Ricoh FAX2700L SPECIFICATIONS fx1700

FX7

RICOH FAX1700L

SERVICE MANUAL

July 30th , 1996

Subject to change

FX7

infotec 3671/3671F

SERVICE MANUAL

July 30th , 1996

Subject to change

WARNING

I

THIS MACHINE CONTAINS A LASER BEAM GENE RATOR. LASE R

BEAMS CAN CAUSE PERMANENT EYE DAMAGE. DO NOT OPEN THE

LASER UNIT OR LOOK ALONG THE LASER BEAM PATH WHILE THE

MAIN POWER IS ON.

Lithium Batteries (Memory Back-up)

CAUTION

I

The danger of explosion exists if a battery of this type is inc orr ectly

replaced. Replace only with the same or an equiv alent type

recommended by the manufacturer. Discard used batteri es in

accordance with the manufactur er’s instructions.

July 24th, 1996 OVERALL MACHINE INFORMATION

SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

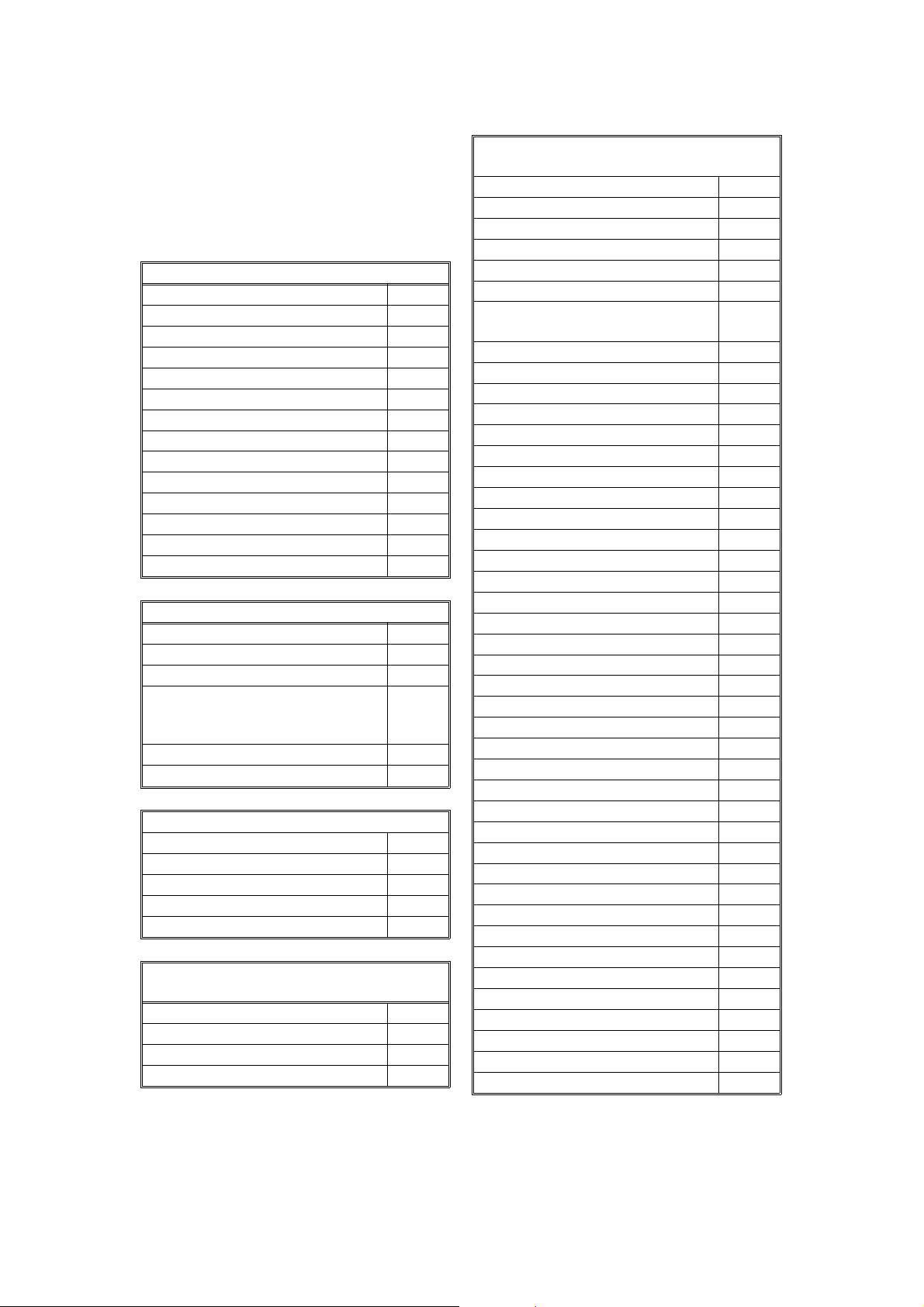

1.1. SPECIFICATIONS

Type

Desktop type transceiver

Circuit

PSTN, PABX

Connection

Direct couple

Document Size

Length:

105 - 355.6 mm [4.1 - 14 ins]

(automatic feed)

Up to 600 mm [23.6 ins] (manually assisted)

Width:

148 - 216 mm [5.8 - 8.5 ins]

Thickness:

0.05 to 0.2 mm [2 to 8 mils]

(equivalent to 50 - 90 g/m

Document Feed

Automatic feed, face up

ADF Capacity

30 sheets (using 20 lb. or 80 g/m

Scanning Method

Contact image sensor

Maximum Scan Width

204 mm [8.0 ins]

Scan Resolutions

Main scan: 8 dots/mm [203 dpi]

Sub scan:

Standard - 3.85 lines/mm [98 lpi]

Detail - 7.7 lines/mm [196 lpi]

Fine - 15.4 lines/mm [392 lpi]

Memory Capacity

ECM: 128 kbytes

SAF: 240 kbytes (18 pages/ITU-T #1 test

document), extra 1 Mbyte memory card

available (102 pages) or 2 Mbyte memory

card available (186 pages)

Compression

MH, MR, EFC, MMR, SSC

Protocol

Group 3 with ECM

2

)

2

paper)

Modulation

V.17 (TCM), V.29 (QAM), V.27ter (PHM),

V.21 (FM)

Data Rate (bps)

14400/12000/9600/7200/4800/2400

Automatic fallback

Transmission Time

6 s at 14,400 bps; Measured with G3 ECM

using memory for a ITU-T #1 test document

(Slerexe letter) at standard resolution

Printing System

Laser printing, plain paper, dry toner

Paper Size and Capacity

Standard Tray: 150 sheets

(using 20 lb. or 80 g/m

A4, Letter, Legal, F4

Paper Feed Unit (Optional): 250 sheets

(using 20 lb. or 80 g/m

A4, Letter, Legal

Maximum Printing Width

216 mm [8.5 ins]

Print Resolutions

Fax and Copy Mode:

Main scan: 16 dots per mm [406 dpi]

Sub scan: 15.4 lines/mm [391 lpi]

Power Supply

USA: (110 - 120 Vac) ± 10%, 60 ± 3 Hz

Europe/Asia: (220 - 240 Vac) ± 10%,

50/60 ± 3 Hz

Power Consumption (Base Machine Only)

USA: Maximum 390 W

Europe/Asia: Maximum 470 W

Operating Environment

Temperature: 15 - 25 °C [59 - 77 °F]

Humidity: 35 - 70 %Rh

Dimensions (W x D x H)

380 x 341 x 219 mm [15.0 x 13.4 x 8.6 ins]

Excluding handset, trays, and optional units

Weight

Approx. 7 kg [15 lb.]

Excluding consumables, handset, trays, and

optional units

2

paper)

2

paper)

1-1

OVERALL MACHINE INFORMATION July 24th, 1996

FEATURES

1.2. FEATURES

KEY: O = Used, X = Not Used,

A = With optional memory only,

B = With optional paper feed unit only

C = With optional handset only

Equipment

ADF O

Book scan X

Built-in handset X

Bypass feed: 1 sheet X

Optional paper feed unit B

Cabinet X

Mechanical Counter X

Cutter X

Handset C

Hard disk X

Manual feed mechanism X

Marker (Stamp) X

Monitor speaker O

Optional printer interface (RS422) X

Video Processing Features

Contrast O

Halftone (Basic & Error Diffusion) O

MTF O

Enlarge/Reduction: Three en-

largements, 4 reductions (50%200%)

Resolution O

Smoothing to 16 x 15.4 l/mm O

Communication Features - Auto

Automatic fallback O

Automatic redialing O

Confidential reception X

Dual Access O

Substitute reception O

Communication Features -

User Selectable

Action as a transfer broadcaster X

AI Redial X

Answering machine interface O

Authorized Reception O

Communication Features -

User Selectable

Auto-answer delay time O

Auto dialing (pulse or DTMF) O

Auto Document X

Auto image density selection X

Auto paper size selection X

Automatic Voice Message X

Batch Transmission (max 35

files)

Broadcasting O

Chain Dialing O

Communication Result Display X

Confidential ID Override O

Confidential Transmission X

Direct Fax Number Entry O

Economy Transmission X

Fax on demand X

Forwarding X

Free Polling O

Groups (3 groups) O

Group Transfer Station X

Hold X

ID Transmission O

Immediate Redialing O

Immediate transmission O

Keystroke Programs X

X

Memory transmission O

Multi-step Transfer X

Next Transfer Station X

OMR X

On Hook Dial O

Ordering Toner X

Page Count O

Personal Codes X

Personal Codes with Conf. ID X

Polling Reception O

Polling Transmission X

Polling tx file lifetime in the SAF O

Quick Dial (10 stations) O

Reception modes (Fax, Tel, Auto) O

Length Reduction O

Remote control features X

Remote Transfer X

Restricted Access X

Secured Polling O

O

1-2

July 24th, 1996 OVERALL MACHINE INFORMATION

FEATURES

Communication Features -

User Selectable

Secured Polling with Stored ID

Override

Secure Transmission X

Send Later O

Silent ringing detection X

Specified Image Area X

Speed Dial (50 stations) O

Super Fine Resolution

(16 x15.4 l/mm : 400 x 400 dpi)

Telephone Directory X

Tonal Signal Transmission O

Transfer Request X

Transmission Deadline (TRD) X

Turnaround Polling X

Two- step Transfer X

Two in one X

Voice Request X

Communication Features -

Service Selectable

AI Short Protocol O

Auto-reduction override option O

Busy tone detection O

Closed Network (tx and rx) X

Continuous Polling Reception X

Dedicated tx parameters O

ECM O

EFC O

Inch-mm conversion X

Page retransmission times O

Page separation mark O

Protection against wrong conn. O

Resol’n stepdown override option X

Short Preamble X

Well log X

Other User Features

Area code prefix X

Automatic service call Service

Center mark X

Checkered mark X

Clearing a memory file O

Clearing a polling file O

Clock O

O

X

Other User Features

Confidential ID X

Copy editing (Erase Center/Mar-

gin)

Copy mode O

Copy Mode Restriction X

Counters O

Daylight Saving Time O

Destination Check X

Direct entry of names O

File Retention Time X

File Retransmission X

Function Programs X

ID Code X

Label Insertion X

Language Selection O

LCD contrast control Service

Memory Lock X

Memory Lock ID X

Modifying a memory file X

Multi Sort Document Reception X

Multicopy mode O

Own telephone number O

Power Saver (Night Timer and

standby mode)

