Page 1

RICOH FAX220/240

SERVICE MANUAL

Copyright © 1992, Ricoh Company Ltd., Japan

Subject to change

Page 2

1. INTRODUCTION

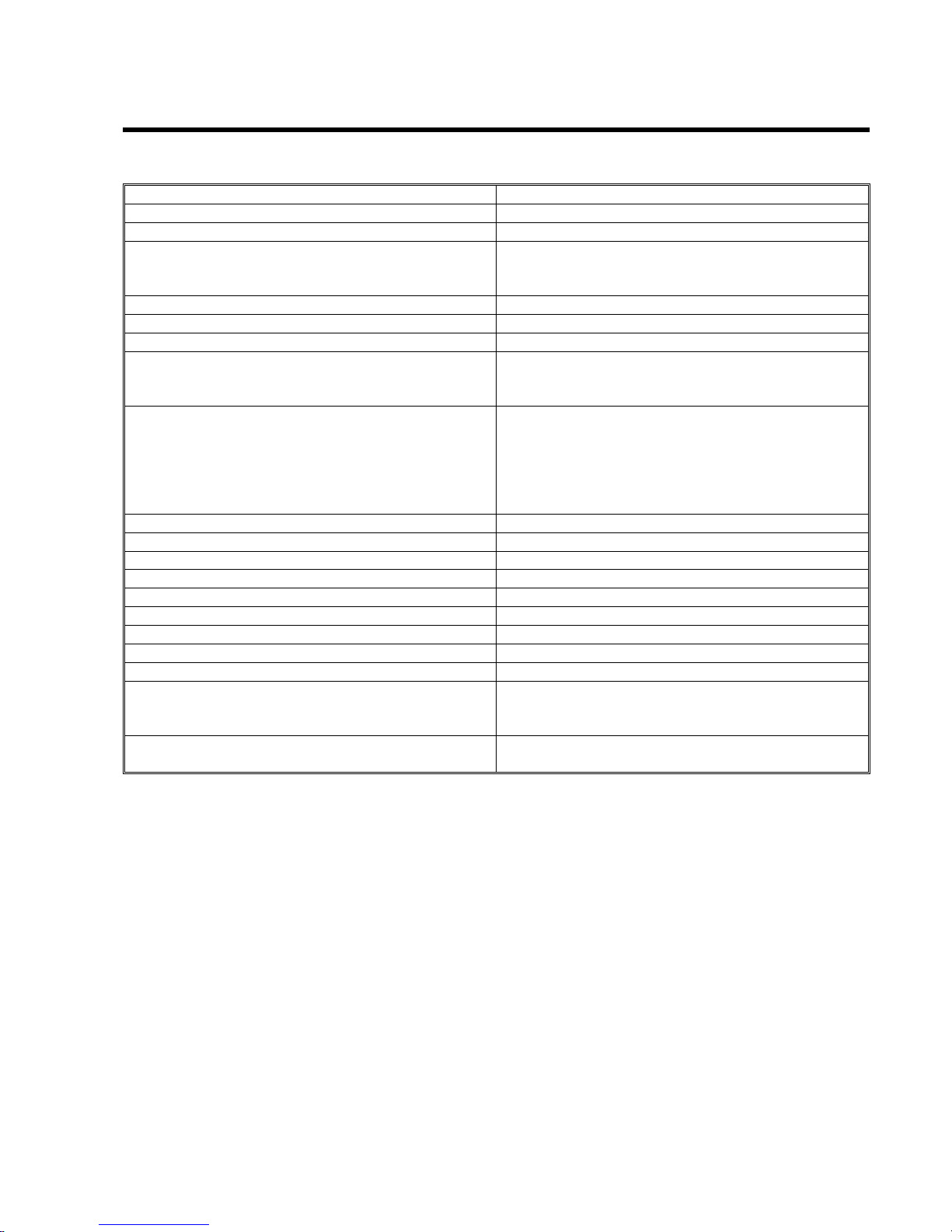

1-1. General Specifications

Item Specification

Type Desktop transceiver

Telephone Circuit PSTN/PBX

Document Size Width: 148 - 218 mm

Length: 105 - 600 mm

Thickness: 0.05 - 0.15 mm

Scanning Method Flat bed, CCD

Scanning Width 216 ± 1 mm

Effective Printing Width 210 mm (minimum)

Scan Resolution Standard: 8 x 3.85 dots/mm

Detail: 8 x 7.7 dots/mm

Fine: 8 x 15.4 dots/mm

Transmission Time FAX220 - 15 s (Measured using a CCITT #1 test chart,

Slerexe Letter, at 9,600 bps, MH coding with EFC,

10 ms/line I/O rate, standard resolution)

FAX240 - 11 s (Measured using a CCITT #1 test chart,

Slerexe Letter, at 9,600 bps, MMR coding with ECM, 10

ms/line I/O rate, standard resolution)

Data Compression Method MH, EFC, SSC, MR, MMR* (*: FAX240 only)

SAF Memory Capacity 128 kbytes (9 CCITT #1 test charts can be stored.)

Modulation Method V29, V27ter, V21

Transmission Data Rate 9600/7200/4800/2400 bps (Automatic fallback)

Protocol CCITT T.30 standard (NET 30)

Printing Method Thermal printing

Printer Paper Size 216 mm x 50 m roll

Dimensions 355 x 454 x 203 mm

Weight 4.6 kg

Input Voltage H501-50, 51, 52, 53, 54, H502-50, 51, 52, 53, 54:

