Page 1

[B]

Technical Bulletin No. CRO-001

SUBJECT: Service Manual Correction

PREPARED BY: A. Ishiyama

CHECKED BY:

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

This information includ es corre ctions to the CRO service manual.

FROM: 1st T.S. Section

MODEL: CRO Europe and Asia

Version

DATE:

October 25, 1993

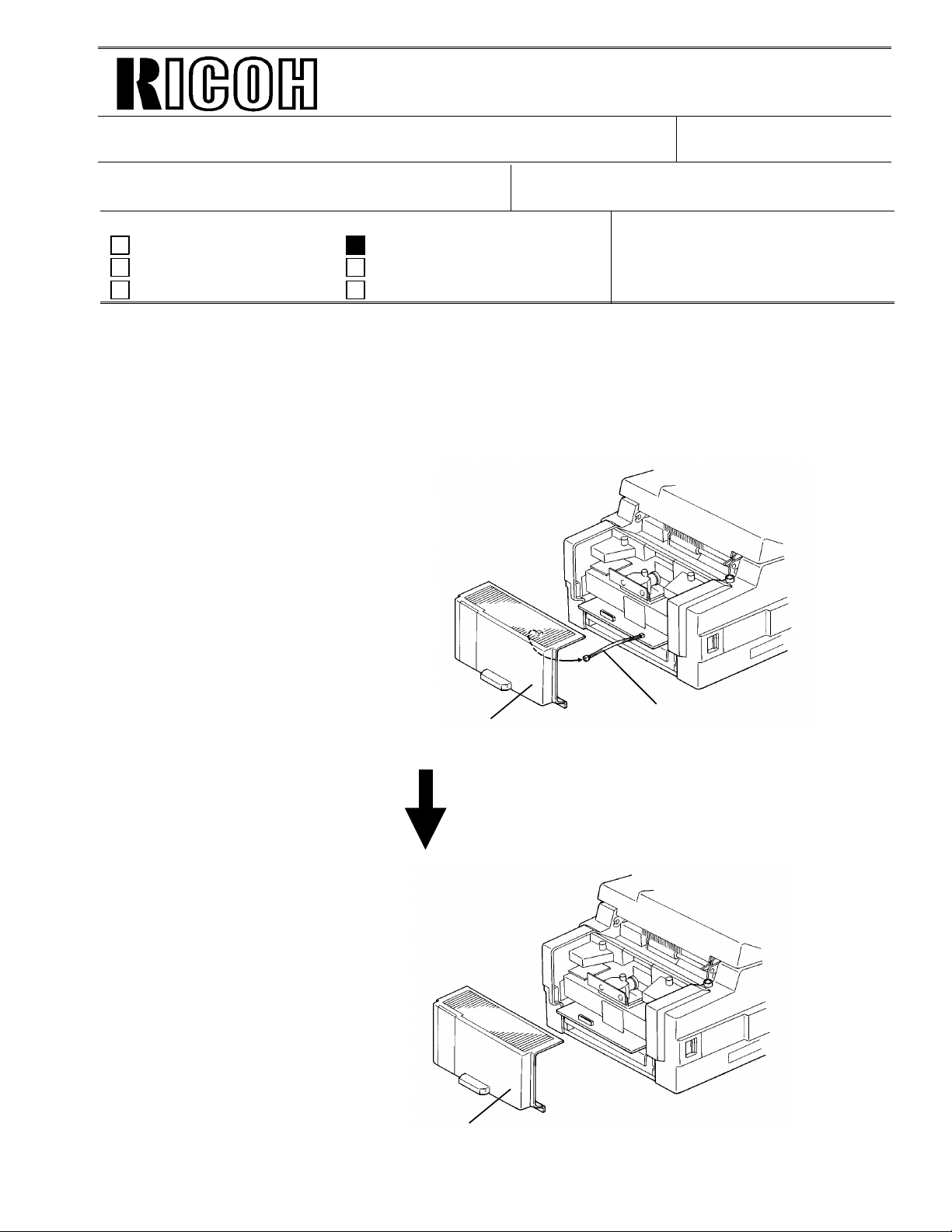

1. Section 3.2.4. (Page 3-6)

The item 4 has been changed, because the CRO does not have the monitor speaker.

4. Take off the rear cover [A] and

disconnect the monito r sp ea ker [B ].

‘

4. Take off the rear cover [A].

[A]

[A]

Page 2

Technical Bulletin No. CRO-002

SUBJECT: Service Manual Crrection

PREPARED BY: H. Yokoyama

CHECKED BY:

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

The attached page is addition al inf orma tion for the service manual.

FROM: 2nd T.S. Section

MODEL:

CRO Europe and Asia version.

DATE: Nov. 2, 1993

Reissued Jan.10. 19994

Page 3

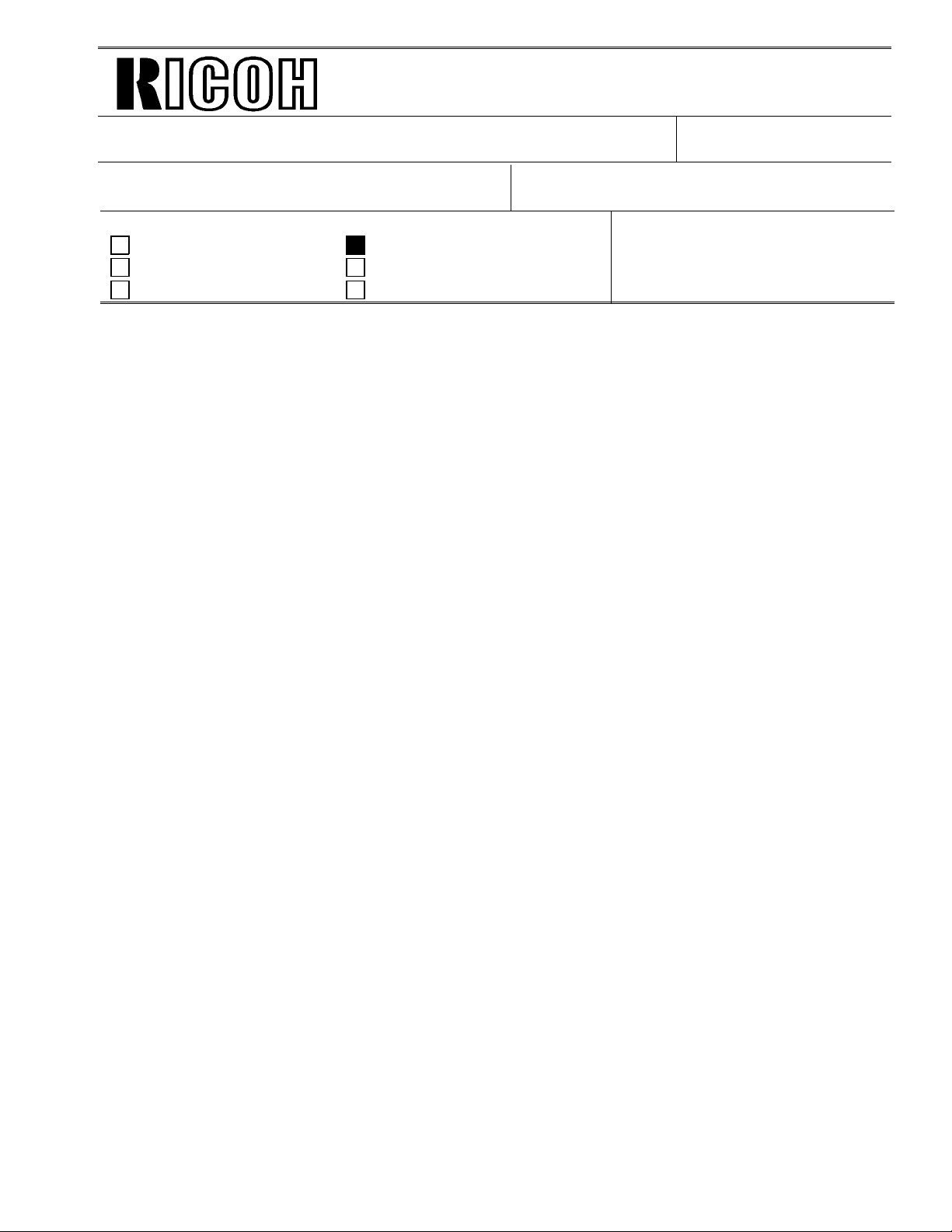

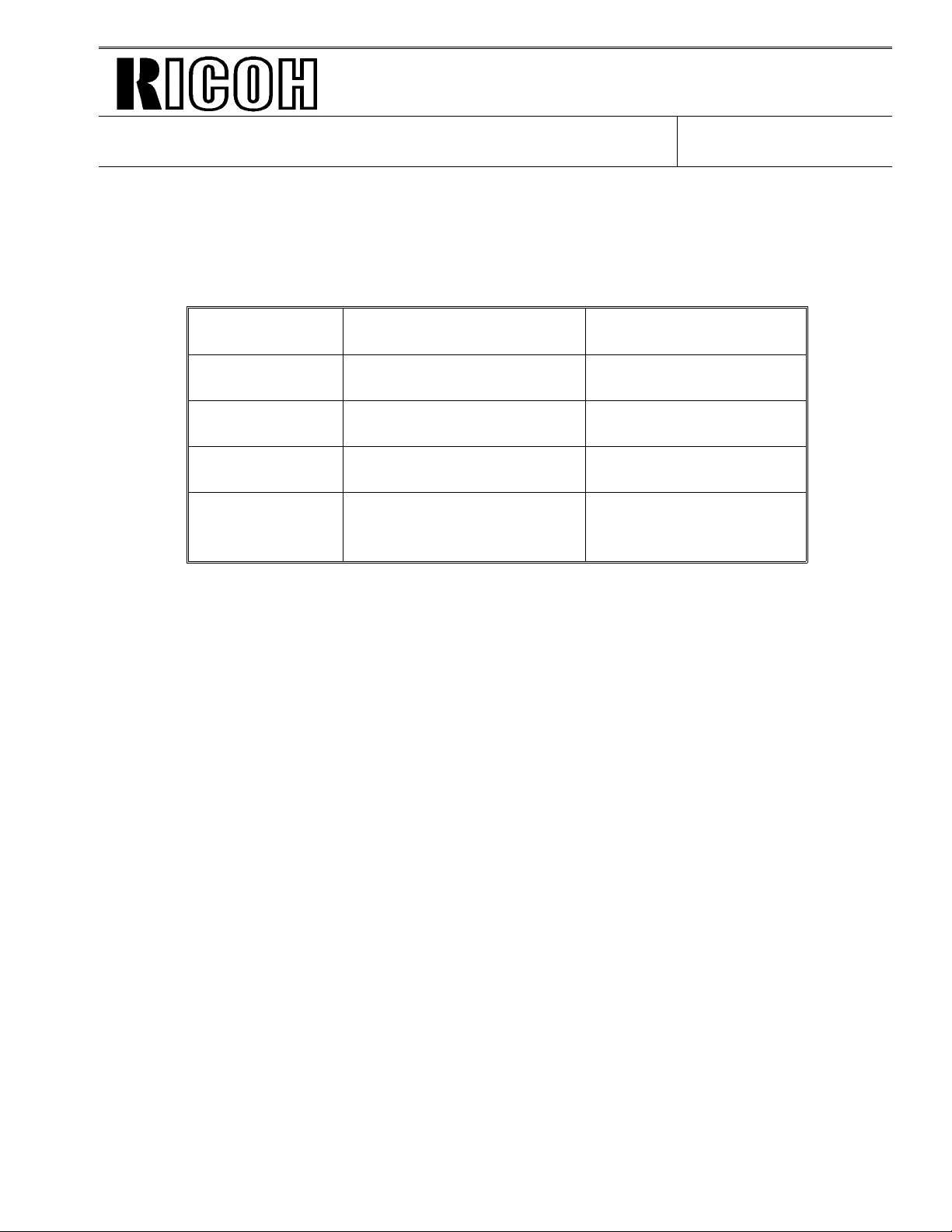

2-1-2. NCU

C

1. Signal and Jumper Settings

The following table shows the jumper po sitio ns fo r each country, and the status of the relay

control signals (CN3-A7, B7 and A8 ). The coun try is selected by the Country Code for NCU

Parameters (NCU Parameter 00 ; use Function 96 ).

