Page 1

SCHMIDT 3

RICOH FAX2900L

SERVICE MANUAL

21 May, 1999

Subject to change

Page 2

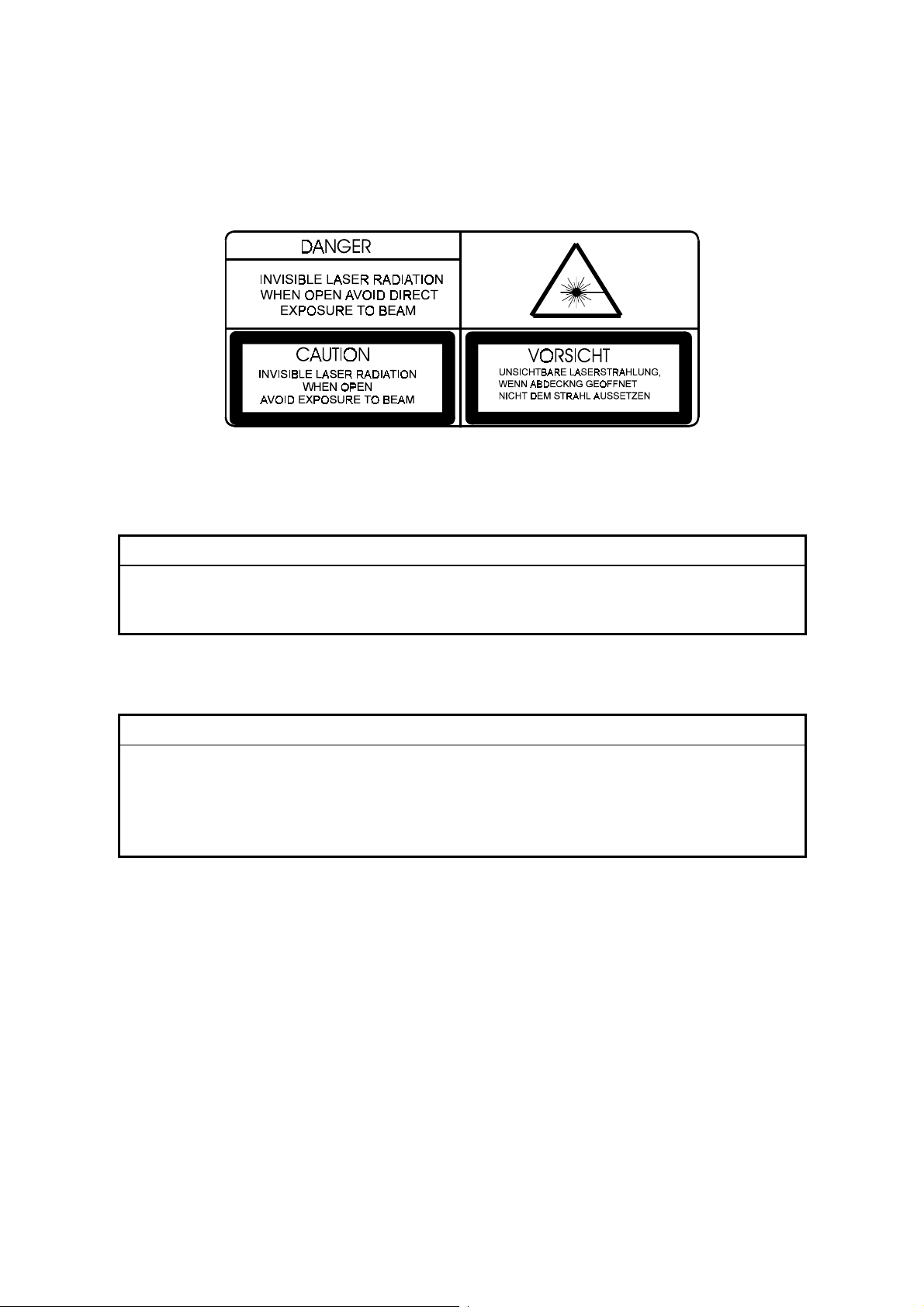

Important Safety Notices

H547R500.WMF

Laser Safety

WARNING FOR LASER UNIT

ø

This machine contains a laser beam generator. Laser beams can cause

permanent eye damage. Do not open the laser unit or look along the laser

beam path while the main power is on.

Lithium Batteries (Memory Back-up)

CAUTION

ø

The danger of explosion exists if a battery of this type is incorrectly

replaced.

Replace only with the same or an equivalent type recommended by the

manufacturer. Discard used batteries in accordance with the

manufacturer's instructions.

Page 3

Trademarks

Windows 95/98, and Windows NT are registered trademarks of Microsoft

Corporation.

General Notice:

Other product names used herein are for identification purposes only and may be

trademarks of their respective companies. We disclaim any and all rights in those

marks.

