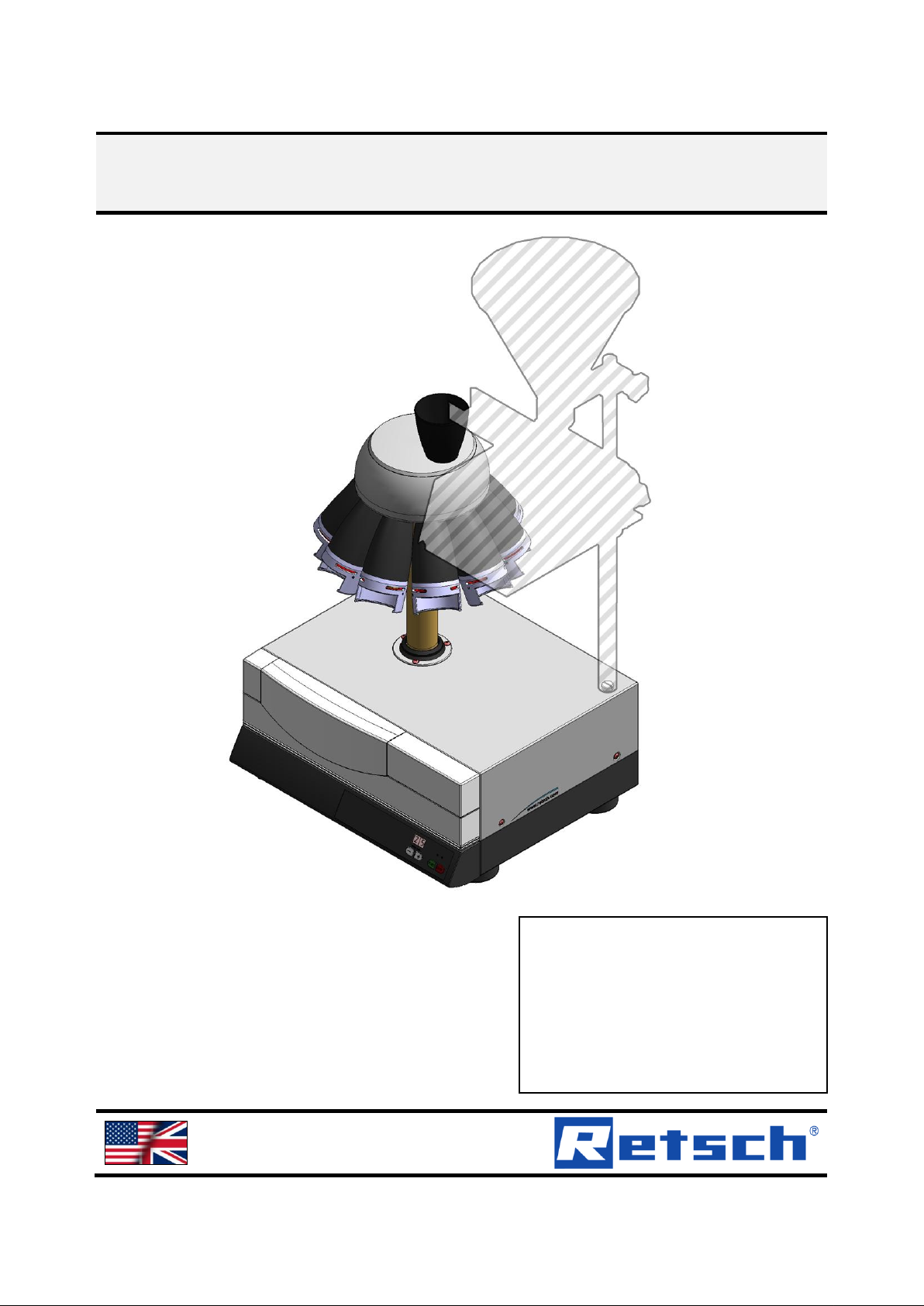

Page 1

Manual

Sample Divider PT100

Translation

© Retsch GmbH, 42781 Haan, Retsch-Allee 1-5, Germany 07.11.2012 0002

Page 2

Copyright

© Copyright by

Retsch GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

2

Page 3

1 Notes on the Operating Manual ............................................................................................................ 5

1.1 Explanations of the safety warnings .................................................................................................. 6

1.2 General safety instructions ................................................................................................................ 7

1.3 Repairs ............................................................................................................................................... 8

2 Confirmation ........................................................................................................................................... 9

3 Transport, scope of delivery, installation .......................................................................................... 10

3.1 Packaging ........................................................................................................................................ 10

3.2 Transport.......................................................................................................................................... 10

3.3 Temperature fluctuations and condensed water ............................................................................. 10

3.4 Conditions for the place of installation ............................................................................................. 10

3.5 Installation of the machine ............................................................................................................... 10

3.6 Type plate description ...................................................................................................................... 10

3.7 Electrical connection ........................................................................................................................ 11

4 Technical data ....................................................................................................................................... 11

4.1 Use of the machine for the intended purpose.................................................................................. 12

4.2 Emissions......................................................................................................................................... 12

4.3 Degree of protection ........................................................................................................................ 12

4.4 Drive output...................................................................................................................................... 12

4.5 Rotation speed ................................................................................................................................. 13

4.6 Rated power .................................................................................................................................... 13

4.7 Feed size ......................................................................................................................................... 13

4.8 Receptacle volume .......................................................................................................................... 13

4.9 Dimensions and weight .................................................................................................................... 13

4.10 Required floor space ........................................................................................................................ 15

5 Operating the machine ........................................................................................................................ 16

5.1 Views of the Instrument ................................................................................................................... 16

5.2 Overview table of the parts of the device ........................................................................................ 17

5.3 Operating elements and displays .................................................................................................... 18

5.4 Overview Table of the Operating Elements and the Display ........................................................... 18

5.5 Mounting the dividing head/dg_bm "text_mod_1315215336450_0001"> ....................................... 18

5.6 Inserting sample vessel ................................................................................................................... 19

5.6.1 Inserting the sample container into the quick-release sample outlet........................................... 20

5.7 Switching On and Off ....................................................................................................................... 21

5.8 Starting, Interrupting, Stopping ........................................................................................................ 21

5.8.1 Starting ......................................................................................................................................... 21

5.8.2 Interrupting ................................................................................................................................... 21

5.8.3 Stopping ....................................................................................................................................... 21

5.9 Process Run Duration ...................................................................................................................... 22

3

Page 4

5.9.1 Process run times ........................................................................................................................ 22

5.9.2 Continuous run............................................................................................................................. 22

5.10 Attaching vibratory feeder ................................................................................................................ 22

5.11 Creating interface connection .......................................................................................................... 24