Standby Mode

CN-3 CN-3 TB1 TB2 TB3 TB5 TB4 TB7 TB8 TP2-3

Country A7 B7 A8 A7 B7 A8

Germany L L L H H L O S A S O S S

U.K. L H L H H L O S A S O S S

Italy H H L H H L O S B S O S S

Austria H H L L L L O S A S O S S

Belgium H H L L L L O S A S O S S

Denmark H H L L L L O S A O O S S

Finland H H L H H L O S A S O S S

Ireland HHLLLHOS C SOSS

Norway L H L L L H O S A S O S S

Sweden H L L L L L O S A S O S S

Switzerland L H L L L L S S A O S S O

Portugal H H L L L L O S A S O S S

Holland H H L L L H O S A S O S S

Spain H H L L L L O S B S O S S

Israel H H L H H L O S A S O S S

Asia L H L H H L O S A S O S S

Hong Kong L H L H H L O S A S O S S

S. Africa HHLHHLOS C SOSS

Australia L H L H H L O S A S O O S

New

Zealand

Singapore H H L H H L O S A S O S S

Malaysia L H L H H L O S A S O S S

Turkey

(U.K.)

Keys H = High; L = Low O = Open; S = Short.

LHLHHLOSASOSS

LHLHHLOO A SOSS

In Turkey, use the “U.K.” country code, NCU parameters manually.

After Ring

Detection

Jumper Tips and Wires

For “A”, “B” and “C” in the TB3/TB5 columns, refer to

the following diagrams.

TB3 TB5

A

TB3 TB5

B

TB3 TB5

Page 4

Base

Technical Bulletin No. CRO-003

SUBJECT: Paper not lifted up

DATE: Dec. 10. 1993

PREPARED BY: H. Yokoyama

CHECKED BY: FROM: 2nd T.S. Section

CLASSIFICATION:

MODEL: CRO

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

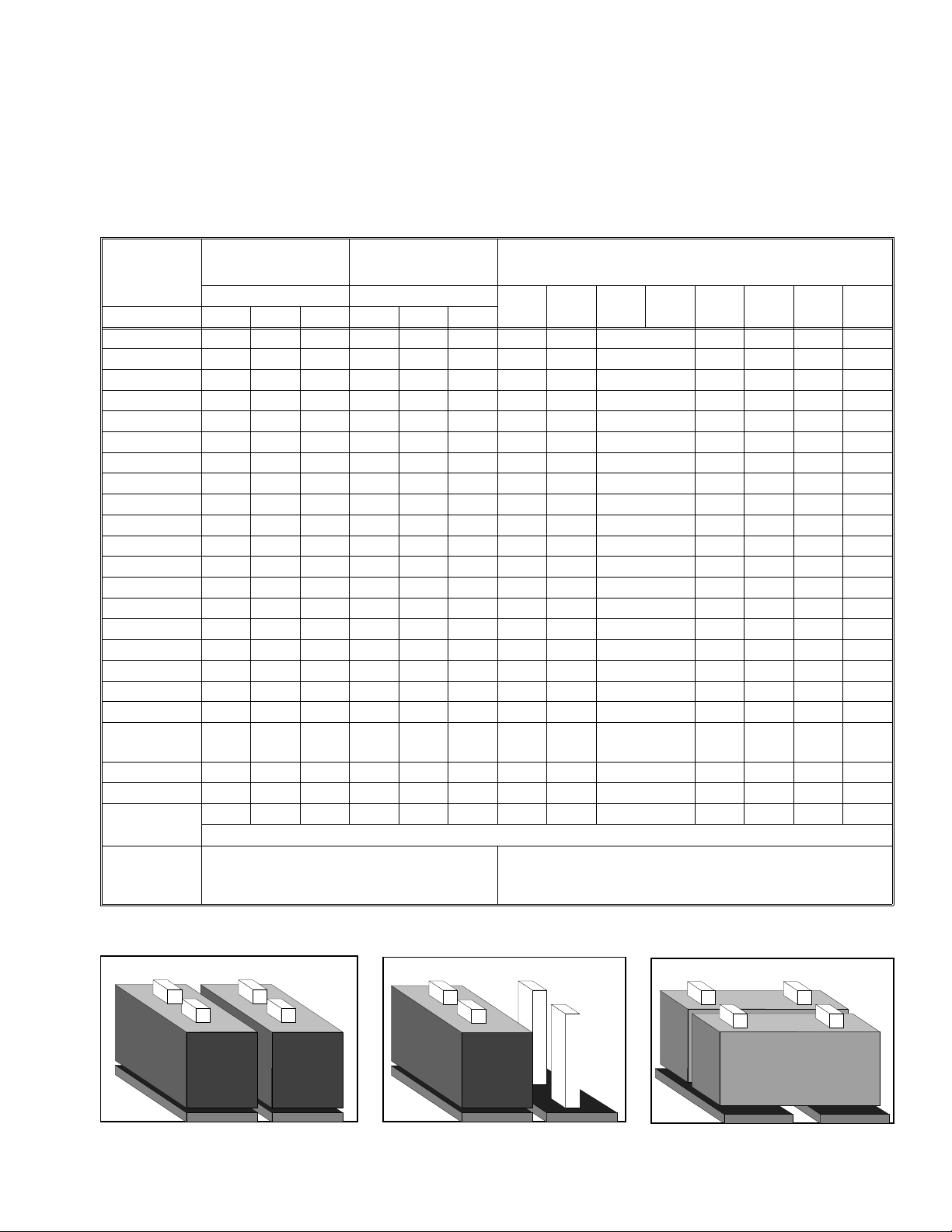

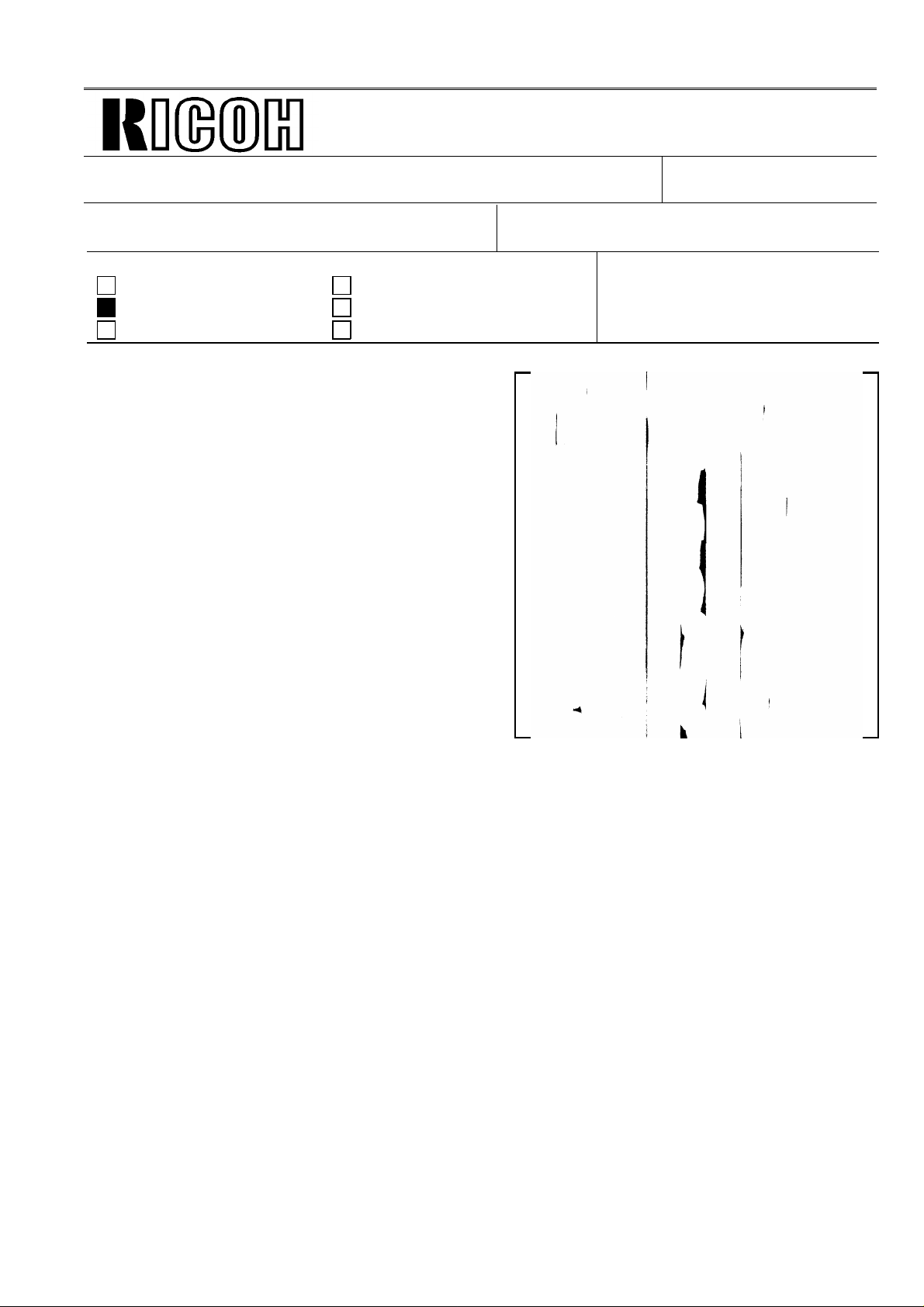

[Problem]

The bottom plate of the A4 (letter) size standard cassette is not lifted up eve n if the cassette is

inserted into the machine.

[Reason]

When installing the cassette, the slider [A] should

contact the Boss [B ] on t he base .

However [A] does not contact [B], because of the warp of

the cassette and the base plate of the machien.

Machine

Cassette

[A]

[Modification]

[B]

Temporary: Insert a washer (t=0.5mm, P/N: 07010030B) between the Boss [B] and the

Base plate of the machine

<Effective Date>

• H510-20: R8831000001~ • H5 10-30: 4671130001~

• H510-21: 6403100136 ~ • H510-40: U2731100001~

• H510-22: L4231000309~ • H510-51 : A1431000001~

• H510-27: 0831000146 ~ • H510-60: 6353110001~

Permanent: The heig ht of the Boss [B] (P/N: H081 35 61 ) has be en chan ge d fro m 6 mm to

7mm.

<Effective Date>

• From December 1st production

[Countermeasure]

• Install a plastic cap (which packed with this RTB) on to the Boss.

Use a glue for plastic.

or

• Insert a washer(P/N: 07010030B) or an M4 E-ring (P/N: 07200040E) between the Boss and

the Base Plate.

