Page 1

Technical Bulletin No. F/L Series-001

SUBJECT: Introduction of the New Tools for ROM/RAM Data Change

PREPARED BY: Y. Okunishi

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

The following service tools have been de velo pe d to chan ge ROM a nd RAM dat a fo r F/ L serie s

machines.

1. RRW ( Remote ROM Writer )

Software in ROM can be changed remo te ly sin ce a Flash ROM is use d fo r F/L series machines.

The RRW is a software package that runs in a Personal Computer with an external class 1

modem of a type recommended by Ricoh and can change the RO M dat a in F/L series

machines through th e te lephone network.

Please contact Ricoh to order t he RRW. It will be rele ase d in May 1995 .

FROM: 2nd T.S. Section

MODEL:

DATE:

Apr. 30, 19 95

FX6, FX4, LSO

2. RDS Version 2.0

The new RDS Version 2.0 runs in a Personal Comp ut er with an external class 1 modem of a

type recommended by Ricoh and can change RAM data such as Quick Tel. Numb ers,

Bit switches, RTI etc. ... in remo te fax mach ines made by Ricoh through the tele phon e network.

This RDS can also change ROM data in Ricoh made fa x machines that use flash ROMs.

Please contact Ricoh to order RDS Versio n 2.0. It will be rele ase d in Jun e 1995 .

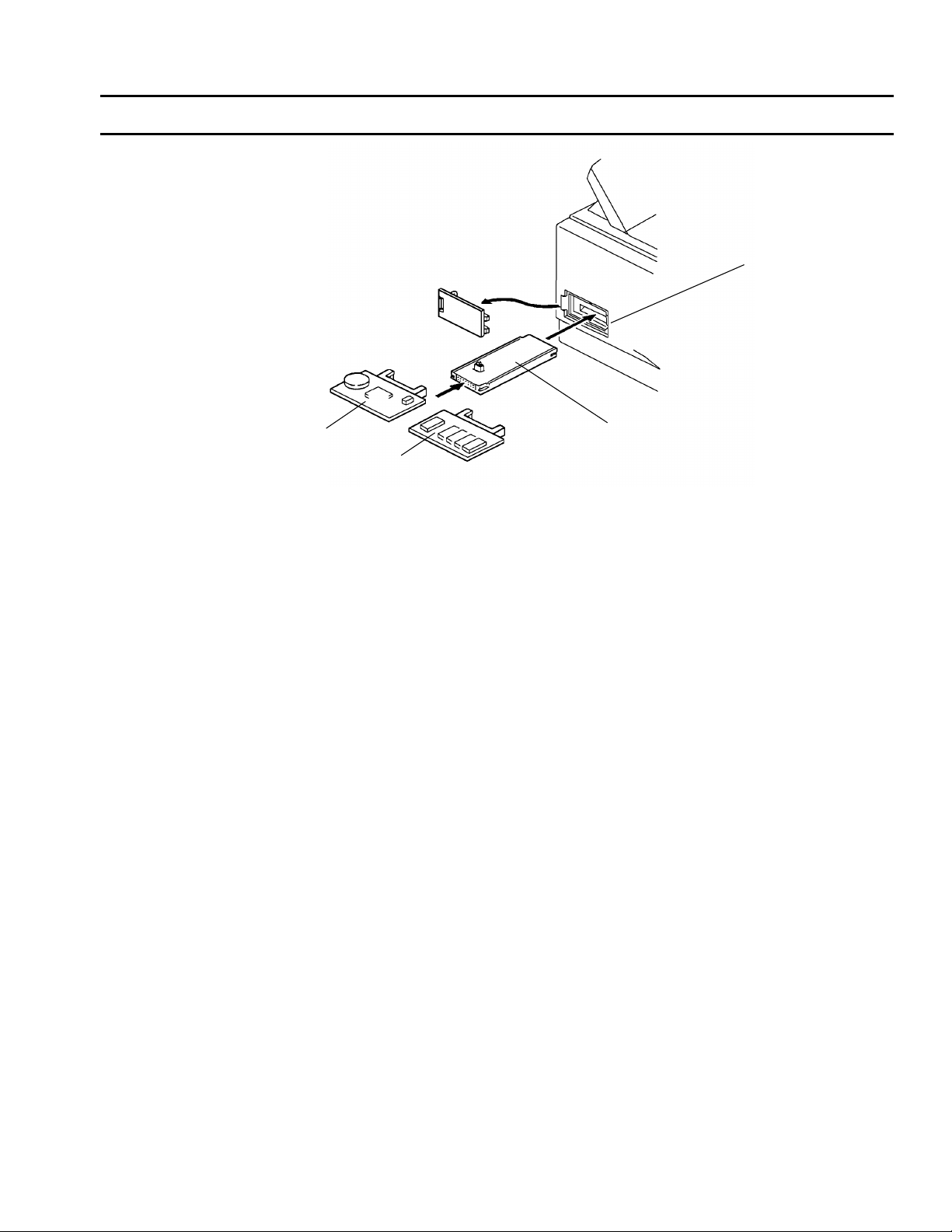

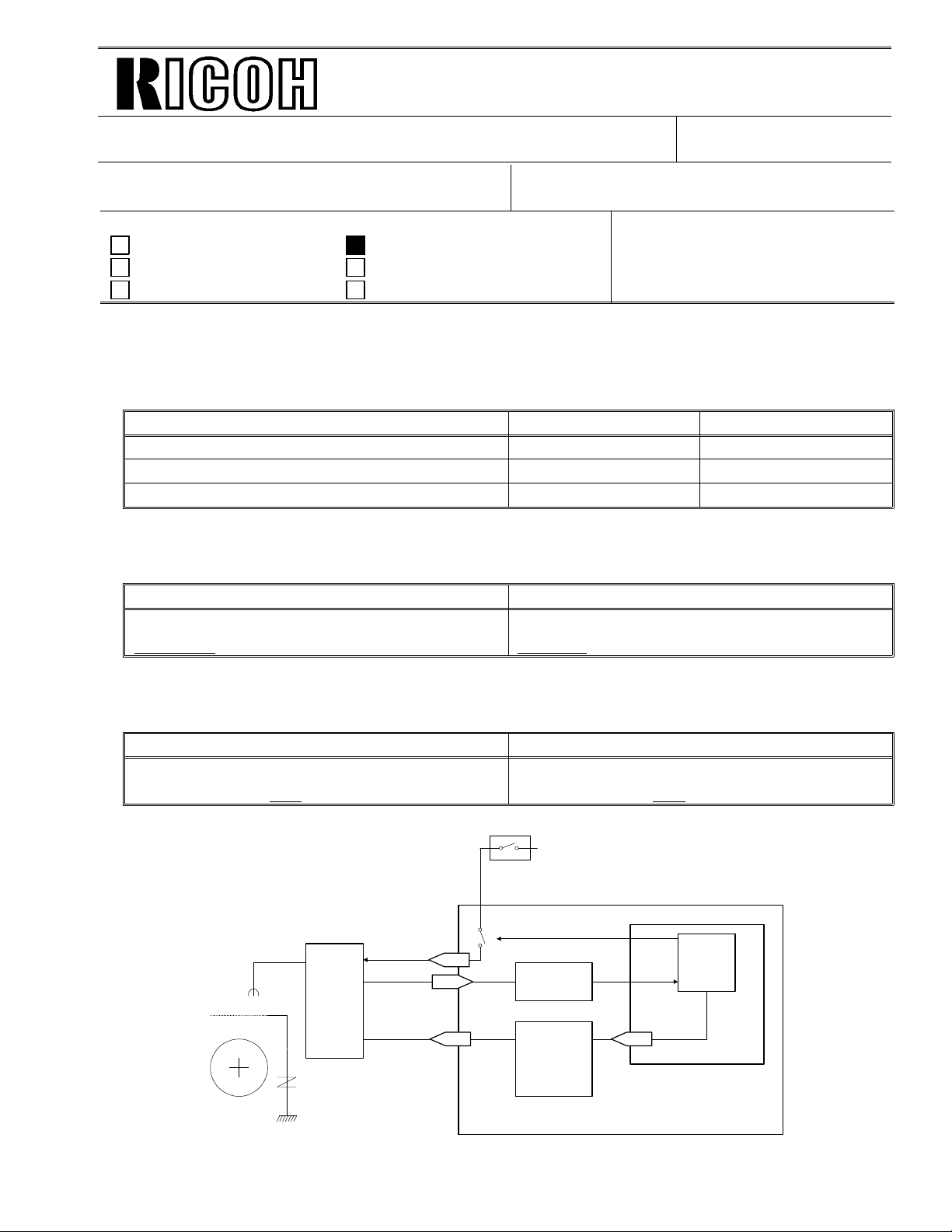

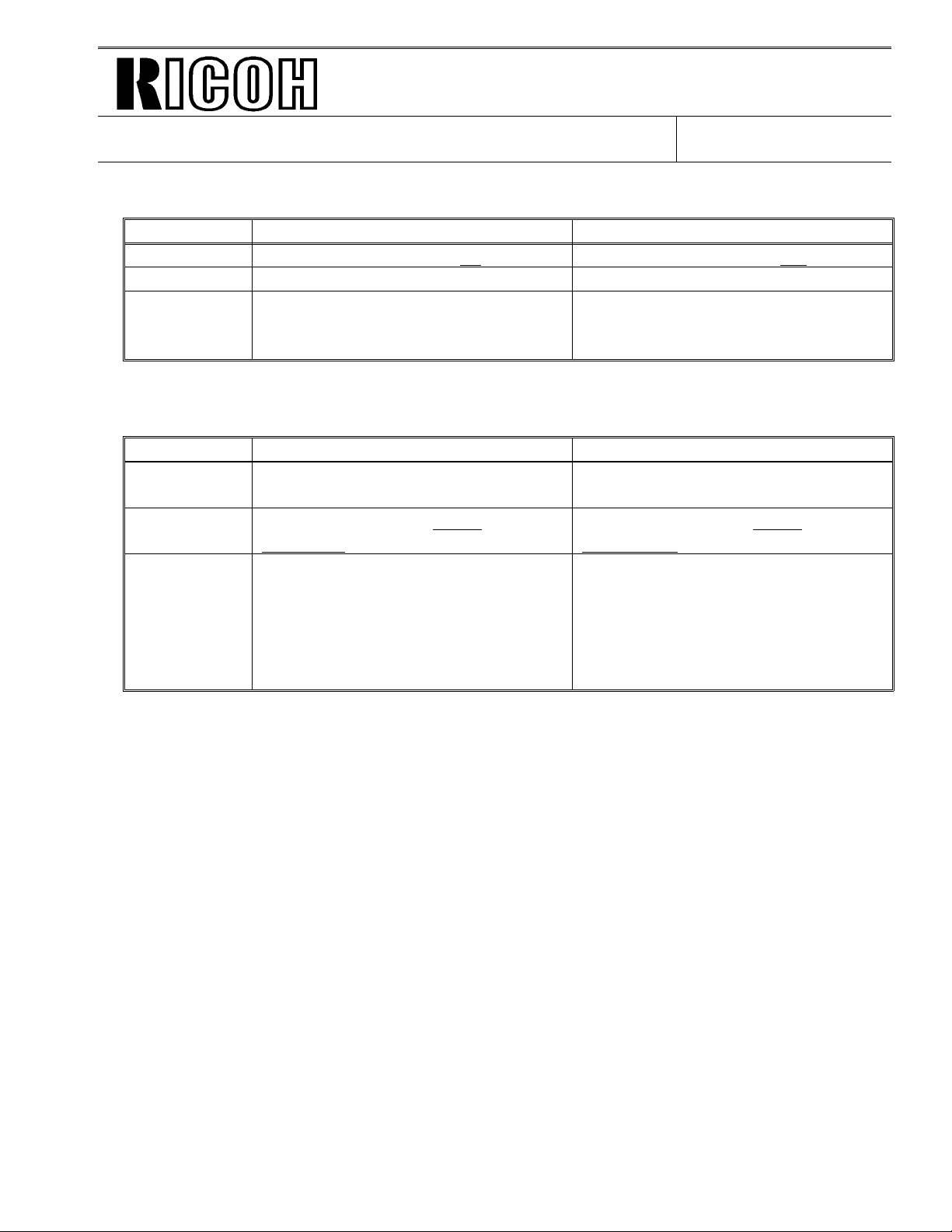

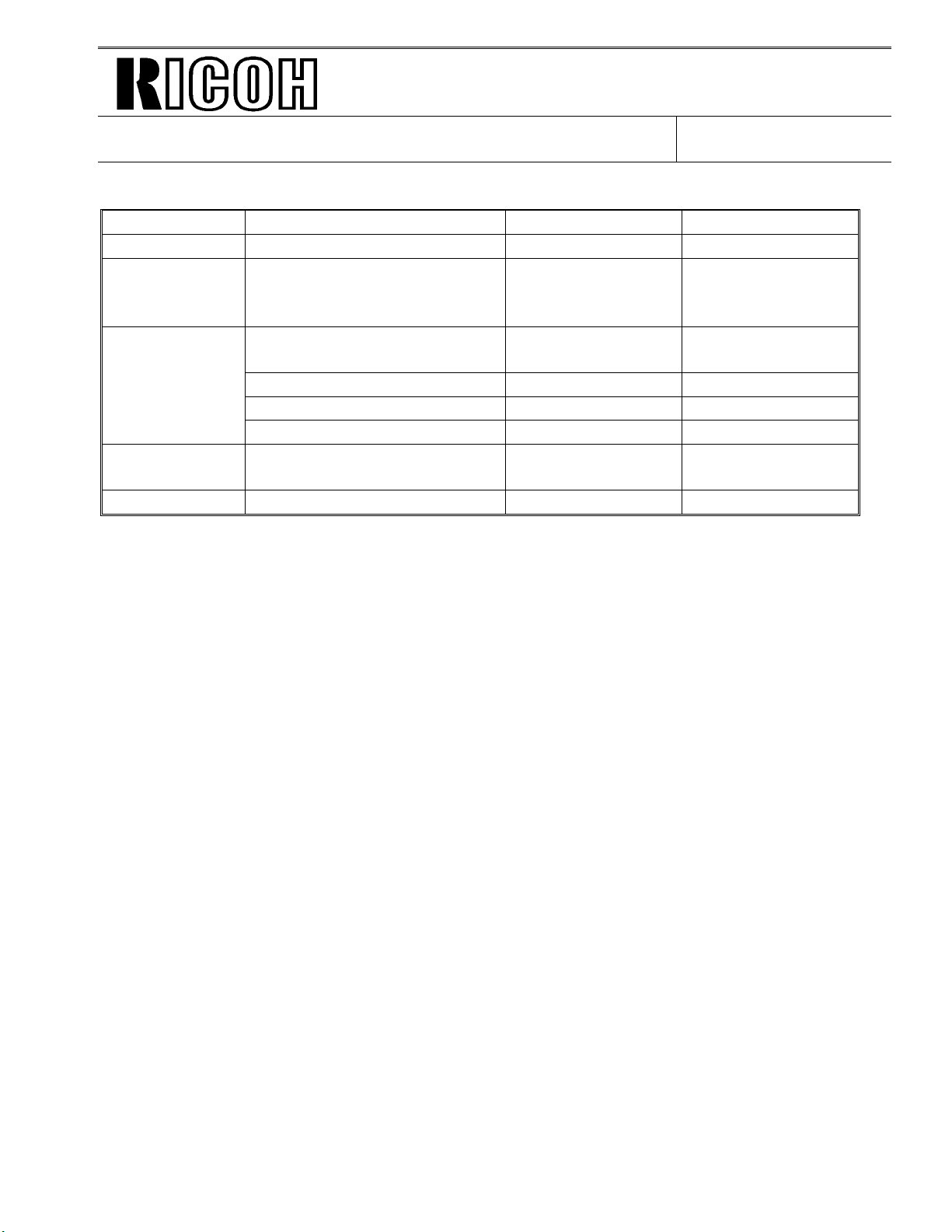

3. Flash ROM/SRAM Copy Tool ( P/N: H5159100 )

This is an interface card between the FCE inside the machin e an d an FCE outside the machine.

There are three purposes for this tool.

[1] Transferring user data in the RAM su ch as Qu ick Tel. Numb ers, Bit Switches, etc. ...

in an FCE removed from a defective machine to a new FCE installed in the machine.

[2] Updating the ROM inside the machine from an FCE or EPROM Board outside the machine

without replacing the ROM.

[3] Copying the ROM data inside the machine into the ROM on an FCE outside the machine.

This tool is available at the Spare Parts Center.

Page 2

Technical Bulletin No. F/L Series-001

SUBJECT: Introduction of the New Tools for ROM/RAM Data Change

4. EPROM Board

This is a tool for updating the ROM inside the machine without repla cing the ROM.

Programmed EPROM(s) can be installed on the EPROM board .

The EPROM Board is connected to the Flash ROM/SRAM Copy Tool and the data in the

EPROM is transferred to the Flash RO M inside the machine through the Flash ROM/SRA M

Copy Tool.

Please contact Ricoh to order EPROM Board.

DATE:

Apr. 30, 19 95

Page 3

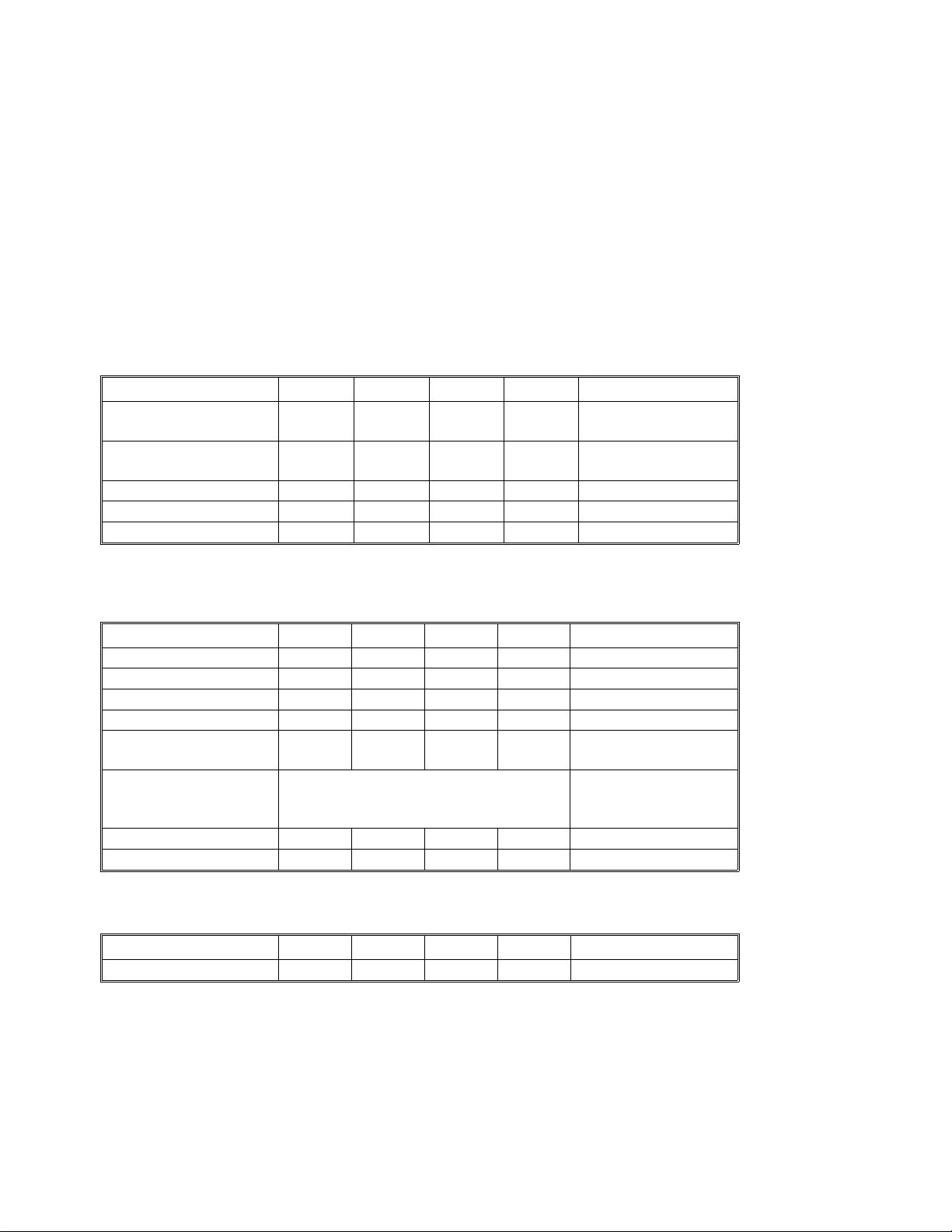

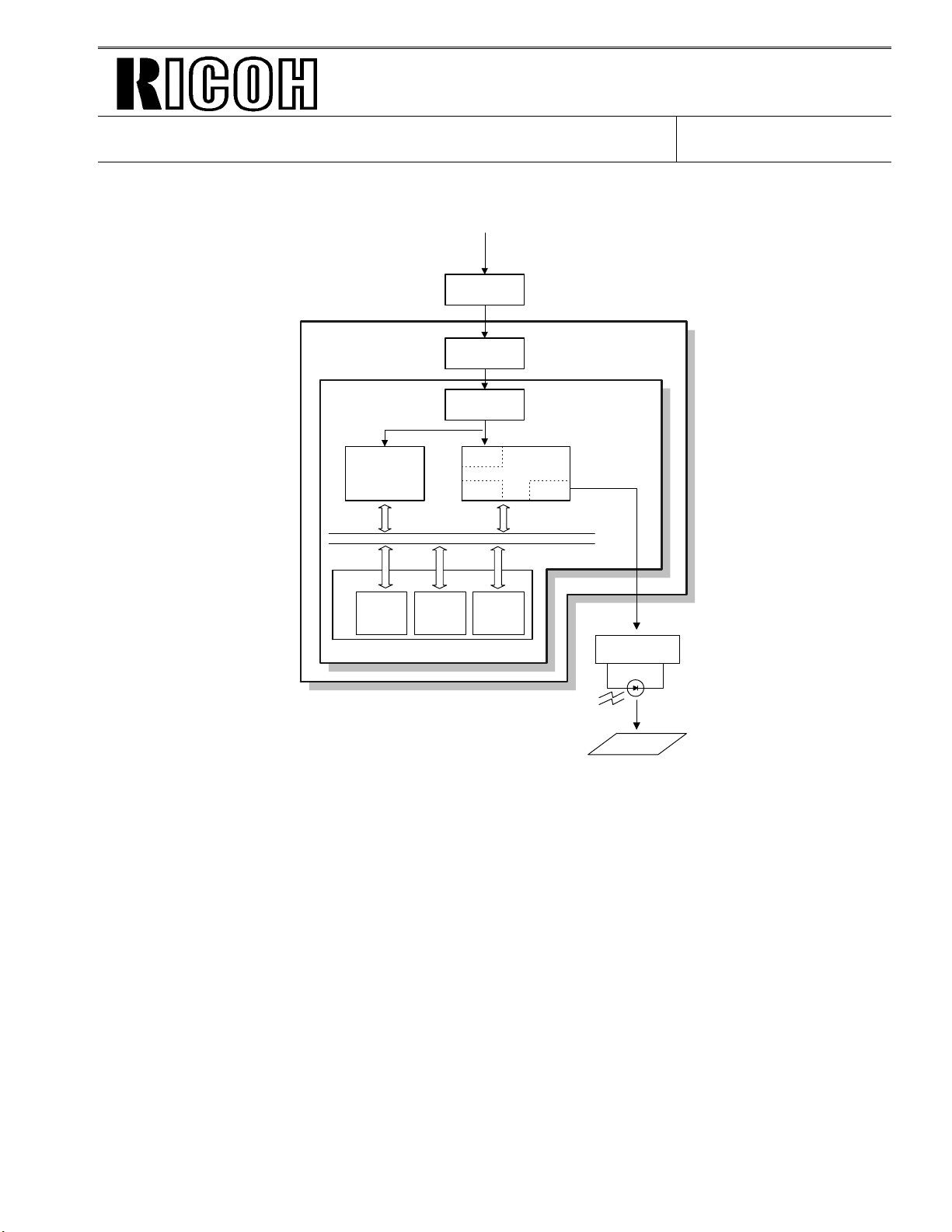

Data Copy Tools for the F/L Series

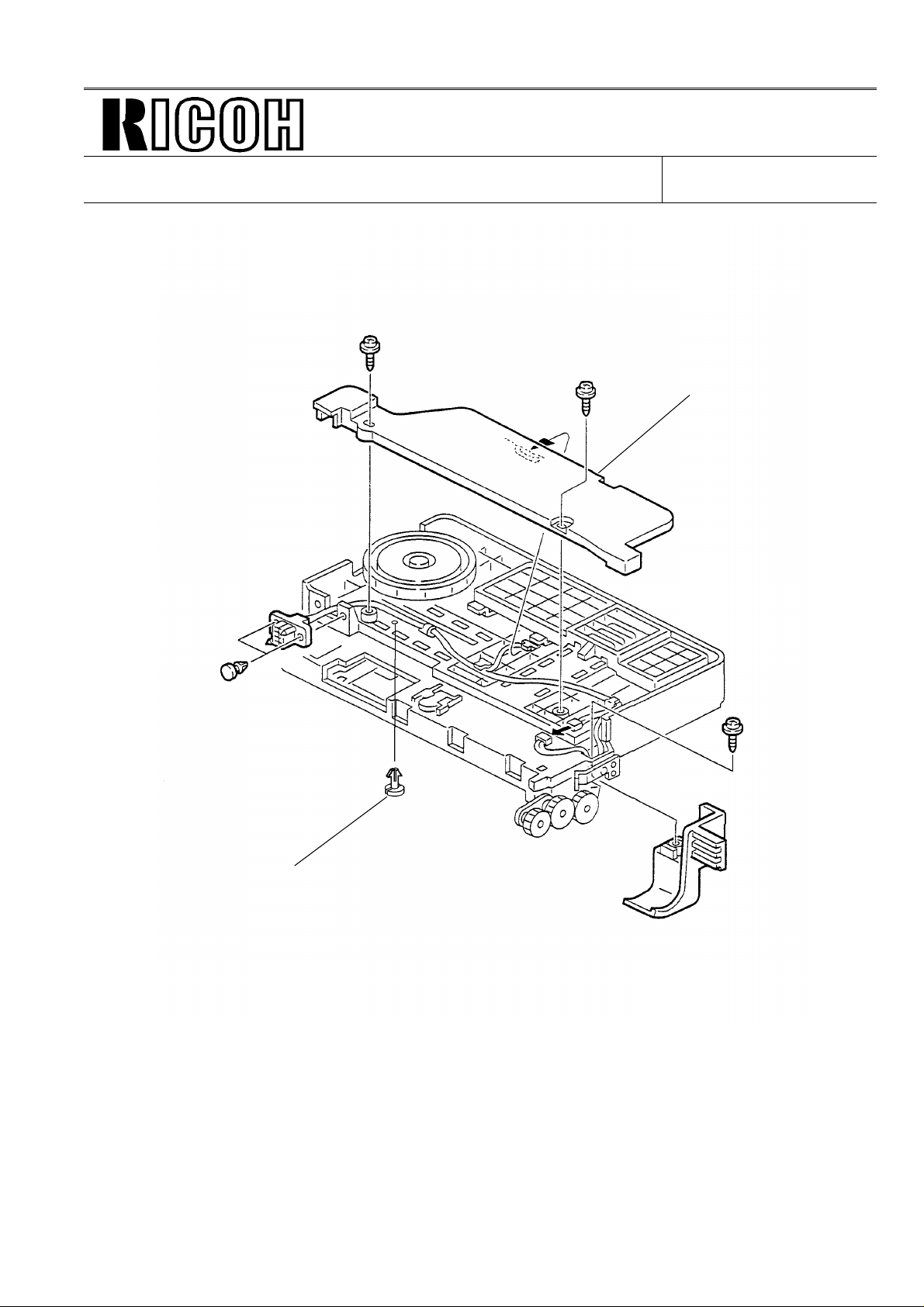

[A]

April 21st, 1995

[D]

[B]

[C]

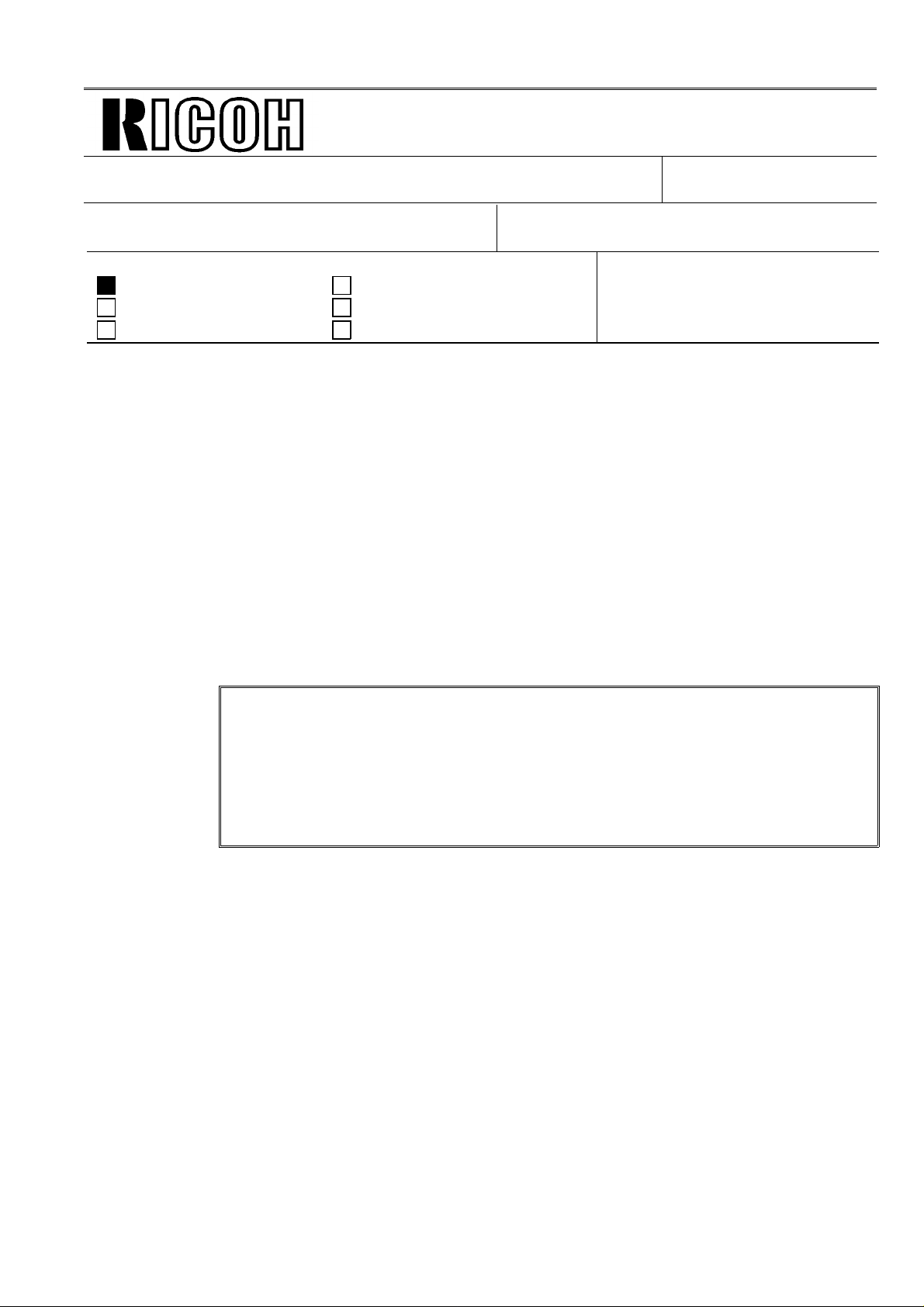

A: Flash ROM / SRAM Copy Tool (H515 9100)

B: PCB-FCE

C: EPROM Board

D: Memory card slot

Note: In the LSO, the

NCU Cover, Front Cover

and Left Cover have to be

removed to set the Flash

ROM/SRAM Copy Tool.

The Flash ROM / SRAM Copy Tool [A] is inserte d int o the memory card slot [D],

then the FCE [B] or EPROM Board [C] with new software is connected to the opposite side

of the tool.

ROM Data Download

This function copies soft ware from an exte rnal medium to the Flash ROM on the machine’s

FCE. The external medium for the new sof twa re can be an FCE [B] or an EP ROM Board [C].

ROM Data Upload

This function copies the soft ware from the machine’s built-in FCE to an ext ern al FCE [B ].

This function does not work with an EPRO M Boa rd [C] .

SRAM Data Download

This function copies all the dat a stored in the SRAM on an external FCE [B] to the ma chin e’s

FCE. Use this after replacing a damaged FCE to save any previous settings that were

programmed in the damaged FCE.

Page 4

Note:

1) SRAM data upload is not available .

2) Refer to the service manual for the opera tio n pro cedure.

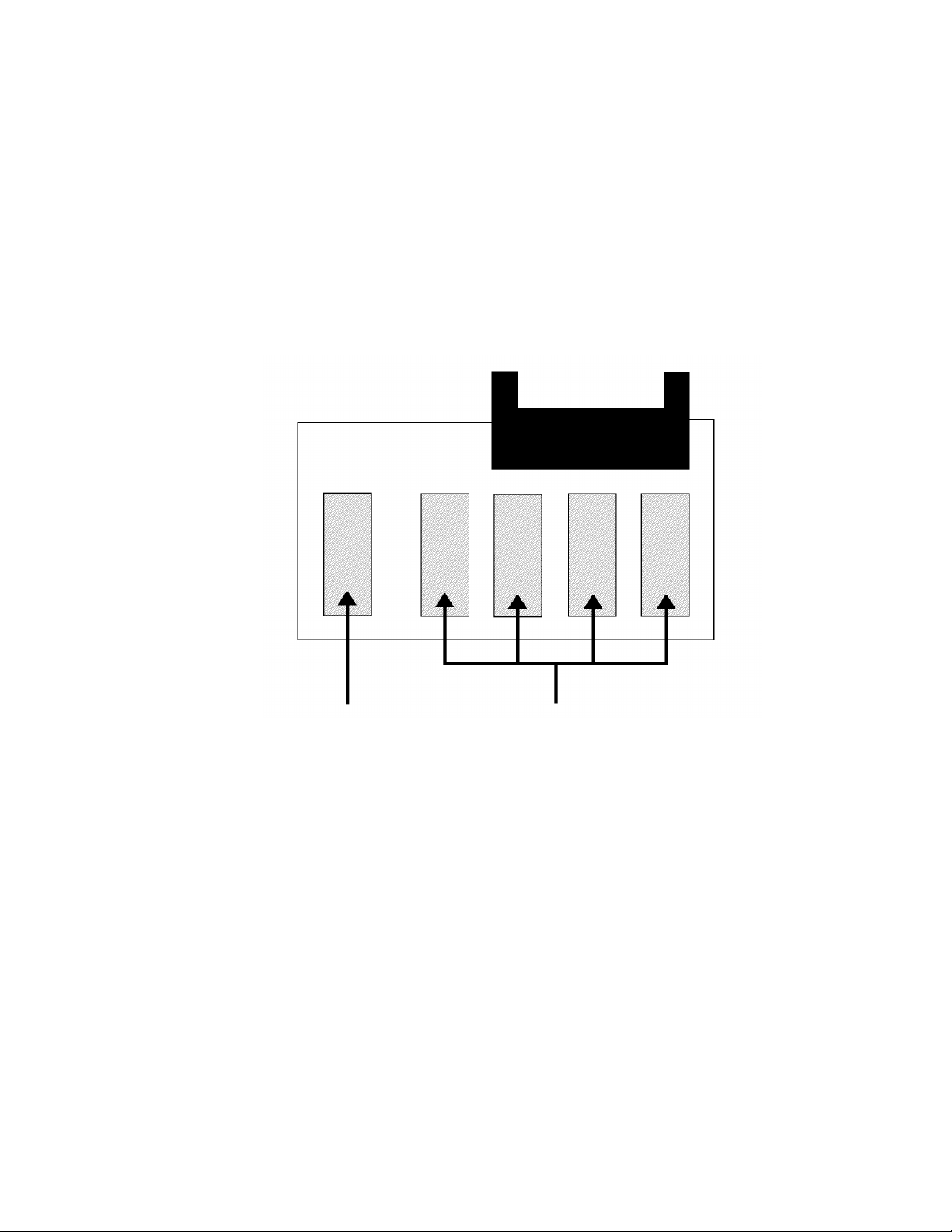

3) The blank EPROM (P/N H082 7110) wh ich is 150 ns or 120n s spee d fo r the CFO can be

used for the FX4. However, it cannot be used fo r t he FX6 an d the LSO.

The blank EPROM (P/N 19050020) which is 100ns spee d can be used fo r the FX6,

the LSO, and the FX4.

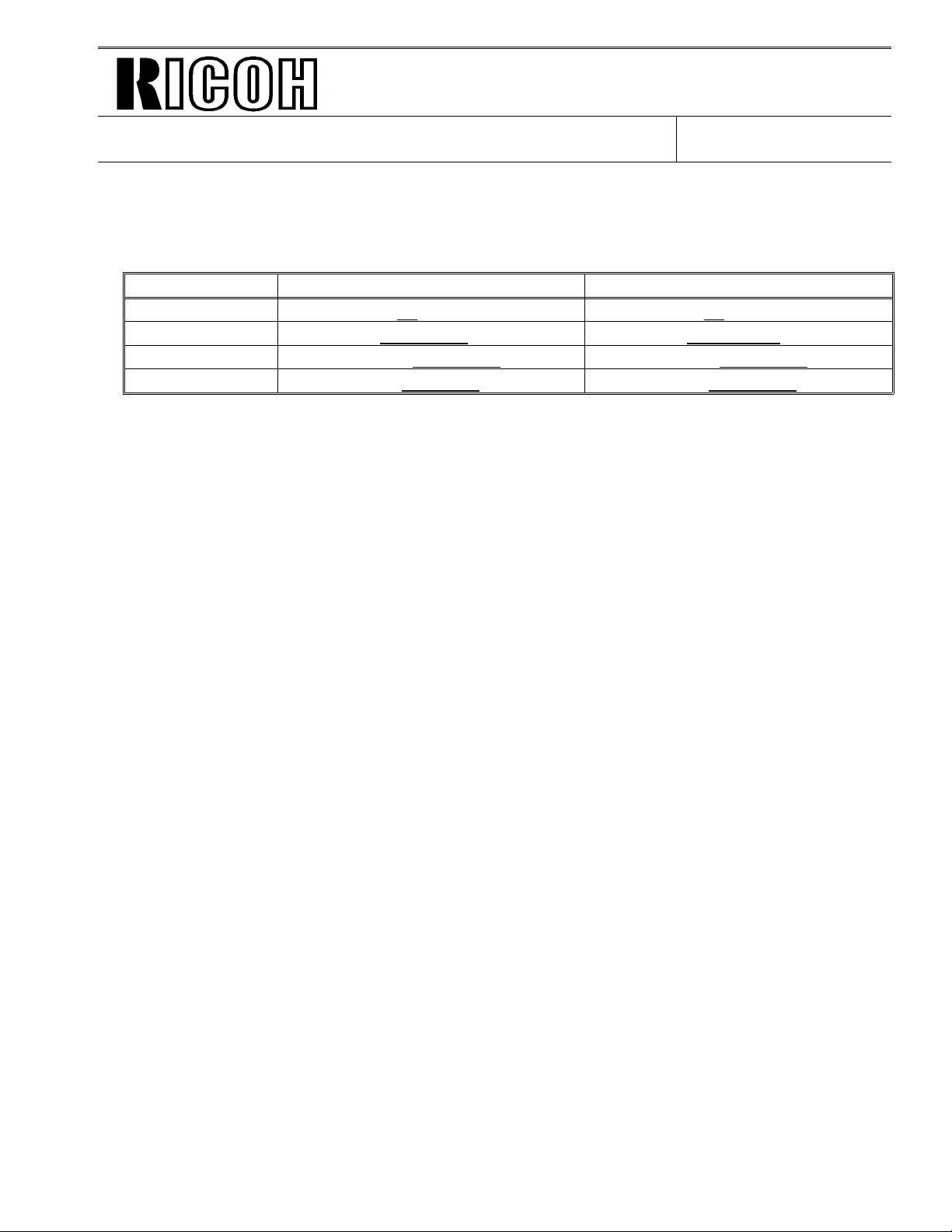

SLOT

EPROM BOARD

6 5 4 3 2 1

FX6 / LSO EPROM (1)