5.12 Starting device and vibratory device simultaneously ....................................................................... 26

5.13 Replacing the machine fuses........................................................................................................... 27

6 Cleaning and service ........................................................................................................................... 27

7 Fault messages ..................................................................................................................................... 28

8 Disposal ................................................................................................................................................. 29

9 Index ...................................................................................................................................................... 30

Appendix ............................................................................................................................... following pages

4

Page 5

Notes on the Operating Manual

Pos: 1.1 /00005 Überschriften/1. Übersc hriften/1 Hinweise zur Bedienungsanleitung @ 0\mod_1222347415287_9.doc @ 26 31 @ 1 @ 1

1 Notes on the Operating Manual

Pos: 1.2 /00010 Bedienungsanleitungen Kapitelsammlungen/CryoMill/0001 Hinweis e zur Bedienungsanleitung/Modul Hinweis zur Bedienungsanleitung @ 0\mod_122 2347341773_9.doc @ 2540 @ @ 1

This operating manual is a technical guide on how to operate the device safely and

it contains all the information required for the areas specified in the table of

contents. This technical documentation is a reference and instruction manual. The

individual chapters are complete in themselves.

Familiarity (of the respective target groups defined according to area) with the

relevant chapters is a precondition for the safe and appropriate use of the device.

This operating manual does not contain any repair instructions. If faults arise or

repairs are necessary, please contact your supplier or get in touch with Retsch

GmbH directly.

Application technology information relating to samples to be processed is not

included but can be read on the Internet on the respective device’s page at

Pos: 1.3 /00010 Bedienungsanleitungen Kapitelsammlungen/CryoMill/0001 Hinweis e zur Bedienungsanleitung/Modul Änderung en @ 0\mod_1222347341241_9.doc @ 2 526 @ @ 1

www.retsch.com.

Changes

Pos: 1.4 /00010 Bedienungsanleitungen Kapitelsammlungen/CryoMill/0001 Hinweis e zur Bedienungsanleitung/Modul Urheberrech t @ 0\mod_1222347342038_9.doc @ 2 547 @ @ 1

Subject to technical changes.

Pos: 2.1 /00010 Bedienungsanleitungen Kapitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @ @ 1

Copyright

Disclosure or reproduction of this documentation, use and disclosure of its contents

are only permitted with the express permission of Retsch GmbH.

Infringements will result in damage compensation liability.

5

Page 6

Notes on the Operating Manual

WARNING

Type of danger / personal injury

Source of danger

– Possible consequences if the dangers are not observed.

• Instructions on how the dangers are to be avoided.

WARNING

CAUTION

Type of danger / personal injury

Source of danger

– Possible consequences if the dangers are not observed.

• Instructions on how the dangers are to be avoided.

CAUTION

NOTICE

Nature of the property damage

Source of property damage

– Possible consequences if the instructions are not observed.

• Instructions on how the dangers are to be avoided.

Pos: 2.2 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Erklärunge n zu den Sicherheitswarnungen @ 0\m od_1222344569771_9.doc @ 2484 @ 2 @ 1

1.1 Explanations of the safety warnings

Pos: 2.3 /00003 Standard Kapitel/General Modul Warnhinweise Erklärung neu @ 0\ mod_1234858329746_9.doc @ 6190 @ @ 1

In this Operating Manual we give you the following safety warnings

Serious injury may result from failing to heed these safety warnings. We give you

the following warnings and corresponding content.

We also use the following signal word box in the text or in the instructions on action

to be taken:

Moderate or mild injury may result from failing to heed these safety warnings.

We give you the following warnings and corresponding content.

Pos: 2.4 /00010 Bedienungsanleitungen Kapitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @ @ 1

We also use the following signal word box in the text or in the instructions on action

to be taken:

In the event of possible property damage we inform you with the word

“Instructions” and the corresponding content.

We also use the following signal word in the text or in the instructions on action to

be taken:

NOTICE

6

Page 7

Notes on the Operating Manual

CAUTION

Read the Operating Manual

Non-observance of these operating instructions

– The non-observance of these operating instructions can

result in personal injuries.

• Read the operating manual before using the device.

• We use the adjacent symbol to draw attention to the

necessity of knowing the contents of this operating

manual.

CAUTION

Changes to the machine

– Changes to the machine may lead to personal injury.

• Do not make any change to the machine and use spare parts and

accessories that have been approved by Retsch exclusively.

NOTICE

Changes to the machine

– The conformity declared by Retsch with the European Directives will lose

its validity.

– You lose all warranty claims.

• Do not make any change to the machine and use spare parts and

accessories that have been approved by Retsch exclusively.

Pos: 2.5 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Generelle Sicherheitshinweise @ 0\mod_12223445 68974_9.doc @ 2463 @ @ 1

1.2 General safety instructions

Pos: 2.6 /00004 Warnhinweise/V0002 V ORSICHT Bedienungsanleitung lesen @ 2\ mod_1263894982815_9.doc @ 18630 @ @ 1

Pos: 2.7 /00003 Standard Kapitel/General Modul Zielgruppe und Sicherheit @ 0\mo d_1228722955300_9.doc @ 4100 @ @ 1

Target group : All persons concerned with the machine in any form

This machine is a modern, high performance product from Retsch GmbH and

complies with the state of the art. Operational safety is given if the machine is

handled for the intended purpose and attention is given to this technical

Pos: 2.8 /00003 Standard Kapitel/General Modul Sicherheitshinweise @ 0\mod_12 28722954800_9.doc @ 4086 @ @ 1

Pos: 2.9 /00004 Warnhinweise/V0015 VORS ICHT + HINWEIS Sach- und Person enschäden @ 1\mod_1236238456676_9.doc @ 7642 @ @ 1

documentation.

You, as the owner/managing operator of the machine, must ensure that the people

entrusted with working on the machine:

• have noted and understood all the regulations regarding safety,

• are familiar before starting work with all the operating instructions and

specifications for the target group relevant for them,

• have easy access always to the technical documentation for this machine,

• and that new personnel before starting work on the machine are familiarised

with the safe handling of the machine and its use for its intended purpose,

either by verbal instructions from a competent person and/or by means of

this technical documentation.

Improper operation can result in personal injuries and material damage. You are

responsible for your own safety and that of your employees.

Make sure that no unauthorised person has access to the machine.

Pos: 2.10 /00010 Bedienungsanleitungen K apitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.d oc @ 2386 @ @ 1

7

Page 8

Notes on the Operating Manual

The Retsch representative in your country

Your supplier

Retsch GmbH directly

Pos: 2.11 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Reparature n @ 0\mod_1223624336511_9.doc @ 2978 @ @ 1

Reperaturen

1.3 Repairs

Pos: 2.12 /00003 Standard Kapitel/Gen eral Modul Reparaturen @ 0\mod_12287229 54535_9.doc @ 4079 @ @ 1

This operating manual does not contain any repair instructions. For your own

safety, repairs may only be carried out by Retsch GmbH or an authorized

representative or by Retsch service engineers.

