Page 1

PRINTER INTERFACE KIT

TYPE 60

SERVICE MANUAL

Page 2

This manual contains proprietary in formation that is protected by copyright.

No part of this publication may be rep rod uced in any form without the express

written consent of Ricoh Compan y Ltd .

The contents of th is ma nual are subject to change without notice.

Every effort has been made to ensure the accuracy of this manual. However,

Ricoh Compay Ltd. makes no expre ss or imp lied warranty of any kind in regard to the contents of the manua l, and can assume no liab ility fo r any erro rs

or their consequences.

T ra demark Notices

EPSON FX-850 is a trademark of Seiko Epso n Corp oration.

HP LaserJet III is a trad ema rk o f Hewle tt -Packard Company.

Hewlett-Pckard, PCL (Printer Control Language), and GL (Graphic

Language) are trademarks o f Hewle tt -Pa ckard Company.

LAYOUT is a trademark of Clan Systems.

IBM, IBM Proprinter XL2 4E , and IB M P erso na l Compu ter are trademarks of

International Business Machines Corporation.

Centronics is a trademark of Centronics Data Compu te r Corpo ration.

Page 3

Aug. 11, 1993 OVERALL INFORMATION

SPECIFICATIONS

11. OVERALL INFORMATION

1.1. SPECIFICATIONS

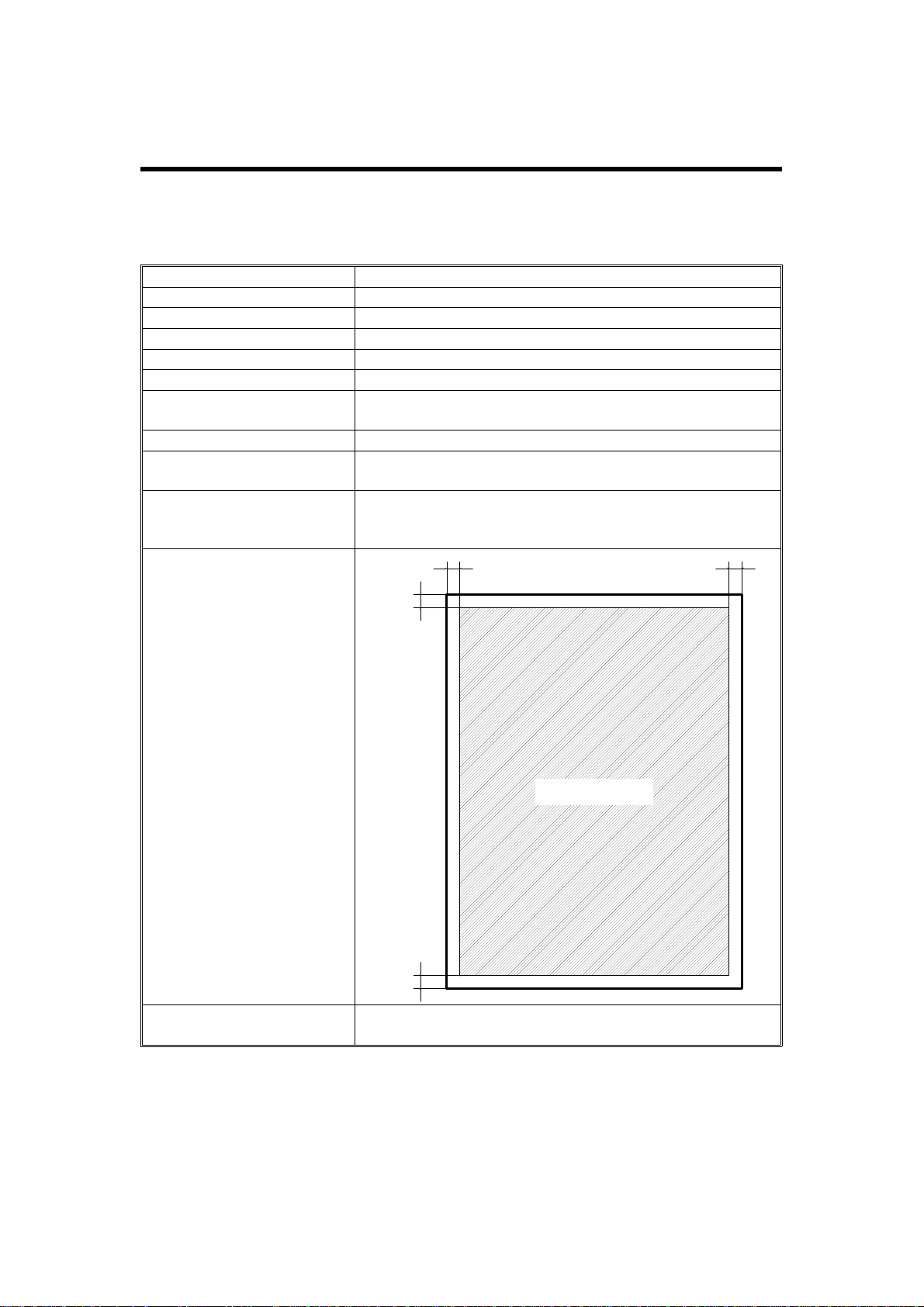

Items Specifications

Printing Resolution 300 dpi

Printing Speed 10 ppm (L T / A4 )

