Page 1

Technical Bulletin No.CGO-001

SUBJECT: Service Manual Correction

PREPARED BY: H.Yokoyama

CHECKED BY: S.Hamano

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

Following pages have been corrected.

Page: 2-18, 19

6-1~28

A floppy disk with corrected pages except page 2-18 and 19, is enclosed.

FROM: 2nd T.S. Section

MODEL:

FAX5600L

DATE:

Sep. 14, 1994

Page 2

TROUBLESHOOTING 1st August, 1994

COPY QUALITY TROUBLESHOOTING

6. TROUBLESHOOTING

6.1. COPY QUALITY TROUBLESHOOTING

If there is a copy quality problem that cannot be solved easily, try using the

following troubleshooting flow chart, while referring to the point-to-point diagram. The flow chart may not be exhaustive, but it may help you to find the

problem.

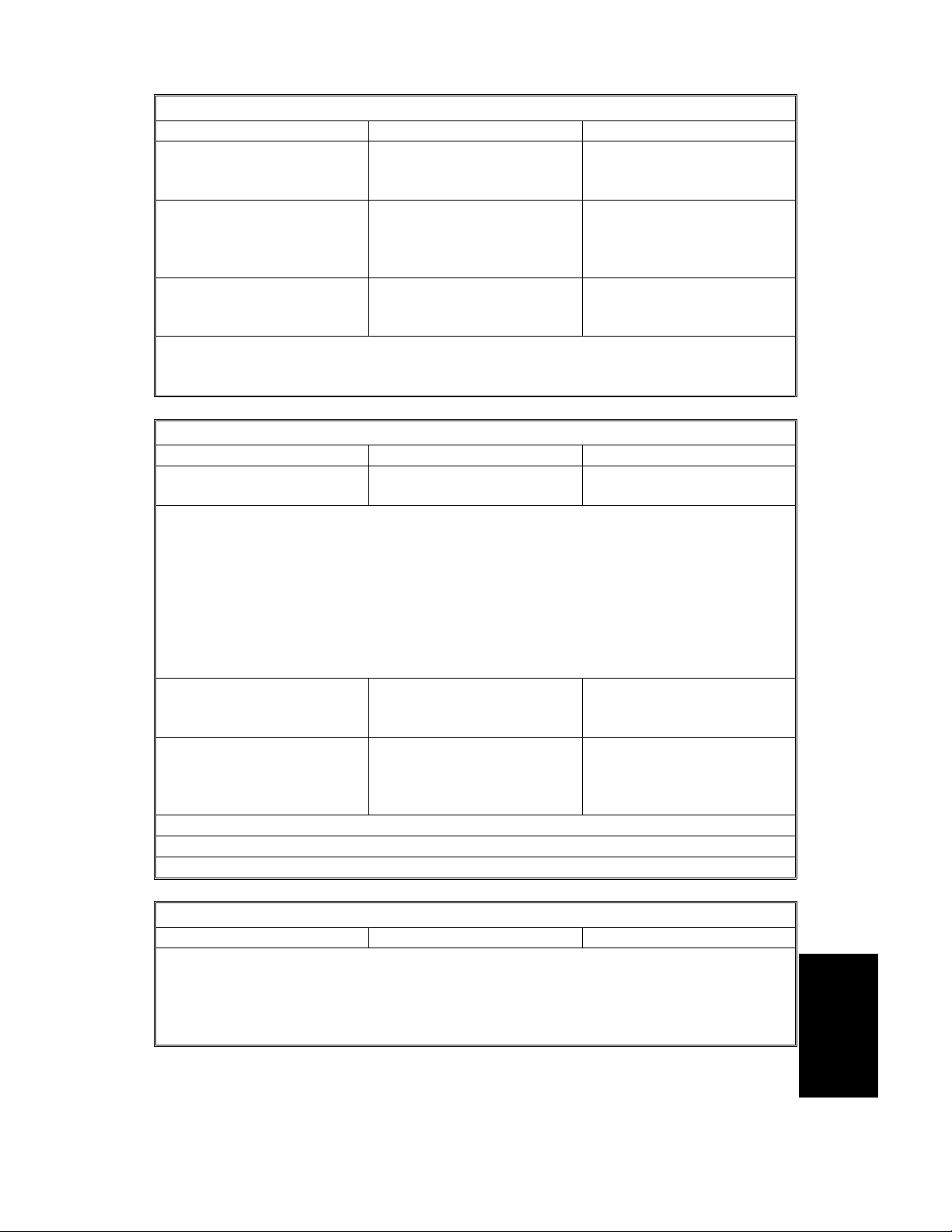

Symptom: Blank copies

Check Action if Yes Action if No

1. Make a printer test (see

section 4-1-13). Is it OK?

2. Is the master installed correctly?

3. Does the master rotate

correctly during the copy

cycle?

4. Is the master grounded

properly?

5. Are any of the laser optical components broken,

blocked, or misaligned?

6. Are the transfer corona

unit and wire correctly installed?

7. Does the FCU output the

power and corona trigger

signal to the power pack?

8. Does the problem go

away if you change the

power pack?

9. Does the development

bias terminal reach the

correct voltage

(about -530 Vdc)?

10. Does the FCU output the

power and bias trigger

signal to the power pack?

11. Does the problem go

away if you change the

power pack?

12. Does the development

roller attract toner?

There may be a scanner

problem; go to step 15.

Go to step 3. Install it properly.

Go to step 4. Correct any problems with

Go to step 5. Check the grounding wire,

Correct the problem. Go to step 6.

Check the connections

between the corona wire

and the FCU. Go to step 7.

Clean the transfer corona

unit. Go to step 8.

Finished. Go to step 9.

Go to step 12. Go to step 10. Do not adjust

Clean the area around the

bias terminal. Go to step 11.

Finished. Clean the development

Check all LDDR - FCU interlock switch

connections. Go to step 13.

Go to step 2.

the mechanism.

terminals and plates. Clean

or replace if necessary.

Correct the problem.

Change the FCU.

the variable resistors on the

power pack.

Change the FCU.

roller. Go to step 12.

Replace the roller.

6-1

Troubleshooting

Page 3

1st August, 1994 TROUBLESHOOTING

COPY QUALITY TROUBLESHOOTING

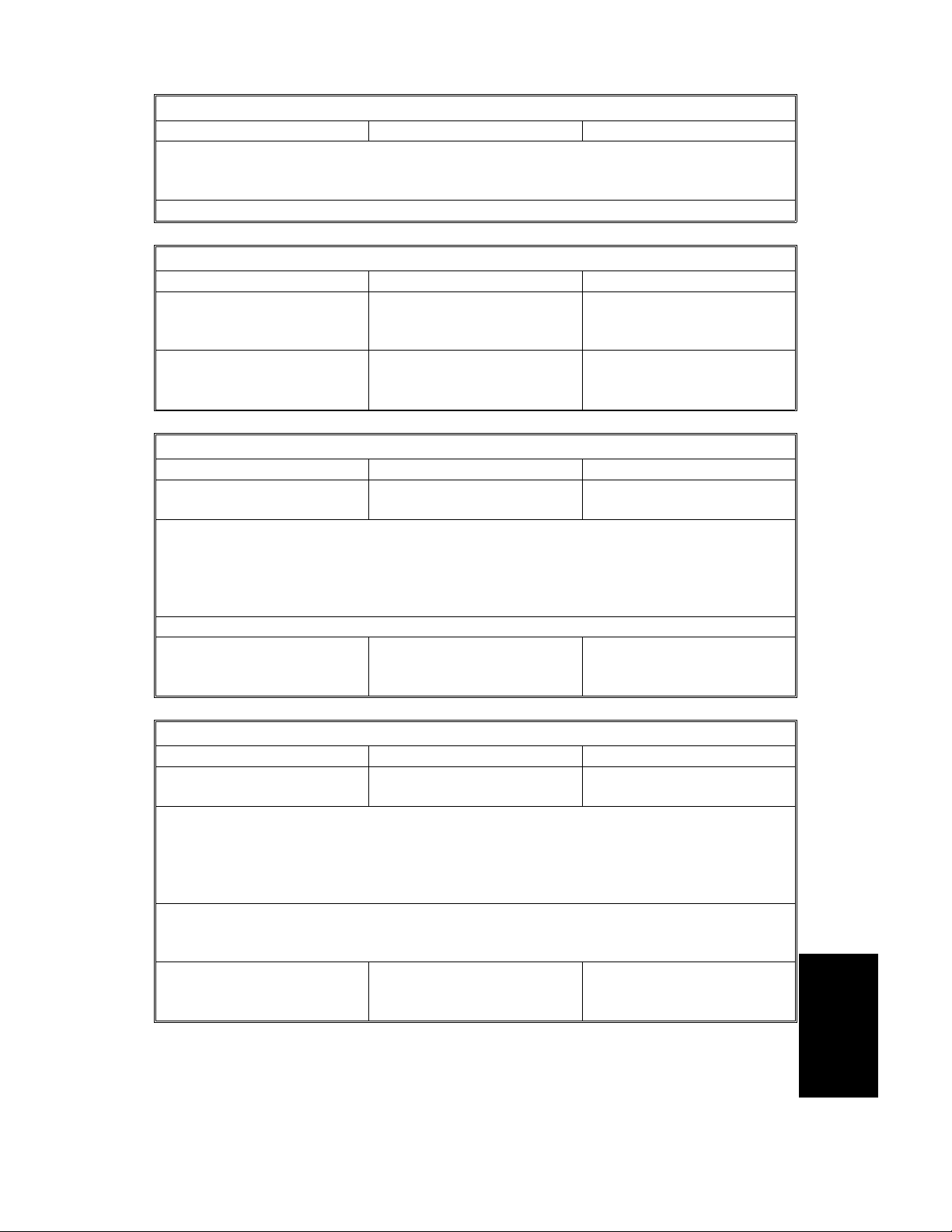

Symptom: Blank copies

Check Action if Yes Action if No

13. Is the laser diode unit

screwed in properly?

14. Do the interlock switches

close when the cover is

closed, and do they pass

power to the LDDR?

15. Check the FCU - SBU

connection. Is there a

signal from the SBU

(AVIDEO)?

