Page 1

FAX3000L/3200L

SERVICE MANUAL

Throughout this manual, the machines are

referred to as follows.

Type A: FAX3000L

Type B: FAX3200L

Page 2

WARNING

DANGER

INVISIBLE LASER RADIATION

WHEN OPEN AVOID DIRECT

EXPOSURE TO BEAM

DANGER

RAYON LASER INVISIBLE

LORS DE L’OUVERTURE

EVITER L’EXPOSITION DIRECTE

VORSICHT

Unsichtbare Laserstrahlung

unter dieser Abdeckung. Nicht

in den laserstrahl blicken.

PELIGRO

RADIACION LASER INVISIBLE

AL ABRIR. EVITAR LA

EXPOSICION DIRECTA AL HAZ

THIS MACHIN E CONTAINS A LASER BEAM GENERATOR. LASER

BEAM S CAN CAUSE PERM ANENT EYE DAM AGE. DO NOT OPEN

THE LASER UNIT O R LOOK ALONG TH E LASER BEAM PATH

WHILE THE M AIN POWER I S ON.

Lithium Batteries (Memory Back-up)

CAUTION:

The danger of explosion exists if a battery of this type is incorrectly replaced.

Replace only with the same or an equivalent type recommended by the

manufacturer. Discard used batteries in accordance with the manufactu rer’s

instructions.

Page 3

OVERALL MACHINE INFORMATION November 30th, 1991

SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1. SP ECIFICATIONS

Type

Desktop transceiver

Circuit

PSTN, PABX

Connection

Direct couple

Document Size

Length: 105 - 1200 mm

[4.1 - 47.2 ins]

Up to 100 m [328 ft] after adjustment

Width: 148 - 304 mm

[5.8 - 12.0 ins]

Thickness: 0.05 to 0.2 mm

[2 to 8 mils]

Document Feed

Automatic feed, face down

ADF Capacity

50 sheets (using 20 lb paper)

Scanning Method

Flat bed, with CCD

Maximum Scan Width

256 mm [10.1 ins] ± 1%

Scan Resolution

Main scan: 8 dots/mm [203 dpi]

Sub scan:

Standard - 3.85 lines/mm [98 lpi]

Detail - 7.7 lines /mm [196 lpi]

Fine - 15.4 lines/mm [392 lpi]

Memory Capacity

ECM: 128 kbytes (double buffer)

SAF: Type A - 256 kbytes (14 pages)

Type B - 256 kbytes (14 pages), with

optional extra 1 Mbyte or 2 Mbytes

(max 71 or 128 pages respectively)

Compression

MH, MR, E FC, MMR , SSC

Storage to SAF memory for tx: MH

MMR only with ECM

Modulation

V.29 (QAM), V.27ter (PHM), V.21 (FM)

Data Rate

9600/7200/4800/2400 bps; automatic fallback

I/O Rate

With ECM : 0 ms/line

Without ECM: 5, 1 0, 20, or 40 ms/line

Transmi ssi o n Time

10 s at 9600 bps (G3 ECM using memory)

for a CCITT #1 test document (Slerexe letter) using standard resolution

Printing System

Las er printing, using the Ricoh CS (Compact

Seamless) E ngine, plain paper, dry toner

Pap er Size

Standa rd Cassette

Letter, Legal

Lower Ca ssette

Letter, Legal, A4, B4

Maximum Printout Width

210 mm [8.3 ins]

Ma ximu m Printer Resolutio n

Main scan: 16 dots per mm [406 dpi]

Sub scan: 15. 4 lines/mm [392 lpi]

Power Supply

115 ± 20 V ac, 60 ± 1 Hz

Power Consumption (Base Machine Only)

Standby: 40 W

Transmit: 50 W

Receive: 210 W

Copying: 300 W

Operating Environment

Temperature: 17 - 28 °C [63 - 82 °F]

Humidity: 40 - 70 %Rh

Dimensions (W x D x H)

496 x 459 x 293 mm [19.5 x 18.1 x 11.5 ins]

Excluding handset, trays, and optional units

Weight

19 kg [41.8 lbs]

Excluding handset, trays, and optional units

1

Protocol

Group 3 with ECM

1-1

Page 4

November 30th, 1991 OVERALL MACHINE INFORMATION

FEATURES

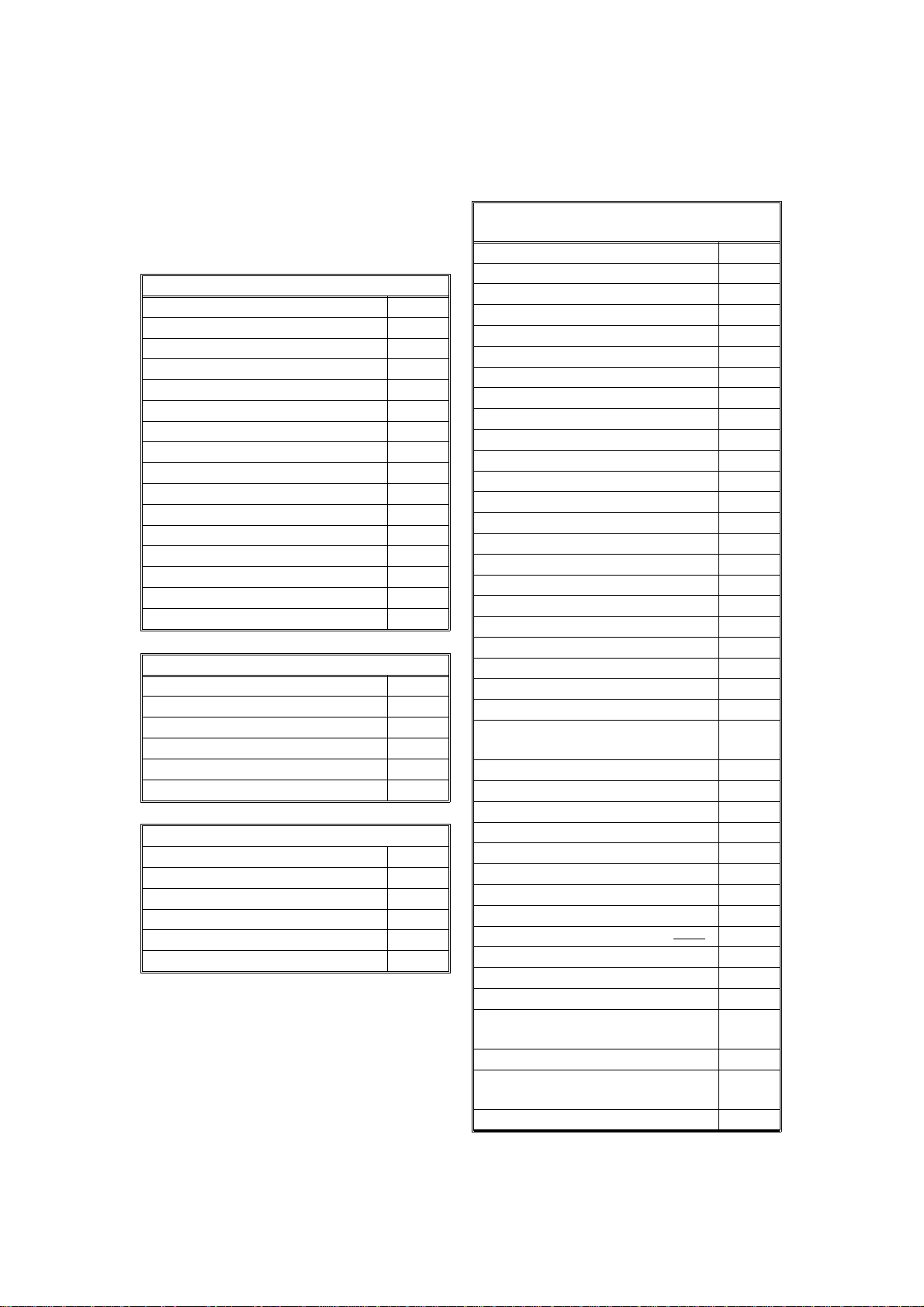

1.2. FEATURES

KEY: O = Used, X = Not Used,

A = Type B with optional memory only,

B = Type B only

Equipment

ADF O

Bar code reade r X

Built-in handset X

Cabinet X

Connection for ans. machine X

Connection for handset O

Cutter X

Handset (option only) O

Hard disk X

Magnetic card reader X

Manual f eed mechanism O

Marker O

Microphone X

Monitor speaker O

R emaining memory indicator O

Speakerphone X

Video Processing Features

Contrast O

Halftone (B asic & Error Dif fusion) O

MTF O

Reduction O

R e s olution O

Smoothing to 16 x 15.4 l/mm O

Communication Features - Auto

Automatic fallback O

Automatic redialing O

Confidential reception A

Dual Acce ss O

Substitute r eception O

Transmission Reserve X

Communication Features -

User Selectable

Action as a transfer broadcaster X

AI Redial O

Alternative Destination O

Answering machine X

Authorize d Reception O

Auto-answer dela y time X

Auto dialing (pulse or DTMF) O

Auto Docume n t O

Automatic V oice Message X

Auto-note X

Batch Transmission (max 5 files) A

Broadcasting O

Chain Dialing O

Confidential ID O v erride O

Confidential Transmission O

Forwarding (4 stations) A

Fre e Polling O

Gr oups (7 groups) O

Hold X

Immediate Redialing O

Immediate transmission O

Keystr oke Program s O

Mailbox X

Memory transmission (this is the

default mode)

Notify X

On Hook Dial O

Page C ount O

Per sonal Codes O

Personal Codes with Conf ID O

Polling R eception O

Polling Transmission O

Quick Dial (32 stations) O

Reception mode s (Fax, Tel ,

Reduction O

Remote control features X

Remote Transfer X

Restricted Access (10 codes,

without cards)

Secured Polling O

Secured Polling with Stored ID

Override

Send Later O

Auto) O

O

O

O

1-2

Page 5

OVERALL MACHINE INFORMATION November 30th, 1991

FEATURES

Communication Features -

User Selectable

Silent ringing detection X

Speed Dial (100 stations) O

Telephone Di rector y O

Tonal Signal Transmission O

Transfer Request O

Transmission Deadline X

Turnaround Polling X

Voice Request (immed. tx only) O

Communication Features -

Service Selectable

AI Short Protocol X

Auto-reduction override option O

Bus y tone detection O

Closed Ne twork (tx an d rx) O

Continuous Polling Re ception O

Dedicate d t x paramete r s O

ECM O

EFC O

MV1200 compatibility X

Page retransmission O

Page separation m ark O

Polling tx file lifetime in the SAF O

Protection against wrong conn. O

R esol’n stepdown override option X

Short Preamble O

W ell log O

Other User Features

Auto Service Call O

Ce n ter mark O

Checkered mark X

Clea ring a memory file O

Clea ring a polling file O

Clock O

Confidential ID O

Copy m ode O

Counters O

Dialed number check X

Direct entry of names O

Function Progr ams O

ID Code O

Label Insertion O

Language Selection O

LCD contrast control S ervic e

Memory L ock A

Memory L ock ID A

Modifying a memory file X

Mu lti So rt Document Rece p t ion A

Multicopy m ode A

Night Timer O

Own t elephone number O

Printing a memory file O

RDS on/off O

R eception Mode S witching T ime r X

Reception Time (non- memory rx

only)

Re mote ID X

R everse Order Printing A

RTI, TTI, CSI O

Speaker volume control O

Specified Cassette S election B

Substitute r eception on/off O

Telephone line type O

TTI on/off O

Use r Function Keys X

User Parameters O

Wild Cards O

Reports - Automatic

Charge Control Report X

Communication Failure Report O

Confidential File Report O

Error Report O

Memory Storage Report O

Mode Chan ge Report X

Polling Clea r Report O

Polling R eserve Report O

Polling R esult Report O

Power Failure Report O

TCR O

Transfer Result Report X

Transmission Result Report O

Reports - User-initiated

Authorized R eception List O

Charge Control Report X

File L is t O

Forwarding List A

Gr oup List O

Per sonal Code List O

Program List O

O

1

1-3

Page 6

November 30th, 1991 OVERALL MACHINE INFORMATION

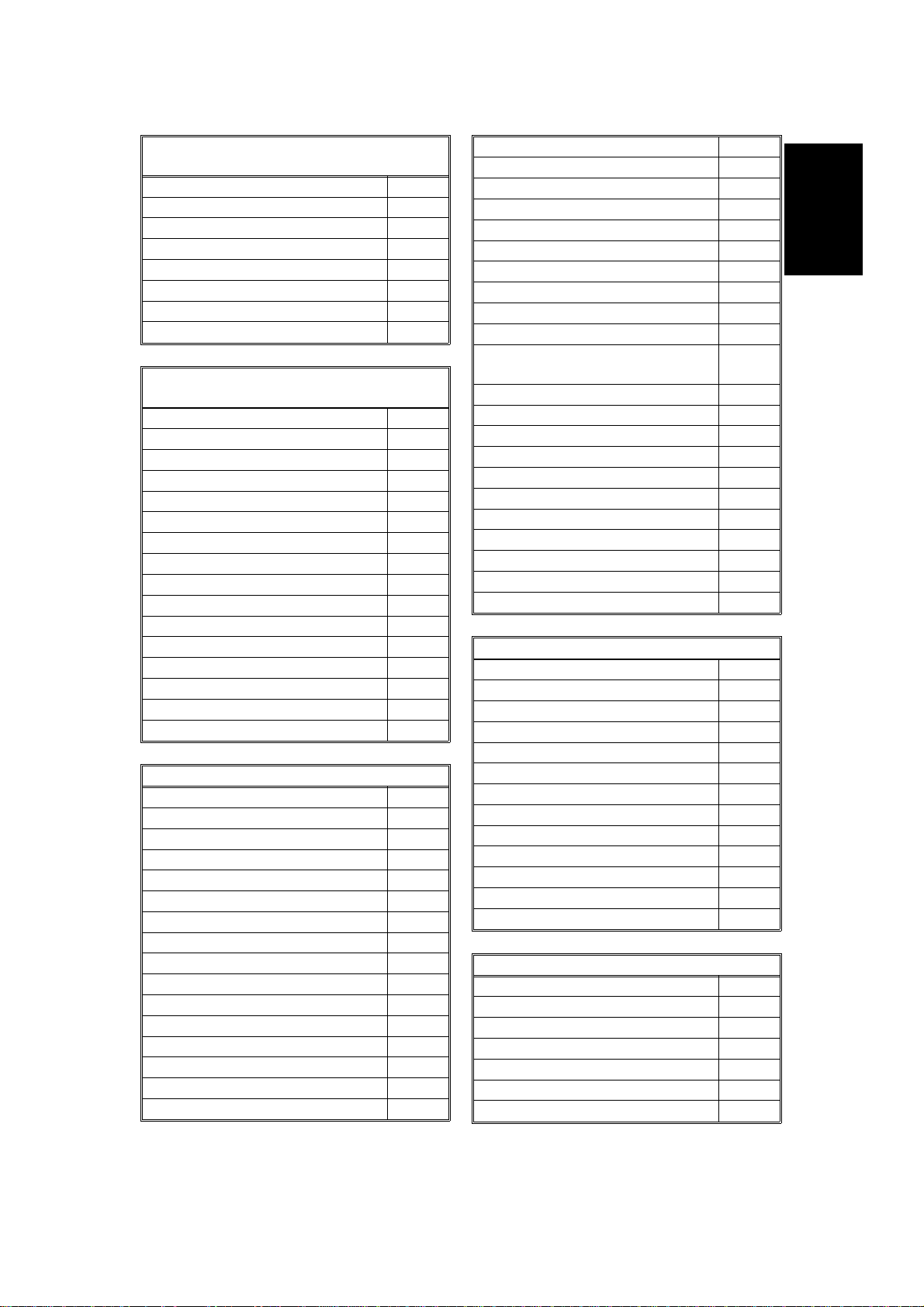

FEATURES

Reports - User-initiated

Quick Dial List O

Specified Cassette Selection List B

Speed Dial List O

TCR O

Transmission Status Report X

User Function List X

Use r Paramete r List O

Service Mode Features

Back-to-back t est O

Bit switch programming O

Buzzer test O

Cable equalizer (rx only) O

Comm. par ameter display O

DTMF tone test O

Echo countermeasure O

Error code display O

LCD contrast adjustment O

Memory file forwarding O

Memory file printout (all files) O

Modem te st O

NCU parameters O

Operation panel test O

Printer mechanism test X

Printer te st patterns O

Progra mmable atten u ation X

Protocol dum p list O

R AM display/rewrite O

RAM dump O

R inger tes t X

Scanner la mp test O

Scan n er mechanism test O

Sens or initialization X

Serial number O

Service m onitor repor t O

Serv ice s tation numbe r O

Syste m parameter list O

Technical data on the TCR O

T h ermal head parameters X

Transmission Status Report X

Memory Files

Max. number of files: 100

Max. number of stations/file: 142

Max. number of stations overall: 299

Max. number of pages overall: 200

(including pages stored as Auto

Documents)

1-4

Page 7

OVERALL MACHINE INFORMATION November 30th, 1991

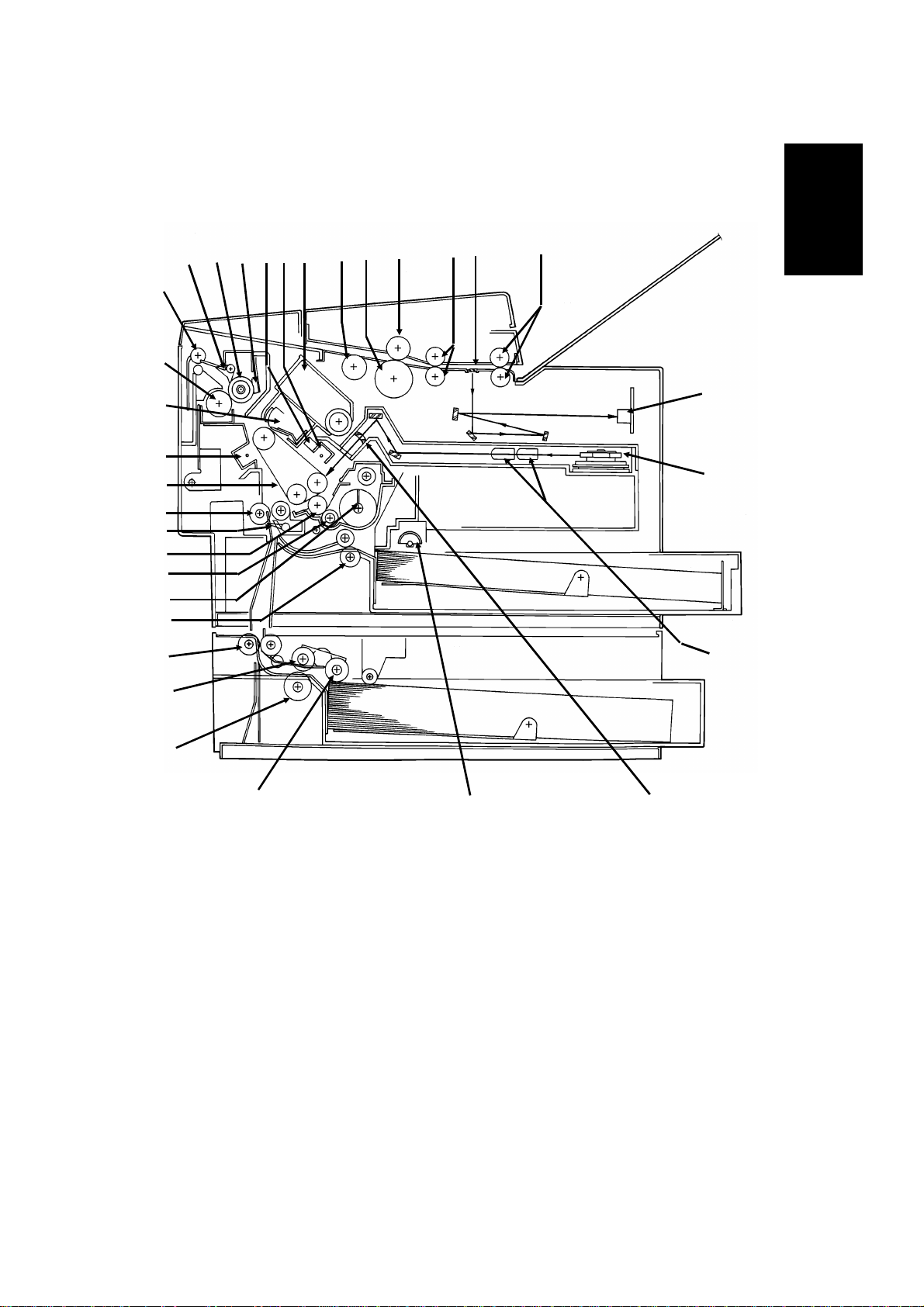

COM PONEN T LAYOUT

1.3. COMPONENT LAYOUT

1.3.1. Mechanical Components

1

14

15

16

17

18

19

20

21

22

23

24

13

12

11

10

2

6789

45

3

1

32

31

30

25

26

27

1. R2 Rollers Feed the document through the scanner.

2. Exposure Glass Exposes the original to light from the xenon lamp.

3. R1 Rollers Feed the document through the scanner.

4. Separat ion Roller Allows on e page i nto the scann er.

5. Document Feed Roller Feeds the document into the scanner.

6. Pick -up R oller Picks up pages of the document from the document

table .