Page 4

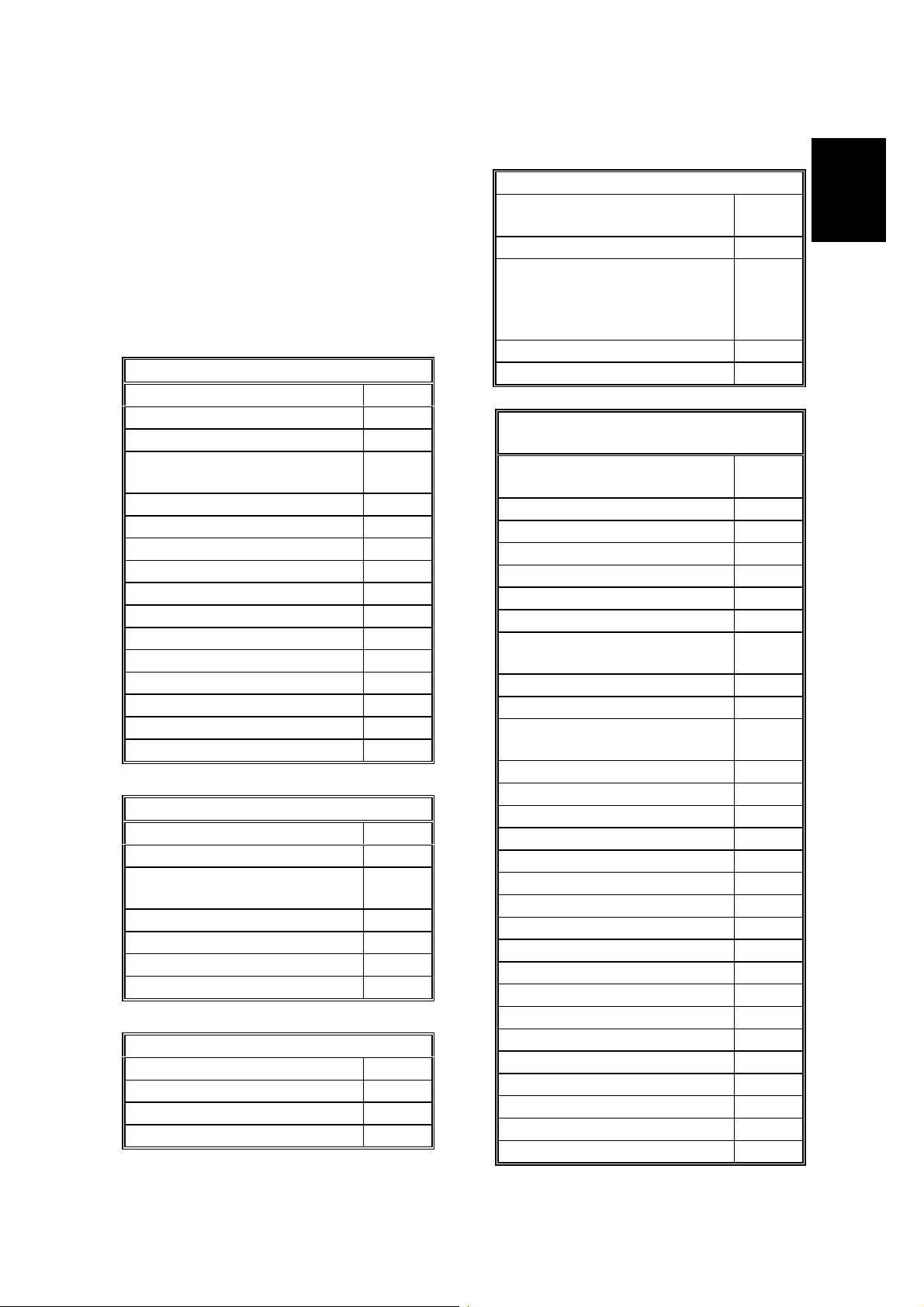

TABLE OF CONTENTS

1. OVERALL MACHINE INFORMATION........................................1-1

1.1 SPECIFICATIONS.................................................................................... 1-1

1.2 FEATURES............................................................................................... 1-3

1.3 COMPONENT LAYOUT...........................................................................1-7

1.3.1 MECHANICAL COMPONENTS....................................................... 1-7

1.3.2 ELECTRICAL COMPONENTS........................................................ 1-9

1.4 OVERALL MACHINE CONTROL........................................................... 1-13

1.5 VIDEO DATA PATH ............................................................................... 1-14

1.5.1 TRANSMISSION............................................................................ 1-14

1.5.2 RECEPTION.................................................................................. 1-15

1.5.3 COPYING...................................................................................... 1-16

1.5.4 CLASS2 FAX COMMUNICATION................................................. 1-17

1.6 POWER DISTRIBUTION........................................................................ 1-19

1.6.1 DISTRIBUTION DIAGRAM............................................................ 1-19

1.6.2 MEMORY BACK-UP CIRCUIT ...................................................... 1-20

2. DETAILED SECTION DESCRIPTIONS.......................................2-1

2.1 SCANNER................................................................................................ 2-1

2.1.1 MECHANISMS................................................................................. 2-1

2.1.2 JAM CONDITIONS.......................................................................... 2-4

2.1.3 RESOLUTION UNIT CONVERSION............................................... 2-5

2.2 PRINTING................................................................................................. 2-6

2.2.1 PRINTING PROCESS - OVERVIEW............................................... 2-6

2.2.2 OPC DRUM ..................................................................................... 2-7

2.2.3 CHARGE ......................................................................................... 2-7

2.2.4 LASER EXPOSURE........................................................................ 2-8

2.2.5 TONER SUPPLY........................................................................... 2-10

2.2.6 DEVELOPMENT............................................................................ 2-12

2.2.7 PAPER FEED................................................................................ 2-16

2.2.8 REGISTRATION............................................................................ 2-21

2.2.9 TRANSFER AND SEPARATION................................................... 2-23

2.2.10 CLEANING................................................................................... 2-25

2.2.11 FUSING....................................................................................... 2-26

2.3 SYSTEM FEATURES............................................................................. 2-30

2.3.1 ENERGY SAVER MODES ............................................................ 2-30

2.3.2 AUTOMATIC SERVICE CALLS..................................................... 2-32

2.3.3 SEP/SUB CODING........................................................................ 2-33

2.3.4 PAGE SEPARATION AND DATA REDUCTION............................ 2-36

2.3.5 MEMORY RECEPTION CONDITIONS ......................................... 2-37

2.3.6 V.8/V.34 PROTOCOL.................................................................... 2-38

2.3.7 BLANK SHEET DETECTION......................................................... 2-40

2.3.8 PARALLEL MEMORY TRANSMISSION....................................... 2-41

2.4 PCBS...................................................................................................... 2-43

2.4.1 FCU ............................................................................................... 2-43

i

Page 5

2.4.2 PSU ............................................................................................... 2-45

2.4.3 NCU (USA) .................................................................................... 2-46

2.4.4 NCU (EUROPE/ASIA) ................................................................... 2-47

3. INSTALLA T ION...........................................................................3-1

3.1 INSTALLING THE MACHINE................................................................... 3-1

3.2 INITIAL PROGRAMMING......................................................................... 3-1

3.3 INSTALLALING OPTIONAL UNITS.......................................................... 3-2

3.3.1 ISDN G4 UNIT................................................................................. 3-2

3.3.2 COUNTER....................................................................................... 3-3

3.3.3 PC FAX EXPANDER....................................................................... 3-5

4. SERVICE TABLES AND PROCEDURES...................................4-1

4.1 SERVICE LEVEL FUNCTIONS................................................................ 4-1

4.1.1 BIT SWITCH PROGRAMMING (FUNCTION 01)............................. 4-1

4.1.2 SYSTEM PARAMETER LIST (FUNCTION 02)................................ 4-2

4.1.3 ERROR CODE DISPLAY (FUNCTION 03)...................................... 4-2

4.1.4 SERVICE MONITOR REPORT (FUNCTION 04)............................. 4-2

4.1.5 GROUP 3 PROTOCOL DUMP (FUNCTION 05) ............................. 4-2

4.1.6 PC PROTOCOL DUMP (FUNCTION 05) ........................................ 4-3

4.1.7 RAM DISPLAY/REWRITE (FUNCTION 06)..................................... 4-3

4.1.8 RAM DUMP (FUNCTION 06)........................................................... 4-3

4.1.9 COUNTER DISPLAY/REWRITE (FUNCTION 07)........................... 4-4

4.1.10 NCU PARAMETERS (FUNCTION 08)........................................... 4-5

4.1.11 MODEM TEST (FUNCTION 08).................................................... 4-5

4.1.12 DTMF TONE TEST (FUNCTION 08)............................................. 4-6

4.1.13 V.8 MODEM TEST (FUNCTION 08).............................................. 4-6

4.1.14 V.34 MODEM TEST (FUNCTION 08)............................................ 4-6

4.1.15 RINGER TEST (FUNCTION 08).................................................... 4-7

4.1.16 DIAL PULSE TEST (FUNCTION 08)............................................. 4-7

4.1.17 OPERATION PANEL TEST (FUNCTION 09)................................ 4-7

4.1.18 LED ARRAY TEST (FUNCTION 10).............................................. 4-8

4.1.19 ADF TEST (FUNCTION 10)........................................................... 4-8

4.1.20 PRINTER TEST PATTERNS (FUNCTION 11).............................. 4-8

4.1.21 PRINTER MECHANISM TEST - FREE RUN (FUNCTION 11)...... 4-9

4.1.22 RAM TESTS (FUNCTION 12)........................................................ 4-9

4.1.23 SOFTWARE DOWNLOAD (FUNCTION 12)................................ 4-10

4.1.24 SOFTWARE UPLOAD (FUNCTION 12)...................................... 4-11

4.1.25 SRAM DATA UPLOAD (FUNCTION 12) ..................................... 4-12

4.1.26 SRAM DATA DOWNLOAD.......................................................... 4-12

4.1.27 ISDN G4 SOFTWARE DOWNLOAD........................................... 4-13

4.1.28 SERVICE STATION FAX NUMBER (FUNCTION 13) ................. 4-14

4.1.29 SERIAL NUMBER (FUNCTION 14)............................................. 4-14

4.2 BIT SWITCHES...................................................................................... 4-15

4.2.1 SYSTEM SWITCHES.................................................................... 4-15

4.2.2 SCANNER SWITCHES ................................................................. 4-25

4.2.3 PRINTER SWITCHES................................................................... 4-26

4.2.4 COMMUNICATION SWITCHES.................................................... 4-29

4.2.5 G3 SWITCHES.............................................................................. 4-36

ii

Page 6

4.3 NCU PARAMETERS .............................................................................. 4-42

4.4 DEDICATED TRANSMISSION PARAMETERS..................................... 4-51

4.4.1 PROGRAMMING PROCEDURE................................................... 4-51

4.4.2 PARAMETERS.............................................................................. 4-52

4.5 SERVICE RAM ADDRESSES................................................................ 4-55

5. PREVENTIVE MAINTENANCE....................................................5-1

5.1 SPECIAL TOOLS AND LUBRICANTS ..................................................... 5-1

5.2 PM TABLE................................................................................................ 5-1

6. REPLACEMENT AND ADJUSTMENT........................................ 6-1

6.1 EXTERIOR ............................................................................................... 6-1

6.1.1 TOP COVER.................................................................................... 6-1

6.1.2 OPERATION PANEL....................................................................... 6-2

6.2 ADF........................................................................................................... 6-2

6.2.1 FEED ROLLER ASSEMBLY............................................................ 6-2

6.2.2 SEPARATION ROLLER .................................................................. 6-3

6.3 SCANNER................................................................................................ 6-3

6.3.1 SCANNER UNIT DISASSEMBLY.................................................... 6-3

6.3.2 SCANNER MOTOR......................................................................... 6-4

6.3.3 R1/R2 ROLLERS............................................................................. 6-5

6.3.4 CONTACT IMAGE SENSOR ASSEMBLY....................................... 6-6

6.3.5 SCANNER UNIT.............................................................................. 6-6

6.4 LASER PRINTING COMPONENTS......................................................... 6-7

6.4.1 LASER UNIT.................................................................................... 6-7

6.5 DEVELOPMENT....................................................................................... 6-9

6.5.1 TRANSFER ROLLER...................................................................... 6-9

6.6 FUSING.................................................................................................. 6-10

6.6.1 FUSING UNIT................................................................................ 6-10

6.6.2 THERMISTOR............................................................................... 6-11

6.6.3 HOT ROLLER STRIPPERS........................................................... 6-11

6.6.4 FUSING LAMP AND HOT ROLLER.............................................. 6-12

6.6.5 PRESSURE ROLLER.................................................................... 6-13

6.6.6 THERMOSTAT AND THERMOFUSE............................................ 6-13

6.7 PCBS...................................................................................................... 6-14

6.7.1 NCU............................................................................................... 6-14

6.7.2 PSU ............................................................................................... 6-14

6.7.3 POWER PACK............................................................................... 6-15

6.7.4 FCU ............................................................................................... 6-15

6.8 PAPER FEED......................................................................................... 6-16

6.8.1 SEPARATION PAD ....................................................................... 6-16

6.8.2 PAPER FEED UNIT ASSEMBLY AND PAPER FEED MOTOR .... 6-17

6.8.3 PAPER END SENSOR AND REGISTRATION SENSOR.............. 6-18

6.8.4 PAPER FEED ROLLER/CLUTCH AND TRANSPORT ROLLER... 6-18

6.9 OTHERS................................................................................................. 6-19

6.9.1 INTERLOCK SWITCHES .............................................................. 6-19

6.9.2 MAIN MOTOR................................................................................ 6-20

6.9.3 REGISTRATION ROLLER............................................................. 6-21

6.9.4 TONER END SENSOR.................................................................. 6-22

iii

Page 7

6.10 PAPER FEED UNIT (OPTIONAL)........................................................ 6-23

6.10.1 TRANSPORT ROLLER ............................................................... 6-23

6.10.2 PAPER FEED ROLLER AND PAPER FEED CLUTCH ............... 6-23

6.10.3 CONNECTOR.............................................................................. 6-24

6.11 MULTI-PURPOSE FEEDER (OPTIONAL)........................................... 6-25

6.11.1 PAPER FEED ROLLER, SEPARATION PAD, PAPER FEED

CLUTCH AND SOLENOID........................................................... 6-25

6.11.2 PCB ............................................................................................. 6-26

6.12 IMAGE ADJUSTMENT......................................................................... 6-27

6.12.1 OVERVIEW ................................................................................. 6-27

6.12.2 SCANNER PARAMETERS.......................................................... 6-28

6.12.3 PRINTER PARAMETERS............................................................ 6-29

6.12.4 SCANNER VIDEO PROCESSING PARAMETERS..................... 6-31

7. TROUBLESHOOTING................................................................. 7-1

7.1 COPY QUALITY TROUBLESHOOTING.................................................. 7-1

7.1.1 BLANK COPIES............................................................................... 7-2

7.1.2 BLACK COPIES............................................................................... 7-2

7.1.3 DIRTY BACKGROUND ................................................................... 7-3

7.1.4 UNEVEN IMAGE DENSITY............................................................. 7-4

7.1.5 VERTICAL BLACK LINES............................................................... 7-5

7.1.6 HORIZONTAL BLACK LINES.......................................................... 7-6

7.1.7 VERTICAL WHITE LINES ............................................................... 7-7

7.1.8 HORIZONTAL WHITE LINES.......................................................... 7-8

7.1.9 BLACK DOTS/SPOTS..................................................................... 7-9

7.1.10 WHITE SPOTS IN BLACK IMAGE AREAS ................................. 7-10

7.1.11 FAINT COPIES............................................................................ 7-11

7.1.12 VERTICAL BLACK BAND............................................................ 7-13

7.1.13 UNFUSED COPIES..................................................................... 7-14

7.1.14 GHOST IMAGE............................................................................ 7-14

7.1.15 TONER ON THE BACK OF THE PRINTER PAPER ................... 7-15

7.1.16 INCORRECTLY ALIGNED OUTPUT........................................... 7-15

7.1.17 INCORRECTLY ALIGNED OUTPUT/REDUCED IMAGE ........... 7-16

7.2 MECHANICAL PROBLEMS ................................................................... 7-17

7.2.1 ADF/SCANNER............................................................................. 7-17

7.2.2 PRINTER....................................................................................... 7-20

7.3 ERROR CODES..................................................................................... 7-26

7.4 ELECTRICAL COMPONENT DEFECTS................................................ 7-35

7.4.1 DEFECTIVE SENSOR TABLE...................................................... 7-35

7.4.2 BLOWN FUSE TABLE................................................................... 7-35

iv

Page 8

21 May, 1999 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Type

Desktop transceiver

Circuit

PSTN, PABX

Connection

Direct couple

Document Size

Length:

105 - 364 mm [4.1 - 14.3 ins]

Up to 1.2 m [47.2 ins], manually

assisted

Width:

148 - 218 mm [5.8 - 8.5 ins]

Thickness:

0.05 to 0.2 mm [2 to 8 mils]

(equivalent to 50 - 90 g/m

Document Feed

Automatic feed, face down

ADF Capacity

30 sheets (using Letter size 20 lb paper

or A4 size 80 g/m2)

15 sheets (using LG size 20 lb. paper)

Scanning Method

Contact image sensor, with LED lamp

Maximum Scan Width

216 mm [8.5 ins] ± 0.25%

(Effective scan width: 210 mm)

Scan Resolutions

Main scan:

8 dots/mm [203 dpi]

Sub scan:

Standard - 3.85 lines/mm [98 dpi]

Detail - 7.7 lines/mm [196 dpi]

Fine - 15.4 lines/mm [392 dpi]

Memory Capacity

ECM:

128 Kbytes

SAF:

Standard: 960 KB (76 pages/ITU-T #1)

With 1 MB option: (156 pages)

With 2 MB option: (236 pages)

With 4 MB option (396 pages)

2

)

Compression

MH, MR, MMR, JBIG (only for the USA

model)

Protocol

Group 3 with ECM

Group 4 (ISDN G4 option required)

Modulation

V.34, V.33 (Ricoh mode only),

V.17 (TCM), V.29 (QAM), V.27ter

(PHM), V.21 (FM)

Data Rate (BPS)

G3:

33,600/31,200/28,800/26,400/24,000/

21,600/19,200/16,800/14,400/12,000/

9600/7200/4800/2400

G4 (option):

64 kbps/56 kbps

I/O Rate

With ECM: 0 ms/line

Without ECM: 2.5, 5, 10, 20, or 40

ms/line

Transmission Time

3 seconds at 28,800 bps;

G3:

Measured with G3 ECM using memory

for an ITU-T #1 test document (Slerexe

letter) at standard resolution

G4 (option):

3 seconds at 64 kbps

Measured with an ITU-T #1 test

document (Slerexe letter) at detail

resolution

Printing System

Laser printing, plain paper, dry toner

Printing Time

10 ppm for letter, or A4 size paper

Overall

Information

1-1

Page 9

SPECIFICATIONS 21 May, 1999

Paper Size and Capacity

Standard Cassette:

250 sheets

Letter, Legal, A4, A5 sideways, F4

Multi-purpose Feeder (Optional):

100 sheets: Letter, Legal, A4,

A5 sideways, F4

Paper Feed Unit (Optional):

500 sheets: Letter, Legal, A4,

A5 sideways, F4

Paper Weight:

2)

16 lb (60 g/m

to 24 lb (90 g/m2)

Maximum Printing Width

212 mm [8.3 ins] (Letter)

206 mm [8.1 ins] (A4)

Print Resolutions

Fax and Copy Mode:

Main scan: 16 dots/mm [406 dpi]

Sub scan: 15.4 lines/mm [392 lpi]

PC Fax (Optional)

Application Programming Interface

TR29, EIA592: Class - 2

Transmission Speed

14,400/12,000/9,600/7,200/4,800/2,400

bps

(depending on software applications)

Power Supply

115 ± 20 Vac, 60 ± 3 Hz

USA:

Europe/Asia:

220 - 240 ±15% Vac,

50/60 ± 3 Hz

Power Consumption (Base Machine

Only)

Standby:

Transmit:

Receive:

Copying

Minimum 2 W; Normal 30 W

50 W

250 W

: 300 W

Operating Environment

Temperature:

Humidity:

15 - 25 °C [59 - 77 °F]

30 - 70 %Rh

Dimensions (W x D x H)

410 x 730 x 323 mm

[16.1 x 28.7 x 12.7 ins]

Including trays (Maximum dimensions)

Weight

Approx. 13 kg [28.7 lbs.]

Including cartridge and trays.

NOTE:

1) ISDN G4 unit is a standard component for the I-Schmidt 3.

However, the NCU is not installed in the I-Schmidt 3.

2) JBIG compression is available only in the USA model.

3) The PC Fax Expander option is available only in Europe and Asia.

1-2

Page 10

21 May, 1999 FEATURES

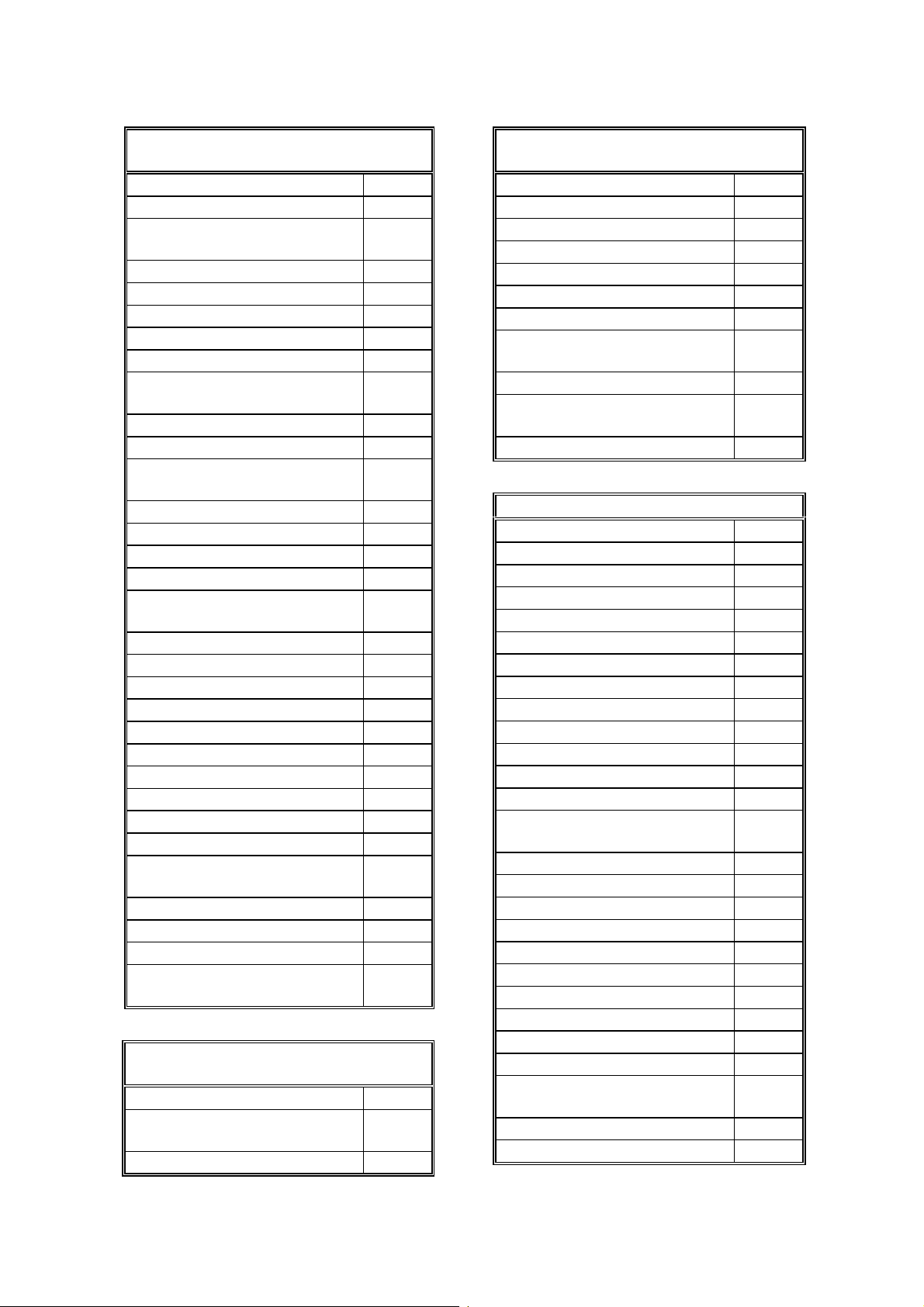

1.2 FEATURES

KEY: O = Used, X = Not Used,

A = With optional memory only,

B = With optional multi-purpose feeder only

C = With optional handset only

D = With optional counter only

E = With optional paper feed unit only

F = With optional G4 unit only

G= With optional PCFE only

Equipment

ADF O

Book scan X

Bypass feed: 1 sheet X

Optional cassette

(100 sheets)

Optional cassette: Universal O

Optional paper feed unit E

Cabinet X

Mechanical counter D

Cutter X

Handset C

Hard disk X

Manual feed mechanism X

Marker (Stamp) O

Monitor speaker O

Optional memory O

Optional printer interface X

Video Processing Features

Automatic image density O

Contrast X

Halftone

(Basic & Error diffusion)

MTF O

Reduction before TX X

Scanning resolution O

Smoothing to 16 x 15.4 l/mm O

Communication Features - Auto

AI short protocol O

Automatic fallback O

Automatic redialing O

Confidential reception O

B

O

Communication Features - Auto

JBIG compression

(USA model only)

Dual access O

Resolutions available for

reception

Fine

Super fine

Substitute reception O

V.34 communication O

Communication Features -

User Selectable

Action as a transfer

broadcaster

AI Redial (last ten numbers) O

Answering machine interface O

Authorized Reception O

Auto dialing (pulse or DTMF) O

Auto document O

Automatic voice message X

Batch transmission

(max 50 files)

Broadcasting O

Chain dialing O

Communication result

display

Confidential ID override O

Confidential transmission O

Direct fax number entry O

Economy transmission X

Fax on demand X

Forwarding O

Groups (7 groups) O

Hold X

ID transmission O

Immediate redialing O

Immediate transmission O

ISDN F

Keystroke programs O

Memory transmission O

Multi-step transfer X

OMR X

On hook dial O

Ordering toner X

O

X

X

X

O

X

Overall

Information

1-3

Page 11

FEATURES 21 May, 1999

Communication Features -

User Selectable

Page count O

Page separation mark O

Parallel memory

transmission

O

Personal codes O

Personal codes with conf. ID O

Partial image area scanning X

Polling reception O

Polling transmission O

Polling tx file lifetime in the

SAF

X

PWD (tx only) O

Quick dial (30 stations) O

Reception modes

(Fax, Tel, Auto)

O

Remote control features X

Remote transfer X

Restricted access O

Secured polling reception O

Secured polling reception

with Stored ID override

O

Send later O

SEP (tx only) O

SID (tx only) O

Silent ringing detection X

Specified Image area X

Speed dial (100 stations) O

SUB O

Telephone directory O

Tonal signal transmission O

Transfer request O

Transmission deadline

(TRD)

O

Turnaround polling X

Two-step transfer X

Two in one O

Voice request (immediate TX

X

only)

Communication Features -

Service Selectable

AI short protocol O

Auto-reduction override

O

option

Busy tone detection O

Communication Features -

Service Selectable

Cable equalizer O

Closed network (TX and RX) O

Continuous polling reception O

Dedicated TX parameters O

ECM O

EFC X

Inch-mm conversion O

JBIG compression

(USA model only)

O

Page retransmissi o n ti me s O

Protection against bad

connections

O

Short preamble X

Other User Features

Automatic service call

Service

Center mark O

Checkered mark O

Clearing a memory file O

Clearing a polling file O

Clock O

Confidential ID O

Copy mode O

Copy mode restriction X

Counters O

Daylight saving time O

Destination check X

Direct entry of names O

Energy saver (Night timer

O

and standby mode)