In that case please inform:

Your Service Address:

Pos: 3.1 /00020 BDA Software/20005 PM GC Kapitelsammlung/- - - - Seitenumbruc h - - - - @ 0\mod_1208857688413_0.doc @ 337 @ @ 1

8

Page 9

Confirmation

I have read and taken note of the contents of all chapters in this operating

manual as well as all safety instructions and warnings.

User

Surname, first name (block letters)

Position in the company

Signature

Service technician or operator

Surname, first name (block letters)

Position in the company

Place, date and signature

Pos: 3.2 /00020 BDA Software/20005 PM GC Kapitelsammlung/Überschriften/1. Üb erschriften/1 Bestätigung (Formular für den Be treiber) @ 0\mod_1208870841095_9.d oc @ 430 @ 1 @ 1

Bestätigung

2 Confirmation

Pos: 3.3 /00003 Standard Kapitel/General Modul Bestätigung @ 0\mod_122872296 2707_9.doc @ 4114 @ @ 1

This operating manual contains essential instructions for operating and maintaining

the device which must be strictly observed. It is essential that they be read by the

operator and by the qualified staff responsible for the device before the device is

commissioned. This operating manual must be available and accessible at the

place of use at all times.

The user of the device herewith confirms to the managing operator (owner) that

(s)he has received sufficient instructions about the operation and maintenance of

the system. The user has received the operating manual, has read and taken note

of its contents and consequently has all the information required for safe operation

and is sufficiently familiar with the device.

As the owner/managing operator you should for your own protection have your

employees confirm that they have received the instructions about the operation of

the machine.

Pos: 4.1 /00010 Bedienungsanleitungen Kapitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @ @ 1

9

Page 10

Transport, scope of delivery, installation

NOTICE

Transport

– Mechanical or electronic components may be damaged.

• The machine may not be knocked, shaken or thrown during

transport.

NOTICE

Temperature fluctuations

The machine may be subject to strong temperature fluctuations during transport

(e.g. aircraft transport)

– The resultant condensed water may damage electronic components.

• Protect the machine from condensed water.

NOTICE

Ambient temperature

– Electronic and mechanical components may be damaged and the

performance data alter to an unknown extent.

• Do not exceed or fall below the permitted temperature range of the

machine (5°C to 40°C / ambient temperature).

Pos: 4.2 /00005 Überschriften/1. Überschri ften/1 Verpackung, Transport und Aufst ellung @ 0\mod_1226494451893_9.doc @ 3380 @ 1 @ 1

3 Transport, scope of delivery, installation

Pos: 4.3 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Verpackung @ 0\mod_1226495088973_9.doc @ 33 92 @ 2 @ 1

3.1 Packaging

Pos: 4.4 /00003 Standard Kapitel/General Modul Verpackung @ 0\mod_12289846 18355_9.doc @ 4892 @ @ 1

Pos: 4.5 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Transport @ 0\mod_1226495164391_9.doc @ 3398 @ 2 @ 1

3.2 Transport

Pos: 4.6 /00004 Warnhinweise/H0017 H INWEIS Transport @ 0\mod_1228918883 019_9.doc @ 4802 @ @ 1

Pos: 4.7 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Temperatursc hwankungen @ 0\mod_1226495190 738_9.doc @ 3404 @ 2 @ 1

3.3 Temperature fluctuations and condensed water

Pos: 4.8 /00004 Warnhinweise/H0016 H INWEIS Temperaturschwankungen @ 0\ mod_1233564121287_9.doc @ 5570 @ @ 1

The packaging has been adapted to the mode of transport. It complies with the

generally applicable packaging guidelines.

Pos: 4.9 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Bedingung en für den Aufstellort @ 0\mod_1226497 029322_9.doc @ 3428 @ 2 @ 1

3.4 Conditions for the place of installation

Pos: 4.10 /00003 Standard Kapitel/Gen eral Modul Umgebungstemperatur 5°C - 40°C @ 0\mod_1228918538881_9.doc @ 47 45 @ @ 1

Pos: 4.11 /00004 Warnhinweise/H0021 HIN WEIS Umgebungstemperatur 5°C bis 40°C @ 0\mod_1228918883441_9.doc @ 4 816 @ @ 1

Pos: 4.12 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Aufstell en des Gerätes @ 0\mod_1226498849756 _9.doc @ 3464 @ 2 @ 1

3.5 Installation of the machine

Pos: 4.13 /00003 Standard Kapitel/Gen eral Modul Aufstellungshöhe @ 0\mod_122 8918538349_9.doc @ 4724 @ @ 1

Pos: 4.14.1 /00005 Überschriften/1.1 Ü berschriften/1.1 Überschriften BDA/11 T ypenschild Beschreibung @ 3\mod_128093395 3941_9.doc @ 22302 @ 2 @ 1

Installation height: maximum 2000 m above sea level

3.6 Type plate description

Pos: 4.14.2 /00003 Standard Kapitel/Gen eral Modul Typenschild @ 3\mod_1280 931092443_9.doc @ 22278 @ @ 1

10

Page 11

Technical data

WARNING

1 2 3 4 5 6 7 8 9

10

11

12

14

13

Fig. 1: Type plate lettering

1 Device designation

2 Year of production

3 Part number

4 Serial number

5 Manufacturer’s address

6 CE marking

7 Disposal label

8 Bar code

9 Power version

10 Mains frequency

11 Capacity

12 Amperage

13 Number of fuses

14 Fuse type and fuse strength

In the case of questions please provide the device designation (1) or the part

Pos: 4.15 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Elektrisc her Anschluss @ 0\mod_122656506744 5_9.doc @ 3500 @ 2 @ 1

number (3) and the serial number (4) of the device.

3.7 Electrical connection

Pos: 4.16 /00003 Standard Kapitel/Gen eral Modul Elektrischer Anschluss @ 0\m od_1228918538521_9.doc @ 4731 @ @ 1

When connecting the power cable to the mains supply, use an external fusethat

complies with the regulations applicable to the place of installation .

• Please check the type plate for details on the necessary voltage and

• Make sure the levels agree with the existing mains power supply.

• Use the supplied connection cable to connect the device to the mains power

Pos: 5.1 /00005 Überschriften/1. Übersc hriften/1 Technische Daten @ 0\mod_12 22344525522_9.doc @ 2407 @ 1 @ 1

4 Technical data

Pos: 5.2 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Einsatz der M aschine bei bestimmungsgemäßer Ver wendung @ 0\mod_1226476732248_9.do c @ 3243 @ 2 @ 1

frequency for the device.

supply.