16. Does the problem only

occur when printing from

memory?

17. If the problem only occurs during communication, check the FCU - NCU - line

connections. Check for severe line problems. If the problem cannot be found, replace

the NCU or FCU.

Go to step 14. Install it properly.

Change the LD unit, FCU,

master unit, or varistor.

Go to step 16. Light the xenon lamp. Align

Check the connection to the

memory card. Change the

memory card, FCU, or MBU.

Change them.

the SBU (see section 5-2-9);

replace the FCU or SBU if

impossible.

Go to step 17.

Symptom: Black copies

Check Action if Yes Action if No

1. Make a printer test (see

section 4-1-13). Is it OK?

2. Are the charge corona

unit and wire correctly

installed?

3. Does the FCU output the

power and corona trigger

signal to the power pack?

4. Does the problem go

away if you change the

power pack?

5. Is the varistor shorted? Change the varistor. Go to step 6.

6. Is the master grounded

properly?

7. Does the development

bias terminal reach the

correct voltage

(about -530 Vdc)?

8. Does the FCU output the

power and bias trigger

signal to the power pack?

9. Does the problem go

away if you change the

power pack?

10. Check the connections

from the FCU to the

xenon lamp. Does the

lamp work?

There may be a scanner

problem; go to step 10.

Check the connections

between the corona wire

and the FCU. Go to step 3.

Clean the charge corona

unit. Go to step 4.

Finished. Go to step 5.

Go to step 7. Check the grounding wire,

Go to step 10. Go to step 8. Do not adjust

Clean the area around the

bias terminal. Go to step 9.

The laser beam may always

be on. Change the FCU or

LD unit.

Go to step 12. Go to step 11.

Go to step 2.

Correct the problem.

Change the FCU.

terminal and plate. Clean or

replace if necessary.

the variable resistors on the

power pack.

Change the FCU.

Clean the development

roller. Go to step 10.

6-2

Page 4

TROUBLESHOOTING 1st August, 1994

COPY QUALITY TROUBLESHOOTING

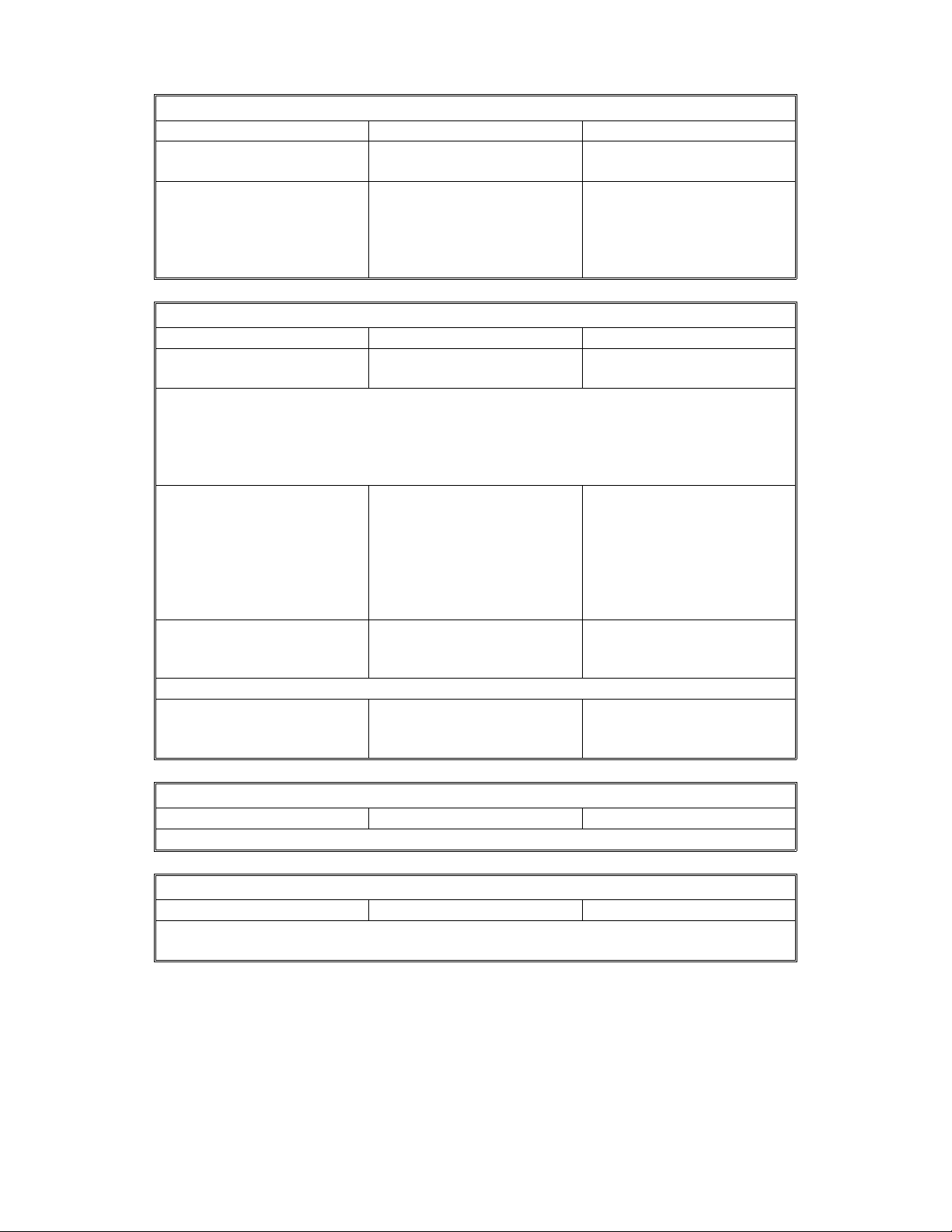

Symptom: Black copies

Check Action if Yes Action if No

11. Does the FCU output the

power and drive signals

to the lamp driver?

12. Check the FCU - SBU

connection. Is there a

signal from the SBU

(AVIDEO)?

13. Does the problem only

occur when printing from

memory?

14. If the problem only occurs during communication, check the FCU - NCU - line

connections. Check for severe line problems. If the problem cannot be found, replace

the NCU or FCU.

Change the xenon lamp or

the drive board.

Go to step 13. Light the xenon lamp. Align

Check the connection to the

memory card. Change the

memory card, FCU, or MBU.

Change the FCU.

the SBU (see section 5-2-9);

replace the FCU or SBU if

impossible.

Go to step 14.

Symptom: Faint copy

Check Action if Yes Action if No

1. Make a printer test (see

section 4-1-13). Is it OK?

2. Try the following steps (a to f) to solve the problem. If they fail, check the connections

through the machine between the FCU, toner near-end sensor, and toner supply motor.

Then go to step 3.

a) Replace the master.

b) If the Add Toner indicator is lit, add toner.

c) Clean or replace the corona wires.

d) Clean the toner metering blade (soft cloth and alcohol).

e) If the copy paper is damp, replace it.

f) If the toner contains dirt or paper particles, replace it.

3. Has the toner run out

even though the Add

Toner indicator is not lit?

4. Does the toner supply

motor turn just after the

main power is switched

on?

5. Work through steps 4 to 12 of "Blank copies".

6. Change the varistor, FCU, or LD unit .

7. Clean the exposure glass and the white plate in the scanner.

There may be a scanner

problem; go to step 7.

Check the sensor actuator

mechanism. Change the

sensor if necessary.

Go to step 5. Change the toner supply

Go to step 2.

Go to step 4.

motor or the FCU.

Symptom: Faint copy at leading or trailing edge

Check Action if Yes Action if No

The paper in the cassette may be curled at the leading edge

The paper in the cassette may be damp.

The paper may be too thick or too thin.

Instruct the user how to store paper, and instruct them to use recommended types and

weights of copy paper.

6-3

Troubleshooting

Page 5

1st August, 1994 TROUBLESHOOTING

COPY QUALITY TROUBLESHOOTING

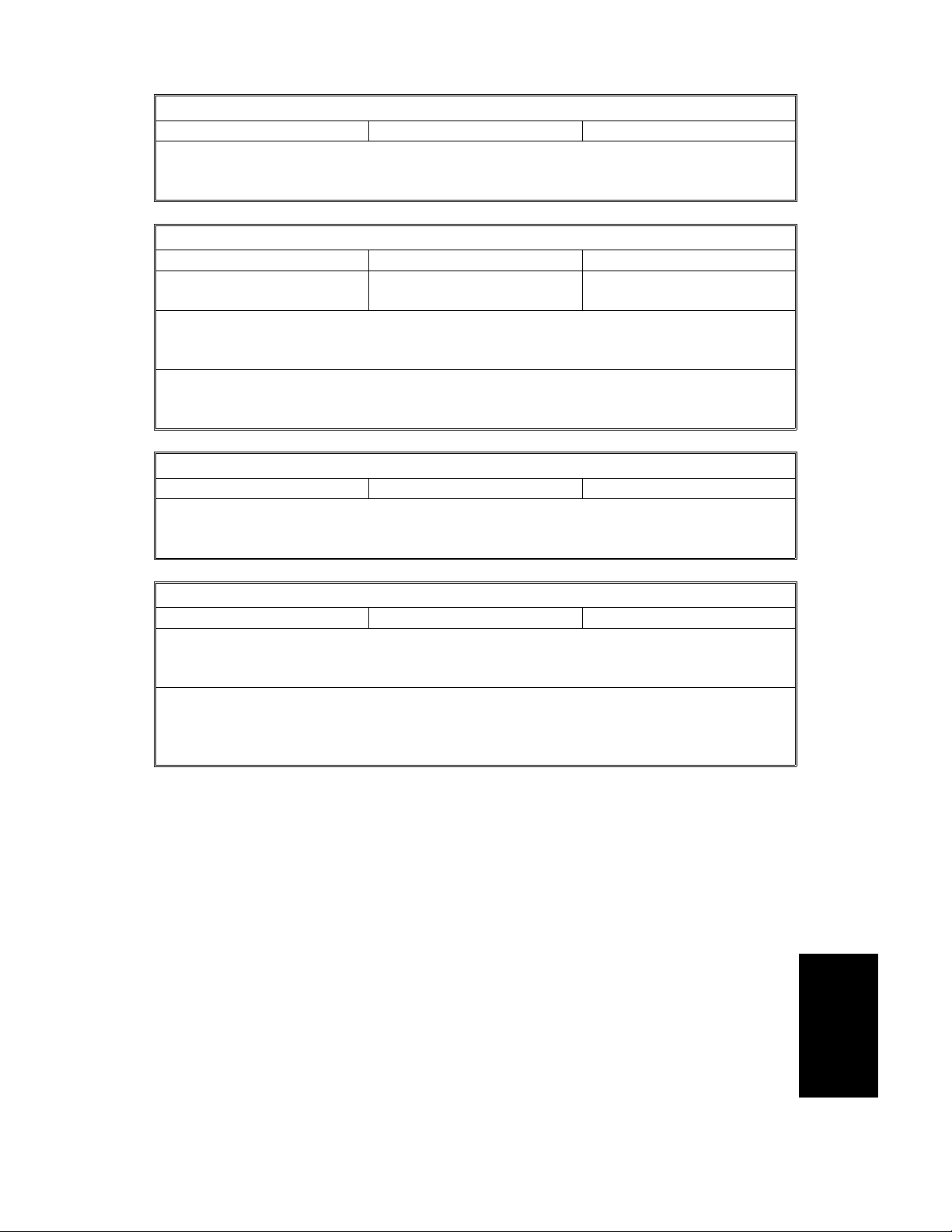

Symptom: Dirty background all over the copy

Check Action if Yes Action if No

1. Make a printer test (see

section 4-1-13). Is it OK?