First Page Printout TIme Less than 20 s

Paper Size Letter, Legal, A4

Controller CPU 68000 (16.6 MHz)

RAM Capacity Standard - 1.0 MB

Upgradable to 5.0 MB with an optional memory board

ROM Font - 6.5 MB, Program - 0.5 MB

Host PC Interface 1 Serial Port - RS232C

1 Parallel Port - Centronics

Emulation Modes HP LaserJet III (PCL5)

EPSON LQ, FX (ESC/P)

IBM Proprinter

Printable Area

1/4 inch

(6.4 mm)

1/4 inch

(6.4 mm)

1/4 inch

(6.4 mm)

1/4 inch

(6.4 mm)

Others IC Card Slot - 1

Font Cartridge Slot - 1

Printable Area

1-1

Page 4

OVERALL INFORMATION Aug. 11, 1993

OVERALL SYSTEM CONTROL

1.2. OVERALL SYSTEM CONTROL

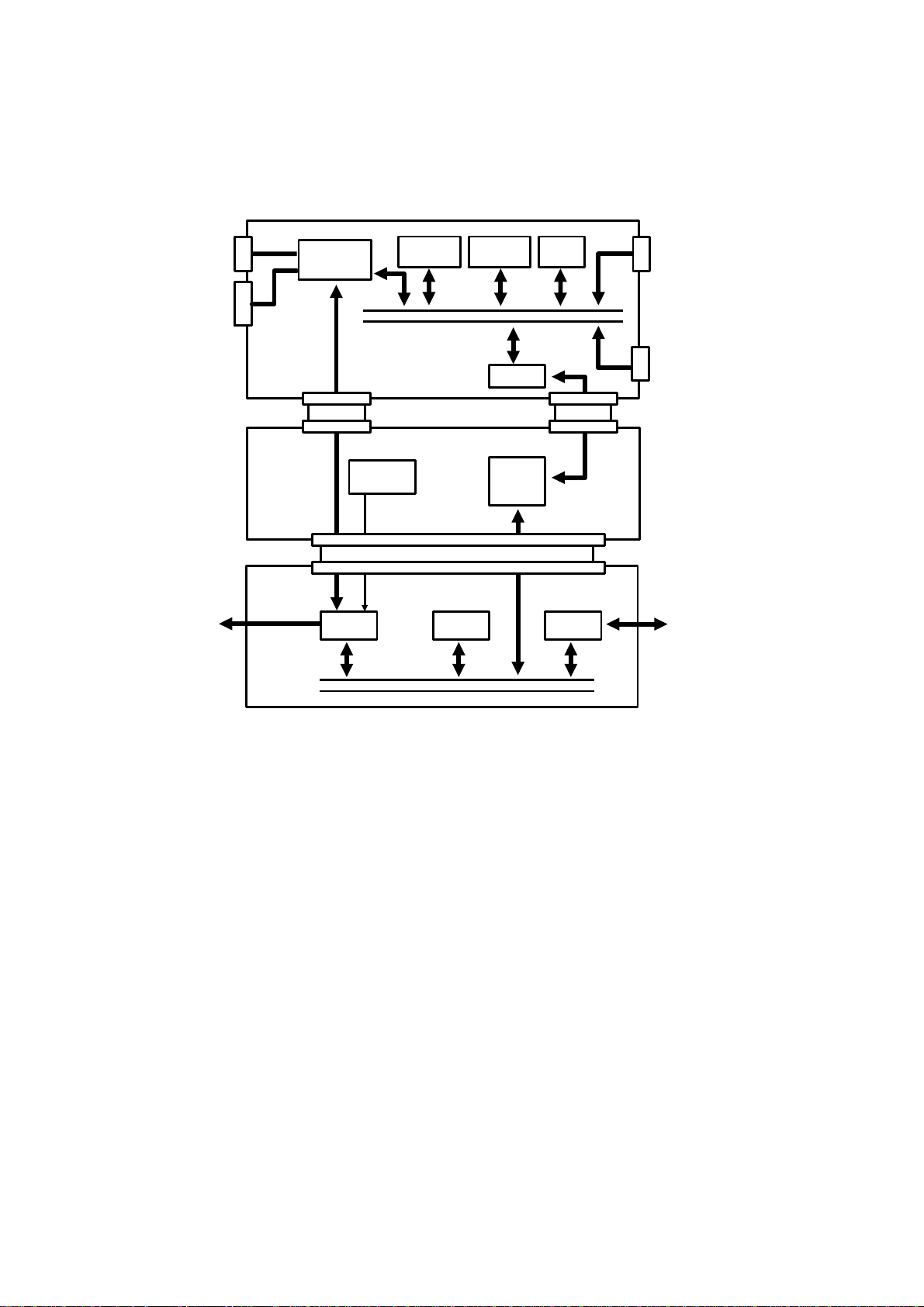

Serial I/F

Parallel I/F

To Printer

Mechanism

Printer Data I/F

Interface

Controller

LIF

Memory

Controller

Oscillator

24.1 MHz

ADDRESS/DATA BUS

Page

Optional

Memory

ADDRESS/DATA BUS

PIF

FCU

CPU

CPU

CPU

Font

ROM

LIOP

IC Card

Font Cartridge

LCD/LED Data

To/ From

Operation Panel

The printer interface kit consists of two PCB s, th e printe r cont rolle r board

(Controller) and the printer interface board (PIF).

