Page 1

Color Controller E-7000

(Machine Code: G815-01/-02)

SERVICE MANUAL

Page 2

Read this "Safety Information" carefully before you use this product.

For safety, please follow the instructions in information slip.

SAFETY INFORMATION

When using this machine, the following safety precautions should always be

followed.

Safety During Operation

In this manual, the following important symbols are used:

!WARNING

Indicates a potentially hazardous situation which, if instructions are not

followed, could result in death or serious injury.

!CAUTION

Indicates a potentially hazardous situation which, if instructions are not

followed, may result in minor or moderate injury or damage to property.

!WARNING

• Connect the power cord directly into a wall outlet and never use an extension

cord.

• Disconnect the power plug (by pulling the plug, not the cable) if the power

cable or plug becomes frayed or otherwise damaged.

• To avoid hazardous electric shock, do not remove any covers or screws other

than those specified in this manual.

• Turn off the power and disconnect the power plug (by pulling the plug, not the

cable) if any of the following occurs:

− You spill something into the machine.

− You suspect that your machine needs service or repair.

− The external housing of your machine has been damaged.

!CAUTION

• Protect the machine from dampness or wet weather, such as rain and snow.

• Unplug the power cord from the wall outlet before you move the machine.

While moving the machine, you should take care that the power cord will not

be damaged under the machine.

• When you disconnect the plug from the wall outlet, always pull the plug (not the

cable).

• Risk of explosion if battery is replaced by an incorrect type.

• Dispose of used batteries according to the instructions.

Page 3

!ACHTUNG (Deutch)

• Die batterie darf nur durch eine des gleichen Typs ersetzt warden, da

anderenfalls Explosionsgefahr besteht.

• Sie die debrauchten Batterien entsprechend den gegebenen Anweisungen.

Power Cord Precautions:

To reduce the risk of electric shock or damage to the equipment:

• User the appropriate power cord which was set up by your manufacturer's

authorized service provider.

• Do not place objects on AC power cords or cables. Arrange then so that no one

may accidentally step on or trip over them.

• Do not pull on a cord or cable. When unplugging from the electrical outlet, grasp

the cord by the plug.

• Do not disable the power cord grounding plug. The grounding plug is an

important safety feature.

• Plug the power cord into a grounded (earthed) electrical outlet that is easily

accessible at all times.

Power Supply:

The socket-outlet shall be installed near the product and shall be easily accessible.

Netzanschluss: (Deutch)

Die Wandsteckdose sollte in der Nähe Geräts installiert und leicht zugänglich sein.

Warning:

Use of controls, adjustment or performance of procedures other than those

specified in this manual may result in hazardous radiation exposure.

Page 4

!IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the controller, make sure that

the AC power cord is unplugged.

2. The wall outlet should be near the controller and easily accessible.

3. Note that some components of the controller are supplied with electrical

voltage even if the main power switch is turned off.

4. If any operation check has to be made with exterior covers off while the main

switch is turned on, keep hands away from electrified or mechanically driven

components.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The controller must be installed and maintained by a customer service

representative who has completed the training course on the controller.

2. The danger of explosion exists if the battery on the motherboard is

incorrectly replaced. Replace the battery only with the equivalent type

recommended by the manufacturer. Discard the used motherboard battery in

accordance with the manufacturer’s instructions and local regulations.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Dispose of replaced parts in accordance with local regulations.

2. When keeping used lithium batteries in order to dispose of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

Page 5

This manual uses several symbols.

Symbol What it means

☛

Refer to section number/document

!

Screw

"

Connector

Trademarks

• Windows ® are registered trademarks of Microsoft Corporation in the United

States and /or other countries.

• Fiery ® is a registered trademark of Electronics For Imaging, Incorporated.

• PostScript

® is a registered trademark of Adobe Systems, Incorporated.

• Ethernet

® is a registered trademark of Xerox Corporation.

• Macintosh ® is a registered trademark of Apple Computer, Incorporated.

• Pentium ® is a registered trademark of Intel Corporation.

• Other product names used herein are for identification purposes only and may be

trademarks of their respective companies. We disclaim any and all rights

involved with those marks.

Page 6

i

TABLE OF CONTENTS

1 INSTALLATION .......................................................................... 1-1

1.1 INSTALLATION REQUIREMENTS ............................................................1-1

1.1.1 ENVIRONMENT ................................................................................1-1

1.1.2 MACHINE LEVEL..............................................................................1-1

1.1.3 MINIMUM SPACE REQUIREMENTS ...............................................1-2

1.1.4 POWER REQUIREMENTS ...............................................................1-2

1.2 INSTALLATION FLOW CHART .................................................................1-3

1.3 MACHINE INSTALLATION.........................................................................1-4

1.3.1 SETTING CUSTOMER EXPECTATIONS .........................................1-4

1.3.2 UNPACKING THE E-7000 ................................................................1-5

1.3.3 FRONT AND BACK PANELS............................................................1-6

1.3.4 CONNECTING E-7000 TO THE COPIER.........................................1-7

1.3.5 STARTUP AND INITIAL SETUP .......................................................1-9

1.3.6 VERIFYING THE CONNECTION (LOCAL TEST PRINT) ...............1-12

1.3.7 VERYFYING CONNECTION TO THE NETWORK .........................1-13

1.4 INSTALLING OPTIONAL FEATURES .....................................................1-14

1.4.1 OVERVIEW .....................................................................................1-14

1.4.2 ACTIVATE / DEACTIVATE AN OPTIONAL FEATURE

USING A DONGLE ..........................................................................1-15

2 GENERAL OPERATIONS FOR SERVICING.............................. 2-1

2.1 START-UP, SHUT-DOWN, AND REBOOT PROCEDURES......................2-1

2.1.1 STARTING THE COPIER AND THE E-7000 ....................................2-1

2.1.2 SHUTTING DOWN THE COPIER AND THE E-7000........................2-2

2.1.3 SHUTTING DOWN THE E-7000 ONLY ............................................2-2

2.1.4 RESTARTING THE E-7000...............................................................2-3

2.1.5 REBOOTING THE E-7000 ................................................................2-3

2.2 CANCELLING THE CURRENT PRINT JOB ..............................................2-4

2.3 PRINTING THE CONFIGURATION SHEET OR TEST SHEETS...............2-4

2.4 RUNNING THE E-7000 SETUP .................................................................2-5

2.4.1 TO ACCESS THE SETUP MENU .....................................................2-5

2.4.2 TO EXIT FROM THE SETUP MENU ................................................2-5

3 REPLACEMENT ......................................................................... 3-6

3.1 GENERAL CAUTION .................................................................................3-6

3.2 NAMES OF MAIN PARTS/UNITS ..............................................................3-7

3.3 COVER REMOVAL ....................................................................................3-8

3.3.1 SIDE COVER FOR THE E-7000 .......................................................3-8

3.4 UNIT REMOVAL.........................................................................................3-9

3.4.1 VIDEO BOARD..................................................................................3-9

3.4.2 DIAGNOSTIC LED BOARD ............................................................3-10

3.4.3 HARD DISK DRIVE (HDD)..............................................................3-10

3.4.4 POWER SUPPLY UNIT ..................................................................3-11

3.4.5 FAN .................................................................................................3-11

3.4.6 MOTHERBOARD ............................................................................3-12

3.4.7 MEMORY - 512 MB DIMM ..............................................................3-13

Page 7

ii

3.4.8 CPU AND COOLING ASSEMBLY...................................................3-13

3.4.9 LITHIUM BATTERY.........................................................................3-15

3.4.10 EXTENSION CARD...................................................................3-15

4 SOFTWARE MAINTENANCE..................................................... 4-1

4.1 GENERAL NOTES AND CAUTIONS .........................................................4-1

4.2 CLEARING THE QUEUED PRINT JOBS IN THE E-7000..........................4-2

4.3 RESTORING THE E-7000 TO FACTORY DEFAULTS..............................4-3

4.4 SYSTEM SOFTWARE INSTALLATION PROCEDURE .............................4-4

4.4.1 OVERVIEW .......................................................................................4-4

4.4.2 INSTALLING SYSTEM SOFTWARE

OVER THE NETWORK PORT...........................................................4-5

4.4.3 INSTALLING SYSTEM SOFTWARE

USING A USB FLASH DRIVE............................................................4-8

4.5 PATCH INSTALLATION PROCEDURE ...................................................4-10

5 TROUBLESHOOTING .............................................................. 5-11

5.1 OVERVIEW ..............................................................................................5-11

5.2 LED DIAGNOSTIC CODES......................................................................5-12

5.3 ERRORS AND SUGGESTED ACTIONS .................................................5-16

5.3.1 START-UP PROBLEMS..................................................................5-16

5.3.2 SYSTEM PROBLEMS.....................................................................5-18

5.3.3 SYSTEM SOFTWARE INSTALLATION ..........................................5-19

5.3.4 NETWORK PROBLEMS .................................................................5-20

5.3.5 PRINTING PROBLEMS ..................................................................5-21

5.4 TESTING THE VOLTAGE SUPPLIES......................................................5-26

6 DETAILED SECTION DESCRIPTIONS ...................................... 6-1

6.1 BLOCK DIAGRAM AND FUNCTIONS .......................................................6-1

6.2 PRINT DATA PROCESSING .....................................................................6-3

6.2.1 FLOW CHART...................................................................................6-3

6.2.2 MULTI-COPY PRINT JOBS ..............................................................6-3

7 SPECIFICATIONS....................................................................... 7-1

7.1 GENERAL SPECIFICATIONS....................................................................7-1

7.2 SUPPORTED PAPER SIZES.....................................................................7-3

7.3 SUPPORTED MEDIA TYPES ....................................................................7-4

Page 8

20 March, 2006 INSTALLATION REQUIREMENTS

1-1

InstallationInstallationInstallation

1 INSTALLATION

1.1 INSTALLATION REQUIREMENTS

1.1.1 ENVIRONMENT

1. Temperature Range:

5°C to 40°C (41°F to 104°F)

2. Humidity Range:

10% to 90% RH

3. Ambient Illumination:

Less than 1500 lux (do not expose to direct sunlight

or strong light)

4. Ambient Dust:

Less than 0.10 mg/m3

5. If the place of installation is air-conditioned or heated, do not place the machine

where it will be:

1) Subjected to sudden temperature changes

2) Directly exposed to cool air from an air-conditioner

3) Directly exposed to heat from a heater

6. Do not place the machine where it will be exposed to corrosive gases.

7. Do not install the machine at any location over 3,048 m (10,000 feet) above sea

level.

8. Place the controller on a strong and level base.

9. Do not place the machine where it may be subjected to strong vibrations.

10. Do not connect the machine to a power source shared with another electrical

appliance.

11. The machine can generate an electromagnetic field, which could interfere with

radio or television reception.

1.1.2 MACHINE LEVEL

1. Front to back:

Within ±5° (0.2") away from level

2. Right to left:

Within ±5° (0.2") away from level

Page 9

INSTALLATION REQUIREMENTS 20 March, 2006

1-2

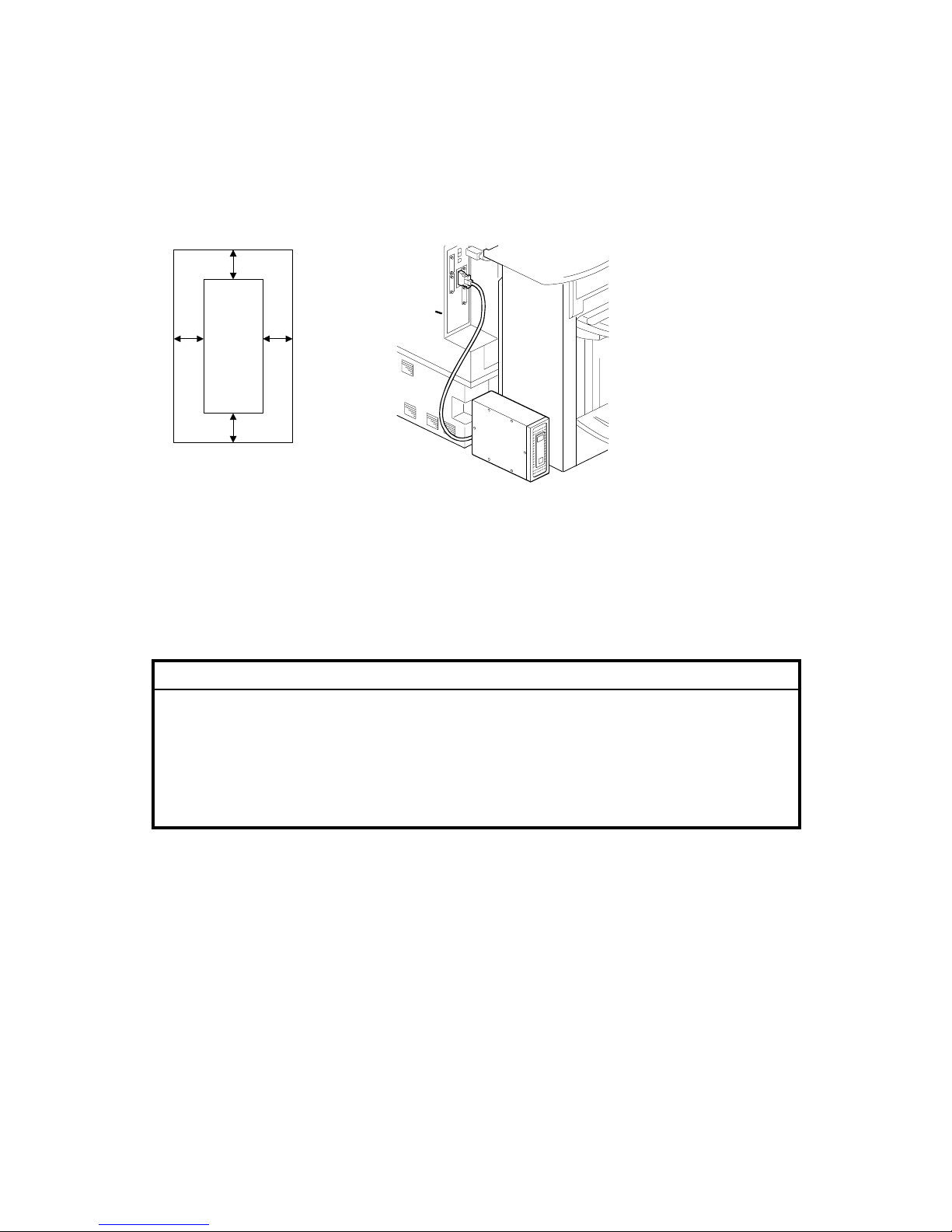

1.1.3 MINIMUM SPACE REQUIREMENTS

Place the machine near the power source, providing clearance as shown.

