Page 1

Operating Instructions for Vibratory Disc Mill

Type RS200

Retsch GmbH, 42781 Haan, Retsch-Allee 1-5, Germany, 19.09.2012 0004

Page 2

Notes on these operating instructions......................................... 3

Warning instructions............................................................... 3

Repairs ................................................................................. 3

Safety ......................................................................................... 4

Safety instructions ................................................................. 4

Safety instructions – summarised, part 1 .................................. 5

Safety instructions – summarised, part 2 .................................. 6

Confirmation ......................................................................... 7

Technical data ............................................................................ 8

Use according to the intended purpose ...................................... 8

Milling cup – nominal volume ................................................... 8

Maximum charged grain size ................................................... 8

Driving power ........................................................................ 8

Motor speed .......................................................................... 8

Emissions ............................................................................. 9

Materials and analyses of milling tools ...................................... 9

Systems of protection ............................................................. 9

Protective equipment .............................................................. 9

Mode of operation .................................................................. 9

Machine dimensions ............................................................... 9

Required floor space ............................................................... 9

Transport and installation ........................................................... 10

Packing ................................................................................ 10

Transport .............................................................................. 10

Temperature variations ........................................................... 10

Temperature variations ........................................................... 11

Intermediate storage .............................................................. 11

Erection ................................................................................ 11

Parameters for the place of installation ..................................... 11

Ambient temperature: 5°C to 40°C........................................... 11

Atmospheric humidity ............................................................. 11

Installation height: max. 2000 m above sea level ....................... 11

Transport safety device ........................................................... 11

Electrical connection ............................................................... 12

Important instructions for electrical connection .......................... 13

Serial interfaces ..................................................................... 13

Operation ................................................................................... 14

Connecting the power supply ................................................... 14

Opening / closing / emergency unlocking .................................. 14

Insertion and clamping of the milling set of the RS200 ................ 15

Preparation of the milling process............................................. 16

Before starting the RS200 ....................................................... 18

Suitable milling sets for the RS200 ........................................... 18

Milling set filling level ............................................................. 18

Guide values for material quantity and grain size ....................... 18

Cleaning the milling cups ........................................................ 19

Drying the milling cups ........................................................... 19

Operation via the display unit of the RS200 ............................... 20

Symbols in the display unit...................................................... 20

Setting possibilities via the display menu .................................. 21

Languages ............................................................................. 21

False language selection .......................................................... 21

Manual operation .................................................................... 21

Milling programme .................................................................. 21

Milling time ............................................................................ 21

Speed ................................................................................... 21

Speed with agate .................................................................... 22

Starting time .......................................................................... 23

Opening automatic .................................................................. 23

Warning sound ....................................................................... 23

Service .................................................................................. 23

Contrast / Brightness............................................................... 24

Date / Time ............................................................................ 24

Stand-by monitor .................................................................... 24

Fault signals in the display ......................................................... 25

F02 to F13 ............................................................................ 25

General ....................................................................................... 26

Cleaning ............................................................................... 26

Maintenance .......................................................................... 26

Maintenance of the rubber springs ............................................ 26

Opening the cover .................................................................. 27

Wearing parts ........................................................................ 27

Copyright .............................................................................. 27

Alterations ............................................................................ 27

Appendix ............................................................... following pages

15.11.2006 Retsch GmbH 2 Doc. Nr. D 98.725.9998

Page 3

Notes on these operating instructions

Injury to persons

Damage to equipment

Follow the instructions for use

The Retsch agency in your country

Your supplier

Retsch GmbH directly

These operating instructions for the vibratory disc mill, type

RS200, give all the necessary information with regard to the

areas mentioned in the contents.

Instructions are given for the definite target group(s) in

each area, in order to ensure safe operation of the RS200

for its intended purpose. Knowledge of the relevant section

is essential for safe, proper handling in each target group or

groups.

This technical documentation is intended as a reference and

instruction manual. The individual sections are complete in

themselves.

These operating instructions do not include repair

instructions. If repairs are necessary please contact your

supplier or Retsch GmbH direct.

http://www.retsch.com

Warning instructions

Warnings are given by the following symbols:

Repairs

These operating instructions do not include repair

instructions. For your own safety repairs must be carried out

only by Retsch GmbH, an authorised agent or by Retsch

service technicians.

In this case please contact:

Your service address:

15.11.2006 Retsch GmbH 3 Doc. Nr. D 98.725.9998

Page 4

Safety

We exclude any claims for damages of any kind for injury to

persons and damage to equipment arising from non-observance of

the following safety instructions.

The RS200 is an ultra-modern, highly efficient product of

Retsch GmbH, and corresponds to state of the art. If the

machine is used according to the intended purpose with a

knowledge of this technical documentation it is completely

safe and reliable to operate.

Safety instructions

As the operating authority it is your duty to ensure that all

persons charged with working on the RS200:

have read and understood all the instructions on safety,

from the beginning of work know all the instructions and

regulations for the target group relevant to their work,

have access to the technical documentation for this machine

at all times without problems.

New personnel should be familiarized with safe, proper

handling of the machine before beginning work on the

RS200, either by verbal instruction from a competent

person or through this technical documentation.

Improper operation can cause injury to persons or damage

to the equipment. Your are responsible for your own safety

and that of your employees.

Ensure that no unauthorised persons have access to the

RS200.

For your own safety have your employees confirm that they

have been instructed in operation of the RS200. The draft of

a suitable form is given at the end of the section on safety.

15.11.2006 Retsch GmbH 4 Doc. Nr. D 98.725.9998

Page 5

Safety instructions – summarised, part 1

We exclude any claims for damages of any kind for injury to persons and damage to equipment arising from non-observance

of the following safety instructions.

Do not make any alterations to the machine and use only spare parts and accessories approved by Retsch. Otherwise the

Declaration of Conformity to the European directives declared by Retsch will lose its validity.

Furthermore this will lead to loss of any kind of guarantee claims.

The rings used could otherwise become damaged.

Please keep the packing material for the duration of the guarantee period, since if you have a complaint and the equipment

is returned in inadequate packing your guarantee claim is at risk.

The RS200 must not be knocked, shaken or thrown during transport. Otherwise the electronic and mechanical components

can be damaged.

If the RS200 is subjected to high temperature variations (e.g. during air transport) it must be protected against condensed

water. Otherwise there may be damage to the electronic components.

If the supplied items are incomplete and/or there is transport damage you must inform the transporter and Retsch GmbH

immediately (within 24 hrs). Later complaints may possibly be no longer considered.

If the temperature drops below or exceeds ambient temperature the electrical and mechanical components can become

damaged and performance data can change to an unknown extent.

At high atmospheric humidity the electrical and mechanical components can become damaged and performance data can

change to an unknown extent.

If the values on the type plate are not observed the electrical and mechanical components can become damaged.

Electrical connection should be carried out only by a qualified electrician. Danger through current surge.

The serial interface cables must not be longer than 2.5 m.

If the cables are longer this can result in disturbances during transmission of data.

Never start the RS200 without the clamped milling set.

Mechanical components can become damaged through high unbalance.

If the values on the type plate are not observed the electrical and mechanical components can become damaged.

The emergency unlocking device must never be operated when the machine is running – only when the machine is at a

standstill and is disconnected from the mains supply.

Danger of injury through unbraked after-running of the drive.