FX4 EPROMs (4)

Page 5

Technical Bulletin No.F/L Series-002

SUBJECT: Fax FX6CD (FAX2400L) Information DATE: June 30, ’95

PAGE: 1 of 1

PREPARED BY: K. Misugi

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

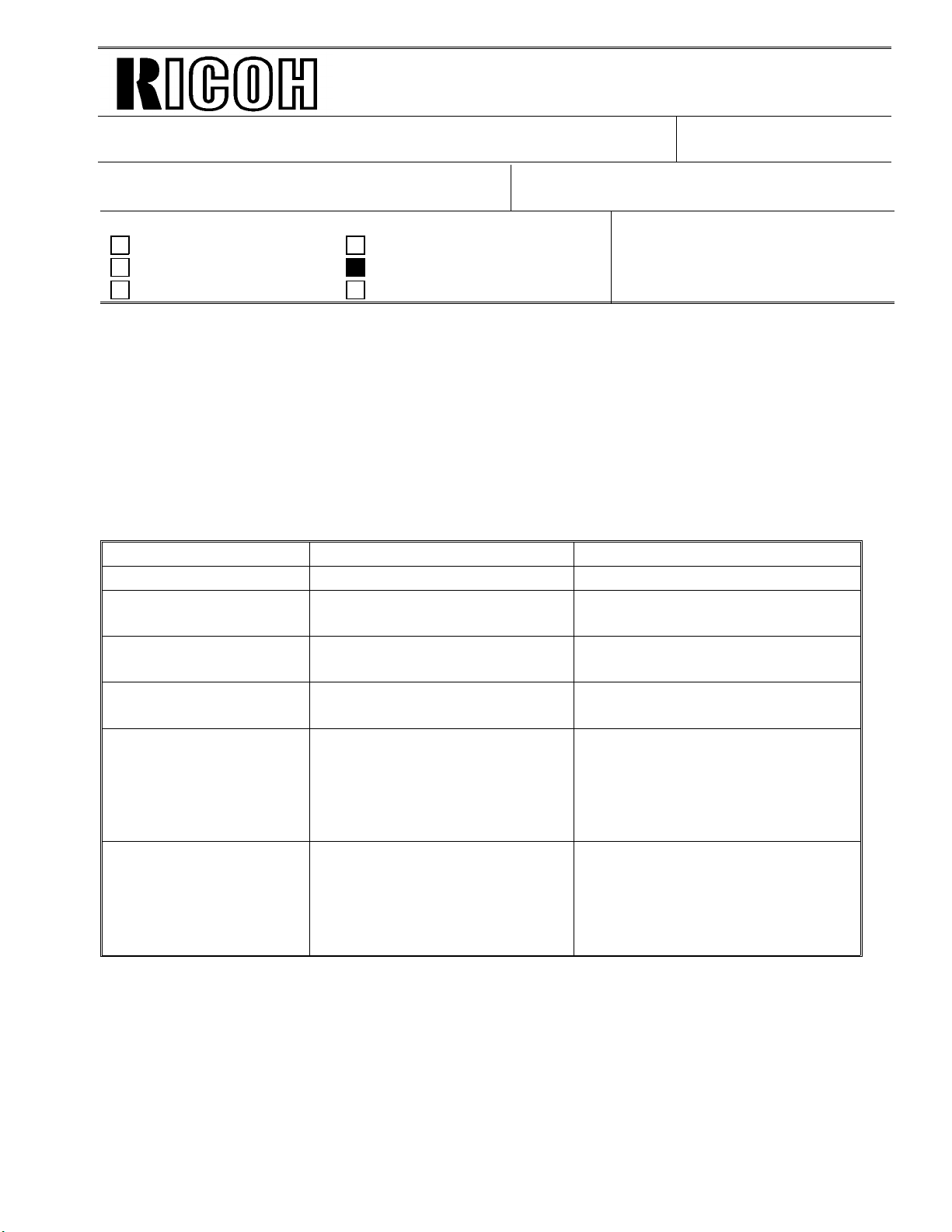

The new model FX6CD has been released in the line-up of FX6 (FAX 2700L) series.

The FX6CD is almost the same as the FX6. Please see the folllowing table for the

differences in specifications between the two machines.

Optional 100 sheet cassette Available Not Available

Optional Mech. Counter Available Not Available

Bypass Feeding Available Not Available

SAF Memory Backup Available Not Available

Stamp Available Not Available

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

FAX 2400L

FX6 FX6CD

The following parts for the FX6CD are different from the FX6.

Index Name

FX6 FX6CD

1 PCB - FCE H5166002 H5276002

2 PCB - FDU H5166003 H5276003

3 Manual Feed Table H5163437 H5273437

4 Cover - Operation Panel H5164221 H5274221

5 Stamp Solenoid H5155005 Not used

6 Harness - 100 sheet cassette H5155085 Not used

7 Polygonal Mirror Motor H5215061 H5275061

8 Laser Plotter Unit H5212040 H5272040

9 Operator’s Manual H5168600 H5278600

Note:

Since the stamp is not available in the FX6CD, the Stamp Key on the operation panel is

used as the Printer Function Key when the optional printer interface unit is installed.

Please refer to the operation manual for details.

Part Number

Page 6

Technical Bulletin No. F/L Series-003

SUBJECT: Service Manual Corrections

DATE:

June 30, 1995

PREPARED BY: Y. Furuya

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required Revision of service manual

FROM: 2nd T.S. Section

MODEL:

FX6

Troubleshooting Information only

Retrofit Information Other

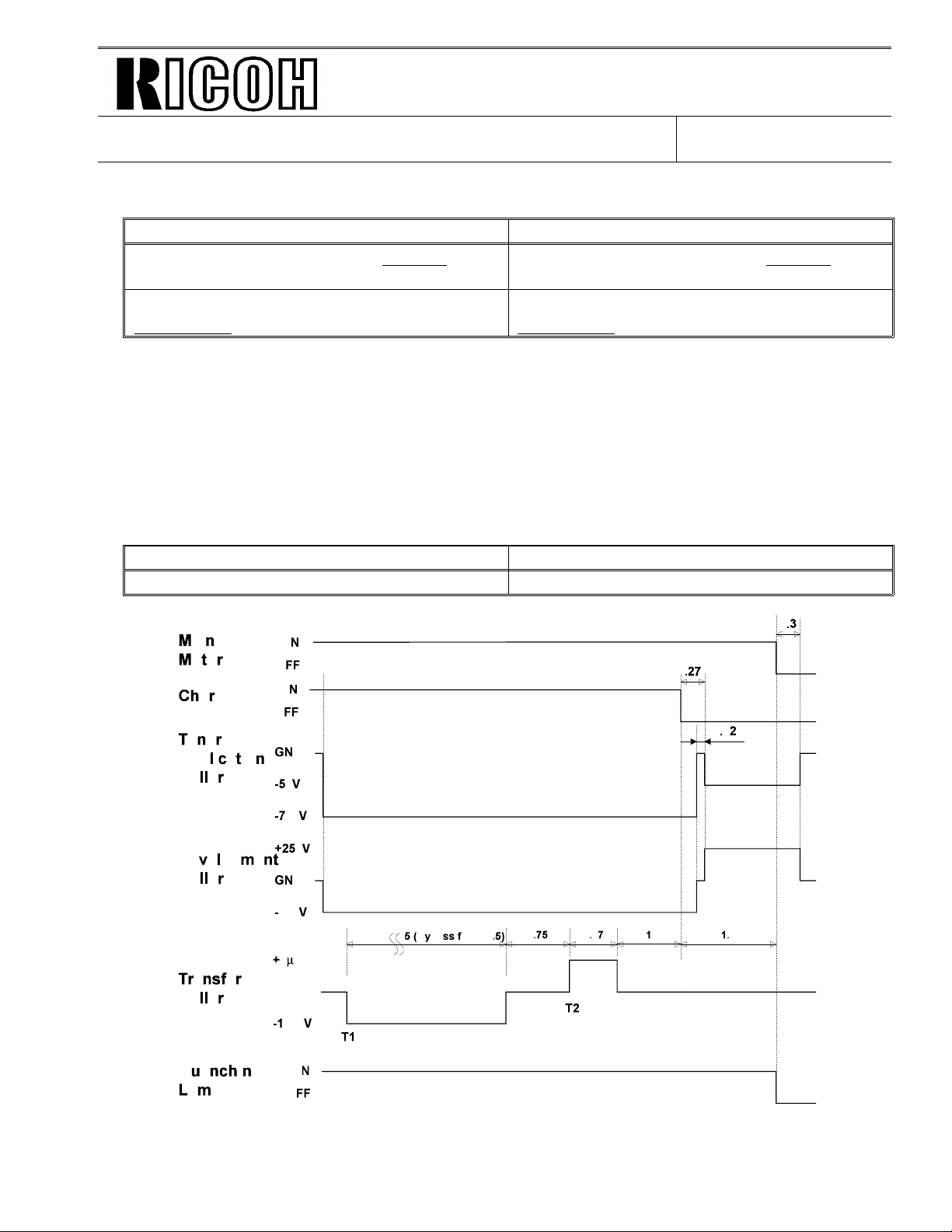

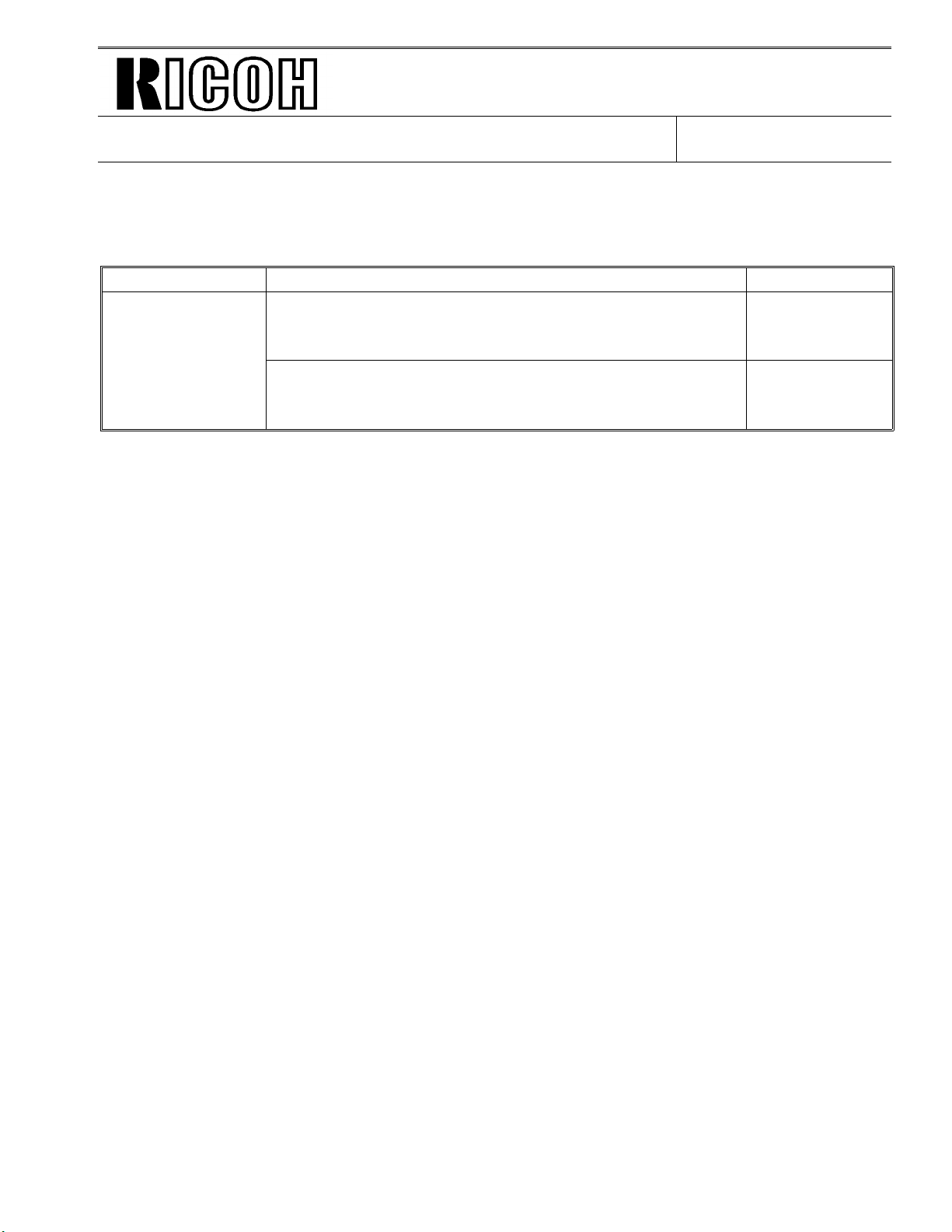

Chapter 2

Section 2.2.1. Printing Process - Overview

Wrong Correct

Charge bias current and voltage -5.4 kV/ 305 µA -5.3 kV/ 300 µA

Zenor diode voltage 715V 698V

Transfer current +5 µA+4 µA

Section 2.2.2. OPC Drum

Wrong Sentence Correct Sentence

The toner application roller .. .. ., and

transport roller [E] are ...

Section 2.2.3. Charge

Wrong Sentence Correct Sentence

The corona wire [A] generate s ... . (th e

voltage is about -5.4 kV).

Power

Pack

-698 V

24VM

Leak Signal

Charge

21-1

21-8

21-3

The toner application roller ....., and

transfer roller [E] are ...

The corona wire [A] generate s ... . (th e

voltage is about -5.3 kV).

Fusing Unit Cover

Interlock Switch

ON/OFF

IC8

EXIO

IC4

Power

Pack

Driver

1-43

CPU

FCE

FDU

H516D557.wmf

Page 7

Technical Bulletin No. F/L Series-003

SUBJECT: Service Manual Corrections

DATE:

June 30, 1995

Section 2.2.4. - 2. Block Diagram

Wrong Sentence Correct Sentence

The LIF block in the .... . (FDU CN26-6) and

transfers ...

Speed of hexagonal mirror motor is:

7977.9 rpm

The LIF block in the .... . (FDU CN26-2) and

transfers ...

Speed of hexagonal mirror motor is:

7977.8 rpm

Section 2.2.7. Paper Feed - 1. Overview

Delete the following sentence from the first paragraph.

“The bypass feed slot can only be used in copy mode.”

Section 2.2.9. Transfer and Separatio n

Wrong Sentence Correct Sentence

A constant current of +5 +/- 0.2 µA is ... A const an t curre nt of +4 +/- 0.2 µA is ...

H516D563.wmf

Page 8

Technical Bulletin No. F/L Series-003

SUBJECT: Service Manual Corrections

DATE:

June 30, 1995

Section 2.2.11. Fusing - Service Call Conditions

Wrong Correct

Sub-code 05 ... more than 40 seconds ... ... more than 18 seco nds ...

Sub-code 02 ... to reach 150 deg.C from ... ... to reach 165 deg.C from ...

Sub-code 01 ... stays above 175 deg.C for ... ... stays above 190 deg.C for ...

Sub-code 03/04 ... go down to the standby

temperature when ...

... go down to 100 deg.C when ...

Chapter 3

Section 3.2. INITIAL PROGRAMMING

Add “Protocol Requirements (G3 Bit Switch 0B) - Function 01” in the “Items to Program

(Service Level)“ section. This is because these bit switch es must be enabled manu ally at

installation.

Chapter 4

Section 4.1.20. Software Download (Function 12) - Step 9

Section 4.1.21. Software Upload (Function 1 2) - Step 8

Section 4.1.22. SRAM Data Download (Function 12) - St ep 9

Wrong Sentence Correct Sentence

Turn off the machine, then turn it back on. Turn off the mach ine and disconnect the

tool. Then turn the mach ine back on .

Page 9

Technical Bulletin No. F/L Series-003

SUBJECT: Service Manual Corrections

Section 4.2. BIT S WITCHES

Switch Bit No. Wrong Correct

Third and fourth numbers:

... The left hand figure is the

low byte and the right hand

System 00 2

System-0F 0 - 7

G3-03 3

G3-08 0 - 3

G3-0B 0 - 5

figure is the high byte. ...

Cross reference NCU parameter 00

1: ECM reception is disabled,

which enlarges the SAF

memory.

Not used. PABX cable equalizers

These bits are automatically

set to the appropriate settin gs

after a country code (S yste m

Switch 0F) is programmed.

DATE:

June 30, 1995

Third and fourth numbers:

... The left hand figure is th e

high byte and the right hand

figure is the low byte. ...

Refer to “How to calculate the

rx level listed on the TCR

(Journal)“ below, for details.

Cross reference NCU parameter CC

1: The machine transmits with

a frame size of 64 bytes in

ECM. Set this bit to 1 when the

other terminal only has only a

64 byte frame size.

The bit assignments are

completely the same as PSTN

cable equalizer (G3 switch 07).

Manually program these bit

switches to match local

requirements.

How to calculate the rx lev el listed on the TCR (Journal)

Example: V29 96 L 01 0C 00 00

High byte

If bit 2 of system switch 00 is set to 1, the 4-digit hexadecimal value (=N) after t he lett er “L”

indicates the rx level. The calculation to get the actual rx level is given belo w.

[ Rx

level

(−dB) ] =

In the above example, the decima l va lue of 010C (H) is 268.

So, the actual rx level is -16.75 dB.

Decimal value of N

Low byte

16

Page 10

Technical Bulletin No. F/L Series-003

SUBJECT: Service Manual Corrections

Section 4.3. NCU PARAMETERS

Address (H) Wrong Correct

807F00 Function 08 (parameter 00) Function 08 (parameter CC)

807FA1/FA2 Factory setting: 2100 Hz See Note 2.

If the addresses for t one de te ction

Notes - 2

parameters contains FF(H), tone

detection is disabled.

Section 4.5. SERV ICE RAM ADDRE SSES

Address (H) Wrong Correct

80001E

8003AD

8003B2

8003FD

to

800404

Setting (1, 1, 1, 0) is Legal

sideways

Bit assignments:

Bits 0 to 2: Not used.

Unit of the update counter is

hexadecimal.

