Page 1

FAX 2500L/2600L/3500L

SERVICE MANUAL

Throughout this manual, the machines are re-

ferred to as follows:

CRO: FAX2500L

CS1: FAX3500L

New CRO: FAX2600L

Page 2

NRG 9650/9665

SERVICE MANUAL

Throughout this manual, the machines are re-

ferred to as follows:

CRO: NRG 9650

CS1: NRG 9665

Page 3

SAVINFAX 3630/3670

SERVICE MANUAL

Throughout this manual, the machines are re-

ferred to as follows:

CRO: SAVINFAX 3630

CS1: SAVINFAX 3670

Page 4

OMNIFAX L42/L46

SERVICE MANUAL

Throughout this manual, the machines are re-

ferred to as follows:

CRO: OMNIFAX L42

CS1: OMNIFAX L46

Page 5

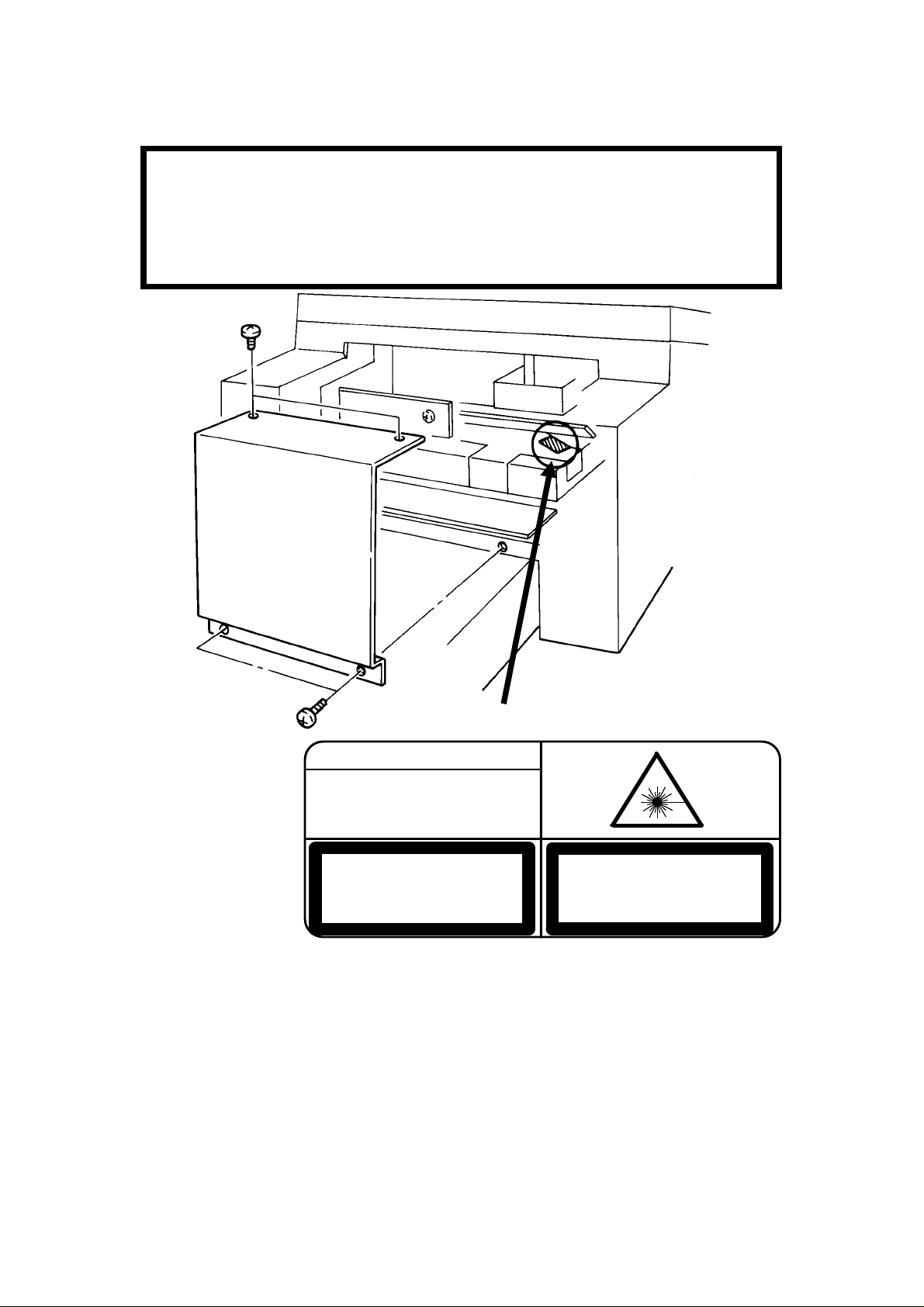

WARNING

DANGER

INVISIBLE LASER RADIATION

WHEN OPEN AVOID DIRECT

EXPOSURE TO BEAM

CAUTION

LASER RADIATION WHEN

OPEN AVOID EXPOSURE

TO BEAM

VORSICHT

UNSICHTBARE LASERSTRAHLUNG,

WENN ABDECKNG GEOFFNET

NICHT DEM STRAHL AUSSETZEN

THIS MACHINE CONTAINS A LASER BEAM GENERATOR. LASER

BEAMS CAN CAUSE PERMANENT EYE DAMAGE. DO NOT OPEN

THE LASER UNIT OR LOOK ALONG THE LASER BEAM PATH

WHILE THE MAIN POWER IS ON.

Lithium Batteries (Memory Back-up)

CAUTION: The danger of explosion exists if a battery of this type is incor-

rectly replaced. Replace only with the same or an equivalent type recommended by the manufacturer. Discard used batteries in accordance with the

manufacturer’s instructions.

Page 6

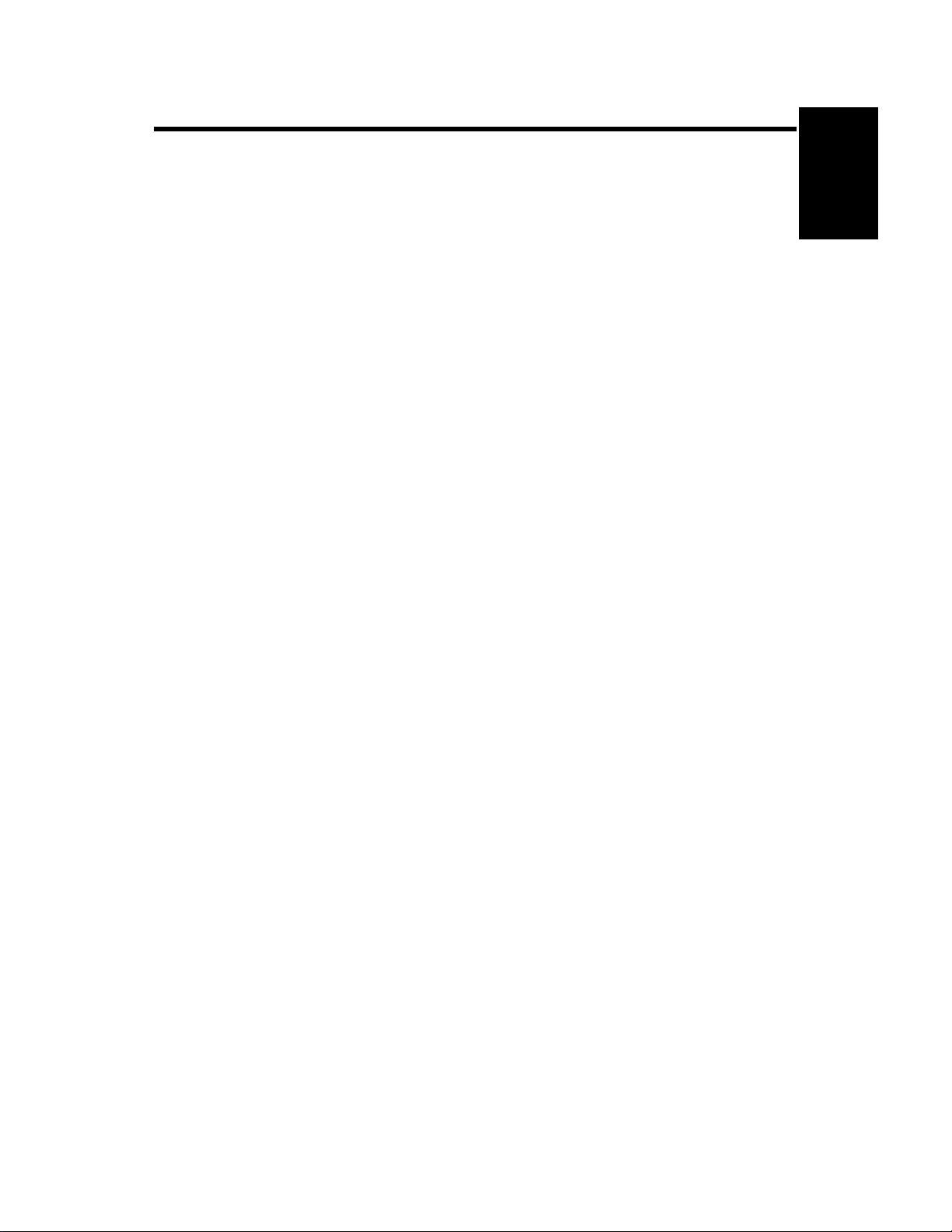

OVERALL MACHINE INFORMATION May 7th, 1993 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1. SPECIFICATIONS

Type

Desktop transceiver

Circuit

PSTN, PABX

Connection

Direct couple

Document Size

Length: 105 - 1200 mm

[4.1 - 47.2 ins]

Up to 100 m [328 ft] after adjustment

Width: 148 - 304 mm

[5.8 - 12.0 ins]

Thickness: 0.05 to 0.2 mm

[2 to 8 mils]

Document Feed

Automatic feed, face down

ADF Capacity

CRO: 30 sheets (using 20 lb paper)

CS1: 50 sheets (using 20 lb paper)

Scanning Method

Flat bed, with CCD

Maximum Scan Width

256 mm [10.1 ins] ± 1%

Scan Resolution

Main scan: 8 dots/mm [203 dpi]

Sub scan:

Standard - 3.85 lines/mm [98 lpi]

Detail - 7.7 lines/mm [196 lpi]

Fine - 15.4 lines/mm [392 lpi]

Memory Capacity

ECM: 128 kbytes (double buffer)

SAF: CRO - 128 kbytes (7 pages), with

optional extra 1 Mbyte or 2 Mbytes

(max 64 or 121 pages respectively)

CS1 - 384 kbytes (21 pages), with

optional extra 1 Mbyte or 2 Mbytes

(max 78 or 135 pages respectively)

Compression

MH, MR, EFC, MMR, SSC

Storage to SAF memory for tx: MH

MMR only with ECM

Protocol

Group 3 with ECM

Modulation

CRO: V.29 (QAM), V.27ter (PHM), V.21 (FM)

CS1: V.33/V.17 (TCM), V.29 (QAM), V.27ter

(PHM), V.21 (FM)

Data Rate (bps)

CRO: 9600/7200/4800/2400

CS1: 14400/12000/9600/7200/4800/2400

Automatic fallback

I/O Rate

With ECM: 0 ms/line

Without ECM: 5, 10, 20, or 40 ms/line

Transmission Time

CRO: 10 s at 9600 bps, CS1: 6 s at 14400

bps; Measured with G3 ECM using memory

for a CCITT #1 test document (Slerexe letter) using standard resolution

Printing System

Laser printing, using the Ricoh CS (Compact

Seamless) Engine, plain paper, dry toner

Paper Size

Standard Cassette:

CRO - Letter, CS1 - Letter, Legal

Lower Cassette (CS1 only):

Letter, Legal, A4, B4

Maximum Printout Width

210 mm [8.3 ins]; 250 mm [9.8 ins] with optional paper feed unit (CS1 only)

Maximum Printer Resolution

Main scan: 16 dots per mm [406 dpi]

Sub scan: 15.4 lines/mm [392 lpi]

Power Supply

115 ± 20 Vac, 60 ± 1 Hz

Power Consumption (Base Machine Only)

Standby: 41 W, Transmit: 46 W

Receive: 176 W, Copying: 269 W

Operating Environment

Temperature: 17 - 28 °C [63 - 82 °F]

Humidity: 40 - 70 %Rh

Dimensions (W x D x H)

496 x 475 x 293 mm [19.5 x 18.7 x 11.5 ins]

Excluding handset, trays, and optional units

Weight

19 kg [41.8 lbs]

Excluding handset, trays, and optional units

1-1

Information

Overall Machine

Page 7

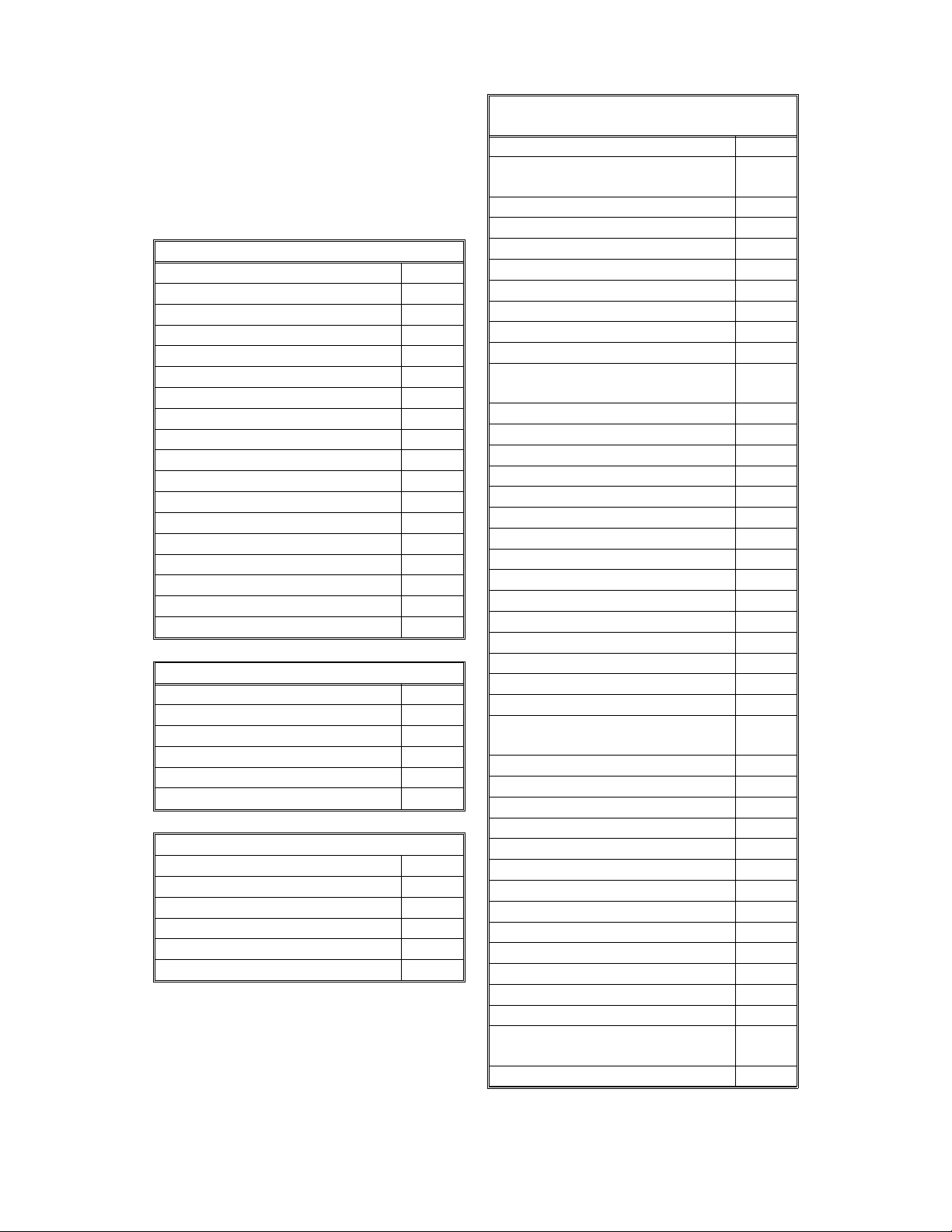

May 7th, 1993 OVERALL MACHINE INFORMATION

FEATURES

1.2. FEATURES

KEY: O = Used by both CRO and CS1

CS1: Used in CS1 only, X = Not used,

A = With optional memory only,

B = With lower cassette only,

C = With printer interface kit only

Equipment

ADF O

Bar code reader X

Built-in handset X

Cabinet X

Connection for ans. machine X

Connection for handset O

Counter (optional) O

Cutter X

Handset (optional) O

Hard disk X

Magnetic card reader X

Manual feed mechanism CS1

Microphone X

Monitor speaker CS1

Printer interface kit (optional) O

Remaining memory indicator O

Speakerphone X

Stamp CS1

Video Processing Features

Contrast O

Halftone (Basic & Error Diffusion) O

MTF O

Reduction O

Resolution O

Smoothing to 16 x 15.4 l/mm O

Communication Features - Auto

Automatic fallback O

Automatic redialing O

Confidential reception A

Dual Access O

Substitute reception O

Transmission Reserve O

Communication Features -

User Selectable

Action as a transfer broadcaster X

AI Redial (CRO: Last one

number, CS1: last ten numbers)

Alternative Destination O

Answering machine X

Authorized Reception CS1

Auto-answer delay time X

Auto dialing (pulse or DTMF) O

Auto Document CS1

Automatic Voice Message X

Auto-note X

Batch Transmission (max 5

batches)