Never start the RS200 without the clamped milling set.

Mechanical components can become damaged through high unbalance.

Please take necessary measures, depending on the dangerous nature of your milling material, in order to avoid danger to

persons.

When removing and opening hot milling cups it is essential to wear protective gloves.

Danger of burning the hands.

Rub the rubber gasket in the clamping plate from time to time with talcum powder and do not leave the milling set in the

RS200 after milling.

Strongly heated milling sets can stick together with the rubber of the clamping plate and are very difficult to remove.

The filling quantity of the milling set must not exceed 1/3 of the nominal volume.

The rings used could otherwise become damaged.

Safety instructions

Use according to the intended purpose

Milling cup nominal volume

The filling quantity of the milling sets must be more than1/3 of the nominal volume.

Packing

Transport

Temperature variations

Supplied items

Ambient temperature

Atmospheric humidity

Electrical connection

Serial interface

Connecting the power supply

Emergency unlocking

Insertion and clamping of the milling set of the RS200

Preparation of the milling process

15.11.2006 Retsch GmbH 5 Doc. Nr. D 98.725.9998

Page 6

Safety instructions – summarised, part 2

Before starting the machine ensure that the milling set is clamped.

The milling set can be ejected. Danger of injury and damage to the equipment.

When using easily flammable materials it is essential to observe the section „Wet milling of easily flammable materials”.

Danger of explosion.

If the filling level of the milling set is too high or too low the milling result will be impaired and this can cause damage

(increased abrasion) to the milling set.

Please take necessary measures, depending on the dangerous nature of your milling material, to avoid danger to persons.

When removing and opening hot milling cups it is essential to wear protective gloves.

Danger of burning the hands.

Do not subject milling cups with ceramic inserts to rapidly changing temperature differences when rinsing.

The ceramic units can crack through sudden temperature changes.

Before using easily flammable materials as millling auxiliary agents it is essential to specify in writing the

explosion protection documentation of the EC-directive, according to article 118 and 118a, as laid d own in

directive 89/391/EEC.

Do not clean the RS200 with running water.

Danger to life through current surge.

Use only a cloth moistened with water.

Solvents are not permitted.

Easy running of roller 1 on the closing pin is necessary for reliable closing via the automatic closing mechanism of the RS200.

These operating instructions do not include repair instructions. For your own safety repairs should be carried out only by

Retsch GmbH, an authorised agent or service technicians.

Safety instructions when starting the RS200

Tips for fine milling

Guide values for the material quantity

Cleaning the milling cups

Wet milling of easily flammable materials.

Cleaning

Maintenance

Wearing parts

15.11.2006 Retsch GmbH 6 Doc. Nr. D 98.725.9998

Page 7

Confirmation

I have taken note of the section „Notes on these

operating instructions” and the section on “Safety”

__________________________________

Signature of operating authority

__________________________________

Signature of service technician

15.11.2006 Retsch GmbH 7 Doc. Nr. D 98.725.9998

Page 8

Technical data

Do not make any alterations to the machine and use only spare

parts and accessories approved by Retsch.

Otherwise the Declaration of Conformity with the European

directives declared by Retsch loses its validity. Furthermore this

will result in the loss of any kind of guarantee claims.

The rings used could otherwise become damaged.

Machine type designation: RS200

Use according to the intended purpose

Retsch vibratory disc mills are used for rapid, loss-free, fine milling

of medium-hard, hard/brittle and hard/tough materials. Both dry

and wet milling operations can be carried out. Milling with solvents

is permitted. In this case, however, the supplementary notes in the

section „Wet milling with easily flammable materials“ must be

observed.

Soil samples, ores, coal, coke, corundum, metal oxides,

minerals, plant samples, slags, silicates, cement and many

other substances can be milled, easily, quickly and without loss.

These oscillating disc mills are used successfully in practically all

areas of industry and research, particularly where stringent

requirements are set on purity, quickness, fineness and

reproducibility.

They are not designed as production machines, but as laboratory

equipment, intended for 8-hour single shift operation.

Milling cup – nominal volume

Special steel: 50 / 100 / 250 ml

Agate: 50 / 100 ml

Tungsten carbide: 50 / 100 ml

The filling quantity of the milling sets must be more than 1/3 of

the nominal volume.

Maximum charged grain size

The maximum charged grain size depends on the milling cup

volume and the degree of hardness of the milling material.

Milling set 50 ml = max. grain size < 5mm

Milling set 100 ml = max. grain size <10mm

Milling set 250 ml = max. grain size <15mm

Driving power

1500 W

Motor speed

The speed is adjustable in the following range:

700 - 1500 min

-1

For agate sets adjustment of a speed greater than 700 min-1 is not

possible.

If no milling set is clamped in position the speed is also limited to

700 min-1.

15.11.2006 Retsch GmbH 8 Doc. Nr. D 98.725.9998

Page 9

Emissions

Noise characteristic values of RS200:

Noise measurement according to DIN 45635-31-01-KL3

The noise characteristic values are influenced mainly by the

machine speed, material to be milled and the milling set.

Workplace-related emission value L

pAeq

= up to 84 dB(A)

Noise power level LWA = 99 dB(A)

Conditions of measurement:

Milling set : 250 ml steel with ring (90/125) and Puk (65)

Milling material : 100g cement clinker, grain size <2mm,

6 milling aid tablets C20

Speed : 1450 min-1

Noise level measuring instrument: Brüel & Kjaer 2237 Controller

Materials and analyses of milling tools

See: www.retsch.com/english/docs/grinding_tools.pdf

Systems of protection

IP40

Protective equipment

The RS200 is fitted with an automatic lid shutting device which

prevents the machine being started in an unsafe condition. The

machine can be started only with the lid closed.

The lid can be opened only when the machine is at a standstill.

Mode of operation

S1

Operation with constant load, the duration of which is sufficient for the

thermal steady state condition to be reached (DIN VDE 0530 T1)

Machine dimensions

Height: up to approx. 1220 mm / width: 820 mm / depth: up to

approx. 780 mm

Weight : RS 200 net approx. 210 kg

Required floor space

Height (open hood): 1900 mm / width: 820 mm /

depth: 780 mm;

A safety distance of 100 mm on the rear side is necessary so that

the main switch can be operated.

15.11.2006 Retsch GmbH 9 Doc. Nr. D 98.725.9998

Page 10

Transport and installation

Please keep the packing material for the duration of the

guarantee period since if there is a complaint and the

machine is returned with inadequate packing your

guarantee claim will be at risk.

