Page 1

RICOH FAX 4500F

SERVICE MANUAL

Page 2

Lithium Batteries (Memory Back-up)

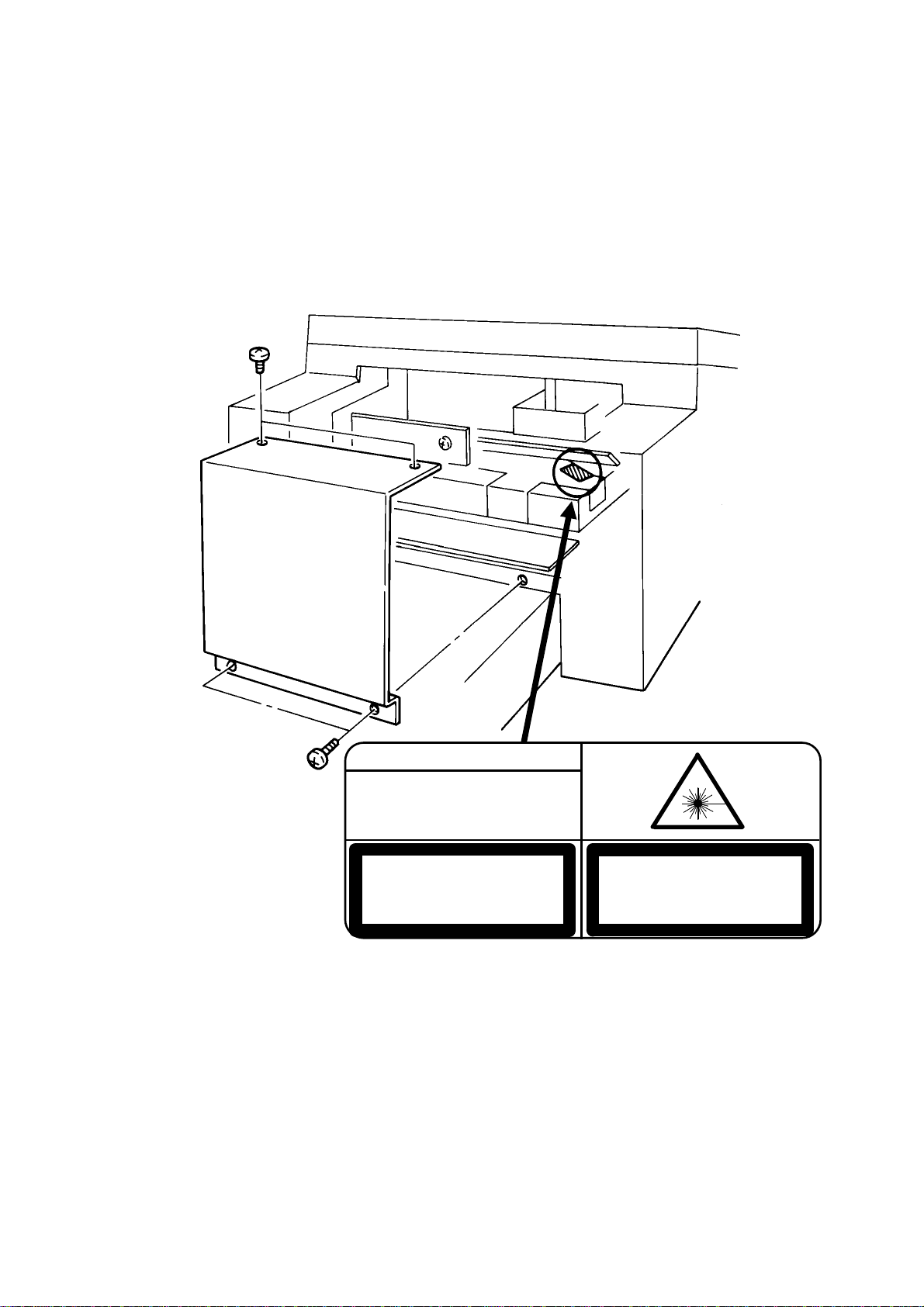

DANGER

INVISIBLE LASER RADIATION

WHEN OPEN AVOID DIRECT

EXPOSURE TO BEAM

CAUTION

LASER RADIATION WHEN

OPEN AVOID EXPOSURE

TO BEAM

VORSICHT

UNSICHTBARE LASERSTRAHLUNG,

WENN ABDECKNG GEOFFNET

NICHT DEM STRAHL AUSSETZEN

CAUTION:

The danger of explosion exists if a battery of this type is incorrectly replace d.

Replace only with the same or an eq uiva lent type recommended by th e

manufacturer. Discard used batteries in accordance with the manufa ctu rer’s

instructions.

Page 3

CONTENTS

1. OVERALL MACHINE INFORMATION

1.1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . 1-1

1.2. FEATURES . . . . . . . . . . . . . . . . . . . . . 1-2

1.3. COMPONENT LAYOUT . . . . . . . . . . . . . . . . 1-5

1.4. OVERALL MACHINE CONTROL . . . . . . . . . . . . 1-5

1.5. VIDEO DATA PATH . . . . . . . . . . . . . . . . . . 1-6

1.5.1. Transmission . . . . . . . . . . . . . . . . . . . 1-6

1.5.2. Recept ion . . . . . . . . . . . . . . . . . . . . 1-6

1.6. Power Distributi on . . . . . . . . . . . . . . . . . . 1-7

1.6.1. Memory Back-up Circuit . . . . . . . . . . . . . . 1-7

2. DETAILED SECTION DESCRIPTIO N S

2.1. SCANNER . . . . . . . . . . . . . . . . . . . . . 2-1

2.2. PRINTER . . . . . . . . . . . . . . . . . . . . . . 2-3

1. Laser Optics . . . . . . . . . . . . . . . . . . . 2-3

2. Paper Feed . . . . . . . . . . . . . . . . . . . . 2-3

3. Fusing Unit . . . . . . . . . . . . . . . . . . . . 2-5

2.3. PCBs AND THEI R FUNCTIONS . . . . . . . . . . . . . 2-7

2.3.1. FCU . . . . . . . . . . . . . . . . . . . . . . 2-7

3. INSTALLATION

3.1. INSTALLING OPTIONAL UNITS . . . . . . . . . . . . . 3-1

3.1.1. Lower Cassette . . . . . . . . . . . . . . . . . . 3-1

3.1.2. Hard Disk . . . . . . . . . . . . . . . . . . . . 3-2

3.2. INITIAL PROGRAMMING . . . . . . . . . . . . . . . 3-4

Page 4

4. SERVICE TABLES AND PROCEDURES

4.1. SERVICE LEV E L FUNCTIONS . . . . . . . . . . . . . 4-1

4.1.1. Bit Switch Prog ramming (Function 01) . . . . . . . . . 4-1

4.1.2. System Parame te r L ist (Fun ction 02) . . . . . . . . . 4-2

4.1.3. Error Code Display (Fun ction 03) . . . . . . . . . . . 4-2

4.1.4. Service Monitor Report (Function 04) . . . . . . . . . 4-2

4.1.5. Protocol Dump (Fu nct ion 05) . . . . . . . . . . . . 4-2

4.1.6. RAM Display/Rewrite/P rintout (Function 06) . . . . . . 4-3

4.1.7. Checking the Coun te rs (Fu nct ion 07) . . . . . . . . . 4-4

4.1.8. Clearing the Coun te rs (Fu nct ion 08) . . . . . . . . . . 4-4

4.1.9. NCU Parameters (Function 09) . . . . . . . . . . . . 4-4

4.1.10. Modem/DTMF Tone Tests (Function 09) . . . . . . . . 4-5

4.1.11. Operation Panel Tests (Function 10) . . . . . . . . . 4-5

4.1.12. Scanne r Tests (Function 11) . . . . . . . . . . . . 4-6

4.1.13. Printe r Tests (Function 12) . . . . . . . . . . . . . 4-6

4.1.14. RAM Tests (Function 13) . . . . . . . . . . . . . . 4-7

4.1.15. Service Station Telephone Numbe r (Fun ction 14) . . . . 4-7

4.1.16. Serial Numbe r (Fu nct ion 15) . . . . . . . . . . . . 4-8

4.1.17. File Transfer (Funct ion 16 ) . . . . . . . . . . . . . 4-8

4.1.18. Hard Disk Initialization (Function 17) . . . . . . . . . 4-8

4.1.19. Group 4 Commu nica tion Parameters (Function 18) . . . 4-8

4.1.20. Programming th e CSI (Function 19) . . . . . . . . . 4-9

4.1.21. Setting the Teleph on e L ine Type (Function 20 ) . . . . . 4-9

4.2. BIT SWITCHES . . . . . . . . . . . . . . . . . . . 4-10

4.3. NCU PARAMETERS . . . . . . . . . . . . . . . . . 4-27

4.4. DEDICATED TRANSMISSION PARAMETERS . . . . . . . 4-43

4.4.1. Programming Procedure . . . . . . . . . . . . . . 4-43

4.4.2. Parameters . . . . . . . . . . . . . . . . . . . 4-44

4.5. SERVI CE RAM ADDRESSES . . . . . . . . . . . . . . 4-47

4.6. SPECIAL TOOLS AND LUBRICANTS . . . . . . . . . . 4-51

4.7. PM TABLE . . . . . . . . . . . . . . . . . . . . . 4-52

Page 5

5. REPLACEMENT AND ADJUSTMENT

5.1. SCANNER . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1. Xenon Lamp . . . . . . . . . . . . . . . . . . . 5-1

5.2. DEVELOPMENT . . . . . . . . . . . . . . . . . . . 5-1

5.2.1. Develop men t Unit . . . . . . . . . . . . . . . . . 5-1

5.3. PCBs . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3.1. Operation Panel PCB [D] . . . . . . . . . . . . . . 5-1

6. TROUBLESHOOTING

6.1. SERVICE CALL CONDITIONS . . . . . . . . . . . . . 6-1

6.2. ERROR CODES . . . . . . . . . . . . . . . . . . . 6-3

Page 6

OVERALL MACHINE INFORMATION June 19th, 1993

SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1. SPECIFICATIONS

Type

Desktop transceiver

Circuit

PSTN, PABX

Connection

Direct couple

Document Size

Length: 105 - 1200 mm [4.1 - 47.2 ins]

Up to 100 m [328 ft] after adjustment

Width: 148 - 304 mm [5.8 - 12.0 ins]

Thickness: ADF 0.05 to 0.2 mm

Manual Feed 0.04 to 0.4 mm

Document Feed

Automatic feed, face down

ADF Capacity

50 sheets (using 80 g/m

Scanning Method

Flat bed, with CCD

Maximum Scan Width

296 mm [11.7 ins] ± 1%

Scan Resolution

Main scan: 200 dpi

Sub scan:

Standard 100 dpi

Detail 200 dpi

Fine 400 dpi

Memory Capacity

ECM: 128 kbytes (double buffer)

SAF: Base machine - 1 Mbyte (62 pages),

with optional extra 1 Mbyte or 2 Mbytes

(max 123 or 185 pages respectively), or 20

Mbyte hard disk (1,200 pages total)

Compression

MH, MR, EFC, MMR, SSC

Storage to SAF memory for tx: MH

MMR only with ECM

2

paper)

Data Rate

14,400/12,000/9,600/7,200/4,800/2,400 bps;

automatic fallback

I/O Rate

With ECM: 0 ms/line

Without ECM: 5, 10, 20, or 40 ms/line

Transmission Time

6 s at 14,400 bps (G3 ECM) for a CCITT #1

test document (Slerexe letter) using standard resolution

Printing System

Laser printing, using the Ricoh CS (Compact

Seamless) Engine, plain paper, dry toner

Paper Size

Standard Cassette

Europe: A4, A5, B4

Asia: A4, A5, F, F4, B4

Lower Cassette

Europe: A4, A5, B4

Asia: A4, A5, F, F4, B4

Maximum Printout Width

210 mm [8.3 ins]

250 mm [9.8 ins] if a lower cassette is installed

Maximum Printer Resolution

Main scan: 400 dpi

Sub scan: 400 dpi

Power Supply

220 - 240 Vac, 50 Hz

Power Consumption (Base Machine Only)

Standby: 25 W Transmit: 35 W

Receive: 250 W Copying: 290 W

Operating Environment

Temperature: 17 - 28 °C [63 - 82 °F]

Humidity: 40 - 70 %Rh

Dimensions (W x D x H)

496 x 477 x 305 mm [19.5 x 18.8 x 12.0 ins]

Excluding handset, trays, and optional units

Modulation

V.33/V.17 (TCM), V.29 (QAM), V.27ter

(PHM), V.21 (FM)

Protocol

Group 3 with ECM, Group 4 kit available

Weight

19 kg [41.8 lbs]

Excluding handset, trays, and optional units

1-1

Page 7

June 19th, 1993 OVERALL MACHINE INFORMATION

FEATURES

1.2. FEA TURES

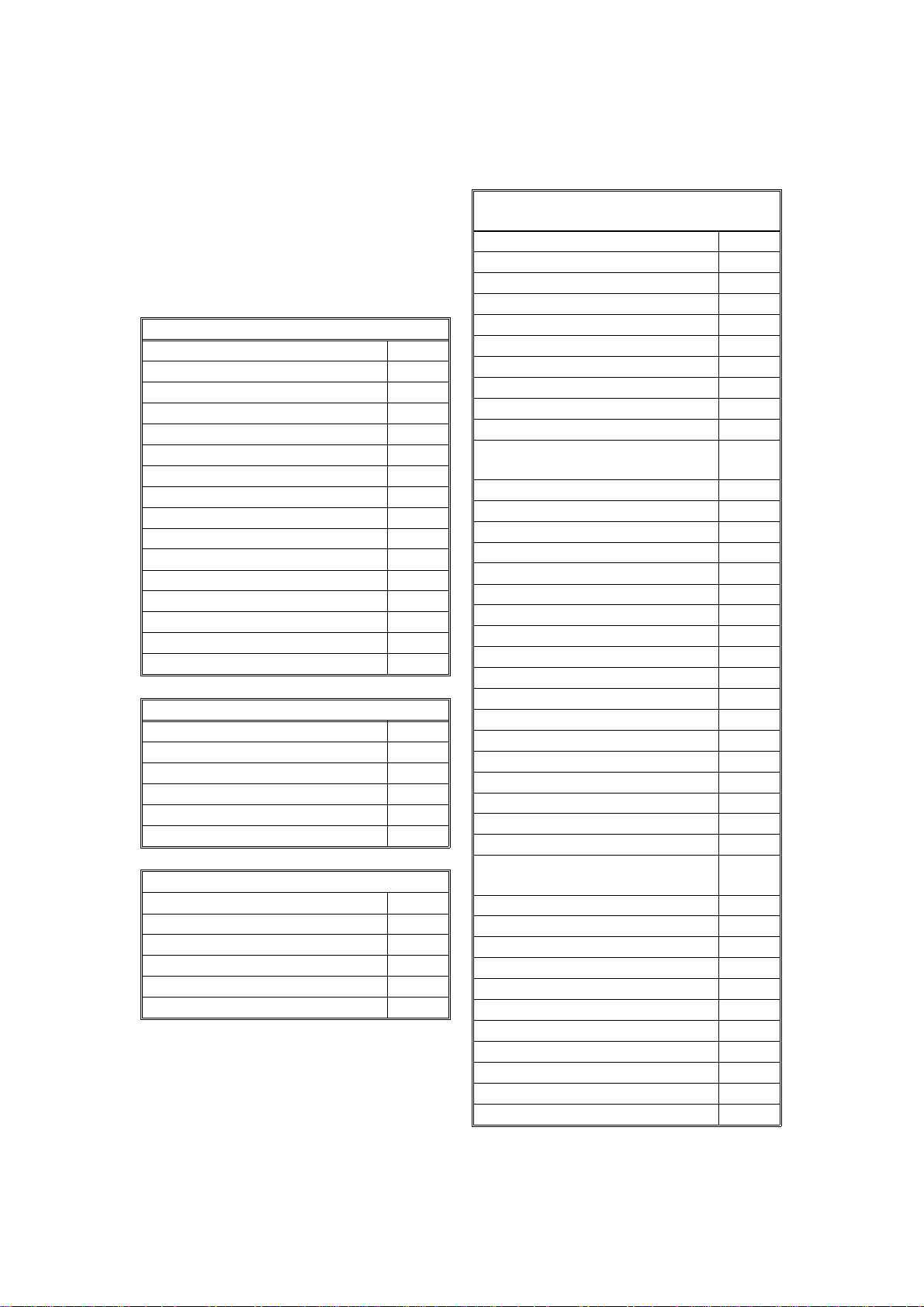

KEY: O = Used, X = Not Used,

A = With optional memory or hard disk only,

B = With lower cassette only,

C = With Group 4 kit only,

G = Not used in Germany,

S = Service mode in some countries

Equipment

ADF O

Bar code reader X

Built-in handset X

Cabinet X

Connection for ans. machine X

Connection for handset O

Cutter X

Handset (option only in Europe) O

Hard disk (option only) O

Magnetic card reader X

Manual feed mechanism O

Marker O

Microphone X

Monitor speaker O

Remaining memory indicator O

Speakerphone X

Video Processing Features

Contrast O

Halftone (Basic & Error Diffusion) O

MTF O

Reduction O

Resolution O

Smoothing to 16 x 15.4 l/mm O

Communication Features - Auto

Automatic fallback O

Automatic redialling O

Confidential reception A

Dual Access O

Substitute reception O

Transmission Reserve X

Communication Features -

User Selectable

Action as a transfer broadcaster A

AI Redial O

Alternative Destination X

Answering machine X

Authorized Reception O

Auto-answer delay time X

Auto dialling (pulse or DTMF) O

Auto Document X

Automatic Voice Message X

Auto-note X

Batch Transmission (max 200

batches)