Page 5

Technical Bulletin No. CRO-004

SUBJECT: Paper not lifted up

PREPARED BY: A. Ishiyama

CHECKED BY:

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

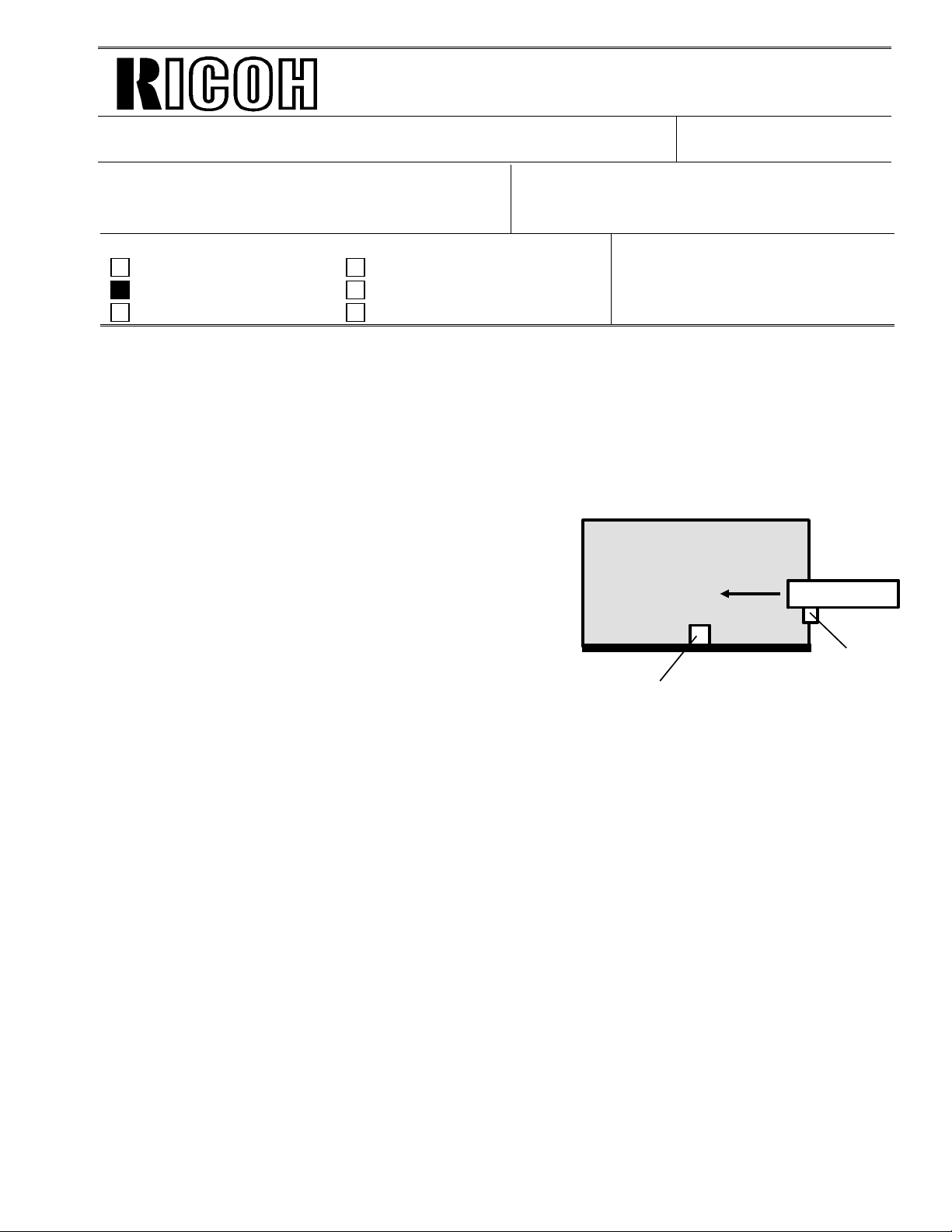

To improve image quality, the OBM (mast er un it) has bee n mod ifie d, as shown below.

FROM: 1st T.S. Section

MODEL: CRO/ CS1

DATE:

Dec. 15. 1993

Paper path

When the paper passes over the maste r belt , to ne r sometimes does not transfer to the pape r

properly.

Therefore, the paper path inside the master has been changed, and the paper makes be tter

contact with the master.

This has been executed from October production.

Paper path

Page 6

Technical Bulletin No. CRO-005

SUBJECT: Hot Roller Down

PREPARED BY:H Yokoyama

CHECKED BY:

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

FROM: 2nd T.S. Section

MODEL:

CRO(Europe & Asia)

DATE:

Apr, 11th , 1994

<Problem>

Auto service call (Hot Roller Down) may occur during sta nd by mod e.

<Cause>

TRC (Triac)1 and/or 2 on the PSU may be damaged (short ed ) in the field by severe impulse

noise or power supply drop out. (The TRCs switch the ac power supply to the fusing lamp

on/off.)

This may cause continuou s power supply to the fusing lamp an d this will genarate the above

auto service call condition.

(There are two safety circuits for the power supply to the fusing lamp . The safety circuits cut the

power supply to the fusing lamp.)

<Modification>

Change the capacitors (C8 and C9) to th e surg e killers (10 0Ω +0.01µF) to increase the safety

margin against unstable ac power conditions in the field.

This will be effective from Feb. 1994 production.

Europe: H51 0 56 01B → C

Asia: H510 5602B → C

Page 7

Technical Bulletin No. CRO-006

SUBJECT: Rx problem from PC Fax modems

"Paper Size Error" indication

PREPARED BY: H.Yokoyama

CHECKED BY: S.Hamano

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

FROM: 2nd T.S. Section

MODEL:

CRO (Europe only)

DATE:

May 26th, 1994.

<Rx problem from PC Fax modems>

-ProblemCRO may not receive messages from PC Fax modems.

-CauseSome PC Fax modems can not recognize th e extended DIS frame (6 bytes) which was recently

recommended by CCITT.

-ActionAsk your customer to request th e sen de r (PC Fa x modem o wne r) to con tact a service engineer

to modify their software to solve th e pro ble m.

However we have prepared a coun te rmea sure ROM for this problem. This RO M should be

used only when the problem is not solved even if the sen der co nt acts the PC Fax board maker.

When this ROM is used, the DIS fra me is f ixed at 4 byt es so that the Fine Resolution

(8 X 15.4 l/mm) will not be used for transmittion.

<"Paper Size Error" indication>

-ProblemThe machine may display "Pape r Size Erro r" in the following conditions.

⋅ Machine Software : H5107130C, D or E

⋅ Printer Firmware : 930801 or 930319

-CauseSoftware of the machin e

-ActionWe have prepared a counterme asu re ROM fo r this problem.

Page 8

Technical Bulletin No. CRO-006

SUBJECT: Rx problem from PC Fax modems

"Paper Size Error" indication

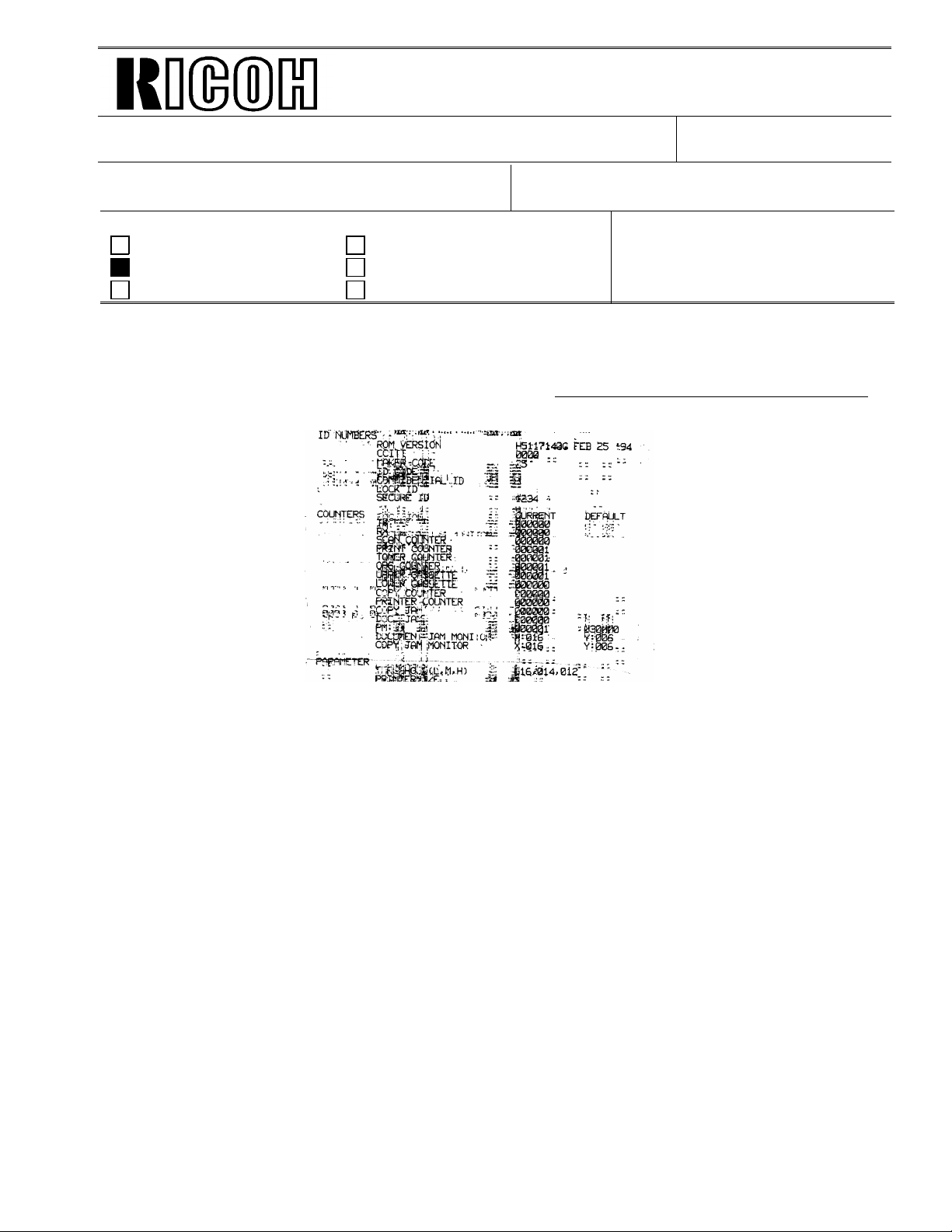

There are two kinds of problem for the CRO, so the following is a summary of the

countermeasure ROMs.

Checksum

EB51 H5107130E 24 DEC. ’93 Norma l ma ss prod uction

E64F Same as above PC Fax problem

E387 Same as above "Paper Size Error"

E305 Same as above PC Fax problem and

Indication on the System

Parameter List

ROM

problem

"Paper Size Error"

problem

DATE:

May 26th, 1994.

Contents

The solution for the "Paper Size Error" indication problem will be introduced into the production

machines from Septembe r prod uction. (This is not fixed yet.)

Page 9

Technical Bulletin No. CRO-007

SUBJECT: Rx problem from PC Fax modems

"Paper Size Error" indication

PREPARED BY: H.Yokoyama

CHECKED BY: S.Hamano

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

FROM: 2nd T.S. Section

MODEL:

CRO (Asia only)

DATE:

July, 30, 1994.

<Rx problem from PC Fax modems>

-ProblemCRO may not receive messages from PC Fax modems.

-CauseSome PC Fax modems can not recognize th e extended DIS frame (6 bytes) which was recently

recommended by CCITT.

-ActionAsk your customer to request th e sen de r (PC Fa x modem o wne r) to con tact a service engineer

to modify their software to solve th e pro ble m.

However we have prepared a coun te rmea sure ROM for this problem. This RO M should be

used only when the problem is not solved even if the sen der co nt acts the PC Fax board maker.

When this ROM is used, the DIS fra me is f ixed at 4 byt es so that the Fine Resolution

(8 X 15.4 l/mm) will not be used for transmittion.

<"Paper Size Error" indication>

-ProblemThe machine may display "Pape r Size Erro r" in the following conditions.

⋅ Machine Software : H5107132C, D or E

⋅ Printer Firmware : 930801 or 930319

-CauseSoftware of the machin e

-ActionWe have prepared a counterme asu re ROM fo r this problem.

Please contact us if this prob lem happ en ed.

Page 10

Technical Bulletin No. CRO-008

SUBJECT: Rx problem from PC Fax modems

"Paper Size Error" indication

PREPARED BY: H.Yokoyama

CHECKED BY: S.Hamano

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

FROM: 2nd T.S. Section

MODEL:

CRO (USA only)

DATE:

July, 30, 1994.

<Rx problem from PC Fax modems>

-ProblemCRO may not receive messages from PC Fax modems.

-CauseSome PC Fax modems can not recognize th e extended DIS frame (6 bytes) which was recently

recommended by CCITT.

-ActionAsk your customer to request th e sen de r (PC Fa x modem o wne r) to con tact a service engineer

to modify their software to solve th e pro ble m.

However we have prepared a coun te rmea sure ROM for this problem. This RO M should be

used only when the problem is not solved even if the sen der co nt acts the PC Fax board maker.

When this ROM is used, the DIS fra me is f ixed at 4 byt es so that the Fine Resolution

(8 X 15.4 l/mm) will not be used for transmittion.

Please contact us if this prob lem happ en ed.

<"Paper Size Error" indication>

-ProblemThe machine may display "Pape r Size Erro r" in the following conditions.

⋅ Machine Software : CS1: H5117140 E, F or G

CRO: H5107140 D, E or F

⋅ Printer Firmware : 930801 or 930319

-CauseSoftware of the machin e

-ActionUse the following ROMs if this problem happened.

CS1: H5117140H

CRO: H5107 140G

The above ROMs will be used for massproduct ion from July production.

Page 11

Technical Bulletin No. CRO-009

SUBJECT: Printing Problem

PREPARED BY: Y.Okunishi

CHECKED BY: S.Hamano

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

[Problem]

Intermittent resideual image on receptions and reports when the unit has a PIF60 installed.

See below.

