Retsch ZM 200 User Manual

Operating Instructions Ultra Centrifugal Mill

Type ZM 200

Retsch GmbH, 42781 HaanRetsch-Allee 1-5, Germany, 08.02.2012 0003

|

|

Information on these operating instructions............................................... |

|

3 |

|

|

Warnings................................................................................................ |

|

3 |

|

|

Repairs .................................................................................................. |

|

3 |

|

|

Safety.............................................................................................................. |

|

4 |

|

|

Safety instructions.................................................................................. |

|

4 |

|

|

Safety directive summarised, part 1 ....................................................... |

|

5 |

|

|

Safety directive summarised, part 2 ....................................................... |

|

6 |

|

|

Confirmation .................................................................................................. |

|

7 |

|

|

Technical specifications ............................................................................... |

|

8 |

|

|

Intended use .......................................................................................... |

|

8 |

|

|

Maximum feed quantity .......................................................................... |

|

8 |

|

|

Maximal feed grain size.......................................................................... |

|

8 |

|

|

Maximal end fineness achievable........................................................... |

|

8 |

|

|

Drive output............................................................................................ |

|

8 |

|

|

Rotor speed ........................................................................................... |

|

8 |

|

|

ZM200 emissions ................................................................................... |

|

9 |

|

|

Materials and analyses of the grinding tools ........................................... |

|

9 |

|

|

Protection systems................................................................................. |

|

9 |

|

|

Protective equipment ............................................................................. |

|

9 |

|

|

Operating mode ..................................................................................... |

|

9 |

|

|

Device dimensions ................................................................................. |

|

9 |

|

|

Base area required................................................................................. |

|

9 |

|

|

Transport and assembly ............................................................................... |

|

10 |

|

|

Packaging .............................................................................................. |

|

10 |

|

|

Transport................................................................................................ |

|

10 |

|

|

Temperature fluctuations........................................................................ |

|

10 |

|

|

Intermediate storage .............................................................................. |

|

10 |

|

|

Assembly ............................................................................................... |

|

10 |

|

|

Requirements for the assembly site ....................................................... |

|

11 |

|

|

Electrical connection .............................................................................. |

|

11 |

|

|

Serial interfaces ..................................................................................... |

|

12 |

|

|

Operation ....................................................................................................... |

|

13 |

|

|

Connect the power ................................................................................. |

|

13 |

|

|

Opening / closing / emergency unlocking of the grinding chamber ......... |

13 |

|

|

|

Inserting the grinding tools ..................................................................... |

|

15 |

|

|

Operation via the ZM200 display unit ..................................................... |

|

16 |

|

|

Symbols in the display unit..................................................................... |

|

16 |

|

|

Adjustment options via the display menu ............................................... |

|

17 |

|

|

LANGUAGES......................................................................................... |

|

17 |

|

|

Incorrect language selection .................................................................. |

|

17 |

|

|

Pre-selecting the SPEED ....................................................................... |

|

17 |

|

|

Preselection of the starting time ............................................................. |

|

17 |

|

|

STARTING the ZM200 ........................................................................... |

|

18 |

|

|

OPENING MECHANISM........................................................................ |

|

18 |

|

|

AUTOMATIC STOP ............................................................................... |

|

18 |

|

|

ALARM .................................................................................................. |

|

18 |

|

|

SERVICE ............................................................................................... |

|

18 |

|

|

CONTRAST/BRIGHTNESS ................................................................... |

|

18 |

|

|

DATE / TIME.......................................................................................... |

|

19 |

|

|

Stand-by monitor.................................................................................... |

|

19 |

|

|

Feeding in comminution material ........................................................... |

|

19 |

|

|

Unsuitable comminution material ........................................................... |

|

19 |

|

|

Suitable comminution material ............................................................... |

|

20 |

|

|

Comminution methods ........................................................................... |

|

20 |

|

|

Ultra-fine grinding with Conidur ring sieves............................................. |

|

20 |

|

|

Pre-comminution with round hole ring sieves ......................................... |

|

20 |

|

|

Comminution by cold grinding ................................................................ |

|

21 |

|

|

Comminution with distance ring sieves................................................... |

|

21 |

|

|

Comminution of extremely small volumes .............................................. |

|

21 |

|

|

Assembly of accessories .............................................................................. |

|

22 |

|

|

Paper filter with retainer ......................................................................... |

|

22 |

|

|

Installation procedure ............................................................................. |

|

22 |

|

|

Cyclone separator with collecting container............................................ |

