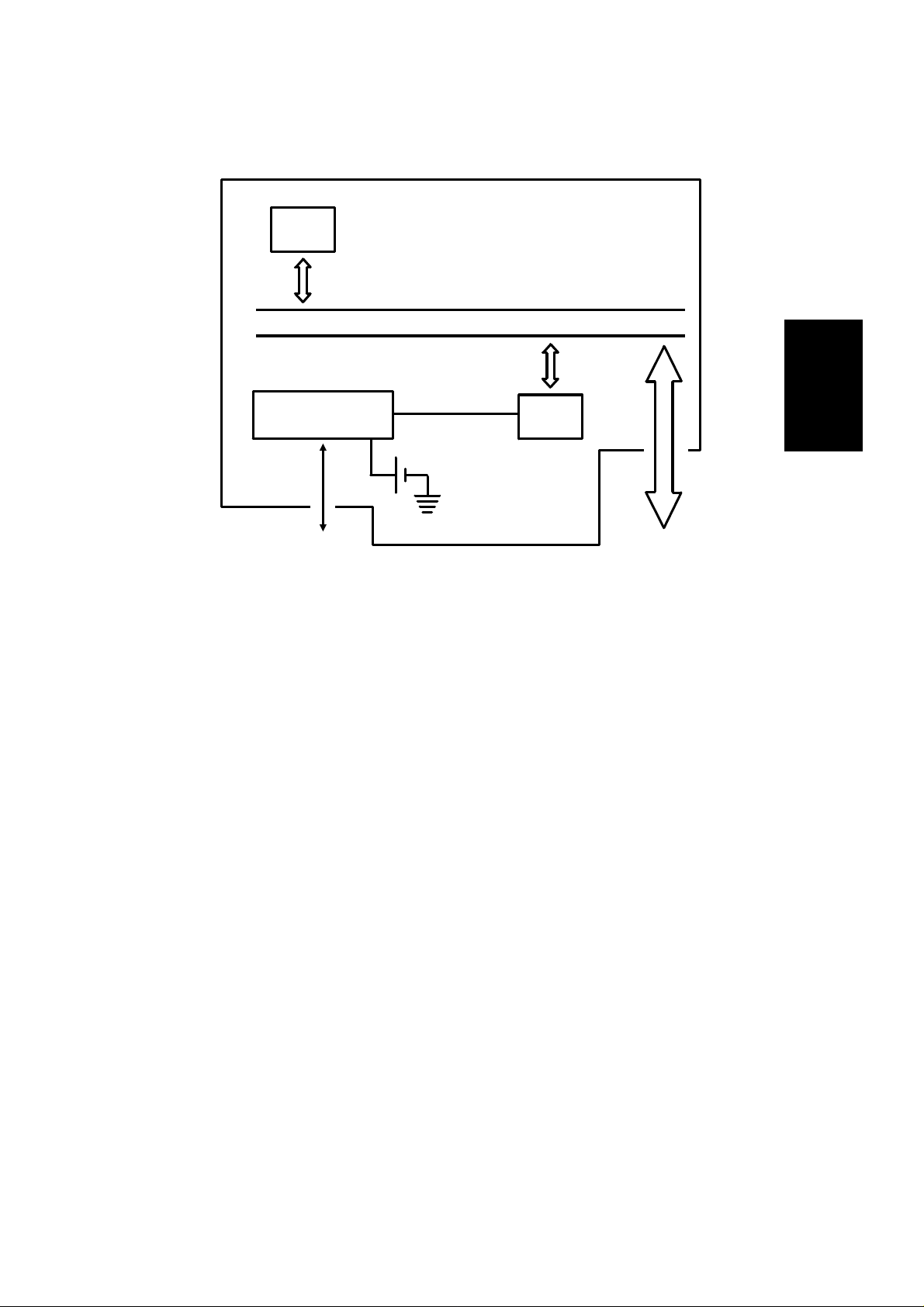

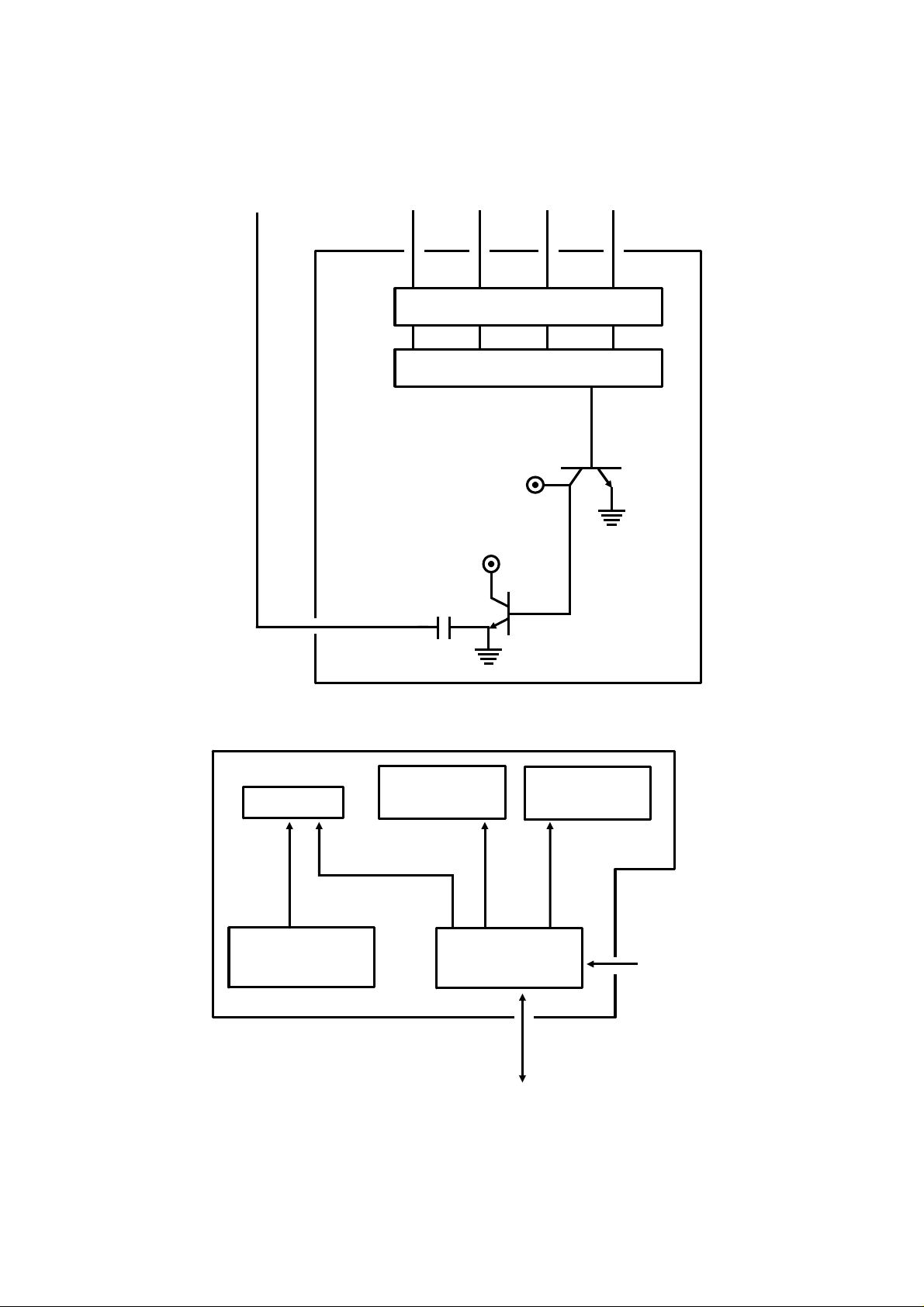

1.6.2. Memory Back-up Circuit

+5V

Voltage

Detector

Switching

Circuit

MBU

RAM

1-11 1-11

FCU

Reference:

Group 3

Facsimile

Manual,

sect io n 1-4-3,

Circuit type 1

+24V

5-1

[A]

+5V

Regulator

5-2

1-9

Battery

Switch

Battery

Switching

Circuit

1-9

Real Time

Clock

CPU

Memory

Monitor

SAF

Memory

[B]

Battery

The battery [A] on the MBU backs up the RAM on the MBU, which contains

system parameters. It also backs up the real time clock in the cpu. This battery is not rechargeable. CN1-9 tells the cpu whether the back-up power

(CN1-11) comes from the battery or from the + 5V supply.

A rechargeable battery [B] backs up the SAF memory and the real time clock

for 1 hour. When the main power is switched on, the + 24V supply charges

the battery. If there is data in the SAF, the battery also backs up the real time

clock, to preserve the MBU battery.

1-12

ADF Clutch

DETAILED SECTION DESCRIPTIONS November 30th, 1991

SCANNER

2. DETAILED SECTION DESCRIPTIONS

2.1. SCANNER

2.1.1. Mechanisms

1. Document Detection

Trailing Edge

Sensor

Scan Line Sensor

2

Document

Sensor

Separation

Plate

Feed

Roller

• The machines in this ser ies have an A4-width [8.3"] scanner. There is

Separation Rolle r

Pick-up Roller

no document width detector.

• The scanner contains a xeno n lamp.

• Th ere is no shutter mechanism.

Reference: Group 3 Facsimile Manual, section 2-1

2-1

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

SCANNER

2. Pick-up and Feed

Mechanism

Refere nce :

Group 3

Facsimile

Manual,

sect io n 2-2-1.

Tx Motor

• This machine uses an electrical clutch mechanism with trailing edge sen-

ADF Clutch

sor.

