Page 1

Operating Instructions for Rotor Bea te r M i l l Type SR 200

© Retsch GmbH 42781-Haan, Retsch-Allee 1-5, Germany, 2/8/2012 0002

Page 2

Guide to Operating Instructions

The present operating instructions for the rotor beater mill of

the type SR 200 give all the information necessary for the areas

indicated in the table of contents. They give instructions to the

target group(s) defined for the respective areas on how to

handle the SR 200 in a safe and proper fashion. Knowledge of

the relevant chapters is, for the respective target group(s), a

prerequisite for safe and proper handling. The present technical

documentation is a work of reference and a training manual.

Each of the individual chapters is an independent unit. These

operating instructions do not include any repair instructions. In

the case of any necessary repairs, please contact your supplier or

Retsch GmbH directly.

2/8/2012 Retsch GmbH 2 0002

Page 3

Guide to Operating Instructions .................................................... 2

Safety .............................................................................................. 4

Safety instructions .................................................................................... 4

Warning signs ............................................................................................ 5

Repairs ........................................................................................................ 5

Confirmation ............................................................................................. 5

Technical Data ............................................................................... 6

Application in the case of proper use .................................................... 6

Drive ........................................................................................................... 7

Speed .......................................................................................................... 7

Rated power .............................................................................................. 7

Feed grain size ........................................................................................... 7

Volume of collecting pan ........................................................................ 7

Noise data .................................................................................................. 7

Type of protection .................................................................................... 7

Unit dimensions ........................................................................................ 7

Unit weights .............................................................................................. 7

Required standing area ............................................................................. 7

