RT9396

I2C Interface PMIC with 6-Channel WLED Driver and 4-LDO

General Description

The RT9396 is a power management IC (PMIC) for

backlighting and phone camera applications. The PMIC

contains a 6-Channel charge pump white LED driver and

four low dropout linear regulators.

The charge pump drives up to 6 white LEDs with regulated

constant current for uniform intensity. Each channel

(LED1 to LED6) supports up to 25mA of current. These

6-Channels can be also programmed as 4 plus 2-Channels

or 5 plus 1-Channel with different current setting for

auxiliary LED application. The RT9396 maintains highest

efficiency by utilizing a x1/ x1.5/ x2 fractional charge pump

and low dropout current regulators. An internal 6-bit DAC

is used for backlight brightness control. Users can easily

configure up to 64 steps of LED current via the I2C interface

control.

The RT9396 also comprises low noise, low dropout

regulators, which provide up to 200mA of current for each

of the four channels. The four LDOs deliver 3% output

accuracy and low dropout voltage of 200mV @ 200mA.

Users can easily configure LDO output voltage via the I2C

interface control. The LDOs also provide current limiting

and over temperature functions.

Features

zz

Tri-Mode (x1/x1.5/x2) Charge Pump

z

zz

zz

z Maximum 25mA x 6-Channel LED Backlighting

zz

Output Current

zz

z Support Main/Sub (4+2/5+1) LED Function

zz

zz

z 64 Steps Programmable LED Current

zz

zz

z Support PWM Dimming Function

zz

zz

z Fade In/Out Via I

zz

zz

z 4 Low Dropout Regulators

zz

zz

z Maximum 200mA x 4-Channel LDO Output Current

zz

zz

z 16-Level LDO Output V oltage Setting

zz

2

zz

z I

C Programmable Independent LDO Channel

zz

2

C Control

ON/OFF Control

zz

z Over Temperature Protection

zz

zz

z Thin 24-Lead WQFN Package

zz

zz

z RoHS Compliant and Halogen Free

zz

Applications

z Cellular Phones

z PDAs and Smart Phones

Pin Configurations

(TOP VIEW)

The RT9396 is available in a WQFN-24L 3x3 package.

Ordering Information

RT9396

Package Type

QW : WQFN-24L 3x3 (COL) (W-Type)

Lead Plating System

G : Green (Halogen Free and Pb Free)

Note :

VOUT

PGND

C2N

C1N

C1P

C2P

1

2

3

4

5

6789 1110

AGND

WQFN-24L 3x3 (COL)

LED1

VIN

LED2

LDOIN

LED3

LED5

LED4

21 20 1924 2223

18

17

SCL

16

SDA

15

EN

14

PWM

13

CF

12

LDO1 LED6

LDO2

LDO3

LDO4

Richtek products are :

RoHS compliant and compatible with the current require-

ments of IPC/JEDEC J-STD-020.

Suitable for use in SnPb or Pb-free soldering processes.

DS9396-01 April 2011 www.richtek.com

1

RT9396

Marking Information

JP= : Product Code

JP=YM

DNN

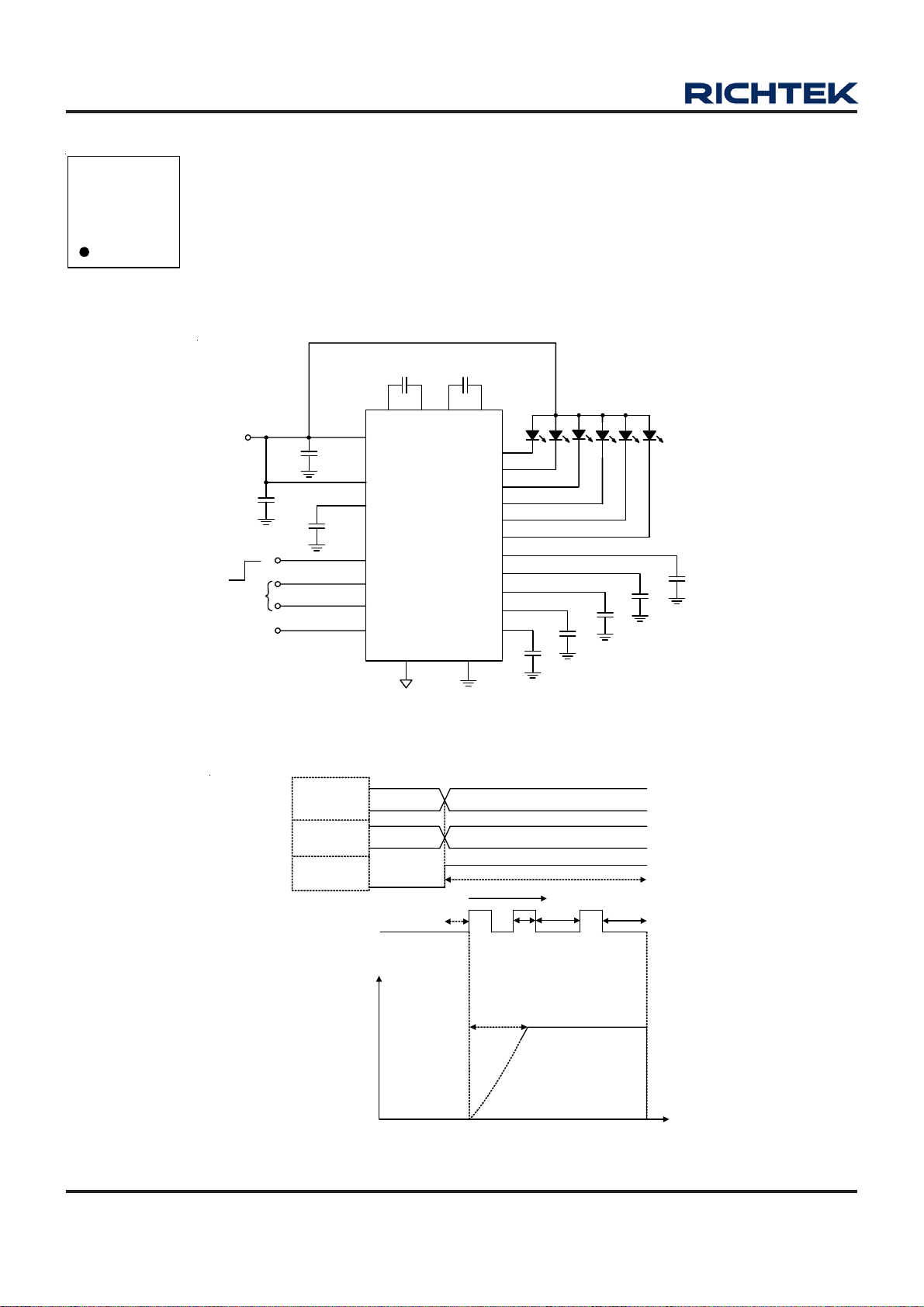

Typical Application Circuit

YMDNN : Date Code

V

Chip Enable

Timing Diagram

Note:

PWM signal rise after

internal PWMEN is

enabled

BAT

I2C

PWM

2

C

I

Reg. Addr.

