Page 1

Subject:

Issued on

January 13th, 1992.

Software probl em

Model(s): FAX3000L

Classification

1. Problem

• Phenominon

1. The RX image may be reduced (3/4).

2. The end of the RX image (af te r B 5 len gt h) may be blurred.

3. The parts (left side) of the RX image may be rep eate d o n the righ t.

Technical Bulletin

No.CSO-001

FA X T.S. Section T.S. Department

Assistant General Manager

H. Motojima

Control No. f or Each Area

R.C. -- Asia 001

SAVIN -- LAM --

Europe -- A T&T --

HCS --

• Conditions

1. The specified cassette sele ction is on.

2. More than 2 pages are received.

3. The PFU is installed.

4. Memory RX (substitute reception, night timer, etc).

Under all of the above conditio ns, the prob lem may occu r.

2. Cause.

Software mistake.

3. Countermeasure

When installing the PFU (Paper Fee d Unit ) re pla ce the ROM on the machine.

(The ROMs will be provided from Ricoh Tokyo (FTSG). )

After replace the ROMs, che ck the ma chin e, in accord an ce with the att ach ed check she et ,

and return the sheets to Ricoh Tokyo (Attn. Mr Motojima) by air mail once a mont h.

4. Serial No.

December (1991) product ion only

A06112XXXXX

Page 2

Issued on

January 27th,1992

Technical Bulletin

No. CSO-002

Subject:

Model(s):

Classification

[Problem]

The document may not fee d at all if the customer place s 50 sheets in the ADF.

Document non-feed

FA X T.S. Section T.S. Department

Assistant General Manager

H. Motojima

Control No. f or Each Area

R.C. 0 01 Asia --

SAVIN 001 LAM 001

Europe 001 A T&T --

HCS 001

[Cause]

1. Static electricity. (In low humidity environment)

2. Some types of pap er, such as rough or thick types.

[Action]

Normally documents should be set with the edges even, because the CS O ha s a shut ter .

However, if the customer faces this problem, instruct the customer to do the following.

1. Shuff le the stack

2. Place the document in the fee de r a s follo ws

0~10mm

Inserting Direction

Page 3

Issued on

February 15, 1992

Technical Bulletin

No. CSO-003

Subject:

Model(s): AFO/AF2/CSO

Classificati on

Action Required

Troubleshooting

Retrof it Information

Revision of Service Manual

Inform a tion Only

Others

[Problem]

1. When a telephone call is incoming, the contact of the NCU OH relay may melt after quite a

few repetition of incoming calls. then no fax reception becomes available. (AFO/AF2/CSO)

AFO/AF2/CSO Software problem

FAX T.S. Section T.S. Depa rtmen t

Assistant General Manager

H. Motojima

Control No. for Each Area

R.C. -- Asia 002

SA V IN -- LAM 002

Europe 002 AT&T -HCS 002

2. The first printing page for a reception, a substitute file output, a report or a pattern output

may be blank. (AFO/AF2)

[Cause]

1. By a software fault, the DC loop over the OH relay is closed during an incoming call to result

in putting the ringing voltage (energy) through the DC loop.

The current faulty program allows the rin gin g off signal be enabled during a r inging sequence, so the OH relay is to be switched on.

Possible occurrence rate is ;

1/1800 ∼ 1/8300 at incoming calls.

(For more details, refer to page 3.)

2. By a software fault, the command for 24V power supplying to the thermal head may be

turned off instantly.

However, the printing sequence continues to result in a blank page outputted.

This is caused by the faulty priority assignment of the signals of 24V power on, of status

check and of RXSTART trigger.

It may occur at random as 36 µs/160 ms ≅ 1/4400.

Page 4

Issued on

February 15, 1992

Technical Bulletin

No. CSO-003

Subject:

[Countermeasure]

1. The program is corrected.

So, exchange the ROM on the MBU to the new one.

2. The program is corrected.

So, exchange the ROM on the MBU to the new one.

Part numbers

AFO/AF2/CSO Software problem

Version Old New ROM

Ricoh Europe/NRG H0847140C H0847140D

AFO

AF2

CSO

HCS H0847143C H0847143D

Language kit H0847150A H0847150B

Asia H0847141C H0847141D

Ricoh Europe/NRG H0867140C H0867140D

HCS H0867143C H0867143D

Language kit H0867150B H0867150C

Asia H0867141C H0867141D

Ricoh Europe/NRG H0817130G H0817130H

HCS H0817131G H0817131H

Language kit H0817159D H0817159E

Asia H0817132G H0817132H

[Affected machines]

The machines produced in Nov and Dec ’91 and in Jan ’92.

Note: Some of the above machines have been modified in Japa n before shipment.

Page 5

Subject:

Issued on

February 15, 1992

1. Faulty program

Ringing on/off flag

Ringing detection

Ringing detecting

prohibition flag

Technical Bulletin

No. CSO-003

AFO/AF2/CSO Software problem

Ringing

OH relay

2. Corrected prog ram

Ringing

Ringing on/off flag

Ringing detection

Ringing detecting

prohibition flag

OH relay

Page 6

Issued on

February 19th, 1992

Technical Bulletin

No. CSO-004

Subject:

Model(s): AFO/AF2

Classification

When installing the above mod els in Holla nd /I ta ly/B elg ium, change the NCU parpameter to

meet the PTT require men t as fo llows.

NCU parameter setting for Hol land

CSO

FA X T.S. Section T.S. Department

Assistant General Manager

H. Motojima

Control No. f or Each Area

R.C. -- Asia --

SAVIN -- LAM --

Europe 003 A T&T --

HCS 003

1. Change the country codes for NCU parameter and bitswitch.

2. Change the following parameters and RAM addresse s as follo ws.

[Holland]

NCU Parameter 002=020

NCU Parameter 003=080

NCU Parameter 004=020

NCU Parameter 005=080

NCU Parameter 006=002

NCU Parameter 010=058

NCU Parameter 011=058

NCU Parameter 012=042

NCU Parameter 013=042

Address 4144=5EH

Address 4152=5EH

Address 416A=5EH

Address 417F=02H

[Italy]

Address 4157=06H

Address 4158=00H

Address 4159=01H

Address 415A=00H

Address 4158=15H

Address 415C=15H

Address 4164=40H

[Belgium]

Address 413F=05H

Address 4140=20H

Address 4141=03H

Address 4142=00H

Address 414D=05H

Address 414E=20H

Address 414F=03H

Address 4150=00H

Address 4151=1EH

Address 4152=13H

Address 4153=1EH

Address 4154=04H

The above correction will be applied in to the soft ware from the 1st productions of March ’92.

Page 7

Issued on

March 3rd, 1992

Technical Bulletin

No. CSO-005

Subject:

Model(s): CSO

Classification

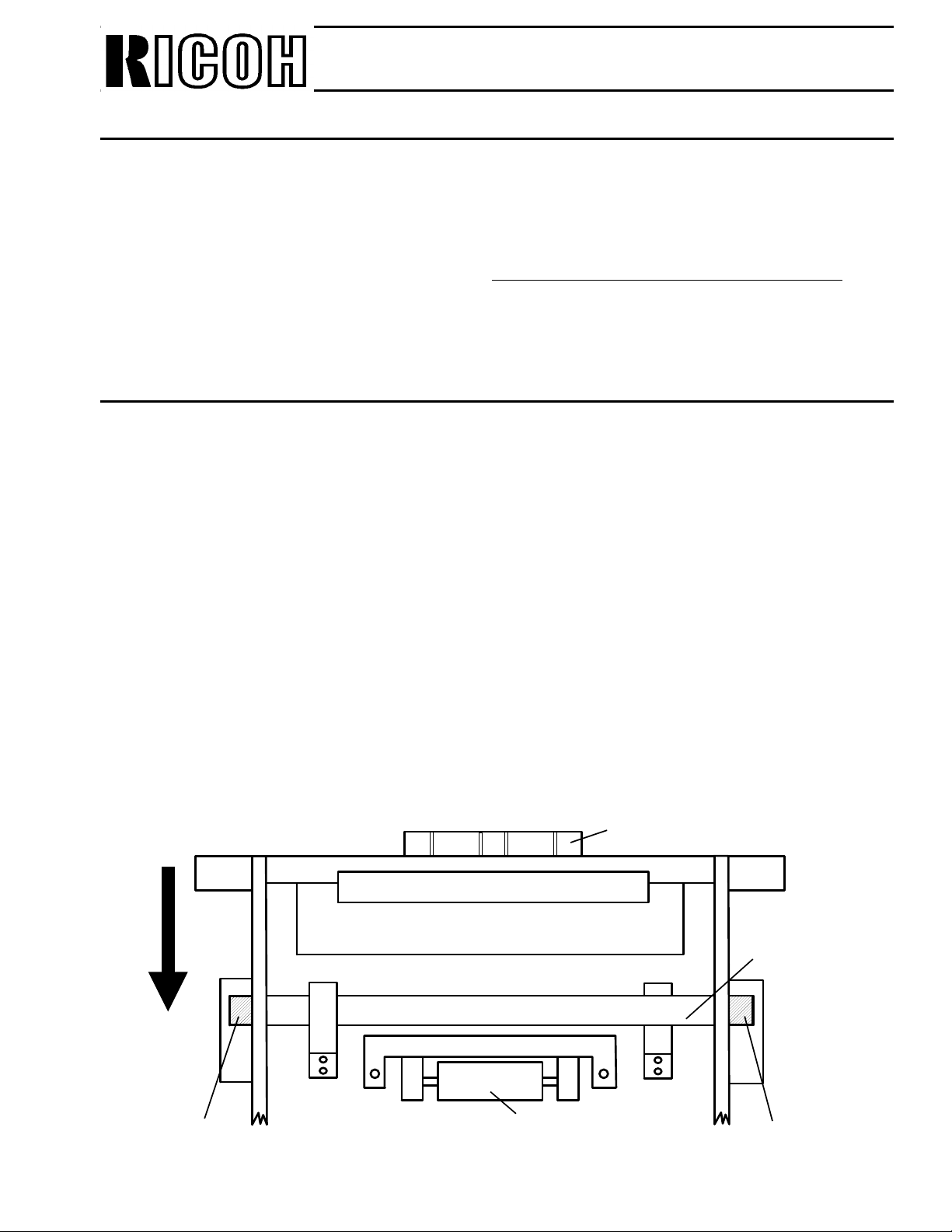

If the customer require A5 size pa pe r in t he pape r feed unit, adjust the spring pressure as

follows in order to prevent do uble feeding.