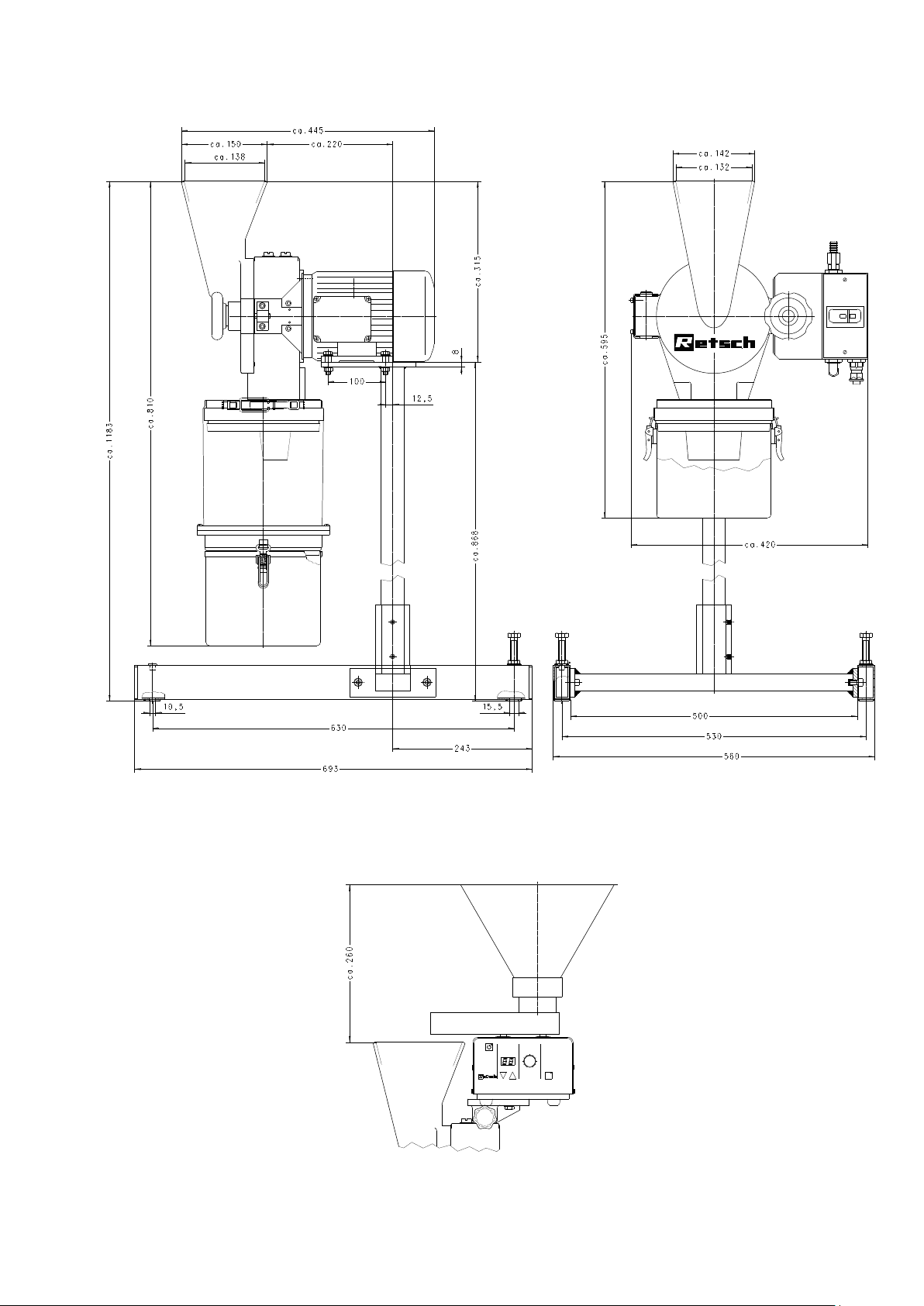

Dimensions Sheet ........................................................................... 8

Transport and setting up ................................................................ 9

Packing ....................................................................................................... 9

Transport ................................................................................................... 9

Temperature fluctuations ......................................................... 9

Intermediate storage .................................................................. 9

Parameters for setting-up location ......................................................... 9

Setting up with underframe ..................................................................... 9

Setting up on the laboratory table .......................................................... 11

Electrical connection ............................................................................... 11

Operation ....................................................................................... 12

Operating elements and operation ......................................................... 12

Graphic view of the operating elements: ................................... 12

Overview of operating elements.................................................. 13

Opening and closing of mill housing ..................................................... 14

Insert sieve frame 360° with ring sieve ................................................. 14

Insert grinding insert 180° with frame and sieve insert ...................... 15

Start or stop the SR 200 ........................................................................... 15

Filter hose and collecting pan ................................................................. 16

Feed material to be crushed .................................................................... 16

Assembly of feed device .......................................................................... 17

Working Instructions..................................................................... 18

General ....................................................................................................... 18

End fineness .............................................................................................. 18

The SR 200's mode of working .............................................................. 18

General ........................................................................................... 19

Cleaning ..................................................................................................... 19

SR 200 ............................................................................................. 19

Sieves, grinding inserts and rotor ........................................... 19

Maintenance .............................................................................................. 19

Necessary inspections .............................................................................. 19

Accessories ................................................................................................ 20

Copyright ................................................................................................... 20

Changes ...................................................................................................... 20

Appendix ............................................................... following pages

2/8/2012 Retsch GmbH 3 0002

Page 4

Safety

!

We exclude any claims for compensation for material damage and

personal injury caused by non-observance of the following safety

instructions.

Target group: All persons concerned in any way with the machine.

The SR 200 is a highly modern, efficient product from Retsch

GmbH. It is state of the art. If the user handles the machine in a

proper fashion and with knowledge of the technical

documentation present here, it is completely safe operationally.

Safety instructions

You, as the operator, must ensure that the persons instructed to work

with the SR 200:

have noted and understood all the regulations for the safety area,

know all instructions for what action to take as well as the regulations

of the relevant target groups before work is commenced,

have access to the technical documentation at all times and without

problem,

that new personnel is familiarised before commencement of work on

the SR 200 with the safe and proper handling either by a verbal

introduction from a competent person and/or by means of the

present technical documentation.