220 - 240 Vac, 50 Hz single phase

H501-55, H502-55: 120 Vac, 50/60 Hz, single phase

Recommended Operating Environment Temperature: 17 - 28 °C

Humidity: 30 - 85 %RH

1-1

Page 3

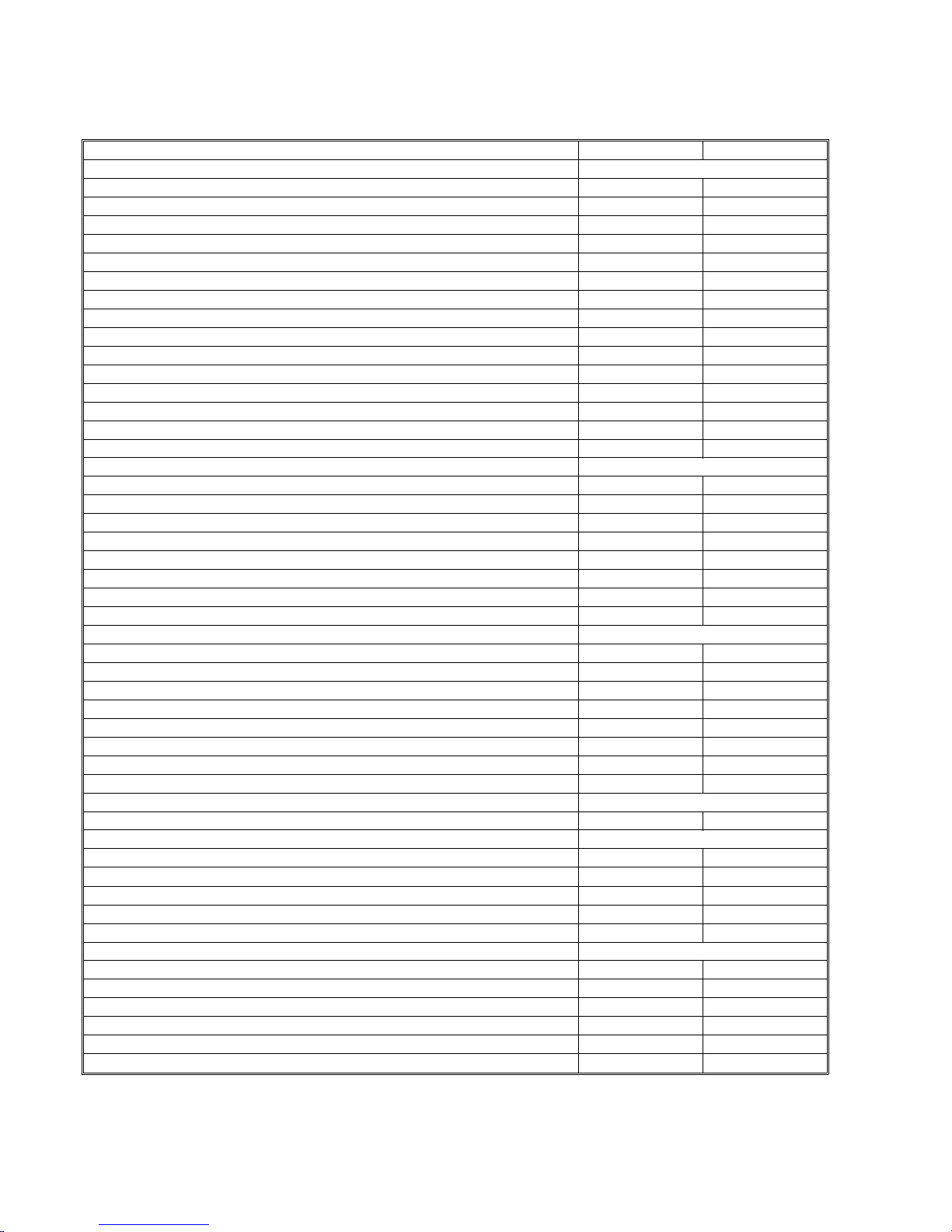

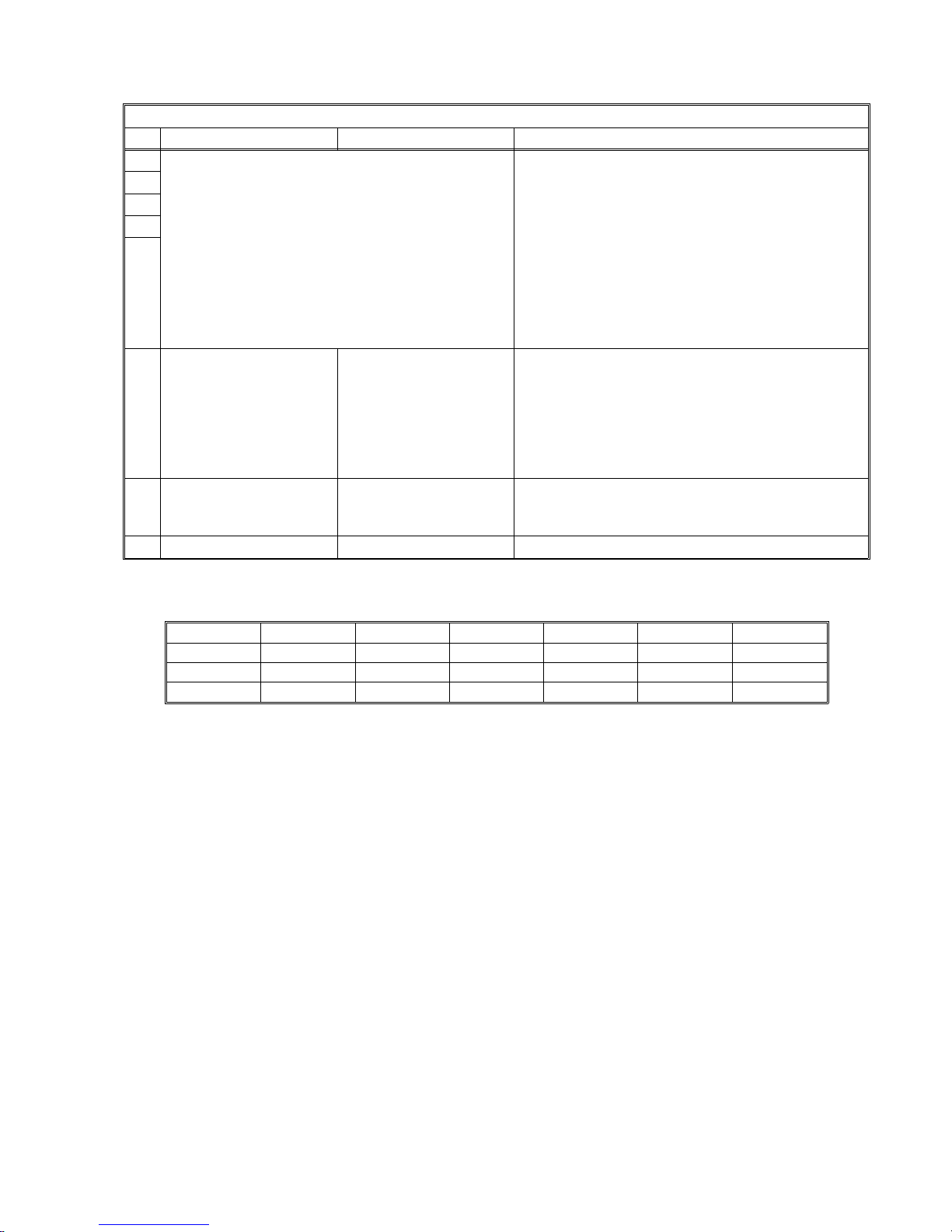

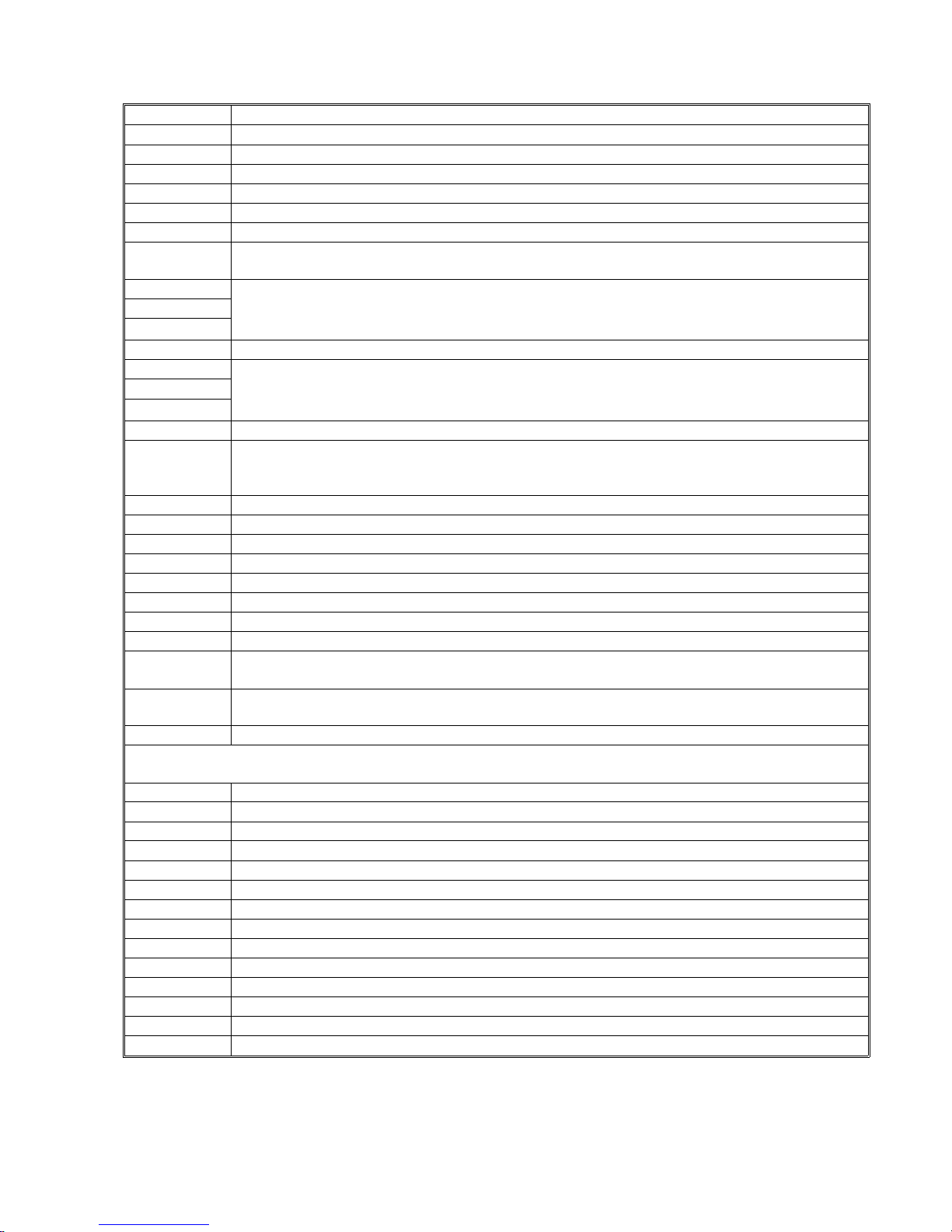

1-2. Features LIst

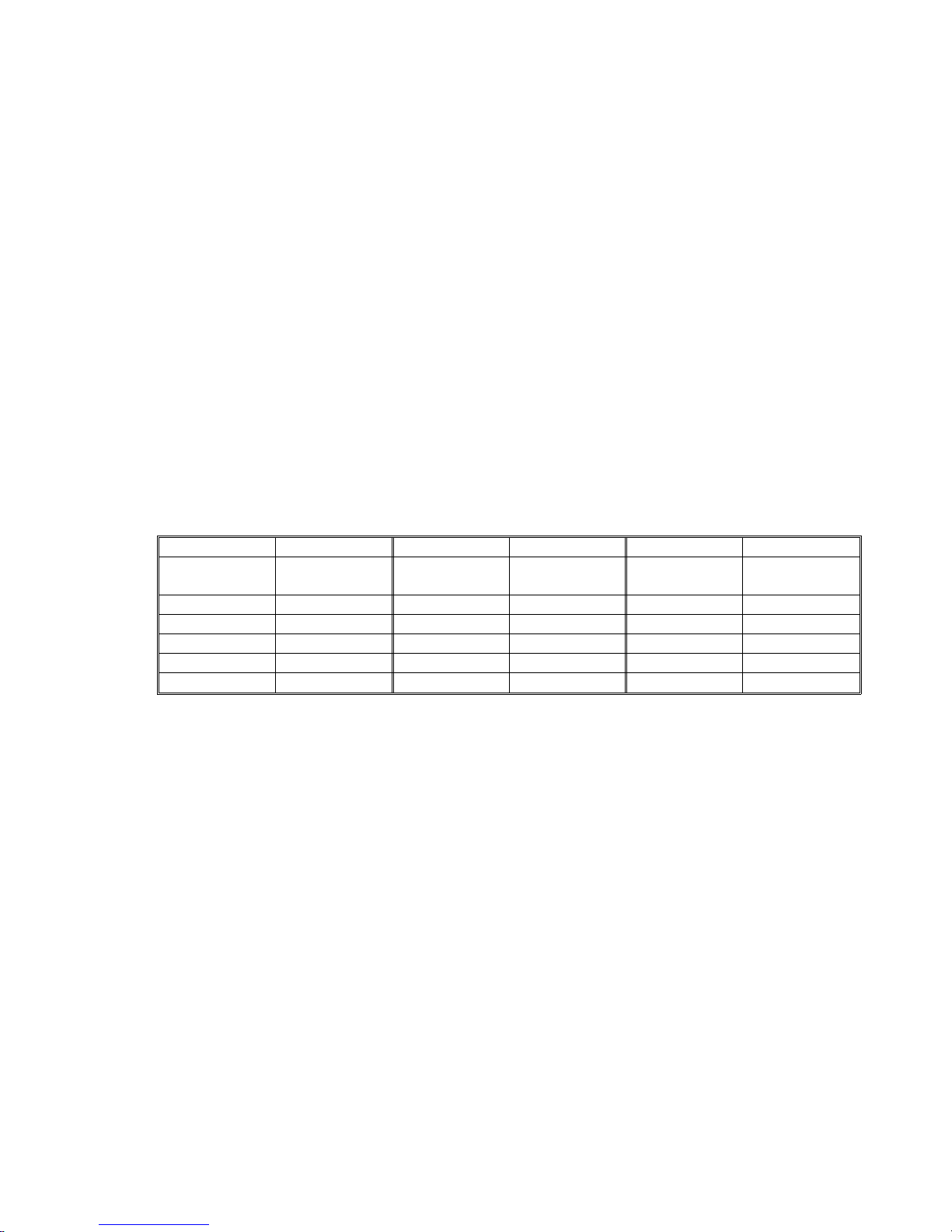

Features FAX220 FAX240

Transmission

Automatic transmission yes yes

Manual transmission yes yes

ADF capacity 5 5

Automatic Contrast Control yes yes

Polling transmission yes yes

Send later yes yes

Dial via dialpad yes yes

Quick dial (one touch) 10 10

Speed dial (two touch) 40 40

Automatic redial yes yes

Manual redial yes yes

Label programming for Quick/Speed dials yes yes

Page indicator CSI + P.1 yes yes

Page indicator TTI + P.1 or P.1/10 yes yes

Automatic page retransmission in normal tx mode no yes

Reception

Automatic reception yes yes

Manual reception yes yes

Polled reception yes yes

Automatic cutter no yes

Manual cutter yes no

Authorized reception (with TSI) yes yes

Decurler no yes

Printing of the TSI on received copies yes yes

Communication

TTI (page header with name) yes yes

RTI (own phone number or text) yes yes

CSI (own phone number) yes yes

Counters (user function) no no

Voice request no no

PD/DTMF change by switch yes yes

Modified read (MR) yes yes

ECM with MMR compression no yes

Compatibility

CCITT group 3 yes yes

Copy quality

Halftone (16 level) with image/text separation yes yes

Auto shading yes yes

MTF yes yes

8 x 15.4 lines/mm yes yes

Automatic contrast (threshold) control yes yes

Reports

TCR yes yes

Transmission Report yes yes

Quick dial list yes yes

Speed dial list yes yes

Group dial list yes yes

Error report yes yes

1-2

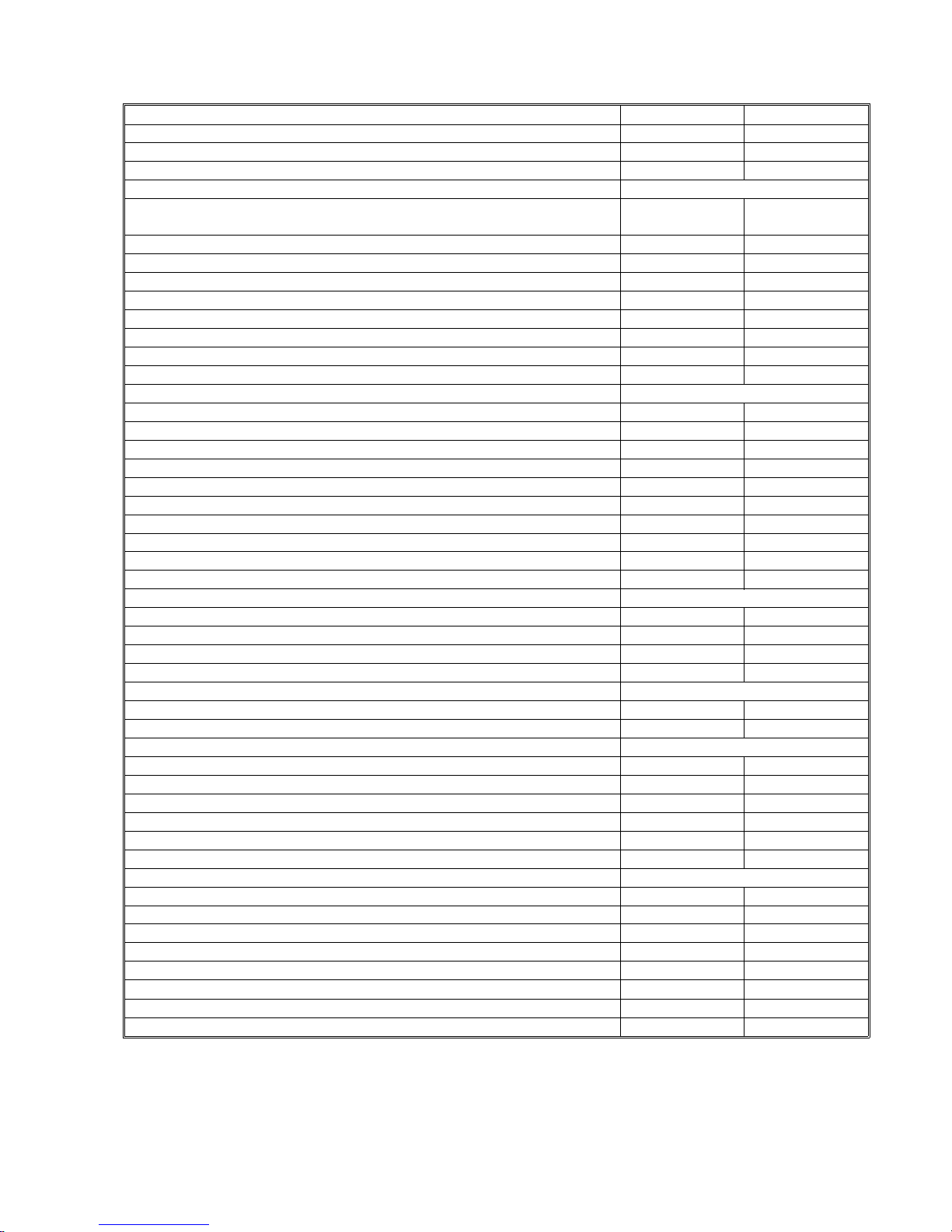

Page 4

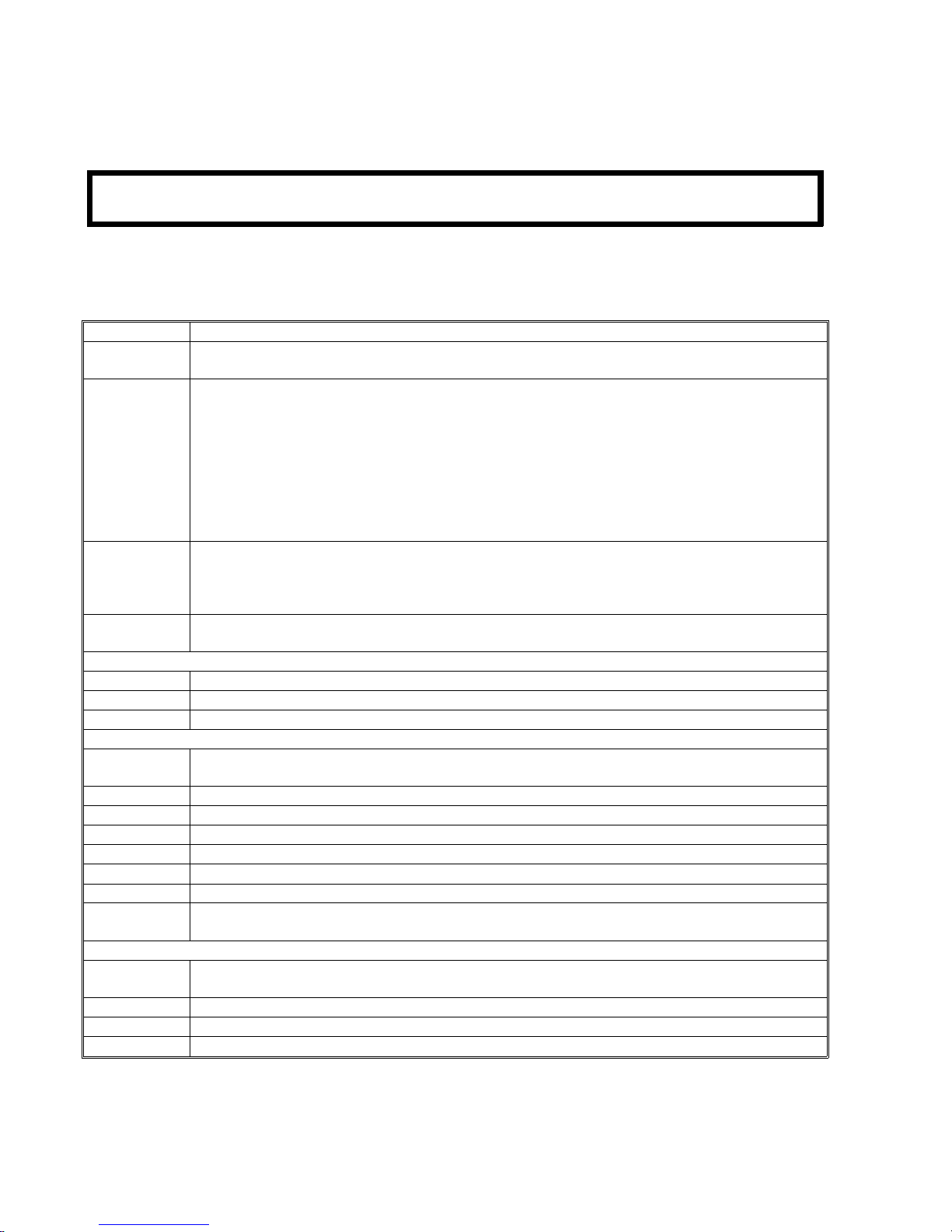

Features FAX220 FAX240

Rejected Call Report in Authorized Reception yes yes

Stored document list yes yes

Power failure report no yes

SAF features (9 pages memory)

SAF capacity in kbytes

no

128 (256 if ECM

off)

Memory transmission no yes

Serial broadcasting no yes

Substitute reception no yes

Forwarding (1 number) no yes

File confirmation/clearance no yes

Automatic page retransmission in memory tx no yes (if ECM on)

Remaining memory indication on LCD (during scanning) no yes

Group dial no yes

Telephone features

Built-in handset yes yes

On-hook dial yes yes

Monitor speaker yes yes

Music on hold yes yes

Speakerphone no no

AI Redial (last 5 numbers) yes yes

12 key dialpad yes yes

Volume control for speaker yes yes

Volume control for ringer yes yes

Power down function (Ring, Dial, Speech) yes yes

FAX/PHONE switch

Auto receive/manual receive switch yes yes

Auto answer delay time adjustment no no

Automatic fax/tel switch yes yes

Speech generation (AVM) yes yes

Interfaces

Telephone answering machine (TAM) interface yes yes

PC interface no no

Others

Copy mode (normal, detail, fine, halftone) yes yes

Time indicator yes yes

Clock adjustment yes yes

LCD display prompt yes yes

LCD size 2 x 20 2 x 20

Battery backed-up RAM size in kbytes 32 32

Service features

Remote diagnostics yes yes

Printer test pattern yes yes

Bit switch setting yes yes

ROM/RAM data display/list yes yes

NCU parameter setting yes yes

Pulse width setting no no

Service report (last 10 errors) yes yes

Service counters yes yes

1-3

Page 5

1-3. Detailed Features Description

1-3-1. Auto Select Mode

There are three reception modes, AUTO, TAM and FAX, one of which can be programmed in the Auto Select key

on the operation panel using function 04 ‘‘SET FAX SWITCH’’.

AUTO mode allows the machine to capture the line without any rings being heard by the users. Then, the machine

starts to detect CNG for about 30 s while sending back ring-back tone or AVM (Artificial Voice Message) in one or

two languages selected by the user. After that, it automatically receives the fax message or, if CNG is not detected,

it calls the user by ringing from the speaker.

TAM mode allows connection to telephone answering machines (TAM) connected on the same line. There are two

types of TAM interface software used depending on the connection between the machine and the telephone answering machine.

The first type of TAM interface is used in the countries where the TAM is connected to the machine as an external

device. When the external device captures the line, the machine detects dc at the LIU. Then, the machine starts listening to the line. If the machine detects one or two CNG signals or a period of silence, the machine will capture the

line and send CED/NSF/DIS to receive a fax message.

The second type of TAM interface is prepared for the countries (e.g., Germany) where the machine is connected to

the TAM as an external device. In this case, the machine cannot detect dc when the TAM goes off-hook. So, it monitors the ringing signal. After the programmed number of rings, the machine listens to the line for about 30 s. If the

machine detects one or two CNG signals, the machine will capture the line and send CED/NSF/DIS to receive a fax

message. With the second type of TAM interface, the machine cannot receive fax messages from machines which

do not send a CNG.

FAX mode allows the machine to receive all incoming fax messages.

1-3-2. Authorized Reception

The machine automatically stores in RAM the TSI (or RTI) from the terminals programmed in the Quick Dials and

Speed Dials, once the user sends a document to these terminals. Then, if Authorized Reception is switched on, the

machine compares the TSI from the remote terminal with these TSIs memorized in the RAM, when the machine receives a fax call from any terminal. So, Authorized Reception prevents reception from terminals which are not programmed in the Quick/Speed Dials.