2

I

C

Reg. Data

C

IN2

2.2µF

LED<1:6>

Current Level

PWMEN Reg.

Main I

C

IN1

2.2µF

C

F

1µF

010

On/Off

Main BL

Internal

PWM Pin

LED

C1P C1N C2P

7

VIN

8

LDOIN

1

3

CF

1

5

EN

1

7

SCL

1

6

SDA

1

4

PWM

00000000

00000000

[1:6]

C

FLY1

1µF

4

AGND

6

C

FLY2

1µF

3

5

2

C2N

2

3

LED1

2

2

RT9396

LED2

2

1

LED3

2

0

LED4

1

9

LED5

1

8

LED6

2

4

VOUT

1

2

LDO1

1

1

LDO2

1

0

LDO3

9

LDO4

PGND

1

01011111

6CH PWM Mode

01111101

Fade in/out time = 8ms/step, I

PWM control Backlight

THi > 0.5µs

Fade in

time

C

L2

1µF

C

L3

C

1µF

L4

1µF

[1~6] = 62/64 x 25mA

LED

PWM Dimming

0.5µs < T

I

[1~6] Current =

LED

62/64 x 25mA x PWM Duty

LO

T

< 500µs

SHD

C

L1

1µF

= 16m s

WLED

C

1µF

OUT

0

Time (s)

Figure 1. Timing Diagram

DS9396-01 April 2011www.richtek.com

2

RT9396

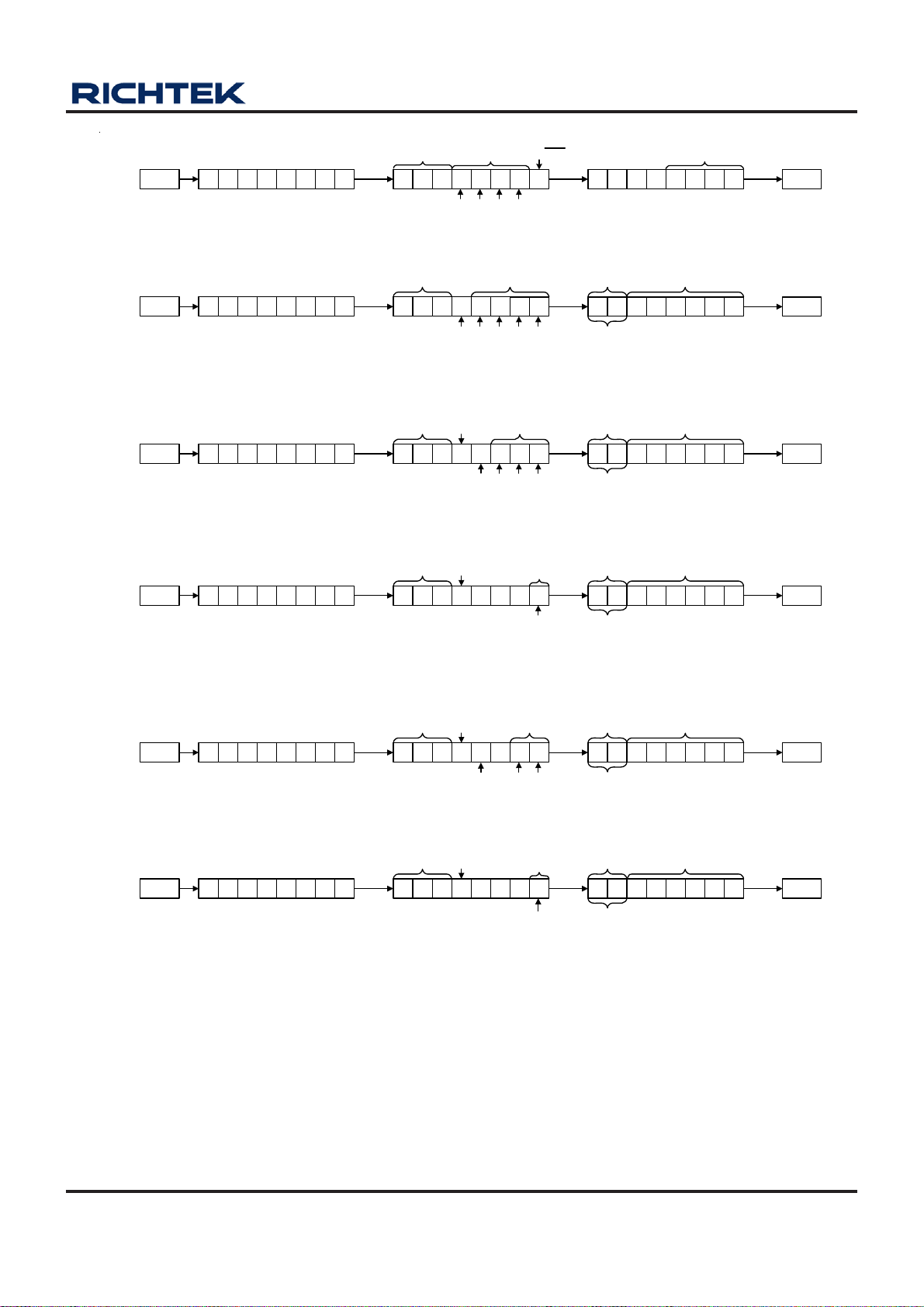

2

• I

C Writing Cycles of LDOX

2

• I

C Writing Cycles of Backlighting I (LED1~6)

1 0 1 0 1 0 0 0

2

• I

C Writing Cycles of Backlighting II (Main: LED1~5, Sub: LED6)

1 0 1 0 1 0 0 0

1 0 1 0 1 0 0 0

LDO

Address

0 0 1 B4 B3 B2 B1 B0 0 0 0 0 C3 C2 C1 C0Start Stop1 0 1 0 1 0 0 0

Backlight

Address

Backlight

Address

Backlight

Address

LDO4

PWMEN

Main

Sub

Channel

Selection

LDO3

Channel

ON/OFF

LED6

Channel

ON/OFF

PWMENPWMEN

LDO2

LED5

LED5

ON/OFF

LDO1

LED4

LED1~3

LED4

LED1~3

Channel

ON/OFF

16-step Voltage

Setting

Fade In/Out

Setting

C7 C6 C5 C4 C3 C2 C1 C00 x x x x x0 1 0 B4 B3 B2 B1 B0

Fade In/Out Setting:

