Page 1

© Retsch GmbH, 42781 Haan, Rheinische Strasse 36, Germany

Operation Manual Paddle Blender

Typ PB100

Page 2

2

Copyright

Copyright by

Retsch GmbH

Rheinische Strasse 36

D-42781 Haan

Federal Republic of Germany

Page 3

3

1 Notes on the Operating Manual ............................................................................................................ 5

1.1 Explanations of the safety warnings .................................................................................................. 6

1.2 General safety instructions ................................................................................................................ 7

1.3 Repairs ............................................................................................................................................... 8

2 Confirmation ........................................................................................................................................... 9

3 Transport, scope of delivery, installation .......................................................................................... 10

3.1 Packaging ........................................................................................................................................ 10

3.2 Transport.......................................................................................................................................... 10

3.3 Temperature fluctuations and condensed water ............................................................................. 10

3.4 Conditions for the place of installation ............................................................................................. 11

3.5 Installation of the machine ............................................................................................................... 11

3.6 Electrical connection ........................................................................................................................ 12

4 Technical data ....................................................................................................................................... 13

4.1 Use of the machine for the intended purpose.................................................................................. 13

4.1.1 Programmable motor speed and process run duration ............................................................... 13

4.1.2 Utilisation convenience and volume ............................................................................................ 13

4.1.3 Cleaning ....................................................................................................................................... 13

4.2 Protective equipment ....................................................................................................................... 13

4.3 Emissions......................................................................................................................................... 14

4.4 Degree of protection ........................................................................................................................ 14

4.5 Rated power .................................................................................................................................... 14

4.6 Rated voltage ................................................................................................................................... 14

4.7 Dimensions and weight .................................................................................................................... 14

4.8 Required floor space ........................................................................................................................ 14

4.9 Technical Data ................................................................................................................................. 15

5 Operating the machine ........................................................................................................................ 16

5.1 Views of the Instrument ................................................................................................................... 16

5.2 Overview table of the parts of the device ........................................................................................ 17

5.3 Overview Table of the Operating Elements and the Display ........................................................... 19

5.4 Commissioning ................................................................................................................................ 19

5.5 Selecting the Language for the Menu .............................................................................................. 20

5.6 Inserting the sample ........................................................................................................................ 20

5.7 Size Reduction ................................................................................................................................. 22

5.7.1 Timer Operation ........................................................................................................................... 22

5.7.1.1 Continuous Operation .......................................................................................................... 22

5.7.2 Faults during Size Reduction ....................................................................................................... 23

5.8 Process Run Duration ...................................................................................................................... 23

5.9 Motor rotation speed ........................................................................................................................ 23

Page 4

4

5.9.1 Plate movements per minute depending on speed ..................................................................... 23

5.10 Log Display ...................................................................................................................................... 24

6 Cleaning and service ........................................................................................................................... 25

6.1 Taking out the Size Reduction Plates .............................................................................................. 26

6.2 Lubricating the Fulcrum Pins ........................................................................................................... 26

6.3 Replacing the chamber sealing ....................................................................................................... 27

7 Fault messages ..................................................................................................................................... 28

8 Disposal ................................................................................................................................................. 29

9 Index ...................................................................................................................................................... 30

Page 5

Notes on the Operating Manual

5

Pos: 1.1 /00005 Überschriften/1. Überschrift en/1 Hinweise zur Bedienungsanleitung @ 0\ mod_1222347415287_9.doc @ 2631 @

1 Notes on the Operating Manual

Pos: 1.2 /0001 Bedienungsanleitungen/0010 0 Kapitelsammlung CryoMill/0001 Hinw eise zur Bedienungsanleitung/Modul Hinweis z ur Bedienungsanleitung @ 0\mod_1222347 341773_9.doc @ 2540 @

This operating manual provides all the necessary information on the topics

specified in the Table of Contents.

It instructs the target group(s) defined for the respective areas on the safe and

purpose-conformant use. Familiarity with the relevant chapter is a precondition for

the safe and purpose-conformant use of the machine.

This technical documentation is a reference work and learning guide. The

individual chapters are complete by themselves.

This operating manual does not contain any repair instructions. In case of any

faults or repairs being required, please contact your supplier or directly get in touch

with

Retsch GmbH http://www.retsch.com/

Pos: 1.3 /0001 Bedienungsanleitungen/0010 0 Kapitelsammlung CryoMill/0001 Hinweise zur Bedienungsanleitung/Modul Änderungen @ 0\mod_1222347341241_9.doc @ 252 6 @

Changes

Subject to technical changes.

Pos: 1.4 /0001 Bedienungsanleitungen/0010 0 Kapitelsammlung CryoMill/0001 Hinweise zur Bedienungsanleitung/Modul Urheberrecht @ 0\mod_1222347342038_9.doc @ 254 7 @

Copyright

Disclosure or reproduction of this documentation, use and disclosure of its contents

are only permitted with the express permission of Retsch GmbH.

Infringements will result in damage compensation liability.

Pos: 2.1 /00010 Bedienungsanleitungen/------- Seitenum bruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @

Page 6

Notes on the Operating Manual

6

Pos: 2.2 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Erklärungen zu den Sicherheitswarnungen @ 0\mod_ 1222344569771_9.doc @ 2484 @

1.1 Explanations of the safety warnings

Pos: 2.3 /00003 Standard Kapitel/General Mo dul Warnhinweise Erklärung neu @ 0\m od_1234858329746_9.doc @ 6190 @

In this Operating Manual we give you the following safety warnings

Serious injury may result from failing to heed these safety warnings. We give you

the following warnings and corresponding content.

WARNING

Type of danger / personal injury

Source of danger

– Possible consequences if the dangers are not observed.

• Instructions on how the dangers are to be avoided.

We also use the following signal word box in the text or in the instructions on action

to be taken:

WARNING

Moderate or mild injury may result from failing to heed these safety warnings.

We give you the following warnings and corresponding content.

CAUTION

Type of danger / personal injury

Source of danger

– Possible consequences if the dangers are not observed.

• Instructions on how the dangers are to be avoided.

We also use the following signal word box in the text or in the instructions on action

to be taken:

CAUTION

In the event of possible property damage we inform you with the word

“Instructions” and the corresponding content.

NOTICE

Nature of the property damage

Source of property damage

– Possible consequences if the instructions are not observed.

• Instructions on how the dangers are to be avoided.

We also use the following signal word in the text or in the instructions on action to

be taken:

NOTICE

Pos: 2.4 /00010 Bedienungsanleitungen/------- Seitenum bruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @

Page 7

Notes on the Operating Manual

7

Pos: 2.5 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Generelle Sic herheitshinweise @ 0\mod_12223445689 74_9.doc @ 2463 @

1.2 General safety instructions

Pos: 2.6 /00004 Warnhinweise/General VOR SICHT Bedienungsanleitung lesen @ 2\ mod_1263894982815_9.doc @ 18630 @

CAUTION

Read the Operating Manual

Non-observance of these operating instructions

– The non-observance of these operating instructions can

result in personal injuries.