Improper operation can result in personal injury and damage to

property. You are responsible for your own safety and that of your

personnel.

Ensure that no unauthorised persons have access to the SR 200.

For your own protection, make sure that you are given

confirmation that your personnel have received instruction in

the use of the SR 200. You will find a draft of a related form

after the chapter on safety.

2/8/2012 Retsch GmbH 4 0002

Page 5

Warning signs

!

Personal injury

Material damage

the Retsch agency in your country

your supplier

Retsch GmbH directly

___________________________________________

___________________________________________

___________________________________________

___________________________________________

___________________________________________

We give warnings using the following symbols:

Repairs

These operating instructions do not include any repair instructions. For

your own safety, repairs may only be carried out by Retsch GmbH or an

authorised agent (service technicians).

Should the need arise, please notify:

Your service address:

Confirmation

I have noted the foreword and the chapter on safety.

____________________________________________

Operator's signature

____________________________________________

Service technician's signature

2/8/2012 Retsch GmbH 5 0002

Page 6

Technical Data

Do not make any modifications to the machine and use only RETSCH

approved spares and accessories.

Failure to comply will invalidate the CE declaration and guarantee.

Chemicals

Fertiliser

Drugs

Dolomite

Flue ash

Fruit

Animal feed

Gypsum

Vegetables

Corn

Spices

Artificial

resins

Limestone

Kaolin

Potassium salts

Coal

Pellets

Plants

Seeds

Salts

Tobacco

Peat

Cellulose

Machine type designation: SR 200

Application in the case of proper use

For uses where very frequently different materials have to be ground

and it is necessary to open the door to clean the grinding chamber after

every grinding operation.

The SR 200 is not designed as a production machine, but as a

laboratory unit, meant for 8-hour single-shift operation.

The SR 200 crushes dry, soft to medium-hard materials with a hardness

of up to about 4 according to Mohs.

It is especially suitable for the materials listed below:

and many other, similar materials.

The achievable end fineness depends on the hold width of the sieve

and the crushing properties of the material to be ground. In favourable

cases it is possible to achieve finenesses of < 60 µm.

For further information, please contact our application laboratory.

