Page 1

User’s Guide

© 2005 Ricoh Printing Systems, Ltd.

N905363

Read and keep this manual

Read Safety Summary carefully and

understand them before starting your

operation.

Keep this manual at hand for reference.

Page 2

© 2005 Ricoh Printing Systems, Ltd. All right s reserved.

No part of this document may be reproduced without the express permission of Ricoh Printing

Systems, Ltd.

The material in this document is for informational purposes and is subject to change without

notice. Ricoh Printing Systems, Ltd. assumes no responsibility for errors or omissions in this

document. No liability is assumed for any damages resulting from the use of the information it

contains.

TRADEMARK

Adobe and Postscript are registered tr ademarks of Adobe Systems Incorprated.

PCL and PCL5e are trademark of Hewlett-Packard Company.

Ethernet is a trademark of Xerox Corporati on.

Appletalk, Ethertalk and TrueType are trademark of Apple Computer, Inc.

Netware is a trademark of Novell, Inc.

WindowsXP is a trademark of Microsoft Corporation.

All other terms and product names may be trademarks or registered trademarks of their

respective owners, and are hereby acknowledged.

NOTICE TO USER

In an effort to meet the demands of a r apidly changing technology, the manuf acturer is c ontinually

developing new features and functions to meet your changing printing or printer needs. As a

result, this manu al may n ot exactl y ref lect futur e cha nges ma de to t he prod uct . Pleas e be sure t o

consult all manual updates or addenda when using this product’s documentation.

Contains TrueType fonts from Monotype Imag eing Inc. Reproduction of t hese fonts is prohibi ted.

The software embedded i n this product is based i n part on t he work of I ndependent JPEG Group .

The software embedded in this product uses the software by CMU.

Copyright 1988, 1989 by Carnegie Mellon University. All rights reserved.

Permission to use copy, modify, and distribute this software and its documentation for any

purpose and without fee i s here by gr anted, provi ded that t he above copyr ight notice appea r in all

copies and that both that copyright notice and this permission notice appear in supporting

documentation, and that the name of CMU not be used in advertising or publicity pertaining to

distribution of the software without specific, written prior permission.

The software embedded in this product uses the software by Sam Leffler and Silicon Graphics.

Copyright (c) 1988-1997 Sam Leffle r

Copyright (c) 1991-1997 Sili con Graphics Inc.

Permission to use, copy, modify, distribute and sell this software and its documentation for any

purpose is hereby granted without fee, provided that (i) the above copyright notice and this

permission notice appear in all copies of the software and related documantation, and (ii) the

names of Sam Leffler and Silicon Graph ics may not be u sed in any adverti sing or publicit y relating

to the software without the specific, prior written permissi on of Sam Leffler and Silicon Graphics .