• There is no manual feed.

Resolution

Standard - The tx moto r feeds the document at 7.7 lines/mm. The vid e o

proc essor executes OR pro cessing to convert the data into 3.85 lines/mm.

Detail - The tx motor feeds the docu ment at 7.7 lines/mm. There is n o OR

processing, and the data is transmitted at 7.7 lines/mm

Fine - The tx motor feeds the document and transmits data at 15.4 lines/mm.

If the other terminal cannot receive at this resolution, the tx motor feeds the

paper at 7.7 lines/mm, and the data is transmitted using Detail resolution.

Jam Conditions

The cpu detects a document jam if one of the fo llowing conditions occurs.

• The scan line sensor does not switch on within 3.5 s of the Star t key be-

ing pressed.

• The scan line sensor does not tu rn o ff after th e maximum docum e nt

length has been fed since it turned on.

• The scan line sensor switches on while the document sensor is off.

2-2

DETAILED SECTION DESCRIPTIONS November 30th, 1991

SCANNER

2.1.2. Video Data Processing

Output from the CCD

A

Auto Shading

Memory

WHITE

WAVEFORM

FEEDBACK

Peak

Hold

DATA

DC

Filter

Amplifier

A/D

Converter

CORRECTED

Data Processing

Circuits

2

Reference:

Group 3

Facsimile

Manual,

sect io n 2-3.

VIDEO

PROCESSOR

Corrected Data from the Auto Shading Circuit

Comparator

Background

Detection

OR

Processing

Gamma

Correction,

MTF

Edge

Detection

NON-EDGE

ELEMENTS

Reduction

Halftone

To the CPU

and Modem

Basic

Halftone

Process

EDGE

ELEMENTS

Error

Diffusion

Halftone

Process

Image/Text

Detection

Reduction

A

B

Process Selector

To CPU and Modem

2-3

B’