11

Page 12

Technical data

CAUTION

Risk of explosion or fire

– On account of its design, the device is not suitable for use in hazardous

(potentially explosive) atmospheres.

• Do not operate the device in a hazardous atmosphere.

NOTICE

Area of use of the machine

– This machine is a laboratory machine designed for 8-hour single-shift

operation.

• This machine may not be used as a production machine nor is it

intended for continuous operation.

4.1 Use of the machine for the intended purpose

Pos: 5.3 /00004 Warnhinweise/V0005 VORS ICHT explosionsgefärdete Atmosphäre @ 1\mod_1239868668923_9.doc @ 814 0 @ @ 1

Pos: 5.4 /00010 Bedienungsanleitungen Kapitelsammlungen/PT100 (2011)/0010 PT1 00 Technische Daten/1505 PT100 Einsatz der Maschine bei bestimmungsgemäßer Verwendung @ 3\mod_1302779503916_9 .doc @ 24775 @ @ 1

This device is suitable for the representative divisionand reduction of free-flowing,

dispersed bulk material (Powder or Granulate) with a grain size of up to a

maximum 10 mm.

It is possible to divide into 6, 8 or 10 representative sub-samples. When using the

10-outlet dividing head, the maximum feed quantity amounts to 5,000cm3. 10

individual samples in glass bottles with a maximum of 500cm3 volume each can be

held.

For a precise division of the sample it is recommendable to feed the sample

Pos: 5.5 /00004 Warnhinweise/H0007 H INWEIS Einsatzbereich des Gerätes 8 Stün diger @ 1\mod_1236240219096_9.doc @ 7693 @ @ 1

uniformly and continuously through a Retsch vibratory feeder.

Pos: 5.6 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Emmisio nen @ 0\mod_1226487095021_9.doc @ 3 310 @ @ 1

4.2 Emissions

Pos: 5.7 /00010 Bedienungsanleitungen Kapitelsammlungen/PT100 (2011)/0010 PT 100 Technische Daten/0540 PT100 E missionen @ 3\mod_1302779502119_9.doc @ 24730 @ @ 1

Pos: 5.8 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Schutzart @ 0\mod_1226491839164_9.doc @ 3328 @ @ 1

4.3 Degree of protection

Pos: 5.9 /00010 Bedienungsanleitungen Kapitelsammlungen/PT100 (2011)/0010 PT 100 Technische Daten/0545 PT100 Schutz art @ 3\mod_1302779502369_9.doc @ 24739 @ @ 1

Pos: 5.10 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Antrieb @ 1\mod_1240475743011_9.doc @ 8557 @ @ 1

4.4 Drive output

Pos: 5.11 /00010 Bedienungsanleitungen K apitelsammlungen/PT100 (2011)/0010 PT 100 Technische Daten/0520 P1T00 A ntrieb @ 3\mod_1302779501322_9.doc @ 24703 @ @ 1

Pos: 5.12 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Drehzahl @ 1\mod_1240476189383_9.doc @ 8 585 @ @ 1

Noise data

Noise measurement in conformance to DIN 45635-31-01-KL3

The noise characteristics are also influenced by the properties of the sample.

Example idle speed

Workplace-related emission level LpAeq = 35.3 dB(A)

Example quartz

Workplace-related emission level LpAeq = 36.1 dB(A)

Operating conditions:

Dividing ratio = 8-outlet dividing head made of aluminium

Container = 8 wide-mouth bottles

Material to be divided = quartz

IP40

Stepper motor

12

Page 13

Technical data

4.5 Rotation speed

Pos: 5.13 /00010 Bedienungsanleitungen K apitelsammlungen/PT100 (2011)/0010 PT 100 Technische Daten/0530 PT100 Motordr ehzahl Teilrohr @ 3\mod_13027795018 54_9.doc @ 24721 @ @ 1

Driving head speed:

Pos: 5.14 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Nennleistu ng @ 0\mod_1226491873164_9.doc @ 3334 @ @ 1

110 rpm at 50/60Hz (± 3 min-1)

4.6 Rated power

Pos: 5.15 /00010 Bedienungsanleitungen K apitelsammlungen/PT100 (2011)/0010 PT 100 Technische Daten/0525 PT100 Nennl eistung @ 3\mod_1302779501588_9.doc @ 24712 @ @ 1

100V AC – 240 V AC 50/60Hz

Pos: 5.16 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Aufgab ekorngröße @ 3\mod_1302161462732_9.d oc @ 24620 @ 2 @ 1

65 watts / 1.6A

4.7 Feed size

Pos: 5.17 /00010 Bedienungsanleitungen K apitelsammlungen/PT100 (2011)/0010 PT 100 Technische Daten/0510 PT100 Aufga bekorngröße @ 3\mod_1302779499119_ 9.doc @ 24685 @ @ 1

– max. 10 mm for the 6-, 8- and 10-outlet dividing head large

Pos: 5.18 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Aufnahm evolumen @ 1\mod_1241508533945_ 9.doc @ 8777 @ @ 1

– max. 5 mm for the 8-outlet dividing head small

4.8 Receptacle volume

Pos: 5.19 /00010 Bedienungsanleitungen K apitelsammlungen/PT100 (2011)/0010 PT 100 Technische Daten/0560 PT100 Auffang behälter @ 3\mod_1302779503650_ 9.doc @ 24766 @ @ 1

The maximum holding capacity is 5 litres.

(Dividing head with 10 sample outlets and 10 sample vessels, each with a holding

capacity of 500 ml)

The minimum filling volume is 180 ml.

(Dividing head with 6 sample outlets and 6 sample vessels, each with a holding

Pos: 5.20 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Abmessu ngen und Gewicht @ 0\mod_1226492 212173_9.doc @ 3352 @ @ 1

capacity of 30 ml)

4.9 Dimensions and weight

Pos: 5.21 /00010 Bedienungsanleitungen K apitelsammlungen/PT100 (2011)/0010 PT 100 Technische Daten/0550 PT100 Abmess ung und Gewicht @ 3\mod_13027795 02650_9.doc @ 24748 @ @ 1

13

Page 14

Technical data

Ca. 870

Ca. 584

Ca. 510

Ca. 187

Ca. 192

Ca. 400

Ca. 150

Ca. 348

Fig. 2: Dimensions PT100 incl. sample dividers

Dimensions with vibratory feeder (without sample jars)

Height: 870 mm

Width: 400 mm

14

Page 15

Technical data

Depth: 348 mm

Dimension without vibratory feeder, dividing head and sample flasks

Height: 510 mm

Width: 572 mm

Pos: 5.22 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Erforderlich e Standfläche @ 0\mod_12264926784 14_9.doc @ 3364 @ 2 @ 1