If an unauthorized sender sends a fax message while this feature is switched on, the machine rejects the call and

notifies the users by printing a rejection report with the unauthorized sender’s TSI or RTI.

1-3-3. Automatic Tx Speed Updating (AI Dial)

The machine memorizes the last five modem speeds that were used during transmission to the Forwarding terminal

and each destination programmed in the Quick/Speed dials. Then, the machine chooses the most appropriate modem speed from the record for the next transmission, in order to reduce the time for modem rate fallback (approx. 5

s). This feature works only when the machine has more than two modem speed records fdor that destination. The

modem speed is recorded in the memory if there are no error pages during transmission. This feature can work with

other manufacturers’ terminals.

1-3-4. Page Retransmission in Normal Tx Mode - FAX240 only

In the normal transmission mode, the machine can retransmit failed pages as if in memory tx mode, if ECM is on.

While sending the document, the machine backs up the document in the ECM memory in case page retransmission

is needed. If the machine receives a negative code (RTN or PIN) after a page, the machine retransmits the whole

page from the ECM memory.

1-3-5. Forwarding - FAX240 only

The machine can forward all received messages to the programmed Forwarding terminal. You can program the

month, date and time for Forwarding to be switched on and for it to be switched off. Also, local printing of forwarded

messages can be switched on and off.

1-4

Page 6

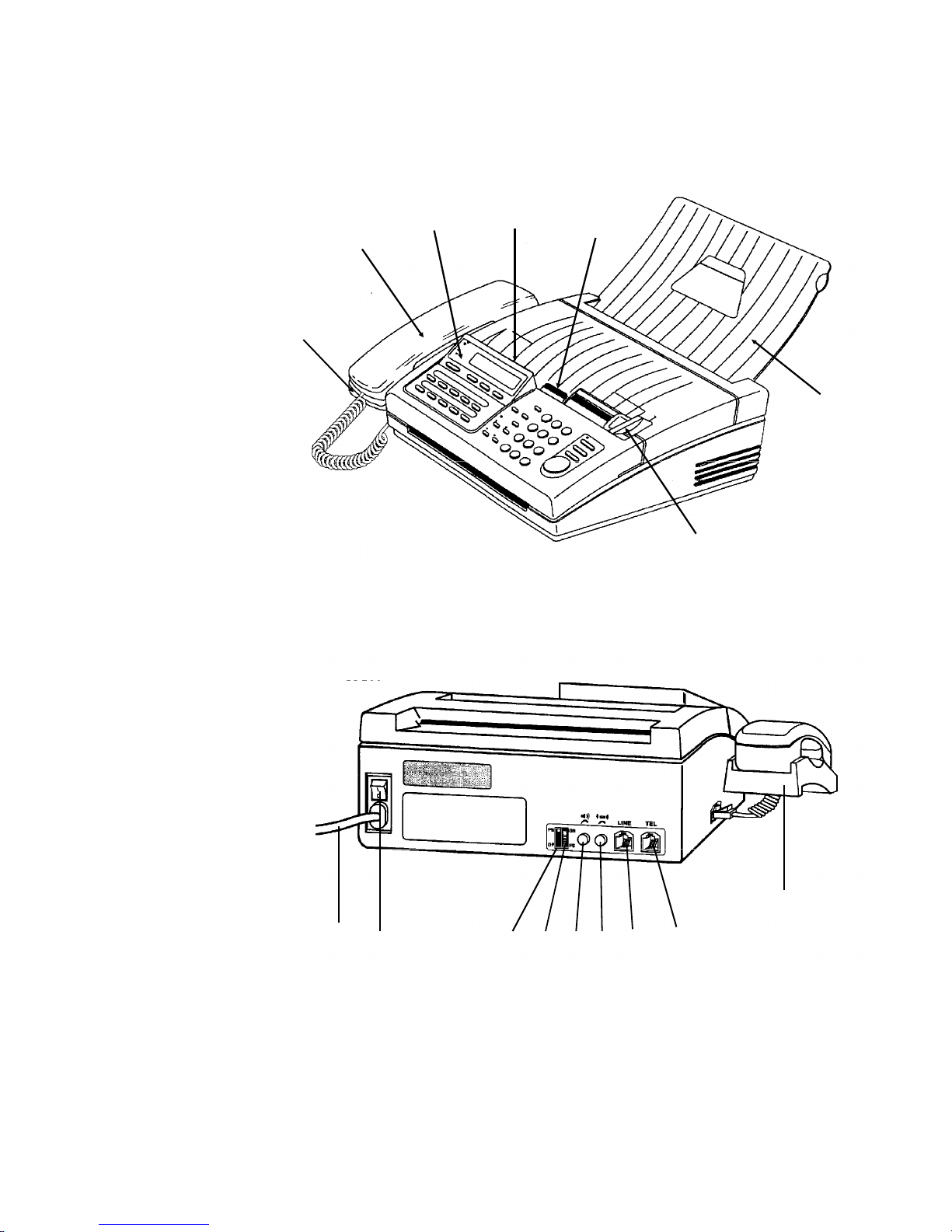

1-4. Exterior

1-4-1. Component Layout

1. Handset Cradle

This contains a

hook switch and a

ringer.

2. Telephone Handset

This contains a microphone and an

earphone.

3. ADF

Up to 5 pages can

be fed automatically.

4. Operation Panel

Refer to section 1-4-

2.

5. Printer Cover/Cover

Release Lever

To open the cover,

push the release

lever forward and

pull up the cover.