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

PRINTER

2.2. PRINTER

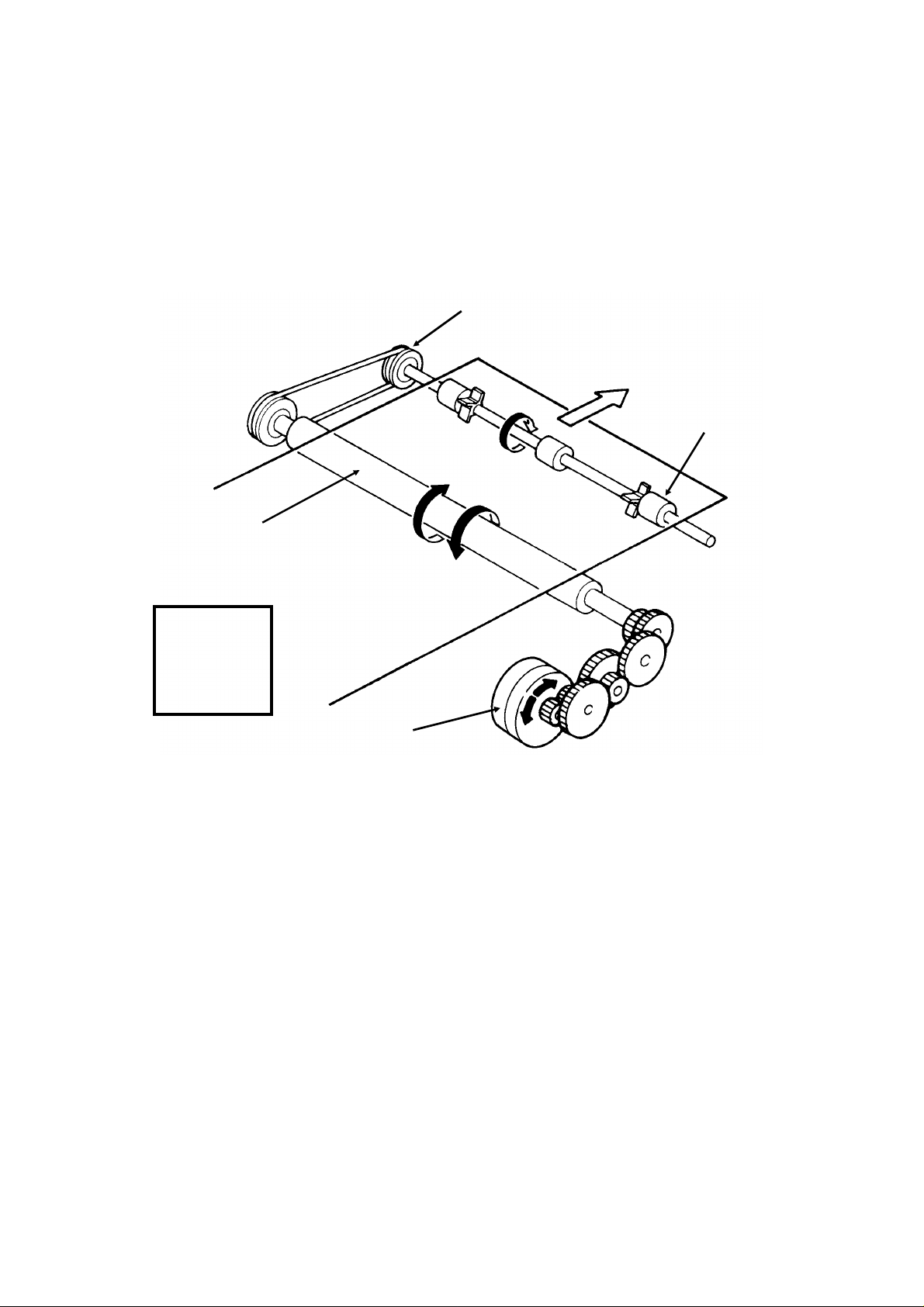

2.2.1. Mechanisms

1. Paper Feed

Mechanis m

One-way Clutch

Feed-out

Roller

Platen Roller

Refere n ce:

Group 3

Facsimile

Manual,

sect i o n 3-4-1.

Rx Motor

The printer is an A4-width [8.3"] printer.

Resolution

Standard - Each received line is printed 4 times

Detail - Each received line is printed twice

Fine - Each received line is printed once.

2-4

DETAILED SECTION DESCRIPTIONS November 30th, 1991

PRINTER

Jam Detection

The cpu detects a copy jam if one of the following conditions occurs:

• If the printer jam sensor still does not detect paper after the minimum

cop y length has been fed since the start of printing.

• Between pages of a multipage printout, the printer jam sensor switches

off. A jam is detected if the sensor does not switch back on after the

minimum copy length has been fed since it turned off.

• If the printer jam sensor still detects paper after the end of the feed-out

procedure for the last page of a print run.

2. Cutting

Cutter

Blade

2

Reference:

Group 3

Facsimile

Manual,

sect i o n 3-6.

Cutter

Sensor

Cutter

Motor

The cutter mechanism is exactly as described in section 3-6 of the Group 3

Facsimile Manual.

3. Cutter Jam Detectio n

A cutter jam is detected if one of the following conditions occurs:

• If the cutter sensor do es not open within 0.25 s after the cutter starts to

move

• If the cutter sensor stays open for more than 1.0 s

If a cutter jam is detected, the cutter motor reverses to return the cutter to the

standby position.

2-5

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

PRINTER

2.2.2. Circuits

1. Video Data Processing

• Smoothing is as described in section 3-5-1 of the Group 3 Facsim ile

Manual

• There is no reduction.

2. Thermal Head

Both machines use an A4-width [8.3"] thermal head. Refer to sec tion 3- 5- 2 of

the Group 3 Facsimile Manual for a circuit diagram.

The operation of the thermal head is as explained in the Group 3 Facsimile

Manual, except that when printing a line, blocks 0 and 1 are printed together,

then blocks 2 and 3 are printed together.

The data are p rinted as exp lained in section 3-5-3 of the Group 3 Facsimile

Manual. In Fine mode, the pulse width is automatically increased by 50%.

The machine prevents overheat protection by adjusting the pulse width in accord ance with the temperature measured by the thermistor on the thermal

head.

Reference: Group 3 Facs imile Man ual, s ectio ns 3-5-1, 3-5-2, and 3-5-3.

