Page 1

Model TI-P1

Machine Code: M109

Field Service Manual

18 December, 2012

Page 2

Important Safety Notices

Important Safety Notices

Prevention of Physical Injury

1. Before disassembling or assembling parts of the main machine and peripherals, make sure that the

power cord of the main machine is unplugged.

2. The wall outlet should be near the machine and easily accessible.

3. Note that some components of the machine and the paper tray unit are supplied with electrical

voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off or open while the

main switch is turned on, keep hands away from electrified or mechanically driven components.

5. The inside and the metal parts of the fusing unit become extremely hot while the machine is

operating. Be careful to avoid touching those components with your bare hands.

• To prevent a fire or explosion, keep the machine away from flammable liquids, gases, and

aerosols.

Health Safety Conditions

1. Toner and developer is non-toxic, but if you get either of them in your eyes by accident, it may

cause temporary eye discomfort. Immediately wash eyes with plenty of water. If unsuccessful, get

medical attention.

2. This machine, which uses a high voltage power source, can generate ozone gas. High ozone

density is harmful to human health. Therefore, the machine must be installed in a well-ventilated

room.

Observance of Electrical Safety Standards

1. This machine and its peripherals must be serviced by a customer service representative who has

completed the training course on those models.

2. The NVRAM on the system control board has a lithium battery which can explode if replaced

incorrectly. Replace the NVRAM only with an identical one. The manufacturer recommends

replacing the entire NVRAM. Do not recharge or burn this battery. Used NVRAM must be handled

in accordance with local regulations.

1

Page 3

Handling Toner

• Work carefully when removing paper jams or replacing toner bottles or cartridges to avoid spilling

toner on clothing or the hands.

• If toner is inhaled, immediately gargle with large amounts of cold water and move to a well

ventilated location. If there are signs of irritation or other problems, seek medical attention.

• If toner gets on the skin, wash immediately with soap and cold running water.

• If toner gets into the eyes, flush the eyes with cold running water or eye wash. If there are signs of

irritation or other problems, seek medical attention.

• If toner is swallowed, drink a large amount of cold water to dilute the ingested toner. If there are

signs of any problem, seek medical attention.

• If toner spills on clothing, wash the affected area immediately with soap and cold water. Never use

hot water! Hot water can cause toner to set and permanently stain fabric.

• Always store toner and developer supplies such as toner and developer packages, cartridges, and

bottles (including used toner and empty bottles and cartridges) out of the reach of children.

• Always store fresh toner supplies or empty bottles or cartridges in a cool, dry location that is not

exposed to direct sunlight.

• Do not use a vacuum cleaner to remove spilled toner (including used toner). Vacuumed toner may

cause a fire or explosion due to sparks or electrical contact inside the cleaner. However, it is

possible to use a cleaner designed to be dust explosion-proof. If toner is spilled over the floor,

sweep up spilled toner slowly and clean up any remaining toner with a wet cloth.

Safety and Ecological Notes for Disposal

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly when exposed to an

open flame.

2. Dispose of used toner, the maintenance unit which includes developer or the organic

photoconductor in accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do not put more than 100

batteries per sealed box. Storing larger numbers or not sealing them apart may lead to chemical

reactions and heat build-up.

2

Page 4

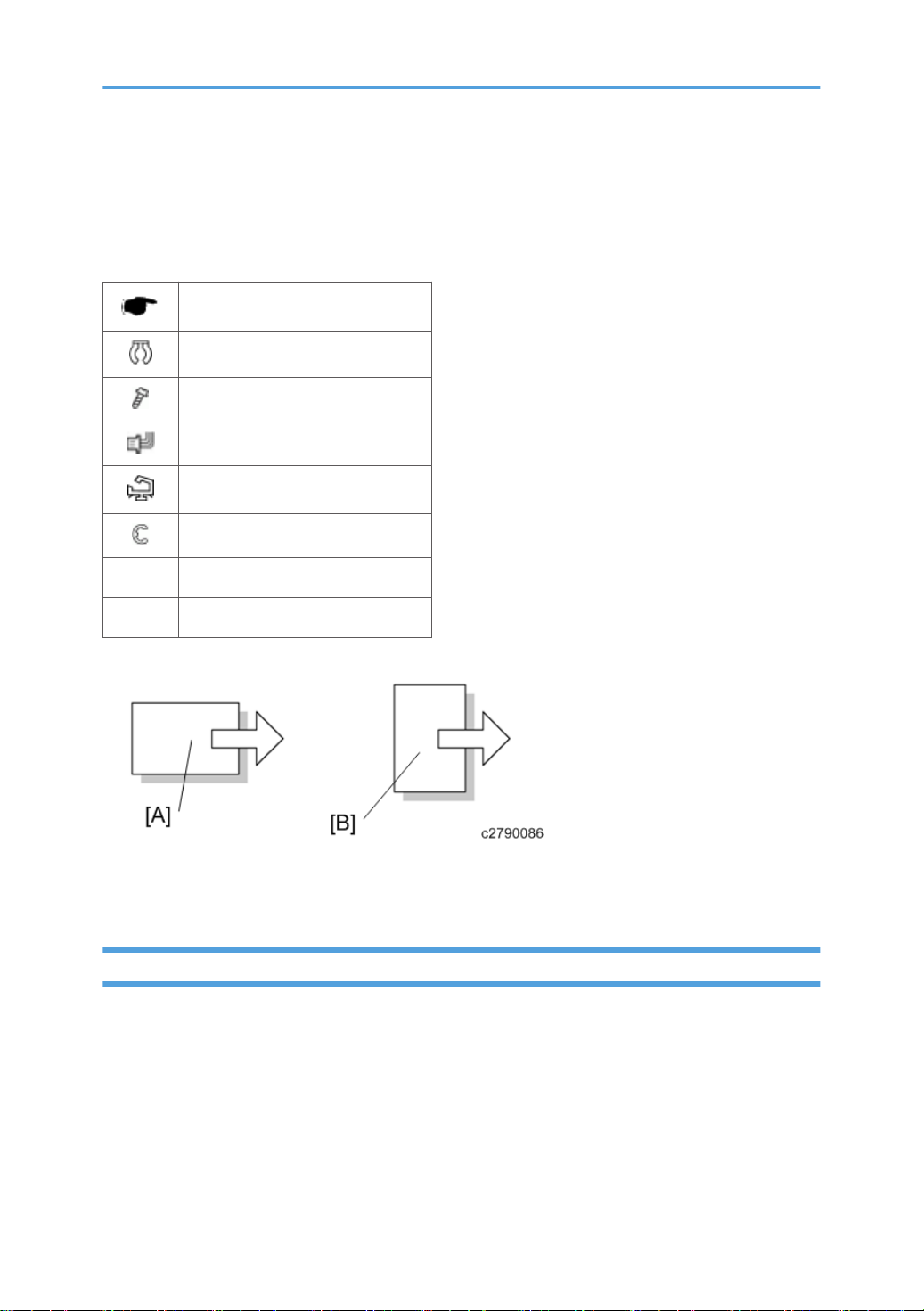

Symbols, Abbreviations and Trademarks

This manual uses several symbols and abbreviations. The meaning of those symbols and abbreviations

are as follows:

See or Refer to

Clip ring

Screw

Connector

Clamp

E-ring

SEF Short Edge Feed

LEF Long Edge Feed

[A] Short Edge Feed (SEF)

[B] Long Edge Feed (LEF)

Trademarks

Microsoft®, Windows®, and MS-DOS® are registered trademarks of Microsoft Corporation in the

United States and /or other countries.

PostScript® is a registered trademark of Adobe Systems, Incorporated.

PCL® is a registered trademark of Hewlett-Packard Company.

Ethernet® is a registered trademark of Xerox Corporation.

PowerPC® is a registered trademark of International Business Machines Corporation.

3

Page 5

Other product names used herein are for identification purposes only and may be trademarks of their

respective companies. We disclaim any and all rights involved with those marks.

4

Page 6

TABLE OF CONTENTS

Important Safety Notices................................................................................................................................... 1

Important Safety Notices............................................................................................................................... 1

Prevention of Physical Injury................................................................................................................. 1

Health Safety Conditions...................................................................................................................... 1

Observance of Electrical Safety Standards.........................................................................................1

Handling Toner...................................................................................................................................... 2

Safety and Ecological Notes for Disposal................................................................................................... 2

Symbols, Abbreviations and Trademarks.........................................................................................................3

Trademarks..................................................................................................................................................... 3

1. Product Information

Product Overview.............................................................................................................................................13

Component Layout.......................................................................................................................................13

Paper Path.................................................................................................................................................... 14

Drive Layout..................................................................................................................................................15

Machine Codes and Peripheral Configuration............................................................................................. 17

Main Frame..................................................................................................................................................17

Options......................................................................................................................................................... 17

Specifications....................................................................................................................................................18

2. Installation

Installation Requirements................................................................................................................................. 19

Check Image Quality / Setting.................................................................................................................. 19

Environment......................................................................................................................................... 19

Moving the Machine................................................................................................................................... 20

3. Preventive Maintenance

Preventive Maintenance Tables...................................................................................................................... 23

Image Quality Standards................................................................................................................................ 24

Paper Transfer Quality Standards.................................................................................................................. 25

Preparation for PM...........................................................................................................................................26

Cleaning Points.................................................................................................................................................27

4. Replacement and Adjustment

General Cautions.............................................................................................................................................29

Special Tools ................................................................................................................................................... 30

Exterior Covers................................................................................................................................................. 31

5

Page 7

Rear Cover................................................................................................................................................... 31

Paper Exit Cover (with Operation Panel)...................................................................................................32

Right Cover ..................................................................................................................................................34

Left Cover......................................................................................................................................................35

Front Cover Unit...........................................................................................................................................35

LED Optics........................................................................................................................................................ 49

LED Head......................................................................................................................................................49

Toner End Sensor.........................................................................................................................................51

PCDU.................................................................................................................................................................52

PCDU............................................................................................................................................................ 52

PCDU Cover (Right).....................................................................................................................................53

Image Transfer..................................................................................................................................................54