Optional paper feed unit adjustment

FA X T.S. Section T.S. Department

Assistant General Manager

H. Motojima

Control No. f or Each Area

R.C. -- Asia --

SAVIN -- LAM --

Europe 004 A T&T --

HCS 004

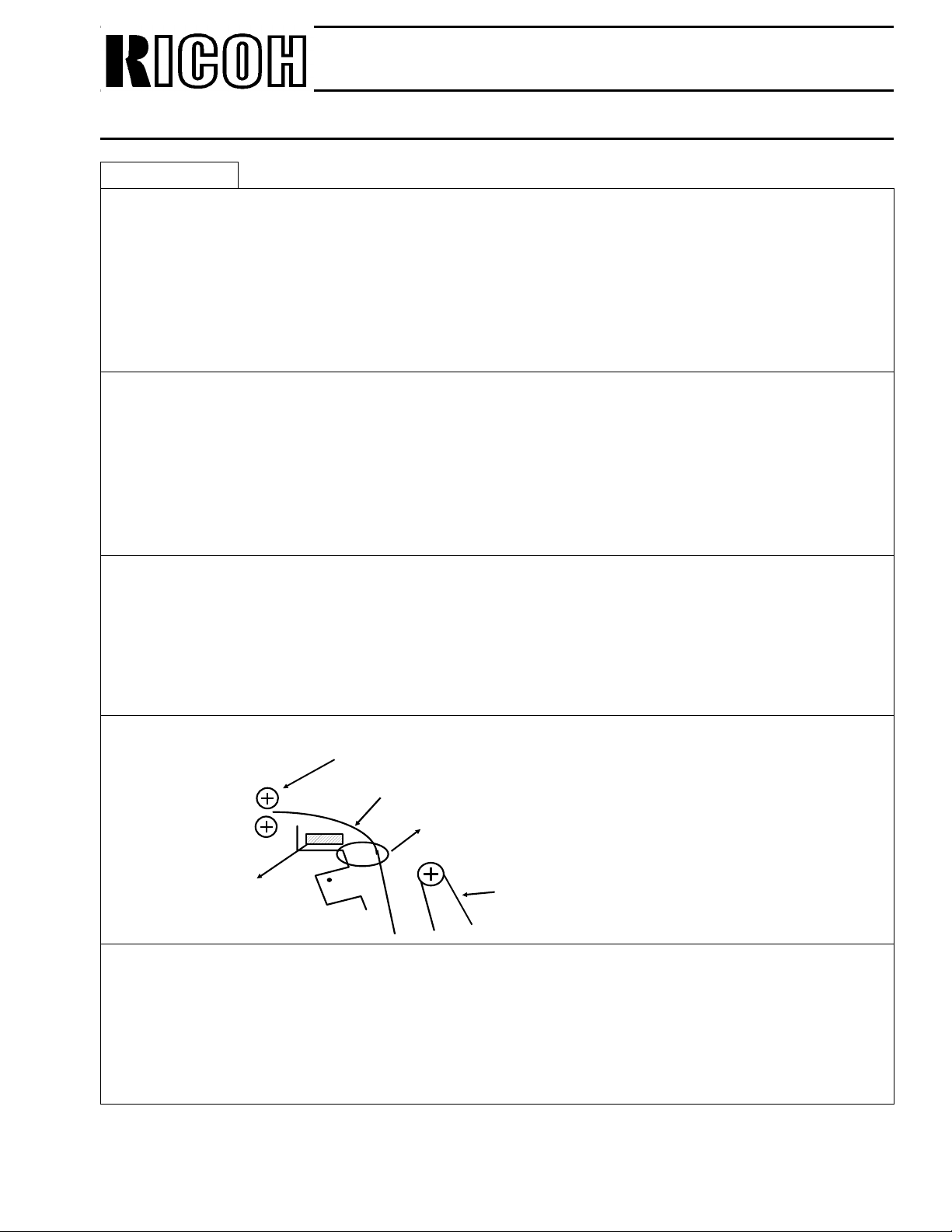

1. Remove the right cover.

2. Adjust the spring pressu re by th e ad justment bracket as shown belo w. (by loosening 2

screws)

3. Put the cover back.

Page 8

Duct

Remaining Toner

Issued on

March 5th, 1992.

Technical Bulletin

No. CSO-006

Subject:

Model(s): CSO

Classificati on

Action Required

Troubleshooting

Retrof it Information

Revision of Service Manual

Inform a tion Only

Others

Once the machine is installed (with the Toner Cassette installed in the machine), the toner will

be transferred to the developing unit. As a result, when the Toner Cassette is removed from the

machin e, some residual toner may s pill out from the de veloping unit when the ma chine is

moved.

Duct cover for the development unit

FAX T.S. Section T.S. Depa rtmen t

Assistant General Manager

H. Motojima

Control No. for Each Area

R.C. 002 Asia 003

SA V IN 002 LAM 003

Europe 005 AT&T ---

HCS 005

If it is necessary to transport the machine after installation, please do the following:

1. Switch off the power, and r emove the toner cassette.

2. Remove the remaining toner at the duct entrance by

tapping the duct.

3. Close the front cover without putting back the toner

cassette.

4. Using the test mode, rotate the toner supplier as follows.

(1) Enter test mode: Function 5 1 9 9 1

(2) 9 7 Yes

(3) 8

(4) After the noise from the toner supply mechanism stops, press Stop

5. Push the duct cover (H0812487) into the development un it with a screwdriver.

Longer

Duct

H0812487

H0812487

6. Switch off the power.

7. Move the machine.

Shorter

15mm

Page 9

Issued on

March 16 , 1992

Technical Bulletin

No. CSO-007

Subject:

Model(s): CSO

Classification

When the power is kept on, the PCB-PFU will be bro ken aft er connecting/disconnecting the

connectors during instalation/checking th e lower paper feed unit.

Lower paper feed unit

FA X T.S. Sectio n, T.S. Department

Assistant General Manager

H. Motojima

Control No. f or Each Area

R.C. 003 Europe 006

SAVIN 003 HCS 006

NRG-

USA

-- NRG --

Asia/LAM 004

Therefore, before connecting/disconnecting the paper fee d un it, plea se make sure that the

power is switched off.

Page 10

Issued on

March 18th, 1992

Technical Bulletin

No. CSO-008

Subject:

Model(s): AFO/AF2/CSO

Classification

-Problem-

If the T1 timer is set with a value of over 100 for a speed dial code by d ed icated Tx parameter

programming, the other parame te r for th e spe ed dial cod es will not be programmed.

Dedicated Tx parameter programming problem

FA X T.S. Sectio n, T.S. Department

Assistant General Manager

H. Motojima

Control No. f or Each Area

R.C. 004 Europe 007

SAVIN 004 HCS 007

NRG-

USA

001 NRG 001

Asia/LAM 005

-Cause-

Software bug.

-Countermeasure-

Temporary- Set the T1 timer with a value less than 100 for spe ed dia l codes.

Permanent - We will correct the software from the May mass pro duction.

Page 11

Page

418E=12H

1

Technical Bulletin

KMxml

Subject:

Model(s): AFO/AF2

Classification

Action Required

u-

Troubleshooting

❑

Retrofit Information

❑

Revision of Service Manual

Information Only

El

❑

Others

When installing the above models in Sweden, change the

PTT/sales

the

NCU

Cso

requirements as follows.

No.cso-009

parameter setting

for

FAX

Assistant General Manager

H.

Control No. for Each Area

Sweden

T.S.

Section

McWinTJii-nTJ>z~

R.C. --

SAVIN

NRG-USA

Issued on

March 19th, 1992

T.S.

Department

j

,

)

(Y

Europe

--

--

NCU

parameter in accordance with

HCS

NRG

Asia/LAM

008

008

002

--

1. Change the country codes for NCU parameter and bitswitches.

2. Change the and RAM addresses and bit switch as follows.

(PTT requirement)

Address 4172 = 60H

Address 4173 = 20H

Address 4174 = 60H

Address 4175 = 03H

Address 4176 = 19H

The above correction will be applied into the software from the

(Sales requirement)

Address 406C bit 5 =

Address 4063 bit 7 = O

Bit sw SW06 = F0H

1st

bit6=l

0,

productions of May ’92.

4143=28H

4145=28H

4151=28H

4153=28H

4172=28H

4174=28H

Page 12

Issued on

April 15th, 1992

Technical Bulletin

No.CSO-010

Subject:

Model(s): CSO (Europe and Asia)

Classificati on

Action Required

Troubleshooting

Retrof it Information

Revision of Service Manual

Inform a tion Only

Others

We issue the correction for the service manual for CSO.

Please refer to the attached.

Service Manual Correction

FAX T.S. Section, T.S. D epartment

Assistant General Manager

H. Motojima

Page 13

Issued on

April 24th, 1992

Technical Bulletin

No.CSO-011

Subject:

Model(s): AFO AF2/CSO

Classificati on

Action Required

Troubleshooting

Retrof it Information

Revision of Service Manual

Inform a tion Only

Others

When installing the above models in Switzerland, you have to apply the modification as th e

following steps.

NCU Modifi cation for Switzerland

(Europe only)

FAX T.S. Section, T.S. D epartment

Assistant General Manager

H. Motojima

1. Prepare the following parts at your side.

(1) Resister - 10Ω: 1/10W

(2) Capacitor - 0.047µF /250V

(3) C oil - TDK ELF 1010 SKI-332k (3.3m H)

2. Remove the NCU from the machine, then apply the modification.

(1) Replace the R17 with the above resister (10Ω)

(2) Add the capacitor and coil, and cut the pattern as shown on the next page.

3. Put the NCU back, and reassemble the machine.

4. Check the machine for the following items.

• Dialling (PD/DTMF)

• Transmission

• Reception

Page 14

Issued on

April 30th, 1992

Technical Bulletin

No.CSO-012

Subject:

Model(s): CSO

Classification

If you have any copy quality pro blems, make sure of the causes and solve the problem,

in accordance with the following pages.

T roubl es hooti ng

FA X T.S. Sectio n, T.S. Department

Assistant General Manager

H. Motojima

Page 15

Subject:

Issued on

April 30th, 1992

Troubleshooting

No. 1

Problem

OPC fragmentation

Image sample

Technical Bulletin

No.CSO-012

Characteristics of t he problem

The above image will appear every 188mm (one cycle of the OPC).

Cause

As a result of shock or scratching th e OPC, part of the OPC will come of f .

Action

Replace the OPC.

Page 16

Subject:

Issued on

April 30th, 1992

No. 2

Problem

Toner spillage.

Image sample

Technical Bulletin

No.CSO-012

Troubleshooting

Characteristics of t he problem

A lot of toner is attached on the copy.

Cause

There is a defective cleanin g rolle r b lad e in the used toner tank, or th e use d toner tank is full.

Action

Replace the CTM.