Broadcasting O

Chain Dialing O

Communication Result Display X

Confidential ID Override O

Confidential Transmission O

Direct Fax Number Entry O

Economy Transmission CS1

Economy Transmission Time CS1

Forwarding (5 stations) CS1, A

Free Polling O

Groups (7 groups) O

Group Transfer Station X

Hold X

ID Transmission Option X

Immediate Redialing O

Immediate transmission (this is

the default mode)

Keystroke Programs O

Mailbox X

Memory transmission O

Multi-step Transfer X

Next Transfer Station X

Notify X

On Hook Dial CS1

Page Count O

Personal Codes O

Personal Codes with Conf ID O

Polling Reception O

Polling Transmission O

Polling tx file lifetime in the SAF CS1

Quick Dial (CRO: 16 stations,

CS1: 32 stations)

Reception modes (Fax, Tel) O

O

A

O

O

1-2

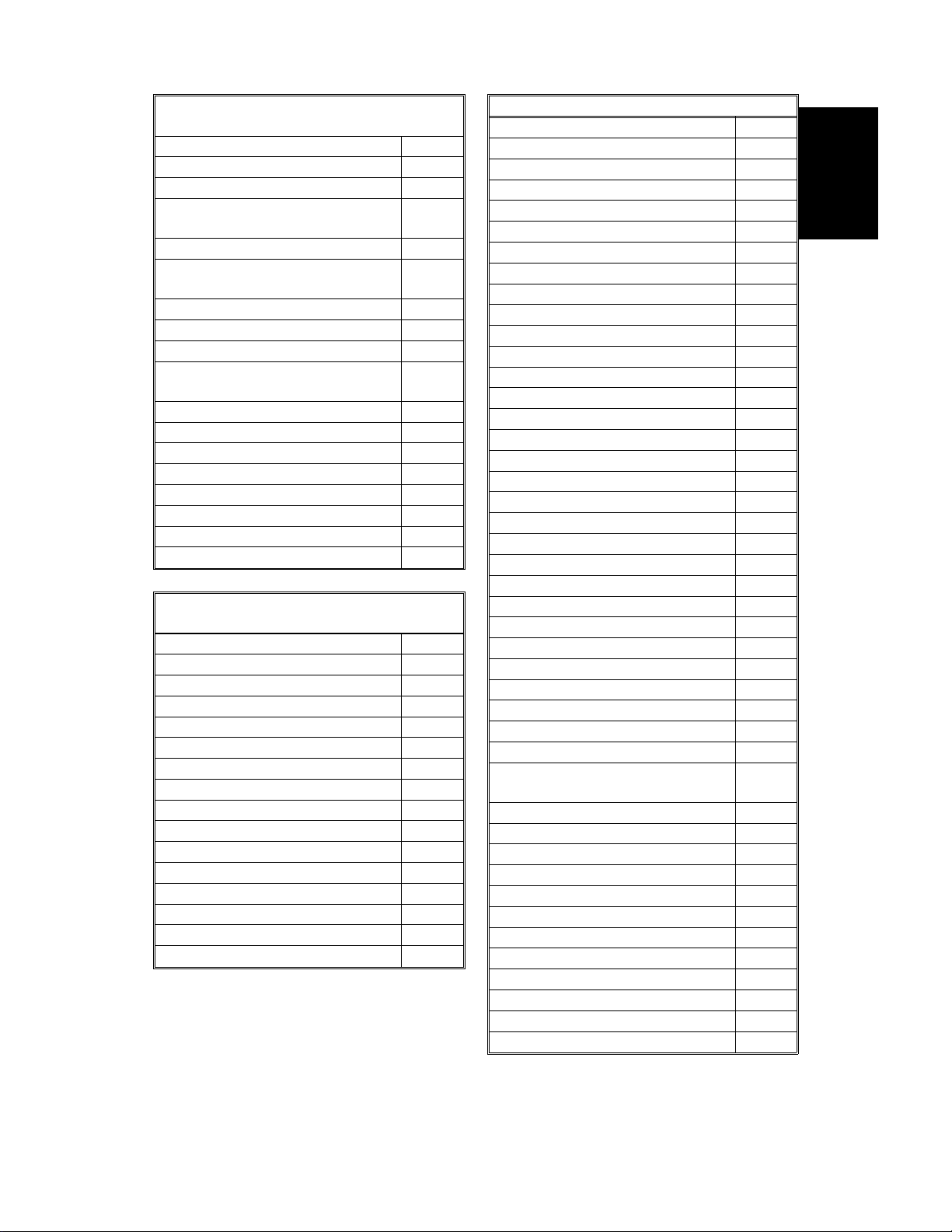

Page 8

OVERALL MACHINE INFORMATION May 7th, 1993

FEATURES

Communication Features -

User Selectable

Reduction O

Remote control features X

Remote Transfer X

Restricted Access (30 codes,

without cards)

Secured Polling O

Secured Polling with Stored ID

Override

Secure Transmission CS1

Send Later O

Silent ringing detection CS1

Speed Dial (CRO: 50 stations,

CS1: 100 stations)

Telephone Directory CS1

Tonal Signal Transmission O

Transfer Request O

Transmission Deadline CS1

Turnaround Polling X

Two in One CS1

Two-step Transfer X

Voice Request (immed. tx only) O

Communication Features -

Service Selectable

AI Short Protocol O

Auto-reduction override option O

Busy tone detection O

Closed Network (tx and rx) O

Continuous Polling Reception O

Dedicated tx parameters O

ECM O

EFC O

Inch-mm conversion X

MV1200 compatibility X

Page retransmission O

Page separation mark O

Protection against wrong conn. O

Resol’n stepdown override option X

Short Preamble O

Well log O

CS1

O

O

Other User Features

Area Code Prefix X

Auto Service Call O

Center mark O

Checkered mark CS1

Clearing a memory file O

Clearing a polling file O

Clock O

Confidential ID O

Copy mode O

Counters O

Country code X

Daylight Saving Time O

Destination Check X

Direct entry of names O

Function Programs O

ID Code O

Label Insertion CS1

Language Selection O

LCD contrast control Service

Memory Lock A

Memory Lock ID A

Modifying a memory file X

Multi Sort Document Reception CS1, A

Multicopy mode A

Night Timer O

OMR Sheet CS1

Ordering Toner O

Own telephone number O

Printing a memory file O

RDS on/off O

Reception Mode Switching Timer X

Reception Time (non-memory rx

only)

Remote ID X

Reverse Order Printing CS1, A

RTI, TTI, CSI O

Secure ID CS1

Speaker volume control CS1

Specified Cassette Selection CS1, B

Substitute reception on/off O

Telephone line type O

TTI on/off O

User Function Keys X

User Parameters O

Wild Cards CS1

CS1

Information

Overall Machine

1-3

Page 9

May 7th, 1993 OVERALL MACHINE INFORMATION

FEATURES

Reports - Automatic

Charge Control Report X

Communication Failure Report O

Confidential File Report A

Error Report O

Memory Storage Report O

Mode Change Report X

Polling Clear Report CS1

Polling Confirmation List CS1

Polling Reserve Report O

Polling Result Report O

Power Failure Report O

TCR O

Transfer Result Report X

Transmission Deadline Report CS1

Transmission Result Report O

Reports - User-initiated

Authorized Reception List CS1

Charge Control Report X

File List O

Forwarding List CS1, A

Group List O

Personal Code List O

Program List O

Quick Dial List O

Specified Cassette Selection List CS1, B

Speed Dial List O

TCR O

Transmission Status Report X

User Function List X

User Parameter List O

Service Mode Features

Back-to-back test O

Bit switch programming O

Buzzer test O

Cable equalizer O

Comm. parameter display O

Counter check X

DTMF tone test O

Echo countermeasure O

Effective term of service calls O

Error code display O

Excessive jam calls O

File Transfer O

Fusing lamp test O

Service Mode Features

LCD contrast adjustment O

Memory file printout (all files) O

Modem test O

NCU parameters O

Operation panel test O

Ozone fan test O

Periodic service call O

PM call O

Printer mechanism test X

Printer test patterns O

Programmable attenuation X

Protocol dump list O

RAM display/rewrite O

RAM dump O

RAM test O

Ringer test X

Scanner lamp test O

Scanner mechanism test O

Sensor initialization X

Serial number O

Service monitor report O

Service station number O

System parameter list O

Technical data on the TCR O

Thermal head parameters X

Transmission Status Report X

Memory Files

CRO

Max. number of files: 20

Max. number of stations/file: 20

Max. number of stations overall: 21

Max. number of pages overall: 128

CS1

Max. number of files: 100

Max. number of stations/file: 142

Max. number of stations overall: 298

Max. number of pages overall: 200

(including pages stored as Auto

Documents)

1-4

Page 10

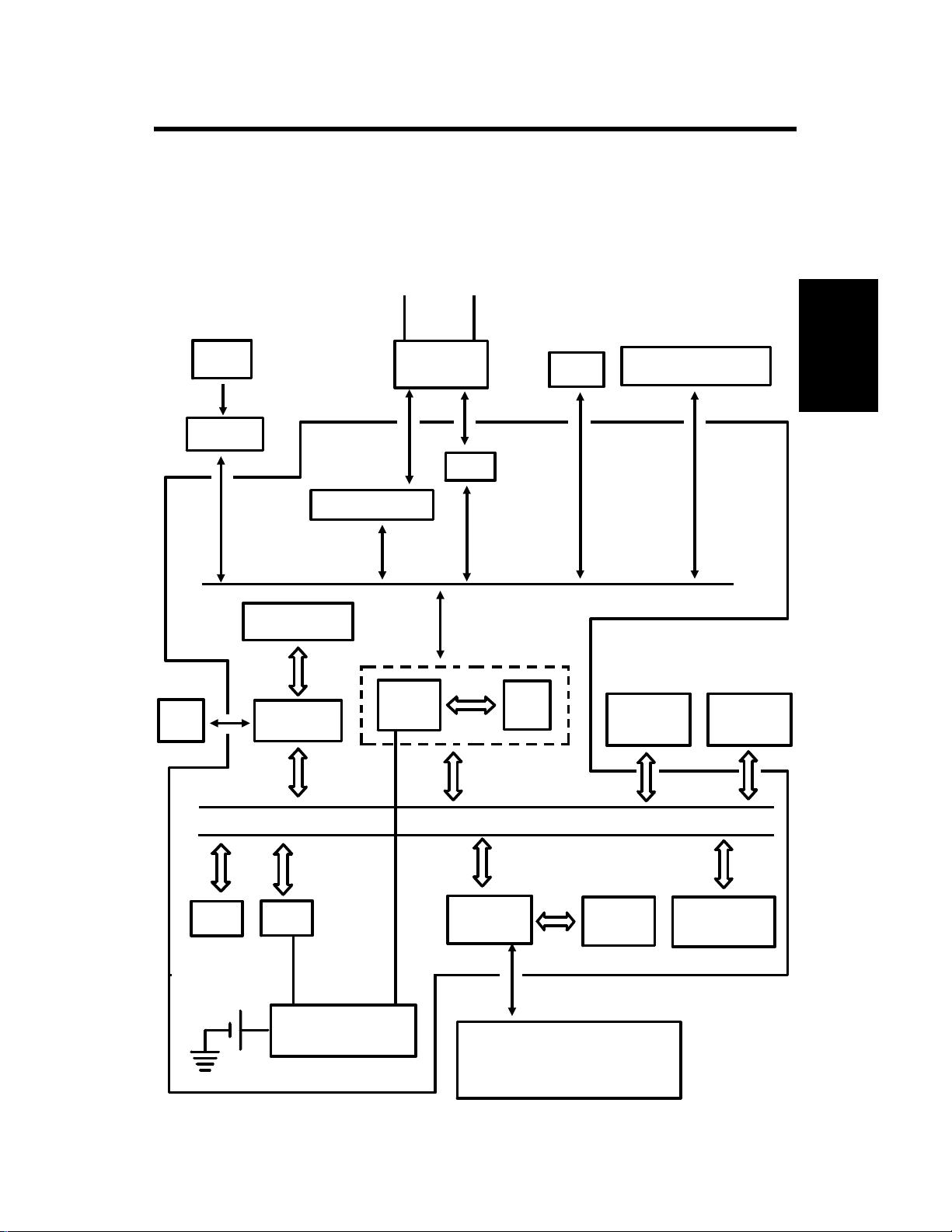

DETAILED SECTION DESCRIPTIONS May 7th, 1993 PCBs AND THEIR FUNCTIONS

2. DETAILED SECTION DESCRIPTIONS

2.1. PCBs AND THEIR FUNCTIONS

2.1.1. FCU

1. CRO

HandsetLine

SBU

(CCD)

Scanner

Sensors

Operation

Panel

Video Processing

Memory

Video

Processor

Modem AFE

CPU

NCU

HIC

CONTROL SIGNALS

I/O

Port

PSU

Scanner and Printer Drive

Components and Sensors

RS-232C

Interface

Descriptions

Detailed Section

FCU

Printer

Interface

ROM

RAM

+

Memory Back-up

Control

DATA AND ADDRESS BUS

Laser

Interface

Page

Memory

Laser Diode Driver

Main Scan Start Detector

Interlock Switch

2-1

ECM/SAF

Memory

Page 11

May 7th, 1993 DETAILED SECTION DESCRIPTIONS

PCBs AND THEIR FUNCTIONS

1. CPU (AFSP)

65C02 compatible microprocessor

•

• Interrupt and DMA control

•

Data compression and reconstruction (high speed MH coding for 4.5second scanning)

• Modem (digital operations)

• Real time clock (battery backed-up)

•

Memory control

• Control of all mechanisms (directly or through other chips)

• NCU control (through the I/O Port)

2. I/O Port (LIOP)

• Clock control

• Sensor monitoring (including A/D conversion where necessary)

•

Tone detection

• Motor drive

• Operation panel control

• Laser Interface control

3. Laser Interface (ALIF)

• Page memory control

•

Laser diode control

•

Smoothing

• Hexagonal mirror motor control

•

Printer interface control

4. Modem Analog Front End (AFE2)

• Modem (analog operations)

• Attenuation

5. Video Processor (VPP4A)

•

Analog/digital video signal processing

6. Hybrid IC (LHIC)

• Filters

7. RAM

•

256k ECM/SAF memory (no battery back-up)

768k page memory

•

•

32k SRAM and 32k PSRAM for parameter storage, line buffer, FIFO,

SAF memory administration

8. ROM

• 256k system ROM for the machine’s software

2-2

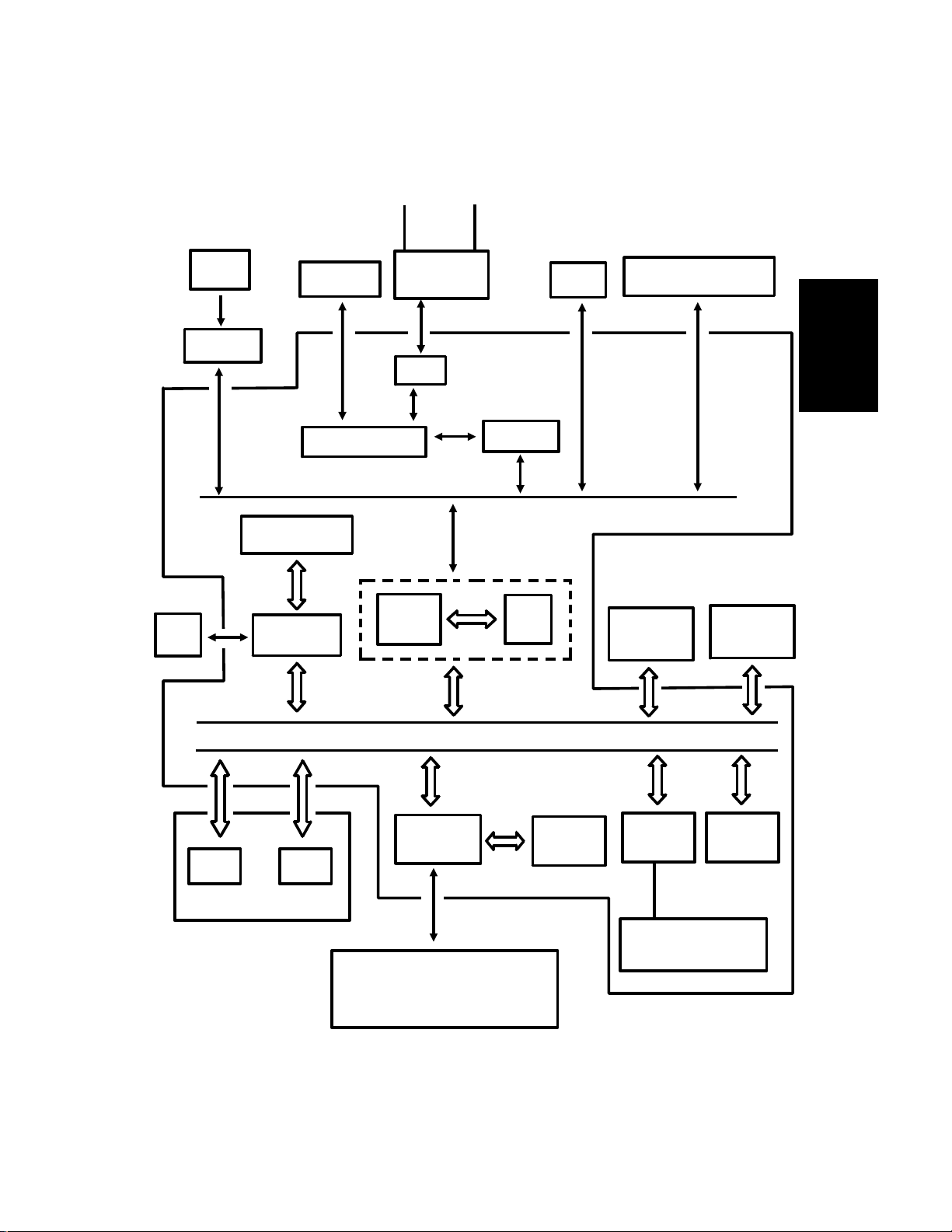

Page 12

DETAILED SECTION DESCRIPTIONS May 7th, 1993

PCBs AND THEIR FUNCTIONS

2. CS1

HandsetLine

SBU

(CCD)