File retention time X

File retransmission X

Function programs O

ID code O

Label insertion ("From xxx") O

Language selection O

LCD back light O

LCD contrast control

Memory lock O

Modifying a memory file X

Multi-sort document

X

reception

Multi-copy mode (up to 99) O

Own telephone number O

X

1-4

Page 12

21 May, 1999 FEATURES

Other User Features

PC scanner G

PC fax G

PC print G

Print density control X

Printing a memory file O

Printing a quick dial sheet O

Quick dial label printing O

RDS on/off O

Reception mode switching

X

timer

Reception time printing O

Remaining memory indicator O

Remote ID X

Reverse order printing O

RTI, TTI, CSI O

Service report transmission X

Speaker volume control O

Specified cassette selection E

Substitute reception on/off O

Telephone line type O

Toner saving mode X

User function keys (2 keys) O

User parameters O

Wild cards O

Reports - Auto ma tic

Charge control report X

Communication failure report O

Communication result report O

Confidential file report O

Error report O

File clear report X

File reserve report X

Journal O

Power failure report O

Toner cassette order form X

Transfer result report O

Transmission result report O

Reports - User-initiated

Charge control report X

File list O

Group list O

Help list O

Reports - User-initiated

Journal O

Personal code list O

Program list O

Programmed special

numbers list

O

Quick dial / User function list O

Speed dial list O

Transmission status report X

User parameter list O

Service Mode Features

Back-to-back test O

Bit switch programming O

Book mode test X

Cable equalizer O

Comm. Parameter display O

Counter check O

Country code O

DTMF tone test O

Echo countermeasure O

Effective term of service calls O

Error code display O

Excessive jam alarm O

File transfer (all files) O

LCD contrast adjustment X

Line error mark O

Memory file printout (all files) O

Modem software download X

Modem test O

NCU parameters O

Operation panel test O

Periodic service call O

PM call O

Printer mechanism test O

Printer test patterns O

Programmable attenuation X

Protocol dump list O

RAM display/rewrite O

RAM dump O

RAM test O

RDS O

Ringer test X

Scanner lamp test O

Scanner mechanism test O

Sensor initialization X

Overall

Information

1-5

Page 13

FEATURES 21 May, 1999

Service Mode Features

Serial number O

Service monitor report O

Service station number O

Software upload/download O

SRAM data download O

System parameter list O

Technical data on the

Journal

Thermal head parameters X

O

Memory Files

Maximum number of files: 100

Maximum number of stations/file: 140

Maximum number of stations: 300

1-6

Page 14

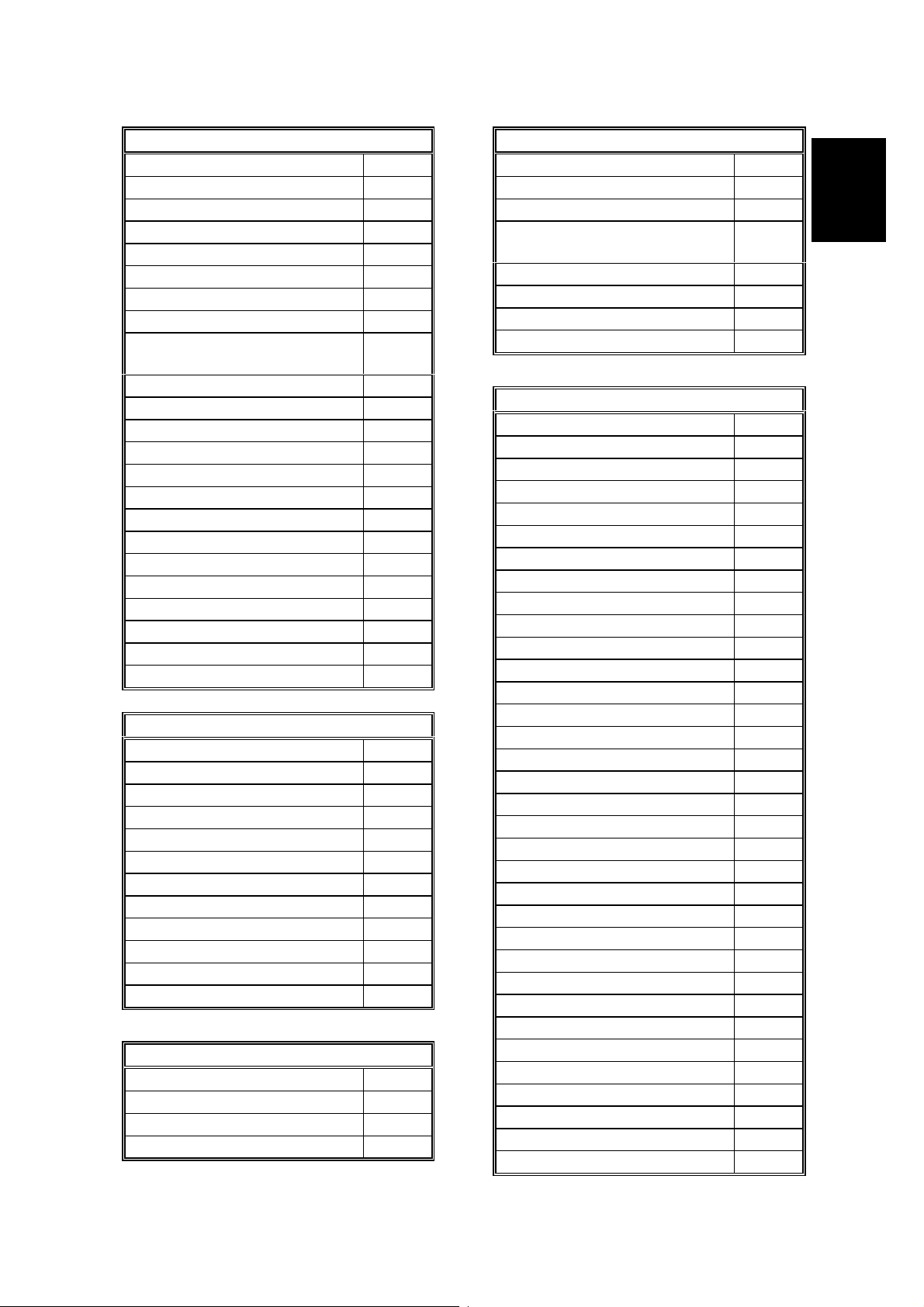

21 May, 1999 COMPONENT LAYOUT

1.3 COMPONENT LAYOUT

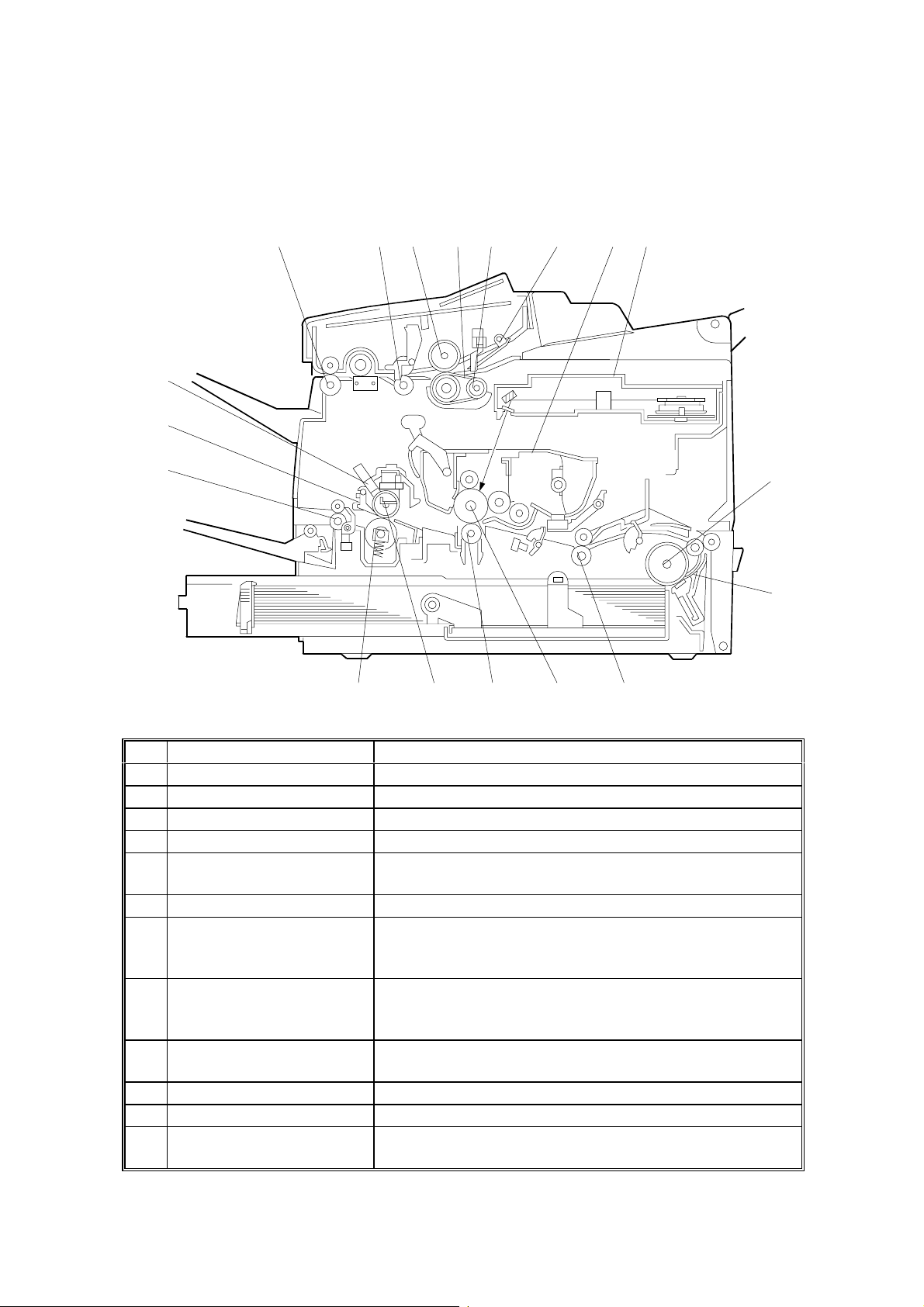

1.3.1 MECHANICAL COMPONENTS

18

17

16

1 52 3 4 6 8

12

7

11131415

9

10

H547V501.WMF

No Name Description

1 R2 Roller Feeds the document through the scanner.

2 R1 Roller Feeds the document through the scanner.

3 Separation Roller Allows one page into the scanner.

4 Document Feed Belt Feeds the document into the scanner.

5 Pick-up Roller

6 Pressure Plate Applies pressure against the pick-up roller.

7 All-in-One Cartridge Consists of the toner cartridge, cleaning unit, used

8 Laser Unit

9 Paper Feed Roller

10 Separation Pad Allows one sheet of paper into the printer.

11 Registration Roller Carries out the registration process.

12 OPC Drum The latent image is written to this organic

Picks up document pages from the document table

one at a time.

toner tank, charge brush roller, application roller,

development roller and OPC drum.

Consists of the LDDR (Laser Diode Driver), focusing

lens, hexagonal mirror motor, and other laser optic

components.

Picks up the top sheet of paper from the stack in the

cassette, and feeds it into the printer.

photoconductor drum.

1-7

Page 15

COMPONENT LAYOUT 21 May, 1999

No Name Description

13 Transfer Roller

14 Hot Roller Heat from this roller fuses the toner to the copy paper.

15 Fusing Pressure Roller Applies pressure to the paper during the fusing

16 Paper Feed-out Rollers Feed the paper out of the printer.

17 Hot Roller Strippers Take the paper off the hot roller after fusing.

18 Cleaning Pad Cleans up and spreads silicone oil on the surface of

Applies a charge to the paper to pull the toner off the

drum and onto the copy paper.

process.

the hot roller.

1-8

Page 16

21 May, 1999 COMPONENT LAYOUT

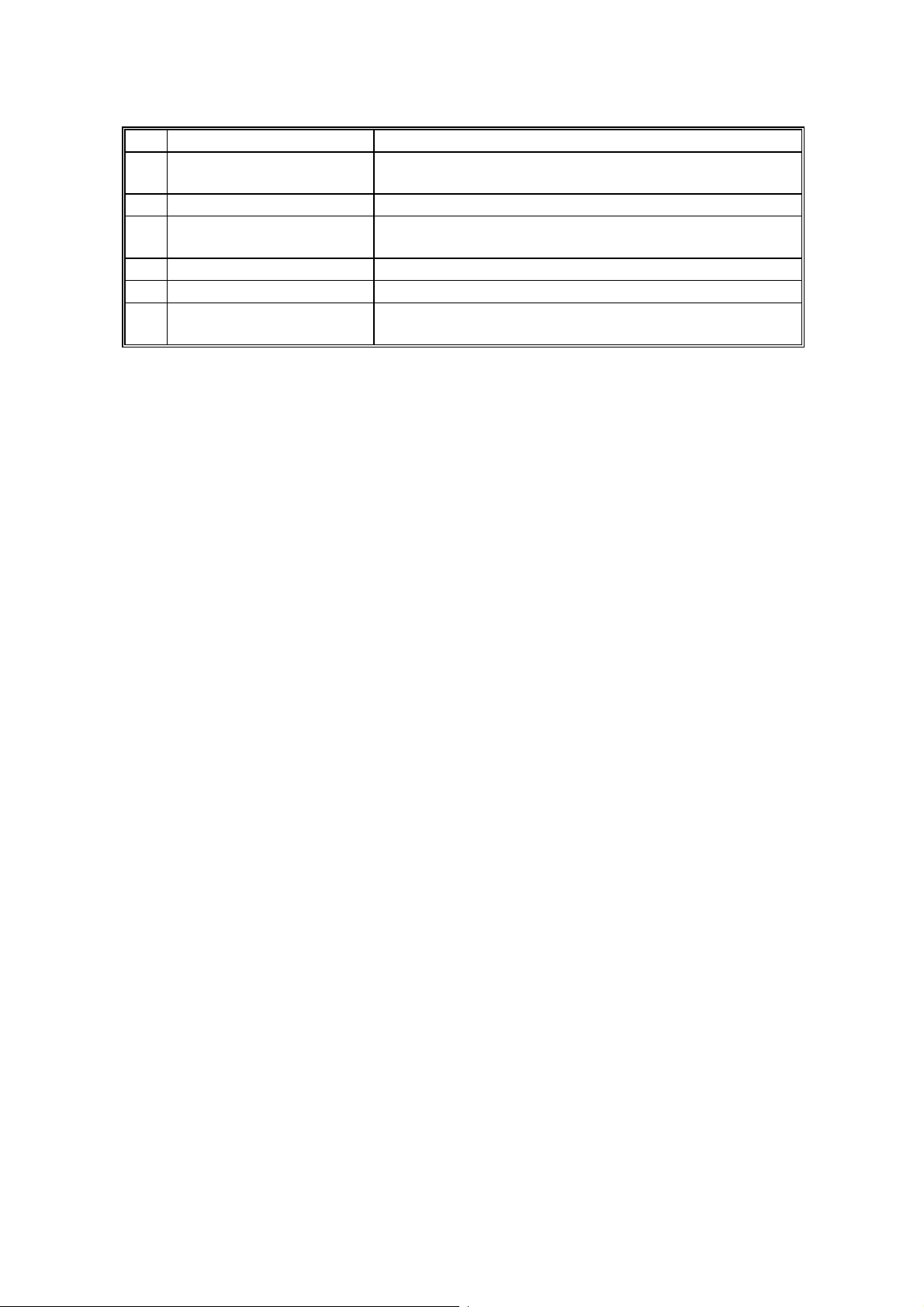

1.3.2 ELECTRICAL COMPONENTS

21

20

22

19

23

18

1

2

3

4

5

6

7

8

9

10

11

H547V502.WMF

12

13

17

16

15

14

29

24

25

30

26

27

28

H547V503.WMF

1-9

Page 17

COMPONENT LAYOUT 21 May, 1999

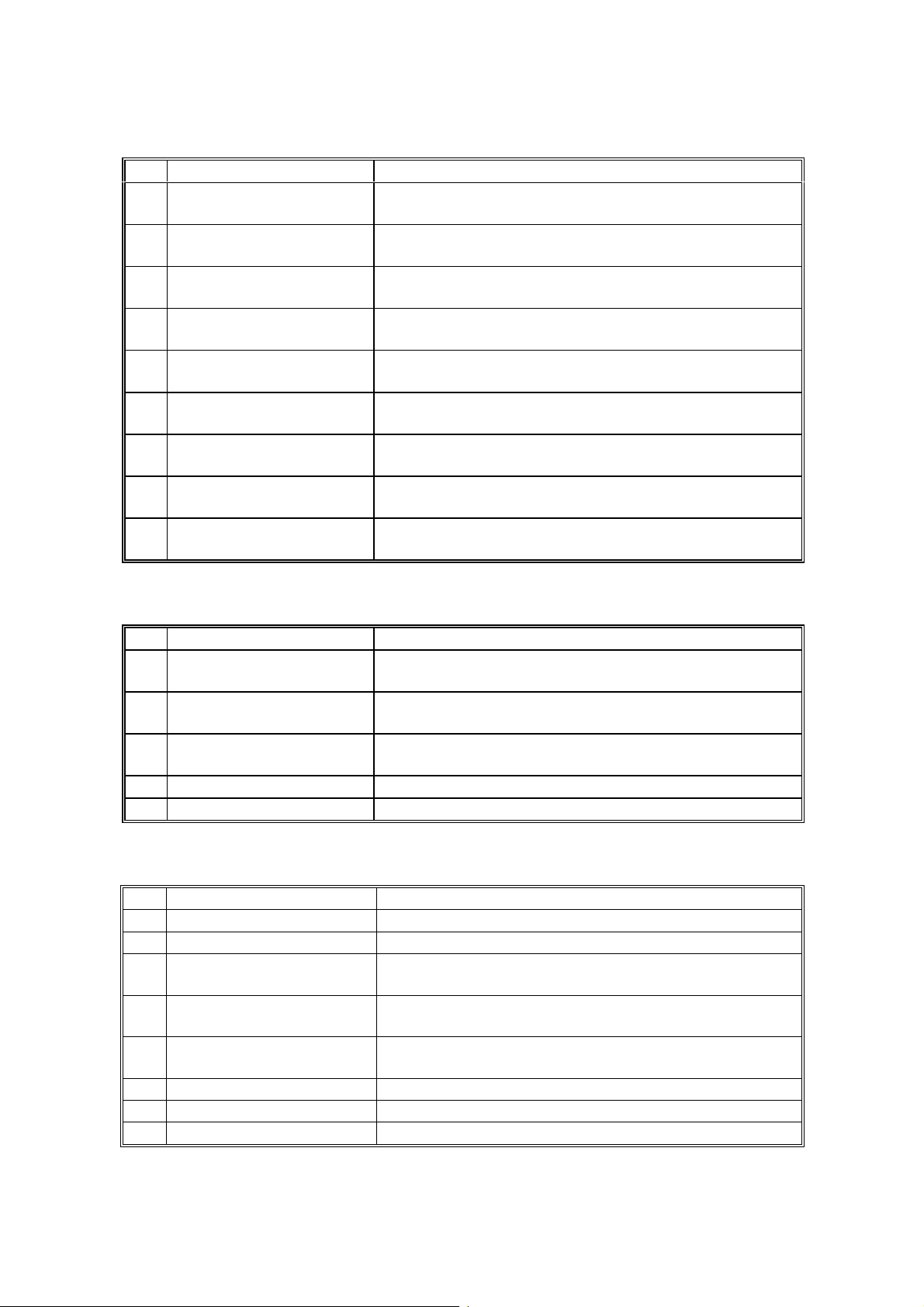

1. PCBs

No Name Description

CIS (Contact Image

2

Sensor)

5 LDDR (Laser Diode

Driver)

24 NCU (Network Control

Unit)

25 DIU (Digital Interface

Unit) for PCFE Option

26 OPU (Operation Panel

Unit)

FCU (Facsimile Control

27

Unit)

28 G4 Interfac e (S iG4

option)

29 Power Pack Supplies hig h voltage to the charge brush roller,

PSU (Power Supply

30

Unit)

This sensor reads and converts the light reflected from

the document into an analog video signal.

This board drives the laser diode.

This board contains relays and switches for interfacing

the machine with the network and the handset.

This is an interface board for an optional PC Fax

Expander (not available in some countries).

This board controls the operation panel.

This board controls the machine. It contains the main

CPU, flash ROM, system RAM, etc.

This is an interface for the machine and an ISDN

network.

transfer roller and development rollers.

This board supplies power to the machine, and

switches the fusing lamp on/off.

2. Motors

No Name Description

4 Polygon Mirror Motor This high-speed dc motor drives the hexagonal mirror

in the laser printer optics.

7 Main Motor This stepper motor drives the All-in-One cartridge and

the fusing unit.

11 Paper Feed Motor This stepper motor drives the registration roller and

the paper feed mechanisms in the cassettes.