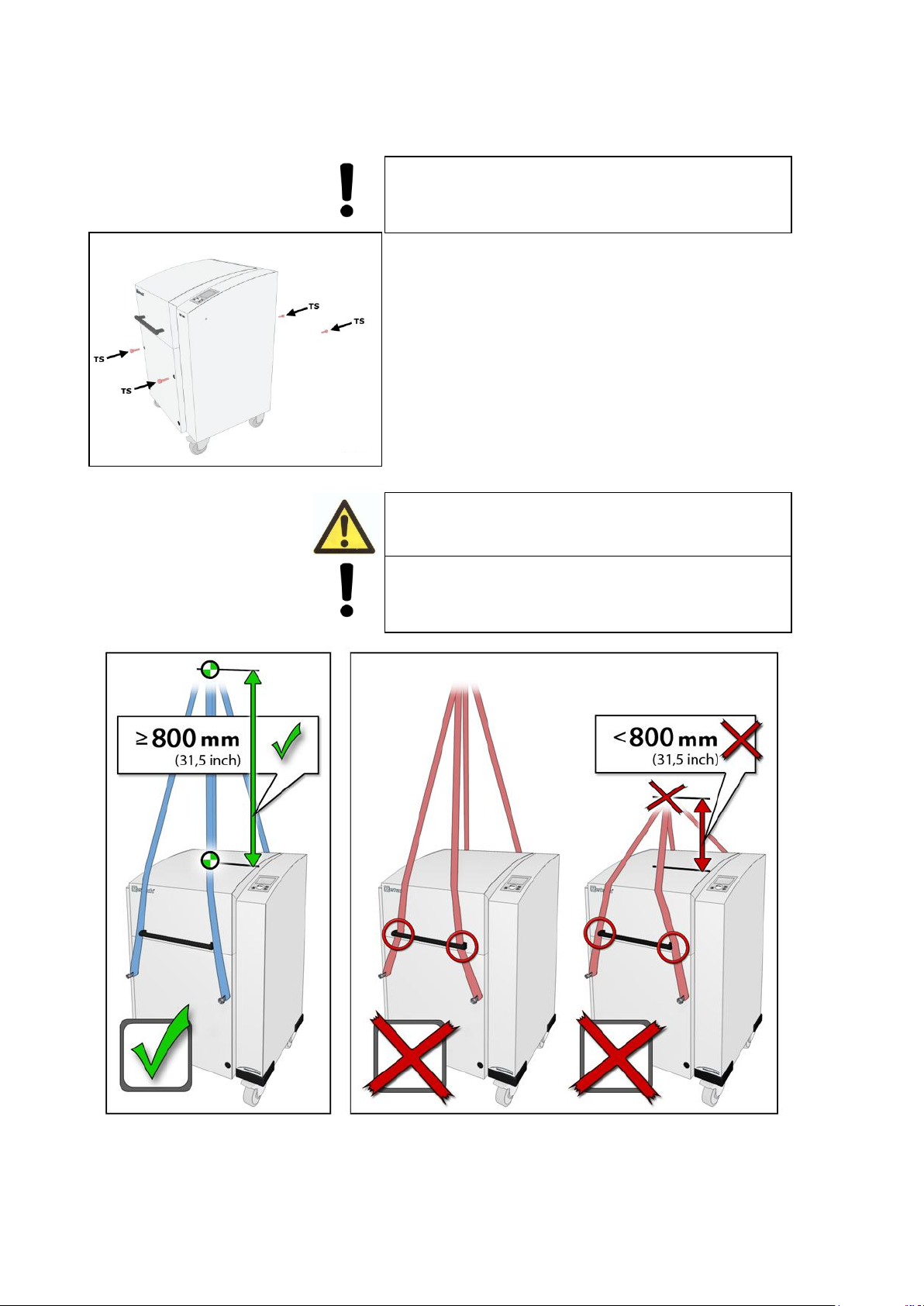

Transport

The RS200 (210 kg) is to be lifted and transported only

be the transport screws TS supplied with the machine.

(Fig. 2 Fitting the transport screws)

Net weight of RS200 approx. 210 kg

Lifting above head height is not permitted.

The RS200 must not be knocked, shaken or thrown

during transport. Otherwise the electronic and

mechanical components can become damaged.

Fig. 2 Fitting the transport screws

Packing

Packing is adapted to the transport route and conforms to

the generally applicable packaging guidelines.

15.11.2006 Retsch GmbH 10 Doc. Nr. D 98.725.9998

Page 11

Temperature variations

If temperature variations are high (e.g. during air

transport) the RS200 must be protected against

condensed water. Otherwise the electronic components

can become damaged.

Erect the RS200 on a firm base. Further parameters are given

in the section „Technical data”.

Net weight of RS200: approx. 210 kg

The machine must be locked in position before starting up.

For this purpose press the locking lever F of the two front

rollers downwards.

If the ambient temperature drops below or exceeds these

values the electrical and mechanical components can become

damaged and performance data are changed to an unknown

extent.

At higher atmospheric humidity the electrical and mechanical

components can become damaged, and performance data are

changed to an unknown extent.

Transport safety device

The driving unit of the RS200 is locked for transport.

Before starting up for the first time the two cheese-head

screws Z fitted under the rubber cover G must be

removed (Fig. 3 Transport safety device).

To do this lift the rubber cover G upwards and unscrew

the cheese-head screws. Then pull out the cheese-head

screws side wards together with the sleeve P (Fig. 4

Removing the transport safety device).

Keep the cheese-head screws for further transport.

Z Z G

Fig. 3 Transport safety device

F

Intermediate storage

Ensure that the RS200 is also stored dry during

intermediate storage.

Erection

Parameters for the place of installation

Ambient temperature: 5°C to 40°C

Atmospheric humidity

Maximum relative humidity = 80% at temperatures up to 31°C,

decreasing linearly down to 50% relative humidity at 40°C.

Installation height: max. 2000 m above sea level

15.11.2006 Retsch GmbH 11 Doc. Nr. D 98.725.9998

Page 12

Electrical connection

Voltage and frequency for the RS200 are given on the

type plate.

Ensure that these values correspond to the available

power supply system.

Connect the RS200 to the power supply system using

the supplied connection cable.

Protection by external fusing is to be carried out when

connecting the mains cable to the power supply,

according to the regulations at the place of installation.

If the values on the type plate are not observed this can

cause damage to the electronic and mechanical

components.

Electrical connection should be carried out only by a

qualified electrician. Danger through current surge.