• Read the operating manual before using the device.

• We use the adjacent symbol to draw attention to the

necessity of knowing the contents of this operating

manual.

Pos: 2.7 /00003 Standard Kapitel/General Mo dul Zielgruppe und Sicherheit @ 0\mod_1 228722955300_9.doc @ 4100 @

Target group : All persons concerned with the machine in any form

This machine is a modern, high performance product from Retsch GmbH and

complies with the state of the art. Operational safety is given if the machine is

handled for the intended purpose and attention is given to this technical

documentation.

Pos: 2.8 /00003 Standard Kapitel/General Mo dul Sicherheitshinweise @ 0\mod_122 8722954800_9.doc @ 4086 @

You, as the owner/managing operator of the machine, must ensure that the people

entrusted with working on the machine:

• have noted and understood all the regulations regarding safety,

• are familiar before starting work with all the operating instructions and

specifications for the target group relevant for them,

• have easy access always to the technical documentation for this machine,

• and that new personnel before starting work on the machine are familiarised

with the safe handling of the machine and its use for its intended purpose,

either by verbal instructions from a competent person and/or by means of

this technical documentation.

Improper operation can result in personal injuries and material damage. You are

responsible for your own safety and that of your employees.

Make sure that no unauthorised person has access to the machine.

Pos: 2.9 /00004 Warnhinweise/General VOR SICHT Sach- und Personenschäden HIN WEIS @ 1\mod_1236238456676_9.doc @ 7 642 @

CAUTION

Changes to the machine

– Changes to the machine may lead to personal injury.

• Do not make any change to the machine and use spare parts and

accessories that have been approved by Retsch exclusively.

NOTICE

Changes to the machine

– The conformity declared by Retsch with the European Directives will lose

its validity.

– You lose all warranty claims.

• Do not make any change to the machine and use spare parts and

accessories that have been approved by Retsch exclusively.

Pos: 2.10 /00010 Bedienungsanleitungen/------- Seitenu mbruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @

Page 8

Notes on the Operating Manual

8

Pos: 2.11 /00005 Überschriften/1.1 Überschrift en/1.1 Überschriften BDA/11 Reparaturen @ 0\mod_1223624336511_9.doc @ 297 8 @

Reperaturen

1.3 Repairs

Pos: 2.12 /00003 Standard Kapitel/General M odul Reparaturen @ 0\mod_122872295 4535_9.doc @ 4079 @

This operating manual does not contain any repair instructions. For your own

safety, repairs may only be carried out by Retsch GmbH or an authorized

representative or by Retsch service engineers.

In that case please inform:

The Retsch representative in your country

Your supplier

Retsch GmbH directly

Your Service Address:

Pos: 3.1 /00020 BDA Software/20005 PM GC Kapitelsammlung/- - - - Seitenumbruch - - - - @ 0\mod_1208857688413_0.doc @ 3 37 @

Page 9

Confirmation

9

Pos: 3.2 /0010 BDA Software/Überschriften /1. Überschriften/1 Bestätigung (Formular für d en Betreiber) @ 0\mod_1208870841095_ 9.doc @ 430 @ 1

Bestätigung

2 Confirmation

Pos: 3.3 /00003 Standard Kapitel/General Mo dul Bestätigung @ 0\mod_122872296270 7_9.doc @ 4114 @

This operating manual contains essential instructions for operating and maintaining

the device which must be strictly observed. It is essential that they be read by the

operator and by the qualified staff responsible for the device before the device is

commissioned. This operating manual must be available and accessible at the

place of use at all times.

The user of the device herewith confirms to the managing operator (owner) that

(s)he has received sufficient instructions about the operation and maintenance of

the system. The user has received the operating manual, has read and taken note

of its contents and consequently has all the information required for safe operation

and is sufficiently familiar with the device.

As the owner/managing operator you should for your own protection have your

employees confirm that they have received the instructions about the operation of

the machine.

I have read and taken note of the contents of all chapters in this operating

manual as well as all safety instructions and warnings.

User

Surname, first name (block letters)

Position in the company

Signature

Service technician or operator

Surname, first name (block letters)

Position in the company

Place, date and signature

Pos: 3.4 /00020 BDA Software/20005 PMGC Kapitelsammlung/- - - - Seitenumbruch - - - - @ 0\mod_1208857688413_0.doc @ 3 37 @

Page 10

Transport, scope of delivery, installation

10

Pos: 4.1 /00005 Überschriften/1. Überschrift en/1 Verpackung, Transport und Aufstellung @ 0\mod_1226494451893_9.doc @ 3380 @ 1

3 Transport, scope of delivery, installation

Pos: 4.2 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Verpackung @ 0\mod_1226495088973_9.doc @ 3392 @