Broadcasting O

Chain Dialling O

Communication Result Display O

Confidential ID Override O

Confidential Transmission O

Direct Fax Number Entry O

Economy Transmission O

Economy Transmission Time O

Forwarding (5 stations) A

Free Polling O

Groups (10 groups) O

Group Transfer Station O

Hold X

ID Transmission Option O

Immediate Redialling O

Immediate transmission O

Keystroke Programs O

Mailbox X

Memory transmission (this is the

default mode)

Multi-step Transfer O

Next Transfer Station C

Notify X

On Hook Dial O (G)

Page Count O

Personal Codes O

Personal Codes with Conf ID O

Polling Reception O

Polling Transmission O

Polling tx file lifetime in the SAF O

Quick Dial (32 stations) O

O

O

1-2

Page 8

OVERALL MACHINE INFORMATION June 19th, 1993

FEATURES

Communication Features -

User Selectable

Reception modes (Fax, Tel,

Reduction O

Remote control features X

Remote Transfer X

Restricted Access (50 codes,

without cards)

Secured Polling O

Secured Polling with Stored ID

Override

Secure Transmission O

Send Later O

Silent ringing detection X

Speed Dial (100 stations) O

Telephone Directory O

Tonal Signal Transmission O

Transfer Request O

Transmission Deadline O

Turnaround Polling X

Two- step Transfer C

Voice Request (immed. tx only) O

Communication Features -

Service Selectable

AI Short Protocol O

Auto-reduction override option O

Busy tone detection O

Closed Network (tx and rx) O

Continuous Polling Reception O

Dedicated tx parameters O

ECM O

EFC O

Inch-mm conversion O

MV1200 compatibility X

Page retransmission O

Page separation mark O

Protection against wrong conn. O

Resol’n stepdown override option X

Short Preamble O

Well log O

Auto) O

O

O

Other User Features

Area Code Prefix O

Auto Service Call O

Center mark O

Chequered mark O

Clearing a memory file O

Clearing a polling file O

Clock O

Confidential ID O

Copy mode O

Counters O

Country code O

Destination Check O

Direct entry of names O

Function Programs O

ID Code O

Label Insertion O

Language Selection O

LCD contrast control Service

Memory Lock A

Memory Lock ID A

Modifying a memory file X

Multi Sort Document Reception A

Multicopy mode A

Night Timer O

Own telephone number O

Printing a memory file O

RDS on/off O

Reception Mode Switching Timer X

Reception Time (non-memory rx

only)

Remote ID X

Reverse Order Printing A

RTI, TTI, CSI O (S)

Secure ID O

Speaker volume control O

Specified Cassette Selection B

Substitute reception on/off O

Telephone line type O (S)

TTI on/off O

User Function Keys O

User Parameters O

Wild Cards O

O

1-3

Page 9

June 19th, 1993 OVERALL MACHINE INFORMATION

FEATURES

Reports - Automat ic

Charge Control Report X

Communication Failure Report O

Confidential File Report O

Error Report O

Memory Storage Report O

Mode Change Report X

Polling Clear Report O

Polling Reserve Report O

Polling Result Report O

Power Failure Report O

Journal O

Transfer Result Report O

Transmission Deadline Report O

Transmission Result Report O

Reports - User-initiated

Authorized Reception List O

Charge Control Report X

File List O

Forwarding List A

Group List O

Personal Code List O

Program List O

Quick Dial List O

Specified Cassette Selection List B

Speed Dial List O

Journal O

Transmission Status Report X

User Function List O

User Parameter List O

Service Mode Features

Operation panel test O

Printer mechanism test X

Printer test patterns O

Programmable attenuation X

Protocol dump list O

RAM display/rewrite O

RAM dump O

RAM test O

Ringer test X

Scanner lamp test O

Scanner mechanism test O

Sensor initialization X

Serial number O

Service monitor report O

Service station number O

System parameter list O

Technical data on the Journal O

Thermal head parameters X

Transmission Status Report X

Memory Files

Max. number of files: 200

Max. number of stations/ file : 20 0

Max. number of stations ove rall: 500

Max. number of pages overall: 1, 200

Service Mode Features

Back-to-back test O

Bit switch programming O

Buzzer test O

Cable equalizer O

Comm. parameter display O

Counter check O

DTMF tone test O

Echo countermeasure O

Error code display O

File Transfer O

LCD contrast adjustment O

Memory file printout (all files) O

Modem test O

NCU parameters O

1-4

Page 10

OVERALL MACHINE INFORMATION June 19th, 1993

COMPONENT LAYOUT

1.3. COMPONENT LAYOUT

The only diff ere nce is in the document width se nso r, which has an A3-width

sensor and a B4-width se nso r. See section 2 for a drawing.