1.2.1. Printer Data Path

Through the serial and/or parallel interfa ce(s), the Cont rolle r han dsh ake s wit h

the host(s) and receives print data, using one of the available emulation

modes. Then the CPU creates an imaginary page in the memory using the

fonts stored in the font ROM a nd th e f on t ca rtridge. After one page of print

data has been created, the Controller sends the video data through the video

interface to the LIF on the FCU for print ing . The PIF supplies the 24.1 MHz

clock signal to the LIF for 300 dpi printing.

1-2

Page 5

Aug. 11, 1993 OVERALL INFORMATION

POWER DISTRIBUTION

1.2.2. LCD/LED Data Path

The three LEDs on the operation panel are always dedicated to the Controller. They indicate the status during printing, and are directly co nt rolled by the

Controller.

In Printer Mode (Function 35), the LCD display and four one-touch dial keys

are dedicated to the Controller to access SelecTyp e functions. Within the SelecType functions, some settings are not ava ilable because of limitations to

the machine’s hardware. So, the CPU on the PIF monitors the functio n sta tus

and the settings to indicat e on the LCD, and mod ifies the data if necessary

(e.g., Half Letter size paper will not be displayed as a possible paper size ).

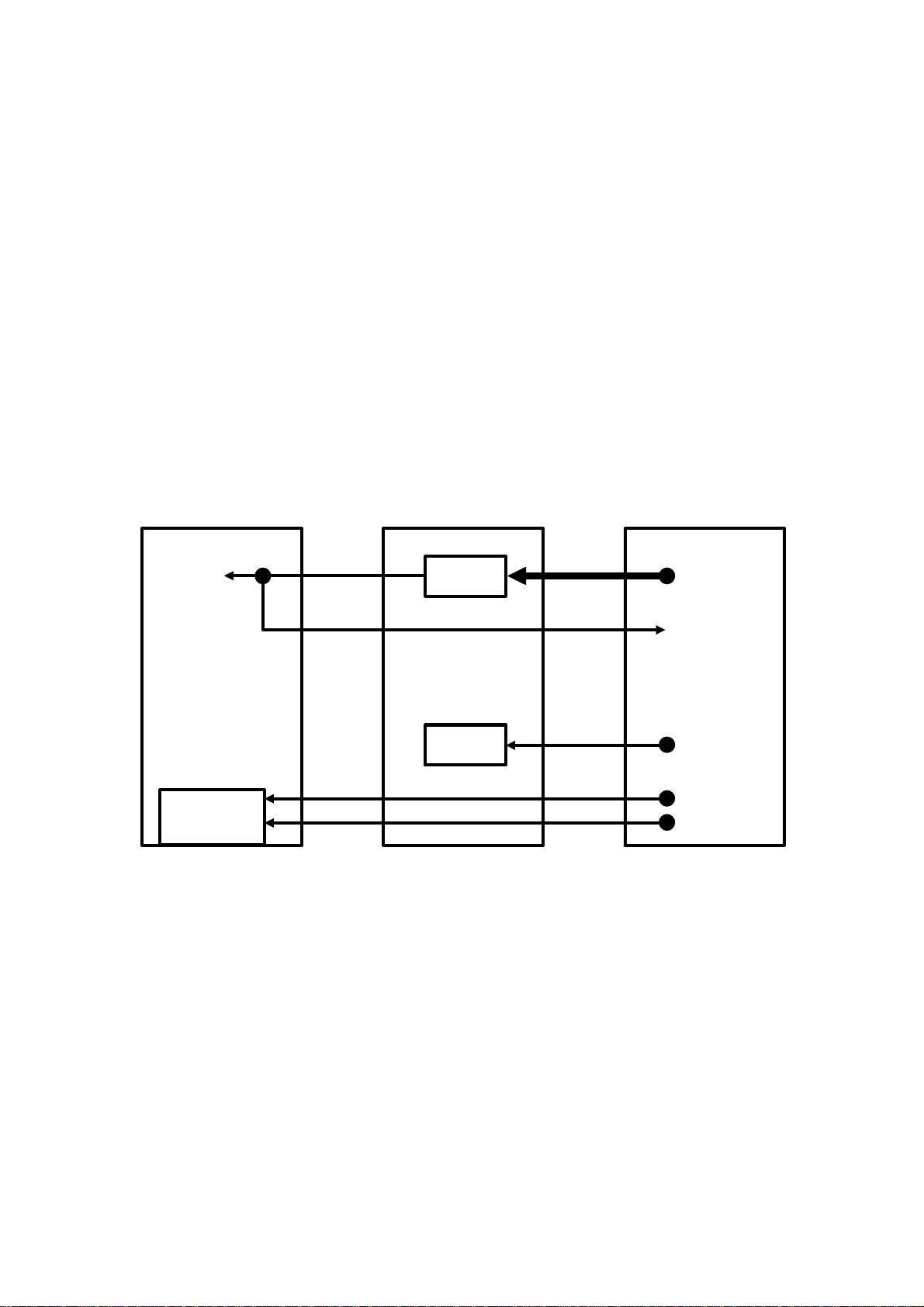

1.3. POWER DISTRIBUTI O N

Controller PIF FCU

To ICs

+5VD

DC/DC +24VS

+5VDMON

CPU +5V

+12V

Serial I/F

-12V

The PIF generates +5VD for the Controller. The +5VD line is returned to the

FCU as +5VDMON, so that the FCU can detect whether the printer inte rfa ce

is installed or not.