FROM: 2nd T.S. Section

MODEL:

CS1 America version

CRO America and Europ e

version

DATE:

July, 30th, 1994

[Cause]

Imcomplete switching at the clock to the fax and report page memory.

The clock to the printer page memory may be mixed with the clock to the fax and report page

memory sometimes.

[Countermeasu re]

The following ROMs will be changed.

<America>

H5117140G → H Programmed ROM - CS1 (From July production)

H5107140F → G Programmed ROM - CRO (From July production)

<Europe>

H5107130E → F Programmed ROM - EUR -CRO (From Aug. production)

H5107133B → C Programmed ROM - FRN -CRO (From Aug. production)

Page 12

Technical Bulletin No. CRO-010

SUBJECT: New CRO Information

PREPARED BY: M. Tasaka

CHECKED BY:

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

The New CRO will be launched from Sept. ’94 prod uct ion .

Please find the attached she et s which are described the additional information and the

difference of the parts numbers for the old CRO prod uct .

FROM: Over Sea T.S. Section

MODEL:

New CRO

DATE:

Aug 30th, 1994

Page 13

FAX 2500L/2600L/3500L

SERVICE MANUAL

Throughout this manual, the machin es are referrend to as follows:

CRO: FAX 2500L

CS1: FAX3500L

New CRO: FAX2600L

Page 14

Additional In formation for New CRO

The new CRO is a successor to the CRO. Theref ore, most features of the new CRO are the

same as the old CRO.

The differences betwe en the new CRO and old CRO are listed below.

1. Hardware

Items New CRO Old CRO

1.1 Specification

*Memory Capacity

*Paper Size

2.1.1 FCU

*SAF Memory Battery back-up(1H) No battery back-up

2. Software

Almost same as the CRO, excep t th e following

256 Kbytes

Letter , Legal

128 Kbytes

Letter

-The Direct Number Entry feature is available by pressin g the quick dial key(8 ).

This feature is programmed in the quick dia l key, as a de fault setting.

Part Number Information for FAX2600L Parts Catalo g

Item New CRO CRO

1. Cassette H081 3350 H081 3355 1-13- 8

2. Paper Size Detector Pin-LG H081 3388 — 1-13-28

3. PCB - FCU H081 6064 H510 6110 1- 5-49

4. Operators Manual H081 4444 H510 4300 1- 3- *

5. Op-Port ass’y H081 4725 H510 4200 1- 3-11

6. Standard Pin H081 3409 — 1-11-78

7. Film - Regist Guide Rail - Left H081 3521 — 1-13-17

8. Connector - Cover H081 3558 — 1-11-82

9. Quick Dial List: NA H081 4728 H510 4255 1- 3- 2

Parts Catalog Index

Page 15

Page 1/2

Technical Bulletin No. GENERAL-004

SUBJECT: Black bands/lines on the receive d cop y

PREPARED BY: H.Yokoyama

CHECKED BY:

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

FROM: 2nd T.S. Section

MODEL: USA only

CSO, CFO, CS1/CRO

DATE:

November 11th, 1993

[Problem]

On the received copies, bla ck ban ds or line s may

be printed, especially on the right hand side.

[Cause]

Toner or dust is attached to the charge corona wire.

[Modification]

The electric current of the charge coron a will be

increased to avoid applying uneren charg to the

master which is caused by a dirty corona wire.

Because of the increase of the ele ctric curre nt , th e

distance betwee n th e grid plate and the coro na

wire will be changed to keep the charge on the

master belt the same as before modification.

• H081 2870 → H081 2854 Eraser Ass’y

• H081 5030 → H081 5020 Power pack (CSO/CFO)

H510 5030 → H510 5020 Power pack (CRO/CS 1)

<Eraser Ass’y>

• The thickness of the clean ing blad e of the cleaner will be changed to incre ase the

cleaning ability (4mm → 5mm)

• The distance between the gride pla te and charg e wire will be cha ng ed (6mm → 8mm)

<Power pack>

• The range and initial value of the VRC (VR for the charg e coro na ) will be change d.

The above modification will ta ke pla ce fro m t he De cemb er 1st prod uction.

Page 16

Page 2/2

Technical Bulletin No. GENERAL-004

SUBJECT: Black bands/lines on the receive d cop y

DATE:

November 11th, 1993

[Countermeasure in the field]

The countermeasu re method depends on the CV (Cop y Volume) of the machine.

• If the CV is less than 400 sheets/month

Turn VRC on the power pack to the maximum (Turn the VR clockwise until it stops)

• If the CV is more than 400 sheet s/mo nth

Change the Eraser to the modified one and turn VRC on the power pack to the maximum.

Note:The increase in the powe r of VRC may de crease the life time of the master unit, so for

customers whose ACV/month is more than 400 sheets, the Erase r sh ould be change d.

[Request]

The essence of this problem is a dirty cha rge corona wire, so please do the follo wing

• When a sales or service person visits a customer (at PM or EM), clean the charge

corona wire with the built-in cleaner

• Advise the customer to clea n th e charge corona wire at a certain interval or if the

customer sees black bands/lines on the received copy.

Page 17

Page 1/2

Technical Bulletin No. GENERAL-005

SUBJECT: Black bands/lines on the receive d cop y

PREPARED BY: H.Yokoyama

CHECKED BY:

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

FROM: 2nd T.S. Section

MODEL: Europe, Asia

CSO, CFO, CRO

DATE:

Feb. 3rd, 1994

[Problem]

On the received copies, bla ck ban ds or line s may

be printed, especially on the right hand side.

[Cause]

Toner or dust is attached to the charge corona wire.

[Modification]

The electric current of the charge coron a will be

increased to avoid applying uneren charg to the

master which is caused by a dirty corona wire.

Because of the increase of the ele ctric curre nt , th e

distance betwee n th e grid plate and the coro na

wire will be changed to keep the charge on the

master belt the same as before modification.

• H081 2870 → H081 2854 Eraser Ass’y

• H081 5030 → H081 5020 Power pack (CSO/CFO)

H510 5050 → H510 5051 Power pack (CRO)

<Eraser Ass’y>

• The thickness of the clean ing blad e of the cleaner will be changed to incre ase the

cleaning ability (4mm → 5mm)

• The distance between the gride pla te and charg e wire will be cha ng ed (6mm → 8mm)

<Power pack>

• The range and initial value of the VRC (VR for the charg e coro na ) will be change d.

The above modification will take pla ce fro m t he Feb. 1st pro du ctio n.

Page 18

Page 2/2

Technical Bulletin No. GENERAL-005

SUBJECT: Black bands/lines on the receive d cop y

DATE:

Feb. 3rd, 1994

[Countermeasure in the field]

The countermeasu re method depends on the CV (Cop y Volume) of the machine.

• If the CV is less than 400 sheets/month

Turn VRC on the power pack to the maximum (Turn the VR clockwise until it stops)

• If the CV is more than 400 sheet s/mo nth

Change the Eraser to the modified one and turn VRC on the power pack to the maximum.

Note:The increase in the powe r of VRC may de crease the life time of the master unit, so for

customers whose ACV/month is more than 400 sheets, the Erase r sh ould be change d.

[Request]

The essence of this problem is a dirty cha rge corona wire, so please do the follo wing

• When a sales or service person visits a customer (at PM or EM), clean the charge

corona wire with the built-in cleaner

• Advise the customer to clea n th e charge corona wire at a certain interval or if the

customer sees black bands/lines on the received copy.

Page 19

Page 1/1

Technical Bulletin No. GENERAL-008

SUBJECT: Replacing th e toner cassette

PREPARED BY:H. Yokoyama

CHECKED BY:

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

The instruction of the operator’s manual for replacing the toner cassette (CTM) is wrong.

We will insert the errata sheet to the operator’s manual.

Wrong: 1. Switch off the machine.

Correct: Keep the power switch on whe n replacing the toner cassette.

FROM: 2nd T.S. Section

MODEL:

CSO, CFO, CRO, CS1

DATE:

April, 11th, 1994

Page 20

Page 1/1

Technical Bulletin No. GENERAL-009

SUBJECT: Vertical Black Lines

PREPARED BY: H.Yokoyama

CHECKED BY: S.Hamano

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

[Problem]

Vertical black lines appear on the printed image.

[Cause]

The toner may stick on the Hot Roller, Fusing Stripper, Thermisto r, and Thermostat and this

toner may damage the surf ace of th e Hot Roller. Then, during copying toner is transferred by

the scratched part of the roller to cause vertical bla ck lines on the print ed image .

FROM: 2nd T.S. Section

MODEL:

CSO, CFO, CRO, CS1

DATE:

Jury. 30, 1994

[Countermeasu re]

The material of the surface of the Hot Roller ha s bee n cha nged to pre ven t th e tone r from

sticking on the Roller by the following modification

H0812100D → E

Because of the ab ove mo dif ication, the vender has been changed.

[Effective S/N]

H081-24, 40, 46, 51, 54, 59, 60: Oct., 1993 ~

H510-20: R8831000609 ~

21, 22, 27, 30, 40, 51, 59, 60: Nov., 1993 ~

H082-20, 23, 30, 40, 51 , 59 , 60 : Nov. , 19 93 ~

H511-20, 21, 22, 27: Nov. , 19 93 ~

[Action]

Clean the Fusing Stripper, The rmisto r and Thermo stat and take out the tone r from them when

visit the customer.

Page 21

Leak Current

(On CFO / CS1 FCU)

Diode

COM

COM

Regulator

Technical Bulletin No. Multi-001

SUBJECT: Memory Back-up Battery

DATE:

Jan. 19, 1995

PREPARED BY: Y.Okunishi

CHECKED BY: S.Hamano

CLASSIFICATION:

Action Required Revision of service manual

FROM: 2nd T.S. Section

MODEL:

CSO, CFO, CS1, LHO

Troubleshooting Information only

Retrofit Information Other

[Symptom]

Stored documents in the me mory migh t be erase d when the main power goes down.

A power failure report is printed with the following informa tion.

• Memory Tx Files: Destination names or fax numbers are print ed.

• Substitute Recept ion Files: The Sender’s RTI or CSI is printed if they are pro gra mmed.

CSO rejects incoming messages without RTI or CSI because

of the factory setting.

• Memory Lock Files: Programmed Quick Numbers are printed.

[Cause]

Power loss from the memory back-up battery on FCU caused by excessive charge current, for

the following reasons.

(1) Leak current from Diode

The battery is charged after it is already

24V

24V

fully charged. This type of battery

is damaged if this occurs.

(2) Excessive charge voltage (CFO,

CS1,LHO) The target charge voltage

was 6.2V against 6. 4V or und er which is

recommended by the battery maker.

This margin was too small for this battery.

Zener

Diode

Battery

COM

[Modification]

See MB C Series-048A.

OUT

Page 22

Technical Bulletin No. Multi-001

SUBJECT: Memory Back-up Battery

[Action Taken]

1. Install the modified FCU to deal with customer claims.

2. Request technicians not to turn off the main power if a do cume nt is stored

in the memory.

[Note]

• Stored data other than docume nts is not erased even if the main power goes do wn.

DATE:

Jan. 19, 1995

Page 23

Technical Bulletin No. Multi-002

SUBJECT: Toner Spillage during Transportation

PREPARED BY: Y. Okunishi

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Preventive Action

Background: Machines have been sent to cu sto mers after pre-installation and sent back to the

service center for repair.

Problem: Toner had spread inside the machin e du ring transportation.

Cause: Toner leaked from the development unit, the toner ca rtrid ge , or somewhere

in the toner path during tran sportation.

Preparation for transportation:

(1) Transportation withou t he avy vibra tio n

(Example: A technician should carry the machine with care.)

• F/L series fax machines:

The development unit can be connected to a CTM with toner.

However, the toner path under the CTM must be covered by some

adhesive tape. See the attached illust rat ion.

• C series fax machines:

Follow RTB No. CSO-006

• Other order machines:

Follow (2) below.

FROM: 2nd T.S. Section

MODEL:

All laser plain paper fax

machines

DATE:

Jul. 15.1995

(2) Transportation with heavy vibration

(If a third party handles the transportation, follow this procedure.)

• F/L series fax machines:

Remove the development unit and the CTM fro m the machin e if toner

has been installed. They must not be delivered in the same box as the

machine, because they contain toner which may spill out. The toner

inside the machine must be clean ed away or th e toner path under the

CTM must be covered with tape.