7. Toner Cartridge This supplies toner to the development unit. It is part of

the CTM (Cleaning/Toner Magazine).

8. Charge Corona Unit This applies a charge to the master at the start of the

print cycle.

9. Quenching L amp This removes excess charge from the master at the end

of the print cycle.

10. Thermistor This me asures the temperature in the f using unit.

11 . H ot Roller Hea t from this r oller f uses the toner to the copy paper.

28

29

1-5

Page 8

November 30th, 1991 OVERALL MACHINE INFORMATION

COM PONEN T LAYOUT

12 . H ot Roller Strippers These take the paper off th e hot roller af ter fusing.

13. Copy F eed-out R ollers These feed the paper out of the printer.

14. Pressure Roller (Fusing) This applies pressure to the paper during the fusing

process.

15. Cleaning Unit/Used Toner

Tan k

16. Transfe r C orona Unit This applies a charge to the paper to pull the toner off

17. Master Belt Also known as the CS (Compact Seamless) Engine. The

18. Registration R olle r This carries out the registration process.

19. Registration Sens or This dete cts when pape r is approaching the registra tion

20. Development Roller This roller applies toner to the latent image on the

21. Toner Supply Bar This feeds toner to the development roller.

22. Toner Mixing Bar This stirs up the toner in the development unit, so that it

23. Upper Rel ay Rollers The se fe ed paper from the u pper cassette into th e

24. Lower Relay Rollers These feed paper from the lower cassette into the

25. Lower Paper Feed Roller This feeds paper out of the lower cassette.

26. L owe r Paper Se pa ration

Roller

27. Lowe r Paper Pick-up Roller This picks up the t op sheet of paper from the stack in

28. Upper Paper Feed Rollers T hese pick up the top shee t of paper from th e stack in

29. Focusing Lens This focuses the laser beam onto the master belt.

30. Fθ Lenses These ensure that the thickness of the laser beam is

31. He xagonal Mirror This passes the laser beam across the mas ter belt.

32. CCD (Charge Coupled

Device)

This removes excess toner from the master after image

transfer and stores it. It is part of the CTM

(Cleaning/Toner Magazine).

the master a nd onto the copy paper.

latent image is writte n to this organic photoconductor

belt.

roller .

master belt.

does not collect into lumps.

printer .

printer.

This ensure s that only one shee t of paper at a time

leave s the lower cassette.

the lower cassette and pas ses it to the f eed roller.

the upper cassette a n d fe ed it into the printer.

uniform across the main scan.

This converts the light reflected from the document into

an analog video signal.

1-6

Page 9

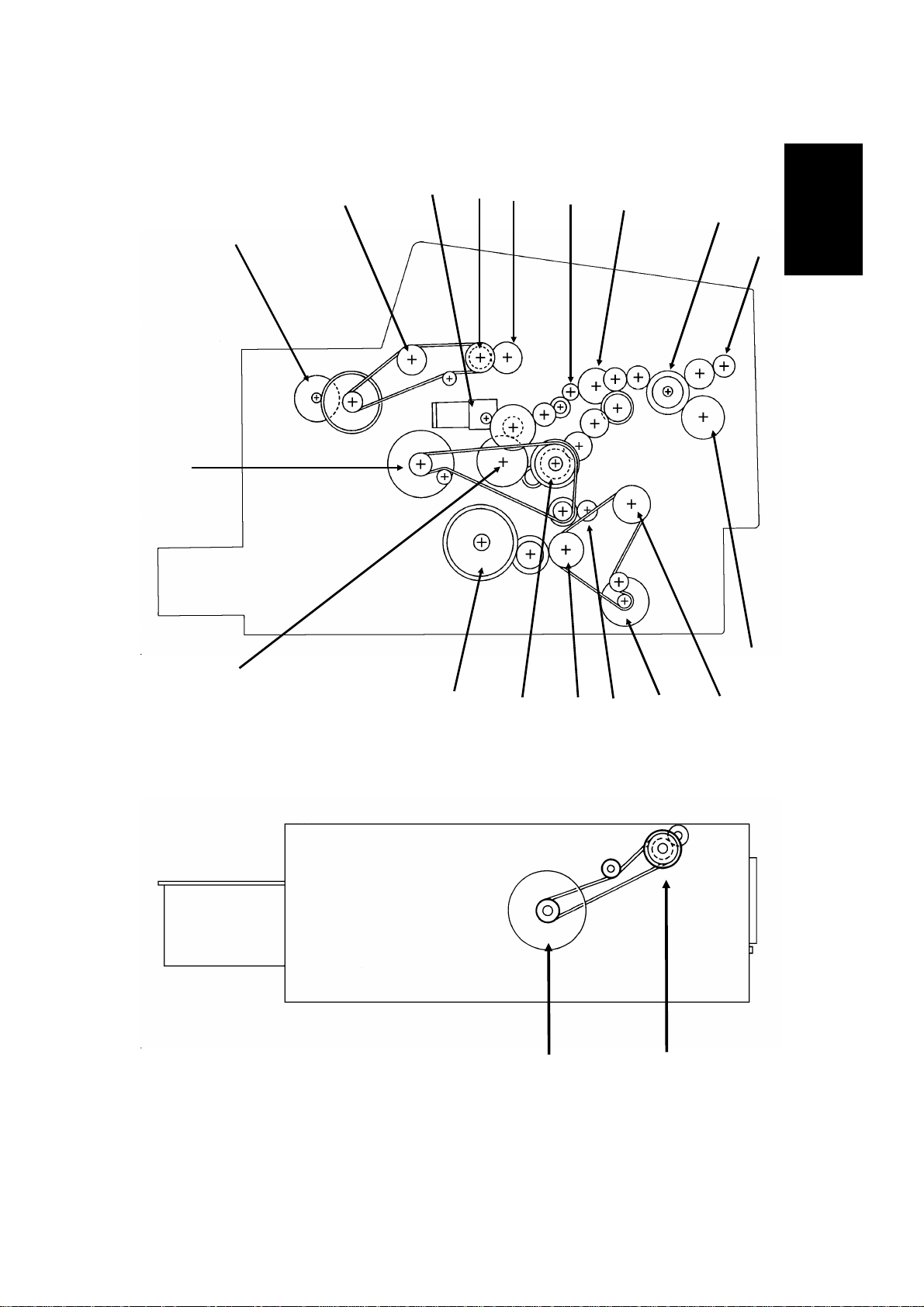

567

13

14

15

OVERALL MACHINE INFORMATION November 30th, 1991

COM PONEN T LAYOUT

1.3.2. Drive Components

18

2

1

3

4

8

1

9

17

16

19

12

20

10

11

1-7

Page 10

November 30th, 1991 OVERALL MACHINE INFORMATION

COM PONEN T LAYOUT

1. Tx Motor This stepper motor drives the scanne r.

2. R2 Roller This feeds the original through the s canner.

3. Toner Supply Motor This dc motor drives the toner supply mechanism.

4. R1 Roller This feeds the original through the s canner.

5. Shutter Dri ve Gear This ensures that the shutter moves out of th e

document feed path at the correct time.

6. Toner Supply Gear (C TM) This ensure s the supply of toner from the CTM into the

development unit. It is part of the CTM.

7. Cleaning Brush Drive Gear This drives the cleaning brush in the C TM.

8. Hot Roller This fus es the toner to the copy pape r.

9. Copy Feed-out Roller This feeds printouts out of the machine.

10. Pressure Roller This applies pre ssure t o t he copy paper in t he fusing

unit.

11. Registration Roller Drive

Gear

12. Upper Paper Feed Motor This dr ives the paper feed mech anism in the upper

13. Development Roller Drive

Gear

14. Upper Paper Feed Roller

Drive Gear

15. Master Belt Drive Gear This drives the master belt.

16. Paper Feed Clutch This transfers drive from the upper paper feed motor to

17. Toner Supply Gear

(Development)

18. Ma in M otor T his brushless dc motor drives the ma s te r belt, fus ing

19. Lower Paper Feed Motor This drives the paper feed mechanism in the lower

20. Lower Paper Feed Clutch This transfers drive from the lower paper feed motor to

This drives the registration roller.

cassette.

This drive s the de velopme nt roller.

This drives the upper paper fee d roller.

the uppe r paper feed mechanis m.

This ensure s the collection of toner from the CTM, and

its distribution across the full length of the development

unit.

unit, development unit, and cleaning unit.

cassette.

the lower paper fe ed mechanis m.

1-8

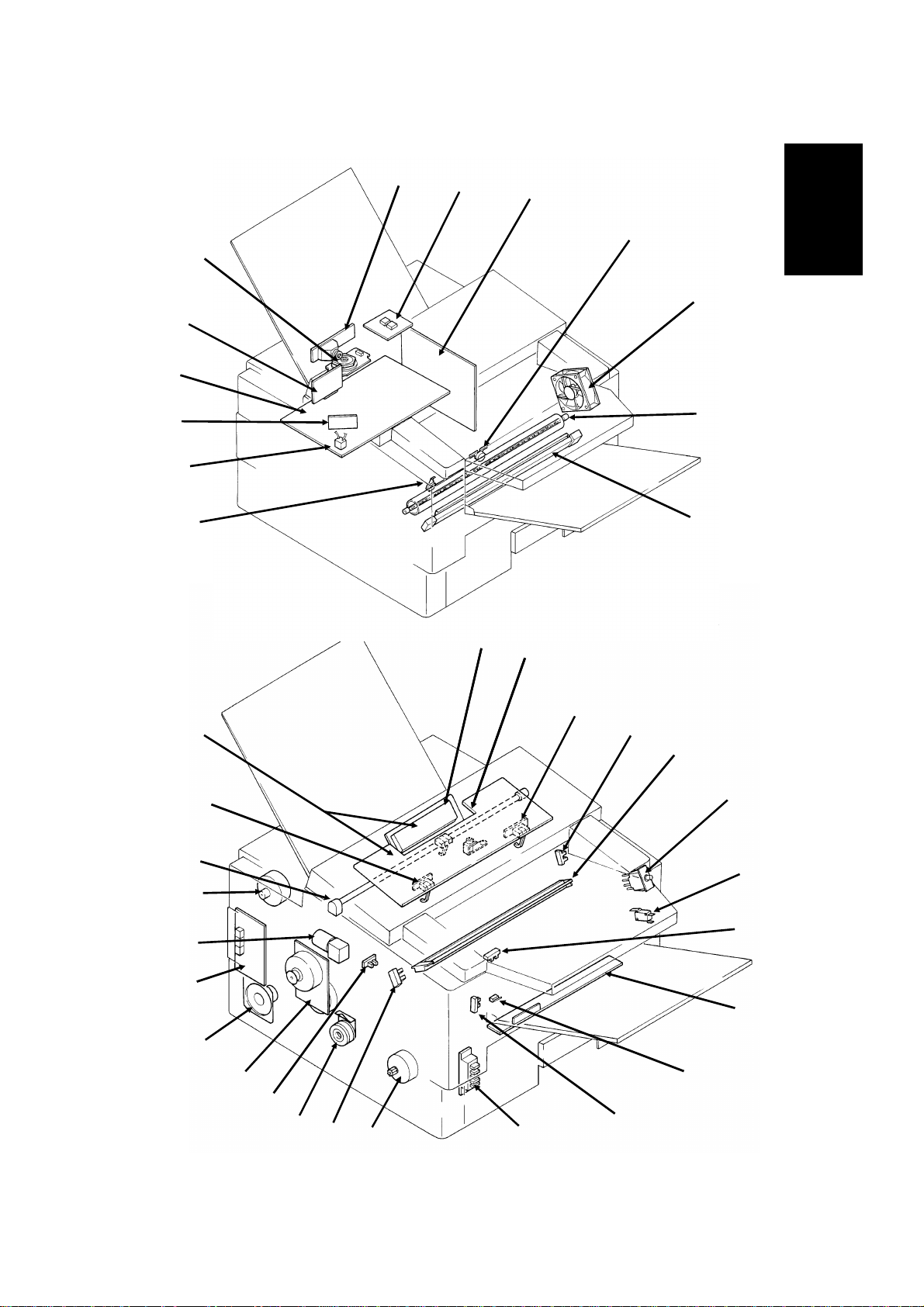

Page 11

16

24

9

12

OVERALL MACHINE INFORMATION November 30th, 1991

COM PONEN T LAYOUT

1.3.3. Electrical Components

1

13

11

2

3

4

5

1

10

8

37

35

34

36

14

14

15

15

6

7

17

18

19

20

33

32

31

30

29

28

27

26

21

22

23

25

1-9

Page 12

November 30th, 1991 OVERALL MACHINE INFORMATION

COM PONEN T LAYOUT

Lower Ca ssette

44

43

42

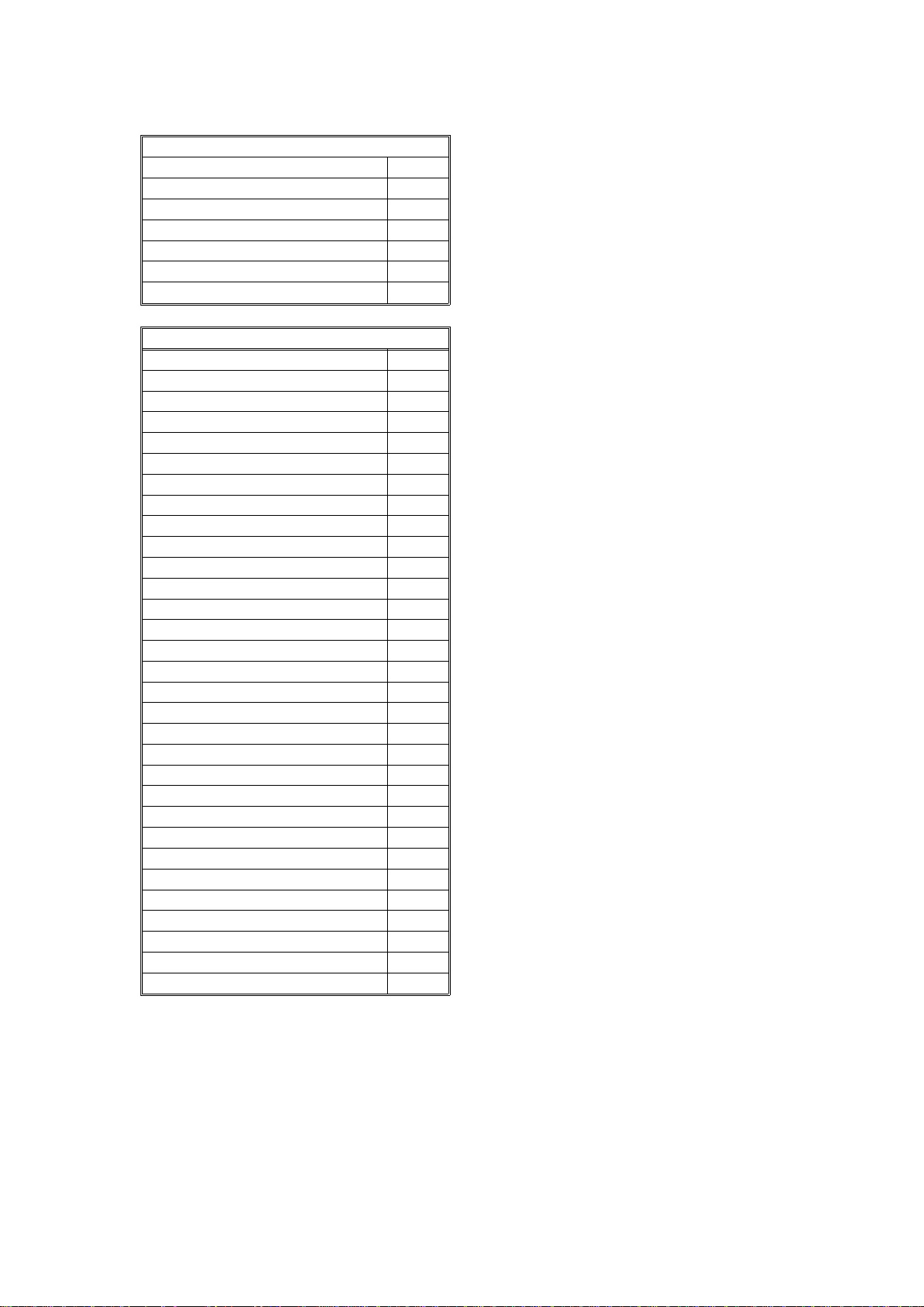

Name Description No.

PCBs

FCU This board controls the machine. 11

MBU This board contains the system ROM and RAM for storing

system parameters such as bit switch settings and programmed

telephone numbers.

SBU This board contains the CCD. 1

OP- PORT Th is board controls t he operation panel. 37

NCU This board contains relays and switches for interfacing the

machine to the network and the handset.

PSU This board supplies power to the ma chine. 3

LD Unit This board drives the laser diode. 10

PF U T his board controls the lower paper fe ed unit. 4 4

MOTORS

Tx M otor This ste pper motor drives the scanner. 34

Main Motor This dc motor drive s the fusing unit, master belt, dev elopment

roller, and cleaning unit.

Upper Paper

Feed Motor

Lower Paper

Feed Motor

Toner Sup p l y

Moto r

Hexagonal Mirror

Motor

Ozone F an This removes ozone-laden air from the vicinity of the master unit,

This stepper motor drives the upper paper feed mechanism and

the registra ti on roller.

This stepper motor drives the lower pape r f eed mechanism. 43

This dc motor drives the toner s u pply mechanism. 33

This high-speed dc motor drive s the hexagonal mirror in the

lase r printer optics.

an d filter s out the ozone.

38

39

40

41

12

32

30

26

13

5

1-10

Page 13

OVERALL MACHINE INFORMATION November 30th, 1991

COM PONEN T LAYOUT

Name Description No.

CLUTCHES

Upper Paper

Feed Clutch

Lower Paper

Feed Clutch

SENSORS

Docum ent Sensor This detects the presence of a document in the feeder. 36

Scan Line Se nsor This detects when a page is approaching the auto sha ding

Document Width

Sensor

Toner Near-end

Sensor

Upper Paper Size

Detector

Upper Paper End

Sensor

Registration

Sensor

Paper Feed-out

Sensor

Front Cover

Switch

CT M Sensor This detects when a CTM has been ins ta lled in the machine. 27

Lower Paper Size

Detector

Lower Paper End

Sensor

Lower Paper

Feed Sensor

INT ERLOCK S WITCHES

Front Cover

Interlock

Switches

OTHERS

Spe aker This allows the user to listen to th e condition of th e telephone

Xenon Lamp This lamp illuminates the document. 35

Xenon Lamp

Driver

Charge Corona

and Quenching

Lamp Unit

Transfer Corona

Unit

Varistor This ensures that the charge given to the master by the charge

Marker This stamps a re d circle on each page that is successf ully f ed

T h i s transfe r s drive from the upper pape r feed motor to the

paper feed roller in the upper cassette.