2. Try the following steps (a to f) to solve the problem. If they fail, go to step 3.

a) Clean the quenching lamp and cleaning blade.

b) Tighten the toner metering blade securing screws (see section 5-6-2).

c) If the toner contains dust or paper particles, change the CTM.

d) Clean the area around the bias terminal of the development unit.

e) If the pattern is constant down the page, clean the laser optics with a blower brush, or

clean or replace the corona wires.

3. Is the master grounded

properly?

4. Is the varistor shorted? Change the varistor. Go to step 5.

5. Does the development

bias terminal give a

constant correct voltage

(about -530 Vdc)?

6. Does the FCU output

constant power and bias

trigger signals to the

power pack?

7. Does the problem go

away if you change the

power pack?

8. Are the charge corona

unit and wire correctly

installed?

9. Does the FCU output

constant power and

corona trigger signals to

the power pack?

10. Does the problem go

away if you change the

power pack?

11. Does the quenching lamp

operate correctly?

12. Does the FCU send

constant power and drive

signals to the lamp?

13. Try replacing the master unit.

14. Clean the scanner optics, exposure glass, and white plate.

Check the SBU white waveform for peaks, dropouts, or noise in the signal. Change the

SBU or FCU if such wave patterns are present.

Adjust the RAM addresses containing contrast threshold levels.

There may be a scanner

problem; go to step 13.

Go to step 4. Check the grounding wire,

Go to step 8. Go to step 6. Do not adjust

Clean the area around the

bias terminal. Go to step 7.

Finished. Go to step 8.

Check the connections

between the corona wire

and the FCU. Go to step 9.

Clean the charge corona

unit. Go to step 10.

Finished. Go to step 11.

Go to step 13. Check the connections

Replace the quenching

lamp.

Go to step 2.

terminals and plates. Clean

or replace if necessary.

the variable resistors on the

power pack.

Change the FCU.

Correct the problem.

Change the FCU.

between the FCU and lamp.

Go to step 12.

Replace the FCU.

6-4

Page 6

TROUBLESHOOTING 1st August, 1994

COPY QUALITY TROUBLESHOOTING

Symptom: Stray toner flecks fused into the copy

Check Action if Yes Action if No

1. Clean the inside of the machine, especially around the development and transfer unit.

Clean the cleaning blade.

Clean the rollers in the fusing unit.

2. Replace the master unit or CTM.

Symptom: Previous copy shows faintly

Check Action if Yes Action if No

1. Does the quenching lamp

operate correctly?

2. Does the FCU send

constant power and drive

signals to the lamp?

Clean or replace the master. Check the connections

between the FCU and lamp.

Go to step 2.

Replace the quenching

lamp.

Replace the FCU.

Symptom: Density changes gradually across the printout

Check Action if Yes Action if No

1. Make a printer test (see

section 4-1-13). Is it OK?

2. Check that the charge corona wire is clean and that it is installed correctly.

Check that none of the laser optic components are out of position.

Check that toner is being distributed evenly across the development unit. If it is not,

change the CTM, development unit, or toner supply motor.

Try changing the master unit, quenching lamp, or the charge corona wire.

3. The xenon lamp may need to be changed.

4. Is the SBU scan line

alignment is correct (see

section 5-2-9)?

There may be a scanner

problem; go to step 3.

Change the FCU. Change the SBU.

Go to step 2.

Symptom: Uneven density in vertical bands

Check Action if Yes Action if No

1. Make a printer test (see

section 4-1-13). Is it OK?

2. Clean or change the charge corona wire.

Clean or change the quenching lamp.

Clean the laser optic components with a blower brush or dry cloth.

Check that toner is being distributed evenly across the development unit. If it is not,

change the CTM, development unit, or toner supply motor.

3. Clean the exposure glass, white plate, and scanner optics.

Change the xenon lamp, especially if bands appear on the sides of copies made using

copy mode.

4. Are there any bands in

the SBU white waveform

(see section 5-2-9)?

There may be a scanner

problem; go to step 3.

Change the SBU. Change the FCU.

6-5

Go to step 2.

Troubleshooting

Page 7

1st August, 1994 TROUBLESHOOTING

COPY QUALITY TROUBLESHOOTING

Symptom: Uneven density in horizontal bands

Check Action if Yes Action if No

1. Does the xenon lamp

flicker?

2. Is there a clear boundary

between the bands?

Change the lamp. Go to step 2.

Clean the charge and

transfer corona units (there

could be a leak, so check if

any Auto Service Calls were

made).

Clean the development unit,

its bearings, and drive

mechanism. or replace the

master unit and/or

development unit.

Symptom: Thin vertical white lines

Check Action if Yes Action if No

1. Make a printer test (see

section 4-1-13). Is it OK?

2. Clean the grid plate, toner metering blade, and laser optics.

Clean or replace the corona wires.

Add toner if the toner supply is getting low.

Check for foreign objects around the master that could cause leakage of charge form

the belt.

3. Is the surface of the hot

roller scratched?

4. Is the master scratched? Replace the component that

5. Clean the white pressure plate above the exposure glass.

6. Are there any peaks in the

SBU white waveform

(see section 5-2-9)?

There may be a scanner

problem; go to step 5.

Replace the component that

is damaging the hot roller,

then replace the hot roller.

If the hot roller strippers are

badly stained with toner,

replace them, and the

thermistor (or FCU or PSU).

is doing the damage, then

replace the master.

Change the SBU. Change the FCU.

Go to step 2.

Go to step 4.

Finished

Symptom: Fuzzy vertical white lines

Check Action if Yes Action if No

Clean or replace the corona wires.

Symptom: Wavy vertical black lines or bands

Check Action if Yes Action if No

The cleaning blade or toner metering blade may be dirty or damaged.

Replace the hexagonal mirror motor.

6-6

Page 8

TROUBLESHOOTING 1st August, 1994

COPY QUALITY TROUBLESHOOTING

Symptom: Vertical dotted lines

Check Action if Yes Action if No

1. If the master is scratched, replace the master, and the component that is scratching it.

2. If the development roller is scratched, replace the roller, and the component that is

scratching it.

3. Clean the corona wires.

Symptom: Vertical black band at the left or right edge of the printout

Check Action if Yes Action if No

1. Make a printer test (see

section 4-1-13). Is it OK?

2. Make sure that the charge corona wire cleaner is at home position.

Clean the laser optics with a blower brush or soft dry cloth.

3. Clean the scanner optics.

Replace the xenon lamp.

There may be a scanner

problem; go to step 3.

Go to step 2.

Symptom: Vertical black lines or bands at constant positions on the copy

Check Action if Yes Action if No

1. Make a printer test (see

section 4-1-13). Is it OK?

2. Clean the thermistor, hot

and pressure rollers, and

hot roller strippers.

Change the cleaning pad

if it is dirty.

Is the surface of the hot

roller scratched?

3. Is the master scratched? Replace the component that

4. Clean the corona wires and guide plates in the paper feed path.

Clean the quenching lamp.

Replace the toner metering blade if it is damaged.

Clean the laser optics carefully with a blower brush or soft dry cloth.

If the problem remains, change the FCU or LD unit.

5. Clean the white pressure plate above the exposure glass.

6. Are there any peaks in the

SBU white waveform

(see section 5-2-9)?

There may be a scanner

problem; go to step 5.

Replace the component that

is damaging the hot roller,

then replace the hot roller.

If the hot roller strippers are

badly stained with toner,

replace them, and the

thermistor (or FCU or PSU).

is doing the damage, then

replace the master.

Change the SBU. Change the FCU.

Go to step 2.

Go to step 3.

Go to step 4.

Symptom: Defects at repeating intervals on the printout

Check Action if Yes Action if No

There is a defect on the master belt or on one of the rollers (the most likely ones are the

hot roller, pressure roller, or development roller

Symptom: Black streaks at the leading edge

Check Action if Yes Action if No

Clean the hot roller strippers or change the master unit.

6-7

Troubleshooting

Page 9

1st August, 1994 TROUBLESHOOTING

COPY QUALITY TROUBLESHOOTING

Symptom: Black spots at the leading edge

Check Action if Yes Action if No

Clean inside the machine, especially around the fusing unit and transfer unit entrances.

Clean the transfer corona wire and check that it is installed properly.

If the problem remains, change the transfer corona wire or the power pack.

Symptom: Horizontal white lines or stripes across printouts

Check Action if Yes Action if No

1. Make sure that the user is using the correct type of copy paper, and storing it in a dry

place.

2. Does the printout have a

crease mark where the

white band appears?

3. Does the development

bias terminal stay at a

constant voltage

(about -530 Vdc)?

4. Does the FCU output the

power and bias trigger

signal to the power pack?