01: Every Step of Fade In/Out = 8 ms

BLON

10: Every Step of Fade In/Out = 16 ms

11: Every Step of Fade In/Out = 32 ms

Fade In/Out

Setting

C7 C6 C5 C4 C3 C2 C1 C00 x x x x x0 1 1 0 B3 B2 B1 B0

Main Fade In/Out Setting:

01: Every Step of Fade In/Out = 8 ms

10: Every Step of Fade In/Out = 16 ms

Main ON

11: Every Step of Fade In/Out = 32 ms

Fade In/Out

Setting

C7 C6 C5 C4 C3 C2 C1 C00 x x x x x0 1 1 1 0 0 0 B0

64-step Current Setting

Main 64-step Current Setting

Sub 64-step Current Setting

StopStart

StopStart

StopStart

2

• I

C Writing Cycles of Backlighting III (Main: LED1~4, Sub: LED5~6)

1 0 1 0 1 0 0 0

1 0 1 0 1 0 0 0

Figure 2. Control Sequences of LDO Setting and LED Dimming

Backlight

Address

Backlight

Address

Main

Sub

Channel

ON/OFF

LED4

Channel

ON/OFF

Sub Fade In/Out Setting:

LED6

LED1~3

LED5~6

01: Every Step of Fade In/Out = 8 ms

10: Every Step of Fade In/Out = 16 ms

Sub ON

11: Every Step of Fade In/Out = 32 ms

Fade In/Out

Setting

C7 C6 C5 C4 C3 C2 C1 C00 x x x x x1 0 0 0 B2 0 B1 B0

Main Fade In/Out Setting:

01: Every Step of Fade In/Out = 8 ms

10: Every Step of Fade In/Out = 16 ms

Main ON

11: Every Step of Fade In/Out = 32 ms

Fade In/Out

Setting

C7 C6 C5 C4 C3 C2 C1 C00 x x x x x1 0 0 1 0 0 0 B0

Sub Fade In/Out Setting:

01: Every Step of Fade In/Out = 8 ms

10: Every Step of Fade In/Out = 16 ms

Sub ON

11: Every Step of Fade In/Out = 32 ms

Main 64-step Current Setting

StopStart

Sub 64-step Current Setting

StopStart

DS9396-01 April 2011 www.richtek.com

3

RT9396

Functional Pin Description

Pin No. Pin Name Pin Function

1 PGND Charge Pump Ground.

2 C2N Fly Capa ci tor 2 Negative Conne cti on.

3 C1N Fly Capa ci tor 1 Negative Conne cti on.

4 C1P Fly Capacitor 1 Positi ve Connection.

5 C2P Fly Capacitor 2 Positi ve Connection.

6 AGND Ground for LDO1 to LDO4.

7 VIN Charge Pump Power I npu t. Con nect th is pi n to LDOIN pin.

8 LDOIN LDO Power Input. Connect this pin to VIN pin.

9 LDO4 LDO4 Out put.

10 LDO3 LDO3 Out put.

11 LDO2 LDO2 Output.

12 LDO1 LDO1 Out put.

13 CF PWM Fi lter Ca paci tor Connection.

14 PWM PWM Dimming Control Input.

15 EN Chip Enable (Active High).

16 SDA I2C Data Input.

17 SCL I2C Clock Input.

18 LED6 Current Sink for LED6.

19 LED5 Current Sink for LED5.

20 LED4 Current Sink for LED4.

21 LED3 Current Sink for LED3.

22 LED2 Current Sink for LED2.

23 LED1 Current Sink for LED1.

24 VOUT Charge Pump Output. Connect a 1μF ceramic capacitor be tween VOUT and GND.

DS9396-01 April 2011www.richtek.com

4

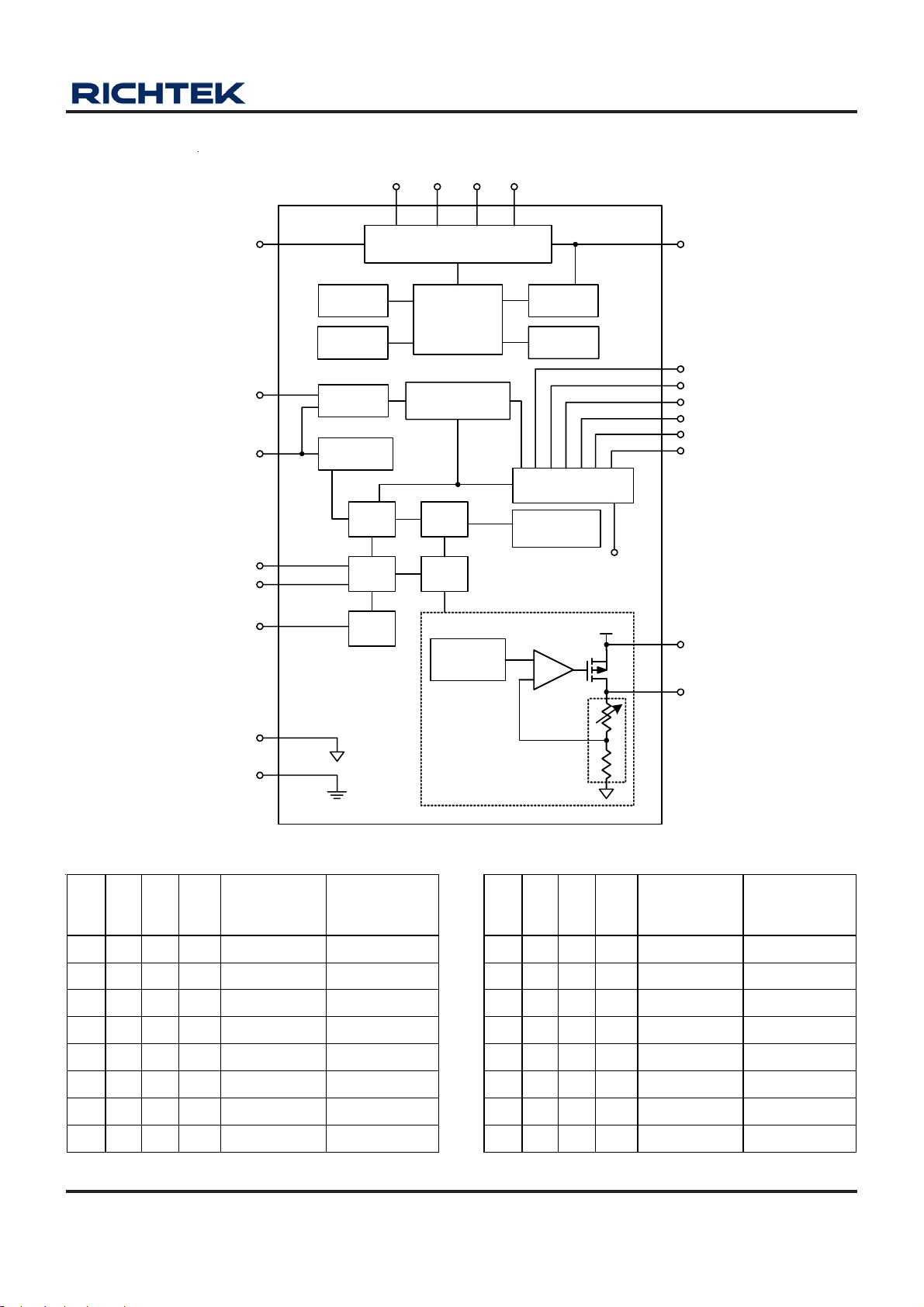

Function Block Diagram

RT9396

VIN

CF

PWM

SDA

SCL

1MHz

Oscillator

Mode

Decision

PWM

Dimming

Shutdown

Delay

LED

Ctrl.

I2C

C1P

C1N

x1/x1.5/x2

Charge Pump

Gate Driver

Current Setting

OR

Gate

LDO

Ctrl.

C2P

C2N

OVP

Soft Start

Current Source

OTP &

Current Bias

V

VOUT

LED1

LED2

LED3

LED4

LED5

LED6

OUT

EN

AGND

PGND

POR

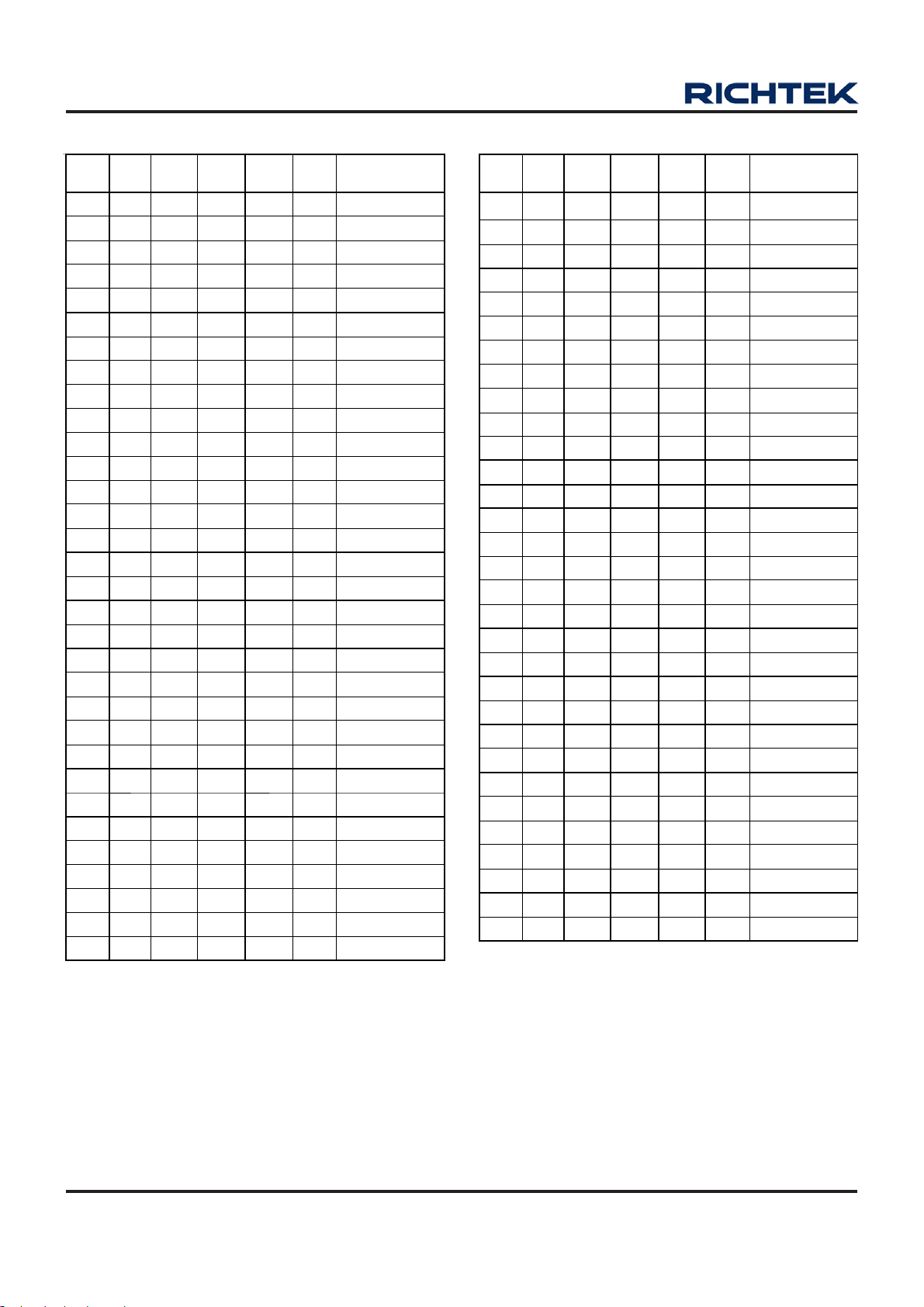

Table 1. 16-Step LDO Output Voltage Setting

C3 C2 C1 C0

LDO1 &

LDO2 Ou tp ut

Voltag e (V)

LDO3 & LDO4

Output

Volt age (V)

0 0 0 0 1 1.1

0 0 0 1 1.1 1.2

0 0 1 0 1.2 1.4

0 0 1 1 1.3 1.7

0 1 0 0 1.5 1.8

BandGap

Reference

LDOIN

+

RES Divider

Voltage Setting

x4

C3 C2 C1 C0

LDOIN

LDO1 to

LDO4

LDO1 &

LDO2 Output

Vol ta ge (V)

LDO3 & LDO4

Output

Voltage (V)