Print density control O

Printing a memory file O

RDS on/off O

Reception Mode Switching Timer X

Reception time printing X

Reduction/Enlargement X

Remaining memory indicator O

Remote ID X

Reverse Order Printing X

RTI, TTI, CSI O

Secure ID X

Service Report Transmission O

Speaker volume control O

Specified Cassette Selection X

Substitute reception on/off O

Telephone line type O

Toner Saving Mode O

TTI on/off O

User Function Keys X

User Parameters O

Wild Cards O

X

O

1-3

OVERALL MACHINE INFORMATION July 24th, 1996

FEATURES

Reports - Automat ic

Charge Control Report X

Communication Failure Report O

Confidential File Report X

Error Report O

Memory Storage Report O

Mode Change Report X

Polling Clear Report O

Polling Reserve Report O

Polling Result Report O

Power Failure Report O

TCR (Journal) O

Toner Cassette Order Form X

Transfer Result Report X

Transmission Result Report O

Reports - User-initiated

Authorized Reception List O

Charge Control Report X

File List O

Forwarding List X

Group List O

Personal Code List O

Program List X

Quick Dial List O

Specified Cassette Selection List X

Speed Dial List O

TCR O

Transmission Status Report X

User Function List X

User Parameter List O

Service Mode Features

File Transfer O

LCD contrast adjustment O

Line error mark O

Memory file printout (all files) O

Modem test O

NCU parameters O

Operation panel test O

Periodic service call O

PM Call O

Printer mechanism test O

Printer test patterns O

Programmable attenuation X

Protocol dump list O

RAM display/rewrite O

RAM dump O

RAM test O

Ringer test X

Scanner lamp test O

Scanner mechanism test O

Sensor initialization X

Serial number O

Service monitor report O

Service station number O

Software upload/download O

SRAM data download O

System parameter list O

Technical data on the TCR O

Thermal head parameters X

Transmission Status Report X

User data transfer O

Service Mode Features

Auto Paper Select test X

Back-to-back test X

Bit switch programming O

Book mode test X

Buzzer test O

Cable equalizer O

Comm. parameter display O

Counter check O

Country code O

DTMF tone test O

Echo countermeasure O

Effective term of service calls O

Error code display O

Excessive jam alarm O

Memory Files

Max. number of files: 100

Max. number of stations/ file : 30

Max. number of stations ove rall: 100

1-4

4

5

6

July 24th, 1996 OVERALL MACHINE INFORMATION

COMPONENT LAYOUT

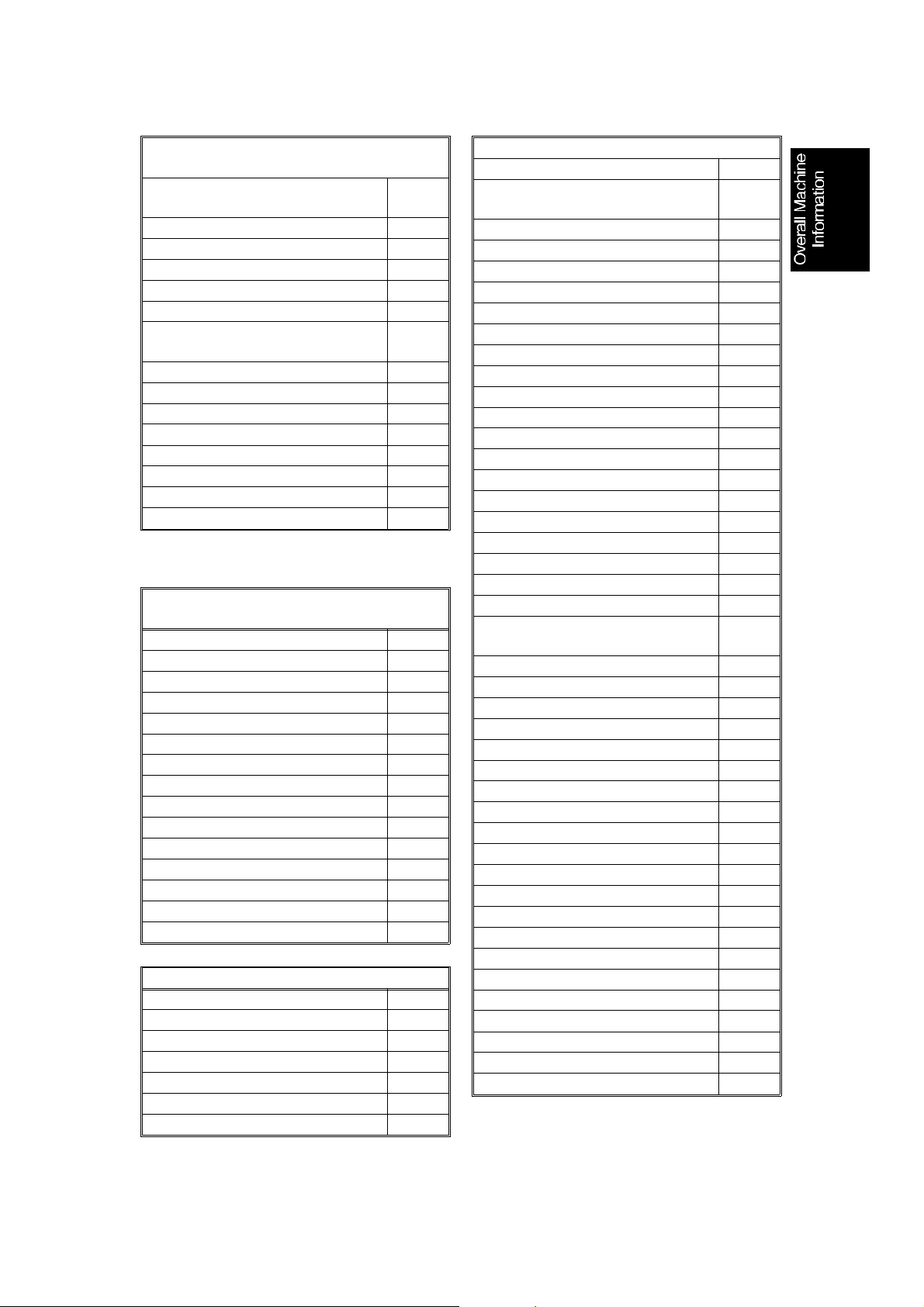

1.3. COMPONENT LAYOUT

19

2

1

3

7

8

18

17

16

15

14

13

12

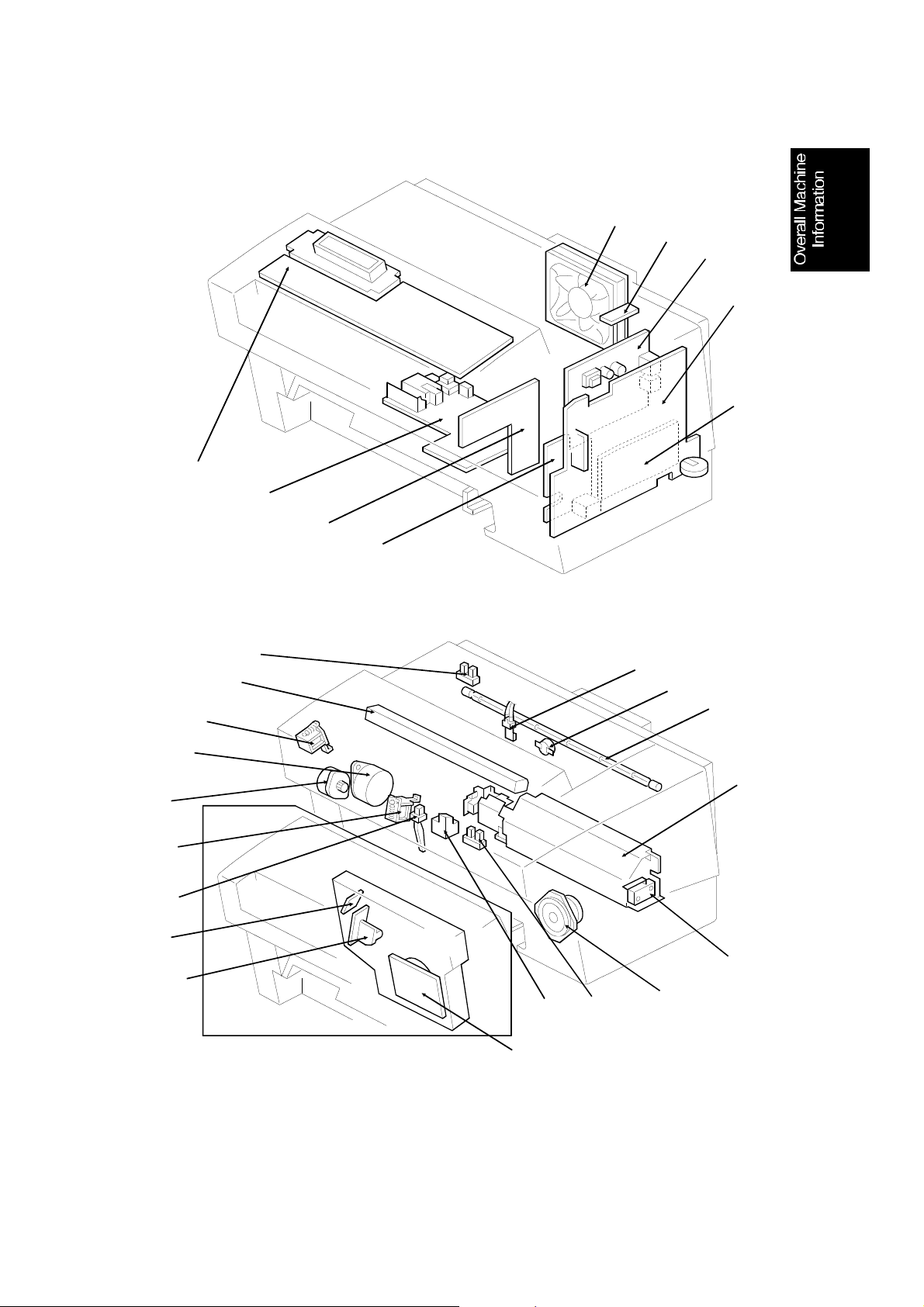

1.3.1. Mechanical Components

No. Name Description

Document Pick-up Roller Picks up the top sheet of the document from the

1

Scanner Roller Feeds the document through the scanner.

2

Laser Unit Consists of the LDDR (Laser Diode Driver), focusing

3

Development Toner

4

Magazine

Paper Feed-out Roller Feeds paper out of the machine.

5

Hot Roller Heat from this roller fuses the toner to the copy paper.

6

Fusing Pressure Roller Applies pressure to the paper during the fusing process

7

document table.

lens, Fθ Lenses, square mirror motor, and other laser

optic components.

Consists of the toner supply mechanisum, the toner

tank, and the development unit.

9

10

11

H528V501.wmf

1-5

OVERALL MACHINE INFORMATION July 24th, 1996

COMPONENT LAYOUT

No. Name Description

Fusing Fan Cools the interior of the machine.

8

Transfer Roller Applies a charge to the paper to pull the toner off the

9

Charge Brush Roller Applies a charge to the drum.

10

Paper Feed Roller Feeds paper from the paper tray into the printer.

11

Paper Separation Pad Allows one sheet into the printer.

12

Paper Pick-up Roller Picks up the top sheet of paper from the tray.

13

OPC Drum Organic Photoconductor Drum.

14

Toner Supply Roller Supplies the toner to the development roller.

15

Development Roller Applies toner to the latent image on the drum.

16

Toner Agitator Stirs up toner in the toner tank.

17

Document Feed-out

18

Roller

Document Separation Pad Allows one sheet into the scanner.

19

drum and onto the paper.

Feeds the document out of the scanner.

