Rexel RSS1830, RSS2230, RSX1530 ILLUSTRATED PARTS LIST

PAPER SHREDDER MERCURY

PAPER SHREDDER

MERCURY

RSS1830,RSS2230,RSX1530

ILLUSTRATED

PARTS LIST

Acco Service Division,

Halesowen Industrial Estate, Hereward Rise, Halesowen, West Midlands B62 8AN

Telephone 0845 658 6600 Fax 0121 501 3991

D Mead Issue 1 Page 1 of 24 February 2007

PAPER SHREDDER MERCURY

ILLUSTRATED PARTS MANUAL

MERCURY SHREDDERS – 230 VOLTS

TABLE OF CONTENTS

Index Page 2 & 3

Preface Page 4

Machine Description Page 5

SPARES ASSEMBLIES

Model RSS1830 S2-4 Pages 6

RSS2230 S2-6

Model RSX1530 S3 Page 7

D Mead Issue 1 Page 2 of 24 February 2007

PAPER SHREDDER MERCURY

TABLE OF CONTENTS COMT’D

SECTION A. TO REMOVE CUTTING HEAD FROM CABINET Page 8 & 9

SECTION B. TO REMOVE TOP COVER FROM CUTTING HEAD. Page 10.

SECTION C. TO ADJUST ANTI JAM MECHANISM. Page 11.

SECTION D. TO REMOVE ANTI JAM MODULE. Page 11.

SECTION E. TO REPLACE PRONG AND ACTUATOR ASSEMBLY. Page 12.

SECTION F. TO REPLACE REAR ANTI JAM CASTING Page 12.

AND PAPER SENSOR

SECTION G. TO REPLACE FRONT ANTI JAM CASTING Page 13

AND PAPER SENSOR

SECTION H. TO REPLACE GEARS Page 13 & 14

SECTION I. TO REPLACE MOTOR CAPACITOR Page 15

SECTION J. TO REPLACE MOTOR Page 15

SECTION K. TO REPLACE MAIN PCB Page 15

SECTION L. TO REPLACE CD FLAP AND PCB Page 16

SECTION M. TO REPLACE INFEED ILLUMINATION UNIT Page 17

SECTION N. TO REPLACE LED PCB Page 17

SECTION O. TO REPLACE SWITCH PCB AND SWITCH UNIT Page 17

SECTION P. TO REPLACE MAINS LEAD Page 18

SECTION Q. TO REPLACE BIN SENSING SWITCH Page 18

SECTION R. TO REPLACE BIN FULL SENSORS Page 19

LOGIC DIAGRAM Page 21 & 22

WIRING DIAGRAM Page 23

AMENDMENT SHEET Page 24

SERVICE INSTRUCTIONS.

FLOW DIAGRAM – OPERATING SEQUENCE Page 20

D Mead Issue 1 Page 3 of 24 February 2007

PAPER SHREDDER MERCURY

PREFACE

SERVICE PREPARATION

This manual provides the instructions for the replacement of all the components that

may become worn or damaged during normal usage of the machine.

“Illustrated Parts Lists”

replacement part numbers with supporting

diagrams to show the location of the components.

“Service Instructions”

servicing procedure with supporting

pictorial diagrams for added clarity

WARNING

1. Check the machine RATING PLATE DETAILS are compatible with the electrical

mains supply.

2. Disconnect the electrical mains supply before removing any covers.

3. The machine MUST have a sound Electrical Earth Connection.

NOTE: THE ELECTRIC MOTOR IS PROTECTED BY AN AUTOMATIC

THERMAL OVERLOAD CUT-OUT

Product Testing after Servicing or Repair.

IMPORTANT. If any electrical component has been changed, an electrical connection

broken and remade, or any wiring disturbed, the product being repaired or serviced

must be flash tested or PAT tested. This test must be carried before a product is

handed back or returned to the customer or returned to stock. The test must be

appropriate for the machine being repaired. E.g. double insulated of earthed. A

competent person should conduct the test and keep a log of all machines tested, the

serial number of the machine, the details of the test, the test results and th e date the

test was carried out.

- For each machine give full details of the

- For each machine give the recommended

D Mead Issue 1 Page 4 of 24 February 2007

PAPER SHREDDER MERCURY

DESCRIPTION

A range of straight and crosscut shredders using either built up or solid shafts.

ANTI JAM FEATURE

All models include an anti jam feature if documents above a set thickness

are fed into the infeed slot. The documents will not have entered the

cutters. The thickness is equal to the nominal sheet capacity of 70gsm

paper. The documents can then be easily removed from the machine and

sheets removed. The device will also stop the machine if an increase in

document thickness is detected while shredding again allowing easy

removal of the access sheets before they enter the cutters.

The document thickness is measured by a trigger coupled to an accurate

measuring sensor.

A pair of rollers and servo operated pressure pads are incorporated to

prevent movement of the paper, passing through the cutters, generating

false signals.

It is possible to reverse the machine if necessary.