T h i s transfe r s drive from the lower paper feed motor to the paper

fee d roller in the lower cassette.

position.

This detects when a B4-width [10.1"] document has been placed

in the feeder.

This detects when the toner has almost run out. 17

T h i s de tects th e paper s i ze installed in th e upper cassette. Th e

use r mu st install th e correct actuator.

This detects when the paper in the upper cassette ha s run out. 29

This detects when paper has arrived at the re gis tra tion rollers. 21

This detects when the paper has been fe d out of the printer. 24

This detects wheth er the front cove r is open or closed. 23

T h i s de tects th e paper s i ze installed in th e lower cass ette. T h e

use r mu st install th e correct actuator.

This detects when the paper in the lower cas sette has run out. 3 8

This sensor detects the presence of paper at t he lowe r paper

feed roller.

If the front cover is open, these interlock switches interrupt the

+ 5VLD power supply for the laser diode and the + 24VD power

supply f or t he power pack, motors, and oth er componen t s.

line.

This drives the xenon lamp. 2

The charge corona unit charges the ma s te r belt a t the s ta rt of

the print cycle. The quenching lamp re move s excess charge

from the master belt at the end of the print cycle .

This pulls the toner off the maste r and onto the copy paper. 7

corona wire does not exceed -750 Volts.

through the scanner.

28

42

14

16

25

41

39

19,

20

31

18

9

15

1

1-11

Page 14

November 30th, 1991 OVERALL MACHINE INFORMATION

COM PONEN T LAYOUT

Name Description No.

Power Pack This s upplies high voltages to the corona wires and the

developme nt bias terminal.

F using Lamp This fuses the toner to the paper. 6

Thermistor This monitors the te mperature inside the f us ing unit. 8

Thermostat This inte rrupts the ac power supply to the fusing lamp if the

temperature exceeds 400 °C.

Lower Cassette

Indicat or Pane l

T h i s conta i n s indicators to show the sta tu s of th e lower cass ette. 40

22

4

1-12

Page 15

OVERALL MACHINE INFORMATION November 30th, 1991

OVERALL MACHINE CONTROL

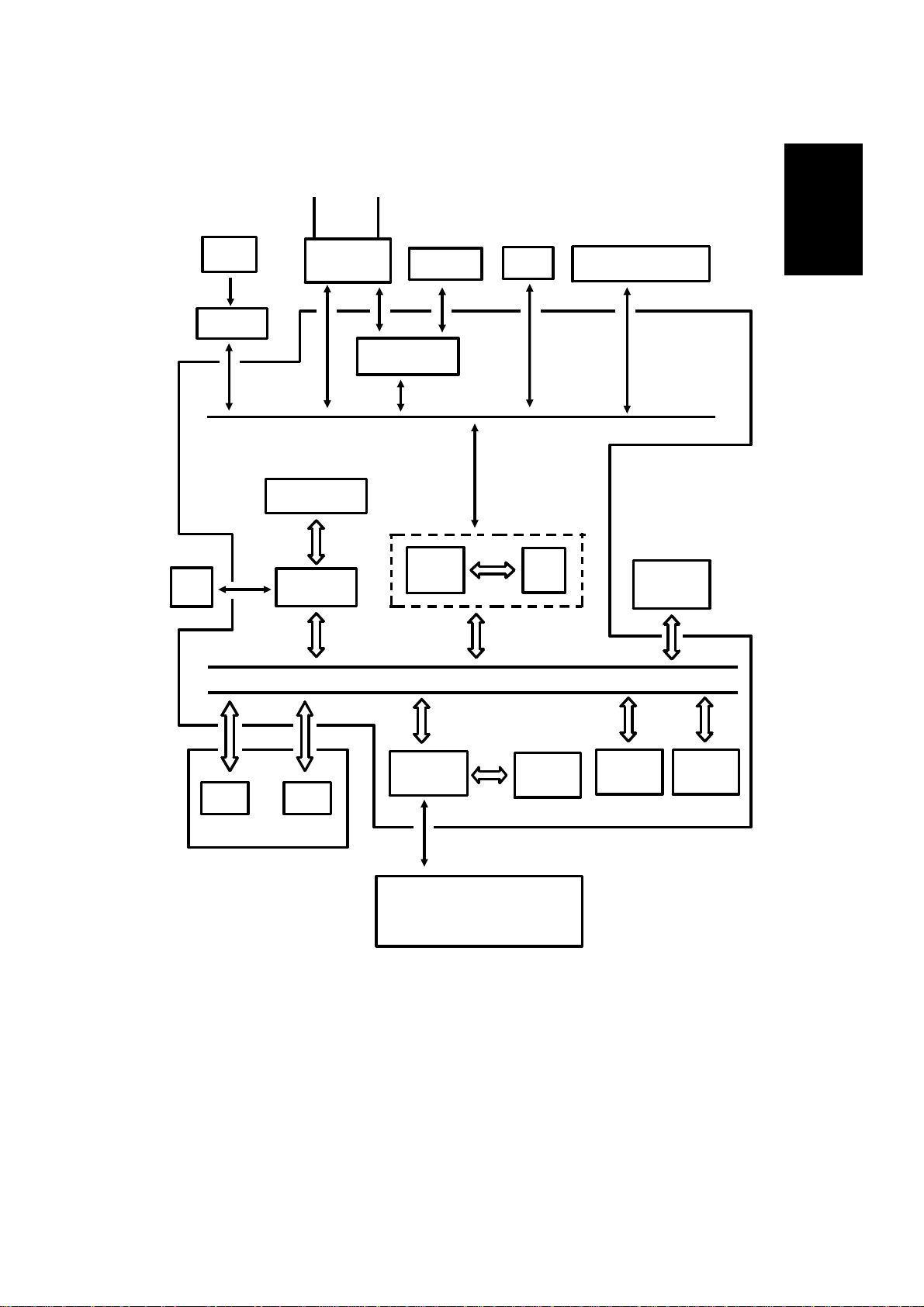

1.4. OVERALL MACHINE CONTROL

HandsetLine

1

SBU

(CCD)

Scanner

Sensors

Operation

Panel

NCU

CONTROL SIGNALS

Video Processing

Memory

Video

Processor

Speaker

Modem AFE

CPU

DATA AND ADDRESS BUS

PSU

Port

Scanner and Printer Drive

Components and Sensors

FCU

I/O

RS-232C

Interface

Laser

Interface

Page

Memory

SAF

Memory

ECM

Memory

RAMROM

MBU

Laser Diode Driver

Main Scan Start Detector

Interlock Switch

The cpu on the FCU board controls the machine, as shown in the above

drawing.

There is no modem board in the machine. The cpu pe rforms the digital functions of a modem and carries out digital to analog conversion of facsimile

data. There is a separate analog modem chip, called the Modem AFE, which

does the rest of the modem operations.

1-13

Page 16

November 30th, 1991 OVERALL MACHINE INFORMATION

VIDEO DATA PATH

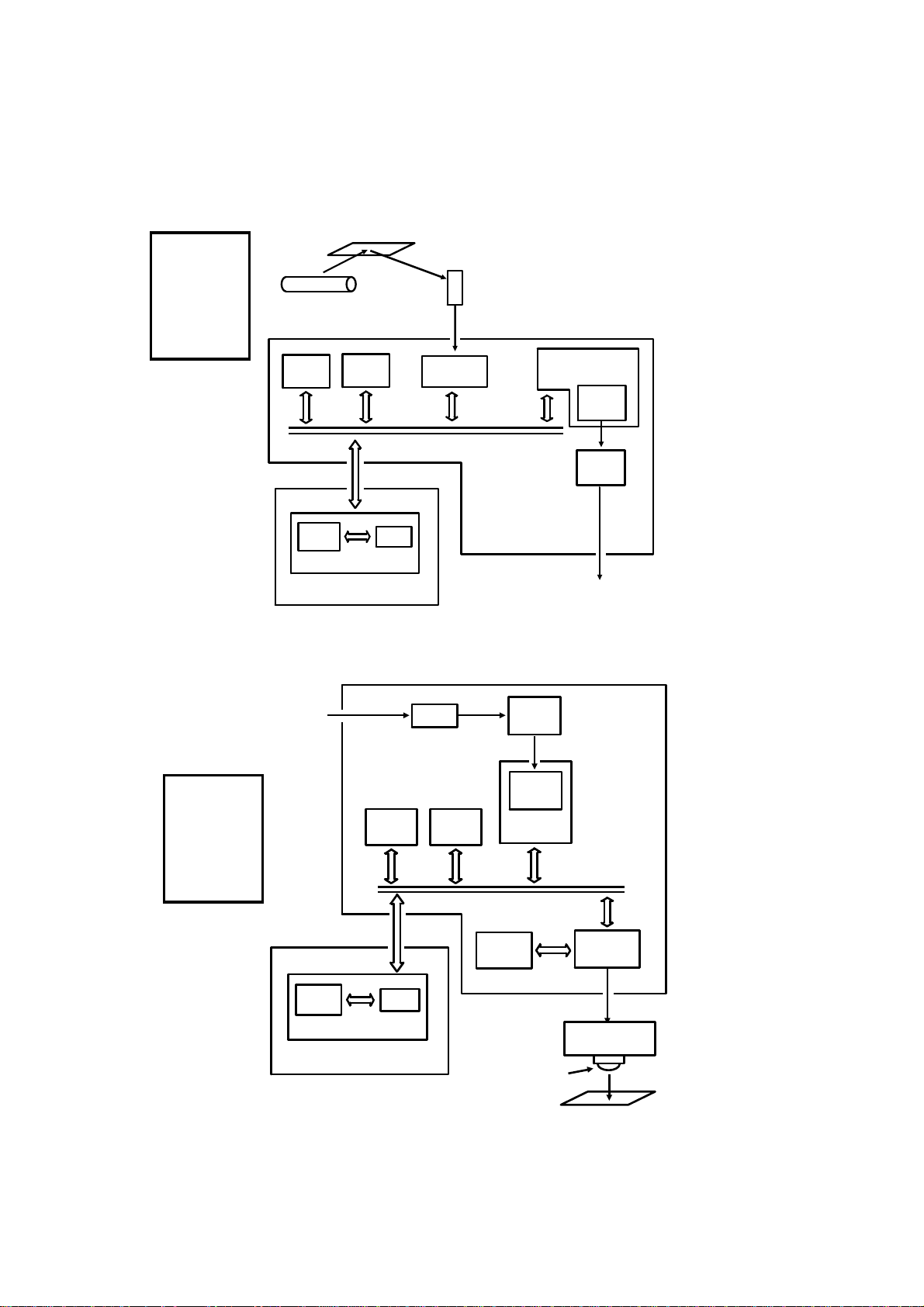

1.5. VIDEO DATA PATH

1.5.1. Transmis sion

Original

Reference:

Group 3

Facsimile

Manual,

section

1-3-1

Xenon

Lamp

ECM

Memory

Line

Buffer

SAF

Memory

RAM

MBU

FIFO

Video

Processor

The fo llowing diag rams show

the data path for this model.

There is no programmable resis-

CCD

Analog Signal

FCU

MODEM

AFE

Modem

(Digital)

Modem

(Analog)

Network

(via the NCU)

tor in this model.

CPU

To the

1.5.2. Reception

From the

Network

(via the NCU)

Reference:

Group 3

Facsimile

Manual,

section

1-3-2

Line

Buffer

RAM

MBU

FCU

Memory

SAF

FIFO

Filter

HYBRID IC

Memory

ECM

Page

Memory

Laser Diode

Modem

(Analog)

Modem

(Digital)

CPU

MODEM

AFE

Laser

Interface

Laser Diode

Driver

1-14

Copy Paper

Page 17

OVERALL MACHINE INFORMATION November 30th, 1991

POWER DISTRIBUTI O N

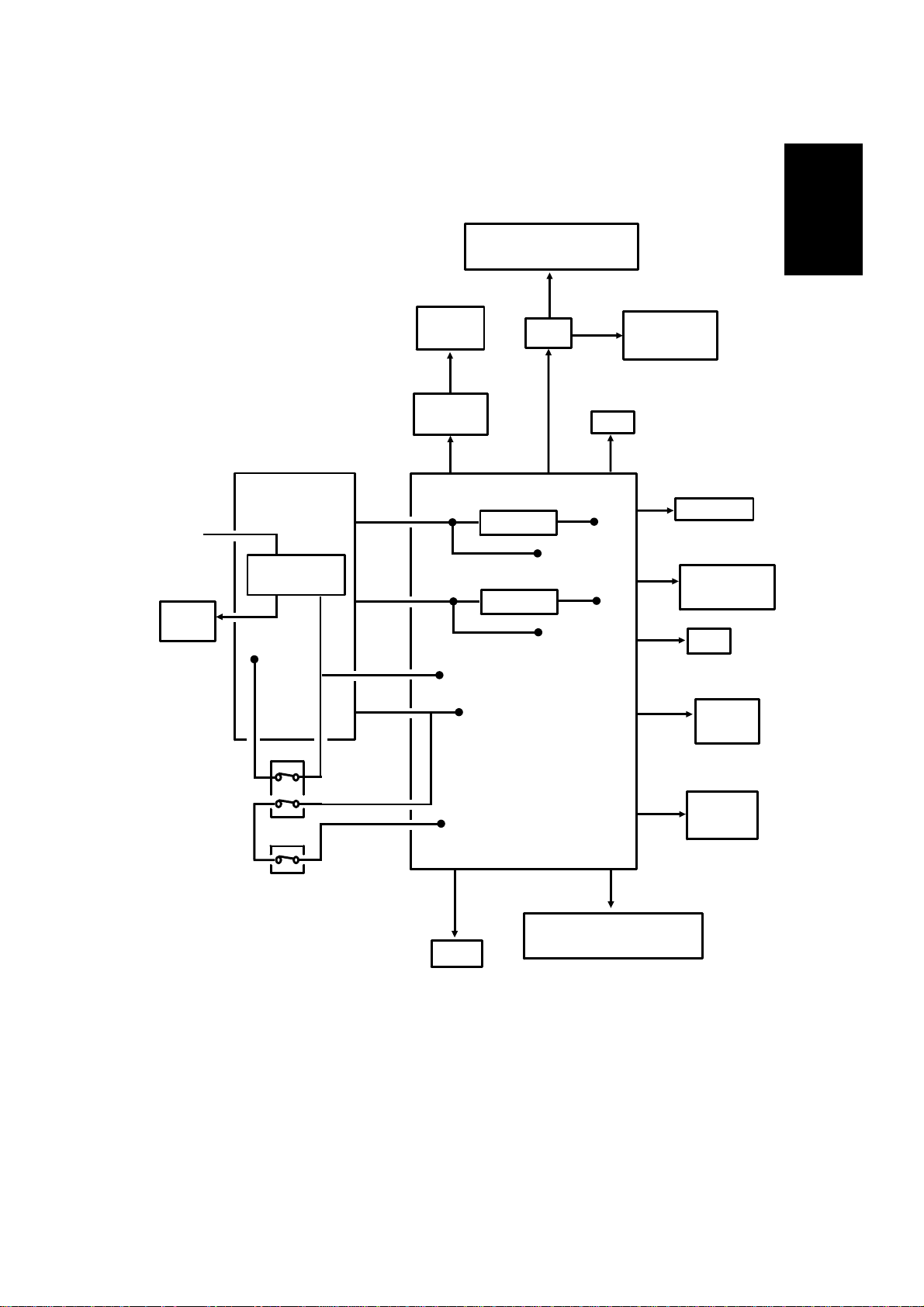

1.6. POWER DISTRIBUTION

1.6.1. Distribution Diagram

Lower Paper Feed Motor

Lower Paper Feed Clutch

+24VD

1

AC Main

Power

Fusing

Lamp

PSU

AC Switching

Circuit

+24V

-12V

+24VS

+24VD

+5V

Scanner

Sensors

+5V

Operation

Panel

+5V

+24VD

Regulator

Regulator

+5V

+24VD

+5V

PFU

- 12V

+5V

+24VS

+24VS

+5V

NCU

FCU

- 5V

+12V

Sensors and

Indicators

FUSING UNIT

Thermistor

+5V

+5V

MBU

SAF Memory

+5V

SBU

+12V

+5V

Printer

Sensors

Front Cover

Interlock Switch

Front Cover

Microswitch

+5VLD

+5VLD

LDDR

Laser Diode

+24VD

Motors, Clutches, Lamps,

Marker, Power Pack

+5V

The laser diode is powered by a special + 5V supply, called + 5VLD.

There are two + 24V po wer supplies:

• + 24VS: This is always on when the main switch is on.

• + 24VD: Th is is interrupted if the front cover interlock switch opens.

There is no + 24VD activation sign al from the cpu to the PSU.

1-15

RS-232C

Interface

Page 18

November 30th, 1991 OVERALL MACHINE INFORMATION

POWER DISTRIBUTI O N

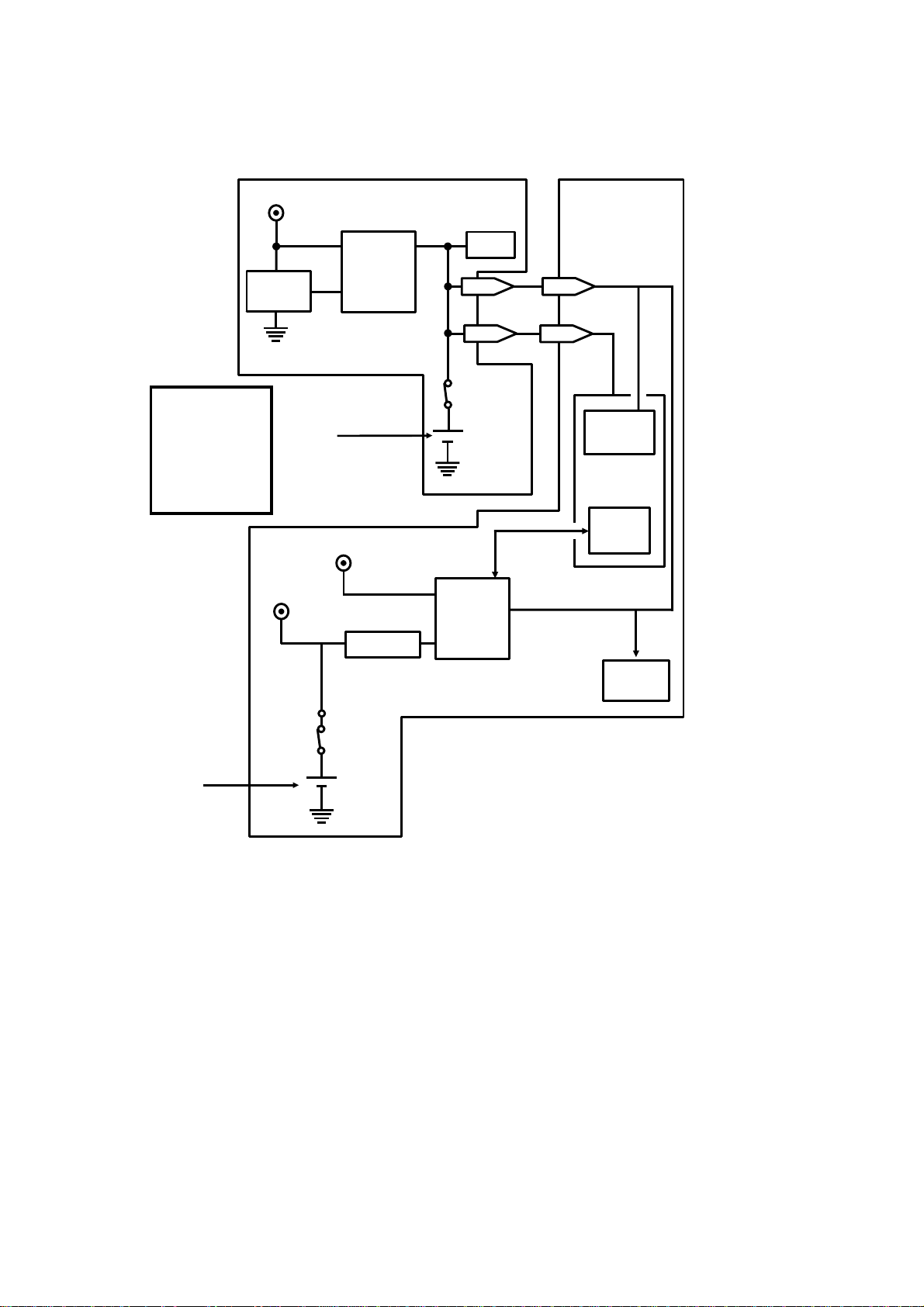

1.6.2. Memory Back-up Circuit

Reference:

Group 3

Facsimile

Manual,

sect i o n 1-4-3,

Circuit type 1

+5V

Voltage

Detector

+24V

[A]

+5V

Switching

Circuit

Regulator

MBU

RAM

1-11

1-9

Battery

Switch

Battery

Switching

Circuit

FCU

17-11

17-9

Real Time

Clock

CPU

Memory

Monitor

SAF

Memory

Battery

Switch

[B]

Battery

The battery [A] on the MBU backs up the RAM on the MBU, which contains

system parameters. It also backs up the real time clock in the cpu. This battery is not rechargeable. CN1-9 tells the cpu whether the back-up power

(CN1-11) comes from the battery or from the + 5V power supply.