1-6

11

22

July 24th, 1996 OVERALL MACHINE INFORMATION

COMPONENT LAYOUT

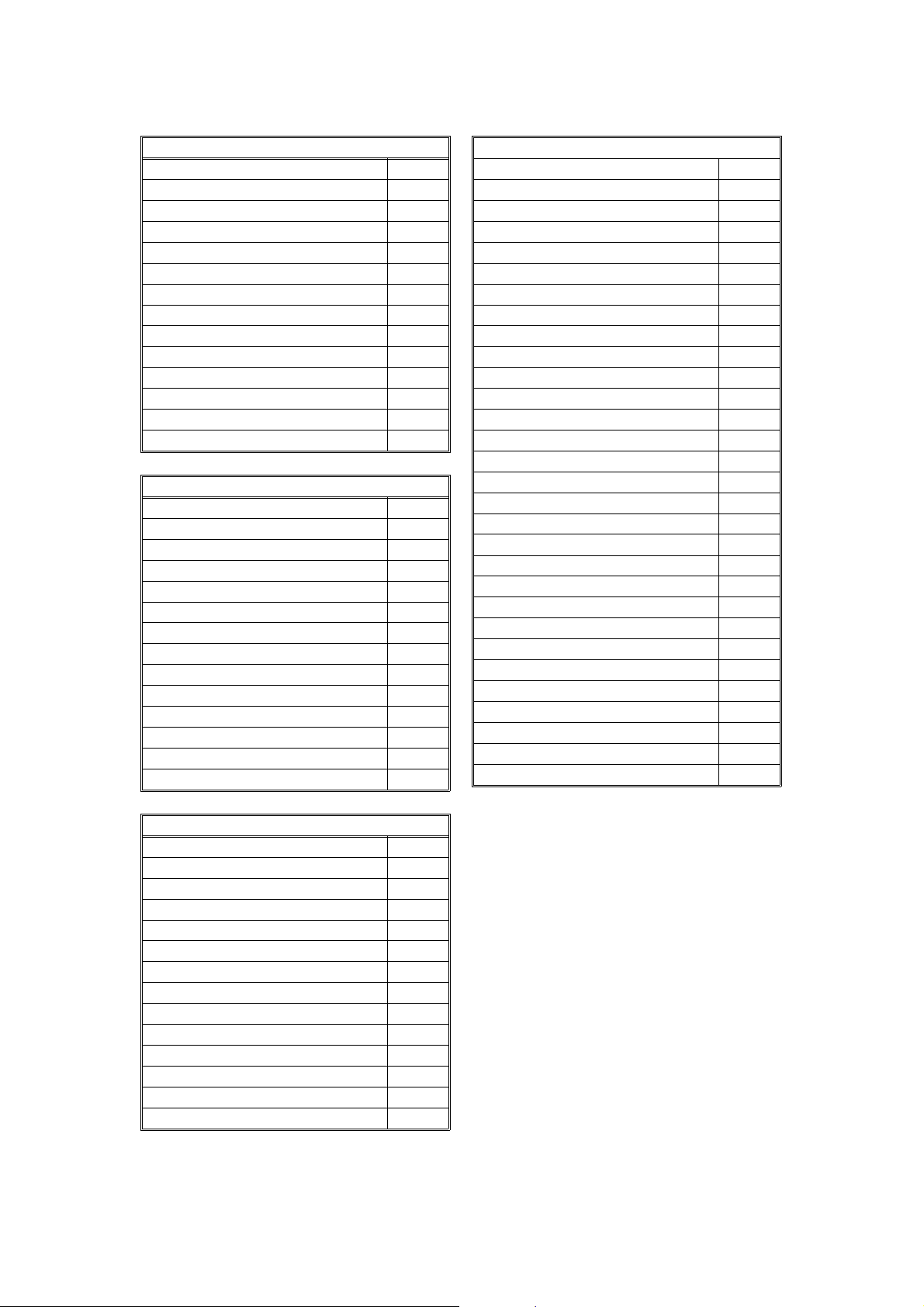

1.3.2. Electrical Components

5

4

3

2

1

6

7

8

9

20

27

19

16

21

18

17

15

14

13

10

H528V504.wmf

12

25

23

26

24

H528V503.wmf

1-7

OVERALL MACHINE INFORMATION July 24th, 1996

COMPONENT LAYOUT

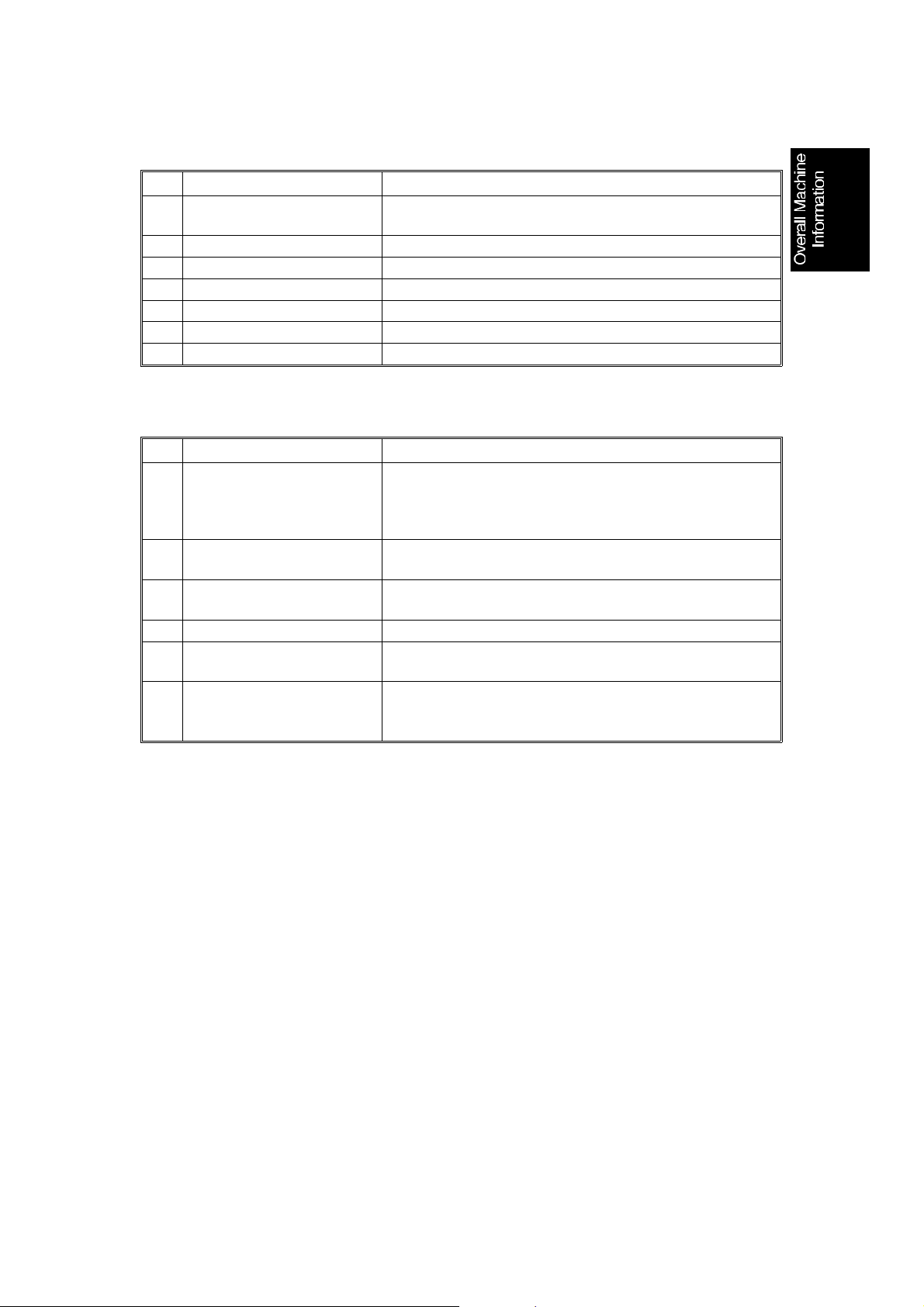

1. PCBs

No. Name Description

MCB (Mechacincal

1

Control Board)

FCU (Facsimile Control

2

Unit)

NCU (Network Control

3

Unit)

PCB-R Contains the resistors in the transfer bias circuit,

4

OPU (Operation Panel

6

Unit)

High-voltage Power

7

Supply

Scanner Sensor Board Contains the scanner sensors (document, scan line,

8

5V Power Board Generates the +5VE supply.

9

LDDR (Laser Diode

21

Driver)

PSU (Power Supply Unit) Supplies power to the machine.

23

Controls the printer part of the machine.

Controls the machine.

Contains a relay and switches to interface the machine

to the network and the handset.

between the ground plate and ground.

Consists of the LCD and the key switches.

Supplies high voltages to the charge, transfer, and

development bias.

document exit), and the ADF cover open sensor.

Drives the laser diode.

2. Motors

No. Name Description

Tx Motor Drives the scanner rollers.

20

Main Motor This DC stepper motor drives the printer mechanism.

18

Square Mirror Motor This high-speed servomotor drives the square mirror in

22

Fusing Unit Fan Motor Cools the interior of the machine.

5

the laser unit.

1-8

July 24th, 1996 OVERALL MACHINE INFORMATION

COMPONENT LAYOUT

3. Sensors

No. Name Description

Thermostat Cuts off the ac power supply to the fusing lamp if the

11

Thermistor Is used to monitor the hot roller surface temparature.

12

Toner End Sensor Is used to detect the toner end condition.

13

Registration Sensor Is used to detect when paper is fed into the printer.

10

Paper Exit Sensor Is used to detect when paper is at the fusing unit.

14

Paper End Sensor Is used to detect when the paper tray is empty.

16

Synchronization Detector Is used to synchronize the laser main scan.

27

surface temperature exceeds 180°C.

4. Others

No. Name Description

Contact Image Sensor Reads and converts the light reflected from the

15

Document Pick-up

17

Solenoid

Paper Pick-up Solenoid When this is energized, main motor drive is transmitted

19

Fusing Lamp The heat from this lamp fuses the toner to the paper.

25

Speaker Allows the user to listen to the condition of the machine

24

Interlock Switch If the top cover is open, this switch cuts off the

26

document into an analog video signal.

An LED array which illuminates the document is

included.

When this is energized, tx motor drive is transmitted to

the document pick-up roller.

to the paper pick-up roller.

and the telephone line.

+24V(SW) power supply. This component is also used

as a top cover open sensor.

