Page 1

E-800A

INSTALLATION AND SERVICE GUIDE

A guide for service technicians

Part Number: 45012878

Page 2

Page 3

Copyright © 2000 Electronics For Imaging. All rights reserved.

This publication is protected by copyright, and all rights are reserved. No part of it may be reproduced or transmitted in any form or by any means for any purpose without express prior

written consent from Electronics For Imaging, except as expressly permitted her ein. Information in this document is subject to change without notice and does not r epresent a commitment

on the part of Electronics For Imaging.

The software described in this publication is furnished under license and may only be used or copied in accordance with the terms of such license.

Patents: 5,867,179; 5,835,788; 5,666,436; 5,553,200; 5,543,940; 5,537,516; 5,517,334; 5,506,946; 5,424,754; 5,343,311; 5,212,546; 4,941,038; 4,837,722; 4,500,919; D406,117

Trademarks

EFI, the EFI logo, Fiery, the Fiery logo, Fiery Driven, the Fiery Driven logo, EFICOLOR, ColorWise, and Rip-While-Print are trademarks registered in the U.S. Patent and Trademark

Office. Fiery ZX, Fiery X2, Command WorkStation, AutoCal, Starr Compression, Memory Multiplier, NetWise, and VisualCal are trademarks of Electronics For Imaging, Inc.

Adobe, the Adobe logo, Adobe Illustrator, PostScript, Adobe Photoshop, Adobe Separator, and Adobe PageMaker are trademarks of Adobe Systems Incorporated, registered in certain

jurisdictions. EPS (Encapsulated PostScript) is a trademark of Altsys Corporation. Apple, the Apple logo, AppleShare, AppleTalk, EtherTalk, LaserWriter, and Macintosh are registered

trademarks, and MultiFinder is a trademark of Apple Computer, Inc. Microsoft, MS, MS-DOS, and Windows are registered trademarks of Microsoft in the US and other countries.

QuarkXPress is a registered trademark of Quark, Inc. Times, Helvetica, and Palatino are trademarks of Linotype AG and/or its subsidiaries. ITC Avant Garde, ITC Bookman, ITC Zapf

Chancery, and ITC Zapf Dingbats are registered trademarks of International Typeface Corporation. Ethernet is a registered trademark of Xerox Corporation. NetWare and Novell are

registered trademarks and Internetwork Packet Exchange (IPX) is a trademark of Novell, Inc. UNIX is a registered trademark of UNIX System Laboratories, a wholly owned subsidiary of

Novell, Inc. PANTONE is a registered trademark of Pantone, Inc.

All other terms and product names may be trademarks or registered trademarks of their respective owners, and are hereby acknowledged.

Legal Notices

APPLE COMPUTER, INC. (“APPLE”) MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION THE IMPLIED WARRANTIES OF

MERCHANT ABILITY AND FITNESS FOR A P AR TICULAR PURPOSE, REGARDING THE APPLE SOFTWARE. APPLE DOES NOT WARRANT, GU ARANTEE, OR MAKE

ANY REPRESENTATIONS REGARDING THE USE OR THE RESULTS OF THE USE OF THE APPLE SOFTWARE IN TERMS OF ITS CORRECTNESS, ACCURACY,

RELIABILITY, CURRENTNESS, OR OTHER WISE. THE ENTIRE RISK AS TO THE RESUL T S AND PERFORMANCE OF THE APPLE SOFTW ARE IS ASSUMED BY YOU.

THE EXCLUSION OF IMPLIED WARRANTIES IS NOT PERMITTED BY SOME STATES. THE ABOVE EXCLUSION MAY NOT APPLY TO YOU.

IN NO EVENT WILL APPLE, ITS DIRECTORS, OFFICERS, EMPL O YEES OR AGENTS BE LIABLE TO YOU FOR ANY CONSEQ UENTIAL, INCIDENT AL OR INDIRECT

DAMAGES (INCLUDING DAMAGES FOR LOSS OF BUSINESS PROFITS, BUSINESS INTERRUPTION, LOSS OF BUSINESS INFORMATION, AND THE LIKE)

ARISING OUT OF THE USE OR INABILITY TO USE THE APPLE SOFTWARE EVEN IF APPLE HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

BECAUSE SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, THE ABOVE

LIMITATIONS MAY NOT APPLY TO YOU. Apple’s liability to you for actual damages from any cause whatsoever, and regardless of the form of the action (whether in contract, tort

[including negligence], product liability or otherwise), will be limited to $50.

Restricted Rights Legends

For defense agencies: Restricted Rights Legend. Use, reproduction, or disclosure is subject to restrictions set forth in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer

Software clause at 252.227.7013.

For civilian agencies: Restricted Rights Legend. Use, reproduction, or disclosure is subject to restrictions set forth in subparagraph (a) through (d) of the commercial Computer Software

Restricted Rights clause at 52.227-19 and the limitations set forth in Electronics For Imaging’s standard commercial agreement for this software. Unpublished rights reserved under the

copyright laws of the United States.

Printed in the United States of America on recycled paper.

CE Mark

The CE marking applied to this product symbolises Ricoh’s declaration of conformity with the following applicable directives of the European Union as of the dates indicated.

January 1, 1996—Council Directive 73/23/EEC amended by Council Directive 98/68/EEC. Approximation of the laws of the member states related to low voltage equipment.

January 1, 1996—Council Directive 89/336/EEC. Approximation of the laws of the member states related to electromagnetic compatibility.

CE Marking (Declaration of Conformity)

We declare under our sole r esponsibility that the copier and options to which this declaration relates is in conformity with the specification below. This declaration is valid for the area of the

European Union (EU) only.

WARNING: In order to allow this equipment to operate in proximity to industrial, scientific, and Medical (ISM) equipment, the external radiation from ISM equipment may

have to be limited or special migration measures taken.

FCC Class B Compliance

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to P art 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, and uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the interference at his own expense.

WARNING: The design and production of this unit conform to FCC regulations, and any changes or modifications must be registered with the FCC and are subject to FCC control. Any

changes made by the purchaser or user without first contacting the manufacturer will be subject to penalty under FCC regulations.

Page 4

Industry Canada Class B Notice

This Class B digital apparatus complies with Canadian ICES-003.

Avis de Conformation Classe B de l’Industrie Canada

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Software License Agreement

Before using the Software, please carefully read the following terms and conditions. BY USING THIS SOFTWARE, YOU SIGNIFY THAT Y OU HAVE ACCEPTED THE TERMS OF

THIS AGREEMENT. If you cannot or do not accept these terms, you may return the entire package within ten (10) days to the Distributor or Dealer from which you obtained them for

a full refund.

Electronics For Imaging grants to you a non-exclusive, non-transferable license to use the software and accompanying documentation (“Software”) included with the E-800A you have

purchased, including without limitation the PostScript software provided by Adobe Systems Incorporated.

You may:

a. use the Software solely for your own customary business purposes and solely with E-800A;

b. use the digitally-encoded machine-readable outline and bitmap programs (“Font P rograms”) provided with E-800A in a special encrypted format (“Coded Font Programs”) to reproduce

and display designs, styles, weights, and versions of letters, numerals, characters and symbols (“Typefaces”) solely for your own customary business purposes on the display window of the

E-800A or monitor used with E-800A;

c. use the trademarks used by Electronics For Imaging to identify the Coded Font Programs and Typefaces reproduced therefrom (“Trademarks”); and

d. assign your rights under this Agreement to a transferee of all of your right, title and interest in and to E-800A provided the transferee agrees to be bound by all of the terms and conditions

of this Agreement.

You may not:

a. make use of the Software, directly or indirectly , to print bitmap images with print resolutions of 600 dots per inch or greater , or to generate fonts or typefaces for use other than with E-800A;

b. make or have made, or permit to be made, any copies of the Software, Coded Font Programs, accompanying documentation or portions thereof, except as necessary for use with the

E-800A unit purchased by you; provided, however , that under no circumstances may y ou make or have made, or permit to be made, any copies of that certain portion of the Software which

has been included on the E-800A hard disk drive. You may not copy the documentation;

c. attempt to alter, disassemble, decrypt or reverse engineer the Software, Coded Font Programs or accompanying documentation.

d. rent or lease the Software.

Proprietary Rights

You acknowledge that the Software, Coded Font Programs, Typefaces, Trademarks and accompanying documentation are proprietary to Electronics For Imaging and its suppliers and that

title and other intellectual property rights therein remain with Electronics For Imaging and its suppliers. Except as stated above, this Agreement does not grant you any right to patents,

copyrights, trade secrets, trademarks (whether registered or unregistered), or any other rights, franchises or licenses in respect of the Software, Coded Font Programs, T ypefaces, Trademarks

or accompanying documentation. You may not adapt or use any trademark or trade name which is likely to be similar to or confusing with that of Electronics For Imaging or any of its

suppliers or take any other action which impairs or reduces the trademark rights of Electronics For Imaging or its suppliers. The trademarks may only be used to identify printed output

produced by the Coded Font Programs. At the reasonable request of Electronics For Imaging, you must supply samples of any Typeface identified with a trademark.

Confidentiality

You agree to hold the Software and Coded Font Programs in confidence, disclosing the Software and Coded Font Programs only to authorized users having a need to use the Software and

Coded Font Programs as permitted by this Agreement and to take all reasonable precautions to prevent disclosure to other parties.

Remedies

Unauthorized use, copying or disclosure of the Software, Coded F ont Programs, Typefaces, Trademarks or accompanying documentation will result in automatic termination of this license

and will make available to Electronics For Imaging other legal remedies.

Limited Warranty And Disclaimer

Electronics For Imaging warrants that, for a period of ninety (90) days from the date of delivery to you, the Software under normal use will perform without significant errors that make it

unusable. Electronics For Imaging’s entire liability and your exclusive remedy under this warranty (which is subject to you returning E-800A to Electronics For Imaging or an authorized

dealer) will be, at Electronics For Imaging’s option, to use reasonable commercial efforts to attempt to correct or work around errors, to replace the Software with functionally equivalent

software, or to refund the purchase price and terminate this Agreement. Some states do not allow limitations on duration of implied warranty, so the above limitation may not apply to you.