Page 17

Subject:

Issued on

April 30th, 1992

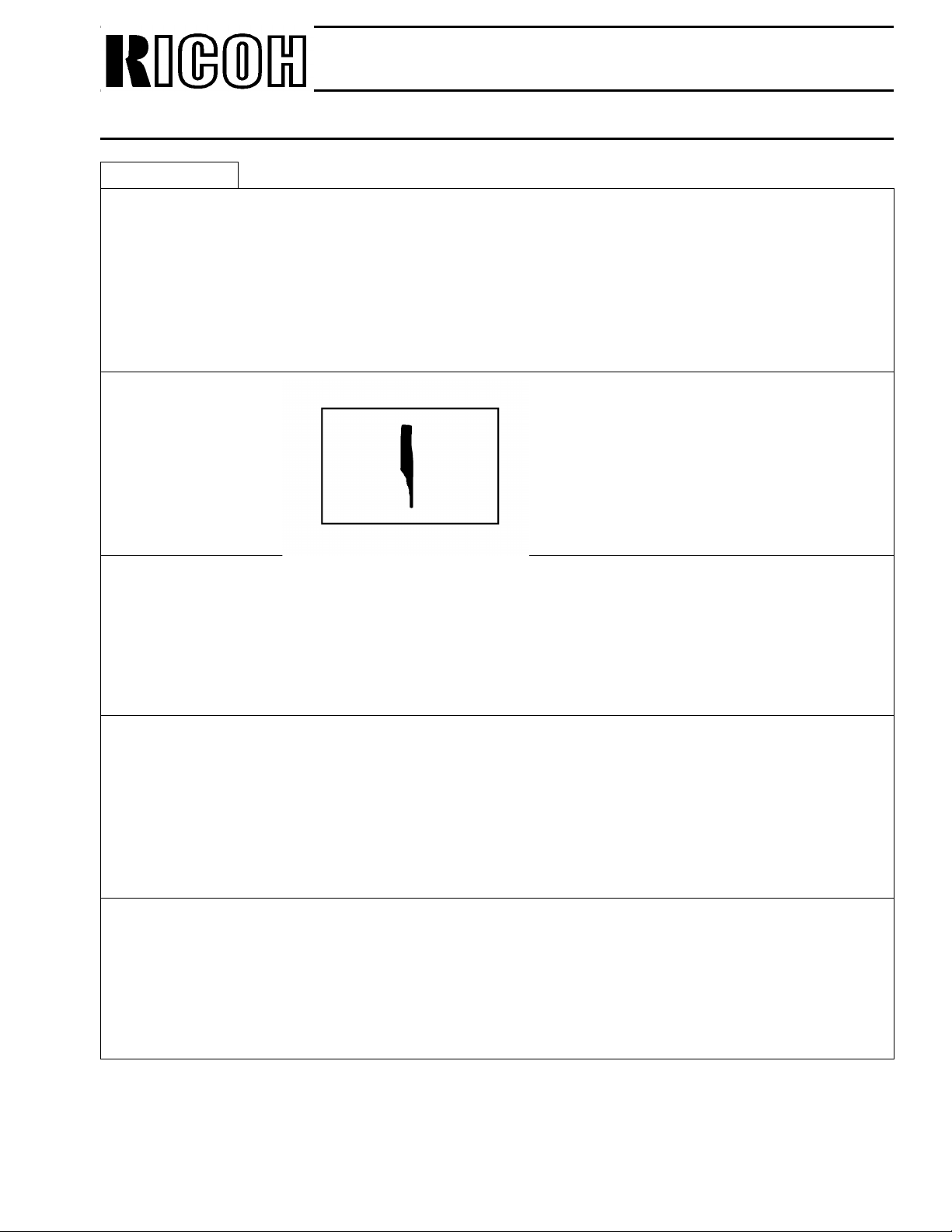

No. 3

Problem

Image flow.

Image sample

Technical Bulletin

No.CSO-012

Troubleshooting

Characteristics of t he problem

•The image has flowed in the sub scan direction.

•The boundary of the flow is not clear.

Cause

The OPC guide is attached to the OPC belt at point A .

Action

Replace the OPC.

Point A

Page 18

Subject:

Issued on

April 30th, 1992

Troubleshooting

No. 4

Problem

Incomplete transf er

Image sample

Technical Bulletin

No.CSO-012

Characteristics of t he problem

Part of image data is omitted in the same pla ce acro ss t he page.

Cause

Toner stuck to the transfer corona wire.

Action

Clean the transfer corona wire.

Page 19

Subject:

Issued on

April 30th, 1992

No. 5

Problem

Dirty Backgrand.

Image sample

Technical Bulletin

No.CSO-012

Troubleshooting

Characteristics of t he problem

Many clean black dots.

Cause

Shortage of change, cau sed by OPC stress.

Action

Rreplace the OPC.

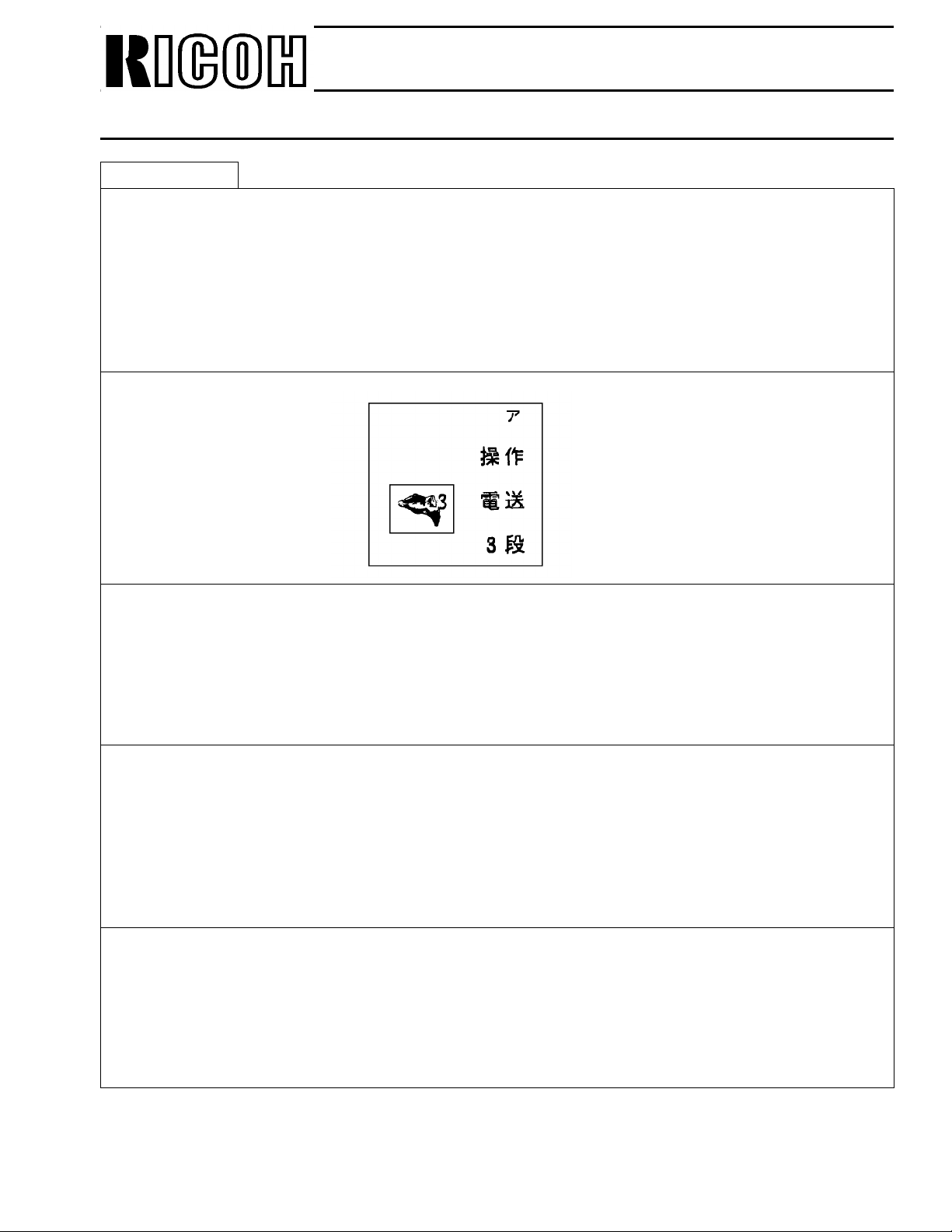

Page 20

Subject:

Issued on

April 30th, 1992

Troubleshooting

No. 6

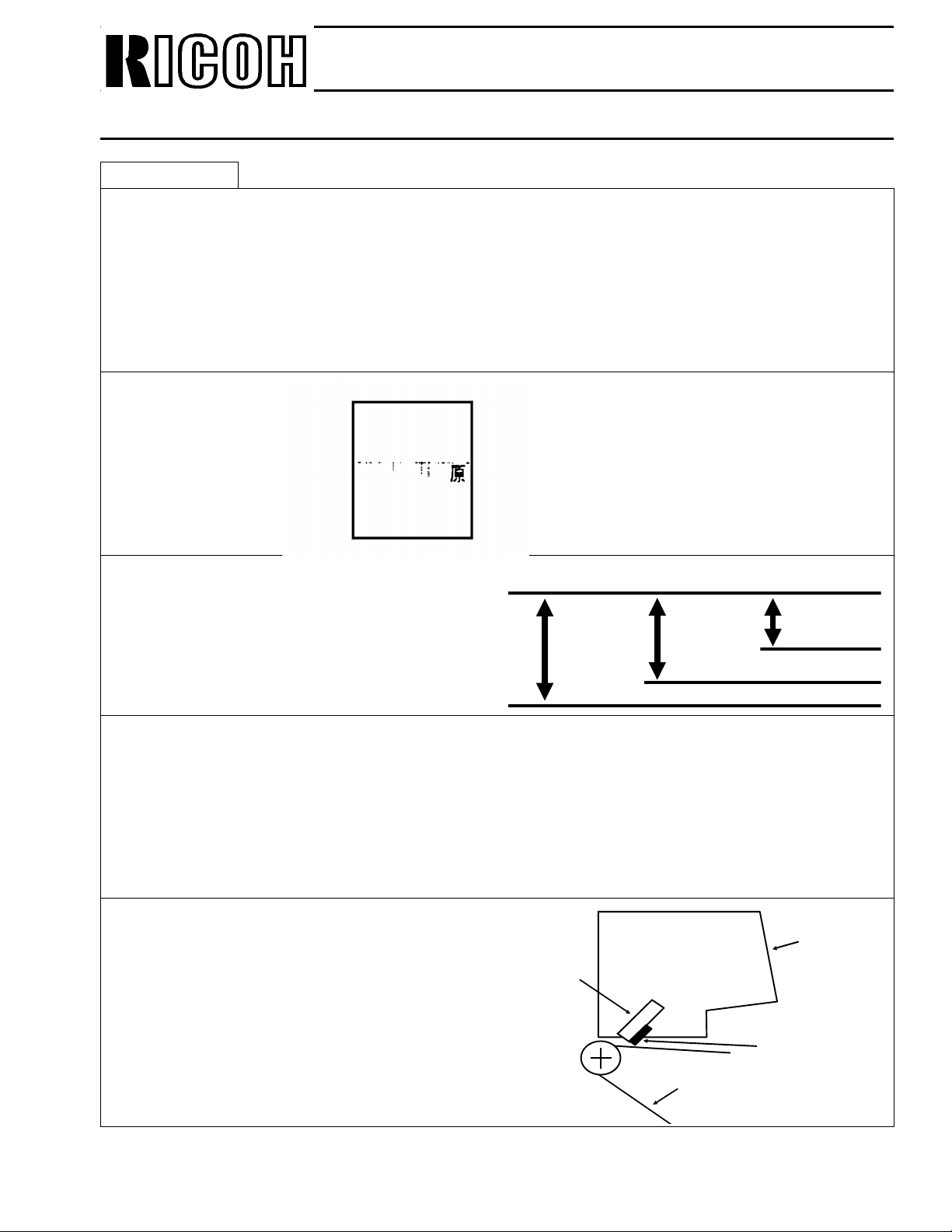

Problem

Tortoiseshell putterning

Image sample

Technical Bulletin

No.CSO-012

Characteristics of t he problem

This problem occurs in areas of inte rmed iat e de nsit y.

Cause

Pressure Roller

Copy Paper

Point A

Antistatic

sheet or brush

OPC

Action

Attach an antistatic she et or brush.

Toner has burst out due to a leak at

point A.

Page 21

Subject:

Issued on

April 30th, 1992

No. 7

Problem

Black dots.

Image sample

Technical Bulletin

No.CSO-012

Troubleshooting

Characteristics of t he problem

Dots appear at an interval of 14mm or 188mm.

Cause

(1) 14 mm interval → Defective develo pment roller

(2) 88mm interval → Defective OPC

Action

(1) Replace the developmen t unit.

(1) Replace the OPC.

Page 22

Subject:

Issued on

April 30th, 1992

No. 8

Problem

Dirty background.