P

G

Fig. 4 Removing the transport safety device

15.11.2006 Retsch GmbH 12 Doc. Nr. D 98.725.9998

Page 13

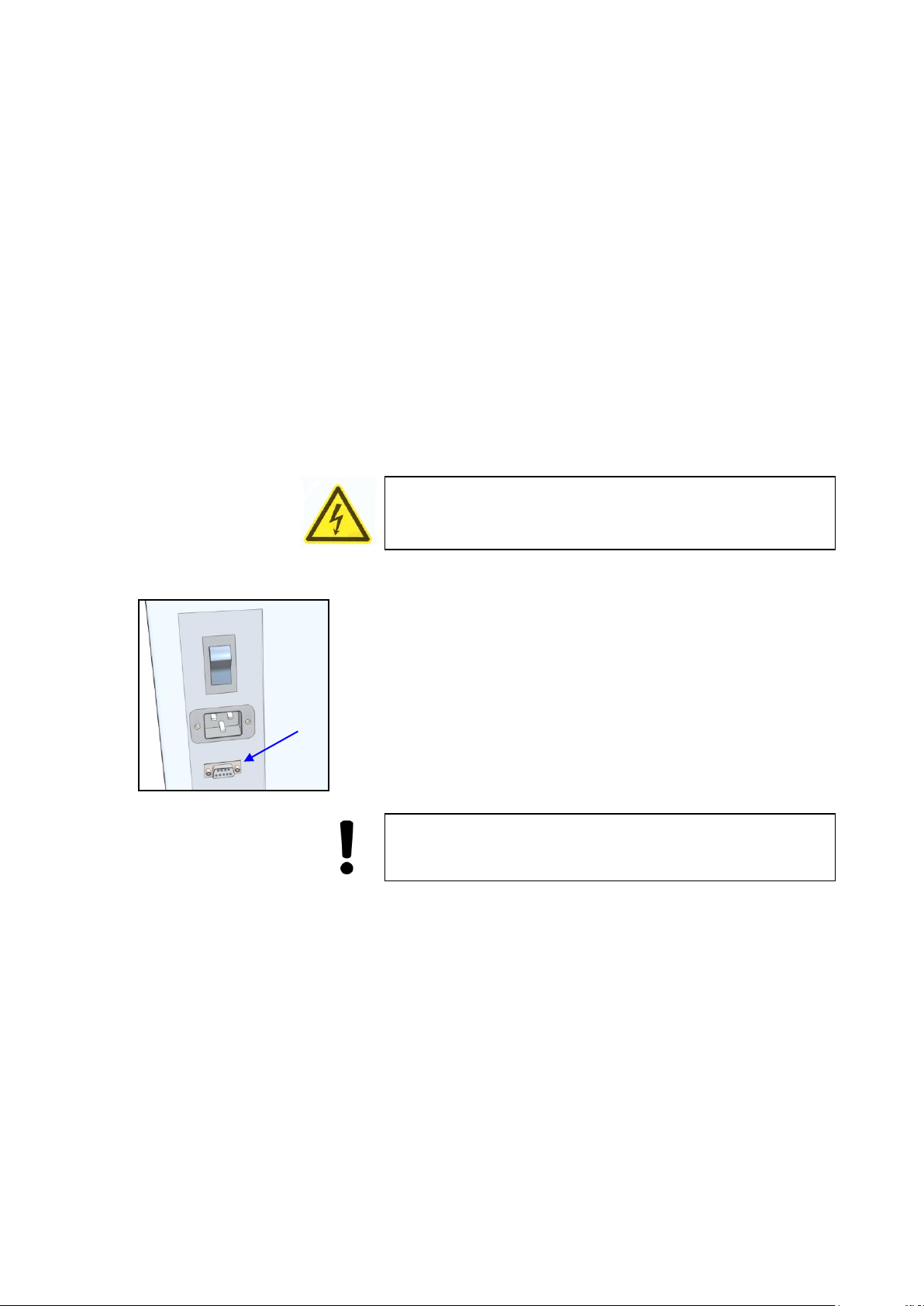

Important instructions for electrical connection

If the values on the type plate are not observed this can

result in damage to the electrical and mechanical

components.

Inactive interface Sc for optional data communication

with an external device. This necessitates updating of

the software.

(Fig. 5 Serial interface)

The interface cables must not be longer than 2.5 m.

Longer cables can cause disturbances during transmission of

data.

Sc

Fig. 5 Serial interface

1. Electrical connection without a protective conductor PE is not

permissible.

2. The drive of your RS200 is fitted with a frequency converter. To

fulfil the EMC directive this is fitted with a line filter and shielded

cables to the motor. If your RS200 includes a fault-current

protective system, fault throwing may result through the antiinterference wiring of the frequency converter when this is

switched on (switching on takes place each time the milling

chamber hood is closed). This can occur without there being a

fault on your RS200 or your mains installation.

According to state of the art selective a.c.-d.c. sensitive faultcurrent protective systems are recommended for such cases. The

tripping current must be adequately dimensioned since

capacitive compensating currents occurring only for a short time

(shielded cables, line filter) when switching on can easily cause

fault throwing.

Under certain circumstances it may be necessary to operate the

RS200 without a fault-current protective system. In this case,

however, it should be checked whether this is inconsistent with

the local regulations of the electricity supply company or other

applicable institutions or standards.

Serial interfaces

15.11.2006 Retsch GmbH 13 Doc. Nr. D 98.725.9998

Page 14

Operation

Ensure that the voltage and frequency of your mains supply

correspond to the values on the type plate of the RS200. The

mains supply must be fused up to at leasts 16A.

(Fig. 6 Receiving socket and main switch)

Plug the mains cable into the receiving socket Au on

the rear side of the equipment.

Plug the mains plug into the mains socket.

Switch on the main switch H.

Never start the RS200 without the clamped milling set.

Mechanical components can become damaged through

too high unbalance.

If the values on the type plate are not observed this can

result in damage to the electrical and mechanical

components.

When the RS200 is switched on for the first time the language

menu is displayed.

The language of your country must now be selected by

turning the control knob E. By pressing this knob selection is

confirmed and the display shows “Open lid”.

(Fig 7 Control panel)

Opening / closing / emergency unlocking

Opening

The following steps are necessary in order to insert the

milling cup(s) and to clamp it (these):

Connect RS200 to the mains supply

Switch on the main switch on the rear side

Press button A -

The safety closing device opens and the lid D can be swung

open. The milling chamber is now freely accessible.

Closing

Locking the milling chamber is possible only if the RS200 is

connected to the mains supply and the main switch on the

rear side of the machine is switched on.

Close the housing lid D

(Fig. 8 Housing lid)

A sensor senses the closing pin of the housing lid and the

motor-driven lid closing mechanism is switched on.

The housing lid D is automatically locked.

H

Au

D

Fig 6 Receiving socket and main switch

Fig7 Control panel

E

A

Fig 8 Housing lid

Connecting the power supply

15.11.2006 Retsch GmbH 14 Doc. Nr. D 98.725.9998

Page 15

Emergency unlocking

A key for the machine is included in the delivery, with which

the RS200 can be manually opened if there is a power failure.

(Fig. 9 Emergency unlocking)

(I) Insert the (S) key into the (O) opening on the

right-hand side.

(II) To unlock the gear, the key must be pushed in

further with some degree of force. While pushing the

key in, turn it in a clockwise direction as far as it will

go.

The cover can now be opened.