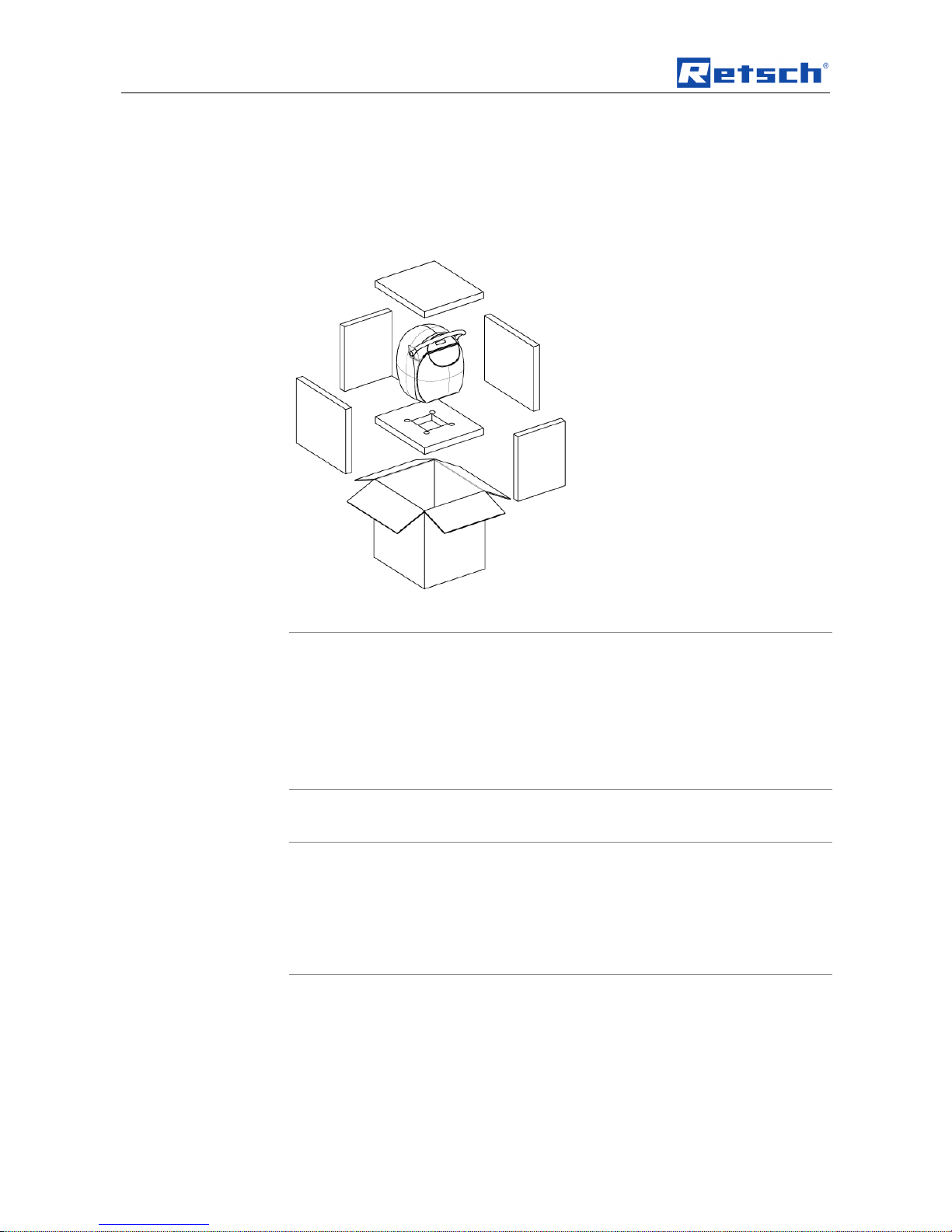

3.1 Packaging

Pos: 4.3 /00003 Standard Kapitel/General Mo dul Verpackung @ 0\mod_122898461835 5_9.doc @ 4892 @

The packaging has been adapted to the mode of transport. It complies with the

generally applicable packaging guidelines.

Pos: 4.4 /00010 Bedienungsanleitungen/001 40 Kapitelsammlung Paddle Blender/0001 Pa ddle Blender Kapitel Transport und Aufstell ung/0101 PB Modul Auspacken des Gerät es @ 2\mod_1262772677787_9.doc @ 182 10 @

Fig. 1: Unpacking the Paddle Blender

Pos: 4.5 /00004 Warnhinweise/General HINW EIS Aufbewahrung der Verpackung @ 0\ mod_1228918881595_9.doc @ 4753 @

NOTICE

Storage of packaging

– In the event of a complaint or return, your warranty claims may be

endangered if the packaging is inadequate or the machine has not been

secured correctly.

• Please keep the packaging for the duration of the warranty period.

Pos: 4.6 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Transport @ 0 \mod_1226495164391_9.doc @ 3398 @

3.2 Transport

Pos: 4.7 /00004 Warnhinweise/General HINW EIS Transport @ 0\mod_1228918883019 _9.doc @ 4802 @

NOTICE

Transport

– Mechanical or electronic components may be damaged.

• The machine may not be knocked, shaken or thrown during

transport.

Pos: 4.8 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Temperatursch wankungen @ 0\mod_1226495 190738_9.doc @ 3404 @

3.3 Temperature fluctuations and condensed water

Pos: 4.9 /00004 Warnhinweise/General HINW EIS Temperaturschwankungen @ 0\mod _1233564121287_9.doc @ 5570 @

Page 11

Transport, scope of delivery, installation

11

NOTICE

Temperature fluctuations

The machine may be subject to strong temperature fluctuations during transport

(e.g. aircraft transport)

– The resultant condensed water may damage electronic components.

• Protect the machine from condensed water.

Pos: 4.10 /00005 Überschriften/1.1 Überschrift en/1.1 Überschriften BDA/11 Bedingunge n für den Aufstellort @ 0\mod_122649702 9322_9.doc @ 3428 @

3.4 Conditions for the place of installation

Pos: 4.11 /00003 Standard Kapitel/General M odul Umgebungstemperatur 15°C - 30°C @ 2\mod_1262860184078_9.doc @ 18333 @

Ambient temperature: 15°C to 30°C

Pos: 4.12 /00004 Warnhinweise/General HIN WEIS Umgebungstemperatur 15°C bis 30°C @ 2\mod_1262860320012_9.doc @ 183 41 @

NOTE

Ambient temperature

- Electronic and mechanical components can be damaged and the performance

characteristics can change to an unknown extent.

• Keep within the permissible temperature range for the device. (15°C to

30°C/ambient temperature).

Pos: 4.13 /00003 Standard Kapitel/General M odul Luftfeuchtigkeit @ 0\mod_122891 8538693_9.doc @ 4738 @

Atmospheric humidity:

Maximum relative humidity 80% at temperatures up to 31°C, decreasing linearly up

to 50% relative humidity at 40°C

Pos: 4.14 /00004 Warnhinweise/General HIN WEIS Luftfeuchtigkeit @ 0\mod_122891 8882628_9.doc @ 4788 @

NOTICE

Atmospheric humidity

– Electronic and mechanical components may be damaged and the

performance data alter to an unknown extent.

• Do not exceed the admissible range for atmospheric humidity.

Pos: 4.15 /00005 Überschriften/1.1 Überschrift en/1.1 Überschriften BDA/11 Aufstellen des Gerätes @ 0\mod_1226498849756_9.doc @ 3464 @

3.5 Installation of the machine

Pos: 4.16 /00004 Warnhinweise/General VOR SICHT Herabfallen des Gerätes / Standfestig keit @ 1\mod_1248178329919_9.doc @ 11690 @

CAUTION

Device falling down

Incorrect assembly or unsuitable workplace

- The appliance is very heavy and can therefore cause serious personal injuries if

it falls down.

Operate the device only on a sufficiently large, firm, skid-resistant and

steady workplace.

Make sure that all equipment feet are steady.

Pos: 4.17 /00010 Bedienungsanleitungen/00 140 Kapitelsammlung Paddle Blender/0001 P addle Blender Kapitel Transport und Aufstell ung/0103 PB Modul Aufstellen Untergru nd Erschütterung @ 2\mod_1262773774506_ 9.doc @ 18224 @

While the device is running, it vibrates normally. The device must stand on an

even, stable and balanced supporting surface.

The work surface, on which the device is standing, must be clean and dry.

Pos: 4.18 /00003 Standard Kapitel/General M odul Aufstellungshöhe @ 0\mod_12289 18538349_9.doc @ 4724 @

Installation height: maximum 2000 m above sea level

Pos: 4.19 /00004 Warnhinweise/General HIN WEIS Aufstellung Zugang Gerätesteckdose @ 0\mod_1233836960983_9.doc @ 582 0 @

Page 12

Transport, scope of delivery, installation

12

NOTICE

Installation of the machine

– It must be possible to disconnet the machine from the mains at any time.

• Install the machine such that the connection for the mains cable is

easily accessible.