Image sample

Technical Bulletin

No.CSO-012

Troubleshooting

Characteristics of t he problem

Blurred horizontal stripes on the backg round.

Cause

• OPC Over charged OP C Icorrect setting of OPC voltag e. (1)

Incorrect setting of OPC. (2)

Under charged OPC Incorrect setting of OPC voltage. (3)

Incorrect setting of OP C. (4)

Defective OPC (5)

•Defective development unit (6)

Action

(1), (3) Replace the power pack.

(2), (4) Check the OPC insta llat ion or replace the OPC

(5) Replace the OPC.

(6) Replace the developmen t unit.

Page 23

Subject:

Issued on

April 30th, 1992

No. 9

Problem

White dots.

Image sample

Technical Bulletin

No.CSO-012

Troubleshooting

Characteristics of t he problem

The dots appear at intervals of 14mm or 188 mm.

Cause

14mm → Defective development unit.

188mm → Defective OPC

Action

(1) Replace the developmen t unit.

(2) Replace the OPC.

Page 24

Subject:

Issued on

April 30th, 1992

Troubleshooting

No. 10

Problem

Black Band (sub scan)

Image sample

Technical Bulletin

No.CSO-012

Characteristics of t he problem

Wide Black band

It may not be straight; it may be oblique, curved or broken.

Cause

Something such as toner ha s att ached itself to the charge co ron a wire.

Action

Clean the charge corona wire.

Page 25

Subject:

Issued on

April 30th, 1992

Troubleshooting

No. 11

Problem

Black line (sub scan)

Image sample

Technical Bulletin

No.CSO-012

Characteristics of t he problem

Pale, thin, straight line s.

Cause

Incorrect cleaning, caused by cracks on the edge of the cleaning blade(CTM).

Action

Check the CTM installation, or replace the CTM.

Page 26

OPC

Blade

CTM

Toner

188mm

160mm

48mm

Printing start position

Subject:

Issued on

April 30th, 1992

Troubleshooting

No. 12

Problem

Black lines (Main scan)

Image sample

Technical Bulletin

No.CSO-012

Characteristics of t he problem

The lines appear as follows

Cause

•Dirt on the reverse side of the cleaning blade (CTM) or incorrect size of CTM or blade

Action

•Clean the reverse side of the cleaning blade .

•Replace the CTM

Page 27

Issued on

May 12th, 1992

Technical Bulletin

No.CSO - 013

Subject:

Model(s): AFO / AF2 / CSO

Classification

[Problem]

The above models may not transmit to the following models.

(Error code 0 - 21 / 0 - 23)

The document may stop during scanning, then th e mach ine will reset after 1 ∼ 2 min, and the

power failure report will be printed.

During transmission, th e stop key does not function.

Condition : I / O rate 40ms (standard), 20ms (Detail)

Models : UF32H • UF23 (Matsushita)

Communication Problem

FA X T.S. Sectio n, T.S. Department

Assistant General Manager

H. Motojima

[Cause]

A sof tware error

On the Tx side, the fill bit will be added if the 1 line data is less than the min Tx time for 1 line,

however on the above AFO / AF2 / CSO, the counting may be inco rrect .

[Countermeature]

Temporary : Using the dedicated Tx paramete r, select 4800bps of the initial modem rate.

Permanent : The 1st production of March ’92 will con ta in t he correct software.

Page 28

Issued on

May 12th, 1992

Technical Bulletin

No. CSO - 014

Subject:

Model(s): AFO / AF2 / CSO

Classification

[Problem]

The avove models can not re ceive using ECM from the machines which use 64 fra mes, such as

Canofax 470.

Communication Problem

FA X T.S. Sectio n, T.S. Department

Assistant General Manager

H. Motojima

[Cause]

A sof tware error

The frame size (256 / 64 frame) can no t be chan ge d in the software.

[Countermeature]

Temporary

If you face this problem, switch off the ECM function.

(Bit sw 07, bit 5 0 → 1)

In the field, most of facsimile machines use 256 frame, so, this proble m may occur rarely.

Permanent

The 1st production of May ’92 will con ta in the corre ct software.

Page 29

Handle

Subject:

Issued on

May 25th, 1992

Model(s): CSO

Classification

[Problem]

Technical Bulletin

No.CSO-015

Difficult to remove the upper cassette

FA X T.S. Sectio n, T.S. Department

Assistant General Manager

H. Motojima

It is difficult to remove the upper cassette fro m the machine when adding the pa pe r.

[Cause]

Friction between the Cassette Retaining Shaft and Cassette Guide Rail.

[Countermeasure]

Lubricate both sides of the Cassette Retaing Shaft .

(Refer to the diagram b elo w).

Use P/N 52 039501 Grease 501

This modification was completed from March, 1992.

Direction of Insertion

+

-

+

Cassette

Retaining Shaf t

Lubrecate Here

Roller

Lubricate Here

[ Viewed from the bottom of the cassette]

Page 30

Issued on

May 15th, 1992

Technical Bulletin

No. CSO - 016

Subject:

Model(s): CSO

Classification

[Problem]

The CSO may not receive from th e following models, with 9600 bps / 72 00 bps.

(1) SANFAX 1 / 515

(2) PC FAX (Mac, PC98, IBM 400)

(3) Pana FAX UF 1000

Communication Trouble

FA X T.S. Sectio n, T.S. Department

Assistant General Manager

H. Motojima

[Cause]

The signalling rates in the ab ove ma chin es (1) (2) an d (3) are out of CCITT recommendation,

therefore, the CSO can not receive V29 signal corre ctly.

Capture Rang e of CSO : 9600 bps ± 0.01% (100ppm)

CCITT recommendatio n : 96 00 bps ± 0.01%

[Countermeasure]

Temporary - At present, these is no way of solving this problem from the Ricoh side.

Please ask the possibility of solving this pro ble m (su ch as exch an gin g

modem) from the Tx side.

Permanent - We are correcting the capture range of the CSO as follows.

9600 bps +230 ppm - 300 ppm (temporary range)

From the result of the test, fin ally we will fix it and apply to th e machine.

Page 31

Issued on

May 22nd, 1992

Technical Bulletin

No. CSO - 017

Subject:

Model(s): AFO / AF2 / CSO (Europe)

Classification

[Problem]

When installing the above mode ls in De nma rk, S witzerland and Austria, change the f ollo wing

addresses in accordance with the PTT requierments it the mach ine Serial Number is prior to the

following excution date.

1. Change the country codes for NCU parameter and bit switch.

2. Change the RAM addresses as follows.

NCU parameter setting for Denma rk, Switz erland and Aus tr ia

FA X T.S. Sectio n, T.S. Department

Assistant General Manager

H. Motojima

[Denmark]

4149 =04H, 414A =60H, 414B =03H, 414C =90H, 415B =OCH, 415C =OCH,

415D =08H, 415E =17H, 414D =05H, 41 4E =1 2H, 414F =0 3H, 4150 =40 H,

4151 = 41H, 4152 = 3FH, 4153 = 41H, 4154 = 04H, 4155 = 19H, 4157 = 04H,

4158 =60H, 4159 =03H, 415A =90H, 4164 =42H

These corrections have bee n applie d fro m t he 1st pro du ctio n of March ’92 .

[Switzerland]

4181 =05H, 4143 =28H, 4145 =28H, 41 64 =51H, 415B =18, 415C =1EH,

415D =OFH, 415E =16H, 415F =OBH, 4160 =OBH, 4161 =08H, 4162 =1EH,

4064(bit 5) =1

These corrections have bee n applie d fro m t he 1st pro du ctio n of May ’92.

Page 32

Subject:

Issued on

May 22nd, 1992

NCU parameter setting for Denma rk, Switz erland and Aus tr ia

[Austria]

AFO/AF2/CSO

Addr.

4058: → 0AH

4059: → 01H

4143: → 28H

4178: → 64H

417D: → 0EH

417E: → 0AH

417F: → 01H

4182: → 14H

4183: → 50H

4187: → 09H

4190: → 50H

4191: → 50H

4192: → 07H

Technical Bulletin

No. CSO - 017

CSO

Bit SW

Bit SW 01: → 03H

Bit SW 02: → 40H

Bit SW 03: → 4AH

Bit SW 05: → 27H

Bit SW 07: → 46H

Bit SW 0B: → 06H

Depending on the sales req uire ment, change

the followings.

User SW

User Bit SW 01: → 41H

User Bit SW 02: → 0BH

User Bit SW 03: → F5H

User Bit SW 06: → 0BH

AFO/AF2

Bit SW

Bit SW 01: → 07H

Bit SW 02: → 58H

Bit SW 03: → 4AH

Bit SW 05: → 27H

Bit SW 07: → 06H

Bit SW 0B: → 06H

Depending on the sales req uire ment, change

the followings.

User SW

User SW 03: → F5H

After correcting the sof tware, we will apply to the machine(except user SW).

Page 33

Issued on

June 1st, 1992

Technical Bulletin

No. CSO - 018

Subject:

Model(s): CSO

Classification

[Problem]

The toner guide gear may break because of stress caused by too mu ch to ne r in the

development unit, into which toner is being supplied cont inu ou sly.

As a result white lines will appear on the cop y.

Toner Guide Gear (H0812437) breakage

FA X T.S. Sectio n, T.S. Department

Assistant General Manager

H. Motojima

[Cause]

• The toner end detection lever be nds easily when it suffers from some ext ern al sho ck, be -

cause the material is not th ick eno ug h.

• The position of the toner end sensor or the toner detection lever mylar is in corre ct.

• If the lever is bent, or the positio n of the sensor or the mylar is incorrect, to ne r is supplie d

continuously and fills up over the maximum level, beca use the toner en d dete cto r doe s not

work properly.

• Ultimately, the toner trough is not retu rne d to its initial position, and the toner guide gear

breaks, because it expe rien ces too much stress during toner sup ply.

[Action]

• We have modified the fo llowin g part s f rom April production.

Regarding the serial no., refe r t o the atta ched list.

Lever : T oner End Detector → H0812422D

Spring : Lever → H0812462D

Shutter : Toner End Detector → Deleted

• If you face the above problem in the field, please throw some toner away, and replace the

toner guide gear (H0812473) with the abo ve parts (H0812422 and H0812462).

Also, please make sure tha t th e other parts of the develo pme nt unit such as the agitator or

gears, are not damaged.

Page 34

Issued on

June 1st, 1992

Technical Bulletin

No. CSO - 018

Subject:

[Probability]

Around 0.2% .... . acco rding to the Japanese domest ic ma rket dat a

Note: Probability does not mean the F/R per month.

[Serial Nos]

Toner Guide Gear (H0812437) breakage

<H081-20 > R6720401099~

<H081-23 > R7320401001~

<H081-60> 6012241354~

<Others> From 1st production of May, ’92

Page 35

Issued on

June 5th, 1992

Technical Bulletin

No.CSO-019

Subject:

Model(s): CSO

Classification

[Problem]

Toner leakage inside unit or on the copy durin g no rmal op era tion.

Toner Leakage

FA X T.S. Sectio n, T.S. Department

Assistant General Manager

H. Motojima

[Cause]

The adhesion of th e bru sh on to the toner retainer blade in the cleaning part of the toner

cassette became poor, opening a small gap(s).

Then, the cleane d off toner leaked out through the above poor adhesion gap.

Cause of the poor adhesion

a. Application of stress to mount the brush with double sided adhesive tape was not even.

b. The area where the adhesive tap e was applie d was n ot well cleaned.