Page 3

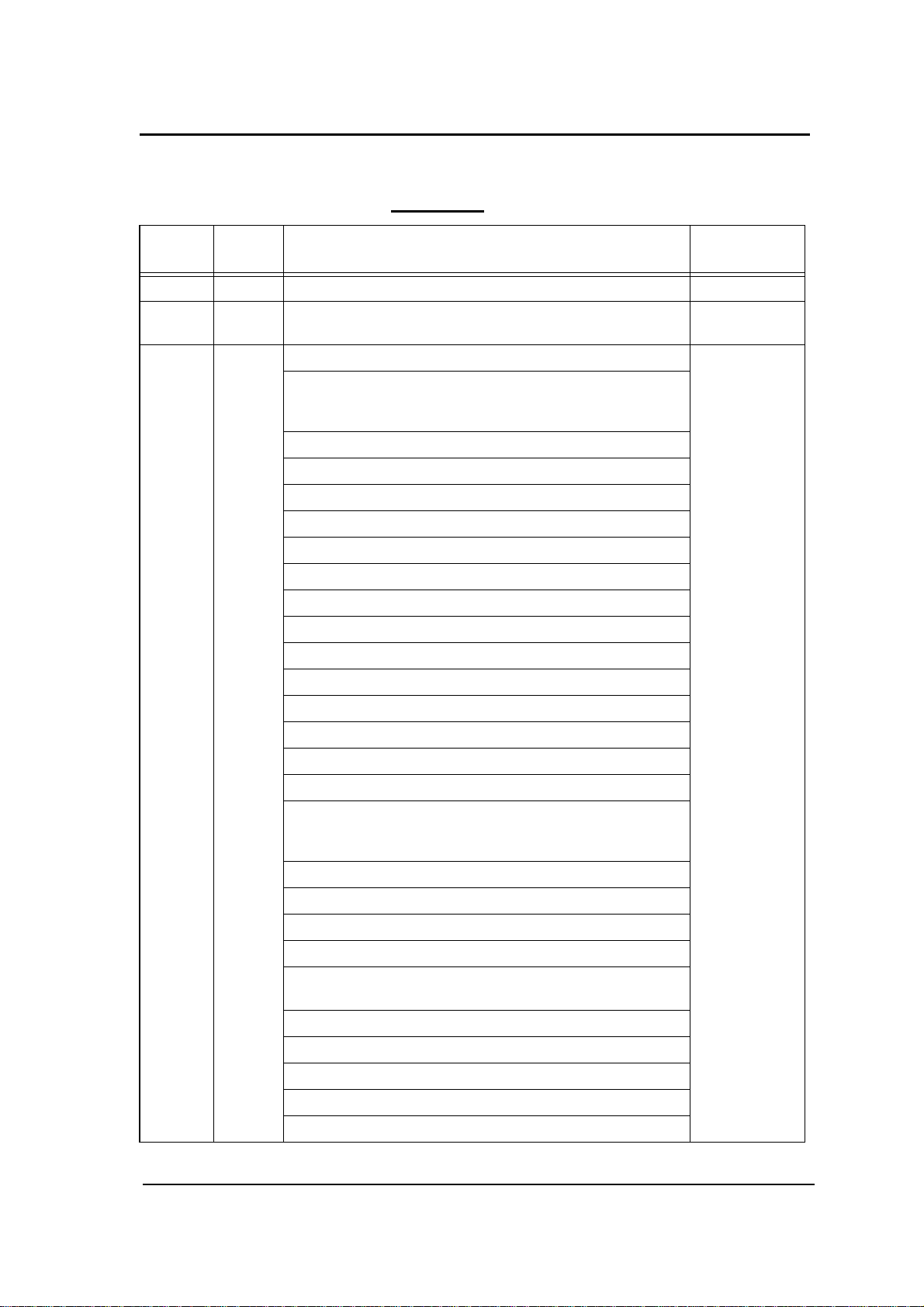

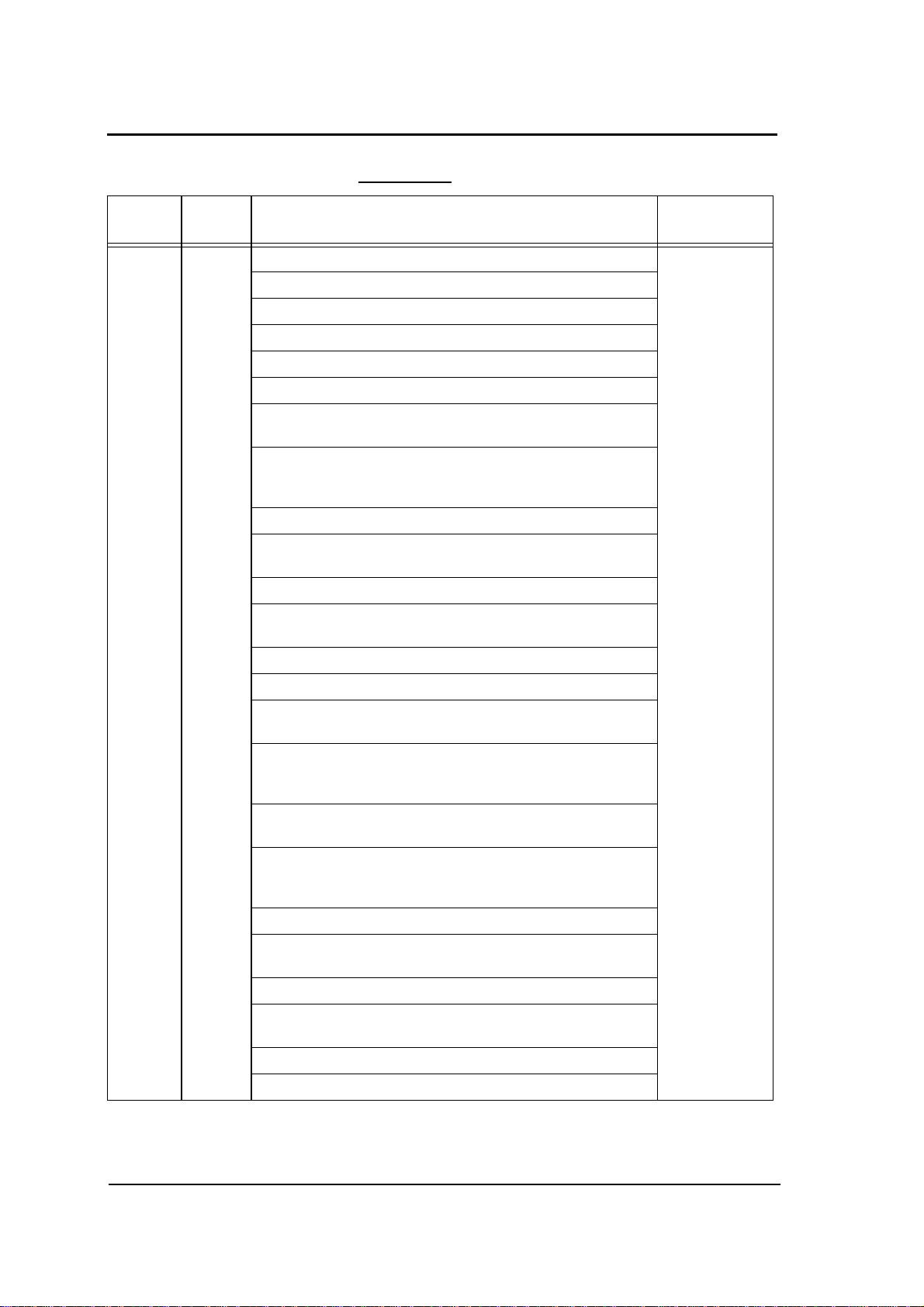

Rev. Table

Rev. for

Manual

00 - First Edition Jul. 21, 2005

01 - vi, 2-11, 2-12, 2-14, 2-16, 2-17, 2-20 - 2-22, 3-3, 3-5 - 3-30, 6-2,

02 - v(01), vi(02), viii(01) : Some headings and Page No. are modified. Nov. 17, 2005

Machine

Rev.

Page No. (Contents) Date

Sep. 15, 2005

6-5 - 6-41

Safety Summary-2(01) ~ Safety Summary-4(01) :

Some WARNING statements and CAUTION statements are

modified.

2-7(01) : Figure is changed.

2-11(02) : Figure is changed, and “Paper Color” is added.

2-12(02) : “HCF Tray Control” is added.

2-13(01), 2-14(02) : Contents are moved from previous page.

2-15(01) : “PCL” is added.

2-16(02) : Contents are moved from previous page.

2-17(02) : “Paper Color” is added.

2-18(01) : “HCF Tray Control” and “PCL” are added.

2-19(01) : Figure is corrected.

2-20(02) : Contents are moved from previous page.

2-21(02), 2-22(02) : “Language” is changed.

2-23(01) : Figure is changed, and “Configuration” is added.

2-24(01), 2-25(01) : Contents are moved from previous page.

2-26(01) : Page is added.

3-1(01), 3-3(02):

Title is changed to “Paper Size, Paper Weights, Paper Types and

Paper Color”.

3-5(02) : “Tracing Paper” is added.

3-6(02) : “Paper Color” is added.

3-7(02) ~ 3-30(02) : Contents are moved from previous page.

4-11(01) ~ 4-15(01) : Figure number is changed.

4-33(01) ~ 4-36(01) :

Procedure of step 8 ~ step 13 is modified, and a caution is added.

4-37(01) ~ 4-41(01) : Step number is changed.

4-42(01) ~ 4-59(01) : Contents are moved from previous page.

4-60(01) : Page is added.

5-7(01) : Add the notation for the HCF Tray Control.

6-2(02) : Language is changed.

Page 4

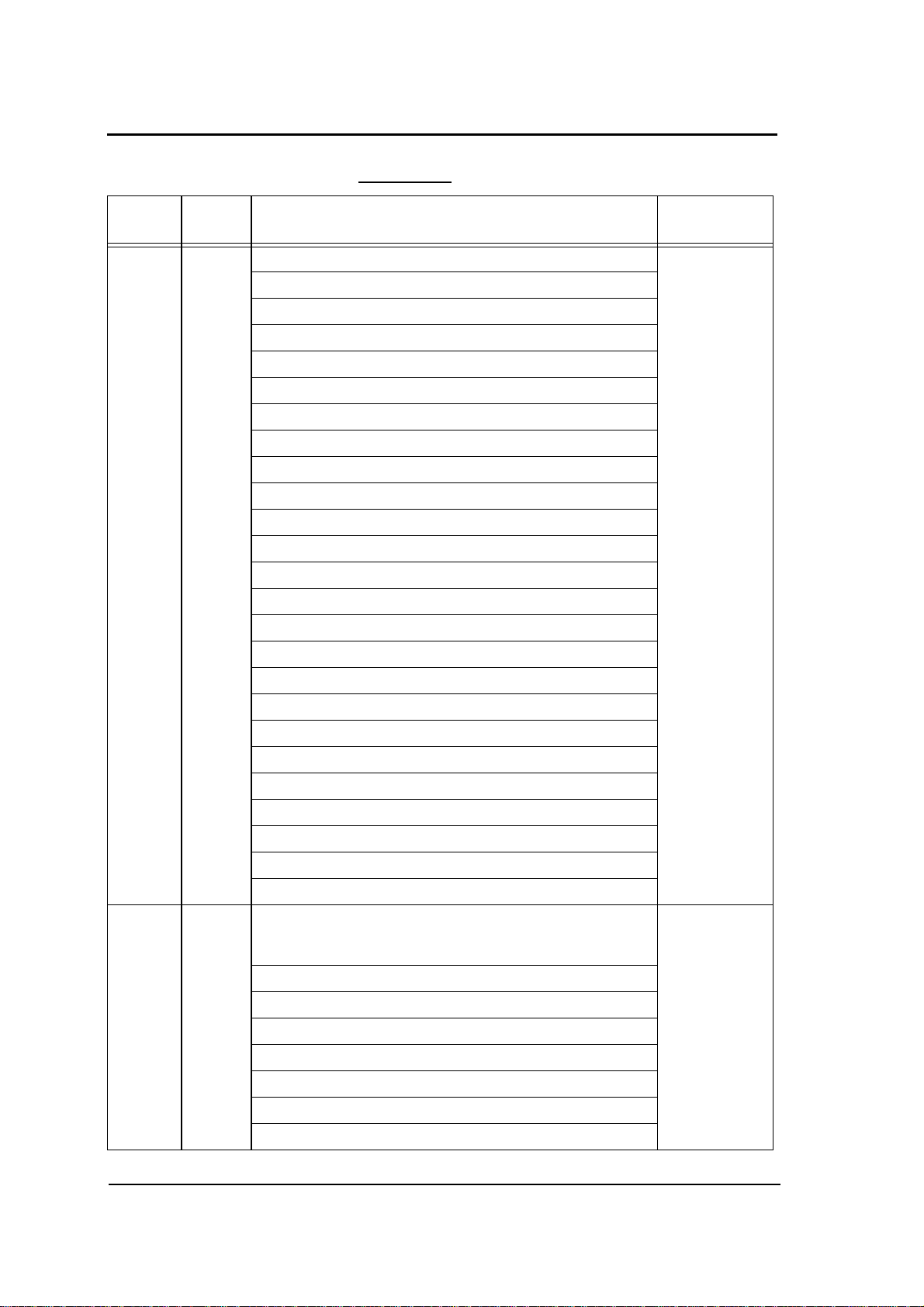

Rev. Table

Rev. for

Manual

02 - 6-4(01) : Figure is changed. Nov. 17, 2005

Machine

Rev.

Page No. (Contents) Date

6-5(02) : Language is changed, and Figure is changed.

6-6(02) : Figure is changed.

6-7(02) : “Error Information” is deleted.

6-8(02) : Contents of “Tray” is changed.

6-9(02) ~ 6-17(02) : Figure is changed.

6-18(02) : Contents of “Tray” is changed.

6-19(02) ~ 6-21(02) : Figure is changed, and explanation is modified.

6-22(02) : Explanation is added.

6-23(02), 6-24(02) : Figure is changed.

6-25(02) : Figure is changed, and explanation is modified.

6-26(02) ~ 6-28(02) : Figure is changed.

6-29(02), 6-30(02) : Figure is changed, and explanation is added.

6-31(02) : Explanation is added.

6-32(02) ~ 6-36(02) : Figure is changed, and explanation is added.

6-37(02) ~ 6-39(02) : Figure is changed.

6-40(02) : Contents are moved from previous page.

6-41(02) ~ 6-43(02) : Figure is changed.

6-44(02), 6-45(02) : Figure is changed, and explanation is added.

6-46(02), 6-47(01) : Figure is changed, and explanation is modified.

6-48(01) : Figure is changed, and explanation is added.

6-49(01) : Explanation is added.

6-50(01) : Figure is changed.

6-51(01), 6-52(01) : Figure is changed, and explanation is added.

6-53(01) ~ 6-56(01) : Contents are moved from previous page.

03 - TOC-1(02), TOC-2(03), TOC-3(01), TOC-4(02) :

Page Number of Table of Contents are changed.

Some headings and Page No. are modified.

Safety Summary-12(01) : Caution Plates are changed.

1-5(01) : Figure 1-2 is changed.

4-17(01) ~ 4-19(01) : Figures are changed.

4-31(01) : Figure 4-56 is changed.

4-33(02) : Figure and CAUTION statement are changed.

4-34(02) ~ 4-36(02) : Figures are changed.

4-51(02) : Add the cleaning items, and correct the misentry.