Except for the above express limited warranty, Electronics For Imaging makes and you receive no warranties or conditions on the Products, express, implied, or statutory , and E lectronics F or

Imaging specifically disclaims any implied warranty or condition of merchantability or fitness for a particular purpose.

For warranty service, please contact your authorized service/support center.

EXCEPT FOR THE ABOVE EXPRESS LIMITED WARRANTY, ELECTRONICS FOR IMAGING MAKES AND YOU RECEIVE NO WARRANTIES OR CONDITIONS ON

THE SOFTWARE OR CODED FONT PR OGRAMS, EXPRESS, IMPLIED, ST A TUTOR Y , OR IN ANY OTHER PR OVISION OF THIS AGREEMENT OR COMMUNICA TION

WITH YOU, AND ELECTRONICS FOR IMAGING SPECIFICALLY DISCLAIMS ANY IMPLIED WARRANTY OR CONDITION OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. Electronics F or Imaging does not warrant that the operation of the software will be uninterrupted or error fr ee or that the Software will meet your specific

requirements.

Page 5

Limitation Of Liability

IN NO EVENT WILL ELECTRONICS FOR IMAGING OR ITS SUPPLIERS BE LIABLE FOR ANY DAMAGES, INCLUDING LOSS OF DATA, LOST PROFITS, COST OF

COVER OR OTHER SPECIAL, INCIDENTAL, CONSEQUENTIAL OR INDIRECT DAMAGES ARISING FROM THE USE OF THE SOFTWARE, CODED FONT

PROGRAMS OR ACCOMPANYING DOCUMENTATION, HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY. THIS LIMITATION WILL APPLY EVEN IF

ELECTRONICS FOR IMAGING OR ANY AUTHORIZED DEALER HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGE. YOU ACKNOWLEDGE THAT THE

PRICE OF THE UNIT REFLECTS THIS ALLOCATION OF RISK. BECAUSE SOME STATES/JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION OF

LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

Export Controls

You agree that you will not export or re-export the Software or Coded Font Programs in any form without the appropriate United States and foreign government licenses. Your failure to

comply with this provision is a material breach of this Agreement.

Government Use

Use, duplication or disclosure of the Software by the U nited S tates Go vernment is subject to r estrictions as set forth in subdivision (c) (1) (ii) of the Rights in Technical Data and Computer

Software clause at DFARS 252.227-7013 or in subparagraphs (c) (1) and (2) of the Commercial Computer Software—Restricted Right Clause at 48 CFR 52.227-19, as applicable.

Third Party Beneficiary

You are hereby notified that Adobe Systems Incorporated, a California corporation located at 345 Park Avenue, San Jose, CA 95110-2704 (“Adobe”) is a third-party beneficiary to this

Agreement to the extent that this Agreement contains provisions which relate to your use of the Fonts, the Coded Font Programs, the Typefaces and the Trademarks licensed her eby. Such

provisions are made expressly for the benefit of Adobe and are enforceable by Adobe in addition to Electronics For Imaging.

General

This Agreement will be governed by the laws of the State of California.

This Agreement is the entire agreement held between us and supersedes any other communications or advertising with respect to the Software, Coded Font Programs and accompanying

documentation.

If any provision of this Agreement is held invalid, the remainder of this Agreement shall continue in full force and effect.

If you have any questions concerning this Agreement, please write to Electronics For Imaging, Attn: Licensing Dept. or see Electronics For Imaging’s web site at www.efi.com.

Electronics For Imaging

303 V elocity Way

Foster City, CA 94404

Page 6

Page 7

Contents

Preface

About this guide

About the illustrations in this guide xi

Terminology and conventions xii

Precautions

Tools you will need

Chapter 1: Introduction

Features

How the E-800A operates

Print options

User software

Fiery WebTools 1-5

Chapter 2: Preparing for Installation

Installation sequence

Checking the customer site

Setting customer expectations 2-4

Unpacking the E-800A

E-800A panels

xi

xiii

xv

1-1

1-2

1-3

1-4

2-1

2-3

2-5

2-7

Chapter 3: Connecting the E-800A

Preliminary checkout

Connecting to the copier

Verifying the connection

Printing the E-800A Test Page and Configuration page 3-6

Installing additional options

Connecting to the network

Using the Control Panel

Activity light 3-12

Buttons 3-12

Control Panel screens and icons 3-13

Shutting down and restarting the E-800A

3-1

3-4

3-6

3-9

3-9

3-11

3-18

vii

Page 8

Contents

Chapter 4: Service Procedures

Overview

System software service 4-1

Accessing E-800A internal components

Accessing front panel components 4-6

Checking E-800A internal connections

Restoring E-800A functionality after service

Removing and replacing boards

IX UIB board 4-14

AGP video board 4-16

Copier interface board 4-18

User interface board 4-20

Motherboard

Removing the E-800A motherboard 4-23

Replacing the motherboard 4-28

Replacing parts on the motherboard 4-30

Motherboard jumpers and switches 4-36

Fans

Front fan 4-36

Back panel fan 4-38

Power supply

Checking voltages 4-40

Removing and replacing the power supply 4-42

Hard disk drive

ZIP drive

CD-ROM drive

Front panel components

Jewels 4-54

Buttons 4-54

E-800A system software service

Retrieving backup system software 4-56

Installing system software from a CD 4-57

4-1

4-3

4-8

4-11

4-13

4-23

4-36

4-40

4-43

4-47

4-50

4-53

4-55

viii

Page 9

Contents

Chapter 5: Troubleshooting

The troubleshooting process

Where problems occur

Before you go to the customer site

Preliminary on-site checkout

Checking interface cables 5-5

Checking internal components 5-6

Checking the E-800A as a stand-alone unit

Errors and beep codes during startup diagnostics 5-9

General E-800A system error conditions 5-12

Copier interface board diagnostics 5-17

Checking the entire E-800A system

Checking the copier interface 5-18

Checking network connections 5-20

Printing to the E-800A 5-21

Appendix A: Specifications

Hardware features

Networking and connectivity

User software

Safety and emissions compliance

Output voltage

5-1

5-2

5-3

5-5

5-8

5-18

A-1

A-1

A-1

A-1

A-2

Appendix B: Interface Unit and Extender Board Installation Procedures

Index

ix

Page 10

Page 11

About this guide

Preface

The Installation and Service Guide is intended for certified E-800A

™

and copier service

technicians installing or servicing the E-800A Color Server. If you have not received

installation and service certification, you should not attempt to install or service the

E-800A Color Server. Electronics For Imaging does not warrant the performance if

installed or serviced by non-certified personnel.

About this guide

This guide is divided into the following topics:

• “Preface”

General information about this guide and about installing the E-800A

• Chapter 1, “Introduction”

General information about the E-800A

• Chapter 2, “Preparing for Installation”

Unpacking and the steps you need to take before you install the unit

• Chapter 3, “Connecting the E-800A”

How to connect the E-800A to the copier and the network and verify that the system

is working correctly; overview of the Control Panel

• Chapter 4, “Service Procedures”

Removal and replacement procedures for E-800A components

• Chapter 5, “Troubleshooting”

Common problems and ways of correcting them; startup error codes

OTE

E-800A customers should not use the technical service documentation. Please

N

:

don’t leave your copy of the Installation and Service Guide after you make a service call.

About the illustrations in this guide

The illustrations in this guide reflect the current shipping version of the E-800A at the

time of publication. Components shown in these illustrations are subject to change. To

receive information about any E-800A components that do not match the illustrations in

this guide, contact your authorized service/support center.

xi

Page 12

Preface

Terminology and conventions

The term “ network administrator” refers to the person responsible for maintaining the

network at the customer site.

The term “Control Panel” refers to the area on the front of the E-800A including the

green/red activity light, the display window (LCD—liquid crystal display), and the

buttons to the right of and below the display window.

The term “system software” refers to the software installed on the E-800A hard disk

drive.

Client utilities can be installed onto the E-800A from the User Software CD if the Fiery

Advanced Controller Interface option is installed. Do not install any other applications

onto the E-800A. Other applications are not supported and can cause system problems.

References to other E-800A manuals, such as the Configuration Guide, are displayed in

italics.

OTE

The note format highlights important messages and additional information.

N

:

The caution icon indicates a need for special care and safety when handling the

!

equipment.

xii

Page 13

Precautions

Precautions

Always observe the following general precautions when installing and servicing the

E-800A:

1. Report any shipping damage.

If there is any evidence of shipping or handling damage to the E-800A packing boxes or

their contents, save the damaged boxes and parts, call the shipper immediately to file a

claim, and notify your authorized service/support center.

2. Never alter an existing network without permission.

The E-800A will probably be connected to an existing Local Area Network (LAN) based

on Ethernet hardware. The network is the link between the customer ’s computer, existing

laser printers, and other prepress equipment. Never disturb the LAN by breaking or

making a network connection, altering termination, installing or removing networking

hardware or software, or shutting down networked devices without the knowledge and

express permission of the system or network administrator or the shop supervisor.

3. Never assign an IP address in the E-800A Network Setup.

Only the network administrator should assign an IP address to a network device.

Assigning the E-800A an incorrect IP address may cause unpredictable errors on any or

all devices connected to the network.

4. Always disconnect power before opening the E-800A.

5. Handle the E-800A Control Panel display window with care.

The E-800A display window is made of glass. If the glass breaks and the liquid crystal

inside leaks out, avoid contact with it. If you do come in contact with the liquid crystal,

wash it off with soap and water immediately.

6. Avoid pressing the surface of the display window.

Applying pressure to the display window will cause it to change color.

7. Use a soft cloth moistened with isopropyl or ethyl alcohol to clean the surface of the

E-800A display window.