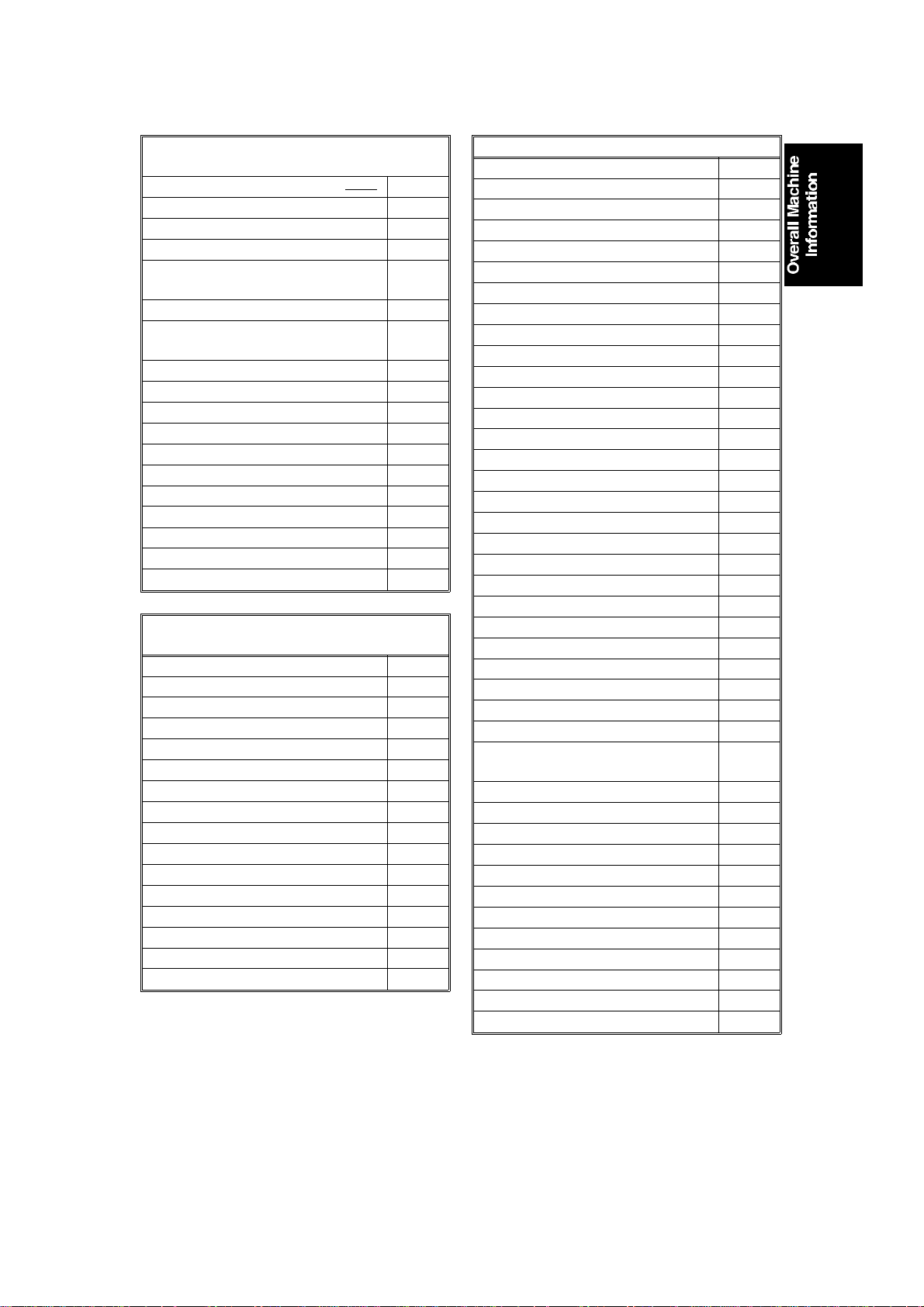

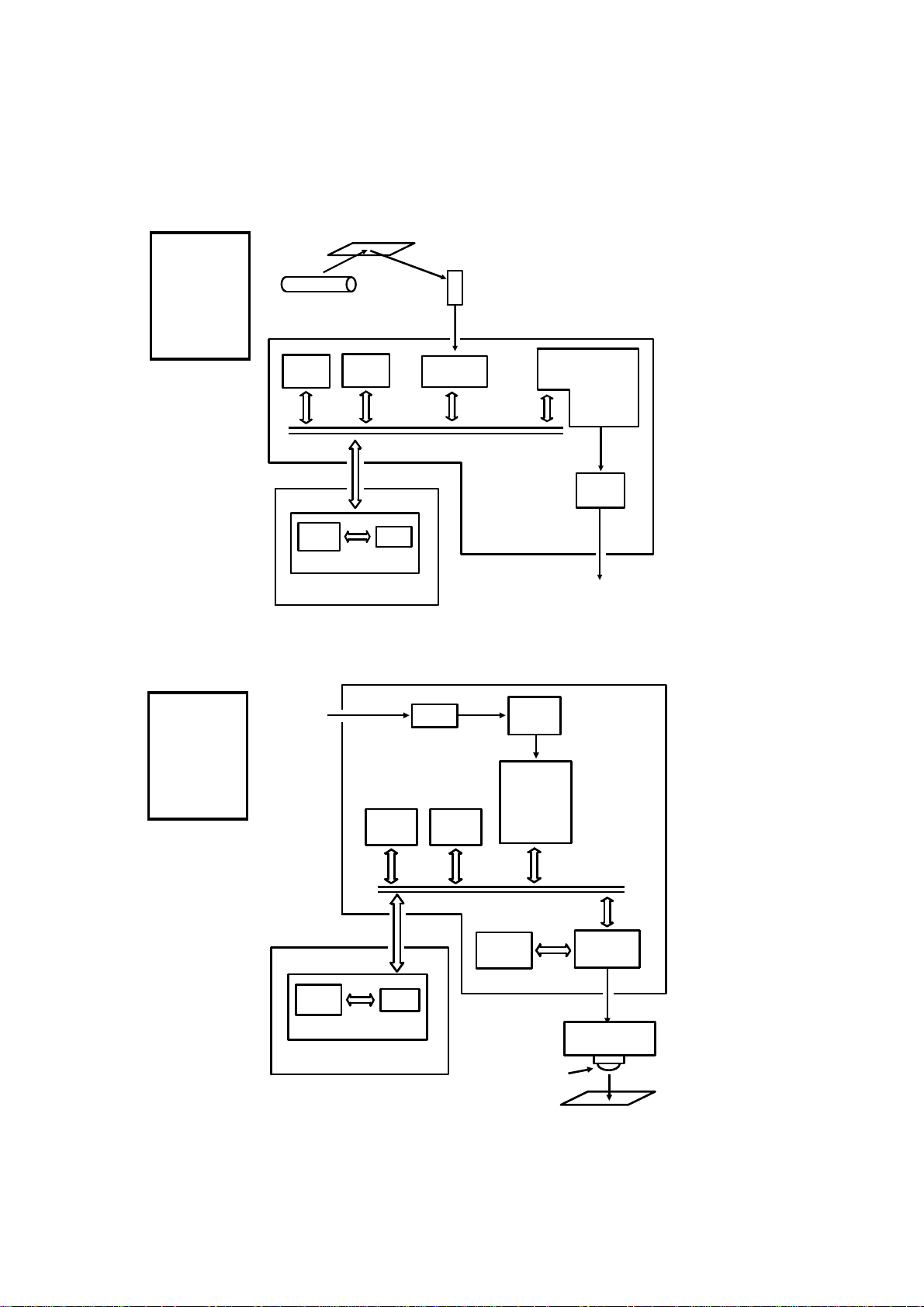

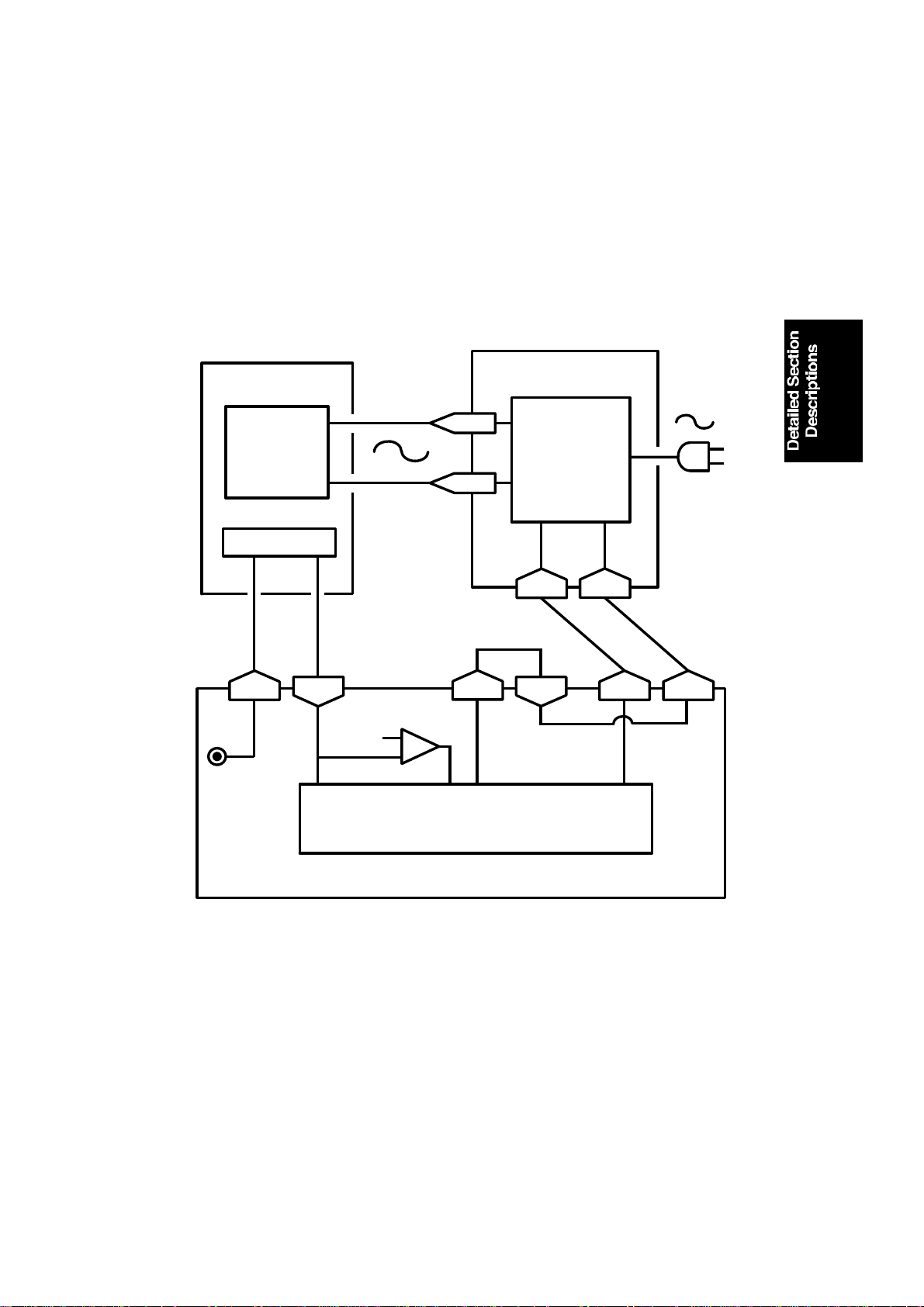

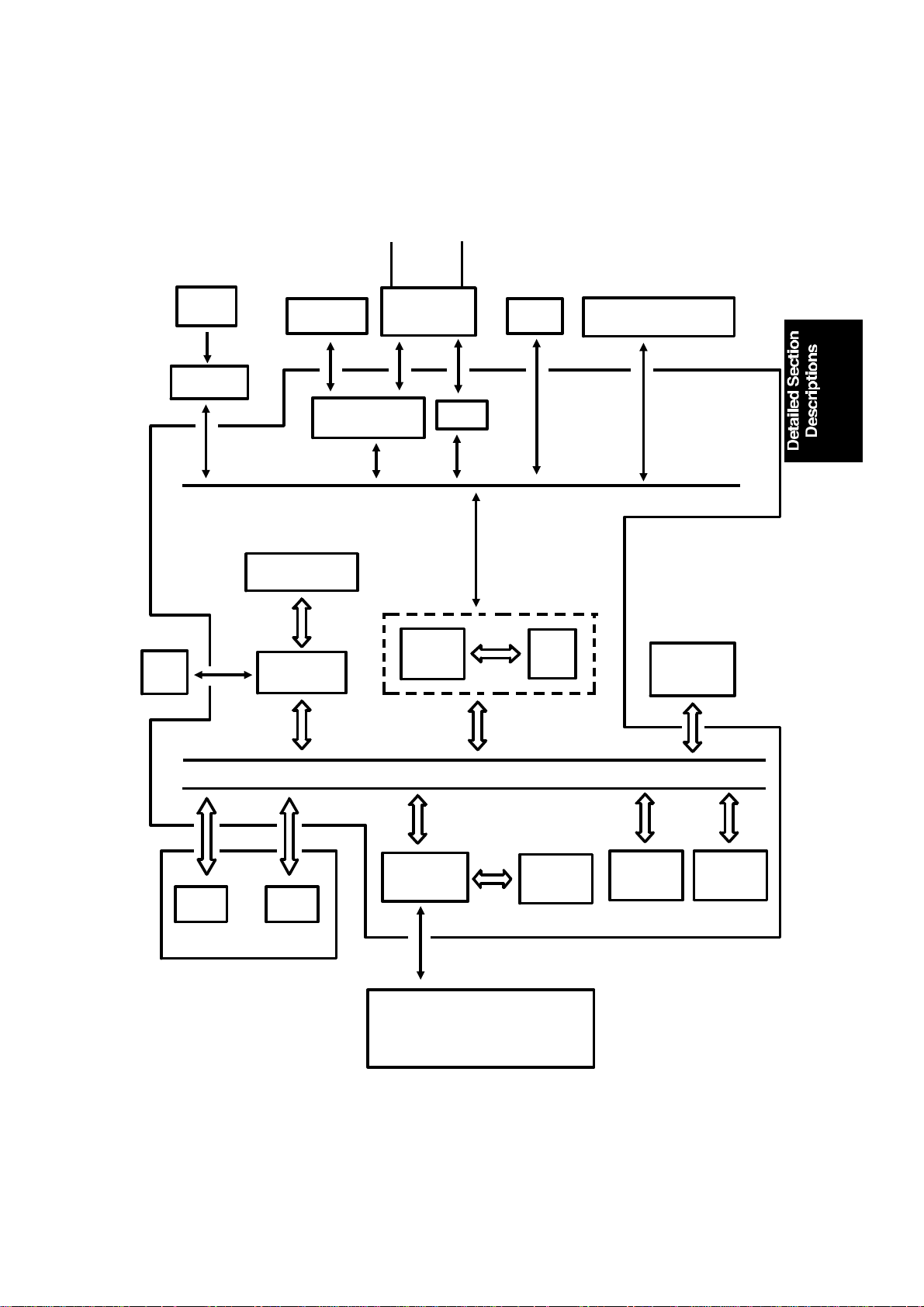

1.4. OVERALL MACHINE CONTROL

HandsetLine

SBU

(CCD)

Scanner

Sensors

Operation

Panel

NCU

CONTROL SIGNALS

Video Processing

Memory

Video

Processor

Speaker

Modem

CPU

DATA AND ADDRESS BUS

PSU

Port

Scanner and Printer Drive

Components and Sensors

FCU

I/O

RS-232C

Interface

Laser

Interface

Page

Memory

SAF

Memory

ECM

Memory

RAMROM

MBU

Laser Diode Driver

Main Scan Start Detector

Interlock Switch

The cpu on the FCU board controls the machine, as shown in the above

drawing. There is no modem board in th e machine; the modem consists o f a

chip on the FCU board that carries out all the analog and digital functions of a

fax modem.

1-5

Page 11

June 19th, 1993 OVERALL MACHINE INFORMATION

VIDEO DATA PATH

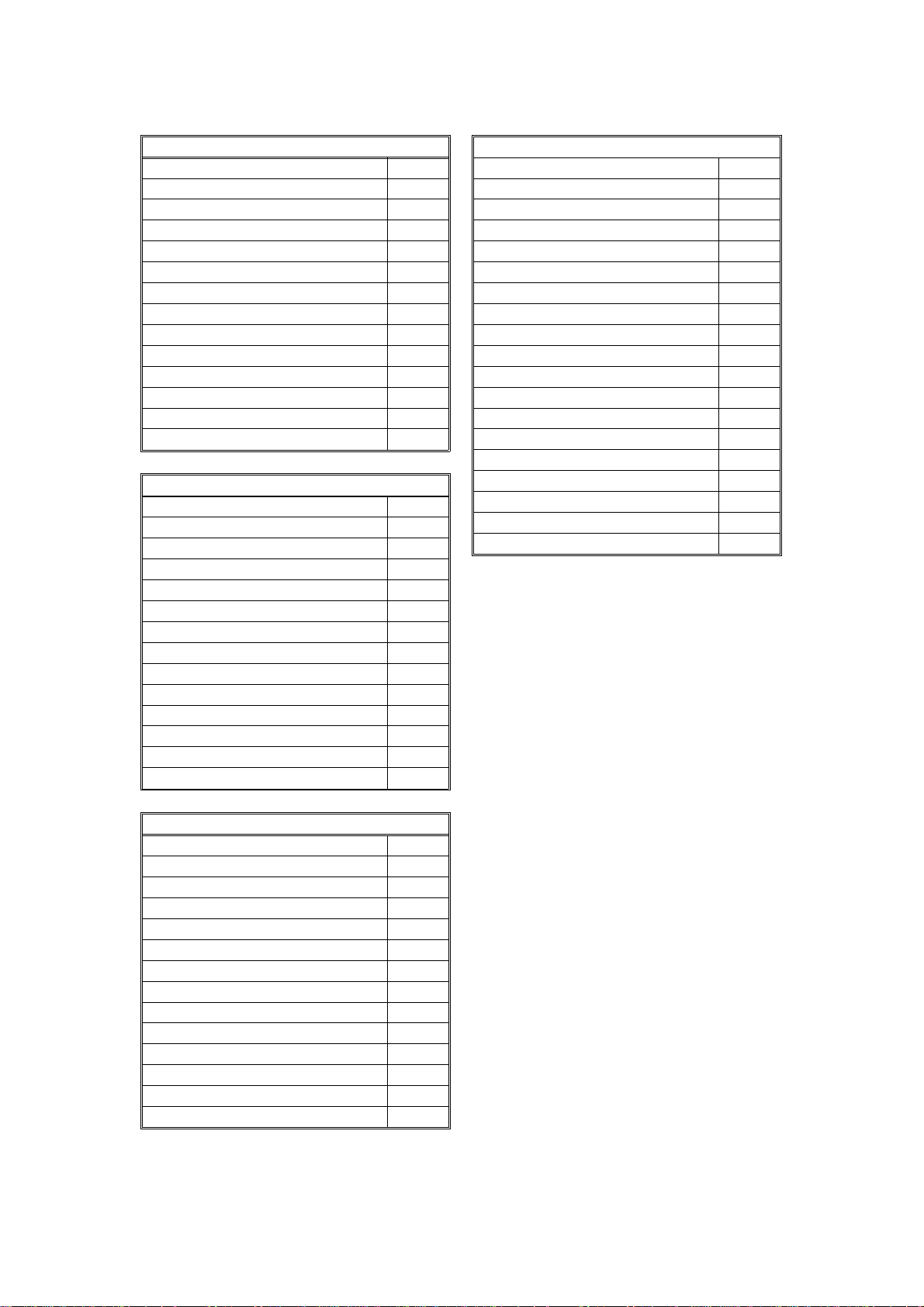

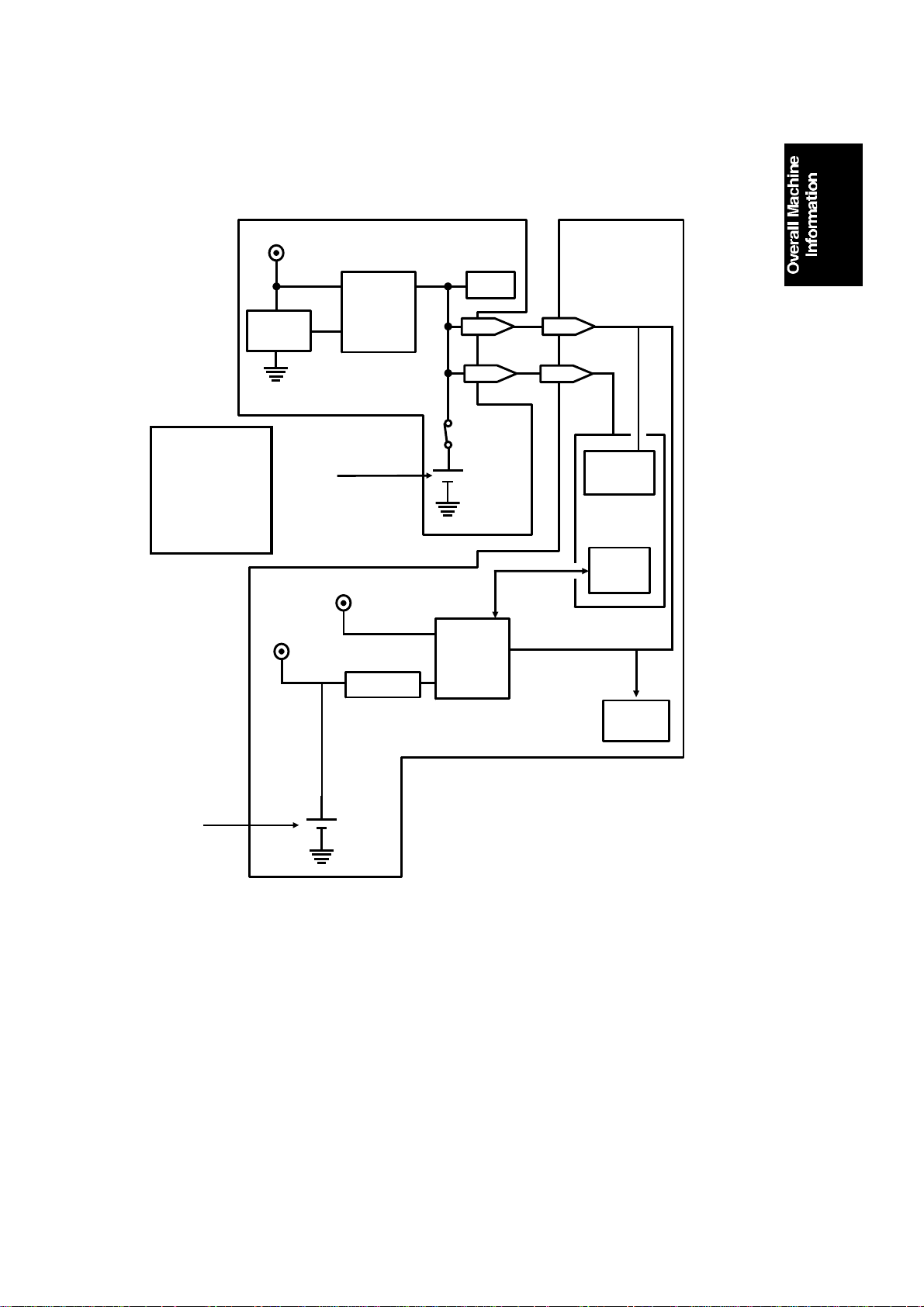

1.5. VIDEO DATA PATH

1.5.1. Transmission

Original

Reference:

Group 3

Facsimile

Manual,

section

1-3-1

Xenon

Lamp

ECM

Memory

Line

Buffer

SAF

Memory

RAM

MBU

FIFO

Analog Signal

Video

Processor

The following diagrams show

the data path for this mod el.

CCD

CPU

Modem

FCU

To the

Network

(via the NCU)

1.5.2. Reception

Reference:

Group 3

Facsimile

Manual,

section

1-3-2

From the

Network

(via the NCU)