• C series fax machines and others:

Remove the development unit and CTM (or Toner Cartridge) from

the machine if toner has been inst alle d, and clean the toner from

inside the machine.

The removed development unit and CTM must not be delivered

in the same box as the machine.

Page 24

Technical Bulletin No. Multi-002

SUBJECT: Toner Spillage during Transportation

Inside of FX6 and LSO

Drum

DATE:

Jul. 15.1995

Toner path

Note: Adhesion of the tap e sho uld not be strong. Otherwise, it may not be ta ken off

cleanly from the machine, or th e toner path may be damaged whe n it is t ake n

off.

Please request tape samples for th e FX6 and LSO from Ricoh.

Adhesive tape

Page 25

Technical Bulletin No. Multi-003

Page 1/2

SUBJECT: Harness for PFU

PREPARED BY: Y. Okunishi

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

Problem: The Paper Feed Unit may not work correctly.

Cause: Wires of the harness (H511 5528) from the FCU to the relay connect ors for the paper

feed unit (PFU) are not allocated properly.

Affected machines:

Fax 3500L S/N R8750600001 ~ R875070 0600

NRG9665 S/N 6355060620 ~ 6355060671

Savin Fax 3670 S/N 0950600001 ~ 0950700120

Fax 5600L S/N M2050600001 ~ M205070 0500

Lanier Fax 7550 S/N L7555060677 ~ L7555060780

Omnifax L540 S/N L5405060271 ~ L5405060330

FROM: 2nd T.S. Section

MODEL: Fax3500L(USA),

NRG9665(USA), Savin Fax3670

Fax5600L(USA),

Lanier Fax7550, Omnifax L540

DATE:

July 31, 1995

Action Required:

The harness should be checked before the start of th e PFU installation because the

FCU or the PFU PCB may become damaged.

Follow the attached proce du re be fo re PFU installation and change the harness

to a new one if it is bad.

Page 26

CN B

RTB No. Multi-003

Page 2/2

Harness Check Procedure

1. Remove the Rear Cover and Left Cover.

2. Unplug the connector CN28 on the FCU.

3. Unplug the connect ors CN A and CN B on the relay con ne ctor board located at the bot to m of

Main Frame.

Harness from FCU

(CN A & B)

Main Frame

Paper Feed Unit (PFU)

Relay connectors

Harness from PFU

4. Check the continuity of the harness pin by pin using a multimeter.

See below for what the correct allocation of all wires of the harness should be.

ABCDEFGHI

CN28 (to FCU)

J1234

5

6XX1234XX

CN A

(to PFU)

View from the side without the plastic cove r

Check the continuity of the following.

A of CN28 to 4 of CN B

⇓ ⇓

D of CN28 to 1 of CN B

E of CN28 to 6 of CN A

⇓ ⇓

J of CN28 to 1 of CN A

Page 27

Page 1/3

Technical Bulletin No. Multi - 004A

SUBJECT: Fusing Unit

PREPARED BY: Y.Okunishi

CHECKED BY: S.Fujii

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

A: "NOTE" is added to page 2/3.

SYMPTOM:

Background on received and copied documents.

Cause:

Hot Roller failure as a result of not changing the Cleaning Pad at the 10K PM.

Failure to change the Cleaning Pad results in dirty Strippers and Thermostat and

then Hot Roller failure.

As the machine warms up from the standby temperature to the fusing

temperature, it is exposed to slight overheating before the temperature levels

off. This leads to softening of the Teflon layer on the Hot Roller. As a result, the

Teflon layer peels off in the areas where the Strippers and other parts come in

contact with it. Dirty Strippers and Thermostat put more stress on the Hot Roller and

cause premature Hot Roller failure.

Also, the dirty Thermistor causes the Hot Roller to overherat and fail prematurely.

FROM: Quality Assurance Center

DATE:

Oct. 15, 1996

MODEL:

CSO, CRO, CS1, CFO,

CGO

A second cause can be a damaged (bent ) Thermistor from a previous service visit.

The damaged Thermistor causes the Hot Roller to overheat and fail prematurely.

SOLUTION:

Ricoh recommends replacing the Cleaning Pad at the 10K PM. However, this is

sometimes ignored. Realizing this, Ricoh will conduct the following modifications to

protect the Hot Roller from the failure mentioned above.

No. Old Part New Part Description Qty Used Interchangeability

1 H0812121 H0812123 Stripper Spring 2 → 2 X / O

H0812120 H5132119 Stripper

2

3

H0812137

H0815035

H0812141

03130080B

(Separation Pawl)

Thermistor Assembly

Thermistor

Bracket

Screw - M3x8

2 → 2 X / O

1 → 0

1 → 1

1 → 1

0 → 1

X / O as an

assembly

4 H0812100 H0819600 Hot Roller Kit 1 → 1 X / O

Page 28

Page 2/3

Technical Bulletin No. Multi - 004A

SUBJECT: Fusing Unit

DATE:

Oct. 15, 1996

Hot Roller Kit:

The hot rollers shipped from the SPC in Japan will be replaced by the

Hot Roller Kit in July.

This kit will be comprised of the following: Hot Roller, Cleaning Pad, Thermistor,

Thermistor Bracket, Screw, Strippers (2), Stripper Springs (2) and Installation Sheet.

The individual Hot Roller will be no longer available. The Cleaning Pad will

continue to be a Service Part.

Ricoh recommends change of the above modified parts and Cleaning Pad when the failed

Hot Roller is replaced with the new one.

NOTE

(A): Please refer to the following instructions and fix the cover to the fusing unit

and check that the harness is not pinched before installing the fusing unit in the

machine.

If the metal wire of the harness contacts the thermistor bracket, a no power

condition may occur. Please check the thermistor harness if this occurs.

Fusing Cover

(Bad)

Edge of the cover may damage

the harness

Edge

(Good)

Fusing Unit

Page 29

Installation Procedure for the Thermistor

1. Assemble the thermistor and the bracket

with the screw.

Bracket - Thermistor

H0812141

Thermistor - Fusing Unit

H0815035

Do not bendthis part

2. Install the

Thermistor Ass’y

( ✻ 4)

Thermistor - Fusing Unit

H0815035

Harness - Thermostat

(✻ 3)

Page 3/3

Thermostat - Fusing Unit

H0812134

Screw - M3 x 8

03130080B

(✻ 1)

Note: Set the projection on

the thermistor into

the hole in the bracket.

Note: ✻ 1 Place the thermostat harness under the part of the bracket.

✻ 2 Do not cross the thermostat harness and the thermistor harness.

✻ 3 Push the thermistor head (sensor) gently against the hot roller witha finger to make sure that the thermistor

head touches the hot roller surface. Do not push it strongly.

✻ 4 Do not bend the thermistor neck (spring plate) when installing or cleaning it .

If the thermistor is bent, replace it.

(✻ 2)

Bracket - Thermistor

H0812141

Stay - Fusing Unit - Upper

H0812175

Page 30

T

Model:

K105 (FAX4000L)

echnical

B

ulletin

Date:

15-Sep-97

No:

PAGE: 1/1

015

Subject:

From:

Classification:

The V.33 standard for 14.4 kbps modems has not been supported by FX4 and FX6MK2

because V.33 has been deleted from the ITU (CCITT) recommendations.

So, data transfer at 14.4 kbps speed between a FAX4000L which supports only V.33 and

products which support only V.17 will not be successful, and 9.6 kbps is the highest speed

for data transfer between them .

See the following list.

Only V.33 is supported V.33 and V.17 are

14.4 Kbps Modem

QAC 2nd Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

K105 (FAX4000L) CFO, CS1, CGO FX6MK2, FX4

Part information

Electrical

Transmit/receive

supported

Prepared by:

Action required

Service manual revision

Retrofit information

Only V.17 is supported

Y.Okunishi

RC RE ASIA

✶✶

Page 31

T

Model:

General

echnical

B

ulletin

Date:

31-Oct-97

No:

PAGE: 1/3

011

Subject:

From:

Classification:

Check Items

The following function s for which the clock timer is used were checked to see whether or

not they will function correctly at 0:00 on Jan. 1, 2000.

1) Display and print of the date and time

2) Clock adjustment

3) Send later mode with memory and without memory

Year 2000 Problem

QAC 2nd Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

The year must be changed to 2000 or 00 from 1999 or 99 and the date must be kept

correctly after the start of the year 2000.

The date and time can be adjusted after the start of the year 2000.

The dialling time must be at the set time after the start of the year 2000.

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

Y.Okunishi

4) Automatic re-transmission.

When a communication error happens, the machine dials the same destination again

automatically at an in terval. This must function correctly after the start of the year

2000.

5) Weekly timer and night timer

The energy saver mode (fusing unit) contro l must work correctly.

6) Displayed date after a power failure

The correct date must be kept by the battery back-up feature.

Models Checked

1) K50 series (FAX10, 20, 60, etc.)

2) K70 series (FAX90, 95, 105, etc.)

3) K90 series (FAX80, 85, 75, 86, etc.)

4) LE series (FAX08, 09, Phone fax for ATT, etc.)

5) B series (B1, RF810, FAX12, FAX300, etc.)

6) ZB series (FAX220, FAX240, Innfax, etc.)

7) BARBARA series (RF01, 02, 03, 05, 06, etc.)

8) OX series (FAX21, 22)

9) PF series (PF-1, PF-2)

10) A series (FAX500, 550, etc.)

Page 32

T

Model:

11) B60 series (FAX170, 180, etc.)

12) K100 series (FAX1000L, 1010L, etc.)

13) K105 series (FAX4000L, etc.)

14) K200 series (FAX7000L, etc.)

15) KV series (FAX2800L, 1200L, etc.)

16) C series (FAX3000L, 4500L, 5600L, etc.)

17) L80 (MV715)

18) I series (FAX800, 880, 680, etc.)

19) F\L series (FAX2700L, 4700L, MV310, etc.)

20) FX7, LX7 (FAX1700L, MV106, FAX1750MP, etc.)

21) L20 series (Aficio FX10)

General

echnical

B

ulletin

Date:

31-Oct-97

No:

PAGE: 2/3

011

Problems found

1) AF0 (FAX500, 550, etc.), CS0 (FAX3000L, 3100L, 3200L, etc.)

a) The day of week that appears on the display only in the clock adjustment mode

goes back to SUNDAY every time the clock is adjusted after the start of the

year 2000.

So, the programmed weekly timer does not work correctly.

If the clock is not adjusted after the start of the year 2000, the date and the day

of the week are kept correctly.

b) Clock adjustment is available only for years 91 through 99. The other years

cannot be set. (Month, day, and time can be adjusted.)

2) K200 (FAX7000L)

a) Clock adjustment is available only for years 88 through 99. The other years

cannot be set. (Month, day, and time can be adjusted.)

b) The send later mode does not function (no dialling occurs) if it passes the time

into the year 2000.

No report is printed and the remaining message in the memory is not cleared

automatically but it can be cleared by user operation.

c) Automatic re-transmission is not done if the year 2000 starts after the

transmission failure.

The remaining message in the memory is not cleared automatically but it can

be cleared by user operation.

d) The display year is returned back to 88 after a power failure after the start of

the year 2000.

Page 33

T

Model:

The other functions in these models work correctly.

Schedule for the countermeasure ROMs

1) AF0 (FAX500, 550, etc.), CS0 (FAX3000L, 3100L, 3200L, etc.)

2) K200 (FAX7000L)

General

In January 1998.

In April 1998.

echnical

B

ulletin

Date:

31-Oct-97

No:

PAGE: 3/3

011

RC RE ASIA

Page 34

T

echnical

B

ulletin

MB Correction

Reissue date: 15-Nov-97

The items in bold italic have been corrected or added.

Model:

General

Date:

31-Oct-97

No:

PAGE: 1/3

011

A

Subject:

From:

Classification:

Check Items

The following functions for which the clock timer is used were checked to see whether or

not they will function corr ectly at 0:00 on Jan. 1, 2000.

1) Display and print of the date and time

2) Clock adjustment

3) Send later mode with memory and without memory

Year 2000 Problem

QAC 2nd Field Inf or mation Dept .

Troubleshooti ng

Mechanical

Paper path

Other

The year must be changed to 2000 or 00 from 1999 or 99 and the date must be kept

correctly after the year 2000.

The date and time can be adjusted after the time becomes the year 2000.

The calling time must be the set time after the time becomes the year 2000.