Other solvents, such as water, may damage the polarizer on the display window.

xiii

Page 14

Preface

8. Use care when handling parts of the E-800A as some edges on the unit may be sharp. For

example, be careful when:

• Accessing the CD-ROM/ZIP drive (keep the drive door closed when not in use)

• Plugging in cables at the back of the unit

• Using the power switch to power on/off the unit

9. Follow standard ESD (electrostatic discharge) precautions while working on the internal

components of the E-800A.

Static is always a concern when servicing electronic devices. It is highly unlikely that the

area around the copier and the E-800A is static-free. Carpeting, leather-soled shoes,

synthetic clothing fibers, silks, and plastics may generate a static charge of more than

10,000 volts. Static discharge is capable of destroying the circuits etched in silicon

microchips, or dramatically shortening their life span. By observing standard precautions,

you may avoid extra service calls and save the cost of a new board.

When possible, work on a ground-connected antistatic mat. Wear an antistatic

grounding strap, grounded at the same place as the antistatic mat. If that is not possible:

• Attach a grounding strap to your wrist. Attach the other end to a good ground.

• When you unpack the E-800A from the carton for the first time, touch a metal area of

the copier to discharge the static on your body.

• Before you remove the E-800A side panel and before y ou handle internal components,

touch a metal part of the E-800A.

• Leave new electronic components inside their antistatic bags until you are ready to

install them. When you remove components from an antistatic bag, place them on a

grounded antistatic surface, component-side up.

• When you remove an electronic component, place it into an antistatic bag

immediately. Do not walk across a carpet or vinyl floor while carrying an unprotected

board.

10. Handle printed circuit boards by their opposing edges only, and avoid touching the

contacts on the edge of the board.

11. Never set a cup of coffee—or any liquid—on or near the E-800A or the copier.

xiv

Page 15

Tools you will need

Tools you will need

To install or service the E-800A, you should bring the following tools and parts:

• ESD wrist grounding strap and antistatic mat

• Wire cutters

• #0 and #1 Phillips head screwdrivers (non-magnetic)

• PROM extractor

You should also bring this guide and any technical notes for the E-800A.

xv

Page 16

Page 17

Features

Chapter 1:

Introduction

1

The E-800A Color Server adds computer connectivity and highly efficient Adobe

PostScript 3 color printing capability to color copiers. It is optimized for high-speed

network communications, processing, rasterization, and printing of continuous tone

color and monochrome pages.

Features

The E-800A, as an integral part of a color printing system, enables users to:

• Send images over AppleTalk, TCP/IP, and Novell networks to print on E-800A

supported devices.

• Spool print jobs and select a printing priority for each job. Users can control spooled

print jobs sent to the E-800A with remote user software running on networked PC

and Mac OS computers.

• Print files in color, grayscale, and black and white.

• Use the copier as a high-resolution color scanner with Fiery Scan software.

• Use 136 resident fonts (126 Adobe Type 1 PostScript, and 10 TrueType), plus two

Adobe Multiple Master fonts used for font substitution when printing PDF files.

Fiery Downloader or any third-party LaserWriter downloader, such as the A dobe Font

Downloader, can be used to download additional fonts.

• Use resident fonts. The customer can download additional fonts as needed.

• Use built-in ColorWise

Copier

E-800A

™

color management and NetWise

™

network features.

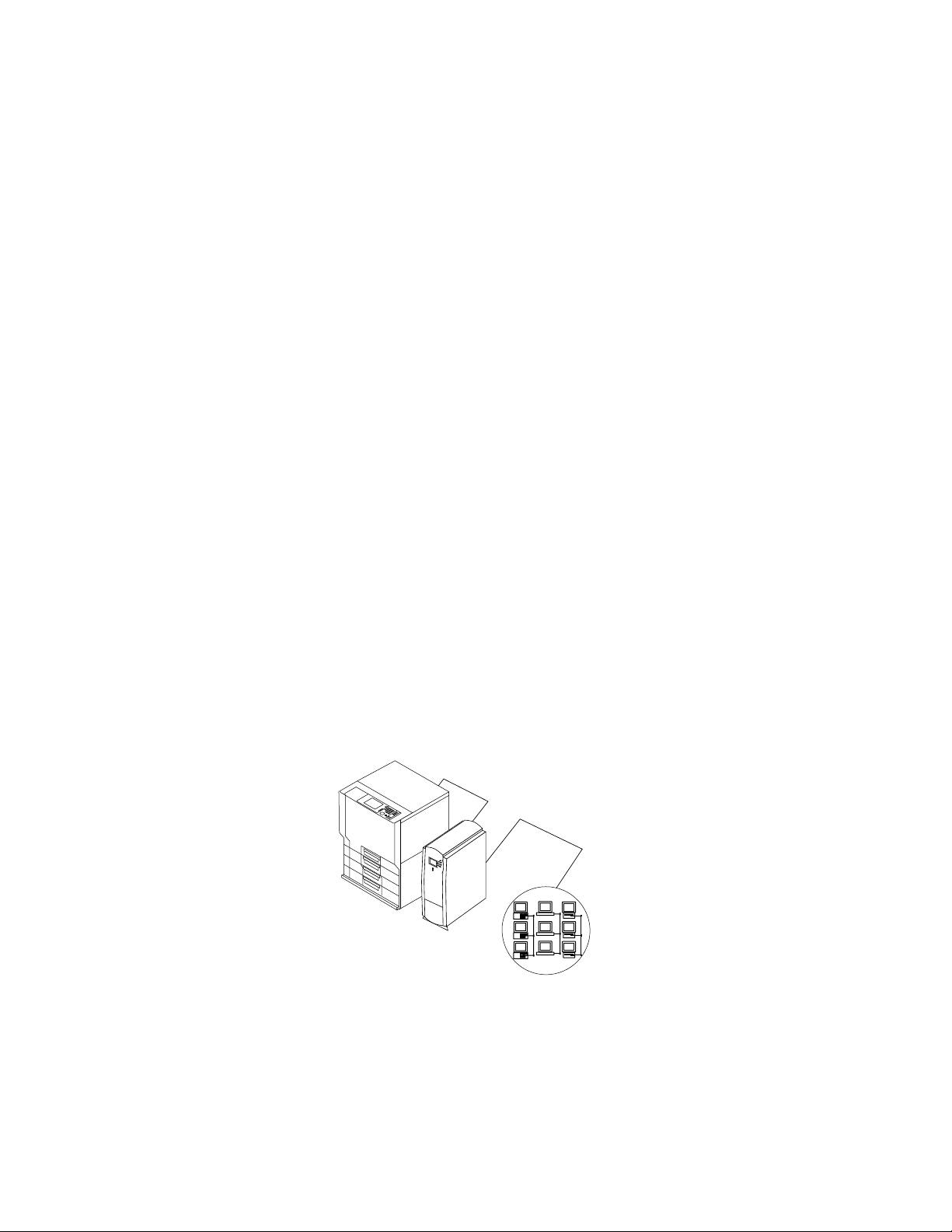

Networked computers

or workstations

IGURE

F

The E-800A is one of several imaging products engineered and manufactured by

Electronics For Imaging.

E-800A printing system

1-1

1-1

Page 18

Introduction

1

How the E-800A operates

The E-800A enables the customer to use a color copier as a printer and scanner. Users

can print to the E-800A from networked PCs running Microsoft Windows, from

networked Mac OS computers, and from networked UNIX workstations running

TCP/IP.

The E-800A custom-designed boards and system software are responsible for efficient

image processing and printing controls. The main functions of E-800A components and

software are described below.

The E-800A uses specialized circuit boards, the motherboard and the copier interface

board to process image data for printing and scanning images.

The motherboard includes a 500MHz CPU which controls the image data transfer to

and from the copier interface board and runs the interpreter. The interpreter rasterizes

the page description file and then compresses the image pattern into memory using

compression technology.

The interpreter outputs compressed raster data through the image frame buffer memory

to the E-800A copier interface board. The copier interface board decompr esses the image

data and sends it to the copier through the copier interface cable. The raster data supplied

to the laser in the copier charges the drum and renders the final image on paper at full

copier engine speed.

High-speed DIMMs (dual in-line memory modules) on the motherboard hold the image

data during printing. The E-800A is configured with 320MB of memory.

When Fiery Scan™ uses the copier as a scanner, the E-800A acquires RGB (red, green,

and blue) image data from the copier, stores it in memory, and transmits it to the

computer that requested the scan.