Setting (1, 1, 1, 0) is Legal

lengthwise

Bit assignments:

Bit 0: Edge detection du ring the

halftone process 0:Off, 1: On

Bit 2: Edge detection threshold

during the halfton e pro cess

0: Normal, 1: High

DATE:

June 30, 1995

Page 11

Technical Bulletin No. F/L Series-003

SUBJECT: Service Manual Corrections

Chapter 5

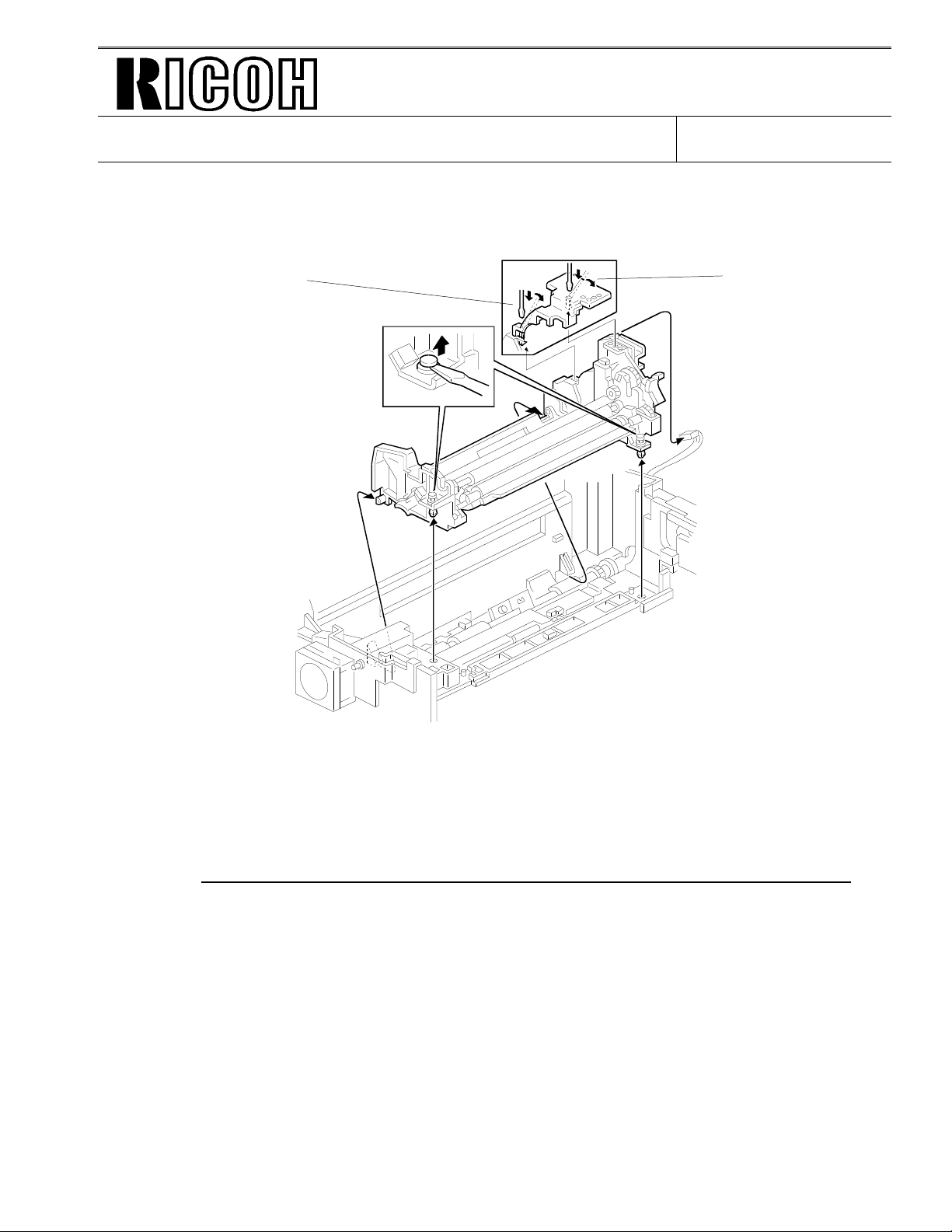

Section 5.6. DEVELOPMENT UNIT

[A]

DATE:

June 30, 1995

[B]

H516R521.wmf

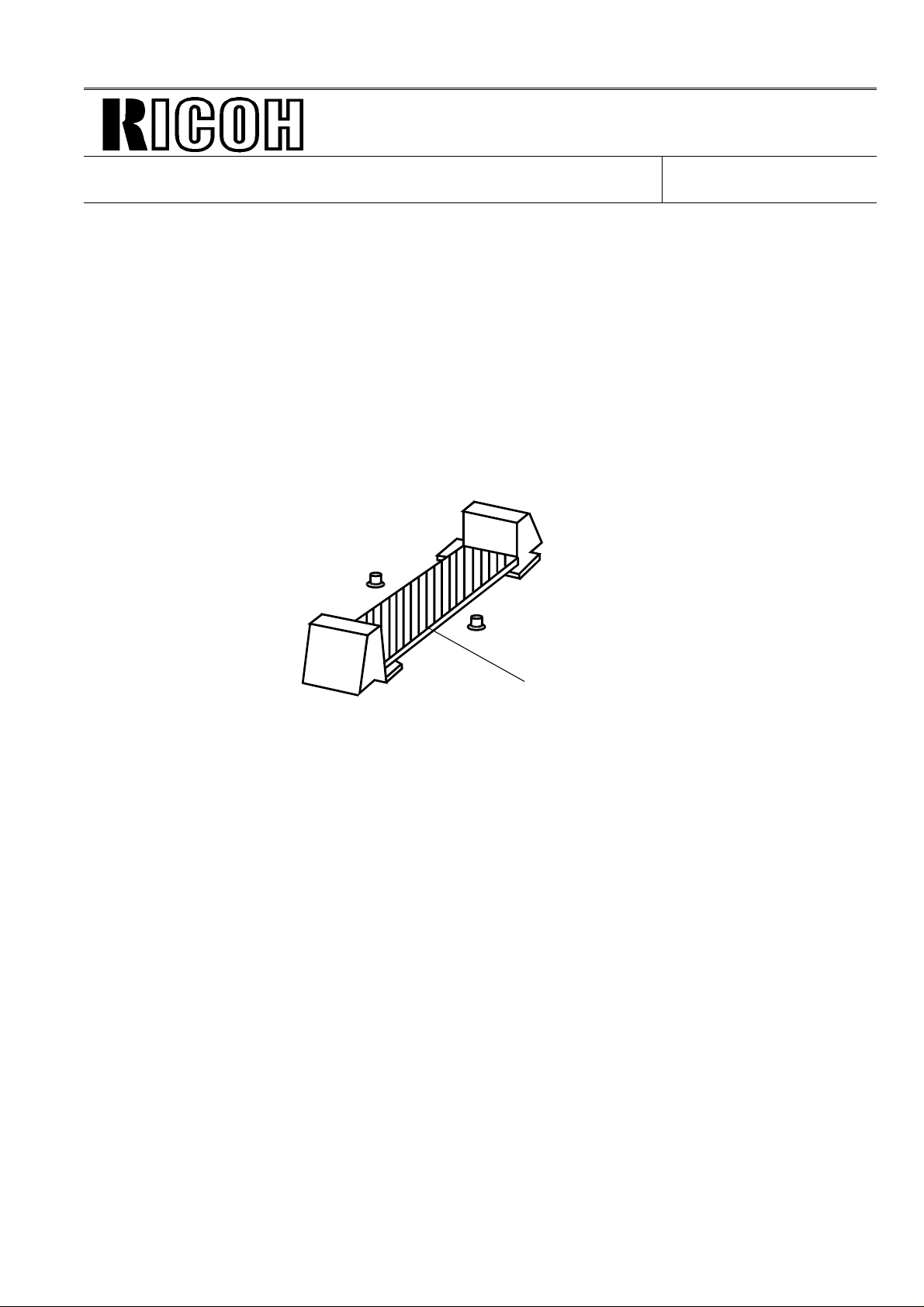

Use a small ( -) screw driver to release the ho oks [A ] an d [B] off the developme nt unit.

Section 5.9.3. Power Pack

Add a note “Do not touch the dials on the power pack when replacing the power pack.”

The three dials on the power packs are to be seale d with plast ic. However, the power packs

that were produced earlier do not have plastic seals on the dials. If you have power packs on

which the dials are not sealed, be caref ul no t to turn the dials.

Section 5.12.3. Margins (Main Scan Direction) - Parameter W1

Delete the following sentence from “Formu la”:

“2. How a setting affe cts printer interface outp ut. W1PIF = (Current settin g x 0.5 )/ 0.68 mm”

Page 12

Technical Bulletin No. F/L Series-003

SUBJECT: Service Manual Corrections

DATE:

June 30, 1995

Chapter 6

Section 6.3. SERVICE CALL CONDITIONS - Fusing Unit Failure

Wrong Correct

Sub-code 05 ... more than 40 seconds ... ... more than 18 seco nds ...

Sub-code 02 ... to reach 150 deg.C. ... to reach 165 deg.C.

Sub-code 01 ... stays above 175 deg.C for ... ... stays above 190 deg.C for ...

Sub-code 03/04 ... fall back to 80 deg.C. ... fall back to 100 deg.C.

Section 6.4. ERROR CODES - Error Code 0-24

Delete the followin g sentences from “Suggest ed Cause/Action”, because there is no such

adjustment available.

“Try changing the post-message command tx timin g.”

“Cross reference: Post message command tx timing”

Page 13

Page 1/1

Technical Bulletin No. F/L series-004

SUBJECT: Possibility of paper misfeed

PREPARED BY: T. Kimura

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

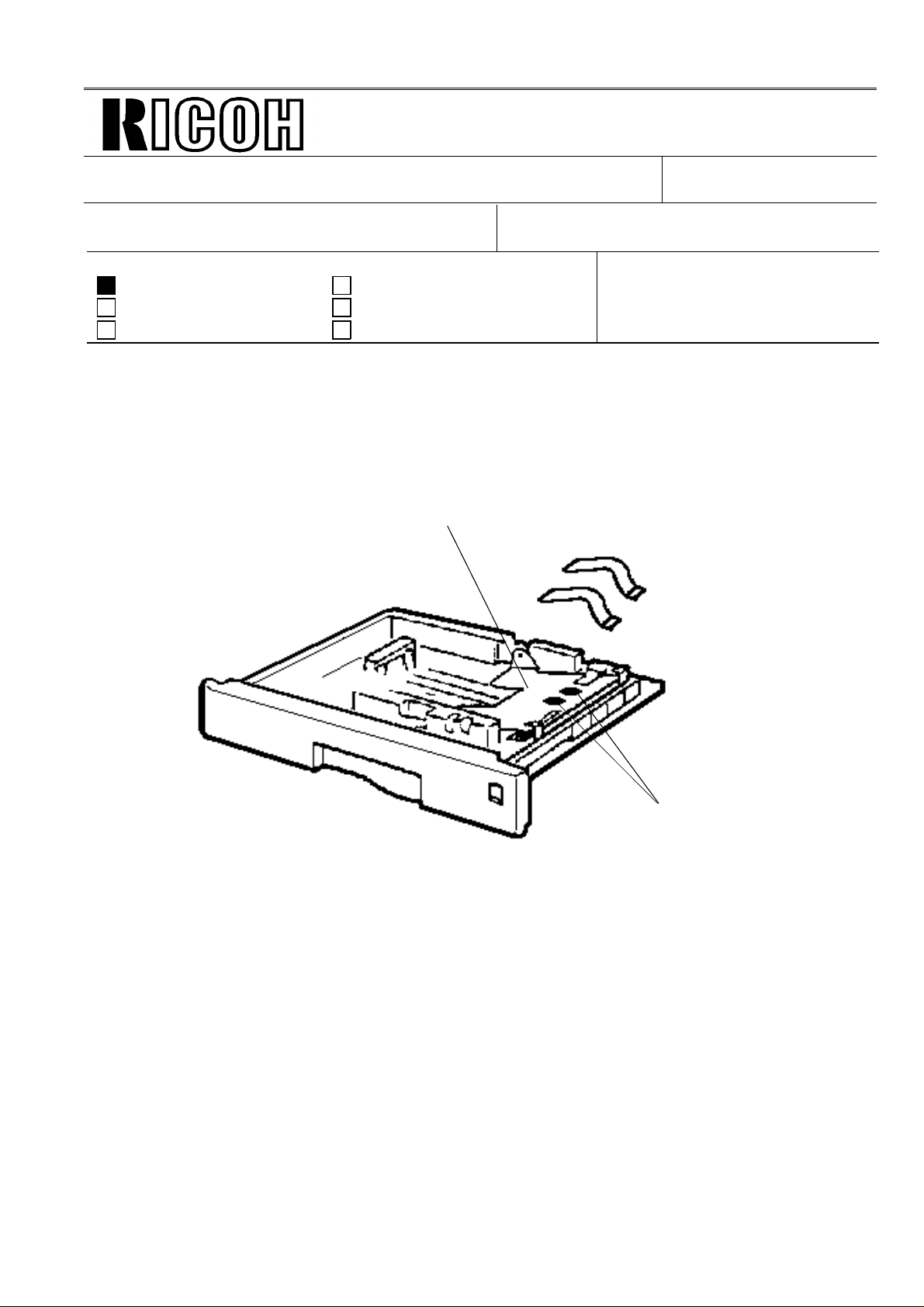

When peeling off tapes, in particular for the pape r ca sset te, please check if the glue from the

tape has been completely remo ved from the paper cassette bot to m p lat e.

If not, a paper misfeed may occur when the last shee t is fed , since it sticks to th e bott om plate.

Bottom plate

FROM: 2nd T.S. Section

MODEL:

DATE:

Aug. 31, 19 95

MV310

Glue from the tape

Page 14

Page 1/2

Technical Bulletin No. F/L series-005

SUBJECT: Unreleased side cassette locks

PREPARED BY: T. Kimura

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

When installing the opt ion al side cassette, there may be a pro blem in which the lock of the

bottom plate is not released . If it is not released, paper end will be detecte d. This is becau se th e

height margin between the protuberan ce on the bot to m plate and the release lock lever is n ot

sufficient for the two parts to cont act .

To prevent this proble m, th e he ight adjustment part should be attached befo re inst alling the side

cassette.

Installation procedure:

See the atta che d procedure.

The machines to be modified:

The July production run or earlier, and the 633 August production run.

The serial numbers of the 633 machines are as follows:

FROM: 2nd T.S. Section

MODEL:

DATE:

Aug. 31,1 995

MV310

M0350800 001~032, 034~055, 059~097, 099, 101~103, 105~164, 169~386,

395~408, 417~476, 478~483, 485, 487, 489, 492, 494, 496, 498,

507~519, 522~532, 541, 543, 545, 548, 550, 552, 556, 558, 560,

562, 564, 566, 567, 569, 571, 573, 575~582, 584, 586, 588, 590,

591, 593, 595, 597, 645, 648, 649, 652~709, 711, 713, 715, 718,

720, 722, 724, 734, 736, 738, 740, 760, 761, 763, 765, 768, 770,

772, 774~ 807, 890, 891

Page 15

Clean here

Page 2/2

Technical Bulletin No. F/L series-005

SUBJECT: Unreleased side cassette locks

DATE:

Aug. 31,1 995

<Attachment>

Installation Procedur e

1. Clean the portion on which th e pa rt will b e at ta ched with alcohol or wet cloth .

2. Peel off the backing of the part.

3. Attach the part.

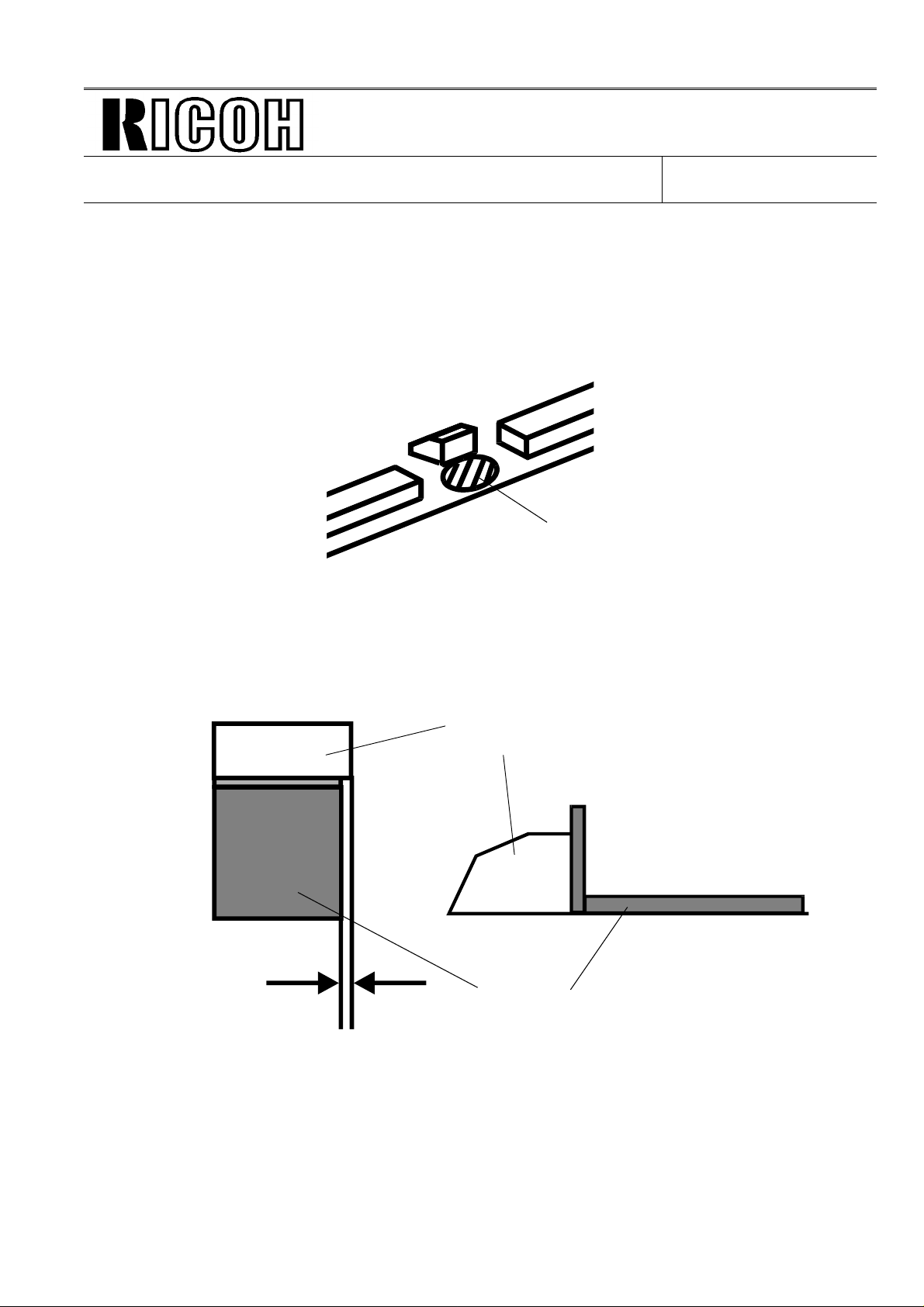

Top view

0 ~ 0.5 mm

Side view

Protuberance

Height adjustment part

Page 16

Drop

Page 1/5

Technical Bulletin No. F/L series-006

SUBJECT: Paper size sensor out of posit ion

PREPARED BY: T. Kimura

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

After installing th e side cassette, it may be found that th e pape r size cann ot be set prop erly in

spite of setting th e pa per size indicator dial. If this prob lem occu rs, the machine cannot det ect

any size other than LT/LEGAL.

In this case, it is assumed tha t th e pa pe r size senso r is out of position because of tra nsp ortation

damage.

The drop test was checked up to a heig ht of 80 cm (our sp ecif ication) but no problem was fou nd .

If it is dropped from a heig ht excee ding 80 cm, it is considered that the problem may occur

because the bottom plate rebounds and presses down the paper size sensor.

FROM: 2nd T.S. Section

MODEL:

DATE:

Aug. 31, 19 95

MV310 / FX6

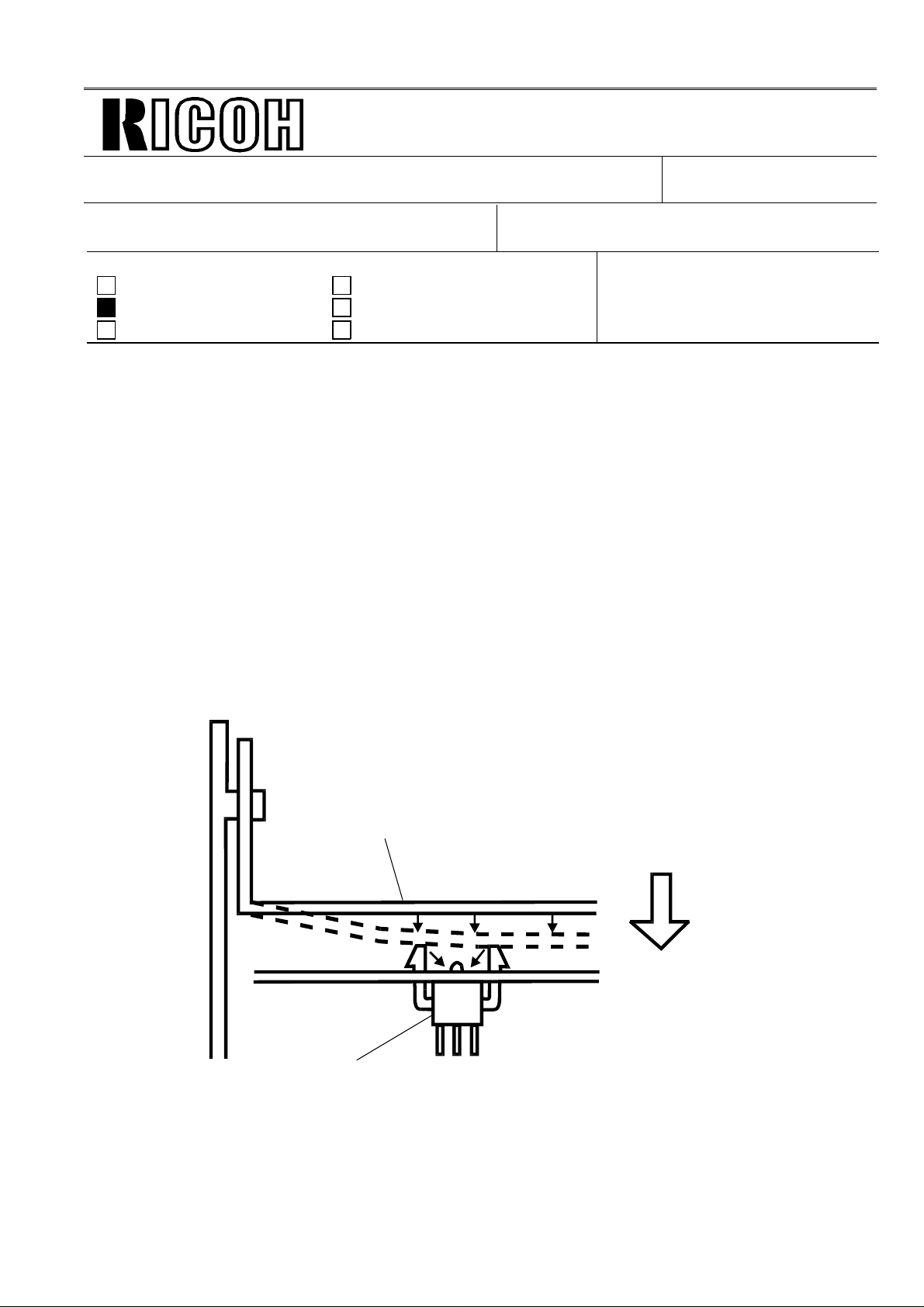

Bottom plate

Paper size sensor

Page 17

Page 2/5

Technical Bulletin No. F/L series-006

SUBJECT: Paper size sensor out of posit ion

The procedure to cure the problem:

This problem does NOT occur in normal operatio n.