A rechargeable battery [B] on the FCU board backs up the SAF memory and

the real time clock for 1 hour. While the main power is on, the + 24V supply

recharges the battery.

If there is data in the SAF memory, the rechargeable battery [B] also backs

up the real time clock, to preserve the MBU battery.

1-16

Page 19

[A]

DETAILED SECTION DESCRIPTIONS November 30th, 1991

SCANNER

2. DETAILED SE CTION DESCRIPTIONS

2.1. SCANNER

2.1.1. Mechanisms

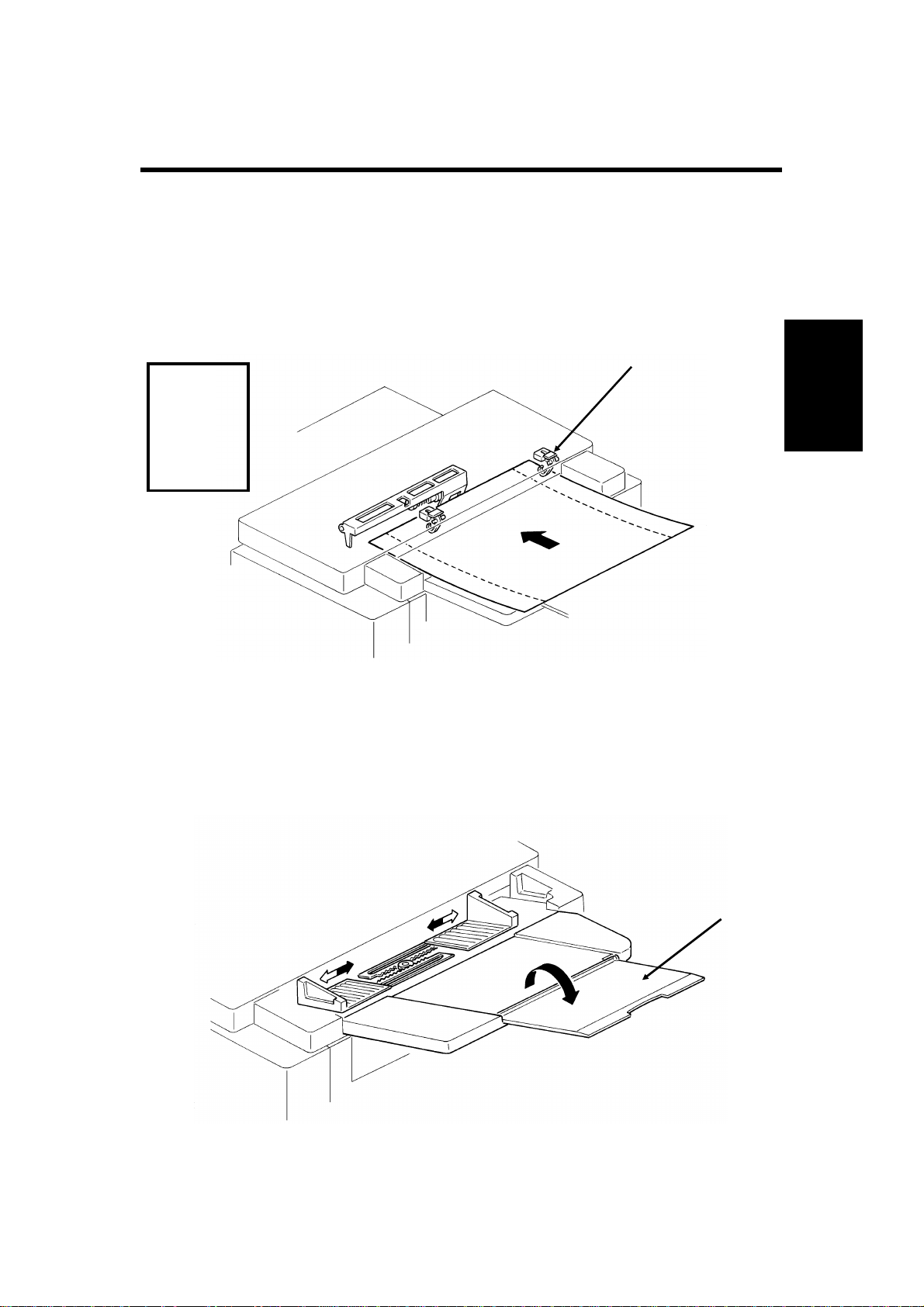

1. Document Detection

Document Table

Reference:

Group 3

Facsimile

Manual,

section

2-1-1.

• The scanner is B4-width [10.1"] , with a B4 document width detector [A].

The scanner can feed paper u p to 304 mm [12"] wide. However, only

10.1" of this width will be scanned. The extra width allows users to feed

wide originals with wide margins, such as computer form printouts.

• The scanner contains a xenon lamp.

• There is a fold-down extension [B] to suppo rt long d ocuments.

2

[B]

2-1

Page 20

[A]

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

SCANNER

Shutter

[C]

[B]

Reference:

Group 3

Facsimile

Manual, section

2-1-1.

In standby mode, tab [A] rests on cam [B]. When the tx motor starts, the motor rotates forwards (white arrows), the cam lifts the tab, and the shutter [C]

rises. After the last page has been fed through the scanner, the tx motor reverses (black arrows), the cam drops back to the standby position, and the

shutter blocks the scanner path again.

2. Pick-up and Feed

Drive Mechanism

Reference:

Group 3

Facsimile

Manual,

sect i o n 2-2-1.

[A]

[B]

[C]

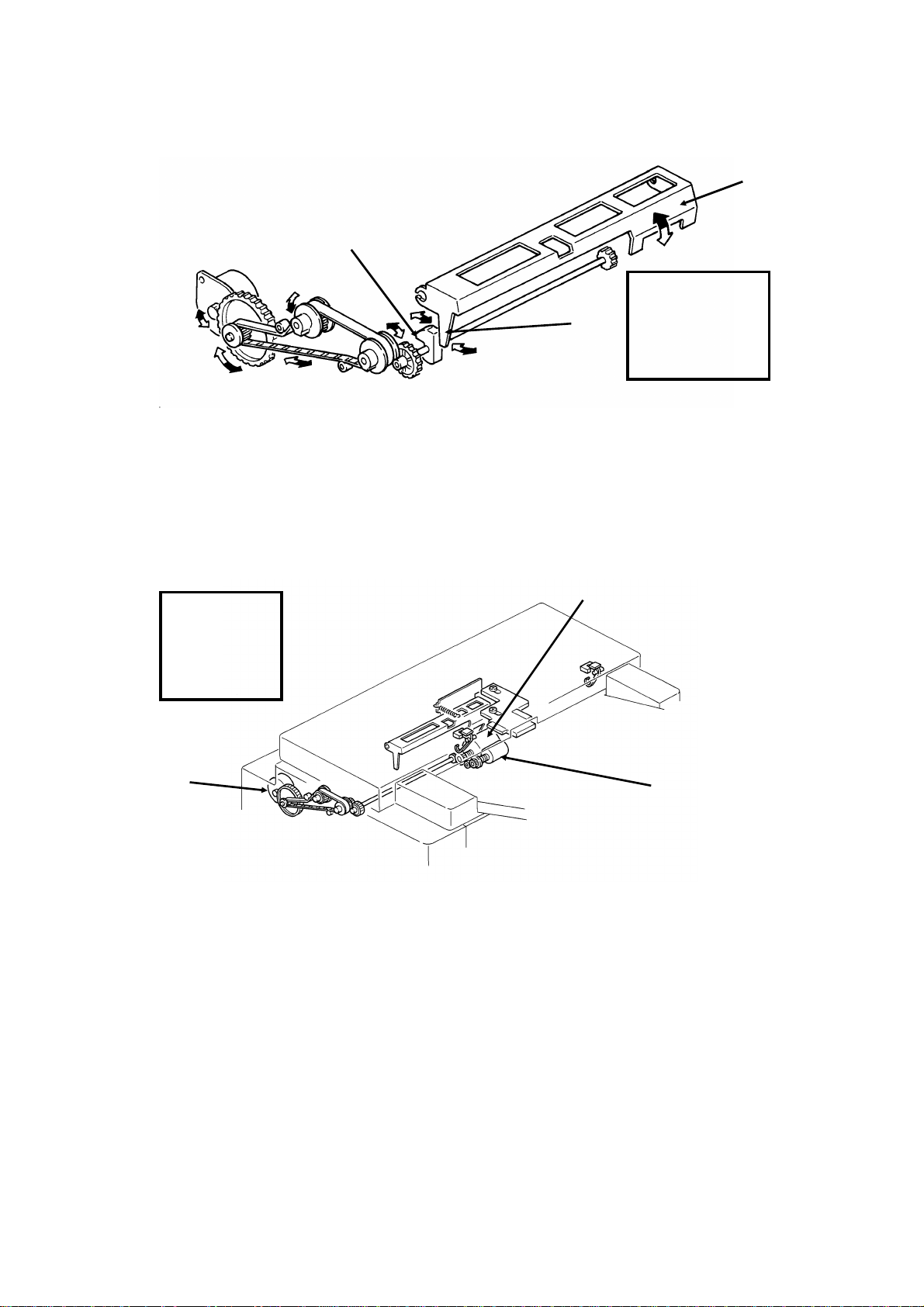

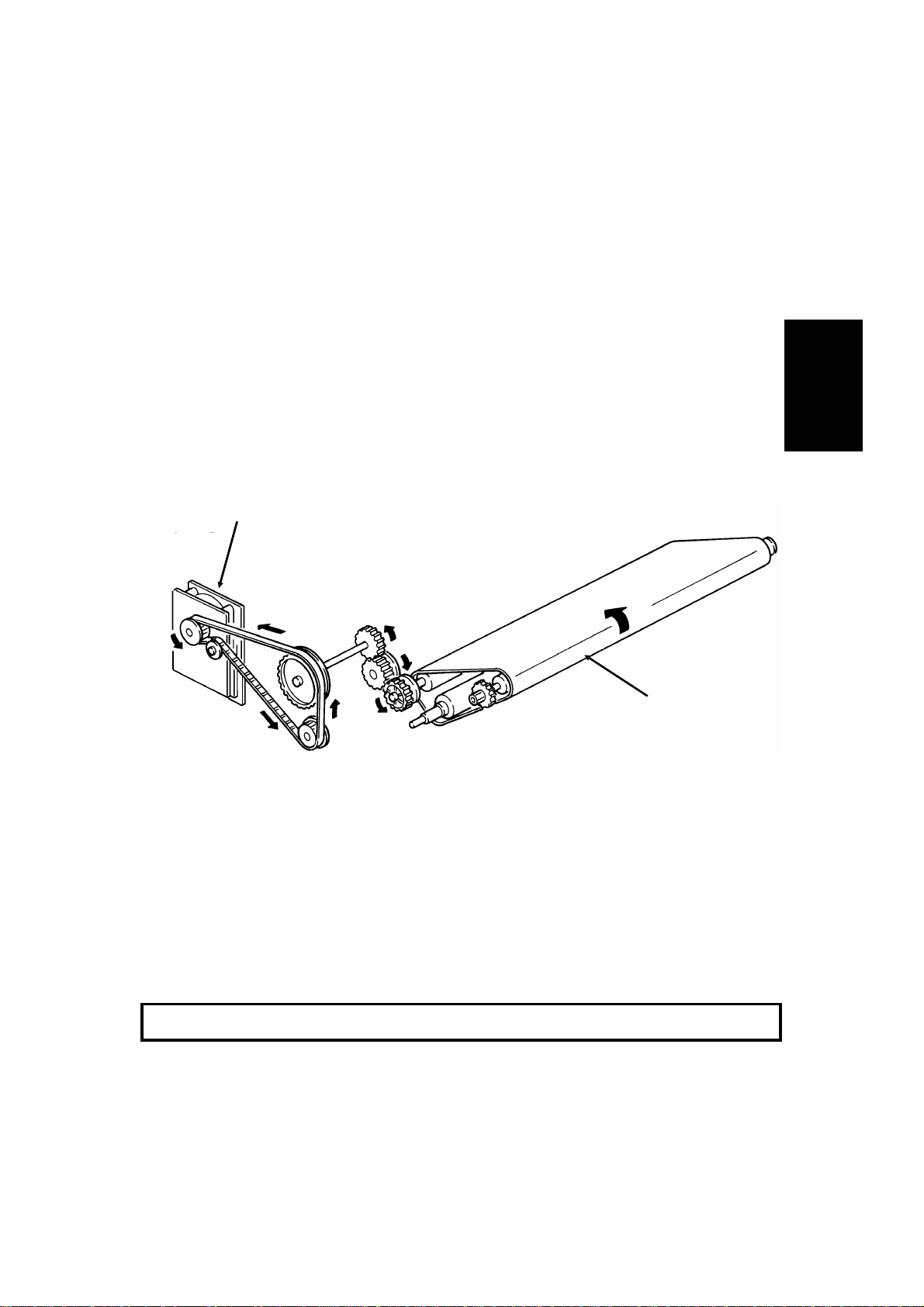

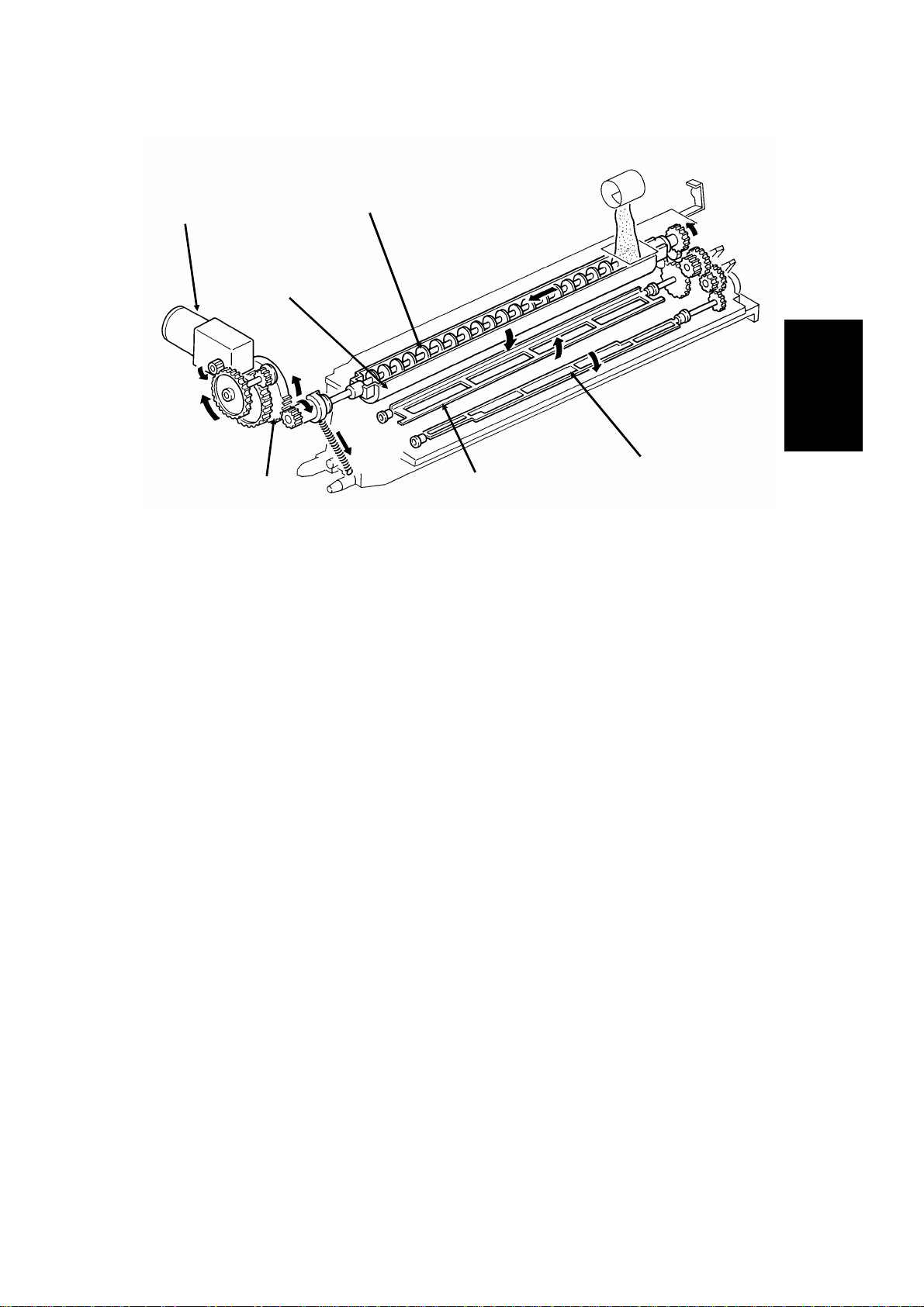

This ma chine has a Mechanical Clutch Mechanism. The tx motor [A] drives

the feed roller [B] and pick-up roller [C].

Resoluti on

Standard - The tx motor fe eds the document at 7 . 7 lines/mm. T he video processor executes

OR processing to convert the data into 3.85 lines/mm.

Detail - The tx motor feeds the document at 7.7 lines/mm. There is no OR processing, and

the data is transmitted at 7.7 lines/mm.

Fine - The tx motor feeds the document and transmits data at 15.4 lines /mm. If the other terminal cannot receive at this re solution, alternate lines of data are deleted, so the effective resolution of the transmitted data is 7.7 lines/mm.

2-2

Page 21

DETAILED SECTION DESCRIPTIONS November 30th, 1991

SCANNER

Jam Conditions

The cpu detects a document jam if one of the fo llowing conditions occurs.

• Th e scan line sensor do es not switch on within 9 s of the Start key be-

ing pressed.

• The scan line sensor does not turn off after the maximum document

length has been fed since it turned on.

• The scan line sensor switches on while the document sensor is off.

• The document width sensor switches on while the document sensor is

off.

• The scan line sensor does not turn on within 5 s of the end of stamping,

if the document sensor is on.

Separation

Reference: Group 3 Facsimile Manual, section 2-2-2

2

3. Manual Feed

[B]

[A]

The manual feed button [A] lifts the separation roller [B] out of the doc um ent

feed path. There is no manual feed switch.

Reference: Group 3 Facsimile Manual, section 2-2-3

2-3

Page 22

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

SCANNER

2.1.2. Video Data Processing

Output from the CCD

A

Auto Shading

Memory

WHITE

WAVEFORM

FEEDBACK

Reference:

Group 3

Facsimile

Manual,

sect io n 2-3.

DC

Filter

VIDEO

PROCESSOR

Corrected Data from the Auto Shading Circuit

Amplifier

Gamma

Correction,

MTF

A/D

Converter

Data Processing

Circuits

Halftone

Process

Edge

Detection

To the CPU

and Modem

Basic

EDGE

ELEMENTS

Peak

Hold

CORRECTED

DATA

Error

Diffusion

Halftone

Process

Comparator

Background

Detection

OR

Processing

Reduction

A

NON-EDGE

ELEMENTS

Reduction

Halftone

B

Process Selector

To CPU and Modem

2-4

Image/Text

Detection

B’

Page 23

DETAILED SECTION DESCRIPTIONS November 30th, 1991

PRINTER

2.2. PRINTER

2.2.1. Mechanisms

1. Master Unit

This printer uses a "write to black" system, using negative toner.