2-6

DETAILED SECTION DESCRIPTIONS November 30th, 1991

PCBs AND THEIR FUNCTIONS

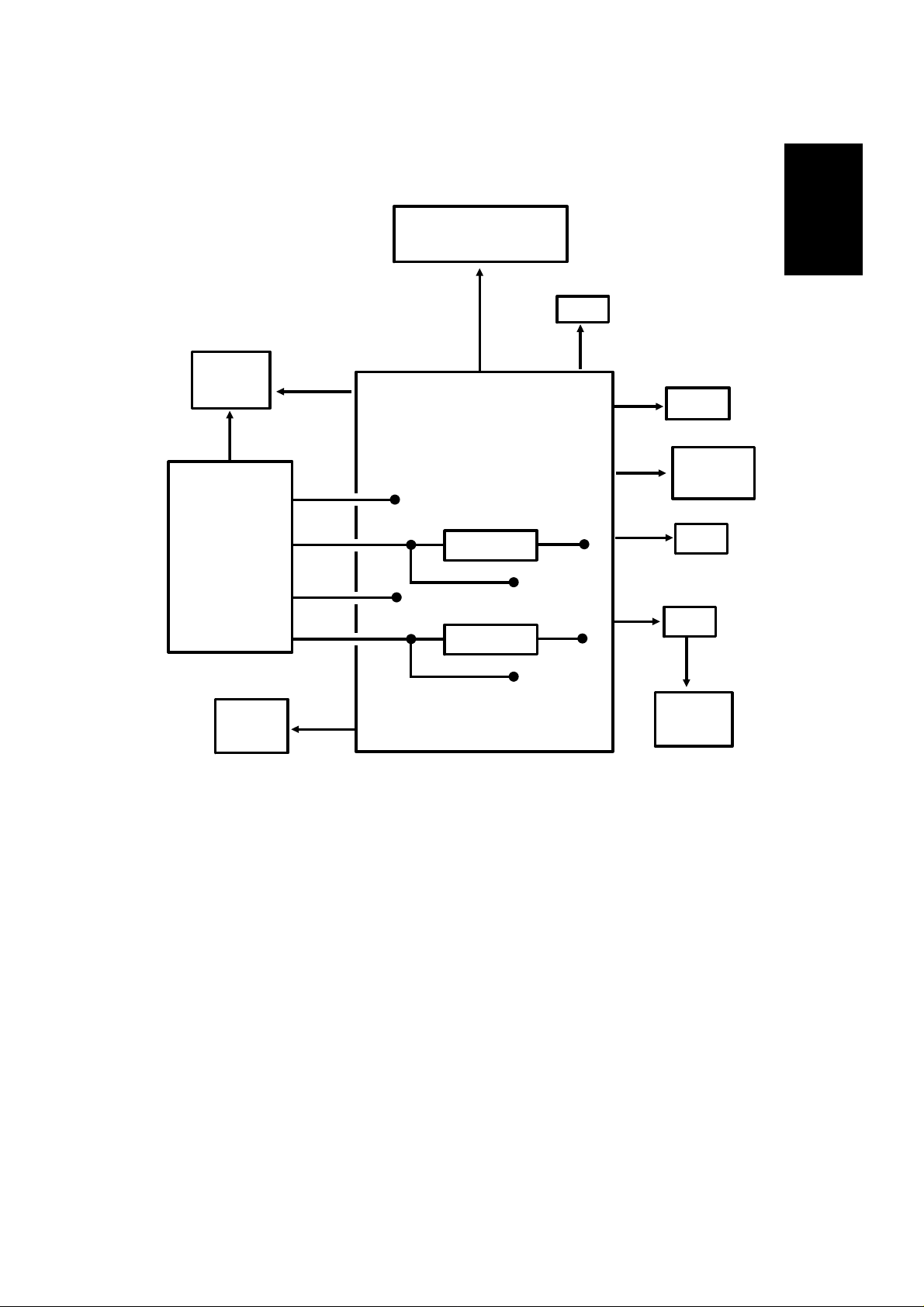

2.3. PCBs AND THEIR FUNCTIONS

2.3.1. FCU

HandsetLine

SBU

(CCD)

Scanner

Sensors

Operation

Panel

Speaker

Modem AFE

CONTROL SIGNALS

Video Processing

Memory

Video

Processor

NCU

CPU

HIC

PSU

FCU

I/O

Port

Scanner and Printer Drive

Components and Sensors

2

Drivers

Thermal

Head

RS-232C

Interface

MBU

DATA AND ADDRESS BUS

Memory Back-up

Control

SAF

Memory

ECM

Memory

RAMROM

2-7

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

PCBs AND THEIR FUNCTIONS

1. CPU (AFSP)

• 65C02 compatible microprocessor

• Interrupt control

• DMA control

• Data compression and reconstruction (high speed MH coding for 4.5-

second scanning)

• Modem (digital operations)

• Real time clock (battery backed-up)

• Memory control

• Control of all mechanisms (directly or through other chips)

• NCU control (through the I/O Port)

2. I/ O Port (LIOP)

• Clock control

• Sensor monitoring (including A/D conversion where necessary)

• Tone detection

• Thermal head control

• Tx/Rx/cutter motor drive control

• Operation p anel control

3. Modem Analog Front End (Modem AFE)

• Modem (analog operations)

• Attenuati on

4. Video Processor (VPP)

• Analog/digital video signal processing

5. Driver (MFPD)

• Tx/Rx/cutter motor drive

6. Driver Array

• Xenon lamp/ADF clutch drive

7. Hybrid IC (HIC)

• Gain control for rx data

• Filters

8. RAM

• 128k for ECM (no bac k-up)

• 256k SAF memory (with battery back-up)

