Reznor RIHN 30 Installation Manual

Form I-RIH (4-16)

Obsoletes Form I-RIH (10-14)

Installation/Operation/Maintenance

Applies to: Models RIH, RIHV, RIHVN, and RIHVL

Gas-Fired High-Intensity Infrared Heaters

Models RIH/RIHV

WARNING

Improper installation, adjustment, alteration, service or maintenance can

cause serious property damage, injury, or death. Read these instructions

thoroughly before installing or servicing this equipment.

WARNING

Gas-red appliances are not designed for use in hazardous atmospheres

containing ammable vapors or combustible dust, or atmospheres

containing chlorinated or halogenated hydrocarbons. See Hazard Intensity

Levels, page 2.

FOR YOUR SAFETY

If you smell gas:

1. Open Windows

2. Don’t touch electrical switches

3. Extinguish any open ame

4. Immediately call your gas supplier.

The use and storage of gasoline or other ammable vapors and liquids in the vicinity

of this appliance is hazardous.

P/N 131793R11, Page 1

Table of Contents

1.0 General ...............................2-4

1.1 Hazard Labels and Notices ..........................2

1.2 General Information ......................................2

1.3 Warranty ........................................................3

1.4 Installation Codes .........................................3

2.0 Location ..............................4-5

2.1 Recommended Mounting Height and

Distance from a Wall .................................4

2.2 Ventilation Requirements .............................5

3.0 Receiving................................5

4.0 Dimensions and Clearances ..............6-7

4.1 Dimensions....................................................6

4.2 Clearances .....................................................6

5.0 Suspending the Unit.....................7-9

6.0 Gas Supply ...........................9-10

6.1 Gas Supply Line ............................................9

6.2 Gas Pressure ..............................................10

7.0 Electrical ............................10-13

7.1 Electrical Supply .........................................10

7.2 Electrical Requirements by Voltage

and Control Types ...................................11

7.3 Wiring Diagrams .........................................12

8.0 Ignition and Operation ....................14

9.0 Commissioning and Startup ...............15

10.0 Accessories............................16

11.0 Maintenance and Service..............17-19

11.1 Maintenance Procedures .........................17

11.2 Troubleshooting Guide .............................18

Index .....................................19

INSTALLATION RECORD ....................20

1.0 General

1.1 Hazard Labels and Notices

There are warning labels on the heater and throughout this manual. For your safety,

read the denitions below and comply with all boxes labeled CAUTION, WARNING,

and DANGER during installation, operation, maintenance, and service.

HAZARD INTENSITY LEVELS

1. DANGER: Failure to comply will result in severe personal injury or

death and/or property damage.

2. WARNING: Failure to comply could result in severe personal injury or

death and/or property damage.

3. CAUTION: Failure to comply could result in minor personal injury or

death and/or property damage.

1.2 General Information

Model RIH/RIHV infrared heaters are designed and manufactured in compliance with

the American National Standards Institute. They are design-certied by the Canadian

Standards Association to ANSI Standards for installation in the United States and to

CAN/CSA Standards for installation in Canada. These units are approved for indoor

commercial and industrial installation only. Installation should be done by a qualied

agency in accordance with these instructions and in compliance with all codes and

requirements of authorities having jurisdiction.

DANGER

These infrared heaters are operated without venting. Comply

with ventilation requirements in Paragraph 2.2, page 5.

Model RIH and RIHV series heaters SHOULD NOT BE USED in the following

applications:

• Enclosed swimming pool areas

• Areas with contaminated atmospheres

• Outdoor applications

• Residential applications

• Areas requiring explosion-proof equipment

• Process heating applications

P/N 131793R11, Page 2

Infrared heaters should not be installed in buildings with uninsulated metal roof decks.

Uninsulated metal roof decks will cause condensation of water vapor (contained in

the unvented heater ue gas) on the inside of the building. Metal roof decks must be

insulated using built-up insulation and roong on the exterior or inside insulation that is

not permeable to water vapor. Interior insulation that is permeable to water vapor must

be completely sealed with a vapor barrier.

High Altitude

Heaters are manufactured for use at the specic altitude range stated on the heater

rating plate. Do not install a heater that is not rated for the correct altitude.