6. Copy Tray

7. Document Guide

8. Power Switch

9. Power Cord

10. Speaker Volume Control

11. Ringer Volume Control

12. Pulse/Tone Switch

13. GS/FS Switch

… Not used

14. Telephone Jack

15. Line Jack

6

7

5

34

2

1

9

8

12

13

10

11 15 14

1

1-5

Page 7

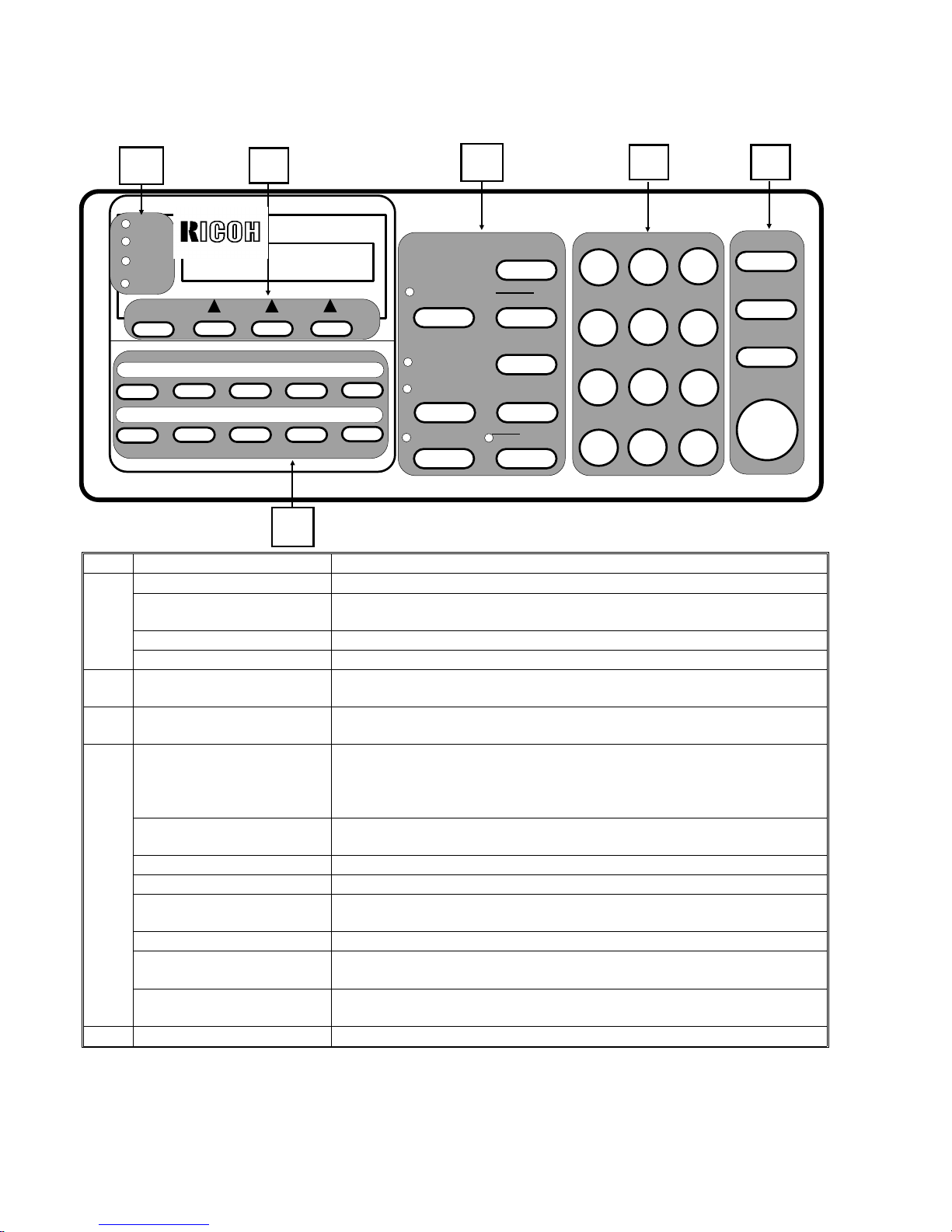

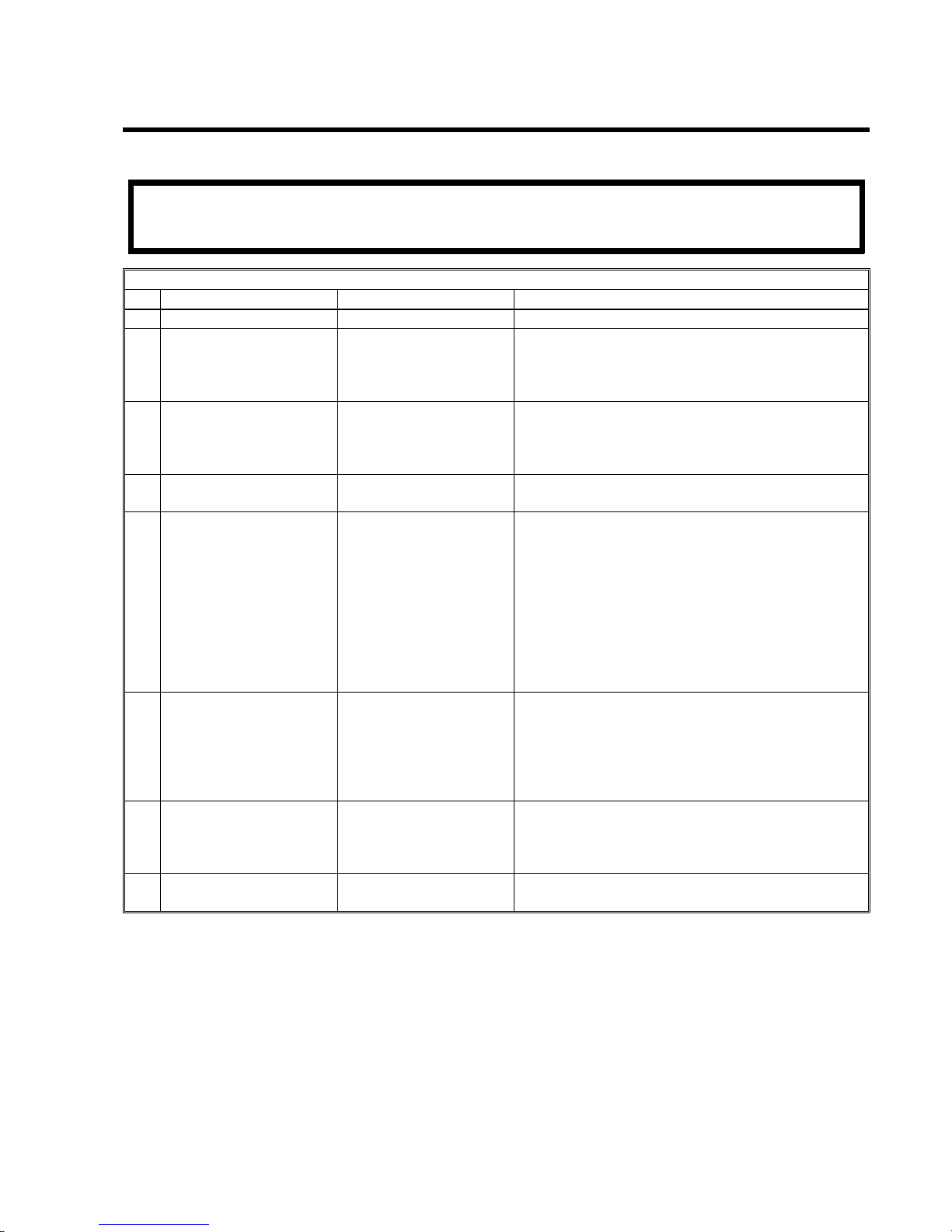

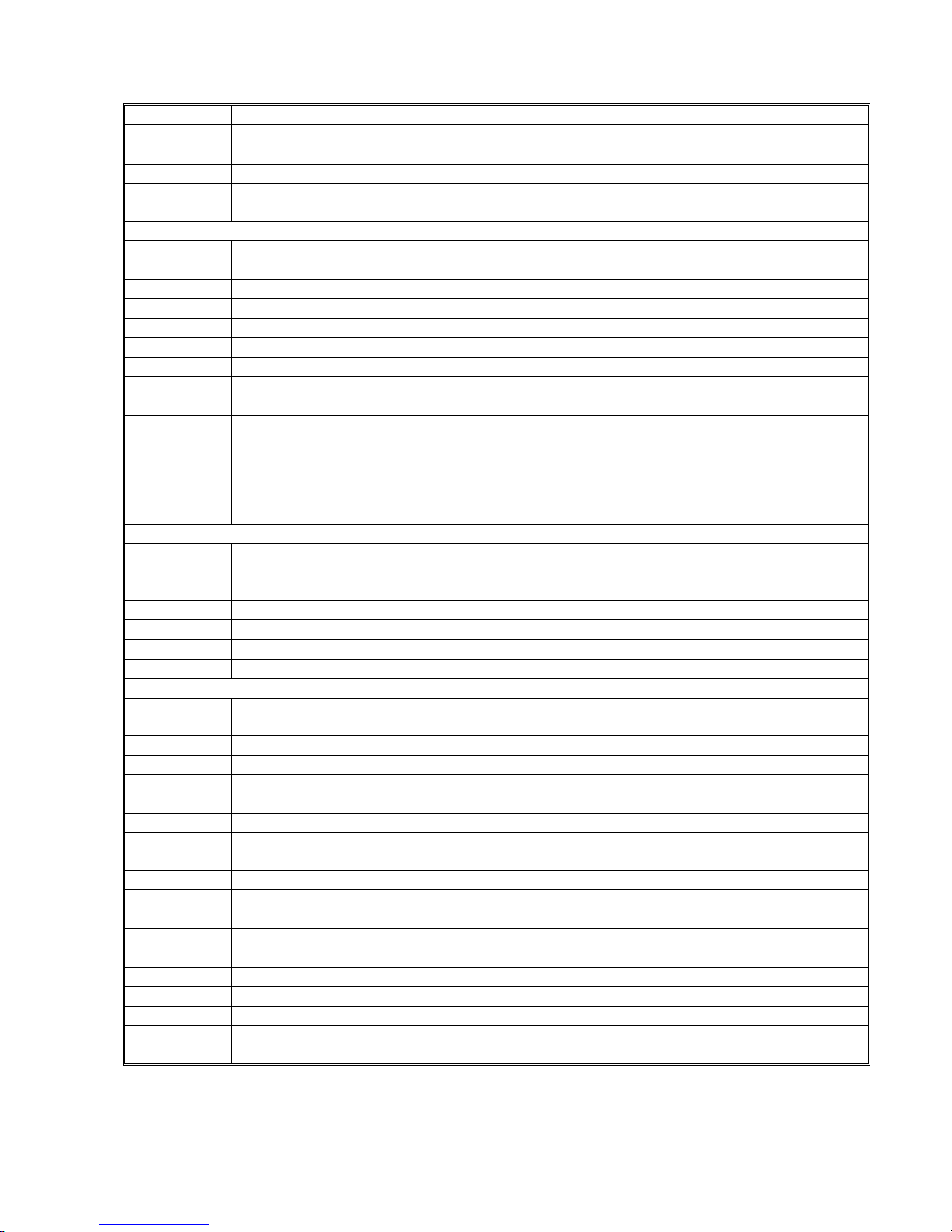

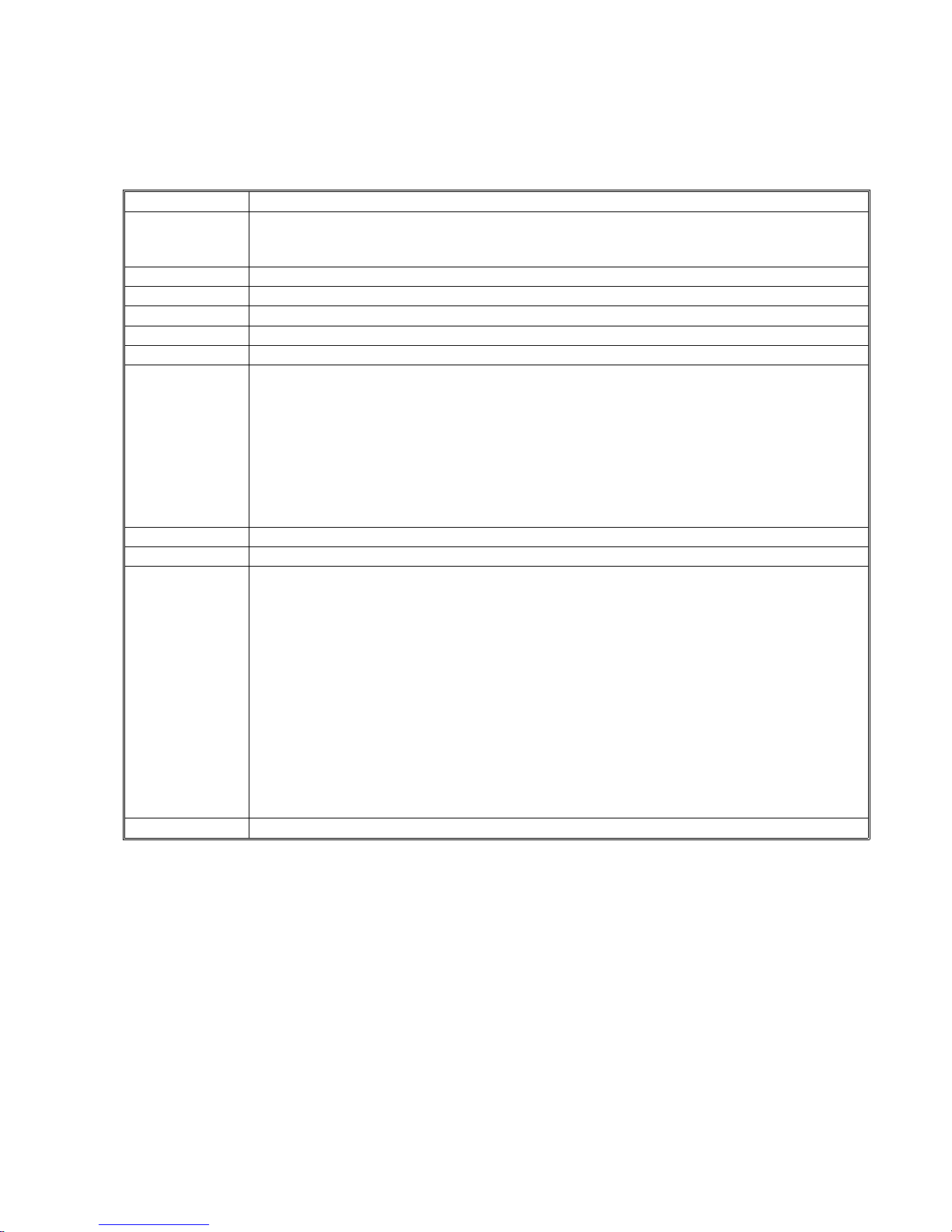

1-4-2. Operation Panel

No. Name Function

1

Power indicator Lights when the power is switched on.

Receive File indicator Lights when received messages are stored into memory because of a

printer problem. Up to 10 messages can be stored.

Check Display indicator Lights when the machine has a problem.

Replace Paper indicator Lights when the paper has been used up.

2

Function key and three

softkeys

Press to access a function in the function list, and choose one of the soft

keys below the required instruction indicated on the LCD.

3

Quick Dial keys Each of these keys can be programmed with a telephone number and a

label.

4

Auto Select key and indicator If it is not lit, Tel (manual receive) mode is selected.

If it is lit, either FAX (automatic receive) mode, AUTO (automatic Tel/Fax

switch) mode, or TAM (Telephone Answering Machine) mode is selected,

depending on the mode selected with function 04.

Resolution key and indicators Press this key to change the resolution. If neither of the Detail or Fine

indicators are lit, Standard resolution is selected.

Halftone key and indicator Press this key when you wish to send a photograph.

Speed Dial key Press this key to use a Speed Dial code.

Pause/Redial key Press this key when you want to enter a pause in a telephone number, or

when you want to redial one of the last five numbers dialed.

Clear key Press this during programming to erase the last character.

‘‘R’’(Recall) key* Press this key when you want to access the PSTN from behind a PBX

which requires the Flash Start method.

Hold/On Hook Dial key and

indicator*

Press this key to dial without picking up the handset. Also, press this key to

place the other party on hold during a telephone conversation.

5 Dialpad* Dial using these keys and use to input characters during programming.

>

>

>

RICOH FAX 240

Receive

File

Power

Check

Display

Replace

Paper

Function

A B

C D E

F

G H I J

Auto Select

Fine

Detail

Halftone

1

4

GHI

7

PRS

*

<

0

2

ABC

5

JKL

8

TUV

3

DEF

6

MNO

9

WXY

#

>

Memory

Stop

Copy

Start

Speed Dial

Pause

Redial

Clear

R

DIAL NUMBER

THEN INSERT DOCUMENT

11:22AM

Hold

On Hook Dial

OPER

1 2

3

4 5 6

1-6

Page 8

No. Name Function

6

Memory key (FAX240 only) Press to use memory transmission.

Stop key Press to stop the machine and return it to standby mode.

Copy key Press to copy the document now in the feeder.

Start key Press to start sending or receiving a fax message.

The keys with an asterisk (*) can be used for making a telephone call if the main power is switched off.

1-7

Page 9

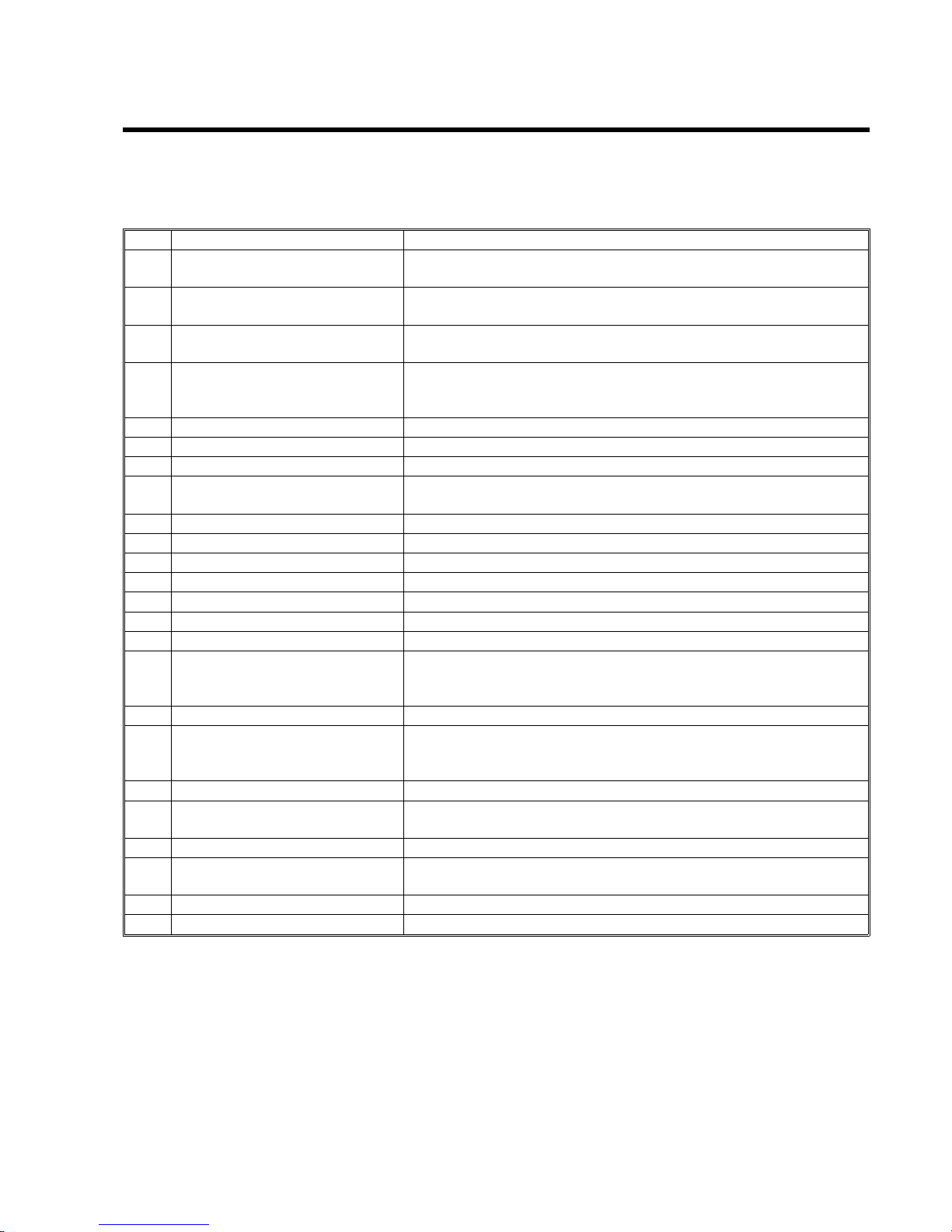

2. PROGRAMMING, TESTING, AND PRINTING REPORTS

2-1. USER LEVEL PROGRAMMING

Function List

No. Function Brief Explanation

01

Quick Dial Programming Use to program a telephone number and a label in each Quick Dial

key.

02

Speed Dial Programming Use to program a telephone number and a label in each Speed Dial

code.

03

Telephone List Printing Use to print the telephone list, which contains Quick Dials, Speed

Dials, and Groups.

04

Set Fax Switch Use to select the function of Auto Select mode from among AUTO

mode (Auto Tel/Fax switch), TAM mode, and FAX mode (Automatic

Receive).

05 Send Later Use to program the machine to send a document at a later time.

06 Polling Transmission Use to set up a document to be polled from a remote terminal.

07 Polling Reception Use to program the machine to poll documents from remote terminals.

08

TCR Printing and On/Off Use to print a TCR or to set the machine up to print reception only on

the TCR.

09 Transmission Report On/Off Use to switch automatic Transmission Report output on or off.

10 Page Header (TTI) On/Off Use to switch the TTI printout on each transmitted page on or off.

11 Enter Page Header (TTI) Use to program the TTI.

12 Enter Your Name (RTI) Use to program the RTI.

13 Enter Your Fax Number (CSI) Use to program the CSI.

14 Clock Adjustment Use to adjust the date and time.

15 Set PBX Use to program the machine for the actual PBX type.

16

ID Code Programming Use to program the ID code, which is used for secured polling and the

closed network feature (closed network can only be switched on in

service mode).

17 Key Touch Tone On/Off Use to switch the key touch tone off or on.

18

RDS On/Off Use to switch RDS on or off.

This function cannot be accessed by the users, unless bit 6 of bit

switch 1 is set to 1 by RDS installation operation or by service later.

19 Set Language Use to change the LCD and report language.

20

Authorized Reception On/Off Use to prevent reception from terminals other than those programmed

in the Quick/Speed Dials.

21 Reviewing Stored Documents Use to review the documents stored in the memory.

22

Forwarding Use to program the machine to forward received messages to a

programmed terminal.

23 Group Dial Programming Use to make dialing groups (up to 5 groups can be made).

24 ECM On/Off Use this to switch ECM on or off.

2-1

Page 10

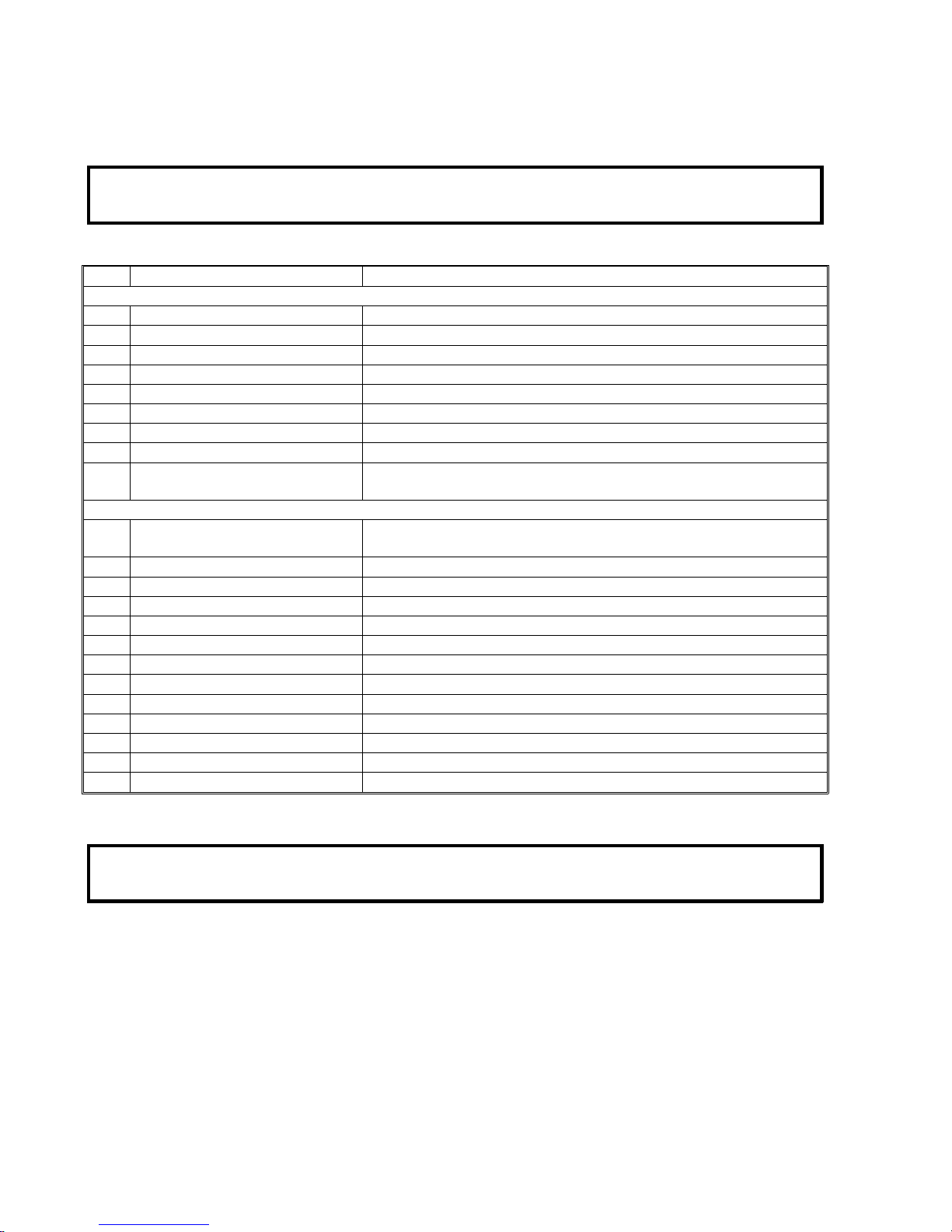

2-2. SERVICE LEVEL OPERATION

2-2-1. Entering and Exiting Service Mode

ENTERING SERVICE MODE

Press Start → Stop → Start → Stop → Start sequentially within 5 seconds.

After entering service mode, the following service functions are available.

No. Function Brief Explanation

Functions 30 to 38 are mainly prepared for factory use.