Depth: 348 mm

4.10 Required floor space

Pos: 5.23 /00010 Bedienungsanleitungen Kapitelsammlungen/PT100 (2011)/0010 PT 100 Technische Daten/0555 PT100 Erford erliche Standfläche @ 3\mod_130277950 3369_9.doc @ 24757 @ @ 1

PT 100 incl. 10-outlet dividing head, quick-release sample outlet and 500-ml widemouth bottles:

Width: 480 mm

Pos: 6 /00010 Bedienungsanleitungen Ka pitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @ @ 1

Depth: 420 mm

15

Page 16

Operating the machine

A

B

C

K

E

Vibratory feeder

K

E

Pos: 7.1 /00005 Überschriften/1. Überschri ften/1 Bedienung des Gerätes @ 0\mod_ 1226565880211_9.doc @ 3519 @ 1 @ 1

5 Operating the machine

Pos: 7.2 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Ansichte n des Gerätes @ 0\mod_1228990581782_ 9.doc @ 4966 @ 2 @ 1

5.1 Views of the Instrument

Pos: 7.3 /00010 Bedienungsanleitungen Kapitelsammlungen/PT100 (2011)/0015 PT1 00 Bedienung/1510 PT100 Modul Ansich ten des Gerätes @ 3\mod_1302779708 679_9.doc @ 24946 @ @ 1

Fig. 2: General view of the device and the individual parts

Fig. 3: View of the on/off switch and control panel

16

Page 17

Operating the machine

Element

Description

Function

A

Dividing head hopper

Accommodates a feed hopper, available as an

accessory, or guides the sample material from the

vibratory feeder into the tube dividers.

B

Dividing head

Divides the sample among the sample containers.

C

Adapter tube with quick-release sample

outlet

Holds the sample vessels

E

Main switch

Switches the device on and off.

K

Control panel

START / STOP, time display, runtime setting

L

Fuse tray

Contains two glass fuses

M

Interface to the vibratory feeder

Links the connection cable to the vibratory feeder

N

Power socket

Connection for the mains power cable

M L N

Fig. 4: Back of the device – power connection and interface

Pos: 7.4 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Übersichtsta belle der Geräteteile @ 0\mod_122899 0616846_9.doc @ 4972 @ @ 1

5.2 Overview table of the parts of the device

Pos: 7.5 /00010 Bedienungsanleitungen Kapitelsammlungen/PT100 (2011)/0015 PT1 00 Bedienung/1515 PT100 Modul Übersich tstabelle Geräteteile @ 3\mod_130277 9708867_9.doc @ 24955 @ @ 1

Pos: 7.6 /00010 Bedienungsanleitungen Kapitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @ @ 1

17

Page 18

Operating the machine

Element

Description

Function

K1

Display

Displays the set dividing time and the error messages

K2

- button

Reduces the dividing time

K3

+ button

Increases the dividing time

K4

Green LED

Display device switched on / running

K5

Red LED

Device stopped

K6

STOP button

Stopping the device/ pause

K7

START button

Starting the device

K1

K2

K3

K7

K5

K4

K6

Pos: 7.7 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Grafische Ansichten der Bedienelemente und der A nzeige @ 0\mod_1226566362336_9.doc @ 3537 @ @ 1

5.3 Operating elements and displays

Pos: 7.8 /00010 Bedienungsanleitungen Kapitelsammlungen/PT100 (2011)/0015 PT1 00 Bedienung/1520 PT100 Modul Ansicht der Bedienelemente @ 3\mod_1 302779709117_9.doc @ 24964 @ @ 1

Pos: 7.9 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Übersichts tabelle der Bedienelemente und der Anz eige @ 0\mod_1228990697273_9.doc @ 4978 @ @ 1

Fig. 5: Control panel

5.4 Overview Table of the Operating Elements and the Display

Pos: 7.10 /00010 Bedienungsanleitungen K apitelsammlungen/PT100 (2011)/0015 PT 100 Bedienung/1515 PT100 Modul Übersic htstabelle Bedienelement @ 3\mod_13 02779928520_9.doc @ 25072 @ @ 1

Pos: 7.11 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Teilkrone montieren @ 4\mod_1315215336450_ 9.doc @ 25590 @ 2 @ 1

5.5 Mounting the dividing head/dg_bm "text_mod_1315215336450_0001">

Pos: 7.12 /00010 Bedienungsanleitung en Kapitelsammlungen/PT100 (2011)/0015 PT 100 Bedienung/1520 PT100 Modul Teil krone montieren @ 4\mod_131582580099 1_9.doc @ 25600 @ @ 1

18

Page 19

Operating the machine

A B MN

RS

DA

NT

B (from

below/inside)

Fig. 6: Mounting the dividing head

• Put the dividing head (B) on the shaft (MN) as shown in the illustration.

• Put the dividing head hopper (A) onto the axle (DA).

Fig. 7: Locking disk on the driver and dividing head viewed from below

Pos: 7.13 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Probeng efäß einsetzen @ 3\mod_1302780091987 _9.doc @ 25081 @ 2 @ 1

Make sure that one of the four grooves (NT) engages with the locking disk (RS).

5.6 Inserting sample vessel

Pos: 7.14 /00004 Warnhinweise/V0062 VOR SICHT Glassplitter @ 3\mod_130269 0193882_9.doc @ 24640 @ @ 1

19

Page 20

Operating the machine

CAUTION

1.V0062

Injuries in the form of cuts and other personal injuries

Danger from glass splitters

– Injuries in the form of cuts can be caused by damaged sample flasks and

glass splitters.

• Replace damaged sample flasks

• Do not touch glass splitters with your hands.

CAUTION

Danger of personal injury

Dangerous nature of the sample

– Depending on the dangerous nature of your sample, take the

necessary measures to rule out any danger to persons.

• Observe the safety guidelines and datasheets of your

sample material.

NOTICE

2.H0057

– It must be ensured that all tube dividers are fitted with sample containers.

Otherwise, the sample will be scattered through the missing sample

containers into the environment. (Loss of material)

– Make sure the sample containers are positioned correctly on the

mountings. If the glass bottles are inserted incorrectly, they can be

hurled out of the dividing head by centrifugal force.

H J P

Pos: 7.15 /00004 Warnhinweise/V0006 VOR SICHT Gefahr von Personenschäden G efährliche Stoffe @ 1\mod_12362384562 69_9.doc @ 7634 @ @ 1

Pos: 7.16 /00004 Warnhinweise/H0057 HIN WEIS korrekter Sitz der Probenbehälter (PT 100) @ 4\mod_1316678999198_9.doc @ 25610 @ @ 1

Pos: 7.17 /00010 Bedienungsanleitungen K apitelsammlungen/PT100 (2011)/0015 PT 100 Bedienung/1525 PT100 / PT200 Modul Einsetzen der Probengefäße @ 3\ mod_1302779709429_9.doc @ 24973 @ 3 @ 1

5.6.1 Inserting the sample container into the quick-release sample outlet

Fig. 4:

Fig. 5: Inserting the sample container (quick-release sample outlet)

• Position the sample container (H) in relation to the compression disk (J

[shaded]).