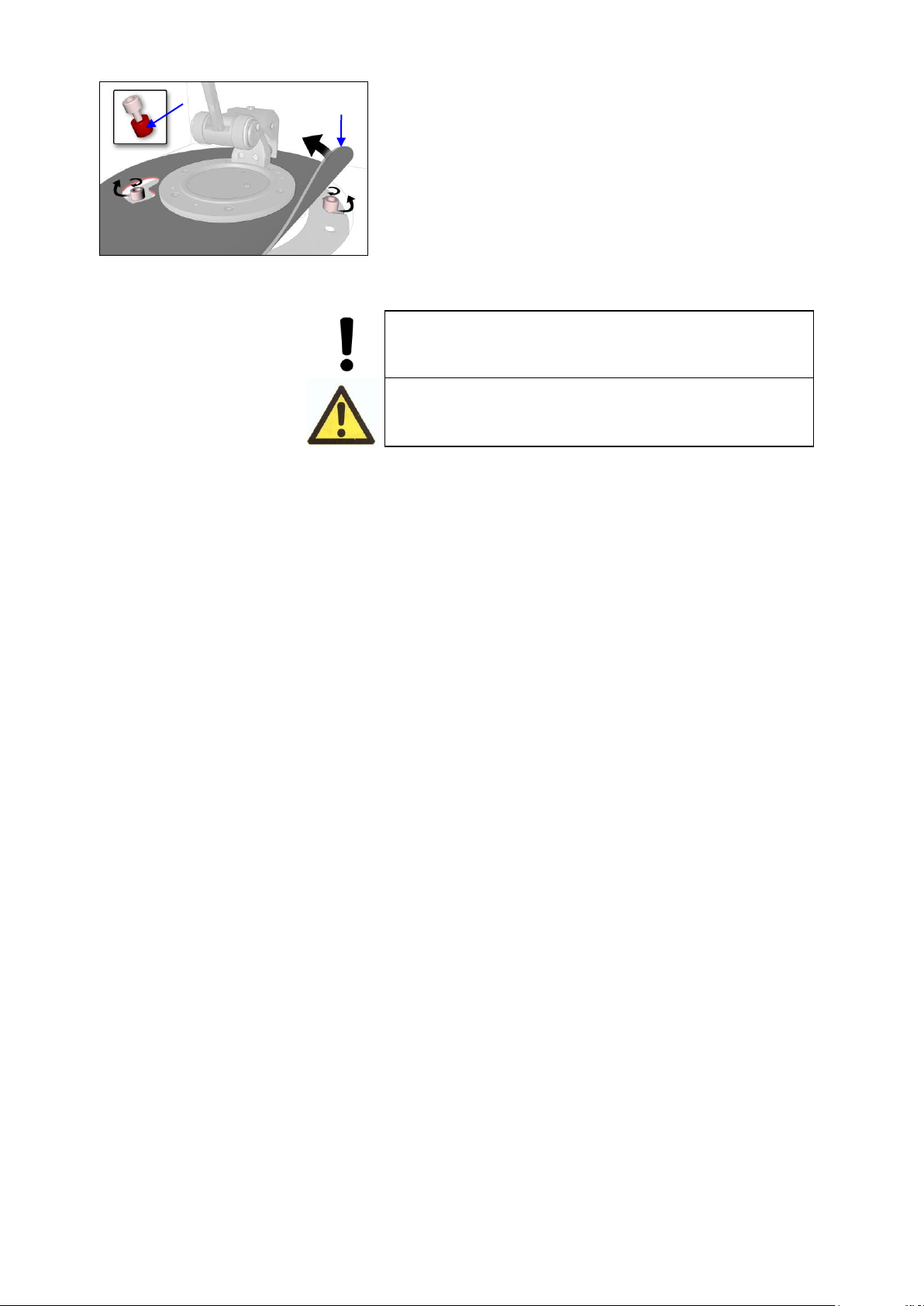

The emergency unlocking device must never be operated

when the machine is running – only when the machine is at a

standstill and is disconnected from the mains supply.

Danger of injury through unbraked, after-running of the

drive.

Wolframcarbid Tungsten carbide (WC) grinding sets

(01.462.0177 • 01.462.0265 • 01.462.0264)

NOTE: RS 200: Operate WC grinding sets only at speeds

≤1200 min-1.

RS 100 max. speed ok.

Do not use the grinding jar if it has 4 identical 13-mmdiameter boreholes on the bottom.

These grinding jars may only be used in RS200 devices that

do not have a change index after the serial number. This

means that if a change index (e.g. xxxxxxxxx-F) is specified

behind your device’s serial number, you may not use the

older grinding jar described in the above.

Older grinding jars with 4 identical boreholes on the bottom

(13mm) can be reworked free of charge.

Fig. 9 Emergency unlocking

RS 200 Max. Speed

≤ 1200 min

-1

RS 100 Max. Speed

ok

Insertion and clamping of the milling set of the

RS200

15.11.2006 Retsch GmbH 15 Doc. Nr. D 98.725.9998

Page 16

In the RS200 a Retsch milling set of volumes 50 / 100 / 250

ml and materials special steel / agate / tungsten carbide can

be used.

Never start the RS200 without the clamped milling set.

Mechanical components can become damaged.

Fit the milling cup with a disc and a ring. Two rings can

also be inserted, depending on the milling set.

Position the rings and disc as shown in the

illustration opposite.

(Fig. 10 Positioning the ring and disc)

The material to be milled is filled into the space R

between the milling cup wall and the first ring. For an

optimum milling result do not fill any material into the

space between the inner ring and disc.

(Fig. 11 Filling volume of milling cup)

Remove any residues of the milling material adhering to

the milling cup (e.g. with a brush).

Close the milling cup with the lid, not forgetting the seal.

Engage the milling set in the locking bolt B of the holding

device by turning slightly.

(Fig. 12 Locking bolt)

The milling set is clamped with the eccentric lever S

You can then close the hood and start the RS200

(Fig. 13 Eccentric lever)

Please take necessary measures, depending on the

dangerous nature of your milling material, to avoid danger

to persons.

S B R

Fig. 10 Positioning ring and disc

Fig.11 Filling volume of milling cup

Fig. 12 Locking bolt

Fig.13 Eccentric lever

Preparation of the milling process

15.11.2006 Retsch GmbH 16 Doc. Nr. D 98.725.9998

Page 17

When removing and opening hot milling sets it is essential

to wear protective gloves.

Danger of burning the hands.

Rub the rubber gasket in the clamping plate from time to

time with talcum powder and do not leave the milling set in

the RS200 after milling.

Strongly heated milling sets can stick together with

the rubber in the clamping plate and are then very

difficult to remove.

15.11.2006 Retsch GmbH 17 Doc. Nr. D 98.725.9998

Page 18

Before starting the RS200

The milling cup clamping device has proved itself for

many years, and is easy and reliable to handle. In order

to guarantee safety of the operator and a long service

life of the machine components the milling cups must

be clamped carefully.

Please remember that the RS200 is a milling machine

with a very high power input into the milling material;

therefore the milling cups must be fixed properly.

Before starting the machine ensure that the milling set is

clamped.

Milling set can be ejected; danger of injury and damage

to equipment.

Do not use the grinding jar if it has 4 identical 13-mmdiameter boreholes on the bottom.

These grinding jars may only be used in RS200 devices that

do not have a change index after the serial number. This

means that if a change index (e.g. xxxxxxxxx-F) is specified

behind your device’s serial number, you may not use the

older grinding jar described in the above.

Older grinding jars with 4 identical boreholes on the bottom

(13mm) can be reworked free of charge.

The RS200 is suitable only for milling sets with a nominal

volume of 50 – 250 ml.

These are available in the following materials:

Special steel 50/100/250ml

Free of heavy metal 100/250ml

Agate 50/100ml

Tungsten carbide 50/100ml

Zirconium oxide 50/100ml

The milling sets have been developed specially for extreme

test conditions, such as long-term trials, high mechanical

loading and maximum rotary speeds – also for mechanical

alloying.