+5V for the PIF CPU, and ± 12V for the serial interfa ce on the Controlle r are

directly supplied by th e FCU.

1-3

Page 6

Aug 11th, 1993 DETAILED SECTION DESCRIPTIONS

INTERFACE SPECIFICATIONS

2. DETAILED SECTION DESCRIPTIONS

2.1. INTERFACE SPECIFICATIONS

2.1.1. Parallel Interface

1. Pin Assignments

The printer has an 8-bit parallel int erf ace. The pin assignments are as follows.

Signal

Pin

119

2 - 9 20 - 27 DATA1-8 IN Parallel data bits 1 to 8. A HIGH represents a ’1’.

10 28

11 29 BUSY OUT

12 30 PE OUT A HIGH indicates that the printer is out of paper.

13 - SLCOUT OUT Pulled up to 5 V through a 3.3 kΩ resistance.

14 -

16 - GND - Logic ground

17 - CH-GND - Printer’s chassis ground

19 - 30 - GND - Twisted pair return signal ground level

31 -

32 33 - GND - Logical ground

35 - + 5V - Pulled up to 5 V through a 3.3 kΩ resistance.

36 -

Return

Pin

Signal

STROBE IN

ACKNLG OUT

Autofeed IN

INIT IN

ERROR OUT

SLCIN in

Direct-

ion

Description

The strobe pulse from the host to read data in.

The received pulse width must be more than 0.5

µs. Normally HIGH; data reception starts when

the signal goes LOW.

A 10 µs pulse. LOW indicates that data has been

received and the printer is ready to receive more

data. This signal is output as a pair with BUSY.

A HIGH indicates that the printer cannot receive

data. The signal is high when data is entering,

when the printer is off line, and when there is a

printer error.

When LOW, paper is automatically fed when CR

is received (the active signal level can be

selected by a user adjustment). Sampling is

carried out when power is on or when the printer

is initialized at the operation panel.

When this goes low, the printer controller ignores

the STROBE signal.

This becomes low when the printer is out of

paper, off line, or in an error condition.

The DC1/DC3 control codes are valid only when

this signal is HIGH (SLCIN is OFF). This setting

can be changed with a user adjustment.

Sampling is only done when the power is on.

Pins 15, 18, and 34 are no t use d.

2-1

Page 7

DETAILED SECTION DESCRIPTIONS Aug 11th, 1993

INTERFACE SPECIFICATIONS

Notes: • All interface conditions are based on TTL level. Both the rise and

fall of each signal must be less than 0. 2 µs.

• Data transfer must be carried out by observing the ACKNLG or

BUSY signal. (Data transfer to the printer can be carried out only

after the receipt of the ACKNLG signal or when BUSY is LOW.)

• The "Direction" column refers to the direction of sign al flo w as

viewed from the printer.

• "Return Pin" denotes the twisted-pair return to be conn ect ed at sig-

nal ground level. For the int erf ace wirin g, a twiste d-p air cable

should be used for each signal an d the connection should be completed on the return side. These cables should be shielded and

connected to th e cha ssis o f th e ho st computer and the printer.