1-2

Page 19

Print options

1

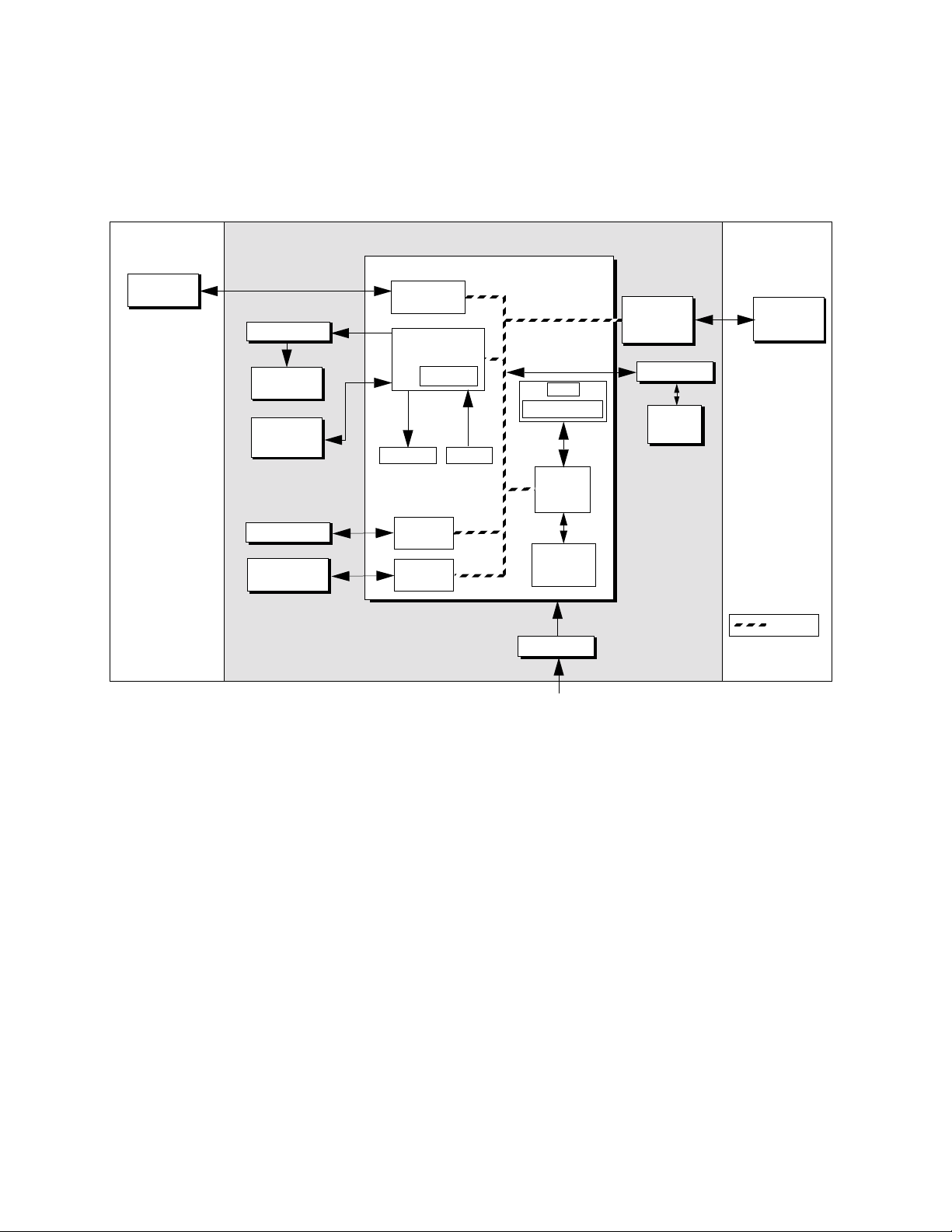

External Devices CopierE-800A

Networked

computers

AGP video board

Monitor

(option)

Keyboard &

mouse

(option)

Hard disk drive

ZIP drive and

CD-ROM drive

Network

interface

I/O Control

BIOS

Speaker Reset

SCSI

interface

IDE

interface

Motherboard

CPU1

CPU2 (option)

PCI/

Memory

Controller

Memory

Interpreter

Power supply

AC power

&

+3.3/+5/±12V DC

Copier

interface

board

IX UIB board

User

interface

board

Print/Scan

Copier

PCI Bus

F

IGURE 1-2 E-800A functional diagram

Print options

The E-800A’s efficient capabilities allow users to use a variety of applications to create

and print pages of text and/or images.

Printing over a network allows E-800A users to print documents directly from

applications in which they were created. In addition, the E-800A offers an efficient way

to print files that have been saved in PostScript, EPS (Encapsulated PostScript), or PDF

(Portable Document Format). These files can be downloaded directly to the E-800A

using Fiery Downloader™, one of the remote utilities for use with the E-800A.

1-3

Page 20

Introduction

1

User software

The following user software is provided on the User Software CD.

Adobe PS Printer Driver Enables users to print to the E-800A from Windows

95/98, Windows NT 4.0, and Mac OS computers; also

supports special E-800A and PostScript 3 features.

PostScript Printer

Description files (PPDs)

PostScript Screen Fonts

(for Mac OS only)

Fiery Downloader Enables the user to print PostScript files, Encapsulated

Fiery Spooler

(Mac OS only)

Fiery Scan Plug-in modules for Photoshop that enable the user to

Files for use with the P ostScript printer driv er that allows

the E-800A to appear in popular applications’ Print and

Page Setup dialog boxes. The E-800A PPD provides

information about the E-800A and the particular copier

model to the application and printer driver.

PostScript screen fonts for the 136 PostScript printer

fonts installed on the E-800A (126 Adobe Type 1 and 10

TrueType).

PostScript (EPS) files, and Portable Document Format

(PDF) files directly to the E-800A without opening the

application in which they were created. Fiery

Downloader also enables the user to manage the printer

fonts installed on the E-800A.

Enables the user to view the order and priority of print

jobs, customize printer settings for jobs, delete jobs, and

move jobs between queues. The user can also use it to

view job accounting information.

scan images from the copier directly into the application.

1-4

Command W or kS tation

software

Color management files ColorSync and ICM color management files that enable

Color reference files Reference pages that users can print to view the range of

Enables the operator to control the E-800A functions

from Windows 95/98 and Windows NT 4.0

workstations. For more information on the Command

WorkStation, see the Job Management Guide.

the user to maintain consistent color from original

artwork to the colors displayed on the monitor to the

printed output.

colors available on your E-800A. For the most

predictable color results, refer to these pages when

defining colors in applications.

Page 21

User software

1

ColorWise Pro Tools Enables the customer to use calibration and color

management tools. It also enables the user to edit and

download ICC profiles.

Fiery Link Enables the customer to monitor the status of connected

E-800A servers.

Calibration files Includes measurements files and targets that you can use

with ColorWise Pro Tools.

Fiery WebTools

The E-800A can support Internet or intranet access with Fiery WebTools, which include

Status, WebSpooler, Installer, WebLink, WebSetup, and WebD o wnloader. For more

information on WebTools, see the user documentation.

1-5

Page 22

Page 23

Installation sequence

Chapter 2:

Preparing for

Installation

2

This chapter includes the following information:

• Summary of the installation sequence

• Checking the customer site

• Unpacking the E-800A

• E-800A front and back overview

Installation sequence

Familiarize yourself with Chapters 2 and 3 of this guide before you attempt an

installation. The installation sequence described in this chapter is designed to make your

job as easy as possible. Installation problems are easier to avoid and diagnose if you

proceed from the component to the system level and verify functionality at each stage.

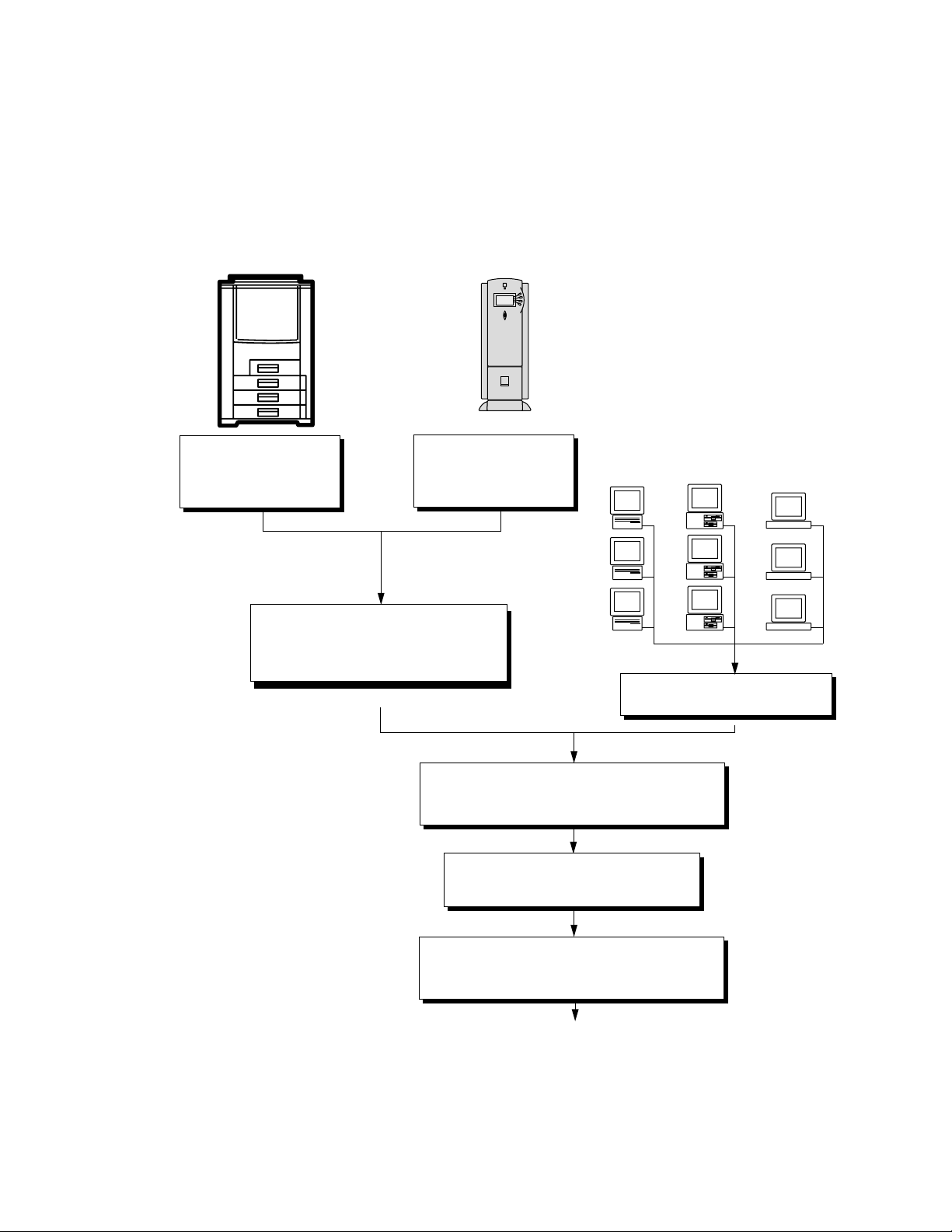

Figure 2-1 on page 2-2 outlines the recommended installation procedure for connecting

the E-800A to the copier.

