Page 1

Operating Instructions Ball Mills

Type PM100 / PM200 / PM100cm

Retsch GmbH, 42781 Haan, Retsch-Alle 1-5, Germany, 10/31/2014 0006

Page 2

Information on these operating instructions .................................. 4

Warnings ..................................................................................... 4

Repairs ........................................................................................ 4

Safety .................................................................................................. 5

Safety instructions ....................................................................... 5

Safety directives summarised, part 2 .......................................... 7

Confirmation ...................................................................................... 8

Technical specifications ................................................................... 9

Intended use ............................................................................... 9

Maximum feed volume ................................................................ 9

Maximum feed grain size ............................................................ 9

Drive output ................................................................................. 9

Emissions .................................................................................... 9

Materials and analyses of the grinding tools ............................... 9

Protection systems ...................................................................... 9

Protective equipment .................................................................. 10

Operating mode .......................................................................... 10

Device dimensions ...................................................................... 10

Base area required ...................................................................... 10

Transport and assembly ................................................................... 11

Packaging ................................................................................... 11

Transport ..................................................................................... 11

Temperature fluctuations ............................................................ 11

Intermediate storage ................................................................... 11

Assembly ..................................................................................... 11

Requirements for the assembly site ............................................ 12

Electrical connection ................................................................... 12

Serial interfaces .......................................................................... 13

Operation ............................................................................................ 14

Connect the power ...................................................................... 14

Opening / closing / emergency unlocking of

the grinding chamber .................................................................. 14

Inserting and clamping grinding bowls in the PM100 .................. 16

Removing the grinding bowl fastening device in the PM100 ....... 17

Tightening and unscrewing the grinding bowl fastening

device using a counter spanner .................................................. 17

Safety Instructions for starting the PM 100 ................................. 18

Balancing – only required for the PM100 .................................... 20

Balancing – only for PM 100 with additional balance weight ....... 20

Inserting and clamping grinding bowls in the PM200 .................. 21

Tightening and loosening the grinding bowl clamping

fixture using the counter spanner ................................................ 21

Safety instructions for starting the PM 200 .................................. 22

Suitable grinding bowls for the PM100 ........................................ 23

Grinding bowl filling level ............................................................. 23

Guide values for material volumes and balls .............................. 23

Stacking of 50 ml milling cups of type “C” ................................... 23

Stacking of milling cups less than 50 ml ..................................... 23

Suitable grinding bowls for the PM200 ........................................ 24

Grinding bowl filling level ............................................................. 24

Guide values for material volumes and balls .............................. 24

Stacking 50ml grinding bowls of type "C" .................................... 24

Handling grinding bowls of type "C" ............................................ 24

Carrying and holding ................................................................... 24

Torsion lock ................................................................................. 24

Heating the grinding bowls .......................................................... 24

Grinding bowl identification ......................................................... 25

Customer marking of grinding bowls ........................................... 25

Cleaning the grinding bowls ........................................................ 25

Drying the grinding bowls ............................................................ 25

Tips for ultra-fine milling .............................................................. 25

Use of the closing device for milling cups ................................... 26

Operation via the PM100/200 display unit ................................... 27

Symbols in the display unit .......................................................... 27

Menu structure of the display unit ............................................... 28

Adjustment options via the display menu .................................... 29

Languages .................................................................................. 29

Incorrect language selection ....................................................... 29

Manual mode............................................................................... 29

Grinding program 01 .................................................................. 29

Grinding time ............................................................................... 29

Retsch GmbH 2

Page 3

Speed .......................................................................................... 29

Interval ........................................................................................ 30

Start time ..................................................................................... 31

Opening mechanism ................................................................... 31

Energy ......................................................................................... 31

Alarm ........................................................................................... 32

Service ........................................................................................ 32

Contrast / brightness ................................................................... 33

Date / Time .................................................................................. 33

Stand-by monitor ......................................................................... 33

Error messages on the display ......................................................... 34

F01 to F12 ................................................................................... 34

F13 to F26 ................................................................................... 35

General points .................................................................................... 36

Cleaning ...................................................................................... 36

Maintenance ................................................................................ 36

Parts subject to wear and tear..................................................... 37

Copyright ..................................................................................... 38

Changes ...................................................................................... 38

Appendix ..................................................................... following pages

Retsch GmbH 3

Page 4

Information on these operating

Personal injuries

Material damage

Your local Retsch representative

Your supplier

Retsch GmbH direct

instructions

The present operating instructions for the ball mills of type

PM100/200 provide all the necessary information on the

headings contained in the table of contents.

They act as a guide for the target group(s) of readers defined

for each topic for the safe use of the PM100/200 in accordance

with its intended purpose. Familiarity with the relevant

chapters on the part of each target group(s) of readers is

essential for the safe and proper use of the equipment.

The present technical documentation has been designed both

as a source of reference and as a learning tool. Each chapter is

a self-contained unit.

The operating instructions do not contain any repair

instructions. Should repairs ever become necessary, please

contact your supplier or talk directly to Retsch GmbH.

http://www.retsch.de

Warnings

The following signs are used to warn of hazards:

Repairs

These operating instructions do not contain any repair

instructions. In the interests of your own safety, repairs

should only be performed by Retsch GmbH, an authorised

representative or by Retsch service technicians.

In this case, please notify the following:

Your address for service:

Retsch GmbH 4

Page 5

Safety

We reject herewith any and all claims relating to personal injury or

material damage that result from the failure to comply with the

following safety instructions.

The PM100/200 is a modern, high-performance product

manufactured by Retsch GmbH. It incorporates the latest

technology. The machine is entirely safe in its operation

when used for the intended purpose and in accordance with

the present technical documentation.

Safety instructions

You, as the owner/operator, must ensure that the persons

who are entrusted to work on the PM100/200:

have read and understood all the regulations contained in

the chapter on safety,

have made themselves familiar, before starting work, with

all the operating instructions and regulations relevant to

that particular target group,

have unrestricted access to the technical documentation for

this machine at all times,

new personnel must have familiarised themselves with the

safe use of the PM100/200 and its intended purpose before

starting work with the machine, either through verbal

instruction by a competent person and / or with the help of

the present technical documentation.

Incorrect operation can result in injuries to persons and

damage to property. You bear the responsibility for your

own safety and that of your staff.

Ensure that no unauthorised persons have access to the

PM100/200.

As a precaution, have your staff certify in writing that they

have received instruction in the operation of the ZM200. A

draft for such a form can be found at the end of the chapter

on safety.

Retsch GmbH 5

Page 6

Safety directives summarised, part 1

We reject herewith any and all claims relating to personal injury or material damage that result from the

failure to comply with the following safety instructions.

Do not make any modifications to the machine and only use Retsch approved spares and accessories.

The conformity to the European guidelines declared by Retsch otherwise loses its validity.

It furthermore leads to the loss of all warranty claims.

Please retain the packaging for the duration of the warranty since, in case of complaint, returning in unsuitable packaging

can jeopardize your warranty claims.

During transportation, do not subject the PM100/PM200 to impacts, jolts or vibrations. The electronic and mechanical

components could otherwise be damaged.

In case of wide temperature fluctuations (during shipment by air, for instance), protect the PM100/PM200 from condensation. The electronic components could otherwise be damaged.

If the shipment is incomplete and / or has suffered transport damage, you must notify the forwarder and Retsch GmbH

immediately (within 24 hours). Under certain circumstances, claims lodged at a later date may not be considered valid.

When the ambient temperature exceeds or falls below that specified, the electronic and mechanical components may be

damaged, and performance data changed to an unknown extent.

At a higher air humidity, electronic and mechanical components may be damaged, and performance data changed to an

unknown extent.

Failure to observe the values on the data plate can cause damage to electronic and mechanical components.