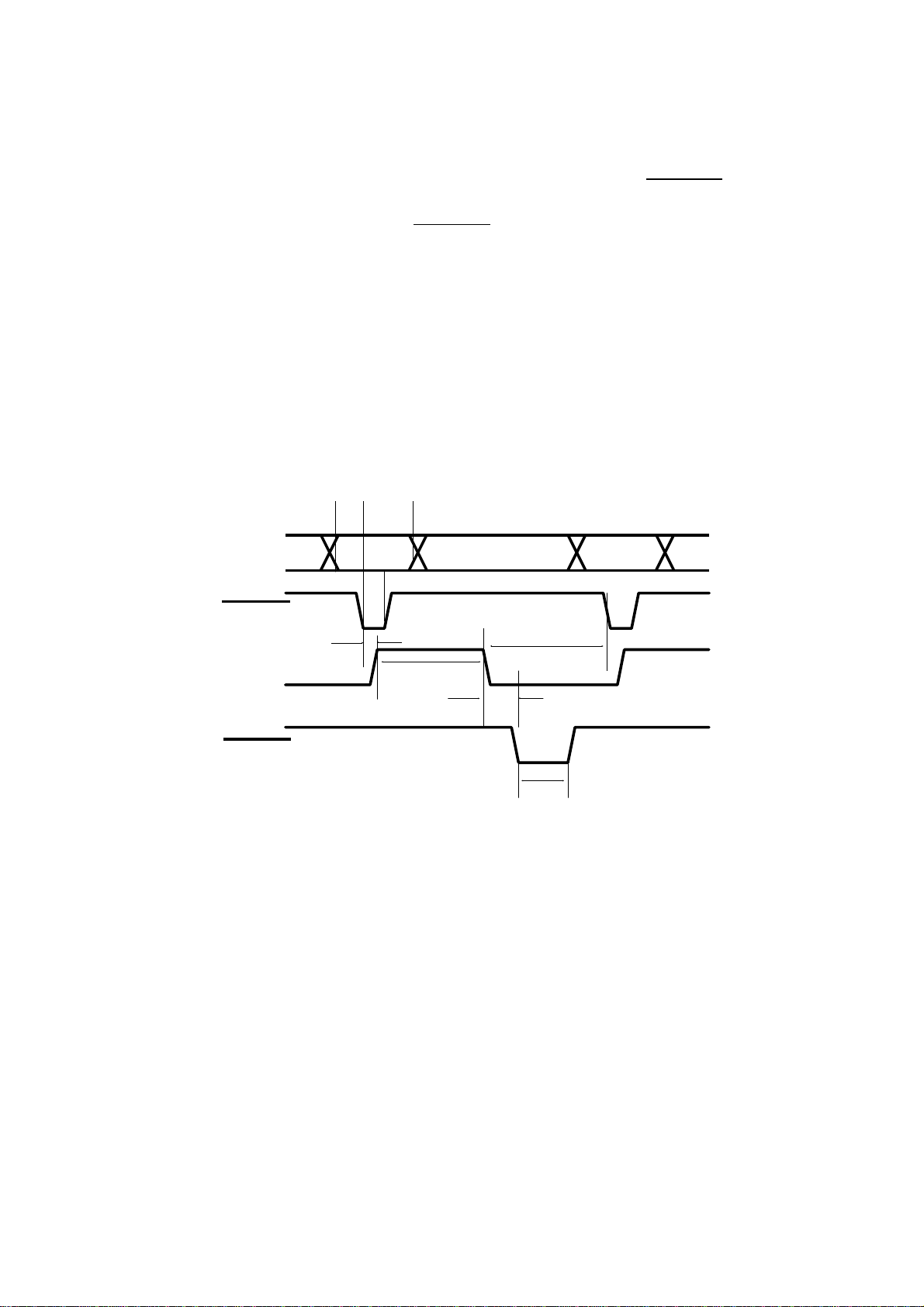

2. Interface Timing

The following diagram shows the timing for the parallel interface.

AB

DATA 1-8

VALID VALID

A

STROBE

C

BUSY

ACKNLG

A: 0.2 microseconds minimum

B: 0.1 microseconds minimum

C: 0.15 microseconds maximum (normally 0.12)

D: 0.3 microseconds minimum (normally 0.5)

E: 0.07 microseconds maximum (normally 0.03)

F: 1 to 2 microseconds (normally 1.7)

G: Always at least zero

Signal Level: TTL Compatible

G

D

E

F

2-2

Page 8

Aug 11th, 1993 DETAILED SECTION DESCRIPTIONS

INTERFACE SPECIFICATIONS

2.1.2. Serial Interface

1. Data Format

Word Length: 7 or 8 bits

Parity: None, odd, or even

Stop Bits: 1 or 2

Printer Ready Protocol: Enabled (DTR and XON/XOFF protocol set to ON)

The data format settings can be adjusted by user level features.

Baud Rate: 300, 600, 1200, 2400, 4800, 96 00, 19200 bps

Signal Level: RS-2 32C; conforms to EIA

Connector: D-sub 25-pin connector

2. Pin Assignments

The serial interface pin assign ments are described below. The d irect ion of the

signal is given relative to the prin te r.

Signal

Pin

1 FG - Connected to the printer chassis.

2 TXD OUT Serial data from printer to computer.

3 RXD IN Serial data from computer to printer.

4 RTS OUT Request To Send. Held HIGH by the printer.

5CTSIN

6 DSR IN

7 SG - Signal Ground. Provides a ground for all signal lines.

20 DTR OUT

Signal

Direct-

ion

Description

Clear To Send. The computer is ready to receive from

the printer. The printer will not proceed unless the

signal is HIGH. The active signal level can be changed

with a user adjustment.

Data Set Ready. The computer is ready to receive from

the printer. The active signal level can be changed with

a user adjustment.

Data Terminal Ready. Indicates whether the printer is

ready to receive data. If the printer ready protocol is not

selected, DTR is always HIGH (always ready to

receive). If printer ready protocol is selected, the printer

can only accept data when DTR is HIGH. When DTR

goes LOW, the computer must stop sending data within

128 characters. The active signal level can be changed

with a user adjustment.

2-3

Page 9

DETAILED SECTION DESCRIPTIONS Aug 11th, 1993

INTERFACE SPECIFICATIONS

3. Handshaking

The serial interface can use DTR signal le vels and XON/XOFF communication protocols either separately or in combination.