You may place the machine on the rear side of the finisher as shown in the

illustration.

1.1.4 POWER REQUIREMENTS

!CAUTION

1. Insert firmly the plug in the outlet.

2. Avoid using an outlet extension plug or cord.

3. Ground the machine. Avoid using a 3-prong adapter in a 2-hole ungrounded

outlet.

4. Use the supplied AC power cord with this product.

1. Input voltage level: 100 – 240V, 50-60Hz; 3A

2. Do not put anything on the AC power cord.

Front Panel

Back Panel

100 mm

100 mm

100 mm

100 mm

Left Panel

Right Panel

G815I906.WMF

G815R022.WMF

Page 10

20 March, 2006 INSTALLATION FLOW CHART

1-3

InstallationInstallationInstallation

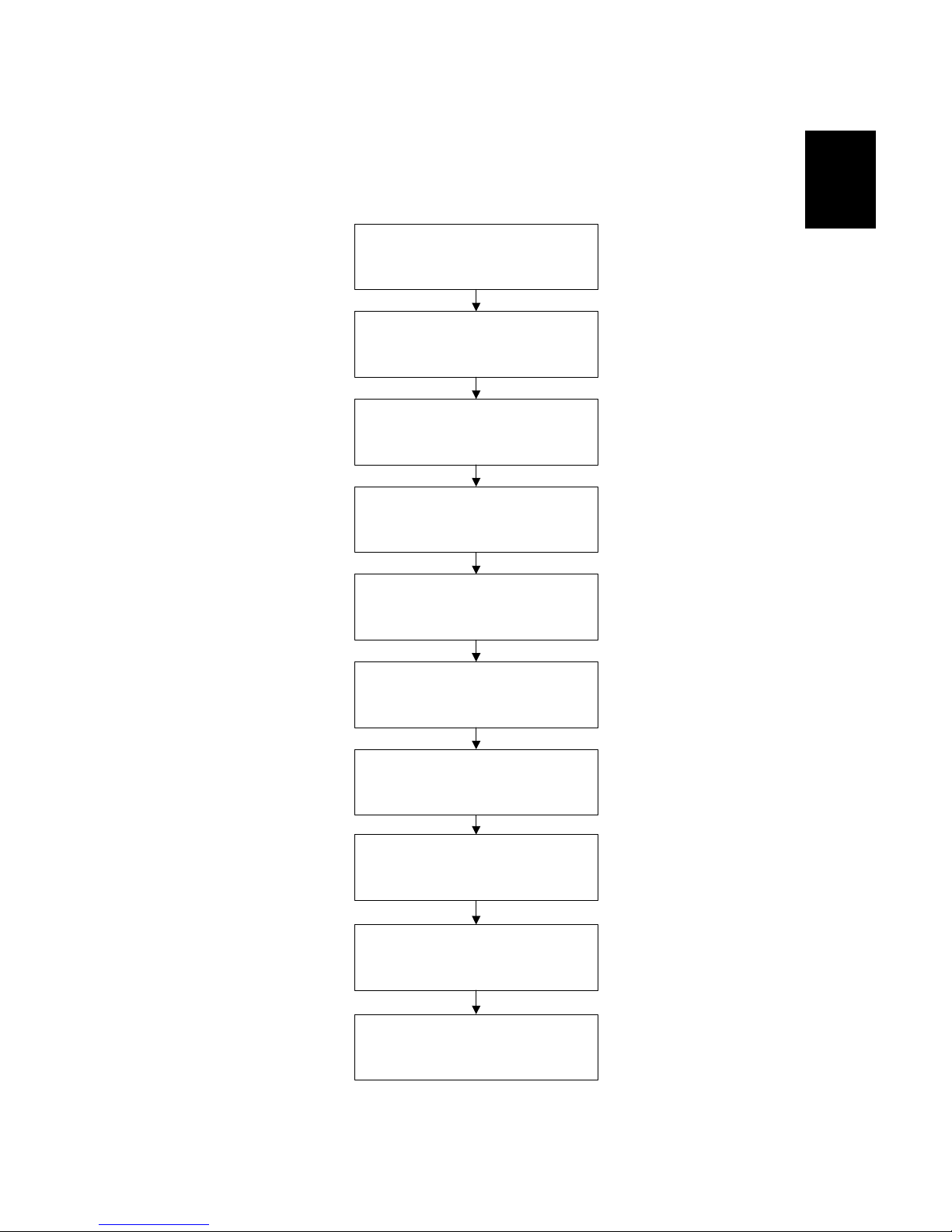

1.2 INSTALLATION FLOW CHART

Recommended installation steps are as follows:

Make sure that the copier

is ready to use.

Unpack the E-7000

Connect the E-7000

to the copier

Print Test Pages and a

Configuration Page

The site administrator connects

the E-7000 to the network

and verifies the connections.

The site administrator installs user

software on networked computers

that print to the E-7000.

Finished

Select the language and

do the minimum setup

The site administrator

configures the setup options.

The site administrator performs

the color calibration.

G815V900.WMF

Page 11

MACHINE INSTALLATION 20 March, 2006

1-4

1.3 MACHINE INSTALLATION

1.3.1 SETTING CUSTOMER EXPECTATIONS

Before installation, the customer should be informed of the following:

• Some nodes on the network may be unavailable for up to one hour.

• The copier may be unavailable for up to one hour

• The site administrator should be available during the installation for network

connectivity.

• Equipment downtime and impact on the network can be minimized if the site

administrator installs a network connector for the E-7000 and confirms network

connection for the E-7000 installation.

• The site administrator should have a networked computer available during the

installation. The appropriate software should already be installed.

Documentation for the networked computer and the network operating software

should be available.

• The site administrator should install the user software shipped with the E-7000

(user documentation is also included) onto the networked PCs and Mac OS

computers that will print to the E-7000.

NOTE: This guide covers hardware installation and service. It provides general

information on connecting the E-7000 to the customer’s network. For

network setup and configuration information, refer the site administrator to

the Configuration and Setup manual.

Page 12

20 March, 2006 MACHINE INSTALLATION

1-5

InstallationInstallationInstallation

1.3.2 UNPACKING THE E-7000

1. Open the box and remove the packing material.

2. Remove the contents from the top container. Inspect the contents for visible

damage. The top container should include the following items:

3. Give the Media Package to the site administrator.

4. Take the remaining components out of the top container.

5. Remove the top container and any packing materials.

6. Carefully lift the E-7000 out of the box.

G815I901.WMF

• [A] AC Power Cord

• [B] Interface Cable

• [C] Extension Card

• [D] Fierydriven Keytops

• [E] Fierydriven Logo

• [F] Base for Keytop

• [G] Media Package

[A]

[B]

[C]

[D]

[E]

[F]

[G]

Page 13

MACHINE INSTALLATION 20 March, 2006

1-6

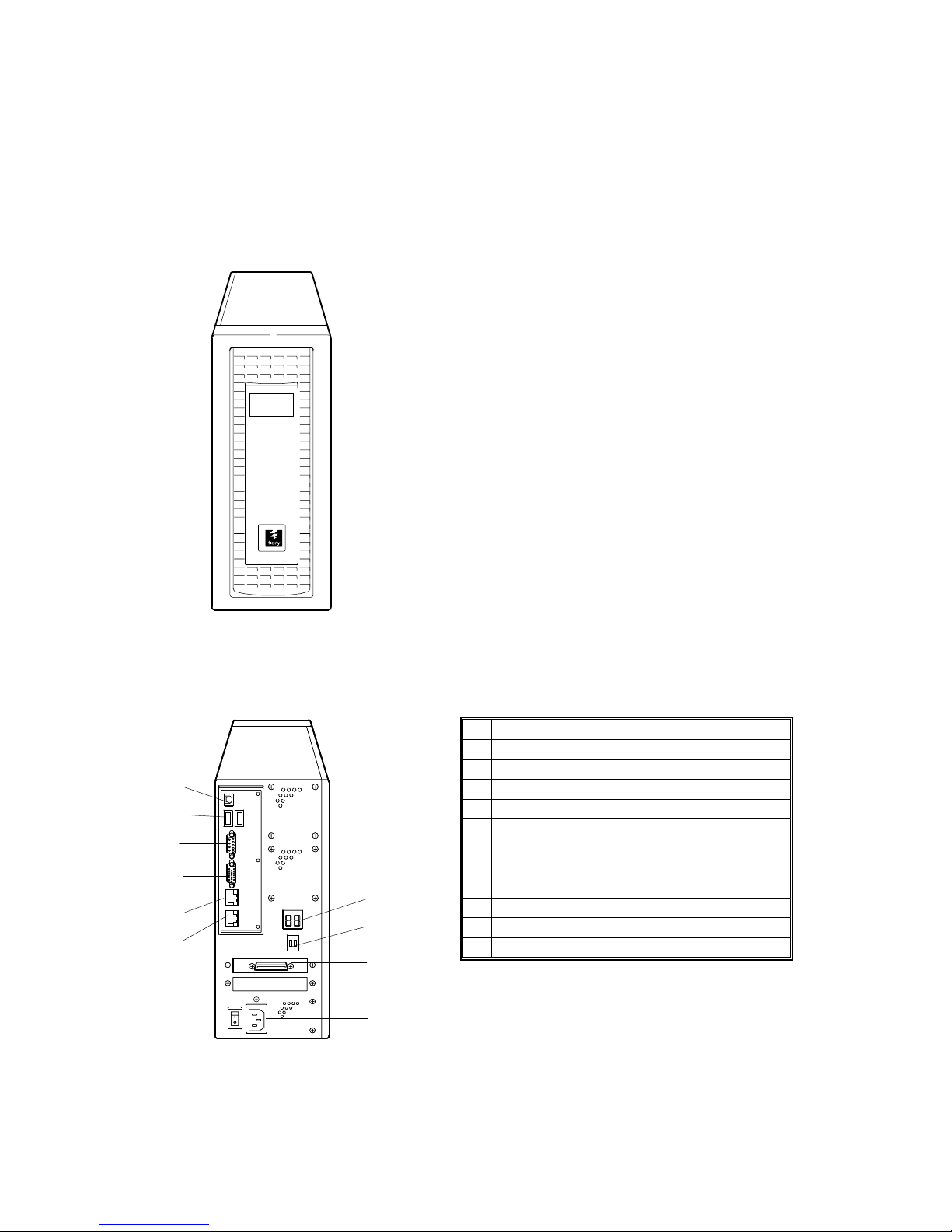

1.3.3 FRONT AND BACK PANELS

After unpacking the E-7000, familiarize yourself with the front and back panels

before you connect the E-7000 to the copier.

• Front Panel

• Back Panel

Color Controller

E-7000

driven

G815R001.WMFMF

ON

1 2ON1 2

G815R002.WMF

A Diagnostic LEDs (for service use only)

B Service Switches (for service use only)

C Video Interface

D Power Connector

E Power Switch

F Not Used

G RJ-45 Connector

(10BaseT/100BaseTX/1000BaseT)

H Not used (Monitor port)

I Not used (Serial Port)

J USB Ports

K Not used (USB Type B port)

[A]

[B]

[C]

[D]

[E]

[F]

[G]

[H]

[I]

[J]

[K]

Page 14

20 March, 2006 MACHINE INSTALLATION

1-7

InstallationInstallationInstallation

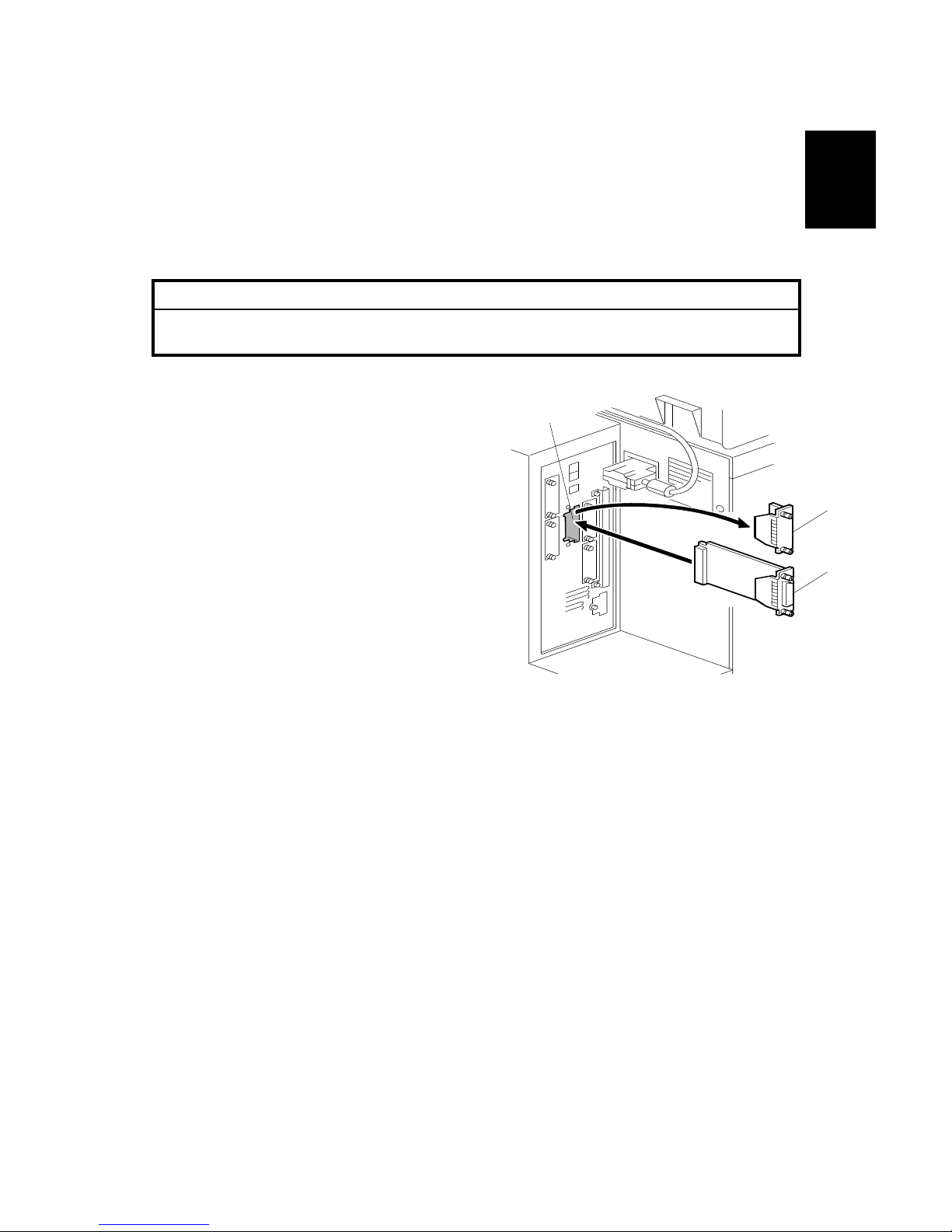

1.3.4 CONNECTING E-7000 TO THE COPIER

After you unpack the E-7000, connect the E-7000 to the copier before you connect

it to the network. This is to confirm that there are no problems with the hardware

and controller itself.