1.3 Warranty

WARRANTY IS VOID IF……

• Unit is used in atmosphere containing ammable vapors; atmosphere

containing chlorinated or halogenated hydrocarbons; or atmosphere containing

explosive dust.

• Unit is installed without proper clearance to combustible materials or in a

location where the heater controls can be subjected to ambient temperatures

in excess of 150°F (66°C) or below -40°F (-40°C).

• Unit is installed at an angle not approved for that model.

• Unit is installed for other than space heating application. NOTE: Use of this

heater for processing applications voids the certication and the warranty.

• Unit is installed for residential use. This heater is NOT for residential use.

• Unit is installed outdoors.

• Unit is installed in an enclosed swimming pool area.

• Unit is altered. Units are completely factory assembled and tested.

Special Space

Heating Installations

1.4 Installation Codes

These units must be installed in accordance with local building codes. In the absence

of local codes, in the United States, the unit must be installed in accordance with the

National Fuel Gas Code ANSI Z223.1/NFPA 54 (latest edition). A Canadian installation

must be in accordance with the CAN/CSA B149.1, Natural Gas and Propane Installation

Code. These codes are available from CSA Information Services, 1-800-463-6727.

Local authorities having jurisdiction should be consulted before installation is made to

verify local codes and installation procedure requirements.

All electrical wiring including electrical grounding must be in accordance with the

National Electric Code ANSI/NFPA No. 70 (latest edition) or, in Canada, the Canadian

Electrical Code, Part I and Part II, CAN/CSA C22.1.

The installing contractor must be familiar with all of the various requirements and is

responsible for installing the heater in compliance with the applicable codes.

Aircraft Hangars: In the United States, the heaters must be installed in accordance

with ANSI/NFPA 409 (latest edition). Publications are available from the National Fire

Protection Association, Batterymarch Park, Quincy, MA 02269. In Canada, installations

in an aircraft hangar must comply with CAN/CSA-B149.1. Both the ANSI/NFPA 409

(latest edition) and the CAN/CSA-B149.1 (latest edition) specify that the heater shall

not be located in an area of an aircraft hangar where it may be subjected to physical

damage by aircraft, cranes, moveable scaffolding, or other objects.

NFPA 409 (latest edition) species a clearance of 10 feet (3M) to the bottom of the

heater from the highest surface of the wings or engine enclosures of the highest aircraft

which may be housed in the hangar. The measurement shall be made from the wing or

engine enclosure, whichever is higher from the oor, to the bottom of the heater.

CAN/CSA-B149.1 (latest edition) species that a heater located in an aircraft storage

or servicing area shall be installed so that no portion of an aircraft that can occupy the

area is within the "clearance to combustible material" as marked on the heater rating

plate.

Both NFPA 409 (latest edition) and CAN/CSA-B149.1 (latest edition) specify a minimum

clearance of eight feet (2.5M) from the oor to the heater in other sections, such as

ofces or shops, that communicate with the aircraft hangar.

P/N 131793R11, Page 3

1.0 General

(cont'd)

1.4 Installation

Codes (cont'd)

Special Space Heating Installations (cont'd)

Repair Garages - U.S.: In the United States, heaters installed in public garages must

be in accordance with the Standard for Motor Fuel Dispensing Facilities and Repair

Garages, NFPA 30A (latest edition) (Formerly the Standard for Repair Garages (NFPA

88B). Heat producing appliances using gas or oil fuel listed for use in garages shall be

permitted to be installed in lubrication rooms, service rooms, or fuel dispensing ares

where Class I liquids are dispensed or transferred, provided the equipment is installed

at least 8 ft (2.4M) above the oor.

Parking Structures - U.S. - These overhead heaters are suitable for use in parking

structures when installed in accordance with the Standard for Parking Structures,

NFPA 88A (latest edition). All ames associated with the heating equipment shall be

located a minimum of 18 inches (500mm) below the oor-ceiling assembly or 18 inches

(500mm) above the oor.