Feb. 4, 2006

Page 5

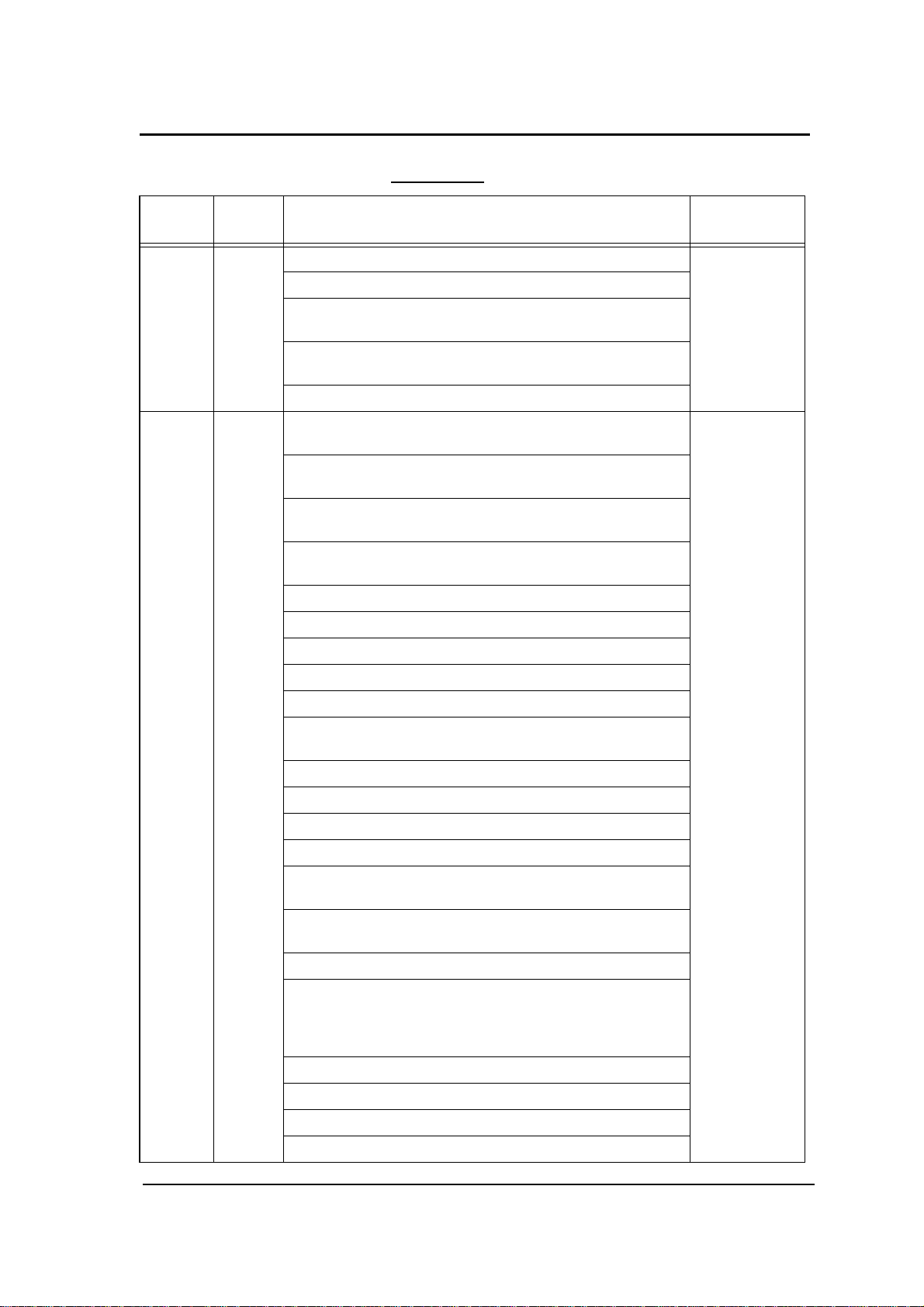

Rev. Table

Rev. for

Manual

03 - 4-55(02) : Figure 4-110 is changed, and misentries are corrected. Feb. 4, 2006

04 - TOC-1(03), TOC-2(04), TOC-3(02), TOC-4( 03):

Machine

Rev.

Page No. (Contents) Date

4-56(02), 4-57(02) : Misentries are corrected.

4-58(02), 4-59(02) : All contents of “Cleaning the paper guide of the

Fuser Unit” are added.

4-60(02), 4-61(02) : All contents of “Cleaning the paper guide of the

Discharger Unit” are added.

4-62(01) ~ 4-64(01) : Contents are moved from previous page.

Mar. 22, 2006

Some page number are modified.

Safety Summary-3(02), Safety Summary-4(02) :

Some caution statements are added.

SafetySummary-7(01) :

All contents are added.

SafetySummary-8(01) ~ SafetySummary-13(01) :

Contents are moved from previous page.

SafetySummary-14(01): Page is added.

1-9(01) : Caution statement is added.

2-6(01) : NOTE statement is added.

2-7(02) : Fugire 2-5 is changed.

2-10(01) : Network name is changed.

2-14(03) : “Exit Jam Recovery” is deleted.

“LPD Queuing” is modified.

2-16(03) : “Paper Size” is modified.

2-17(03) : “Paper Color” is modified.

2-18(02) : “Exit Jam Recovery” is deleted.

2-19(02) : NOTE Statement is added.

2-20(03) : Network name is changed.

“Exit Jam Recovery” is added.

2-21(03) : “Auto Online”, “Auto Backup Time” and “Output

Cascade” are added.

2-22(03) : Contents are moved from previous page.

2-23(03) : Network name is cahnged.

“Exit Jam Recovery”, “Auto Online”, “Auto Backup

Time” and “Output Cascade” are added.

“Note 8” is added.

2-24(02) ~ 2-26(02) : Contents are moved from previous page.

3-3(03) : “Letter Tab Stock “ and “A4 Tab Stock” are added.

3-6(03) : Custom color number is changed from 16 to 80.

3-14(03) : Contents are modified.

Page 6

Rev. Table

Rev. for

Manual

04 - 3-15(03) : All contents are added. Mar. 22, 2006

Machine

Rev.

Page No. (Contents) Date

3-16(03) : Figure 3-13 is changed.

3-17(03) : Figure 3-15, 3-16 are changed.

3-18(03) ~ 3-31(01) : Contents are moved from previous page.

3-32(01) : Page is added.

5-8(01) : Some statements are added.

5-9(01) : Contents are moved from previous page.

Table Number is changed.

5-10(01) : Contents are moved from previous page.

Corective action of “Insufficient Disk Space”

is modified.

5-24(01) : CAUTION Statement is added.

6-15(03) : Figure 6-12 is changed.

Network name is changed.

6-17(03) : Figure 6-14 is changed.

6-24(03) : Figure 6-19 is changed.

Custom color number is changed from 16 to 80.

6-28(03) : Contents are modified.

6-29(03) : “LPD Banner Page” is modified.

6-30(03) : Figure 6-25 is modified.

Contents of each option are modified.

6-31(03) : Contents of each option are modified.

“Paper Color”, “Rotation”, “Reverse Order” and “Job

Partial Page Print” are added.

6-33(03) : Figure 6-27 is changed.

“Paper Color” is deleted.

6-44(03) : Figure 6-38 is changed.

Contents of each option are modified.

“Auto Online” and “Output Cascade - ...” are added.

6-45(03) : “Use Time Server” is modified.

6-48(02) : Figure 6-42 is changed.

Network name is changed.

6-49(02) : “Host Name” and “DNS Server Address” are added.

6-50(02) ~ 6-52(02) : Figures are cahnged.

Network name is changed.

6-56(01) ~ 6-59(01) : All contents are added.

6-60(01) : Blank page is added.