Line

Buffer

RAM

MBU

FCU

Memory

SAF

FIFO

Filter

HYBRID IC

Memory

ECM

Page

Memory

Laser Diode

Modem

CPU

Laser

Interface

Laser Diode

Driver

1-6

Copy Paper

Page 12

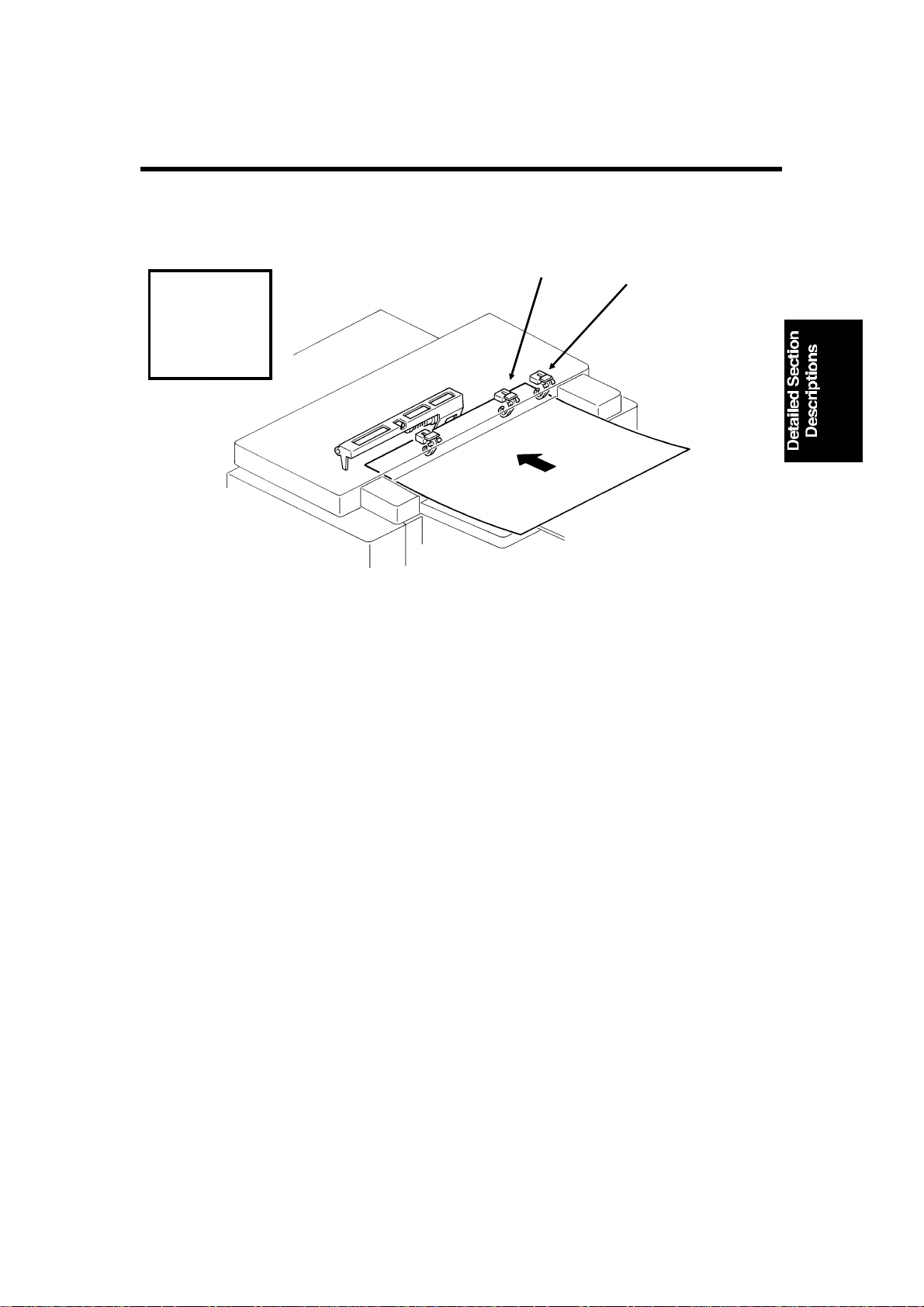

OVERALL MACHINE INFORMATION June 19th, 1993

Power Distribution

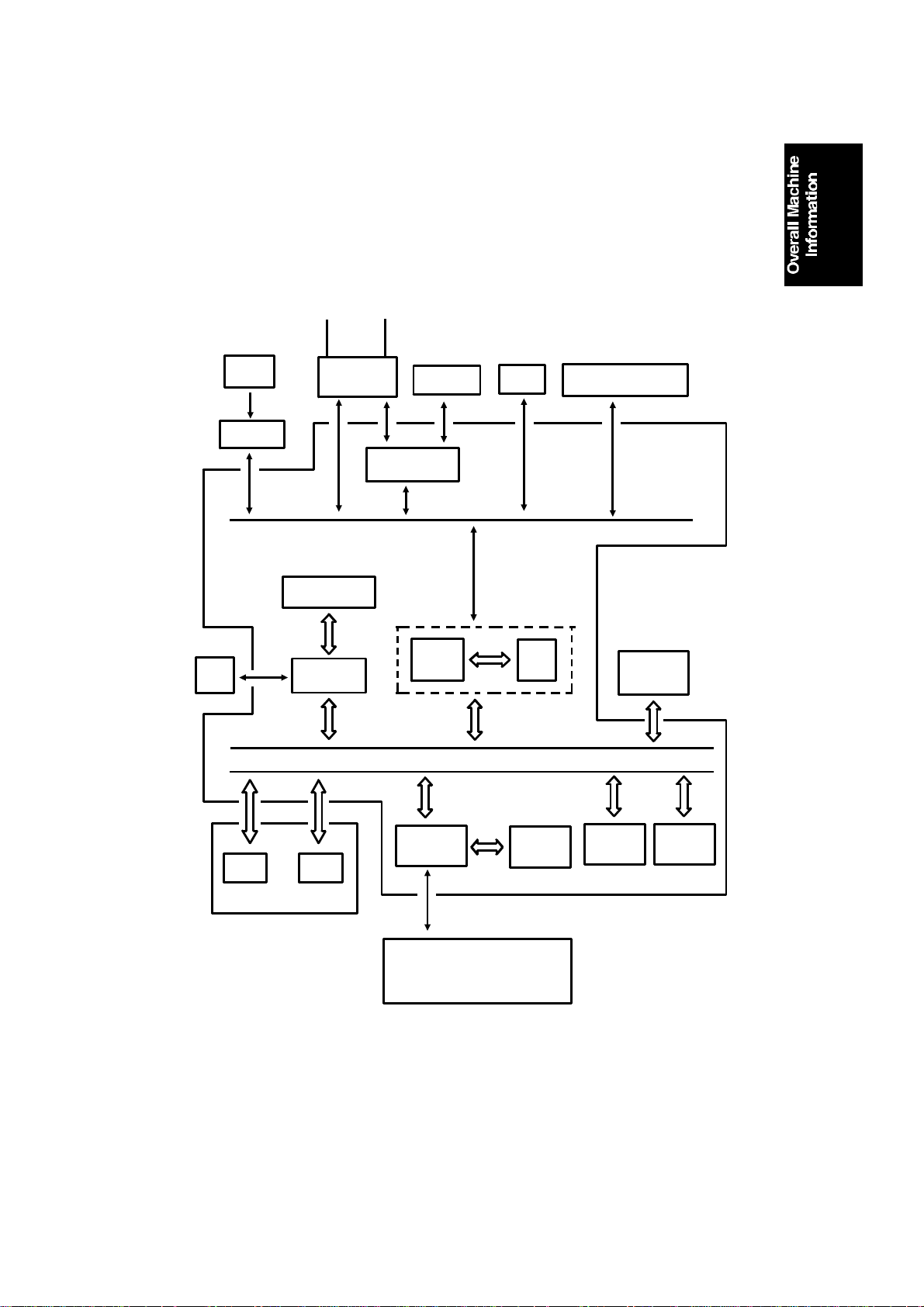

1.6. Power Distribution

1.6.1. Memory Back-up Circuit

Reference:

Group 3

Facsimile

Manual,

section 1-4-3,

Circuit type 1

+5V

Voltage

Detector

+24V

[A]

+5V

Switching

Circuit

Regulator

MBU

RAM

1-9

1-7

Battery

Switch

Battery

Switching

Circuit

FCU

17-9

17-7

Real Time

Clock

CPU

Memory

Monitor

SAF

Memory

[B]

Battery

The battery [A] on the MBU backs up the RA M on the MBU, which con ta ins

system parameters. It also backs up the rea l time clock in t he cpu . This battery is not rechargeable. CN1-7 te lls the cpu whe th er the ba ck-up powe r

(CN1-9) comes from the battery or fro m t he +5 V power supply.

A rechargeable battery [B ] on the FCU board backs up the SAF memo ry and

the real time clock for 1 hour. While the main power is on, the +24V supply recharges the battery. There is no battery switch.

If there is data in the SAF memory, the rechargeable batt ery [B ] also backs

up the real time clock, to preserve the MBU battery.

1-7

Page 13

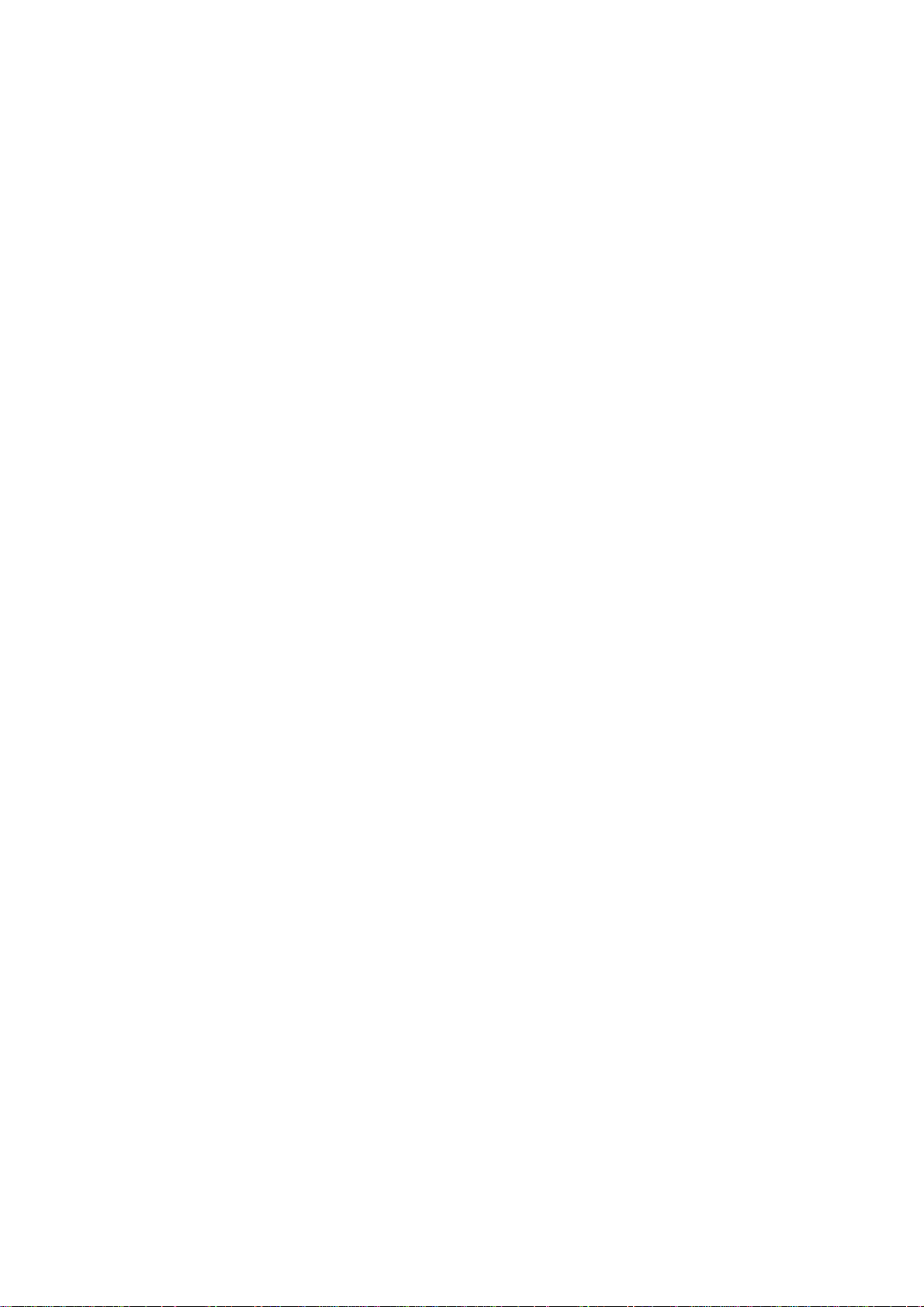

DETAILED SECTION DESCRIPTIONS June 19th, 1993

SCANNER

2. DETAILED SECTION DESCRIPTIONS

2.1. SCANNER

Document Table

Reference:

Group 3

Facsimile

Manual,

section 2-1-1.

• The scanner is A3-width [11.7"], with a B4 document widt h d etector [A]

[A]

[B]

and an A3 document width sensor [B] .

Resolution

This machine scans in dots per inch , to meet Group 4 stand ards. The various

scan resolutions are ach ieved as follows.

Standard - Immediate transmission: The tx motor feeds the documen t a t 200

lines per inch. The video processor executes OR processing t o co nve rt t he

data into 100 lines per inch .

Memory transmission: The motor feeds the docu men t at 10 0 lines per in ch,

and no OR processing is needed.

Detail - The tx motor fee ds th e do cument at 200 lines pe r in ch. There is no

OR processing, and the da ta is transmitted at 200 lines pe r inch.

Fine - The tx motor feeds the documen t and tra nsmits data at 400 lines per

inch. If the other t ermin al cannot receive at this resolut ion , alternate lines of

data are deleted, so the effective resolution of the transmitted da ta is 200

lines per inch.

2-1

Page 14

June 19th, 1993 DETAILED SECTION DESCRIPTIONS

SCANNER

Document Jam Conditions

The cpu detects a document jam if one of the following cond itions occurs.

• The scan line sensor does not switch on within 5 s of the tx motor start-

ing.

• The scan line sensor does not turn off afte r t he maximum do cume nt

length has been fed since it turn ed on; this is 12 s (stan da rd reso lut ion),

24 s (detail), or 48 s (fine) for a 1.2 m long document.

• The scan line sensor switches on while the document sensor is off.

• The document width sensor switches on while the document sensor is

off.

• The scan line sensor does no t tu rn on within 2 s of the end of stamping,

if the document senso r is on.

2-2

Page 15

DETAILED SECTION DESCRIPTIONS June 19th, 1993

PRINTER

2.2. PRINTER

1. Laser Optics

Hexagonal mirror motor speed: 9, 26 7. 7 rpm (G3 and G4 l/mm mod e), 9448. 8

rpm (G4 dpi mode)

2. Paper Feed

Page Separation and Data Reducti on

Incoming pages that are similar in lengt h to the copy pa per ma y be red uce d

in the sub-scan direction to fit on the paper. Whether or not this happens depends on the settings of bits 1 and 2 of bit switch 02 .

Reduction Enabled

If bit 2 of bit switch 02 is at 0, the data will be reduced in the page memory to

fit on the copy paper. However, data will only be redu ced if the leng th of th e

incoming page is between 5 mm shorter and a certain maximum length. This

maximum incoming page lengt h that can be reduced depen ds on the co py paper size and on the reduction ratio sto red in RAM addresses 00014F and

000150.

Each paper size can be progra mmed wit h a sep arate reduction ratio. In ea ch

of the two RAM addresses, th ere is one bit for each p ossible paper size. The

combination of the bit sett ing s det ermines the ratio for that paper size.

Bit 7: Not used Bit 5: Legal Bit 3: A4 Bit 1: B5

Bit 6: B4 Bit 4: F4 Bit 2: Letter Bit 0: A5

The ratio is determined in accordan ce with the follo wing tab le.

Bit in

00014F

Bit in 000150 0 0 1 1

0: Not used 1: 4/3 0: 8/7 1: 12/11

2-3

Page 16

June 19th, 1993 DETAILED SECTION DESCRIPTIONS

PRINTER

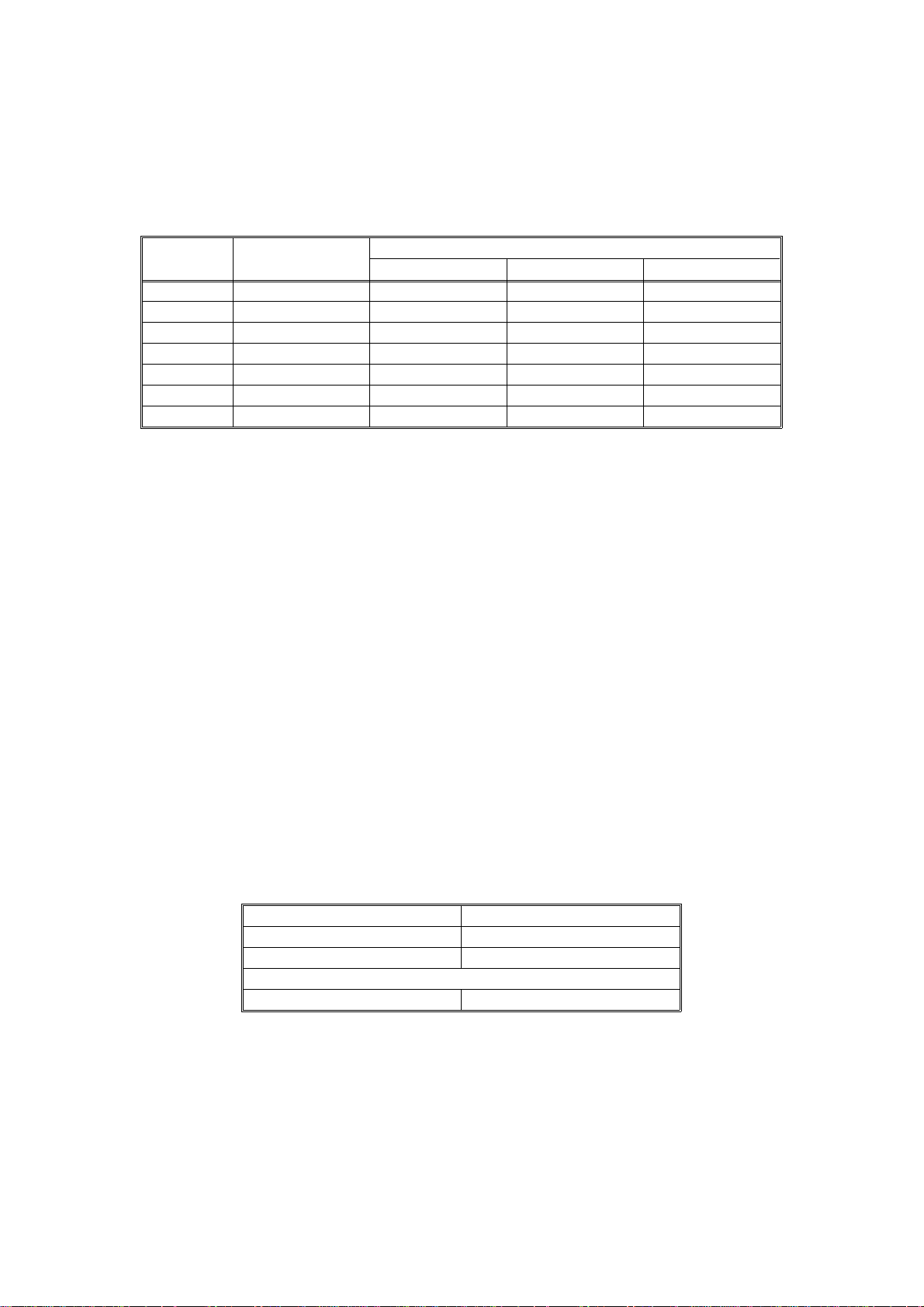

The following table shows the maximum incoming page length s that can be

reduced for each copy p aper size. All lengths are in millimet res. The factory

setting of the reduction ratio is 4/3.