The master unit contains a durable OPC master belt. The expected lifetime of

each master unit is about 60,000 copies (this is the target value). Because of

this long lifetime, the user is not expected to change the master; there is no

Replace Master indicator.

The master belt does not have a bond seam, so no master home position detection is needed. There is also no master unit interlock switch; there is an interlock switch on the front cover.

[A]

2

[B]

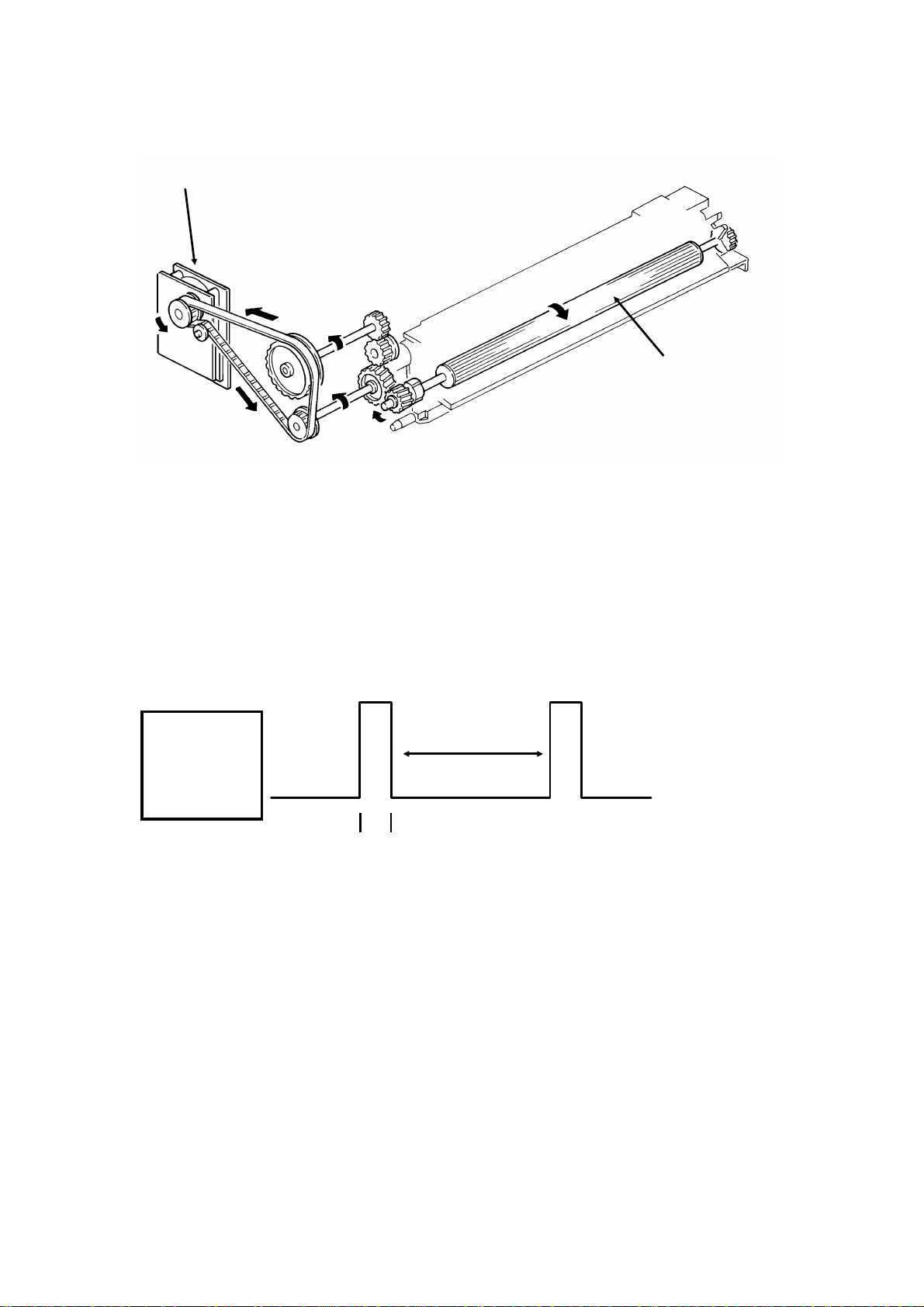

The main motor [A] dr ives the master belt [B].

• At the start of printing, it turns on briefly and the master belt moves un-

der the quenching lamp to ensure that it is fully discharged.

• Then, when the fusing lamp is at the correct temperature and the page

memory contains a complete page of data, and the hexagonal mirror

motor is running at the correct speed, the main motor switches on

again.

• When the main motor is running at the correct speed, the laser diode

turns on for automatic power control.

Reference: Group 3 Facsimile Manual, section 4-1

2-5

Page 24

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

PRINTER

2. C harge Corona Unit

[D]

[B]

[E]

[A]

[C]

The charge corona unit [A] gives a -750 V charg e to the master belt. The

varistor [B] ensures that the charge does not exceed this value.

The connection between the power pack [C] and the corona unit is not broken when the front cover is opened. However, the front cover interlock switch

cuts the + 24V power line to the power pack if the cover is opened.

The charge corona unit contains a wire cleaner [D].

The charge corona switches on at the same time as the laser diode starts its

power control procedure.

There is one ozone fan on the right hand side of the machine. It sucks air out

of the mac hine through the ozone filter, which is part of the ozone fan assembly. The ozone fan switches on when a ringing signal is detected, and stays

on until the fusing lamp temperature falls back below 130 °C at the end of the

printing run.

The inset shows how the grid plate [E] connects to the varistor.

Reference: Group 3 Facsimile Manual, section 4-2

2-6

Page 25

DETAILED SECTION DESCRIPTIONS November 30th, 1991

PRINTER

3. Laser Optics

[E]

[F]

[B]

[D]

[A]

[C]

2

The optics are the same as those illustrated in section 4-3-3 of the Group 3

Facsimile Manual, except that there are two mirrors [A] at the "Second Mirror" position.

Other points to note are as follows:

• The focusing lens [B] is a barrel toroidal lens.

• The shield glass [C] pr events toner from entering the laser optics area,

and may need cleaning occasionally.

• An optical fiber [D] p asses the reflected laser beam to the main scan

start detector [E]. This detector is situated on the laser diode drive

board [F], unlike shown in the diagram.

• The strength of the b eam is 0.436 mW at a w avelength of 780 nm.

• The dimensions of the dot on the master belt are 65 µm (main scan di-

rection) by 75 µm (sub-scan direction).

The charge on the exposed parts of the belt drops to abo ut -150 V, while nonexposed areas remain at abo ut -750 V.

The laser engine characteristics are as follows (refer to page 4-3-21 of the

Group 3 Facsimile manual for background).

• Motor speed: 9,240 rpm

• Motor type: Hexagonal

• LD clock frequency: 5.3311 MHz

• Time between main scan synchronization signals: 1.082 ms

• Number of dots per main scan: 5769

2-7

Page 26

[A]

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

PRINTER

4. Development

Overview

This machine uses a ’write-to-black’ development system using negative

toner.

The toner cassette is part of a disposable unit known as the CTM (Cleaning/Toner Magazine). The CTM contains a toner cassette, toner supply

mechanism, cleaning unit, and used toner tank. When the toner is all used

up, the CTM is replaced.

Reference: Group 3 facsimile Manual, section 4-4

Toner Supply

[B]

[C]

[E]

[D]

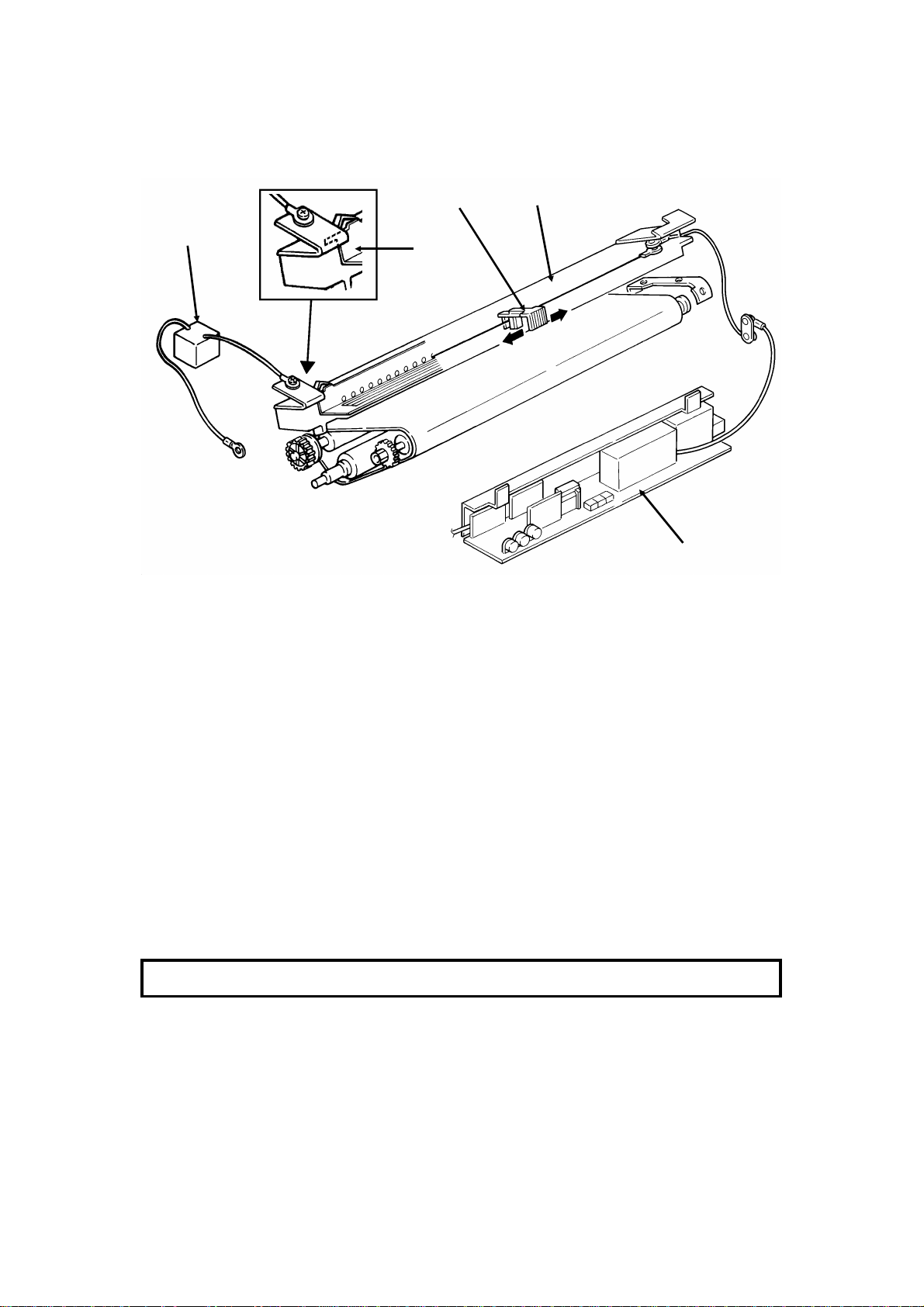

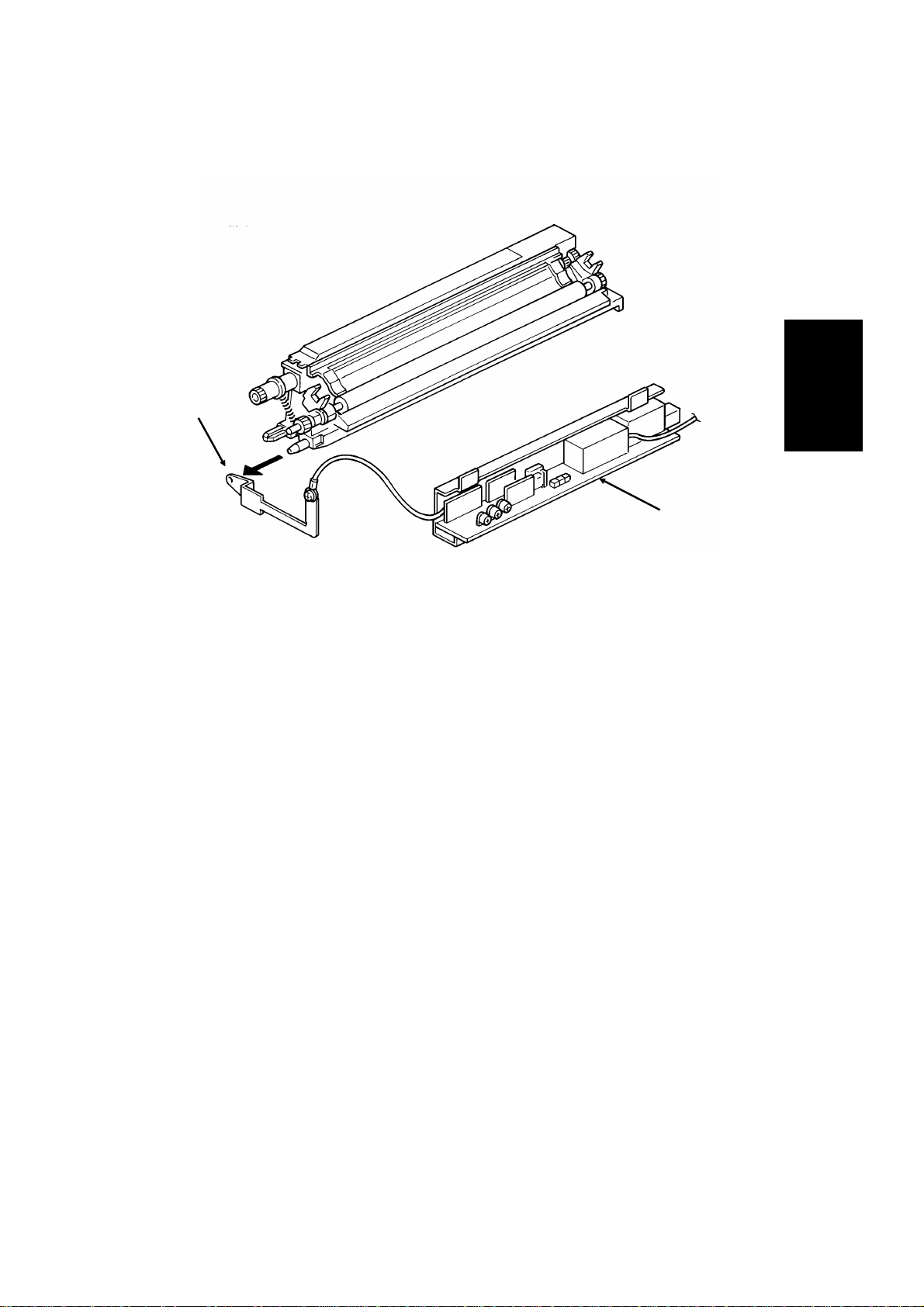

When a new CTM is installed in the machine and the front cover is closed,

the main motor and toner supply mo tor turn on. When the front cover is

closed, a tab [ A] on the fusing unit cover forces the hopper [B] to open.

Also, tab [C] on the CTM pushes bracket [D], which moves the CTM sensor

actuator into the sensor.

Continued on the next page

2-8

Page 27

DETAILED SECTION DESCRIPTIONS November 30th, 1991

PRINTER

[F]

[H]

[I] [J]

[G]

[K]

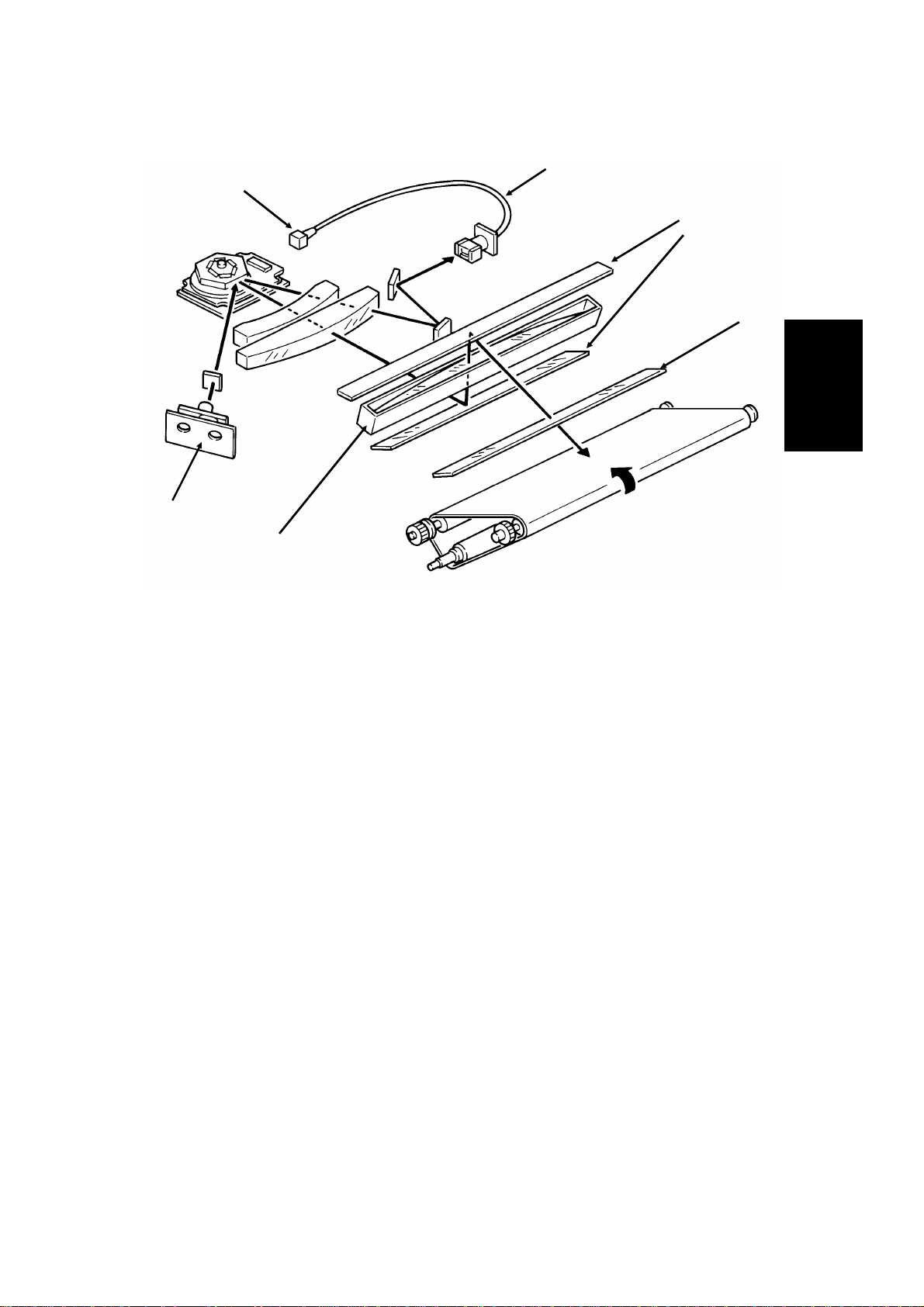

The toner supply motor [F] drives the toner supply shaft ([E] in the diagram

on the previous page). This spiral shaft feeds toner to the hopper.

Inside the development unit is another spiral shaft [G]. This shaft, driven by

the main motor, distributes toner across the length of trough [H]. The toner

supply motor drives gear [I], and once every rotation, it tips the trough upside down, dropping the toner into the development unit. A spring immediately pulls the trough back upright so that it can continue to receive toner.

2

The toner m ixing b a r [J], driven b y the main motor, k eeps the toner agitated

as it builds up at the bottom of the development unit. The toner supply bar

[K] supplies toner to the development roller.