[Action]

We conclude that this problem would occur rarely, this means that only few toner cassettes may

have the possibility of this proble m a t very low rat e.

So, if you face this prob lem in the field, you can solve by rep lacin g the toner cassette with other

cassette.

Also, we have improved th e production procedure of on e to ne r cassette in our factory, in order

to increase the reliability.

Page 36

White tape

Subject:

Issued on

June 8th, 1992

Model(s): CSO

Classification

[Problem]

Technical Bulletin

No.CSO-020

Caution when installing the OPC(Mas ter Unit)

FA X T.S. Sectio n, T.S. Department

Assistant General Manager

H. Motojima

Black dots or lines on the printed image at 88mm intervals.

[Cause]

Defective OPC.

(The OPC might fall down during installation, rese tt ing or replacement of th e OP C.)

[Reason]

The OPC may drop if the tech nician removes the two white tap es on the OPC ho lder before

installation.

[Action]

Remove the two white tapes on the OPC holder afte r ins t al li ng the OPC in the ma chi ne.

Page 37

Issued on

June 23rd, 1992

Technical Bulletin

No.CSO-021

Subject:

Model(s): CSO

Classification

Action Required

Trou bleshooting

Retrofit Information

Revision of Service Manual

Information Only

Others

[Problem]

When printing, you may h ear noise from around the bushing fo r the pap er feed roller.

Noise when printing

FA X T.S. Sectio n, T.S. Department

Assistant General Manager

H. Motojima

Some customers may complain about this no ise if th e mach ine is used in a quiet place.

However, this noise level is within our specificat ion s.

[Countermeasure]

We have already add ed the sp ring plat e (H0813410) to the machine in order to decrease the

noise.

So, if you receive a complain t ab ou t a mach ine which has not received the mod ification,

concerning the ab ove noise, please add the sp ring plate, as shown on the ne xt pa ge .

Regarding the serial n os, plea se refer to the next page.

Page 38

3

Issued on

June 23rd, 1992

Technical Bulletin

No.CSO-021

Subject:

1. Remove the left cover.

2. Remove gears and belt ( 1, 2 , 3, 4 ).

1

2

Noise when printing

4

3. Attach the spring pla te (H0813 410).

4. Reassemble the machine.

H081 - 20 R6720400001

H081 - 21 61022700 63

H081 - 22 6112240110

H081 - 23 R7320400001

H081 - 24 R7420600001

H081 - 26 S2320400 001

H081 - 27 S1920400 001

H081 - 28 L4020401 601

H081 - 29 L4120401 401

H081 - 51 A0620400 001

H081 - 59 60222401 36

H081 - 30 45805200 01

H081 - 40 U1720500001

H081 - 60 60122515 04

H0813410

Page 39

Technical Bulletin No. CSO-022

Page 1/3

SUBJECT: Modem Capture Range Problem

PREPARED BY: N.Mihar a

CHECKED BY:

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

FROM: FAX T.S. Section

MODEL: CSO, AFO, AF2

DATE: August 21st, 1992

Reissued: Sept 29, 1992

[Problem]

The CSO/AFO/AF2 may not receive at 9600bp s/7200bps from the certain machines, with the

following phenomenon.

• Error code: 0-21, 23

• Only the 1st few inches (cm) of the imag e data would be received and then the line would

be disconnected, or the error would occur as the usual Line fail.

[Cause]

On the CCITT recommendation, the signalling r a te o f the TX terminal is defined to be 9600bps

± 0.01% (100ppm), and all makers design the facsimile models in accordance with the CCITT

recommendation. However, on the some of the models (Tx side) , the signallin g rate may be out of

CCITT recommendation, due to the possible production variation of modem, or other factors.

The capture range (Rx capability) of t he CSO/AFO/AF2 is designed as 9600bps ± 100ppm(there is

no margin). Therefor e, if the signalling rate of Tx terminal is out of CCITT recom mendation, the

CSO/AFO/AF2 can not receive the V29 signal correctly. It means that, if a modem is produced

precisely, there will not be the prob lem.

Tx side: Signalling rate of CCITT recommendation - 9600bps ± 100ppm

Rx side: Capture range of CCITT recommendation - none

[Countermeasure]

Permanent: We have re-designed the modem, to have cert ain margin fo r reception and the new

modem will be ap plied from Oct. produ ctions of ’92 except the fo llowing.

CSO (Productions at RIF factory) → From November, 1992

AFO/AF2 (Productions at RIF factory) → From December, 1992.

The P/Ns of the FCUs will be changed as follows.

Old New

H08160xx → H08161xx ( The last two digits will not be changed)

H08460xx → H084603x

H08660xx → H086603x

(The last digit will not be changed)

Page 40

Technical Bulletin No. CSO-022

Page 2/3

SUBJECT: Modem Capture Range Problem

DATE: August 21st, 1992

Reissued: Sept 29, 1992

[Action in the field]

(1) Make sure the exact causes of the communication problem. By referring to the attached

troubleshooting flow, because there are other communication problems which are caused by

other reasons. If the problem is caused by this modem capture range problem, go to the next

steps.

(2) Drop the starting modem rate of the terminal for Rx or Tx.

(3) Ask the Tx terminal to replace the modem.

(4) If (3) is not possible, replace the FCU with the new FCU which contains the new modem.

[Sample]

Until now, we have been reported on this pro blem with the following models at few rate, and as

the result of our investigation, the signalling rates of the machines are as follows.

Models Signalling rate

SANFAX 2100 Unknown (The modem has been

rep laced on the tx side)

SANFAX 1 -163ppm

SANFAX 515 Unknown

Panafax UF1000 -120ppm

PC98 FAX (Star FA X) + 120ppm

PC FAX Mac -180ppm

IBM PC FAX Unknown

Please note that the above table is just the samples of the problem, and the problem should not

always occur with the above models in your field.

The estimated occurrence rate is as low as 0.05%/mo.

However, we like to keep watching the field performance.

We like you to log this case monthly.

Page 41

Technical Bulletin No. CSO-022

Page 3/3

SUBJECT: Modem Capture Range Problem

Phenominom: -Frequent Error Reports (User)

-Frequent Error Co des (Service) 0-20/0-21/ 0-23

START

Error Condition

R x Error(s) occur only in a few

cases and always from the same

Tra ns mitting Terminal

DATE: August 21st, 1992

Reissued: Sept 29, 1992

Error Condition

R x Error(s) occur often from

different Transmitting Terminals.

Change Rx Speed to 7200 bps

OK: E rror(s) caused by bad line

condition.

NG: P roceed with the next step.

Change Rx Speed to 4800 bps

OK: We suspect the AFSP chip

(modem) on the FCU.

Please find out the machine

type at the Tx side.

NG: Proceed with the next step.

Change Rx Speed to previous Speed.

Change Training Error Tolerance

OK: Error(s) cause d by bad

line condition.

NG: Proceed with the next step.

Change Line Error Threshold

OK: Error(s) cause d by bad

line condition.

NG: Proceed with the next step

Change Rx Speed to 4800 bps

OK: Error(s) cause d by bad

line condition.

NG: We suspect the AFE chip on

the FCU. Replace the FCU

with a another FCU

Page 42

Technical Bulletin No. CSO-023

SUBJECT: CSO Swiss Version

PREPARED BY: H.Yokoya ma

CHECKED BY:

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

We inform you that we will make a version of CSO for Switzerland, in which it is not necessary

to change any jumpers at installation.

The details are as follows.

FROM: FAX T.S. Section

MODEL:

DATE:

December 11th, 1992

CSO

-Mass Production-

September, 1992

-Difference-

MBU (P/N: H0816025)

NCU (P/N: H0846020)

Other parts are the s ame as CSO European version.

-Production Code-

H081-46

Page 43

Technical Bulletin No. CSO-024

SUBJECT: Softwa re Problem

PREPARED BY: A. Ishiyama

CHECKED BY:

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

FROM: FAX T.S. Section

MODEL:

CSO for Ricoh and NRG

DATE:

Decem ber, 3rd, 1992

[ Problem]

When receiving, the machine alw ays sends out a CFR (Confirmation to Receive) as a response

to modem training.

As a result, communication fails (reception error) if the telephone line is poor, because the

transmission modem rate never falls back.

(This will not happen with ECM communication)

[Cause]

When some of the software modifications were executed, a bug was introduced.

[Countermeasure]

The program has been corrected.

So, change the ROM or the MBU.

ROM Part Numbers

Version Old P/No. Ne w P/N o.

Ricoh FAX3000L H081 7140J H081 7140K

Eurpe H081 7130M H081 7130N

Swiss H081 7131M H081 7131N

Asia H081 7132M H081 7132N

[Affected Machines]

The machines produced in November 1992.

Notes: 1. Most of the abo ve machines have been modified in Japan before ship ment .

2. Only for Ricoh brand CSO 115 Volt version, Please note that the serial numbers

earlier than xx21100602 are out of the app licab le machines, because those are

equipped with the o lder ROM(H 081 7140H) which does not contain t he problem.

Page 44

Technical Bulletin No. CSO-026

SUBJECT: Scratch on the OPU

PREPARED BY: N. Mihara

CHECKED BY:

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

FROM: FAX T.S. Section

Problem

The OPU may be damaged when using the machine, as shown

below. However, there is no problem on the printed image.

Cause

1. Both sides of the development roller may touch the metal

blade on the development roller. By this, the shaved

corpuscles may get in the space between the OPU belt and

the development roller, the both sides of the OPU belt may be

damaged.

DATE:

April 15th, 1993

MODEL: CSO

Scratch

OPU guide

2. The position of the OPU guide may be changed for some

reason, then the OPU belt may touch the plastic pins on

the develpment unit.

Action

1. If the above problem occurs, do not replace the OPU, because, there will be no problem on

the printed image, in the lifetime of the OPU.

2. Do not adjust and change the position of the OPU guide.

Note

Do not touch the sorface of the OPU belt and not clean with alcohol.

Page 45

Technical Bulletin No. CSO-027

SUBJECT: Tx cable Equ alizer

PREPARED BY: N. Mihara

CHECKED BY:

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

We have added the tx equalizer feature an d char ged th e setting for the r x equ alizer by changing

the s oftware and the hardware as show n below. (MB CSO-027)

With these charge, more proper setting will be available for the communication quality.

FROM: FAX T.S. Section

MODEL: CSO

DATE:

April 14th, 1993

1. New setting

Bit SW 0A (Rx cable equalizer)

Bit SW 08 (Tx cable equalizer)

bit 7 bit 6

0 0 (OFF) 00

0 1 (Middle) 10

10(High) 20

1 1 (Not used) Do not change

Regarding the Tx equalizer, it will be available only with the following combination.

Equalizer information on the TCR

(Journal)

(When Bit SW 00, bit 1 = 1)

2. Combination of the parts

FCU (MB CSO-035) MBU (MB CSO-027) ROM (MB CSO-027)

USA H0816153: USα

H0816152: USβ

H0816155: Telα

H0816154: Telβ

EUR H0816151 H0816025 R

Asia H0816156 H0816027 R H0817132 N

Regarding the affected date, please refer to the above MBS.

H0816026 N H0817140K

H0816039 E H0817139D

H0817131N HCS

H0816024 R

H0816029 F

--

H0817130N RICOH/ NRG

H0817133E France

H0817159K Language kit

Page 46

[2]

[1]

3rd mirror

Technical Bulletin No. CSO-028

SUBJECT: Dirty Mirrors

PREPARED BY: N. Mihara

CHECKED BY:

CLASSIFICATION:

FROM: FAX T.S. Section

MODEL: CSO

DATE:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

— Problem —

In the field, the scanner mirrors may become dusty (poor scanning quality).