Copy

Paper Type

A5 148 190.7 163.4 156

B5 182 236 202.3 193.1

Letter 279.4 365.9 313.6 299.3

A4 297 389.3 333.7 318.5

F4, F 330.2 433.6 371.7 354.8

Legal 355.6 467.5 400.7 382.5

B4 364 478.7 410 391.6

Copy Paper

Length

Maximum reducable incoming page lengths

Ratio = 4/3 Ratio = 8/7 Ratio = 12/11

The values are calculate d as follows.

Maximum incoming page lengt h that can be reduced =

(Copy Paper Length - 5) x Reduction Ratio

For example, for A 5 wit h a reduction ratio o f 4/3

Max incoming data length = (148 - 5) x 4/3 = 1 90.7

Incoming pages that are longer than the maximum le ngth will not be reduced ,

but will be printed on two pages and treated in accord an ce with the sett ing of

bit 1 of bit switch 02. If this bit is 1, the bottom few lines of the page will be repeated at the top of the next page. If this bit is 0, the next page will continue

from where the first page left off.

Reduction Disabled

If bit 2 of bit switch 02 is at 1, the data will not be reduced . Howe ver, if the in-

coming page is up to x mm longer than the copy pa pe r, the excess portion

will not be printed. The value of x can be from 0 to 15 mm. It is determined by

the setting of RAM address 00015 1 (cop y mode : bit s 3 to 0, receive mode :

bits 7 to 4; bits 3 and 7 are the most signif icant bits).

Hex value Value of x

0 0

1 1

and so on until

15 15

Messages more than x mm longer than the copy paper will be printed out on

two pages in accordance with the sett ing of bit 1 of bit switch 02 , as explained above.

2-4

Page 17

DETAILED SECTION DESCRIPTIONS June 19th, 1993

PRINTER

3. Fusing Unit

Fusing Unit Control Temperatures

Stancby temperature: 80 °C

Printing start temperature: 150 °C

Maximum printing temperat ure : 17 0 °C (monitored by a comparato r )

Thermistor maximum: 280 °C

Thermostat maximum: 400 °C

FUSING UNIT

Fusing

Lamp

Thermistor

36-2

+5V

36-1

LIVE

NEUTRAL

170 C [A]

4-1,4

4-3,6

36-3

I/O

Port

PSU

AC Switching

Circuit

3-1

36-4

3-2

1-8

Main

Power

Supply

1-7

FCU

The circuit shown in the above dia gram controls the fusing unit .

• The I/O Port monito rs the fusing unit temperature at CN36 -1.

• The signal from the compa r at or [A] remains high if the fusing unit tem-

perature is below 170 °C.

• The I/O Port switches th e fu sing unit on/off usin g the signal on CN1-8.

• If the thermistor is accidentally disconnect ed, th e link betwe en CN3 6-3

and CN36-4 will also be bro ken. When the cpu d et ects this, an Auto

Service Call will be sent.

2-5

Page 18

June 19th, 1993 DETAILED SECTION DESCRIPTIONS

PRINTER

Standby mode

• If the fusing lamp is belo w 8 0 °C, th e I/ O Po rt makes CN1-8 go high.

This switches on the fusing lamp.

• If the fusing lamp goes above 80 °C, CN1-8 goes lo w, which switches

off the fu sing lamp.

Printing

• When a ringing signal is detect ed, CN1-8 goes high, to switch on the

fusing lamp. Also, t he o zone fan switches on.

• During printing, the temperature is kept at 170 °C. If the temperature

rises above 170 °C, the output from the comp arator changes state. This

causes CN1-8 to go low, which switches off the fusing lamp.

• If the comparator fails, there are additional safety cutoffs at 280 °C (th er-

mistor) and at 400 °C (thermostat).

After printing

• When the fusing lamp temp erature falls back below 150 °C, th e ozo ne

fan switches off.

Service Note

When an error occurs, the I/O Port switches off the fusing lamp by raising

CN1-7 to high. The print er will b e d isab led , a nd an Auto Service Call will be

sent to the service station (t he me ssag e will be HOT ROLLER DOWN). Details concerning these erro rs are give n in section 6-1 (Service Call Conditions).

2-6

Page 19

DETAILED SECTION DESCRIPTIONS June 19th, 1993

PCBs AND THEIR FUNCTIONS

2.3. PCBs AND THEIR FUNCTIONS

2.3.1. FCU

HandsetLine

SBU

(CCD)

Scanner

Sensors

Operation

Panel

Speaker

CONTROL SIGNALS

Video Processing

Memory

Video

Processor

Modem

NCU

CPU

HIC

PSU

Port

Scanner and Printer Drive

Components and Sensors

FCU

I/O

RS-232C

Interface

MBU

DATA AND ADDRESS BUS

Laser

Interface

Page

Memory

SAF

Memory

ECM

Memory

RAMROM

Laser Diode Driver

Main Scan Start Detector

Interlock Switch

2-7

Page 20

June 19th, 1993 DETAILED SECTION DESCRIPTIONS

PCBs AND THEIR FUNCTIONS

1. CPU (MFCP)

• 65C02 compatible microprocessor

• Interrupt control

• DMA control

• Data compression and re con struction (high speed MH coding fo r 2. 8-

second scanning)

• Real time clock (battery backed-up)

• Memory control

• Control of all mechanisms (dire ctly or th rou gh othe r chip s)

• NCU control (through the I/O Po rt)

2. I/O Port (MIOP)

• Clock control

• Sensor monitoring (includ ing A/D con version whe re necessa ry)

• Tone detection

• Motor drive

• Operation panel con tro l

• Laser Interface control

3. Laser Interface (LIF)

• Page memory control

• Laser diode contro l

• Smoothing

4. Modem

• Modulation/demodulation (analog and digital operations)

5. Video Process or (VP P )

• Analog/digital vide o sign al processing

6. Hybrid IC (HIC)

• Filters

• Amplifiers

7. RAM

• 256k for ECM and system RAM (no back-up)

• 1 Mbyte SAF memory (with battery back-up)

• 1 Mbyte page memory

• 24 kbyte image memory for th e VPP

2-8

Page 21

INSTALLATION August 19th, 1992

INSTALLING OPTIONAL UNITS

3. INSTALLA TION

3.1. INSTALLING OPTIONAL UNITS

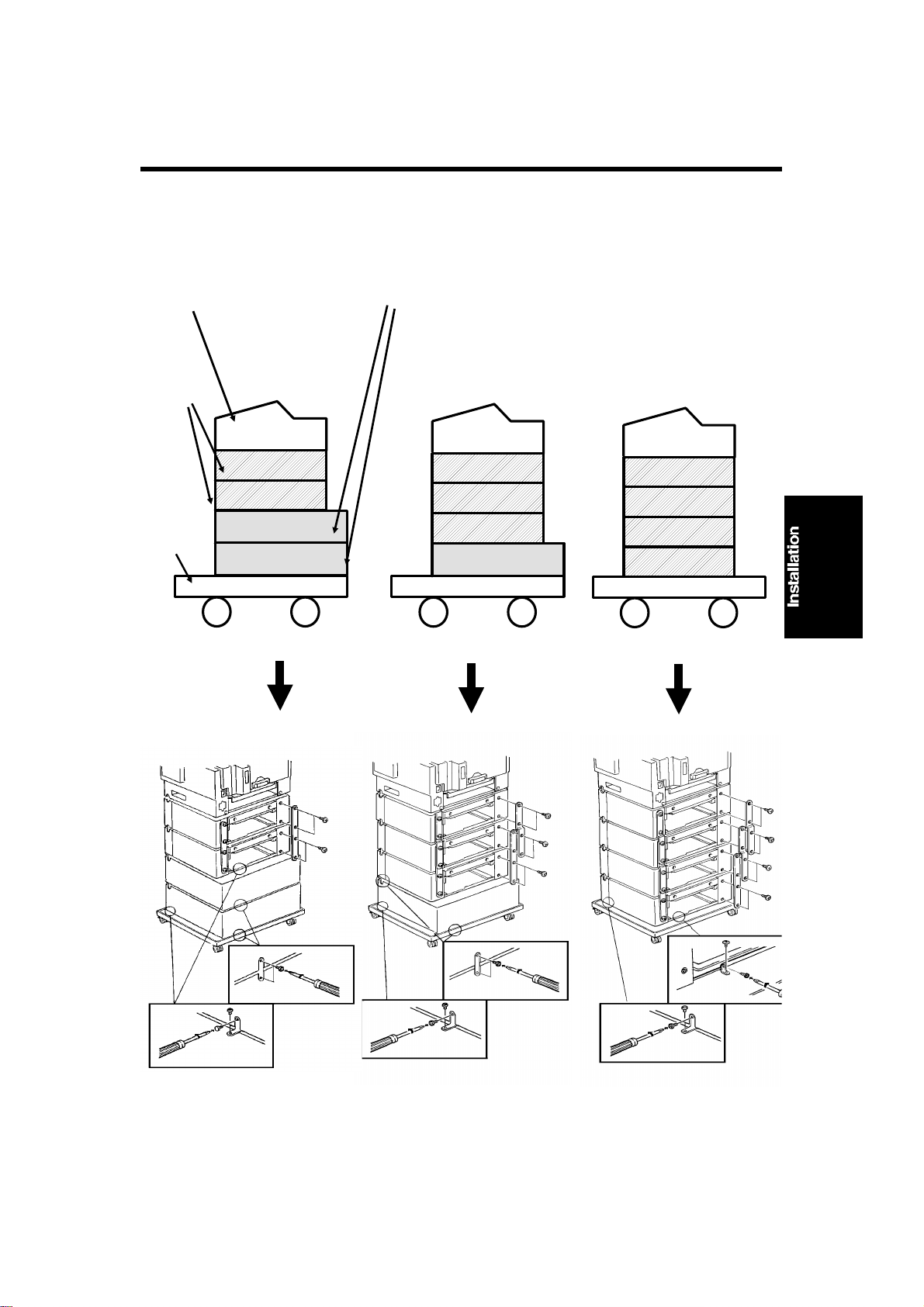

Up to 4 of these paper feed units can be added

3.1.1. Lower Cassette

Machine

Drawers

to the machine. However, if more than one is installed, you have to install drawer and base

units in one of the following ways.

Paper

Feed

Units

Base

2 Paper

Feed Units

3 Paper

Feed Units

4 Paper

Feed Units

3-1

Page 22

[D]

[C]

August 19th, 1992 INSTALLATION

INSTALLING OPTIONAL UNITS

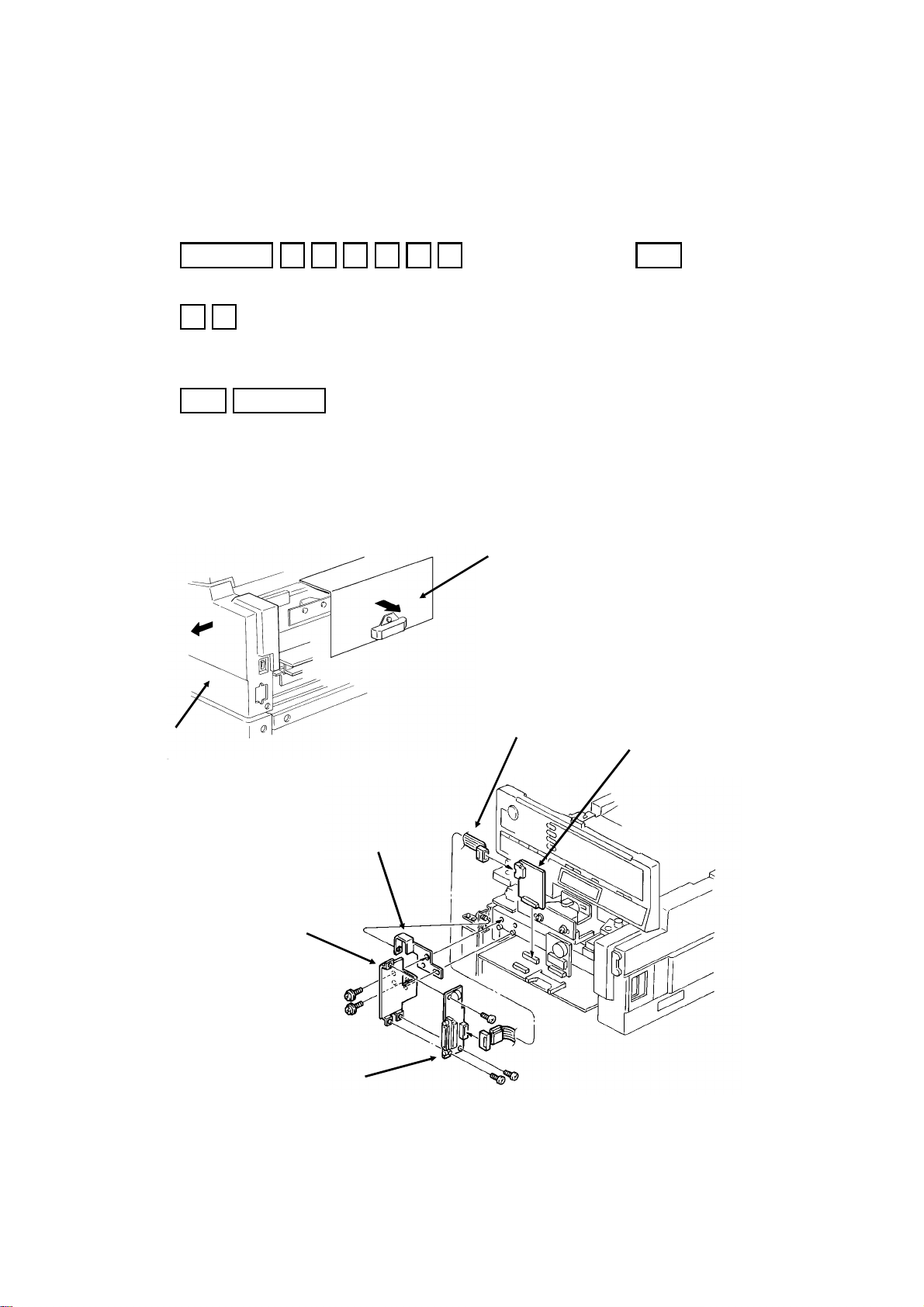

3.1.2. Hard Disk

SAF Memory Initialization

1. Function 6 0 1 9 9 1 then immediately Yes

2. 0 1

3. Set bit 2 of bit switch 00 to 1.

4. Yes Function

Installation Procedure

Switch off the power and unplug the machine from the wall socket. Then remove the cassettes.