1 0 0 0 2.5 2.2

1 0 0 1 2.6 2.3

1 0 1 0 2.7 2.4

1 0 1 1 2.8 2.5

1 1 0 0 2.9 2.8

0 1 0 1 1.6 1.9

0 1 1 0 1.8 2

0 1 1 1 2.1 2.1

DS9396-01 April 2011 www.richtek.com

1 1 0 1 3 2.85

1 1 1 0 3.1 3.2

1 1 1 1 3.3 3.3

5

RT9396

Table 2. 64-Step WLED Current Setting

C5 C4 C3 C2 C1 C0

0 0 0 0 0 0 0.39

0 0 0 0 0 1 0.78

0 0 0 0 1 0 1.17

0 0 0 0 1 1 1.56

0 0 0 1 0 0 1.95

0 0 0 1 0 1 2.34

0 0 0 1 1 0 2.73

0 0 0 1 1 1 3.13

0 0 1 0 0 0 3.52

0 0 1 0 0 1 3.91

0 0 1 0 1 0 4 .3

0 0 1 0 1 1 4.69

0 0 1 1 0 0 5.08

0 0 1 1 0 1 5.47

0 0 1 1 1 0 5.86

0 0 1 1 1 1 6.25

0 1 0 0 0 0 6.64

0 1 0 0 0 1 7.03

0 1 0 0 1 0 7.42

0 1 0 0 1 1 7.81

0 1 0 1 0 0 8 .2

0 1 0 1 0 1 8.59

0 1 0 1 1 0 8.98

0 1 0 1 1 1 9.38

0 1 1 0 0 0 9.77

0 1 1 0 0 1 10 .16

0 1 1 0 1 0 10 .55

0 1 1 0 1 1 10 .94

0 1 1 1 0 0 11 .33

0 1 1 1 0 1 11 .72

0 1 1 1 1 0 12 .11

0 1 1 1 1 1 12.5

WLED

Current (mA)

C5 C4 C3 C2 C1 C0

1 0 0 0 0 0 12 .89

1 0 0 0 0 1 13 .28

1 0 0 0 1 1 14 .06

1 0 0 1 0 0 14 .45

1 0 0 1 0 1 14 .84

1 0 0 1 1 0 15 .23

1 0 0 1 1 1 15 .63

1 0 1 0 0 0 16 .02

1 0 1 0 0 1 16 .41

1 0 1 0 1 0 16.8

1 0 1 0 1 1 17 .19

1 0 1 1 0 0 17 .58

1 0 1 1 0 1 17 .97

1 0 1 1 1 0 18 .36

1 0 1 1 1 1 18 .75

1 1 0 0 0 0 19 .14

1 1 0 0 0 1 19 .53

1 1 0 0 1 0 19 .92

1 1 0 0 1 1 20 .31

1 1 0 1 0 0 20.7

1 1 0 1 0 1 21 .09

1 1 0 1 1 0 21 .48

1 1 0 1 1 1 21 .88

1 1 1 0 0 0 22 .27

1 1 1 0 0 1 22 .66

1 1 1 0 1 0 23 .05

1 1 1 0 1 1 23 .44

1 1 1 1 0 0 23 .83

1 1 1 1 0 1 24 .22

1 1 1 1 1 0 24 .61

1 1 1 1 1 1 25

WLED

Current (mA)

6

DS9396-01 April 2011www.richtek.com

Absolute Maximum Ratings (Note 1)

RT9396

z Supply Input Voltage, V

z Output Voltage, V

z Other Pins ----------------------------------------------------------------------------------------------------------------- −0.3V to 6V

z Power Dissipation, P

OUT

---------------------------------------------------------------------------------------------- −0.3V to 6V

IN

-----------------------------------------------------------------------------------------------------------------------------------------------

@ T

D

= 25°C

A

−6V to 0.3V

WQFN-24L 3x3 ----------------------------------------------------------------------------------------------------------- 1.667W

z Package Thermal Resistance (Note 2)

WQFN-24L 3x3, θJA----------------------------------------------------------------------------------------------------- 60°C/W

z Junction Temperature --------------------------------------------------------------------------------------------------- 150°C

z Lead Temperature (Soldering, 10 sec.) ----------------------------------------------------------------------------- 260°C

z Storage Temperature Range ------------------------------------------------------------------------------------------- −65°C to 150°C

z ESD Susceptibility (Note 3)

HBM (Human Body Mode) --------------------------------------------------------------------------------------------- 2kV

MM (Machine Mode) ---------------------------------------------------------------------------------------------------- 200V

Recommended Operating Conditions

z Supply Input Voltage, V

z Junction Temperature Range ------------------------------------------------------------------------------------------ −40°C to 125°C

z Ambient Temperature Range ------------------------------------------------------------------------------------------ −40°C to 85°C

, V

IN

------------------------------------------------------------------------------------ 2.8V to 5V

LDOIN

(Note 4)

Electrical Characteristics

(V

= V

IN

specification)

Input Power Supply

Under -Voltage Lock out Threshold V

Under -Voltage Lockout Hysteresis ΔV

Quies cent of x1 Mode I

Quies cent of x2 Mode I

Shutdown Current I

Charge Pump WLED Driver

Backlight I

Backlight Current Matching −3 0 3 %

Dropou t Voltage -- 70 -- mV

Charge Pump

Oscilla tor F requency -- 100 0 -- kHz

LDOIN

= 3.6V, C

= 2.2μF, C

IN

= 1μF, C

OUT

FLY1

= C

= 1μF, VF = 3.5V, I

FLY2

= 25mA, TA = 25°C, unless otherwise

LEDx

Parameter Symbol Test Conditions Min Typ Max Unit

VIN Rising. 1.8 2.1 2.5 V

UVLO

-- 200 -- mV

UVLO

Q_x1

Q_x2

SHDN

Accuracy −5 0 5 %

LEDx

LDO[1:4] OFF

x2 Mode, V

LDO[1:4] OFF

VIN = 5V, VEN = 0V -- 0.5 1 μA

x1 Mode, V

= 5V, No Load,

IN

= 3.5V, No Load,

IN

-- 1 2 mA

-- 3.5 5 mA

x1 Mode to x1.5 Mode

Transition Voltage (V

falling)