(Info only)

Part information

Electri cal

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofi t information

Y.Okunishi

4) Automatic re-transmission.

When the communication error happens, the machine calls to the same destination

again automatically with an interval. This must function correctly after the time

becomes the year 2000.

5) Weekly timer and night timer

The energry saver mode (heater) control must work correctly.

6) Displayed date after a power failure

The correct date must be kept by the battery.

Models Checked

1) K50 series (FAX10, 20, 60, etc.)

2) K70 series (FAX90, 95, 105, etc.)

3) K90 series (FAX80, 85, 75, 86, etc.)

4) LE series (FAX08, 09, Phone fax for ATT, etc.)

5) B series (B1, RF810, FAX12, FAX300, etc.)

6) ZB series (FAX220, FAX240, Innfax, etc.)

7) BARBARA series (RF01, 02, 03, 05, 06, etc.)

Page 35

T

Model:

8) OX series (FAX21, 22)

9) PF series (PF-1, PF-2)

10) A series (FAX500, 550, etc.)

11) B60 series (FAX170, 180, etc.)

12) K100 series (FAX1000L, 1010L, etc.)

13) K105 series (FAX4000L, etc.)

14) K200 series (FAX7000L, etc.)

15) KV series (FAX2800L, 1200L, etc.)

16) C series (FAX3000L, 4500L, 5600L, etc.)

17) L80 (MV715)

18) I series (FAX800, 880, 680, etc.)

19) F\L series (FAX2700L, 4700L, MV310, etc.)

General

echnical

B

ulletin

Date:

31-Oct-97

No:

PAGE: 2/3

011

A

20) FX7, LX7 (FAX1700L, MV106, FAX1750MP, etc.)

21) L20 series (Aficio FX10)

Problem found

Most of the models except the following model s, will not experience any problems.

1) AFO (FAX 500/550/580, NGR 9620, Infotec 3301/3305, Nashua F492)

CSO (FAX 3000/3100/3200, NGR 9660/9661/9662, Omnifax L40/41,

Savin FAX 3660/3620, Infotec 3660)

CS1 (FAX 3500L,NRG 9665, Omnifax L46, Savin FAX 3670)

CRO (FAX 2500L/2600L, NRG 9650, Omnifax L42, Savin FAX 3630, Infotec 3661)

a) The day of week, that appears on the display only in the clock adjustment

mode, is returned back to SUNDAY every time when the clock adjustment is

done after the time becomes the year 2000.

So, the programmed weekly timer does not work correctly.

have the weekly timer.)

If the clock adjustment is not done after the time becomes the year 2000, the

date and the day of week is kept correctly.

(AFO’ s do not

b) Clock adjustment is available only for the year 91 through 99. The other years

cannot be set. (Month, day and time can be adjusted.)

Page 36

T

Model:

2) K200 (FAX7000L)

General

a) Clock adjustment is available only for the years 88 through 99. The other years

cannot be set. (Month, day and time can be adjusted.)

b) The send later mode does not function (no calling happens) if it passes the

time into the year 2000.

No report is printed and the rest message in the memo ry is not cleared

automatically but it is cleared by the user operation.

c) Automatic re-transmission is not done if the time becomes the year 2000 in the

interval after the transmission failure.

The rest message in the memory is not cleared automatically but it is cleared

by the user operation.

d) The display year is returned back to 88 after the power failure after the time

becomes the year 2000.

echnical

B

ulletin

Date:

31-Oct-97

No:

PAGE: 3/3

011

A

The other functions in these models work correctly.

Schedule of the countermeasure ROMs

1) AFO, CSO, CS1, CRO:

In January 1998.

2) K200(FAX7000L):

In April 1998.

RC RE ASIA

∗ ∗ ∗

Page 37

T

echnical

B

ulletin

MB Correction

Reissue date: 15-Jan-98

The items in bold italic have been corrected or added.

PAGE: 1/3

Model:

Subject:

From:

Classification:

Check Items

The following function s for which the clock timer is used were checked to see whether or

not they will function correctly at 0:00 on Jan. 1, 2000.

1) Display and print of the date and time

2) Clock adjustment

3) Send later mode with memory and without memory

General

Year 2000 Problem

QAC 2nd Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other (Info only)

The year must be changed to 2000 or 00 from 1999 or 99 and the date must be kept

correctly after the year 2000.

The date and time can be adjusted after the time becomes the year 2000.

The calling time must be the set time after the time becomes the year 2000.

Part information

Electrical

Transmit/receive

Date:

15-Jan-98

Prepared by:

Action required

Service manual revision

Retrofit information

No:

Y.Okunishi

011

B

4) Automatic re-transmission.

When the communication error happens, the machine calls to the same destination

again automatically with an interval. This must function co rrectly after the time

becomes the year 2000.

5) Weekly timer and night timer

The energry saver mode (h eater) control must work correctly.

6) Displayed date after a power failure

The correct date must be kept by the battery.

Models Checked

1) K50 series (FAX10, 20, 60, etc.)

2) K70 series (FAX90, 95, 105, etc.)

3) K90 series (FAX80, 85, 75, 86, etc.)

4) LE series (FAX08, 09, Phone fax for ATT, etc.)

5) B series (B1, RF810, FAX12, FAX300, etc.)

6) ZB series (FAX220, FAX240, Innfax, etc.)

7) BARBARA series (RF01, 02, 03, 05, 06, etc.)

Page 38

T

echnical

B

ulletin

PAGE: 2/3

Model:

8) OX series (FAX21, 22)

9) PF series (PF-1, PF-2)

10) A series (FAX500, 550, etc.)

11) B60 series (FAX170, 180, etc.)

12) K100 series (FAX1000L, 1010L, etc.)

13) K105 series (FAX4000L, etc.)

14) K200 series (FAX7000L, etc.)

15) KV series (FAX2800L, 1200L, etc.)

16) C series (FAX

17) L80 (MV715)

18) I series (FAX800, 880, 680,

19) F\L series (FAX2700L,

20) FX7, LX7 (FAX1700L, MV106, FAX1750MP, etc.)

General

2500L

,3000L,

3700L

3500L

MV74

, 4500L, 5600L, etc.)

, etc.)

, 4700L, MV310, etc.)

Date:

15-Jan-98

No:

011

B

21) L20 series (Aficio FX10)

Problem found

Most of the models except the following models, will not experience any problems.

1) AFO (FAX 500/550/580,

CSO (FAX 3000/3100/3200,

Savin FAX 3660/3620, Infotec 3660)

CS1 (FAX 3500L,NRG 9665, Omnifax L46, Savin FAX 3670)

CRO (FAX 2500L/2600L, NRG 9650, Omnifax L42, Savin FAX 3630, Infotec 3661)

a) The day of week, that appears on the display only in the clock adjustment

mode, is returned back to SUNDAY every time when the clock adjustment is

done after the time becomes the year 2000.

So, the programmed weekly timer does not work correctly. (AFO’ s do not

have the weekly timer.)

If the clock adjustment is not done after the time becomes the year 2000, the

date and the day of week is kept correctly.

b) Clock adjustment is available only for the year 91 through 99. The other years

cannot be set. (Month, day and time can be adjusted.)

9620, Infotec 3301/3305, Nashua F492)

NRG

9660/9661/9662, Om nifax L40/41,

NRG

Page 39

T

echnical

B

ulletin

PAGE: 3/3

Model:

2) K200 (FAX7000L)

The other functions in these models work correctly.

General

a) Clock adjustment is available only for the years 88 through 99. The other years

cannot be set. (Month, day and time can be adjusted.)

b) The send later mode does not function (no calling happens) if it passes the

time into the year 2000.

No report is printed and the rest message in the memory is not cleared

automatically but it is cleared by the user operation.

c) Automatic re-transmission is not done if the time becomes the year 2000 in the

interval after the transmission failure.

The rest message in the memory is not cleared automatically but it is cleared

by the user operation.

d) The display year is returned back to 88 after the power failure after the time

becomes the year 2000.

Date:

15-Jan-98

No:

011

B

Schedule of the countermeasure ROMs

1) AFO, CSO, CS1, CRO:

In January 1998.

2) K200(FAX7000L):

In April 1998.

RC RE ASIA

∗ ∗ ∗

Page 40

T

Model:

General

echnical

B

ulletin

Date:

15-Apr-98

No:

PAGE: 1/3

014

Subject:

From:

Classification:

The year 2000 issue was explained in RTB No. General-011B.

That RTB explains only the technical matters of what will happen after the year 2000 in

some models, and the countermeasures.

At this time, we would explain how to talk with customers about the year 2000 issues

related to fax machines.

Basically, we can say to the customers that there is no major issue reated to basic

operation after the year 2000, and they don't need to take any preventative action before

the year 2000.

The only thing that the customers need to know is that the following operations will be

changed after the year 2000.

Action Plan for the Year 2000 Issues

QAC Field Inf or mation Dept .

Troubleshooti ng

Mechanical

Paper path

Other (Info only)

Part information

Electri cal

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofi t information

Y.Okunishi

1. AF0 (FAX 500/550/580, NRG 9620, Infotec 3301/3305, Nashua F492)

CS0 (FAX 3000/3100/3200, NRG 9660/9661/9662, Omnifax L40/41,

Savin FAX 3660/3620, Infotec 3660)

CS1 (FAX 3500L,NRG 9665, Omnifax L46, Savin FAX 3670)

CR0 (FAX 2500L/2600L, NRG 9650, Omnifax L42, Savin FAX 3630, Infotec 3661)

First, please do not forget to inform the customers that they don't need to do anything if

they do not go into the clock adjustment mode.

A) Adjustment of the year

A-1) For the year 2000

①Set the clock to 11:59 PM (or 23:59) on December 31 1999, and wait for one minute.

②The year changes to 2000 automatically, then set the current time.

(Do not change the year.)

A-2) For the year 2001

③After the above step ①, set the clock to 11:59 PM (or 23:59) on December 31 2000, and

wait for one minute.

④The year changes to 2001 automatically, then set the current time.

(Do not change the year.)

A-3) For years 2002 and later, repeat the same procedure as above.

Page 41

T

Model:

General

echnical

B

ulletin

Date:

15-Apr-98

No:

PAGE: 2/3

014

B) Adjustment of the weekly timer (Heater timer)

This is only for customers who use the weekly timer. (We do not think that many

customers are using this function.)

Please recommend adjusting the timer on Sunday if the customer can do it.

If they cannot do it on Sunday, the ROM should be changed to the new one.

The new ROM includes the countermeasure for the above A) also.

2. K200 (FAX7000L)

A) Adjustment of the year

First, please do not forget to inform the customers that they don't need to do anything if

they do not go into the clock adjustment mode.

A-1) For the year 2000

Set the clock to 11:59 PM (or 23:59) on December 31 1999, and wait for one minute.

①

The year changes to 2000 automatically, then set the current time.

②

(Do not change the year.)

A-2) For the year 2001

Except AF0

••••

After the above step ①, set the clock to 11:59 PM (or 23:59) on December 31 2000,

③

and wait for one minute.

The year changes to 2001 automatically, then set the current time.

④

(Do not change the year.)

A-3) For years 2002 and later

Repeat the same procedure as above.

If the customer switches off the machine after the year 2000, the year displayed re turns to

1988. In this case, follow the above procedure to adjust the clock.

B) Send later mode

Please notify the customer that they should not use send later mode on December 31st

1999, if the transmission will be done on the next day.

If the customer cannot guarantee that they will follow this advice, the ROM should be

changed.

Page 42

T

Model:

Schedule of the countermeasure ROMs

1) AFO, CSO, CS1, CRO:

2) K200 (FAX7000L):

Both are delayed.

∗

General

In May 1998.

In May 1998.

echnical

B

ulletin

Date:

15-Apr-98

No:

PAGE: 3/3

014

RC RE ASIA

∗ ∗ ∗

Page 43

RICOH Technical

Model:

LSO, CRO, CS1, AFO, AF2, K200

Bulletin

Date:

31-May-98

No:

PAGE:

Multi - 008

1/8

Subject:

From:

Classification:

Attached please find the list of the ROMs for the year 2000 problem and the procedure for

making R200 ROMs from the ROM file s.

Note:

Please refer to RTB nos. General 11 and 14 for details.