• Press the compression disk (J) along with the sample container (H)

upwards.

• Push the sample container backwards into the support (P) and lower it until it

Pos: 7.18 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Ein- / A usschalten @ 0\mod_1229416527496_9.d oc @ 5058 @ @ 1

20

locks into place.

3.

Page 21

Operating the machine

WARNING

Risk of a fatal electric shock

- An electric shock can cause injuries in the form of burns and cardiac

arrhythmia, respiratory arrest or cardiac arrest.

• Do not clean the blender under running water. Use only a cloth dampened

with water.

• Disconnect the power supply plug before cleaning the blender.

E

5.7 Switching On and Off

Pos: 7.19 /00004 Warnhinweise/W0002 WARNUNG Kabelbruch Stromstoß @ 2\ mod_1278055276120_9.doc @ 20557 @ @ 1

Pos: 7.20 /00010 Bedienungsanleitungen K apitelsammlungen/PT100 (2011)/0015 PT 100 Bedienung/1526 PT100 Modul Ein A us Schalten @ 3\mod_1303206207409_9. doc @ 25226 @ @ 1

Fig. 8: On/off switch

There is an on-and-off switch (E) located on the left side of the device under the

operating element.

Pos: 7.21 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Starten, U nterbrechen, Stoppen @ 0\mod_122941 7133049_9.doc @ 5070 @ @ 1

• Press the switch (E) to turn the device on or off.

5.8 Starting, Interrupting, Stopping

Pos: 7.22 /00010 Bedienungsanleitungen K apitelsammlungen/PT100 (2011)/0015 PT 100 Bedienung/1530 PT100 Modul Starten des Gerätes @ 3\mod_130277970967 9_9.doc @ 24982 @ 333 @ 1

5.8.1 Starting

• Press the (K7) START button.

– The green (K4) LED lights up over the (K7) START button.

– The preset dividing time can be seen in the (K1) display.

– The dividing head starts to rotate.

– The remaining dividing time minutes are shown in the display.

(except in the co mode Continuous operation)

5.8.2 Interrupting

• Press the (K6) STOP button.

– The dividing head is decelerated and the DR 100 (if one is used) switches

off.

– The dividing time is interrupted and the (K5) LED lights up in red.

– The remaining dividing time appears in the display.

5.8.3 Stopping

• Press the (K6) STOP button twice.

– The device is put into readiness mode. (Standby)

Pos: 7.23 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Durchlauf dauer @ 2\mod_1263289874150_9.doc @ 18528 @ @ 1

• Press the (K7) START button to reactivate the device.

21

Page 22

Operating the machine

K1

K2

K3

5.9 Process Run Duration

Pos: 7.24 /00010 Bedienungsanleitungen Kapitelsammlungen/PT100 (2011)/0015 PT 100 Bedienung/1535 PT100 Modul Laufzeit einstellen @ 3\mod_1302779709820_9. doc @ 24991 @ 33 @ 1

Fig. 1: Setting the processing time

5.9.1 Process run times

You can set the division process time by pressing the + button (K3) or - button

(K2).

• Press the + button (K3) repeatedly until you reach the appropriate process

run time.

You can select the following time intervals: (in minutes)

co (continually) – 1 – 3 – 5 – 10 – 20 – 30 – 40 – 50 – 60

5.9.2 Continuous run

• Press the + (K3) or (K2) button repeatedly until co appears in the display.

During the dividing time, the speed is kept at a constant level within the set

Pos: 7.25 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Zuteilger ät anbauen @ 3\mod_1302780202188 _9.doc @ 25089 @ 2 @ 1

tolerance.

5.10 Attaching vibratory feeder

Pos: 7.26 /00010 Bedienungsanleitungen K apitelsammlungen/PT100 (2011)/0015 PT 100 Bedienung/1545 PT100 Modul Anbau des Zuteilgerätes @ 3\mod_130277971 0210_9.doc @ 25009 @ @ 1

To prepare the vibratory feeder, you need the DR100 operating manual. For a

precise sample division, it is recommendable to feed the sample uniformly through

a vibratory feeder. The DR 100 vibratory feeder, which is available as an

accessory, is suitable for that purpose. The connection between the device and the

DR 100 is established by means of an interface cable, which is included in the DR

100 scope of supply. Both the device and the DR 100 require a mains power

socket, each with the same phase position, providing the appropriate voltage and

frequency (see type plate on the devices). Multi-distributor power sockets, to which

both devices can be connected, are suitable for this purpose.

22

Page 23

Operating the machine

HT

GS

GF

KN

SCH

ST

RS

Fig. 2: Mounting the vibratory feeder

– The support (HT) is already completely pre-assembled with the stand rod (ST).

• Unscrew the two rubber feet (GF) at the back of the DR100.

• Loosen the hand screw (KN).

• Take the support (HT) off the stand rod (ST).

• Connect the DR 100 and the support (HT) by means of the hexagonal cap

screws and washers (SCH).

Pay attention to the side position of the DR100 vibratory feeder. The position of the

hopper opening varies depending on the dividing head being used.

Fig. 3: Positioning the vibratory feeder

23

Page 24

Operating the machine

ST

KS1

• Remove the plastic screw (KS1).

• Screw the stand rod (ST) onto the housing.

Fig. 4: Inserting the stand rod

• Mount the (HT) support.

• Adjust the swivel distance. To do so, loosen the threaded pin (GS) in the

locking disk (RS).

Adjust the swivel distance so that the feeding chute is positioned in the centre over

the feed hopper at the anti-clockwise limit stop and the support (HT) is swung out

at the clockwise limit stop.

• Tighten the threaded pin (GS) in the locking disk (RS) again.

• Align the DR 100 chute over the PT 100 feed hopper.

The (KN) hand screw at the back of the support (HT) serves to lock the DR 100 in

position.

When the (KN) hand screw is loosened, the DR100 can be swivelled 60°. The feed

hopper with the dividing head is therefore accessible before and after the dividing

process.

NOTICE

PT 100 and DR 100 must be suitable for the same electrical mains supply (see

type plate).

Failure to comply with the ratings on the type plates on the PT 100 and DR 100

can cause damage to the electronic and mechanical components.

Pease read the DR 100 operating instructions for information on the further

Pos: 7.27 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Schnittstell enverbindung herstellen @ 3\mod_13 03201613915_9.doc @ 25210 @ 2 @ 1

operation of the DR 100.