Page 7

Rev. Table

Rev. for

Manual

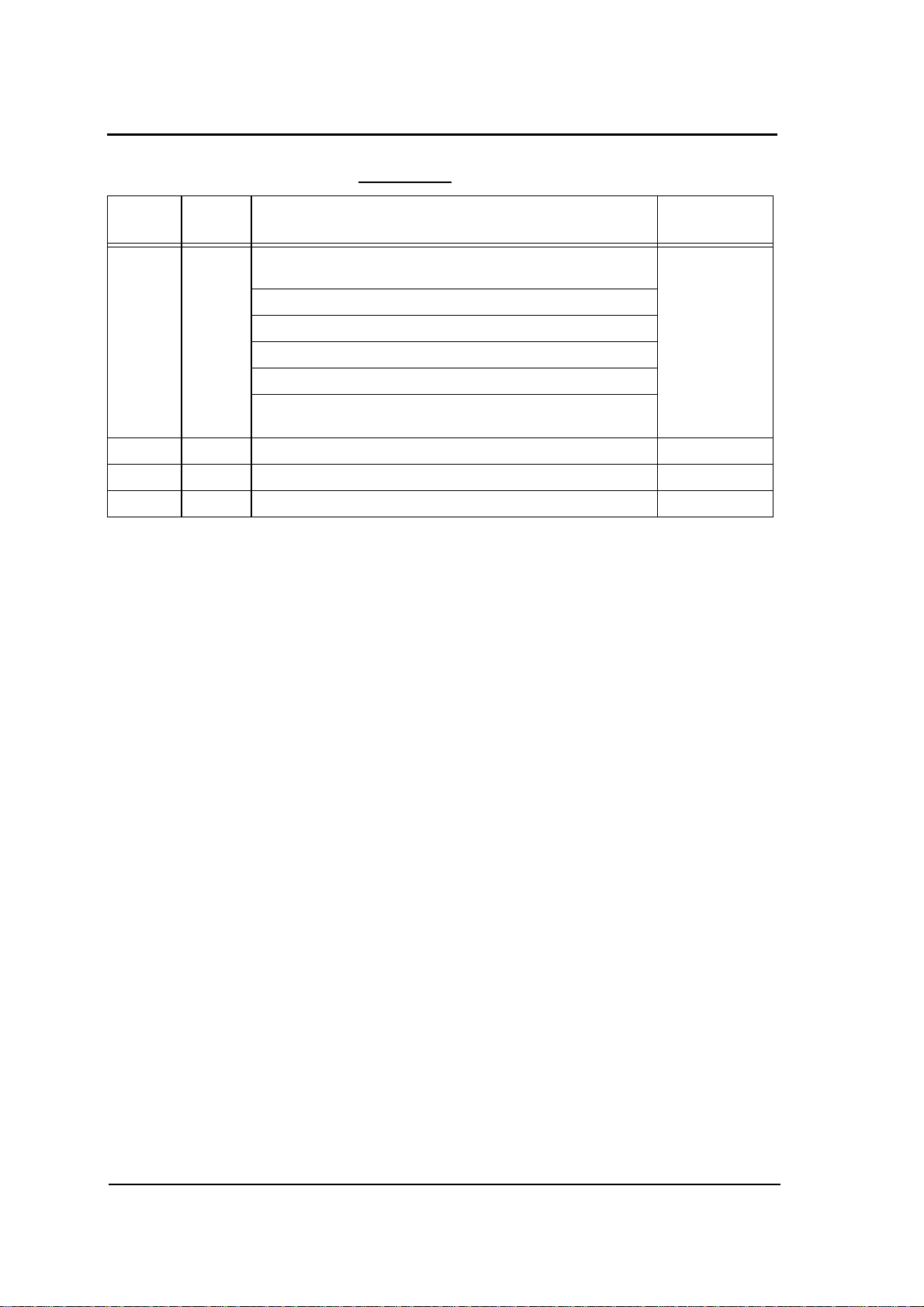

05 - Cover sheet : “Reed and keep this manual” is added. Sep. 21, 2006

Machine

Rev.

Page No. (Contents) Date

Back of cover sheet : “TRADEMARK” is added.

“NOTICE TO USER” is modified.

TOC-2(05) ~ TOC-4(04) : Some headings and Page No. are

modified.

1-4(01) : Transit Pass Unit T ype 156 is added.

1-10(01) : Figure 1-9 is changed.

2-10(02) : “Usage - Click Charge Counter” is added.

2-14(04) : “Cover Insert Mode” is added.

2-16(04) : “Letter TAB LEF” and “A4 TAB LEF” are deleted.

2-18(03) : “Paper Output - Default Output” is modified.

“Options - Cover Insert Mode” is added.

3-3(04) : “Letter Tab Stock” and “A4 Tab Stock” are deleted.

3-14(04) : Table 3-4 and NOTE statement are modified.

3-15(04) : “Loading Tab Stock Paper” is deleted.

3-16(04) : Figure3-15 and 3-16 are changed.

3-17(04) ~ 3-30(04) : Pages are shifted.

3-31, 3-32 : Pages are deleted.

4-24(01) : Figure4-40 and Figure4-41 are changed.

4-27(01) : Figure4-46 is changed.

4-29(01) : Figure4-51 is changed.

4-31(02) : Figure4-55 is changed.

4-42(02) : Figure4-83 is changed.

4-48(02) : Figure4-98 is changed.

4-51(03), 4-52(02) : All contents are added.

4-53(02) : Interval of “Discharger, Detach Corotoron” is modified.

4-54(02) ~ 4-66(01) : Contents are moved from previous page.

5-8(02) : Some notations are modified.

5-12(02) : Error code “E011” is added.

5-13(02) : Some contents are shifted.

5-14(02) : Error codes “E064”, “E065” and “E067” are added.

5-15(02) : Some contents are shifted.

5-16(02) : Error Codes “E0B2” and “E0B3” are added.

5-17(02) : Error code “E0D0” is added.

5-18(02) ~ 5-23(02) : Some contents are shifted.

Page 8

Rev. Table

Rev. for

Manual

05 - 5-24(02) : Error codes “E1E0”, “E1E1”, “E1E2” and “E1E3” are

Machine

Rev.

Page No. (Contents) Date

added

6-8(03) : “Click Charge Counter” is added to “Usage”.

6-9(03), 6-11(03) : Figure and contents are modified for Post Device.

6-14(03) : Figure 6-11 and contents are modified.

6-31(04) : “Paper Output” is modified.

6-44(04) : Figure 6-38 is changed.

“Cover Insert Mode” is added.

Sep. 21, 2006

Page 9

Table of Contents

SAFETY SUMMARY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Safety Summary-1

Introduction

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-1

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-1

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-2

For More Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-2

Chapter 1. Printer Overview

What This Chapter Provides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Printer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

I/O Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Operator Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

External View of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Internal View of the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Powering On the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Powering Off the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Clearing Error Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Space Required for Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Chapter 2. Control Panels

What This Chapter Provides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Description of Control Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

OCP Menu Icons and Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Using the OCP Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Using the Option Button Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Using the Ten Key Pad Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Using the + / - Change Button Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Using the Enable/Disable Change Button Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

OCP Menu Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Information Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2- 9

Printer Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Setup Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Reports Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Jobs Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Sub Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

OG L

Table of Contents TOC-1

0 3

Page 10

Chapter 3. Paper Handling

What This Chapter Provides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Unacceptable Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Storing Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Paper Sizes, Paper Weights, Paper Types and Paper Color . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Paper Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Paper Size Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Paper Weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Paper Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Loading Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Proper Paper Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Loading Paper in Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Loading Special Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Setting the Non-Standard Paper Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Setting the Paper Weight Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Setting the HV Adjust Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Setting the Table Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Setting the Paper Moisture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Preparing the Stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Set the Basket into the Stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Removing Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Removing Paper from the Stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Chapter 4. Care and Maintenance

What This Chapter Provides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Replacing Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Adding Toner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Replacing the Toner Bag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Replacing the Developer Mix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Replacing the Fuser Cleaning Web . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Replacing the Fine Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Winding the OPC Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Clearing Paper Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Regist Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Input Station Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Regist Station Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Paper Feed Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Container Stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

High Capacity Feeder (HCF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

Transit Pass Unit Type 156 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

Cleaning the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

Cleaning the Printer Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

Cleaning Trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

Cleaning the Container Baskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

Cleaning the Toner Bottle Joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-56

TOC-2 Table of Contents

OG L

0 5

Page 11

Cleaning the Discharger and the Detach Corotron. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-57

Clearing the Inverter Valve Piece. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

Cleaning the paper guide of the Fuser Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-60

Cleaning the paper guide of the Discharger Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

Handling and Storing Supplies and Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-64

Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-64

Toner and Developer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-65

Chapter 5. Troubleshooting

What This Chapter Provides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Guidelines Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Basic Troubleshooting Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

General Printing Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Print Quality Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Duplex Printing Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Printer Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

OCP Display Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Printer Status Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Printer Warning Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Printer Error Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Chapter 6. Web Utilities

What This Chapter Provides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Access and Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Accessing the Web Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Web Page Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Manage Status Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Status-General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Status-Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Status-Paper Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Status-Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Status-Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Status-Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Status-Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Status-Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Status-Revision. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Manage System Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

System-General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

System-Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

System-Paper Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

System-Virtual Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

System-Accounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

System-Jobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-38

System-Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-39

Manage Configuration Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-40

OG L

Table of Contents TOC-3

0 3

Page 12

Configuration-General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-41

Configuration-Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-42

Configuration-Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-43

Configuration-Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-48

Using the Accounting File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-53

Accounting Slip Sheet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-56

Appendix A . Specifications

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Base Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Consumables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Append ix B. Pa per S pecifications

Media Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

General Media Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Paper Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

Paper Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

Paper Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Paper Cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

Paper Smoothness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

Paper Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

Moisture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Paper Curl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-6

Recycled Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-7

Grain Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-7

Paper Smoothness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-7

Special Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-8

Preprinted Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-8

Prepunched Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-10

Adhesive Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-12

Perforated Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-15

Printing Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-17

Printable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-17

Preprinted Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-18

Preprint Inhibited Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-18

Glossary

TOC-4 Table of Contents

OG L

0 4

Page 13

SAFETY SUMMARY

General Safety Guidelines

Before operating the machine, read the following instructions carefully:

■ Allow all the operating procedures provided in this manual.

■ Pay special attention to and follow all the hazard warning on the machine and in

the manual. Failure to do so can cause injury to yourself or damage to the

machine.

■ The hazard warnings which appear on the warning labels on the machine or in the

manual have one of the following alert headings consisting of an alert symbol and

a signal ward, DANGER, WARNING, or CAUTION.

DANGER! : indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING!: indicates a potentially hazardous situation which, if not avoided,

can result in death or serious injury.

CAUTION!: indicates a hazardous situation which, if not avoided, will or can

result in minor or moderate injury, or serious damage of product.

The alert symbol shown left precedes every signal word for hazard

warnings, and appears in safety related descriptions in the manual.

The signal word ’NOTE’ is used to present warnings which are not directly related to

personal injury hazards.