!WARNING!

Turn the controller main power switch and copier main power switch to off

and disconnect the power cords before you do these procedures.

1. Remove the I/F slot cover [A] of Slot C

[C] (this is the slot for the external

controller) (! x 2).

2. Touch a metal surface to remove static

charge from your hands before you

touch the extension card.

3. Insert the extension card [B] into Slot

C [C] and fasten it with the screws. (!

x 2).

NOTE: Make sure that the extension

card is inserted straight and

firmly.

G815R015.WMF

[A]

[B]

[C]

Page 15

MACHINE INSTALLATION 20 March, 2006

1-8

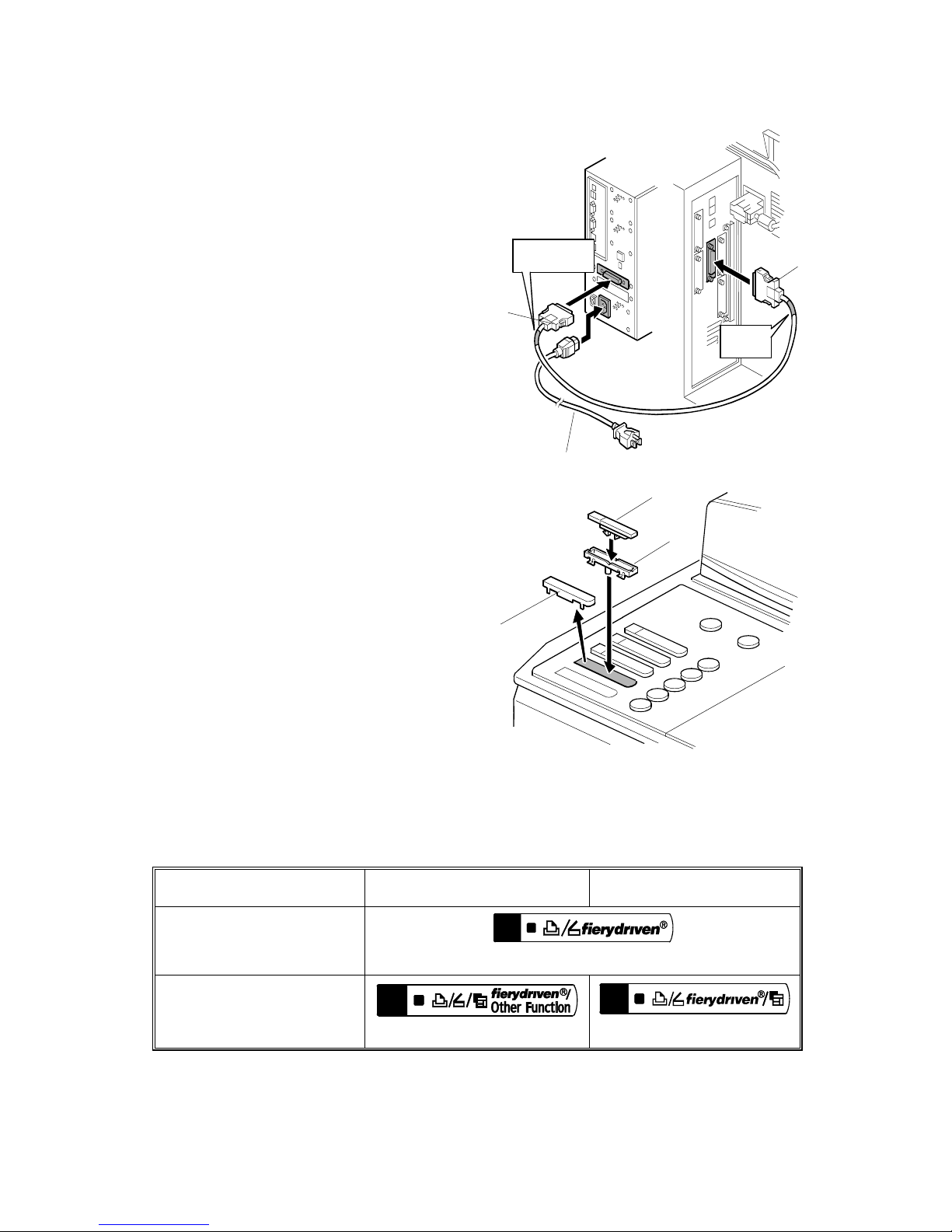

4. Connect the interface cable as follows:

− “Copier Side” [D]:

Connect this to the extension card

and fasten the screws.

− “Controller Side” [E]:

Connect this to the video interface

on the rear of the E-7000.

NOTE: If the interface cable is

connected in the opposite

direction, the copier engine will

fail to communicate with the

controller.

5. Connect the appropriate AC power

cord [F] to the power connector at the

back of the E-7000.

6. On the operation panel of the copier,

remove the Slot Cover [A] and discard

it.

7. Install the base key top [B] and

Fierydriven key top [C] in the position

indicated in the illustration.

Use the correct keytops, as shown in

the table below.

US Model (English)

International Model

(Symbols)

Only the E-7000 is

connected.

B1328890.WMF

The E-7000 and the Copy

Connector Kit (for the

Tandem Copy feature) are

connected.

B1328892.WMF

B1328893.WMF

COPIER

SIDE

CONTROLLER

SIDE

G815R018.WMF

G815R016.WMF

[D]

[E]

[F]

[A]

[B]

[C]

Page 16

20 March, 2006 MACHINE INSTALLATION

1-9

InstallationInstallationInstallation

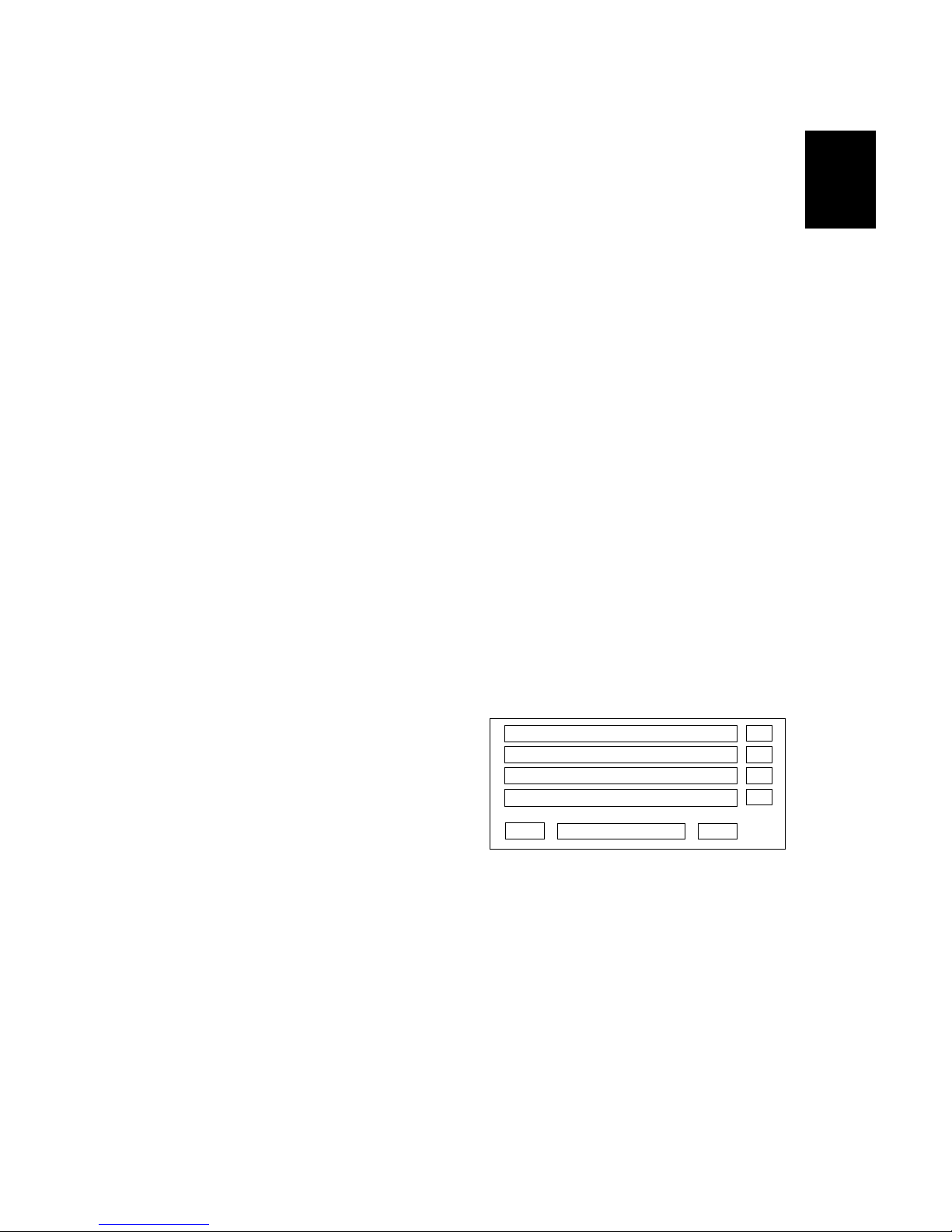

Select Language

English

OK

#

Main Menu/Cancel

$

%

%

%

%

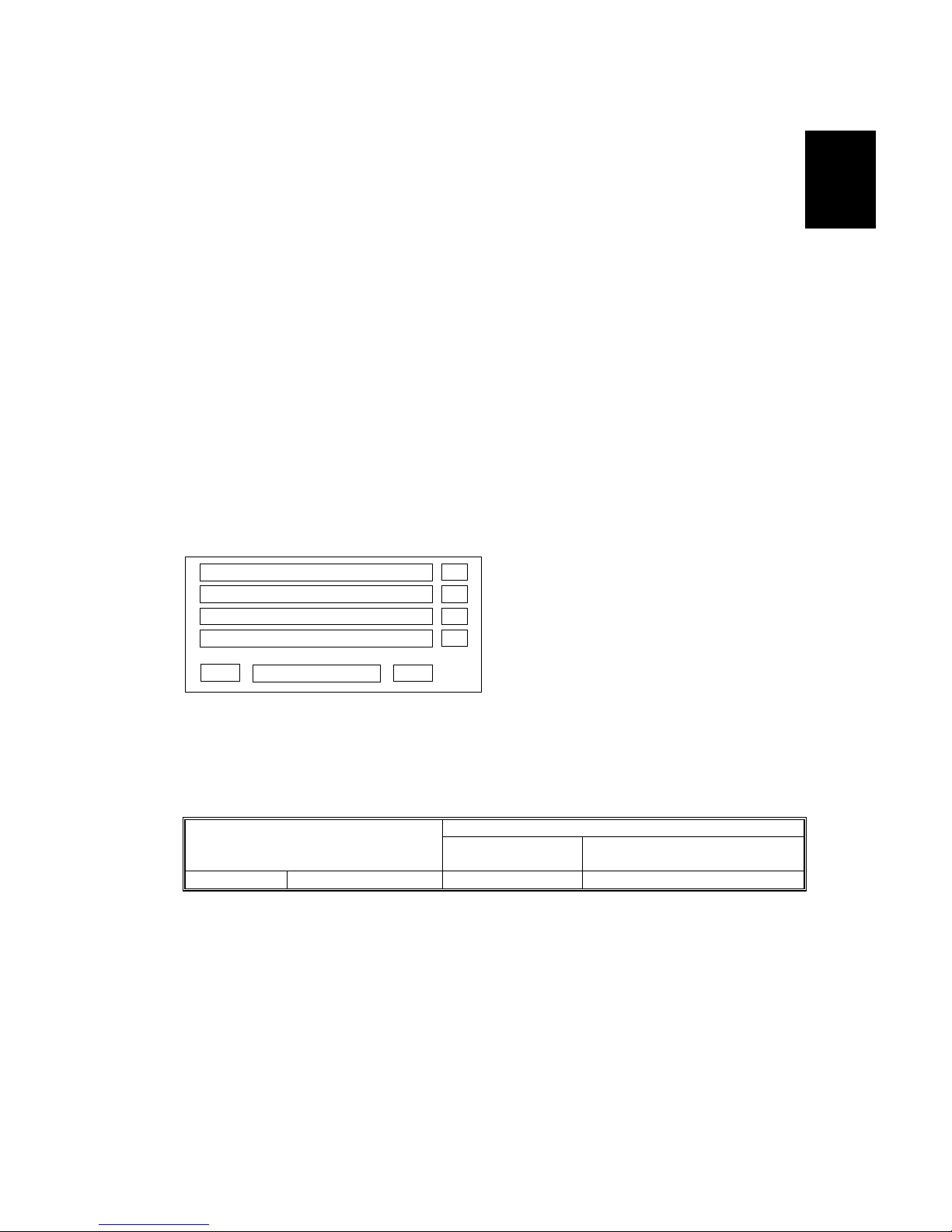

1.3.5 STARTUP AND INITIAL SETUP

1. Connect the power cord of the copier to a power outlet and switch on the copier

main power.