Garages - Canada - In Canada, these overhead heaters are suitable for use in garages

when installed in accordance with the Canadian Natural Gas and Propane Installation

Code,CAN/CSA B149.1 (latest edition). The minimum clearance from the radiant face

of the infrared heater to the upper surface of the highest vehicle shall not be less than

the certied clearance from combustible material as indicated on the heater (installed in

a garage or a car wash). Provision shall be made to maintain these minimum specied

clearances by an interlock that shuts off the gas supply until the required clearances

have been re-established, a protective bar, or a device that provides a warning when

the clearances are not being maintained. Where an infrared heater is installed in a

garage and the clearance from combustible material cannot be maintained when the

vehicle is raised on a hoist, an electrical interlock shall be provided to shut off the

burner and prevent its operation until the required clearance has been re-established.

2.0 Location

2.1 Recommended Mounting Height and Distance from a Wall

NOTE: Clearances to combustibles must be observed; see Paragraph 4.2.

Heaters should be located with respect to building construction and equipment to

provide accessibility for servicing and cleaning.

Do not angle the heater more than 30°. Unit must be level.

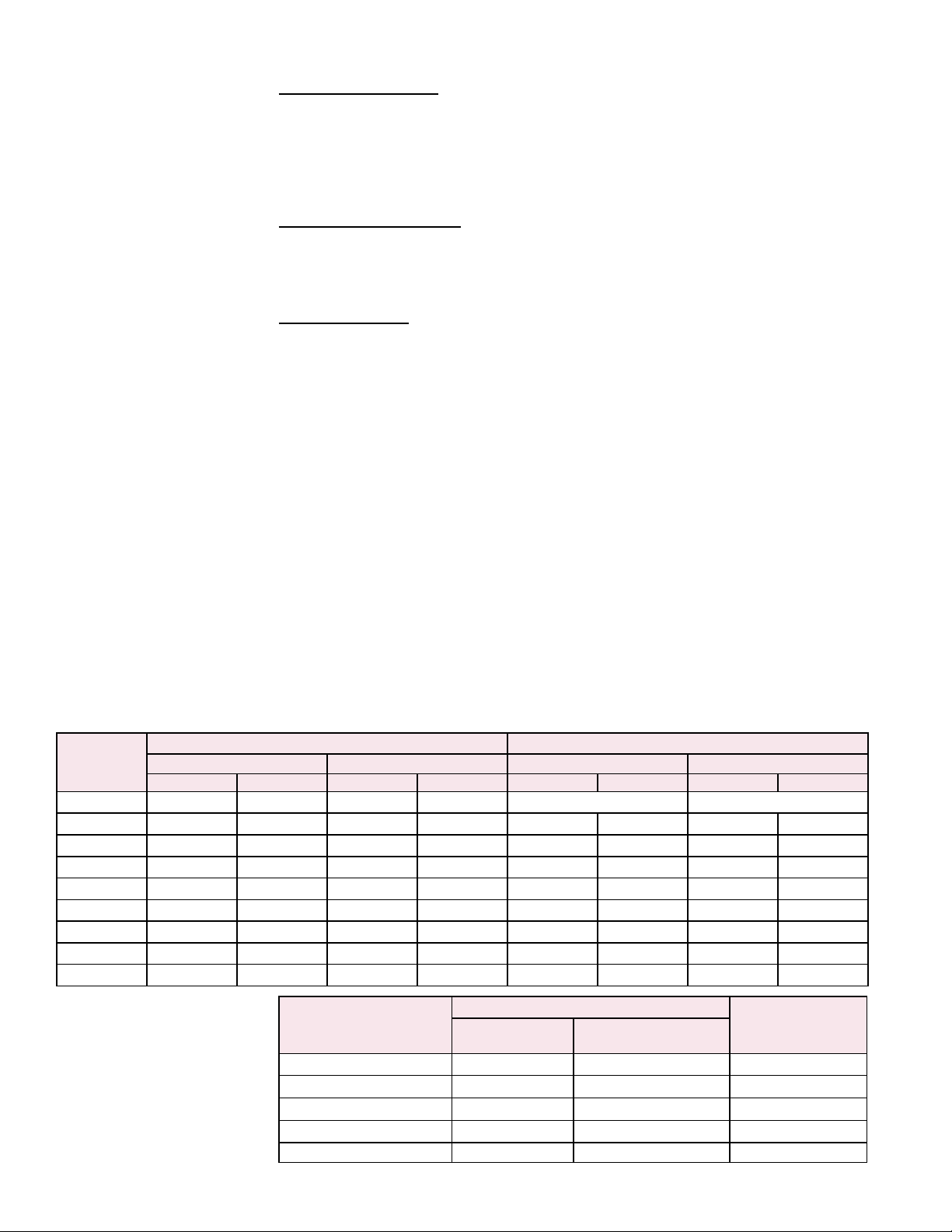

Recommended Mounting Height (feet and meters)

Lower mounting height may be used if personnel are not kept directly under the heater.