|

23 |

|

|

Assembly procedure .............................................................................. |

|

23 |

|

|

Distributor DR100 with tripod.................................................................. |

|

24 |

|

|

Assembly procedure .............................................................................. |

|

24 |

|

|

General points ............................................................................................... |

|

25 |

|

|

Cleaning................................................................................................. |

|

25 |

|

|

Maintenance .......................................................................................... |

|

25 |

|

|

Adjusting the lock if the cassette cover leaks ......................................... |

|

26 |

|

|

Copyright................................................................................................ |

|

26 |

|

|

Changes................................................................................................. |

|

26 |

|

|

Error messages on the display..................................................................... |

|

27 |

|

|

F03 to F12.............................................................................................. |

|

27 |

|

|

F13 to F26.............................................................................................. |

|

28 |

|

|

Appendix ............................................................................... |

following pages |

|

08.02.2012 |

Retsch GmbH |

2 |

|

0003 |

Information on these operating instructions

The present operating instructions for the Ultra Centrifugal Mill of type ZM200 provide all the necessary information on the headings contained in the table of contents.

They act as a guide for the target group(s) of readers defined for each topic for the safe use of the ZM200 in accordance with its intended purpose. Familiarity with the relevant chapters on the part of each target group(s) of readers is essential for the safe and proper use of the equipment.

The present technical documentation has been designed both as a source of reference and as a learning tool. Each chapter is a self-contained unit.

The operating instructions do not contain any repair instructions. Should repairs ever become necessary, please contact your supplier or talk directly to Retsch GmbH. http://www.retsch.com

Warnings

The following signs are used to warn of hazards:

Personal injuries

Material damage

Material damage

Repairs

These operating instructions do not contain any repair instructions. In the interests of your own safety, repairs should only be performed by Retsch GmbH, an authorised representative or by Retsch service technicians.

In this case, please notify the following:

Your local Retsch representative

Your supplier

Retsch GmbH direct

Your address for service:

08.02.2012 |

Retsch GmbH |

3 |

0003 |

Safety

The ZM200 is a modern, high-performance product manufactured by Retsch GmbH. It incorporates the latest technology. The machine is entirely safe in its operation when used for the intended purpose and in accordance with the present technical documentation.

Safety instructions

You, as the owner/operator, must ensure that the persons who are entrusted to work on the ZM200:

have read and understood all the regulations contained in the chapter on safety,

have made themselves familiar, before starting work, with all the operating instructions and regulations relevant to that particular target group,

have unrestricted access to the technical documentation for this machine at all times,

new personnel must have familiarised themselves with the safe use of the ZM200 and its intended purpose before starting work with the machine, either through verbal instruction by a competent person and / or with the help of the present technical documentation.

Incorrect operation can result in injuries to persons and damage to property. You bear the responsibility for your own safety and that of your staff.

Ensure that no unauthorised persons have access to the ZM200.

As a precaution, have your staff certify in writing that they have received instruction in the operation of the ZM200. A draft for such a form can be found at the end of the chapter on safety.

We reject herewith any and all claims relating to personal injury or material damage which result from the failure to comply with the following safety instructions.

08.02.2012 |

Retsch GmbH |

4 |

0003 |

Safety directive summarised, part 1

Safety instructions

We reject herewith any and all claims relating to personal injury or material damage which result from the failure to comply with the following safety instructions.

Intended use

Do not make any modifications to the machine and only use Retsch approved spares and accessories.

The conformity to the European guidelines declared by Retsch otherwise loses its validity. It furthermore leads to the loss of all warranty claims.

Packaging

Please retain the packaging for the duration of the warranty since, in case of complaint, returning in unsuitable packaging can jeopardize your warranty claims.

Transport

During transportation, do not subject the ZM200 to impacts, jolts or vibrations. The electronic and mechanical components could otherwise be damaged.

Temperature fluctuations

In case of wide temperature fluctuations (during shipment by air, for instance), protect the ZM200 from condensation. The electronic components could otherwise be damaged.

Scope of supply

If the shipment is incomplete and / or has suffered transport damage, you must notify the forwarder and

Retsch GmbH immediately (within 24 hours). Under certain circumstances, claims lodged at a later date may not be considered valid.

Ambient temperature :

When the ambient temperature exceeds or falls below that specified, the electronic and mechanical components may be damaged, and performance data changed to an unknown extent.

Air humidity :

At a higher air humidity, the electronic and mechanical components may be damaged, and performance data changed to an unknown extent.