1-9

OVERALL MACHINE INFORMATION July 24th, 1996

OVERALL MACHINE CONTROL

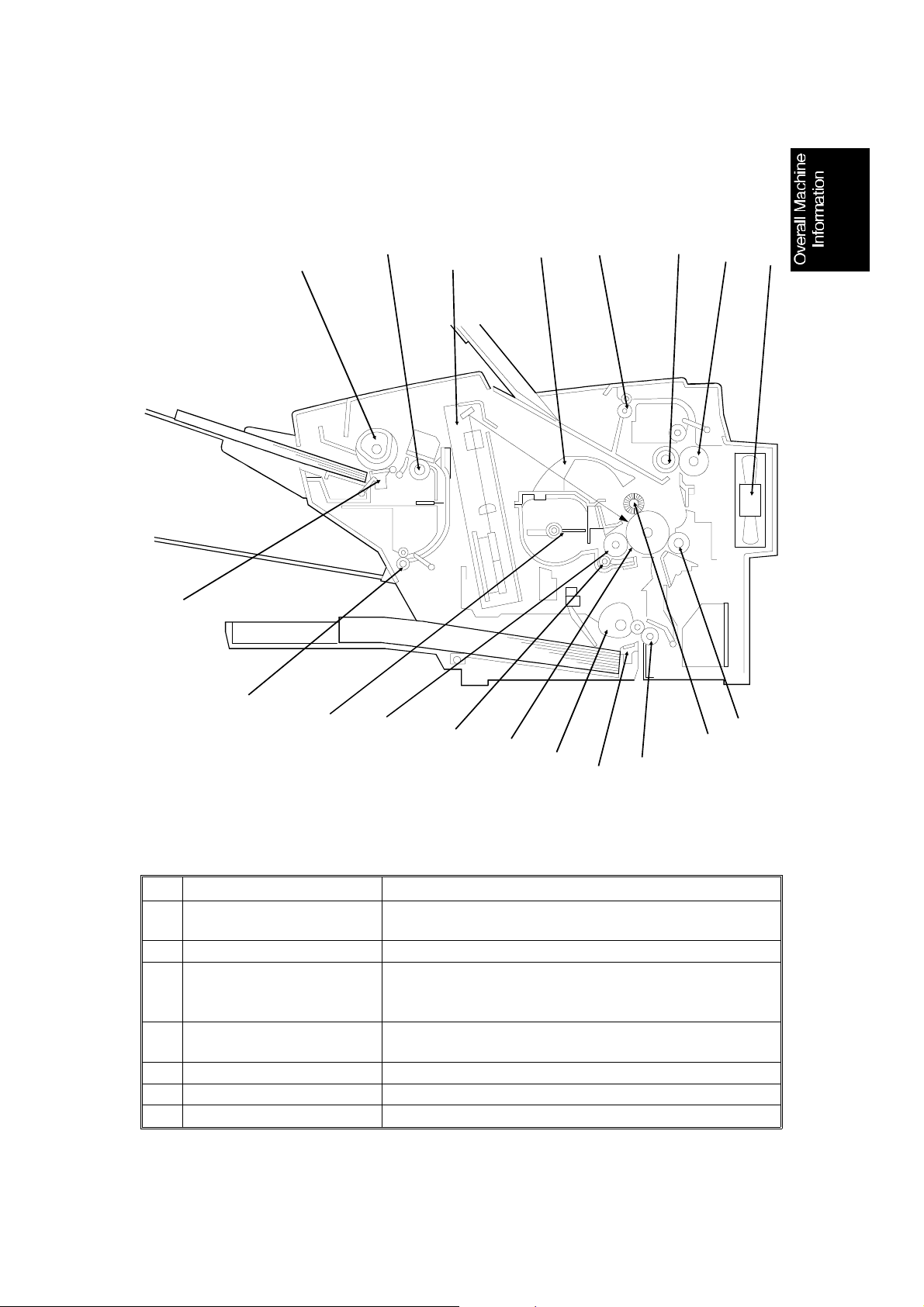

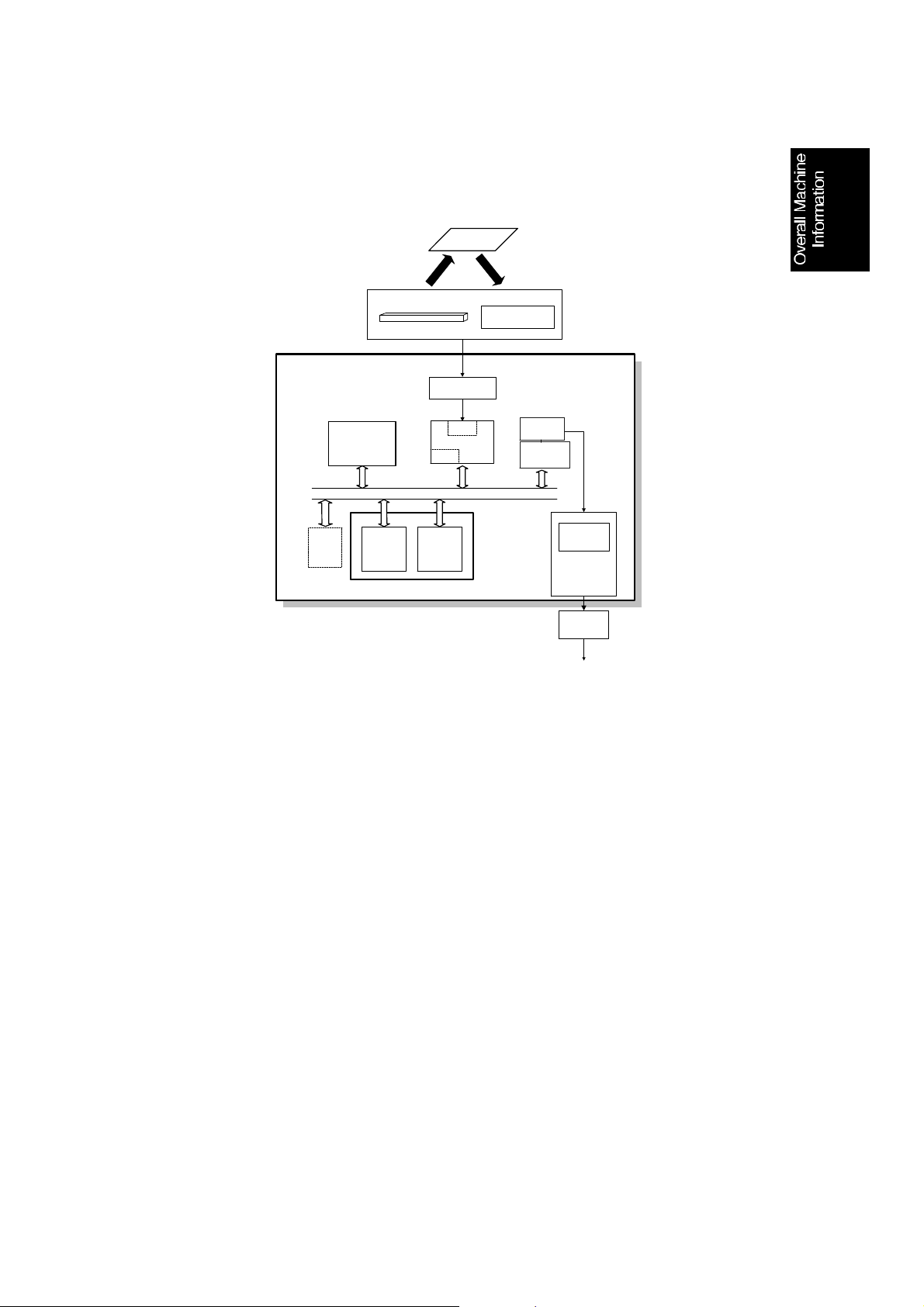

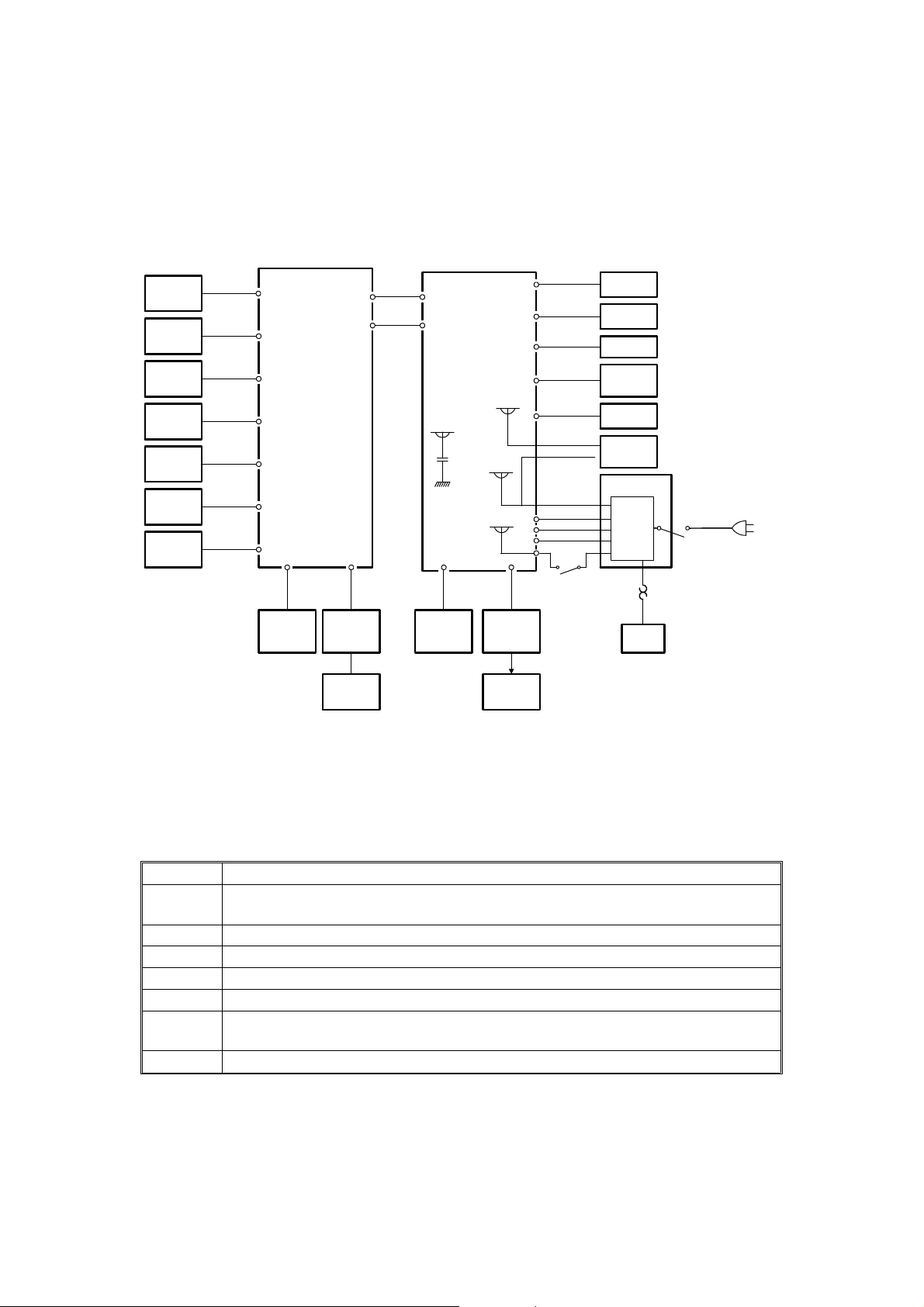

1.4. OVERALL MACHINE CONTROL

Printer

Components

/STS

/SOD

Data &

MCB

FCU

FCIP

Control

Scanner

Components

Optional

Paper Feed

Unit

AVIDEO

Data &

Control

TRXD

Serial

The FCU controls the entire system of the machine.

NCU

To the Network

Operation

Panel

OP-LSI

H528D501.wmf

The printer components and the optional paper feed unit are controlle d by th e

MCB. The FCIP in the FCU is connected with the CPU in the MCB t hro ugh a

synchronized 8-bit serial in te rface. The line synchronization signal for laser

printing is sent to the FCIP from the MCB.

The scanner components are controlled by the FCU. Video data coming from

the CIS is processed in the FCIP and then sent to the MCB for copying or

sent to the NCU through the modem for transmission.

The operation panel is controlled by the FCU through a serial interface .

1-10

July 24th, 1996 OVERALL MACHINE INFORMATION

VIDEO DATA PATH

1.5. VIDEO DATA PATH

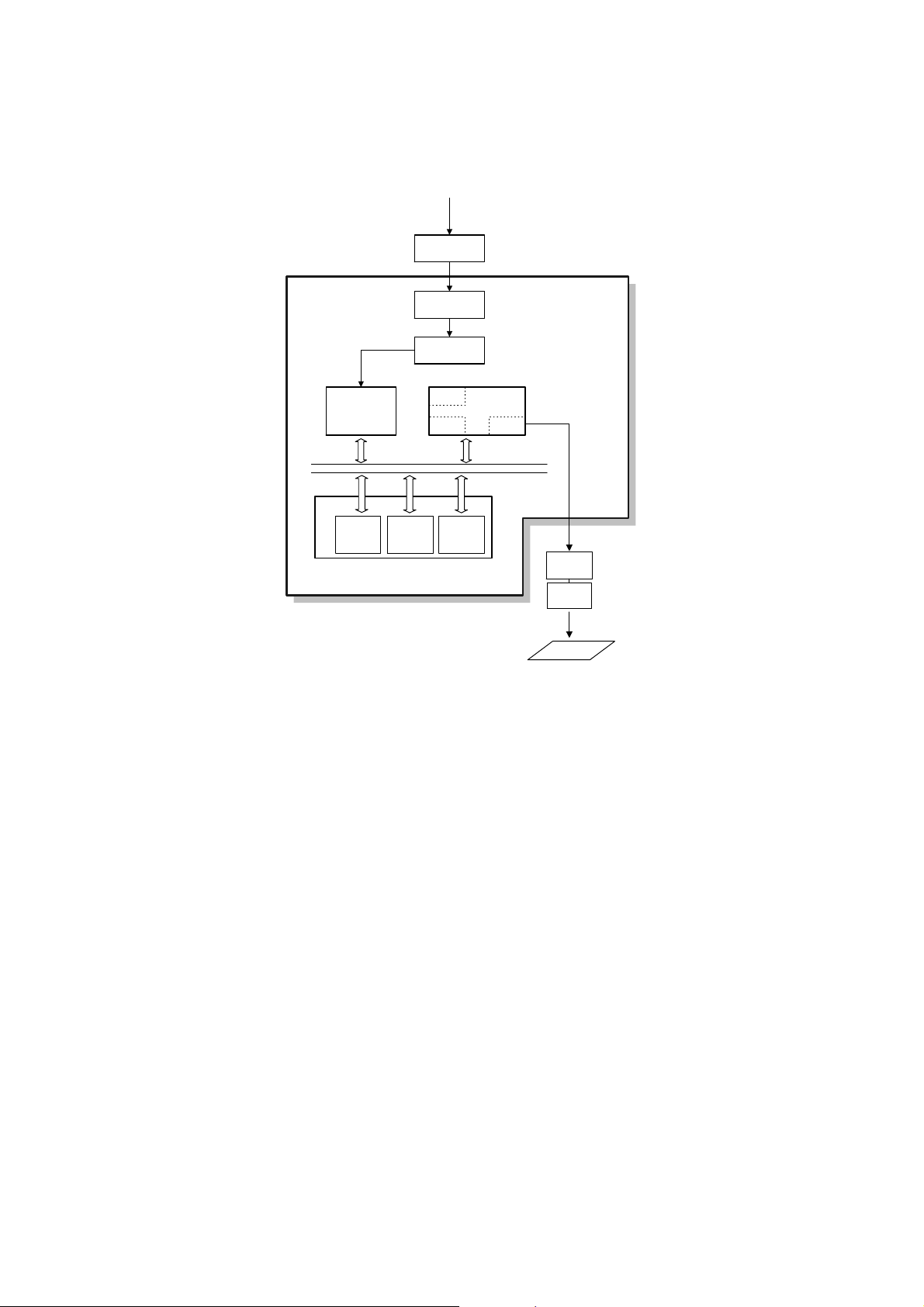

1.5.1. Transmission

Original

Contact Image Sensor

Assembly

LED Array

Image Sensor

FCU

Amp

Attenuator

HIC

NCU

To the

network

H528v507.wmf

Processing

SAF IC

Card

DIP:Digital Image Processor

DCR:Data Compression &

Reconstruction

Video

Memory

DRAM

Line

Buffer

/FIFO

Memory

CIS Video

Amplifier

DIP

FCIP

DCR

DATA/ADDRESS BUS

ECM/SAF

Memory

R144EFXL

Modem

Immediate Transmission:

Scanned data from the contact imag e sen sor pa sses to the DI P block in the

FCIP. After analog/digital vide o p roce ssing, the DCR block compresses the

data for transmission. The compressed data th en passe s eit he r to the FIFO

memory or to the ECM memory before it is sent to the telephone line through

the modem.

Memory Transmission:

First, the scanned data is sto red in the SAF memory after compression in the

DCR block.

At the time for transmission, the DCR block decompre sses th e data from the

SAF memory, then compresses it again after handshaking with the other terminal is done. The compressed data then passes either to the FI FO me mory

or to the ECM memory, before it is sent to the telephone line thro ugh th e modem.