Because the E-800A is a node on the customer’s computer network, make sure you

coordinate your scheduled installation with the network administrator at the customer

site. Refer the network administrator to the Configuration Guide for network setup

information.

2-1

Page 24

Preparing for Installation

2

Copier

Check installation

requirements and verify site

conditions; page 2-3

Connect copier interface cable; page 3-4

Print an E-800A Test Page and Configuration

Page; page 3-6

E-800A

Unpack the E-800A,

page 2-5

Initial startup; page 3-1

Mac OS

computers

Verify network operation with out the

PC

computers

E-800A connected.

workstations

UNIX

2-2

Network administrator connects the E-800A to the

network and verifies the connection; see page 3-9 and

the Configuration Guide

Network administrator configures Setup

options; see the Configuration Guide

Network administrator installs E-800A user software on

networked computers that print to the E-800A; see

Getting Started

Full E-800A functionality

IGURE 2-1 Recommended installation steps and references

F

Page 25

Checking the customer site

2

Checking the customer site

Before you install the E-800A, check site conditions and inform the customer of any

installation requirements.

Copier model

❑ What copier model is installed?

❑ Is there space near the copier for the E-800A?

Make sure that there is space for the E-800A. You may need to move the copier out from

the wall for easier access to the connectors.

❑ Does the copier require service or adjustments?

Copy the copier color test page before you install the E-800A.

If the copied image indicates that the copier needs adjustment, inform the customer.

After getting approval, complete the copier service needed.

Power

❑ Is there a dedicated grounded electrical outlet near the copier for the E-800A?

Locate the grounded electrical outlet that will supply power to the E-800A. You should

not run the E-800A and the copier on the same circuit. Use a surge suppressor for the

E-800A.

• Do not use a 3-prong adapter in a 2-hole ungrounded outlet.

• Do not use an extension cord.

• Do not plug the E-800A into a circuit with heating or refrigeration equipment

(including water coolers).

• Do not plug the E-800A into a switchable wall outlet. This can result in the E-800A

being turned off accidentally.

Network

❑ What is the network cable and connection type?

• Unshielded twisted pair (10BaseT/100BaseT)

• Optional Token Ring (shielded twisted pair or unshielded twisted pair)?

❑ Is the network connection ready and tested for E-800A installation?

To verify that the network is functioning before you attach the E-800A:

• Ask the network administrator to print a document on a shared printer over the

network.

2-3

Page 26

Preparing for Installation

2

• Ask the network administrator to verify the computer and network requirements as

specified in Getting Started.

System contact person

❑ Will the person responsible for the computers and the network be available at the time

set for installation? Get a name as a contact.

Setting customer expectations

If the site is ready, installation takes about one hour. The customer should be informed of

the following:

• Some nodes on the network may be unavailable for up to one hour.

• The copier may be unavailable for up to one hour.

• The network administrator needs to be available during the installation for network

connectivity.

Equipment downtime and impact on the network can be minimized if the network

administrator installs a network connector for the E-800A and confirms network

functionality with the connector in place before the date scheduled for the E-800A

installation.

• The network administrator should have a networked computer available during the

installation. The appropriate software should already be installed. Documentation for

the networked computer and the network operating software should be available.

• The network administrator should install the user software shipped with the E-800A

(user documentation is also included) onto networked PC and Mac OS computers

that will print to the E-800A.

NOTE: This guide covers E-800A hardware installation and service. It provides general

information on connecting the E-800A to the customer’s network. Network setup and

configuration information goes beyond the scope of this guide. For network setup and

configuration information, the network administrator should use the Configuration

Guide.

2-4

Page 27

Unpacking the E-800A

2

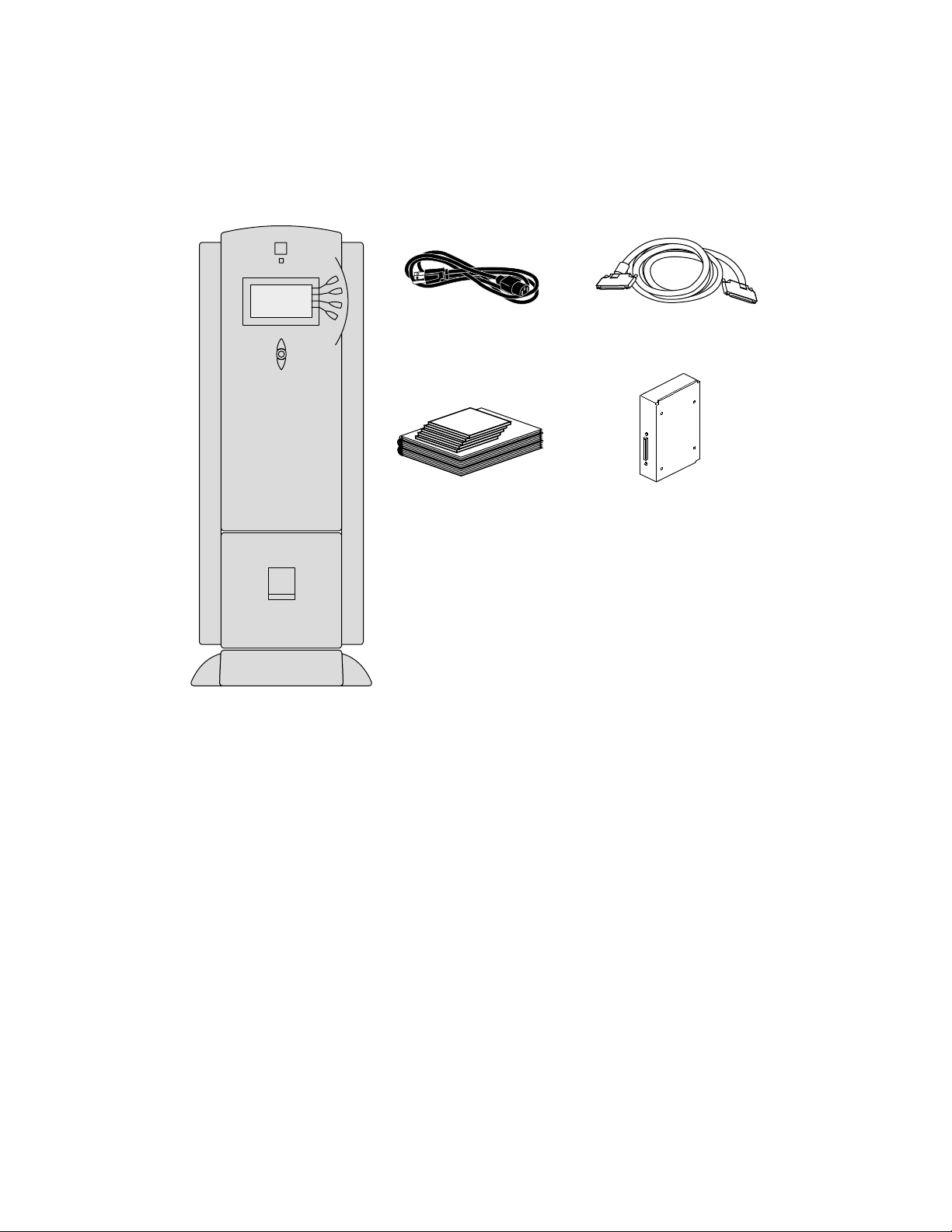

Unpacking the E-800A

The E-800A is assembled and shipped from the factory in a box that includes all

necessary cables and documentation, as shown in Figure 2-2 on page 2-6.

TO UNPACK THE E-800A

1. Open the E-800A Color Server box and remove the packing material.

Save the original boxes and packing materials. If you need to transport the E-800A at a

later date, the original box and packing material will ensure safe shipment.

2. Remove the contents from the top container. Inspect the contents for visible damage.

The top container should include the following items:

• Bags containing one copier interface cable and an AC power cable.

• Interface extender board

• Media package (includes a package of user documentation and software).

NOTE: A service kit containing system software is provided separately.

3. Give the media package to the customer or the network administrator.

Let the customer or network administrator know that in order to take full advantage of

the E-800A, the user software must be installed on computers that will print to the

E-800A.

4. Set aside the remaining components from the top container.

5. Remove the top container and any packing materials.

Set aside the packing material and note the orientation of the E-800A inside the shipping

container in case you need to repack it later.

6. Carefully lift the E-800A out of the box.

If you notice shipping damage to any E-800A component, be sure to save the shipping

container in case the carrier needs to see it. Call the carrier immediately to report the

damage and file a claim, then call your authorized service/support center. Be ready to

furnish the serial number printed on the back of the E-800A.