Electrical connection / connecting the power

Failure to observe the values on the data plate can cause damage to electronic and mechanical components.

Inserting the grinding tools

Set the openings for the torsion lock on the collecting vessel and the ring sieve over the torsion lock pin.

Otherwise the ZM200 cannot be started.

When cold grinding, do not forcibly remove the plug-on rotor, which jams easily for physical reasons, but rather wait for the temperature to level out.

Forced removal causes damage to the motor shaft and the rotor.

Do not forget to re-install the cassette cover.

Without the cassette cover, the motor is blocked by the thrust pins in the housing cover.

08.02.2012 |

Retsch GmbH |

5 |

0003 |

Safety directive summarised, part 2

Feeding in comminution material

Do not feed in comminution material until the machine has been started.

Mechanical components could be damaged when starting from standstill with the comminution material already fed in.

When feeding in comminution material, the anti-rebound fitting must be installed.

Danger that the comminution material will be sprayed about.

Unsuitable comminution material

Some comminution materials form explosive atmospheric mixtures. Check the properties of your comminution material.

Explosion hazard

Dusty comminution material can escape through the filling hopper during grinding. Use suction extractors if the comminution material is toxic or otherwise hazardous to health.

Danger of breathing in dust hazardous to health.

Comminution methods

Do not pre-grind without the ring sieve.

The collecting base can suffer serious damage

The rotor can damage the cassette cover.

Comminution by cold grinding

When cold grinding with liquid nitrogen, always fit the anti-rebound fitting X into the filling hopper.

Danger of injuries to eyes and skin from extreme freezing.

Wear safety gloves and goggles, The temperature of the liquid nitrogen is -196°C

Danger of injuries to eyes and skin from extreme freezing.

When cold grinding, do not forcibly remove the plug-on rotor, which jams easily for physical reasons, but rather wait for the temperature to level out.

Forced removal causes damage to the motor shaft and the rotor.

Paper filter with retainer

The volume able to be taken up by the paper filter depends on the density of the grinding material and the hole width of the ring sieve.

The paper filter can be destroyed by overfilling and by the weight of the comminution material

Cleaning

Do not clean the ZM200 with flowing water.

Mortal danger from electric shock

Only use a cloth dampened with water. solvents are not permitted.

Maintenance

The easy running of roller 1 on the trannion piece is essential for secure closing of the housing cover.

These operating instructions do not contain any repair instructions. In the interests of your own safety, repairs should only be performed by Retsch GmbH, an authorised representative or by Retsch service technicians.

08.02.2012 |

Retsch GmbH |

6 |

0003 |

Confirmation

I have read and understood the chapters Information on these

operating instructions and on Safety.

__________________________________

Signature of operator/owner

__________________________________

Signature of service technician

08.02.2012 |

Retsch GmbH |

7 |

0003 |

Technical specifications

Machine type designation: ZM200

Intended use

The Retsch Ultra Centrifugal Mill ZM200 is deployed for rapid fine grinding of soft to medium hard and fibrous materials up to a grain size of 10 mm.

See the section in the chapter on "Operation" below for examples:

"Unsuitable comminution material" "Suitable comminution material" "Comminution methods" "Comminution by cold grinding"

The end fineness achievable is determined by : The type of rotor

The speed of the rotor The ring sieve

The shearing properties of the comminution material

The effective grinding technology and the extensive range of accessories mean that the ZM200 can quickly prepare samples ready for analysis in a way which preserves the material.

It is not designed as a production machine, but rather as a laboratory device intended for single-shift, 8-hour operation.

Do not make any modifications to the machine and only use Retsch approved spares and accessories.

The conformity to the European guidelines declared by Retsch otherwise loses its validity.

It furthermore leads to the loss of all warranty claims.

Maximum feed quantity

Max. up to 20 ml with the collection container for minimum quantities

The max. recommended feed quantity with the standard collection container is 300ml, which corresponds to approx. 1/3 of the cassette’s filling capacity. If more is filled into the cassette, the sample and the appliance may overheat.

Do not fill too much into the collecting container. Do not exceed a max. 1/3 of the filling capacity.

Excessive filling can cause overheating and damage to the plastic housing.

Max. 5000 ml with components obtainable as accessories

Maximal feed grain size

Up to 10 mm

Maximal end fineness achievable

< 40 µm, in dependence on the feed material and ring sieve

Drive output

750 W / power draw approx. 1300 W

Rotor speed

Can be regulated from 6,000 – 18,000 r.p.m.