1-11

OVERALL MACHINE INFORMATION July 24th, 1996

VIDEO DATA PATH

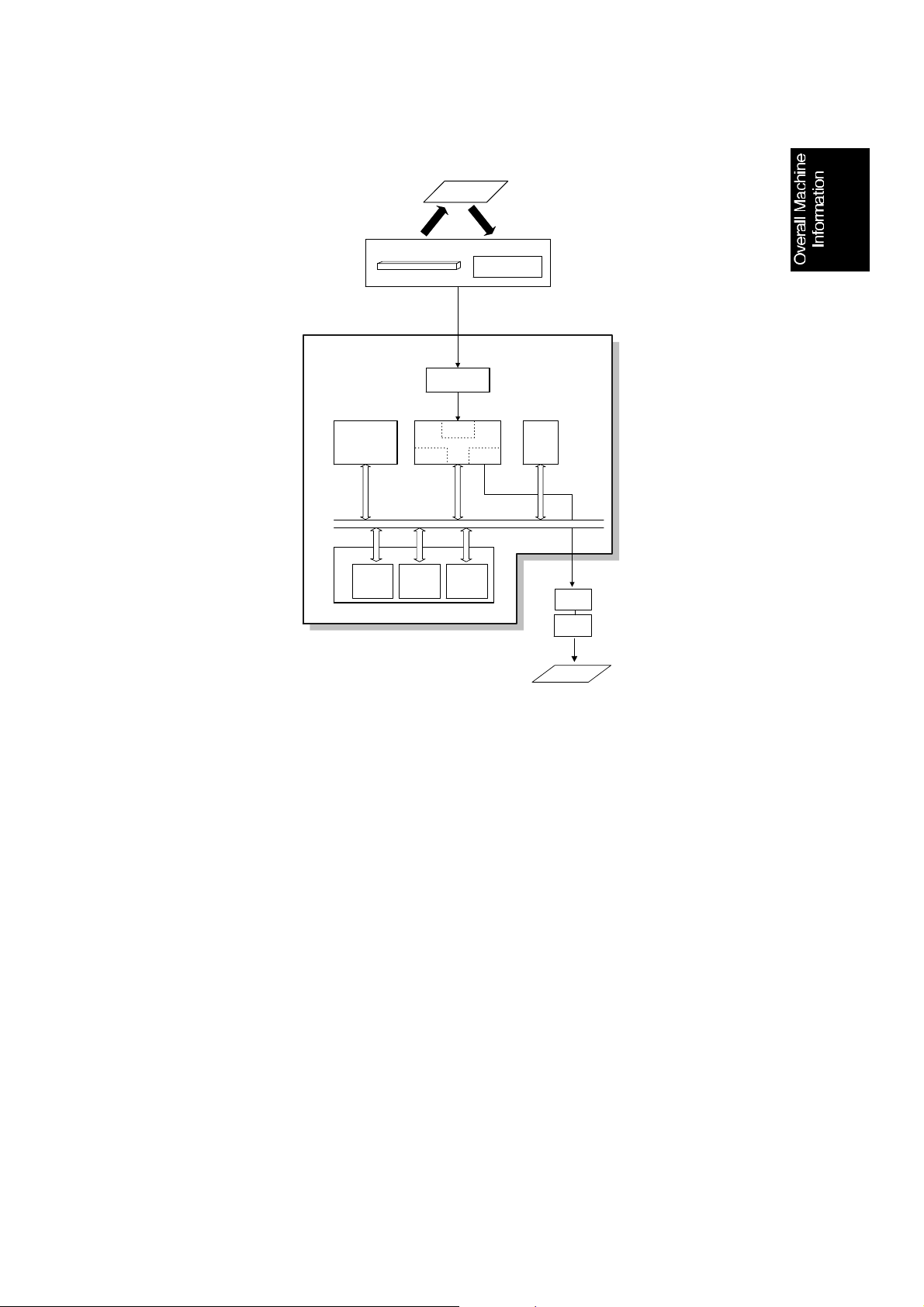

1.5.2. Reception

From the Network

NCU

HIC

FCU

Amplifier

E144EFXL

Modem

DRAM

Line Buffer

/FIFO

Memory

LIF: Laser Interface

DCR:Data Compression &

Reconstruction

MDM: Modem

Data from the line p asse s to the modem throu gh th e NCU a nd hyb rid IC. After the modem demodulate s the data, the dat a passes to the DCR blo ck,

through either the FIFO or the ECM memory, where the data is decompressed to raster image data.

MDM

DCR LIF

DATA/ADDRESS BUS

ECM/SAF

Memory

Page

Memory

FCIP

MCB

LDDR

Copy Paper

H528v508.wmf

The raster image data is the n passe d to the page memory for printing. After a

page of data has been stored in the page memory, the data is sent to the

MCB through the LIF block in the FCIP, and then to the LDDR.

1-12

July 24th, 1996 OVERALL MACHINE INFORMATION

VIDEO DATA PATH

1.5.3. Copying

Original

Contact Image Sensor

Assembly

LED Array

Image Sensor

Video

Processing

Memory

DRAM

Line Buffer

/FIFO

Memory

CIS Video

Amplifer

DCR LIF

DATA/ADDRESS BUS

ECM/SAF

Memory

DIP

FCIP

Page

Memory

SAF

Memory

IC Card

FCU

MCB

LDDR

LIF: Laser Interface

DCR:Data Compression &

Reconstruction

Copy Paper

H528v509.wmf

DIP:Digital Image Processor

Single copy / Multi-page copy

The scanned data passe s to th e pa ge memory after video processing in the

DIP block in the FCIP. After a page of data has been stored in the page memory, the data is sent to the MCB through the LIF block, and then to the LDDR.

This process is the same for multi-pa ge copyin g.

1-13

OVERALL MACHINE INFORMATION July 24th, 1996

POWER DISTRIBUTION

1.6. POWER DISTRI BUTI O N

1.6.1. Distribution Diagram

+5V

+5VD

LDDR

Square

Mirror Motor

Toner End

Sensor

Fusing Fan

Paper

Pick-up

Solenoid

Thermistor

Main Motor

+5V

+5V

+24V(SW)

+5V

+24V(SW)

+24V(SW)

+5V

+24V(SW)

MCB

+24V(SW)

+5V

+5VD

+12VD

+5VE

+5V

+24V

+5VE

+24V(SW)

+5VE

FCU

+

-

+24V

+24V(SW)

+24V(SW)

+24V

+24V

+12V

+5V

-5V

IC Card

Option

Panel

NCU

Document

Pick-up

Solenoid

Tx Motor

5V

Power Board

Power

Board

PSU

AC Main Power

Main Switch

Interlock

+24V(SW)

High

Voltage

Paper Supply

+5V

+24V(SW)

Optional

Paper

Feed Unit

(SW)

+24V

Paper

Pick-up

Solenoid

+5V

+5VE

Scanner

Sensor

Board

-5V

+5V

+12V

CIS

Sensor

+12V

LED Array

Switch

Fusing

Lamp

Thermostat

H528v510.wmf

The PSU supplies +24V, +24V(SW), +12V, and ±5V dc power to the FCU.

The +5V Power Board generat es +5V E from the +24V suply. The dc supplies

are used as follows.

+24V

+5VE

+12V

-5V

+5V

+12VP

+5VD

+24V(SW)

This is normally on when the main switch is on.

This is used for the document sensor, operation panel, and NCU. This is

supplied even if the machine is in power saver mode.

This supplies the LED Array in the CIS.

This is used for the image sensor.

This is normally on when the main switch on.

This is supplied the to Flash ROM and the optional IC card.

This supplies back up power for the system RAM and the optional IC card. A

lithium battery is used to generate +5VD.

This is interrupted if the interlock switch opens.

1-14

July 30th, 1996 DETAILED SECTION DESCRIPTIONS

SCANNER

2. DETAILED SECTION DESCRIPTIONS

2.1. SCANNER

2.1.1. Mechanisms

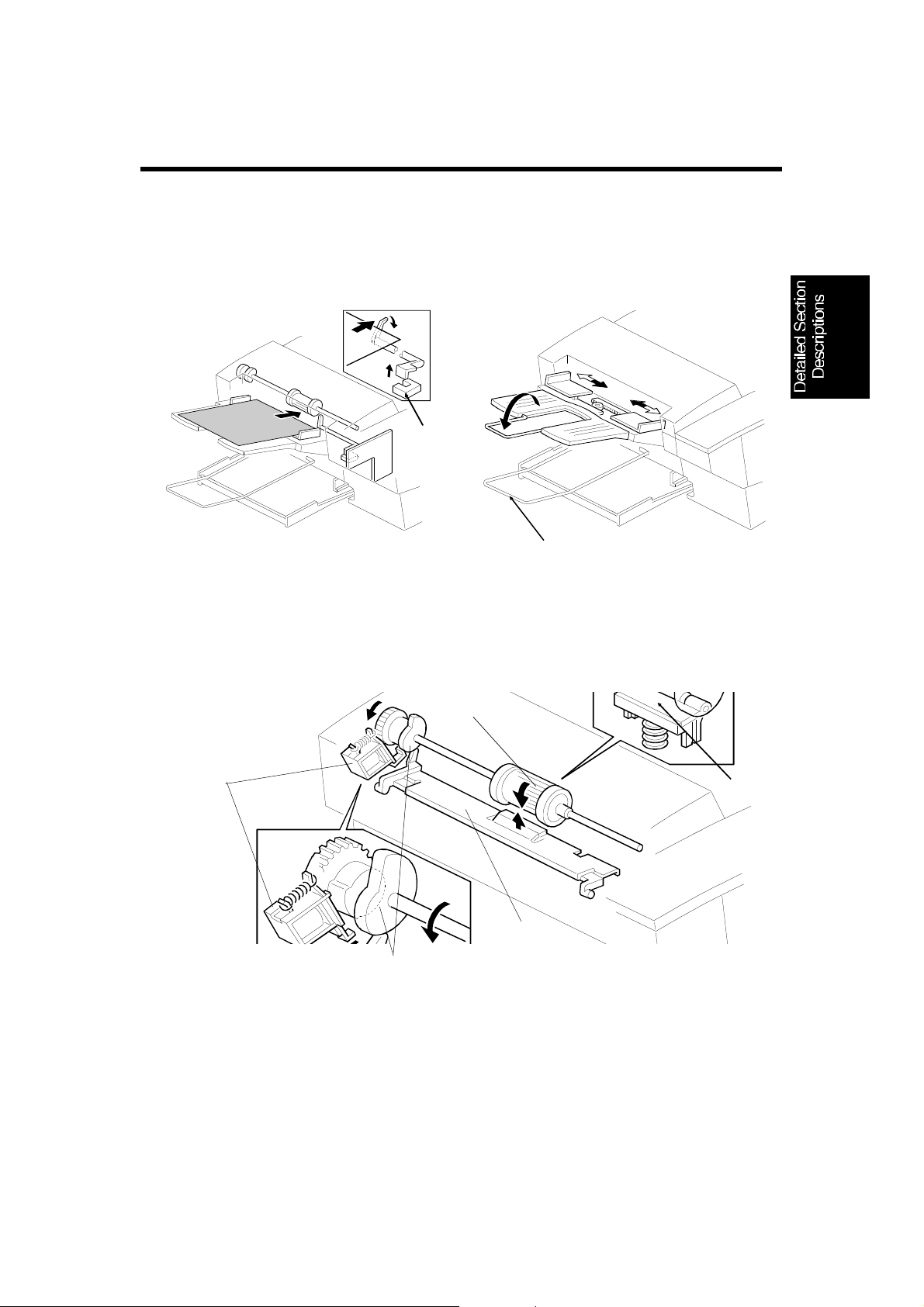

1. Document Detection

[A]

H528D51 1.wm f

[B]

H528D510.wmf

The document sensor [A] detects when a document is placed in the ADF. The

fold-out extension [B] helps support longer documents.

2. Pick-up and Separation

[D]

[A]

[B]

[C]

H528D509.wmf

[E]

When the document pick-up sole no id [A ] is turn ed on, it allows th e tra y lif tin g

cam [B] to rotate. This a llows th e do cument plate [C] to be pu she d u p b y a

spring under the plate. The docu men t pick-u p rolle r [ D] fe eds th e t op sheet of

the document int o th e scanner. The separation pad [E] prevents the document pick-up roller from feeding more than one she et at the time .