While toner is being supplied, th e main motor is also operating the toner nearend detection mechanism. When a fresh toner cassette is installed, the sensor detects toner near-end, because there is not much toner in the

development unit. When some toner has been transferred, the signal from

the toner near-end sensor returns to normal. About 22 s after that, the toner

supply motor stops and no more toner is transferred into the development

unit.

During printing, if toner near-end is detected, the toner supply mechanism will

start up again. Toner will be supplied until the sensor signal returns to normal. If the toner cassette in the CTM is empty, no toner will be transferred,

and the sensor signal will not return to normal. If the sensor outputs the nearend signal for more than 5 minutes, the cpu blinks the Add Toner indicator.

See "Toner Near-en d Detection" fo r more details.

2-9

Page 28

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

PRINTER

Development Unit Drive

[A]

[B]

During p rinting, d rive from the main motor at gear [A] drives the development

roller [B]. The main motor also drives the master belt, so the development

roller and the master belt always move at the same time; therefore, no development clutch is needed.

Toner Near-end Detection

The toner near-en d det ection mechanism is exactly the same as described in

section 4-4- 4 of the Group 3 Facsimile Manual. The sensor signal is as

shown in the following diagram.

Reference:

Group 3

Facsimile

Manual,

sect i o n 4-4-4.

1.9 s

0.1 ms

The cpu starts to blink the Add Toner indicator under the following conditions:

• At power up: If the sensor output indicates toner near-end for 6 s

• During printing: If the sensor output indicates toner near-end for more

than 5 minutes, totaled over consecutive print runs (when the motor

stops, the sensor mechanism is deactivated, so time between printing

runs does not count towards the 5 minute time limit)

After 100 more pages have been printed, the Add Toner indicator remains lit,

and printing is disabled until a new CTM has been added.

2-10

Page 29

DETAILED SECTION DESCRIPTIONS November 30th, 1991

PRINTER

Development Bias

[B]

[A]

2

The development bias and switching bias are supplied from the power pack

[A] at the same terminal [B].

• Development bias: - 530 ± 20 Vdc (BIASL)

• Switching bias: + 70 ± 20 Vdc (BIASH)

The switchin g bias is used at the following times :

• Between pages of a print run, while the development bias is off

• While toner is bein g transferred from the CTM to the development unit

2-11

Page 30

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

PRINTER

5. Paper Feed

There are two cassettes, a 250-sheet cassette, and a 500-sheet cassette. In

some models, the 500-sheet cassette is an optional unit.

The sizes of paper that the cassettes can take are listed in the specifications

(section 1-1).

[A]

Paper feeds from the rear towards the front. The lower paper feed path

bends upward thro u gh the front part of the upper cassette. The two p ap er

feed paths merge just before the registration roller [A].

2-12

Page 31

[B]

[B]

DETAILED SECTION DESCRIPTIONS November 30th, 1991

PRINTER

Paper Lift

Standard Cassette

[C]

[A]

A mec hanical paper lift mechanism is used. When the us er places the cassette into the machine, a pin [A] in the base of the cassette activates a spring

loaded lever mechanism [B], which forces up the paper lift arm [C] until the

top of the stack touches the paper height positioner.

Lower Cassette

[A]

[C]

[E]

2

[D]

A mec hanical paper lift mechanism is used. When the us er places the cassette into the machine, a tab [A] on the rear of the cassette pushes a plate

[B] towards the rear of the machine as the user slides in the cassette. This

plate, driven by a spring [C], fo rces u p the paper lift arm [D]. The paper

height positioner [E] ensures that the paper is not pushed up too far.

Reference: Group 3 Facsimile Manual, section 4-5-2

2-13

Page 32

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

PRINTER

Pick-up and Feed Mechanism

Standard Cassette (Clutch Driven Single Roller Mechanism)

Reference:

Group 3

Facsimile

Manual,

sect io n 4-5-3.

[B]

[D]

[G]

[C]

[A]

[E] [F]

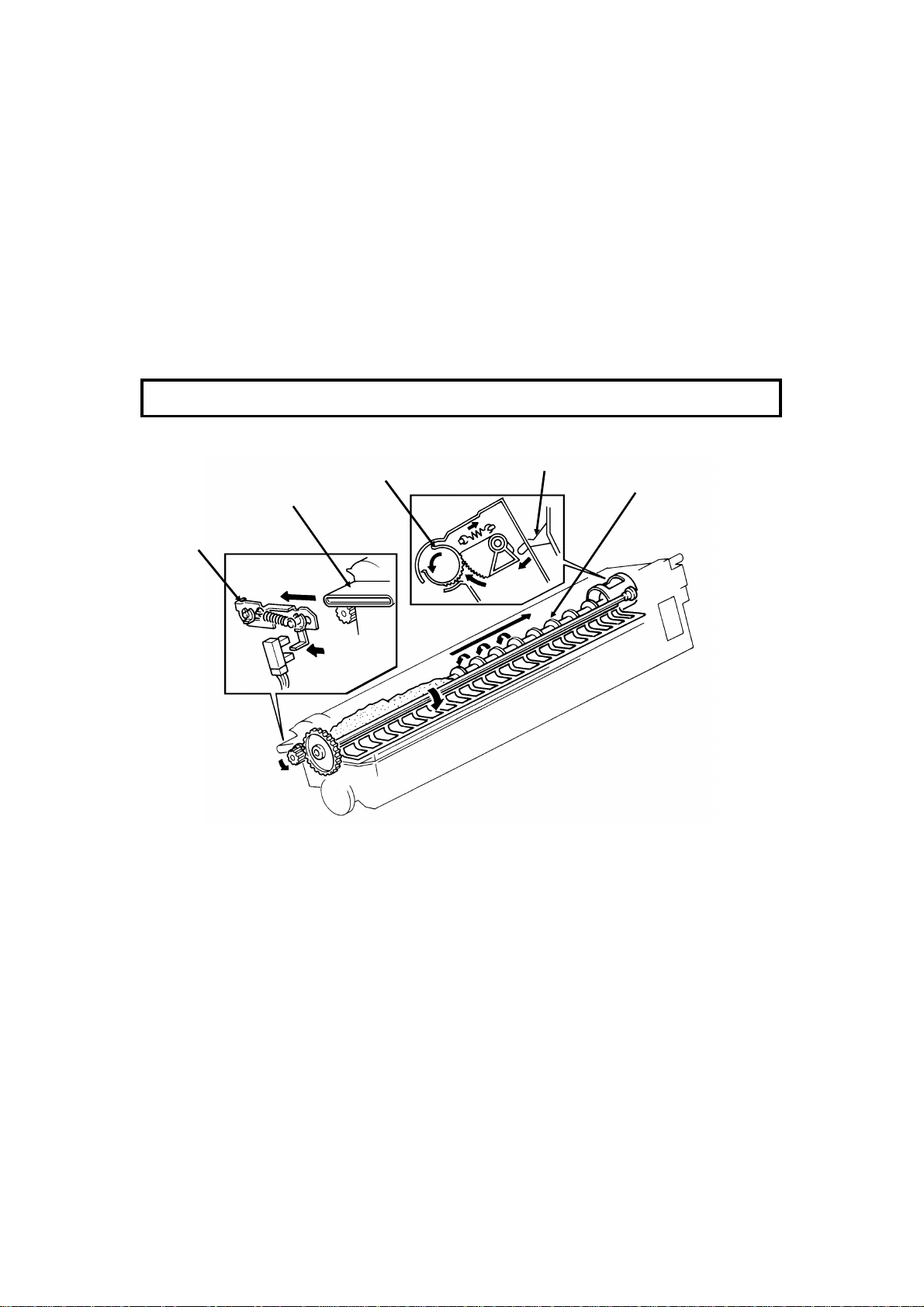

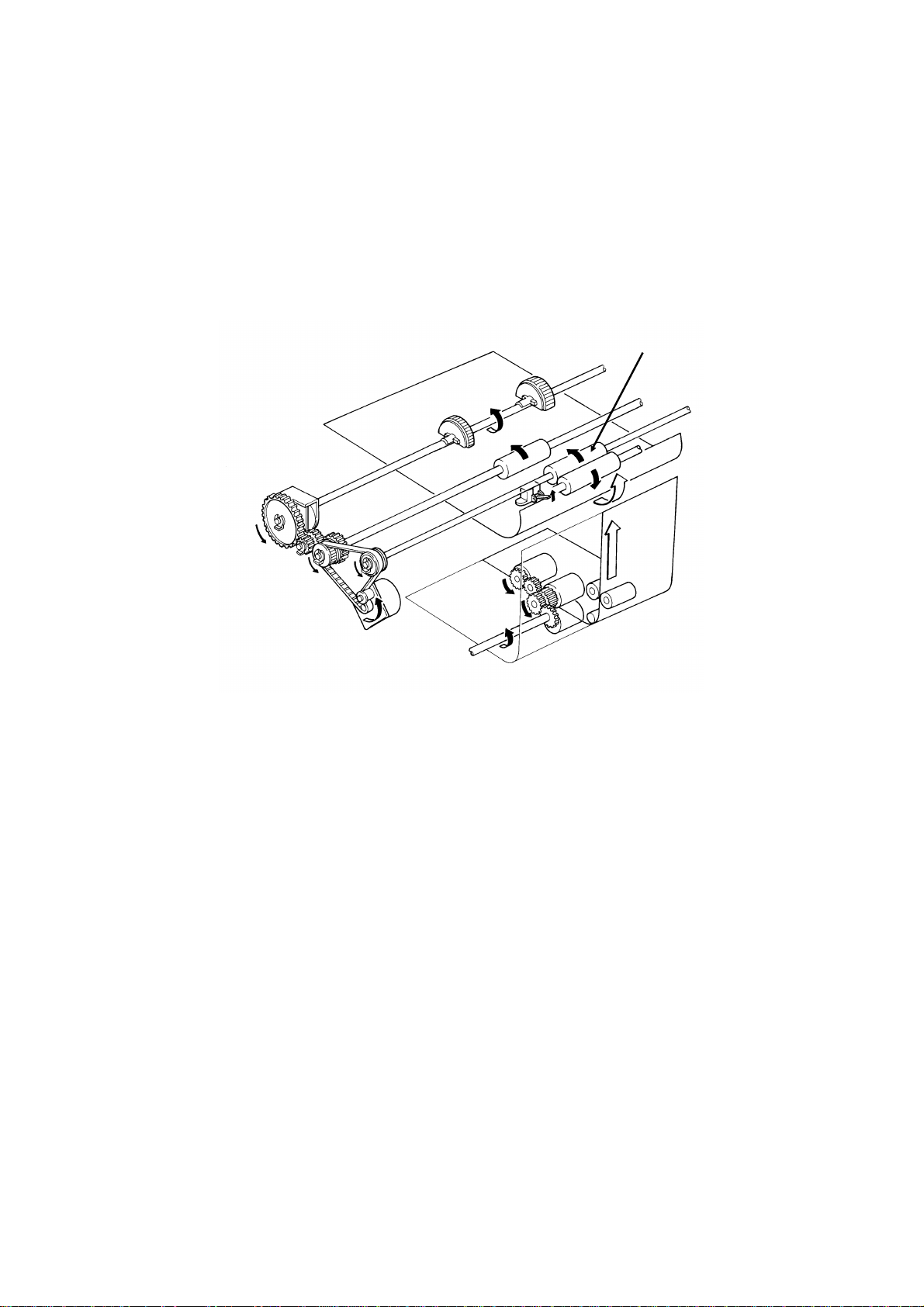

The upper paper feed motor [A] drives the pick-up and feed mechanism. The

paper feed clutch [B] transfers drive from this motor to the feed rollers [C].

When the paper feed clutch turns on, a metal plate [D] moves aw ay from

gear [E]. A pin [F] on this plate releases the gear, and the paper feed roller

turns. However, the clutch switches off after only 0.3 s, and a spring forces

the plate back to the starting position. After one revolution, the rib [G] on the

inside of the gear comes against the pin, and the paper feed roller stops.

When the page memory is full, the upper paper feed motor turns on. At the

beginning, it rotates at a slower speed (202.5 pps) to avoid excessive startup noise and start-up current peak.

At 0.1 s after the main m otor reaches the correct speed, the motor turns at a

higher speed (405 pps). This higher speed, us ed for pick-up and feed, ensures that time is not wasted getting paper into the printer. At the same time,

the upper paper feed clutch turns on and paper is fed into the printer.

Shortly after the registration sensor turns on, the main motor has the leading

edge of the paper, so the upper paper feed motor rotates at 202.5 pps again

to match the feed speed of the main motor.

When the trailing edge of the paper has left the registration sen sor, the pap e r

is no longer affected by the up per p aper feed motor. The upper paper feed

motor goes back to 405 pps ready for feeding the next page.

2-14

Page 33

DETAILED SECTION DESCRIPTIONS November 30th, 1991

PRINTER

Lower Cassette (Clutch Driven Two Roller Mechanism)

Reference:

Group 3

Facsimile

Manual,

sect io n 4-5-3.

[A]

[C]

[D]

[E]

2

[B]

The lower paper feed motor [A] drives the lower paper feed mechanism, and

the lower paper feed clutch [B] transfers drive from the motor to the lower

pick-up [C] and feed [D] rollers at the correct time.

When the page memory is full, the lower pape r feed motor turns on. At the

beginning, it rotates at a slower speed (266 pps) to avoid excessive start-up

noise and start-up current peak. After 0.1 s, the motor rotates at a higher

speed (800 pps). This higher speed of rotation, used during pick-up and

feed, ensures that little time is wasted in getting paper out of the cassette and

into the printer.

When main motor lock is achieved, the lower paper feed clutch turns on and

paper is fed into the printer. Shortly after the paper feed sensor [E] is activated, the clutch turns off.

After registration, the upper paper feed and main motors turn on to drive the

registration rollers and feed the pap er into the printer. However, rollers driven

by the lower paper feed motor still hold the t railing edge of the paper. So the

lower paper feed motor rotates at 266 pps to match the feed speed of the upper feed and main motors.

When the trailing edge of the paper has left the paper feed senso r, the paper

is no longer affected by the lo wer paper feed motor. The lower paper feed

motor goes back to 800 pps ready for feeding the next page.

2-15

Page 34

[B]

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

PRINTER

Separation Mechanism

Standard Cassette

The standard cassette uses a semicircular roller and corner separator

method of separation.

Lower Cassette

This cassette uses a feed and reverse roller mechanism.

Reference: Gro up 3 Facsim ile Manu al (sect ion 4-5-4).

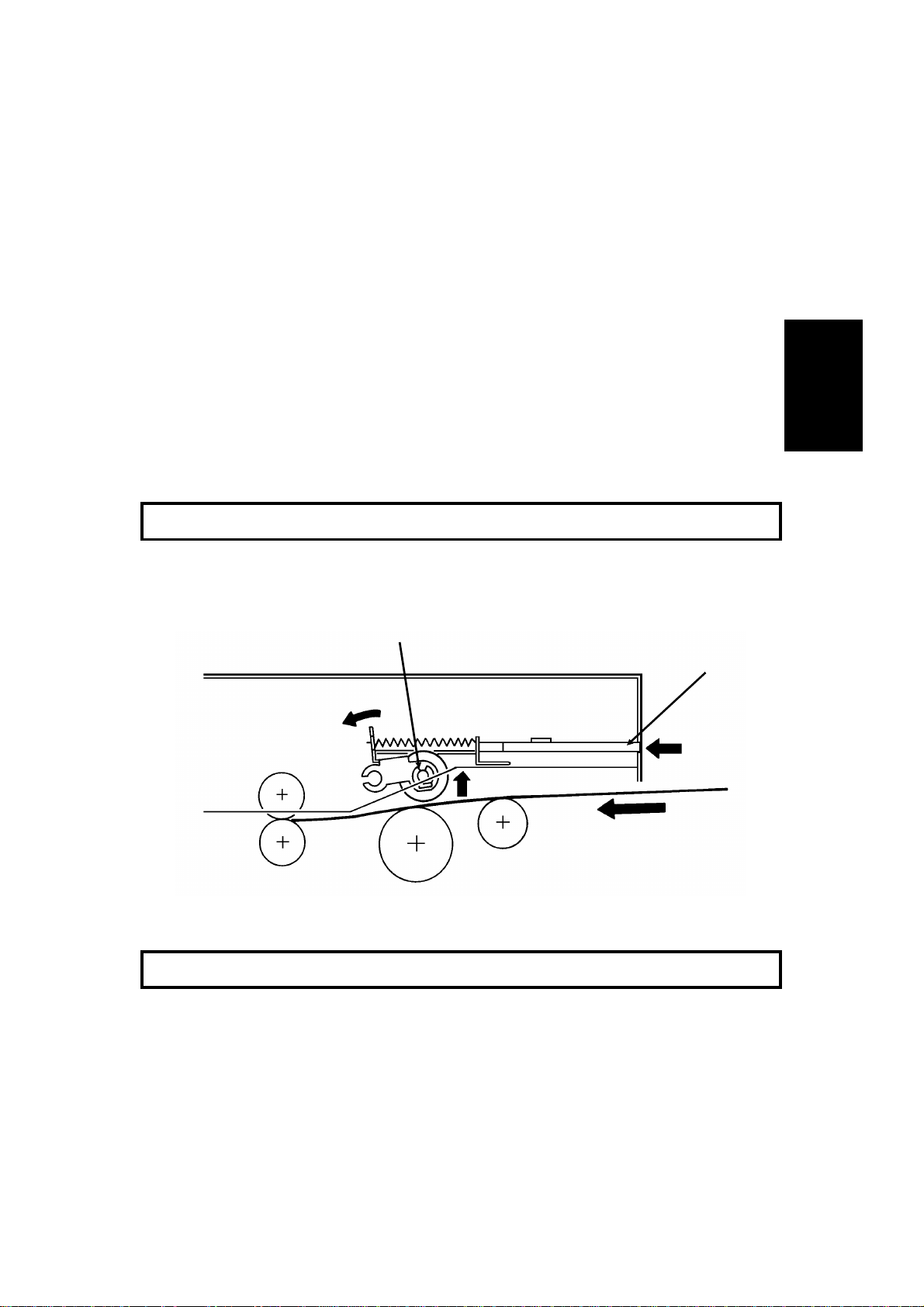

Registration

[C]

[D]

Reference:

Group 3

Facsimile

Manual,

sect io n 4-5-5.

[A]

[E]

Standard Cassette

There is no registration. This is because the upper paper feed motor [A]

drives the registration roller [B] and the upper paper feed rollers [C], and

there is no registration clutch. This means that the registration roller and the

paper feed rollers stop at exactly the same time.

Just after the paper’s leading edge reaches the registration sensor [D], the

upper paper feed motor stops briefly.

Lower Cassette

The upper paper feed motor is off when the leading edge of the paper acti-

vates the registration sensor. The lower paper feed roller [ E] continues to

feed the paper for a short while after this, so registration is done in the normal manner (see section 4-5-5 o f the Group 3 Facsimile Manual).

2-16

Page 35

[A]

DETAILED SECTION DESCRIPTIONS November 30th, 1991

PRINTER

Jam Detection

The machine detects a jam if one of the following conditions exists.

• The registration sensor or copy feed-out sensor is activated while the

machine is in standby m ode.

• The registration sensor s till detects paper 9.0 s after th e paper feed

clutch turned on.

• The copy feed-out sensor still does not detect paper 9.0 s after the pa-

per feed clutch turned on.

• The copy feed-out sensor still detects the presence of paper 9.0 s after

it first detected the latest sheet of paper.

• Standard Cassette Only: The registration sensor does not turn on within

2.0 s after the upper paper feed clutch turned on.

• Lower Cassette Only: The lower paper feed sensor does not turn on

within 1.2 s after the lower paper feed clutch turned o n .

There is no err or detection during paper lift.

2

Paper Size Detection

Reference:

Group 3

Facsimile

Manual,

sect io n 4-5-9.

[B]

For both cassettes, the paper size actuator [A] is on the front of the cassette.

The pa per size sensor [B] is a row of microswitches. The above diagram

shows the upper paper size sensor.

The cpu disables paper feed from a cassette if the paper size cannot be detec ted. If the paper size actuato r is miss ing or broken, or if there is no cassette in the cavity, the Add Paper indicator will light.