Image Transfer Belt Unit.............................................................................................................................. 54

After installing a new Image Transfer Belt Unit.................................................................................55

Image Transfer Belt Cleaning Unit..............................................................................................................55

Transfer Roller.............................................................................................................................................. 56

After installing a new Transfer Roller................................................................................................. 57

Drive Unit.......................................................................................................................................................... 59

Paper Feed Motor........................................................................................................................................59

Image Transfer Unit Motor..........................................................................................................................60

Fusing Motor................................................................................................................................................ 61

Drum Motor: K............................................................................................................................................. 61

Drum Motor: CMY.......................................................................................................................................62

Duplex Junction Gate Solenoid.................................................................................................................. 62

Duplex Inverter Solenoid.............................................................................................................................64

Drive Gears and Clutches........................................................................................................................... 67

Registration Clutch....................................................................................................................................... 68

Toner Supply Clutch.................................................................................................................................... 69

Bypass Clutch...............................................................................................................................................71

Duplex Intermediate Clutch.........................................................................................................................72

Duplex Paper Exit Clutch.............................................................................................................................74

Fusing................................................................................................................................................................ 76

Fusing Unit.................................................................................................................................................... 76

6

Page 8

Thermistor..................................................................................................................................................... 76

Thermostat.................................................................................................................................................... 80

Fusing Belt Unit.............................................................................................................................................81

Fusing Lamp..................................................................................................................................................84

Thermopile....................................................................................................................................................86

Paper Feed........................................................................................................................................................87

Paper Feed Roller........................................................................................................................................ 87

Friction Pad...................................................................................................................................................87

Bypass Tray Unit.......................................................................................................................................... 88

Bypass Feed Roller...................................................................................................................................... 89

Bypass Friction Pad......................................................................................................................................90

Paper Size Switch........................................................................................................................................ 91

Paper End Sensor.........................................................................................................................................91

Bypass Paper End Sensor............................................................................................................................92

Bypass Bottom Plate Home Position Sensor...............................................................................................93

Paper Transport................................................................................................................................................ 96

Fusing Entrance Sensor............................................................................................................................... 96

Duplex Sensor..............................................................................................................................................97

Registration Sensor...................................................................................................................................... 98

Reinstalling the Transport guide.......................................................................................................102

Paper Exit Sensor.......................................................................................................................................103

Paper Exit Full Sensor................................................................................................................................104

Registration Roller (Drive)......................................................................................................................... 104

Registration Roller (Driven).......................................................................................................................106

Driven Roller (Relay)................................................................................................................................. 108

Transport Roller (Relay)............................................................................................................................ 109

Paper Exit/Reverse Roller.........................................................................................................................109

Duplex Entrance Roller............................................................................................................................. 110

Duplex Intermediate Roller....................................................................................................................... 111

Duplex Exit Roller...................................................................................................................................... 111

Waste Toner...................................................................................................................................................114

Waste Toner Bottle....................................................................................................................................114

Waste Toner Bottle Sensor....................................................................................................................... 114

7

Page 9

Waste Toner Full Sensor........................................................................................................................... 115

Waste Toner Duct......................................................................................................................................116

Electrical Components...................................................................................................................................117

ID Chip Relay Board................................................................................................................................. 117

Temperature & Humidity Sensor.............................................................................................................. 118

Engine Board............................................................................................................................................. 118

When installing the new engine board...........................................................................................119

Controller Board........................................................................................................................................120

When installing the new controller board...................................................................................... 122

PSU............................................................................................................................................................. 123

High Voltage Power Supply Board (Separation)................................................................................... 123

High Voltage Power Supply Board..........................................................................................................125

PCDU Sensor Board..................................................................................................................................125

TM (ID) Sensor...........................................................................................................................................127

Before TM (ID) sensor replacement................................................................................................ 127

Replacement......................................................................................................................................129

Adjustment after the TM (ID) sensor replacement..........................................................................131

Operation Panel........................................................................................................................................ 131

Fusing Fan Motor.......................................................................................................................................134

Cooling Fan Motor....................................................................................................................................135

Reinstalling the cooling fan motor................................................................................................... 136

PSU Fan Motor.......................................................................................................................................... 137

Interlock Switch..........................................................................................................................................138

NVRAM......................................................................................................................................................139

NVRAM on the controller................................................................................................................ 139

EEPROM on the engine board........................................................................................................ 140

5. Service Table

Service Program Mode ................................................................................................................................143

SP Tables....................................................................................................................................................143

Enabling and Disabling Service Program Mode....................................................................................143

Accessing the Required Program.................................................................................................... 143

Inputting a Value or Setting for a Service Program....................................................................... 143

Exiting Service Mode....................................................................................................................... 144

8

Page 10

Service Table Key......................................................................................................................................145

SP Mode Tables.............................................................................................................................................146

SP1-XXX (Feed)......................................................................................................................................... 146

SP2-XXX (Drum).........................................................................................................................................148

SP3-XXX (Process)..................................................................................................................................... 152

SP5-XXX (Mode)....................................................................................................................................... 166

SP7-XXX (Data Log) ................................................................................................................................. 185

Updating the Firmware..................................................................................................................................202

Updating Firmware................................................................................................................................... 202

Preparation........................................................................................................................................202

Updating Procedure......................................................................................................................... 202

Error Messages.................................................................................................................................203

Firmware Update Error.....................................................................................................................203

Recovery after Power Loss............................................................................................................... 203

Handing Firmware Update Errors............................................................................................................204

Error Message Table........................................................................................................................204

Uploading/Downloading NVRAM Data....................................................................................................206

Uploading Content of NVRAM to an SD card....................................................................................... 206

Downloading an SD Card to NVRAM....................................................................................................206

Using the Debug Log.....................................................................................................................................208

Overview....................................................................................................................................................208

Switching ON and Setting UP Save Debug Log.....................................................................................208

Retrieving the Debug Log from the HDD................................................................................................. 211

Debug Log Codes..................................................................................................................................... 211

SP5857-015 Copy SD Card-to-SD Card: Any Desired Key.......................................................211

SP5857-016 Create a File on HDD to Store a Log...................................................................... 211

SP5857-017 Create a File on SD Card to Store a Log................................................................212

SMC List Card Save Function....................................................................................................................... 213

Overview....................................................................................................................................................213

SMC List Card Save......................................................................................................................... 213

Procedure...................................................................................................................................................213

File Names of the Saved SMC Lists......................................................................................................... 214

Error Messages..........................................................................................................................................215

9

Page 11

6. Troubleshooting

Self-Diagnostic Mode................................................................................................................................... 217

Self-Diagnostic Mode at Power On.........................................................................................................217

Service Call.................................................................................................................................................... 218

Service Call Conditions.............................................................................................................................218

Scanning.................................................................................................................................................... 218

LED Optics..................................................................................................................................................219

Image Processing – 1............................................................................................................................... 220

Image Processing – 2............................................................................................................................... 225

Paper Feed and Fusing............................................................................................................................. 228

Device Communication.............................................................................................................................241

Peripherals................................................................................................................................................. 243

Controller................................................................................................................................................... 244

Jam Detection.................................................................................................................................................265

Sensor Position...........................................................................................................................................265

Sensor Position...........................................................................................................................................266

Paper Feed........................................................................................................................................ 266

Bypass Tray.......................................................................................................................................266

Bank...................................................................................................................................................266

Duplex .............................................................................................................................................. 267

Electrical Component Defects.......................................................................................................................268

Image Quality................................................................................................................................................ 270

Overview....................................................................................................................................................270

Checking a Sample Printout..................................................................................................................... 271

Printer Driver Setting for Printing a Sample.....................................................................................272

Other Problems.............................................................................................................................................. 275

Blown Fuse Conditions.................................................................................................................................. 276

EGB Fuses.................................................................................................................................................. 276

PSU Fuses...................................................................................................................................................278

7. Energy Save

Energy Save................................................................................................................................................... 281

Energy Saver Modes................................................................................................................................ 281

Timer Settings.................................................................................................................................... 281

10

Page 12

Eco Night Mode............................................................................................................................... 282

Weekly Timer.................................................................................................................................... 282

Fusing Off Mode...............................................................................................................................282

Return to Stand-by Mode.................................................................................................................283

Recommendation..............................................................................................................................283

Energy Save Effectiveness........................................................................................................................ 283

Paper Save.....................................................................................................................................................286

Effectiveness of Duplex/Combine Function............................................................................................ 286

1. Duplex:..........................................................................................................................................286

2. Combine mode:............................................................................................................................286

3. Duplex + Combine:...................................................................................................................... 287

Recommendation..............................................................................................................................287