Therefore, please put the sensor back into place.

For how to access the sensor, please refer to the atta chme nt.

Others:

To increase the safety marg in fo r dr op ping, a holder has been added as sho wn

below from July production at th e factory.

DATE:

Aug. 31, 19 95

Holder

Page 18

Page 3/5

Technical Bulletin No. F/L series-006

SUBJECT: Paper size sensor out of posit ion

< Attachment >

DATE:

Aug. 31, 19 95

Harness cover

Paper guide stopper

1. Remove the two screws and take off the harn ess cover.

2. Remove the paper guid e sto pp er.

Page 19

Page 4/5

Technical Bulletin No. F/L series-006

SUBJECT: Paper size sensor out of posit ion

Sensor stay

DATE:

Aug. 31, 19 95

3. Remove the sensor stay.

Page 20

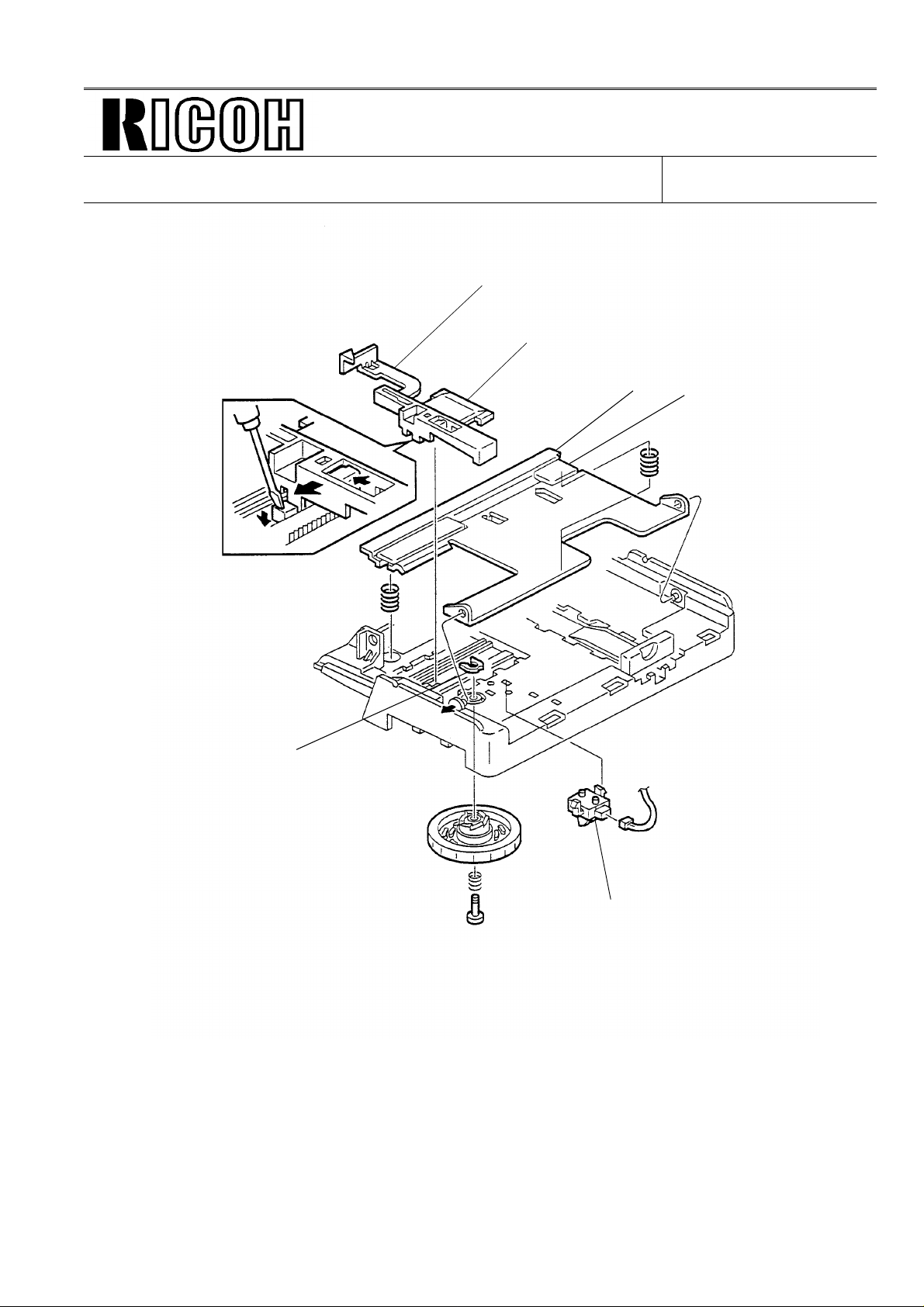

[B]

Page 5/5

Technical Bulletin No. F/L series-006

SUBJECT: Paper size sensor out of posit ion

DATE:

Aug. 31, 19 95

[4]

[A]

[5]

Clip

A: Paper Guide

B: Bottom Plate (2 springs)

C: Paper Size Indicator (1 clip, 1

spring)

4. Remove the paper guide.

5. Remove the bottom plate.

6. Take off the clip and remo ve th e pa pe r size in dica tor.

7. Reinstall the paper size sensor.

Paper size sensor

Page 21

5V

Technical Bulletin No. F/L Series-007

SUBJECT: Auto Service Call 0-05

DATE:

Sep. 15, 19 95

PREPARED BY: Y. Okunishi

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required Revision of service manual

FROM: 2nd T.S. Section

MODEL:

FX6

Troubleshooting Information only

Retrofit Information Other

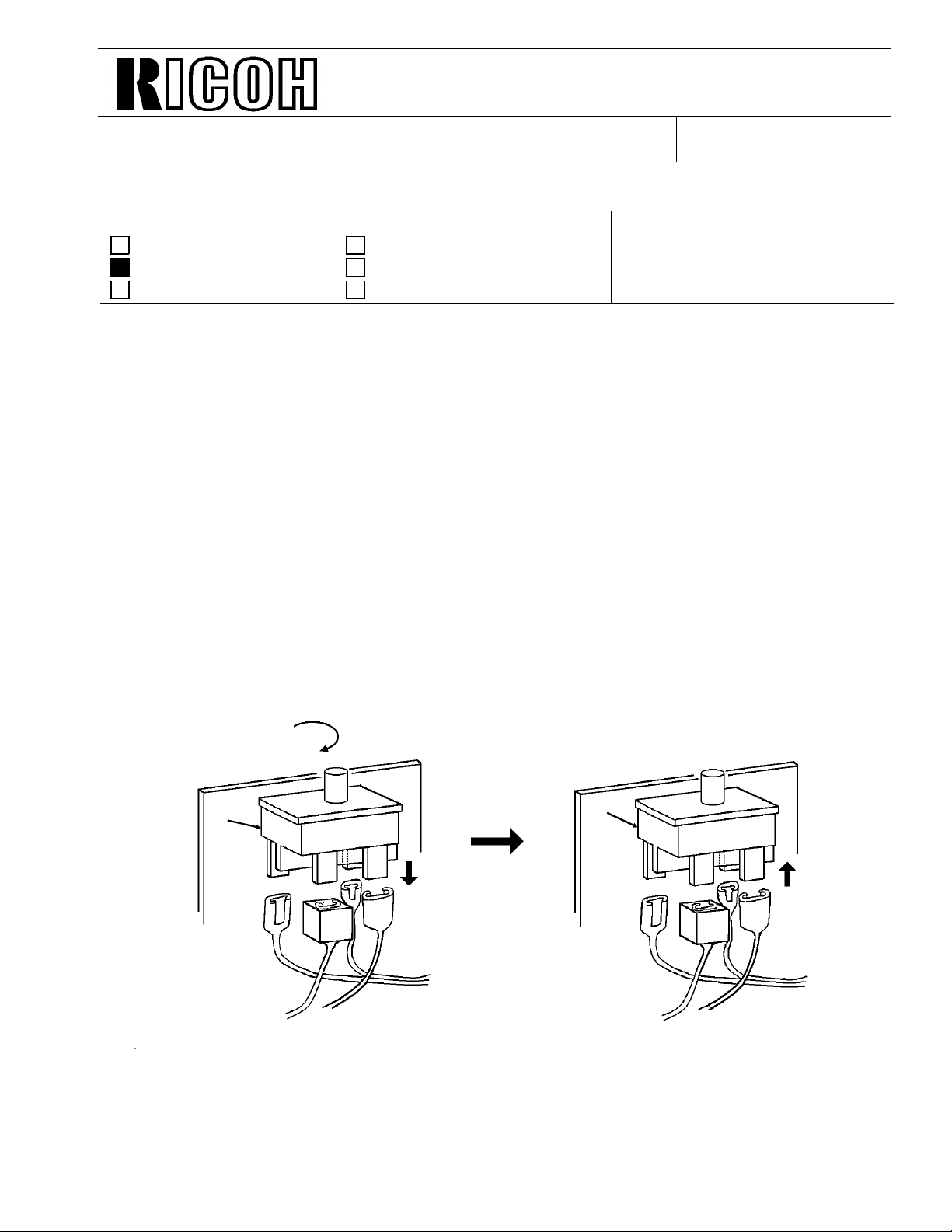

Problem:

Auto Service Call 0-05 (Fusing Unit Failure; see page 6-26 of the Service Man ual )

Cause:

There are two switches, for the 5V line and th e 24V line , in th e Safe ty Switch (Index no.133

on page 1-16 of Parts Catalog). If the Top Cover or Front Cover is not closed completely,

there is a possibility that the 5V switch will turn on but the 24V switch will not.

In this case, "Cover Closed" is detected but the fusing lamp is n ot turn ed on, and this is the

cause of the Auto Service Call.

Action Taken:

1) Remove the Right Cover.

2) Disconnect the 5V lines and th e 24 V lines.

3) Remove the Safety Switch.

4) Turn the Safety Switch 180 degrees.

5) Connect the 5V lines and 24 V line s.

B

A

24V

5V

A

B

Note:

RAM reset is required to escape from the Au to Service Call.

For the production:

A modification will be implemen te d to tu rn on th e 24 V line and 5V line at th e same time.

24V

Page 22

Technical Bulletin No. F/L Series-008

SUBJECT: Service Manual Correction

PREPARED BY: Y. Okunishi

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

The PM table in the service manual has been correct ed .

See the attached sheet.

FROM: 2nd T.S. Section

DATE:

Sep. 15, 19 95

MODEL:

FX6

Page 23

SERVICE TABLES AND PROCEDURES

F/L Series-008

SPECIAL TOOLS AND LUBRICANTS

April 7th, 1995

4.6 SPECIAL TOOLS AND LUBRICANTS

• Flash/SRAM data copy harness (P/N: H5159100)

4.7 PM RABLE

Scanner

Item 30K 60K 90K 1 year Notes

Exposure Glass C(user) C(user) C(user) C(user) Soft cloth and

alcohol

R1 and R2 Rollers C(user) C(user) C(user) C(user) Soft cloth and

alcohol

White Plate C(user) C(user) C(user) C(user) Soft cloth and water

ADF Roller Assy R(user) R(user) R(user) C(user) Soft cloth and water

Separation Pad R(user) R(user) R(user) C(user) Soft cloth and water

Printer

Item 30K 60K 90K 1 year Notes

Paper Feed Roller (*) C Soft cloth and water

Registration Roller C(user) C(user) Soft cloth and alcohol

Thermistor R

Hot Roller Strippers R

Pressure Roller

(Fusing)

Cleaning Pad R(user)

Replaced when a new CTM (toner

Transfer Roller (*) R Dry paper

Development Unit R

100 Sheet Cassette (Optional)

R

A cleaning pad is

enclosed in the CTM.

cassette) is installed.

Item 30K 60K 90K 1 year Notes

Feed Roller (*) C(user) Soft cloth and water

C: Clean, R: Replace

* : Corrected

4-84

Page 24

Page 1/1

Re-issued on: Nov. 15, 1995

Technical Bulletin No. F/L Series-009

SUBJECT: Dedicated Tx Parameters

PREPARED BY: Y. Okunishi

CHECKED BY: M. Iwasa

FROM: 2nd T.S. Section

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

RAM Addresses for Dedicated Tx Parameters

Quick Dials

01: 807166

02: 80716A

4 bytes

03: 80716E

I

I

I

I

32: 8071E2

DATE:

Sep. 15, 19 95

MODEL:

FX6, FX6MΙΙ, FX6CD

Speed Dials

00: 8071E6

01: 8071EA

02: 8071EE

89: 80734A

4 bytes

I

I

I

I

Page 25

Technical Bulletin No. F/L Series - 010

SUBJECT: New Model FAX FX6MkII (FAX 3700L)

PREPARED BY: K. Misugi

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

The new model FX6MkII (FAX 3700L) has been released in the line-up of the FX6 (FAX 2700L)

series.

This technical bulletin contains informat ion on dif ferences between the FX6MkI I an d the FX6.

They are listed in order of section s tha t appe ar in th e service manual.

FROM: 2nd T.S. Section

MODEL:

DATE:

1995. 9. 14

FAX 3700L

RC Only

1. OVERALL MACHINE INFORMATION

1.1. SPECIFICATIONS

FX6 FX6MkII

Maximum Scan Width 216 mm [8.5 ins] ± 0.25% 256 mm [10.0 ins] ± 0.25%

SAF 244 kbytes

(19 pages/Slerexe letter)

Modulation

Data Rate (bps)

Transmission Time 9 s at 9600 bps;

Paper Size and

Capacity

V.29, V27ter, V21

9600/7200/4800/2400

(Measured with G3 ECM

using memory for a ITU-T #1

test document at stand ard

resolution)

Not Available

(38 pages/Slerexe letter)

(Measured with G3 ECM using

memory for a ITU-T #1 test

document at standard resolution)

Paper Feed Unit (Optional):

500 sheets, available paper size

Europe: A4, A5 sideways

Asia: A4, A5 sideways, F/F4

512 kbytes

V.33/V.17 (TCM),

V.29, V.27 ter, V21

14,400/12,000/

9600/7200/4800/2400

6 s at 14,400 bps;

USA: Letter, Legal

Page 26

Technical Bulletin No. F/L Series - 010

SUBJECT: New Model FAX FX6MkII (FAX 3700L)

1.2. FEATURES

Sub-Title Item FX6 FX6MkII

Equipment Optional paper feed unit Not available Available

Video

Processing

Features

Communication

Features

Other User

Features

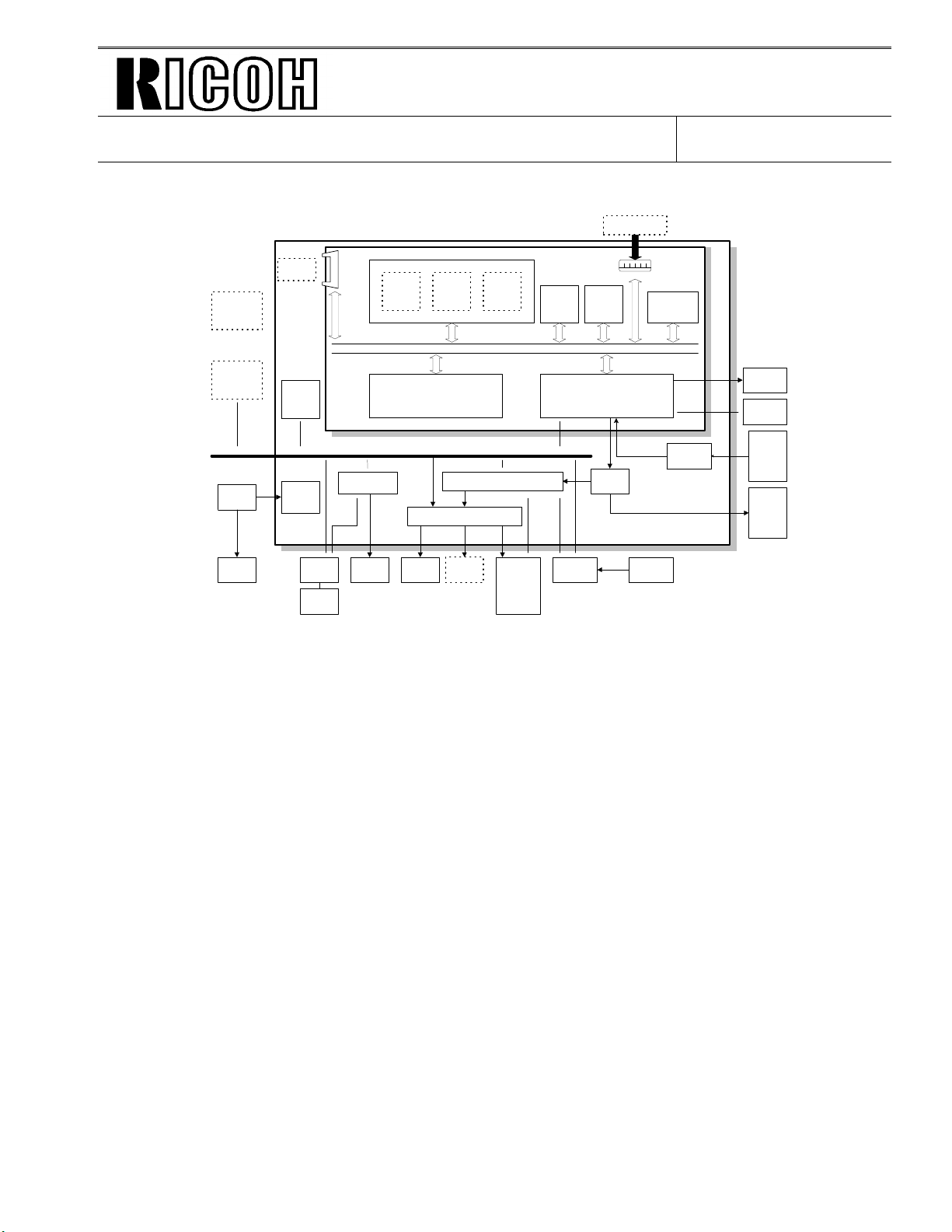

1.4. OVERALL MACHINE CONTROL (Please re fe r t o pa ge 4.)

Reduction (B4 to A4)

Not available Available

AI Redial

(last ten numbers)

Telephone Directory Not available Available

Two in one Not available Available

Continuous Polling Not available Available

Checkered mark

Reception time printing Not available Available

Not available Available

Not available Available

DATE:

1995. 9. 14

1.5. VIDEO DATA PATH (Please refer to page 5 and 6.)

1.6. POWER DISTRIBUTION DIAGRAM (P lea se refer to page 7.)

2. DETAILED SECTION DE SCRIPTIONS

2.1. Scanner

2.1.1. Mechanisms

3. Drive Mechanism: The actual scan width for FX6MkII is 256 mm (10.1").

4. Image Scanning: The nu mber of photosensitive elements in the image sensor is 204 8.

2.2. PRINTING

2.2.7. Paper Feed

5. Drive Mechanism

Paper Feed Priority

If all the cassettes con ta in pa pe r of the same size, the machine uses the paper in the optional

paper feed unit first, the paper in the standard cassette second, and the paper in the op tio na l

100 sheet cassette last. Howe ver, this order can be changed with printer bit switch 02 bit 0.