2-17

Page 36

Lower Cassette

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

PRINTER

Paper End Detection

Upper Cassette

[A]

[B]

Reference: Gro up 3 Fac sim i le Man ual , sec t io n 4-5-8.

[A]

[B]

In both cassettes, the paper end sensor actuator [ A] falls through a slot [B]

in the bottom of the tray.

There are no paper height sensors or paper near-end sensors.

Page Separation and Data Reduction

Incoming pages that are similar in length to the copy paper may be reduced

in the sub-scan direction to fit on the paper. Whether or not this happens depends on the settings of bits 1 and 2 of bit switch 02.

Reduction Enabled

If bit 2 of bit switch 02 is at 0, the data will be reduced in the page memory to

fit on the copy paper. However, data will only be reduced if the length of the

incoming page is between 5 mm shorter and a certain maximum length. This

maximum incoming page length that can be reduced depends on the copy

paper size and on the reduction ratio stored in RAM addresses 2404F and

24050.

Each paper size can be programmed with a separate reduction ratio. In each

of the two RAM addresses, there is one bit for each possible paper size. The

comb ination of the bit settings determines the ratio for that paper size.

Bit 7: Not used Bit 5: Legal Bit 3: A4 Bit 1: B5

Bit 6: B4 Bit 4: F4 Bit 2: Letter Bit 0: A5

The ratio is determined in accordance with the following table.

Bit in 2404F 0: 3/2 1: 4/3 0: 8/7 1: 12/11

Bit in 24050 0 0 1 1

2-18

Page 37

DETAILED SECTION DESCRIPTIONS November 30th, 1991

PRINTER

The following table shows the maximum incoming page lengths that can be

reduced for each copy paper size. All lengths are in millimetres. The factory

setting of the reduction ratio is 4/3.

Copy

Pap er Type

A5 148 214.5 190.7 163.4 156

B5 182 265.5 236 202.3 193.1

Letter 279.4 385

A4 297 385

F4, F 330.2 385

Legal 355.6 385

B4 364 385

1

: The page memory cannot reduce incoming pages longer than 385 mm.

Copy Paper

Length

Maximum reducable incoming page lengths

Ratio = 3/2 Ratio = 4/3 Ratio = 8/7 Ratio = 12/11

1

1

1

1

1

365.9 313.6 299.3

1

385

385

385

385

1

1

1

333.7 318.5

371.7 354.8

385 1 382.5

385 1 385

1

The values are calculated as follows.

Maximum incoming page length that can be reduced =

(Copy Paper Length - 5) x Reduction Ratio

For example, for A5 with a reductio n ratio of 4/3

Max incoming data length = (148 - 5) x 4/3 = 190.7

Incoming pages that are longer than the maximum length will not be reduced, but will be printed on two pages and treated in accordance with the

sett ing of bit 1 of bit switch 02. If this b it is 1, th e bottom few lines of the page

will be repeat ed at the top of the next page. If this bit is 0, the next page will

continue from where the first page left off.

2

Reduc tion Dis abled

If bit 2 of bit switch 02 is at 1, the data will not be reduce d. However, if the in-

coming page is up to x mm longer than the copy paper, the excess portion

will not be printed. The value of x can be from 0 to 15 mm. It is determined by

the setting of RAM addres s 24051 (copy mode: bits 3 to 0, receive mode:

bit s 7 to 4; bits 3 and 7 are the most significant bits).

Hex value Value of x

0 0

1 1

and so on until

15 15

Messages more than x mm longer than the copy paper will be printed out on

two pages in accordance with the setting of bit 1 of bit switch 02, as explained above.

2-19

Page 38

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

PRINTER

Paper Size Selection

If there are two cassettes in the machine, the paper size to use is decided in

accordance with a few simple rules.

• If both cassettes contain the same paper size, the lower cassette will be

used.

• If the received page has to be split up and printed on two pages, both

pages will be the same size.

• If the cassettes contain different sizes, the paper size chosen for print-

ing the received fax m essage is selected in accordance with the following table of priorities. The table assumes that reduction is enabled and

that the reduct ion ratio is 4/3.

Paper Size

A5 Letter A4 F, F4 Legal B4

Recv’d

Fax

Message

Size

A5123456

Letter6(SR)12345

A4 6(SR) 2(R) 1 3 4 5

F, F4 6(SR) 5(R) 4(R) 1 2 3

Legal 6(SR) 5(R) 4(R) 3(R) 1 2

B4 6(SR) 5(R) 4(R) 3(R) 2(R) 1

• 1 is top priority.

• S: The data has to be separated and printed on more than one page.

• R: The data is reduced to fit on the printer paper.

• If Specified Cassette Selection has been switched on, messages from

specified senders will always go to the upper cassette, regardless of the

paper size or message size.

• Some of the reports can be printed on A5 paper without page separa-

tio n. However, if only A5 paper is in the cassettes, reports that need

larger paper sizes will require page separation.

2-20

Page 39

DETAILED SECTION DESCRIPTIONS November 30th, 1991

PRINTER

6. Transfer Corona Unit

[B]

[A]

2

The voltage o f the transfer coro na unit [A] is between 3.8 and 5.5 kV. It gives

a 200 V charge to the paper to pull the negative toner off the master belt. The

bend [B] in the m aster belt also helps the paper to leave the belt. There is no

antistatic brush to aid separation.

Reference: Group 3 Facsimile Manual, section 4-6

2-21

Page 40

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

PRINTER

7. Fusing Unit

Fusing Unit Drive

[A]

The main motor [A] drives the fusing unit through a train of gears.

Fusing Unit Control

• Standby temperature: 65 °C

• Printing start tem perature: 130 °C

• Maximum printing temperature: 170 °C (monitored by a comparator)

• Thermistor maximum: 220 °C

• Thermostat maximum: 400 °C

When the main power is switched on, the fusing lamp heats up to 65 °C in

about 10 s.

When a ringing signal is detected (or when the user presses Start or Copy

for taking a copy), the fusing lamp heats up to 130 °C in about 15 s.

At the end of printing, the ozone fan stays on until the fusing unit temperature

has falle n below 130 °C.

Reference: Group 3 Facsimile Manual, section 4-7

2-22

Page 41

[A]

DETAILED SECTION DESCRIPTIONS November 30th, 1991

PRINTER

8. Cleaning

[C]

[B]

[C]

[A]

2

The CTM c ontains the cleaning unit and the used toner tank.

When the CTM is out of the machine, the cleaning blade [A] is forced against

a mylar plate, which prevents used toner from falling out.

When the CTM is placed inside the machine, a tab on the copy exit cover

pushes plate [B], which moves the cleaning blade away from the mylar and

against the master belt.

The cleaning blade wipes toner off the master belt as it passes the cleaning

unit. The toner goes to the used toner tank. The cleaning roller [C], driven by

the main motor removes any toner that may remain attached to the cleaning

blade.

There is no toner overflow detection me chanism. This is because the used

toner tank is removed with the old CTM when the toner cassette is empty;

the toner near-end sensor detects this.

Reference: Group 3 Facsimile Manual, section 4-9

2-23

Page 42

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

PRINTER

9. Quenching

[A]

[B]

The quenching lamp [A] is an LED array. After quenching, the charge on t he

master [B] is about -20 V.

Reference: Group 3 Facsimile Manual, section 4-10

2-24

Page 43

DETAILED SECTION DESCRIPTIONS November 30th, 1991

PRINTER

2.2.2. Circuits

1. Laser Diode

Laser Diode Drive

Front Cover

Interlock Switch

AC/DC

Converter

+24V

1-1

Front Cover

Microswitch

PSU

1-2

3-8

2-1

+5V

1-1

20-5

8-1

8-2

FCU

+5V

2

+24VD

+5VLD

9-1

1-8

LDDR

Laser

Diode

Controller

Laser

Diode

The laser diode is powered by a special + 5V supply, called + 5VLD.

There are two s witches activated by the front cover; the fro nt cover interlock

switch, and the front cover microswitch. If either of these switches is open,

the power supply to the laser diode is interrupted.

The laser diode is not started until the following conditions have been met:

• The main and hexagonal mirror motor s are rotating at the correct

speeds

• The page memory contains a complete page

• The fusing lamp is at the printing temperature

2-25

Page 44

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

PRINTER

Laser Diode Power Control

Laser

Power

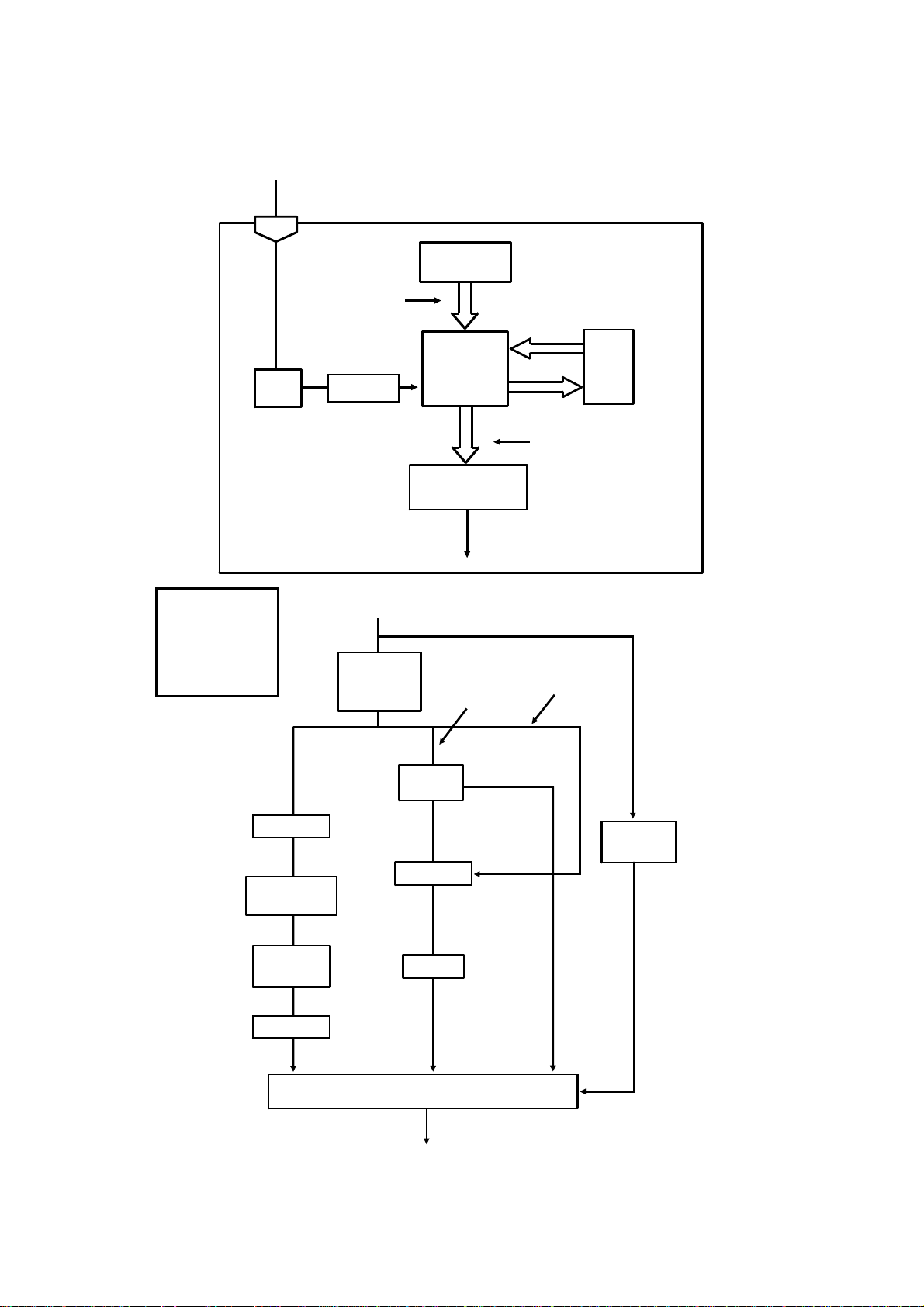

Controller

1-2 1-4 1-5

DATA

Laser

Interface

Laser

Diode

LDDR

1-6

CONTROL FEEDBACKDISABLE

9-49-59-7

9-3

FCU

I/O

Port

CPU

The Laser Interface sends a constant signal to the laser diode on CN9-7, forcing the diode to stay on. The feedback signal returns to the FCU on CN9-3. If

necessary, the cpu adjusts the laser diode power to the correct value by altering the control signal (CN9-4).

If the cpu determines that laser diode power control has failed, it sends CN95 to low, which disables the laser diode.

Service Note

If one of the following occurs, the printer will be disabled, and an Auto Service Call will be sent to the service station (the message will be LD POWER

CONTROL FAILURE).

• If there is no response to laser power control (the cpu sends CN9-5

low).

• If the laser diode power supply (+ 5VLD) is cut.

2-26

Page 45

DETAILED SECTION DESCRIPTIONS November 30th, 1991

PRINTER

2. Fusing Unit

FUSING UNIT

Fusing

Lamp

Thermistor

36-2

+5V

36-1

LIVE

NEUTRAL

170 C [A]

4-1,4

4-3,6

36-3

I/O

Port

AC Switching

Circuit

3-1

36-4

[B]

PSU

3-2

[C]

1-8

Main

Power

Supply

1-7

2

FCU

The circuit shown in the above diagram controls the fusing unit.

• The I/O Port monitors the fusing unit temperature at CN36-1.

• The signal at CN36-4 (from the comparator [A]) remains low if the fus-

ing unit temperature is below 170 °C.

• The I/O Port switches the fusing unit on/off using signal [B].

• If the thermistor is accidentally disconnected, the link between CN36-3

and CN36-4 will also be broken. When the cpu detects this, an Auto

Service Call will be sent.

Standby mode

• If the fusing lamp is below 65 °C, t he I/O Port sends signal [B] low,

which makes CN1-8 go high. This switches on the fusing lamp.

• If the fusing lamp goes abo ve 65 °C, [B] goes high, and CN1-8 goes

low, which switches off the fusing lamp.

Continued on the next page

2-27

Page 46

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

PRINTER

Printing

• When a rin ging signal is detected, CN1-8 goes high, to switch on the

fusing lamp. Also, the ozone fan switches on.

• During printing, the temperature is kept at 170 °C. If the temperature

rises above 170 °C, the output from the comparator changes state.

CN36-4 goes high, while [B] remains low. This causes CN1-8 to go low,

which switches off the fusing lamp.

• If the comparator fails, there are additional safety cutoffs at 220 °C (ther-

mistor) and at 400 °C (thermostat).

After printing

• When the fusing lamp temperature falls back below 130 °C, the ozone

fan switches off.

Service Note

When one of the following error conditions occurs, the I/O Port switches off

the fusing lamp by raising CN1-7 to high. The printer will be disabled, and an

Auto Service Call will be sent to the service station (the message will be HOT

ROLLER DOWN).

Standby mode

• If the fusing lamp takes more than 30 s to reach 65 °C

During printing

• If the fusing lamp takes more than 40 s to r ise to 130 °C from 65 °C

• If the fusing lamp stays above 170 °C for more than 5 s

After printing

• If the fusing lamp takes more than 10 minutes to fall back to 130 °C

At any time

• If the fusing lamp temperature reaches 220 °C

• If the thermistor is accidentally disconnected (see the previous page for

details)

2-28

Page 47

DETAILED SECTION DESCRIPTIONS November 30th, 1991

PCBs AND THEIR FUNCTIONS

2.3. PCBs AND THEIR FUNCTIONS

2.3.1. FCU

HandsetLine

SBU

(CCD)

Scanner

Sensors

Operation

Panel

Speaker

Modem AFE

CONTROL SIGNALS

Video Processing

Memory

Video

Processor

NCU

CPU

HIC

PSU

I/O

Port

Scanner and Printer Drive

Components and Sensors

2

FCU

RS-232C

Interface

MBU

DATA AND ADDRESS BUS

Laser

Interface

Page

Memory

SAF

Memory

ECM

Memory

RAMROM

Laser Diode Driver

Main Scan Start Detector

Interlock Switch

2-29

Page 48

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

PCBs AND THEIR FUNCTIONS

1. CPU (AFSP)

• 65C02 compatible microprocessor

• Interrupt control

• DMA control

• Data compression and reconstruction (high speed MH coding for 4.5-

second scanning)

• Modem (digital operations)

• Real time clock (battery backed-up)

• Memory control

• Control of all mechanisms (directly or through other chips)

• NCU control (through the I/O Port)

2. I/ O Port (LIOP)

• Clock control

• Sensor monitoring (including A/D conversion where necessary)

• Tone detection

• Motor drive

• Operation panel control

• Laser Interface control

3. Laser Interface (LIF)

• Page memory control

• Laser diode control

• Smoothing

4. Modem Analog Front End (Modem AFE)

• Modem (analog operations)

• Attenuation

5. Video Processor (VPP)

• Analog/digital video signal processing

6. Hybrid IC (HIC)

• Filters

7. RAM

• 128k for ECM (no back-u p)

• 256k SAF memory (with battery back-up)

• 768k page memory

2-30

Page 49

DETAILED SECTION DESCRIPTIONS November 30th, 1991

PCBs AND THEIR FUNCTIONS

2.3.2. MBU

System

ROM

DATA AND ADDRESS BUS

Memory Back-up

Control

+

To/From

FCU

1. System ROM

• Contains the software to run the machine

MBU

2

System

RAM

To/From

FCU

2. System RAM

• 32k SRAM and 32k PSRAM for parameter storage, line buffer, FIFO,

SAF memory administration

The SRAM is backed up by the battery on the MBU.

2-31

Page 50

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

PCBs AND THEIR FUNCTIONS

2.3.3. SBU

Analog Video

To the FCU

Drive Clocks

From the FCU

Drivers

CCD

+12V

+12V

+

Emitter

Follower

Inverter

Amplifier

SBU

2.3.4. OPU

LCD Panel

LCD Panel

Controllers

Operation Panel

Keys

Operation Panel

Operation Panel

Controller

Serial Interface

To/From FCU

LEDs

Output

from the

Scanner

Sensors

2-32

Page 51

DETAILED SECTION DESCRIPTIONS November 30th, 1991

PCBs AND THEIR FUNCTIONS

2.3.5. LDDR

2.3.6. PFU

Lower Cassette

Sensors

DATA

Laser

Power

Controller

CONTROL

To/From FCU

PFU

POWER

Indicator

Panel

Lower Cassette

Controller

Driver

Laser

Diode

LDDR

2

Lower Cassette

Mechanical

Components

Serial Interface

To/From FCU

2-33

Page 52

November 30th, 1991 DETAILED SECTION DESCRIPTIONS

PCBs AND THEIR FUNCTIONS

2.3.7. NCU

TIP

RING

T1

R1

To

Network

To

Handset

Protection

Circuit

FG

Line

Current

Detector

Oh

Relay

Di Switch

Ringing

Signal

Detector

Tx/Rx Data

To/From FCU

To FCU

+24V

Off-Hook

Detector

From FCU

To FCU

NCU

• For simplification, relay drive signals and detector outputs to/from the

FCU are not shown on this diagram.

• In the above diagram, the relays are shown in the standby position for

Auto Receive (Fax) Mode.

2-34

Page 53

DETAILED SECTION DESCRIPTIONS November 30th, 1991

PCBs AND THEIR FUNCTIONS

2.3.8. PSU

LIVE

NEUTRAL

GROUND

AC Power

to the

Fusing Lamp

Prevention

Arrestor

Fusing Lamp

Enable

From FCU

Surge

+24VD

AC Switching

Circuit

To

FCU

Main

Switch

+24VD

From

Front Cover

Interlock

Switch

Noise

Filter

+24V

To

Front Cover

Interlock

Switch

Surge Current

Prevention

+24V

To

FCU

Power Supply

Generation

Circuits

+5V

To

FCU

PSU

2

-12V

To

FCU

Overhea t Protection in the PSU

If the PSU thermistor temp erature exceeds about 100 °C, the power supply

outputs from the PSU are disabled.

If this happens:

1. Switch off t he machine.

2. Take out the PSU and examine it for damage. Take care because it may

be hot.