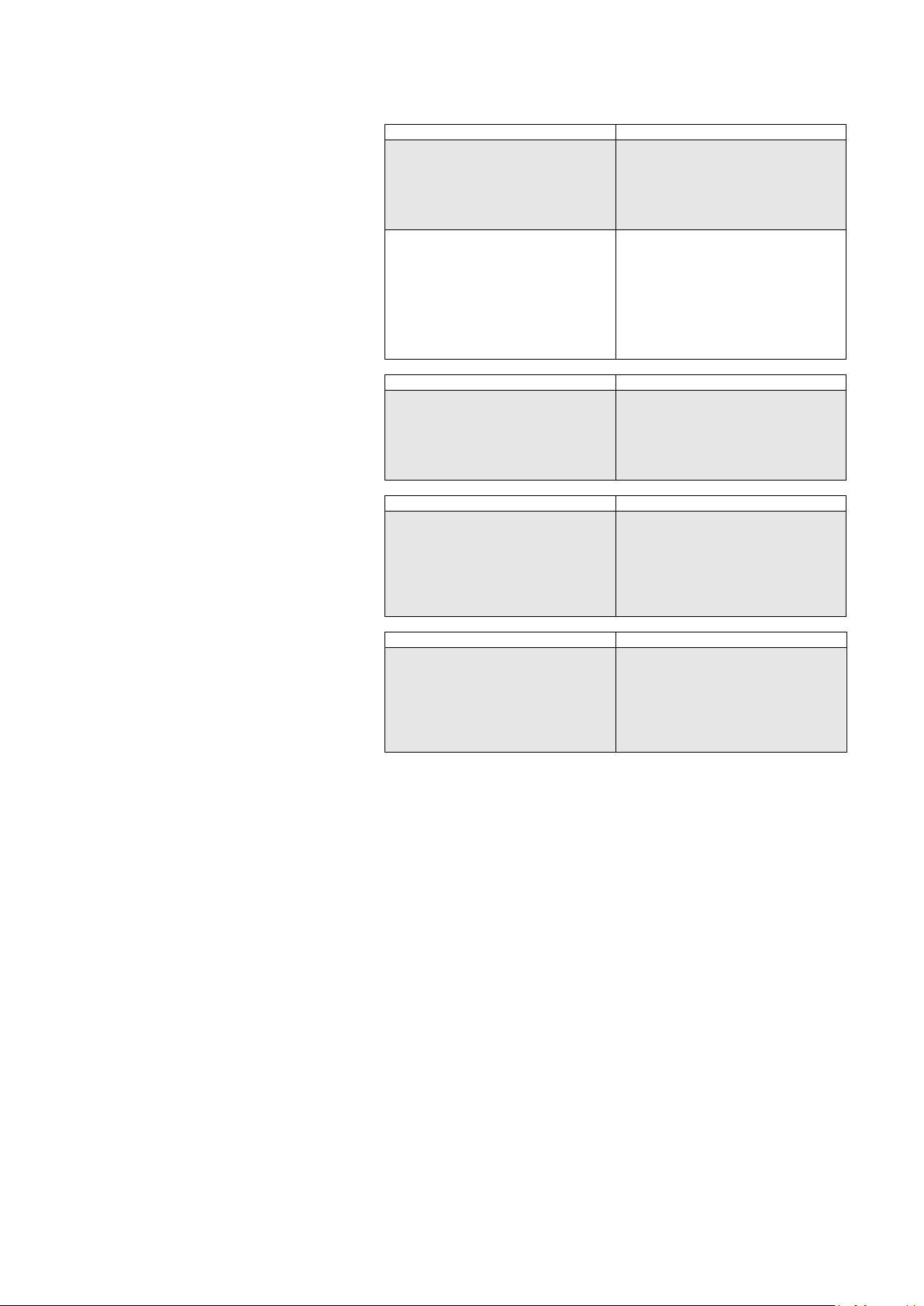

Milling cup

nominal

volume

Max.

charged grain size

Sample quantity

max./recommende

d

50 ml

< 5 mm

< 50/35 ml

100 ml

< 10 mm

< 100/75 ml

250 ml

< 15 mm

< 250/150 ml

Fig. 14 Milling sets

Suitable milling sets for the RS200

Milling set filling level

Guide values for material quantity and grain size

15.11.2006 Retsch GmbH 18 Doc. Nr. D 98.725.9998

The milling set to be used is determined by the sample

volume and max. charged grain size. Selection of the milling

set material depends on the degree of hardness of the milling

material and the effect of possible abrasion on the

subsequent analysis.

Page 19

If the filling level of the milling set is too high or too low the

milling result will be impaired and damage (wear increase) to

the milling set can result.

Please take necessary measures, depending on the dangerous

nature of your milling material, to avoid danger to persons.

When removing and opening hot milling cups it is essential to

wear protective gloves.

Danger of burning the hands.

Do not subject milling cups with ceramic inserts to sudden

temperature variations during rinsing.

The ceramic inserts can crack through sudden

temperature differences.

Drying the milling cups

The milling cups can be dried in a drying oven, at any time

after cleaning, at the temperatures given below.

Milling cup material

Temperature

Special steel

Up to 200°C

Stainless steel

Up to 200°C

Tungsten carbide

Up to 150°C

Agate

Up to 120°C

Zirconium oxide

Up to 120°C

Cleaning the milling cups

To clean the milling cups the seal between the lid and milling

cup must be removed.

Milling cups, including those with bonded ceramic inserts,

can be cleaned with alcohol or petrol, or can also be boiled

out briefly.

15.11.2006 Retsch GmbH 19 Doc. Nr. D 98.725.9998

Page 20

The mill has a new, very comfortable operator control system.

All relevant data can be entered or called via a graphic display

with one knob operation.

The menu system is multilingual.

Name

Function

A

Display

Displays the menu, parameter settings, operating instructions and fault

signalling.

B

START button

Starts the milling process

C

STOP button

Stops the milling process

D

Button

Opens the milling chamber hood

E

Setting knob

By turning and pressing, all menu points can be selected and parameters set.

Turning 1

By turning, the various menu points can be selected. Selected menu points

are displayed inversely.

Turning 2

Setting of parameters in the opened menu points (see Pressing 1)

Pressing 1

Selected menu points are opened

Pressing 2

Short pressing confirms setting of parameters

Pressing 3

Continuous pressing: jump back to the 1st menu level

Programme mode – Take over parameters

Programme mode – Change programme

Programme mode – Delete programme

Warning sound off

Service due

Motor or frequency converter too hot

°C

Fig. 15 Control panel

A B C E D

Operation via the display unit of the RS200

Symbols in the display unit

15.11.2006 Retsch GmbH 20 Doc. Nr. D 98.725.9998

Page 21

Setting possibilities via the display menu

Languages

Menu

Display

Languages

False language selection

If the wrong language is accidentally selected switch off the unit at the main switch.

Keep the buttons pressed simultaneously and switch on the unit again.

After selecting the correct language switch off the equipment and then immediately on again.

Confirm your selection by pressing the setting knob.

The unit is now set permanently in your language and you are in the main menu.

Manual operation

If this function is set you can call and change all parameters and functions at any time.

This is also possible during milling.

Milling programme

To get to the „Milling programme“ function press the setting knob with “Manual

operation” set. Milling programme 1 appears, flashing, in the display. Furthermore

data which may already have been stored in Milling programme 1 are also

displayed.

By turning the setting knob to the right you can select other milling programmes 2-

10. Any parameters which may have been stored are displayed each time.

You can start the machine directly with the selected milling programme.

To return to „manual operation“ turn the setting knob completely to the left and

confirm with the setting knob.

Milling time

00:01 bis 99:00

The RS200 is started with the preselected milling time and the speed last used.

Speed

700 to 1500 rpm

The RS200 is started with the preselected milling time and the preselected speed.

For milling cups with agate lining the speed is limited to

700 rpm and cannot be changed.

The same applies if no milling cup is clamped.

For setting possibilities on the display described below please observe the menu structure on this page. The

selection bar in the display should be operated as follows:

Vertical manoeuvering through the structure by turning the setting knob

Horizontal manoeuvering through the menu structure by pressing the setting knob

Setting of numerical values or decisions by turning the setting knob

Confirmation of settings by pressing the setting knob

With “RETURN” you go to the previous menu structure level

By continuous pressing of the setting knob you return to the basic screen

You can select the language here. After selection and pressing the setting knob the complete menu structure is

shown in this language.