Only use grinding bowls of type "C".

This, in conjunction with the grinding bowl fixture, is a safety component.

Working with old or third-party grinding bowls in the PM100/PM200 risks unforeseeable hazards.

Never allow threaded spindle 3 to lie loose in the grinding bowl fixture without the grinding bowls clamped in.

Danger of being hurled out!

Always ensure that the red sleeve has latched in properly. Otherwise the grinding bowl is not securely clamped.

Danger of being hurled out!

Only use grinding bowl of the type "C".

This, in conjunction with the grinding bowl fixture, is a safety component.

Working with old or third-party grinding bowls in the PM100/PM200 risks unforeseeable hazards.

Never allow threaded spindle 4 to lie loose in the grinding bowl fixture without the grinding bowls clamped in.

Danger of being hurled out!

Always ensure that the red sleeve has latched in properly. Otherwise the grinding bowl is not securely clamped.

Danger of being hurled out!

Only use grinding bowls of type "C" and only up to a nominal volume of 125ml

The PM200 will otherwise be overloaded and mechanical components could be damaged!

Only ever use 2 grinding bowls with the same gross weight.

Otherwise the PM200 generates unpleasant vibrations!

Safety instructions

Intended use

Packaging

Transport

Temperature fluctuations

Scope of supply

Ambient temperature :

Air humidity :

Electrical connection / Connecting the power

Inserting and clamping grinding bowls in the PM100

Inserting and clamping grinding bowls in the PM200

Retsch GmbH 6

Page 7

Safety directives summarised, part 2

If the filling level of the grinding bowl is too high or too low, the end result will be impaired and the milling set could become

damaged (increased wear and tear).

It is not possible to stack 50ml grinding bowls in the PM200.

Please take the action necessary - depending on how dangerous the material you are grinding is - to ensure that people are

not exposed to danger.

It is essential to wear protective gloves when removing and opening heated grinding bowls.

Danger of burning hands.

Do not expose grinding bowls with ceramic inserts to temperature fluctuations during rinsing.

The ceramic inserts can crack if subject to sudden changes of temperature.

Before deploying easily inflammable materials as milling aids, compile explosion protection documentation in

accordance with articles 118 and 118a of EC directive 89/391/EEC

Make certain that the grinding bowls have been securely clamped and balanced before letting the machine start unattended.

Even though it is not possible to start the machine without the cover closed, ensure that the cover is closed before letting

the machine start unattended.

Do not clean the PM100/200 with flowing water.

Mortal danger from electric shock

Only use a cloth dampened with water.

Solvents are not permitted.

The easy running of the threaded spindle and the locking sleeve is essential for secure clamping of the grinding bowl

Locking sleeves which do not move downwards solely by spring power cannot properly prevent the threaded spindle from

working loose. The grinding bowls could be hurled out.

The easy running of roller 1 on the locking block is essential for secure closing of the PM100/200 via the automatic closure

mechanism.

If the values D1 and H1 are undershot, operational safety is no longer assured.

The grinding bowls could be hurled out.

The operating instructions do not contain any repair instructions. In the interests of your own safety, repairs should only be

performed by Retsch GmbH, an authorised representative or by Retsch service technicians.

Grinding bowl filling level

Stacking 50ml grinding bowls of type "C"

Heating the grinding bowls

Cleaning the grinding bowls

Wet grinding with easily inflammable materials

Start time

Cleaning

Maintenance

Parts subject to wear and tear

Retsch GmbH 7

Page 8

Confirmation

I have read and understood the

chapters Foreword and Safety.

__________________________________

Signature of operator/owner

__________________________________

Signature of service technician

Retsch GmbH 8

Page 9

Technical specifications

Do not make any modifications to the machine and only use

Retsch approved spares and accessories.

The conformity to the European guidelines declared by

Retsch will otherwise lose its validity.

It will furthermore lead to the loss of all warranty claims.

Machine type designation: PM100/PM200

Intended use

Retsch ball mills are used to grind and mix materials that are soft,

medium hard to extremely hard, brittle or fibrous. Dry and wet

grinding is possible, grinding with solvents is permissible, although

in this case it is essential to observe the supplementary instructions

given in the chapter "Wet grinding with easily inflammable

materials". Minerals, ores, alloys, chemicals, glass, ceramics,

vegetable matter, soil, slurry, domestic and industrial waste

and many other substances can be comminuted simply, quickly

and without loss. The ball mills are successfully deployed in

virtually all fields of industry and research, particularly where

there are high requirements on cleanliness, speed, fineness and

reproducibility.

Only type "C" grinding bowls may be used.

In the PM100 1x of 50-500ml, 2x50ml, 2x25ml and 2x12ml can be

stacked.

In the PM200 the 12ml and 25ml grinding bowls can be stacked but

the 50ml and 125ml are not stackable.

They are not designed as production machines, but rather as

laboratory devices intended for single-shift, 8-hour operation.

Maximum feed volume

PM100 = up to 300ml, depending on the grinding bowl volume.

PM200 = up to 2x50ml, depending on the grinding bowl volume.

Maximum feed grain size

PM100 up to <10 mm, but dependent on the material

PM200 up to <4 mm, but dependent on the material

Drive output

750 W / power draw approx. 1250 W

Emissions

Noise levels PM100:

Noise measured in accordance with DIN 45635-31-01-KL3

The noise levels are basically influenced by the speed of the

machine, the size of the grinding bowl and the diameter of

the grinding balls used.

Workplace related emission value L

Noise levels PM200:

Noise measured in accordance with DIN 45635-31-01-KL3

The noise levels are basically influenced by the speed of the

machine, the size of the grinding bowl and the diameter of

the grinding balls used.

Workplace related emission value L

= up to 85 dB(A)

pAeq

= up to 80 dB(A)

pAeq

Materials and analyses of the grinding tools

See :

www.retsch.de/english/docs/grinding_tools.pdf

Protection systems

IP20

Retsch GmbH 9

Page 10

Protective equipment

The PM100 and PM200 are equipped with fixtures to automatically

close the cover. This prevents the devices being started in an

unsafe state.

The machines cannot be started unless the cover is closed.

It is only possible to open the cover when the machines are at

standstill.

Operating mode

S1

An operating mode with constant loading, the duration of which

suffices to reach the state of thermal rigidity. (DIN VDE 0530 T1)

Device dimensions

Height: Up to approx. 835 mm / Width: 630 mm / Depth : Up to

approx. 505 mm

Weight : PM100 net approx. 86 kg / PM200 net approx. 80 kg

Base area required

630 mm x 505 mm;

A safe distance of 200mm is required at the rear to allow the fan

to fulfil its function.

Retsch GmbH 10

Page 11

Transport and assembly

Please retain the packaging for the duration of the

warranty since, in case of complaint, returning in

unsuitable packaging can jeopardize your warranty

claims.

During transportation, do not subject the PM100/PM200

to impacts, jolts or vibrations. The electronic and

mechanical components could otherwise be damaged.

In case of wide temperature fluctuations (during

shipment by air, for instance), protect the

PM100/PM200 from condensation. The electronic

components could otherwise be damaged.

Packaging

The packaging has been adapted to the mode of transport.

It corresponds to the generally applicable packaging

guidelines.

Transport

Temperature fluctuations

Intermediate storage

Likewise for intermediate storage, ensure that the

PM100/PM200 are stored in a dry place.

Assembly

If the device is transported with a forklifter or lift truck, it must

be placed on the transport pallet.

4 people are required to carry the device.

Only place the PM100 or PM200 on a stable laboratory bench, as

they might otherwise be subjected to disagreeable vibrations.

The table base must be clean and skid-resistant.