2-8

DETAILED SECTION DESCRIPTIONS November 30th, 1991

PCBs AND THEIR FUNCTIONS

2.3.2. MBU

System

ROM

DATA AND ADDRESS BUS

Memory Back-up

Control

+

To/From

FCU

1. System ROM

• Contains the software to run the machine

MBU

2

System

RAM

To/From

FCU

2. System RAM

• 32k SRAM and 32k PSRAM for parameter storage, line buffer, FIFO,

SAF memory administration

The SRAM is backed up by the battery on the MBU

2-9

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

PCBs AND THEIR FUNCTIONS

2.3.3. SBU

Analog Video

To the FCU

Drive Clocks

From the FCU

Drivers

CCD

+12V

+12V

Inverter

Amplifier

2.3.4. OPU

LCD Panel

Auxiliary Operation

Panel Controller

+

Operation Panel

Keys

Operation Panel

Controller

Emitter

Follower

Operation Panel

LEDs

SBU

Output

from the

Scanner

Sensors

Serial Interface

To/From FCU

2-10

DETAILED SECTION DESCRIPTIONS November 30th, 1991

PCBs AND THEIR FUNCTIONS

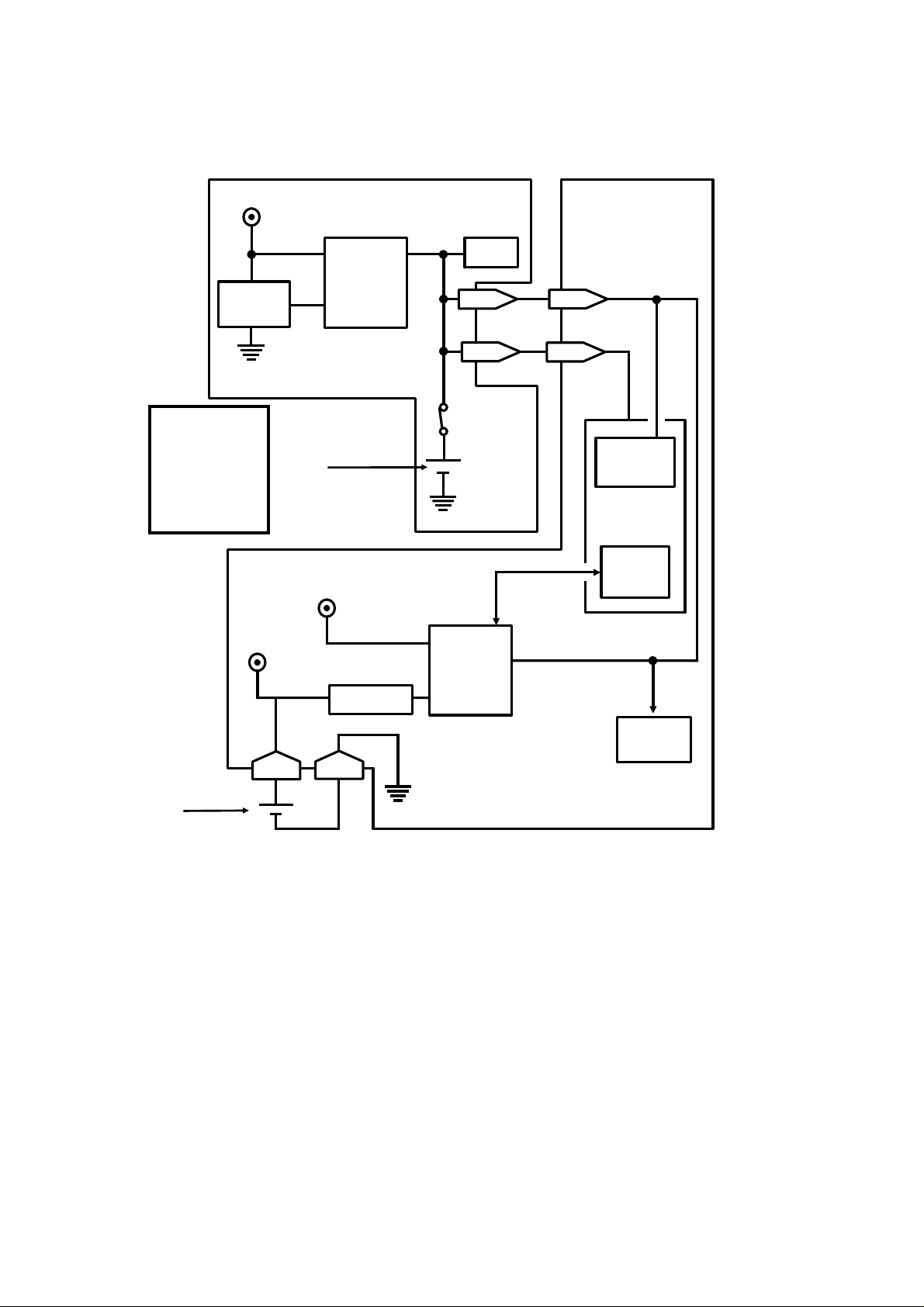

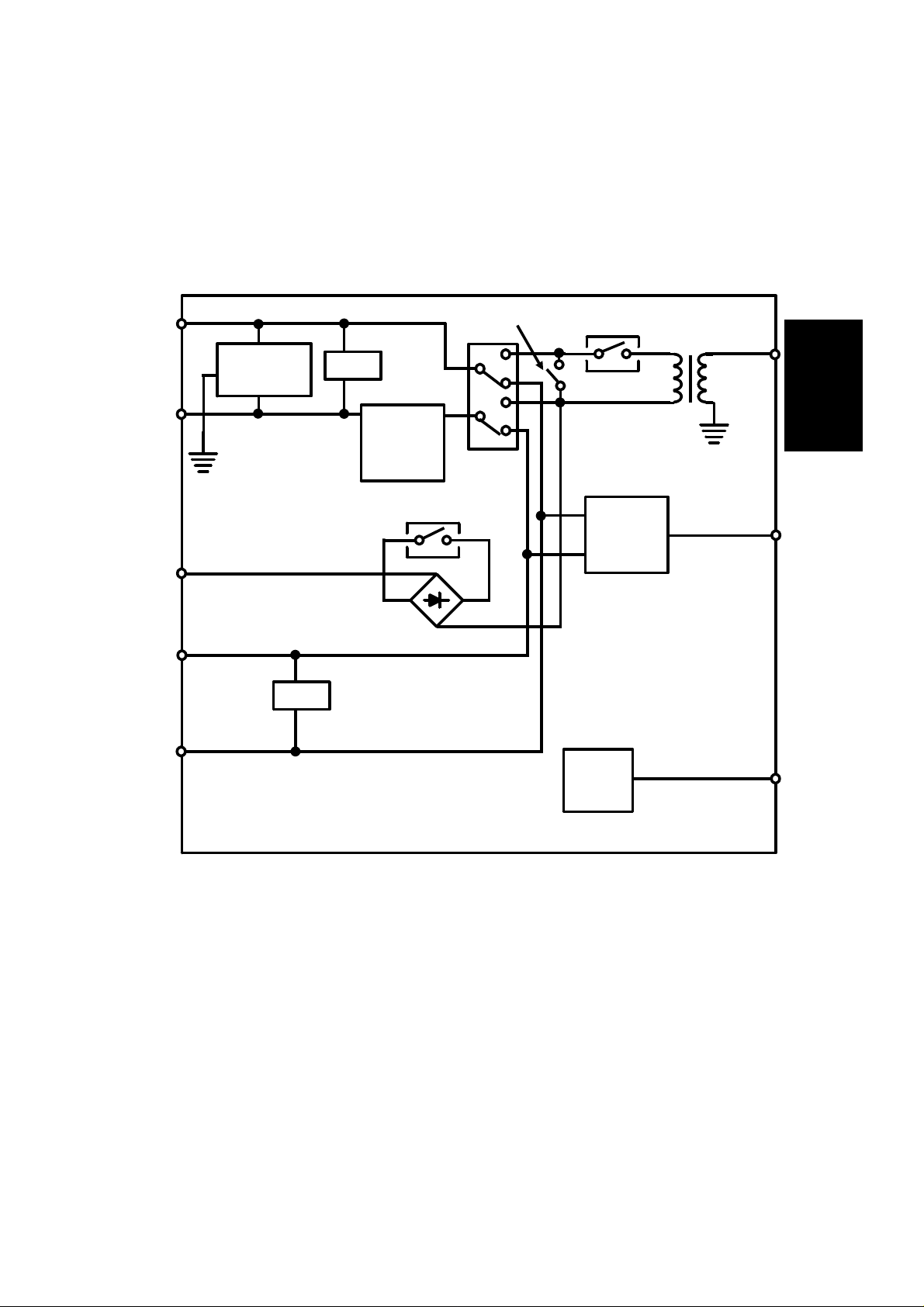

2.3.5. NCU

1. PCB Block Diagram

L1

L2

GS

T2

T1

Protection

Circuit

FG

To

Handset

To

Network

Filter

Filter

Line

Current

Detector

Gs Relay

Di Relay

Oh

Relay

Ds Relay

Ringing

Signal

Detector

Relay

Driver

Tx/Rx Data

To/From FCU

2

To

FCU

From FCU

NCU

• For simplification, relay drive signals and detector outputs to/from the

FCU are not shown on this diagram.

• In the above diagram, the relays are shown in the standby position for

Auto Receive (Fax) Mode.