08.02.2012 |

Retsch GmbH |

8 |

0003 |

ZM200 emissions

Noise levels :

Noise measured according to DIN 45635-31-01-KL3

The noise levels are basically influenced by the speed of the machine, the feed material, the feed grain size, the rotor used and the ring sieve deployed.

Workplace related emission value LpAeq = up to 77.5 dB(A) Measuring conditions :

Machine speed = 18,000 r.p.m. Feed material = burnt lime Feed grain size = <5 mm

Ring sieve deployed = 0.5 mm Conidur perforation Rotor deployed = 12-tooth rotor

Materials and analyses of the grinding tools

See : http://www.retsch.de/english/docs/grinding_tools.pdf

Protection systems

IP20

Protective equipment

The ZM200 is equipped with a fixture to automatically close the cover. This prevents the device being started in an unsafe state.

The device cannot be started unless the cover is closed.

It is only possible to open the device when the device is at standstill.

Operating mode

S1

An operating mode with constant loading, the duration of which suffices to reach the state of thermal rigidity. (DIN VDE 0530 T1)

Device dimensions

Height: Up to approx. 665 mm / Width: 410 mm / Depth : 365 up to 590 mm

Weight: Net approx. 38 kg

Base area required

410 mm x 590 mm;

A safe distance of 200mm is required at the rear to allow the fan to fulfil its function.

08.02.2012 |

Retsch GmbH |

9 |

0003 |

Transport and assembly

Packaging

The packaging has been adapted to the mode of transport. It corresponds to the generally applicable packaging guidelines.

Please retain the packaging for the duration of the warranty since, in case of complaint, returning in unsuitable packaging can jeopardize your warranty claims.

Transport

During transportation, do not subject the ZM200 to impacts, jolts or vibrations. The electronic and mechanical components could otherwise be damaged.

Temperature fluctuations

In case of wide temperature fluctuations (during shipment by air, for instance), protect the ZM200 from condensation. The electronic components could otherwise be damaged.

Intermediate storage

Likewise for intermediate storage, ensure that the ZM200 is stored in a dry place.

Assembly

Place the ZM200 on a sturdy laboratory bench. 2 people are required to carry the device.

The net weight of the ZM200 is approx. 38 kg

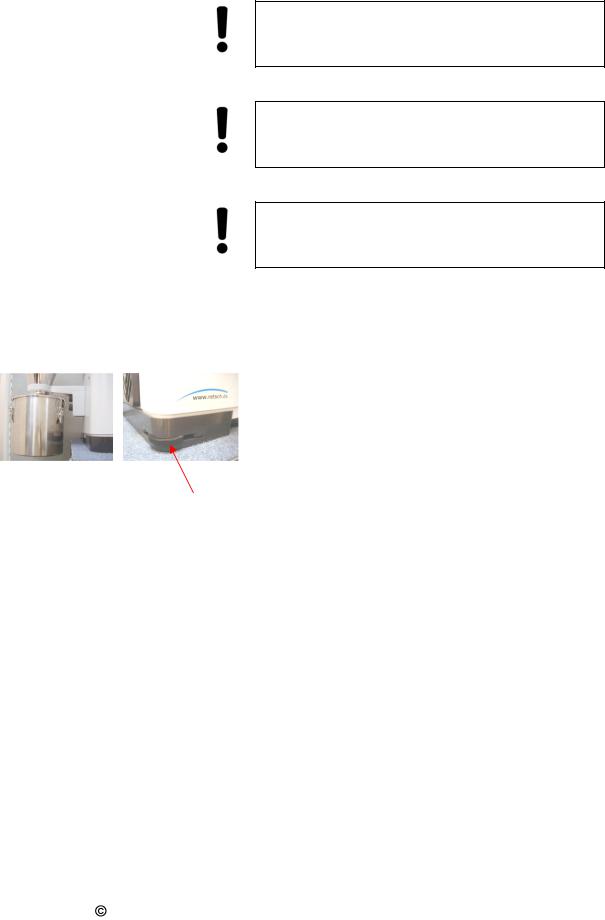

When installing a cyclone with a 5000ml collecting container, there must be sufficient free space to the left of the ZM200, see figure, because the cyclone's collecting container is located below the feet of the ZM200. This is not necessary for a cyclone with a

R3000ml collecting container.

There is the option of compensating for unevenness on the bench by adjusting the left rear foot of the ZM200 by up to 3mm. Turn wheel R on the foot until the ZM200 is standing securely on all feet.

08.02.2012 |

Retsch GmbH |

10 |

0003 |

Loading...

Loading...