The net weight of the PM100 is approx. 86 kg

The net weight of the PM200 is approx. 80 kg

Retsch GmbH 11

Page 12

Requirements for the assembly site

When the ambient temperature exceeds or falls below that

specified, the electronic and mechanical components may be

damaged, and performance data changed to an unknown

extent.

At a higher air humidity, electronic and mechanical

components may be damaged, and performance data

changed to an unknown extent.

Failure to observe the values on the data plate can cause

damage to electronic and mechanical components.

Ambient temperature :

5°C to 40°C

Air humidity :

Maximum relative humidity 80% at temperatures up to 31°C,

declining in linear manner down to 50% relative humidity at 40°C

Assembly height :

Max. 2000 m above sea level

Electrical connection

The voltage and frequency for the PM100 or PM200 are

shown on the data plate.

Ensure that these values agree with the mains power

supply.

Connect the PM100 or PM200 to the mains power supply

with the power cable supplied.

When connecting the power cable to the mains supply, use

an external fuse which complies with the regulations

applicable to the assembly site.

Important notes :

1. Electrical connections must use PE conductors !

2. A frequency converter is fitted to the drive unit of your PM100 /

PM200. In order to fulfil the EMV directive, this is equipped with a

mains filter and screened cables to the motor. If your mains power

installation for the PM100 / PM200 contains a residual-current

protective device, then when the frequency converter switched on

(switched on each time the grinding chamber hood is closed), its

interference suppression circuit can cause spurious tripping of the

residual-current protective device, without this being due to a

defect in your PM100 / PM200 or mains power supply.

The state-of-the-art recommends selective, all-current sensitive

residual-current protective devices in such cases. The trip current

needs to be sufficiently dimensioned because short-lived, capacitive

transient currents generated at switch on (screened cables, mains

filter) can easily cause spurious tripping.

Under certain conditions, it may be necessary to operate the PM100

/ PM200 without a residual-current protective device. It must

nevertheless then first be ensured that this does not contradict the

regulations of the local electricity supply utility, or those of other

institutions or applicable standards.

Retsch GmbH 12

Page 13

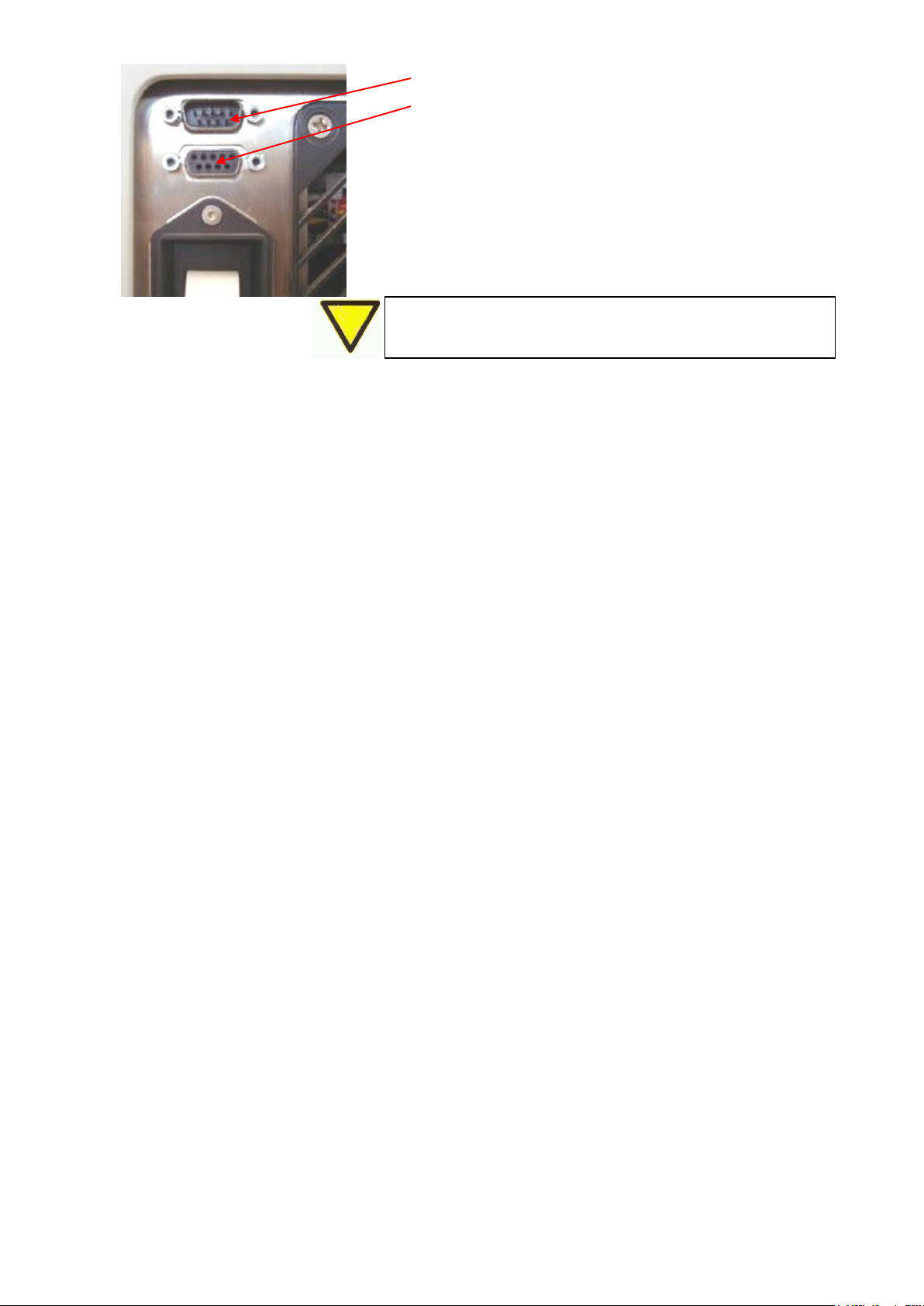

Serial interfaces

Interface to update the software

Inactive interface for optional data communication

with an external device. Software update required.

The interface cables may not be longer than 2.5 m.

Longer cables can cause faults in the transmission of data.