2-5

Page 28

Preparing for Installation

2

Copier interface cable (80-pin)E-800A power cable

E-800A

Media Package

F

IGURE 2-2 Contents of E-800A shipping box

Interface extender board

2-6

Page 29

E-800A panels

2

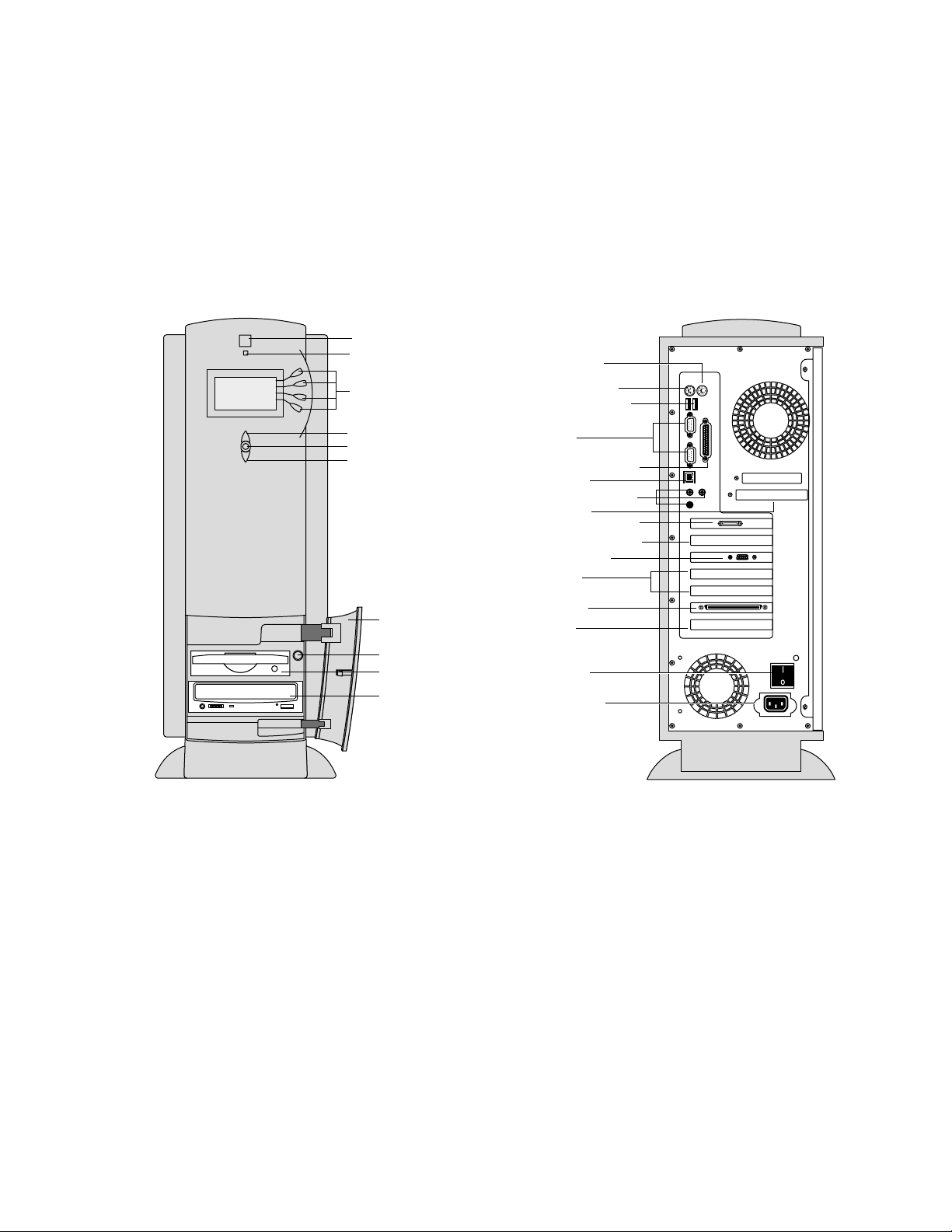

E-800A panels

Once you have unpacked the E-800A, you can familiarize yourself with the front and

back of the E-800A before you install it.

Jewel

Activity light

Line selection

buttons

Up button

Menu button

Down button

Drive door

Mouse (option)

Keyboard (option)

USB ports (not used)

Serial ports

(not used)

Parallel port (not used)

10/100BaseT

Sound ports (not used)

Option slots

Parallel port (not used)

Token Ring option slot

Monitor (option)

Empty slots

Copier interface

(80-pin)

Empty slot

Front panel

Reset button

ZIP drive

CD-ROM drive

FIGURE 2-3 Front and back panels

Power switch

Power connector

Back panel

2-7

Page 30

Page 31

Preliminary checkout

Chapter 3:

Connecting the

E-800A

3

After you unpack or service the E-800A, power on the system and allow diagnostics to

run before you connect the E-800A to the copier and the network. Diagnostics run

automatically during startup to check the E-800A for internal problems.

The interface extender board must be installed on the copier before the E-800A can be

connected to the copier. See Appendix B for the procedure to install the interface

extender board.

Preliminary checkout

The following procedure describes how to connect power to the E-800A.

TO CONNECT POWER AND START THE E-800A

1. Connect the E-800A power cable to the power connector at the back of the E-800A (see

Figure 3-1).

2. Make sure the E-800A power switch is in the o ff position (press 0), and then connect the

other end of the E-800A power cable to a wall outlet.

Power switch

Power connector

F

IGURE 3-1 E-800A power

3-1

Page 32

Connecting the E-800A

3

3. Power on the E-800A using the power switch on the back panel. The power supply

automatically senses the correct voltage.

If you need the language of the system to be in English, skip steps 4 through 8 and allow

the startup to proceed to Idle as described in step 9. Initial startup could take up to 30

minutes to complete.

4. When diagnostics begin, press the fourth line selection button to open the Service menu

if you need the system to be in a language other than English.

If you do not press the fourth line selection button before the end of the diagnostics

(about 20 seconds), the E-800A continues startup and you must restart the system and

try again.

5. Select Install Software from the service menu.

Install Software

Restore Backup

Install Option

Start System

Service

6. At the following screen, insert the appropriate language-specific system CD from the

media pack in the CD-ROM drive.

Insert System

Software CD and

press any key.

If an error message appears, verify that the correct System Software CD is inserted.

7. When the following screen is displayed, make sure “Yes” is displayed and then select

OK. The installation process will begin immediately.

All data will be

deleted. Continue?

Yes

OK

Install Software

Wait while the E-800A Control Panel displays screens that indicate that the software is

being installed.

Select

Select

3-2

Page 33

Preliminary checkout

3

8. At the message “To complete installation, remove CD and recycle power,” remove the

System Software CD and po w er off and on the s ystem using the po w er switch on the back

panel.

After the system software is installed, the E-800A will initialize the system and will also

run diagnostics and create a system backup.

9. To confirm that the E-800A is operating properly, allow E-800A startup to proceed

without interruption while you watch the Control P anel. Do not pr ess an y b uttons on the

Control Panel.

Be sure to allow the system to boot completely. Initial startup could take up to 30

minutes to complete.

10. Allow the system to proceed to Idle to confirm that the E-800A is operating correctly.

Before the system reaches the Idle screen, it creates a backup of the system software

configuration. If at some point you need to restore the default configuration of the

system software, see “Retrieving backup system software” on page 4-56.

Once the E-800A reaches the idle state, you are ready to connect it to the copier and the

network. Setup options should be configured after making these connections. It is the

network administrator’s responsibility to configure Setup according to the network and

user environment. Refer the network administrator to the Configuration Guide for Setup

information.

Server Name

Idle

3744MB X.0

Info

NOTE: The message Check power and cable may appear in the Control Panel during the

startup process. Once the E-800A is connected to the copier, the message should no

longer be displayed.

11. Following a successful startup, shutdown the E-800A from the Functions menu and then

power off using the power switch.

3-3

Page 34

Connecting the E-800A

3

Connecting to the copier

After completing the preliminary checkout, install the interface extender board on the

copier as described in Appendix B of this guide.

After installing the extender board on the copier, connect the E-800A to the copier. The

E-800A communicates with the copier through one cable from the copier interface board

to the connector on the extender board.

TO CONNECT THE E-800A TO THE COPIER

1. Power off the E-800A and the copier.

You may need to get permission from the network administrator or supervisor to turn off

the power to the copier.

2. Connect the E-800A copier interface cable to the extender board on the copier.

3. Connect the other end of the cable to the E-800A copier interface connector (see

Figure 3-2).

Tighten the screws completely on both ends of the copier interface cable.

3-4

Page 35

3

Slot 1

Slot 2

Slot 3

Slot 4

Slot 5

Slot 6

Slot 7

Connecting to the copier

E-800A back panel

F

IGURE 3-2 Copier interface cable connection

Copier interface cable

3-5

Page 36

Connecting the E-800A

3

Verifying the connection

After you connect the E-800A to the copier, print the Test Page as well as the

Configuration Page to verify that the connection between the E-800A and the copier is

good.

Printing the E-800A Test Page and Configuration page

Before connecting the E-800A to the network, print the Test P age and the Configuration

page.

• Test Page—printing the Test P age verifies that all components of the E-800A-to-copier

• Configuration page—printing the Configuration page can be helpful during

interface work. The Test Page is a color file that resides on the E-800A hard disk drive.

installation, setup, and service. After installation of the E-800A and before any default

settings are changed, you can obtain a record of the defaults by printing the

Configuration page.

After the physical connection to the network is made, the network administrator can

customize Setup options according to the network and user environment. Using the

Configuration page as a guide can help speed up this process. For more information,

see the Configuration Guide.

Before you perform any service procedure, you should print the E-800A Configuration

page, if possible, so that you are prepared to return the settings to their former

configuration, if necessary.

TO PRINT THE TEST PAGE

1. Power on the copier and allow it to warm up.

2. Power on the E-800A from the power switch on the back panel.

Messages appear on the Control P anel as the E-800A runs through its startup diagnostics.

3. Before proceeding, make sure that the copier is not in use. The E-800A Info screen

should read Idle.

3-6

Page 37

Verifying the connection

3

4. At the Idle screen, press the menu button once (see “Using the Control Panel” on

page 3-11). The Functions menu appears as shown in Figure 3-3.

Print Pages

Suspend Printing

Resume Printing

Shut Down

Functions

Clear Server

Run Setup

Run Diagnostics

Calibration

Functions

F

IGURE 3-3 Functions menu

5. Press the line selection button to the right of Print Pages and then select Test Page.

The E-800A sends the Test Page to the copier and displays the RIP and Print status

screens so you can monitor the job.

6. Examine the quality of the Test Page from the copier.

If the Test P age prints, you kno w that the E-800A print engine is functional and that the

connection between the E-800A and the copier/printer is good. When you examine the

Test Page, keep in mind that:

• All color patches should be visible, even though they may be very faint in the 5% and

2% range.

Use the up and down buttons to

scroll through these options. Use

the line selection buttons to the

right to select Print Pages.

• Each color’s patch set should show uniform gradation from patch to patch as the color

lightens from 100% to 0%.

Poor image quality may indicate a need to calibrate the system or service the

copier/printer. Information on the Test Page includes the date and time of the last

calibration so the Test Page can be kept for future reference. For more information, see

the Reference Guide.