15 Scanner Motor This stepper motor drives the scanner.

21 Cooling Fan Motor Cools the interior of the machine.

3. Sensors

No Name Description

1 Document Sensor Detects the presence of a document in the feeder.

3 Paper End Sensor Detects when the paper in the cassette has run out.

6 Paper Edge Sensor

8 Rear Upper Cover Switch Detects whether the rear upper cover is open or

9 Rear Lower Cover Switch Detects whether the rear lower cover is open or

16 Registration Sensor Detects when paper reaches the registration roller.

19 Fusing Exit Sensor Detects when the paper feeds out of the printer.

23 Toner End Sensor Detects when the toner has run out.

Detects when the paper has passed the paper feed

components.

closed.

closed.

1-10

Page 18

21 May, 1999 COMPONENT LAYOUT

4. Interlock Switches

No Name Description

1213 Interlock Switches

If the fusing unit cover and/or top cover are open,

these switches interrupt the +5VLD power supply for

the laser diode and the +24VD power supply for the

power pack, motors, and other components.

5. Others

No Name Description

10 Paper Feed Clutch Transfers drive from the paper feed motor to the paper

feed roller.

14 Monitor Speaker Allows the user to hear the telephone line condition.

17 Fusing Lamp The heat from this lamp fuses the toner to the paper.

18 Thermistor Monitors the temperature on the hot roller surface.

20 Thermostat Interrupts the ac power supply for the fusing lamp if

the thermostat temperature exceeds 400°C.

22 Stamp Solenoid This turns on to stamp the document.

1-11

Page 19

COMPONENT LAYOUT 21 May, 1999

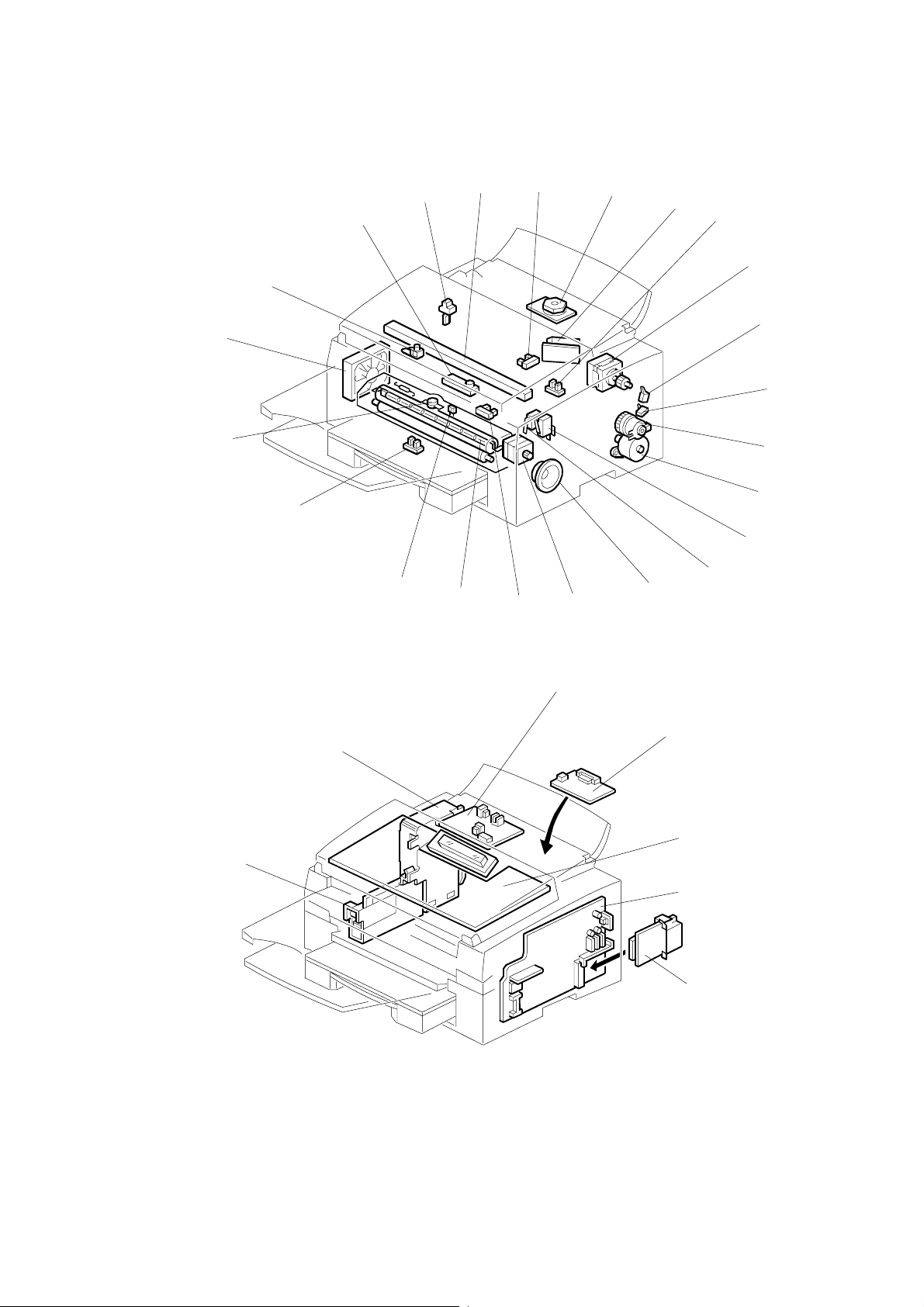

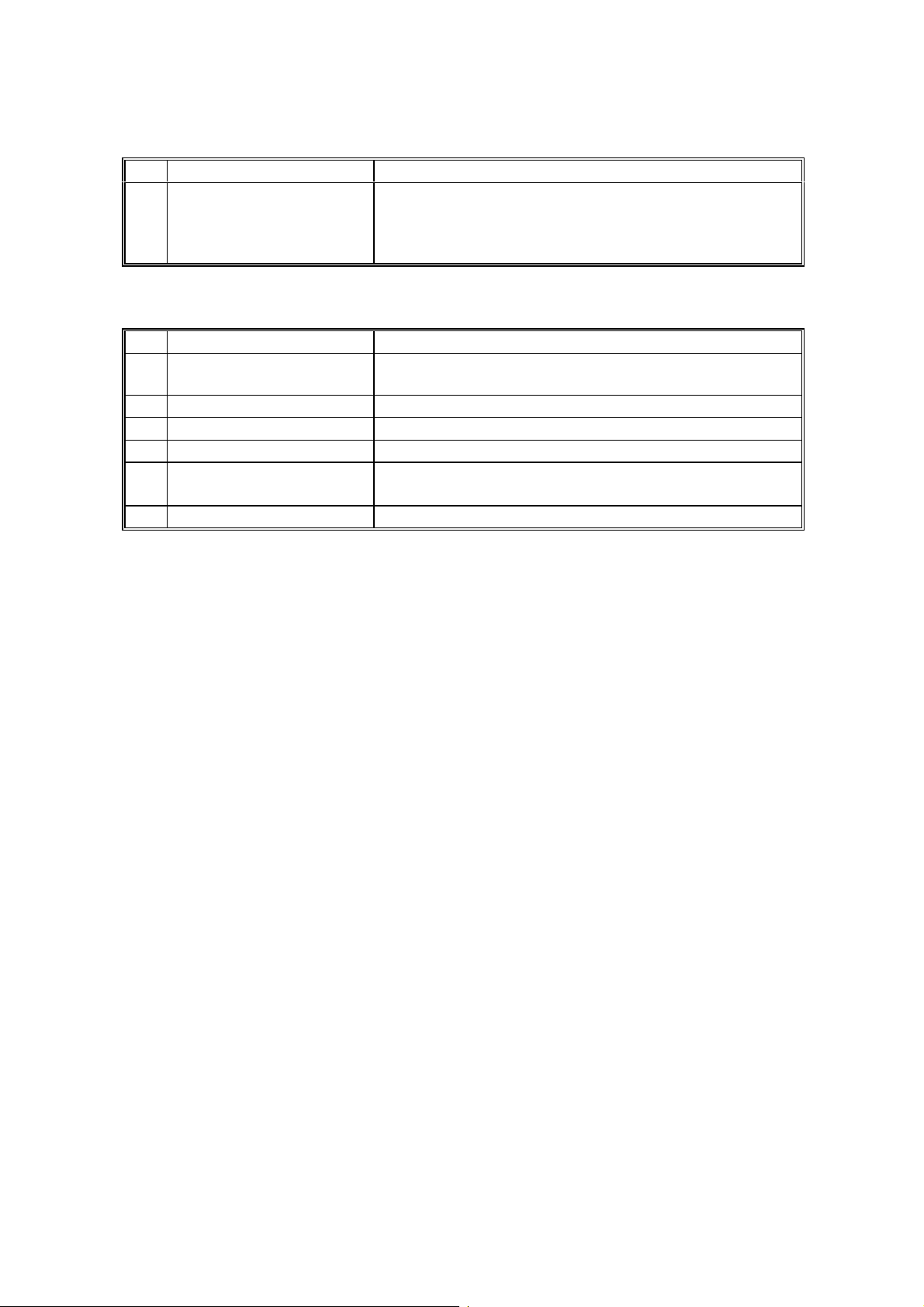

6. Optional Paper Feed Unit and Multi Purpose Feeder

1

2

5

3

8

H547V504.WMF

4

No Name Description

Paper End Sensor

1

(Paper Feed Unit)

2 Paper Feed Roller

(Paper Feed Unit)

3 Paper Feed Clutch

(Paper Feed Unit)

Cassette Switch

4

(Paper Feed Unit)

5 Rear Cover Switch

(Paper Feed Unit)

Paper Feed Roller

6

(Multi-purpose Feeder)

7 Paper Feed Solenoid

(Multi-purpose Feeder)

8 Paper End Sensor and

Paper Width Sensor

(Multi-purpose Feeder)

This detects when the paper in the cassette has run

out.

Picks up the top sheet of paper from the stack in the

cassette, and feeds it into the printer.

Transfers drive from the paper feed motor in the

mainframe to the paper feed roller in the cassette.

This detects whether the cassette is installed or not.

This detects whether the rear cover is open or close.

Picks up the top sheet of paper from the stack in the

feeder, and feeds it into the printer.

Transfers drive from the paper feed motor in the

mainframe to the paper feed roller in the feeder.

Paper end sensor: This detects when the paper in the

feeder has run out.

Paper width sensor: This detects the paper width

installed in the feeder.

7

6

H547V516.WMF

1-12

Page 20

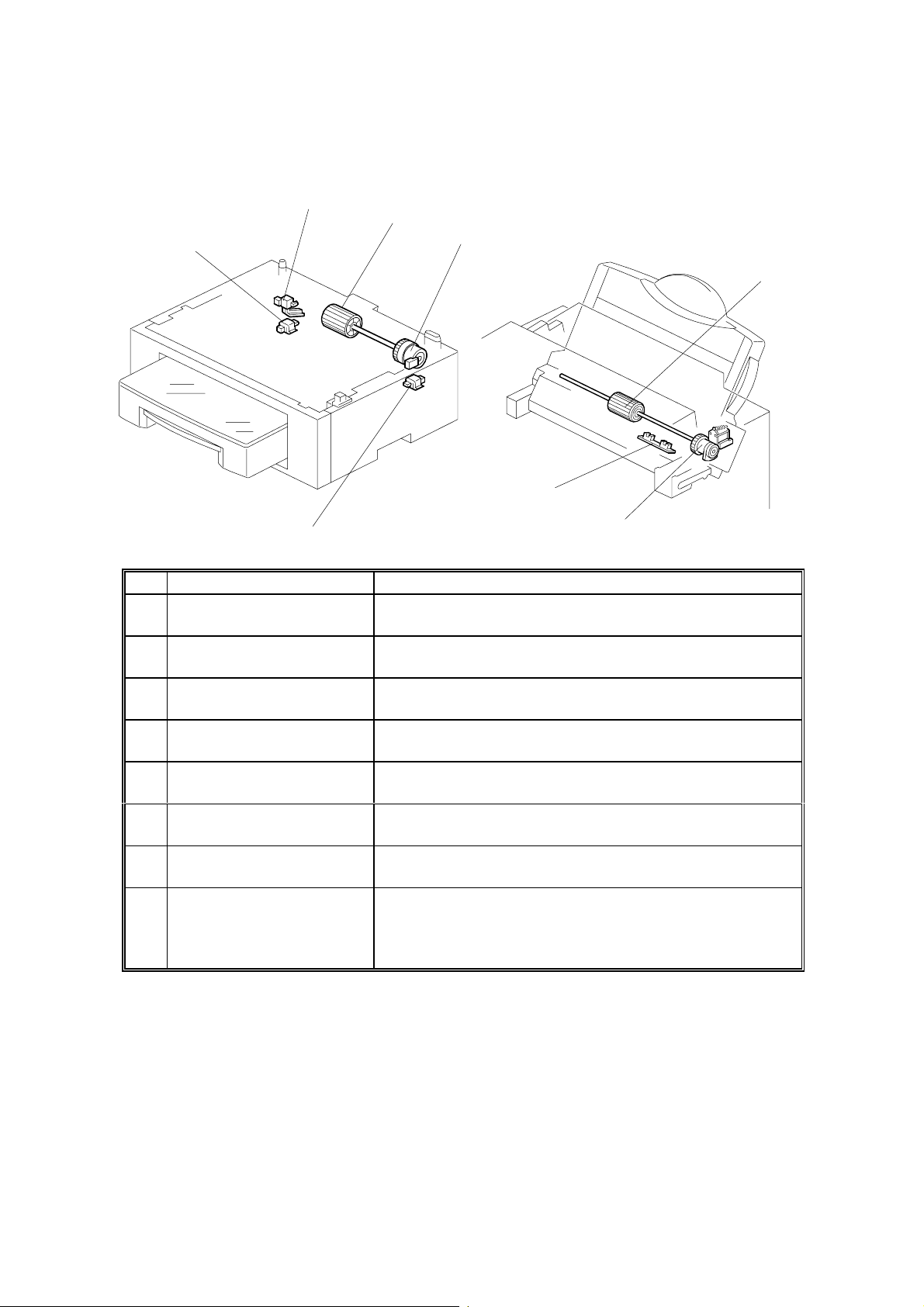

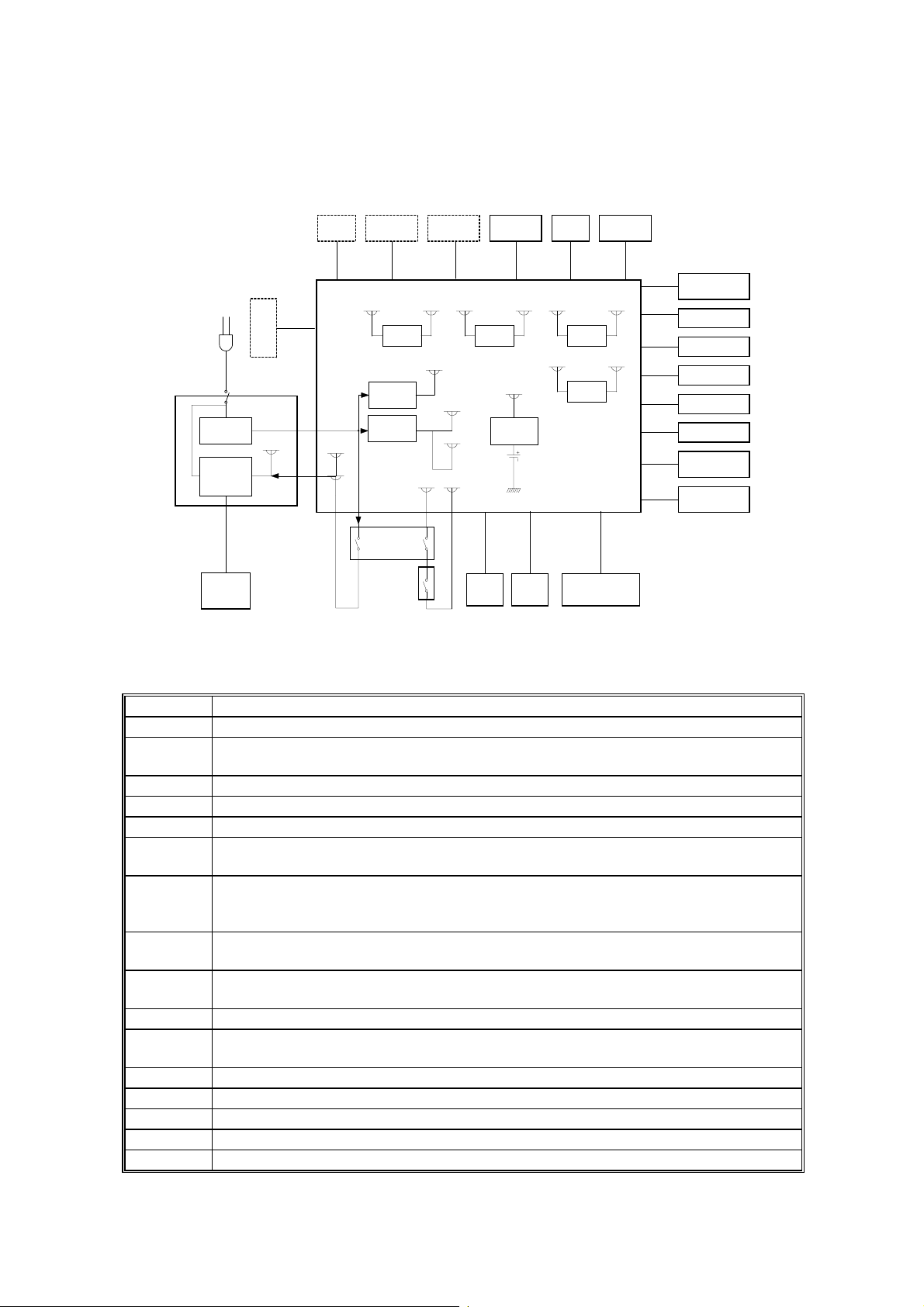

21 May, 1999 OVERALL MACHINE CONTROL

1.4 OVERALL MACHINE CONTROL

Optional

IC Card

Flash

ROM

Modem FCIP05

AFE

NCU

Energy

Saver

CPU

Optional

PFU

24V Driver

Stamp

DRAMSRAM

SYSTEM BUS

EXIO

Polygon

Motor

Interface

Operation

Panel

SiG4

RS232C

Interface

FCU

I/O Driver

Motor

Driver

Amplifier

LDDR

Power Pack

Main Motor

Tx and Paper

Feed Motors

Contact

Image Sensor

H547V505.WMF

The FCU (Facsimile Control Unit) contains logical components for overall system

control, and a direct in terface to the IC card, G4 interface (SiG4), and an RS232C

interface.