2/8/2012 Retsch GmbH 6 0002

Page 7

Drive

Height approx.560

Width approx.420

Depth approx.445

with underframe

Height approx..1183

Width approx.560

Depth approx.700

with underframe and DR 100

Height approx.1443

Width approx.560

Depth approx.700

SR 200

net approx. 35kg

with underframe

net approx. 57kg

with underframe and DR 100

net approx. 65kg

1-phase AC motor with brake or

Three-phase current motor with brake

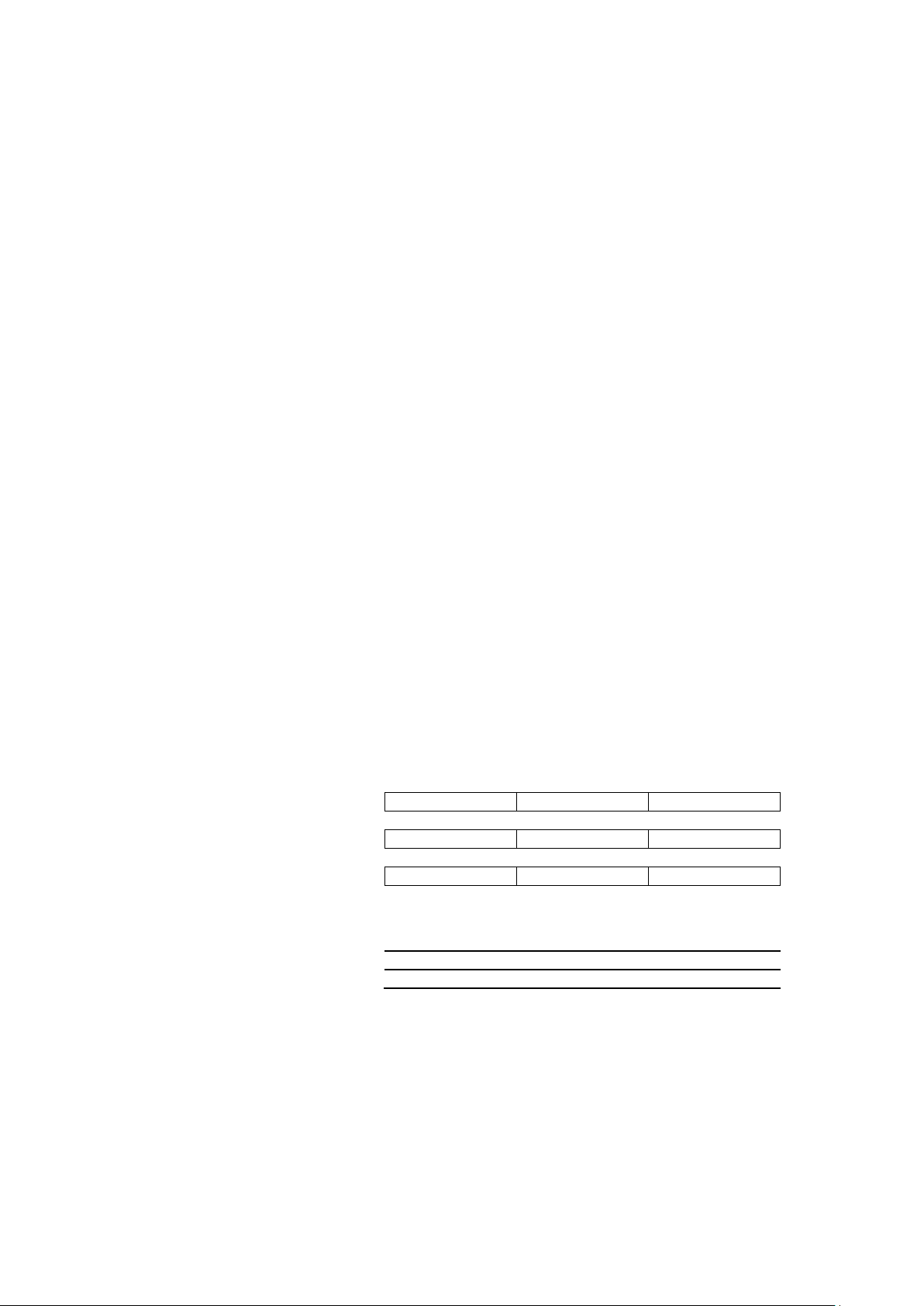

Speed

2850min-1 at 50Hz

3420min-1 at 60Hz

Rated power

1100 Watt

Feed grain size

max. 15mm

With single-piece feed also up to 20mm

Volume of collecting pan

5,000 ml or

30,000ml

Noise data

Noise measurement according to DIN 45635-31-01-KL3

Noise data are dependent on the fracturing properties fo the

product beeing ground.

Example:

Sound power level: LWA = 86 dB(A)

Workplace-related emission L

= 81 dB(A)

pAeq

Operating conditions:

Ring sieve : 0,5mm

Sample material: rye, grain size up to 15 mm

Filling ratio of grinding chamber: feeding quantity each until

motor rated power is reached.

Type of protection

IP 54

Unit dimensions

Unit weights

Required standing area

(700 mm x 560 mm; no safety distances necessary!)

2/8/2012 Retsch GmbH 7 0002

Page 8

Dimensions Sheet

0 I

with DR 100/75

2/8/2012 Retsch GmbH 8 0002

Page 9

Transport and setting up

Please keep the packing for the whole of the guarantee period. If,

in the case of a complaint, the unit is returned in inadequate

packing, your guarantee rights may be jeopardised.

Fig.1

Transport

To transport the SR 200 use the ring bolt H. Fig.1

The SR 200 may not be subjected to shocks, shaken or thrown

during transport. Otherwise the electrical and mechanical

components may be damaged.