(Please refer to the bit switch section in this bulle tin.)

Page 27

Technical Bulletin No. F/L Series - 010

SUBJECT: New Model FAX FX6MkII (FAX 3700L)

2.2.8. Registration

Jam Detection

New error codes have been added for the optio na l pap er fe ed unit (5 00 shee ts).

Condition Error Code

When the

optional paper

feed unit is used

2.2.11. Fusing

The fusing (printing ) t emp erature is 185 °C.

The printing start te mperature is 160 °C.

2.2.13. Paper Size Selection

When the relay sensor in the paper f eed unit is n ot

turned on within 2.0 seco nd s aft er the paper feed clutch

is enabled .

When the registration sensor in the fax machine is not

turned on within 2.0 seco nd s aft er the paper feed motor

started.

DATE:

1995. 9. 14

9-50

9-51

Same as the previous page for the Paper Feed Priorit y.

2.4. PCBs

2.4.1. FCE2 (Please refer to page 8.)

2.4.2. FDU (Please refer to page 9.)

4. SERVICE TABLES AND PROCEDURES

Please see the attach ment for section 4.

The settings and the switches that are dif fe ren t from the FX6 are shaded.

Page 28

Technical Bulletin No. F/L Series - 010

SUBJECT: New Model FAX FX6MkII (FAX 3700L)

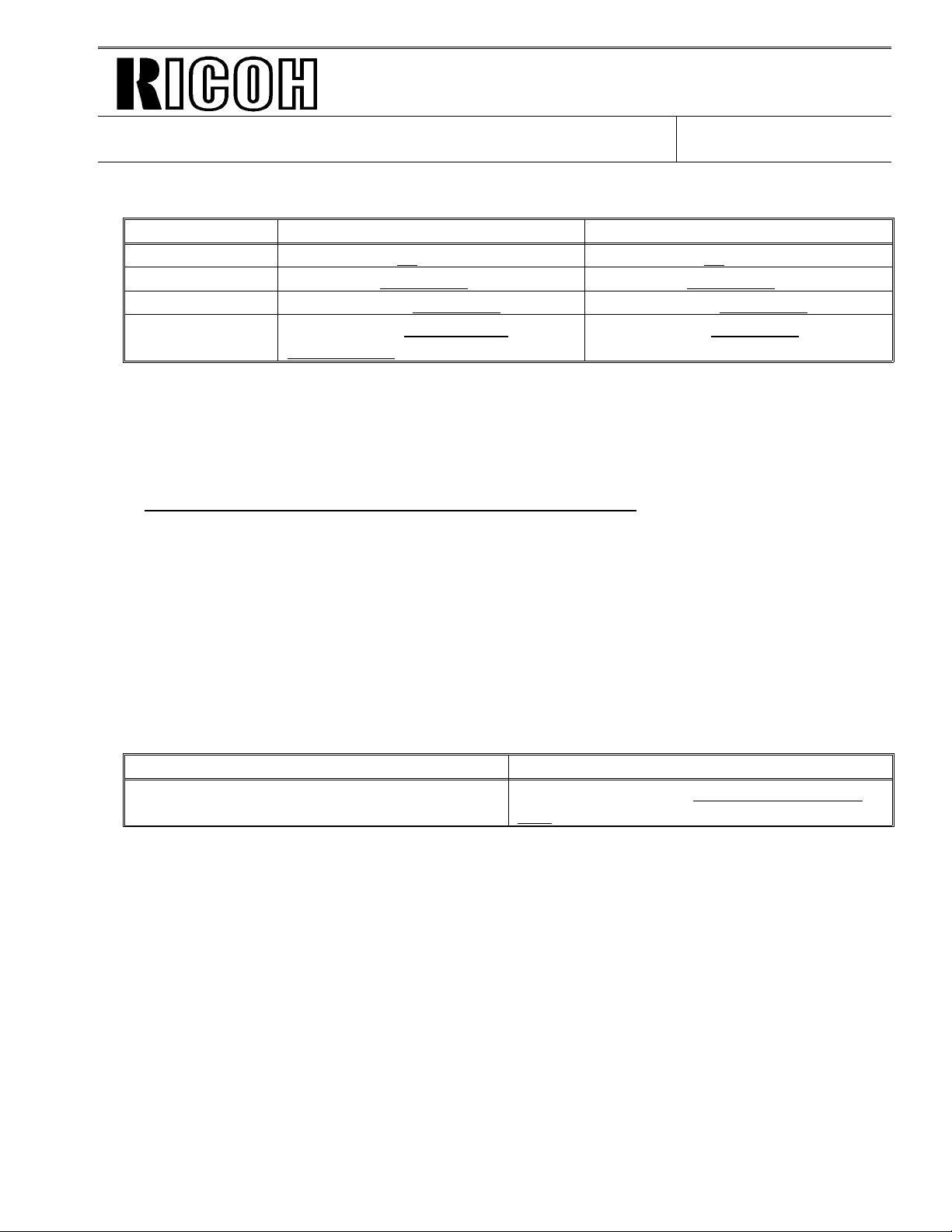

1.4.OVERALL MACHINE CONTROL

Optional

100 Sheet

Cassette

Optional

Printer I/F

PSU

Fusing

Lamp

Optional

IC Card

FDU

Energy

Saver

CPU

DC-DC

Converter

Handset

FCE2

Hybrid IC

Working

Control Signals

(HIC)

SpeakerNCU

RAM

R144EFXL

Modem

Power

Pack

DRAM

ECM/SAF

Memory

DATA/ADDRESS BUS

External I/O (EXIO)

Driver

Optional

Counter

Page

Memory

components

Scanner

sensors

and

printer

and

System

ROM

(Flash)

Operation

Panel

System

RAM

(SRAM)

FCIP

Drivers

(FPD)

Optional

RS232C I/F

Sensors

Video

SRAM

Amplifier

DATE:

1995. 9. 14

LDDR

Thermistor

Contact

Image

Sensor

Tx

and

paper

feed

motors

H516V506.wmf

The FCE2 (Facsimile Control Engine) conta ins the FCIP (Facsimile Control and Image

Processor), DRAM, SRAM, System ROM, R14 4E FXL mode m, and vide o processing

memory, and controls the entire syste m through the FDU (Facs im il e Dri ver Unit).

There are two cpus in the mach ine: the main cpu (FCIP) on the FCE an d the energy saver cpu

on the FDU. In energy saver mode, th e main CPU swit che s off and the energy save r CP U take s

over.

The FCIP consists of the fo llowing component blocks:

• RU8 CPU - Main CPU • MDM - Modem

• LIF- Laser Interface • DMAC - DMA Controller

• PRIF - Printer Interface • DIP - Digital Image Processor

• DCR - Data Compression and Reconstruct ion

The modem inside the FCIP is used for V.29, V27.te r, and V.21 com muni ca tions . In

addition, the Rockwell R144 EFX L modem is used for V.17 and V.33 communications.

The 1.5 MB DRAM contains the SAF memory, ECM buffer memor y, work area, and page

memory. The SAF memory can be extended by 2 or 4 Mbytes with an IC car d.

A 512 kB (4 Mbit) flash ROM is used for the system ROM. Software in this ROM can be

rewritten from the IC card slot or by RDS. Another 128 kB mask ROM contai ns LCD

wording data.

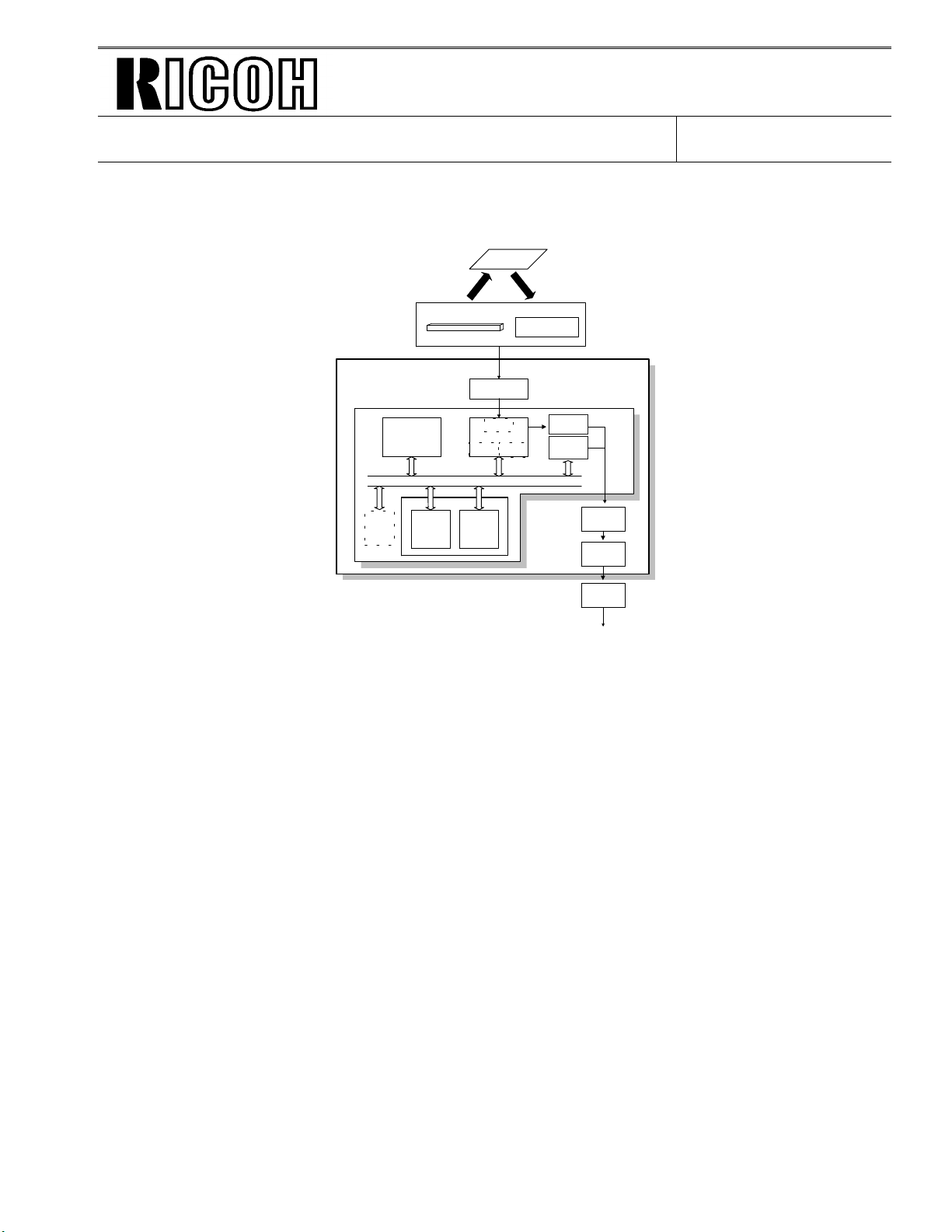

Page 29

Technical Bulletin No. F/L Series - 010

SUBJECT: New Model FAX FX6MkII (FAX 3700L)

1.5.VIDEO DATA PATH

1.5.1. Transmis sion

Original

Contact Image Sensor

Assembly

LED Array

Amplifier

FCIP

DCR

DATA/ADDRESS BUS

ECM/

SAF

Memory

DIP

MDM

SAF IC

Card

Video

Processing

Memory

DRAM

Line

Buffer

/FIFO

Memory

Image Sensor

E144EFL

Amp

Modem

DATE:

1995. 9. 14

FDU

FCE

Attenuator

HIC

NCU

To the network

H516V507.wmf

DIP: Digital Image Processor

DCR: Data Compression & Reconstruction

MDM: Modem

Immediate Transmission:

Scanned data from the contact imag e sen sor pa sses to the DI P blo ck in the FCIP. Aft er

analog/digital vide o pro cessin g, the DCR block compresses the data for tra nsmission. The

compressed data then passe s eith er to the FIFO memo ry o r to th e ECM memo ry b ef ore it is

sent to the telephone line through the modem. If a data rate of 12,000 or 14,400 bps is used,

the data passes through the E14 4E FL Mod em.

Memory Transmission:

First, the scanned data is sto red in the SAF memo ry aft er compression in the DCR block.

At the time for transmission, the DCR block decompre sses th e data from the SAF me mory, then

compresses it again after ha nd sha king with the other termin al is don e. The compressed data

then passes either to the FIFO memory or to the ECM memory, before it is sent to the

telephone line t hro ug h the modem.

Page 30

Technical Bulletin No. F/L Series - 010

SUBJECT: New Model FAX FX6MkII (FAX 3700L)

1.5.2. Reception

From the Network

NCU

HIC

Amplifier

E144EFXL

DRAM

Line Buffer

Modem

/FIFO

Memory

DATA/ADDRESS BUS

ECM/SAF

Memory

MDM

FCIP

DCR LIF

Page

Memory

DATE:

1995. 9. 14

LDDR

LIF: Laser Interface

DCR: Data Compression & Reconstruction

MDM: Modem

Copy Paper

H516V508.wmf

Data from the line passe s to th e modem through the NCU and hyb rid IC. Aft er the modem

demodulates the da ta , the decompressed data passe s to th e DCR b lock, through either the

FIFO or the ECM memory, where th e da ta is decompressed to raster image dat a. At the same

time, the compressed data passes to the SAF memo ry as a backu p in case of mech an ical

problems during printing (substitute reception).

The raster image data is th en passe d to the pag e memo ry f or prin ting. After a page of data has

been stored in the page memory, the data is sent to the LDDR thro ug h the LIF block.

Page 31

Technical Bulletin No. F/L Series - 010

SUBJECT: New Model FAX FX6MkII (FAX 3700L)

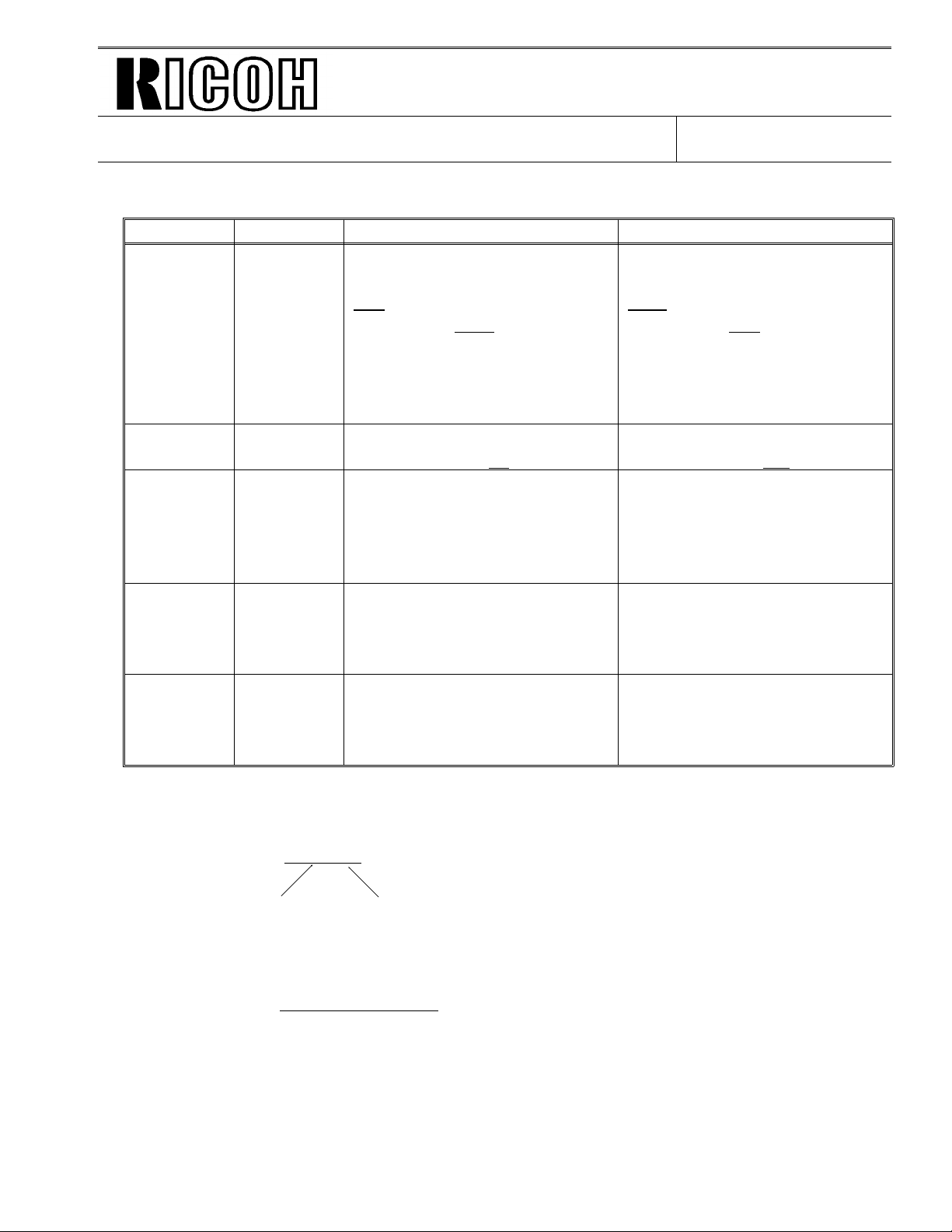

1.6. POWER DISTRI BUTION

1.6.1. Distribution Diagram

+24VD

-5V

Optional 100

+5VBAT

Sheet

Cassette

12VP

+5V

+5VE

+5vv

+5VLD

+24VM

+5V

AC Switching

Circuit

Fusing Lamp

ON/OFF

Circuit

AC115V or 230V

Fusing

Lamp

AC

Main

Power

Main Switch

PSU

24VIN

Card

+24VM

+24VD

IC

+24V

Optional

Counter

+12VP

+5V

+5VD

+12VD

FCE

+5VD

+5V

DC-DC

Converter

DC-DC

Converter

Fusing Unit

Interlock

Switches

+5VLD

LDDR

Printer

I/F

DC-DC

Converter

+24V

NCU

+5VD

+5VE

+24V

+5V

RS232C

I/F

+5V

FDU

+24VM

+5V

+5VV

-5V

Image Sensor

+24VM

LED Array

+24VM

+24VM

+24VD

+24VD

+24VD

+24VD

+5V

+5V

+5V

+5VE

+5V

DATE:

1995. 9. 14

Optional PFU

Motors

Feed Clutch

Stamp

Cooling Fan

Ozone Fan

Power Pack

Thermistor

Printer Sensors

Operation Panel

+5VE

Scanner Sensors

H516V511.wmf

The PSU supplies +24V dc power to the FDU. The FDU conve rts th e +24 V dc po wer sup ply to

the following supplies.

+5V This is normally on when the main switch is on.

+5VE This is used for detecting an activation signal from the NCU, documen t fe ed er, or

operation panel when the machin e is in energy savin g mod e.

+5VLD This supplies the laser diode. It is interru pt ed if the fusing unit cover interlock

switch opens.

+5VV This is a more stable power supply than +5V. It is use d fo r the Contact Image

Sensor.

+5VD This supplies back up power for the DRAM and th e op tio na l IC card on the FCE .

It can back up stored data for one hour aft er th e power is switched off. A

rechargeable batte ry on th e FDU is use d to gen erate +5VD.

+5VBAT This supplies back up power to the system RAM on the FCE to back up the

programmed data. A lithium batt ery is used to generate +5VBAT.

+24V This is normally on when the main switch is on.

+24VD This is interrupted if the fusing unit cover int erlo ck swit ch open s.

+24VIN This supplies +24V to the fusing unit on/off switching circu it. It is interru pted if the

fusing unit cover interlock switch op en s.

+24VM This is interrupted if the machine enters en erg y saving mode.

-5V This is used for the imag e sen sor.

+12VP This is su pp lied to th e Flash ROMs on the FCE and the optio na l IC ca rd.