3. Put back the PSU and switch the machine on. If the machine does not operate, change the PSU.

2-35

Page 54

INSTALLATION November 30th, 1991

CONNECTING UP THE MACHINE

3. INSTA LLA TION

3.1. CONNECTING UP THE MACHINE

POWER SWITCH

115 ± 20V

60 ± 1 Hz

Grounded

3

Phone

Company’s

Jack

HANDSET

3-1

Page 55

Installation Procedure

1. Install the master unit. (refer to the Installation Manual for Ricoh Master Unit Type 30)

2. Install the toner cartrige. (refer to the Installation Procedure on the carton box)

3. Install the handset and connect the line. (refer to the Installation Manual)

4. Install the paper cassette. (refer to the Operation Manual)

5. Attach the trays and document table.

Page 56

[B]

[A ]: 1 screw

November 30th, 1991 INSTALLATION

INSTALLING ADDITIONAL UNITS

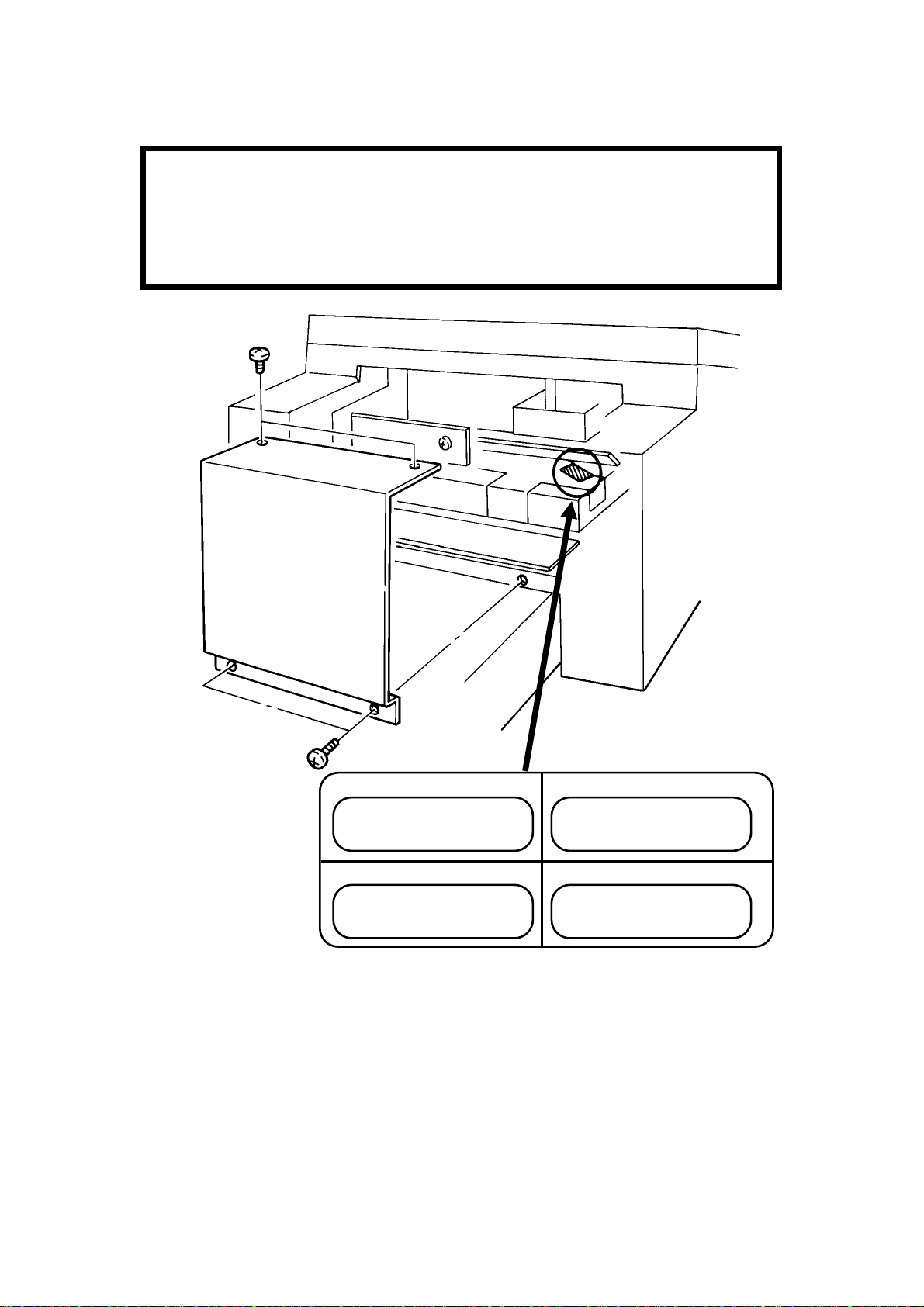

3.2. INSTALLING ADDITIONAL UNITS

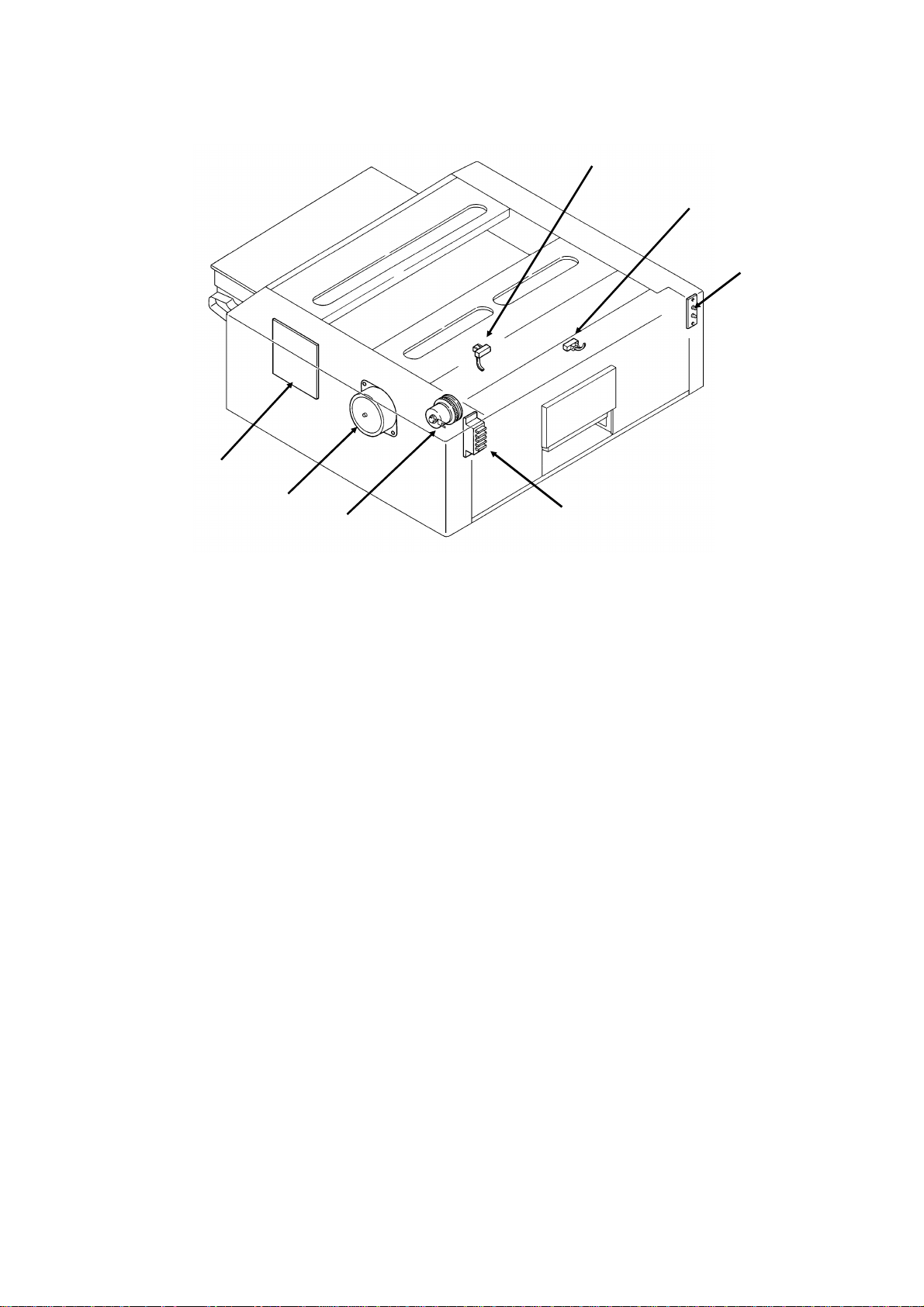

3.2.1. Lower Cassette

Check whether there are any messages in the memory. If there are, you

must install the lower cassette and turn the power back o n within an hour.

[A ]

[B]

[D]

[C]

[C]

Fit pegs [B] into holes [C].

[D]: 5 screws

3-2

Page 57

[F]

[G]

[H]

INSTALLATION November 30th, 1991

INSTALLING ADDITIONAL UNITS

[F]

[E]

[E]: 2 connectors

3

Re move two screws [F].

[G]

Install brackets [G] (2 screws each).

Screws [H]: Use previously re moved

screws [F].

Screws [I]: In the accessories bag.

[I]

3-3

Page 58

November 30th, 1991 INSTALLATION

INSTALLING ADDITIONAL UNITS

[J]

Adjust the cassette in accordance

with customer requirements.

3-4

Page 59

INSTALLATION November 30th, 1991

INSTALLING ADDITIONAL UNITS

3.2.2. Memory Card

• Tur n off the power before installing or removing a memory c a rd.

• Make sure that 100% is displayed on the operation panel before install-

ing or removing a memory card, or data will be lost.

3

3-5

Page 60

November 30th, 1991 INSTALLATION

INSTALLING ADDITIONAL UNITS

3.2.3. Cassette (250 Sheets)

3-6

Page 61

INSTALLATION November 30th, 1991

INSTALLING ADDITIONAL UNITS

3.2.4. Cassette (500 Sheets)

3

3-7

Page 62

[B]: 2 screws

November 30th, 1991 INSTALLATION

INSTALLING ADDITIONAL UNITS

3.2.5. Handset

[A]

[A]: 2 screws

[B]

3-8

Page 63

INSTALLATION November 30th, 1991

INITIAL PROGRAMMING

3.3. INITIAL PROGRAMMING

Check the following:

• Is the country code in the NCU parameters (Function 96, parameter 00)

correct for the country of installation? In the USA, it should be 17.

• Do any bit switch or other settings have to be changed to match line

conditions or user requirements?

• Have you programmed the serial number (Function 98, section 4-1-18)?

The user should program the following items after installation:

• Telephone Line Type

• RTI, TTI, and CSI

• ID Codes (ID Code, Remote ID, Confidential ID, Memo ry Lock ID)

• The fax mac hine’s own teleph one number

• Date and Time

• Language Selection

3

3-9

Page 64

SERVICE TABLES AND PROCEDURES November 30th, 1991

SERVICE LEVEL FUNC TIONS

4. SERVICE TABL ES A ND PROCEDURES

4.1. SERVICE L EVEL FUNCTI ONS

4.1.1. Bit Switch Programming (Function 91)

1. Function 5 1 9 9 1

then immediately Yes

2. 9 1 Yes

FUNCTION Y/∇

9 SERVIC E FUNCTI ONS

DEFAULT: 0000 0000

BITSW 00: 0000 0000

Bit 7 is displayed at the left, and bit 0 at

the right.

3. Increment bit switch: #

Decrement bit switch:

*

Example: Display bit switch 3: # x 3 DEFAULT: 0000 0000

BITSW03: 0000 0000

4. Adjust the bit switch.

Example: To change the value of bit

7, press 7

DEFAULT: 0000 0000

BITSW03: 1000 0000

5. Either:

• Adjust more bit switches - go to step 3.

4

• Finish - Function

4.1.2. System Parameter List (Function 92)

1. Function 5 1 9 9 1

then immediately Yes FUNCTION Y/∇

9 SERVIC E FUNCTI ONS

2. 9 2 Yes START

SYSTEM REPORT

3. Start

After printing, press Function

4-1

Page 65

November 30th, 1991 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNC TIONS

4.1.3. Error Code Display (Function 93)

1. Function 5 1 9 9 1

then immediately Yes FUNCTION Y/∇

9 SERVIC E FUNCTI ONS

2. 9 3 Yes ERROR CODE #/∇

1-01 JAN 01 17:30

3. Either:

Scroll through the error codes - #

Finish - Function

4.1.4. Service Monitor (Function 93)

1. Function 5 1 9 9 1

then immediately Yes FUNCTION Y/∇

9 SERVIC E FUNCTI ONS

2. 9 3 Yes ERROR CODE #/∇

1-01 JAN 01 17:30

3. No/∇ Start

4.1.5. Protocol Dump (Function 94)

1. Function 5 1 9 9 1

then immediately Yes FUNCTION Y/∇

9 SERVIC E FUNCTI ONS

2. 9 4 Yes

START

PROTOCOL DUMP LIST

3. Start

4-2

Page 66

SERVICE TABLES AND PROCEDURES November 30th, 1991

SERVICE LEVEL FUNC TIONS

4.1.6. RAM Display/Rewrite (Function 95)

1. Function 5 1 9 9 1

then immediately Yes FUNCTION Y/∇

9 SERVIC E FUNCTI ONS

2. 9 5 Yes Y/∇

DISPLAY MEMORY

3. Ye s ADDRESS = 2044C

DATA = 03

4. Input the address that you wish to see. Example: Addr ess 20202

2 0 2 0 2 ADDRESS = 20202

DATA = 00

Note: The first digit must always be 2.

5. If you wish to change the data, type in the new data.

Example: 80, press 8 0 ADDRESS = 20202

DATA = 80

Note: If you wish to move the cursor, press

→

6. Either:

• View more addresses - go to step 4.

• Finish - Yes Function

4.1.7. RAM Dump (Function 95)

1. Function 5 1 9 9 1

then immediately Yes FUNCTION Y/∇

9 SERVIC E FUNCTI ONS

2. 9 5 Yes Y/∇

DISPLAY MEMORY

3. ∇ Ye s MEMORY DUMP START/N

B= 2, ST-0000,END-00FF

4

4. Input the bank number (B) and the start and

end addresses. Max. range: 256 bytes

Example: Start at 1200, end at 12FF.

1 2 0 0 1 2 F F Start MEMORY DUMP START

4-3

The value of B is always 2.

B= 2, ST-1200,END-12FF

Page 67

November 30th, 1991 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNC TIONS

4.1.8. NCU Parameters (Function 96)

1. Function 5 1 9 9 1

then immediately Yes FUNCTION Y/∇

9 SERVIC E FUNCTI ONS

2. 9 6 Yes NCU PARAMETER KPAD/Y

NO.00 001

3. Scroll through the parameters - Yes

Enter new values at the keypad.

Example: Set NCU parameter 04 to 005.

Yes Yes Ye s Ye s 0 0 5 NCU PARAMETER KPAD/Y

NO.04 005

4. To finish: Function

Note: Parameter 00 is the Country Code, and Parameter 01 is the Tx Level

(if the Tx level should be -9 dB, input 9).

Refer to section 4-3 for full details on NCU parameters.

4.1.9. ADF Test (Function 97)

1. Function 5 1 9 9 1

then immediately Yes FUNCTION Y/∇

9 SERVIC E FUNCTI ONS

2. 9 7 Yes

3. 1

SCN-1 DT-2 PL-3 LD-4

MDM -5 RI-6 CK-7 SN-8

SCANNER TEST KPAD

ADF-1 LAMP-2

4. 1

5. Function Function

6. Place a docu ment in the feeder,

then press Copy Start

4-4

Page 68

SERVICE TABLES AND PROCEDURES November 30th, 1991

SERVICE LEVEL FUNC TIONS

4.1.10. Xenon Lamp Test (Function 97)

1. Function 5 1 9 9 1

then immediately Yes FUNCTION Y/∇

9 SERVIC E FUNCTI ONS

2. 9 7 Yes SCN-1 DT-2 PL-3 LD-4

MDM -5 RI-6 CK-7 SN-8

3. 1 SCANNER TEST KPAD

ADF-1 LAMP-2

4. 2 SCANNER LAMP TEST

The xenon lamp lights up for 5 minutes.

4.1.11. DTMF Tone Test (Function 97)

1. Function 5 1 9 9 1

then immediately Yes

2. 9 7 Yes

3. 2

FUNCTION Y/∇

9 SERVIC E FUNCTI ONS

SCN-1 DT-2 PL-3 LD-4

MDM -5 RI-6 CK-7 SN-8

DTMF TEST

DUAL-1 SINGLE-2

4. Either:

• Test dual tones - 1 . Go to step 5.

• Test single tones - 2 . Go to step 8.

5. The display is as shown opposite. DUAL TONE

PRESS KEYPAD

Press a key on the ten key pad.

Example: 1 Start

4

6. To stop the test: Stop

7. Either:

Test another tone: Go to step 5.

Finish: Function

4-5

Page 69

November 30th, 1991 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNC TIONS

8. The display is as shown opposite.

Press the required key.

697 Hz 1 852 Hz 3 1209 Hz 5 1477 Hz 7

770 Hz 2 941 Hz 4 1336 Hz 6 1633 Hz 8

Example: To test 1633 Hz, press 8 Start

9. To stop the test: Stop

10. Either:

Test another tone: Go to step 8.

Finish: Function

4.1.12. Printer Test Patterns (Function 97)

SINGLE TONE

PRESS KEYPAD

1. Function 5 1 9 9 1

then immediately Yes FUNCTION Y/∇

9 SERVIC E FUNCTI ONS

2. 9 7 Yes SCN-1 DT-2 PL-3 LD-4

MDM -5 RI-6 CK-7 SN-8

3. 3 PATTERN PRINT KPAD

1-7

4. Press a key from 1 to 7, excluding 5 and 6. (Patterns 5 and 6 are not

used in this model.) A test pattern is printed.

4.1.13. Operation Panel Test (Function 97)

1. Function 5 1 9 9 1

then immediately Yes FUNCTION Y/∇

9 SERVIC E FUNCTI ONS

2. 9 7 Yes SCN-1 DT-2 PL-3 LD-4

MDM -5 RI-6 CK-7 SN-8

3. 4

4-6

Page 70

SERVICE TABLES AND PROCEDURES November 30th, 1991

SERVICE LEVEL FUNC TIONS

4.1.14. Modem Test (Function 97)

1. Function 5 1 9 9 1

then immediately Yes FUNCTION Y/∇

9 SERVIC E FUNCTI ONS

2. 9 7 Yes SCN-1 DT-2 PL-3 LD-4

MDM -5 RI-6 CK-7 SN-8

3. 5 MODEM TEST

G3-1 TONE-2

4. Either:

Test G3 carrier signals - 1 . Go to step 5.

Test frequencies - 2 . Go to step 8.

5. The display is as shown opposite. 9600-1 7200-2

4800-3 2400-4 300-5

Press the required key.

Example: Test the 9600 bps carrier 1 Start

6. To stop the test: Stop

7. Either:

Test another tone: Go to step 5.

Finish: Function

8. The display is as shown opposite. 2100-1 1100-2 800-3

PRESS KEYPAD

Press the required key.

Example: To test 1100 Hz, press 2 Start

9. To stop the test: Stop

10. Either:

• Test another tone: Go to step 8.

4

• Finish: Function

4-7

Page 71

November 30th, 1991 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNC TIONS

4.1.15. Ringer Test (Function 97)

Not used; do not try to use this function.

4.1.16. Buzzer Test (Function 97)

1. Function 5 1 9 9 1

then immediately Yes

2. 9 7 Yes

FUNCTION Y/∇

9 SERVIC E FUNCTI ONS

SCN-1 DT-2 PL-3 LD-4

MDM -5 RI-6 CK-7 SN-8

3. 7

Press the St op key to stop the buzzer.

4.1.17. Ozone Fan Test (Function 97)

1. Function 5 1 9 9 1

then immediately Yes FUNCTION Y/∇

9 SERVIC E FUNCTI ONS

2. 9 7 Yes SCN-1 DT-2 PL-3 LD-4

MDM -5 RI-6 CK-7 SN-8

3. 8