With Standard Reector With Parabolic Reector, Option DM2

Model

RIHN 30 11.0 - 13.0 3.4 - 4.0 10.0 - 12.0 3 - 3.7 N/A N/A

RIHL 50 13.5 - 15.5 4.1 - 4.7 12.5 - 14.5 3.8 - 4.4 15.5 - 18.5 4.7 - 5.6 14.0 - 17.0 4.3 - 5.2

RIHN 60 14.5 - 16.5 4.4 - 5.0 13.0 - 15.0 4.0 - 4.6 16.0 - 20.0 4.9 - 6.1 15.0 - 18.0 4.6 - 5.5

RIHVL 90 16.0 - 18.5 4.9 - 5.6 14.5 - 17.0 4.4 - 5.2 19.5 - 22.5 5.9 - 6.9 17.5 - 20.5 5.2 - 6.2

RIHVN 100 17.0 - 19.5 5.2 - 5.9 15.0 - 17.5 4.6 - 5.3 20.5 - 23.5 6.2 - 7.2 18.5 - 21.5 5.6 - 6.6

RIHVL 120 17.5 - 21.0 5.3 - 6.4 15.5 - 18.5 4.7 - 5.6 21.5 - 25.0 6.6 - 7.6 20.0 - 23.0 6.1 - 7.0

RIHVN 150 18.5 - 22.5 5.6 - 6.9 16.5 - 20.0 5.0 - 6.1 24.0 - 27.5 7.3 - 8.4 21.5 - 24.5 6.6 - 7.5

RIHVN 160 19.0 - 23.0 5.8 - 7.0 17.0 - 20.5 5.2 - 6.2 25.0 - 28.5 7.7 - 8.7 22.5 - 25.5 6.9 - 7.8

RIHVN 200 20.5 - 25.0 6.2 - 7.6 18.5 - 22.5 5.6 - 6.9 27.0 - 31.0 8.2 - 9.4 24.5 - 28.0 7.5 - 8.5

Recommended

Distances (feet and

meters) for Units

Mounted at a 5° Angle

at 5° Angle at 30° angle at 5° Angle at 30° angle

ft M ft M ft M ft M

Applies to Units

Mounted at a 5° Angle

RIHN 30 8 ft (2.4M) 5 ft (1.5M) 90 ft (27.4M

RIHL 50 & RIHN 60 12 ft (3.7M) 9 ft (2.7M) 100 ft (30.5M)

RIHVL 120 18 ft (5.5M) 14 ft (4.3M) 115 ft (35.1M)

RIHVN 150 20 ft (6.1M) 15 ft (4.6M) 120 ft (36.6M)

RIHVN 160 & RIHVN 200 24 ft (7.3M) 20 ft (6.1M) 130 ft (39.6M)

With Standard

Distance from the Wall

Reector

Reector, Option DM2

With Parabolic

Maximum Distance

Between Heater

Rows

P/N 131793R11, Page 4

2.2 Ventilation

Requirements

WARNING

Insufcient ventilation may result in health problems, carbon

monoxide poisoning, or death. Always vent enclosed spaces

and buildings according to national, state, provincial, and

local codes.

These heaters are the unvented type. Products of combustion generated are

released into the space being heated. Sufcient ventilation of fresh air is required to

provide adequate air for efcient combustion and to dilute and remove the products

of combustion.

In the United States, the minimum intake and exhaust air openings shall provide for

not less than 4 CFM per 1,000 BTUH (0.38m3 a minute per kW). In the United States,

this may be accomplished by either gravity or mechanical means. Both exhaust fans

and inlet air openings are required in tight buildings. Exhaust openings for removing

ue products shall be above the level of the heater (ANSI Z223.1/NFPA 54, section

10.18, Infrared Heaters).