Page 32

Technical Bulletin No. F/L Series - 010

SUBJECT: New Model FAX FX6MkII (FAX 3700L)

2.4. PCBs

2.4.1. FCE2

+12VP +5V

Flash ROM

(512kB)

R144EFXL

Modem

DRAM

(1.5MB)

DATA/ADDRESS BUS

29.952MHz

32.768kHz

Video SRAM

(8kB)

FCIP

Mask ROM

(128kB)

SRAM

(32kB)

DATE:

1995. 9. 14

FCE

+5V

IC6

+5VBAT

Battery

Parallel IO

Memory Card (Optional)

RS232C Interface (Optional)

FDU

1. FCIP (Facsimile Controlle r and Im age Processor)

• CPU

• Modem (V.29, V. 27, V.21)

• Data compression and reconstruction (DCR)

• Digital image processor (DIP)

• Laser interface (LIF)

• DMA controller

• Clock generation

• Stepper motor control

• Serial interface to the FDU

• DRAM backup control

• Ringing signal/Tone detection

• Fusing lamp control

Serial IO

H516D530.wmf

Page 33

Technical Bulletin No. F/L Series - 010

SUBJECT: New Model FAX FX6MkII (FAX 3700L)

DATE:

1995. 9. 14

2. Modem (Rockwell R144EFXL)

• V.17, V.33 modem

3. ROM

• 512 kB (4 Mbit) flash ROM for system software stora ge .

• 128 kB (1 Mbit) mask ROM for LCD wording data storage (not used in the US model)

4. DRAM

• 1.5 MB DRAM shared between the Line Buffer (32 kB), ECM Bu ff er (128 kB), Page Memory

(768 kB), and SAF memory (512 kB).

• 5. Backed up by the battery on the FDU.

5. SRAM

• 32 kB SRAM for system and user parameter storage.

• Backed up by the battery on the FCE.

6. Video SRAM

• 8 kB SRAM for video processing.

7. Oscillators

• 29.952 MHz oscillator for system clock generation.

• 32.768 MHz oscillator for the real time clock. This is backed up by th e ba tt ery on the FCE.

• 38.00053 MHz oscillator for the R144EFXL modem.

8. Jumpers, Switche s, and Test Poi nts

Item Description

SW1 Switches the backup battery ON/ OFF

Page 34

Technical Bulletin No. F/L Series - 010

SUBJECT: New Model FAX FX6MkII (FAX 3700L)

2.4.2. FDU

FCE

M

M

Fusing

Lamp

PSU

AC Input

Video I/F

TX Motor

Paper Feed Motor

+24V

Control

MFPD

+24VD

ON/OFF

Converter

Converter

DC/DC

DC/DC

+24VM

ON/OFF

Power Saver

Flash ROM

Boot Block

Overwrite

ON/OFF

+12VP

TB1

+5VE +5V

Printer

I/F

Interlock Switch (+24V)

Serial I/F

CPU

+5V

+5VV

TX DATA

RX DATA

HIC

+5V +5VLD

Serial I/F

External IO

DATE:

TX/RX DATA

1995. 9. 14

Clutches

Solenoids

M

CL

SOL

Sensors

OPU

Optional

PFU

NCU

Main Motor

Serial I/F

Interlock Switch

(+5V)

1. Power Saver CPU

• 4 bit CPU for controlling the machine during powe r sa ver mod e.

2. FPD (Facsimile Powe r Dri ve r)

• Stepper motor driver.

3. EXIO (External I/O)

• Serial interface to the FCE and OPU.

• Serial interface to an optional paper feed unit.

• Parallel interface to the main motor, clutches, and sensors.

4. HIC (Hybrid IC)

• 2-4 wire switching

• Filters and amplifiers

• Monitor speaker driver

5. DC/DC Converters

• +5V generation

+12V generation

H516D531.wmf

Page 35

Technical Bulletin No. F/L Series - 010

SUBJECT: New Model FAX FX6MkII (FAX 3700L)

The following parts for the FX6MkII are different from the FX6.

Index F16 F16mkII Description

3-2 H5164040 H5264040 Cover - PIF

3-3 H5164045 H5264045 Cover - Rear - 2

3-9 H5212041 H5152040 Laser Unit

3-10 H5166002 H5266002 PCB - FCE - FX6MkII - US

3-11 H5166043 H5266003 PCB - FDU - FX6MkII - US

3-* H5168600 H52 68 600 Operator’s Man ual - FX6 MkII - US

7-2 H5164225 H5264291 Cover - Operation Panel - FX6MkI I

7-24 H5164303 H5264309 Quick Dial Sheet - US

9-15 H5161066 H5261066 Contact Image Senso r - B4

9-19 H5161062 Not used Spacer - Image Sensor

11-12 H5215061 H5155040 Polygonal Motor - DC24V; 0.35A

19-2 H5163342 H5263391 Base - Main Board

21-5 H5163407 H5163401 Cassette Base - Universal

21-42 H5163465 H5153465 Suppo rt Plate - End Fence

H5155318 PFU Harness

H5163430 Paper Size Detecto r - LG

H5153466 Plastic Rivet (Cassette End Fence)

18-36* H5153693 Positioning Pin

H5164088 Cassette Cover

2-42* H5263395 Spacer - FCE - Front

2-43* H5263396 Spacer - FCE - Rear

DATE:

1995. 9. 14

Note: * Please see the next page for the loca tion of the parts.

Page 36

Technical Bulletin No. F/L Series - 010

SUBJECT: New Model FAX FX6MkII (FAX 3700L)

DATE:

1995. 9. 14

Page 37

August 2nd, 1995 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNCTIONS

4. SERVICE TABLES AND PROCEDURES

4.1. SERV ICE LEVEL FUNCTIONS

In this section, frequently used keys are referred to with the following

symbols.

S

- Start key

FU

- Function key

Y

- Yes key

^

- Up arrow key

>

- Right arrow key

4.1.1. Bit Switch Programming (Function 01)

s

- Stop key

N

- No key

_

- Down arrow key

<

- Left arrow key

1. FU 6 1 9 9 5

then immediately Y

2. 0 1 Y

Bit 7 is displayed at the lef t, and bit 0 at

the right.

3. Scroll through the bit switch menu: * or

#

Example: To see the communication

switches : # × 3

Then scroll through the bit switches.

Increment bit switch: >

Decrement bit switch: <

Example: Display bit switch 3: > x 3

4. Adjust the bit switch.

Example: To change the value o f bit 7,

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

SYS DF : 0000 0000

BITSW 00: 0000 0000

COM DF : 0000 0000

BITSW 00: 0000 0000

COM DF : 0000 0000

BITSW 03: 1000 0000

press 7

5. Either:

• Adjust more bit switches - go to step 3.

• Finish - FU

4-1

Page 38

SERVICE TABLES AND PROCEDURES August 2nd, 1995

SERVICE LEVEL FUNCTIONS

4.1.2. System Parameter List (Function 02)

The format of the list is as follows.

* * * SYSTEM PARAMETER LIST (Date and Time) * * *

SERIAL NO. - Serial number programmed by function 14)

ROM VER. [Version] [Software release no.] [Software release date]

ROM NO. [Software part no.] [Check sum values (total) (boot) (main)]

R T I

T T I

C S I

ID CODE

MEMORY LOCK ID

NUMBER

OWN NUMBER

SERVICE NUMBER

NCU PARAMETER

COUNTER

PARAMETER

SCAN THRESHOLD

2MB or 4MB - Optional memory card capacity installed

CASSETTE 2 - Optional paper feed unit installed

SWITCH (UPPER:DEFAULT LOWER:CURRENT)

(SWUSR) - User Parameter Settings

CONFIDENTIAL ID

TTI

SWITCH (UPPER:DEFAULT LOWER:CURRENT)

(SWSYS) - System Bit Switch Settings

(SWSCN) - Scanner Bit Switch Settings

(SWPLT) - Printer Bit Switch Settings

(SWCOM) - Communication Bit Switch Settings

(SWG3) - G3 Bit Switch Settings

1. FU 6 1 9 9 5

then immediately Y

2. 0 2 Y S

H526M510.wmf

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

3. Finish: FU

4-2

Page 39

August 2nd, 1995 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNCTIONS

4.1.3. Error Code Display (Function 03)

1. FU 6 1 9 9 5 ,

then immediately Y

2. 0 3 Y

3. Either:

Scroll through the error code s - > or <

Finish - FU

4.1.4. Service Monitor Report (Function 04)

1. FU 6 1 9 9 5

then immediately Y

2. 0 4 Y S

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

ERROR CODE < >

1-01 JAN 01 17:30

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

3. Finish: FU

4-3

Page 40

SERVICE TABLES AND PROCEDURES August 2nd, 1995

SERVICE LEVEL FUNCTIONS

4.1.5. Protocol Dump (Function 05)

1. FU 6 1 9 9 5

then immediately Y

2. 0 5 Y

3. S

4. Finish: FU

4.1.6. RAM Display/Rewrite (Function 06)

1. FU 6 1 9 9 5

then immediately Y

2. 0 6 Y

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

START

PROTOCOL DUMP

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

0-MEM.R/W 1-MEM.DUMP

3. 0

4. Input the address that you wish to see.

Example: A ddress 800020

8 0 0 0 2 0

Note: If you wish to move the cursor,

press > .

5. If you wish to change the data, type in

the new data.

Example: 80, press 8 0

Note: If you wish to move the cursor,

press > .

6. Either:

• View more addresses - go to step 4.

• Finish - FU

ADDRESS = 000000

DATA = 00

ADDRESS = 800020

DATA = 20

ADDRESS = 800020

DATA = 80

4-4

Page 41

August 2nd, 1995 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNCTIONS

4.1.7. RAM Dump (Function 06)

1. FU 6 1 9 9 5

then immediately Y

2. 0 6 Y

3. 1

4. Enter the first four digit s of th e start an d

end addresses . For example, en te r

“8000” for start address 800000(H), and

enter 8001 for end address 8001FF(H).

Then, press "Start" to print the dump list.

Example: Start at 800000, end at 8001FF.

80008001S .

5. Finish: FU

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

0-MEM.R/W 1-MEM.DUMP

MEMORY DUMP START/N

ADD.000000 - 0000FF

MEMORY DUMP START/N

ADD. 800000- 8001FF

MEMORY DUMP

4.1.8.4.1.8. Counter Display/Rewrite (Function 07)

1. FU 6 1 9 9 5

then immediately Y

2. 0 7 Y

3. Either:

Check the transmitted, received,

scanned and printed pa ge coun te rs, an d

the printer and scanner jam counters -

press 0

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

0-COUNTER 1-PM

2-CTM 3-OPU

TX: 012345

RX: 012345

4-5

Page 42

SERVICE TABLES AND PROCEDURES August 2nd, 1995

SERVICE LEVEL FUNCTIONS

(To see the scanned and printed

page counters, press #.

To see the printer and scann er jam cou nt -

ers, press # again.)

Check the PM counter - press 1

Check the CTM counter - press 2

Check the OPU counte r - press 3

4. To change the contents of a counter,

input the new value, then press Y .

5. To finish: FU

SCAN : 012345

PRINT : 012345

S.JAM: 000000

P.JAM: 000000

PM COUNTER: 001234

CTM COUNTER: 001234

OPU COUNTER: 001234

4.1.9. NCU Parameters (Function 08)

1. FU 6 1 9 9 5

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

then immediately Y

2. 0 8 Y

3. 0

4. Scroll through the parameters using

0-NCU 1-MODEM

2-DTMF 3-DETECT

NCU KPAD/<>

NO.04 = 005

> or < . If you want to change a

value, enter the ne w va lue at the keypad,

then press Y .

Example: Set NCU parameter 04 to 005.

>>>> 0 0 5 Y

5. To finish : N FU.

Note: Parameter CC is the Country Code, Parameter 01 is the Tx le vel.

Refer to section 4.3 for full details on NCU parameters.

4-6

Page 43

August 2nd, 1995 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNCTIONS

4.1.10. Modem Test (Function 08)

1. FU 6 1 9 9 5

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

then immediately Y

2. 0 8 Y

3. 1

0-NCU 1-MODEM

2-DTMF 3-DETECT

MODEM TEST START/< >

800Hz

4. Scroll through the available tests using > or < .

5. S

6. To stop the test: s

7. To finish: N FU

4.1.11. DTMF Tone Test (Function 08)

1. FU 6 1 9 9 5

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

then immediately Y

2. 0 8 Y

3. 2

0-NCU 1-MODEM

2-DTMF 3-DETECT

DTMF TEST START/<>

TONE 0

4. Scroll through the available tests using > or < .

5. S

6. To stop the test: s

7. To finish: N FU

4-7

Page 44

SERVICE TABLES AND PROCEDURES August 2nd, 1995

SERVICE LEVEL FUNCTIONS

4.1.12. Modem Detection Test (Function 08)

Note: This function can be used only when G3 bit switch 0B bit 5 (French

PTT requirements) is 1 in Euro pean mode ls. It cann ot be used in

USA models.

1. FU 6 1 9 9 5

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

then immediately Y

2. 0 8 Y

3. 3

0-NCU 1-MODEM

2-DTMF 3-DETECT

MODEM DET START/<>

V21 300BPS

4. Scroll through the available tests using > or <

5. S

6. To stop the test: s

7. To finish: N FU

4.1.13. Ringer Test (Function 08)

1. FU 6 1 9 9 5

then immediately Y

2. 0 8 Y

3. 4

5. S

6. To stop : s

7. To finish: N FU

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

0-NCU 1-MODEM

2-DTMF 3-DETECT

START

RINGER

4-8

Page 45

August 2nd, 1995 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNCTIONS

4.1.14. Operation Panel Test (Function 09)

1. FU 6 1 9 9 5

then immediately Y

2. 0 9 Y

3. 0

4. S

5. To stop the test, press s

6. To finish: N FU

4.1.15. LED Array Test (Function 10)

1. FU 6 1 9 9 5

then immediately Y

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

0-LED/LCD

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

2. 1 0 Y

3. 0

4. S

5. To stop the test, press s

6. To finish: N FU

0-LAMP 1-ADF

START

LAMP 0 0 0

4-9

Page 46

SERVICE TABLES AND PROCEDURES August 2nd, 1995

SERVICE LEVEL FUNCTIONS

4.1.16. ADF Test (Function 10)

1. FU 6 1 9 9 5

then immediately Y

2. 1 0 Y

3. 1

4. Place a document in the feeder,

then press S .

5. To stop the test, press s

6. Finish: N FU

4.1.17. Printer Test Patterns (Function 11)

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

0-LAMP 1-ADF

START

ADF

1. FU 6 1 9 9 5

then immediately Y

2. 1 1 Y

3. 0

5. Press a key from 0 to 4.

6. Press S .

A test pattern is printed.

7. To finish: N FU

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

0-PATTERN 1-MECH

PATTERN PRINT KPAD

0-4

4-10

Page 47

August 2nd, 1995 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNCTIONS

4.1.18. Printer Mechanism Test - Free Run (Function 11)

1. FU 6 1 9 9 5

then immediately Y

2. 1 1 Y

3. 1

4. S

5. To stop the test, press s

6. To finish: N FU

4.1.19. RAM Tests (Function 12)

1. FU 6 1 9 9 5

then immediately Y

FUNCTION KPAD/NEXT

9 SERVICE FUNCTIONS

0-PATTERN 1-MECH

START

MECH

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

2. 1 2 Y

0-SRAM 1-SAF

2-SAFCARD 3-M-->R

3. Either:

Test the SRAM: Press 0 S

Test the SAF: Press 1 S

Test the SAF card: Press 2 S

If test is successful, the disp lay shows "OK".

If test is unsuccessful, the disp lay shows "ADDRESS=".

4. To finish: N FU.

4-11

Page 48

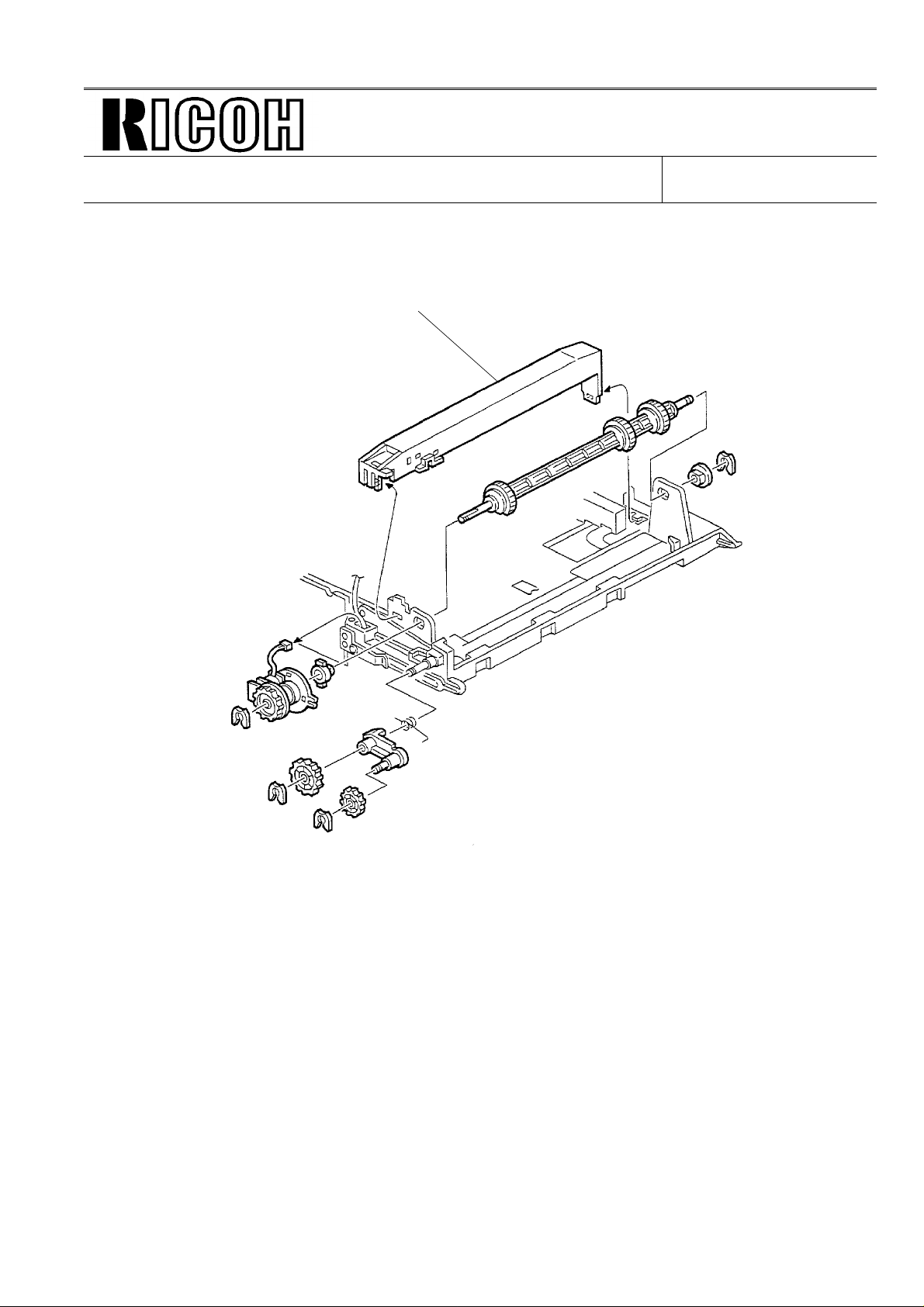

[A]

SERVICE TABLES AND PROCEDURES August 2nd, 1995

SERVICE LEVEL FUNCTIONS

4.1.20. Software Download (Function 12)

Instead of replacing an EPROM to update the mach ine’s software , use this

procedure to update th e software in the machine’s Flash ROM.

This function copies softwa re fro m an ext ernal medium to the Flash ROM on

the machine’s FCE. The external medium for the new software can be an

FCE or an EPROM board.

1. Turn off the mach ine.

Do this only if rewriting

the boot block.

See the note at the end

of this procedure.

[B]

[D]

[C]

H516M501.wmf

2. Insert the Flash/S RAM Cop y Tool [A] into the IC card slo t [ B] , t hen co n-

nect the FCE or EPROM board with new software [C] to the opposite side

of the tool.

Note: The switch [D] on the tool [A] must be at the ON position.

3. Turn o n t he mach ine.

4. FU 6 1 9 9 5

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

then immediately Y

5. 1 2 Y >

0-SRAM 1-SAF

2-SAFCARD 3-M-->R

6. 4

4-12

Page 49

August 2nd, 1995 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNCTIONS

7. S

If the software is successfully downloaded, the display shows "OK".

OK!!

COPY MACH <- FLROM

If the software download fails, the displa y

shows "NG".

NG!!

COPY MACH <- FLROM

8. To finish, press FU.

9. Turn off the mach ine and disconnect the tool. Then turn the machine back

on.