[B]

[A]

[F]

[G]

[E]

3-2

Page 23

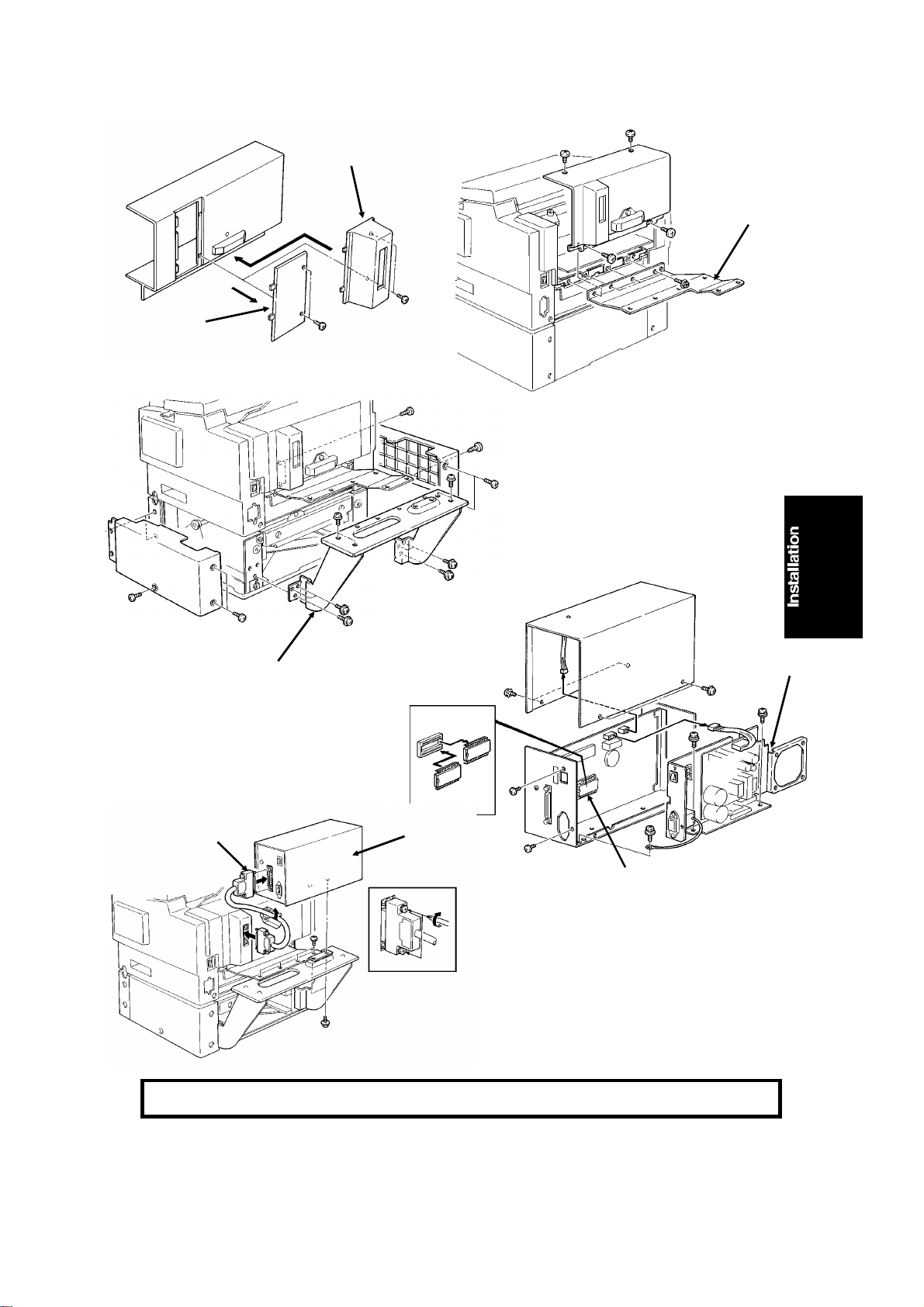

[H]

INSTALLATION August 19th, 1992

INSTALLING OPTIONAL UNITS

[ I ]

[J]

Before attaching [K], remove the side covers of

the paper feed unit.

Then, after attaching [K],

put the covers back.

[K]

[O]

[N]

[M]

Change the ROM [M]

on the HDIF board before reassembling the

hard disk unit.

Caution: Do not plug in or switch on until everything is connected up.

[L]

3-3

Page 24

August 19th, 1992 INSTALLATION

INITIAL PROGRAMMING

Software Initialization

1. Function 6 0 1 9 9 1 , then immediately Yes

2. 0 1

3. Set bit 0 of bit switch 0D to 1.

4. Yes Function

5. Tu rn off the power, the n tu rn on the power after a fe w seconds.

3.2. INITIAL PROGRAMMING

Check the following:

• Are the country codes for NCU parameters (Fun ctio n 09, parame te r 00)

and bit switch settings (bit switch 0F) correct fo r the coun try of insta llation?

• Are the NCU jumper settings correct for th e cou nt ry of inst allation?

• Do any bit switch or other setting s have to be chan ge d to match line

conditions or user requirements?

• Have the correct operation pane l deca ls a nd Quick Dial sheets been in-

stalled from the language kit?

• Have you programmed th e serial number (Function 15, sect ion 4-1-18)?

In some countries, the use r ca nn ot prog ram the following items, so program

them before you lea ve th e machine.

• Telephone Line Type (Function 19, section 4-1 - 23 )

• CSI (Function 20, section 4-1-2 2)

The user should program the follo wing items after installation :

• Telephone Line Type (in some countries, this is not a user adjustment )

• RTI, TTI, and CSI (in some coun trie s, CSI is not a u ser a dju stme nt)

• ID Codes (ID Code, Confidential ID, Memory Lock ID)

• The fax machine’ s own telephone number

• Country code

• Area code prefix (if applicable)

• Date and Time

• Language Selection

3-4

Page 25

SERVICE TABLES AND PROCEDURES June 19th, 1993

SERVICE LEVEL FUNCTIONS

4. SERVICE TABLES AND PROCEDURES

4.1. SERVICE LEVEL FUNCTIONS

To enter service mode, press the following sequence of keys:

Function 6 0 1 9 9 1

then immediately Yes

SERVICE FUNCTION NO. _

01BIT SW. 02PARA LIST

03ERROR CODE 04SVC MONITOR

4.1.1. Bit Switch Programming (Function 01)

1. After entering se rvice mode,

press 0 1

BIT SWITCH

DF: 00000000

SW:00 00000000

Bit 7 is displayed at the left , an d bit 0 at the right. The de fa ult settings are

shown on the top line, and the current settings on the bottom.

2. • Increment bit switch: ↓

• Decrement bit switch: ↑

Example:

Display bit switch 3: ↓ x 3

BIT SWITCH

DF: 00000000

3. Adjust the bit switch.

Example: To change the value of

bit 7, press 7

4. Either:

• Adjust more bit switches - go to step 2.

• Finish - Yes

SW:03 00000000

BIT SWITCH

DF: 00000000

SW:03 10000000

4-1

Page 26

June 19th, 1993 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNCTIONS

4.1.2. System Parameter List (Function 02)

1. After entering se rvice mode,

press 0 2

G3 SYSTEM PARAMETER LIST

PRESS START

2. Start

3. After printin g, pre ss Function

4.1.3. Error Code Display (Function 03)

1. After entering se rvice mode,

press 0 3

ERROR CODE

CODE=0-14 JUL 10 15:15

2. Either:

• Scroll through the error co des using ↑ and ↓

• Finish - Yes

4.1.4. Service Monitor Report (Function 04)

1. After entering se rvice mode,

press 0 4

SERVICE MONITOR REPORT

2. Start

4.1.5. Protocol Dump (Function 05)

1. After entering se rvice mode,

press 0 5

G3 PROTOCOL DUMP LIST

PRESS START

PRESS START

2. Start

4-2

Page 27

SERVICE TABLES AND PROCEDURES June 19th, 1993

SERVICE LEVEL FUNCTIONS

4.1.6. RAM Display/Rewrite/Printout (Function 0 6)

1. After entering se rvice mode,

press 0 6

RAM NO. _

0.MEMORY R/W 1. MEMORY DUMP

2. Either:

• Display or rewrite RAM data: 0

Go to step 3.

• Print a RAM dump list: 1 . Go

to step 6.

MEMORY R/W

ADDRESS= 000000 DATA=FF

MEMORY DUMP

ADD. H - ADD. FFH

3. Input the address th at you wish to

see.

Example: 0 0 1 1 2 2

If necessary, use ↑ and ↓ to

MEMORY R/W

ADDRESS= 001122 DATA=00

increment or decrement the RAM

address.

4. If you wish to change the con te nt s

of the RAM address, press → to

move the cursor to the data side.

Then input the new data.

Example: F F

MEMORY R/W

ADDRESS= 001122 DATA= FF

5. Either:

• View more addresses - ← then go to step 3.

• Finish - Yes . Go to step 2.

6. Input the range of addresses that you wish to print.

Example: Addresses 22AA00 to 22BBFF

2 2 A A 2 2 B B Start

4-3

Page 28

June 19th, 1993 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNCTIONS

4.1.7. Checking the Counters (Function 07)

1. After entering se rvice mode,

press 0 7

COUNTER R/W NO. _

0 COUNTER 1 PM COUNTER

2 CTM COUNTER 3 OPU COUNTER

2. Either:

• Check the scanned, printed, transmitted, and received page counters,

and the printer and scanner jam counters: 0 . (To see the jam

counters, press 0 then ↓ . )

• Check the PM counter: 1

• Check the CTM counter: 2

• Check the OPU counter: 3

3. To change the contents of a counter, press → until the required

counter is highlighte d on the scre en, then input the new value.

4.1.8. Clearing the Counters (Function 08)

1. After entering service mode,

press 0 8

COUNTER CLEAR NO. _

0 PM COUNTER 1 CTM COUNTER

2 OPU COUNTER

2. Either:

• Clear the PM counter: 0

• Clear the CTM counter: 1

• Clear the OPU counter: 2

4.1.9. NCU Parameters (Function 09)

1. After entering se rvice mode,

press 0 9

NCU NO. _

0 NCU 1 MODEM/DTMF

2. 0

4-4

NCU

NO.00= 019

PRESS YES/NO

Page 29

SERVICE TABLES AND PROCEDURES June 19th, 1993

SERVICE LEVEL FUNCTIONS

3. Scroll through the parameters using ↑ and ↓ .

Enter new values at the keypa d where necessary.

Example: Set NCU parameter 04 to 005.

↓ ↓ ↓ ↓ 0 0 5 Yes

4. To go to the n ext parameter: Yes

5. To finish: No Yes

Note: Parameter 00 is the Country Code, and Parameter 01 is th e Tx Level

(Input the value of the Tx level x -1 ; f or e xamp le, if the Tx level should

be -9 dB, input 9).

4.1.10. Modem/DTMF Tone Tests (Function 09)

1. After entering se rvice mode,

press 0 9 then 1

MODEM/DTMF

NO.01=V29 9600 BPS

PRESS START

2. Scroll through the available tests using ↑ and ↓ .

Example: To do an 1100 Hz tone test. ↓ ↓ ↓ Start

To finish a test: Stop

3. To finish: Yes x 2

4.1.11. Operation Panel Tests (Function 10)

1. After entering se rvice mode,

press 1 0

OP.PANEL NO. _

0 LED 1 ALARM

2 RINGER 3 LCD

2. Either:

• Test the LEDs on the operation pane l: 0 Start

• Test the alarm tone: 1 Start

• Test the ringer: This test is not use d in this machine.

• Test the LCD: 3 Start

4-5

Page 30

June 19th, 1993 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNCTIONS

3. To finish a test: Stop

4. To finish: Yes x 2

4.1.12. Scanner Tests (Function 11)

1. After entering se rvice mode,

press 1 1

SCANNER NO. _

0 XE LAMP 1 ADF

2. Either:

• Switch on the xenon lamp: 0 Start

• Test the auto document feeder: Place a shee t of paper in the document

feeder, then 1 Start

3. To finish a test: Stop

4. To finish: Yes x 2

4.1.13. Printer Tests (Function 12)

1. After entering se rvice mode,

press 1 2

PRINTER NO. _

0 P ATTERN 1 MECH TEST

2 FAN MOTOR 3 CTM MOTOR

2. Either:

PATTERN NO. _

• Print a test pattern : 0 . Go to

step 3.

• Test the printer mechanism: 1 Start

• Test the fan motor: 2 Start

• Test the CTM motor: First, remove the CTM, then pre ss 3 Start

0 DIAGONAL 1 1 DIAGONAL 2

2 VERTICAL 3 GRAND PRIX

To finish a test: Stop

4-6

Page 31

SERVICE TABLES AND PROCEDURES June 19th, 1993

SERVICE LEVEL FUNCTIONS

3. Press a key from 0 to 5, depending on the required pattern. Use ↑

and ↓ to see what pattern s are available.

4. Start

A test pattern is printed.

5. To finish: Yes x 2

4.1.14. RAM Tests (Function 13)

1. After entering se rvice mode,

press 1 3

RAM TEST NO. _

0 SRAM 1 SAF

2 PAGE MEMORY

2. Either:

• Test the SRAM: 0 Start

• Test the SAF: 1 Start

• Test the page memory: 2 Start

If there is a problem, a display of the following type will occur.

SAF

PRESS START

ADDRESS=300002 W=55 R=00

Keep a note of the information on the display, then press Start to resume

testing.

3. When the test has fin ishe d, "OK" is displayed. Press Yes to finish.

4.1.15. Service Station Telephone Number (Function 14)

1. After entering se rvice mode,

press 1 4

S.S.NO ENTER FAX NUMBER

NO

TO CANCEL

2. Input the telephone number of the service station that will receive Auto

Service calls from this machine.

Then press Yes .

If the ISDN Option kit has bee n inst alle d, press the Line Selector key to

select either G3 or G4 before inputting the number.

4-7

Page 32

June 19th, 1993 SERVICE TABLES AND PROCEDURES

SERVICE LEVEL FUNCTIONS

4.1.16. Serial Number (Function 15)

1. After entering se rvice mode,

press 1 5

SERIAL NO.

2. Enter the machine ’s serial no at the keypad.

To correct a mistake: No

3. If the display is correct: Yes

4.1.17. File T ra nsfe r (Functi on 16)

1. After entering se rvice mode,

press 1 6

FILE TRANSFER ENTER FAX NUMBER

NO

TO CANCEL

2. Input the teleph on e nu mbe r o f th e fax machine to which you wish to tra nsfer all the files. Then pre ss Yes Start .

If the ISDN Option kit has bee n inst alle d, press the Line Selector key to

select either G3 or G4 before inputting the number.

4.1.18. Hard Disk Initialization (Function 17)

1. After entering se rvice mode,

press 1 7

HD NO. _

0 INITIAL

2. 0

The hard disk is initialized.

4.1.19. Group 4 Communication Parameters (Functi on 18)

This function is described in the service manual for the optio nal I SDN kit.

4-8

Page 33

SERVICE TABLES AND PROCEDURES June 19th, 1993

SERVICE LEVEL FUNCTIONS

4.1.20. Programming the CSI (Function 19)

This procedure is for use in countrie s where CSI programming is a service

mode.

1. 1. After entering se rvice mode,

press 1 9

2. Input the CSI (not more than 20 dig-

CSI

CSI

YES

TO END

YES OR CLR . NO

its)

+44712121234

Note: If you wish to input a ’+’ sign to signify the international dial ac-

cess code, press 31 then 1

4. Yes Function

4.1.21. Setting the Telephone Line Type (Function 20 )

This procedure is for use in countries where telephone line type selection is a

service mode.

1. After entering se rvice mode,

PSTN LINE TYPE SELECT

press 2 0

PD TT

2. If the setting needs changing,

press ← or → until the re-

quired setting is highlighted in reverse video.

3. Yes Function

4-9

YES

TO END

Page 34

June 19th, 1993 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

4.2. BIT SWITCHES

WARNING

Do not adjust a bit switch that is described as "Not used", as this

may cause the machine to malfunction or to operate in a manner

that is not accepted by local regulations. Such bits are for use only

in other areas, such as Japan.

Bit Switch 00

FUNCTION COMMENTS

0 MTF process

0: Enabled 1: Disabled

1 RAM reset level 2

1: Reset

2 RAM reset level 3

1: Reset

Note: RAM reset level

1 is a RAM

adjustment. It is not

described in this

manual.

3 Not used Do not change the factory setting.

4 Inclusion of technical

data on the TCR

0: No 1: Yes

5 Monitor speaker

during video data

communication (tx

and rx)

0: Disabled 1:

Enabled

6 Not used Do not change the factory setting.

7 Communication

parameter display

0: Disabled

1: Enabled

0: The MTF process is used when required by the software.