Retsch GmbH 13

Page 14

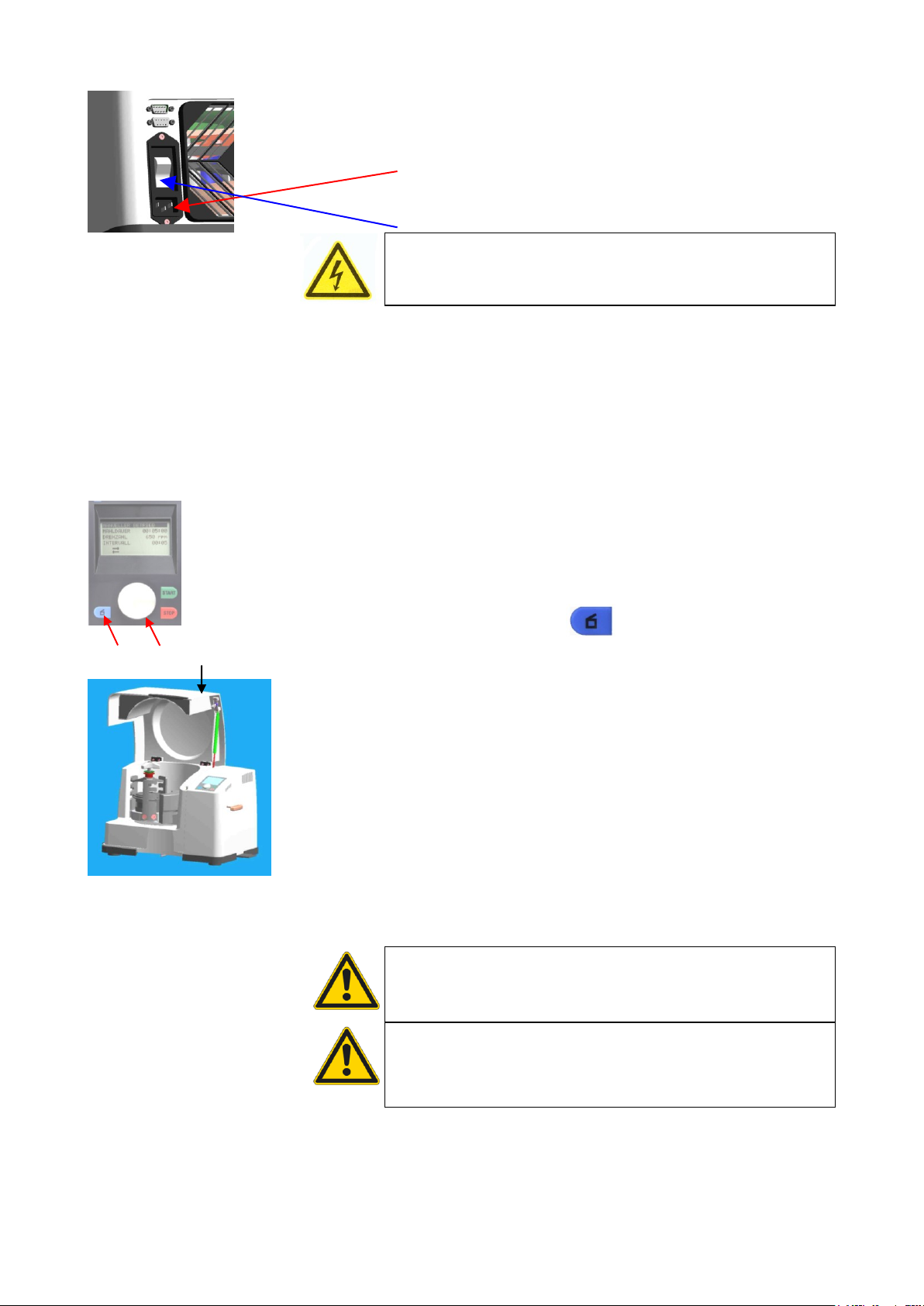

Operation

Ensure that the voltage and frequency of your mains power

supply agree with the data plate of the PM100 or PM200.

Plug the power cable into the socket at the rear of the

device

Plug the cable into the mains power socket

Turn the main switch on

Failure to observe the values on the data plate can cause

damage to electronic and mechanical components.

A E D

Opening

The following are necessary before the grinding bowl(s) can

be inserted and clamped.

Plug the PM100/200 into the mains power supply

Switch on the main switch at the rear

Press button A -

The safety lock opens and cover D can be folded back. The

grinding chamber is now freely accessible.

Closing

The grinding chamber cannot be closed unless the PM100 or

PM200 is connected to the mains power supply and the main

switch at the rear of the device is switched on.

Close the housing cover

A sensor recognises the locking block on the housing cover

and the motorised cover closure is switched on.

The housing cover is locked automatically

The PM100/PM200/PM100CM may be operated only if the housing

cover is free of any damage.

If the housing cover is damaged mechanically, it must be

replaced for safety reasons.

Never actuate the emergency unlocking feature whilst the machine is

running, only do so with the machine at standstill and the mains

power disconnected.

Considerable danger of injuries from a long drive run-on time

without braking.

Connect the power

The language menu is displayed the first time the

PM100/200 is switched on.

The language required can be selected here by turning

operating button E. The selection is confirmed by pressing it

and the display shows "Open cover".

Opening / closing / emergency unlocking of the grinding chamber

Retsch GmbH 14

Page 15

S

Emergency unlocking

A key is fixed underneath the unit. This can be used to open

the PM100 or PM200 manually in case of a power failure.

Lift the unit

Remove key S

(I) Insert the (S) key into the (O) opening on the

right-hand side.

(II) To unlock the gear, the key must be pushed in

further with some degree of force. While pushing the

key in, turn it in a clockwise direction as far as it will

go.

The cover can now be opened.

S S O

O

S

Retsch GmbH 15

Page 16

Inserting and clamping grinding bowls in the PM100

Before starting the machine ensure that the milling cup

is clamped.

Milling cup can be ejected, danger of injury and damage to

equipment.

Wear of safety slider

In case of wear at the screws and/or slits as well as an

substantially increased play of the safety slider, it should be

replaced. (See chapter on wearing parts)

3 4 5 1 2

6

Retsch GmbH 16

Page 17

5 Up = free 5 Down = locked

Clean the grinding bowl disk with torsion lock pin 1

Turn the label on the grinding bowl 2 to the same side as

the torsion lock pin, the borehole in the grinding bowl is

located here.

Insert the grinding bowl into the grinding bowl fixture

Pay attention to the torsion lock in 250 and 500 ml grinding

bowls. The borehole in the base of the grinding bowl to take

up the torsion lock pin is located on the side of the marking

areas.

Insert grinding bowl clamping arrangement 3 into latching

brackets 4

Pull red sleeve 5 upwards and clamp the grinding bowl by

turning the three-point grip to the right

Let red sleeve 5 latch audibly downwards, if necessary,

retighten gently from the three-point grip

The three-point grip should now not be able to be turned

Should the red locking sleeve not move completely

downwards when released (audible clacking), briefly retighten

from the three-point grip.

The red locking sleeve, which is now in the locked position,

prevents the threaded spindle from working loose.

Removing the grinding bowl fastening device in the PM100

Pull the red sleeve 5 upwards and unscrew the

grinding bowl by turning the three star grip to the

left.

Continue to turn the three star grip to the left until

the grinding bowl fastening device can be removed.

Using a counter spanner prevents the drive from turning, which can otherwise easily occur when

tightening or loosening the grinding bowl.

Retsch GmbH 17

Tightening and unscrewing the grinding bowl

fastening device using a counter spanner

Page 18

Insert the counter spanner 6

under the red sleeve 5. The

spindle is now unlocked.

Turn the three star grip to the right (clockwise) for

tightening and to the left (anticlockwise) for

loosening. The drive now turns only until a latched

bracket 4 is in contact with the counter spanner 6.

Easy tightening or loosening is then possible.

For the PM200 the counter spanner 6 must be turned

180° and inserted when the grinding bowl fastening

device is in the highest lock-in position.

Only use type "C" grinding bowls.

This, in conjunction with the grinding bowl fixture, is a safety

component.

Unforeseen risks may arise if third-party or old grinding

bowls are used in the PM100.

Never allow grinding bowl clamping arrangement 3 to lie

loose in the grinding bowl fixture without the grinding bowls

being clamped in.

Danger of being hurled out!

Especially in cases of lengthy grinding periods, check at the

intervals in the following schedule that the grinding bowl is

sitting securely:

after 3 mins, after 1h, after 5h and then every 10-12h. A

gripping force of 10Nm is the optimum for the grinding bowl

clamping fixture.

Risk of being hurled out!

6 4 6

Safety Instructions for starting the PM 100

The grinding bowl clamping fixture has proven its worth over many years as an easy-to-manage and

reliable appliance. A precondition here both for the operator’s safety and also to ensure that the

components have a long service life is that the grinding bowl must be clamped conscientiously.

Please bear in mind that the PM 100/200 is a grinder that inputs a very high level of energy into the

material being ground and the grinding bowl must therefore be clamped conscientiously.

To avoid operating errors, the correct grinding bowl clamping is queried each time before the

machine starts.

Personnel who are particularly well trained and very familiar with how the PM is operated may hide

this safety instruction permanently. However, we particularly advise against this if the operating

personnel vary!