10. Print out the system paramete r list and check th e ROM versio n on it.

Note: In rare cases, the boot block will have to be rewritten. In such cases,

you must do the following in addition to the above procedure.

• Before step 1, open th e rea r cover an d cha ng e t he jumper at TB1

on the FDU as shown in the diagram on the previous pa ge.

• After step 3, set bit 5 of system switch 02 to 1.

• Before switching on the mach ine again in step 9, put TB1 b ack t o

the default position (pins 2-3 sho rte d).

4.1.21. Software Upload (Function 12)

This function copies the sof tware from the machine’ s bu ilt-in FCE to an exte rnal FCE.

1. Turn off the mach ine.

2. Connect the Flash/SRAM Copy Tool and an FCE as shown in the pre-

vious section.

Note: The switch [D] on the tool must be at th e OFF position.

3. T urn on the machine.

4. FU 6 1 9 9 5

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

then immediately Y

5. 1 2 Y

0-SRAM 1-SAF

2-SAFCARD 3-M-->R

4-13

Page 50

SERVICE TABLES AND PROCEDURES August 2nd, 1995

SERVICE LEVEL FUNCTIONS

6. 3 S

OK!!

COPY MACH -> FLROM

If the software is successfully uploaded,

the display shows "OK".

If the software upload fails, the display

shows "NG".

NG!!

COPY MACH -> FLROM

7. Finish : FU

8. Turn off the mach ine and disconnect the tool. Then turn the machine back

on again.

4.1.22. SRAM Data Download (Function 12)

This function copies all th e da ta stored in the SRAM on an externa l FCE to

the machine’s FCE. Use this af ter replacing a damaged FCE to save an y previous settings that were programmed in the damage d FCE.

1. Turn o ff the machine.

2. Connect the Flash/SRAM Copy Tool [A] and the damaged FCE [C] as

shown in section 4.1.20.

Note: The setting of switch [D] on the too l will not affect the resu lt of

this procedure.

3. Turn o n t he mach ine.

4. FU 6 1 9 9 5

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

then immediately Y

5. 1 2 Y >

0-SRAM 1-SAF

2-SAFCARD 3-M-->R

6. 5

7. S

OK!!

COPY MACH <- SRAM

If the SRAM data is successfully down loaded, the display shows "OK".

If the SRAM download fails, the display

shows "NG".

NG!!

COPY MACH <- SRAM

8. Finish : FU

9. Turn off the mach ine and disconnect the tool. Then turn the machine back

on.

4-14

Page 51

August 2nd, 1995 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNCTIONS

4.1.23. Serial Number (Function 14)

1. FU 6 1 9 9 5

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

then immediately Y

2. 1 4 Y

3. Enter the machine’s serial number a t th e

keypad.

SERIAL # KPAD

SERIAL # KPAD/Y/N

RICOH 1234567

To correct a mistake: N

4. If the display is correct: Y

5. Finish: FU

4.1.24. Service Station Fax Number (Function 13)

1. FU 6 1 9 9 5

FUNCTION KPAD/NEXT

SERVICE FUNCTIONS

then immediately Y

2. 1 3 Y

S.S. NO. KPAD

_

3. Input the telephone number of the service station that will receive Aut o

Service calls from this machine.

To erase the telephone number: press N

S.S. NO. KPAD

2125555242

4. If the display is correct: Y FU

4-15

Page 52

SERVICE TABLES AND PROCEDURES August 2nd, 1995

BIT SWITCHES

4.2. BIT SWITCHES

WARNING

I

Do not adjust a bit switch that is described as "Not used", as this may

cause the machine to malfunction or to operate in a manner that is not

accepted by local regulations. Such bits are for use only in other

areas, such as Japan.

Note: Default settings for bit switch es are not listed in this manual. Refer to

the System Paramete r List prin ted by the machine.

4.2.1. System Switches

System Switch 00

No FUNCTION COMMENTS

RAM Reset

Bit 1 Bit 0 Reset Level

0 0 No reset

0 1 Reset Level 2

1 0 Reset Level 3

1 1 Not used

0

1

Reset Level 3: Erases all image data files stored in

the SAF memory and communciation files (e.g. polling

rx file). This setting is recommended for use when it is

necessary to clear the SAF.

Reset Level 2: In addition to those items erased by

Reset Level 3, the following items are erased: own

telephone number, bit switches, RTI/TTI/CSI, report

data, programmed telephone numbers (Quick/Speed/

Groups, service station, etc.), NCU parameters,

personal codes.

After erasing, the machine changes these two bits

back to 0 automatically.

No reset: Normal operation

Cross reference

RAM Reset Level 1 (Factory reset):

Change the data in RAM address 800000(H) to FF(H),

then turn the machine off and on. In addition to those

items erased by Reset Level 2, the clock and

scan/print registration settings are erased.

4-16

Page 53

August 2nd, 1995 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

System Switch 00

No FUNCTION COMMENTS

Technical data printout on

TCR (Journal)

0: Disabled

1: Enabled

2

Line quality data output

method

0: Measure of error rate

3

(during image data

transmission only)

1: Rx level

Line error marks

0: Disabled

4

1: Enabled

Communication parameter

display

0: Disabled

5

1: Enabled

Protocol dump list output

after each communication

6

0: Off 1: On

Not used Do not change the settings.

7

1: Instead of the personal code, the following data are

listed on the TCR for each analog G3 communication.

e.g. V33 14 01 03 00 02

First number: Final modem type used

Second number: Final modem rate (for example, 14

means 14.4 kbps)

Third and fourth numbers: Line quality data. Either a

measure of the error rate or the rx level is printed,

depending on the bit 3 setting below. (An M on the

report indicates that it is error rate, and an L indicates

Rx level.) The left hand figure is the high byte and the

right hand figure is the low byte (see the note below

this table for how to read this value). If it is a measure

of the error rate; a larger number means more errors.

Fifth number (rx mode only): Total number of error

lines that occurred during non-ECM reception.

Sixth number (rx mode only): Total number of burst

error lines that occurred during non-ECM reception.

The fifth and sixth numbers are fixed at 00 for

transmission records and ECM reception records.

This bit determines the data type to be printed on the

TCR (Journal) when technical data printout is enabled

by bit 2 above.

If this bit is 1, a mark will be printed on the left edge of

the page at any place where a line error occured in the

data. Such errors are caused by a noisy line, for

example.

This is a fault-finding aid. The LCD shows the key

parameters (see the next page). This is normally

disabled because it cancels the CSI display for the

user.

Be sure to reset this bit to 0 after testing.

This is only used for communication troubleshooting. It

shows the content of the transmitted facsimile protocol

signals. Always reset this bit to 0 after finishing testing.

How to calculate the rx level listed on the TCR (when bit 2 of system switch 00 is set to 1)

Example: V29 96 L 01 0C 00 00

The four-digit hexadecimal value (N) after L indicates the rx level. Divide the decimal value of

N by -16 to get the rx level.

In this example, the decimal value of 010C(H) is 268.

So, the actual rx level is 268/16 = -16.75 dB.

4-17

Page 54

SERVICE TABLES AND PROCEDURES August 2nd, 1995

BIT SWITCHES

Communication Parameters

Mode DCS: ITU-T standard NSS: Non-standard G3

Modem rate 144: 14400 bps

120: 12000 bps

96: 9600 bps

72: 7200 bps

48: 4800 bps

24: 2400 bps

Communication

mode

Compression

mode

Resolution SSF: Fine, transmitted at 8 x 15.4 dots per mm

I/O rate 0M: 0 ms/line 10M: 10 ms/line

Width and

reduction

ECM: With ECM SSC: Using SSC

EFC: Using EFC NML: With no ECM, SSC, or EFC

MMR: MMR compression

MR: MR compression

MH: MH compression

DTL: Detail, transmitted at 8 x 7.7 dots per mm

STD: Standard, transmitted at 8 x 3.85 dots per mm

2/M: 2.5 ms/line 20M: 20 ms/line

5M: 5 ms/line 40M: 40 ms/line

=A4: A4 (8.3"), no reduction

=B4: B4 (10.1") no reduction

>A4: Reduced to A4 (8.3") before transmission

System Switch 01

No FUNCTION COMMENTS

PM call

0: Disabled

1: Enabled

0

Not used Do not change the settings.

1-7

This bit switch determines whether the machine will

send an Auto Service Call to the service station when it

is time for PM.

Cross reference

Auto service calls: Section 2.3.2

4-18

Page 55

August 2nd, 1995 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

System Switch 02

No FUNCTION COMMENTS

Memory file transfer

0: Disabled

1: Enabled

0

Programmed data transfer

(Back-to-back)

0: Disabled

1: Enabled

1

Not used Do not change the setting.

2

Memory file printout

0: Disabled

3

1: Enabled

Not used Do not change the settings.

4

Software download area

0: All except the boot block

1: All areas, including the

boot block

5

Keep this bit at 0 except for

the rare cases when the

Flash ROM boot block has

to be rewritten.

Memory read/write by RDS

Bit 7 6 Setting

0 0 Always disabled

0 1 User selectable

6

1 0 User selectable

1 1 Always enabled

7

1: All messages in the memory (including confidential

rx messages) are sent to the fax number which is

programmed as the service station.

Always reset this bit to zero after transfer.

Cross reference

Service station number programming: Function 13

Do the following steps to transfer the data.

1. Connect two machines of the same type back to

back and enable back-to-back communication on both

machines. (For this machine, set bit 7 of the G3 bit

switch 00 to 1.)

2. Set this switch to 1 on the receiving machine.

3. Insert a sheet of paper in the ADF, and press Start

on both machines. The data is transferred.

4. Disable back-to-back comminication and set this bit

to 0 after finishing.

1: All SAF files, including confidential messages, can

be printed using Function 54 or 55.

Always reset this bit after printing the messages.

0: This is the normal setting. For normal software

downloads, do not change this bit switch.

1: Set this bit to 1 only when you need to rewrite the

boot block in the Flash ROM using Function 12.

Cross reference

Software Download: Section 4.1.20

(0,0): All RDS systems are always locked out.

(0,1), (1,0): Normally, RDS systems are locked out, but

the user can temporarily switch RDS on to allow RDS

operations to take place. RDS will automatically be

locked out again after a certain time, which is stored in

System Switch 03 (see below). Note that if an RDS

operation takes place, RDS will not switch off until this

time limit has expired.

(1,1): At any time, an RDS system can access the

machine.

4-19

Page 56

SERVICE TABLES AND PROCEDURES August 2nd, 1995

BIT SWITCHES

System Switch 03

No FUNCTION COMMENTS

Length of time that RDS is

0

temporarily switched on

when bits 6 and 7 of

to

System Switch 02 are set to

7

"User selectable"

System Switch 04

No FUNCTION COMMENTS

LCD contrast

Bit 2 1 0 Contrast

0

0 0 0 Brightest

0 0 1 ↓

1

↓ ↓

2

1 1 0 ↓

1 1 1 Darkest

Dedicated transmission

parameter programming

3

0: Disabled 1: Enabled

Inclusion of the Start key in

Keystroke Programs

4

0: Not needed

1: Needed

OPC (master drum)

replacement level

0: User

1: Service

5

CSI programming level

0: User level

6

1: Service level

Telephone line type

programming mode

7

0: User level

1: Service level

00 - 99 hours (BCD).

This data is only valid if bits 6 and 7 of System Switch

02 are set to "User selectable".

The default setting is 24 hours.

Use these bit switches to adjust the contrast of the

LCD on the operation panel.

This bit must be set to 1 before changing any

dedicated transmission parameters.

0: The user does not need to press the Start key when

operating a keystroke program.

0: The machine asks the user to replace the OPC

drum at 30,000 print intervals (default interval).

After the user replaces the drum, the machine asks the

user if the drum is replaced or not. If the user answers

yes, the machine resets the OPC counter to zero. The

drum replacement interval is programmed at

addresses 8001E5 to 8001E7(H). Refer to section 4.5

for more details.

1: The machine will not ask the user to replace the

drum.

1: The CSI can only be programmed using a service

function.

1: Telephone line type selection can only be

programmed using a service function.

4-20

Page 57

August 2nd, 1995 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

System Switch 05

No FUNCTION COMMENTS

0 Not used Do not change the settings.

1

Display of both RTI and CSI

on the LCD

2

0: Disabled 1: Enabled

Not used Do not change the settings.

3-7

System Switch 06

No FUNCTION COMMENTS

Use of the Stop key during

memory transmission

0

0: Disabled 1: Enabled

Not used Do not change the settings.

1-7

System Switch 07 - Not used (do not change the settings)

System Switch 08 - Not used (do not change the settings)

1: Both RTI and CSI will be displayed alternately on

the LCD.

1: Memory transmissions can be stopped by pressing

the Stop key. However, users might accidentally cancel

another person’s memory transmission in progress.

System Switch 09

No FUNCTION COMMENTS

Addition of part of the image

data from confidential

transmissions on the

0

transmission result report

0: Disabled 1: Enabled

Inclusion of communications

on the TCR when no image

data was exchanged.

1

0: Disabled 1: Enabled

Automatic error report

printout

2

0: Disabled 1: Enabled

Printing of the error code on

the error report

3

0: No 1: Yes

Listing of Confidential IDs

on the Personal Code List

4

0: Disabled 1: Enabled

Power failure report

0: Disabled 1: Enabled

5

Not used Do not change the settings.

6

If this feature is enabled, the top half of the first page

of confidential messages will be printed on

transmission result reports.

0: Communications which reached phase C (message

tx/rx) of the T.30 protocol are listed on the TCR

(Journal).

1: Communications which reached phase A (call setup)

of T.30 protocol are listed on the TCR (Journal). This

will include telephone calls.

0: Error reports will not be printed.

1: Error reports will be printed automatically after failed

communications.

1: Error codes are printed on the error reports.

1: Confidential IDs registered with Personal Codes by

the users will appear on the Personal Code List.

1: A power failure report will be automatically printed

after the power is switched on if a fax message

disappeared from the memory when the power was

turned off last.

4-21

Page 58

SERVICE TABLES AND PROCEDURES August 2nd, 1995

BIT SWITCHES

System Switch 09

No FUNCTION COMMENTS

Priority given to various

types of remote terminal ID

when printing reports

0: RTI > CSI > Dial label >

7

Tel. number

1: Dial label > Tel. number

> RTI > CSI

System Switch 0A

No FUNCTION COMMENTS

0

Not used Do not change the settings.

to

2

This bit determines which set of priorities the machine

uses when listing remote terminal names on reports.

Dial Label: The name stored with the Quick/Speed Dial

number by the user.

Continuous polling reception

3

0: Disabled 1: Enabled

Dialing on the ten-key pad

when the handset is off-hook

4

0: Disabled 1: Enabled

On hook dial

5

0: Disabled 1: Enabled

6 Not used Do not change the settings.

7

System Switch 0B

No FUNCTION COMMENTS

Automatic reset timer

Bit 1 Bit 0 Timer setting

0

0 0 1 minute

0 1 3 minutes

1

1 0 5 minutes

1 1 No limit

Power Saver mode timer

Bit 3 Bit 2 Time Limit

2

0 0 1 minute

0 1 3 minutes

3

1 0 5 minutes

1 1 No limit

4

Not used Do not change the settings.

to

7

1: The machine repeats polling reception to the same

station until the polling file is manually erased.

1: The user can dial on the machine’s ten-key pad

when the handset is off-hook.

0: On hook dial is disabled.

(1, 1): Automatic reset is disabled.

(Other): The machine returns to the standby mode

when the timer expires after the last operation.

(1, 1): Automatic Power Saver mode is disabled.

(Other): The machine goes into a Power Saver mode

when the timer expires after the last operation.

Cross reference

Power Saver modes: Section 2.3.1

4-22

Page 59

August 2nd, 1995 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

System Switch 0C - Not used (do not change the settings)

System Switch 0D - Not used (do not change the settings)

System Switch 0E - Not used (do not change the settings)

System Switch 0F

No FUNCTION COMMENTS

Country code for functional settings

(Hex)

00: France 10: Not used

01: Germany 11: USA

02: UK 12: Asia

03: Italy 13: Japan

04: Austria 14: Hong Kong

05: Belgium 15: South Africa

0

06: Denmark 16: Australia

to

7

07: Finland 17: New Zealand

08: Ireland 18: Singapore

09: Norway 19: Malaysia

0A: Sweden 1A: China

0B: Switz. 1B: Taiwan

0C: Portugal 20: Turkey

0D: Holland 21: Greece

0E: Spain

0F: Israel

This country code determines the factory

settings of bit switches and RAM addresses.

However, it has no effect on the NCU

parameter settings and communication

parameter RAM addresses.

Cross reference

NCU country code: Function 08, parameter

CC.

System Switch 10 - Not used (do not change the settings)

System Switch 11 - Not used (do not change the settings)

System Switch 12

No FUNCTION COMMENTS

TTI print position

0: Inside the image area

0

1: Outside the image area

1

Not used. Do not change the settings.

to

7

System Switch 12

No FUNCTION COMMENTS

TTI printing position in the

main scan direction

0

to

7

1: The TTI will be added without overwriting the image

data.

08 to 92 (BCD) mm. Input even numbers only.

This setting determines the TTI print start position from

the left edge of the paper. If the TTI is moved too far to

the right, it may be obscured by the file number which

is on the top right of the page.

4-23

Page 60

SERVICE TABLES AND PROCEDURES August 2nd, 1995

BIT SWITCHES

System Switch 13 - Not used (do not change the settings)

System Switch 14

No FUNCTION COMMENTS

Wait time between pages in

printer mode (with an

optional printer interface

unit)

0

to

7

System Switch 15 - Not used (do not change the settings)

System Switch 16 - Not used (do not change the settings)

System Switch 17 - Not used (do not change the settings)

System Switch 18 - Not used (do not change the settings)

System Switch 19 - Not used (do not change the settings)

System Switch 1A - Not used (do not change the settings)

System Switch 1B - Not used (do not change the settings)

System Switch 1C - Not used (do not change the settings)

System Switch 1D - Not used (do not change the settings)

System Switch 1E - Not used (do not change the settings)

System Switch 1F - Not used (do not change the settings)

05 to 64 (H) (5 to 100s) - This setting determines the

machine’s wait time between pages in printer mode.

A longer setting forces the fax machine to wait until the

end of printer interface output before printing any

incoming fax message.

A shorter setting allows the fax machine to print

incoming fax messages while printing from a computer.

If the controller takes more than the specfied time to

process a page of data from the host computer, the fax

machine releases the printer resources for fax output.

4-24

Page 61

August 2nd, 1995 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

4.2.2. Scanner Switches

Scanner Switch 00

No FUNCTION COMMENTS

Not used Do not change the settings.

0

Not used Do not change the settings.

1

Maximum transmittable

document length

Bit 3 2 Setting

2

0 0 600 mm

3

0 1 1200 mm

1 0 14 m

1 1 Not used

OR processing in immediate

tx and copying (Standard

resolution)

4

0: Disabled

1: Enabled

5

Not used Do not change the settings.

to

7

If the user wants to send very long documents such as

well logs, select 14 m or a higher setting.

0: The machine scans the document in 3.85 line/mm

steps, then transmits or makes copies.

1: The machine scans the document in 7.7 line/mm

steps. Each pair of lines is OR processed before

transmission or making copies. Toner may be used up

earlier if OR processing is enabled.

Scanner Switch 01 - Not used (do not change the settings)

Scanner Switch 02

No FUNCTION COMMENTS

Contrast threshold with

0

halftone disabled - Normal

to

7

setting

Scanner Switch 03

No FUNCTION COMMENTS

Contrast threshold with

0

halftone disabled - Lighten

to

7

setting

Scanner Switch 04

No FUNCTION COMMENTS

Contrast threshold with

0

halftone disabled - Darken

to

7

setting

The value can be between 00 to FF. For a darker

threshold, input a lower value.

Default setting - 08(H)

The value can be between 00 to 0F. For a darker

threshold, input a lower value.

Default setting - 0A(H)

The value can be between 00 to 0F. For a darker

threshold, input a lower value.

Default setting - 06(H)

4-25

Page 62

SERVICE TABLES AND PROCEDURES August 2nd, 1995

BIT SWITCHES

Scanner Switch 05

No FUNCTION COMMENTS

Contrast threshold with

0

halftone enabled - Normal

to

7

setting

Scanner Switch 06

No FUNCTION COMMENTS

Contrast threshold with

0

halftone enabled - Lighten

to

7

setting