3-7

Page 38

Connecting the E-800A

3

TO PRINT A CONFIGURATION PAGE

1. Power on the copier and allow it to warm up.

2. Power on the E-800A from the power switch on the back panel.

Messages appear on the Control P anel as the E-800A runs through its startup diagnostics.

3. Before proceeding, make sure that the copier is not in use. The E-800A Info screen

should read Idle.

4. At the Idle screen, press the menu button once (see “Using the Control Panel” on

page 3-11). The Functions menu appears as shown in Figure 3-4.

Print Pages

Suspend Printing

Resume Printing

Shut Down

Functions

Clear Server

Run Setup

Run Diagnostics

Calibration

Functions

F

IGURE 3-4 Functions menu

5. Press the line selection button to the right of Print Pages and then select Configuration

page.

The E-800A sends the Configuration page to the copier and displays the RIP and Print

status screens so you can monitor the job.

Use the up and down buttons to

scroll through these options. Use

the line selection buttons to the

right to select Print Pages.

3-8

Page 39

Installing additional options

3

Installing additional options

If the customer has purchased additional E-800A options, install those before connecting

the E-800A to the network. For installation instructions, see the documentation included

in each option kit.

After installing options, print the Test Page to v erify that the system is operating properly.

Checking the installation at each stage makes it easier to pinpoint the cause of problems

should they occur.

Connecting to the network

The motherboard in the E-800A has an external 10/100BaseT Ethernet network

connector for a twisted pair cable (see Figure 3-5). For additional network information,

see the Configuration Guide.

RJ-45 connector for 10BaseT/

100BaseT twisted pair Ethernet

FIGURE 3-5 E-800A network connector

Token Ring compatibility is available with the optional Token Ring kit (see the

documentation included with that kit for more information).

3-9

Page 40

Connecting the E-800A

3

TO CONNECT A TWISTED PAIR CABLE TO THE E-800A

Twisted pair (unshielded twisted pair cable or 10BaseT/100BaseT) uses a RJ-45

connector that connects to the back of the E-800A (see Figure 3-5 on page 3-9).

1. Power off the E-800A before connecting it to any network device.

If the system has just finished processing, wait 5 seconds after the system reaches the idle

state before using the power switch to power off the unit.

2. Connect the network cable to the RJ-45 connector on the back of the E-800A.

A Category 5 unshielded twisted pair cable (UTP) network cable must be used for

100BaseT.

3. Configure Setup options.

It is the network administrator’s responsibility to configure Setup according to the

network and user environment. Refer the network administrator to the Configuration

Guide for Setup information.

4. After configuring Setup options, verify the network connection.

Once the network connection has been made and the E-800A has the correct Setup

configuration, the E-800A should be available on the network.

The network administrator should perform any additional network setup, verify the

network connection, verify that the E-800A appears in the list of printers, and print a few

test documents from a networked computer that will use the E-800A. (See the

Configuration Guide for more information.)

3-10

Page 41

Activity light

Using the Control Panel

3

Using the Control Panel

This section describes the Control Panel on the front of the E-800A. Once you install the

E-800A and verify that it powers up correctly, you can use the Control Panel to access

and monitor different functions of the E-800A.

The current status of the E-800A and Setup information are displayed in the E-800A

display window. E-800A activity can be monitored in the display window, and functions

of the E-800A (such as printing a Test Page and installing or updating system software)

can be controlled using the buttons on the Control Panel.

Display window

Menu button

Line selection buttons

Up button

Down button

FIGURE 3-6 The E-800A Control Panel

3-11

Page 42

Connecting the E-800A

3

Activity light

The activity light indicates current E-800A activity. If the light is:

Flashing or solid

red

Solid green The E-800A is idle or starting up.

Flashing green The E-800A is processing or printing a job.

No light The E-800A is powered off.

Buttons

Line selection

buttons

Up and down

buttons

Menu button Press this button to view other display screens. There are

There is an error causing printing to be disabled. The activity

light also flashes red briefly during startup.

There are four line selection buttons on the right side of the

Control Panel. Use these buttons to select the command

displayed on the corresponding line of the display window. A

special character ( ) appears in the display window next to a

button when it is available.

Use these buttons to scroll to different screens in multi-screen

lists, to select Setup options from a list, and to select

alphanumeric characters.

several different display screens, showing different types of

information about the E-800A.

3-12

Page 43

Using the Control Panel

3

Control Panel screens and icons

When the E-800A is in Print mode, pressing the menu button cycles among four screens:

three status screens (Info, RIP, and Print) and the Functions menu (see Figure 3-7).

When the E-800A is idle, pressing the menu button cycles between the Info screen and

the Functions menu.

The bottom line of the screen displays the name of the current screen with the icon for

that screen highlighted. Icons for other active screens are also displayed but are not

highlighted.

The E-800A screens display the following information:

Cancel Job >

Cancel Job >

Job name

doc.eps

User name

Jack D.

Processed: bytes

Busy #####K

RIP

RIP

Server Name

Idle

3744MB X.0

Info

FIGURE 3-7 Control Panel screens during printing

If an error occurs, the Alert screen is displayed with a message describing the error.

Load LTR paper in

tray

Cancel Job >

Jane D.

Copies: 1/100

Print

Print Pages

Suspend Printing

Resume Printing

Shut Down

Functions

Alert

FIGURE 3-8 Alert screen

3-13

Page 44

Connecting the E-800A

3

The display window screens and icons are:

Alert Status If there is a problem during printing or processing, the

Alert Status screen is activated, displaying an error message.

For information on user error messages, see the Printing

Guide.

Print Status When the E-800A is printing, the Print Status screen is

activated. This screen displays the following:

Cancel Job—Press the top line selection button to cancel

the job currently printing.

User name—The name of the user who sent the job that is

currently being processed.

Pages/Total—The number of copies of the current page

that have been printed so far, and the total number of

copies of this page that were requested.

RIP Status When the E-800A is processing a job, the RIP Status screen

is activated. This screen displays the following:

Cancel Job—Press the top line selection button to cancel

the job currently processing. The E-800A cancels the job

before printing begins.

Document name—The name of the document currently

processing.

User name—The name of the user who sent the job that is

currently being processed.

Kilobytes—The amount in kilobytes of the job that has

been processed so far.

3-14

Page 45

Using the Control Panel

3

Info Status The Info Status screen displays information about the

server’s current activity, and software version. This screen is

always active, and it appears in the display window when no

other screen is selected. It displays the following

information:

Server Name—The E-800A name as it is configured in

Setup.

Status—The current status of the E-800A. The E-800A

status can be: Idle, Initializing, Busy, Processing, or

Printing.

Number of MB—The space in megabytes available on the

E-800A hard disk.

Version—The system software version running on the

E-800A.

Functions The Functions screen also is always active, but it appears in

the display window only when the user has pressed the

Menu button to select it. Use the up and down buttons to

scroll through the list of menu command options. Press the

line selection button to the right of a command to select it.

Network The Network icon appears in the bottom left corner of the

display window when the E-800A is communicating over

the network. The Network icon can appear while any

screen is displayed.

3-15

Page 46

Connecting the E-800A

3

Functions menu

The Functions menu allows you to perform a variety of administrative functions that do

not affect print jobs of other users. Use the up and down buttons to scroll through the list

of options. Press the line selection button next to the option you want to select.

The following options are available from the Functions menu:

Print Pages—Enables you to print special pages from the E-800A. You can print the

following pages from the submenu that appears:

• Test Page—Enables you to confirm that the E-800A-to-copier interface is

functioning properly. The Test Page provides sample images that can be used to

troubleshoot the E-800A. The following information is also listed: S erver name,

printer model, output profile, calibration information, RGB source, rendering

style, date and time printed, CMYK simulation, simulation method, and

compression information.

• Configuration—Prints the current server and device configuration. This includes

information about all current Setup settings, calibration profile, and the

Ethernet address of the E-800A. The Configuration page also provides version

information for the BIOS chip and information on any options installed in the

E-800A.

• Job Log—Prints the log of the last 55 jobs by default. For more information

about the job log, see the Printing Guide.

• Control Panel Map—Prints the Setup screen help pages. These pages are useful

when navigating through the different Setup screens.

• Color Charts—Prints the color reference charts. These pages include swatches of

the RGB, CMY, and PANTONE colors available from the E-800A.

• Font List—A list of all fonts resident on the E-800A hard disk.

Suspend Printing—Disconnects the E-800A from the copier. This option interrupts the

current print job so you can use the copier to make copies; after you make the copies you

can select

Resume Printing—Connects the copier to the E-800A so you can resume printing after

interrupting the print job to make copies (used with

Resume Printing and the copier continues processing and printing jobs.

Suspend Printing).

3-16

Page 47

Using the Control Panel

3

Shut Down—When you select this option, you can choose from the following:

NOTE: A reset button on the front panel is also available and should only be used after

selecting Shut Down System first.

Clear Server—Clears all jobs from the server queues. It also clears the Job Log, all jobs

saved on the server hard disk drive, and the index of all archived jobs.

Run Setup—Allows you to access the Setup options in order to configure the network

and printing environment. Typically it is the network administrator’s responsibility to

configure Setup according to the network and user environment. Setup is required the

first time the E-800A is powered on and after E-800A system software is installed. See the

Configuration Guide for a list of options and detailed descriptions of each Setup option.

• Restart Server—resets the E-800A server software but does not reboot the entire

system. Network access to the E-800A is temporarily interrupted and all

currently processing jobs are aborted and might be lost.

• Shut Down System—Shuts down all E-800A properly so that you can power off

the system using the power switch on the back panel. You should always select

this option before powering off the system or using the reset button.

• Reboot System—Shuts down all E-800A activity properly and then restarts.

Run Diagnostics—When you select this option, you can choose the following:

• Test I/F board—Runs diagnostics on the E-800A copier interface board.

Select the line selection button next to the option.

Calibration—Allows the customer to calibrate the E-800A using AutoCal. See the Color

Guide for more information.