In the case of major temperature fluctuations (e.g. with

transportation by air), the SR 200 must be protected against

condensation. Otherwise the electrical components may be

damaged.

When the ambient temperature exceeds or falls below that specified,

the electronic and mechanical components may be damaged, and

performance data changed to an unknown extent.

At higher humidity, the electronic and mechanical components may

be damaged, and performance data changed to an unknown extent.

Target group: Operators, Forwarders, Users

Packing

The packing is adjusted to the transport route. It complies with

the generally applicable packing regulations.

Temperature fluctuations

Intermediate storage

Ensure that the SR 200 is also kept dry when subject to

intermediate storage.

Parameters for setting-up location

Ambient temperature

The ambient temperature should be between 5°C and 40°C.

Relative humidity

Maximum relative humidity 80 % at temperatures of 31°C, falling in a

linear fashion to 50 % relative humidity at 40°C.

Setting-up altitude

max. 2000 m above sea level

2/8/2012 Retsch GmbH 9 0002

Setting up with underframe

Page 10

8

9

1

2

3

4

5

6

7

Fig.2

Fig.3

We recommend that the SR 200 be mounted on an

underframe, which can be supplied as an accessory. Fig.2

Mounting:

* Connect centre cross-piece 9 base side pieces 8 using the

cylinder-head screws 1

* Push covering caps 2 onto the projecting thread

* Place stand tube 3 in the sleeve 4 and fasten tight with the

headless screws 5

* If necessary, the underframe can be aligned using the

cylinder-head screws 6

So as to be able to fasten the underframe with screws,

maximum diam. 10mm possible, to the ground, the two setting

screws 6 and the front plastic caps 7 must be removed.

* Place SR 200 on the underframe Fig.3

* To fasten hexagon-head bolts SCH M8x35 supplied with

the underframe, use spring washers and hexagon nuts

2/8/2012 Retsch GmbH 10 0002

Page 11

Setting up on the laboratory table

Fig.4

You can also mount the SR 200 on your laboratory table. Fig.4

* Measure thickness of laboratory table. The thickness

should not be less than 30mm to ensure that safe working

with the SR 200 is not adversely affected.

* Use screws with a max. diam. of 8mm and a length of

laboratory table thickness + 25mm

* Stand the SR 200 on the table

* Draw holes for the table using the holes present in the

motor of the SR 200

The distance from the holes to the front edge of the table

must be such that it is possible without difficulty to mount and

dismount the collecting pan or the filter hose.

Electrical connection

The electrical connection may only be made by an electrician.

* The voltage and frequency of the SR 200 can be found on the nameplate.

* Ensure that the values agree with the applicable power

supply.

* Connect the SR 200 to the power supply using the

connection cable supplied.

The power cable supplied does not have a plug because the

type of plug depends on the setting-up location and the

relevant regulations in the country concerned

* When connecting the power cable to the power supply,

provide an external fuse in accordance with the regulations

of the setting-up location.

If the values on the nameplate are not observed, electronic and

mechanical components may be damaged.

Before operating for the first time, the direction of rotation must be

checked, see rotation arrow on the motor.

If the direction of rotation is incorrect the grinding will be inadequate

and mechanical parts may be damaged.

2/8/2012 Retsch GmbH 11 0002

Page 12

Operation

0 I

Target group: Users

Operating elements and operation

Graphic view of the operating elements:

Fig.5

2/8/2012 Retsch GmbH 12 0002

Page 13

Operating elements and their function

Item

Element

Figure

Function

A

Power switch with

ON/OFF button

0 I

Isolates and connects the SR 200 from/with the power supply

I depressed = SR 200 is switched on

0 depressed = SR 200 is switched off

A1

Power switch with

knob

Isolates and connects the SR 200 from/with the power supply

ON = SR 200 is switched on

OFF = SR 200 is switched off

B

Door lock

Opens and closes the door of the SR 200, clamps the door seal

Depressed and turned clockwise = locks the door

Depressed and turned anticlockwise = opens the door

D

Feed funnel at door

Takes the material to be crushed, but is not used to store this

material.