NOTE: 1) The copier must be turned on before you turn the E-7000 on.

2) Make sure that all firmware modules for the copier are updated to

the newest versions. If they are not, update them before you turn on

the E-7000.

(☛ Copier Service Manual)

2. Turn the power switch on the E-7000 back panel to ON.

3. Allow startup to proceed without interruption, while you watch the diagnostic

LEDs on the back panel of the E-7000.

4. When the diagnostic LEDs show ‘00’, go to the copier operation panel and

press the Fierydriven key. ‘Please wait’ may be shown on the copier operation

panel.

5. The language selection screen is shown. (If this screen is not shown, then

press the Fierydriven key again.)

Select the desired language with the down arrow “$” key and up arrow “#”

key, and touch “OK”.

• English

• Dutch

• Spanish

• Italian

• German

• French

NOTE: 1) After you have selected a language, you cannot change the

language unless you do “Factory Defaults (☛ 4.3)” or re-install the

system software.

2) The default settings for the E-7000 depends on the language

selection as follows:

Selected Language & Market Region

English - US

English – UK/Dutch / Spanish/

Italian /German/French

PS Setting Default Paper Sizes

US Metric

Page 17

MACHINE INSTALLATION 20 March, 2006

1-10

Select Market Region

U.S.

O

K

#

Main Menu/Cancel

$

%

%

%

%

Exit Setup

Server Setup

Network Setup

Printer Setup

#

Main Menu/Cancel

$

%

%

%

%

Exit Setup

Server Setup

Network Setup

Printer Setup

#

Main Menu/Cancel

$

%

%

%

%

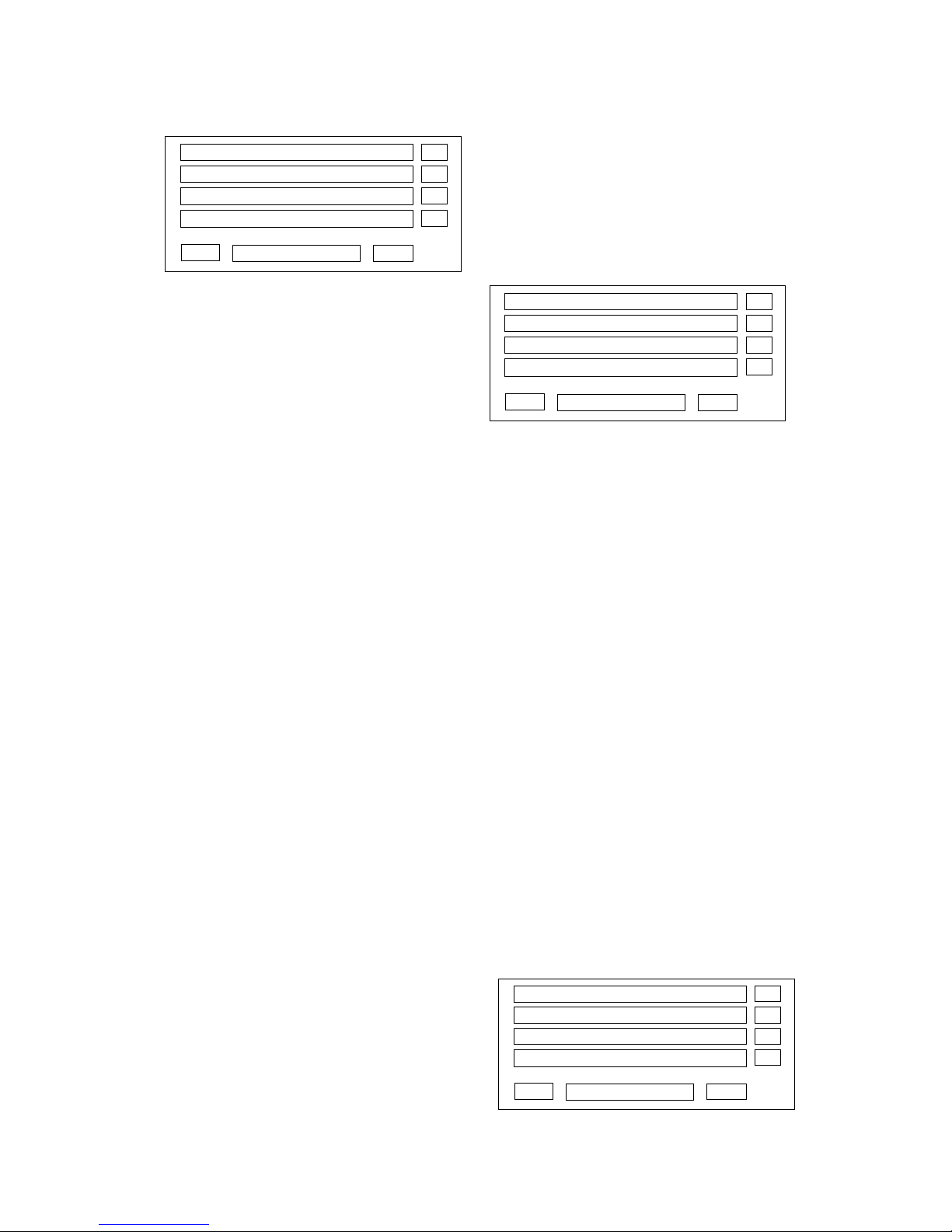

If you selected “English” at the language

selection screen, you are prompted to

select the market region. Select either

“US” or “UK” with the down arrow “$”

key and up arrow “#” key, then touch

“OK”.

6. “Please wait…” will be indicated on

the Fiery menu screen, then the Fiery

menu screen will disappear from the

operation panel.

7. Wait for a moment, then press the

Fierydriven key again on the

operation panel. The Setup main

menu will appear on the Fiery menu screen.

NOTE: The E-7000 setup options should be configured later by the site

administrator. However, during the installation, a field technician must

check that the E-7000 controller works correctly with the default

configuration.

Therefore, the next steps show the steps for minimum configuration.

8. “Enter Password” message will appear.

Enter the default administrator password: “Fiery.1”.

9. Touch the keys in the following order, to configure the minimum setup.

1) “Server Setup” key

2) “Main Menu/Cancel” key

3) (When you see “Save Changes for Server Setup / YES”)

“OK” key

4) “Network Setup” key

5) “Exit Network” key

6) (When you see “Save Changes for Server Setup/ YES”)

“OK” key

7) “Printer Setup” key

8) “Main Menu/Cancel” key

9) (When you see “Save Changes for Printer Setup / YES”)

“OK” key

NOTE: If you need to specify the system date and time, enter the Server Setup

menu and set them.

10. Select “Exit Setup”.

Page 18

20 March, 2006 MACHINE INSTALLATION

1-11

InstallationInstallationInstallation

Server Name

Idle

XXXXXMB (Version)

#

Main Menu/Cancel

$

%

%

%

%

11. The system will reboot. The Fierydriven

key will have no effect until after the

system reboots. To confirm that the

reboot was successful, press the

Fierydriven key. The Fiery Menu

screen will appear on the operation

panel of the copier.

12. Attach the Fiery Decal [A] to the copier

front cover.

G815R024.WMF

[A]

Page 19

MACHINE INSTALLATION 20 March, 2006

1-12

1.3.6 VERIFYING THE CONNECTION (LOCAL TEST PRINT)

After you connect the E-7000 to the copier, print the Test Page and the

Configuration Page to verify that the connection between the E-7000 and the

copier is good.

1. Make sure that the copier is not in use.

2. Check the settings in the following table, and make sure that Letter or A4 paper

is loaded in at least one of the paper trays of the copier.

PS Setting Default Paper Size

Setup Option “US” “Metric”

Configuration

Page requires…

Letter A4

PS Test Page

requires…

Letter A4

3. On the operation panel of the copier, press the Fierydriven key to access the

printer initial menu screen.

4. Access the menu list. To do this, touch the “Main Menu/Cancel” key, and

select “Print Pages”.

5. Print the following pages:

• Configuration Page

• PS Test Page

6. Examine the quality of the test pages.

• All patches should be visible, but it is acceptable if they are very faint in the

5% and 2% ranges.

• Each patch set should show uniform gradation from patch to patch as the

shade lightens from 100% to 0%.

• Poor image quality may indicate that the copier needs service. For more

information, see the documentation provided with the copier.

Page 20

20 March, 2006 MACHINE INSTALLATION

1-13

InstallationInstallationInstallation

Exit

Server Setup

Network Setup

Printer Setup

#

Main Menu/Cancel

$

%

%

%

%

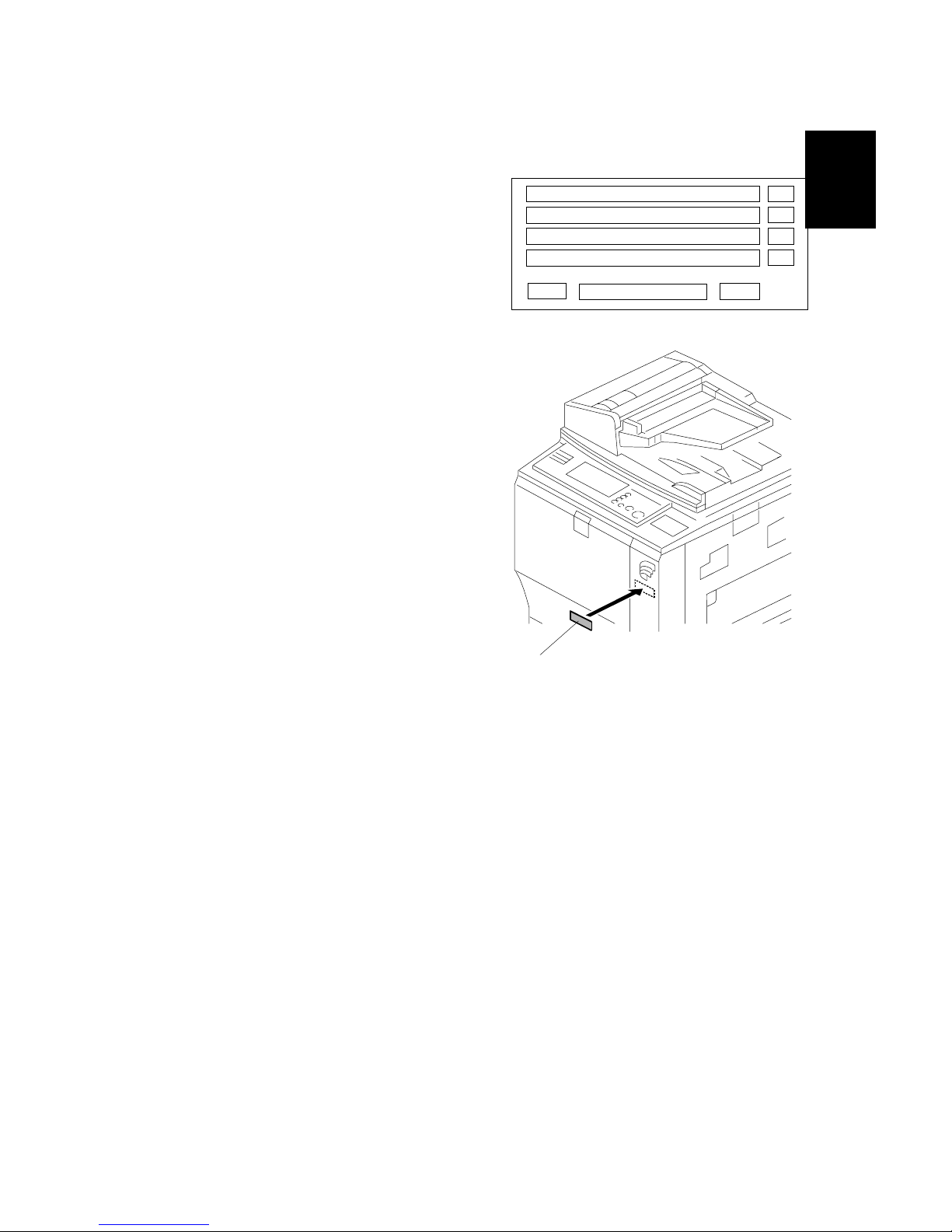

1.3.7 VERYFYING CONNECTION TO THE NETWORK

The E-7000 provides twisted pair connectivity to an Ethernet network.

Cable requirements:

• 10BaseT (Ethernet): Unshielded Twisted Pair (UTP), Category 3 or higher

• 100BaseTX (Fast Ethernet): UTP, Category 5 or higher (4-pair/8-wire, short

length)

• 1000BaseT (Gigabit Ethernet): UTP, Category 5e or higher (4-pair/8-wire,

short-length)

NOTE: If the print engine is 230V, use a shielded network cable.

1. Turn off the E-7000 power before connecting the E-7000 to any network

device.

2. Connect the network cable to the RJ-45 connector (upper connector) on the E-

7000. (The lower connector cannot be used.)

3. Make sure that the copier power is switched on.

4. Turn the power switch on the E-7000 back panel to ON.

5. Allow startup to proceed without interruption, while you watch the diagnostic

LED on the back panel of the E-7000. When the diagnostic LEDs show ‘00’, go

to the copier operation panel.

6. Configure the Setup options.

1) Press the Fierydriven key on the copier operation panel. (‘Please wait’ may

be shown on the copier operation panel. If the next screen is not shown after

‘Please wait’, then press the Fierydriven key again.)

2) Touch the “Main Menu/Cancel” key.

3) Touch the down arrow “$” key.

4) Select “Run Setup”.

5) Touch “OK”.

6) Wait for a while and then press the

Fierydriven key again.

7) Wait until the setup main screen

appears.

8) Ask the site administrator to configure the Setup options.

NOTE: It is the site administrator’s responsibility to configure the correct setup

options for the network and user environment. The default settings in

the setup may be adequate, but they may not be optional for the user’s

environment. Refer the site administrator to the Configuration and

Setup manual for setup information.

7. After configuring the Setup options, verify the network connection.

Ask the site administrator to install the printer driver on a client PC, and to

make a test print from that PC.

Page 21

INSTALLING OPTIONAL FEATURES 20 March, 2006

1-14

1.4 INSTALLING OPTIONAL FEATURES

1.4.1 OVERVIEW

The system software for the E-7000 contains the following optional features:

• EFI Spot-On

• EFI Hot Folders

• EFI Auto Trap

Initially, the above three optional functions cannot be used. When the customer

purchases any of these functions, a hardware USB dongle which includes a license

for the optional feature will be provided.