5.11 Creating interface connection

Pos: 7.28 /00010 Bedienungsanleitungen K apitelsammlungen/PT100 (2011)/0015 PT 100 Bedienung/1546 PT100 Modul Schnittst elle anschließen @ 3\mod_13032026 86288_9.doc @ 25218 @ @ 1

• Before mounting the DR 100, read the DR 100 operating instructions.

24

Page 25

Operating the machine

DF

VK

Fig. 5: Connection of the PT100 to the DR 100

Use the interface cable contained in the scope of supply for the retrofit kit to

establish the connection between the DR 100 and the PT100.

• Insert the connection cable (VK) into the interface (DF) on the back of the

DR 100.

Fig. 6: Inserting the DR 100 connection cable

• Insert the connection cable (VK) into the interface (PF) at the back of the

PT100.

25

Page 26

Operating the machine

DS

DK

DN

DZ

VK

PF

Pos: 7.29 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Gerät un d Zuteilgerät gleichzeitig starten @ 3\ mod_1302780258781_9.doc @ 25097 @ 2 @ 1

Fig. 7: Inserting the PT100 connection cable

5.12 Starting device and vibratory device simultaneously

Pos: 7.30 /00010 Bedienungsanleitungen K apitelsammlungen/PT100 (2011)/0015 PT 100 Bedienung/1550 PT100 / PT200 Mod ul Gerät und Zuteilgerät starten @ 3\mo d_1302779710476_9.doc @ 25018 @ @ 1

• Put sample vessels onto all sample outlets on the device.

Fig. 4: Rear view of the DR100

NOTE

PT 100 and DR100 must be suitable for the same electrical mains supply, (see

type plate).

Failure to comply with the ratings on the type plate on the PT 100 and DR100 can

cause damage to electronic and mechanical components.

26

• Connect the DR100 to the mains power supply using the C13 panel-

mounted male connector (inlet) (DZ).

• Set the switch (DS) on the back of the DR100 to “Standard”.

Fig. 5: Setting the DR100 feeding speed

• Set the feeding speed regulator (DK) on the DR100 to the required position

(depending on the material to be divided).

• Fill the DR100 feed hopper.

• Adjust the slot width between the feed hopper outlet and the push-fit chute base

(feed level).

Page 27

Cleaning and service

WARNING

Risk of a fatal electric shock

- An electric shock can cause injuries in the form of burns and cardiac

arrhythmia, respiratory arrest or cardiac arrest.

• Do not clean the blender under running water. Use only a cloth dampened

with water.

• Disconnect the power supply plug before cleaning the blender.

B

The setting of the gap between the push-fit chute and the feed hopper depends on

the maximum particle size of the feed material. It should be about 3 times as large

as the max. particle size.

• Press the ON/OFF switch (DN) on the DR100 .

• Turn on the sample divider and start it.

The DR100 does not start until the sample divider has reached the nominal speed.

The DR100 switches off automatically when the nominal speed of the sample

divider varies too much or drops. If this fluctuation lasts only for a short time (<5s),

the DR100 switches on again once the nominal speed has been reached again

and the feeding process is continued. As soon as you stop the sample divider, the

Pos: 7.31 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Austausc h der Gerätesicherung @ 0\mod_12272 60127023_9.doc @ 3952 @ @ 1

DR100 stops too and the sample is not fed.

5.13 Replacing the machine fuses

Pos: 7.32 /00010 Bedienungsanleitungen K apitelsammlungen/PT100 (2011)/0015 PT100 Bedienung/1560 PT100 Modul Austa usch der Gerätesicherung @ 3\mod_130 2780460732_9.doc @ 25121 @ @ 1

Fig. 8: Fuse holder

Required fuses:

2 glass fuses T 2A (5x20mm)

• Disconnect the mains plug.

• Pull out the fuse holder (B).

• Replace the fuses.

• Insert the fuse holder.

Pos: 8.1 /00005 Überschriften/1. Überschri ften/1 Reinigung und Wartung @ 0\mod_ 1231167007723_9.doc @ 5450 @ @ 1

Only after-sales service may replace the fuses inside the device.

6 Cleaning and service

Pos: 8.2 /00004 Warnhinweise/W0003 WARNUNG Reinigung Stromstoß neu @ 1\mod_1236239978437_9.doc @ 7686 @ @ 1

Pos: 8.3 /00004 Warnhinweise/H0006 H INWEIS Defekt von Bauteilen durch Flüssig keitenEindringen von Flüssigkeiten ins Gehä useinne @ 1\mod_1248181032171_9.do c @ 11723 @ @ 1

27

Page 28

Fault messages

NOTICE

4.H0006

Defective components due to liquids

Penetration of liquids into the inside of the device

– Components are damaged and the function of the device is no longer

ensured.

• Clean the device under running water. Only use a moist cloth

NOTICE

Damage to the machine through solvents

– Solvents may damage plastic parts and the paint finish.

• It is not allowed to use solvents.

Error code

Error

Measure

F1

Motor is not running or

the rotation of the

dividing head has been

stopped manually

Press the STOP button; if the error

persists, after-sales service must be

consulted

F3

Speed too high or too

low

Press the STOP button; if the error

persists, after-sales service must be

consulted

F5

Keypad defective

Service necessary

Pos: 8.4 /00004 Warnhinweise/H0009 H INWEIS Geräteschaden durch Lösungsmit tel @ 0\mod_1231165437212_9.doc @ 544 1 @ @ 1

Pos: 8.5 /00010 Bedienungsanleitungen Kapitelsammlungen/PT100 (2011)/0025 PT1 00 Reinigung und Wartung /2505 PT100 M odul Reinigung und Wartung @ 3\mod _1302848234736_9.doc @ 25178 @ @ 1

The PT 100 laboratory sample divider is designed to allow all parts coming into

contact with materials to be removed easily without tools. In detail these are:

• dividing head or

• Wide-mouth and DURAN® laboratory bottles

• Feed hopper and DR 100 push-fit chute

When these parts are removed from the device, they can be cleaned in a water

Pos: 9.1 /00005 Überschriften/1. Überschri ften/1 Fehlermeldungen @ 2\mod_12590 56589728_9.doc @ 17580 @ @ 1

bath, under running water and in a dishwasher.