In this case, we recommend that you do procedures 1 and 2.

— Procedure —

Proce dure 1.

Clean the mirrors with the mirror cleaning kit.

It is easy to clean the mirrors (there is no need to remove the ADF base).

June 30, 1993.

P/N: H0819300 (for CSO) Mirror C leaning Kit

• Mirror Cleaning Tool × 1pc

• Cleaning Felt × 30pcs

• Vinyl Bag × 1pc

[Preparation]

Attach the cleaning felts [1] to the mirror cleaning tool [2]. (Fig. 1)

(With one set of felts, you can clean the mirror up to 10 times)

[Cleaning Method]

(1) Remove the exposure glass.

(2) Insert the cleaning tool into the scanner. (Fig. 2)

(3) Clean the mirrors by sliding the tool.

(3~ 4 times for each mirror)

Front

Fig. 1

[1]

[1]

1st mirror

2nd mirror

Fig. 2

Page 47

Dust Protection S heet 2

FCU Sheet

Technical Bulletin No. CSO-028

SUBJECT: Dirty Mirrors

DATE:

June 30, 1993.

Procedure 2.

Install the mirror protection sheet kit. The sheets in the kit will prevent the mirrors from

becomeing dirty.

P/N: H0819900 Dust Protection Sheet Kit

• FCU Sh eet × 1pc

• Dust Protection Sheet 1 × 1pc

• Dust Protection Sheet 2 × 1pc

• CTM Sheet × 1pc

CTM Sheet

[CTM Shee t Installation]

(1) Open the front cover, then cover the OPC belt with

a piece of paper (do not touch the belt surface by

hand).

(2) Attach the CTM sheet. (Fig. 3)

Toner Duct

Fig. 3

[FCU Sheet I nstallation]

(1) Remove the rear/ left/ right/ lens covers.

(2) Insert the FCU sheet under the mirrors, then

attach the sheet to the right side and interior of

the ADF base. (Fig. 4)

[Dust Protection Sheet 1 and 2 Installation]

(1) Attach the dust protection sheet 1 to the left

side of the scanner and the upper side of the

shading plate. (Fig. 4)

(2) Attach the dust protection sheet 2 to the right

side of the scanner and the upper side of the

shading plate. (Fig. 4)

— Countermeasure —

Lens Cover

Dust Protection S heet 1

Fig. 4

We have applied the modification (attaching the protection sheets to the productions) from the

June. productions.

Page 48

Technical Bulletin No. CSO-028

SUBJECT: Dirty Mirrors

CTM Sheet

DATE:

June 30, 1993.

FCU Sheet

Dust Protection S heet

Page 49

Technical Bulletin No. CSO-029

SUBJECT: ADF Non Feed Prob lem

PREPARED BY: N. Mihara

CHECKED BY:

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

FROM: FAX T.S. Section

MODEL: CSO

DATE: July 27, 1993

[Problem]

Non feed at the ADF may occur if copier paper which has silicone oil on the sorface is used as

a orig inal.

[Reason]

Some copier machines may leave too much silicone oil on copies.

[Countermeasure]

Please replace the pick-up roller with the following countermeasure part.

Part No. H0819504: Pick up roller (Carborundum)

Note: Please note that the ADF capacity will be decreased.

if the Carborundum roller is installed.

ADF capacity: 50 sheets (Normal rubber roller)

20 sheets (Carborundum)

Page 50

Technical Bulletin No. CSO-030

SUBJECT: Treatment for the Rx image when error occur

PREPARED BY: H.Yokoya ma

CHECKED BY: S.Hamano

CLASSI FICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

The following function has been added.

- Address 24061 (H) bit 3. (Default setting is 1)

0 : Even if an Rx error occurs during memory Rx, the machine keeps

the image in the memory.

1 : The data is erased.

- ROM suffix no.s which contain the above function.

• H0817130P~ (Europe version)

• H0817131P~ (HCS version)

• H0817133F~ (French version)

FROM: 2nd T.S. Section

DATE:

Dec. 15, 1994

MODEL:

CSO (Europe and French)

Page 51

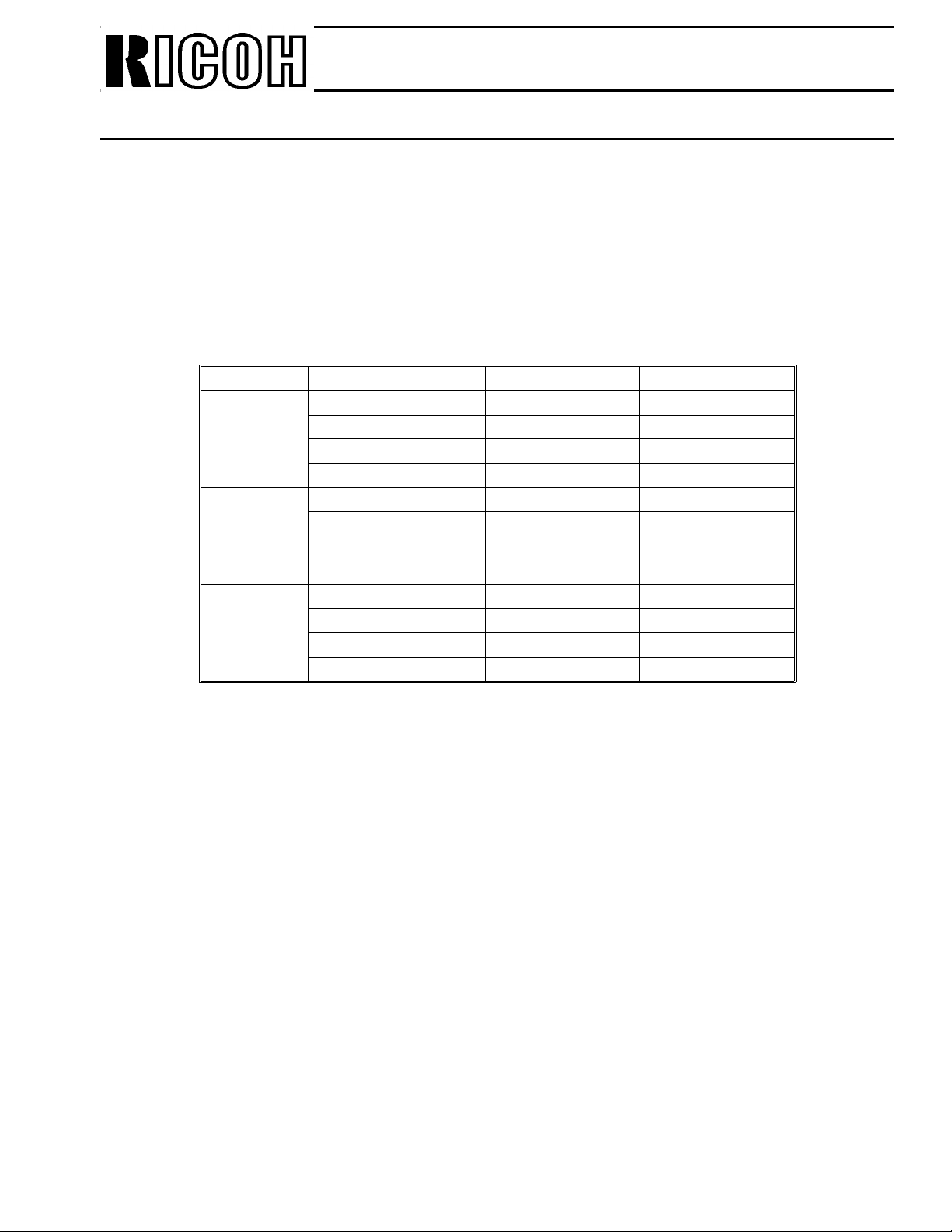

DETAILED SECTION DESCRIPTIONS

PRINTER

April 8th, 1992

The following table shows the maximum incoming page lengths

reduced for each copy paper size. All lengths are in

millimetres.

that can be

The factory

setting of the reduction ratio is 4/3.

copy Copy Paper Maximum

Paper Type Length

A5

B5

Letter 279.4

A4 297

F4, F

Legal

B4

* ● The page

148

182

330.2

355.6

364

memory cannot reduce incoming pages longer than 341 mm

Ratio = 3/2

214.5

265.5 236

341/385 *

341/385 *

341/385 *

341/385 *

-

341/385 * 341/385 *

reducable

Ratio = 4/3

190.7

341/365.9 *

341/385 *

341/385 *

341/385 *

incoming page lengths

Ratio =

163.4

202.3

313.6 299.3

333.7 318.5

341/371 .7 *

341/385 *

341/385 *

8/7 Ratio = 12/11

156

193.1

341/354.8 *

341/382.5 *

341/385 *

(Europe) or 385 mm (other areas).

The values are calculated as follows.

Maximum incoming page length that can be reduced =

(Copy Paper Length - 5) x Reduction Ratio

For example, for A5 with a reduction ratio of 4/3

Max incoming data length = (148 -5) x 4/3 = 190.7

Incoming pages that are longer than the maximum length will not be

reduced, but will be printed on two pages and treated in accordance with the

02.

setting of bit 1 of bit switch

If this bit is 1, the bottom few lines of the page

will be repeated at the top of the next page. If this bit is O, the next page will

continue from where the first page left off.

Reduction Disabled

If bit 2 of bit switch 02 is at 1, the data will not be reduced. However, if the incoming page is up to x mm longer than the copy paper, the excess portion

will not be printed. The value of x can be from O to 15 mm. It is determined by

the setting of RAM address 24051 (copy mode: bits 3 to O, receive mode:

bits 7 to 4; bits 3 and 7 are the most significant bits).

Hex value

o

1

and so on until .

15

Value of x

0

1

15

Messages more than x mm longer than the copy paper are printed on two

pages and treated in accordance with the setting of bit 1 of bit switch 02.

2-19

Page 52

April 8th, 1992

DETAILED SECTION DESCRIPTIONS

PCBS AND THEIR FUNCTIONS

1. CPU (AFSP)

.

65C02

compatible microprocessor

. Interrupt control

. DMA control

. Data compression and reconstruction (high speed MH

second scanning)

. Modem (digital operations)

. Real time clock (battery backed-up)

. Memory control

. Control of all mechanisms (directly or through other chips)

. NCU control (through the I/0 Port)

coding

for 4.5-

2.110

Port

(LIOP)

. Clock control

. Sensor monitoring (including A/D conversion where necessary)

/

. Tone detection

. Motor drive

. Operation panel control

. Laser Interface control

3.

Laser Interface

(LIF)

. Page memory control

. Laser diode control

. Smoothing

4. Modem Analog Front End (Modem AFE)

. Modem (analog operations)

. Attenuation

5.

Video Processor

.

Analog/digital video signal processing

6. Hybrid IC

(HIC)

(VPP)

. Filters

7. RAM

.

128k

● 256k

. 768k

576k

for ECM (no back-up)

SAF memory (with battery

page memory (USA, Asia)

page memory (Europe)

2-30

back-up)

Page 53

April 8th, 1992

SERVICE TABLES AND PROCEDURES

NCU PARAMETERS

On the following pages, there are tables of factory settings for each country.

To enable the factory settings for a particular nation, program the Country

Code (RAM address 413B [use hex codes] or use Function 96 [input the

decimal value]) to the appropriate setting. The country code also affects the

NCU signal status (see section 2-3-7).

.