After the license for the feature is transferred to the E-7000, the dongle will be

locked to that particular E-7000 (a unique value will be written to the dongle).

• To transfer the license from the dongle to the E-7000, you turn off the E-7000

power, connect the dongle, turn on the E-7000 power, wait for the E-7000 to get

to the idle condition, then remove the dongle. The feature is now activated. There

is a detailed procedure on the next page.

After this, the same dongle cannot be used on another E-7000, unless the license

is first removed from the original E-7000 using that dongle. (You must use the

same dongle.)

• To remove the license from the E-7000, do exactly the same procedure that you

use when you transfer the license from the dongle to the E-7000. This

deactivates the feature.

When the feature is removed from the original E-7000, the unique value will be

removed from the dongle. The dongle can now be used on another E-7000.

If a dongle that has already a unique value (had its unit ID locked to a E-7000) is

inserted into another E-7000 unit, the dongle will have no effect.

The number of times the license can be removed from the E-7000 is limited as

shown in the table below. (Activate 4 times and deactivate 3 times.) When this limit

is reached, the dongle can no longer be used to remove the license, so the license

will stay on the E-7000. If a dongle is inserted to remove a feature but the limit has

been reached, there will be no effect.

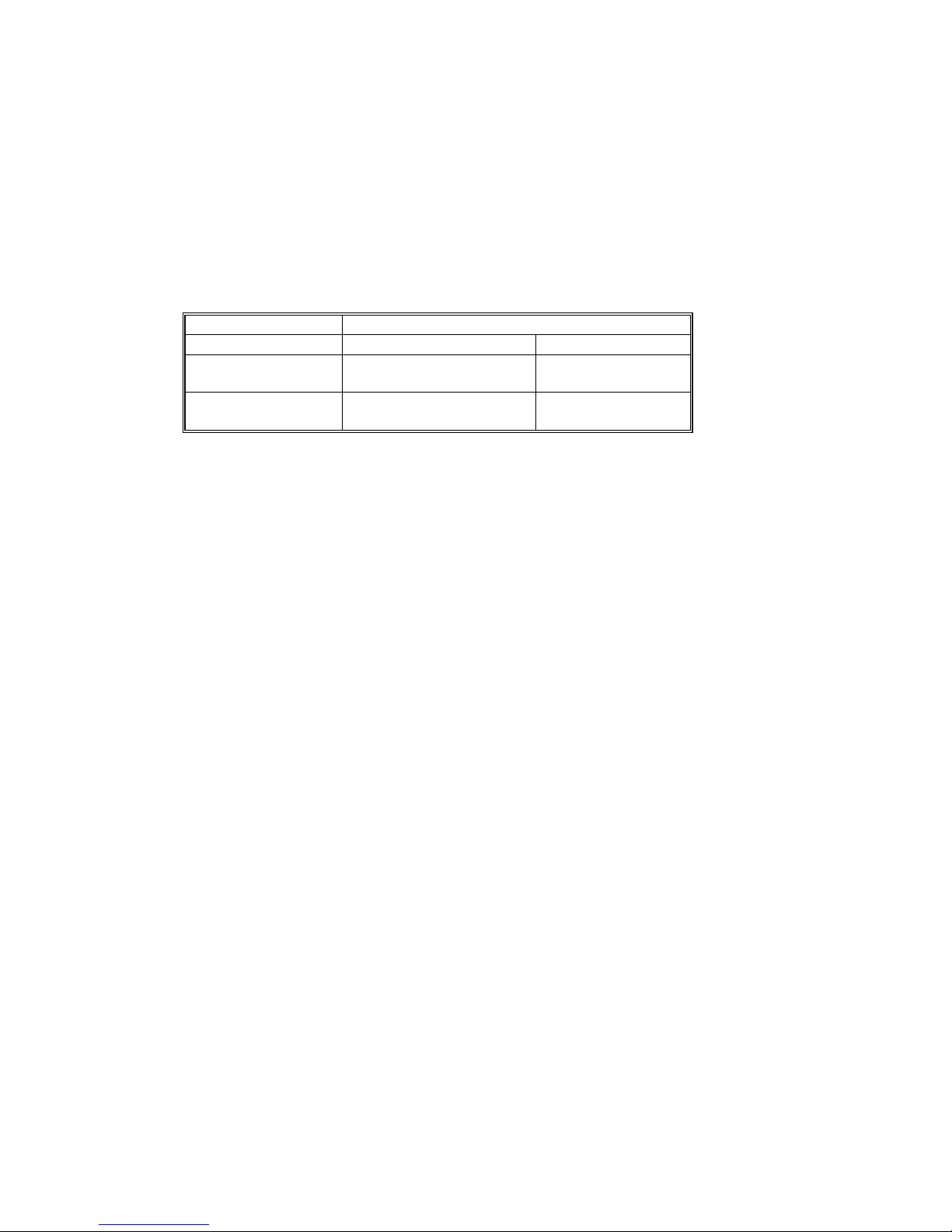

E-7000 Power Turned On (or

E-7000 Rebooted) with

Dongle Connected

Activates/Deactivates the

feature on the E-7000

License Transferred

to

1st time Activates E-7000

2nd time Deactivates Original Dongle

3

rd

time Activates E-7000

4

th

time Deactivates Original Dongle

5

th

time Activates E-7000

6

th

time Deactivates Original Dongle

7

th

time Activates E-7000

8

th

time and after No effect No effect

Page 22

20 March, 2006 INSTALLING OPTIONAL FEATURES

1-15

InstallationInstallationInstallation

1.4.2 ACTIVATE / DEACTIVATE AN OPTIONAL FEATURE USING A

DONGLE

The optional feature dongle can be used to either activate or deactivate a feature.

The operation for both of these procedures is exactly the same, and the successful

activation or deactivation can be confirmed by printing the configuration page.

The purpose of the ability to remove the license (deactivation) is to handle cases

where the license was accidentally installed on the wrong E-7000 unit.

Immediately after the E-7000 main power is turned on or the E-7000 is rebooted,

the E-7000 checks for the presence of the feature activation dongle.

1. Print the configuration sheet of the E-7000. (☛ 2.3)

2. With the configuration sheet, check the condition of the optional feature that

you will activate/deactivate. (Disabled/Enabled).

3. Shut down the E-7000 and turn the power of the E-7000 OFF. (☛ 2.1.3)

4. Insert the dongle in a USB port.

(There are two USB ports in the back panel of the E-7000. Any of the USB

ports can be used.)

5. Make sure that the copier main power is already ON.

6. Turn the power switch of the E-7000 ON.

7. Wait for the E-7000 to come to the idle status.

During this startup sequence, the optional feature will be activated/deactivated.

NOTE: If the E-7000 already has a particular feature activated, and a new

dongle for the same feature is inserted, the license will not be affected

and the new dongle will remain active.

If the E-7000 already has a particular feature activated and the

matching dongle is inserted, the feature will be removed, and the

dongle can then be re-used on another E-7000 unit.

8. Remove the dongle from the USB port.

!CAUTION

Do not forget to remove the dongle at this time.

If you leave the dongle in the USB port and the E-7000 main power is

restarted or the E-7000 is rebooted, then the condition of the optional

feature will be reversed. (For example, if you wanted to activate the feature,

it is now deactivated.) The only exception is that after you activate a feature

for the 4th time, it cannot be deactivated.

Page 23

INSTALLING OPTIONAL FEATURES 20 March, 2006

1-16

9. Print a configuration sheet (☛ 2.3).

10. On the configuration sheet, check if the desired optional feature is

activated/deactivated.

If you have activated an optional feature, keep the configuration sheet. You

may need it later for troubleshooting purposes, as shown in the following

caution.

!CAUTION

After an optional feature has been activated, the optional feature license

information is kept inside the U38 chip on the video board of the E-7000.

If the U38 chip becomes defective, the following are needed as evidence in

order to get a new U38 chip and optional feature dongle:

• The defective U38 chip

• The configuration sheet that shows that the defective U38 chip had

the optional feature license installed.

Therefore, always print a configuration sheet and keep it when you activate

a new optional feature on the E-7000.

11. 3 tags with 6 labels are attached to each optional feature dongle.

a) Optional Feature Name: Printed

b) Optional dongle serial number: Printed

c) Installed Controller Model Name: Blank

d) Installed Controller Serial Number: Blank

e) 4 check boxes for Activation: Not checked

f) 3 check boxes for Deactivation: Not

checked

For the labels c) to f), you can fill in the related

information or check the boxes, if you want to keep a record of the status of

each dongle.

G815R023.WMF

Page 24

20 March, 2006 START-UP, SHUT-DOWN, AND REBOOT PROCEDURES

2-1

Replacement

Server Name

Idle

XXXXXMB (Version)

#

Main Menu/Cancel

$

%&

%&

%&

%&

2 GENERAL OPERATIONS FOR SERVICING

2.1 START-UP, SHUT-DOWN, AND REBOOT

PROCEDURES

The copier and the E-7000 have separate power switches. During normal

operation, you can leave the E-7000 switch in the ON (|) position.

If you turn off the main power of the copier, this shuts down the E-7000 correctly.

If you turn the copier power back on, this will wake up the E-7000 correctly.

2.1.1 STARTING THE COPIER AND THE E-7000

1. Turn on the copier using the main power switch.

2. Turn on the E-7000 using its power switch.

The E-7000 takes less than 3 minutes to reach the idle condition. The copier

may need several minutes to warm its components.

NOTE: Always turn on the copier main power first. If the copier main power is

off (or disconnected from the E-7000), the E-7000 will begin to start up

but it will shut down automatically before it reaches the idle condition.

This feature protects the E-7000 from incorrect shutdown.

3. After the E-7000 and the copier

become idle, press the Fierydriven

key. The Fiery menu screen will

appear on the copier operation

panel.

Page 25

START-UP, SHUT-DOWN, AND REBOOT PROCEDURES 20 March, 2006

2-2

Restart Server

Shut Down System

Reboot System

#

Main Menu/Cancel

$

%

%

%

%

2.1.2 SHUTTING DOWN THE COPIER AND THE E-7000

1. Make sure the On indicator on the copier operation panel is off. If not, press the

operation switch and wait until the On indicator is off.

NOTE: Do not turn off the main power switch of the copier when the On

indicator is on or blinking. Failure to observe this may result in damage

to the copier’s HDD or memory, leading to a malfunction.

2. Turn the main switch of the copier OFF.

3. Wait for the E-7000 diagnostic LEDs to turn off.

The E-7000 is now ready to turn back on automatically when the copier power

is turned on.

4. If the E-7000 is being taken out of service, turn off the E-7000 using its power

switch. (For example, if someone needs to move the E-7000, disconnect cables,

or open the chassis.)

2.1.3 SHUTTING DOWN THE E-7000 ONLY

1. Press the Fierydriven key on the operation panel of the copier. The Fiery

menu screen appears.

2. Touch the “Main Menu/Cancel” key to

access the menu list.

3. Scroll through the menu list by

touching the down arrow “$” key.

4. Touch the “Shut Down” key, then

press the “Shut Down System” key.

5. Wait for the diagnostic LEDs on the E-7000 to turn off.

6. Turn off the E-7000 using its power switch.

The Fiery will remain OFF even when the copier power is turned on or on/off.

Page 26

20 March, 2006 START-UP, SHUT-DOWN, AND REBOOT PROCEDURES

2-3

Replacement

Restart Server

Shut Down System

Reboot System

#

Main Menu/Cancel

$

%

%

%

%

Restart Server

Shut Down System

Reboot System

#

Main Menu/Cancel

$

%

%

%

%

2.1.4 RESTARTING THE E-7000

When restarting the E-7000 to recover from a problem, try this procedure first.

However, this procedure will only restart the E-7000 application software that is

now running on the system OS. To reboot the system OS (for example, after

downloading a patch), see the next section “Rebooting the E-7000 (☛ 2.1.5)”.

1. Make sure that the E-7000 is not in use.

2. Press the Fierydriven key on the operation panel of the copier. The Fiery

menu screen appears.

3. Press the “Main Menu/Cancel” key to

access the menu list.

4. Scroll through the menu list by

pressing the down arrow “$” key.

5. Touch the “Shut Down” key, then

touch the “Restart Server” key.

6. Wait until the E-7000 becomes idle.

2.1.5 REBOOTING THE E-7000

Use this procedure to reboot the system OS (for example, after downloading a

patch).

1. Make sure that the E-7000 is not in use.

2. Press the Fierydriven key on the operation panel of the copier. The Fiery

menu screen appears.

3. Press the “Menu/Cancel” key to

access the menu list.

4. Scroll through the menu list by

pressing the down arrow “$” key.

5. Touch the “Shut Down” key, then

touch the “Reboot Server” key.

6. Wait until the E-7000 becomes idle.

NOTE: Do not reboot the E-7000 by turning the copier main switch OFF and ON.

Recycling power to the copier does not reboot the E-7000 properly.

Page 27

CANCELLING THE CURRENT PRINT JOB 20 March, 2006

2-4

Server Name

Printing

XXXXXMB (Version)

#

Main Menu/Cancel

$

%

%

%

%

Cancel Job

(User Name)

(Job Name)

#

Main Menu/Cancel

$

%

%

%

%

2.2 CANCELLING THE CURRENT PRINT JOB

When you want to cancel the current print job, do the following:

1. Press the Fierydriven key on the

operation panel of the copier to access

the Fiery menu screen.

2. Press the “Main Menu/Cancel” key to

access the menu list.

3. Press “Cancel Job”.

For how to cancel print jobs, please also

refer to the Configuration and Setup

manual.

2.3 PRINTING THE CONFIGURATION SHEET OR TEST

SHEETS

1. Make sure that the E-7000 is not in use.

2. Press the Fierydriven key on the operation panel of the copier to access the

Fiery menu screen.

3. Press the “Main Menu/Cancel” key to access the menu list.

4. Touch the ”Print Pages” key, then touch the desired key.

• “PS Test Page”

• “Configuration Page”

Page 28

20 March, 2006 RUNNING THE E-7000 SETUP

2-5

Replacement

Exit Setup

Server Setup

Network Setup

Printer Setup

#

Main Menu/Cancel

$

%

%

%

%

2.4 RUNNING THE E-7000 SETUP

The following procedures show how to access the Setup menu from the Fiery

menu screen.