7 Fault messages

Pos: 9.2 /00010 Bedienungsanleitungen Kapitelsammlungen/PT100 (2011)/0035 PT 100 Fehlermeldungen/3505 PT100 Modul Fe hlermeldung @ 3\mod_1302781252066 _9.doc @ 25129 @ @ 1

Pos: 10.1 /00010 Bedienungsanleitungen K apitelsammlungen/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.d oc @ 2386 @ @ 1

28

Page 29

Disposal

Pos: 10.2 /00005 Überschriften/1. Überschrif ten/1 Entsorgung @ 0\mod_123425874 6831_9.doc @ 6173 @ @ 1

8 Disposal

Pos: 10.3 /00003 Standard Kapitel/Gen eral Modul Entsorgung @ 0\mod_1234269 404935_9.doc @ 6180 @ @ 1

Please observe the respective statutory requirements with respect to disposal.

Information on disposal of electrical and electronic machines in the European

Community.

Within the European Community the disposal of electrically operated devices is

regulated by national provisions that are based on the EU Directive 2002/96/EC on

Waste Electrical and Electronic Equipment (WEEE).

Accordingly, all machines supplied after 13.08.2005 in the business-to-business

area to which this product is classified, may no longer be disposed of with

municipal or household waste. To document this they have the following label:

=== Ende der Liste für Textmarke Inhalt ===

Fig. 5: Disposal label

Since the disposal regulations within the EU may differ from country to country we

would request you to consult your supplier.

29

Page 30

9 Index

4

45635-31-01-KL3 ................................................ 12

5

5,000cm3 ............................................................. 12

500cm3 ................................................................ 12

A

Amperage ........................................................... 11

attaching vibratory feeder ................................... 22

B

Back of the device .............................................. 17

Bar code ............................................................. 11

Bulk material ....................................................... 12

C

Capacity .............................................................. 11

CE marking ......................................................... 11

Division .............................................................. 12

Drive output ........................................................ 12

E

Electrical connection .......................................... 11

Emissions ........................................................... 12

Explanations of the safety warnings .................... 6

External fuse ...................................................... 11

F

F1 ....................................................................... 28

F3 ....................................................................... 28

F5 ....................................................................... 28

Fault messages .................................................. 28

feed size ............................................................. 13

free-flowing ........................................................ 12

Function ....................................................... 17, 18

Fuse strength ..................................................... 11

Changes ............................................................... 5

Cleaning and service .......................................... 27

Conditions for the place of installation ................ 10

Confirmation ......................................................... 9

Connection cable ................................................ 11

continuously ........................................................ 12

Copyright .............................................................. 5

creating interface connection .............................. 24

D

Degree of protection ........................................... 12

Description .................................................... 17, 18

Device designation ............................................. 11

Dimensions ......................................................... 14

Dimensions and weight....................................... 13

DIN 45635-31-01-KL3 ......................................... 12

dispersed ............................................................ 12

Disposal .............................................................. 29

Fuse type ........................................................... 11

G

General safety instructions .................................. 7

Grain size ........................................................... 12

Granulate ........................................................... 12

H

Holding capacity, minimum, maximum .............. 13

I

Inserting sample vessel ..................................... 19

Installation height ............................................... 10

Installation of the machine ................................. 10

M

Mains frequency ................................................. 11

Manufacturer’s address ..................................... 11

Moderate or mild injury ........................................ 6

Mounting the dividing head ................................ 18

Disposal label ..................................................... 11

Disposal label ..................................................... 29

30

N

Noise characteristics .......................................... 12

Page 31

Noise data ........................................................... 12

Noise measurement ............................................ 12

Notes on the Operating Manual ............................ 5

Number of fuses ................................................. 11

O

On/off switch ....................................................... 16

Operating elements and displays ....................... 18

Operating the machine ....................................... 16

Overview Table of the Operating Elements and

the Display ...................................................... 18

Overview table of the parts of the device ........... 17

P

Packaging ........................................................... 10

Part number ........................................................ 11

Powder ................................................................ 12

Power version ..................................................... 11

Process Run Duration ......................................... 22

property damage ................................................... 6

Q

Quick-release sample outlet ............................... 20

R

Rated power ....................................................... 13

Receptacle volume ............................................. 13

Reduction ............................................................ 12

Regulations for the place of installation .............. 11

Repairs.................................................................. 8

Replacing the machine fuses ............................. 27

Required floor space ........................................... 15

Serial number ..................................................... 11

serious injury ........................................................ 6

Service Address ................................................... 8

Speed ................................................................. 13

starting device and vibratory device

simultaneously ............................................... 26

Starting, Interrupting, Stopping .......................... 21

Stepper motor .................................................... 12

Switching On and Off ......................................... 21

T

Target group ........................................................ 7

Technical data .................................................... 11

Temperature fluctuation and condensed water . 10

Transport ............................................................ 10

Transport, scope of delivery, installation ........... 10

Type plate .......................................................... 11

type plate description ......................................... 10

Type plate lettering ............................................ 11

U

uniformly ............................................................ 12

Use ..................................................................... 12

Use of the machine for the intended purpose .... 12

V

View of the control panel ................................... 16

View of the device .............................................. 16

Views of the Instrument ..................................... 16

Volume ............................................................... 12

W

Rotation speed .................................................... 13

S

Safety warnings .................................................... 6

Workplace-related emission level ...................... 12

Y

Year of production .............................................. 11

31

Page 32

Page 33

Authorized person for the compilation of technical documents:

J. Bunke (technical documentation)

The following records are held by Retsch GmbH in the form of Technical Documentation:

Detailed records of engineering development, construction plans, study (analysis) of the measures required for

conformity assurance, analysis of the residual risks involved and operating instructions in due form according to

the approved regulations for preparation of user information data.

The CE-conformity of the Retsch Laboratory Sample Divider PT100 is assured herewith.

In case of a modification to the machine not previously agreed with us as well as the use of not

licensed spare parts and accessories this certificate will lose its validity.

Retsch GmbH Haan, October 2011

Dr.-Ing. Frank Janetta

Manager Development

Ret s c h GmbH Retsch-Al lee 1-5 42781 Haan Germ a n y www.retsch.com

Certificate of CE-Conformity according to:

EC Mechanical Engineering Directive 2006/42/EC

Applied harmonized standards, in particular:

DIN EN ISO 12100 Security of machines

EC Directive Electromagnetic Compatibility 2004/108/EC

Applied standards, in particular:

DIN EN 55011 Emission

DIN EN 61000-3-2 DIN EN 61000-3-3 Emission

DIN EN 61326-1 DIN EN 61000-6-2 Immunity

Additional applied standards, in particular

DIN EN 61010-1 Safety prescriptions concerning measuring-, operating-, controlling- and laboratory

equipment

DIN EN 60950-1 Information technology equipment – Safety

LABORATORY SAMPLE DIVIDER

PT100

FB-EW-805-075 (E) Änderungsstand B 01.2012

CERTIFICATE OF CE-CONFORMITY

Translation

33

Page 34

Page 35

Page 36

Copyright

® Copyright by

Retsch GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

Loading...

Loading...