■ Do not perform any operation or action in any way other than as provided in this

manual. When in doubt, call the designated field engineer.

■ Keep in mind that the hazard warnings in this manual or on the machine cannot

cover every possible case, as it is impossible to predict and evaluate all

circumstances beforehand. Be alert and use your common sense.

OG L

Safety Summary -1

0 0

Page 14

SAFETY SUMMARY

Hazard Warning Statements

WARNING Statement

■ “Use of controls, adjustments or pe rformance of procedures ot her than those

specified in this manual may result in hazardous laser radiation exposure.” on

page S afe ty Sum mary-5

■ “Connect the power plug only to a properly rated power outlet. Otherwise, a fire

or shock hazard may resul t.” on page Safety Summary- 8

■ “Never use multi-plug adaptors to plug multiple power plugs into the same power

source. Be sure to operate the printer on a sole-use receptacle. Multiple

connectors can cause overheating and a fire could result.” on page Safety

Summary-8

■ “The pri nter must be connected to the gro unding power outlet for safe and proper

operation.” on page Safety Summary-8

■ “Apparatet må kun tilkoples jordet stikkontakt.” on page Safety Summary-8

■ “Apparaten skall ansulatas till jordat uttag när den ansluts till ett nätverk.” on

page S afe ty Sum mary-8

■ “Für einen sicheren und ordnungsgemäßen Betrieb muß der Drucker an eine

geerdete Steckdose angeschlossen werden.” on page Safety Summary-8

■ “Do not throw the toner bottle into a fire because it may suddenly burn, causing a

risk of fire or personal injury.” on page 4-6

■ “Dispose the toner bottle as incombustible waste.” on page 4-6

■ “Waste materials should be disposed of or incinerated under conditions which

meet all federal, state and local environmental regulations. Since regulations may

vary from one region to another, check with the agency that governs waste

disposal i n your area for proper procedures.” on page 4-8

■ “Do not throw the developer bottle into a fire because it may suddenly burn,

causing a risk of fire or personal injury.” on page 4-16

■ “The Fuser Unit is very hot. Do not touch any parts of the Fuser Unit ex cept those

parts which are used to replace the Fuser Cleaning Web.” on page 4-17

■ “The Fuser Unit is very hot. Do not touch any parts of the Fuser Unit ex cept those

parts which are used to remove the paper. It is better to use the Bamboo Tweezers

to remove the paper. (The Bamboo Tweezers is an attached accessory.)” on page

4-35

CAUTION Statement

■ “Never unplug or rep lug the printer while it is on.” on page Safety Summa ry-9

■ “Do not place the printer near heaters or volatile, flammable, or combustible

materials.” on page Safety Summary-10

Safety Summary -2

OG L

0 1

Page 15

SAFETY SUMMARY

■ “Once the printer is powered off, wait at least 5 seconds to next power on.” on

page 1-6

■ “If the message “Open the Fuser cover, and check that there is no paper” is

displayed on the OCP, open the Fuser cover and check the Fuser unit refer to

Chapter 4.” on page 1-9

■ “If the printer does not power on, power off the printer, wait at least 30 seconds,

then power on the printer again.” on page 1-6

■ “You must set the correct paper weight value. The incorrect paper weight value

may cause pa per jam.” on page 3-20

■ “Depending on amount of paper, the Basket is very heavy. Take care not to hurt

your back when lifting a heavy Basket.” on page 3-30

■ “Toner is not harmful to the human body, but if some toner has come in contact

with your skin or clothes, you should wash it immediately with cold water.” on

page 4-3

■ “The toner is not harmful to the human body . However, take care not to inhale or

swallow it because you may feel sick. ” on page 4-6

■ “If the toner goes into your eyes, immediately rinse with running water. If

affected eyes are not rinsed, it may become injured. If the skin or clothing is

contacted, wash with soap and water” on page 4-6

■ “Hold the developer bottle when you turn the cap so that the bottle is not turned

together with the cap.” on page 4-10

■ “Hold the developer bottle when you turn the cap so that the bottle is not turned

together with the cap.” on page 4-13

■ “Incorrect setting of the Developer Bottle cause damage to the Developer Unit.

Make sure the setting of the Developer Bottle before go to next step.” on page 413

■ “If the developer is spilled out on the floor, the floor becomes very slippy. This

may result in a fall and/or injury. Clean up the spilled developer with a toner-safe

vacuum cleaner.” on page 4-15

■ “If the developer goes into your eyes, immediately rinse with running water. If

affected eyes are not rinsed, it may become injured. If the skin or clothing is

contacted, wash with soap and water” on page 4-15

■ “Surface of the Photoconductor Drum (OPC Sheet) is very sensitive. Carefully

remove a paper to avoid scratch the surface of the Photoconductor Drum.” on

page 4-32

■ “The paper i n the Fus er Unit mu st be re moved by step 8 to step 14 wh en the Fuse r

Jam is happened. If the paper remains in the Fuser Unit, paper is scorched, or it

causes an other paper jam, or it causes some mechanical damage.” on page 4-33

■ “Incompletion of closing the Fuser Unit Cover and the Paper Guide cause damage

to the Fuser Unit. Make sure the Fuser Unit Cover and the Paper Guide are

completely closed.” on page 4-36

■ “Power off the printer prior to cleaning.” on page 4-51

Safety Summary -3

OG L

0 2

Page 16

SAFETY SUMMARY

■ “Do not use solvent on the printer. Using solvent may dissolve the plastic and

paint of t he printer.” on page 4-51

■ “Do not use c leaning solut i ons to clean inside and around the printe r. Use only a

water-moistened cloth.” on page 4-51

■ “For cleaning up toner or developer spillage, use a specially-designed toner-safe

vacuum cleaner. If you use a regular vacuum cleaner, the drawn toner/developer

powder may scatter in the air. If you inhale or your eyes come into contact with

such powder, you may feel sick or injure your eyes. Further, the drawn toner/

developer powder may render the vacuum cleaner defective when it enters the

vacuum cleaner’s motor section.” on page 4-51

■ “The Paper Height Sensor in the Tray is sensitive. Carefully cleaning a Tray to

avoid a damage to the Paper Height Sensor.” on page 4-52

■ “If the message “Open the Fuser cover, and check that there is no paper” is

displayed with E31x Call for Service error, open the Fuser cover and check the

Fuser unit refer to Chapter 4.” on page 5-24

■ “Do not use paper that contains CaCO3 as it can drastically reduce fuser life.” on

page B-4

■ “Adhesive that comes in contact with the printer may contaminate the

photoconductor and the internal printer mechanism. To test label stock for

adhesive exposure, press a sheet of plain paper against a sheet of label stock. The

plain pap er should not adhere to the label stock at all.” on page B-12

Safety Summary -4

OG L

0 2

Page 17

Laser Safety

This printer is certified as a Class 1 laser pr oduct under the U.S. Department of Health

and Human Services (DHHS) Radiation Performance Standard according to the

Radiation Control for Health and Safety Act of 1 968. Th is means that the printer does

not emit hazardous laser radiation.

Since radiation emitted inside the printer is completely confined within the protective

housings and external covers, the laser beam cannot escape from the machine during

any phase of user operation.

The Center for Devices and Radiological Health (CDRH) of the U.S. Food and Drug

Administration implemented regulations for laser products on August 1976. These

regulations apply to laser products marketed in the United States. The label on the

printer indicates compliance with the CDRH regulations and must be attached to laser

products marketed in the United States.

This printer is classified as a Class 1 laser product both under EN60825 and the Code

of Federal Regulations, 1040.10 of Title 21.

SAFETY SUMMARY

LOUKAN 1 LASERLAITE

CLASS 1 LASER APPARA T

Internal Laser Radiation

Maximum Radiation Power: 10mW x 4 diodes

Wave Lengt h: 780nm

WARNING!

Use of controls, adju st ments or perform ance of procedures other than

those specified in this manual may result in hazardou s laser radiation

exposure.

OG L

Safety Summary -5

0 0

Page 18

Certifications

FCC Notice

This equipment has been tested and found to comply with the limits for a Class A

digital device pursuant to Part 15 of FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with this user’s guide,

may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference. If this occurs, users are

required to correct the interference at their own expense.

Use of shielded cables is required to comply with Class A limits in Subpart B of

Part 15 of FCC Rules.

Do not make any changes or modifications to the equipment other than those specified

in this user’s guide.

You may find the following booklet prepared by the Federal Communications

Commission helpful: How to Identify and Resolve Radio - TV Interference Problems.

This booklet is available from the U.S. Government Printing Office, Washington, D.C.

20402, Stock N o. 00 4- 000-00345-4.

SAFETY SUMMARY

Canadian Certification

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

VCCI Notice (Japan)

This is a class 1 product based on the standard of the Voluntary Control Council for

Interference by Information Technology Equipment (VCCI). If this equipment is used

in a domestic environment, radio disturbance may arise. When such trouble occurs, you

may be required to take corrective actions.

Safety Summary -6

OG L

0 0

Page 19

SAFETY SUMMARY

Declaration of Conformity for Safety/EMI

The Printer, High Capacity Feeder and Container Stacker conform to the directives and

standards shown below . For further information or to request a copy of the Declaration

of Confor mity, contac t your Distri butor.