NOTE: When the network settings (protocol, IP Address, etc.) are already

configured and the “Enable Web Service” option is set to ON, you can also

configure the E-7000 setup from “Fiery Web Setup”. To do this, use a web

browser on a personal computer which is connected on the network.

For more detailed instructions, please refer to the Configuration and Setup

manual.

NOTE: When you try to get access to the Setup menu, you are always asked to

input an administrator password. (The default password is “Fiery.1”) Ask

the site administrator to input the administrator password when you must

get access to the Setup menu.

2.4.1 TO ACCESS THE SETUP MENU

1. Make sure that the E-7000 is not in use.

2. Press the Fierydriven key on the operation panel of the copier to access the

Fiery menu screen.

3. Press the “Main Menu/Cancel” key to access the menu list.

4. Scroll through the menu list by pressing the down arrow “$” key.

5. Touch the ”Run Setup” key.

6. When you are prompted “Continue to

Setup? / YES”, press “OK”.

The Fiery menu screen will disappear.

7. Press the Fierydriven key to access

the Fiery menu screen.

8. You may be asked to enter an administrator password. (Ask the site

administrator to enter the password. The default password is “Fiery.1”)

9. The main setup screen appears.

For the details of each setup option value, refer to the Configuration and Setup

manual.

2.4.2 TO EXIT FROM THE SETUP MENU

1. At the main setup screen, touch ”Exit Setup” key.

The Fiery menu screen will disappear.

2. Press the Fierydriven key to access the Fiery menu screen.

Page 29

GENERAL CAUTION 20 March, 2006

3-6

3 REPLACEMENT

3.1 GENERAL CAUTION

!

WARNING

Turn off the power and unplug the E-7000 before attempting any of the

procedures in this section.

• Before accessing internal components, position the E-7000 so that it is resting on

its right-hand side on a flat, anti-static surface.

Page 30

20 March, 2006 NAMES OF MAIN PARTS/UNITS

3-7

Replacement

3.2 NAMES OF MAIN PARTS/UNITS

Name Refer to Name Refer to

A Base of case - N Video board ☛ 3.4.1

B Front cover - O Video board bracket ☛ 3.4.1

C Fierydriven keytops ☛ 1.3.4 P 14-pin LED cable ☛ 3.4.2, 3.4.6

D Fierydriven decal ☛ 1.3.4 Q Motherboard ☛ 3.4.6

E Base for keytop ☛ 1.3.4 R CPU cooling assembly ☛ 3.4.8

F Extension card ☛ 1.3.4 S CPU ☛ 3.4.8

G AC power cord ☛ 1.3.4 T Power supply unit ☛ 3.4.4

H Interface cable ☛ 1.3.4 U Fan(s) ☛ 3.4.5

I HDD ☛ 3.4.3 V Diagnostic LED board ☛ 3.4.2

J HDD bracket ☛ 3.4.3 W Bracket K Memory ☛ 3.4.7 X U38 chip ☛ 3.4.1

L IDE cable ☛ 3.4.3, 3.4.6 Y U39 chip ☛ 3.4.1

M Side cover ☛ 3.3.1 Z Lithium Battery ☛ 3.4.9

G815V903.WMF

[A]

[B]

[C]

[D]

[E]

[F]

[G]

[H]

[I]

[J]

[K]

[L]

[M]

[N]

[O]

[P]

[Q]

[R]

[S]

[T]

[U]

[V]

[W]

[X]

[Y]

[Z]

Page 31

COVER REMOVAL 20 March, 2006

3-8

3.3 COVER REMOVAL

3.3.1 SIDE COVER FOR THE E-7000

[A]: Side cover (! x 6)

G815R003.WMF

Page 32

20 March, 2006 UNIT REMOVAL

3-9

Replacement

3.4 UNIT REMOVAL

3.4.1 VIDEO BOARD

[A]: Video board with bracket (! x 2)

[B]: Bracket (! x 2)

[C]: U38 Chip

[D]: U39 Chip

NOTE: The video board that you use as a

spare part does not include the

U38 and U39 ROMs.

When you replace the video board,

do not forget to move the U38 and

U39 ROMs from the old board to

the new board.

• U38 Chip:

Contains option upgrade information and licensing information for the E-7000.

• U39 Chip:

Contains the following printer-related configuration settings.

• Shift Operation (E-7000 Printer Setup)

• Bypass Tray Priority (E-7000 Printer Setup)

• Bypass Tray Paper Size (Copier User Tool Menus)

• Paper Tray Priority: Printer (Copier User Tool Menus)

• Printer Auto Reset Timer (Copier User Tool Menus)

• Printer Authentication Mode (Copier User Tool Menus)

• Output Tray Priority: Printer (Copier User Tool Menus)

G815R007.WMF

G815R019.WMF

[A]

[B]

[C]

[D]

Page 33

UNIT REMOVAL 20 March, 2006

3-10

3.4.2 DIAGNOSTIC LED BOARD

[A]: 14-pin LED cable (" x 1)

[B]: LED board

Notes for Re-assembling:

• The red line on the LED cable must face

down when you connect the cable to the

LED board (see the illustration).

3.4.3 HARD DISK DRIVE (HDD)

[C]: IDE cable (" x 1)

[D]: Power cable (" x 1)

[E]: HDD with bracket (! x4)

[C]: HDD (! x4)

Notes for Re-assembling:

• [C]: Make sure to connect the black side

(“MASTER” side) of cable to the HDD.

G815R009.WMF

ULTRA ATA133 CABLE

MASTER

G815R008.WMF

[A]

[B]

[C]

[D]

[F]

[E]

Page 34

20 March, 2006 UNIT REMOVAL

3-11

Replacement

3.4.4 POWER SUPPLY UNIT

Power supply cable (" x 4).

• [A]: Harness from Main Power

Switch.

• [B]: HDD power connector from

HDD

• [C]: 4-pin power connector from

the J1 socket on the

motherboard.

• [D]: 20-pin power connector

from the JB3 socket on the

Motherboard.

• [E]: Power Switch

[F]: Power supply unit (! x 5)

3.4.5 FAN

Cables (" x2):

• [G-2] from FAN2

• [G-3] from FAN3

[FAN2]: Fan (! x 4)

[FAN3]: Fan (! x 4)

Notes for Re-assembling:

• Connect the [G-2] cable (Short) to FAN2

on the motherboard.

• Connect the [G-3] cable (Long) to FAN3

on the motherboard.

G815R011.WMF

G815R012.WMF

[A]

[B]

[C]

[D]

[E]

[F]

[G-2]

[G-3]

[

FAN2

]

[FAN3]

Page 35

UNIT REMOVAL 20 March, 2006

3-12

3.4.6 MOTHERBOARD

1. Video board (☛ 3.4.1)

2. Fan case (☛ 3.4.5)

3. Cables (" x4):

• [A]: 4-pin power connector from J1

• [B]: 20-pin power connector from J18

• [C]: Fan cable from FAN2

• [D]: Fan cable from FAN3

• [E]: IDE cable from JB2

• [F]: LED cable from J29

4. Screws (! x 5)

5. Memory (☛ 3.4.7)

6. CPU Cooling Assembly (☛ 3.4.8)

7. CPU (☛ 3.4.8)

NOTE: When you replace the

motherboard, remove the

CPU and memory and

attach them to the new

motherboard. (☛ 3.4.8)

Notes for Re-assembling:

• Make sure of where to connect

the connectors for each cable.

Make sure that all connectors are

inserted firmly in the sockets.

Also, do not put the connectors in

the sockets the wrong way

around.

No. Connector Location

[A] 4-pin power connector J1

[B] 20-pin power connector J18

[C] Fan cable from FAN2 FAN2

[D] Fan cable from FAN3 FAN3

[E] IDE cable JB2

[F] LED cable J29

[G] CPU fan cable FAN1

[H] Memory DIMM1

ULT RA ATA133 CABL E

SYSTEM

G815R010.WMF

J1

FAN1

J29

PCI1PCI2

JB3 JB2

J18

DIMM1

DIMM2

FAN2

FAN3

G815R014.WMF

[A]

[B]

[C]

[D]

[E]

[F]

[A]

[B]

[C]

[D]

[E]

[F]

[G]

[H]

Page 36

20 March, 2006 UNIT REMOVAL

3-13

Replacement

3.4.7 MEMORY - 512 MB DIMM

1. Push outward on the levers [A-1], [A-2]

on each side of the DIMM.

2. Slide the DIMM [B] straight out of the

socket.

Notes for Re-assembling:

• Always attach the DIMM [D] to the

DIMM1 socket (closer to the CPU unit).

• Gently slide the DIMM straight down into

the socket and press so that the levers

lock the DIMM into place. Make sure that

the levers close securely around the

ends of the DIMM.

• DIMMs fit in the socket only one way.

The two notches [D] on the bottom of the

DIMM should line up with the notches in

the socket.

3.4.8 CPU AND COOLING ASSEMBLY

You can replace the following parts.

• Cooling Assembly [D] only

• CPU [F] and Cooling Assembly [D] (as a set): If you replace the CPU, you must

replace the cooling assembly also, as a set.

The cooling assembly consists of a fan with heat sink and a clip assembly.

NOTE: 1) Be careful not to damage the motherboard, the CPU, or the CPU socket

when you replace the cooling assembly.

Remove the memory before you remove the cooling assembly.

2) When you want to replace the CPU, replace the CPU and the cooling

assembly as a set.

This is very important, because the thermal pad that is attached to a

new heat sink will make a good contact between the CPU and the heat

sink when heated.

If you attach a used cooling assembly to a new CPU by mistake, the

heat sink will not contact the CPU properly, and this will cause the CPU

to overheat.

G815R006.WMF

[A-1]

[B]

[A-2]

Page 37

UNIT REMOVAL 20 March, 2006

3-14

Cooling assembly removal procedure:

1. Remove the CPU fan cable [A] from

the motherboard FAN1 (" x 1).

2. Open the clip levers [B-1] [B-2] by

lifting them up.

3. Insert a flathead screwdriver

between fan shroud and clip frame

[C]. Push the screwdriver down until

it hits the clip hook.

4. Push down on the clip hook and at

the same time turn the screwdriver

towards the fan heat sink to free the

clip hook. Repeat this process for

the remaining clip hooks.

5. Remove the fan heat sink. [D].

Notes for re-assembling the CPU cooling assembly:

• Make sure to close the clip levers one at a time. Close the clip levers [B-1] while

holding the topside of the fan heat sink with your other hand. Then, close the clip

lever [B-2], while holding the topside of the fan heat sink with your other hand.

CPU removal procedure:

1. Lift the CPU socket lever [E] to release

the CPU [F] from the socket.

2. Grasp the CPU [F] by its edges and

gently lift it from the socket.

Notes for re-attaching the CPU:

• Check the location of the arrow [G] on

the CPU [F] when you insert the CPU [F]

into the socket [H]. (See the illustration.)

• Be careful not to bend the pins when you

insert the CPU into the socket.

• Set the CPU in the socket completely and without forcing it.

• Close the socket lever [E] to secure the CPU [F] in place.

G815R004.WMF

G815R005.WMF

[A]

[B-1]

[C]

[B-2]

[D]

[E]

[F]

[G]

[H]

Page 38

20 March, 2006 UNIT REMOVAL

3-15

Replacement

3.4.9 LITHIUM BATTERY

!CAUTION

There is danger of explosion if the battery is replaced with the incorrect

type. Replace with only with the same lithium battery supplied as a spare

part.

Discard the used motherboard battery in accordance with the

manufacturer’s instructions and local regulations.

Note for Re-assembling:

• You need to re-configure the system

date and time.

To configure the system date and time,

enter the ‘Server setup’ menu from the

Setup main menu. (☛ 2.4.1)

3.4.10 EXTENSION CARD

1. Extension Card (! x 2), on the copier

Note for Re-assembling:

• Make sure that the extension card is inserted straight.

G815R013.WMF

Page 39

Page 40

20 March, 2006 GENERAL NOTES AND CAUTIONS

4-1

Trouble-

shooting

4 SOFTWARE MAINTENANCE

4.1 GENERAL NOTES AND CAUTIONS

You may use one of the following when you have a problem with the system

software or the HDD.