11

Page 13

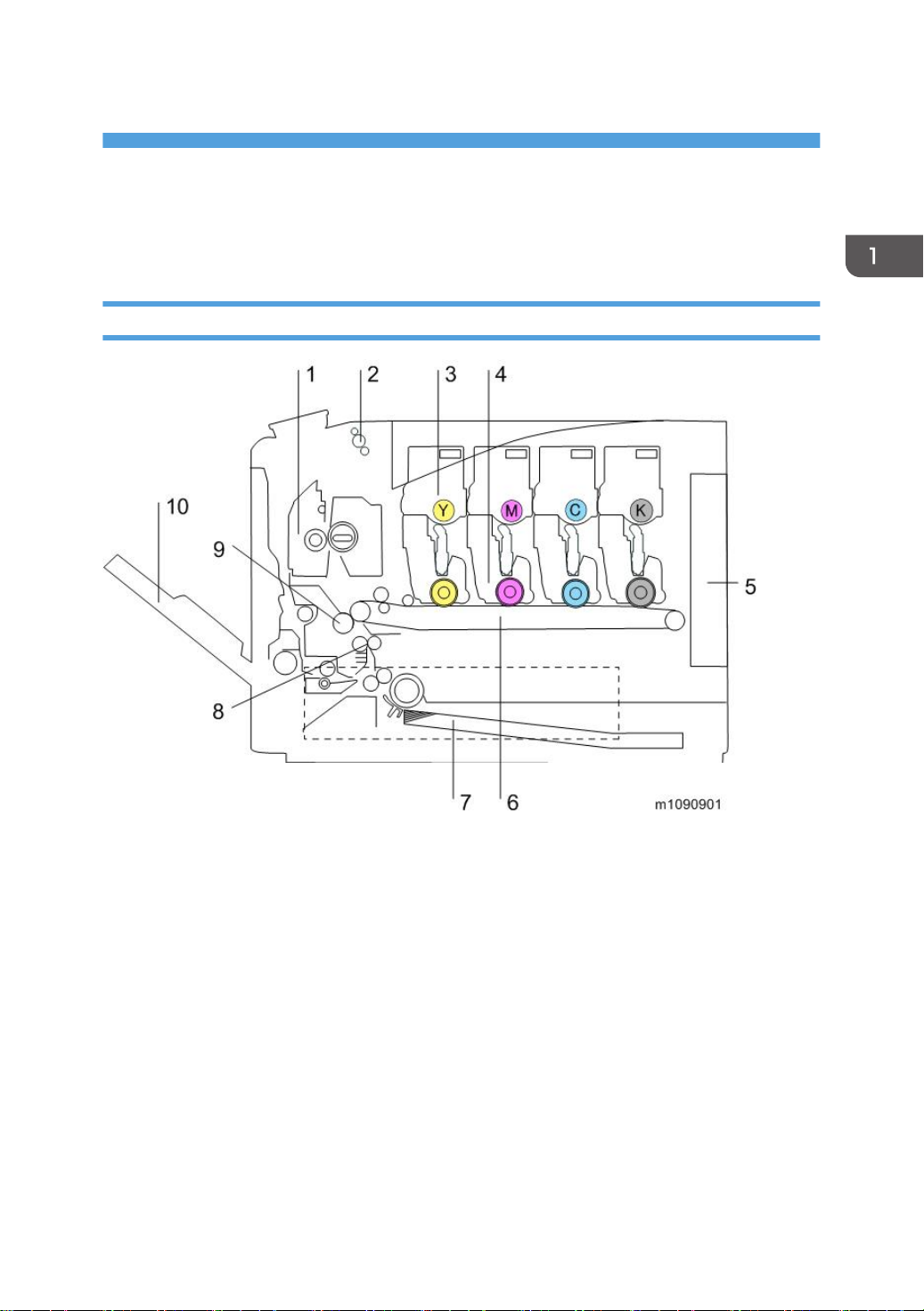

1. Product Information

Product Overview

Component Layout

1. Fusing Unit

2. Paper Exit/Reverse Roller

3. Toner Bottle

4. PCDU

5. Engine Board/Controller Board

6. Image Transfer Belt Unit

7. Paper Feed Tray

8. Registration Roller

9. Transfer Roller

10. Bypass Tray Unit

13

Page 14

1. Product Information

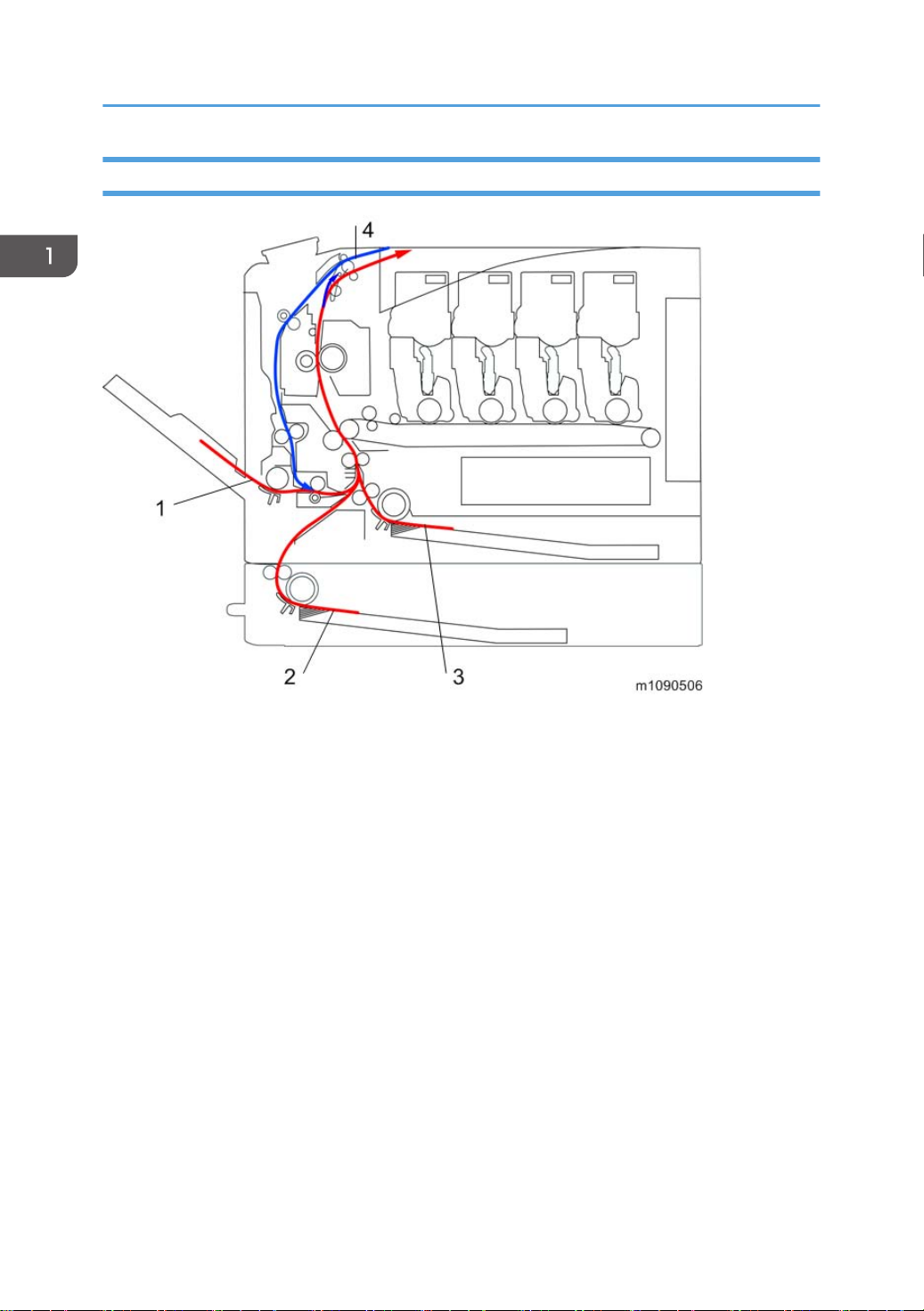

Paper Path

1. Bypass Tray

2. Optional Paper Feed Tray

3. Standard Paper Feed Tray

4. Duplex Feed Path

14

Page 15

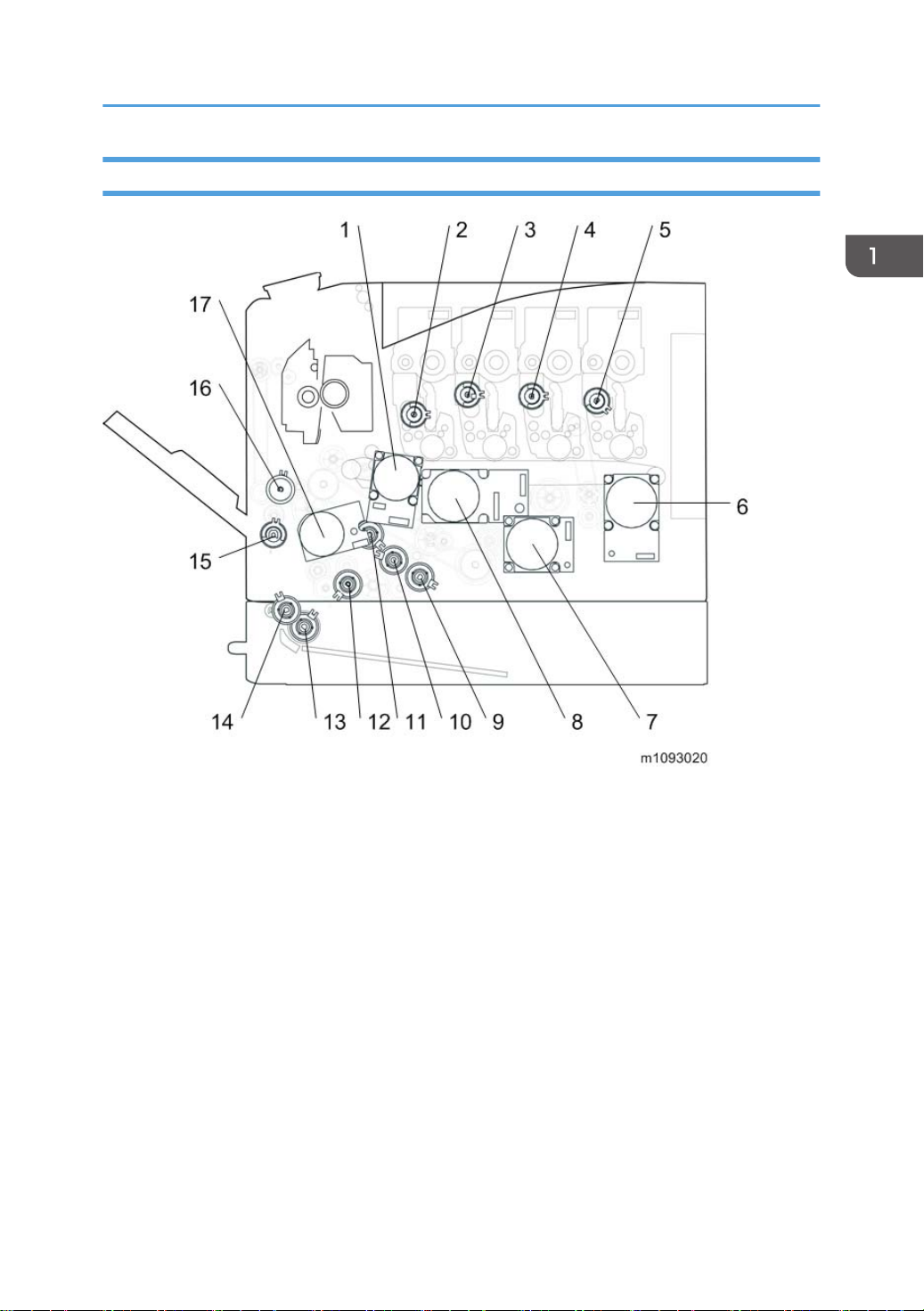

Drive Layout

Product Overview

1. Image Transfer Unit Motor

2. Toner Supply Clutch (Y)

3. Toner Supply Clutch (M)

4. Toner Supply Clutch (C)

5. Toner Supply Clutch (K)

6. Drum Motor: K

7. Fusing Motor

8. Drum Motor: CMY

9. Paper Feed Clutch

10. Relay Clutch

11. ITB (Image Transfer Belt) Contact Clutch

12. Registration Clutch

13. Paper Feed Clutch

15

Page 16

1. Product Information

14. Grip Roller Clutch

15. Duplex Intermediate Clutch

16. Bypass Clutch

17. Paper Feed Motor

16

Page 17

Machine Codes and Peripheral Configuration

Machine Codes and Peripheral Configuration

Main Frame

item Machine Code Remarks

SP C730DN M109 NEW

Options

item Machine Code Remarks

Paper Feed Unit TK2000 M406 NEW

Hard Disk Drive Option Type C730 M417-01 NEW

Memory Unit Type N 1GB M417-03 NEW

IEEE802.11 Interface Unit Type O M417-06 NEW, *1

IPDS Unit Type C730 M417-10(NA)

M417-11(EU)

M417-12(Asia/CHN)

Camera Direct Print Card Type L M417-15 NEW

SD card for NetWare printing Type M M417-16 NEW

IEEE1284 Interface Board Type A B679 *1

VM CARD Type W M417-19(NA)

M417-20(EU)

M417-21(Asia/CHN)

*1: You can only install one of these at a time.

*2: You cannot install this without the HDD.

NEW

NEW, *2

17

Page 18

1. Product Information

Specifications

See "Appendices" for the following information:

• General Specifications

• Supported Paper Sizes

• Software Accessories

• Optional Equipment

• Other Specifications

18

Page 19

2. Installation

Installation Requirements

Check Image Quality / Setting

This machine is installed by the user.

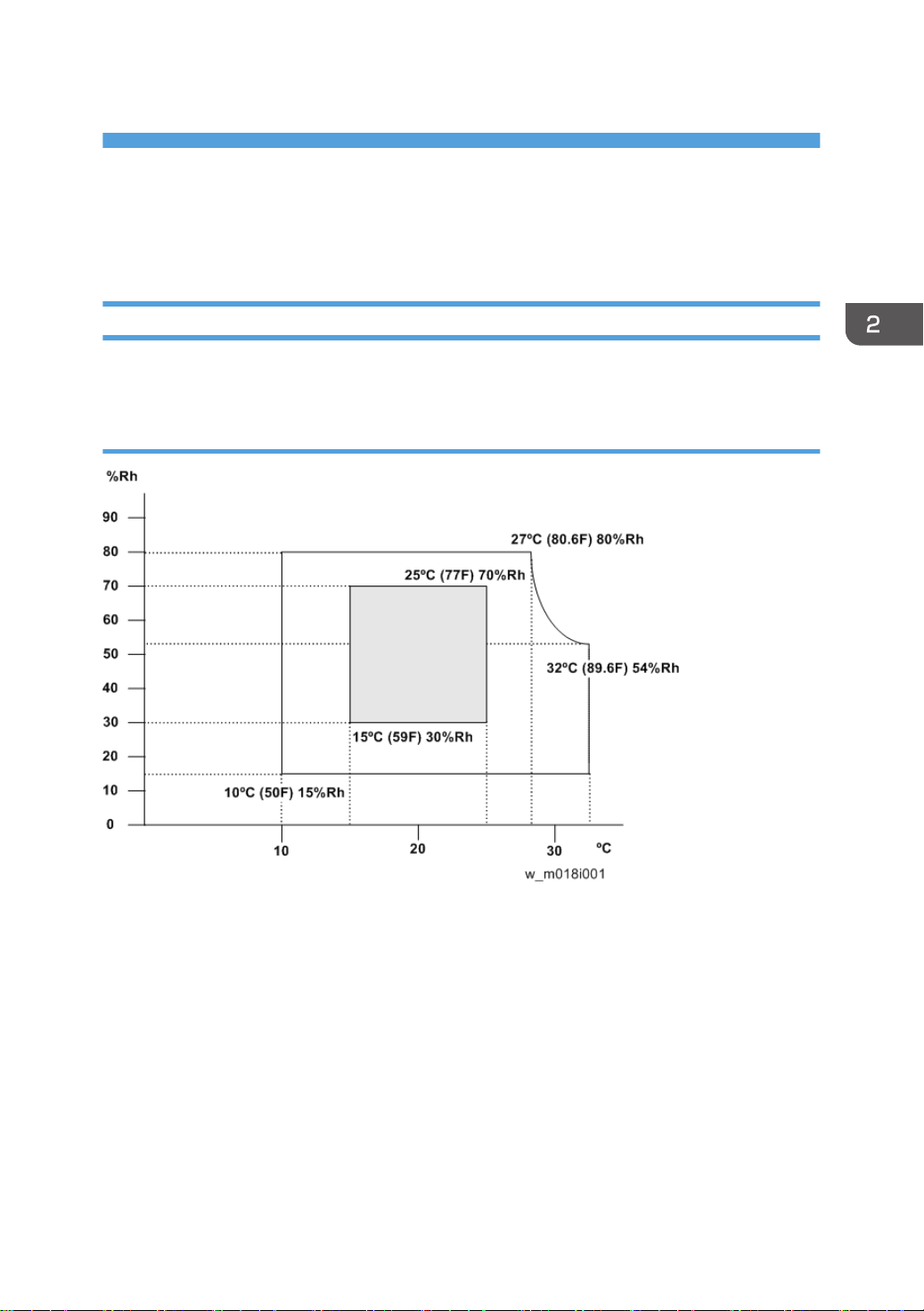

Environment

1. Temperature Range: 10°C to 32°C (50°F to 89.6°F)

2. Humidity Range: 15% to 80% RH

3. Ambient Illumination: Less than 2,000 lux (do not expose to direct sunlight)

4. Ventilation: 3 times/hr/person

5. Do not install the machine at locations over the following heights above sea level.