. For each RAM address, there are two columns. The left hand column

shows the actual value of the parameter. The right hand column shows

the value of the factory setting that is stored in the RAM. The factory settings are quoted either in hexadecimal code (the actual contents of the

RAM address) if there is a H after the value in the table, or in decimal

(converted from the actual hex contents of the RAM address) if there is

no H after the value.

. Some RAMs must be stored using

BCD;

see the

NCU

Parameter defini-

tion table for details.

. If the table entry is blank, this means that the value is not

used,

Country Code for NCU Parameters [or RAM Address

France: 00, Germany: 01, UK: 02, Italy: 03, Austria: 04, Belgium: 05, Denmark: 06, Finland: 07,

Ireland: 08, Norway: 09, Sweden: 10 [OA], Switzerland: 11 [OB], Portugal: 12 [OC],

Holland: 13

Hong kong:20[14],

Singapore: 24 [18], Malaysia:25 [19]

Tx Level (RAM Address 4181): Ail countries 6 (- 6dB), except the UK (10 [-10dB]), USA

9dB]), and Australia(12[-12dB]).

Country

[OD],

Spain: 14[OE], Israel: 15 [OF], USA: 17 [11], Asia: 18 [12], Japan: 19 [13],

South

Africa: 21 [15],

413C

Australia:

413D

22 [16],

France

Germany

1.1s

55

4.1 s 205

1.06

413B,

in hex code]:

New

Zealand:23 [17],

413E

S

53

413F/4140

474 Hz

498

HZ 04(H)

04(H)

(9[-

74(H)

98(H)

UK/Univ

Italy

Austria

Belgium

Denmark

Finland

Ireland

Norway

Sweden

Switz.

Portugal

Holland

Spain

Israel

1.1s

1.1s

1.1s

55 4.1 s 205

55

55

4.1 s

205

4.1 s 205

1.06

1,06

04(H)

512 Hz

471 Hz

512 Hz

536 Hz

S

53

S

53

450

512 Hz

512 Hz

608 Hz

450 Hz

563 Hz

480 Hz

498

05(H)

04(H)

05(H)

05(H)

HZ

04(H) 50(H)

05(H)

05(H)

06(H)

04(H)

05(H)

04(H)

HZ

04(H) 98(H)

71 (H)

12(H)

71 (H)

12(H)

36(H)

12(H)

12(H)

08(H)

50(H)

63(H)

80(H)

471

Hz

USA

Asia

Australia

450 Hz

04(H)

50(H)

4-30

Page 54

I

12.17.91 DRAWN

I

PCB ASS’

Y

(4/4)

H081 6040

NCU–EUROPE/ASIA

Page 55

9W++7

XT1

XL

XL 2

X12

Gsrnw

XNCUS16

WCUB

Howl

LQTC14

1

+

—

2

NCUSL2

NCUSL3

NCU3L4

NCUSL5

00

.24V

SHUNT

11

12

G3T!3R1

& A-,

II

FG

1

z

2 3

[

.

[

I

1

02 12

01 11

.

I

z

I

CN2-

1

CN2-2

CN2-3

CN2- 4

CN2’-6

CNZ-6

E

01

P-~

‘—————P ‘“”

k,

A

-1---

-0,

e.!w

I

t---+-t

*

cowl

PC B-NO:

1’

I

.

FG

I

~~

H0816040C

lDIAcRAt--NO: H08l0640A/

—

ma-w

—

CW-06

CN3-S5

w-m

+==

-1

cNs-n2

CW-BI

CIRCUIT-DIAGRAM

PCB-NCU-EUR

NCUSL

Ncu3Le

OWM

019

RITM

RING

RvWJB

wmJ 1

EXTO1

.5V

C,(WII

C12M2

1

Page 56

Page 1/2

Technical Bulletin No. GENERAL-004

SUBJECT: Black bands/lines on the received copy

PREPARED BY: H.Yokoyama

CHECKED BY:

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

FROM: 2nd T.S. Section

MODEL: USA only

CSO, CFO, CS1/CRO

DATE:

November 11th, 1993

[Problem]

On the received copies, bla ck ban ds or line s may

be printed, especially on the right hand side.

[Cause]

Toner or dust is attached to the charge corona wire.

[Modification]

The electric current of the charge coron a will be

increased to avoid applying uneren charg to the

master which is caused by a dirty corona wire.

Because of the increase of the ele ctric curre nt , th e

distance betwee n th e grid plate and the coro na

wire will be changed to keep the charge on the

master belt the same as before modification.

• H081 2870 → H081 2854 Eraser Ass’y

• H081 5030 → H081 5020 Power pack (CSO/CFO)

H510 5030 → H510 5020 Power pack (CRO/CS1)

<Eraser Ass’y>

• The thickness of the cleaning blade of the clean er will b e cha ng ed to increase the

cleaning ability (4mm → 5mm)

• The distance between the gride plate and charge wire will be changed (6mm → 8mm)

<Power pack>

• The range and initial value of the VRC (VR for the charge corona) will be changed.

The above modification will ta ke pla ce fro m t he De cemb er 1st prod uction.

Page 57

Page 2/2

Technical Bulletin No. GENERAL-004

SUBJECT: Black bands/lines on the received copy

DATE:

November 11th, 1993

[Countermeasure in the field]

The countermeasu re method depends on the CV (Copy V olu me) of the machine.

• If the CV is less tha n 40 0 she ets/month

Turn VRC on the power pack to the maximum (Turn the VR clockwise until it stops)

• If the CV is more than 40 0 she ets/month

Change the Eraser to the modified one and turn VRC on the power pack to the maximum.

Note:The increase in the powe r of VRC may de crease the life time of the maste r u nit , so for

customers whose ACV/month is more than 400 sheets, the Erase r shou ld be chan ged.

[Request]

The essence of this problem is a dirty cha rge corona wire, so please do the following

• When a sales or service person visits a customer (at PM or EM), clean the cha rge

corona wire with the built-in cleaner

• Advise the customer to clean the charge coron a wire at a certain interval or if the

customer sees black bands/lines on the received copy.

Page 58

Page 1/2

Technical Bulletin No. GENERAL-005

SUBJECT: Black bands/lines on the received copy

PREPARED BY: H.Yokoyama

CHECKED BY:

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

FROM: 2nd T.S. Section

MODEL: Europe, Asia

CSO, CFO, CRO

DATE:

Feb. 3rd, 1994

[Problem]

On the received copies, bla ck ban ds or line s may

be printed, especially on the right hand side.

[Cause]

Toner or dust is attached to the charge corona wire.

[Modification]

The electric current of the charge coron a will be

increased to avoid applying uneren charg to the

master which is caused by a dirty corona wire.

Because of the increase of the ele ctric curre nt , th e

distance betwee n th e grid plate and the coro na

wire will be changed to keep the charge on the

master belt the same as before modification.

• H081 2870 → H081 2854 Eraser Ass’y

• H081 5030 → H081 5020 Power pack (CSO/CFO)

H510 5050 → H510 5051 Power pack (CRO)

<Eraser Ass’y>

• The thickness of the cleaning blade of the clean er will b e cha ng ed to increase the

cleaning ability (4mm → 5mm)

• The distance between the gride plate and charge wire will be changed (6mm → 8mm)

<Power pack>

• The range and initial value of the VRC (VR for the charge corona) will be changed.

The above modification will take pla ce fro m t he Feb. 1st pro du ctio n.

Page 59

Page 2/2

Technical Bulletin No. GENERAL-005

SUBJECT: Black bands/lines on the received copy

DATE:

Feb. 3rd, 1994

[Countermeasure in the field]

The countermeasu re method depends on the CV (Copy V olu me) of the machine.

• If the CV is less tha n 40 0 she ets/month

Turn VRC on the power pack to the maximum (Turn the VR clockwise until it stops)

• If the CV is more than 40 0 she ets/month

Change the Eraser to the modified one and turn VRC on the power pack to the maximum.

Note:The increase in the powe r of VRC may de crease the life time of the maste r u nit , so for

customers whose ACV/month is more than 400 sheets, the Erase r shou ld be chan ged.

[Request]

The essence of this problem is a dirty cha rge corona wire, so please do the following

• When a sales or service person visits a customer (at PM or EM), clean the cha rge

corona wire with the built-in cleaner

• Advise the customer to clean the charge coron a wire at a certain interval or if the

customer sees black bands/lines on the received copy.

Page 60

Magnet

Page 1/1

Technical Bulletin No. GENERAL-006

SUBJECT: CTM modification

DATE:

April, 11th, 1994

PREPARED BY: H.Yokoyama

CHECKED BY:

CLASSIFICATION:

Action Required Revision of service manual

FROM: 2nd T.S. Section

MODEL:

CSO, CFO, CS1

Troubleshooting Information only

Retrofit Information Other

To avoid toner from being spilt inside the machin e, the toner collection roller of th e CTM will be

modified.

<Figure>

Previous

Type A Type B

Brush 4 Magnets Magnet surface

After modification

Magnet

Black lot no. is printed on the

carton box.

<Expected arrival period>

Previous Type

Type A

Type B

’94.1

Red lot no. will be printed on

the carton box.

’94.6

’94.8

’94.6

Blank lot no. will be printed

on the carton box.

Page 61

Page 1/1

Technical Bulletin No. GENERAL-008

SUBJECT: Replacing the toner cassette

PREPARED BY:H. Yokoyama

CHECKED BY:

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

The instruction of the operator’s manual for replacing the toner cassette (CTM) is wrong.

We will insert the errata sheet to the operator’s manual.

Wrong: 1. Switch off the machine.

Correct: Keep the power switch on when replacing the toner cassette.

FROM: 2nd T.S. Section

MODEL:

CSO, CFO, CRO, CS1

DATE:

April, 11th, 1994

Page 62

Page 1/1

Technical Bulletin No. GENERAL-009

SUBJECT: Vertical Black Lines

PREPARED BY: H.Yokoyama

CHECKED BY: S.Hamano

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

[Problem]

Vertical black lines appear on the printed image.

[Cause]

The toner may stick on the Hot Roller, Fusing Stripper, Thermistor, an d The rmost at and this

toner may damage the surf ace of th e Hot Roller. Then, during copyin g toner is transferred by

the scratched part of the roller to cause vertical bla ck lines on the print ed image .

FROM: 2nd T.S. Section

MODEL:

CSO, CFO, CRO, CS1

DATE:

Jury. 30, 1994

[Countermeasu re]

The material of the surface of the Hot Roller ha s bee n cha nged to pre ven t th e tone r from

sticking on the Roller by the following modification

H0812100D → E

Because of the ab ove mo dif ication, the vende r has be en changed.

[Effective S/N]

H081-24, 40, 46, 51, 54 , 59 , 60: Oct., 199 3 ~

H510-20: R88310006 09 ~

21, 22, 27, 30, 40, 51, 59, 60: Nov., 1993 ~

H082-20, 23, 30, 40, 51 , 59 , 60 : Nov. , 19 93 ~

H511-20, 21, 22, 27: Nov. , 19 93 ~

[Action]

Clean the Fusing Stripper, The rmisto r and Thermo stat and take out the toner f rom th em whe n

visit the customer.

Page 63

Leak Current

(On CFO / CS1 FCU)

Diode

COM

COM

Regulator

Technical Bulletin No. Multi-001

SUBJECT: Memory Back-up Battery

DATE:

Jan. 19, 1995

PREPARED BY: Y.Okunishi

CHECKED BY: S.Hamano

CLASSIFICATION:

Action Required Revision of service manual

FROM: 2nd T.S. Section

MODEL:

CSO, CFO, CS1, LHO

Troubleshooting Information only

Retrofit Information Other

[Symptom]

Stored documents in the me mory migh t be erase d when the main power goes down .