• Clear Server: Deletes all queued print jobs from the E-7000

• Factory Default: Restores the E-7000 to the factory defaults

• System Software Reinstallation

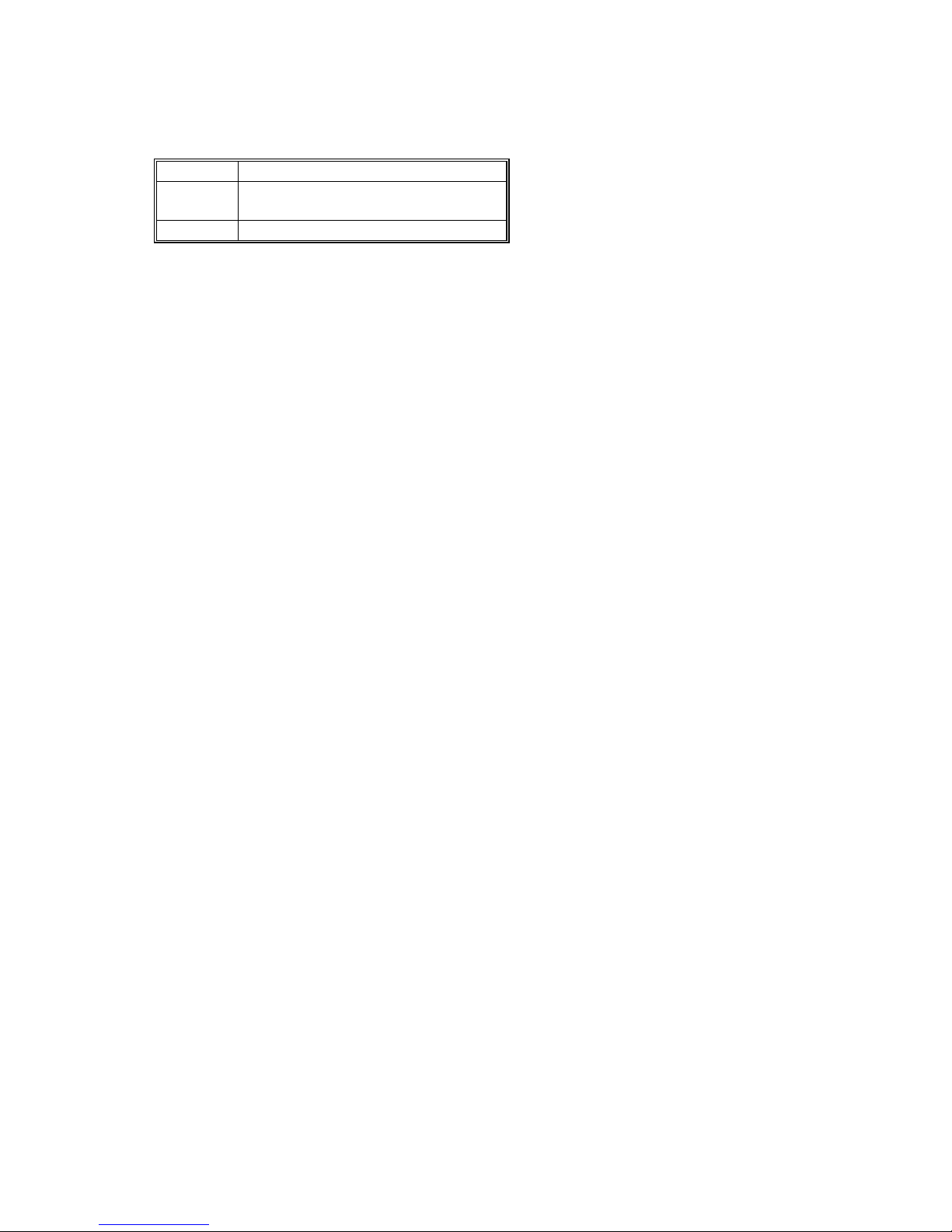

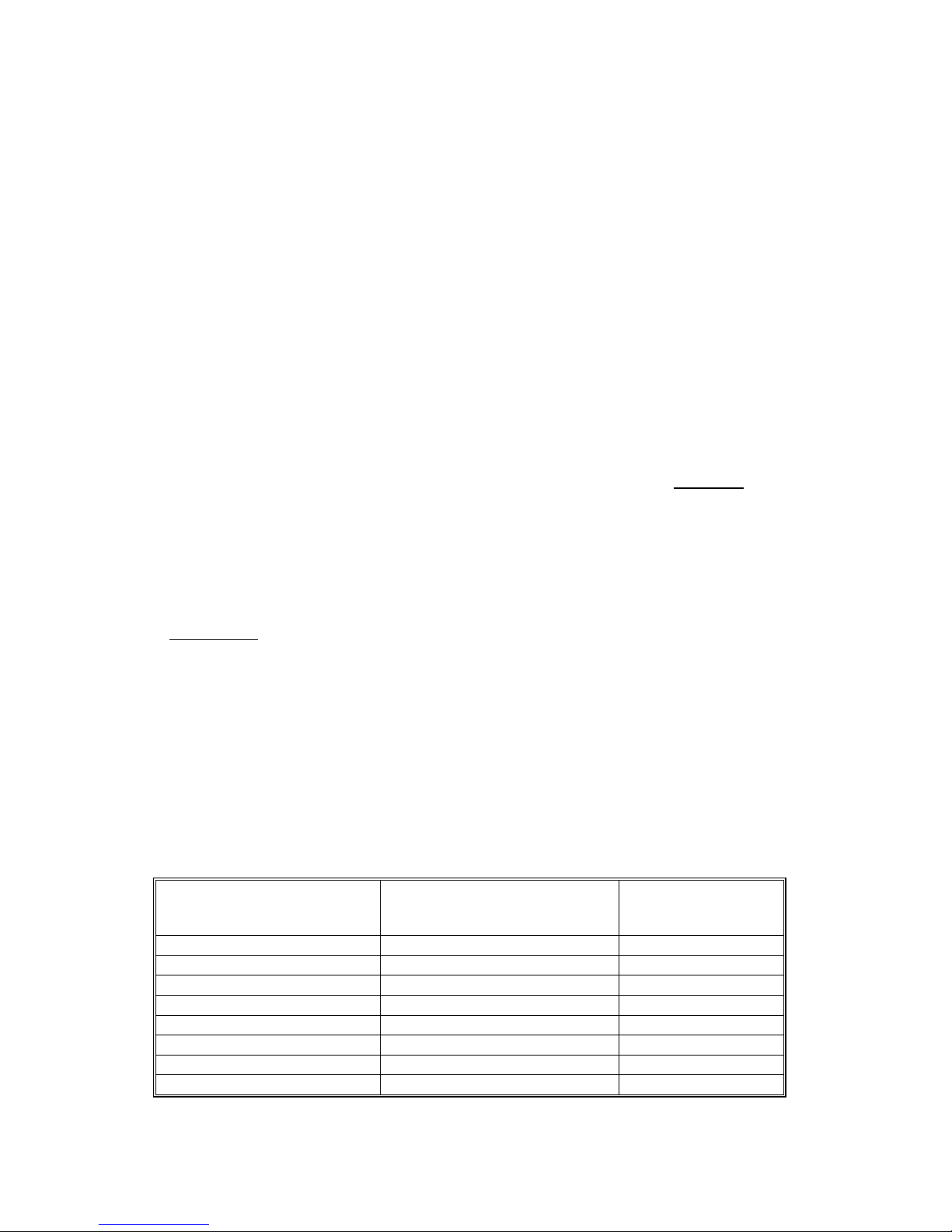

The following table shows whether the current data on the E-7000 will remain or be

deleted when each of these is used.

“Clear

Server”

“Factory Default”

System Software

Reinstallation / Upgrade

Job Log Deleted Deleted Deleted

Queued Jobs Deleted Deleted Deleted

Scanned Jobs Deleted Deleted Deleted

MailBox Deleted Deleted Deleted

Archived Jobs Deleted Deleted Deleted

FreeForm masters Deleted Deleted Deleted

Resident Fonts Not Deleted Not Deleted Deleted

Downloaded Fonts Not Deleted Deleted Deleted

Language

Selection

Not Deleted Deleted Deleted

Setup Options Not Deleted Deleted Deleted

Patches Not Deleted Not Deleted Deleted

Administrator

Password

Not Deleted Not Deleted Deleted

Option Activation Not Deleted Not Deleted Not Deleted

NOTE: In ‘System Software Reinstallation/Upgrade’, ‘Upgrade’ refers to replacing

the software with a new version. It does not refer to the application of

patches. When you apply a patch, data is not deleted.

Before you use any of the above features, make sure you inform the site

administrator that the indicated data and settings will be deleted and should be reinstalled after the feature has been used.

• Job Log

The list of jobs in the Job Log and all jobs in the queues are deleted. The site

administrator can use Fiery Spooler to save a current list of jobs from the Job

Log (the actual jobs are not saved, only a list of them).

• Queued Jobs

All queued print jobs (in the Print, Hold, and Printed queues) will be deleted.

Page 41

CLEARING THE QUEUED PRINT JOBS IN THE E-7000 20 March, 2006

4-2

• Archived Jobs and Free Form masters

Archived jobs on the E-7000 HDD and FreeForm masters are deleted. The lists

of archived jobs and FreeForm masters are deleted as well.

• Fonts

All fonts on the HDD are deleted when you reinstall the system software.

Resident fonts are reinstalled when you reinstall the system software. Any

customer-supplied fonts will need to be reinstalled by the site administrator using

Fiery Downloader.

• Administrator Password

The administrator password will be deleted when system software is re-installed.

(The administrator password will return to “Fiery.1” after the system software is

re-installed.)

• Configuration

Make sure to print a configuration page before reinstalling the system software.

The Setup configuration will be lost when you reinstall the system software.

Compatibility

When you upgrade the system software, make sure the latest user software is

installed onto all computers that print to the E-7000. Using incompatible versions of

the system and user software can result in system problems.

4.2 CLEARING THE QUEUED PRINT JOBS IN THE E-7000

The ”Clear Server” command allows you to clear all queued print jobs from the E-

7000 – jobs in the E-7000 Print, Hold, and Printed queues. Clear Server also clears

all jobs archived on the E-7000 hard disk, the index of archived jobs, and finally, all

Fiery FreeForm masters and the index of Fiery FreeForm masters.

NOTE: Before using Clear Server, inform the site administrator that data on the E-

7000 hard disk will be deleted.

1. Make sure the E-7000 is not in use.

2. Run the setup menu. (☛ 2.4)

3. Scroll through the setup main menu list by pressing the down arrow “$” key

twice.

4. Touch the “Clear Server” key.

5. When you are prompted “Clear all jobs from all queues?/NO”, press the down

arrow “$” key so that the second line will be changed to “YES”

6. Touch the “OK” key.

The Fiery menu screen will disappear and data will be cleared before the

system restarts.

7. Press the Fierydriven key and check if the E-7000 becomes idle.

Page 42

20 March, 2006 RESTORING THE E-7000 TO FACTORY DEFAULTS

4-3

Trouble-

shooting

4.3 RESTORING THE E-7000 TO FACTORY DEFAULTS

When E-7000 system software is first installed, a backup copy is made

automatically. You or your customer can recover the system from this backup

without having to reload the software from the CD (or USB Flash drive).

Also use “Factory Default” when you want to change the language selection.

NOTE: Before using “Factory Default”, inform the site administrator that all data

(including the downloaded fonts) stored on the HDD and setup options will

be deleted.

NOTE: Performing “Factory Default” will not delete the current administrator

password, which was set for E-7000 (the initial password is “Fiery.1”).

Before performing “Factory Default”, check if the site administrator can

input the current administrator password after the system software is

restored.

If a unique administrator password is already set for the E-7000, but the

site administrator does not remember the password, re-install the system

software from the CD (or from USB flash drive).

1. Make sure the E-7000 is not in use.

2. Print a configuration page (you may refer to this configuration page when you

re-enter the setup options). (☛ 2.3)

3. Run the setup menu. (☛ 2.4)

4. Scroll through the setup main menu list by pressing the down arrow “$” key

twice.

5. Touch the “Factory Default” key.

6. When you are prompted “Reset server to factory settings?/NO”, press the down

arrow “$” key so that the third line will be changed to “YES”

7. Touch the “OK” key.

The Fiery menu screen will disappear.

8. Go to the copier and press the Fierydriven key.

9. The language selection screen will appear. Start to configure the E-7000.

(For details, go to step 23 of the system software installation procedure. ☛ 4.4)

Page 43

SYSTEM SOFTWARE INSTALLATION PROCEDURE 20 March, 2006

4-4

4.4 SYSTEM SOFTWARE INSTALLATION PROCEDURE

4.4.1 OVERVIEW

System software should be installed in the following cases:

• You replace the HDD with a new one (on which the System Software is not

installed)

• You update to a more recent version of the system software (this is not

necessary when you apply a patch; it is necessary when you install a major

version change)

• You have trouble with the system software (i.e. software corruption) and the

problem cannot be solved by performing “Factory Default”.

• The site administrator forgets the administrator password for the E-7000.

The system software is provided as a CD set as follows:

1) System Software CD

System software and an installation program are included.

2) USB Flash Tool CD

This utility will copy the contents of the system software CD to the USB

Flash drive, and at the same time make the USB Flash drive bootable.

There are two ways to install/reinstall system software on the E-7000.

a) Installing system software over the network port.

Connect a PC to the E-7000 directly, or through a hub using a network

cable. Install the system software from the System Software CD.

b) Installing system software by booting the E-7000 from a USB Flash drive.

With the System Software CD, USB Flash Tool CD, and a PC which can

boot from a CD-ROM, first make a bootable USB flash drive that includes

E-7000 system software and the installation program.

At the customer site, connect the USB flash drive to the E-7000’s USB

port and turn the power ON. System installation will be done

automatically.

NOTE: Before you start system installation, give the site administrator the

opportunity to print the Job Log and to save any custom simulations.

Also, print the following from the Print menu.

1. Configuration page

2. Font Lists

Page 44

20 March, 2006 SYSTEM SOFTWARE INSTALLATION PROCEDURE

4-5

Trouble-

shooting

4.4.2 INSTALLING SYSTEM SOFTWARE OVER THE NETWORK

PORT

The system software CD contains the system software and Fiery System Software

Installer. To install system software using the LAN port on the E-7000, you need:

• Either

• Two Ethernet cables and an isolated hub/switch

Cables must be 4-pair/8-wire, short-length Cat 5 (for 100BaseT) or Cat 5e

(for 1000BaseT)

Or

• For 100BaseTX: One Category 5 or higher Ethernet cross-over cable (4-

pin/8-wire, short-length)

For 1000BaseT: One Category 5e or higher Ethernet cross-over cable (4pin/8-wire, short-length)

• A Windows XP/2000 computer with:

• A CD-ROM drive, built in or attached

• Support for 100BaseTX or 1000BaseT

NOTE: This procedure describes using one cross-over cable. Instead of using a

cross-over cable, you may use two Ethernet cables and an isolated

hub/switch. (Do not connect any other devices to the hub/switch. Do not

put the hub/switch on the LAN. Do not use the hub’s optical port or uplink

switch.)

NOTE: If the print engine is 230V, use shielded network cables.

1. Print the Configuration Page. Then perform the Shut Down procedure from the

copier operation panel (☛ 2.1.3)

2. When the E-7000 power is down (that is when the diagnostic LEDs are off),

turn the main switch of the E-7000 to OFF.

3. Disconnect all cables from the E-7000 connector panel. Disconnect the LAN

cable that was connected to the customer’s LAN.

4. Connect the Ethernet cross-over cable to the LAN port and to the Windows

XP/2000 PC.

5. Turn on the PC’s power and insert the System Software CD into the PC’s CDROM drive.

6. If the PC is connected to a wireless LAN, disable the wireless LAN connection.

Otherwise the Fiery Installer cannot find E-7000 automatically.

7. Navigate to the CD-ROM drive and click the icon for the Installer.exe file, if it

does not start automatically.

Page 45

SYSTEM SOFTWARE INSTALLATION PROCEDURE 20 March, 2006

4-6

8. Click Next at the Welcome screen. Read the Software License Agreement and

click the “I Agree” checkbox if you wish to continue the installation process,

then click Next.