All areas except for China: 2,500 m (8,125 ft.)

China: 2,000 m (6,562 ft.)

6. Atmospheric pressure: more than 740 hPa.

19

Page 20

2. Installation

Moving the Machine

• It is dangerous to handle the power cord plug with wet hands. Doing so could result in electric

shock.

• Unplug the power cord from the wall outlet before you move the machine. While moving the

machine, take care that the power cord is not damaged under the machine. Failing to take these

precautions could result in fire or electric shock.

• When disconnecting the power cord from the wall outlet, always pull the plug, not the cord. Pulling

the cord can damage the power cord. Use of damaged power cords could result in fire or electric

shock.

• The printer weighs approximately 40 kg (88.2 lb.). When moving the printer, use the inset grips on

both sides, and lift slowly in pairs. The printer will break or cause injury if dropped.

• When moving the printer after use, do not take out any of the toners, nor the waste toner bottle to

prevent toner spill inside the printer.

• Do not hold the control panel while moving the printer. Doing so may damage the control panel,

cause a malfunction, or result in injury.

• Be careful when moving the printer. Take the following precautions:

• Turn off the main power.

• Close all covers and trays, including the front cover and bypass tray.

• If optional paper feed units are attached, remove them from the printer and move them separately

• Be sure to place the printer on a smooth and stable place.

• Keep the printer level and carry it carefully, taking care not to jolt or tip it. Rough handling may

cause a malfunction or damage the hard disk or memory, resulting in loss of stored files.

• Protect the printer from strong shocks. Impact can damage the hard disk and cause stored files to

be lost. As a precautionary measure, files should be copied to another computer.

20

Page 21

Installation Requirements

1. Be sure to check the following:

The power switch is turned off.

The power cord is unplugged from the wall outlet.

The interface cable is unplugged from the printer.

2. If Paper Feed Unit are attached, remove them.

3. Lift the printer with two people by using the inset grips on both sides of the printer, and

then move it horizontally to the place where you want to install it.

4. If you removed Paper Feed Unit, reattach them.

• Be sure to move the printer horizontally. To prevent toner from scattering, move the printer

slowly.