Scanner

Sensors

Operation

Panel

Speaker

Analog Circuit

Video Processing

Memory

Video

Processor

HIC

CPU

NCU

Modem

I/O

Port

PSU

CONTROL SIGNALS

Scanner and Printer Drive

Components and Sensors

RS-232C

Interface

Descriptions

Detailed Section

FCU

Printer

Interface

MBU

DATA AND ADDRESS BUS

Laser

Interface

Page

Memory

SAF

Memory

ECM

Memory

RAMROM

Memory Back-up

Control

Laser Diode Driver

Main Scan Start Detector

Interlock Switch

2-3

Page 13

May 7th, 1993 DETAILED SECTION DESCRIPTIONS

PCBs AND THEIR FUNCTIONS

1. CPU (VFSP)

65C02 compatible microprocessor

•

• Interrupt and DMA control

•

Data compression and reconstruction (high speed MH coding for 4.5second scanning)

• Real time clock (battery backed-up)

• Memory control

•

Control of all mechanisms (directly or through other chips)

• NCU control (through the I/O Port)

2. I/O Port (LIOP)

• Clock control

• Sensor monitoring (including A/D conversion where necessary)

• Tone detection

•

Motor drive

• Operation panel control

• Laser Interface control

3. Laser Interface (ALIF)

• Page memory control

• Laser diode control

•

Smoothing

•

Hexagonal mirror motor control

• Printer interface control

4. Modem (Rockwell R144EFX)

• Modem

5. Analog Circuit

• Attenuation

• Speaker volume control

•

Circuit for extra Rx equalizer

6. Video Processor (VPP4A)

• Analog/digital video signal processing

7. Hybrid IC (MHIC)

•

Filters

Amplifiers

•

8. RAM

•

128k for ECM (no back-up)

• 384k SAF memory (with battery back-up)

• 768k page memory

2-4

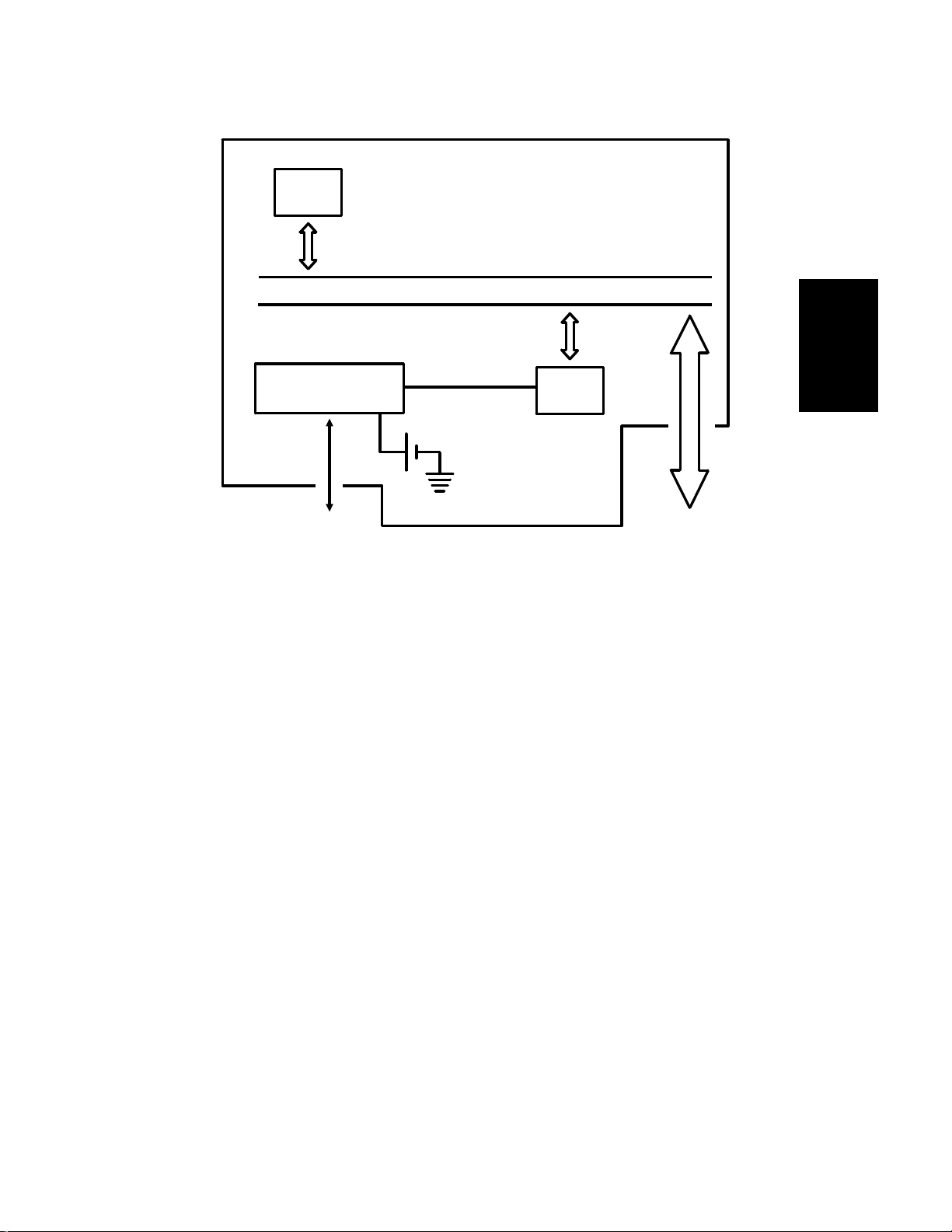

Page 14

DETAILED SECTION DESCRIPTIONS May 7th, 1993

PCBs AND THEIR FUNCTIONS

2.1.2. MBU (CS1 only)

System

ROM

DATA AND ADDRESS BUS

Memory Back-up

Control

+

To/From

FCU

1. System ROM

•

256k for the software to run the machine

System

RAM

MBU

Descriptions

Detailed Section

To/From

FCU

2. System RAM

• 32k SRAM and 32k PSRAM for parameter storage, line buffer, FIFO,

SAF memory administration

The SRAM is backed up by the battery on the MBU.

2-5

Page 15

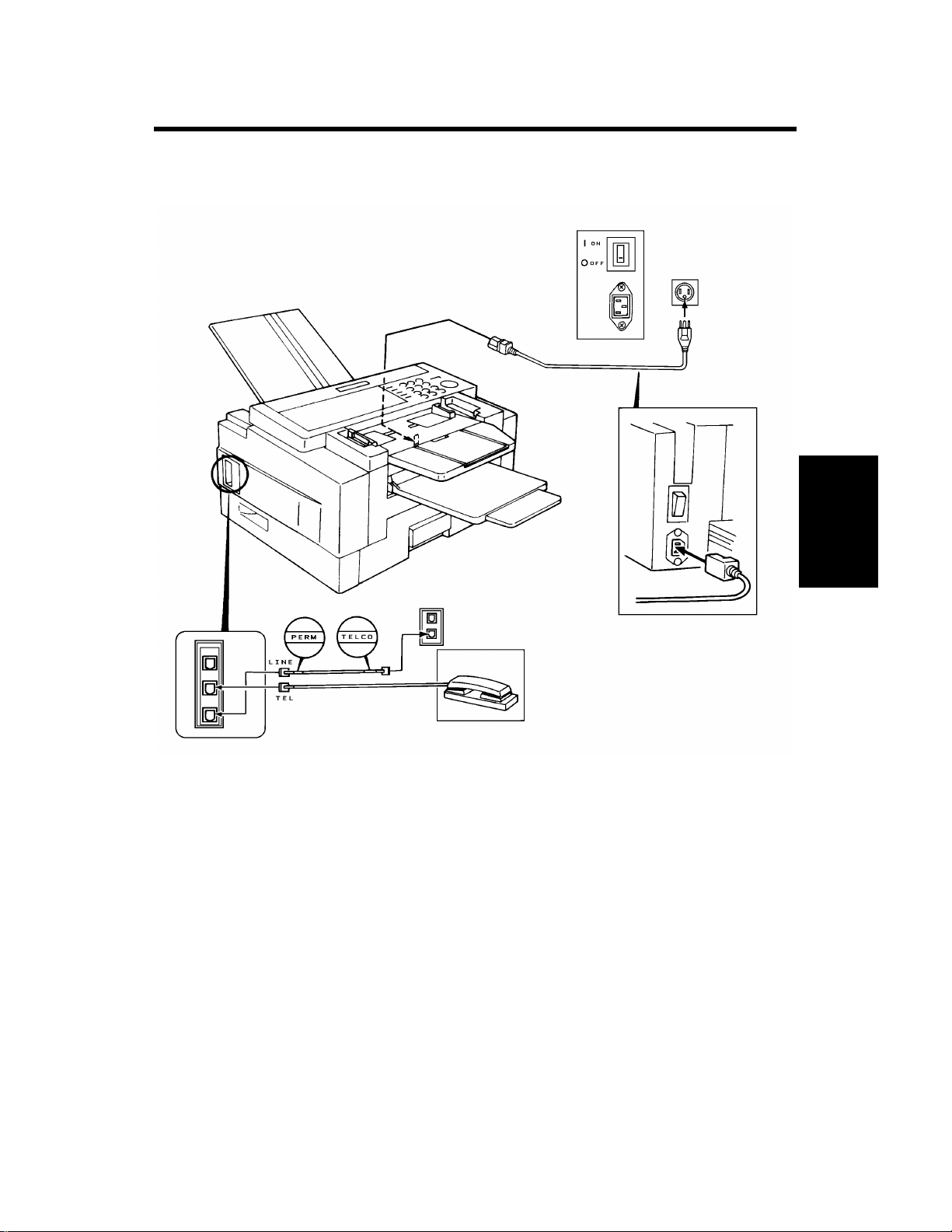

INSTALLATION May 7th, 1993

CONNECTING UP THE MACHINE

3. INSTALLATION

3.1. CONNECTING UP THE MACHINE

POWER

SWITCH

115 ±20V

60 ±1 Hz

Grounded

Phone

Company’s

Jack

HANDSET

Installation

3-1

Page 16

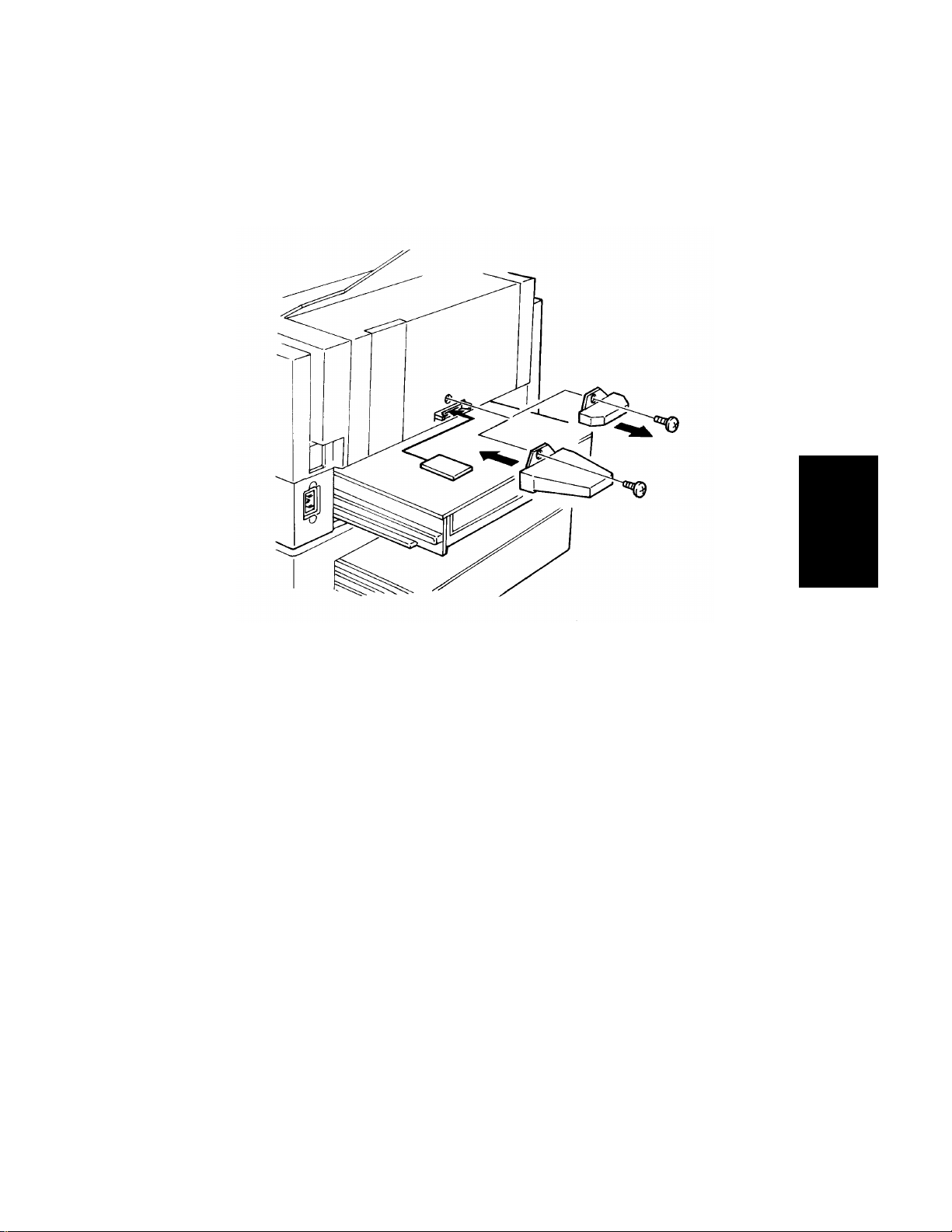

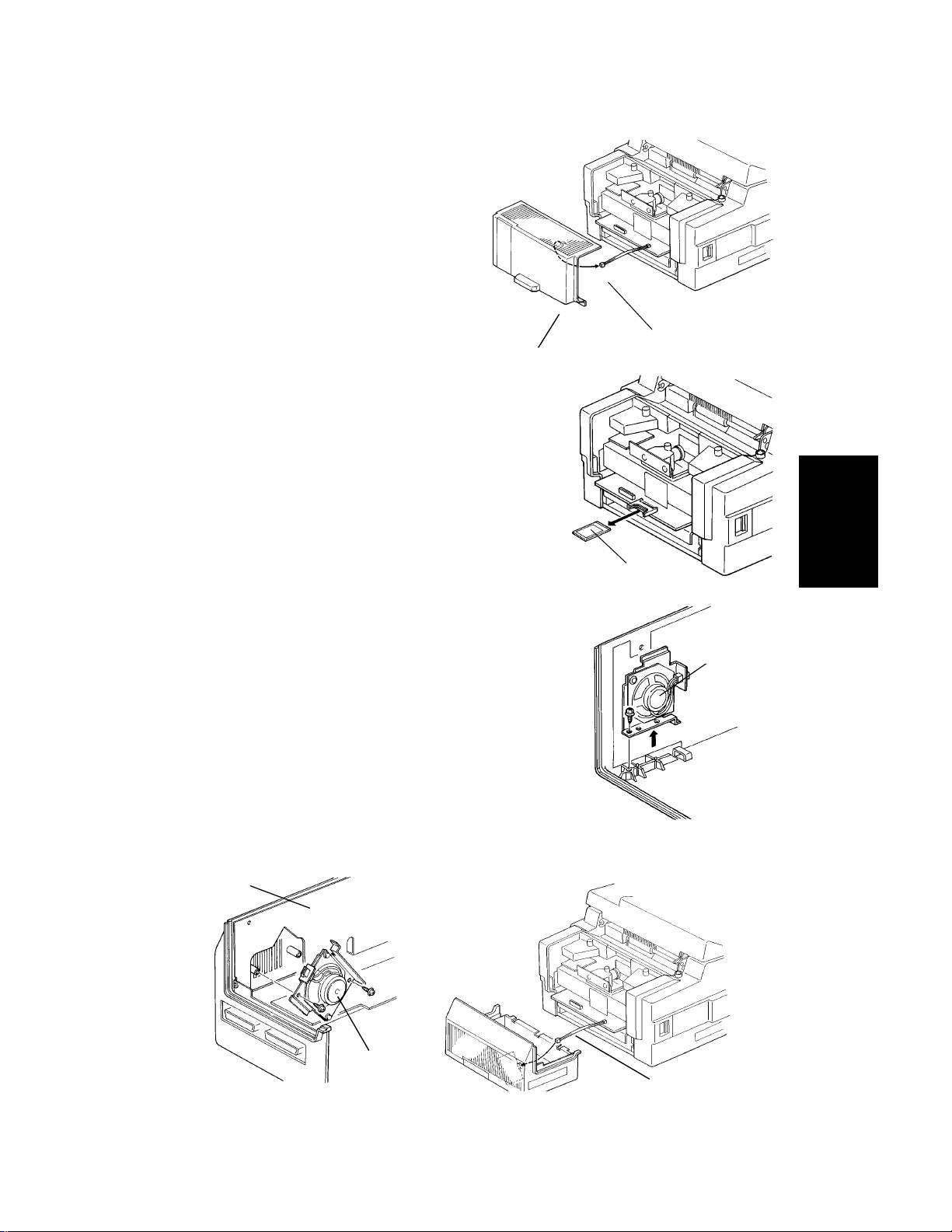

[B]