Air for combustion, ventilation, and dilution of ue gases shall be obtained by application

of one of several methods described in the National Fuel Gas Code, ANSI Z223.1/

NFPA 54, section 9.3, Air for Combustion and Ventilation.

The ventilation technical information outlined in the current ASHRAE Handbooks

should be observed when locating vents. When mechanical means are provided to

supply and exhaust, a positive interlock with the heater thermostat must be provided by

the installer so that the heater cannot operate unless the supply and exhaust system

is operating.

Mechanical exhaust fans are typically located at high points of the building. For at

roof areas, a series of small exhausters should be distributed over the roof areas and

interlocked with various heating zones. Local codes may permit the use of humidistat

control to remove water vapor and products of combustion. Humidistat settings will

typically be in the 40 to 55% relative humidity range.

Fresh air intake openings are typically located high on the building sidewalls at or above

the level of the heaters. One square inch of net free inlet area per 1,000 BTUH (22cm2

per kW) is required. Multiple inlets, well distributed, should be used and should direct

air upward to prevent drafts at oor level. Inlets are typically limited to 1 to 2 square feet

(900-1800cm2) in size. Total area required can be computed by dividing exhaust

CFM by 500 feet per minute. (Total area required can be computed by dividing

exhaust cubic meters per minute by 152 meters per minute.)

In Canada, the Natural Gas and Propane Installation Code CAN/CSA B149.1 (latest

edition) requires the use of mechanical ventilation. The heater shall be provided with

mechanical ventilation for combustion and ventilation air:

(1) that is so located that products of combustion from each heater are

effectively removed outdoors;

(2) that has a ventilation volume of at least 3 CFM per 1,000 BTUH (0.29m3

a minute per kW) for natural gas and 4 CFM per 1,000 BTUH (0.38m3 a

minute per kW) for LP/propane; and

(3) is sufcient to maintain the level of carbon dioxide at less than 5000 ppm

measured 6 ft (2M) above the work area.

3.0 Receiving

Check for any damage that may have been incurred during shipment.

If damage is found, document the damage with the transporting agency and immediately

contact your distributor. If you are an authorized Distributor, follow the FOB freight

policy procedures.