A power failure report is printed with the following informa tion.

• Memory Tx Files: Destina tio n names or fax numb ers are print ed.

• Substitut e Rece ption Files: The Sender’s RTI or CSI is print ed if they are pro grammed.

CSO rejects incoming messages without RTI or CSI because

of the factory setting.

• Memory Lock Files: Progra mmed Quick Numb ers are printed.

[Cause]

Power loss from the memory back-up battery on FCU caused by excessive charge current, for

the following reasons.

(1) Leak current from Diode

The battery is charged after it is already

24V

24V

fully charged. This type of battery

is damaged if this occurs.

(2) Excessive charge voltage (CFO,

CS1,LHO) The target charge voltage

was 6.2V against 6.4V or under which is

recommended by the battery maker.

This margin was too small for this battery.

Zener

Diode

Battery

COM

[Modification]

See MB C Series-048A.

OUT

Page 64

Technical Bulletin No. Multi-001

SUBJECT: Memory Back-up Battery

[Action Taken]

1. Install the modified FCU to deal with customer claims.

2. Request technicians no t to turn off the main power if a docume nt is stored

in the memory.

[Note]

• Stored data ot he r tha n docume nts is not erased even if the main power goes down.

DATE:

Jan. 19, 1995

Page 65

Technical Bulletin No. Multi-002

SUBJECT: Toner Spillage during Transportation

PREPARED BY: Y. Okunishi

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Preventive Action

Background: Machines have been sent to customers af ter pre-installation and sent back to the

service center for repair.

Problem: Toner had spread inside the ma chin e du ring tran sportation.

Cause: Toner leaked from the development unit , the toner cartridge, or some where

in the toner path during tran sportation.

Preparation for transportation:

(1) Transportation withou t he avy vibra tio n

(Example: A technician should carry the machine with care.)

• F/L series fax machines:

The development unit can be connected to a CTM with toner.

However, the toner path under the CTM must be covered by some

adhesive tape. See the attached illust rat ion.

• C series fax machines:

Follow RTB No. CSO-006

• Other order machines:

Follow (2) below.

FROM: 2nd T.S. Section

MODEL:

All laser plain paper fax

machines

DATE:

Jul. 15.1995

(2) Transportation with heavy vibration

(If a third party handles the transportation, follow this procedure.)

• F/L series fax machines:

Remove the development unit and the CTM fro m the machin e if toner

has been installed. They must not be delivered in the same box as the

machine, because they contain toner which may spill out. Th e to ne r

inside the machine must be clean ed away or th e toner path under the

CTM must be covered with tape.

• C series fax machines and others:

Remove the development unit and CTM (or Toner Cartridge) from

the machine if toner has been inst alle d, and clean the toner from

inside the machine.

The removed development unit and CTM must not be delivered

in the same box as the machine.

Page 66

Technical Bulletin No. Multi-002

SUBJECT: Toner Spillage during Transportation

Inside of FX6 and LSO

Drum

DATE:

Jul. 15.1995

Toner path

Note: Adhesion of the tap e sho uld not be strong. Otherwise, it ma y not be ta ken off

cleanly from the machine, or th e toner path may be damaged whe n it is taken

off.

Please request tape samples for th e FX6 and LSO from Ricoh.

Adhesive tape

Page 67

Page 1/3

Technical Bulletin No. Multi - 004A

SUBJECT: Fusing Unit

PREPARED BY: Y.Okunishi

CHECKED BY: S.Fujii

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

A: "NOTE" is added to page 2/3.

SYMPTOM:

Background on received and copied documents.

Cause:

Hot Roller failure as a result of not changing the Cleaning Pad at the 10K PM.

Failure to change the Cleaning Pad results in dirty Strippers and Thermostat and

then Hot Roller failure.

As the machine warms up from the standby temperature to the fusing

temperature, it is exposed to slight overheating before the temperature levels

off. This leads to softening of the Teflon layer on the Hot Roller. As a result, the

Teflon layer peels off in the areas where the Strippers and other parts come in

contact with it. Dirty Strippers and Thermostat put more stress on the Hot Roller and

cause premature Hot Roller failure.

Also, the dirty Thermistor causes the Hot Roller to overherat and fail prematurely.

FROM: Quality Assurance Center

DATE:

Oct. 15, 1996

MODEL:

CSO, CRO, CS1, CFO,

CGO

A second cause can be a damaged (bent ) Thermistor from a previous service visit.

The damaged Thermistor causes the Hot Roller to overheat and fail prematurely.

SOLUTION:

Ricoh recommends replacing the Cleaning Pad at the 10K PM. However, this is

sometimes ignored. Realizing this, Ricoh will conduct the following modifications to

protect the Hot Roller from the failure mentioned above.

No. Old Part New Part Description Qty Used Interchangeability

1 H0812121 H0812123 Stripper Spring 2 → 2 X / O

H0812120 H5132119 Stripper

2

3

H0812137

H0815035

H0812141

03130080B

(Separation Pawl)

Thermistor Assembly

Thermistor

Bracket

Screw - M3x8

2 → 2 X / O

1 → 0

1 → 1

1 → 1

0 → 1

X / O as an

assembly

4 H0812100 H0819600 Hot Roller Kit 1 → 1 X / O

Page 68

Page 2/3

Technical Bulletin No. Multi - 004A

SUBJECT: Fusing Unit

DATE:

Oct. 15, 1996

Hot Roller Kit:

The hot rollers shipped from the SPC in Japan will be replaced by the

Hot Roller Kit in July.

This kit will be comprised of the following: Hot Roller, Cleaning Pad, Thermistor,

Thermistor Bracket, Screw, Strippers (2), Stripper Springs (2) and Installation Sheet.

The individual Hot Roller will be no longer available. The Cleaning Pad will

continue to be a Service Part.

Ricoh recommends change of the above modified parts and Cleaning Pad when the failed

Hot Roller is replaced with the new one.

NOTE

(A): Please refer to the following instructions and fix the cover to the fusing unit

and check that the harness is not pinched before installing the fusing unit in the

machine.

If the metal wire of the harness contacts the thermistor bracket, a no power

condition may occur. Please check the thermistor harness if this occurs.

Fusing Cover

(Bad)

Edge of the cover may damage

the harness

Edge

(Good)

Fusing Unit

Page 69

Installation Procedure for the Thermistor

1. Assemble the thermistor and the bracket

with the screw.

Bracket - Thermistor

H0812141

Thermistor - Fusing Unit

H0815035

Do not bendthis part

2. Install the

Thermistor Ass’y

( ✻ 4)

Thermistor - Fusing Unit

H0815035

Harness - Thermostat

(✻ 3)

Page 3/3

Thermostat - Fusing Unit

H0812134

Screw - M3 x 8

03130080B

(✻ 1)

Note: Set the projection on

the thermistor into

the hole in the bracket.

Note: ✻ 1 Place the thermostat harness under the part of the bracket.

✻ 2 Do not cross the thermostat harness and the thermistor harness.

✻ 3 Push the thermistor head (sensor) gently against the hot roller witha finger to make sure that the thermistor

head touches the hot roller surface. Do not push it strongly.

✻ 4 Do not bend the thermistor neck (spring plate) when installing or cleaning it .

If the thermistor is bent, replace it.

(✻ 2)

Bracket - Thermistor

H0812141

Stay - Fusing Unit - Upper

H0812175

Page 70

T

Model:

General

echnical

B

ulletin

Date:

31-Oct-97

No:

PAGE: 1/3

011

Subject:

From:

Classification:

Check Items

The following functions for which the clock timer is used were checked to see whether or

not they will function correctly at 0:00 on Jan. 1, 2000.

1) Display and print of the date and time

2) Clock adjustment

3) Send later mode with memory and without memory

Year 2000 Problem

QAC 2nd Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

The year must be changed to 2000 or 00 from 1999 or 99 and the date must be kept

correctly after the start of the year 2000.

The date and time can be adjusted after the start of the year 2000.

The dialling time must be at the set time after the start of the year 2000.

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

Y.Okunishi

4) Automatic re-transmission.

When a communication error happens, the machine dials the same destination again

automatically at an interval. This must function correctly after the start of the year

2000.

5) Weekly timer and night timer

The energy saver mode (fusing unit) control must work correctly.

6) Displayed date after a power failure

The correct date must be kept by the battery back-up feature.

Models Checked

1) K50 series (FAX10, 20, 60, etc.)

2) K70 series (FAX90, 95, 105, etc.)

3) K90 series (FAX80, 85, 75, 86, etc.)

4) LE series (FAX08, 09, Phone fax for ATT, etc.)

5) B series (B1, RF810, FAX12, FAX300, etc.)

6) ZB series (FAX220, FAX240, Innfax, etc.)

7) BARBARA series (RF01, 02, 03, 05, 06, etc.)

8) OX series (FAX21, 22)

9) PF series (PF-1, PF-2)

10) A series (FAX500, 550, etc.)

Page 71

T

Model:

11) B60 series (FAX170, 180, etc.)

12) K100 series (FAX1000L, 1010L, etc.)

13) K105 series (FAX4000L, etc.)

14) K200 series (FAX7000L, etc.)

15) KV series (FAX2800L, 1200L, etc.)

16) C series (FAX3000L, 4500L, 5600L, etc.)

17) L80 (MV715)

18) I series (FAX800, 880, 680, etc.)

19) F\L series (FAX2700L, 4700L, MV310, etc.)

20) FX7, LX7 (FAX1700L, MV106, FAX1750MP, etc.)

21) L20 series (Aficio FX10)

General

echnical

B

ulletin

Date:

31-Oct-97

No:

PAGE: 2/3

011

Problems found

1) AF0 (FAX500, 550, etc.), CS0 (FAX3000L, 3100L, 3200L, etc.)

a) The day of week that appears on the display only in the clock adjustment mode

goes back to SUNDAY every time the clock is adjusted after the start of the

year 2000.

So, the programmed weekly timer does not work correctly.

If the clock is not adjusted after the start of the year 2000, the date and the day

of the week are kept correctly.

b) Clock adjustment is available only for years 91 through 99. The other years

cannot be set. (Month, day, and time can be adjusted.)

2) K200 (FAX7000L)

a) Clock adjustment is available only for years 88 through 99. The other years

cannot be set. (Month, day, and time can be adjusted.)

b) The send later mode does not function (no dialling occurs) if it passes the time

into the year 2000.

No report is printed and the remaining message in the memory is not cleared

automatically but it can be cleared by user operation.

c) Automatic re-transmission is not done if the year 2000 starts after the

transmission failure.

The remaining message in the memory is not cleared automatically but it can

be cleared by user operation.

d) The display year is returned back to 88 after a power failure after the start of

the year 2000.

Page 72

T

Model:

The other functions in these models work correctly.

Schedule for the countermeasure ROMs

1) AF0 (FAX500, 550, etc.), CS0 (FAX3000L, 3100L, 3200L, etc.)

2) K200 (FAX7000L)

General

In January 1998.

In April 1998.

echnical

B

ulletin

Date:

31-Oct-97

No:

PAGE: 3/3

011

RC RE ASIA

Page 73

T

echnical

B

ulletin

MB Correction

Reissue date: 15-Nov-97

The items in bold italic have been corrected or added.

Model:

General

Date:

31-Oct-97

No:

PAGE: 1/3