21

Page 22

3. Preventive Maintenance

Preventive Maintenance Tables

See "Appendices" for the following information:

• Preventive Maintenance Items

23

Page 23

3. Preventive Maintenance

Image Quality Standards

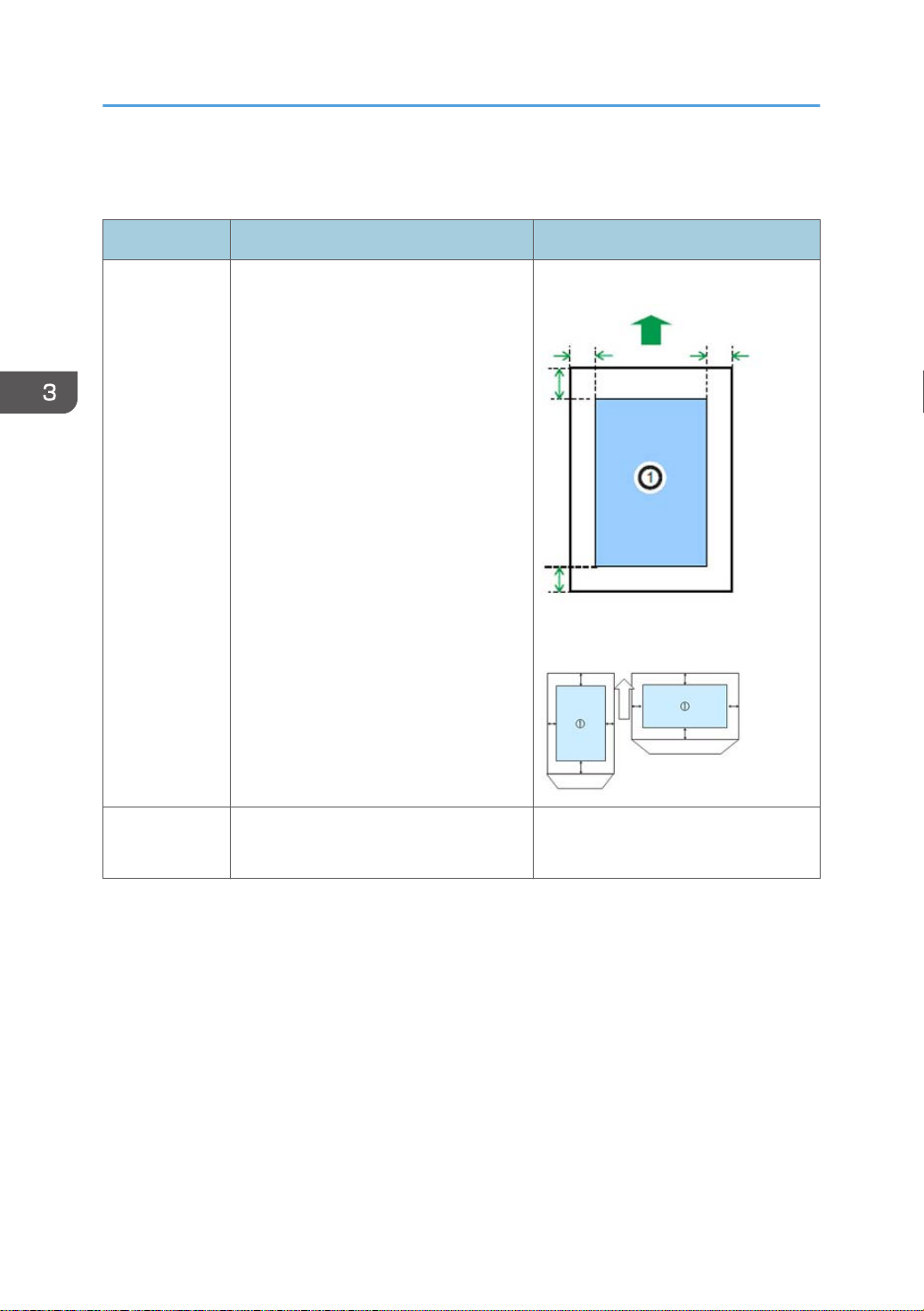

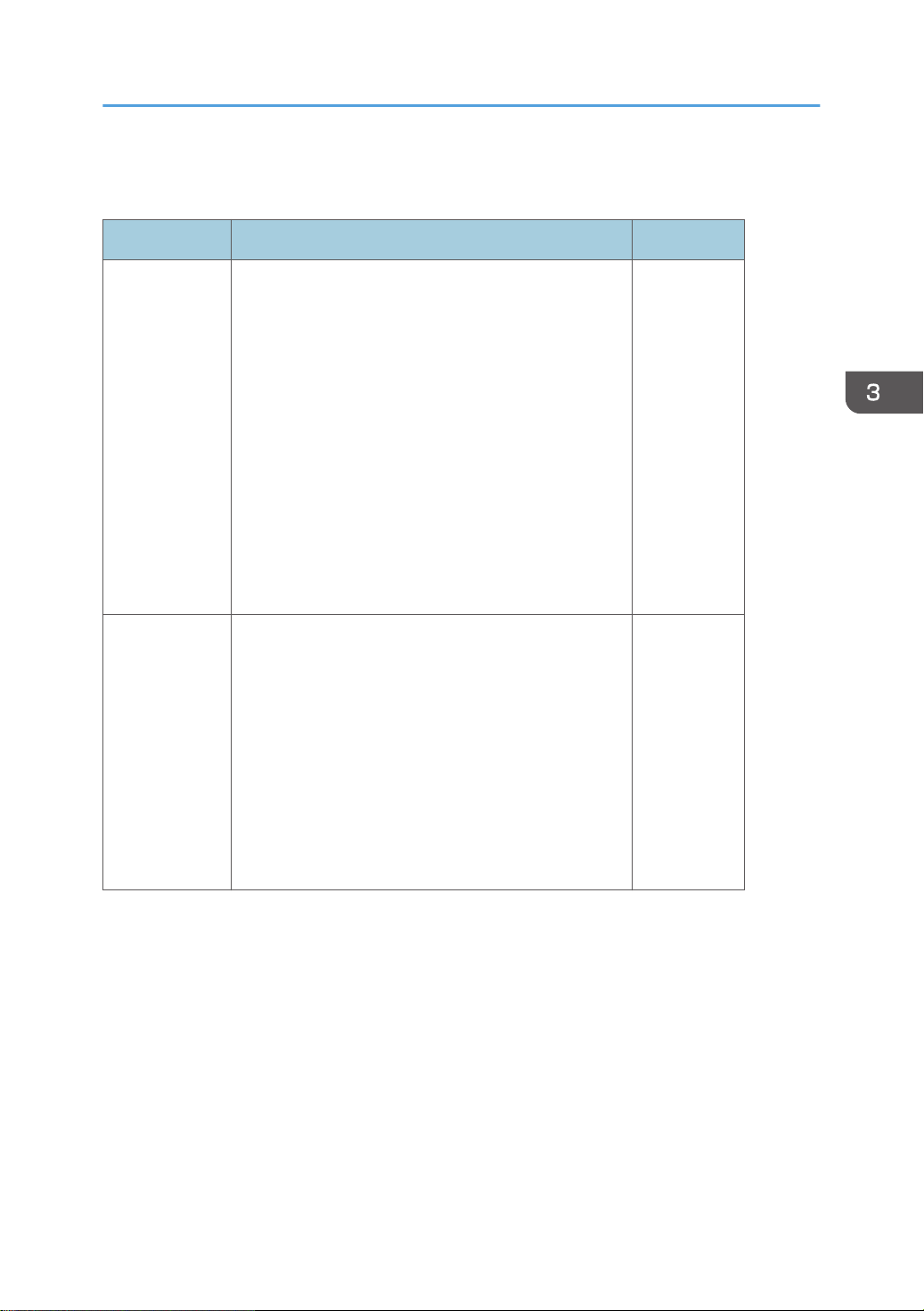

Item Specification Remarks

Except Envelopes

Except Envelopes

The standard print area of a sheet is the

area enclosed by margins of 4.3 mm

Assured Image

Area

from all sides of the sheet.

Envelopes

The 15mm excluding the flap portion

from the rear end / tip of the sheet,

except for the region of the left and right

ends 10mm.

Envelopes

24

Magnification

Error

Main: ±0.50% or more

Scale

Sub: ±0.50% or less

Page 24

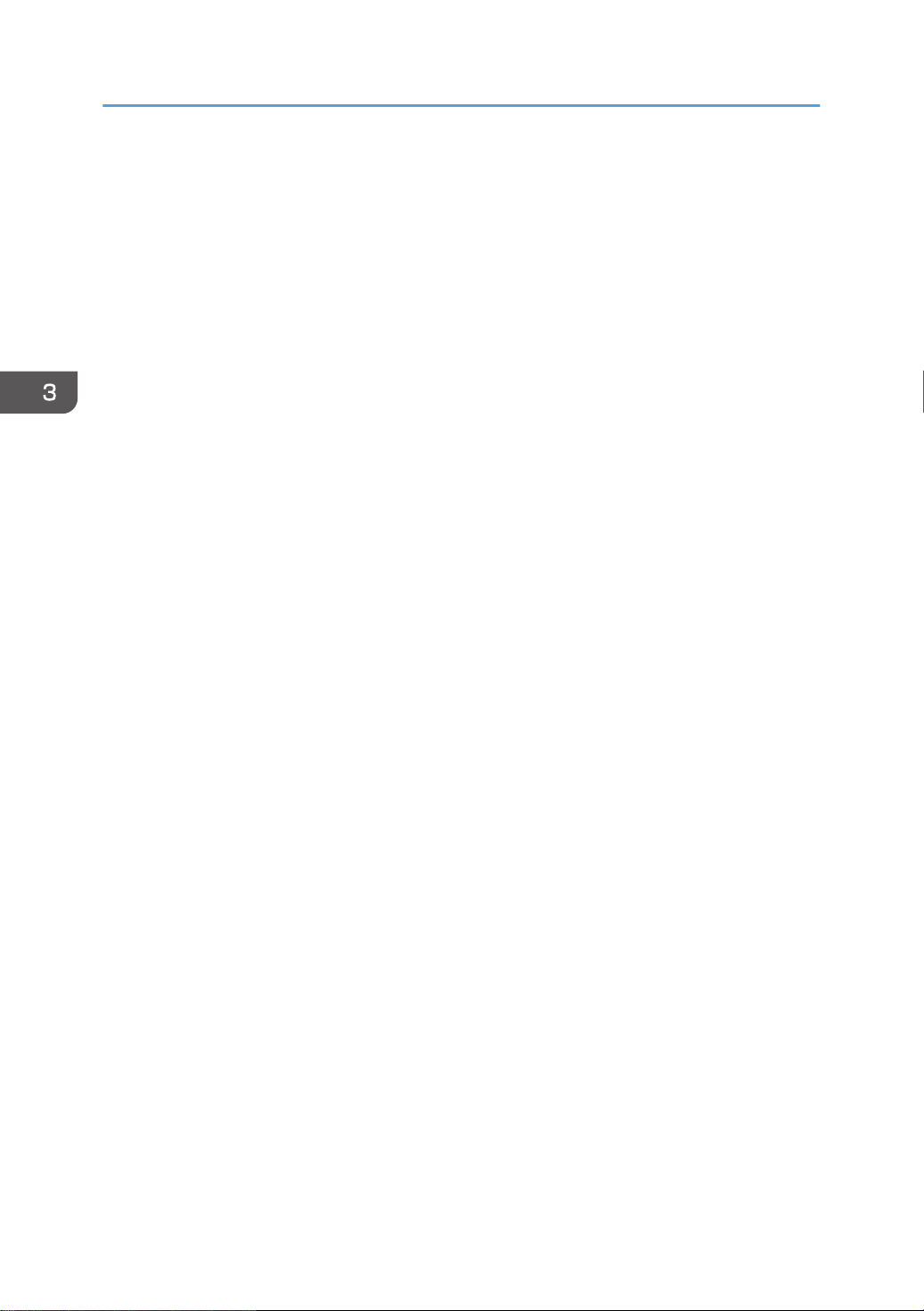

Paper Transfer Quality Standards

Item Specification Remarks

Single Side:

Width: 0±2.0mm (Main Scan Direction)

Vertical: Office / All Environments 0±2.0mm (Sub Scan

Direction)

(In an environment of 23 deg C / 50% is vertical: 0 ±

1.5mm

Registration

Duplex:

Width: 0±3.0mm (Main Scan Direction)

Vertical: Office / All Environments 0±4.0mm (Sub Scan

Direction)

(In an environment of 23 deg C / 50% is vertical: 0 ±

3.5mm

Paper Transfer Quality Standards

Scale

Single Side:

±1.0mm/100mm or less (Less than B5 SEF)

±1.0mm/200mm or less (B5 SEF or more, tray 1 /

Bypass tray)

Skew

These standards are determined using the standard paper with the standard conditions. The value may

change depend on the environmental conditions such as temperature, humidity, and used paper, etc.

±1.2mm/200mm or less (B5 SEF or more, Optional

Tray)

Duplex:

±1.5mm/100mm or less (Less than B5 SEF)

±1.0mm/100mm or less (B5 SEF or more)

Except if the

paper is

longer than

432mm.

25

Page 25

3. Preventive Maintenance

Preparation for PM

See "Appendices" for the following information:

• Meter Click Mode

26

Page 26

Cleaning Points

See "Appendices".

Cleaning Points

27

Page 27

4. Replacement and Adjustment

RTB 54

Avoid touching areas of the PSU that may carry charge.

General Cautions

• Do not hold down the power switch for 6 seconds or longer when turning off the machine. Doing

so may result in damage to the hard disk or memory, leading to malfunctions.

• Before disassembling or assembling parts of the main machine and peripherals, make sure that the

power cord of the main machine is unplugged.Since this machine uses a DC switch, there is a weak

current even after the power cord is unplugged.

Follow the steps below when disassembling the machine.

1. Press the power switch off.

2. Unplug the power cord.

3. Press the power switch once to discharge the remaining current.

When the power cord is plugged in, the machine may power itself on even though the power switch

button is not pressed.

29

Page 28

4. Replacement and Adjustment

Special Tools

Part Number Description Q’ty

B6455010 SD Card 128MB 1

B6455020 SD Card 1GB 1

• A PC (Personal Computer) is required for creating the Encryption key file on an SD card when

replacing the controller board for a model in which HDD encryption has been enabled.

30

Page 29

Exterior Covers

Rear Cover

1. Memory/HDD cover [A]

2. Cable cover [B]

Exterior Covers

31

Page 30

4. Replacement and Adjustment

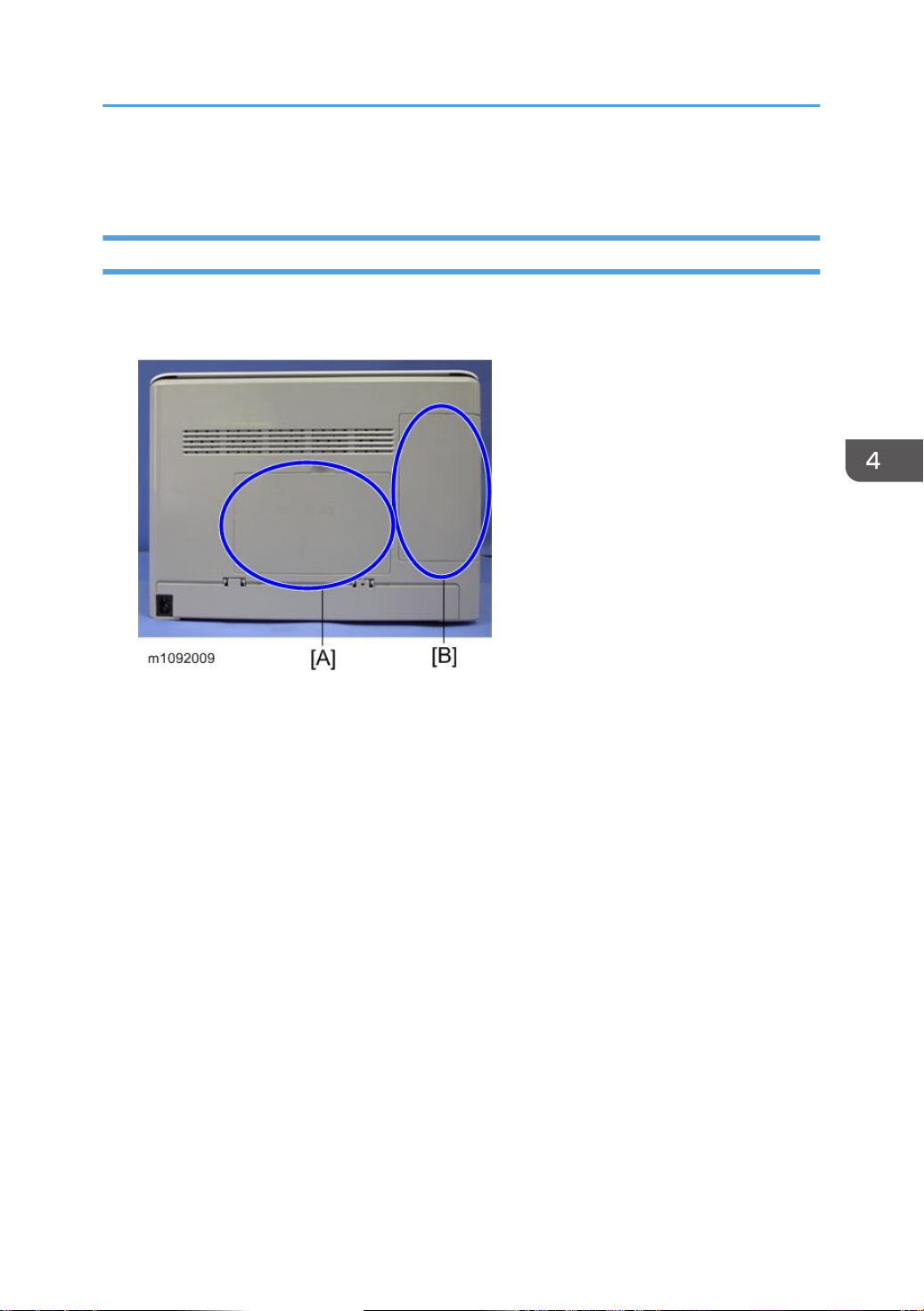

3. Rear cover ( ×6)

Paper Exit Cover (with Operation Panel)

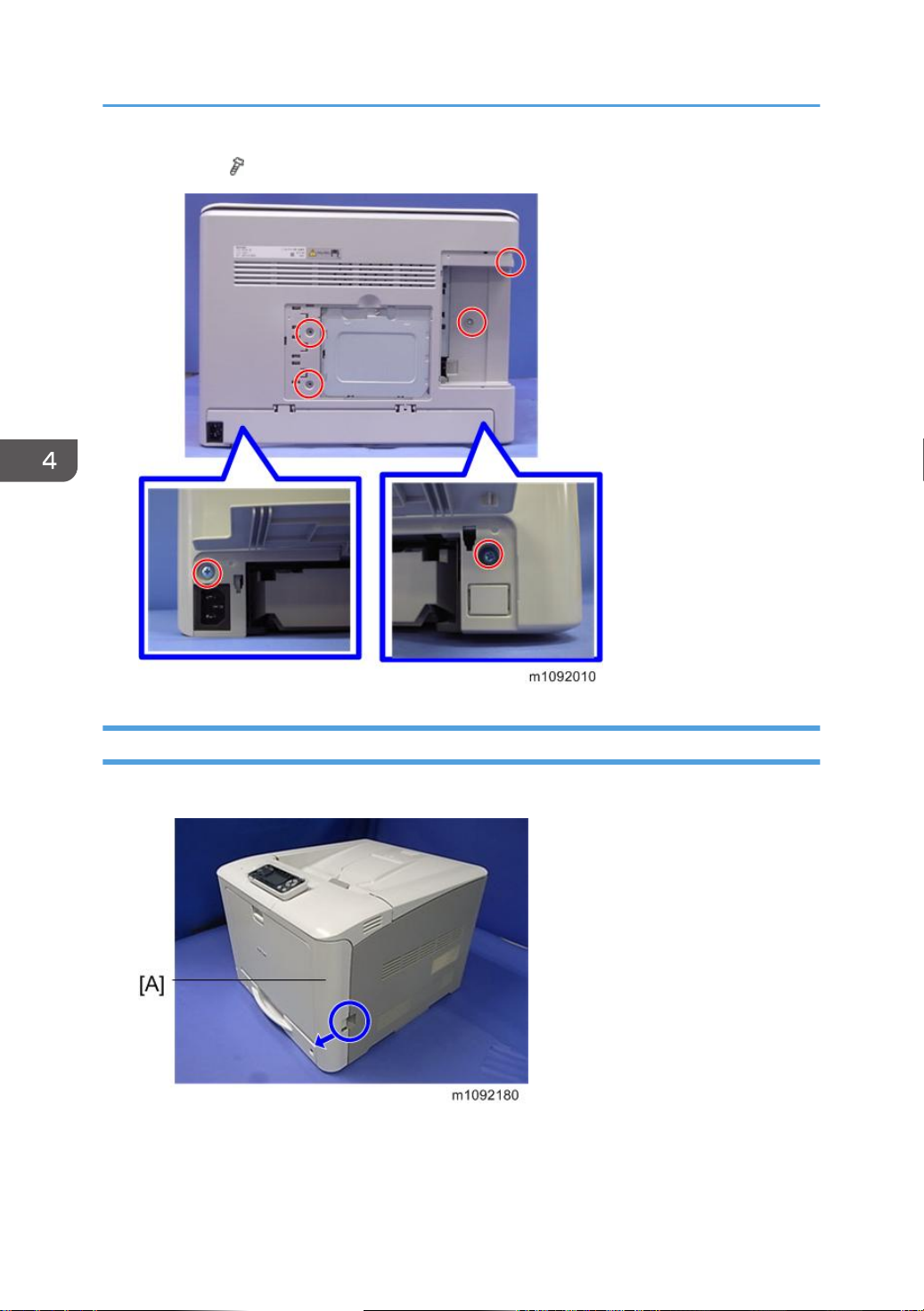

1. Open the Front cover [A]

32

Page 31

2. Open the Upper cover [A]

3. Connector cover [A] ( ×1)

Exterior Covers

33

Page 32

4. Replacement and Adjustment

4. Paper exit cover [A] ( ×3, ×1)

34

Right Cover

1. Paper exit cover ( page 32)

2. Rear cover ( page 31)

3. Open the inner cover

Page 33

4. Right cover ( ×4)

Left Cover

Exterior Covers

• Remove the Waste Toner Bottle before you remove the Left Cover, so as not to disperse the toner.