1: The MTF process is never used.

When this bit is set to 1, all items stored in the RAM are

reset except the clock, and then this bit changes back to 0

automatically. Also, all image files in the SAF memory are

erased.

When this bit is set to 1, some items stored in the RAM are

reset, then this bit changes back to 0. All items are reset

except the bit switch and NCU parameter settings, clock,

own tel. no., CSI, RTI, TTI, Quick Dials, Speed Dials,

Groups, and the TCR memory. Also, all image files in the

SAF memory are erased.

This bit switch is recommended for use when it is necessary

to clear the SAF, as fewer RAMs will need reprogramming.

1: Instead of the personal code, the following data are listed

on the TCR.

First number: Final modem rate (for example, 14.4K means

14,400 bps)

Second and third numbers (Rx mode only): These are a

measure of the errorrate. The left hand figure is the low byte

and the right hand figure is the high byte. In general, a

larger number means more errors. These numbers are fixed

at 0 for tx mode.

Fourth number: Cable equalizer; 00 = Equalizer is Off, 01 =

Low, 10 = Medium, 11 = High

Used for testing. Set this bit to 1 to hear the fax data signal

(phase C of CCITT T.30 protocol).

Make sure that you reset this bit after testing.

This is a fault-finding aid. The LCD shows the key

parameters (see the next page). This is normally disabled

because it cancels the CSI display for the user.

Make sure that you reset this bit after testing.

4-10

Page 35

SERVICE TABLES AND PROCEDURES June 19th, 1993

BIT SWITCHES

Communication paramete r dis play

Mode DCS: CCITT G3

NSS: Non-standard G3

Modem rate 144S: 14,400 bps with short trainng (V.17)

144L: 14,400 bps with long trainng (V.33)

120S: 12,000 bps with short trainng (V.17)

120L: 12,000 bps with long trainng (V.33)

96TS: 9,600 bps using TCM, with short training (V.17)

96TL: 9,600 bps using TCM, with long training (V.33)

72TS: 7,200 bps using TCM, with short training (V.17)

72TL: 7,200 bps using TCM, with long training (V.33)

96: 9600 bps

72: 7200 bps

48: 4800 bps

24: 2400 bps

Communica

tion mode

Compression mode

Resolution SSF: Fine, transmitted at 8 x 15.4 dots per mm

I/O Rate 0M: 0 ms/line

Width and

reduction

ECM: With ECM

SSC: Using SSC

EFC: Using EFC

NML: With no ECM, SSC, or EFC

MMR: MMR compression

MR: MR compression

MH: MH compression

PSF: Fine, transmitted at 8 x 7.7 dots per mm and smoothed at the rx side

DTL: Detail

STD: Standard

2/M: 2.5 ms/line

5M: 5 ms/line

10M: 10 ms/line

20M: 20 ms/line

40M: 40 ms/line

=A4: A4 (8.3"), no reduction

=B4: B4 (10.1"), no reduction

=A3: A3 (11.7"), no reduction

>A4: Reduced to A4 (8.3") before transmission

>B4: Reduced to B4 (10.1") before transmission

4-11

Page 36

June 19th, 1993 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

Bit Switch 01

FUNCTION COMMENTS

LCD contrast

0

Bit 2 1 0 Contrast

1

0 0 0 Brightest

0 0 1 ↓

2

↓ ↓

1 1 0 ↓

1 1 1 Darkest

Memory read/write by RDS

Bit 4 3 Setting

3

0 0 Always enabled

0 1 User selectable

4

1 0 User selectable

1 1 Always disabled

5 Dedicated transmission parameter

programming/printing all SAF

files/erasing all SAF files

0: Disabled 1: Enabled

6 Not used Do not change the factory setting.

7 Auto Service Call for PM

0: Enabled 1: Disabled

Use these bit switches to adjust the brightness

of the LCD on the operation panel.

(0,0): At any time, an RDS system can read or

write RAM data such as TTI and bit switches.

(0,1), (1,0): Normally, RDS systems are locked

out, but the user can temporarily switch RDS

on to allow an RDS operation to take place.

RDS will automatically switch off again after a

certain time, which is stored in a RAM address

(see section 4-5). Note that, if an RDS

operation takes place, RDS will not switch off

until this time limit has expired.

(1,1): All RDS systems are always locked out.

This bit must be set to 1 before attempting to

program dedicated transmission parameters

(using Function 31 or 32), or printing all files

stored in the SAF memory (using Function 24)

or erasing all files stored in the SAF memory

(using Function 21).

After finishing with these operations, return this

bit to 0.

0: The machine will send an Auto Service Call

when the PM interval has expired. This interval

is adjustable by RAM address. The default

setting is every 30,000 copies (based on the

Print counter).

1: The user will do maintenance as explained

in the Operator’s Manual whenever problems

occur.

4-12

Page 37

SERVICE TABLES AND PROCEDURES June 19th, 1993

BIT SWITCHES

Bit Switch 02

FUNCTION COMMENTS

0 Page separation mark

0: Enabled 1: Disabled

1 Repetition of data when the

received page is longer than the

printer paper

0: Disabled 1: Enabled

2 Reduction of the length of

received data

0: Enabled 1: Disabled

3 Not used Do not change the factory settings.

4

5 Text/photo determination during

scanning

0: Enabled 1: Disabled

Maximum transmittable document

length

6

Bit 7 6 Setting

0 0 600 mm

7

0 1 1200 mm

1 0 14 m

1 1 100 m

0: If a received page has to be printed out on two

sheets, an "x" inside a small box is printed at the

bottom right hand corner of the first sheet, and a

"2" inside a small box is printed at the top right

hand corner of the second sheet. This helps the

user to identify pages that have been split up.

1: No marks are printed.

0: The next page continues from where the

previous page left off

1: The final few mm of the previous page are

printed at the top of the next page.

See section 2-2 for details.

This bit determines whether incoming pages are

reduced to fit on the copy paper if they are

almost the same length as the copy paper in the

cassette. See section 2-2 for details.

If this is set at 0, the scanner will detect whether

a pixel is part of a photograph or part of a text

area, and process it accordingly.

If the user wants to send very long documents

such as well logs, use the 14 m or 100 m setting.

4-13

Page 38

June 19th, 1993 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

Bit Switch 03

FUNCTION COMMENTS

0 Dialing with the handset off-hook

0: Enabled

1: Disabled

1 Lifetime of polling standby files in

the memory

0: Erased after being polled

1: Kept until user erases

2 Inclusion of communications on

the TCR when no image data was

exchanged.

0: No 1: Yes

3 Printing of the error code on the

error report

0: No 1: Yes

4 Line error marks on received

pages

0: Disabled 1: Enabled

5 Printing the TTI in copy mode

0: No 1: Yes

6 Printing the received RTI/CSI

0: No 1: Yes

7 Reconstruction time for the first

line in receive mode

0: 6 s 1: 10 s

If this bit is 1, the user will not be able to dial if

the handset is off hook.

0: Messages stored for polling transmission will

be erased immediately after polling.

1: This setting allows the user to keep messages

in the memory to be polled by more than one

station.

If communication did not reach phase 3 of

CCITT T.30 protocol (such as for a telephone

call), this communication can be listed on the

TCR if this bit is at 1.

If this bit is 1, error codes are printed on the error

reports for the user.

If this bit is 1, a mark will be printed on the left

edge of the page at any place where a line error

occured in the data. Such errors are caused by a

noisy line, for example.

If this bit is 1, the TTI stored in the machine is

printed at the top of the copy.

In addition to the TTI, the other end’s RTI or CSI

will be printed on top of the pages that the

machine receives.

When the sending terminal is controlled by a

computer, there may be a delay in receiving

page data after the local machine accepts set-up

data and sends CFR. If this occurs, set this bit to

1 to give the sending machine more time to send

data.

4-14

Page 39

SERVICE TABLES AND PROCEDURES June 19th, 1993

BIT SWITCHES

Bit Switch 04

FUNCTION COMMENTS

Compression modes available in

receive mode

0

Bit 1 0 Modes

0 0 MH only

1

0 1 MR or MH

1 0 MR or MH, with

EFC

1 1 MMR, MR, or

MH, with EFC

2 Error counting method

0: 10 (20) [40]

1: In accordance with the settings

of bits 3 to 7

Burst error threshold

3

Bit 4 3 Threshold

0 0 3 (6) [12]

4

0 1 4 (8) [16]

1 0 5 (10) [20]

1 1 6 (12) [24]

Error line ratio

5

Bit 7 6 5 Value

0 0 0 5%

6

0 0 1 6%

0 1 0 7%

7

0 1 1 8%

1 0 0 9%

1 0 1 10%

These bits determine what capabilities are

informed to the transmitting side in the protocol

exchange.

The machine counts data errors caused by a

noisy line or defective machine.

0: If the count reaches 10 (Standard mode), 20

(Detail mode), or 40 (Fine mode), the machine

sends RTN to the other end in reply to the postmessage command. As 10 (or 20 or 40) good

lines cause the count to decrement, RTN will

only occur in bad conditions.

If there are more consecutive error lines in the

received page than the threshold specified by

these bits, the page is rejected. Values in

parenthesis are for Detail resolution, and those

in square brackets are for Fine resolution.

If the number of error lines divided by the total

number of lines reaches the value determined

by the settings of these bits, RTN will be sent to

the other end.

4-15

Page 40

June 19th, 1993 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

Bit Switch 05

FUNCTION COMMENTS

Compression modes available in

transmit mode

0

Bit 1 0 Modes

0 0 MH only

1

0 1 MR or MH

1 0 MR or MH, with

EFC

1 1 MMR, MR, or

MH, with EFC

2 PABX dial tone detection

0: Enabled

1: Disabled

3 PSTN dial tone detection

0: Enabled

1: Disabled

4 Busy tone detection

0: Enabled

1: Disabled

5 Not used Do not change the factory setting.

PSTN access method through

6

PABX

Bit 7 6 Method

7

0 0 No PABX

0 1 Loop Start

1 0 Ground Start

1 1 Flash Start

These bits determine what capabilities are

informed to the receiving side in the protocol

exchange.

0: PABX dial tone is detected in accordance

with the parameters programmed in RAM. The

machine will wait for the dial tone before trying

to gain access to the PSTN.

0: PSTN dial tone is detected in accordance

with the parameters programmed in RAM. The

machine will wait for the dial tone before dialing

out.

0: Busy tone is detected in accordance with the

parameters programmed in RAM. The machine

will not have to wait out the CCITT T1 time

before hanging up if the line is busy.

Set these bits to match the type of signal

accepted by the PABX. If there is no PABX

between the machine and the network, set both

bits to 0.

Bit Switch 06

FUNCTION COMMENTS

PSTN access number

0

1

Access No. Hex value of bit switch

0 F0

2

↓ ↓

9 F9

3

00 00

4

↓ ↓

99 99

5

6

7

Program this bit switch if the machine is

behind a PABX. The access number is

the number the user must dial to get an

outside line. If the machine detects the

access number at the start of a

telephone number, it will connect with

the PABX, pause for a few seconds,

then dial the number.

Example: If the access number for the

PABX is 9, the bit switch must be F9. To

do this, set all bits to 1 except bits 1 and

2.

If there is no PABX, set all bits to 1.

4-16

Page 41

SERVICE TABLES AND PROCEDURES June 19th, 1993

BIT SWITCHES

Bit Switch 07

FUNCTION COMMENTS

0 Back to back test

0: Disabled

1: Enabled

1 Short preamble

0: Enabled 1: Disabled

2 AI short protocol (transmission and

reception)

0: Enabled 1: Disabled

3 Echo countermeasure

0: Enabled

1: Disabled

4 DIS detection number

0: 1

1: 2

5 ECM

0: On 1: Off

6 Post-message response timing (rx)

0: After feed-out

1: When the leading edge reaches the

copy feed-out sensor

7 FTZ protocol

0: Disabled 1: Enabled

Set this bit to 1 when you wish to do a back

to back test. Note that this machine has

jumpers on the NCU for supplying line

voltage during a back to back test.

If this bit is 0, the Short Preamble feature is

switched on.

If this bit is 0, the AI Short Protocol feature is

switched on.

If the setting is 1, the machine will hang up if

it receives the same signal twice. If the

setting is 0, the machine will ignore echoes

from the line.

The machine will send DCS (G3 set-up

signal) if it receives DIS. If echoes are

frequent, setting this bit to 1 will allow the

machine to wait for the second DIS before

sending DCS.

If this bit is 0, ECM is switched on.

0: Data cannot be stored in the SAF during

reception if the memory is full, so, if this bit is

set to 0, the machine will wait until the page

has been fed out. However, communication

will take longer to complete.

1: The post message response is sent

earlier, but the paper has not been fed out

yet, so if there is a jam after this, data may

be lost.

This bit is ignored during memory reception.

Set this bit to 1 in Germany.

4-17

Page 42

June 19th, 1993 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

Bit Switch 08 (Transmission)

FUNCTION COMMENTS

Initial Tx modem rate

0

Bit 3 Bit 2 Bit 1 Bit 0 Setting

1

(bps)

1 1 0 1 14,400

2

1 1 0 0 12,000

1 0 1 1 9,600 TCM

3

0 0 1 1 9,600

1 0 1 0 7,200 TCM

0 0 1 0 7,200

0 0 0 1 4,800

0 0 0 0 2,400

4 Modem training type when sending at

12,000 or 14,400 bps

0: V.17 (short) 1: V.33 (long)

5 Not used Do not change the factory setting.

67Cable equalizer (tx mode)

Bit 7 Bit 6 Setting

0 0 None

0 1 Low

1 0 Medium

1 1 High

These bits set the initial starting modem

rate for transmission. This rate may fall

back to a slower rate depending on line

conditions and the remote terminal’s

capabilities.

0: Training is shorter so communication

costs are reduced. However, the

communication is not so reliable.

1: The longer training time ensures a

higher reliability for the communication.

Use a higher setting if there is signal loss

at higher frequencies because of the

length of wire between the modem and the

telephone exchange.

Also, try using the cable equalizer if one or

more of the following symptoms occurs.

•Communication error

•Modem rate fallback occurs frequently.

4-18

Page 43

SERVICE TABLES AND PROCEDURES June 19th, 1993

BIT SWITCHES

Bit Switch 09 (Transmission)

FUNCTION COMMENTS

0 CNG signal transmission in

manual transmission mode

0: Disabled

1: Enabled

12Wrong connection prevention

method

Bit 2 Bit 1 Setting

0 0 None

0 1 8 digit CSI

1 0 4 digit CSI

1 1 CSI/RTI

3 Closed network (transmission)

0: Disabled

1: Enabled

4 Monitor speaker status during

memory transmission

0: Off 1: On

5 Not used Do not change the factory settings.

6

7

CNG (calling tone) is normally used by auto-dial fax

machines to alert a manual machine operator that

an auto-transmitting machine is on the line waiting

to transmit. This tone is not needed for manual

operation (full number dialing).

(0,1) - The machine will not transmit if the last 8

digits of the received CSI do not match the last 8

digits of the dialed telephone number. This does not

work for manual dialing.

(1,0) - The same as above, except that only the last

4 digits are compared.

(1,1) - The machine will not transmit if the other end

does not identify itself with an RTI or CSI.

(0,0) - Nothing is checked; transmission will always

go ahead.

1: Transmission will not go ahead if the ID code of

the other terminal does not match the ID code of

this terminal. This feature may not be reliable when

communicating with another maker’s product.

If this bit is 1, the speaker will operate during

memory transmission. Keep this bit at 0 if the user

complains about the noise from the speaker.

4-19

Page 44

June 19th, 1993 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

Bit Switch 0A (Reception)

FUNCTION COMMENTS

Initial Rx modem rate

0

Bit 3 Bit 2 Bit 1 Bit 0 Setting

1

(bps)

1 1 0 1 14,400

2

1 1 0 0 12,000

1 0 1 1 9,600 TCM

3

0 0 1 1 9,600

1 0 1 0 7,200 TCM

0 0 1 0 7,200

0 0 0 1 4,800

0 0 0 0 2,400

4 Modem training type when receiving at

12,000 or 14,400 bps

0: V.17 (short) 1: V.33 (long)

5 Hardware equalizer (rx mode)

0: On 1: Off

67Cable equalizer (rx mode)

Bit 7 Bit 6 Setting

0 0 None

0 1 Low

1 0 Medium

1 1 High

The setting of these bits is used to inform

the sending machine of the initial starting

modem rate for the machine in receive

mode. If 9,600 bps presents a problem

during reception, use a lower setting.