Pos: 4.20 /00005 Überschriften/1.1 Überschrift en/1.1 Überschriften BDA/11 Elektrischer A nschluss @ 0\mod_1226565067445_9.doc @ 3500 @

3.6 Electrical connection

Pos: 4.21 /00004 Warnhinweise/General HIN WEIS Aufstellung Zugang Gerätesteckdose @ 0\mod_1233836960983_9.doc @ 582 0 @

NOTICE

Installation of the machine

– It must be possible to disconnet the machine from the mains at any time.

• Install the machine such that the connection for the mains cable is

easily accessible.

Pos: 4.22 /00003 Standard Kapitel/General M odul Elektrischer Anschluss @ 0\mod_ 1228918538521_9.doc @ 4731 @

The voltage required and the frequency of the machine are provided on the type

plate.

• Ensure that the values agree with the available power supply system.

• Connect the machine to the power supply system using the connecting cable

supplied.

CAUTION

An external fusing at the connection of the mains cable to the power supply must

be provided in accordance with the conditions of the place of installation.

Pos: 4.23 /00010 Bedienungsanleitungen/00 140 Kapitelsammlung Paddle Blender/0001 P addle Blender Kapitel Transport und Aufstell ung/0102 PB Modul Steckdose Stromkabel @ 2\mod_1262773446408_9.doc @ 182 17 @

The Paddle Blender must be set up near a power outlet socket.

NOTE

Use only the provided power cable. No liability will be accepted for any damage

caused by the use of another cable.

110-120 V

220-240 V

Voltage

115 V +/-10%

230 V +/- 10%

Maximum voltage

1 A

0.5 A

Frequency

50-60 Hz

50-60 Hz

Power consumption

100 W

100 W

Fuse size

2AT

2AT

Check before connecting the device that the voltage selector switch at the back is

set tothe characteristics of the given source of voltage (triangle pointing to the line ,

see description on the back of the device).

NOTE

In the as-delivered state the pointer is at 230 V +-10 %.

Pos: 5.1 /00010 Bedienungsanleitungen/------- Seitenum bruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @

Page 13

Technical data

13

Pos: 5.2 /00005 Überschriften/1. Überschrift en/1 Technische Daten @ 0\mod_1222344 525522_9.doc @ 2407 @

4 Technical data

Pos: 5.3 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Einsatz der M aschine bei bestimmungsgemäßer Verwendu ng @ 0\mod_1226476732248_9.doc @ 32 43 @ 2

4.1 Use of the machine for the intended purpose

Pos: 5.4 /00010 Bedienungsanleitungen/001 40 Kapitelsammlung Paddle Blender/0002 PB Kapitel Technische Daten/0201 PB Modul Zielg ruppe Maschinentypbezeichnung @ 2\ mod_1262780708625_9.doc @ 18240 @

Target group: Operators

Machine type designation: Paddle Blender

Pos: 5.5 /00010 Bedienungsanleitungen/001 40 Kapitelsammlung Paddle Blender/0002 PB Kapitel Technische Daten/0202 PB Modul bestimmungsgemäße Verwendung @ 2\ mod_1262780918530_9.doc @ 18247 @ 333

The smasher is a size reducer that produces a homogenised, liquid suspension to

represent the sample to be analysed.

The size of the sample is reduced with the aid of two stainless steel plates (450 640 movements per minute) in a grinding chamber made of ABS.

If the material is difficult to cut up, the motor switches into reverse gear to help

accelerate the speed of the plates and process the sample with increased impact

power.

4.1.1 Programmable motor speed and process run duration

The size reduction operates either in programmable runs of 10 - 180 sec. or in

continuous operation.

The motor speed can be suited to the sample which is to be cut up. There is a

choice of 3 speeds: slow, normal and fast.

4.1.2 Utilisation convenience and volume

The smasher, which is equipped with vibration-proof feet, works efficiently and also

quietly. Its ergonomically shaped handle allows a choice of right-handed or lefthanded operation.

4.1.3 Cleaning

Cleaning the interior is made easier by the rounded form of the size reduction

chamber and by the possibility of tilting the device backwards.

As a standard feature in the series, the device is equipped with an integrated waste

collecting receptacle.

Thanks to the removable plates, all areas in the size reduction chamber are easy

to access.

Pos: 5.6 /00004 Warnhinweise/General HINW EIS Einsatzbereich des Gerätes 8 Stündig er @ 1\mod_1236240219096_9.doc @ 76 93 @

NOTICE

Area of use of the machine

– This machine is a laboratory machine designed for 8-hour single-shift

operation.

• This machine may not be used as a production machine nor is it

intended for continuous operation.

Pos: 5.7 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Schutzeinrichtu ngen @ 0\mod_1226486316130_9.doc @ 3304 @

4.2 Protective equipment

Pos: 5.8 /00010 Bedienungsanleitungen/001 40 Kapitelsammlung Paddle Blender/0002 PB Kapitel Technische Daten/0203 PB Modul Sch utzeinrichtungen @ 2\mod_126278183 5223_9.doc @ 18254 @

The motor is protected by an electronic system.

When the door is closed, the inside of the size reduction chamber is inaccessible.

Pos: 5.9 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Emmisionen @ 0\mod_1226487095021_9.doc @ 3310 @

Page 14

Technical data

14

4.3 Emissions

Pos: 5.10 /00010 Bedienungsanleitungen/0 0140 Kapitelsammlung Paddle Blender/00 02 PB Kapitel Technische Daten/0208 PB Modul Lärmmessung @ 2\mod_1262868735111 _9.doc @ 18385 @

The noise is measured with two different samples at the three speeds:

Noise level with 250ml water:

slow speed: 49.6 db (A)

normal speed: 53.2 db (A)

high speed: 55.3 db (A)

Noise level with 225ml water + 25g Babybel (processed cheese):

slow speed: 51.4 db (A)

normal speed: 52.4 db (A)

high speed: 55.2 db (A)

Pos: 5.11 /00005 Überschriften/1.1 Überschrift en/1.1 Überschriften BDA/11 Schutzart @ 0\mod_1226491839164_9.doc @ 3328 @

4.4 Degree of protection

Pos: 5.12 /00010 Bedienungsanleitungen/00 140 Kapitelsammlung Paddle Blender/0002 P B Kapitel Technische Daten/0209 PB Mo dul Schutzart @ 2\mod_1262870442240_9.d oc @ 18392 @

– IP40 total device

– IP54 interior

Pos: 5.13 /00005 Überschriften/1.1 Überschrift en/1.1 Überschriften BDA/11 Nennleistung @ 0\mod_1226491873164_9.doc @ 3334 @

4.5 Rated power

Pos: 5.14 /00010 Bedienungsanleitungen/00 140 Kapitelsammlung Paddle Blender/0002 P B Kapitel Technische Daten/0205 PB Modul Ne nnleistung @ 2\mod_1262860862995 _9.doc @ 18364 @

Power consumption: max. 100 W

Pos: 5.15 /00005 Überschriften/1.1 Überschrift en/1.1 Überschriften BDA/11 Nennspannu ngen @ 1\mod_1240476024494_9.doc @ 8 571 @ 2