Minutes: Seconds

15.11.2006 Retsch GmbH 21 Doc. Nr. D 98.725.9998

Page 22

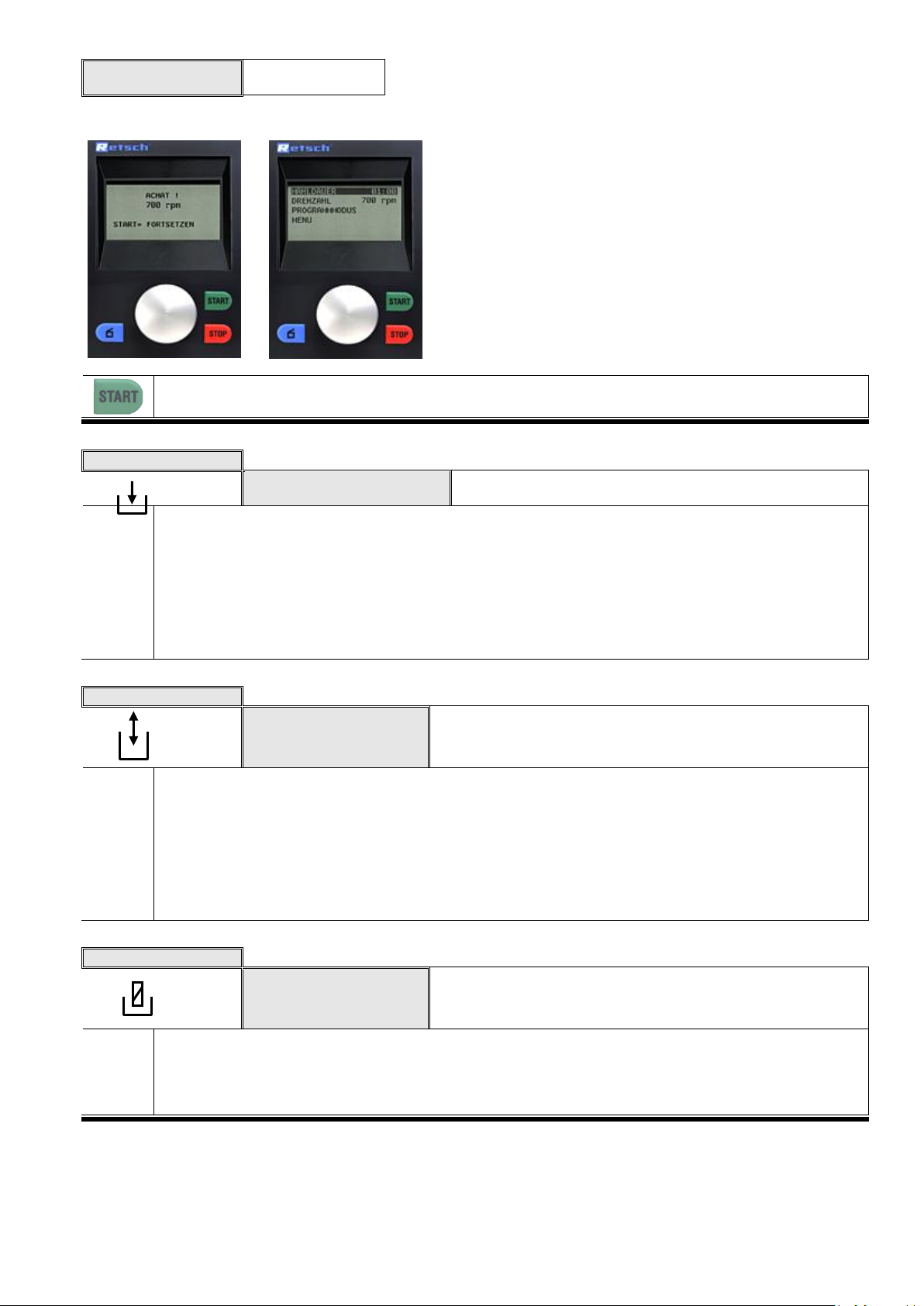

Speed with agate

700 rpm

Figure 1

Figure 2

If no milling cup, or a milling cup with agate lining, is

clamped the display in fig. 1 appears.

After confirmation with the START button the menu (fig. 2)

appears in the display and all parameters except speed can

be changed.

The RS200 is started with the preselected milling time.

Programme mode

Take over parameters

Here all the previously set parameters, such as milling

time, speed, interval and pause, can be stored in a store.

Set the required parameter.

Change to „Programme mode“ in the menu, press the setting knob and confirm „Take over

parameters” again. The menu shows „Milling programme“ and on the right the storage

location number.

Turn the setting knob to the right until you have found a milling programme with empty

storage locations, or one which you wish to overwrite.

By pressing the setting knob you can reserve the selected storage location.

You can now choose between „Store parameter?” or “Cancel”.

You will then be returned again into the “Programme mode” level.

Programme mode

Change programme

Here all previously stored parameters, such as milling time,

speed, interval and pause, can be changed.

It is also possible to enter new parameters.

Select „Programme mode“, „Change programme“ and confirm with the setting knob. The

display shows the milling programme with storage location number again.

To select the „Milling programme“ to be changed press the setting knob; only the storage

location numbers are inverse – the milling programme is changed by turning the setting

knob.

Confirm the milling programme to be changed by pressing; you can now change the

parameters.

After this you can „Store (the changed) parameters” or “Cancel”.

You will then be returned again to the “Programme mode” level.

Programme mode

Delete programme

Here all the previously stored parameters can be deleted.

Select „Programme mode“, press the setting knob and confirm „Delete programme” again.

Select the milling programme to be deleted by turning the setting knob, and confirm by

pressing.

You can now “Delete programme” or “Cancel”.

You will then be returned again to the programme mode level

If no milling cup, or a milling cup with agate lining, is clamped, the speed is limited to 700 rpm and cannot be

changed.

15.11.2006 Retsch GmbH 22 Doc. Nr. D 98.725.9998

Page 23

Starting time

Start in xxh xxm

Cancel

Starting can be preselected here in steps of 01 to 99 hrs or

01 to 60 min.

The RS200 is started with the preselected milling time and speed after the set starting time has

elapsed.

Ensure that the milling cups have been clamped properly before

you start the machine unattended.

Even though starting without the lid closed is not possible, make

sure that the lid is closed before you start the machine

unattended.

You can interrupt running of the starting time at any time with the STOP button and with the main

switch on the rear side of the unit. You then have to reprogramme the starting time.

Opening automatic

MENU

SETTINGS

OPENING AUTOMATIC

Service

MENU

SETTINGS

SERVICE

Warning sound

MENU

SETTINGS

WARING SOUND

Here you can preselect whether the milling chamber lid is automatically lifted at the end of milling, or is to be

opened only by pressing the knob. If the function is switched off the

pictogram appears in the display to confirm this.

Fault signals through incorrect operation can be supported acoustically by a warning sound.

With the function switched off the corresponding pictogram appears

The service menu is divided into four sub-menus:

SERVICE INSTRUCTIONS

Service instructions are filed here in the form of a checklist which is intended to facilitate effective,

regular service and to improve the operating state of the machine. See also the section General /

Maintenance.