5. Does the problem go

away if you change the

power pack?

6. Clean the transfer corona unit (wire, endblocks, casing).

Check and replace any parts that may be causing the corona charge to leak.

7. Check that the development roller and master unit are both rotating smoothly, and that

the start and stop at the same time. If there are any problems, do the following:

a) Check the roller, master unit, and drive mechanism for any defective components,

such as gears.

b) Try changing the main motor.

Check the paper feed

mechanism and path from

paper feed through transfer;

correct any faults.

Go to step 6. Go to step 4. Do not adjust

Clean the area around the

bias terminal. Go to step 5.

Finished. Clean the development

Go to step 3.

the variable resistors on the

power pack.

Change the FCU.

roller. Go to step 6.

Symptom: Black page with horizontal white stripes

Check Action if Yes Action if No

Replace the optic fiber cable from the main scan start detector.

If the problem remains, change the LD unit or FCU.

Symptom: Random black spots on the printout

Check Action if Yes Action if No

The grid plate may not be grounded properly. If the problem cannot be corrected, try

changing the charge corona unit, which contains the grid plate.

If the surface of the development roller is dirty, clean it.

The laser diode may be out of control. Change the LDDR or FCU.

Symptom: Horizontal black stripes

Check Action if Yes Action if No

6-8

Page 10

TROUBLESHOOTING 1st August, 1994

COPY QUALITY TROUBLESHOOTING

Symptom: Horizontal black stripes

1. Is the Call Service

indicator lit?

2. Check that the master unit is installed properly and correctly grounded.

Change the master unit if it is damaged.

If the problem only occurs in copy mode, the xenon lamp may be flickering: change the

lamp, driver, or FCU.

If the problem remains, go to step 3.

3. Does the development

bias terminal stay at a

constant voltage

(about -530 Vdc)?

4. Does the FCU output the

power and bias trigger

signal to the power pack?

5. Does the problem go

away if you change the

power pack?

6. Check that the toner metering blade is screwed in securely.

Replace the LD unit or FCU. Go to step 2.

Go to step 6. Go to step 4. Do not adjust

the variable resistors on the

power pack.

Clean the area around the

bias terminal. Go to step 5.

Finished. Clean the development

Change the FCU.

roller. Go to step 6.

Symptom: White spots in black areas

Check Action if Yes Action if No

Clean the development roller (soft cloth and alcohol).

Clean the corona wires.

If the problem cannot be solved, change the development unit, master, or power pack.

Symptom: Data missing at the leading edge

Check Action if Yes Action if No

1. Does the problem only

occur during copying?

2. Check that the scan line sensor is in the correct position.

Try changing the FCU.

3. Is the correct type of copy paper being used, and is it curled at the leading edge?

Check for dust on the rollers in the paper feed path.

Lower cassette: Is the registration mechanism working correctly?

Go to step 2. Go to step 3.

6-9

Troubleshooting

Page 11

1st August, 1994 TROUBLESHOOTING

COPY QUALITY TROUBLESHOOTING

Symptom: Part of the copy missing at the left or right edges

Check Action if Yes Action if No

1. Does the problem only

occur during copying?

2. Check the scanner optic path.

Change the SBU or FCU.

3. Check the laser optic path.

Change the FCU.

Go to step 2. Go to step 3.

Symptom: Distorted printout

Check Action if Yes Action if No

1. Does the problem only

occur during copying?

2. Check that the document feed mechanism is operating smoothly.

3. Poorly installed or defective hexagonal mirror motor.

Blockage in the paper path.

Check that the main motor, gears, rollers, and drive belts are moving smoothly.

Go to step 2. Go to step 3.

Symptom: Fuzzy copy

Check Action if Yes Action if No

1. Does the problem only

occur during copying?

2. Does the ozone fan turn

on?

3. Does the fan receive the

power and drive signals?

4. Change the ozone filter.

Check for obstructions between the transfer unit and the fusing unit.

Check that the master is grounded properly.

Change the master unit.

Clean or replace the corona wires.

Clean the laser optics carefully with a blower brush or soft dry cloth.

If the problem remains, go to step 5.

5. Does the development

bias terminal stay at a

constant voltage

(about -530 Vdc)?

6. Does the FCU output the

power and bias trigger

signal to the power pack?

7. Does the problem go

away if you change the

power pack?

8. Clean the scanner optics and the xenon lamp.

Check the SBU waveforms, especially MTF and reduction rate (section 5-2-9).

Go to step 8. Check the connections

between the ozone fan and

the FCU. Go to step 2.

Go to step 4. Go to step 3.

Replace the fan. Replace the FCU (or PSU).

Go to step 8. Go to step 6. Do not adjust

the variable resistors on the

power pack.

Clean the area around the

bias terminal. Go to step 7.

Finished. Clean the development

Change the FCU.

roller.

6-10

Page 12

TROUBLESHOOTING 1st August, 1994

COPY QUALITY TROUBLESHOOTING

Symptom: Unfused copy

Check Action if Yes Action if No

Clean the thermistor in the fusing unit.

Check the pressure roller spring mechanism.

Change the thermistor, fusing unit, FCU, or PSU.

Symptom: Jitter, image stretched down the page

Check Action if Yes Action if No

1. Does the problem only

occur during copying?

2. Check the paper feed drive mechanism (motors, gears, timing belts).

Check for obstructions in the paper feed path.

Jitter: Try changing the LD unit or FCU.

3. Check the document feed drive mechanism (motors, gears, timing belts).

Check the tx motor timing belt tension (see section 5-2-7).

Replace the FCU or tx motor if the motor is making abnormal noise.

Go to step 3. Go to step 2.

Symptom: Magnification or reduction, filled-in characters

Check Action if Yes Action if No

Adjust the SBU reduction rate (see section 5-2-9).

If the problem only occurs in copy mode, check the paper size sensors. Replace the

sensors or the FCU (or the PFU for the lower cassette).

Symptom: Misaligned output - data shifted to the left or right

Check Action if Yes Action if No

1. Check that the laser diode unit is screwed in properly.

Check that the laser optics are not misaligned.

Try changing the LD unit or FCU.

2. Adjust the SBU scan start position (see section 5-2-9).

Check that the scanner optics are not misaligned.

Check that the document table is aligned properly (see section 5-2-3).

Try changing the LD unit or FCU.

6-11

Troubleshooting

Page 13

1st August, 1994 TROUBLESHOOTING

MECHANICAL PROBLEMS

6.2. MECHANICAL PROBLEMS

The following flow charts may help you find the problem. They do not include

such obvious steps as checking the power connection or changing the PSU

or FCU if nothing appears on the operation panel.

6.2.1. ADF/Scanner

Symptom: Non feed

Check Action if Yes Action if No

1. Are the covers closed

properly?

2. Are the pick-up and feed

rollers clean?

3. Is the shutter mechanism

blocked? (If the shutter

does not lift up after

pressing Start, the tx

motor may be defective;

see step 10.)

4. Is the problem corrected

by adjusting the

separation roller (see

section 5-2-2)?

5. Are the gears and spring

clutches clean and

working properly?

6. Are the connections

between the operation

panel, FCU, and

document sensor loose?

7. Does the LCD prompt

change when a

document is placed in the

feeder?

8. Are the connections

between the PSU and

FCU and the tx motor

loose?

9. Does the tx motor work? This troubleshooting

10. Does the FCU receive

+ 24V from the PSU?

11. Does the FCU output

power and phase drive

signals to the tx motor?

Go to step 2. Close the covers securely.

Go to step 3. Clean the rollers with a soft

cloth and water. Replace

them if they are damaged.

Free the mechanism. Go to step 4.

Finished Put the separation roller

adjustment back to the

original setting. Try

replacing the separation

roller. If that does not help,

go to step 5.

Go to step 6. Clean the gears and

clutches. Remove any

debris from the mechanism.

Connect the cables properly. Go to step 7.

Go to step 8. Replace the document

sensor, operation panel

PCB, or FCU.

Connect the cables properly. Go to step 9.

Go to step 10.

procedure has finished.

Go to step 11. Change the PSU.

Replace the tx motor. Replace the FCU.

6-12

Page 14

TROUBLESHOOTING 1st August, 1994

MECHANICAL PROBLEMS

Symptom: Skew caused by the scanner mechanism

Check Action if Yes Action if No

1. Are the scanner rollers

clean?

Replace the separation

roller and or separation

plate.

Clean the rollers using a oft

cloth and water

Symptom: Jam

Check Action if Yes Action if No

1. Are the scanner rollers

clean?

2. Is the document feed

path blocked?

3. Is the scanner

mechanism in good

shape, and is the tx

motor timing belt tension

correct?

4. Are the connections

between the operation

panel, FCU, document

width sensor, and scan

line sensor loose?

5. Does the operation panel

PCB receive signals from

the scan line sensor and

the document width

sensor?

Go to step 2. Clean the rollers using a soft

cloth and water

Go to step 3. Remove any debris.

Go to step 4. Correct the problem.

Connect the cables properly. Go to step 5.

Replace the operation panel

PCB or FCU.

Replace the document

width sensor and/or scan

line sensor.

Symptom: Abnormal noise

Check Action if Yes Action if No

1. Is the machine assembled

properly.

2. Are the springs and

clutches in the feed/pickup mechanism clean?

Symptom: Double feed

Check Action if Yes Action if No

1. Is the problem solved by

cleaning or lubricating

the separation roller?

2. Does adjusting the

separation roller solve the

problem (see section 5-2-

2)?

Go to step 2. Correct the problem.

Replace the tx motor or the

FCU.

Finished Try cleaning or replacing the

Finished Put the adjustment back to

Clean them.

separation plate. If that does

not help, go to step 2.

the original position, and

replace the separation roller.

Troubleshooting

6-13

Page 15

1st August, 1994 TROUBLESHOOTING

MECHANICAL PROBLEMS

Symptom: Dirty document

Check Action if Yes Action if No

Clean the rollers and guide plates using a soft cloth and water.

Symptom: Second page not fed in

Check Action if Yes Action if No

1. Clean the rollers using a soft cloth and water.

2. Are the connections

between the operation

panel, FCU, and scan line

sensor loose?

3. Does the operation panel

PCB receive signals from

the scan line sensor?