[A]: 1 screw

May 7th, 1993 INSTALLATION

INSTALLING ADDITIONAL UNITS

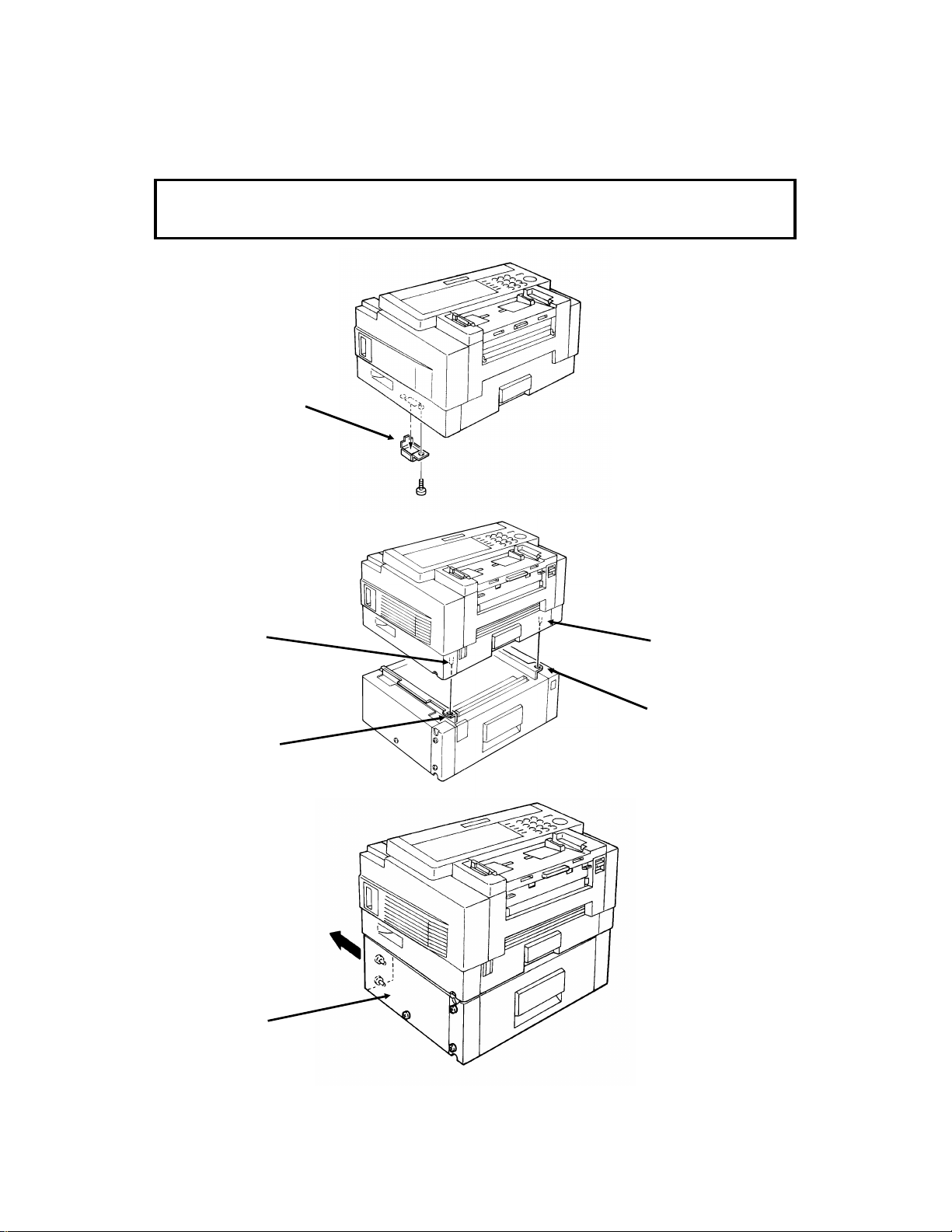

3.2. INSTALLING ADDITIONAL UNITS

3.2.1. Lower Cassette (CS1 only)

Check whether there are any messages in the memory. If there are, you

must install the lower cassette and turn the power back on within an hour.

[A]

[B]

[D]

[C]

[C]

Fit pegs [B] into holes [C].

[D]: 5 screws

3-2

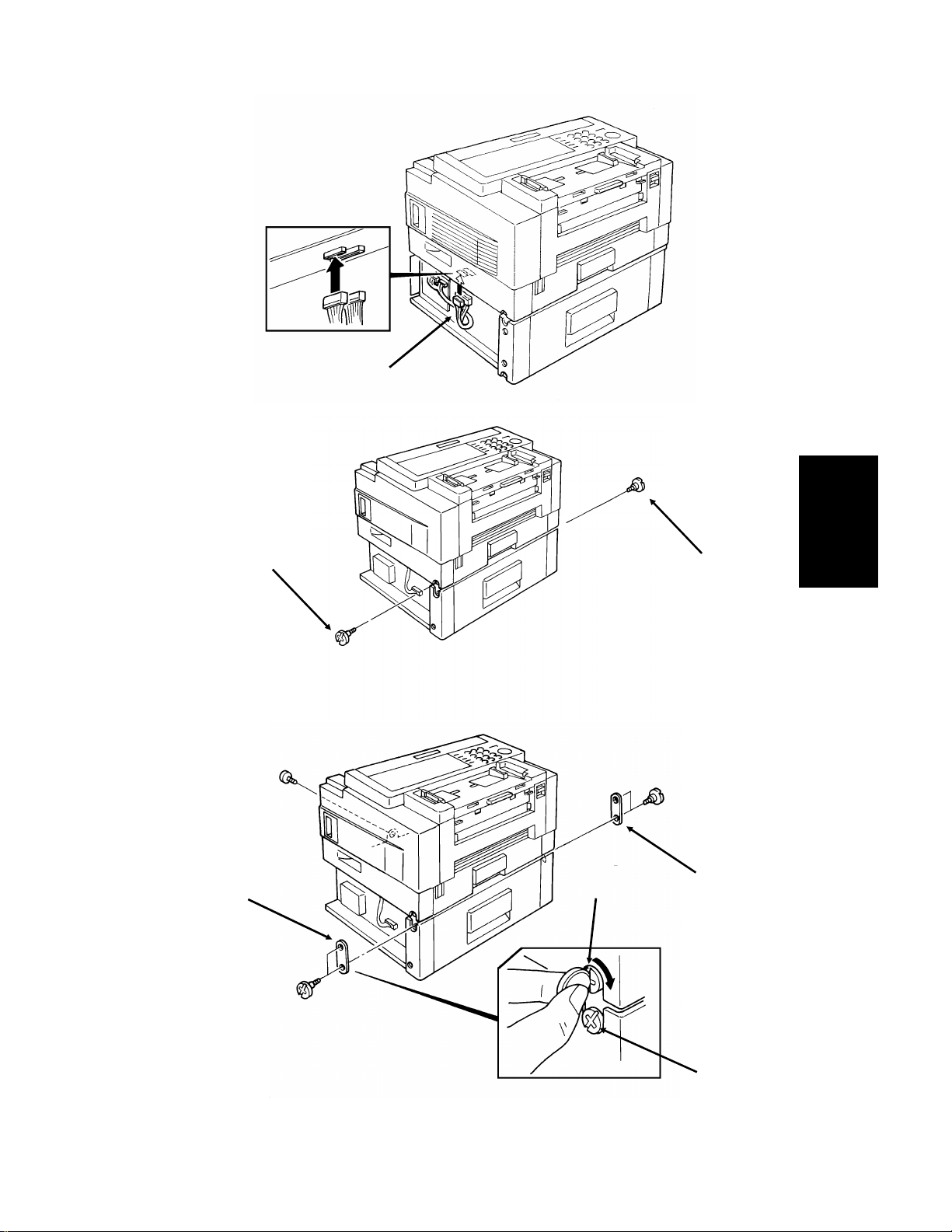

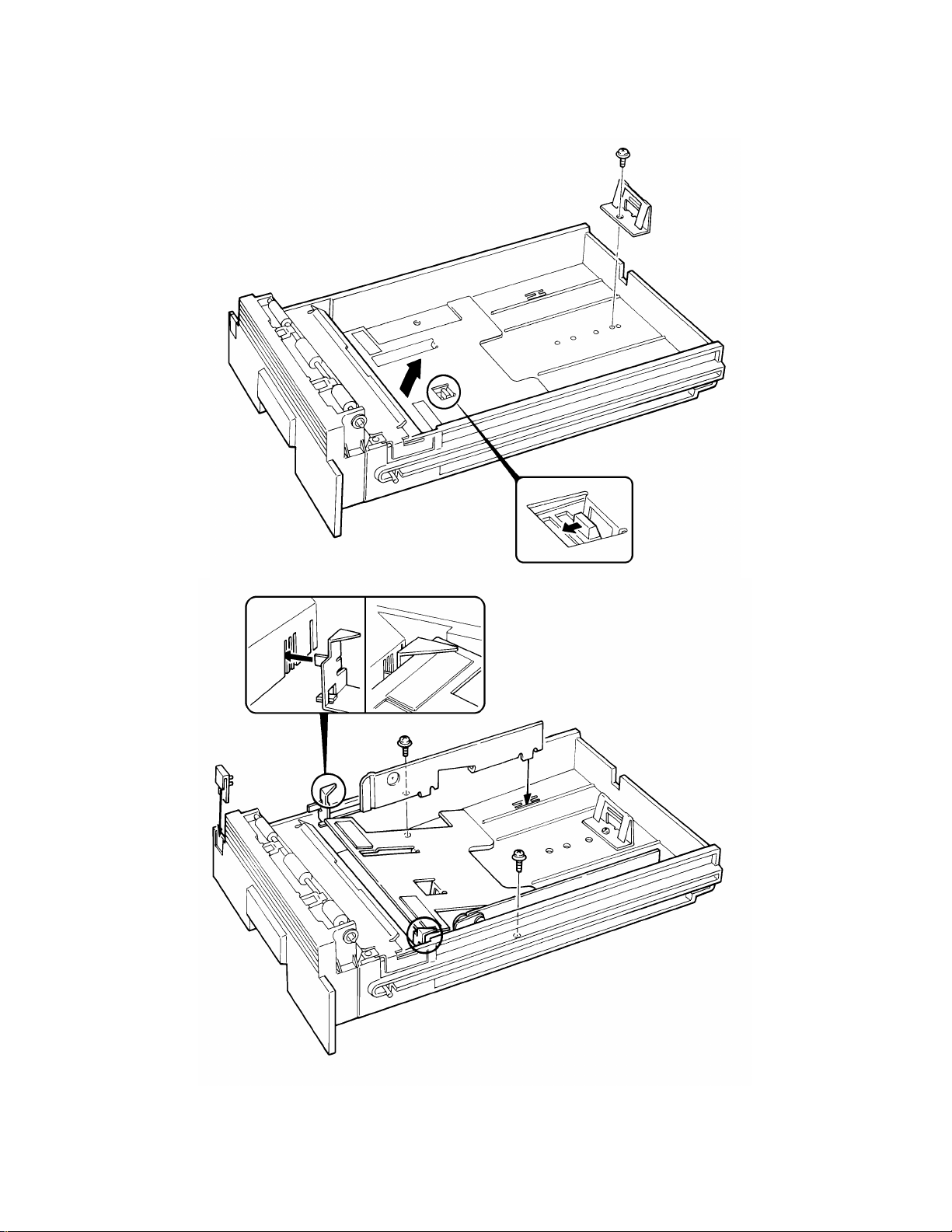

Page 17

[F]

[G]

[H]

INSTALLATION May 7th, 1993

INSTALLING ADDITIONAL UNITS

[F]

[E]

[E]: 2 connectors

Installation

Remove two screws [F].

[G]

Install brackets [G] (2 screws each).

Screws [H]: Use previously removed

screws [F].

Screws [I]: In the accessories bag.

[I]

3-3

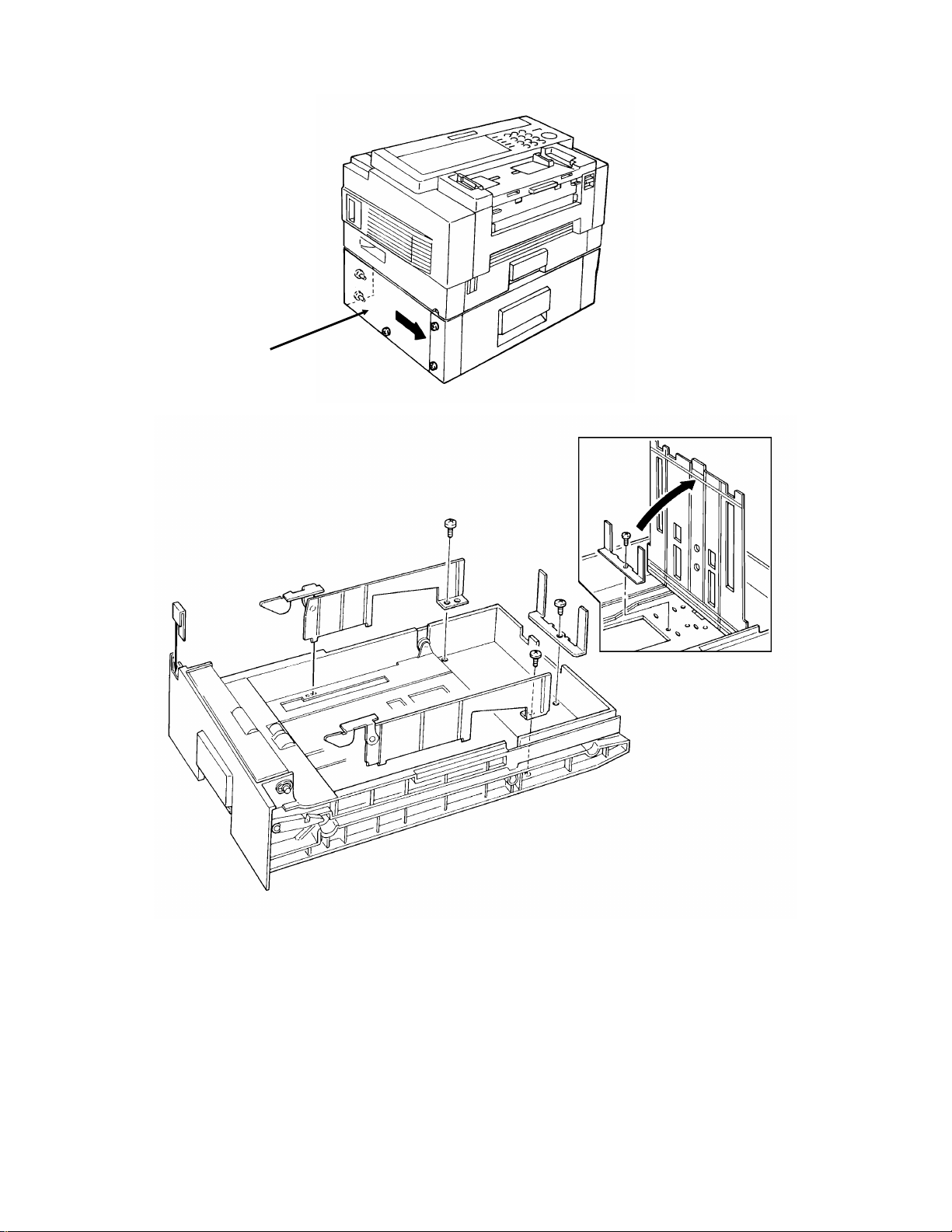

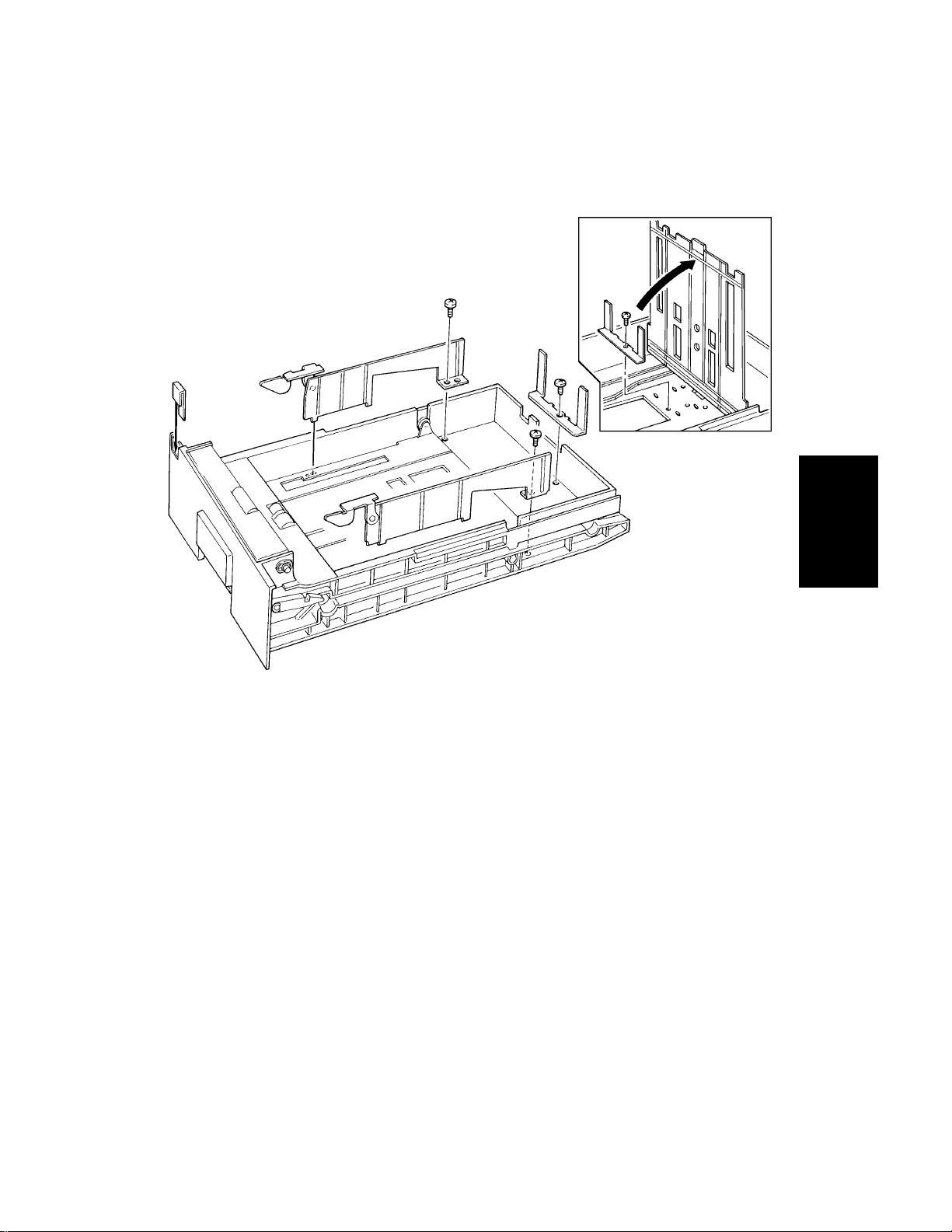

Page 18

May 7th, 1993 INSTALLATION

INSTALLING ADDITIONAL UNITS

[J]

Adjust the cassette in accordance

with customer requirements.