30 RAM Test Use to test the SRAM and DRAMs on the FCE.

31 Key Test Use to test all keys on the operation panel.

32 LED Test Use to test all LEDs on the operation panel.

33 LCD Test Use to test the LCD on the operation panel.

34 Speaker Test Use to test the monitor speaker.

35 Printer Test Use to print a test pattern.

36 PTT Test Use to test the modem signals, DTMF tones, and transmission level.

37 Frequency Test Use to generate signals of the desired frequency and level.

38

Burn-in Test Do not use this function. If this function is used, the RAM will all be

cleared.

The following functions are prepared for service use.

40

Factory Adjustment Use to check the ROM version, to adjust the tx level and to clear the

RAM.

41 Not used

42 Not used

43 Bit Switch Programming Use to change the bit switch settings.

44 Scanner Adjustment Mode Use to switch on the LED array for scanner adjustment.

91 Display ROM/RAM Data Use to display and change the ROM/RAM data.

92 Print System Report Use to print the system report.

93 Print ROM/RAM Data Use to print ROM/RAM data.

94 Not used

95 Print Service Report Use to print the service report.

96 Not used

97 Not used

98 NCU Parameter Programming Use to adjust the NCU parameters.

EXITING SERVICE LEVEL

Press Stop, Function, or EXIT at any time.

The machine will automatically exit service mode 40s after you enter it.

Note: In the functions, the new settings will not be saved by pressing the Function key. To save the new set-

tings, you have to press ‘‘SET’’ or ‘‘OK’’, then exit the service mode.

2-2

Page 11

2-2-2. RAM Test (Function 30)

1. Enter the service mode (see section 2-2-1).

2. Press Function, enter 30, then press SET.

3. The machine starts to check the SRAM and the two DRAMs without clearing any RAM data stored.

If the RAM test succeeded, the machine prints ‘‘RAM TEST OK’’, and goes to the Key Test.

If the RAM test failed, the machine displays ‘‘RAM ERROR AT ##AAAA’’ (## = type of RAM; AAAA = address)

for 3 s, then ‘‘RAM TEST FAILED’’ is printed

(Type of RAM: 09 = SRAM, 00 - DRAM0, 10 - DRAM1)

After this test, the machine automatically goes into function 31.

2-2-3. Key Test (Function 31)

1. Enter the service mode (see section 2-2-1).

2. Press Function, enter 31, then press SET.

3. The display shows the name of a key. If the key is pressed the display shows the next one until the last key ‘‘J’’

is pressed.

If the key test was successful, the machine prints ‘‘KEY TEST OK’’.

If the key test was failed or aborted, the machine prints ‘‘KEY TEST FAILED.

After this test, the machine automatically goes to the LED test.

Display Key Display Key Display Key

1 through # Keys in the

dialpad

ONL On Hook Dial CLR Clear

SPE Speed Dial FUN Function FIN Detail/Fine

MLT Memory LEF Softkey (Left) STO Stop

AUT Auto Select MID Softkey (Middle) CPY Copy

RED Redial RIG Softkey (Right) STA Start

HOL R PHO Halftone A through J Quick Dial keys

2-2-4. LED Test (Function 32)

1. Enter the service mode (see section 2-2-1).

2. Press Function, enter 32, then press SET.

3. All the LEDs on the operation panel blink sequentially until OK or ERROR is pressed.

If OK is pressed, the machine prints ‘‘LED TEST OK’’ and goes to the LCD test.

If ERROR is pressed, the machine prints ‘‘LED TEST FAILED’’, and goes to the LCD test.

2-2-5. LCD Test (Function 33)

1. Enter the service mode (see section 2-2-1).

2. Press Function, enter 33, then press SET.

3. The two lines on the LCD alternately show a line of solid black characters until OK or ERROR is pressed.

If OK is pressed, the machine prints ‘‘LCD TEST OK’’ and goes to the Speaker Test.

If ERROR is pressed, the machine prints ‘‘LCD TEST FAILED’’, and goes to the Speaker Test.

2-3

Page 12

2-2-6. Speaker Test (Function 34)

1. Enter the service mode (see section 2-2-1).

2. Press Function, enter 34, then press SET.

3. The machine emits a tone from the speaker until OK or ERROR is pressed.

If OK is pressed, the machine prints ‘‘VOL TEST OK’’ and goes to the Printer Test.

If ERROR is pressed, the machine prints ‘‘VOL TEST FAILED’’ and goes to the Printer Test.

2-2-7. Printer Test (Function 35)

1. Enter the service mode (see section 2-2-1).

2. Press Function, enter 35, then press PRINT.

3. A test pattern with diagonal lines is printed. After printing, the machine goes to standby mode.

2-2-8. PTT Test (Function 36)

1. Enter the service mode (see section 2-2-1).

2. Press Function, enter 36, then press SET.

3. Press ‘‘MDM’’ for modem test, ‘‘DTMF’’ for DTMF test, or ‘‘LEV.’’ for tx level adjustment.

4.1 Modem Test

The test starts from silence (the machine only goes off-hook), then by pressing the # key consecutively, the signal changes to 9,600bps - 7,200bps - 4,800bps - 2,400bps - 300bps - 600Hz - 1100Hz - 2100Hz. (Press the *

key to go backwards through the sequence.)

After you have finished the test, press Stop to go back to step 3.

4.2 DTMF Test

Press a key on the dialpad (0 - 9, * and #) to test the DTMF signal.

After you have finished the test, press Stop to go back to step 3.

Note that the machine will emit a DTMF signal of the correct length for the country code, even if the slide

switch on the rear of the machine is not set at ‘‘Tone’’.

If you wish to get a continuous DTMF tone, set the slide switch at ‘‘Tone’’, switch off the power, then press the

required key on the dialpad.

4.3 Tx Level Adjustment

The current tx level setting is displayed in the upper right corner of the LCD. To change the setting, press # to

increment or press * to decrement. After adjustment, press Stop to save the setting.

2-2-9. Frequency Test (Function 37)

1. Enter the service mode (see section 2-2-1).

2. Press Function, enter 37, then press SET.

3. The machine emits a sine wave of the displayed frequency. The frequency can be changed in units of 100Hz

by pressing # (increment) or * (decrement). Also, the output level can be changed by pressing LEV.

2-2-10. Burn-in Test (Function 38)

Do not use this function.

2-4

Page 13

2-2-11. Factory Adjustment (Function 40)

1. Enter the service mode (see section 2-2-1).

2. Press Function, enter 40, then press SET.

The upper line on the LCD shows the ROM version ‘‘VER x.xx dd.mm.yy c’’ (x.xx = version, dd.mm.yy = date, c

= country setting). The lower line on the LCD shows ‘‘CLK 0.LEV RAMC’’.

3. Press RAMC for RAM clear.

4.1 Clock Oscillator Adjustment

This function is not for service.

WARNING: Do not use this function.

4.2 Tx Level Fine Adjustment

This function is not for service.

WARNING: Do not use this function.

4.3 RAM Clear

RAM is all reset to the initial settings and the CPU is restarted.

WARNING: With this function, all the previous settings will be reset to the initial settings for Hong Kong.

Program the correct country code after clearing the RAM (bit switch 2; see section 3-1).

2-2-12. Bit Switch Programming (Function 43)

1. Enter the service mode (see section 2-2-1).

2. Press Function, enter 43, then press SET.

3. The setting of bit switch 0 is displayed.

To change the setting of a bit, press the bit number on the dialpad (0 - 7). Press < or > to display other bit

switches.

4. To store the new setting, press OK.

Important Notice for Back-to-Back Mode (Bit Switch 0, Bit 7)

When in back-to-back mode, you cannot enter service mode unless you exit back-to-back mode first. This is because the machine starts communication if you press Start - Stop - and so on while you are in back-to-back mode.

To exit back-to-back mode, do the following:

1. Make sure that the machine is not communicating.

2. Press Halftone to light the Halftone LED, then press Stop.

3. Enter the service mode.

4. After finishing with service mode, re-enter back-to-back mode if required.

2-2-13. Scanner Adjustment (Function 44)

1. Enter the service mode (see section 2-2-1).

2. Press Function, enter 44, then press SET.

3. The LED array is switched on until ‘‘OK’’ is pressed. Refer to section 4-5 for more details on scanner adjustment.

2-5

Page 14

2-2-14. Display and Rewrite ROM/RAM Data (Function 91)

1. Enter the service mode (see section 2-2-1).

2. Press Function, enter 91, then press SET.

3. The upper line on the LCD shows ‘‘ADD: aaaa VAL: ddd/hh’’ (aaaa = address, ddd = decimal value of the data,

and hh = hexadecimal value of the data).

4. Select the address where the data you want to display or change is stored, using keys 0 through 9 and Quick

Dial keys A through F, or using the * key to decrement the address and the # key to increment the address.

5. Press EDIT if you want to rewrite the data.

6. Rewrite the data in the hexadecimal data field. (The ‘‘<’’ and ‘‘>’’ keys are used to move the cursor in the data

field.)

7. Press OK to save the new data.

8. Press Stop to exit this function or go back to step 3 to change another address.

2-2-15. System Report (Function 92)

1. Enter the service mode (see section 2-2-1).

2. Press Function, enter 92, then press PRINT. The system report will be printed.

2-2-16. Print ROM/RAM Data (Function 93)

1. Enter the service mode (see section 2-2-1).

2. Press Function, enter 93, then press SET.

3. Enter the start address then press OK.

The address field has 5 digits, as the first digit is used for bank identification and the following 4 digits are for

the actual address. Use the bank identification number ‘‘0’’ for addresses 0000 - 3FFF(H) and C000 - FFFF(H),

and ‘‘9’’ for addresses 4000 - 7FFF(H).

4. Enter the end address then press OK. The machine prints a list of ROM/RAM data in the selected address

range.

2-2-17. Service Report (Function 95)

1. Enter the service mode (see section 2-2-1).

2. Press Function, enter 95, then press PRINT. The service report will be printed.

2-2-18. NCU Parameter Programming (Function 98)

1. Enter the service mode (see section 2-2-1).

2. Press Function, enter 98, then press SET.

3. The upper line on the LCD shows ‘‘ADD: aa VAL: ddd/hh’’ (aa = parameter number, ddd = decimal value of the

data, and hh = hexadecimal value of the data).

4. Select the required parameter number with keys 0 through 9, or press # or * to scroll through the parameters.

5. Press EDIT if you want to change the data.

6. Rewrite the data in the decimal data field. (The ‘‘<’’ and ‘‘>’’ keys are used to switch the cursor between the address and data fields, and the * and # keys are used to decrement/increment the data value.)

Refer to section 3-2-1 (address 0377 - 0381 (H)) for the definition of NCU parameters.

2-6

Page 15

3. SERVICE TABLES

3-1. BIT SWITCHES

WARNING

Do not adjust a bit switch that is described as "Not used", as this may cause the machine to

malfunction or to operate in a manner that is not accepted by local regulations.

Bit Switch 0

FUNCTION SETTINGS COMMENTS

0 Not used

1 Rx cable equalizer 0: Disabled

1: Enabled

Set this bit to 1 when there is a serious signal loss at

higher frequencies during reception. The cable

equalizer will amplify the signal in this range by +3

dBm.

2 DIS detections 0: Once

1: Twice

The machine will send DCS (G3 set-up signal) if it

receives DIS. If echoes are frequent, setting this bit

to 1 will allow the machine to wait for the second DIS

before sending DCS.

3 TSI (RTI) printout on

received copies

0: Disabled

1: Enabled

If this bit is 1, the TSI or RTI received from the

sender will be printed on the top of each page.

4 Burst error threshold/

error line ratio

0: 6 (12) [24] lines/10%

1: 3 (6) [12] lines/5%

If there are more consecutive error lines in the

received page than the threshold specified by this bit,

the page is rejected. Values in parenthesis ( ) are for

Detail resolution, and those in square brackets [ ] are

for Fine resolution.

Also, if the number of error lines divided by the total

number of lines reaches the ratio determined by this

bit, the machine will send RTN to the other end.

If you want to receive messages with fewer error

lines, set this bit to 1.

5 Training error threshold 0: 4 bits

1: 1 bit

If the machine detects more errors during training

than the number set by this bit, training fails and the

machine will send FTT to ask the other terminal for

modem rate shift-down.

Set this bit to 1 if you want to receive messages at a

more reliable modem speed.

6 Initial Rx modem rate 0: 9,600 bps

1: 4,800 bps

The setting of this bit is used to inform the sending

machine of the initial starting modem rate for the

machine in receive mode. If 9,600 bps presents a

problem during reception, use 4,800 bps.

7 Back to back test 0: Disabled

1: Enabled

Set this bit to 1, when you want to test a back-toback communication.

Important Notice for Back-to-Back Mode

When in back-to-back mode, you cannot enter service mode unless you exit back-to-back mode first. This is because the machine starts communication if you press Start - Stop - and so on to enter service mode while you are

still in back-to-back mode.

Refer to the notice in section 2-2-12 for how to exit back-to-back mode.

3-1

Page 16

Bit Switch 1

FUNCTION SETTINGS COMMENTS

0 Reconstruction time for

the first line

0: 6 seconds

1: 10 seconds

When the sending terminal is controlled by a

computer, there may be a delay in receiving page

data after the local machine accepts set-up data and

sends CFR. If this occurs, set this bit to 1 to give the

sending machine more time to send data.

1 Substitute reception file

forwarding (FAX240 only)

0: Normal operation

1: Forward all files

Set this bit to 1 if the printer is out of order.

The machine will forward all files to the Forwarding

terminal.

2 ECM

transmission/reception

(FAX240 only)

0: Enabled

1: Disabled

Set this bit to 1 when you want to switch off ECM.

3 PSTN/PBX dial tone and

busy tone detection

0: Enabled

1: Disabled

Set this bit to 1 when you wish to disable tone

detection.

4 Closed network in

reception

0: Disabled

1: Enabled

Set these bits to 1 to switch on Closed Network.

With Closed Network, communication will not go

ahead if the ID code of the other terminal does not

match the ID code of this terminal.

The ID code has to be programmed with function 16

before switching on these bits.

This feature may not be reliable when

communicating with another maker’s machine.

5 Closed network in

transmission

0: Disabled

1: Enabled

6 Remote read/write request 0: Always enabled

1: User selectable

0: RDS is always enabled. The user cannot switch it

off.

1: If a technician or RDS operator sets this to 1 after

installation, the user can select either ‘‘ON for 24

hours’’ or ‘‘OFF’’.