Connect the cables properly. Go to step 3.

Replace the operation panel

PCB or FCU.

Replace the scan line sensor.

6-14

Page 16

TROUBLESHOOTING 1st August, 1994

MECHANICAL PROBLEMS

6.2.2. Printer

Symptom: Non-feed

Check Action if Yes Action if No

1. Check that non-feed is not due to another problem, such as "Call Service" being lit, or

the power cord not being plugged in.

Check that the feed-in area is not jammed with debris.

Check that the covers are closed properly.

Clean or replace the pick-up and feed rollers, and check that the paper lift and feed

mechanisms are working properly.

Lower cassette: Check the separation roller and spring clutch. Clean/replace if

necessary.

If the problem only happens during communication, check the connections between the

FCU, NCU, and telephone line.

2. Are the connections

between the FCU and the

upper paper size and end

sensors loose? If the

problem is in the lower

cassette, check the

connections from the

FCU to the PFU and

lower paper size and end

sensors.

3. Do the upper or lower

cassettes’ Add Paper

indicators light even if

paper is present?

4. Do the upper or lower

cassettes’ Add Paper

indicators light when the

cassettes are installed in

the machine?

5. Do the signals from the

paper size sensor change

when the cassette is

installed?

6. Does the signal from the

paper end sensor change

when paper is added?

7. Are the connections

between the PSU, FCU,

front cover switch and

front cover interlock

switch cover loose?

8. Does the signal from the

front cover switch change

when the cover is closed?

Connect the cables properly. Go to step 3.

Go to step 4. Go to step 7.

Go to step 5. Go to step 6.

Change the PFU (lower

cassette only) or FCU.

Change the PFU (lower

cassette only) or FCU.

Connect the cables properly. Go to step 8.

Go to step 9. Change the switch and/or

Change the sensor and/or

the actuator mechanism.

Change the sensor and/or

the actuator mechanism.

the actuator mechanism.

6-15

Troubleshooting

Page 17

1st August, 1994 TROUBLESHOOTING

MECHANICAL PROBLEMS

Symptom: Non-feed

Check Action if Yes Action if No

9. Does the front cover

interlock switch pass

+ 24V and + 5V from the

FCU through to the FCU?

10. Do the upper and lower

paper feed motors and

clutches operate?

11. Are the connections

between the FCU and the

upper and lower paper

feed motors loose?

12. Does the FCU output

power and drive signals

to the motors?

13. Are the connections

between the FCU and the

upper and lower paper

feed clutches loose?

14. Does the FCU output

power and drive signals

to the clutches?

15. If the main and paper feed motors do not turn on but are in good condition, the basic

starting conditions for printing may not have been met. The conditions are as follows:

The fusing lamp must be at the correct temperature. See "Service Call Conditions: Hot

Roller Down".

The hexagonal mirror motor must have reached the correct speed. See "Service Call

Conditions: Mirror Motor Locked".

One page must have been stored in the page memory. Check the connections between

the components of the video data path (see section 1-5-2) and replace any defective

PCBs.

Go to step 10. Change the switch and/or

the actuator mechanism.

Go to step 15 Go to step 11 (motors) or 13

(clutches).

Connect the cables properly. Go to step 12.

Replace the defective motor. Replace the FCU.

Connect the cables properly. Go to step 14.

Replace the defective clutch. Replace the FCU.

Symptom: Copy Jam - General

Check Action if Yes Action if No

1. Is the printer jammed with

debris?

2. Is the correct type of paper being used, and is it correctly loaded in the cassette?

3. Is a paper jam indicated

when the power is

switched on, even if there

is no jam.

4. Does the FCU receive the

correct signals from the

registration, lower paper

feed, and copy feed-out

sensors?

5. Is the correct paper size

sensor actuator being

used?

Clear the debris. Go to step 2.

Go to step 4. Go to step 5.

Change the PFU (lower

cassette only) and/or FCU.

Go to step 6. Install the correct actuator.

6-16

Change the defective sensor.

Page 18

TROUBLESHOOTING 1st August, 1994

MECHANICAL PROBLEMS

Symptom: Copy Jam - General

Check Action if Yes Action if No

6. Is the paper size sensor

(upper/lower) outputting

the correct signals for the

installed actuator? The

signals that should be

seen are shown in the

following table.

FCU Connector (Upper Cassette) 32-4 32-3 32-2

PFU Connector (Lower Cassette) 4-6 4-5 4-4

A5 L L L

Letter H L L

A4 L H L

F, F4 L H H

Legal H H L

B4 H L H

If you suspect that the FCU

or PFU is processing the

sensor signals wrongly,

change the FCU and/or PFU.

Change the sensor.

7. Are the connections

between the FCU and the

main motor loose?

8. Does the main motor

work?

9. Does the FCU output

power and drive signals

to the main motor?

10. Do the upper/lower paper feed motors and clutches work? See steps 10 to 14 of "Nonfeed".

Connect the cables properly. Go to step 8.

Go to step 10. Go to step 9.

Replace the main motor. Replace the FCU.

Symptom: Copy jam in the paper feed entrance (error code 9-07)

Check Action if Yes Action if No

1. Clean the rollers in the paper feed entrance. Replace any defective rollers

2. Check the registration sensor and lower paper feed sensor (see steps 3 and 4 of "Copy

jam - General").

3. Do the upper/lower paper feed motors and clutches work? See steps 10 to 14 of "Nonfeed".

Symptom: Copy jam inside the machine (error code 9-08)

Check Action if Yes Action if No

1. Clean the registration rollers (metal rollers - soft cloth and alcohol, rubber rollers - soft

cloth and water).

Check the paper feed path and mechanism, especially the area around the entrance to

the transfer/fusing unit.

Check the fusing unit drive mechanism. Replace the pressure springs or fusing unit

rollers or gears if necessary.

2. Check the registration sensor and copy feed-out sensor (see steps 3 and 4 of "Copy jam General").

Troubleshooting

6-17

Page 19

1st August, 1994 TROUBLESHOOTING

MECHANICAL PROBLEMS

Symptom: Copy jam at the feed-out area (error code 9-09)

Check Action if Yes Action if No

1. Clean the rollers in the copy feed-out area.

2. Check the copy feed-out sensor (see steps 3 and 4 of "Copy jam - General").

Symptom: Double feed

Check Action if Yes Action if No

Upper cassette: Check the corner separator mechanism and side fences, and replace if

necessary.

Lower cassette: Clean, lubricate, or replace the separation roller.

Symptom: Dog-eared copies

Check Action if Yes Action if No

Excessive copy paper curl

Defective hot roller stripper

Incorrect corner separator/side fence position

Symptom: Wrinkled copies

Check Action if Yes Action if No

Check whether the problem can be solved by using another stack of paper.

Check paper transport through the printer and replace the defective component.

Replace the fusing unit pressure springs, or the entire fusing unit.

Symptom: Soiled copy paper

Check Action if Yes Action if No

Clean the rollers in the printer. If the dirt is part of the image, then clean the ADF and

scanner rollers. Also, see Copy Quality Troubleshooting (section 6-1).

Symptom: Dirt along the leading edge on the reverse side

Check Action if Yes Action if No

See "Soiled Copy Paper" above.

Clean the following components: transfer corona unit and vicinity, paper feed path,

registration rollers (soft dry cloth), feed-out rollers.

Symptom: Skew caused by the printer mechanism

Check Action if Yes Action if No

Clean the rollers in the cassettes and paper feed path. Replace any defective rollers.

Symptom: Ozone odor

Check Action if Yes Action if No

1. Is the ozone fan working? Change the ozone filter. Go to step 2.

2. Does the FCU send

power and drive signals

to the fan?

Change the ozone fan. Change the FCU.

6-18

Page 20

TROUBLESHOOTING 1st August, 1994

SERVICE CALL CONDITIONS

6.3. SERVICE CALL CONDITIONS

If the Call Service indicator is lit, one of the following conditions has occurred.

• Mirror Motor Locked (hexagonal mirror motor lock failure)

Hot Roller Down (fusing lamp failure)

•

• LD Power Control Failure (laser diode power control failure)

•

Main Motor Locked (main motor lock failure)

• Charger Leak (transfer corona charge leak)

To find out which problem has occurred, either:

• See the Auto Service Call report that was sent to the service station for

the problem with the machine. This report lists a sub-code, as well as

the error message; this sub-code may help you find the problem.

•

Check the error code history using function 93.

• Try to clear the service call condition: switch the power off, wait 10 sec-

onds, then switch back on.

If the problem remains, work through the appropriate troubleshooting procedure from the following pages.

After each troubleshooting attempt, reset the machine and try to operate it. If

the machine still does not work, continue troubleshooting.

Symptom: Charger Leak (Error Code 9-17)

This error occurs if FCU CN27-3 stays high for 3 s or more while the transfer corona is on

(sub-code 31)

Check Action if Yes Action if No

Clean the transfer corona wire and unit.

Check that the FCU outputs the power and trigger signals to the power pack. If not,

replace the FCU.

Replace the FCU, power pack or transfer corona unit if the problem still occurs.

Symptom: LD Power Control Failure (Error Code 9-20)

This error occurs in either of the following conditions:

• Error in the Laser Interface (LIF) chip on the FCU (sub-code 41 or 42)

• Laser power failure (sub-code 43)

Check Action if Yes Action if No

1. Do the front cover

interlock switch and front

cover microswitch both

pass + 5V?

Replace the FCU or laser

diode drive board.

Replace the defective switch

or actuator mechanism.

6-19

Troubleshooting

Page 21

1st August, 1994 TROUBLESHOOTING

SERVICE CALL CONDITIONS

Symptom: Hot Roller Down (Error Code 9-22)

This error occurs in any of the following conditions:

Standby mode: If the fusing lamp takes more than 40 s to reach 80 °C (sub-code 01)

Standby mode: If the fusing lamp is accidentally disconnected for more than 15 s (subcode 06)

During printing: If the fusing lamp takes more than 30 s to rise to 150 °C from 80 °C (subcode 02)

During printing: If the fusing lamp stays below 150 °C for more than 10 s (sub-code 04)

During printing: If the thermistor is accidentally disconnected (sub-code 07)

After printing: If the fusing lamp takes more than 10 minutes to fall back to 150 °C (subcode 03)

At any time: If the fusing lamp temperature reaches 280 °C (sub-code 05)

Check Action if Yes Action if No

Is the fusing unit thermistor disconnected (FCU CN30)?