3-4

Page 19

INSTALLATION May 7th, 1993

INSTALLING ADDITIONAL UNITS

3.2.2. Memory Card

• Turn off the power before installing or removing a memory card.

•

Make sure that 100% is displayed on the operation panel before installing or removing a memory card, or data will be lost.

Installation

3-5

Page 20

May 7th, 1993 INSTALLATION

INSTALLING ADDITIONAL UNITS

3.2.3. Cassette (250 Sheets)

3-6

Page 21

INSTALLATION May 7th, 1993

INSTALLING ADDITIONAL UNITS

3.2.4. Cassette (500 Sheets; CS1 only)

Installation

3-7

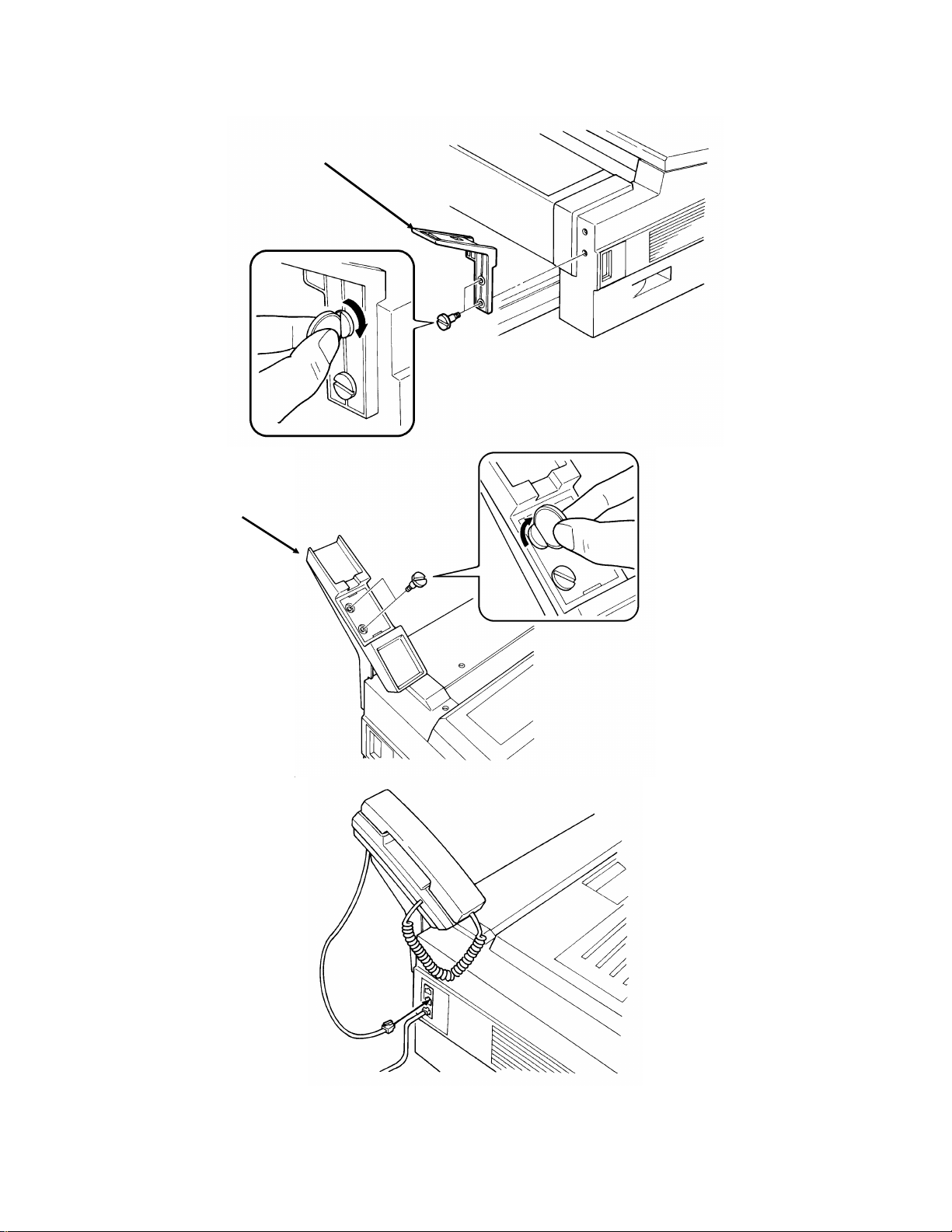

Page 22

[B]: 2 screws

May 7th, 1993 INSTALLATION

INSTALLING ADDITIONAL UNITS

3.2.5. Handset

[A]

[A]: 2 screws

[B]

3-8

Page 23

INSTALLATION May 7th, 1993

INSTALLING ADDITIONAL UNITS

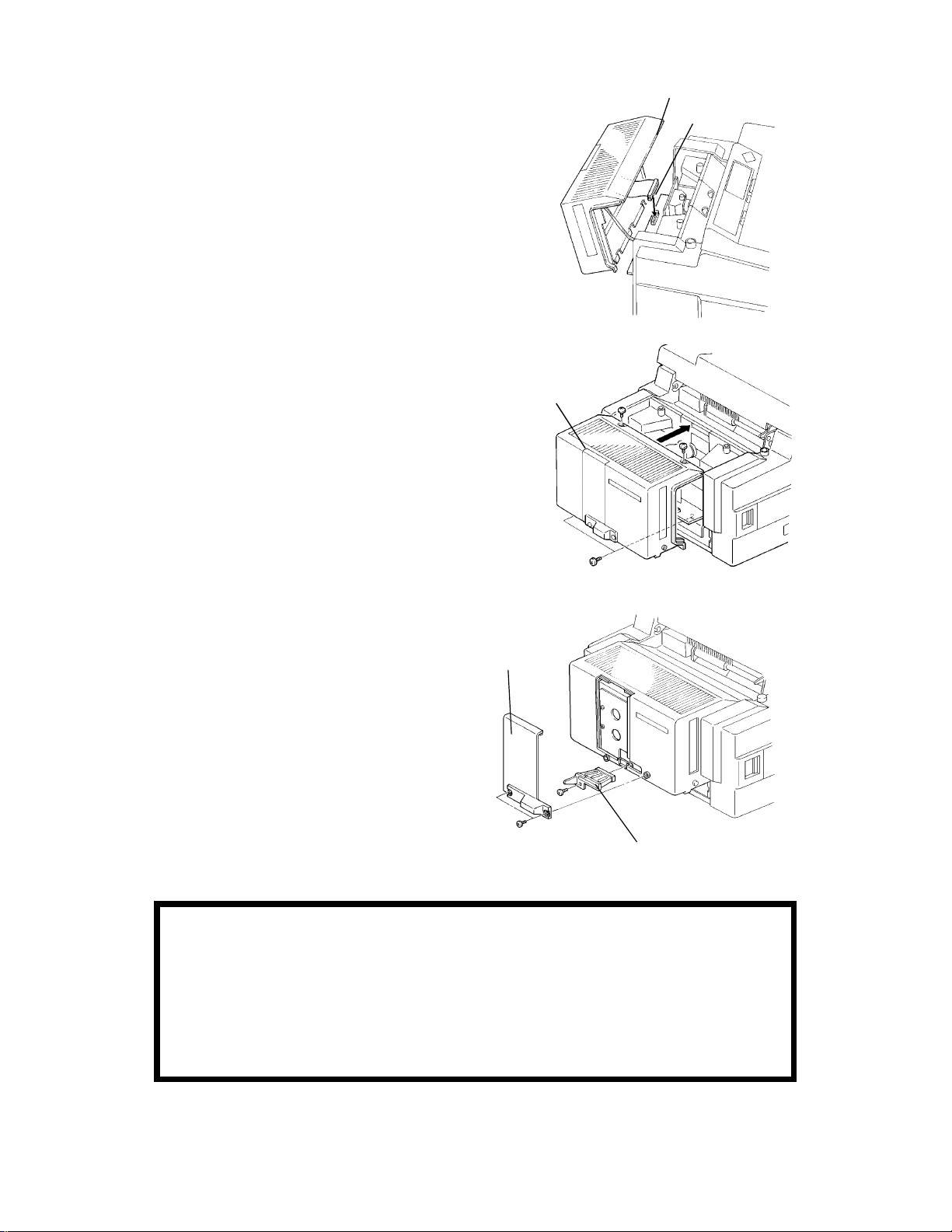

3.2.6. Printer Interface Kit

Installing the Interface Kit

1. First, print any messages still

stored in the SAF.

2. Turn off the power, and unplug the

machine from the wall socket.

[B]

3. Slide out the cassettes.

[A]

4. Take off the rear cover [A] and disconnect

the monitor speaker [B].

5. If a memory card [C] is installed on the machine, remove it.

Note for CRO: Go to step 8.

[C]

Installation

6. Take off the monitor speaker [D] from the rear

cover.

7. Attach the monitor speaker [E] to the printer

interface unit [F].

Then reconnect the monitor speaker [G].

[F]

[E]

[D]

[G]

3-9

Page 24

May 7th, 1993 INSTALLATION

INSTALLING ADDITIONAL UNITS

8. Hold the printer interface unit [H] near the

[H]

[ I ]

machine with one hand, and plug the flat

cable [ I ] into the connecter on the FCU

board.

9. Attach the printer interface unit [J].

[J]

10. Remove the memory option cover

[K].

[K]

11. Attach the memory card guide [L].

Then install the memory card if necessary.

12. Put back the option memory cover.

13. Put back the cassettes.

14. Plug in the machine, then turn on the

power.

[L]

CAUTION

If an optional memory card is used with the printer interface unit

and you wish to disassemble the machine, be sure to remove the

memory card first, before removing the printer interface unit.

Removing the printer interface unit without removing the memory

card will cause the card or the connector on the FCU to be

physically damaged.

3-10

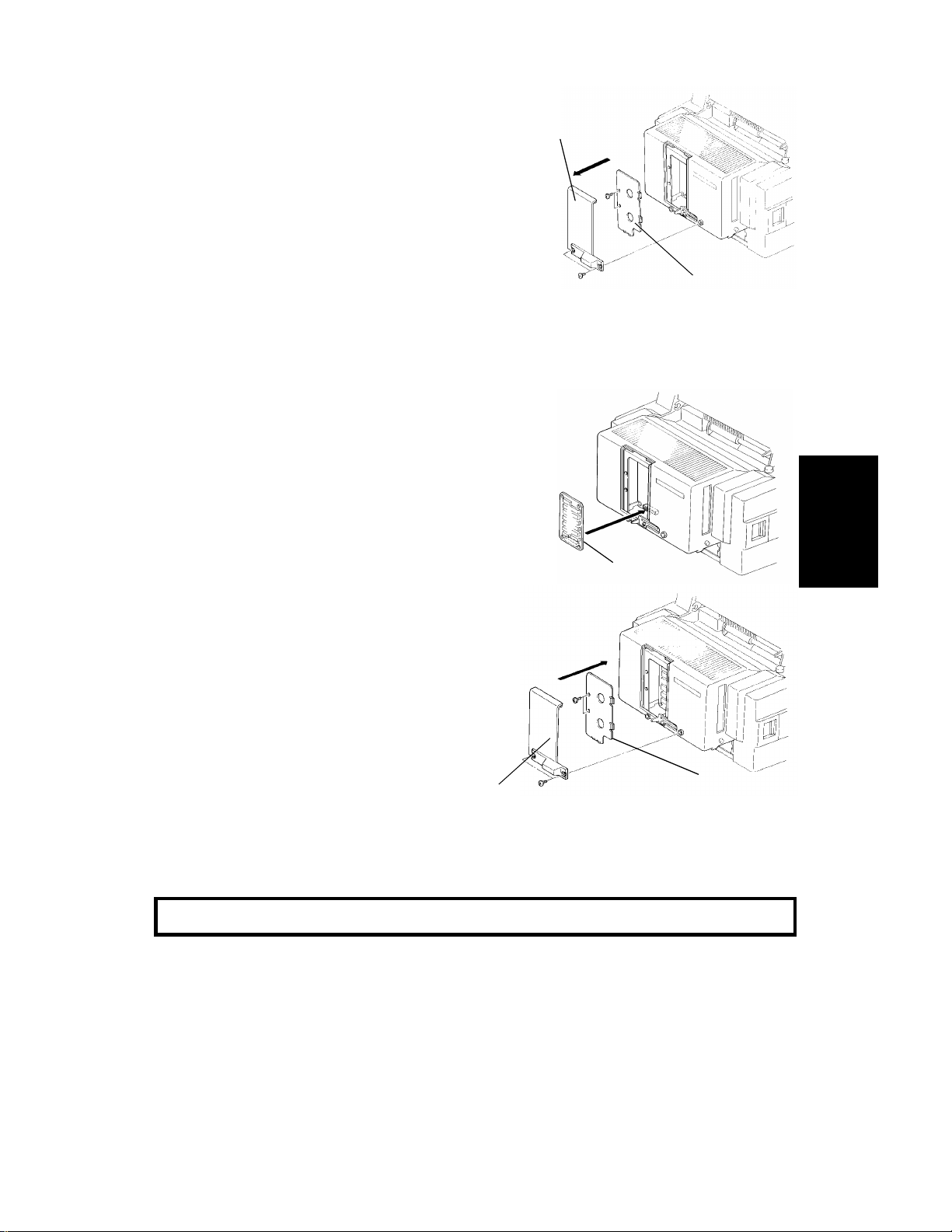

Page 25

[N]

INSTALLATION May 7th, 1993

INSTALLING ADDITIONAL UNITS

Installing the Memory Expansion Board

[M]

1. Print any messages still stored in the SAF.

2. Turn off the power and unplug the machine from the wall socket.

3. Remove the memory option cover [M] and

the memory board cover [N].

4. Insert the memory expansion board [O].

5. Put back the memory board cover [P] and

[O]

the memory option cover [Q].

6. Plug in the machine, then turn on the

power.

[Q]

[P]

Caution: Do not plug in or switch on until everything is connected up.

Installation

3-11

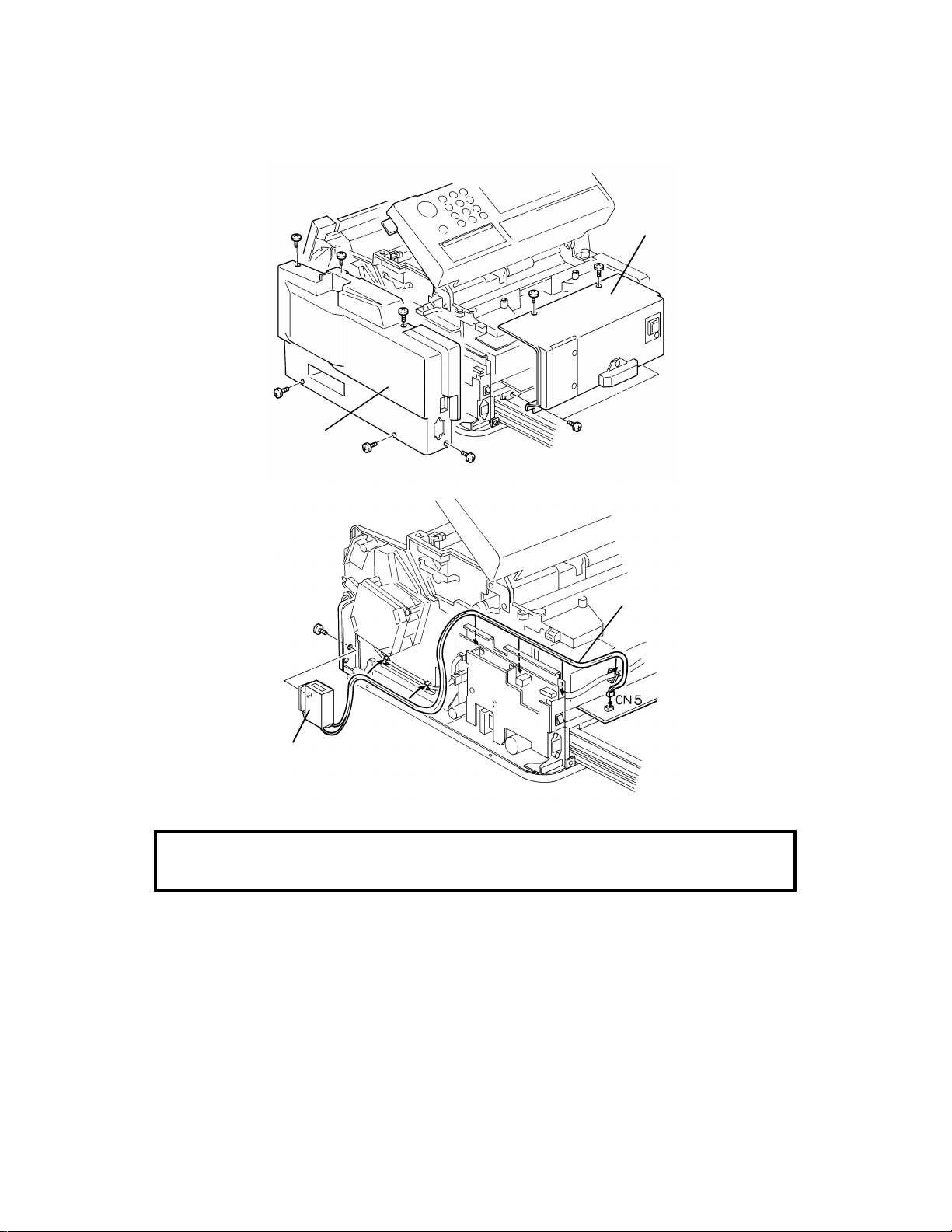

Page 26

[A]: 4 screws

[B]: 6 screws

[D]

May 7th, 1993 INSTALLATION

INSTALLING ADDITIONAL UNITS

3.2.7. Counter

Turn off the power before beginning this procedure.