Reliably prevents the material to be crushed from splashing back.

E

Filter hose

Page 15

Prevents build-up of the air pressure generated by the rotating rotor

and thus accelerates material throughput.

F

5l collecting pan

Page 15

Takes the crushed material.

G

Release lever for

motor brake

When pressed to the rear, facilitates release of the motor brake and

thus makes it possible to rotate the rotor manually for cleaning

purposes.

H

Transport screw

Prevents damage to mechanical and electrical components during

transport.

I

Setting screws on

underframe

Make it possible to align the underframe when the floor is not even.

When screwed out, they expose the openings with which it is

possible to fasten the underframe to the floor, diam. 10mm

Overview of operating elements

2/8/2012 Retsch GmbH 13 0002

Page 14

Opening and closing of mill housing

0 I

Fig.6

Only open when the SR 200 is switched off.

* Press button 0 on power switch A or, with A1, turn to OFF

position Fig.6

* Press hand wheel B and turn in anticlockwise direction

* Hand wheel locks into end position

* the door can be opened

* close in reverse order

Only close the door when the contact surfaces are absolutely free of

material to be crushed or other contaminants.

Mechanical components and the seal may be damaged.

!

Do not open the SR 200 when motor is running.

When crushing toxic or otherwise health-endangering materials,

there is a danger that health-hazardous dust may be inhaled.

!

Do not open the SR 200 and release the motor brake at the same time.

Danger of injury from unbraked rotor.

Fig.7

A selection of sieve frames which are chromium-plated, of stainless

steel and ring sieves of stainless steel with Conidur or round

perforations are available as accessories. Fig.7

Conidur 0.08/0.12/0.20/0.25/0.50/

0.75/1.0/1.25/1.5/2.0mm

Round hole 3.0/4.0/5.0/6.0/8.0/10.0mm

* Undo screws S2

* Remove ring R1 and insert sieve SI in the groove NU of the ring

R2

* Carefully mount the ring R1 until the sieve SI slides in the

groove NU

* Turn in screws S2 and tighten well

* Open door

* Insert sieve frame with ring sieve, ring R1 is to the front and ring

R2 to the rear

* Screw heads S3 on the ring R2 belong to the holes of the mill

housing

* Close door

Ensure that a collecting pan is mounted.

* Start the SR 200

Insert sieve frame 360° with ring sieve

2/8/2012 Retsch GmbH 14 0002

Page 15

Insert grinding insert 180° with frame and sieve insert

Fig.8

A selection of grinding inserts with frames and sieve inserts of

stainless steel with Conidur or round perforations are available as

accessories. Fig.8

Conidur 0.08/0.12/0.20/0.25/0.50/

0.75/1.0/1.25/1.5/2.0mm

Round hole 3.0/4.0/5.0/6.0/8.0/10.0mm

* Undo screws S2

* Remove ring R1 and insert sieve SI in the groove NU of the

ring R2

* Carefully mount the ring R1 until the sieve SI slides in the

groove NU

* Turn in screws S2 and tighten well

* Open door

* Insert sieve frame with ring sieve, ring R1 is to the front and

ring R2 to the rear

* Insert sieve frame with ring sieve, ring R1 is to the front and

ring R2 to the rear

* Screw heads S3 on the ring R2 belong to the holes of the mill

housing

* Close door

Ensure that a collecting pan is mounted.

* Start the SR 200

0 I

Fig.9

The SR 200 is started or stopped at the power switch A or A1.

Fig.9

* Insert sieve frame or grinding insert

* Close door

* Mount collecting pan

Start

* Press button “I“ on switch A or turn knob on switch A1

to “ON“

Stop

* Press button “0“ on switch A or turn knob on switch A1

“OFF“

Start or stop the SR 200

2/8/2012 Retsch GmbH 15 0002

Page 16

Filter hose and collecting pan

Fig.10

Fig.11

With the use of a cloth filter hose or a Conidur filter, available as

an accessory, between the SR 200 and the collecting pan, the air

stream caused by the rotating rotor is taken off and conveyed

downward to the material discharge. Furthermore, it accelerates

the material throughput and ensures a gentle crushing process.