Is the thermistor open or shorted? If so replace it. Otherwise clean it.

Replace the fusing lamp if it is open circuit.

Replace the thermostat if it is broken.

Replace the FCU or PSU.

Replace the front cover interlock switch if it does not pass + 24V from the PSU to the

FCU.

Symptom: Mirror Motor Locked (Error Code 9-23)

This error occurs in either of the following conditions:

• If FCU CN9-2 does not go low within 10 s of the hexagonal mirror motor being switched

on (sub-code 21)

• If FCU CN9-2 goes back to high for 10 s or more during hexagonal mirror motor

operation (sub-code 22)

Check Action if Yes Action if No

1. Check the connections through the machine between the PSU, FCU, interlock switches,

hexagonal mirror motor and laser diode unit.

2. Does the FCU receive

+ 24V from the PSU?

3. Does the FCU send

+ 24V to the motor?

Go to step 3. Change the PSU or the front

cover interlock switch.

Replace the motor and

driver.

Replace the FCU.

Symptom: Main Motor Locked (Error Code 9-24)

This error occurs in either of the following conditions:

• If FCU CN22-4 does not go low within 10 s of the main motor being switched on (subcode 11)

• If FCU CN22-4 goes back to high for 10 s or more during main motor operation (subcode 12)

Check Action if Yes Action if No

1. Check that the mechanism is not obstructed.

2. Does the front cover

interlock switch pass

+ 24V?

Replace the FCU or the

main motor.

Replace the defective switch

mechanism.

6-20

Page 22

TROUBLESHOOTING 1st August, 1994

ERROR CODES

6.4. ERROR CODES

If an error code occurs, retry the communication. If the same problem occurs, try to fix the problem as suggested below. Note that error codes 4-00,

01, 02, and 10 only appear in the error code display and on the service report.

Code Meaning Suggested Cause/Action

0-00 DIS/NSF not detected

within 40s of Start being

pressed

0-01 DCN received

unexpectedly

0-03 Incompatible modem at

the other end

0-04 CFR or FTT not received

after modem training

0-05 Unsuccessful after

modem training at 2400

bps

0-06 The other terminal did

not reply to DCS

Check the line connection

Check the NCU - FCU connectors.

The machine at the other end may be incompatible.

Replace the NCU or FCU.

Check for DIS/NSF with an oscilloscope.

If the rx signal is weak, there may be a bad line.

The other party is out of paper or has a jammed

printer.

The other party pressed Stop during communication.

The other terminal is incompatible.

Check the line connection.

Check the NCU - FCU connectors.

Try changing the tx level (use NCU parameter 01 or a

dedicated tx parameter for that address).

Replace the FCU or NCU.

The other terminal may be faulty; try sending to

another machine.

If the rx signal is weak or defective, there may be a

bad line.

Check the line connection.

Check the NCU - FCU connectors.

Try adjusting the tx level (use NCU parameter 01 or a

dedicated tx parameter for that address).

Replace the FCU or NCU.

Check for line problems.

Check the line connection.

Check the FCU - NCU connectors.

Try adjusting the tx level (use NCU parameter 01 or a

dedicated tx parameter for that address).

Replace the NCU or FCU.

The other end may be defective or incompatible; try

sending to another machine.

Check for line problems.

6-21

Troubleshooting

Page 23

1st August, 1994 TROUBLESHOOTING

ERROR CODES

Code Meaning Suggested Cause/Action

0-07 No post-message

response from the other

end after a page was sent

0-08 The other end sent RTN

or PIN after receiving a

page, because there

were too many errors

0-14 Non-standard post

message response code

received

0-15 The other end does not

have the confidential or

transfer function

0-16 CFR or FTT not detected

after modem training in

confidential or transfer

mode

0-20 Facsimile data not

received within

6 s of retraining

0-21 EOL signal (end-of-line)

from the other end not

received within 5 s of the

previous EOL signal

Check the line connection.

Check the FCU - NCU connectors.

Replace the NCU or FCU.

The other end may have jammed or run out of paper.

The other end user may have disconnected the call.

Check for a bad line.

The other end may be defective; try sending to

another machine.

Check the line connection.

Check the FCU - NCU connectors.

Replace the NCU or FCU.

The other end may have jammed, or run out of paper

or memory space.

Try adjusting the tx level (use NCU parameter 01 or a

dedicated tx parameter for that address).

The other end may have a defective

modem/NCU/FCU; try sending to another machine.

Check for line problems and noise.

Check the FCU - NCU connectors.

Incompatible or defective remote terminal; try sending

to another machine.

Noisy line: resend.

Try adjusting the tx level (use NCU parameter 01 or a

dedicated tx parameter for that address).

Replace the NCU or FCU.

Incompatible remote terminal.

Remote terminal memory full.

Check the line connection.

Check the FCU - NCU connectors.

Replace the NCU or FCU.

Try adjusting the tx level (use NCU parameter 01 or a

dedicated tx parameter for that address).

The other end may have disconnected, or it may be

defective; try calling another machine.

If the rx signal level is too low, there may be a line

problem.

Check the line connection.

Check the FCU - NCU connectors.

Replace the NCU or FCU.

Check for line problems.

Try calling another fax machine.

Change the reconstruction time from 6 s to 10 s (bit

switch 03, bit 7).

Switch the rx cable equalizer on (bit switch 0A, bit 6).

Check the connections between the FCU, NCU, & line.

Check for line noise or other line problems.

Replace the NCU or FCU.

The remote machine may be defective or may have

disconnected.

6-22

Page 24

TROUBLESHOOTING 1st August, 1994

ERROR CODES

Code Meaning Suggested Cause/Action

0-22 The signal from the other

end was interrupted for

more than 0.2 s

0-23 Too many errors during

reception

0-24 Printer failure occurred

while the memory was

full during non-ECM

reception; negative

response returned

0-52 Polarity has changed

during communication

0-70 A ’disc’ signal was

received during ISDN G3

reception

1-00 Document jam Improperly inserted document or unsuitable

1-01 Document length

exceeded the maximum

1-17 Document jam in the

feed-out area

1-71 Cover has been opened

or cassette has been

pulled out during printing

2-10 The modem cannot enter

tx mode

2-11 Only one V.21 connection

flag was received

2-12 Modem clock irregularity Replace the FCU.

2-20 Abnormal

coding/decoding (cpu

not ready)

2-50 The machine reset itself Change the FCU.

4-00 One page took longer

than 8 minutes to transmit

Check the line connection.

Check the FCU - NCU connectors.

Replace the NCU or FCU.

Defective remote terminal.

Check for line noise or other line problems.

Check the line connection.

Check the FCU - NCU connectors.

Replace the NCU or FCU.

Defective remote terminal.

Check for line noise or other line problems.

Ask the other end to adjust their tx level.

There is no memory space available, or substitute

reception is disabled. Try the following:

Change bit 6 of bit switch 07 to 1.

Ask the user to change bit 0 of user parameter 05 to 1.

Check the line connection.

Retry communication.

Network or remote terminal error.

document type.

Clean the document jam sensor.

See "Mechanical Operation - Document Jam".

Divide the document into smaller pieces.

Clean the sensors in the ADF/scanner.

See "Mechanical Operation - Document Jam".

Clear debris from the sensor actuator.

Clean the sensors in the ADF/scanner.

Check the connections between the sensors and FCU.

Replace defective sensor, operation panel board, or

FCU.

Close the cover or put back the cassette.

Replace the FCU.

Change the FCU.

Check the connections from the FCU to the MBU.

Replace the FCU or MBU.

Check for a bad line.

Try the communication at a lower resolution, or

without halftone.

Change the FCU.

Troubleshooting

6-23

Page 25

1st August, 1994 TROUBLESHOOTING

ERROR CODES

Code Meaning Suggested Cause/Action

4-01 Line current was cut Check the line connector.

Check the connection between the FCU and the NCU.

Check for line problems.

Replace the FCU or the NCU.

4-02 The other end cut the

received page as it was

longer than the maximum

limit.

4-10 Communication failed

because of ID Code

mismatch (Closed

Network) or Tel. No./CSI

mismatch (Protection

against Wrong

Connections)

4-80

4-81

4-82

4-83

4-84

4-85

4-89

4-90

5-00 Data reconstruction not

5-20 Storage impossible

5-21 Memory overflow

5-25 SAF file access error Change the FCU, memory card, or hard disk.

5-30 Mode table for the first

Start mark not detected at

the top of OMR sheet

OMR sheet placed in the

ADF the wrong way

Skew detection mark not

detected

Skew was detected before

scanning the OMR data

field

Guide mark not detected

while scanning an OMR

sheet

Skew was detected while

scanning the OMR data

field

End mark not detected at

the bottom of the OMR

sheet

Reduction rate in the main

scan direction not

acceptable while scanning

an OMR sheet

possible

because of a lack of

memory

page to be printed was

not effective

Ask the other end to change their maximum receive

length setting, then resend.

Get the ID Codes the same and/or the CSIs

programmed correctly, then resend.

The machine at the other end may be defective.

See section 6.6.

If the problem remains, replace the FCU.

Replace the FCU.

Temporary memory shortage; otherwise, replace the

FCU or memory PCB.

Change the FCU.

6-24

Page 26

TROUBLESHOOTING 1st August, 1994

ERROR CODES

Code Meaning Suggested Cause/Action

6-01 ECM - no V.21 signal was

received

6-02 ECM - EOR was received

6-05 Facsimile data frame not

received within 18 s of

CFR, but there was no

line fail (G3 ECM)

6-06 Coding/decoding error

(G3 ECM)

6-08 PIP/PIN received in reply

to PPS.NULL (G3 ECM)

6-09 ERR received (G3 ECM) Check for a noisy line.

6-10 Error frames still received

at the other end after all

communication attempts

at 2400 bps (G3 ECM)

9-07 Copy jam at the cassette

entrance

9-08 Copy jam inside the

machine

9-09 Copy jam in the copy

feed-out area

9-17 Transfer corona power

leak

9-20 Laser diode power

control failed

9-22 Fusing lamp failure See section 6-3 (Hot Roller Down).