2-11

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

PCBs AND THEIR FUNCTIONS

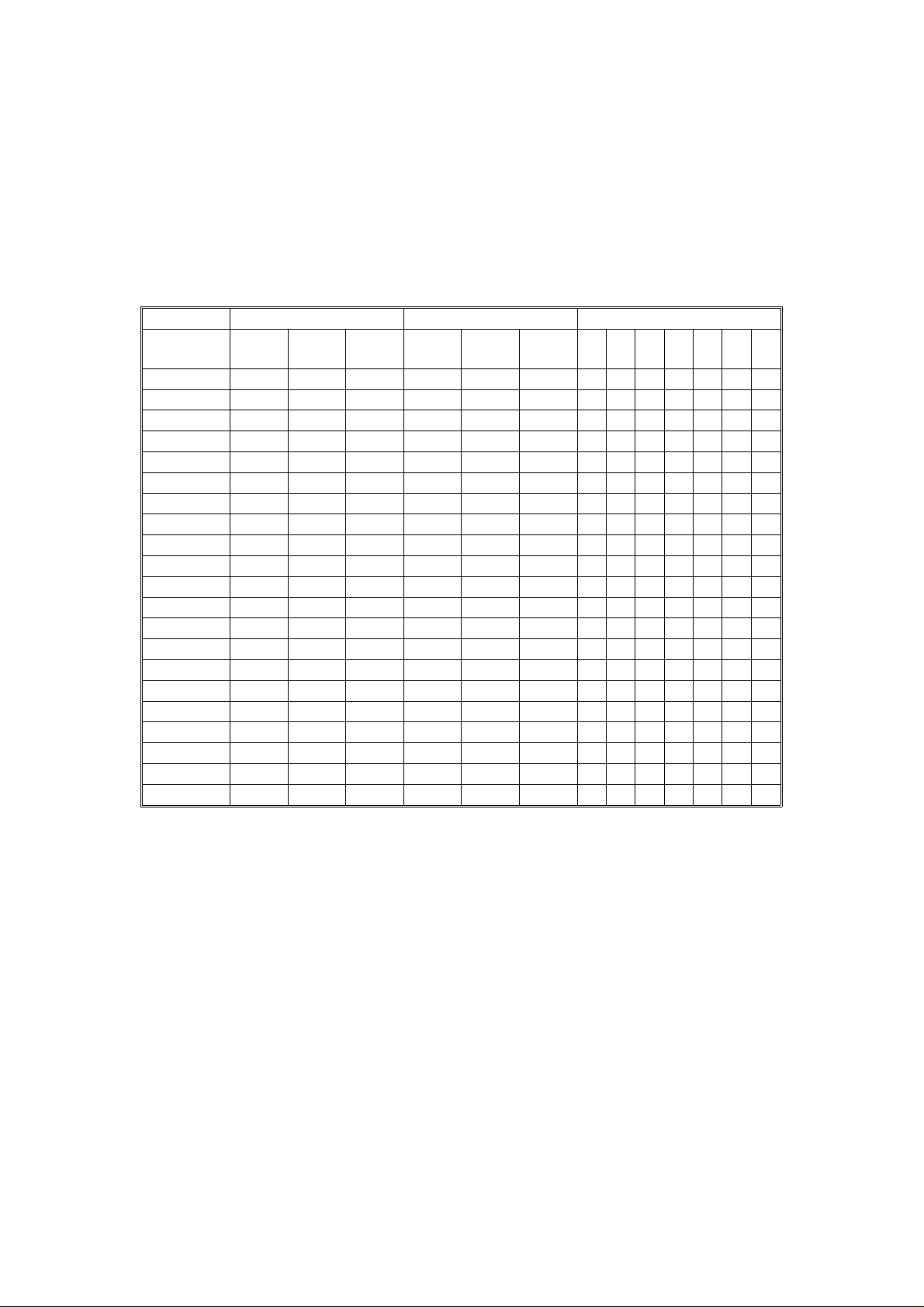

2. Signal and Jumper Settings

The following table shows the jumper positions for each country, and the

status of the relay control signals (CN3-A7, B7, and A8). The country is selected by the Country Code for NCU Parameters (NCU Parameter 00; use

Function 96).

Standby Mode After Ringing Detection Jumpers

CN3-A7CN3-B7CN3-A8CN3-A7CN3-B7CN3-A8TB1

& 2TB3TB8TB4TB5TB6JP1

Germany X X X O O X OXXXXXX

UK XOXOOXOXXXXXX

Italy O O X O O X OXXXXXX

Austria OOXXXXOXXOXXX

BelgiumOOXXXXOXXXXXX

DenmarkOOXXXXOXXXXOX

Finland O O O O O X O X X X X X X

Ireland O O X X X O OXXXXXX

Norway X O X X X O OXXXXXO

SwedenXXXXXXOXXXXXX

Switz. XOXXXXOOOXXXX

PortugalOOXXXXOXXXXOX

Holland O O X X X O OXXXOXX

Hg KongXOXOOXOXXXXXX

S. Africa O O O O O X OXXXXXX

AustraliaXOXOOXOXXXXXX

N. Z’landXOXOOXOXXXXXX

Israel O O X O O X OXXXXXX

Spain OOXXXXOXXXXOX

Singapore O O X O O X OXXXXXX

Malaysia X O X O O X O X X X X X X

Key

Signal Status: O = High, X = Low

Jumper Settings: O = Closed, X = Open

2-12

Loading...

Loading...