4.6 Rated voltage

Pos: 5.16 /00010 Bedienungsanleitungen/00 140 Kapitelsammlung Paddle Blender/0002 P B Kapitel Technische Daten/0206 PB Mo dul Nennspannungen @ 2\mod_12628609294 02_9.doc @ 18371 @

115 V +/- 10 %, 50-60 Hz

230 V +/- 10 %, 50-60 Hz

Pos: 5.17 /00005 Überschriften/1.1 Überschrift en/1.1 Überschriften BDA/11 Abmessungen und Gewicht @ 0\mod_122649221217 3_9.doc @ 3352 @

4.7 Dimensions and weight

Pos: 5.18 /00010 Bedienungsanleitungen/00 140 Kapitelsammlung Paddle Blender/0002 P B Kapitel Technische Daten/0204 PB Modul A bmessungen und Gewicht @ 2\mod_1 262860636573_9.doc @ 18357 @

Height: 400 mm (without lid)

Width: 330 mm

Depth: 380 mm

Weight: approx. 20.3 kg

Pos: 5.19 /00005 Überschriften/1.1 Überschrift en/1.1 Überschriften BDA/11 Erforderliche Standfläche @ 0\mod_1226492678414_ 9.doc @ 3364 @

4.8 Required floor space

Pos: 5.20 /00010 Bedienungsanleitungen/00 140 Kapitelsammlung Paddle Blender/0002 P B Kapitel Technische Daten/0207 PB Modul Er forderliche Standfläche und Mindestabs tand @ 2\mod_1262868173258_9.doc @ 1 8378 @

400 mm x 600 mm; no safety spacing required

Pos: 5.21 /00010 Bedienungsanleitungen/------- Seitenu mbruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @

Page 15

Technical data

15

Pos: 5.22 /00005 Überschriften/1.1 Übersc hriften/1.1 Überschriften BDA/11 Technische Daten @ 0\mod_1222344569224_9.doc @ 2470 @ 2

4.9 Technical Data

Pos: 5.23 /00010 Bedienungsanleitungen/00 140 Kapitelsammlung Paddle Blender/0002 P B Kapitel Technische Daten/0210 PB Modul Technische Daten weitere @ 2\mod_12 62870614038_9.doc @ 18399 @

Fuse size

2AT

Air pressure

700 HPa -1100 Hpa

Degree of contamination

2

Installation category

II in conformance to EU Directive 1664

Number of knife

movements/min.

(when device is empty)

Movements

Slow speed:

Normal speed:

Fast speed:

450 - 490

520 - 560

600 - 640

Spacing between plates and

door

Advanced position:

Reversed position:

1 mm +/- 1 mm

34 mm +/- 1 mm

Adjustable motor speed

slow

normal

fast

Duration of the size reduction

process

adjustable from 10 - 180 sec. (or unlimited)

- Backlit alphanumeric display 2x 16 characters

- Membrane keypad

- Left-handed and right-handed use of handle

- Integrated waste collecting receptacle

- Intelligent management when plates get stuck

(5 attempts before final blockage)

Pos: 6.1 /00010 Bedienungsanleitungen/------- Seitenum bruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @

Page 16

Operating the machine

16

Pos: 6.2 /00005 Überschriften/1. Überschrift en/1 Bedienung des Gerätes @ 0\mod_ 1226565880211_9.doc @ 3519 @

5 Operating the machine

Pos: 6.3 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Grafische Ansic hten des Gerätes @ 0\mod_122899058 1782_9.doc @ 4966 @ 2

5.1 Views of the Instrument

Pos: 6.4 /00010 Bedienungsanleitungen/001 40 Kapitelsammlung Paddle Blender/0003 PB Kapitel Bedienung/0301 PB Modul Geräteansic hten @ 2\mod_1262782307866_9.d oc @ 18269 @

Fig. 2: View of the front

Fig. 3: View of the rear

C A B D G

E C H

I

F

Page 17

Operating the machine

17

Fig. 4: View of the interior

Pos: 6.5 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Übersichtsta belle der Geräteteile @ 0\mod_122899061 6846_9.doc @ 4972 @

5.2 Overview table of the parts of the device

Pos: 6.6 /00010 Bedienungsanleitungen/001 40 Kapitelsammlung Paddle Blender/0003 PB Kapitel Bedienung/0303 PB Modul Gerätet eile Tabelle @ 2\mod_1262787026464_9.d oc @ 18278 @

Element

Description

Function

A

Membrane keypad

Control functions

B

LCD

Display of control functions and parameters

C

Handle

Opening and closing door

D

Door

Sealing the grinding chamber

E

Feet

-

F

Power switch

Contains voltage selector switch, fuse holder

power supply connection and ON/OFF switch

G

Voltage selector switch + fuse holder

Setting the supply voltage and replacing the

device’s fuse

H

IEC C14 power inlet

Power connection

I

ON/OFF switch

Disconnects the device from mains

J

Bag stop

Positions the sample bag in a vertical direction

K

Door hinge

- L Sealing size reduction chamber

Seals the size reduction chamber

M

Size reduction plates

Cuts up the sample property

N

Waste collecting receptacle

Collects sample

J K M

N L P

Page 18

Operating the machine

18

P

Black rubber band for bag

Holds the bag in place

Pos: 6.7 /00010 Bedienungsanleitungen/------- Seitenum bruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @

Page 19

Operating the machine

19

Pos: 6.8 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Übersichtstab elle der Bedienelemente und der Anzeige @ 0\mod_1228990697273_9.doc @ 4978 @

5.3 Overview Table of the Operating Elements and the Display

Pos: 6.9 /00010 Bedienungsanleitungen/001 40 Kapitelsammlung Paddle Blender/0003 PB Kapitel Bedienung/0305 PB Modul Bedienel ement und Anzeige @ 2\mod_1262946 152205_9.doc @ 18410 @

Fig. 5: Two-line display

Element

Description

Function

O

Selected mode of operation

60s (timer switching with a run duration of 10 - 180

sec.) or Cont. (continuous operation)

W

Selected motor speed

(normal, slow or fast)

Q

The following information appears in

the lower line:

- device status

“READY” appears when the size reducer is

READY to conduct a size reduction run.

“Finished” when the size reduction run has come to

an end.

- progress of a run during continuous operation

- error message or display of the device data

Fig. 6: Control panel

Pressing the ◄ and ► keys moves the cursor on the display to the left or right.

You can use the ▼ and ▲ keys to scroll through the list of the options.

The ▼ key is also used to confirm a selection.

Pos: 6.10 /00005 Überschriften/1.1 Überschrift en/1.1 Überschriften BDA/11 Erstinbetriebn ahme @ 2\mod_1262857956229_9.doc @ 18290 @ 2

5.4 Commissioning

Pos: 6.11 /00004 Warnhinweise/General VOR SICHT Explosions- oder Brandgefahr Ver mahlen @ 1\mod_1236238455830_9.doc @ 7626 @

CAUTION

Danger of explosion or fire

Changing sample properties

– Please note that the properties, and therefore the dangerous nature of

your sample, can change during the grinding process.