9-23 Hexagonal mirror motor

lock failure, or laser main

scan synch failure

9-24 Main motor lock failed See section 6-3 (Main Motor Locked).

9-50 Copy jam in the PFU See section 6-2-2.

Try adjusting the rx cable equalizer.

Replace the FCU or NCU.

Check the line connection.

Check connections from the FCU to the NCU.

Check for a bad line or defective remote terminal.

Replace the FCU, NCU or MBU.

Switch the rx cable equalizer on (bit switch 0A, bit 6).

Defective FCU.

The other terminal may be defective.

The other end pressed Stop during communication.

The other terminal may be defective.

Adjust the tx levels of the communicating machines.

See code 6-05.

Check for line noise.

Adjust the tx level (use NCU parameter 01or the

dedicated tx parameter for that address).

Check the line connection.

Defective remote terminal.

See section 6-2-2.

If the problem remains, replace the FCU.

See section 6-2-2.

If the problem remains, replace the FCU.

See section 6-2-2.

If the problem remains, replace the FCU.

See section 6-3 (Charger Leak).

If the problem remains, replace the FCU.

See section 6-3 (LD Power Control Failure).

If the problem remains, replace the FCU.

If the problem remains, replace the FCU.

See section 6-3 (Mirror Motor Locked).

If the problem remains, replace the FCU.

If the problem remains, replace the FCU.

If the problem remains, replace the FCU.

6-25

Troubleshooting

Page 27

1st August, 1994 TROUBLESHOOTING

ELECTRICAL COMPONENT DEFECTS

6.5. ELECTRICAL COMPONENT DEFECTS

6.5.1. Defective Sensor Table

Sensor Symptoms if Defective

Document sensor "CLEAR ORIGINAL" or "ENTER FAX NO" is

displayed at power-up.

"SET DOCUMENT" is still displayed after a

document is placed in the feeder.

Document width sensor Reduction should take place if the original is

wide enough to actuate the sensor and the

copy paper is not wide enough to. However,

there is no reduction.

"CLEAR ORIGINAL" is displayed at powerup.

Scan line sensor "CLEAR ORIGINAL" is displayed at power-

up.

"CLEAR ORIGINAL" is displayed soon after

the start of copying.

Front cover sensor There is no alarm on opening the cover, and

"CLOSE COVER" is not displayed.

"CLOSE COVER" is displayed at power-up.

CTM sensor "ADD TONER" is displayed at power-up.

Toner near-end sensor Toner is never transferred from the CTM to

the development unit.

Upper paper size sensor "ADD PAPER" is displayed at power-up.

Page separation may be done even if the

original is the same size as the copy paper.

Upper paper end sensor The Replace Paper indicator lights even if

paper is remaining.

The Replace Paper indicator does not light

when the paper has run out.

Lower paper size sensor "ADD PAPER" is displayed at power-up.

Page separation may be done even if the

original is the same size as the copy paper.

If the original and the paper in the two

cassettes are all of the same size, paper will

be fed from the upper cassette.

Lower paper end sensor The Replace Paper indicator on the lower

cassette’s operation panel lights even if

paper is remaining.

The Replace Paper indicator on the lower

cassette’s operation panel does not light

when the paper has run out.

Registration sensor

Copy feed-out sensor

"CLEAR COPY" is displayed at power-up.

"CLEAR COPY" is displayed soon after the

start of copying.

6-26

Page 28

TROUBLESHOOTING 1st August, 1994

OMR SHEET

Sensor Symptoms if Defective

Lower paper feed sensor The Copy Jam indicator on the lower

cassette’s operation panel lights at power-

up.

The Copy Jam indicator on the lower

cassette’s operation panel lights soon after

the start of copying.

6.5.2. Blown Fuse Table

The only service-replaceable fuse is the following.

Fuse Symptoms if Defective

PSU - F1 No power to the machine

6.6. OMR SHEET

6.6.1. Possible Errors with OMR Sheets

If one of the following errors occurs while scanning an OMR sheet, the

scanned data are not stored and an error code is stored in the memory.

Symptom Action Error

Start mark not detected Check the ADF/scanner mechanisms.

Skew detection mark not

detected

Guide mark not detected

while scanning the data field

End mark not detected

after the data field

OMR sheet placed in the

ADF the wrong way

Skew detected at the skew

detection mark

Skew detected while

scanning the data field

Reduction rate not

acceptable

Check if a photocopy of the sheet was used.

Check if a cut-off portion of the sheet was used.

Check if the document guides are adjusted

correctly.

Check if the sheet is dirty.

Check for any adhesive tapes on the sheet.

Place the sheet correctly in the ADF.

Check the ADF mechanisms.

Check if a photocopy of the sheet was used.

Checjk for any adhesive tapes on the sheet.

Check if the document guides are adjusted

correctly.

Check if a reduced photocopy was used.

Adjust the scanner correctly.

Code

4-80

4-82

4-84

4-89

4-81

4-83

4-85

4-90

6-27

Troubleshooting

Page 29

1st August, 1994 TROUBLESHOOTING

OMR SHEET

6.6.2. Sample OMR Sheet Format

The following marks on the OMR sheet are used to detect errors. Refer to the

following diagram for the locations of these marks.

A

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

B

1

2

3

4

5

6

7

8

9

SAMPLE OMR SHEET FORMAT

Data Field

C

B

D

E

D

Name Usage

A Start mark Used to detect the start of an OMR sheet.

B Skew detection marks Used to detect skew before scanning the data field.

C End mark Used to detect the end of the data field.

Guide marks Used to detect lines in the data field, and to detect

D

Wrong way insertion

E

detection mark

skew while scanning the data field.

Used to detect worng way insertion. On the

transfer request program sheet, this mark is also

used as the end mark.

6-28

Page 30

Technical Bulletin No. CGO-002

SUBJECT: S/M Correction, New Feature

PREPARED BY: H.Yokoyama

CHECKED BY: S.Hamano

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

1. Service Manual Correction

The description for the toner supply RAM address on page 5-14 of the service man ual

is not correct.

Current : 000418 to 40 (H)

↓

Correct : 080412 to 44 (H)

2. The RAM address for inch-to-mm conversion will be modifie d as foll ows .

FROM: 2nd T.S. Section

MODEL:

DATE:

Dec. 15, 1994

CGO

Current : 08004A (Page 4-26)

Bit 2 inch-to-mm conversion (Transmission)

↓

After Modification : 08004A

Bit 2 inch-to-mm conversion (Immediate Tx)

0: Disabled, 1: Enabled

08026B

Bit 0 inch-to-mm conversion (Memory Tx)

0: Disabled, 1: Enabled

Dedicated Tx parameters

Byte 3. bit 4 (inch-to-mm conversion)

0: According to the above setting

1: Enabled for Immediate Tx and Memory Tx

- Modification -

H513-20, 23, 28

H5136014E → F:PCB-MBU

(H5137108D → E:PROM)

(H5137109D → E:PRO M )

H513-53

H5136021 → A:PCB-MBU: TWN

(H5137117 → A:PROM)

(H5137118 → A:PROM)

The modification is in effect fro m Dec. 19 94 prod uct ion (Not fixed yet).

Page 31

HDIF

Technical Bulletin No. CGO-003

SUBJECT: SBU Harness

PREPARED BY: Y.Okunishi

CHECKED BY: S.Hamano

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

Problem : Damage to the SBU harness

Reason : Pin edges of the HD Interface Board and the Prin ter Interface Board da mag e the

harness if the harness is not re-located correctly, causing it to be pinched

between the base mold and the board. When the HD Interface Boa rd or

Printer Interface Board is installe d.

Action taken :

Re-locate the SBU harness as follo ws aft er fising the HD Interface Board or

the Printer Interface Board :

FROM: 2nd T.S. Section

MODEL:

DATE:

Dec. 15, 1994

CGO

Might be

pinched

HDIF

SBU

MBU

Not good

SBU

Base

Base

Mold

Mold

MBU

FCU FCU

Good

Base

Mold

Page 32

Technical Bulletin No. CGO-004

SUBJECT: CGO Service Manual

PREPARED BY: Y.Okunishi

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

Page 3-12 to 3-14 of CGO Service Manual for Hard Disk have been corrected.

FROM: 2nd T.S. Section

MODEL:

DATE:

1995

CGO

Page 33

INSTALLATION

INSTALLING ADDITIONAL UNITS

Page 2/4

RTB: CGO-004

3.2.6. Hard Disk

If the ISDN option is installed at the same time, the hard disk option

must be installed prior to the ISDN option.

The installation has t hre e ph ases.

A. SAF memory initialization

B. Bit switch programming

C. Software initialization

D. Hard disk formatting

A. SAF Memory Initialization

1. Functi on 6 0 1 9 9 1 , then immediately Yes

2. 0 1

3. Set bit 2 of bit switch 00 to 1.

4. Yes Function

B. Installation Procedure

Cuation: Print any messages still stored in the SAF.

Ensure that 100% memo ry is disp laye d on the ope rat ion panel

before installing a hard disk, or data may be lost.

1. Turn off the power switch, and unplug the machine from the wall socket.

Caution: Do not plug in or switch on until the entire insta llat ion is

completed.

2. Remove the rear cover [A], and

disconnect the monitor speaker

[B]

harness [B].

3. Take off the right cover [C].

3-12

[C]

[A]

Page 34

[J]

INSTALLATION

INSTALLING ADDITIONAL UNITS

4. Attach the ground plate [D] to the

PSU.

5. Disconnect the connector CN9 [E]

from the FCU, and thread the harness through the opening in the I/F

board [F].

Page 3/4

RTB: CGO-004

[F]

[D]

6. Plug the I/F board into CN10 [G] on

the FCU, and reconnect the harness to CN9.

7. Change the position of the jumper

switch on the hard disk interface

board [H] to turn on the battery

switch.

8. Connect the flat cable [ I ] to the

I/F board and the hard disk unit

[J].

Note: Connect the " ▼ " markings

together.