IN

Mode Transiti on Hysteresis Vf = 3.5V, I

Over Voltag e Protecti on V

V

= 3.5V, I

f

= 4.5V 5.2 5.5 5.8 V

IN

= 150mA -- 3.6 3.75 V

OUT

= 150mA -- 250 -- mV

OUT

T o be continued

DS9396-01 April 2011 www.richtek.com

7

RT9396

Parameter Symbol Test Conditions Min Typ Max Unit

LDO1 to L DO4

Input Voltag e VIN = 2.8V to 5V 2.8 -- 5 V

Dropou t Voltag e VIN ≥ 2.8 V, I

Ou tput voltage Range By I2C Sett ing 1.1 -- 3. 3 V

VOUT Accuracy I

Line Regulation

Load Regulation 1mA < I

Current Limit I

R

LIM

= 1mA −3 3 %

OUT

= (V

V

IN

OUT

> 2.5V, whichever is larg er

V

IN

OUT

= 1Ω 230 350 600 mA

LOAD

Qu ies cent Current IQ 4-Chan nel All Turn O n -- 140 200 μA

Shutdown Current I

-- -- 1 μA

SHDN

Thermal Shutdown TSD -- 160 -- °C

Thermal Shutdown Hysteresis ΔTSD -- 20 -- °C

I2C interface

EN, SDA,SCL Pull Low Current IEN -- 5 10 μA

EN, SDA, SCL

Threshold Voltage

Logic-High VIH 1.4 -- -- V

Logic-Low V

-- -- 0.4 V

IL

SDA Output Low Voltage VCL -- -- 0.4 V

SCL Clock Frequ enc y f

SCL Clock Low Period t

SCL Clock High Period t

Hold Time START Co ndition t

Setup Time fo r Repe at START t

SDA Data Setup Time t

SDA Data HOLD Time t

Setup Time fo r STOP Condition t

Bus Free Time Between STOP and

START Condition

-- -- 400 kHz

SCL

1.3 -- -- μs

Low

0.6 -- -- μs

High

HD_STR

SU_STR

SU_DAT

HD_DAT

SU_STO

t

BUF

0.6 -- -- μs

0.6 -- -- μs

100 -- -- ns

0.05 -- 0.9 μs

0.6 -- -- μs

1.3 -- -- μs

PWM Dimming Control

PW M Dimmin g Frequency 1 -- 200 kHz

= 200 mA -- -- 200 mV

OUT

+ 0.3V) to 5V or

-- -- 0.2 %/V

< 200mA -- -- 0.6 %

PWM Dimming High Time 0.5 -- -- μs

PW M Dimmin g Lo w Time 0.5 -- 500 μs

Shutdown Delay 16 -- -- ms

Note 1. Stresses listed as the above “Absolute Maximum Ratings” may cause permanent damage to the device. These are for

stress ratings. Functional operation of the device at these or any other conditions beyond those indicated in the

operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions for extended

periods may remain possibility to affect device reliability.

Note 2. θ

Note 3. Devices are ESD sensitive. Handling precaution is recommended.

Note 4. The device is not guaranteed to function outside its operating conditions.

8

is measured in the natural convection at TA = 25°C on a high effective thermal conductivity four-layer test board of

JA

JEDEC 51-7 thermal measurement standard.

DS9396-01 April 2011www.richtek.com

)

Typical Operating Characteristics

For Charge Pump

Efficiency vs. Input Voltage

100

90

80

70

60

50

40

Efficiency (%)

30

20

10

0

2.5 3 3.5 4 4.5 5 5.5

Input Voltage (V)

Vf = 3.5V, I

LEDx

= 25mA

RT9396

LED Current vs . Input Voltage

30

29

28

27

26

25

24

23

22

21

20

LED Current (mA)

19

18

17

16

15

2.533.544.555.5

LED1

LED2

LED3

LED4

LED5

LED6

Vf = 3.5V

Input Voltage (V)

x1 Mode Quiescent Current vs. Input Voltage

3.0

2.5

2.0

1.5

1.0

Quiesent Cu rrent (mA)

0.5

0.0

2.533.544.555.5

Input Voltage (V)

Shutdown Current vs. Input Voltage

0.650

0.625

x2 Mode Quiescent Current vs. Input Voltage

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

Quiesent Current (mA)

1.0

0.5

0.0

2.5 3 3.5 4 4.5 5 5.5

Input Voltage (V)

x2 Mode Inrush Current Response

V

OUT

(1V/Div)

0.600

C1P

(2V/Div)

0.575

Shutdown Current (μA

0.550

2.5 3 3.5 4 4.5 5 5.5

Input Voltage (V)

I

IN

(500mA/Div)

VIN = 2.8V, Vf = 3.5V, I

Time (100μs/Div)

LEDx

= 25mA

DS9396-01 April 2011 www.richtek.com

9

RT9396

V

OUT

(1V/Div)

C1P

(2V/Div)

I

IN

(200mA/Div)

x1.5 Mode Inrush Current Response

VIN = 3V, Vf = 3.5V, I

Time (100μs/Div)

LEDx

= 25mA

V

OUT

(20mV/Div)

V

IN

(20mV/Div)

V

C1P

(2V/Div)

Ripple & Spike

VIN = 3.35V, Vf = 3.5V, I

Time (500ns/Div)

LEDx

= 25mA

10

DS9396-01 April 2011www.richtek.com

For LDO

RT9396

3.34

3.33

3.32

3.31

3.30

Output Voltage (V)

3.29

3.28

SCL

(5V/Div)

Output Voltage vs. Temperature

LDO2

LDO3

LDO1

LDO4

VIN = 4.3V, V

-50-25 0 25 50 75100125

LDO

= 3.3V

Temperature (°C)

Power On

250

200

150

100

Dropout Voltage (V)

SCL

(5V/Div)

Dropout Voltage v s . Load Current

LDO1

LDO3

LDO4

50

0

0 50 100 150 200 250

LDO2

Load Current (mA)

Power On

V

LDO1

(2V/Div)

V

LDO2

(2V/Div)

I

IN

(500mA/Div)

V

IN

(V)

V

LDO2

(20mV/Div)

V

LDO1

(20mV/Div)

4.8

3.8

VIN = 4.3V, V

LDO1

= V

LDO2

= 3.3V, I

Time (25μs/Div)

Line Transient Response

V

= V

LDO1

LDO2

= 2.8V, I

= 200mA

LOAD

V

= 3.8V to 4.8V

IN

LOAD

= 200mA

V

LDO3

(2V/Div)

V

LDO4

(2V/Div)

I

IN

(500mA/Div)

4.8

V

IN

(V)

3.8

V

LDO4

(20mV/Div)

V

LDO3

(20mV/Div)

VIN = 4.3V, V

LDO3

= V

LDO4

= 3.3V, I

Time (25μs/Div)

Line Transient Response

V

= V

LDO4

= 2.8V, I

LDO3

= 200mA

LOAD

V

= 3.8V to 4.8V

IN

LOAD

= 200mA

Time (100μs/Div)

Time (100μs/Div)

DS9396-01 April 2011 www.richtek.com

11

RT9396

V

LDO1

(100mV/Div)

I

LDO1

(200mA/Div)

V

LDO2

(100mV/Div)

I

LDO2

(200mA/Div)

20

10

0

-10

-20

-30

-40

-50

PSRR (dBm)

-60

-70

-80

-90

-100

Load Transient Response

VIN = 4.3V, V

Time (10μs/Div)

LDO1

= V

LDO2

= 3.3V

PSRR

VIN = 4.3V, V

10 100 1000 10000 100000 1000000

Frequency (Hz)

= 3.3V, I

LDO

LOAD

= 200mA

V

LDO3

(100mV/Div)

I

LDO3

(200mA/Div)

V

LDO4

(100mV/Div)

I

LDO4

(200mA/Div)

(0.2mV/Div)

Load Transient Response

VIN = 4.3V, V

Time (10μs/Div)

LDO3

= V

LDO4

Noise

VIN = 4.3V, V

Time (50ms/Div)

= 3.3V, No Load

LDO

= 3.3V

(0.2mV/Div)

12

Noise

VIN = 4.3V, V

Time (50ms/Div)

LDO

= 3.3V, I

LOAD

= 50mA

DS9396-01 April 2011www.richtek.com

Applications Information

RT9396

The RT9396 is an I2C interface PMIC with one 6-Channel

charge pump white LED driver and four LDOs. The charge

pump provides 6-Channel low dropout voltage current

source to regulate up to 6 white LEDs. For high efficiency,

the RT9396 implements a smart mode transition for charge

pump operation. The four LDOs are capable of delivering

low dropout voltage of 200mV @ 200mA with 3% output

accuracy. The I2C dimming function allows for a 64 steps

LED brightness control and 16 steps LDO voltage control.