The software for the PM 100/200 is set up in such a way that each time before the machine starts

up, when the starting button is activated, it is necessary to confirm in the following display that the

grinding bowl has been clamped.

Retsch GmbH 18

Page 19

Make sure the grinding bowl is clamped before you start the

machine.

The grinding bowl can be hurled out, risk of injury and

damage to property!

Our recommendation is that you do not hide the safety instruction.

Yes

GRINDING BOWL CLAMPED?

NO

The grinding process starts after this confirmation.

This safety instruction can be hidden in the “settings” menu.

Retsch GmbH 19

Page 20

Balancing – only required for the PM100

K

S

In order to ensure that the machine runs smoothly, the

PM100 must be balanced after the grinding bowl has been

inserted and clamped in.

Weight the grinding bowl with cover, ball filling and

the material to be ground

Move the balancing weight using the knob until edge

K on scale S shows the determined weight.

Caution:

When using the following grinding bowls with safety locking

device an additional balance weight of 1 kg is necessary.

Combination 1:

- 250 ml grinding bowl of tungsten carbide

01.462.0222

- Safety locking device 22.867.0004

- Grinding bowl lid for gassing 22.107.0006

Combination 2:

- 500 ml grinding bowl of zirconium oxide 01.462.0227

- Safety locking device 22.867.0005

When the additional balance weight is used please note that

the scale no longer shows the correct weight.

(See below)

Order number for additional weight: 22.221.0002

Additional balance weight 1kg

Balancing – only for PM 100 with additional balance weight

In order to fix the additional weight both protective caps on the

top side of the counterweight must be removed.

Screw the additional weight onto the counterweight with the

two cheese-head screws. Tightening torque for the cheesehead screws = 20 Nm.

After mounting the additional weight the extra weight of 1.0 kg

must be taken into account when reading the scale.

Example:

If the grinding bowl weighs 8.2 kg the counterweight must be

set to a scale reading of 7.2 kg.

Note:

When using light (small) grinding bowls the additional weight

must be removed again.

Retsch GmbH 20

Page 21

Inserting and clamping grinding bowls in the PM200

1 2 3 4

5 Up = free 5 Down = locked

Only operate the PM200 with grinding bowls up to a

maximum nominal volume of 125ml. In order to avoid

unpleasant vibrations, 2 grinding bowls with the same gross

weight must always be inserted.

Clean grinding bowl disk 1

Insert grinding bowl 2 into the grinding bowl fixture

Insert threaded spindle 4 with pressure piece into the

latching brackets 3

Pull red sleeve 5 upwards and clamp the grinding bowl by

turning the three-point grip to the right

Let red sleeve 5 latch audibly downwards, if necessary,

retighten gently

It should now be impossible to turn the three-point grip.

Should the red locking sleeve not move completely

downwards when released (audible clacking), briefly retighten

threaded spindle 4.

The red locking sleeve, which is now in the locked position,

prevents the threaded spindle becoming loose.

Push the counter spanner 6

under the red sleeve 5, the

spindle is now released

To clamp, pull the three-point grip to the right

(clockwise direction) and to loosen, pull to the left

(anticlockwise). The drive now turns only as far as till

a latching bracket 4 rests against the counter spanner

6. Easy tightening or loosening is then possible.

For the PM200 the counter spanner 6 must be turned

180° and inserted when the grinding bowl fastening

device is in the highest lock-in position.

6 4 6

Tightening and loosening the grinding bowl clamping fixture using the counter spanner

The counter spanner prevents the drive turning while the grinding bowl clamping fixture is being

tightened or loosened!

Retsch GmbH 21

Page 22

Safety instructions for starting the PM 200

Make sure the grinding bowl is clamped before you start the

machine.

The grinding bowl can be hurled out, risk of injury and

damage to property!

Our recommendation is that you do not hide the safety

instruction.

Only use “C” type grinding bowls.

This, in conjunction with the grinding bowl fixture, is a safety

component.

Unforeseen risks may arise if third-party or old grinding

bowls are used in the PM200.

Never allow threaded spindle 4 to lie loose in the grinding

bowl fixture without the grinding bowls clamped in.

Danger of being hurled out!

Only use grinding bowls of type "C" and only up to a nominal

volume of 125ml

The PM200 will otherwise be overloaded and

mechanical components could be damaged!

YES

GRINDING BOWL CLAMPED ?

NO

The grinding bowl clamping fixture has proven its worth over many years as an easy-to-manage and

reliable appliance. A precondition here both for the operator’s safety and also to ensure that the

components have a long service life is that the grinding bowl must be clamped conscientiously.

Please bear in mind that the PM 100/200 is a grinder that inputs a very high level of energy into the

material being ground and the grinding bowl must therefore be clamped conscientiously.

To avoid operating errors, the correct grinding bowl clamping is queried each time before the

machine starts.

Personnel who are particularly well trained and very familiar with how the PM is operated may hide

this safety instruction permanently. However, we particularly advise against this if the operating

personnel vary!

The software for the PM 100/200 is set up in such a way that each time before the machine starts

up, when the starting button is activated, it is necessary to confirm in the following display that the

grinding bowl has been clamped.

The grinding process starts after this confirmation.

This safety instruction can be hidden in the “settings” menu.

Retsch GmbH 22

Page 23

Suitable grinding bowls for the PM100

The PM100 is only suitable for grinding bowls of the type

"Comfort" with a nominal volume of 12-500 ml.

They are available in the following materials:

Agate

Sintered corundum

Zirconium oxide

Stainless steel

Special steel

Tungsten carbide

The "Comfort" grinding bowl program was developed

especially for extreme test conditions, such as long-term

trials, high mechanical loadings, maximum speeds and for

mechanical alloying.

Nominal

volume

Utility

volume

Max. feed

grain size

Recommended ball filling

10mm

20mm

30mm

40mm

12 ml

- 5 ml

1 mm

5 pieces

- - -

25 ml

- 10 ml

1 mm

8 pieces

- - -

50 ml

5 – 20 ml

3 mm

10 pieces

3 pieces

- - 80 ml

10 – 35 ml

4 mm

25 pieces

5 pieces

- - 125 ml

15 – 50 ml

4 mm

30 pieces

7 pieces

- - 250 ml

25 – 120 ml

6 mm

50 pieces

15 pieces

6 pieces

-

500 ml

75 – 220 ml

10 mm

100 pieces

25 pieces

8 pieces

4 pieces

If the filling level of the grinding bowl is too high or too low,

the end result will be impaired and the milling set could

become damaged (increased wear and tear).

It is possible to stack two 50 ml milling cups one on top of the

other. For stacking an adapter is required, which is available as

an accessory.

Stacking procedure

Place milling cup M1 in the milling cup plate

Place the adapter A1 on the lid of M1

Place milling cup M2 in position

Clamp the milling cups as described in the section “Clamping the

milling cups”.

Stacking of milling cups less than 50 ml

It is also possible to stack milling cups with a capacity of less

than 50 ml one on top of the other.

Stacking procedure

Place milling cup M2 on milling cup M1

Clamp milling cups as described in the section “Clamping the

milling cups”.

M2

M1

A1

M2

M1

Grinding bowl filling level

Guide values for material volumes and balls

Stacking of 50 ml milling cups of type “C”

Retsch GmbH 23

Page 24

Suitable grinding bowls for the PM200

The PM200 is only suitable for grinding bowls of type

"Comfort" with a nominal volume of 50-125 ml.

Nominal

volume

Utility

volume

Max. feed

grain size

Recommended ball filling

10mm

20mm

30mm

40mm

12 ml

- 5 ml

1 mm

5 pieces

- - -

25 ml

- 10 ml

1 mm

8 pieces

- - -

50 ml

5 – 20 ml

3 mm

10 pieces

3 pieces

- - 80 ml

10 – 35 ml

4 mm

25 pieces

5 pieces

- - 125 ml

15 – 50 ml

4 mm

30 pieces

7 pieces

-

-

If the filling level of the grinding bowl is too high or too low,

the end result will be impaired and the milling set could

become damaged (increased wear and tear).