1. EMC directive 89/336/EEC, 92/31/EEC

Emission:EN 55022 (Class A) / 1998 / A1: 2000 / A2: 2003

EN61000-3-2: 2001

EN61000-3-3 / 1995 / A1 : 2001

Immunity:EN55024 / 1998 / A1: 2001 / A2: 2003

IEC6100 0-4-2 / 1995/A1:1998 / A2: 2001

IEC61000-4-3 / 2002

IEC61000-4-4 / 1995 / A1:2000 / A2: 2001

IEC6100 0-4-5 / 1995 / A1: 2001

IEC6100 0-4-6 / 1996/ A1: 2001

IEC6100 0-4-8 / 1993 / A1: 2000

2. Low Voltage Directive 73/23/EEC incl. Amendments:

EN60950:1: 2001

EN60825-1:1993 / A1: 1997 / A2: 2001

3. CE Marking Directive 93/68/EEC

This equipment has been tested and found to comply with the limits for a class A

Information Technology Equipment in accordance with the European Standard

EN55022.

These limits are designed to provide reasonable protection against unacceptable

interference in either commercial or industrial environments. This equipment

generates, uses, and can radiate radio signals and if it is not installed and used in

accordance with the instructions detailed in this user’s guide, it may cause unacceptable

interference to radio communication installations and equipment. The operation of this

equipment in a residential area is likely to cause unacceptable interference in which

case you may be required to correct the source of the interference at your own expense.

In order to maintain compliance to the class A regulations, shielded cables must be used

with this equipment. Operation of this equipment without shielded cables is likely to

cause interference to radio and television receivers thereby degrading their reception.

Please be aware that changes and modifications made to the equipment without prior

approval of the manufacturer could negate your permission to operate the equipment.

Declaration of Conformity for RoHS

The Printer, High Capacity Feeder, and Container Stacker conform to the directives and

standards shown below . For further information or to request a copy of the Declaration

of Confor mity, contac t your Distri butor.

1. Restriction of Hazardous Substances (RoHS) Directive2002/95/EC

Safety Summary -7

OG L

0 1

Page 20

SAFETY SUMMARY

When Installing and Relocating the Printer

Power Specifications

Power Cords

WARNING!

Connect the power plug only to a properly rated power outlet. Otherwise,

a fire or shock hazard may result.

Never use multi-plug adaptors to plug multiple power plugs into the same

power source. Be sure to operate the printer on a sole-use receptacle.

Multiple connectors can cause overheating and a fire could result.

Ensure that the plug connection is free of dust. In a damp environment, a contaminated

connector can draw a non-negligible amount of current that can generate heat and

eventually cause a fire over an extended period of time.

To prevent the risk of electric shocks and personal injury, fire, and printer damage:

■ Always use the power cord provided with your printer. When an extension power

cord is required, always use a properly rated cord.

Rated Voltage

200/208/220/230/240V 50/60Hz 21A

380/400/415V 50/60Hz 21A

Rated

Frequency

Rated Current

If the power cord is not provided, use the following types of power cords:

❒ For North America:

❒ For Europe

WARNING!

The printer must be connected to the grounding power outlet for safe and

proper operation.

Apparatet må kun tilkoples jordet stikkontakt.

Apparaten skall ansulatas till jordat uttag när den ansluts till ett nätverk.

Für einen s i cheren und ordnungsgemäßen Betrieb muß der Drucker an

eine geerdete Steckdose angeschlossen werden.

Safety Summary -8

2

4 wires, Type SJT 4x12 AWG (4x4.0 mm

) or thicker

Rated min. 30 0V/ 2 5A (w it h gr ounding plu g) .

5 wires, min. 5x4.0 mm

2

Harmoni zed (<HAR>), Rated mi n. 300V/25A (with grounding plug).

OG L

0 1

Page 21

SAFETY SUMMARY

■ Do not attempt to rework, pull, bend, chafe, or otherwise damage the power cord.

Do not place a heavy object on the cord.

■ Never touch a power cord with wet hands.

■ If your printer produces smoke, excessive heat, unusual noises or odors, or if any

liquid is spilled into the printer, immediately switch off and unplug the printer.

■ If the power cord is broken or insulated wires are exposed, be sure to get them

replaced. (Do not use the damaged cord.)

CAUTION!

Never unplug or replug the printer while it is on.

■ When unplugging the printer, grasp the plug instead of the cord.

■ Be sure to switch off and unplug the printer before accessing its interior for

cleaning or maintenance.

■ When the printer is not used over an extended period of time, switch it off and

unplug it.

■ Once a month, unplug the printer and check that:

❒ t he power cord is plugged firmly into a receptacle.

❒ t he power cord is not cracked or frayed.

❒ t he plug is not excessively heated, rusted, or bent.

❒ t he plug and receptacle are free of dust.

NOTE:

If you notice any unusual conditions, contact your service representative.

OG L

Safety Summary -9

0 1

Page 22

SAFETY SUMMARY

Position in g the Printer Saf el y

To prevent the risk of electric shocks and personal injury, fire, and printer damage:

■ Switch off the printer before connecting the interface cable or optional accessory.

CAUTION!

Do not place the printer near heaters or volatile, flammable, or

combustible materials.

■ Place the printer on a level and sturdy surface that can withstand the printer’s

weight. If tilted, the printer may fall over and cause injuries.

■ Do not place the printer in a hot, humid, dusty , or poorly ventilated environment.

■ When moving the printer, be sure to unplug the power cord from the outlet. If the

printer is moved with the power cord connected, it can cause damage to the cord.

■ When moving the printer, do not tilt it more than 10 degrees. If tilted excessively,

the printer may fall over and cause injuries.

■ If you need to move the printer over a long distance, consult your Technical

Representative.

Environmental Limit

■ The printer is capable of operating normally within the following recommended

environmental limits:

❒ Temperature range: 60°-89°F (16°-32°C).

❒ Humidity range: 20-80% RH ( no condensation).

NOTE:

Sudden temperature fluctuations can affect print quality. Rapid heating of

a cold room can cause condensation inside the printer, directly interfering

with image transfer.

■ Do not expose the printer to direct sunlight, or the printer's performance may

decline.

Safety Summary -10

OG L

0 1

Page 23

SAFETY SUMMARY

Operating Precaution s

■ Take care not to allow ties, sleeves, shirts, or long hair to be caught in the printer

while operating.

■ Be careful not to touch the hazardous parts near the caution labels.

■ Be sure to avoid accidentally powering on the printer or pressing switches on the

operator’s panel while operating the printer.

■ Never touch the high voltage portions of the printer, where caution labels are

attached, when the printer is on. It may cause personal injuries if accidentally

touched.

■ Make sure that the printer paper complies with the supplies specifications.

Printing on paper which does not comply with the specifications may result in

paper jams and print quality degradation.

■ Properly load the paper into the hopper to prevent paper skew and paper jams.

■ It is absolutely necessary to follow the procedures and instructions described in

this manual in order to optimize the printer’s performance and to assure its safe

operation.

OG L

Safety Summary -11

0 1

Page 24

SAFETY SUMMARY

SAFETY PREC A U T I O NS

■ Always keep the area around the printer tidy. Use the printer under the proper

lighting (500-1,000 lux.). Keep sufficient space around the printer so the hoppers

can be pulled forward. Space required in the vicinity of the printer is as follows:

Front side: 1 meters

Left, right and rear side: 1 meter

■ Do not place anything on the printer.

■ Do not open any covers during printing operation. It may cause personal injuries

if moving elements or electrical parts are accidentally touched.

■ Be particularly careful when working in the fuser unit area. Do not touch the

inside of the fuser unit. The fuser unit becomes very hot (approx. 374°F [190°C])

and it may cause personal injuries if accidentally touched.

■ Toner and de veloper are comprised of powdery particles. Avoid inhaling to ner or

developer when it accidentally spills and circulates. If it spills on the floor,

immediately clean it with water-damped cloth. Do not leave it on the floor. I t may

cause accidents if stepped on as they are slippery beads of metal.

■ Limit your operations to those described in this manual. Contact the field engineer

or service technician for further operations which are not explained in this

manual.

■ This equipment generates ozone. Long-term exposure should be limited to 0.1

ppm calculated as an 8 hr. time weighted average concentration. Provide proper

ventilation. Avoid installing the unit in a small room (smaller than 27cubic

meter). If installing in a space smaller than 27cubic meter, frequent ventilation is

necessary

Safety Summary -12

OG L

0 2

Page 25

SAFETY SUMMARY

Care of Printer Supplies

■ Store the paper, toner , and other supplies in a place free from direct sunlight and

away from any heating apparatus. Keep them in a dry, cool, clean environment.

■ Store paper that has been removed from its wrapper, but not loaded into the

drawer, in a sealed, plastic bag in a cool, dark place.

■ If your hands become soiled with toner, wash them with soap and water

immediately.

Caution Labels

Following figure shows the caution labels affixed on the printer.

OG L

Safety Summary -13

0 1

Page 26

SAFETY SUMMARY

Blank

Safety Summary -14

OG L

0 1

Page 27

About This Manual

This manual provides easy access to the information you need to operate the 156PPM

(Pages Per Minute) laser printer.