XON/XOFF Protocol

When the vacant area for data in the input buffer drops to 128 bytes, the

printer outputs an XOFF code, ind icating that the printer cannot receive more

data. Once the va can t area for data in the buffer recovers to 256 bytes, the

printer outputs an XON code, ind icating that the printer is again ready to receive data. XON/XOFF protocol can be selected with a user adjustment. The

factory setting is ENABLE D.

DTR/DSR Protocol

When the printer can receive data, the printer sets DTR to HIGH. When the

printer cannot receive data , it sets DTR to LOW. If the user’s DTR on/off adjustment is set to OFF, the DTR signal is always treated as HIGH. Th e p rint er

sends data on TXD only when DSR is HIGH, unless the user’s DSR on/of f adjustment is set to OFF, in which case the DSR signal is always treated as

HIGH.

2-4

Page 10

Aug 11th, 1993 DETAILED SECTION DESCRIPTIONS

INTERFACE SPECIFICATIONS

2.1.32.1.3. Printer Data Interface

1. 1. Signals

Name Description

VSREQ(X)

HSYNC(X) Clock signal to synchronize each line of image data.

VIDEO(X) Raster data for printing.

WCLK(X) Clock signal to synchronize raster data.

CPRDY(X) Inactive (high) when initializing or resetting the printer mechamism.

PRINT(X) Active (low) before transferring one page of image data to the FCU.

PRRDY(X)

CTBSY(X) Active (low) while the controller is sending a command to the FCU.

ETBSY(X) Active (low) while the FCU is sending status data to the controller.

CMD(X) Command data (8 bit serial).

STS(X) Status data (8 bit serial).

SRCLK(X) Clock signal to synchronize commands and status data.

Active (low) while the controller transfers one page of image data to the

FCU.

Active (low) while the printer mechanism is in standby status. Inactive

(high) while the printer is busy or has a problem.

Signal Directions

Controller PIF FCU

VSREQX

HSYNCX

VIDEOX

WCLKX

CPRDYX

PRINTX

PRRDYX

CTBSYX

ETBSYX

CMDX

STSX

SRCLKX

VSREQ

HSYNC

VIDEO

WCLK

CPRDY

PRINT

PRRDY

CTBSY

ETBSY

CMD

STS

SRCLK

Printer I/F Unit FAX Unit

2-5

Page 11

DETAILED SECTION DESCRIPTIONS Aug 11th, 1993

INTERFACE SPECIFICATIONS

2.2. Power-On Timing

CPRDY(X)

High

Low

Power On

Don’t

Care

1.5s (min.)

Communication

Impossible

0.5s

(min.)

2.5s (min.)

Initializing

Communication

Possible

When the power is switched on, the controller raises CPRDY(X) to high for

more than 0.5 s, then initializes it self with in 2 .5 s. A ft er in itializing is completed, the controller will be rea dy to commun icat e with the host PC(s) and

the FCU.

3.3. Reset Timing

CPRDY(X)

High

Low

Reset

0.5s (min.)

Communication

Impossible

2.5s (min.)

Initializing

Communication

Possible

When the user resets the prin ter using function 35, the controller activat es

CPRDY(X) for more than 0.5 s, then the controller initia lizes itself and the

printing process is canceled . A ft er initializing is completed, the controller will

be ready to communicate with the host PC(s) and the FCU.

2-6

Page 12

Aug 11th, 1993 DETAILED SECTION DESCRIPTIONS

INTERFACE SPECIFICATIONS

4.4. Image Data Synchronization (Horizontal)

HSYNC(X)

H

L

8 x WCLK(X)

VIDEO(X)

H

L

1 line of print data

8 x WCLK(X)

2550 x WCLK(X)

WCLK(X)

H

L

The FCU drops HSYNC(X) to low for eight WCLK(X) clock cycles befo re receiving each line of image data. Then, after the next eight cycles of WCLK(X)

has passed, the contro ller starts to transfer one line of image data.

The frequency of the WCLK(X) clock is between 1.3 MHz and 1.96 MHz.

HSYNC(X)

H

L

VIDEO(X)

1/4 inch

(6.4 mm)

Printable Area

1/4 inch

(6.4 mm)

2-7

Page 13

DETAILED SECTION DESCRIPTIONS Aug 11th, 1993

INTERFACE SPECIFICATIONS

5.5. Image Data Synchronization (Vertical)

PRINT(X)

H

L

VSREQ(X)

T3

H

L

VIDEO(X)

H

1st Page 2nd Page

L

T1 T2

PRINT(X)

Monitor Timing

The FCU monitors the PRINT(X) sign al fro m t he controller every 2 ms to detect if a print reque st is co ming from the controller or not. After T1 ha s passed

since the FCU detected the PRINT(X) signal to be active, the FCU drop s

VSREQ(X) to low so that the controller can acknowledge that the printer is

ready to receive one page of image data. After one page of data h as b ee n re ceived from the controller, the FCU inactivates the VSREQ(X) signal until

PRINT(X) is activate d again for printing the next page.

The times T1, T2 and T3 vary depen ding on the following conditions.

Parameter Time Condition

T1

Parameter Paper Size Time

T2

T3

1.0 s When the hexagonal mirror motor is active.

6.0 s When the hexagonal mirror motor is inactive.