2-1

[D]

DETAILED SECTION DESCRIPTIONS July 30th, 1996

SCANNER

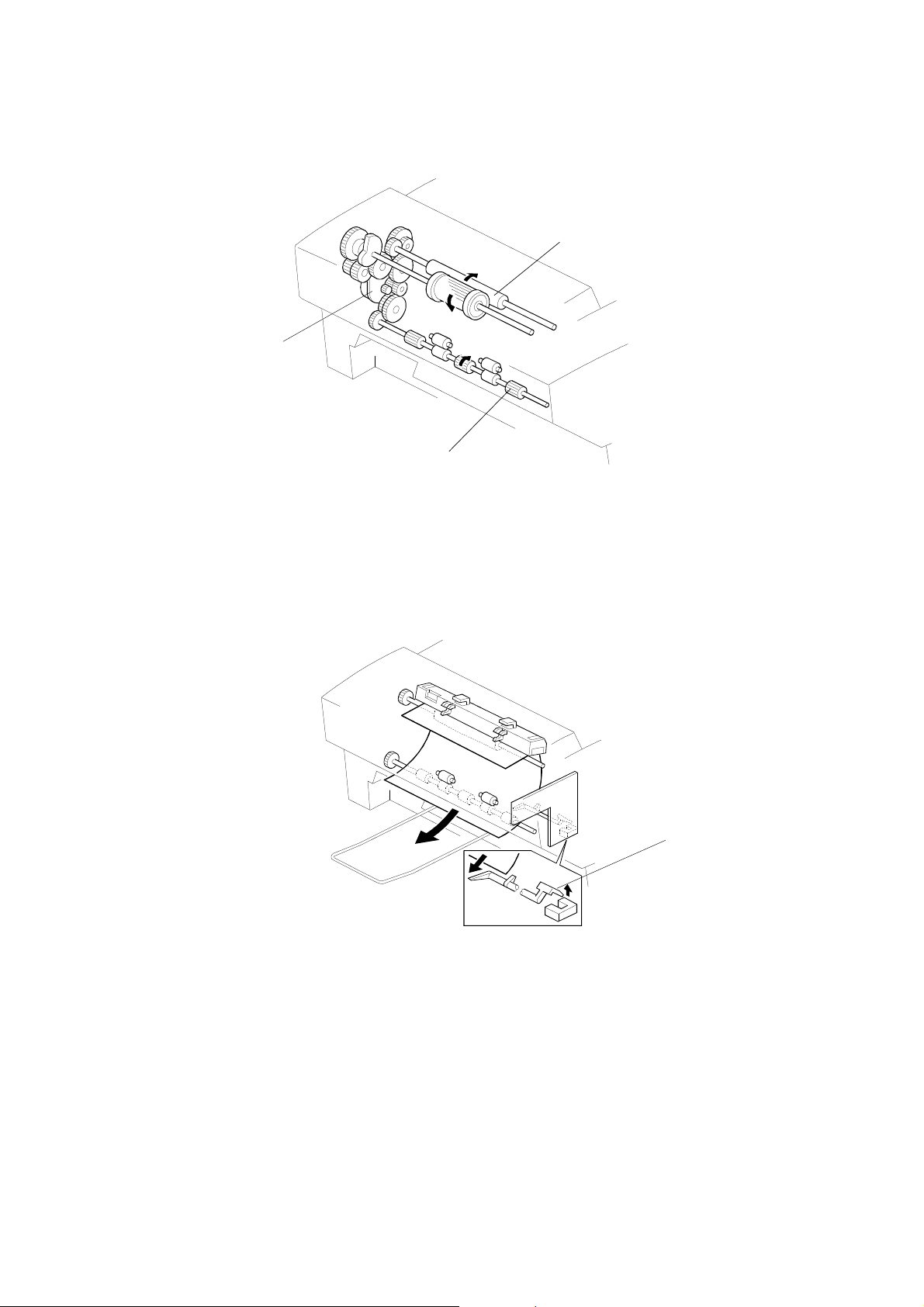

3. Drive Mechanism

[A]

[C]

[B]

H528D512.wmf

The document is fed int o th e scanner by the scanner roller [ A] , an d fe d ou t by

the exit roller [B]. The tx motor [C] drives the scanner roller and the exit roller.

The document exit sensor de tects when the document leave s t he scann er.

H528D513.wmf

Note: When a communication error occu rrs in imme dia te tx, the machine

stops scanning the document, then feeds it out of the scanner.

2-2

[B]

[F]

July 30th, 1996 DETAILED SECTION DESCRIPTIONS

SCANNER

4. Image Scanning

[E]

[A]

[D]

[C]

H528D515.wmf

The scanner consists of a conta ct imag e sensor (CIS) assembly [A] and a

scanner roller [B]. Inside the CI S are an exposure glass [C], a rod lens array

[D], an image sensor [E], and an LED array [F].

The image sensor consists of a row of 1728 photo sen sitive elements (216

mm width x 8 dots/mm). Light from the LED array is reflected from the document and focused ont o the image sensor by the rod lens array. Because of

the short optical path inside the CIS, the focal depth is much shorter than for

a CCD type scanner.

The white level adjustme nt is performed at the fa cto ry, then the white level is

stored in the FCU’s SRAM. The white leve l must be ad just ed whe n t he FCU

or the CIS is replaced, or the SRAM is cleared in the field.

The CIS scans the docume nt one line at a time, and outputs an analog signal

for each line. The voltage from ea ch ele men t de pe nds on t he intensity of the

light reflected by th e do cument onto the element; the intensity of the light depends on the darkness of the area reflected.

Cross reference

White level adjustment: Service Tables and Procedures (chapter 4) - Function 10,

Shading Test

2-3

DETAILED SECTION DESCRIPTIONS July 30th, 1996

SCANNER

Standard resolution (Scanni ng to memor y)

• 3.85 line/mm resolution.

• One line is read each motor step.

• Scan speed: 2.75 s /A4 size.

• The tx motor rotates at 800 pps to scan the document into the memory.

• OR processing is always disabled to make scanning faster.

Standard resolution (Imme dia te tx)

• 3.85 line/mm resolution.

• One line is read every two motor steps.

• Scan speed: 5.5 s /A4 size.

• The tx motor rotates at 400 pps to scan the do cument.

• OR processing is done, to prevent narrow vertical lines from bein g bro-

ken up (OR processing can be disabled with sca nner switch 00, bit 4).

Detail resolution

• 7.7 line/mm resolution.

• One line is read every motor step.

• Scan speed: 5.5 s /A4 size.

• The tx motor rotates at 400 pps to scan the do cument.

• In copy and halftone mode , scanning always uses detail resolution.

Fine resolution

• 15.4 line/mm resolution.

• One line is read every motor step.

• Scan speed: 11.0 s /A4 size.

• The tx motor rotates at 400 pps to scan the do cument.

2-4

July 30th, 1996 DETAILED SECTION DESCRIPTIONS

SCANNER

2.1.2. Scanner Timing Chart

1. Timing Chart

TX Motor

CIS LED

Document

Pick-up

Solenoid

Scan Line

Sensor

Data

Read

Document

Exit

Sensor

Document

Sensor

1

800PP

S

400PP

S

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

500ms

START

[T1]

38 Steps

Pre-feeding 2.05 S

187 Steps

[L2]

EXIT

3

4

2

[L1]

[L3]

37 Steps

H528d543.wmf

The following describes wh at is happ en ing for the standard resolution at

points 1 to 4 on the timing chart.

1. When the Start key is pressed, the pick-up solenoid turn on, then the tx

motor feeds the documen t to the scan line sensor (400 pps).

2. The tx motor feeds the document through the scanner (800 pps).

3. The tx motor feeds the document out of the scanner.

4. The tx motor stops 82 steps after the document exit se nso r was t urned off.

2-5

DETAILED SECTION DESCRIPTIONS July 30th, 1996

SCANNER

2. Jam Conditions

The main cpu detects a docume nt jam if one of the followin g conditions occurs.

Jam Condition Description Error

Code

The scan line sensor does not switch on within

Non-feed

Maximum document

length exceeded

Document jam

Cover open

Others

3.9 s [T1] of the tx motor starting.

The jam condition is reset when the document,

scan line, and exit sensors are turned off.

The scan line sensor does not turn off after the

maximum document length [L1] has been fed

since it turned on.

The jam condition is reset when the document,

scan line, and exit sensors are turned off.

The document exit sensor does not turn off after

the maximum document length [L3] has been fed

since the scan line sensor turned off.

The jam condition is reset when the document,

scan line, and exit sensors are turned off.

The document exit sensor does not turn on when

the tx motor has rotated for 160 mm feed length

[L2] after the scan line sensor turned on.

The jam condition is reset when the document,

scan line, and exit sensors are turned off, and the

ADF cover opened then closed.

When the document exit sensor is off while the

scan line sensor goes to off.

The jam condition is reset when the document,

scan line, and exit sensors are turned off, and the

ADF cover opened then closed.

The top cover is opened while the machine is

working.

The jam condition is reset when the top cover and

the ADF cover are closed.

The scan line, document, or document exit sensor

is on during initialization.

The jam condition is reset when the document,

scan line, and exit sensors are turned off.