[A]

[B]

[C]: 1 screw

[D]: To CN5 on the FCU

[C]

Make sure that the harness is fed through the machine without getting

entangled around components.

Test the counter before reassembling the machine.

1. Carefully turn on the power.

Caution: Do not touch the PSU.

2. Copy a few sheets.

3. Check that the counter increments correctly.

Then turn off the power, put back the covers, and switch on the machine.

3-12

Page 27

INSTALLATION May 7th, 1993

INITIAL PROGRAMMING

3.3. INITIAL PROGRAMMING

Check the following:

•

Is the country code in the NCU parameters (Function 96, parameter 00)

correct for the country of installation? In the USA, it should be 17.

• Do any bit switch or other settings have to be changed to match line

conditions or user requirements?

• Have you programmed the serial number (Function 98, section 4-1-19)

The user should program the following items after installation:

• Telephone Line Type (Europe only)

• RTI, TTI, and CSI

• ID Codes (ID Code, Secure ID [CS1 only], Confidential ID, Memory

Lock ID)

• The fax machine’s own telephone number

• Date and Time

• Daylight Saving Time On/Off

•

Language Selection

Installation

3-13

Page 28

SERVICE TABLES AND PROCEDURES July 16th, 1993 SERVICE LEVEL FUNCTIONS

4. SERVICE TABLES AND PROCEDURES

4.1. SERVICE LEVEL FUNCTIONS

4.1.1. Bit Switch Programming (Function 91)

Function 5 1 9 9 1

1.

then immediately

Yes

2. 9 1 Yes

Bit 7 is displayed at the left, and bit 0 at

the right.

3. Increment bit switch:

Decrement bit switch:

Example: Display bit switch 3:

#

*

# x 3

4. Adjust the bit switch.

Example: To change the value of bit

7, press

7

5. Either:

• Adjust more bit switches - go to step 3.

•

Finish - Function

FUNCTION Y/∇

9 SERVICE FUNCTIONS

DEFAULT: 0000 0000

BITSW 00: 0000 0000

DEFAULT: 0000 0000

BITSW03: 0000 0000

DEFAULT: 0000 0000

BITSW03: 1000 0000

Service Tables

and Procedures

4-1

Page 29

July 16th, 1993 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNCTIONS

4.1.2. System Parameter List (Function 92)

1.

Function 5 1 9 9 1

then immediately Yes

FUNCTION Y/∇

9 SERVICE FUNCTIONS

2. 9 2 Yes Start

After printing, press

Function

4.1.3. Error Code Display (Function 93)

1. Function 5 1 9 9 1

then immediately Yes

FUNCTION Y/∇

9 SERVICE FUNCTIONS

2. 9 3 Yes ERROR CODE #/∇

1-01 JAN 01 17:30

3. Either:

Scroll through the error codes -

#

Finish - Function

4.1.4. Service Monitor (Function 93)

1.

Function 5 1 9 9 1

then immediately

Yes

2. 9 3 Yes

3. No/∇ Start

4.1.5. Protocol Dump (Function 94)

1. Function 5 1 9 9 1

then immediately Yes

2. 9 4 Yes

3. Start

FUNCTION Y/∇

9 SERVICE FUNCTIONS

ERROR CODE #/∇

1-01 JAN 01 17:30

FUNCTION Y/∇

9 SERVICE FUNCTIONS

START

PROTOCOL DUMP LIST

4-2

Page 30

SERVICE TABLES AND PROCEDURES July 16th, 1993

SERVICE LEVEL FUNCTIONS

4.1.6. RAM Display/Rewrite (Function 95)

1.

Function 5 1 9 9 1

then immediately Yes

FUNCTION Y/∇

9 SERVICE FUNCTIONS

2. 9 5 Yes Y/∇

DISPLAY MEMORY

3. Yes

ADDRESS = 2044C

DATA = 03

4. Input the address that you wish to see. Example: Address 20202

2 0 2 0 2

ADDRESS = 20202

DATA = 00

Note: The first digit must always be 2.

5. If you wish to change the data, type in the new data.

Example: 80, press 8 0 ADDRESS = 20202

DATA = 80

Note: If you wish to move the cursor, press

→

6. Either:

• View more addresses - go to step 4.

• Finish - Yes Function

4.1.7. RAM Dump (Function 95)

1.

Function 5 1 9 9 1

then immediately Yes FUNCTION Y/∇

9 SERVICE FUNCTIONS

2. 9 5 Yes Y/∇

DISPLAY MEMORY

3. ∇ Yes MEMORY DUMP

B=02, S=0000,E=00FF

START/N

4-3

Service Tables

and Procedures

Page 31

July 16th, 1993 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNCTIONS

4. Input the bank number. The value of parameter “B” is always “02”. Then,

input the first two digits of start and end addresses at “S=” and “E=”

prompts. For example, enter “12” for start address 1200(H), and enter 13

for end address 13FF(H). Then, press Start to print the dump list.

Example: Start at 1200, end at 13FF.

0 2 1 2 1 3 Start

MEMORY DUMP START

B=02, S=1200,E=13FF

4.1.8.4.1.8. SAF/ECM Memory Test (Function 95)

1. Function 5 1 9 9 1

then immediately

2. 9 5 Yes

Yes

FUNCTION Y/∇

9 SERVICE FUNCTIONS

Y/∇

DISPLAY MEMORY

3. ∇ ∇ Yes . The machine starts to check the DRAMs used as ECM

and SAF memory.

BUSY

CHECK DRAM

4. After the test, either “PASS” or “ERR (Error)” will be displayed.

If “ERR: B=nnH ADR=mmmm” is displayed, replace the FCU (“nn” and

“mmmm” represents the bank number and the address of the defective

portion of the memory.

5. Stop

4.1.9. Page Memory Test (Function 95)

1.

Function 5 1 9 9 1

then immediately Yes

2. 9 5 Yes

4-4

PASS

CHECK DRAM

FUNCTION Y/∇

9 SERVICE FUNCTIONS

Y/∇

DISPLAY MEMORY

Page 32

SERVICE TABLES AND PROCEDURES July 16th, 1993

SERVICE LEVEL FUNCTIONS

3. ∇ ∇ ∇ Yes . The machine starts to check the DRAMs used as

page memory.

BUSY

CHECK PAGE MEMORY

4. After the test, either “PASS” or “ERR (Error)” will be displayed.

If “ERR: B=nnH ADR=mmmm” is displayed, replace the FCU (“nn” and

“mmmm” represents the bank number and the address of the defective

portion of the memory.

PASS

CHECK PAGE MEMORY

5. Stop

4.1.10. NCU Parameters (Function 96)

Function 5 1 9 9 1

1.

then immediately

2. 9 6 Yes

Yes FUNCTION Y/∇

9 SERVICE FUNCTIONS

NCU PARAMETER KPAD/Y

NO.00 017

3. Scroll through the parameters - Yes

Enter new values at the keypad.

Example: Set NCU parameter 04 to 005.

Yes Yes Yes Yes 0 0 5 NCU PARAMETER KPAD/Y

NO.04 005

4. To finish: Function

Note: Parameter 00 is the Country Code, and Parameter 01 is the Tx Level

(if the Tx level should be -9 dB, input 9).

Refer to section 4-3 for full details on NCU parameters.

4.1.11. ADF Test (Function 97)

1. Function 5 1 9 9 1

Service Tables

and Procedures

then immediately

Yes FUNCTION Y/∇

9 SERVICE FUNCTIONS

2. 9 7 Yes SCN-1 DT-2 PL-3 LD-4

MDM-5 RI-6 CK-7

4-5

Page 33

July 16th, 1993 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNCTIONS

3. 1

SCANNER TEST KPAD

ADF-1 LAMP-2

4. 1

5.

Function Function

6. Place a document in the feeder,

then press Copy Start

4.1.12. Xenon Lamp and Fusing Lamp Test (Function 97)

Function 5 1 9 9 1

1.

then immediately Yes

2. 9 7 Yes

FUNCTION Y/∇

9 SERVICE FUNCTIONS

SCN-1 DT-2 PL-3 LD-4

MDM-5 RI-6 CK-7

3. 1

4. 2

SCANNER TEST KPAD

ADF-1 LAMP-2

SCANNER LAMP TEST

The xenon lamp lights up for 5 minutes,

and the fusing lamp is switched on.

4.1.13. DTMF Tone Test (Function 97)

1.

Function 5 1 9 9 1

then immediately Yes FUNCTION Y/∇

9 SERVICE FUNCTIONS

2. 9 7 Yes

3. 2

SCN-1 DT-2 PL-3 LD-4

MDM-5 RI-6 CK-7

DTMF TEST

DUAL-1 SINGLE-2

4-6

Page 34

SERVICE TABLES AND PROCEDURES July 16th, 1993

SERVICE LEVEL FUNCTIONS

4. Either:

• Test dual tones - 1 . Go to step 5.

• Test single tones - 2 . Go to step 8.

5. The display is as shown opposite. DUAL TONE

PRESS KEYPAD

Press a key on the ten key pad.

Example: 1 Start

6. To stop the test:

Stop

7. Either:

Test another tone: Go to step 5.

Finish: Function

8. The display is as shown opposite.

Press the required key.

697 Hz 1 852 Hz 3 1209 Hz 5 1477 Hz 7

770 Hz 2 941 Hz 4 1336 Hz 6 1633 Hz 8

Example: To test 1633 Hz, press 8 Start

9. To stop the test: Stop

10. Either:

Test another tone: Go to step 8.

SINGLE TONE

PRESS KEYPAD

Service Tables

and Procedures

Finish:

Function

4.1.14. Printer Test Patterns (Function 97)

1. Function 5 1 9 9 1

then immediately Yes

2. 9 7 Yes

4-7

FUNCTION Y/∇

9 SERVICE FUNCTIONS

SCN-1 DT-2 PL-3 LD-4

MDM-5 RI-6 CK-7

Page 35

July 16th, 1993 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNCTIONS

3. 3

PATTERN PRINT KPAD

1-7

5. Press a key from 1 to 7, excluding 5 and 6. (Patterns 5 and 6 are not

used in this model.) A test pattern is printed.

4.1.15. Operation Panel and Ozone Fan Test (Function 97)

1.

Function 5 1 9 9 1

then immediately

Yes FUNCTION Y/∇

9 SERVICE FUNCTIONS

2. 9 7 Yes SCN-1 DT-2 PL-3 LD-4

MDM-5 RI-6 CK-7

3. 4

4. To stop the test, press Stop .

4.1.16. Modem Test (Function 97)

1. Function 5 1 9 9 1

then immediately

Yes

2. 9 7 Yes

3. 5

4. Either:

Test G3 carrier signals -

1 . Go to step 5.

Test frequencies - 2 . Go to step 8.

5. The display is as shown opposite.

Press the required key.

Example: Test the 9600 bps carrier

6. To stop the test:

Stop

FUNCTION Y/∇

9 SERVICE FUNCTIONS

SCN-1 DT-2 PL-3 LD-4

MDM-5 RI-6 CK-7

MODEM TEST

G3-1 TONE-2

9600-1 7200-2

4800-3 2400-4 300-5

1 Start

4-8

Page 36

SERVICE TABLES AND PROCEDURES July 16th, 1993

SERVICE LEVEL FUNCTIONS

7. Either:

Test another tone: Go to step 5.

Finish:

Function

8. The display is as shown opposite.

Press the required key.

Example: To test 1100 Hz, press 2 Start

9. To stop the test: Stop

10. Either:

• Test another tone: Go to step 8.

Finish: Function

•

4.1.17. Ringer Test (Function 97)

Not used; do not try to use this function.

4.1.18. Buzzer Test (Function 97)

1. Function 5 1 9 9 1

2100-1 1100-2 800-3

PRESS KEYPAD

then immediately

Yes

2. 9 7 Yes

3. 7

Press the Stop key to stop the buzzer.

FUNCTION Y/∇

9 SERVICE FUNCTIONS

SCN-1 DT-2 PL-3 LD-4

MDM-5 RI-6 CK-7

Service Tables

and Procedures

4-9

Page 37

July 16th, 1993 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNCTIONS

4.1.19. Serial Number (Function 98)

1.

Function 5 1 9 9 1

then immediately Yes

FUNCTION Y/∇

9 SERVICE FUNCTIONS

2. 9 8 Yes SERIAL # KPAD

3. Enter the machine’s serial no at the keypad.

SERIAL # KPAD/Y/N

7940479186

To correct a mistake: No

4. If the display is correct:

Yes

4.1.20. Service Station Telephone Number (Function 99)

Function 5 1 9 9 1

1.

then immediately Yes

2. 9 9 Yes

FUNCTION Y/∇

9 SERVICE FUNCTIONS

TEL NUMBER KEYPAD

3. Input the telephone number of the service station that will receive Auto

Service calls from this machine.

TEL NUMBER KPAD/Y/N

2125555242

4. Yes Function

4-10

Page 38

SERVICE TABLES AND PROCEDURES July 16th, 1993

SERVICE LEVEL FUNCTIONS

4.1.21. Bypassing Restricted Access

Use this procedure if the user has switched on Restricted Access. This enables you to use the machine without having to input a Personal Code. It is

also useful if the user cannot operate the machine because they cannot remember any of the Personal Codes.

1.

2 2 2 2

2. Immediately press Quick Dial key

11

Then operate the machine as you wish. When the machine is returned to

standby mode, Restricted Access is reimposed immediately.

4.1.22. Printing all Memory Files (Function 24)

First, set bit 5 of bit switch 01 to 1.

1. Function 2 4 Yes

FILE NO

2. Press No/∇ Yes Start .

All files in the memory, including confidential messages, will be printed one

by one. The files will not be erased.

After you have finished, set bit 5 of bit switch 01 back to 0.

Note: To erase memory files, set bit 2 of bit switch 00 to 1. All files will be

erased, and some RAM addresses will also be cleared.

Service Tables

and Procedures

4-11

Page 39

July 16th, 1993 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNCTIONS

4.1.23. CSI Programming

This procedure is for use in countries where CSI programming is a service

function.

First, set bit 5 of bit switch 01 to 1.

1.

Function 5 2 2 2 2

5 3 Yes

2. Press No twice.

Y/∇

SET RTI

Y/∇

SET CSI

3. Press Yes . CSI KPAD

4. Input the CSI.

CSI KPAD/Y/N

Note: Not more than 20 digits.

2015559456

5. Press Yes Function .

After you have finished, set bit 5 of bit switch 01 back to 0.

4.1.24. Telephone Line Type Selection

This procedure is for use in countries where telephone line type selection is a

service function.

First, set bit 5 of bit switch 01 to 1.

1.

Function 5 2 2 2 2

7 1 Yes Y/∇

SELECT TT/DP

2. Press Yes .

LINE = TT Y

TT=1 DP=2

3. Either:

Select tone dialing -

1 .

Select pulse dialing - 2 .

Finish: Function

After you have finished, set bit 5 of bit switch 01 back to 0.

4-12

Page 40

SERVICE TABLES AND PROCEDURES July 16th, 1993

BIT SWITCHES

4.2. BIT SWITCHES

WARNING

Do not adjust a bit switch that is described as "Not used", as this

may cause the machine to malfunction or to operate in a manner

that is not accepted by local regulations. Such bits are for use only

in other areas, such as Japan.

Bit Switch 00

FUNCTION COMMENTS

MTF process

0

0: Enabled 1: Disabled

RAM reset level 2

1: Reset

1

RAM reset level 3

1: Reset

Note: RAM reset level

2

1 is a RAM

adjustment. It is not

described in this

manual.

Memory file forwarding

1: Forward the files

3

Continued on the nest page

0: The MTF process is used when required by the software.

1: The MTF process is never used.

When this bit is set to 1, all items stored in the RAM are

reset except the clock, and then this bit changes back to 0

automatically. Also, all image files in the SAF memory are

erased.

When this bit is set to 1, some items stored in the RAM are

reset, then this bit changes back to 0. All items are reset

except the bit switch and NCU parameter settings, clock,

own tel. no., CSI, RTI, TTI, Quick Dials, Speed Dials,

Groups, and the TCR memory. Also, all image files in the

SAF memory are erased.