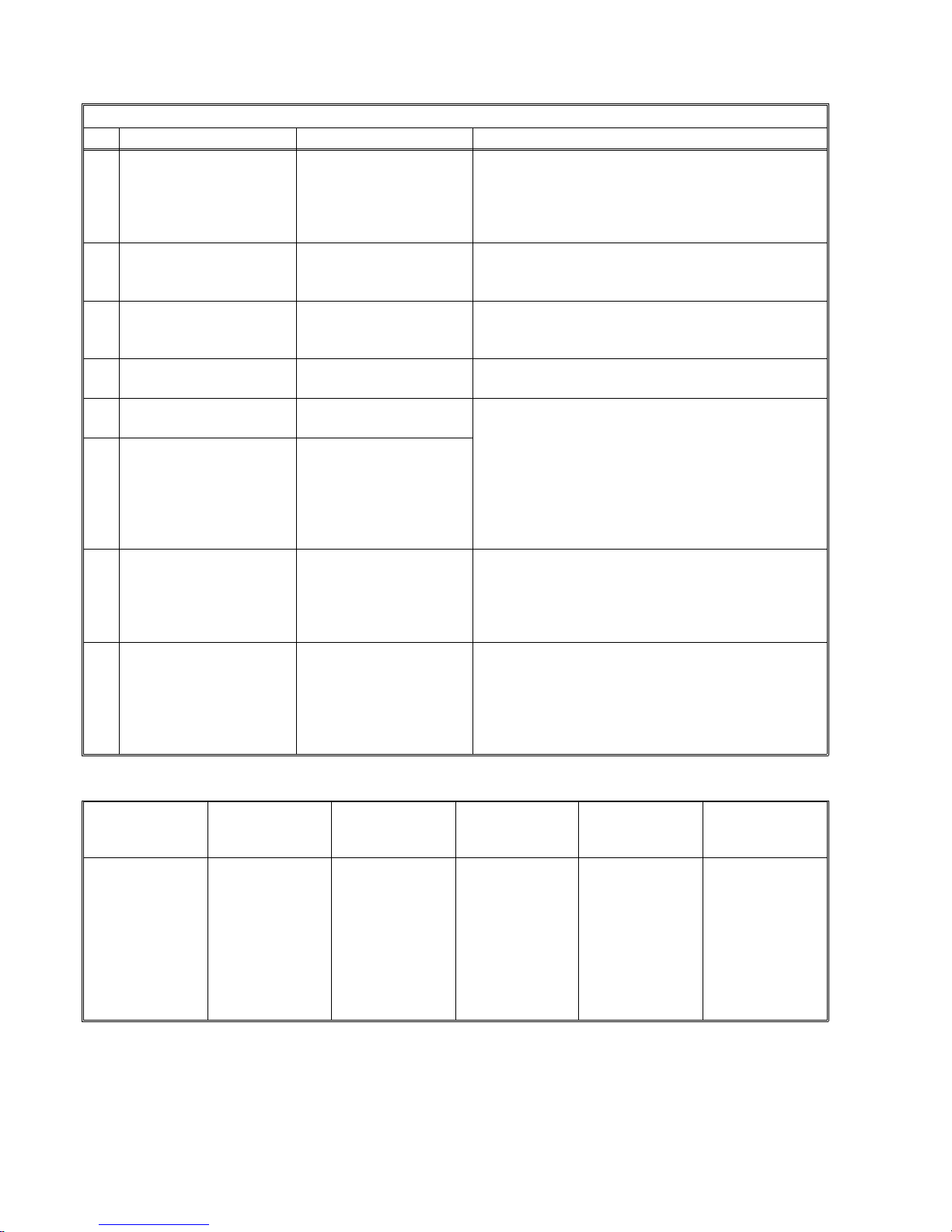

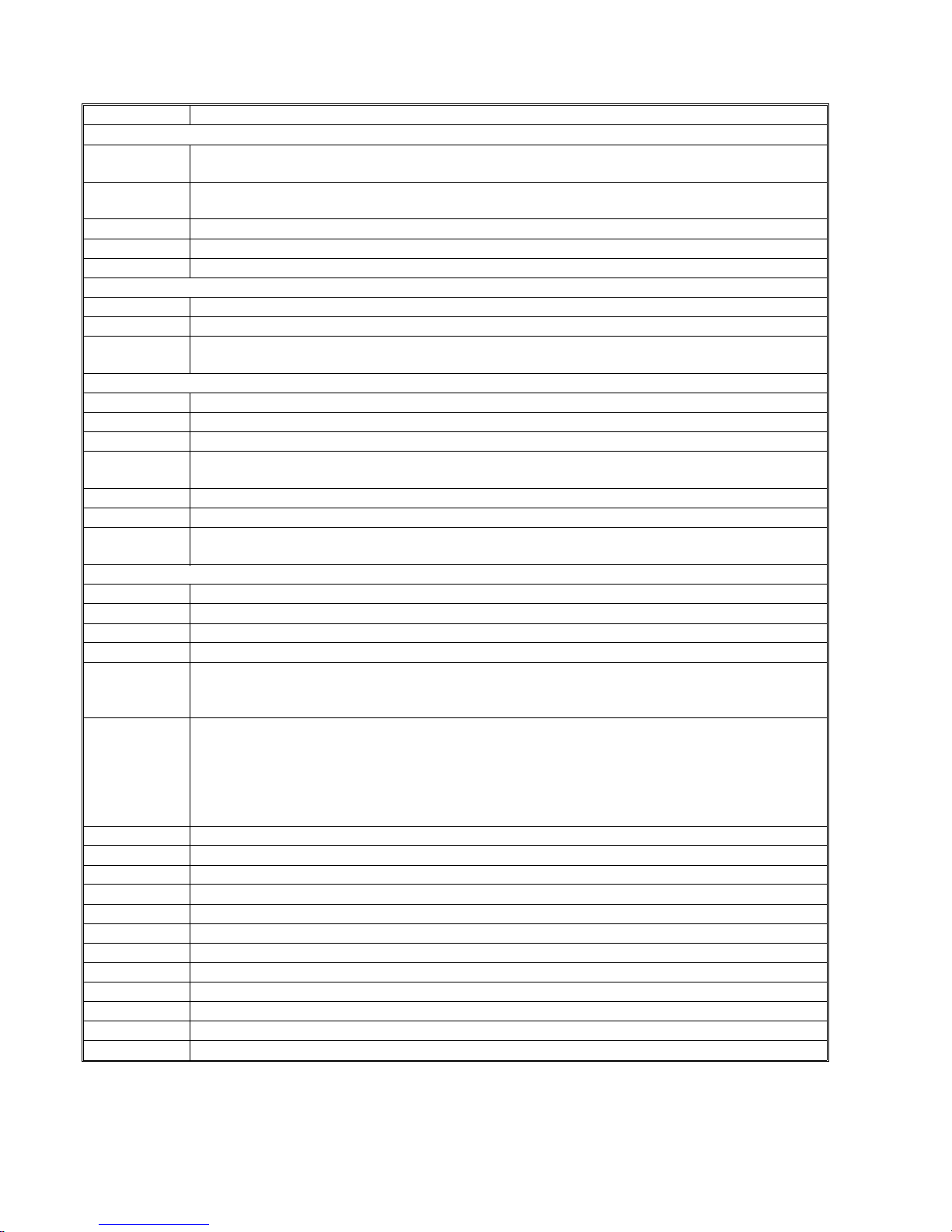

7 Communication

parameter display and

line monitoring after

handshaking

0: Disabled

1: Enabled

This is a fault-finding aid. If this bit is set to 1, the

LCD shows the key parameters (see below) and the

speaker is enabled during message transmission and

reception.

This should be normally disabled because it cancels

the CSI/TSI (RTI) display for the user.

Modem rate

(bps)

Sub-scan

resolution

(lines/mm)

Coding Width and

reduction

Mode I/O rate

(ms/line)

96: 9,600

72: 7,200

48: 4,800

24: 2,400

S: 3.85

D: 7.7

F: 15.4

1D: MH

2D: MR

1E: MH + EFC

2E: MR + EFC

1S: MH + SSC

2S: MR + SSC

1C: MH + ECM

2C: MR + ECM

MC: MMR + ECM

A: A4

N: No reduction

DCS: CCITT G3

NSS:

Non-standard G3

0M: 0

5M: 5

10M: 10

20M: 20

40M: 40

3-2

Page 17

Bit Switch 2

FUNCTION SETTINGS COMMENTS

0 Country code

Bit 4 3 2 1 0 Country

1 0 0 0 1 USA

1 0 1 0 0 Hong Kong

1 0 1 0 1 Australia

1 0 1 1 0 New Zealand

1 0 1 1 1 Israel

1 1 0 0 0 Thailand

1 1 0 0 1 Singapore

1 1 0 1 0 Indonesia

Set the country code after clearing the RAM.

1

2

3

4

5 TAM interface type 0: Normal

1: German type

0: The normal type of TAM interface monitors the line

current on the LIU, to detect whether the external

TAM goes off-hook or on-hook.

1: The German type of TAM interface does not

monitor the line current on the LIU, because the TAM

and the fax are connected in parallel to the line.

Refer to section 1-3-1 for more details.

6 TAM (Telephone

Answering Machine)

interface

0: Enabled

1: Disabled

If this bit is 1, TAM mode cannot be selected with

function 04 by the user.

7 Not used

Default Settings

Bit Switch H501/502-50 H501/502-51 H501/502-52 H501/502-53 H501/502-54 H501/502-55

0 00 00 00 00 00 00

1 00 00 00 00 00 00

2 14 15 16 1A 17 11

3-3

Page 18

3-2. USEFUL RAM ADDRESSES

In the equations that occur in the following tables, N represents the decimal value stored in the RAM address.

WARNING

Changing any RAM data that are not listed in this table may cause the machine to malfunction.

3-2-1. Address Table

Use service function 91 to view or adjust the contents of a RAM address. See section 2-2-14 for details.

Address (Hex) Function

0000 - 0002

Bit switches 00 to 02 (0000 = Bit switch 00, 0001 = Bit switch 01, and so on); refer to section 3-1

for details.

0009

User function parameters

Bit 7: Transmission Report On/Off [Function 09] (1: On)

Bit 6: TTI (Page Header) On/Off [Function 10] (1: On)

Bit 5: Key Touch Tone On/Off [Function 17] (1: On)

Bit 4: RDS On/Off [Function 18] (1: On for 24 hours)

Bit 3: AM/PM Indication on LCD clock Note 1 (1: On)

Bit 2: Forwarding On/Off [Function 22] Note 2 (1: On)

Bit 1: Forwarding Mode [Function 22] Note 2 (0: Now or Later mode, 1: Daily mode)

Bit 0: Forwarding File Local Printing On/Off [Function 22] (1: On)

000A

User function parameters

Bit 7: Communication record listing on TCR [Function 08] (1: On)

Bit 6: Authorized Reception On/Off [Function 20] (1: On)

Bits 5 through 0: Not used

0039

Exchanger type connected to the machine Bit 2 = 0: PSTN

Bit 2 = 1: PBX

0300 - 0302: Line current detection parameters

0300 Line current detection time [Time = N x 10 (ms), detection disabled if N = FF]

0301 Line current reset time [Time = N x 20 (ms)]

0302 Line current dropout detection time [Time = N x 10 (ms)]

0303 - 0320: PSTN tone detection parameters

0303 - 030E

Modem data for PSTN dial tone frequency range

Caution: Do not adjust.

030F PSTN dial tone detection time [Time = N x 20 (ms), detection disabled if N = FF]

0310 PSTN dial tone reset time [Time = N x 0.16 (s)]

0311 PSTN dial tone continuous tone time [Time = N x 20 (ms)]

0312 PSTN dial tone permissible dropout time [Time = N x 20 (ms)]

0313 PSTN pause time [Time = N x 0.16 (s)]

0314 PSTN ringback tone detection time [Time = N x 20 (ms), detection disabled if N = FF]

0315 - 0320

Modem data for PSTN busy tone frequency range

Caution: Do not adjust.

0321 - 033E: PBX tone detection parameters

0321 - 032C

Modem data for PBX dial tone frequency range

Caution: Do not adjust.

032D PBX dial tone detection time [Time = N x 20 (ms), detection disabled if N = FF]

032E PBX dial tone reset time [Time = N x 0.16 (s)]

032F PBX dial tone continuous tone time [Time = N x 20 (ms)]

3-4

Page 19

Address (Hex) Function

0330 PBX dial tone permissible dropout time [Time = N x 20 (ms)]

0331 PBX pause time [Time = N x 0.16 (s)]

0332 PBX ringback tone detection time [Time = N x 20 (ms), detection disabled if N = FF]

0333 - 033E

Modem data for PBX busy tone frequency range

Caution: Do not adjust.

033F - 0348: Busy tone detection parameters

033F Busy tone ON time (range 1) [Time = N x 10 (ms)]

0340 Busy tone OFF time (range 1) [Time = N x 10 (ms)]

0341 Busy tone ON time (range 2) [Time = N x 10 (ms)]

0342 Busy tone OFF time (range 2) [Time = N x 10 (ms)]

0343 Busy tone ON time (range 3) [Time = N x 10 (ms)]

0344 Busy tone OFF time (range 3) [Time = N x 10 (ms)]

0345 Busy tone ON time (range 4) [Time = N x 10 (ms)]

0346 Busy tone OFF time (range 4) [Time = N x 10 (ms)]

0347 Continuous busy tone detection time [Time = N x 10 (ms)]

0348

Bits 0 to 3: Busy tone signal state time tolerance (for all ranges)

Bit 3 2 1 0 Tolerance

0 0 0 1 ± 50%

0 0 1 0 ± 25%

0 0 1 1 ± 12.5%

Bits 4 to 7: Number of cycles required for detection

0349 - 0359: International dial tone detection parameters

0349 - 0354

Modem data for international dial tone frequency range

Caution: Do not adjust.

0355 International dial tone detection time [Time = N x 20 (ms), detection disabled if N = FF]

0356 International dial tone reset time [Time = N x 0.16 (s)]

0357 International dial tone continuous tone time [Time = N x 20 (ms)]

0358 International dial tone permissible dropout time [Time = N x 20 (ms)]

0359 International dial pause time [Time = N x 0.16 (s)]

035A - 036A: National dial tone detection parameters

035A - 0365

Modem data for domestic dial tone frequency range

Caution: Do not adjust.

0366 National dial tone detection time [Time = N x 20 (ms), detection disabled if N = FF]

0367 National dial tone reset time [Time = N x 0.16 (s)]

0368 National dial tone continuous tone time [Time = N x 20 (ms)]

0369 National dial tone permissible dropout time [Time = N x 20 (ms)]

036A National dial pause time [Time = N x 0.16 (s)]

036B - 036C

International dial access number

Example: If the number is 100, store F1 in address 036B, and 00 in address 036C.

036D PBX operator pause [Time = N x 20 (ms)]

036F CCITT T1 time [Time = N x 2.56 (s)]

0370 Maximum number of dialing attempts to the same station in normal tx mode

0371 Redial interval in normal tx [Time = N (minutes)]

0372 Maximum number of dialing attempts to the same station in memory tx mode

0373 Interval between dialing to different stations [Time = N x 2.56 (s)]

0374 Dial tone detection level [Level = 0 - N x 0.375 (dBm)]

0375 Busy tone detection level [Level = 0 - N x 0.375 (dBm)]

0376

Minimum signal detection level [Level = 0 - N x 0.375 (dBm)]

3-5

Page 20

Address (Hex) Function

0377 - 037B: Ringing signal detection parameters (Use function 98 to change)

0377

NCU Parameter 00: Acceptable ringing signal frequency, upper limit

[Frequency = 1/(N x 10-3) (Hz)]

0378

NCU parameter 01: Acceptable ringing signal frequency, lower limit

[Frequency = 1/(N x 10-3) (Hz)]

0379 NCU parameter 02: Number of rings until a call is detected [Number = N x 1]

037A NCU parameter 03: Minimum required length of a ring [Length = 20 x N (ms)]

037B NCU parameter 04: Minimum required length of an interval between rings [Length = 40 x N (ms)]

037C - 037D: Pulse dial parameters (Use function 98 to change)

037C NCU parameter 05: Time between closing the dc loop and the first dialed digit [Time = N (ms)]

037D NCU parameter 06: Pause between dialed digits (pulse dial mode) [Time = N x 20 (ms)]

037E

NCU parameter 07: Time waited when a pause is entered at the operation panel [Time = N x 20

(ms)]

037F - 0380: Tone dial parameters (Use function 98 to change)

037F NCU parameter 08: DTMF tone length [Time = N x 5 + 60 (ms)]

0380 NCU parameter 09: Time between dialed digits (DTMF dial mode) [Time = N x 5 + 60 (ms)]

0381 NCU parameter 10: Modem transmission level [Level = - N (dBm)]

0382

Language selected for LCDs and reports

0(D): English 1(D): Spanish 3(D): French

0386 Redial interval for memory transmission [ N x 1 (min.)] (Default: 5 minutes)

0387 - 0388 Intercity access code for France: 16(D) [0386 = FF(H), 0387 = 16(BCD)]

039A

Ringing time in Auto mode [Time = N (s)]

The value of N should be a multiple of 5 between 5 and 25.

039E - 03A1: CNG detection parameters

039E Maximum acceptable CNG OFF-time [Time = N x 20 (ms)] Note 3

039F Minimum acceptable CNG OFF-time [Time = N x 20 (ms)] Note 3

03A0 Maximum acceptable CNG ON-time [Time = N x 20 (ms)] Note 3

03A1 Minimum acceptable CNG ON-time [Time = N x 20 (ms)] Note 3

03A2

Country code

11: USA 14: Hong Kong 15: Australia 16: New Zealand 17: Israel 18: Thailand

19: Singapore 1A: Indonesia

03C5

Mode selection in Auto Select mode

Bit 3 2 1 0 Mode

0 0 0 1 Auto Tel/Fax switch with AVM

0 0 1 0 Auto Tel/Fax switch with ringback tone

0 0 1 1 Semi-Auto (TAM) mode

0 1 0 0 Fax mode

03C9 Continuous silent period detection time in TAM mode [Time = N x 65 (ms)]. See Note 4.