Letter 8.5 s

Legal 10.6 s

A4 9.0 s

Letter 7.58 s

Legal 9.64 s

A4 8.06 s

2-8

Page 14

Aug 11th, 1993 DETAILED SECTION DESCRIPTIONS

INTERFACE SPECIFICATIONS

6.6. Command / Status Signal Timing

CTBSY(X)

ETBSY(X)

CMD(X)

STS(X)

SRCLK(X)

(153.6 kHz)

H

L

H

L

H

L

T3

T1

T2

T4 T5 T6

T7

STS informs the controller of stat us inf ormation, such as the current paper

size and any mechanical problems tha t are enco untered.

The FCU informs the controller of the printer status (STS ) in an 8 bit serial format, in response to a command (CMD) fro m the cont rolle r. If a status signal

(STS) is not received within T5 (100 ms) after the controller sends a command, the controller will resend the command to the FCU.

Refer to the above diagram and to the following table be low for t he timing .

Parameter Time

T1 62.7 µs

T2 Less than 30 ms

T3 9.77 µs

T4 4.07 µs

T5 Less than 100 ms

T6 9.77 - 10.58 µs

2-9

Page 15

Aug. 11, 1993 INSTALLATION

PRINTER INTERFACE UNIT

3. INSTALLATION

Throughout this chapter, the machine types are referred to as model codes H510 and H511.

This installation must only be done by qualified service personnel.

Note: The H510 does not have a monitor speaker.

Ignore the steps regarding the monitor speaker.

3.1. PRINTER INTERFACE UNIT

1. First, print any messages still stored in the SAF.

2. Turn off the power, and unplug the machine from the wall socket.

3. Slide out the cassettes.

4. Take off the rear cover [A] and disconnect the monitor speaker [B].

[A]

5. If a memory card [C] is installed, remove it.

[C]

[B]

3-1

Page 16

INSTALLATION Aug. 11, 1993

PRINTER INTERFACE UNIT

6. Take off the monitor speaker [D] from the rear cover.

7. Attach the monitor speaker [E] to the printer interface unit [F].

Then reconnect the monitor speaker [G].

[F]

[D]

[E]

3-2

[G]

Page 17

Aug. 11, 1993 INSTALLATION

PRINTER INTERFACE UNIT

8. Hold the printer interface unit [H] near the machine with one hand, and plug the flat cable

[ I ] into the connector on the FCU board.

[ I ]

[H]

9. Attach the printer interface unit [J].

[J]

3-3

Page 18

INSTALLATION Aug. 11, 1993

PRINTER INTERFACE UNIT

10. Remove the memory option cover [K].

1 1. Attach the memory card guide [L]. Then install the memory card if necessary.

[L]

[K]

Caution: To avoid damaging the memo ry card, always remove the mem-

ory card first before removing the printer interface unit.

12. Put back the memory option cover.

13. Put back the cassettes.

14. Plug in the machine, then turn on the power.

3-4

Page 19

[N]

[M]

Aug. 11, 1993 INSTALLATION

MEMORY EXPANSION BOARD (OPTIONAL)

3.2. MEMORY EXPANSION BOARD (OPTIONAL)

1. Print any messages still stored in the SAF.

2. Turn off the power and unplug the machine from the wall socket.

3. Remove the memory option cover [M] and the memory board cover [N].

4. Insert the memory expansion board [O].

5. Put back the memory board cover [P] and the memory option cover [Q].

6. Plug in the machine, then turn on the power.

[P]

[O]

[Q]

Caution:

Do not plug in or switch on until everything is connected up.

3-5

Page 20

Aug. 11, 1993 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNCTIONS

4.4. SERVICE TABLES AND PROCEDURES

4.1.4.1. SERVICE LE VE L FUNCTIONS

There are no special service operations. Refer to the operation manual for all

printer operation proced ure s.

4.2.4.2. SERVICE RAM ADDRESSES

4B8B

Data wait time after the last page has been printed, when print ing from th e

printer interface. (Hex; unit 2.56 s)

4-1

Page 21

Aug. 11, 1993 TROUBLESHOOTING

ERROR CODES

5. TROUBLESHOOTING

5.1. ERROR CODES

The following error messag es may appe ar on the screen while the printer interface is in operation.