• Do not grind any substances in this machine which can cause an

explosion or a fire.

Pos: 6.12 /00010 Bedienungsanleitungen/00 140 Kapitelsammlung Paddle Blender/0003 PB Kapitel Bedienung/0304 PB Modul Erstin betriebnahme @ 2\mod_126285724415 1_9.doc @ 18311 @

60s NORMAL

STARTKLAR

O W Q

Page 20

Operating the machine

20

Connect the smasher to the power grid and press the ON/OFF switch to turn on

the device.

The following initialisation sequence is shown in the display:

The message is displayed for 3 sec.

NOTE

The following are the factory settings for the device:

- Run duration 60 sec.

- Motor speed “normal”

- Menu language English

It is recommendable to conduct the following functional test first:

• Lift the handle to open the door.

The size reduction chamber must be empty.

• Close the door again so that the size reduction can begin.

If you have maintained the factory settings, the device runs through a size

reduction process lasting 60 sec.

Pos: 6.13 /00005 Überschriften/1.1 Ü berschriften/1.1 Überschriften BDA/11 Sprache des Menüs auswählen @ 2\mod_126285 8032822_9.doc @ 18297 @ 2

5.5 Selecting the Language for the Menu

Pos: 6.14 /00010 Bedienungsanleitungen/0 0140 Kapitelsammlung Paddle Blender/00 03 PB Kapitel Bedienung/0302 PB Modul Sprac he des Menüs @ 2\mod_1262858135023_ 9.doc @ 18304 @

Select the menu language by pressing the ▼ and ▲ keys for 5 sec as you are

switching on the device. Use the ▼ key to scroll to the next screen:

Press the ◄ and ► keys to scroll through the list of the available menu

languages.

Press the ▼ key to confirm the selected menu language.

Pos: 6.15 /00005 Überschriften/1.1 Überschrift en/1.1 Überschriften BDA/11 Einsetzen d er Probe @ 2\mod_1262858832798_9.doc @ 18318 @ 2

5.6 Inserting the sample

Pos: 6.16 /00004 Warnhinweise/General VOR SICHT Gefahr von Personenschäden Gefährl iche Stoffe @ 1\mod_1236238456269 _9.doc @ 7634 @

CAUTION

Danger of personal injury

Dangerous nature of the sample

– Depending on the dangerous nature of your sample, take the

necessary measures to rule out any danger to persons.

• Observe the safety guidelines and datasheets of your

sample material.

LANGUAGE

FRENCH

60s NORMAL

READY

AES Laboratoire

SMASHER 2.00A

Page 21

Operating the machine

21

Pos: 6.17 /00004 Warnhinweise/General VOR SICHT Explosions- oder Brandgefahr Ver mahlen @ 1\mod_1236238455830_9.doc @ 7626 @

CAUTION

Danger of explosion or fire

Changing sample properties

– Please note that the properties, and therefore the dangerous nature of

your sample, can change during the grinding process.

• Do not grind any substances in this machine which can cause an

explosion or a fire.

Pos: 6.18 /00010 Bedienungsanleitungen/00 140 Kapitelsammlung Paddle Blender/0003 P B Kapitel Bedienung/0306 PB Modul Eins etzen der Probe @ 2\mod_1262947010197_ 9.doc @ 18417 @

Fig. 7: Opening the Flap

• Lift the handle to open the door.

The collecting receptacle must be inserted and the device must be free of solid or

liquid waste.

Fig. 8: Inserting the bags

• Place the bag with the sample and the dilution in the size reduction chamber

(max. bag contents: 400 ml).

• Push the bag downwards along the door to remove any air out of the interior and

accordingly avoid leakages as the door is being closed.

Page 22

Operating the machine

22

Fig. 9: Closing the Flap

• Press the handle downward to close the door.

The size reduction process starts automatically.

CAUTION

The device must be switched off and disconnected from the power grid before

anyone reaches into the device for cleaning or maintenance purposes.

NOTE

It is recommendable to use tear-resistant Retsch sample bags as far as possible.

Do not use any frozen samples or samples containing bones. The bags can be

damaged by shells.

Pos: 6.19 /00005 Überschriften/1.1 Überschrift en/1.1 Überschriften BDA/11 Zerkleinerung @ 2\mod_1263290014496_9.doc @ 18 542 @ 2

5.7 Size Reduction

Pos: 6.20 /00010 Bedienungsanleitungen/00 140 Kapitelsammlung Paddle Blender/0003 P B Kapitel Bedienung/0308 PB Modul Zerkleiner ung @ 2\mod_1263290086522_9.doc @ 18549 @ 343

The messages shown in the display depend on the selected mode of operation.

5.7.1 Timer Operation

The 1st line shows the time that has elapsed (in sec.), the programmed time and

the selected speed.

In the 2nd line a bar display provides information on the progress of the run.

28/ 60s NORMAL

ooooooooo

This screen appears at the end of the size reduction process.

60/ 60s NORMAL

FINISHED

Whenever the door is opened, the main screen appears.

60s NORMAL

READY

5.7.1.1 Continuous Operation

The 1st line shows the elapsed time and the selected motor speed.

In the 2nd line a movable cursor indicates the fault-free operation of the device.

The elapsed time is indicated in seconds (0 - 99999 sec.).

Page 23

Operating the machine

23

3474s/- NORMAL

o

Opening the door interrupts the size reduction process and the main menu is

shown again.

CONT. NORMAL

READY

NOTE

If the plates get stuck (hard sample), the device switches automatically into reverse

gear to start the plates moving again with maximum momentum. After 5

unsuccessful automatic attempts, the process is stopped.

5.7.2 Faults during Size Reduction

Fault

Cause and possible remedy

Sample material escapes

Check contents in bag (samples that are too hard,

e.g. shells, can damage the bag). Examine the bag

quality (e.g. for weak seams). If the fault occurs

repeatedly, please ask customer service.

Message

“Size reduction failed”

Take the bag out and check if the sample is not too

large.

If the reason for the message is not apparent, please

read through the “Fault diagnosis” section.

Note: When technical faults occur, please refer to the error messages section.

Pos: 6.21 /00005 Überschriften/1.1 Überschrift en/1.1 Überschriften BDA/11 Durchlaufdau er @ 2\mod_1263289874150_9.doc @ 18 528 @ 2

5.8 Process Run Duration

Pos: 6.22 /00010 Bedienungsanleitungen/00 140 Kapitelsammlung Paddle Blender/0003 P B Kapitel Bedienung/0309 PB Modul Durchla ufdauer @ 2\mod_1263290871222_9.doc @ 18556 @

The size reducer can run either in continuous operation or for a time which can be

adjusted from 10 - 180 sec.