It is not possible to stack 50ml grinding bowls in the PM200.

X

H

Carrying and holding

The gripping edges X on the grinding bowl itself and its

cover provide secure handling.

Torsion lock

All 250 and 500ml grinding bowls of type "C" also have a

torsion lock borehole to the steel shell in the bottom of the

grinding bowl. This is only deployed in the PM100 and is

located on the labelled side of the grinding bowl shell.

Heating the grinding bowls

Depending on the grinding time and the filling level, the

grinding bowl can be heated up to 150°C during

comminution.

When the fixture is undone, the pressure which builds up in

the bowl during grinding escapes, and can also take

powered ground material with it.

When the grinding bowls are put to one side to cool, a

vacuum develops inside the bowl, which can make it difficult

to open. Grinding bowls of type "C" can therefore be levered

open by inserting a wooden bar H, for example, between

the gripping edges of the cover and the bowl.

Please take the action necessary - depending on how

dangerous the material you are grinding is - to ensure that

people are not exposed to danger.

It is essential to wear protective gloves when removing and

opening heated grinding bowls.

Danger of burning hands.

Grinding bowl filling level

Guide values for material volumes and balls

Stacking 50ml grinding bowls of type "C"

Handling grinding bowls of type "C"

Retsch GmbH 24

Page 25

Grinding bowl identification

All grinding bowls of type "C" are easily identified by a

marking area SCH1, including the article No. and material.

Customer marking of grinding bowls

In addition to the aforesaid marking area, you can affix one

of the labels supplied (or available as accessories) to an

area SCH2 on the grinding bowl; this makes it possible to

apply extra markings, such as grinding bowl capacity etc.

The label is heat-resistant up to 150°C and the markings

you apply can be removed using alcohol, benzene or

acetone, for example.

Cleaning the grinding bowls

To clean the grinding bowls, the O-ring can be easily levered

out of groove Z on the underside of the cover.

Grinding bowls, including those with adhered ceramic

inserts, can be cleaned with alcohol, benzene or with normal

household washing-up liquid.

Do not expose grinding bowls with ceramic inserts to

temperature fluctuations during rinsing.

The ceramic inserts can crack if subject to sudden

changes of temperature.

Drying the grinding bowls

Grinding bowls can be dried at any time after cleaning in the

drying cabinet at the temperature indicated below.

Grinding bowl material

Temperature

Special steel

Up to 200°C

Stainless steel

Up to 200°C

Tungsten carbide

Up to 150°C

Sintered corundum

Up to 120°C

Agate

Up to 120°C

Zirconium oxide

Up to 120°C

Silicon nitride

Up to 120°C

Tips for ultra-fine milling

In many cases high finenesses can be achieved only by wet

milling.

In dry milling processes an improved fineness of milling can be

achieved by the addition of a few drops of stearic or acetic acid,

and use of milling balls with a diameter < 10 mm and a filling

level of 70-80% of the milling cup volume.

Retsch GmbH 25

Page 26

Use of the closing device for milling cups

For wet milling in milling cups with material inserts do

not use old closing devices which clamp only the

gripping edges of the milling cups. The material inserts

can be pressed out by possible internal pressure.

After filling the milling cups these must be closed with

closing devices available as accessories.

For milling cups with material inserts, ceramics or

tungsten carbide use only closing devices which support

the material insert of the milling cup lid. This is

absolutely essential owing to the anticipated internal

pressure.

Use of agate milling cups for wet milling with solvents

should be particularly carefully considered owing to the

internal pressures produced and the non-homogeneous

material properties of this natural product.

Tighten the clamping screws of the closing device with

a torque of 2.5 Nm. Internal pressures of up to max. 5

bar are permissible only with this preliminary tension.

NOTE

Damage to the grinding chamber cover and to the

device

The three screws on the safety clamp on the aeration

cover can become loose and damage the inside of the

device.

After tightening the clamping mechanism, check if the

three screws on the safety clamp are still tight.

Please note that the milling cups can easily be heated

to above 100°C, depending on the milling cup size, ball

filling, speed and milling time.

The PM400 is fitted with a ventilator which sucks the

waste heat produced during milling directly out of the

milling chamber.The suction volume per hour is greater

than 20 times the milling chamber volume. The

ventilator has a standstill monitor with signalling.

If necessary the air stream of the ventilator should be

carried off into a duct during milling.

Check firm fitting of the closing device before removing

the milling cups.

Remove the milling cups only with closing device and

open only in a safe position (extraction unit) after

cooling.

Retsch GmbH 26

Page 27

Operation via the PM100/200 display unit

The mills offer new, very userfriendly operating functions. All

relevant data can be entered or

called up from a graphic display

operated with a single button.

The menu is multi-lingual.

D E

A

B

C

Designation

Function

A

Display

Displays the menu, the parameter settings, operating information and error

messages.

B

START key

Starts the grinding process

C

STOP key

Stops the grinding process

D

Key

Opens the grinding chamber hood

E

Setting button

All menu items can be selected and parameters adjusted by turning and

pressing this button.

Turn 1

The different menu items can be selected by turning.

Selected menu items are shown inversely.

Turn 2

Adjust parameters in opened menu items (see Press 1)

Press 1

Selected menu items are opened

Press 2

A short press confirms the adjustment of the parameters

Press 3

Return to the 1st level menu by continuously pressing the button.

°C

°C

Symbols in the display unit

Reverse rotation switched on

Program mode – Store parameters

Program mode – Edit program

Program mode – Delete program

Opening mechanism off

Alarm off

Retsch GmbH 27

Motor or frequency converter too hot

Page 28

Menu structure of the display unit

1. Level

2. Level 3. Level 4. Level 5. Level

1 MANUAL OPERATION

GRINDING PROGRAM 01 bis 09

2 TIME

3 SPEED

4

INTERVAL

REVERSE ROTATION

YES / NO

INTERVAL BREAK 00:00

5

PROGAM MODE

STORE PARAMETERS

EDIT PROGRAM

DELETE PROGRAM

6 SET START TIME START IN XXX h

7 MENU SETTINGS

OPENING MECHANISM

YES / NO

ENERGY

DETERMINE

IDLING NERGY

INSERT JAR

START=MACHINE START

STOP=CANCEL

PREPARE JAR

BALANCED ?

CLOSE COVER

PRESS START TO CONTINUE

ENERGY INPUT

MEASURE

SET

ALARM

SERVICE SERVICE HELP

DETAILS IN MANUAL

CLEAN SREW

CHECK RUBBER DISK

UNDER

CLAMPING SYSTEM

CHECK CLOAMPING ARMS

AND FASTENING BRACKET

FOR WEAR AND TEAR

CLEAN LUBRICATE

LOCK WHEEL

SERVICE INTERVAL

SET SERVICE INTERVAL

SET TIME xx h

REMANING TIMET xx h

TOTAL OPERATION HOURS

TOTAL GRINDING TIME:: xxx h

SOFTWARE VERSION

SOFTWARE VERSION: V 1.03

SOFTWAREUPDATE? YES/NO

BACK

BACK

DISPLAY CONTRAST LOW - HIGH

BRIGTHNESS LOW - HIGH

LANGUAGES SET

BACK

DATE 01.04.03 SET

TIME 12:05:00 SET

BACK

E

All menu items can be selected and parameters adjusted by turning and pressing

setting button E.

Turn 1

The different menu items can be selected by turning.

Selected menu items are shown inversely.