·

8 ROMs for the K200 are combined in one file.

·

ROMs for the year 2000 problem

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

Y.Okunishi

RC RE ASIA

* * *

Page 44

RICOH Technical

Model:

LSO, CRO, CS1, AFO, AF2, K200

Bulletin

Date:

31-May-98

No:

PAGE:

Multi - 008

2/8

ROMs for the year 2000 May 29, 1998

Y.Okunishi

Product

Code

CSO H0817138 yes CSO7138 8552 c30usa H081-20 3000L RICOH US 91/12 93/4 16,747 2M ROM (1ROM/unit)

CS1 H5117150B yes CS17150B 6A91 c31usa H511-20 3500L RICOH US 93/6 96/3 31,766

CR0 H5107121B yes CRO7121B 23AB c60usa H510-20 2500L RICOH US 93/5 95/4 26,535

New ROM

No.

H0817136A yes CSO7136S 77A7

H0817139E yes CSO7139E 3C77 c30tel 28 L40 L41 Omnifax US 92/1 93/5 5,181

H0817124A yes CSO7124A 0772 c30eur 40 3000L 3000L RICOH Europe 92/3 95/11 37, 716

H0817123A no CSO7123A 0078 c30fra 70 3000LF RICOH France 93/4 95/9 393

H0817121A yes CSO7121A FA57 c30hcs 30 3660 Infotec Europe 92/10 94/8 15,528

H0817122A yes CSO7122A D225 c30asi 51 3000L RICOH Asia 92/3 96/10 18,523

H0817140M yes CSO7140M 859C c30tai 23 3000L RICOH Taiwan 92/3 95/11

H0817128B no CSO7128B E8C5 c30chi 54 3000L RICOH China 93/7 95/11

H0817159N yes CSO7159N C3CE c30opt

Test File name Check

sum

ROM Code Model code Model Brand Area Sold from Sold by No. of sold

23 3200L 91/12 95/11 18, 242

24 3100L 93/2 95/2 21,863

21 9660 NRG 92/3 92/7 71

22 9661 92/3 94/ 2 1,651

26 3660 SAVIN 92/2 93/4 1,372

27 3620 92/1 93/ 4 1,917

TOTAL

c30usa

•

H151-65•SW:HCS•,H151-

73(•:RE),H151-83(•:GES)

25 2600L RICOH US 94/9 95/3

29 L41 92/1 93/5 8,008

TOTAL

46 3000L RICOH Switzerland 92/10 95/6 4,179

60 9660 NRG Europe 93/3 95/8 15,659

TOTAL

80 92/4 95/9 6,206

90 9660F NRG 92/4 95/9 2,164

TOTAL

59 9660 NRG 94/3 96/4 2,837

55 - Ricoh Korea ?

TOTAL

Option Europe ? Language Kit

21 9669 NRG 93/6 95/9 700

22 L46 Omnifax 93/6 95/12 11,472

27 3670 SAVIN 93/7 95/9 3,106

3/8

21 9650 NRG 93/7 95/7 832

TOTAL

units

61,863

8,000

13,189

57,554

8,763

36,888

1,251

981

47,044

Note

Page 45

RICOH Technical

H5107120B yes CRO7120B F5BF c60eur 30 3661 Infotec Europe 93/9 94/9 5,564

H5107123B yes CRO7123B 0E88 c60fra 33 3661F Infotec France 94/4 95/9 242

H5107132G yes CRO7132G 37F5 c60asi 51 2500L RICOH Asia 93/12 96/1 5,955

H5107131B yes CRO7131B 23A3 c60tai 53 2500L RICOH Taiwan 94/10 97/6

AFO H0847130K yes AFO7130K D8D3 a20usa H084-20 500 RICOH Taiwan 92/4 93/4

H0847140L yes AFO7140L 6B6A a20eur 44 500 RICOH Europe 91/8 94/10

H0847142H no AFO7142H 94D0 a20fra 83 500 RICOH France 92/4 94/3

H0847143L yes AFO7143L 350F a20hcs 34 3301 Infotec Europe 91/8 95/4

H0847141L yes AFO7141L 3F13 a20asi 51 500 RICOH Asia 91/10 96/11 13,696

H0847150K yes AFO7150K 2A40 a20opt

AF1 H0857135B yes AF17135B FCDF a21chi H085-54 580 RICOH China 93/ 8 96/5

AF2 H0867130K yes AF27130K 9BDF a22usa 20 550 RICOH US 92/1 96/2

H0867140L yes AF27140L 3C35 a22eur 44 550 RICOH Europe 91/8 95/3 10,824

H0867142H checkingAF27142H 583D a22fra 73 3305 Infotec France - - 0 RIF is checking the

H0867143L yes AF27143L 0CE0 a22hcs 34 3305 Infotec Europe 91/8 95/9

H0867141L yes DAD8 a22asi 51 550 RICOH Asia 92/2 96/2 12,181

H0867131A yes AF27131A 9BC3 a22tai 53 550 RICOH Taiwan 94/8 96/2

H0867150L yes AF27150L E725 a22opt

Bulletin

22 L42 Omnifax 93/9 95/3 6,848

27 3630 SAVIN 93/7 95/3 2,136

40 2500L RICOH 93/9 95/7 11,418

60 9650 NRG 93/9 95/8 5,632

43 2500LF RICOH 93/10 95/9 2,012

63 9650F NRG 93/10 95/9 931

59 9650 NRG 94/1 95/9 1,107

56 500 RICOH Vietnam 92/11 94/5 1,650 KD

H15146(•:RICOH),H

151-54(SW:HCS)

90 9620 NRG 92/4 93/9 1,446

83 550 RICOH 95/4 95/9 100

93 9620 NRG 92/4 94/9 170

59 Nashua Asia 92/2 96/1 1,662

H15147(•:RICOH),H

15155(SW:HCS),H15193(•:NASHUA)

- Option Europe ? Language K i t

- Option Europe ? Language Kit

PAGE:

TOTAL

TOTAL

TOTAL

TOTAL

TOTAL

TOTAL

TOTAL

TOTAL

36,351

22,614

3,185

7,062

777

365

6,817

1,231

2,892

15,346

5,040

14,934

12,270

ROM.

270

6,583

13,843

109

Page 46

RICOH Technical

Bulletin

PAGE:

4/8

K200 H0087260J

H0087261J

H0087262J

H0087263J

H0087264J

H0087265J

H0087266J

H0087267J

H0087270F

H0087271F

H0087272F

H0087273F

H0087274F

H0087275F

H0087276F

H0087277F

H0087320F

H0087321F

H0087322F

H0087323F

H0087324F

H0087325F

H0087326F

H0087327F

H0087280H

H0087281H

H0087282H

H0087283H

H0087284H

H0087285H

H0087286H

H0087287H

H0087330H

H0087331H

H0087332H

H0087333H

H0087334H

H0087335H

H0087336H

H0087337H

H0087290C

H0087291C

H0087292C

H0087293C

H0087294C

H0087295C

H0087296C

H0087297C

yes H0087260 FC1E

EBE0

B88F

08B2

7AA0

C2F0

28D7

CE5E

yes H0087270 451C

78BA

3FA2

C44F

7B14

4DA3

7C16

380B

yes H0087320 4527

7967

3FA2

C44F

7B14

4DA3

7C16

380B

yes H0087280 1956

CB16

4E46

C3F4

799D

33A8

3EE5

6478

yes H0087330 1D20

64B7

4FAF

D4A1

7830

1EBB

C591

854A

yes H0087290 4A5D

5B24

416A

C54D

8882

683D

D331

E525

USA 20 7000L RICOH US 89/9 95/6

GMN 30 7000L RICOH Germany 89/10 93/7

GMN 40 6765 Infotec Germany 89/9 90/8

ENG 41 7000L RI COH UK 89/10 94/8

ENG 31 6765 Infotec UK 89/10 92/12

ITY 42 7000L RICOH Italy 89/10 91/10

790

1M ROM (8 ROMs/unit)

119

180

85

125

29

Page 47

RICOH Technical

H0087340C

H0087341C

H0087342C

H0087343C

H0087344C

H0087345C

H0087346C

H0087347C

H0087300E

H0087301E

H0087302E

H0087303E

H0087304E

H0087305E

H0087306E

H0087307E

H0087350E

H0087351E

H0087352E

H0087353E

H0087354E

H0087355E

H0087356E

H0087357E

H0087310H

H0087311H

H0087312H

H0087313H

H0087314H

H0087315H

H0087316H

H0087317H

H0087360H

H0087361H

H0087362H

H0087363H

H0087364H

H0087365H

H0087366H

H0087367H

yes H0087340 4A68

5BD1

416A

C54D

8882

683D

D331

E525

yes H0087300 4A2A

3680

403B

9F7C

8900

DB80

6C4A

1B91

yes H0087350 4A35

372D

403B

9F7C

8900

DB80

6C4A

1B91

yes H0087310 196E

CB4C

4E46

C3F4

799A

3385

3EE5

6478

yes H0087360 1D38

64ED

4FAF

D4A1

782D

1E98

C591

854A

ITY 32 6765 Infotec Italy 89/10 92/9

FRN 43 7000L RICOH France 89/10 92/3

FRN 33 6765 Infotec France 90/7 91/3

UNV 44 7000L RICOH Europe/Asia 89/9 94/1

UNV 34 6765 Infotec Europe 90/1 92/11

Bulletin

PAGE:

5/8

41

137

156

387

38

END

Page 48

RICOH Technical

Bulletin

ROM writing procedure for K200 ROMs

1. ROM Writing

This will vary depending on the ROM writer buffer capacity.

This is an example with a buffer RAM capacity of 512KB.

During the first load, 512KB is sent.

During he first load, 0H~7FFFFH can be loaded.

During the second, 800000H~FFFFFH can be loaded.

Since the K200 is 1MB, the sending is completed after 512KB worth has been sent

twice.

First Time

1-1) Transfer to the ROM writer.

Motorola-S Format

Receiving location address 00000000

Send/Receive buffer RAM start 00000000

Sending buffer RAM end Device capacity

1-2) Program on the ROM

Set program 16-bit series

Device Count 4

Device Start 00000000

Buffer RAM Start 00000000

Data Type BIGENDIAN

PAGE:

6/8

Second Time

2-1) Transfer to the ROM writer.

Motorola-S Format

Receiving location address 00080000

Send/Receive buffer RAM start 00000000

Sending buffer RAM end Device capacity

2-2) Program on the ROM

Set program 16-bit series

Device Count 4

Device Start 00000000

Buffer RAM Start 00000000

Data Type BIGENDIAN

When the buffer RAM capacity is 1MB, the RAM writing is as follows.

1MB can be sent during the first load.

OH~FFFFFH can be loaded.

Since the K200 is 1MB, it can be transferred all at once.

Page 49

RICOH Technical

First Time

1-1) Transfer to the ROM writer.

Motorola-S Format

Receiving location address 00000000

Send/Receive buffer RAM start 00000000

Sending buffer RAM end Device capacity

1-2) Program on the ROM

Set program 16-bit series

Device Count 4

Device Start 00000000

Buffer RAM Start 00000000

Data Type BIGENDIAN

Second Time

2-1) Transfer to the ROM writer.

Since 1MB can be sent the first time, this is not necessary.

2-2) Program on the ROM

Set program 16-bit series

Device Count 4

Device Start 00000000

Buffer RAM Start 00080000

Data Type BiGENDIAN

Bulletin

PAGE:

7/8

ROM locations (Top view of MBU)

3-8 (3’) 3-0 (4’)

2-8 (1’) 2-0 (2’)

1-8 (3) 1-0 (4)

0-8 (1) 0-0 (2)

() The number in the parentheses is the ROM writer socket number.

[‘] The second time is indicated.

The ROM part numbers start from 0-8.