NOTE:

This User’s Guide is intended to be viewed online. When viewing it online,

use the bookmarks and page reference links for easy navigation

throughout the do c ume n t .

To find out about a specific topic, refer to:

■ SAFETY SUMMARY – For safety information and printer characteristics,

including environmental and electrical requirements.

■ Chapter 1: Printer Overview – For printer components and features.

■ Chapter 2: Operator Control Panel – To access and use the liquid crystal display

(LCD) window and the menus screens.

■ Chapter 3: Paper Handling – For media recommendations and paper handling

procedures.

Introduction

Audience

This manual is written for those persons responsible for operating the printer. A basic

understanding of computer equipment and its operations is required.

■ Chapter 4: Care and Maintenance – For detailed instructions on replacing

consumables, clearing paper jams, and cleaning and maintaining the printer.

■ Chapter 5: Troubleshooting – For information on printing problems and printer

error and warning messages .

■ Chapter 6: Web Utilities – For information on accessing the printer via the

Internet or your company’s Intranet.

■ Appendix A: Specifications – For printer specifications.

■ Appendix B: Paper Specifications – For media specifications and printing

guidelines.

■ Glossary – For definitions of terms and acronyms.

OG L

Introduction 0-1

0 0

Page 28

Manual Conventions

The following conventions are used in this manual:

■ Bold and Italics are used sparingly for emphasis.

■ Information you e n ter: Looks Like This.

■ Key Names (or Labels): Look Like This.

■ System message s: Look Like This.

■ Variable user information: Looks Like This.

Pay particular attention to Notes, Cautions, and Warnings. These alert you to critical

information, as follows:

NOTE:

Provides important additional information.

CAUTION!

Alerts you to an operating procedur e, practice, or condition that, if not

strictly observed, might result in damage to the equipment.

WARNING!

Alerts you to an operating procedur e, practice, or condition that, if not

strictly observed, can result in safety hazards to personnel, severe injury,

or loss of life.

For More Information

Refer to the following related documents for more details about your printer.

■ Installation Guide

■ Engine Maint enance Manu al

■ Controller Maintenance Manual

■ Parts Catalog

0-2 Introduction

OG L

0 0

Page 29

What This Chapter Provides

This chapter describes the parts and functions of the printer.

■ Printer Features

■ External View of the Printer

■ Internal View of the Printer

■ Powering On the Printer

■ Powering Off the Printer

■ Space Required for Installation

Chapter 1

Printer Overview

OG L

Printer Overview 1-1

0 0

Page 30

Printer Features

The printer is a high-speed, heavy duty laser printer for a 1.5M page/month printing

environment. It incorporates a wide variety of features:

■ High-Speed and High-Quality Printing.

❒ Print speed is up to 156 pages per minute (ppm), A4/Letter/Legal (Simplex).

❒ The printing output is at a reso lut i o n of 60 0 dots per inch (dpi), assuring

razor-sharp graphic and text output, even at very small point sizes.

■ Flexible Paper Source and Delivery.

Paper Source:

❒ Standard – One 2,500-she et and one 1,000-sheet universal paper trays.

❒ Option – High Capacity Feeder with 3,000 to 12,000-sheet capacity.

Paper Delivery:

❒ Standard – Container Stacker with 2,000 to 4,00 0-sheet capacity and st acking

capability.

❒ Option – Additional Container S tacker with 2,000 to 4 ,000-sheet capacity and

stacking capability.

■ Multiple Original Printing (MOP) – for printing of multiple collated document

sets without multiple file transfers. Processes PCL and PostScript jobs once,

stores the images on disk, and prints each set from disk (after the first set).

■ Virtual Printer Technology (VPT) – allows a single printer to offer print services,

or virtual printers, each of which is configured by the Network Administrator.

■ Web Utilities – for remote access to the printer through the Internet or your

company’s Intranet.

■ Ergonomic operati on.

❒ The easy-to-read display clearly shows the operational status of the printer.

1-2 Printer Overview

OG L

0 0

Page 31

■ High-volu me pr i nti ng .

❒ Two standard paper trays with approximately 3,500-sheet capacity total.

❒ Optional High Capacity Feeder (HCF) adds up to 12,000 additional sheets.

❒ Together they allow continuous printing of up to 15,500 sheets.

■ Supports a wide-range of media types (plain, bond, letterhead, special application,

recycled, labels) and sizes. See “Paper” on page 3-2 for more information.

■ Printer Language Support.

❒ PCL5e and PCL XL printer langua g e.

❒ PostScript Level III (Adobe) printer language.

❒ P DF and TIFF files printing.

NOTE:

PDF Files printing is only supported for PDF Version 1.3.

■ Network.

❒ Ethernet 10/100/1000 Base-T with onboard network

❒ Additional Ethernet 10/100 Base-T with Multi-protocol NIC option.

■ Network Protocol.

❒ TCP/IP, LPR/LPD and IPP with onboard network.

❒ TCP/IP, LPR/LPD, NetWare IPX/SPX, Ethertalk with Multi-protocol NIC

option.

■ Easy installation of additional fonts and macros using the PCL Startup File.

I/O Configurations

■ Ethernet 10/100/1000 Base-T with onboard network.

■ Additional Ethernet 10/100Base-T with Multi-protocol NIC option.

Operator Control Panel

The Operator Control Panel (OCP) is your physical interface to the printer's features

and functions. From the control panel, you can monitor the printer's operating status

and configure the specific printer functions.

See Chapter 2 for detailed information about the OCP.

OG L

Printer Overview 1-3

0 0

Page 32

External View of th e Printer

The following illustration shows the printer with optional Container Stacker, optional

High Capacity Feeders, optional Finisher Transfer Unit and optional Attention Light

are installed.

7. High Capacity Feeder 1

10. High Capacity Feeder 2

12. HCF2 Upper Tray

11. HCF2 Lower Tray

3. Toner Supply Cover

9. HCF1 Upper Tray

8. HCF1 Lower Tray

Figure 1-1. External View of the Printer

1. Power Switch

6. Tray 2

4. Operator Control Panel

13. Sample Tray

2. Front Cover

5. Tray 1

21. T r a nsit Pass Unit

20. Attention Light

14. Container Stacker 1

16. Container1 Upper Tray

17. Container Stacker 2

19. Container 2

Upper Tray

15. Container1 Lower Tray

Type 156

18. Container 2

Lower Tray

Table 1-1. External View of the Printer

Key Component Description

1 Power Switch Press to turn the printer on and off.

2 Front Cover Open to replace units, clear paper j ams, or clean the print er.

3 Toner Supply C over Open to replenish the toner supply.

4 Operator Control Panel (OCP) Displays printer status and menu information.

5 Tray 1 Holds up to 2,500 sheets of paper.

6 Tray 2 Holds up to 1,000 sheets of paper.

7 High Capacity Feeder 1 Two 3,000-sheet input trays.

8 HCF1 Lower Tr ay Holds up to 3,000 sheets of paper.

9 HCF1 Upper Tr ay Holds up to 3,000 sh eets of paper.

10 High Capacity Feeder 2 Two 3,000-sheet input trays.

11 HCF2 Lower Tray Holds up to 3,000 sheets of paper.

12 HCF2 Upper Tr ay Holds up to 3,000 sheets of paper.

13 Sample Tray 100-sheet output tray

14 Container Stacker 1 Two 2,000-sheet output trays

15 Container1 Lower Tray Stacks up to 2,000 sheets of paper.

16 Container1 Upper Tray Stacks up to 2,000 sheets of paper.

17 Container Stacker 2 Two 2,000-sheet output trays

18 Container2 Lower Tray Stacks up to 2,000 sheets of paper.

19 Container2 Upper Tray Stacks up to 2,000 sheets of paper.

20 Attention Light Indicates er ror, warning and printer ready status.

21 Transit Pass Unit Type 156 Paper transport unit for Post Device.

1-4 Printer Overview

OG L

0 1

Page 33

Internal View of the Printer

1. Toner Supply Cover

2. Developer Duct

3. Drum Unit

4. Fuser Unit

6. SF Cover

5. Toner Bottle / Toner Bag

7. Main AC Power Switch

Figure 1-2. Internal V iew of the Printer

Table 1-2. Internal View of the Printer

Key Component Description

1 Toner Supply Cover Open this cover when supplying the new toner.

2 Developer Duct

3 Drum Unit OPC drum.

4 Fuser Unit Fuses the toner on the paper.

5 Toner Bottle/Toner Bag Collect the waste toner.

6 SF Cover Open this cover when replacing the Fine Filter.

7 Main AC Power Switch Turn the printer main AC power on and off

Mount the developer bot tle onto th e devel op er du ct to repla ce

consumed developer

OG L

Printer Overview 1-5

0 1

Page 34

Powering On the Printer

The printer has two power switches, the Main AC Power Switch and the Power

Switch. The location of switches are shown below. Both switches are marked “I” for

power on.

Main AC Power Switch

When the printer is powered on, the printer go through a power-up sequence that takes

approximately 5 minutes. During the power-up sequence, the printer runs a series of

internal tests.

CAUTION!

Once the printer is powered off, wait at least 5 seconds to next power on.

If the printer does not power on, power off the printer, wait at least 30

seconds, then power on the printer again.