1-00

1-01

1-17

No error

code

No error

code

No error

code

2-6

DETAILED SECTION DESCRIPTIONS June 30th, 1996

PRINTING

2.2. PRINTING

2.2.1. Printing Process - Overview

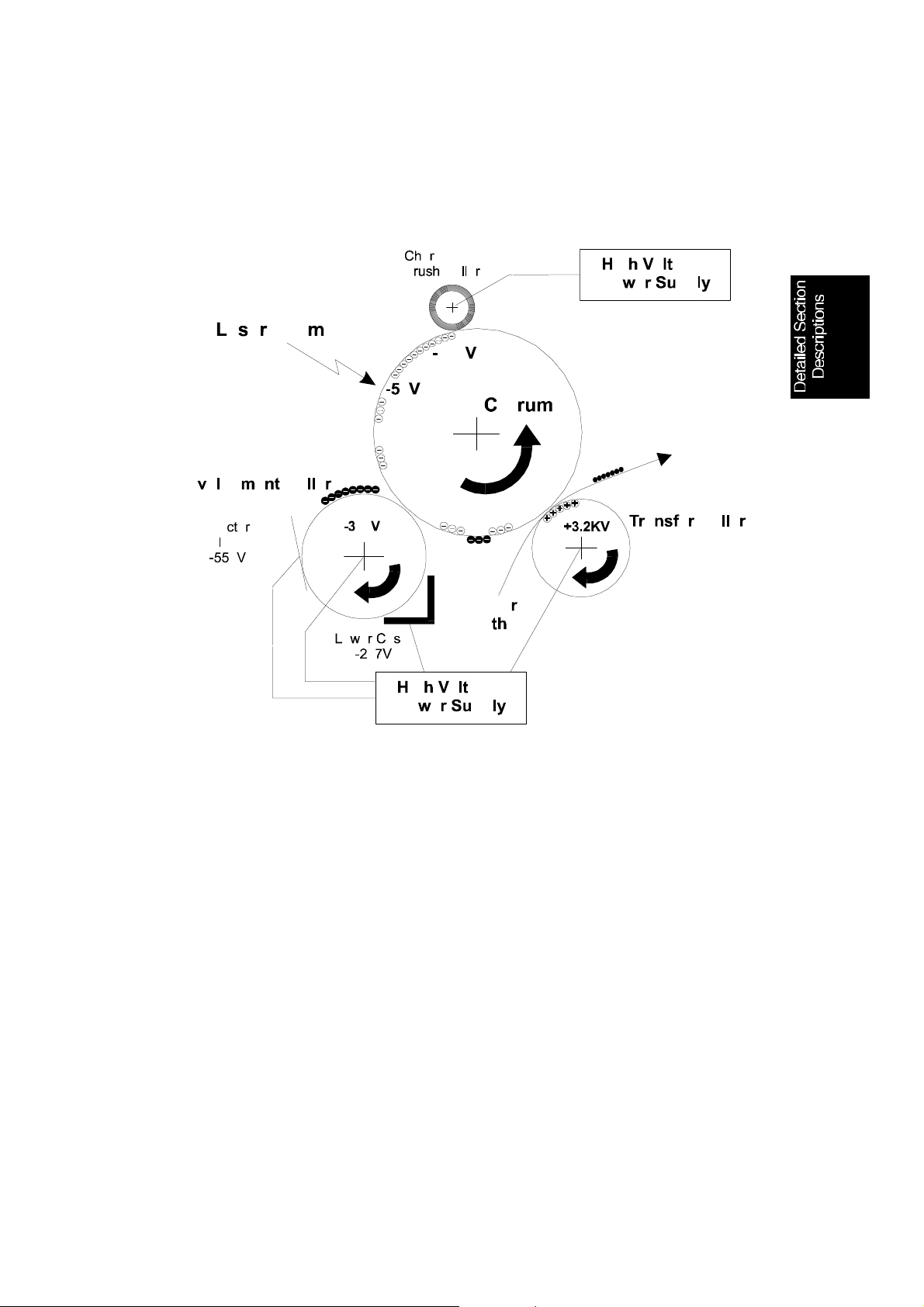

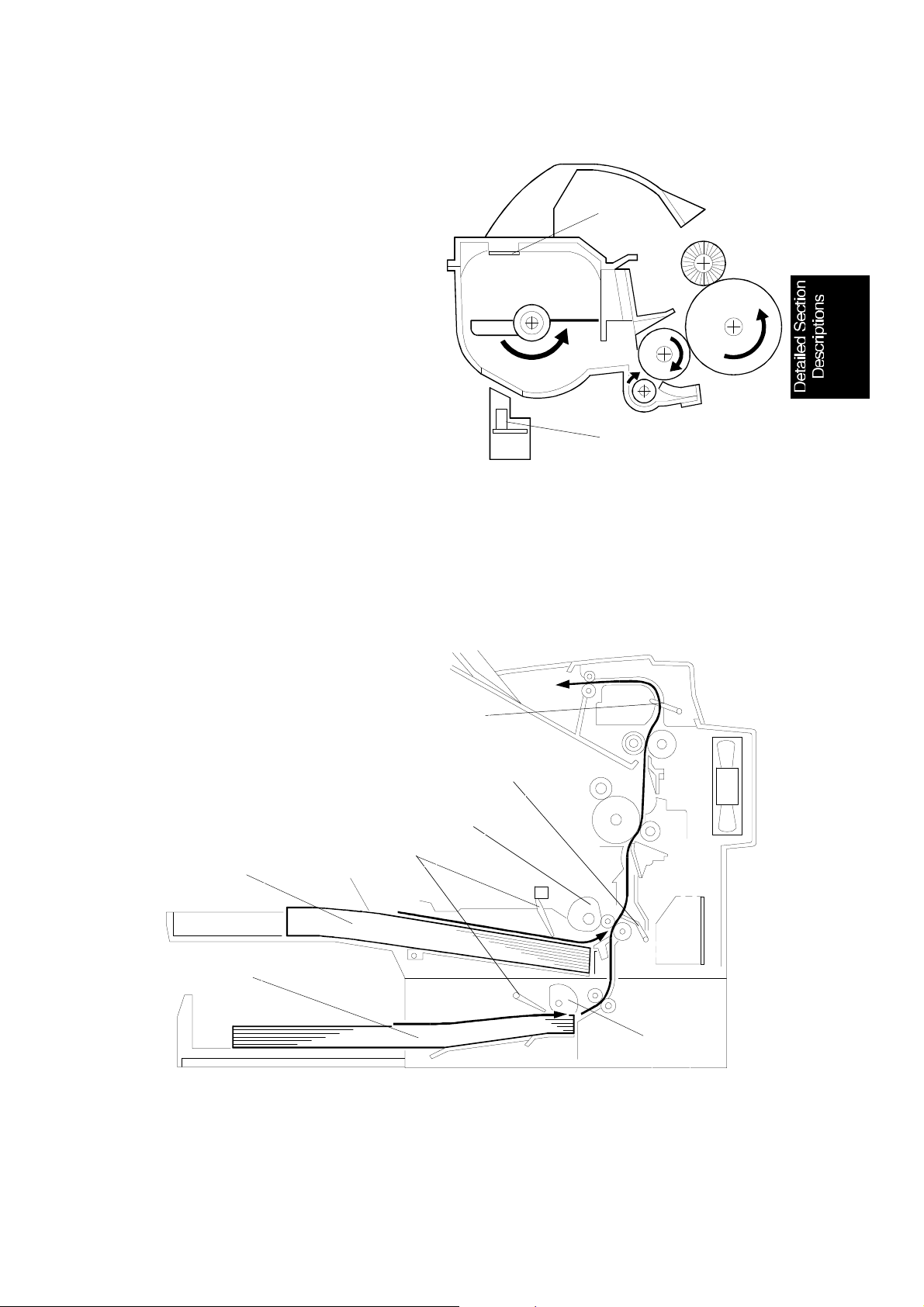

H528D545.wmf

This machine uses a "write to black" syste m, usin g ne ga tive ton er.

• The charge brush roller ap plie s a neg at ive charge to the drum of -350 V

to -1350 V, switched at 30 Hz.

• The surface voltage of the drum is appro ximat ely -80 0 V.

• The laser ex posed a rea o n th e dru m dr ops to abou t -50 V.

• The development roller carries ton er to the latent image on the drum

surface. The bias voltag es d urin g p rint ing :

Development roller : -300 V

Doctor blade: -550V

Lower case: -287 V

• The transfer roller attracts toner from the drum onto the pap er. The bias

applied is +3.2 kV.

• This machine has no cleanin g un it or wast e toner tank.

2-7

[D]

[A]

July 30th, 1996 DETAILED SECTION DESCRIPTIONS

PRINTING

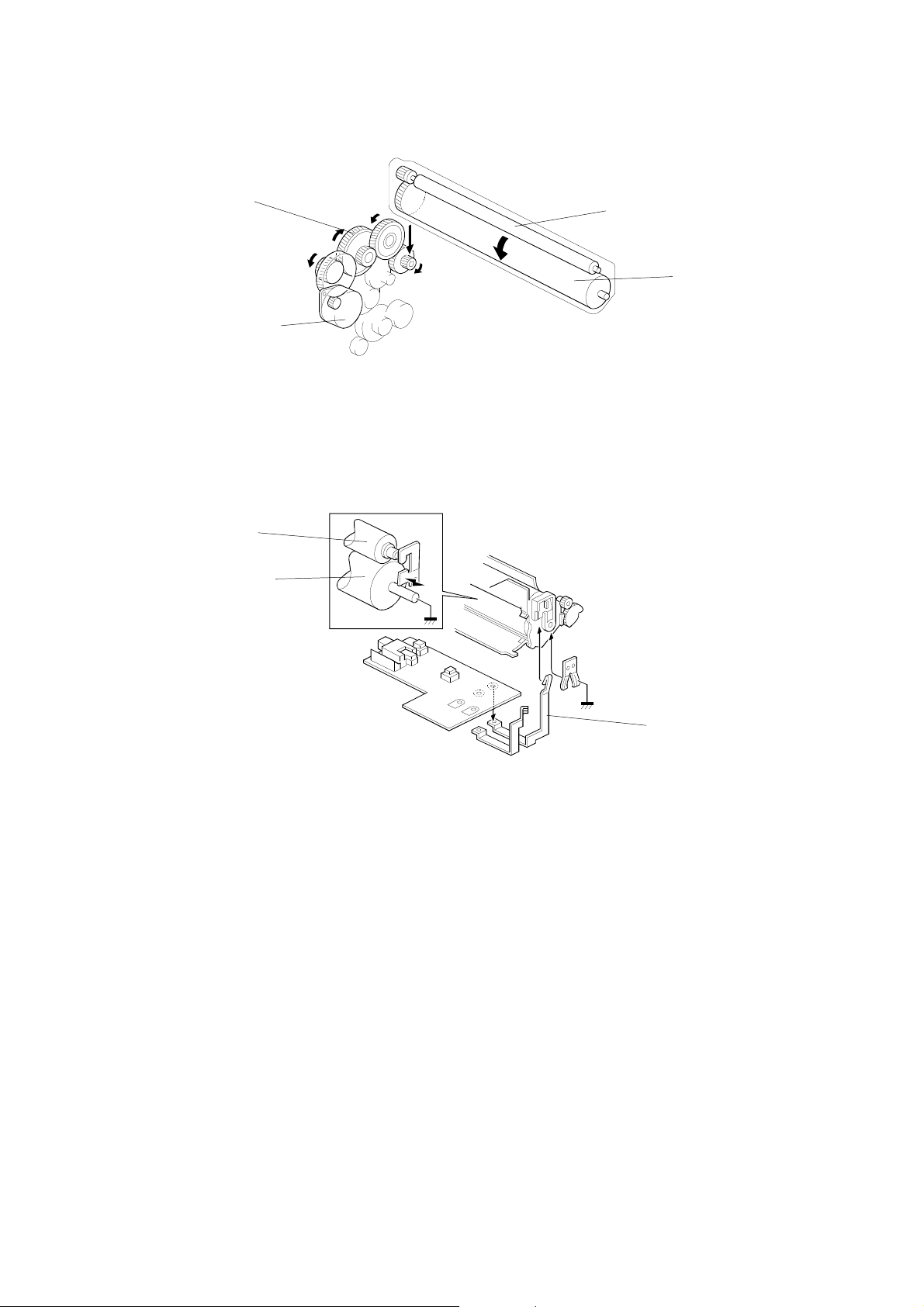

2.2.2. OPC Drum

[C]

[B]

H528D506.wmf

This machine uses an organic pho to con du ctor drum [A]. The diamet er o f t he

drum is 30 mm. It is driven by the main motor [B] through a gear train [ C]. The

charge brush roller [D] is also driven by the main moto r.

The drum cartridge is replace ab le by the user.

2.2.3. Charge

[A]

[B]

[C]

H528D517.wmf

The charge brush roller [A] is loca ted in the drum u nit. It a pplies the

char ge b ia s in di r e ct c on t ac t wi th t he d ru m [B ]. The high voltage power

supply applies a high voltage of -350 V to -13 50 V, switched at 30 Hz,

through plate [C].

Since the machine uses a ch arg e bru sh roller, the ozone product ion is greatly

reduced and the charge bias applied to a roller is relative ly low compared to

that for a corona wire.

The charge brush roller rot at es faster than the drum. (The speed ratio is

about 4 : 1.)

There is no cleaning me chanism. Also, toner is tran sfe rred back to the drum

by the transfer roller in cleanin g mod e. The charge brush roller picks up some

of this toner. In extreme cases, this may lead to vertical black lines on copies

in areas corresponding to places on the brush th at have excessive toner.