03CA PSTN access code from behind Loop Start PBX (BCD)

03CF Number of rings until a call is detected in TAM mode [N (times)]

20A1 Forwarding start date and time Minute (BCD)

20A2 Forwarding start date and time Hour (BCD)

20A3 Not used

20A4 Forwarding start date and time Day (BCD)

20A5 Forwarding start date and time Month (BCD)

20A6 Forwarding start date and time Year (BCD)

20A7 Forwarding end date and time Minute (BCD)

20A8 Forwarding end date and time Hour (BCD)

20A9 Not used

3-6

Page 21

Address (Hex) Function

20AA Forwarding end date and time Day (BCD)

20AB Forwarding end date and time Month (BCD)

20AC Forwarding end date and time Year (BCD)

20AD - 226E TCR generation area (30 bytes x 15 communications)

2272 - 2433 Service report and error report generation area (45 bytes x 10 communications)

2438 - 24F7 Error code memory (up to 32 codes x 6 bytes)

2736 - 2737

Polling ID code Example: ABCD 2736 (High) = A, (Low) = B

2737 (High) = C, (Low) = D

2A7B Received page counter High: Tens digit Low: Units digit

(BCD) High: Thousands digit Low: Hundreds digit

High: Hundred thousands digit Low: Ten thousands digit

2A7C

2A7D

2A7E - 2A80 Transmitted page counter (Refer to the received page counter)

2A81 Printed page counter High: Tens digit Low: Units digit

(BCD) High: Thousands digit Low: Hundreds digit

High: Hundred thousands digit Low: Ten thousands digit

2A82

2A83

2A84 - 2A86 Scanned page counter (Refer to the printed page counter)

5002 - 5100

Modem rates used in the last five communications to the terminals programmed in the

Quick/Speed dials and to the forwarding terminal. (5 bytes x 51 destinations)

[0: No history, 1: 2400 bps, 2: 4800 bps, 3: 7200 bps, 4: 9600 bps]

5101 Number of characters in the RTI - 14 (H)

5102 - 5115 RTI (ASCII)

5116 Number of characters in the CSI - 14 (H)

5117 - 512A CSI (ASCII)

512B Number of characters in the TTI - 20(H)

512C - 514B TTI (ASCII)

514C Number of digits in the forwarding terminal’s telephone number

514D - 516C Forwarding terminal’s telephone number (ASCII)

63F6

Continuous silent period detection time in TAM mode indicated on the LCD [Time = N (s)].

See Note 4.

6408

AVM language in AUTO and TAM modes.

1(D): English 2(D): German 3(D): Dutch 4(D): French

6409 Second AVM language in AUTO and TAM modes. (Same as above)

ROM Version •

The following addresses are ROM addresses. The data in these addresses cannot be changed.

C00C Version (High) (ASCII)

C00D A period ‘‘ . ’’ (ASCII)

C00E Version (Low) (ASCII)

C00F Version (Low) (ASCII)

C010 A blank space ‘‘ ’’ (ASCII)

C011 Day (Tens digit) (ASCII)

C012 Day (Units digit) (ASCII)

C013 A period ‘‘ . ’’ (ASCII)

C014 Month (Tens digit) (ASCII)

C015 Month (Units digit) (ASCII)

C016 A period ‘‘ . ’’ (ASCII)

C017 Year (Tens digit) (ASCII)

C018 Year (Units digit) (ASCII)

C019 A blank space ‘‘ ’’ (ASCII)

3-7

Page 22

Address (Hex) Function

C01A Hour (Tens digit) (ASCII)

C01B Hour (Units digit) (ASCII)

C01C A colon ‘‘:’’ (ASCII)

C01D Minute (Tens digit) (ASCII)

C01E Minute (Units digit) (ASCII)

C01F A blank space ‘‘ ’’ (ASCII)

C020 Suffix (ASCII)

C021 Machine code 13 (H) - FAX 220/240

Notes:

1. This bit only changes the language displayed on the LCD. The report language cannot be changed.

2. Forwarding requires the following switches and data.

ON/OFF

Bit 2 of 0009 (H)

Mode

Bit 1 of 0009 (H)

Start Date and Time

20A1 - 20A6 (H)

End Date and Time

20A7 - 20AC (H)

OFF

(0)

ON

(1)

NOW (0) Current date and time is stored. End time and date is stored

here (user programmable).

If ‘‘UNDEFINED’’ is selected,

the start date and time is copied

here.

LATER (0)

Start date and time is stored

here (user programmable).

DAILY (1)

The daily start time is stored

here.

The daily end time is stored

here.

3. These addresses are cleared if the power is switched off.

4. If you change RAM address 63F6, you must also change RAM address 03C9, and vice versa.

3-8

Page 23

3-2-2. Format of the TCR and Transmission Report Generation Areas

The TCR and the Transmission Report are generated in addresses 20AD - 226E (H). The record of each communication is stored in blocks of 30 bytes as explained in the following table.

Byte No. Functions

0

Header Bit 7: Transmission Report (1: Enabled)

Bit 6: TCR (1: Enabled)

Bits 5 through 0: Not used

1 Communication start time Month (BCD)

2 Communication start time Day (BCD)

3 Communication start time Hour (BCD)

4 Communication start time Minute (BCD)

5 - 24 Remote terminal’s RTI, TSI or CSI (ASCII)

25

Communication mode

Bit 7: Resolution step down (1: Yes)

Bit 6: Reduction (1: Yes)

Bit 5: 0: Standard 0: Fine 1: Detail 1: Not used

4 0 1 0 1

Bit 3: Forwarding (1: On)

Bit 2: Memory tx/rx (1: Yes)

Bit 1: ECM (0: Non-ECM, 1: ECM)

Bit 0: Tx or Rx (0: Rx, 1: Tx)

26 Communication time Minutes (BCD)

27 Communication time Seconds (BCD)

28

Communication result and causes of error

Bit 7: Result (0: OK, 1: Error)

Bit 6: Document jam (1: Yes)

Bit 5: Authorized reception (0: Not rejected, 1: Rejected)

Bit 4: Not used

Bit 3 - 0: Cause of error (BCD)

7 (BCD): Not used

6 (BCD):

5 (BCD): 8 minutes close

4 (BCD): Busy

3 (BCD): T1 time over during a telephone call

2 (BCD): T1 time over during a fax call

1 (BCD): Errors during fax communication

0 (BCD): No error

29 Total page(s) (BCD)

3-9

Page 24

3-2-3. Format of the Service Report and Error Report Generation Area

The Service Report and the Error Report are generated in addresses 2272 - 2433 (H). The record of each error

communication is stored in blocks of 45 bytes as explained in the following table. There can be up to 10 records.

Byte No. Functions

0

Header Bit 7: Service Report or Error Report (1: Enabled)

Bit 6 through 0: Not used

1 - 29 Same as the TCR memory

30 Error page #1 (BCD)

31 Error page #2 (BCD)

32 Error page #3 (BCD)

33 Error page #4 (BCD)

34 Error page #5 (BCD)

35 Error code #1 (High) (BCD)

36 Error code #1 (Low) (BCD)

37 Error code #2 (High) (BCD)

38 Error code #2 (Low) (BCD)

39 Error code #3 (High) (BCD)

40 Error code #3 (Low) (BCD)

41 Error code #4 (High) (BCD)

42 Error code #4 (Low) (BCD)

43 Error code #5 (High) (BCD)

44 Error code #5 (Low) (BCD)

3-2-4. Format of the Error Code Memory

The error codes are stored in 2438 - 24F7 (H). Each error code is stored in blocks of 6 bytes as explained in the following table. The machine can store up to 32 error codes.

Byte No. Functions

0 Error code (High) (BCD)

1 Error code (Low) (BCD)

2 Month (BCD)

3 Day (BCD)

4 Hour (BCD)

5 Minute (BCD)

3-10

Page 25

3-3. JUMPERS

LIU

1

TB1

1

TB2

1 TB3

1

TB4

The jumper wires are set as shown below in the factory for each version.

WARNING: Service parts for types 1, 4, and 6 are set to type 6, and service parts for types 2 and

3 are set to type 2. When installing a new LIU, make sure that it is at the correct setting for the machine. Also, note that the LIU for type 2 has a dummy jumper on pin 4 of TB3; this is a spare

jumper for use if you wish to install the LIU board in a type 3 machine.

1

TB1

1

TB2

1 TB3

1

TB4

1

TB1

1

TB2

1 TB3

1

TB4

1

TB1

1

TB2

1 TB3

1

TB4

1

TB1

1

TB2

1 TB3

1

TB4

1

TB1

1

TB2

1 TB3

1

TB4

H501/502-50

(Type 1)

H501/502-52

(Type 3)

H501/502-53

(Type 4)

H501/502-54

(Type 5)

H501/502-55

(Type 6)

1

TB1

1

TB2

1 TB3

1

TB4

H501/502-51

(Type 2)

Dummy Jumper

3-11

Page 26

3-4. VARIABLE RESISTORS AND SWITCHES

PCB Address Function

LIU

VR1 Ringer volume adjustment (user adjustable)

VR2 Speaker volume adjustment (user adjustable)

VR3 DTMF signal Tx level adjustment

SW1 GS/FS select switch (not used)

PSU S001

A thermostat; this switches the power off automatically when the temperature goes higher

than 95 ± 5 °C, and recovers after switching the power switch off and on

3-5. SENSORS

No. Name Function

SB-1

Document Sensor Detects whether a document is placed in the feeder or not. The 58th bit on

the SBU is used as this sensor.

SB-2

Scan Line Sensor Detects when the top of a page is at the scan line position. The 4th bit on

the SBU is used as this sensor.

SB-4 Paper End Sensor Detects whether paper is in the paper holder or not.

SB-5 Paper Jam Sensor Detects whether paper is jammed in the printer or not.

SB-7 Cutter Start Sensor Detects whether the cutter blade is at the home (start) position or not.

SB-8

Cutter End Sensor Detects whether the cutter blade is at the end position or not. If the cutter

blade is detected at the cutter end position, the cutter motor reverses to

move the blade to the cutter start position.

SB-10 Cover Sensor Detects whether the printer cover is closed or not.

3-12

Page 27

4. REMOVAL AND ADJUSTMENT

CAUTION

1.Unplug the machine from the power outlet before removing any of the covers.

2. The danger of explosion exists if the lithium battery on the FDU is incorrectly replaced. Replace

only with the same or an equivalent type recommended by the manufacturer. Discard used batteries

in accordance with the manufacturer’s instructions.

4-1. COVERS

4-1-1. Operation Panel Assembly

1. Open the ADF.

2. Remove the operation panel cover [A] as shown below.

3. Disconnect three connectors.

4. Remove the lower cover [B] (1 ground wire).

[A]

[B]

4-1

Page 28

4-1-2. Paper Holder and Scanner Cover

1. Open the printer cover.

2. Remove the paper holder [A] (4 screws, 1 connector).

3. Remove the operation panel assembly (see section 4-1-1).

4. Remove the scanner cover [B] with a screwdriver as shown below (2 screws).

[A]

[B]

4-2

Page 29

4-1-3. Thermal Head and Printer Cover

1. Open the printer cover.

2. Remove the thermal head cover [A] (4 screws).

3. Remove the thermal head [B] and the spring plate [C] (2 connectors, 2 springs, 2 screws).

Reassembly Note

• The dents on the thermal head bracket must fit into the slots on the thermal head.

4. Remove the printer cover [D] (2 screws).

[D]

[A]

[C]

[B]

4-3

Page 30

4-2. SCANNER

4-2-1. Separation Rubber Plate

1. Remove the operation panel assembly (see section 4-1-1).

2. Remove the rubber plate [A].

4-2-2. LED Array

1. Remove the operation panel assembly, the paper holder and the scanner cover (see section 4-1).

2. Remove the LED array [A] (2 screws, 1 connector).

[A]

[A]

4-4

Page 31

4-2-3. Feed Roller

1. Remove the operation panel assembly, the paper holder and the scanner cover (see section 4-1).

2. Remove the metal bracket [A] (1 screw).

3. Remove the feed roller [B].

Note for Reassembly

• Pin [C] on the document sensor actuator must be under the feed roller shaft.

[A]

[B]

[C]

4-5

Page 32

4-3. PRINTER

4-3-1. Rear Cover, Cutter Unit (FAX240 only), and Platen Roller

1. Remove the rear cover [A] (2 screws).

2. Remove the paper guide bracket [B] (FAX220), or the paper holder and the cutter unit [C] (FAX240) (4 screws,

2 connectors).

[C]

[A]

FAX240

[B]

FAX220

[A]

4-6

Page 33

3. Remove the FCE, FDU, PSU and LIU (see section 4-4).

4. Remove the mono-chassis [D] (2 screws, 1 ground wire).

5. Remove two gears [E] (1 E-ring).

6. FAX220: Remove the platen roller [F] (2 E-rings, 2 bushings).

FAX240: Remove the decurler bracket [G] and platen roller [F] (2 E-rings, 2 bushings, 1 spring).

Reassembly Note

• Be careful not to assemble the gears the wrong way round.

• The left platen roller bushing is smaller than right bushing.

• FAX240: Lubricate the left shaft of the platen roller all the way round after changing the platen roller or the

spring clutch for the decurler (Use Mobil Temp 78, part no. 54479078).

[D]

[E]

[F]

FAX220

[G]

[D]

[E]

[F]

FAX240

4-7

Page 34

4-4. PCBs

4-4-1. FCE, FDU, and PSU

1. Remove the paper holder (see section 4-1-2).

2. Remove the FCE [A] (3 connectors).

3. Remove the FDU [B] (9 connectors).

4. Remove the rear cover (2 screws).

5. Remove the PSU [C] (2 connectors).

[A]

[B]

[C]

3

2

3

5

6

4

1

4-8

Page 35

4-4-2. LIU

1. Remove the paper holder and the scanner cover (see section 4-1-2).

2. Remove the LIU [A] (2 screws, 6 connectors).

4-4-3. HSB

1. Remove the paper holder (see section 4-1).

2. Remove the cradle unit as shown below.

3. Remove the HSB [A] (3 connectors).

[A]

5

3

4

1

1

2

[A]

(1)

(2)

4-9

Page 36

4-4-4. OPU

1. Remove the operation panel cover (see section 4-1-1).

2. Remove the OPU [A].

[A]

4-10

Page 37

4-5. SBU REPLACEMENT AND SCANNER/SENSOR ADJUSTMENT

4-5-1. SBU Adjustment Tools

1. Adjustment Kit (P/No. H0809600)

2. Test PCB (P/No. H0939650)

Additionally, the test chart which is included in the adjustment kit is available as part number H0809602.

4-5-2. SBU Replacement

1. Unplug the machine from the wall outlet.

2. Remove the printer cover, operation panel assembly, and scanner cover (see sections 2-1 and 2-3).

3. Remove the SBU (2 screws, 1 connector at CN7 on the FDU).

4-5-3. Scanner/Sensor Adjustment

Every time you replace the SBU or when the machine has a document non-feed or jam problem because of incorrect scanner/sensor adjustment, adjust the scanner/sensor mechanism as shown in the following pages.

As the scanner has 2 features, scanning document and detecting sensor actuator movement, the scanner needs exact adjustment. Refer to Appendix D for more details on the scanner/sensor mechanism.

This section is divided into 4 parts:

1. Preparation

2. Horizontal Scan Line Adjustment

3. Vertical Scan Line Adjustment

4. Focusing

‘‘Preparation’’ explains how to set up the SBU adjustment tools in the machine.

‘‘Horizontal Scan Line Adjustment ’’ explains how to adjust the horizontal position of the SBU with the tools.

This section is quite important because the machine cannot detect sensor movement unless the SBU is adjusted

properly.

‘‘Vertical Scan Line Adjustment ’’ explains how to adjust the vertical position of the SBU with the tools.

The new test chart is designed so that the SBU can be adjusted vertically.

‘‘Focusing’’ explains how to adjust focusing on the CCD. Adjusting the lens position is a bit more difficult than for

other current models.

4-11

Page 38

1. Preparation

1. Install a new SBU in the machine. (Do not connect the harness to the FDU.)

2. Clamp the bracket to the scanner base. Set the left side of the bracket first as shown below.

Notes:

3. Connect the harness from the FDU (CN7) to CN2 on the test PCB, then connect the harness from the test

PCB to the SBU.

1. The dents on the bracket must be

fit to the

edge of scanner base. Otherwise,

the pins of the HIC might crack

as shown in the diagram.

2. The shape of the bracket might be

different from the drawing.