D Mead Issue 1 Page 5 of 24 February 2007

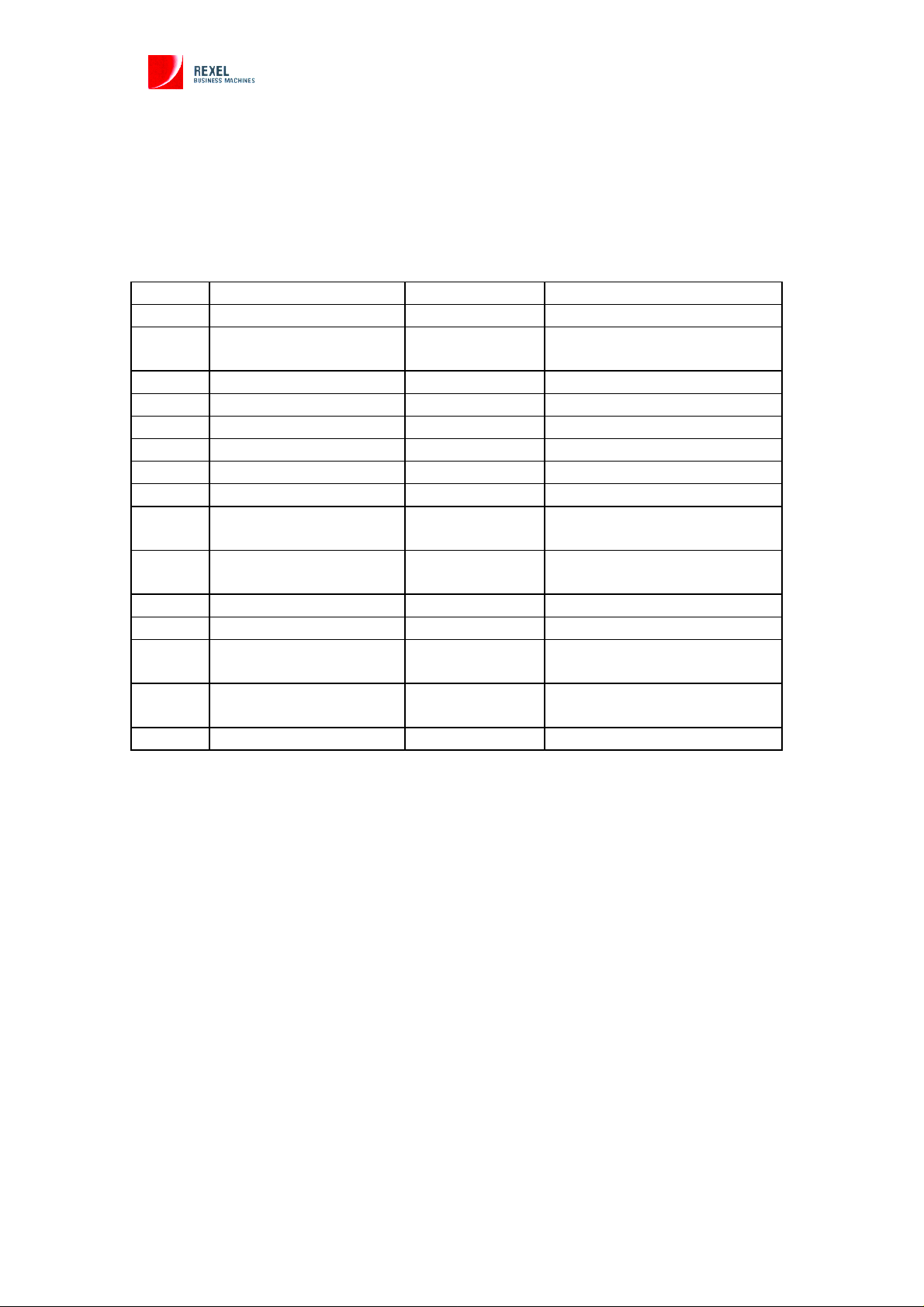

PAPER SHREDDER MERCURY

MODEL RSS1830 S2-4 & RDS2230 S2-6 SPARES ASSEMBLIES

Section Description Part No Comments

D Anti Jam Module. 1001314

E Prong and Actuator

Assy.

F Anti jam Assy Rear. 1001316 Including paper Sensor

G Anti jam Assy Front 1001318 Including paper Sensor

H Gear Kit 1001324 Including circlips

I Motor Capacitor 1001322

J Motor 1001320

K Main PCB 1001326

L CD Flap and Switch

PCB Assy

M Infeed Illumination

Unit

N LED PCB 1001311

O Switch PCB Assy 1001310 Including switch buttons.