2-8

DETAILED SECTION DESCRIPTIONS June 30th, 1996

PRINTING

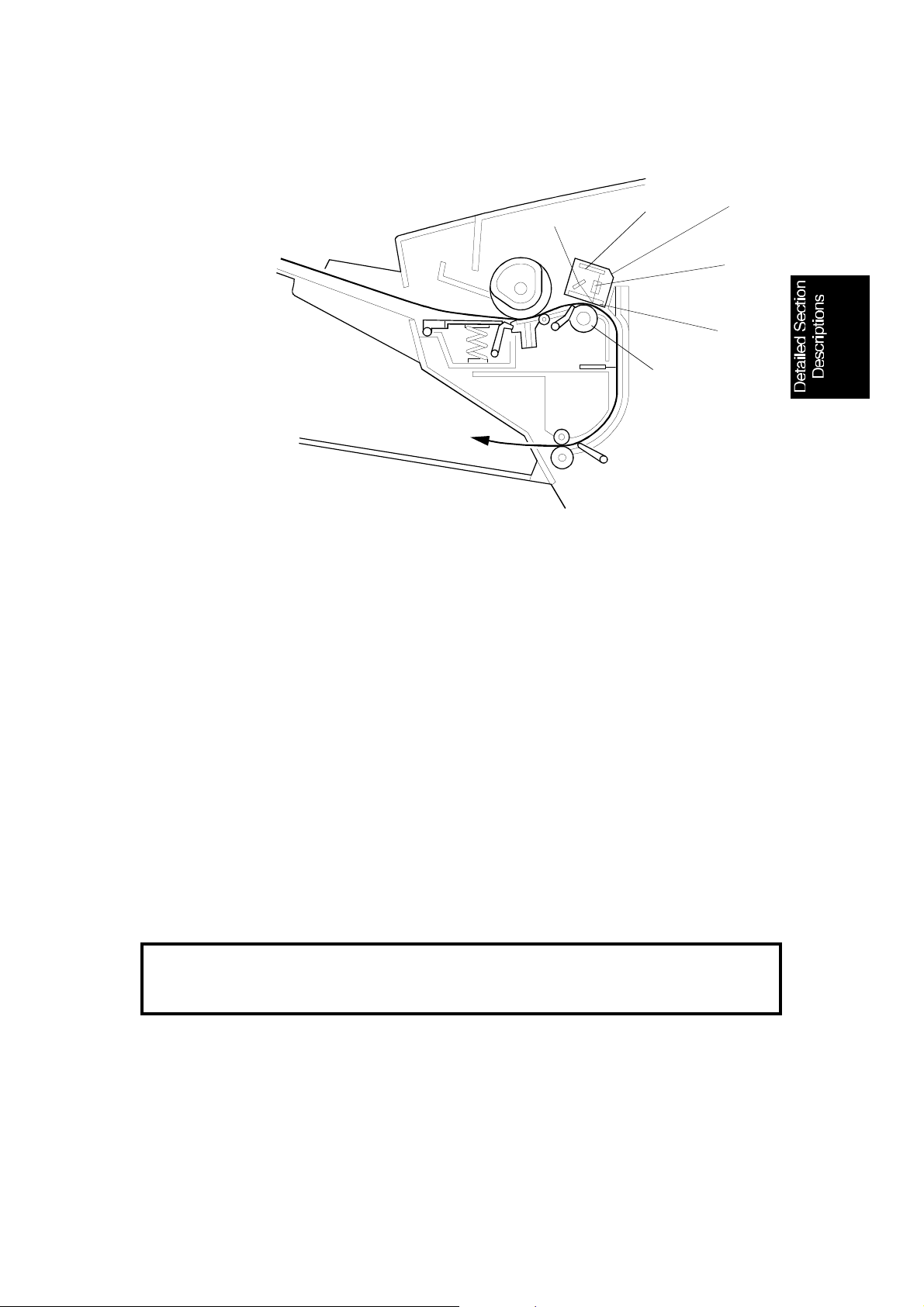

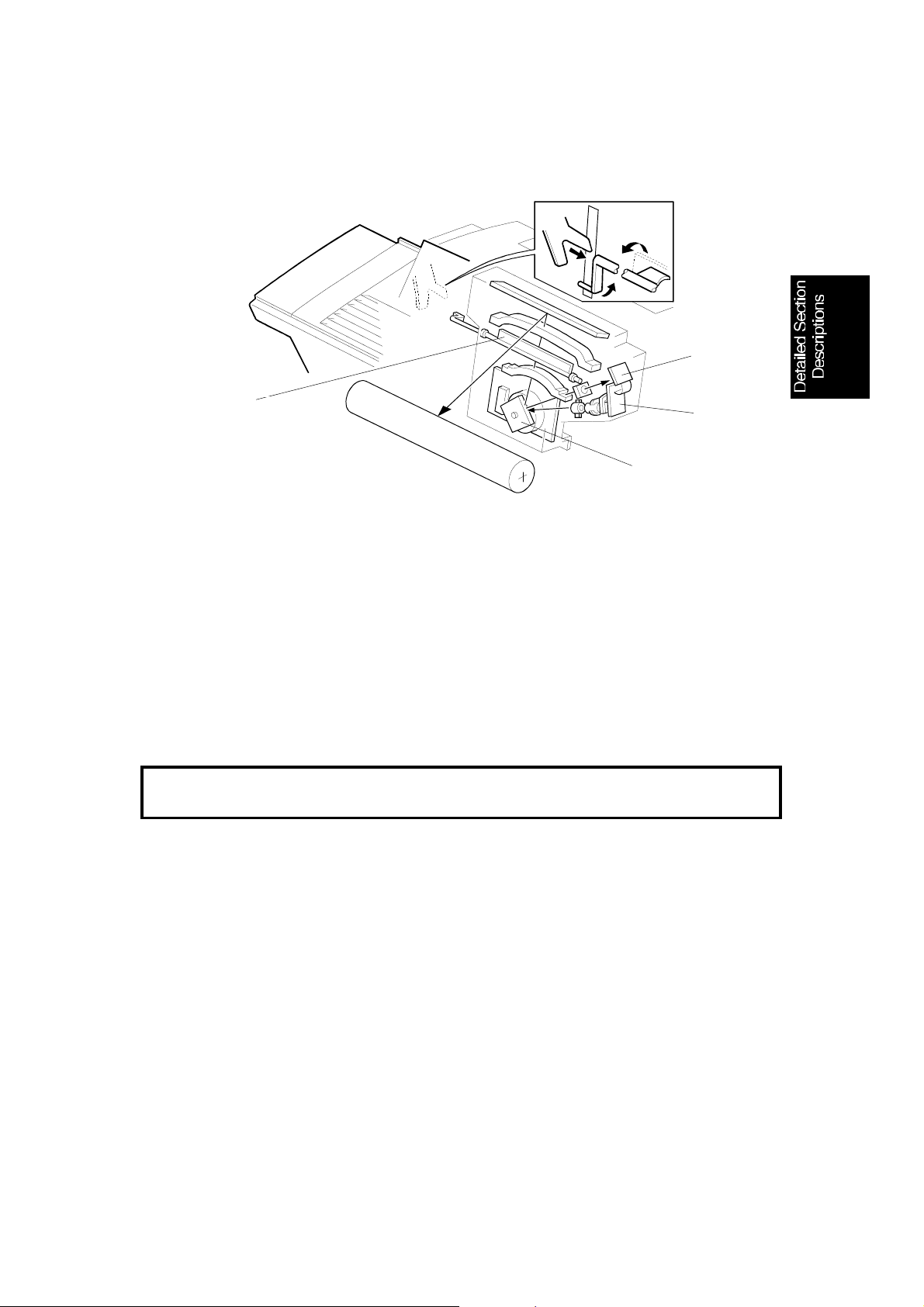

2.2.4. Laser Exposure

1. Overview

[C]

[D]

[A]

[B]

H528D505.wmf

The components of the laser sect ion create a latent imag e o n t he drum. The

charge on the exposed areas of the drum drops to about -50 V while

non-exposed areas rema in at about -800 V.

This machine uses a rotatin g square mirror [A]. The beam emitted from the

LDDR [B] is reflected by the square mirror to the line synchronization detector

[C] for line synchronizat ion in the ma in scan direction. The mirror’s rotation

speed is 8431.7 rpm.

As a safety feature , th e shutter [D] closes to block the laser beam path

whenever the top cover is opened.

Cross reference

Group 3 Facsimile Manual: section 4-3-3

2. Error Conditions

LD Failure:

The mechanical control board de te cts an LD failu re when the laser power is

out of the specified ran ge . When this occurs, the machine warns the user on

the LCD panel (SC code 2-22).

2-9

July 30th, 1996 DETAILED SECTION DESCRIPTIONS

PRINTING

Mirror Motor Failure:

The machine detects a mirror mo to r error when the MCB does not detect the

line synchronization det ect or signal within 1 second of the mirror motor being

turned on. The machine also detects a mirror motor error when the mo to r

rotation is not within 8431.7 rpm ± 5% at 4.2 seconds after the motor turns on

or if the motor is not within 8431.7 rpm ± 3% for more than 0.5 second during

mirror motor operation. Since this e rror is detected with the line

synchronization detector signal, the machine may detect LD malfunct ion as a

mirror motor failure. When these errors occur, the machine warns the user on

the LCD panel (SC code 3-31).

Cross reference

Service Call Conditions: section 7-3

3. T oner Saving Mode

In this machine, toner saving is done by reducing th e nu mbe r of do ts actually

printed, not by varying th e de velo pment bias. In toner saving mode, the

image data is filtered through the following four-lin e mat rix.

1st line 1 0 1 0 1 0 1 0 1 0 . . . . .

2nd line 0 0 0 0 0 0 0 0 0 0 . . . . .

3rd line 0 1 0 1 0 1 0 1 0 1 . . . . .

4th line 0 0 0 0 0 0 0 0 0 0 . . . . .

(1: Actual data printed, black or white; 0: Always a whit e pixel)

Note: • Toner saving mode only works when prin tin g fa x me ssag es an d re-

ports. (However, toner saving is disabled when receiving a halftone mode message in NSF/NSS mod e. )

• When toner saving mode is selected, the print image density is

automatically set to "Norma l"; in some cases, the image may become invisible if the Lighter setting is used.

Cross Reference

Toner Saving Mode: User parameter 12, bit 2

Edge Enhancement

In toner saving mode, the mach ine prints a black pixel whenever the data

changes from white to black in the main scan direction. In this way, edges on

the image are printed more clearly.

2-10

DETAILED SECTION DESCRIPTIONS June 30th, 1996

PRINTING

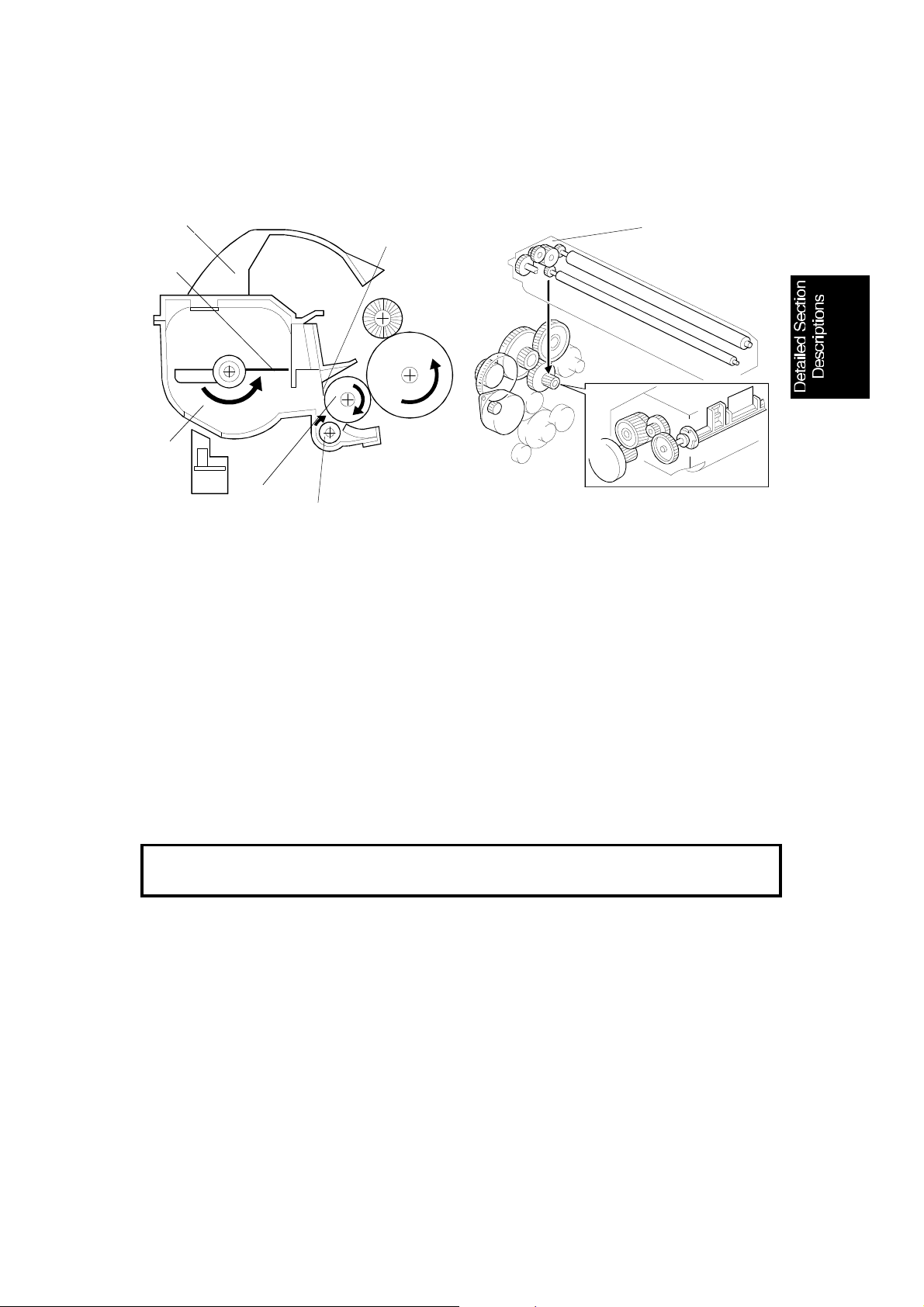

2.2.5. Development

1. Overview

[A]

[E]

[B]

[F]

[A]

[C]

[D]

H528D508.wmf

H528D507.wmf

This machine contains a develo pment toner magazine (DTM) [A] , which

contains the toner agita to r [ B] , development roller [C], toner supp ly roller [D],

doctor blade [E], and the toner tank [F].

At toner end, the entire DTM is replaced by the user.

There are two rollers in the DTM: the toner application roller [D] and the

development roller [C].

The toner agitator [B] stirs th e tone r and carries it to the toner supply roller

[D]. The toner is then carried from the toner supply roller to th e deve lop men t

roller. As the development roller turns past the docto r bla de [E ], only a thin

coating of negatively charg ed ton er pa rticle s stay ad he red .

Cross reference

Group 3 Facsimile Manual: section 4-4-2

During printing, a bias voltage of -280 V is applied to the developme nt roller

(when a print density setting of Normal is selected). The development bias

changes in accordance with the print density selection (user parameter 12,

Bit 3 and 4).

Since the laser exposed areas on the drum are reduced to -50 V, the toner is

trasnferred from th e de velo pment roller onto these areas of the latent image

as they turn past the drum.

There is no DTM detection in this machin e.

2-11

July 30th, 1996 DETAILED SECTION DESCRIPTIONS

PRINTING

2. Development Bias

[D]

[A]

[B]

[C]

H528D516.wmf

The high voltage power supply [A] ap plie s different voltages to the

components of the DTM. The applied voltages are:

• Development roller: -280 V [B] (dep en din g on the user’s print densit y

selection)

• Doctor blade: -550 V [C]

• Lower casing: -287 V [D]

The toner is negatively charged by the friction generated by the toner ag ita to r.

2-12

[B]

DETAILED SECTION DESCRIPTIONS June 30th, 1996

PRINTING

3. Toner End Detection

The toner end sensor [A] (a

reflective photosensor) is located

under the DTM. When the toner is

almost empty, the sensor’s light is

reflected by the mirror [B] at the top

of the toner tank. The machine

monitors this sensor only when the

main motor is on. If the sensor

detects the reflected ligh t 5 time s in

a row, within a specified period, the

MCB detects a toner near end

condition, and informs the FCU. Th e

machine can then print 10 0 more

sheets, at which time the FCU

disables printing (tone r end

condition). At this time the DTM

must be replaced.

2.2.6. Paper Feed

1. Paper Path

[B]

[A]

H528D508.wmf

[A]: Paper Pick-up Roller

[B]: Paper Feed Unit Pick-up Roller

[C]: Registration Sensor

[D]: Paper Exit Sensor

[E]: Paper End Sensor

[F]: Standard Tray

[G]: Optional Paper Feed Unit

[E]

[F]

[G]

[D]

[C]

[A]

H528D547.wmf

2-13

Loading...

Loading...