Input UVLO

An under voltage lockout (UVLO) function is provided to

prevent unstable occurrences during start-up. The UVLO

threshold is set at an input rising voltage of 2.1V typically

with a hysteresis of 0.2V. The input operating voltage range

of the RT9396 is from 2.8V to 5V. An input capacitor should

be placed near the VIN pin to reduce ripple voltage. It is

recommended to use a ceramic 2.2μF or larger capacitance

as the input capacitor.

Soft-Start

The RT9396 includes a soft-start circuit to limit the inrush

current at power on and mode switching. The soft-start

circuit limits the input current before the output voltage

reaches a desired voltage level.

Mode Decision

The RT9396 uses a smart mode decision method to

choose the working mode for maximum efficiency. The

charge pump can operate at x1, x1.5 or x2 mode. The

mode decision circuit senses the output voltage and LED

voltage to determine the optimum working mode.

Power Sequence

In order to assure normal operating condition, the input

voltage and EN should be active before the RT9396 receives

the I2C signal, as shown in Figure 3. The RT9396 can be

shut down by pulling EN low. When EN is reset, the I2C

signal also needs to be re-applied to resume normal

operating condition.

EN

SDA

SCL

……………

……………

Figure 3. The Power Sequence

I2C Compatible Interface

Figure 4 shows the timing diagram of the I2C interface.

The RT9396 communicates with a host (master) using

the standard I2C 2-wire interface. The two bus lines of

SCL and SDA must be pulled high when the bus is not in

use. Internal pull-up resistors are installed. After the START

condition, the I2C master sends 8-bits data, consisting of

seven address bits and a following data direction bit (R/

W). The RT9396 address is 1010100 (54h) and is a receive-

only (slave) device. The second word selects the register

to which the data will be written. The third word contains

data to write to the selected register.

Figure 2 shows the writing information for voltage of the

four LDOs and current of the six LEDs. In the second

word, the sub-address of the four LDOs is “001” and the

sub-address of the LED Driver for different dimming modes

are respectively “010”, “011” and “100”. For the LDO

output voltage setting, bits B1 to B4 represent each LDO

channel respectively where a “1” indicates selected and

a “0” means not selected. The B0 bit controls on/off (1/

0) mode for the selected LDO channel(s). Then, in the

third word, bits C0 to C3 control a 16-step setting of LDO1

to LDO4. The voltage values are listed in Table 1.

For LED dimming, there are three operating modes

(Backlight I, Backlight II and Backlight III) to select from

by writing respectively “010”, “011” and “100” into the

first three bits of the second word. When Backlight I is

selected, all six LEDs have the same behavior. Their 64-

step dimming currents are set by bits C0 to C5, which

are listed in Table 2. The bits C6 and C7 determine the

fade in/out time of each step as shown in Figure 2. For

Backlight II and Backlight III, two sets of LEDs, called

main and Sub, can work separately and turn on solely. It

should be noticed that no matter which mode is selected,

the B0 bit must be a “1” in order for te LEDs in the main

set to be turned on.

DS9396-01 April 2011 www.richtek.com

13

RT9396

In Backlight II, the main set consists of LED1 to LED5

and LED6 is the Sub set. In Backlight III, the main set

consists of LED1 to LED4, while the Sub set comprises

of LED5 and LED6. The RT9396 has another dimming

function called PWM dimming, which can be enabled by

selecting the B4 bit in Backlight I, B3 bit in Backlight II,

The 1st Word (Chip

Address, R/W)

2

I

C Address

S P

SCL

SDA

12345678912

0B4

S = Start Condition

W = Write (SDA =“0")

R = Read (SDA =“1")

ACK = Acknowledge

P = Stop Condition

R/W

The 2nd Word (Sub

Address, Data)

Channel

Sub

selection

Adress

B7 B6 B5 B4 B3 B2 B1 B0 C7 C6C5C4 C3 C2C1C0Start StopA6 A5 A4 A3 A2 A1 A0 0

A0A1A2A3A4A5A6 B5 C7 C6B3ACK ACK ACK

B7

ON/OFF

3456789

B6 B2 B1 B0

Figure 4. I2C Communication Sequence

and B2 bit in Backlight III. Once the function is enabled, a

PWM signal is applied to the PWM pin to perform PWM

dimming. The LED current value is the current value set

by C0 to C5 multiplied by the duty cycle. It is important to

note that the PWM dimming function applies only to the

main set.

The 3rd Word (data)

Data IITest Mode

123456789

C5 C4 C3 C2 C1 C00

Flying Capacitors Selection

To attain better performance of the RT9396, the selection

of peripherally appropriate capacitor and value is very

important. These capacitors determine some parameters

such as input/output ripple voltage, power efficiency and

maximum supply current by charge pump. To reduce the

input and output ripple effectively, low ESR ceramic

capacitors are recommended. For LED driver applications,

the input voltage ripple is more important than the output

voltage ripple. The input ripple is influenced by the input

capacitor, CIN. Increasing the input capacitance can further

reduce the ripple. The flying capacitors ,C

FLY1

and C

FLY2

determine the supply current capability of the charge pump,

which in turn influences the overall efficiency of the system.

A lower capacitance will improve efficiency, but it will limit

the LED's current at low input voltage. For a 6 x 25mA

load over the entire input voltage range of 2.8V to 5V, it is

recommended to use a 1μF ceramic capacitor for C

C

FLY2

and C

OUT

.