P Mains lead assy 1001330

Q Bin Sensor Micro

Switch

R Bin Full Sensor Kit. 1001327

1001315

1001312

1001313

UK

1001331

1001329

EU

D Mead Issue 1 Page 6 of 24 February 2007

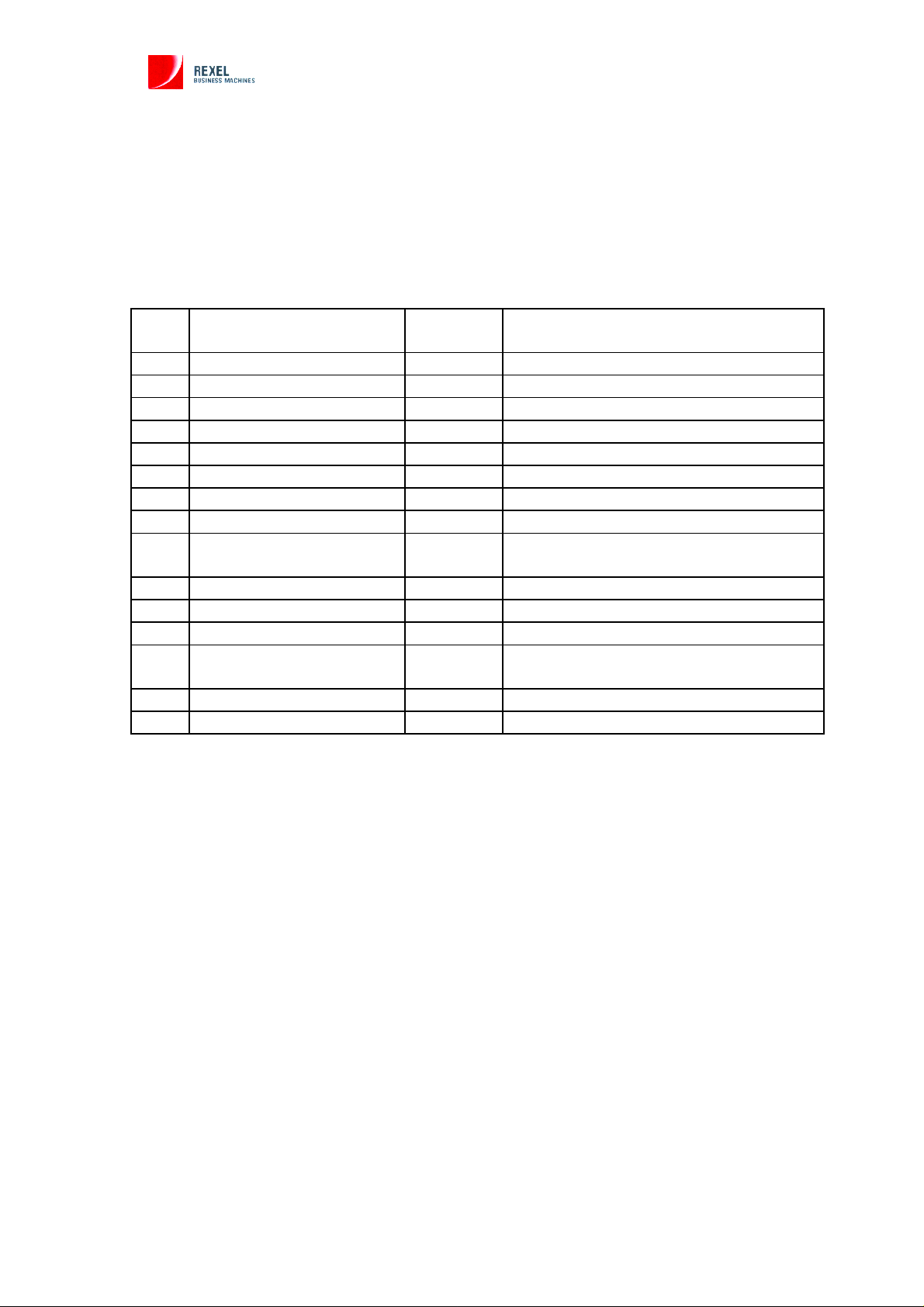

PAPER SHREDDER MERCURY

MODEL RSX1530 SPARES ASSEMBLIES

Secti

on

D Anti Jam Module. 1001314

E Prong and Actuator Assy. 1001315

F Anti jam Assy Rear. 1001317 Including paper Sensor

G Anti jam Assy Front 1001319 Including paper Sensor

H Gear Kit 1001325 Including circlips

I Motor Capacitor 1001323

J Motor 1001321

K Main PCB 1001326

L CD Flap and Switch PCB

M Infeed Illumination Unit 1001313

N LED PCB 1001311

O Switch PCB Assy 1001310 Including switch buttons.

P Mains lead assy 1001330

Q Bin Sensor Micro Switch 1001329

R Bin Full Sensor Kit. 1001328

Description Part No Comments

1001312

Assy

UK

1001331

EU

D Mead Issue 1 Page 7 of 24 February 2007

PAPER SHREDDER MERCURY

REPAIR PROCEDURES FOR MODELS RSS1830 S2-4, RDS2230

S2-6 & RSX1530.

A. TO REMOVE CUTTING HEAD FROM CABINET

1. Slide out waste bin and put to one side.

2. Ensure CD flap is in the position for shredding CDs. Fig 1.

Fig 1

3. Release mains cable from clips at rear of cabinet. Fig 2.

Fig 2

4. Turn unit upside down so that it is resting on the top of the cutting

head.

D Mead Issue 1 Page 8 of 24 February 2007

Loading...

Loading...