60s NORMAL

READY

Starting with the main screen, set a process run duration of XXXs

(flashes) with the ◄ or ► key.

When put into operation for the first time, the device’s default setting is a

process run duration of 60 sec.

60s NORMAL

READY

Use the ▲ or ▼ keys to scroll through the list of the size reduction times,

ending with continuous operation.

Tests have shown that a process run duration of 30 - 60 sec. is sufficient

for the size reduction of most samples.

Pos: 6.23 /00005 Überschriften/1.1 Überschrift en/1.1 Überschriften BDA/11 Motordrehzahl @ 1\mod_1241508280705_9.doc @ 876 3 @ 2

5.9 Motor rotation speed

Pos: 6.24 /00010 Bedienungsanleitungen/00 140 Kapitelsammlung Paddle Blender/0003 P B Kapitel Bedienung/0310 PB Modul Motordr ehzahl @ 2\mod_1263291329108_9.doc @ 18563 @ 3

60s NORMAL

READY

Starting with the main screen, use the ◄ or ► keys to set a motor

speed (flashes).

60s NORMAL

READY

Use the ▼ or ▲ keys to scroll through the list of speeds (normal, slow, fast).

When put into operation for the first time, the default setting is “normal”

speed.

5.9.1 Plate movements per minute depending on speed

Speed

Movements per min.

Movements per min.

Page 24

Operating the machine

24

(Blender empty*)

(Blender with load*)

Slow

471

424

Normal

541

500

Fast

622

592

average number of plate movements per minute, determined with a selection of

new empty blenders

** average number of plate movements per minute, determined with a selection of

new loaded blenders (with 250 ml of water). The number of plate movements per

minute depends on the type and size of the cut up sample.

Pos: 6.25 /00005 Überschriften/1.1 Überschrift en/1.1 Überschriften BDA/11 Protokoll A nzeige @ 2\mod_1263289563465_9.doc @ 1 8514 @ 2

5.10 Log Display

Pos: 6.26 /00010 Bedienungsanleitungen/00 140 Kapitelsammlung Paddle Blender/0003 P B Kapitel Bedienung/0307 PB Modul Protokoll Anzeige @ 2\mod_1263289656307_9.doc @ 18521 @

• • Switch the blender to maintenance mode by pressing the ▼ and ▲ keys for

5 sec. as you are switching the blender on.

TOTAL DURATION:

3256427:54

The total duty cycleis displayed.

Hours and minutes).

Press ▼ to call up the next screen.

NUMBER OF RUNS:

324221

The display shows the number of runs already conducted.

Press ▼ to call up the next screen.

MOTOR OVERLOADING:

23

The display shows the number of motor blockages that have occurred so

far.

Press ▼ to call up the next screen.

LANGUAGE:

FRENCH

The display shows the selected menu language.

Press the ◄ and ► keys to scroll through the list of available menu

languages.

Press the ▼ key to confirm the menu language selection.

60s NORMAL

READY

The main menu displays the standard run duration andstandard motor

speed (60 sec., speed “normal”) in size reduction.

Pos: 7.1 /00010 Bedienungsanleitungen/------- Seitenum bruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @

Page 25

Cleaning and service

25

Pos: 7.2 /00005 Überschriften/1. Überschri ften/1 Reinigung und Wartung @ 0\mod_ 1231167007723_9.doc @ 5450 @

6 Cleaning and service

Pos: 7.3 /00004 Warnhinweise/General WARN UNG Reinigung Stromstoß neu @ 1\m od_1236239978437_9.doc @ 7686 @

WARNING

Risk of a fatal electric shock

- An electric shock can cause injuries in the form of burns and cardiac

arrhythmia, respiratory arrest or cardiac arrest.

• Do not clean the blender under running water. Use only a cloth dampened

with water.

• Disconnect the power supply plug before cleaning the blender.

Pos: 7.4 /00010 Bedienungsanleitungen/001 40 Kapitelsammlung Paddle Blender/0004 PB R einigung/0401 PB Modul Reinigung @ 2\ mod_1262948196805_9.doc @ 18439 @

The rounded easily accessible surfaces allow effortless access to the size

reduction chamber.

Use kitchen towels or a soft cloth soaked in warm water to clean the size reduction

chamber at the end of every day.

Never spray cleaning agents directly onto the plate shafts.

Disinfect the size reduction chamber afterwards with alcohol 70%.

Fig. 10: Preparing for Cleaning

• Lift the door so that the size reduction chamber is completely free (1).

• Pull the waste collecting receptacle out.

Page 26

Cleaning and service

26

Fig. 11:

• Tilt the blender backwards and support it on its back feet.

• Then clean the size reduction chamber and the flap.

Pos: 7.5 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Herausnehmen der Zerkleinerungs-Platten @ 2\mod_1262 948122804_9.doc @ 18432 @ 2

6.1 Taking out the Size Reduction Plates

Pos: 7.6 /00010 Bedienungsanleitungen/001 40 Kapitelsammlung Paddle Blender/0004 PB R einigung/0405 PB Modul Platten entn ehmen @ 2\mod_1262958799616_9.doc @ 1 8460 @

Fig. 12: Removing the Size Reduction Plates

• Check if the waste collecting receptacle was taken out.

• Tilt the blender backwards.

• Hold the upper and lower ends of the plate with both hands and then turn it

towards the wall of the size reduction chamber.

• Then take the plate off the fulcrum pin.

• To reinsert it, simply hold the knife at the fulcrum pin and press it in until it

engages audibly (“click”).

Pos: 7.7 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Schmierung der Dr ehachsen @ 2\mod_1262960520152 _9.doc @ 18467 @ 2

6.2 Lubricating the Fulcrum Pins

Pos: 7.8 /00010 Bedienungsanleitungen/001 40 Kapitelsammlung Paddle Blender/0004 PB R einigung/0402 PB Modul Schmierung Vaseli ne Öl @ 2\mod_1262960693251_9.doc @ 18474 @

Page 27

Cleaning and service

27

• Lubricate the fulcrum pins with Vaseline oil once a month.

Fig. 13: Lubricating the Fulcrum Pins

Pos: 7.9 /00005 Überschriften/1.1 Überschrif ten/1.1 Überschriften BDA/11 Austausch d er Kammerdichtung @ 2\mod_126296136095 4_9.doc @ 18481 @ 2

6.3 Replacing the chamber sealing

Pos: 7.10 /00010 Bedienungsanleitungen/00 140 Kapitelsammlung Paddle Blender/0004 P B Reinigung/0403 PB Modul Austausch der Dic htung @ 2\mod_1262961411105_9.doc @ 18488 @

Fig. 14: Replacing the sealing

NOTE

The sealing on the size reduction chamber must be replaced at least once a year

and at shorter intervals when damaged.

It is recommendable to leave the door open a bit when the blender is not in use so

that the sealing does not stick together or get warped.

• Before inserting the sealing, clean the sealing groove with 70% alcohol.