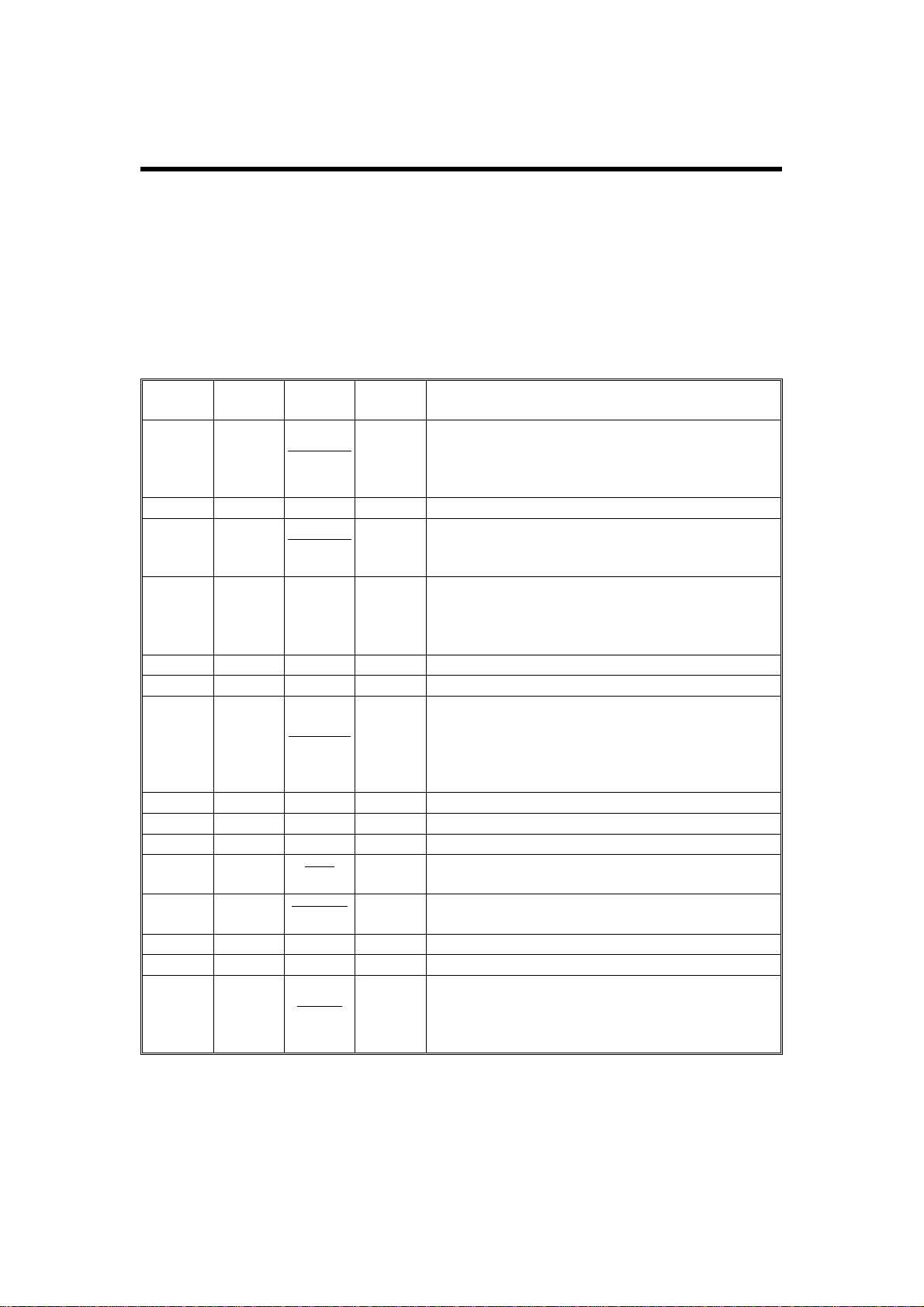

Code Cause Required Action

C0002 Bus error Switch the printer off, wait a

C0003 Address error

C0004 Illegal instruction

C0005 Division by zero

C0006 CHK instruction executio n

C0007 TRAPV instruction execu tion

C0008 Privilege violation

C0009 Tr a ce mode execution

C0010 Implemented instruction

C0011 Implemented instruction

C0015 Unitialized interrupt

C0024 Spurious interrupt

C1110 ROM error (0 - 80 KH)

C1130 ROM error (100 - 180 KH)

C1140 ROM error (100 - 200 KH)

C1200 EEPROM write error

C1300 No ready task

C1310 Re-generation of existing task

C1400 Auto vector interrupt level 7

C9999 Undefined are a ema ncipation

few seconds, and switch back

on. If the error occurs again,

change the FCU or the printer

interface board.

5-1

Page 22

Aug. 11, 1993 PARTS CATALOG

PARTS LAYOUT

66. PARTS CATALOG

6.1. PARTS LAYOUT

100

1

100

3

2

101

13

101

12

14

101

5

100

6

7

8

3

4

11

10

101

101

9

102

10

6-1

Page 23

PARTS CATALOG Aug. 11, 1993

PARTS LIST

6.2. PARTS LIST

Index Part Number Description

1 H5105321 Flat Cable: PIF - FCU

2 H5106005 PCB: CNT: USA

3 H1443167 Stud - PIF

4 H5105610 PCB: PIF: USA

5 H5105320 Flat Cable: PIF-CNT: USA

6 G0111250 Screw: Con: NA: M

7 H1443168 Cover - Option Memory Board

9 H1444146 Guide - Option Memory Card

10 H0814141 Screw - Handset

11 H1444145 Rear Cover - Memory - PIF

12 H1444111 Rear Cover - Printer Option

13 H1444144 Cover - RS232C

14 H1444140 Cover - Left - PIF: USA

* H1444141 Cover - Cartridge

* H1444128 Spring - Cover Cartridge

100 09513006B Philips Screw with Flat Washer - M3 x 6

101 03530060Z Philips Truss Head Screw - M3 x 6

102 09513010B Philips Screw with Flat Washer - M3 x 10

* H1444301 Operator’s Manual

* 09653008B Tapping Screw - M3 x 6

6-2

Loading...

Loading...