P/N 131793R11, Page 5

4.0 Dimensions and Clearances

B

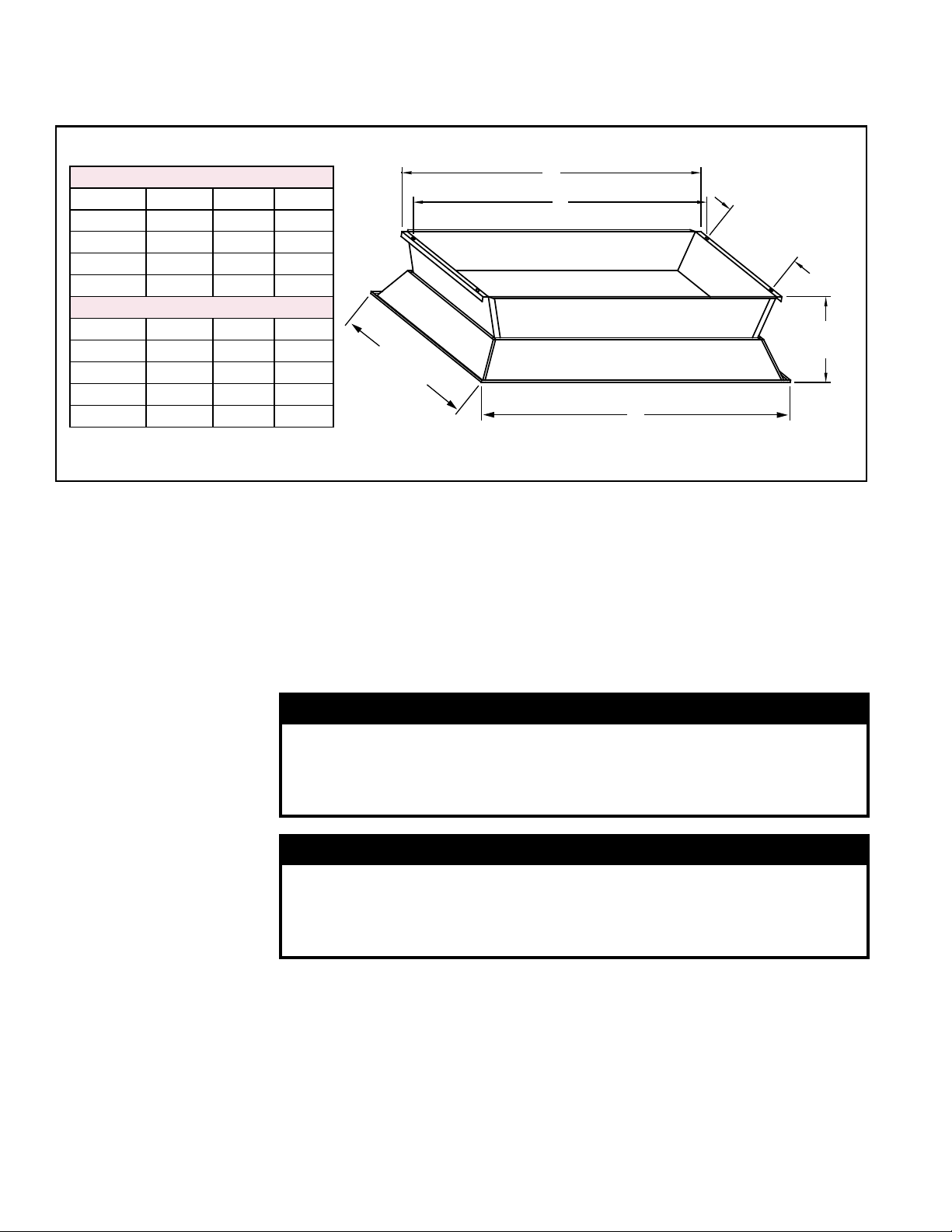

4.1 Dimensions

FIGURE 1 - Model RIH Dimensions - inches and (mm)

Dimensions - inches

Size A B C

30, 50, 60 15-5/16 16-5/8 14-5/8

90, 100 23-15/16 25-1/4 23-1/4

120, 150 32-9/16 33-7/8 31-7/8

160, 200 41-3/16 42-1/2 40-1/2

Dimensions - mm

Size A B C

30, 50, 60 389 422 371

90, 100 608 641 591

120, 150 827 860 810

160, 200 1046 1080 1029

NOTE: Four (4) mounting holes 3/8” (9.5mm) diameter for balanced

suspension are located by dimensions C x 13” (330mm).

4.2 Clearances

This heater model must be mounted with minimum clearances between the combustion

surface and combustibles. The stated clearance to combustibles represents a surface

temperature of 90°F (50°C) above room temperature. Building materials with a low

heat tolerance (such as plastic, vinyl siding, canvas, tri-ply, etc.) may be subject to

degradation at lower temperatures. It is the installer's responsibility to assure that

adjacent materials are protected from degradation.

Locate the heater with respect to building construction and equipment so to provide

sufcient clearance and accessibility for servicing and cleaning.

23-23/32"

(603mm)

A

C

13"

(330mm)

8-1/2"

(216mm)

WARNING

Single or multi-heater placement must be such that continuous

operation of the heater or heaters will not cause combustible

materials or materials in storage to attain a temperature in excess

of 150°F (66°C). See Hazard Levels, page 2.

WARNING

Under no circumstances should this heater be installed in

a combustible atmosphere or in a location where the heater

controls can be subjected to ambient temperatures in excess of

150°F (66°C). See Hazard Levels, page 2.

It is recommended that more distance than the minimum clearance be maintained

above the unit whether or not the construction is combustible. This will reduce and/or

eliminate hot spots and possible staining of painted ceiling surfaces. If the unit must

be close to the roof or ceiling, interpose a non-combustible bafe (twice the size of the

reector) between the unit and the roof or ceiling. Allow at least 2" (52mm) between the

roof or ceiling and the non-combustible bafe. Allow at least 12" (305mm) between the

non-combustible bafe and the top of the heater.

To assure clearances to combustibles are maintained, signs must be posted specifying

the maximum stacking height of material under and near the heater.

P/N 131793R11, Page 6

Loading...

Loading...