1. Waste toner bottle. ( page 114)

2. Paper exit cover ( page 32)

3. Rear cover ( page 31)

4. Left cover ( ×3)

Front Cover Unit

1. Bypass tray unit ( page 88)

35

Page 34

4. Replacement and Adjustment

2. Open the Front cover.

3. Bracket [A] ( ×2)

4. Close the Front cover slightly, and than remove the wire [A].

36

Page 35

5. Brackets [A] and [B]. ( ×2)

6. Connectors ( ×2)

Exterior Covers

7. Duplex paper exit clutch [A]( ×1)

8. Bypass clutch [B]( ×1)

37

Page 36

4. Replacement and Adjustment

9. Gear [A] and Duplex intermediate clutch [B] ( ×1)

• [A]: Gear (This gear has a round hole.)

• [B]: Duplex intermediate clutch

10. Gear unit [A] ( ×2)

11. Spacer [A]

38

Page 37

12. Gears [B], [C], [D] ( ×1)

Exterior Covers

• The hole in the gear [B] is in the form of a ‘D’.

39

Page 38

4. Replacement and Adjustment

13. Cam [A]

14. Loosen the tension of the spring [A], and then remove the Harness guide [B]. ( ×2)

15. Cover [A] ( ×2)

40

Page 39

16. Power switch [A] ( ×1)

17. Harness guide [B] ( ×1, ×1)

18. Harness guide [A] (hook×2)

Exterior Covers

41

Page 40

4. Replacement and Adjustment

19. Connectors ( ×3)

20. Ground plate [A] ( ×2)

42

Page 41

21. Gears [A], [B] ( ×1)

Exterior Covers

• The hole in the gears [A] and [B] is in the form of a ‘D’.

43

Page 42

4. Replacement and Adjustment

22. Bearing [A]

23. Close the Front cover slightly.

24. Paper feed roller ( page 87)

44

Page 43

25. Snaps ( ×3)

Exterior Covers

• Be careful not to lose the spring [A].

26. Open the Front cover.

45

Page 44

4. Replacement and Adjustment

27. Shaft [A]

28. Close the Front cover slightly.

29. Shaft [A]

30. Open the Front cover.

46

Page 45

31. Transport unit [A] ( ×8)

Exterior Covers

47

Page 46

4. Replacement and Adjustment

32. Front cover unit [A] ( ×6)

48

• Be careful not to break the Mylar [A] during the exchange.

Page 47

LED Optics

LED Optics

LED Head

1. Open the Upper inner cover, and then cover the PCDUs with a sheet of paper, to prevent

foreign objects from falling into the PCDUs. ( page 52)

2. Remove the snaps and flat cable from the LED head [A].

49

Page 48

4. Replacement and Adjustment

3. Slide the Toner end sensor unit [A].

4. Remove the connector from the Toner end sensor [A].

50

5. LED head [A]

• The Flat cables of the LED heads have different colors. They have a fixed order.

• If you remove the Flat cables of the LED heads, during re-assembly connect them so that they

overlap in the order of Y / M / C / K.

Page 49

[A]: Flat cable: EGB: LED head Y

[B]: Flat cable: EGB: LED head M

[C]: Flat cable: EGB: LED head C

LED Optics

[D]: Flat cable: EGB: LED head K

Toner End Sensor

1. LED head ( page 49)

2. Toner end sensor [A] ( ×1)

51

Page 50

4. Replacement and Adjustment

RTB 27

Important Information about Installing a Used PCDU

PCDU

PCDU

1. Open the Upper cover.

2. Release the lock [A], and open the Upper inner cover [B].

3. PCDUs [A]

• All PCDUs (Cyan, Magenta, Yellow, and Black) have a new unit detecting mechanism.

Technicians do not need to reset counters after replacing, even if not all the PCDUs are

replaced at the same time.

52

Page 51

PCDU Cover (Right)

1. PCDU ( page 52)

2. PCDU cover [A] (hook ×2)

PCDU

53

Page 52

4. Replacement and Adjustment

Image Transfer

Image Transfer Belt Unit

1. Open the Front cover.

2. Fusing unit ( page 76)

3. Release the locks [A], and then pull out the Image transfer belt unit [B].

• Before you install the image transfer belt, make sure that the white lever [A] is pulled out to the

position shown in this photo.

54

Page 53

Image Transfer

After installing a new Image Transfer Belt Unit

• Print out the logging data using SP5-990-004 before you replace either the transfer belt unit or the

transfer roller.

• The Image Transfer Belt Unit as a supply part is equipped with a new unit detection mechanism and

does not require counter reset. The Paper Transfer Roller as a supply part is kitted together with the

Image Transfer Belt unit and does not require counter reset, since it will be replaced at the same

time as the Image Transfer Belt Unit.

Part replaced Action

1 Image Transfer Belt Unit

2 Paper Transfer Roller

As mentioned above, action is necessary only in the following two cases:

1.If you are replacing the image transfer belt unit

SP7-804-017 (PM Counter Clear ITB Unit)

SP7-804-060 (PM Counter Clear Life: ITB Unit)

If you are replacing the image transfer belt unit, you should execute SP7-804-017, for correct

control depending on the rotation distance. But, if you execute only SP7-804-017, the counter for

displaying the unit life is not cleared. So you must also clear the counter by executing

SP7-804-060 (PM Counter Clear Life: ITB Unit).

2.If you are replacing the paper transfer roller

SP7-804-022 (PM Counter Clear PTR Unit)

SP7-804-061 (PM Counter Clear Life: PTR Unit)

If you are replacing the paper transfer roller, you should execute SP7-804-022, for correct control

depending on the rotation distance. But, if you execute only SP7-804-022, the counter for

displaying the unit life is not cleared. So you must also clear the counter by executing

SP7-804-061 (PM Counter Clear Life: PTR Unit).

1. Execute SP7-804-017 and SP7-804-060

2. Turn off the machine, and then turn it back on.

1. Execute SP7-804-022 and SP7-804-061

2. Turn off the machine, and then turn it back on

Image Transfer Belt Cleaning Unit

1. Image transfer belt unit ( page 54)

55

Page 54

4. Replacement and Adjustment

2. Belt guide roller [A] (hook×2)

3. Image transfer belt cleaning unit [A] ( ×2)

• When you change the Transfer belt cleaning unit, dust the new one with toner as a lubricant.

Transfer Roller

1. Open the Front cover.

56

Page 55

Image Transfer

2. Remove the Transfer roller [A] with green handles.

After installing a new Transfer Roller

• Print out the logging data using SP5-990-004 before you replace either the transfer belt unit or the

transfer roller.

Part replaced Action

1. Execute SP7-804-017 and SP7-804-060

1 Image transfer belt unit

2. Turn off the machine, and then turn it back on.

1. Execute SP7-804-022 and SP7-804-061

2 Paper transfer roller

2. Turn off the machine, and then turn it back on

As mentioned above, action is necessary only in the following two cases:

1.If you are replacing the image transfer belt unit

SP7-804-017 (PM Counter Clear ITB Unit)

SP7-804-060 (PM Counter Clear Life: ITB Unit)

If you are replacing the image transfer belt unit, you should execute SP7-804-017, for correct

control depending on the rotation distance. But, if you execute only SP7-804-017, the counter for

displaying the unit life is not cleared. So you must also clear the counter by executing

SP7-804-060 (PM Counter Clear Life: ITB Unit).

2.If you are replacing the paper transfer roller

SP7-804-022 (PM Counter Clear PTR Unit)

SP7-804-061 (PM Counter Clear Life: PTR Unit)

57

Page 56

4. Replacement and Adjustment

If you are replacing the paper transfer roller, you should execute SP7-804-022, for correct control

depending on the rotation distance. But, if you execute only SP7-804-022, the counter for

displaying the unit life is not cleared. So you must also clear the counter by executing

SP7-804-061 (PM Counter Clear Life: PTR Unit).

• The Paper Transfer Roller as a supply part is kitted together with the Image Transfer Belt unit

and does not require counter reset, since it will be replaced at the same time as the Image

Transfer Belt Unit.