FLY1

LDO Capacitor Selection

Like for any low dropout regulator, the external capacitors

used for the RT9396 must be carefully selected for

regulator stability and performance. A capacitor with

capacitance larger than 1μF is placed close to the RT9396

supply input to reduce ripple. The value of this capacitor

can be increased without limit. The input capacitor must

be located at a distance of not more than 0.5 inch away

from the input pin of the IC and tied to a clean analog

ground. Any good quality ceramic or tantalum capacitor

can meet the requirement. The capacitor with larger value

and lower ESR (equivalent series resistance) provides

better PSRR power supply rejection ratio and line-transient

response. The output capacitor must meet minimum

requirement for both capacitance and ESR in all LDO's

applications. For stability consideration, a ceramic

capacitor with minimum capacitance of 1μF and minimum

ESR of 20mΩ is recommended for the output capacitor.

For space-saving and performance consideration, the

RT9396 is designed to work with ceramic capacitor of low

ESR. However, because of it's wide ESR range tolerance,

the RT9396 can work stably with output capacitor of other

,

types as well. Figure 5 shows the stable region for various

load current and output capacitor conditions. Large output

capacitance can reduce noise and improve load transient

response, stability, and PSRR. The capacitor must be

located at a distance not more than 0.5 inch away from

the VOUT pin and tied to a clean analog ground.

14

DS9396-01 April 2011www.richtek.com

RT9396

)

Region of Stable C

100

10

ESR (Ω)

ESR (Ω)

OUT

OUT

1

0.1

0.01

Region of Stable C

Region of Stable C

0.001

0 50 100 150 200 250 300

Unstable Range

Stable Range

Simulation Verify

ESR vs. Load Current

OUT

V

= 5V

IN

C

= C

IN

OUT1

C

= 1uF/X7R

OUT2

2.00

=

1.75

1.50

1.25

1.00

0.75

0.50

0.25

Maximum Power Dissipation (W

0.00

0 25 50 75 100 125

Four- Layer PCB

Ambient Temperature (°C)

Load Current (mA)

Figure 5. Stable C

ESR Range

OUT

Thermal Considerations

For continuous operation, do not exceed absolute

maximum junction temperature. The maximum power

dissipation depends on the thermal resistance of IC

package, PCB layout, rate of surrounding airflow and

temperature difference between junction to ambient. The

maximum power dissipation can be calculated by following

the formula :

P

D(MAX)

= (T

J(MAX)

− TA ) / θ

JA

Figure 6. Derating Curve for RT9396 Package

Layout Considerations

The RT9396 is a high-frequency switched-capacitor

converter. For best performance, careful PCB layout is

necessary. Place all peripheral components as close as

possible to the IC. Place C

CL4, C

FLY1

, and C

near to VIN, LDOIN, VOUT, LDO1,

FLY2

IN1

, C

IN2

, C

, CL1, CL2, CL3,

OUT

LDO2, LDO3, LDO4, C1P, C1N, C2P, C2N, and GND pin

respectively. A short connection is highly recommended.

The following guidelines should be strictly followed when

designing a PCB layout for the RT9396.

Where T

the ambient temperature and θ

thermal resistance.

is the maximum junction temperature, T

J(MAX)

is the junction to ambient

JA

is

A

The exposed GND pad must be soldered to a large

ground plane for heat sinking and noise prevention. The

through-hole vias located at the exposed pad is

For recommended operating conditions specification of

connected to the ground plane of internal layer.

the RT9396, the maximum junction temperature is 125°C

and TA is the ambient temperature. The junction to ambient

thermal resistance θJA is layout dependent. For

WQFN-24L 3x3 package, the thermal resistance θJA is

60°C/W on the standard JEDEC 51-7 four-layer thermal

test board. The maximum power dissipation at TA = 25°C

can be calculated by the following formula :

P

= (125°C − 25°C) / (60°C/W) = 1.667W for

D(MAX)

WQFN-24L 3x3 package

The maximum power dissipation depends on operating

ambient temperature for fixed T

resistance θJA. For RT9396 package, the derating curve

and thermal

J(MAX)

in Figure 6 allows the designer to see the effect of rising

ambient temperature on the maximum power dissipation

VIN traces should be wide enough to minimize

inductance and handle high currents. The trace running

from the battery to the IC should be placed carefully

and shielded strictly.

Input and output capacitors must be placed close to the

IC. The connection between pins and capacitor pads

should be copper traces without any through-hole via

connection.

The flying capacitors must be placed close to the IC.

The traces running from the pins to the capacitor pads

should be as wide as possible. Long traces will also

produce large noise radiation caused by the large dv/dt

on these pins. Short trace is recommended.

allowed.

DS9396-01 April 2011 www.richtek.com

15

RT9396

All the traces of LEDs and VIN running from pins to

LCM module should be shielded and isolated by the

ground plane. The shielding prevents the interference of

high frequency noise coupled from the charge pump.

Output capacitor must be placed between

GND and VOUT to reduce noise coupling

from charge pump to LEDs.

GND

The flying capacitors

must be placed close

to the IC.

VIN traces should

be wide enough.

Battery

GND

PGND

C2N

C1N

C1P

C2P

LED3

VOUT

LED1

LED2

21 20 1924 2223

1

2

3

4

5

6789 1110

VIN

LDO4

AGND

LDOIN

GND

LED5

LED4

18

17

SCL

16

SDA

15

EN

14

PWM

13

CF

12

LDO3

LDO2

LDO1 LED6

Input capacitors must be

placed close to the IC.

Figure 7. PCB Layout Guide

GND

16

DS9396-01 April 2011www.richtek.com

Outline Dimension

RT9396

Symbol

A 0.700 0.800 0.028 0.031

A1 0.000 0.050 0.000 0.002

A3 0.175 0.250 0.007 0.010

b 0.150 0.250 0.006 0.010

D 2.900 3.100 0.114 0.122

E 2.900 3.100 0.114 0.122

e 0.400 0 .01 6

L 0.350 0.450

L1 0.950 1.050

Dimensions In Millimeters Dimensions In Inches

Min Max Min Max

0.014 0.018

0.037 0.041

W-Type 24L QFN 3x3 (COL) Package

Richtek Technology Corporation

Headquarter

5F, No. 20, Taiyuen Street, Chupei City

Hsinchu, Taiwan, R.O.C.

Tel: (8863)5526789 Fax: (8863)5526611

Information that is provided by Richtek Technology Corporation is believed to be accurate and reliable. Richtek reserves the right to make any change in circuit

design, specification or other related things if necessary without notice at any time. No third party intellectual property infringement of the applications should be

guaranteed by users when integrating Richtek products into any application. No legal responsibility for any said applications is assumed by Richtek.

DS9396-01 April 2011 www.richtek.com

Richtek Technology Corporation

Taipei Office (Marketing)

5F, No. 95, Minchiuan Road, Hsintien City

Taipei County, Taiwan, R.O.C.

Tel: (8862)86672399 Fax: (8862)86672377

Email: marketing@richtek.com

17

Loading...

Loading...