9. Attach the hard disk unit .

Note: Tighten the screws [K ] th at

attach the hard disk unit to the

ground plate [L] and the I/F board

holder [M].

[G]

[E]

[I]

[L]

[H]

[K]

[M]

10. Remove the option cover [N] from

the rear cover.

11. Reconnect the monitor speaker

harness, and install the rear co ver

[A] and right cover [C].

[O]

12. Attach the hard d isk cover [O].

13. Plug in the machine, and turn on

the power.

[N]

3-13

Page 35

INSTALLATION

INSTALLING ADDITIONAL UNITS

Page 4/4

RTB: CGO-004

C. Software Initialization

1. Function 6 0 1 9 9 1 , then immediately Yes

2. 1 1

3. Set bit 0 of bit switch 0D to 1.

4. Yes Function

5. Turn off th e po wer, then turn it back on after a few seconds.

6. Function 6 0 1 9 9 1 , then immediately Yes

7. 0 1

8. Set bit 2 of bit switch 00 to 1.

9. Yes Function

10. Turn off the power, then turn on the power after a few seconds.

D. Hard Disk format (Function 17)

1. Function 6 0 1 9 9 1 , then immediately Yes

2. 1 7

HD NO.

0. INITIAL 1. FORMAT

2. TEST

3. Format the hard disk: 1 Start

Caution: Do not turn off the switch until formatting is completed.

Formatting the hard disk takes about 10 minutes.

__

4. Print the system parameter list and ensure that the Total Memory Size indicates “HD”. Refer to page 4-2.

5. Return to the standby mode and ensure that the remaining memory

indicator shows “100%”.

3-14

Page 36

Technical Bulletin No. Multi-003

Page 1/2

SUBJECT: Harness for PFU

PREPARED BY: Y. Okunishi

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

Problem: The Paper Feed Unit may not work correctly.

Cause: Wires of the harness (H511 5528) from the FCU to the relay connectors for the paper

feed unit (PFU) are not allocated properly.

Affected machines:

Fax 3500L S/N R8750600001 ~ R8750700600

NRG9665 S/N 6355060620 ~ 6355060671

Savin Fax 3670 S/N 0950600001 ~ 0950700120

Fax 5600L S/N M2050600001 ~ M2050700500

Lanier Fax 7550 S/N L7555060677 ~ L7555060780

Omnifax L540 S/N L5405060271 ~ L5405060330

FROM: 2nd T.S. Section

MODEL: Fax3500L(USA),

NRG9665(USA), Savin Fax3670

Fax5600L(USA),

Lanier Fax7550, Omnifax L540

DATE:

July 31, 1995

Action Required:

The harness should be checked before the start of th e PFU inst allation because the

FCU or the PFU PCB may become damaged.

Follow the attached proce du re be fo re PFU installation and chang e th e ha rness

to a new one if it is bad.

Page 37

CN B

RTB No. Multi-003

Page 2/2

Harness Check Procedure

1. Remove the Rear Cover and Left Cover.

2. Unplug the connector CN28 on the FCU.

3. Unplug the connect ors CN A and CN B on the relay con ne ctor board located at the bot to m of

Main Frame.

Harness from FCU

(CN A & B)

Main Frame

Paper Feed Unit (PFU)

Relay connectors

Harness from PFU

4. Check the continuity of the harness pin by pin using a mult imeter.

See below for what the correct allocation of all wires of the harness should be.

ABCDEFGHI

CN28 (to FCU)

J1234

5

6XX1234XX

CN A

(to PFU)

View from the side without the plastic cove r

Check the continuity of the following.

A of CN28 to 4 of CN B

⇓ ⇓

D of CN28 to 1 of CN B

E of CN28 to 6 of CN A

⇓ ⇓

J of CN28 to 1 of CN A

Page 38

Page 1/3

Technical Bulletin No. Multi - 004A

SUBJECT: Fusing Unit

PREPARED BY: Y.Okunishi

CHECKED BY: S.Fujii

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

A: "NOTE" is added to page 2/3.

SYMPTOM:

Background on received and copied documents.

Cause:

Hot Roller failure as a result of not changing the Cleaning Pad at the 10K PM.

Failure to change the Cleaning Pad results in dirty Strippers and Thermostat and

then Hot Roller failure.

As the machine warms up from the standby temperature to the fusing

temperature, it is exposed to slight overheating before the temperature levels

off. This leads to softening of the Teflon layer on the Hot Roller. As a result, the

Teflon layer peels off in the areas where the Strippers and other parts come in

contact with it. Dirty Strippers and Thermostat put more stress on the Hot Roller and

cause premature Hot Roller failure.

Also, the dirty Thermistor causes the Hot Roller to overherat and fail prematurely.

FROM: Quality Assurance Center

DATE:

Oct. 15, 1996

MODEL:

CSO, CRO, CS1, CFO,

CGO

A second cause can be a damaged (bent ) Thermistor from a previous service visit.

The damaged Thermistor causes the Hot Roller to overheat and fail prematurely.

SOLUTION:

Ricoh recommends replacing the Cleaning Pad at the 10K PM. However, this is

sometimes ignored. Realizing this, Ricoh will conduct the following modifications to

protect the Hot Roller from the failure mentioned above.

No. Old Part New Part Description Qty Used Interchangeability

1 H0812121 H0812123 Stripper Spring 2 → 2 X / O

H0812120 H5132119 Stripper

2

3

H0812137

H0815035

H0812141

03130080B

(Separation Pawl)

Thermistor Assembly

Thermistor

Bracket

Screw - M3x8

2 → 2 X / O

1 → 0

1 → 1

1 → 1

0 → 1

X / O as an

assembly

4 H0812100 H0819600 Hot Roller Kit 1 → 1 X / O

Page 39

Page 2/3

Technical Bulletin No. Multi - 004A

SUBJECT: Fusing Unit

DATE:

Oct. 15, 1996

Hot Roller Kit:

The hot rollers shipped from the SPC in Japan will be replaced by the

Hot Roller Kit in July.

This kit will be comprised of the following: Hot Roller, Cleaning Pad, Thermistor,

Thermistor Bracket, Screw, Strippers (2), Stripper Springs (2) and Installation Sheet.

The individual Hot Roller will be no longer available. The Cleaning Pad will

continue to be a Service Part.

Ricoh recommends change of the above modified parts and Cleaning Pad when the failed

Hot Roller is replaced with the new one.

NOTE

(A): Please refer to the following instructions and fix the cover to the fusing unit

and check that the harness is not pinched before installing the fusing unit in the

machine.

If the metal wire of the harness contacts the thermistor bracket, a no power

condition may occur. Please check the thermistor harness if this occurs.

Fusing Cover

(Bad)

Edge of the cover may damage

the harness

Edge

(Good)

Fusing Unit

Page 40

Installation Procedure for the Thermistor

1. Assemble the thermistor and the bracket

with the screw.

Bracket - Thermistor

H0812141

Thermistor - Fusing Unit

H0815035

Do not bendthis part

2. Install the

Thermistor Ass’y

( ✻ 4)

Thermistor - Fusing Unit

H0815035

Harness - Thermostat

(✻ 3)

Page 3/3

Thermostat - Fusing Unit

H0812134

Screw - M3 x 8

03130080B

(✻ 1)

Note: Set the projection on

the thermistor into

the hole in the bracket.

Note: ✻ 1 Place the thermostat harness under the part of the bracket.

✻ 2 Do not cross the thermostat harness and the thermistor harness.

✻ 3 Push the thermistor head (sensor) gently against the hot roller witha finger to make sure that the thermistor

head touches the hot roller surface. Do not push it strongly.

✻ 4 Do not bend the thermistor neck (spring plate) when installing or cleaning it .

If the thermistor is bent, replace it.

(✻ 2)

Bracket - Thermistor

H0812141

Stay - Fusing Unit - Upper

H0812175

Page 41

T

Model:

K105 (FAX4000L)

echnical

B

ulletin

Date:

15-Sep-97

No:

PAGE: 1/1

015

Subject:

From:

Classification:

The V.33 standard for 14.4 kbps modems has not been supported by FX4 and FX6MK2

because V.33 has been deleted from the ITU (CCITT) recommendations.

So, data transfer at 14.4 kbps speed between a FAX4000L which supports only V.33 and

products which support only V.17 will not be successful, and 9.6 kbps is the highest speed

for data transfer between them .

See the following list.

Only V.33 is supported V.33 and V.17 are

14.4 Kbps Modem

QAC 2nd Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

K105 (FAX4000L) CFO, CS1, CGO FX6MK2, FX4

Part information

Electrical

Transmit/receive

supported

Prepared by:

Action required

Service manual revision

Retrofit information

Only V.17 is supported

Y.Okunishi

RC RE ASIA

✶✶

Page 42

T

Model:

ISDN Option

echnical

ulletin

B

Date:

30-Nov-97

No:

PAGE: 1/1

Multi - 006

Subject:

From:

Classification:

This technical bulletin informs of the settings required when a machine is connected to the

US National ISDN network

Models: CFO, CGO, LHO, FX4, ADAM

• Subscriber Number

Input the subscriber number given by the telephone company at :

1.G4 SUBSCRIBER NO.1 (MAIN)

2.G3 SUBSCRIBER NO.1 (MAIN)

• SPID Number (Service Profile Identification Number)

Input the SPID number given by the telephone company at :

US National ISDN

IPP Business Division Technica l Service Dpt.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

H.Kamiya

1.G4 SUBSCRIBER NO.2 (Sub)

2.G3 SUBSCRIBER NO.2 (Sub)

Note: Input a ”_” (pause) before the SPID number.

• G4 Internal Switches

SW No. Bit Setting Definition

SW11 Bit1 0: Dynamic TEI Type of TEI used (Layer 2) (Default)

Bit2 1: Yes Attachment of calling p arty number (L3 SET UP)SW13

Bit5 1: Yes Attachment of channel information element (L3

CONN)

Bit0 1: Speech ISDN G3 information transfer capability (L3)SW14

Bit5 1: Keypad facility Called ID mapping (L 3)

SW15 Bit7 1: On Transmission of STAT in reply to STAT_ENQ

received in the U0 state.

SW19

Bit0 1: Permanent Permanence of the link (L2)

Bit2 1: On SPID procedure (L2)