NOTE:

The RS232C interf ace is not available in some countries.

There are two CPUs in the machine: the main CPU (FCIP05) and the energy saver

CPU. The FCIP05 contains components such as the 8 bit CPU (RU8), DIP (Digital

Image Processor), LIF (Laser Interface), DCR (Data Compression and

Reconstruction) and DMA Controller.

In energy saver mode, the main CPU switches off and the energy saver CPU takes

over.

1-13

Page 21

VIDEO DATA PATH 21 May, 1999

1.5 VIDEO DATA PATH

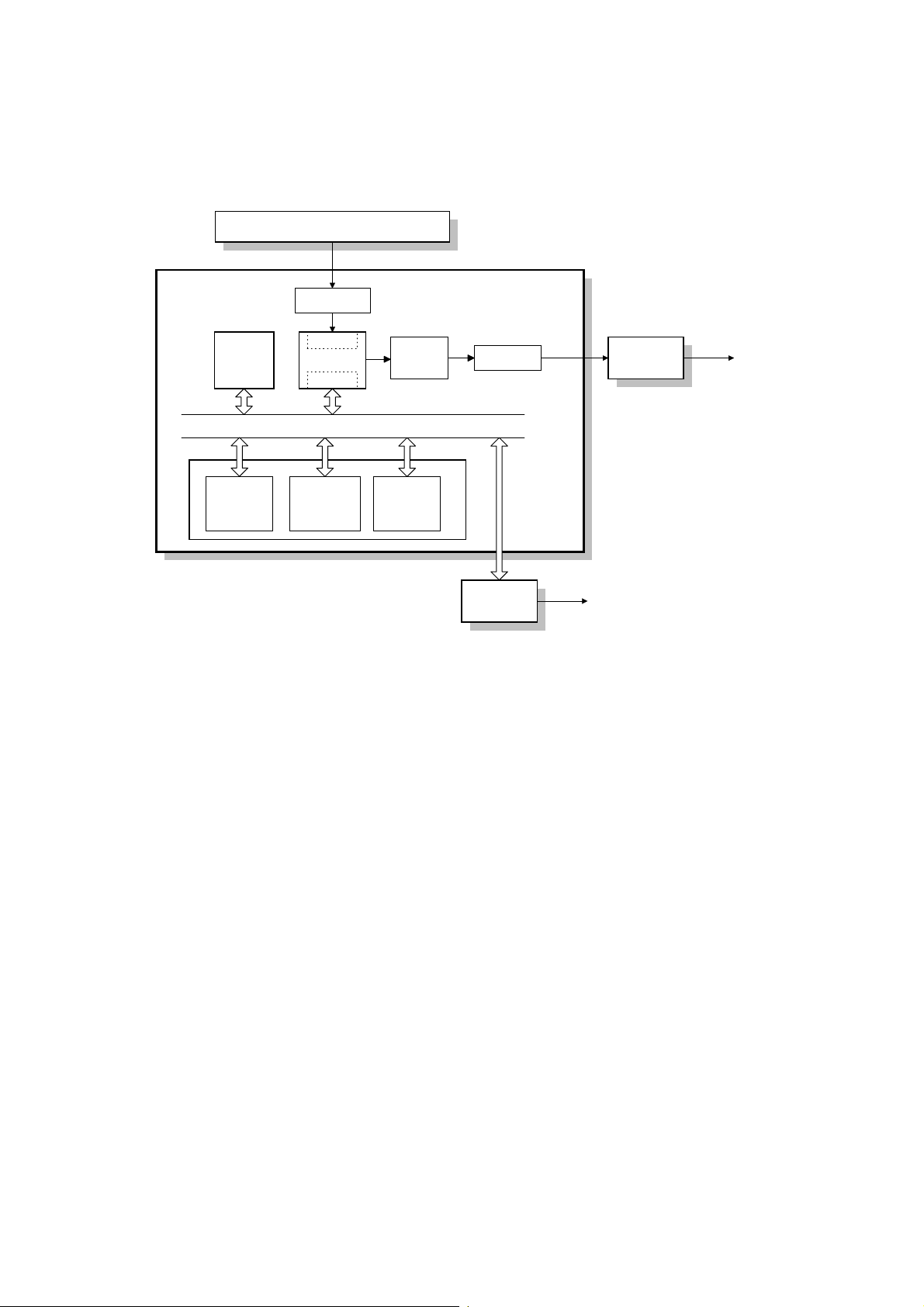

1.5.1 TRANSMISSION

Contact Image Sensor

HIC

SiG4

FCU

NCU

To PSTN

To ISDN

H547V509.WMF

Amplifier

DIP

JBIG FCIP05

DCR

DATA/ADDRESS BUS

Line

Buffer

ECM/DCR

Buffer

Modem

DRAM

SAF

Memory

Immediate Transmission:

Scanned data from the contact image sensor passes to the DIP in the FCIP05.

After analog/digital video processing, the DCR (or the JBIG LSI if JBIG

compression is to be used) compresses the data for transmission. The compressed

data passes through the DCR buffer, then to the ECM memo ry before entering the

telephone line through the modem.

Memory Transmission:

First, the scanned data is stored in the SAF memory after compression in the DCR.

At the time of transmission, the DCR decompresses the data from the SAF

memory, then compresses it again (or the JBIG LSI compresses the data if JBIG

compression is to be used) for transmission. The compressed data passes through

the DCR buffer, then to the ECM memory before entering the telephon e line

through the modem.

During G4 transmission, the compressed data from the DCR buffer passes through

the SiG4 board.

Parallel Memory Transmission

This feature allows the machine to scan a document into the SAF memory and

send the same document simultaneously.

The machine stores the processed video data in the SAF memory and sends the

data through modem at the same time.

1-14

Page 22

21 May, 1999 VIDEO DATA PATH

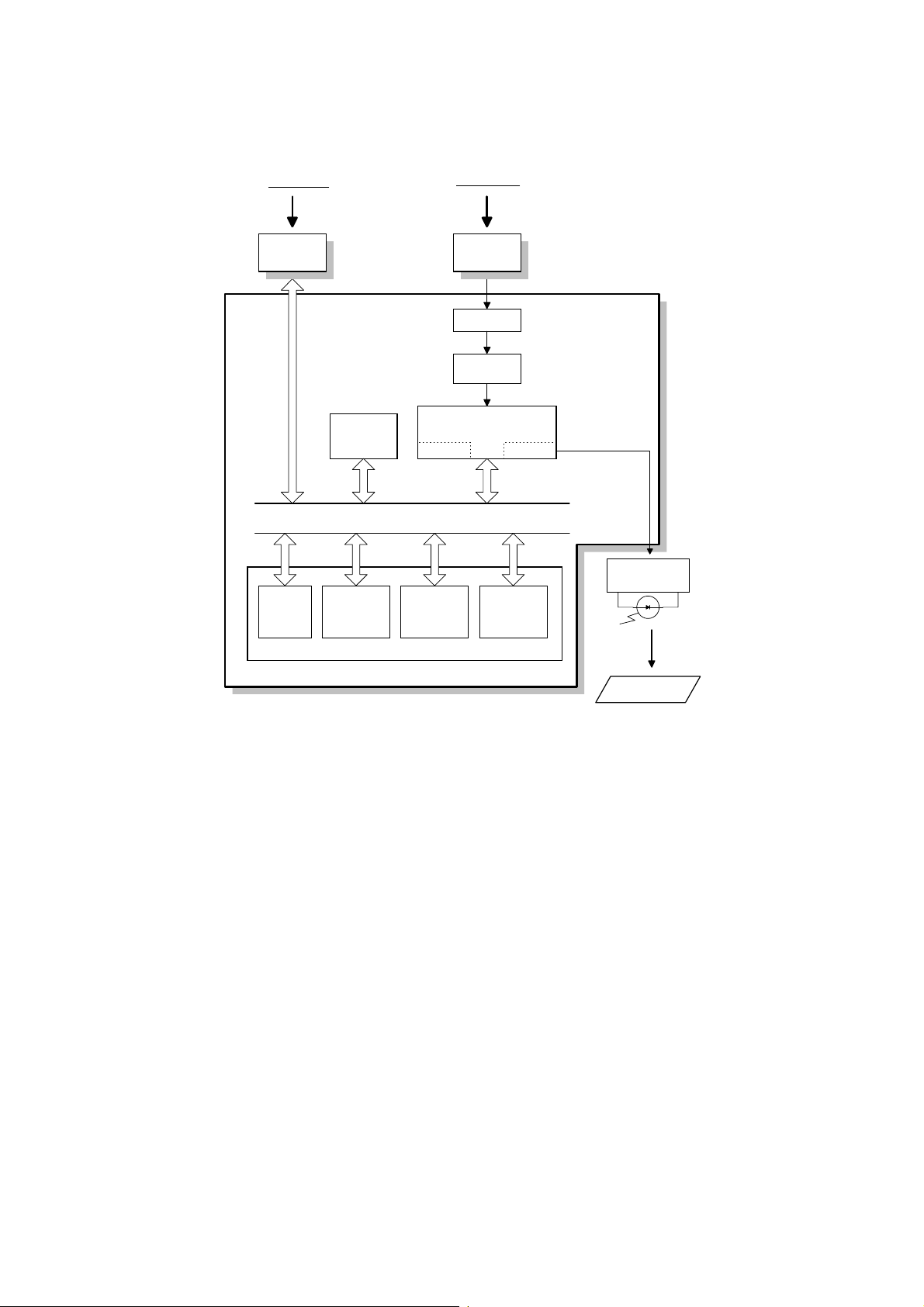

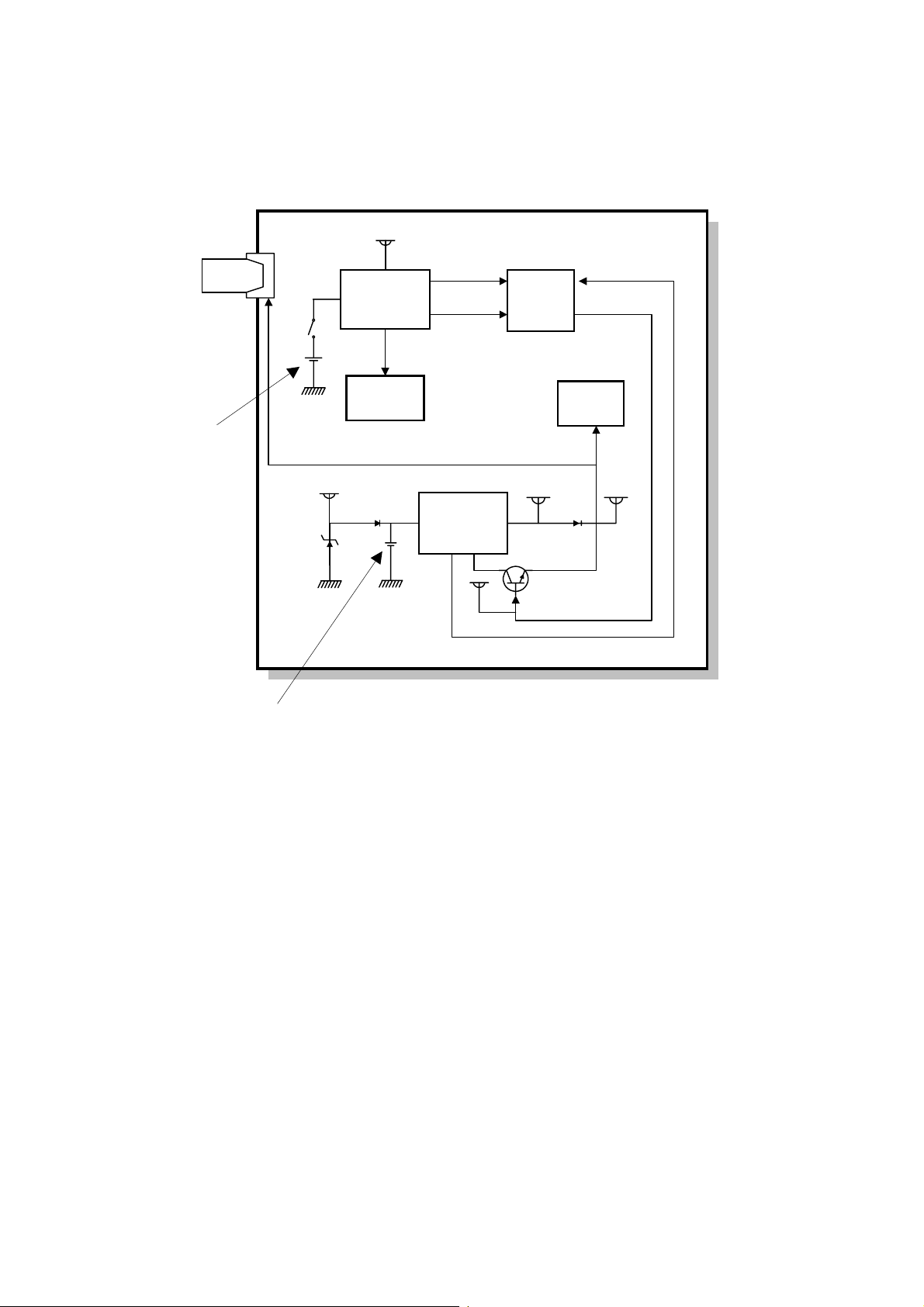

1.5.2 RECEPTION

From ISDN

SiG4

Line

Buffer

JBIG

Data/ Address Bus

SAF

Memory

ECM/DCR

From PSTN

NCU

HIC

Modem

FCIP05

DCR LIF

Buffer

Page

Memory

FCU

LDDR

DRAM

Copy Paper

H547V510.WMF

Data from the line passes to the modem through the NCU and hybrid integra ted

circuit (HIC). After the modem demodulates the data, it passes through the ECM

memory, DCR buffer, then to the DCR (or the JBIG LSI), which decompresses it

into raster image data. At the same time, the compressed data passes to the SAF

memory as a backup in case of mechanical problems during printing (substitute

reception).

During G4 reception, data from the ISDN line passes to the DCR for

decompression.

The raster image data then passes to the page memory for printing. After a page of

data has been stored in the page memory, the data is sent to the LDDR through

the LIF.

1-15

Page 23

VIDEO DATA PATH 21 May, 1999

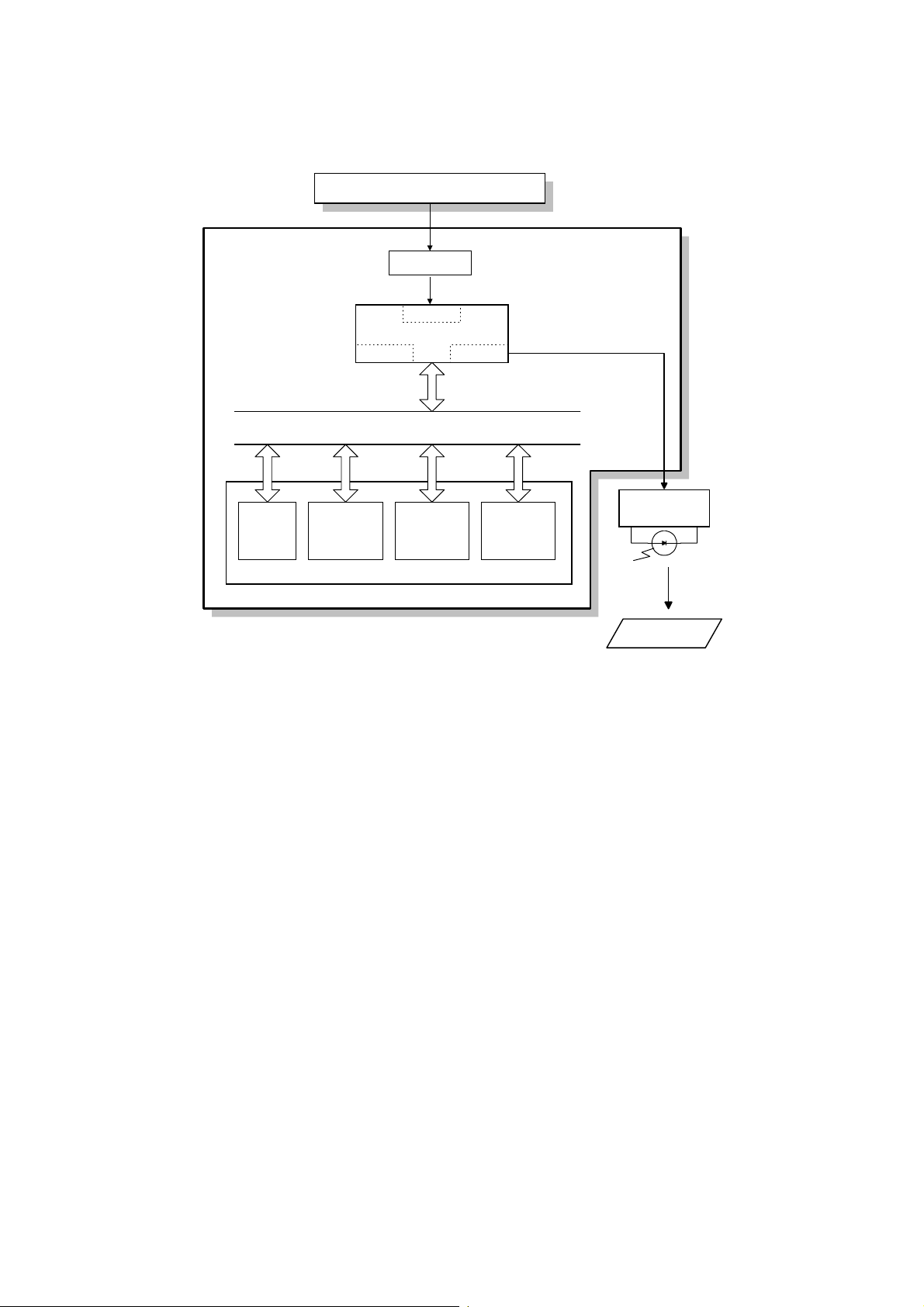

1.5.3 COPYING

Contact Image Sensor

Line

Buffer

Amplifier

FCIP05

DCR LIF

Data/ Address Bus

SAF

Memory

ECM/DCR

DRAM

DIP

Buffer

FCU

LDDR

Page

Memory

Copy Paper

H547V511.WMF

Single copy

The scanned data passe s to the page memory after video processing in the DIP.