This bit switch is recommended for use when it is necessary

to clear the SAF, as fewer RAMs will need reprogramming.

Use this if the printer does not work, but the user wishes to

print the files. First, change the fax machine’s telephone

number (Function 51) to the number to which you wish to

forward the files, then set this bit to 1. All files in the memory

will be forwarded. This bit resets to 0 automatically.

However, you must return the fax machine’s telephone

number to the original setting. The files stay in memory.

Service Tables

and Procedures

4-13

Page 41

July 16th, 1993 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

Bit Switch 00

FUNCTION COMMENTS

Inclusion of technical

data on the Journal

0: No 1: Yes

4

Monitor speaker

during video data

communication (tx

5

and rx) (CS1 only)

0: Disabled

1: Enabled

6 Not used Do not change the factory setting.

Communication

parameter display

7

0: Disabled

1: Enabled

(CRO)

1: Instead of the personal code, the following data are listed

on the TCR as a six-figure number.

First two numbers: Final modem rate (for example, 96

means 9,600 bps)

Second two numbers (Rx mode only): Rx signal level (Level

= 0 - 0.375x, where x is the value on the report; accurate to

3 dB)

Third two numbers (Rx mode only): Rx cable equalizer; 00 =

Equalizer is Off, 01 = Equalizer is On

(CS1)

1: Instead of the personal code, the following data are listed

on the TCR.

First number: Final modem rate (for example, 14.4K means

14,400 bps)

Second and third numbers (Rx mode only): These are a

measure of the error rate. The left hand figure is the low

byte and the right hand figure is the high byte. In general, a

larger number means more errors. These numbers are fixed

at 0 for tx mode.

Fourth number: Cable equalizer; 00 = Equalizer is Off, 01 =

Low, 10 = Medium, 11 = High

Used for testing. Set this bit to 1 to hear the fax data signal

(phase C of CCITT T.30 protocol).

Make sure that you reset this bit after testing.

This is a fault-finding aid. The LCD shows the key

parameters (see below). This is normally disabled because

it cancels the CSI display for the user.

Make sure that you reset this bit after testing.

4-14

Page 42

SERVICE TABLES AND PROCEDURES July 16th, 1993

BIT SWITCHES

Communication parameter display

Mode DCS: CCITT G3

NSS: Non-standard G3

Modem rate 144S: 14,400 bps with short training (V.17)

144L: 14,400 bps with long training (V.33)

120S: 12,000 bps with short training (V.17)

120L: 12,000 bps with long training (V.33)

96TS: 9,600 bps using TCM, with short training (V.17)

96TL: 9,600 bps using TCM, with long training (V.33)

72TS: 7,200 bps using TCM, with short training (V.17)

72TL: 7,200 bps using TCM, with long training (V.33)

96: 9600 bps

72: 7200 bps

48: 4800 bps

24: 2400 bps

Communication

mode

Compression

mode

Resolution SSF: Fine, transmitted at 8 x 15.4 dots per mm

I/O Rate 0M: 0 ms/line

Width and

reduction

ECM: With ECM

SSC: Using SSC

EFC: Using EFC

NML: With no ECM, SSC, or EFC

MMR: MMR compression

MR: MR compression

MH: MH compression

PSF: Fine, transmitted at 8 x 7.7 dots per mm and smoothed at the rx

side

DTL: Detail

STD: Standard

2/M: 2.5 ms/line

5M: 5 ms/line

10M: 10 ms/line

20M: 20 ms/line

40M: 40 ms/line

=A4: A4 (8.3"), no reduction

=B4: B4 (10.1"), no reduction

=A3: A3 (11.7"), no reduction

>A4: Reduced to A4 (8.3") before transmission

>B4: Reduced to B4 (10.1") before transmission

Service Tables

and Procedures

4-15

Page 43

July 16th, 1993 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

Bit Switch 01

FUNCTION COMMENTS

LCD contrast

Bit 1 0 Contrast

0

0 0 Brightest

0 1 ↓

1

1 0 ↓

1 1 Darkest

2 Not used Do not change the factory setting.

Memory read/write by RDS

Bit 4 3 Setting

0 0 Always enabled

0 1 User selectable

1 0 User selectable

3

1 1 Always disabled

4

Dedicated transmission parameter

programming/printing all SAF files

0: Disabled 1: Enabled

5

6 Not used Do not change the factory setting.

Auto Service Call for PM

0: Enabled 1: Disabled

7

Use these bit switches to adjust the brightness

of the LCD on the operation panel.

(0,0): At any time, an RDS system can read or

write RAM data such as TTI and bit switches.

(0,1), (1,0): Normally, RDS systems are locked

out, but the user can temporarily switch RDS

on to allow an RDS operation to take place.

RDS will automatically switch off again after a

certain time, which is stored in a RAM address

(see section 4-5). Note that, if an RDS

operation takes place, RDS will not switch off

until this time limit has expired.

(1,1): All RDS systems are always locked out.

This bit must be set to 1 before attempting to

program dedicated transmission parameters or

printing all files stored in the SAF memory. If

CSI and /or telephone line type is a service

mode in your area, this bit must also be at 1

before programming.

0: The machine will send an Auto Service Call

when the PM interval has expired. This interval

is adjustable by RAM address. The default

setting is every 30,000 copies (based on the

Print counter).

1: The user will do maintenance as explained

in the Operator’s Manual whenever problems

occur.

4-16

Page 44

SERVICE TABLES AND PROCEDURES July 16th, 1993

BIT SWITCHES

Bit Switch 02

FUNCTION COMMENTS

Page separation mark

0: Enabled 1: Disabled

0

Repetition of data when the

received page is longer than the

1

printer paper

0: Disabled 1: Enabled

Reduction of the length of

received data

2

0: Enabled 1: Disabled

3 Not used Do not change the factory settings.

4

5

Maximum transmittable document

length

Bit 7 6 Setting

6

0 0 600 mm

0 1 1200 mm

7

1 0 14 m

1 1 100 m

0: If a received page has to be printed out on two

sheets, an "x" inside a small box is printed at the

bottom right hand corner of the first sheet, and a

"2" inside a small box is printed at the top right

hand corner of the second sheet. This helps the

user to identify pages that have been split up.

1: No marks are printed.

0: The next page continues from where the

previous page left off

1: The final few mm of the previous page are

printed at the top of the next page.

This bit determines whether incoming pages are

reduced to fit on the copy paper if they are

almost the same length as the copy paper in the

cassette.

If the user wants to send very long documents

such as well logs, use the 14 m or 100 m setting.

4-17

Service Tables

and Procedures

Page 45

July 16th, 1993 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

Bit Switch 03

FUNCTION COMMENTS

Dialing with the handset off-hook

0

0: Enabled

1: Disabled

Lifetime of polling standby files in

the memory

1

0: Erased after being polled

1: Kept until user erases

Inclusion of communications on

the TCR when no image data was

2

exchanged.

0: No 1: Yes

Printing of the error code on the

3

error report

0: No 1: Yes

4 Not used Do not change the factory setting.

Printing the TTI in copy mode

5

0: No 1: Yes

6 Not used Do not change the factory setting.

Reconstruction time for the first

line in receive mode

0: 6 s 1: 10 s

7

If this bit is 1, the user will not be able to dial if

the handset is off hook.

0: Messages stored for polling transmission will

be erased immediately after polling.

1: This setting allows the user to keep messages

in the memory to be polled by more than one

station.

If communication did not reach phase 3 of

CCITT T.30 protocol (such as for a telephone

call), this communication can be listed on the

TCR if this bit is at 1.

If this bit is 1, error codes are printed on the error

reports for the user.

If this bit is 1, the TTI stored in the machine is

printed at the top of the copy.

When the sending terminal is controlled by a

computer, there may be a delay in receiving

page data after the local machine accepts set-up

data and sends CFR. If this occurs, set this bit to

1 to give the sending machine more time to send

data.

4-18

Page 46

SERVICE TABLES AND PROCEDURES July 16th, 1993

BIT SWITCHES

Bit Switch 04

FUNCTION COMMENTS

Compression modes available in

receive mode

Bit 1 0 Modes

0 0 MH only

0

0 1 MR or MH

1 0 MR or MH, with

1

EFC

1 1 MMR, MR, or

MH, with EFC

Error counting method

0: 10 (20) [40]

1: In accordance with the settings

of bits 3 to 7

2

Burst error threshold

Bit 4 3 Threshold

3

0 0 3 (6) [12]

0 1 4 (8) [16]

4

1 0 5 (10) [20]

1 1 6 (12) [24]

Error line ratio

Bit 7 6 5 Value

5

0 0 0 5%

0 0 1 6%

6

0 1 0 7%

0 1 1 8%

7

1 0 0 9%

1 0 1 10%

These bits determine what capabilities are

informed to the transmitting side in the protocol

exchange.

The machine counts data errors caused by a

noisy line or defective machine.

0: If the count reaches 10 (Standard mode), 20

(Detail mode), or 40 (Fine mode), the machine

sends RTN to the other end in reply to the postmessage command. As 10 (or 20 or 40) good

lines cause the count to decrement, RTN will

only occur in bad conditions.

The number of good lines for counter decrement

and the value of error threshold can be changed

by rewriting the RAM addresses 40CB(H) and

40CC(H).

If there are more consecutive error lines in the

received page than the threshold specified by

these bits, the page is rejected. Values in

parenthesis are for Detail resolution, and those

in square brackets are for Fine resolution.

If the number of error lines divided by the total

number of lines reaches the value determined

by the settings of these bits, RTN will be sent to

the other end.

Service Tables

and Procedures

4-19

Page 47

July 16th, 1993 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

Bit Switch 05

FUNCTION COMMENTS

Compression modes available in

transmit mode

Bit 1 0 Modes

0 0 MH only

0

0 1 MR or MH

1 0 MR or MH, with

1

EFC

1 1 MMR, MR, or

MH, with EFC

PABX dial tone detection

0: Enabled

2

1: Disabled

PSTN dial tone detection

0: Enabled

3

1: Disabled

Busy tone detection

0: Enabled

4

1: Disabled

5 Not used Do not change the factory setting.

PSTN access method through

PABX

Bit 7 6 Method

6

0 0 No PABX

0 1 Loop Start

7

1 0 Ground Start

1 1 Flash Start

These bits determine what capabilities are

informed to the receiving side in the protocol

exchange.

0: PABX dial tone is detected in accordance

with the parameters programmed in RAM. The

machine will wait for the dial tone before trying

to gain access to the PSTN.

0: PSTN dial tone is detected in accordance

with the parameters programmed in RAM. The

machine will wait for the dial tone before dialing

out.

0: Busy tone is detected in accordance with the

parameters programmed in RAM. The machine

will not have to wait out the CCITT T1 time

before hanging up if the line is busy.

Set these bits to match the type of signal

accepted by the PABX. If there is no PABX

between the machine and the network, set both

bits to 0.

Bit Switch 06

FUNCTION COMMENTS

0

PSTN access number

1

Access No. Hex value of bit switch

0 F0

2

↓ ↓

9 F9

3

00 00

4

↓ ↓

99 99

5

6

7

Program this bit switch if the machine is

behind a PABX. The access number is

the number the user must dial to get an

outside line. If the machine detects the

access number at the start of a

telephone number, it will connect with

the PABX, pause for a few seconds,

then dial the number.

Example: If the access number for the

PABX is 9, the bit switch must be F9. To

do this, set all bits to 1 except bits 1

and 2.

If there is no PABX, set all bits to 1.

4-20

Page 48

SERVICE TABLES AND PROCEDURES July 16th, 1993

BIT SWITCHES

Bit Switch 07

FUNCTION COMMENTS

Back to back test

0

0: Disabled

1: Enabled

Short preamble

1

0: Enabled 1: Disabled

AI Short Protocol (transmission and

2

reception)

0: Enabled 1: Disabled

Echo countermeasure

0: Enabled

3

1: Disabled

DIS detection number

0: 1

4

1: 2

ECM

5

0: On 1: Off

Post-message response timing (rx)

0: After feed-out

1: When the leading edge reaches the

copy feed-out sensor

6

FTZ protocol

7

0: Disabled 1: Enabled

Set this bit to 1 when you wish to do a back

to back test.

If this bit is 0, the Short Preamble feature is

switched on.

If this bit is 0, the AI Short Protocol feature is

switched on.

If the setting is 1, the machine will hang up if

it receives the same signal twice. If the

setting is 0, the machine will ignore echoes

from the line.

The machine will send DCS (G3 set-up

signal) if it receives DIS. If echoes are

frequent, setting this bit to 1 will allow the

machine to wait for the second DIS before

sending DCS.

If this bit is 0, ECM is switched on.

0: Data cannot be stored in the SAF during

reception if the memory is full, so, if this bit is

0, the machine will wait until the page has

been fed out. However, communication will

take longer to complete.

1: The post message response is sent

earlier, but the paper has not been fed out

yet, so if there is a jam after this, data may

be lost.

This bit is ignored during memory reception.

This bit must be set to 1 in Germany.

Service Tables

and Procedures

4-21

Page 49

July 16th, 1993 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

Bit Switch 08 (Transmission)

FUNCTION COMMENTS

0

Initial Tx modem rate

Bit 3 Bit 2 Bit 1 Bit 0 Setting (bps)

1

1 1 0 1 * 14,400

1 1 0 0 * 12,000

2

1 0 1 1 * 9,600 TCM

1 0 1 0 * 7,200 TCM

3

0 0 1 1 9,600

0 0 1 0 7,200

0 0 0 1 4,800

0 0 0 0 2,400

4 Modem training type when sending at

12,000 or 14,400 bps (CS1 only)

0: V.17 (short) 1: V.33 (long)

5 Not used. Do not change the factory setting.

67Cable equalizer (tx mode)

(CRO)

Bit 7 Bit 6 Setting

0 0 None

0 1 Medium

1 0 High

1 1 Not used

(CS1)

Bit 7 Bit 6 Setting

0 0 None

0 1 Low (1.8 km)

1 0 Medium (3.6 km)

1 1 High (7.2 km)

These bits set the initial starting modem

rate for transmission. This rate may fall

back to a slower rate depending on line

conditions and the remote terminal’s

capabilities.

Notes

1. The settings with an asterisk (*) can

only be used with CS1.

2. CR0: Do not change the factory settings

of bits 2 and 3.

0: Training is shorter so communication

costs are reduced. However, the

communication is not so reliable.

1: The longer training time ensures a

higher reliability for the communication.

Use a higher setting if there is signal loss

at higher frequencies because of the

length of wire between the modem and the

telephone exchange.

Also, try using the cable equalizer if one or

more of the following symptoms occurs.

•Communication error

•Modem rate fallback occurs frequently.

4-22

Page 50

SERVICE TABLES AND PROCEDURES July 16th, 1993

BIT SWITCHES

Bit Switch 09 (Transmission)

FUNCTION COMMENTS

CNG signal transmission in

manual transmission mode

0

0: Disabled

1: Enabled

Wrong connection prevention

method

Bit 2 Bit 1 Setting

0 0 None

1

0 1 8 digit CSI

1 0 4 digit CSI

2

1 1 CSI/RTI

Closed network (transmission)

0: Disabled

3

1: Enabled

Monitor speaker status during

memory transmission

4

(CS1 only)

0: Off 1: On

5 Not used Do not change the factory settings.

6

7

CNG (calling tone) is normally used by auto-dial fax

machines to alert a manual machine operator that

an auto-transmitting machine is on the line waiting

to transmit. This tone is not needed for manual

operation (full number dialing).

(0,1) - The machine will not transmit if the last 8

digits of the received CSI do not match the last 8

digits of the dialed telephone number. This does not

work for manual dialing.

(1,0) - The same as above, except that only the last

4 digits are compared.

(1,1) - The machine will not transmit if the other end

does not identify itself with an RTI or CSI.

(0,0) - Nothing is checked; transmission will always

go ahead.

1: Transmission will not go ahead if the ID code of

the other terminal does not match the ID code of

this terminal. This feature may not be reliable when

communicating with another maker’s product.

If this bit is 1, the speaker will operate during

memory transmission. Keep this bit at 0 if the user

complains about the noise from the speaker.

4-23

Service Tables

and Procedures

Page 51

July 16th, 1993 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

Bit Switch 0A (Reception)

FUNCTION COMMENTS

0

Initial Rx modem rate

Bit 3 Bit 2 Bit 1 Bit 0 Setting

1

(bps)

1 1 0 1 * 14,400

2

1 1 0 0 * 12,000

1 0 1 1 * 9,600 TCM

3

1 0 1 0 * 7,200 TCM

0 0 1 1 9,600

0 0 1 0 7,200

0 0 0 1 4,800

0 0 0 0 2,400

4 Modem training type when receiving at

12,000 or 14,400 bps (CS1 only)

0: V.17 (short) 1: V.33 (long)

5 Not used. Do not change the factory setting.

67Cable equalizer (rx mode)

(CRO)

Bit 7 Bit 6 Setting

0 0 None

0 1 Medium

1 0 High

1 1 Not used

(CS1)

Bit 7 Bit 6 Setting

0 0 None

0 1 Low (1.8 km)

1 0 Medium (3.6 km)

1 1 High (7.2 km)

The setting of these bits is used to inform

the sending machine of the initial starting

modem rate for the machine in receive

mode. If 9,600 bps presents a problem

during reception, use a lower setting.

Notes

1. The settings with an asterisk (*) can

only be used with CS1.

2. CR0: Do not change the factory settings

of bits 2 and 3.

0: Training is shorter so communication

costs are reduced. However, the

communication is not so reliable.

1: The longer training time ensures a

higher reliability for the communication.