SERVICE INTERVAL

An individual service interval can be seet here, according to the environment of the machine. After this

time the operator is required to have the machine serviced. The time to be set is related to the total

sum of milling times (times between START and STOP). A time between 1 – 99 hrs can be set. If the

environmental conditions are rough we recommend that the works preset time is reduced.

OPERATING HOURS

The milling hours are counted, i.e. the total sum of the times between START and STOP. These times

cannot be manipulated.

OPERATING SOFTWARE

The operating software version can be interrogated and, if necessary, updated. When required please

contact your Retsch distributor.

If you have accidentally got into the menu and jumping back into the previous menu is not possible,

switch off the unit at the main switch and restart.

15.11.2006 Retsch GmbH 23 Doc. Nr. D 98.725.9998

Page 24

Contrast / Brightness

MENU

DISPLAY

CONTRAST

BRIGHTNESS

Date / Time

MENU

DATE

TIME

Contrast and brightness can be adapted to each user or to the environment (sunlight, dazzling etc).

If you have accidentally selected the wrong contrast or brightness (the display can no longer be seen), switch

off the unit at the main switch, keep the buttons START, STOP and LID OPEN pressed simultaneously and

switch on again. You are now in the language selection and the setting values CONTRAST and BRIGHTNESS

have the works presettings again.

The actual date and time can be entered here.

The time then appears in the stand-by monitor.

The unit can be disconnected from the mains for up to 30 days without the settings being lost.

Stand-by monitor

After 15 minutes inactivity of the unit (times after a STOP command) the stand-by monitor switches on

automatically.

By pressing one of the buttons, or touching the setting knob, the stand-by monitor disappears without carrying

out the command which has been made.

If you were in a sub-menu when the stand-by monitor was activated, you return to this selection window

automatically.

The stand-by monitor cannot be set and cannot therefore be switched off.

15.11.2006 Retsch GmbH 24 Doc. Nr. D 98.725.9998

Page 25

Fault signals in the display

Appearing in display

Appearing in display

F03

F04

Problem in

Open or close lid,

safety circuit of

otherwise lid lock

lid lock

defective

Service necessary!

Service necessary!

Fault appears with the lid closed if

the lid lock is defective.

Switch off machine at the

main switch and switch on

again.

If the fault reappears this is a

safety problem and servicing is

necessary.

Fault appears with the lid closed if

the lid lock is defective.

Switch off machine at the

main switch and switch

on again.

If the fault reappears this is a

safety problem and servicing is

necessary.

Appearing in display

Appearing in display

F07

F15

Motor speed control

Problem in

is defective

safety circuit of

frequency converter

Service necessary!

Appearing in display

Appearing in display

F16

F17

Motor is overheated

Motor is overheated

No START possible

Has been switched off

Please allow to cool

Please allow to cool

Continue with STOP

Appearing in display

F18

Problem in

safety circuit of

transformer

Service necessary!

F02 to F13

15.11.2006 Retsch GmbH 25 Doc. Nr. D 98.725.9998

Page 26

General

Do not clean the RS200 with running water.

Danger to life through current surge.

Use only a cloth moistened with water. Solvents are not

permitted.

To ensure that your RS200 will function reliably, the following

maintenance work should be done from time to time, but at the

latest every month :

Check that roller 1 in the locking bolt moves easily. If it

doesn’t, oil it, e.g. with sewing machine oil.

(Fig. 17 Locking bolt)

Clean magnets 2 in the locking bolt.

To ensure that the grinding jar can be clamped and

released safely, it is essential that the clamping

mechanism can move easily. It must be checked and

cleaned every day and lubricated when necessary.

(Fig. 17.1 Locking bolt)

To ensure that the housing cover on the RS 200 can close

reliably, it is essential that roller 1 in the locking bolt can move

easily.

Caution! Due to capacitor discharging at the frequency converter

the device conducts voltage for up to 3 minutes after the mains

plug has been disconnected.

Fig. 17 Locking bolt

Fig. 17.1 Clamping mechanism

Clamping

mechanism

Cleaning

Maintenance

Maintenance of the rubber springs

15.11.2006 Retsch GmbH 26 Doc. Nr. D 98.725.9998

Page 27

Opening the cover

Press the “open cover” button or

disconnect the mains plug at the back of the machine

and use the emergency unlocking key

(see chapter on Emergency Unlocking)

Remove only the lower cover caps.

Unscrew the two cheese-head screws.

Take off the lower cover.

The three rubber springs must be greased every 250h operating

hours at the top and bottom ends of the guide bolts. Use the

“Staburags NBU 4MF” heavy-duty lubricant type from Klüber or

another heavy-duty lubricant of the same quality.

To grease, remove the rubber springs and put a

sufficient quantity of grease into the two holes.

Wearing parts

The 3 rubber springs should be replaced after approx. 500

operating hours. Order no. 03.228.0003

The rubber plate should be replaced after approx. 300 operating

hours. Order no. 03.243.0045

rubber plate

These operating instructions do not include any repair

instructions. In the interests of your own safety, repairs should

only be performed by Retsch GmbH or authorised agent or

service technicians.

Copyright

Cover caps

Cheese-head screws

Lowe

r

Rubber springs

Distribution or duplication of this documentation, using or passing

on the contents, is allowed only with the express permission of

15.11.2006 Retsch GmbH 27 Doc. Nr. D 98.725.9998

Retsch GmbH.

Persons violating are liable to pay damages.

Alterations

Subject to technical alterations without notice.

Page 28

Page 29

Authorized person for the compilation of technical documents:

J. Bunke (technical documentation)

The following records are held by Retsch GmbH in the form of Technical Documentation:

Detailed records of engineering development, construction plans, study (analysis) of the measures required for

conformity assurance, analysis of the residual risks involved and operating instructions in due form according to

the approved regulations for preparation of user information data.

The CE-conformity of the Retsch Vibratory Disc Mill Type RS 200 is assured herewith.

In case of a modification to the machine not previously agreed with us as well as the use of not

licensed spare parts and accessories this certificate will lose its validity.

Retsch GmbH Haan, January 2010

Dr. Stefan Mähler

Manager technical services

Retsch GmbH Ret sch-Allee 1- 5 427 81 Haan Germa ny w w w . r e t sc h .c o m

VIBRATORY DISC MILL

RS 200

FB-EW-805-053 (E) Änderungsstand C 01.2012

CERTIFICATE OF CE-CONFORMITY

Translation

Certificate of CE-Conformity according to:

EC Mechanical Engineering Directive 2006/42/EC

Applied harmonized standards, in particular:

DIN EN ISO 12100 Security of machines

EC Directive Electromagnetic Compatibility 2004/108/EC

Applied standards, in particular:

EN 61000-3-2/-3 Electromagnetic compatibility (EMC)

EN 61236 Electrical measuring, operating, controlling and laboratory equipment – EMC-

requirements in conjunction with EN 61000

EN 55011 Limit values and measuring procedures for noise suppression of industrial,

scientific and medical high frequency devices

Additional applied standards, in particular

DIN EN 61010 Safety prescriptions concerning measuring-, operating-, controlling- and

laboratory equipment

Page 30

Page 31

Page 32

Copyright

® Copyright by

Retsch GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

Loading...

Loading...