After a page of data has been stored in the page memory, the data is sent to the

LDDR through the LIF.

Multi-page copy

The scanned data passe s to the SAF memory after video processing (DIP) and

compression (DCR). After a page of data has been stored in the SAF memory, the

data passes to the DCR again for decompression, and then it passes to the page

memory for printing.

1-16

Page 24

21 May, 1999 VIDEO DATA PATH

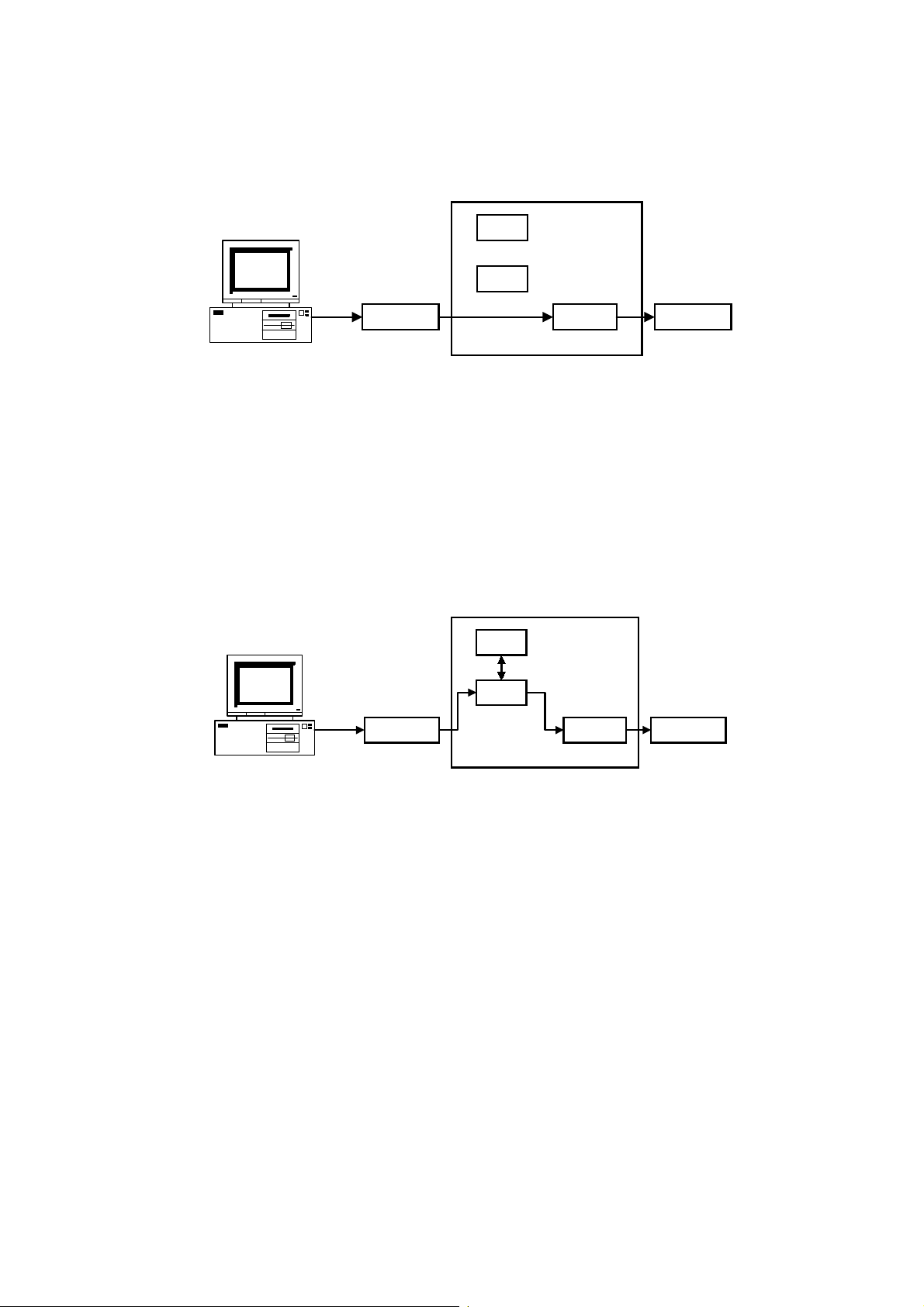

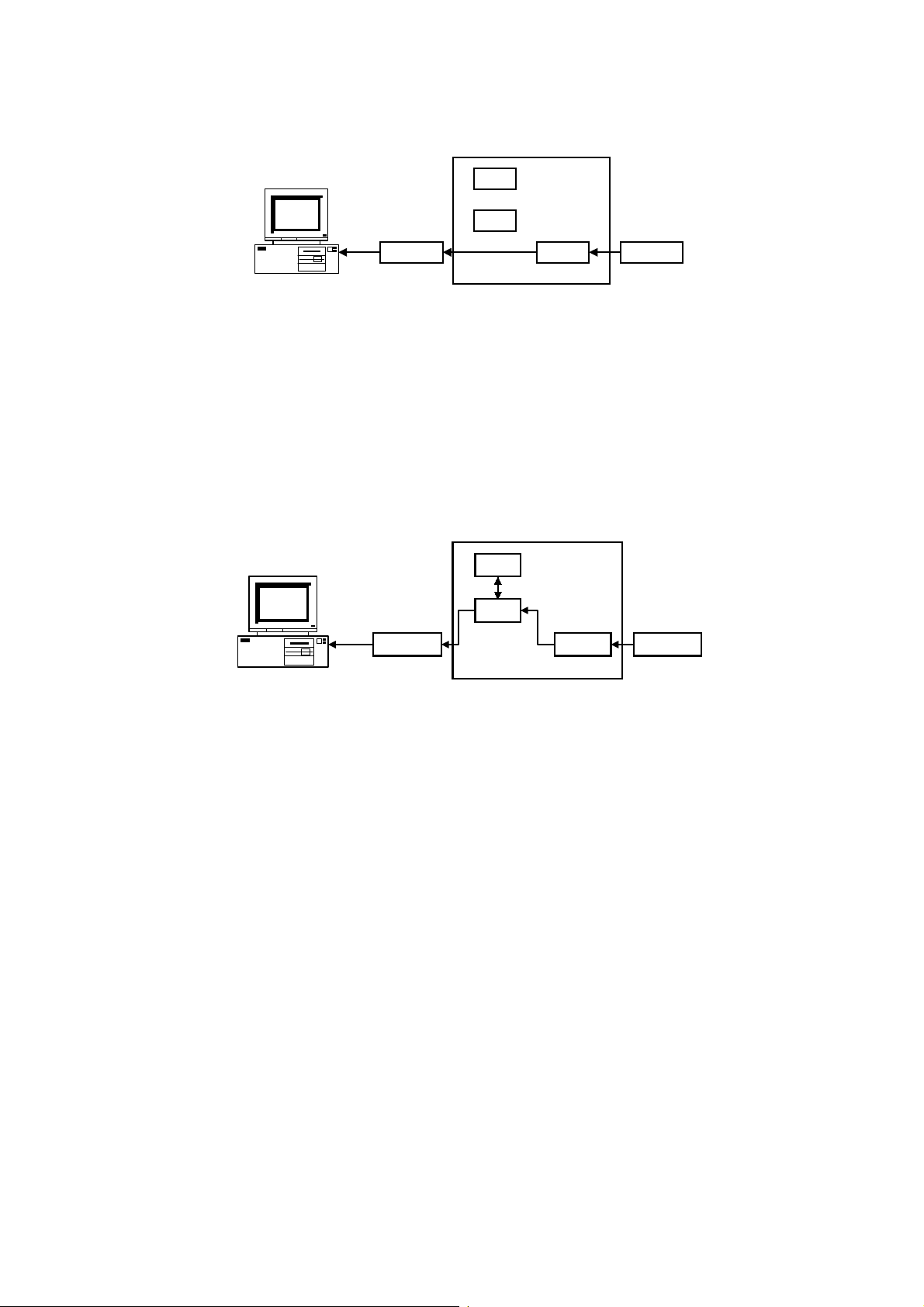

1.5.4 CLASS2 FAX COMMUNICATION

Direct transmission

SAF

DCR

IBM Compatible

FCU

ModemDIU

NCU

H547V520.WMF

The host computer sends commands and image data to the machine through the

DIU (Digital Interface Unit) during transmission.

NOTE:

1) Group dials programmed in the machine cannot be used.

2) T.30 optional protocols (e.g., BFT) are not supported by class 2 fax

communication.

3) ISDN G4 numbers programmed in quick or speed dials cannot be used.

4) ISDN G3 communication is not possible for PC direct transmission.

Memory Transmission

SAF

FCU

DCR

ModemDIU

IBM Compatible

NCU

H547V521.WMF

The host computer sends destination number(s) and image data to the machine

through the DIU during transmission. The machine stores the image in the SAF

memory, then makes a fax transmission.

NOTE:

1) If the memory overf lows while storing the first page into SAF memory,

the machine does not start the transmission.

2) If the memory overflows while storing the second or subsequent page

into SAF memory, the machine transmits all the successfully stored

pages.

3) When fax numbers programmed in the machine’s quick or speed dials

are specified using the PC fax application, all the specified numbers

must have been programmed in the fax machine.

4) T.30 optional protocols (e.g., BFT) are not supported by class 2 fax

communication.

1-17

Page 25

VIDEO DATA PATH 21 May, 1999

Direct Reception

SAF

DCR

IBM Compatible

FCU

ModemDIU

NCU

H547V522.WMF

The machine transf ers received image data directly to the host PC without storing it

into SAF memory.

NOTE:

1) If the host PC is not ready to receive a fax message, the machine

receives the message into SAF memory if the user parameter switch 0E

bit 1 is turned on.

2) Even if the SAF memory is full, the machine starts fax reception if there

is no mechanical error in the printer.

Memory Reception

SAF

DCR

FCU

ModemDIU

IBM Compatible

NCU

H547V523.WMF

The machine receives a fax message in the SAF memory, then transfers data to

the host computer after the reception has finished. The machine prints the received

message after transferring data to the host if user parameter 14 -bit 3 and 4 is set

to “1, 1: Print”.

NOTE:

1) If an error occurs due to cable disconnection, the PC fax application

must be restarted to re ceive the message.

2) Manual reception from the PC fax application is not supported.

1-18

Page 26

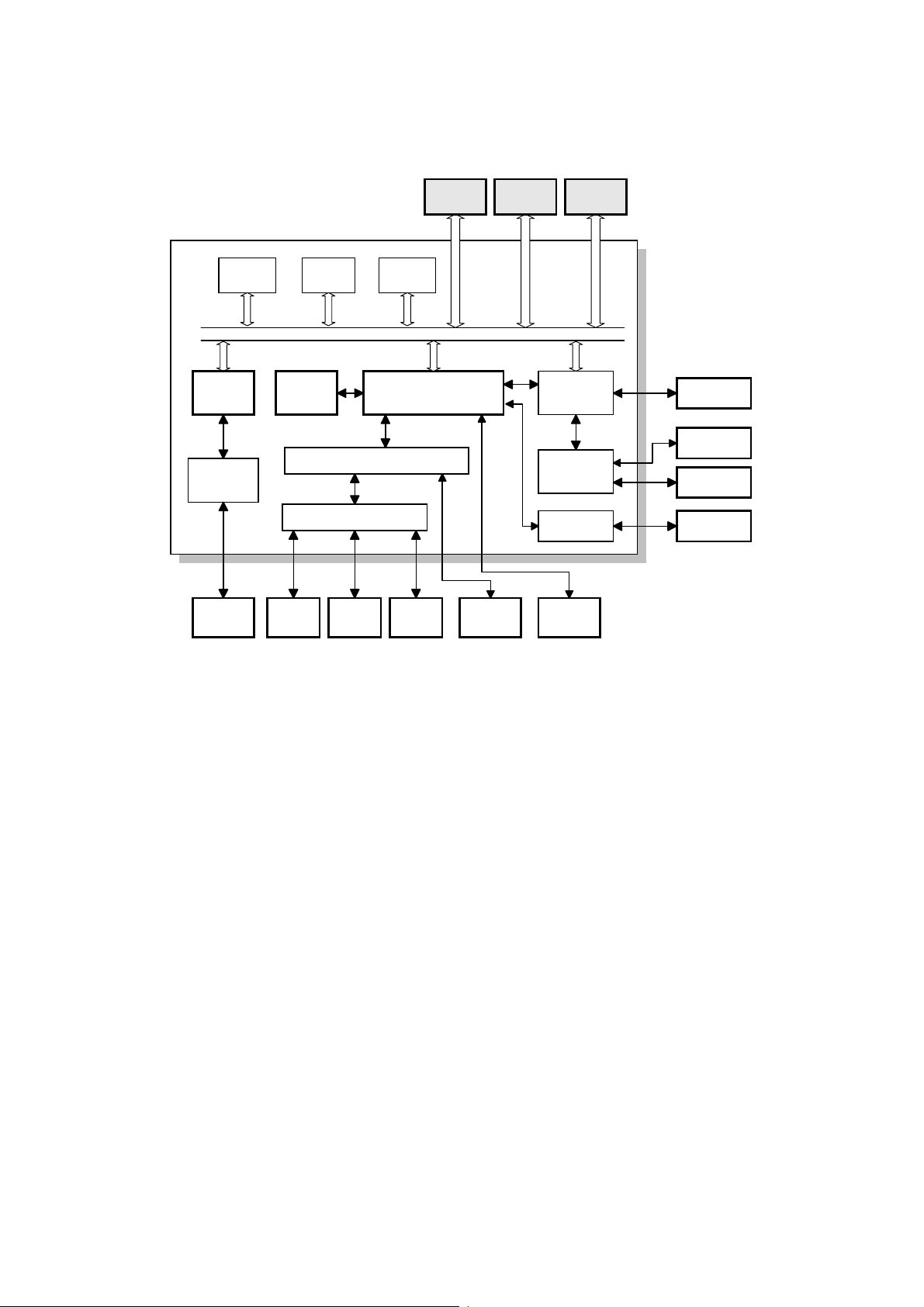

21 May, 1999 POWER DISTRIBUTION

1.6 POWER DISTRIBUTION

1.6.1 DI STRIBUTION DIAGRAM

AC

Main

Power

AC Switching

Fusing Lamp

ON/OFF

Switching

AC115V or

Fusing Lamp

Circuit

Circuit

230V

PC I/F

Main Switch

PSU

24VIN

+5V

+5VE

IC

Card

+5VD

-9V

FCU

+24V

24VM

24VD

Paper Feed

Unit

+5V

+5VD +3VD

DC-DC

Converter

DC-DC

Converter

Interlock

Switch

+24VMS

DC-DC

Converter

Multi Purpose

Feeder

-9V

+5V

+5VE

+5VLD+5V

Polygon

Motor

+24VMS

+5V

+5VBAT +3VBAT

+24VM

DC-DC

Converter

+5VD

DC-DC

Converter

+5VLD

+24V

+5V

+5VEE

LDDR Image Sensor

NCU

Main

Paper Feed

Motor

+5V +3VV

+5V +3V

+24VMM

DC-DC

Converter

DC-DC

Converter

+24VM

-9VV

+5VV

Clutch

+24VMS

+24VMM

+24VM

+5V

-9V

+24VPP

+5VT

+5V

+5VOPP

+5VE

+24VMM

+24V

Paper Feed

Motor

Fusing Fan

Power Pack

Thermistor

Sensors

Operation Panel

Scanner Motor

Toner End

Sensor

H547V515.WMF

The PSU supplies +24V dc power to the FCU. The FCU converts the +24V to the

following supplies.

+24V Normally on when the main switch is.

+24VD This is interrupted if the fusing unit cover interlock switch opens.

+24VIN

Supplies +24V to the fusing unit on/off switching circuit. It is interrupted if the fusing

unit cover interlock switch opens.

+24VMM For the scanner, paper feed, and main motors.

+24VPP For the power pack.

+5V Normally on when the main switch is.

+5VBAT Supplies back up power to the system RAM on the FCU to back up the

programmed data. A lithium battery generates +5VBAT.

+5VD Supplies back up power for the DRAM and the optional IC card on the FCU. It can

back up stored data for one hour after the power is switched off. A rechargeable

battery on the FCU generates +5VD.

+5VE Detects an activation signal from the NCU, SiG4 (G4 Unit), document feeder, or

operation panel when the machine is in energy saving mode.

+5VLD

Supplies the laser diode. It is interrupted if the fusing unit cover interlock switch

opens.

+5VT For the thermistor.

+5VV This is a more stable power supply than +5V. It is used for the contact image

sensor.

+3V For the FCIP05 internal circuits.

+3VBAT For the FCIP05 SRAM backup

+3VD For the FCIP05 DRAM backup.

+3VV For the FCIP05 AD convertor.

-9V For the image sensor.