9. At the Connection Type screen, make sure Ethernet is selected. Click Next to

advance to the Confirmation screen.

10. Set the E-7000 service switches to the service mode position: ON.

NOTE: The illustration shown on the PC

screen, from the software, is

incorrect. It shows the wrong

direction for turning the service

switches to ON.

Set the E-7000 two service

switches in the upper position as

shown in the illustration in this

page.

11. Turn the main power switch of the

E-7000 to ON and wait 10 seconds.

12. Click Next on the PC screen.

13. At the Installation screen, click Next to

start the installation. Wait while the files are copied and installed.

The progress is slow at first.

For most computers, you must wait approximately 25 minutes – do not cancel.

If you do click Cancel: Click Finish then turn the main power switch of the E7000 to OFF. Wait 10 seconds, and then repeat this procedure from the

beginning. If the installation terminates abnormally, you may need to reboot

the PC also.

14. Click Exit when the screen shows that the installation is successful. Remove

the System Software CD from the PC.

15. Turn the main power switch of the E-7000 to OFF.

16. Set the service switches in the normal position (not ON).

17. Disconnect the cross-over cable from the LAN port and

the Windows XP/2000 PC.

18. Reconnect all cables that you removed earlier from the E7000 panel.

19. Turn on the main switch of the copier.

20. Turn on the main power switch of the E-7000.

21. Allow startup to proceed without interruption while you watch the diagnostic

LEDs on the back panel of the E-7000.

ON

1 2ON1 2

G815R020.WMF

G815R021.WMF

Page 46

20 March, 2006 SYSTEM SOFTWARE INSTALLATION PROCEDURE

4-7

Trouble-

shooting

Select Language

English

OK

#

Main Menu/Cancel

$

%

%

%

%

Select Market Region

U.S.

O

K

#

Main Menu/Cancel

$

%

%

%

%

Exit Setup

Server Setup

Network Setup

Printer Setup

#

Main Menu/Cancel

$

%

%

%

%

22. When the diagnostic LEDs show ‘00’, go to the copier operation panel and

press the Fierydriven key. ‘Please wait’ may be shown on the copier operation

panel.

23. The language selection screen is shown. (If this screen is not shown, then

press the Fierydriven key again.)

Select the desired language by using the down arrow “$” key and up arrow

“#” key, and touch “OK”.

• English

• Dutch

• Spanish

• Italian

• German

• French

NOTE: 1) After you select a language, you cannot change the language unless

you do “Factory Defaults (☛ 4.3)” or re-install the system software.

2) The default settings for the E-7000 depend on the language

selection as follows:

Selected Language & Market Region

English - US

English – UK/Dutch / Spanish/

Italian /German/French

PS Setting Default Paper Sizes

US Metric

If you selected “English” at the language

selection screen, you are prompted to

select the market region. Select either

“US” or “UK” by using the down arrow

“$” key and up arrow “#” key, then

touch “OK”.

24. “Please wait…” will be shown on the

Fiery menu screen. Then the Fiery

menu screen will disappear from the

operation panel.

25. Wait for a short time, then press the

Fierydriven key again on the

operation panel. The Setup main

menu will appear on the Fiery menu screen.

26. “Enter Password” will appear.

Enter the default administrator password: “Fiery.1”.

27. Input the customer’s settings from the Configuration Page that you printed

earlier.

Ask the site administrator for the other settings that are not on the configuration

page, or ask the site administrator to input these settings. For more information,

see the Configuration and Setup manual.

Page 47

SYSTEM SOFTWARE INSTALLATION PROCEDURE 20 March, 2006

4-8

4.4.3 INSTALLING SYSTEM SOFTWARE USING A USB FLASH

DRIVE

To prepare a USB flash drive, which is bootable and includes system software and

the software installer program, the following items should be prepared:

• E-7000 System Software CD set.

• System Software CD

• USB Flash Tools CD

• A 1GB-size USB Flash drive.

These USB flash drives can be used with the E-7000.

• SanDisk Mini Cruzer 1G

• Lexar JumpDrive Secure USB Flash 1G

• PNY USB Pen Drive

• A PC

• It must be possible to set this PC to boot from the CD-ROM drive.

The PC must boot from the USB Flash Tools CD.

• The PC must have at least one USB port. (USB 2.0 or later is

recommended)

USB 1.x can also be used, but it will take more time to copy the system

software.

1. Prepare the USB flash drive.

1) Make sure the boot order on the PC is set to boot first from the CD-ROM

drive.

To find out how to change the PC’s BIOS configuration, see the PC

documentation.

2) Insert the USB Flash Tool CD into the PC’s CD-ROM drive.

3) Turn off the PC’s power

4) Attach the USB flash drive to the PC.

5) Turn on the PC’s power.

If the LED on the USB flash drive does not light, turn off the PC’s power.

Remove and reinsert the USB flash drive into the PC. Check that its LED

turns on when the PC is turned on.

NOTE: If the PC boot order is set to boot from the CD-ROM drive, but the PC

still does not boot up properly, try another PC. Your PC may not

compatible with the boot program on the USB Flash Tool CD.

6) Follow the on-screen prompts to set up the flash drive.

You will be prompted to insert the system software CD and install the files

onto the flash drive. Installing the files usually takes 15-30 minutes, but may

take considerably longer depending on your PC. The final step reboots the

PC.

Page 48

20 March, 2006 SYSTEM SOFTWARE INSTALLATION PROCEDURE

4-9

Trouble-

shooting

Select Language

English

OK

#

Main Menu/Cancel

$

%

%

%

%

1. Print the Configuration Page. Then perform the Shut Down procedure from the

copier operation panel (☛ 2.1.3)

2. When the E-7000 power is down (that is when the diagnostic LEDs are off),

turn the main switch of the E-7000 to off.

3. Disconnect all cables from the E-7000 connector

panel.

4. Make sure that the service mode switches are in

the normal (lower) position. (Not ON.)

5. Attach the prepared USB flash drive to one of

the USB ports [A] on the E-7000.

NOTE: If dust covers are attached to the USB

Type A connectors, remove one dust

cover using needle-nose pliers.

6. Turn the main power switch of the E-7000 to On

and wait until installation is complete.

Installation takes approximately 15-25 minutes. The LED on the flash drive

should show that files are being transferred. The E-7000 shuts down

automatically after installation is complete.

7. Turn the main power switch of the E-7000 to Off.

8. Remove the USB flash drive from the E-7000.

9. Reconnect all cables that you removed earlier from the E-7000 panel.

10. Turn on the main switch of the copier.

11. Turn on the main power switch of the E-7000.

12. Allow startup to proceed without interruption while you watch the diagnostic

LEDs on the back panel of the E-7000.

13. When the diagnostic LEDs show ‘00’, go to the copier operation panel and

press the Fierydriven key. ‘Please wait’ may be shown on the copier operation

panel.

14. The language selection screen is shown. (If this screen is not shown, then

press the Fierydriven key again.)

Select the desired language by using the down arrow “$” key and up arrow

“#” key, and touch “OK”.

• English

• Dutch

• Spanish

• Italian

• German

• French

G815I902.WMF

[A]

Page 49

PATCH INSTALLATION PROCEDURE 20 March, 2006

4-10

Select Market Region

U.S.

O

K

#

Main Menu/Cancel

$

%

%

%

%

Exit Setup

Server Setup

Network Setup

Printer Setup

#

Main Menu/Cancel

$

%

%

%

%

NOTE: 1) After you select a language, you cannot change the language unless

you do “Factory Defaults (☛ 4.3)” or re-install the system software.

2) The default settings for the E-7000 depend on the language

selection as follows:

Selected Language & Market Region

English - US

English – UK/Dutch / Spanish/

Italian /German/French

PS Setting Default Paper Sizes

US Metric

If you selected “English” at the language

selection screen, you are prompted to

select the market region. Select either

“US” or “UK” by using the down arrow

“$” key and up arrow “#” key, then

touch “OK”.

15. “Please wait…” will be shown on the

Fiery menu screen. Then the Fiery

menu screen will disappear from the

operation panel.

16. Wait for a short time. Then press the

Fierydriven key again on the

operation panel. The Setup main

menu will appear on the Fiery menu screen.

17. Enter the administrator password “Fiery.1”.

18. Input the customer’s settings from the Configuration Page that you printed

earlier.

Ask the site administrator for the other settings that are not on the configuration

page, or ask the site administrator to input these settings. For more information,

see the Configuration and Setup manual.

4.5 PATCH INSTALLATION PROCEDURE

When a software bug is found and fixed, or a new feature is added, a patch file (ps

file) may be additionally released.

The patch installation procedure may vary depending on the patches; the download

destination queue or system rebooting procedure may be different. Some patches

may require prerequisite patches.

Therefore, when you install a patch, make sure to carefully read the attached

release note and follow the instructions.

Page 50

20 March, 2006 OVERVIEW

5-11

Trouble-

shooting

5 TROUBLESHOOTING

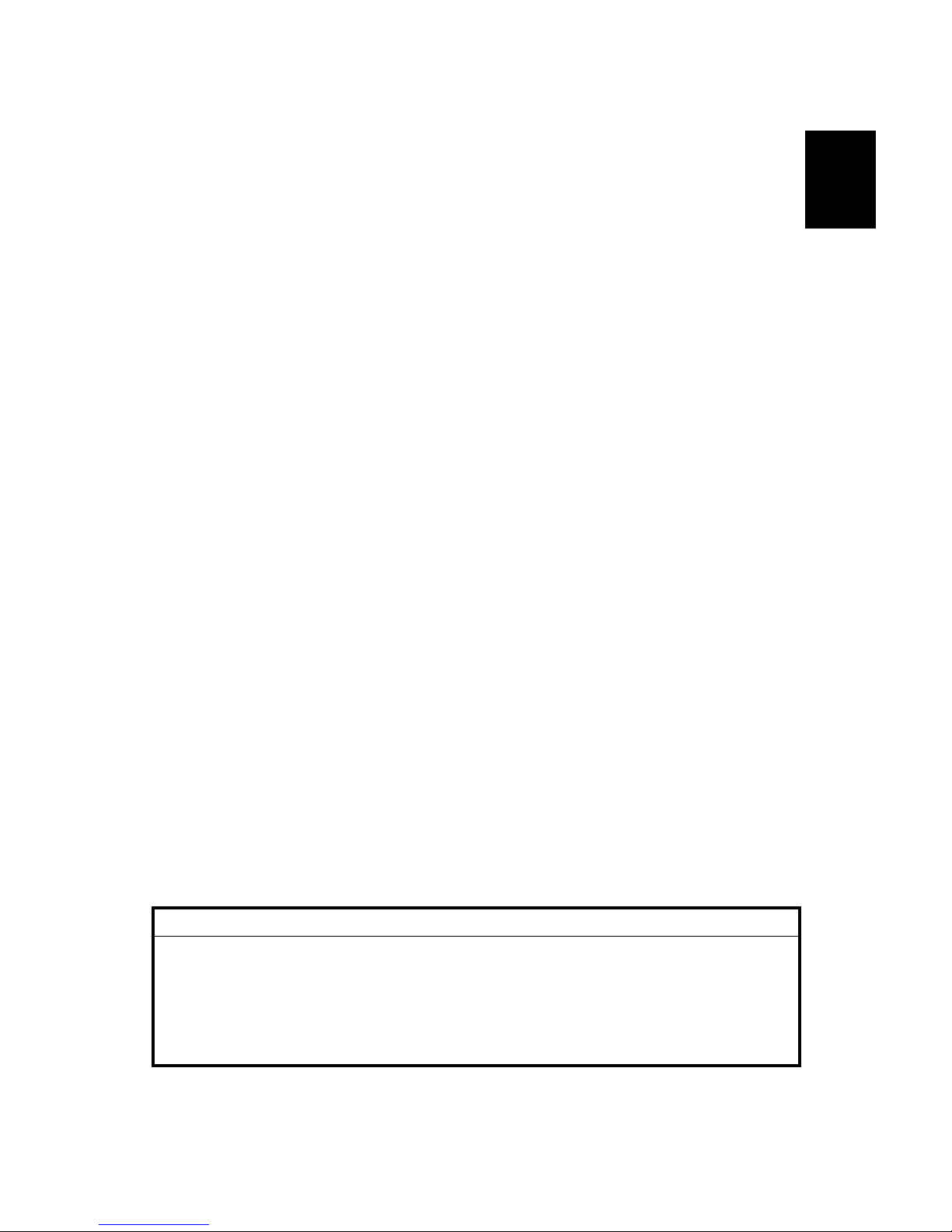

5.1 OVERVIEW

When a problem occurs, check in the following order.

1. Verify that the service switches are in normal mode,

not service mode. (The switches should be in the lower

position.)

2. Check that the Fiery menu appears on the copier’s

operation panel.

3. Verify that the network is functioning, no unauthorized

software or hardware is installed on the E-7000, and

there are no problems with a particular print job or application. The site

administrator can help you to verify these issues.

4. Verify that the E-7000 and connection with the copier has no problem by

printing test pages. (☛ 2.3)

5. If the E-7000 can boot, check if the diagnostic LEDs on the backside of E-7000

stop on a particular diagnostic code. (☛ 5.2)

6. Check that all parts and cables are correctly installed and connected.

(☛ 3)

7. Try to solve the problem by performing “Clear Server” or “Factory Default”.

Inform the site administrator that the data stored in the HDD will be deleted.

( ☛ 4.2, 4.3)

8. Check if a newer version of system software, firmware or patch for the E-7000

and copier has been released. If so, install it. (☛ 4.4)

9. If the problem will not disappear, reinstall the system software. (☛ 4.4)

10. If the problem will still not disappear, replace parts of the hardware. (☛ 5.3)

G815R021.WMF

Page 51

LED DIAGNOSTIC CODES 20 March, 2006

5-12

5.2 LED DIAGNOSTIC CODES

During startup, the EB-7000 advances through a standard diagnostic sequence.

Each diagnostic code flashes rapidly on the LED display during this sequence until

the EB-7000 reaches the Idle condition. In the Idle condition, the LED display

shows the 00 code. This shows that the EB-7000 is in normal operation mode. The

EB-7000 may flicker or drift from 00 during normal operation, but it will always

return to 00.

If the LED display stops on a code other than 00, one or more diagnostic tests may