(Ex: For the FAX7000L(US), 0-8:H0087260, 3-0:H0087267)

Page 50

RICOH Technical

Check Sum Chart

ROM location

Model

K200USA F C1E EBE0 B88F 08B2 7AA0 C2F0 28D7 EC5E

K200GMN-R 451C 78BA 3FA2 C44F 7B14 4DA3 7C16 380B

K200G<M-K 4527 7967 3FA2 C44F 7B14 4DA3 7C16 380B

K200ENG-R 1956 CB16 4E46 C3F4 799D 33A8 3EE5 6478

K200ENG-K 1D20 64B7 4FAF D4A1 7830 1EBB C591 854A

K200ITY-R 4A5D 5B24 416A C54D 8882 683D D 331 E525

K200ITY-K 4A68 5BD1 416A C54D 8882 683D D331 E525

K200FRN-R 4A2A 3680 403B 9F7C 8900 DB80 6C4A 1B91

K200FRN-K 4A35 372D 403B 9F7C 8900 DB80 6C4A 1B91

K200UNV-R 196E CB4C 4E46 C3F4 799A 3385 3EE5 6478

K200UNV-K 1D38 64ED 4FAF D4A1 782D 1E98 C591 854A

R: Ricoh, K : Kalle (Infotec)

0-8 0-0 1-8 1-0 2-8 2-0 3-8 3-0

Bulletin

PAGE:

8/8

Page 51

T

echnical

B

ulletin

RTB Correction

Reissue date: 30-Jun-98

The items in bold italic have been corrected or added.

Model:

General

Date:

15-Jan-98

No:

PAGE: 1/3

C

011

Subject:

From:

Classification:

Check Items

The following function s for which the clock timer is used were checked to see whether or

not they will function correctly at 0:00 on Jan. 1, 2000.

1) Display and print of the date and time

2) Clock adjustment

3) Send later mode with memory and without memory

Year 2000 Problem

QAC 2nd Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other (Info only)

The year must be changed to 2000 or 00 from 1999 or 99 and the date must be kept

correctly after the year 2000.

The date and time can be adjusted after the start of the year 2000.

The calling time must be the set time after the start of the year 2000.

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

Y.Okunishi

4) Automatic re-transmission.

When a communication error occu rs, the machine calls the same destination again

automatically after an interval. This must function correctly after the start of the year

2000.

5) Weekly timer and night timer

The energy saver mode (heater) control must work correctly.

6) Displayed date after a power failure

The correct date must be kept by the battery.

Models Checked

1) K50 series (FAX10, 20, 60, etc.)

2) K70 series (FAX90, 95, 105, etc.)

3) K90 series (FAX80, 85, 75, 86, etc.)

4) LE series (FAX08, 09, Phone fax for ATT, etc.)

5) B series (B1, RF810, FAX12, FAX300, etc.)

6) ZB series (FAX220, FAX240, Innfax, etc.)

7) BARBARA series (RF01, 02, 03, 05, 06, etc.)

Page 52

T

echnical

B

ulletin

PAGE: 2/3

Model:

8) OX series (FAX21, 22)

9) PF series (PF-1, PF-2)

10) A series (FAX500, 550, etc.)

11) B60 series (FAX170, 180, etc.)

12) K100 series (FAX1000L, 1010L, etc.)

13) K105 series (FAX4000L, etc.)

14) K200 series (FAX7000L, etc.)

15) KV series (FAX2800L, 1200L, etc.)

16) C series (FAX2500L,3000L, 3500L, 4500L, 5600L, etc.)

17) L80 (MV715)

18) I series (FAX800, 880, 680, MV74, etc.)

19) F\L series (FAX2700L, 3700L, 4700L, MV310, etc.)

20) FX7, LX7 (FAX1700L, MV106, FAX1750MP, etc.)

21) L20 series (Aficio FX10)

General

Date:

15-Jan-98

No:

011

C

22) K10 series (FX120, Rapicom120, FX210/230, Rapicom210/230, etc.)

23) K20 series (FX5000, Rapicom5000, etc.)

24) K60 series (FAX610, Rapicom610, etc.)

25) K83 series (FAX830, Rapicom830, etc.)

26) FR4, FR6 (FAX4800L, FAX3800L, etc.)

Problem found

Most models, except the following models, will not experience any problems.

1) AFO (FAX 500/550/580, NRG 9620, Infotec 3301/3305, Nashua F492)

CSO (FAX 3000/3100/3200, NRG 9660/9661/9662, Omnifax L40/41,

Savin FAX 3660/3620, Infotec 3660)

CS1 (FAX 3500L,NRG 9665, Omnifax L46, Savin FAX 3670)

CRO (FAX 2500L/2600L, NRG 9650, Omnifax L42, Savin FAX 3630, Infotec 3661)

a) The day of week, that appears on the display only in the clock adjustment

mode, is returned back to SUNDAY whenever the clock adjustment is done

after the start of the year 2000.

So, the programmed weekly timer does not work correctly. (AFO’ s do not

have the weekly timer.)

If the clock adjustment is not done after the start of the year 2000, the date and

the day of week is kept correctly.

b) Clock adjustment is available only for the year 91 through 99. The other years

cannot be set. (Month, day and time can be adjusted.)

Page 53

T

echnical

B

ulletin

PAGE: 3/3

Model:

2) K200 (FAX7000L)

3) K60 series (FAX610, Rapicom610, Infotec6550)

General

a) Clock adjustment is available only for the years 88 through 99. The other years

cannot be set. (Month, day, and time can be adjusted.)

b) The send late r mode does not function (no calling happens) if it passes the time

into the year 2000.

No report is printed. The message in the memory is not cleared automatically

but must be cleared by user operation.

c) Automatic re-transmission is not done if the year 2000 starts in the interval after

the transmission failure.

The message in the memory is not cleared automatically but must be cleared

by user operation.

d) The display year is returned back to 88 after a power failure after the start of

the year 2000.

K83 series (FAX830, Rapicom830, Infotec6750)

Date:

15-Jan-98

No:

011

C

a) The day of week is not displayed correctly after the start of the year 2000.

b) The send later mode does not function (calling at 0:00AM January 1st

2000).

c) The display year is returned back to 85 when the power fails after the

start of the year 2000.

The other functions in these models work correctly.

Schedule for the countermeasure ROMs

1) AFO, CSO, CS1, CRO:

In

K200 (FAX7000L):

2)

In May 1998

3) K60, K83: A ROM will not be available.

April

1998.

(The corrected version will be in July 1998.)

RC RE ASIA

∗ ∗ ∗

Page 54

T

echnical

B

ulletin

RTB Correction

Reissue date: 30-Jun-98

The items in bold italic have been correction or added.

Model:

CSO, CRO, CS1, AFO, AF2, K200

Date:

31-May-98

No:

PAGE: 1/5

Multi-008

A

Subject:

From:

Classification:

Attached please find the list of ROMs for the year 2000

The ROM files have been saved in the Ricoh QAC server except for the K200 ROMs.

(EP ROMs for the K200 will be prepared by the beginning of June.)

Note:

• Please refer to RTB nos. General 11 and 14 for details.

ROMs for the year 2000 problem

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

. (The list was updated.)

Y. Okunishi

Action required

Service manual revision

Retrofit information

RC RE ASIA

∗ ∗ ∗

Page 55

T

Model:

CSO, CRO, CS1, AFO, AF2, K200

echnical

B

ulletin

Date:

31-May-98

No:

PAGE: 2/5

Multi-008

ROMs for the year 2000

Product

Code

CSO H0817138 8552 H081-20 3000L RICOH US 2M ROM

CS1 H5117150B 6A91 H511-20 3500L RICOH US

CR0 H5107121B 23AB H510-20 2500L RICOH US

New ROM

No.

H0817136A 77A7 25 2600L RICOH US

H0817139E 3C77 28 L40 Omnifax US

H0817124A 0772 40 3000L RICOH Europe

H0817123A 0078 70 3000LF RICOH France

H0817121A FA57 30 3660 Infotec Europe

H0817122A D225 51 3000L RICOH Asia

H0817140M 859C 23 3000L RICOH Taiwan

H0817128B E8C5 54 3000L RICOH China

H0817159N C3CE

H5107120B F5BF 30 3661 Infotec Europe

H5107123B 0E88 33 3661F Infotec France

H5107132G 37F5 51 2500L RICOH Asia

H5107131B 23A3 53 2500L RICOH Taiwan

Check

sum

Model code Model Brand Ar ea Note

23 3200L (1ROM/unit)

24 3100L

21 9660 NRG

22 9661

26 3660 SAVIN

27 3620

29 L41

46 3000L RICOH Switzland

60 9660 NRG Europe

80

90 9660F NRG

59 9660 NRG

55 - Ricoh Korea

H151-65•SW:HCS

H151-73(FRN:Ricoh)

H151-83(FRN:GES)

21 9669 NRG

22 L46 Omnifax

27 3670 SAVIN

21 9650 NRG

22 L42 Omnifax

27 3630 SAVIN

40 2500L RICOH

60 9650 NRG

43 2500LF RICOH

63 9650F NRG

59 9650 NRG

•

Option Europe Language Kit

25-Jun-98

Page 56

T

Model:

AFO H0847130K D8D3 H084-20 500 RICOH Taiwan

AF1 H0857135B FCDF H085-54 580 RICOH China

AF2 H0867130K 9BDF 20 550 RICOH US

CSO, CRO, CS1, AFO, AF2, K200

H0847140L 6B6A 44 500 RICOH Europe

H0847142H 94D0 83 500 RICOH France

H0847143L 350F 34 3301 Infotec Europe

H0847141L 3F13 51 500 RICOH Asia

H0847150K 2A40 H151-46(FRN:RICOH)

H0867140L 3C35 44 550 RICOH Europe

H0867142H 583D 73 3305 Infotec France

H0867143L 0CE0 34 3305 Infotec Europe

H0867141L DAD8 51 550 RICOH Asia

H0867131A 9BC3 53 550 RICOH Taiwan

H0867150L E725 H151-47(FRN:RICOH)

echnical

56 500 RICOH Vietnam KD

H151-54(SW:HCS)

90 9620 NRG

83 550 RICOH

93 9620 NRG

59 9620 NRG Asia

H151-55(SW:HCS)

H151-93(FRN:NASHUA)

B

ulletin

Date:

31-May-98

No:

Option Europe Language Kit

Option Europe Language Kit

PAGE: 3/5

Multi-008

K200 H0087260J

H0087261J

H0087262J

H0087263J

H0087264J

H0087265J

H0087266J

H0087267J

H0087270F

H0087271F

H0087272F

H0087273F

H0087274F

H0087275F

H0087276F

H0087277F

H0087320F

H0087321F

H0087322F

H0087323F

H0087324F

H0087325F

H0087326F

H0087327F

FC1E

EBE0

B88F

08B2

7AA0

C2F0

28D7

CE5E

451C

78BA

3FA2

C44F

7B14

4DA3

7C16

380B

4527

7967

3FA2

C44F

7B14

4DA3

7C16

380B

H008-20 7000L RICOH US 1M ROM

(8 ROMs/unit)

30 7000L RICOH Germany

40 6765 Infotec Germany

Page 57

T

Model:

CSO, CRO, CS1, AFO, AF2, K200

echnical

B

ulletin

Date:

31-May-98

No:

PAGE: 4/5

Multi-008

H0087280H

H0087281H

H0087282H

H0087283H

H0087284H

H0087285H

H0087286H

H0087287H

H0087330H

H0087331H

H0087332H

H0087333H

H0087334H

H0087335H

H0087336H

H0087337H

H0087290C

H0087291C

H0087292C

H0087293C

H0087294C

H0087295C

H0087296C

H0087297C

H0087340C

H0087341C

H0087342C

H0087343C

H0087344C

H0087345C

H0087346C

H0087347C

H0087300E

H0087301E

H0087302E

H0087303E

H0087304E

H0087305E

H0087306E

H0087307E

H0087350E

H0087351E

H0087352E

H0087353E

H0087354E

H0087355E

H0087356E

H0087357E

H0087310H

H0087311H

H0087312H

H0087313H

H0087314H

H0087315H

H0087316H

H0087317H

1956

CB16

4E46

C3F4

799D

33A8

3EE5

6478

1D20

64B7

4FAF

D4A1

7830

1EBB

C591

854A

4A5D

5B24

416A

C54D

8882

683D

D331

E525

4A68

5BD1

416A

C54D

8882

683D

D331

E525

4A2A

3680

403B

9F7C

8900

DB80

6C4A

1B91

4A35

372D

403B

9F7C

8900

DB80

6C4A

1B91

196E

CB4C

4E46

C3F4

799A

3385

3EE5

6478

41 7000L RICOH UK

31 6765 Infotec UK

42 7000L RICOH Italy

32 6765 Infotec Italy

43 7000L RICOH France

33 6765 Infotec France

44 7000L RICOH Europe/Asia

Page 58

T

H0087360H

H0087361H

H0087362H

H0087363H

H0087364H

H0087365H

H0087366H

H0087367H

1D38

64ED

4FAF

D4A1

782D

1E98

C591

854A