Power Switch

Figure 1-3. Powering On the Printer

1-6 Printer Overview

OG L

0 0

Page 35

Power ing Off the Prin ter

The printer should only be powered off when it is in a “Ready” state; that is, there are

no jobs printing or proc essing. The following OCP displays indicate nor mal

conditions. In these conditions, wait until printing is complete and the printer is

Ready, then switch off the Power Switch.

Figure 1-4. Normal Conditions

If the printer status is Pause/Offline, touch the “” button to return printer to a Ready

status bef ore pow eri n g off.

Figure 1-5. Pause/Offline

OG L

Printer Overview 1-7

0 0

Page 36

Clearing Error Con di tio ns

OCP Alternates between Ready and Processing

1. Cancel the print job(s). For detail of canceling print job,

Figure 1-6. OCP Alternates between Ready and Processing

E0XX, E1XX Error

1. Correct the error and touch the “” button on the OCP display.

2. Wait until printing is complete and the printer returns to Ready, then switch off

the main power.

1-8 Printer Overview

Figure 1-7. E0XX, E1XX Error

OG L

0 0

Page 37

E2XX, EC#XX Call for Service Error

1. Touch the “” button on the OCP display.

2. Wait until printing is complete and the printer returns to Ready.

Figure 1-8. Call for Service Error

CAUTION!

If the message “Open the Fuser cover , and check that there is no paper” is

displayed on the OCP , open the Fuser cover and check the Fuser unit refer

to Chapter 4.

3. If the Call for Service error persists, cancel the print job(s), power off the printer,

and contact your authorized service technician.

OG L

Printer Overview 1-9

0 1

Page 38

Space Required for Installation

)

Install the printer in a well-ventilated place and keep around the printer as shown

below for safe and effective operation.

Required Sp ace (for Maximum Configuration

1-10 Printer Overview

Figure 1-9. Space Required for Installation

OG L

0 1

(Top View)

Page 39

What This Chapter Provides

This chapter contains information on the following topics.

■ Description of Control Panels

■ OCP Menu Icons and Buttons

■ Using the OCP Menus

■ OCP Menu Struct ure

■ Sub Panel

Chapter 2

Control Panels

OG L

Control Panels 2-1

0 0

Page 40

Description of Control Panels

The Operator Control Panel (OCP) is a touch panel display that you use to set up print

options and monitor job and printer status. It is also used by the Network Administrator

to configure the printer and by the Service Technician to perform maintenance on the

printer.

This prin ter also have sub panel equipped to each In put and Output Trays. S ub panel

has some functions to each Input and Output Trays.

Sub Panel (Input Tray)

Operator Control Panel

Sub Panel

(Output Tra y)

Figure 2-1. Operator Control Panel

2-2 Control Panels

OG L

0 0

Page 41

OCP Menu Icons and Buttons

The menus are accessed via the touch panel. Each OCP menu consists of icons and

buttons that you use to make selections. The icons and buttons are defined below . See

“Main Menu” on page 2-8 for more icons.

Table 2-1. OCP Menu Icons and Buttons

Icon or

Button

?

i

Name Function

Help Touch to display Help on the current screen.

Information From the Main Menu, displays information about the printer and

Pause/Offline Touch to pause the printer.

Resume/Online When the printer is offline, touch to return to Ready status.

Return to Main

Menu

Previous Menu Touch to cancel the current selection and return to the previous screen

More Options Touch to display additional options for the current selection.

Enter or Accept Confirm or Done. Touch to confirm your selection and return to the

consumables.

From relevant scre ens, displ ays an illus tr ation o f the p a per trays

or finisher trays.

Touch to cancel the current selection and return to the Main Menu.

or menu.

previous screen or menu.

Sample Touch to dup lica te a curr ent prin ting page and output to the sample tray.

Clear Button Touch to erase entire entry.

Delete Button Touch to erase last character entered.

–

Ten Key Use to enter numeric values.

Brightness Use to adjust backlight value of the OCP display.

Contrast Use to adjust the contrast level of the OCP display.

Status Bar Displays the current screen name and/or any system messages.

Control Panels 2-3

OG L

0 0

Page 42

Using the OCP Menus

There are 4 types of OCP Menu displays.

■ Option Button

■ Ten Key Pad

■ Change Button (+ / -)

■ Change But t on (E nab l e /D i s abl e )

A brief description of each menu and how to use it follows.

Using the Option Button Menu

The image below is a sample of a menu with Option buttons. The status bar indicates

the current setting. In this sample there is a More Options button indicating there are

more options to choose from on the following page.

Status Bar

Option Buttons

Previous Menu

More Options

Figure 2-2. Option Button Menu

Enter/Accept

To use this menu,

1. Touch the Option button. The selection is highlighted.

2. Touch the Enter/Accept button to activate the selection.

NOTE:

The selection will be ignored if the Enter/Accept button is not touched, or

if any other button is touched prior to touching Enter/Accept.

2-4 Control Panels

OG L

0 0

Page 43

Using the Ten Key Pad Menu

The image below is a sample of a menu with a ten key pad. It is used to enter numeric

values.

Status Bar

Text Box

Ten Key Pad

Figure 2-3. Ten Key Pad Menu

Erase Entire Entry

Erase Last Digit

Unit Value

Previous Menu

Enter/Accept

To enter a value,

1. Touch the appropriate numbers on the pad. The value appears in the T ext Box.

2. Touch the desired Unit Value button (if applicable).

3. Touch the Enter/Accept button to activate the entry.

NOTE:

The entry will be ignored if the Enter/Accept button is not touched, or if

the Previous Menu button is touched prior to touching Enter/Accept.

OG L

Control Panels 2-5

0 0

Page 44

Using the + / - Change Button Menu

The image below is a sample of a menu with a + / - change button. It is used to increase

and decrease the OCP brightness and contrast. The current value is displayed to the

right of the icon.

Decrease -

Increase +

Figure 2-4. + / - Change Button Menu

10

10

Current Value

3

Previous Menu

Enter/Accept

To increase or decrease the value,

1. Touch the + or - to adjust brightness or contrast. The numeric value and the

display will change immediately.

NOTE:

Brightness control is not displayed in the production model after April ‘06.

Touch the Enter/Accept button to activate setting.

NOTE:

The setting will be ignored if the Enter/Accept button is not touched, or if

the Previous Menu button is touched prior to touching Enter/Accept.

2-6 Control Panels

OG L

0 1

Page 45

Using the Enable/Disable Change Button Menu

The image below is a sample of a menu with an Enable/Disable toggle. It is used to turn

an option on or off.

40 seconds

Disabled

Options

Figure 2-5. Enable/Disable Change Button Menu

1. Touch the Option Button to toggle between enable and disable. The current

setting appears to the right.

2. When you are finished, touch the Previous Menu button.

NOTE:

The Enter/Accept button is not used for Enable/Disable options. The

setting is activated immediately.

Disabled

Middle

Current Status

Previous Menu

OG L

Control Panels 2-7

0 2

Page 46

OCP Menu Structure

The OCP menu is structur ed as show n on the fo llowing pages. A top level me nu screen

is shown followed by a description of the options on the screen. A table that outlines

the complete structure of the menu is also provided. Each box in the table represents an

OCP display menu. Use this information to assist you in setting printer options.

Main Menu

The Main Menu screen is shown below. A description of the icons that make up the

screen follows.

Status Bar

Printer Menu

Setup Menu

Jobs Menu

Printer Menu

Touch to display the Printer Menu.

Setup Menu

Touch to display the Setup Menu.

Reports Menu

Touch to display the Reports Menu.

Help

Current Screen

Information

Reports Menu

Sample

Pause/Offline

Figure 2-6. Main Menu

Jobs Menu

Touch to display the Cancel Printing screen and view a list of all jobs.

For other buttons or ic ons, see “Using the Option Button Menu” on page 2-4.

2-8 Control Panels

OG L

0 0

Page 47

Information Menu

When you touch the information icon on the Main Menu this screen is displayed. You

can use it to determine the current settings and status of the options described below.

See Table 2-2 on page 2-10 for the complete Information Menu structure.

Printer

Touch to display information about the engine and controller software revision, error

counts, and the current paper type and source settings.

Consumables

Figure 2-7. Information Menu

Displays the status of the consumables: Toner, Developer Mix., OPC Sheet, and OPC

Sheet Counter.

Usage

Displays current information regarding print density, preventative maintenance, and

page coun ts.

Paper Output

Displays current information regarding the Output Tray of the printer.

Network

Displays information such as MAC and IP Address, Gateway Address, Subnet Mask

and HTTP Port.

OG L

Control Panels 2-9

0 0

Page 48

Table 2-2. Information Menu St ructure

Level 1 Level2 Level 3 Level 4

Informati on Printer 1 Size, Status, Type, Weight

2 Size, Status, T ype, Weight

HCF1 Lower (Note1) Size, Sta tus, Type, Weight

HCF1 Upper (Note1) Size, Status, Type, Weight

HCF2 Lower (Note1) Size, Sta tus, Type, Weight

HCF2 Upper (Note1) Size, Status, Type, Weight

Printer Graphic

Default Paper Source

Error Count of This Period

Controller Revision

Consumable Toner Normal/Low

Developer Mix (current/limit k)

OPC Sheet (current/limit k)

OPC Sheet Counter (curren t/limit k)

Usage Toner Cov erage (current %)