Fig.10

* Push filter hose E over the flange while holding the clamping

clip at an angle.

* Clamp the lock E1

* Hang in the collecting pan F

* Clamp the locks F1

If the collecting pan is mounted without a filter hose, it can be

expected that dust will escape from the feed funnel D, and so you

should never operate the SR 200 without a filter hose or Conidur

filter.

Feed material to be crushed

The maximum feed grain size should not exceed 15mm.

For batch or continuous operation, the SR 200 can be retrofitted

with a 30l plastic collecting receptacle and a feed device of the

type DR 100/75, which are available as accessories.

* Close the SR 200 and switch on

* Slowly feed the material to be crushed into the feed funnel D

Fig.11

The rebound safeguard installed in the feed funnel D prevents the

feed material from bouncing back. Fig.11

Only feed the material to be crushed into the feed funnel slowly and

continuously with the SR 200 running.

The material to be crushed or excessive feed quantity can bring the

SR 200 to a standstill and this may damage mechanical

components.

!

During crushing, material in dust form may escape from the feed funnel.

In the case of toxic or otherwise health-hazardous materials, use an

extraction device.

Danger from inhalation of health-hazardous dust.

!

Many materials form explosive air mixtures. Check the properties of the

material you are crushing.

Explosion hazard!

2/8/2012 Retsch GmbH 16 0002

Page 17

Assembly of feed device

Fig.12 Fig.13 Fig. 14

Fig.15

Prepare the DR 100/75 for feed operation in accordance with its

operating instructions.

Assembly :

* Undo ring screw H, Fig.12

* Turn in bolts BO, Fig.13

* Push on fixture HA with tommy screw, Fig. 14

* Tighten tommy screw

* Mount DR 100/75 and align

* Fasten with the two hexagon-head screws SC

M6x20 DIN933, Fig. 14

* Insert power cable of the DR 100/75 in a socket with

earthing

* You will find the voltage and frequency of the DR100/75 on

the nameplate

If the values on the nameplate are not observed, electronic and

mechanical components may be damaged.

When feeding larger quantities, it is advisable in general to feed

the material to be crushed evenly using a feed device. This

largely prevents any unnecessary load on the grinding tools and

reduces possible friction heat. An appropriate means of ensuring

even material feed is use of the feed device of the type DR

100/75, which is available as an accessory. Fig.15

2/8/2012 Retsch GmbH 17 0002

Page 18

Working Instructions

General sketch

Material is crushed in the SR 200 rotor beater mill by impact,

bouncing and shearing action.

After the material has been fed into the feed funnel, it passes

into the grinding chamber, where the crushing process takes

place between the rotor, the grinding insert and the sieve. see

also general sketch

As soon as the material has reached the relevant end fineness, it

passes the sieve and into the collecting pan.

The use of a cloth filter hose or a Conidur filter, available as an

accessory, which can be fixed between the SR 200 and the

collecting pan, prevents build-up of the air stream generated by

the rotating rotor and partly accelerates the material throughput.

This ensures a gentle crushing process.

Target group: Laboratory personnel

General

The SR 200 is highly modern, high-performance product from

Retsch GmbH.

In view of the wide range of accessories available, the SR 200

rotor beater mill is a unit with many varied uses in the chemical

and pharmaceutical sectors, mineralogy and biology etc. in

industrial and research laboratories.

The SR 200 is used mainly for precrushing and fine crushing of

dry, soft to medium-hard materials with a hardness of up to

approximately 4 according to Mohs.

End fineness

the achievable end fineness depends on the hole width of the

sieve and the crushing properties of the material. In favourable

cases it is possible to achieve finenesses of < 60 µm.