1-19

Page 27

POWER DISTRIBUTION 21 May, 1999

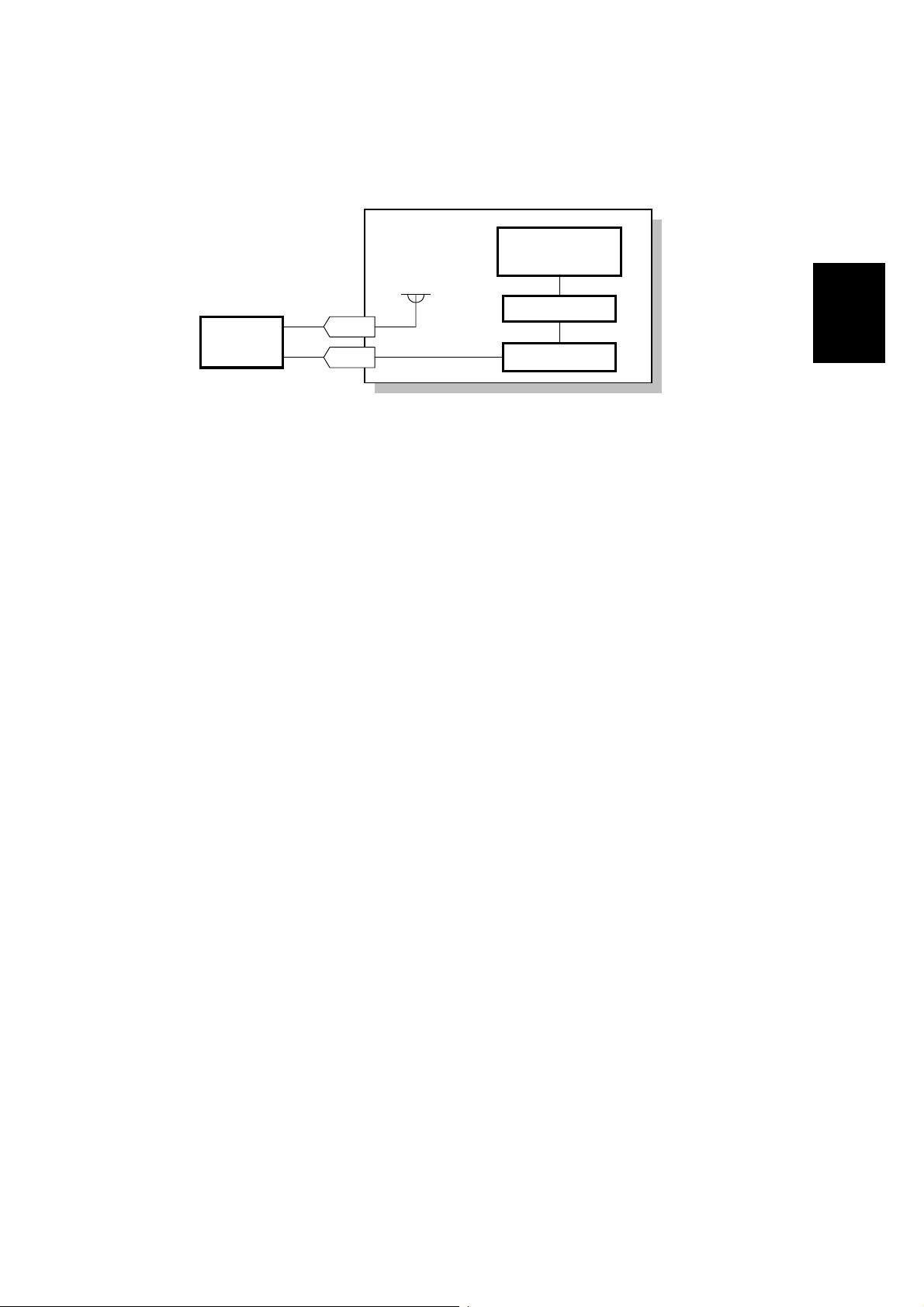

1.6.2 M EM O RY B ACK-UP CI RCUI T

FCU

+5V

POWERS

+5VD

5RTCCS

FCIP05

1VDET

1SAFFG

DRAM

[A]

IC Card

+

-

Switching

Circuit

+5VBAT

System

RAM

+5VBAT+5VD

H547V513.WMF

[B]

+5VE

DC/DC

Converter

+5V

Q29

The +5VBAT supply from the lithium battery [A] backs up the system RAM, which

contains system parameters, programmed telephone numbers, and the real time

clock in the main CPU. The 5RTCCS signal tells the main CPU whether the backup power (+5VBAT) is coming from the battery or from the +5V power supply.

A rechargeable lithium battery [B] and the DC/DC converter on the FCU back up

the DRAM (SAF memory) for one hour, if there is data in the SAF memory and the

power is switched off. While the main power is on, the +5VE supply recharges the

battery. The battery recharges in 5 or 6 days.

The battery [B] generates about 3 volts (max. 3.2 volts). The DC/DC converter

raises this voltage to 5 volts so it can be used as the +5VD supply for the SAF

backup. The CPU monitors the voltage of the +5VD supply with the 1VDET signal.

When the ba ttery has run down, and the voltage is lower than 4.4 volts, the CPU

stops the DC/DC converter by dropping 1SAFFG to low and the machine stops

backing up the memory.

NOTE:

There is no battery switch for the battery [B].

1-20

Page 28

21 May, 1999 SCANNER

2. DETAILED SECTION DESCRIPTIONS

2.1 SCANNER

2.1.1 MECHANISMS

Document Detection

[A]

H547D512.WMF

The document sensor [A] detects a document when it is placed in the ADF.

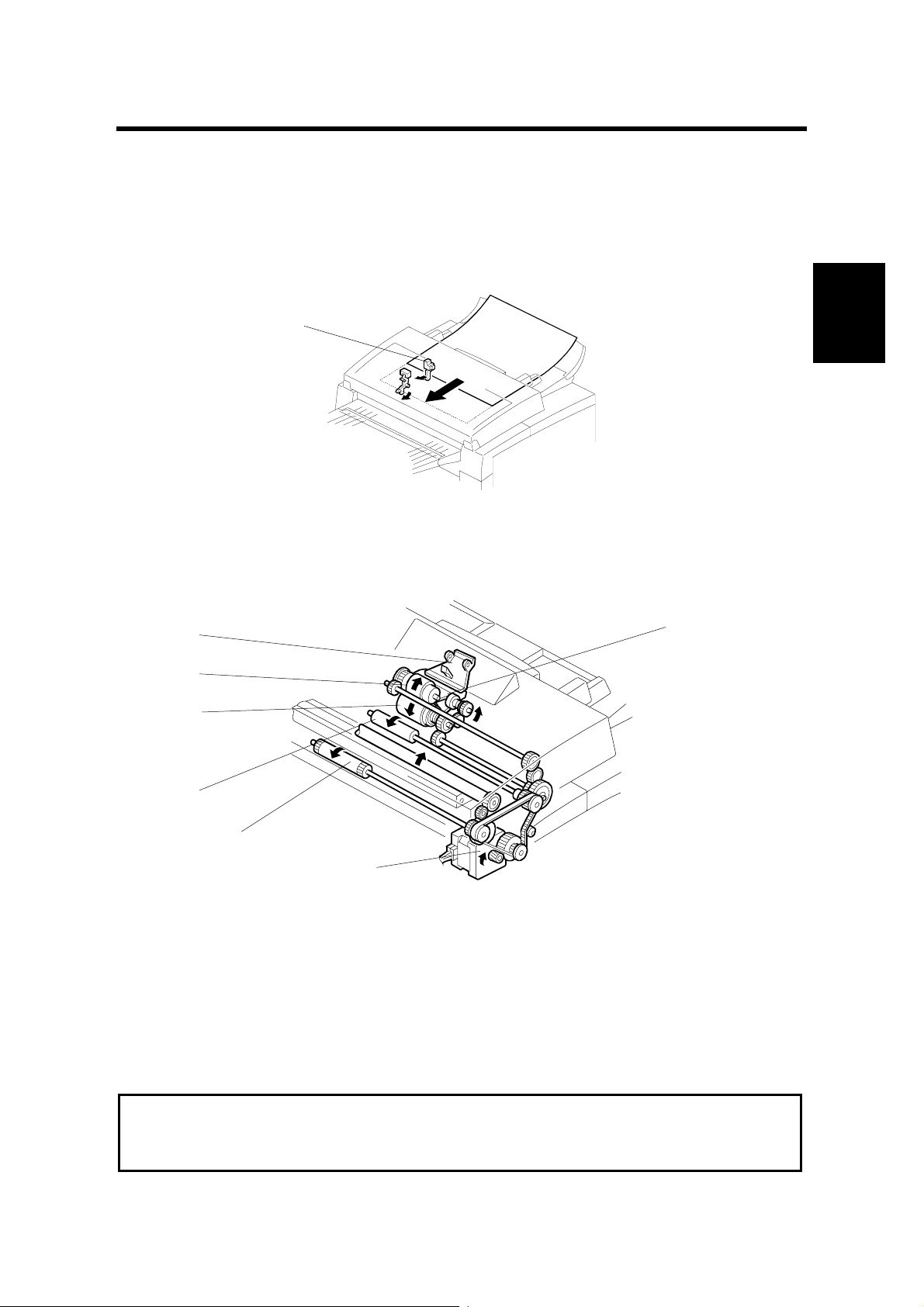

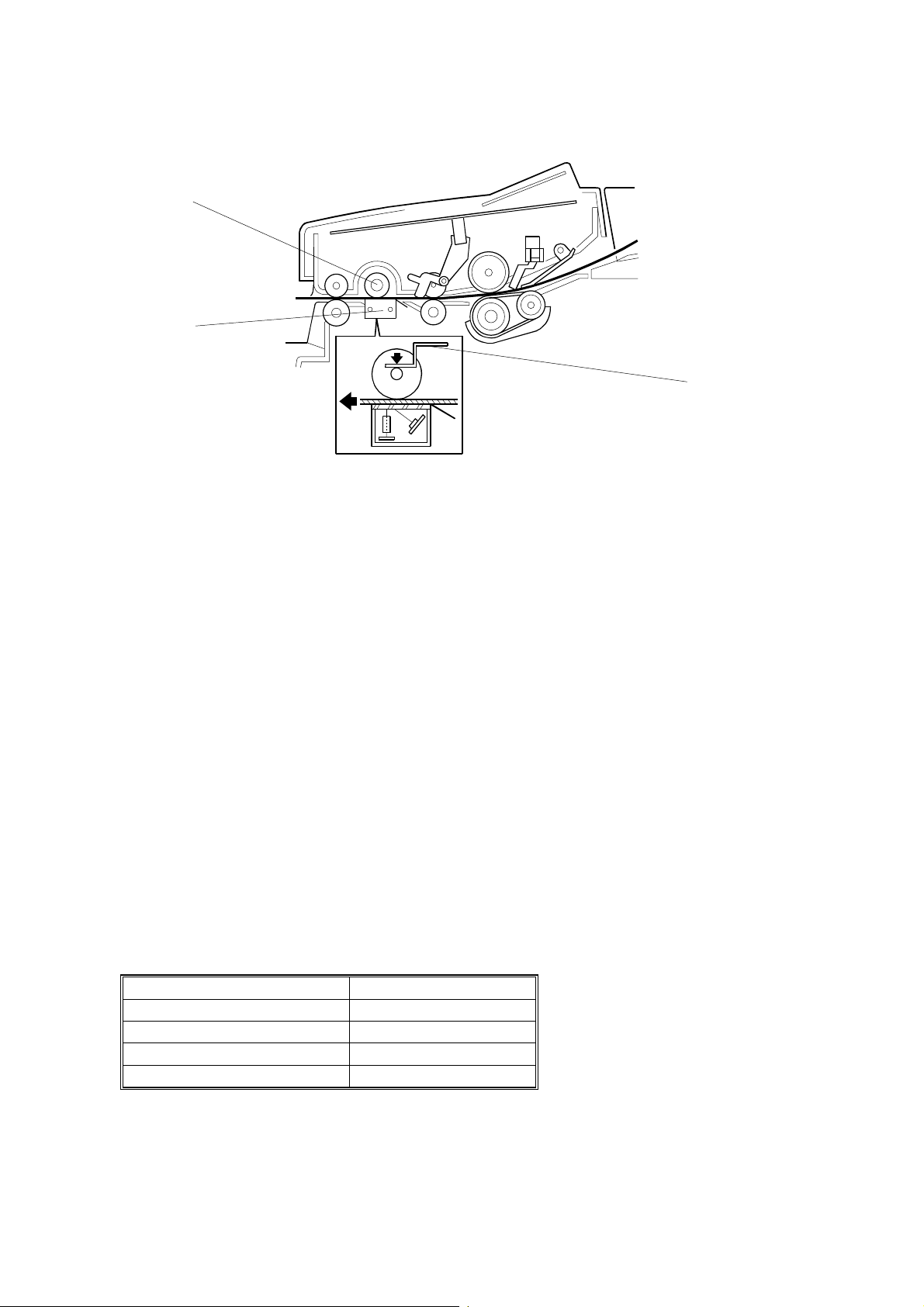

Pick-up and Separation and Drive Mechanism

[A]

[D]

[C]

[B]

Detailed

Descriptions

[F]

[G]

[E]

H547D502.WMF

The pressure plate [A] aligns the leading edges of the pa ges of the document.

When the machine starts feeding the document, the mechanical clutch in the ADF

roller unit lifts up the pick-up rollers [B] to feed the bottom sheet of the document.

Then, the feed belt [C] feeds the sheet into the scanner.

The separation roller [D] prevents the feed belt from feeding more than one sheet

at a time.

The scanner motor [E] drives the pick-up rollers [B], feed belt [C], R1 roller [F], and

R2 roller [G].

Cross Reference

ADF mechanical clutch mechanism: Group 3 Facsimile Manual, page 2-2-8.

Maximum document length: Scanner Switch 0 0, bits 2 and 3.

2-1

Page 29

SCANNER 21 May, 1999

Image Scanning

[A]

[B]

[C]

H547D503.WMF

The image sensor [B] consists of a row of 1728 photosensitive elements (Letter

width x 8 dots/mm). The document reflects light from the LED array and the rod

lens array focuses it onto the image sensor. Because of the short optical path

inside the CIS, the focal depth is mu ch shorter than for a CCD type scanner.

Consequently, the spring plates [C] push the white roller [A] so that the document

surface always touches the exposure glass at the scan line.

The image sensor assembly is factory adjusted, so it does not require adjustment

or replacement in the field.

The image sensor scans the original one line at a time, and outputs an analog

signal for each line. The voltage from each element depends on the intensity of the

light reflected from the original onto the element; the light intensity depends on the

darkness of the document area it was reflected from.

The white roller [A] must be kept clean, because the machine scans it every page

to calibrate the white level (auto shading).

Scanning Speed

The scanning speed for each resolution is as described below.

Resolution Scan Speed (A4)

Standard - Memory Tx 1.85 s

Standard - Immediate Tx 3.68 s

Detail 3.68 s

Fine 7.35 s

2-2

Page 30

21 May, 1999 SCANNER

Stamping

FCU

FCIP05

+24VM

EXIO

Stamp

Solenoid

The machine stops the document at the stamping position after the page is

transmitted (immediate transmission) or scanned into memory (memory reception)

successfully.

30-1

30-3

24V Driver

H547D570.WMF

Detailed

Descriptions

The machine drops the signal at CN30-3 to activate the stamp solenoid. Then the

original is fed out of the sensor.

2-3

Page 31

SCANNER 21 May, 1999

2.1.2 JAM CONDITIONS

The main CPU detects a document jam if one of the following conditions occurs.

Jam Condition Description

Non-feed The feed mechanism attempts to feed the

paper once every second for a maximum of

6 seconds. If the scan line sensor does not

detect the document within 6 seconds, the

monitor displays an error message.

Incorrect sensor

conditions

Maximum document length

exceeded

Cover open While the ADF is working, the ADF cover is

Error during feed-out

The scan line sensor turns on while the

document sensor is off.

The scan line sensor does not turn off after

the maximum document length has fed

through it. This occurs after 11 seconds at

standard resolution for memory TX; 23

seconds at standard resolution for

immediate TX or detail resolution; or 46

seconds at fine resolution (all these times

are for a 1.2-m long document).

opened.

The scanner motor reverses when the final

page of the document feeds out of the

scanner and/or when removing a jammed

document. This error occurs when placing a

document into the feeder while the motor is

rotating.

Error

Code

1-00

1-01

No error

code

No error

code

2-4

Page 32

21 May, 1999 SCANNER

2.1.3 RESOLUTION UNIT CONVERSION

mm-inch Conversion

This machine’s scanner is designed in mm resolution units. However, the other

terminal may have an inch-based printer. The machine can convert the scanned

data into inch-format for transmission.

The following table shows the actual transmitted data resolution units in various

cases.

Please note that other models (such as FX4 and FR4) convert from inches to mm

units whereas this machine converts from mm to inches.

G3 Immediate and Memory Transmission

Receiving terminal’s resolution units inch mm inch/mm

Mm-inch conversion

(com switch 14 bit 0)

G4 Transmission

When the above switch is off (Communication Switch 14 bit 0, the default setting is

off) the machine transmits the data in mm-format without conversion while

informing the other terminal that it is an inch based transmission.

On inch mm mm

Off mm mm mm

Detailed

Descriptions

Cross Reference

Inch to mm conversion (mm to inch): Communication Switch 14, bits 0 and 1

2-5

Page 33

PRINTING 21 May, 1999

2.2 PRINTING

2.2.1 PRINTING PROCESS - OVERVIEW

-1.2kV

-200V

µµµµ

+5.0

A

-650V

(0V)

H547D521.WMF

This machine uses a “write-to-black” system, with negative toner.

•

The charge-brush roller gives the drum surface an approximate negative

charge of -750 V.

•

The exposed area on the drum drops to about -200 V.

•

The development roller carries toner to the latent image on the drum surface.

The bias voltages during printing:

Toner application roller : -650 V

Development roller: -400 V

•

The transfer roller pulls the toner from the drum onto the paper.

A constant current of +5.0 µA is applied. The anti-static brush helps to

separate the paper from the drum.

•

The cleaning blade removes any toner remaining on the drum after the image

transfers to the paper.

•

This machine does not use quenching lamp.

2-6

Page 34

21 May, 1999 PRINTING

2.2.2 OPC DRUM

[C]

[D]

[B]

[A]

[E]

H547D504.WMF

The cartridge contains an organic photo-conductor drum [A]. The diameter of the

drum is 24 mm. The main motor [B] drives it through a gear train. The same gear

train also drives the toner application roller [C], development roller [D], and transfer

roller [E].