Turn 2

Adjust parameters in opened menu items (see Press 1)

Press 1

Selected menu items are opened

Press 2

A short press confirms the adjustment of the parameters

Press 3

Return to the 1st level menu by continuously pressing the button.

Retsch GmbH 28

Page 29

Adjustment options via the display menu

Languages

Menu

Display

Languages

Incorrect language selection

If the wrong language has been selected, switch the device off at the main switch.

Hold down the keys simultaneously and switch the device back on.

Once the correct language has been selected, switch the device off and immediately back on again.

Confirm your selection by pressing the setting button.

The device is now permanently set to your language and you should see the main menu

Manual mode

If this function is set, all parameters and functions can be called up and changed at

any time. This is also possible during comminution.

Grinding

program 01

In order to access the "Grinding program" function, press the setting button

whilst in "Manual mode". The display flashes showing grinding program 1. Any

data already stored in grinding program 1 are also displayed.

Turn the setting button to the right to select the further grinding programs 2-

10, any parameters stored in these are likewise displayed.

The machine can be started directly with the selected grinding program.

Return to "Manual mode“ by turning the setting button fully to the left and

confirm with the setting button.

Grinding time

00:00:01 to 99:59:59

Hours:Minutes:Seconds

The PM100/200 is started at the pre-selected grinding time and a speed of 100 rpm.

Reverse rotation with interval break is not switched on

Speed

100 to 650 rpm

The PM100/200 is started at the pre-selected grinding time and speed.

Reverse rotation with interval break is not switched on

Please consult the menu structure on this page for the setting options on the display explained below. The

selection bar in the display is operated as follows:

Move vertically through the structure by turning the setting button

Move horizontally through the menu structure by pressing the setting button

Adjust numeric values / options by turning the setting button

Confirm settings by pressing the setting button

Return to the previous level of the menu structure with "BACK"

Return to the start screen by prolonged pressing of the setting button

This allows you to select your language. After making the selection and pressing the setting button the

complete menu structure will be displayed in your language.

Retsch GmbH 29

Page 30

Interval

00:01 to 59:59

Minutes:Seconds

Reverse rotation cannot be set until an interval is set.

Reverse rotation

YES

NO

The PM100/200 is started at the pre-selected grinding time, speed and reverse rotation. The

machine rotates with the specified interval time in one direction, runs down and then starts

immediately after coming to a stand still, without interval break, in the other direction.

Interval break

BACK

00:01 to 59:59

Minutes:Seconds

The interval break can be set here from 00:01 to 59:59

Minutes:Seconds.

An interval break cannot be set until an interval is set.

The PM100/200 is started at the pre-selected grinding time, speed, reverse rotation and

specified interval break. The machine rotates with the specified interval time in one direction, runs

down, after coming to a stand still the previously specified interval break is displayed in the

interval and counted down to 00:00.

Once the interval break has expired, the machine starts in the other direction.

Program mode

Store parameters

All previously specified parameters, such as grinding

time, speed, interval and pause can be stored to memory

here.

Set the desired parameters.

In the menu, change to "Program mode", press the setting button and confirm "Store

parameters" again, the menu shows "Grinding program" and the storage place number on

the right.

Turn the setting button to the right until you find a grinding program with free storage

places or one which you want to overwrite.

Press the setting button to reserve the selected storage place.

You can now choose between "Save parameters?" or "Cancel".

You are then returned to the "Program mode" level.

Program mode

Edit program

All previously specified parameters, such as grinding time,

speed, interval and pause can be edited here.

It is likewise possible to enter new parameters.

Select "Program mode", "Edit program“ and confirm with the setting button, the display

shows grinding program again with the storage place number.

Select the "Grinding program" to be edited by pressing the setting button, only the storage

place figures are inverted, change the grinding program by turning the setting button.

Confirm the grinding program to be edited by pressing the button, the parameters can now

be edited.

You can subsequently choose between "Save parameters" or "Cancel"

You are then returned to the program mode level.

Program mode

Delete program

All previously stored parameters can be deleted here.

Select "Program mode", press the setting button, and confirm "Delete program“ again.

Select the grinding program to be deleted by turning the setting button and confirm by

pressing.

You can now choose between "Delete program" or "Cancel"

You are then returned to the program mode level.

Retsch GmbH 30

Page 31

Start time

Start in xx h

Cancel

The start can be pre-selected from 01 to 99 h here.

The PM100/200 is started at the pre-selected grinding time, speed and reverse rotation after the

specified start time has expired.

Make certain that the grinding bowls have been securely clamped

and balanced before letting the machine start unattended.

Even though it is not possible to start the machine without the

cover closed, ensure that the cover is closed before letting the

machine start unattended.

Once running, the start time can be interrupted at any time with the STOP button and from the

main switch at the rear of the machine. The start time must then subsequently be re-programmed.

Opening mechanism

MENU

SETTINGS

OPENING MECHANISM

Energy

MENU

SETTINGS

ENERGY

This allows you to pre-select whether the grinding chamber cover should be raised automatically after grinding

has ended or may only be opened after pressing the button. If the function is switched off the

pictogram appears on the display for confirmation.

This function enables the total energy input into the grinding bowl (comminution energy + loss energy) to be

determined.

This total energy input into the grinding bowl is defined as the difference between the energy drawn from the

machine's drive unit when the grinding bowl is empty and when it is filled with material to be ground and

grinding balls.

Thus it is first necessary to determine the idling energy drawn by the machine when the grinding bowl is empty.

The idling energy level is established over a relatively short period and is taken as the zero point by the

electronics, in a similar way to taring scales.

During subsequent grinding with material, the only energy input taken into account is that which exceeds the

level of idling energy. This difference can be regarded as equal to the energy input into the grinding bowl(s) by

the grinding media and the material being ground.

For the purpose of comparing different combinations of parameters, the energy input can be specified instead

of the grinding time (only the volume of the material being ground and the feed grains need to be the same to

allow a proper comparison to be made). In this case, the grinding process is not ended after a specified time,

but rather after the input of the pre-set energy.

The energy menu is divided into three sub-menus:

DETERMINE IDLING ENERGY

MEASURE

SET

In order to determine the energy input into the grinding bowl during the grinding process, please proceed as

follows:

Specify all the parameters - speed, grinding time, interval - required for the intended grinding process.

Determine the weight of the grinding bowl intended for the subsequent grinding process but still

without the material to be ground and the grinding media.

Set the balancing weight accordingly.

Then change to the sub-menu:

DETERMINE IDLING ENERGY

Clamp the grinding bowl securely into the machine, but still without the material to be ground and the

grinding media.

Retsch GmbH 31

Page 32

Start the machine. The process now started takes about 45 seconds. During this time the PM 100 / PM

Service

MENU

SETTINGS

SERVICE

Alarm

MENU

SETTINGS

Alarm

200 determines the idling energy with the grinding bowl empty at the later operating speed.

The PM 100 stops automatically after the idling energy has been recorded and you are requested to fill

it with the material to be ground and grinding balls.

Determine the increased weight of the grinding bowl filled with material and grinding media.

Please note that the balancing of the PM 100 must be corrected accordingly.

After pressing the start button again, you are requested to choose between "MEASURE“ and "SET" the

energy.

MEASURE

Once the idling energy has been determined, only that energy is determined which is additionally input

into the grinding bowl by the movement of balls and material during the grinding time.

SET

Enter the energy to be input into the grinding bowl in kJ. It is not yet possible to stipulate the grinding

time at the same time. The machine stops once the specified energy has been input.

The error messages generated by false operation can be acoustically supported by an alarm.

If the function is switched off, the appropriate pictogram appears

The service menu is sub-divided into four sub-menus:

SERVICE HELP

Service help is stored here in the form of a check list. This is intended to make effective and regular

service work easier and increase the operational reliability of the unit. Also refer to the chapter

General/Maintenance!