The SR 200's mode of working

2/8/2012 Retsch GmbH 18 0002

Page 19

General

Fig.16

The SR 200 can be cleaned with brushes, paintbrushes and

possibly an industrial vacuum cleaner, as well as compressed air.

To clean the grinding chamber on the SR 200 the motor brake

can be released at the lever G ( Fig.16 ). the rotor is now easy to

turn and this facilitates cleaning.

The SR 200's type of protection is IP54.

!

Do not clean the SR 200 under running water.

Danger of fatal electric shock

Dry all wet parts well after cleaning.

Flash rust or deposited rust may form.

Cleaning

SR 200

Sieves, grinding inserts and rotor

Can be cleaned under running water once they have been

removed from the SR 200.

Maintenance

The SR 200 largely maintenance-free.

Necessary inspections

Every six months the limit switches and the motor brake must

be checked with regard to their serviceability.

Limit switch to the left on the door hinge

* With an opening gap of 3mm max, the limit switch must

shut down the motor

Limit switch to the right on the quick-acting closure

* When the handwheel is turned a maximum of 45°, the

motor brake must be activated.

Motor brake

* Start the SR 200

* Stop the SR 200

* Measure the braking time using a stopwatch

* Should the braking time exceed 0.5 seconds, contact the

service technicians

2/8/2012 Retsch GmbH 19 0002

Page 20

Accessories

* Underframe

* 30l collecting pan

* Filter hose for 30l vessel

* Stand for feed device DR 100/75

* Feed device DR 100/75

* Ring filter with Conidur plate for 5l vessel

* Dust filter with clamping rings for ring filter

* Dirt collection tray of plastic

* 360° sieve frame of chromium-plated steel

* 360° sieve frame of stainless steel

* 180° grinding insert of stainless steel

* 360° ring sieves, Conidur from 0.08 to 2.0 mm

* 360° ring sieves, round hole from 3.0 to 10 mm

* 180° sieve inserts, Conidur from 0.08 to 2.0 mm

* 180° sieve inserts, round hole from 3.0 to 10mm

Copyright

This documentation may only be passed on or duplicated and its

content used or passed on with the express permission of Retsch

GmbH. Any violation will be liable for compensation.

Changes

We reserve the right to make technical changes.

2/8/2012 Retsch GmbH 20 0002

Page 21

Authorized person for the compilation of technical documents:

J. Bunke (technical documentation)

The following records are held by Retsch GmbH in the form of Technical Documentation:

Detailed records of engineering development, construction plans, study (analysis) of the measures required for

conformity assurance, analysis of the residual risks involved and operating instructions in due form according to

the approved regulations for preparation of user information data.

The CE-conformity of the Retsch Rotor Beater Mill Type SR 200 is assured herewith.

In case of a modification to the machine not previously agreed with us as well as the use of not

licensed spare parts and accessories this certificate will lose its validity.

Retsch GmbH Haan, January 2010

Dr. Stefan Mähler

Manager technical services

R e t s c h G m b H R e t s c h -Al l e e 1 - 5 4 2 7 8 1 H a a n G e r m a n y w ww . r e t s c h . c o m

ROTOR BEATER MILL

SR 200

FB-EW-805-019 (E) Änderungsstand G 01.2012

CERTIFICATE OF CE-CONFORMITY

Translation

Certificate of CE-Conformity according to:

EC Mechanical Engineering Directive 2006/42/EC

Applied harmonized standards, in particular:

DIN EN ISO 12100 Security of machines

EC Directive Electromagnetic Compatibility 2004/108/EC

Applied standards, in particular:

DIN EN 50081 Generic standard interference emission - living areas - in conjunction with

EN 55022 and EN 60555

DIN EN 50082 Generic standard interference resistance - living areas

Additional applied standards, in particular

DIN EN 61010 Safety prescriptions concerning measuring-, operating-, controlling- and

laboratory equipment

Page 22

Page 23

Page 24

Copyright

® Copyright by

Retsch GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

Loading...

Loading...