• Put the two ends of the sealing into the upper parts of the groove (1) (2).

• Put the middle part of the sealing into the lower part of the groove (3).

• Push the remaining sealing with even tautness into the groove (4) (5).

Pos: 8.1 /00010 Bedienungsanleitungen/------- Seitenum bruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @

Page 28

Fault messages

28

Pos: 8.2 /00005 Überschriften/1. Überschrift en/1 Fehlermeldungen @ 2\mod_125905 6589728_9.doc @ 17580 @ 1

7 Fault messages

Pos: 8.3 /00010 Bedienungsanleitungen/001 40 Kapitelsammlung Paddle Blender/00150 Fe hlermeldungen/1501 PB Modul Fehlermeldu ngen @ 2\mod_1263288791689_9.doc @ 18507 @

Error

message/problem

Cause

Remedy

Message:

!!! SIZE REDUCTION

FAILED

The sample cannot be

cut up.

Plates get stuck after 5

attempts.

Increase the speed.

If the blender is already running at maximum

speed, cut the sample into smaller pieces and

start the size reduction again.

If this does not remedy the fault, please ask

Customer Service.

Technical Fault

Motor does not turn.

Ask Customer Service.

Display blank

Blender is not switched

on.

Check if the blender is connected correctly

and switched on.

Fuse might be defective.

Check the size and condition of the fuse on

the voltage selector switch at the back of the

blender.

If the size and condition of the fuse are alright

but the fault continues, ask Customer Service.

Faulty connection or

defective display

Ask Customer Service.

During size reduction

sample material

comes out of the bag

Maintenance problem or

incorrectly closed bag

Examine the condition of the black rubber

band that serves to hold the bag.

If necessary, clean with a sponge.

Check that the bag does not pucker when the

door is closed.

If this does not remedy the fault, please ask

Customer Service.

Pos: 9.1 /00010 Bedienungsanleitunge n/------- Seitenumbruch ----------- @ 0\mod_1222344373758_0.doc @ 2386 @

Page 29

Disposal

29

Pos: 9.2 /00005 Überschriften/1. Überschrift en/1 Entsorgung @ 0\mod_12342587468 31_9.doc @ 6173 @

8 Disposal

Pos: 9.3 /00003 Standard Kapitel/General M odul Entsorgung @ 0\mod_12342694049 35_9.doc @ 6180 @

Please observe the respective statutory requirements with respect to disposal.

Information on disposal of electrical and electronic machines in the European

Community.

Within the European Community the disposal of electrically operated devices is

regulated by national provisions that are based on the EU Directive 2002/96/EC on

Waste Electrical and Electronic Equipment (WEEE).

Accordingly, all machines supplied after 13.08.2005 in the business-to-business

area to which this product is classified, may no longer be disposed of with

municipal or household waste. To document this they have the following label:

Fig. 15: Disposal label

Since the disposal regulations within the EU may differ from country to country we

would request you to consult your supplier.

=== Ende der Liste für Textmarke Inhalt ===

Page 30

30

9 Index

!

!!!SIZE REDUCTION FAILED ............................. 28

1

1.1 Overview Table of the Operating Elements

and the Display ............................................... 19

A

Ambient Temperature ......................................... 11

Atmospheric humidity ......................................... 11

C

Changes ............................................................... 5

Characteristics .................................................... 12

Cleaning and service .......................................... 25

Closing the Flap .................................................. 22

Commissioning ................................................... 19

Conditions for the place of installation ................ 11

Conditions of the installation site ........................ 12

Confirmation ......................................................... 9

Connecting cable ................................................ 12

Continuous Operation ......................................... 22

Control panel ...................................................... 19

Copyright .............................................................. 5

D

Degree of protection ........................................... 14

Depth .................................................................. 14

Description .................................................... 17, 19

Dimensions and weight....................................... 14

Display blank ...................................................... 28

Disposal .............................................................. 29

Disposal label ..................................................... 29

E

Electrical connection ........................................... 12

Emissions ........................................................... 14

Error Message / .................................................. 28

Explanations of the safety warnings ..................... 6

External fusing .................................................... 12

F

Fault messages .................................................. 28

Faults during Size Reduction ............................. 23

Frequency .......................................................... 12

Function ....................................................... 17, 19

Fuse size ............................................................ 12

G

General safety instructions .................................. 7

H

Height ................................................................. 14

I

Inserting the bags .............................................. 21

Inserting the Sample .......................................... 20

Installation height ............................................... 11

Installation of the machine ................................. 11

L

Log Display ........................................................ 24

Lubricating the Fulcrum Pins ....................... 26, 27

M

Maintenance Mode ............................................ 24

Maximum relative humidity ................................ 11

Maximum voltage ............................................... 12

Menu Language ................................................. 24

Moderate or mild injury ........................................ 6

Motor Blockages ................................................ 24

Motor rotation speed .......................................... 23

N

Noise Level ........................................................ 14

noise measurement ........................................... 14

Notes on the Operating Manual ........................... 5

O

Opening the Flap ............................................... 21

Operating the machine....................................... 16

Overview table of the parts of the device........... 17

Page 31

31

P

Packaging ........................................................... 10

Power cable ........................................................ 12

Power consumption ............................................ 14

Power consumption ............................................ 12

Preparing for Cleaning ........................................ 25

Problem............................................................... 28

Process Run Duration ......................................... 23

Process runs ....................................................... 24

property damage ................................................... 6

Protective equipment .......................................... 13

R

Rated power ....................................................... 14

Rated voltage ...................................................... 14

Removing the Size Reduction Plates ................. 26

Repairs.................................................................. 8

Replacing the Chamber Sealing ......................... 27

Replacing the Sealing ......................................... 27

Required floor space ........................................... 14

Runs Conducted ................................................. 24

S

Safety Spacing .................................................... 14

Safety warnings .................................................... 6

Selecting the Language for the Menu ................. 20

serious injury ......................................................... 6

Service-Adresse ................................................... 8

Size Reduction .................................................... 22

Standard motor speed ........................................ 24

Standard Run Duration ....................................... 24

T

Taking out the Plates ......................................... 26

Taking out the Size Reduction Plates ................ 26

Target group ........................................................ 7

Technical data .................................................... 13

Technical Data ................................................... 15

Technical Fault ................................................... 28

Temperature fluctuation and condensed water . 10

Timer Operation ................................................. 22

Total Duty Cycle ................................................. 24

Transport ............................................................ 10

Transport, scope of delivery, installation ........... 10

triangular pointer ................................................ 12

Two-line display ................................................. 19

Type plate .......................................................... 12

U

Unpacking the Paddle Blender .......................... 10

Use of the machine for the intended purpose .... 13

V

View of the front ................................................. 16

View of the interior ............................................. 17

View of the rear .................................................. 16

Views of the Instrument ..................................... 16

Voltage ............................................................... 12

Voltage selector switch ...................................... 12

W

Weight ................................................................ 14

Width .................................................................. 14

Loading...

Loading...