0: Training is shorter so communication

costs are reduced. However, the

communication is not so reliable.

1: The longer training time ensures a

higher reliability for the communication.

The effects of this equalizer are similar to

a cable equalizer. However, the machine

may experience problems during ISDN G3

communications if this equalizer is kept on.

Use a higher setting if there is signal loss

at higher frequencies because of the

length of wire between the modem and the

telephone exchange.

Also, try using the cable equalizer if one or

more of the following symptoms occurs.

•Communication error with error codes

such as 0-20, 0-23, etc.

•Modem rate fallback occurs frequently.

4-20

Page 45

SERVICE TABLES AND PROCEDURES June 19th, 1993

BIT SWITCHES

Bit Switch 0B (Reception)

FUNCTION COMMENTS

0 Closed network (reception)

0: Disabled

1: Enabled

1 Training error tolerance

0: Type 1

1: Type 2

23Training error tolerance

Bit 3 2 Type 1 Type 2

0 0 15 14

0 1 10 9

1 0 2 4

1 1 0 1

4 Not used Do not change the factory settings.

5

6 Printout of the message when acting

as a transfer broadcasting station

0: No 1: Ye s

7 Transmission of the Transfer Result

Report to the transfer requesting

station

0: Always

1: Only if an error occurred

1: Reception will not go ahead if the ID code

of the other terminal does not match the ID

code of this terminal. This feature may not be

reliable when communicating with another

maker’s product.

This bit determines the values available with

bits 2 and 3.

Type 1 can be used anywhere. Type 2 is

normally used only in Europe.

If the machine detects more errors during

training than the number set by these bits,

training fails and the machine will send FTT.

The data will be resent at a lower rate.

4-21

Page 46

June 19th, 1993 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

Bit Switch 0C

FUNCTION COMMENTS

0 European protocol requirements

0: Disabled 1: Enabled

1 German dialling requirements

0: Disabled 1: Enabled

2 Austrian dialling requirements

0: Disabled 1: Enabled

3 Norwegian dialling and protocol

requirements

0: Disabled 1: Enabled

4 Danish dialling requirements

0: Disabled 1: Enabled

5 French requirements

0: Disabled 1: Enabled

6 Swiss requirements

0: Disabled 1: Enabled

7 Not used Do not change the factory setting.

Adjust these bits in accordance with the

country of installation.

Bit Switch 0D

FUNCTION COMMENTS

0 Hard disk

0: Not installed 1: Installed

1 Not used Do not change the factory settings.

2

3

4

5

6

7

Set this bit to 1 if you install a hard disk in

the machine.

Bit switch 0E is not used. Do not change any of th e facto ry se tt ing s.

4-22

Page 47

SERVICE TABLES AND PROCEDURES June 19th, 1993

BIT SWITCHES

Bit Switch 0F

FUNCTION COMMENTS

0

Country Code

to

7

00: France 10: Not used

01: Germany 11: USA

02: UK 12: Asia

03: Italy 13: Japan

04: Austria 14: Hong Kong

05: Belgium 15: South Africa

06: Denmark 16: Australia

07: Finland 17: New Zealand

08: Ireland 18: Singapore

09: Norway 19: Malaysia

0A: Sweden

0B: Switzerland

0C: Portugal

0D: Holland

0E: Spain

0F: Israel

This country code determines the factory

settings of a wide range of bit switches and

RAM addresses. However, it has no effect

on the NCU parameter settings and

communication parameter RAM addresses;

these are determined by the setting of NCU

parameter 00 (function 09).

Bit Switch 10

FUNCTION COMMENTS

0 Pulse dialling method

Bit 1 Bit 0 Setting

1

0 0 Normal (P=N)

0 1 Oslo (P=10 - N)

1 0 Sweden (N+1)

1 1 Not used

2 Not used Do not change the factory settings.

3

4

5

6

7

P=Number of pulses sent out, N=Number

dialled.

Do not change the factory settings.

Bit switch 11 to 1A are not used. Do not chan ge the fact ory settings.

4-23

Page 48

June 19th, 1993 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

Bit Switch 1B

FUNCTION COMMENTS

0 Not used Do not change the factory setting.

1 Default reception mode for G4

reception

0: Memory 1: Immediate

2 Not used Do not change the factory settings.

3

4

5

6

7

0: Incoming messages are stored to

memory, printed, and then erased if there

were no problems.

1: Messages are not stored to memory

during reception.

Bit switch 1C is not used. Do not change the fact ory settings.

Bit Switch 1D

FUNCTION COMMENTS

0 Emergency calls using 999

0: Enabled 1: Disabled

1 Not used Do not change the factory settings.

2

3

4

5

6

7

This bit is only used in the UK.

If this bit is at 1, the machine cannot dial 999.

4-24

Page 49

SERVICE TABLES AND PROCEDURES June 19th, 1993

BIT SWITCHES

Bit Switch 1E

FUNCTION COMMENTS

0 Operator call if no reposne is received

in reply to NSF/DIS

0: Yes 1: No

12Scrambling method used for secure

transmission

Bit 2 1 Method

0 0 Type 1

1 0 Type 2

0 1 Type 3

1 1 Type 3

3 Secure transmission demonstration

0: Off 1: On

4 Not used Do not change the factory settings.

5

6

7 Error report printout

0: On 1: Off

Set this bit to 1 if the user complains about

the operator call tone form the buzzer when

no reply is received to NSF or DIS.

There are three types of scrambling

algorithm available for use with this feature.

They are all of about the same complexity.

The type used is informed in the NSF signal.

If this bit is at 1 and if secure transmission is

switched on, received images will be printed

out without being unscrambled. This

demonstrates what anyone intercepting the

signal can expect to pick up.

If this bit is at 1, the error report will not be

printed when an error occurs.

Bit switch 1F is not used. Do not change the fact ory settings.

4-25

Page 50

June 19th, 1993 SERVICE TABLES AND PROCEDURES

BIT SWITCHES

Factory Settings

Switch Settings Switch Settings

00 0 0 0 0 0 0 0 0 10 0 0 0 0 0 0 0 0

01 0 0 0 0 0 1 0 0 11 0 0 0 0 0 0 0 0

02 0 1 0 0 0 0 1 0 12 0 0 0 0 0 0 0 0

03 0 1 0 0 0 0 0 0 13 0 0 0 0 0 0 0 0

04 0 0 0 0 0 0 1 1 14 0 0 0 0 0 0 0 0

05 0 0 1 0 0 0 1 1 15 0 0 0 0 0 0 0 0

06 1 1 1 1 1 1 1 1 16 0 0 0 0 0 0 0 0

07 0 1 0 0 0 0 1 0 17 0 0 0 0 0 0 0 0

08 0 1 0 0 1 1 0 1 18 0 0 0 0 0 0 0 0

09 0 0 0 0 0 0 0 1 19 0 0 0 0 0 0 0 0

0A 0 0 0 0 1 1 0 1 1A 0 0 0 0 0 0 0 0

0B 0 1 0 0 0 0 0 0 1B 0 0 0 0 0 0 0 0

0C 0 0 0 0 0 0 0 1 1C 0 0 0 0 0 0 0 0

0D 0 0 0 0 0 0 0 0 1D 0 0 0 0 0 0 0 0

0E 0 0 0 0 0 0 0 0 1E 0 0 0 0 0 0 0 1

0F 0 0 0 0 0 0 1 0 1F 0 0 0 0 0 0 0 0

When you change the country code to the cod e fo r one of th e followin g cou ntries, the following values will change automatically.

Germany

Bit Switch 02: 01000110 Bit Switch 07: 11000110

Bit Switch 03: 01000001 Bit Switch 0C: 00000011

Bit Switch 05: 00100111 Bit Switch 1D: 00001000

UK Austria

Bit Switch 1D: 00000001 Bit Switch 0C: 00000101

Denmark Norway

Bit Switch 0C: 00010001 Bit Switch 0C: 00001001

Sweden Switzerland

Bit Switch 10: 00000010 Bit Switch 0C: 01000001

France

Bit Switch 04: 10111111 Bit Switch 0F: 00000000

Bit Switch 07: 01001010 Bit Switch 1E: 00100001

Bit Switch 0C: 00100001

4-26

Page 51

SERVICE TABLES AND PROCEDURES June 19th, 1993

NCU PARAMETERS

4.3. NCU PARAMETERS

The following tables give the RAM addresses and units of calcula tio n of the

parameters that the ma chin e use s for ringing signal detection and aut oma tic

dialling. The facto ry se tt ings for each country are also given. Most of these

must be changed by RAM read/write (Function 06), but some can be

changed using NCU Paramet er pro gra mming (Function 09); if Function 09

can be used, this will be indicated in the Remarks column. The RAM is programmed in hex code unless (BCD) is included in the Unit column.

The RAM addresses are quoted as three-figure numbers. When using Function 09, add three zero es. For e xamp le, for address 36D, input 0003 6D

Address Function Unit Remarks

369 Country code [NCU parameters

only]

36D Line current detection time 20 ms Line current is not detected

36E Line current wait time

36F Line current drop detect time

370 PSTN dial tone upper frequency

limit (HIGH)

371 PSTN dial tone upper frequency

limit (LOW)

372 PSTN dial tone lower frequency

limit (HIGH)

373 PSTN dial tone lower frequency

limit (LOW)

374 PSTN dial tone detection time 20 ms If 374 contains FF, the

375 PSTN dial tone reset time (HIGH)

376 PSTN dial tone reset time (LOW)

377 PSTN dial tone continuous tone

time

378 PSTN dial tone permissible drop

time

379 PSTN wait interval (HIGH)

37A PSTN wait interval (LOW)

37B Ringback tone detection time 20 ms Detection is disabled if this

37C PSTN busy tone upper frequency

limit (HIGH)

37D PSTN busy tone upper frequency

limit (LOW)

37E PSTN busy tone lower frequency

limit (HIGH)

37F PSTN busy tone lower frequency

limit (LOW)

Hex Function 09 (parameter 00).

if 36D contains FF.

Hz (BCD) See Note 2.

machine pauses for the

pause time (address

379/37A).

contains FF.

Hz (BCD) If 37C is FF, detection is

disabled. See Note 2.

4-27

Page 52

June 19th, 1993 SERVICE TABLES AND PROCEDURES

NCU PARAMETERS

Address Function Unit Remarks

380 PABX dial tone upper frequency

limit (HIGH)

381 PABX dial tone upper frequency

limit (LOW)

382 PABX dial tone lower frequency

limit (HIGH)

383 PABX dial tone lower frequency

limit (LOW)

384 PABX dial tone detection time 20 ms If 384 contains FF, the

385 PABX dial tone reset time (HIGH)

386 PABX dial tone reset time (LOW)

387 PABX dial tone continuous tone

time

388 PABX dial tone permissible drop

time

389 PABX wait interval (HIGH)

38A PABX wait interval (LOW)

38B PABX ring back tone detection

time

38C PABX busy tone upper frequency

limit (HIGH)

38D PABX busy tone upper frequency

limit (LOW)

38E PABX busy tone lower frequency

limit (HIGH)

38F PABX busy tone lower frequency

limit (LOW)

390 Busy tone ON time: range 1 20 ms

391 Busy tone OFF time: range 1

392 Busy tone ON time: range 2

393 Busy tone OFF time: range 2

394 Busy tone ON time: range 3

395 Busy tone OFF time: range 3

396 Busy tone ON time: range 4

397 Busy tone OFF time: range 4

398 Busy tone continuous tone

detection time

Hz (BCD) See Note 2.

machine pauses for the

pause time (389/38A).

20 ms Detection is disabled if this

contains FF.

Hz (BCD) If this is FF, detection is

disabled. See Note 2.

See Note 2.

4-28

Page 53

SERVICE TABLES AND PROCEDURES June 19th, 1993

NCU PARAMETERS

Address Function Unit Remarks

399 Busy tone signal state time tolerance for all ranges, and number of cycles

required for detection (a setting of 4 cycles means that ON-OFF-ON or OFF-

ON-OFF must be detected twice).

Tolerance (±)

Bit 1 0

0 0 75%

0 1 50%

1 0 25%

1 1 12.5%

Bits 7, 6, 5, 4 - number of cycles required for detection

39A International dial tone upper

frequency limit (HIGH)

39B International dial tone upper

frequency limit (LOW)

39C International dial tone lower

frequency limit (HIGH)

39D International dial tone lower

frequency limit (LOW)

39E International dial tone detection

time

39F International dial tone reset time

(HIGH)

3A0 International dial tone reset time

(LOW)

3A1 International dial tone continuous

tone time

3A2 International dial tone permissible

drop time

3A3 International dial wait interval

(HIGH)

3A4 International dial wait interval

(LOW)

3A5 Country dial tone upper frequency

limit (HIGH)

3A6 Country dial tone upper frequency

limit (LOW)

3A7 Country dial tone lower frequency

limit (HIGH)

3A8 Country dial tone lower frequency

limit (LOW)

Hz (BCD) See Note 2.

20 ms If 39E contains FF, the

machine pauses for the

pause time (3A3/3A4).

Hz (BCD) See Note 2.

4-29

Page 54

June 19th, 1993 SERVICE TABLES AND PROCEDURES

NCU PARAMETERS

Address Function Unit Remarks

3A9 Country dial tone detection time 20 ms If 3A9 contains FF, the

3AA Country dial tone reset time

(HIGH)

3AB Country dial tone reset time (LOW)

3AC Country dial tone continuous tone

time

3AD Country dial tone permissible drop

time

3AE Country dial wait interval (HIGH)

3AF Country dial wait interval (LOW)

3B0 Grounding time (ground start

mode)

3B1 Break time (flash start mode) 1 ms The Di relay is open for this

3B2 International dial access code BCD For a code of 100:

3B3

3B4 PABX pause time 20 ms This time is waited for each

3B5 Progress tone detection level, and

cadence detection enable flags

20 ms The Gs relay is closed for

Bit 7 Bit 6 dBm

1 1 -49.5

1 0 -40.5

0 1 -32.5

0 0 -26.5

machine pauses for the

pause time (3AE/3AF).

this interval.

interval.

3B2 - F1

3B3 - 00

pause input after the PSTN

access code. Up to 7 of

these can be input. If this

address contains FF[H], the

pause time stored in

address 3C9 is used.

Bits 3, 2, 1, 0 - See Note 3.

3B6 CCITT T1 time 2.56 s

3B7 Max. number of dials per station

(not using memory)

3B8 Redial interval (not using memory) 1 min

3B9 Interval between dialling to

different stations

3BB Acceptable ringing signal

frequency: range 1, upper limit

3BC Acceptable ringing signal

frequency: range 1, lower limit

3BD Acceptable ringing signal

frequency: range 2, upper limit

3BE Acceptable ringing signal

frequency: range 2, lower limit

3BF Number or rings until a call is

detected

4-30

1

2.56 s

1000/ N

(Hz). N is

the value

stored

using

Function

09.

1 Function 09 (parameter 06).

Function 09 (parameter 02).

Function 09 (parameter 03).

Function 09 (parameter 04).

Function 09 (parameter 05).

Page 55

SERVICE TABLES AND PROCEDURES June 19th, 1993

NCU PARAMETERS

Address Function Unit Remarks

3C0 Minimum required length of the

first ring

3C1 Minimum required length of the

second and subsequent rings

3C2 Ringing signal detection reset time

(HIGH)

3C3 Ringing signal detection reset time

(LOW)

3C4 Time between opening or closing

the Ds relay and opening the Di

relay

3C5 Break time for pulse dialling See Note 5. Function 09

3C6 Make time for pulse dialling See Note 5. Function 09

3C7 Time between final Di relay

closure and Ds relay opening or

closing

3C8 Minimum pause between dialled

digits (pulse dial mode)

3C9 Time waited when a pause is

entered at the operation panel

3CA DTMF tone on time 1 ms Function 09 (parameter 17).

3CB DTMF tone off time Function 09 (parameter 18).

3CC DTMF tone attenuation value -dBm x

3CD Tx level from the modem - dBm Function 09 (parameter 01).

3CE 2100 Hz tone detection level -1 x 3CD