The drum, development roller, fresh and used toner tanks, and cleaning

mechanism are all included in the cartridge, which is known as the “All-in-One”

cartridge.

Detailed

Descriptions

2.2.3 CHARGE

[A]

H547D517.WMF

The cartridge contains a charge brush roller [A]. The diameter of the roller is 12

mm. The charge brush roller does not generate ozone. The power pack applies a

constant voltage of about –1.2 kV. The charge brush roller gives the drum surface

a negative charge (-750V).

2-7

Page 35

PRINTING 21 May, 1999

2.2.4 LASER EXPOSURE

Overview

[C]

[E]

[A]

[B]

H547D505.WMF

•

The focusing lens [A] is a double toroidal lens that has a barrel toroidal

[D]

[F]

surface on both sides.

•

The shield glass [B] prevents toner and dust from entering the laser optics

area.

•

Mirror motor [C] speed: 10086.2069 rpm (16 dots/mm)

•

The strength of the beam emitted from the LD unit [D] is 4 mW with a

wavelength of 780 nm. The photo transistor [E] inside the LD unit

synchronizes the laser main scan.

•

The mirror [F] reflects the laser beam onto the drum.

The charge on the exposed areas of the drum drops to about -200V while nonexposed areas remain at around -750V.

As a mechanical safety feature, a shutter slides to block the laser beam path

whenever the upper unit is opened.

Cross Reference

Group 3 Facsimile Manual: section 4-3-3

2-8

Page 36

21 May, 1999 PRINTING

Block Diagram

LDDR

Laser

Synch

Detector

Circuit

Laser

Diode

Controller

Laser

Diode

Polygon

Mirror

Drive Unit

Laser Synch

Detector

9-4

LD Enable

DATA

Control

Mirror Motor Lock

Mirror Motor Enable

9-2

9-6

9-3

10-4

10-3

24V Driver

FCU

FCIP05

LIF

EXIO

H547D506.WMF

The LIF (Laser Interface) circuit inside the FCIP5 monitors and controls the laser

diode timing (FCU CN9-3), and transfers data for printing to the laser diode (FCU

CN9-6).

Detailed

Descriptions

Cross Reference

Group 3 Facsimile Manual: page 4-3-13

Error Conditions

LD Failure:

The machine detects LD failure when it does not detect the laser synchronization

signal within 10 ms of the LD ready signal. When this occurs, the machine warns

the customer with the Call Service indicator (error code 9-20).

Mirror Motor Failure:

The machine detects a mirror motor error when the FCU CN10-4 signal does not

go low within 10 seconds of the polygon mirror motor turning on.

The machine also detects a mirror motor error when the FCU CN10-4 signal goes

back to high for 3 seconds or more during mirror motor operation. When either of

these errors occurs, the machine warns the customer with the Call Service

indicator (error code 9-23).

2-9

Page 37

PRINTING 21 May, 1999

2.2.5 TONER SUPPLY

[C]

[A]

[B]

H547D519.WMF

This machine uses mono-comp on ent ton er , comp osed of resin and ferrite. The

toner mixing bar [A] stirs and carries toner to the toner application roller [B]. The

toner application roller supplies toner to the development roller [C].

The main motor drives the toner supply mechanism through a gear train.

Since the toner tank and the development unit is composed in one unit, initial toner

supply mode is not required for this machine.

Cartridge Detection

This machine does not have toner cassette detection mechanism. It only detects

output from the toner end sensor.

At the following times, the toner end sensor detects whether a cartridge is installed

in the machine.

•

At power-up.

•

When the machine comes back to normal mode from the level 2 En ergy

Saver Mode.

•

After opening and then closing the cover.

2-10

Page 38

21 May, 1999 PRINTING

Toner End Detection

[A]

H547D516.WMF

The toner end sensor [A] below the toner tank detects toner near-end.

While the main motor rotates, the machine detects toner end by the voltage output

from the toner end sensor. The voltage from the sensor is close to 5V when the

toner tank is full and decreases when the toner is almost used up.

Detailed

Descriptions

Toner Tank

Toner End

Sensor

Toner near-end condition:

+24VM

13-1

13-2

When the cpu detects a low output (below a certain

FCU

+5V

FCIP05

H547D507.WMF

threshold) from the toner end sensor for a few seconds, the cpu starts to blink the

Add Toner indicator (LED). This is the toner near-end condition.

Toner end condition:

After toner near-end is detected, the machine can print 100

more sheets, then the cpu disables printing (this is the toner end condition).

The machine clears the toner near-end or toner end condition when the power is

switched off and back on or when the cover is opened and closed, if the output

from the toner end sensor goes back high again.

NOTE:

If the toner end sensor is accidentally disconnected, the machine cannot

detect if the cartridge is installed. The machine assumes that there is still

toner, even if the toner tank is empty.

2-11

Page 39

PRINTING 21 May, 1999

2.2.6 DEVELOPMENT

[C][D]

[A]

[B]

[E]

H547D519.WMF

Overview

The toner supply bar [A] stirs and carries toner to the toner application roller [B].

The toner application roller is a sponge-like structure which carries toner to the

development roller [D]. As the development roller [D] turns past the toner metering

blade [C], only a thin coating of negatively charged toner particles stays adhered.

(Refer to section 4-4-2 of the Group 3 Facsimile manual.)

During printing, the power pack applies a bias voltage of -650V to the toner

application roller and another bias voltage of -400V to the development roller. The

potential difference between these two rollers carries the toner from the toner

application roller to the development roller.

The exposed area on the drum [E] is at -200V. The development roller applies

toner to the latent image areas as they turn past the drum.

The development roller is made of soft rubber so it does not damage the surface of

the drum.

2-12

Page 40

21 May, 1999 PRINTING

Development Bias

[C]

[B]

[D]

[A]

H547D518.WMF

The power pack [A] applies one voltage to the toner application roller [B] and toner

metering blade [C], and a different voltage to the development roller [D].

Bias Control (During Printing)

The power pack applies a charge of -650V to the toner application roller, and

-400V to the development roller. Toner transfers from the toner application roller to

the development roller and on to the laser-exposed areas on the drum as shown

below.

Print Data

White Black

Toner

Detailed

Descriptions

GND

- 200V

- 400V

- 650V

- 750V

Drum Exposed Area

Development Roller

Toner Application Roller

Drum Surface Voltage

H547D531.WMF

2-13

Page 41

PRINTING 21 May, 1999

Bias Control (After Each Page)

At the start and the end of any print process (including the cleaning mode), the

power pack applies 0V to the toner application roller, and +250V to the

development roller. This is to prevent toner from transferring to the drum.

Toner

+ 250V

0V

- 750 V

Development Roller

Toner Application Roller

Drum Surface Voltage

H547D533.WMF

Note that the voltage difference between the toner application and development

rollers is kept the same as in printing, at 250 V. This keeps the same amount of

toner on the development roller at all times during the print run.

2-14

Page 42

21 May, 1999 PRINTING

Bias Control Circuit

Toner Application

Roller

Development

Roller

Transfer Roller

Power

Pack

BIASPWM

BIASCTL

Transfer H

Transfer L

11-8

11-7

11-10

11-9

I/O

Controller

FCIP05

FCU

H547D509.WMF

The CPU controls the voltages to the toner application and development rollers

through the I/O Driver, using the BIASCTL and BIASPWM signals as shown in the

following table.

In BIASCTL Low High Low High

BIASPWM On On Off Off

Out T oner Applicat ion Roller - 650 V 0 V Off Off

Development Roller - 400 V + 250 V Off Off

Detailed

Descriptions

2-15

Page 43

PRINTING 21 May, 1999

2.2.7 PAPER FEED

Overview

[B]

[A]

H547D511.WMF

The standard cassette [A] holds 250 sheets.

An optional paper feed unit, which holds up to 500 sheets, is available (only one of

these can be installed). An optional multi-purpose feeder [B] is also available.

2-16

Page 44

21 May, 1999 PRINTING

Paper Lift Mechanism

Standard Cassette

[A]

[C]

[B]

H547D525.WMF

After loading the paper and closing the cassette, the projection [A] pushes the slide

lock [B] off the bottom hook [C].

Once the slide lock comes off, the pressure spring lifts the bottom plate.

Optional Paper Feed Unit

[A]

[B]

Detailed

Descriptions

H547D513.WMF

After loading the paper and closing the cassette, the projection [A] pushes the lever

[B], then the springs raise the bottom plate.

2-17

Page 45

PRINTING 21 May, 1999

Paper End Detection

Standard Cassette/Optional Paper Feed Unit/Optional Multi-purpose Feeder

[A]

H547D527.WMF

When the cassette runs out of pa per, the paper end se nsor actuator [A] drops

through a slot in the bottom plate.

Paper End Sensor

Standard Cassette

Paper End Detector

Paper Feed Unit

Paper End Sensor

Multi Purpose Feeder

FCU

25-6

31-3

32-2

Paper End

EXIO

Paper End

Paper End

FCIP05

H547D659.WMF

2-18

Page 46

21 May, 1999 PRINTING

Pick-up and Separation

Standard Cassette and Optional Paper Feed Unit

The pick-up and separation mechanism is a separation pad type. The separation

pad and the paper feed roller allow only one sheet to feed.

Cross Reference

Group 3 Facsimile Manual: section 4-5-4

The paper feed motor in the mainframe starts to rotate when the printer is ready for

printing.

Drive Mechanism

Standard Cassette

[B]

[C]

[A]

Detailed

Descriptions

H547D522.WMF

The paper feed motor [A] drives the paper feed mechanism. When using the

standard cassette, the paper feed motor turns clockwise, driving the paper feed

roller [B], as shown in the diagram.

The clutch [C] only allows the paper feed roller to turn once for each sheet of

paper.

2-19

Page 47

PRINTING 21 May, 1999

Optional Paper Feed Unit

[A]

[B]

[C]

H547D508.WMF

The paper feed motor in the mainframe drives the paper feed mechanism through

a gear train. When the optional paper feed unit is used, the paper feed motor turns

counter-clockwise, driving the paper feed roller [A] and the transport roller [B], as

shown.

The paper feed clutch [C] in the optional paper feed unit ensures that the paper

feed roller rotates only once for each sheet of paper.

Optional Multi-purpose Feeder

[A]

[B]

H547D515.WMF

[C]

The paper feed mechanism is driven from the paper feed motor in the mainframe

through a gear train. When the machine feeds a sheet of paper from the multipurpose unit, the paper feed motor in the mainframe turns counter-clockwise to

drive the paper feed roller [A] and the transport roller [B] as shown in the diagram.

The paper feed solenoid operates the clutch [C] in the optional multi-purpose unit

to ensure that the paper feed roller rotates only once for each sheet of paper.

2-20

Page 48

21 May, 1999 PRINTING

Paper Feed Priority

If there is an optional paper feed unit and/or multi-purpose feeder installed in the

machine, deciding paper feed priority is in accordance with the following rules:

•

If the machine has an optional multi-purpose feeder and all of the cassettes

contain paper of the same size, the machine uses the optional paper feed

unit first, the standard cassette second, and the multi-purpose feeder third.

•

The multi-purpose feeder can be set to print only from a PC by a user

parameter switch adjustment.

2.2.8 REGISTRATION

[A]

Detailed

Descriptions

H547D523.WMF

When the paper edge sensor [A] turns on, the machine slows the paper feed

motor.

Then, a certain time after the paper’s leading edge turns on the registration sensor,

the machine starts to write the latent image to the drum.

When the paper edge sensor turns off, the machine speeds up the paper feed

motor to feed the next page and stops the laser.

2-21

Page 49

PRINTING 21 May, 1999

Jam Detection

Condition Error Code

Standard Cassette

Any Paper Feed

Station

Optional Paper Feed

Unit

Optional Multipurpose Feeder

When the paper edge sensor does not turn on

within 2.6 seconds of the paper jam timing signal.

When the registration sensor is not turned on

within 5.5 seconds after the paper edge sensor

turns on.

When the paper edge sensor does not turn off

within 9.47 seconds after the registration sensor

turns on.

When the fusing exit sensor does not turn on

within 5.0 seconds after the registration sensor

turns on

When the registration sensor does not turn off

within 4.8 seconds after the paper edge sensor

turned off.

When the fusing exit sensor does not turn off

within 5.0 seconds after the registration sensor

turns off.

When the paper edge sensor does not turn on

within 2.6 seconds after the paper feed clutch

turns on.

When the registration sensor does not turn on

within 5.5 seconds after the paper edge sensor

turns on.

When the paper edge sensor does not turn off

within 9.47 seconds after the registration sensor

turns on.

When the paper edge sensor does not turn on

within 2.6 seconds after the paper feed clutch

turns on.

When the registration sensor does not turn on

within 5.5 seconds after the paper edge sensor

turns on.

When the paper edge sensor does not turn off

within 9.47 seconds after the registration sensor

turns on.

9-07

9-84

9-08

9-09

9-50

9-51

9-82

9-83

2-22

Page 50

21 May, 1999 PRINTING

2.2.9 TR ANSF ER AND SEPARATI ON

[A]

[B]

H547D526.WMF

Instead of using a transfer corona wire, this machine uses a transfer roller, which

touches the drum surface.

The power pack [A] applies a constant current of +5.0 µA to the transfer roller [B].

The positively biased transfer roller pulls negatively charged toner off the drum.

The curvature of the drum and the anti-static brush help the paper to drop away

from the drum.

Detailed

Descriptions

+5.0

µµµµ

A

2-23

H547D536.WMF

Page 51

PRINTING 21 May, 1999

Cleaning Mode

If the paper is smaller than the printed image, or if a paper jam occurs during

printing, toner may transfer to the roller surface. To prevent this f rom occurring, the

transfer roller is cleaned before the next printing run.

While the machine is cleaning the transfer roller, the power pack supplies -1200V

to the transfer roller, and charges the drum to -750V. The negatively charged toner

on the transfer roller transfers back to the drum.

The machine cleans the transfer roller under the following conditions:

•

At power on (when the fusing temperature reaches half of the standby

temperature).

•

When the cover is opened and then closed during the printing process.

•

After clearing a printer jam.

The CPU controls the transfer roller voltage through the power pack using the

following signals.

In

Out Transfer Roller

THTRG On Off On Off

TLPWM Off On On Off

+ 5.0 µA

- 1200 V - Off

2-24

Page 52

21 May, 1999 PRINTING

2.2.10 CLEANING

[A]

[B]

H547D519.WMF

The cartridge contains the cleaning unit and the used toner tank.

The cleaning blade [A] removes any toner remaining on the drum after the image is

transferred to the paper, and then brings the toner into the used toner tank [B].

Detailed

Descriptions

There is no used toner overflow detection mechanism because the used toner tank

is large enough for the lifetime of the cartridge.

2-25

Page 53

PRINTING 21 May, 1999

2.2.11 FUSING

Fusing Lamp Control

During printing, the machine keeps the fusing temperature at 190°C. If the printing

operation continues for more than 3 minutes, the machine keeps the fusing

temperature at 165°C.

When the Energy Saver Key is pressed or the energy saver timer expires, the

machine goes into an energy saver mode. In Level 2 Energy Saver Mode (2-watt

Energy Saver Mode), the fusing lamp shuts off. For Energy Saver Mode Level 1,

the user can select whether to keep the fusing lamp off or at 80°C.

Cross Reference

Energy Saver Modes: Section 2-3

Points to Note:

•

Standby temperature: Room temperature (2 watt-Energy Saver Mode), 80 °C

if users select ‘Fusing Lamp On’

•

Printing temperature: 190 °C, falling back to 165 °C after 3 minutes

If the initial lamp temperature is over 120 °C before printing, the printing

temperature is 165 °C.

•

Thermistor maximum: 250 °C (monitored by a comparator)

•

Thermostat maximum: 150 °C (the temperature of the hot roller would be

about 400 °C)

•

Thermofuse maximum: 169 °C (the temperature of the hot roller would be

about 400 °C) - The thermofuse is not used in USA models.

190 ºC

165 ºC

145 ºC

80ºC

Fusing

ON

OFF

Room Temp.

5 minutes (=Power saver timer)

3 minutes

Print Start

80 ºC or

Room Temp.

H547D538.WMF

2-26

Page 54

21 May, 1999 PRINTING

Fusing Control

FCU

FCIP05

+5V

Comparator

Thermistor Max

Thermistor Temp

THR SEL

4-1 4-2

PSU

+5V

24-1

Detailed

Descriptions

Thermistor

24-2

Fusing Lamp

Thermofuse Thermostat

*

H547D662.WMF

There is no thermofuse in USA and Asia models.

During normal operation, the CPU controls the fusing lamp based on input from the

thermistor using the above circuit.

When the machine is turned on, or when it comes back from the Level 2 Energy

Saver Mode, it checks whether the thermistor circuit is intact by using the THR SEL

signal on the FCU. If the thermistor is connected properly, the machine begins

normal operation. If it is not, it generates an Auto Service Call (error code 9-22,

sub-code 09 ).

As a backup safety measure, when the temperature of the hot roller reaches

approximately 400 °C, the thermostat and/or thermofuse open.

The machine turns on the cooling fan when the fusing temperature reaches 60°C

and shuts it off when the fusing temperature drops below 60°C.

2-27

Page 55

PRINTING 21 May, 1999

Fusing Unit Drive

[A]

[B]

H547D524.WMF

The main motor [A] drives the fusing unit through a gear train. The fusing exit

sensor [B] detects when the paper is fed out of the unit.

After opening the upper unit, the gear train frees up making it easy to remove

jammed paper.

Jam Detection - Paper Feed Out

The machine detects a paper jam when the fusing exit sensor does not turn off

within 5.0 seconds after the registration sensor turns off (Error Code 9-09).

This is the same for all cassettes.

2-28

Page 56

21 May, 1999 PRINTING

Fusing Unit Service Call Conditions

Conditions Error Code (9-22)

Standby mode

During printing

After printing

At any time

If there is a problem with the thermistor.

(Also for when the machine returns to Normal

Mode from Energy Saver Mode Level 2.)

If the machine detects that both jumper 63 and

jumper 64 are s horted. *[The st atus of the