3-17

Page 48

Connecting the E-800A

3

Shutting down and restarting the E-800A

The E-800A will generally be left on all the time at the customer site. Remember that

when the E-800A is powered off, network access to the copier is interrupted.

You should shut down the E-800A when you need to service it or the copier, and before

you remove or attach any cables to the E-800A. Shut down the E-800A when changing

the copier’s toner in order to prevent the fan from drawing toner into the E-800A.

TO SHUT DOWN THE E-800A

1. Make sure that the E-800A Info screen reads Idle.

When Printing or Ripping appears on the Control Panel the E-800A is currently

processing a job. Idle appears in the Info screen when the E-800A is finished processing

the job.

2. At the Idle screen, press the menu button once to display the Functions menu.

Print Pages

Suspend Printing

Resume Printing

Shut Down

Functions

Clear Server

Run Setup

Run Diagnostics

Calibration

Functions

IGURE 3-9 Shut Down command in the Functions menu

F

3. Select Shut Down from the Functions menu.

4. At the next screen, select Shut Down System.

The message It is now safe to power off the system.... is displayed.

5. Power off the E-800A using the power switch on the back panel (press 0).

TO RESTART THE E-800A

1. If the E-800A is already on, ensure that it is not receiving, processing, or printing a

document.

When Printing or Ripping appears on the E-800A Control P anel, the E-800A is currently

processing a print job. Wait until the job is complete and Idle appears in the Info screen.

Use the line selection

button to the right to

select Shut Down.

3-18

2. Press the menu button once, then select Shut Down from the Functions menu and select

Reboot System.

Page 49

Overview

Chapter 4:

Service

Procedures

4

Generally, the E-800A requires no regular service or maintenance. Use the procedures in

this chapter to inspect, remove, reseat, and replace major hardwar e components as well as

to install system software.

Overview

This chapter includes information on servicing the following components:

• Boards

• Cables

• Motherboard components (DIMMs, CPU, BIOS chip, Battery)

• Fans (front and back panel)

• Power supply

• HDD (hard disk drive)

• ZIP drive

• CD-ROM drive

• Front panel components

See Figure 4-1 on page 4-2 for an overview of components. Replacement parts are

available from your authorized service representative.

When performing the service procedures described in this chapter, follow the pr ecautions

listed in “Precautions” on page xiii.

NOTE: The tools required to service the system are listed in “Tools you will need” on

page xv.

System software service

E-800A system software is installed on the HDD at the factory. A backup of the system

software resides on a separate partition on the HDD. You can retrieve a backup of the

system software using the Restore Backup function in the Service menu. In addition

system software is also provided on a CD. Use the System Software CD when you:

• Replace the HDD

• Upgrade to a more recent version of the system software

For information on how to install system software, see “E-800A system softwar e service”

on page 4-55.

4-1

Page 50

Service Procedures

4

24

21

25

23

19

22

26

18

20

i

Key

1. Front panel

2. Drive door

3. User interface board

4. UIB cable

5. UIB enclosure

6. ZIP drive

7. CD-ROM drive

8. IDE cable (CD-ROM/ZIP drive)

9. Reset cable

10. Drive bracket

11. Tray

12. Front fan

13. Board guide

14. Power supply

15. Fan (back panel)

16. Board guide retainer

17. HDD (hard disk drive)

18. HDD bracket

19. Motherboard

20. SCSI cable (HDD)

21. DIMMs

22. CPU

23. Copier interface board

24. AGP video board

25. IX UIB board

26. Side panel

4-2

15

16

14

11

F

IGURE 4-1 Exploded view of E-800A components

13

12

10

17

7

9

8

5

6

4

3

1

2

Page 51

Accessing E-800A internal components

4

Accessing E-800A internal components

If the E-800A is powered on, make sure to shut down the system before you gain access

to the E-800A’s internal components. Always use the following procedures when opening

the E-800A for inspection or service. Remember that when the E-800A is powered off,

network access to the copier is interrupted.

TO SHUT DOWN THE E-800A

Always verify that the E-800A is not being used before you power off or restart it. Make

sure that the E-800A is not ripping or printing a job.

1. Make sure that the E-800A Info screen reads Idle.

When Printing or Ripping appears on the Control Panel the E-800A is currently

processing a job. Idle appears in the Info screen when the E-800A is finished processing

the job.

2. At the Idle screen, press the menu button once to display the Functions menu.

Print Pages

Suspend Printing

Resume Printing

Shut Down

Functions

Clear Server

Run Setup

Run Diagnostics

Calibration

Functions

IGURE 4-2 Shut Down command in the Functions menu

F

3. Select Shut Down from the Functions menu.

4. At the next screen, select Shut Down System.

The message It is now safe to power off the system.... is displayed.

5. Power off the E-800A using the power switch on the back panel (press 0).

6. Disconnect all cables from the back panel of the E-800A.

Always obtain permission from the network administrator before you take the E-800A

off the network.

Use the line selection

button to the right to

select Shut Down.

4-3

Page 52

Service Procedures

4

TO OPEN THE E-800A

1. Make sure you have powered off the E-800A and removed all the cables from the back.

2. Remove the two screws that secure the side panel to the tray.

3. Lift off the side panel (see Figure 4-3).

Press on the front edge of the side panel as you slide the panel off the tray.

Side panel screws

Side panel

(press on front edge while

removing)

FIGURE 4-3 Removing the E-800A side panel

4. The E-800A internal components are now accessible. Attach an ESD wrist strap before

handling internal parts.

The E-800A is shipped from the factory with a standard board configuration, as shown

in Figure 4-4 on page 4-5. If optional components have been installed, see the

documentation that came with the specific kit.

4-4

Page 53

Mouse (option)

Keyboard (option)

USB ports (not used)

Serial ports

(not used)

Parallel port (not used)

10/100BaseT

Sound ports (not used)

Option slots

Parallel port (not used)

Empty slot

Monitor (option)

Empty slot

Copier interface

Empty slot

Power switch

Power connector

Accessing E-800A internal components

4

N

OTE: To service components inside the tray, position the E-800A so that it is resting on

its side and the components inside the tray are facing up.

Slot 1

Slot 2

Slot 3

Slot 4

Slot 5

Slot 6

Slot 7

PCI1

PCI2

AGP

PCI3

PCI4

PCI5

PCI6

or

SlotA1

Power supply

Hard disk driveMotherboard

ZIP drive

CD-ROM drive

Back panel view Side view

Motherboard connectors:

PCI1—IX UIB board

PCI2—Empty (reserved for Token Ring option)

AGP—AGP video board

PCI3—Empty

PCI4—Empty

PCI5—Copier interface board

PCI6—Empty

SlotA1—Empty

FIGURE 4-4 E-800A side view and back panel view

4-5

Page 54

Service Procedures

4

Accessing front panel components

The following procedure describes how to remove the front panel in order to access the

user interface board, the Control Panel buttons, CD-ROM/ZIP drive assembly, and the

top front panel jewel. You do not need to remove the front panel in order to access other

components inside the tray.

TO REMOVE THE FRONT PANEL

1. Remove the E-800A side panel as described on page 4-4.

2. Remove the UIB cable from connector J4 on the IX UIB board.

The other end of the UIB cable is connected to the user interface board inside the front

panel.

3. On the inside front of the tray, squeeze the tabs that secure the front panel to the tray.

4. As you squeeze the tabs, gently rotate the front panel to the right to release the hooks

from the tray.

5. Thread the UIB cable connector through the opening in the front of the tray to

completely remove the front panel.

The front panel components are now accessible.

4-6

Page 55

Accessing E-800A internal components

4

Indicates the 3 hooks

Tab slot

Opening in cover

for UIB cable

Inside of tray

Tab slot

F

IGURE 4-5 Removing the front panel

Tab

UIB enclosure

UIB cable

Front panel

Tab

TO REPLACE THE FRONT PANEL

1. Make sure the UIB enclosure and all front panel components are installed correctly.

2. Thread the end of the UIB cable that connects to the IX UIB board through the opening

in the front of the cover.

The other end of the cable should already be securely connected to the user interface

board.

3. Connect the UIB cable to connector J4 on the IX UIB board.

When you connect the cable, be sure to snap the levers together to ensure that the

connector is securely fastened.

4. Angle the front panel so that the three hooks on the edge of the fr ont panel line up with

the cutouts on the front of the cover (see Figure 4-5).

5. Rotate the front panel into the cover until you hear it snap into place.

4-7

Page 56

Service Procedures

4

Checking E-800A internal connections

The most common causes of hardware problems are faulty and loose connections. Before

you conclude that any board or component has failed, remove, inspect, and reseat all

appropriate connections, and then verify that the problem still occurs.

TO CHECK BOARD AND CABLE CONNECTIONS

1. Before you touch any parts inside the E-800A, attach a grounding wrist strap. Touching

the metal part of the power supply case inside the E-800A also discharges static

electricity.

2. Position the E-800A so it is resting on its side and the internal components of the

E-800A are facing up.

3. Inspect the E-800A boards for secure insertion into the motherboard. Press down firmly

on each board to make sure it is securely installed.

Looking into the tray from the top, the standard board configuration includes the

following (from top to bottom):

Connector PCI1—IX UIB board

Connector PCI2—Empty

Connector AGP—AGP video board

Connector PCI3—Empty

Connector PCI4—Empty

4-8

Connector PCI5—Copier interface board

Connector PCI6—Empty

Connector SlotA1—Empty

4. Inspect ribbon cables to see if they are intact.

Faulty ribbon cables are easily overlooked. Check the contact point between the cable

and the connector to ensure that they have not separated. If a ribbon cable is suspect,

substitute it with a tested cable.

5. Make sure that all E-800A ribbon cables and power cables are seated on connectors. See

Figure 4-6 on page 4-9.

Cable connectors are keyed to fit only when properly oriented.

6. Check the front fan, back panel fan, CPU fan, and reset cable connections to the

motherboard.