TOTAL OPERATION HOURS

This counts the number of grinding hours, thus the sum of the times between START and STOP. The

times cannot be manipulated.

SOFTWARE VERSION

The version of the operating software can be called up and updated as required. If necessary, get in

touch with your Retsch distributor.

Should you have reached this menu by mistake and cannot return to the previous menu, switch the

device off at the main switch and re-start it.

Retsch GmbH 32

Page 33

Contrast / brightness

MENU

DISPLAY

CONTRAST

BRIGHTNESS

Date / Time

MENU

DATE

TIME

The contrast and brightness can be adapted to the particular user or ambient conditions (sunlight, glare etc.).

If the contrast or brightness has been incorrectly set (the display can no longer be read), switch the device off

at the main switch, simultaneously hold down the START, STOP and COVER OPEN keys and switch it on again.

You will now see the language menu and the values for CONTRAST and BRIGHTNESS have returned to the

default settings.

The current data and time can be entered here.

The time then appears on the stand-by monitor.

The power to the device can be turned off for up to 30 days without losing the settings.

Stand-by monitor

The stand-by monitor switches on automatically after the device has been inactive for 15 minutes (timed from a

STOP command).

The stand-by monitor disappears after a key is pressed or the setting button activated without executing the

command issued.

Should you be in a sub-menu when the stand-by monitor is activated, you will be returned automatically to this

selection window.

The stand-by monitor cannot be adjusted, it therefore cannot be switched off.

Retsch GmbH 33

Page 34

Error messages on the display

F02

The display shows

F01

Lock indicator

Close cover

The error appears when the cover

has not been fully closed, or if the

trannion magnets have not been

recognised.

Close the cover

The display shows

The display shows

F03

F04

Problem in the

Close or open cover,

safety circuit of

should problem remain

the interlock

then interlock faulty

Service required!

Service required!

The error appears when the

interlock is defective.

Turn the device off at the

main switch, there is a

safety problem.

The error appears when the

interlock is defective.

Turn the device off at the

main switch, there is a

safety problem.

F05

F06

The display shows

The display shows

F07

F08

Faulty motor

Please select

control

grinding time

Service required!

The display shows

The display shows

F09

F10

Cooling fan is off

Sun wheel does

not rotate

Service required!

Service required!

F12

The display shows

F11

Sun wheel rotate

to slow

Service required!

F01 to F12

Retsch GmbH 34

Page 35

F13 to F26

F13

The display shows

F14

Fault speed sensor

Service required!

The display shows

The display shows

F15

F16

Problem in the

Motor has overheated

safety circuit of the

No START possible

frequency converter

Let motor cool down

Service required!

The display shows

The display shows

F17

F18

Motor has overheated

Problem in the

Was switched off

safety circuit of

Let motor cool down

the transformer

Continue with STOP

Service required!

F19

F20

The display shows

Overload

110% F21

The display shows

The display shows

Overload 120 %

F22

Due to overload

Please reduce to ??? rpm

speed automatically

reduced to ??? rpm

The display shows

The display shows

F23

F24

Problem in the

Balance control is

safety circuit of

out of tolerance

balance control

Please rebalance

Service required!

F25

The display shows

The display shows

F26

Parameters OK?

Frequency converter

START = Machine START

has overheated

STOP = Check

No START possible

Allow to cool down

Retsch GmbH 35

Page 36

General points

Do not clean the PM100/200 with flowing water.

Mortal danger from electric shock

Only use a cloth dampened with water.

Solvents are not permitted.

1 2 3 4 5

The following service work should be performed from time to

time, although at the latest once per month, in order to

guarantee the operational reliability of your PM100/200:

Check roller 1 of the locking trannion for easy running

and oil, if necessary, e.g. with sewing machine oil

Clean magnets 2 on the locking trannion

Check threaded spindle 3 and locking sleeve 4 for easy

running. A drop of oil helps in most cases.

The easy running of the threaded spindle and the locking

sleeve is essential for secure clamping of the grinding bowl

Locking sleeves which do not move downwards solely by spring

power cannot properly prevent the threaded spindle from

working loose. The grinding bowls could be hurled out.

The easy running of roller 1 on the locking trannion is essential

for secure closing of the housing cover of the PM100/200.

The thickness D1 of the three spider feet should be

checked for wear from time to time, although at the

latest every month.

It may not be less than 7.5 mm for the PM100.

It may not be less than 5.5 mm for the PM200.

The heights H1 of the latching brackets should be

checked for wear from time to time, although at the

latest every month.

They may not be less than 17mm.

Check rubber washer 5 in the pressure piece for wear

and ensure that it is securely in place (sticking). At

temperatures up to 120°C use temperature-resistant

rapidly-acting adhesive DELO 2256.

If the values D1 and H1 are undershot, operational safety is no

longer assured.

The grinding bowls could be hurled out.

Cleaning

Maintenance

Retsch GmbH 36

Page 37

Parts subject to wear and tear

The operating instructions do not contain any repair

instructions. In the interests of your own safety,

repairs should only be performed by Retsch GmbH,

an authorised representative or by Retsch service

technicians.

Spider with pressure piece PM100

Art. No. 22.661.0002

Only deployable for PM100.

Spider with pressure piece PM200

Art. No. 22.661.0003

Only deployable for PM200.

For PM100

2x latching brackets

Art.No. 22.623.0001

1x latching brackets SafetySlider

Art.No. 22.623.0008

For PM200

4x latching brackets

Art.No. 22.623.0002

2x latching brackets SafetySlider

Art.No. 22.623.0011

For PM100 and PM200

1x pressure piece with rubber washer

Art. No. 02.108.0073

Retsch GmbH 37

Page 38

Safety slider replacement interlock lug

PM 100: 22.623.0010

PM 200: 22.623.0011

Copyright

Reproducing or distributing this documentation, or utilizing and

distributing the contents is not permitted unless Retsch GmbH has

given express permission to do so.

Violations against this are subject to claims for damages.

Changes

Technical changes are reserved.

Retsch GmbH 38

Page 39

Page 40

Page 41

Authorized person for the compilation of technical documents:

J. Bunke (technical documentation)

The following records are held by Retsch GmbH in the form of Technical Documentation:

Detailed records of engineering development, construction plans, study (analysis) of the measures required for

conformity assurance, analysis of the residual risks involved and operating instructions in due form according to

the approved regulations for preparation of user information data.

The CE-conformity of the Retsch Planetary Ball Mills Type PM 100 and PM 200 is assured herewith.

In case of a modification to the machine not previously agreed with us as well as the use of not

licensed spare parts and accessories this certificate will lose its validity.

Retsch GmbH Haan, January 2010

Dr. Stefan Mähler

Manager technical services

R e t s c h G m b H R e t s c h - Al l e e 1 - 5 4 2 7 8 1 H a a n G e r m a n y w w w . r e t sc h .c o m

PLANETARY BALL MILL

PM 100 and PM 200

FB-EW-805-046 (E) Änderungsstand D 01.2012

CERTIFICATE OF CE-CONFORMITY

Translation

Certificate of CE-Conformity according to:

EC Mechanical Engineering Directive 2006/42/EC

Applied harmonized standards, in particular:

DIN EN ISO 12100 Security of machines

EC Directive Electromagnetic Compatibility 2004/108/EC

Applied standards, in particular:

EN 61236 Electrical equipment for measurement, control and laboratory use in

conjunction with EN 55011 and EN 61000

Additional applied standards, in particular

DIN EN 61010 Safety prescriptions concerning measuring-, operating-, controlling- and

laboratory equipment

Page 42

Page 43

Page 44

Copyright

® Copyright by

Retsch GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

Loading...

Loading...