58

Page 57

Drive Unit

Paper Feed Motor

1. Right cover ( page 34)

2. Bracket ( page 60 "Image Transfer Unit Motor")

3. Harness guide [A] (hook x1)

4. Release the harness guide [B] ( ×1).

Drive Unit

5. Bracket [A] ( ×1, ×3)

59

Page 58

4. Replacement and Adjustment

6. Paper feed motor [A] ( ×3)

Image Transfer Unit Motor

1. Right cover ( page 34)

2. Bracket [A] ( ×4)

60

Page 59

3. Image transfer unit motor [A] ( ×1, ×3)

Fusing Motor

Drive Unit

1. Right cover ( page 34)

2. Fusing motor [A] ( ×1, × 3)

Drum Motor: K

1. Right cover ( page 34)

61

Page 60

4. Replacement and Adjustment

2. Drum motor: K ( ×1, ×3)

Drum Motor: CMY

1. Right cover ( page 34)

2. Drum motor: CMY [A] ( ×1, ×3)

Duplex Junction Gate Solenoid

1. Fusing fan ( page 134)

62

Page 61

2. Bracket [A] ( ×2, ×2)

3. Sensor [A]

4. Remove the solenoid from the bracket ( ×2, ×1, × 1).

Drive Unit

• Push the connector holder [B] out to facilitate access to the screw with a screwdriver.

63

Page 62

4. Replacement and Adjustment

5. Duplex junction gate solenoid [A]

Duplex Inverter Solenoid

1. Right cover ( page 34)

2. Bracket [A] ( ×6, × 3)

3. Gear box bracket [A] ( ×3)

64

Page 63

4. Remove the solenoid from the bracket [B] ( ×5, Spring ×1).

• Be careful not to let gears fall out of the box and become lost.

Drive Unit

• Refer to the picture below showing the location of each gear.

65

Page 64

4. Replacement and Adjustment

5. Remove the cover [A] to pull the connector out.

66

• To remove the cover [A], pull it diagonally as shown by the blue arrow in the picture above.

This cover is fixed by hooks on the lower and right sides.

Page 65

6. Duplex inverter solenoid [A]

Drive Gears and Clutches

Drive Unit

1. Right cover ( page 34)

2. Paper feed motor ( page 59)

3. Harness guide [A] ( ×2)

4. Harness guide (inner) [A] ( ×5)

1. Relay clutch

2. Paper feed clutch

3. ITB (image transfer belt) Contact Clutch

67

Page 66

4. Replacement and Adjustment

5. Drive gears and clutches [A]

Registration Clutch

1. Image transfer unit motor ( page 60)

2. Paper feed motor ( page 59)

3. Drive gears and clutches ( page 67)

68

Page 67

4. Bracket [A] ( ×2)

5. Registration clutch [A]

Drive Unit

Toner Supply Clutch

1. Right cover ( page 34)

69

Page 68

4. Replacement and Adjustment

2. Cover brackets [A] ( ×2 each)

3. Clips and connectors ( ×1, ×1 each)

70

Page 69

4. Toner supply clutch [A]

Bypass Clutch

Drive Unit

1. Open the front cover.

2. Bracket [A] ( x1)

71

Page 70

4. Replacement and Adjustment

3. Bypass clutch [A] ( x1, x1)

Duplex Intermediate Clutch

1. Open the front cover.

2. Brackets [A] [B] ( x2)

72

Page 71

3. Connector x1

4. Gear [A] and clip

Drive Unit

73

Page 72

4. Replacement and Adjustment

5. Duplex intermediate clutch [A]

• Make sure that the harness [A] is installed as shown above when reinstalling the duplex

intermediate clutch.

Duplex Paper Exit Clutch

1. Open the front cover.

74

Page 73

2. Bracket [A] ( x1)

3. Duplex paper exit clutch [A] ( x1)

Drive Unit

75

Page 74

4. Replacement and Adjustment

Fusing

• Make sure that the fusing unit is cool before you touch it. The fusing unit can be very hot. Make sure

to restore the insulators, shields, etc after you service the fusing unit.

Fusing Unit

1. Open the front cover.

2. Hold the fusing unit lock levers [A] while pulling out the fusing unit.

3. Fusing unit [B]

76

Thermistor

1. Fusing unit ( page 76)

Page 75

2. Fusing upper cover [A] (Stepped screw×4)

3. Fusing lower cover [A] (Stepped screw ×2, ×1)

4. Fusing entrance guide [B] (Stepped screw ×2)

5. Thermistor bracket [C] ( ×2)

Fusing

77

Page 76

4. Replacement and Adjustment

78

• Put the fusing lower cover as shown above in order to prevent damaging the thermistor [A].

Page 77

Fusing

• The guide [A] of the fusing lower cover can be adjusted to right and left by removing the two

screws.

6. Thermistor ×2 [A] ( ×1 each)

79

Page 78

4. Replacement and Adjustment

7. Thermistor bracket [A] ( ×1, ×1)

8. Thermistor [A] ( ×1)

80

Thermostat

1. Fusing unit ( page 76)

2. Fusing upper cover ( page 76 "Thermistor")

3. Fusing lower cover ( page 76 "Thermistor")

4. Thermostat (left) [A] ( ×2)

Page 79

5. Thermostat bracket [B] ( ×3)

6. Thermostat (right) [A] ( ×2 each)

Fusing

• The thermostat (right) cannot be attached to the socket for the thermostat (left). But the

thermostat (left) can be attached to the socket for the thermostat (right).

Fusing Belt Unit

1. Fusing unit ( page 76)

2. Fusing upper cover ( page 76 "Thermistor")

3. Fusing lower cover ( page 76 "Thermistor")

81

Page 80

4. Replacement and Adjustment

4. Spring ×2 [A]

5. Guide [A] (spring ×2, hook ×2)

82

Page 81

6. Guide plate [A] (spring ×2, hook ×2)

• Push the lever backward as shown by the blue arrow in the picture above. Then pay attention

to the shape (D-shape) of the joints in order to pull the guide plate off the axis smoothly.

Fusing

7. Bracket [A] ( ×10)

83

Page 82

4. Replacement and Adjustment

8. Fusing belt unit [A] ( × 4)

• To detach easily, move the ends of the fusing belt unit sideways to release the hold. Then try to

pull it out.

84

Fusing Lamp

1. Fusing belt unit ( page 81)

Page 83

2. Pull out the fusing lamp with the base [A] from the belt assembly.

3. Remove the fusing lamp [A] from the base.

Fusing

• When you reassemble, pay attention to the shape (bracket [A] and [B]) as shown in the

picture below.

85

Page 84

4. Replacement and Adjustment

Thermopile

1. Fusing unit ( page 76)

2. Thermopile bracket [A] ( ×2)

3. Thermopile [A] ( ×1, hook ×2)

86

Page 85

Paper Feed

Paper Feed Roller

1. Pull out the Standard paper tray [A].

Paper Feed

2. Slide the Paper feed shaft [A] to the right side, and then slide the Paper feed roller [B] to

the left side, and remove it.

Friction Pad

1. Remove the Paper tray unit from the machine before removing the Friction pad.

87

Page 86

4. Replacement and Adjustment

2. Friction pad [A] (hook×2)

Bypass Tray Unit

1. Open the Front cover.

2. Remove the snaps [A] from the Shaft, and then remove the shaft. ( ×2)

88

Page 87

3. Pull out the Front cover Unit [B].

Paper Feed

Bypass Feed Roller

1. Bypass tray unit ( page 88)

2. Bypass feed roller cover [A]

• Take off the claws [B] on the back of the cover.

89

Page 88

4. Replacement and Adjustment

3. Bypass feed roller [A]

Bypass Friction Pad

1. Bypass feed roller ( page 89)

2. Guide [A] ( ×2)

3. Plate [A] ( ×4)

90

Page 89

4. Bypass friction pad [A]

Paper Size Switch

1. Standard paper tray ( page 89)

2. Paper size switch [A] ( ×1, hook×2)

Paper Feed

Paper End Sensor

1. Standard paper tray ( page 87 "Paper Feed Roller")

91

Page 90

4. Replacement and Adjustment

2. Sensor cover [A] ( ×2)

3. Paper end sensor [A] ( ×1, hook×2)

Bypass Paper End Sensor

1. Bypass tray unit ( page 88)

2. Bypass feed roller cover ( page 89 "Bypass Feed Roller")

92

Page 91

3. Bypass paper end sensor [A] ( ×1, ×1, ×1)

Bypass Bottom Plate Home Position Sensor

Paper Feed

1. Open the Front cover.

2. Cover [A] ( ×2)

3. Power switch [A] ( ×1)

93

Page 92

4. Replacement and Adjustment

4. Harness guide [B] ( ×1, ×1)

5. Harness guide [A] (hook×2)

94

6. Connectors ( ×3)

Page 93

Paper Feed

7. Ground plate [A] ( ×2)

8. Insert a flat-blade screwdriver into the outside of the Bypass bottom plate Home position

sensor [A], and then pull out.

95

Page 94

4. Replacement and Adjustment

Paper Transport

Fusing Entrance Sensor

1. Open the Front cover.

2. Sensor cover [A] (hook×2)

3. Sensor unit [A] ( ×2)

96

Page 95

4. Fusing entrance sensor [A] ( ×1, ×1)

Duplex Sensor

1. Open the Front cover.

Paper Transport

2. Transfer roller (Relay) ( page 109)

3. Roller upper cover [A] ( ×1)

97

Page 96

4. Replacement and Adjustment

4. Sensor unit [A] ( ×1)

5. Duplex sensor [A] ( ×1, hook×2)

Registration Sensor

1. Paper feed tray ( page 87)

2. Open the Front cover.

98

Page 97

3. Loosen the Transport guide [A] ( ×2 )

4. Pull the outside of the Transport guide (left/right).

Paper Transport

5. Pull the inside of the Transport guide (left/right).

99

Page 98

4. Replacement and Adjustment

6. Insert a flat-blade screwdriver into the outside of the Transport guide (left/right), and

then pull out.

7. Transport guide (left/right) [A]

8. Slide the Registration position stopper inside (left/right) [A].

100

Page 99

Paper Transport

9. Pull out the Transport guide (upper), and then remove the Sensor plate [A]. ( ×4 )

• Take care not to catch the harness between the plate and the screw hole.

10. Registration sensor [A] ( ×1, ×1 )

101

Page 100

4. Replacement and Adjustment

Reinstalling the Transport guide

1. Set the Transport guide (left/right) [A] on the Registration roller (Driven).

2. Install the Transport guide (front), and then fit the screws loosely. ( ×2)

102

3. Turn your hands to the back of the Transport guide (front), and then insert the pawls in the

Transport guide (left/right).

Loading...

Loading...