SBU

2nd Mirror

CN3

1 2

3

CN2

CN1

FDU

CN7

SBU

COM2

(Ground)

XVIDEO

(CH2)

DTVLD

(CH1)

Scanner Base

HIC

FDU

Bracket

Crack

4-12

Page 39

1. Preparation

4. Connect the test pins to the oscilloscope as follows:

Pin 1 (DTVLD) - Channel 1 (CH1) on the oscilloscope

Pin 2 (COM2) - Ground

Pin 3 (XVIDEO) - Channel 2 (CH2) on the oscilloscope

5. Attach the test chart to the machine.

6. Connect the operation panel to the machine.

7. Enter the service mode and switch the LED array on (see section 2-2-13).

8. Set up the oscilloscope as follows:

CH2 (XVIDEO) - 0.2 V/div.

TIME - 1 ms/div.

Then, select CH2 (XVIDEO) on the oscilloscope.

9. The XVIDEO signal shows one of the waveforms shown below. One, two or three dropouts should appear at

‘‘A’’ and ‘‘B’’ depending on the vertical scan line position, and moire should appear at ‘‘C’’.

If this waveform cannot be seen on the oscilloscope screen, loosen the SBU securing screws and adjust the

SBU position until this waveform appears on the screen.

The moire sometimes does not appear on the screen unless the lens is well focused. So, if the moire does not

appear on the screen, go to the ‘‘Focusing’’ procedure first, then go to the ‘‘Horizontal/Vertical Scan Line

Adjustment’’ procedures.

If this waveform appears on the screen, go to the ‘‘Horizontal/Vertical Scan Line Adjustment ’’ procedures,

then check that the moire at ‘‘C’’ satisfies the criterion in the ‘‘Focusing’’ section.

Test Chart attached on the Pressure Plate

Scan Start Line "A" part

"B" part

"C"(8 lines/mm) part

"A" "B" part Scan Line

2 dropouts

3 dropouts

1 dropout

4-13

Page 40

2. Horizontal Scan Line Adjustment

1. Set up the oscilloscope as follows:

CH1 (DTVLD) - 5 V/div.

CH2 (XVIDEO) - 0.2 V/div.

TIME - 1 ms/div.

Use ALT mode to display CH1 and CH2 at the same time.

2. Loosen the SBU securing screws.

3. The XVIDEO signal shows one of the waveforms shown below.

4. Enlarge the shaded part of the waveform above by changing the TIME scale to 50 µs/div or 20 µs/div.

The scan start line appears as the first sharp dropout from the left of the XVIDEO signal on the oscilloscope.

The dropout of the waveform has to be within ±4 bits from the rising edge of the DTVLD signal as shown below.

If the scan start line is not at the correct position, go to step 5 to adjust the horizontal scan line position.

4-14

Page 41

2. Horizontal Scan Line Adjustment

5. Adjust the horizontal scan line position as shown below.

If the scan start line is to the left of the rising edge of the DTVLD signal, move the SBU to the left.

If the scan start line is to the right of the rising edge of the DTVLD signal, move the SBU to the right.

6. After adjustment, be sure that the scan start line is within ± 4 bits from the rising edge of the DTVLD signal,

then go to the ‘‘Vertical Scan Line Adjustment ’’ procedure.

Note: Scan end line adjustment is not necessary.

4-15

Page 42

3. Vertical Scan Line Adjustment

1. Set up the oscilloscope as follows:

CH1 (DTVLD) - 5 V/div.

CH2 (XVIDEO) - 0.2 V/div., not inverted

TIME - 1 ms/div.

Use ALT mode to display CH1 and CH2 at the same time.

2. The XVIDEO signal shows one of the waveforms shown below.

At ‘‘A’’ and ‘‘B’’ on the XVIDEO waveform, one, two or three dropouts are seen now.

Enlarge areas ‘‘A’’ and ‘‘B’’ by changing the time scale to 50 µs/div or 20 µs/div.

The ideal waveform should have only one dropout at each of ‘‘A’’ and ‘‘B’’. If the waveform has two or three

dropouts there, go to step 3 to adjust the ‘‘A’’ part (scan start side) and/or step 4 to adjust the ‘‘B’’ part (scan

end side).

4-16

Page 43

3. Vertical Scan Line Adjustment

3. Adjustment at the scan start side.

If the waveform has two dropouts at the scan start side, move down the left side of the SBU to make the distance between peaks narrower. The distance between peaks has to be within 50 µs.

If the waveform has three dropouts at the scan start side, move up the left side of the SBU to make the distance between peaks narrower. The distance between peaks has to be within 50 µs.

4-17

Page 44

3. Vertical Scan Line Adjustment

4. Adjustment at the scan end side.

If the waveform has two dropouts at the scan end side, move down the right side of the SBU to make the distance between peaks narrower. The distance between peaks has to be within 50 µs.

If the waveform has three dropouts at the scan end side, move up the right side of the SBU to make the distance between peaks narrower. The distance between peaks has to be within 50 µs.

5. After adjusting the scan end side, confirm that the scan start side is still adjusted properly, as the adjustment at

one side often changes the waveform at the other side.

4-18

Page 45

4. Focusing

1. Loosen the lens securing screw [A] and pull out the lens 1 or 2 mm from the scanner base surface as

shown on the right.

2. Move back the lens using a small (-) screwdriver so that the amplitude of each moire [A] becomes

more than 20% of the white level output [B].

3. Tighten the lens securing screw.

After finishing the adjustments, switch off the power, take out the adjustment tools, bracket, test lead and the white

pressure plate from the machine. Then reassemble the machine.

4-19

Page 46

5. TROUBLESHOOTING

5-1. COPY QUALITY PROBLEMS

5-1-1. Received Copies

If there is no fault in the receiving terminal or on the line, but the copy quality is bad, do the following:

• Check that the thermal head, platen roller and spring plate assembly are assembled completely.

• Clean the thermal head (soft cloth and alcohol).

• Replace the thermal head or FDU.

5-1-2. Printouts Made in Copy Mode

If printouts of received fax messages are OK but printouts made using copy mode are not, the following faults must

be considered in addition to the printer faults mentioned above.

Symptom Remedies

Blank or black copies • Check the scanner/sensor mechanism and adjust or replace any

defective parts.

• Replace the SBU or FDU.

Vertical black lines on the copy • Clean the scanner optics and LED array (soft cloth).

• Replace the SBU if there are any sharp peaks or dropouts in the CCD

waveform.

Uneven density • Adjust the scan line position (see section 4-5-3).

• Clean the scanner optics and LED array (soft cloth).

• Replace the LED array if it is defective.

Magnification • Check that the mirrors are assembled correctly on the scanner base.

Blurred characters • Adjust the focusing (see section 4-5-3).

Filled-in characters • Adjust the focusing (see section 4-5-3).

Side-to-side registration error • Adjust the scan start position (see section 4-5-3).

One side darker than the other • Adjust the CCD waveform flatness (see section 4-5-3).

• Check the LED array; replace it if it is defective.

Image only partially scanned • Adjust the scan line position and/or scan start position

(see section 4-5-3).

5-1

Page 47

5-1-3. Effects of Line Problems on Copy Quality

Missing lines; shrinkage in the sub scan direction

- Original - - Bad Copy Sample -

Cut off

- Bad Copy Sample -

Some lines may be missing

just before the cut off.

5-2. MACHINE OPERATION

Use the following procedures while referring to the point-to-point diagram and signal tables. The procedures may

not be exhaustive, but they may help you to solve the problem.

5-2-1. Scanner/Document Feeder

1. Non-feed

Test Action if Yes Action if No

1. Is the scanner cover closed properly?

2. Was the document placed in the feeder correctly?

Was the document of a recommended type?

3. Is the document fed into scanner after you place it

in the ADF ?

Finished. Go to test 4.

4. Does the document sensor actuator move correctly. Go to test 5. Reassemble or replace the

actuator. Go back to test 3.

5. Do the two red LEDs on the left hand side of the

LED array light correctly, without a document in the

feeder ?

Go to step 8. Go to step 6.

6. Check the +5V output from the FDU.

Is the output correct ?

Replace the LED array,

then go back to test 3

Go to step 7.

7. Does the PSU output +24V? Check the PSU-FDU

connection or replace the

FDU.

If the wall socket is good,

replace the PSU.

5-2

Page 48

Test Action if Yes Action if No

8. Is the scan start line of the SBU adjusted properly? Go to step 9. Adjust the scan start

position.

9. Check the connection to the tx motor. Does the

FDU both:

a) output +24V to the tx motor,

b) output stepper motor drive phase signals to the

motor?

Replace the FCE. Replace the FDU.

2. Double Feed

Test Action if Yes Action if No

1. Was the document placed in the feeder carefully and in the correct manner?

2. Clean or replace the separation rubber plate.

3. Is the operation panel closed at each side ?

3. Jam

Test Action if Yes Action if No

1. Check that the document is not curled seriously or not longer than 600 mm.

2. Clean the rollers in the feeder/scanner with a soft cloth and water.

3. Check for blockages in the document feed path. Check the scanner drive mechanism.

4. Does the scan line sensor actuator move correctly ? Go to test 5. Reassemble or replace the

actuator.

5. Do the two red LEDs on the left hand side of the

LED array light correctly, without a document in the

feeder ?

Go to step 8. Go to step 6.

6. Does the FDU output +5V output correctly ? Replace the LED array. Go to step 7.

7. Does the PSU output +24V? Check the PSU-FDU

connection or replace the

FDU.

If the wall socket is good,

replace the PSU.

8. Does the CCD on the SBU have defective ele-

ments in the scan line sensor detection part ?

Replace the SBU. Replace the FCE.

4. Skew

Test Action if Yes Action if No

1. Clean the rollers in the feeder/scanner with a soft cloth and water.

2. Clean or replace the separation rubber plate.

3. Is the operation panel closed at each side ?

5. Dirty Document

Test Action if Yes Action if No

1. Clean the rollers in the feeder/scanner with a soft cloth and water.

5-3

Page 49

5-2-2. Printer

1. Non Feed

Symptom: Non feed

Check Action if Yes Action if No

1. Is the printer jammed with debris?

Clear the debris. Go to step 2.

2. Is the printer cover closed properly?

Go to step 3. Close the cover.

3. Are the connections between the

FCE, FDU, and cover sensor loose?

Connect the cables properly. Go to step 4.

4. Does the FDU switch on

+24VSW when a ringing signal is detected or when Copy is pressed?

Go to step 8. Go to step 5.

5. Does the signal from the cover

switch change when the cover is

opened and closed?

If CLOSE PAPER COVER is not

displayed when the cover is open,

change the FCE. Go to step 6.

Change the cover switch and/or the

actuator mechanism.

6. Are the connections between the

FDU, LIU, and telephone line loose?

Connect the cables properly. Go to step 7.

7. Does the FCE send the POWON

signal to the FDU when a ringing signal is detected or when Copy is

pressed?

Replace the PSU. Replace the FDU or LIU.

8. Are the connections between the

FDU and the paper end sensor

loose?

Connect the cables properly. Go to step 9.

9. Does the Replace Paper indicator light when paper is present?

Go to step 11. Go to step 10.

10. Does the signal from the paper

end sensor change in the correct

way?

Change the FCE. Replace the paper end sensor.

11. Are the connections between the

PSU, FDU, and the rx motor loose?

Connect the cables properly. Go to step 12.

12. Does the FDU output power and

phase drive signals to the rx motor?

Replace the rx motor. Replace the FDU.

5-4

Page 50

2. Jam

Symptom: Jam

Check Action if Yes Action if No

1. Is the printer jammed with debris?

Clear the debris. Go to step 2.

2. Is the printer jam sensor good? Go to step 5. Go to step 3.

3. Are the connections between the

printer jam sensor and the FDU

loose?

Connect the cables properly. Go to step 4.

4. Does the signal from the printer

jam sensor change correctly?

Change the FDU. Replace the printer jam sensor.

5. Is the cutter blade at the home

position after cutting (left hand side

of the machine) ?

Replace the FCE. Open the printer cover, set the paper

correctly, and close the printer cover.

Go to step 6.

6. Does the cutter initialize itself ? Go to step 7. Replace the cutter unit.

7. Are the connections between the

FDU and the paper end sensor

loose?

Connect the cables properly. Go to step 8.

8. Does the Replace Paper indicator light when paper is present?

Go to step 10. Go to step 9.

9. Does the signal from the paper

end sensor change in the correct

way?

Change the FDU. Replace the paper end sensor.

10. Are the connections between the

PSU, FDU, and the rx motor loose?

Connect the cables properly. Go to step 11.

11. Does the FDU output power and

phase drive signals to the rx motor?

Replace the rx motor. Replace the FDU.

Symptom: Abnormal noise

Check Action if Yes Action if No

1. Is the cover closed? Go to step 2. Close the cover.

2. Are the printer mechanisms assembled correctly?

Replace the rx motor or the FDU. Assemble the machine properly.

5-5

Page 51

5-3. ERROR CODES

If an error code occurs, retry the communication. If the same problem occurs, try to fix the problem as suggested

below. Note that error codes 4-00, 01, 02, and 10 only appear in the error code display and on the service report.

Code Meaning Suggested Cause/Action

0-00 DIS/NSF not detected within 40 s

of Start being pressed

Check the line connection.

Check the LIU - FDU - FCE connectors.

The machine at other end may be incompatible.

Replace the FDU or LIU.

Check for DIS/NSF with an oscilloscope.

If the rx signal is weak, there may be a bad line.

0-01 DCN received unexpectedly The other party is out of paper or has a jammed printer.

The other party pressed Stop during communication.

0-03 Incompatible modem at other end The other terminal is incompatible.

0-04 CFR or FTT not received after

modem training

Check the line connection.

Check the LIU - FDU -FCE connectors.

Try changing the tx level (use NCU parameter 10).

Replace the FCE, FDU or LIU.

The other terminal may be faulty; try sending to another machine.

If the rx signal is weak or defective, there may be a bad line.

0-05 Unsuccessful after modem

training at 2400 bps

Check the line connection.

Check the FCE - LIU - FDU connectors.

Try adjusting the tx level (use NCU parameter 10).

Replace the FCE, FDU or LIU.

Check for line problems.

0-06 The other terminal did not reply to

DCS

Check the line connection.

Check the FCE - FDU - LIU connectors.

Try adjusting the tx level (use NCU parameter 10).

Replace the FCE, LIU or FDU.

The other end may be defective or incompatible; try sending to

another machine.

Check for line problems.

0-07 No post-message response from

the other end after a page was

sent (3rd try failed)

Check the line connection.

Check the FCE - FDU - LIU connectors.

Replace the FCE, LIU or FDU.

The other end may have jammed or run out of paper.

The other end user may have disconnected the call.

Check for a bad line.

The other end may be defective; try sending to another machine.

0-08 The other end sent RTN or PIN

after receiving a page, because

there were too many errors

Check the line connection.

Check the FCE - FDU - LIU connectors.

Replace the FCE, LIU or FDU.

The other end may have jammed, or run out of paper or memory

space.

Try adjusting the tx level (use NCU parameter 10).

The other end may have a defective modem/NCU/FCU; try sending

to another machine.

Check for line problems and noise.

5-6

Page 52

Code Meaning Suggested Cause/Action

0-10 The other end did not send a

reply to EOP, EOM or MPS

Check the line connection.

Check the FCE - FDU - LIU connection.

Replace the FCE, LIU or FDU.

Try adjusting the tx level (use NCU parameter 10).

The other end may have a defective modem/NCU/FCU; try sending

to another machine.

Check for line problems and noise.

0-14 Non-standard post message

response code received

Check the FCE - FDU - LIU connectors.

Incompatible or defective remote terminal; try sending to another

machine.

Noisy line: resend.

Try adjusting the tx level (use NCU parameter 10).

Replace the FCE, LIU or FDU.

0-20 Facsimile data not received within

6 s of retraining

Check the line connection.

Check the FCE - FDU - LIU connectors.

Replace the FCE, LIU or FDU.

Check for line problems.

Try calling another fax machine.

Change the reconstruction time from 6 s to 10 s (bit switch 01, bit 0).

Switch the rx cable equalizer on (bit switch 00, bit 1).

0-21 EOL signal (end-of-line) from the

other end not received within 5 s

of the previous EOL signal

Check the connections between the FCE, FDU, LIU, & line.

Check for line noise or other line problems.

Replace the FCE, LIU or FDU.

The remote machine may be defective or may have disconnected.

0-22 The signal from the other end

was interrupted for more than

0.2 s

Check the line connection.