Use a higher setting if there is signal loss

at higher frequencies because of the

length of wire between the modem and the

telephone exchange.

Also, try using the cable equalizer if one or

more of the following symptoms occurs.

•Communication error with error codes

such as 0-20, 0-23, etc.

•Modem rate fallback occurs frequently.

4-24

Page 52

SERVICE TABLES AND PROCEDURES July 16th, 1993

BIT SWITCHES

Bit Switch 0B (Reception)

FUNCTION COMMENTS

Closed network (reception)

0: Disabled

0

1: Enabled

Training error tolerance

1

0: Type 1

1: Type 2

Training error tolerance

Bit 3 2 Type 1 Type 2

2

0 0 15 14

0 1 10 9

3

1 0 2 4

1 1 0 1

4 Not used Do not change the factory settings.

5

6

7

1: Reception will not go ahead if the ID code

of the other terminal does not match the ID

code of this terminal. This feature may not be

reliable when communicating with another

maker’s product.

This bit determines the values available with

bits 2 and 3.

Type 1 can be used anywhere. Type 2 is

normally used only in Europe.

If the machine detects more errors during

training than the number set by these bits,

training fails and the machine will send FTT.

The data will be resent at a lower rate.

Bit Switch 0C

FUNCTION COMMENTS

European protocol requirements

0

0: Disabled 1: Enabled

German dialing requirements

1

0: Disabled 1: Enabled

Austrian dialing requirements

2

0: Disabled 1: Enabled

Norwegian dialing and protocol

3

requirements

0: Disabled 1: Enabled

Danish dialing requirements

4

0: Disabled 1: Enabled

French requirements

5

0: Disabled 1: Enabled

Swiss requirements

6

0: Disabled 1: Enabled

7 Not used Do not change the factory setting.

Adjust these bits in accordance with the

country of installation.

Service Tables

and Procedures

4-25

Page 53

July 16th, 1993 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

Bit Switch 0D

FUNCTION COMMENTS

0 Not used Do not change the factory settings.

1

2

3

4

5

Contents of the top line of the LCD

when handset mode is in use

6

0: Telephone number dialed

1: HANDSET MODE

7 Not used Do not change the factory setting.

Bit Switch 0E

FUNCTION COMMENTS

0 Not used Do not change the factory settings.

1

2

3

4

Conditions for reception

5

0: Normal

1: RTI or CSI needed

6 Not used Do not change the factory settings.

7

0: The telephone number being dialed is

displayed.

1: Only HANDSET MODE is displayed.

1: If the sending machine does not transmit

an RTI or CSI, the call will be rejected, and

the machine will send DCN.

4-26

Page 54

SERVICE TABLES AND PROCEDURES July 16th, 1993

BIT SWITCHES

Bit Switch 0F

FUNCTION COMMENTS

Country Code

00: France 10: Not used

01: Germany 11: USA

02: UK 12: Asia

03: Italy 13: Japan

04: Austria 14: Hong Kong

05: Belgium 15: South Africa

0

06: Denmark 16: Australia

to

07: Finland 17: New Zealand

7

08: Ireland 18: Singapore

09: Norway 19: Malaysia

0A: Sweden

0B: Switzerland

0C: Portugal

0D: Holland

0E: Spain

0F: Israel

This country code determines the factory

settings of a wide range of bit switches and

RAM addresses. However, it has no effect

on the NCU parameter settings and

communication parameter RAM addresses;

these are determined by the setting of NCU

parameter 00 (function 96).

Bit Switch 10

FUNCTION COMMENTS

0 Pulse dialing method

Bit 1 Bit 0 Setting

0 0 Normal (P=N)

0 1 Oslo (P=10 - N)

1

1 0 Sweden (N+1)

1 1 Sweden (N+1)

2 Not used Do not change the factory settings.

3

4

5

6

7

P=Number of pulses sent out, N=Number

dialed.

Do not change the factory settings.

Bit switch 11 is not used

Service Tables

and Procedures

4-27

Page 55

July 16th, 1993 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

Bit Switch 12

FUNCTION COMMENTS

Automatic transmission report printout

after transmission operated with an

0

OMR sheet (CS1 only)

0: As defined by user parameter setting

1: Automatically printed

1 Not used Do not change the factory settings.

2

Item displayed if a Quick Dial key is

pressed to dial the other party

3

0: Name stored in the Quick Dial

1: Telephone number

4 Not used Do not change the factory setting.

5

6

7

Bit switches 13 to 1C are not used.

Bit Switch 1D

FUNCTION COMMENTS

0 Not used Do not change the factory setting.

1

2

8-minute close

3

0: Disabled 1: Enabled

4 Not used Do not change the factory settings.

5

6

7

4-28

Page 56

SERVICE TABLES AND PROCEDURES July 16th, 1993

BIT SWITCHES

Bit Switch 1E

FUNCTION COMMENTS

Use of the buzzer to call the user to

the machine if there is no reply to

0

NSF/DIS

0: Enabled 1: Disabled

Scrambling method used for secure

transmission (CS1 only)

1

Bit 2 1 Method

0 0 Type 1

2

0 1 Type 2

1 0 Type 3

1 1 Type 3

Secure transmission demonstration

(CS1 only)

3

0: Off 1: On

4 Not used Do not change the factory setting.

RTI or CSI display selection

0: RTI 1: CSI

5

6 Not used Do not change the factory setting.

Error report output

7

0: Enabled 1: Disabled

Set this bit to 1 if the user complains about

the tone from the buzzer when no reply is

received to NSF or DIS.

There are three types of scrambling

algorithm available for use with this feature.

They are all of about the same complexity.

The type used is informed in the NSF signal.

If this bit is at 1 and if secure transmission is

switched on, received images will be printed

out without being unscrambled. This

demonstrates what anyone intercepting the

signal can expect to pick up.

This bit determines which of the other party’s

identifiers is shown on the display during

communication. If the other terminal is by

another manufacturer, the RTI is not shown

even if this bit is at 0; the CSI will appear.

If this bit is at 1, the error report will not be

printed when an error occurs.

Bit Switch 1F

FUNCTION COMMENTS

V.21 signal detection method

(CRO only)

0

Bit 1 0 Method

0 0 Six consecutive 1’s

1

0 1 A one-byte flag

1 0 A two-byte flag

1 1 A two-byte flag

2 Not used Do not change the factory setting.

3

4

5

6

7

4-29

Service Tables

and Procedures

Page 57

July 16th, 1993 SERVICE TABLES AND PROCEDURES

NCU PARAMETERS

4.3. NCU PARAMETERS

The following tables give the RAM addresses and units of calculation of the

parameters that the machine uses for ringing signal detection and automatic

dialing. The factory settings for each country are also given. Most of these

must be changed by RAM read/write (Function 95), but some can be

changed using NCU Parameter programming (Function 96); if Function 96

can be used, this will be indicated in the Remarks column. The RAM is programmed in hex code unless (BCD) is included in the Unit column.

When using RAM read/write, you must add the bank number before the fourdigit RAM address number. See section 4-1-6 for details.

Address Function Unit Remarks

413B Country code [NCU parameters

only]

413C Line current detection time 20 ms Line current is not detected

413D Line current wait time

413E Line current drop detect time

413F PSTN dial tone upper frequency

limit (HIGH)

4140 PSTN dial tone upper frequency

limit (LOW)

4141 PSTN dial tone lower frequency

limit (HIGH)

4142 PSTN dial tone lower frequency

limit (LOW)

4143 PSTN dial tone detection time 20 ms If 4143 contains FF, the

4144 PSTN dial tone reset time 160 ms

4145 PSTN dial tone continuous tone

time

4146 PSTN dial tone permissible drop

time

4147 PSTN wait interval 160 ms

4148 Ringback tone detection time 20 ms Detection is disabled if this

4149 PSTN busy tone upper frequency

limit (HIGH)

414A PSTN busy tone upper frequency

limit (LOW)

414B PSTN busy tone lower frequency

limit (HIGH)

414C PSTN busy tone lower frequency

limit (LOW)

Hex Function 96 (parameter 00).

if 413C contains FF.

Hz (BCD) See Note 2.

machine pauses for the

20 ms

Hz (BCD) If 4149 is FF, detection is

pause time (4147).

contains FF.

disabled. See Note 2.

4-30

Page 58

SERVICE TABLES AND PROCEDURES July 16th, 1993

NCU PARAMETERS

Address Function Unit Remarks

414D PABX dial tone upper frequency

limit (HIGH)

414E PABX dial tone upper frequency

limit (LOW)

414F PABX dial tone lower frequency

limit (HIGH)

4150 PABX dial tone lower frequency

limit (LOW)

4151 PABX dial tone detection time 20 ms If 4151 contains FF, the

4152 PABX dial tone reset time 160 ms

4153 PABX dial tone continuous tone

time

4154 PABX dial tone permissible drop

time

4155 PABX wait interval 160 ms

4156 PABX ring back tone detection

time

4157 PABX busy tone upper frequency

limit (HIGH)

4158 PABX busy tone upper frequency

limit (LOW)

4159 PABX busy tone lower frequency

limit (HIGH)

415A PABX busy tone lower frequency

limit (LOW)

415B Busy tone ON time: range 1 20 ms

415C Busy tone OFF time: range 1

415D Busy tone ON time: range 2

415E Busy tone OFF time: range 2

415F Busy tone ON time: range 3

4160 Busy tone OFF time: range 3

4161 Busy tone ON time: range 4

4162 Busy tone OFF time: range 4

4163 Busy tone continuous tone

detection time

4164 Busy tone signal state time tolerance for all ranges, and number of cycles

required for detection (a setting of 4 cycles means that ON-OFF-ON or OFF-

ON-OFF must be detected twice).

Hz (BCD) See Note 2.

machine pauses for the

20 ms

20 ms Detection is disabled if this

Hz (BCD) If this is FF, detection is

pause time (4155).

contains FF.

disabled. See Note 2.

See Note 2.

Service Tables

and Procedures

Tolerance (±)

Bit 1 0

0 0 75%

0 1 50%

1 0 25%

1 1 12.5%

Bits 7, 6, 5, 4 - number of cycles required for detection

4-31

Page 59

July 16th, 1993 SERVICE TABLES AND PROCEDURES

NCU PARAMETERS

Address Function Unit Remarks

4165 International dial tone upper

frequency limit (HIGH)

4166 International dial tone upper

frequency limit (LOW)

4167 International dial tone lower

frequency limit (HIGH)

4168 International dial tone lower

frequency limit (LOW)

4169 International dial tone detection

time

416A International dial tone reset time 160 ms

416B International dial tone continuous

tone time

416C International dial tone permissible

drop time

416D International dial wait interval 160 ms

416E Country dial tone upper frequency

limit (HIGH)

416F Country dial tone upper frequency

limit (LOW)

4170 Country dial tone lower frequency

limit (HIGH)

4171 Country dial tone lower frequency

limit (LOW)

4172 Country dial tone detection time 20 ms If 4172 contains FF, the

4173 Country dial tone reset time 160 ms

4174 Country dial tone continuous tone

time

4175 Country dial tone permissible drop

time

4176 Country dial wait interval 160 ms

4177 Grounding time (ground start

mode)

4178 Break time (flash start mode) 1 ms The Di relay is open for this

4179 International dial access code BCD For a code of 100:

417A

417B PABX pause time 20 ms

417C Progress tone detection level, and

cadence detection enable flags

Hz (BCD) See Note 2.

20 ms If 4169 contains FF, the

machine pauses for the

pause time (416D).

20 ms

Hz (BCD) See Note 2.

machine pauses for the

pause time (4176).

20 ms

20 ms The Gs relay is closed for

this interval.

interval.

4179 - F1

417A - 00

Bit 7 Bit 6 dBm

1 1 -52.7

1 0 -32.7

0 1 -40.2

0 0 -28.7

Bits 3, 2, 1, 0 - See Note 3.

417D CCITT T1 time 2.56 s

4-32

Page 60

SERVICE TABLES AND PROCEDURES July 16th, 1993

NCU PARAMETERS

Address Function Unit Remarks

417E Max. number of dials per station

1

(not using memory)

417F Redial interval (not using memory) 1 min

4180 Interval between dialing to

2.56 s

different stations

4181 Tx level from modem - dBm Function 96 (parameter 01).

4182 Acceptable ringing signal

frequency: range 1, upper limit

4183 Acceptable ringing signal

frequency: range 1, lower limit

4184 Acceptable ringing signal

frequency: range 2, upper limit

4185 Acceptable ringing signal

frequency: range 2, lower limit

4186 Number or rings until a call is

1000/

Function 96 (parameter 02).

.672N

(Hz). N is

Function 96 (parameter 03).

the value

stored

Function 96 (parameter 04).

using

Function

Function 96 (parameter 05).

96.

1 Function 96 (parameter 06).

detected

4187 Minimum required length of the

first ring

4188 Minimum required length of the

20 ms See Note 6. Function 98

(parameter 07).

Function 96 (parameter 08).

second and subsequent rings

4189 Ringing signal detection reset time 40 ms Function 96 (parameter 09).

418A Time between opening or closing

the Ds relay and opening the Di

1 ms See Notes 5 and 8.

Function 96 (parameter 10).

relay

418B Break time for pulse dialing See Note 5. Function 96

(parameter 11).

418C Make time for pulse dialing See Note 5. Function 96

(parameter 12).

418D Time between final Di relay

closure and Ds relay opening or

See Notes 5 and 8.

Function 96 (parameter 13).

closing

418E Pause between dialed digits

(pulse dial mode)

418F Time waited when a pause is

20 ms See Note 5. Function 96

(parameter 14).

Function 96 (parameter 15).

entered at the operation panel

4190 DTMF tone on time 1 ms Function 96 (parameter 16).

4191 DTMF tone off time Function 96 (parameter 17).

4192 DTMF tone attenuation value -dBm

(C60)

Function 96 (parameter 18).

See Note 7.

-dBm/2

(C31)

41A0 CED detection interval 20 ms Factory setting: 11 x 20 ms

41A1 CNG detection interval Factory setting: 11 x 20 ms

41A2 800 Hz detection interval Factory setting: 10 x 20 ms

6

41A3 CED detection frequency: upper

limit

41A4 CED detection frequency: lower

limit

/4.873NHzFactory setting: 94 [2183

10

Hz]

Factory setting: 102 [2012

Hz]

Service Tables

and Procedures

4-33

Page 61

July 16th, 1993 SERVICE TABLES AND PROCEDURES

NCU PARAMETERS

Address Function Unit Remarks

41A5 CCITT T4 timer 160 ms Factory setting: 20 x 160 ms

41A6 Monitor speaker volume during

communication (CS1 only)

41A7 Monitor speaker volume during

dialing (CS1 only)

41AA CNG detection frequency: upper

limit

41AB CNG detection frequency: lower

limit

41AC 800 Hz signal detection

frequency: upper limit

41AD 800 Hz signal detection

frequency: lower limit

41B3 Max. time limit to dial a number 2.56 s All countries: 15[H] (53.76 s)

41B4 Max. no of consecutive pauses in

a telephone number

See Note

10.

See Note

11.

6

/4.873NHzFactory setting: 169 [1214

10

See Note9.Factory setting: 29 [720 Hz]

Hex Germany: 1, Others: 250

Factory setting: 90

Factory setting: 90

Hz]

Factory setting: 207 [991

Hz]

Factory setting: 233 [881

Hz]

Notes

1. If a setting is not required, store FF in the address.

2. Tone frequencies are stored in BCD in the following format.

Examples:

a) 380 Hz HIGH 0 3 LOW 8 0

b) 1210 Hz HIGH 1 2 LOW 1 0

3. Italy and Belgium only

RAM address 417C: the lower four bits have the following meaning.

Bit 3 1: Country dial tone cadence detection enabled

Bit 2 1: International dial tone cadence detection enabled

Bit 1 1: PABX dial tone cadence detection enabled

Bit 0 1: PSTN dial tone cadence detection enabled

If bit 3 is 1, the functions of the following RAM addresses are changed.

4172: tolerance for on or off state duration (%), coded as in 4164.

4174: on time, hex code (unit = 10 ms)

4175: off time, hex code (unit = 10 ms)

If bits 2, 1, or 0 are 1, the functions of the following addresses are

changed in a similar way to that described for bit 3 = 1.

Bit 2 = 1: 4169, 416B, 416C

Bit 1 = 1: 4151, 4153, 4154

Bit 0 = 1: 4143, 4145, 4146

4-34

Page 62

SERVICE TABLES AND PROCEDURES July 16th, 1993

NCU PARAMETERS

4. Belgium only

Address 4144 for DTMF dialing is 3.04 s. This can be adjusted by RAM

read/write. However, if pulse dial mode is selected, a value of 20 ms from

the ROM is used, and this cannot be adjusted.

5. Pulse dial parameters (addresses 418A to 418F) are the values for 10

pps. If 20 pps is used, the machine automatically compensates.

6. The first ring may not be detected until 1 to 2.5 wavelengths after the time

specified by this parameter.

7. N must be between 0 and 15. The attenuation levels are as follows.

High frequency tone: - N dBm

Low frequency tone: - N - 2 dBm

8. 418A: Europe - Between Ds opening and Di opening, France - Between

Ds closing and Di opening

418D: Europe - Between Ds closing and Di closing, France - Between Ds

opening and Di closing

9. For address 41AD, the formula is slightly different.

Frequency = 1,000,000/(4.873 x [N+256]) Hz

10. Bits 7, 6, and 5 are for the volume during transmission

Bits 4, 3, and 2 are for the volume during reception

The three bit values range from 0 (off), 1 (minimum), to 7 (maximum)

11. Bits 7, 6, and 5 are for the volume during on-hook dial

Bits 4, 3, and 2 are for the volume during dialing